Patents

Literature

46results about How to "Control deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

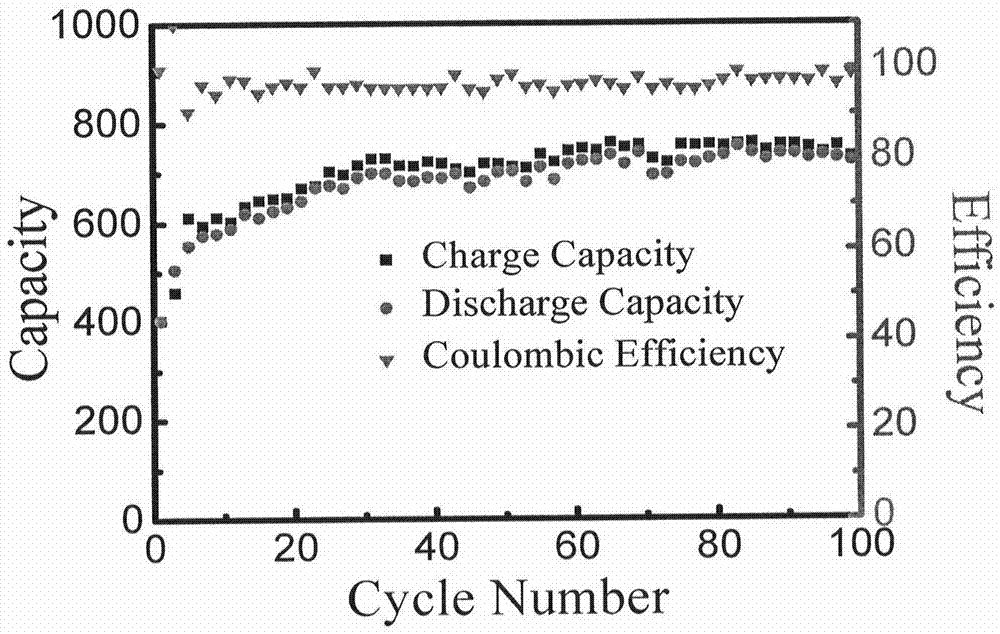

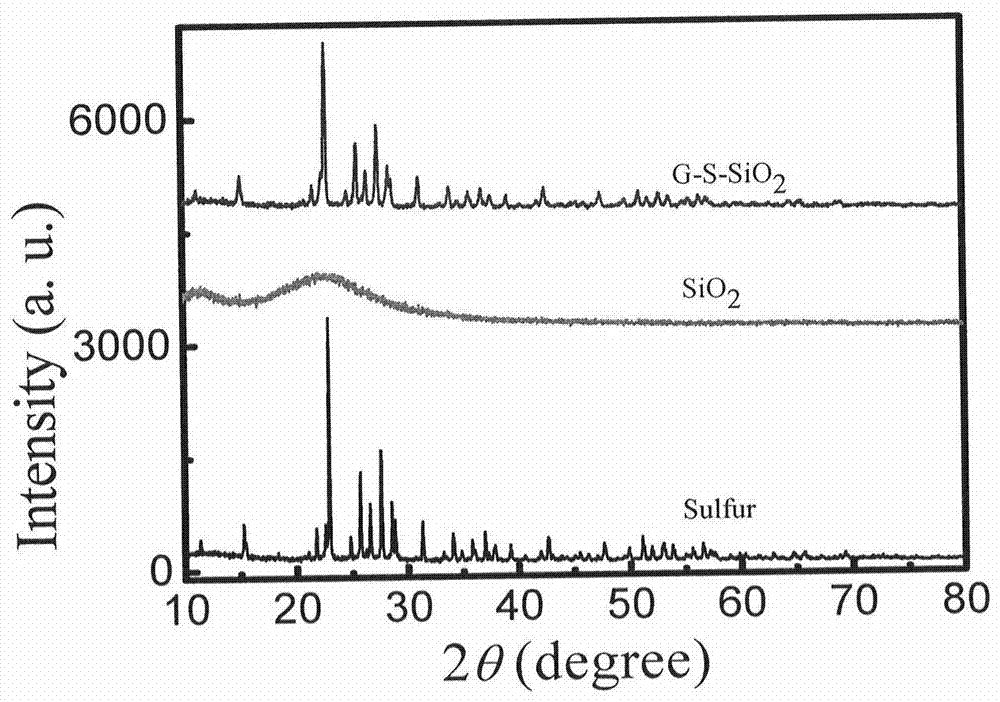

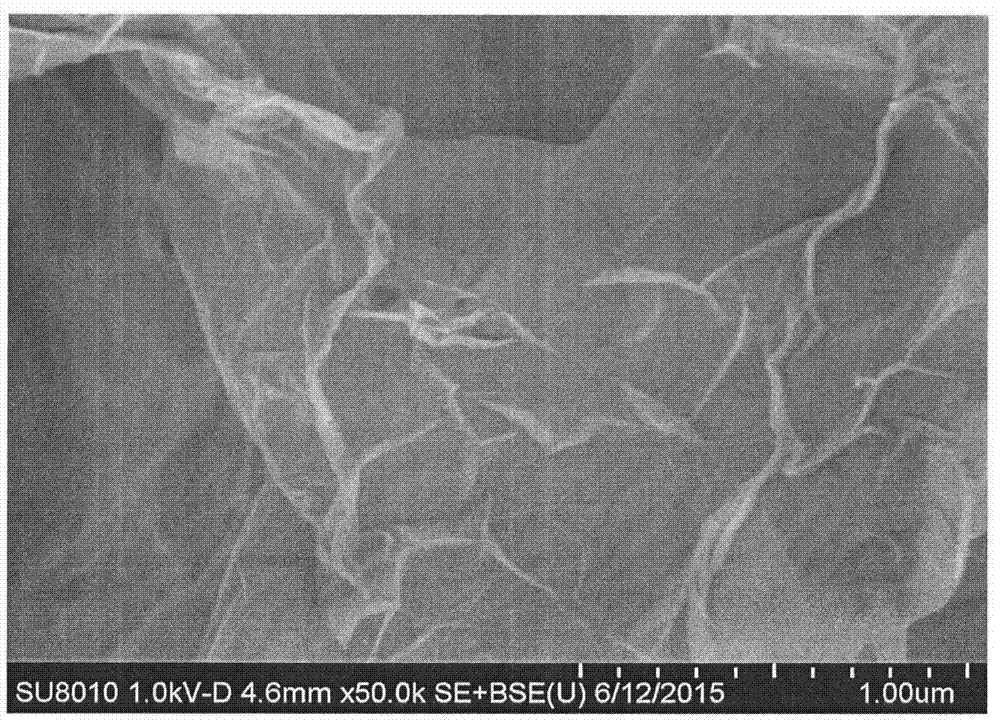

Preparation method of sulfur/carbon/oxide combined electrode material

InactiveCN105006553ASimple processEasy to operateCell electrodesLi-accumulatorsIron(II) oxideCarbon nanotube

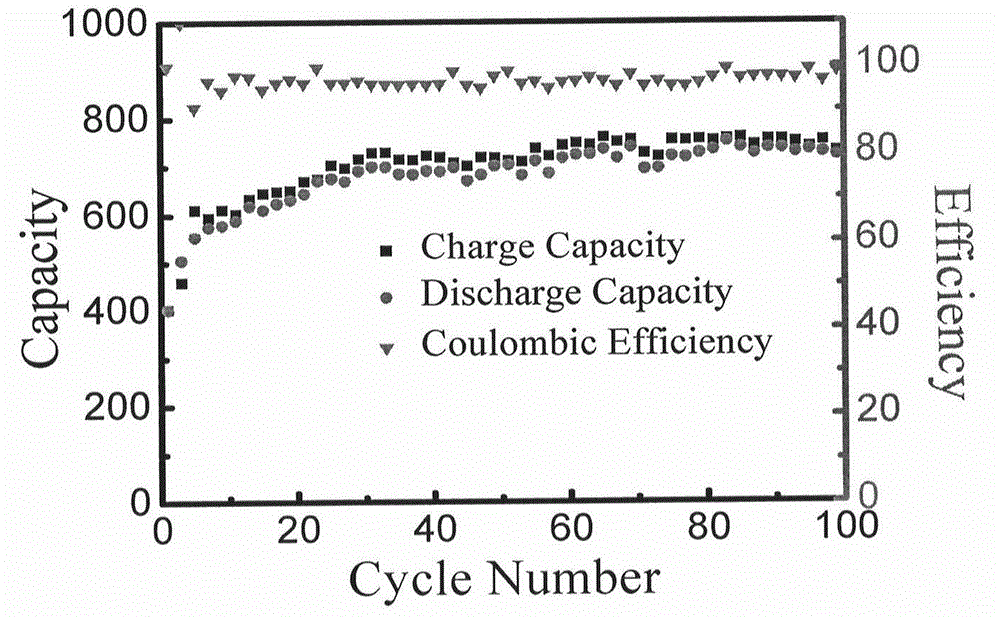

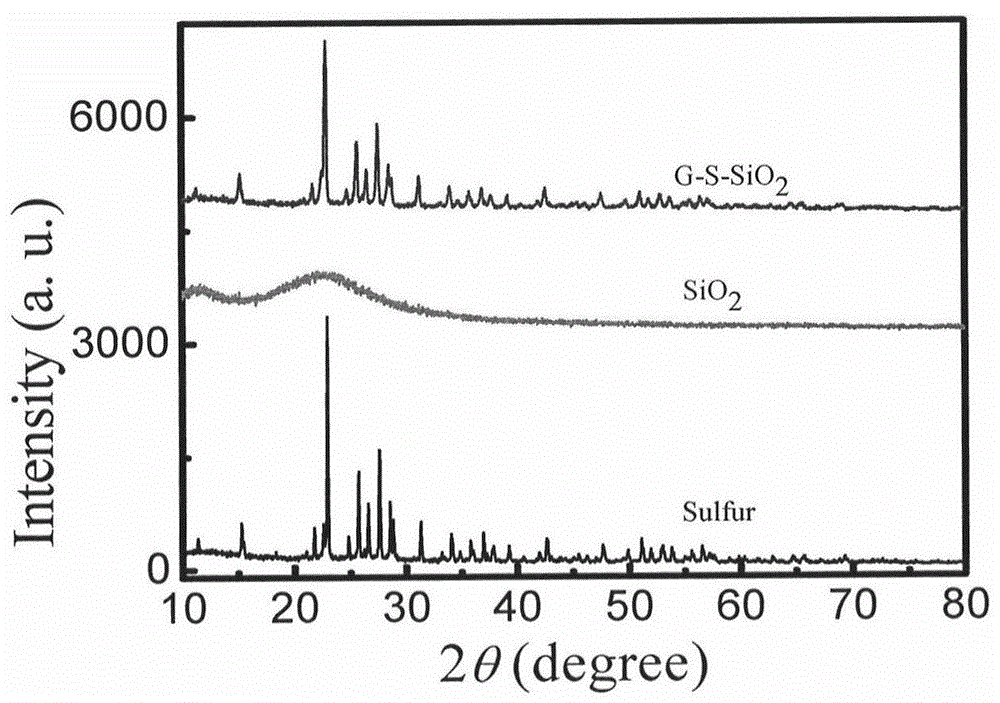

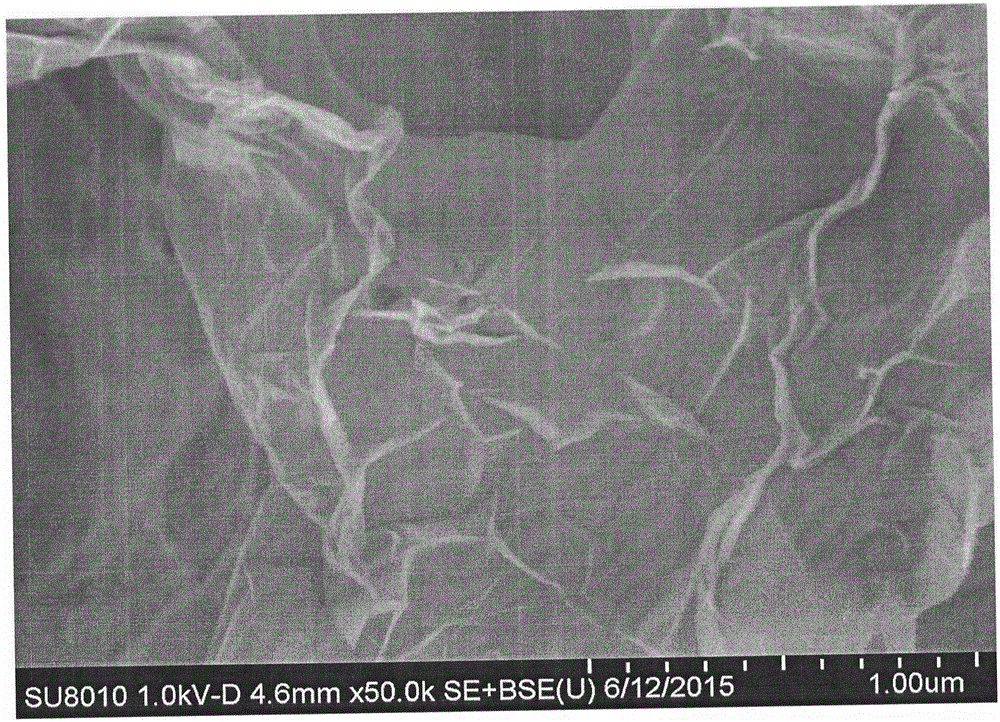

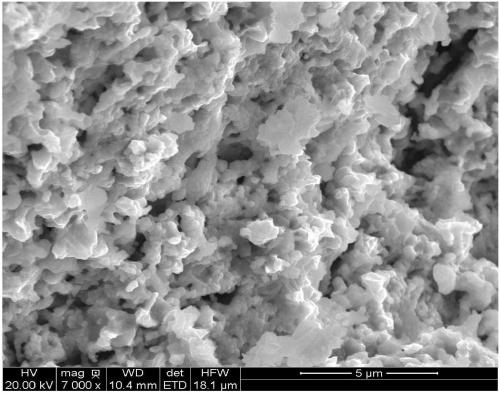

The invention relates to a preparation method of a sulfur / carbon / oxide combined electrode material. The preparation method comprises depositing sulfur and oxide on a carbon material as a carrier with excellent performances to obtain the sulfur / carbon / oxide combined electrode material. The carbon material is one of graphene, CMK-3, carbon nanotubes and carbon black. The oxide is one of silica, copper oxide, silver oxide, nickel oxide, ferrous oxide, tin oxide and titanium oxide. The sulfur / carbon / oxide combined electrode material comprises 50-90wt% of sulfur, 5-20wt% of carbon and 5-30wt% of the oxide. Through control of acid types and pH, and organic solvent types and properties, the sulfur / carbon / oxide combined electrode material with fine particles and high coating uniformity is obtained. The sulfur / carbon / oxide combined electrode material as a lithium-sulfur battery positive pole material has high specific capacity and excellent cycling properties and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

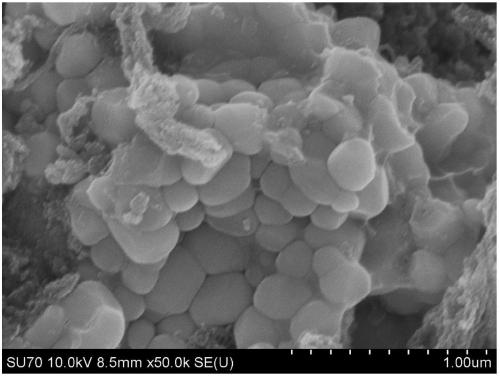

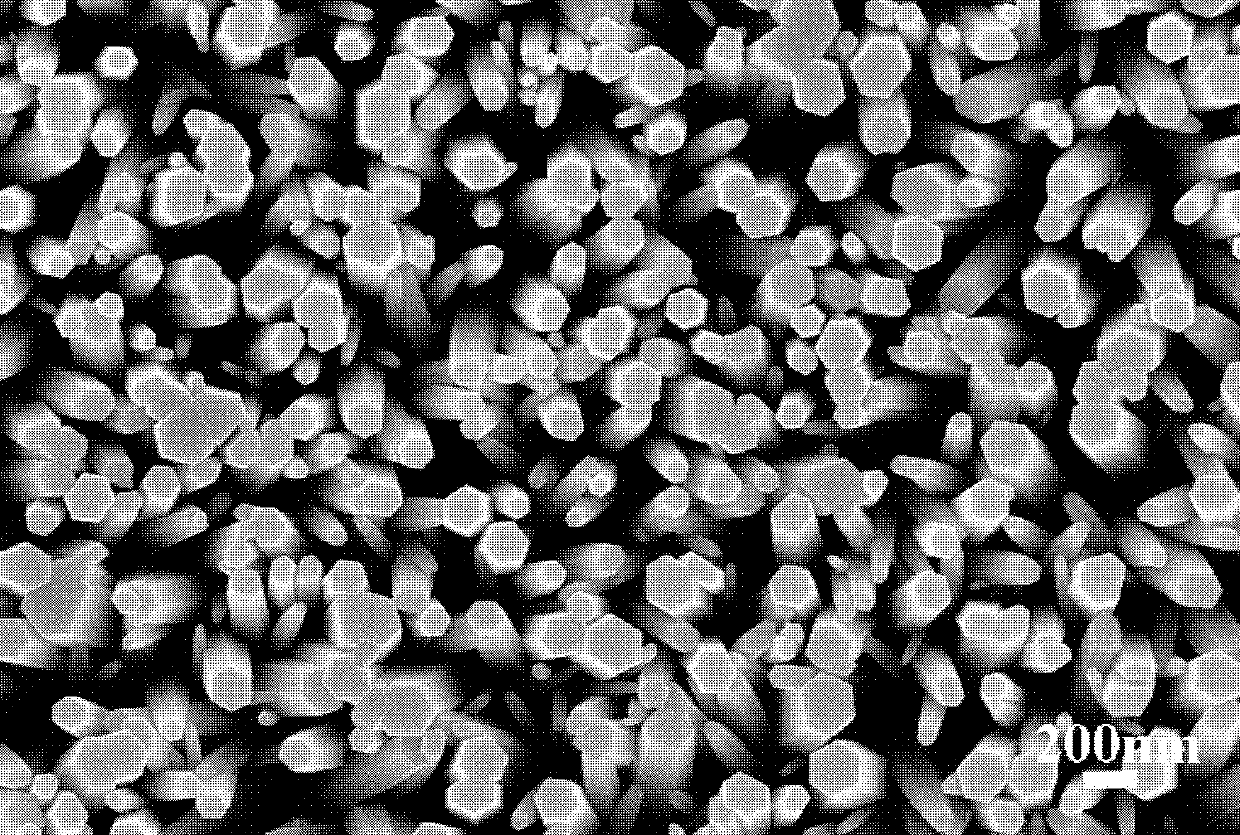

Method for preparing smooth dense silver-coated copper powder through chemical plating method

ActiveCN110551995AHigh solid contentImprove adhesionTransportation and packagingMetal-working apparatusChemical platingRoom temperature

The invention relates to a method for preparing smooth dense silver-coated copper powder through a chemical plating method. The preparing method comprises the following steps that deionized water anda dispersing agent are added into activated copper powder to obtain a copper nano-particle suspension liquid; a complexing agent is added into a silver nitrate water solution to prepare a silver complexing solution; and the above solutions are mixed, a reducing agent solution and a nano-silver suspension liquid are sequentially added, stirring is carried out at room temperature to obtain a silver-coated copper nanoparticle suspension liquid, and standing, washing and drying are carried out to obtain the smooth dense silver-coated copper powder. Compared with the prior art, nano-silver particles are added into a plating solution, so that the obtained silver-coated copper powder is dense in coating, smooth and non-porous in surface, excellent in conductivity and oxidation resistance, and extremely high in application value in the electronic slurry industry.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of tin alloy/silicon/carbon electrode material

InactiveCN105470480ASimple processEasy to operateCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention relates to a preparation method of a tin alloy / silicon / carbon electrode material. The method comprises the following steps: with a porous polymer as a carrier, depositing silicon oxide; mechanically mixing magnesium; carrying out high-temperature thermal reduction and acid treatment; filtering and drying the mixture; mechanically mixing a tin alloy; tabletting the mixture; and carrying out high-temperature sintering to obtain the tin alloy / silicon / carbon electrode material. The porous polymer is one of polyacetylene, polyacrylonitrile, polyaniline, polypyrrole and phenolic resin; the tin alloy is one of a nickel-tin alloy, a copper-tin alloy, an iron-tin alloy and a silver-tin alloy; the silicon source is one of tetraethoxysilane, silicon tetrachloride and trichlorosilane; an inner layer of the tin alloy / silicon / carbon electrode material is carbon and silicon in a porous structure; and an outer layer is the tin alloy with good conductivity and stable structure. The electrode material has the advantages of high specific capacity and long cycle lifetime, and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

