Industrial energy-saving high-frequency impulse electrolytic manganese device

A high-frequency pulse and electrolytic manganese technology, applied in the field of electrolytic manganese, can solve the problems of rectifier transformer iron loss, large copper loss, large overcurrent loss of thyristor devices, and low efficiency of electrolytic manganese, so as to improve power factor and reduce Effect of Harmonic Effects and Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

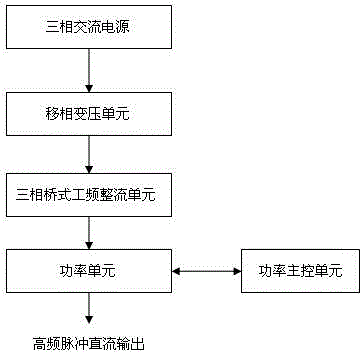

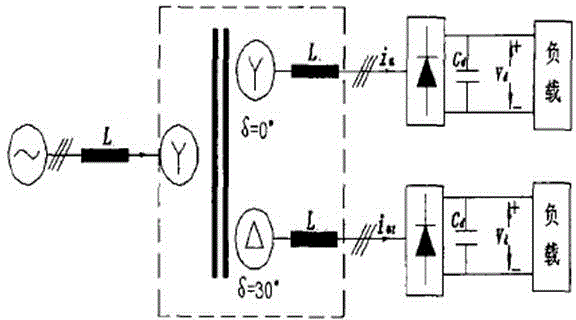

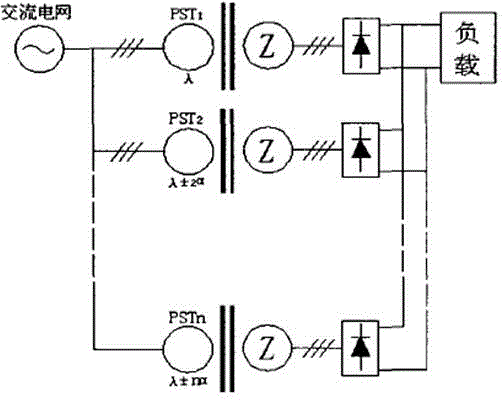

[0047] like figure 1 As shown, an industrial energy-saving high-frequency pulse electrolytic manganese device includes a phase-shifting transformer unit with one or more phase-shifting transformers, a three-phase bridge-type power frequency rectification unit with one or more three-phase rectifier bridge components and power units with one or more high-frequency pulsed power components.

[0048] The primary side of the phase-shifting transformer is connected to the output end of the three-phase AC power supply, the secondary side of the phase-shifting transformer is respectively connected to the input end of the three-phase rectifier bridge assembly, and the output end of the three-phase rectifier bridge assembly is connected to the high-fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com