Patents

Literature

93results about How to "Clear chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

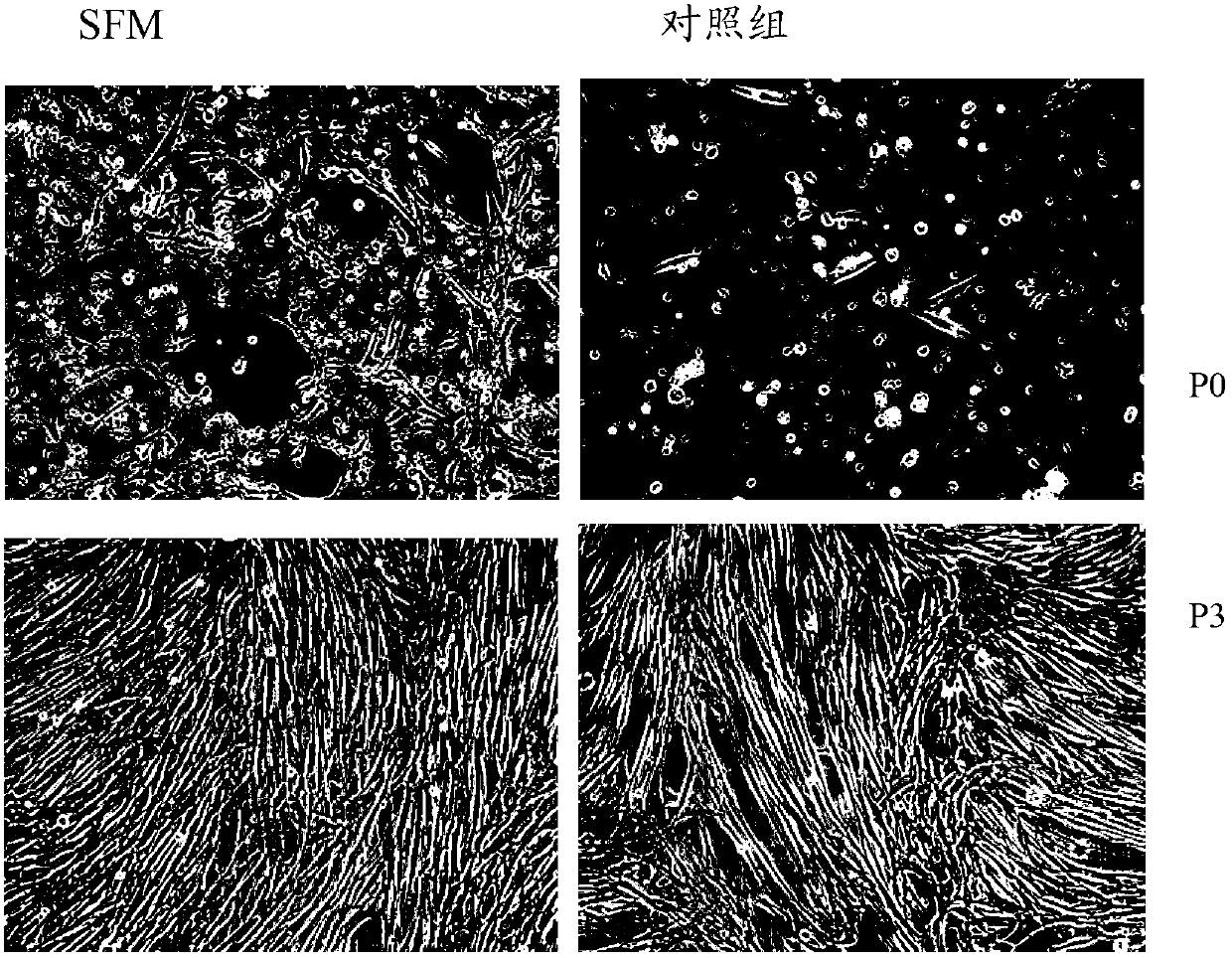

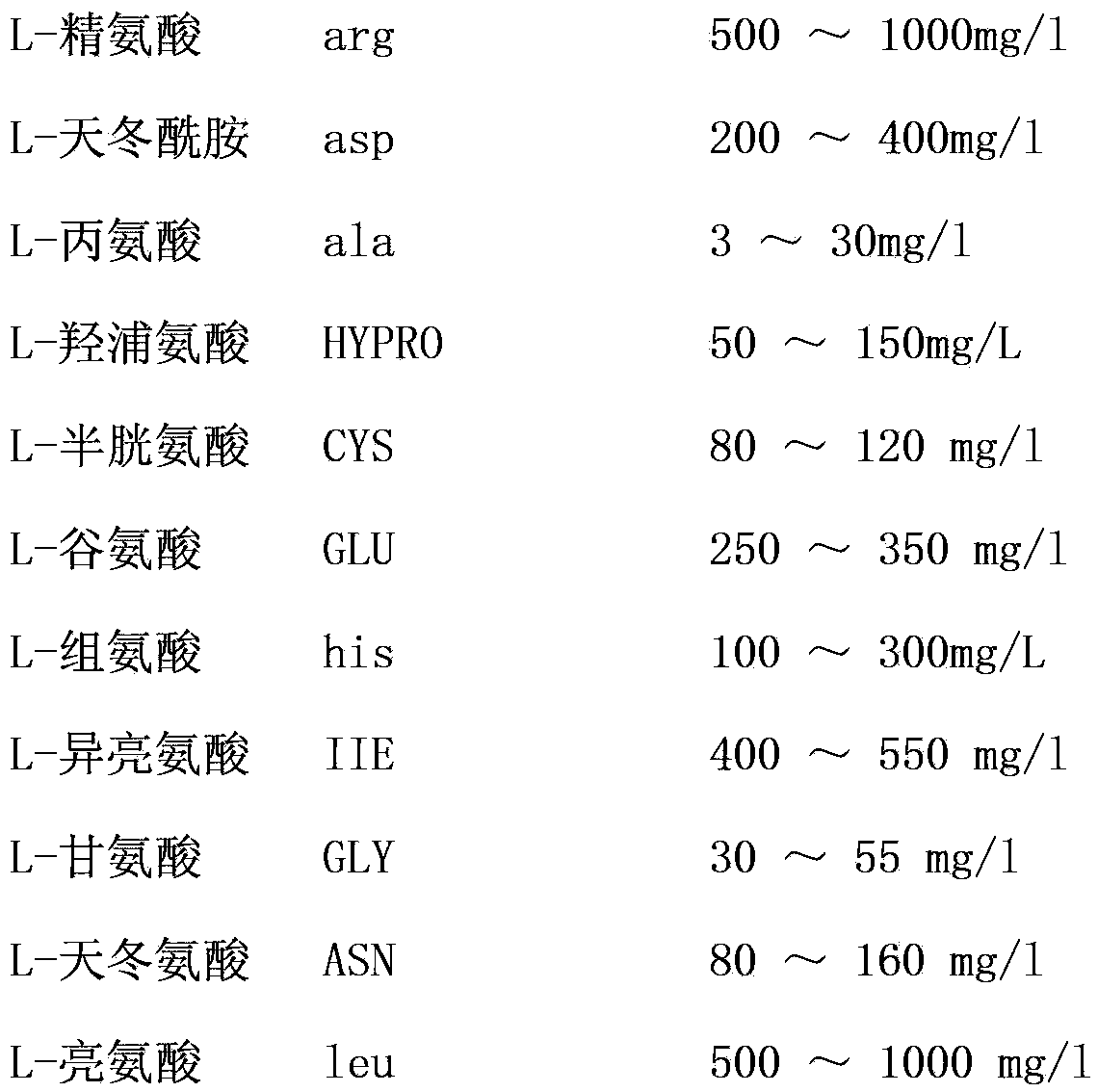

Serum-free culture medium for mesenchymal stem cells

ActiveCN102827807AAvoid instabilityClear chemical compositionSkeletal/connective tissue cellsCell phenotypeSodium bicarbonate

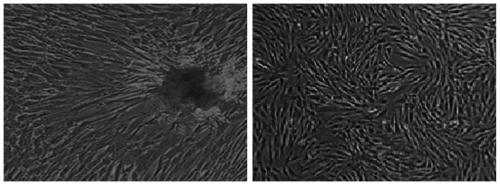

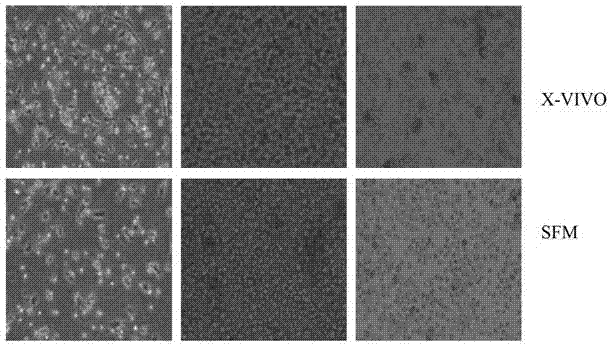

The invention relates to the field of biology, and discloses a serum-free culture medium which essentially comprises an IMDM (Iscove Modified Dulbecco Medium), L-glutamine, sodium bicarbonate, Hepes, recombinant human insulin, recombinant human transferrin, recombinant human albumin, 2-mercaptoethanol, protocatechuic acid, lipid, amino acid, vitamins, trace elements, Pluronic F-68, hydrocortisone, vitamin C, bonding amine or recombinant human fibronectin, progesterone, putrescine, heparin, serotonin, epidermal growth factors (EGFs), b-fibroblast growth factors (FGF), platelet derive growth factor (PDGF)-BB and insulin-like growth factor (IGF)-I. The serum-free culture medium is clear in chemical components, free from animal sources and serum and safe and ideal in cell cultivation and avoids the doped animal components and unstable batches, and the results of the cultured mesenchymal stem cells show that the total cellular score, the cell phenotype and the secretory cell factors are normal, so that the serum-free culture medium has good industrial application prospect.

Owner:内蒙古干细胞医学工程技术研究中心

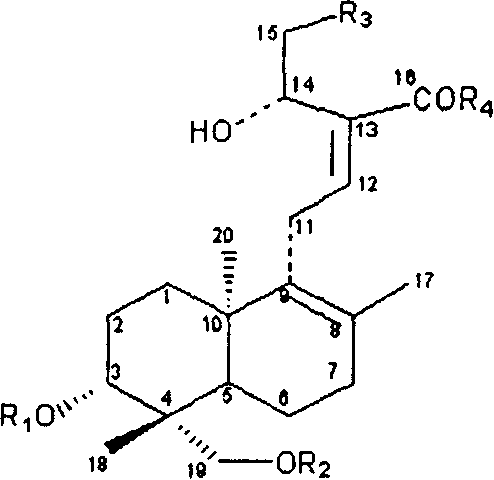

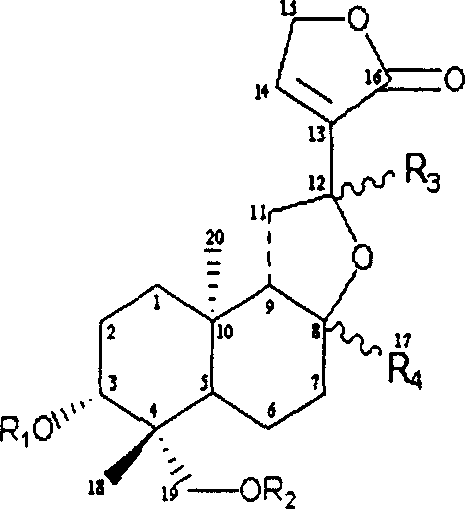

Sulfonated derivative of andrographolide and combination of medication

ActiveCN1687049AClear structureGood antibacterialAntibacterial agentsPowder deliveryDiseaseTonsillitis

The present invention discloses II kinds of andrographolide sulfonated derivatives with the actions of resisting bacteria, relieving inflammation and reducing fever and medicine composition containing them. They can be used for preparing freeze-dried powder, injection or oral preparation, and can be used for curing the diseases of pneumonia, bronchitis, tonsillitis and bacillary dysentery, etc.

Owner:JIANGZI QINGFENG PHARMACEUTICALS INC

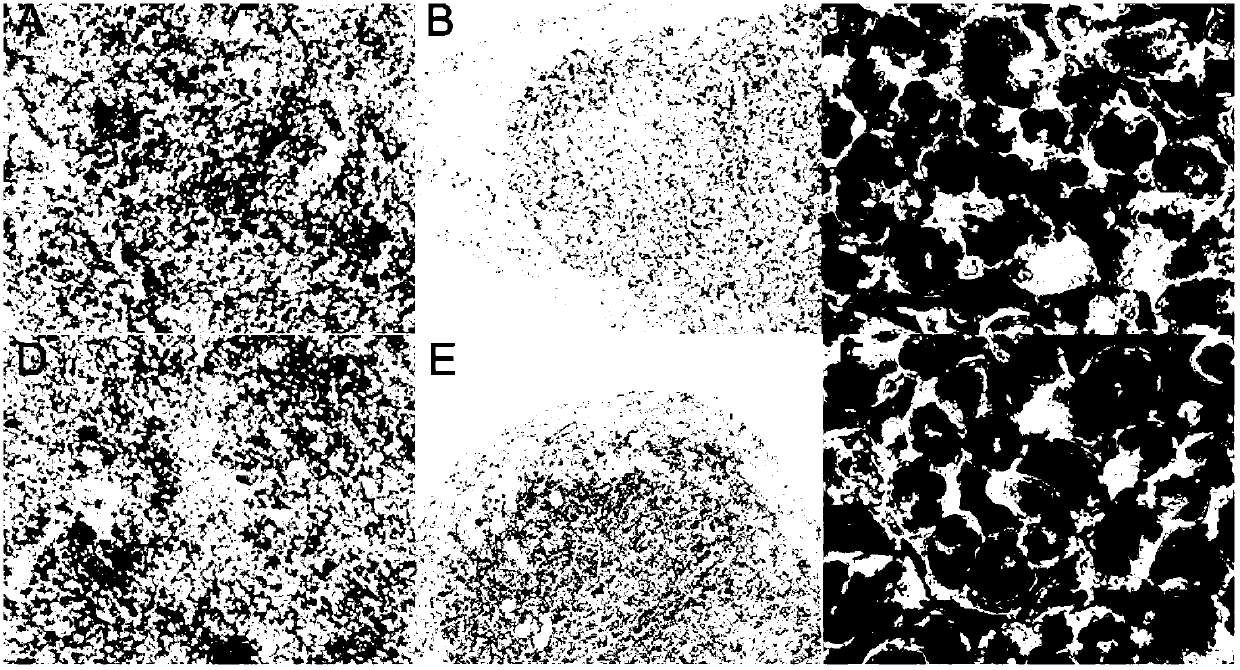

Preparation method of gel containing stem cell exosomes for repairing skin wounds

InactiveCN111420117AImprove application securityHigh clinical safetyCulture processSkeletal/connective tissue cellsMesenchymal stem cellEngineering

The invention relates to a preparation method of a gel containing stem cell exosomes for repairing skin wounds. The method comprises the following steps: 1) primary extraction and culture of human umbilical cord mesenchymal stem cells: 1.1) primary extraction of human umbilical cord mesenchymal stem cells, 1.2) subculture, and 1.3) collection of the culture supernatant; 2) extraction of human umbilical cord mesenchymal stem cell exosomes: 2.1) primary centrifugation, 2.2) secondary centrifugation, 2.3) removal of organelles by centrifugation, 2.4) coarse extraction of exosomes, and 2.5) finalextraction of exosomes; 3) preparation of a gel material: 3.1) preparation of chitosan, 3.2) configuration of beta-glycerol phosphate (beta-GP), and 3.3) preparation of the gel material; and 4) gel loading of the exosomes. The gel containing stem cell exosomes can promote repair of skin wounds, shorten the healing time of wounds and reduce scar formation.

