Patents

Literature

890results about How to "Improve regeneration efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

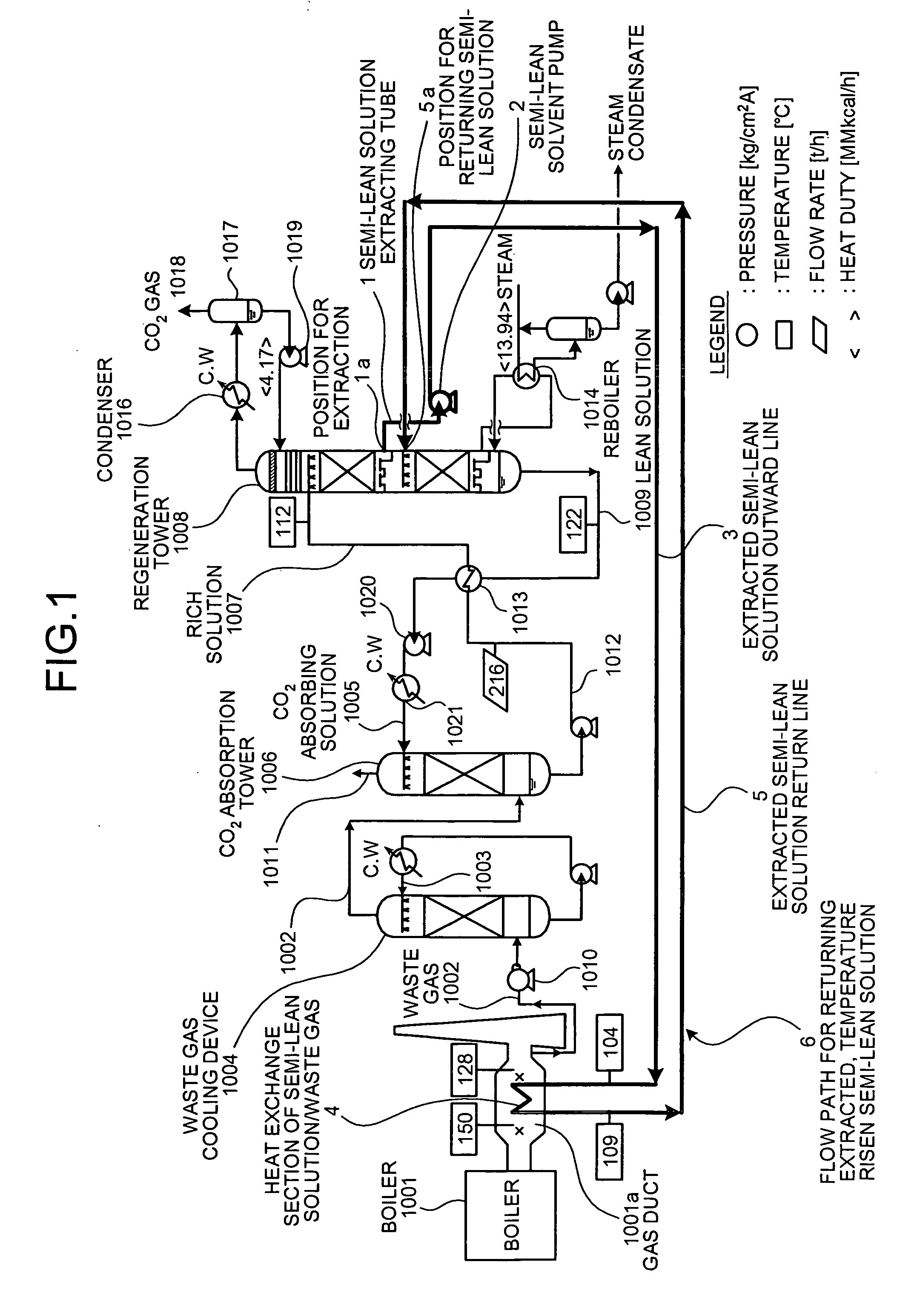

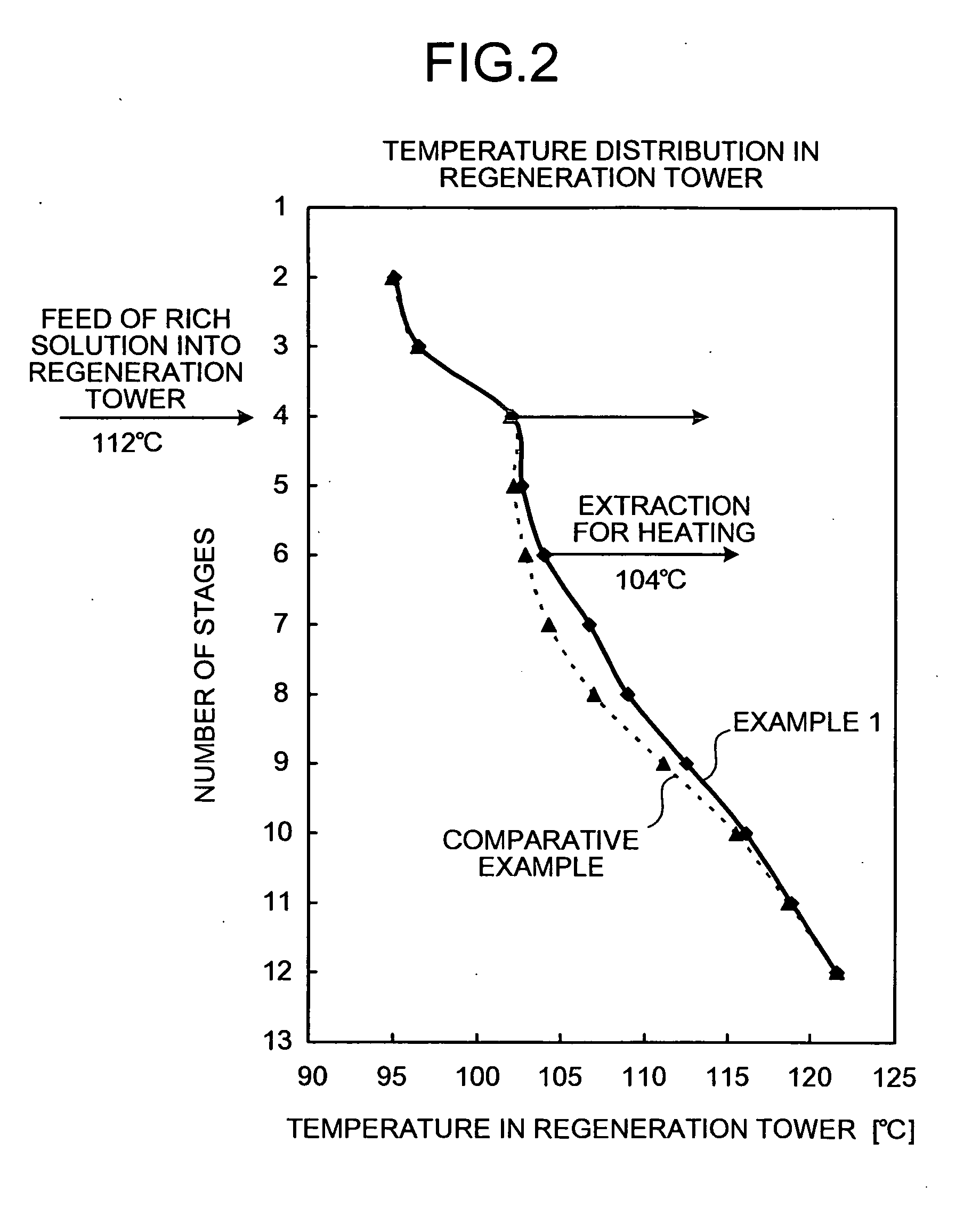

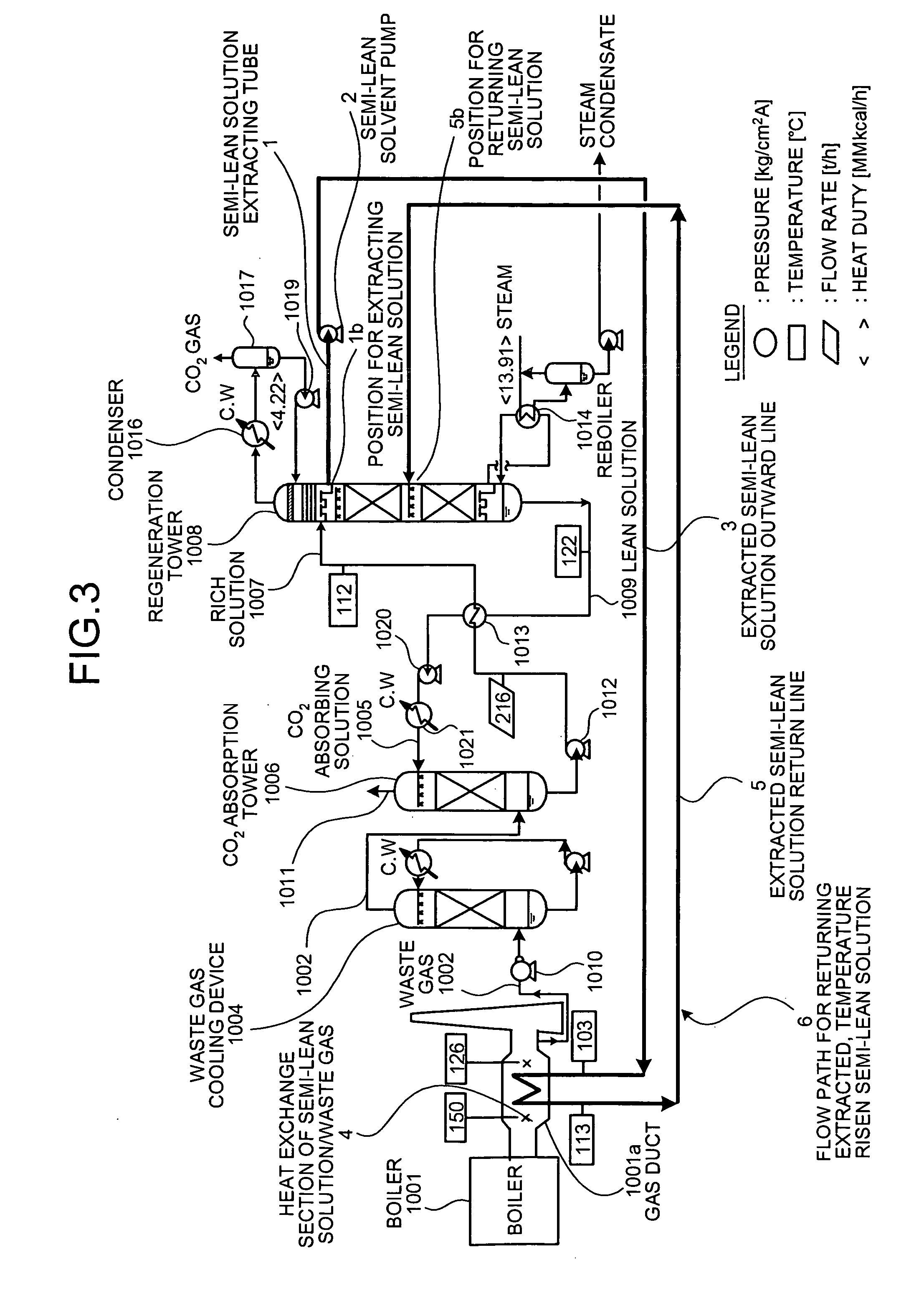

Apparatus and method for CO2 recovery

InactiveUS20060204425A1Improve energy efficiencyImprove regeneration efficiencyCombination devicesCarbon compoundsProduct gasProcess engineering

An apparatus and a method for recovering CO2 are provided in which an energy efficiency is improved. The apparatus for recovering CO2 includes a flow path for returning extracted, temperature risen semi-lean solution into a regeneration tower wherein at least a part of the semi-lean solution obtained by removing a partial CO2 from a rich solution infused in a regeneration tower from an upper part of the regeneration tower is extracted, raised its temperature by heat exchanging with a high-temperature waste gas in a gas duct of an industrial facility such as a boiler, and then returned into the regeneration tower.

