Patents

Literature

49results about How to "Act as a template" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for synthesizing titanium-silicon molecular screen

ActiveCN101190792AReduce generationEliminate local concentration unevennessMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

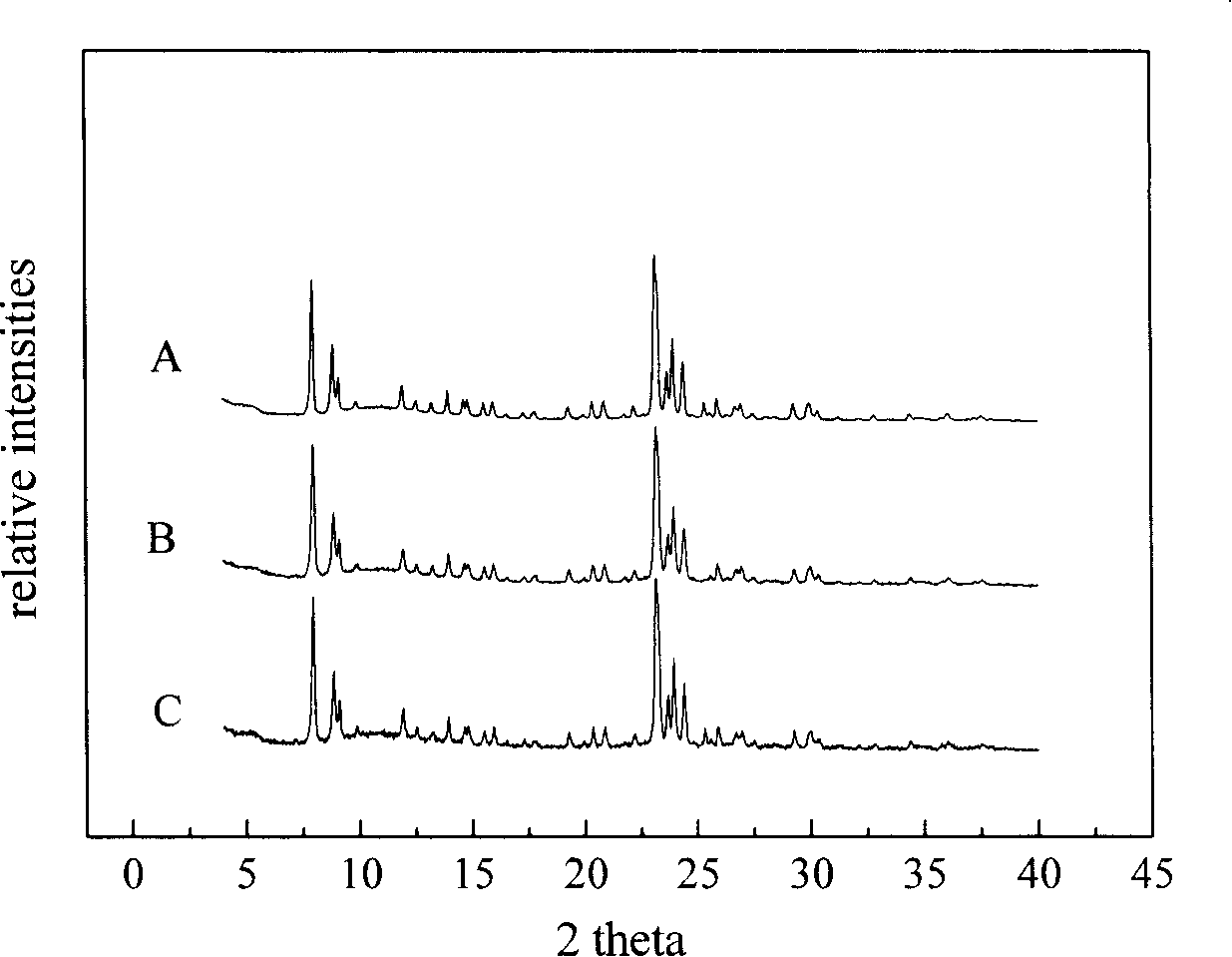

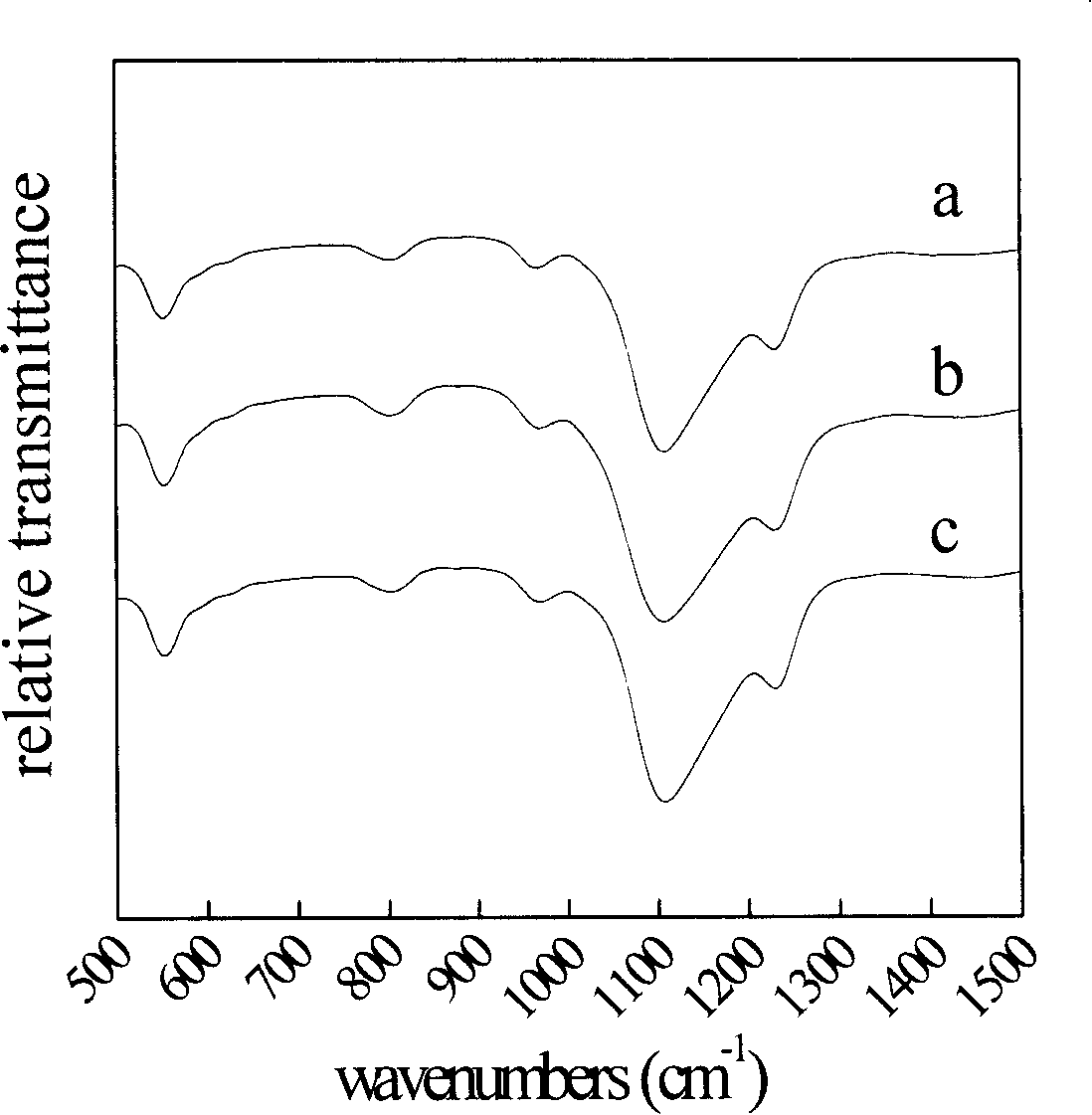

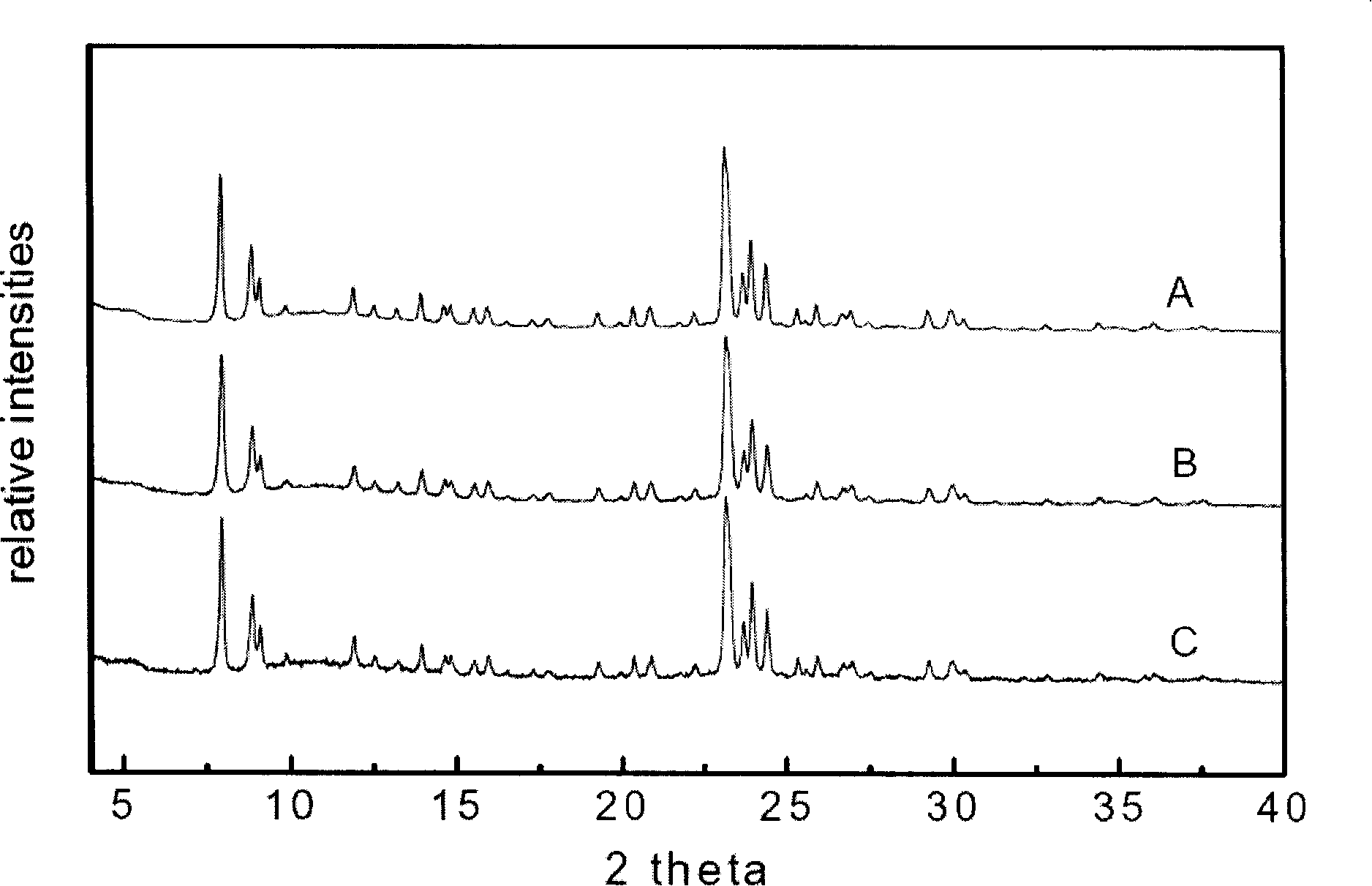

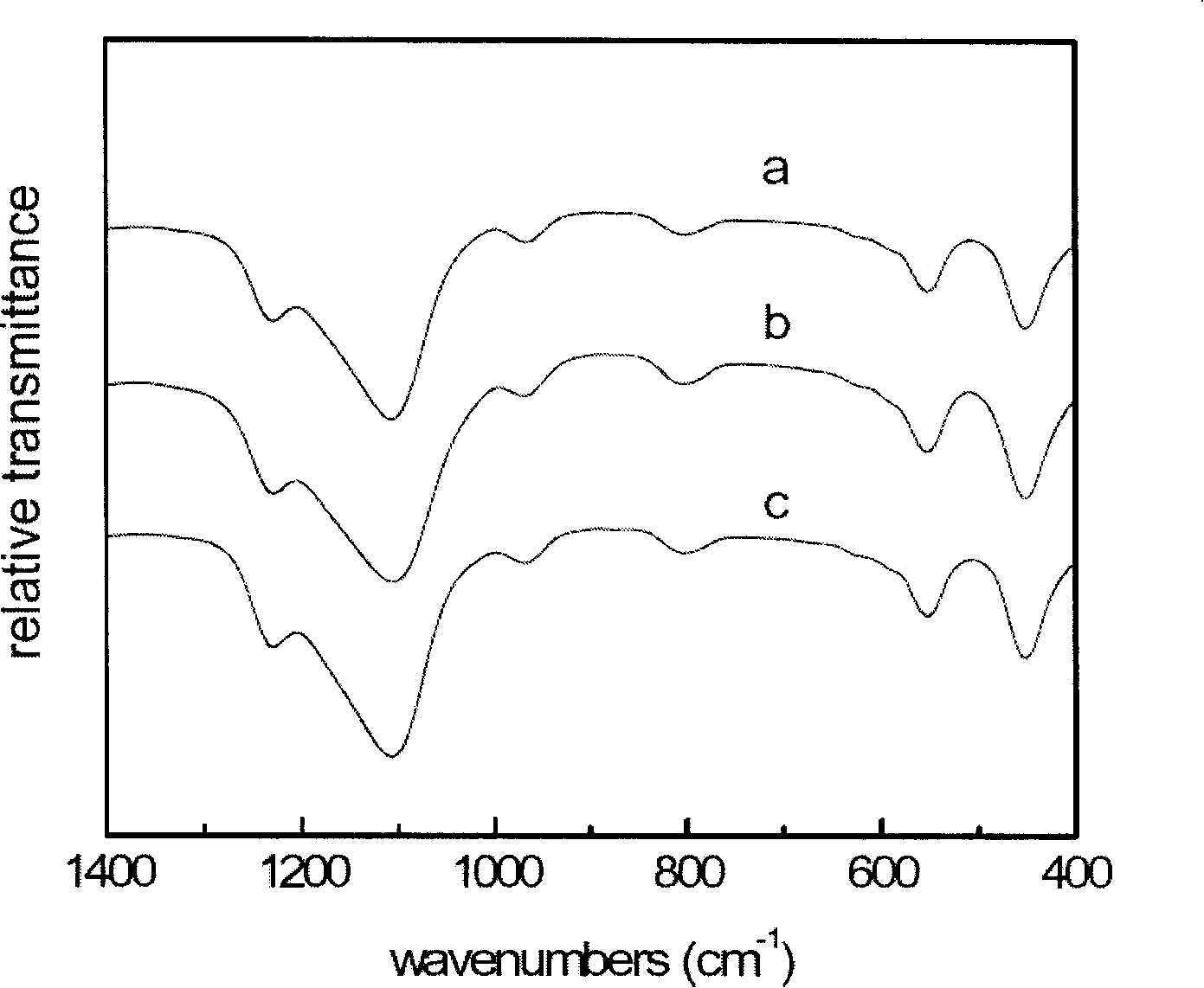

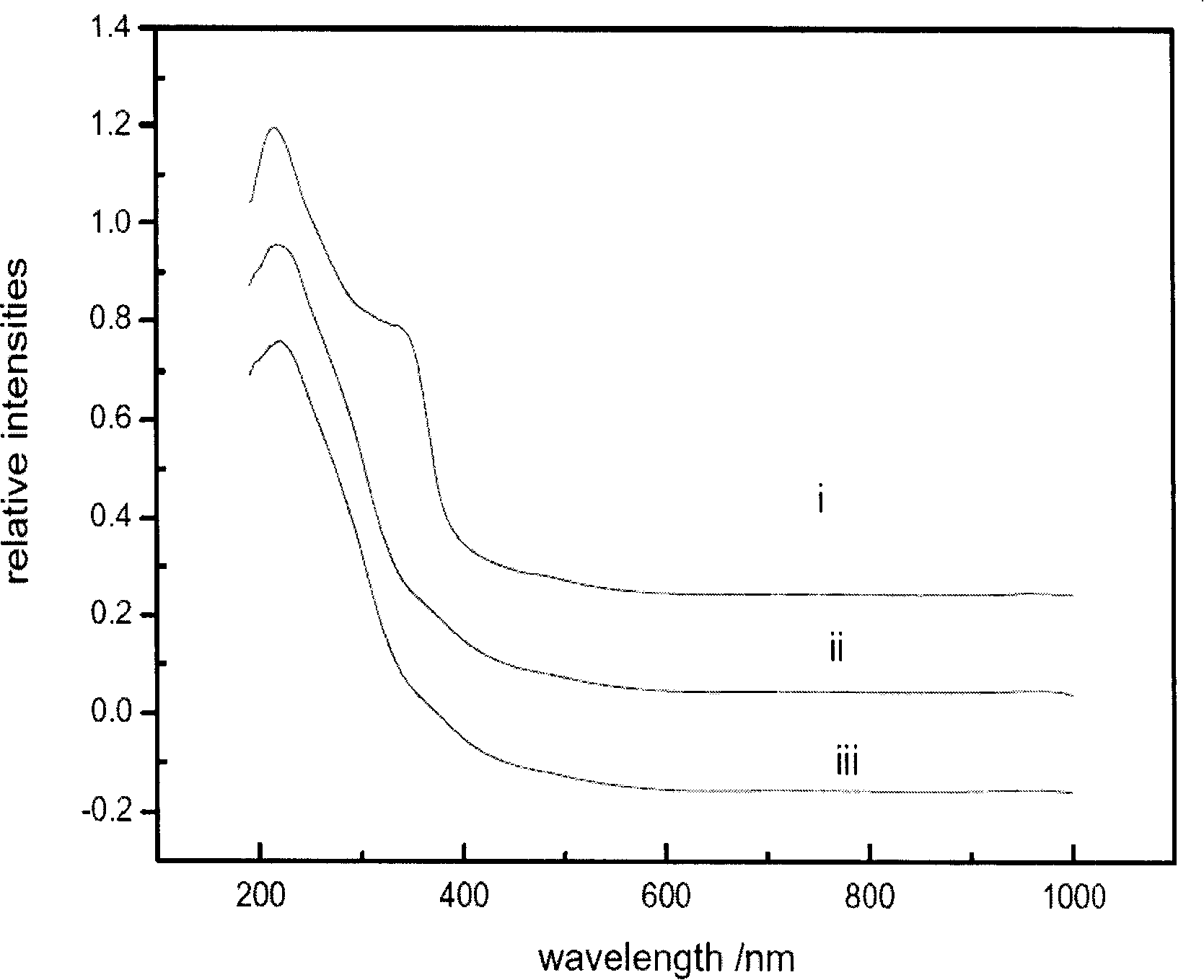

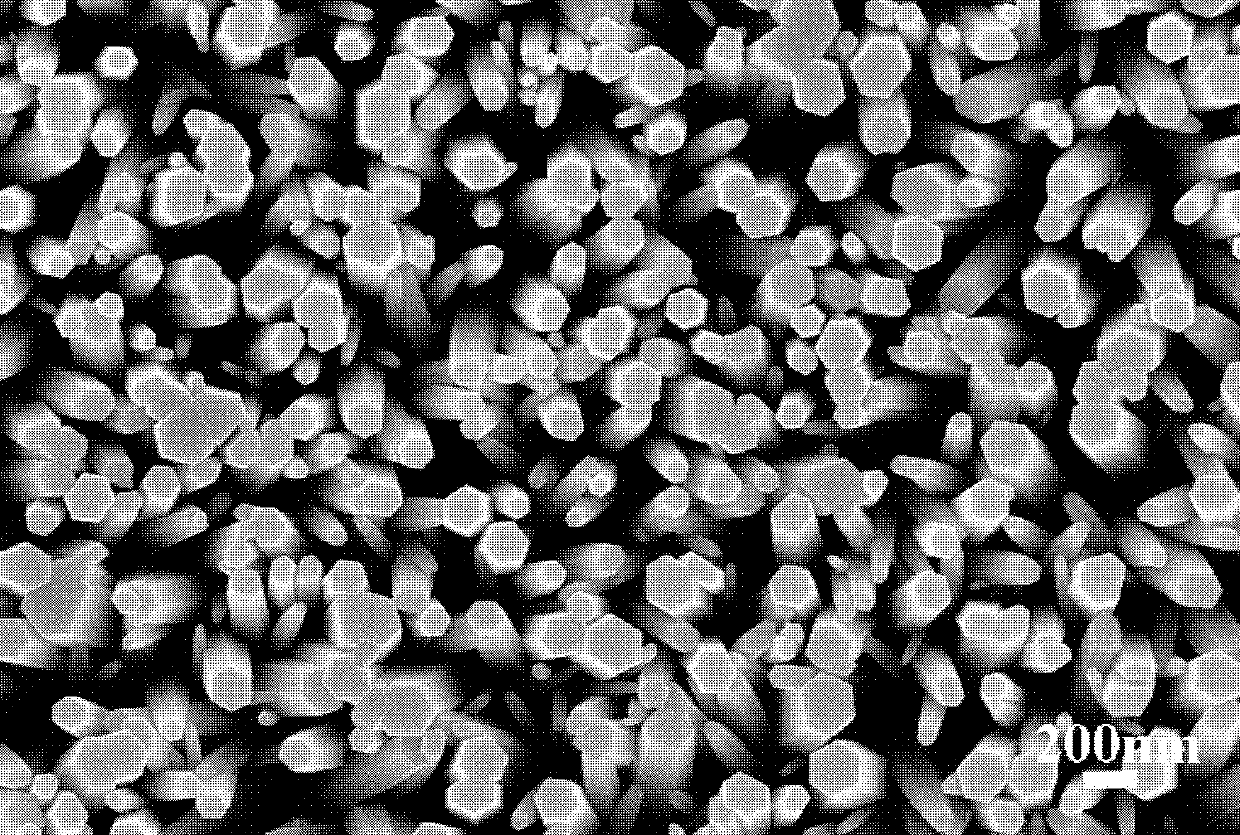

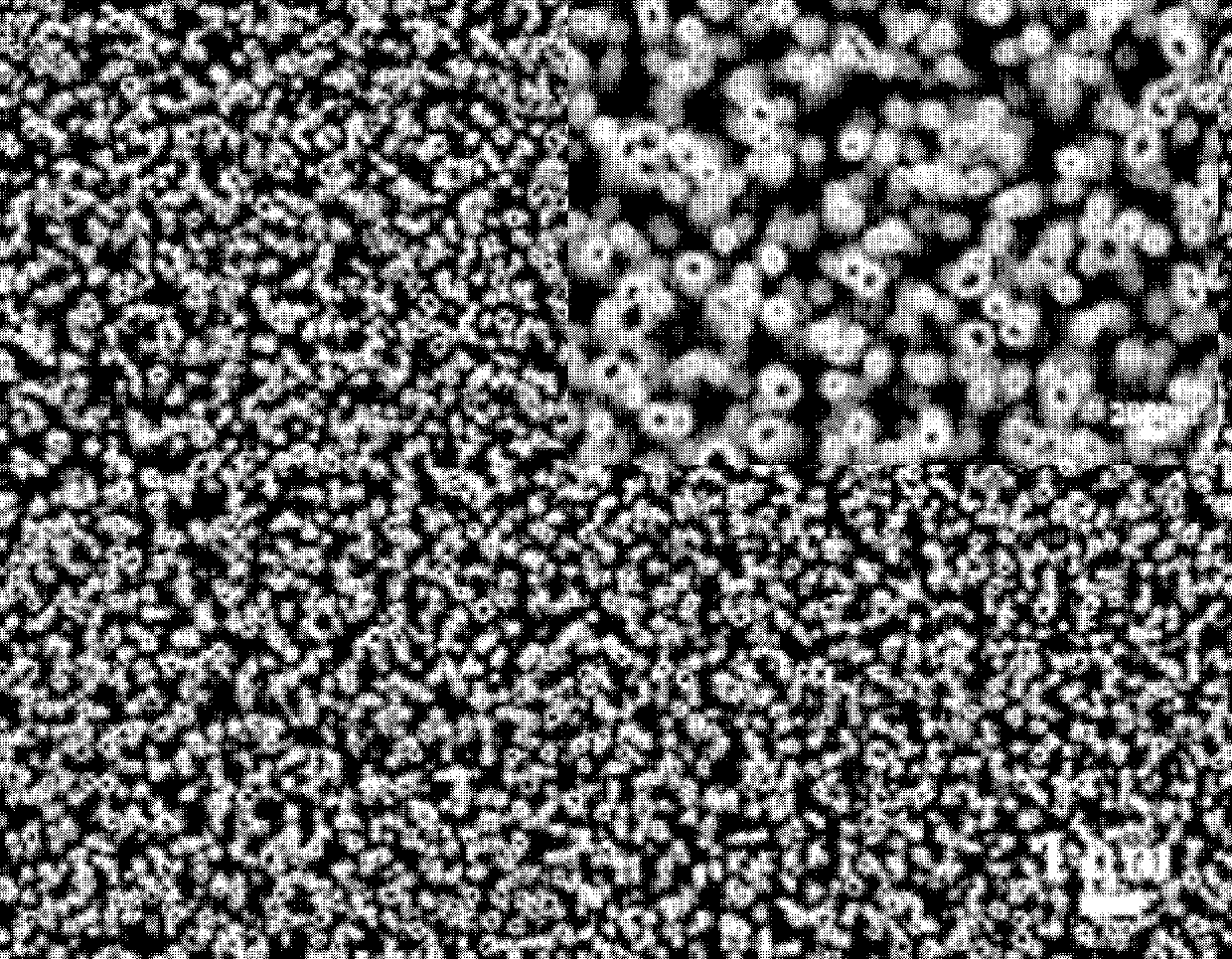

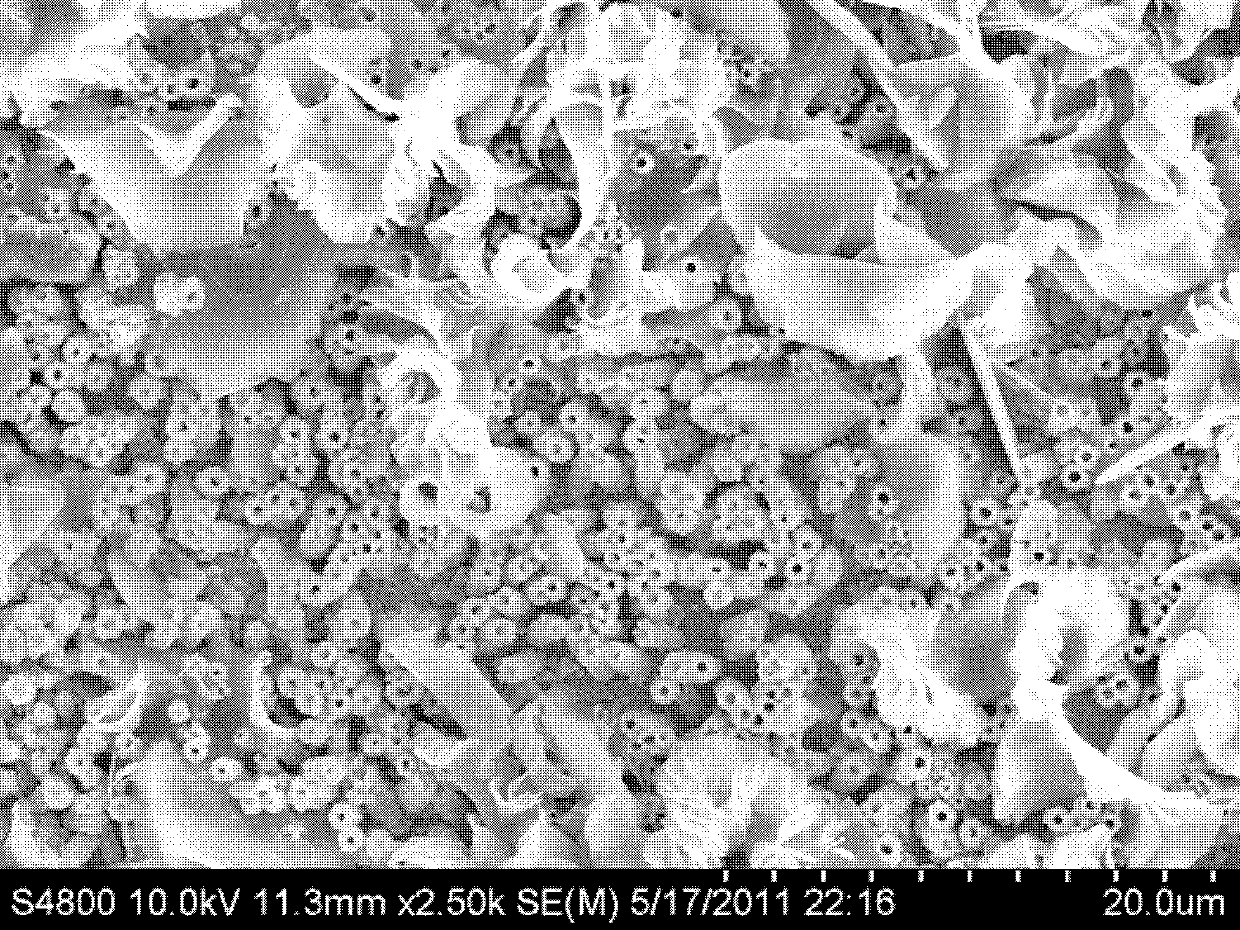

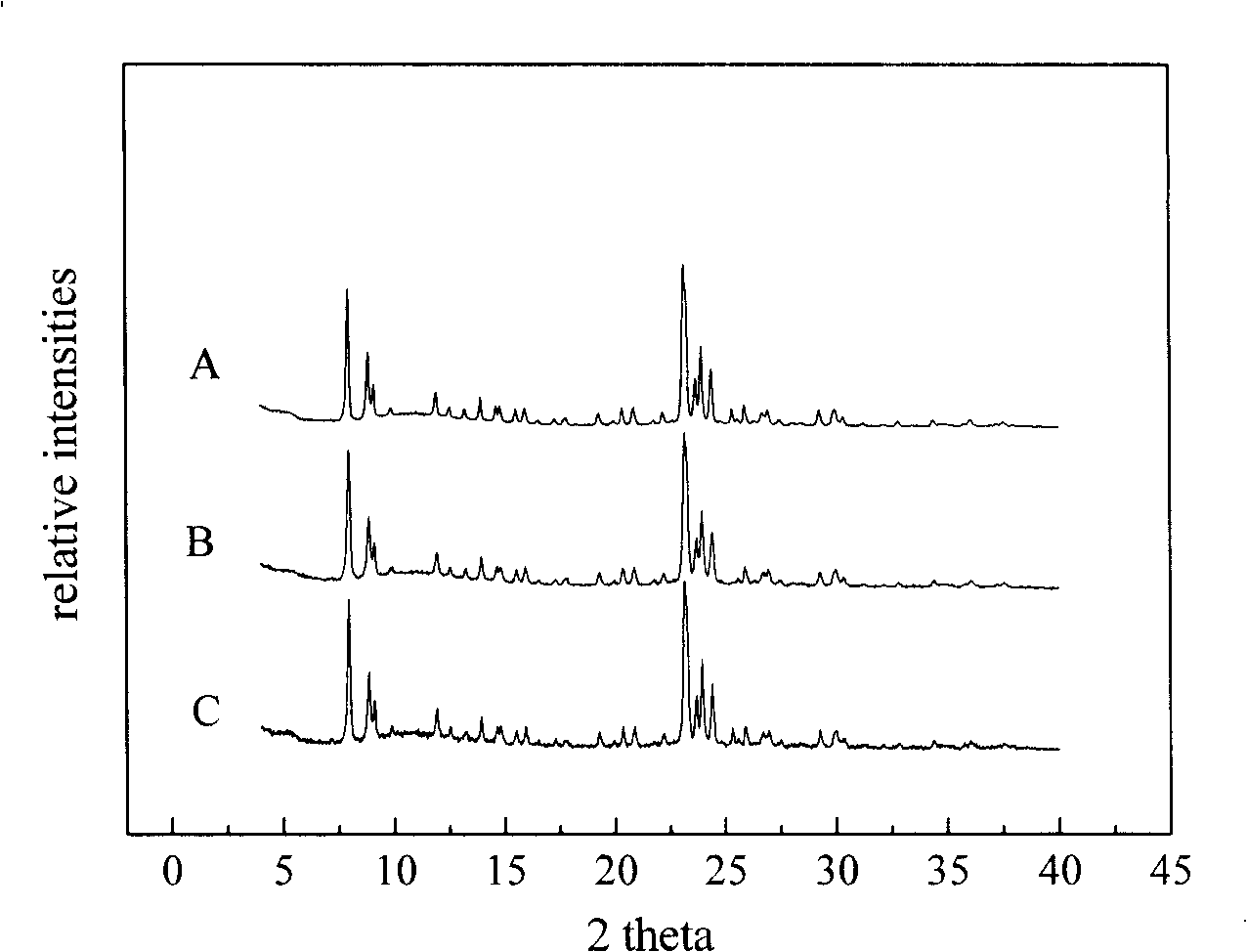

A method of synthesizing titanium silicate molecular sieve is to hydrothermally crystallize the hydrolytic solution of silicon and titanium in a closed reaction vessel and then recycle the product. The method is characterized in that the hydrolytic solution of silicon and titanium is gotten by any one of the following three methods: A. under ultrasonic agitation, silicon source is first hydrolyzedin organo-alkali compound solution and then the titanium source is hydrolyzed in the solution; B. under the ultrasonic agitation, titanium source is first hydrolyzed in organo-alkali compound solution and then the silicon source is hydrolyzed in the solution; C. under the ultrasonic agitation, silicon source and titanium source are respectively hydrolyzed in organo-alkali compound solution and then mixed together. The synthetic method can eliminate partial uneven concentration, leads the amount of TiO2 generated by self agglomeration after the hydrolysis of titanium source to be as little as possible and reduces the production of extra framework titanium. Compared with the prior art, the TS-1 molecular sieve synthesized by the method not only has better catalytic oxidation activity and selectivity but also has better stability of catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing TS-1 molecular screen

