Patents

Literature

69results about How to "Same density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vegetable Oil-Modified, Hydrophobic Polyurethane Dispersions

ActiveUS20160009852A1Reduce usageSame densityPolyurea/polyurethane coatingsPolyurethane dispersionMonoglyceride

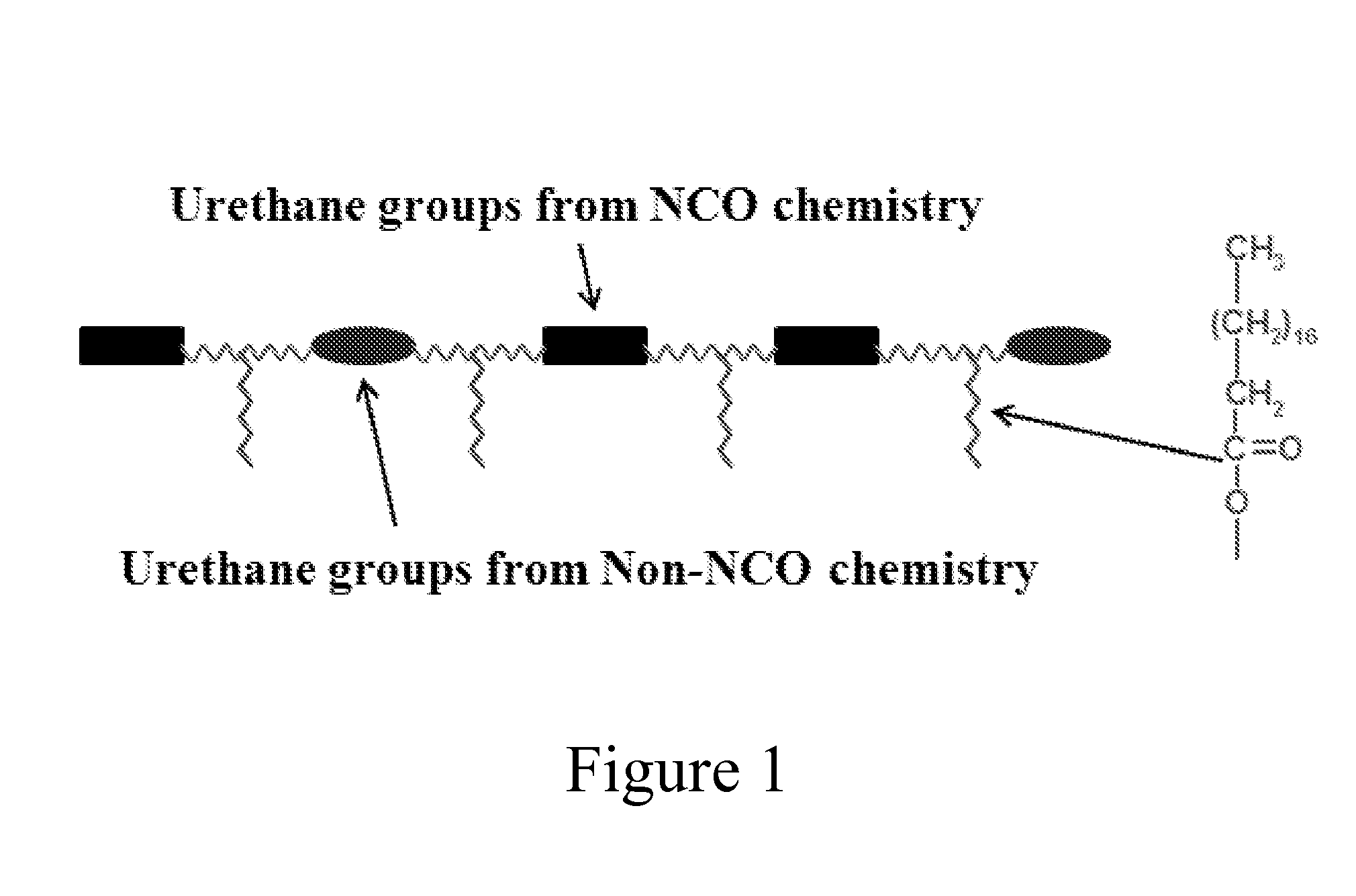

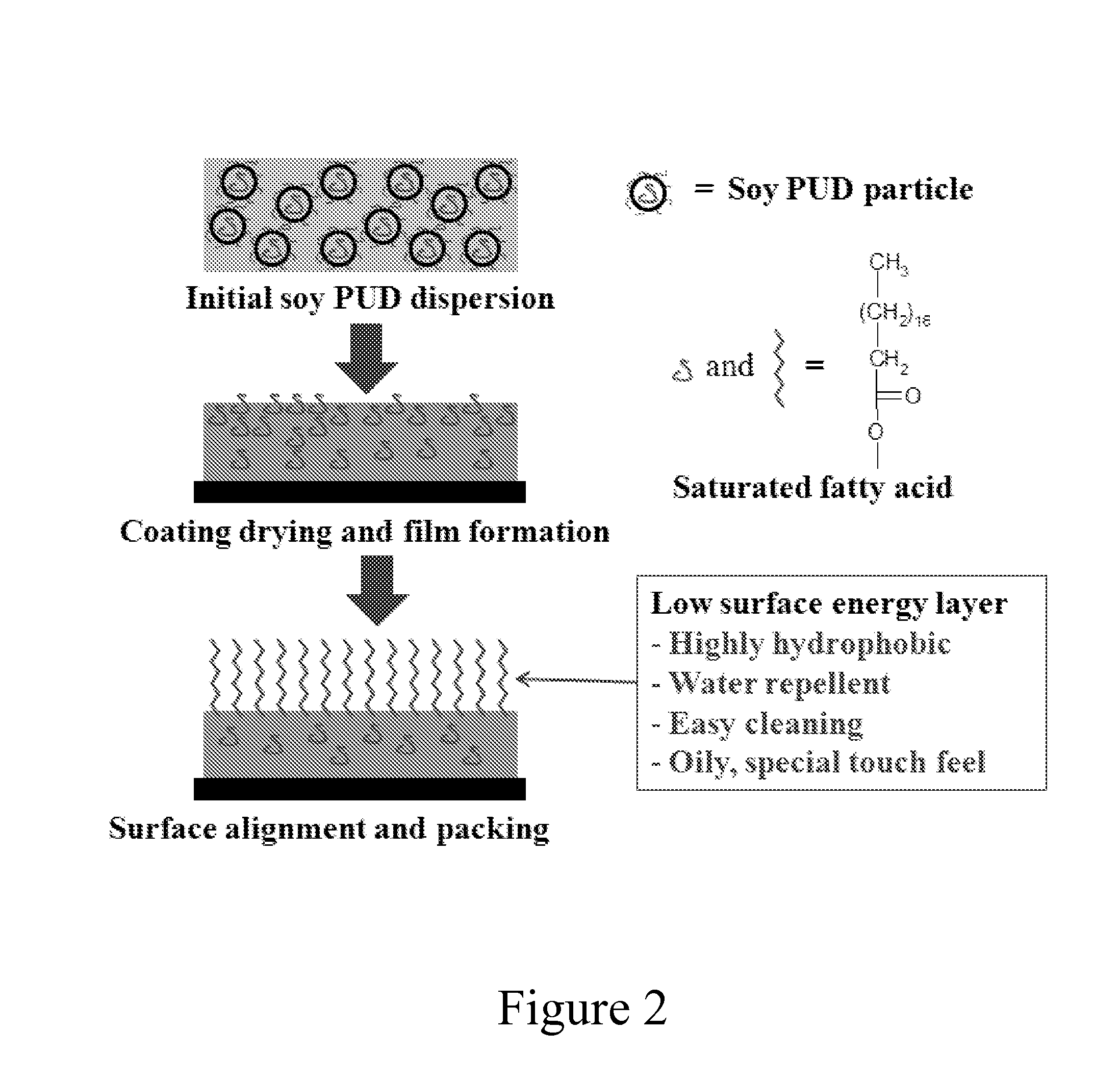

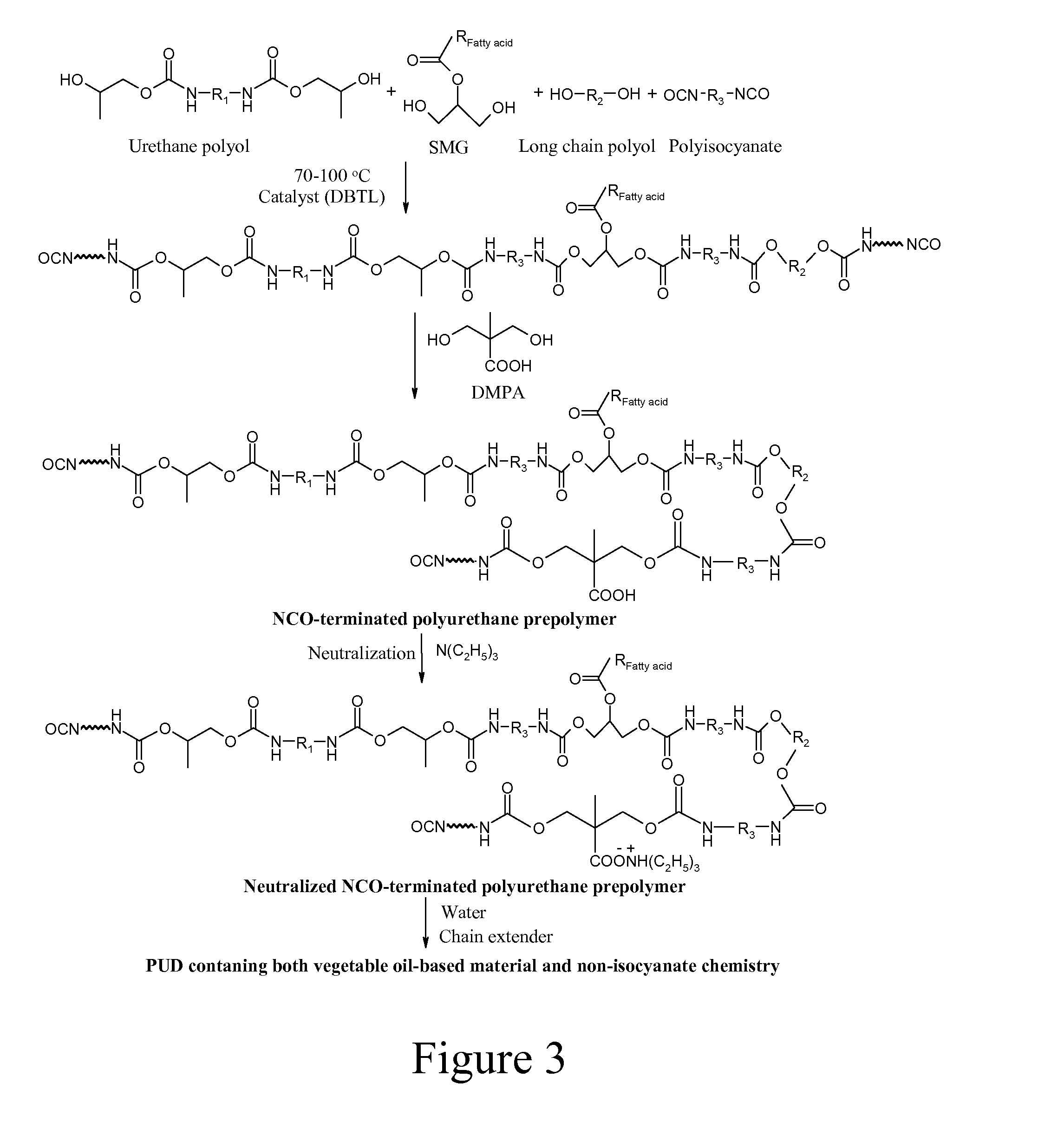

Aqueous hydrophobic polyurethane dispersions are made from urethane prepolymers derived from reacting constituents including at least one polyisocyanate, vegetable oil based saturated monoglycerides, non-isocyanate based urethane polyols prepared from polyamines and cyclic carbonates, at least one long-chain polymeric polyol or long-chain polyol from biorenewable resources, polyols with hydrophilic groups, optional polydimethysiloxane based polyols with hydroxyl functional groups terminated in one end and alkyl groups terminated in another end.

Owner:RUST OLEUM CORP

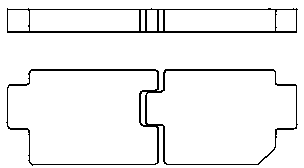

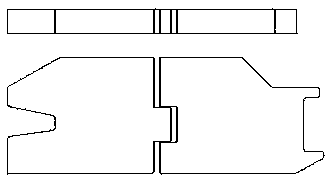

Method for preparing maize straw board

InactiveCN101691044AImprove internal bond strengthIncrease profitAldehyde/ketone condensation polymer adhesivesFlat articlesCorn stoverAmmonium chloride mixture

The invention discloses a method for preparing a maize straw board, which comprises the steps of dehydrating maize straws, cutting off the maize straws, compressing the maize straws into an isopycnic straw board-preparation raw material, drying the raw material, sieving the raw material into a coarse material and a fine material, spraying an adhesive, and performing hot press molding, wherein the weight percentage of the straws and the adhesive is 85-90: 10-15. The adhesive for preparing the board consists of 75 to 90 percent of urea-formaldehyde resin, 5 to 8 percent of ammonia water, 0.5 to 1 percent of polyvinyl alcohol, 6 to 12 percent of melamine, and 0.5 to 1 percent of ammonium chloride (weight proportion). The method is characterized by utilizing all components (peels, pulp and leaves) of the maize straws, adopting special equipment to directly compress the cut straws into the board-preparation raw material with the equidensity of between 0.8 and 1.0g / cm3, ensuring the same density of the raw material in sizing and pressing links of the board, improving the internal bonding strength of products, and also improving the utilization rate of the raw material and simplifying production technology so as to reduce production cost at the same time. The maize straw board has the advantages of adequate raw materials, low cost, high board quality, good biological degradability, and no pollution to the environment.

Owner:王维海

Method and device for transmitting downlink data of relay link

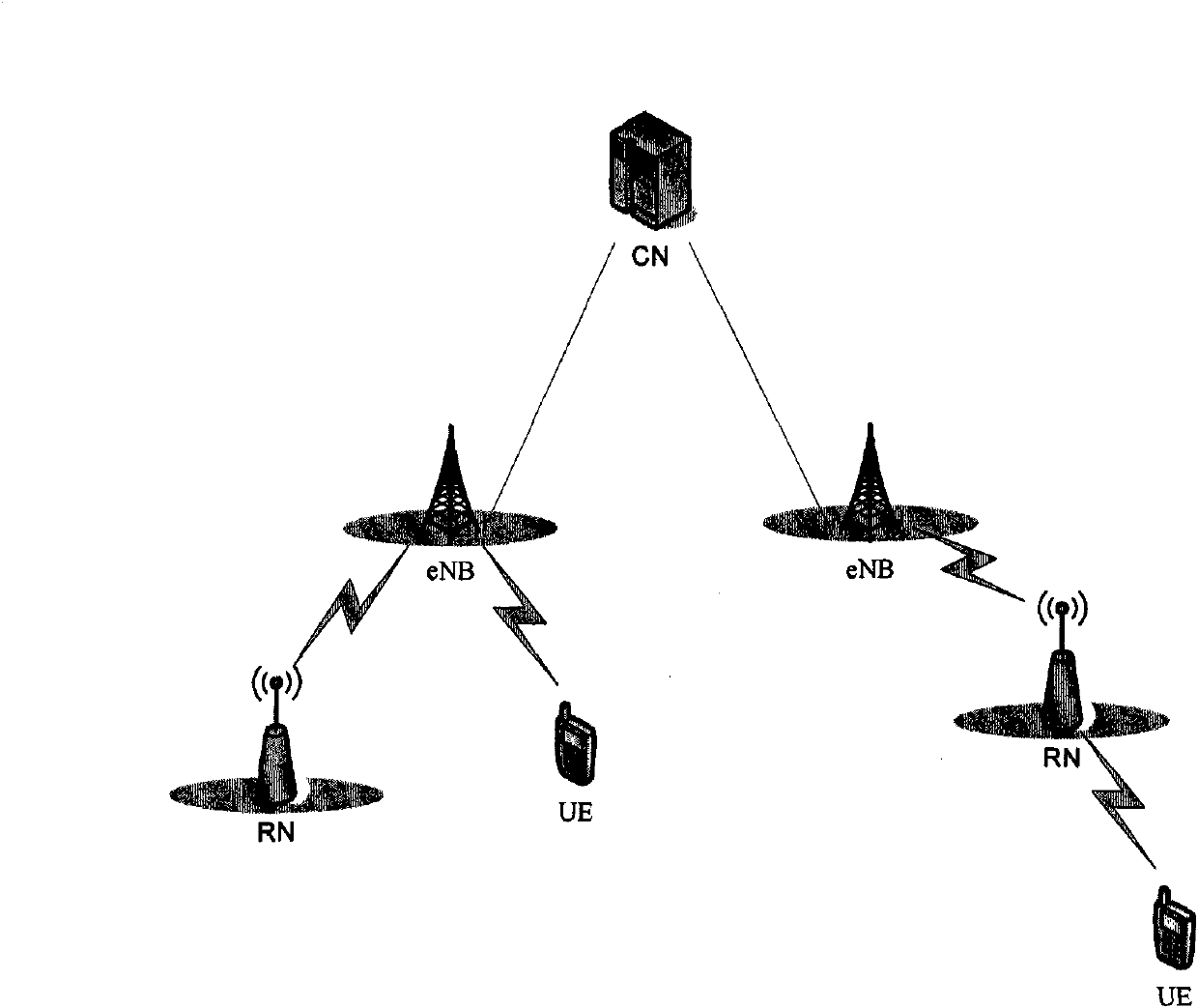

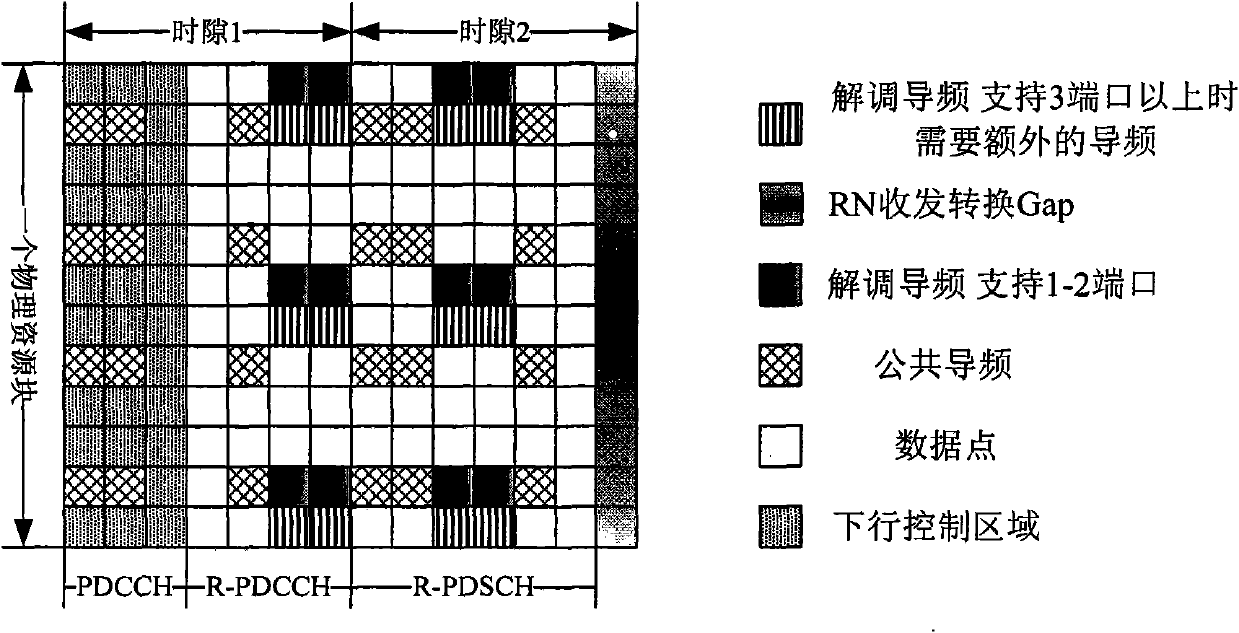

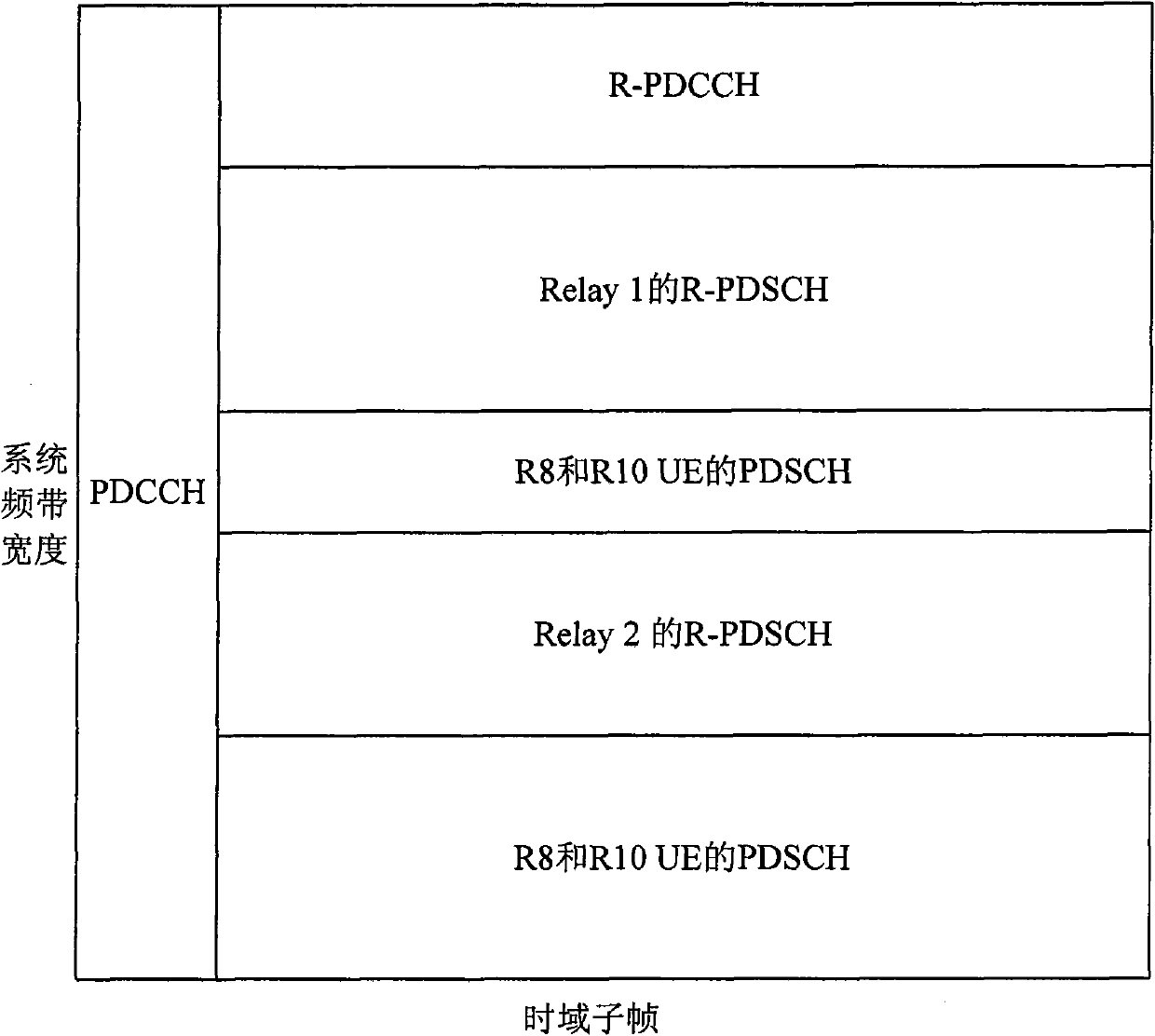

InactiveCN102088312ASame densityTo avoid differences in demodulation performanceNetwork traffic/resource managementRadio transmission for post communicationTrunkingTime-division multiplexing

The invention discloses a method and device for transmitting downlink data of a relay link, which can maintain the consistency for special pilot frequency configuration of a plurality of RPB (Physical Resource Blocks) scheduled by a terminal. The method comprises the step of transmitting downlink data by adopting a TDM (Time Division Multiplexing) mode in an R-PDCCH (Relay-Physical Downlink Control Channel) area and an R-PDSCH (Relay-Physical Downlink Share Channel) area in the same PRB, wherein a resource unit capable of transmitting special pilot frequency in the R-PDCCH area does not transmit the downlink data.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Homogeneous chemiluminescence detection kit and application thereof

