Optical ZnS material and preparation method thereof

An optical and raw material technology, applied in the field of optical ZnS materials and its preparation, can solve the problems of low transmittance at high temperature, low transmittance, high long-wave radiation rate, etc., achieve low emissivity, improve optical quality, and expand the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

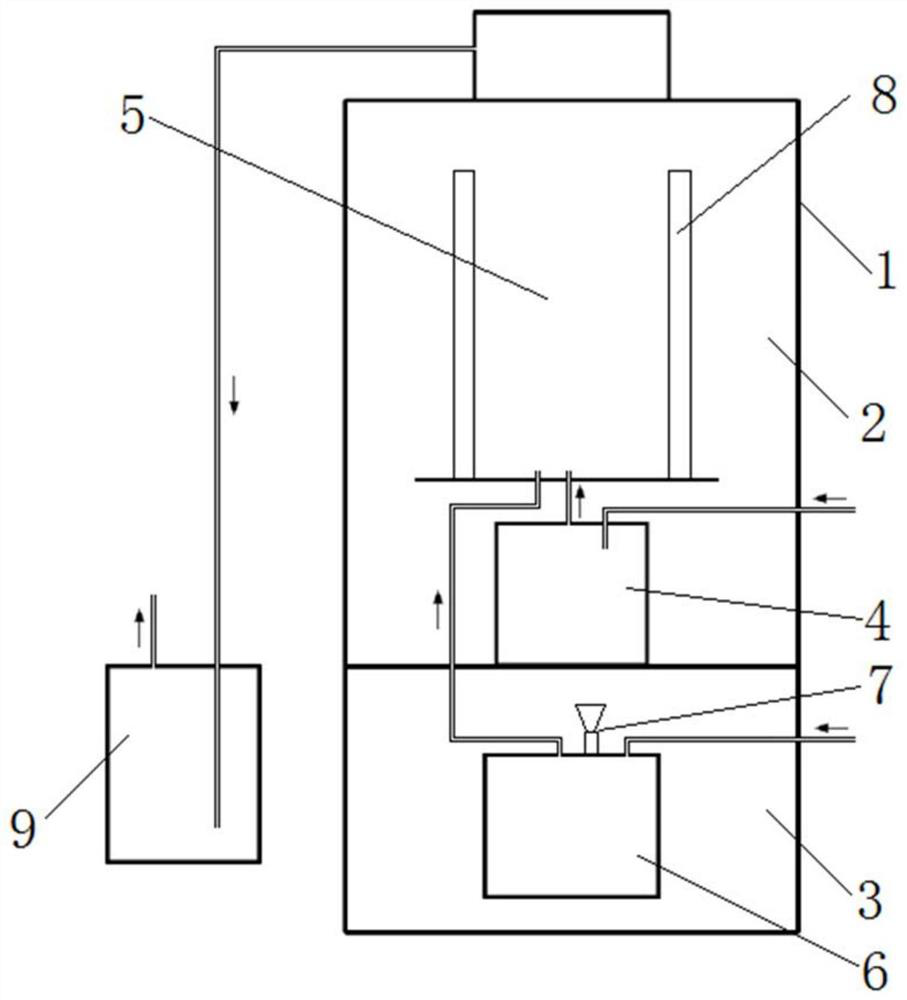

[0032] The invention provides a kind of preparation method of optical ZnS material, comprises the following steps:

[0033] The zinc raw material and the sulfur raw material are respectively charged into the first crucible and the feeding device of the chemical vapor deposition furnace;