Owner:陕西朗泰生物科技有限公司

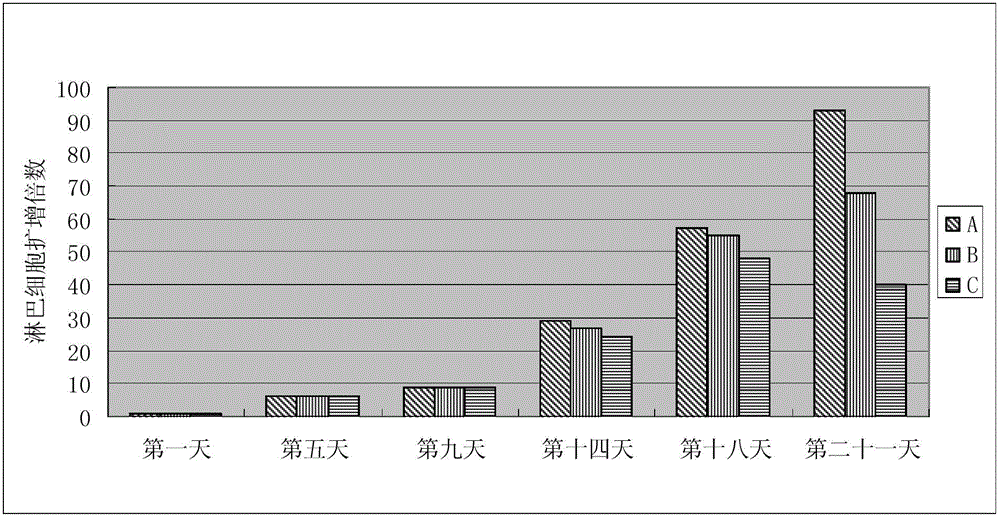

Animal source-free and serum-free culture medium of lymphocyte

InactiveCN103146648AGood amplification factorEnhance cell viabilityBlood/immune system cellsCell phenotypeSodium bicarbonate

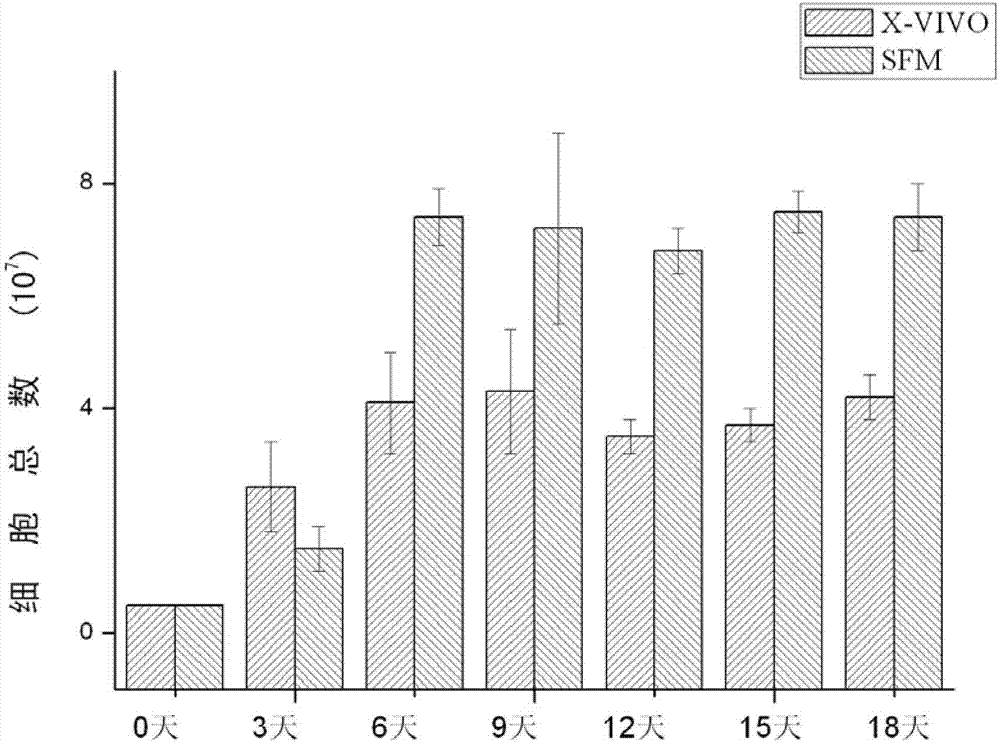

The invention relates to the biological field and discloses an animal source-free and serum-free culture medium of lymphocyte. The culture medium disclosed by the invention essentially consists of IMDM (Iscove Modified Dulbecco Medium), L-glutamine, sodium bicarbonate, recombinant human insulin, human transferrin, human serum albumin, 2-mercaptoethanol, N-acetyl-cysteine, lipid, amino acid, vitamin, microelement, ferric citrate, hydrocortisone, cholamine and non-essential amino acid. The serum-free culture medium disclosed by the invention has the advantages of clear chemical components, no animal source, no serum, safe and ideal culture cells; the instability caused by the doping of animal components and batches is avoided; the result of culturing lymphocyte shows that the total number of the cells and the cell phenotypes are normal; and the serum-free culture medium disclosed by the invention has a good industrial application prospect.

Owner:BEIJING JING MENG STEM CELL TECH

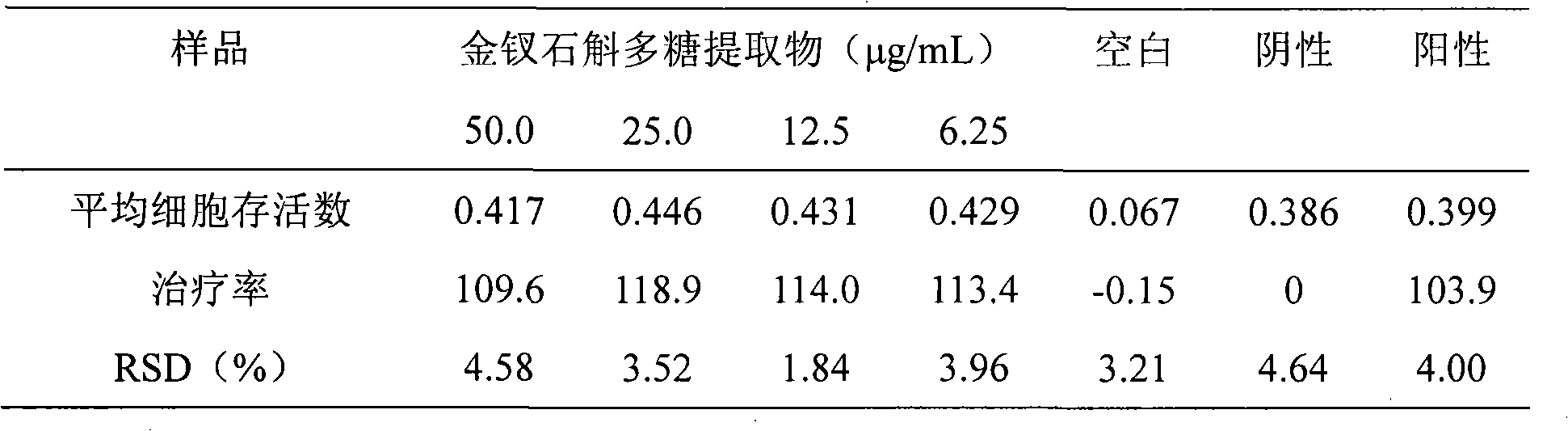

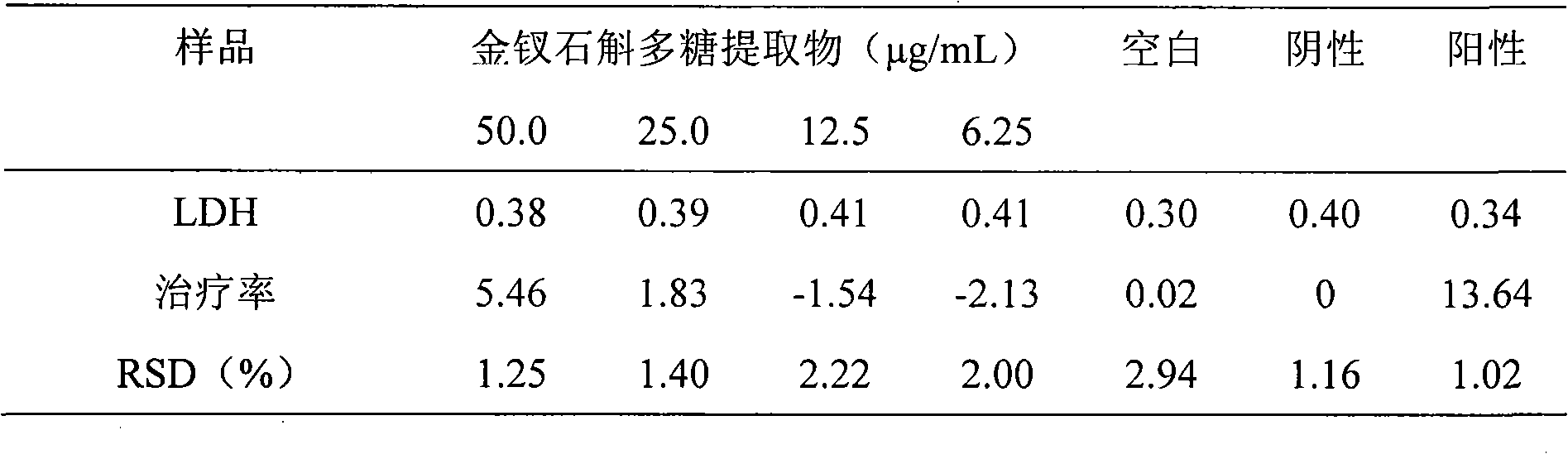

Preparation of Dendrobium nobile polysaccharide extract and use there

InactiveCN101407558AQuality is easy to controlHigh content of active ingredientsOrganic active ingredientsMetabolism disorderBiotechnologyPharmaceutical drug

The invention provides a preparation method of dendrobium nobile polysaccharide extracts. The dendrobium nobile polysaccharide extracts can be realized through steps of degreasing, extracting, alcohol precipitation, deproteinization, removing monosaccharide and oligosaccharide, gel column purification etc. The content of polysaccharide in the polysaccharide extracts is above 90 percent. The polysaccharide extracts are provided with obvious antioxidant activity and can be applied to the preparation of medicaments or medicament complex used for treating and preventing cardiovascular disease after combined with medicament excipients or carriers allowed by the preparation. The preparation method of the extracts has the advantages of reasonable design and easy operation.

