Patents

Literature

421results about How to "Improve distillation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

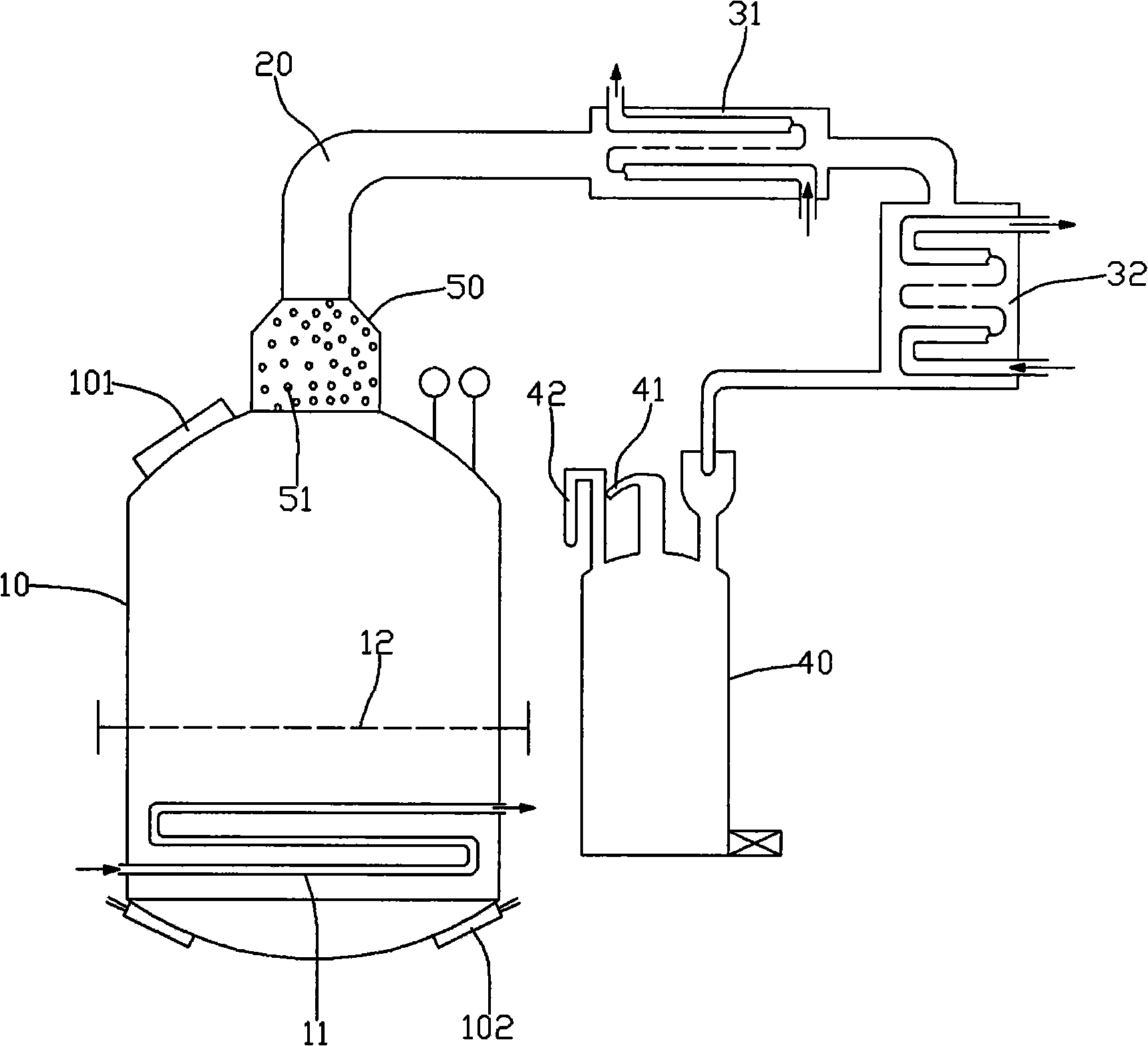

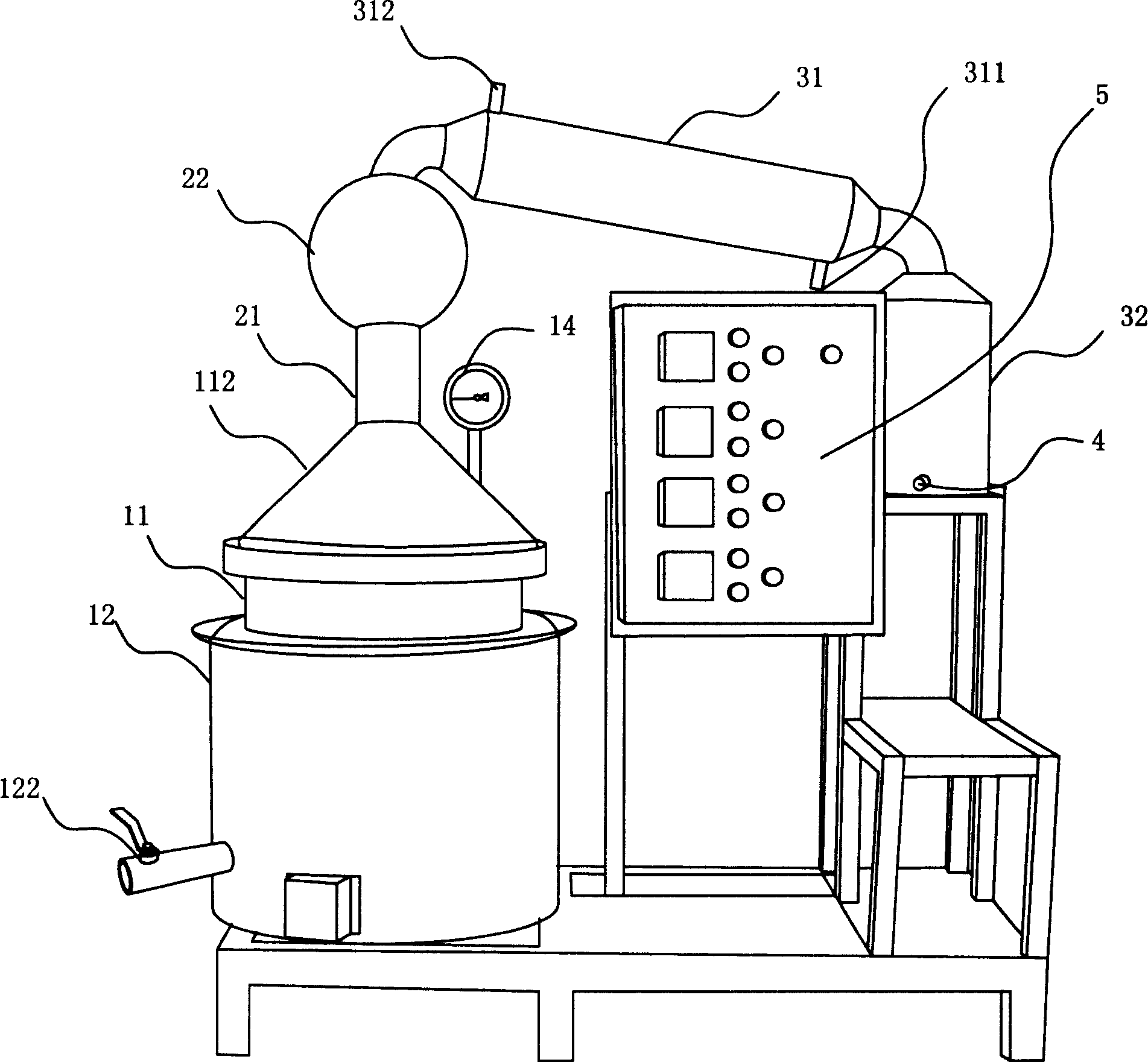

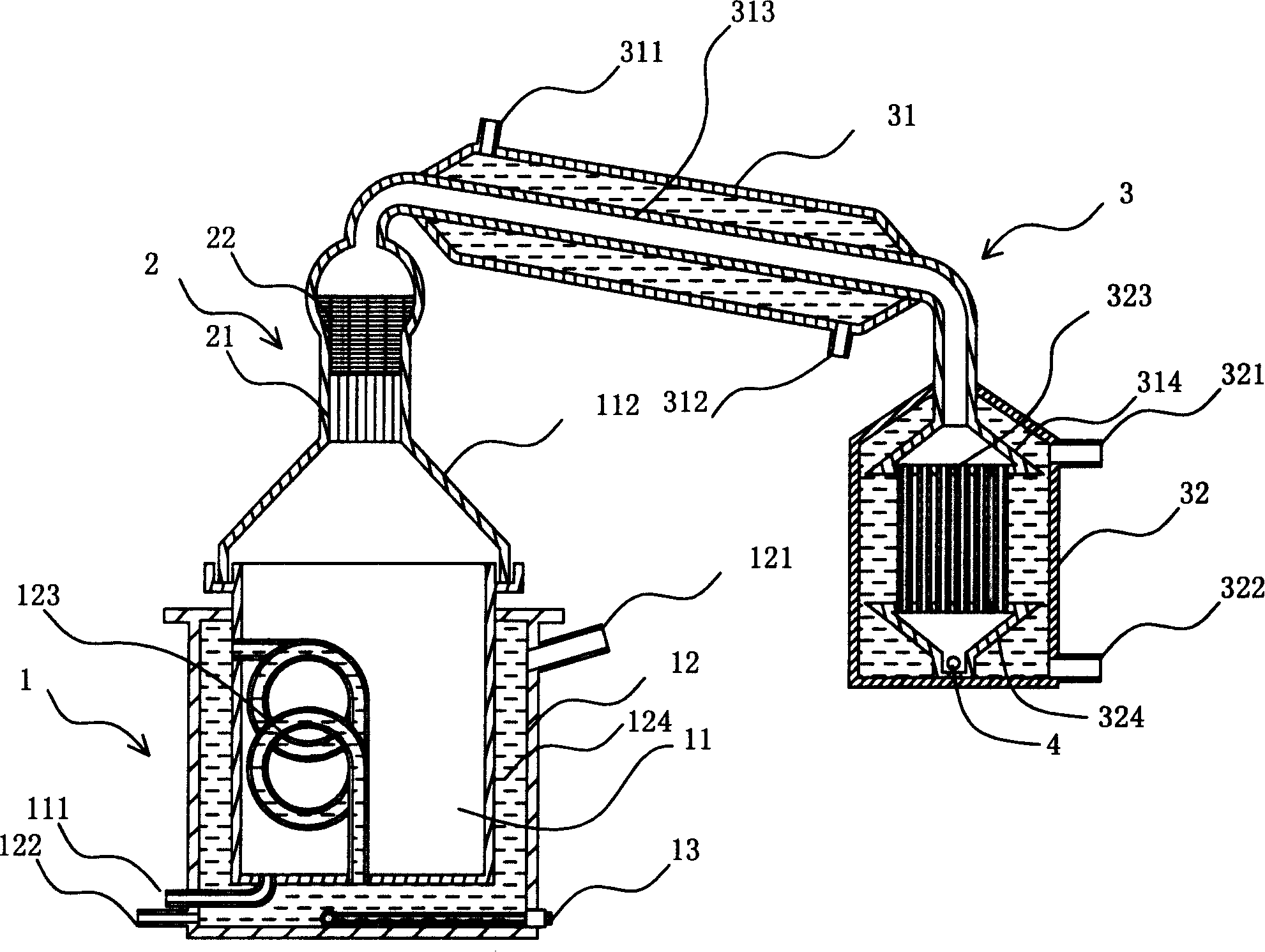

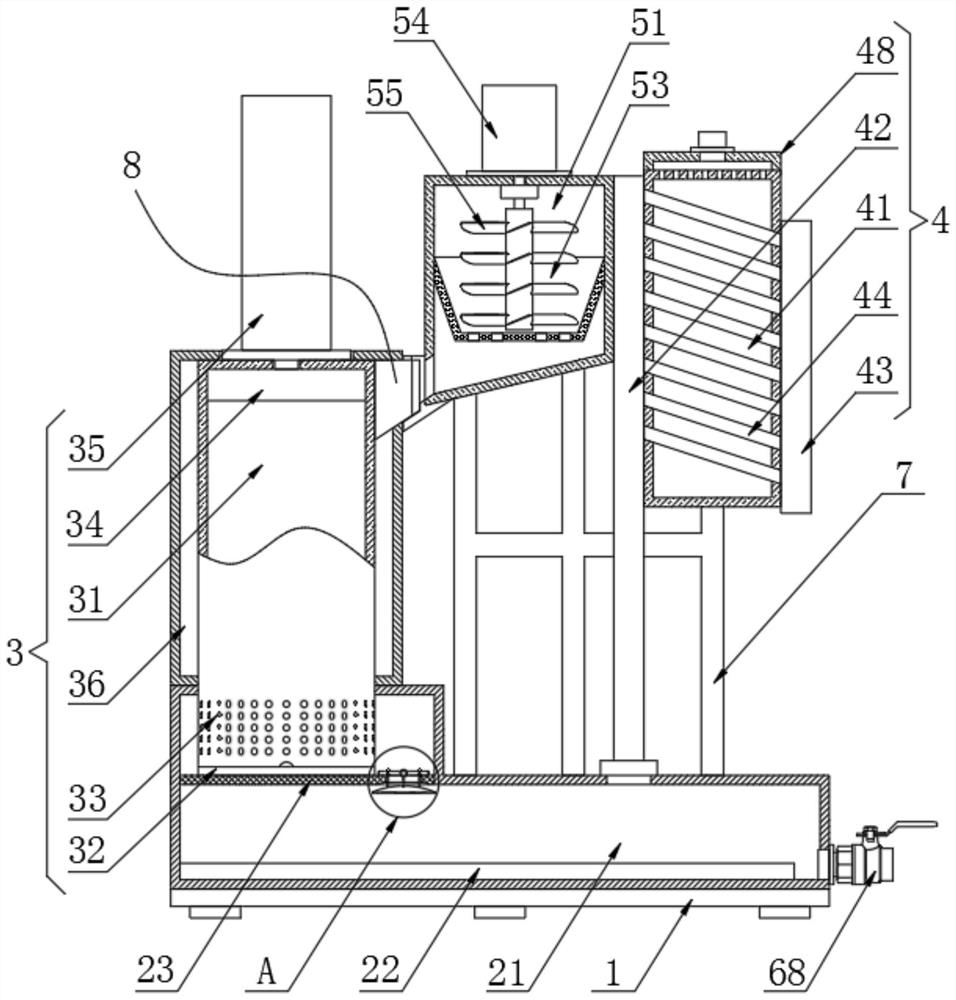

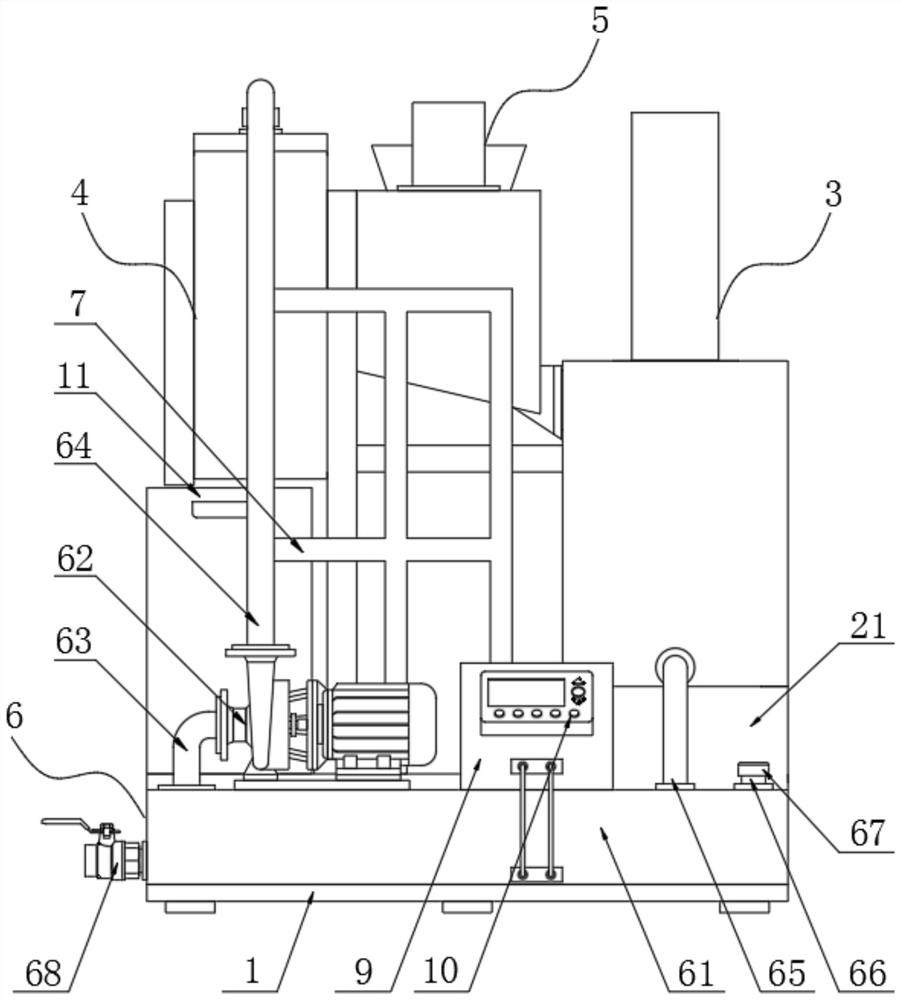

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

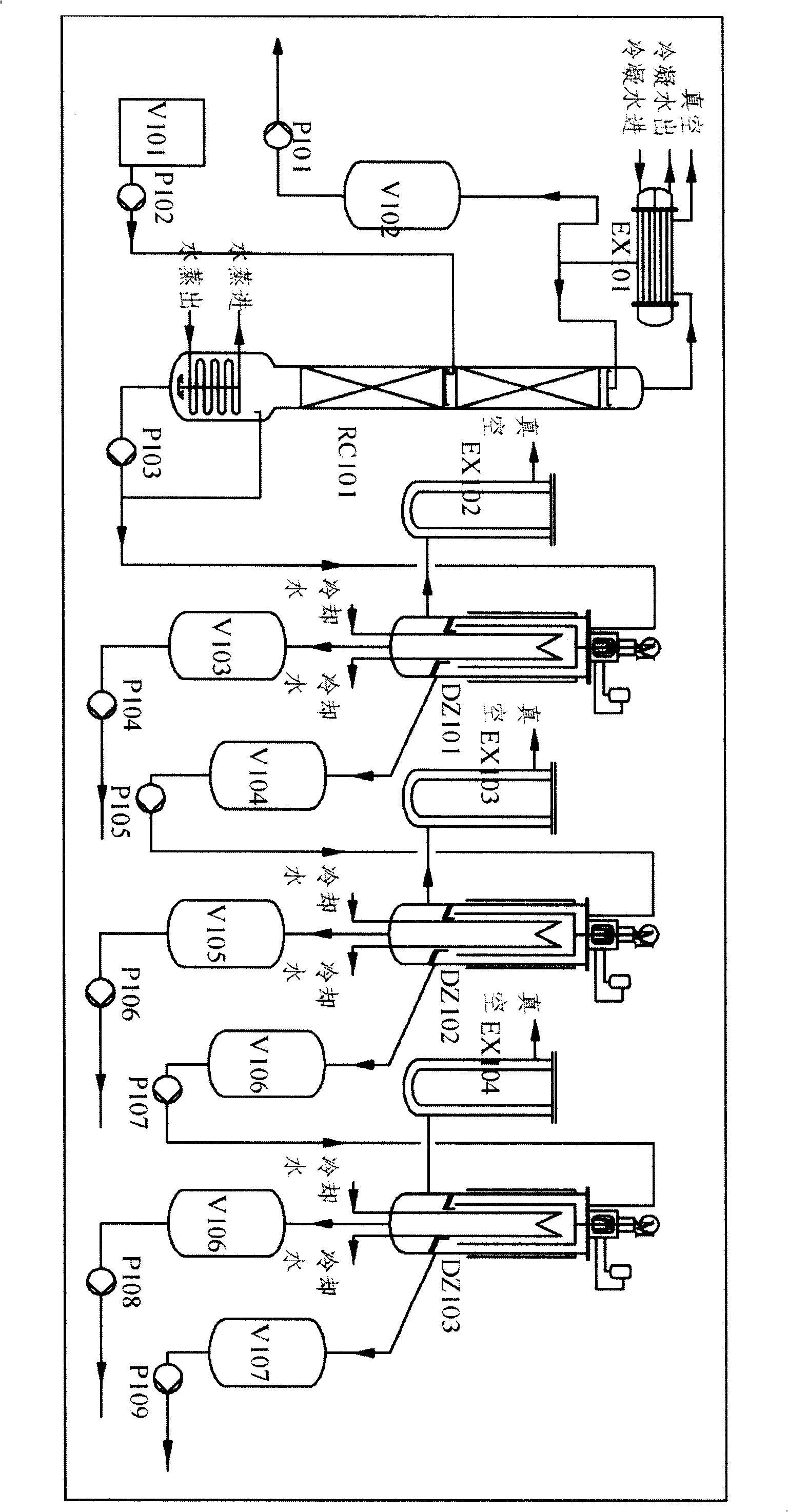

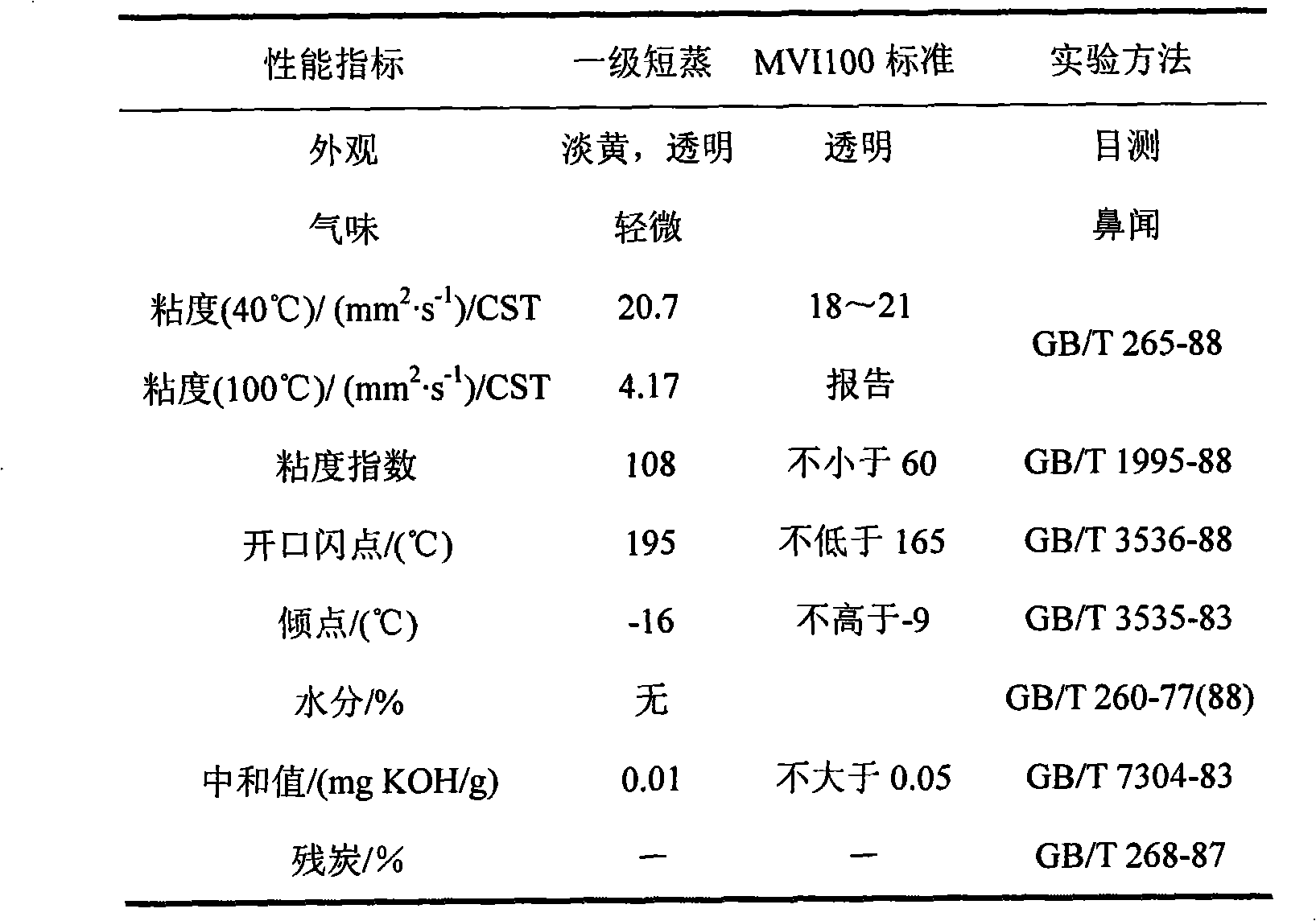

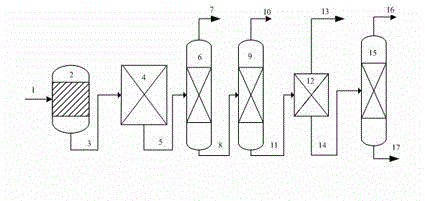

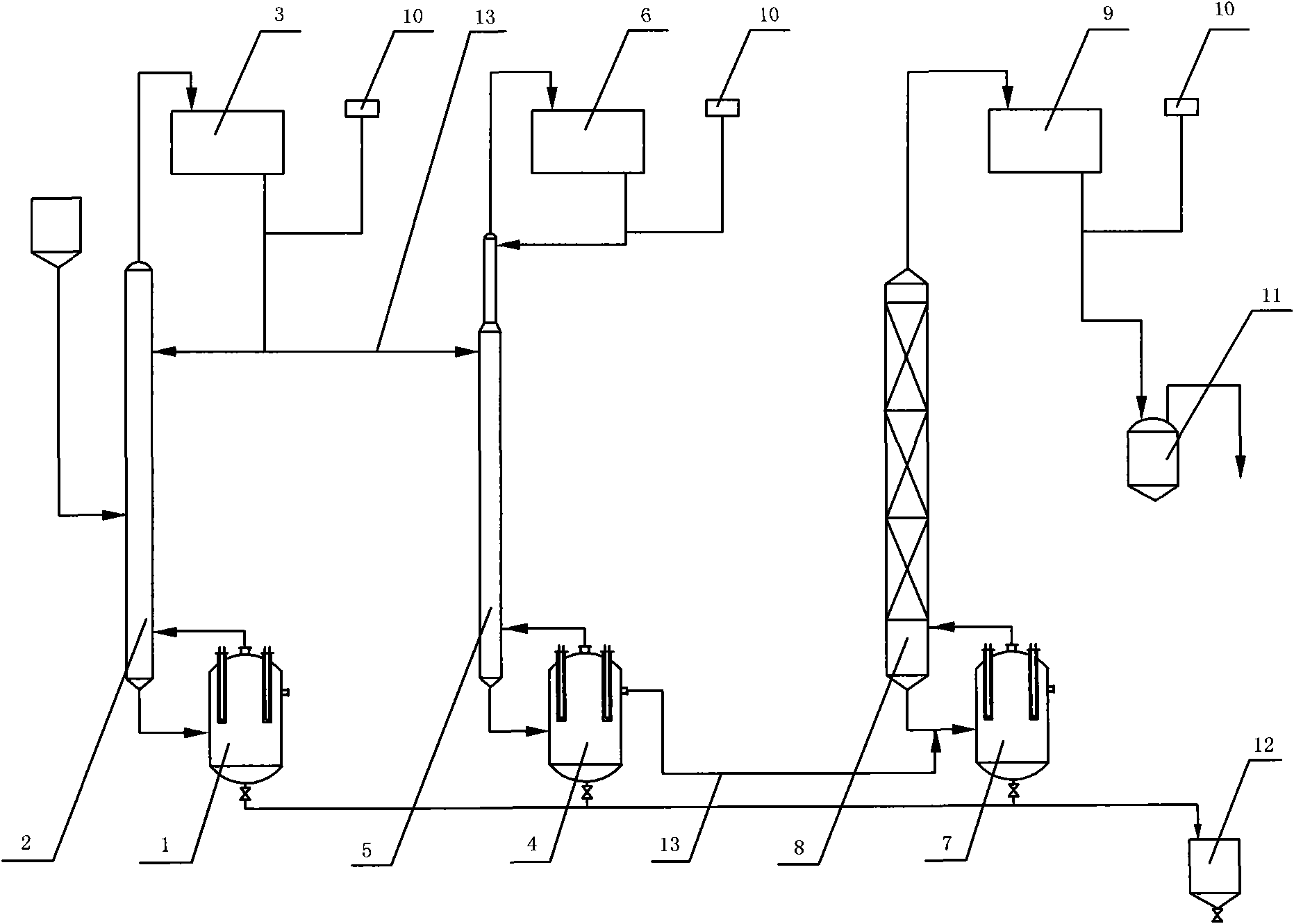

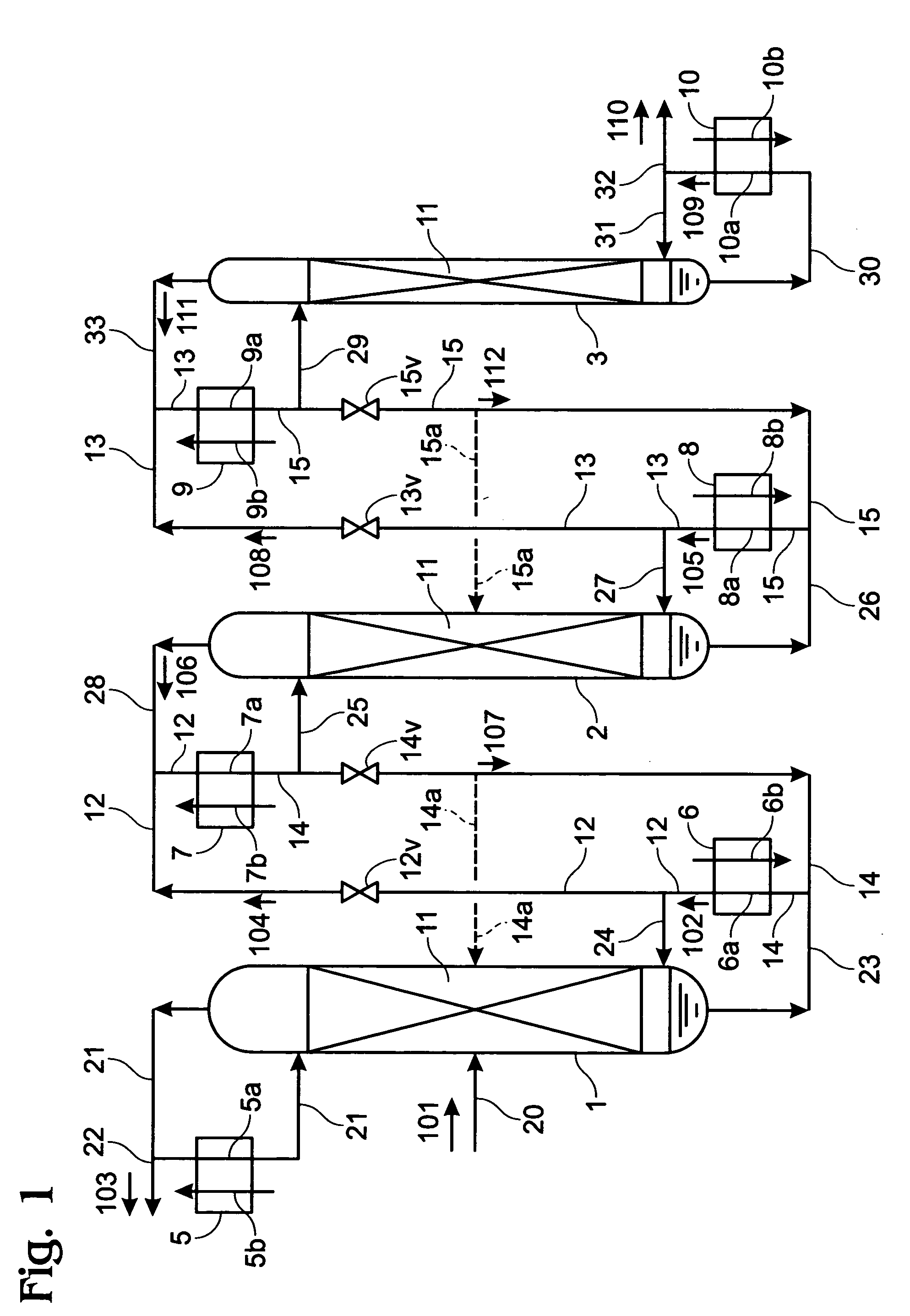

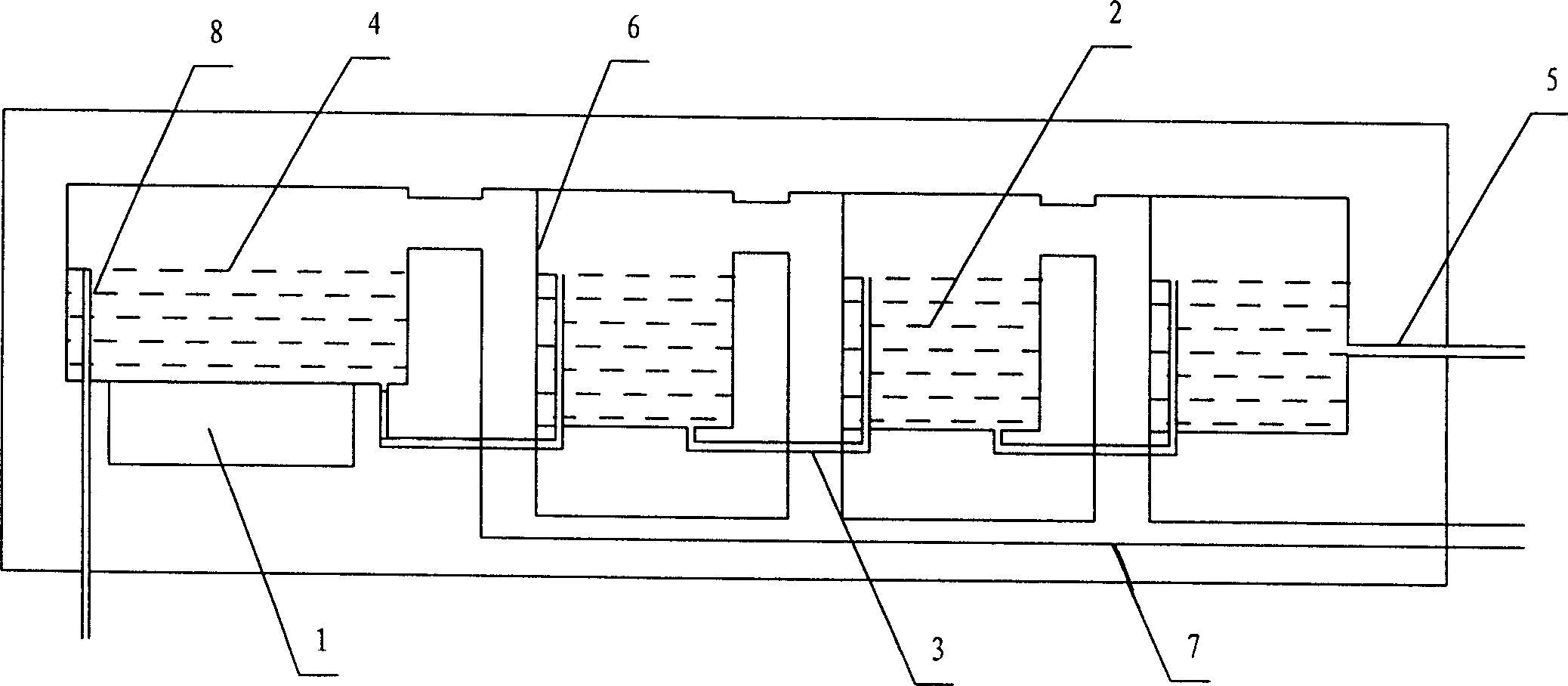

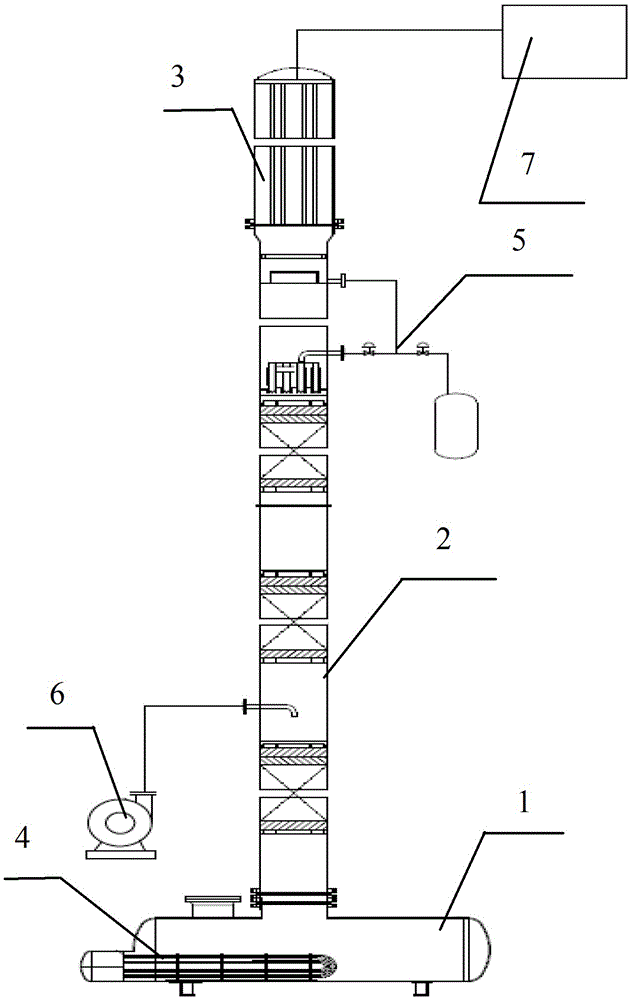

Application of distillation and multi-stage molecular distillation technique in regeneration process for waste lubricant oil

InactiveCN101319166ANot easy to stickShort stayHydrocarbon distillationLubricant compositionDistillationPre treatment

The invention discloses a novel process of regenerating base oil from waste lubricating oil. The process which applies an advanced molecular distillation technology to regenerate base oil from waste lubricating oil can not only regenerate better base oil, but also carry out effluent fraction through multilevel series connections. The waste lubricating oil is deprived of light diesel oil in a rectification tower through pretreatment and deprivation of light components, and then the waste lubricating oil is pumped into a first-level molecular still through a first-level feed pump to distill off a relatively lighter base oil component as a product. Heavier components which are left by the first-level distillation and serves as the raw material of a second-level molecular still are pumped into the second-level molecular still through a second-level feed pump to distill off a component heavier than the first-level molecular distillation product to serve as a product, and the distillation residuals are taken as the raw material of a third-level distillation. The process is repeated in the manner until a required n level is reached, wherein n is more than or equal to 2 and is less than or equal to 5, and the recommended optimal level number is 3 or 2. The process has the advantages that: the obtained product only contains the base oil component, while other impurities including additives are discharged in the form of residuals; the process also can produce a plurality of products with good quality and varied viscosities, thereby bringing about great convenience for the preparation of product lubricating oil.

Owner:尹英遂 +2

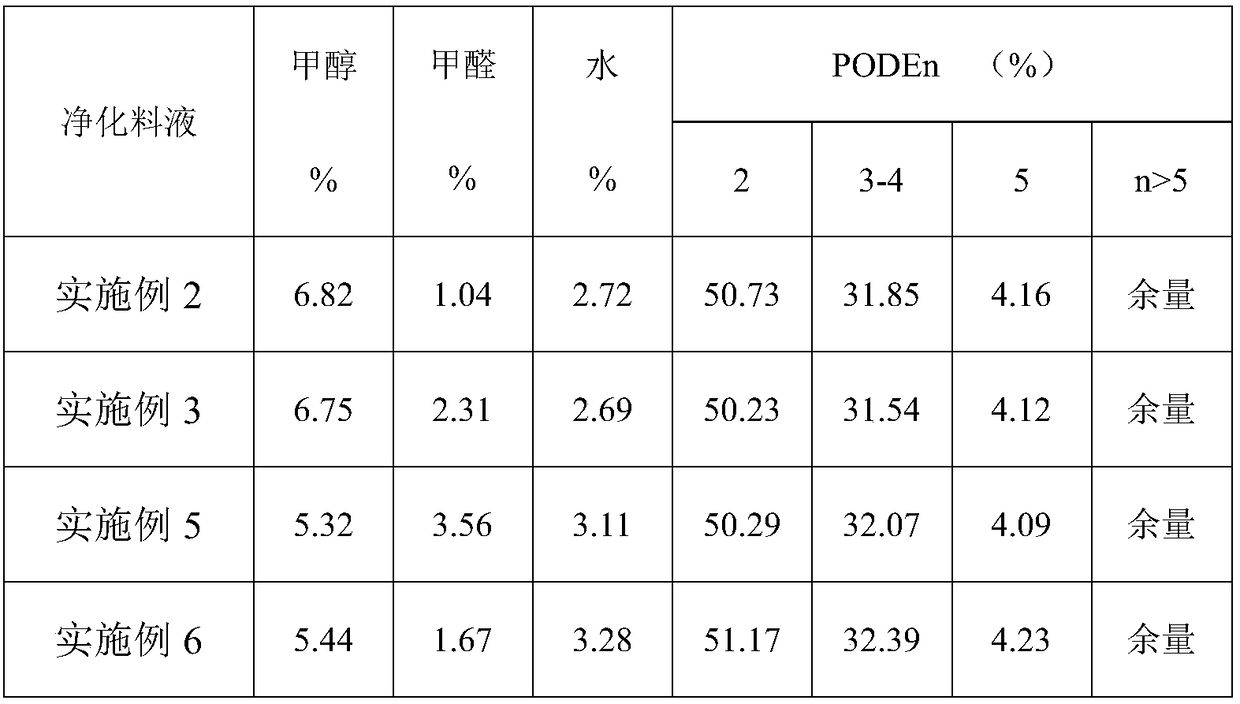

Purification method of polyoxymethylene dimethyl ether

ActiveCN104447236AReduce the possibility of cloggingImprove efficiencyOrganic chemistryOrganic compound preparationChemistryMother liquor