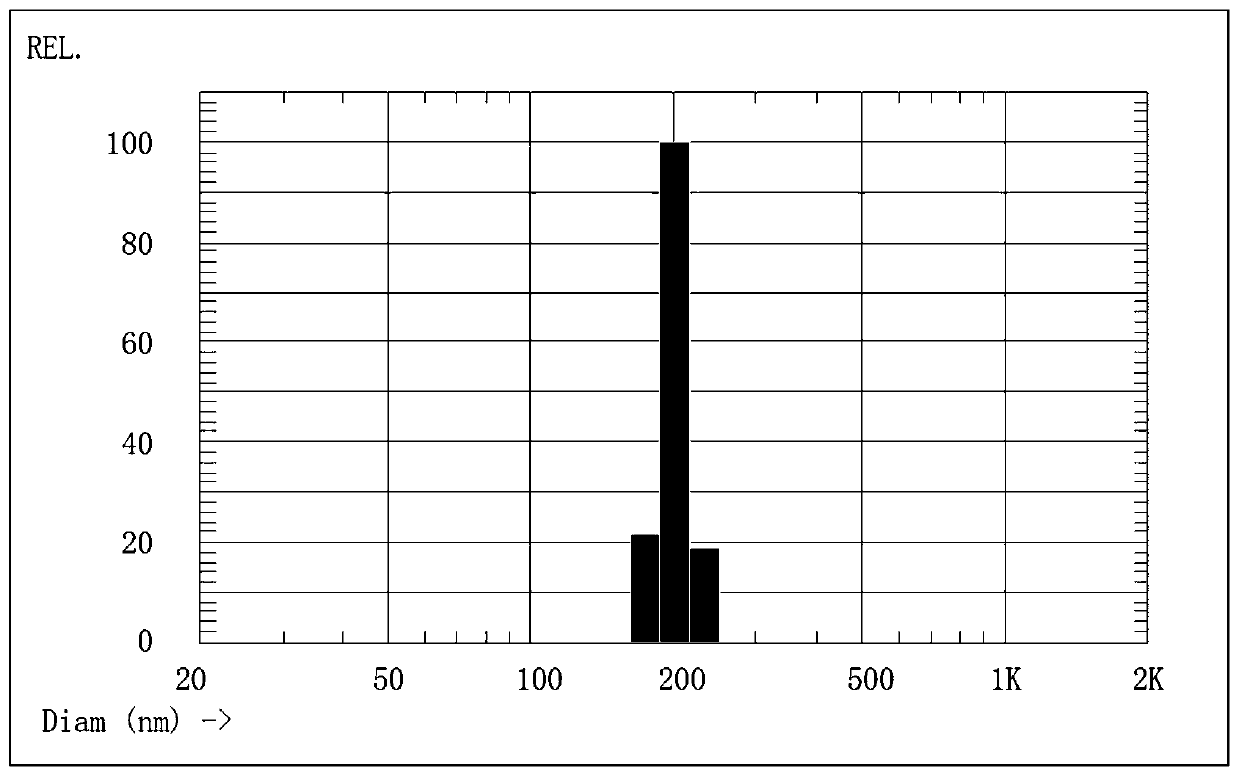

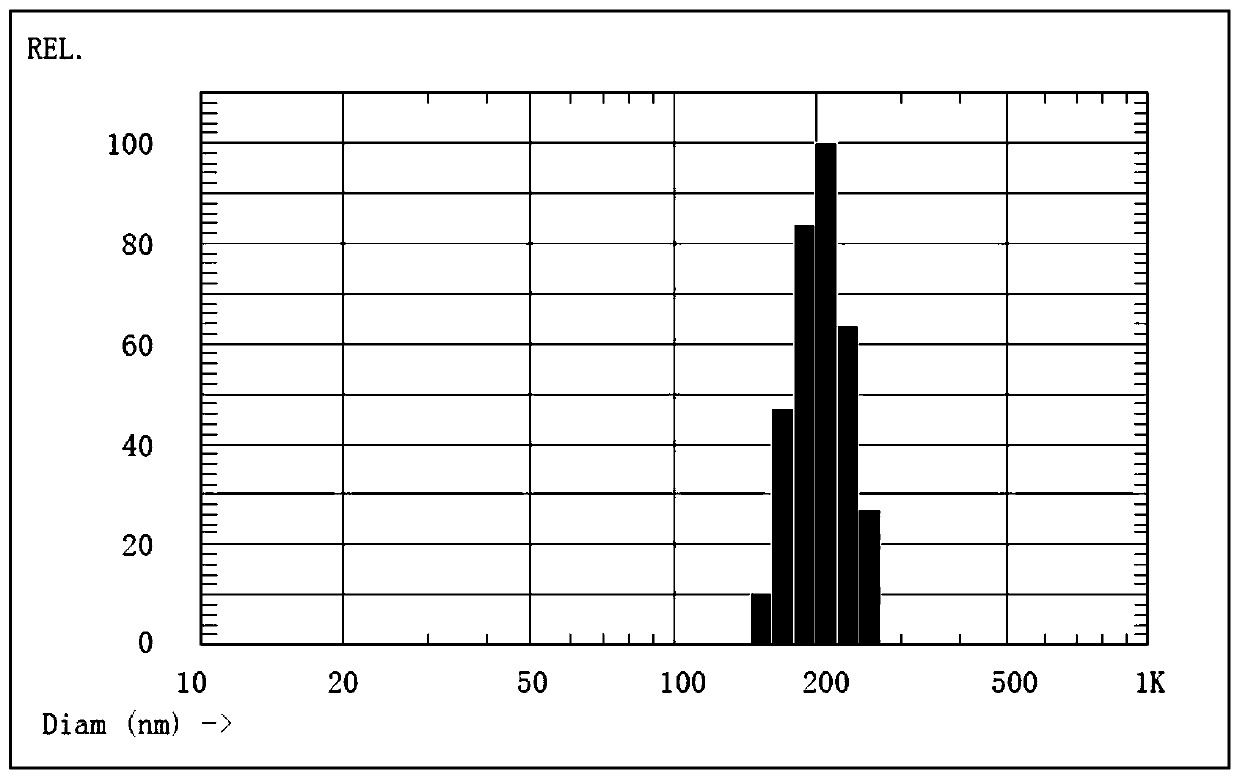

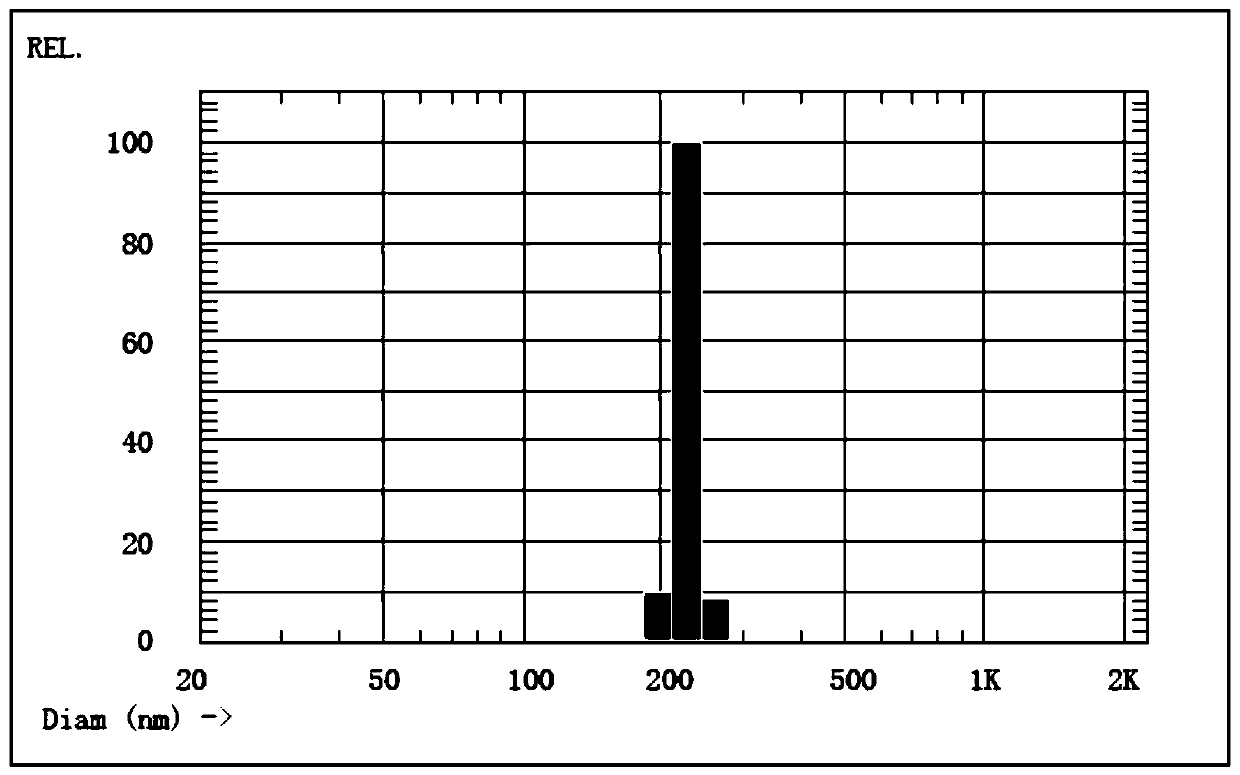

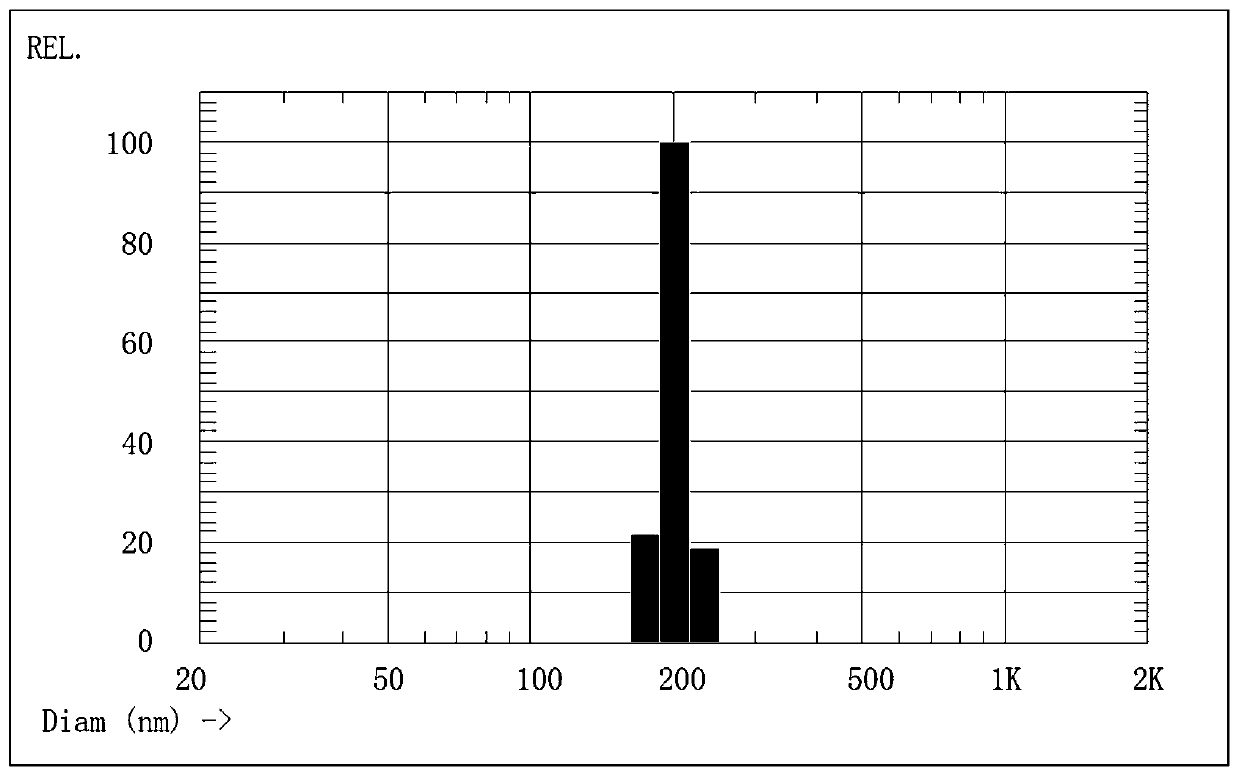

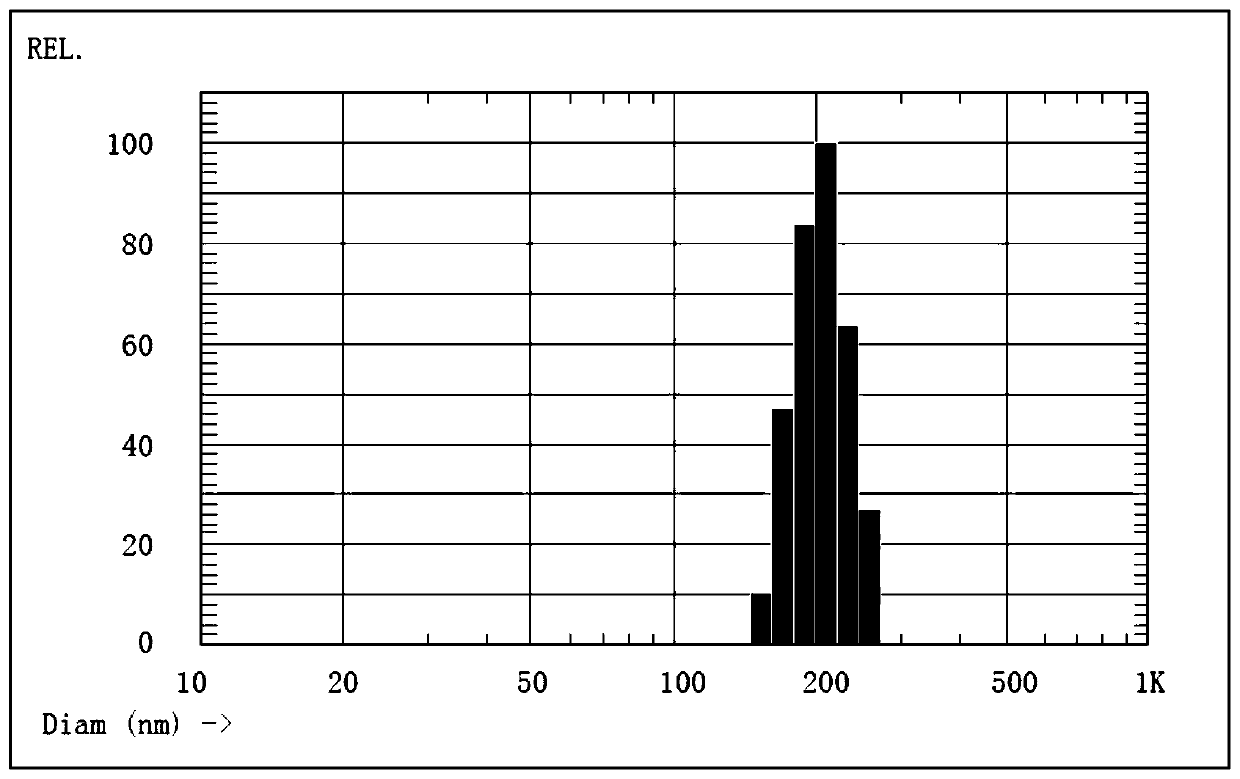

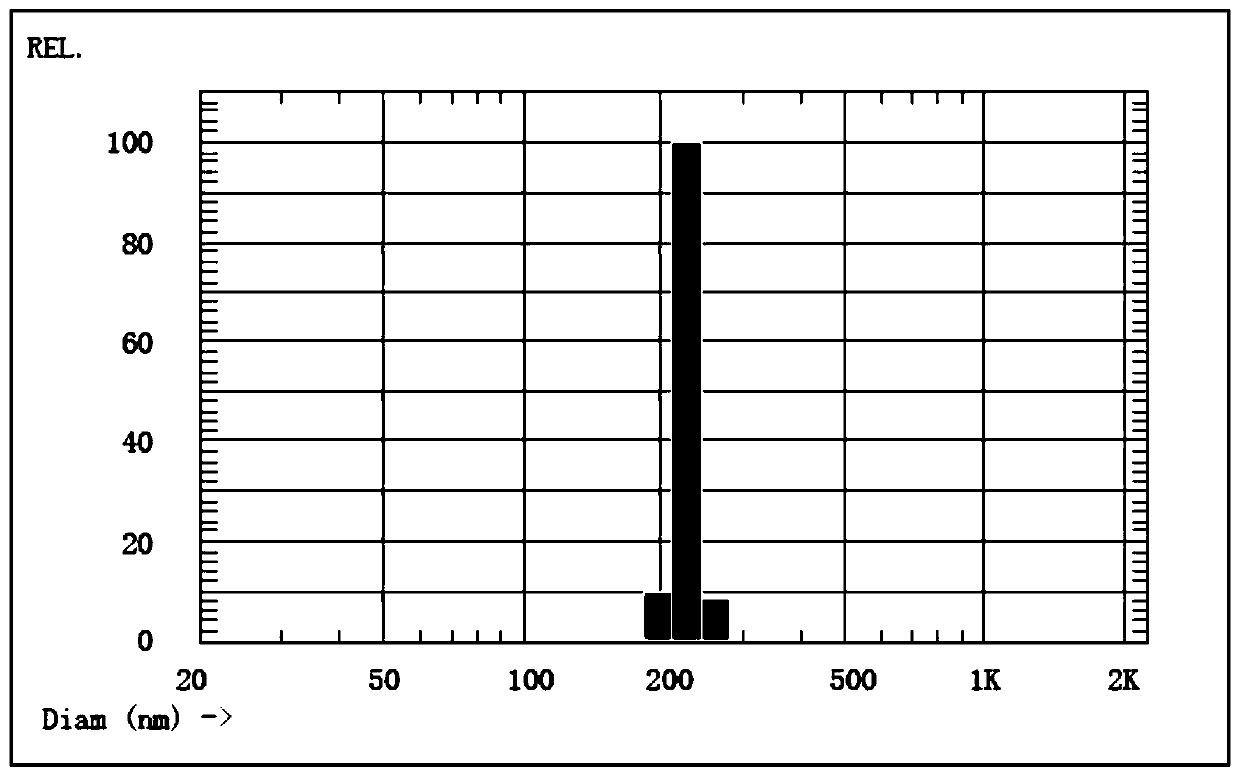

PendingCN110736739AImprove luminous efficiencyImprove accuracyChemiluminescene/bioluminescenceReceptorMicrosphere

The invention relates to a homogeneous chemiluminescence detection kit and application thereof. The kit comprises a donor reagent and a receptor reagent, wherein the donor reagent comprises donor microspheres, the donor microspheres can generate active oxygen in an excited state, and the surfaces of the donor microspheres are coated with markers; the receptor reagent comprises receptor microspheres, the receptor microspheres can react with the active oxygen to generate detectable chemiluminescence signals, the surfaces of the receptor microspheres are coated with biomolecules, and the biomolecules can be specifically combined with target molecules to be detected; the particle size of the receptor microspheres is equal to that of the donor microspheres. The particle size of the donor microspheres in the kit is equal to that of the receptor microspheres, and the precision and sensitivity of the kit are improved.