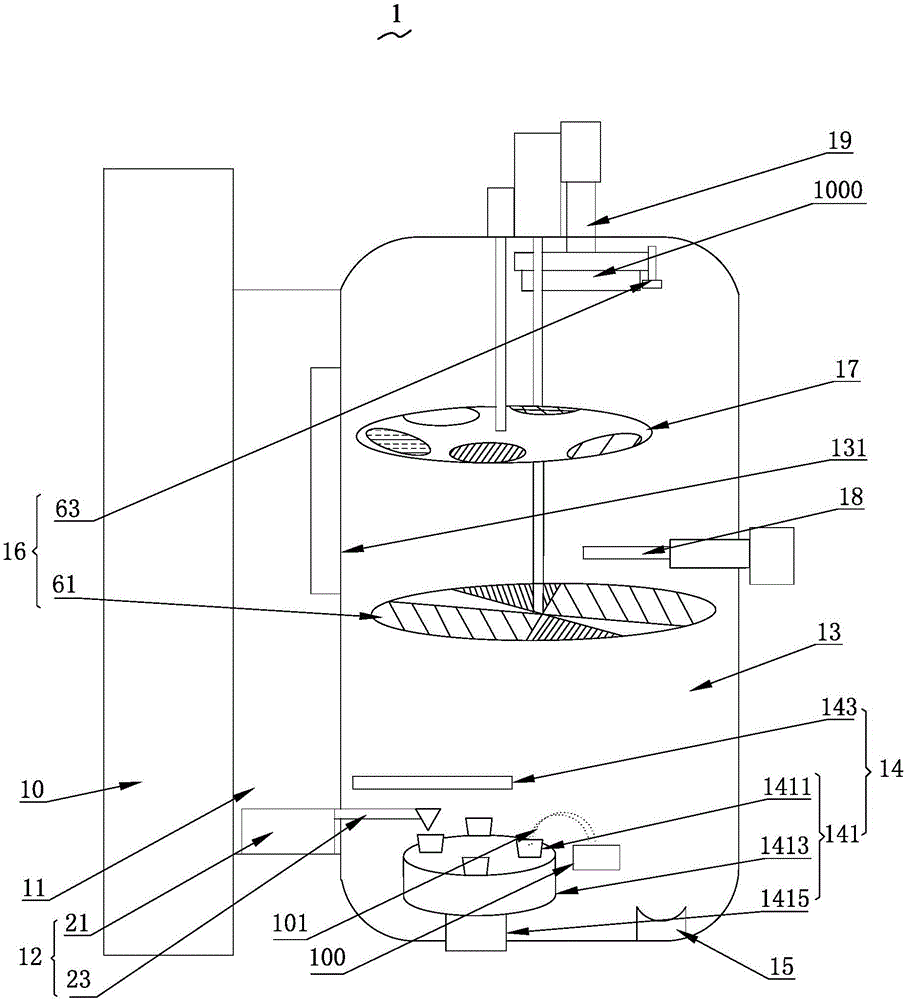

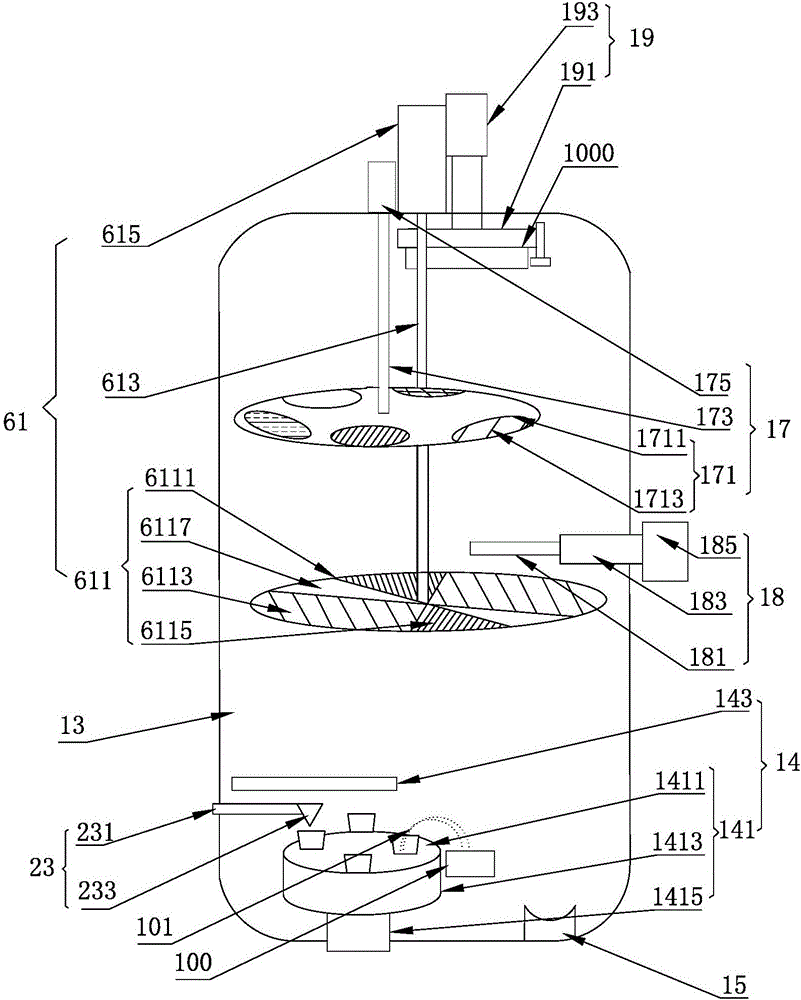

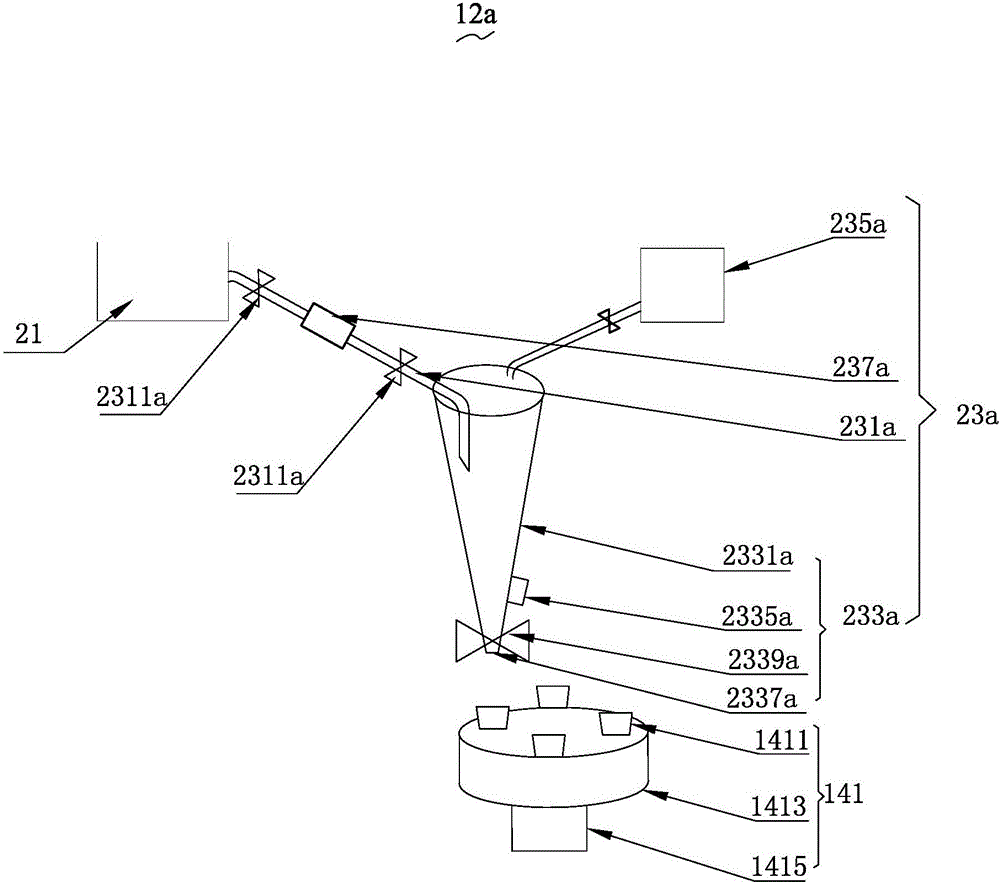

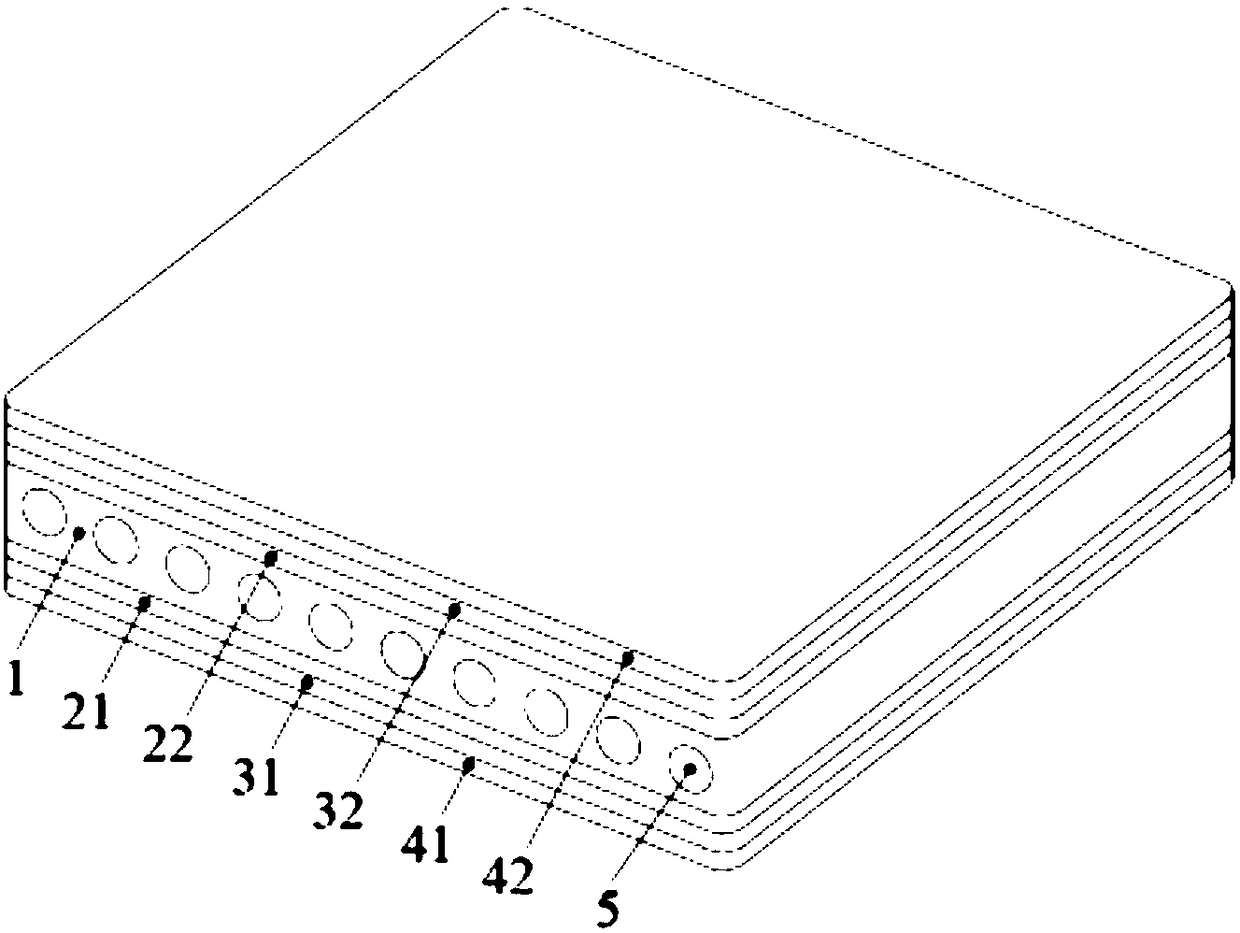

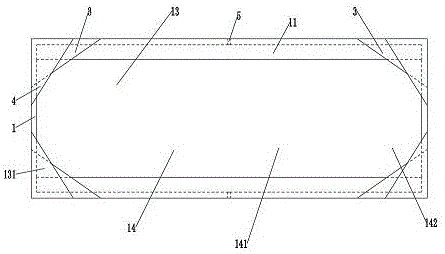

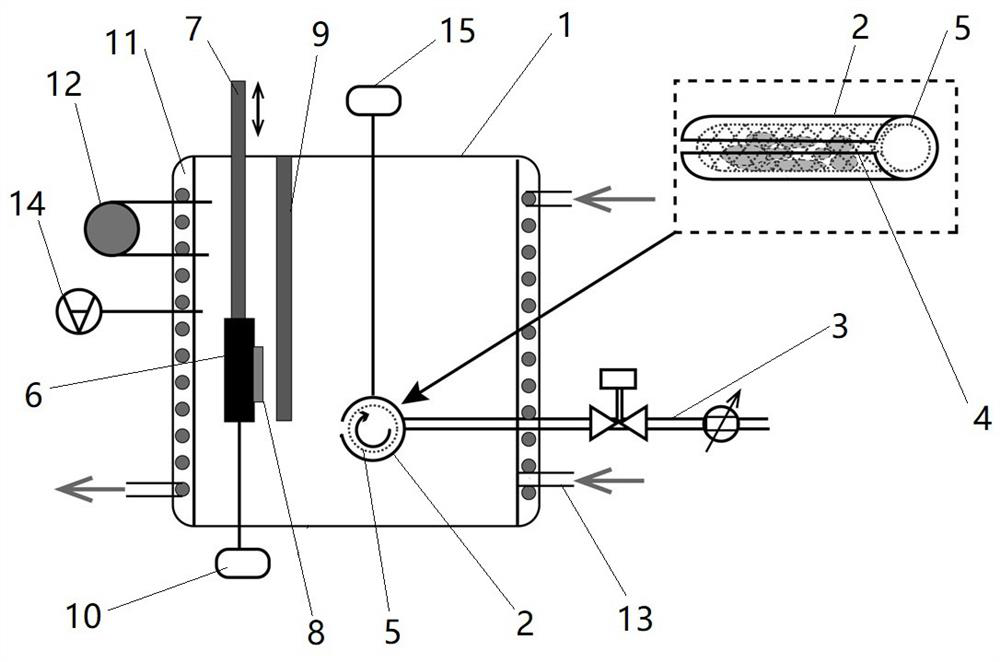

High-throughput composed material chip and preparation method and device thereof

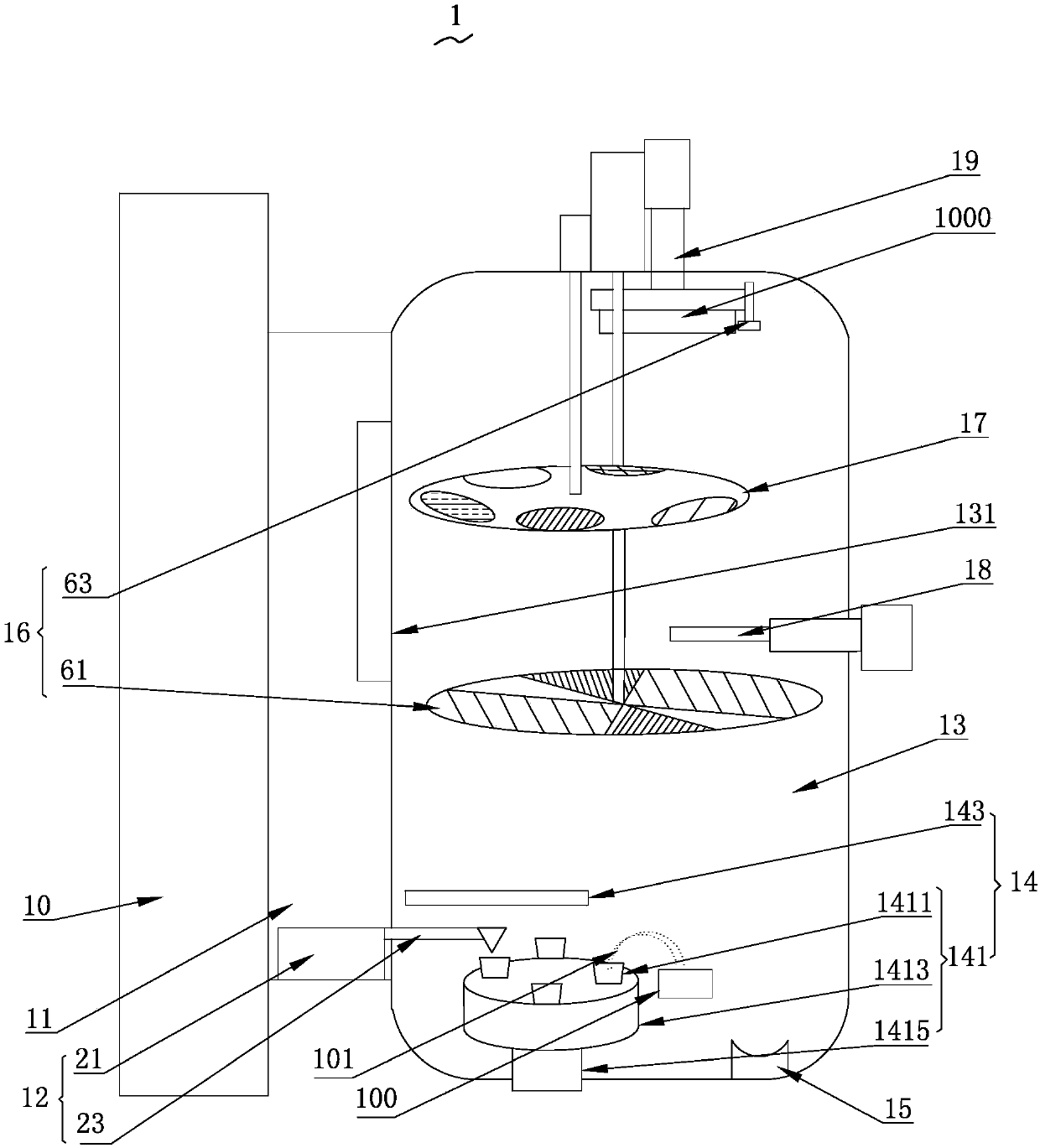

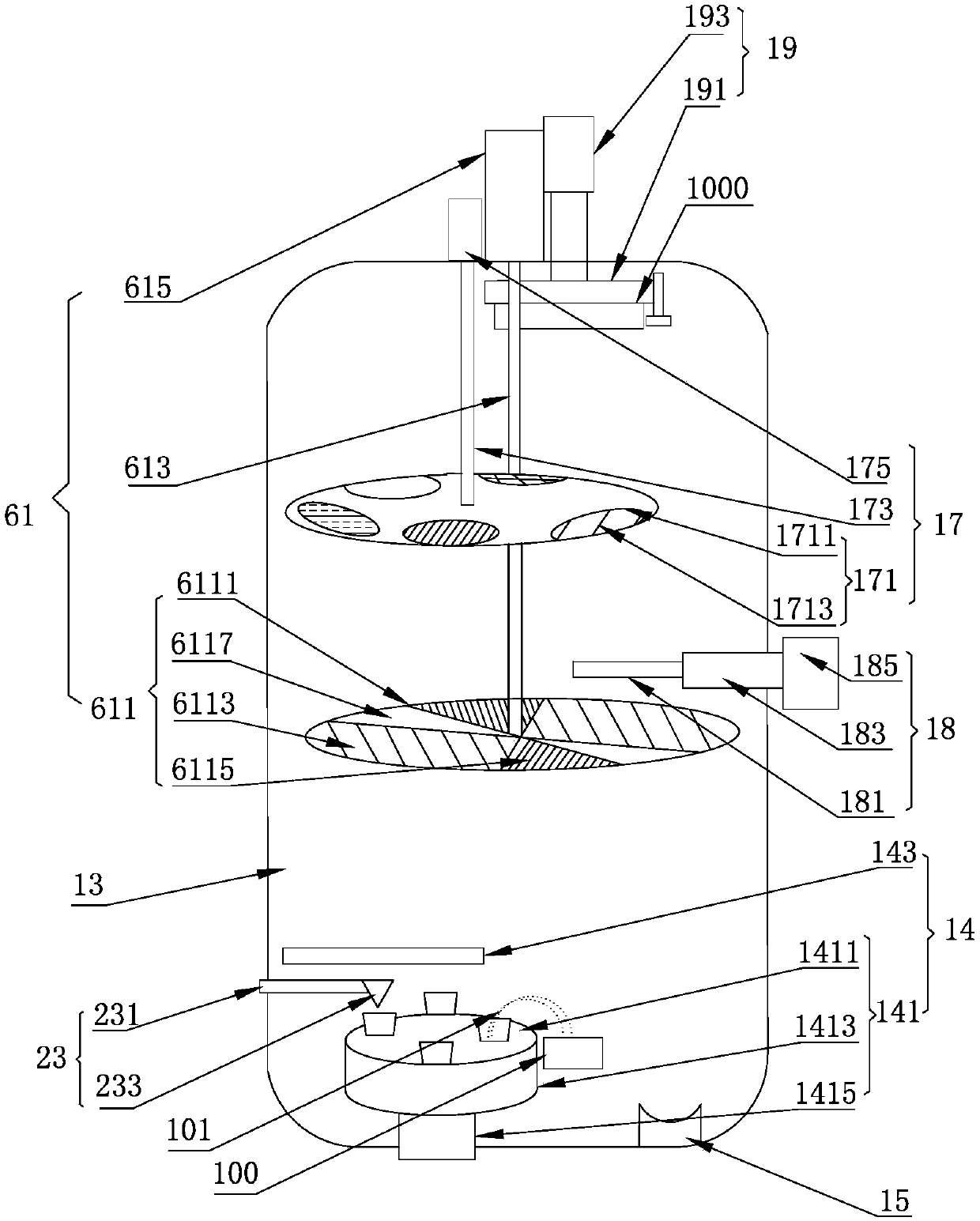

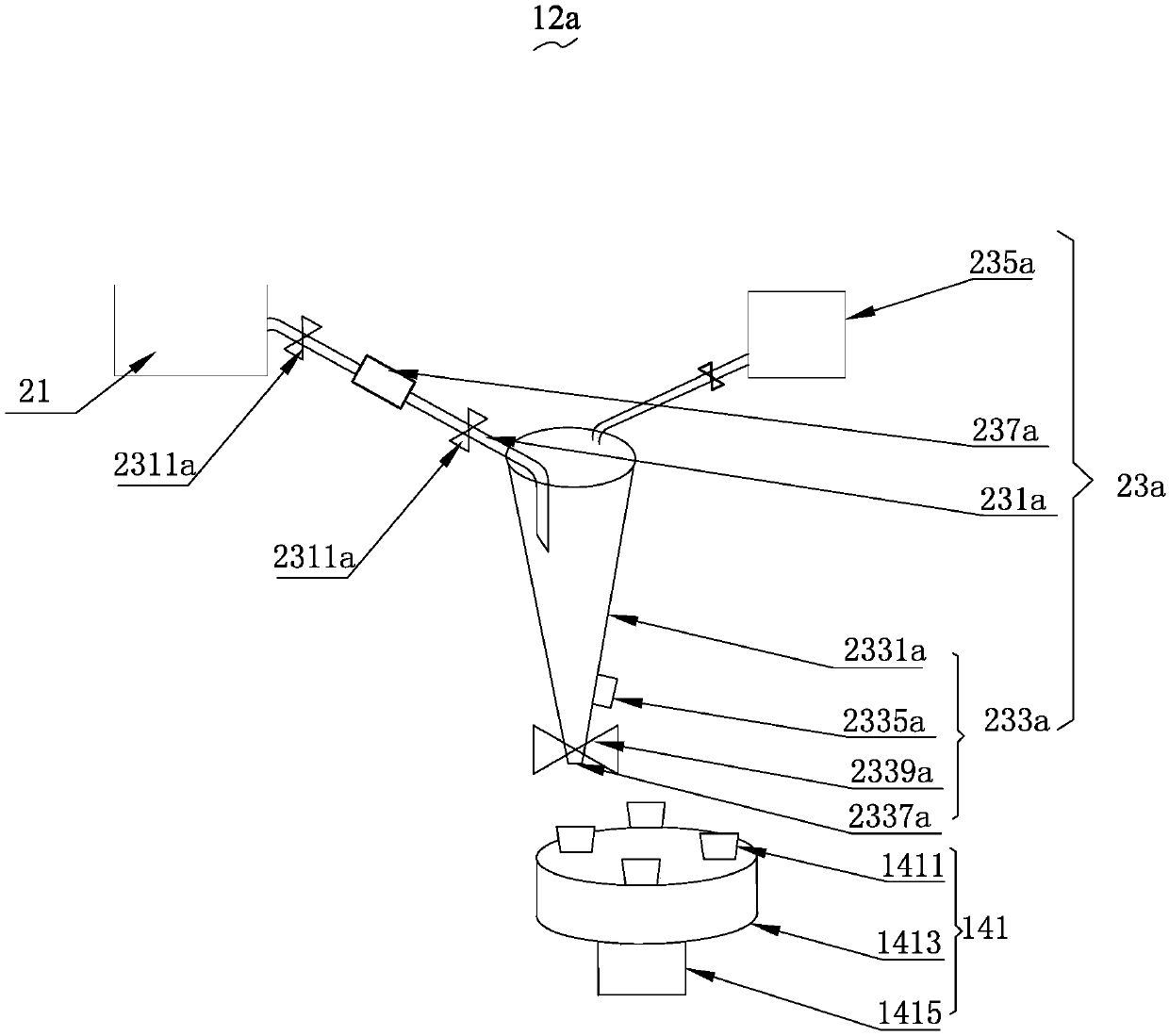

ActiveCN106222615AImprove production efficiencyAchieve diversificationVacuum evaporation coatingSputtering coatingEngineeringOutput device