The invention relates to a purification method of polyoxymethylene dimethyl ether, which is mainly used for solving the technical problem that when polyoxymethylene dimethyl ether in a reaction mixture is purified by a pure serial connection manner of rectifying towers, paraformaldehyde is attached and accumulated on the top of a rectifying tower to block a return pipe and a discharge pipe to cause shut down for maintenance, and thus long-term and continuous production operation is difficult to achieve. The purification method of polyoxymethylene dimethyl ether provided by the invention mainly comprises: (e) cooling second residue to separate out a paraformaldehyde solid, and performing solid-liquid separation to separate paraformaldehyde and obtain mother liquor; (f) rectifying the mother liquor in a second rectifying tower to obtain a third fraction containing n=3-5 polyoxymethylene dimethyl ether and third tower residue containing the rest high polymer components, the technical scheme is used for well solving the above technical problem, and the purification method can be used in the purification production of polyoxymethylene dimethyl ether.

Owner:CHINA PETROLEUM & CHEM CORP +1

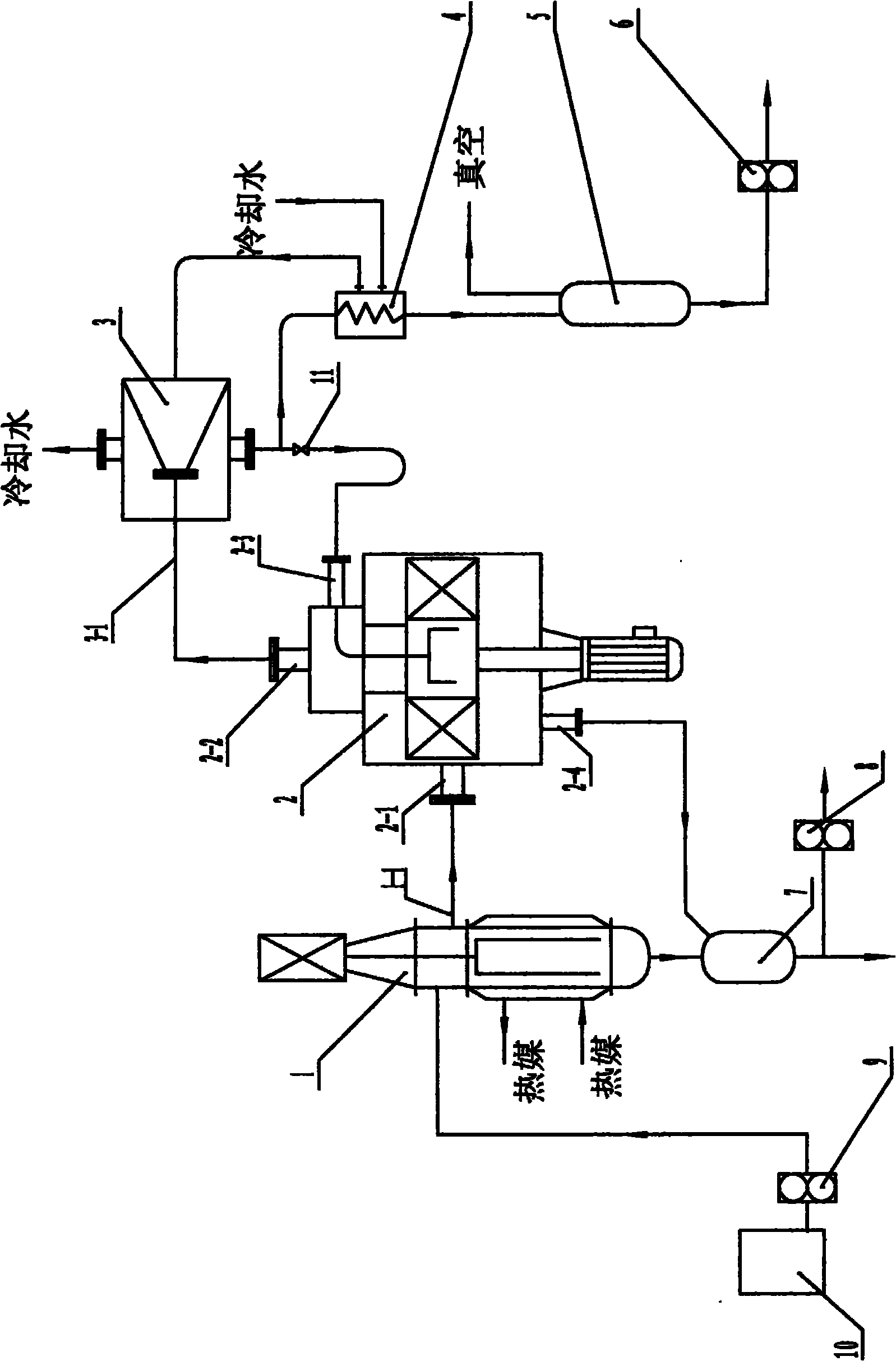

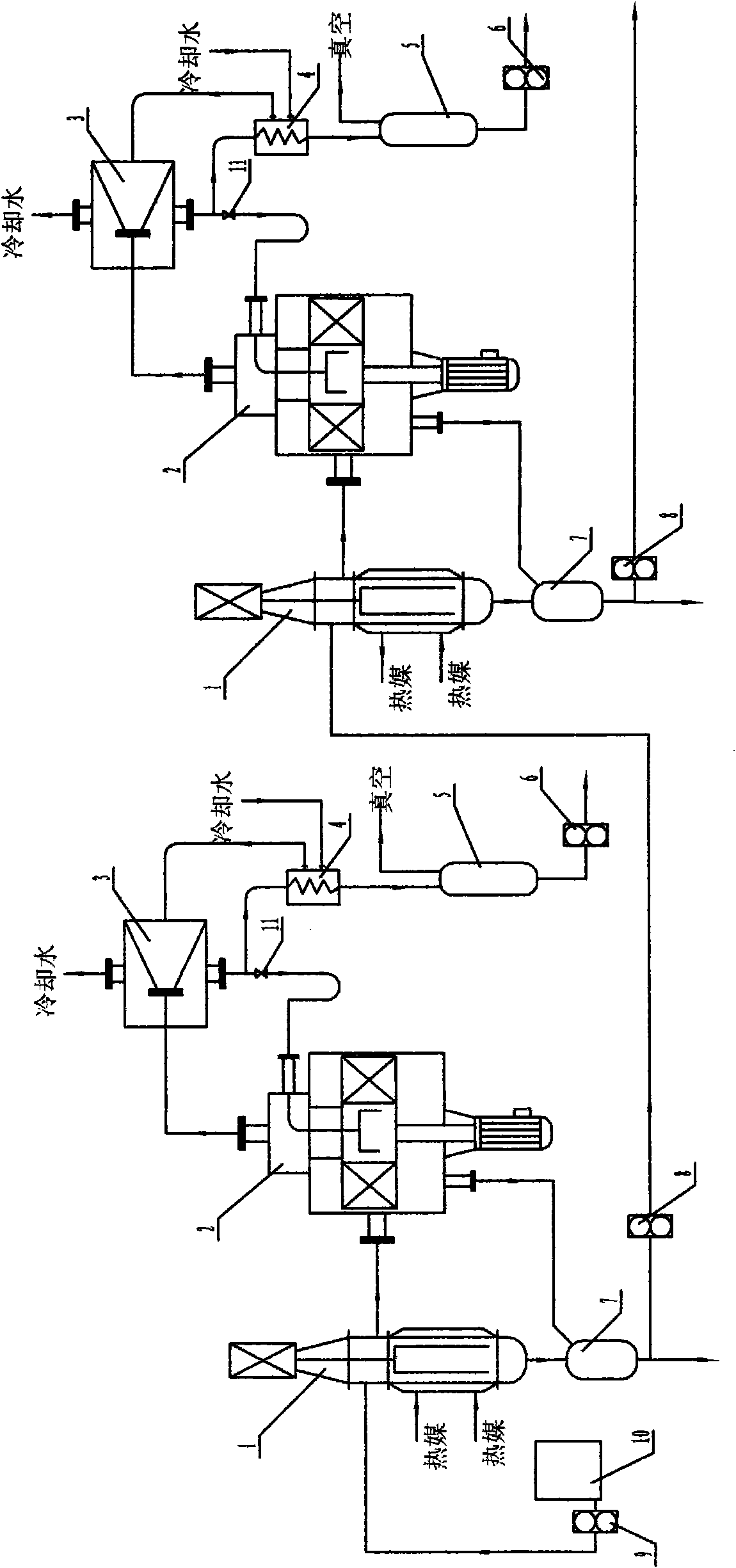

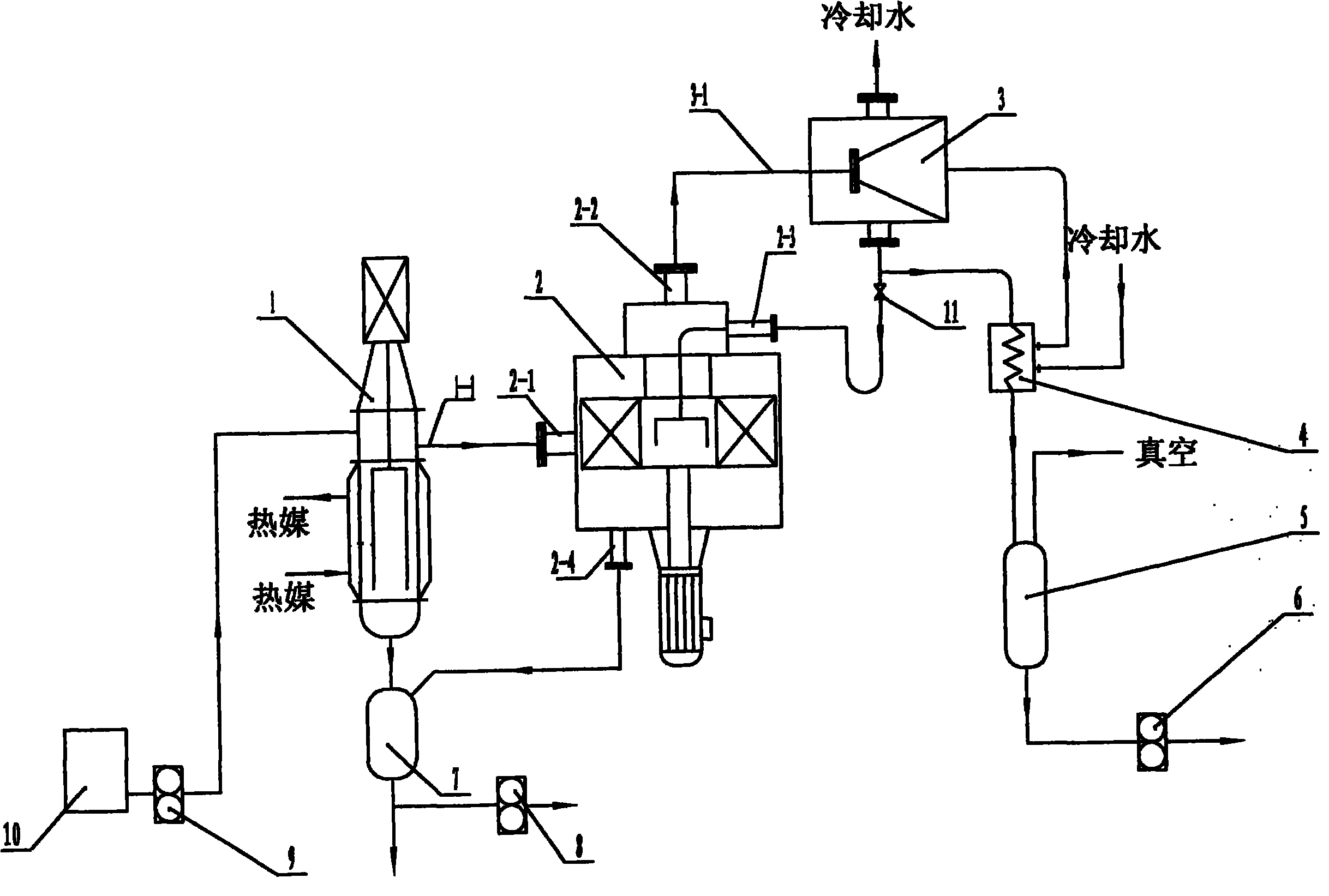

Method for separating and recovering product oil from waste lubricating oil and device thereof

ActiveCN101831348AImprove heating efficiencyShort heating timeLubricant compositionEvaporationEngineering

The invention relates to a method for separating and recovering product oil from waste lubricating oil and a device thereof, which relates to chemical production methods and devices. The method adopts the process that after preliminary treatment of dewatering, degassing and mechanical purity removal, multi-time intermittent rectification or multistage continuous rectification is carried out on the waste lubricating oil by thin-film evaporation and hypergravity revolving field. The device is a 1-4 time intermittent rectifying device or a 1-4 stage multistage continuous rectifying device comprising a raw material tank, a material pump and one to four thin-film evaporators, hypergravity revolving beds, condensers, coolers, finished product tanks, discharging pumps, heavy constituent receiving tanks, material pumps and reflux regulating valves. The method has high rectification speed, good product quality and high recovery rate, and meets the requirements of environmental protection; compared with short path distillation technology, the invention has smaller device volume and higher rectification efficiency and can further refine materials; the device for treating the materials with the same scale has lower requirements for field, less investment and relatively lower vacuum degree requirement.