Owner:MITSUBISHI HEAVY IND LTD +1

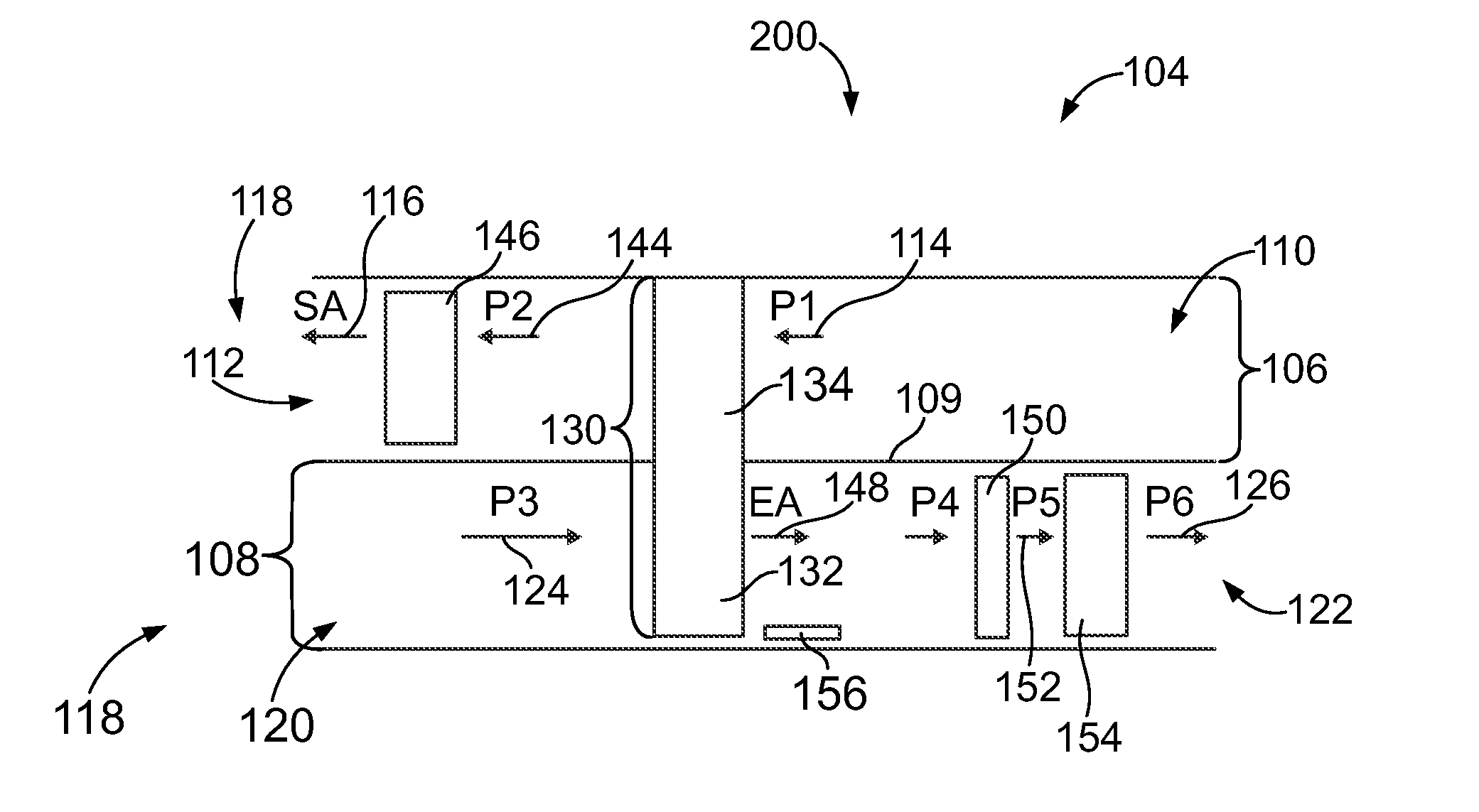

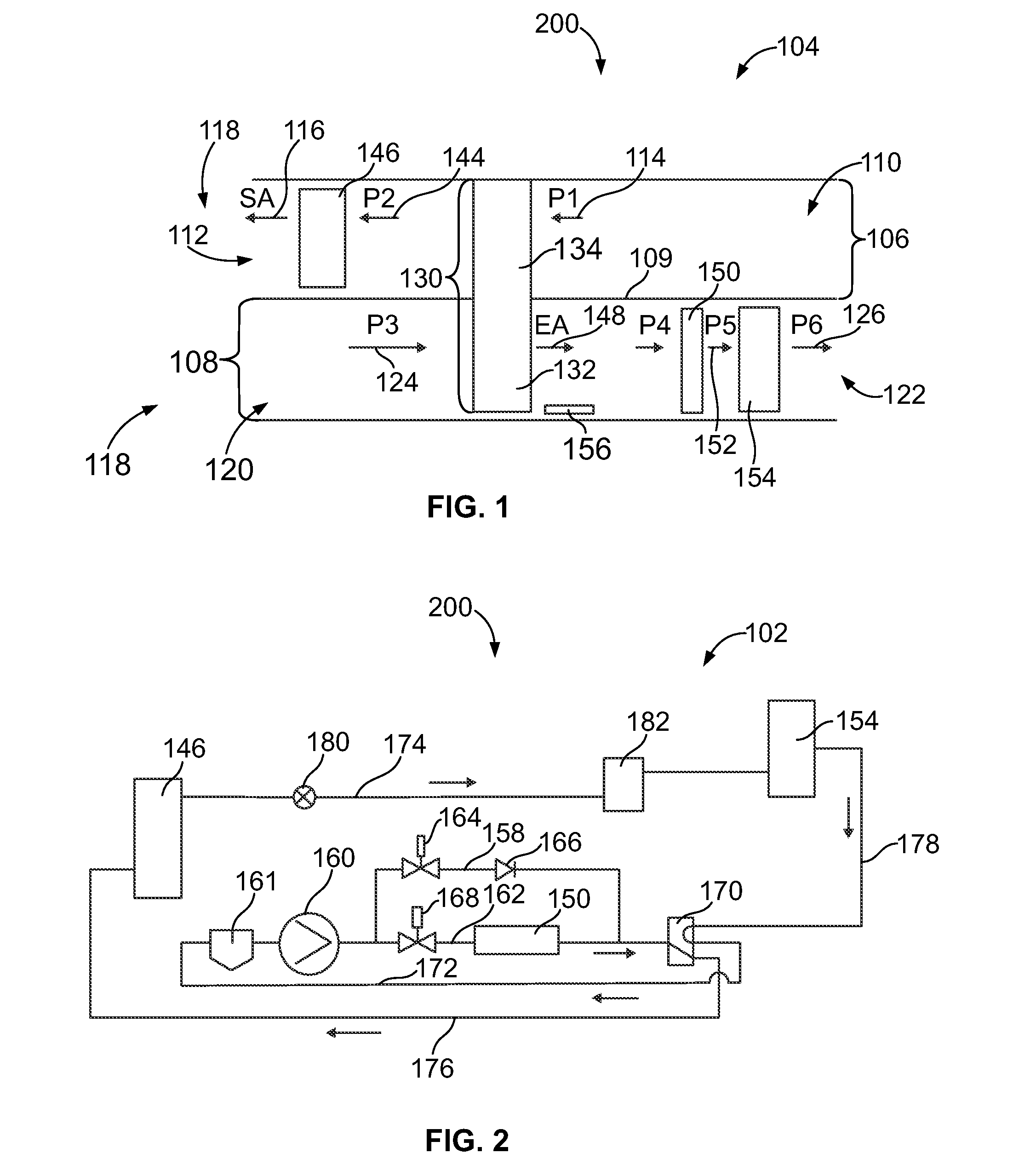

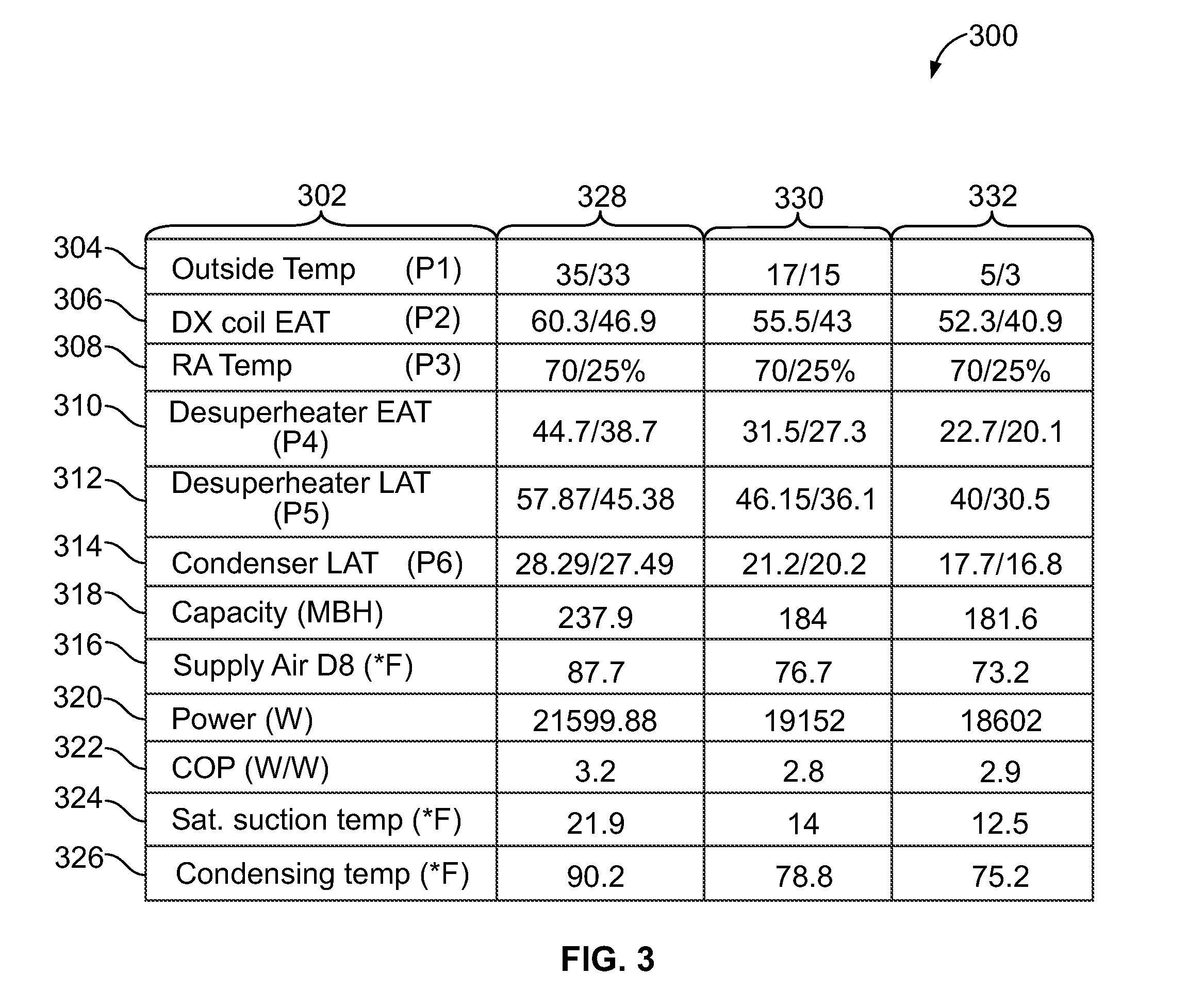

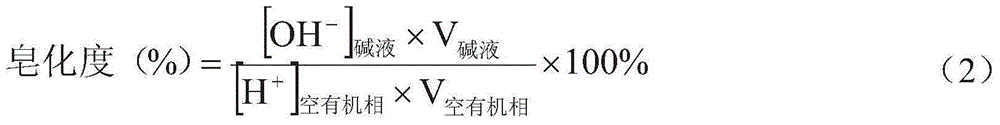

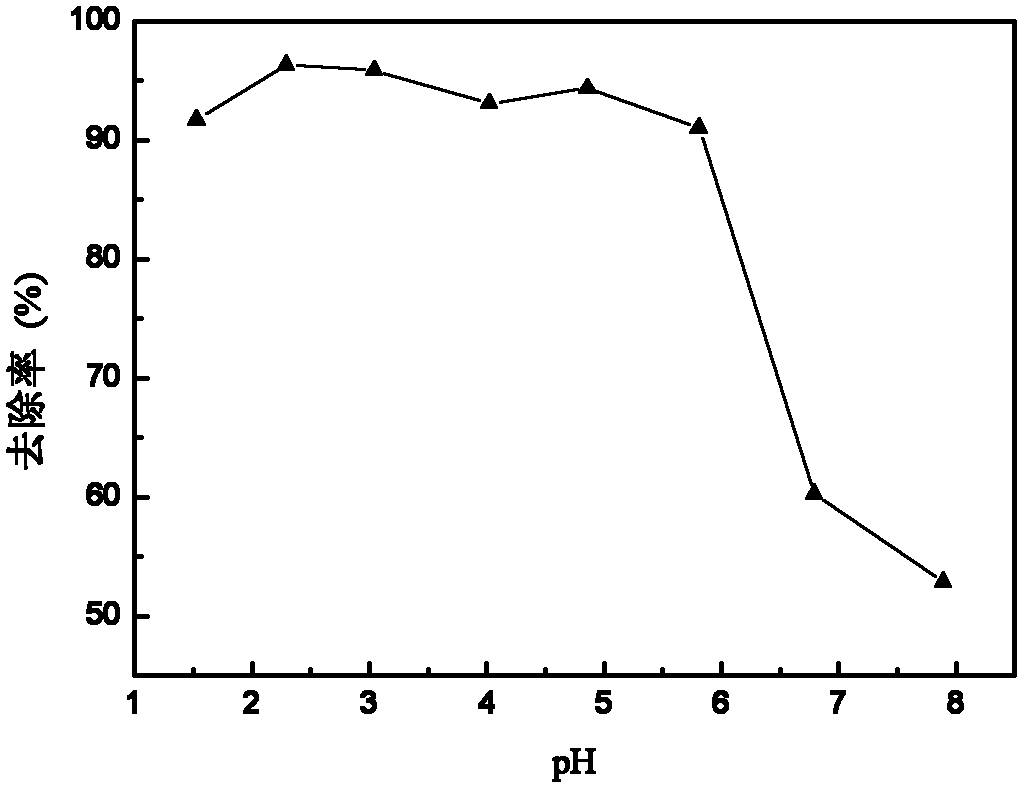

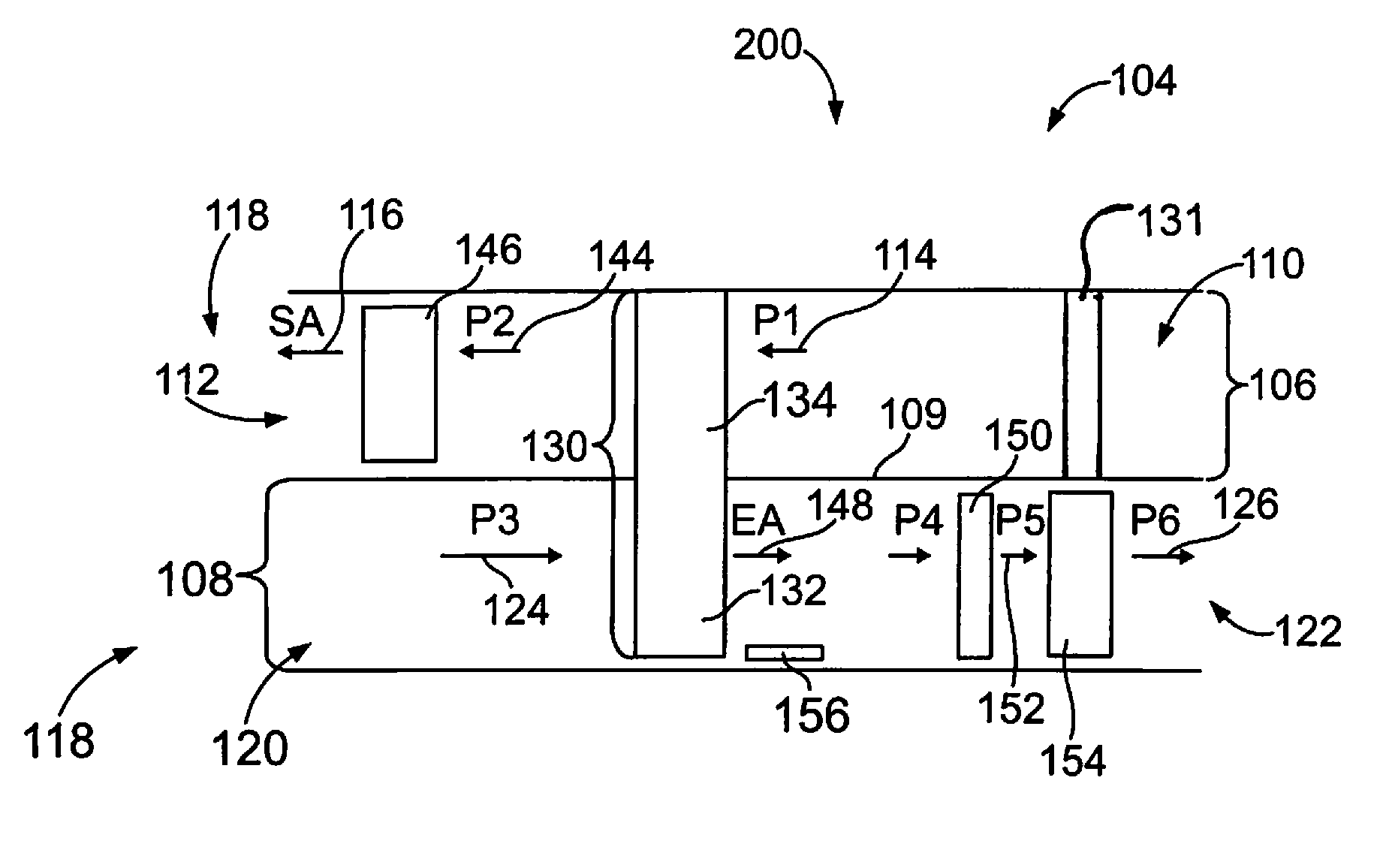

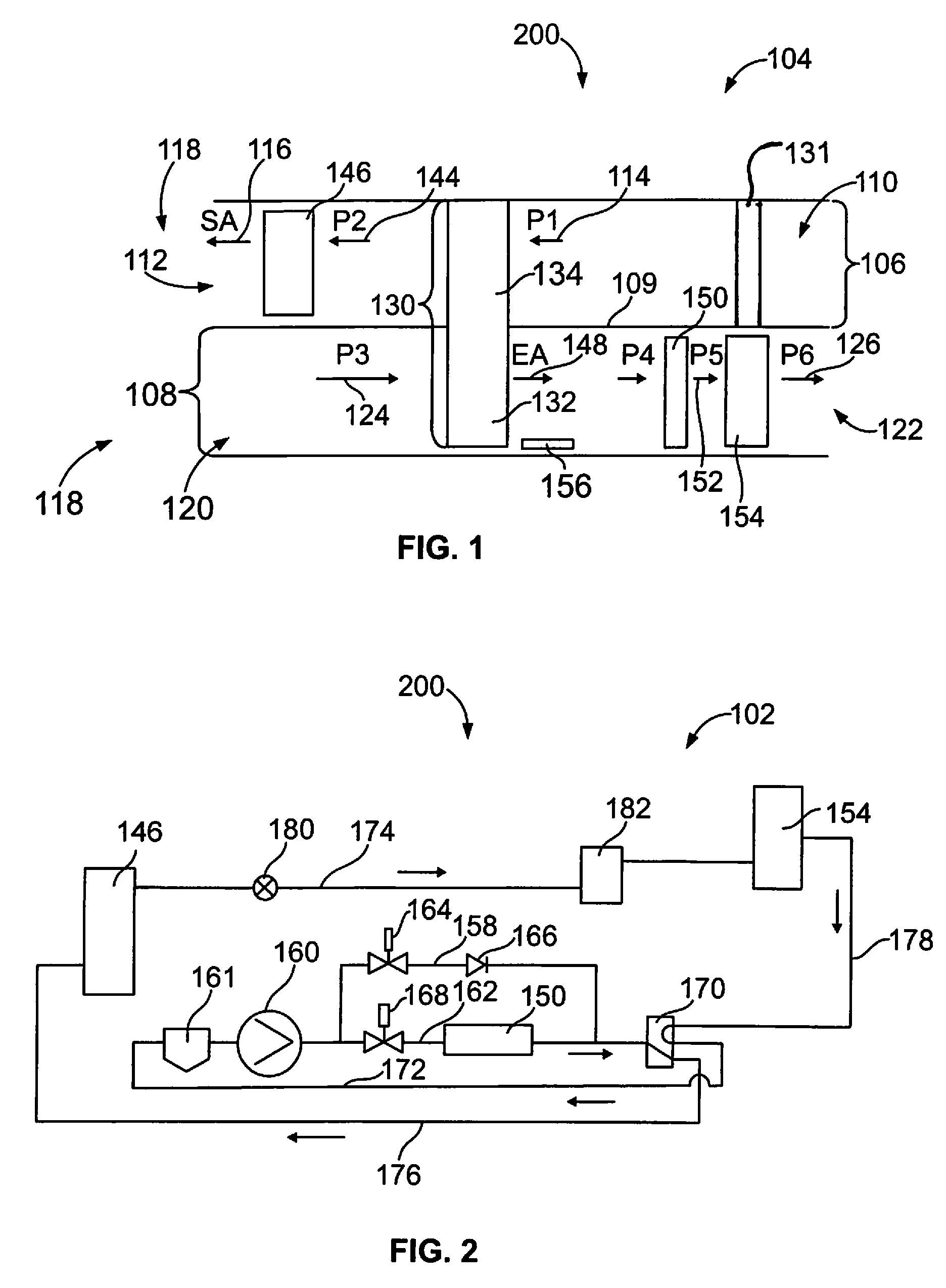

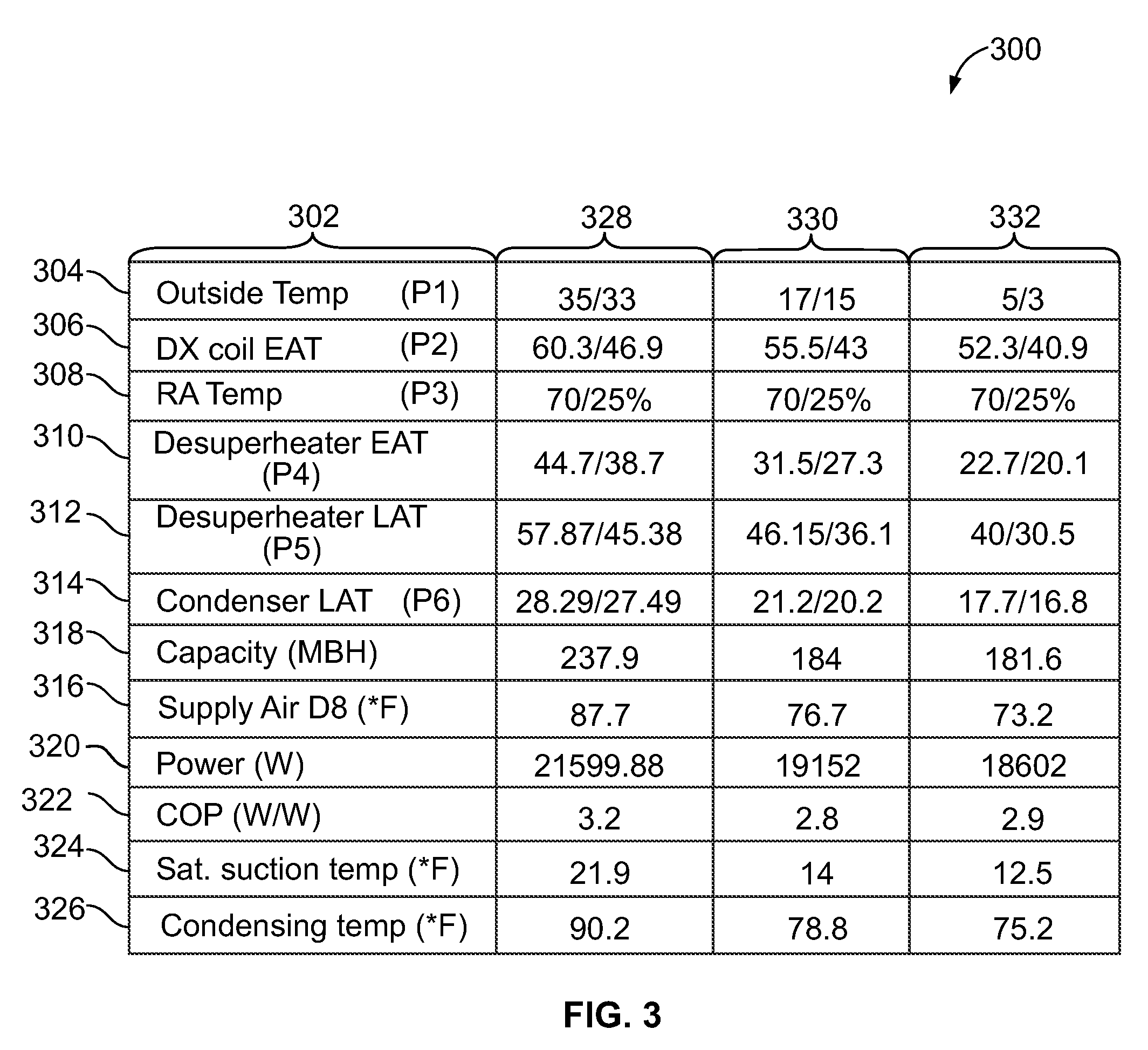

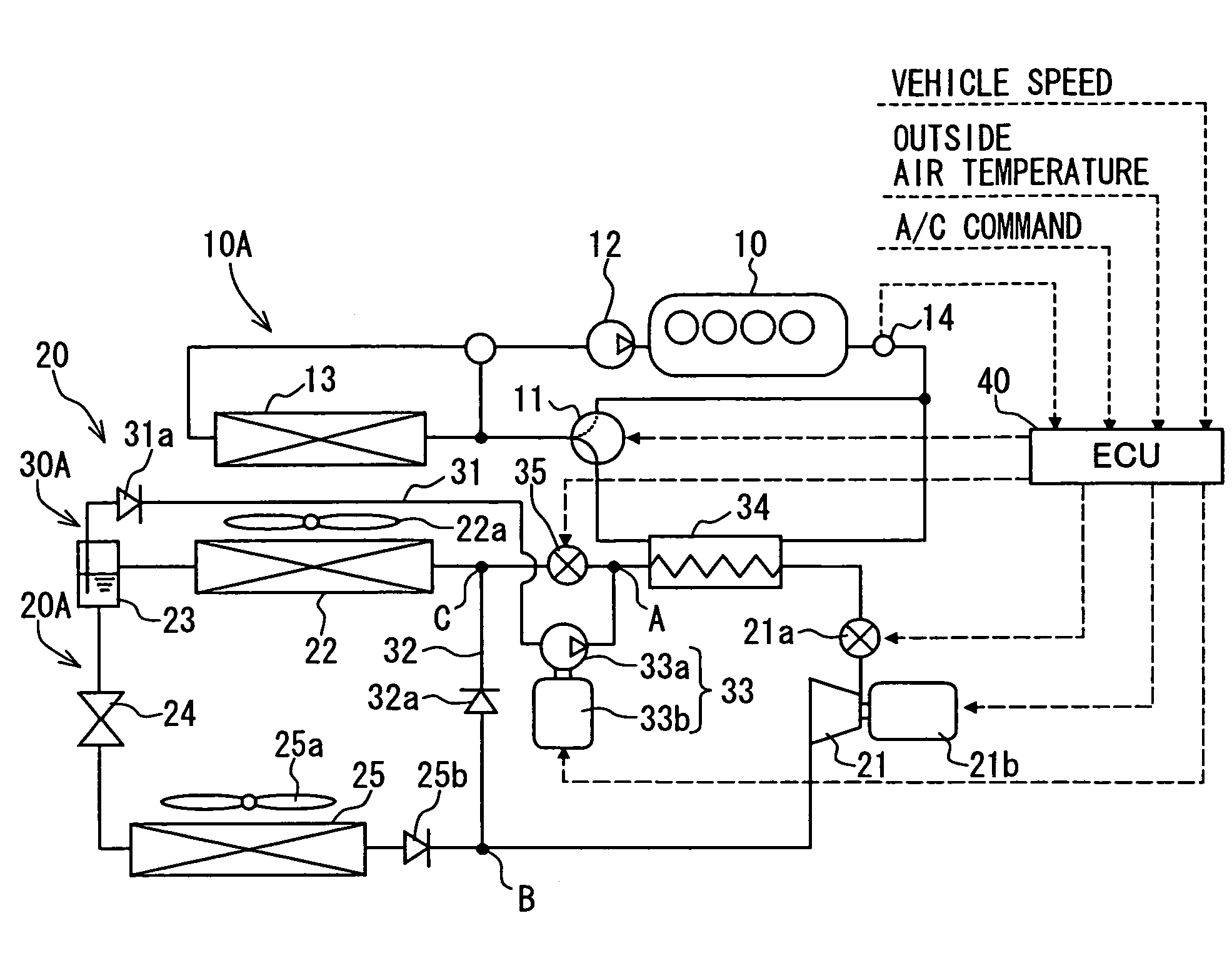

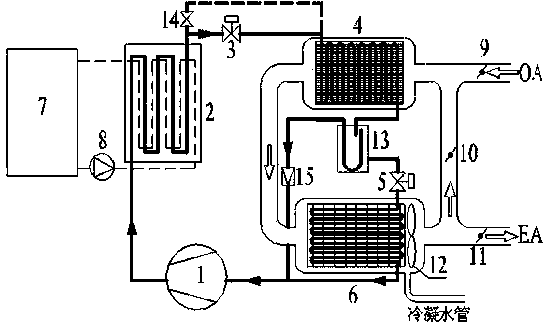

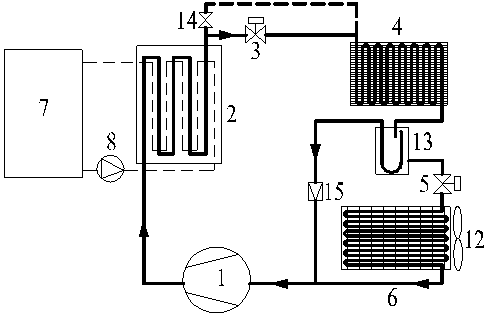

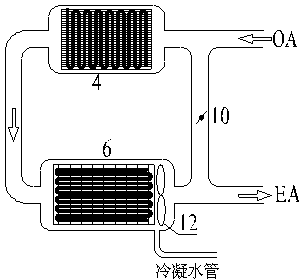

Heat pump system having a pre-processing module

ActiveUS20120180505A1Avoid frostImprove regeneration efficiencyEnergy recovery in ventilation and heatingMechanical apparatusComputer moduleEnergy recovery

A heat pump system is operable in winter mode and / or summer mode, and may be selectively operated in a defrost mode or cycle. The system includes an energy recovery module that receives and conditions air in a regeneration air channel. A pre-processing module is positioned downstream of the energy recovery module. The pre-processing module receives and heats air from the energy recovery module. A regeneration air heat exchanger is positioned downstream of the pre-processing module. The regeneration air heat exchanger receives and conditions air from the pre-processing module. The pre-processing module heats the air from the energy recovery module to increase efficiency of the regeneration air heat exchanger. During the defrost mode, a loop of regeneration air may be recirculated between the supply air channel and the regeneration air channel in order to defrost the regeneration air heat exchanger.

Owner:NORTEK AIR SOLUTIONS CANADA INC

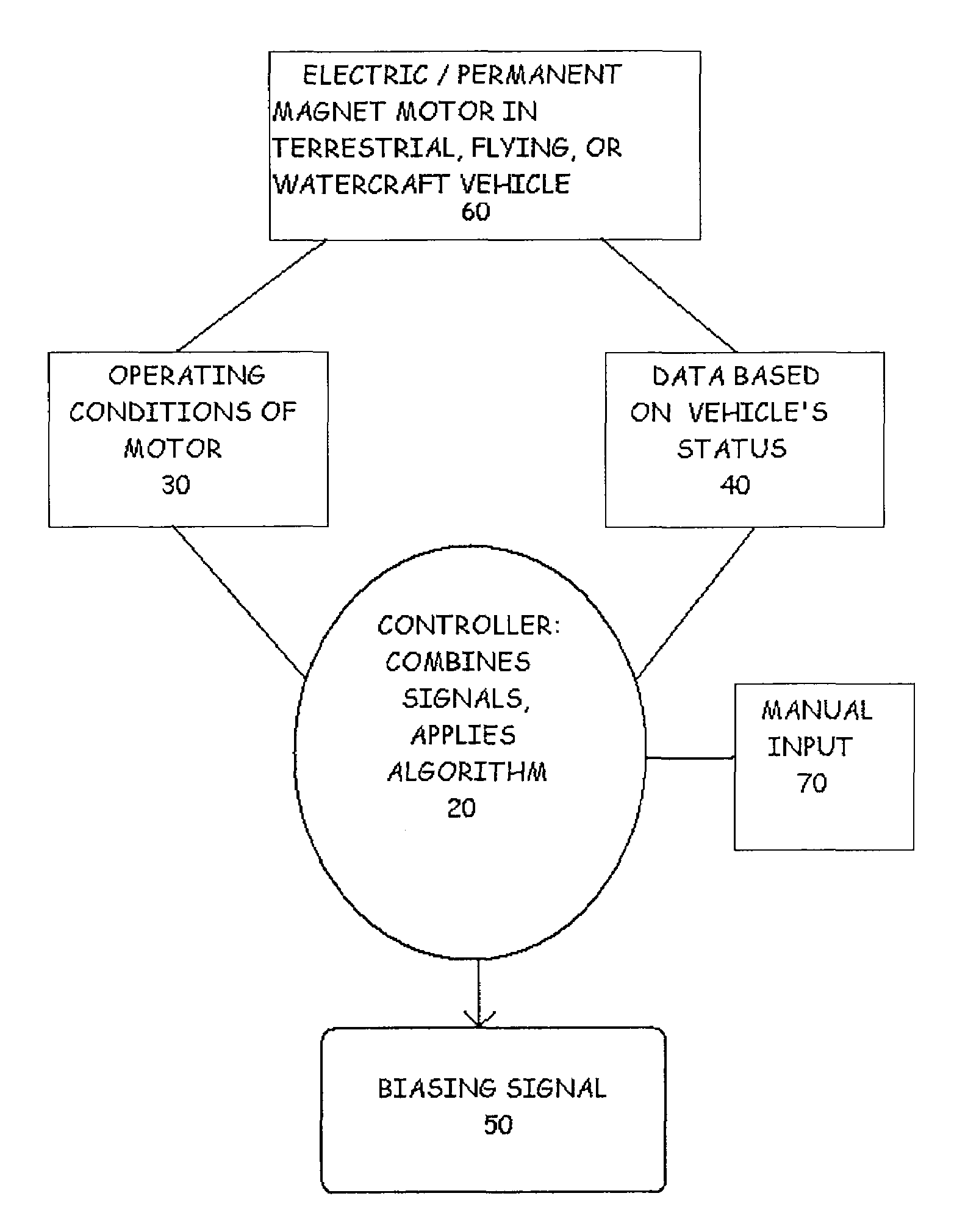

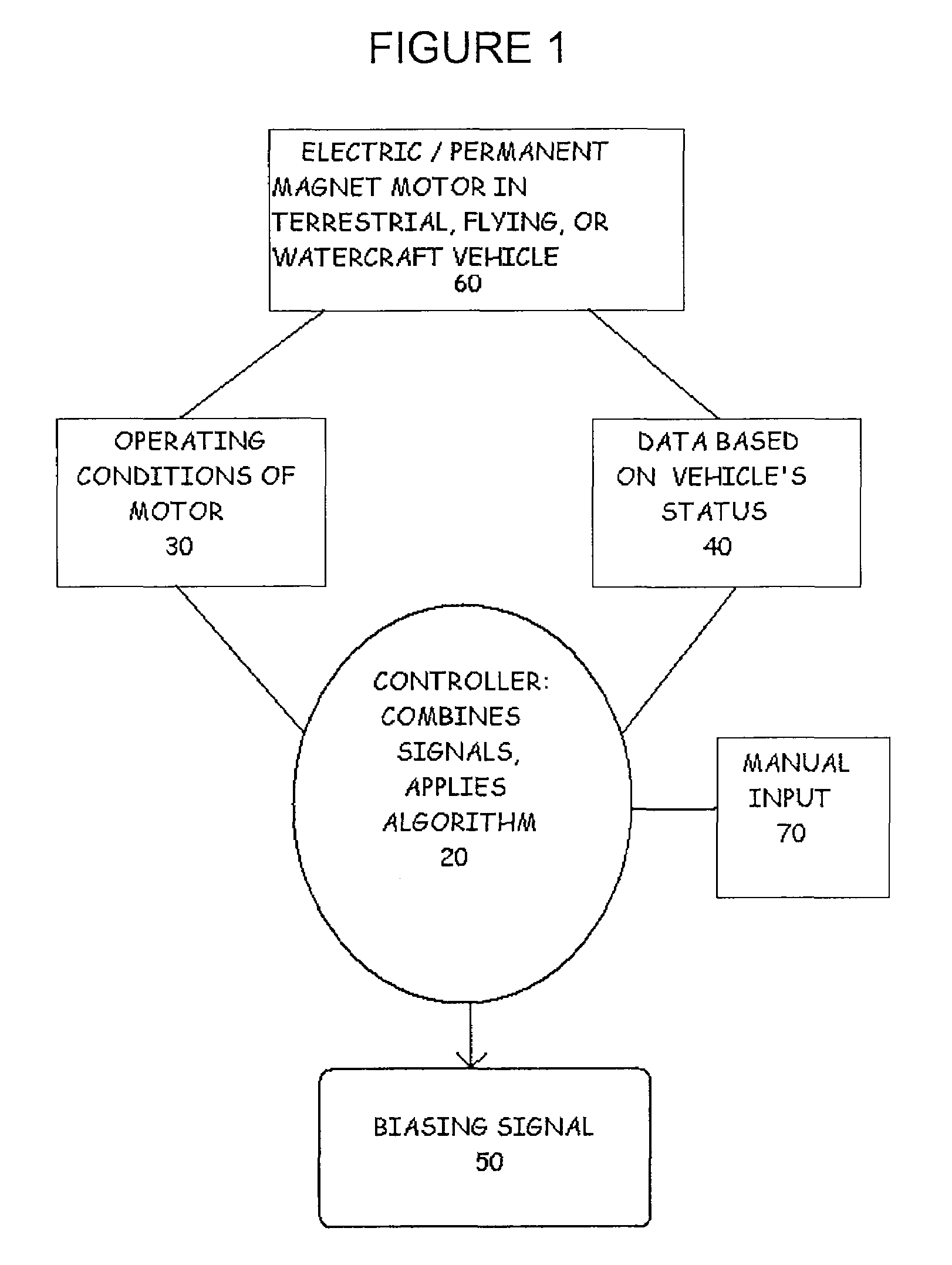

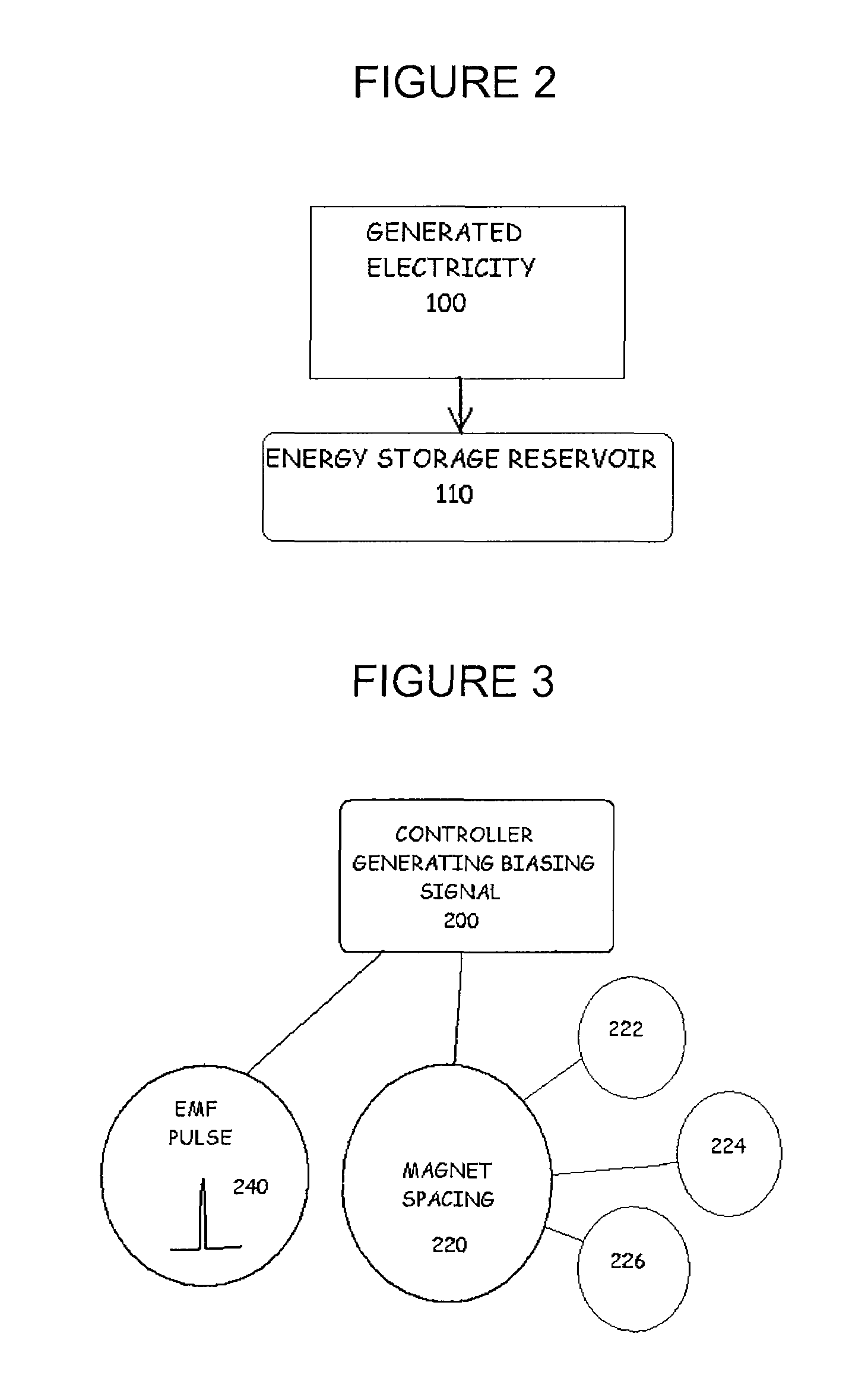

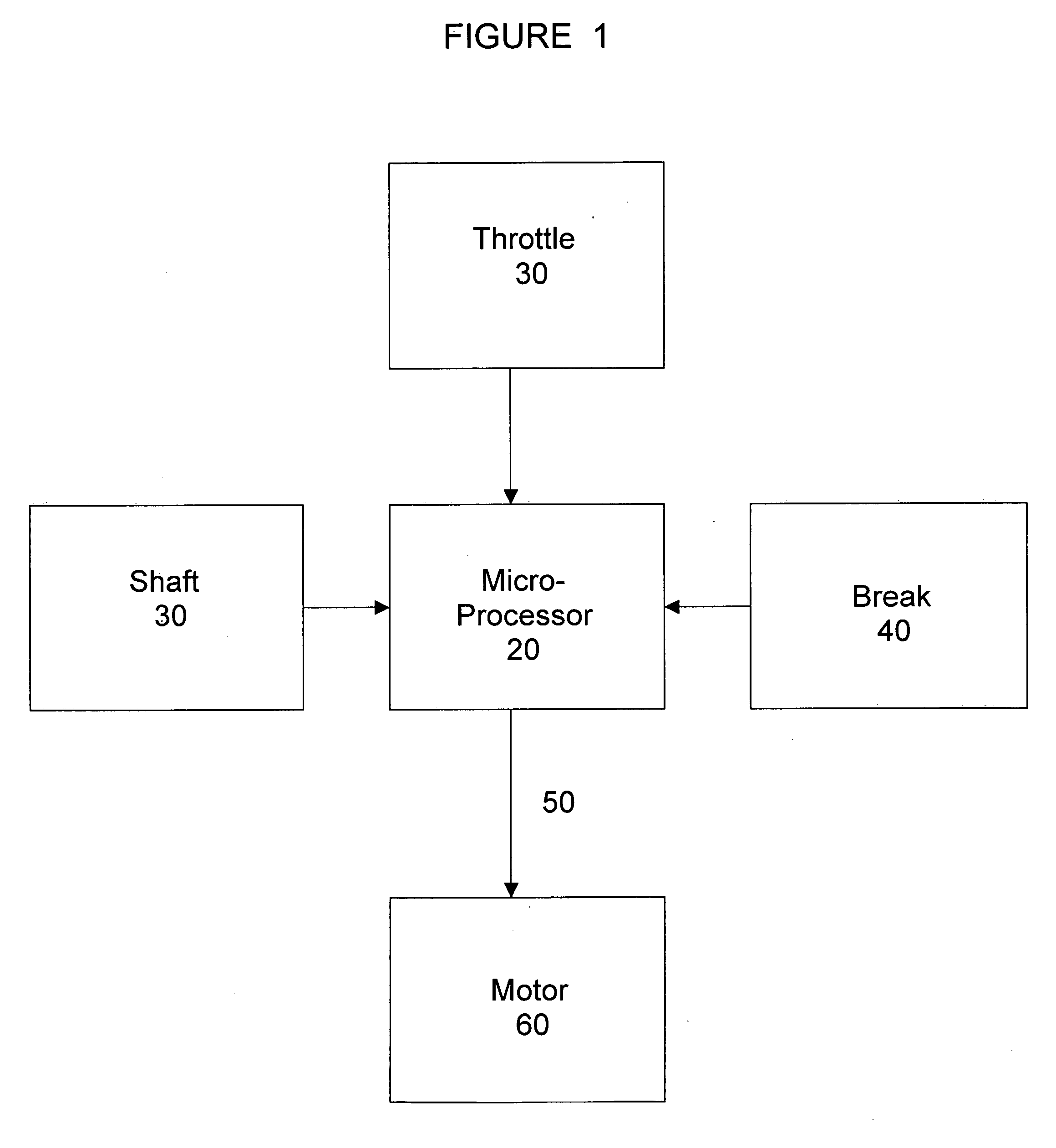

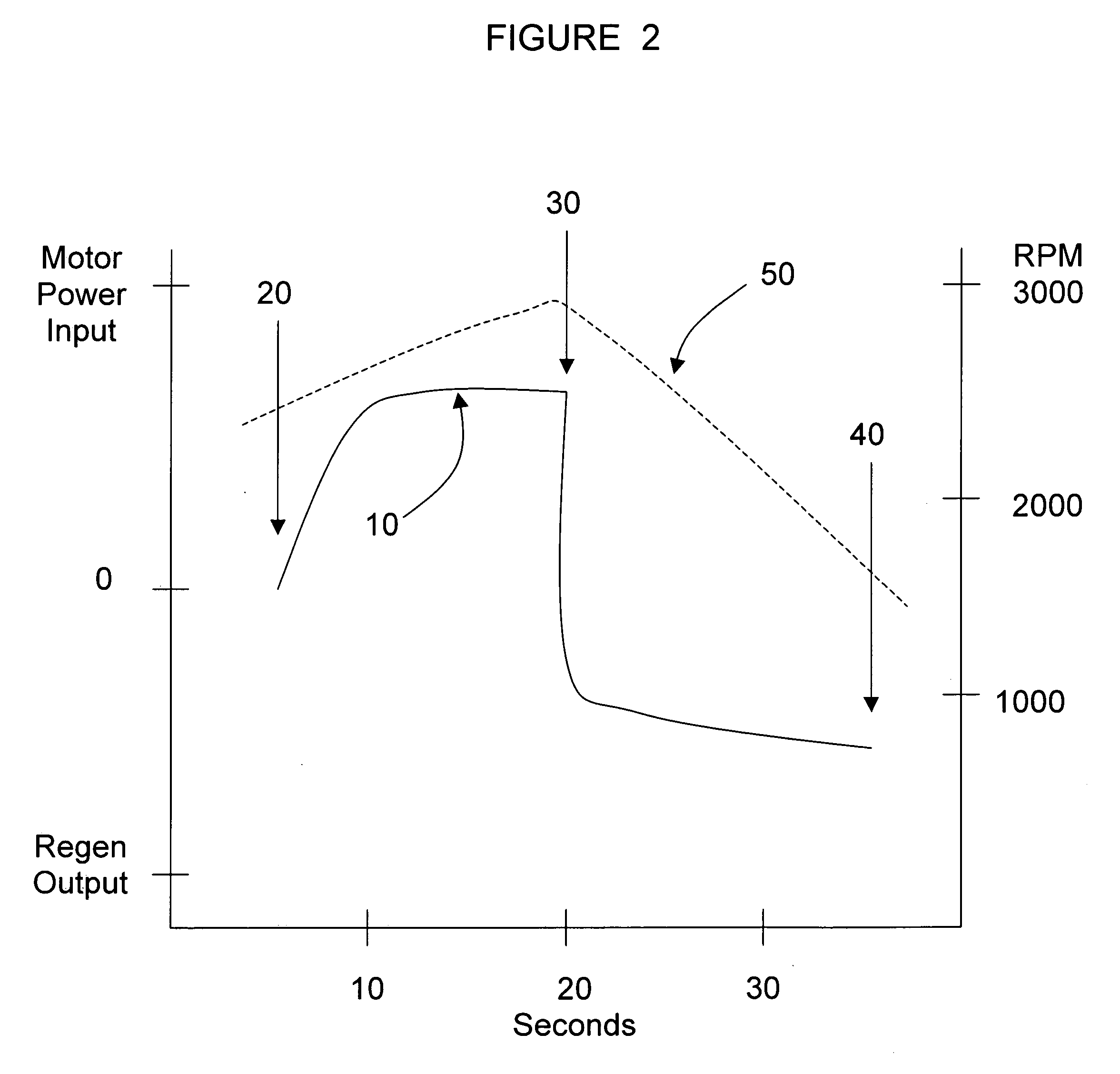

Regenerative motor propulsion systems

InactiveUS7482767B2Improve transportation efficiencyImprove fuel economyDC motor speed/torque controlSynchronous machinesElectricityElectrolysis

A vehicle or watercraft regeneration system includes at least one electric motor capable of generating electricity and a controller for the at least one motor; wherein the controller to optimize the efficiency of the regeneration. The controller can optimize efficiency by including comprises circuitry for biasing the electric motor during regeneration. Also provided is a regeneration system that further comprises an electricity storage device such as a battery, a capacitor, an electrolysis unit that generates hydrogen from water, and a flywheel. In addition, an efficiency enhancing system for a watercraft or vehicle includes at least one electric motor capable of generating electricity; a controller for the at least one motor; and an electrical connection between the at least one motor and the controller, where in the controller adjust one or more magnetic fields of the electric motor during regeneration to optimize the efficiency of the regeneration. Methods for increasing efficiency of regeneration of a watercraft of vehicle powered by at least one electric motor are also disclosed.