The invention relates to a preparation device of a high-throughput composed material chip. The preparation device comprises a preparation cavity, a raw material output device stretching into the preparation cavity, an evaporator module contained in the preparation cavity, a plurality of discrete masks and a continuous mask. The raw material output device is arranged between the evaporator module and the discrete masks / continuous mask and used for quantitatively supplying raw materials to the evaporator module when the air pressure in the raw material output device is the same as that in the preparation cavity. The evaporator module is used for evaporating the raw materials supplied by the raw material output device so that steam can be formed. The steam is deposited on a substrate through the discrete masks and / or the continuous mask, so that the high-throughput composed material chip is formed. The invention further relates to a preparation method of the high-throughput composed material chip adopting the preparation device and the high-throughput composed material chip prepared through the preparation method. According to the preparation device of the high-throughput composed material chip, the raw materials can be supplemented to the evaporator module without destroying the working air pressure, and thus the preparation efficiency of the chip can be improved.

Owner:成都芯曌科技有限公司

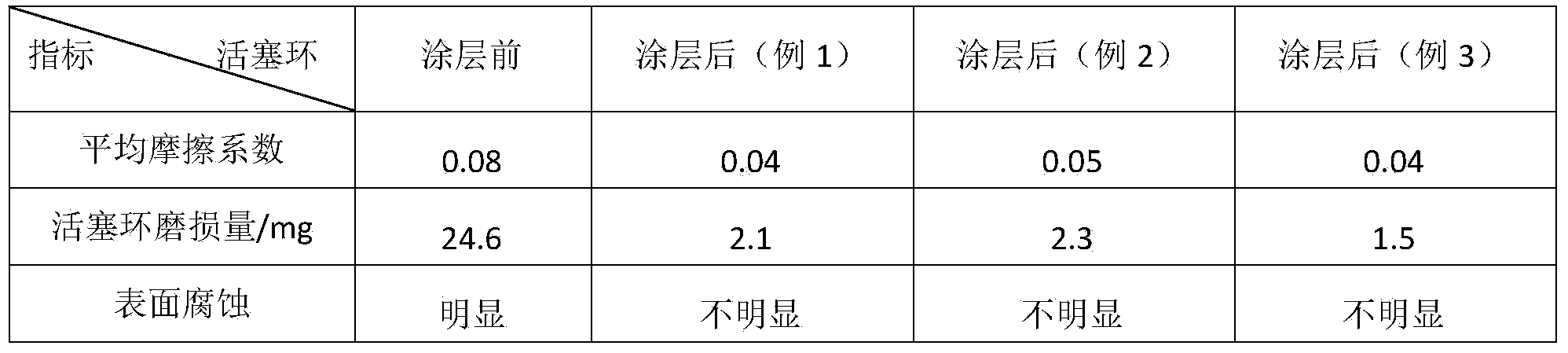

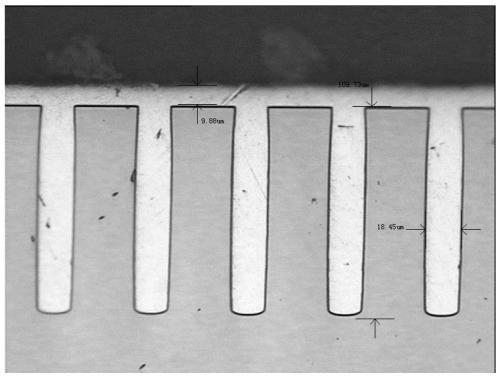

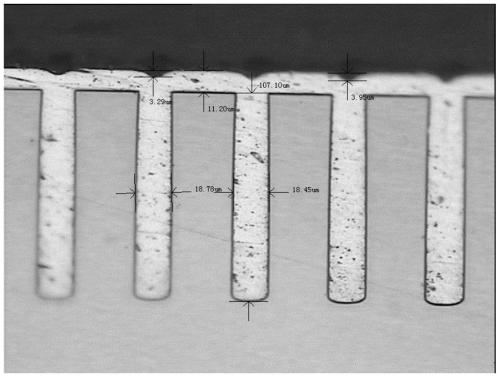

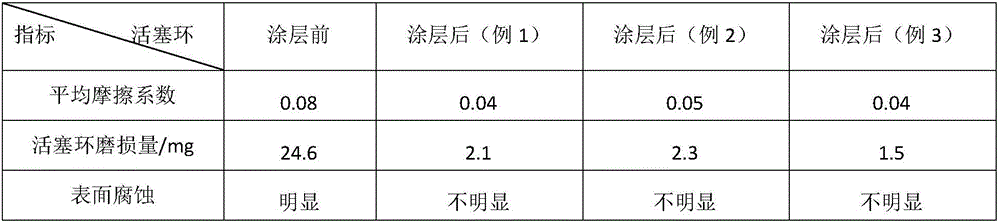

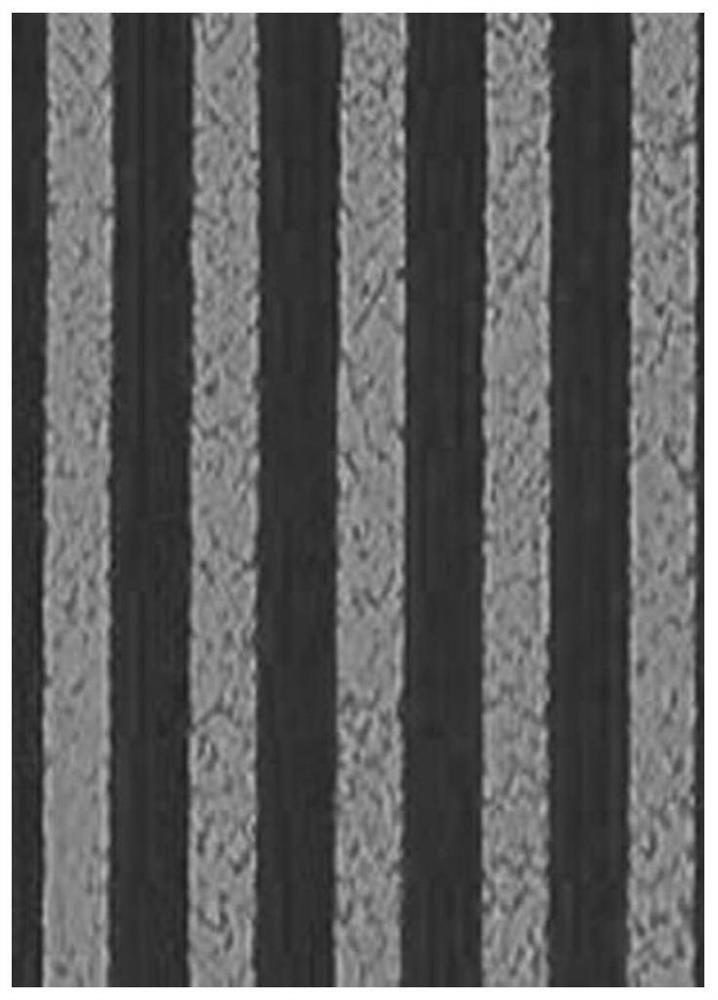

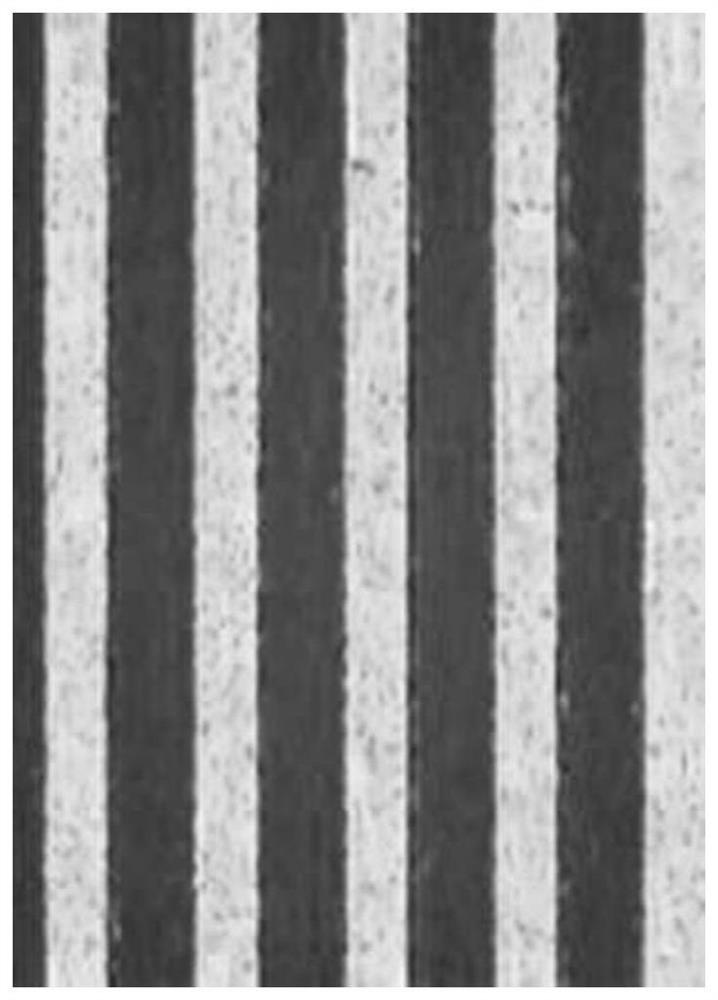

Piston ring friction surface costing for internal combustion engine facing to bio-oil application and preparation method of piston ring friction surface costing for internal combustion engine

ActiveCN104264133AReduce processing stepsSimple and fast operationPiston ringsMachines/enginesCoated surfaceThree dimensional morphology

The invention discloses a piston ring friction surface costing for an internal combustion engine applied facing to bio-oil application and a preparation method of the piston ring friction surface costing for the internal combustion engine. The piston ring friction surface costing for the internal combustion engine is made of a Ni-MoS2-GO-P composite. The preparation method adopts a laser-induced piston ring friction surface microtexturing and electroless plating synchronous coating process and is characterized in that when microtexturing on the friction surface of a piston ring is carried out by utilizing a laser induction method, and Ni, MoS2, GO and P deposit on the friction surface of the piston ring at the same time in a specific proportion, thus preparing a coating with good corrosion and abrasion resistance. The piston ring friction surface costing has the advantages that the preparation process is simple and easy to operate, the cost is low, the binding force of the coating and a matrix is strong, grains on the surface of the coating are uniform and controllable, the microtexture three-dimensional morphology and the thickness of the coating are regulated according to the needs, and thus effective protection function of the friction surface of the piston ring of the internal combustion engine in the bio-oil environment is realized.