Owner:HANDWAY TECH FOSHAN

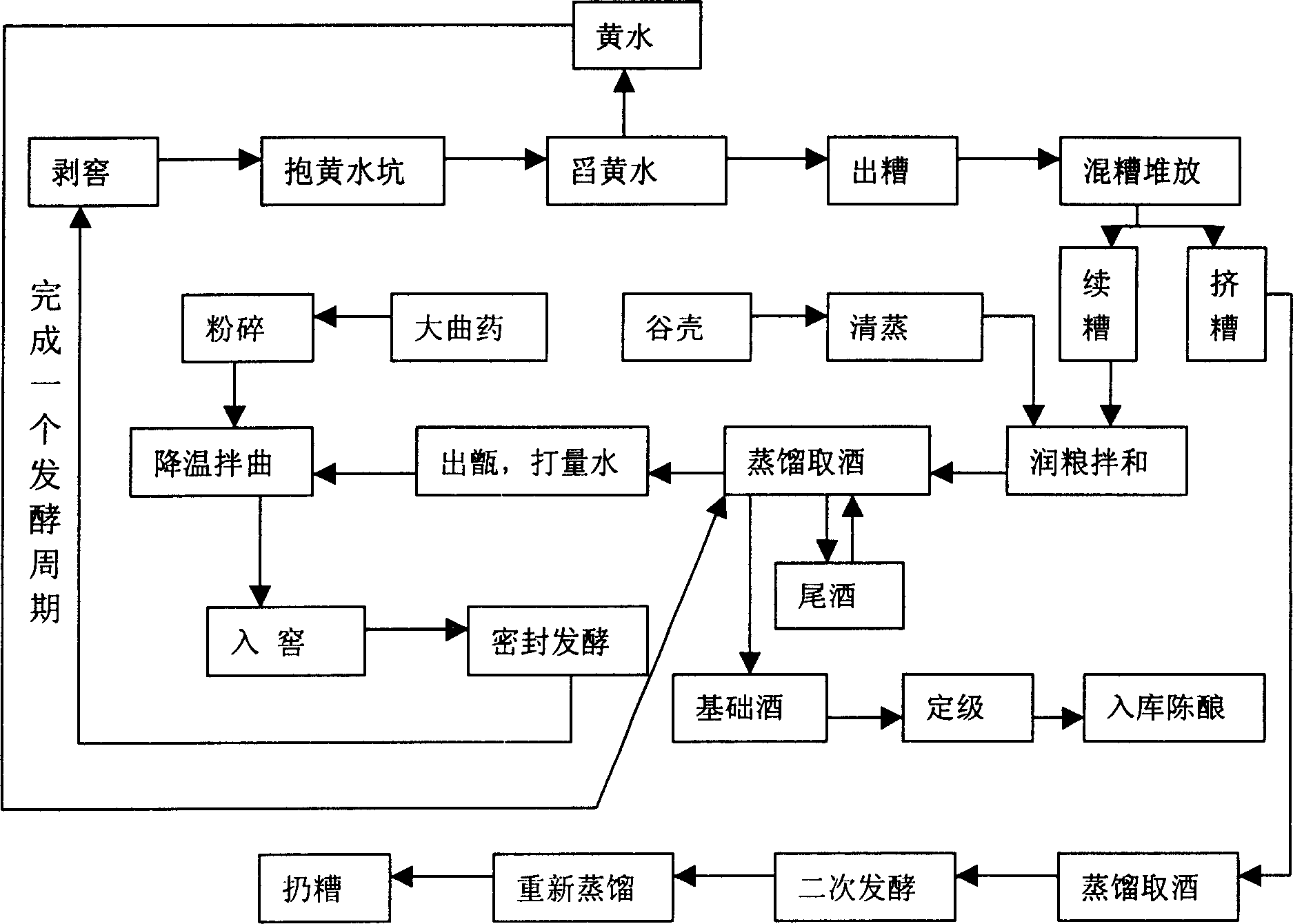

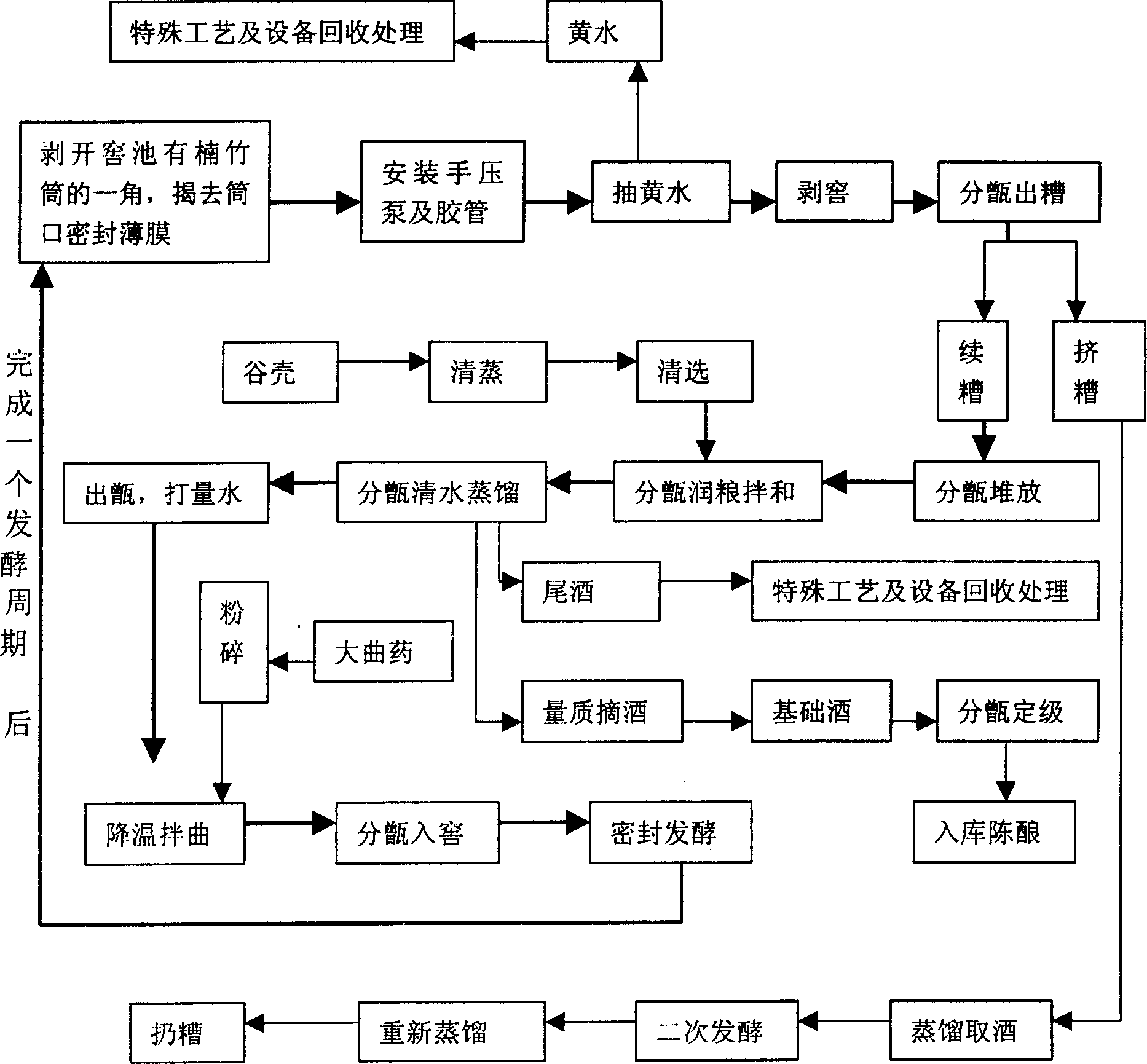

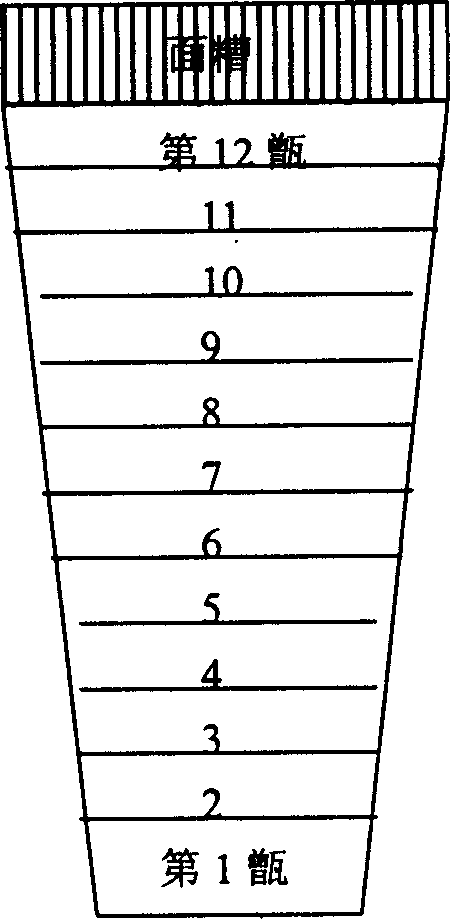

'Whole clear' process of brewing aroma type white spirit

ActiveCN1733888AReduce dosageReduce furfural contentAlcoholic beverage preparationTissue/virus culture apparatusEngineeringDrinking straw

The invention discloses a technique to brew aromatic wine, based on traditional technique, which relates to reform and innovate to draw water, steam supplementary material, distill to obtain wine, and put dreg into cellar clear layered. Wherein, the said four steps are technical core; the cellar is constructed on bottom of pond near wall with inner wall fixed and cover on its head with center hole inserted hollow pipe; after putting dreg into cellar, sealing the pipe and cellar for fermentation; before putting out, stripping off the yellow mud to show pipe mouth, and taking out seal; inserting sucker to draw the yellow water in cellar by connected pump as possible as far; mixing, obtaining wine, storing in cellar; all processes with Zeng(traditional measuring tool) as unit. The method can decrease labor strength, save material, and increases wine quality.

Owner:SICHUAN TUOPAI SHEDE WINE

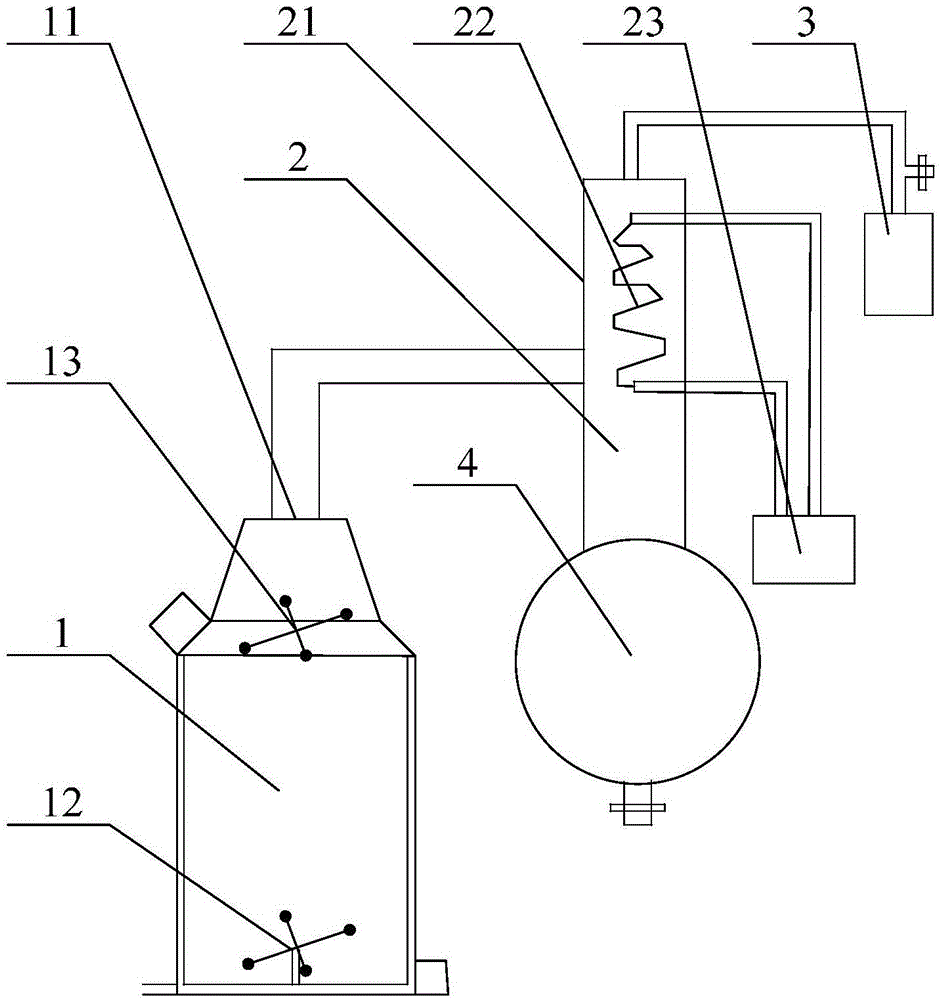

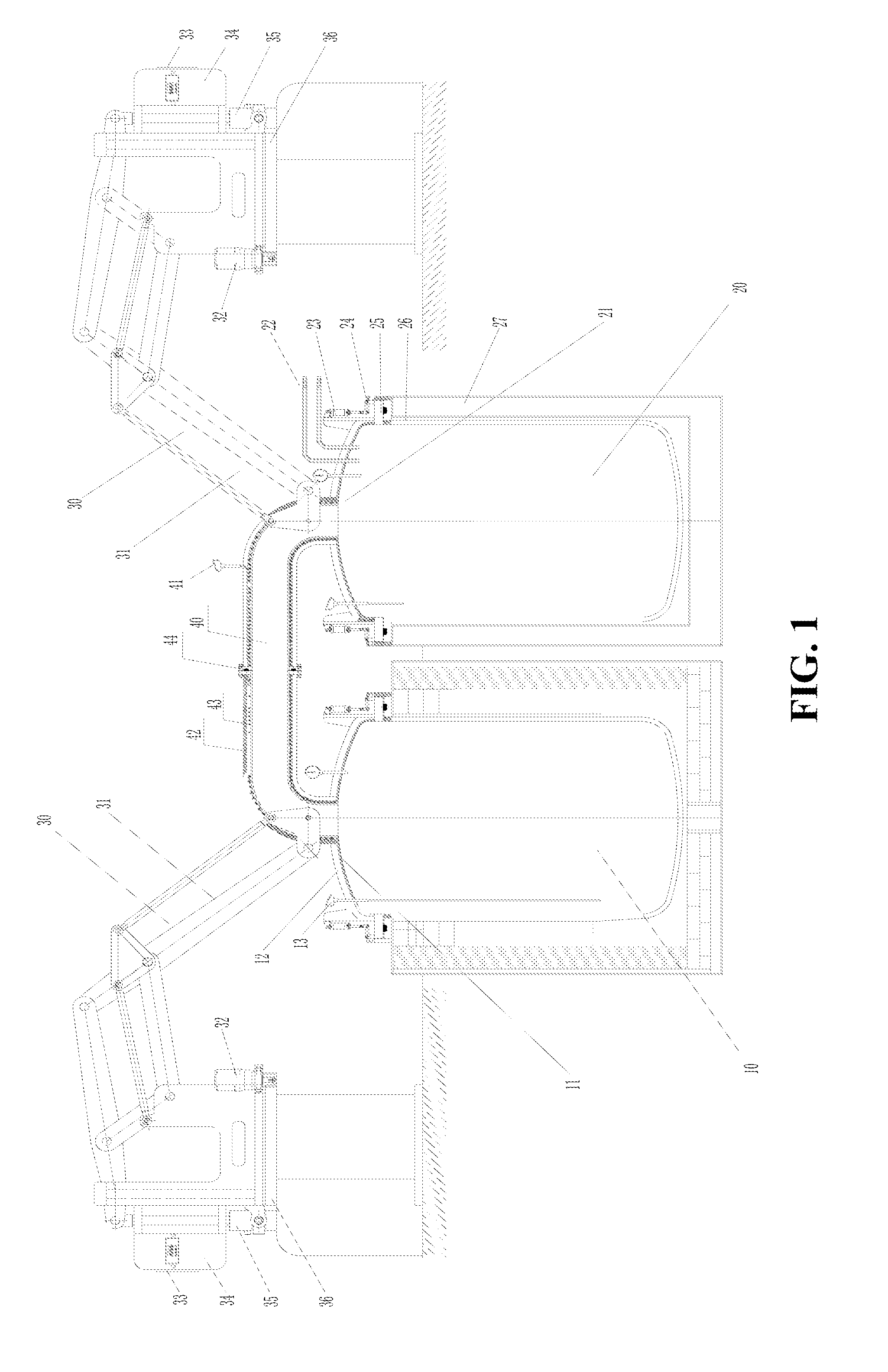

Distilling system and method of distilled liquor

The invention relates to the technical field of alcohol brewing, in particular to a distilling system of distilled liquor. The distilling system comprises a material cooking tank, a condensing device and a vacuum pump. The material cooking tank is communicated with the condensing device. The vacuum pump is communicated with the condensing device. Fermented grains or fermented liquor is contained in the material cooking tank and produces steam under the negative pressure condition, and the steam enters the condensing device. The condensing device is used for condensing the steam. The vacuum pump is used for controlling the gas pressure states in the material cooking tank and the condensing device. The gas pressure of the system is controlled through the vacuum pump, negative-pressure distillation is conducted at a room temperature or a low temperature, and therefore the damage of high temperature to evaporative flavor substances is avoided, the alcoholic strength of raw liquor is improved, loss of flavor components is reduced, the distilling efficiency is improved, and the distilling system is suitable for various types of distilled liquor; by means of the distilling system, corresponding novel room-temperature negative-pressure distilled liquor can be produced.

Owner:TIBET AGRI & ANIMAL HUSBANDRY COLLEGE

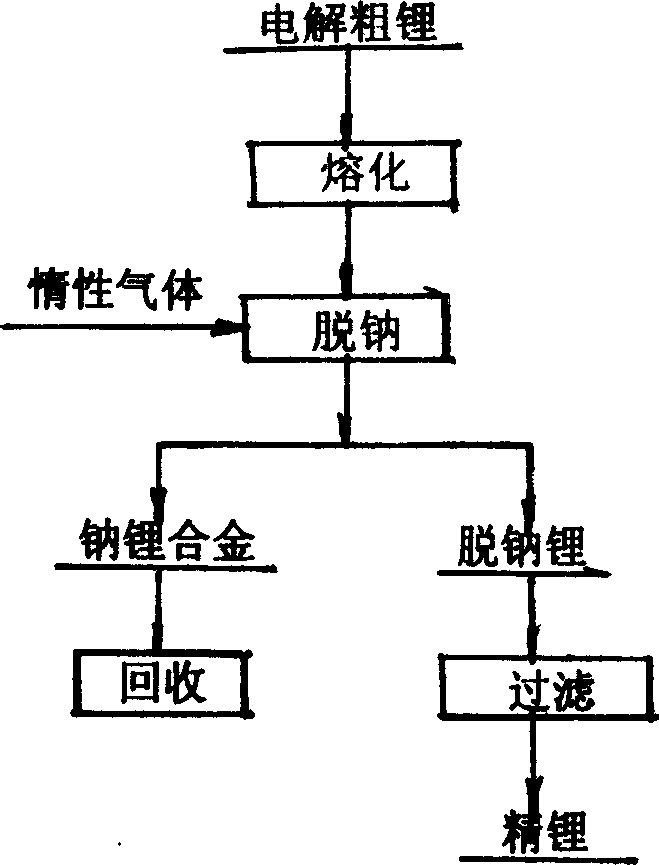

Method for removing sodium from coarse lithium by gas agitation under condition of vacuum, distillation at moderate temperature

A process for removing sodium from the coarse lithium includes smelting the coarse lithium containing Na (0.1-1.5%) in the pot of vacuum furnace at 200+ / -10 deg.C, flowing in vacuum furnace, heating to 400-520 deg.C under 1-5 Pa, flushing inertial gas into molten lithium for stirring for 3-8 hrs while evaporating Na, filtering, and casting ingot.

Owner:KUNMING UNIV OF SCI & TECH

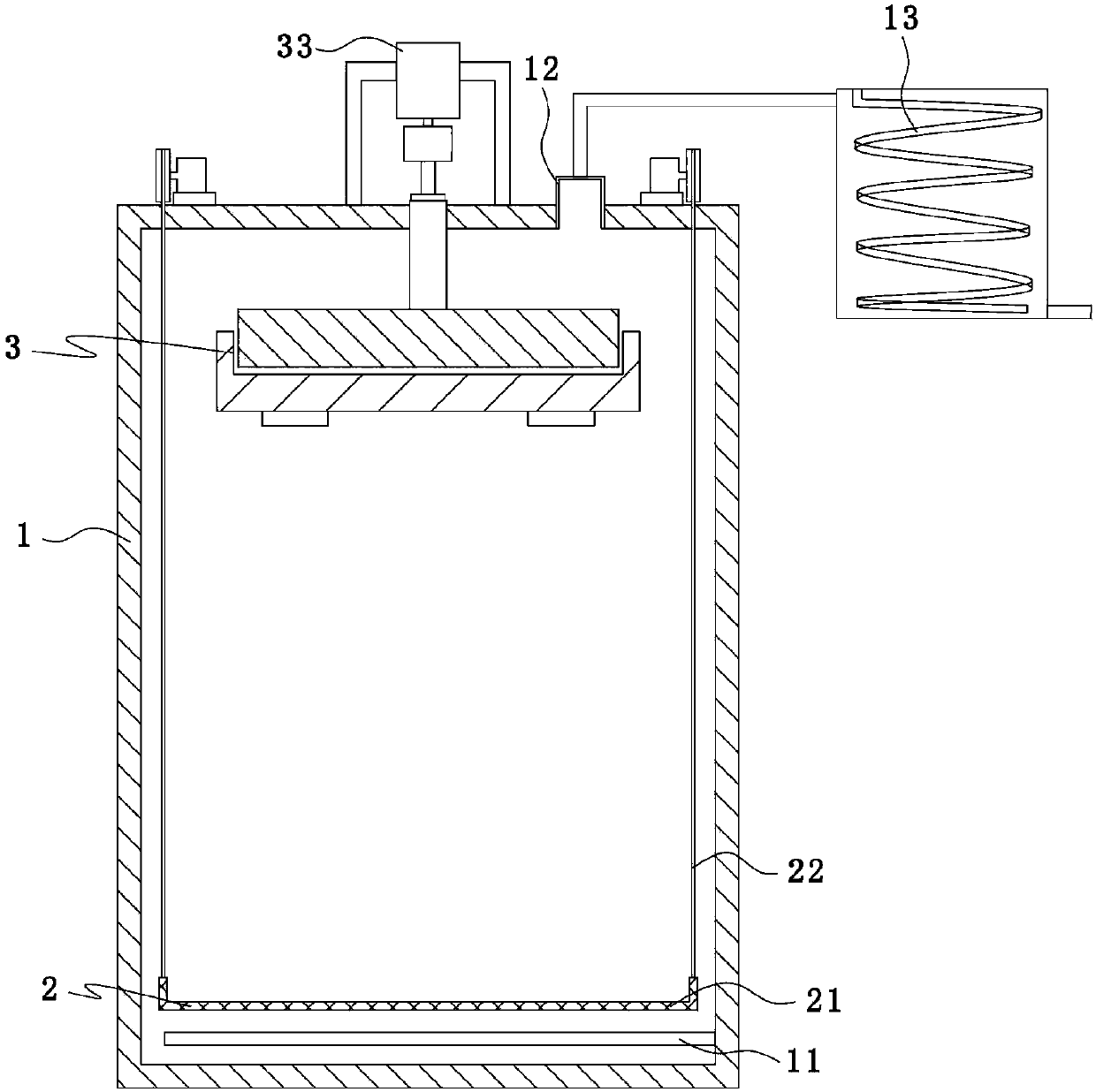

Wine distillation equipment with filtration system

InactiveCN101173208AEfficient removalImprove distillation efficiencyAlcoholic beverage preparationHazardous substanceDistillation

The invention relates to an alcoholic drink distillation apparatus with a filter system, which comprises a distillation system, a filter system and a condensing and cooling system connected through pipelines in sequence. The distillation system comprises a liquid heated kettle and a distillation kettle, the liquid heated kettle comprises a cavity encircling the outside of the distillation and used for holding the heated liquid, and the distillation kettle is provided inside with a spiral pipe with both ends communicated with the cavity of the liquid heated kettle; the filter system comprises a diatomite ceramic filter layer and a brass wires filter layer which are arranged along the vapor stream in sequence; the condensing and cooling system comprises a condensing pipe and a cooling tank filled with cooling water. The invention has the advantages of effectively removing the harmful substance such as pathogenic bacteria, impurity particles, remnants chlorin, heavy metal impurity and organic gas impurity, since the bi-layer filtration system of ceramic filter layer and brass wires filter layer is adopted, simultaneously improving the distillation efficiency and saving the energy due to a spiral pipe which is arranged inside the distillation kettle.

Owner:周清水

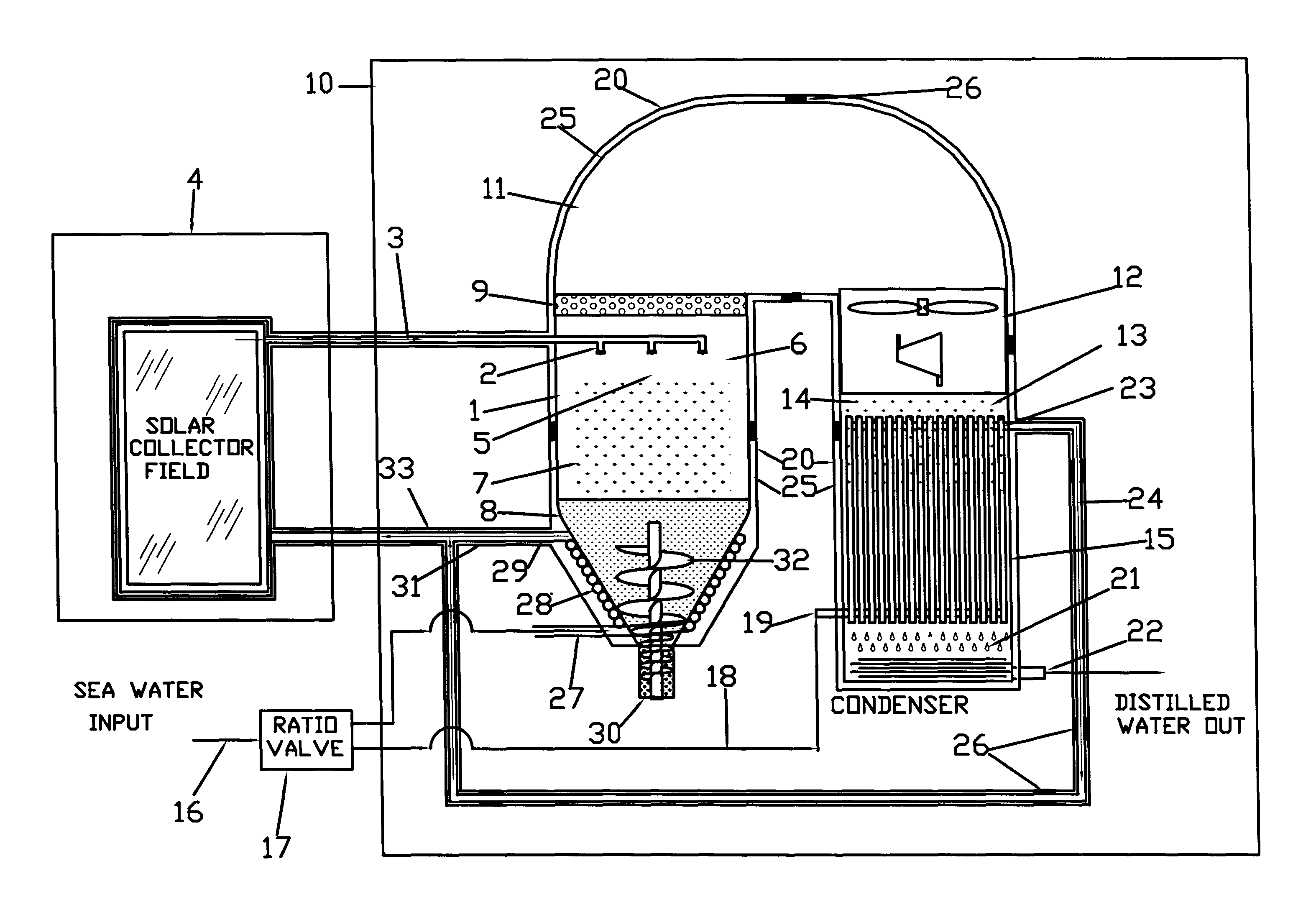

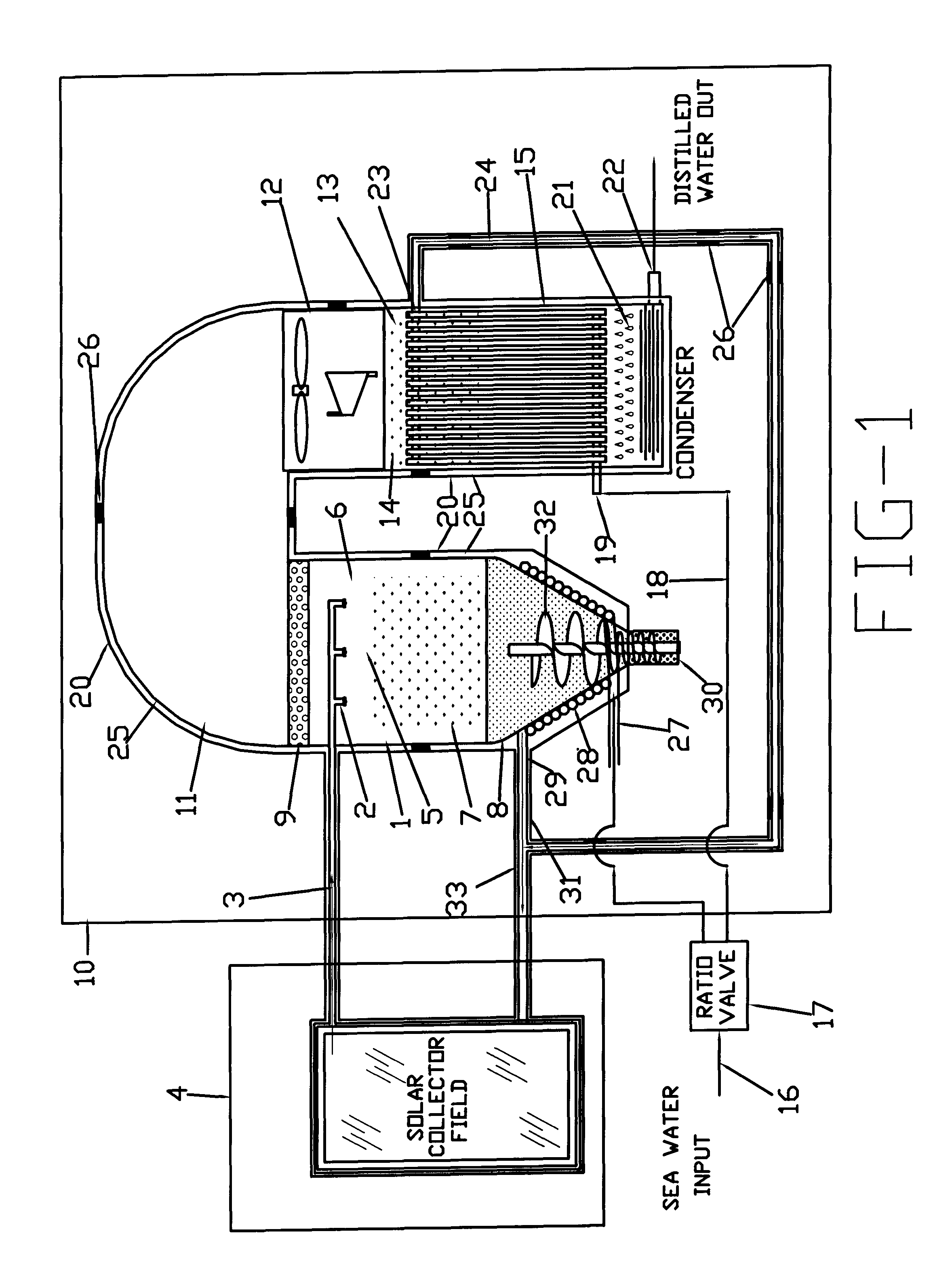

Large scale insulated desalination system

ActiveUS9428403B2Improve efficiencyReduced energy input requirementsAuxillariesGeneral water supply conservationAtmospheric airDesalination

An apparatus and method for the distillation of ocean and brackish water that includes insulation for preventing heat from escaping to the atmosphere is disclosed. The insulation comprises a second wall surrounding the basic assemblies of a desalination system in which the space between the second wall and basic assemblies is under low partial vacuum and is partially or totally filled with an insulation material for structural support. The system allows for flash evaporation of heated input water and condensing the resultant vapors into pure distilled water. The heat of condensation as well as heat from the salt byproduct may be recaptured and used to preheat the input contaminated water.

