Patents

Literature

420results about How to "Realize industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing compound coat between metals

ActiveCN101058881ASimple processReduce manufacturing costPressure inorganic powder coatingSedimentHigh-temperature corrosion

The invention discloses a making method of intermetallic compound coating in the material manufacturing, aeronautical and spatial, metallurgical, electric, mechanic and chemical domain, which is characterized by the following: adopting two or more multiple metal powder as raw material to prepare alloy powder through mechanic alloying method; coating the powder on the sediment layer of base; obtaining the product through heat dispersing alloying disposal; transplanting the phase structure of powder into coating; dispersing fitfully to obtain the product.

Owner:XI AN JIAOTONG UNIV

High-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and preparation method thereof

The invention relates to a high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel and a preparation method thereof. The high-toughness high-boron medium-chrome low-carbon wear-resisting alloy steel comprises the following chemical components by weight percentage: 0.20-0.5% of C, 5-12% of Cr, 0.5-1.2% of Si, 3.5-5.5% of Mn, 0.3-2.8% of B, 0.3-2.1% of Cu, 0.2-0.5% of Ti, 0.05-0.25% of Ca, 0.03-0.3% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.1-0.5% of SiMgRe, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance of Fe and inevitable impurity elements. The preparation method comprises the following steps of: adding a copper plate, silicon iron and ferromanganese iron after steel scrap and chromium iron are melted; after the component adjustment before furnace is qualified, increasing the temperature of the melt to 1560-1620 DEG C, adding a calcium-silicon alloy and aluminum for deoxidation, and orderly adding ferrotitanium and ferroboron, melting, and then discharging; putting a composite inoculant composed of granular rare-earth magnesium alloy with granule size being less than 12mm, metal cerium, Si3N4, VN, Nb and K at the bottom of a steel ladle after baking, and performing inoculation treatment on the molten steel by a rush-into-ladle method, wherein the casting temperature of the molten steel ranges from 1400 DEG C to 1450 DEG C; preserving the heat of castings for 4-6 hours at 700-780 DEG C, and then carrying out subcritical air quenching to obtain the alloy steel.

Owner:丁家伟

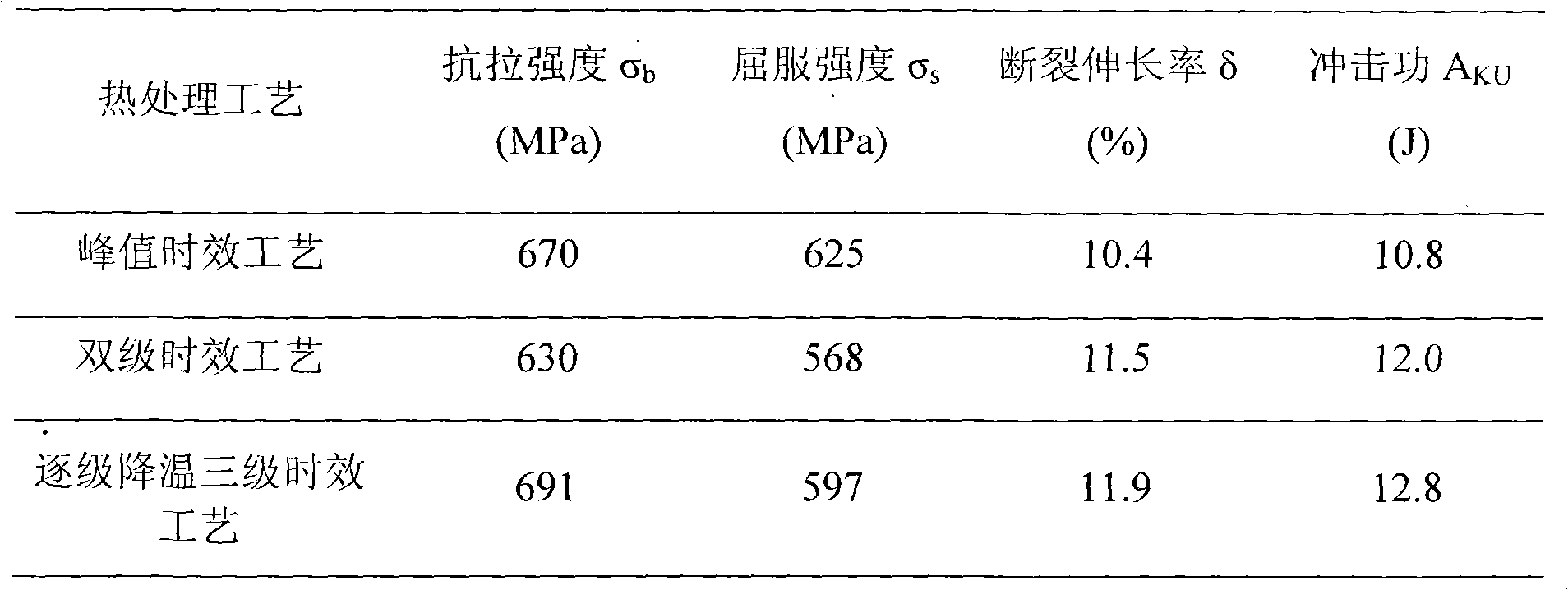

Heat treatment technology of high strength aluminium alloy

InactiveCN101956151AImprove mechanical propertiesImprove heat treatment processSolution treatmentQuenching

The invention relates to a heat treatment technology of high strength aluminium alloy. The technology performs solution treatment, primary quenching treatment, high temperature short time aging treatment, secondary quenching treatment, intermediate temperate short time aging treatment and low temperature long time aging treatment to high strength aluminium alloy in sequence. The technology improves the comprehensive mechanical property of alloy, increases the corrosion resistance and expands the application range of high strength aluminium alloy.

Owner:SICHUAN CITY TRACK TRAFFIC MATERIAL +1

Glass fiber mesh and PVC compound enhanced film and production method thereof

InactiveCN101693419ASimple processRealize industrial applicationSynthetic resin layered productsGlass/slag layered productsFiberglass meshGlass fiber

The invention relates to a glass fiber mesh and PVC compound enhanced film and a production method thereof. The traditional film has very low shock resistance. The compound enhanced film is in a three-layer structure, wherein an upper layer and a lower layer are PVC films, and a middle layer is a glass fiber mesh. The production method of the glass fiber mesh and PVC compound enhanced film comprises the following concrete steps: knitting high-strength glass fiber yarn into a meshed glass fiber mesh; processing the surface of the glass fiber mesh by using chlorinated polyvinyl chloride (CPVC) resin; and compounding the PVC resin and the glass fiber mesh. The compound enhanced film has superior shock resistance; and meanwhile, the production method of the enhanced film has simple technology, the used equipment is common film producing equipment, and the industrial application can be realized.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

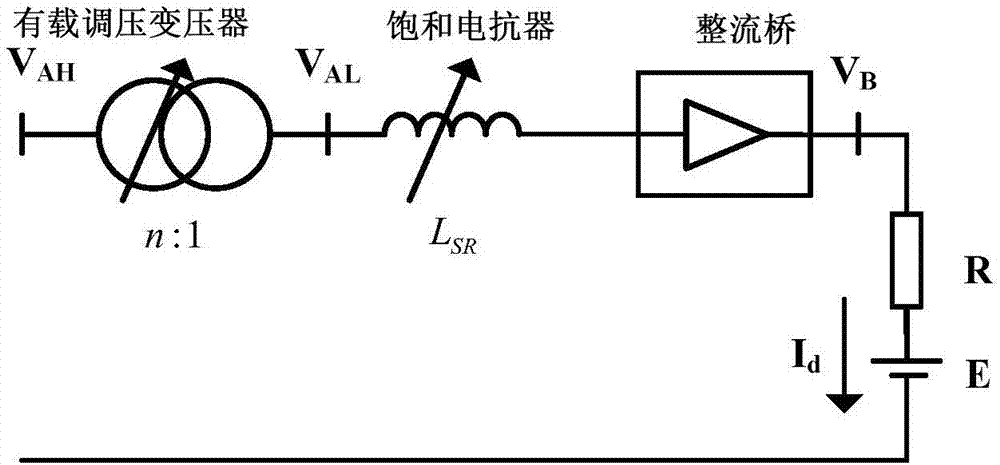

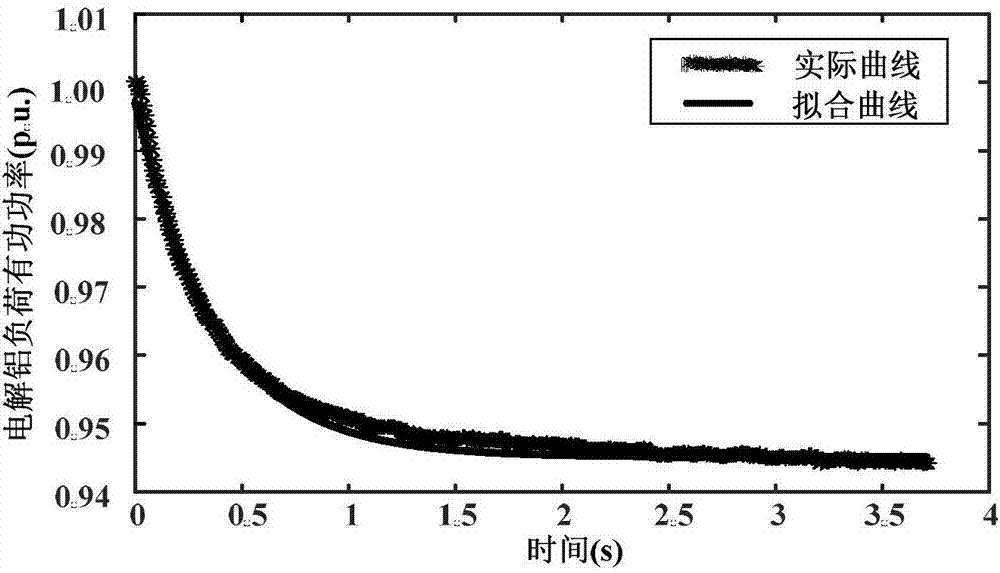

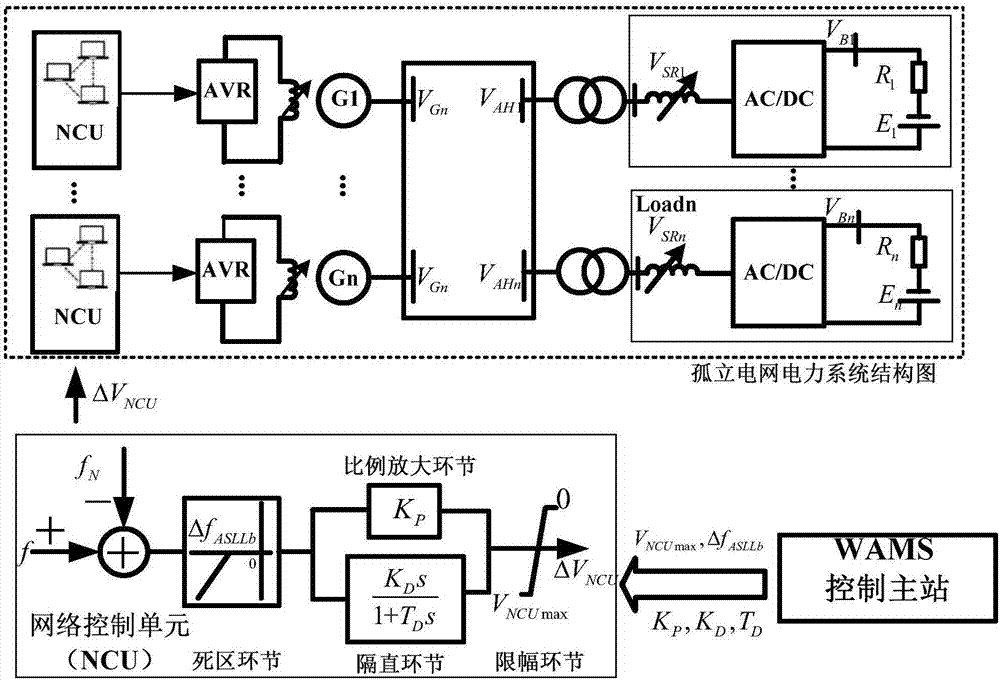

Method for participating in frequency control of isolated power grid by electrolytic load

ActiveCN107317345ARealize industrial applicationActive power regulationSingle network parallel feeding arrangementsPower oscillations reduction/preventionThermal energy storageWashout

The invention belongs to the technical field of operation and control of power systems, and in particular relates to a method for participating in frequency control of an isolated power grid by electrolytic load. System frequency adjustment is realized through an electrolytic aluminium load control system; the electrolytic aluminium load control system comprises a network control unit NCU, a dead zone unit, a proportional amplification unit, a WASHOUT unit and an amplitude limiting unit; the proportional amplification unit and the WASHOUT unit are connected in parallel; furthermore, one end is sequentially connected to the dead zone unit and the NCU; the other end is connected to the amplitude limiting unit; the NCU is connected to an isolated power grid system; and the amplitude limiting unit is connected with a WAMS control master station. The method specifically comprises the steps of: (1), establishing an isolated power grid system model; (2), designing the control logic of an electrolytic aluminium load controller under different power disturbance models; and (3), designing parameters of the electrolytic aluminium load controller under different power disturbance models. According to the method disclosed by the invention, the thermal energy storage characteristic of the electrolytic aluminium load is utilized; therefore, effective power adjustment of the electrolytic aluminium load is realized; and the system frequency is kept steady.

