Plain area highway abutment back structure, highway structure and construction method

A technology for expressways and plains, applied in infrastructure engineering, underwater structures, roads, etc., can solve the problems of difficult earthwork, restricting the progress of high-speed construction, etc., to reduce the impact, speed up the demand for backfill construction, and speed up the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

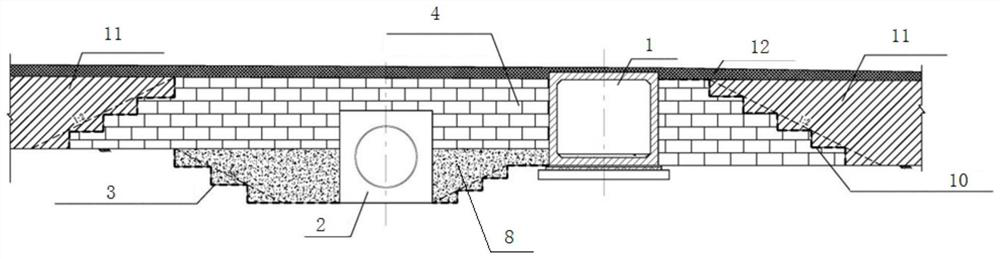

[0033] This embodiment provides a platform back structure of expressways in plain areas, such as Figure 1-Figure 2 As shown, including structures, the structures are buried in the backfill structure, and the two sides of the backfill structure are provided with filling subgrades, and the filling subgrade and the backfill structure together constitute the subgrade of the highway.

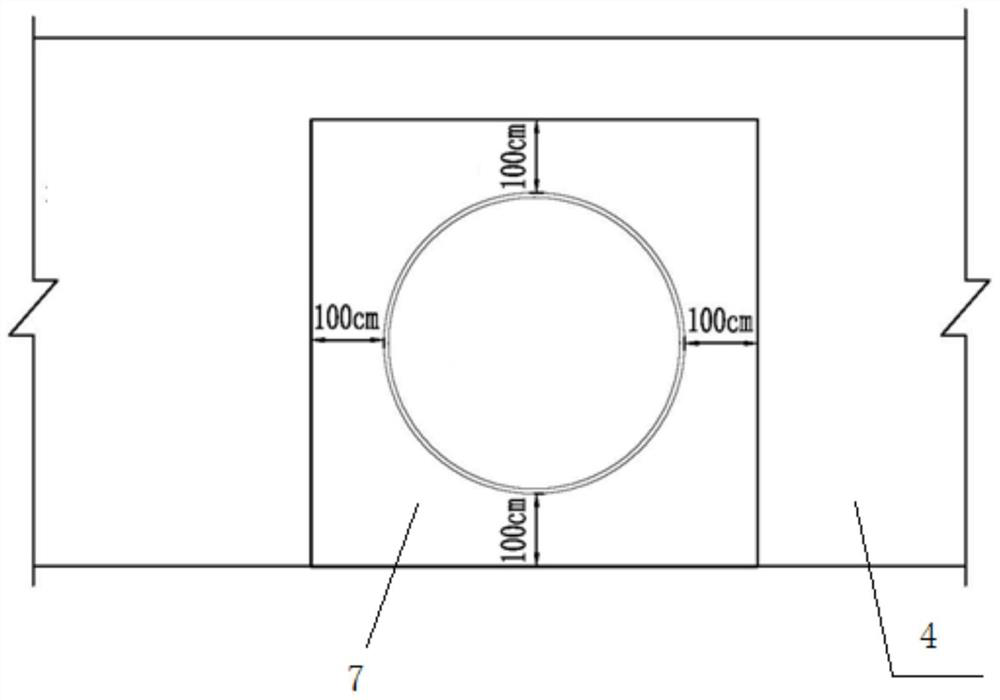

[0034] The structure is set according to actual needs. In this embodiment, two structures are included, namely the first structure 1 and the second structure 2, wherein the first structure 1 is a square box culvert, which is arranged on the base. As a common structure, another second structure 2 is a circular pipe box or a corrugated pipe box for drainage, and the circular pipe culvert or corrugated pipe culvert for drainage is laid in the foundation pit dug at the base.