Owner:BEYOND DIAGNOSTICS (SHANGHAI) CO LTD +1

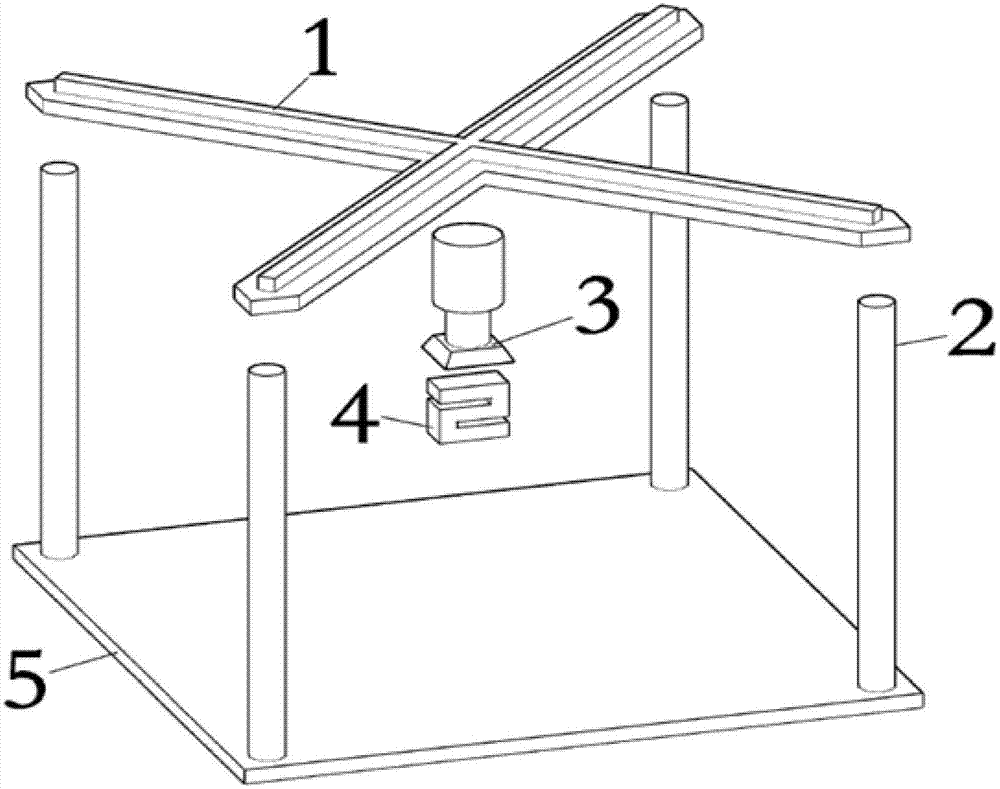

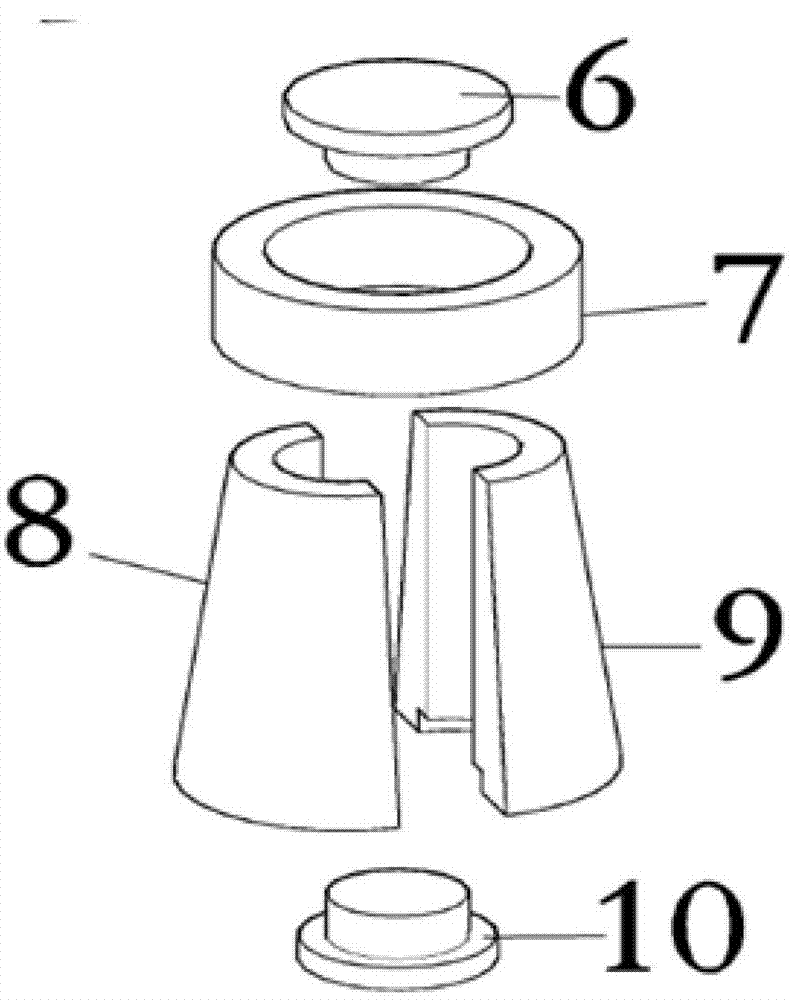

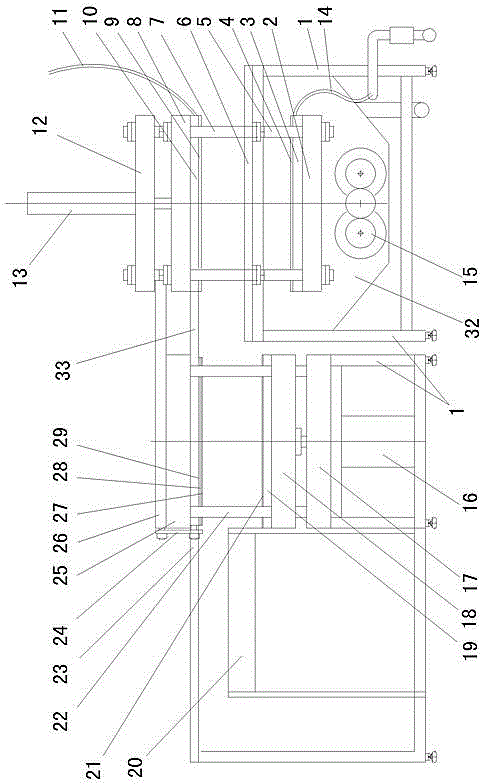

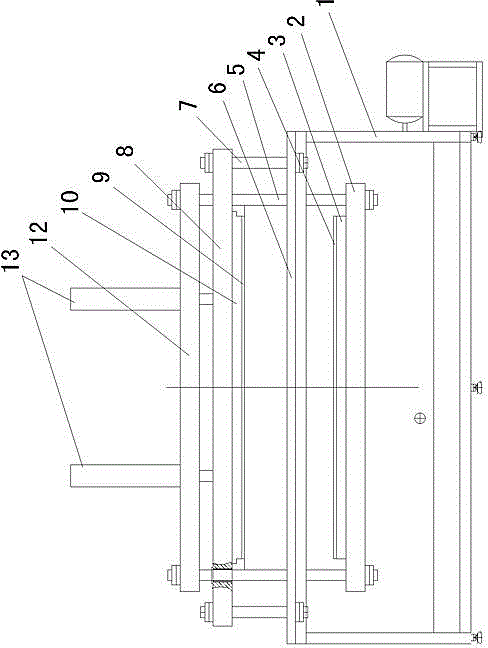

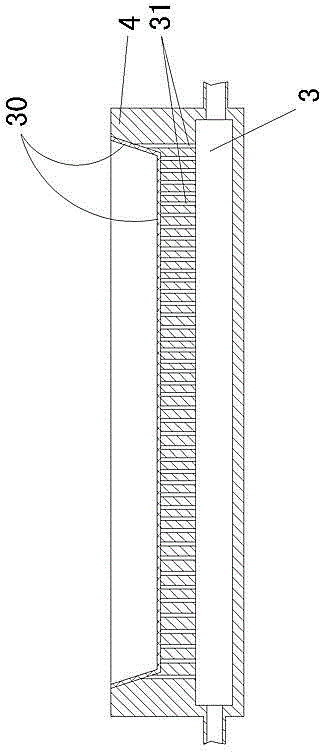

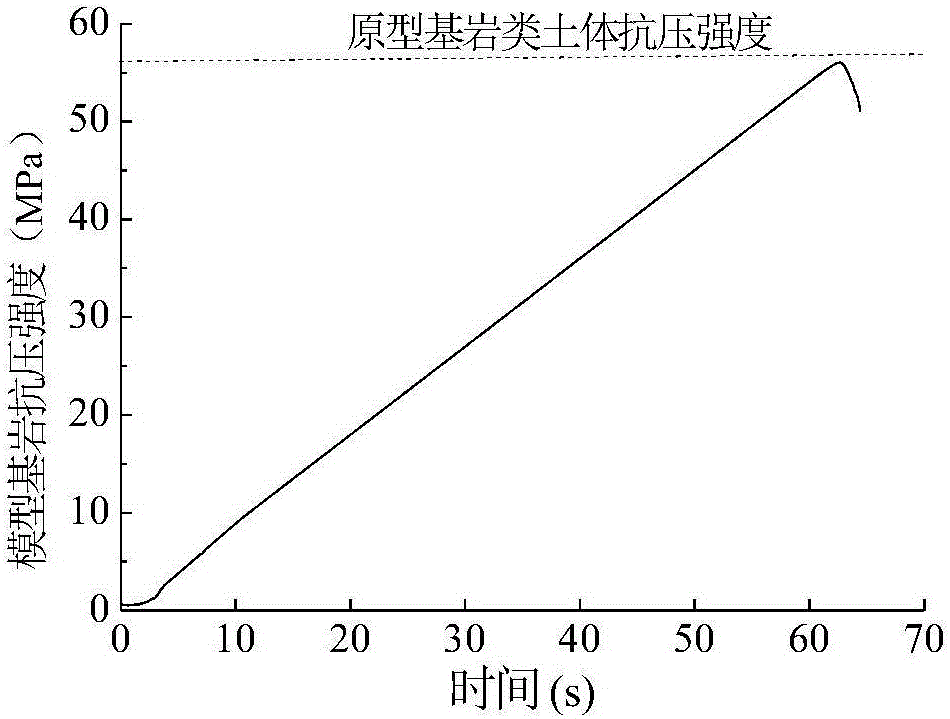

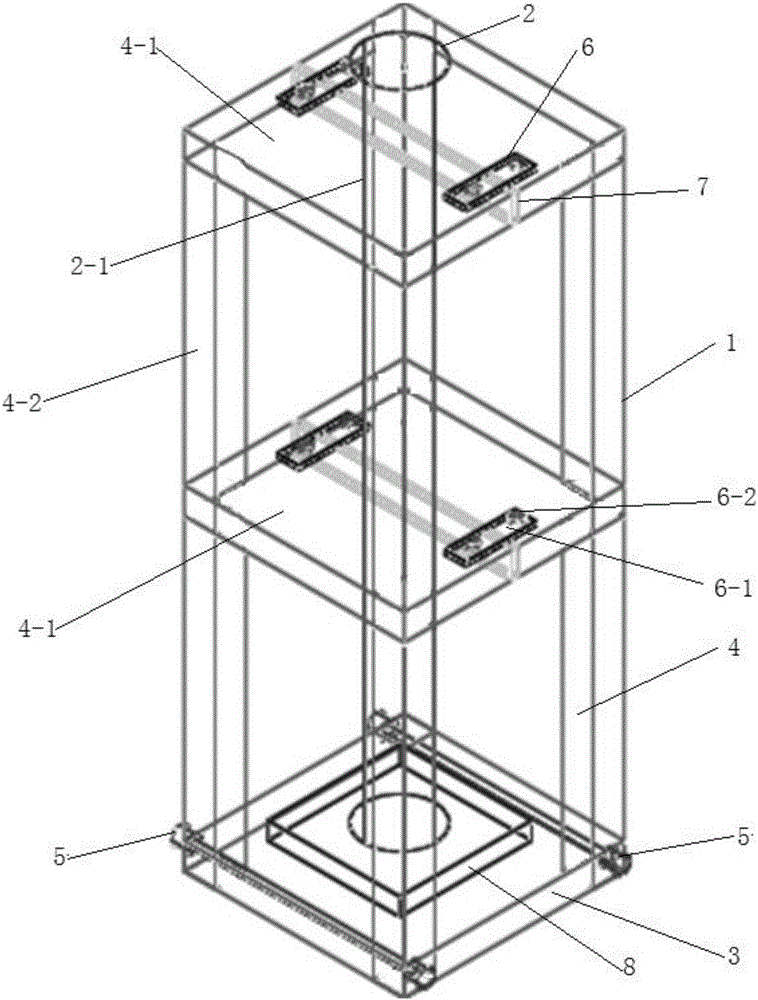

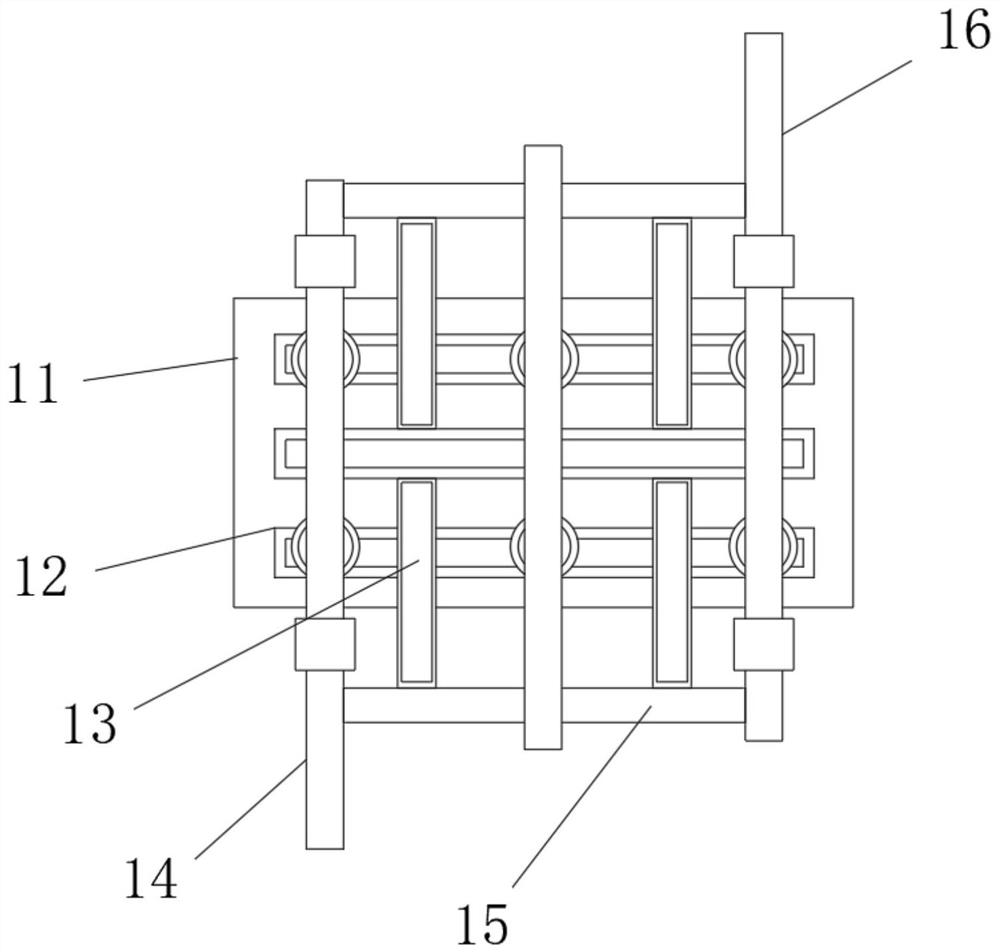

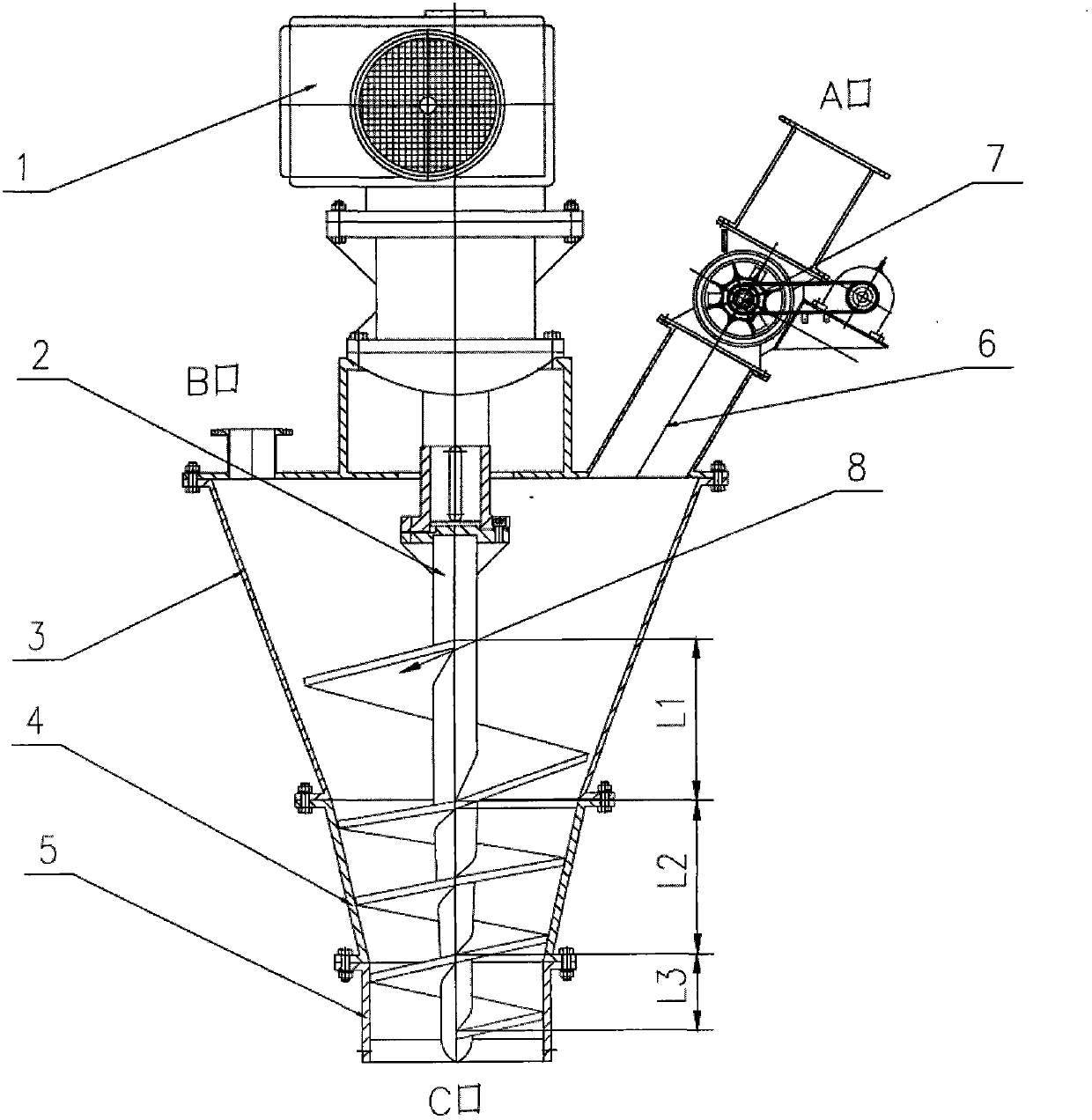

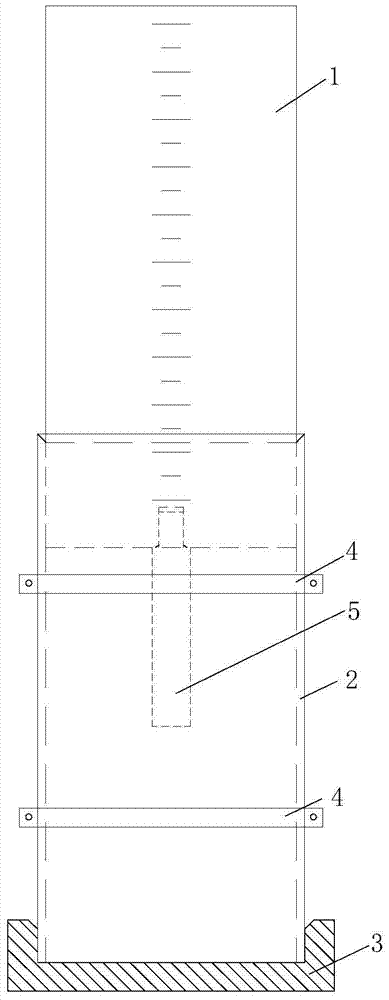

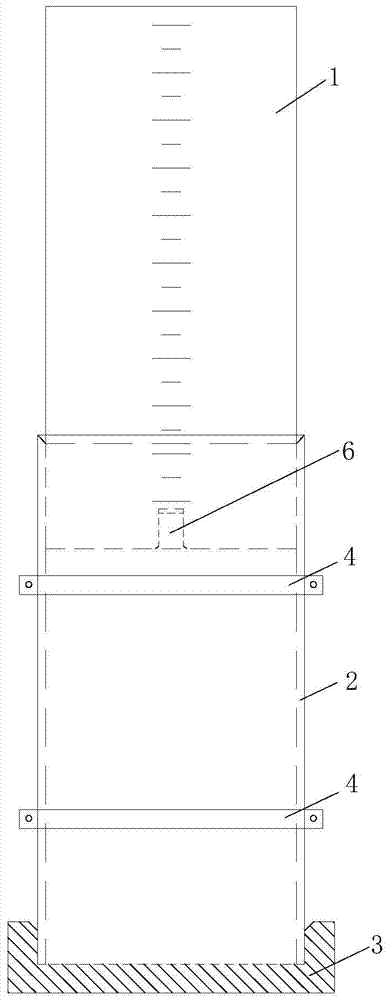

Multi-functional mold and method for preparing artificial core

ActiveCN104502167ASame densitySame sizePreparing sample for investigationEngineeringBiomedical engineering

Owner:CHINA UNIV OF MINING & TECH

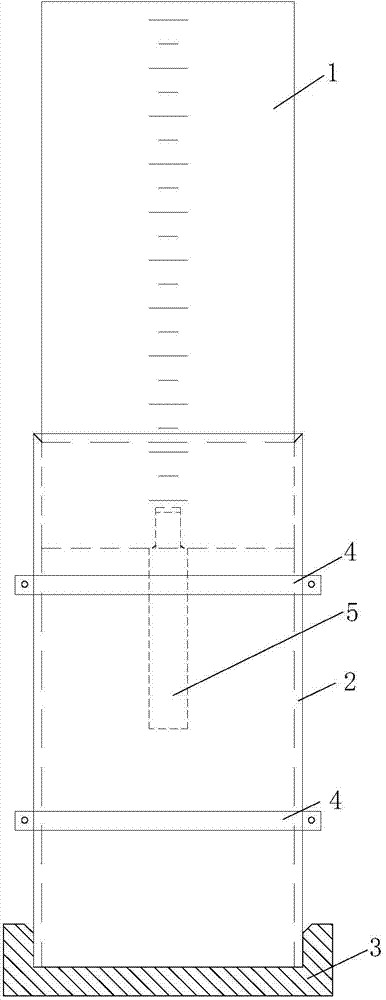

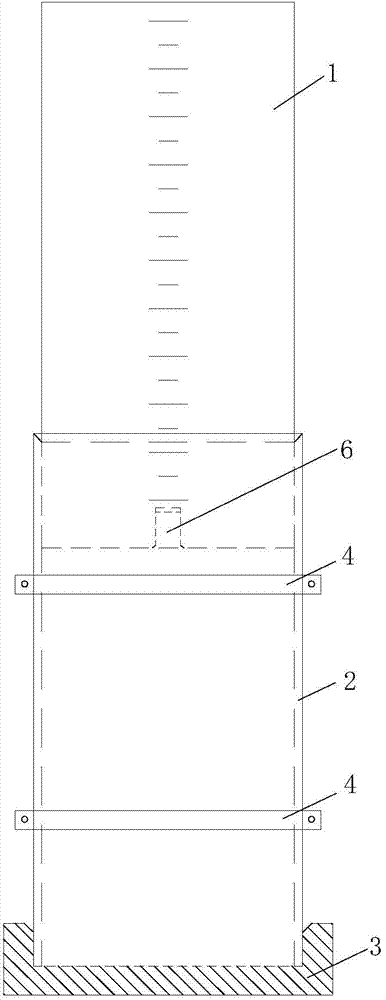

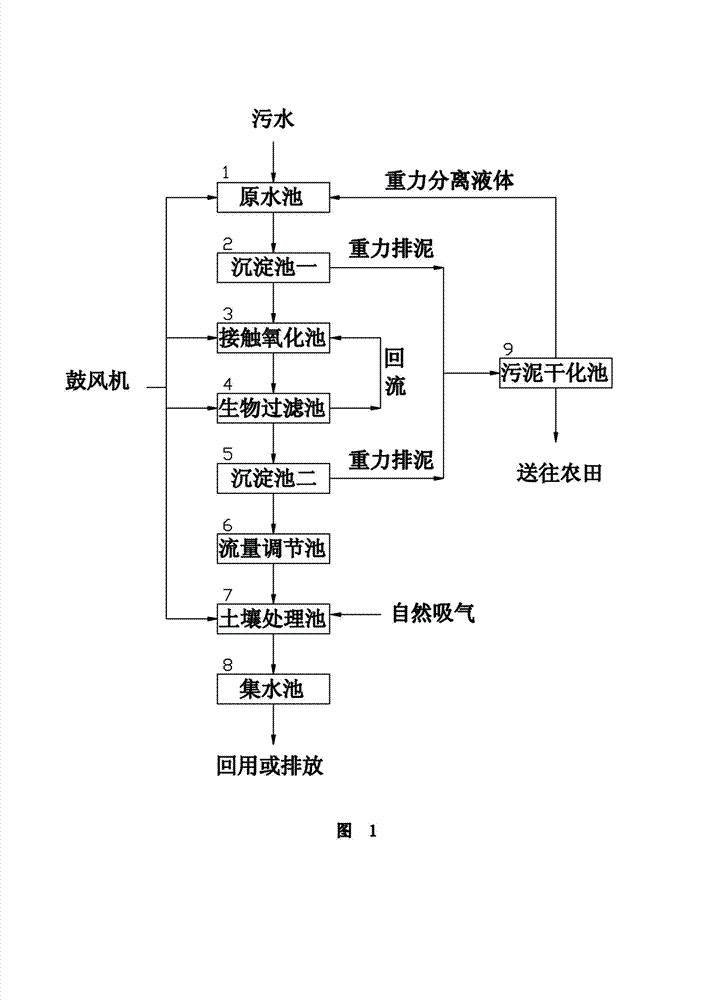

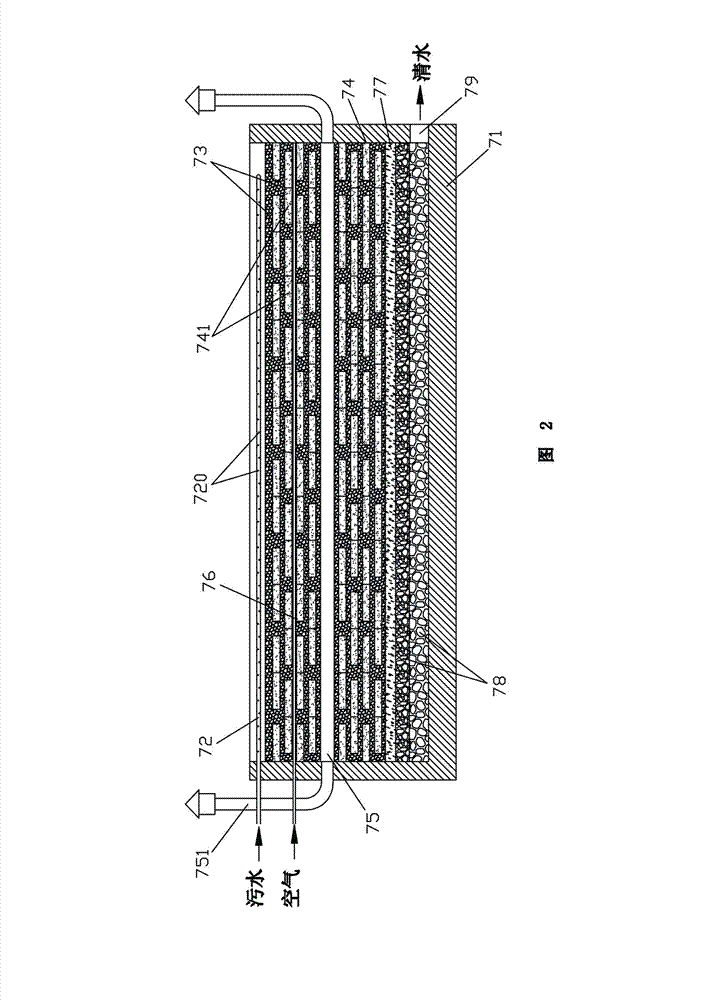

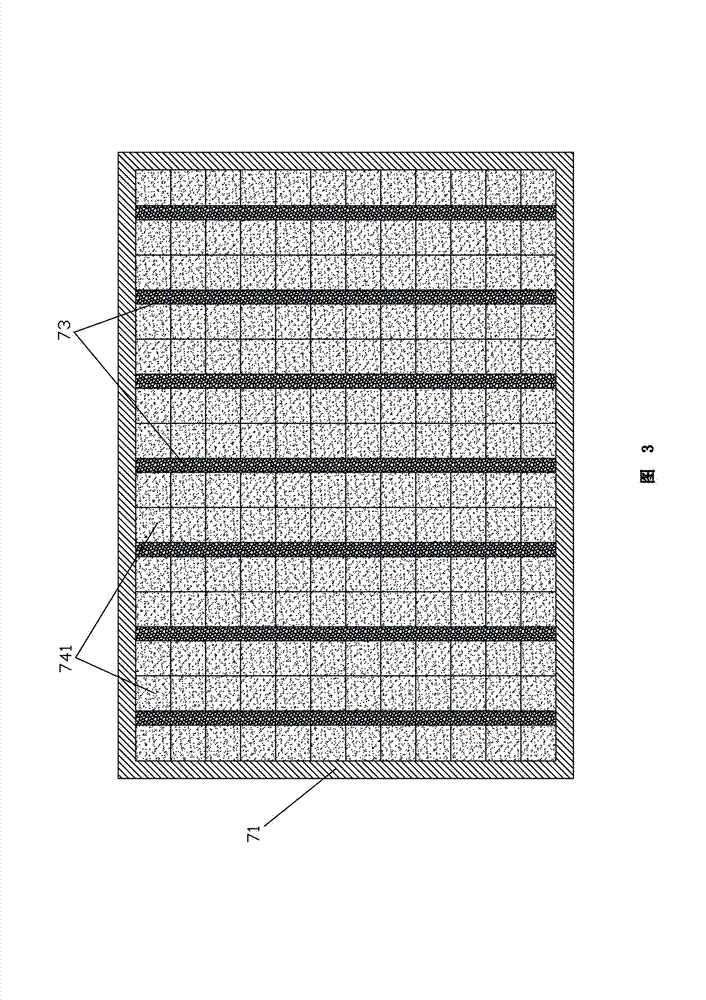

Dispersive sewage multilayer soil ecological treatment device and method

InactiveCN102730915AReduce depositionAvoid cloggingMultistage water/sewage treatmentOsmotic coefficientBiological filter

The invention relates to a dispersive sewage multilayer soil ecological treatment device which comprises a raw water tank, a first sedimentation tank, a contact oxidation tank, a biological filter tank, a second sedimentation tank, a flow regulating tank, a soil treatment tank and a water collection tank which are connected in sequence,, wherein the raw water tank, the contact oxidation tank, the biological filter tank, and the soil treatment tank are respectively connected to an air blower, and the soil treatment tank comprises a tank body, a water distributing pipe, a water passing layer, a soil layer, a ventilation layer, an air layer, a quartz sand layer, a cobblestone layer and a water collecting pipe. A treatment method comprises the following steps of: (1) lifting sewage to the first sedimentation tank for anaerobic sedimentation after collecting the sewage by using the raw water tank; (2) entering the contact oxidation tank, and then making discharged water pass through the biological filter tank; (3) after passing through the second sedimentation tank, making the discharged water enter the flow regulation tank, and then delivering the discharged water to the soil treatment tank; and (4) intermittently performing water intake and ventilation on the soil treatment tank. The invention effectively improves the osmotic coefficient of a soil layer, the hydraulic loading is up to above 2.0-8.0m and is increased by dozens of times higher than the traditional soil treatment method, and the treatment efficiency is obviously improved.

