Method for preparing hydrophobic wood

A hydrophobic and wood-based technology, which is applied in the direction of impregnated wood, wood impregnation, wood processing equipment, etc., can solve the problems of changing wood color, high toxicity of modifiers, and single wood, so as to improve mechanical properties, durability, and mechanical properties And the effect of improving durability and improving dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

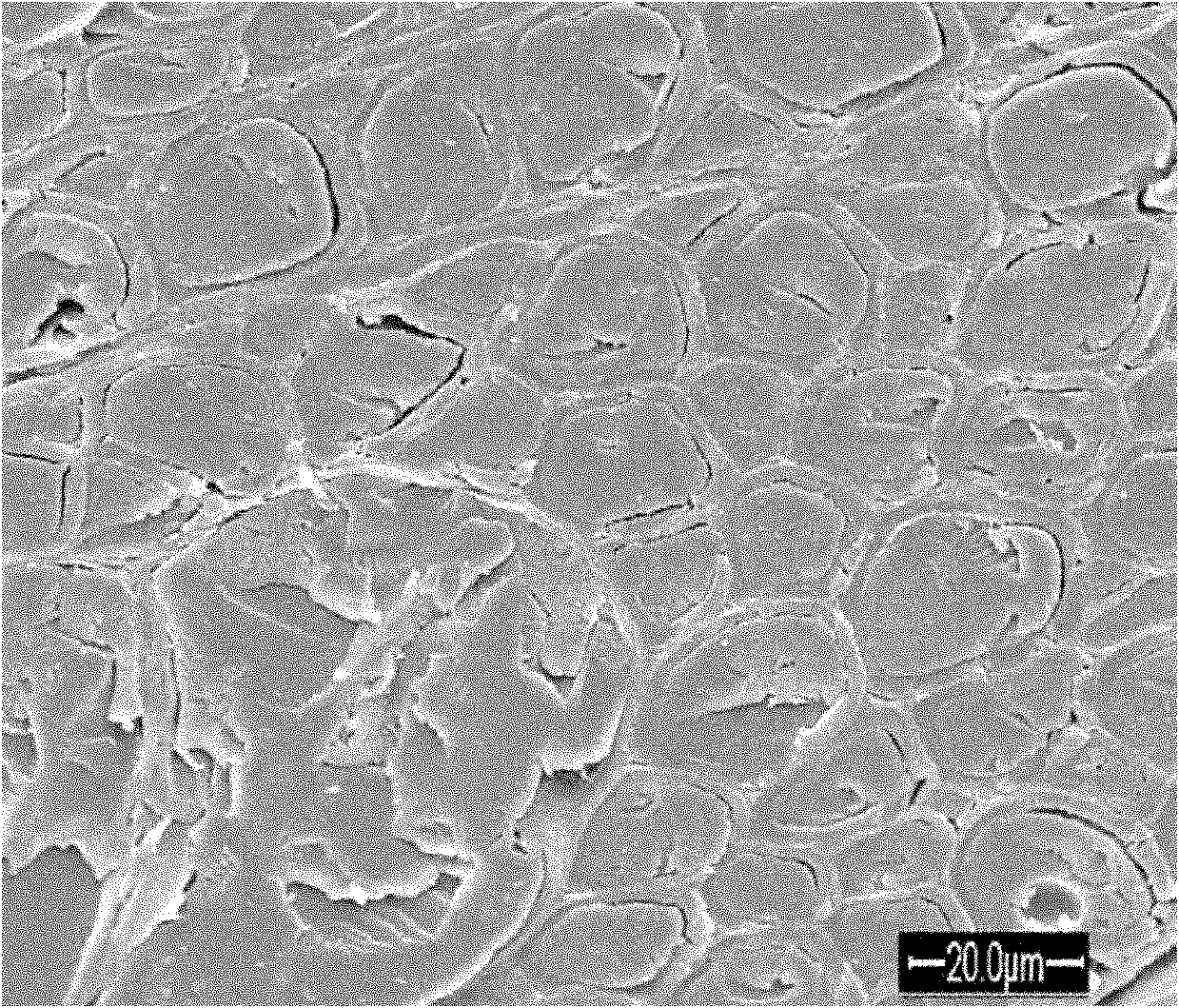

specific Embodiment approach 1

[0007] Specific embodiment one: the preparation method of the hydrophobic wood of the present embodiment is carried out according to the following steps: one, weigh 49%~99.5% of fluorine-containing polymerizable monomers, 0~50% of unsaturated monomers and 0.5% to 1% initiator, and mix evenly to obtain an impregnating solution; 2. Add the wood and the impregnating solution obtained in step 1 into the reaction tank, and immerse the wood in the impregnating solution, seal the reaction tank and pump Vacuum to -0.08MPa~-0.095MPa, and keep it for 15min~25min; 3. Release the vacuum and return to normal pressure, and then feed air into the reaction tank to make the pressure in the reaction tank reach 0.8MPa~1MPa, and keep it for 20min ~30min; 4. Reduce the pressure of the reaction tank to normal pressure, take out the wood, and then wrap the impregnated wood with aluminum foil, first place it at room temperature and normal pressure for 12h~24h, and then heat it to a temperature of 80℃~...

specific Embodiment approach 2

[0010] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, 54.1% to 94.4% of fluorine-containing polymerizable monomers, 5% to 45% of unsaturated monomers and 0.6 % ~ 0.9% of the initiator. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, 79.2% of fluorine-containing polymerizable monomer, 20% of unsaturated monomer and 0.8% of initiator are weighed in mass percentage. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com