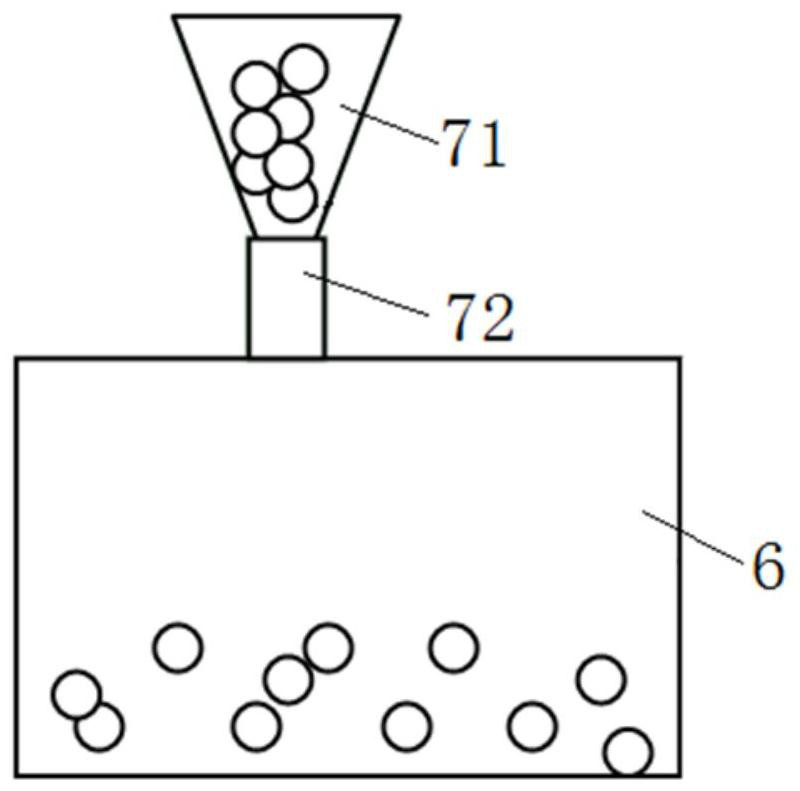

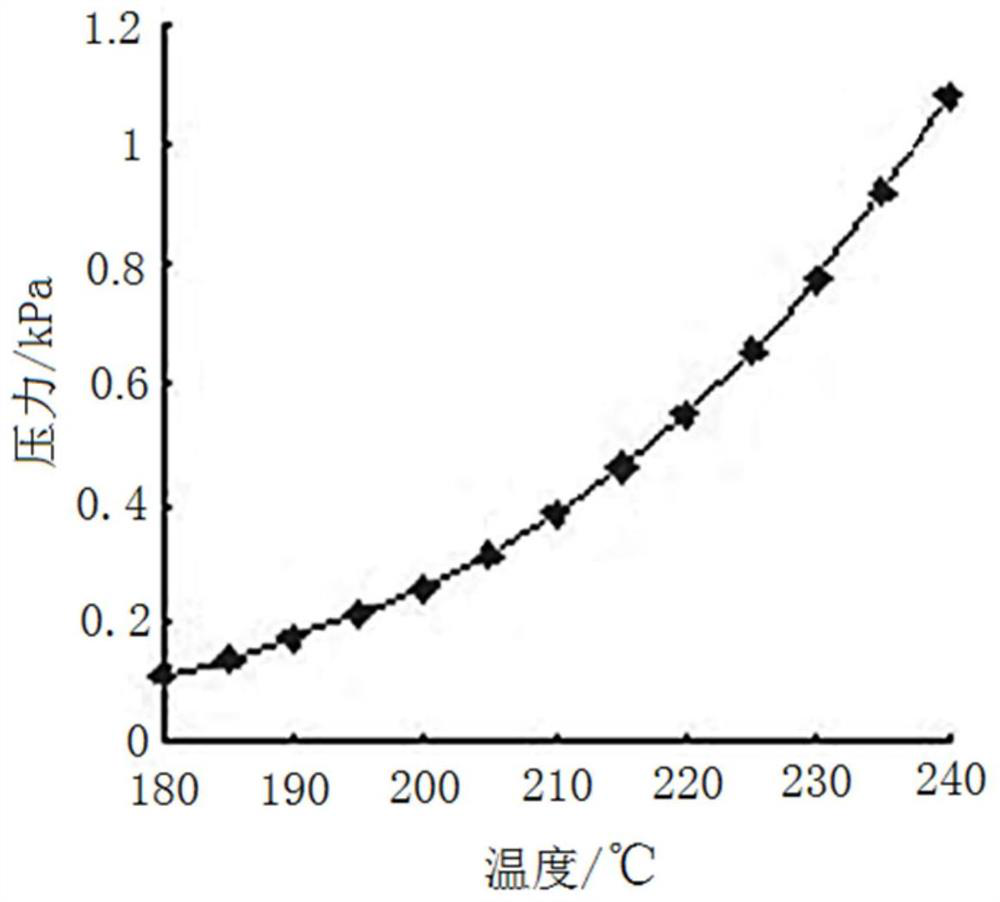

[0034] Heat the first crucible, the second crucible, and the deposition chamber of the chemical vapor deposition furnace, and after the first crucible is heated to 560-640°C, the second crucible is heated to 230-290°C, and the deposition chamber is heated to 560-640°C, Throwing sulfur into the second crucible through the feeding device;

[0035] After the zinc and sulfur are melted, an inert carrier gas is introduced into the first crucible, and a mixture of inert carrier gas and hydrogen is introduced into the second crucible, so that the carrier gas containing zinc vapor and sulfur vapor enters the deposition chamber through the pipeline respectively, and the ZnS is deposited on the deposi...

Embodiment 1

[0069]

[0070] 100kg of zinc raw material and 60kg of sulfur raw material are respectively charged into the first crucible and feeding device of the chemical vapor deposition furnace;

[0071] Heating the first crucible, the second crucible and the deposition chamber, wherein the heating rate of the first crucible and the deposition chamber is 0.6°C / min, the heating rate of the bottom of the second crucible is 0.15°C / min, and the temperature rise of the side wall of the second crucible The rate is 0.1°C / min;

[0072] After the temperature of the first crucible is raised to 560°C, the temperature of the second crucible is raised to 230°C, and the temperature of the deposition chamber is raised to 600°C, the electromagnetic valve of the feeding device is opened, and 60kg of sulfur is put into the second crucible through the feeding device;

[0073] After the zinc in the first crucible and the sulfur in the second crucible are melted, the carrier gas argon is introduced into t...

Embodiment 2

[0080]

[0081] 100kg of zinc raw material and 60kg of sulfur raw material are respectively charged into the first crucible and feeding device of the chemical vapor deposition furnace;

[0082] Heating the first crucible, the second crucible, and the deposition chamber, wherein the heating rate of the first crucible and the deposition chamber is 1.0°C / min, the heating rate of the bottom of the second crucible is 0.2°C / min, and the heating rate of the side wall of the second crucible The rate is 0.2°C / min;

[0083] After the temperature of the first crucible is raised to 580°C, the temperature of the second crucible is raised to 240°C, and the temperature of the deposition chamber is raised to 610°C, the electromagnetic valve of the feeding device is opened, and 60kg of sulfur is put into the second crucible through the feeding device;

[0084] After the zinc in the first crucible and the sulfur in the second crucible are melted, the carrier gas argon is introduced into the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com