ActiveCN101190793AEvenly distributedReduce dosageMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveSynthesis methods

A synthetic method of TS-1 molecular sieve is characterized in that: first mixing silicon source with titanium source, then mixing thereof with organo-alkali compound solution; under the ultrasonic agitation, the hydrolytic solution of silicon and titanium is acquired; then hydrothermally crystallizing the mixture in a reaction vessel and recycling to get TS-1 molecular sieve. The synthetic method can eliminate partial uneven concentration, leads the amount of TiO2 generated by self agglomeration after the hydrolysis of titanium source to be as little as possible and reduces the production of extra framework titanium. Compared with the prior art, the TS-1 molecular sieve synthesized by the method not only has better catalytic oxidation activity and selectivity but also has better stability of catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP

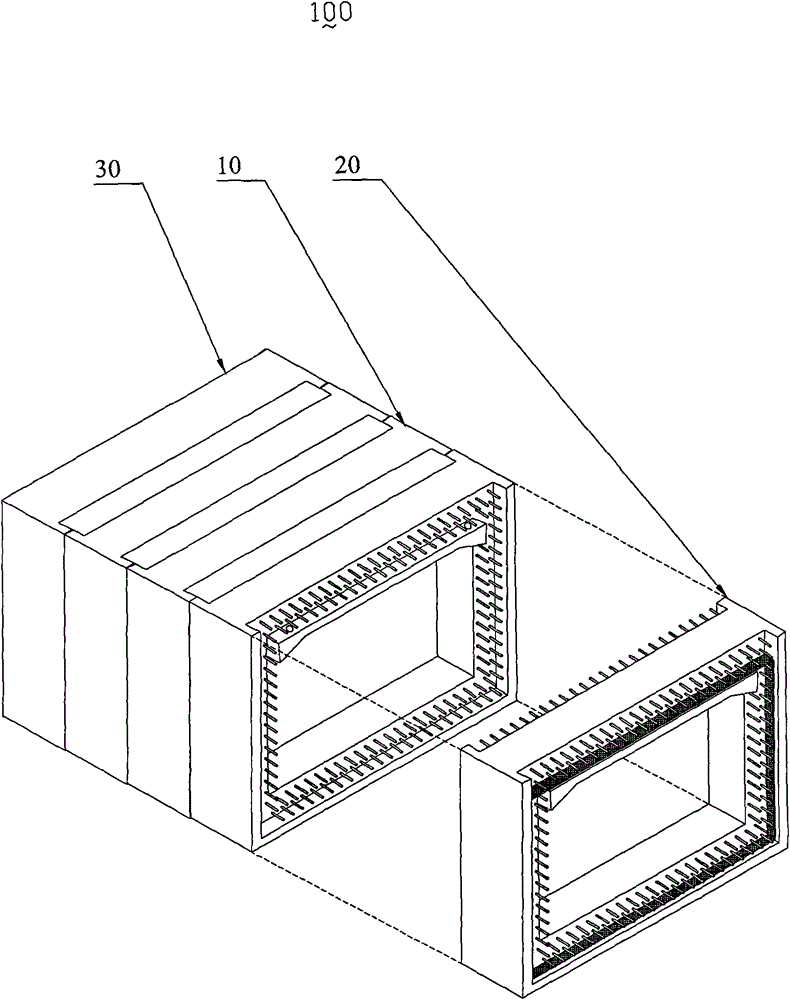

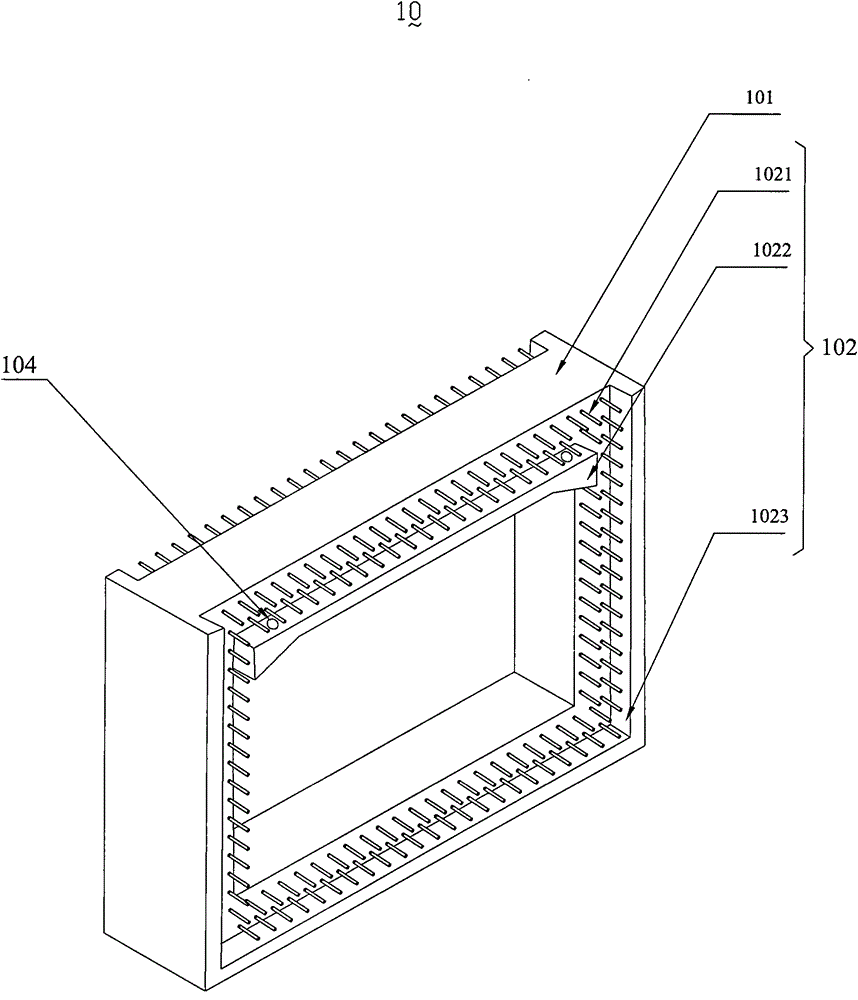

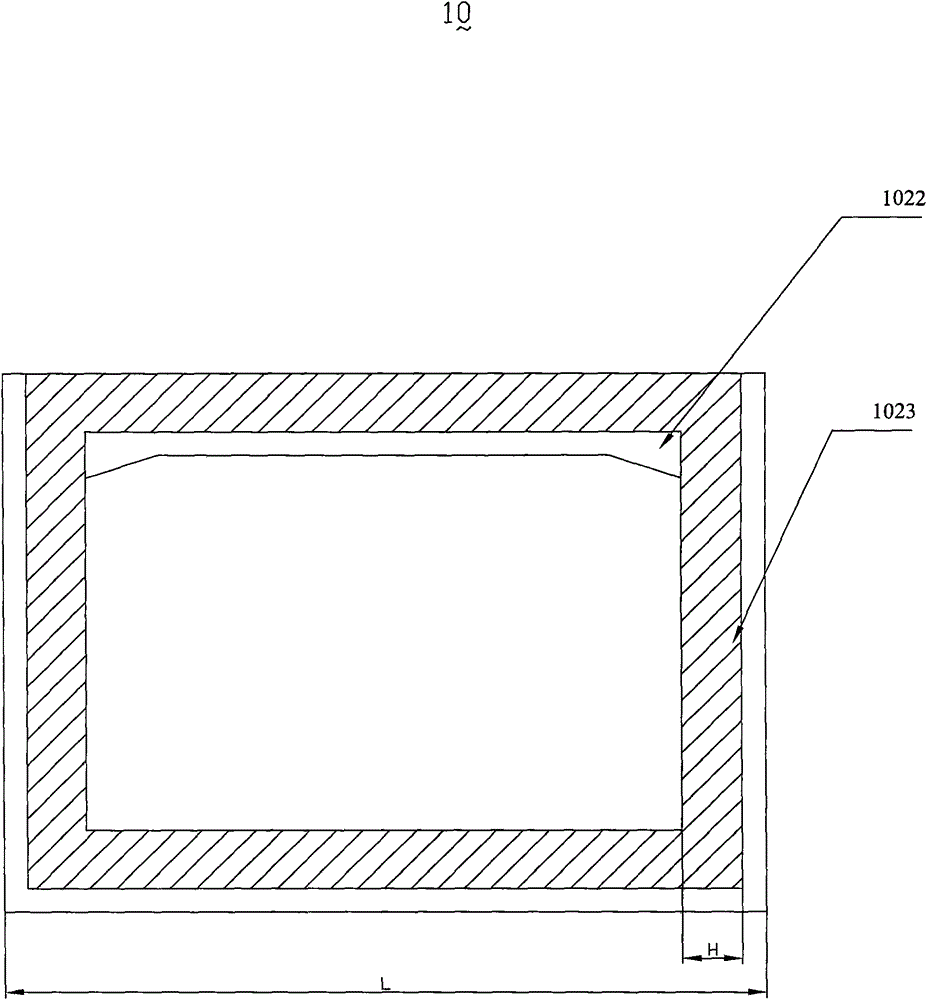

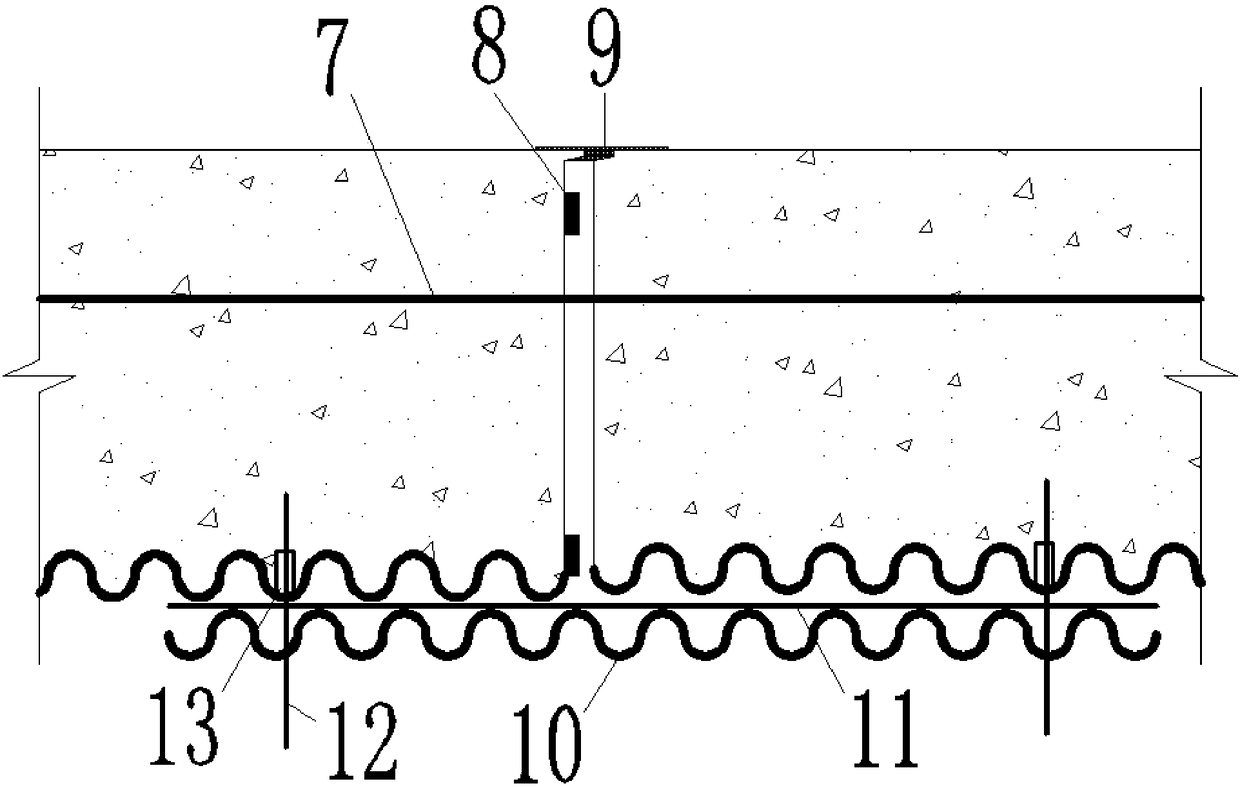

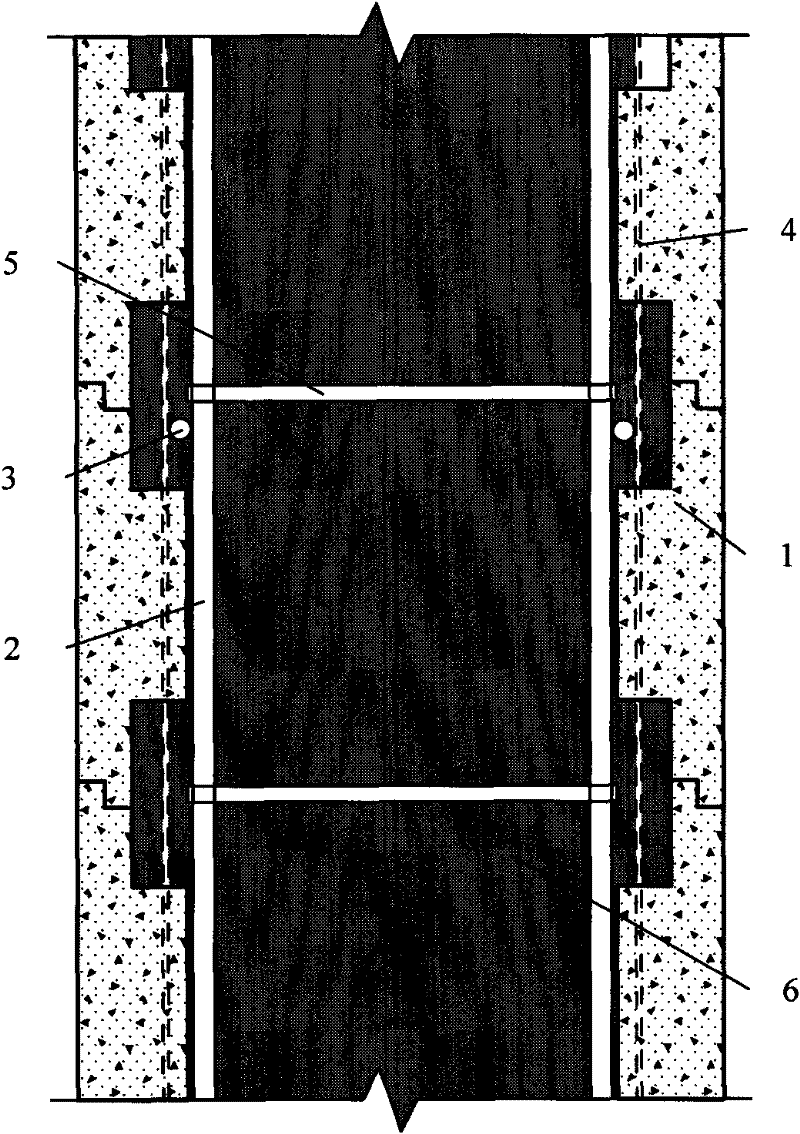

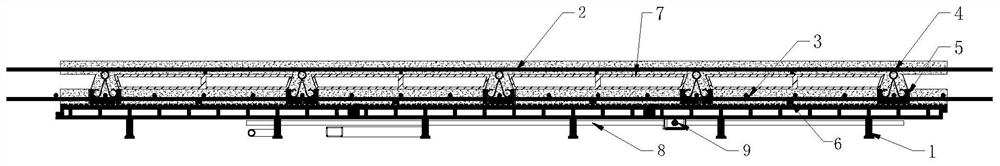

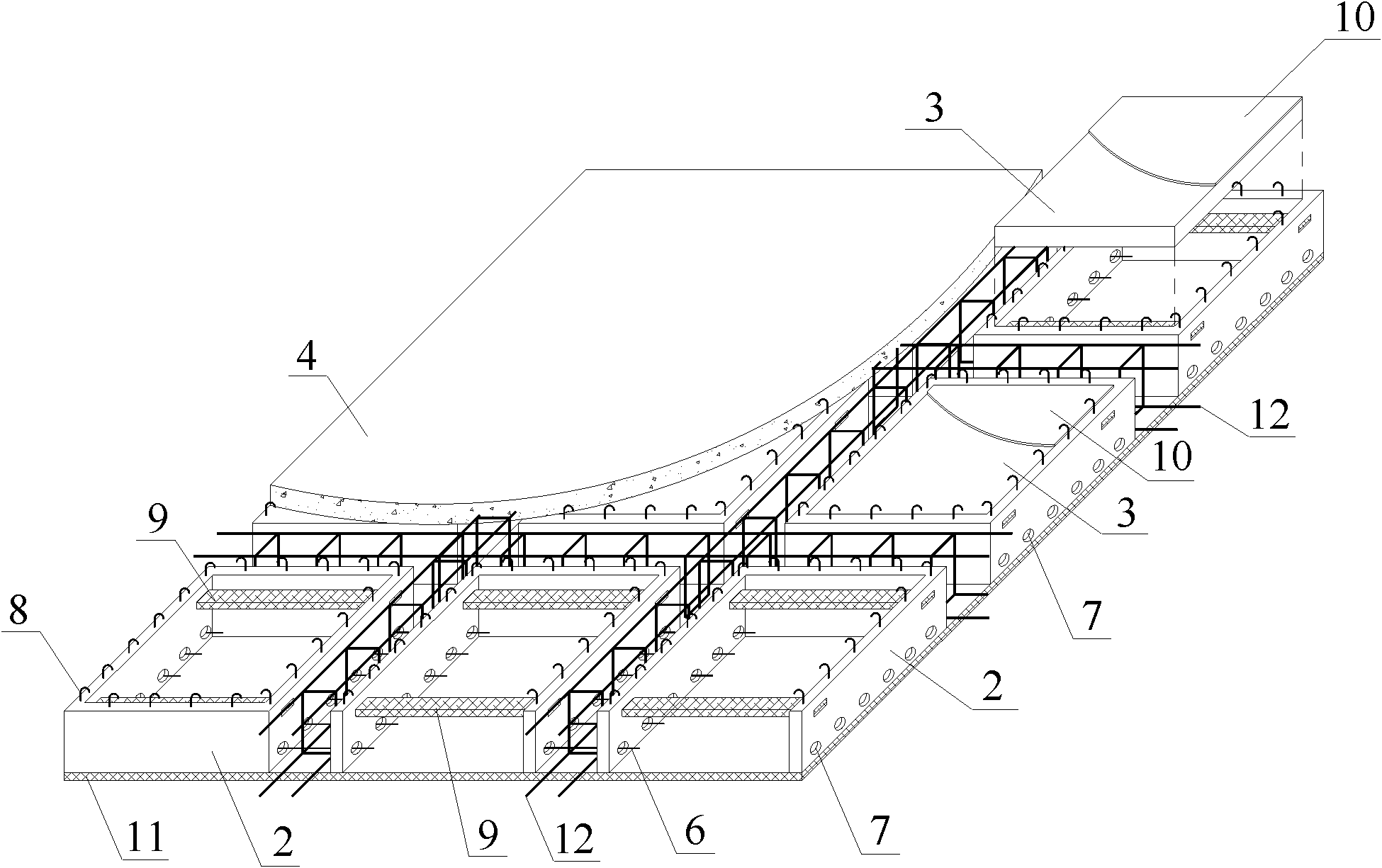

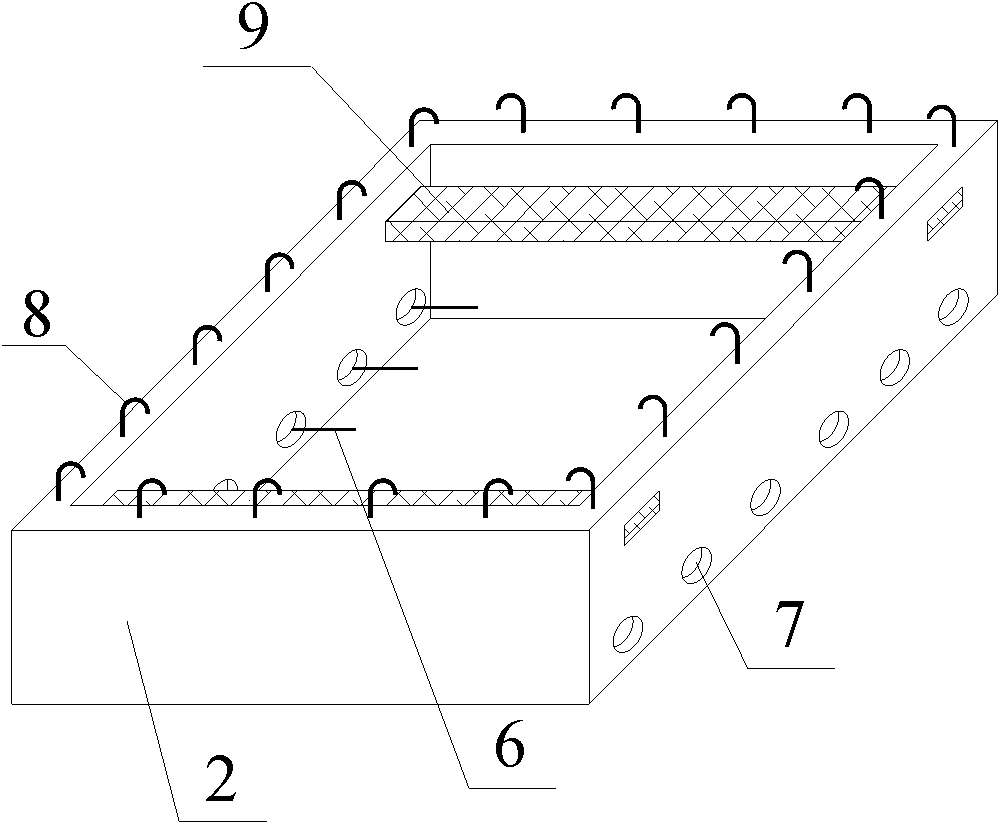

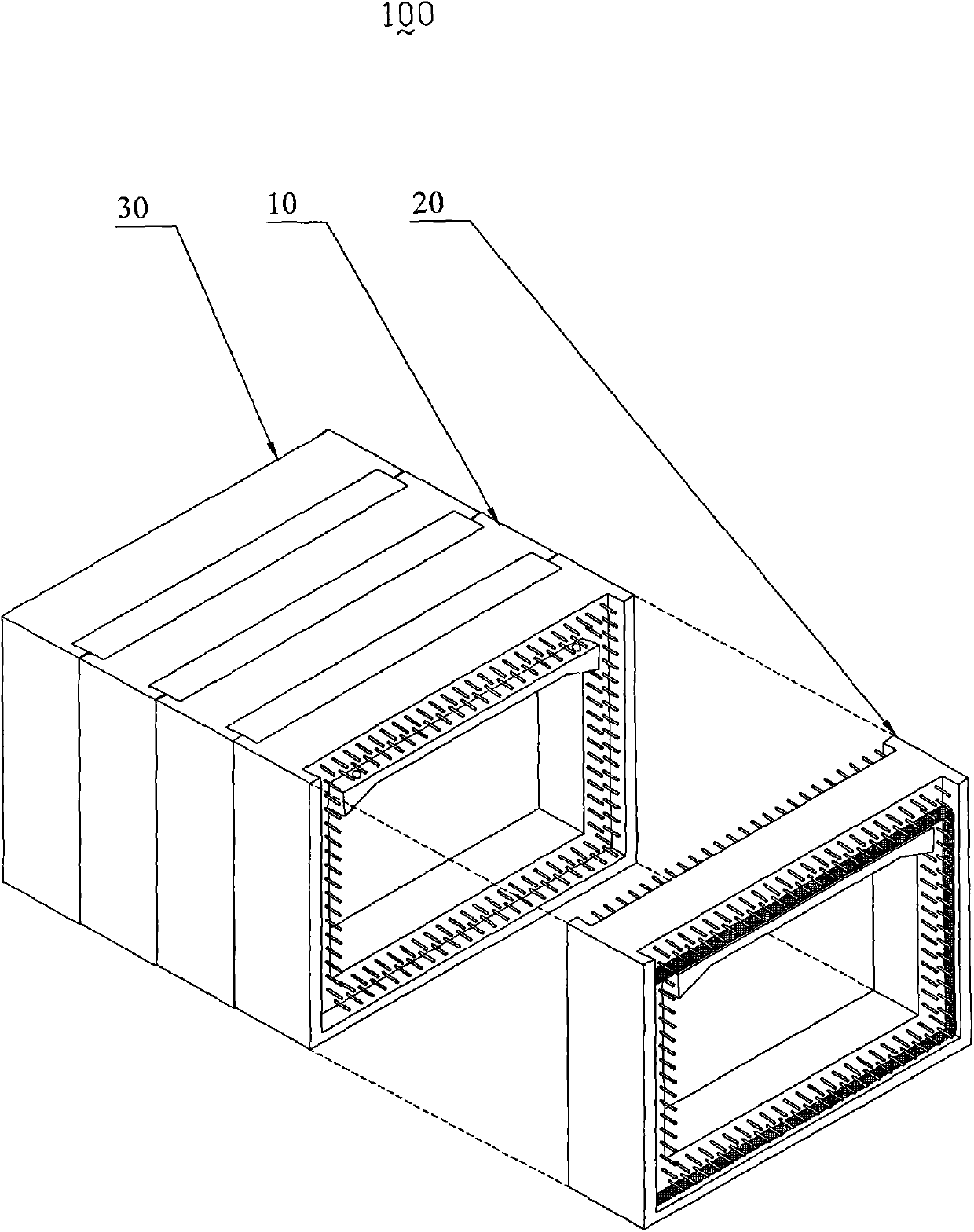

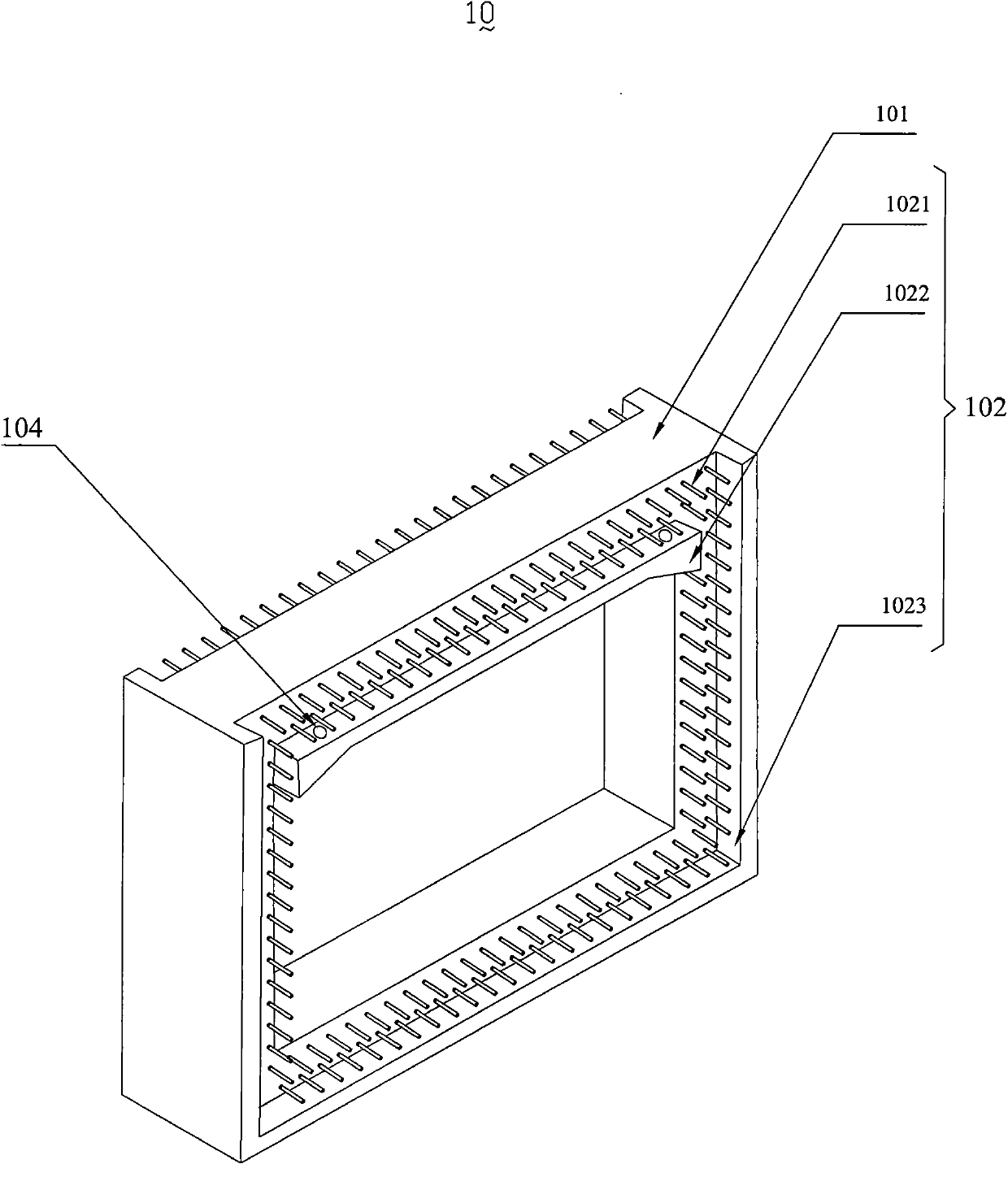

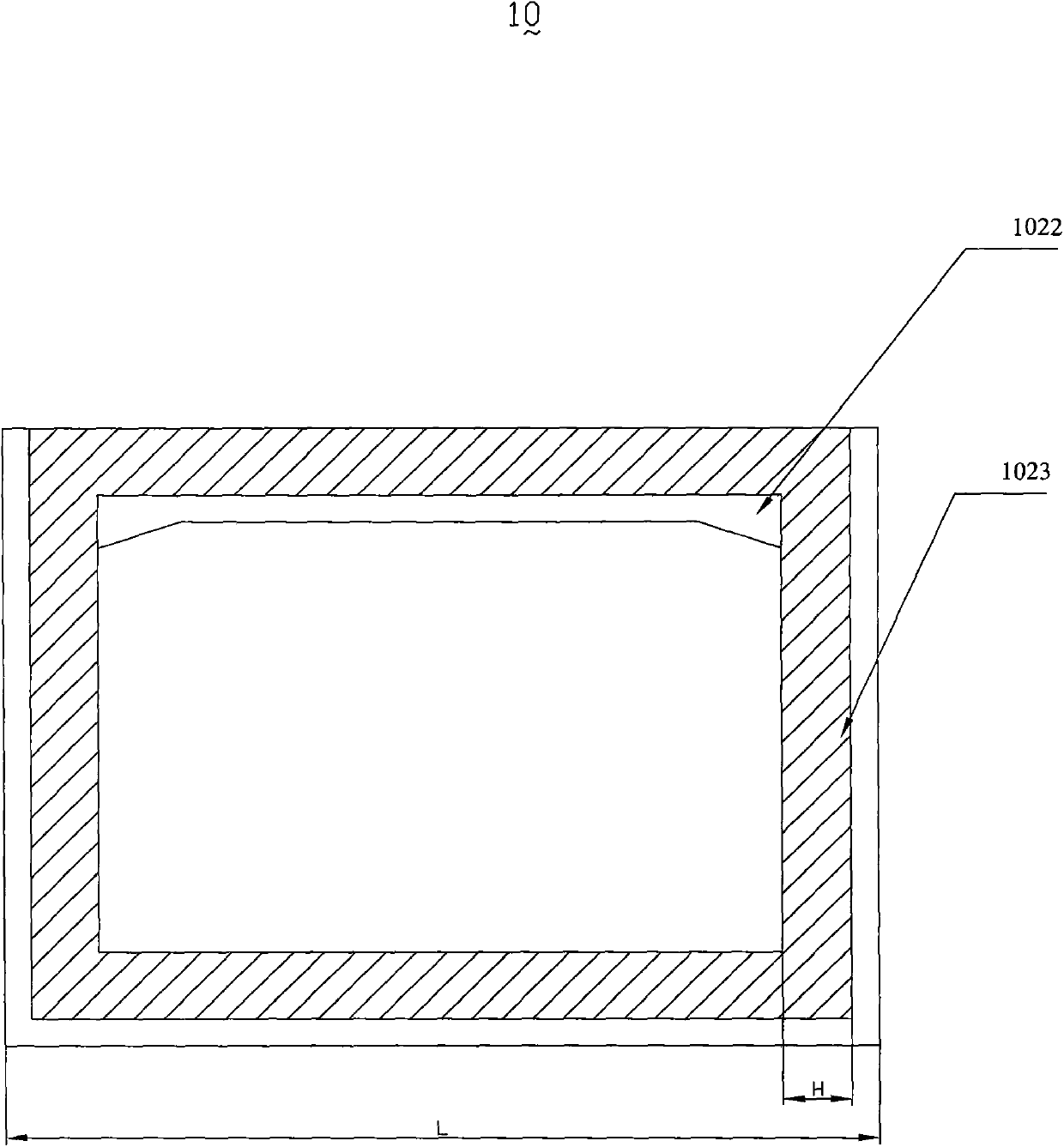

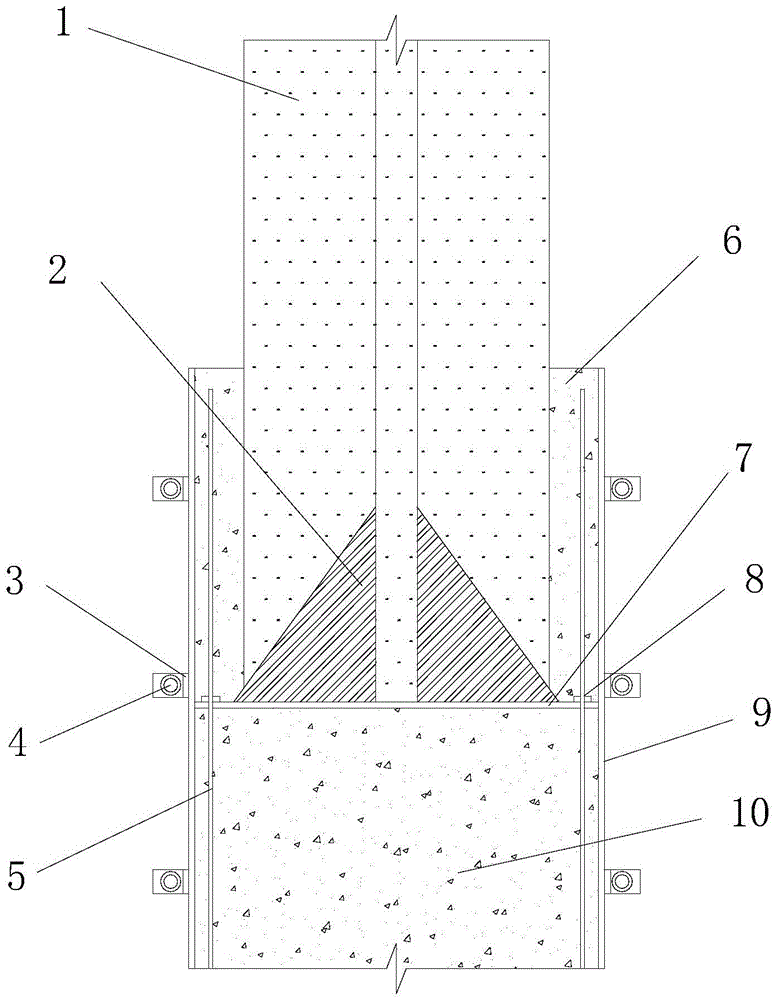

Prefabricated box culvert system and installation method thereof

The invention provides a prefabricated box culvert system. The prefabricated box culvert system comprises at least two prefabricated box culverts. Two prefabricated box culverts are located at the head end and the tail end of the prefabricated box culvert system, the prefabricated box culverts at the head end and the tail end respectively comprise a box body and two connectors, at least one connector of each box culvert comprises a bundle of bars or a pre-buried water stop belt, and the box culverts of the prefabricated box culvert system are connected through bars or the water stop belts formed through overlap welding, and are connected into the integrally-formed box culvert system through poured concrete. The invention further provides an installation method of the prefabricated box culvert system. The installation method is used for connecting the at least two prefabricated box culverts into a whole and laying the box culverts on the bottom face of a road. Compared with the prior art, the prefabricated box culvert system is simple in construction, short in construction period, low in cost, wide in application range, and suitable for municipal engineering and other large-scale traffic construction.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

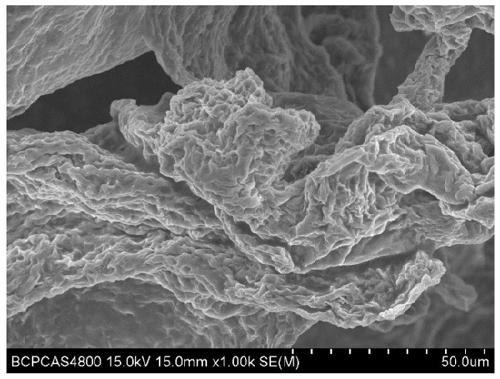

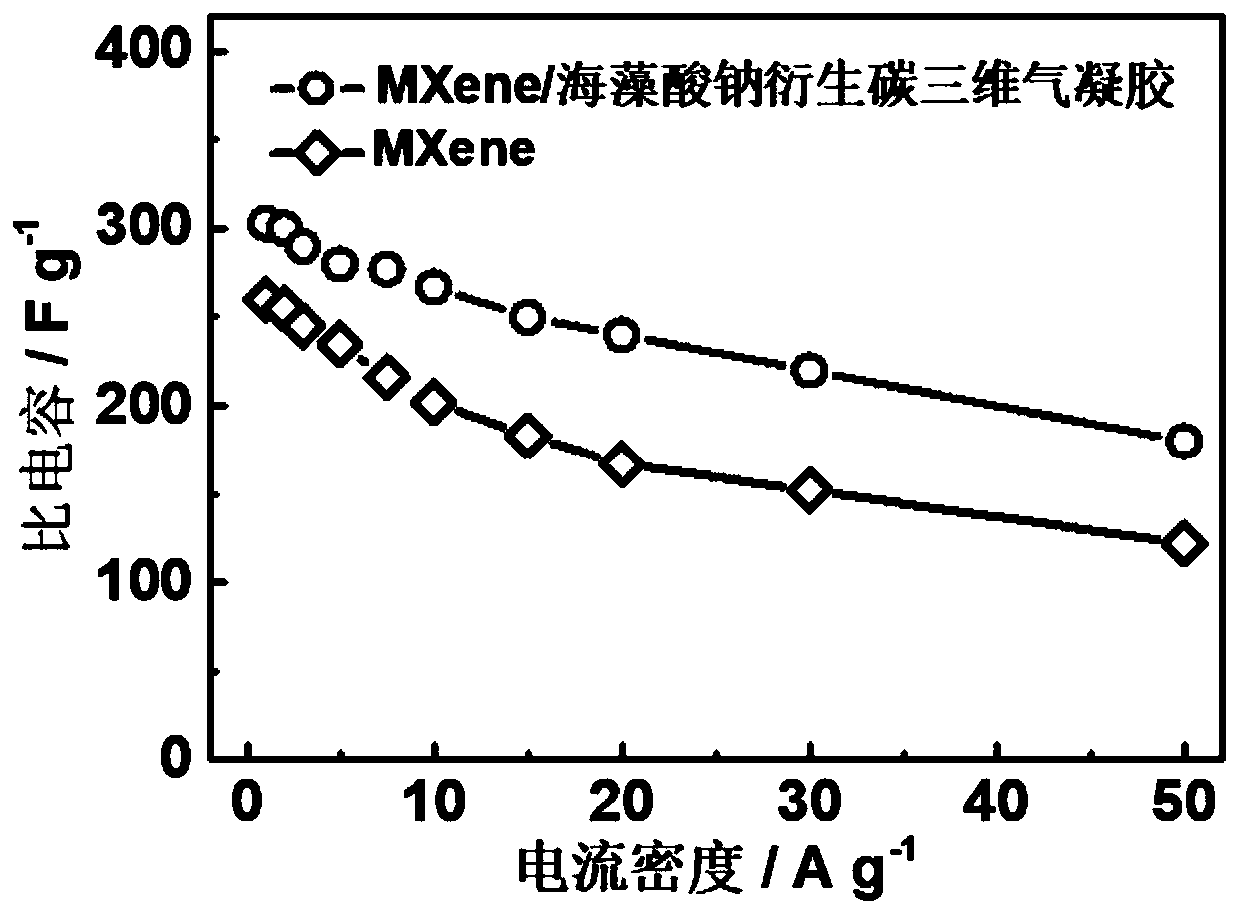