Owner:WUHAN UNIV +2

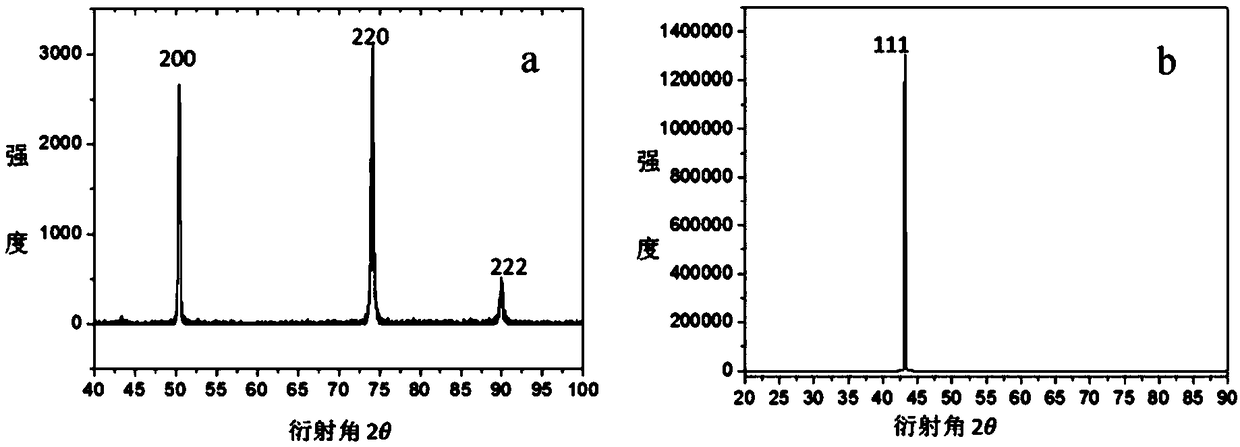

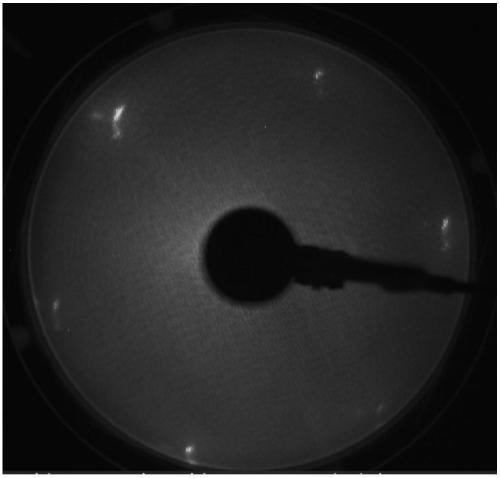

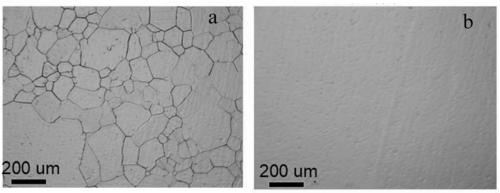

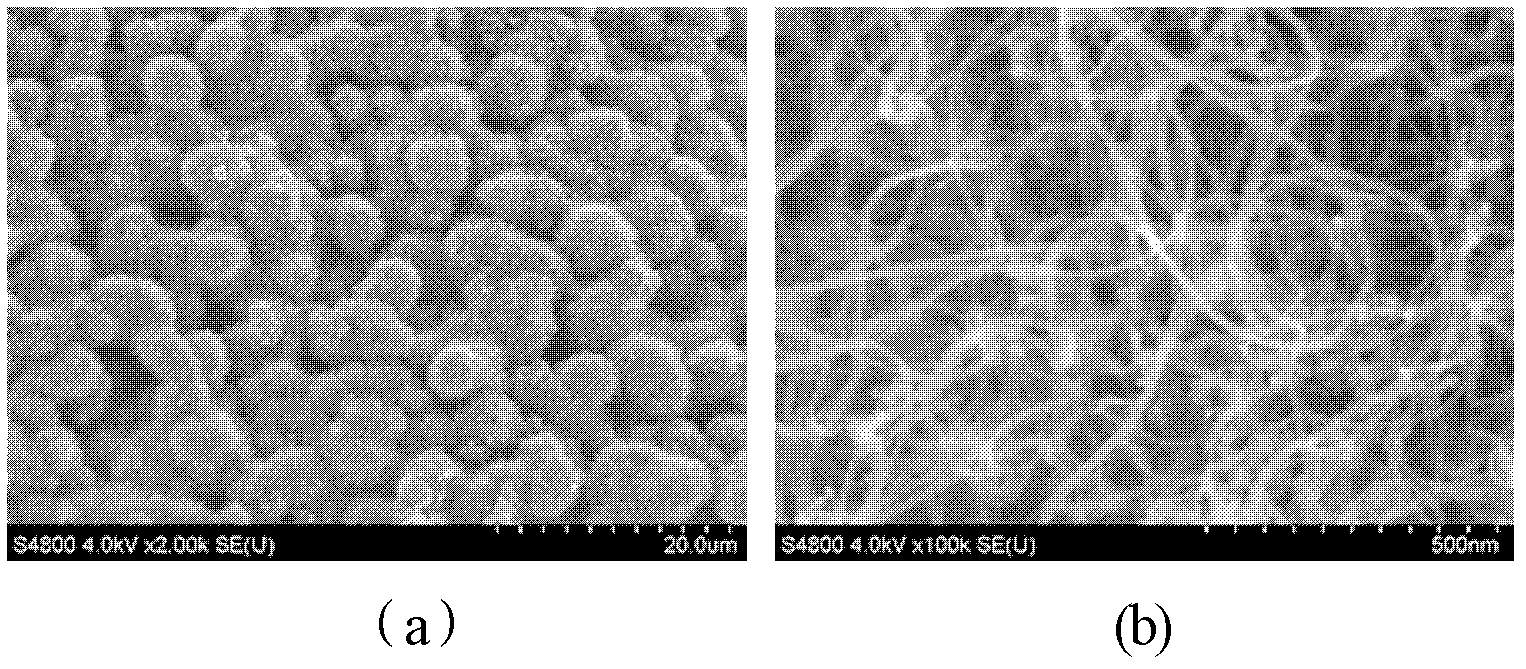

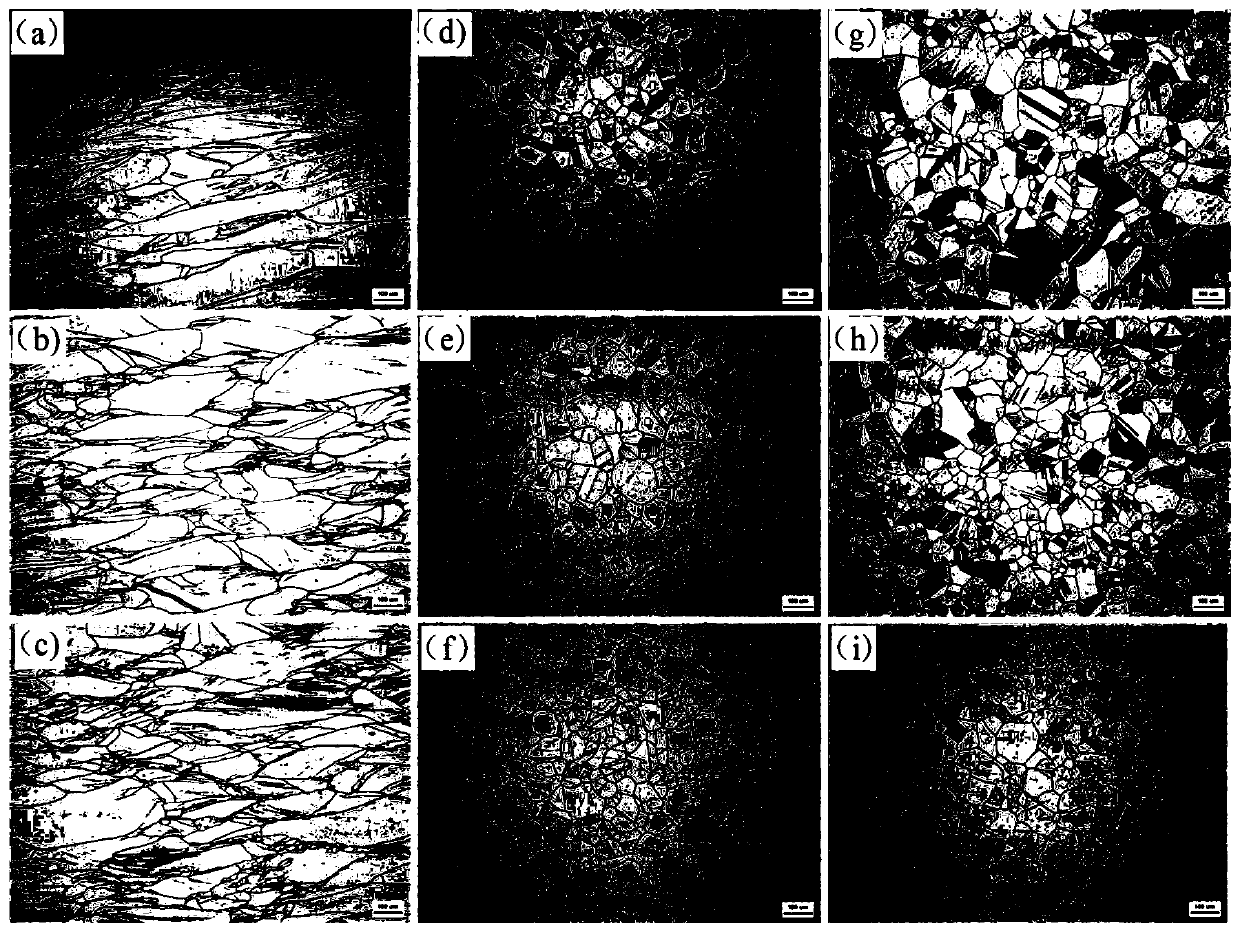

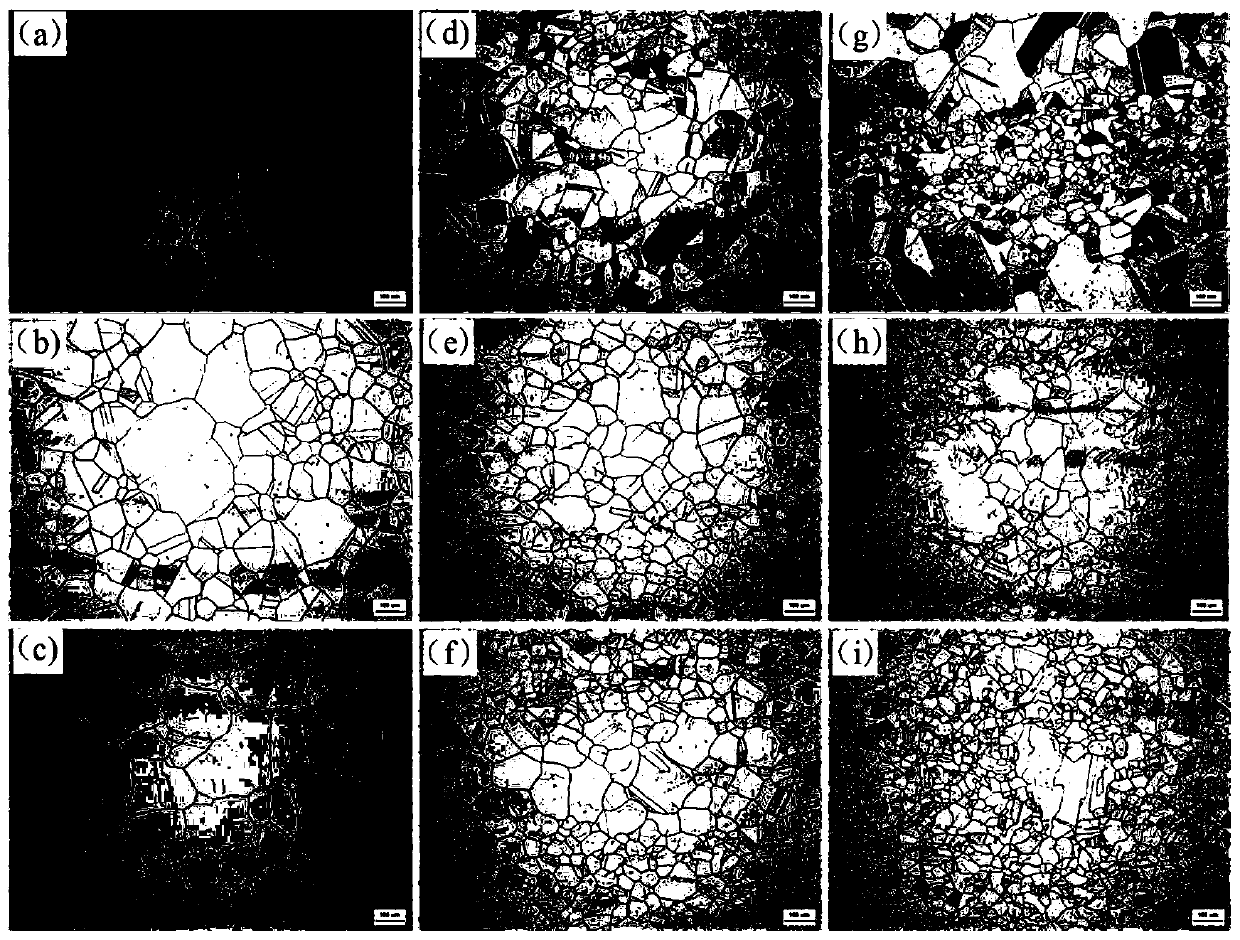

Method for preparing monocrystal metal foil

ActiveCN108950684AQuality improvementEasy to makePolycrystalline material growthFrom solid stateMetal foilMetallurgy

The invention relates to a method for preparing monocrystal metal foil. The method comprises the following steps: (1) placing polycrystal metal foil with a purity of 99.9 wt% or above basically vertically in a heating device, carrying out heating to a temperature which is 10-100 DEG C below the melting point under a vacuum or a protective atmosphere for annealing treatment; and (2) carrying out cooling so as to prepare the monocrystal metal foil. The method provided by the invention is high in universality, can be used for various metal material systems, and can be used to prepare large-area monocrystal metal foil simply and efficiently. Meanwhile, cost is low, energy consumption is low, and the prepared monocrystal metal foil is high in quality and uniform in morphology.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

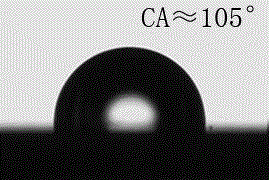

Bionic cleaning water-based paint and preparation method thereof

InactiveCN105733385AAchieve sustained releaseThe effect of long-term lubrication and cleaningAntifouling/underwater paintsPaints with biocidesRough surfaceWater based

The invention discloses cleaning water-based paint with a bionic self-lubricating effect, and a preparation method thereof. By utilizing the characteristic that the surface is self-lubricated through a common nepenthes imitating effect, and adopting a mode of loading silicone oil on aerogel, a silicone oil lubricating fluid with the lubricating effect is sealed into a water-based resin paint base material; by combining adsorption of an aerogel porous structure and transfer behaviors, on a water-based resin surface, of silicone oil, the controlled release effect, on the surface of the water-based paint base material, of the silicone oil lubricating oil is achieved, and long-time self-lubricating cleaning effect is achieved. According to the preparation method, a super-hydrophobic rough surface is not needed to be constructed; the prepared paint has self-cleaning effect, good stability, environmental protection and no pollution; the preparation method is simple, is innovative, is high in implementation, and is more beneficial to industrial application.