Owner:ZHEJIANG UNIV

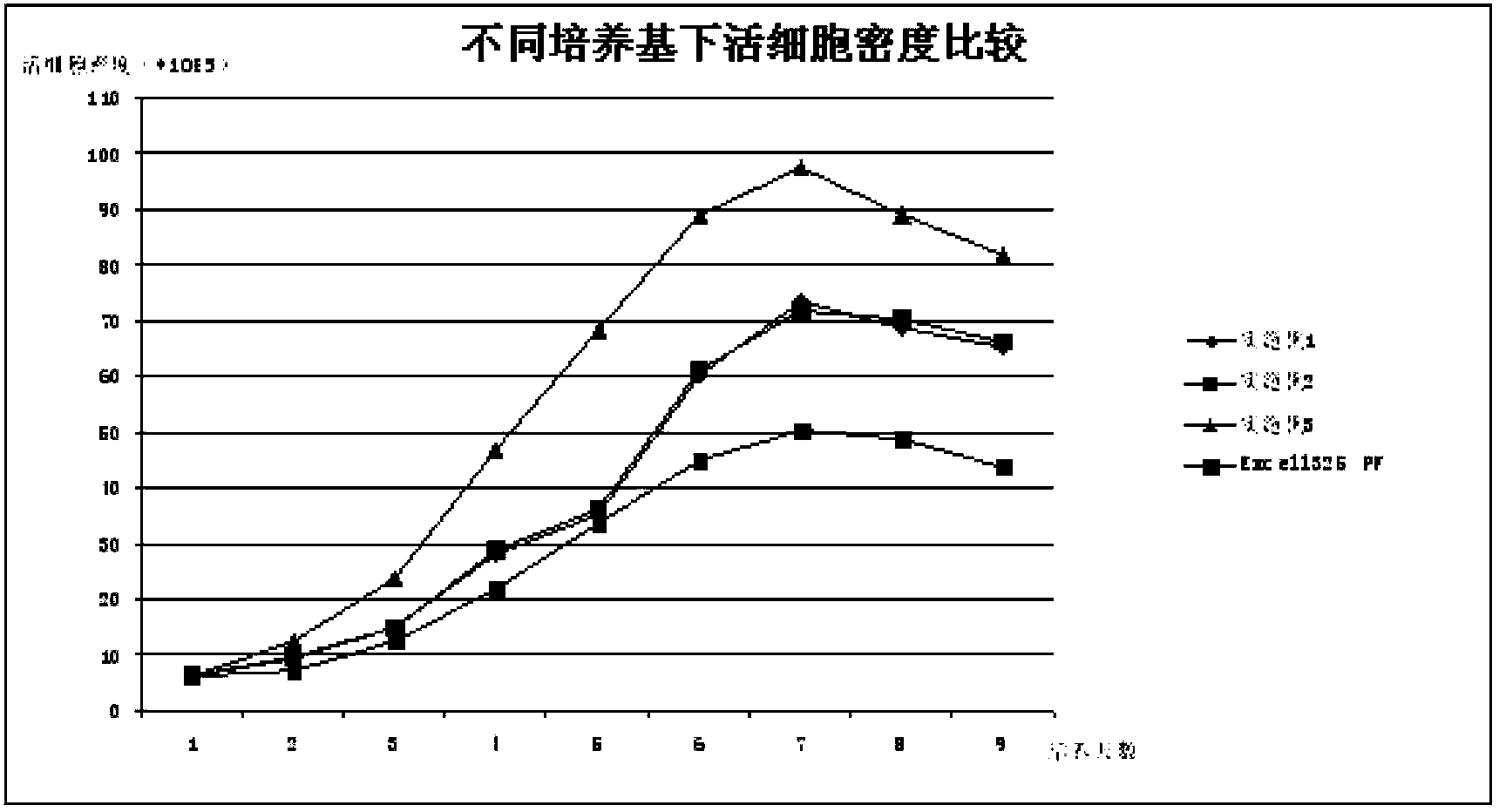

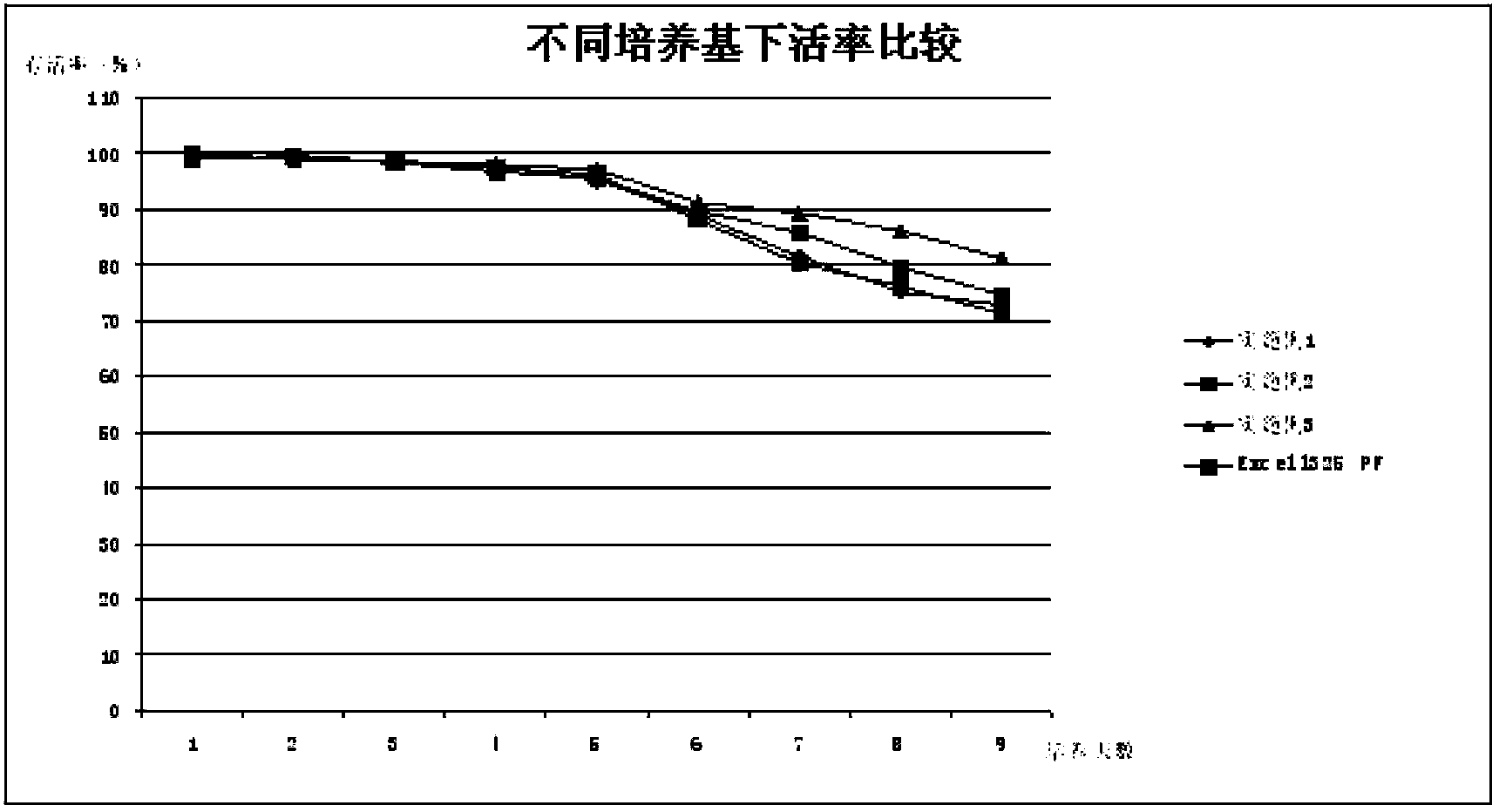

Serum-free protein-free culture medium supporting CHO (Chinese Hamster Ovary Cell) high density suspension culture

ActiveCN104073463AClear chemical compositionReduce the risk of contaminationVertebrate cellsArtificial cell constructsSuspension cultureOrganic molecules

The invention provides a serum-free protein-free culture medium supporting CHO (Chinese Hamster Ovary Cell) high density suspension culture. The culture medium comprises amino acids, microelements, inorganic salts, vitamins, carbohydrates and other organic molecules, wherein culture medium contains steroid hormone but does not contain transferrin or insulin. The culture medium provided by the invention is definite in chemical component, free of animal resource, small in pollution risk, applicable to growth of various different CHO cell strains, good in cell culture effect and beneficial for downstream separation and purification.

Owner:SUNSHINE GUOJIAN PHARMA (SHANGHAI) CO LTD

Non-animal-source serum-free culture medium for umbilical cord blood stem cells

ActiveCN102827810AAvoid instabilityClear natureBlood/immune system cellsCell phenotypeLipid formation

The invention relates to the field of biology, and discloses a non-animal-source serum-free culture medium which essentially comprises an IMDM (Iscove Modified Dulbecco Medium), L-glutamine, sodium bicarbonate, recombinant human insulin, recombinant human transferrin, recombinant human albumin, 2-mercaptoethanol, phytohaemagglutinin (PHA), lipid, amino acid, vitamins, trace elements, interleukin-3(IL-3), stem cell factor, (SCF), Fit3-L, IL-6 and granulocyte colony-stimulating factor (G-CSF). The non-animal source serum-free culture medium is clear in chemical components, free from animal sources and serum and safe and ideal in cell cultivation, avoids the doped animal components and unstability of batches, and the results of cultured umbilical cord blood stem cells show that the total cellular score, the cell phenotype and the secretory cell factors are normal, so that the non-animal-source serum-free culture medium has good industrial application prospect.

Owner:内蒙古干细胞医学工程技术研究中心

CHO (Chinese hamster ovary) cell serum-free protein-free culture medium and preparation method thereof

InactiveCN106190950AGrow fastClear chemical compositionCulture processArtificial cell constructsMinor elementHydrolysate

The invention relates to preparation of a cell culture medium, and particularly provides preparation of a novel serum-free protein-free defined-chemical-component cell culture medium. The culture medium contains multiple amino acids, vitamins, inorganic salts, minor elements, carbohydrates and other supplementary factors. The culture medium is free of any extract or hydrolysate. The culture medium is free of any animal-derived component. The culture medium can well support in-vitro suspension culture of CHO (Chinese hamster ovary) cells, and satisfies the demands for CHO cell culture. The culture medium contains defined chemical components, and is low in cost.

Owner:BEIJING SL PHARMA +2

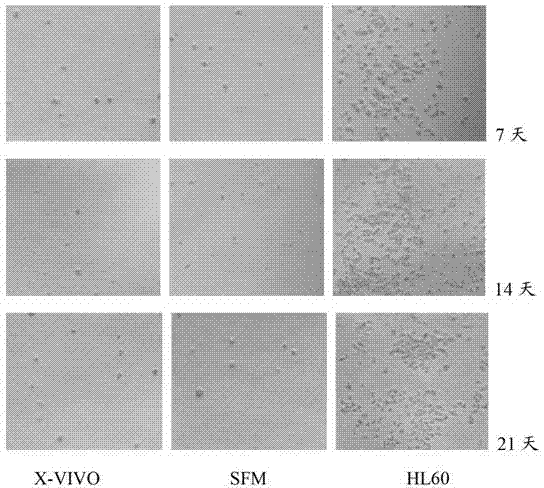

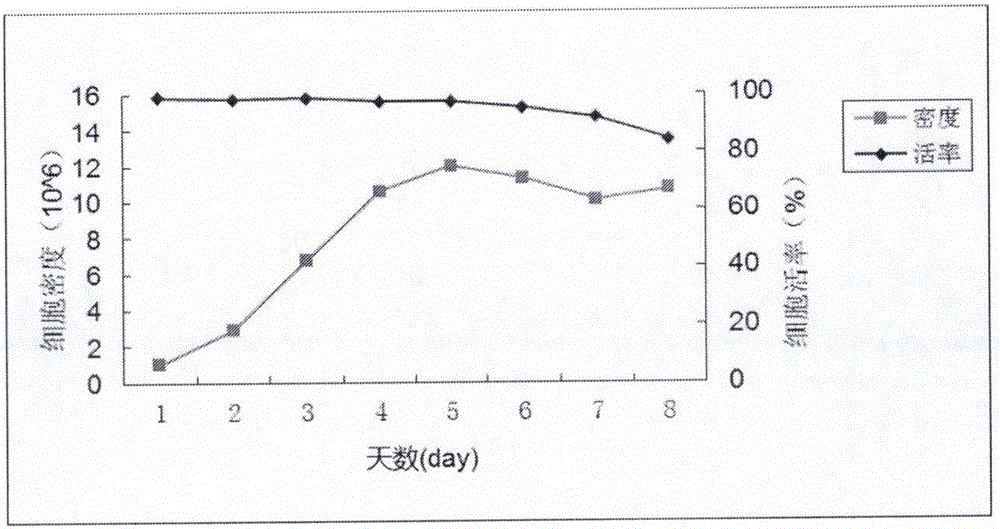

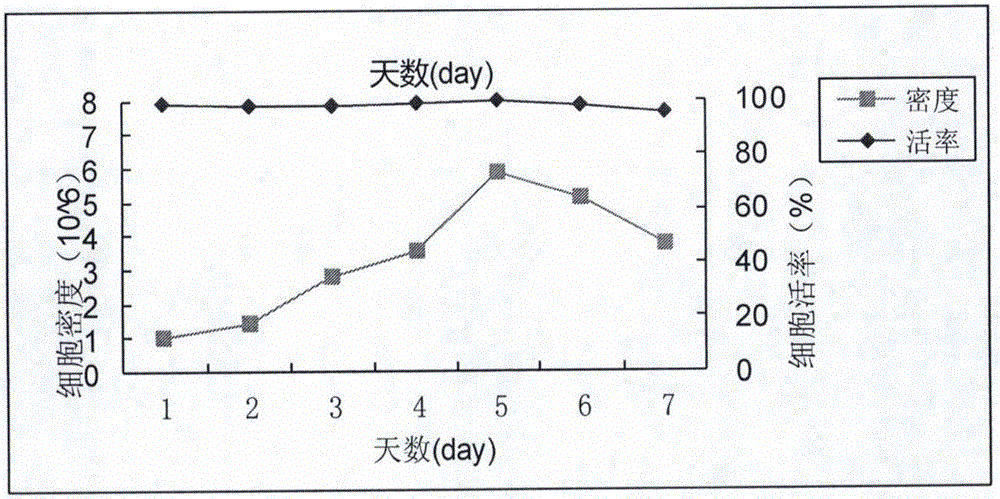

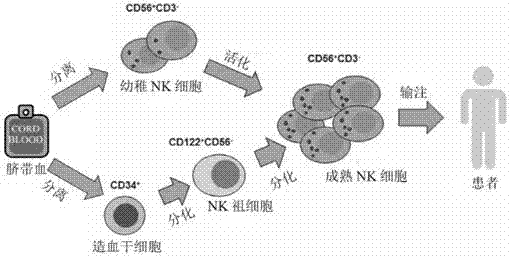

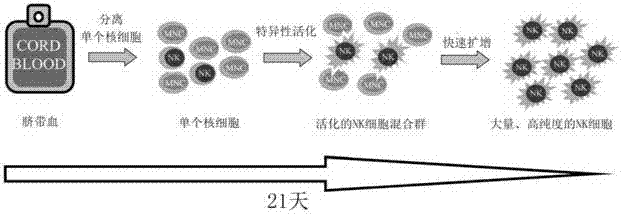

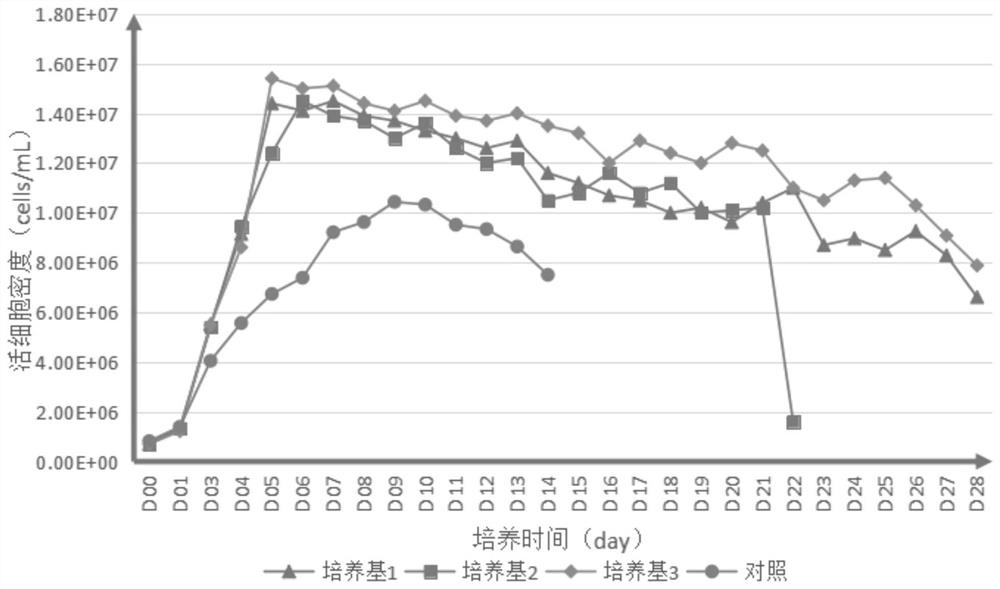

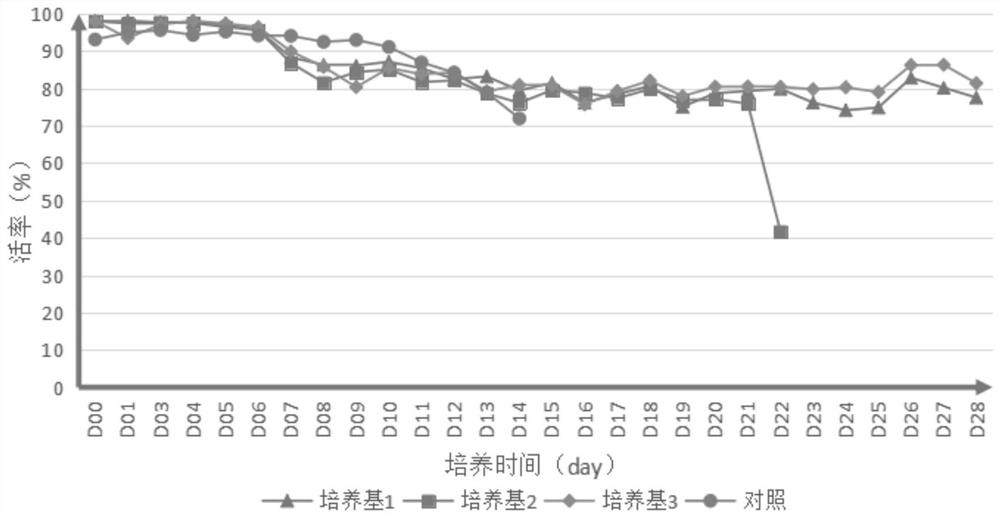

In-vitro expansion method, kit and application of umbilical cord blood NK (nature killer) cells

