Compactor for making fiber module

A technology of fiber modules and compactors, applied in the field of compactors, can solve problems such as poor work efficiency, many processing procedures, and poor flexibility, and achieve the effects of high work efficiency, reasonable structural design, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

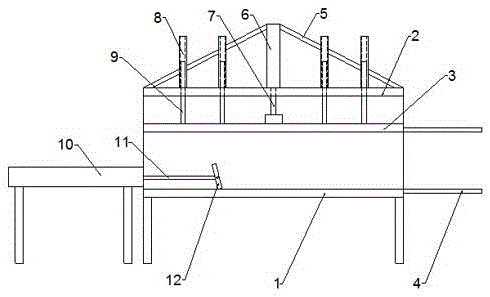

[0014] Such as figure 1 As shown, the present invention discloses a compacting machine for fabricating fiber modules, which includes a compacting machine body, a pressing plate 3 arranged on the compacting machine body and a driving mechanism.

[0015] The compactor body includes a workbench 1 and a mounting plate 2 fixed on the top of the workbench 1. Several round pipes 8 are vertically fixed on the mounting plate 2; 1 parallel, several guide rods 9 are vertically fixed at the same vertical line position on the upper end surface of the pressure plate 3 and the circular pipe 8, the guide rods 9 slide and fit with the circular pipe 8, and the pressure plate 3 and the workbench 1 are far away from the same side where the cylinder 10 is pushed A set of boards 4 are arranged on the sides.

[0016] The drive mechanism includes a compression cylinder 6 vertically fixed on the mounting plate 2 and a push cylinder 10 arranged parallel to the workbench 1; wherein the cylinder piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com