Owner:宁夏金石通新材料有限公司

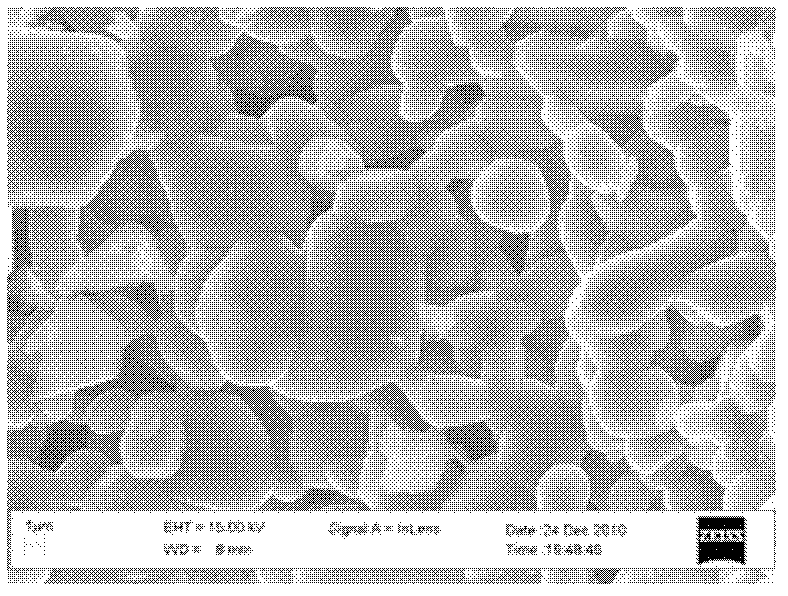

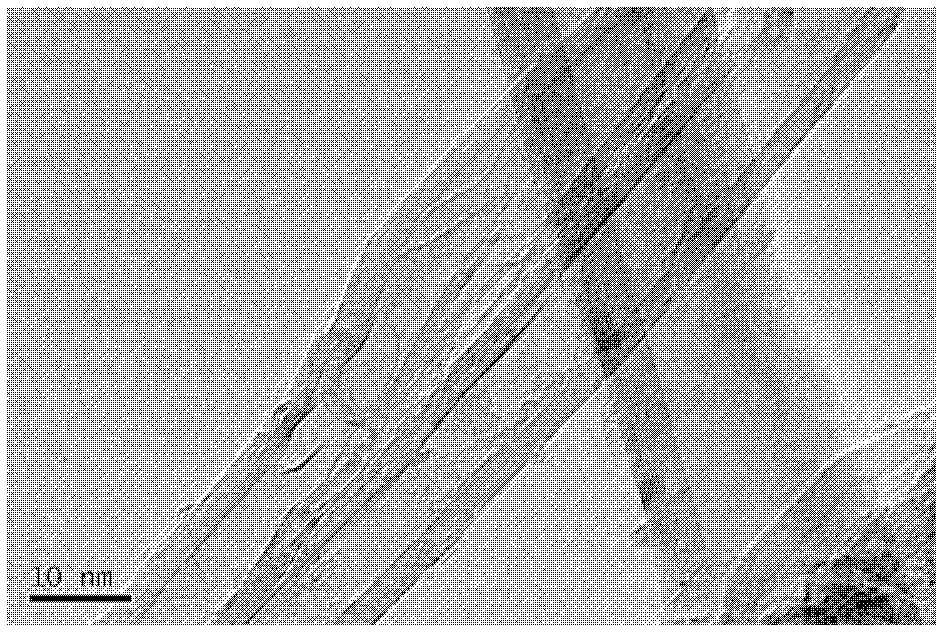

Carbon nanotube/silicon carbide foam catalytic composite material and preparation method thereof

InactiveCN102962087AAchieve macro assemblyRealize industrial applicationPhysical/chemical process catalystsGas phaseCarbon nanotube

The invention provides a carbon nanotube / silicon carbide foam catalytic composite material and a preparation method thereof, and belongs to the technical field of composite materials and preparation thereof. The preparation method of the invention comprises the following steps: firstly pretreating the silicon carbide foam; then loading a Fe-Mg-Al composite catalyst on the pretreated silicon carbide foam by a coprecipitation method; performing in-situ growth of carbon nanotubes on the silicon carbide foam surface loaded with the catalyst by a chemical vapor deposition method. According to the composite material prepared by the method, carbon nanotubes are uniformly loaded on the silicon carbide carrier surface loaded with the composite catalyst, and cover the surface; the carbon nanotubes wind with each other to form a reticulate structure. The invention realizes macroscopic assembly of carbon nanotubes; the prepared composite material has good mechanical strength, can resist pressure drop in a catalytic reactor, prevent deficiency in strength of loose carbon tubes, and realize industrial application of carbon tubes with respect to catalysis.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

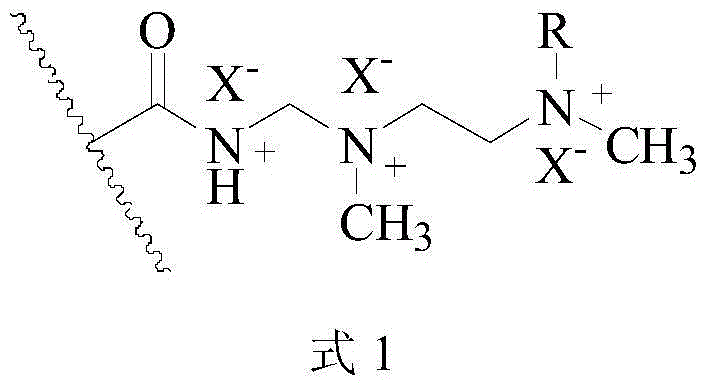

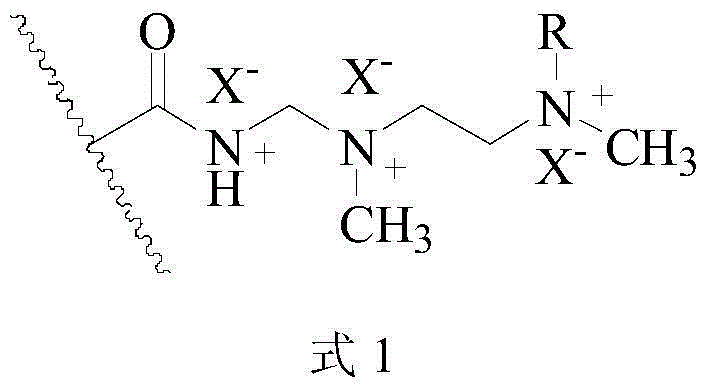

Method for deeply removing molybdenum from tungstate solution through ion exchange process

The invention discloses a method for deeply removing molybdenum from a tungstate solution through an ion exchange process. According to the method, multi-amine weak basic anion exchange resin is employed for selectively adsorbing and removing thiomolybdate anion from the tungstate solution subjected to sulfur substitution. The method is good in molybdenum removal effect and easy for desorption, the desorption process does not need adding an oxidant, and the service life of resin is substantially prolonged. Also the method is short in flow, simple in operation and low in cost, and is easy for industrialized application.

Owner:CENT SOUTH UNIV

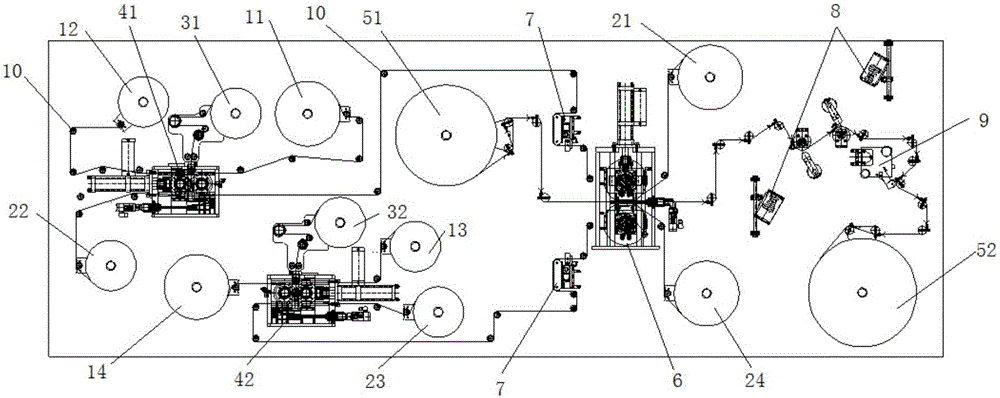

All-in-one machine for rolling, laminating and lithium-supplementing

ActiveCN106025367ASolve the problem of simultaneous lithium coatingCompact structureElectrode manufacturing processesFinal product manufactureLithiumPole piece

The invention discloses an all-in-one machine for rolling, laminating and lithium-supplementing. A first lithium strip is adhered on a first isolating membrane to form a first lithium supplementing strip; a second lithium strip is adhered on a fourth isolating membrane to form a second lithium supplementing strip; the first lithium supplementing strip and the second lithium supplementing strip are respectively located on one side of a pole piece and enter a laminating device with the pole piece simultaneously; the first lithium strip and the second lithium strip are adhered on the pole piece to form a lithium supplementing pole piece and are coiled by a pole piece coiling device; the first isolating membrane is coiled by a first isolating membrane coiling device, and the fourth isolating membrane is coiled by a fourth isolating membrane coiling device. The two procedures of rolling and laminating in the process of supplementing lithium for the pole piece are combined together, a rolling mechanism and a laminating mechanism, which are originally independent, are organically combined together to form a whole set of the all-in-one machine integrating rolling and laminating, so that the problem of laminating lithium membranes on both sides of the pole piece is solved, the structure is compact, the performance is excellent, and industrialized application of the all-in-one machine can be achieved.

Owner:CONTEMPORARY AMPEREX TECH CO

Preparation method of edible ink

InactiveCN101712824AGood printabilityGood resistance to wet frictionInksNatural dyesPreservativeDiluent

The invention relates to a preparation method of an edible ink. Development of present ink which is directly printed on surface of food is not mature. The preparation method of the edible ink comprises the following steps: placing a binder, purified water, monascus red pigment or green pigment, diluent, thickener, emulsifier, stabilizer, defoamer and preservative in part by weight into a container, and mixing the binder, purified water, monascus red pigment or green pigment, diluent, thickener, emulsifier, stabilizer, defoamer and preservative under the condition of a constant temperature of 70 to 90 DEG C to ensure that edible raw materials are primarily mixed; placing the edible raw materials which are primarily mixed into a food mixing machine for mixing for 10 to 30 minutes at a speed of 30 to 50 revolutions per minute; then regulating the rotation speed of the food mixing machine, and remixing for 30 to 40 minutes at a speed of 80 to 120 revolutions per minute to ensure that the edible raw materials are fully mixed to obtain the edible ink. The preparation method of the edible ink has simple process, and can realize industrial application. The prepared edible ink has excellent print adaptability, wet friction resistance, good adhesive force, and can be directly printed on the surface of the food.