PendingCN107267454ASimple and safe operationSimple preparation processCulture processMammal material medical ingredientsAbnormal tissue growthCord Blood NK Cells

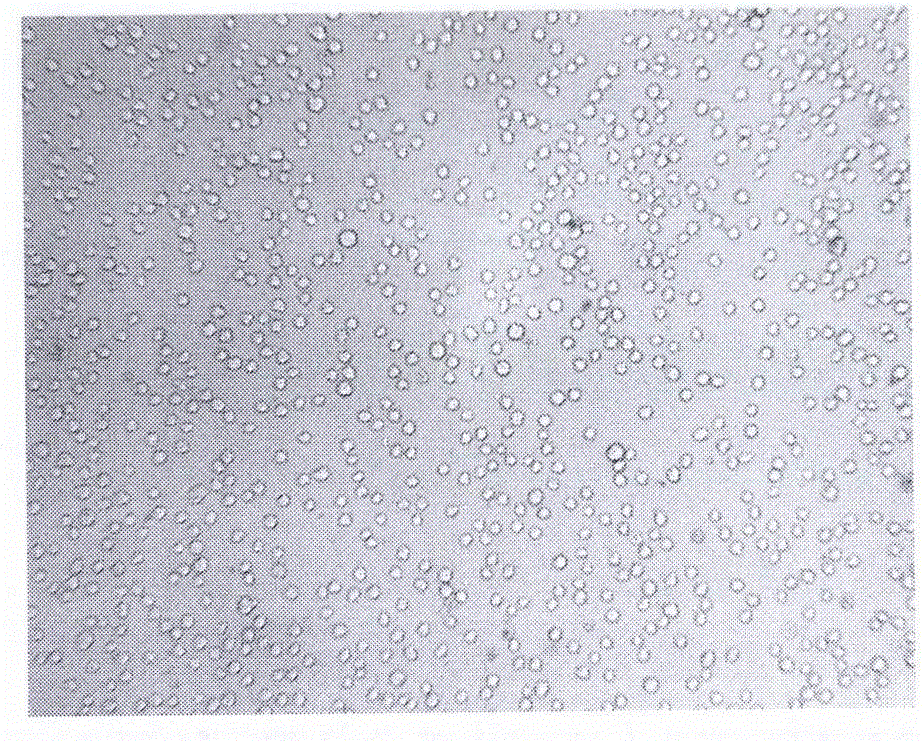

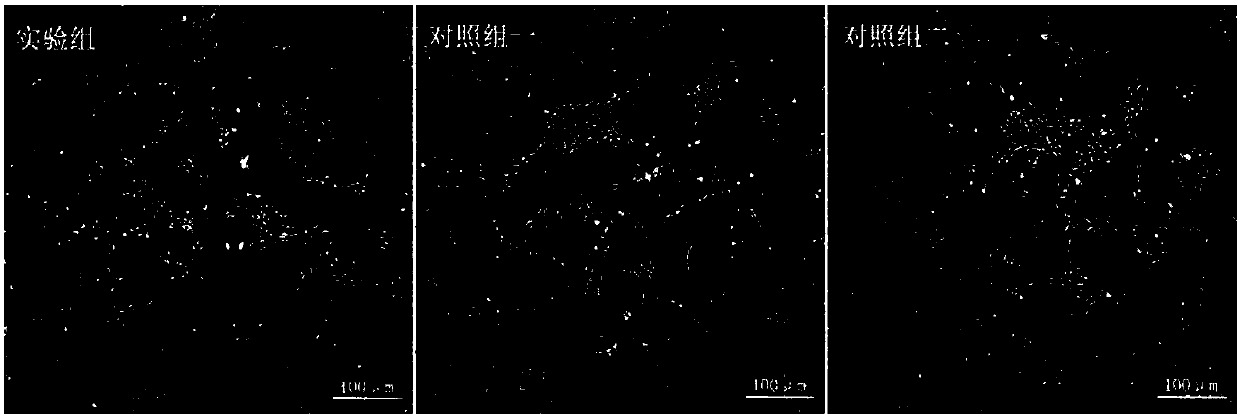

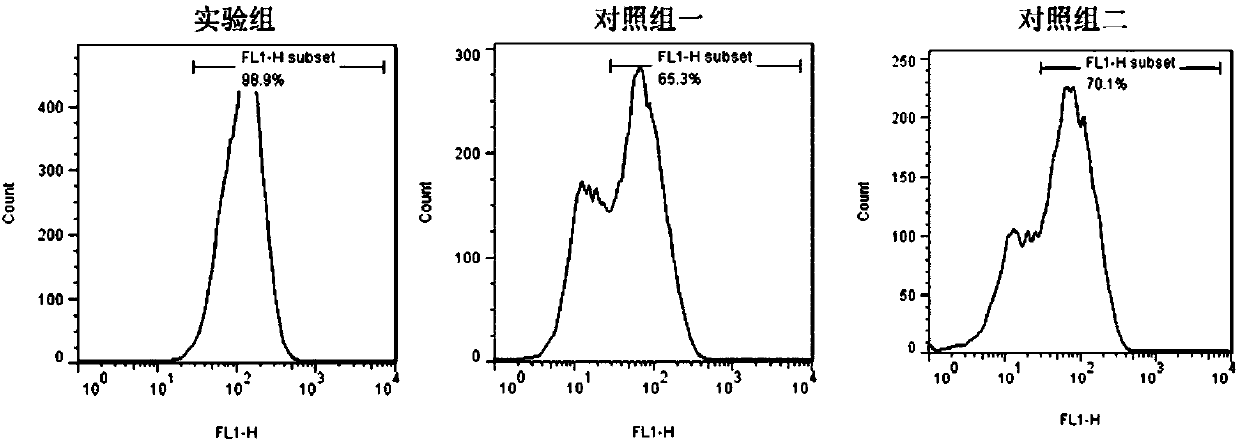

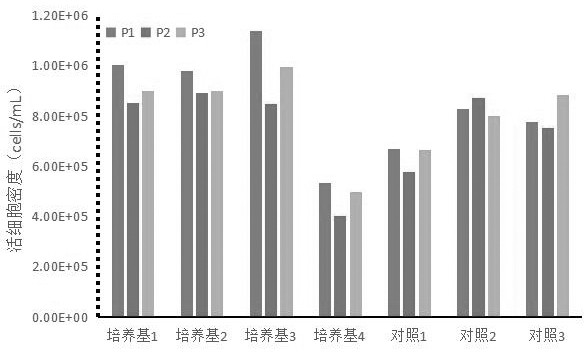

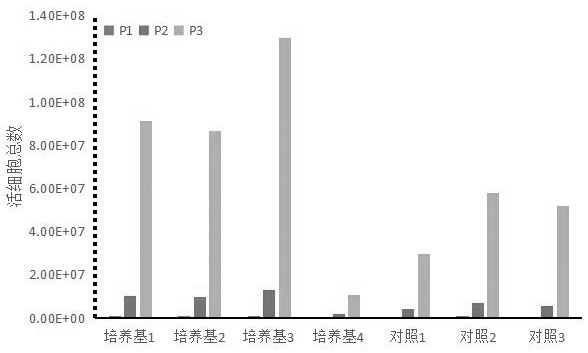

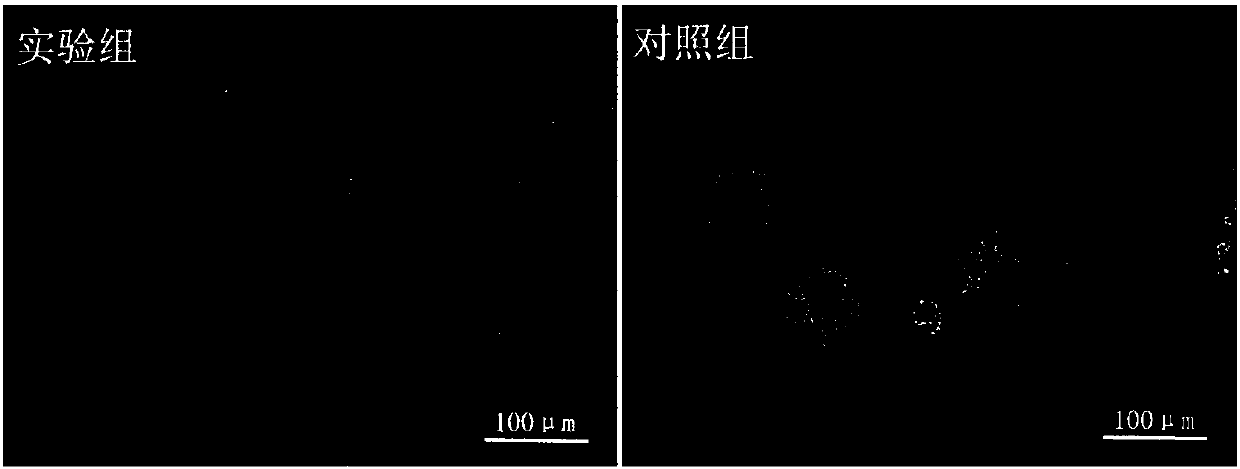

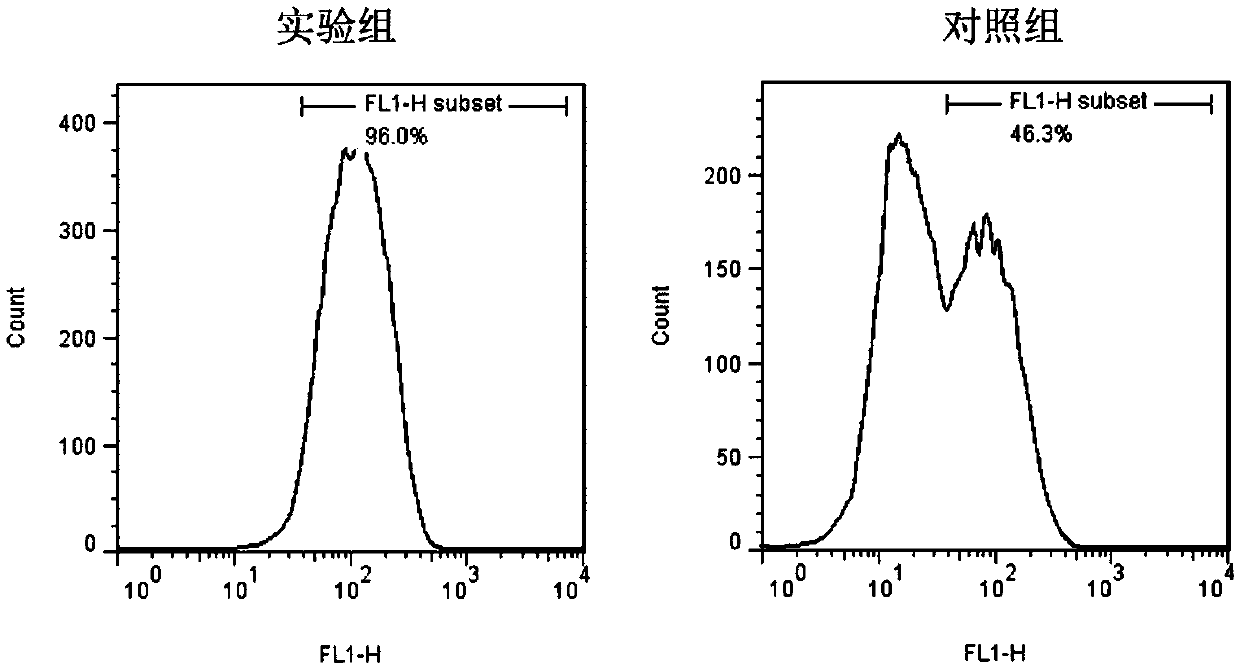

The invention discloses an in-vitro expansion method, a kit and an application of umbilical cord blood NK (nature killer) cells. The in-vitro expansion method of the umbilical cord blood NK cells comprises the processes of activated culture and enrichment culture of the umbilical cord blood NK cells from isolated cord blood mononuclear cells. Compared with existing methods for isolating and expanding the umbilical cord blood NK cells, the in-vitro expansion method has the advantages that cell sorting is needless, trophoblast cells are needless, operation is simple, universality is good, cost is low, adopted reagents do not contain components of animal origin, safety is good, the yield of the NK cells is high, purity of the obtained cord blood NK cells is up to 90% or higher, the total number of the cells can be up to 10<10-11> / part of cord blood, and the killing capacity for tumor cells is high, thereby playing a role in preparation of tumor immunotherapy drugs and tumor immunotherapy.