Owner:TECHNIPOWER SYST INC

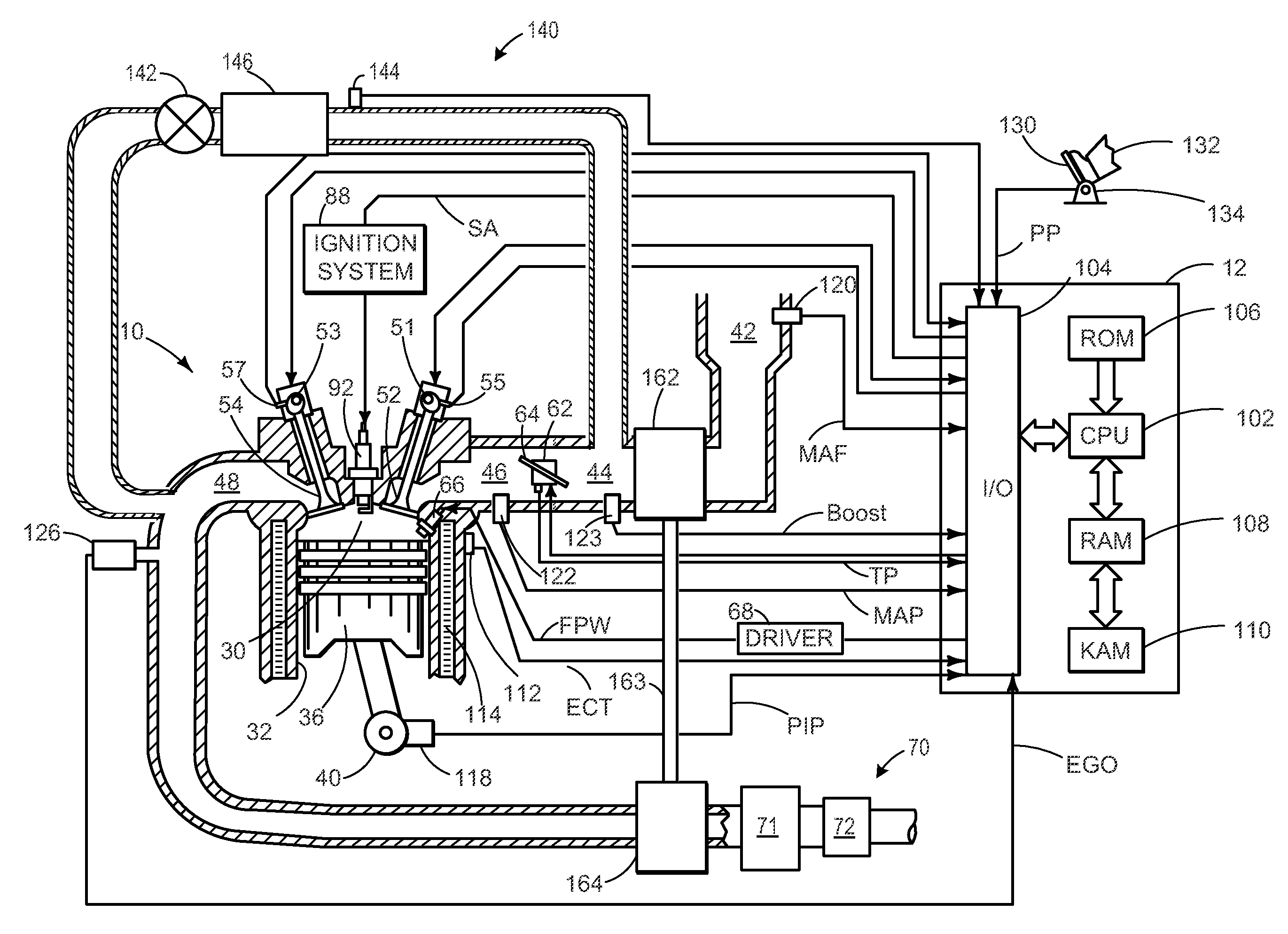

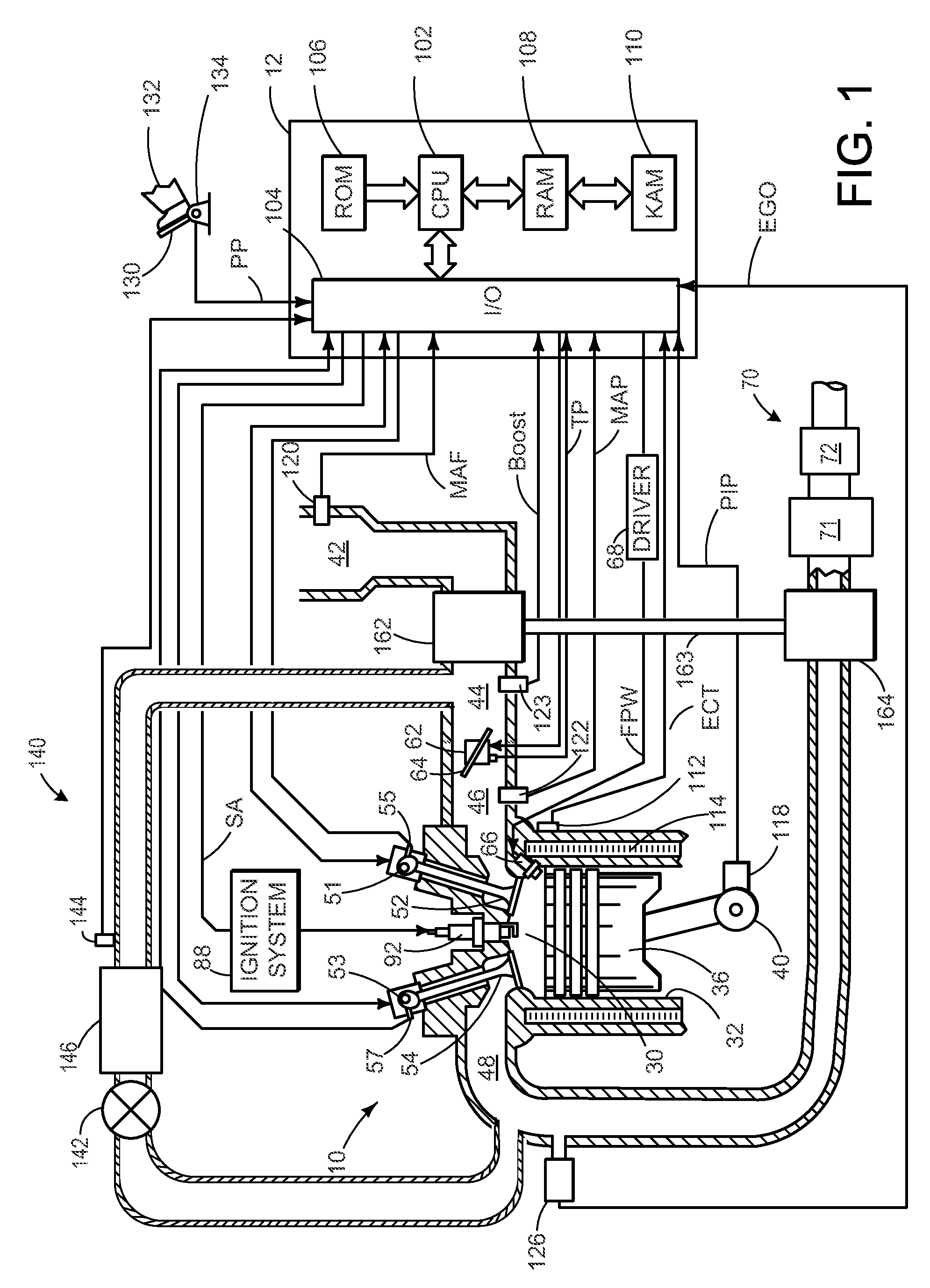

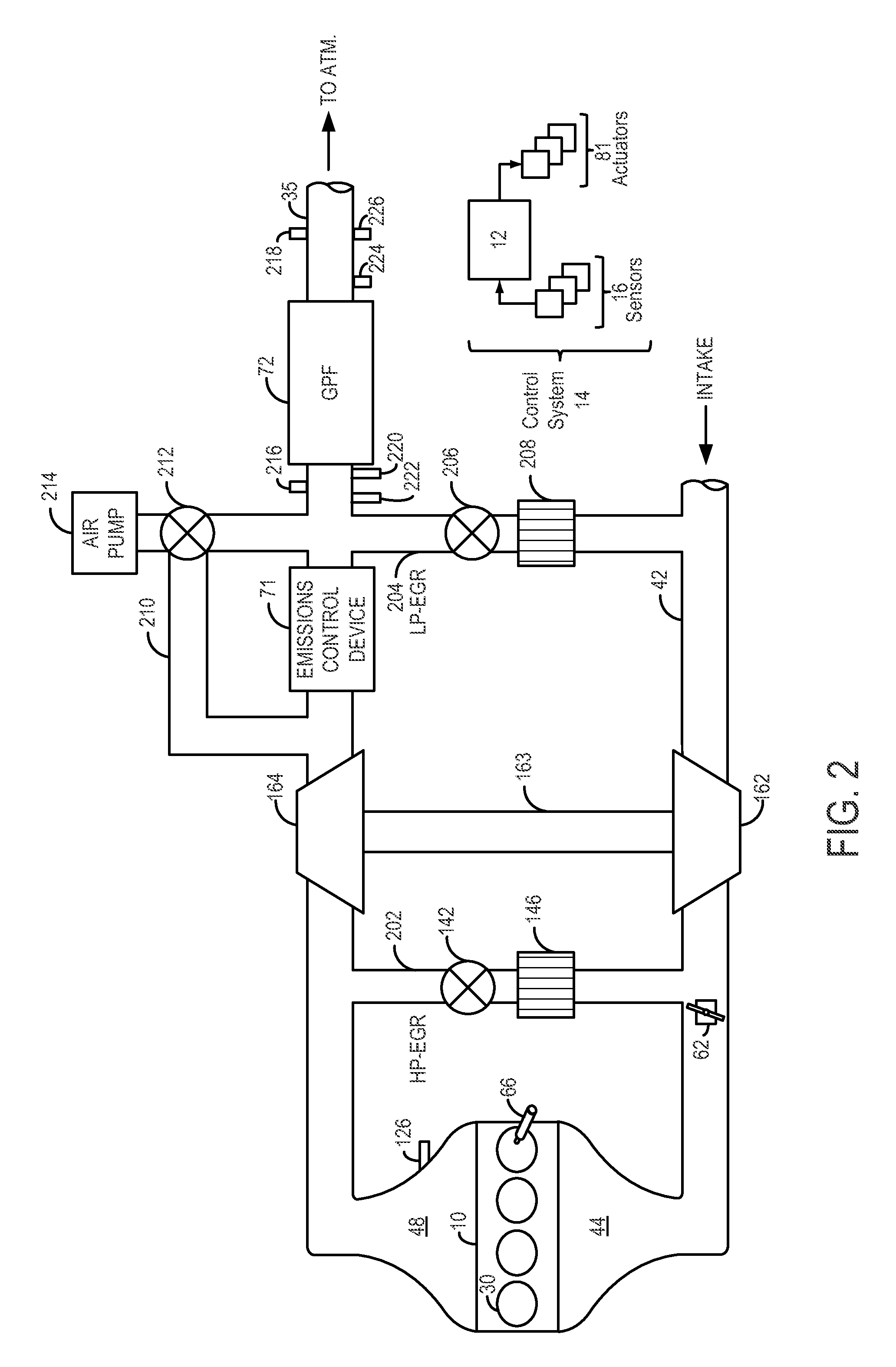

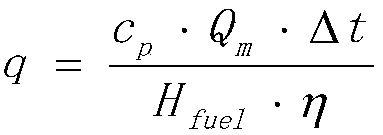

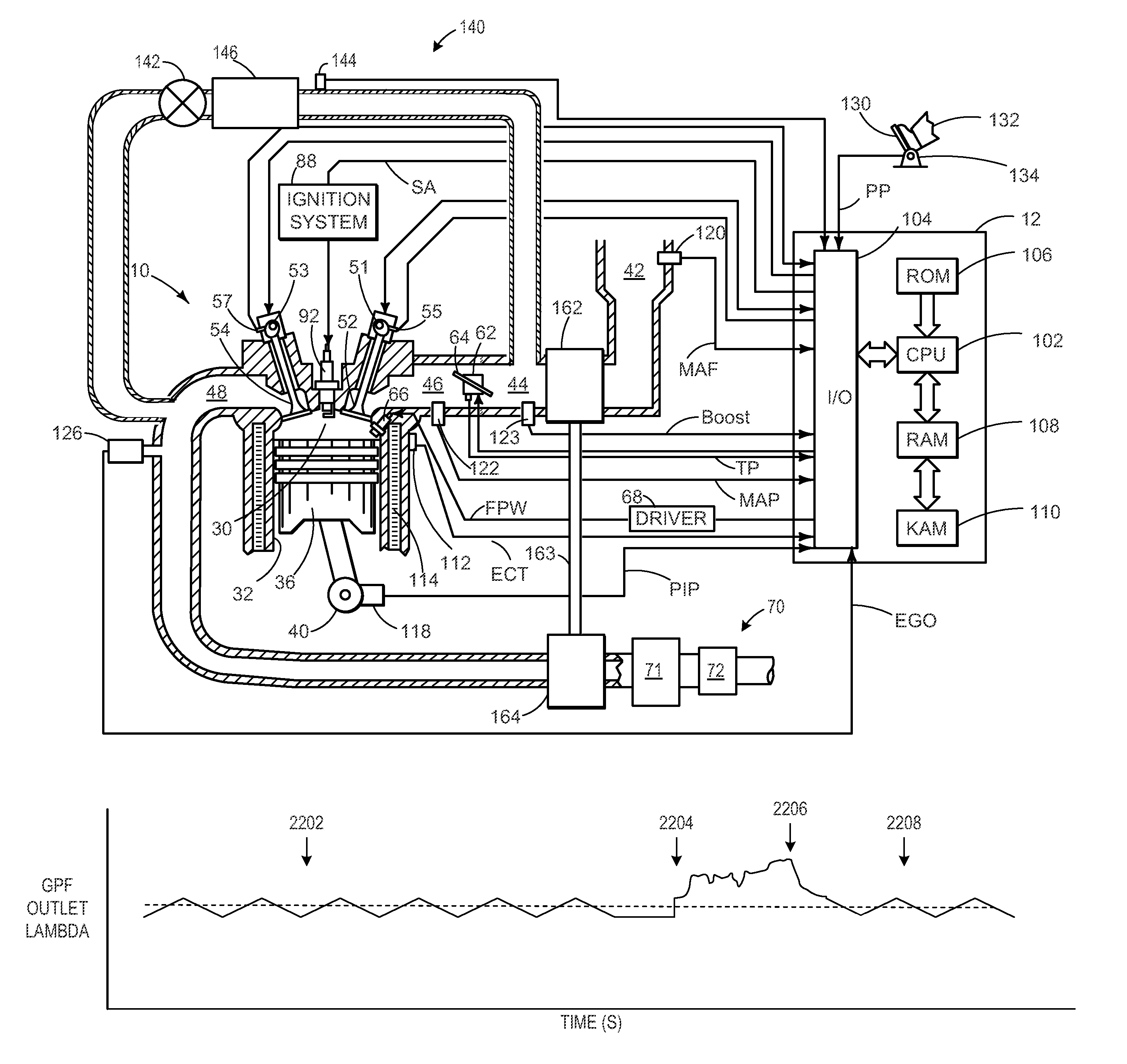

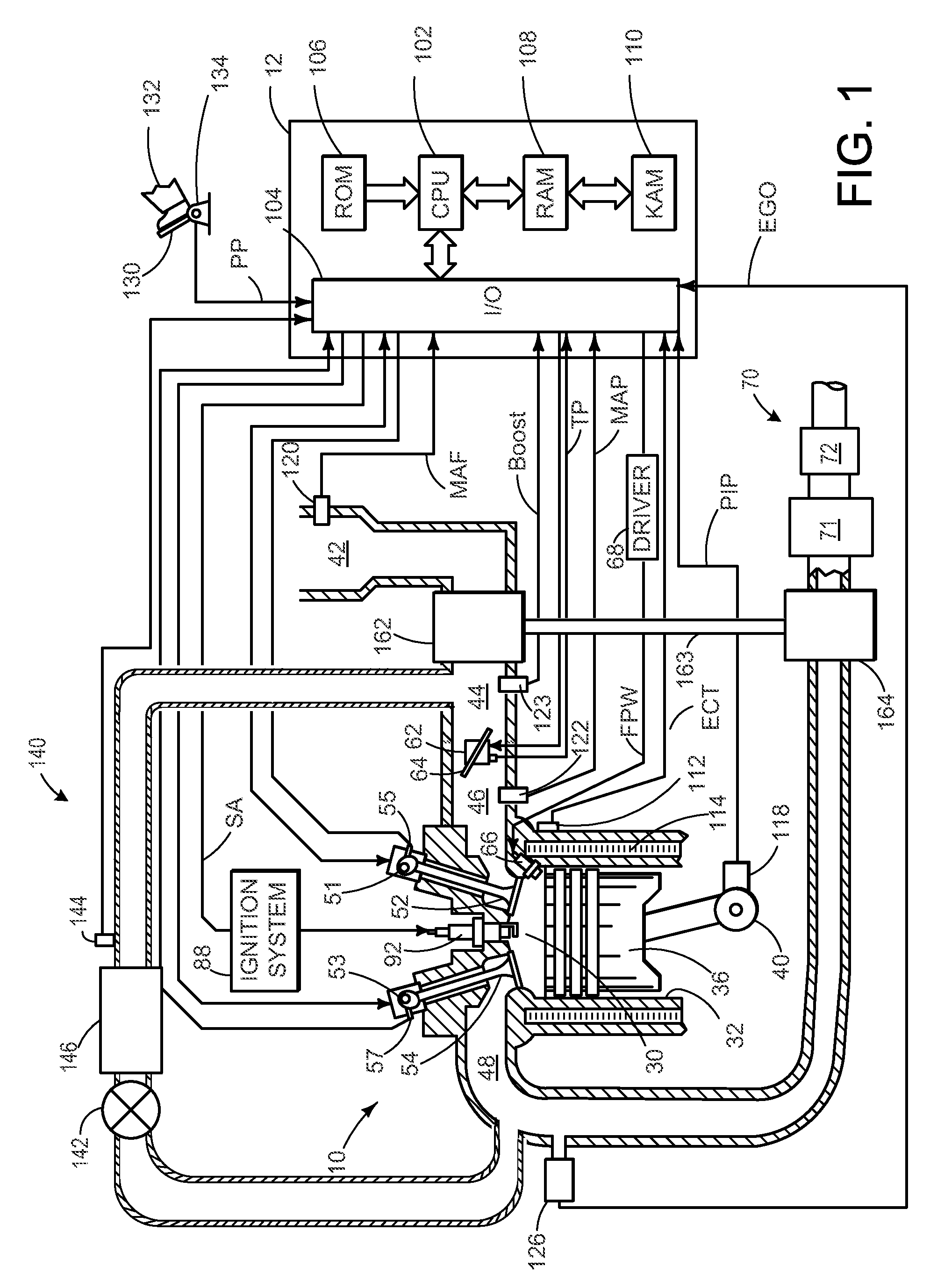

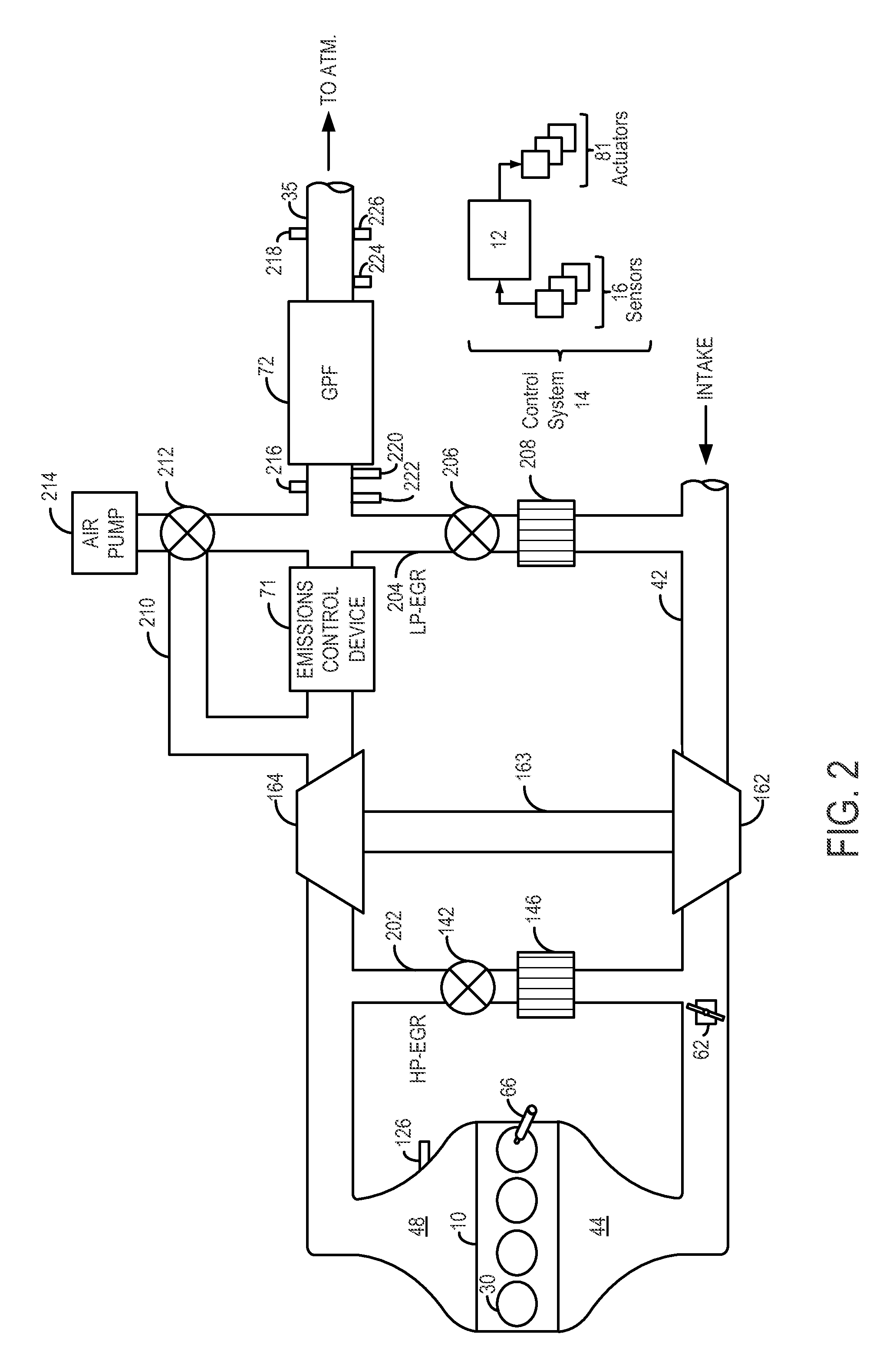

Gasoline particulate filter regeneration and diagnostics

ActiveUS20110072788A1Improve engine performanceReduce transient air-fuel disturbanceElectrical controlNon-fuel substance addition to fuelParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

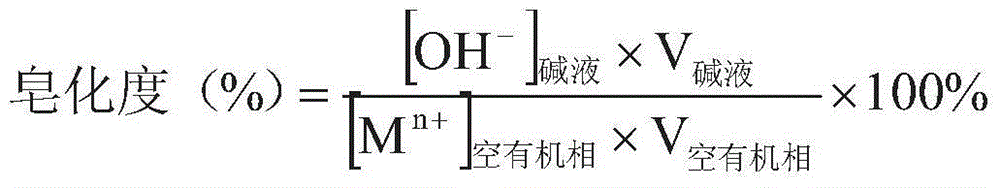

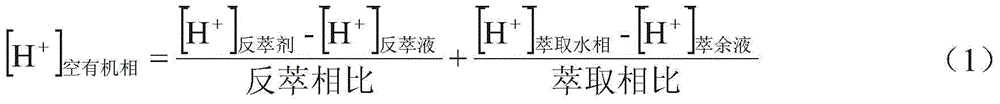

Regeneration method of lithium extraction system

InactiveCN104388677AGuaranteed recyclingSimple regeneration methodProcess efficiency improvementLithiumDiluent

The invention discloses a regeneration method of a lithium extraction system. The lithium extraction system is regenerated by virtue of alkaline saponification and the regeneration method comprises the following steps of mixing empty-loading organic phases subjected to lithium extraction and reverse extraction and alkaline liquor, saponifying and standing for separating phases to obtain a clarified and transparent regenerated and extracted organic phase, wherein the empty-loading organic phases comprise an extractant, a synergistic extractant and a diluent which are involved in the lithium extraction and reverse extraction processes; the synergistic extractant is iron chloride; and the alkaline liquor is any one of sodium hydroxide solution and potassium hydroxide solution. The regeneration method of the lithium extraction system disclosed by the invention has the advantages of simplicity in operation and good saponifying effect; when lithium is extracted by virtue of the saponified, regenerated and recycled extraction organic phase, the extraction efficiency of lithium is high and the extraction effect is good; and by the method, the recycling of the extraction organic phase for extracting lithium is achieved and the process flows of extracting, carrying out reverse extraction, regenerating and extracting for circularly extracting lithium are completed.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