Owner:SERVICE CENT OF COMMLIZATION OF RES FINDINGS HAIAN COUNTY

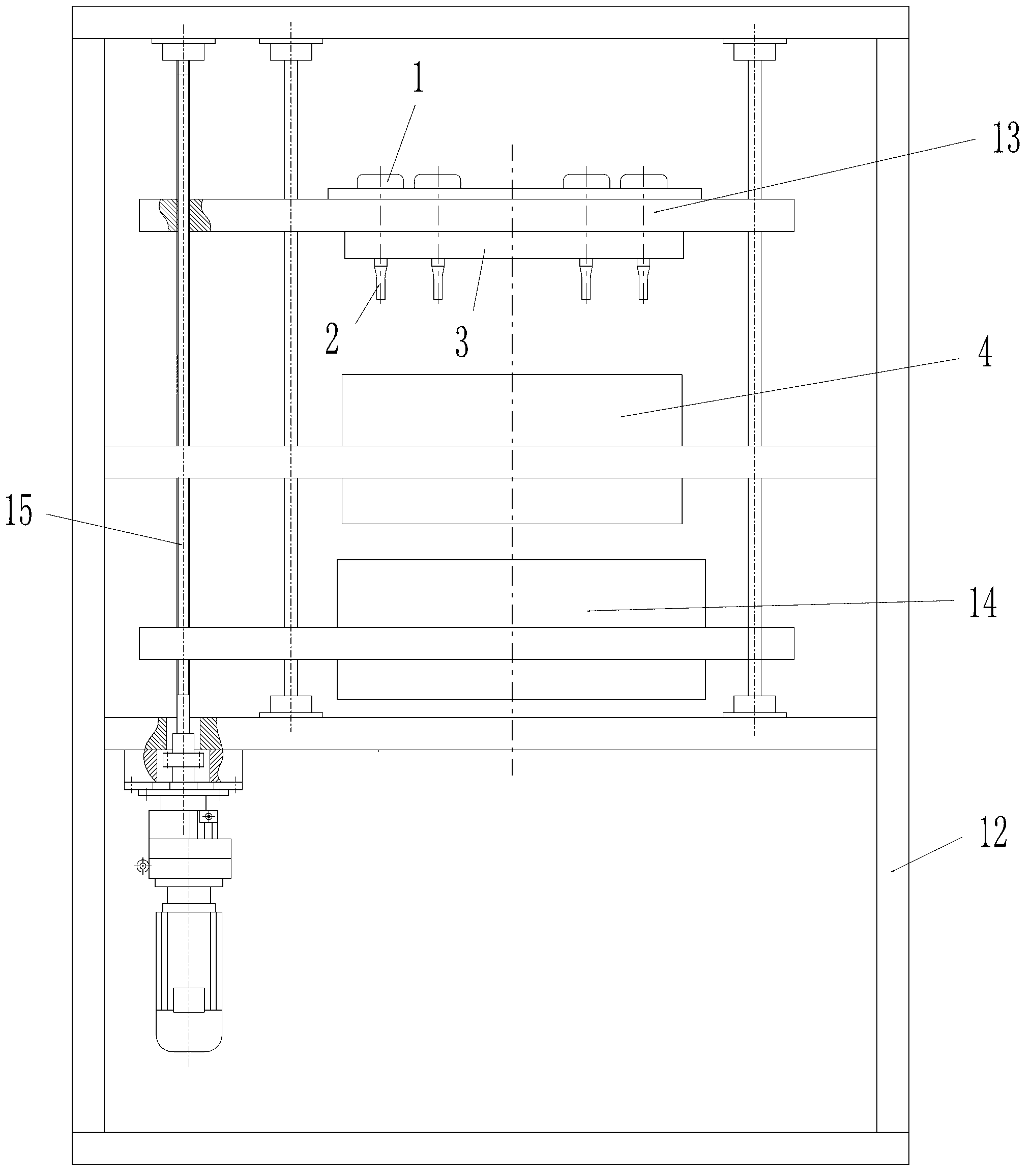

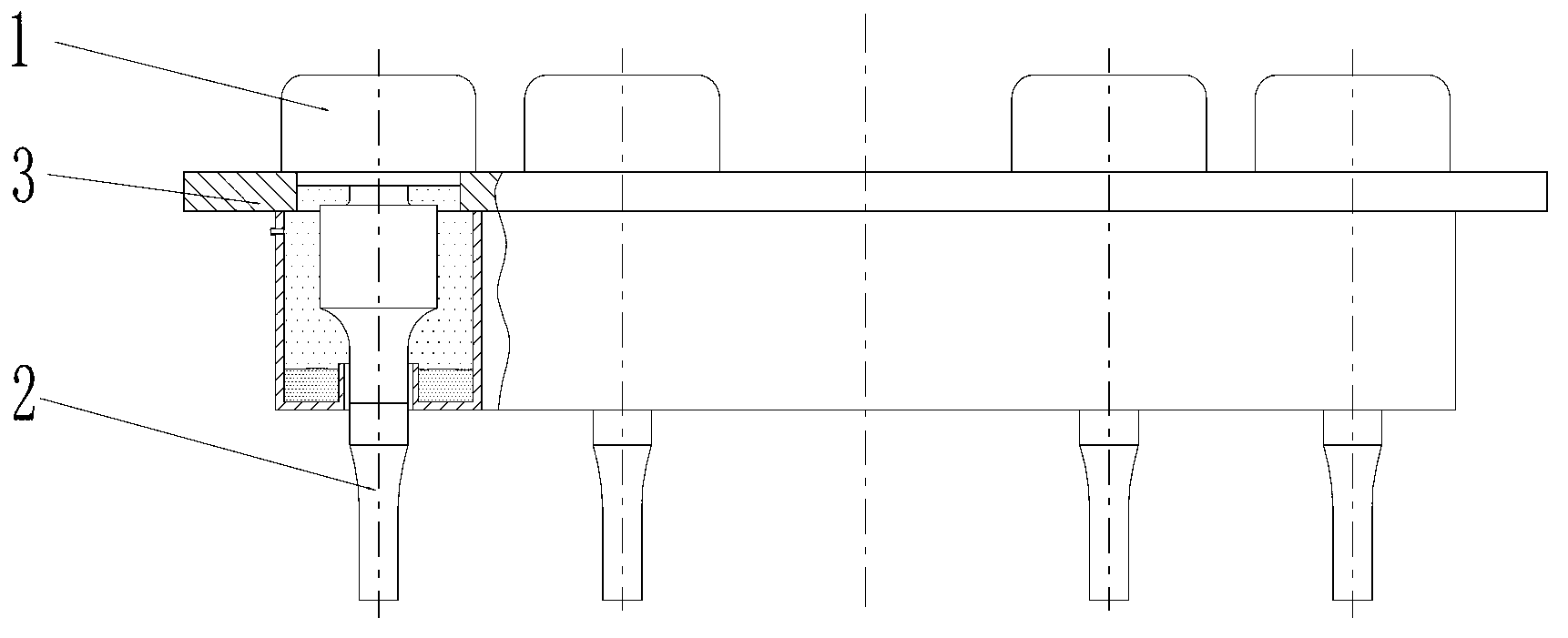

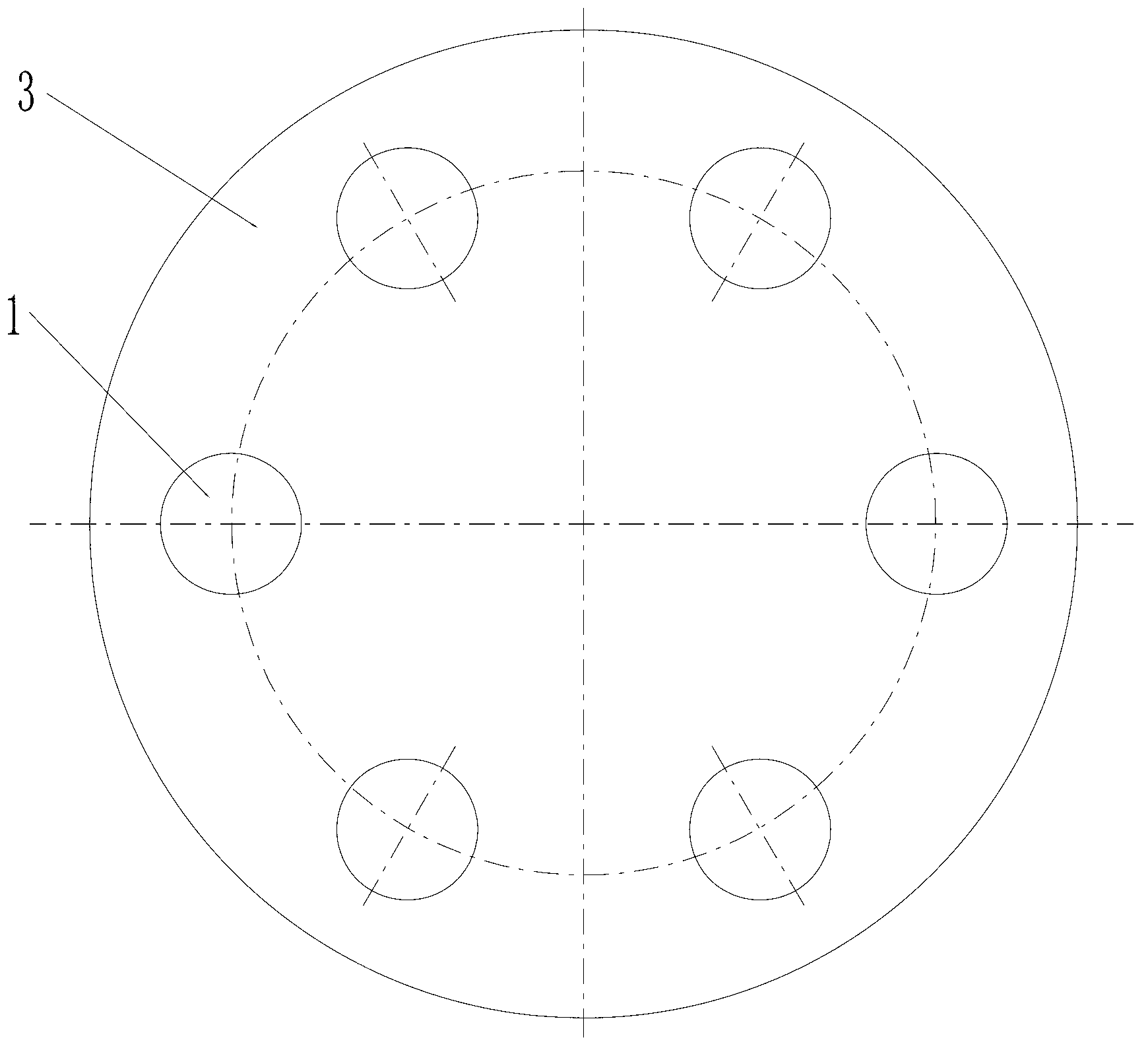

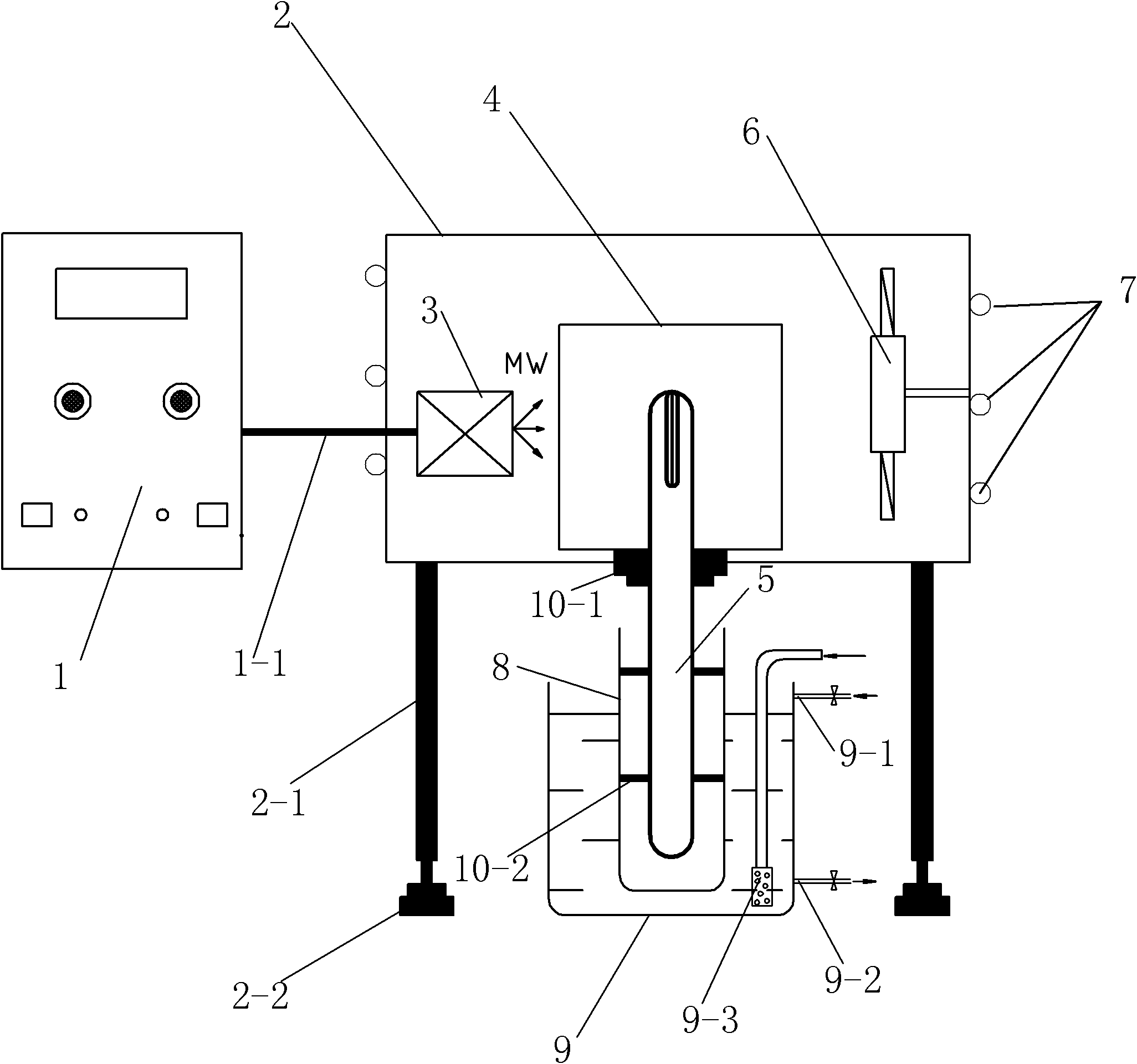

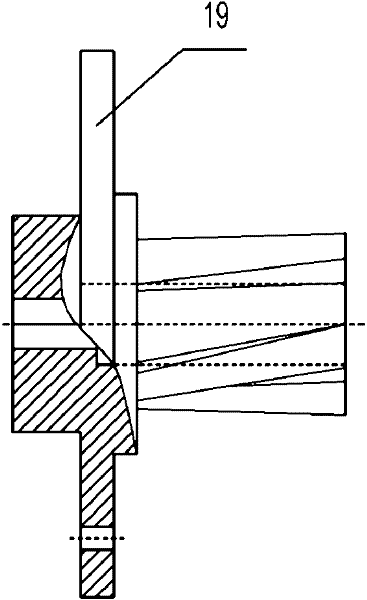

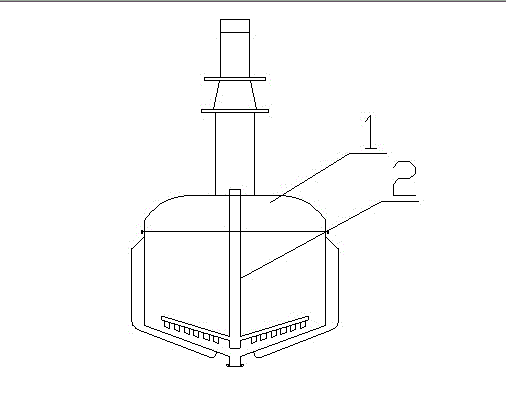

High-capacity ultrasonic crushing and dispersing device

ActiveCN102847479AHigh viscosityImprove uniformityShaking/oscillating/vibrating mixersMixer accessoriesTransformerTransducer

The invention provides a high-capacity ultrasonic crushing and dispersing device, mainly comprising an ultrasonic device, a material container, a magnetic mixing device, an automatic lifting device and a rack, wherein the ultrasonic device is composed of ultrasonic transducers, an ultrasonic amplitude transformer and a transducer cooling sleeve; the ultrasonic amplitude transformer is coaxial with the ultrasonic transducers and is arranged at the lower ends of the ultrasonic transducers; the transducer cooling sleeve is an annular sleeve with a cavity; the ultrasonic transducers are arranged on the transducer cooling sleeve, and vibrating members penetrate through the inner cavity of the transducer cooling sleeve; and a plurality of ultrasonic transducers are uniformly distributed on the transducer cooling sleeve. A small gap is formed between the vibrating member of each ultrasonic transducer and the transducer cooling sleeve, so that the transducer cooling sleeve cannot be contacted with the vibrating members of the ultrasonic transducers to influence an ultrasonic effect; and a soft material can be filled between the vibrating member of each ultrasonic transducer and the transducer cooling sleeve, so that the transducer cooling sleeve can be sealed on the premise of not influencing the vibrating frequency of the ultrasonic transducers, and a coolant cannot leak to pollute materials.