Owner:BEIJING JING MENG STEM CELL TECH

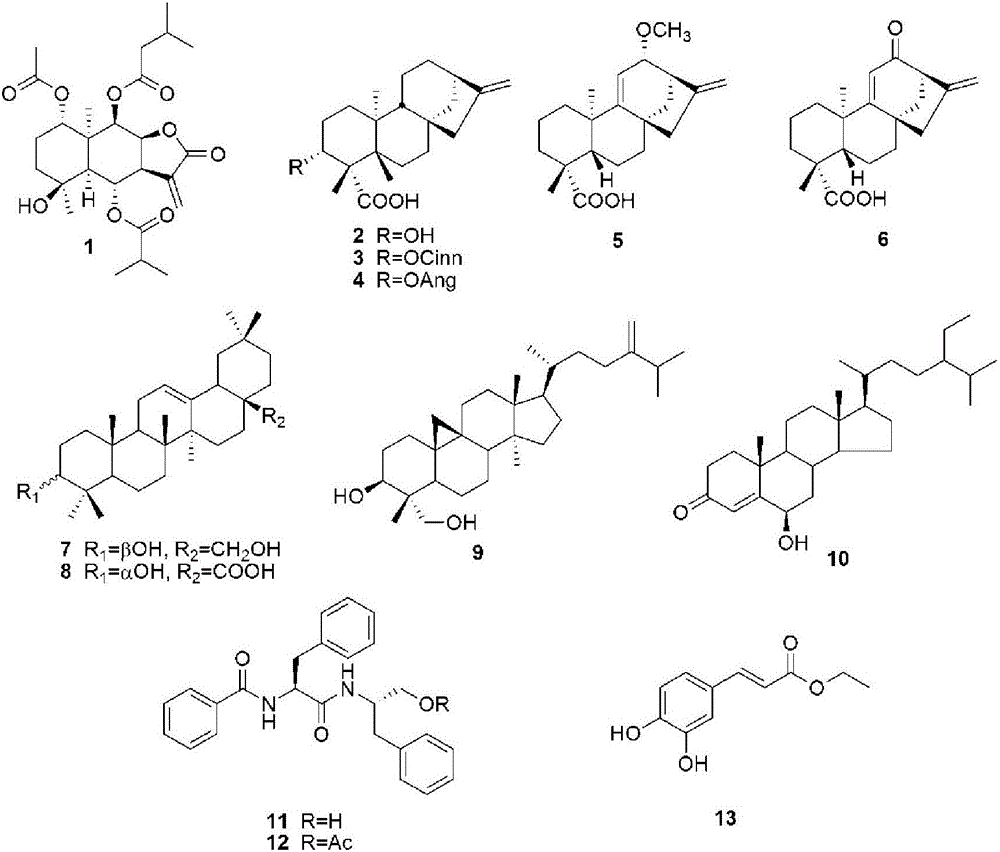

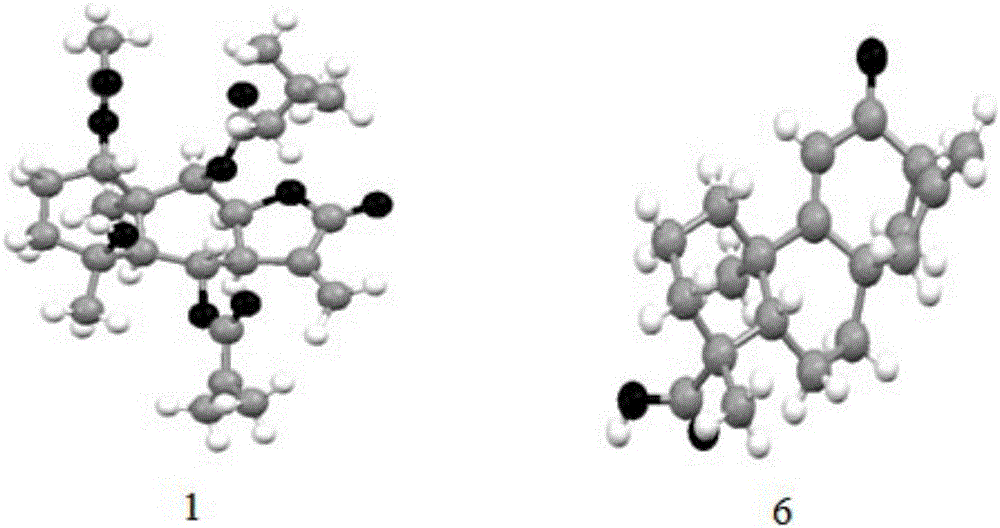

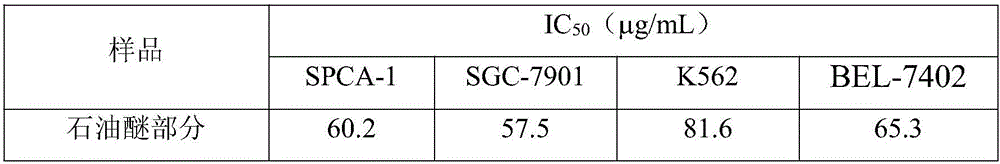

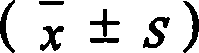

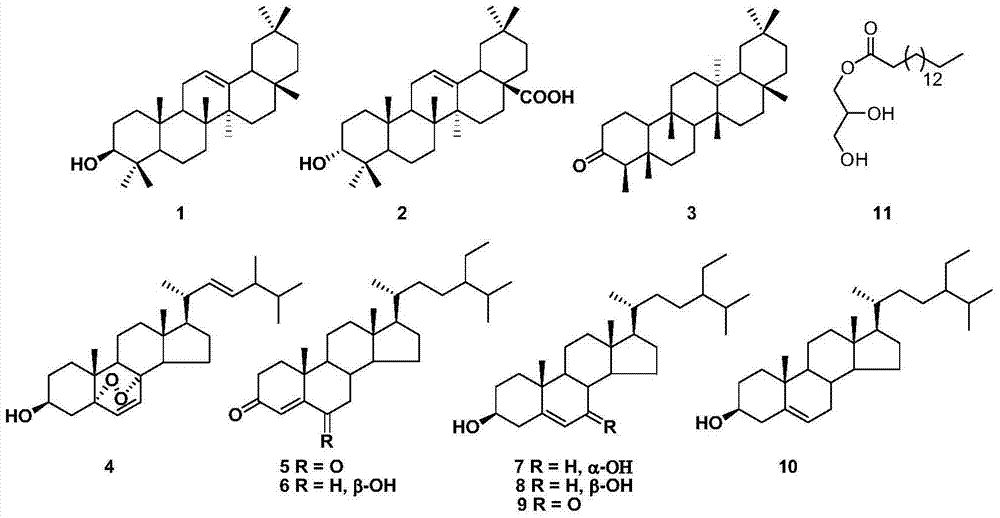

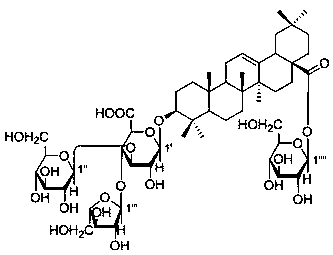

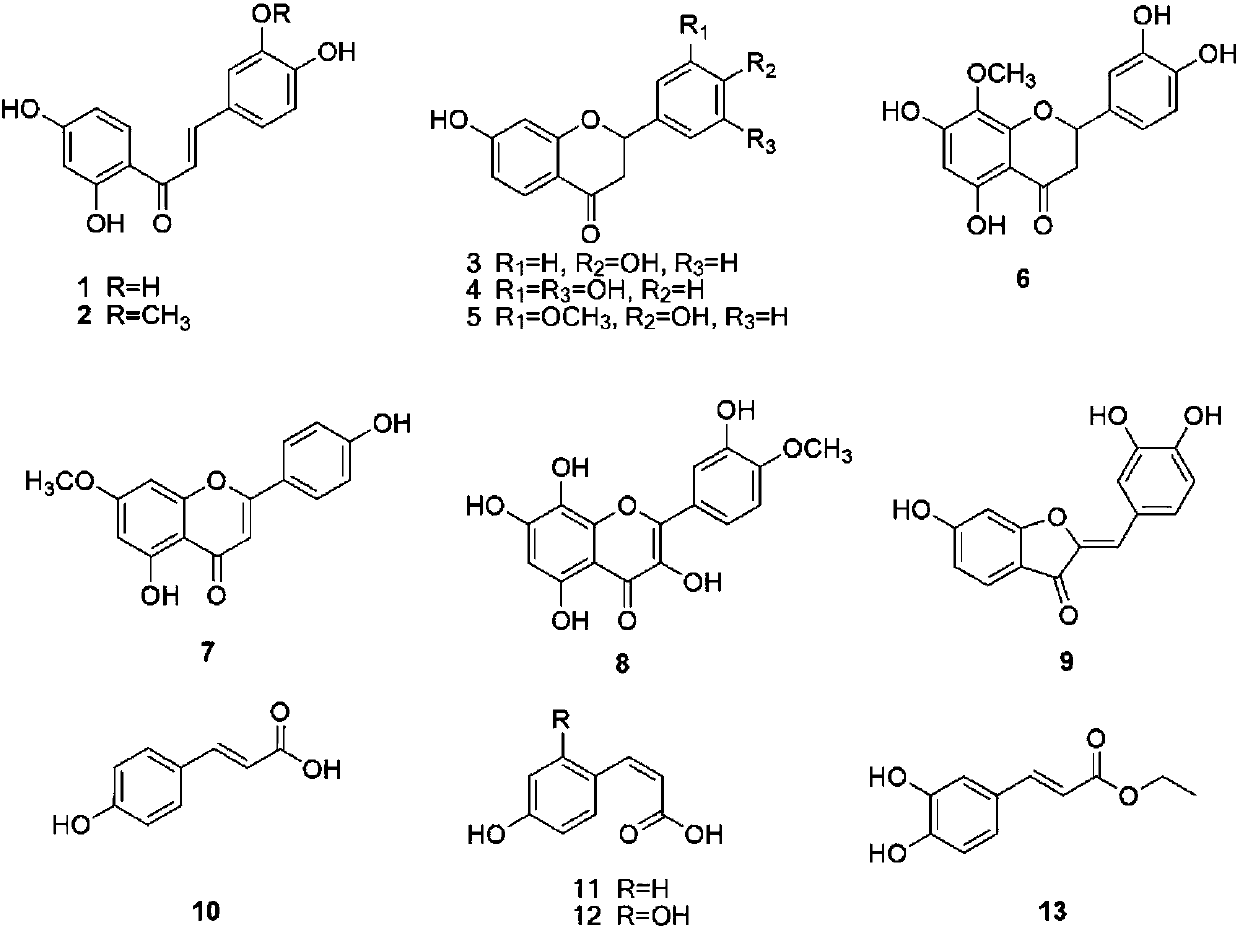

Wedelia trilobata anti-tumor extract and preparation and application methods thereof

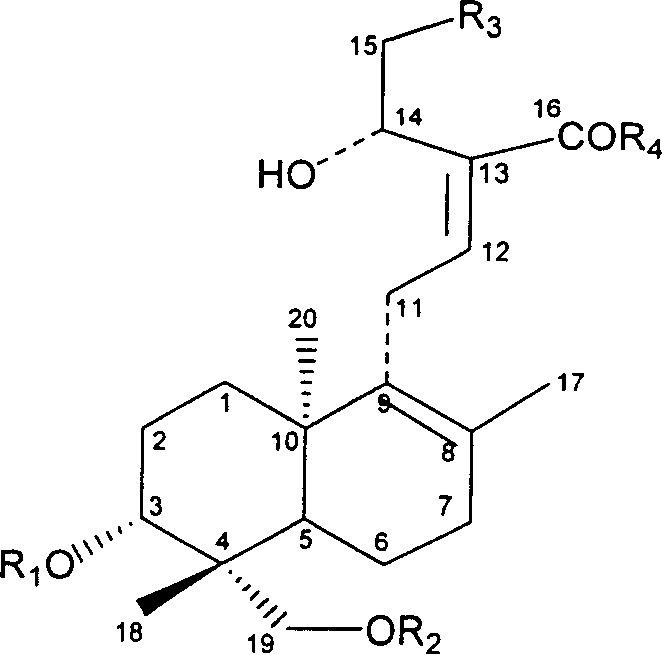

ActiveCN107522680AClarify chemical compositionGood antitumor activityCarboxylic acid amide separation/purificationSteroidsDipeptideEthyl acetate

The invention discloses a wedelia trilobata anti-tumor extract and preparation and application methods thereof. The wedelia trilobata anti-tumor extract is prepared by adding solvent into wedelia trilobata powder for extraction, filtering and decompression-concentrating extracted liquor to obtain a total extract, mixing the total extract with water into a suspension, performing extraction sequentially through petroleum ether and ethyl acetate and performing decompressed recovery to obtain a petroleum ether solution, an ethyl acetate solution and a aqueous solution, wherein the petroleum ether solution contains one eudesmene type sesquiterpene lactone, five enantiotopic kaurane type diterpenoid compounds, two oleanane type triterpenes, one cycloartane type triterpene, one sterol compound, two dipeptide compounds and one caffeate compound. The prepared wedelia trilobata anti-tumor extract is high in yield, simple in technical process, low in cost and applicable to large-scale preparation, and meanwhile, has broad-spectrum anti-tumor activity and can serve as an active component applied to tumor control and treatment drugs.

Owner:HAINAN NORMAL UNIV

Serum free hepatocyte medium

ActiveCN102559581AClear chemical compositionLow costArtificial cell constructsVertebrate cellsSerum free mediaSerum free

The invention provides a novel serum free medium and a preparation method and application of the medium. The serum free medium overcomes defects of the traditional serum media, and is obviously superior to serum free media reported in the conventional documents, improves the possibility of supporting systematical treatment clinical application through cell transplantation, tissue engineering liver and bioartificial liver, and has high practical value.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Refining ganoderam lucidum spore oil and method for preparing same

ActiveCN1907303AClear chemical compositionQuality controllableAntiviralsAntineoplastic agentsSupercritical fluid extractionChemistry

The invention discloses refined lucid ganoderma spore oil and preparing method through ultrasonic reinforced temporary flow technology, which comprises the following parts: 85-95% organic acid and fatty acid, 0.1-3% ergosterin and 0.05-1.2% triterpenes.

Owner:GUANGZHOU HANFANG PHARMA

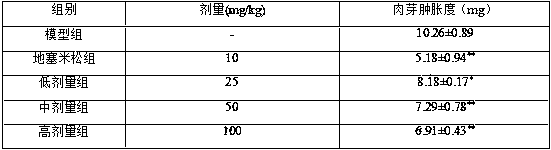

Method for obtaining refined extract from capparis spinosa and application of extract

InactiveCN102091104ASimple processSuitable for industrial productionAntipyreticAnalgesicsElutionCapparis spinosa

The invention discloses a method for obtaining a refined extract from capparis spinosa. The method for obtaining the refined extract from the capparis spinosa is characterized by comprising the following steps of: a) performing macroporous adsorption resin chromatography on a concentrated capparis spinosa crude extract and performing elution by using water and 20 to 30 percent ethanol solution sequentially; and b) performing elution by using 50 to 100 percent ethanol solution to obtain the capparis spinosa refined extract. The invention also provides the capparis spinosa refined extract prepared by the method. A medicament effect test proves that the capparis spinosa refined extract has obvious anti-rheumatoid arthritis activity. The method is simple in process and suitable for industrialized production.

Owner:SHANGHAI INST OF PHARMA IND

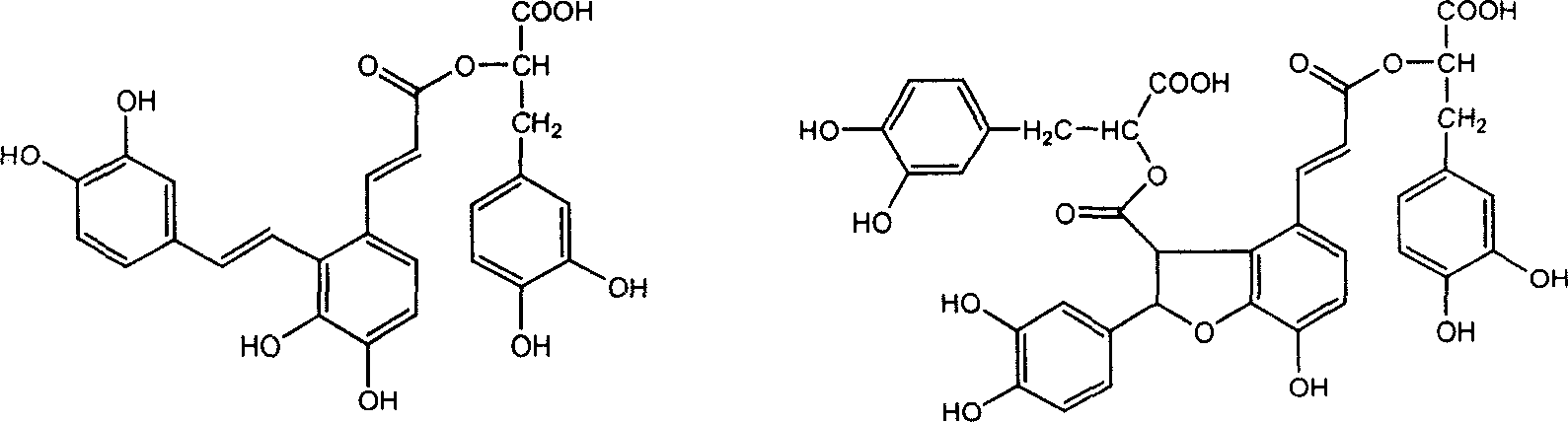

Chinese medicine active component composition and its preparing method and use

ActiveCN1943569AClear chemical compositionHigh content of active ingredientsIon-exchange process apparatusOrganic active ingredientsDiseaseSalvianolic acid B

The invention relates to a Chinese medicine composition of active components and its preparation method, the general amount of salvianolic A and salvianolic acid B, make up more than 50% thereof said composition , and the proportion between Sal A and Sal B is 1:0.01-100, said invention also provides application of said composition in preparation of medicine for treatment and prevention to and against blood vessel disease of heart and brain.