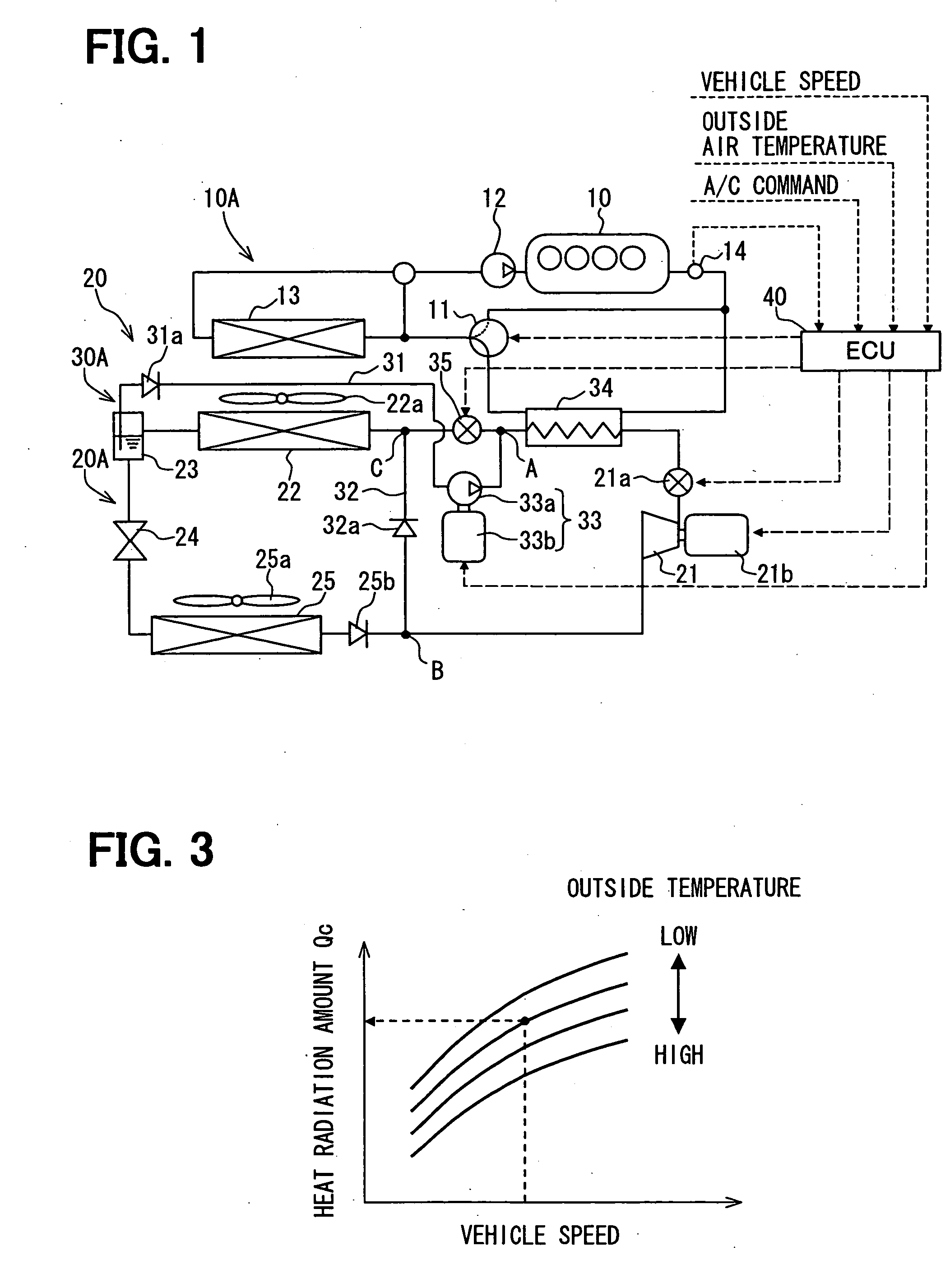

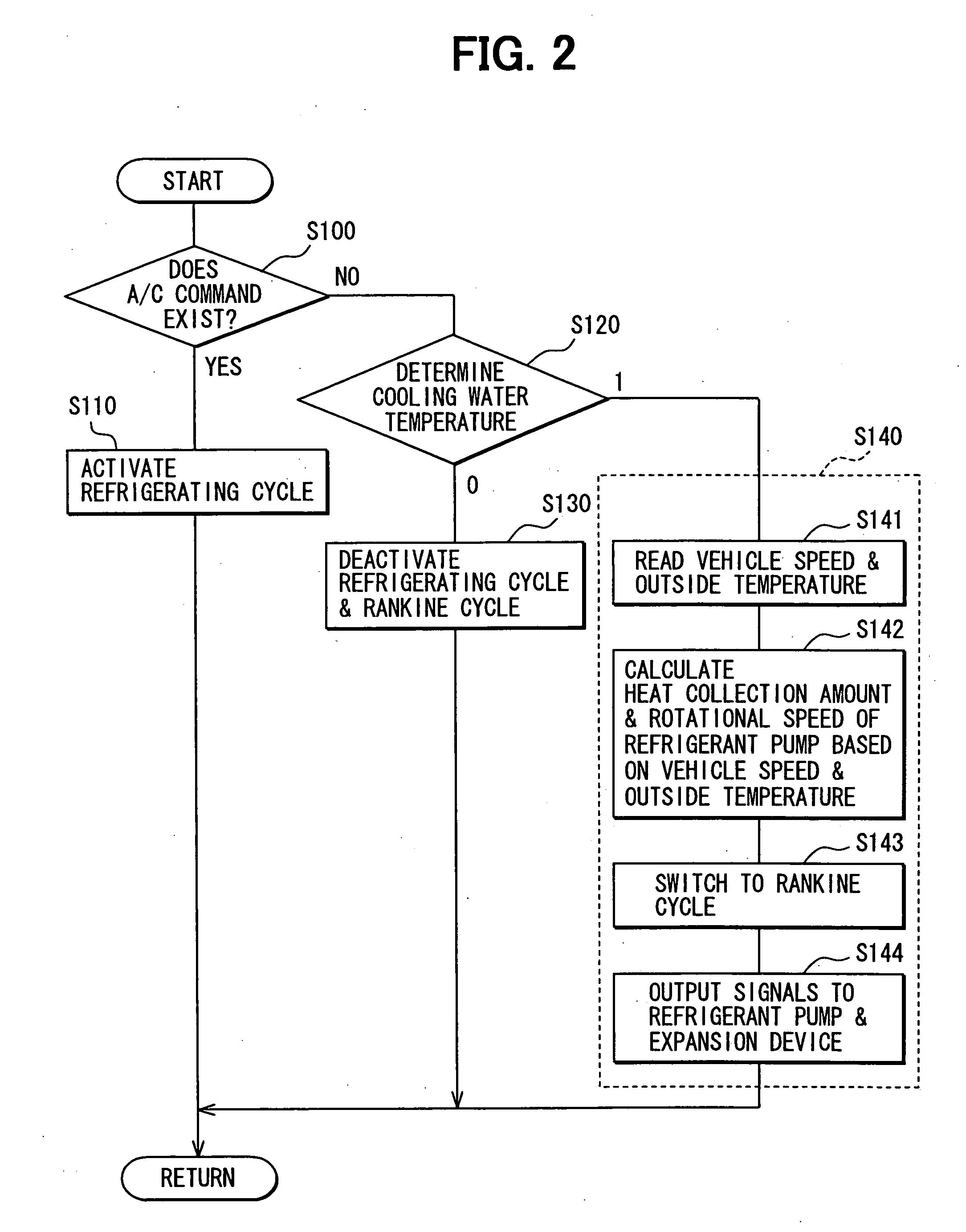

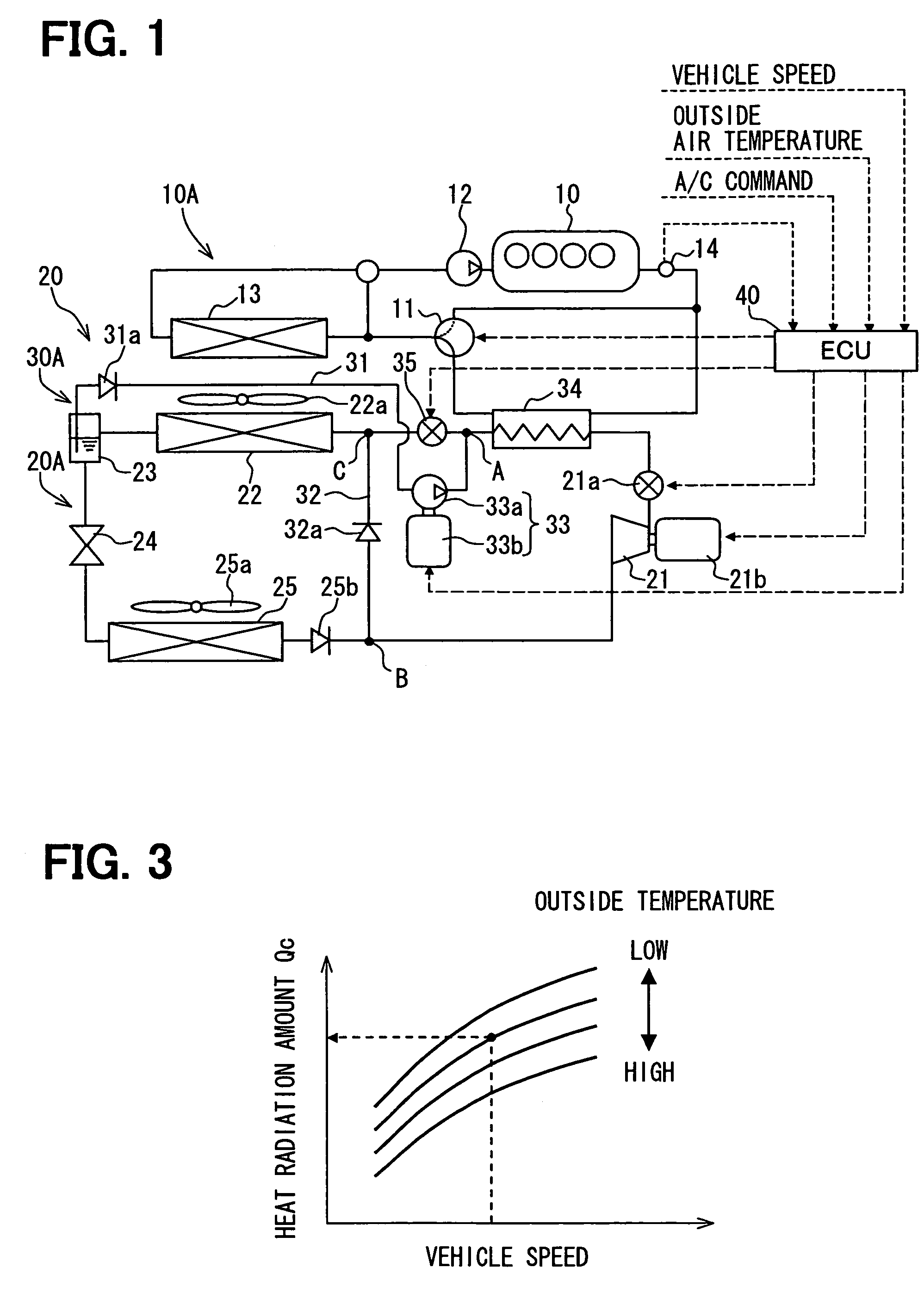

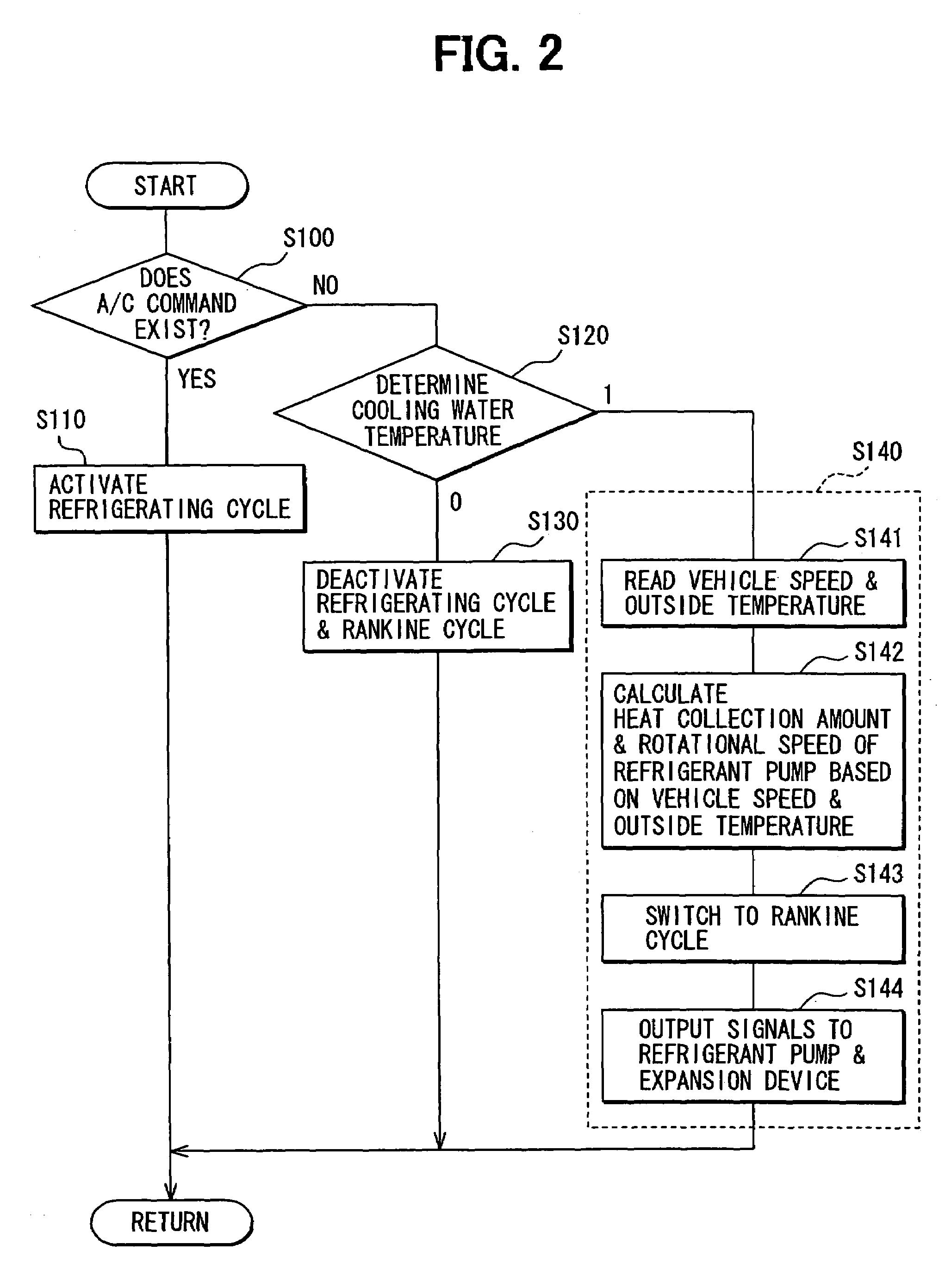

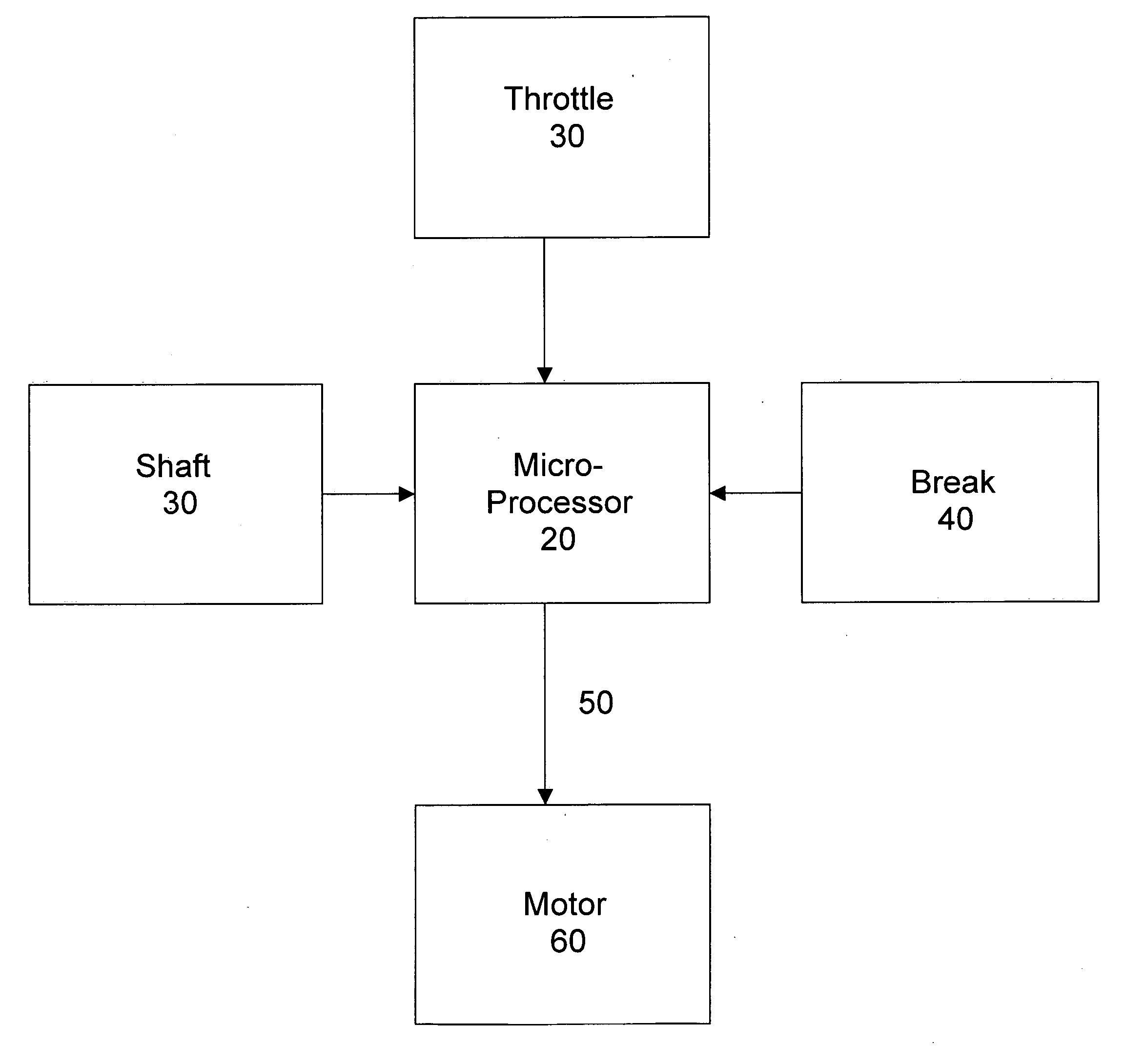

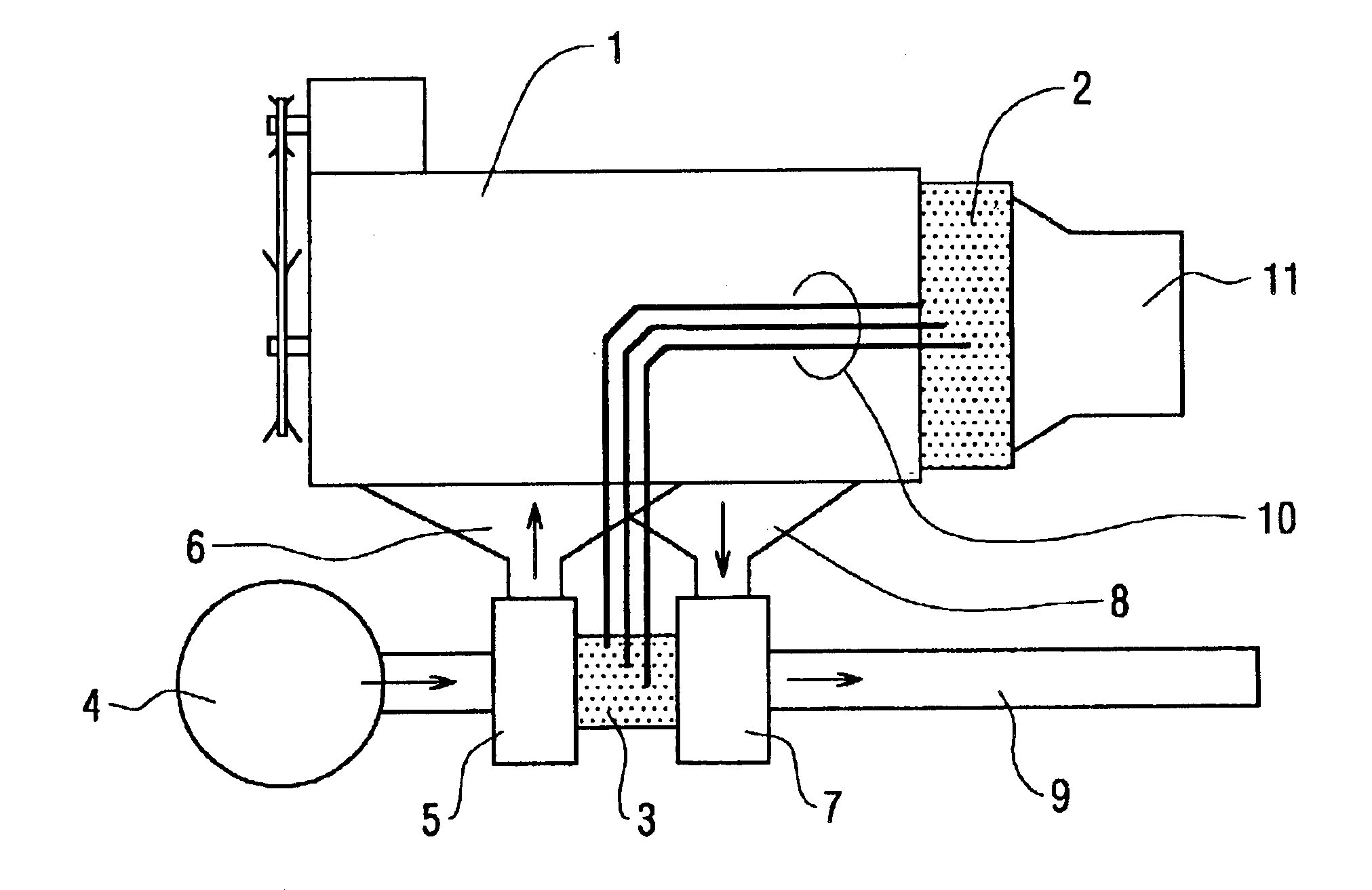

Device for utilizing waste heat from heat engine

InactiveUS20060225421A1Efficient collectionGenerate efficientlyInternal combustion piston enginesEngine componentsRefrigerantWaste heat

A device for utilizing waste heat from a heat engine comprises a Rankine cycle including a pump, a heating device, an expansion device, and a condenser device, and a controller for controlling an operation of the Rankine cycle. The controller calculates an optimum heat collection amount (Qho) as a heat value to be collected from waste heat of the engine, wherein the heat collection amount (Qho) is calculated as an optimum amount in relation to a potential maximum heat radiation amount (Qco) to be radiated at the condenser device. The controller calculates an optimum flow amount (G) of refrigerant corresponding to the optimum heat collection amount (Qho), so that a maximum driving power (L) is generated at the expansion device.

Owner:DENSO CORP

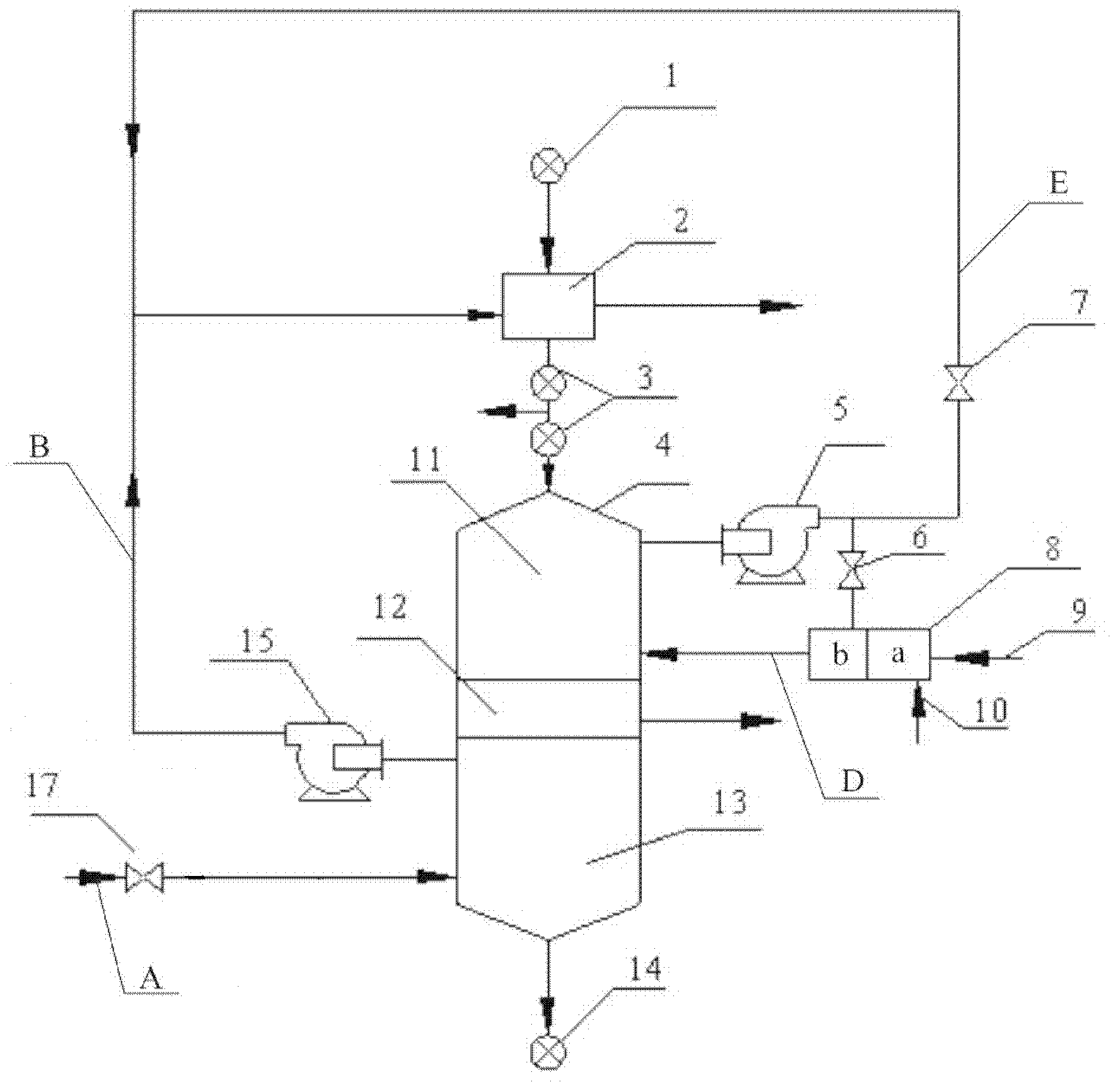

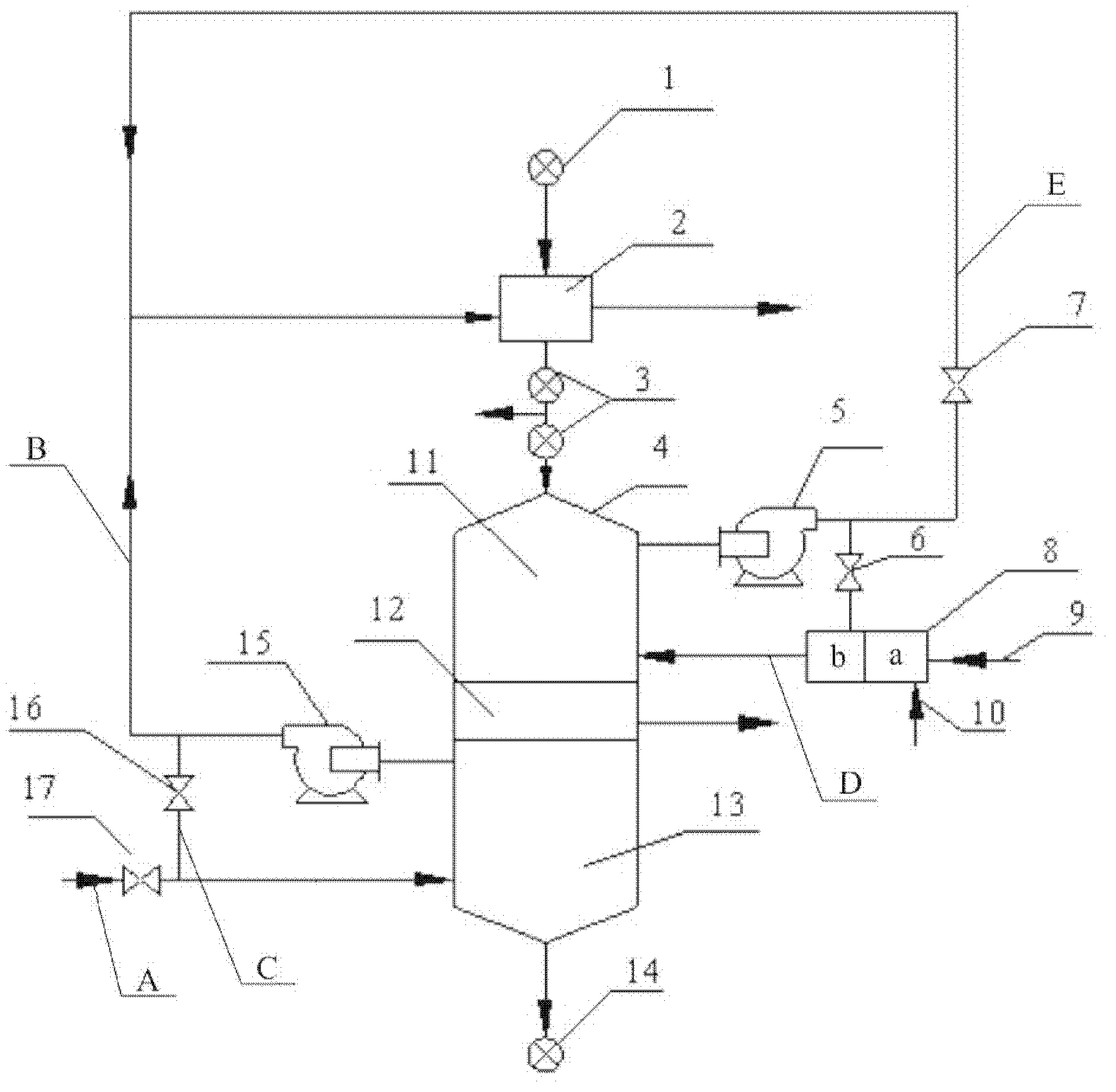

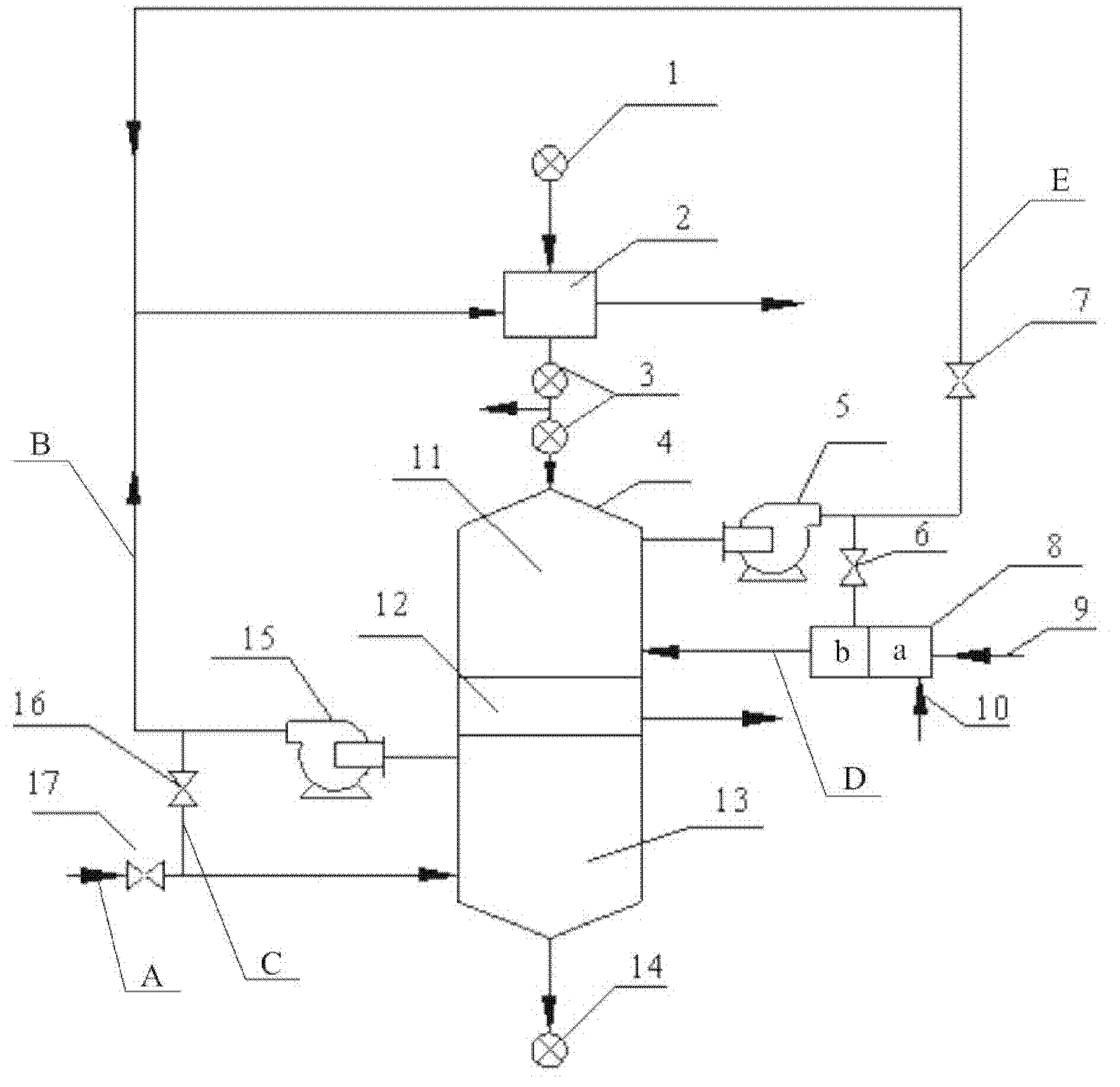

Comprehensive heat energy utilizing type active coke purifying and regenerating process system and active coke purifying and regenerating process method

ActiveCN102580705AImprove regeneration efficiencyIncrease profitOther chemical processesDispersed particle separationProcess systemsHeat conducting

The invention discloses a comprehensive heat energy utilizing type active coke purifying and regenerating process system and an active coke purifying and generating process method. The process system comprises a regenerating device, a preheating device, a heating device and a heat exchanging device, wherein the regenerating device comprises a regenerating tower; the preheating device comprises a drying tower; the heating device comprises a hot-blast stove and a first fan; and the heat exchanging device comprises a second fan, a normal-temperature air input pipeline and a hot air output pipeline, wherein the second fan is used for sending the hot air after heat exchange to the drying tower so as to preheat the active coke. The method comprises the following steps: (1) preheating: preheating the active coke in the drying tower; (b) heating: heating the active coke due to the action of a high-temperature heat-conducting medium; (c) regenerating; and (d) cooling: cooling the regenerated active coke entering a cooling section. The system and method disclosed by the invention are suitable for restoring and regenerating the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

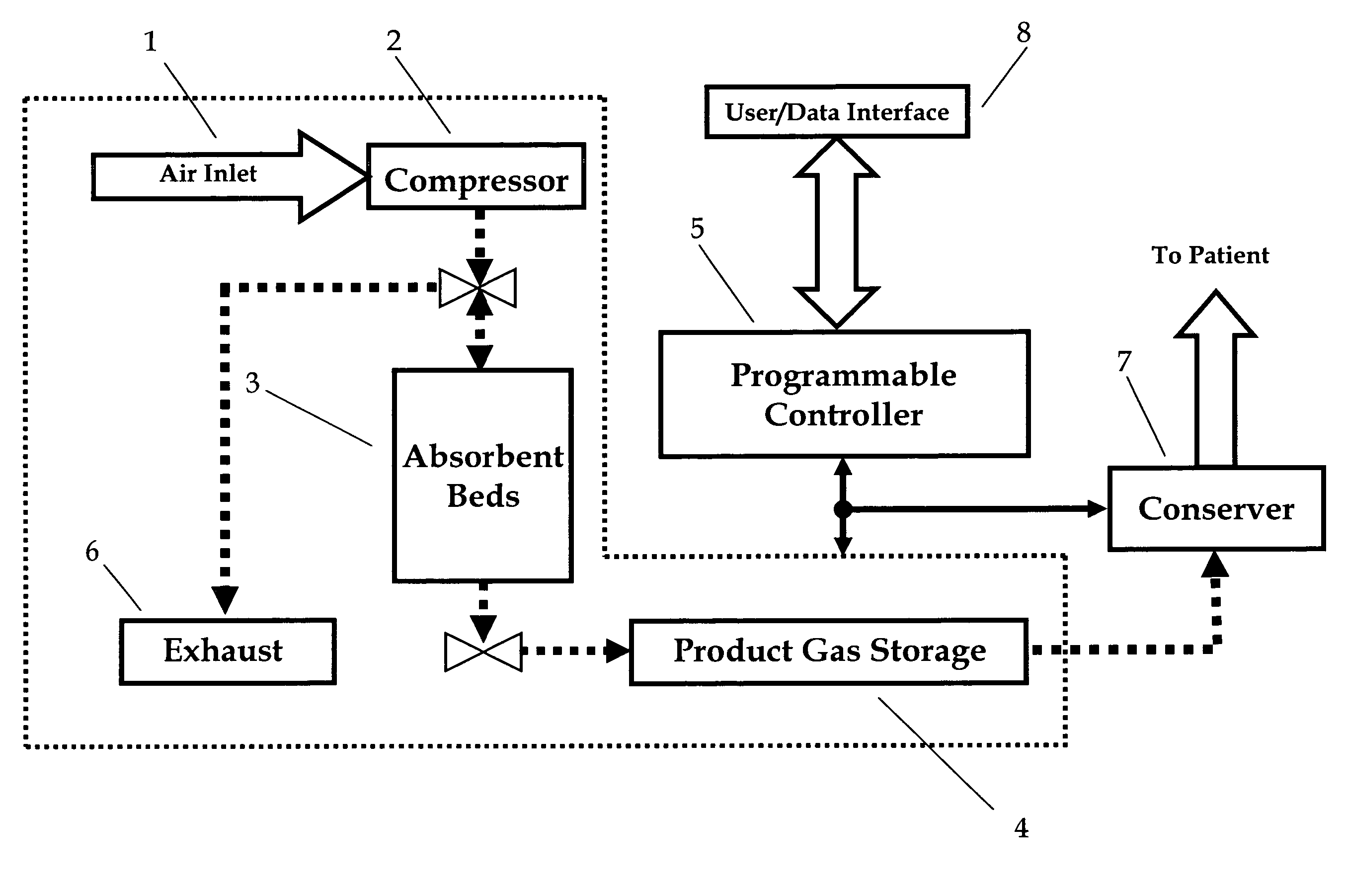

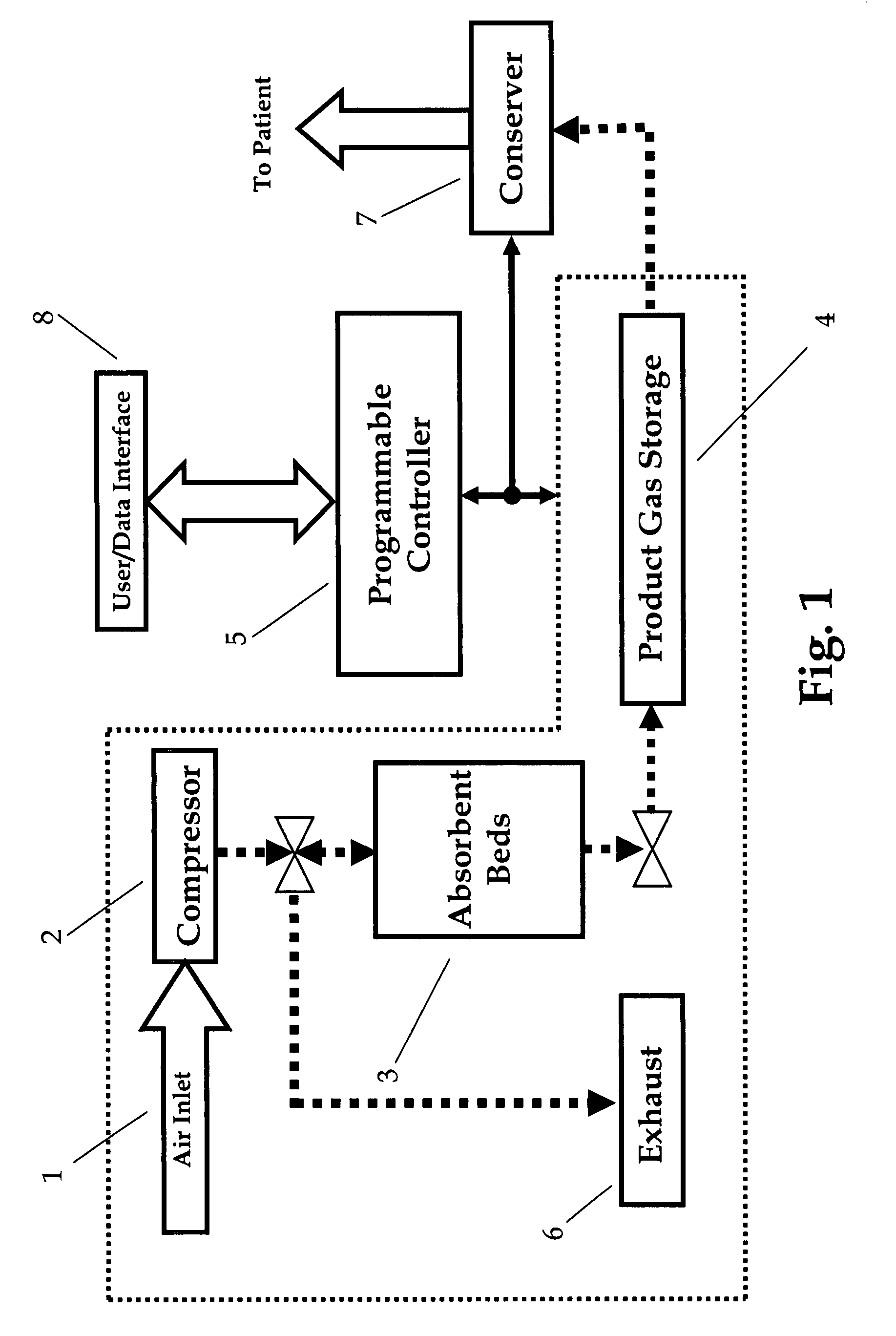

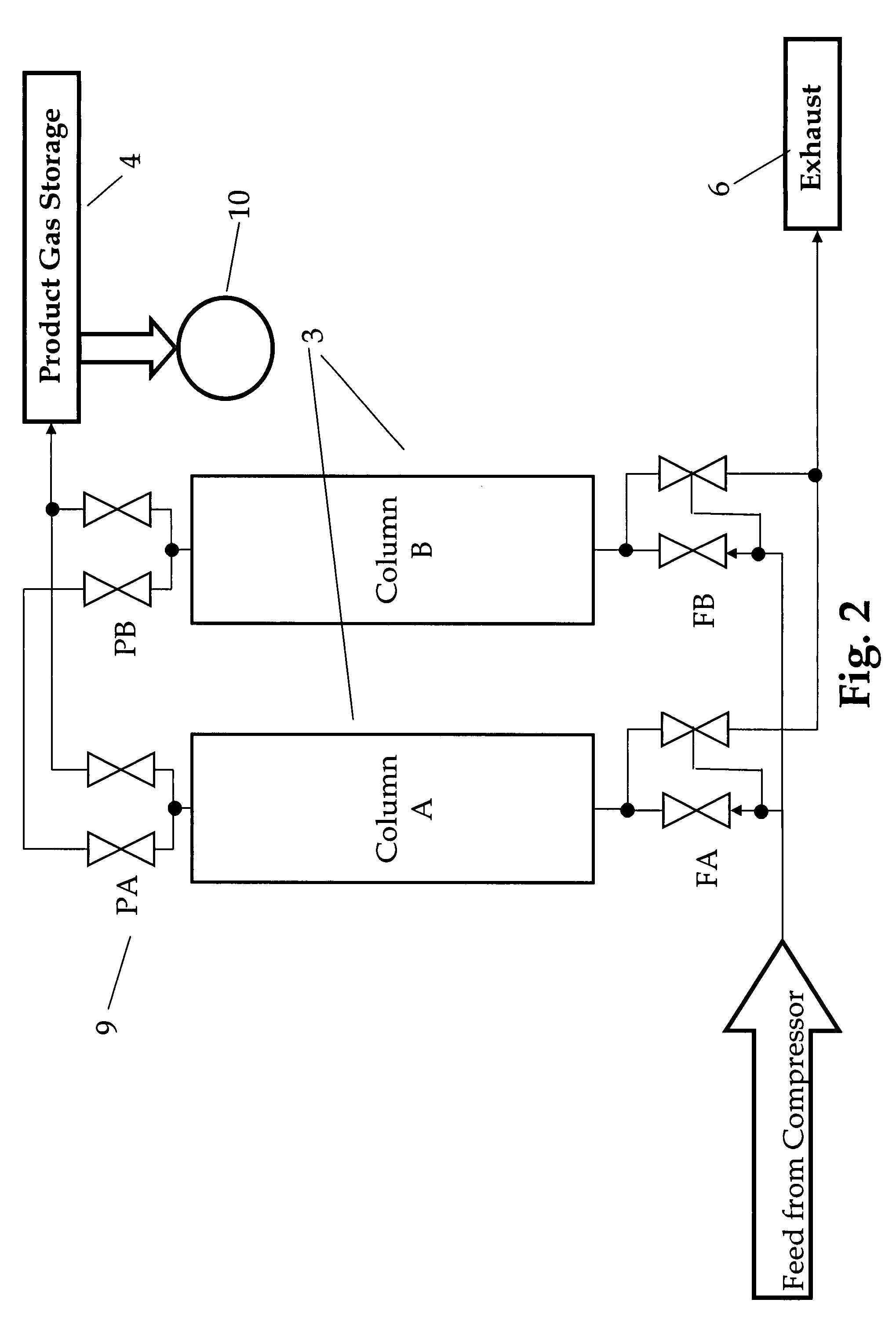

Adsorbent bed pressure balancing for a gas concentrator

ActiveUS7857894B2Reduced purge timeShorten feeding timeRespiratorsGas treatmentEngineeringPressure balance

A system and a method are described for monitoring pressure imbalances in the adsorbent beds of a portable gas concentrator. Using the programmability features found in modern portable concentrators, various mitigative procedures to adjust for pressure imbalances and to predict the need for service are disclosed.