Owner:中科天龙(厦门)环保股份有限公司

Serum-free culture medium without animal origin components for culturing Vero cell micro-carrier

InactiveCN101864393BPromote growthSame densityArtificial cell constructsVertebrate cellsSerotoninVitamin C

Owner:INST OF BIOENG ACAD OF MILITARY MEDICAL SCI OF THE CHINESE

Microsphere composition for chemiluminescence detection and application thereof

PendingCN110736737AReduce pHReduce the influence of electrolytes, etc.Chemiluminescene/bioluminescenceImmune profilingMicrosphere

The invention relates to a microsphere composition for chemiluminescence detection in the technical field of chemiluminescence, and an application thereof. The microsphere composition comprises: respective donor microspheres capable of generating active oxygen in an excited state, wherein the surfaces of the donor microspheres are coated with markers; and acceptor microspheres capable of reactingwith the active oxygen to generate detectable chemiluminescence signals, wherein the surfaces of the acceptor microspheres are coated with biomolecules, and the biomolecules can specifically bind to target molecules to be detected; wherein the particle diameter of the donor microsphere is equal to that of the acceptor microsphere. The microsphere composition provided by the invention improves theluminous efficiency of detection when the luminous microsphere composition is used for immunoassay detection by controlling the matrix and the particle size of luminous microspheres and photosensitivemicrospheres, and the detection sensitivity is very good.

Owner:上海索昕生物科技有限公司

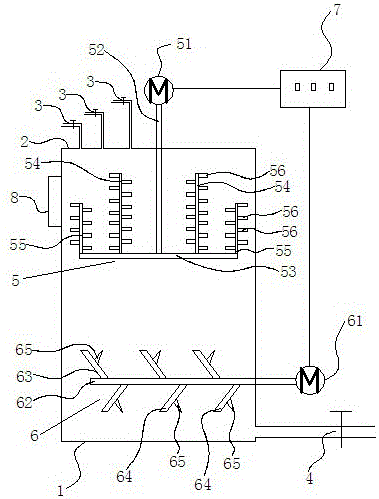

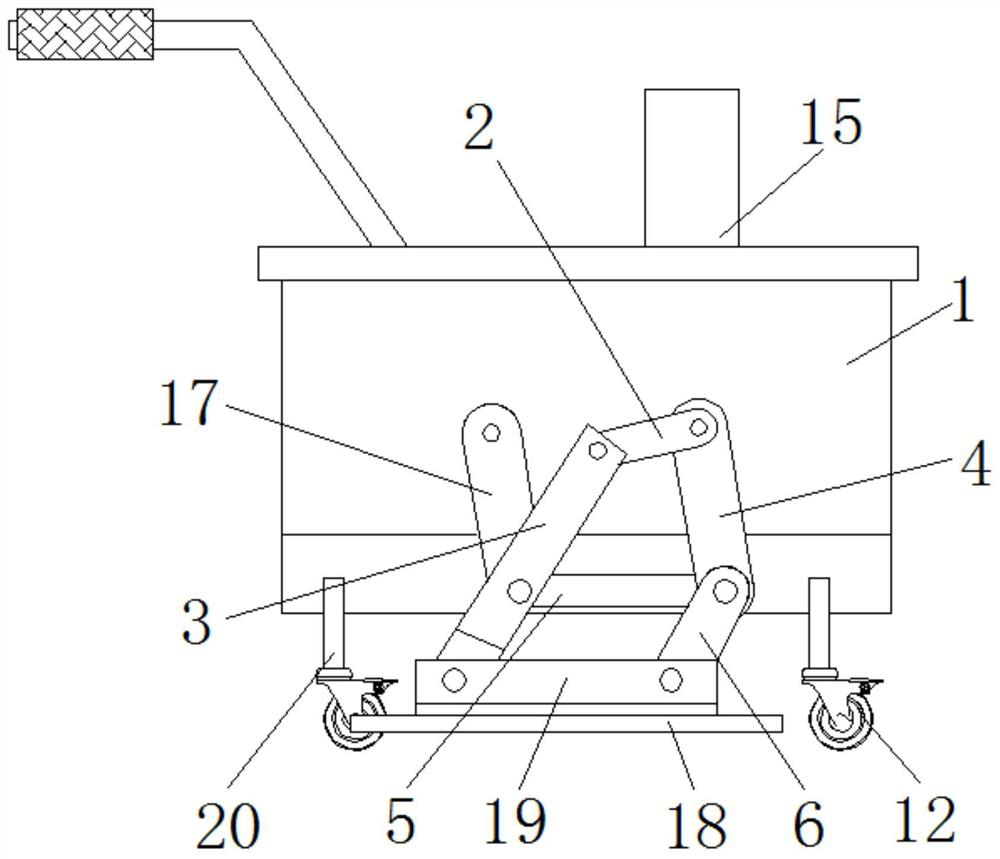

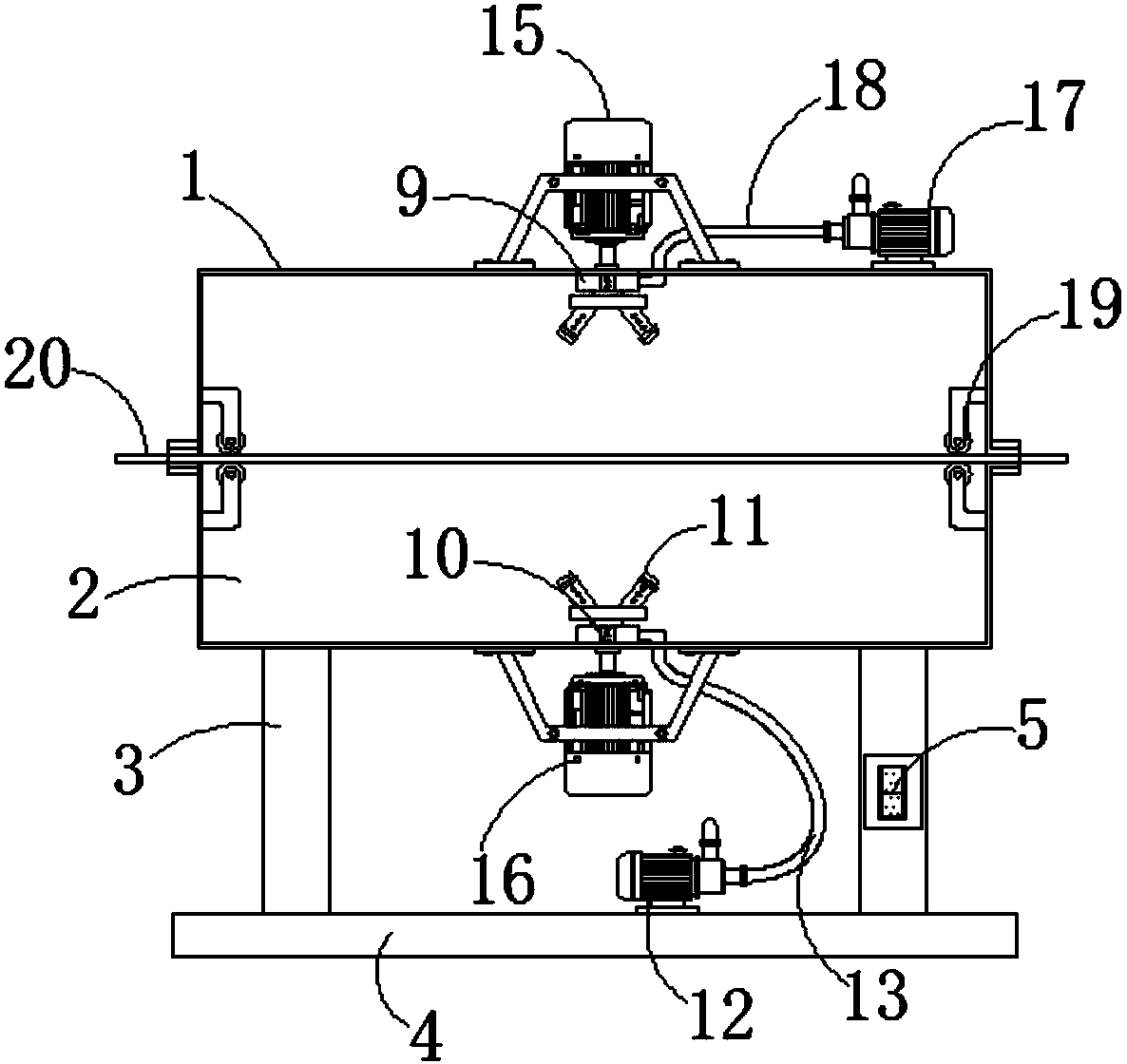

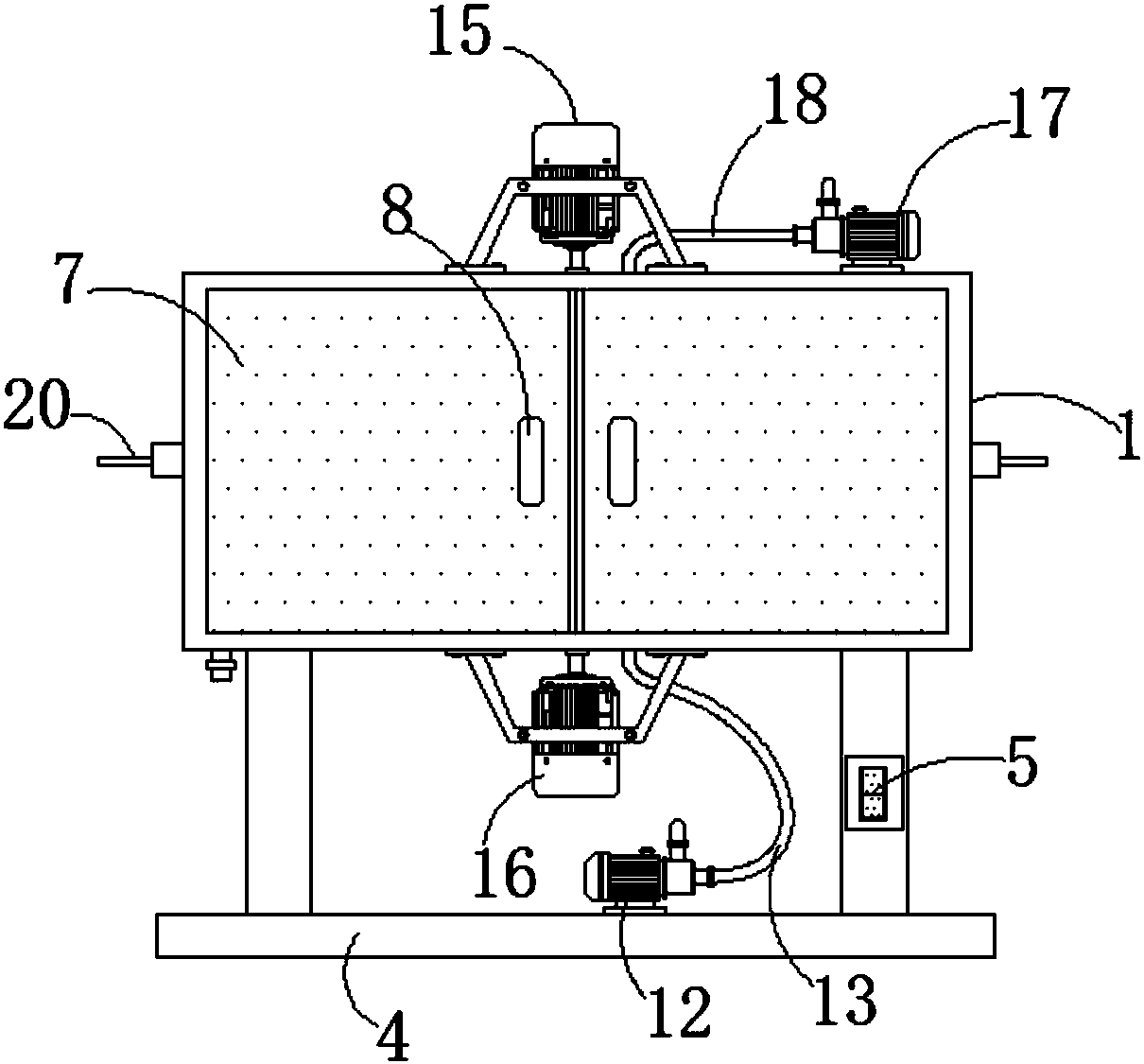

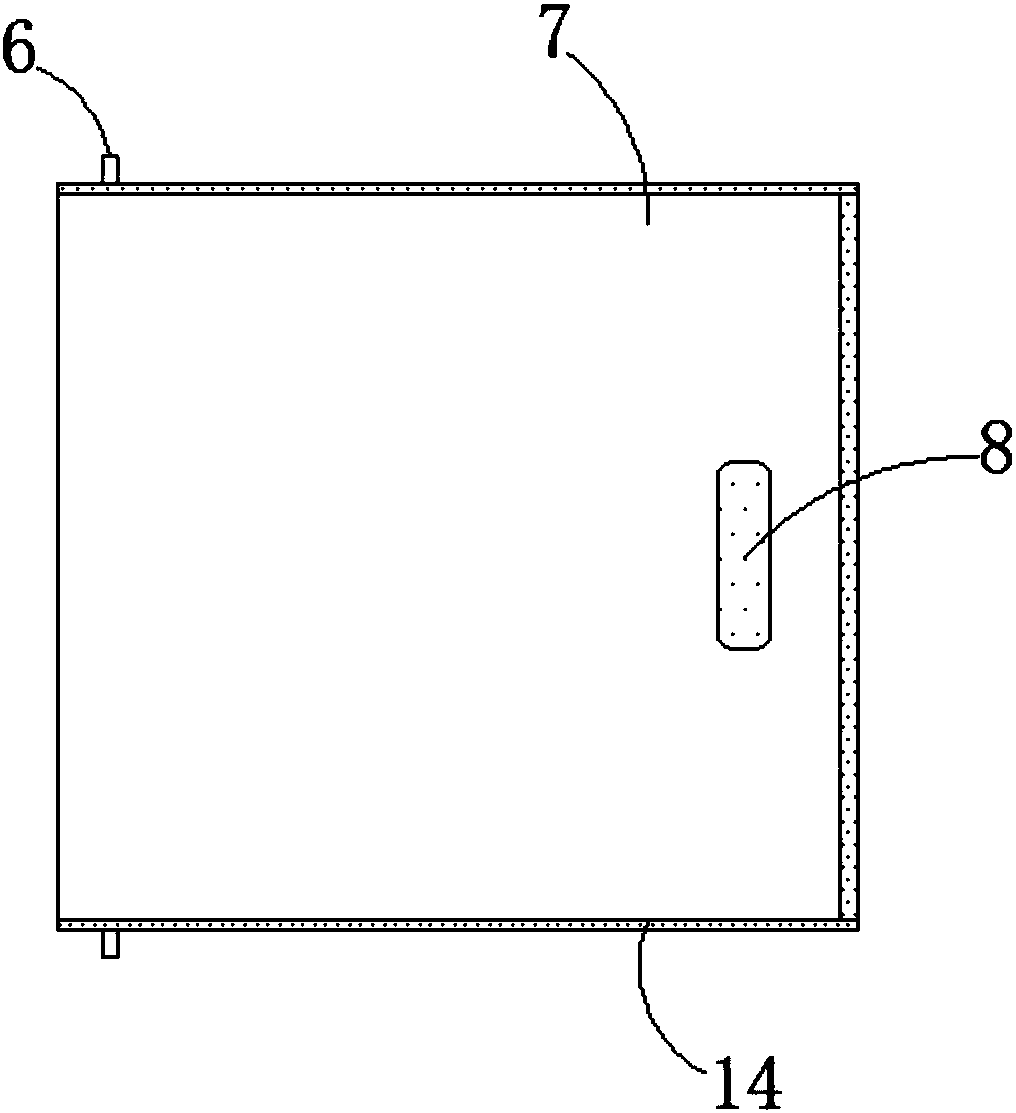

Plant glue stirring device

InactiveCN106731951AWell mixedIncrease viscosityRotary stirring mixersTransportation and packagingEngineeringMetal sheet

The invention provides a plant glue stirring device. The plant glue stirring device structurally comprises a container tank; a first stirring mechanism is mounted in the container tank along the vertical direction; a second stirring mechanism is mounted in the container tank along the horizontal direction; the first stirring mechanism is provided with a first motor and a vertical rotary shaft; the vertical rotary shaft is horizontally provided with a first connecting rod, and a first stirring rod and a second stirring rod which are located on the first connecting rod; metal sheets are arranged at two sides of the first stirring rod and the second stirring rod respectively; the second stirring mechanism is provided with a second motor and a horizontal rotary shaft; a third stirring rod and a fourth stirring rod are arranged at upper and lower sides of the horizontal rotary shaft respectively; metal sheets are arranged on the third stirring rod and the fourth stirring rod, and liquid at the lower part of the container tank and liquid at the upper part of the container tank are sufficiently mixed, so that multilayered and all-directional stirring is realized; plant glue in the container tank is sufficiently mixed to form the plant glue with relatively high viscosity and stable performance.

Owner:HUZHOU GUANGBO BIOTECH

Hot-press forming process of counterweight filler with high specific gravity

ActiveCN107775000ASame densitySame weightTransportation and packagingMetal-working apparatusThermal insulationEngineering

The invention discloses a hot-press forming process of a counterweight filler with high specific gravity. The process comprises steps as follows: material selection, material crushing, material placement in a middle bin, weighing, screening, heating, thermal insulation, hot-press forming and cooling as well as conveying. The production process is simple, the production speed is high, the quality of the counterweight filler can be guaranteed, and manual operation is not required in the whole production process.

Owner:XUANCHENG VALIN PRECISION TECH

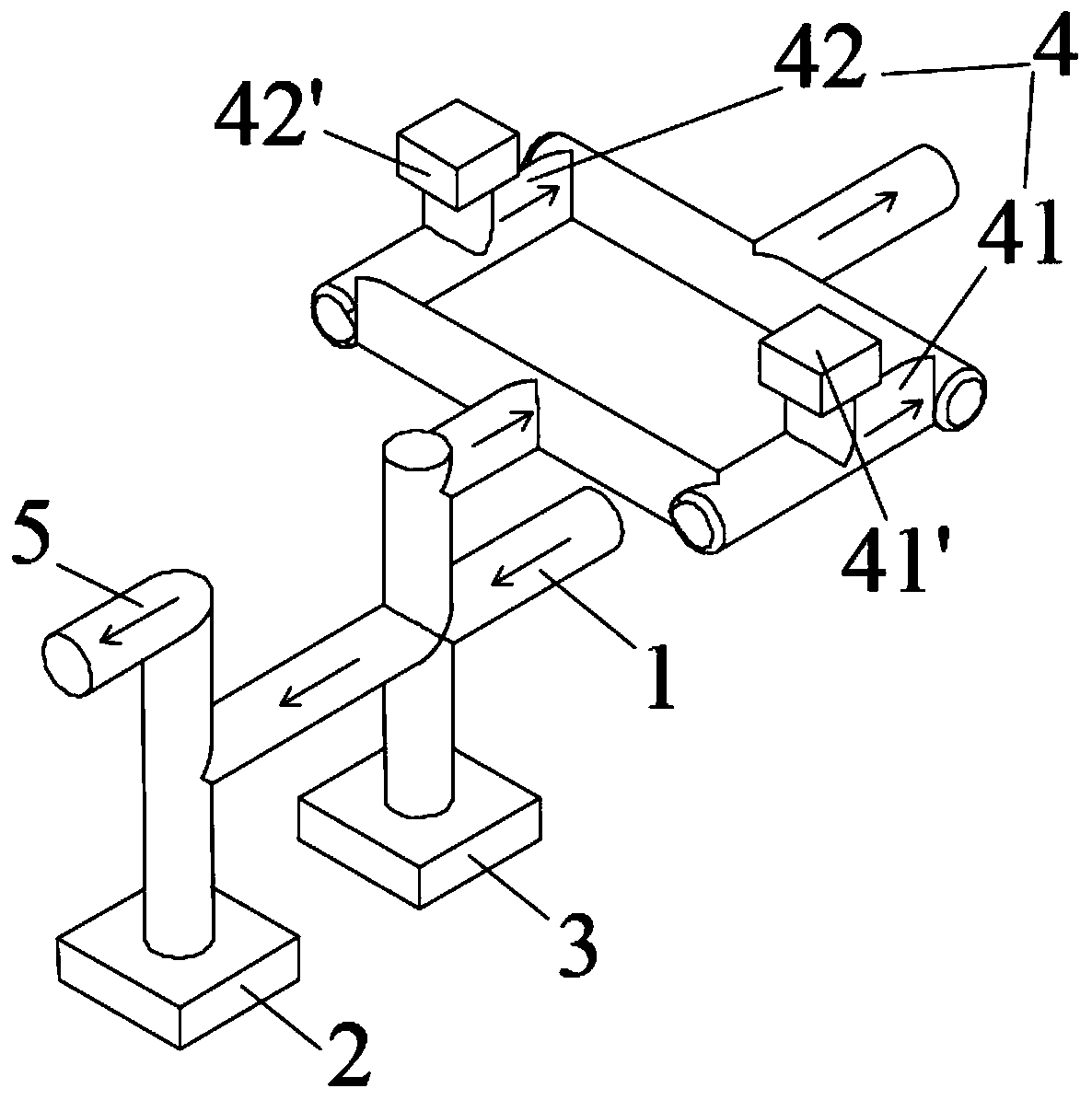

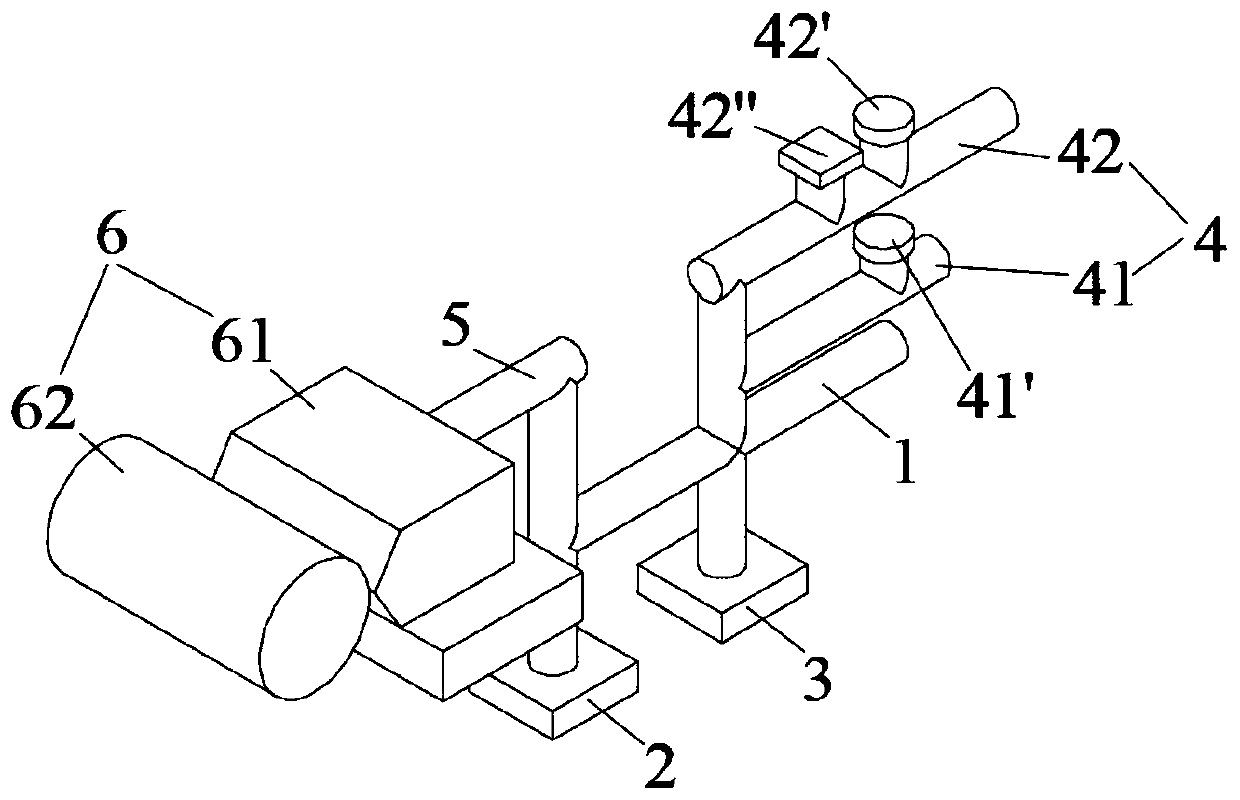

Device and method for accurate compression molding of test piece during similar material confecting process

ActiveCN103196738ASmall quality errorReduce the differencePreparing sample for investigationCompression moldingControl system

The invention relates to a device and a method for accurate compression molding of a test piece during a similar material confecting process. The device comprises a material molding mold and an accurate compression control system, wherein the material molding mold is detachable so as to facilitate the coating of a release agent in early period and de-molding of the test piece in later period; and the accurate compression control system can display the pressure and set the pressure to be applied to compress the test piece. By adopting the accurate compression system of the test piece during the similar material confecting process for a geo-mechanics model test, the problem that the pressure exertion and the material dosage cannot be controlled during the test piece confecting process in a traditional manual mode; and the pressure exertion can be controlled accurately during the manufacturing process of the similar material test piece, and therefore the quality error of the test piece is reduced, the difference of mechanical parameter caused by the manufacturing of various test pieces is reduced, and the obtained experimental data can well guide the confecting of similar materials.

