Plant-mixed warm recycled asphalt mixture and preparation method thereof

A technology for recycling asphalt and mixtures, which is applied in building insulation materials, building components, buildings, etc. It can solve the problems of water stability, low temperature performance and fatigue life decline, poor mixture uniformity, graying materials, etc., and improve the regeneration effect , change the mixing order, and improve road performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

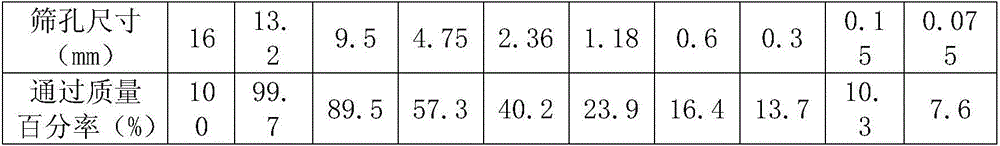

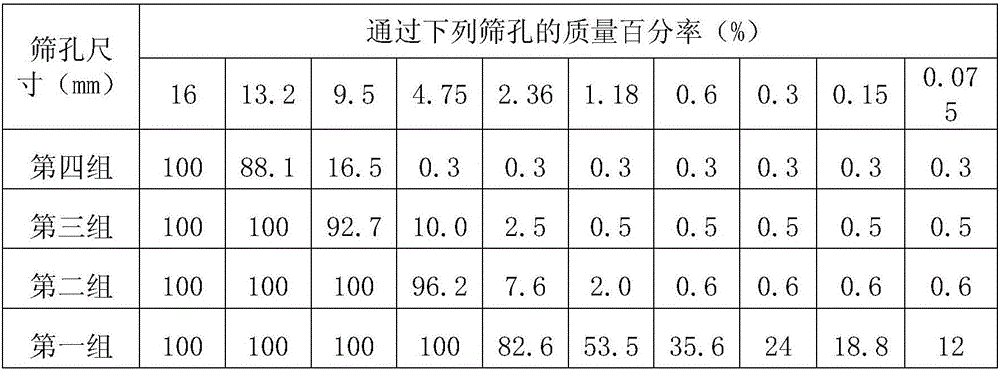

[0028] The embodiment of indoor test: the old broken asphalt pavement (RAP) used in the test is the material of the same source and the same particle size specification. At first, the RAP is sampled in the mixing plant, and then according to the "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" (JTG The method of T 0735 in E20-2011) carries out asphalt content test, and the asphalt ratio that test records this RAP is 4.81%, and the old ore material that test is obtained is carried out sieving test, and sieving test result is shown in Table 1; T 0726 in "Test Regulations for Asphalt and Asphalt Mixture" (JTG E20-2011)

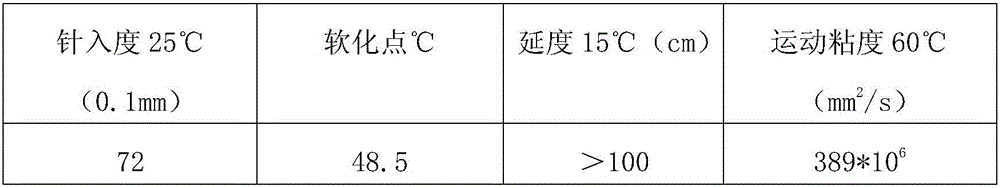

[0029] The extraction test was carried out on RAP by the method, and the old asphalt after the extraction test was recovered, and the performance test was carried out. The test results are shown in Table 2.

[0030] Table 1 Results of old ore grading test in RAP

[0031]

[0032] Table 2 Test results of old asphalt performance indicators in ...

Embodiment 2

[0069] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

[0070] (1) In this embodiment, the amount of new asphalt accounted for 2.23% of the mass percentage of the plant-mixed warm and regenerated asphalt mixture, and the kinematic viscosity at 60°C of the regenerant is 50mm 2 / s domestic regenerant (RA5 type regenerant produced by Jiangsu Tiannuo Road Material Technology Co., Ltd.), the amount of regenerant accounted for 0.38% of the mass percentage of high-performance warm recycled asphalt mixture.

[0071] (2) The heating temperature of RAP is 80°C, the heating temperature of new aggregate is 90°C, and the heating temperature of regenerant is 50°C.

[0072] (3) Divide the mixed material out of the pot into 7 equal samples (W0, W1, W2, W3, W4, W5, W6), and store them in a dedicated growth chamber at 40°C. W0 grows for 0h, W1 grows for 1h, W2 developed for 2 hours, W3 developed for 3 hours, W4 developed for 4 hours, W5 developed ...

Embodiment 3

[0088] This embodiment is basically the same as the above-mentioned embodiment 1, the difference is:

[0089] (1) In this example, the amount of new asphalt accounted for 2.37% of the mass percentage of the plant-mixed warm and regenerated asphalt mixture, and the kinematic viscosity at 60°C of the regenerant is 11520mm 2 / s domestic regenerant (RA250 regenerant produced by Jiangsu Tiannuo Road Material Technology Co., Ltd.), the amount of regenerant accounted for 0.30% of the mass percentage of high-performance warm recycled asphalt mixture.

[0090] (2) The heating temperature of RAP is 130°C, the heating temperature of new aggregate is 170°C, and the heating temperature of regenerant is 80°C.

[0091] (3) Divide the mixed material out of the pot into 7 equal samples (X0, X1, X2, X3, X4, X5, X6), and store them in a special growth chamber at 130°C. X0 grows for 0h, X1 grows for 1h, X2 developed for 2 hours, X3 developed for 3 hours, X4 developed for 4 hours, X5 developed fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com