Owner:INOGEN SA

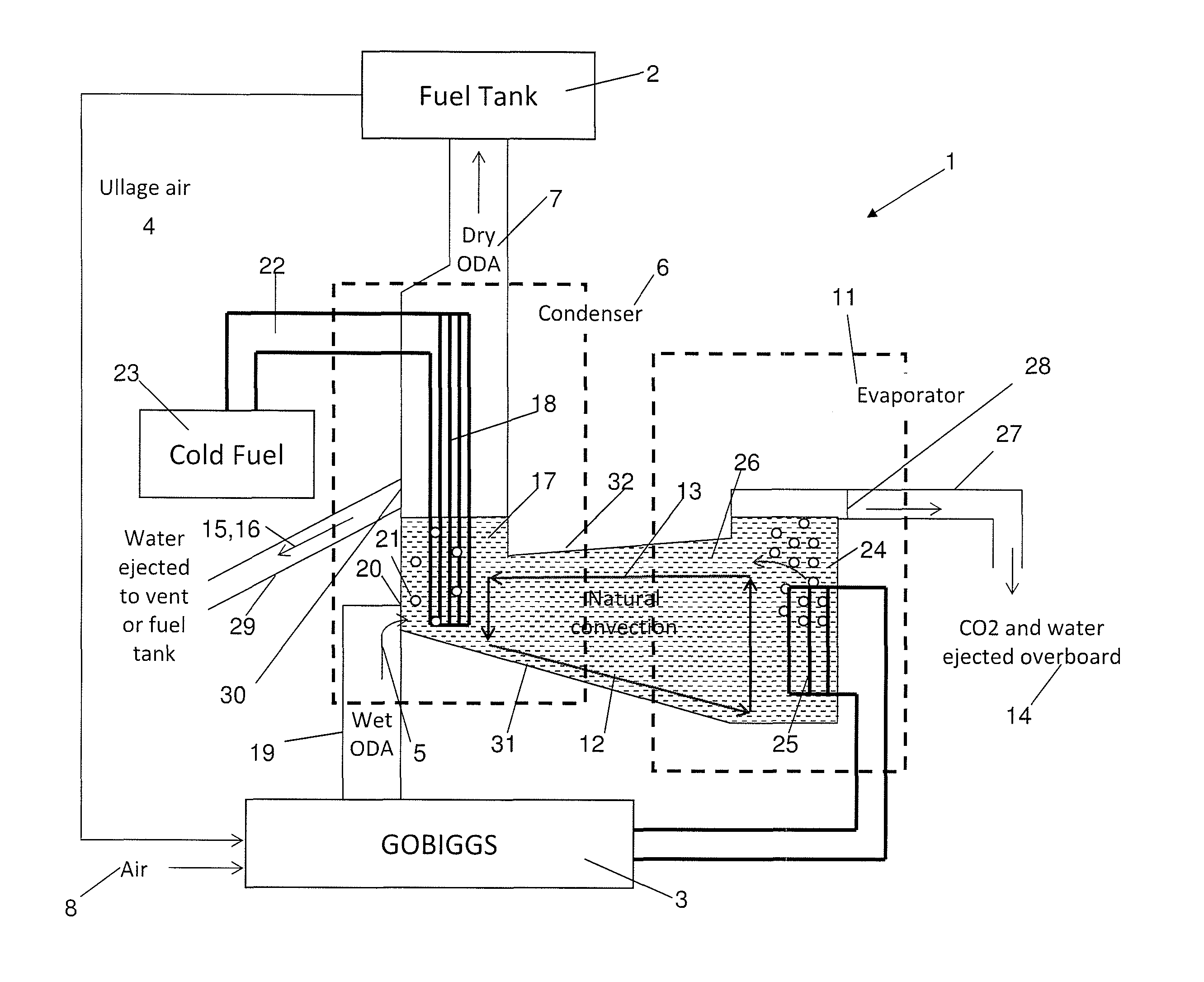

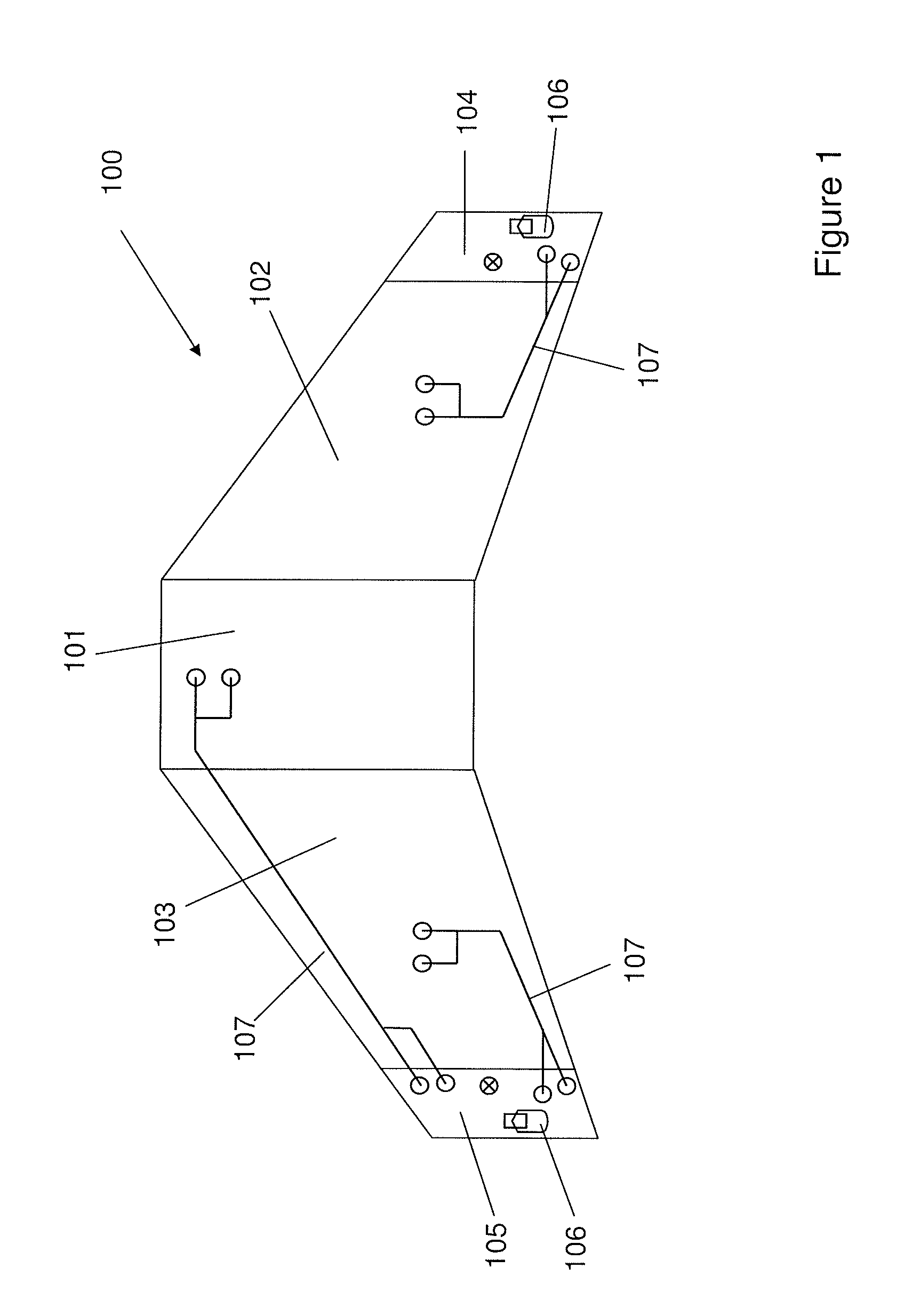

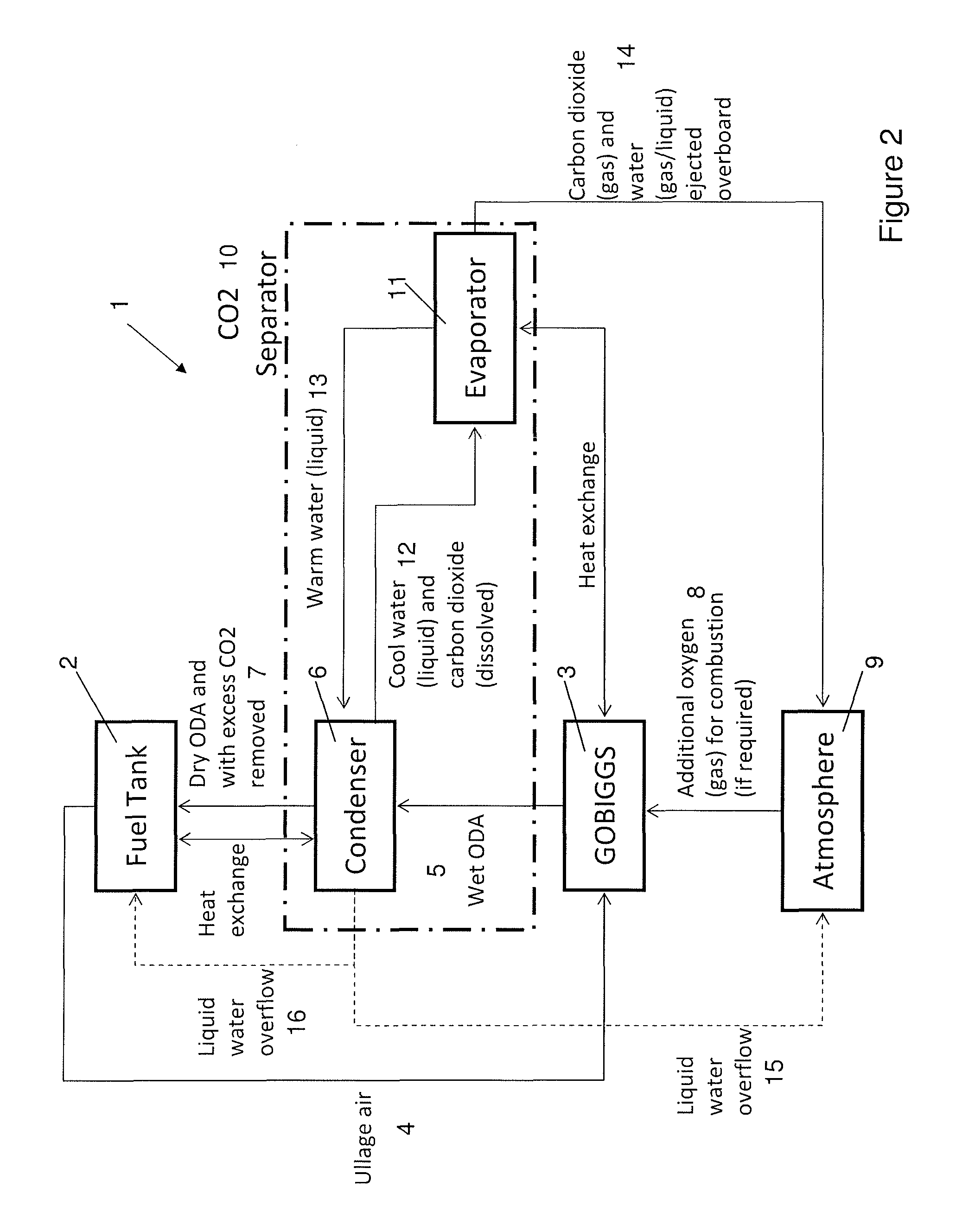

Fuel system inerting

ActiveUS8828344B2Reduce contentTemperature differentialOxygen/ozone/oxide/hydroxideLiquid degasificationProcess engineeringOxygen

A fuel system comprising a fuel tank, a catalytic inerting device for producing oxygen depleted air (ODA) by reaction of fuel vapor from the fuel tank with air, and a separator device for separating carbon dioxide from the ODA gas before feeding the carbon dioxide depleted ODA gas to the fuel tank so as to render the fuel tank ullage atmosphere inert. Also, a method of reducing the carbon dioxide content of oxygen depleted air (ODA) produced by a catalytic inerting device for inerting a fuel tank ullage atmosphere, the method comprising separating carbon dioxide from the ODA gas before feeding the carbon dioxide depleted ODA gas to the fuel tank. The system may be installed in an aircraft.

Owner:AIRBUS OPERATIONS LTD

Flue gas hydrargyrum-removing method by catalytic oxidation

InactiveCN1698931ALittle matrix damageReduce pollutionDispersed particle separationPtru catalystSorbent

This invention relates to a catalytic oxidation smoke gas mercury removing method, which is used for controlling and reclaiming the gas mercury, especially for the brown coal and subbituminous coal smoke gas. The method uses the mercury oxidative catalyst and the adsorbent to oxygenize and absorb mercury in the smoke gas, then dissociate and elution the mercuric oxide in high temperature to regenerate it. The heat of the elution gas can be reclaimed by residual heat utilization device, and the high concentration mercury will be reclaimed through cold-trap or processed by the agent in the mercury reactor. The reclaimed mercury and other by-product can be sold to reduce the cost. Said invention uses the thermal instability of the mercuric oxide, and reclaims in the relative lower temperature; the recovery ratio can reach to 98%, meanwhile, it processes post-treatment with the mercury and has no secondary pollution.

Owner:SHANGHAI JIAO TONG UNIV

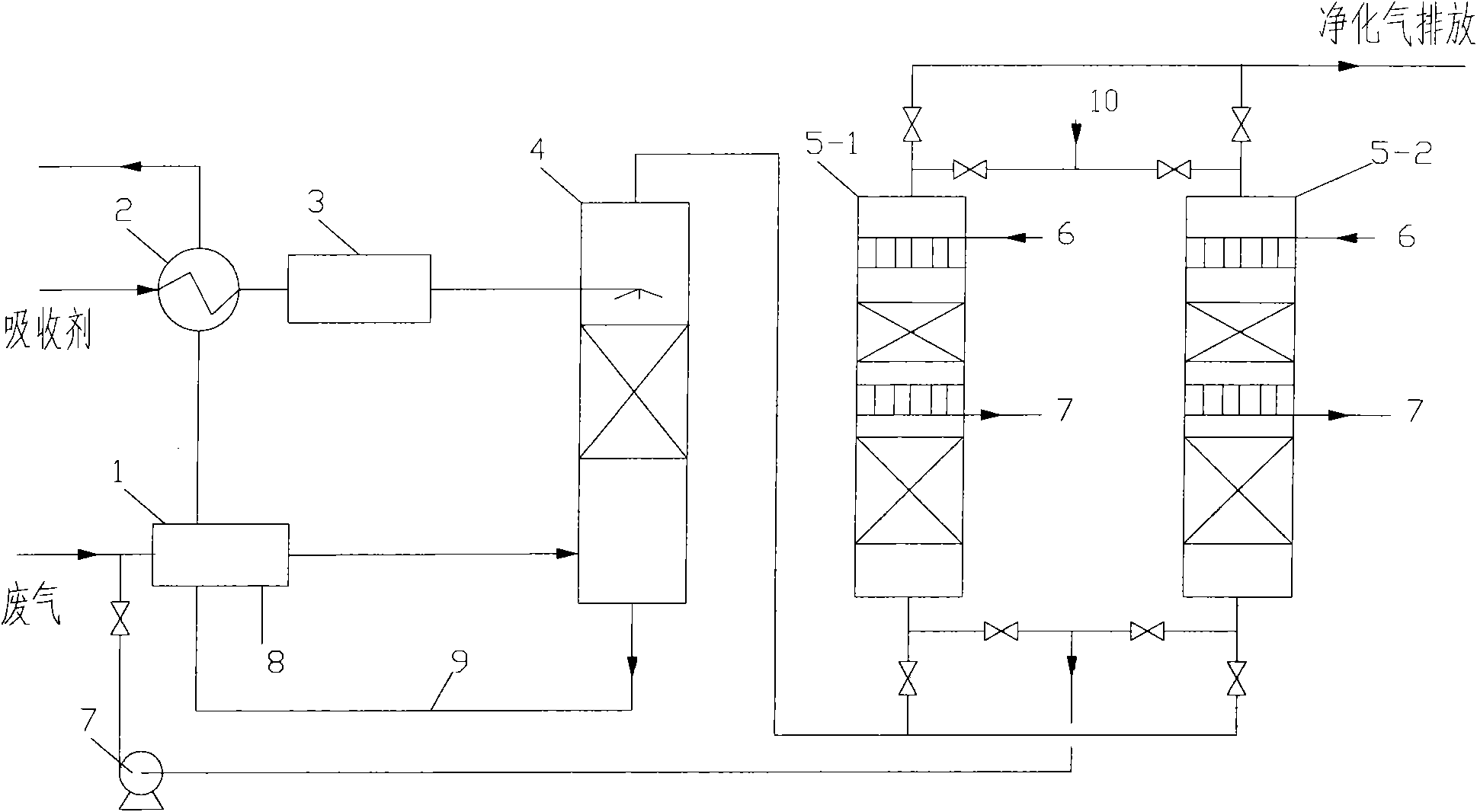

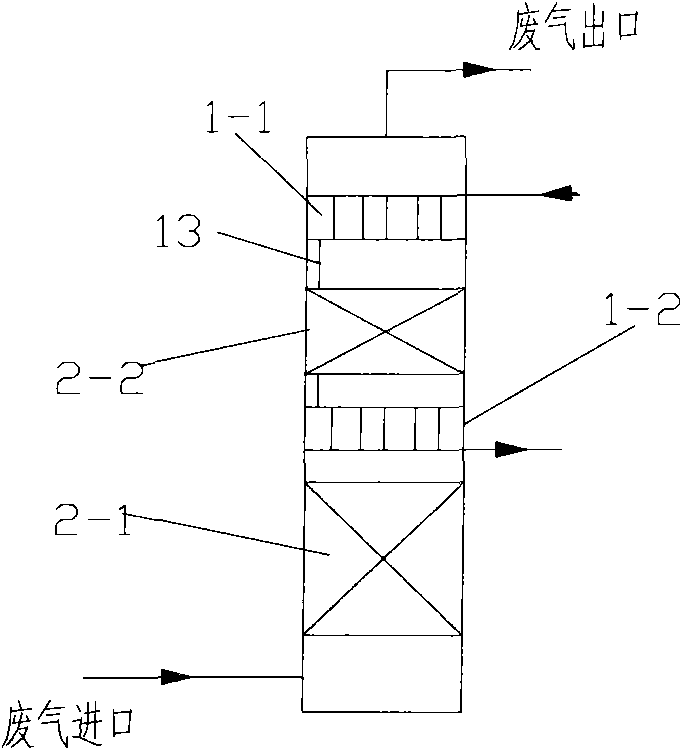

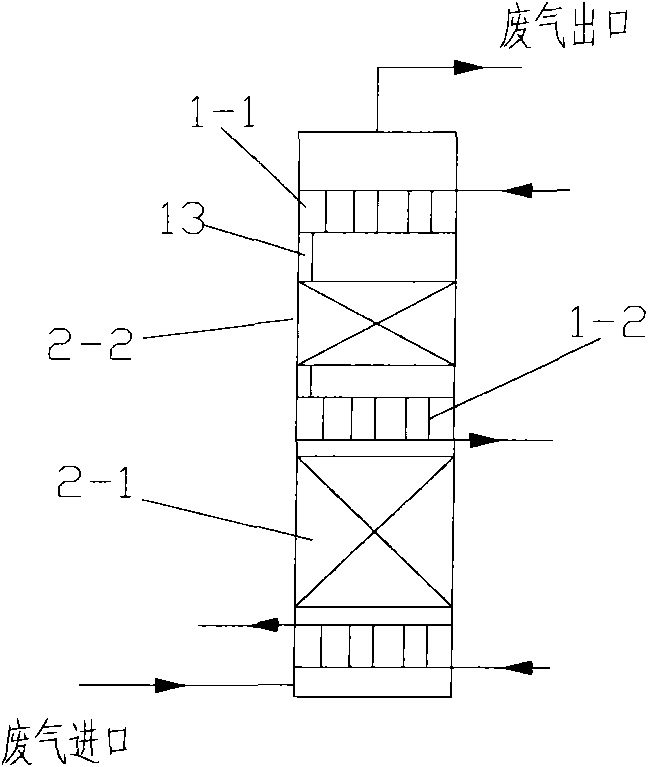

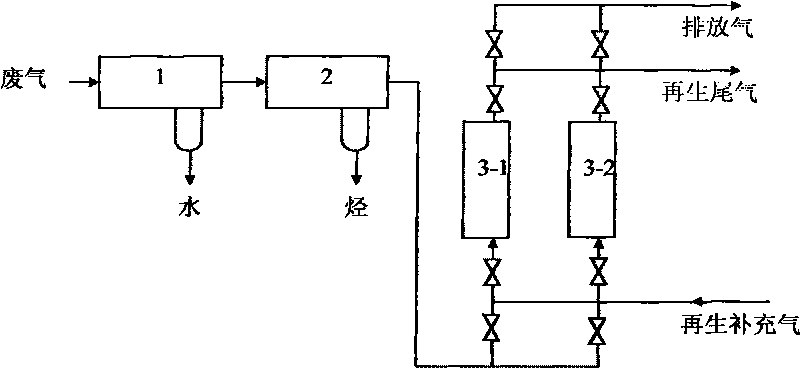

Method for treating sulfur- and hydrocarbon-containing foul waste gas

ActiveCN101898071AIncrease concentrationImprove regeneration efficiencyDispersed particle separationLarge containersSorbentSilica gel

The invention discloses a method for treating sulfur- and hydrocarbon-containing foul waste gas. The waste gas enters a heat exchanger for cooling, condensed water is separated, the cooled waste gas enters an absorption tower to be absorbed by an absorbent distillate, a fresh absorbent exchanges heat with a rich absorbent discharged by the absorption tower and then is cooled by a cooling system, and the cooled absorbent enters the absorption tower; and the waste gas subjected to absorptive purification enters an adsorption tower for adsorptive purification, the adsorption tower is segmentally filled and respectively filled with silica gel adsorbents and activated carbon adsorbents, and heat exchangers are arranged among the adsorbents in each segment. The method can thoroughly purify the sulfur- and hydrocarbon-containing foul waste gas discharged by chemical engineering storage tanks, refining devices and the like, and has the advantages of simple treatment process and no potential safety hazard.

Owner:CHINA PETROLEUM & CHEM CORP +1

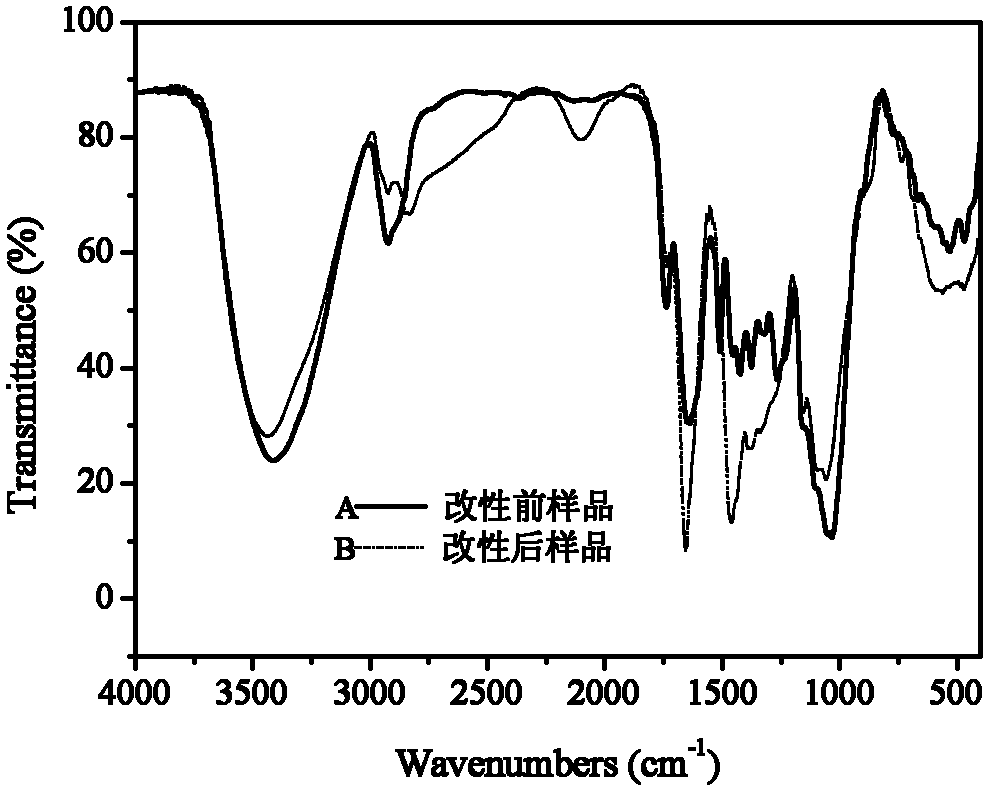

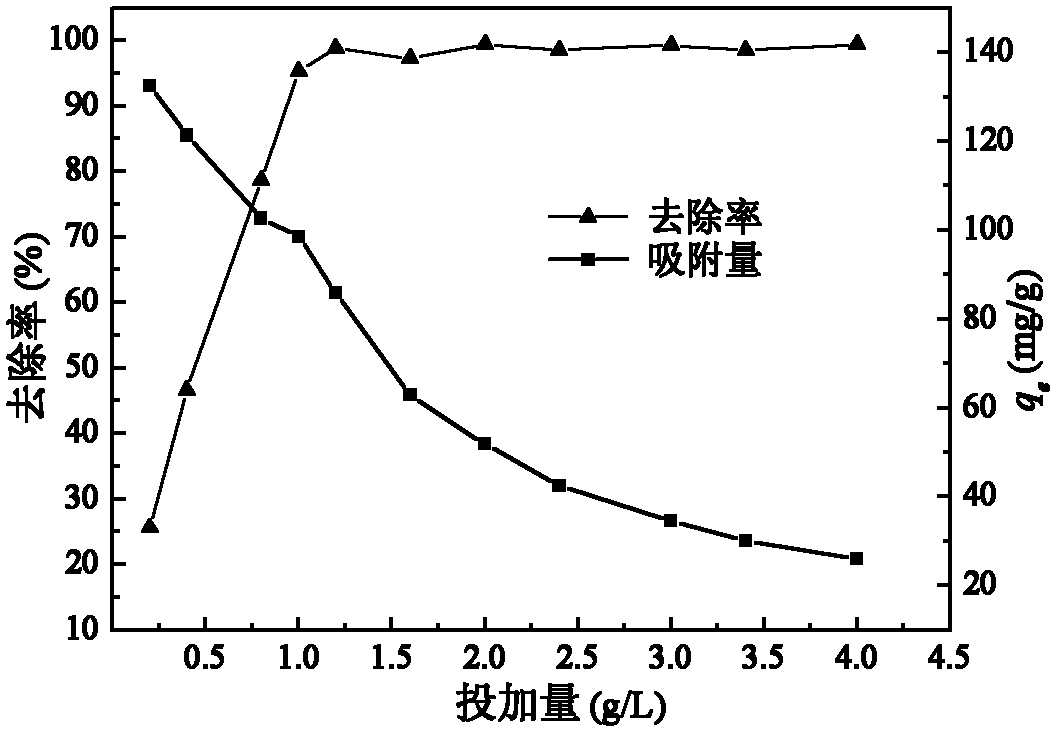

Modified peanut shell cationic adsorbent, preparation method and application

InactiveCN102553538AImprove regeneration efficiencyReduce recycling costsOther chemical processesWater/sewage treatment by sorptionZeta potentialSorbent

The invention discloses a modified peanut shell cationic adsorbent, a preparation method and application. The adsorbent is prepared by using a peanut shell, epichlorohydrin, N, N-dimethyl formamide and triethylenetetramine as raw materials. The modified peanut shell cationic adsorbent is in a brown yellow powder shape, and the Zeta potential is between 31mv and 52mv. The process is simple, the cost of the raw materials is low, the adsorption capacity is high, the adsorbent can be regenerated, and the saturated adsorbent can also be directly incinerated. The modified peanut shell cationic adsorbent provided by the invention is used for adsorption removal of anions in wastewater, and particularly has high adsorption capacity of Cr (VI) ions.

Owner:SHANDONG UNIV

Tissue Culture Rapid Propagation Method of Ginger Lotus

ActiveCN102257963ASpeed up promotionIncrease planting yieldHorticulture methodsPlant tissue cultureLandscapingBud

The invention discloses a rapid tissue culture and propagation method of curcuma alsimatifolia, belonging to the technical field of plant tissue culture. The method comprises the following steps of: firstly, preparation of a culture medium; secondly, culture and sterilization of earthnut budlet; thirdly, culture of explant sterile seedling; fourthly, induction culture of adventitious bud; fifthly, propagation culture of adventitious bud; sixthly, root growing culture of plantlet; and seventhly, seedling adaptation, acclimation and transplanting of tissue culture seedling. The method disclosedby the invention has the advantages that propagation culture period is short (14-20 days), propagation coefficient is high (improved to 5-8 times from 2-4 times), the consistency of the adventitious bud is good, tissue culture breeding cycle is short (50-60 days), seedling quality is good, and transplanting survival rate can reach up to more than 95%, and is a method for efficiently and rapidly providing high-quality curcuma alsimatifolia seedlings. The method disclosed by the invention can be popularized and applied to landscaping and tissue culture seedling enterprises.