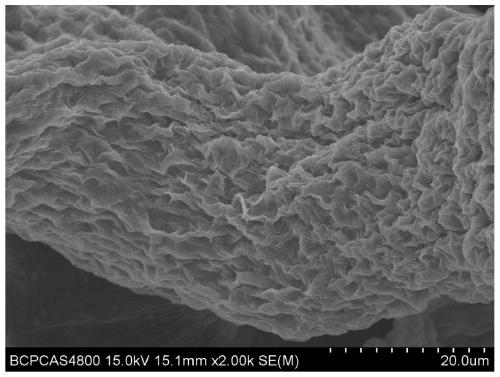

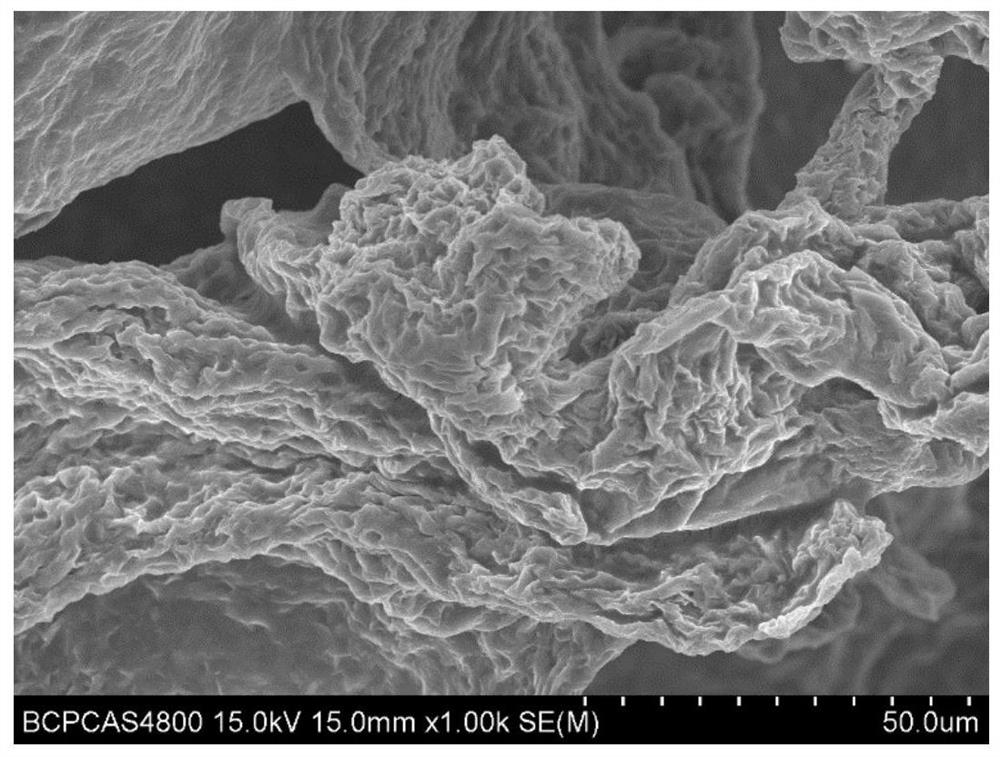

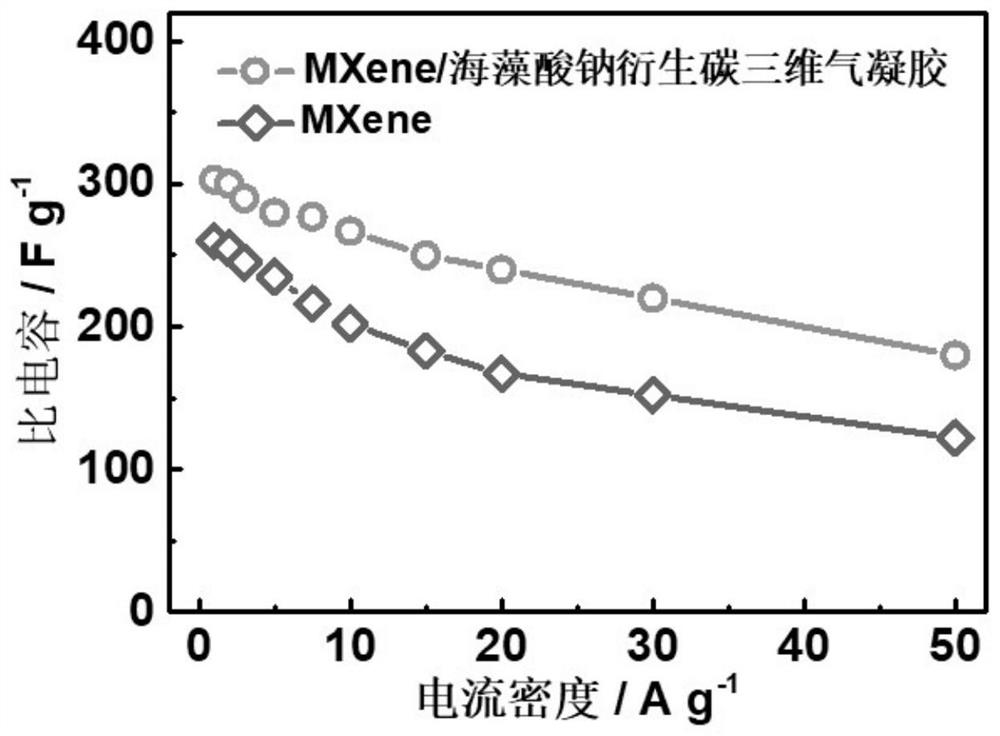

MXene/sodium alginate derived carbon three-dimensional aerogel as well as preparation method and application thereof

ActiveCN111422873AAvoid stackingImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFluid phaseSupercapacitor

The invention provides MXene / sodium alginate derived carbon three-dimensional aerogel as well as a preparation method and application thereof. The preparation method of the MXene / sodium alginate derived carbon three-dimensional aerogel, provided by the invention, comprises the following steps: carrying out liquid-phase mixing on an MXene dispersion liquid and a sodium alginate aqueous solution toobtain an MXene / sodium alginate mixed solution; adding a calcium chloride solution into the MXene / sodium alginate mixed solution, and gelatinizing sodium alginate to obtain MXene / sodium alginate hydrogel; carbonizing sodium alginate through high-temperature treatment, and then washing with 1-3mol / L hydrochloric acid and deionized water to obtain the MXene / sodium alginate derived carbon three-dimensional aerogel material. The MXene / sodium alginate derived carbon three-dimensional aerogel material provided by the invention has good electrochemical performance when used in the field of supercapacitors.

Owner:BEIJING UNIV OF CHEM TECH

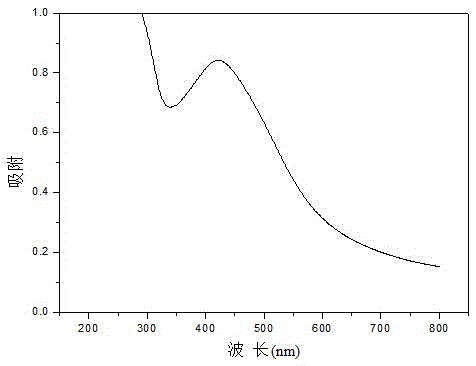

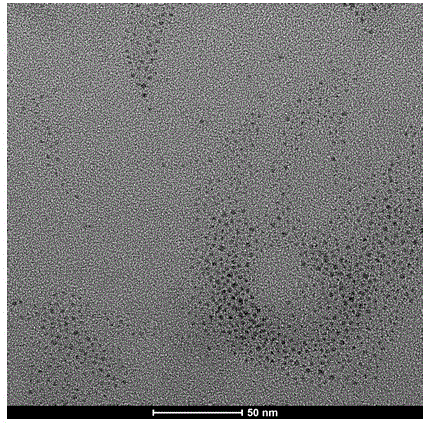

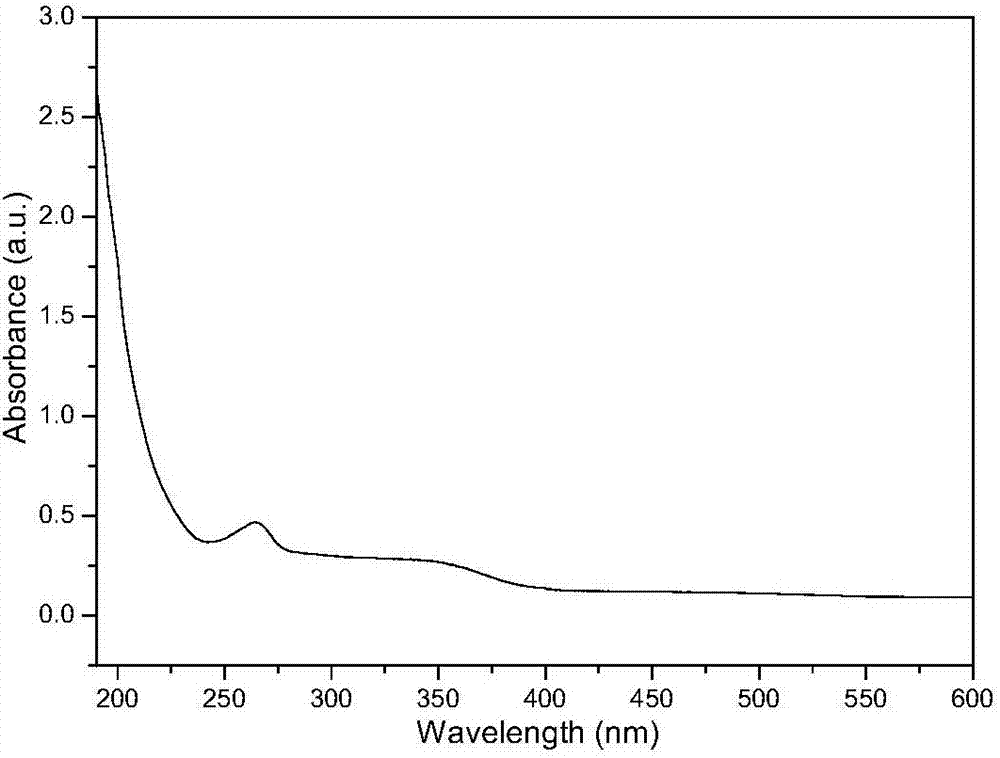

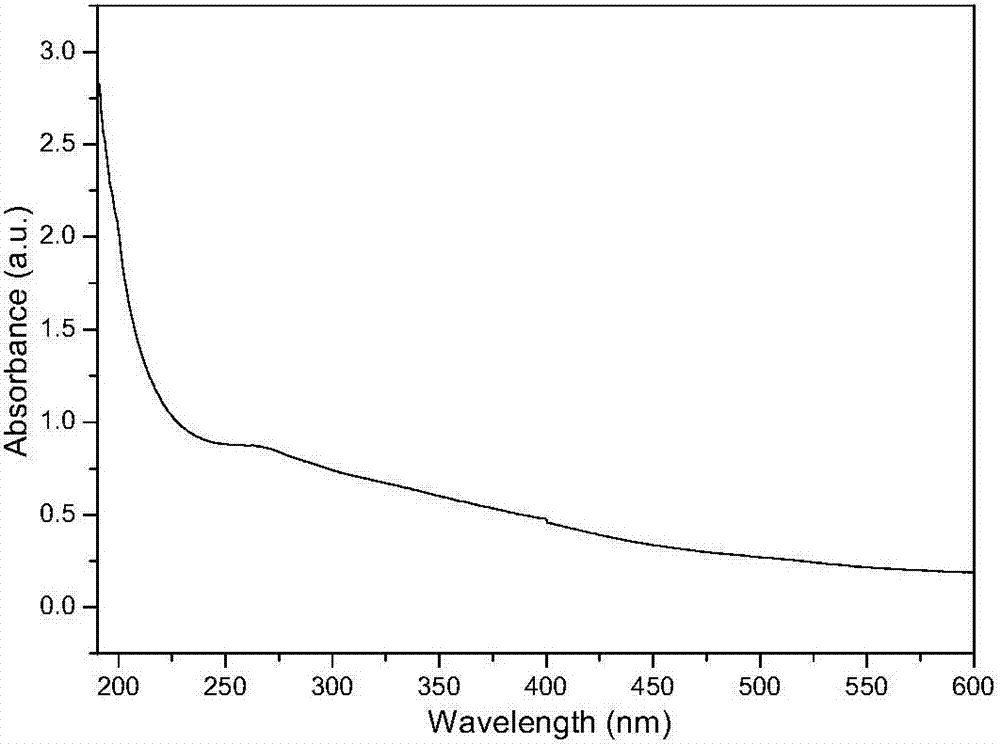

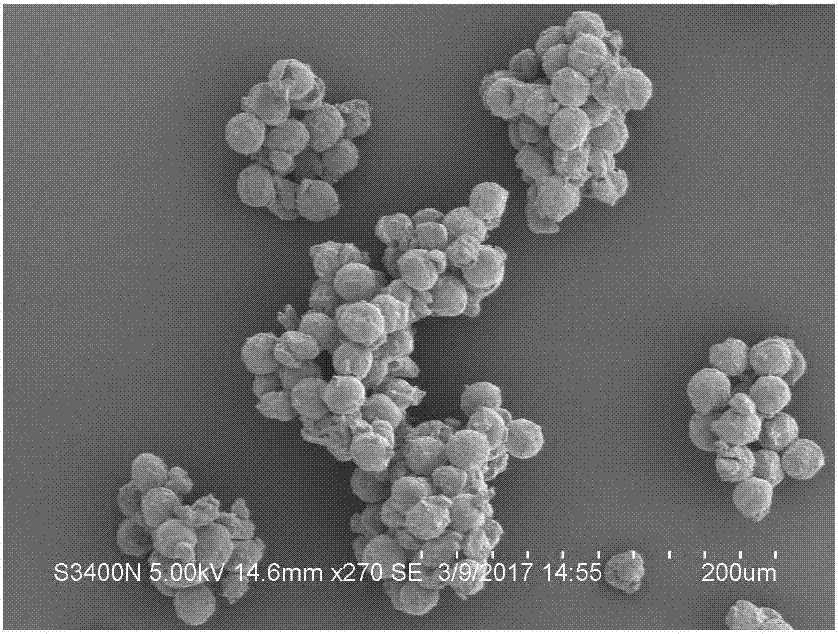

Synthesis method of silver nanoparticles

ActiveCN105642909AAct as a templateReduce usageMaterial nanotechnologyTransportation and packagingSynthesis methodsCarboxymethyl-chitosan

The invention discloses a synthesis method of silver nanoparticles and relates to the technical field of production of green and stable metal nanoparticles. The synthesis method comprises the following steps: uniformly mixing a silver nitrate aqueous solution with a carboxymethyl chitosan aqueous solution, adding a glucose aqueous solution to form a mixed system, and causing the mixed system to react under the stirring condition at the room temperature to obtain silver nanoparticles. The distilled water is used as a dispersion medium; the glucose is used as a reducing agent; the reducing agent is characterized in that the reducing agent is mild, reproducible, cheap and non-toxic; the carboxymethyl chitosan is used as a protection agent; the carboxymethyl chitosan is reproducible polymer chitosan and can be used as a biocompatible and antibacterial derivative. The particles prepared by the method have average particle diameter being smaller than 10nm; the particle diameter is uniformly distributed; the long-term and stable metal nanoparticles can be stored.