Owner:合肥庐阳科技创新集团有限公司

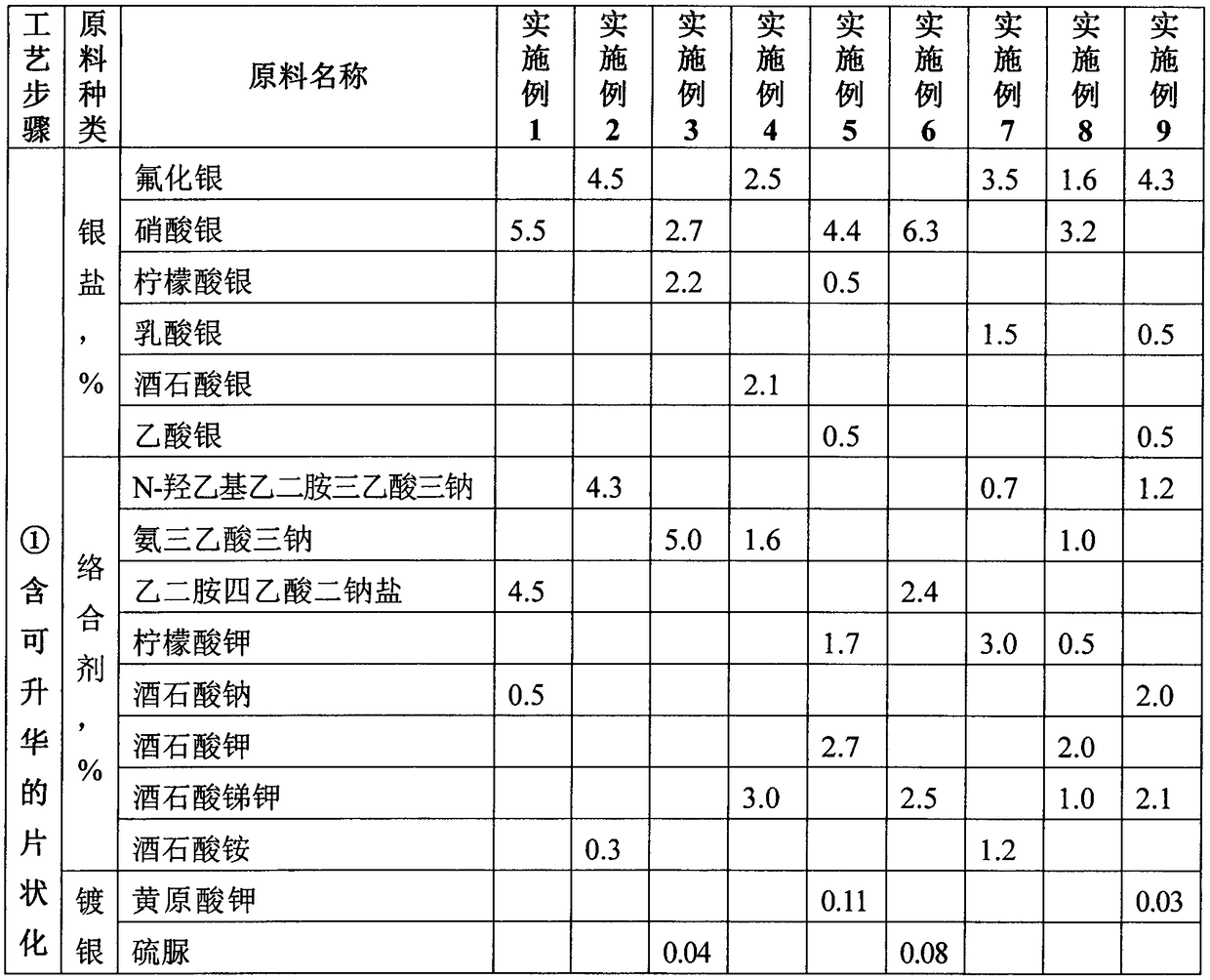

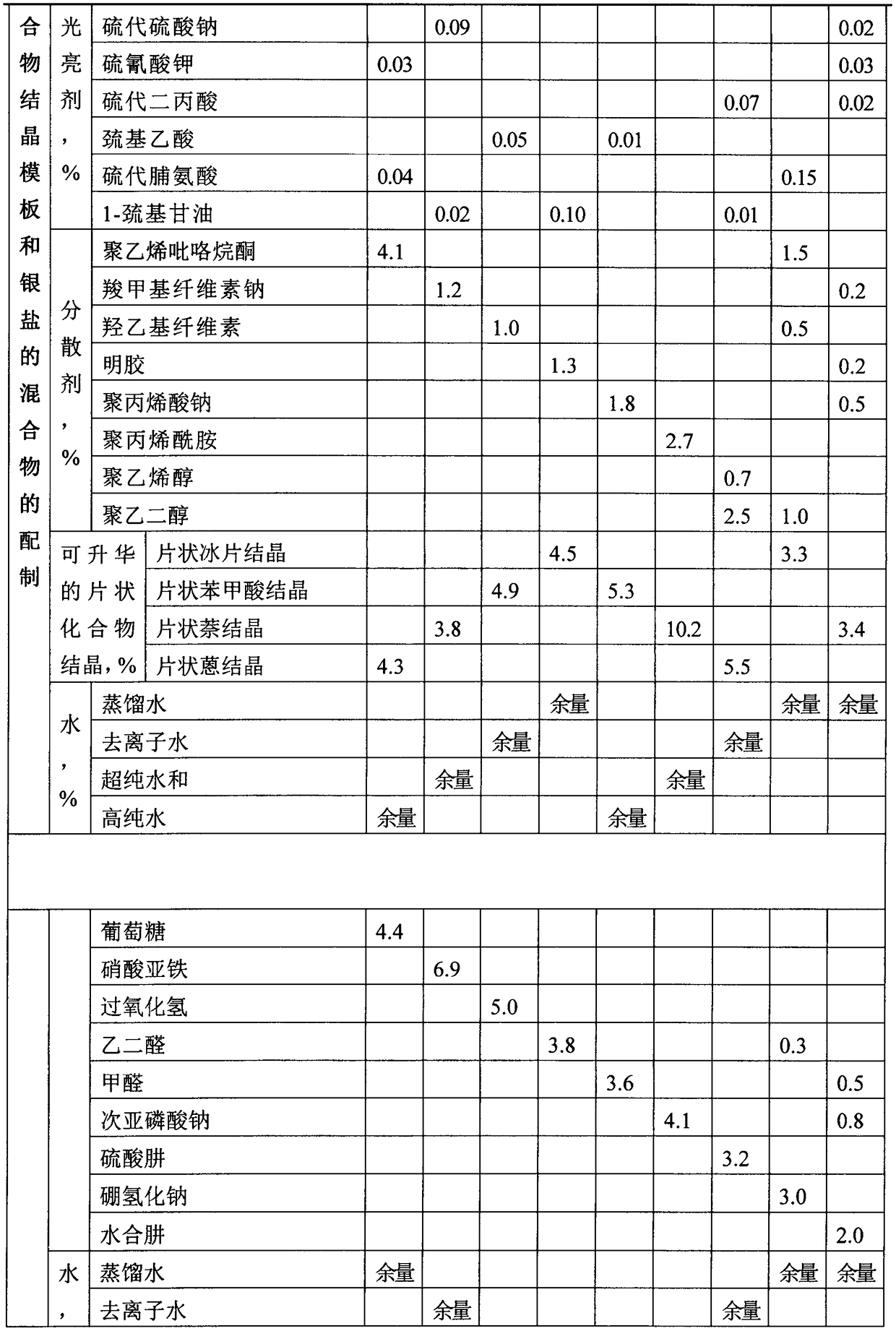

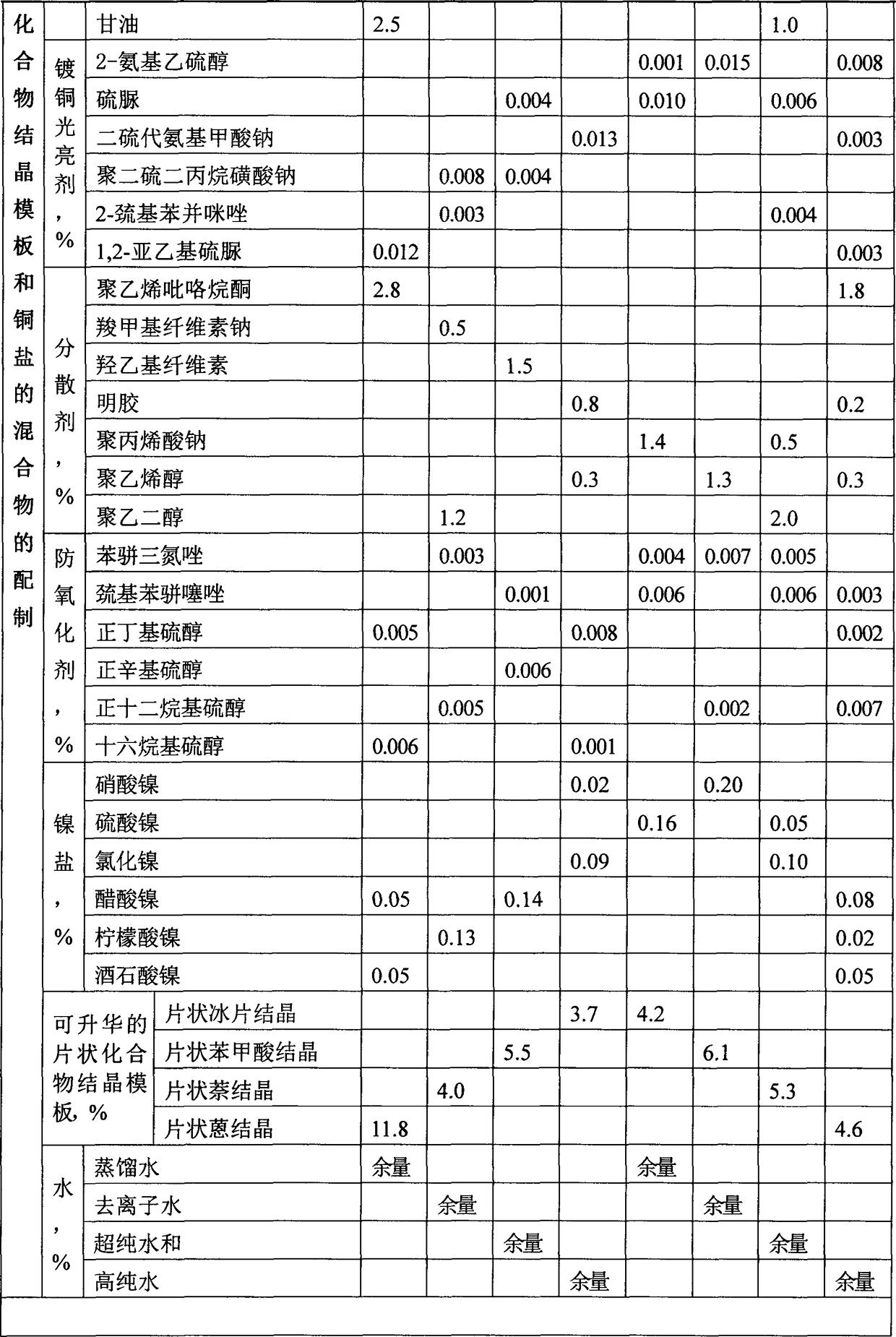

Preparation method of flake silver powder

InactiveCN108580920ASimple purification processHigh product purityMaterial nanotechnologyTransportation and packagingChemical platingEnergy consumption

The invention provides a preparation method of flake silver powder. The method comprises the steps that water, silver salt, a complexing agent, a silver-plated brightener, a dispersing agent, sublimated flake compound crystals and a reducing agent are adopted as raw materials, a chemical plating method is adopted, silver is plated on the surface of the sublimated flake compound crystal until silver ions react completely, and after the reaction is finished, the flake silver powder is directly obtained through separation and purification and processing treatment processes without ball milling. The preparation method has a series of advantages of being low in energy consumption, small in environmental pollution, simple in production process, short in process route, low in the large-scale production equipment investment, high in production efficiency, lower in production cost, good in product dispersion performance, good in product conductivity and the like, the method is suitable for large-scale production, the problems existing in the process of preparing the sheet-like silver powder by a ball milling method are solved, and the method has the good industrialization prospects.

Owner:NANJING FORESTRY UNIV

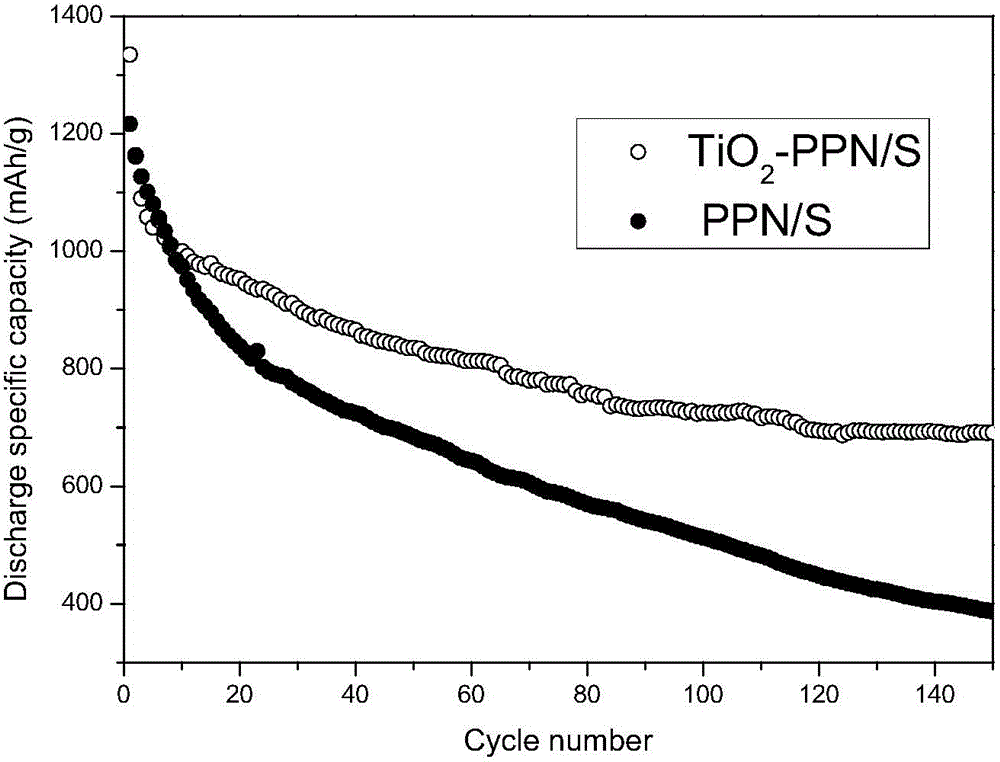

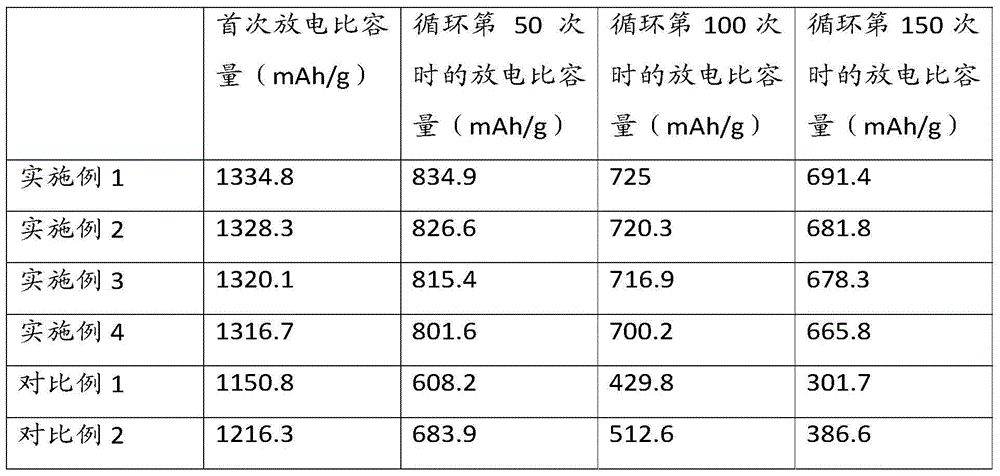

Composite material for anodes of lithium sulfur batteries, method for manufacturing composite material and anodes and batteries which are made of composite material

ActiveCN104835948AImprove adsorption capacityLimit dissolution lossSecondary cellsNon-aqueous electrolyte accumulator electrodesLithium–sulfur batteryLithium sulfur

The invention provides a composite material for anodes of lithium sulfur batteries. The composite material comprises polynaphthylene / sulfur composite materials and porous titanium dioxide. The porous titanium dioxide wraps the surfaces of the polynaphthylene / sulfur composite materials. The invention further provides a method for manufacturing the composite material for the anodes of the lithium sulfur batteries, and the anodes and the batteries which are made of the composite material for the anodes of the lithium sulfur batteries. The composite material for the anodes of the lithium sulfur batteries, the method, the anodes and the batteries have the advantages that the porous titanium dioxide wraps the surfaces of the polynaphthylene / sulfur composite materials, so that lithium polysulfide generated by the anodes when electricity of the batteries is discharged is difficult to dissolve in electrolyte; the S (sulfur) capacity of electrode materials can be greatly improved by the aid of the composite material for the anodes of the lithium sulfur batteries, and the high contents of sulfur in the polynaphthylene / sulfur composite materials can reach 65%-80%; polynaphthylene and the titanium dioxide are elastic to a certain extent and are combined with each other, so that double relief effects can be realized for volume expansion of the anodes.

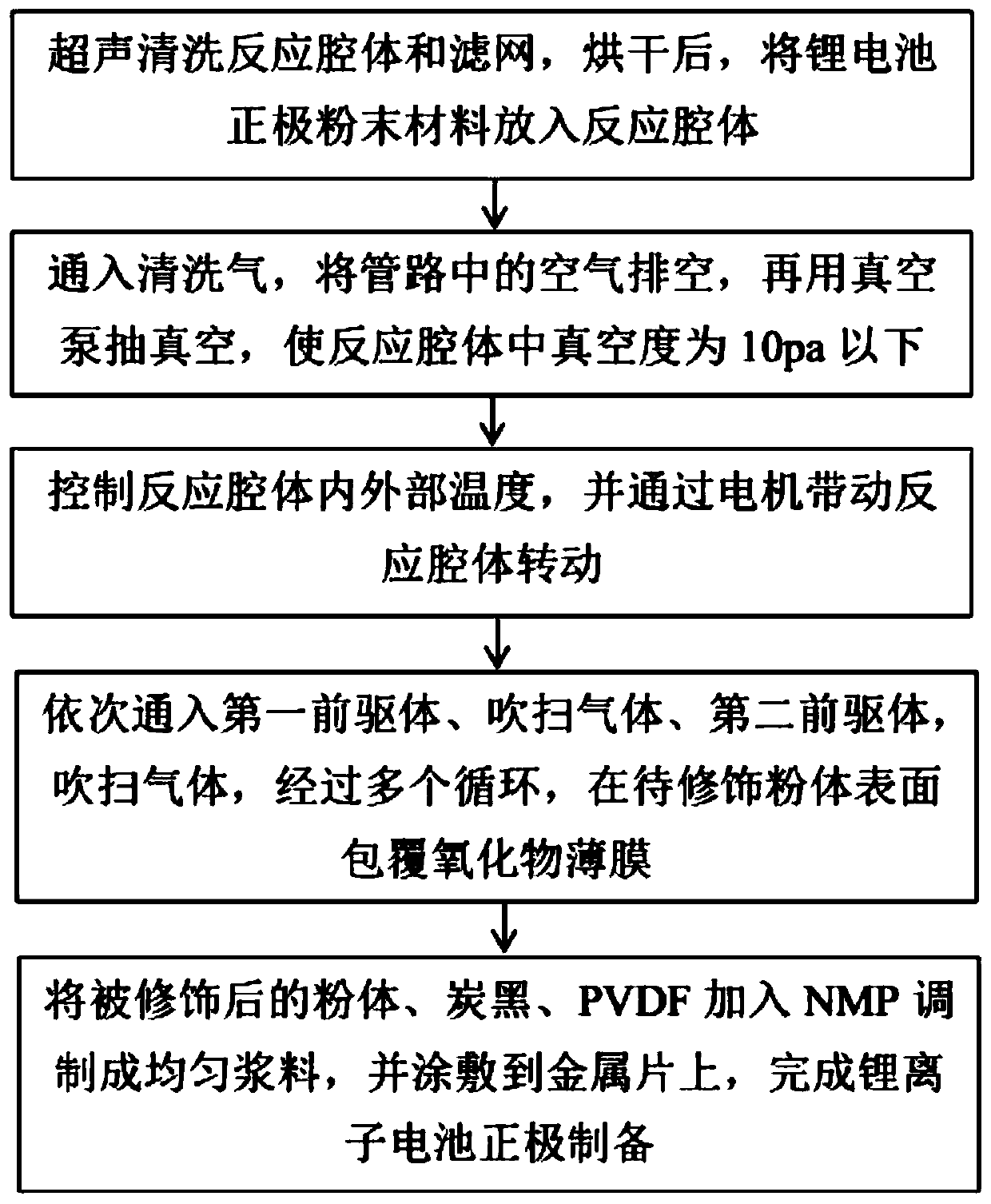

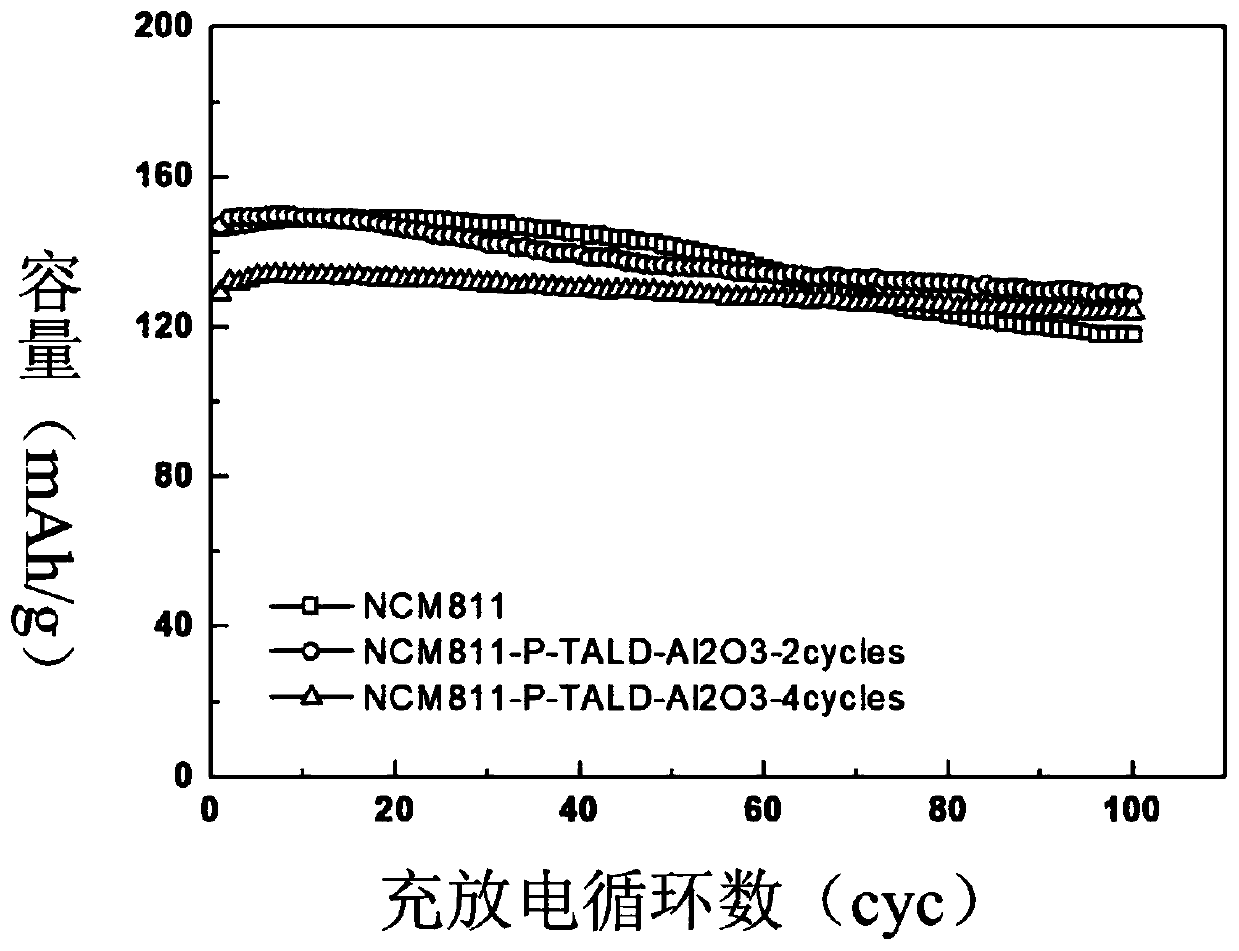

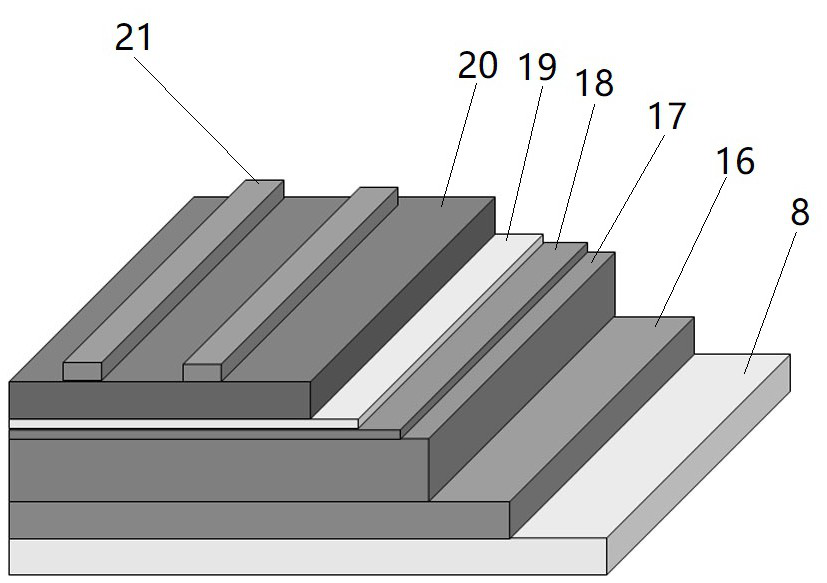

Lithium ion battery anode and preparation method thereof

ActiveCN110931713AGuaranteed stabilityExtended service lifeVapour deposition manufacturingElectrical batteryMetal sheet

The invention belongs to the field of lithium ion batteries, and particularly discloses a lithium ion battery positive electrode and a preparation method thereof. The preparation method comprises thefollowing steps that S1, to-be-modified powder is put into a reaction cavity, the reaction cavity is made to be in a vacuum state, then the reaction cavity is rotated and heated, and the to-be-modified powder is made to be evenly distributed in the reaction cavity; S2, a precursor and purging gas are alternately introduced into the reaction cavity, and the precursor reacts with the to-be-modifiedpowder, so that a layer of oxide film is formed on the surface of the to-be-modified powder; S3, S2 is repeated for multiple times to form multiple layers of oxide films on the surface of the to-be-modified powder so as to finish powder modification; and S4, the modified powder is blended into slurry, a metal sheet is coated with the slurry, and vacuum drying is carried out to complete the preparation of the lithium ion battery positive electrode. By depositing the oxide film on the surface of the lithium ion battery positive electrode material powder, the stability of the lithium ion batterypositive electrode in the charging and discharging processes is improved, and the service life of the lithium ion battery is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

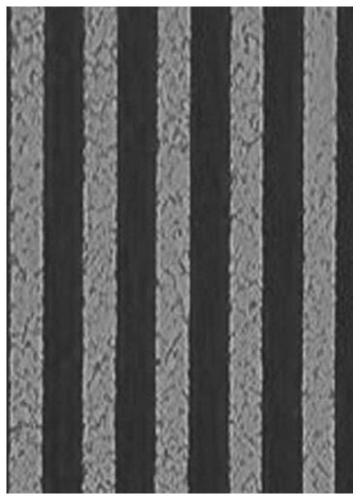

High-efficiency preparation method for nitrogen-doped titanium dioxide film

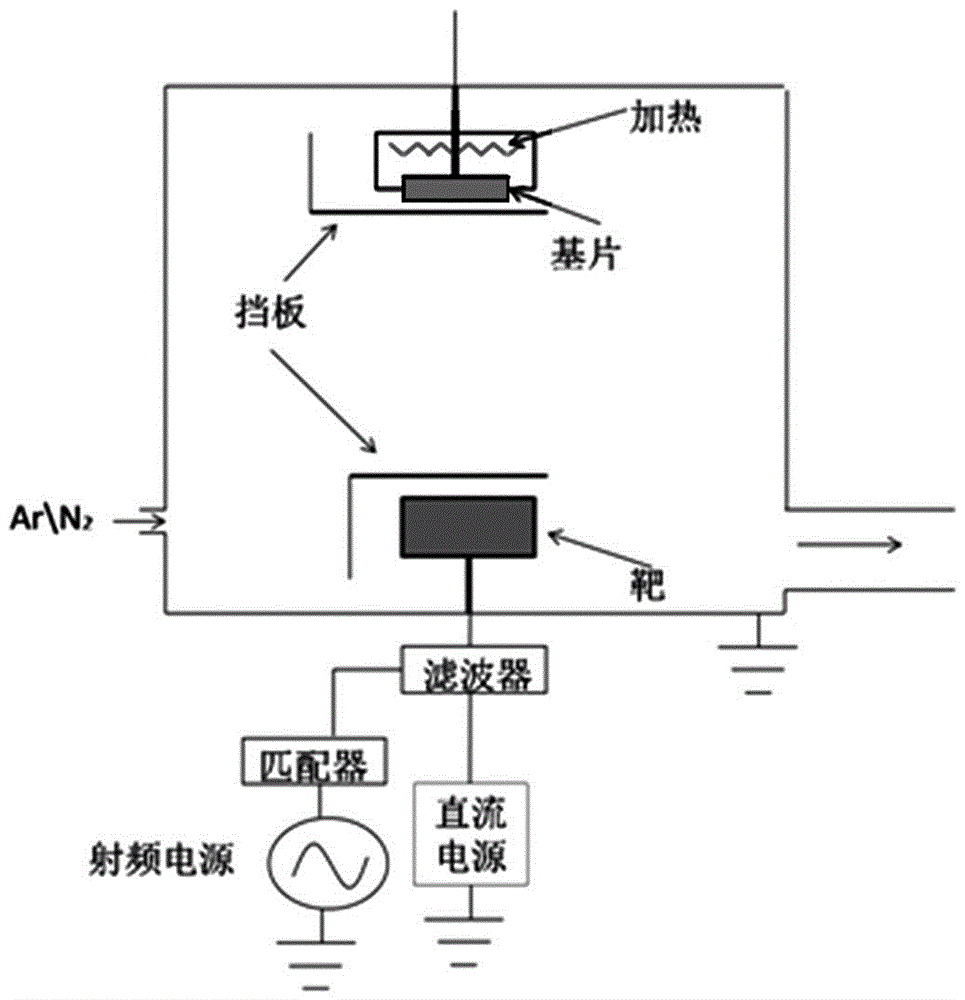

InactiveCN106637117AHigh crystallinityImprove photocatalytic performanceVacuum evaporation coatingSputtering coatingCouplingRadio frequency magnetron sputtering