Owner:ZHEJIANG XIAOSHAN COTTON & FLAX RES INST

Heat pump system having a pre-processing module

ActiveUS8915092B2Avoid frostImprove regeneration efficiencyMechanical apparatusDesuperheatersComputer moduleEnergy recovery

Owner:NORTEK AIR SOLUTIONS CANADA INC

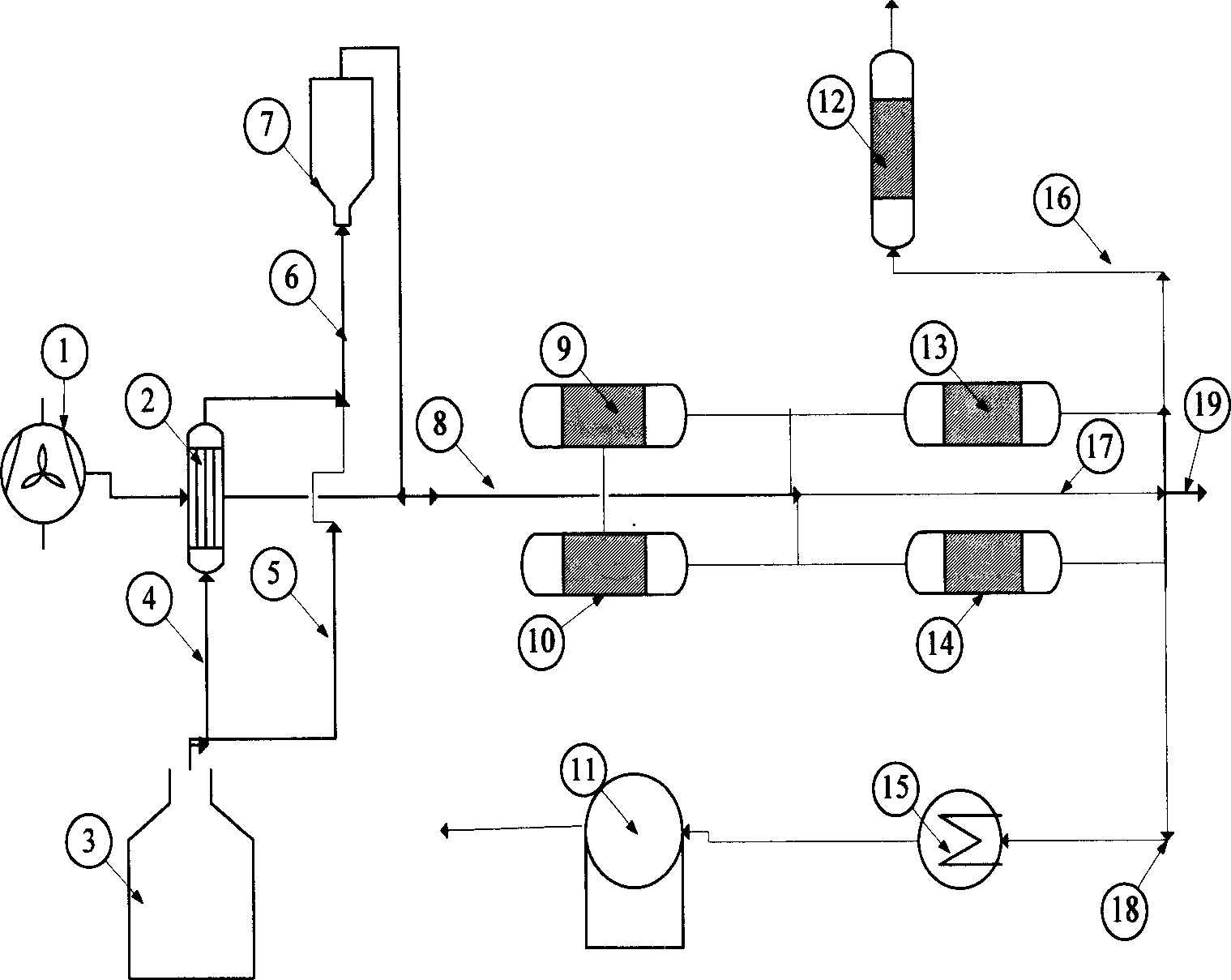

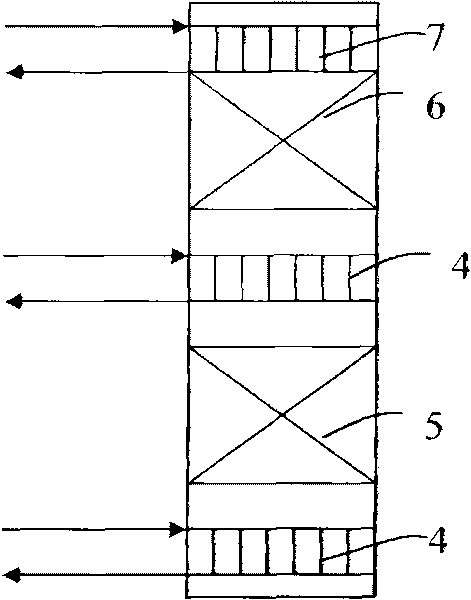

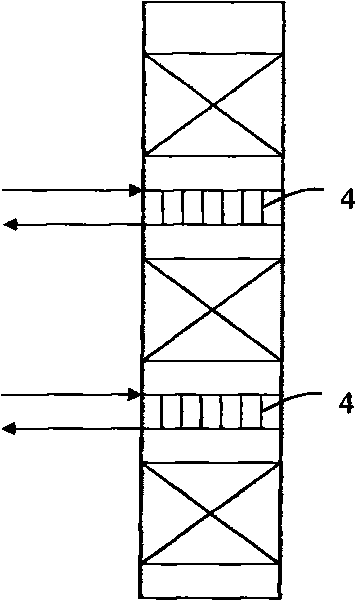

Method for recovering and purifying hydrocarbon wastegas by condensation and adsorption

ActiveCN101721833AIncrease concentrationImprove regeneration efficiencyDispersed particle separationVapor condensationHigh concentrationActivated carbon

The invention relates to a method for recovering and purifying hydrocarbon wastegas by condensation and adsorption, which comprises the following steps: firstly condensing hydrocarbon wastegas to remove water vapor; and recovering hydrocarbon by further condensation, performing activated carbon adsorption on gases not condensed and adsorbing exhaust by activated carbon, wherein the activated carbon adsorption at least comprises two activated carbon adsorption tanks for the switching operation of adsorption and regeneration, the activated carbon adsorption tanks at least comprise two activated carbon bed layers inside; and during the regeneration operation, the regenerative gas is subjected to at least once vapor heat exchange and temperature rise in the process of passing through the activated carbon bed layer. The method for recovering and purifying the hydrocarbon wastegas by condensation and adsorption has the characteristics of high recovery of hydrocarbon substances, high regeneration efficiency of the activated carbon, high concentration and convenient use of the regenerative gas, and the like, and can be applied to recovery and purification treatment of acid tank exhaust gas, oxidative sweetening tail gas and other hydrocarbon wastegas.

Owner:CHINA PETROLEUM & CHEM CORP +1

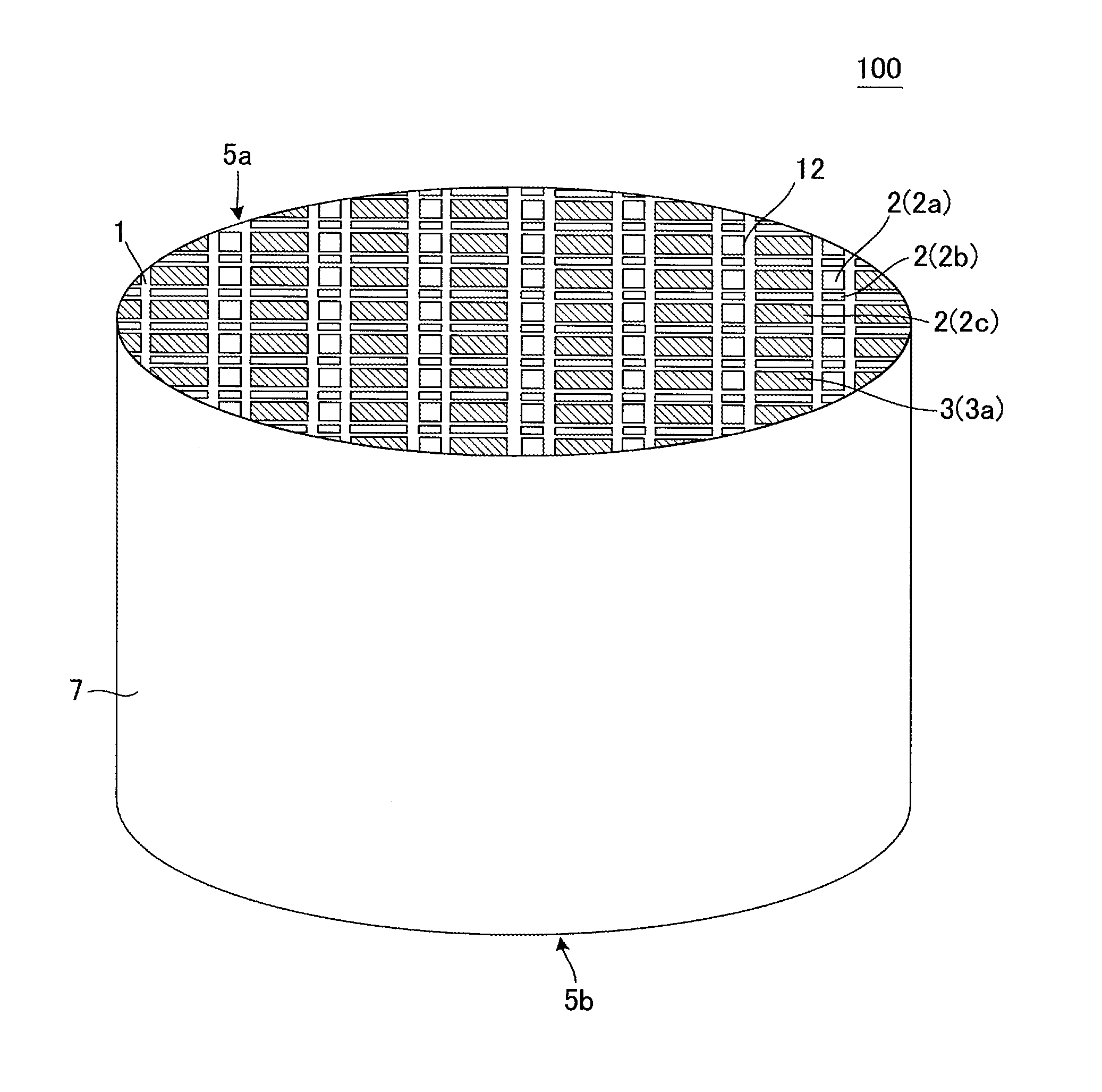

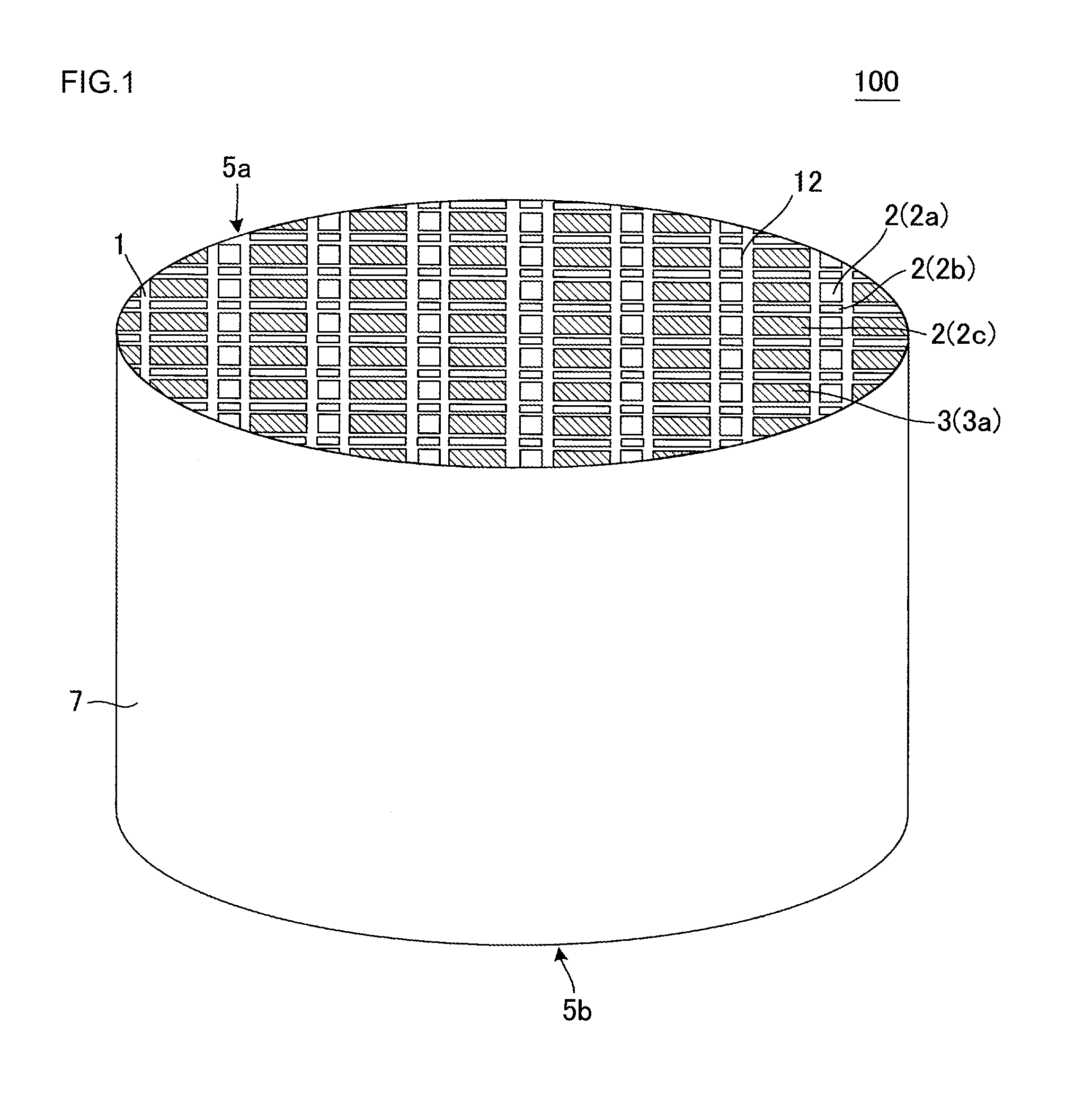

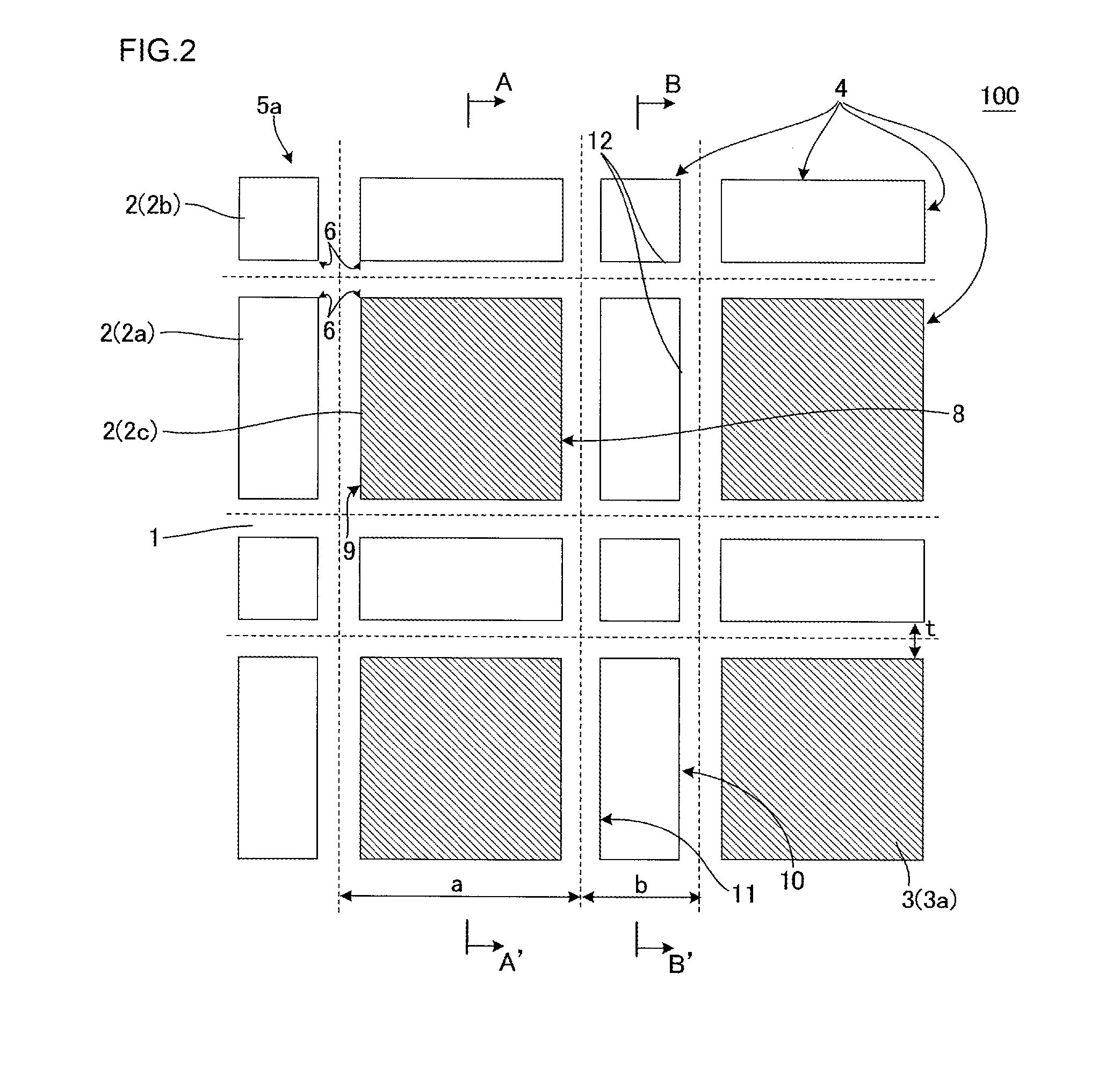

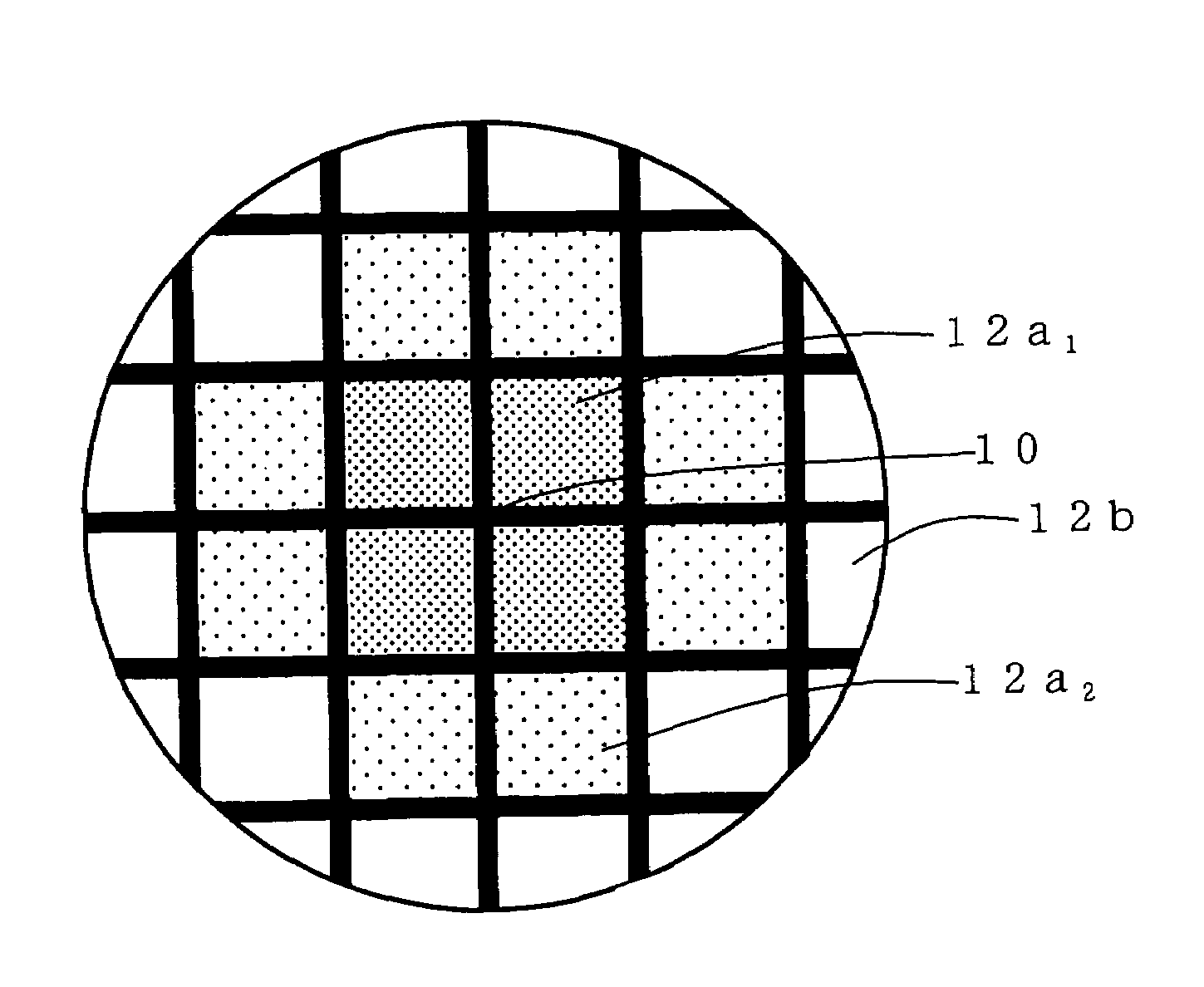

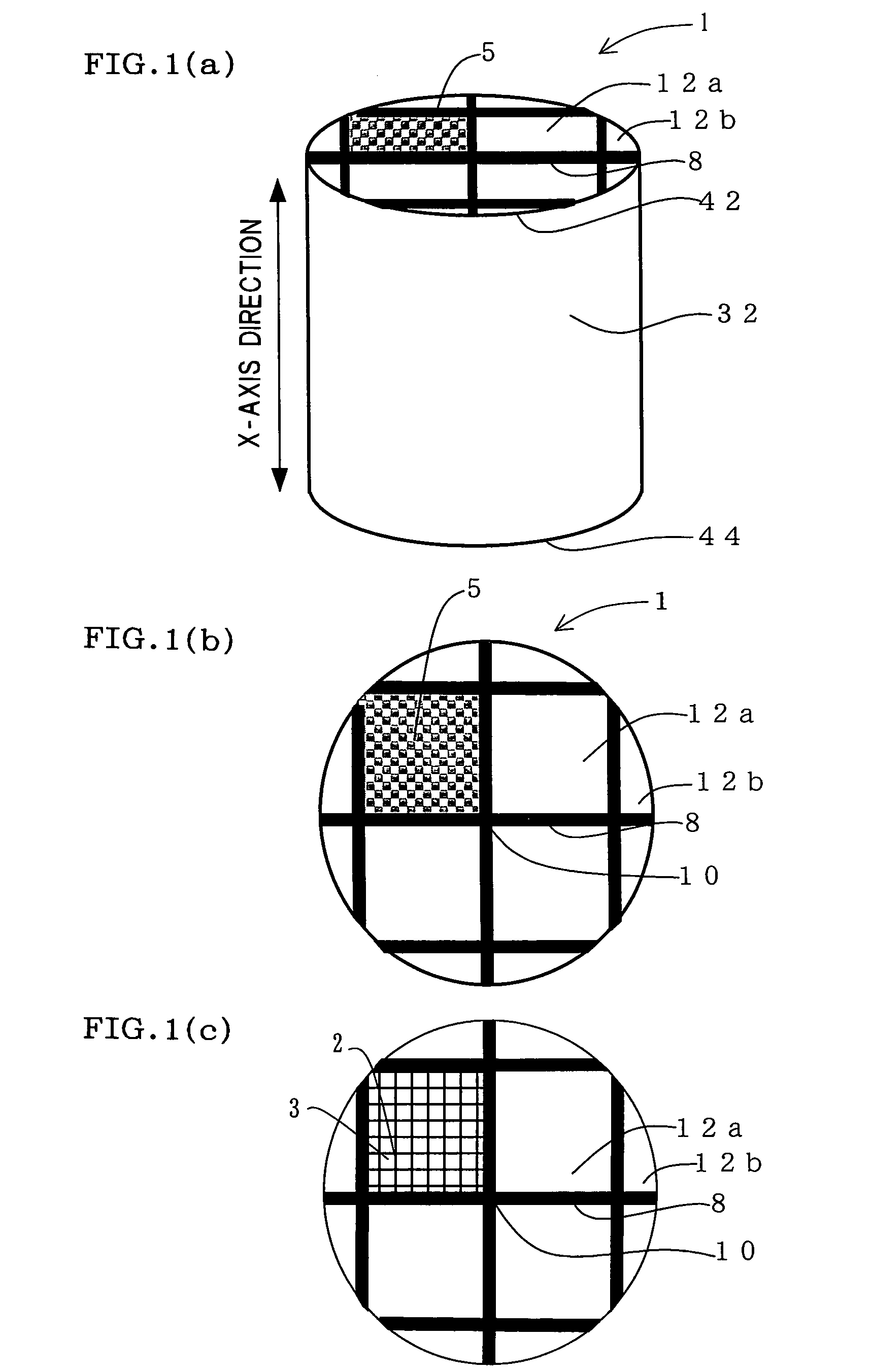

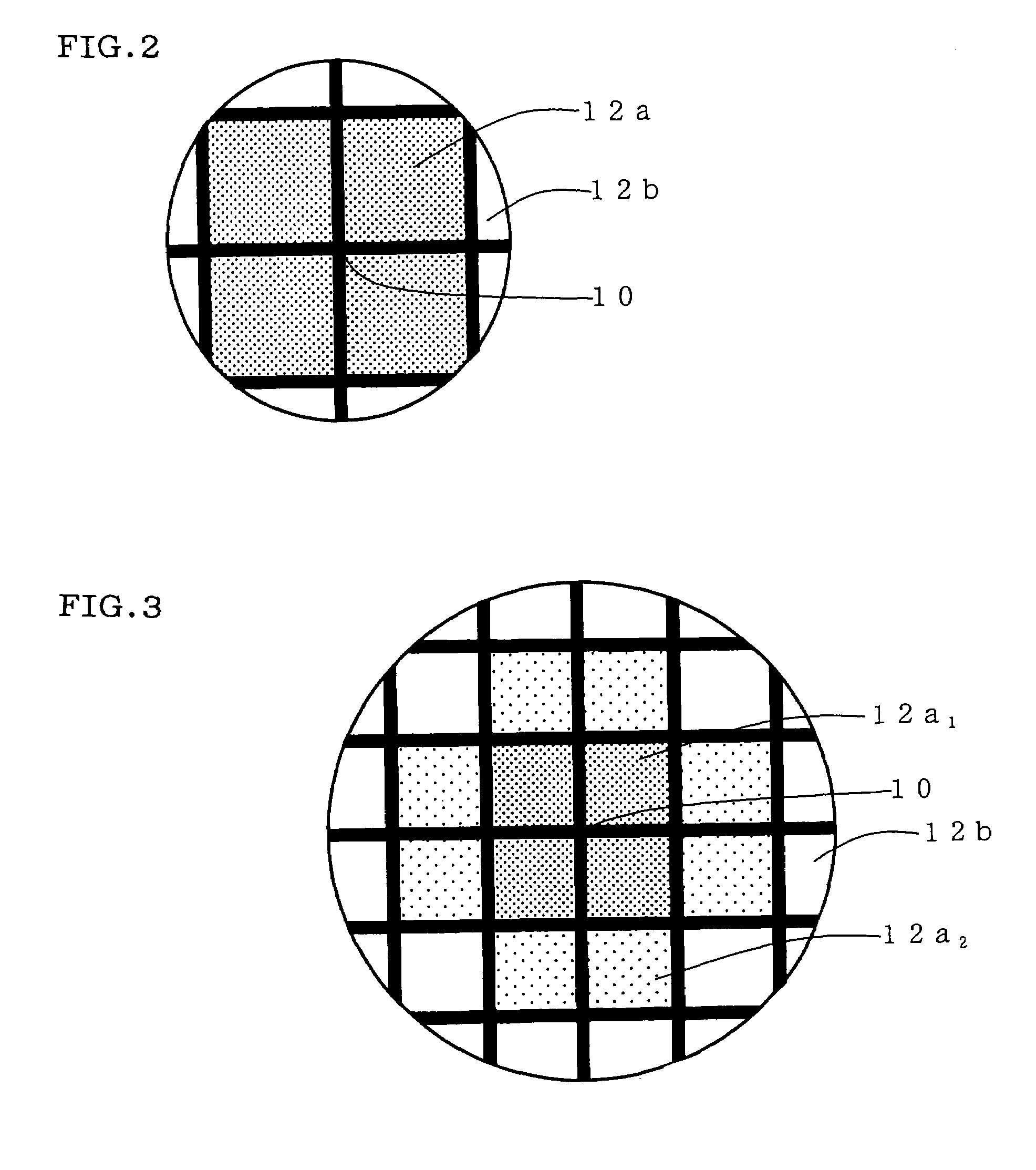

Honeycomb filter

ActiveUS20160067653A1Efficiently regenerateImprove ignitabilityCombination devicesGas treatmentHoneycombUnit volume

In a cross section perpendicular to a central axis direction of the honeycomb substrate, cells are arranged so that a periphery of an inlet plugged cell is surrounded with four rectangular outlet plugged cells and four square outlet plugged cells, and in the cross section, a partition wall center distance a, a partition wall center distance b and a partition wall thickness t satisfy the following equation (1). Additionally, an amount of a catalyst per unit volume of partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the inlet plugged cells is larger than an amount of a catalyst per unit volume of the partition walls which is loaded onto the partition walls defining the rectangular outlet plugged cells and the square outlet plugged cells.0.95<b / at<1.90 (1)

Owner:NGK INSULATORS LTD

Device for utilizing waste heat from heat engine

InactiveUS7454912B2Generate efficientlyImprove regenerative abilityInternal combustion piston enginesEngine componentsRefrigerantWaste heat

A device for utilizing waste heat from a heat engine comprises a Rankine cycle including a pump, a heating device, an expansion device, and a condenser device, and a controller for controlling an operation of the Rankine cycle. The controller calculates an optimum heat collection amount (Qho) as a heat value to be collected from waste heat of the engine, wherein the heat collection amount (Qho) is calculated as an optimum amount in relation to a potential maximum heat radiation amount (Qco) to be radiated at the condenser device. The controller calculates an optimum flow amount (G) of refrigerant corresponding to the optimum heat collection amount (Qho), so that a maximum driving power (L) is generated at the expansion device.

Owner:DENSO CORP

Regenerative motor propulsion systems

InactiveUS20060175996A1Improve transportation efficiencyImprove fuel economyDC motor speed/torque controlSynchronous machinesElectricityElectrolysis

A vehicle or watercraft regeneration system includes at least one electric motor capable of generating electricity and a controller for the at least one motor; wherein the controller to optimize the efficiency of the regeneration. The controller can optimize efficiency by including comprises circuitry for biasing the electric motor during regeneration. Also provided is a regeneration system that further comprises an electricity storage device such as a battery, a capacitor, an electrolysis unit that generates hydrogen from water, and a flywheel. In addition, an efficiency enhancing system for a watercraft or vehicle includes at least one electric motor capable of generating electricity; a controller for the at least one motor; and an electrical connection between the at least one motor and the controller, where in the controller adjust one or more magnetic fields of the electric motor during regeneration to optimize the efficiency of the regeneration. Methods for increasing efficiency of regeneration of a watercraft of vehicle powered by at least one electric motor are also disclosed.