Owner:FLO ONICS LLC

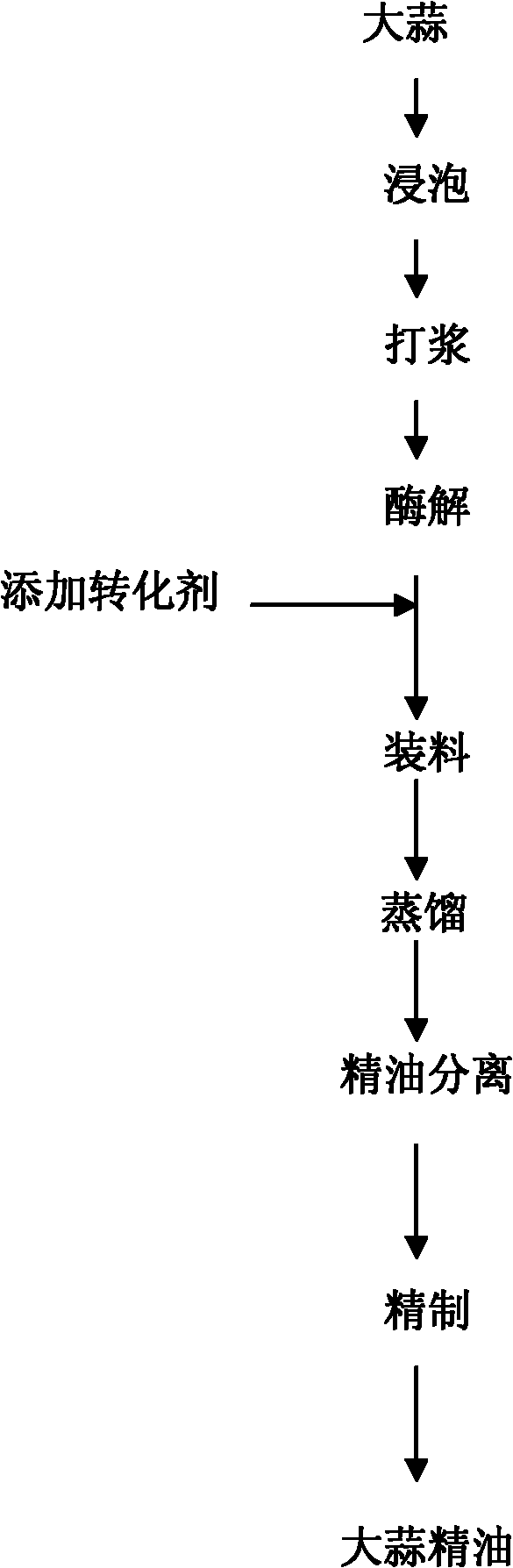

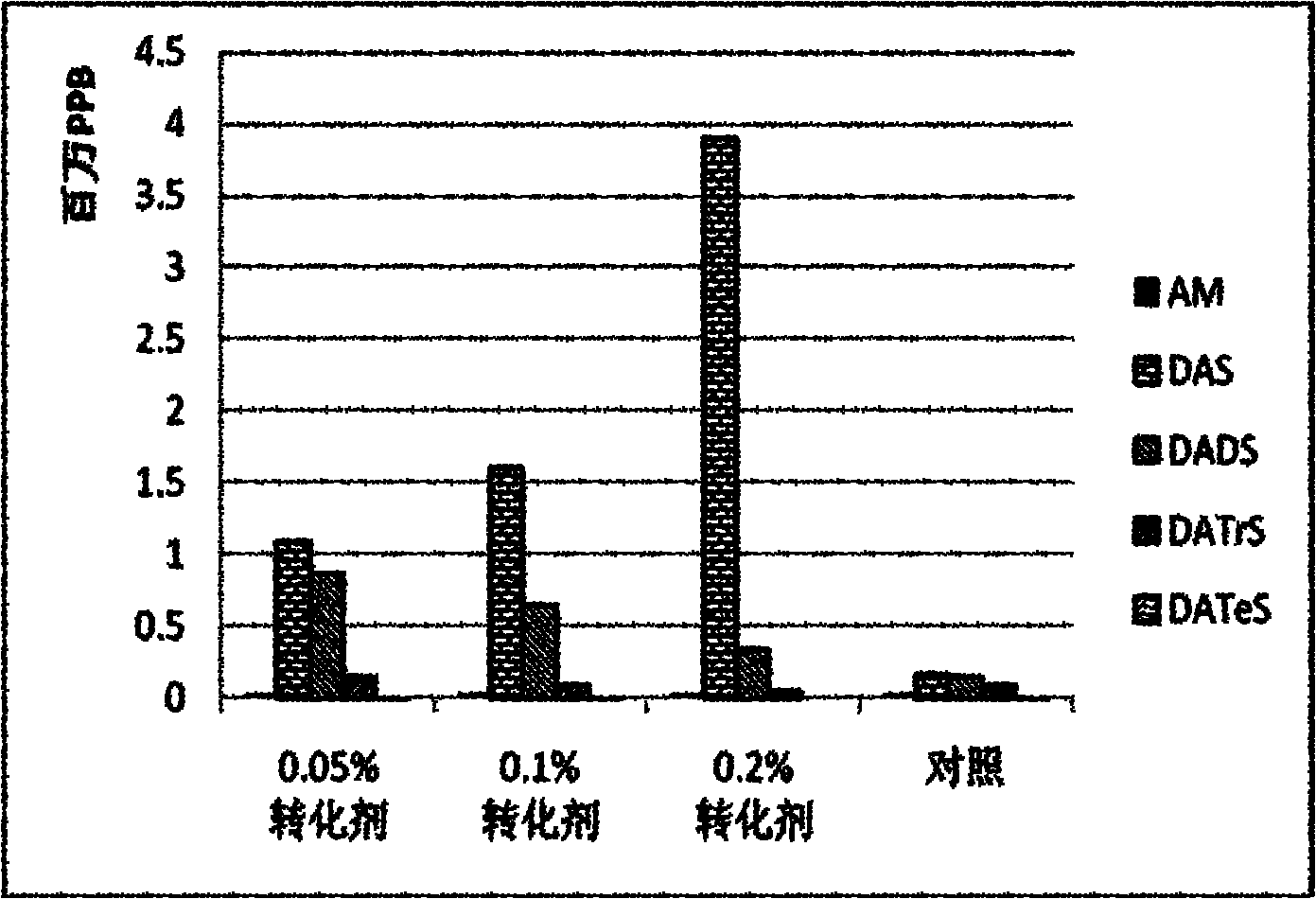

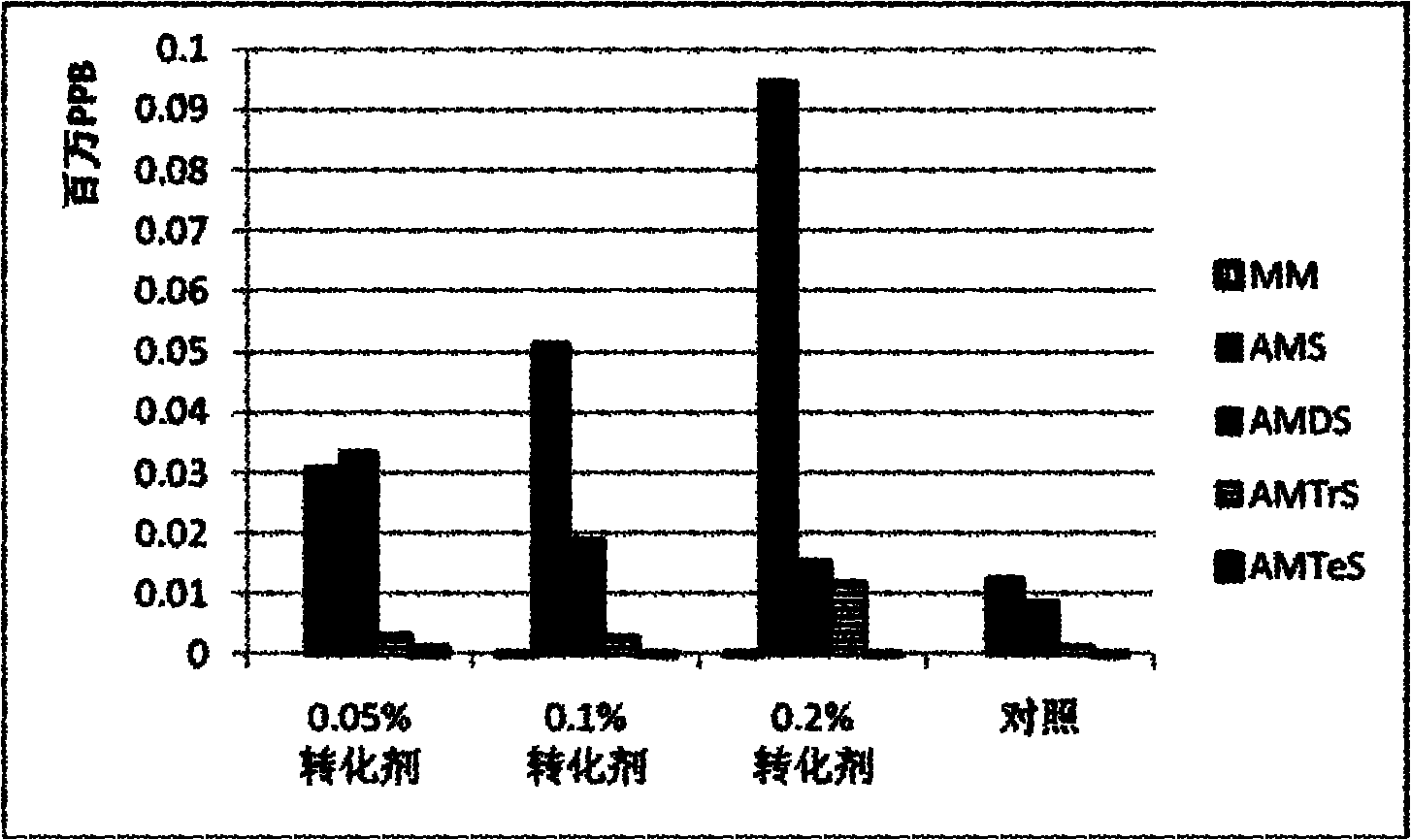

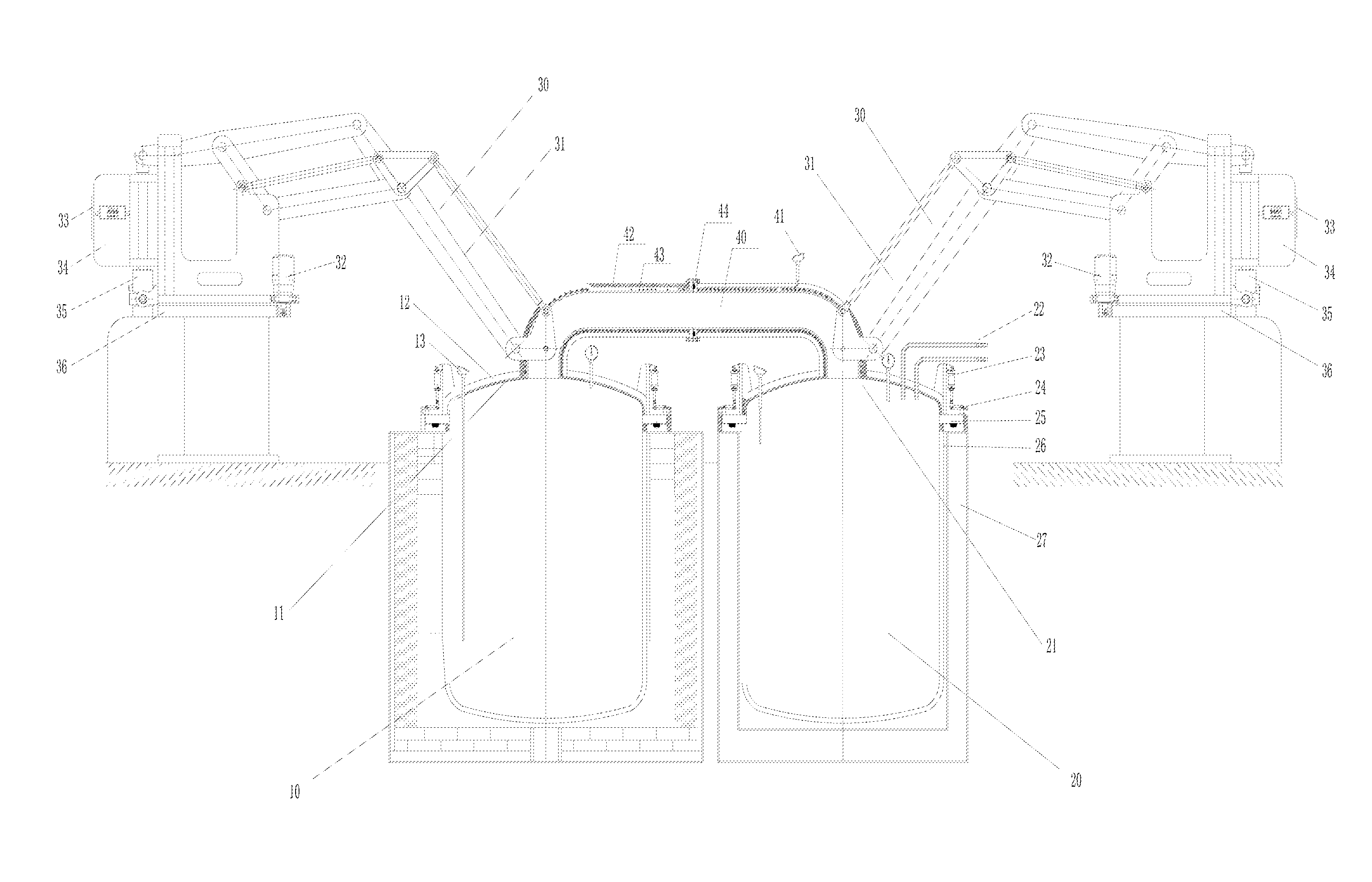

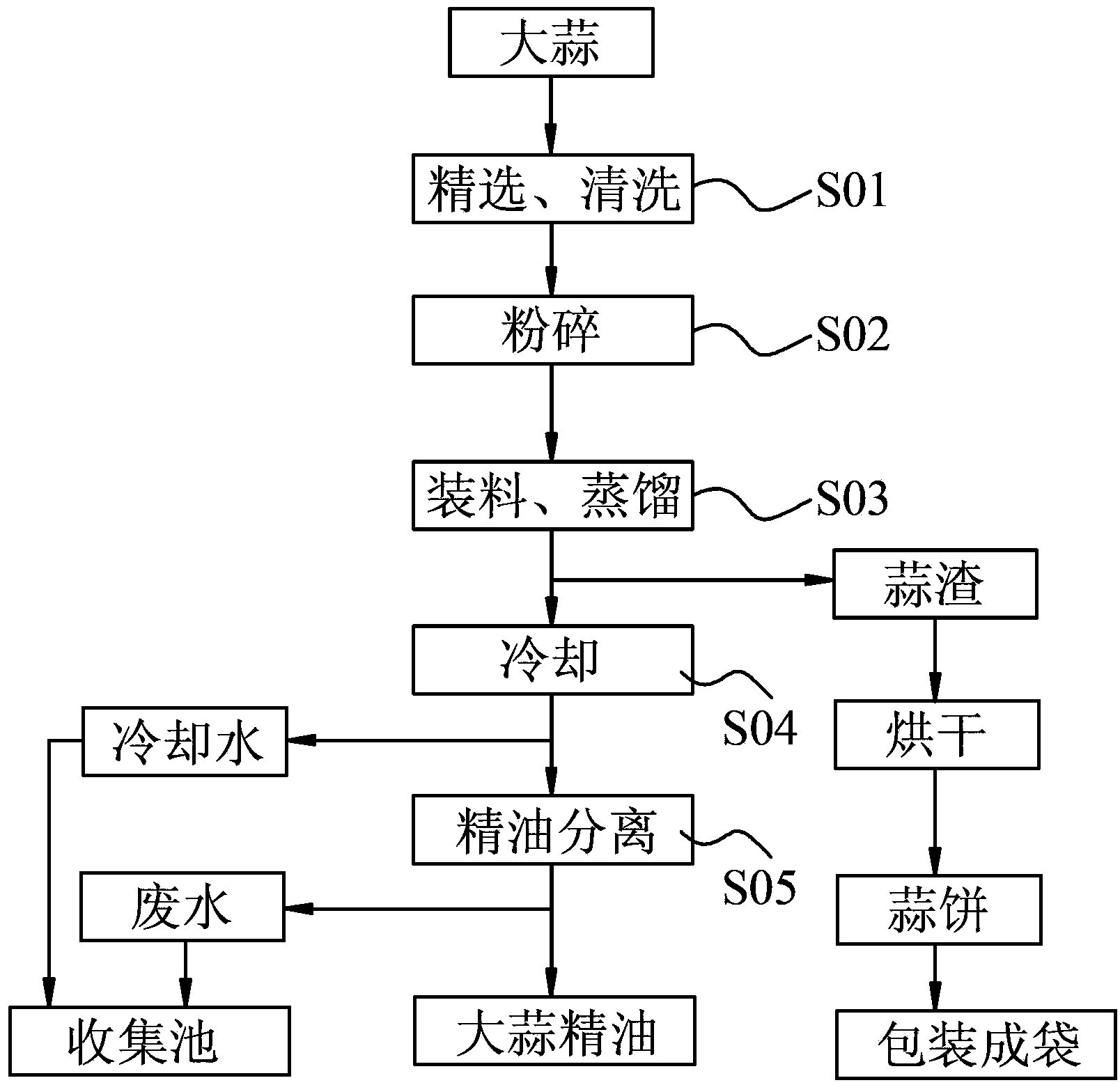

Method for improving garlic oil yield

The invention discloses a method for improving garlic oil yield, which comprises: soaking fresh garlic or dry garlic slices in water; stirring for removing impurities such as soil; feeding the fresh garlic or dry garlic slices in a pulping machine and crushing; adding an allinase activity regulator; performing enzymolysis; adding a transforming agent; feeding; distilling; feeding distillate into distilling equipment; taking an oil phase out, wherein the oil phase is coarse garlic oil; drying the garlic oil by a silicagel column; and removing residual moisture and obtaining the garlic oil. Themethod has the main advantages that: when the proper transforming agent is added, the distillation time is reduced by 20 percent, the garlic oil yield is improved to 1 to 3 times, and the content of each of the components such as diallyl disulfide, diallyl trisulfide, diallyl sulfide, allyl methyl sulfide, allyl methyl disulphide, allyl methyl trisulphide, propenethiol and methyl merecaptan is improved to over 3 times; and equipment investment is not increased, as only a proper amount transforming agent is added on the basis of the original distillation garlic oil production line.

Owner:JINAN UNIVERSITY

Production method of hydrogen iodide

The invention discloses a production method of hydrogen iodide, which adopts a red phosphorus method and comprises a reacting step, a filtering step and a distilling step sequentially. In the reacting step, deionized water is added into reaction equipment; after red phosphorus and iodine are added, the weight ratio of the reaction material liquid is measured and is controlled to be between 1.2 and 1.4; and hydroiodic acid steam is absorbed by a water spraying pump. The filtering step includes two times of filtering. The production method provided by the invention solves the problem of difficult realization of mass production, and avoids the occurance of explosion, has high production efficiency and contributes to environmental protection at the same time.

Owner:自贡市金典化工有限公司

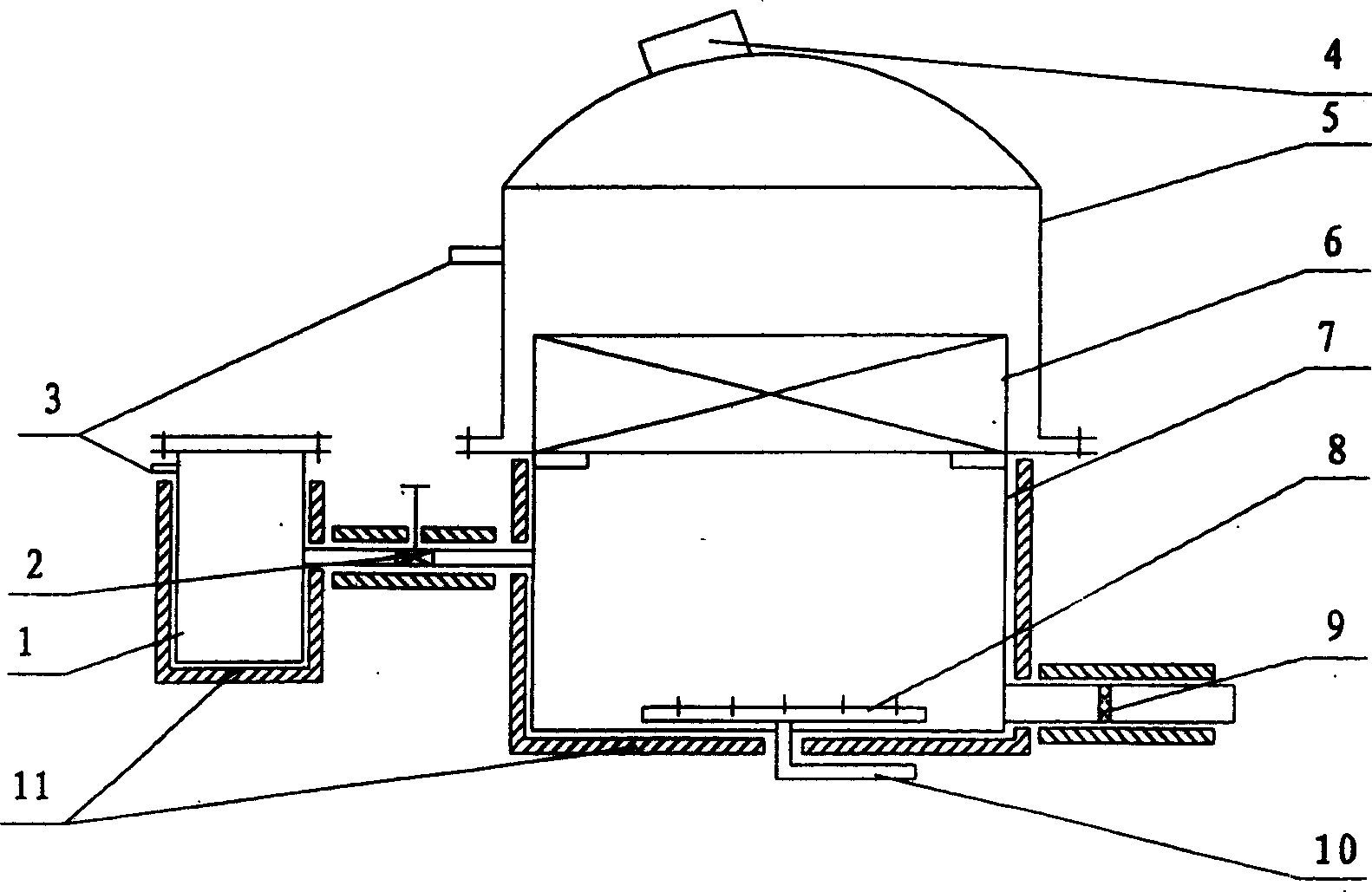

Distillation equipment for producing sponge titanium

The present invention provides a piece of distillation equipment for producing sponge titanium, which includes a heating furnace and a reactor for containing a condensate, wherein a heating furnace cover is arranged above the heating furnace, a reactor cover is arranged above the reactor, the heating furnace cover is connected with the reactor cover by a pipe, a resistance wire is arranged on the pipe, each lifting device is arranged above the heating furnace cover and the reactor cover, a vacuum-pumping pipe is arranged above a heater cover, and a first metal sealing ring is arranged between the reactor cover and the reactor. The present invention has the beneficial effects that the distillation equipment can ensure normal production, and effectively ensure the quality of sponge titanium product. The problem of distillation tube blockage is solved by adopting a metal gasket.