Owner:BEIJING UNIV OF CHEM TECH

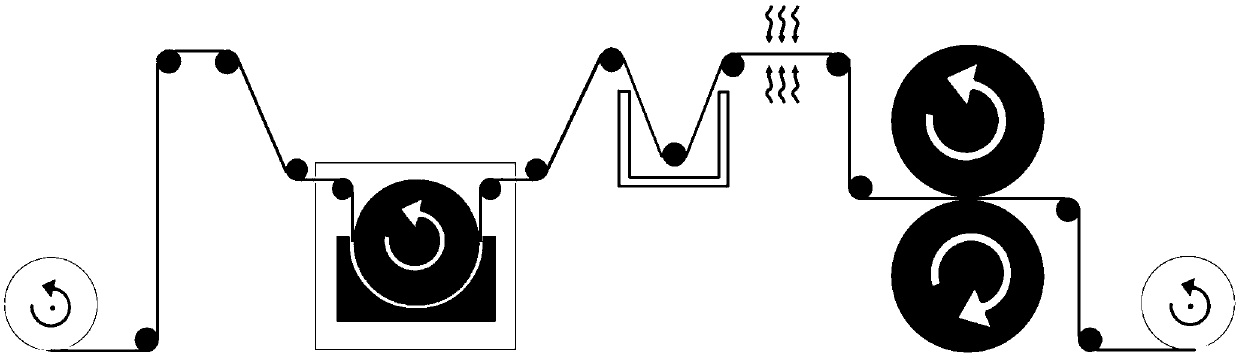

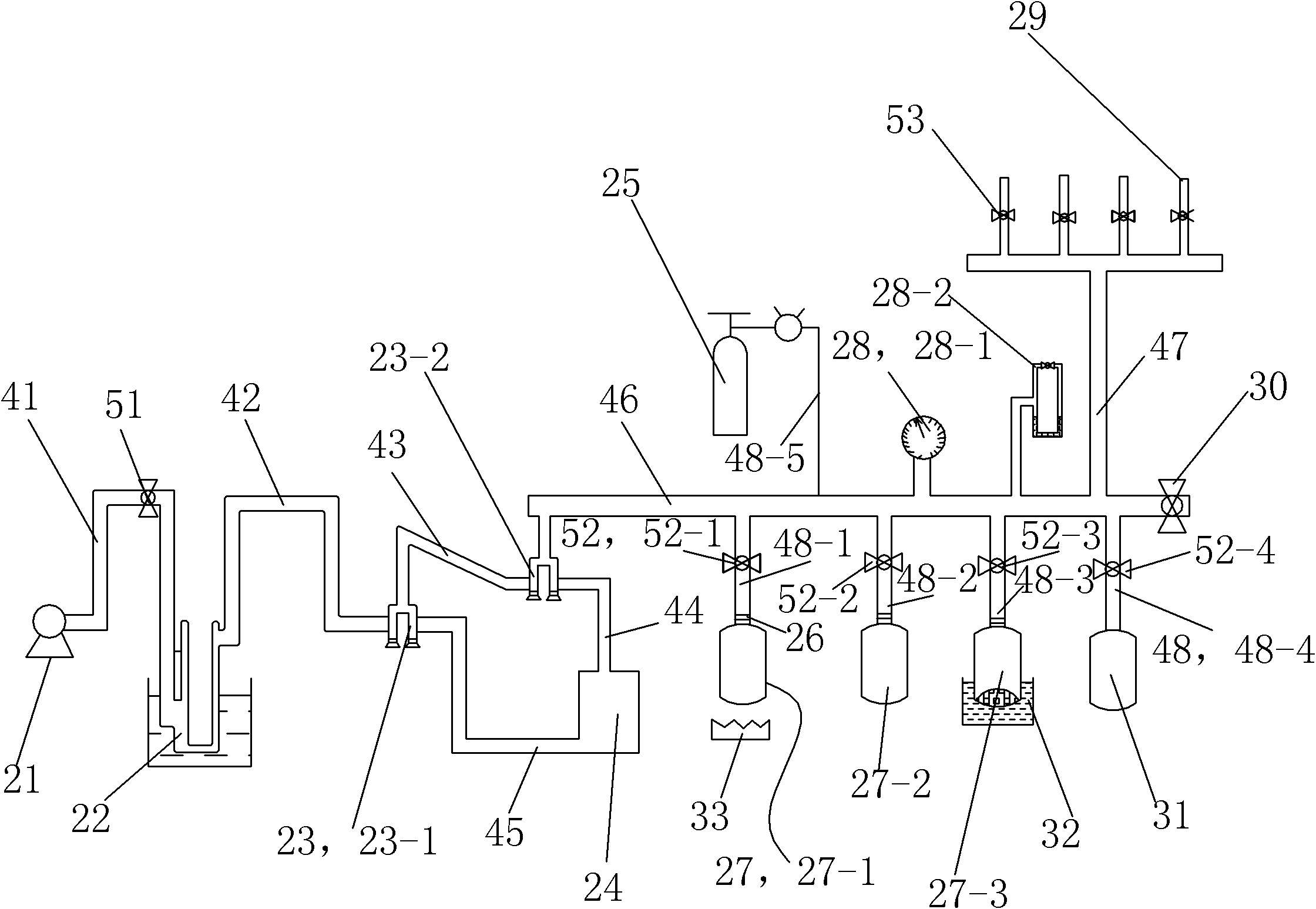

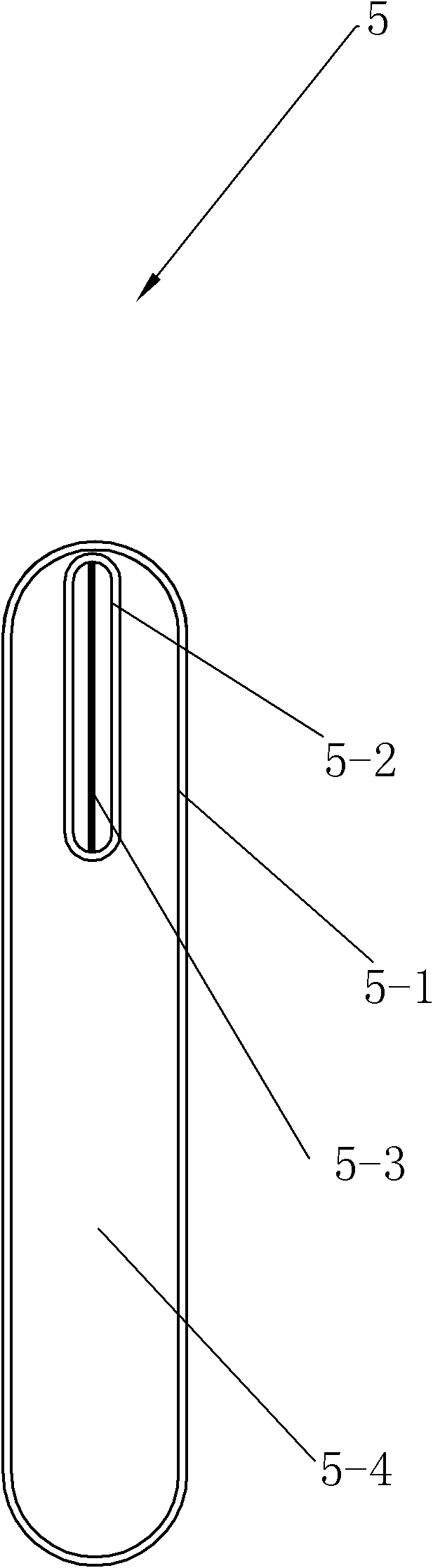

Continuous, controllable and effective pre-lithiation system and lithium supplementing method

ActiveCN111162246AImprove efficiencyIncrease capacityNon-aqueous electrolyte accumulator electrodesMetallic lithiumElectrolytic agent

The invention discloses a continuous, controllable and effective pre-lithiation system and a lithium supplementing method. The pre-lithiation system comprises an unwinding device, a negative-pressureindirect lithiation device, a cleaning device, a drying device, a rolling device and a winding device. The lithium supplementing method comprises the following steps of firstly, coating a metal lithium ingot with a layer of resistance buffer film, enabling a continuous pole piece to pass through a negative pressure indirect buffer device, contacting the pole piece with the metal lithium ingot coated with the resistance buffer film indirectly in the presence of electrolyte, thereby realizing the pre-lithiation of an electrode. The pre-lithiation system can achieve continuous production, the lithiation degree is controllable, lithiation is uniform, the method is simple and convenient, and the industrial production can be achieved easily.

Owner:INST OF CHEM CHINESE ACAD OF SCI

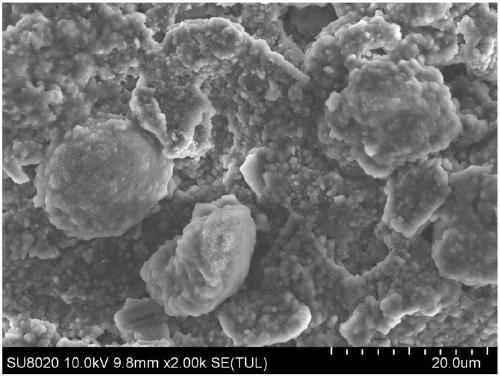

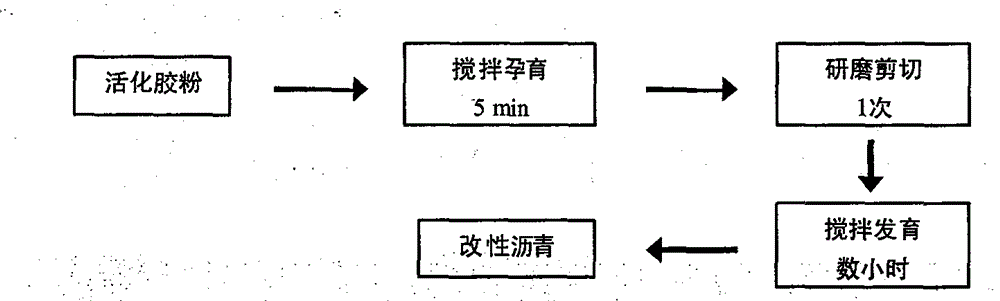

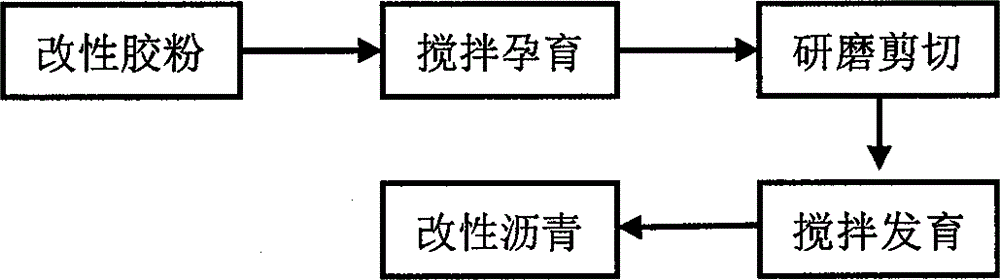

Surface oxidation modification process for waste tire rubber powder for modification of asphalt

ActiveCN103145882AHigh bonding strengthIncrease free energyBuilding insulationsPolymer scienceSurface oxidation

The invention relates to a surface oxidation modification process for waste tire rubber powder for modification of asphalt. The process comprises the following steps: dispersing waste tire rubber powder in water, adding a certain amount of oxidant, stirring at the temperature of 25-80 DEG C for 1.5 hours at constant temperature, wherein the oxidant is one of sodium dichloro isocyanurate, trichloroisocyanuric acid, sodium hypochlorite or hydrogen peroxide; the oxidant amount accounts for 3-30 percent of the mass of the waste tire rubber powder, filtering and drying to obtain the oxidized modified rubber powder after the reaction is ended, wherein the oxidized modified rubber powder serves as an asphalt modifier to prepare the rubber powder modified asphalt, so that the performance of the modified asphalt is regulated. The method is low in energy consumption, the oxidant is low in price and readily available, industrial application is easily realized, and the main performances such as the softening point, needle penetration and ductility of the modified asphalt can be effectively regulated.

Owner:NANKAI UNIV

Device for treating waste water with microwave electrodeless excimer lamp and gas distributing system for lamp

InactiveCN101857283AHigh strengthAdjustable wavelengthWater/sewage treatment by irradiationUltraviolet lightsEngineering

The invention discloses a device for treating waste water with a microwave electrodeless excimer lamp and a gas distributing system for the electrodeless excimer lamp in the device. A waster water treatment pond of the device is arranged below the shell of a microwave generator; 1 / 5 to 1 / 3 of the electrodeless excimer lamp is fixed in a resonant cavity, and the part of the electrodeless excimer lamp, which is not arranged in the resonant cavity, is sheathed with a quartz casing tube with a closed lower end; the microwave generator comprises a fan and a cooling copper tube which are used for cooling the resonant cavity, the fan is fixed on the inner side wall of the shell, and the cooling copper tube is welded around the external surface of the shell; the gas distributing system for the electrodeless excimer lamp is also provided with a cold well in front of a vacuum pump; and the pipeline, which is connected with a third port of a second three-way valve, is connected with a gas bottle, a gas storage bottle, a pressure indicating meter, a buffer bottle and a gas filling pipeline in parallel. The vacuum gas distributing system has a high vacuum degree, and can fill different gases according to the specific ultraviolet wavelength required by waste water treatment, so that the electrodeless excimer lamp can emit ultraviolet light with high intensity and high light effect.

Owner:NANTONG HONGLIAN GARMENTS +1

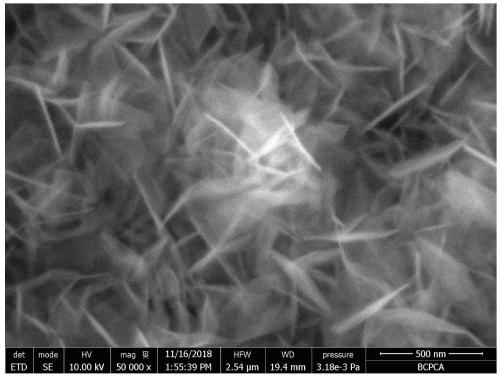

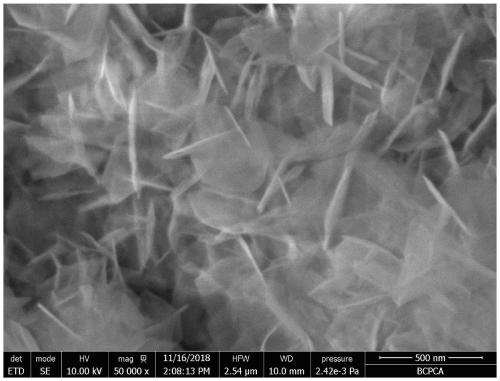

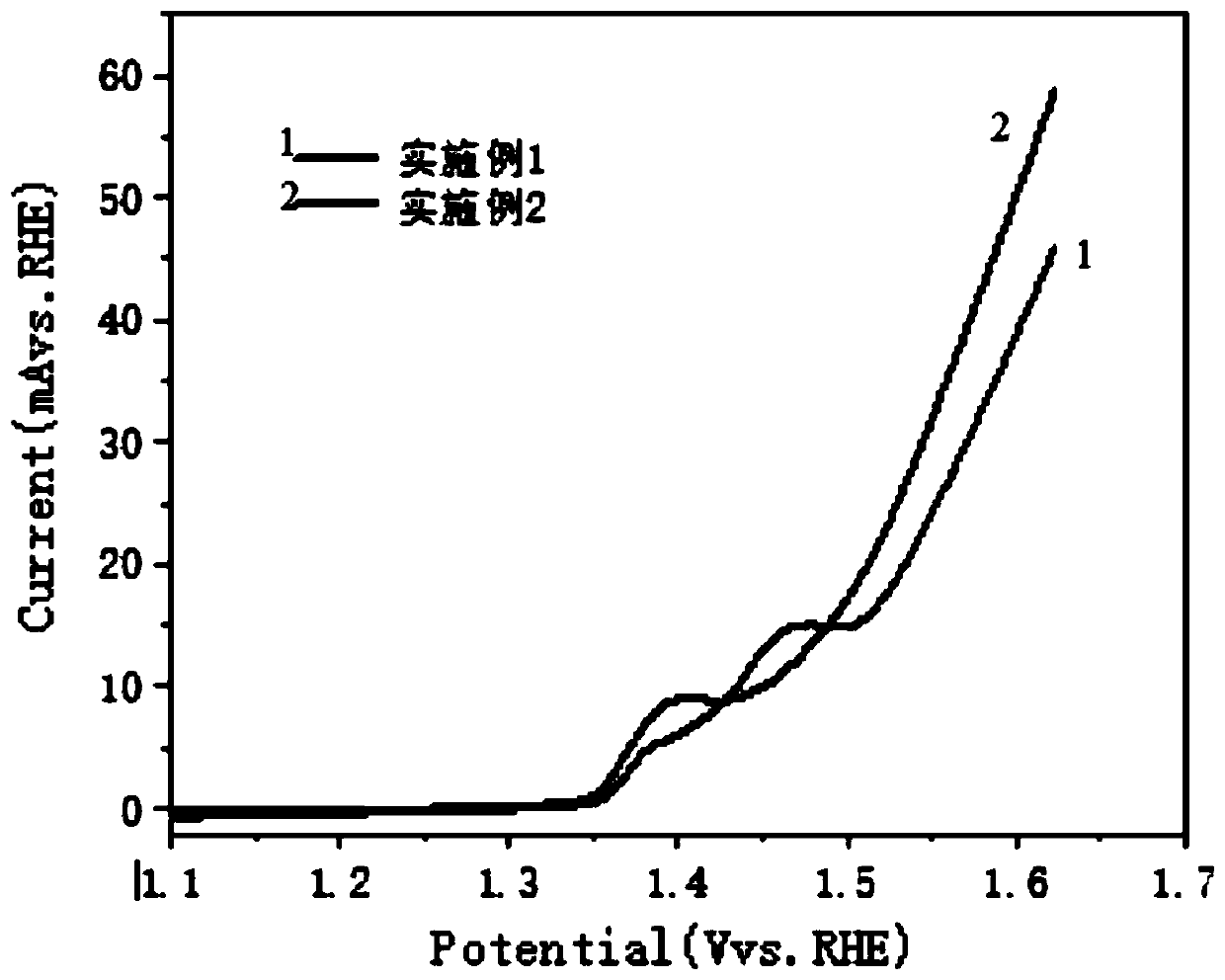

Amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material and preparation and application thereof

InactiveCN109794247AGood catalytic activityImprove uniformityElectrode shape/formsMetal/metal-oxides/metal-hydroxide catalystsBrown iron oxideOxide

The invention discloses an amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material and preparation and application thereof, and belongs to the technical field of electrochemistryenergy converting materials. The amorphous nickel-iron oxide nanometer sheet-shaped thin film material is synthesized in situ on a commercial foamed nickle matrix through a hydrothermal method, and the amorphous nickel-iron oxide nanometer sheet-shaped electrocatalysis material has the advantages of a high specific surface area and many catalytic active sites. The material is applied to a 1M potassium hydroxide solution for electrolysis of water, when the current density is 10 mA.cm<-2>, the overpotential required for oxygen evolution is 206-220 mV, and the performance of the material is better than that of most currently-reported anodic oxygen evolution catalysis materials. Besides, the related preparing technology is simple, raw materials are rich and cheap, the material can replace a precious-metal-based catalyst which is expensive and scarce, and large-scale industrial application of electrolyzed water is promoted.