Owner:TECHNIPOWER SYST INC

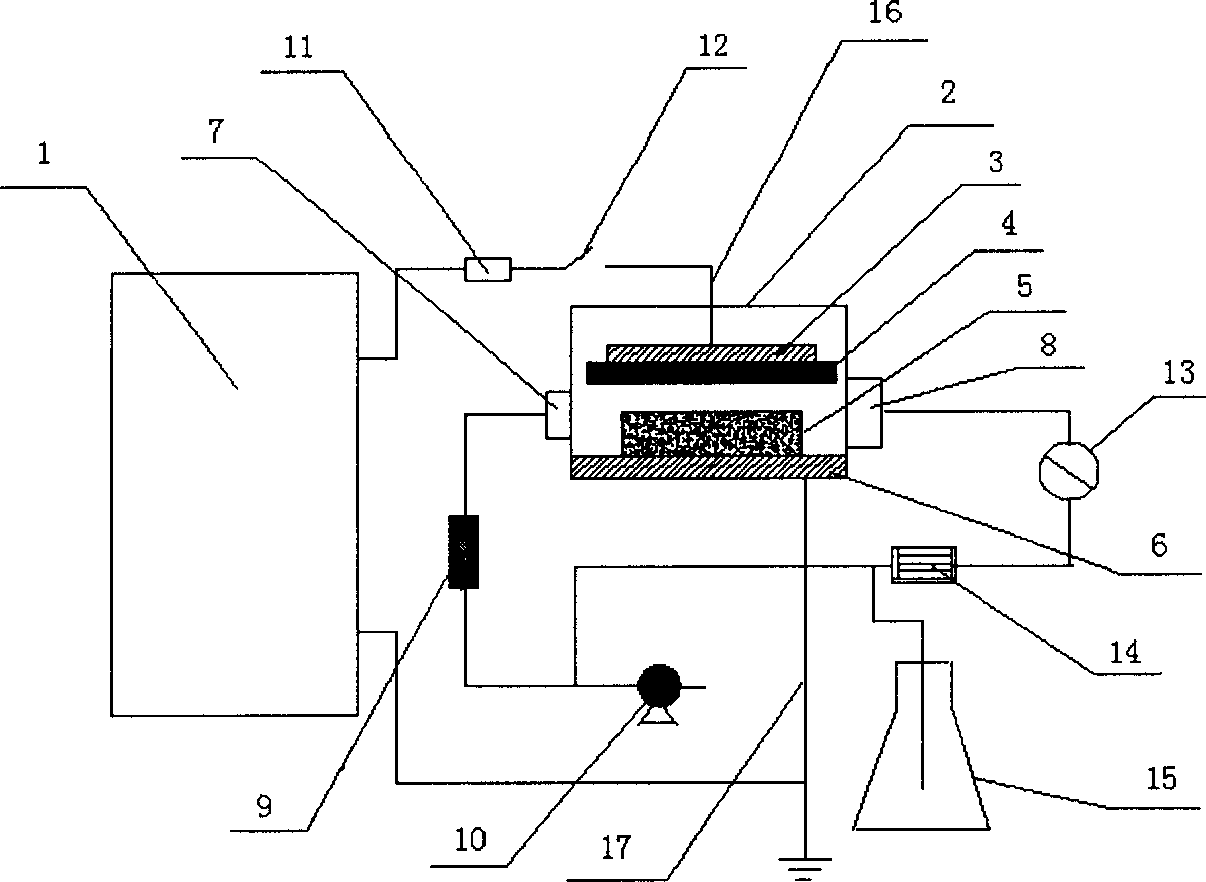

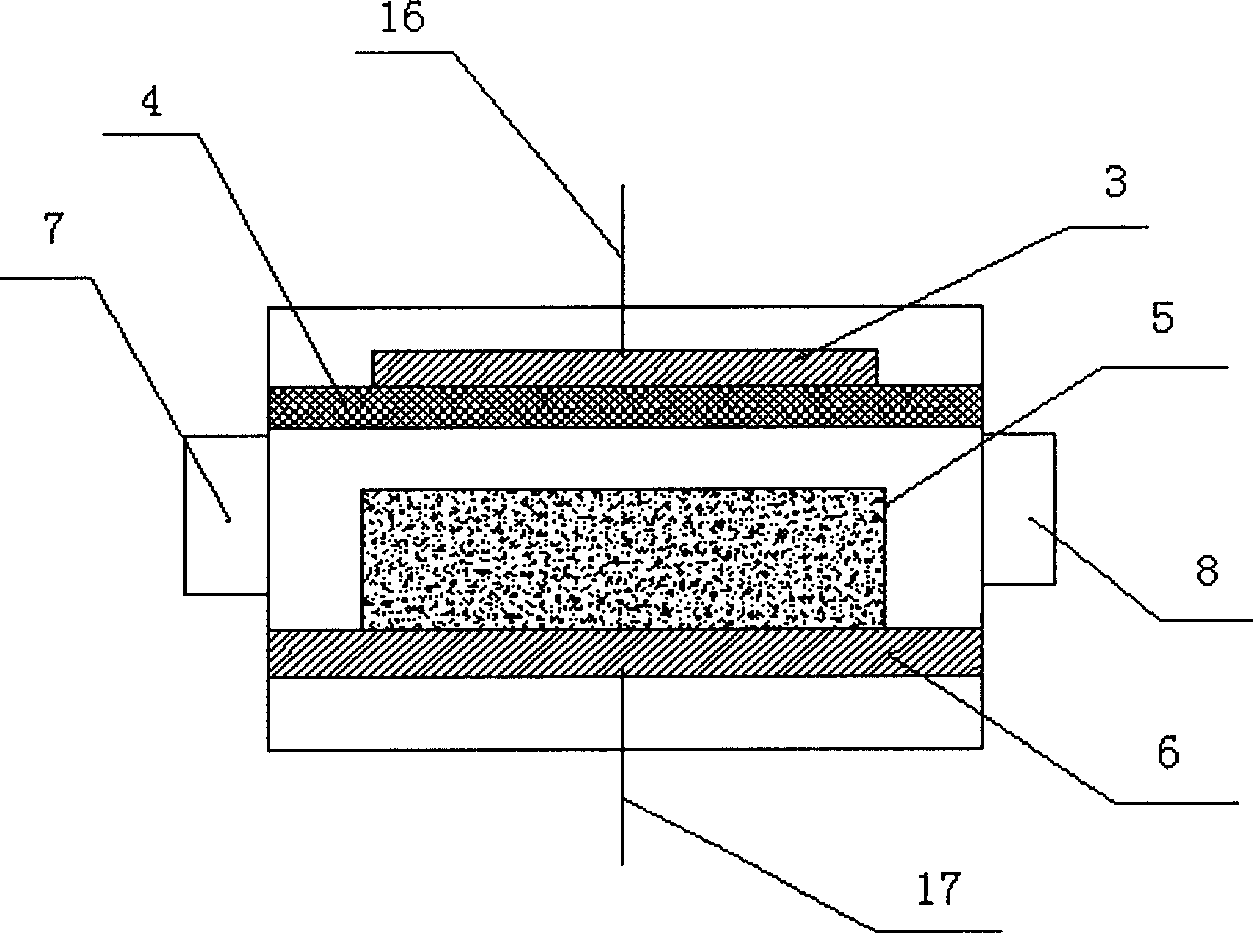

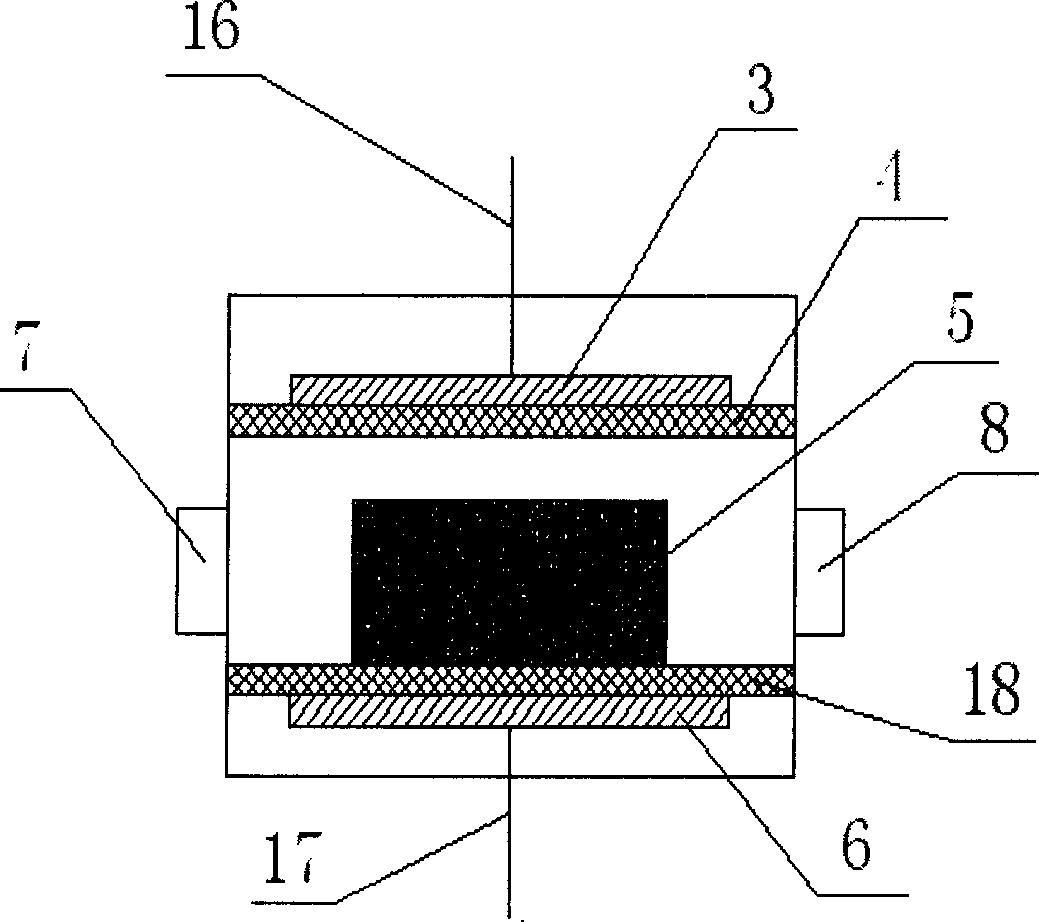

In situ regenerating method and device for medium blocking discharging plasma active carbon

InactiveCN1899685AImprove regeneration efficiencyShort regeneration timeOther chemical processesCombustible gas purificationActivated carbonCompound (substance)

The in situ active carbon regenerating method and apparatus with medium blocking discharge plasma belongs to the field of chemical adsorbing separation and pollutant controlling technology. Under atmospheric pressure, low temperature unbalanced plasma generated through medium blocking discharge is used to in situ regenerate active carbon with adsorbate filled between the discharge electrodes under the action of high activity matter, ultraviolet and high energy electron bombardment, etc. The in situ active carbon regenerating apparatus consists of high voltage AC source, reactor and auxiliary device mainly. The present invention has the advantages of high regeneration efficiency, short regeneration period, no secondary pollution, no need of post-treatment, low active carbon loss, etc; and is suitable for active carbon regeneration mainly.

Owner:DALIAN UNIV OF TECH

System and method for preventing air source heat pump water heater from frosting by using solid dehumidification

InactiveCN103900289AReduce humidityAvoid frostHeat pumpsDispersed particle separationPre conditioningEngineering

The invention provides a system and method for preventing an air source heat pump water heater from frosting by using solid dehumidification. In the method, a heat exchanger with a solid drying agent coating is used for preprocessing water in moist air, and therefore the water in the moist air is prevented from frosting on the surface of an evaporator. According to the system and method, the air of an inlet of the evaporator is dehumidified by means of the solid drying agent coating, so that the frosting problem of the heat pump water heater is resolved, and heating performance of the heat pump water heater is enhanced. When the water absorbed by solid adsorbing agents reaches a limitation, water in the solid adsorbing agents is desorbed by means of heat released by condensation of heat pump work media, at this time, circulation air with desorbed high-temperature moisture has heat exchange and congeals on the surface of the evaporator, the evaporator recycles the heat released in a condenser, and regeneration efficiency of a heat pump is improved.

Owner:SOUTHEAST UNIV

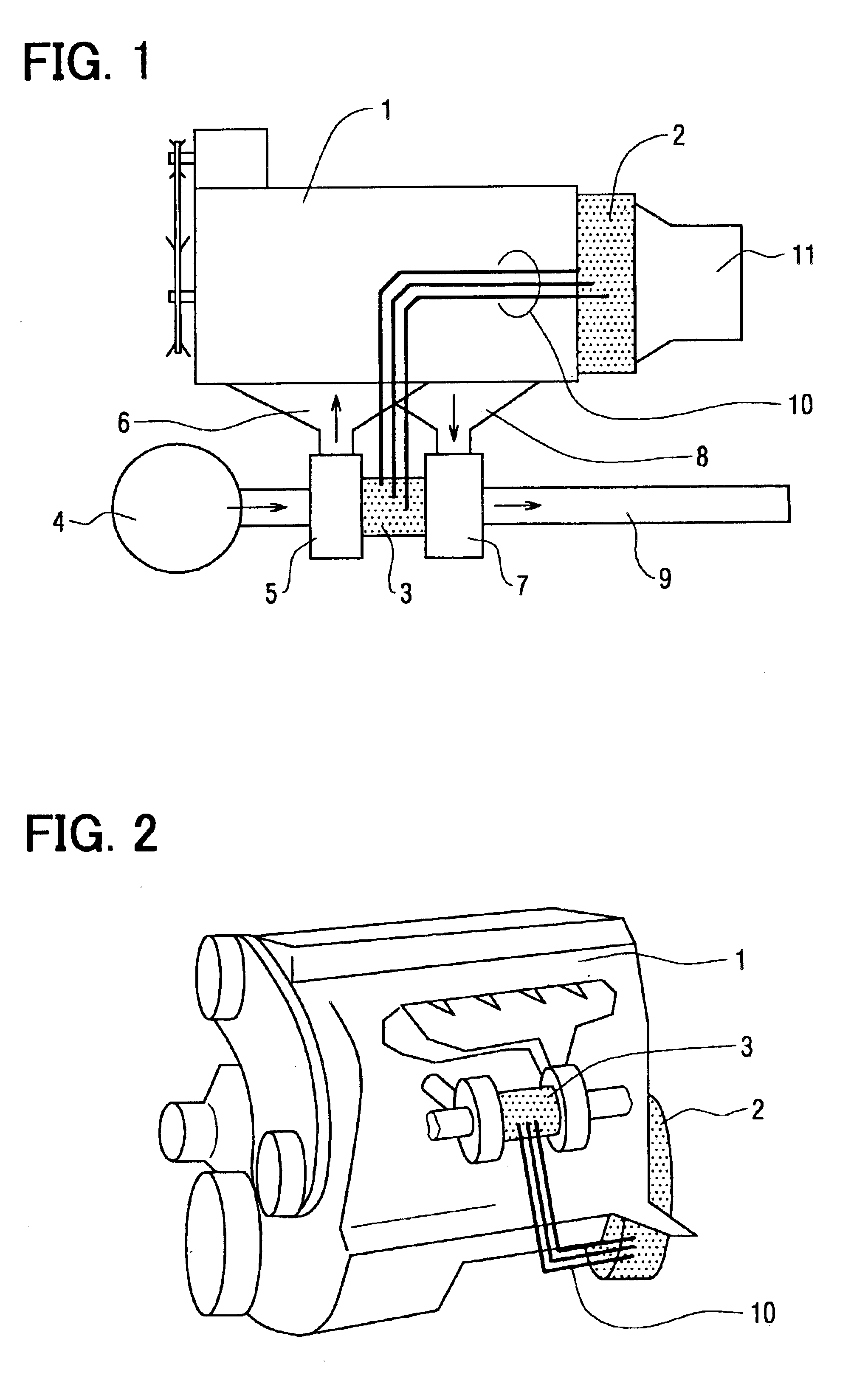

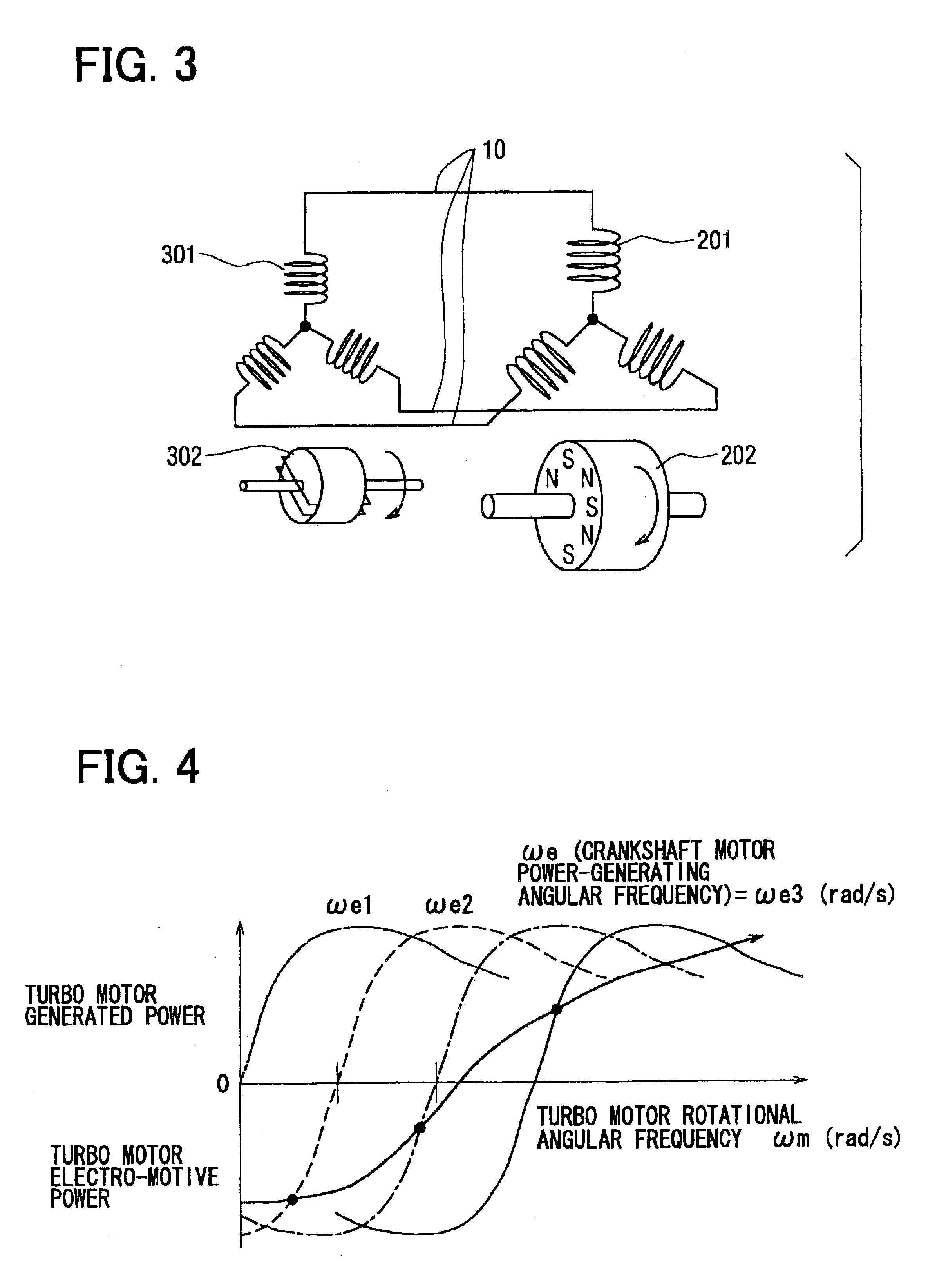

Compound engine dynamo-electric machine

InactiveUS6840045B2Improved fuel consumption and torqueSimple and low-power consumingReciprocating combination enginesInternal combustion piston enginesRotary machineDischarge pressure

A first exhaust turbo rotary machine is able to assist turbo supercharging by operating as a motor on power generated in a second rotary machine connected to a power axis of an engine. Also, when exhaust energy is large, the first turbo rotary machine operates as a generator so as to make the second rotary machine connected to the engine motive power axis operate electrically, thereby making it possible to add exhaust energy to the engine motive power axis. Consequently, that which results is a compound engine dynamo-electric machine that improves total efficiency of the engine by adding exhaust energy, which is otherwise discarded, to the engine motive power axis. This arrangement increases engine torque in a speed region where exhaust pressure is low by utilizing part of the engine's motive power as a supercharging driving force.

Owner:DENSO CORP

Honeycomb filter

ActiveUS7384441B2Partly effectiveLow densityCombination devicesAuxillary pretreatmentHoneycombBiomedical engineering

There is provided a honeycomb filter obtained by bonding, into one piece, a plurality of honeycomb segments comprising partition walls having filtering function, and a number of through-holes divided from each other by the partition walls and extending in an axial direction. Predetermined through-holes are plugged at one end face of the filter, and the remaining through-holes are plugged at the other end face of the filter. The honeycomb filter is characterized in that the honeycomb segment disposed in a peripheral portion of the honeycomb filter has a lower average bulk density than that of the honeycomb segment disposed in a central portion.

Owner:NGK INSULATORS LTD

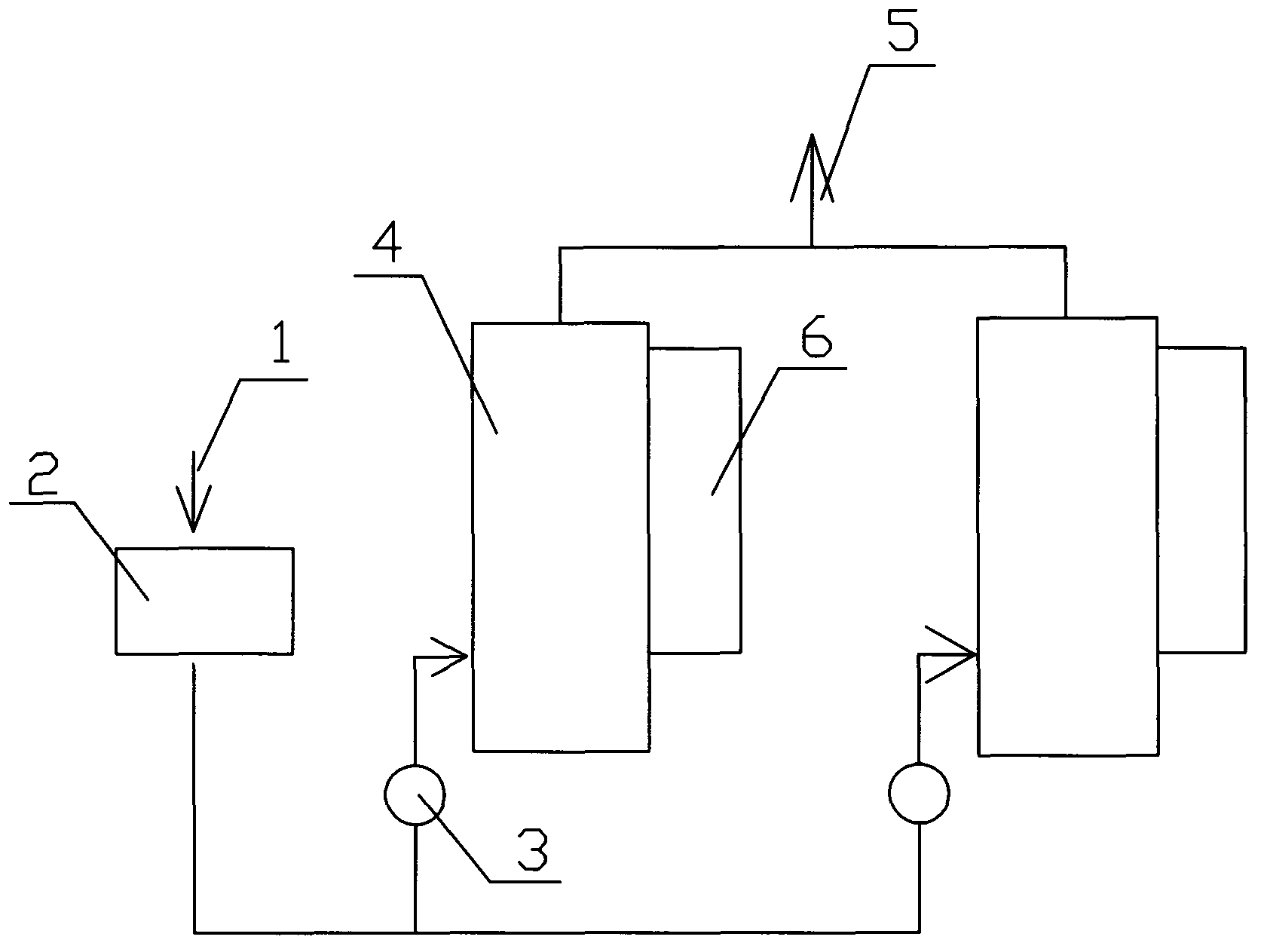

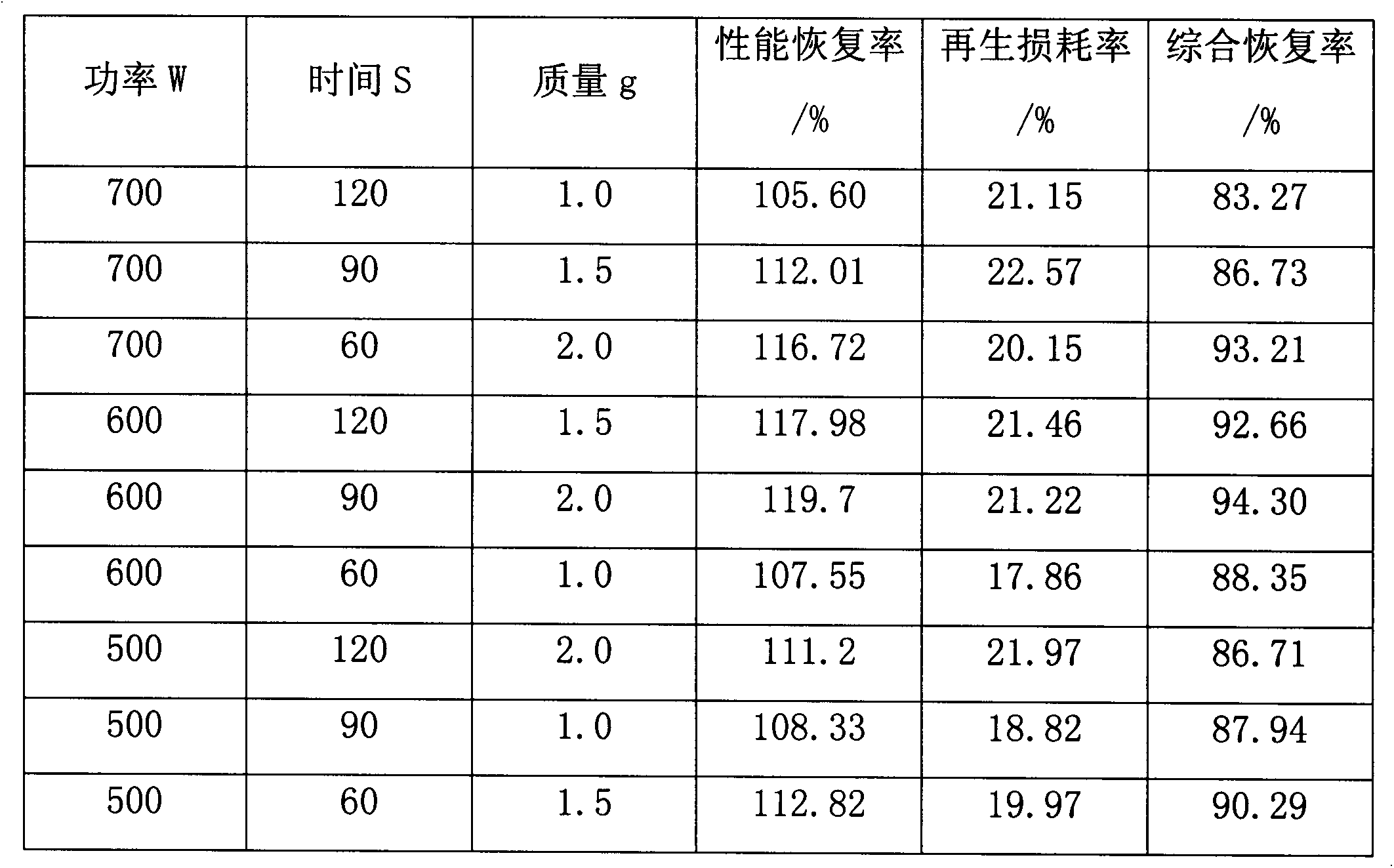

Microwave activated carbon regeneration method and waste gas treatment device thereof

InactiveCN103212391AShorten the timeReduce energy consumptionOther chemical processesDispersed particle separationActivated carbonPhysical chemistry

The invention relates to a microwave activated carbon regeneration method and a waste gas treatment device thereof. According to the method, the activated carbon is radiated by using microwave, the power of the used microwave is 500W to 700W, and the ratio of the radiation time S to the mass g of the activated carbon is 45:1; the device comprises an activated carbon adsorption tower, wherein an air inlet is formed in the bottom of the activated carbon adsorption tower; an air outlet is formed in the top part of the activated carbon adsorption tower; a microwave desorber is arranged on the activated carbon absorption tower; the air inlet is connected with an air valve and an adjusting valve; and a purification unit is formed by the activated carbon adsorption tower, the microwave desorber and the air valve. By adopting the method and the structure, when the activated carbon absorption is accomplished, the activated carbon is regenerated by using microwave radiation, and the activated carbon has the advantages of being short in regeneration time, low in energy consumption, simple in equipment, high in regeneration efficiency, high in adsorption property recovery rate and the like, and secondary pollution is avoided.

Owner:SUZHOU TIANHAO ENVIRONMENTAL PROTECTION TECH

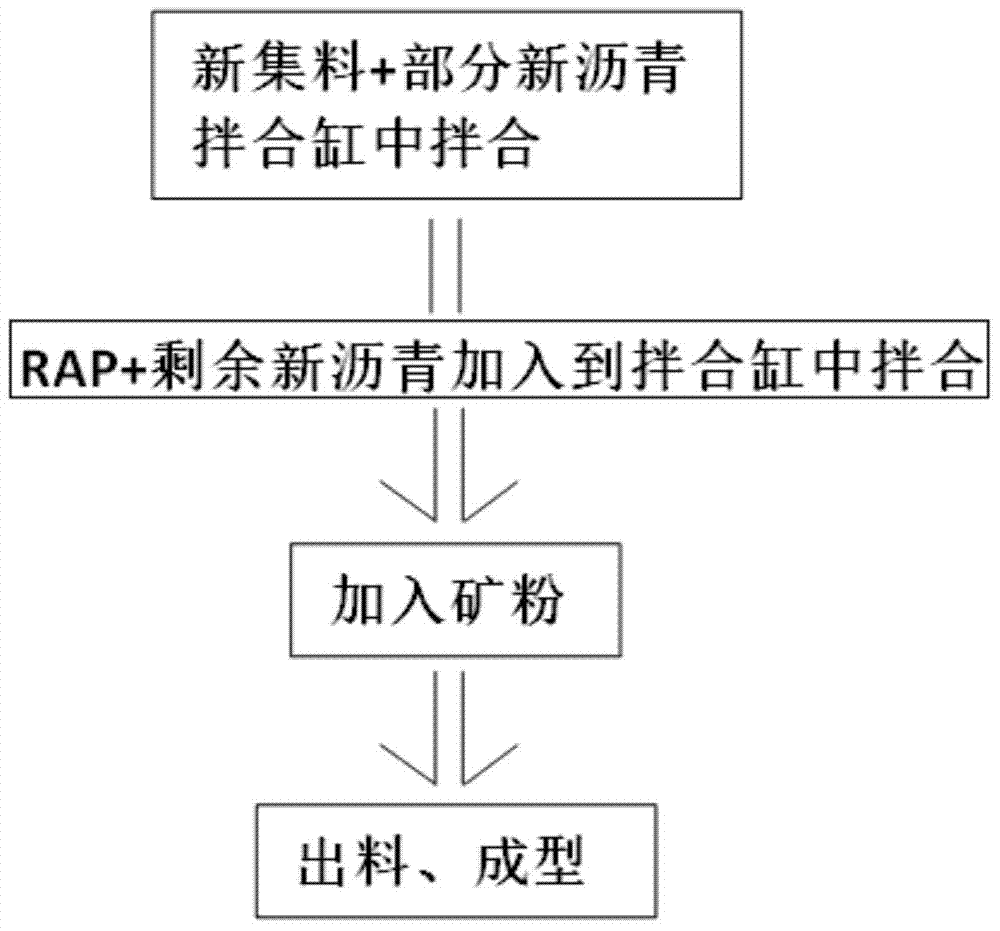

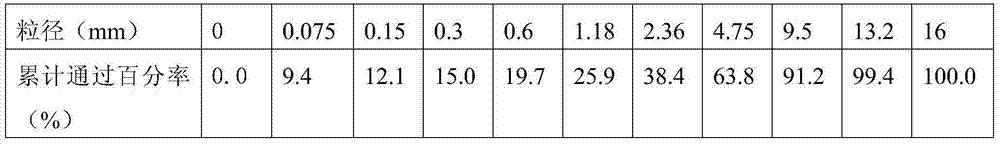

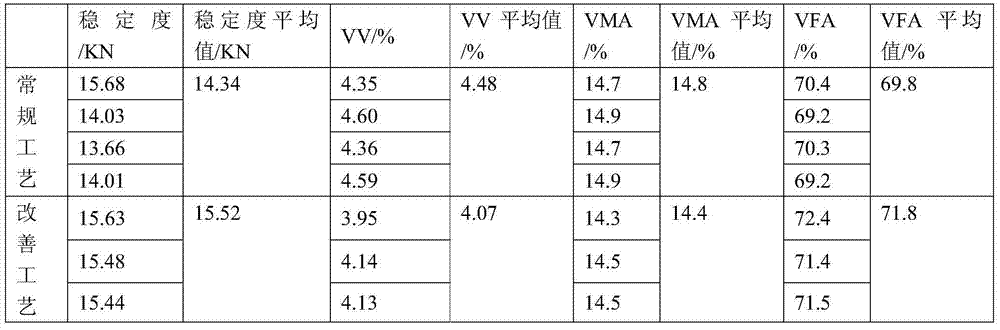

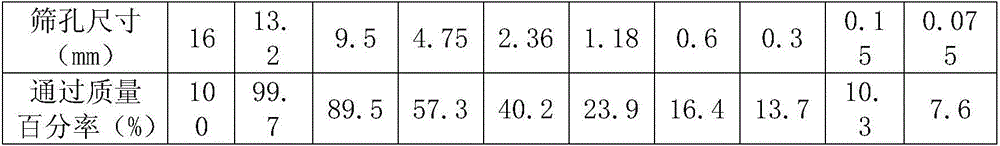

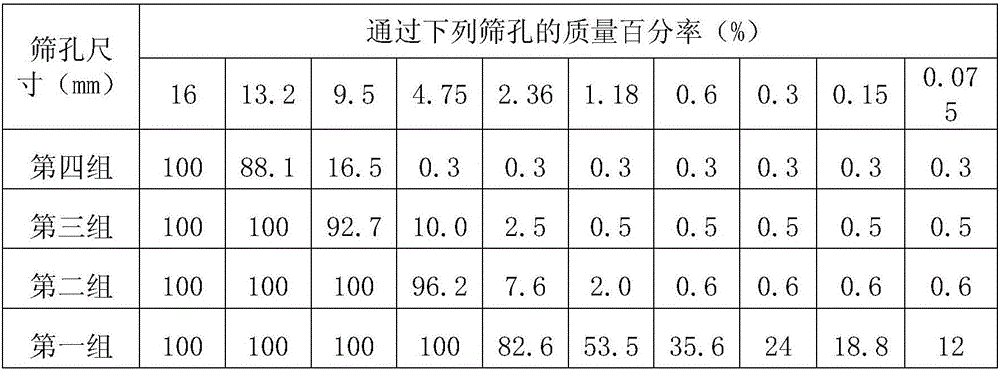

Preparation method of plant-mixed hot recycled asphalt mixture

ActiveCN104844072ASolve the problem of prone to grayingThe mixing time does not changeMaterials scienceAsphalt pavement

The invention discloses a preparation method of a plant-mixed hot recycled asphalt mixture. The preparation method comprises the following steps: (1) after heating new aggregates, adding the new aggregates into a mixing cylinder; (2) after heating part of new asphalt, adding the heated new asphalt into the mixing cylinder for the product obtained in the step (1) for mixing; (3) after heating RAP (recycled asphalt pavement) materials, adding the RAP materials into the mixing cylinder for the product obtained in the step (2); (4) adding the rest of new asphalt into the mixing cylinder with the product obtained in the step (3) for mixing; (5) adding mineral powder into the mixing cylinder for the product obtained in the step (4) for mixing; and (6) taking the mixture obtained in the step (5) out of the cylinder and carrying out forming. The method disclosed by the invention has the advantages of easy implementation, high recycling efficiency of old materials, small use quantity of the new asphalt, effective prevention from generating grizzled materials in the recycled mixture, higher uniformity of the recycled mixture and better performance.