Owner:SHANDONG UNIV

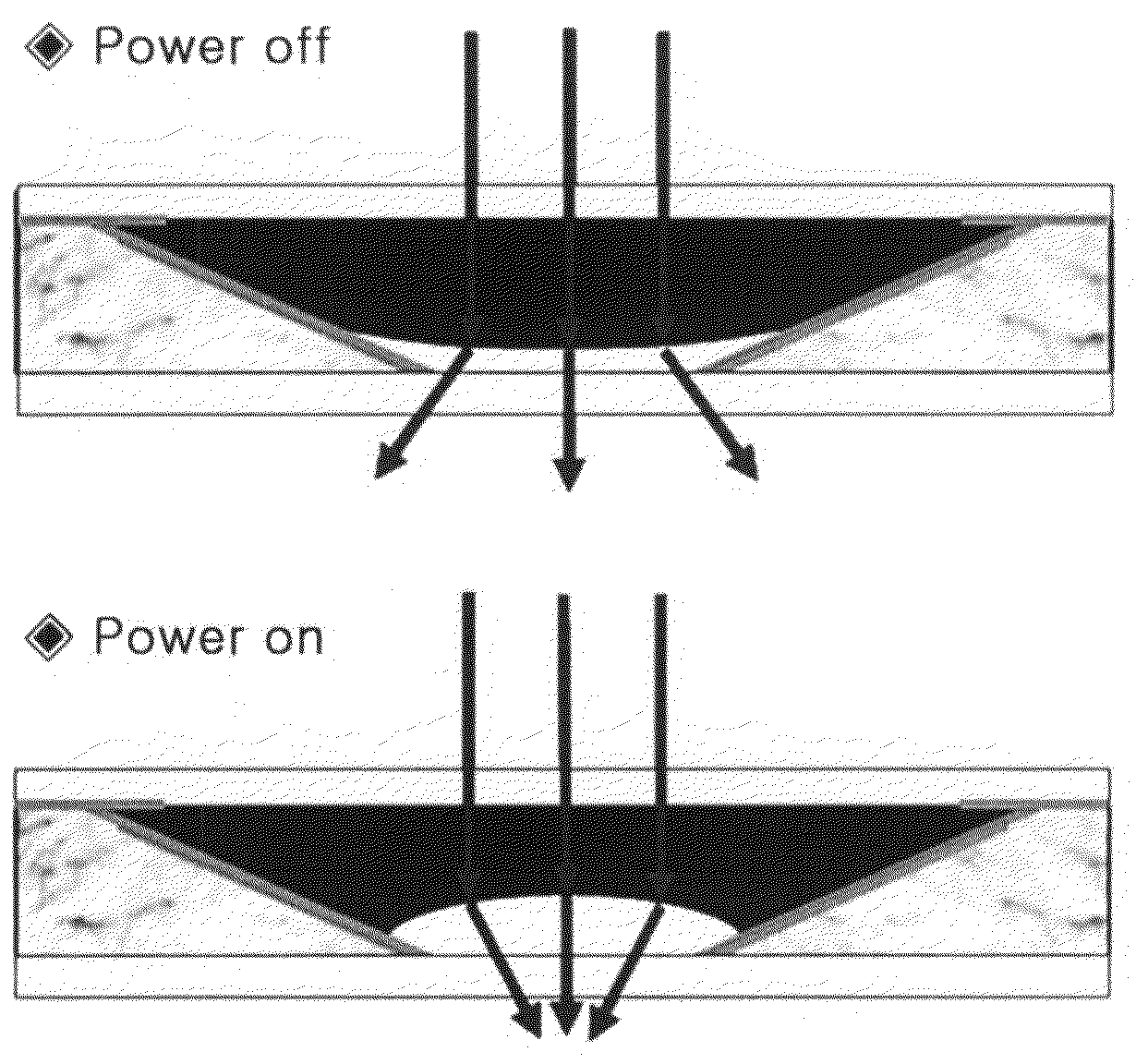

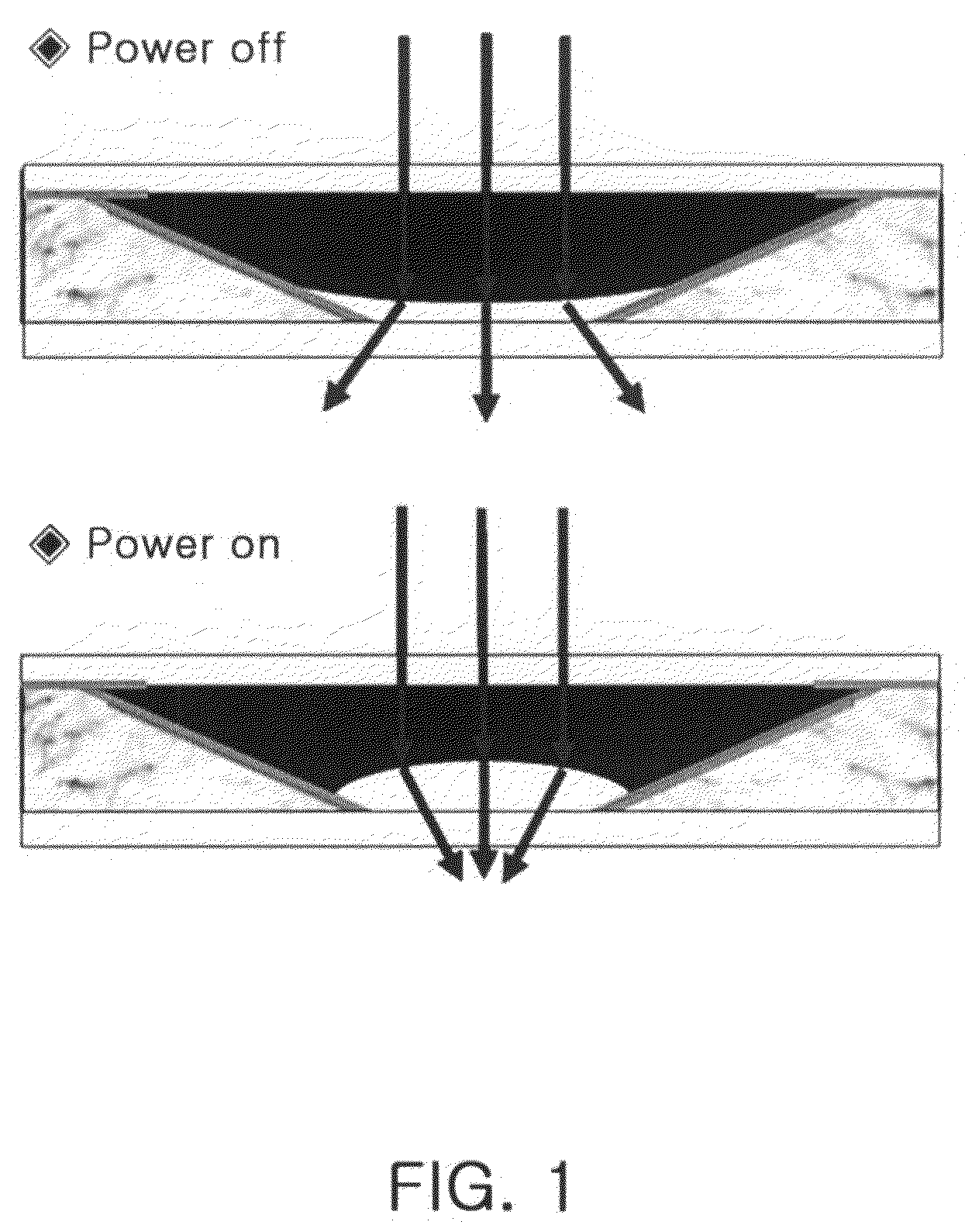

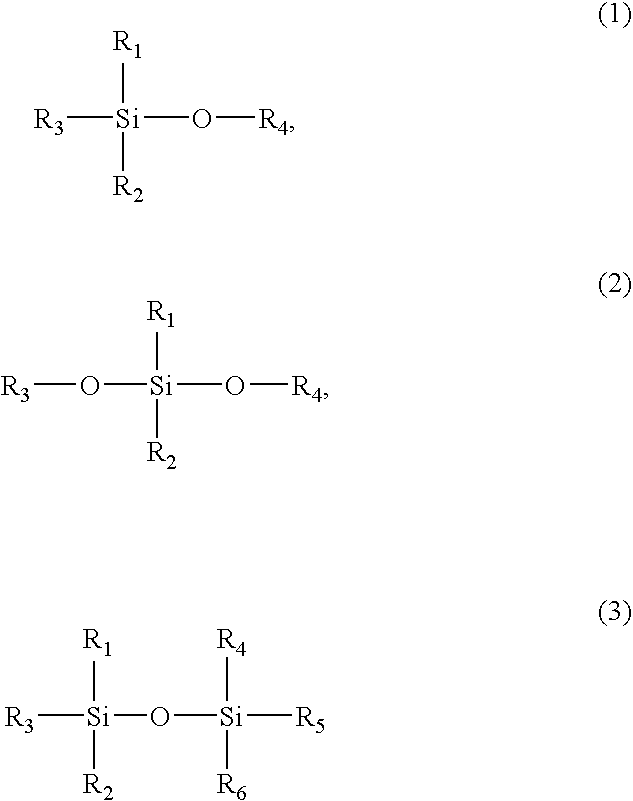

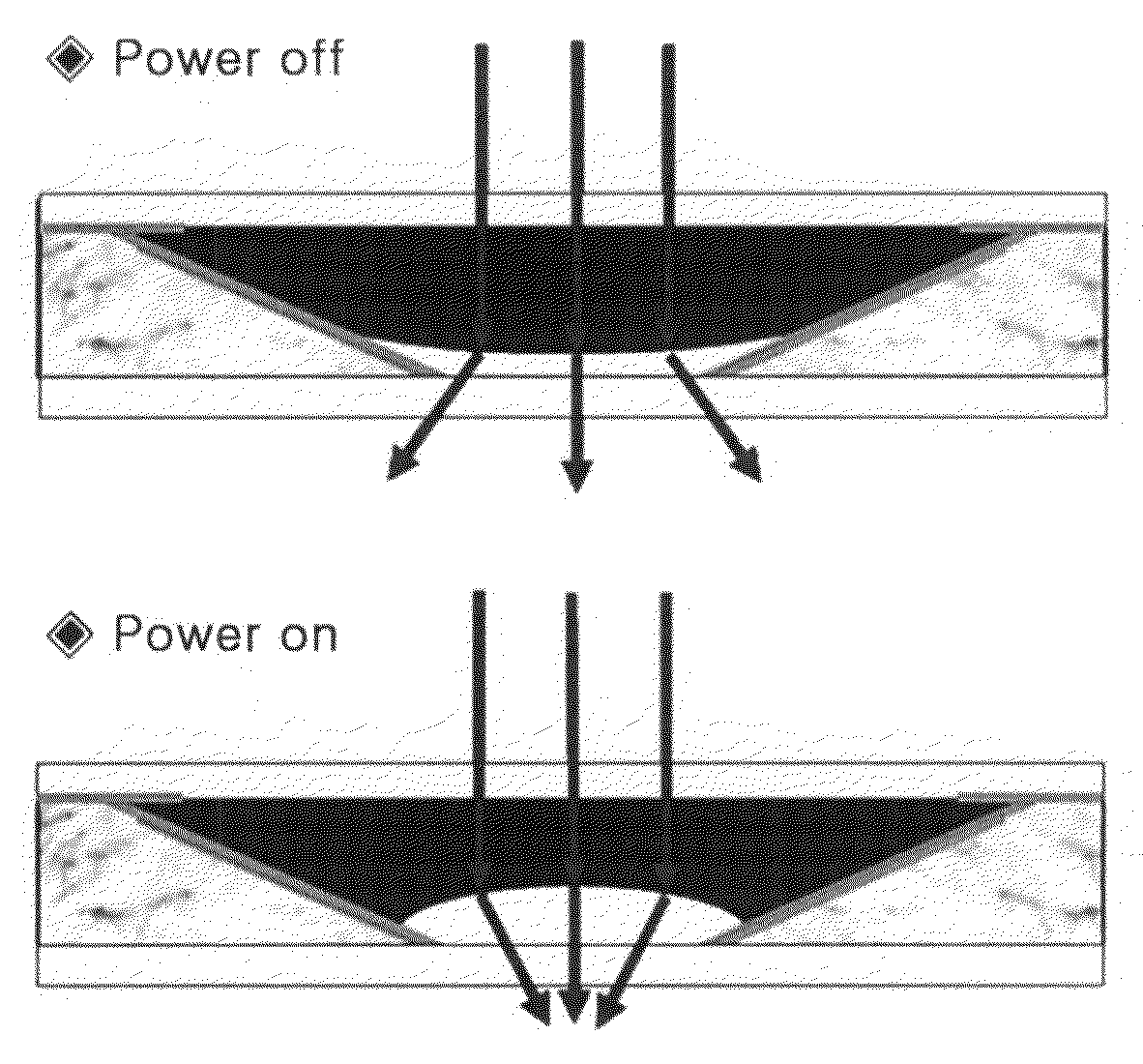

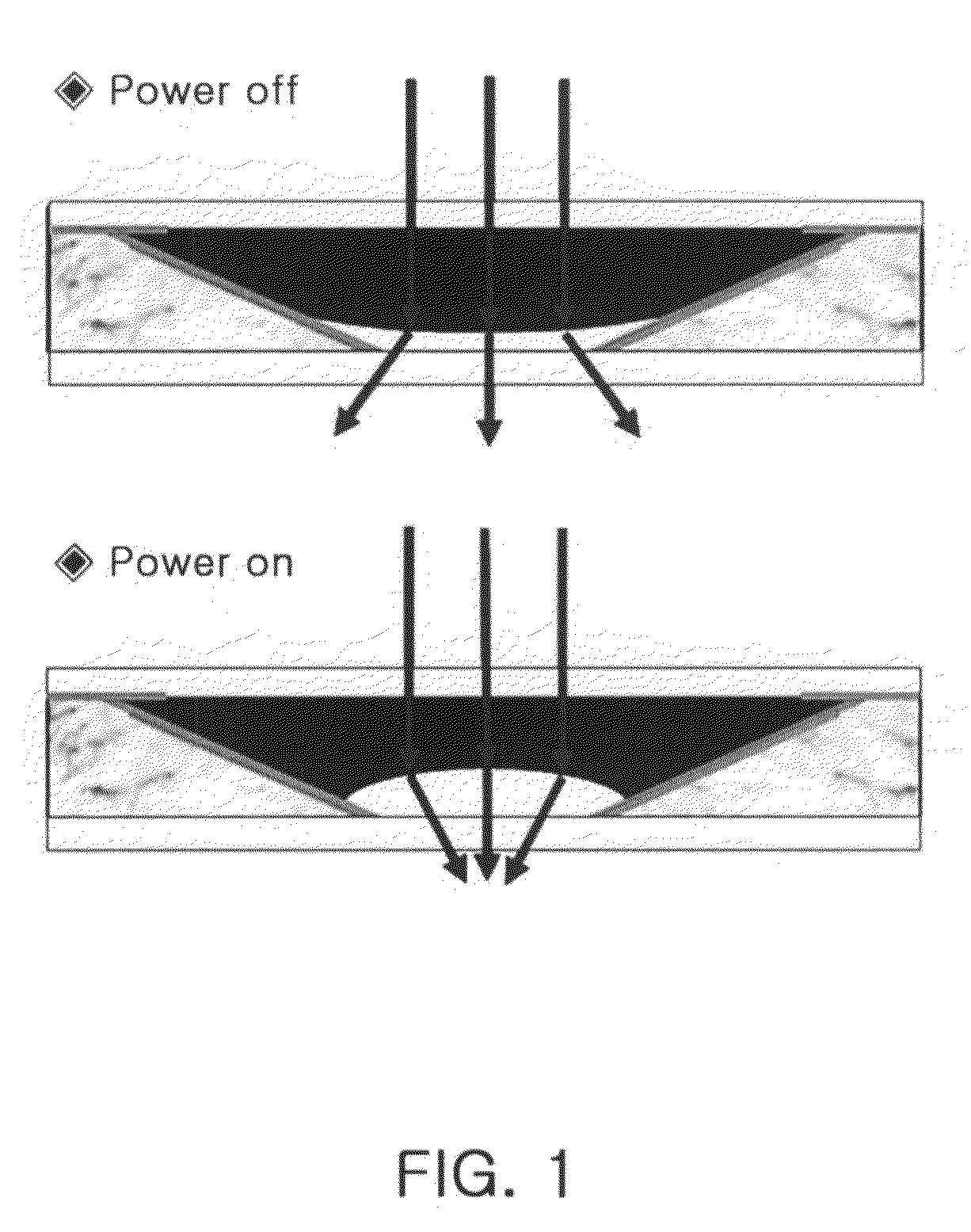

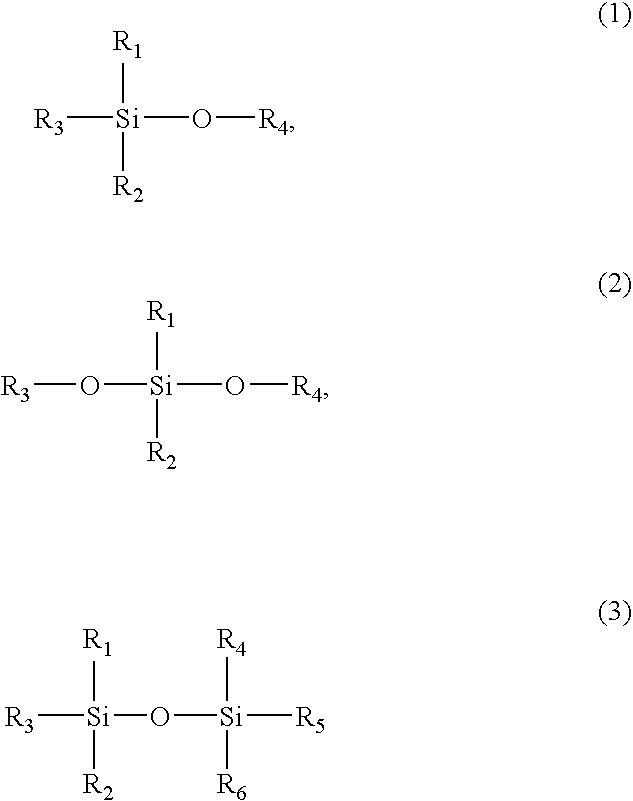

Insulating solution for liquid lens with high reliability and liquid lens using the same

Silicone oil used for an insulating solution for a liquid lens is disclosed which satisfies all of the requirements, i.e., density, viscosity, surface tension and refractive index, required as an insulating liquid for a liquid lens.The silicone oil includes at least one selected from compounds represented by Formulas 1 to 3 below:wherein R1 to R6 are same or different each other; and are independently selected from the group consisting of phenyl being replaced by alkyl or halo in ortho, meta or para position, silanol, alkyl and alkoxy each having a molecular weight of 200 or less.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Preparation method of porous oil-containing lubrication material using UHMWPE as matrix

A preparation method of a porous oil-containing lubrication material using UHMWPE as a matrix comprises the steps that 70-90 parts of the UHMWPE, 1-20 parts of polytetrafluoroethylene and 1-10 parts of a solid lubricant are stirred and mixed; then, the mixed powder is subjected to press forming and sintering treatment; the sintered and formed material is subjected to vacuum oiled immersion.The prepared thermoplastic polyethylene porous oil-containing material having ultra-high molecular weight internally has a rich porous structure, can continuously and stably provide lubricating oil in a working state and has abrasion resistance, impact resistance, chemical corrosion resistance, low temperature resistance and other excellent performances.Oil can be continuously supplied to a mechanical friction pair, and a practical effect is good.