Owner:BEIJING UNIV OF TECH

Preparation method of gravure water-based ink

ActiveCN101705030AGood printabilityGood resistance to wet frictionInksWater basedAntibacterial agent

The invention relates to a preparation method of gravure water-based ink. Most of the existing ink is not environment-friendly enough. The preparation method comprises the following steps: firstly, mixing and evenly stirring acrylic acid, styrene, vinyl acetate, water, an emulsifier and an initiator to obtain acrylic acid-styrene-vinyl acetate copolymer emulsion interpenetrating network-type water-soluble resin; then placing the acrylic acid-styrene-vinyl acetate copolymer emulsion interpenetrating network-type water-soluble resin and pigment, water, isopropyl alcohol, ethanol, a defoamer, a wetting agent, a leveling agent, a dispersant, a coupling agent and an antibacterial agent in an ink preparing barrel, and stirring to form a pasty ink material; and placing the pasty ink material in a three-roller ink grinding mill for ink grinding to lead pigment particles to be smashed completely and uniformly dispersed into a liquid binder, thus preparing the gravure water-based ink. The method is simple in technology, and the prepared ink has good printability, moisture friction resistance, high gloss and good adhesion, therefore, the gravure water-based ink can be used for different types of paper.

Owner:江苏卫星新材料股份有限公司

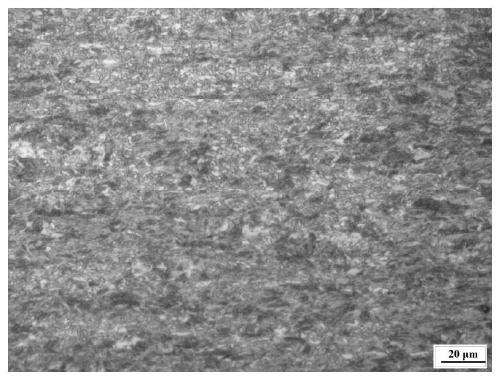

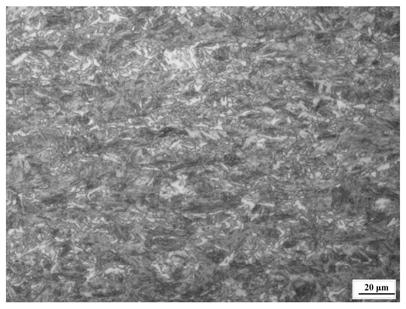

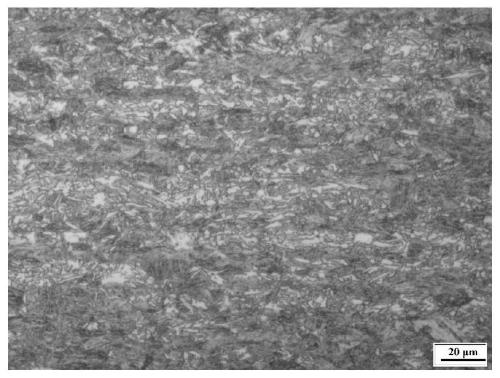

6-8mm TMCP on-line quenching low-yield-ratio high-strength wear-resistant steel NM400 coiled plate and production method thereof

The invention discloses a 6-8mm TMCP on-line quenching low-yield-ratio high-strength wear-resistant steel NM400 coiled plate and a production method of the 6-8mm TMCP on-line quenching low-yield-ratiohigh-strength wear-resistant steel NM400 coiled plate. According to the chemical components of the coiled plate, the coiled plate comprises, by mass percentage, 0.18%-0.22% of C, 0.30%-0.50% Si, 1.30%-1.45% of Mn, smaller than or equal to 0.012% of P, smaller than or equal to 0.003% of S, 0.015%-0.025% of Nb, 0.010%-0.025% of Ti, 0.25%-0.40% of Cr, 0.0005%-0.0020% of B, 0.0010%-0.0030% of Ca, 0.020%-0.050% of Al, smaller than or equal to 2ppm of H, smaller than or equal to 30ppm of O, smaller than or equal to 50ppm of N and the balance Fe and inevitable impurities. The provided coiled plate has excellent mechanical properties, a metallographic structure is a ferrite and martensite two-phase structure, and the application prospect is wide.

Owner:BAOTOU IRON & STEEL GRP

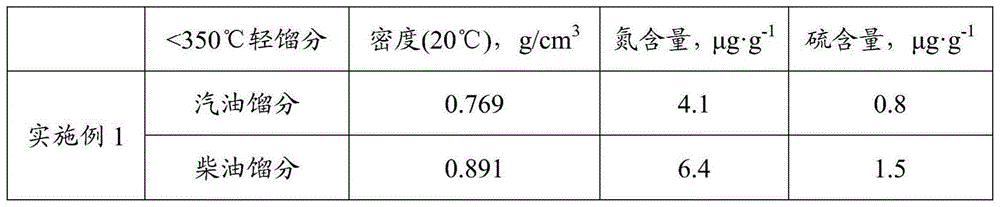

Preparation method of hydrogenation catalyst and slurry bed hydrogenation technology using the catalyst

ActiveCN105126933ALarge specific surface areaGood dispersionCatalyst regeneration/reactivationHydrocarbon oil crackingHydrogenation reactionHydrogenation process

The invention provides a preparation method of hydrogenation catalyst and a slurry bed hydrogenation technology using the catalyst. The preparation method comprises the following steps: a desulphurization waste agent and / or a waste catalyst is placed in a solvent oil at 80-150 DEG C for beating, and a hydrogenation catalyst slurry is obtained. The preparation method of the present invention can increase dispersibility of the catalyst in raw oil and is good for improving activity of the catalyst, and simultaneously can effectively reduce even inhibite the coking problem of slurry bed. According to the slurry bed hydrogenation technology provided by the invention, the desulphurization waste agent generated in the process of slurry bed tail gas desulphurization is prepared into the hydrogenation catalyst, and the hydrogenation catalyst is calculatedly used in the hydrogenation reaction of heavy raw oil, thereby realizing cyclic utilization of catalysts with different functions in the whole slurry bed hydrogenation process flow, solving the coking problem easily generated in the slurry bed hydrogenation technology, and simultaneously developing a low-cost new approach for safety recovery of the desulphurization waste agent, the waste catalyst or the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

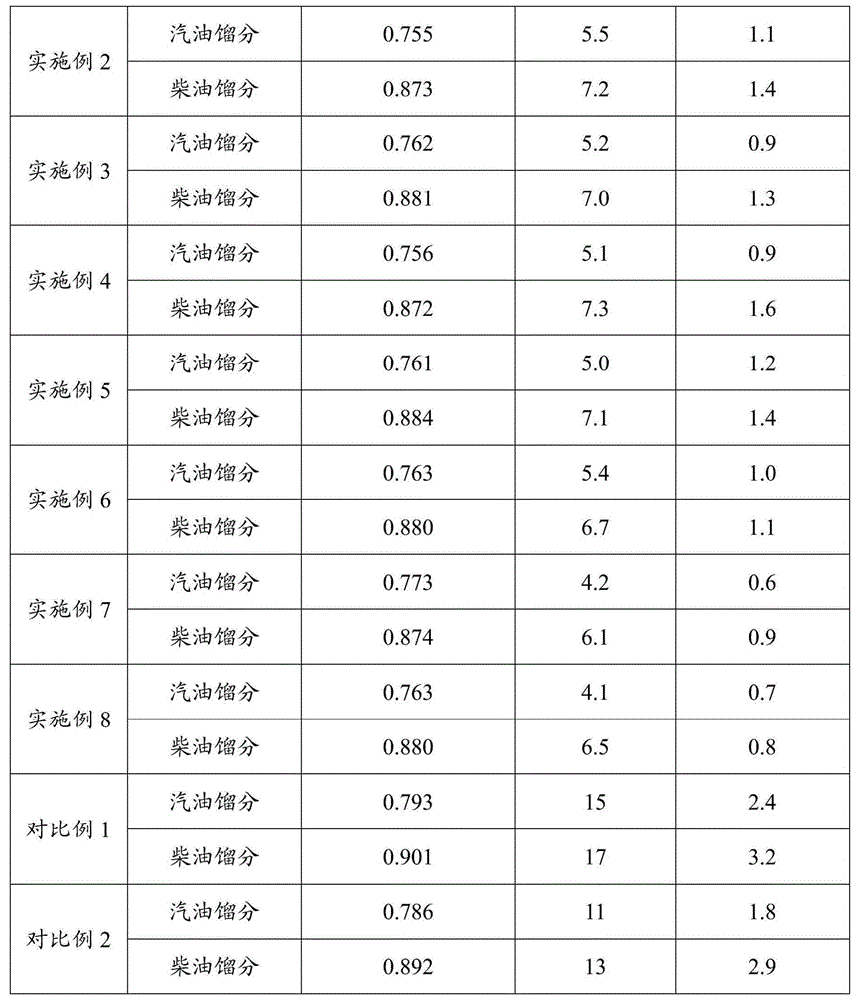

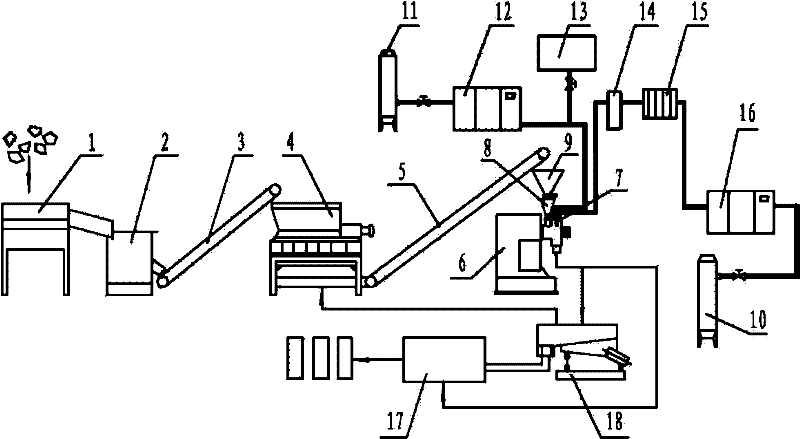

Industrializable waste thermosetting plastic regeneration process and equipment based on mechanical and physical method

InactiveCN102416675AOvercome the shortcomings of being simply crushed and the value of recovered products is lowIncrease valuePlastic recyclingMechanical material recoveryWater vaporPlastic waste

The invention discloses an industrializable waste thermosetting plastic regeneration process and equipment based on a mechanical and physical method. The invention is characterized in that: firstly, waste thermosetting plastics are cleaned and dried to obtain a raw material; secondly, the raw material is crushed to obtain a blocky standby material; finally, the blocky standby material is placed in a regeneration environment of steam with nitrogen as protection gas and is degraded through the treatment processes of shearing, grinding and stirring in the regeneration environment so as to obtain a degraded regeneration product. The invention enables the scope and approach of cyclic reutilization of thermosetting plastic waste to be developed and provides a novel regeneration method for comprehensive utilization of thermosetting plastic waste which is difficult to regenerate.