Owner:兰州和盛堂药物研究院有限公司

Serum-free culture medium without animal origin components for culturing Vero cell micro-carrier

InactiveCN101864393BPromote growthSame densityArtificial cell constructsVertebrate cellsSerotoninVitamin C

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Method for activating calcium magnesium phosphate fertilizer by virtue of low-molecular organic acid

InactiveCN104262020AImprove Phosphorus Utilization EfficiencyClear chemical compositionLiquid fertilisersFertilizer mixturesAgricultural cropsEnvironmental chemistry

The invention provides a method for activating a calcium magnesium phosphate fertilizer by virtue of a low-molecular organic acid. The method comprises the following steps: uniformly mixing water and the low-molecular organic acid according to a proportion to obtain a low-molecular organic acid solution; adding the low-molecular organic acid solution and the calcium magnesium phosphate fertilizer into an oscillatory reactor for oscillation according to a certain liquid-solid ratio; after oscillation, performing filtering treatment on a liquid-solid mixture; air-drying filtered solids at room temperature to obtain an activated calcium magnesium phosphate fertilizer; performing a pot experiment on the activated calcium magnesium phosphate fertilizer, wherein the phosphate content of a crop is increased by 53 to 95 percent, and the crop flourishes. The method is low in cost, the process is simple, a gap between the calcium magnesium phosphate fertilizer and a high-concentration phosphate fertilizer in terms of phosphate utilization rate is closed, an important means is provided for optimizing the calcium magnesium phosphate fertilizer industry, and meanwhile, the application prospect of low-grade phosphate rocks in China is broadened.

Owner:YUNNAN MINZU UNIV

Serum-free medium for vitro amplification culture of immune cells and application thereof

InactiveCN105713873AStable traitsGood lot-to-lot varianceCulture processBlood/immune system cellsCvd riskCell therapy

The invention discloses a serum-free medium suitable for immune cells and a preparation method thereof. According to experimental proof, the immune cells cultured by the serum-free medium for immune cells have more stable characters, and the cell growth and proliferation effects are better. The serum-free medium for immune cells has the advantages of clear chemical components, little batch-to-batch difference and stable quality and can guarantee the consistency among the medium batches; without animal origin or human origin, the serum-free medium has high safety, overcomes potential risk caused by human or animal serum and is conducive to studying the action mechanisms of various immune cells, promoting the safety standardization of domestic cell therapy and reducing the risk of accidental infection of patients and is of great significance in the promotion and application of immunotherapy.

Owner:GUANGDONG XTEM BIOTECH CO LTD

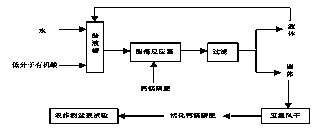

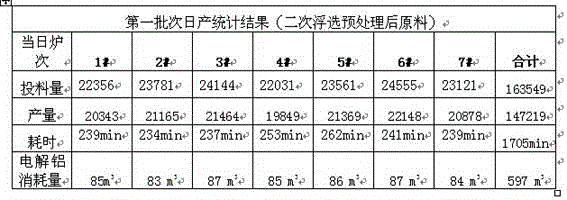

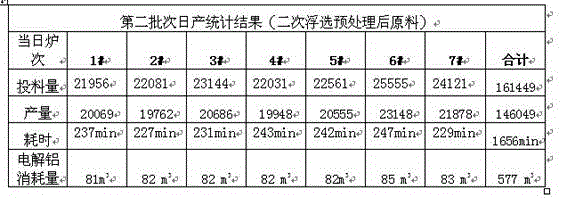

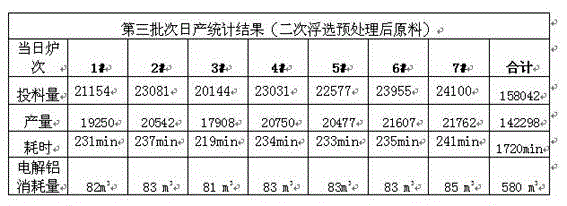

Cleaning, floating and drying integration pre-treating method for scrap aluminum

The invention relates to a cleaning, floating and drying integration pre-treating method for scrap aluminum. The method is characterized in that firstly, pretreatment is carried out, and a scrap aluminum material is cleaned through a two-time rinsing system, so that impurities on the surface of the scrap aluminum material are removed; through one-time floating, magnesium materials and other impurities in the scrap aluminum material are suspended on a liquid surface through one-time floating and then are scraped out; aluminum materials in the scrap aluminum material are screened out through two-time floating; and finally, drying is carried out, the floated aluminum materials are dried through recycled waste heat, and it is ensured that the water content in the aluminum materials is lower than 0.3 percent. The method has the advantages that through cleaning, floating and drying integration treatment, the scrap aluminum material enters a machine device to be cleaned, floated and dried, and a clean pure aluminum material is output; no any repeated production links exist in the method, and therefore before being put into a furnace, the aluminum materials are clear in chemical component and low in water content, and energy consumption is saved; and a smelted renewable aluminum alloy ingot is high in quality.

Owner:南通曼特威金属材料有限公司

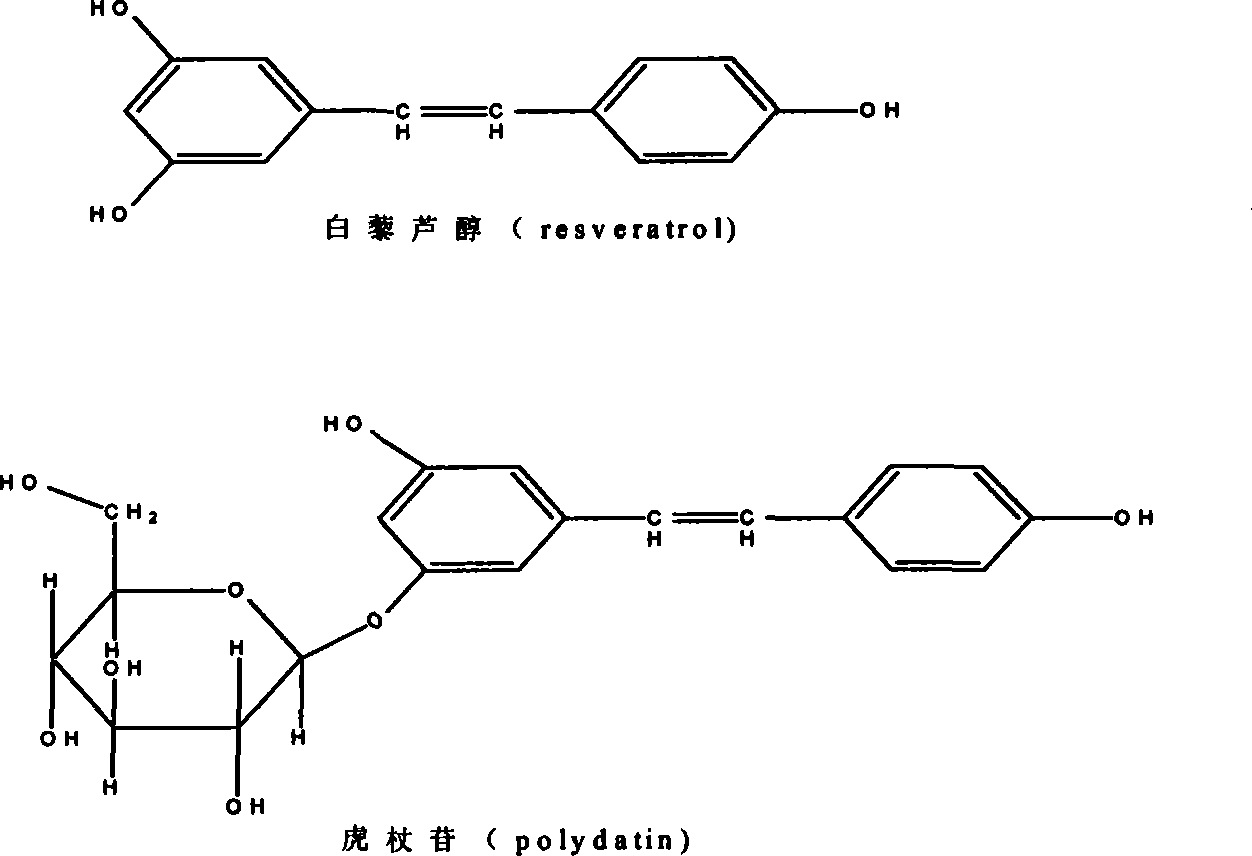

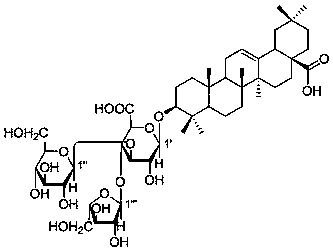

Application of giant knotweed rhizome toluylene total glycosides in preparing medicament for treating rheumatic disease

InactiveCN101194936AImprove yieldStable process routeHydroxy compound active ingredientsAntipyreticDiseaseGlycoside formation

The invention belongs to the new drugs research and development field of traditional Chinese medicine, which relates to a traditional Chinese medicine compound for curing rheumatic diseases, the main component of the invention is an effective part of polygonum cuspidate stilbene total glycoside which is an effective part of polygonum cuspidate and extracted from polygonum cuspidate which is China's traditional Chinese medicine. The invention first utilizes polygonum cuspidate stilbene total glycoside to cure rheumatic diseases, and treatment effect is better.

Owner:北大世佳科技开发有限公司

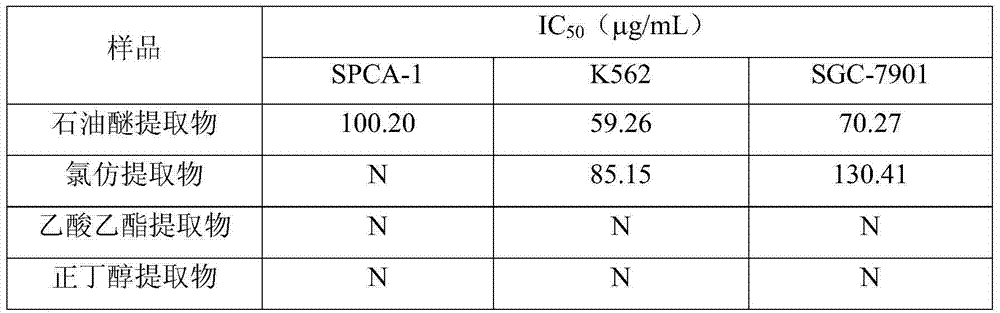

Preparation method of drypetes congestiflora stem extract

InactiveCN103923157AHas antitumor activityClear chemical compositionCarboxylic acid esters separation/purificationSteroids preparationFiltrationSolvent

The invention discloses a preparation method of a drypetes congestiflora stem extract. The preparation method comprises the steps: adding a solvent in dried drypetes congestiflora stem powder for extracting; and performing filtration and vacuum concentration on an extraction solution to obtain a total extract, adding water for suspending, sequentially extracting by using petroleum ether, chloroform, ethyl acetate and normal butanol, and performing decompression recovering to respectively obtain a petroleum ether part, a chloroform part, an ethyl acetate part and a normal butanol part, wherein the petroleum ether part comprises three triterpene compounds, 7 sterols compounds and one glyceride derivative. The extract prepared by adopting the preparation method is high in yield, simple in process, low in cost, suitable for larger-scale preparation, and good in anti-tumor activity, and can be applied to medicines for preventing and treating tumors.

Owner:HAINAN NORMAL UNIV

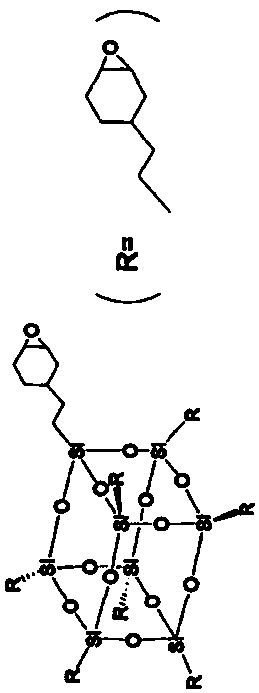

Method for preparing organic-inorganic hybrid octafunctional epoxy POSS resin and method for preparing carbon fiber reinforced composite material

ActiveCN109180941AEasy to operateMild reaction conditionsTetramethylammonium hydroxideRotary evaporator

The invention provides a method for preparing organic-inorganic hybrid octafunctional epoxy POSS resin and a method for preparing carbon fiber reinforced composite material, and belongs to the technical field of POSS resin preparation. The method comprises the following steps: adding an organic solvent, a tetramethylammonium hydroxide aqueous solution and 2-(3,4 epoxycyclohexyl)-ethyltriethoxysilane or 2-(3,4 epoxycyclohexyl)-ethyltrimethoxysilane into a round-bottom flask, stirring and reacting; evaporating away 70 percent of solvent by utilizing a rotary evaporator to obtain a colorless transparent liquid; mixing the transparent liquid with an epoxy resin curing agent, and uniformly stirring to obtain a POSS-based epoxy resin composition; and soaking wound fibers in the transparent liquid, transferring into a die, and starting to heat and cure to obtain the carbon fiber reinforced composite material. The method has the advantages of simple operation steps, mild reaction condition, easily available raw materials, low cost and high yield. The carbon fiber reinforced composite material has relatively high interlaminar shear strength at 200 DEG C.

Owner:HARBIN INST OF TECH

Preparation method and application of anti-inflammatory effective parts of Panax stipuleanatus

InactiveCN107929337AEasy to operateSuitable for industrial productionAntipyreticAnalgesicsSilica gelDigestion

The invention relates to a preparation method and application of anti-inflammatory effective parts of Panax stipuleanatus, and belongs to the technical field of biological medicine. The preparation method comprises the following steps: after smashing Panax stipuleanatus, carrying out digestion on methyl alcohol, and carrying out vacuum concentration on a leach liquor to obtain a methyl alcohol extract; dispersing the obtained methyl alcohol extract with water, and extracting with petroleum ether to obtain an extraction raffinate water solution for removing fat-soluble impurities; extracting the obtained extraction raffinate water solution with saturated n-butyl alcohol, and extracting an organic solution to obtain an n-butyl alcohol extract through vacuum concentration; and separating theobtained n-butyl alcohol extract through silica gel column chromatography, carrying out elution by using a dichloromethane / methyl alcohol solvent system, and concentrating and drying an eluant to obtain the anti-inflammatory effective parts of Panax stipuleanatus. The effective parts of Panax stipuleanatus can be effectively prepared on large scale, and the application of Panax stipuleanatus in the preparation of anti-inflammatory drugs is realized.