Owner:LUOYANG MOTIPU LUBRICATION MATERIAL CO LTD

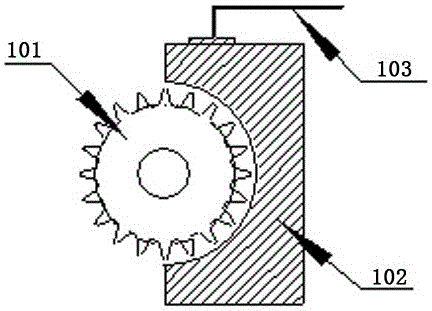

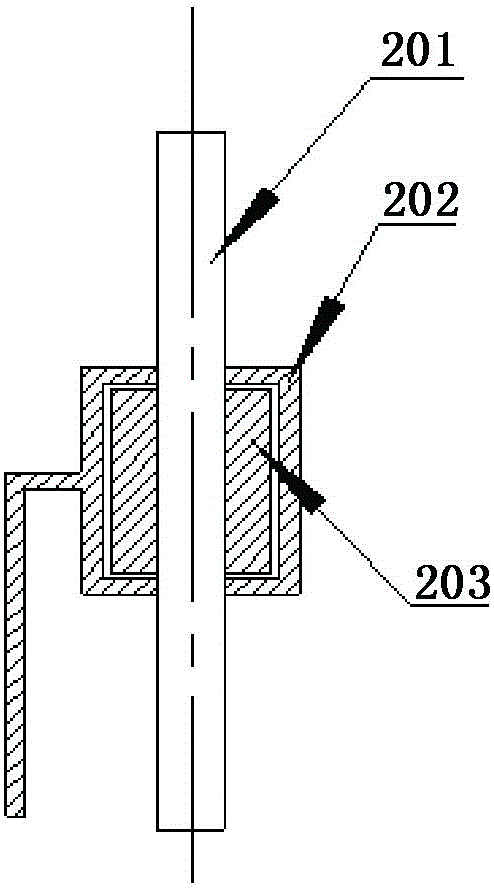

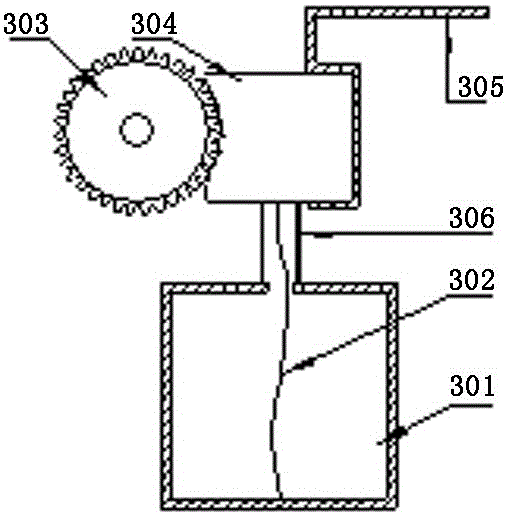

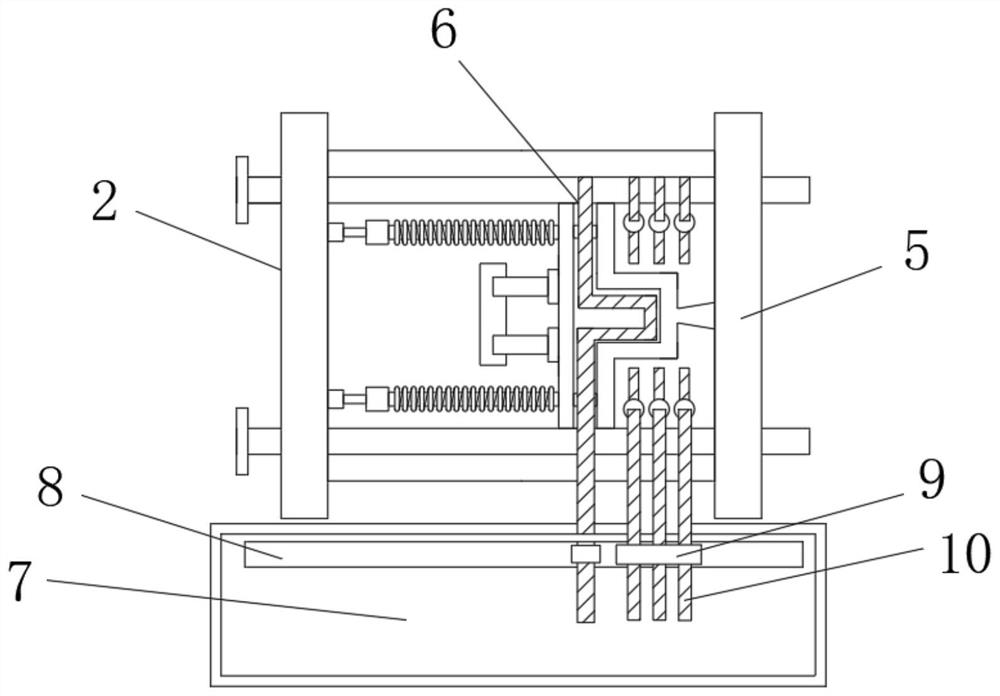

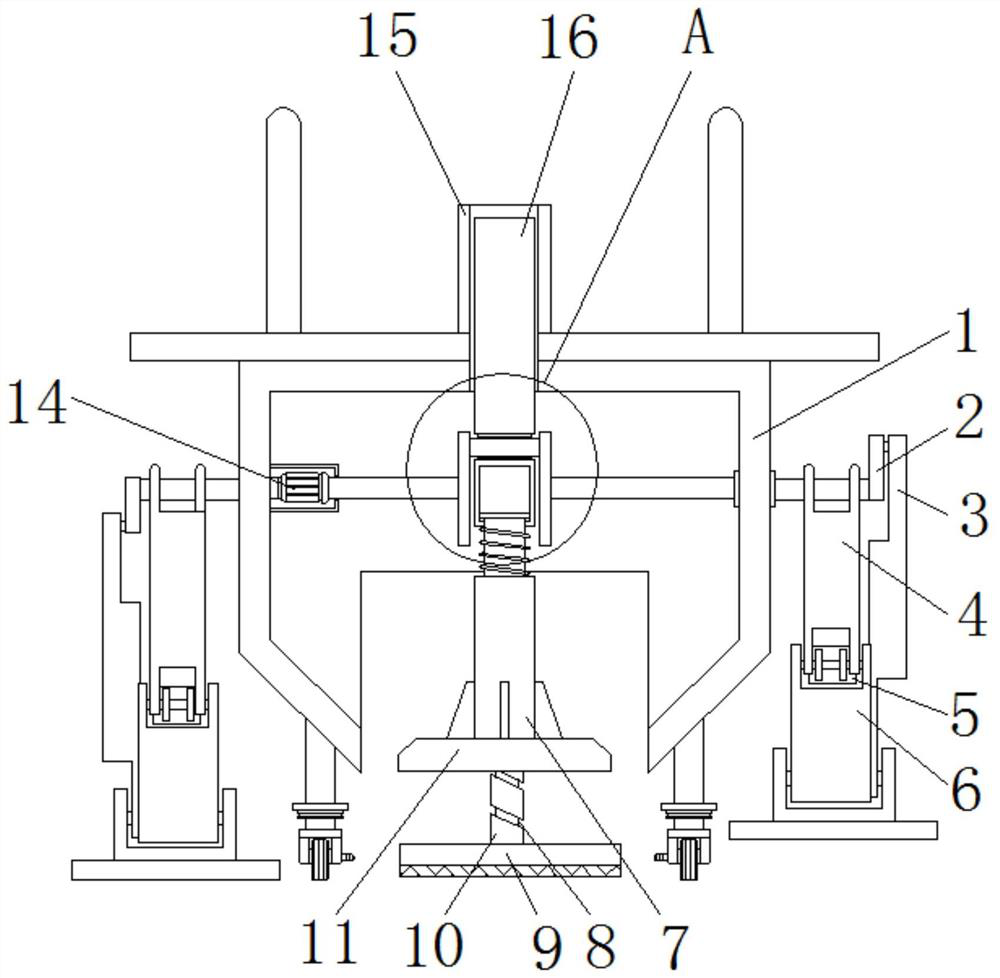

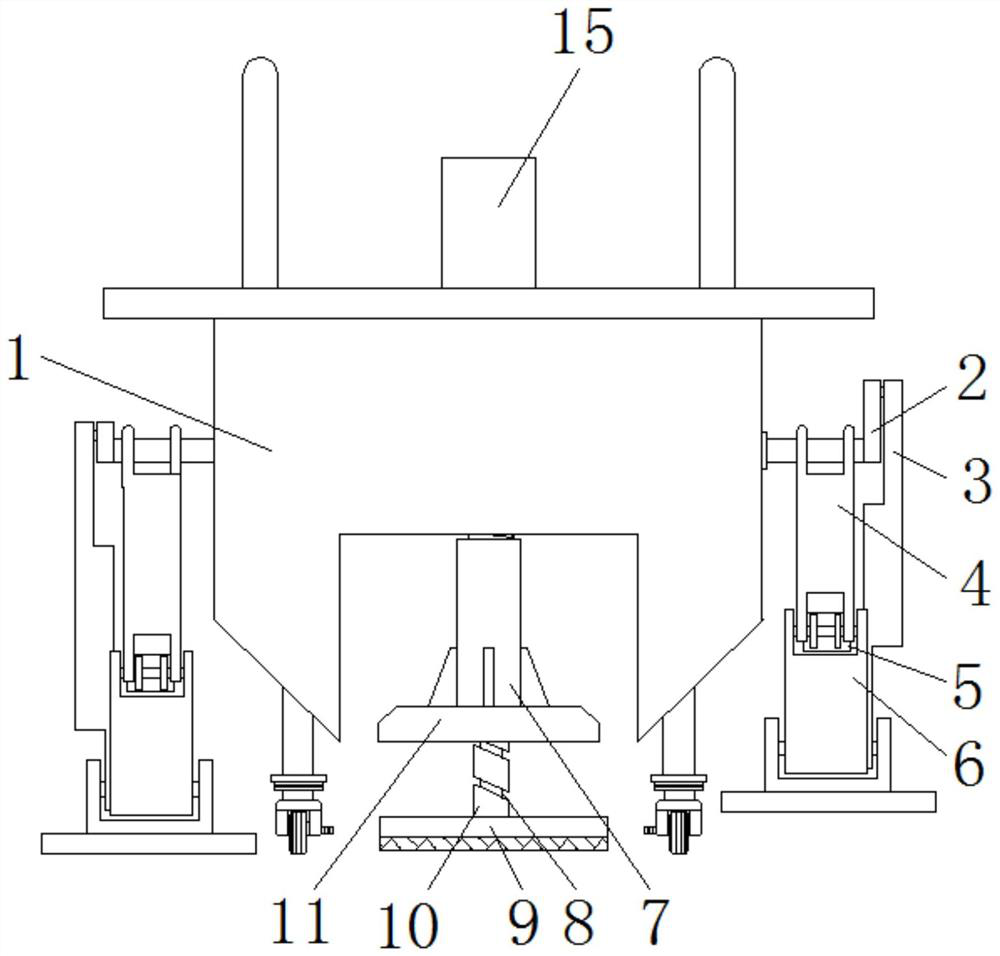

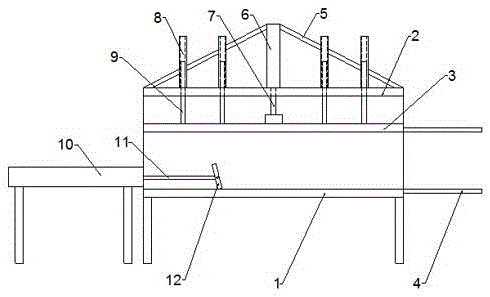

Forming machine for fireproof heat insulating board of outer wall

InactiveCN102490254ASame densityImprove fire insulation performanceCeramic shaping apparatusEngineeringMaterial storage

The invention discloses a forming machine for a fireproof heat insulating board of an outer wall. The forming machine comprises a forming mechanism, a push plate distributing mechanism and a plate conveying mechanism, wherein the forming mechanism comprises a stand; a base is arranged at the lower part of the stand; upright posts comprising guide posts and guide sleeves are arranged at four corners of the base; a lower die head oil jack is arranged on the base; a material storage molding box is arranged at the upper part of the lower die head oil jack; an upper die head is arranged at the upper part of the material storage molding box; the upper part of the upper die head is connected with a molding box oil jack; the upper die head is connected with the guide posts through four synchronous racks; and the material storage molding box is also connected with the guide posts through four synchronous racks. Due to adoption of two-way vibration compaction, two sides of the produced fireproof heat insulating board of the outer wall have same compactness, the fireproof heat insulating effect is improved and the construction is also facilitated.

Owner:黄宜昌

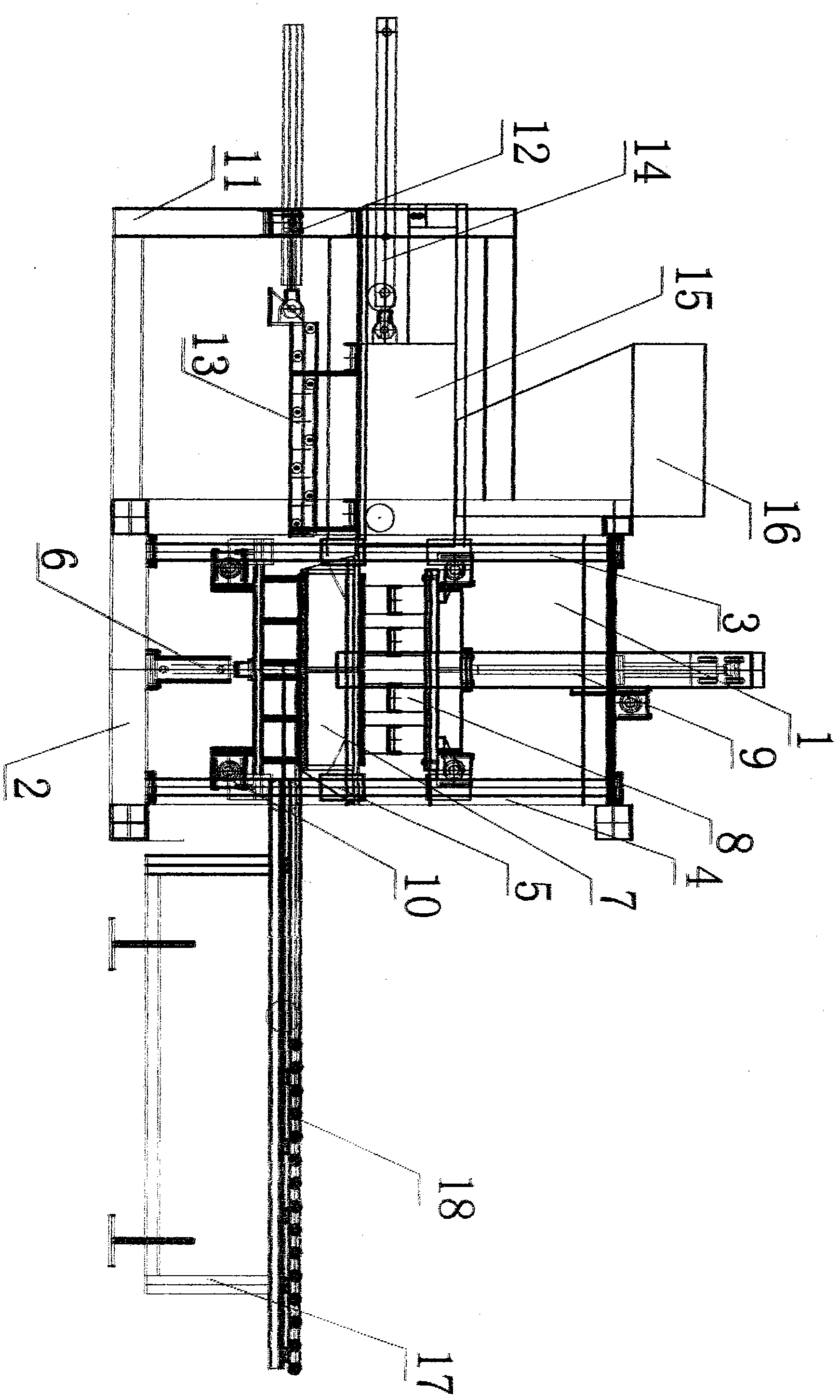

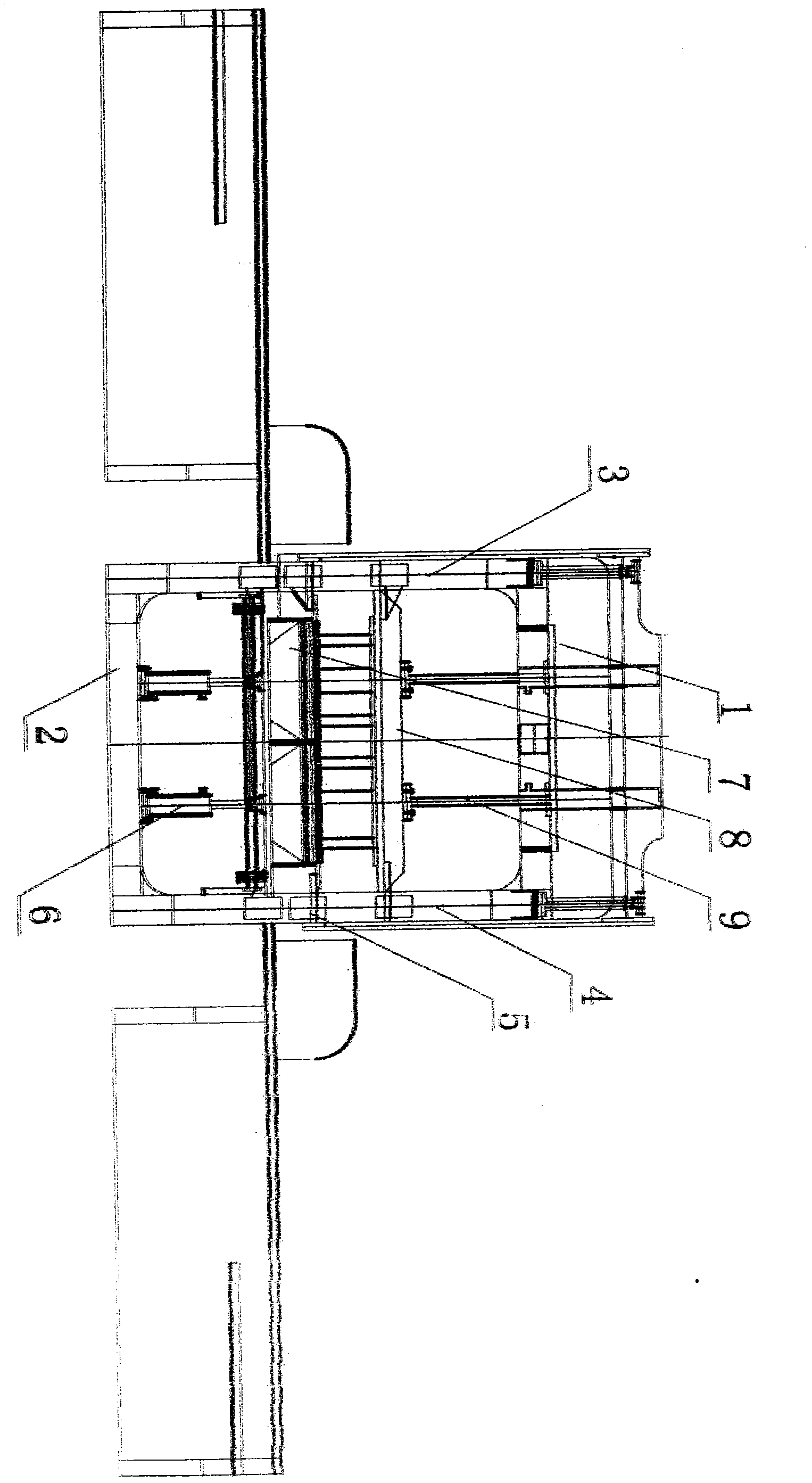

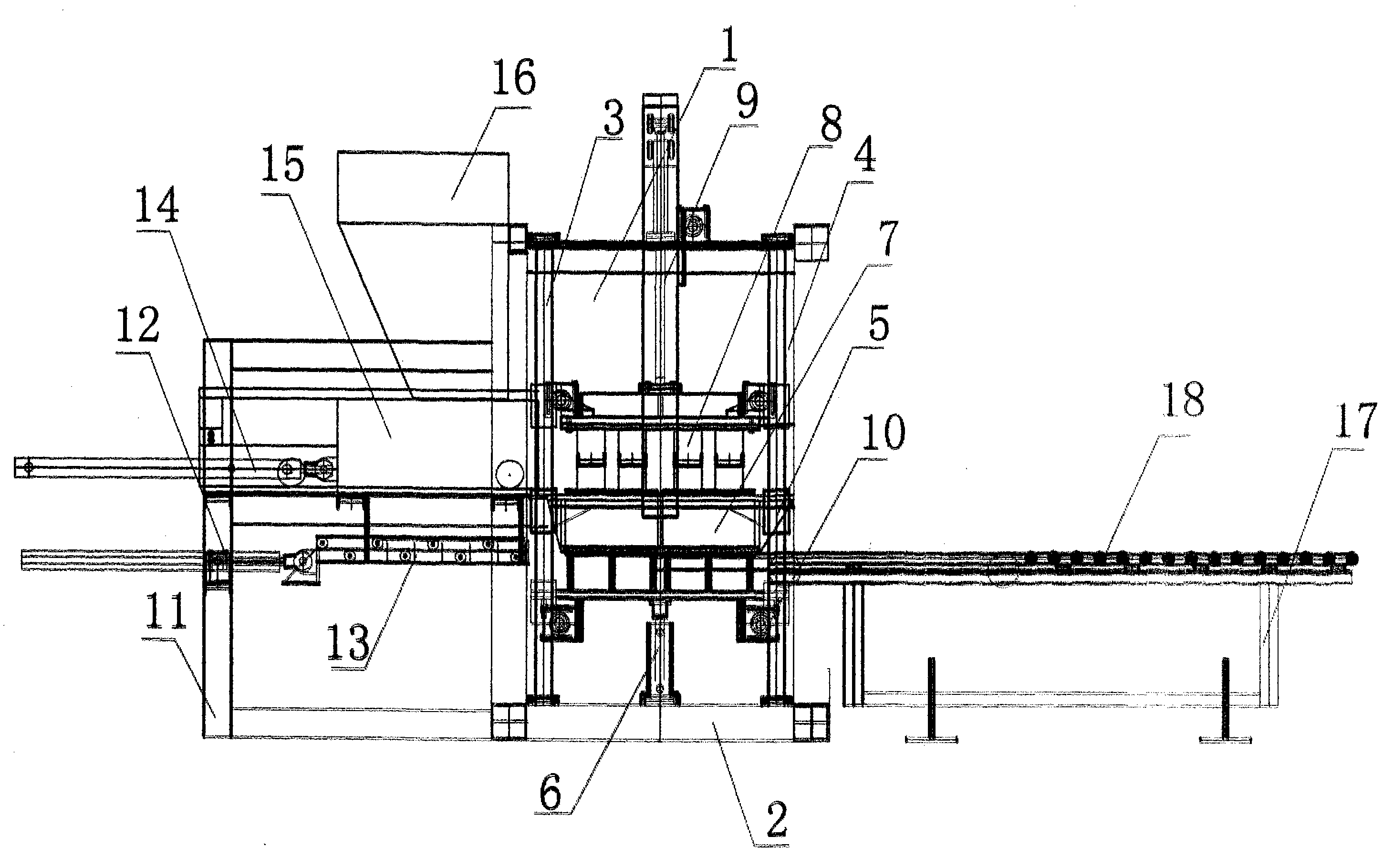

Large and bulky paper pulp die-pressing process and device

ActiveCN104652178AInhibit sheddingIncreasing the thicknessTextiles and paperVegetable fibersPulp and paper industry

The invention relates to a large and bulky paper pulp die-pressing process, which includes the following steps: a pulp box loaded with paper pulp is arranged under a forming unit, a paper pulp agitation mechanism is arranged at the bottom in the pulp box, the recess of a forming female die is upward, and moreover, the forming female die can be driven by a driving mechanism to move down into the pulp box, and thereby is immerged into paper pulp; a vacuumizer is utilized to vacuumize the forming female die, so that a wet green is formed; the forming female die upwardly gets close to a male die, the wet green is transferred, the male die brings the wet green to move onto a shaping unit, and the wet green is heated and shaped. The process disclosed by the invention can prepare bulky and large-sized vegetable fiber die-pressed products, the cost is low, and the rate of finished products is high.

Owner:谷照林

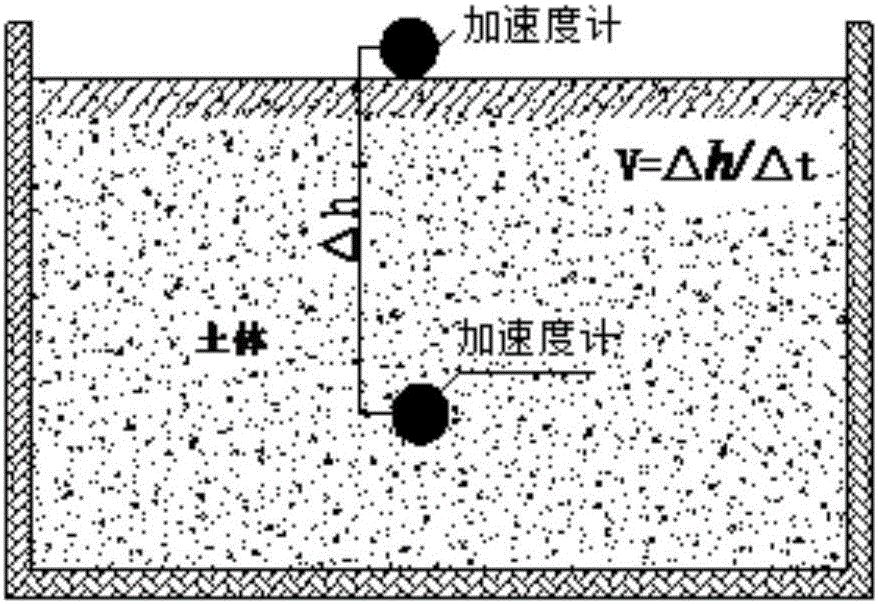

Testing method for dynamic response of model pile foundation

InactiveCN105971024AQuality assuranceEasy to manufactureFoundation testingData acquisitionEngineering

The invention discloses a testing method for the dynamic response of a model pile foundation. The testing method comprises the steps of 1, selecting model soil and model pile material; 2, preparing a model pile through a model pile preparing device; 3, determining the compaction standard of the model soil according to the speed of shear waves; 4, placing the model pile prepared in the step 2 into the center of a model box, placing the model soil into the model box in multiple times and compacting the model soil according to the compaction standard of the model soil obtained in the step 3, wherein the model soil inside the model box comprises a plurality of layers of soil bodies; 5, arranging various testing elements inside the model box; 6, connecting the testing elements to a data acquisition system; and 7, obtaining the data of the dynamic response by the data acquisition system through the various testing elements. According to the testing method, model tests are efficient and can be carried out accurately.