Owner:HEFEI UNIV OF TECH

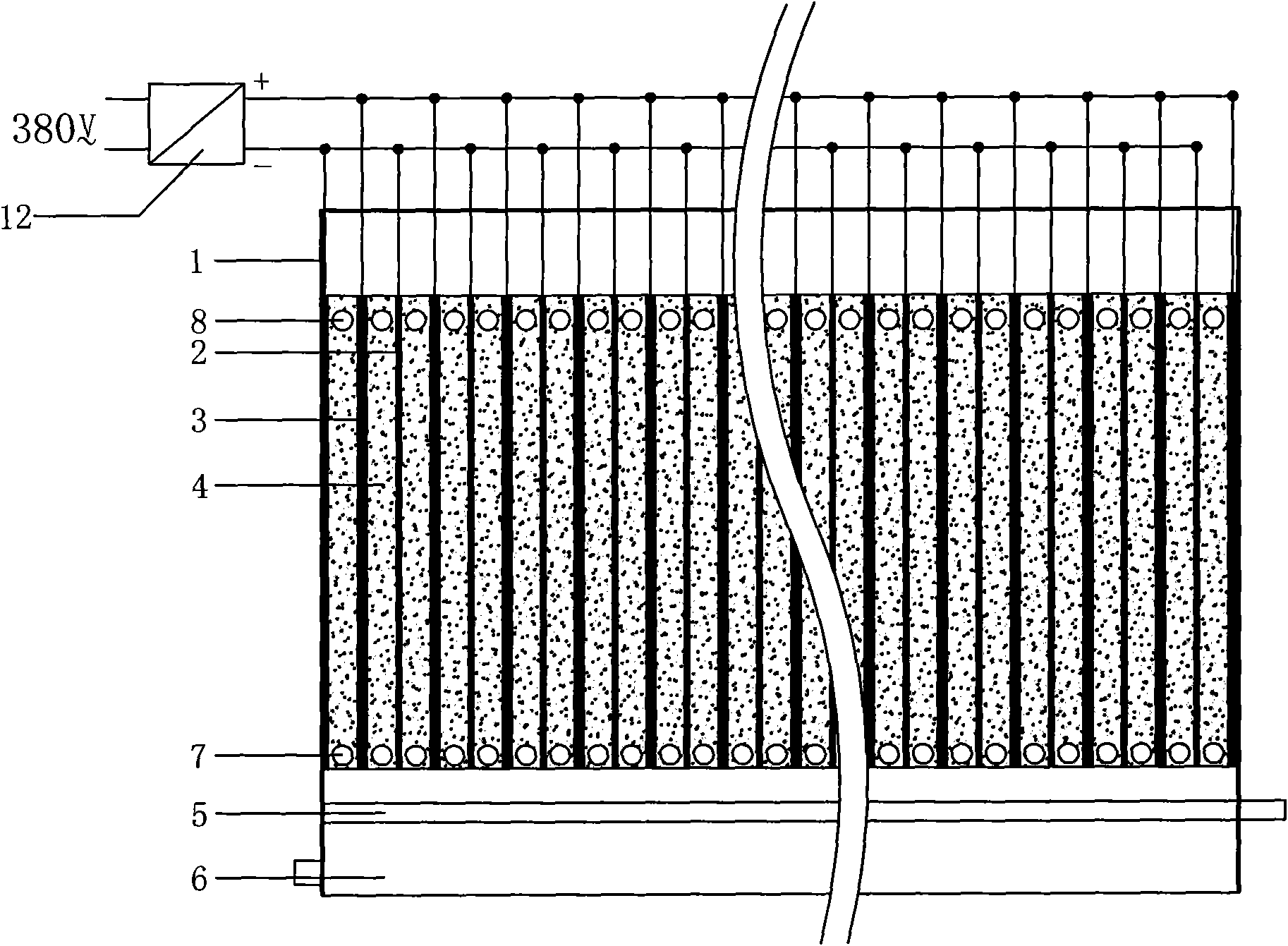

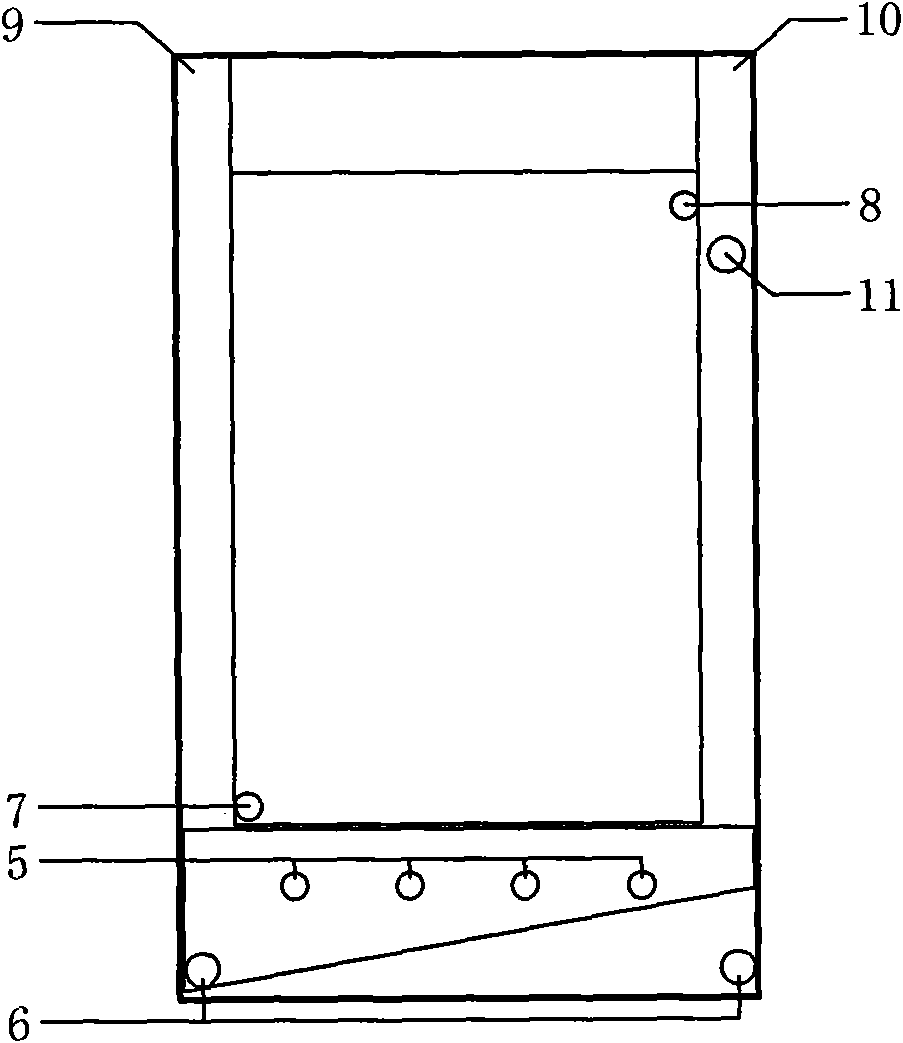

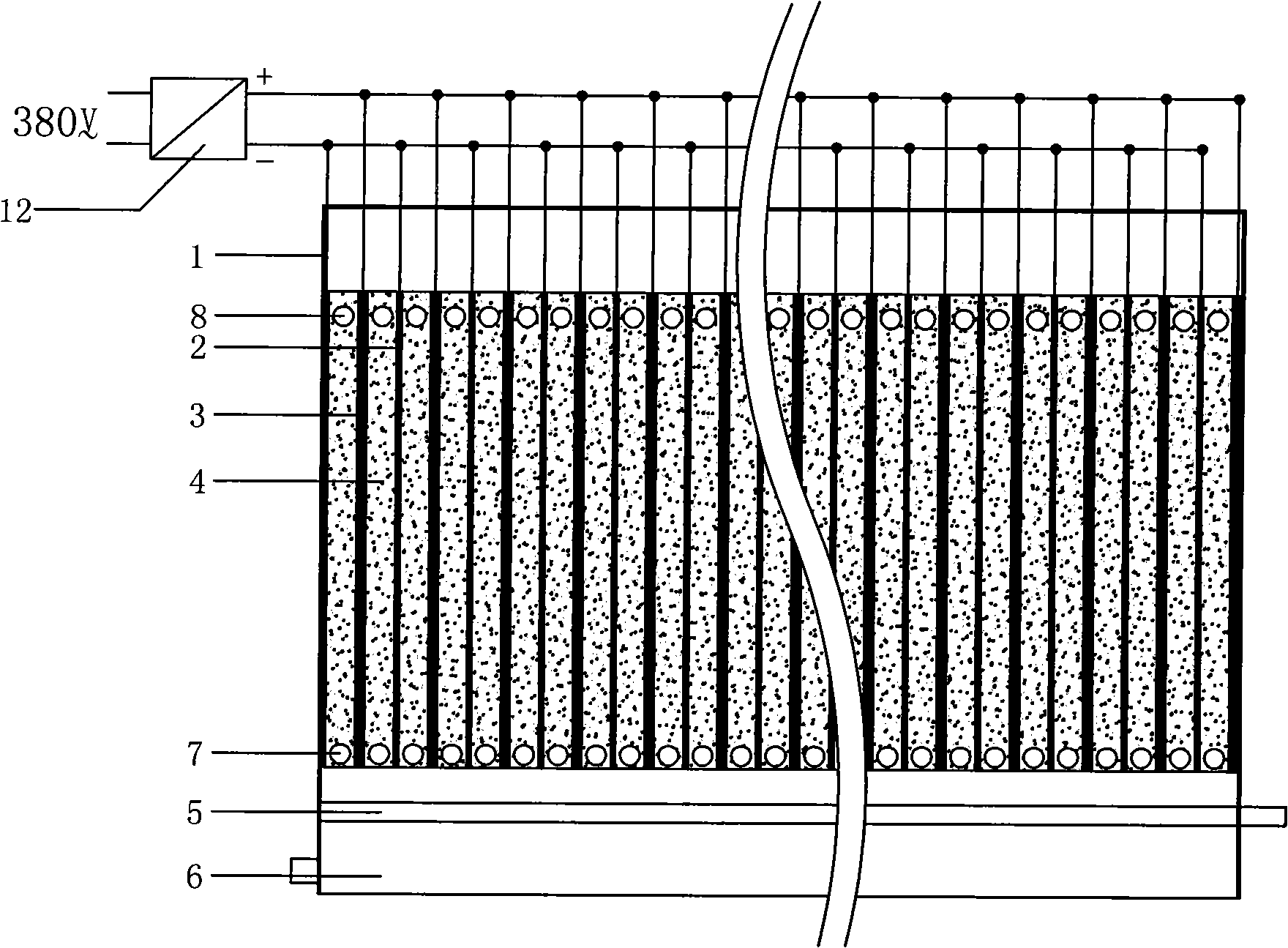

Sewage treatment equipment using expanded anode for electrolytically decomposing cyanide

ActiveCN101781002AAchieving a breakout reactionEfficient responseWater contaminantsWater/sewage treatment using germicide/oligodynamic-processCyanideElectrolysis

The invention relates to sewage treatment equipment using expanded anode for electrolytically decomposing cyanide, which comprises a shell, a cathode plate, an anode plate, a particle electrode filled between the cathode plate and the anode plate, a direct current power supply connected with the cathode plate and the anode plate, a water inlet groove, a water inlet, a water outlet, a water outlet groove, a drain pipe, an aerator pipe and a mud hole. The sewage treatment equipment is improved in the following aspects: the cathode plate and the anode plate are vertically and oppositely fixed in the shell in parallel; an insulating layer is adhered to the surface of the cathode plate; and the particle electrode is made of the same material as the anode plate and together with the anode plate forms an expanded anode. The equipment is divided into a plurality of independent reaction chambers by polar plates in the equipment; the waste water is uniformly distributed by the water inlet groove, flows upwards from the lower water inlets of the reaction chambers to pass through the reactors and flows out from the upper water outlets to converge into the water outlet groove. Each reaction chamber is filled with the particles of a material the same as the anode material, so the anode area is expanded and the mass transfer effect and the reaction efficiency are improved. Thus, the cyanide in the waste water is degraded efficiently.