Owner:KUNMING UNIV OF SCI & TECH

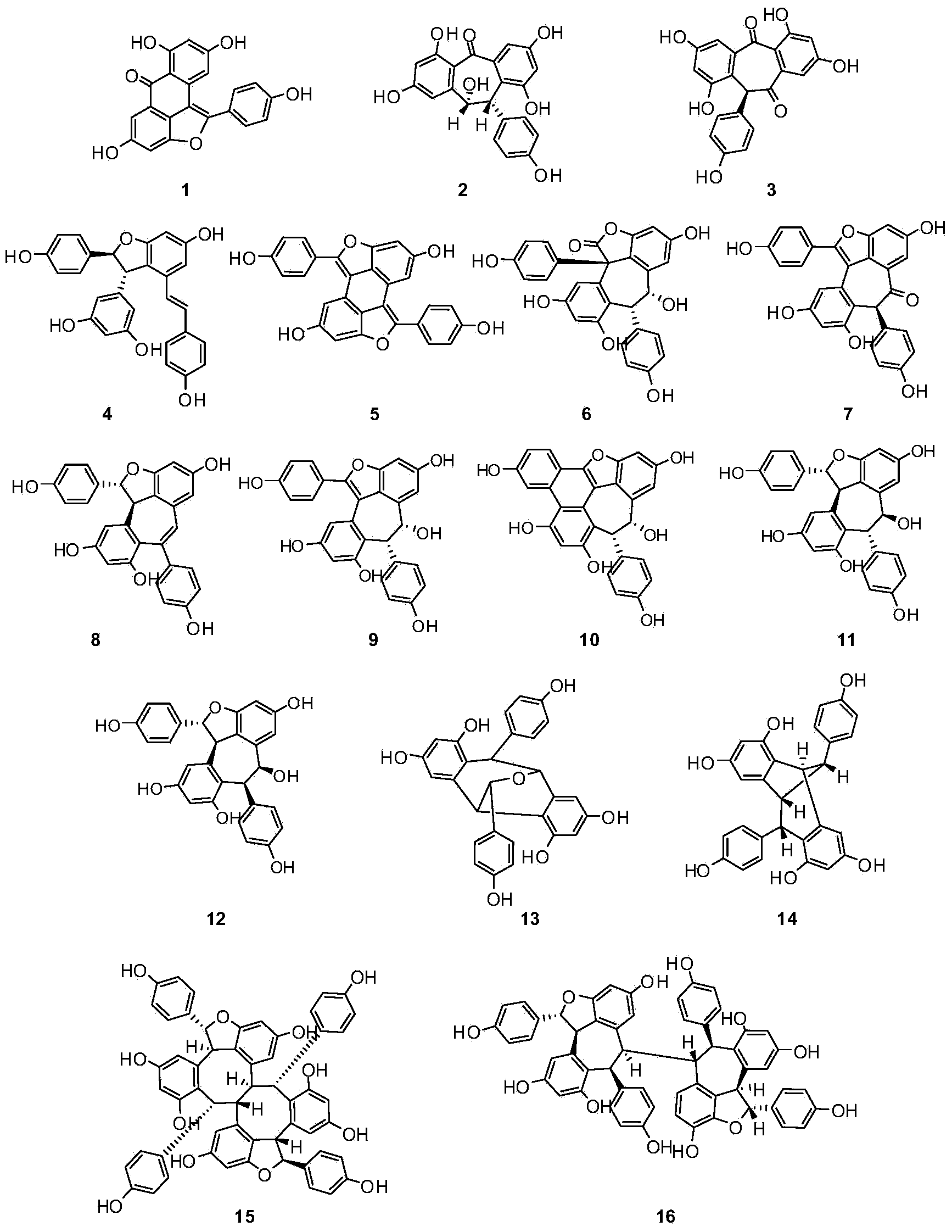

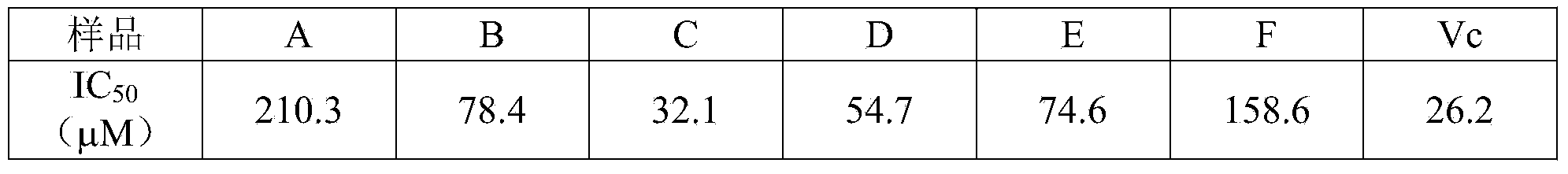

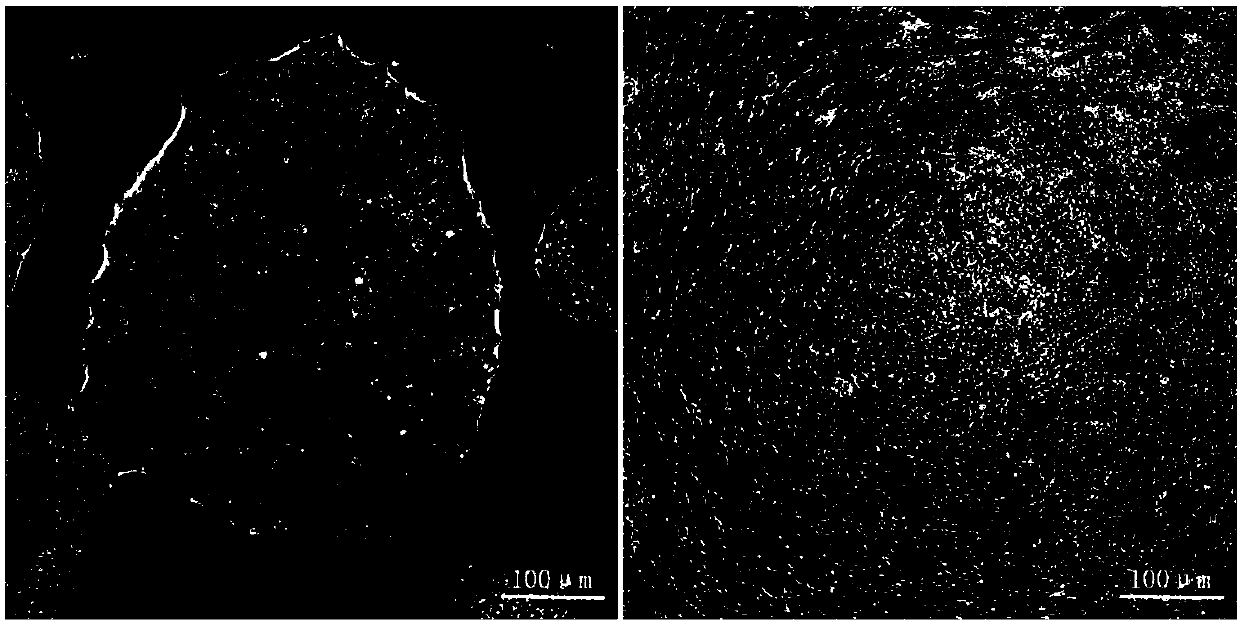

Preparation method of Hainan green plum stem extractive with function of scavenging free radicals

InactiveCN103961383AStrong free radical scavenging activityClarify chemical compositionAntinoxious agentsFood preparationGradient elutionEthyl acetate

The invention discloses a Hainan green plum stem extractive with a function of scavenging free radicals and a preparation method thereof. The preparation method comprises the following steps: adding an organic solvent to Hainan green plum stem drying powder, and extracting; filtering an extracting solution, concentrating the filtered extracting solution under reduced pressure so as to obtain total extract, adding water, suspending, extracting sequentially by using petroleum ether and ethyl acetate, recovering under reduced pressure so as to respectively obtain a petroleum ether part and an ethyl acetate part, carrying out gradient elution on the obtained ethyl acetate part by using a chloroform and methyl alcohol mixed solvent system, wherein the chloroform and methyl alcohol component with the volume ratio of chloroform to methyl alcohol being 100: 30 has excellent free radical scavenging activity and comprises 16 resveratrol oligomers compounds. The Hainan green plum stem extractive prepared by the method is high in yield, simple in technological process, low in cost and suitable for large-scale preparation; and the obtained extractive has excellent free radical scavenging activity and can be applied to healthcare food, medicines and food with functions of resisting oxidation and scavenging free radicals.

Owner:HAINAN NORMAL UNIV

Method for inducing differentiation of human pluripotent stem cells into spinal cord motor nerve precursor cells

ActiveCN107858331AClear chemical compositionPrevent system instabilityNervous system cellsCell culture active agentsInduced pluripotent stem cellStem cell culture

The discloses a method for inducing differentiation of human pluripotent stem cells into spinal cord motor nerve precursor cells. The method comprises the following steps: 1) culturing the human pluripotent stem cells: digesting the human pluripotent stem cells into single cells and inoculating into a coated petri dish to perform adherent culture, wherein a culture solution is a pluripotent stem cell culture solution, and culture is performed in a saturated humidity incubator at the temperature of 37 DEG C with the CO2 concentration being 5% for 20 to 28 h; 2) inducing the differentiation of the spinal motor neural precursor cells: culturing the human pluripotent stem cells obtained in the step 1) in a basic complete medium, adding different spatiotemporal specific signal pathways at different times to regulate small molecules and / or growth factors so as to induce the differentiation, changing the solution once every two days, culturing in the saturated humidity incubator at the temperature of 37 DEG C with the CO2 concentration being 5% for 8 to 20 days, then inducing the differentiation of the human pluripotent stem cells into the spinal cord motor nerve precursor cells. The method disclosed by the invention is high-efficient, rapid, stable, safe, and easy and simple to operate, and can obtain more than 90% of the spinal cord motor nerve precursor cells after the differentiation is performed on the eighth day.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

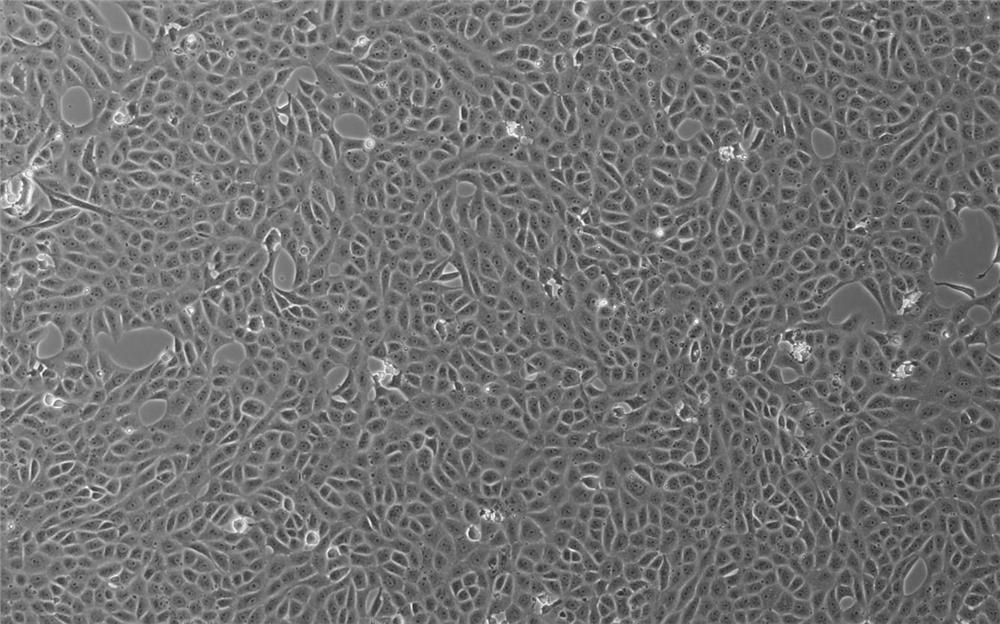

Vero cell serum-free culture medium and application thereof

ActiveCN111733126AClear chemical compositionLow costCulture processArtificial cell constructsBiotechnologyAluminium chloride

The invention relates to a Vero cell serum-free culture medium and an application thereof. The Vero cell serum-free culture medium comprises an amino acid component, a vitamin component, an inorganicsalt component, trace element components, carbohydrate and other molecular compound components, wherein the trace element components include the following components: zinc sulfate heptahydrate, coppersulfate pentahydrate, ferric nitrate nonahydrate, ferrous sulfate heptahydrate, sodium selenite, nickel chloride, stannous chloride, silver nitrate, cobalt chloride and aluminum chloride. The serum-free culture medium provided by the invention has the advantages of definite chemical components and low cost, avoids the biological safety risk caused by the use of serum when the serum is not needed,and provides convenience for the large-scale production of biological products, especially vaccines. Vero cells grow well in the culture medium, and the serum is not used, so that the stability of the production process of the biological products and the stability of the quality of finished products are improved, and particularly, the research, development and production of novel coronavirus (SARS-CoV-2) vaccines are accelerated.