The invention discloses a high-efficiency preparation method for a nitrogen-doped titanium dioxide film. The method comprises the steps that (1) a glass substrate is cleaned and then blow-dried by using high-pressure N2; and (2) the nitrogen-doped titanium dioxide film is deposited by adopting a direct-current coupling radio-frequency magnetron sputtering method, namely, a radio-frequency power supply is connected to a matcher and then together with a direct-current power supply is connected to a wave filter, wherein the wave filter is directly connected to a cathode, and the radio-frequency power supply and the direct-current power supply are used for supplying power to the cathode. According to the high-efficiency preparation method of the nitrogen doped titanium dioxide film, the nitrogen-doped titanium dioxide film is deposited by adopting the direct-current coupling radio-frequency magnetron sputtering method so that the film with a high deposition rate and high film quality can be obtained, the technology is simple, the conditions are easy to control, the preparation period is short, scale preparation is easy, and the prepared nitrogen doped titanium dioxide film is high in crystallinity, firm in combination with a substrate, good in stability and reusable.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

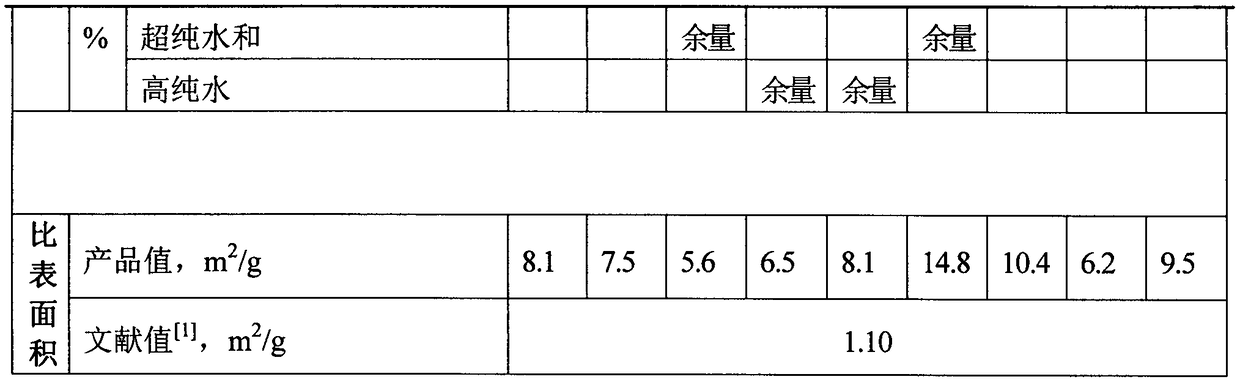

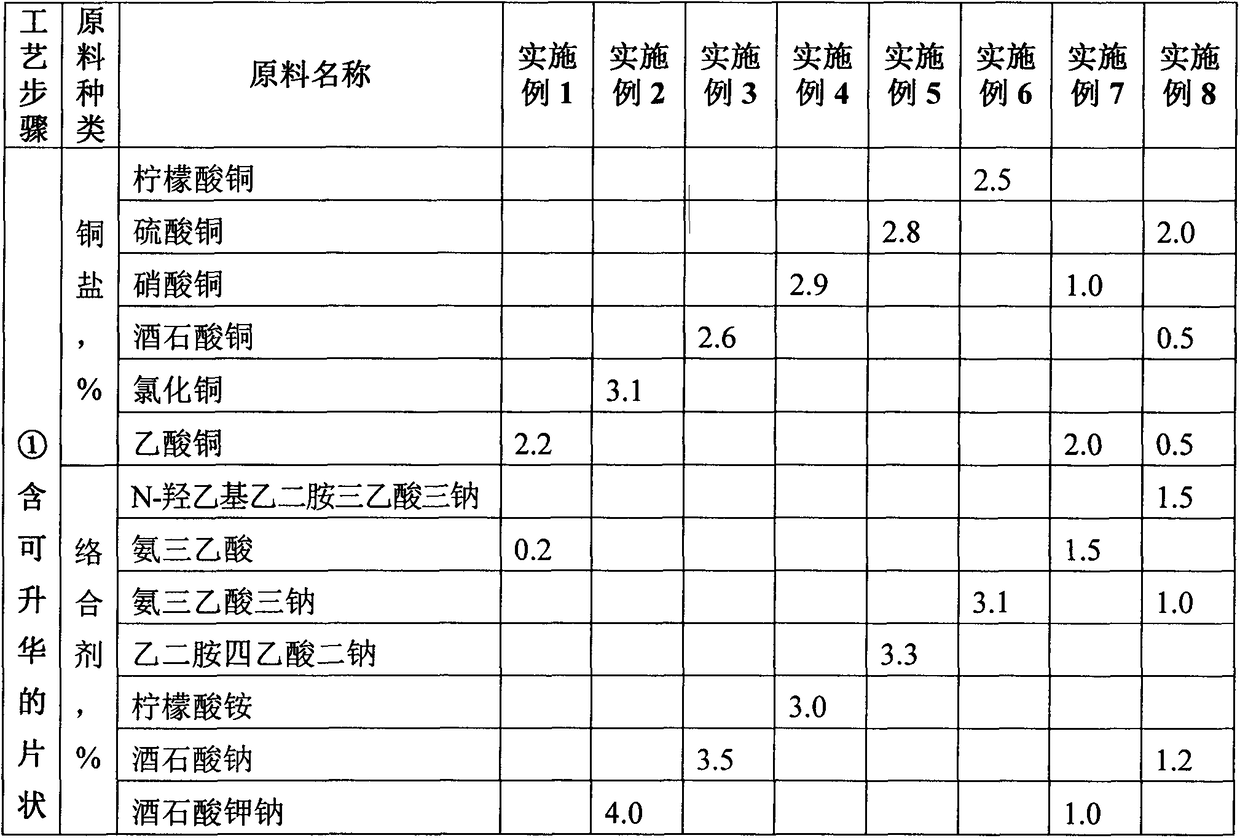

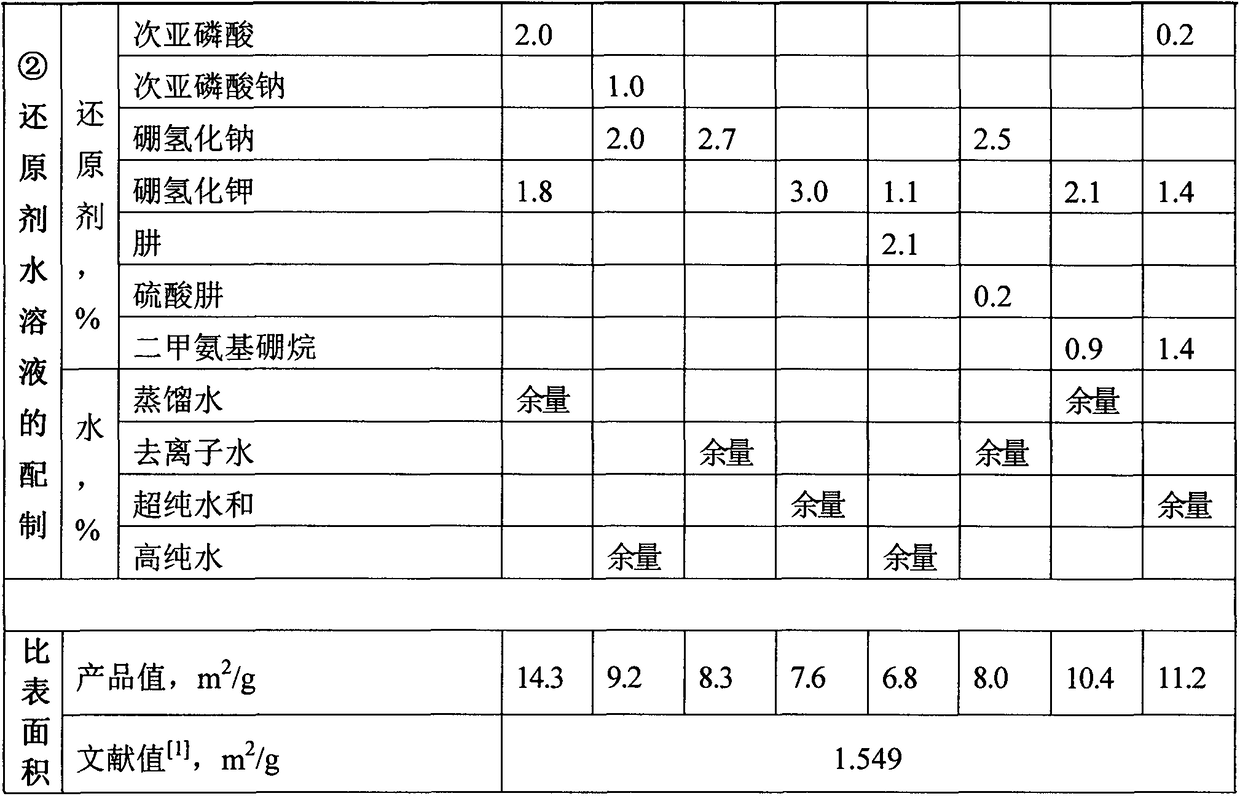

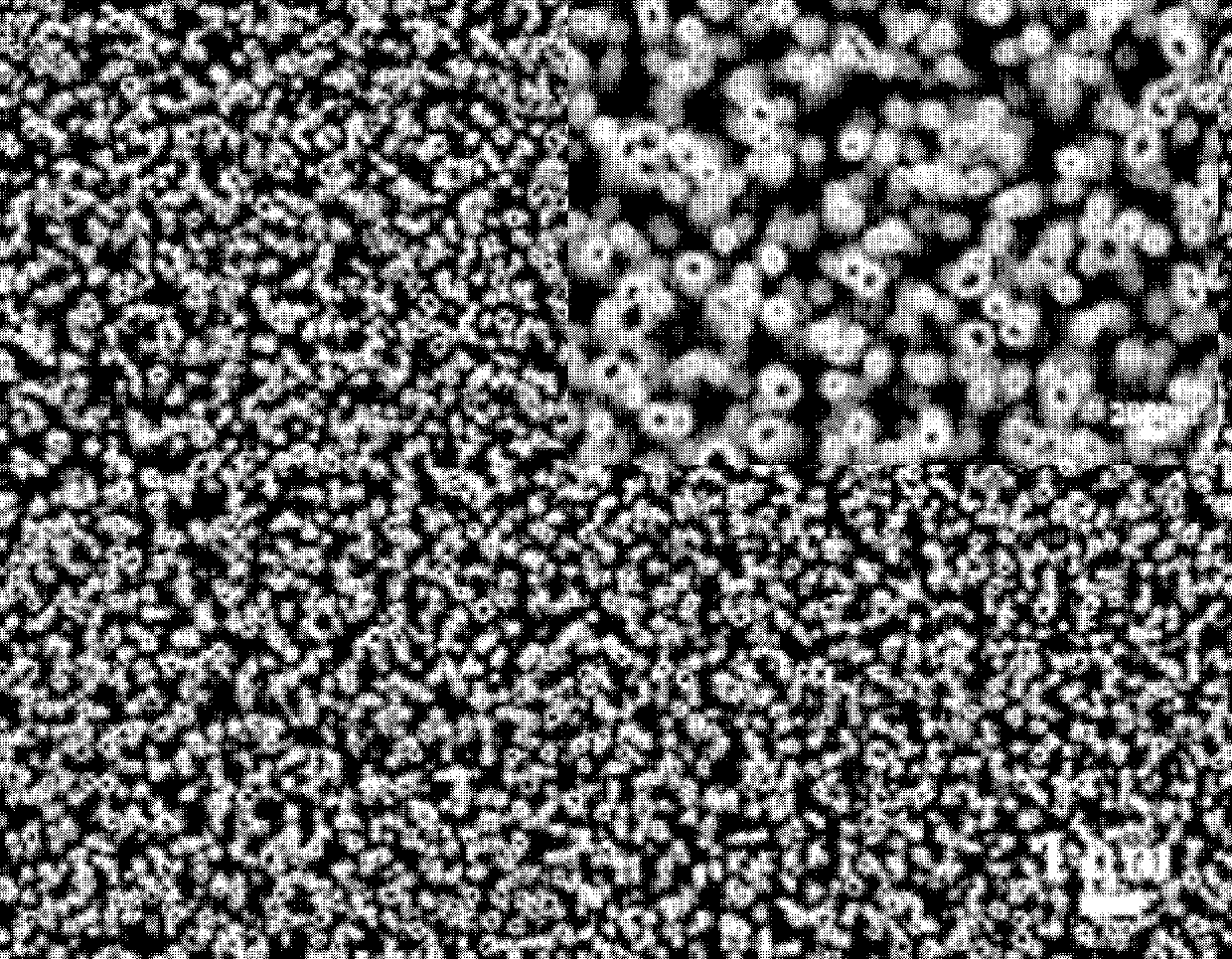

Method for preparing flaky copper powder

InactiveCN108500288AImprove conductivityControl deposition rateTransportation and packagingMetal-working apparatusCopper platingChemical plating

The invention provides a method for preparing flaky copper powder. The method is characterized in that water, copper salt, a complexing agent, a copper plating brightening agent, a dispersing agent, an antioxidant, nickel salt, a sublimable flaky compound crystal template and a reducing agent are taken as raw materials, copper plating is carried out on the surface of the sublimable flaky compoundcrystal template by adopting a chemical plating method until copper ions react completely, and after the reaction is finished, the flaky copper powder is directly obtained through a separation and purification treatment and a processing treatment without ball milling. The technical scheme of the method has the advantages that the energy consumption is low, environmental pollution is low, the production process is simple, the process route is short, the investment to the large-scale production equipment is low, the production efficiency is high, the production cost is low, and the dispersion performance and the conductivity of the products are good; and the method is suitable for large-scale production and capable of solving the problems exist in the ball milling process when the ball milling process is used for preparing the flaky copper powder, and has good industrialization prospect.

Owner:NANJING FORESTRY UNIV

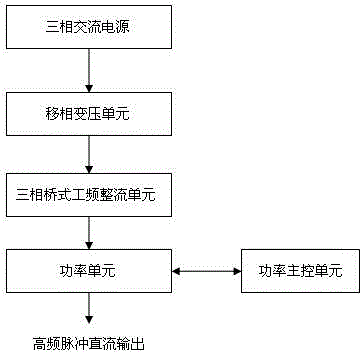

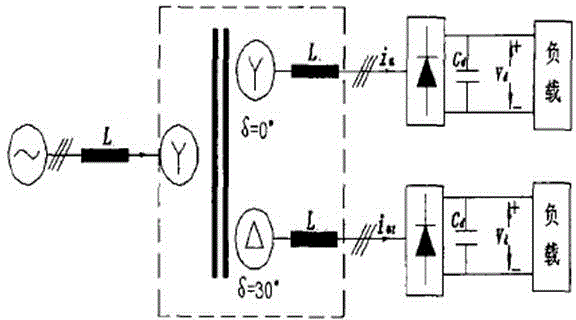

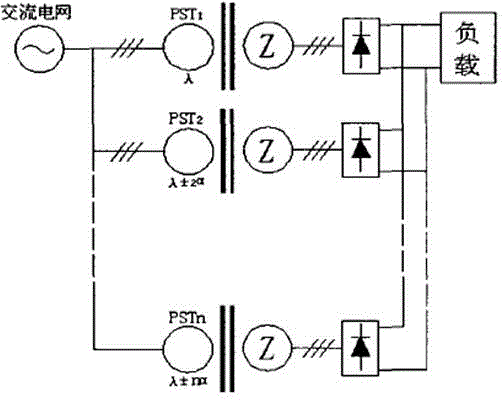

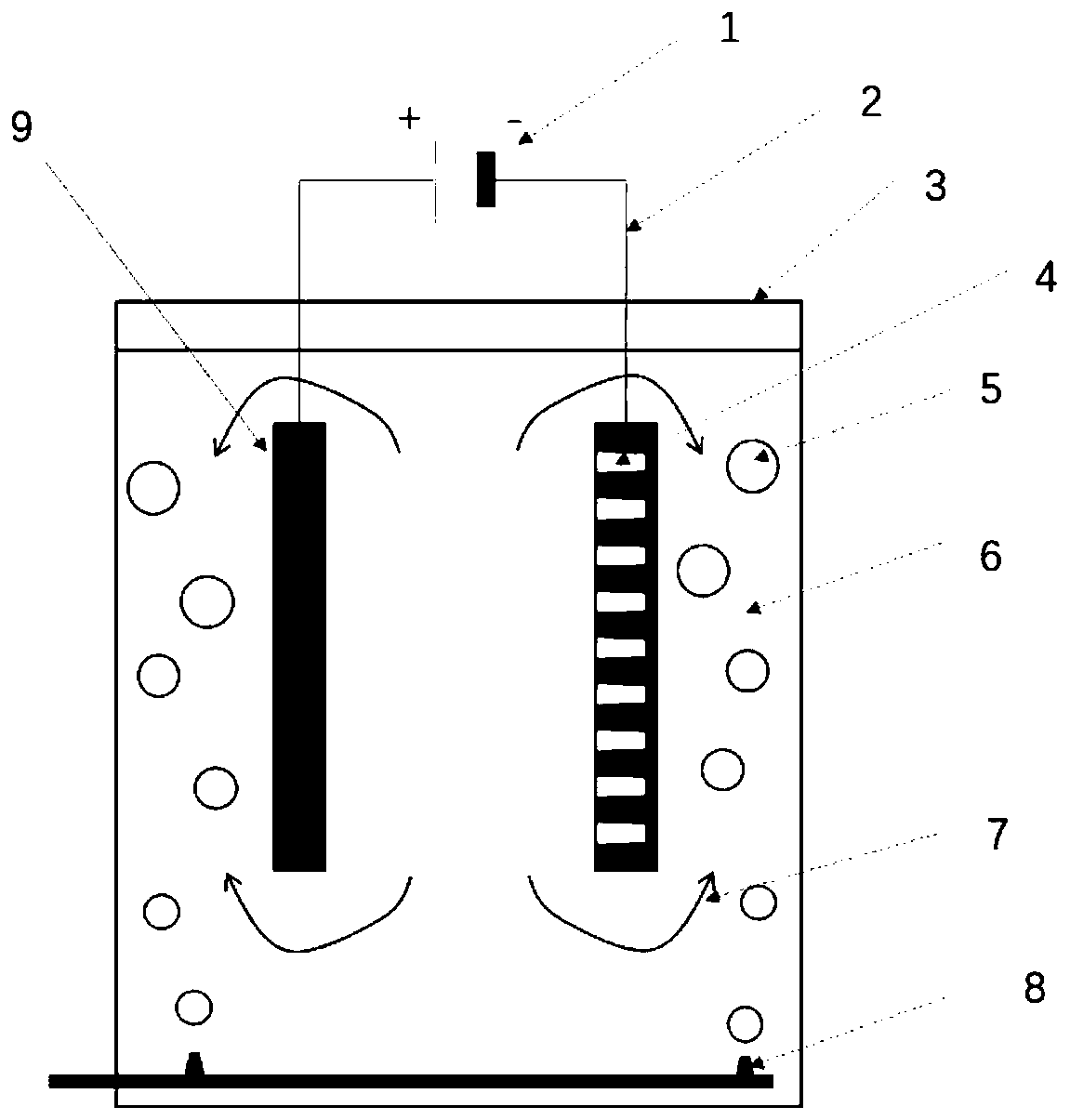

Industrial energy-saving high-frequency impulse electrolytic manganese device

ActiveCN104831314AImprove conversion efficiencyReduce harmonic effectsPhotography auxillary processesAlternating currentPower unit

The invention discloses an industrial energy-saving high-frequency impulse electrolytic manganese device which comprises one or more phase-shifting transformers, one or more three-phase rectifier bridge assemblies, one or more power assemblies and a power master control unit, wherein the primary sides of the phase-shifting transformers are connected with the output end of a three-phase alternating-current supply and the secondary sides of the phase-shifting transformers are in one-to-one corresponding connection with the inputs of the three-phase rectifier bridge assemblies, respectively; the output ends of the three-phase rectifier bridge assemblies are correspondingly connected with the input ends of the power assemblies, and the output ends of the power units output high frequency impulse signals to electrolytic baths; the voltages output by the secondary sides of phase-shifting transforming units are determined according to the quantity of the electrolytic baths connected in series; when a plurality of the phase-shifting transformers are adopted, the phase-shifting transforming units are the phase-shifting transformers in multiple forms for reducing harmonic waves of an alternating current input current and harmonic amplitudes and current impulses of a direct current output voltage; the power master control unit is respectively connected with one or more power assemblies for current-sharing control of the power assemblies.

