Strong-inhibition water-base drilling fluid

A water-based drilling fluid and drilling fluid technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems such as insufficient stability, poor hydrate inhibition ability, and difficulty in meeting the technical requirements of deep-water oil and gas drilling engineering. Achieve the effects of suppressing wellbore instability and good low-temperature-high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1. Preparation of freshwater-based deepwater drilling fluid with strong inhibition

[0046] Prepare the freshwater-based deepwater drilling fluid system, including the following components by weight percentage:

[0047] Bentonite: 4%; strong polyamine inhibitor: 3%; polyacrylamide (PAM, produced by Renqiu Deli Petroleum Auxiliary Co., Ltd.): 0.1%; NaCl: 25%; polyanionic cellulose (PAC-HV, Renqiu Yanxing Chemical Co., Ltd.): 0.1%; sulfonated phenolic resin (SD-101, Dongying Shida Innovation Technology Co., Ltd.): 3%; sodium polyacrylate (Xinxiang Jinghui Synthetic Materials Co., Ltd. production): 1%; water-based lubricant (SD-506, produced by Dongying Shida Innovation Technology Co., Ltd.): 1%; fresh water is 100%.

[0048] The polyamine strong inhibitor used in the present embodiment is prepared by the following method:

[0049]Add 330 g of diethylene glycol bis(3-aminopropyl) ether and 0.33 g of potassium hydroxide into a high-temperature and high-pressure re...

Embodiment 2

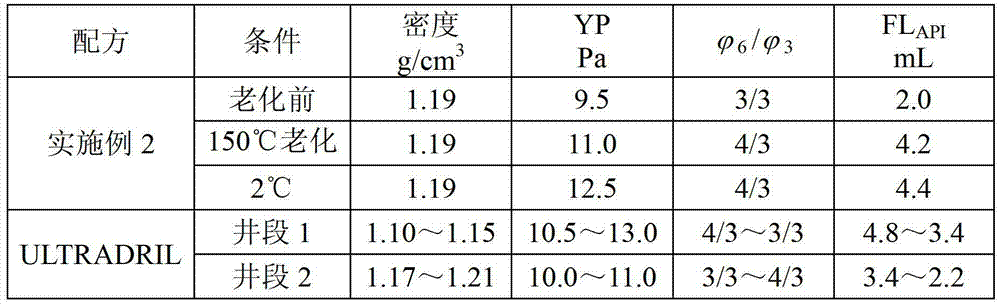

[0050] Example 2. Preparation of seawater-based deep-water drilling fluid with strong inhibition

[0051] Prepare the seawater-based deepwater drilling fluid system, including the following components by weight percentage:

[0052] Bentonite: 3%; strong polyamine inhibitor: 3%; cationic polyacrylamide (CPAM, produced by Dongying Nuoer Chemical Co., Ltd.): 0.1%; xanthan gum (XC, produced by Renqiu Yanxing Chemical Co., Ltd.) : 0.15%; NaCl: 20%; sulfonated phenolic resin (SMP-1, produced by Henan Xinxiang Yikang Drilling Auxiliary Co., Ltd.): 4%; sodium polyacrylate (produced by Xinxiang Jinghui Synthetic Materials Co., Ltd.): 1%; extreme pressure lubricant (SD-505, produced by Dongying Shida Innovation Technology Co., Ltd.): 1%; sulfonated asphalt: 1.5%; sea water (Bohai Sea) is counted as 100%.

[0053] The preparation method of the strong polyamine inhibitor used in this example is the same as that in Example 1.

Embodiment 3

[0054] Example 3. Preparation of seawater-based deepwater drilling fluid with strong inhibition

[0055] Prepare a weighted seawater-based deepwater drilling fluid system, including the following components by weight percentage:

[0056] Bentonite: 3%; strong polyamine inhibitor: 3%; cationic polyacrylamide (CPAM, produced by Dongying Nuoer Chemical Co., Ltd.): 0.1%; xanthan gum (XC, produced by Renqiu Yanxing Chemical Co., Ltd. ): 0.15%; NaCl: 20%; sulfonated phenolic resin (SD-101, produced by Dongying Shida Innovation Technology Co., Ltd.): 4% Sodium polyacrylate (produced by Xinxiang Jinghui Synthetic Materials Co., Ltd.): 1% ; Extreme pressure lubricant (SD-505, produced by Dongying Shida Innovation Technology Co., Ltd.): 1%; sulfonated asphalt: 1.5%; barite: 30%; sea water (Bohai Sea) is 100%.

[0057] The preparation method of the strong polyamine inhibitor used in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com