Mold and method for preparing artificial rock core with non-penetrating holes

A technology of artificial core and non-penetrating holes, which is applied in the field of molds, can solve the problems of not being able to make holes (non-penetrating core specimens, unable to ensure uniform size of specimens, and unable to ensure the same density of specimens), etc., to achieve a wide range of Practicality and popularization, simple production method, same density and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

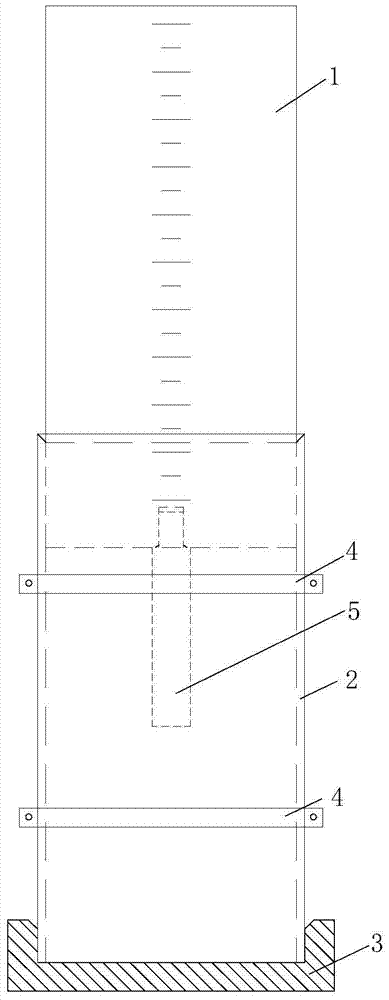

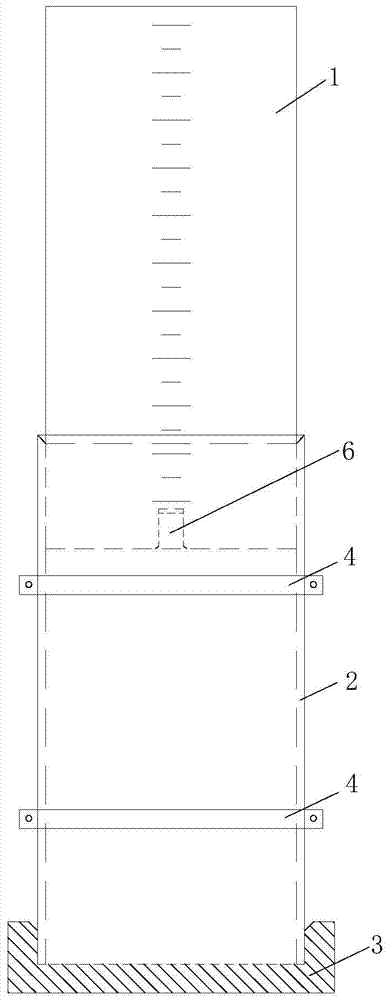

[0022] Such as figure 1 and figure 2 Shown, a kind of multifunctional mold of artificial rock core cylindrical standard test piece, comprises test piece indenter 1, rock core valve 2, base 3 and clip 4;

[0023] The rock core valve 2 has two pieces, the height of the rock core valve 2 is 200 mm, the rock core valve 2 is aligned and spliced to form a cylindrical outer diameter of 60 mm, and the diameter of the hollow cylindrical inner cavity formed is 50 mm;

[0024] The clamp 4 is made up of two semi-circular rings, and the internal diameter of the clamp 4 composed of the two semi-circular rings is 60 mm, which is just adapted to the outside of the rock core valve 2; there are threaded holes on the clamp 4, and bolts and nuts are used to make the clamp Fasten;

[0025] The height of the base 3 is 50 mm, and the middle part of the base 3 is provided with a base ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com