Owner:扬州市维纳复合材料科技有限公司

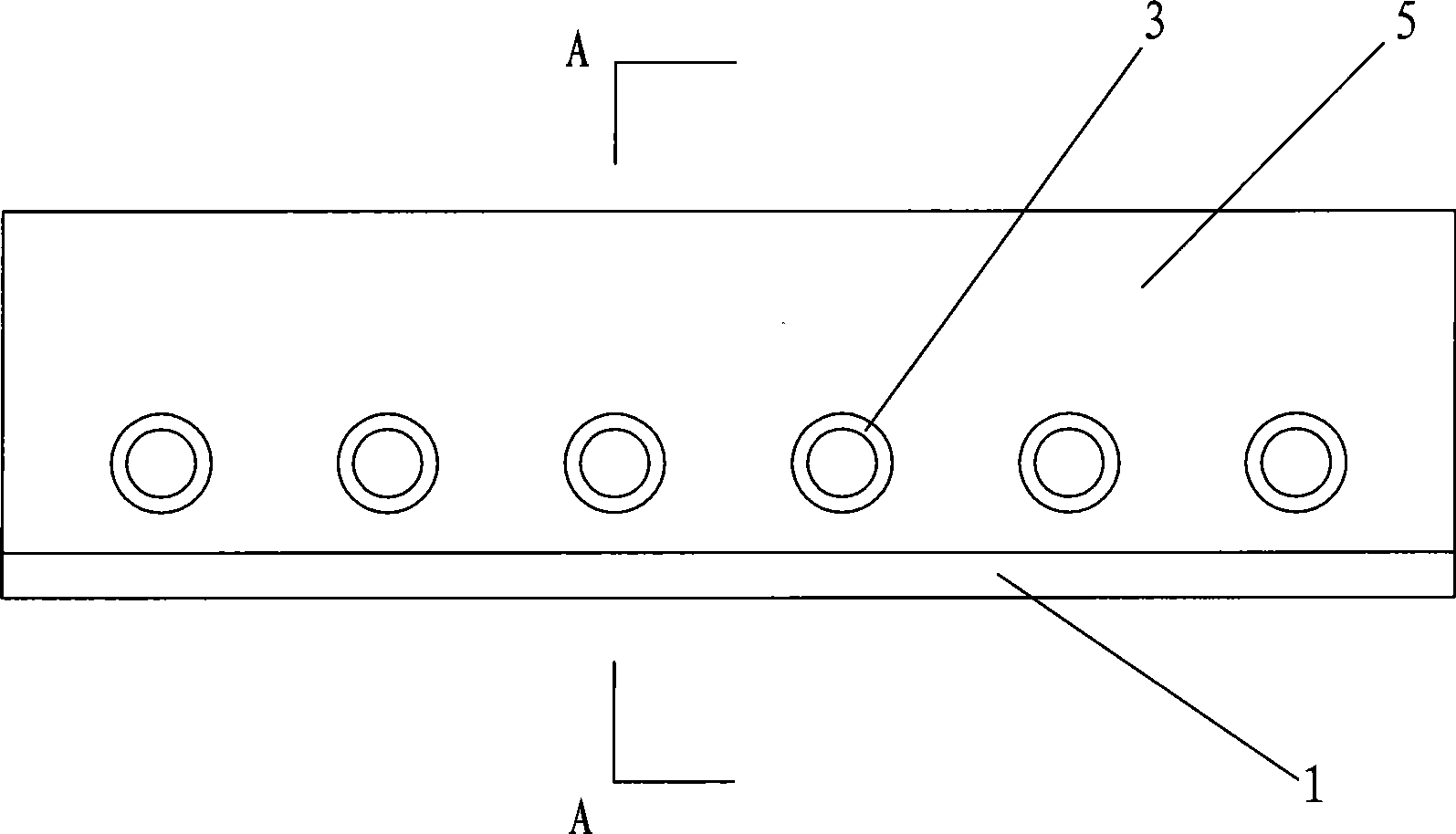

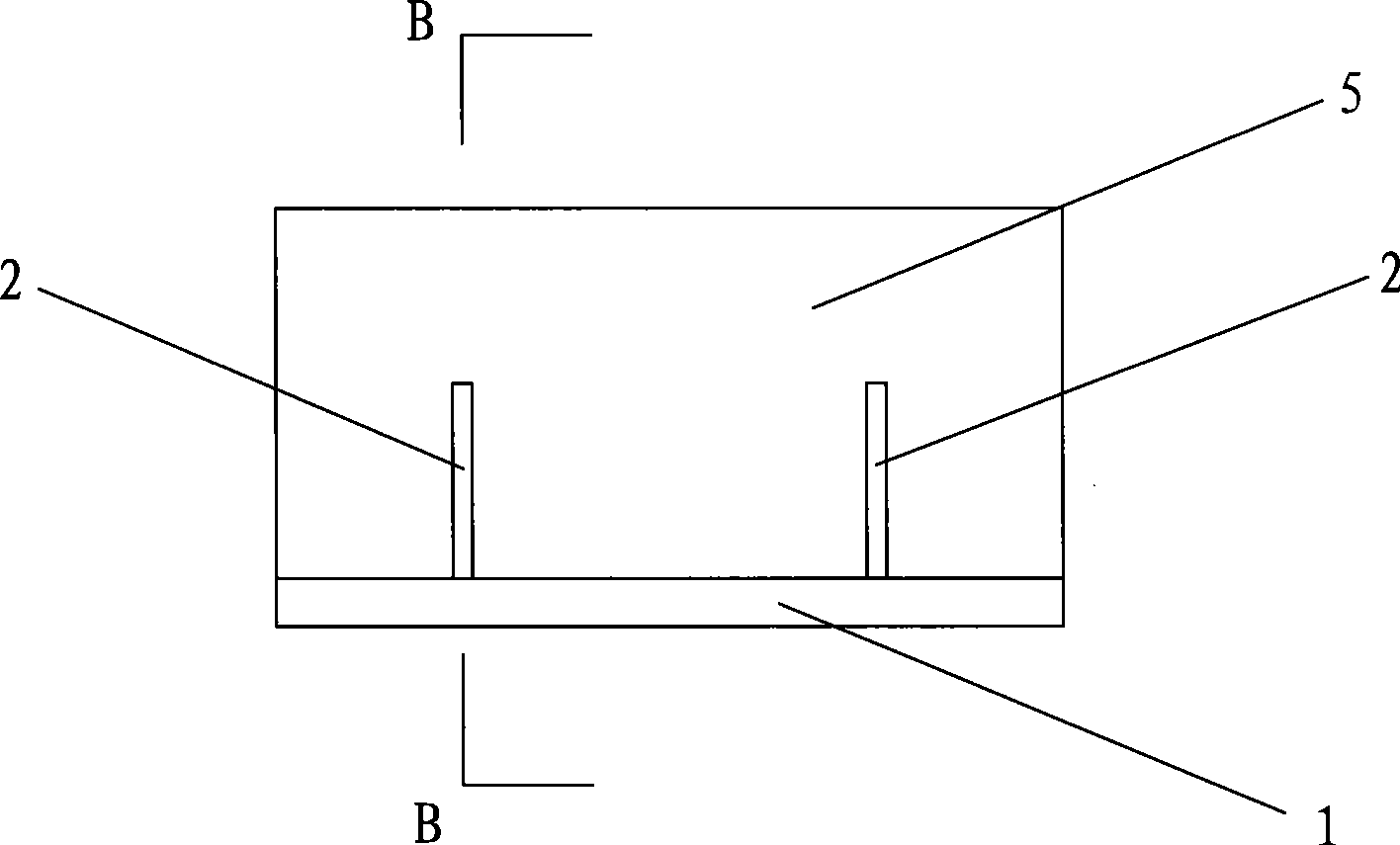

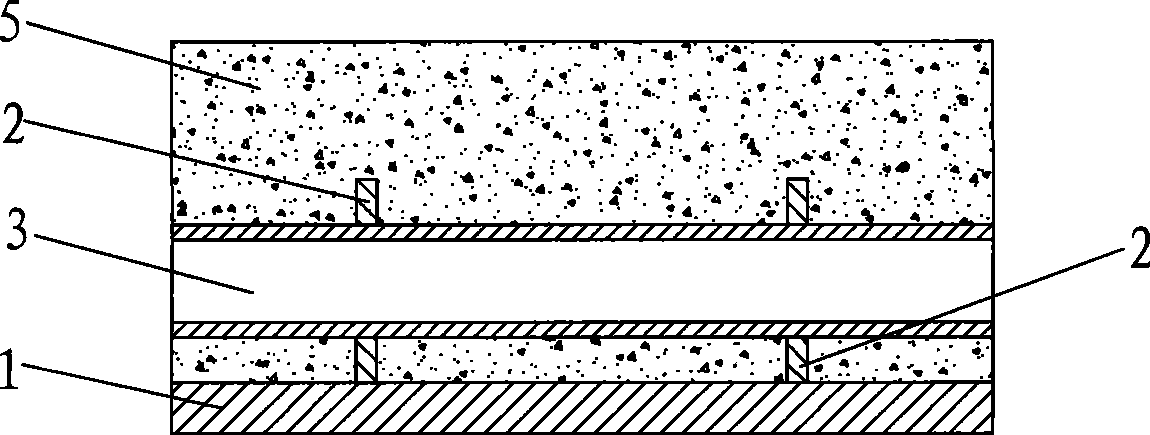

Novel hollow combined board

The invention discloses a novel hollow composite slab, which comprises a flat steel plate, a plurality of holed steel plates, and a plurality of steel pipes, the holed steel plates are parallel and are vertically welded on one plane of the flat steel plate, the plurality of steel pipes respectively pass through corresponding round holes of the holed steel plate and are welded with the round holes, the flat steel plate, the plurality of holed steel plate, and the plurality of steel pipes combine into a hollow slab support, and the hollow slab support is poured with light aggregate concrete to finally form the steel plate-light aggregate concrete hollow composite slab. The novel hollow composite slab of the invention has light weight, convenient construction, higher strength and rigidity, and better bearing performance, can be widely applied to the bridge slabs of new bridges and house buildings, the basement top board or room floor, and can be also applied to the bridge slab replace and maintenance engineering.

Owner:HUAQIAO UNIVERSITY

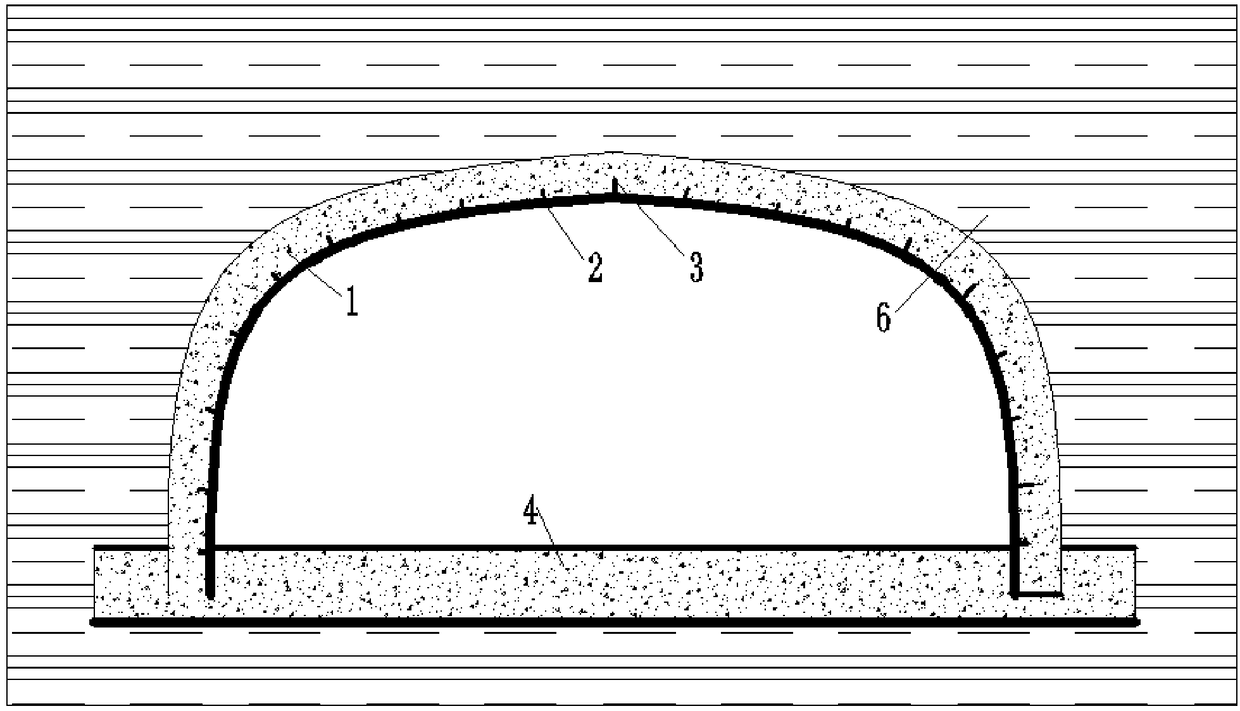

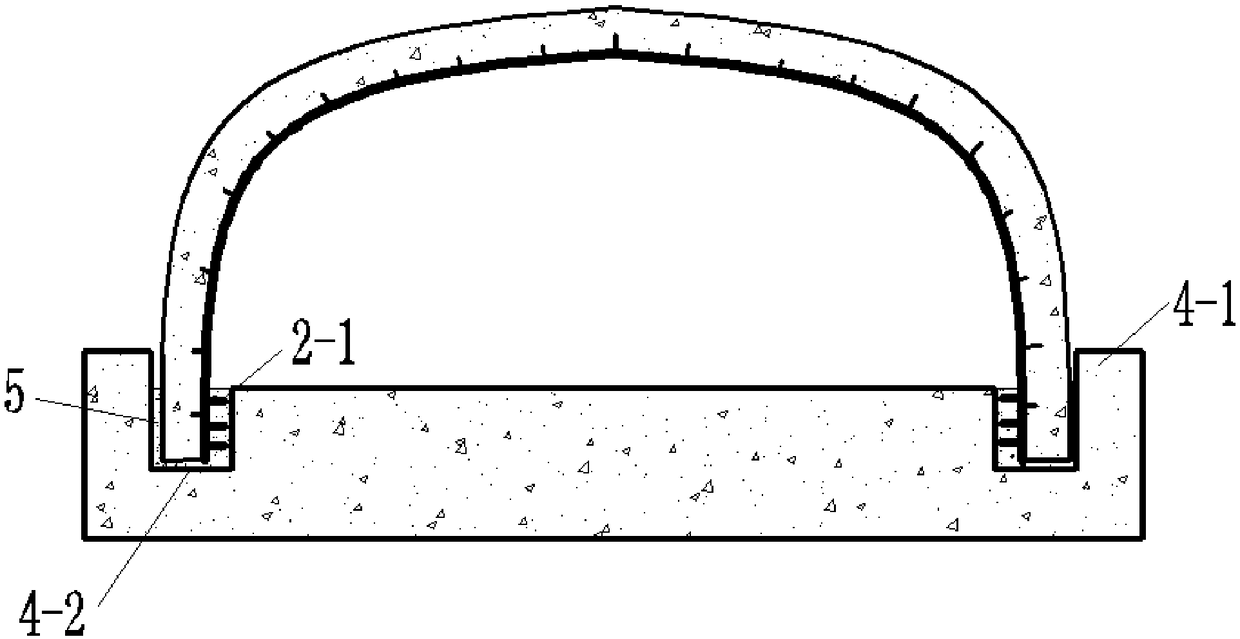

Corrugated steel outside lining concrete structure for underground utility tunnel

InactiveCN108468347AGuaranteed stabilityImprove leak resistanceArtificial islandsUnderwater structuresWater leakageReinforced concrete

The invention discloses a corrugated steel outside lining concrete structure for an underground utility tunnel and relates to underground utility tunnel structures. The problems that existing concretestructures are poor in foundation differential settlement resistance and seepage resistance, fracture and water leakage of connectors of prefabricated tunnels are liable to occur, and corrugated steel tunnel structures are inadequate in stable bearing capacity are solved. The corrugated steel outside lining concrete structure for the underground utility tunnel comprises an outer lining reinforcedconcrete ring, an arch corrugated steel plate and a bottom plate, wherein the outside lining concrete ring covers the outer plate face of the arch corrugated steel plate to form an arch; cup openinggrooves are formed in the transverse left side and the transverse right side of the bottom plate correspondingly; studs are arranged at arch springs of the arch corrugated steel plate; the arc springsare inserted into the cup opening grooves; post-cast arc spring concrete is arranged in the cup opening grooves; and the periphery of the arch and the bottom plate is wrapped with surrounding soil. The corrugated steel outside lining concrete structure is higher in construction speed, and the seepage resistance, the foundation differential settlement resistance and prefabricated section connection convenience of the structure are greatly improved.

Owner:HARBIN INST OF TECH

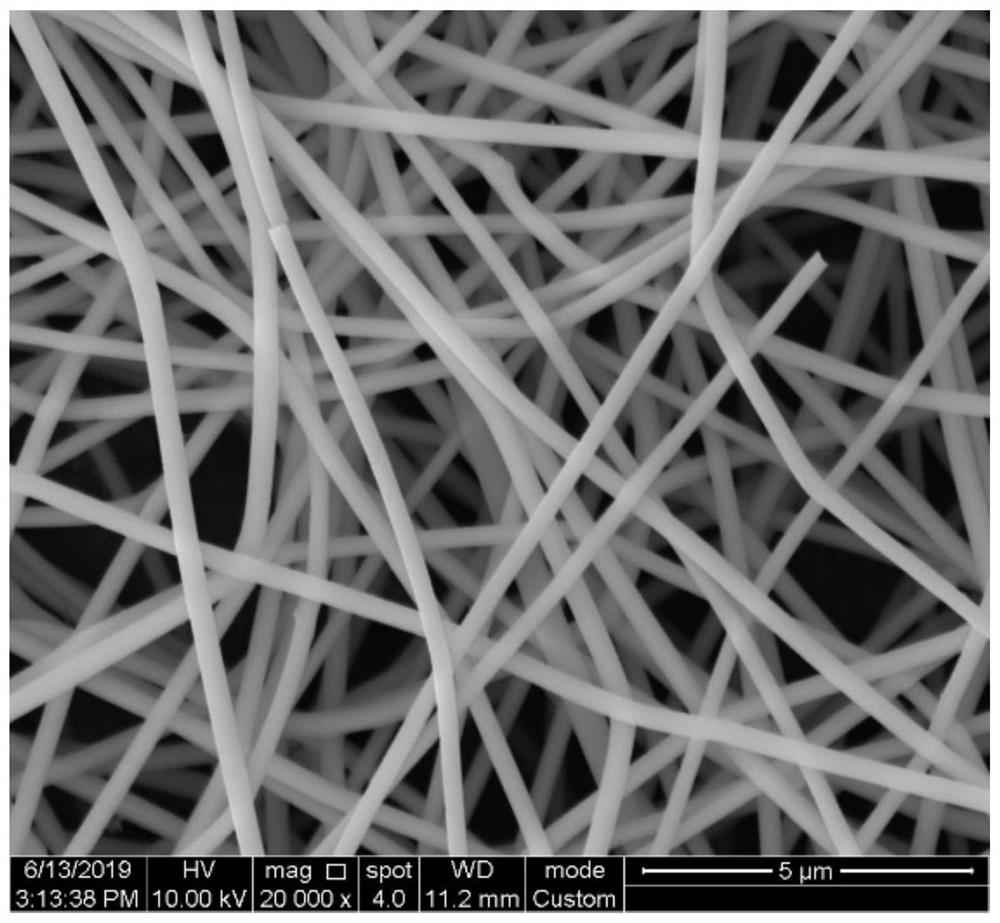

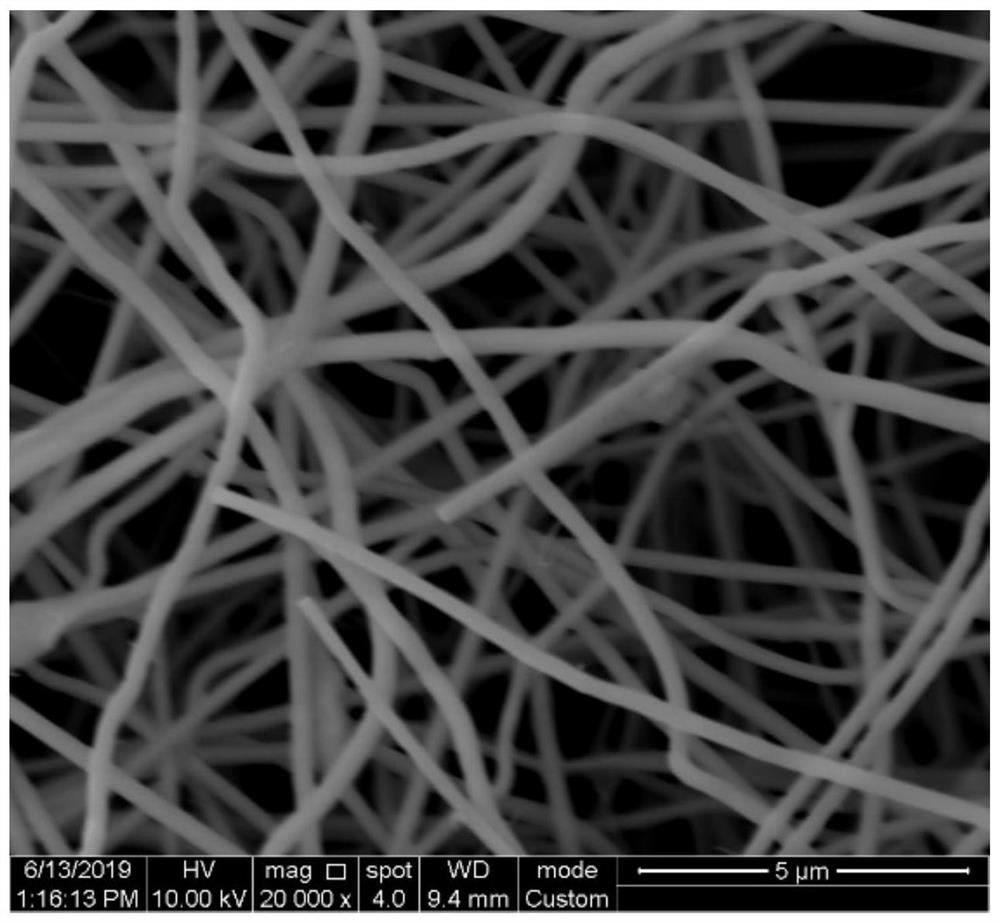

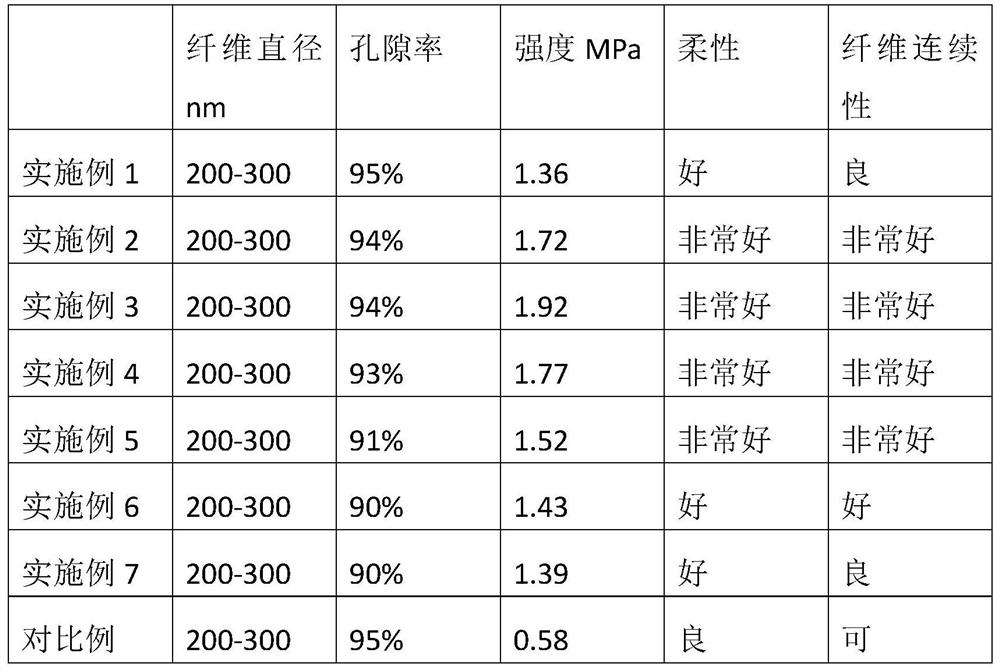

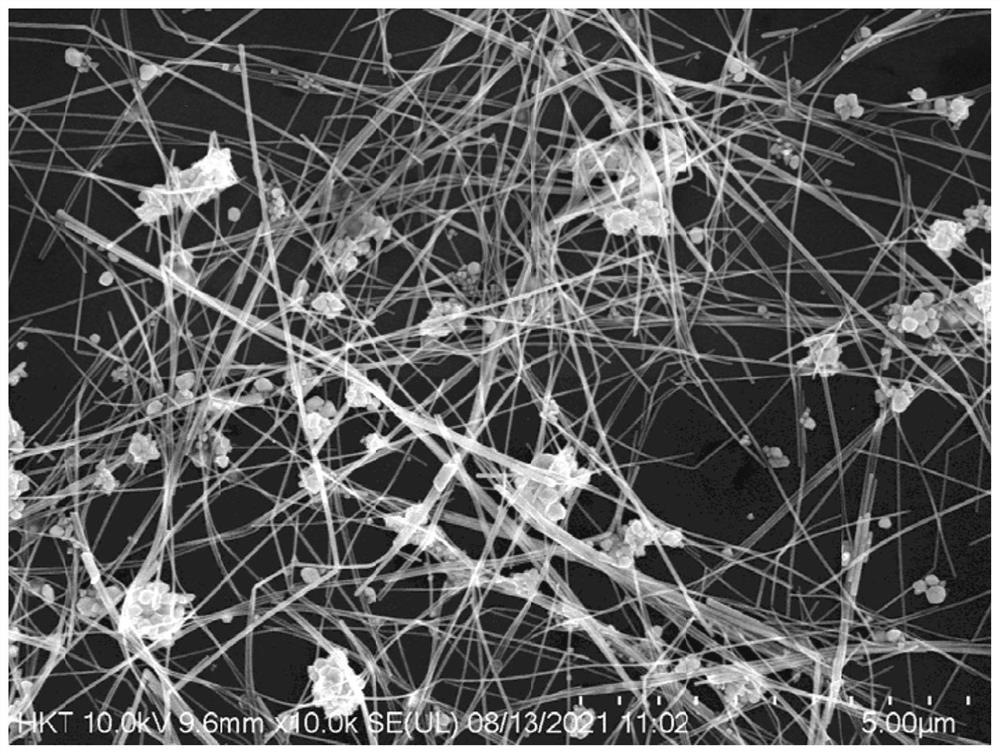

Concave-convex rod enhanced aluminum oxide nanofiber membrane and preparation method thereof

InactiveCN111621921AImprove thermal stabilityFlexible enoughInorganic material artificial filamentsHeating/cooling textile fabricsAl powderSpinning

The invention relates to a concave-convex rod enhanced aluminum oxide nanofiber membrane and a preparation method thereof. Components of the nanofiber membrane comprise concave-convex rods and aluminum oxide with the mass ratio being (1-30):100. The preparation method comprises the steps that inorganic aluminum salt, aluminum isopropoxide and aluminum powder are firstly used for being heated and flowing back under certain conditions of the pH value and temperature to prepare alumina sol, and then the alumina sol is added into the screened concave-convex rods and spinning auxiliaries of a certain proportion to obtain a composite spinning solution; high-pressure electrostatic spinning equipment is used for spinning, and a concave-convex rod enhanced aluminum oxide precursor nanofiber membrane is obtained; and finally through drying and high-temperature heat treatment, the concave-convex rod enhanced aluminum oxide nanofiber membrane is obtained. Compared with existing aluminum oxide nanofiber membranes, the prepared nanofiber membrane is lower in cost and high in productivity and shows more excellent flexibility and higher strength.

