Method for recovering and purifying hydrocarbon wastegas by condensation and adsorption

A technology of condensation recovery and adsorption recovery, applied in chemical instruments and methods, separation methods, vapor condensation, etc., can solve the problems of uneven temperature of activated carbon bed, lowering the performance of adsorbents, and lowering the concentration of regeneration tail gas. The effect of producing secondary pollution, facilitating further treatment or utilization, and increasing the concentration of regeneration gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

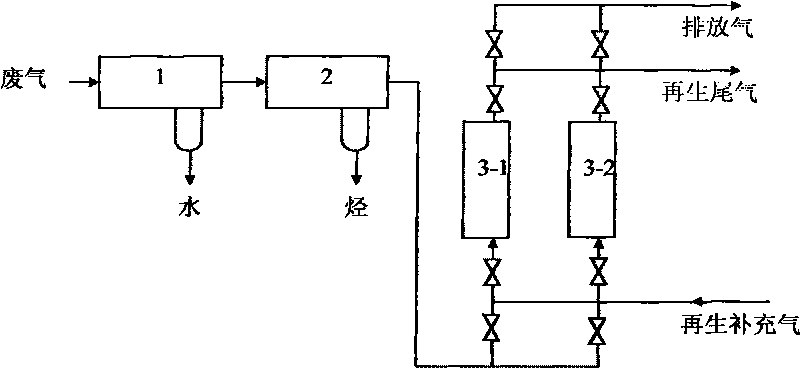

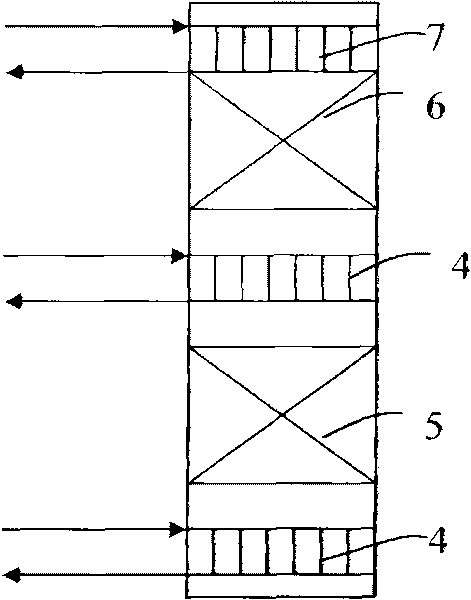

[0026] In the exhaust gas discharged from the sour water storage tank area of an enterprise, the concentration of total hydrocarbons is 20×10 4 ~60×10 4 mg / m 3 , the sulfide concentration is 50mg / m 3 about. First, the sodium hydroxide solution is used to absorb and remove the sulfide. After the sodium hydroxide solution is absorbed, the sulfide is not detected and is close to zero. Then condense to about 4°C in the dehydration steam condenser for dehydration, and then cool to about -65°C in the hydrocarbon recovery condenser, the total hydrocarbon concentration in the discharged non-condensable gas is 4×10 4 mg / m 3 Left and right, the non-condensable gas is adsorbed in the activated carbon tank. There are two activated carbon beds in the activated carbon adsorption tank, and a water vapor heat exchanger is installed between the two activated carbon beds. The total hydrocarbon concentration of the exhaust tail gas is lower than 120mg / m 3 , up to emission standards.

[0...

Embodiment 2

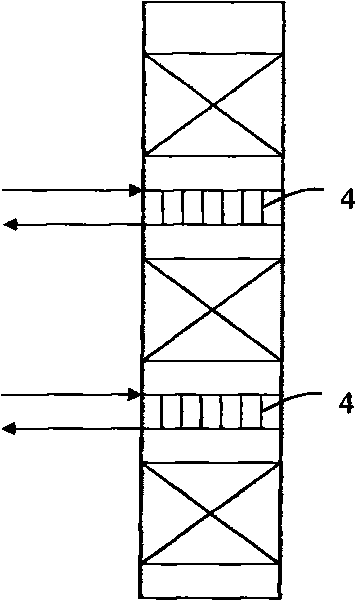

[0031] A gasoline oxidative sweetening tail gas and liquid hydrocarbon oxidative sweetening tail gas, the total hydrocarbon concentration is 30×10 4 ~80×10 4 mg / m 3 . Condensed in the dehydration steam condenser to about 2°C for dehydration, then cooled to about -70°C in the hydrocarbon recovery condenser, the total hydrocarbon concentration in the discharged non-condensable gas is 3×10 4 mg / m 3 Left and right, non-condensable gas is adsorbed in the activated carbon tank. There are three activated carbon beds in the activated carbon adsorption tank, and a water vapor heat exchanger is installed between each two activated carbon beds. The total hydrocarbon concentration of the exhaust tail gas is lower than 120mg / m 3 , up to emission standards.

[0032] In the activated carbon regeneration process, after one activated carbon tank is saturated, it is switched to another activated carbon tank for adsorption operation, and the saturated activated carbon tank is used for regene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com