Owner:CHENGDU XINMING ENERGY SAVING TECH CO LTD

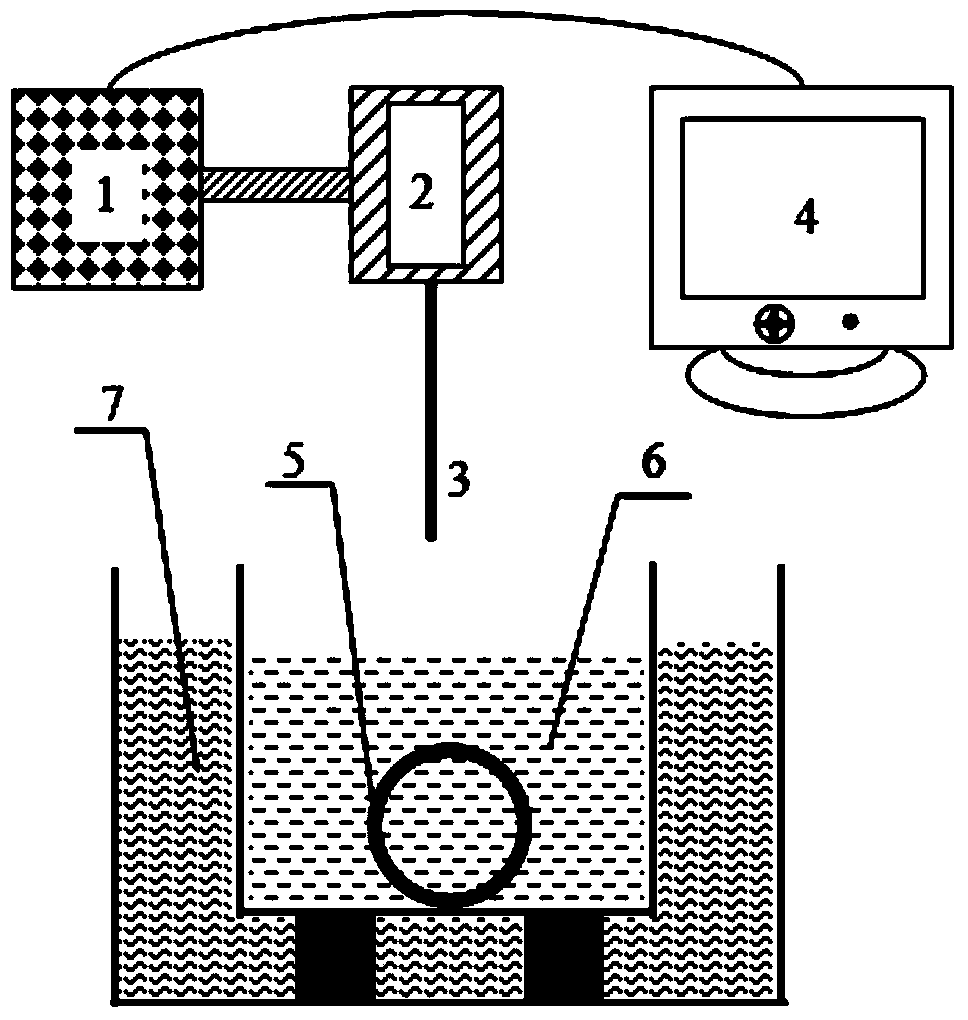

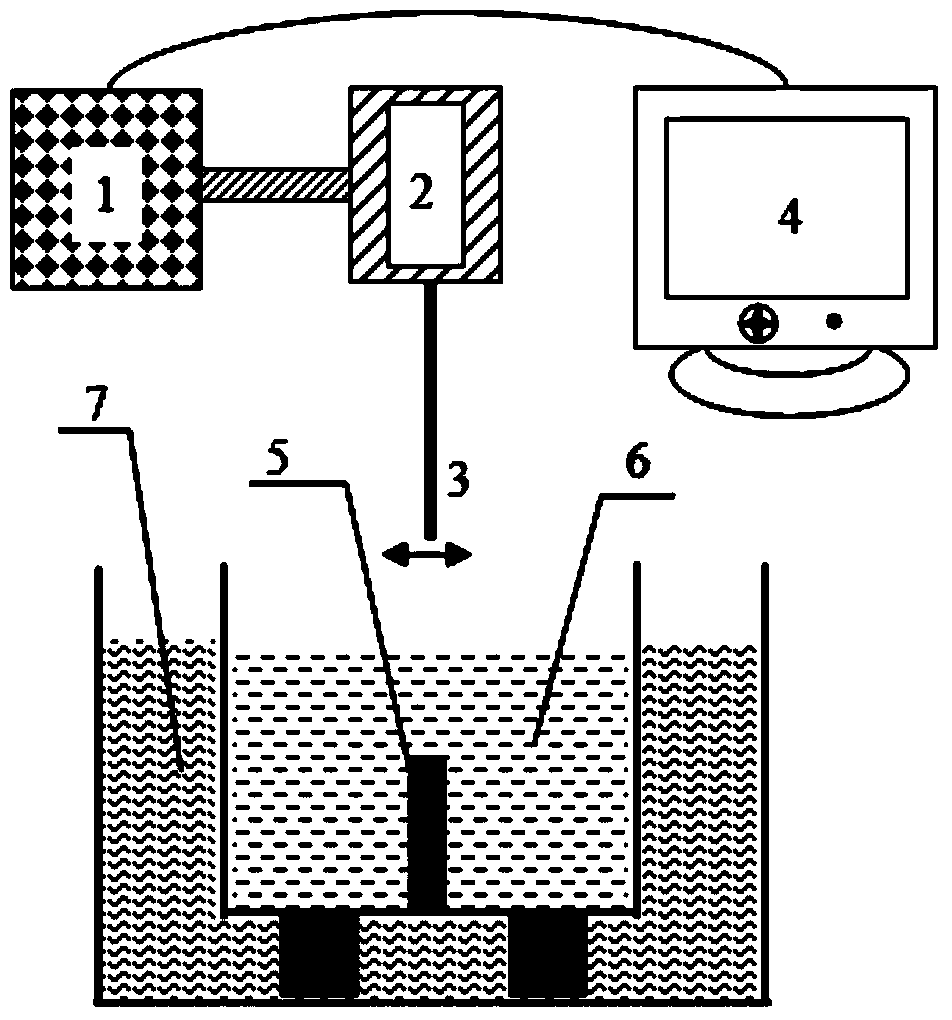

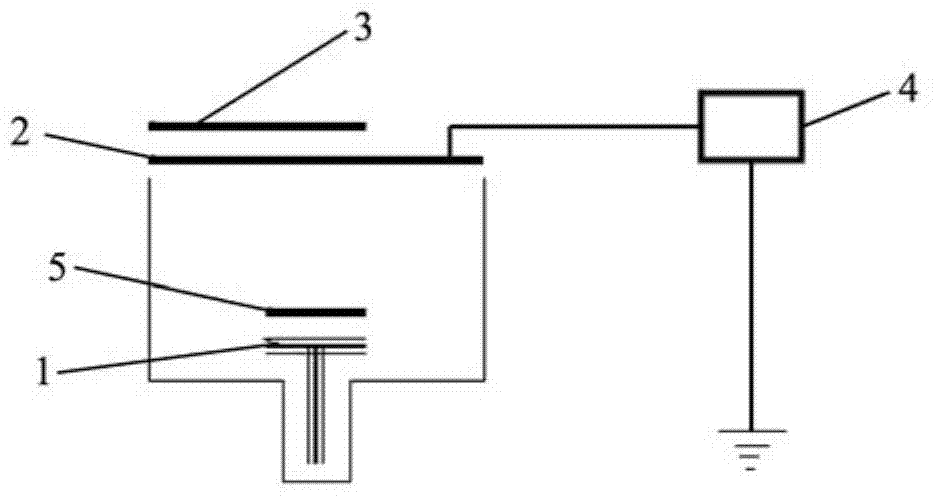

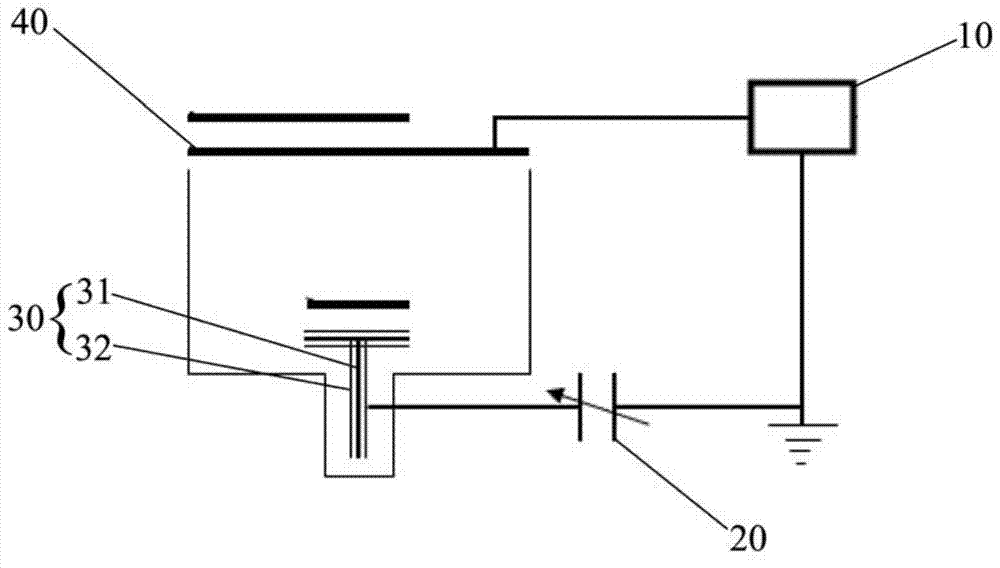

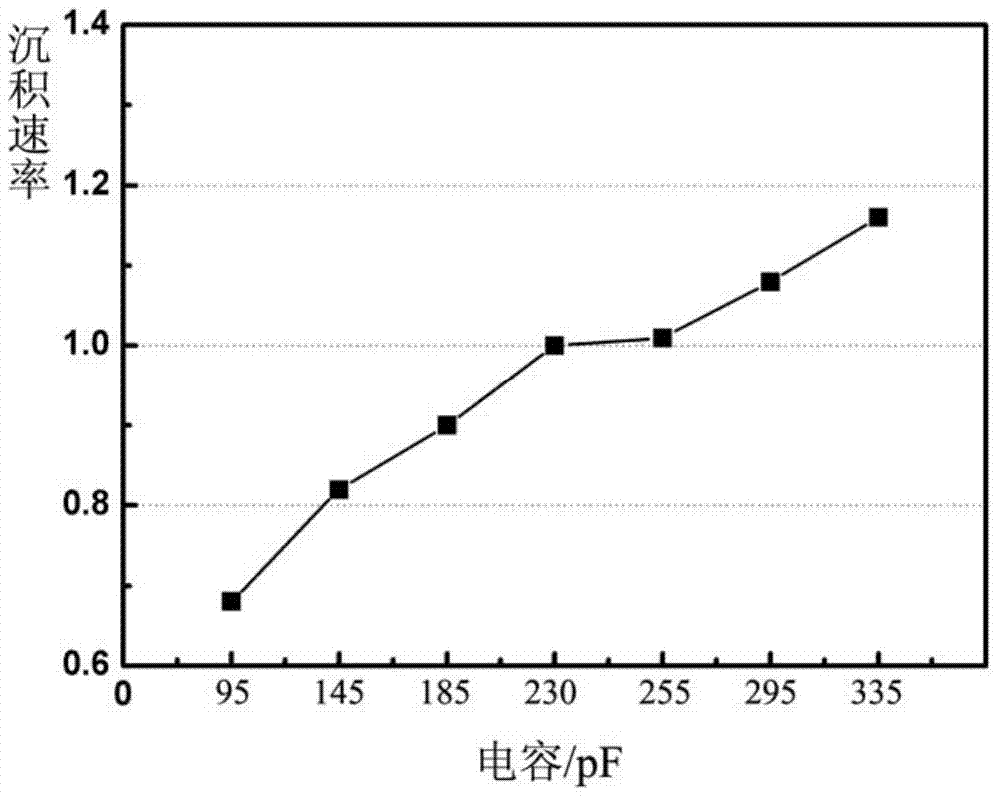

Film deposition equipment

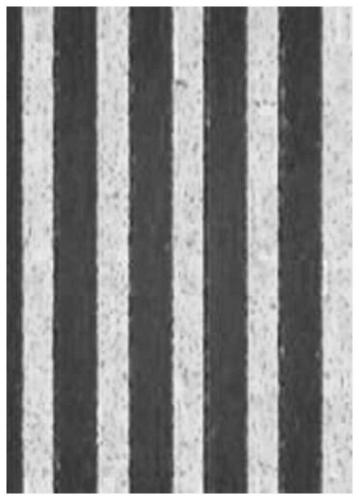

InactiveCN104746026AControl deposition rateImprove performanceVacuum evaporation coatingSputtering coatingCapacitanceEngineering

The invention relates to film deposition equipment, which comprises a reaction cavity, an excitation power supply and a variable capacitor; the reaction cavity comprises a bearing apparatus and a target material, the target material is arranged at top of the reaction cavity and is electrically connected to the excitation power supply; the bearing apparatus is arranged in the reaction chamber and is positioned at a part corresponding to the target material for bearing a substrate; one end of the variable capacitor is connected to the bearing apparatus, and the other end is connected to ground. The film deposition equipment can control the deposition rate of the film deposited on the substrate by changing the capacitance value of the variable capacitor; under the controlled different film deposition rates, the performance of the film deposited on the substrate is essentially constant.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Method for preparing carbon nanomaterial by using high temperature solid oxide fuel cell

InactiveCN109280931ALow cost of preparationSimple processMaterial nanotechnologyCellsOxidePower flow

The invention provides a method for preparing a carbon nanomaterial by using a high temperature solid oxide fuel cell. According to the method, Ni-based anode carbon deposition technology is adopted;a fuel gas composed of ethanol, carbon monoxide and water is selected, and the molar ratio of the ethanol, the carbon monoxide and the water is controlled to be (3-5): (2-4): (1-3); at the same time,the density of a working current of the SOFC is adjusted to be 0.1-1 A / cm<2>; and a uniform and stable carbon nanomaterial is obtained. The method has the advantages of low preparation cost, simple process and continuous stability, and provides a new idea for preparing the carbon nanomaterial.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI +1

Chemical palladium solution applied to PCB chemical gold palladium clad layer

ActiveCN110318047AExtended service lifeControl deposition rateLiquid/solution decomposition chemical coatingPrinted circuit manufactureWire widthPh buffering

The invention discloses a chemical palladium solution applied to a PCB chemical gold palladium clad layer. Main salt, a coordination agent, a reducing agent, a stabilizer, a pH buffering agent and a surface active agent are included. The mass concentration serves as the unit, the components include, by proportion, 0.4-0.6 g / L of the palladium in the main salt according to the concentration, 0.1-30g / L of the coordination agent, 0.1-25 g / L of the reducing agent, 1-150 mg / L of the stabilizer, 1-25 g / l of the pH buffering agent, 0.1-10 mg / L of the surface active agent and the balance pure water.A palladium layer prepared through the palladium solution can meet good welding and bonding requirements, and meanwhile the chemical palladium solution is applicable to surface treatment of a circuitwith the wire width / wire distance being 0.5 mil or below or even smaller.

Owner:深圳市溢诚电子科技有限公司

Electroplating liquid for electroplating pure cobalt and application thereof

ActiveCN111041533AControl deposition rateUniform nucleation growthSemiconductor/solid-state device manufacturingCobalt saltElectrochemistry

The present invention provides an electroplating liquid for electroplating pure cobalt and application thereof. The electroplating liquid for electroplating pure cobalt comprises: a base solution which is an aqueous solution of a soluble cobalt salt; and a complexing agent, wherein the complexing agent contains a conjugated oxime group. According to the electroplating liquid for electroplating pure cobalt, the strong cathodic polarization effect on cobalt ion electrochemical deposition is achieved due to the use of the complexing agent of the conjugated oxime group, the deposition rate of thecobalt can be controlled, the cobalt can evenly nucleate and grow, a high-quality pure cobalt plating layer is obtained and thus electrical interconnection is achieved.

Owner:苏州清飙科技有限公司

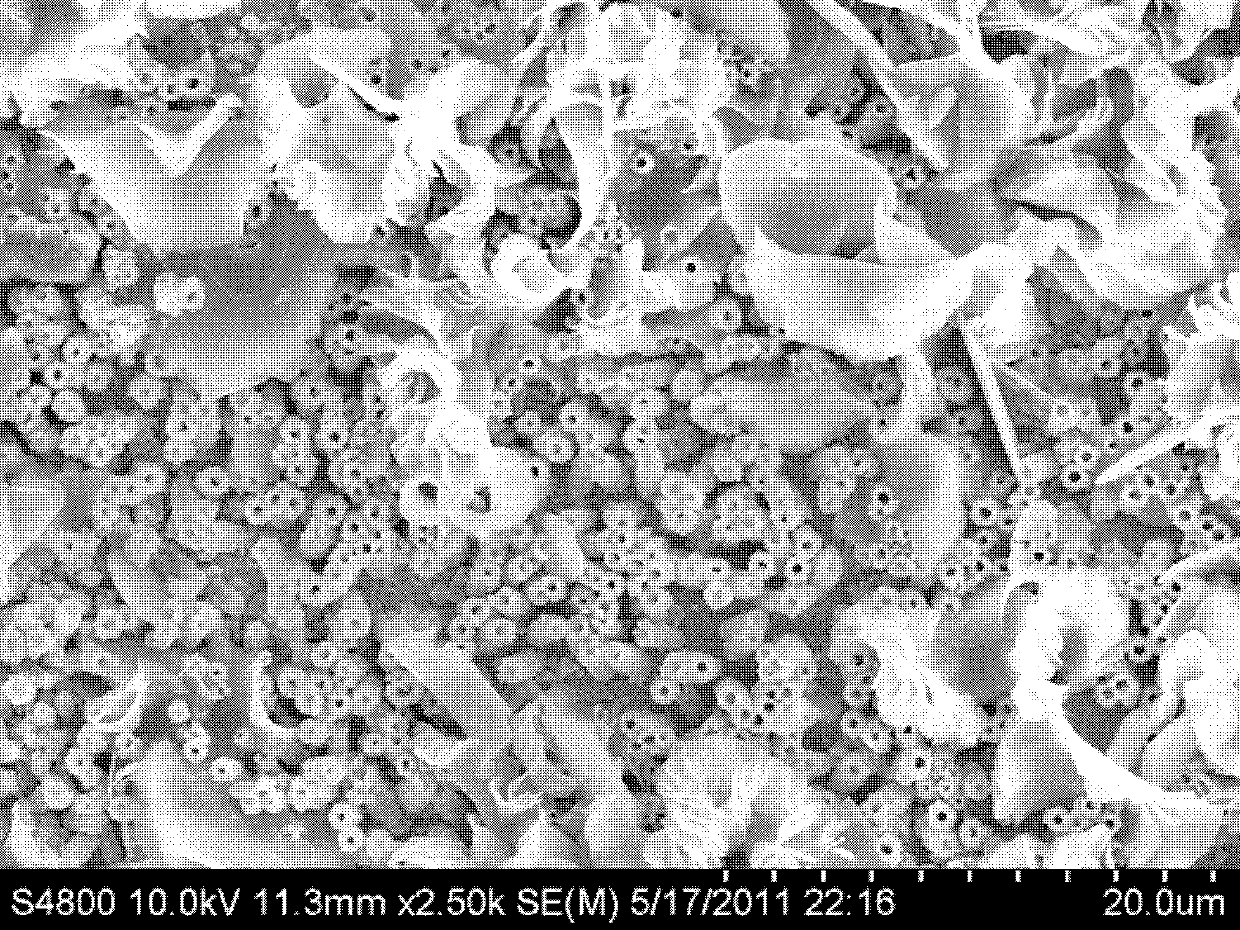

Preparation method of carbon fiber reinforced aluminum-based composite material

InactiveCN110468356AImprove wettabilityImprove bindingLiquid/solution decomposition chemical coatingSuperimposed coating processChemical platingCarbon fibers

The invention discloses a preparation method of a carbon fiber reinforced aluminum-based composite material. The preparation method comprises the following steps of firing carbon fibers, and then carrying out coarsening treatment at room temperature; then adding SnCl2, then adding HCl sensitized treatment, taking out, rinsing in static water, adding a mixed solution of silver nitrate and ammonia water, and carrying out room temperature activation treatment; continuously stirring the activated carbon fibers in a chemical plating solution to complete chemical plating; taking the carbon fibers subjected to chemical plating as a cathode, using metal copper as an anode to perform electroplating treatment in the electroplating solution, adding industrial raw aluminum into a smelting furnace, melting, refining and slagging off, stirring by adopting upper horizontal and lower inclined blades, adding 10%-30% of copper-plated carbon fibers while stirring, carrying out heat preservation treatment, and casting to form the high-strength carbon fiber reinforced aluminum-based composite material. According to the method, the binding force of the carbon fiber and the copper coating is improved, auniform and thick coating can be obtained, the black core phenomenon is avoided, the wettability of the carbon fiber and the aluminum liquid is improved, the material performance is excellent, and thepreparation process is simple and convenient.