Owner:SHENZHEN SUNXING LIGHT ALLOYS MATERIALS CO LTD

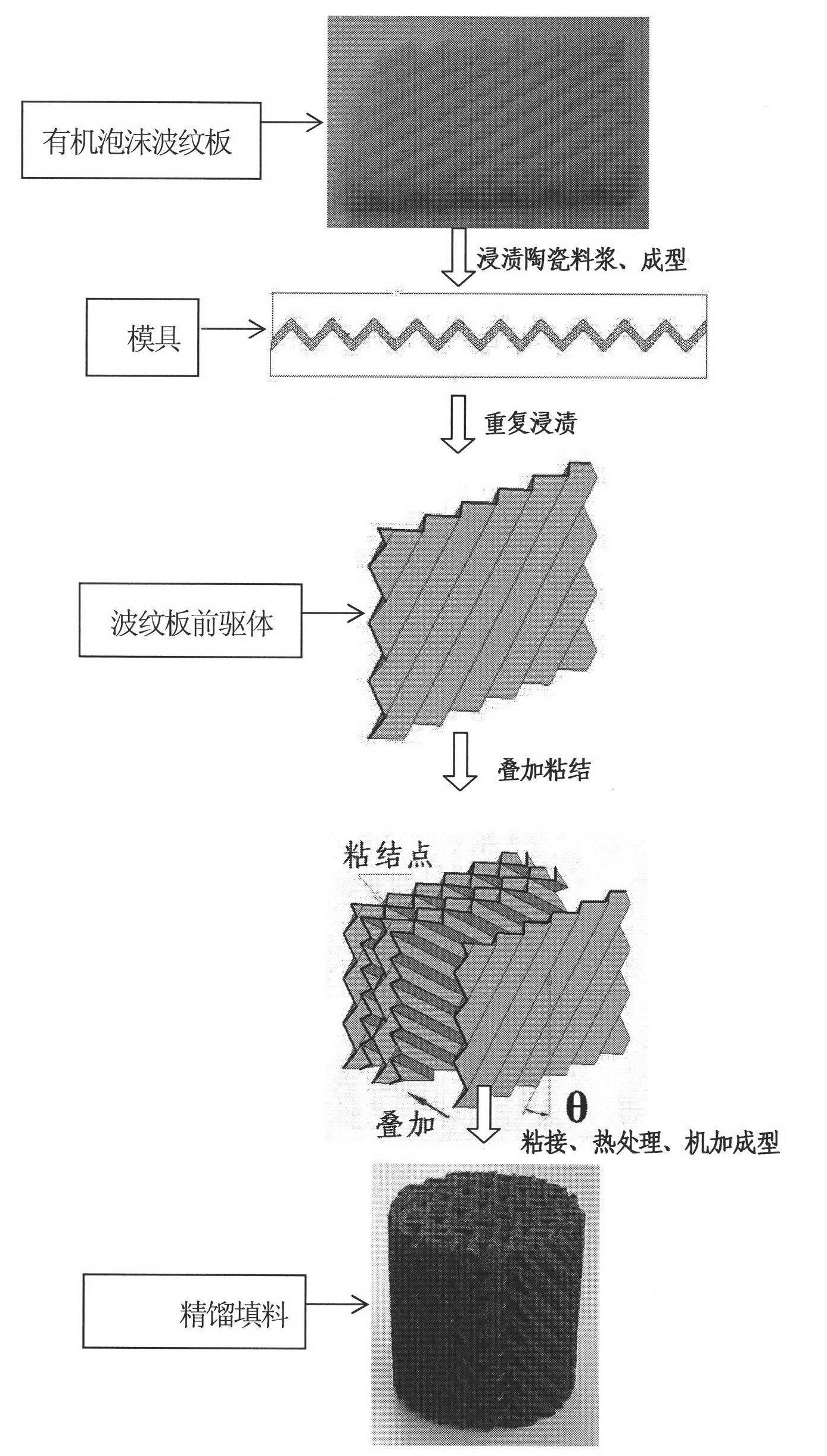

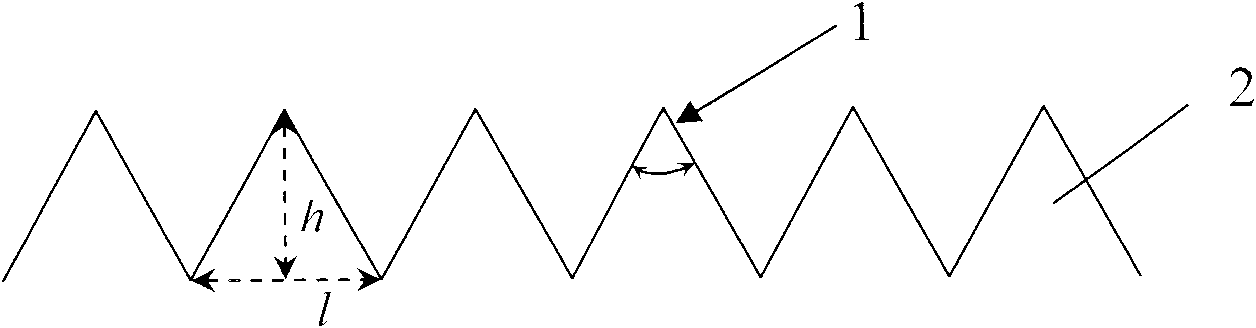

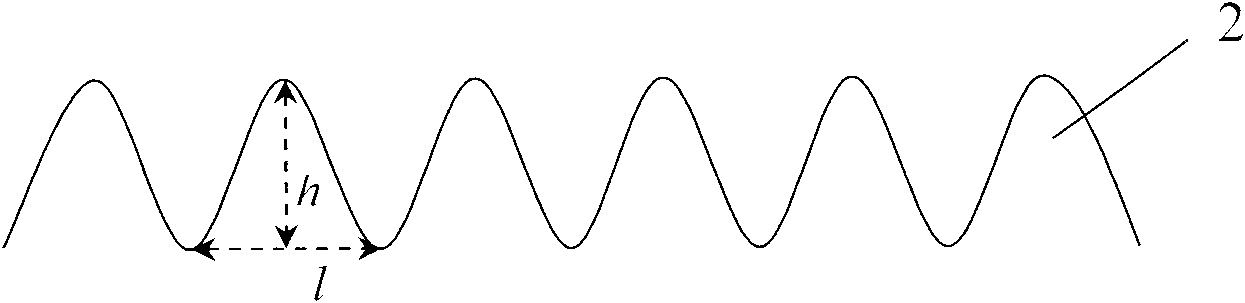

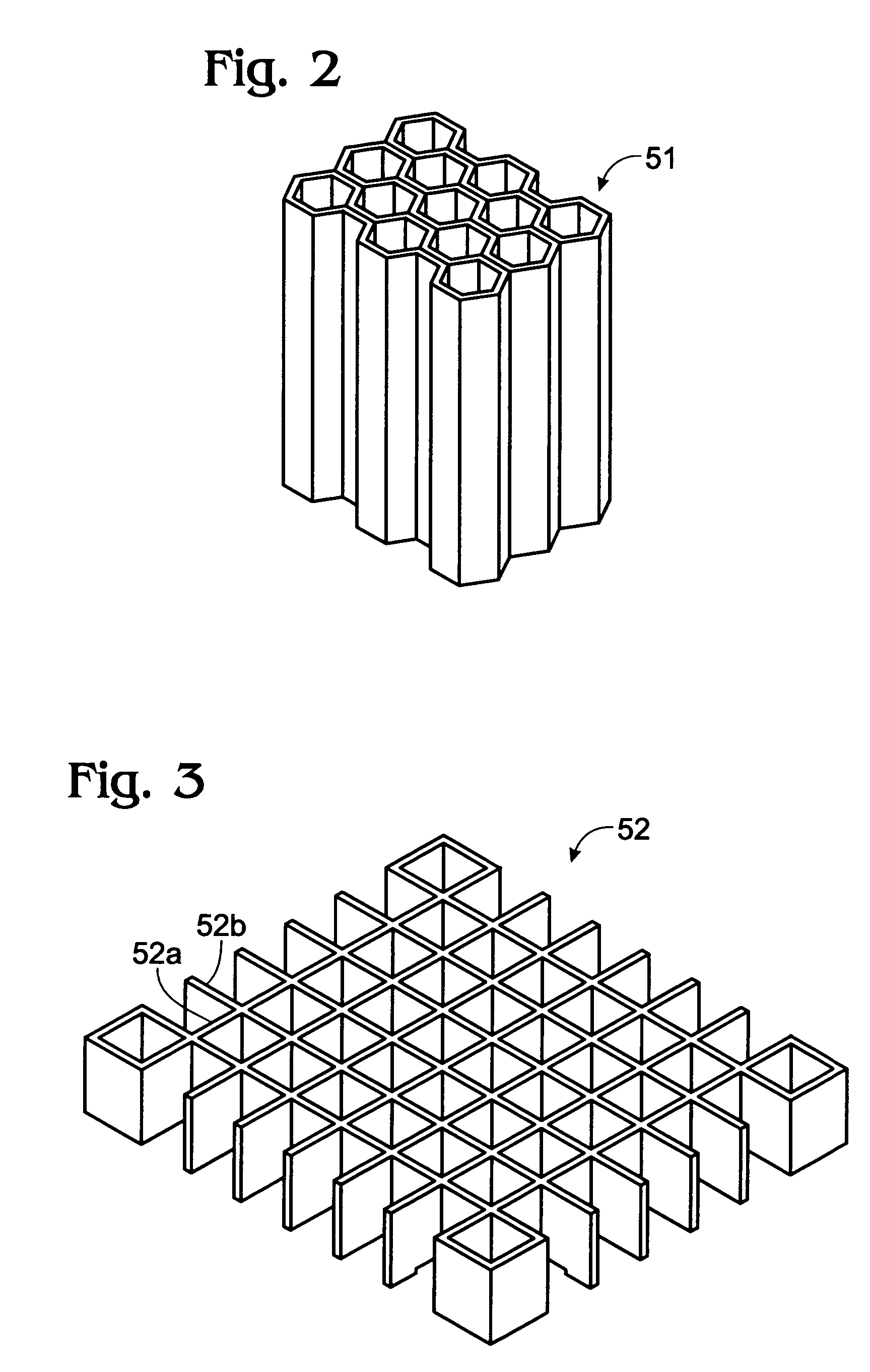

Cheap and high efficiency rectification filler and preparation method thereof

ActiveCN102247795ALarge specific surface areaFully contactedChemical/physical/physico-chemical processesNetwork structureEngineering

The invention which relates to the field of structured fillers concretely relates to a cheap and high efficiency rectification filler and a preparation method thereof. The filler which is suitable for a rectification operation under a temperature of less than 300 DEG C is formed by stacking filler unit plates with corrugated shapes, the filler unit plates are foamed resin-based filler unit plateswith three-dimensional connected network structures, the foam pore sizes are between 10PPi and 80PPi, and the volume fraction is controlled between 10% and 80%. A plurality of the filler unit plates are stacked, the filler unit plates of the odd-numbered layers have a consistent channel direction, and the filler unit plates of the even-numbered layers have a consistent channel direction, and an angle between the channel direction of the filler unit plates of the odd-numbered layers and the channel direction of the filler unit plates of the even-numbered layers is 30-170 DEG; a corrugation angle between a corrugation parallel direction and a vertical direction of a filler disc is 15-85 DEG, corrugations of adjacent filler unit plates have a same angle and opposite directions; and the filler unit plates are bonded after being stacked, and are subjected to a heat treatment to obtain the filler. The foamed resin-based structured filler unit plates of the invention allows the three-dimensional network connectivity characteristic of a polyurethane foamed plastic template to be kept, and has the characteristics of large specific surface area, thin wall, cheapness, high chemical stabilityand the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

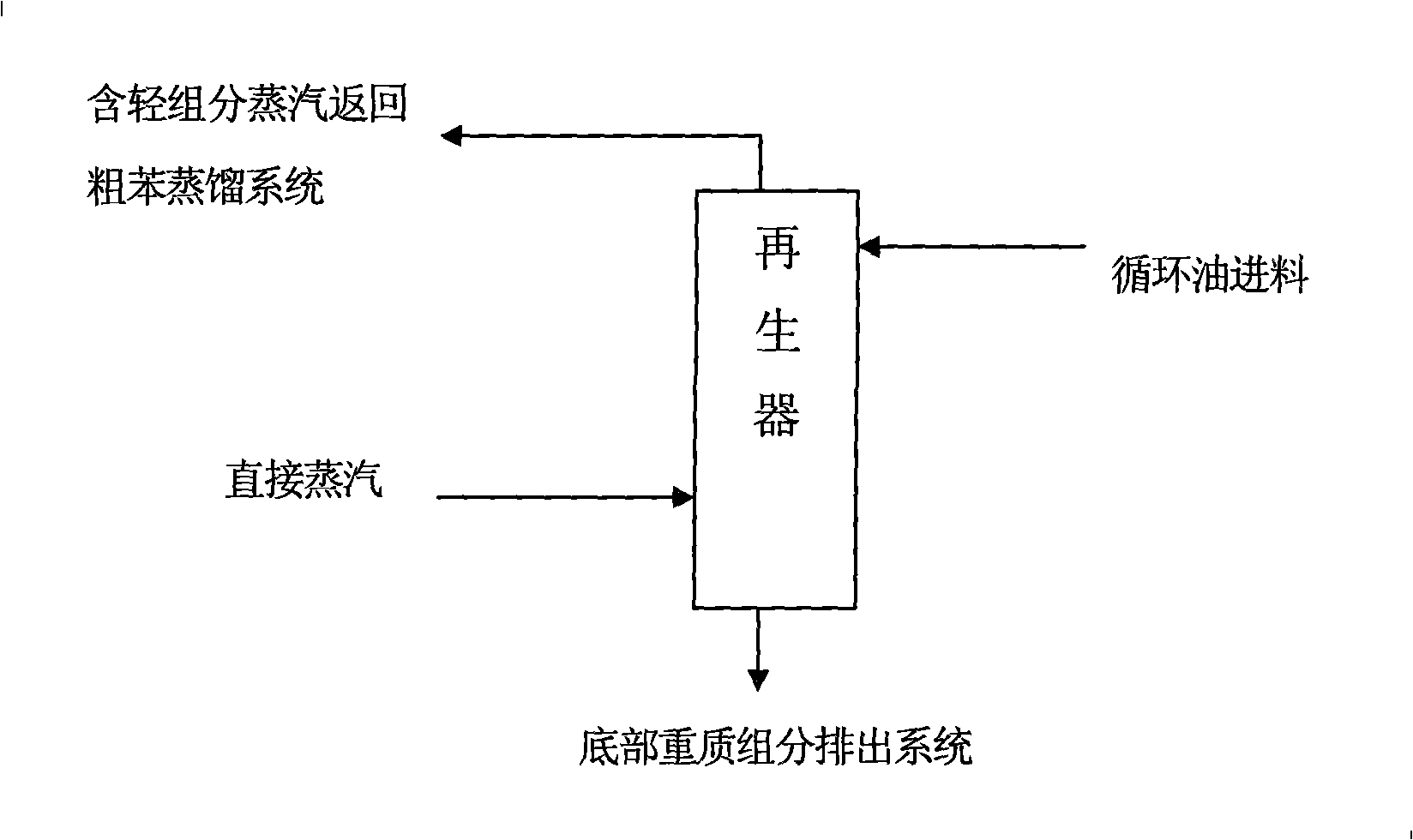

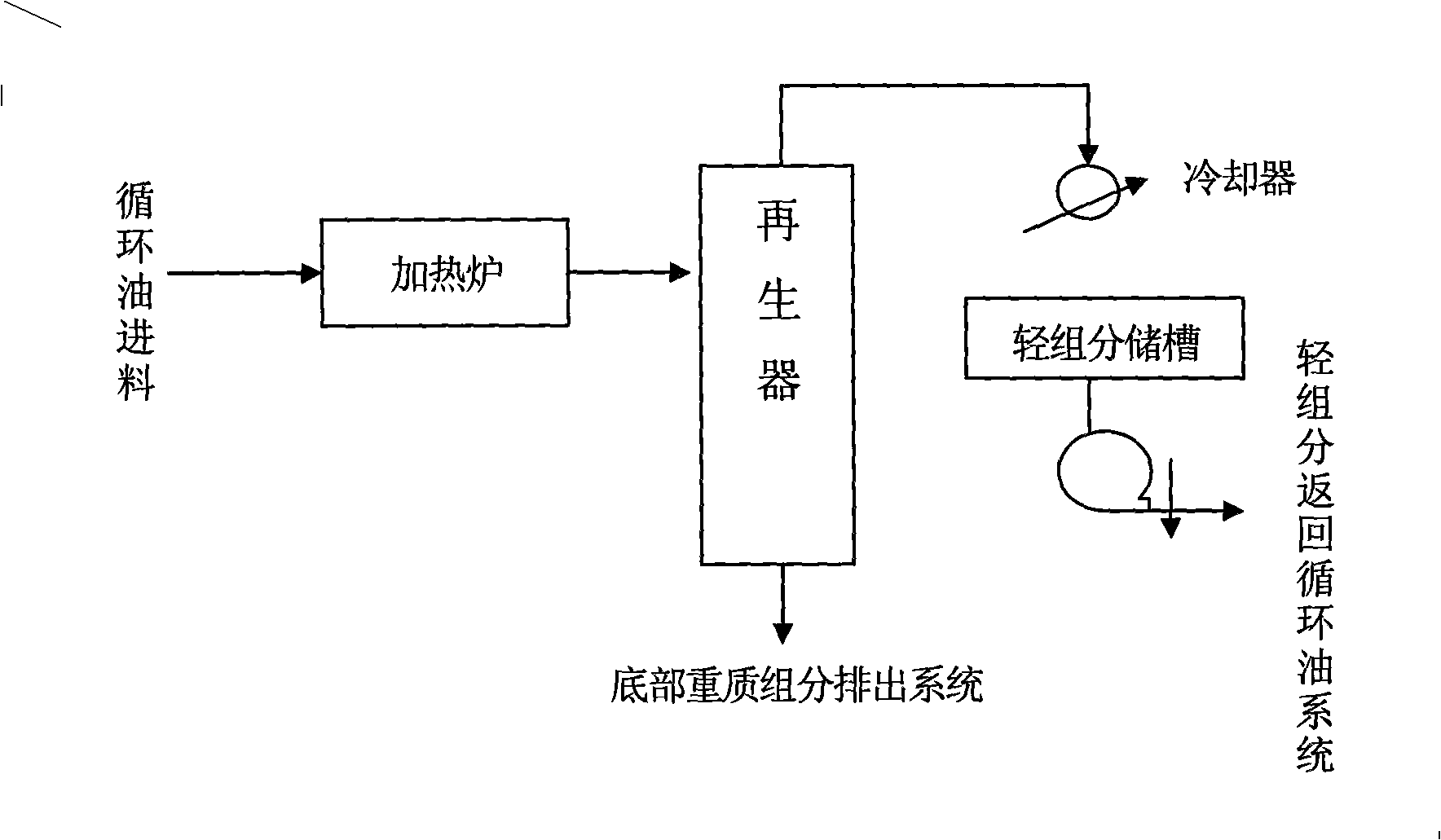

Novel regeneration process for circulation oil of crude benzol device

InactiveCN101289633AIncrease discharge viscosityImprove regeneration efficiencyCombustible gas purificationGas phaseDistillation

The invention discloses a novel method for regenerating crude benzole device cycle oil. The method adopts a flash distillation mode to carry out regeneration of cycle oil; a heating furnace is arranged in front of a regenerator, i.e. a flash tower; an indirect heating mode is adopted to raise the temperature of cycle regeneration feed oil which is fed in the regenerator from the upper part of the flash tower; after flash distillation and regeneration, light compositions in the tower top are cooled down by a top gas phase cooler and then are fed back to a cycle oil system by a pump, while heavy compositions in the bottom of the tower are discharged outside the system; the feeding capacity of regeneration oil is controlled to 1 to 2 percent of the circulating load of the cycle oil of the system; the feed temperature of the cycle regeneration oil at the outlet of the heating furnace is controlled to between 250 and 270 DEG C; the release viscosity of the heavy oil at the bottom of the regenerator is controlled to less than 7 (Engler viscosity); and the viscosity of the light oil at the top of the regenerator is controlled to between 1.0 and 1.2 (Engler viscosity). The method can effectively increase the regeneration efficiency of cycle oil and improves the quality of cycle oil.