Owner:CHANGAN UNIV

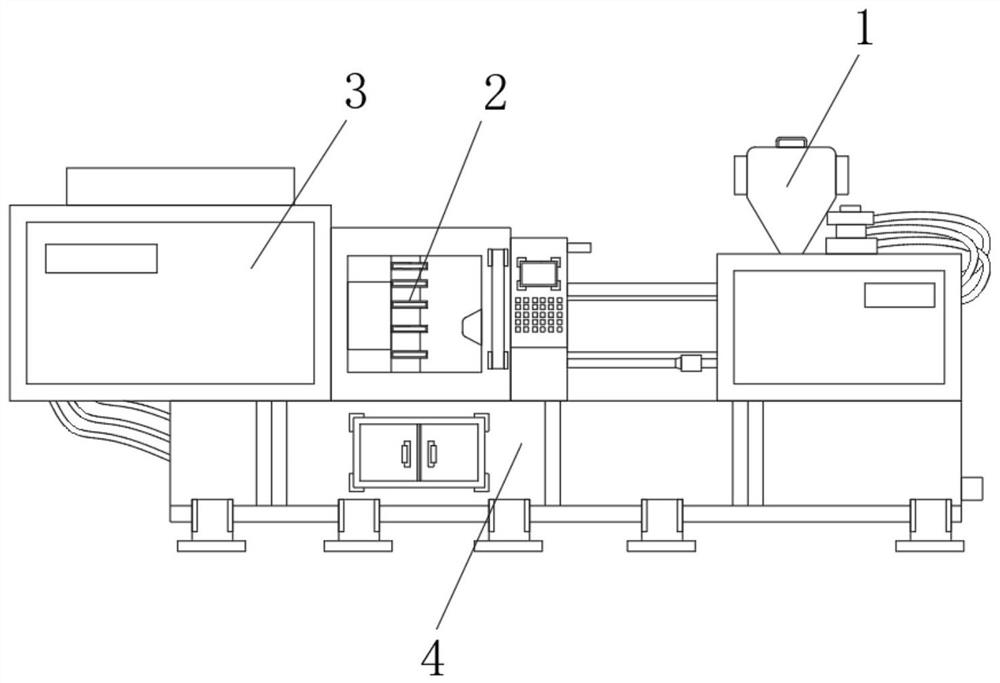

Injection molding equipment with high-efficiency cooling rate

The invention discloses injection molding equipment with the high-efficiency cooling rate. The injection molding equipment comprises a feeding opening, an injection mold is installed on the left sideof the feeding opening, a cooling bin is connected to the left side of the injection mold, a water storage bin is fixedly connected to the bottom end of the injection mold, and an injection molding opening is connected to one end of the right side of the injection mold; and a cooling pipe is arranged in the injection molding opening, a liquid bin is connected to the bottom end of the injection molding opening, a sliding groove is formed in the liquid bin, a water inlet pipe is fixedly connected to the interior of the injection molding opening, and a sliding block is fixedly connected to the outer surface of the water inlet pipe. According to the injection molding equipment, a large amount of heat in the equipment is taken away by accelerating circulation of cooling water, meanwhile, the situation of the inconsistent interior is avoided, the circulation path of the cooling water is greatly shortened, the cooling effect of the cooling water is greatly improved, plastic in a melting statecan be separated notably while efficient work is achieved, and the plastic which is not sufficiently molten is sufficiently molten.

Owner:爱莱克机械(杭州)有限公司

Insulating solution for liquid lens with high reliability and liquid lens using the same

InactiveUS7551364B2Guaranteed uptimeSame densitySilicon organic compoundsLensRefractive indexSilanol

Silicone oil used for an insulating solution for a liquid lens is disclosed which satisfies all of the requirements, i.e., density, viscosity, surface tension and refractive index, required as an insulating liquid for a liquid lens.The silicone oil includes at least one selected from compounds represented by Formulas 1 to 3 below:wherein R1 to R6 are same or different each other; and are independently selected from the group consisting of phenyl being replaced by alkyl or halo in ortho, meta or para position, silanol, alkyl and alkoxy each having a molecular weight of 200 or less.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Compression ratio adjustment method for prepressing spiral structure

InactiveCN103101732AMeet the requirements of different working conditionsApplicable preloadPackagingSpiral bladeFilling rate

The invention discloses a compression ratio adjustment method for a prepressing spiral structure. A spiral transmission system drives spiral blades on a spiral shaft to convey materials in rotating mode, and an input amount of the materials is synchronous with a processing amount of a next segment device; the materials are input into a material inlet pipe through a feed inlet A and input into a material biting bin through an adjustable feeding device in the middle segment; an output amount of the adjustable feeding device regulates a conveying amount according to setting of a compression ratio; and the setting of the compression ratio includes that the compression ratio is regulated between 2.5:1 and 1.05:1, the materials are compressed due to the fact that thread pitches of the spiral blades are changed from big to small and the spiral blades are changed from wide to narrow, and the materials are compressed by the spiral blades in a rotary mode. The compression ratio adjustment method for the prepressing spiral structure is designed to be reasonable, material filling rates among the blades are regulated, the spiral blades are not required to be detached, the compression ratio of the prepressing spiral structure is regulated automatically, the compression ratio adjustment method for the prepressing spiral structure is easy to operate, energy-saving, and consumption-reducing.

Owner:LUOYANG MINING MACHINERY ENG DESIGN & RES INST

Mold and method for preparing artificial rock core with non-penetrating holes

Owner:CHINA UNIV OF MINING & TECH

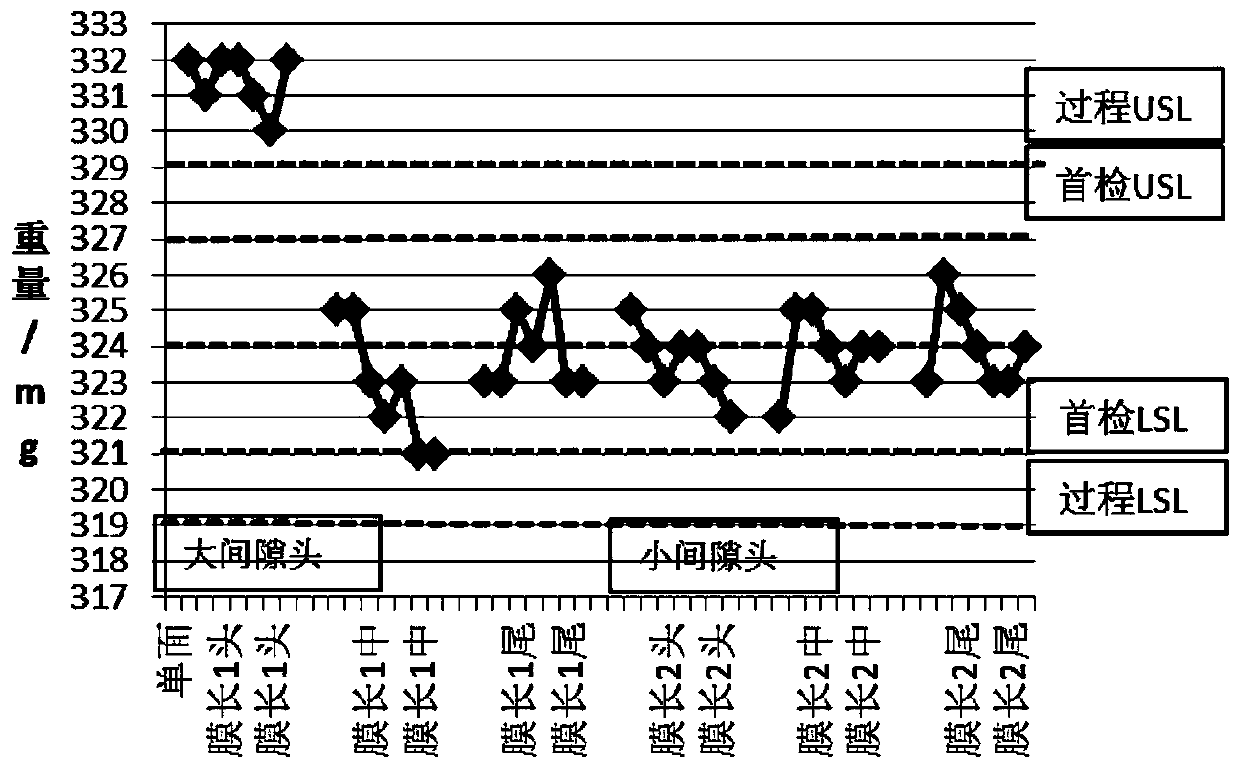

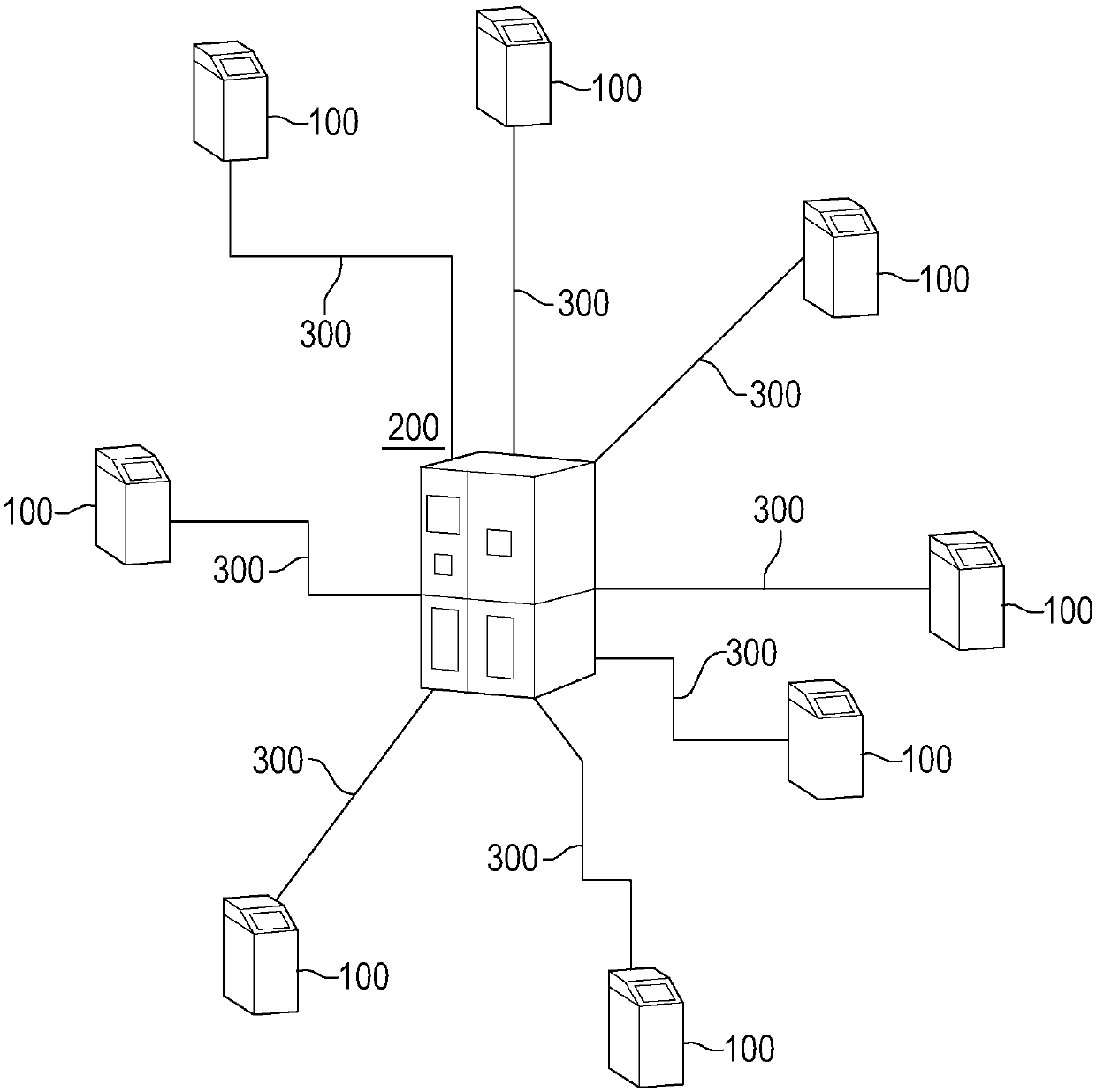

Reflux device for controlling film thickness of multi-gap pole piece and control method thereof

PendingCN110227634ASame densityThe same thicknessLiquid surface applicatorsElectrode collector coatingPole pieceEngineering

The invention belongs to the technical field of batteries, and particularly relates to a reflux device for controlling the film thickness of a multi-gap pole piece. The reflux device comprises a feedpipe, a coating valve, a return valve, a return pipe and a membrane head pipe, the membrane head pipe is in communication with the feeding pipe to form a main trunk line, the coating valve and the return valve are sequentially connected to the main trunk line in series, the return pipe is in communication with the return valve, the return pipe comprises a first pipeline and a second pipeline, andthe first pipeline and the second pipeline are connected in parallel. The reflux device is simple in structure, achieves multi-gap pole piece production, and is simple to operate, stable in work and high in production efficiency. In addition, the invention further provides a control method of the reflux device so as to improve the working stability and efficiency of the reflux device.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

Rapid ground tamping device for housing construction project

InactiveCN113622403APlay a protective effectAvoid damageSoil preservationElectric machineArchitectural engineering

The invention discloses a rapid ground tamping device for a housing construction project. The rapid ground tamping device comprises a bin body, wherein rotating rods are symmetrically arranged at the tops of the two sides of the interior of the bin body, a driving motor is arranged at the top of one side of the interior of the bin body, the output end of the driving motor is connected with the rotating rods, and a rotating disc is arranged on one side of the rotating rods. According to the rapid ground tamping device, the driving motor, a connecting rod A, a limiting rod A, a sleeve, a sliding rod, a spring, the rotating rods and the rotating disc are matched, so that the impact force of a pressing plate for tamping the ground every time is kept consistent, the same density of ground tamping is guaranteed, workers do not need to carry out tamping work on the ground for multiple times, then the working efficiency is reduced, and the project can be completed more quickly; and meanwhile, under the action of the spring, the pressing plate can be protected, the situation that the pressing plate is damaged due to the fact that the downward pressing force of the pressing plate is too large is prevented, and then the shaking amplitude of a machine body is small in the tamping process of the device.

Owner:安徽亿星建设工程有限公司

Textile humidifying device

InactiveCN108611782AAchieve circulationSame densityTextile treatment machine arrangementsTextile treatment cleaning apparatusMechanical engineeringTextile

The invention discloses a textile humidifying device which comprises a humidifying device shell. A spray chamber is arranged in the humidifying device shell, supporting rods are fixedly connected at the bottom of the humidifying device shell through bolts, a base is welded at the bottom of the supporting rods, a switch is mounted on one supporting rod, a safety door is rotatably connected on the front surface of the humidifying device shell through a rotating shaft, a handle is mounted on the front surface of the safety door, a water box is mounted in the spray chamber, a connecting pipe is mounted in the water box, and a spray head is mounted at one end of the connecting pipe. The textile humidifying device is provided with the rotatable spray head and solves the problems that the spray head cannot move, and fog does not circulate in the spray chamber, subsequent processing of textile fabrics is facilitated, the device is provided with the humidifying device shell which can be openedand closed, so that the spray chamber is conveniently cleaned by a user, and the device solves the problem that dust in the spray chamber is inconveniently cleaned.

Owner:长兴明远布艺科技有限公司

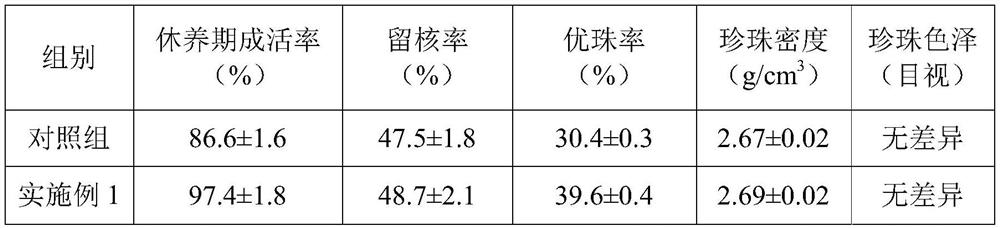

Artificial pearl nucleus and preparation method and application thereof

InactiveCN112471018AConsistent whitenessGood tissue compatibilityClimate change adaptationPisciculture and aquariaAntibacterial activityAnti bacterial

The invention discloses an artificial pearl nucleus as well as a preparation method and application thereof. A high polymer material polylactic acid with histocompatibility is used as a carrier, hydroxyapatite powder and nano silver powder are uniformly mixed according to a certain proportion, then an injection molding method is adopted to produce a pearl nucleus, and the pearl nucleus is boiled and purified for nucleus implantation and pearl cultivation production. The artificial pearl nucleus is simple in preparation process, controllable in shape, pure white in color and proper in density,and has good histocompatibility and antibacterial activity. By cultivating pearls through the artificial pearl nucleus, and the survival rate of pearl cultivating shells and the quality of the pearlscan be remarkably improved. The artificial pearl nucleus can replace the traditional tridacna or clam pearl nucleus to cultivate pearls.

Owner:GUANGDONG OCEAN UNIVERSITY +2

Preparation method of radiator containing complex variable cross-section hole channel

PendingCN113857462ASimplify the manufacturing processIncrease profitGearingCylindersHigh volume manufacturingManufactured material

The invention discloses a preparation method of a radiator containing a complex variable cross-section hole channel, and belongs to the technical field of manufacturing of electronic component radiators. According to the method, alloy used by the radiator is used as a raw material, a complex variable-cross-section pipe is prepared in advance, the shape and size of each part in the complex variable-cross-section pipe are the same as those of each part in a hole of the complex variable-cross-section hole channel in the radiator, and then the complex variable-cross-section pipe is placed into a casting mold to be positioned and fixed; and after poured alloy liquid is solidified, the complex variable-cross-section pipe and the alloy are tightly combined, an integrated casting is formed, and the radiator containing the complex variable-cross-section hole channel is obtained. Compared with a traditional preparation method of the radiator containing the complex variable cross-section hole channel, the method is simple in preparation process, short in production period, high in material utilization rate and low in production cost, and the prepared radiator is high in hole channel size precision and mechanical property, good in heat dissipation effect, long in service life, suitable for mass production and high in application and popularization value.