Owner:XI'AN PETROLEUM UNIVERSITY

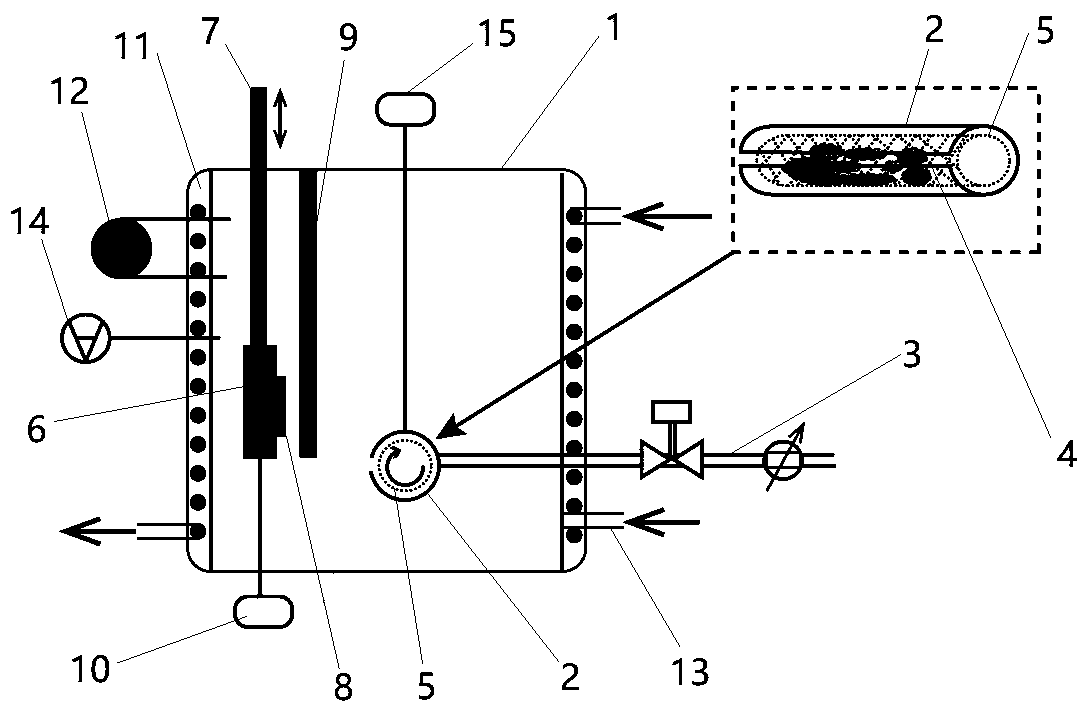

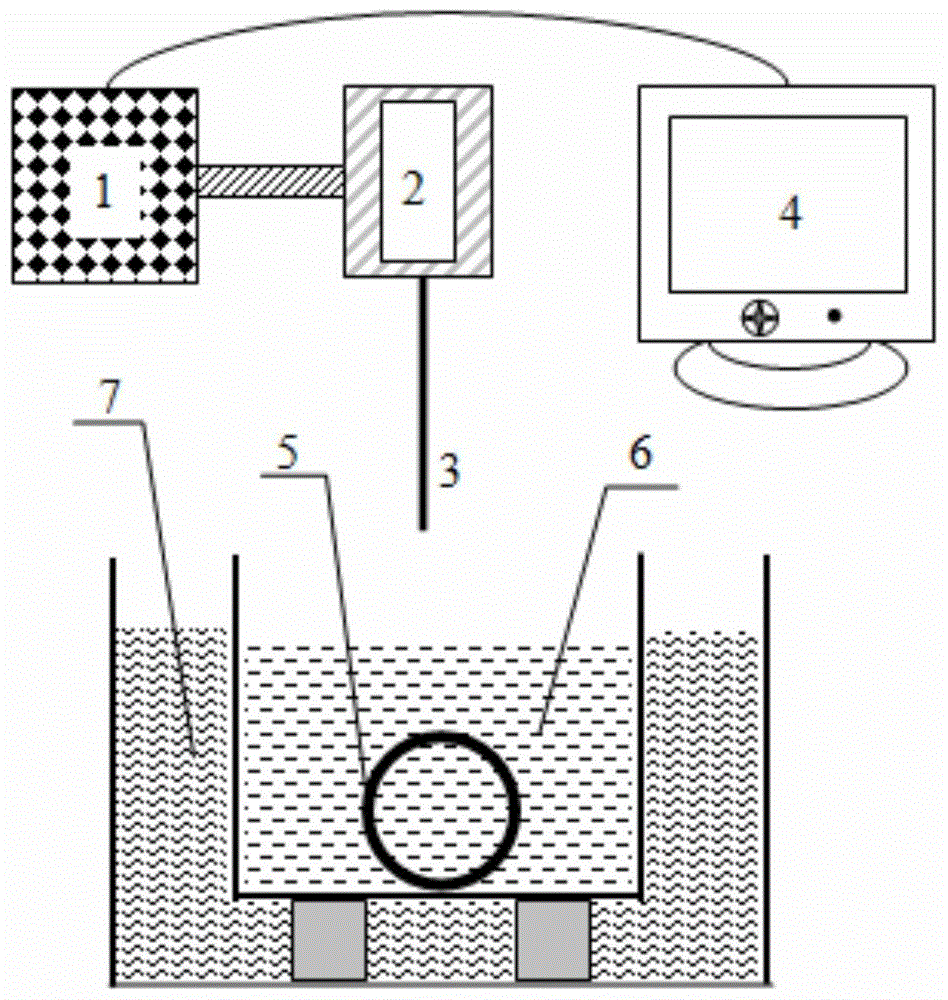

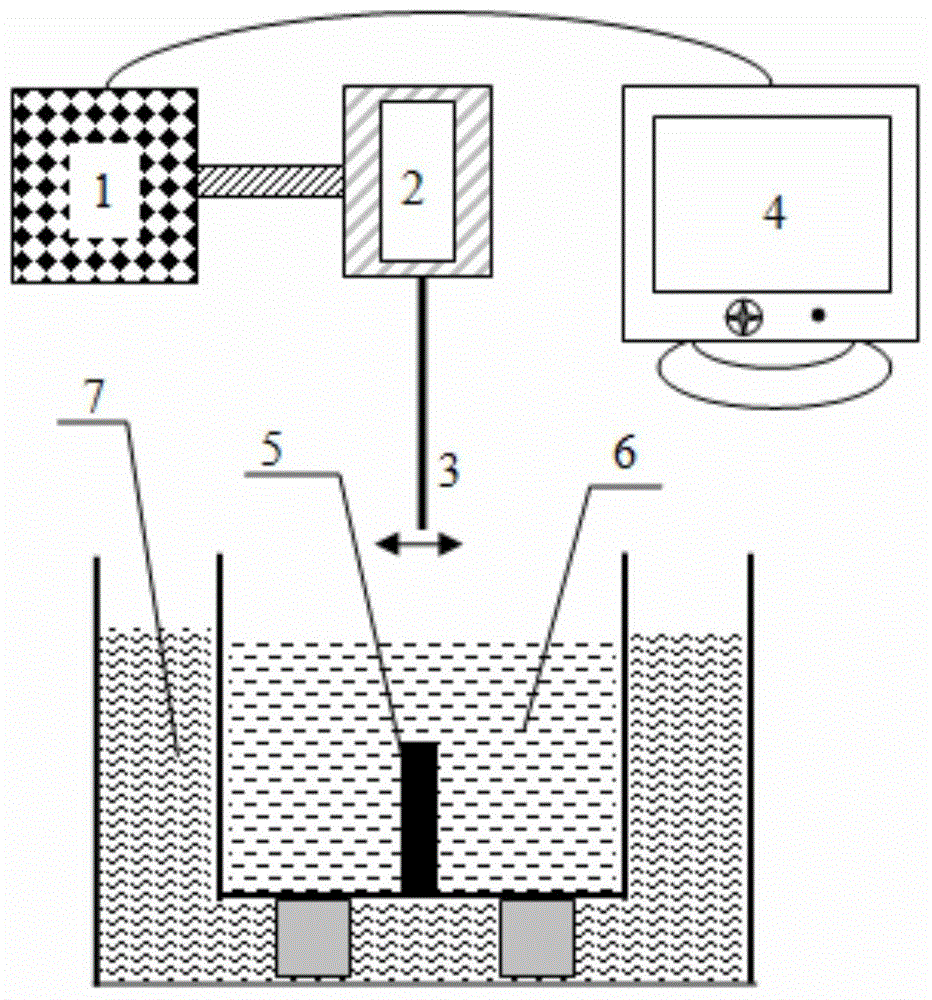

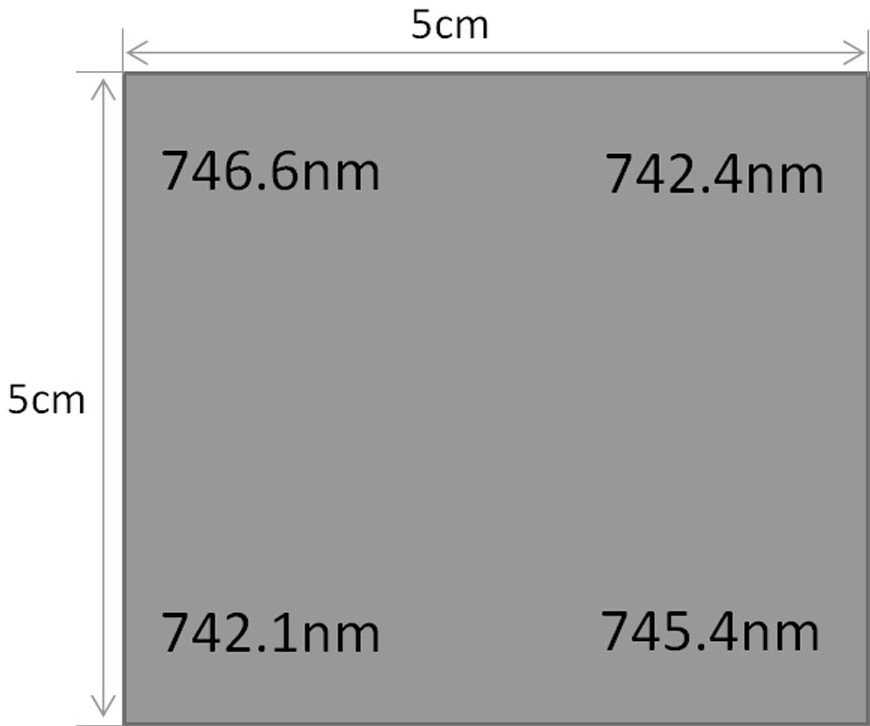

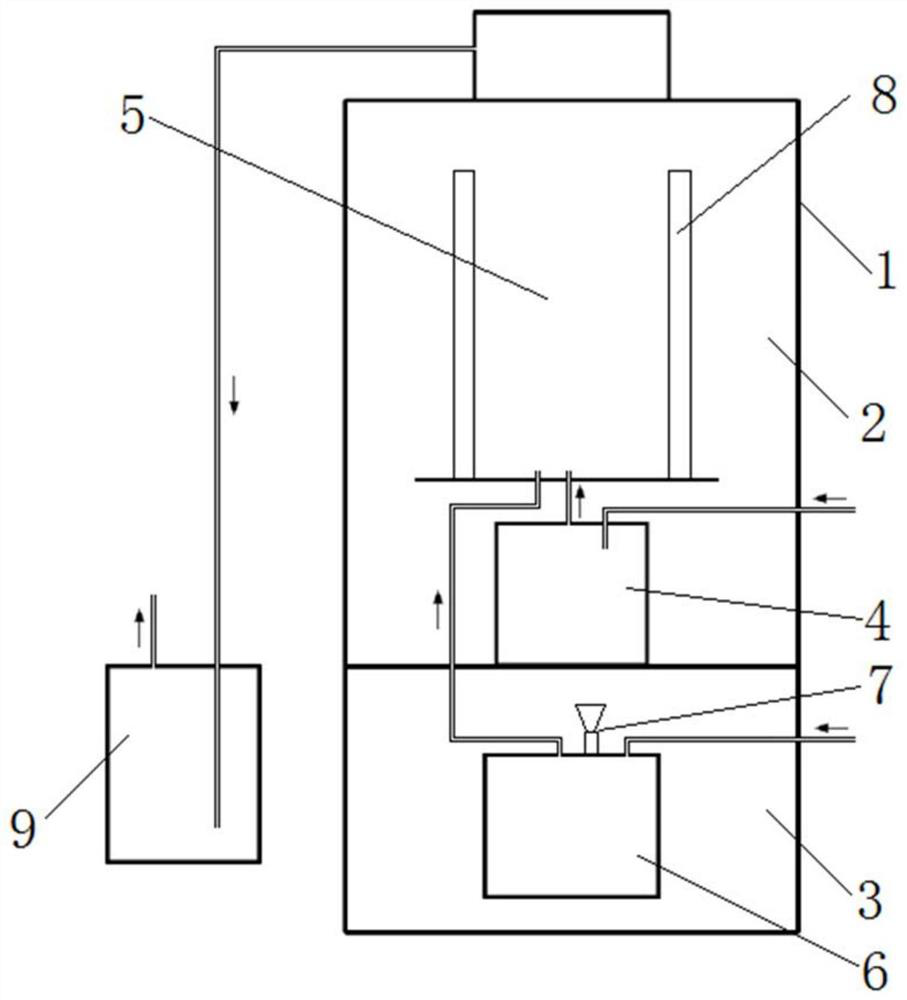

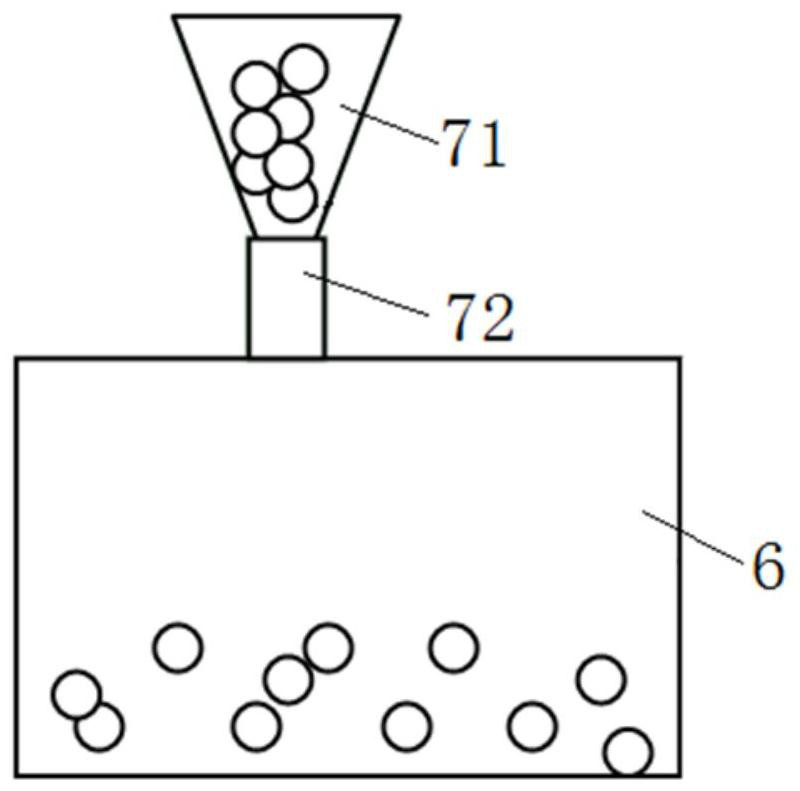

Equipment for preparing a large-area antimony selenide film and method and application of equipment

ActiveCN110444619AGood film uniformitySimple process operation and equipmentFinal product manufactureSemiconductor devicesSelenideEngineering

The invention provides equipment for preparing a large-area antimony selenide film and a method and application of the equipment. The equipment is characterized in that a cylinder is horizontally fixed in a deposition chamber of deposition equipment; one side of the cylinder is communicated with an argon gas supply pipe, and a strip hole extending in the horizontal direction is formed in the otherside of the cylinder; a cylindrical net leak part for containing antimony selenide particles is coaxially arranged in the cylinder, and one end of the net leak part is connected with a rotating shaftand can rotate in the cylinder; a sample table is arranged at the position opposite to the strip hole, the sample table is connected with a lifting rod and can move up and down along with the liftingrod; a substrate is arranged on the table surface, opposite to the strip hole, of the sample table; and a baffle plate is arranged between the sample table and the cylinder. According to the equipment, the large-area antimony selenide film with good crystallization state, high film forming uniformity and relatively small defect density is prepared by regulating and controlling the upper and lowermovement times of the substrate, the temperature of the substrate and the temperature of the source and the gas flow of introduced high-purity argon; and the equipment and the process are simple, andthe large-area antimony selenide film is beneficial to popularization and application.

Owner:HEBEI UNIVERSITY

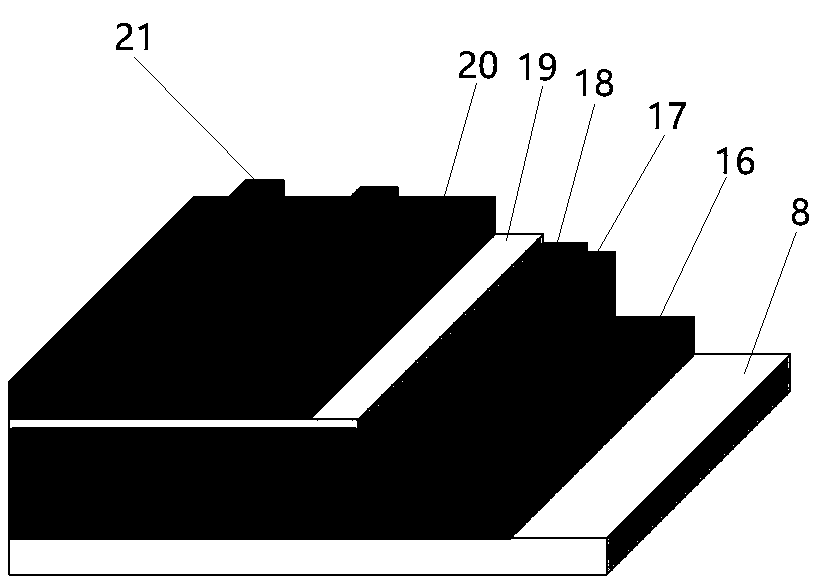

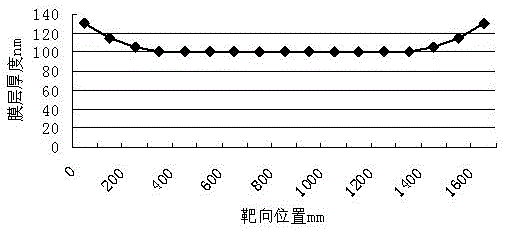

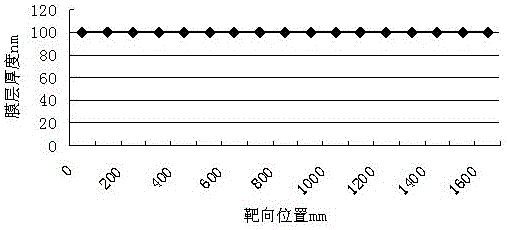

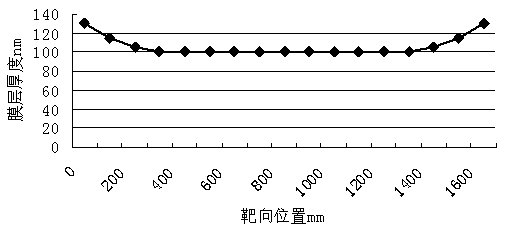

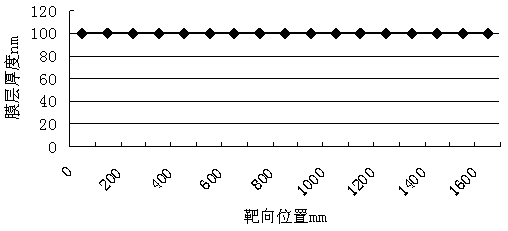

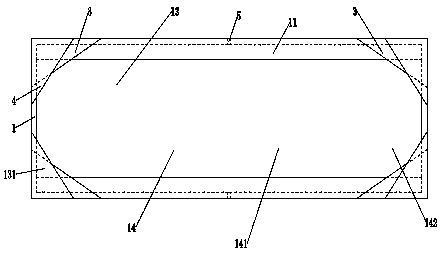

Magnetron sputtering cathode surface gas density distribution control device and method

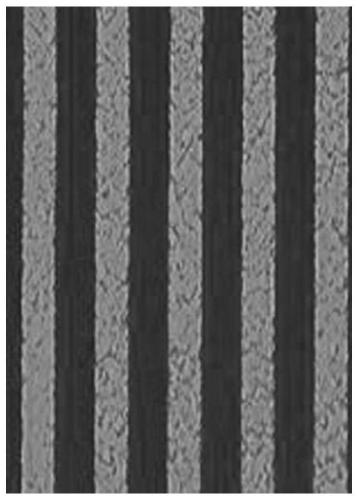

ActiveCN105714259AUniform distribution of gas densityUniform density distributionVacuum evaporation coatingSputtering coatingDensity distributionKidney

The invention provides a magnetron sputtering cathode surface gas density distribution control device. Cathode surface gas density distribution can be even, and then it is guaranteed that the thickness of a coating film is basically the same in the length direction of a cathode target. The device comprises the cathode target located in a shielding cover, a kidney-shaped sputtering hole is formed in a shielding cover panel exactly facing the cathode target, the width of the middle of the kidney-shaped sputtering hole is consistent, and the widths of the two ends of the kidney-shaped sputtering hole are gradually reduced. The length direction of the kidney-shaped sputtering hole is consistent with that of the cathode target.