Owner:明光市铭垚凹凸棒产业科技有限公司 +1

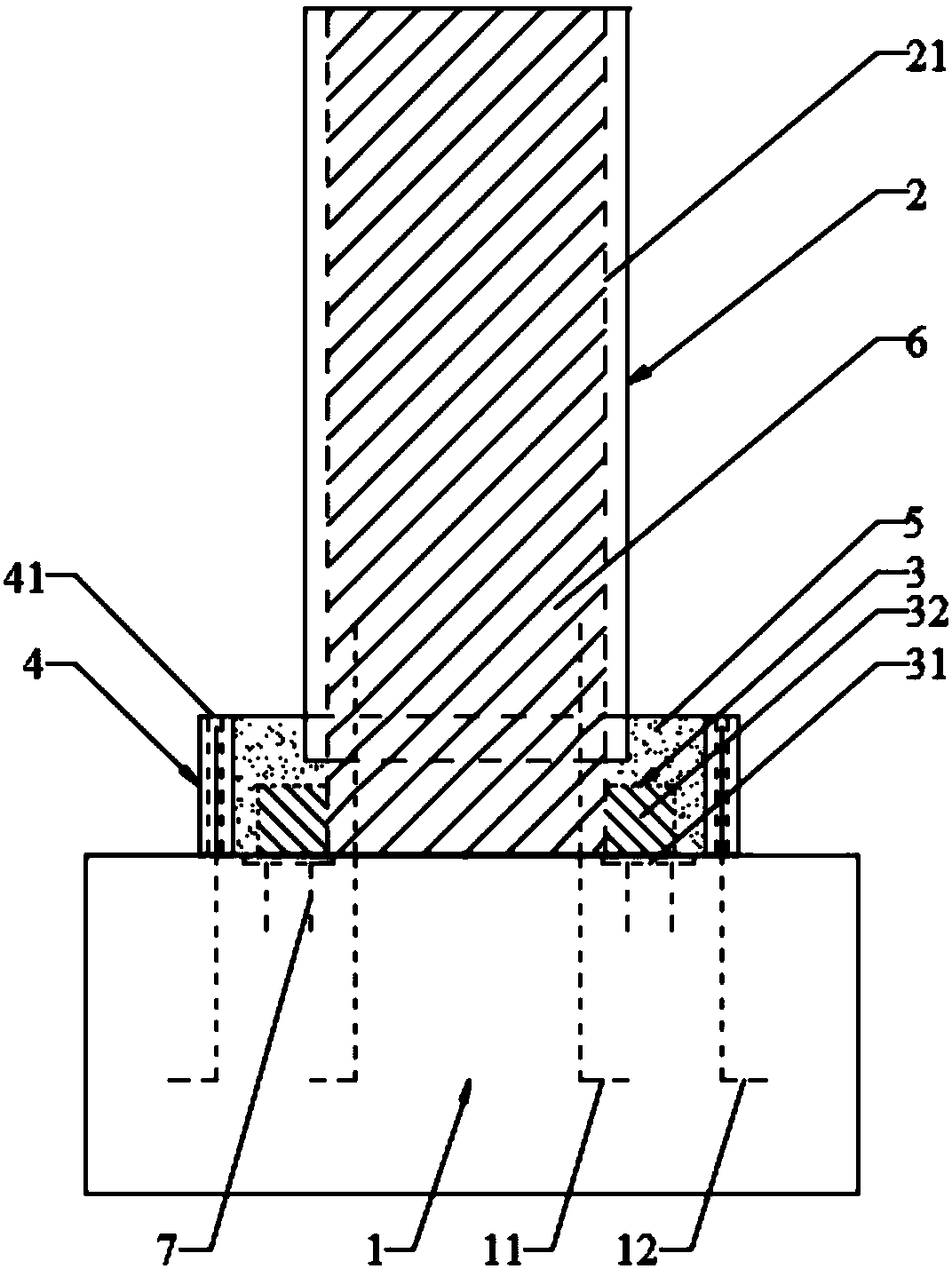

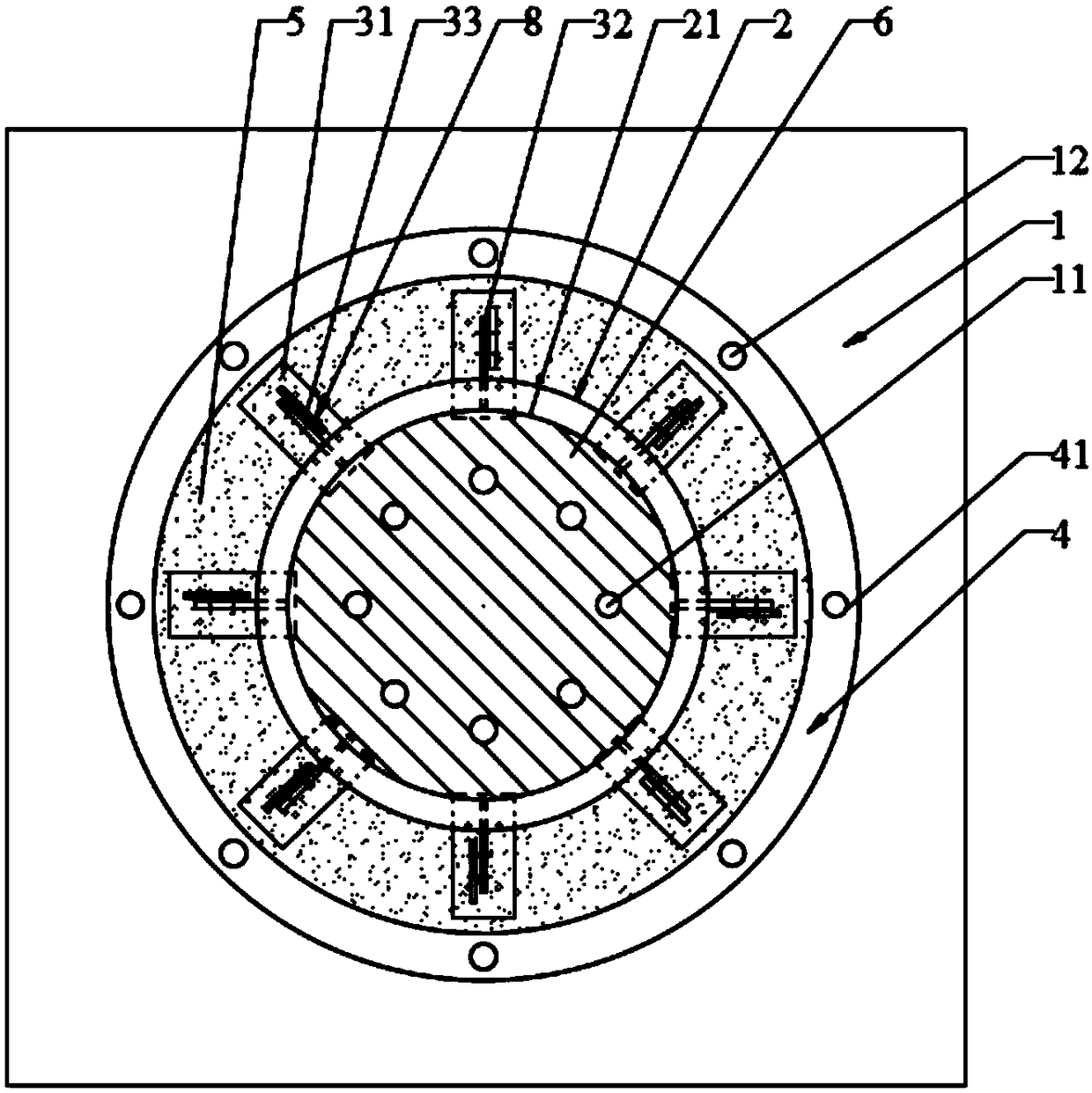

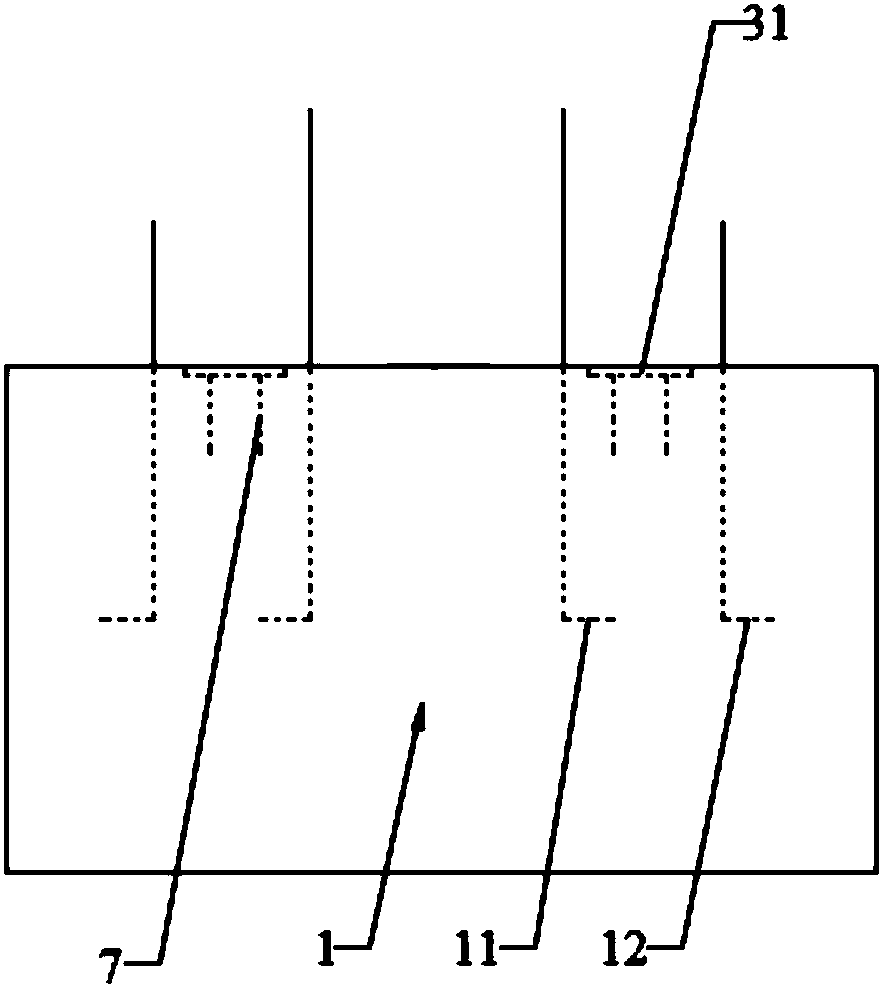

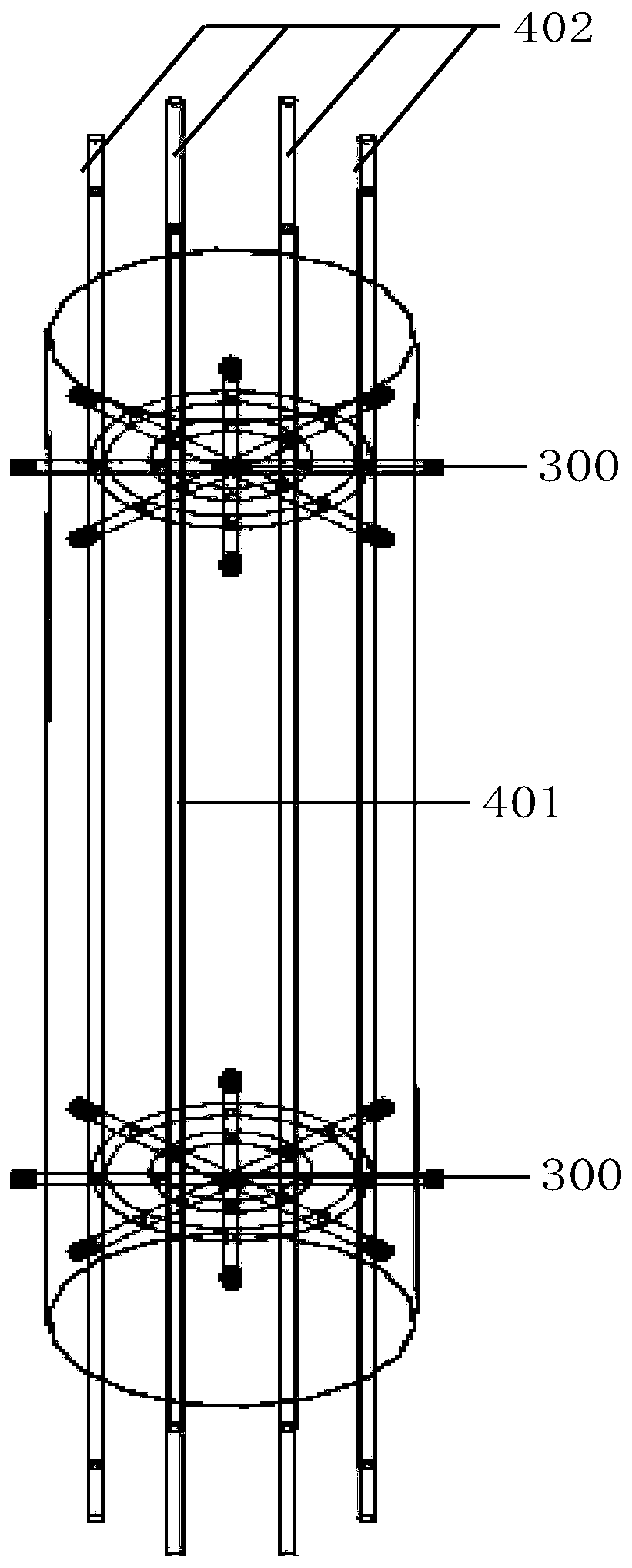

Bridge pier structure and construction method thereof

PendingCN108505433ACorrosion resistanceWear resistanceBridge structural detailsBridge erection/assemblySheet steelEngineering

The invention relates to the technical field of bridge construction, in particular to a bridge pier structure and a construction method thereof. The bridge pier structure comprises a prefabricated bearing platform, a prefabricated bridge pier, a steel plate assembly and a thin-walled circular ring; two groups of first steel rebars and second steel rebars which are arranged in the vertical direction and uniformly distributed in the form of a circumference; the first steel rebars are positioned on the internal sides of the second steel rebars; the top ends of the first steel rebars and the second steel rebars both extend out of the upper surface of the prefabricated bearing platform; a hollow steel tube which runs through the prefabricated bridge pier and is arranged in the vertical direction is embedded in the prefabricated bridge pier; and the prefabricated bridge pier is arranged on the prefabricated bearing platform through the hollow steel tube. The bridge pier structure has the advantages that the structural design is simple; the construction is convenient; as only a small part of later pouring concrete needs to be poured, the construction efficiency is enhanced, and the construction period of the bridge is reduced; the influence of bridge construction on city traffic environment is effectively relieved; and the assembling strength and integrity of the prefabricated bridgepier and the prefabricated bearing platform are also guaranteed.