Owner:BAOSHAN IRON & STEEL CO LTD

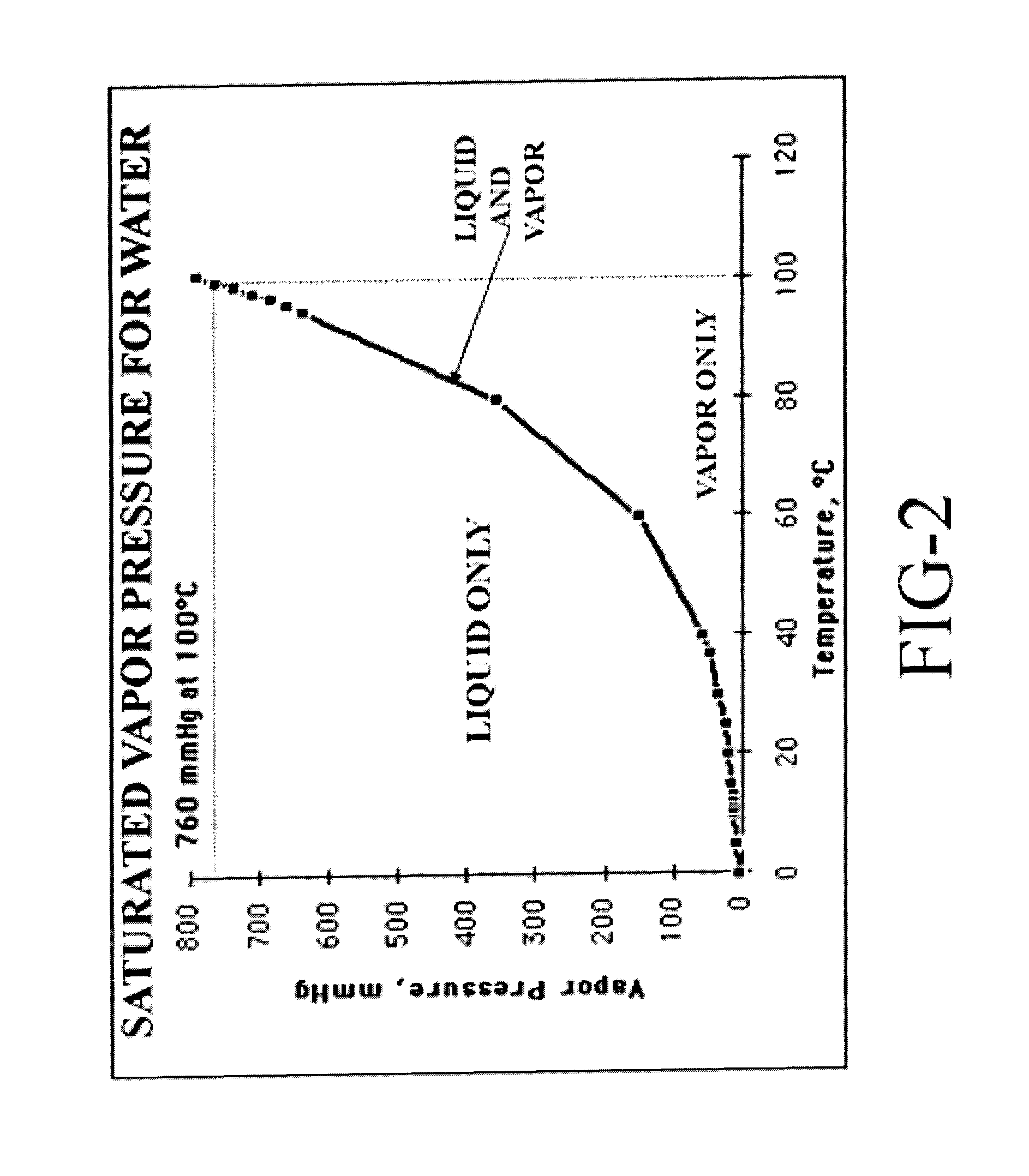

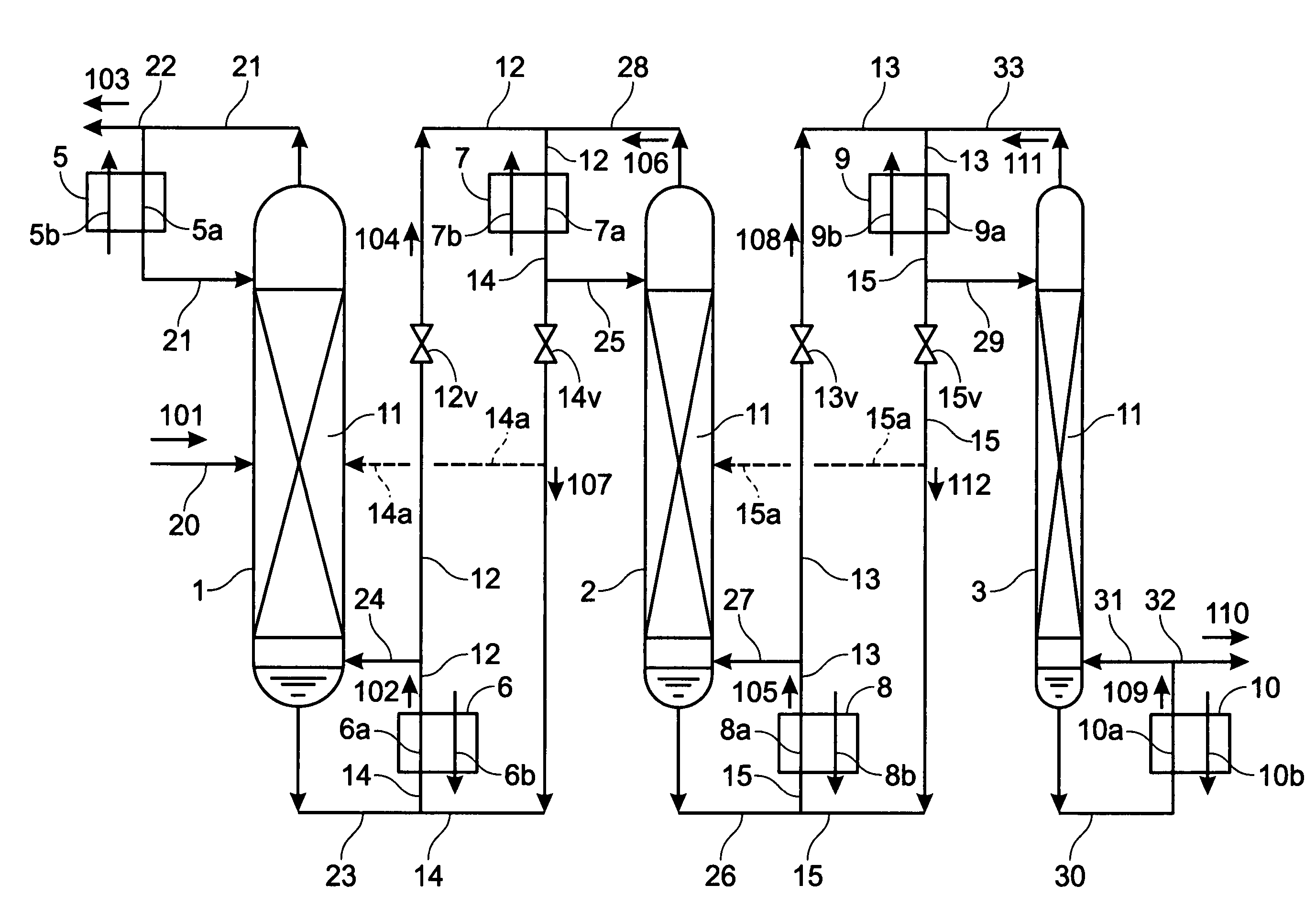

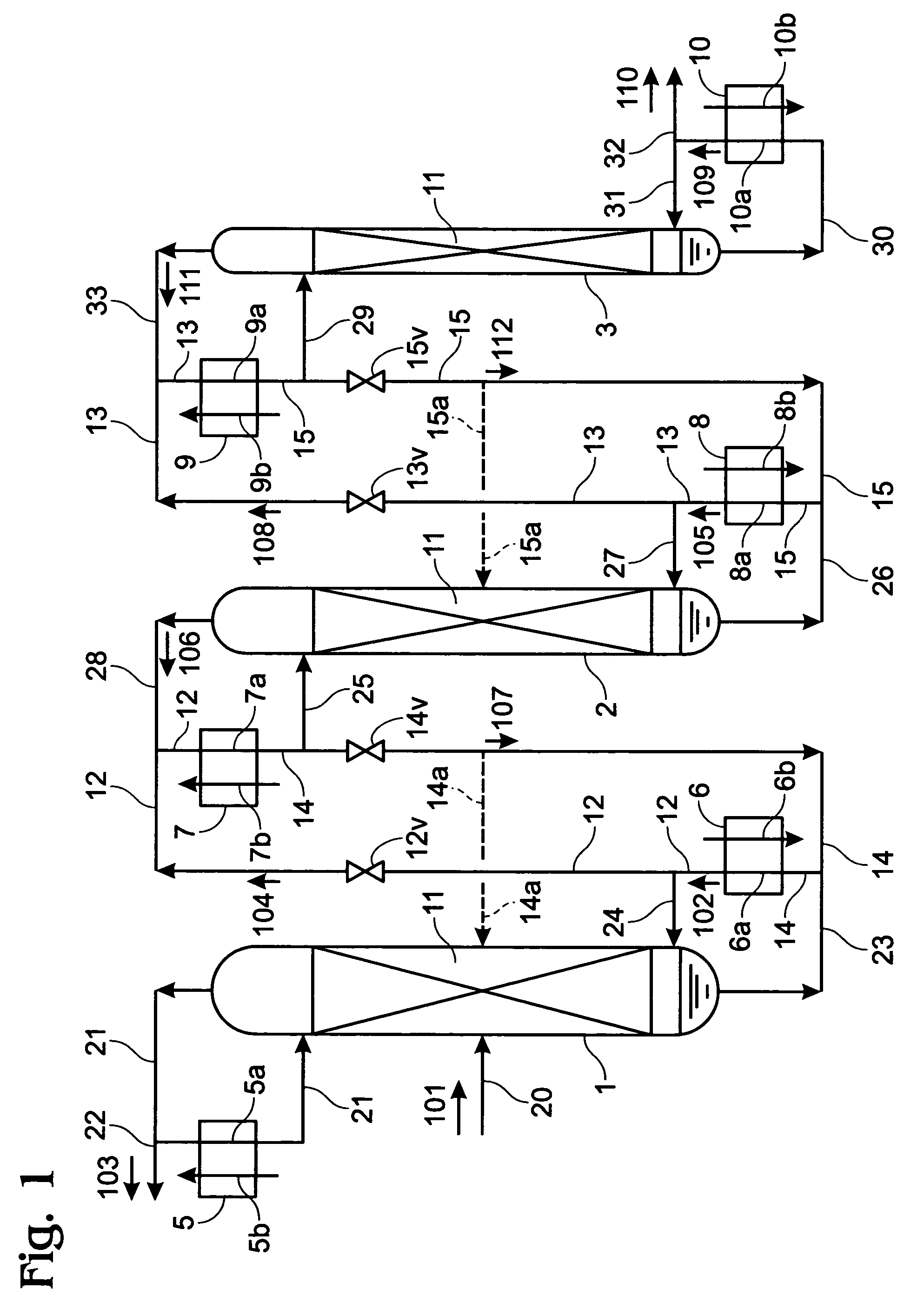

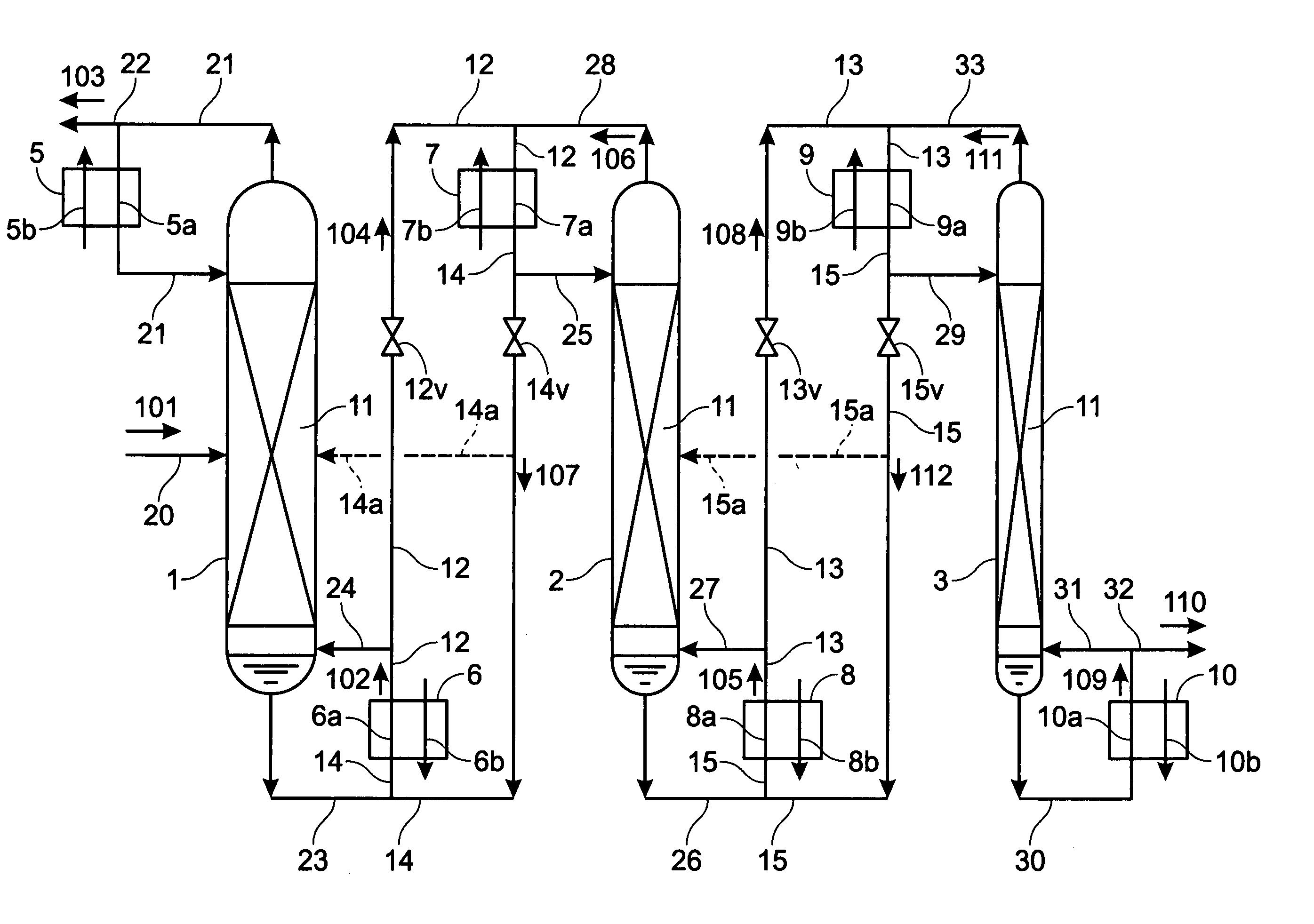

Apparatus, method for enrichment of the heavy isotopes of oxygen and production method for heavy oxygen water

InactiveUS7393447B2Increase vapor pressureImprove distillation efficiencySolidificationLiquefactionReboilerOxygen

An apparatus comprising first to third columns, wherein the outlet of a first column reboiler and the inlet of a second column condenser are connected by a first introduction conduit, and the outlet of a second distillation column reboiler and the inlet of a third column condenser are connected by a second introduction conduit, and additionally the outlet of the second column condenser and the inlet of the first column reboiler are connected by a first return conduit, and the outlet of the third column condenser and the inlet of the second column reboiler are connected by a second return conduit.

Owner:NIPPON SANSO CORP

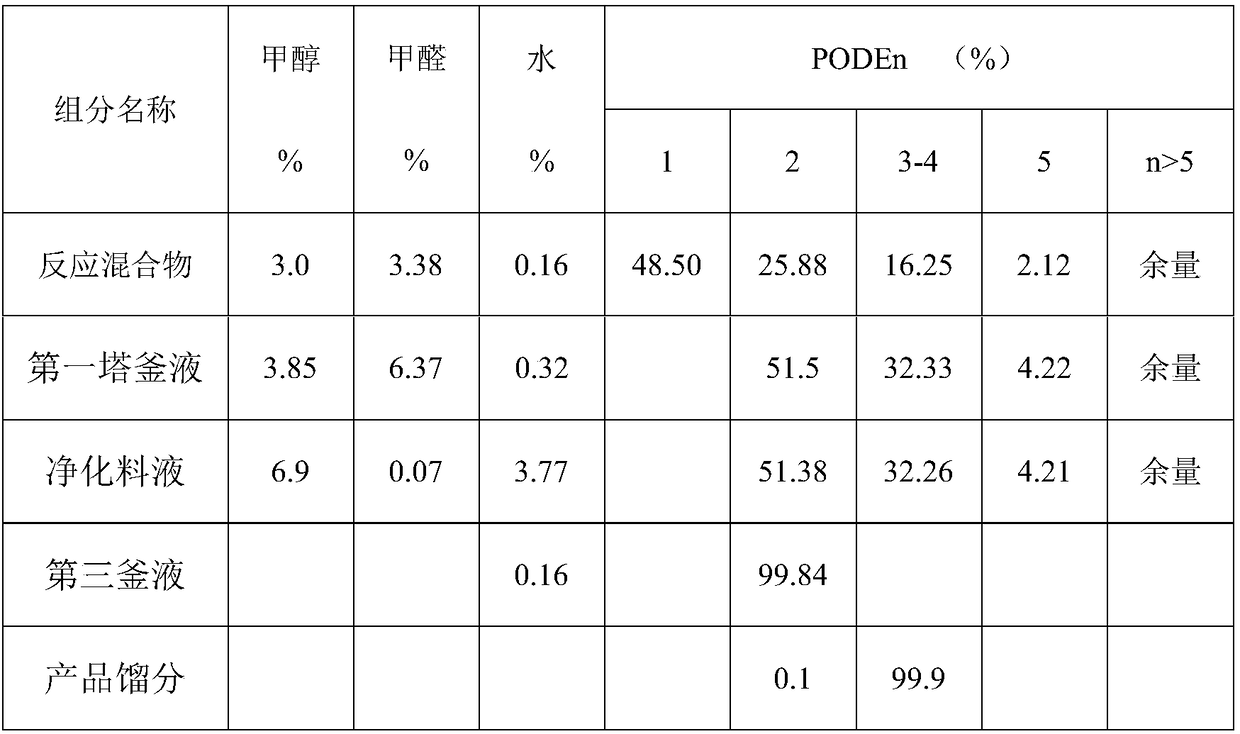

Purification method for polymethoxydimethyl ether

ActiveCN109096062AEnsure smooth continuityEasy to operateOrganic chemistryOrganic compound preparationChemical treatmentPurification methods

The invention relates to a purification method for polymethoxydimethyl ether. The purification method aims at solving the problem that it is difficult to carry out long-term continuous production operation due to the presence of formaldehyde in the process of purifying polymethoxydimethyl ether by means of a rectification method. According to the adopted technical scheme, the purification method includes the following steps that methylal of a reaction equilibrium mixture obtained in a reaction synthesis unit is removed first in a first separation tower to obtain a first tower bottom liquid; the first tower bottom liquid enters a purification kettle to be in contact with a chemical treatment liquid to obtain a purified feed liquid containing PODE2 to PODE8; the purified feed liquid enters asecond rectification tower, a second fraction comprising PODE2, methanol and water is separated out from the top, and a second tower bottom liquid is obtained at the tower bottom; the second fractionenters a third rectification tower, and a third fraction containing methanol and water is separated out from the top of the third rectification tower to obtain a third tower bottom liquid, namely a high-purity PODE2 product; the second tower bottom liquid enters a fourth rectification tower, and a fourth rectification tower product fraction, namely PODE3 to PODE4 or PODE 3 to PODE5, is separatedout from the top of the fourth rectification tower.

Owner:CHINA PETROLEUM & CHEM CORP +1

Rapidly heating distillation device in titanium tetrachloride refining process

InactiveCN101844802AUniform and stable heatingUniform and stable productionTitanium halidesDistillationTower

The invention belongs to the technical field of titanium sponge production by a magnesium method and in particular relates to a rapidly heating distillation device in a titanium tetrachloride refining process. The invention adopts a technical scheme that: the rapidly heating distillation device in the titanium tetrachloride refining process comprises a distillation still, a distillation tower, a cooler, a respiration tank, a ground tank and a finished product storage tank which are connected with one another sequentially through pipelines. The rapidly heating distillation device has the advantages of raising the temperature uniformly and stably, realizing automation easily, increasing production yield by 30 percent, reducing energy consumption by 15 percent, greatly improving the purity of the products, saving energy and reducing consumption, greatly improving the quality of the products and protecting the surrounding environment, along with simple and rapid operation, stable production, good separation effect and low production cost.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Apparatus, method for enrichment of the heavy isotopes of oxygen and production method for heavy oxygen water

InactiveUS20050129592A1Increase vapor pressureImprove distillation efficiencySolidificationLiquefactionReboilerOxygen

An apparatus comprising first to third columns, wherein the outlet of a first column reboiler and the inlet of a second column condenser are connected by a first introduction conduit, and the outlet of a second distillation column reboiler and the inlet of a third column condenser are connected by a second introduction conduit, and additionally the outlet of the second column condenser and the inlet of the first column reboiler are connected by a first return conduit, and the outlet of the third column condenser and the inlet of the second column reboiler are connected by a second return conduit.

Owner:NIPPON SANSO CORP

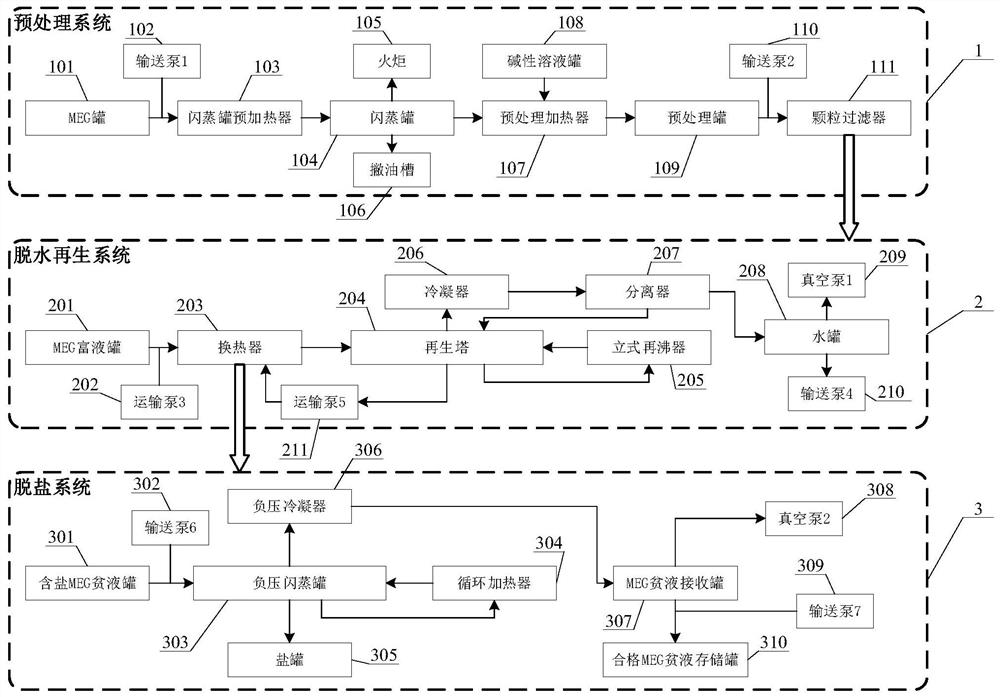

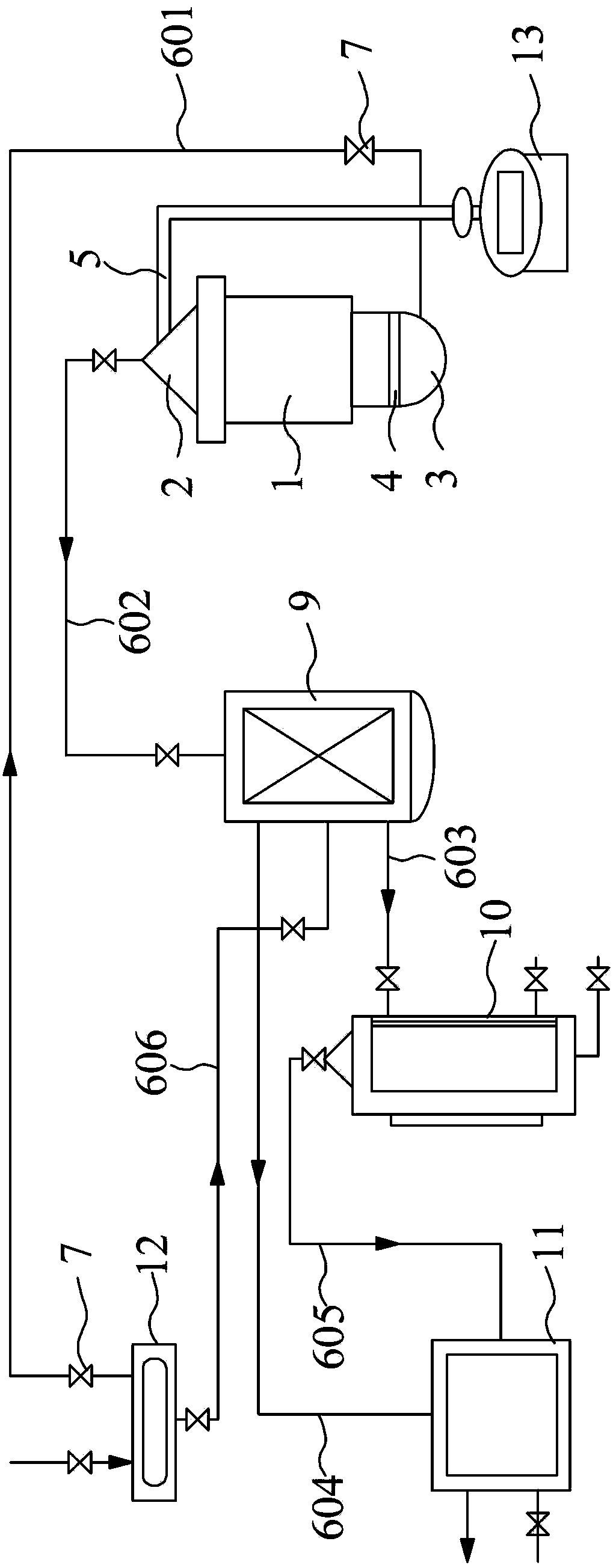

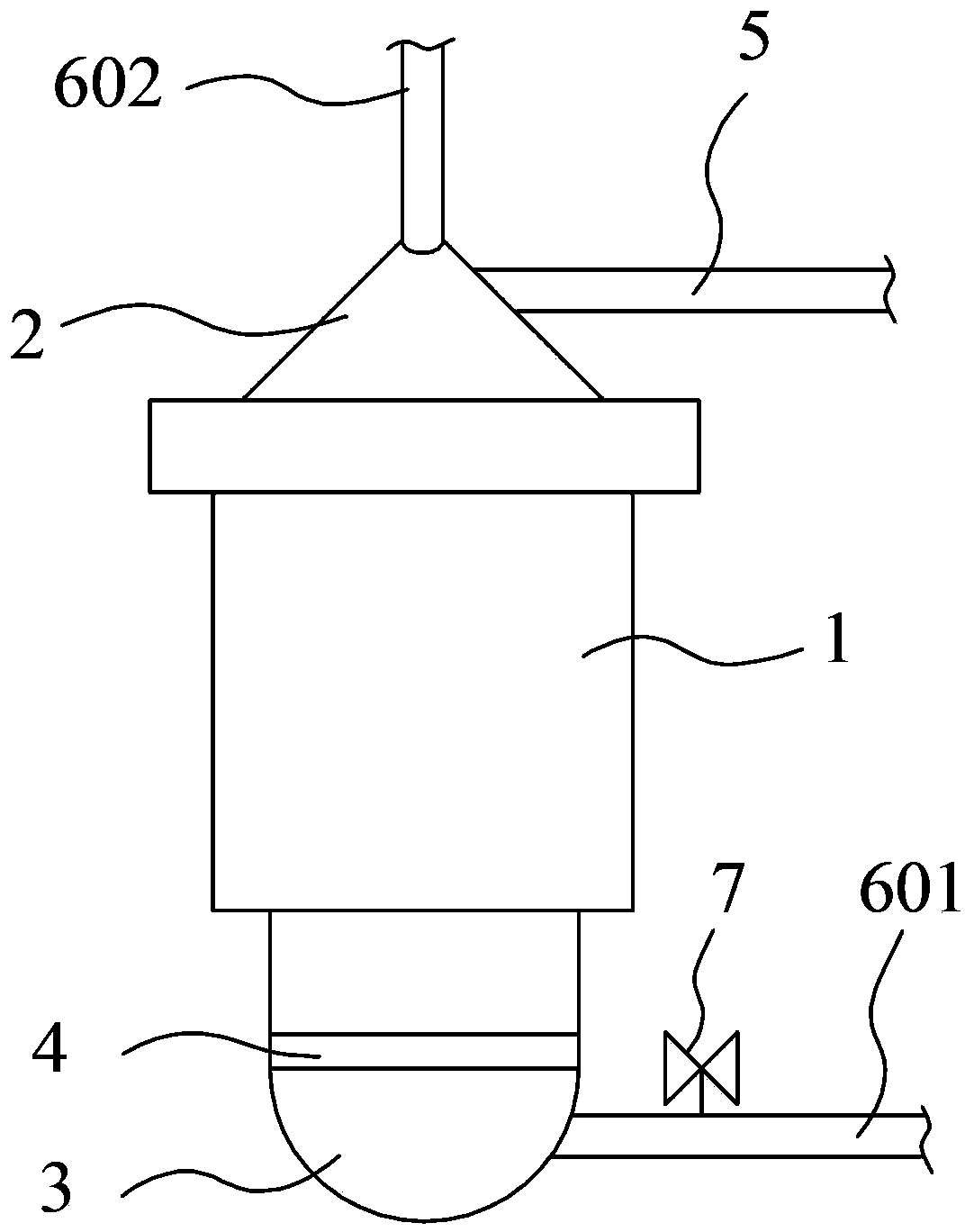

Ethylene glycol regeneration and recovery system in deep sea natural gas extraction process and ethylene glycol recovery method

PendingCN112274958AAvoid pollutionLow costOrganic compound preparationGeneral water supply conservationDesalinationGlycol synthesis

The invention discloses an ethylene glycol regeneration and recovery system in a deep sea natural gas extraction process. The ethylene glycol regeneration and recovery system comprises a pretreatmentdevice for removing light hydrocarbon and divalent salt ions in an ethylene glycol pregnant solution, a dehydration regeneration device for removing water in the ethylene glycol pregnant solution, anda desalting device for removing monovalent salt in a salt-containing ethylene glycol barren solution. According to the system, for the ethylene glycol pregnant solution obtained in the deep sea natural gas extraction process, separation of light hydrocarbon, divalent salt ions, water, high-solubility salt and other impurities in the ethylene glycol pregnant solution is achieved, the ethylene glycol barren solution capable of being reused is obtained, and the deep sea natural gas extraction cost is saved. The invention further discloses an ethylene glycol recovery method of the ethylene glycolregeneration and recovery system in the deep sea natural gas extraction process.