Owner:UNIV OF SCI & TECH BEIJING

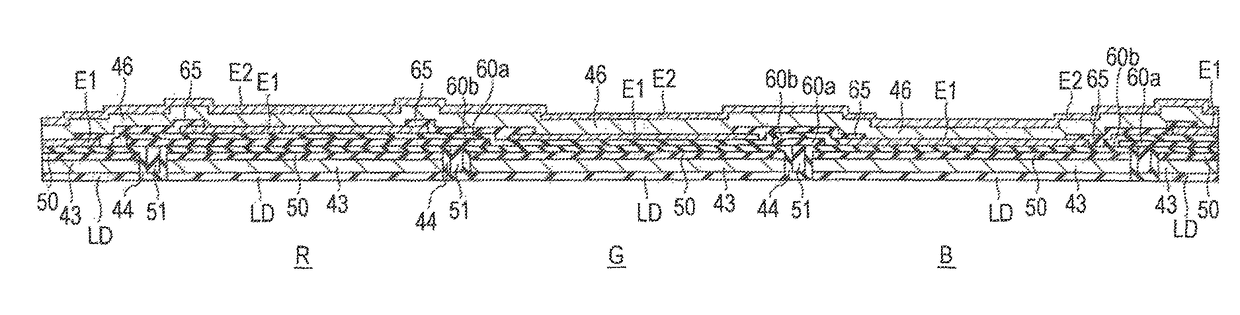

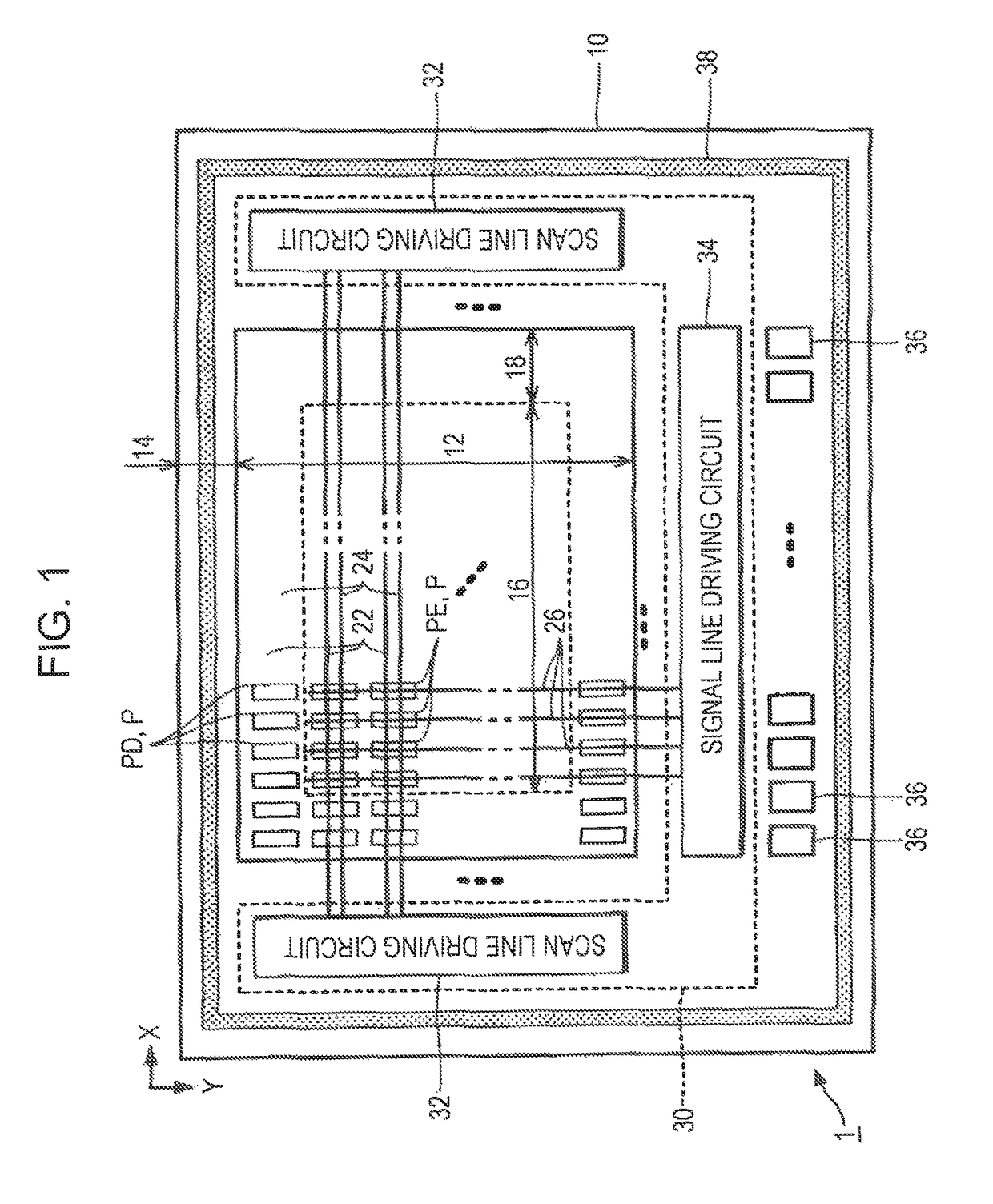

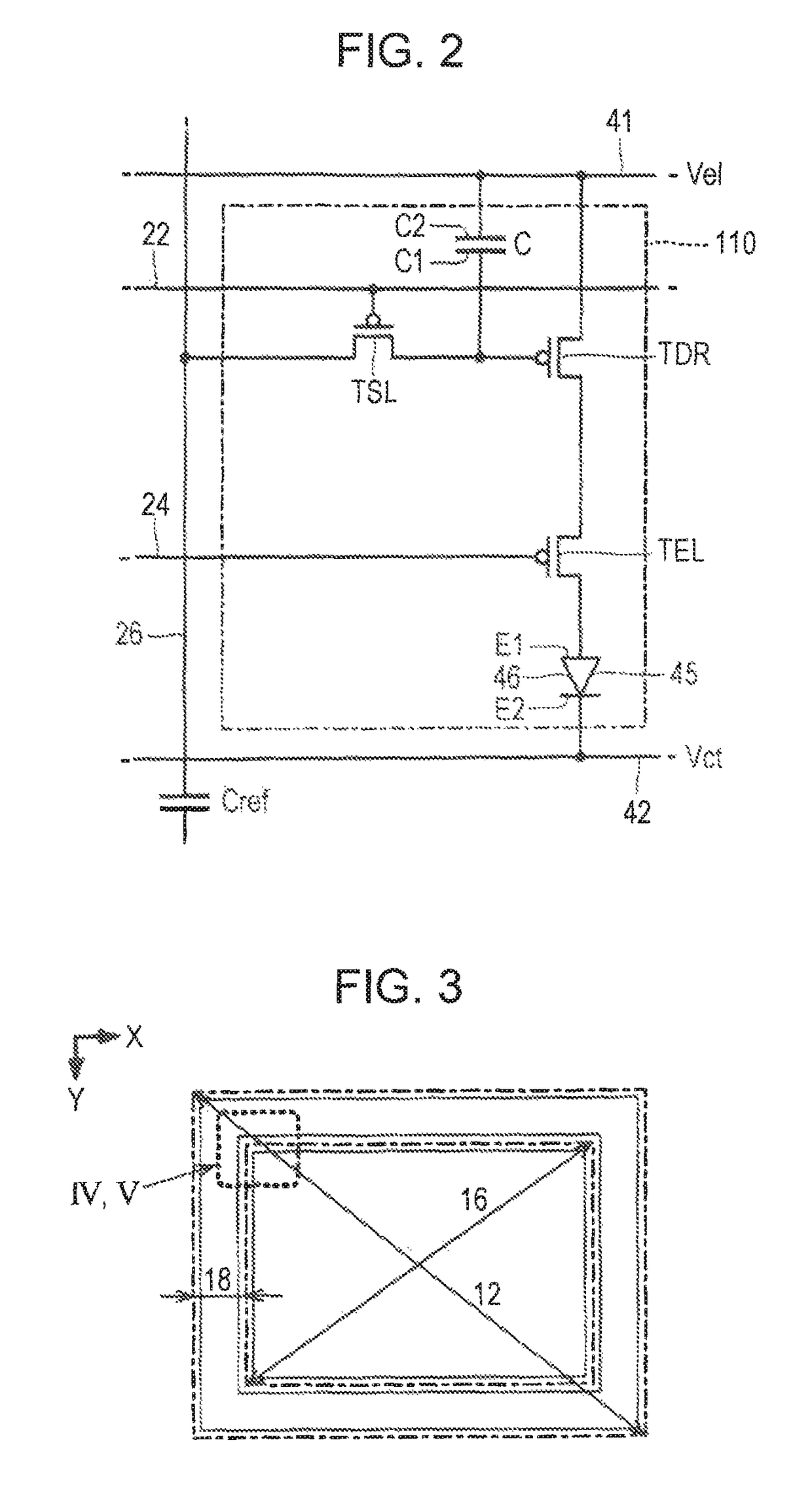

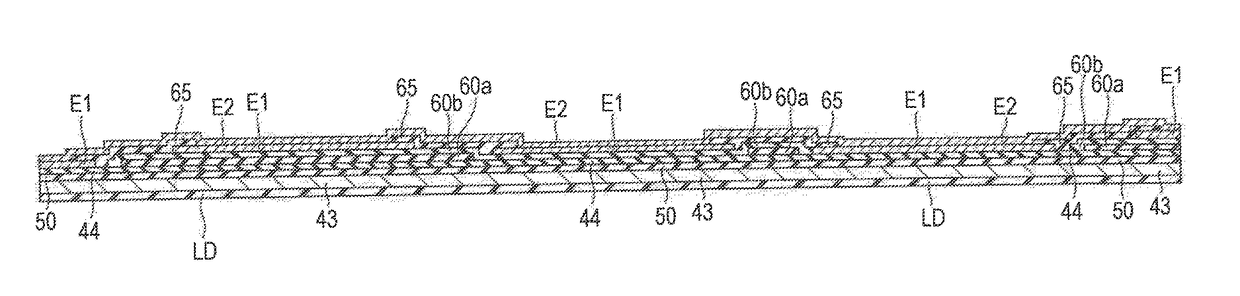

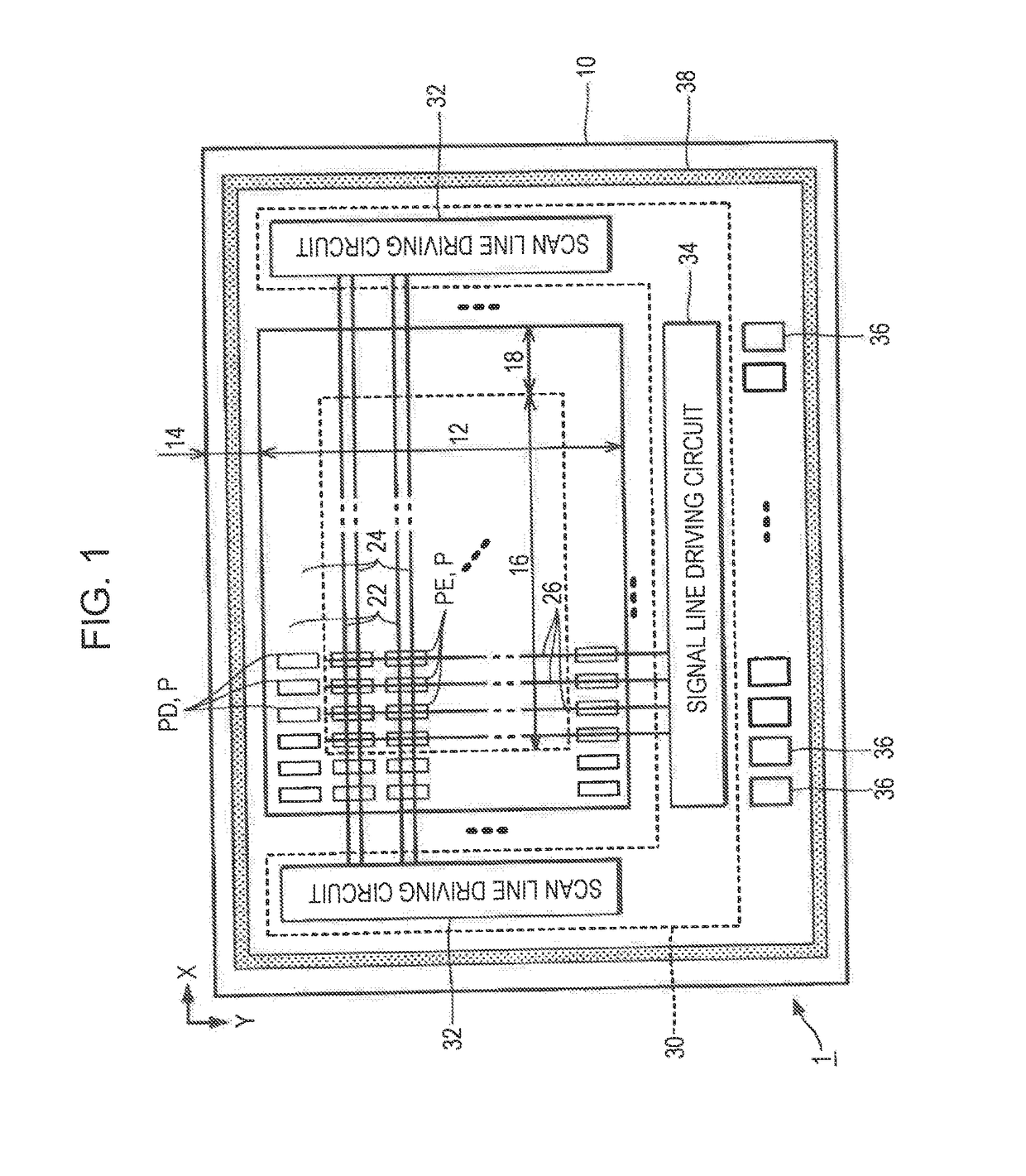

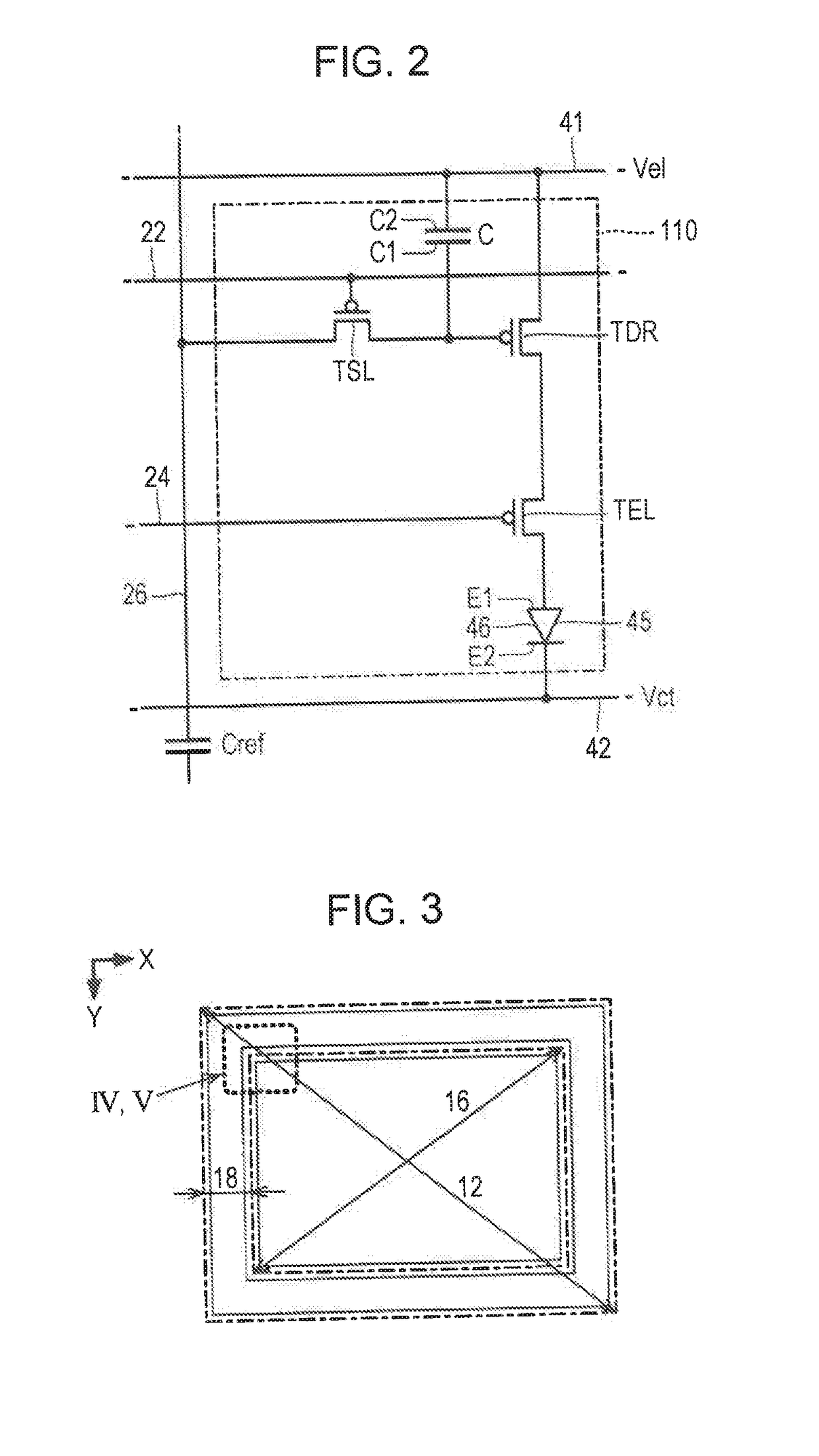

Electrooptical device, electrooptical device manufacturing method, and electronic apparatus

ActiveUS9954201B2Avoid defectsSame densitySolid-state devicesSemiconductor/solid-state device manufacturingElectricityReflective layer

Reflection layers are arranged for respective pixels with predetermined intervals in a row direction (X direction) and a column direction (Y direction) in a display region, and, subsequently to the display region, are arranged in the same manner with the predetermined intervals in the row direction (X direction) and the column direction (Y direction) also in a peripheral region around the display region. First electrodes, first light path adjusting layers, and second light path adjusting layers are arranged for the respective pixels in the display region, and are arranged so as to correspond to the respective reflection layers also in the peripheral region. The respective reflection layers are partially connected to each other in the peripheral region and are electrically connected to a second electrode at a cathode potential.

Owner:LUMITEK DISPLAY TECH LTD

Electrooptical device, electrooptical device manufacturing method, and electronic apparatus

ActiveUS20170237039A1Avoid defectsSame densitySolid-state devicesSemiconductor/solid-state device manufacturingElectricityReflective layer

Reflection layers are arranged for respective pixels with predetermined intervals in a row direction (X direction) and a column direction (Y direction) in a display region, and, subsequently to the display region, are arranged in the same manner with the predetermined intervals in the row direction (X direction) and the column direction (Y direction) also in a peripheral region around the display region. First electrodes, first light path adjusting layers, and second light path adjusting layers are arranged for the respective pixels in the display region, and are arranged so as to correspond to the respective reflection layers also in the peripheral region. The respective reflection layers are partially connected to each other in the peripheral region and are electrically connected to a second electrode at a cathode potential.

Owner:SEIKO EPSON CORP

Compactor for making fiber module

InactiveCN105539961AThe operation process is simple and convenientImprove work efficiencyPackagingEngineeringFiber

The invention relates to a compactor for making a fiber module. The compactor comprises a compactor body, and a pressing plate and a driving mechanism which are arranged on the compactor body; the compactor body comprises a worktable, and a mounting plate fixed above the worktable, and the pressing plate is arranged between the worktable and the mounting plate and parallel to the worktable; the driving mechanism comprises a compacting cylinder vertically fixed on the mounting plate and a pushing cylinder arranged in parallel to the worktable; a cylinder piston rod A of the compacting cylinder is connected with an upper end face of the pressing plate; the pushing cylinder is arranged at a side edge of an upper end face of the worktable, and an end portion of a cylinder piston rod B of the pushing cylinder is hinged to a push plate. The compactor for making the fiber module has the advantages that the compactor for making the fiber module is mainly applied to process the fiber module needed for use in a furnace roof, a fiber blanket is compacted by the compacting cylinder, and then the compacted fiber module is pushed into a plastic thin film sleeve by the pushing cylinder, and the whole operation process is simple, convenient, and high in working efficiency.

Owner:JIANGSU SOUTH ENERGY SAVING TECHNOLOGY CO LTD

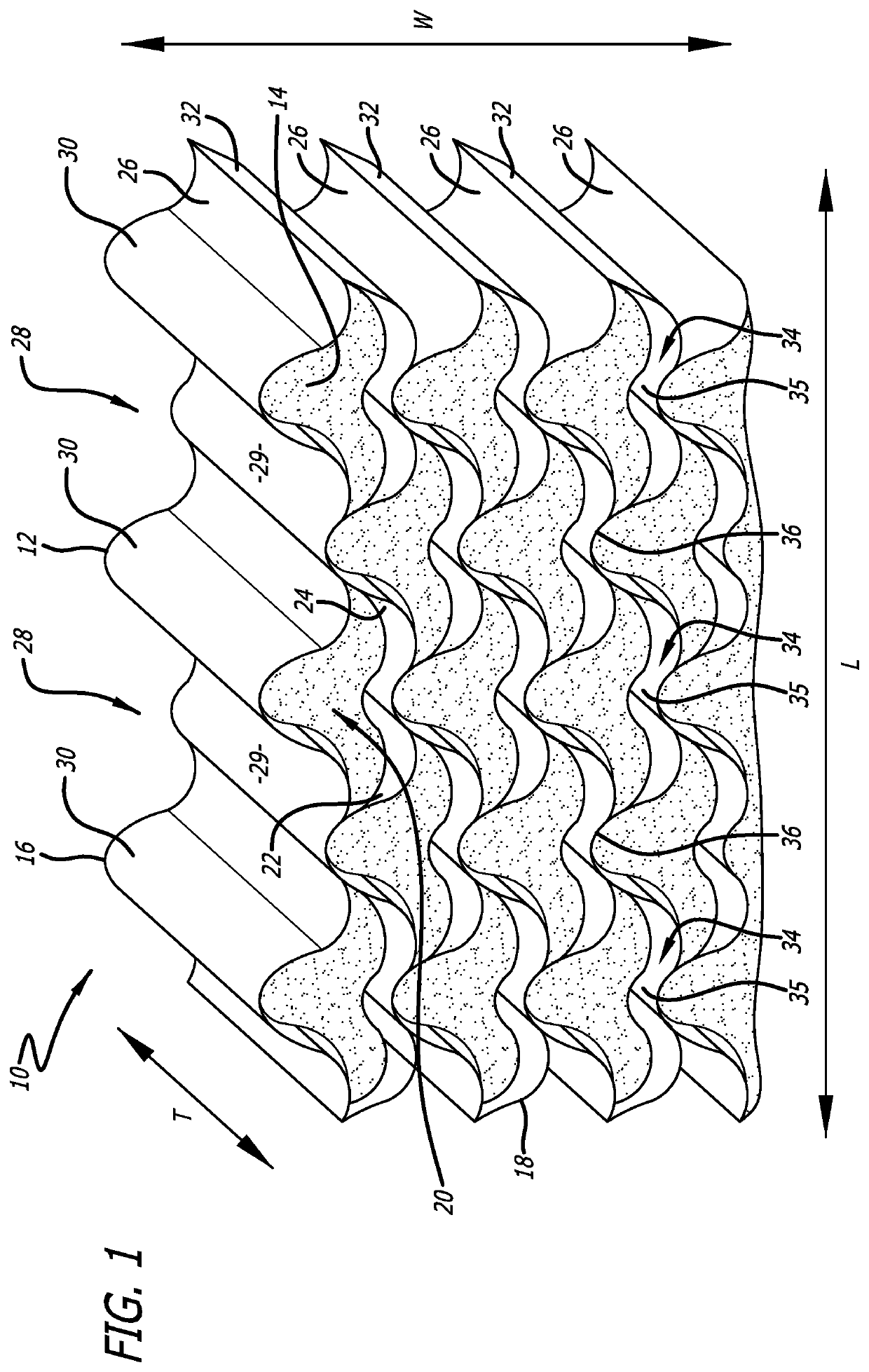

High temperature composite honeycomb

ActiveUS10947354B2Suitable for operationReduce the differenceSynthetic resin layered productsLaminationPolymer scienceHoneycomb like

Owner:HEXCEL

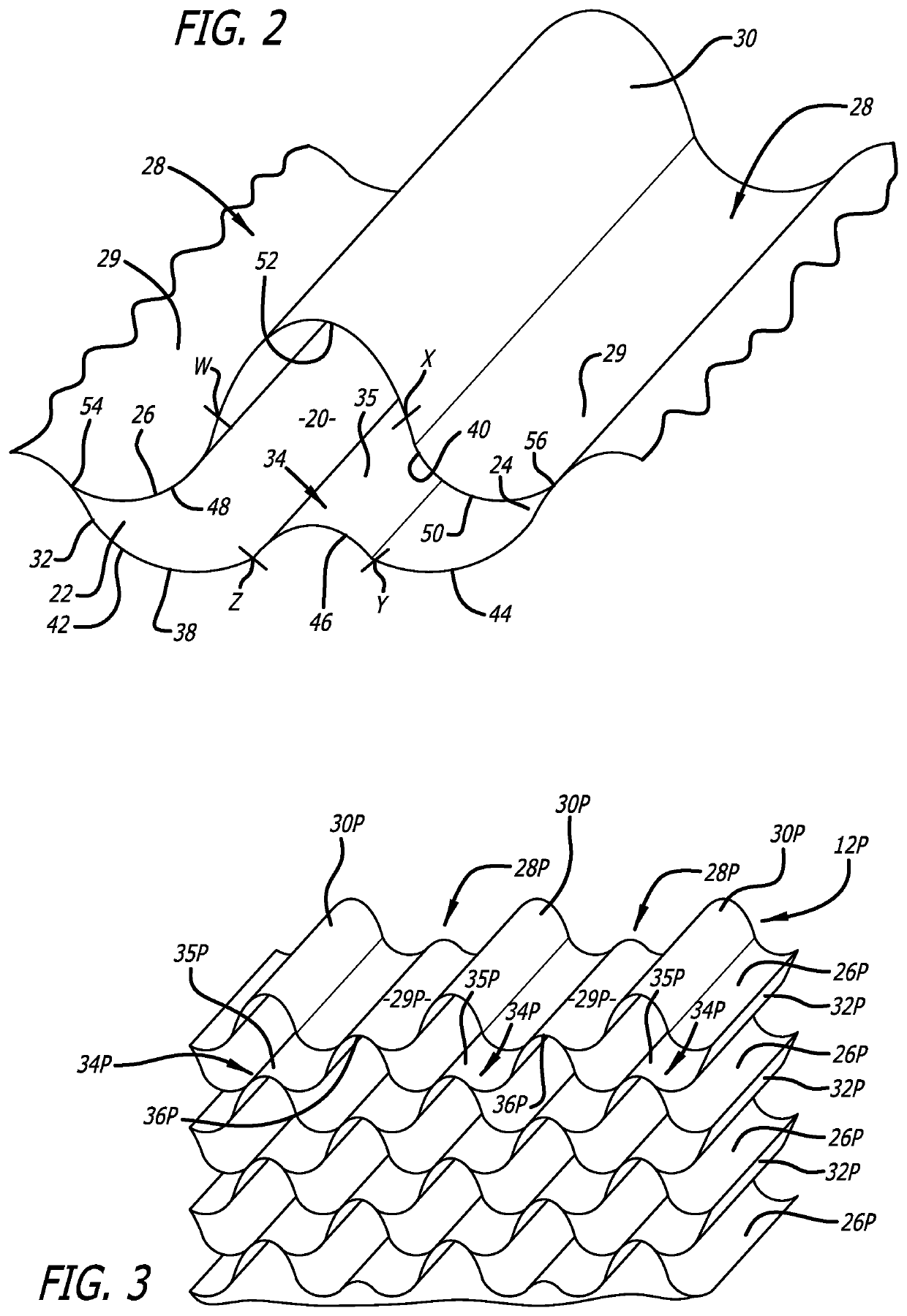

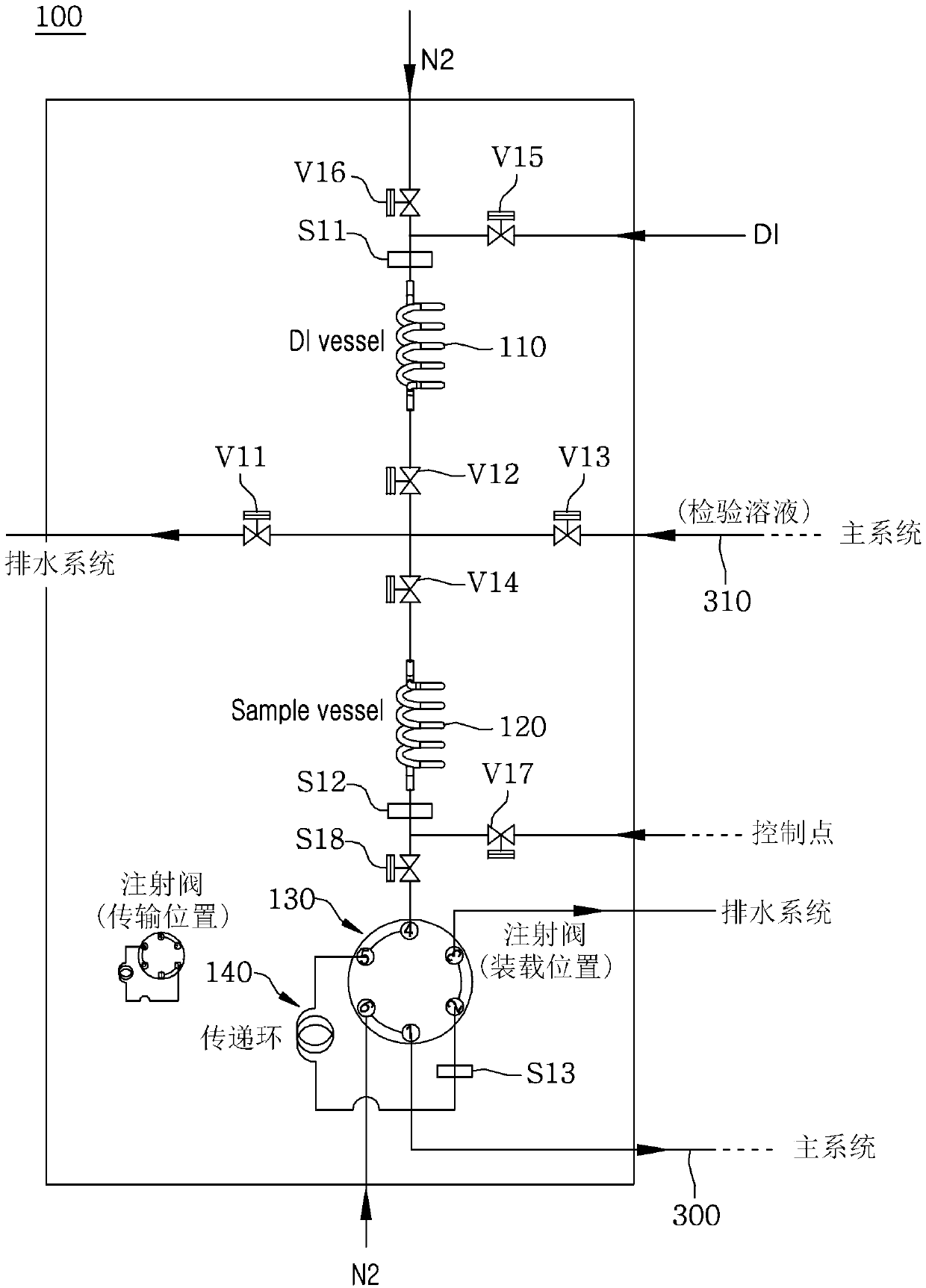

Online pollution monitoring system and method

ActiveCN107845585AGuaranteed reliabilityGuaranteed efficiencySemiconductor/solid-state device manufacturingTransmission lineChemical products

The invention relates to an online pollution monitoring system and an online pollution monitoring method. The online pollution monitoring system provided by the invention is characterized by comprising sampling units (100) and a main system (200), wherein the sampling unit (100) imports a chemical product via a line connected with a point using, storing or supplying the chemical product, and generates a transmission sample to be transmitted; the main system (200) receives the transmission sample from the sampling unit and performs analysis via an analyzer; the main system is connected with transmission lines (300) in a radial manner via a plurality of dispersedly arranged sampling units, and in the transmission lines, non-reactive gases of the transmission sample are in the front and back,so as to be transmitted in a packaged manner.

Owner:NVISANA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com