Owner:FUJIAN UNIV OF TECH

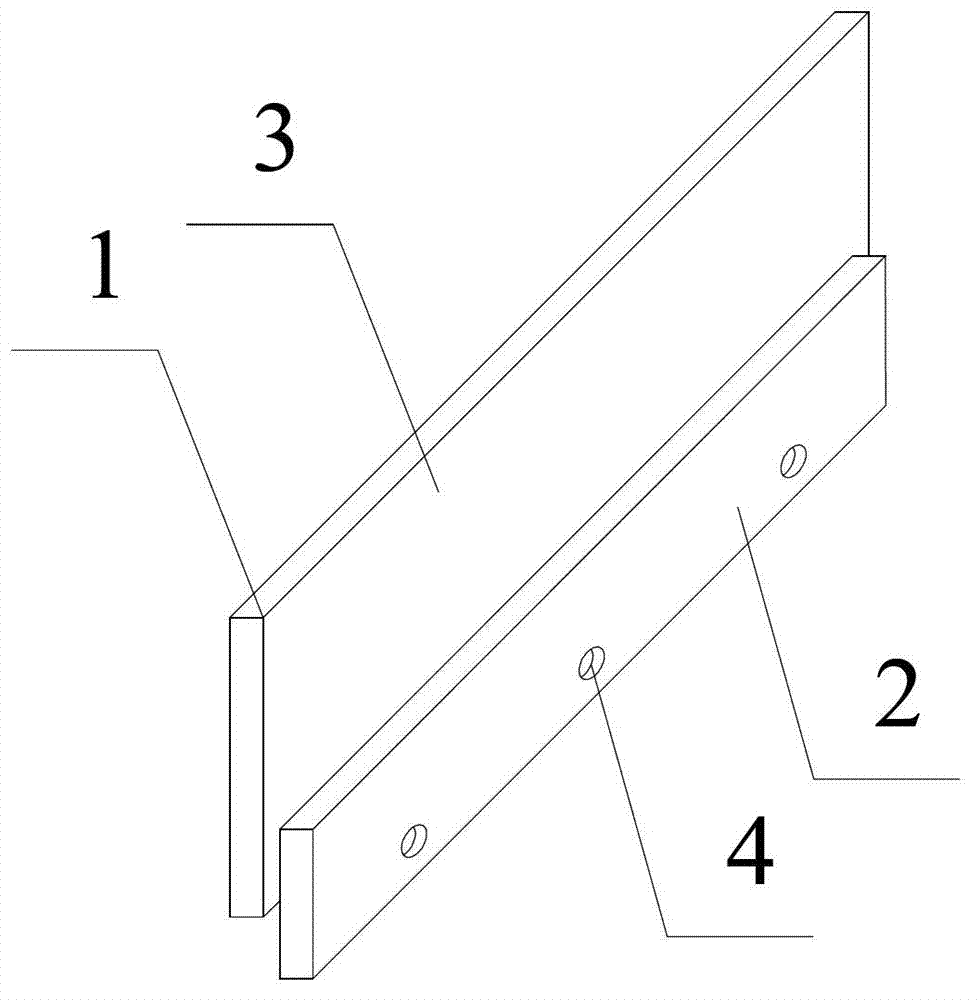

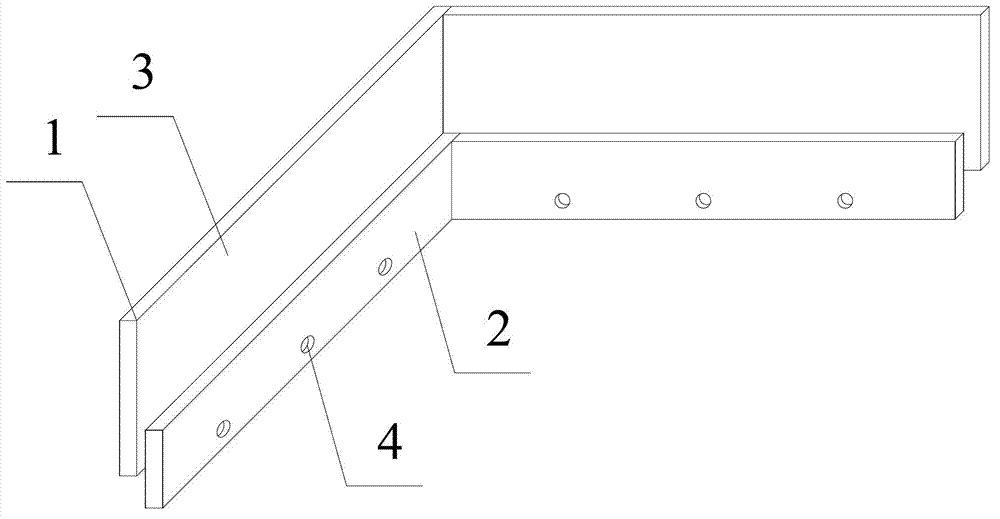

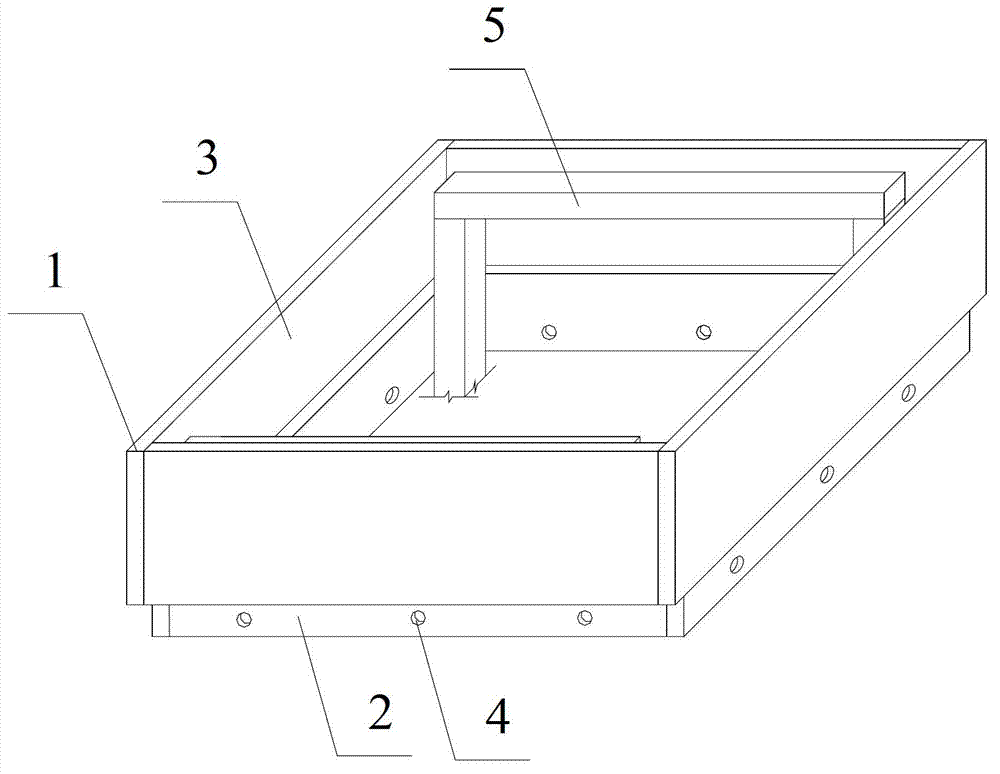

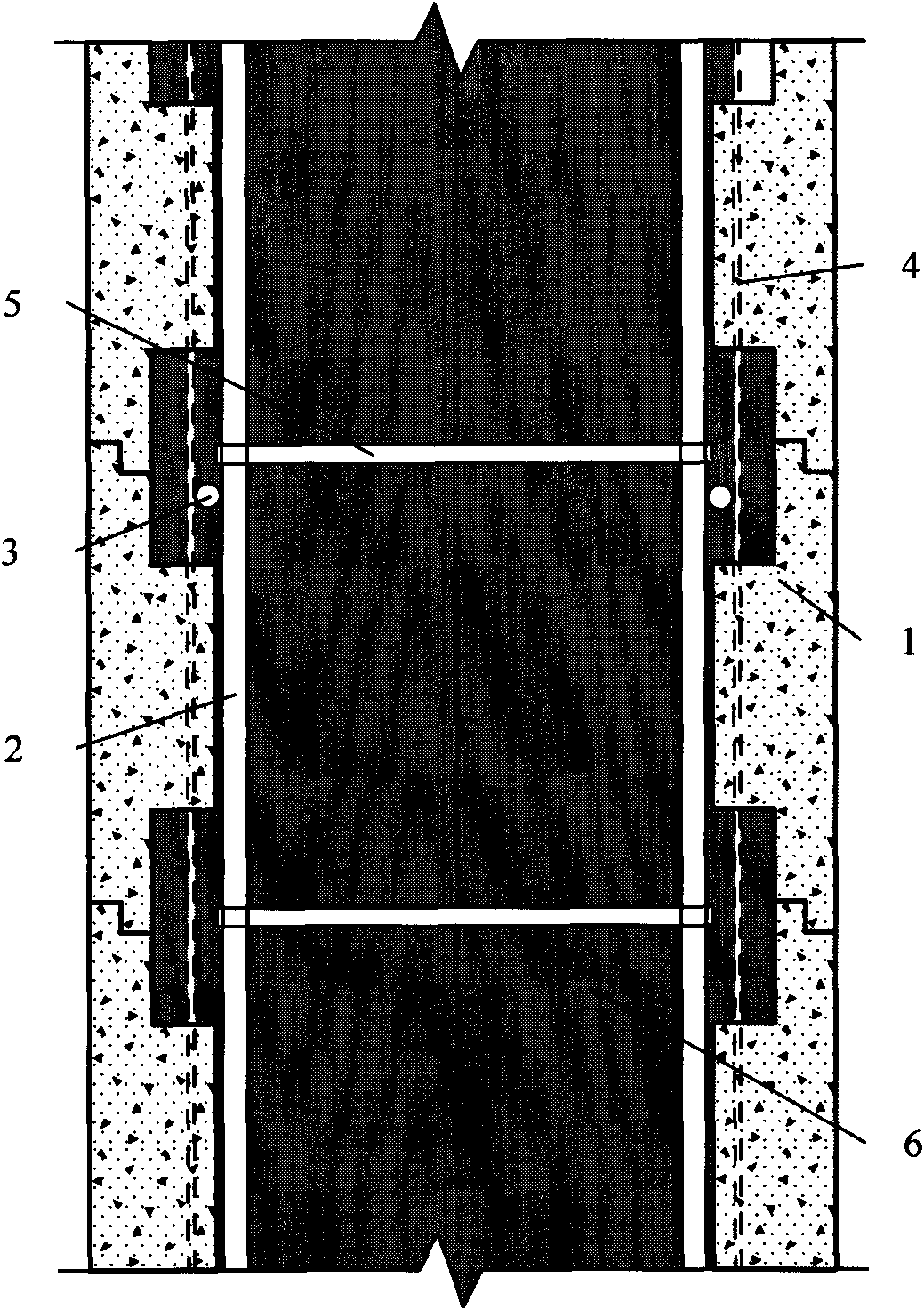

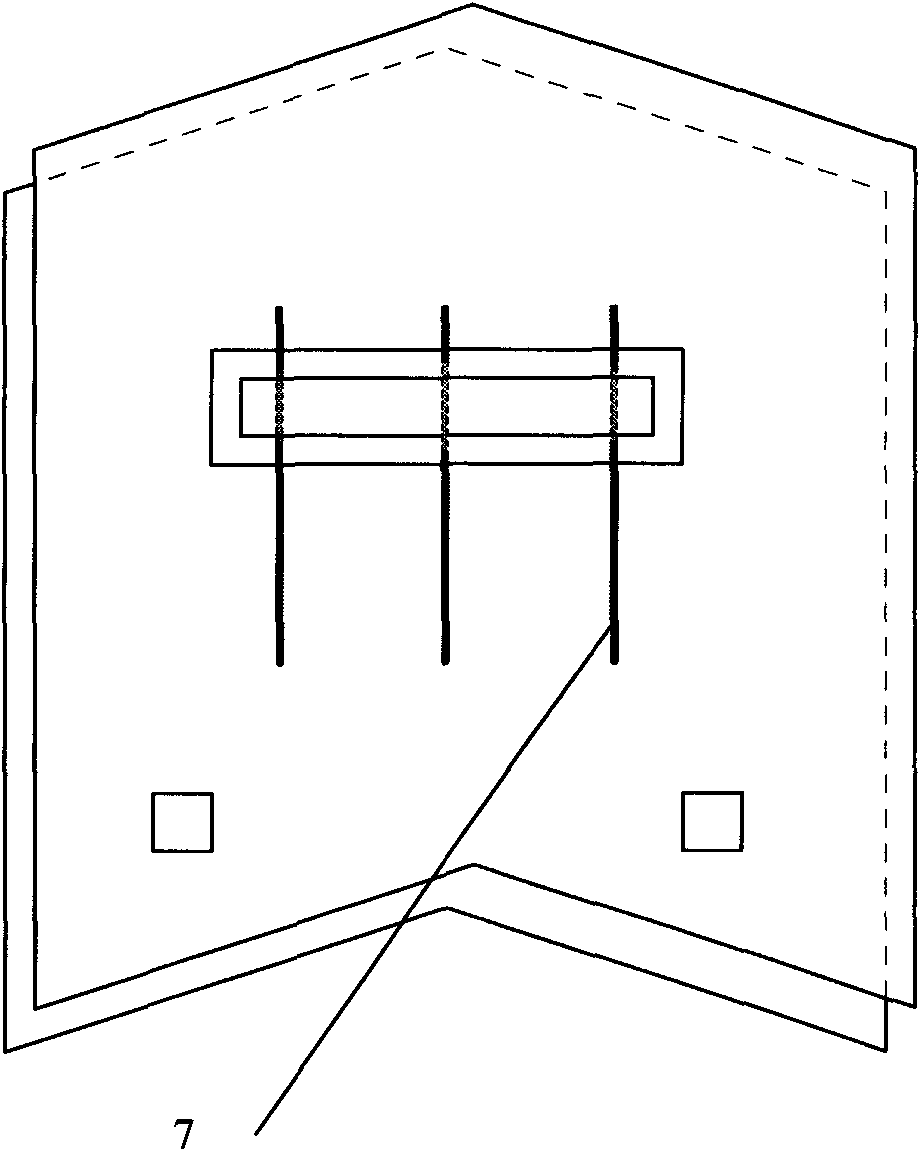

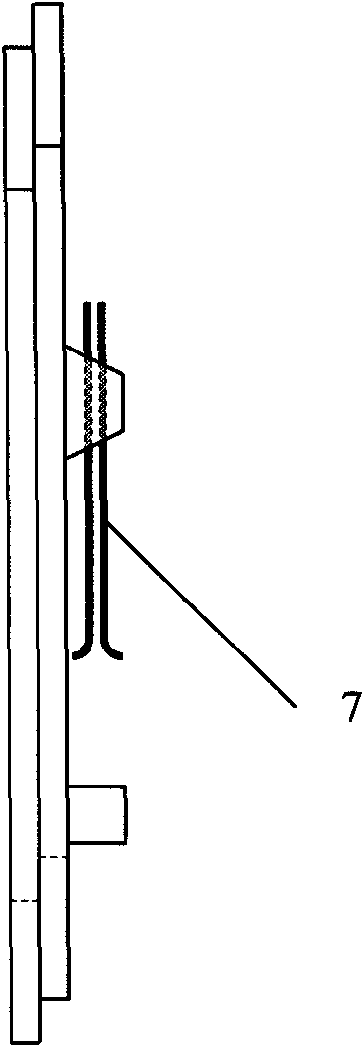

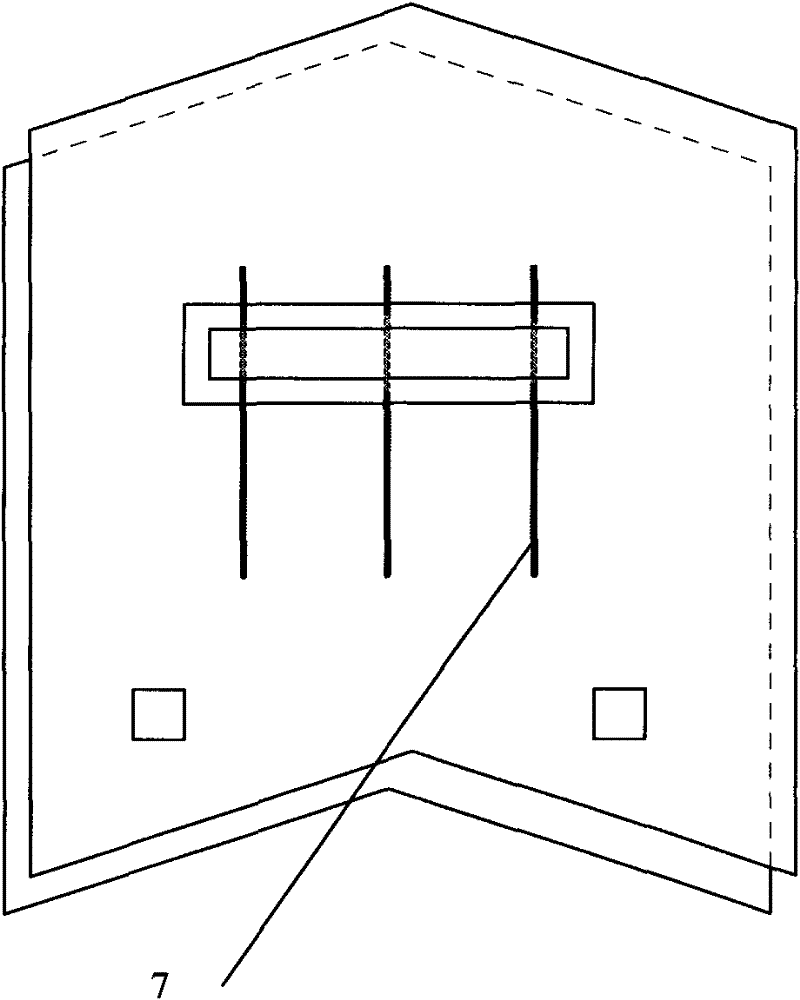

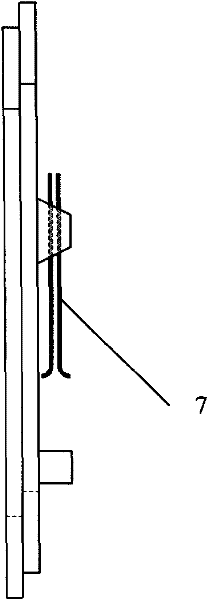

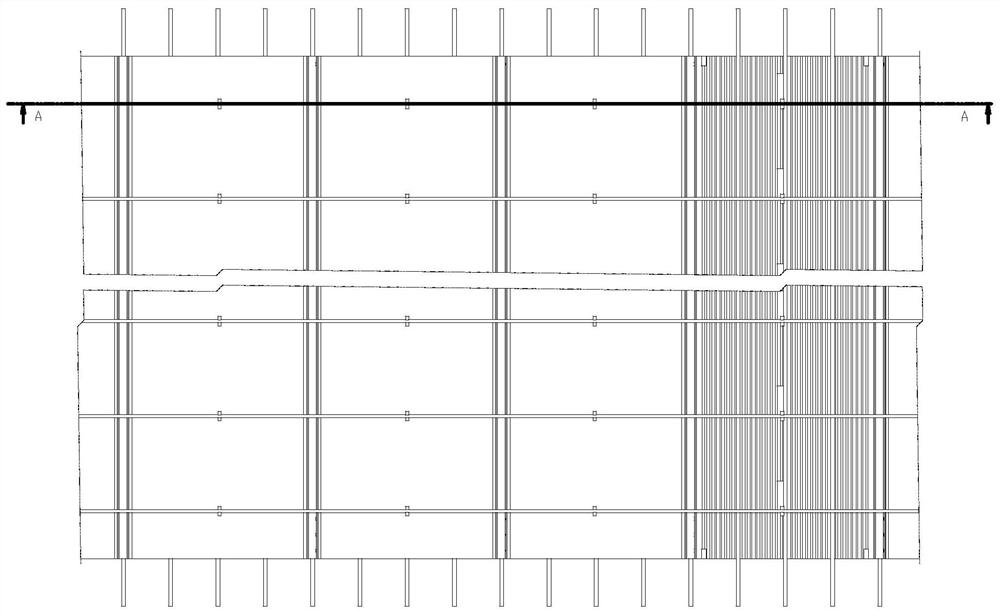

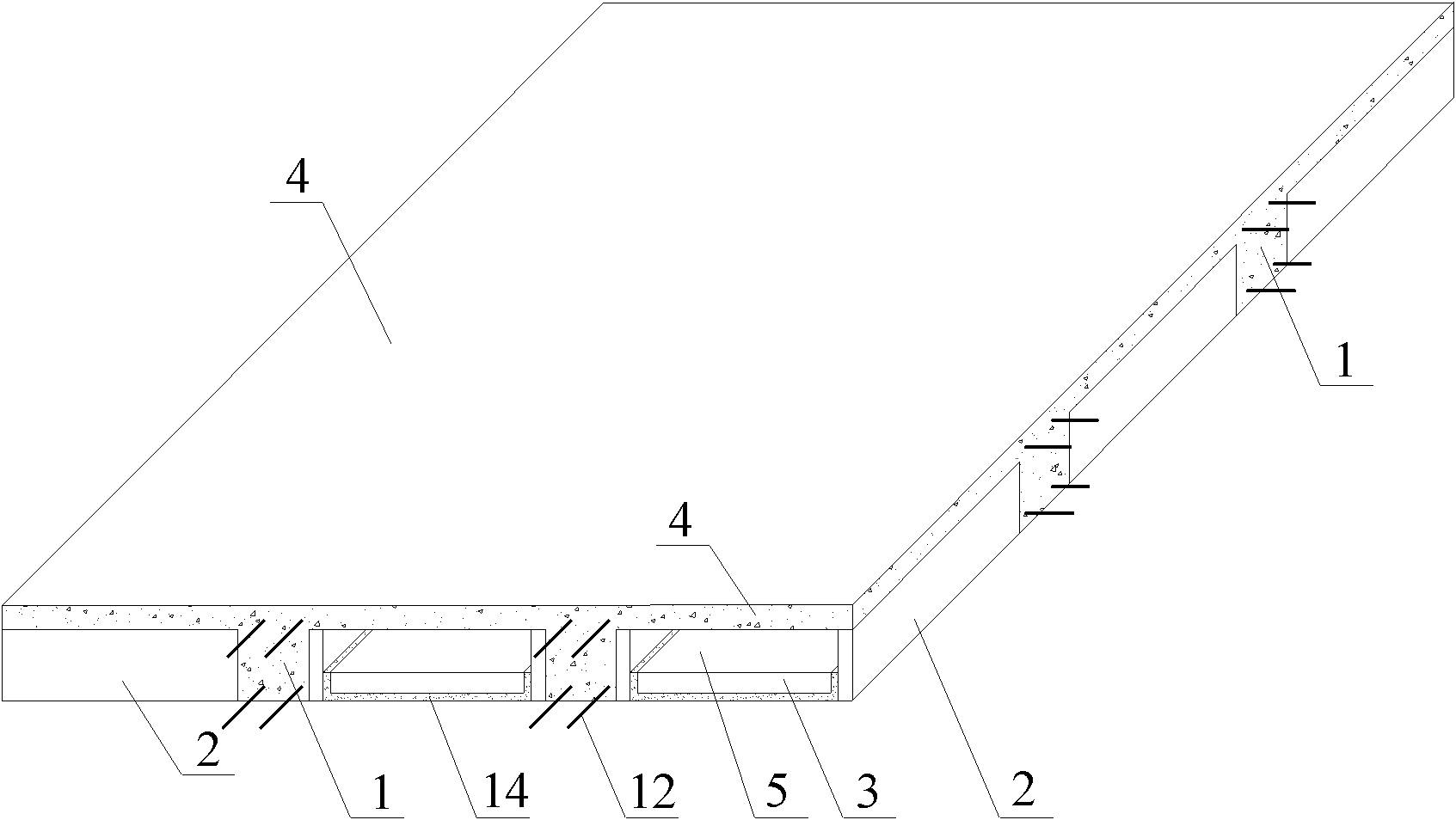

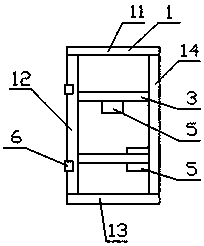

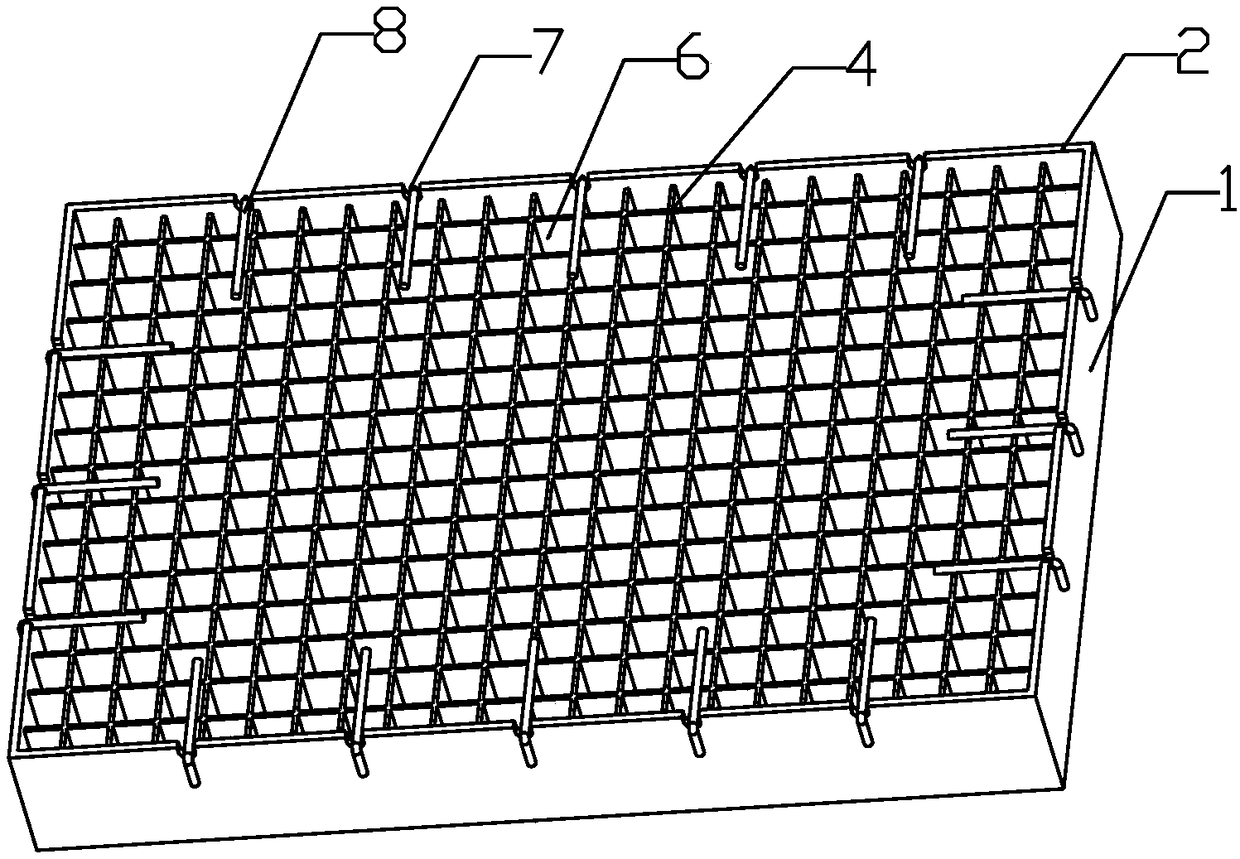

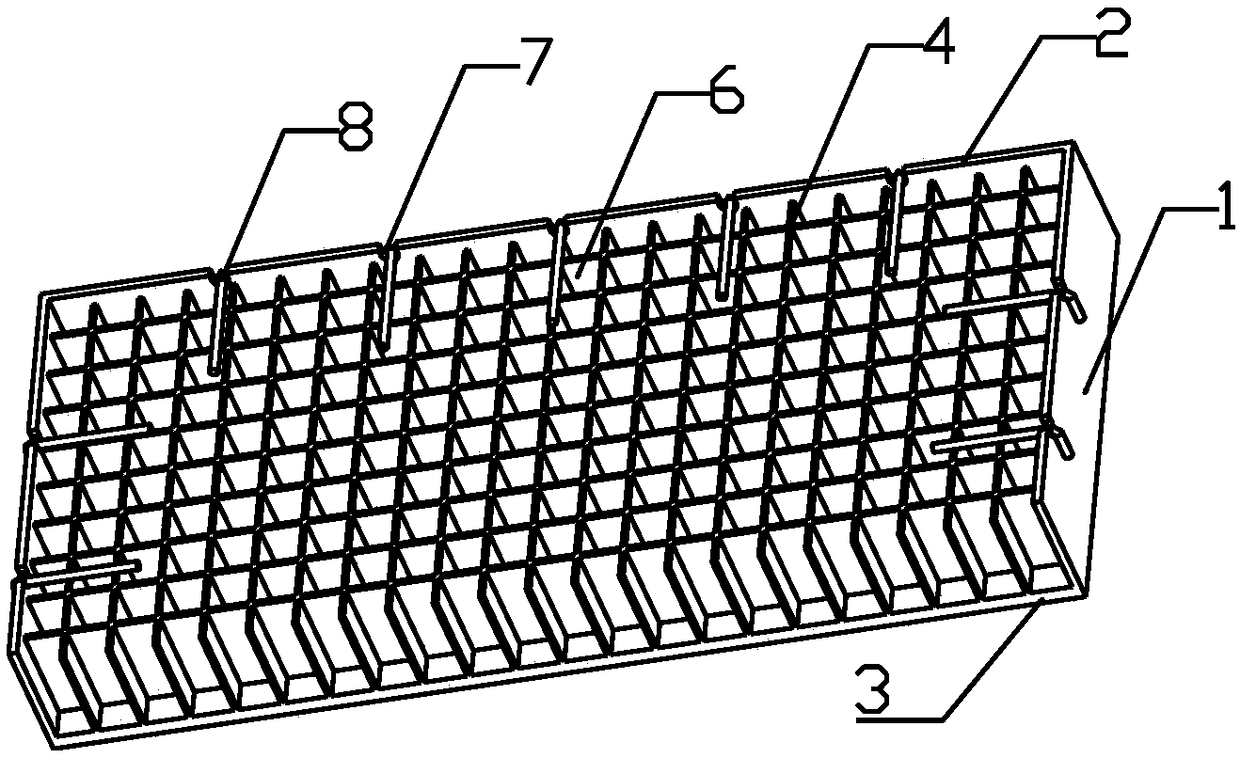

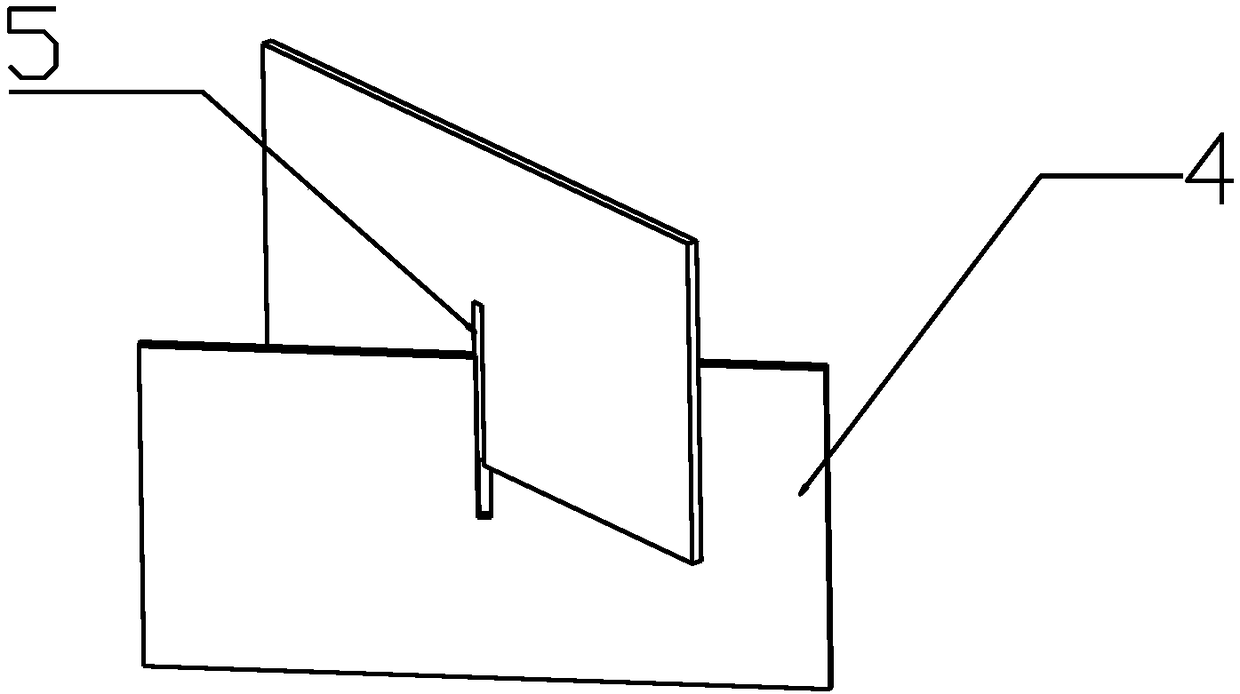

Hollow slab form used for building and construction method

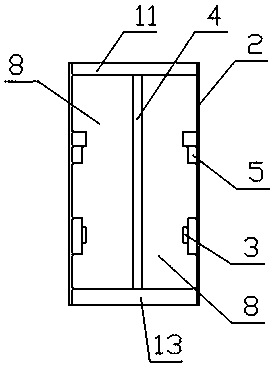

InactiveCN102817473AEasy to obtainEasy to assembleFloorsForms/shuttering/falseworksMaterial consumptionRebar

The invention discloses a hollow slab form used for a building and a construction method. The hollow slab form comprises a side template (1) and a prefabricated soleplate (8), wherein the side template (1) is dislocated and lapped by a lower side template (2) and an upper side template (3), and a hole or a notch (4) is arranged at the bottom of the lower side template (2) and is located at the inner side of the upper side template (3). The construction method comprises the following steps: a bottom template (11) is supported, a rib beam reinforcing steel bar (10) is bound, and the spliced side template (1) is placed; the prefabricated soleplate (8) is placed on a support part (7), and a horizontal support is provided; the concrete is poured, after the concrete reaches a certain intensity, the lower side template (2) is dismounted, the prefabricated soleplate (8) is arranged on the support rib (7), and mortar is painted on the prefabricated soleplate to form the hollow slab. The hollow slab form has the advantages of less material consumption, easiness in splicing, recycling, simple construction, and capability of minimizing widths of seams between the prefabricated soleplate and cast-in-place dense ribs, and improving integrity of the hollow slab.

Owner:湖南航凯建材技术发展有限公司

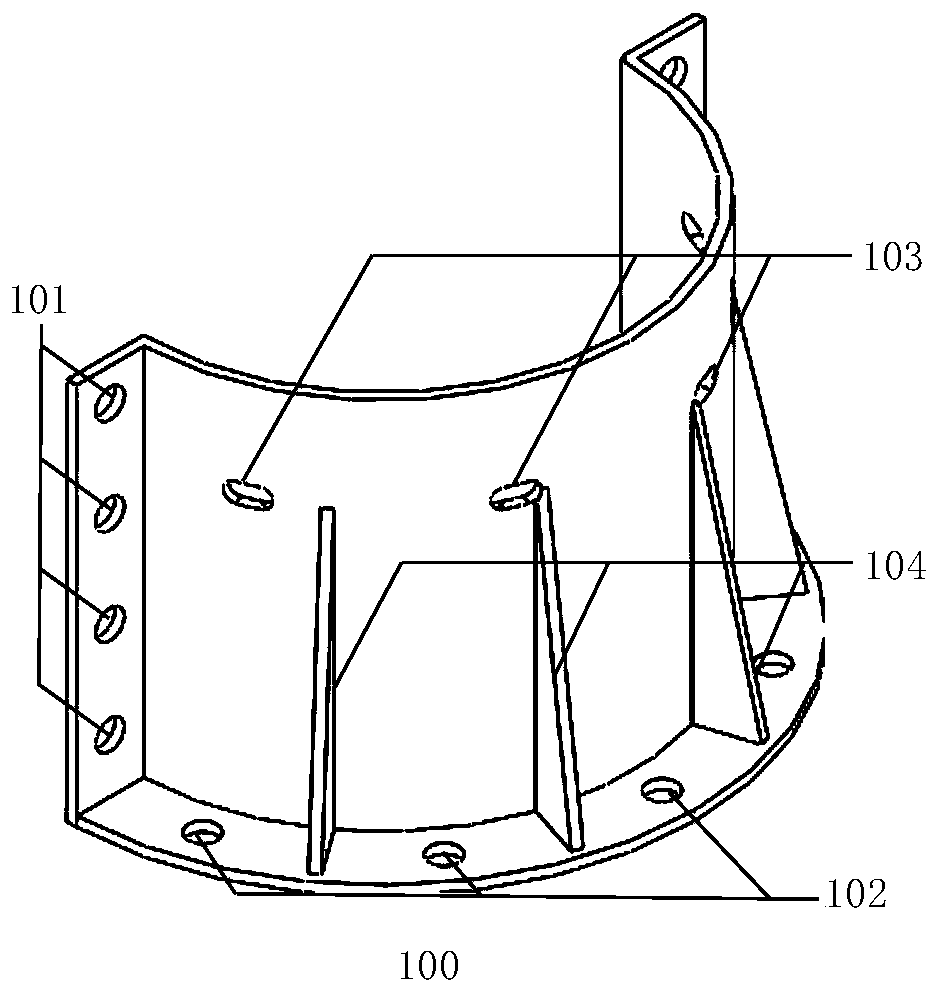

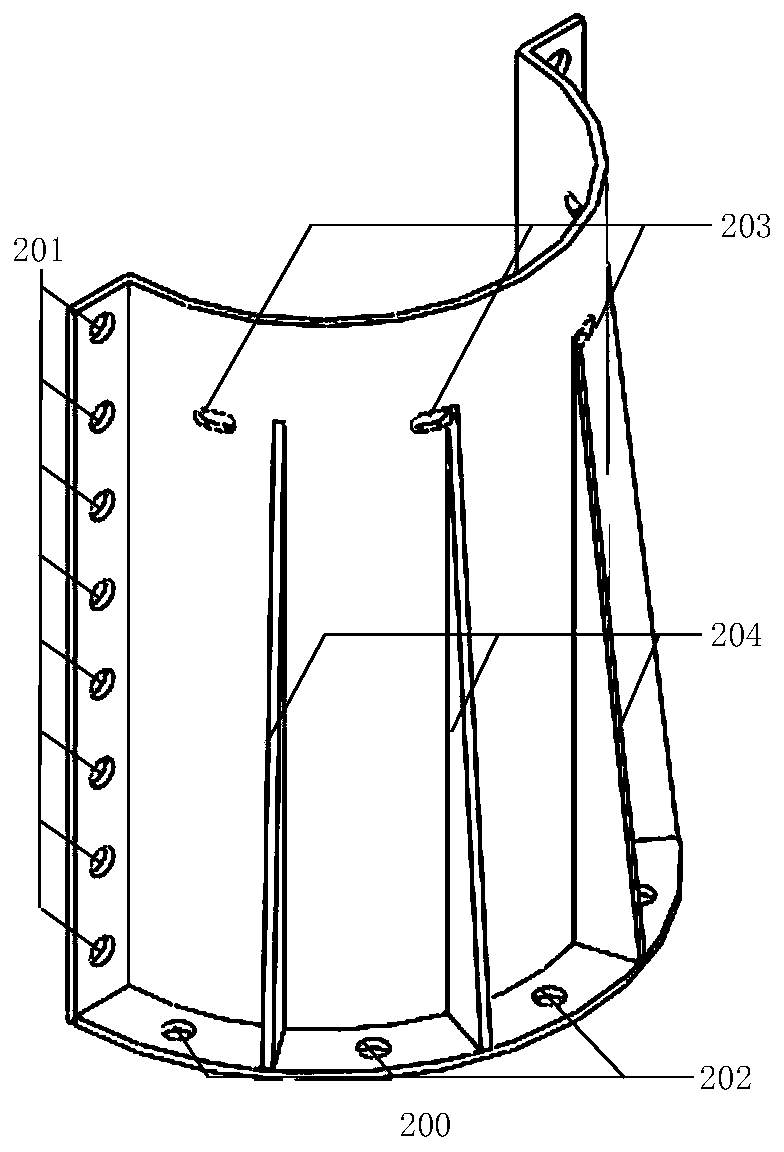

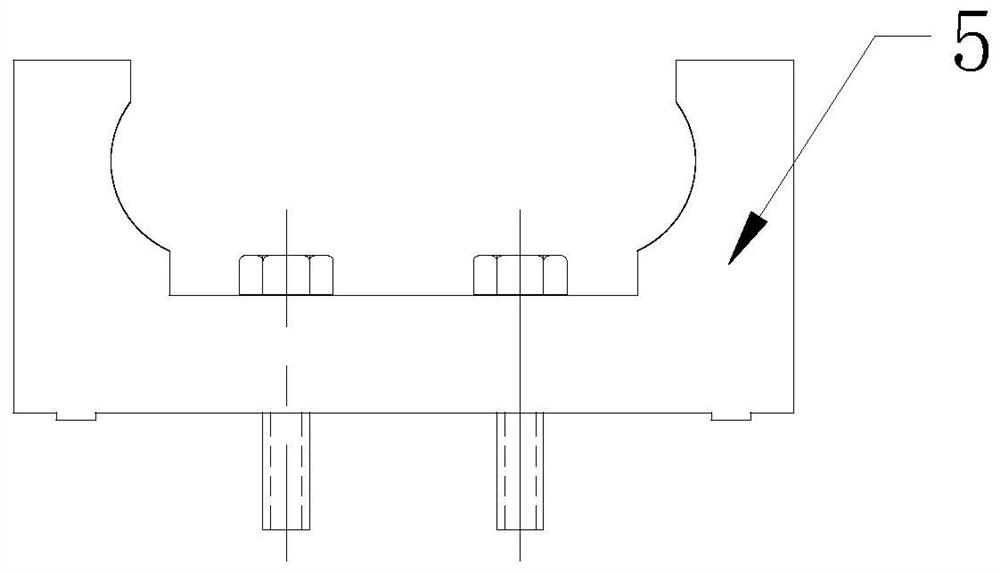

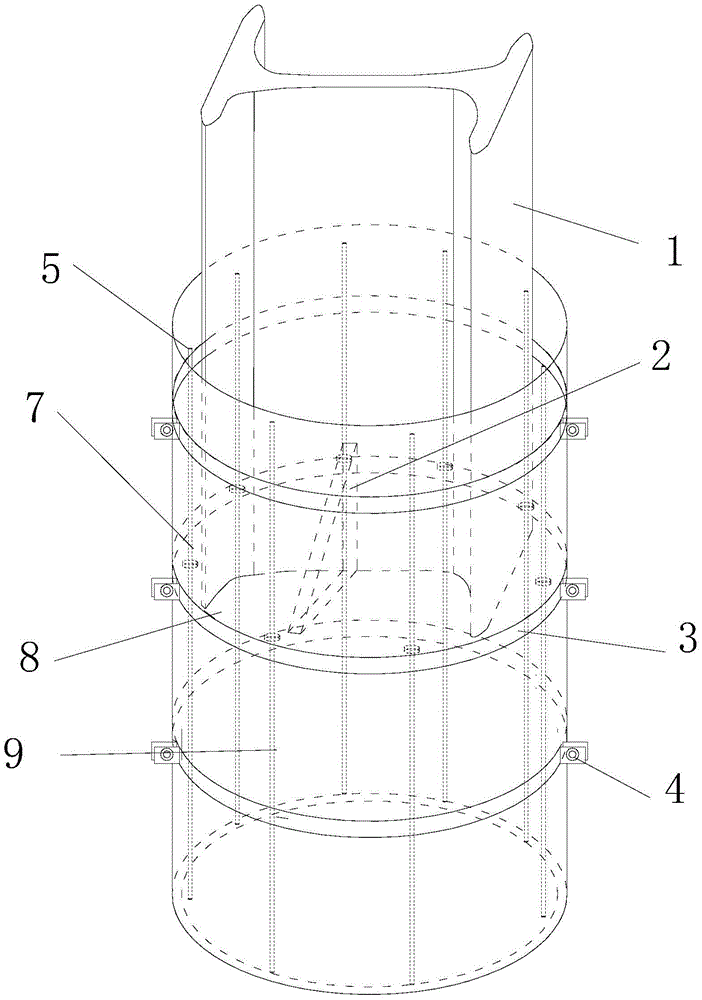

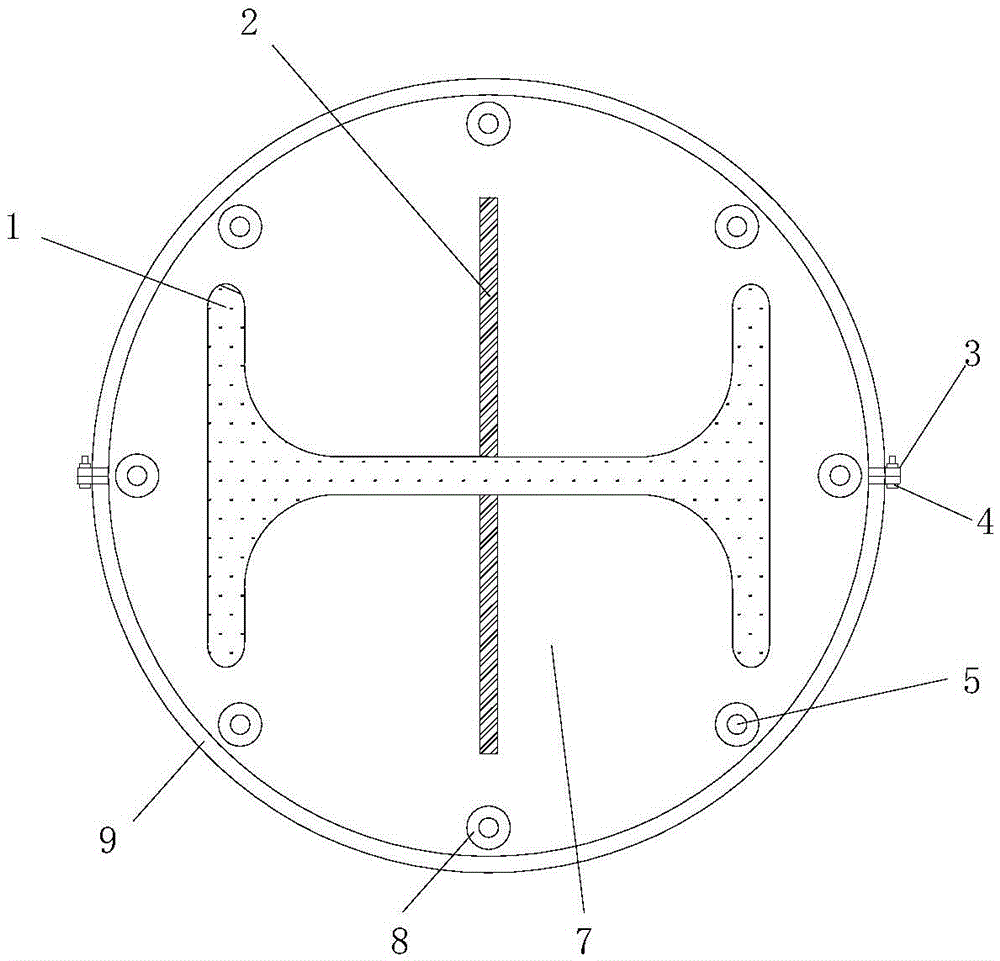

Segment prefabricated assembled pier steel member and construction method and application

ActiveCN110387826AFirmly connectedAct as a templateBridge structural detailsBridge erection/assemblyRebarPrefabrication

The invention discloses a segment prefabricated assembled pier steel member which comprises a short steel component, a long steel component and anchoring positioning steel bars, a plurality of first reinforcing ribs are arranged on the short steel component, first vertical bolt holes are formed in the two ends of the short steel component, and a plurality of first horizontal bolt holes are formedin the lower end steel plate; a plurality of second reinforcing ribs are arranged on the long steel component, second vertical bolt holes are formed in the two ends of the long steel component, and aplurality of second horizontal bolt holes are formed in the lower end steel plate; the anchoring positioning steel bars are uniformly scattered in a steel reinforcement cage, spiral teeth are arrangedat the outer ends of the anchoring positioning steel bars respectively, and a plurality of matched reinforcing steel bars are arranged at the inner sides. The invention further provides a construction method and application adopting the steel component. A structural steel component is used for being adopted as a template and a supporting upper portion structure, temporary anchoring is performed,the construction safety is improved, the component can be disassembled after construction is completed to be recycled, and finally, factory prefabrication and on-site rapid assembling construction operation of bridge piers can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Precast spliced concrete slab wall body

InactiveCN101793068ASave time and effort in the construction processOverall goodConstruction materialWallsThermal insulationSurface plate

The invention discloses a precast spliced concrete slab wall body, which comprises an inner wall panel, an outer wall panel and an intermediate concrete layer. The inner wall panel and the outer wall panel are formed by splicing precast concrete slabs, the middle part of the concrete layer is provided with a steel reinforced frame, the steel reinforced frame is arranged along the whole length direction of the wall body and is connected with a bearing component on the wall edge, and horizontal steel wires are arranged at certain intervals along the height direction of the steel reinforced frame; and the inner surfaces of the inner wall panel and the outer wall panel are respectively provided with a prismatic table type bulge, and positioning steel wires parallel to the plate direction penetrate out of the prismatic table, are arranged in a triangular shape and are in clamping connection with the horizontal steel wires in the steel reinforced frame of the wall body. The invention has the advantages of good wall integrity, convenient construction, no need for formwork removal, low average density and good thermal insulation performance. Moreover, for the wall body constructed in the method, the manufacturing cost per unit area can be reduced.

Owner:叶翼翔 +2

Ag2S/CdS core-shell structure nanometer tetrahedron and preparation method thereof

InactiveCN101319403ARealize integrationContribute to generationPolycrystalline material growthSingle crystal growth detailsSurface-active agentsSilver ion

The invention relates to a Ag2S / CdS core-shell structure nano-tetrahedron and a preparation method thereof. The method comprises the following steps of: obtaining a loaded organic phase containing silver ions or cadmium ions through solvent extraction, then passing through H2S gas into the loaded organic phase containing the silver ions to obtain Ag2S / CdS organic nano-fluid; packing a mixture of the Ag2S organic nano-fluid and the loaded organic phase containing the cadmium ions into a reaction kettle for sealing; and heating the reaction kettle at a temperature of between 130 and 160 DEG C for 12 to 24 hours to separate a product. The method combines the extraction and separation of Ag<+> and Cd<2+> and the preparation of a Ag2S / CdS core-shell structure together to realize the integration of solvent extraction and separation and nano-material preparation. A sulfur-containing extracting agent is used as the extracting agent during the whole process, and is also used as a sulfur source and a surface active agent, thereby facilitating the generation of a nano-sulfide; and silver-sulfide plays a templete role in the forming process of the Ag2S / CdS core-shell structure, thereby facilitating the formation of a tetrahedron structure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Precast spliced concrete slab wall body

InactiveCN101793068BImprove integrityLow densityConstruction materialWallsClamp connectionThermal insulation

The invention discloses a precast spliced concrete slab wall body, which comprises an inner wall panel, an outer wall panel and an intermediate concrete layer. The inner wall panel and the outer wall panel are formed by splicing precast concrete slabs, the middle part of the concrete layer is provided with a steel reinforced frame, the steel reinforced frame is arranged along the whole length direction of the wall body and is connected with a bearing component on the wall edge, and horizontal steel wires are arranged at certain intervals along the height direction of the steel reinforced frame; and the inner surfaces of the inner wall panel and the outer wall panel are respectively provided with a prismatic table type bulge, and positioning steel wires parallel to the plate direction penetrate out of the prismatic table, are arranged in a triangular shape and are in clamping connection with the horizontal steel wires in the steel reinforced frame of the wall body. The invention has the advantages of good wall integrity, convenient construction, no need for formwork removal, low average density and good thermal insulation performance. Moreover, for the wall body constructed in the method, the manufacturing cost per unit area can be reduced.