Owner:CHONGQING QIANWEI SCI & TECH GRP +1

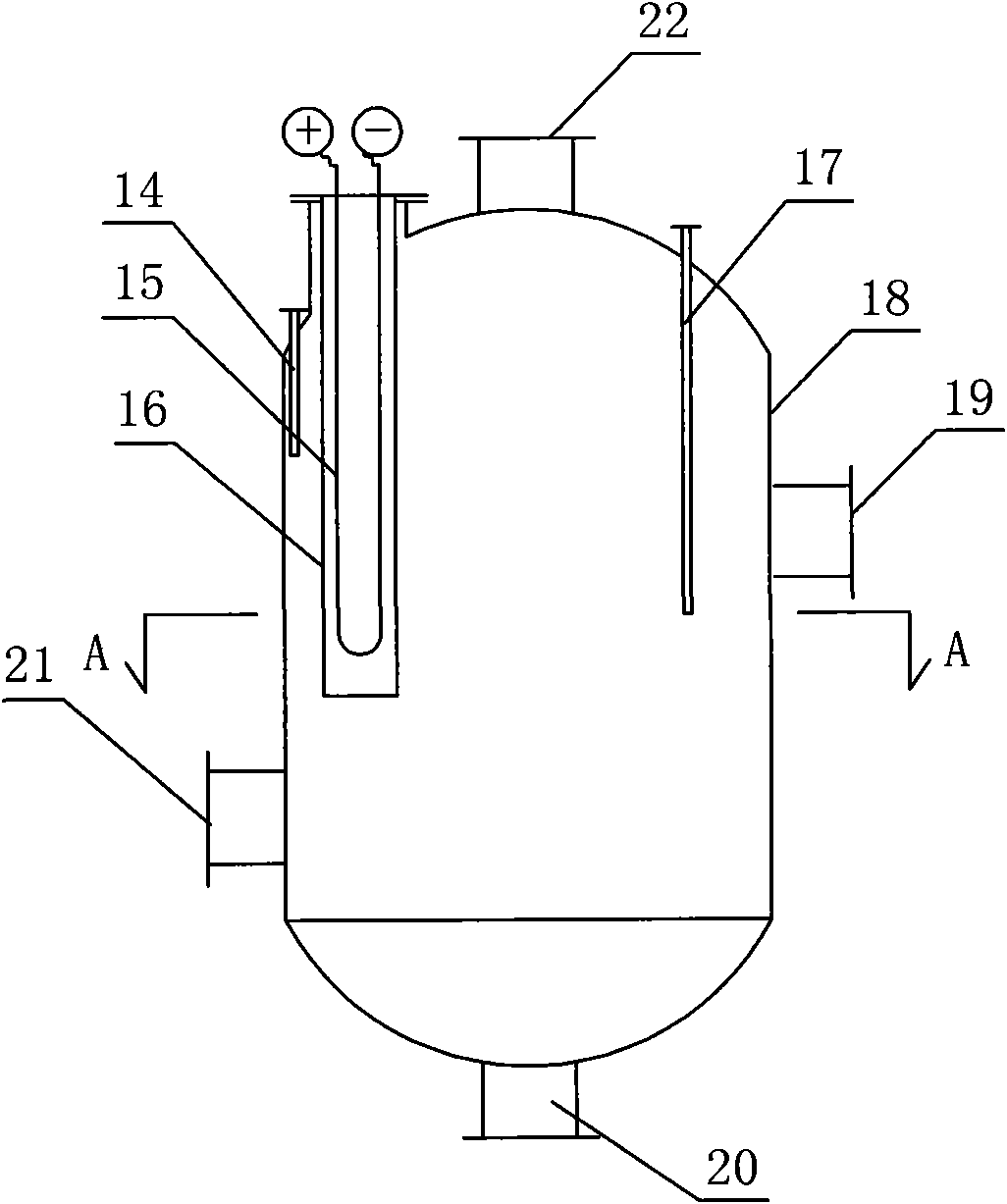

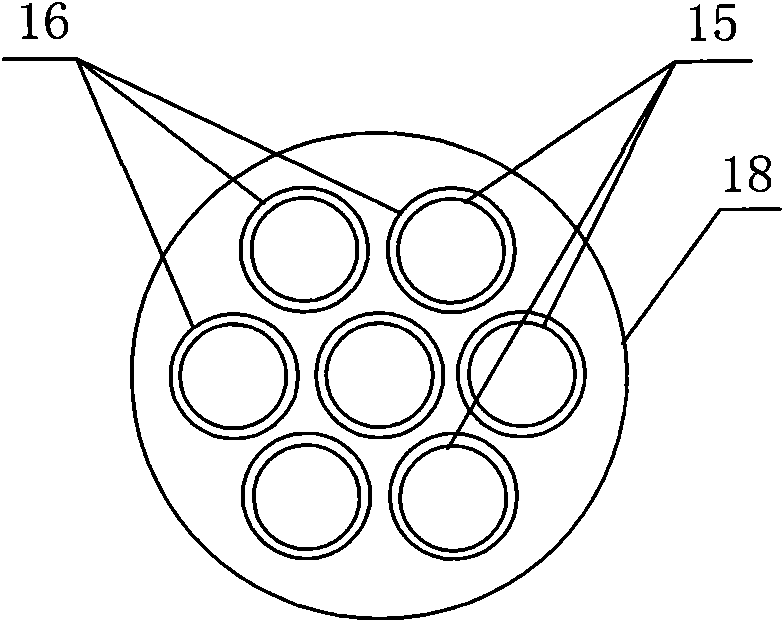

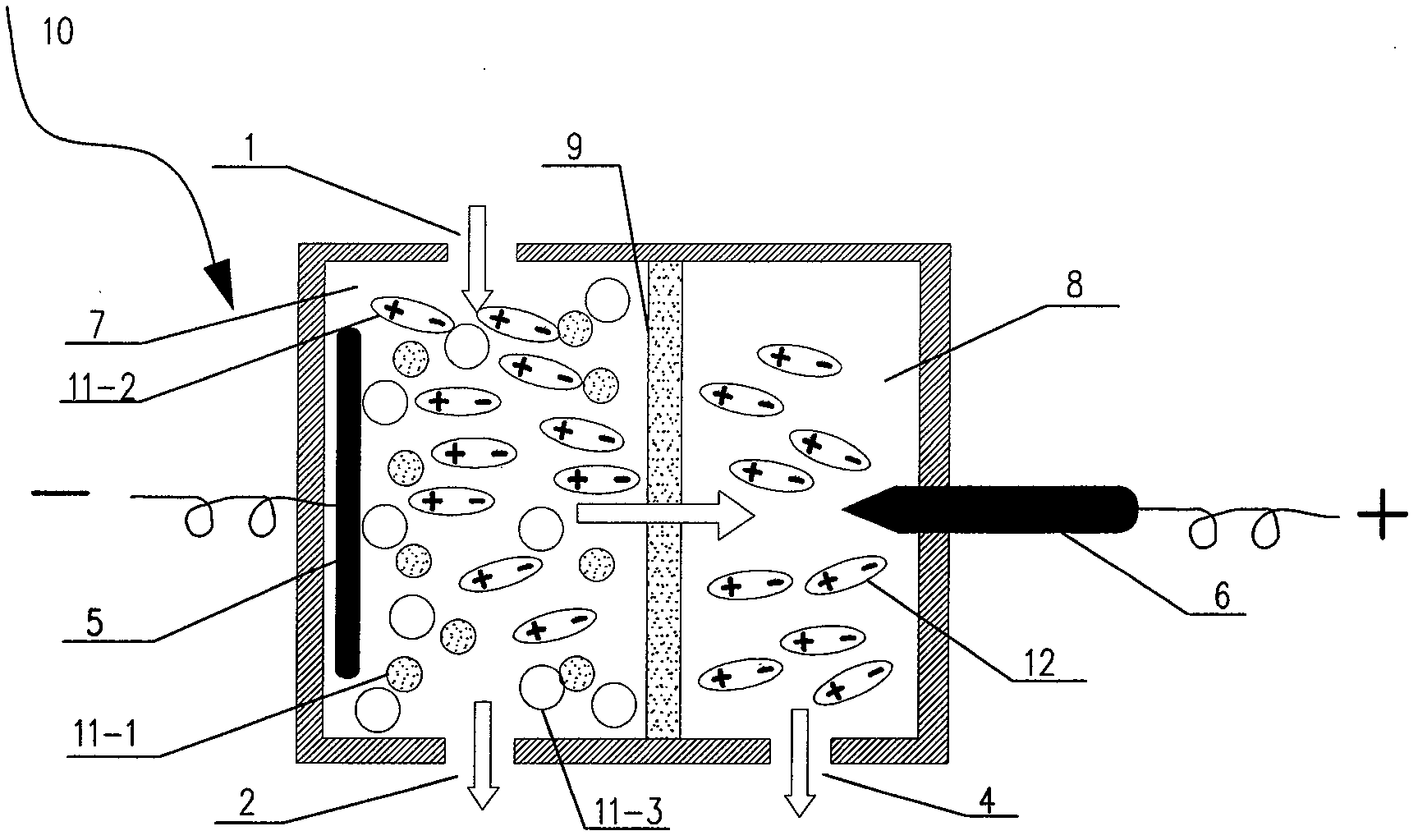

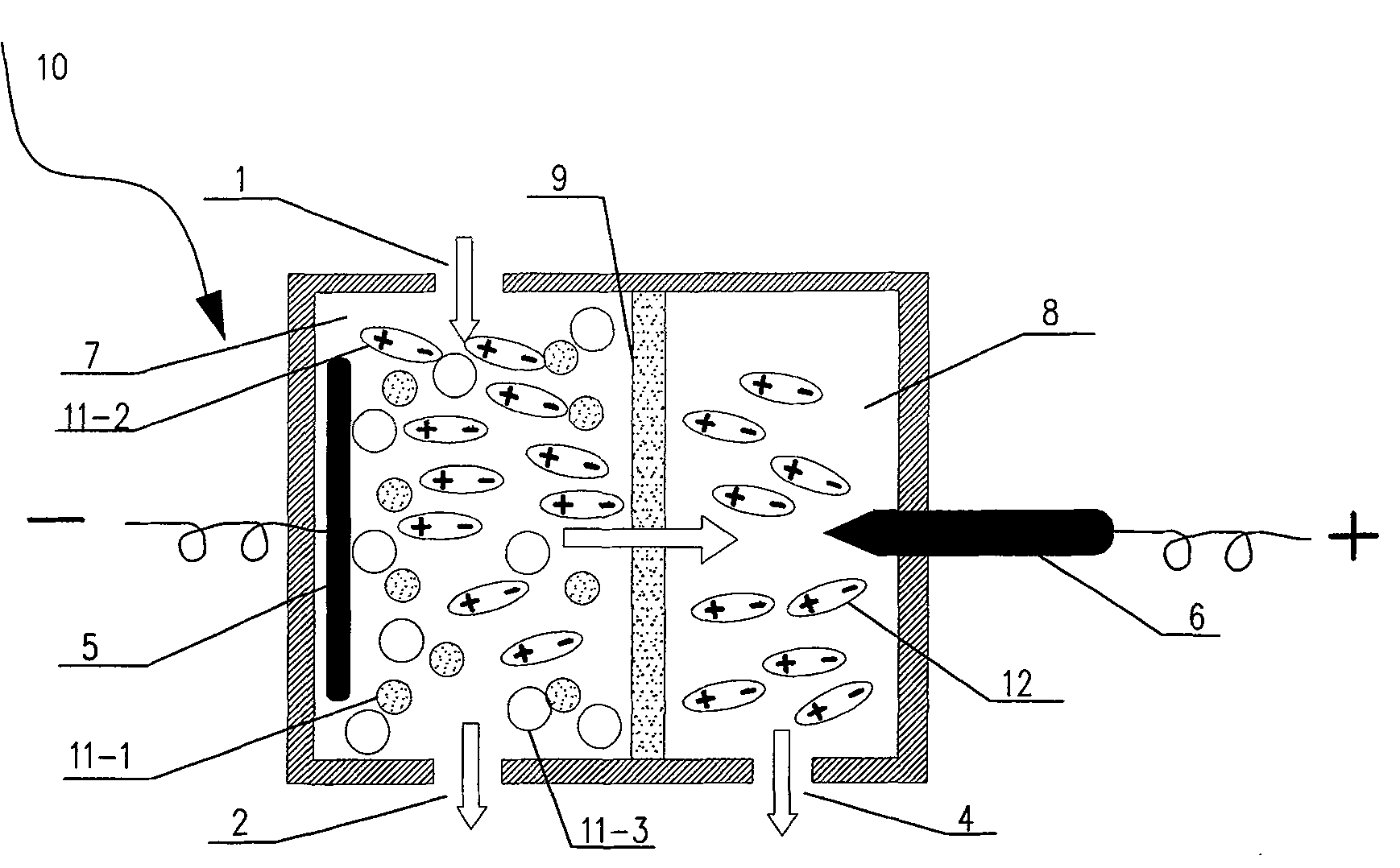

A device and method for membrane distillation

ActiveCN102274691AImprove distillation efficiencyHigh permeation fluxWater/sewage treatment bu osmosis/dialysisEnergy based wastewater treatmentVoltAqueous solution

The invention relates to a device for distilling a coupling membrane in asymmetric electrostatic fields, and the device comprises a raw material chamber, a permeation chamber, a membrane and electrodes, the electrodes enable a formation of the asymmetric electrostatic fields. The electrodes comprise a flat electrode and an acicular electrode. The direct current voltage applied on the electrodes is 101-104 volt. The invention is characterized in that under dual functions of temperature difference and potential gradient of the asymmetric electrostatic fields, the water molecule in an aqueous solution is formed to water vapor on the surface of the membrane by vaporizing, the water vapor is permeated through the membrane with a more rapid speed by taking the only existed temperature difference as the motive force and then enters the permeation chamber. The invention also relates to a method for distilling a coupling membrane of the asymmetric electrostatic fields.

Owner:TIANJIN POLYTECHNIC UNIV

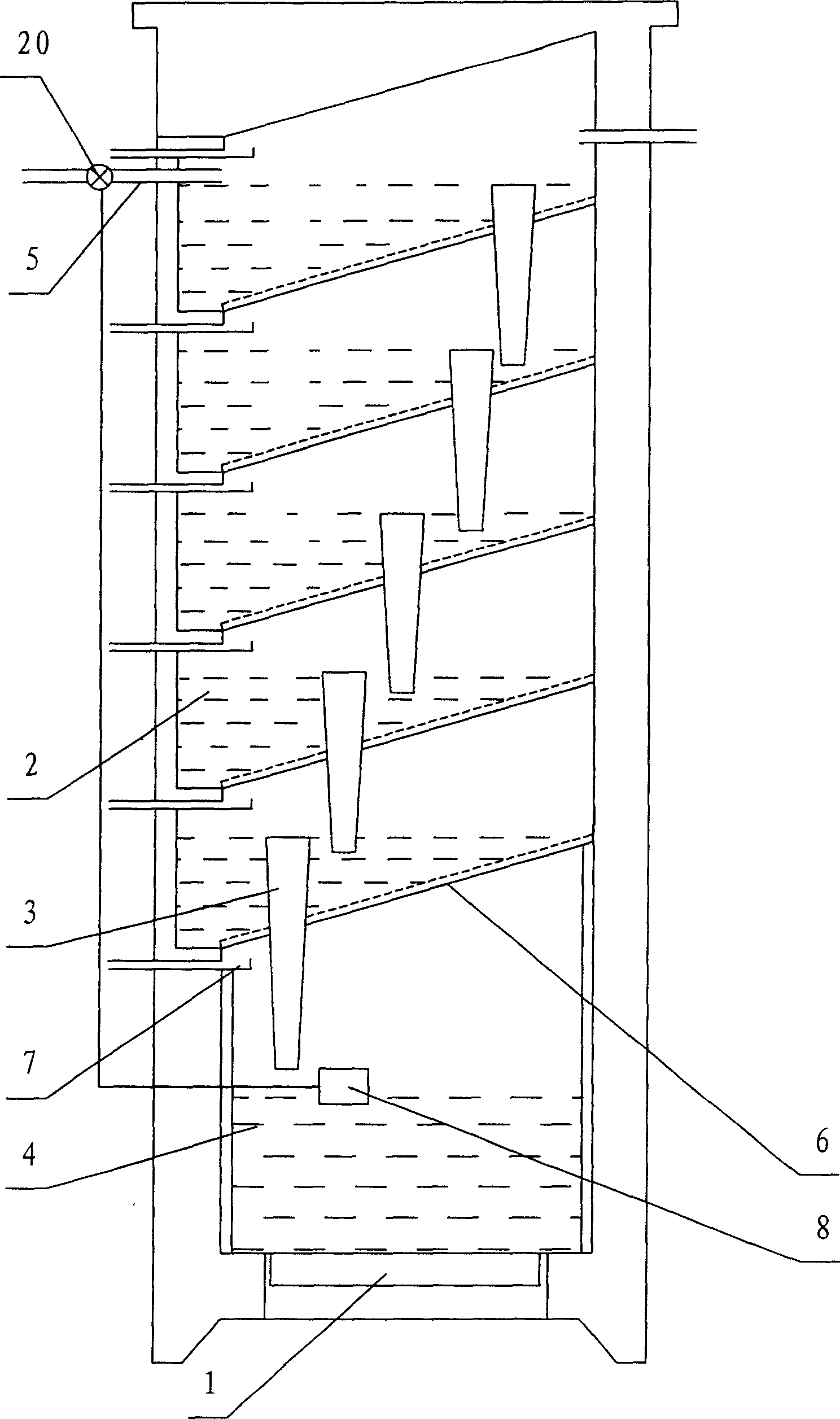

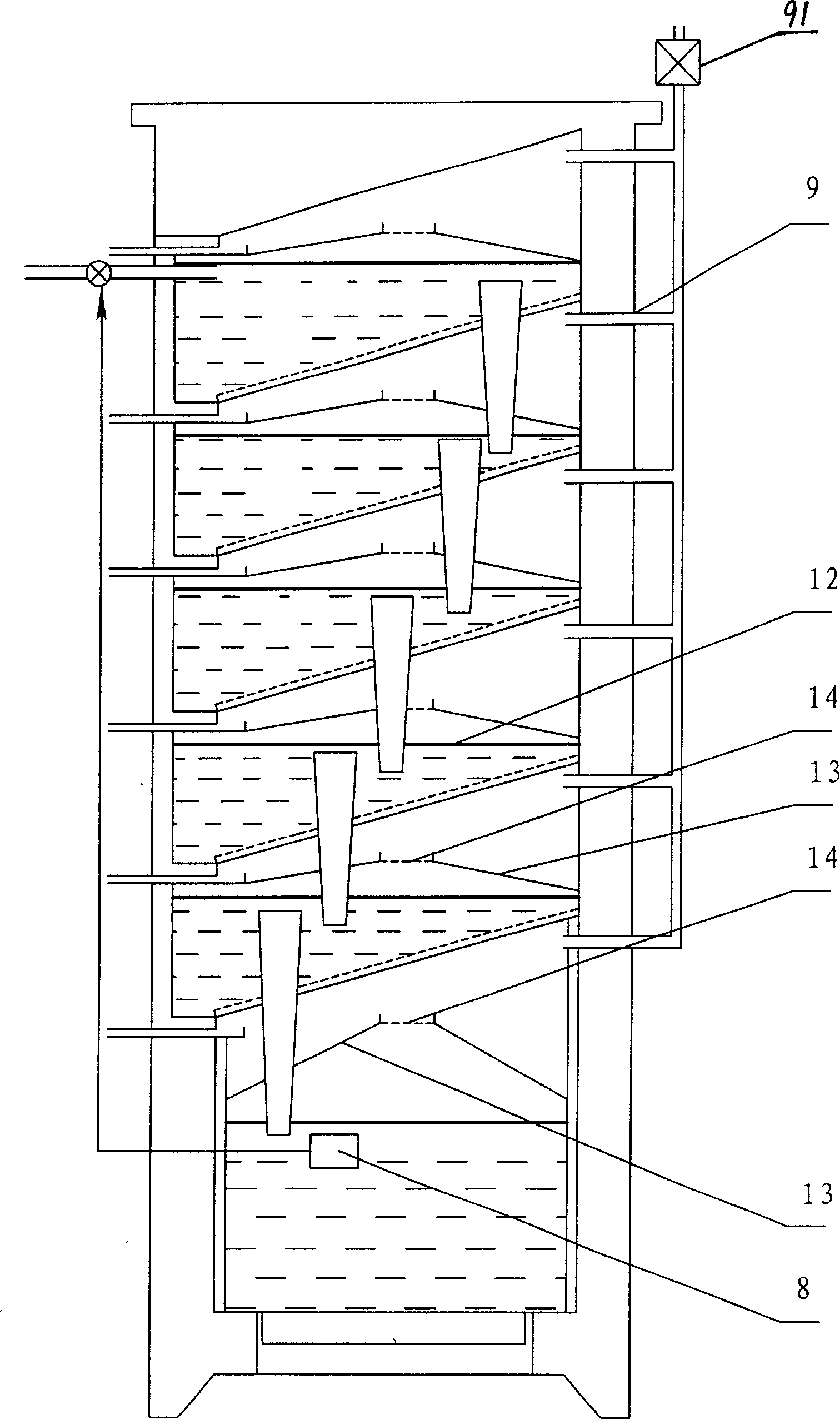

Multi-stage distillation equipment

InactiveCN1745867AFull use of latent heatImprove distillation efficiencyEnergy based wastewater treatmentDistillation separationDistillationEngineering

A multi-stage distilling apparatus is composed of a heater, at least one stage of condensing and distilling container, which can be combined to become multiple stages, the overflow pipes whose number is matched with that of condensing and distilling containers, and a distilling container. Its advantages are high distilling efficiency and utilization rate of energy, simple structure, low cost and multiple functions.

Owner:郑顺清

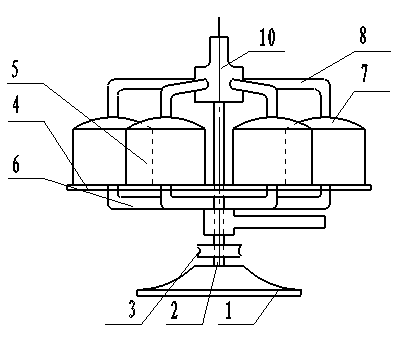

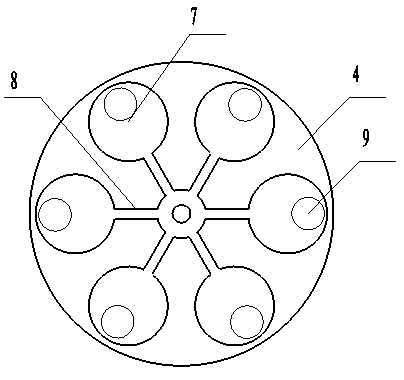

Alcohol distilling device

InactiveCN103657124AReduce volumeFully distilledAlcoholic beverage preparationDistillation separationDrive wheelAqueous alcohol

The invention relates to an alcohol distilling device. The alcohol distilling device comprises a fixed disc, a transmission shaft and a driving wheel, wherein one end of the transmission shaft is movably mounted on the fixed disc, and the driving wheel is mounted on the transmission shaft and is controlled by the driving device; a positioning disc is fixed on the transmission shaft; at least two steaming pots are mounted on the positioning disc, a high-temperature steam delivery pipe communicated with a high-temperature steam source is connected to the lower part of each steaming pot, movable steaming pot covers above the steaming pots are respectively connected with alcohol steam delivery pipes, and the tail end of each alcohol steam delivery pipe is communicated with an alcohol steam outlet. According to the alcohol distilling device, multiple steaming pots are used for replacing the single steaming pot for distilling, so that the volume of fermentation materials in the single steaming pot is reduced, the distilling is thorough, the distilling time is shortened, and the distilling efficiency is increased.

Owner:山西鼎圣精工机械制造股份有限公司

Device for purifying metal by vacuum distillation

ActiveCN104232913AFlexible adjustment of closureFlexible adjustment of vacuumProcess efficiency improvementThree stageControl system

The invention relates to a device for purifying a metal by vacuum distillation and belongs to the field of vacuum metallurgy. A distiller of the device adopts a flow control directional distiller comprising a distiller container, a distillation pipe, a control rod, a magnetic substance and a magnet, wherein the closing degree of a glass ground conical valve can be flexibly regulated by moving the magnet up and down, and thus the vacuum degree of a space between the distillation pipe and the control rod can be regulated. The invention further relates to the device for purifying the metal by vacuum distillation, which comprises a vacuum system, a flow control directional distillation system and a control system, and the device can flexibly increase or decrease the number of stages of the multi-stage flow control directional distiller according to the purity requirements of the metal to be purified so as to achieve the purpose of obtaining the metal with different purities. The device has good effects in vacuum purification of the metal with a low boiling point, and the purity of 99.9999% can be achieved when the three-stage flow control directional distiller is used.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

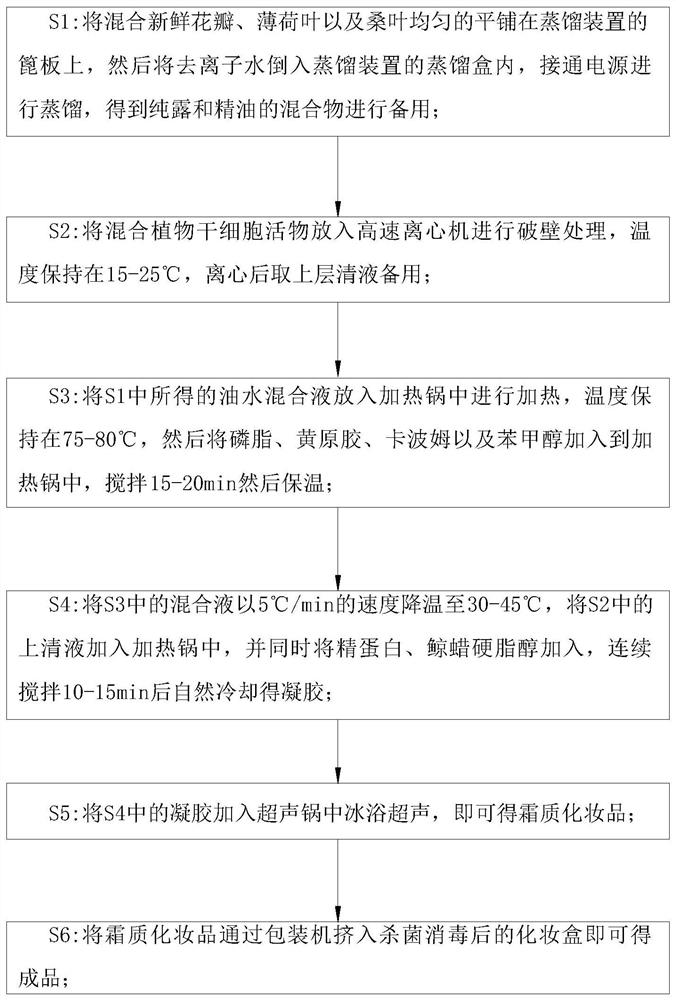

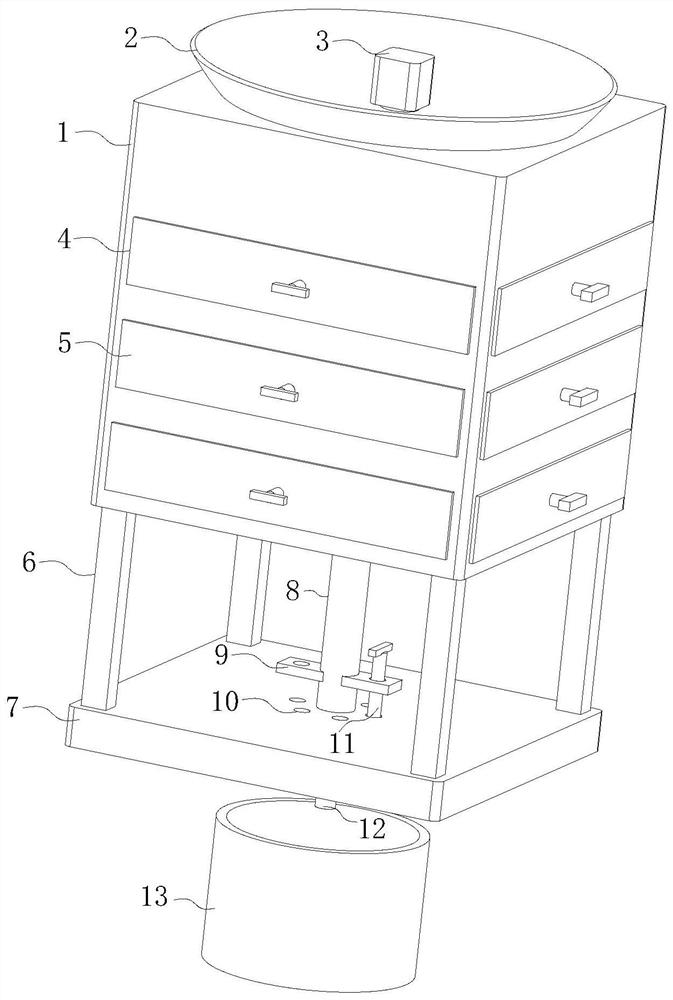

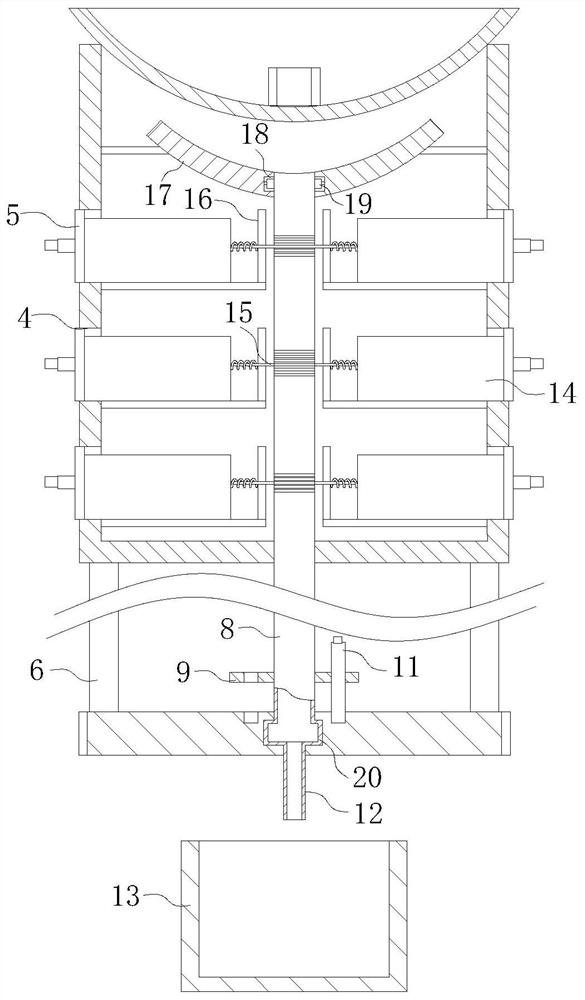

Stem cell complex factor anti-aging moisturizing cosmetic

ActiveCN111632020APlay a sealing effectIncrease the heating areaCosmetic preparationsToilet preparationsBiotechnologyPhospholipid

The invention belongs to the technical field of anti-aging and moisturizing cosmetics, and particularly relates to a stem cell complex factor anti-aging moisturizing cosmetic which consists of the following raw materials: mixed fresh petals, mint leaves, mulberry leaves, mixed plant stem cell active matter, xanthan gum, phospholipid, protamine, deionized water, carbomer, benzyl alcohol and cetostearyl alcohol. The preparation method of the stem cell complex factor anti-aging moisturizing cosmetic comprises the following steps: S1, uniformly spreading mixed fresh petals, mint leaves and mulberry leaves on a grid plate of a distillation device, then pouring deionized water into distillation boxes of the distillation device, and switching on a power supply for distillation to obtain a mixtureof hydrolat and essential oil for later use. Through arrangement of the multiple layers of distillation boxes, petals can be fully spread, the heating area of mixed fresh petals is increased, and distillation efficiency is improved. The petals on the upper layer can be heated and distilled by steam distilled out from the fresh petals at the bottom in the upward moving process, and working efficiency can be further improved.

Owner:GUANGDONG CELL BIOTECHNOLOGY CO LTD

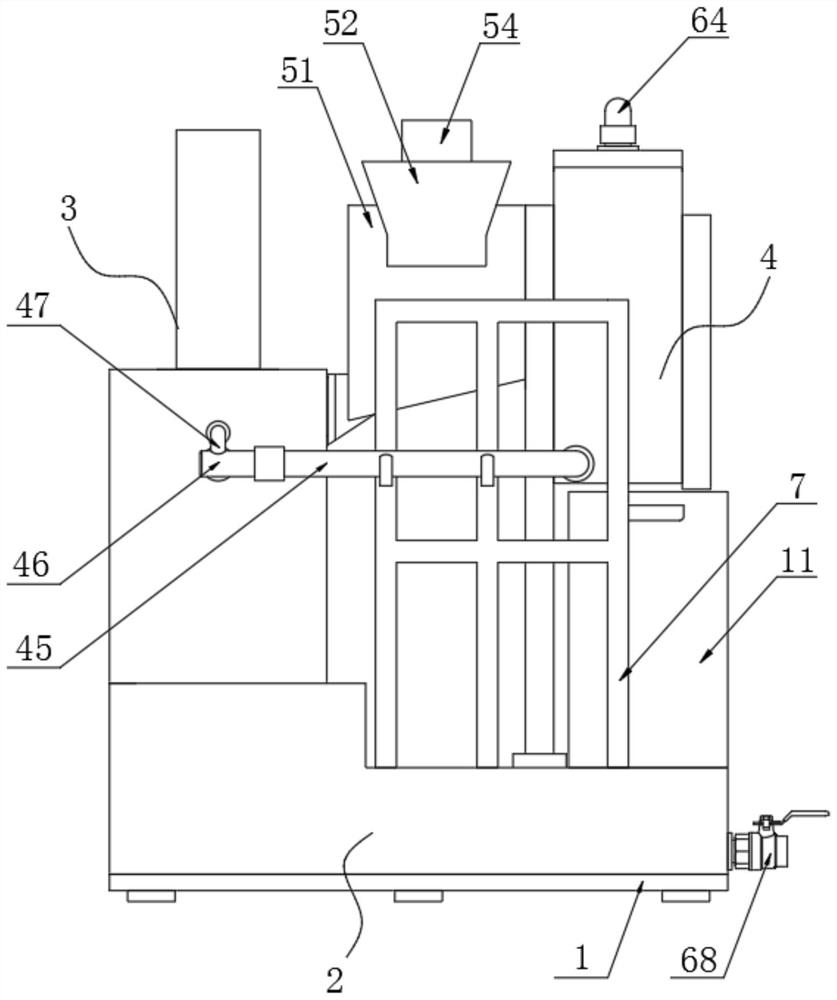

Plant active component extraction device and application thereof in cosmetics

PendingCN111744229ADoes not affect shedAvoid dischargeEnergy recuperation in distillationSolid solvent extractionBiotechnologyProcess engineering

The invention discloses a plant active component extraction device and application thereof in cosmetics. The device comprises a base, a distillation mechanism, an extrusion mechanism, a condensation mechanism, a crushing mechanism and a water circulation mechanism, and the front sides and the rear sides of the condensation mechanism and the crushing mechanism are fixedly connected with the top ofthe distillation mechanism through a rack, the distillation mechanism comprises a distillation box fixed to the front side of the top of the base, and a heating plate is fixedly connected to the bottom of the inner surface of the distillation box. The invention relates to the technical field of distillation equipment. The invention discloses the plant active component extraction device and application thereof in cosmetics. The extrusion mechanism is arranged on the distillation box, juice in plants is fully squeezed out through an extrusion force, then distillation is conducted through the distillation mechanism, compared with direct plant cooking, active substances in the plants can be extracted more fully and thoroughly, waste is little, cost is reduced, the extrusion mechanism is of a movable design, the extrusion mechanism can be directly pulled out upwards, internal residue can be poured out conveniently, and use is convenient.