Owner:高邮市汇金新材料科技有限公司

Chemical gold plating solution applied to PCB chemical gold-palladium plating

ActiveCN110241406ASolve the penetrationSolve the problem of gold on non-metallic holesLiquid/solution decomposition chemical coatingPh bufferingPalladium

The invention discloses a chemical gold plating solution applied to PCB chemical gold-palladium plating. The chemical gold plating solution comprises the following components of, by mass concentration, main salt containing 0.6-1g / L of gold, 1-35g / L of coordination agent, 1-150mg / L of stabilizer, 0.1-10ppm of accelerator and 1-25g / L of pH buffering agent and balance pure water. The method comprises the following steps of adding 50% of water, adding the coordination agent, the stabilizer and the accelerator at one time in the continuous stirring process, adjusting pH value to be within the range of 6.2-6.8, then adding the pH buffering agent, and finally adding gold salt to keep constant volume and form the chemical gold plating solution. According to the gold plating solution, the requirements of a front gold tank and a rear gold tank using the same system of gold plating solution in the gold-palladium process can be met; the gold deposition rate of the gold plating formula is moderate, the gold plating solution is good in stability and can be generally up to more than 10 MTO; and a gold coating with a flat, bright and dense surface and without color difference can be obtained.

Owner:深圳市溢诚电子科技有限公司

Method for preparing one-dimensional self-assembly material with ZnO nanorod array as template

ActiveCN102417201BControl the dissolution rateControl deposition rateZinc oxides/hydroxidesNanotechnologySynthesis methodsRare earth

Owner:PEKING UNIV

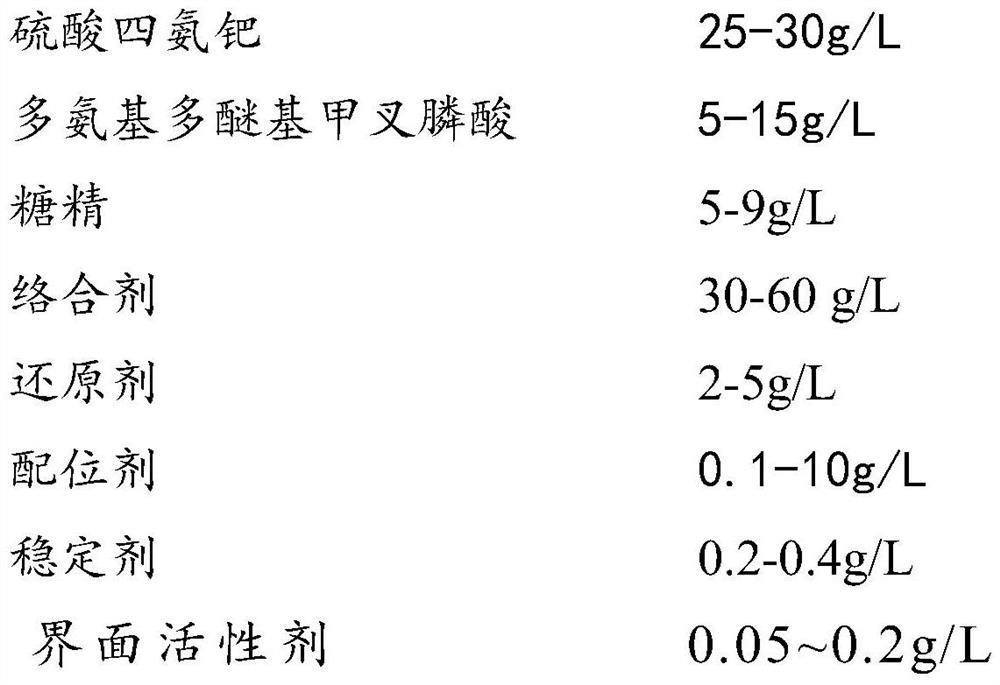

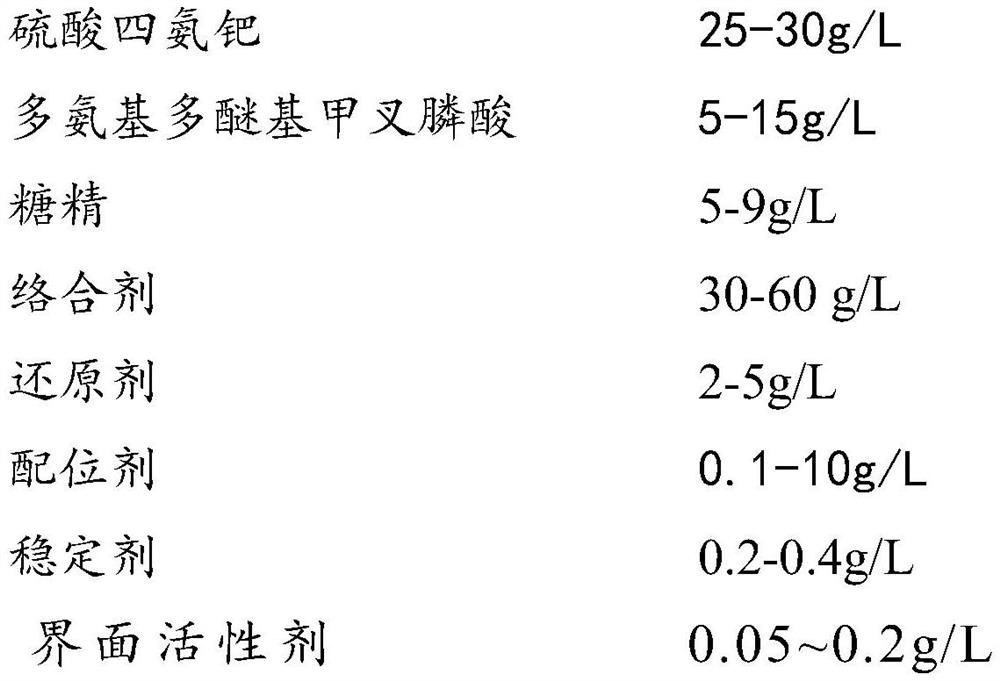

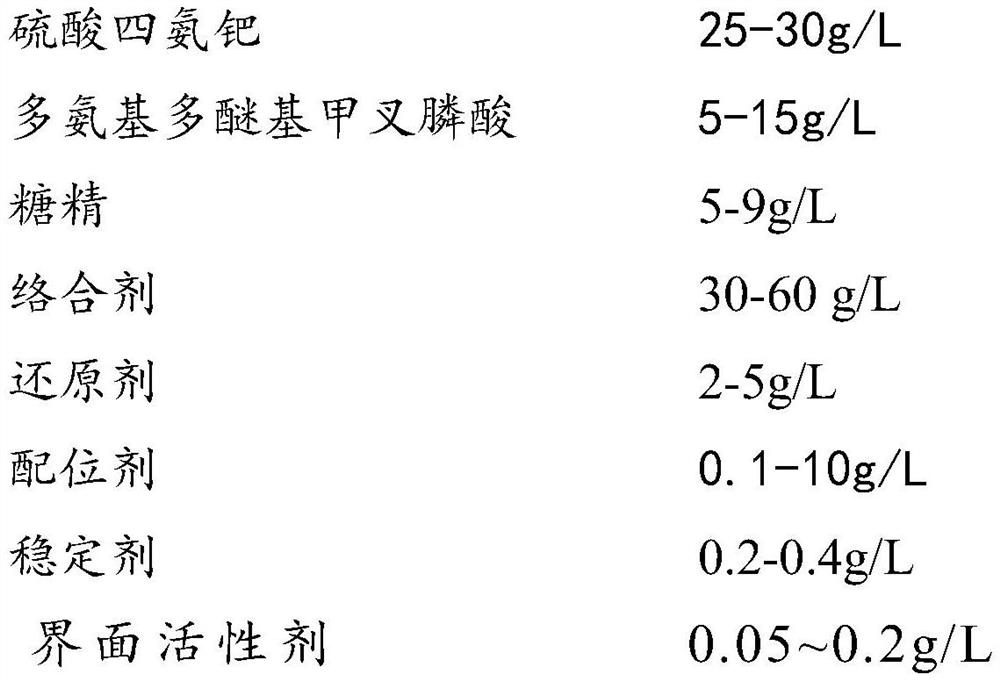

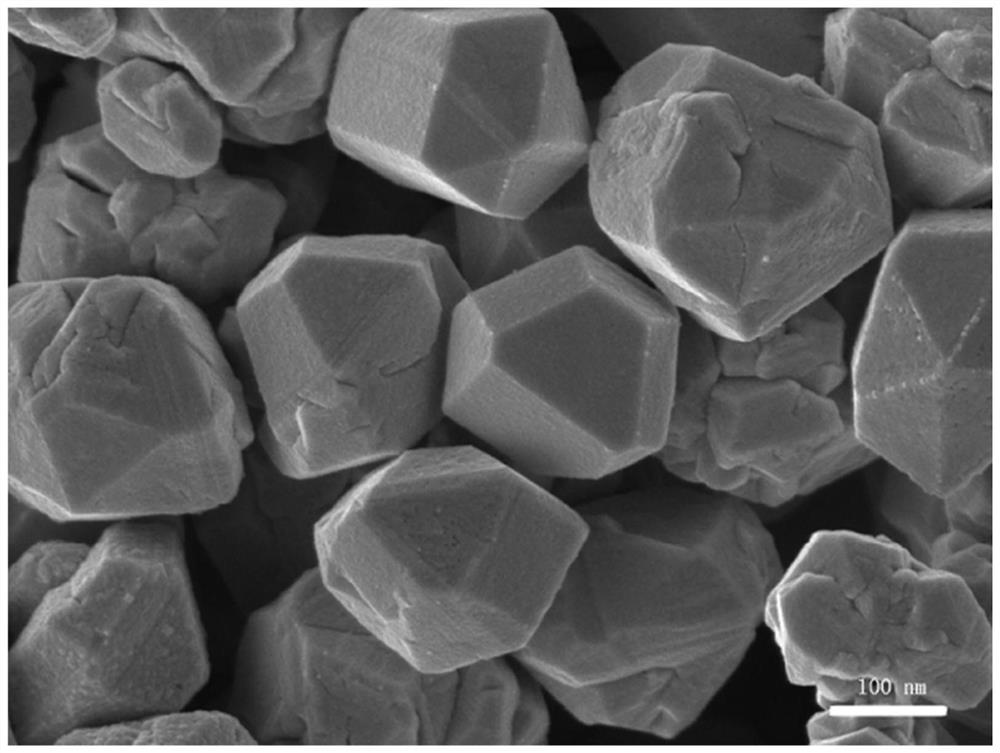

Chemical palladium plating solution used in field of wafer packaging and preparation method thereof

ActiveCN112609172AArranged in orderControl deposition rateLiquid/solution decomposition chemical coatingChemical platingActive agent

The invention discloses a chemical palladium plating solution used in the field of wafer packaging and a preparation method thereof. With the mass concentration as the unit, the chemical palladium plating solution comprises tetraammine palladium sulfate with the concentration being 25-30 g / L, a complexing agent with the concentration being 30-60 g / L, malic acid with the concentration being 5-10 g / L, polyamino polyether methylene phosphonic acid with the concentration being 5-15 g / L, saccharin with the concentration being 5-9 g / L, a reducing agent with the concentration being 2-5 g / L, a coordination agent with the concentration being 0.1-10 g / L, a stabilizing agent with the concentration being 0.2-0.4 g / L and a surfactant with the concentration being 0.05-0.2 g / L. The tetraammine palladium sulfate, citric acid, the malic acid, the polyamino polyether methylene phosphonic acid, the saccharin, the coordination agent, the stabilizing agent and the surfactant are mixed according to the proportion, the pH value is adjusted to 6.5-8.5 through a buffering agent, then the palladium plating solution is formed, the temperature is adjusted to 50-60 DEG C, and the palladium plating time is 5-15 min. A plating layer obtained by using the palladium plating solution is compact in structure, and the plating layer is fine and uniform in crystallization.

Owner:江苏矽智半导体科技有限公司

Method for preparing smooth and dense silver-coated copper powder by chemical plating method

ActiveCN110551995BHigh solid contentImprove adhesionTransportation and packagingMetal-working apparatusChemical platingSlurry

Owner:SHANGHAI JIAOTONG UNIV

High-throughput composite material chip, preparation method and preparation device thereof

ActiveCN106222615BImprove production efficiencyControl deposition rateVacuum evaporation coatingSputtering coatingBiochemical engineeringOutput device

Owner:成都芯曌科技有限公司

Device and method for controlling gas density distribution on magnetron sputtering cathode surface

ActiveCN105714259BUniform density distributionGuaranteed thickness consistencyVacuum evaporation coatingSputtering coatingDensity distributionKidney

The invention provides a magnetron sputtering cathode surface gas density distribution control device. Cathode surface gas density distribution can be even, and then it is guaranteed that the thickness of a coating film is basically the same in the length direction of a cathode target. The device comprises the cathode target located in a shielding cover, a kidney-shaped sputtering hole is formed in a shielding cover panel exactly facing the cathode target, the width of the middle of the kidney-shaped sputtering hole is consistent, and the widths of the two ends of the kidney-shaped sputtering hole are gradually reduced. The length direction of the kidney-shaped sputtering hole is consistent with that of the cathode target.

Owner:高邮市汇金新材料科技有限公司

A kind of preparation method of tin alloy/silicon/carbon electrode material

InactiveCN105470480BSimple processEasy to operateCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention relates to a preparation method of a tin alloy / silicon / carbon electrode material. The method comprises the following steps: with a porous polymer as a carrier, depositing silicon oxide; mechanically mixing magnesium; carrying out high-temperature thermal reduction and acid treatment; filtering and drying the mixture; mechanically mixing a tin alloy; tabletting the mixture; and carrying out high-temperature sintering to obtain the tin alloy / silicon / carbon electrode material. The porous polymer is one of polyacetylene, polyacrylonitrile, polyaniline, polypyrrole and phenolic resin; the tin alloy is one of a nickel-tin alloy, a copper-tin alloy, an iron-tin alloy and a silver-tin alloy; the silicon source is one of tetraethoxysilane, silicon tetrachloride and trichlorosilane; an inner layer of the tin alloy / silicon / carbon electrode material is carbon and silicon in a porous structure; and an outer layer is the tin alloy with good conductivity and stable structure. The electrode material has the advantages of high specific capacity and long cycle lifetime, and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

Internal combustion engine piston ring friction surface coating for bio-oil application and preparation method thereof

ActiveCN104264133BReduce processing stepsSimple and fast operationPiston ringsMachines/enginesCoated surfaceThree dimensional morphology

The invention discloses a piston ring friction surface costing for an internal combustion engine applied facing to bio-oil application and a preparation method of the piston ring friction surface costing for the internal combustion engine. The piston ring friction surface costing for the internal combustion engine is made of a Ni-MoS2-GO-P composite. The preparation method adopts a laser-induced piston ring friction surface microtexturing and electroless plating synchronous coating process and is characterized in that when microtexturing on the friction surface of a piston ring is carried out by utilizing a laser induction method, and Ni, MoS2, GO and P deposit on the friction surface of the piston ring at the same time in a specific proportion, thus preparing a coating with good corrosion and abrasion resistance. The piston ring friction surface costing has the advantages that the preparation process is simple and easy to operate, the cost is low, the binding force of the coating and a matrix is strong, grains on the surface of the coating are uniform and controllable, the microtexture three-dimensional morphology and the thickness of the coating are regulated according to the needs, and thus effective protection function of the friction surface of the piston ring of the internal combustion engine in the bio-oil environment is realized.

Owner:合肥庐阳科技创新集团有限公司

A kind of preparation method of sulfur/carbon/oxide composite electrode material

InactiveCN105006553BSimple processEasy to operateCell electrodesLi-accumulatorsIron(II) oxideCarbon nanotube

The invention relates to a preparation method of a sulfur / carbon / oxide combined electrode material. The preparation method comprises depositing sulfur and oxide on a carbon material as a carrier with excellent performances to obtain the sulfur / carbon / oxide combined electrode material. The carbon material is one of graphene, CMK-3, carbon nanotubes and carbon black. The oxide is one of silica, copper oxide, silver oxide, nickel oxide, ferrous oxide, tin oxide and titanium oxide. The sulfur / carbon / oxide combined electrode material comprises 50-90wt% of sulfur, 5-20wt% of carbon and 5-30wt% of the oxide. Through control of acid types and pH, and organic solvent types and properties, the sulfur / carbon / oxide combined electrode material with fine particles and high coating uniformity is obtained. The sulfur / carbon / oxide combined electrode material as a lithium-sulfur battery positive pole material has high specific capacity and excellent cycling properties and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

A kind of equipment for preparing large-area antimony selenide thin film and its method and application

ActiveCN110444619BImprove uniformityReduce defect densityFinal product manufactureSemiconductor devicesThin membraneMechanical engineering

Owner:HEBEI UNIVERSITY

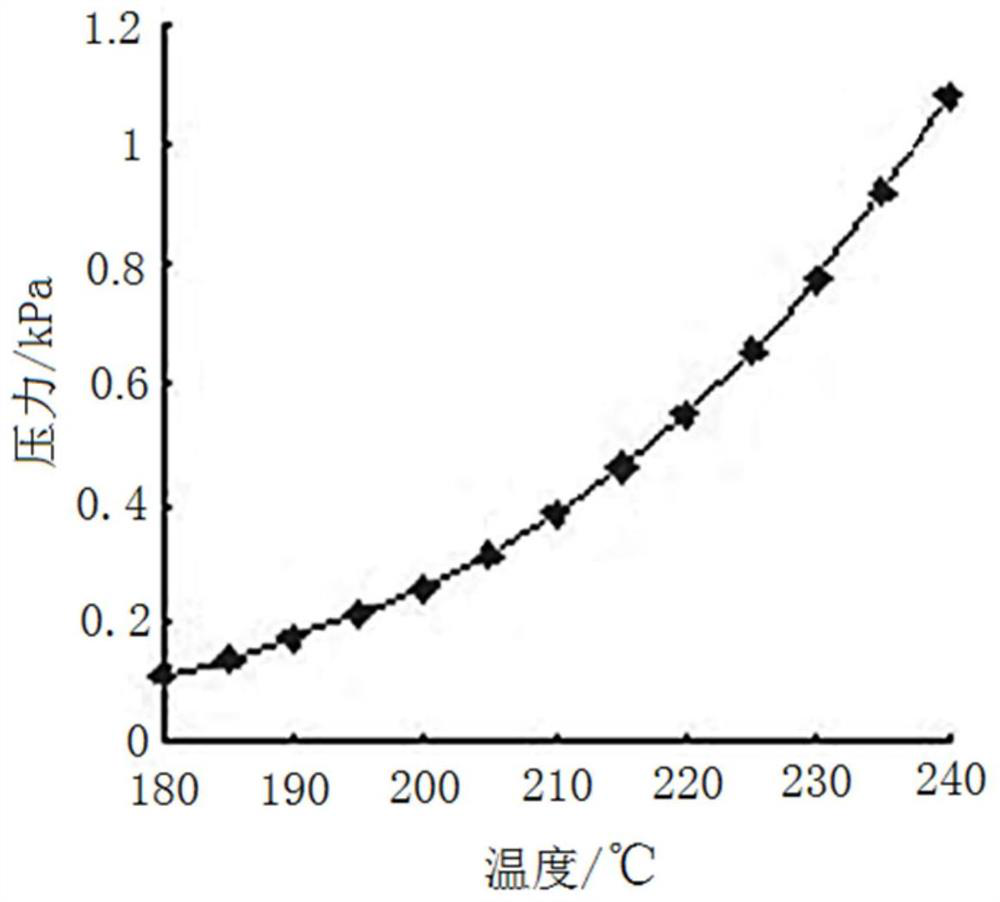

Optical ZnS material and preparation method thereof

ActiveCN112626488AImprove transmittanceHigh emissivityAfter-treatment apparatusPolycrystalline material growthCruciblePhysical chemistry

The invention provides an optical ZnS material and a preparation method thereof. The preparation method comprises the following steps of respectively loading zinc and sulfur into a first crucible and a feeding device of a chemical vapor deposition furnace; heating the first crucible, a second crucible and a deposition cavity, and feeding sulfur into the second crucible through the feeding device; introducing inert carrier gas into the first crucible, and introducing inert carrier gas and hydrogen into the second crucible, so that carrier gas containing zinc vapor and sulfur vapor enters the deposition cavity through pipelines to deposit ZnS, and the sulfur is supplemented to the second crucible regularly and quantitatively through the feeding device in the deposition process so as to maintain the saturated vapor pressure of the sulfur within the range of 0.8-1.8 KPa. According to the preparation method disclosed by the invention, H2S is not generated, so that the influence on the transmittance and emissivity of the ZnS material due to a hydrogen-zinc complex formed by H ions generated by H2S decomposition and Zn vapor can be avoided.

Owner:SINOMA SYNTHETIC CRYSTALS CO LTD +1

Chemical palladium solution applied to chemical gold palladium gold plating on pcb

ActiveCN110318047BExtended service lifeControl deposition rateLiquid/solution decomposition chemical coatingPrinted circuit manufacturePh bufferingActive agent

The invention discloses a chemical palladium solution applied to chemical gold-palladium-gold plating on PCB, including main salt, complexing agent, reducing agent, stabilizer, pH buffering agent and surface active agent, with mass concentration as unit, the above-mentioned composition The ratio of points is: palladium concentration in the main salt: 0.4-0.6g / L; complexing agent: 0.1-30g / L; reducing agent: 0.1-25g / L; stabilizer: 1-150mg / L; pH buffer : 1‑25g / L; Surfactant: 0.1‑10mg / L; The remaining components are pure water. The palladium layer prepared by the palladium solution can meet good welding and bonding requirements, and is also suitable for surface treatment of lines with a line width / space below 0.5mil / 0.5mil or even smaller.

Owner:深圳市溢诚电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com