Owner:苏州依科赛生物科技股份有限公司

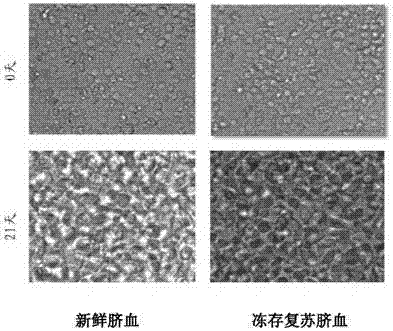

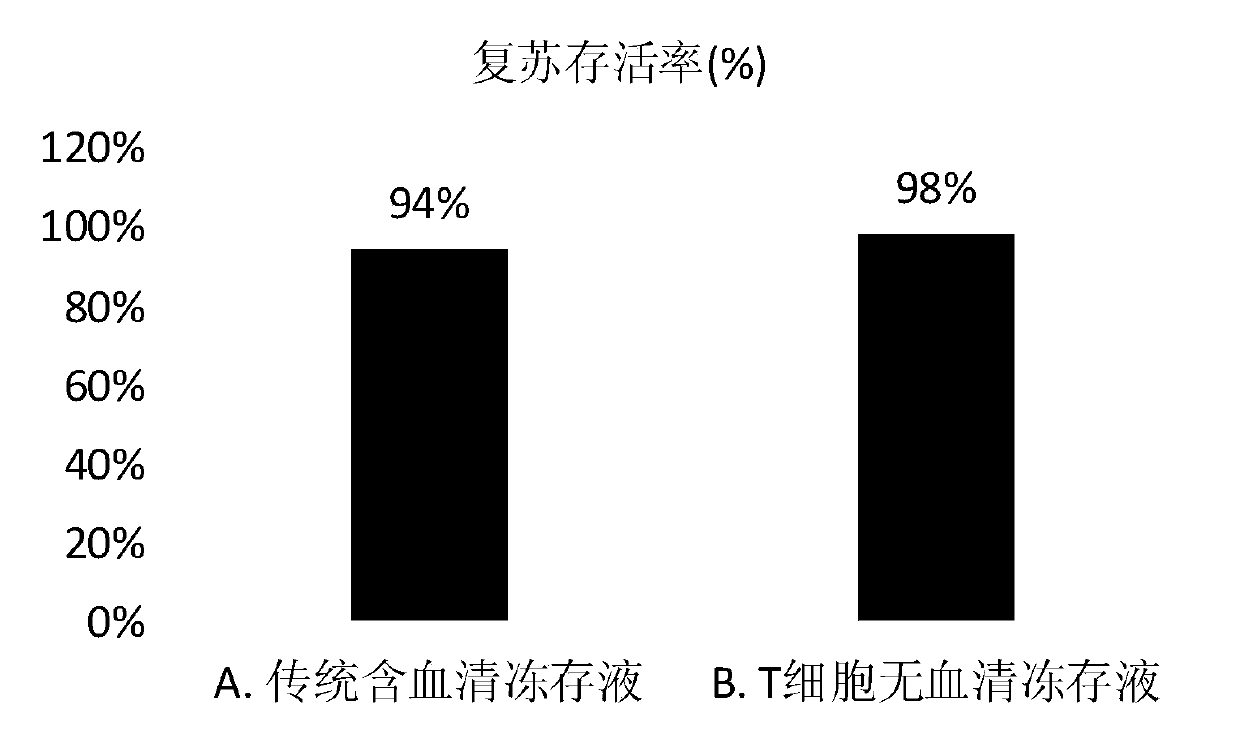

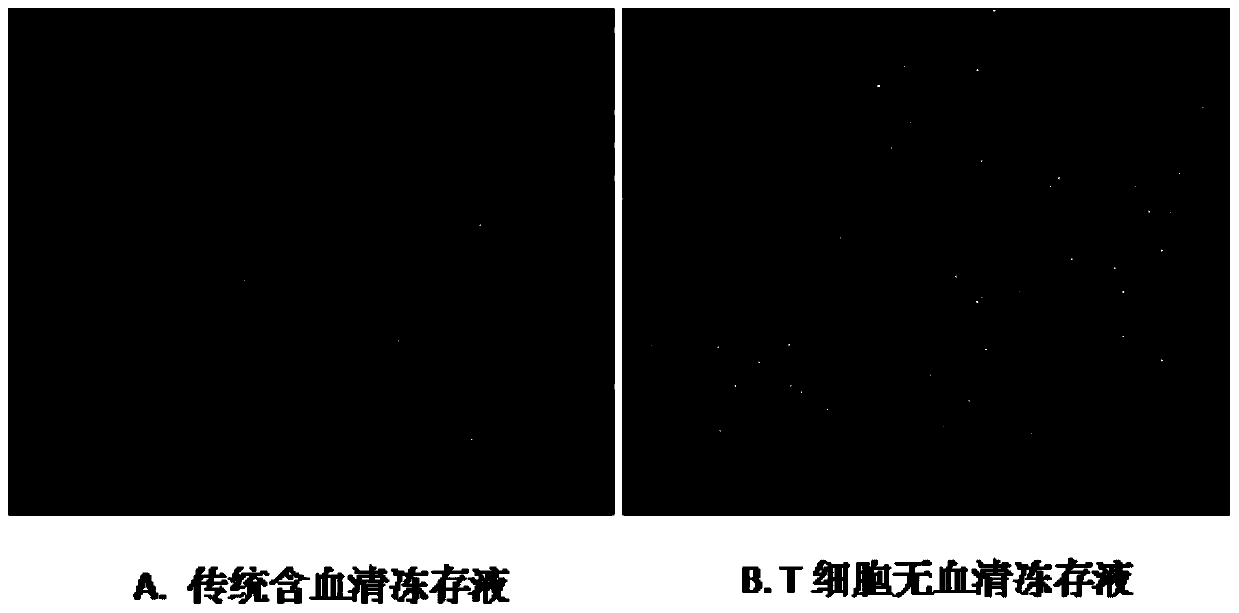

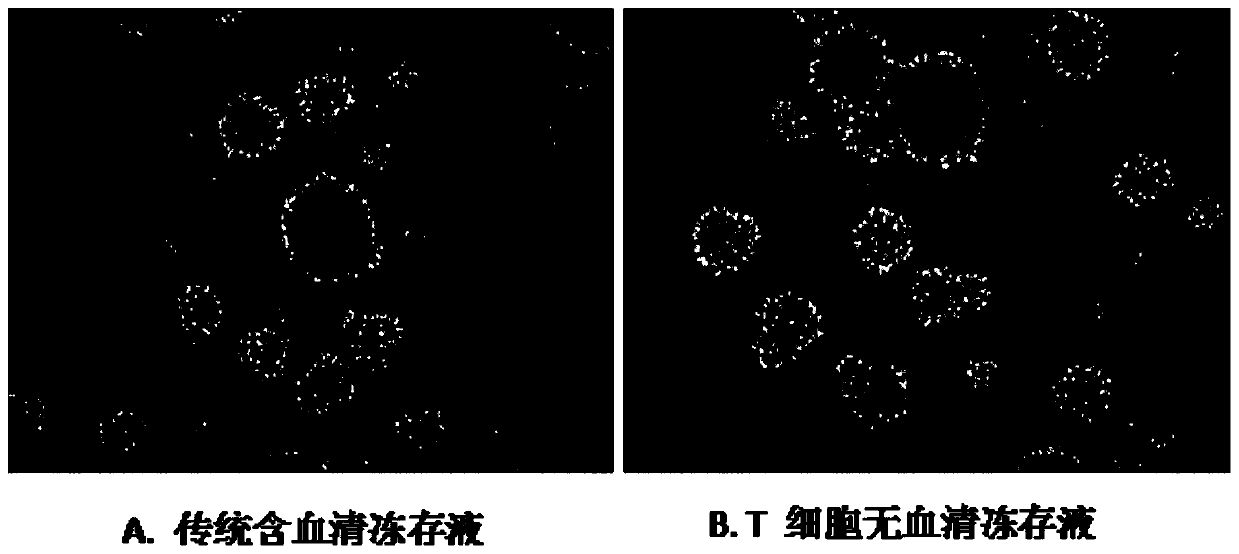

T cell serum-free cryopreservation solution and using method thereof

InactiveCN110583622AClear chemical compositionLow DMSO contentDead animal preservationVitamin CCell membrane

The invention relates to a T cell serum-free cryopreservation solution and a using method thereof. The cryopreservation solution comprises a basic culture medium, a cryopreservation protective agent and adding components which are ethanolamine, insulin, transferrin, human serum albumin, vitamin C and a cell membrane stabilizer. The cryopreservation solution disclosed by the invention has no serum,no human source and no animal source components, and is clear in chemical composition and low in DMSO content, the defect of high DMSO content in the prior art is overcome, the toxicity risk to cellsis avoided, meanwhile, possible clinical application of the cryopreservation solution is not affected, the cryopreservation solution has excellent cryopreservation performance on T cells, the resuscitation survival rate of the T cells is 90% or above after cryopreservation of the T cells, subsequent activation and amplification are not affected, and the T cell serum-free cryopreservation solutionhas high clinical application and scientific research value.

Owner:苏州依科赛生物科技股份有限公司

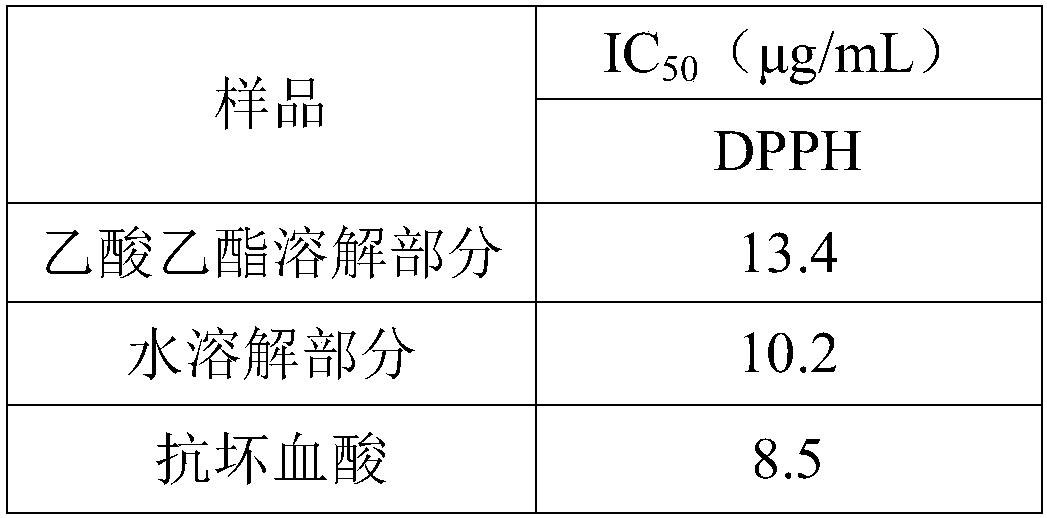

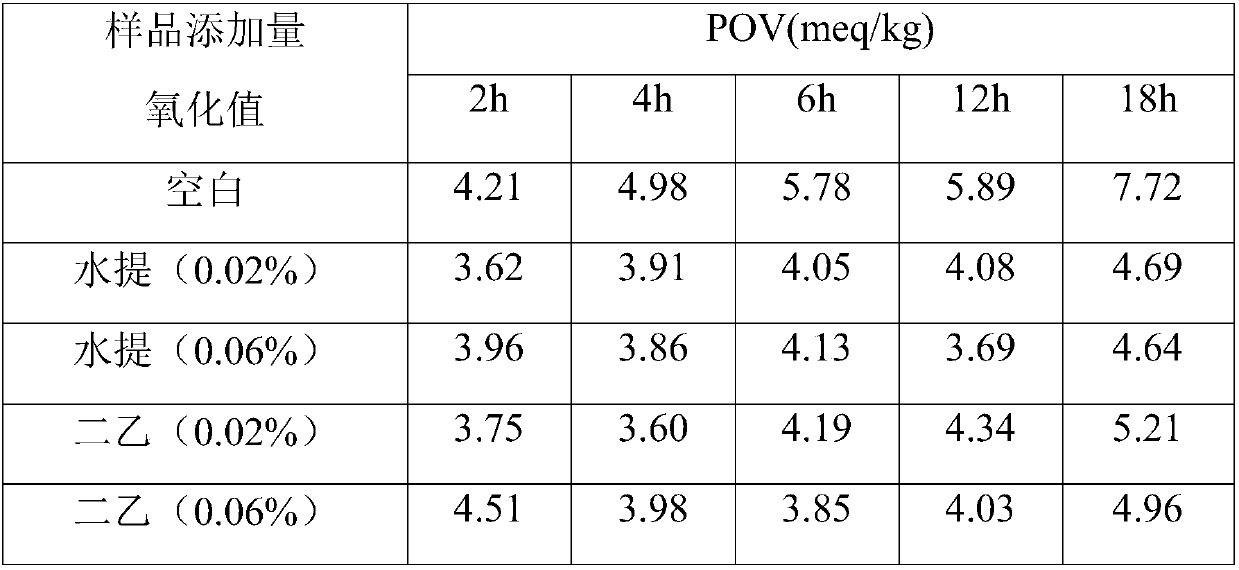

South American wedelia chinensis antioxidant extract as well as preparation method and application of extract

ActiveCN107753542AClarify chemical compositionImproves antioxidant activityFood preservationAntinoxious agentsFiltrationSolvent

The invention discloses a South American wedelia chinensis antioxidant extract as well as a preparation method and application of extract. The extract is extracted from dry powder of South American wedelia chinensis by adding a solvent; extracting solution is subjected to filtration and reduced pressure concentration to obtain total extract, extraction is carried out with petroleum ether and ethylacetate sequentially, reduced pressure recycling is carried out to obtain a petroleum ether part, an ethyl acetate part and a water dissolving part respectively, the obtained ethyl acetate part and water dissolving part respectively have excellent DPPH free radical scavenging activity and oil oxidation resistant activity, and the ethyl acetate part contains nine fiavonoids and four penylpropanoids. The obtained extract is high in yield, technological process is simple, and the extract is applicable to relatively large-scale preparation. The obtained extract has excellent antioxidant activityand can be applied to antioxidant drugs and food preservation as active components.

Owner:HAINAN NORMAL UNIV

Serum free hepatocyte medium

ActiveCN102559581BClear chemical compositionLow costArtificial cell constructsVertebrate cellsSerum free mediaSerum free

The invention provides a novel serum free medium and a preparation method and application of the medium. The serum free medium overcomes defects of the traditional serum media, and is obviously superior to serum free media reported in the conventional documents, improves the possibility of supporting systematical treatment clinical application through cell transplantation, tissue engineering liver and bioartificial liver, and has high practical value.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

CHO cell serum-free protein-free culture medium and application thereof

ActiveCN111996161AExtension of timeEase of mass productionCulture processArtificial cell constructsBiotechnologyPerfusion Culture

The invention relates to a CHO cell serum-free protein-free culture medium and an application thereof. The CHO cell serum-free protein-free culture medium comprises an amino acid component, a vitamincomponent, an inorganic salt component, a microelement component, carbohydrate and other molecular compound components. The serum-free culture medium provided by the invention has the advantages of definite chemical components and low cost, avoids the biological safety risk caused by the use of serum while the serum is not needed, and provides convenience for large-scale production of biological products, especially protein drugs. CHO cells grow well in the culture medium without the use of the serum, so that the stability of the production process of the biological products and the stabilityof the quality of finished products are improved, and particularly, the application of cell perfusion culture is facilitated. The cell perfusion culture technology serves as a future development trendof biomedical cell culture, and the culture medium well fills the blank that no special cell perfusion culture medium exists in the market, and provides a basis for flow line production of CHO cell biomedicines.

Owner:苏州依科赛生物科技股份有限公司

Human neural stem cell culture medium and application

ActiveCN107663516ASimple recipeLow costNervous system cellsCell culture active agentsHydrolysateCulture mediums

The invention discloses a human neural stem cell culture medium. The culture medium is prepared from the following components: a basic culture medium, a nutrient additive, a growth factor and a signalpathway regulation and control micro-molecule. The invention further discloses application of the culture medium to culturing of human neural stem cells. The culture medium disclosed by the inventionhas the advantages of simple formula, low cost and clear chemical components; the culture medium does not contain animal-derived components and does not contain protein extract and hydrolysate; the culture medium of all batches is uniform and stable and has no potential risks of introducing animal-derived and human-derived pathogenic microorganisms, so that the culture medium is safer and can beapplied to the culturing of the human neural stem cells in clinical researches and clinical experiments; furthermore, the signal pathway regulation and control micro-molecule is applied to the culturing of the human neural stem cells for the first time; under the action of the signal pathway regulation and control micro-molecule, rapid proliferation and dryness keeping of the human neural stem cells with various sources can be supported for a long period; the technical problem that the human neural stem cells are easy to differentiate and are difficult to proliferate for a long period when thehuman neural stem cells are cultured in vitro is successfully solved.

Owner:BEIJING TRANSGEN BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com