Owner:叶翼翔 +2

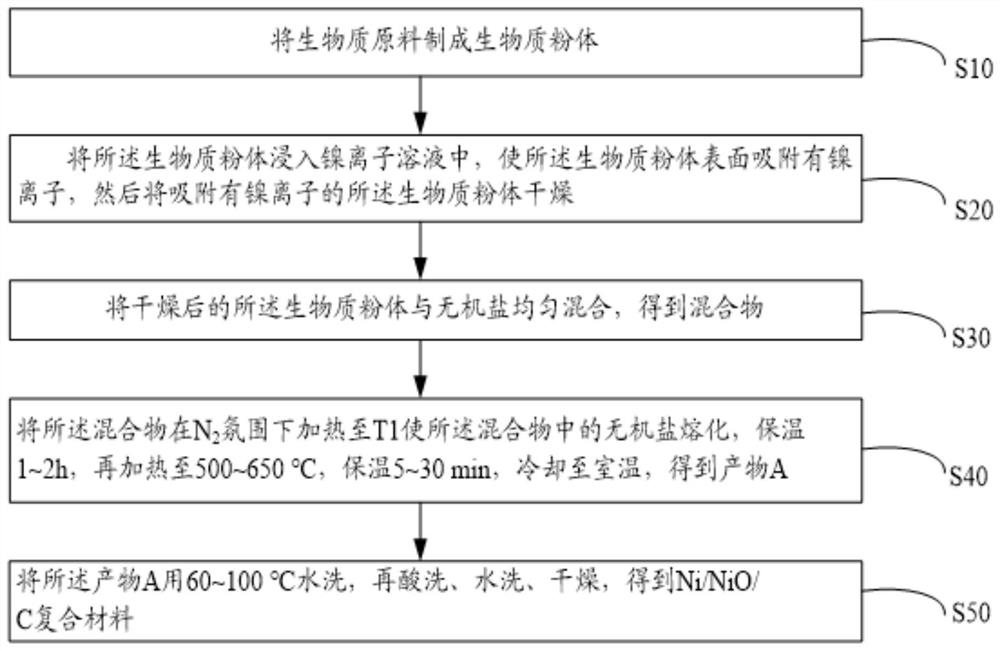

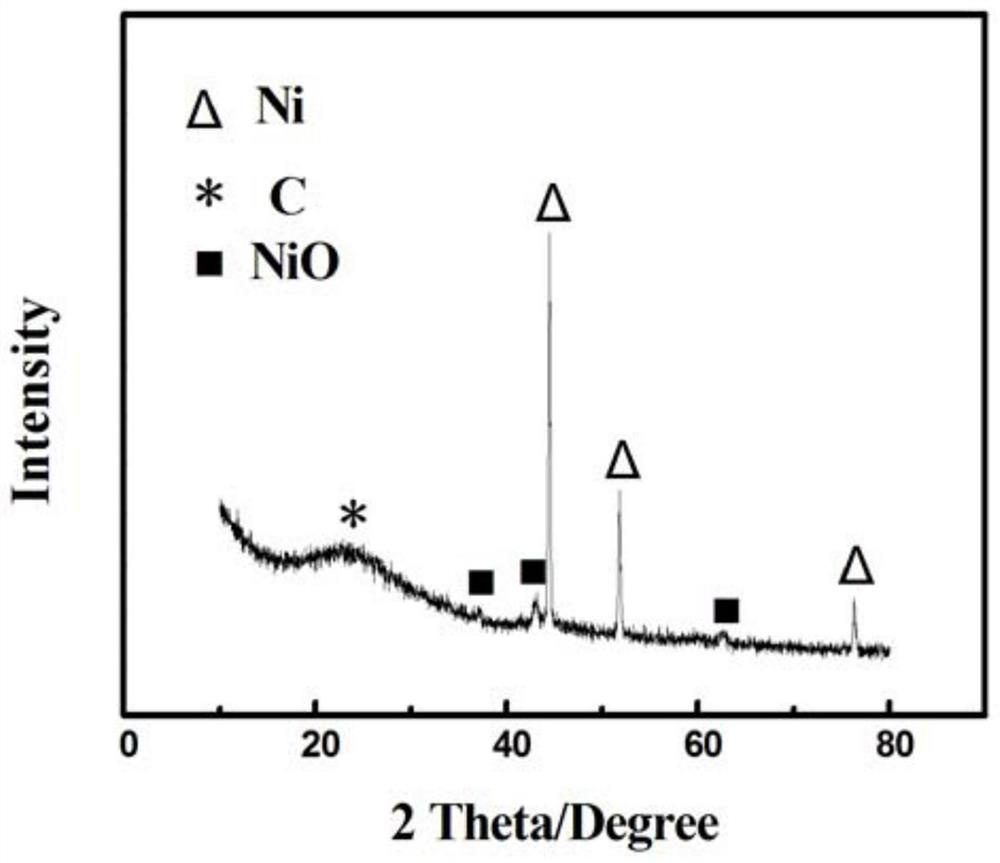

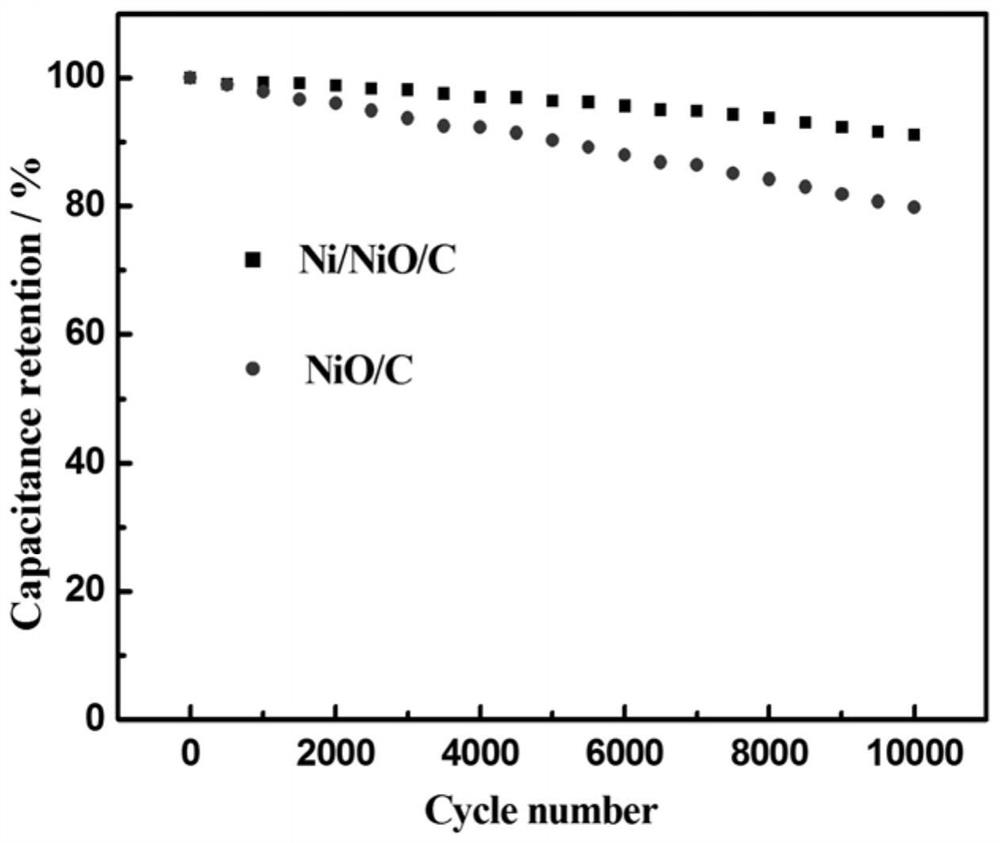

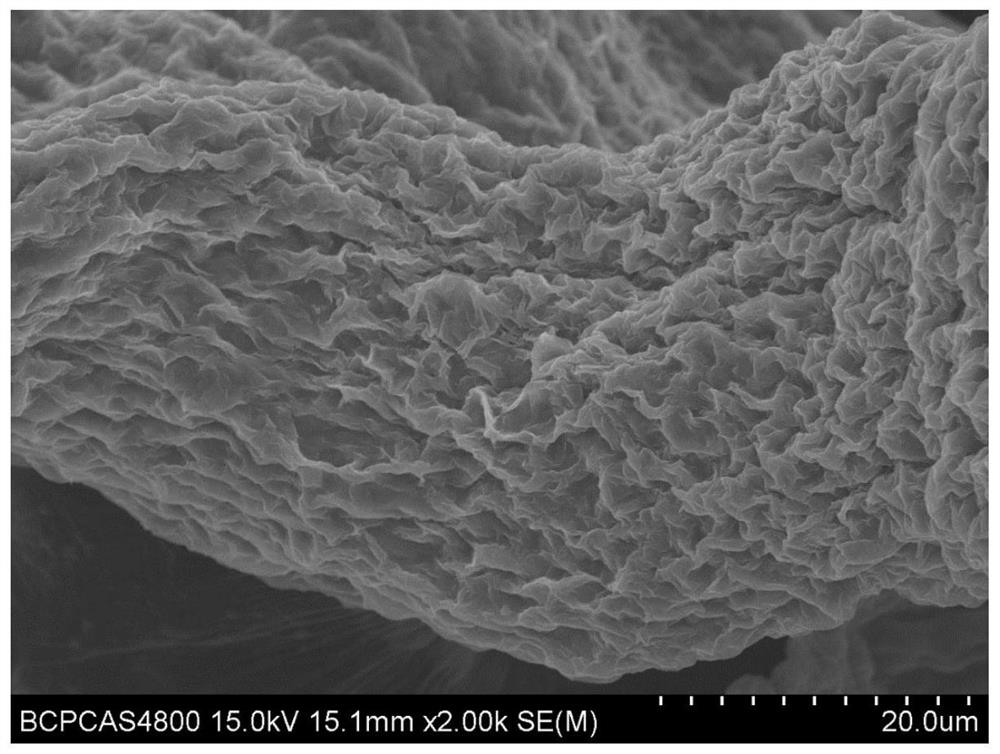

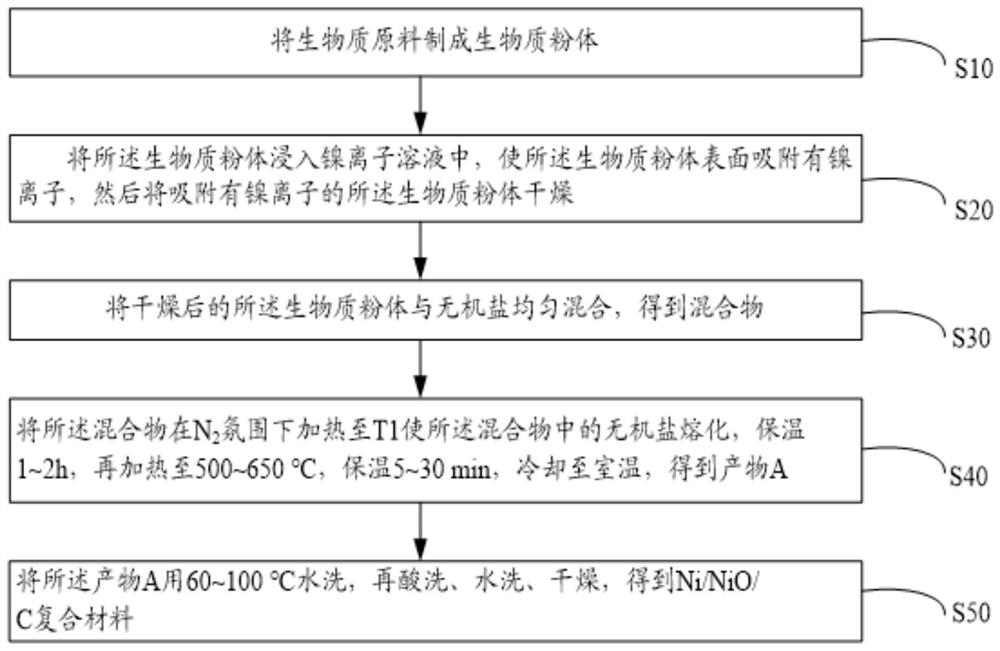

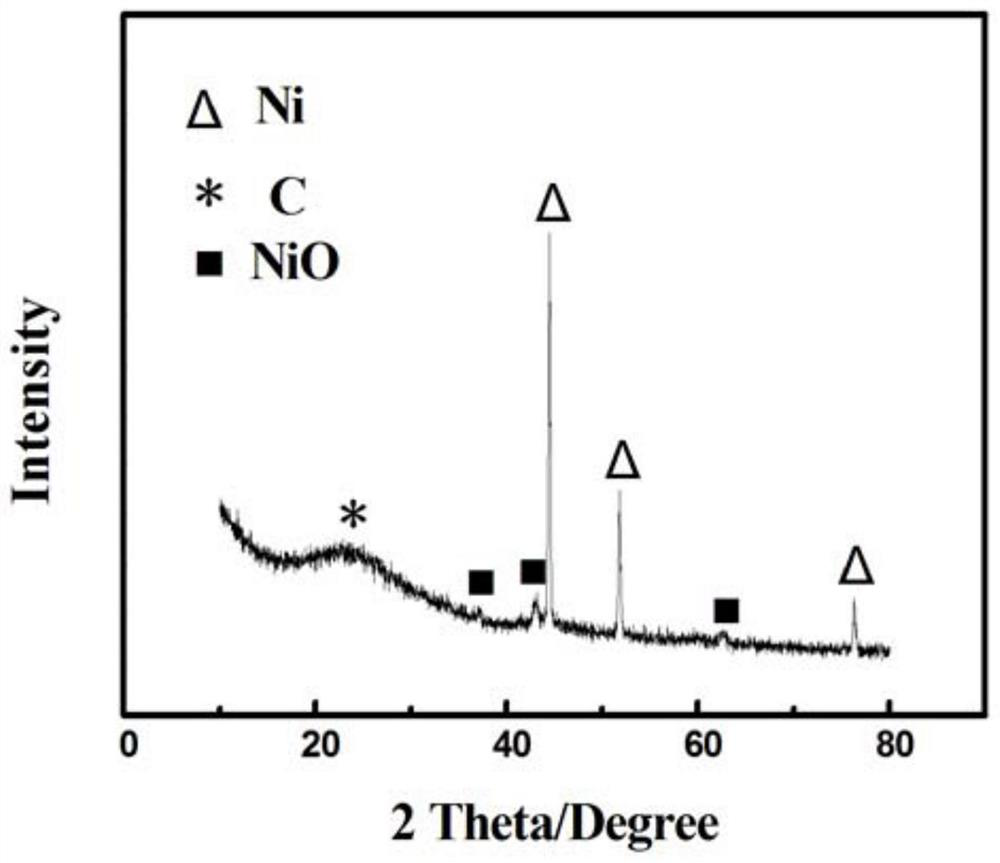

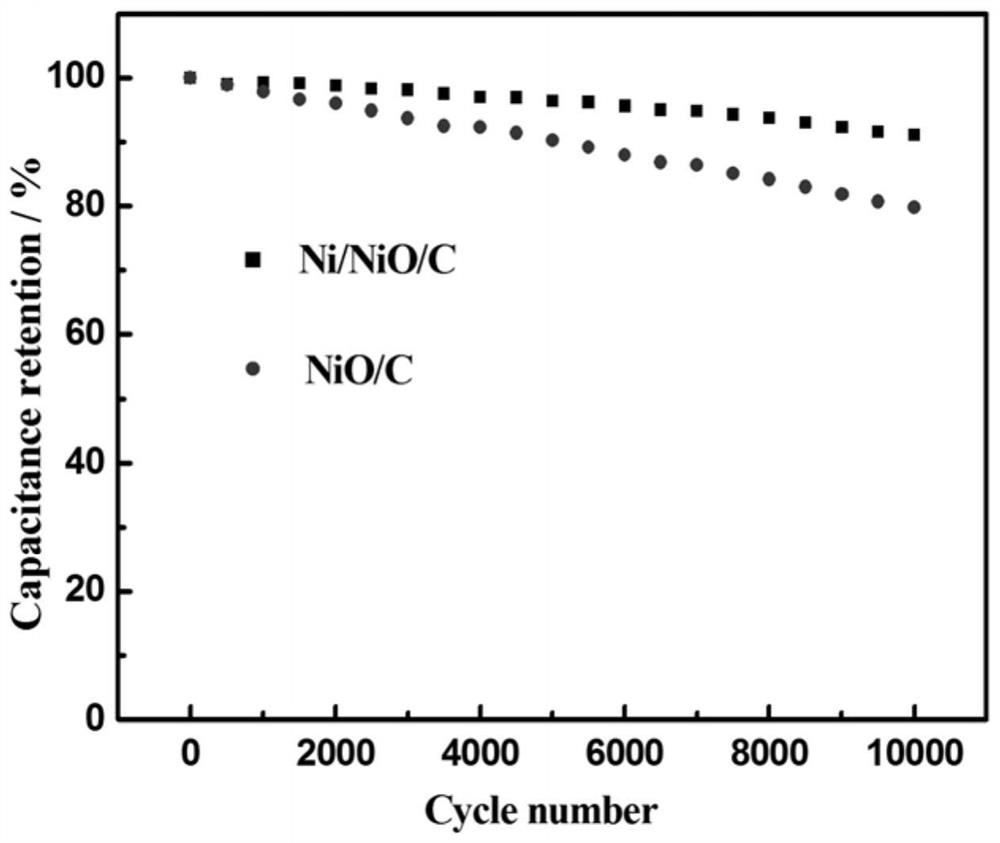

Preparation method of Ni/NiO/C composite material and supercapacitor

ActiveCN111668032AMelted completelyIncrease profitHybrid capacitor electrodesHybrid/EDL manufactureInorganic saltsCapacitor

The invention discloses a preparation method of a Ni / NiO / C composite material and a supercapacitor. The preparation method of the Ni / NiO / C composite material comprises the following steps: preparing biomass powder from a biomass raw material; immersing the biomass powder into a nickel ion solution to enable the biomass powder to adsorb nickel ions, and then drying the biomass powder which adsorbsthe nickel ions; uniformly mixing the dried biomass powder with inorganic salt to obtain a mixture; heating the mixture to T1 in an N2 atmosphere to melt inorganic salt in the mixture, keeping the temperature for 1-2 hours, then heating to 500-650 DEG C, keeping the temperature for 5-30 minutes, and cooling to room temperature to obtain a product A; washing the product A with water at 60-100 DEG C, and then pickling, washing and drying to obtain the Ni / NiO / C composite material. The Ni / NiO / C composite material prepared by the method is good in conductivity, the Ni / NiO / C composite material is used as an electrode material of the supercapacitor, the problem of stability caused by volume change in the NiO charging and discharging process is relieved, the electrochemical performance of the supercapacitor is improved, the cycling stability is relatively good, and the cycle life is long.

Owner:HUBEI UNIV OF ARTS & SCI

Distributed three-dimensional factory floor slab and manufacturing method

InactiveCN111608308ALose weightImproved performance of shock absorption, sound insulation and heat preservationFloorsFloor slabMesh reinforcement

The invention relates to the technical field of building materials, and discloses a distributed three-dimensional factory floor slab and a manufacturing method. The distributed three-dimensional factory floor slab comprises non-dismantling concrete bundle heat preservation double-T formworks, steel bars, steel bar meshes, steel plate cold-extruded trusses, truss clamping parts, cushion blocks, inorganic heat preservation, sound insulation and fireproof floor slab cavities, water-electricity-heating network pipes and threading boxes, wherein high-performance concrete is poured outside the inorganic heat preservation, sound insulation and fireproof floor slab cavities. The distributed three-dimensional factory floor slab disclosed by the invention does not need the links of PC fabrication, transportation and hoisting, saves the PC factory investment, transportation and hoisting cost, and does not need to solve the structural problem of mounting abutted seams. According to the floor slab,floor-after-floor operation is carried out, so that the floor area is saved. The floor slab is provided with the steel bar meshes and the steel plate cold-extruded trusses, so that large-span mounting can be realized. A bottom formwork of the floor slab is of a hollow structure, so that the floor slab has sound insulation, sound absorption and heat preservation functions, and is light in mass andconvenient for transportation and hoisting. The inorganic heat preservation, sound insulation and fireproof floor slab cavities are paved in the middle of the floor slab, so that the dead weight of the floor slab is reduced by 30 to 60 percent.

Owner:黄通

A reinforced concrete hollow floor slab

The invention discloses a reinforced concrete hollow floor slab and a construction method. The hollow floor slab comprises a cast-in-situ multi-rib (1), a prefabricated side wall (2), a prefabricated soleplate (3) and a cast-in-situ crest slab (4). The bottom part of the prefabricated side wall (2) is provided with a hole or a notch (7), and a supporting rib (6) is arranged inside the hole or the notch (7). The construction method of the hollow floor slab comprises the following steps: erecting a hollow floor slab molding plate (11), binding a ribbed reinforced bar (12) and placing the prefabricated side wall (2); placing the prefabricated soleplate (3) on a holding piece (9), pouring the concrete, removing the holding piece (9) after the concrete reaches a given strength, and placing the prefabricated soleplate (3) on the supporting rib (6) on the bottom part of the prefabricated side wall; utilizing the prefabricated side wall (2), the prefabricated soleplate (3) and the cast-in-situ crest slab (4) to form a cavity (5), painting mortar (15) on the bottom of the prefabricated soleplate (3) to form an integral hollow floor slab. The hollow floor slab consists of cast-in-situ concrete and prefabricated components, so the floor slab has light weight and good integrity.

Owner:吴方伯

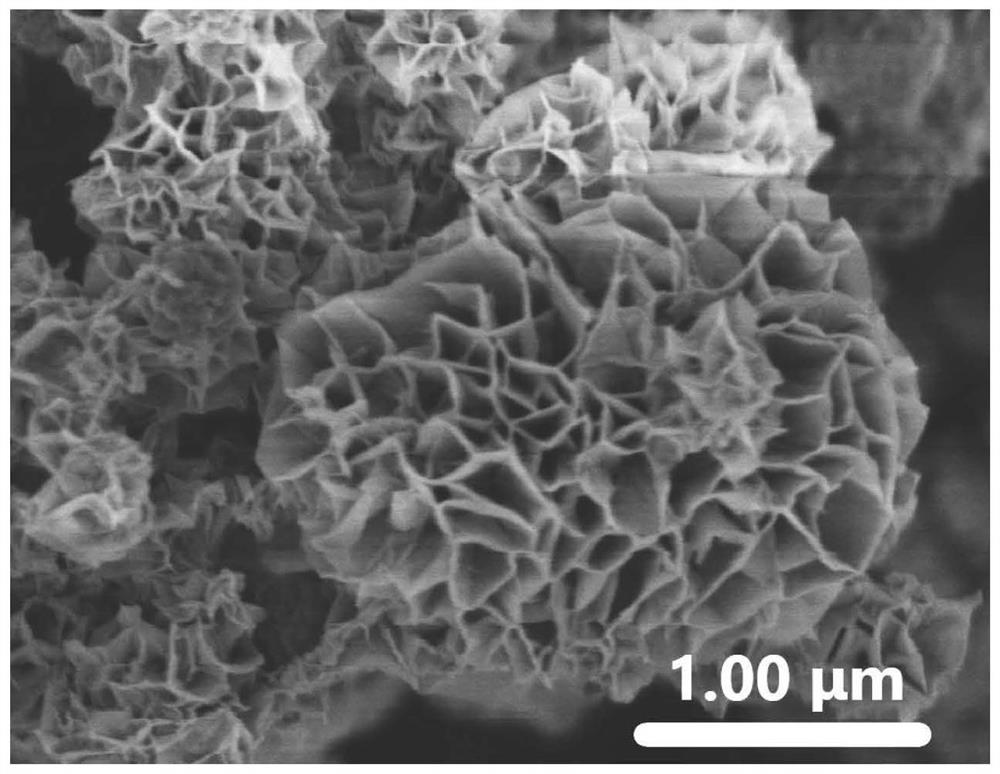

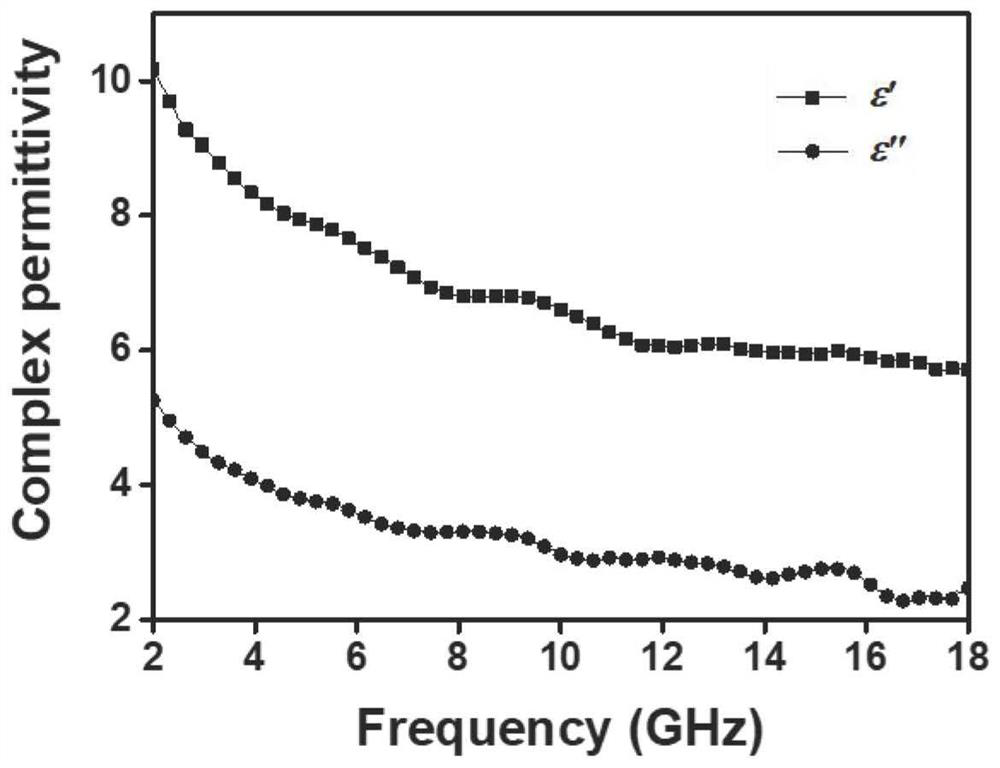

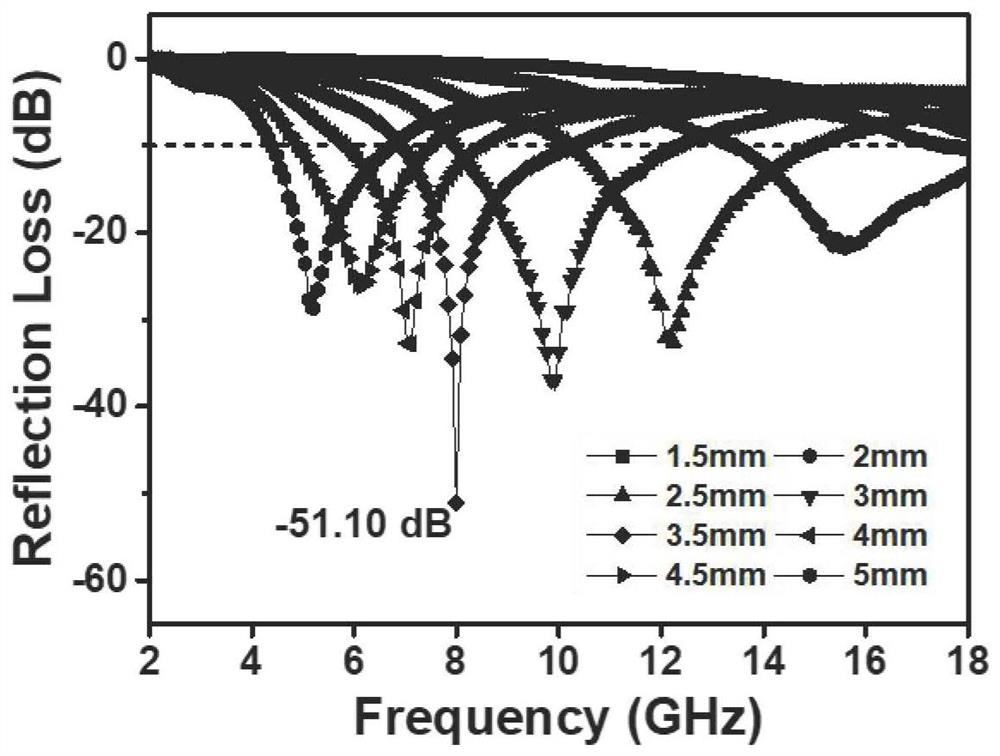

Hollow honeycomb flower-shaped manganese dioxide material

InactiveCN111675242AAct as a templateExcellent electromagnetic wave absorption performanceManganese oxides/hydroxidesHoneycombSilicon dioxide

The invention discloses a hollow honeycomb flower-shaped manganese dioxide material and an application thereof. The preparation method comprises the steps: (1) preparation of silicon dioxide@honeycombflower-shaped manganese dioxide: ultrasonically dispersing silicon dioxide and potassium permanganate into deionized water, adding a certain amount of hydrochloric acid solution, stirring, transferring into a hydrothermal reaction kettle with a polytetrafluoroethylene liner, reacting for a period of time, performing subsequent treatment after the reaction is finished, and thus obtaining the silicon dioxide@honeycomb flower-shaped manganese dioxide.; and (2) preparation of hollow honeycomb flower-shaped manganese dioxide: adding the silicon dioxide@honeycomb flower-shaped manganese dioxide prepared in the step (1) into a concentrated sodium hydroxide solution, carrying out a stirring reaction at a certain temperature, and carrying out subsequent treatment after the reaction is completed, so as to obtain the hollow honeycomb flower-shaped manganese dioxide. The obtained product manganese dioxide is in a hollow honeycomb flower shape, has the characteristics of light weight, strong lossand wide absorption, and plays a quite important role in application of electromagnetic wave absorption.