Owner:陈广建

Method and device for preparing high-purity yellow phosphorus industrially and continuously

InactiveCN105600762AEfficient removalImprove the purification effectPhosphorus compoundsNitrogenNitrogen gas

The invention relates to a method for preparing high-purity yellow phosphorus industrially and continuously. The method comprises the steps that nitrogen is used for purging a rectifying tower at first so as to make the inert environment, and then a vacuum pump is used for vacuumizing a rectification system; an acid solution and liquid yellow phosphorus heated to 70-80 DEG C are mixed through a liquid mixer and then added into a tower kettle of the rectifying tower, yellow phosphorus flowing back from the tower top and yellow phosphorus steam ascending from the tower bottom make sufficient contact inside the tower to be subjected to gas-liquid exchange, and high-purity yellow phosphorus is extracted. A device comprises the tower kettle. The rectifying tower is arranged on the tower kettle. An integrated tower top cooler is arranged on the top of the rectifying tower. A vacuum skid mounted device is arranged on the integrated tower top cooler. A gravity type backflow extraction device is arranged at the upper portion of the rectifying tower and the lower portion of the integrated tower top cooler through guide pipes. Due to rectification, the content of arsenic in a tower top product is smaller than 30 ppb, and the content of antimony in the tower top product is smaller than 100 ppb.

Owner:湖北兴福电子材料股份有限公司

Extraction method of agilawood liquid

PendingCN107629878ASolve the problem of not being able to dry completelyHigh extraction rateEssential-oils/perfumesDistillationFiltration

The invention discloses an extraction method of an agilawood liquid. The method comprises (1) immersion: cutting agilawood into blocks, putting the blocks into an evaporation room and naturally soaking the blocks in water in the evaporation room for 5-8 days, (2) filtration: filtering the agilawood blocks through a filter, retaining the immersion liquid in the evaporation room and putting the agilawood blocks into a grinder at the upper part in the evaporation room, and (3) distillation: heating the immersion liquid in the evaporation room so that the immersion liquid is kept in a boiling state to generate steam, and simultaneously, starting the grinder to gradually grind the agilawood blocks so that agilawood powder is obtained and the remaining essential oil in the agilawood blocks is extracted along with steam. The method solves the problem that the agilawood powder can be precipitated after immersion so that the distillation effect is influenced and substances in the agilawood blocks cannot be completely extracted and has good extraction effect and a high extraction rate of the essential oil.

Owner:曹建华

Distillation device for Baijiu

InactiveCN107418857AEvenly distributedFully distilledAlcoholic beverage preparationDistillationEngineering

The invention discloses a distillation device for Baijiu. The distillation device is characterized in that a steam disperser is fixed at the center of the bottom of a steam tank, a motor is arranged on the outer wall of a steamer, a rotary shaft is connected to the motor, a first gear is fixedly connected to one end of the rotary shaft, a first steam inlet pipe is horizontally rotatably connected into the steamer, two ends of the first steam inlet pipe penetrates the lateral walls of the steamer and extend out of the steamer, the first steam pipe is provided with a plurality of stainless-steel stirring shafts, the stirring shafts are in clearance fit with the bottom of the steamer, one end of the steam inlet pipe is fixedly connected with a second gear in a sleeved manner, the first gear meshes with the second gear, the other end of the first steam inlet pipe is communicated with a second steam inlet pipe, the first steam inlet pipe is rotatably connected with the second steam inlet pipe, one end of the second steam inlet pipe is located in the steam tank and located above the steam disperser, and the steam tank is provided with a steam outlet pipe. When the distillation device is used for brewing the Baijiu, raw materials in the steamer can be thoroughly distilled, and distillation efficiency is increased at the same time.

Owner:ZUNYI JINHONG METAL EQUIP

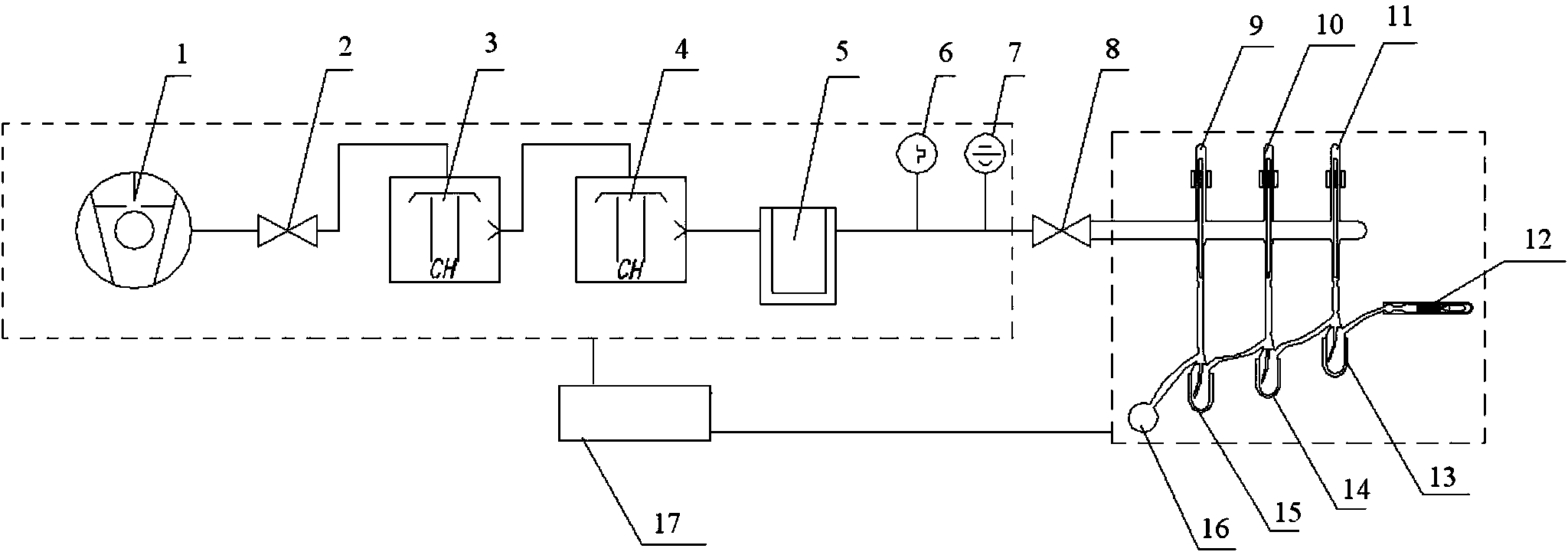

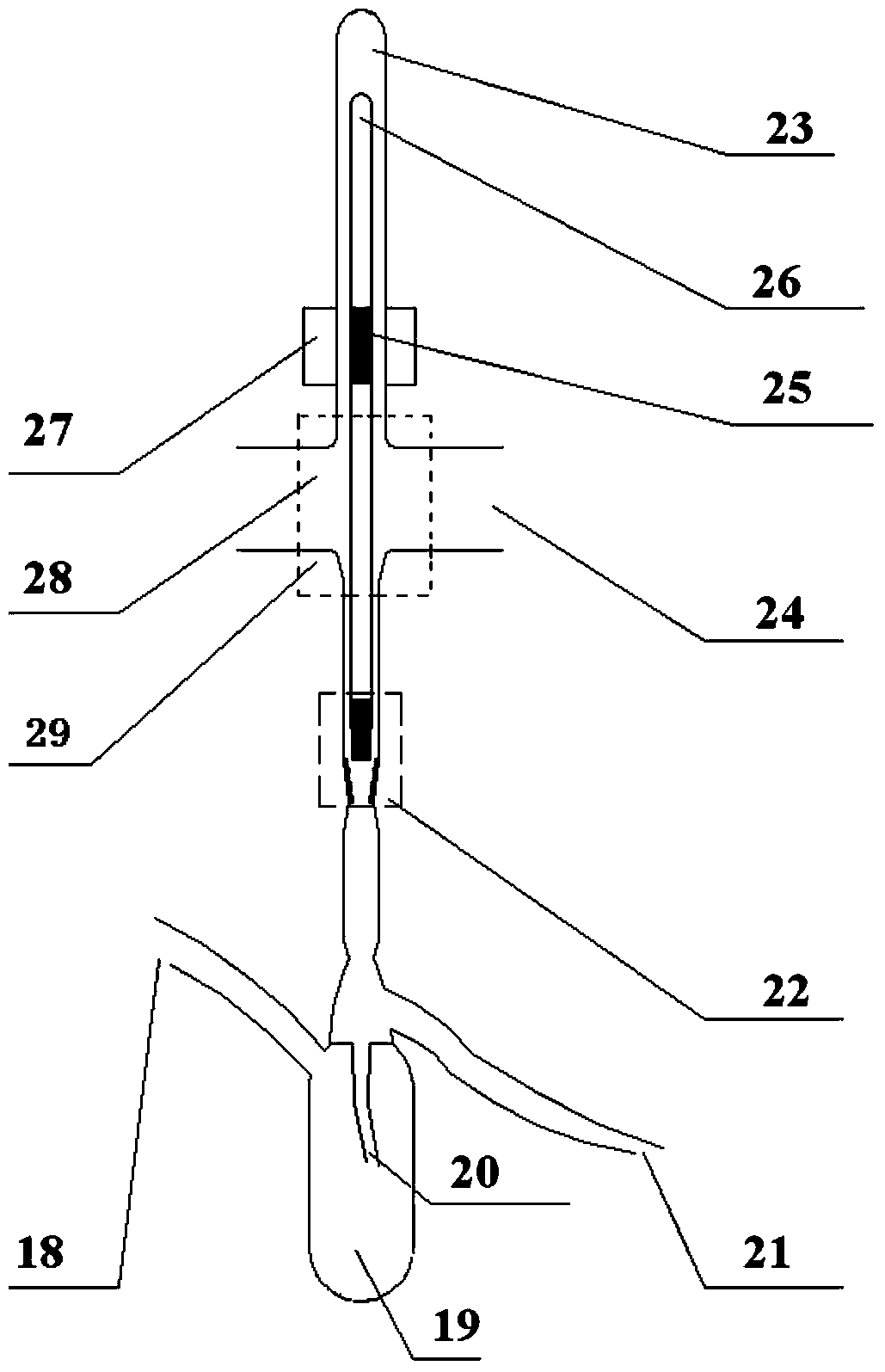

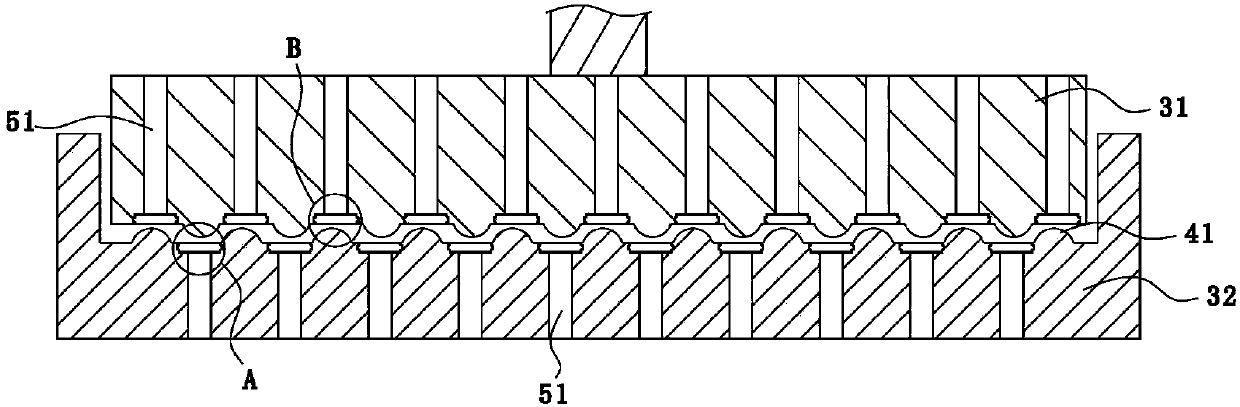

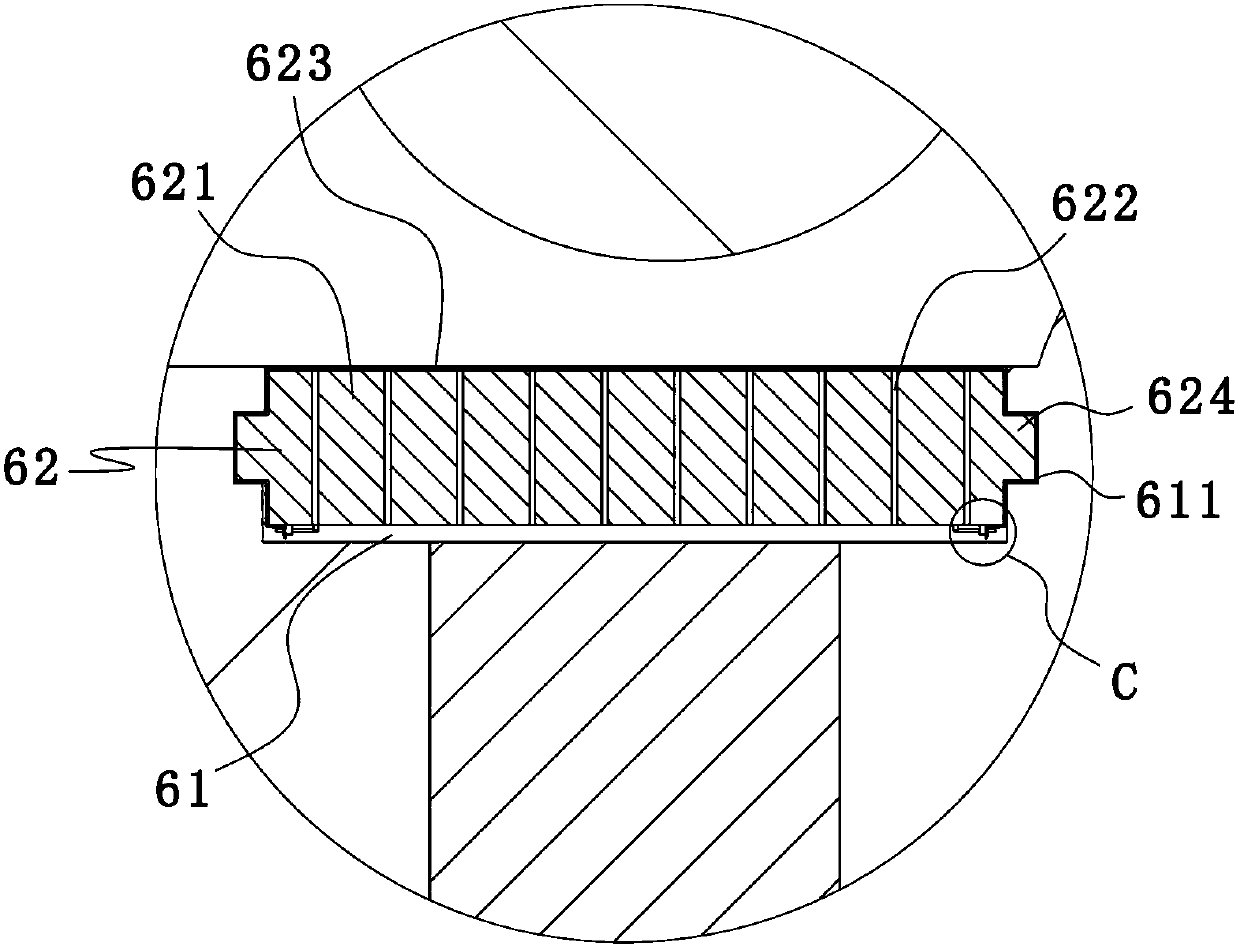

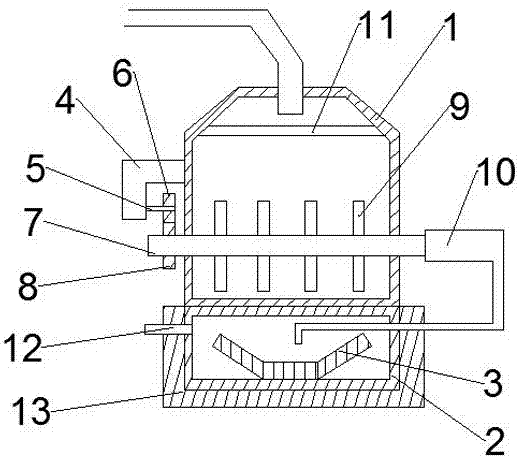

Garlic essential oil extraction method

InactiveCN104046514AImprove distillation efficiencyHigh purityEssential-oils/perfumesCooling towerProcess engineering

The invention discloses a garlic essential oil extraction method which comprises the following steps: carefully choosing and cleaning garlic; crushing the cleaned garlic to powder with diameter of 0.2-0.5mm; sending the crushed garlic powder into a distillation column, adjusting pressure in the distillation column to 0.10-0.20MPa, and keeping distillation for at least 4 hours when temperature in the distillation column rises to 120-150 DEG C; sending a distillate into a cooling tower for cooling; and sending a condensate in the cooling tower into an oil-water separating column to separate garlic essential oil, where a disk-shaped separating disc with several through holes arranged in the surface is also disposed inside the distillation column. Purity of garlic essential oil extracted by the above garlic essential oil extraction method is high; garlic distillation efficiency is raised; and extraction rate of garlic essential oil can reach 0.2-0.5%. In addition, byproducts of garlic essential oil are fully utilized, and economic value is raised. The method provided by the invention is convenient to operate, is cost-saving, and also can be applied in extraction of essential oil of ginger, rapeseed, soybean and the like.

Owner:SHIFANG HENGYUAN GREASE

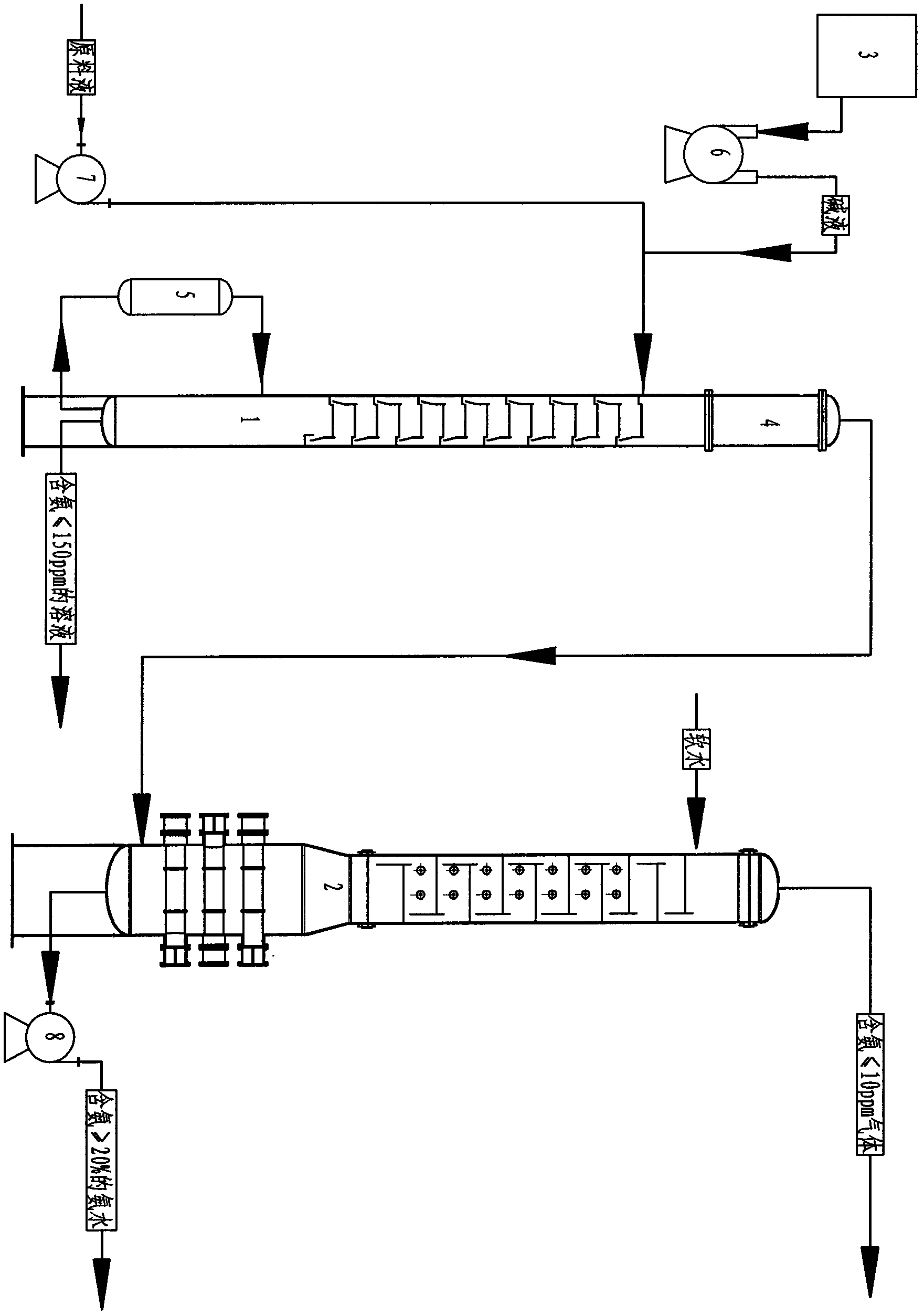

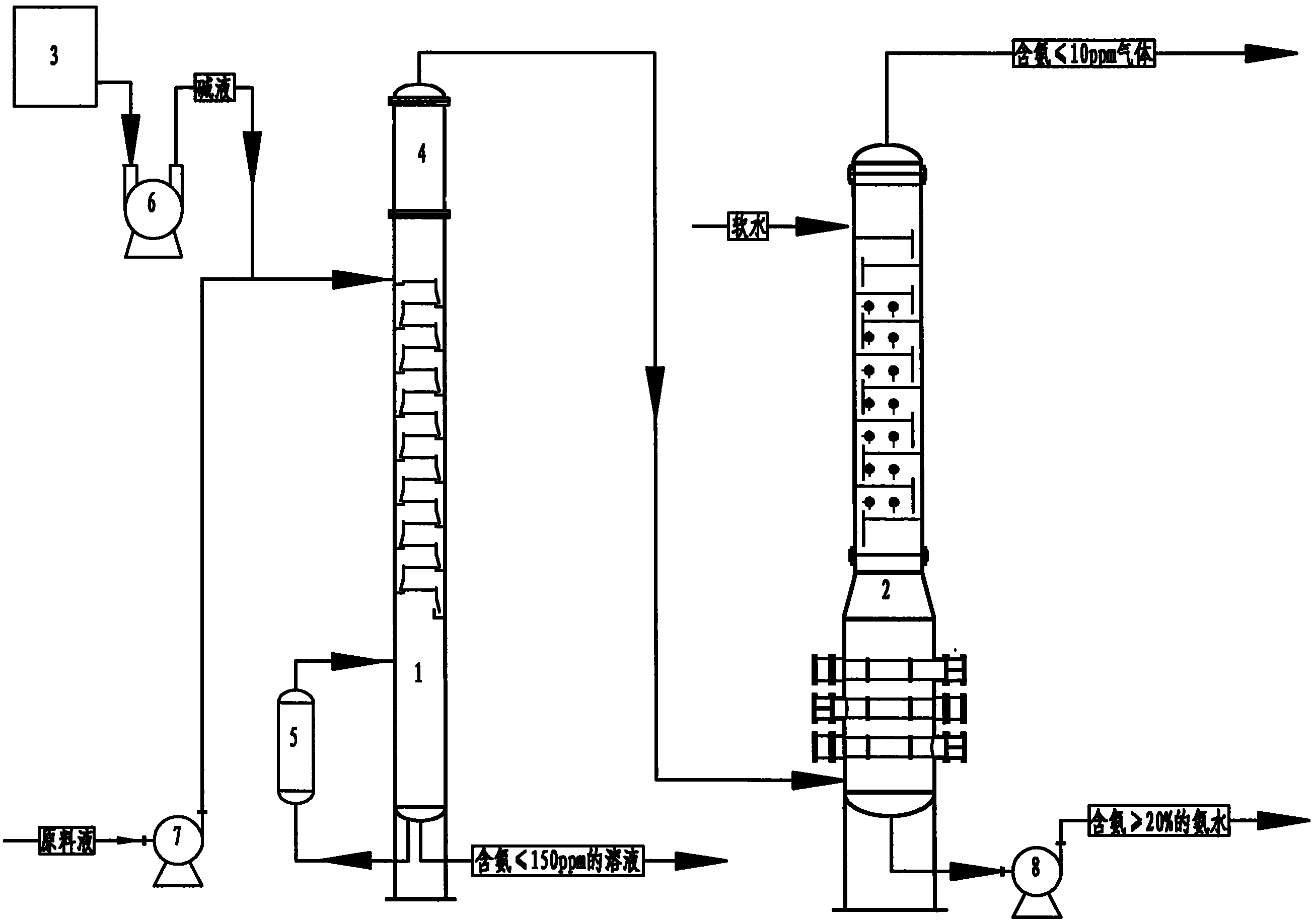

Ammonia recovery process and equipment for non-ferrous metal metallurgical industry

InactiveCN102303873AImprove efficiencyImprove distillation efficiencyAmmonia preparation/separationReboilerChemistry

The invention discloses an ammonia recovery process and equipment for a non-ferrous metal metallurgical industry. The process comprises the following steps: mixing a base liquid with a raw material liquid in a pipeline and then feeding a mixed liquid to the upper part of an ammonia still, and carrying out steam stripping to remove ammonia in the raw material liquid; feeding a low-ammonia aqueous solution obtained at the bottom of the ammonia still to the next process; condensing gas-phase ammonia on the top of the ammonia still in an ammonia dephlegmator so as to obtain high-concentration ammonia gas; feeding the high-concentration ammonia gas into the bottom of an ammonia recovery tower to be absorbed by soft water; and recovering and recycling the high-mass-concentration ammonia water obtained at the bottom of the ammonia recovery tower, and evacuating trace fixed gas at the top of the ammonia recovery tower. The equipment is suitable for the ammonia recovery process disclosed by the invention and mainly comprises the ammonia still and the ammonia recovery tower, wherein the upper part of the ammonia still is in pipe connection with an alkali formulating tank through an alkali liquid pump and in pipe connection with a raw material liquid through a raw material pump; the ammonia dephlegmator is arranged inside the upper part of the ammonia still, and the lower part of the ammonia still is externally connected with a reboiler and is in pipe connection with the upper part of the ammonia still; and the kettle bottom of the ammonia recovery tower is in pipe connection with an ammonia water pump, the upper part of the ammonia recovery tower is in pipe connection with a soft water pipe, and the top of the ammonia recovery tower is provided with a discharge pipe.

Owner:TIANJIN CHUANGJU TECHNOLGOY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com