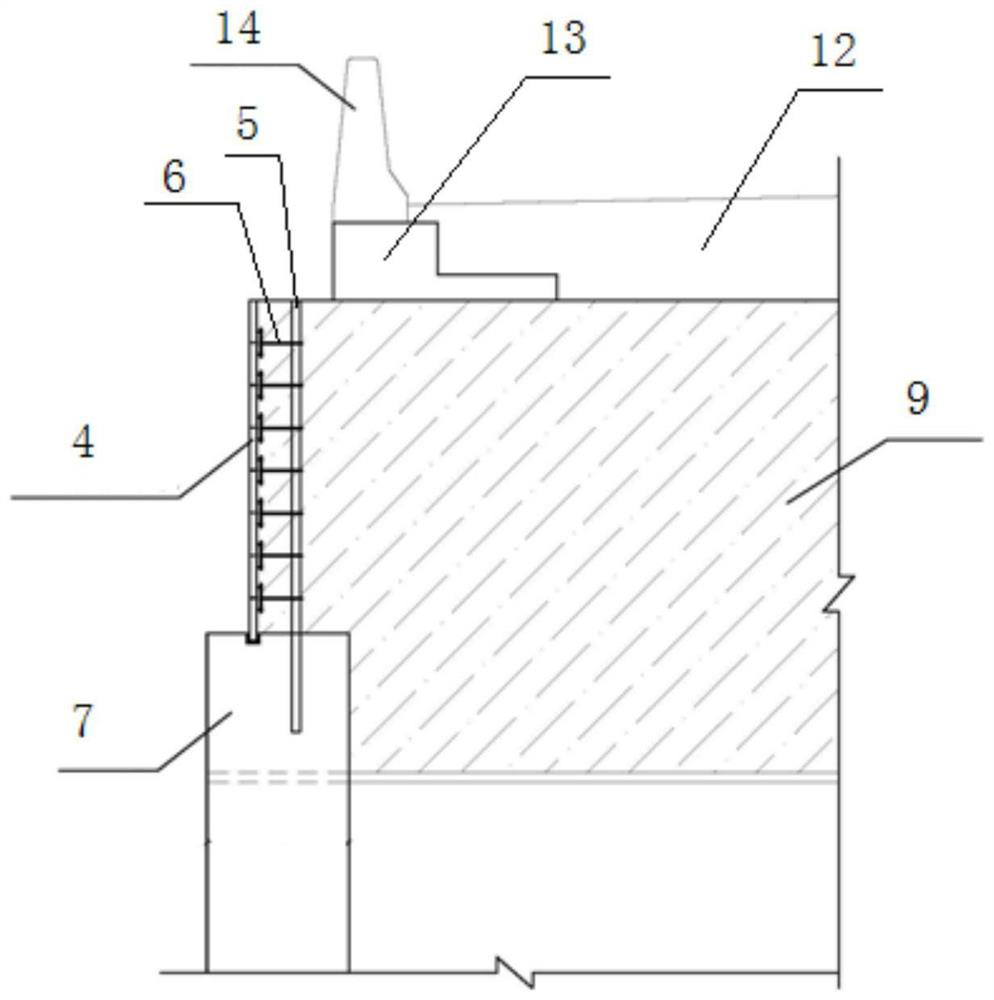

[0035] In this embodiment, the two pit walls along the longitudinal direction of the road are provided with first stepped struct...

Embodiment 2

[0054] This embodiment provides a road structure, which is provided with the platform back structure of the expressway in the plain area described in Embodiment 1. Filled roadbeds 11 are arranged on both sides of the backfill structure to form the roadbed structure of the entire road structure, and the backfill structure has two sides. A composite geomembrane is arranged between the side step structure and the filling roadbed 11 to prevent the freezing and thawing of seepage water and capillary water in the filling roadbed.

[0055] A pavement layer 12 is laid on the subgrade structure, and the pavement layer can adopt an existing pavement layer structure, and a guardrail foundation 13 and a guardrail 14 are arranged on the pavement layer.

Embodiment 3

[0057] This embodiment provides a construction method for the road structure described in Embodiment 2, comprising the following steps:

[0058] Step 1: Excavate the foundation pit at the base, excavate the two pit walls along the longitudinal direction of the road to form the first stepped structure 3, after treating the base, pour the foundation and platform of the first structure and the second structure After the concrete strength of the first structure and the second structure reaches 100%, the construction of the structures is completed.

[0059] Step 2: Pour reinforced concrete protective wall 8 at the end of the foundation pit, pour reinforced concrete protective wall 8 to the reinforced concrete protective wall 8 to level the top surface of the foundation pit, and then start building retaining wall 4 . When the retaining wall 4 is built by masonry, the retaining wall 4 is built into a trapezoidal wall with a narrow top and a wide bottom, and its side parts form a step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com