Owner:TONGJI UNIV

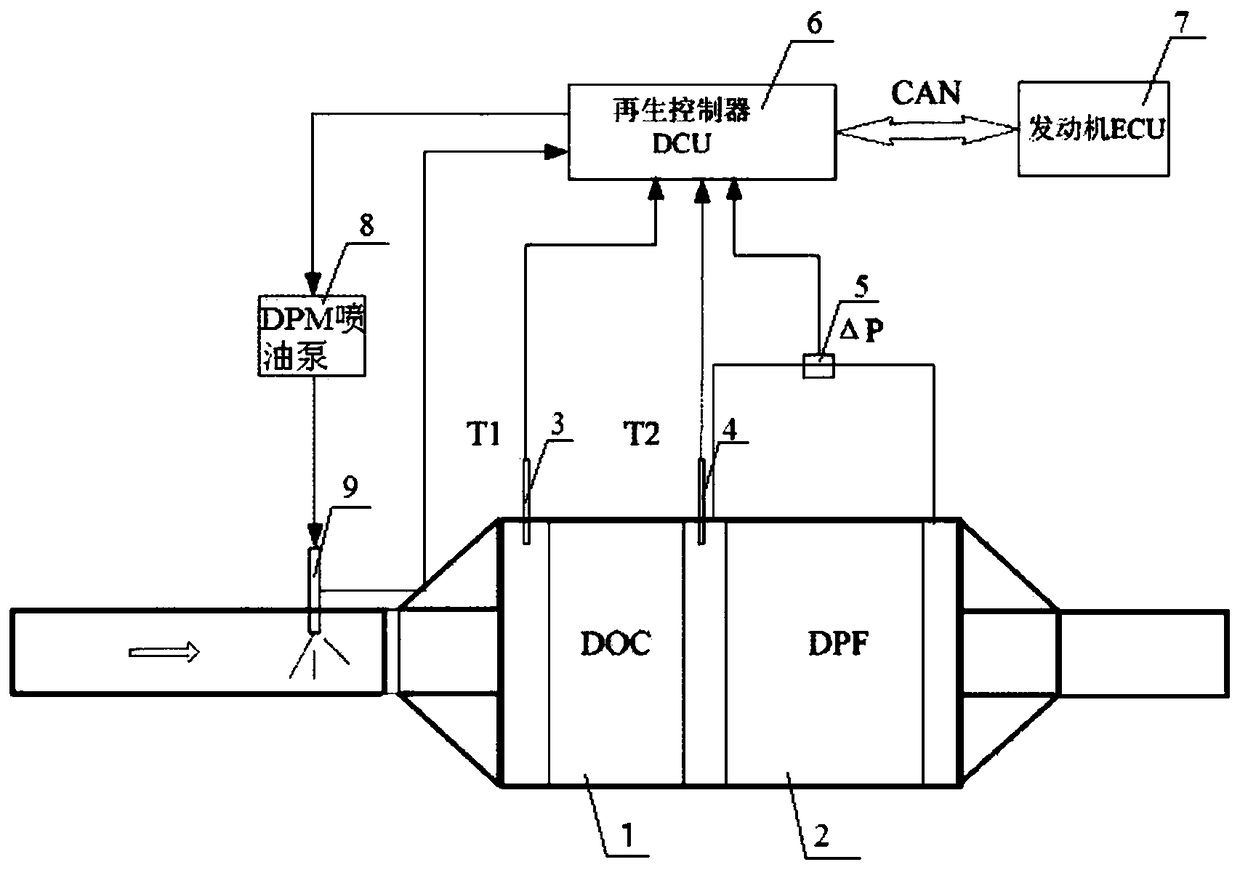

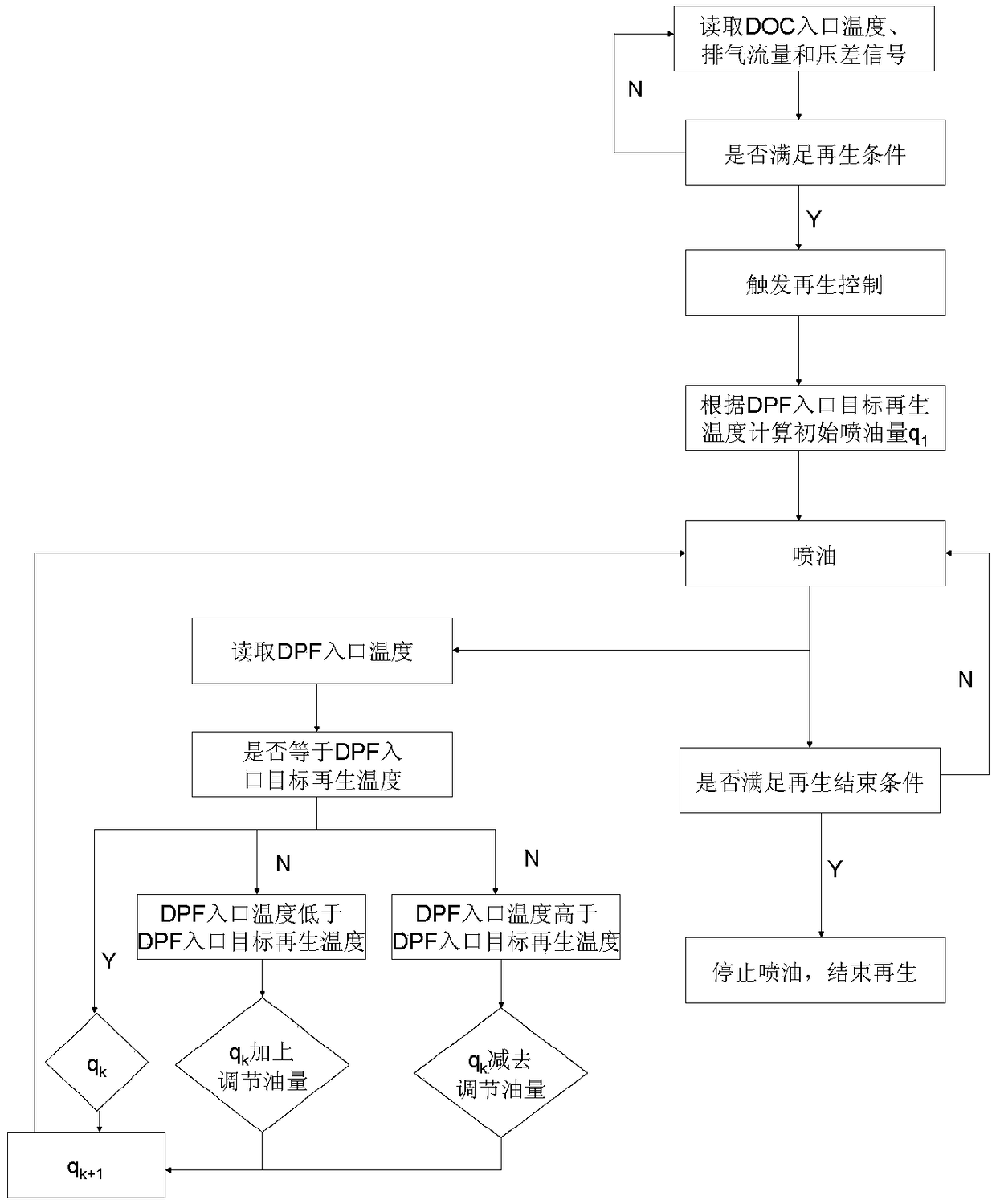

Diesel engine DPF active regeneration control method

ActiveCN109139196AAvoid damageImprove regeneration efficiencyInternal combustion piston enginesExhaust apparatusDiesel engine

The invention discloses a diesel engine DPF active regeneration control method. The diesel engine DPF active regeneration control method comprises the following steps that the exhaust mass flow of anengine, the DOC inlet temperature and the air pressure difference between a DPF outlet and a DPF inlet are acquired, and whether the regeneration triggering condition at the moment is met or not is judged; when the regeneration triggering condition is met, the regeneration control is triggered, the initial oil injection quantity in the current state is calculated; an oil injection device is controlled to start to perform oil injection, and meanwhile, whether the DPF inlet temperature meets the set regeneration target temperature or not is detected; when the DPF inlet temperature meets the setregeneration target temperature, oil injection is carried out at the current oil injection quantity; when the DPF inlet temperature does not meet the set regeneration target temperature, the fuel oilinjection amount is regulated through a regeneration controller, so that a proper oil injection quantity is guaranteed to be regenerated, and meanwhile, whether the air pressure difference before andafter a DPF is reduced to a set lower limit value or not is detected; and when the regeneration end condition is met, oil injection is stopped, and the regeneration process is completed. According tothe diesel engine DPF active regeneration control method, parameters needing to be calibrated are few, the universality is high, the calculation fluctuation under a feed-forward oil quantity transientcondition is reduced, and the regeneration efficiency is improved.

Owner:DONGFENG COMML VEHICLE CO LTD

Gasoline particulate filter regeneration and diagnostics

ActiveUS8327628B2Reduce smoke and dust emissionsImprove engine performanceElectrical controlInternal combustion piston enginesParticulatesGasoline

Owner:FORD GLOBAL TECH LLC

Method for pretreating waste mineral oil and performing hydrogenation regeneration to produce lubricating base oil

ActiveCN106350112AEfficient removalSimple stepsTreatment with hydrotreatment processesLubricant compositionPretreatment methodPetroleum product

The invention discloses a method for pretreating waste mineral oil and performing hydrogenation regeneration to produce lubricating base oil. The method is characterized in that: pretreatment of the waste mineral oil sequentially comprises the following steps of performing sedimentation dehydration, washing, centrifuging by using a disc-type centrifuge, centrifuging by using a horizontal centrifuge, evaporating by using a scraping film evaporator, and performing reduced pressure distillation; preheated lubricating base oil enters a hydrogenating device, enters a pre-hydrogenation protection reactor first and then enters the hydrorefining reactor to produce the high-grade lubricating base oil. By the method for pretreating the waste mineral oil and performing hydrogenation regeneration to produce the lubricating base oil, various non-ideal components in the waste lubricating oil can be effectively removed only after pretreatment provided by the invention; the method is simple in steps and is convenient to operate; manpower and material resources are saved; the lubricating base oil product is good in quality and high in yield, wastes are not produced, and no pollution is caused to the environment; operating conditions are relatively mild, using requirements on equipment are lowered, the regenerating efficiency is increased by 10-15%, continuous operation of the equipment is facilitated, and pollution of the waste oil on the environment and shortage of a petroleum product are relieved.

Owner:新疆聚力环保科技有限公司

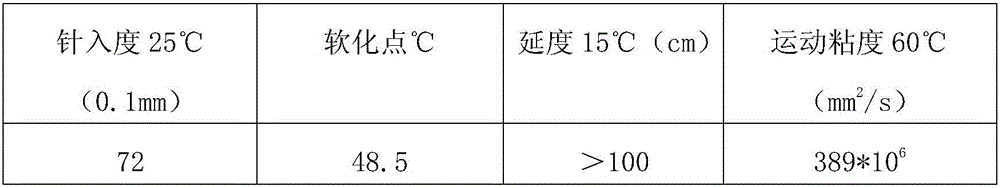

Plant-mixed warm recycled asphalt mixture and preparation method thereof

InactiveCN106009719AAffect low temperature crack resistanceAffects durabilityBuilding insulationsRoad surfaceAsphalt

The invention relates to a road surface construction material, in particular to a plant-mixed warm recycled asphalt mixture and a preparation method thereof. The plant-mixed warm recycled asphalt mixture comprises the following components in percentage by mass: (20-70)% of RAP, (0 to 8)% of new aggregate, (0 to 8)% of limestone mineral powder, (0.5 to 5)% of new asphalt and (0 to 0.5)% of recycling agent, wherein the total mass percentage is 100%, the new asphalt has penetration of less than 75 (0.1mm) and a softening point of more than 48 DEG C, and the recycling agent has kinematic viscosity of (50-60000) mm2 / s at a temperature of 60 DEG C. The plant-mixed warm recycled asphalt mixture provided by the invention has the advantages of simple process, no grey material, good recycling effect, low cost, wide adaptability and good road performance.

Owner:JIANGSU TIANNUO ROAD MATERIAL TECH

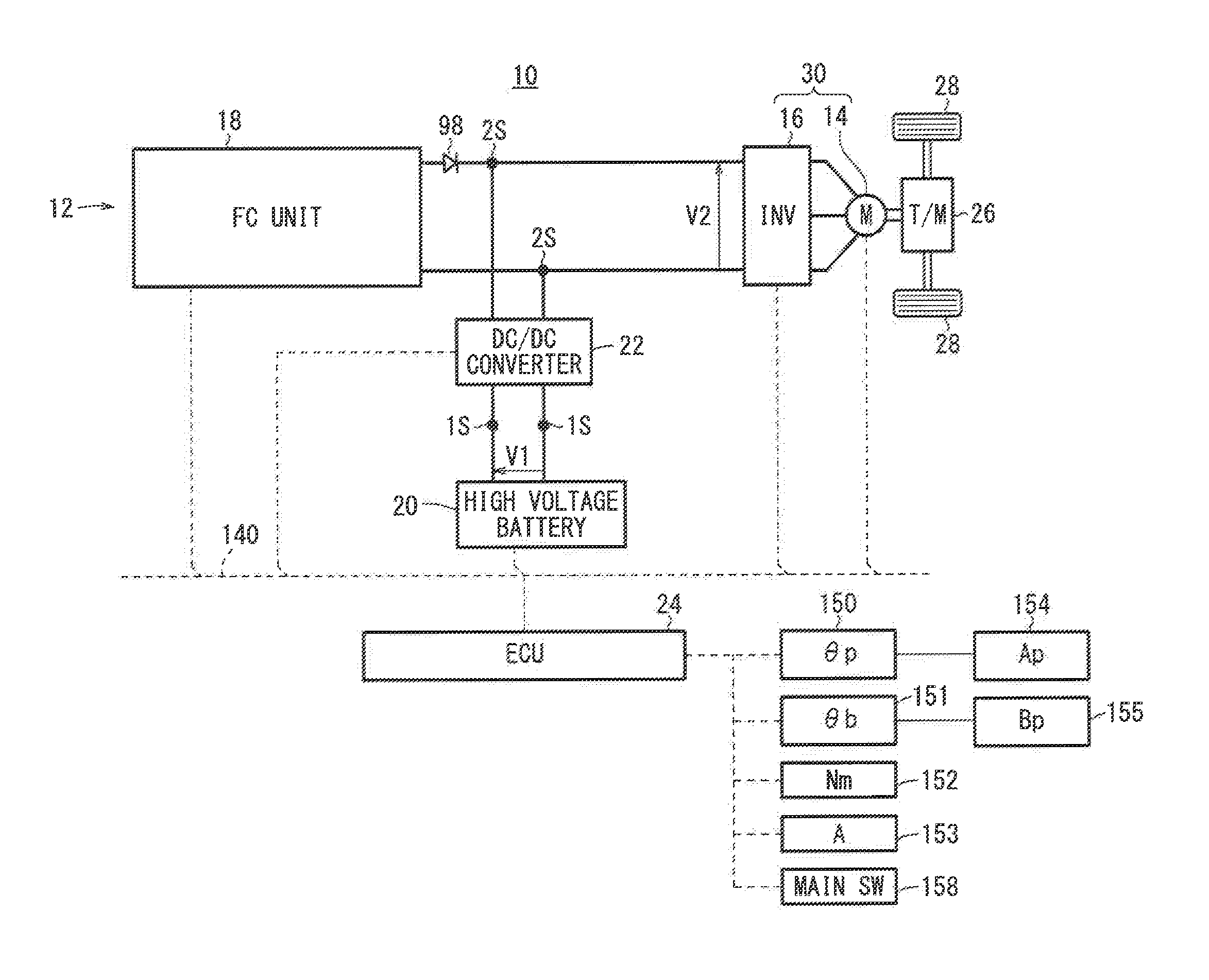

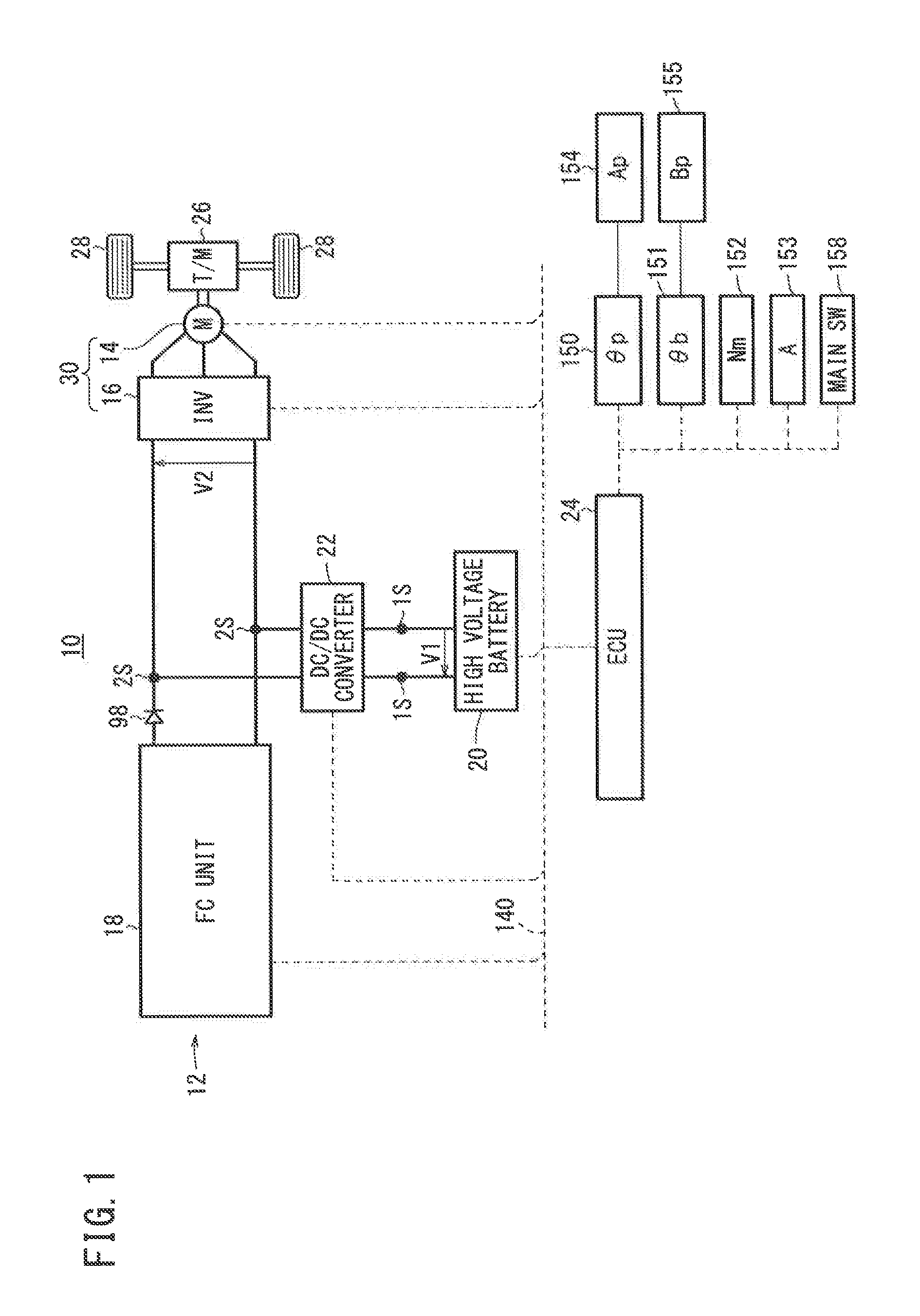

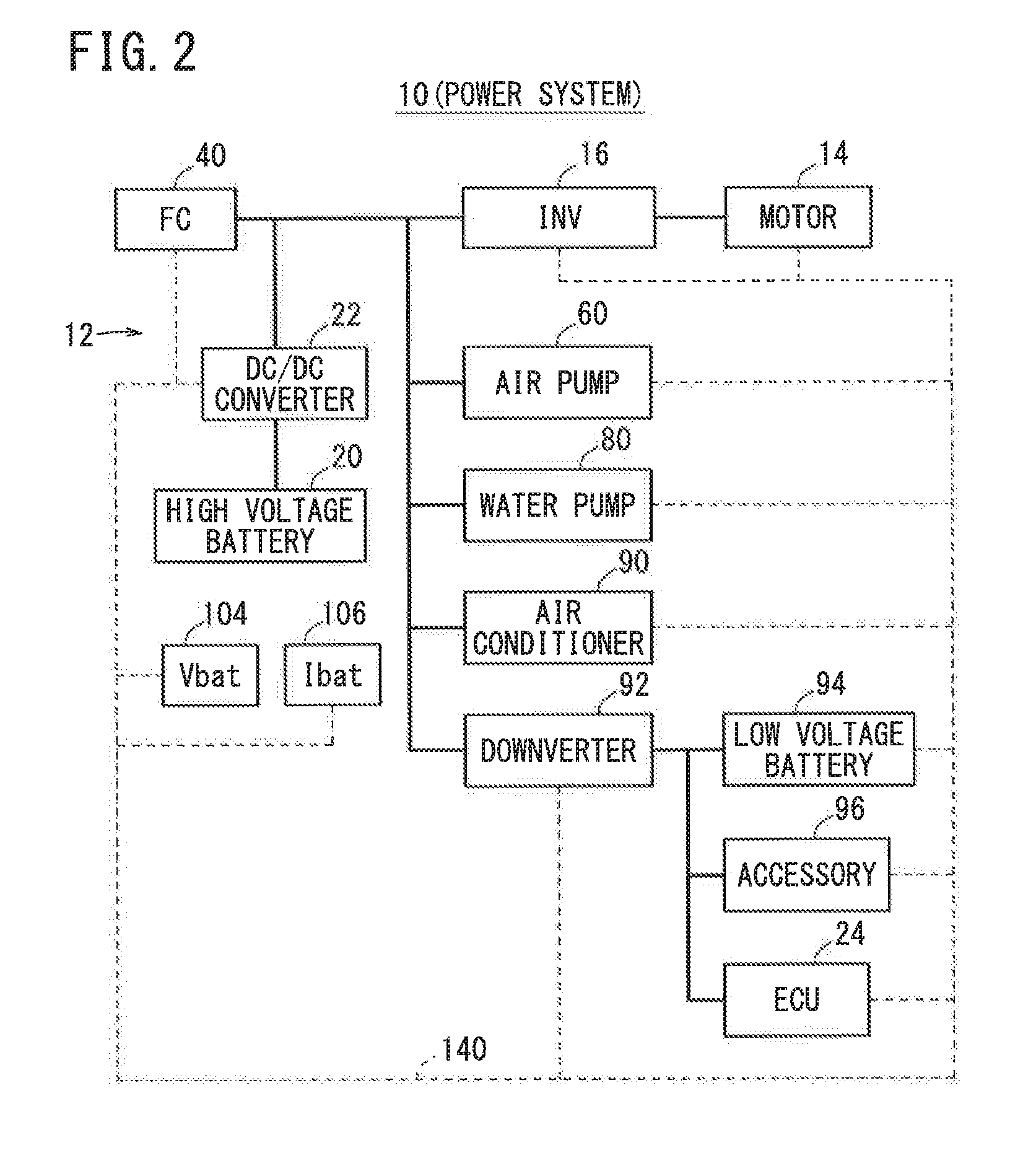

Method of controlling fuel cell system

ActiveUS20130063072A1Prevent degradationEfficient collectionBatteries circuit arrangementsRailway vehiclesFuel cellsVoltage range

In a fuel cell system, regeneration-time voltage fixed control is implemented where during regeneration or when regeneration is expected to occur, output voltage of a fuel cell is set to a voltage value outside an oxidation reduction progress voltage range, and the amount of reactant gas supplied to the fuel cell is changed based on the amount of electric power remaining in an energy storage device. In the regeneration-time voltage fixed control, it is determined whether or not regeneration occurs while a moving body equipped with the fuel cell system is moving down a slope, and in the case where it is determined that regeneration occurs while the moving body is moving down a slope, the amount of the reactant gas supplied to the fuel cell is decreased in comparison with the case where it is determined that regeneration occurs while the moving body is not moving down a slope.

Owner:HONDA MOTOR CO LTD

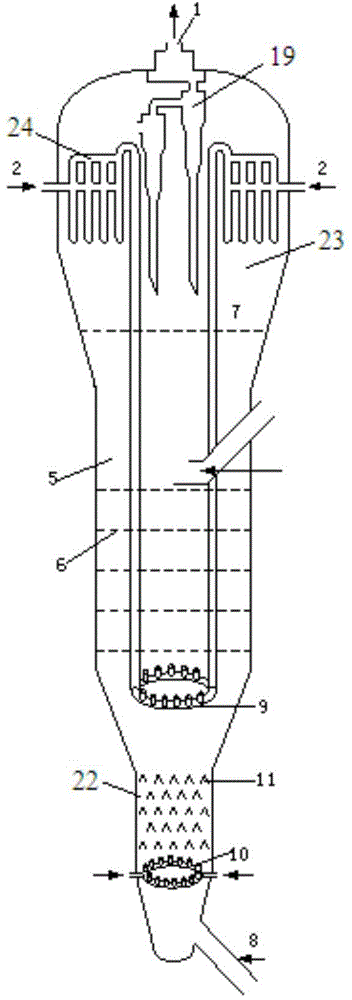

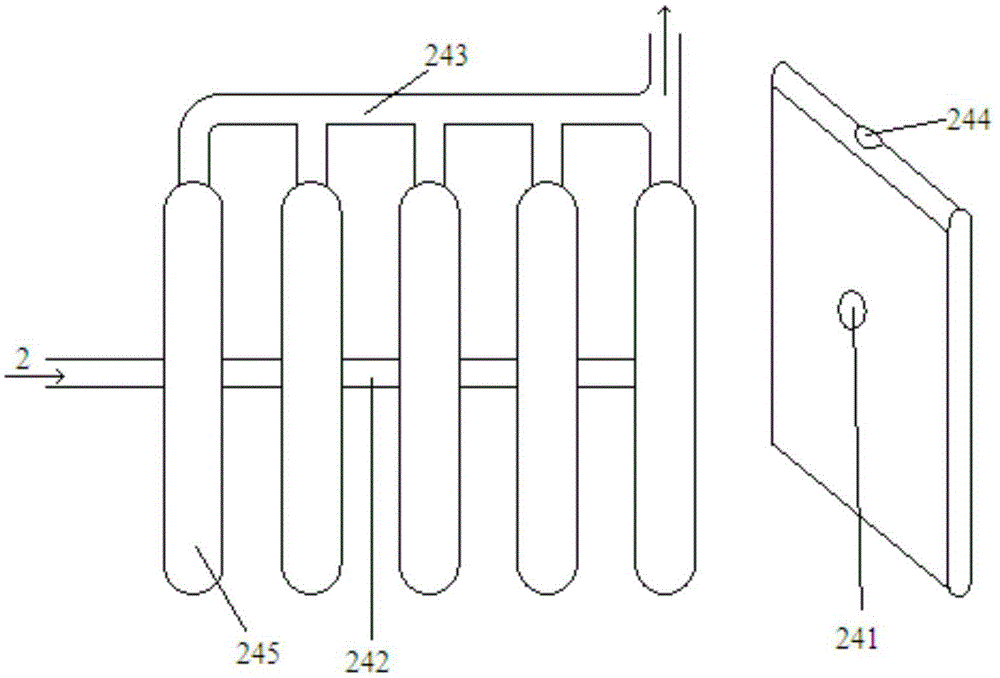

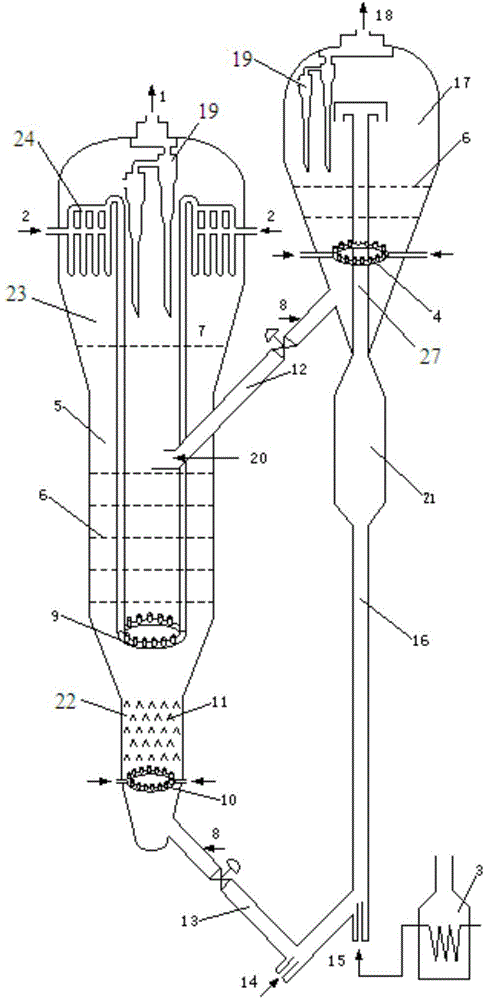

Circulating fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation

ActiveCN104549073AReduce polycondensation reactionResponse blockingHydrocarbonsChemical/physical processesThermal energyAlkane

The invention discloses a fluidized bed reaction device for preparing olefins by using paraffin dehydrogenation and a paraffin dehydrogenation method. The reaction device is a reducing tank body, and the tank body is divided into a gas stripping section, a reaction section and a catalyst settling section from bottom to top, wherein the diameter of the reaction section is larger than the diameter of the gas stripping section; and a heat exchanger is arranged in the settling section. According to the reaction device, raw materials and high-temperature oil gas are subjected to heat exchange in the reaction device, the raw materials are gasified and heated by utilizing the heat energy of the high-temperature oil gas, the high-temperature oil gas is cooled by virtue of heat exchange, the mutual energy is well utilized, coking of the reaction device due to high temperature is avoided, multiple effects are organically combined together, particularly a heat exchanger structure of connecting multiple heat exchange boxes in series together is adopted, the vibration caused by rapid gasification of the raw materials can be effectively avoided, and large temperature difference heat exchange can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com