Owner:ZHEJIANG NIRUAN NEW MATERIAL CO LTD

Prefabricated box culvert system and its installation method

The invention provides a prefabricated box culvert system. The prefabricated box culvert system comprises at least two prefabricated box culverts. Two prefabricated box culverts are located at the head end and the tail end of the prefabricated box culvert system, the prefabricated box culverts at the head end and the tail end respectively comprise a box body and two connectors, at least one connector of each box culvert comprises a bundle of bars or a pre-buried water stop belt, and the box culverts of the prefabricated box culvert system are connected through bars or the water stop belts formed through overlap welding, and are connected into the integrally-formed box culvert system through poured concrete. The invention further provides an installation method of the prefabricated box culvert system. The installation method is used for connecting the at least two prefabricated box culverts into a whole and laying the box culverts on the bottom face of a road. Compared with the prior art, the prefabricated box culvert system is simple in construction, short in construction period, low in cost, wide in application range, and suitable for municipal engineering and other large-scale traffic construction.

Owner:SICHUAN HUASHI GREEN HOMELAND BUILDING MATERIALS

Green preparation method of manganese dioxide

ActiveCN107500361AAct as a reducing agentActs as a biological templateManganese oxides/hydroxidesMalachite greenMalachite green stain

The invention relates to a green preparation method of manganese dioxide. The preparation method comprises the following steps: adding a potassium permanganate solution into a pollen suspension to react; after the reaction, filtering, and washing filter residues; drying and crushing the filter residues, and obtaining an intermediate powder product; calcining the intermediate powder product to obtain a final product manganese dioxide. Pollen is adopted as a reducing agent and a biological template, and the potassium permanganate is used as a manganese source to prepare manganese dioxide microcrystals. The pollen can play a role of the reducing agent in the generation of the manganese dioxide, and the pollen and a special granular structure thereof also play a role of the template in generating the manganese dioxide particles. The obtained manganese dioxide product is adopted to photocatalytically degrade malachite green dye, and the catalytic performance is good. The green preparation method is simple in operation, moderate in condition, energy-saving and environment-friendly.

Owner:HUANGSHAN UNIV

Fabricated light protective door and manufacturing method thereof

InactiveCN108397104AQuick installationEasy to installWar-like protectionDoor leavesSlurryUltimate tensile strength

The invention discloses a manufacturing method of a fabricated light protective door. A door body frame component, a frame connecting steel component, a grille, a pre-embedded piece, a skin and a hinge of the protective door are prepared; a protective door frame wall of the protective door is manufactured and mounted at a mounting site in a matched mode; the components are conveyed to the site, the components are assembled at the site, and a protective door metal frame is obtained; the frame connecting steel component and the steel pre-embedded piece are spliced with the door body frame component, and the grille and the steel skin are arranged in the protective door metal frame and spliced on the surface of the protective door metal frame; and cement concrete slurry is injected into a doorbody, the internal space of the protective door metal frame is filled with the cement concrete slurry, and still standing and curing are conducted till the strength reaches the design strength. According to the manufacturing method, the on-site assembly mode is adopted, the size and weight of one single component are further reduced, and better operating performance and economic performance are obtained accordingly; and through the operating mode of concrete on-site slip casting, the integrality of the fabricated protective door is improved, and weights of the conveyed components are furtherreduced.

Owner:邓安仲 +1

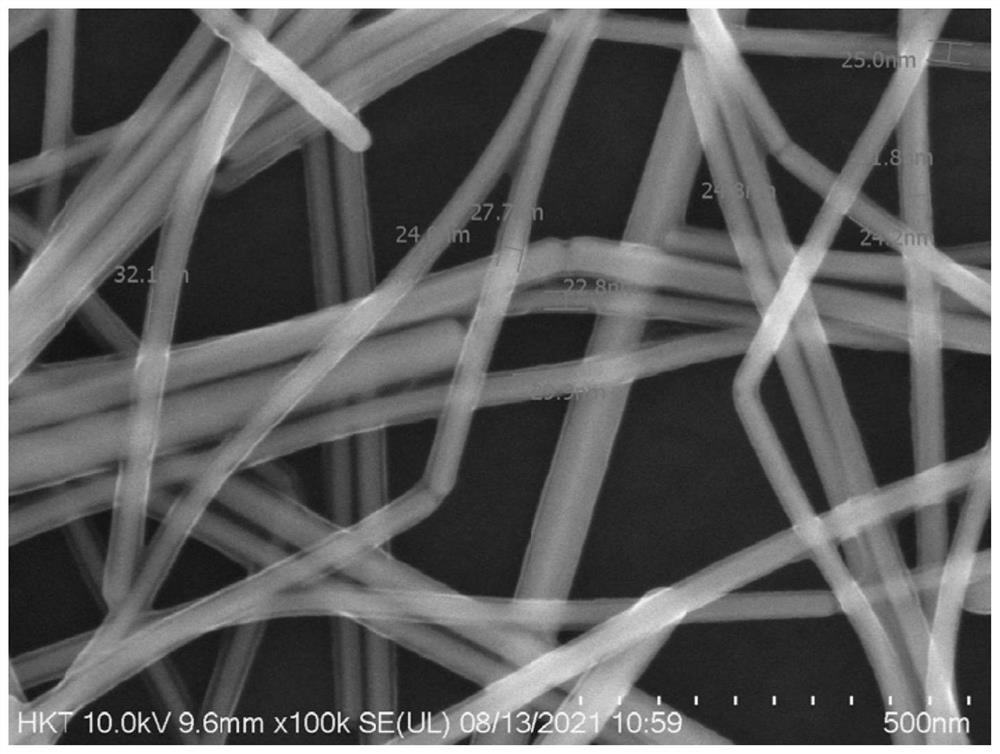

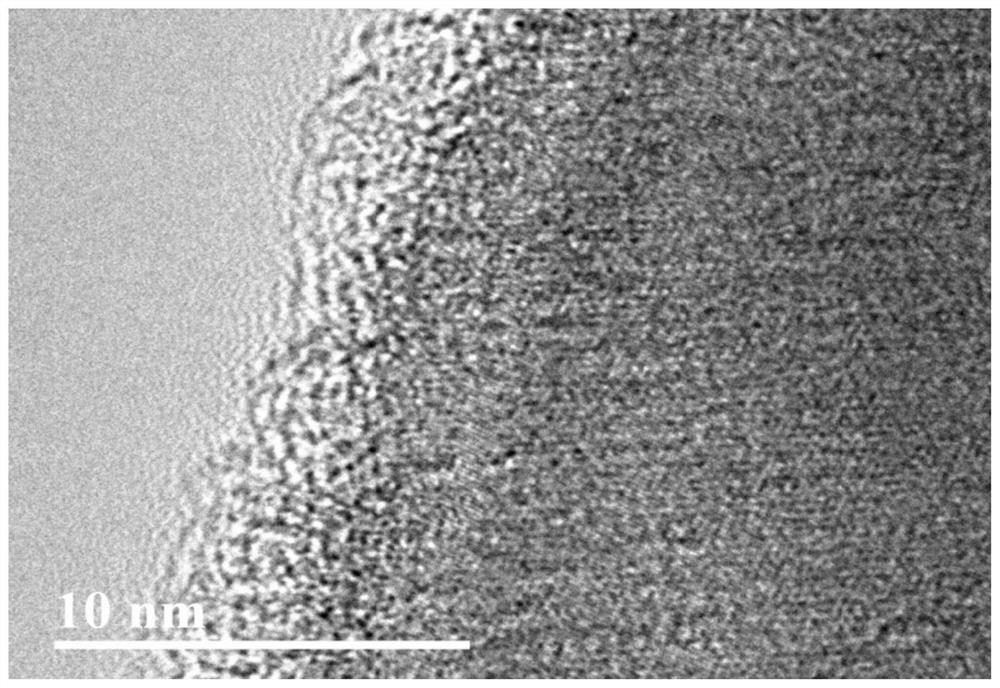

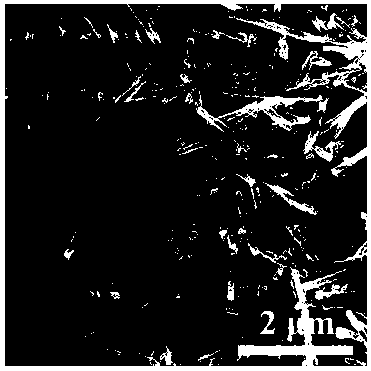

Carbon-coated silver nanowire

ActiveCN114147210AImprove stabilityPrevent oxidationMaterial nanotechnologyTransportation and packagingCarbon layerNanostructured carbon

The invention belongs to the technical field of silver nanowire preparation, and particularly relates to a carbon-coated silver nanowire. The carbon-coated silver nanowire comprises a silver nanowire positioned on a core layer and a nano carbon layer coated on the surface of the core layer; the diameter of the silver nanowire is 10 to 2000 nm, and the length of the silver nanowire is 1 to 100 [mu] m; and the thickness of the nano carbon layer is 1 to 10 nm. According to the carbon-coated silver nanowire disclosed by the invention, the surface of the silver nanowire is coated with the nano-carbon layer, so that oxidation of nano-silver and a silver migration effect can be well prevented, the stability of the silver nanowire is improved, and the reliability of a related silver nanowire device is ensured; moreover, the carbon-coated silver nanowire is uniform in shape and stable in coating, and has good application value.

Owner:SHENZHEN HUAKE COMM TECH CO LTD

Method for preparing one-dimensional self-assembly material with ZnO nanorod array as template

ActiveCN102417201BControl the dissolution rateControl deposition rateZinc oxides/hydroxidesNanotechnologySynthesis methodsRare earth

Owner:PEKING UNIV

Method for synthesizing titanium-silicon molecular screen

ActiveCN101190792BReduce generationEliminate local concentration unevennessMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveCatalytic oxidation

A method of synthesizing titanium silicate molecular sieve is to hydrothermally crystallize the hydrolytic solution of silicon and titanium in a closed reaction vessel and then recycle the product. The method is characterized in that the hydrolytic solution of silicon and titanium is gotten by any one of the following three methods: A. under ultrasonic agitation, silicon source is first hydrolyzed in organo-alkali compound solution and then the titanium source is hydrolyzed in the solution; B. under the ultrasonic agitation, titanium source is first hydrolyzed in organo-alkali compound solution and then the silicon source is hydrolyzed in the solution; C. under the ultrasonic agitation, silicon source and titanium source are respectively hydrolyzed in organo-alkali compound solution and then mixed together. The synthetic method can eliminate partial uneven concentration, leads the amount of TiO2 generated by self agglomeration after the hydrolysis of titanium source to be as little as possible and reduces the production of extra framework titanium. Compared with the prior art, the TS-1 molecular sieve synthesized by the method not only has better catalytic oxidation activity and selectivity but also has better stability of catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

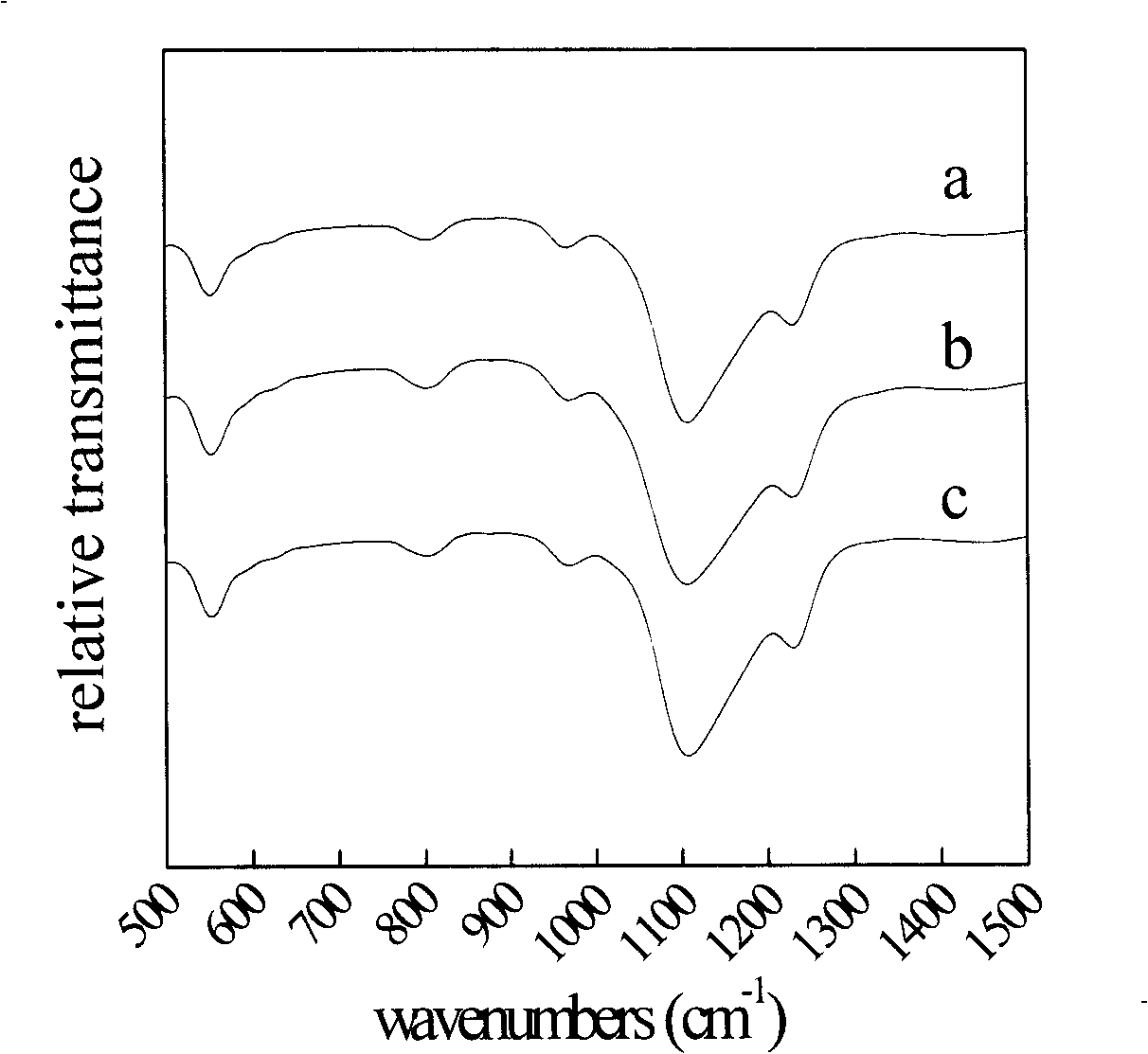

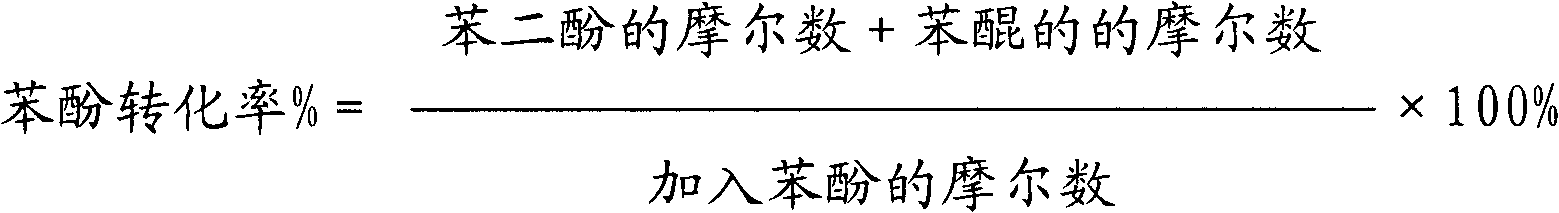

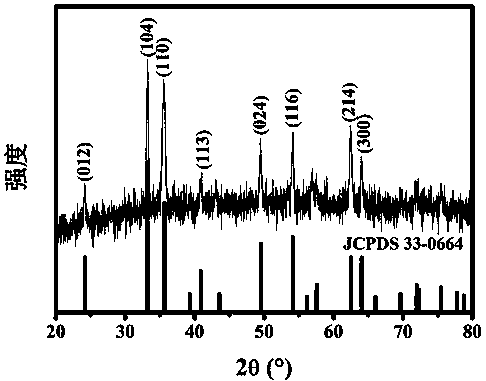

Electrostatic spinning synthesis method for Alpha-Fe2O3 rod-shaped structure

ActiveCN109183196AGood technical innovationAdjustable aspect ratioInorganic material artificial filamentsDimethyl formamideElectrospinning

The invention discloses an electrostatic spinning synthesis method for an Alpha-Fe2O3 rod-shaped structure. The method comprises the following steps: mixing ethanol and DMF (Dimethyl Formamide), adding trivalent ferric salt, polyether F127 and pragmoline into a mixture, stirring for dissolving the raw materials, then adding an L-lysine aqueous solution and PVP, and uniformly stirring the raw materials, thereby obtaining a spinning fluid; preparing the spinning fluid into precursor fibers by virtue of an electrostatic spinning method, and calcining the precursor fibers, thereby obtaining a product. By virtue of designing a precursor reaction system and regulating and controlling the calcining system, an Alpha-Fe2O3 rod-shaped structure with adjustable length-diameter ratio is obtained; themethod is simple in preparation process and easy to regulate and control, adopted raw materials are extensive in source and low in price, the product is unform in microcosmic appearance and good in repetitiveness, and has extensive application prospects in the field of gas sensing, catalysis and the like.

Owner:UNIV OF JINAN +1

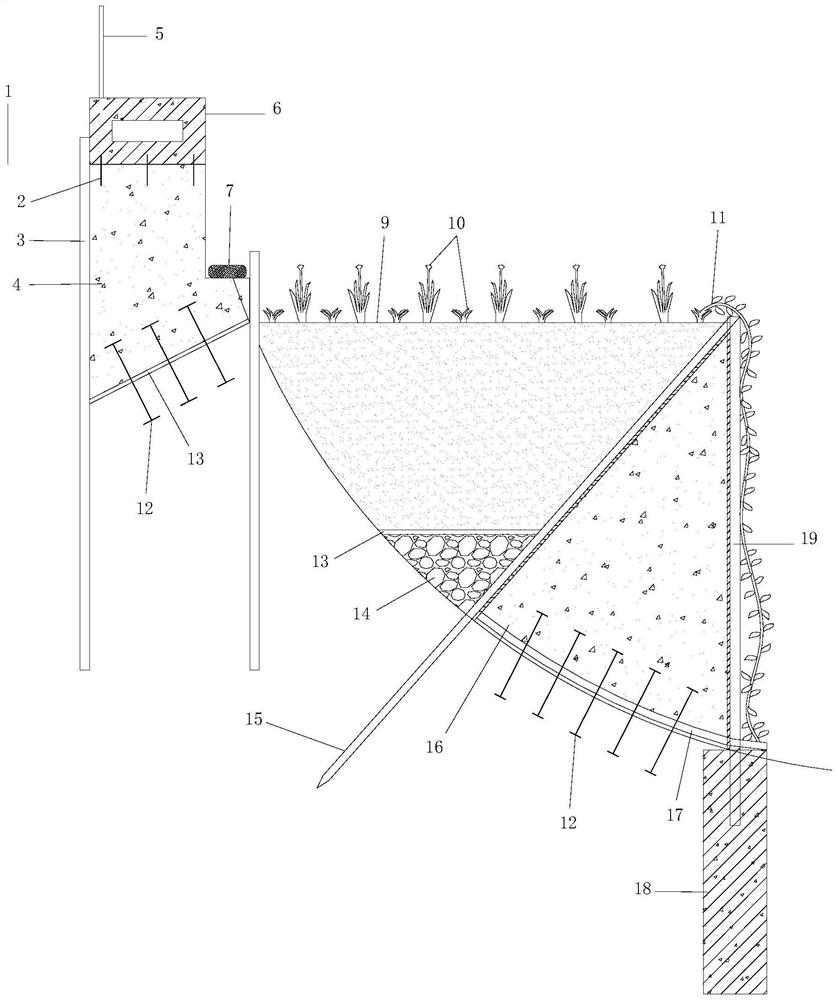

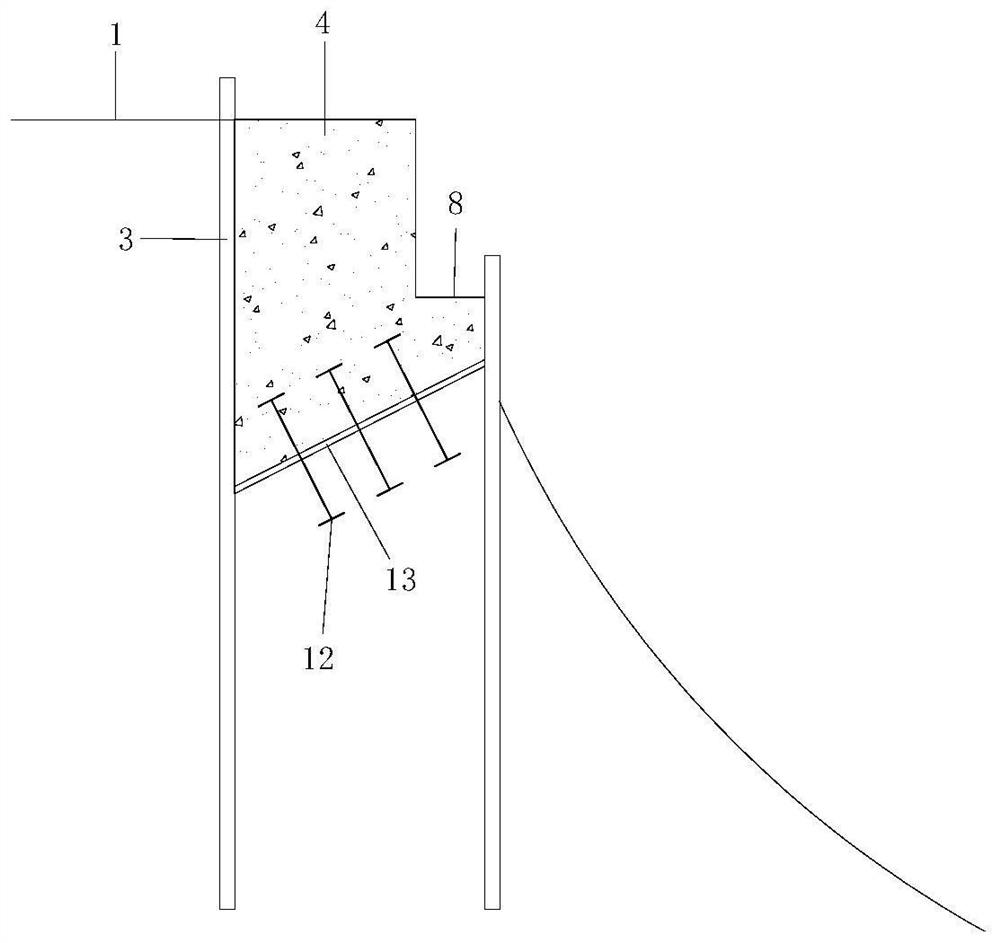

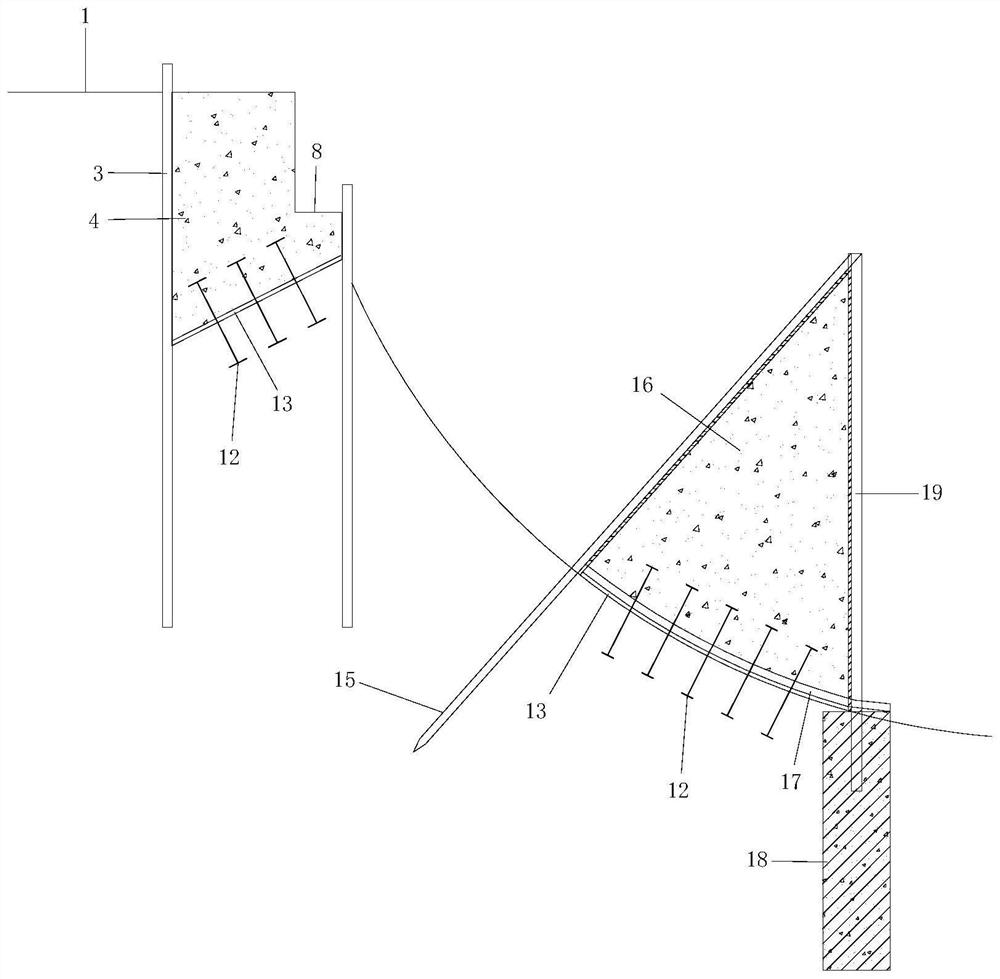

Construction method of foam concrete landscape restoration system

ActiveCN113322731BAct as a templateAvoid large excavationsFlowers cultivationArtificial islandsFoam concreteArchitectural engineering

The invention relates to a construction method of a foam concrete landscape restoration system. Firstly, the surface of the original roadbed side slope is cleared, steel sheet piles are laid, and then foam concrete wedge-shaped retaining walls are constructed. Anchor, followed by the construction of foam concrete fan-shaped retaining wall, and then the backfilling and leveling of the green belt, the construction of hollow concrete roof beams and guardrails, and finally the construction of green landscape layout. The beneficial effects of the present invention are: the present invention adopts the steel sheet piles and then proceeds with the excavation operation, which avoids the large excavation of the slope as far as possible, reduces the disturbance to the original roadbed, and at the same time the steel sheet piles play the role of template, and the After pouring and maintenance of the retaining wall, the steel sheet piles can be recycled, and the advantages of technical benefits are obvious; the present invention is equipped with a green platform, a green belt and a green wall, which has a reasonable structure, convenient construction, and forms a multi-dimensional green landscape, which is extremely attractive to the surrounding environment. big boost.

Owner:ZHEJIANG UNIV CITY COLLEGE

A kind of mxene/sodium alginate derived carbon three-dimensional airgel and its preparation method and application

ActiveCN111422873BAvoid stackingImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesFluid phaseSupercapacitor

The invention provides an MXene / sodium alginate derived carbon three-dimensional airgel, a preparation method and application thereof. The preparation method of the MXene / sodium alginate derived carbon three-dimensional airgel provided by the present invention comprises the following steps: mixing the MXene dispersion liquid and the sodium alginate aqueous solution in liquid phase to obtain the MXene / sodium alginate mixed solution; Calcium chloride solution is added to the sodium alginate mixed solution, and the sodium alginate is gelled to obtain MXene / sodium alginate hydrogel; the sodium alginate is carbonized by high temperature treatment, and then 1‑3mol / L hydrochloric acid and deionized water are used After washing, the MXene / sodium alginate derived carbon three-dimensional airgel material is obtained. The MXene / sodium alginate derived carbon three-dimensional airgel material provided by the invention has better electrochemical performance when used in the field of supercapacitors.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of ni/nio/c composite material, and supercapacitor

ActiveCN111668032BMelted completelyIncrease profitHybrid capacitor electrodesHybrid/EDL manufactureInorganic saltsCapacitor

The invention discloses a method for preparing a Ni / NiO / C composite material and a supercapacitor. The method for preparing the Ni / NiO / C composite material includes the following steps: making biomass raw materials into biomass powder; The body is immersed in the nickel ion solution, so that the biomass powder absorbs nickel ions, and then the biomass powder adsorbed with nickel ions is dried; the dried biomass powder is uniformly mixed with an inorganic salt to obtain a mixture; the mixture is placed in N 2 Heating to T1 under the atmosphere to melt the inorganic salt in the mixture, keeping it warm for 1-2 hours, then heating to 500-650°C, keeping it warm for 5-30 minutes, cooling to room temperature to obtain product A; washing product A with water at 60-100°C, and then Pickling, washing and drying to obtain Ni / NiO / C composite material. The Ni / NiO / C composite material prepared by the present invention has good electrical conductivity, and using it as an electrode material for a supercapacitor alleviates the stability problem caused by the volume change in the charging and discharging process of NiO, and improves the electrochemical performance of the supercapacitor. performance, good cycle stability and long cycle life.

Owner:HUBEI UNIV OF ARTS & SCI

A construction method of a steel column connection structure with reinforced concrete columns

InactiveCN104389437BEasy to installImprove connection strengthBuilding repairsReinforced concrete columnEngineering

Owner:SHENZHEN GOLDEN CENTURY ENG INDAL

Square multi-cavity steel plate-concrete composite floor

The invention discloses a square multi-cavity steel plate-concrete composite floor, and belongs to the field of constructional engineering. The square multi-cavity steel plate-concrete composite floorcomprises a multi-cavity space steel floor and concrete; the concrete is poured into the square multi-cavity steel floor to form a combined integral component; the square multi-cavity steel floor iscomposed of a steel plate shell and steel plate cavities with notches; the steel plate is composed of five steel plates in a welding mode; the steel plate cavities with the notches are connected in aninserted mode up and down and welded in the steel plate shell to form the square multi-cavity steel floor; and the concrete is poured into the steel floor to form the square multi-cavity steel plate-concrete composite floor. The square multi-cavity steel plate-concrete composite floor has the beneficial effect that the problems of liable cracking and exposure cracking of traditional concrete components can be solved, the steel plate cavities have a high lateral restraining effect on the concrete, the compressive property of the concrete can be fully played, the self weight is light, the composite floor after molding has better overall performance, the steel plate shell replaces steel bars and structural steels in a traditional floor slab to play the role of the framework, the constructionoperation of traditional form erecting and form stripping is avoided, the square multi-cavity steel plate-concrete composite floor can replace a traditional framework in the construction site, the construction progress is increased, and the economic benefit is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com