Owner:南京赛佳环保实业有限公司

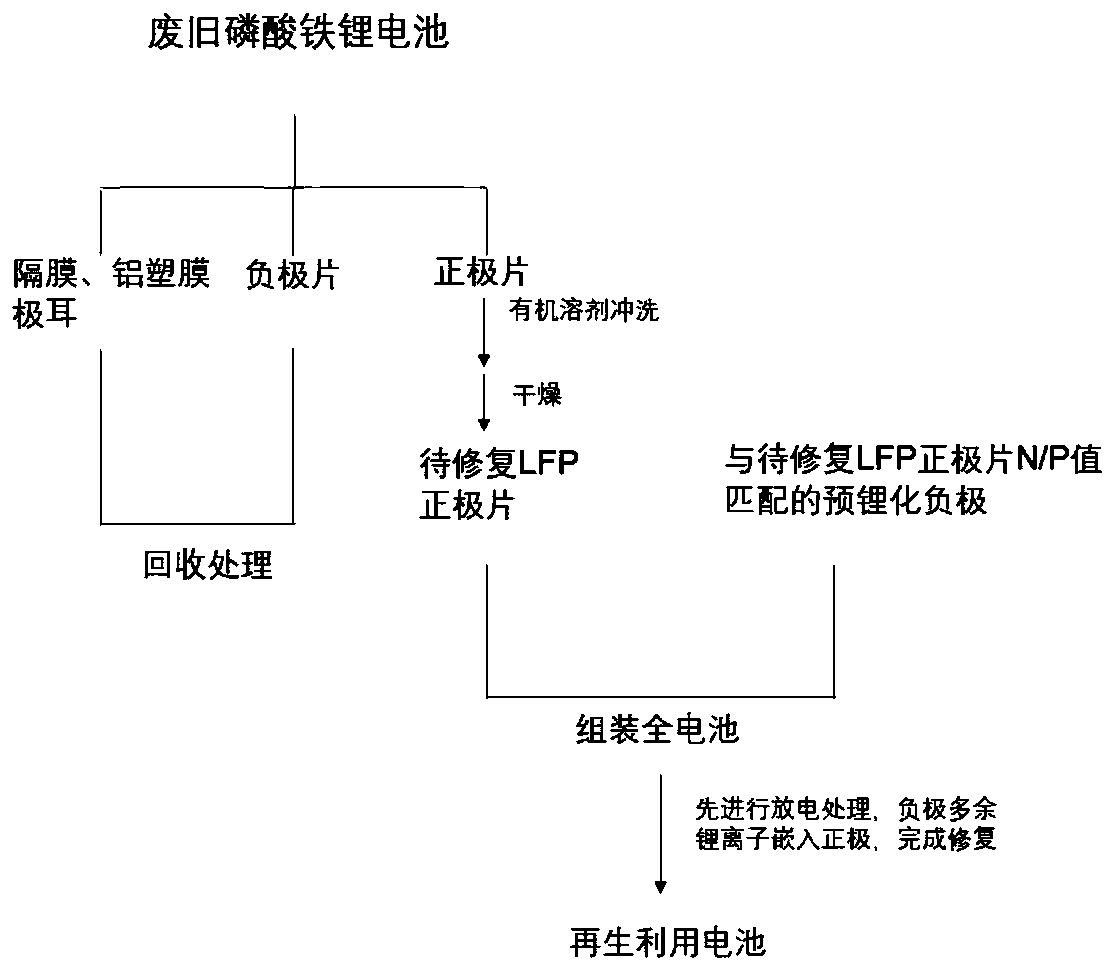

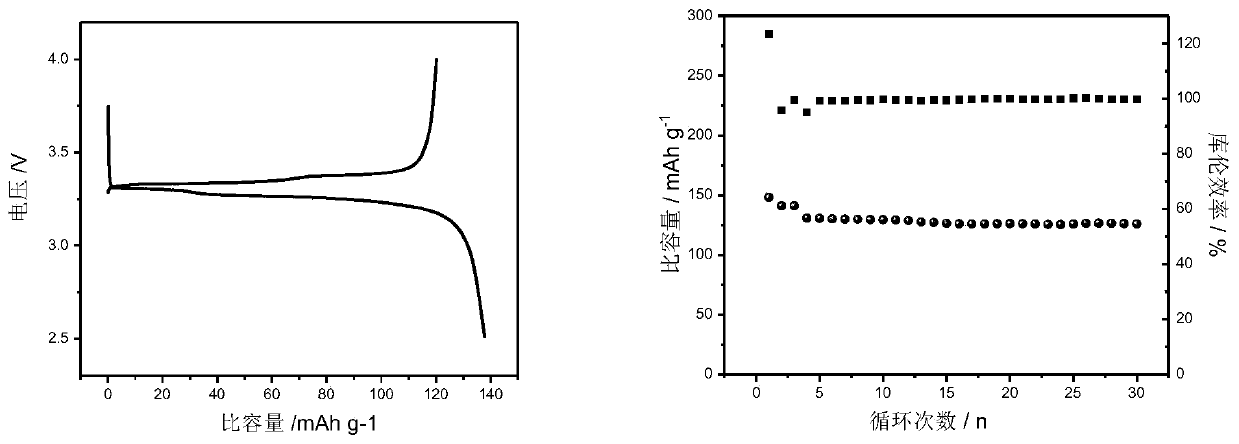

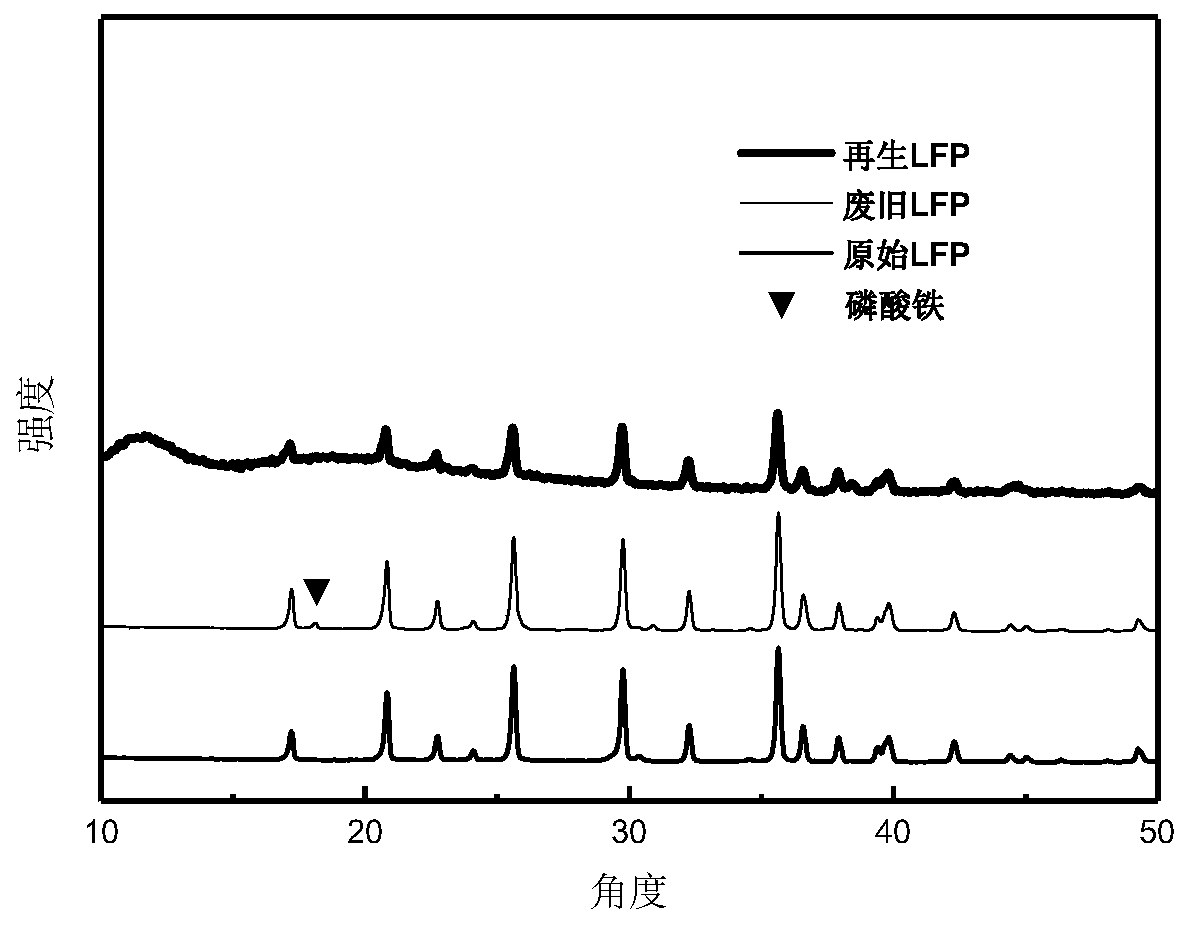

Method for directly repairing and regenerating positive electrode material of waste lithium iron phosphate battery

ActiveCN111224187AImprove efficiencyIncrease capacityFinal product manufactureCell electrodesLithium iron phosphateElectrical battery

The invention provides a method for directly repairing and regenerating a positive electrode material of a waste lithium iron phosphate battery. The method comprises the following steps: 1) performingdisassembling; 2) calculating the capacity; 3) carrying out pre-lithiation operation of the negative plate; 4) assembling the whole battery, and performing discharge treatment under a low current tocomplete lithium supplement to obtain the lithium battery. According to the method, after the recycled waste lithium iron phosphate positive electrode material is obtained through a simple method, thesecondary treatment is not needed, the recycled waste lithium iron phosphate positive electrode material and the pre-lithiated negative electrode are directly assembled into the battery; the discharging is conducted at low current, and performance repairing of the waste lithium iron phosphate positive electrode is completed. The direct regeneration method disclosed by the invention is capable ofrealizing continuous production, free of secondary pollution, simple and convenient, low in cost and beneficial to industrial production.

Owner:INST OF CHEM CHINESE ACAD OF SCI

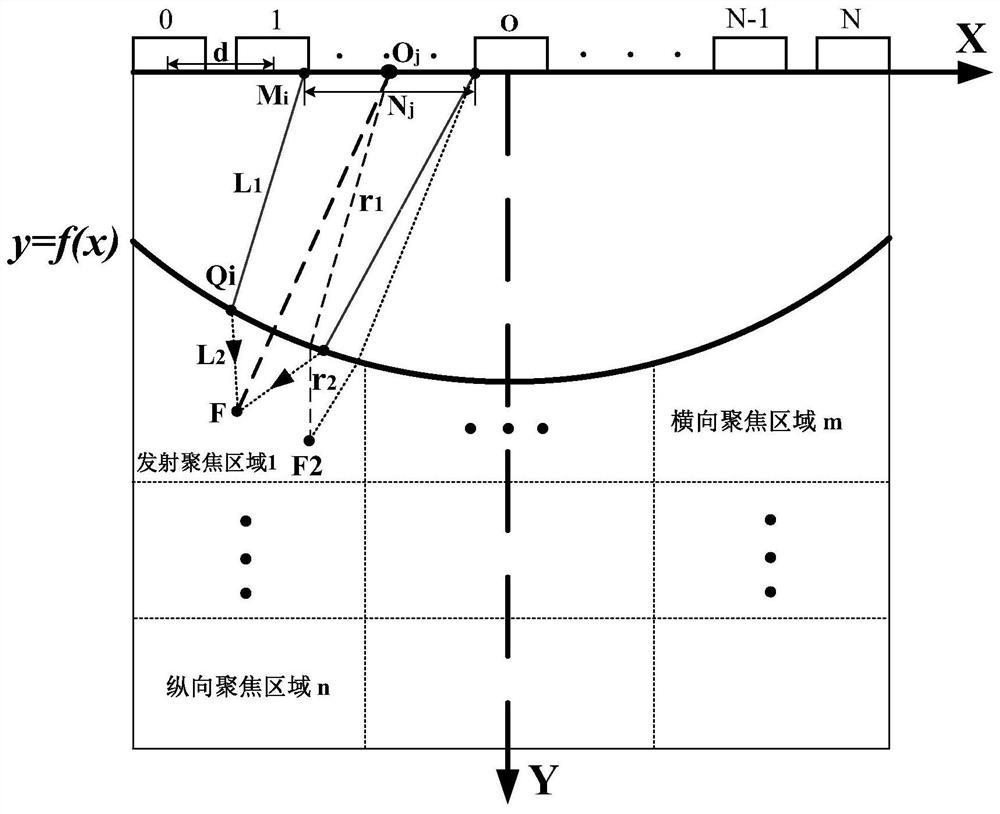

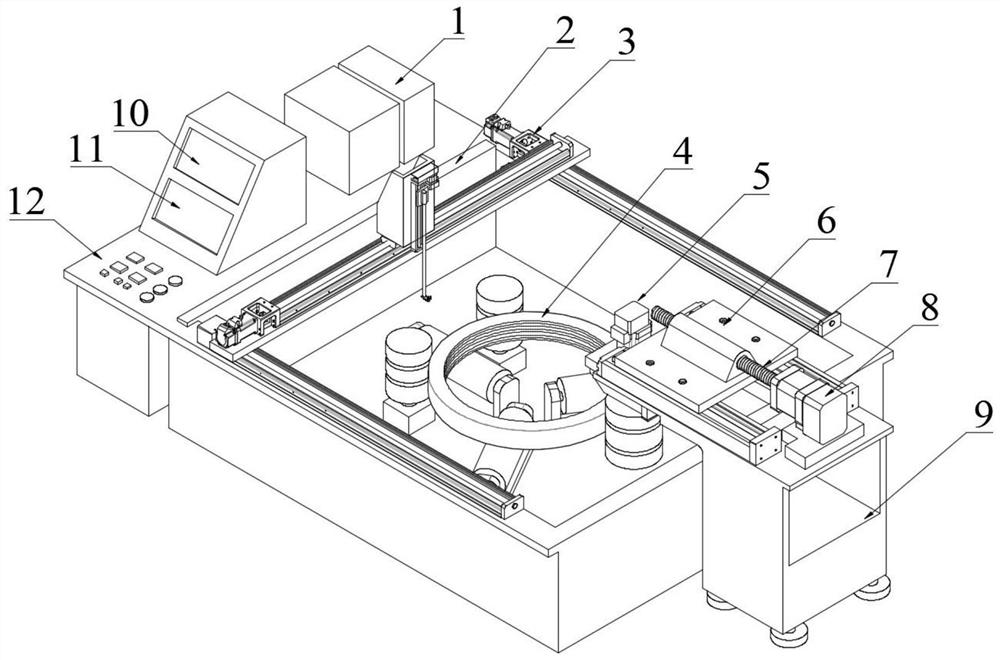

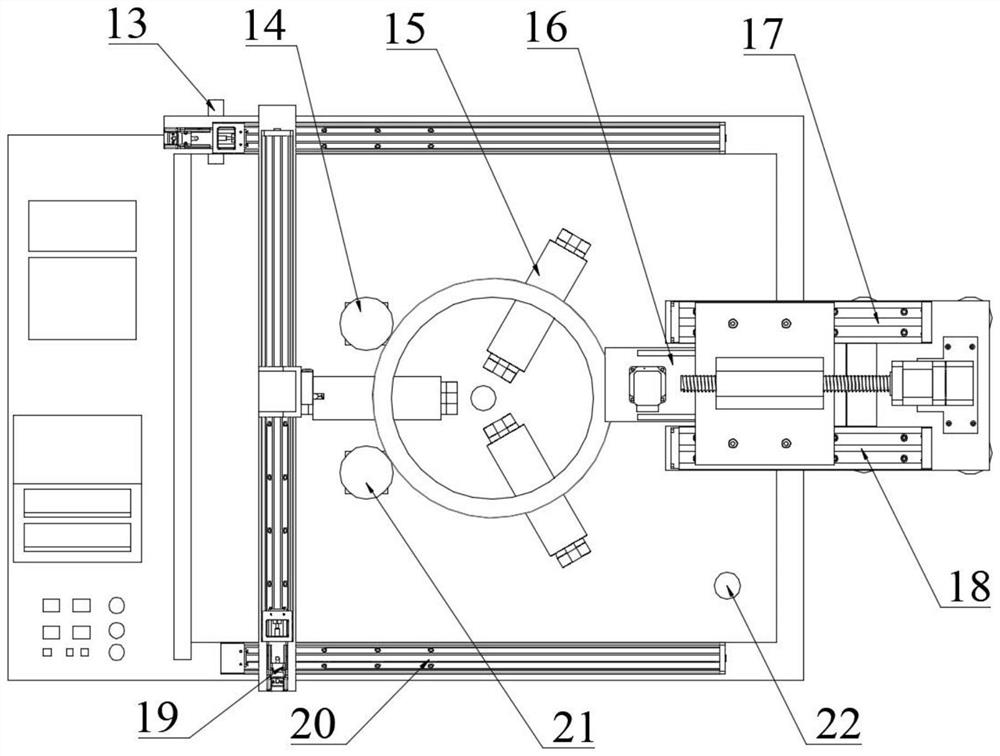

Ultrasonic water immersion automatic detection device and method for complex ring forgings

ActiveCN111796028AEnables high-resolution detectionEnhanced couplingAnalysing solids using sonic/ultrasonic/infrasonic wavesWater immersionDynamic aperture

The invention discloses an ultrasonic water immersion automatic detection device and method for complex ring forgings. The method comprises the steps of: placing a to-be-detected complex ring forgingin a water tank, carrying out the single detection of a complex curved surface through an ultrasonic phased array, and carrying out the regional detection of a flat end surface through a multi-frequency array water immersion probe according to the detection depth; during detection of complex curved surfaces, determining the optimal emission dynamic aperture array center and the array element number of each detection region according to a dynamic aperture emission focusing method; determining array emission delay time of each region according to a curved surface multi-medium emission focusing delay time calculation method, and calculating delay superposition time of all sampling points of each region according to a dynamic received beam synthesizer delay algorithm; during detection of the flat end face, selecting array water immersion probes of various different frequency models, and achieving full-coverage detection of the end face of the ring forging. A complete water immersion methodis adopted, the problem of poor coupling is solved, and full-coverage ultrasonic nondestructive testing can be achieved.

Owner:WUHAN UNIV OF TECH

Method of hydrogenation treatment for coal tar by hypercritical solvent

InactiveCN101033410AImprove thermal stabilityImprove operating conditionsTar working-up by distillationHydrocarbon oils refiningProduction rateChemical reaction

This invention relates to a method for hydroprocessing coal tar with a supercritical solvent, which puts raw coal tar into a reactor and adds a solvent in the volume ratio of 1:1-1:3 to the raw coal tar and a catalyst of 1wt%-18wt% of the raw coal tar to undergo light chemical reaction with hydrogen, then the liquid from the reactor is distilled and cut to get water, solvent, masout and light crude fractions, which turns raw coal tar to light and combines with supercritical fluit to reduce inactivation of catalysts to increase the production rate of light crude and takes a solvent to replace water to react under the supercritical state to reduce operation temperature and pressure.

Owner:XI AN JIAOTONG UNIV

Method for controlling size uniformity of hot rolled high-carbon austenitic stainless steel grains

ActiveCN110724809APrevent precipitationAvoid abnormal growthFurnace typesHeat treatment furnacesSolution treatmentSS - Stainless steel

The invention discloses a method for controlling the size uniformity of hot rolled high-carbon austenitic stainless steel grains. The method comprises the following steps: 1, preparing a high-carbon austenitic stainless steel hot rolled medium plate; 2, putting the medium plate in a heating furnace of 900-920 DEG C for preheating, wherein the preheating time t1 is equal to 0.4-0.6 hour; 3, raisingthe temperature of the preheated plate to 1000-1010 DEG C along with the furnace for recrystallization treatment, or taking the preheated plate out for slow cooling, warming the heating furnace to 1000-1010 DEG C, and then putting the preheated plate in the heating furnace for recrystallization treatment; 4, raising the temperature of the recrystallization plate by 50-100 DEG C along with the furnace for solution treatment, or taking the recrystallization plate out for slow cooling, raising the temperature of the heating furnace by 50-90 DEG C, and then putting the recrystallization plate inthe heating furnace for solution treatment; and 5, carrying out water quenching on a solid solution plate to the normal temperature. According to the method, the recrystallization kinetics and the thermodynamics are taken as the acting points, the multi-stage stepped type annealing technology is adopted to release deformation stored energy step by step, the medium plate with uniform grains and adjustable and controllable grain size is obtained, the maneuverability is high, and industrial application can be realized.

Owner:NORTHEASTERN UNIV

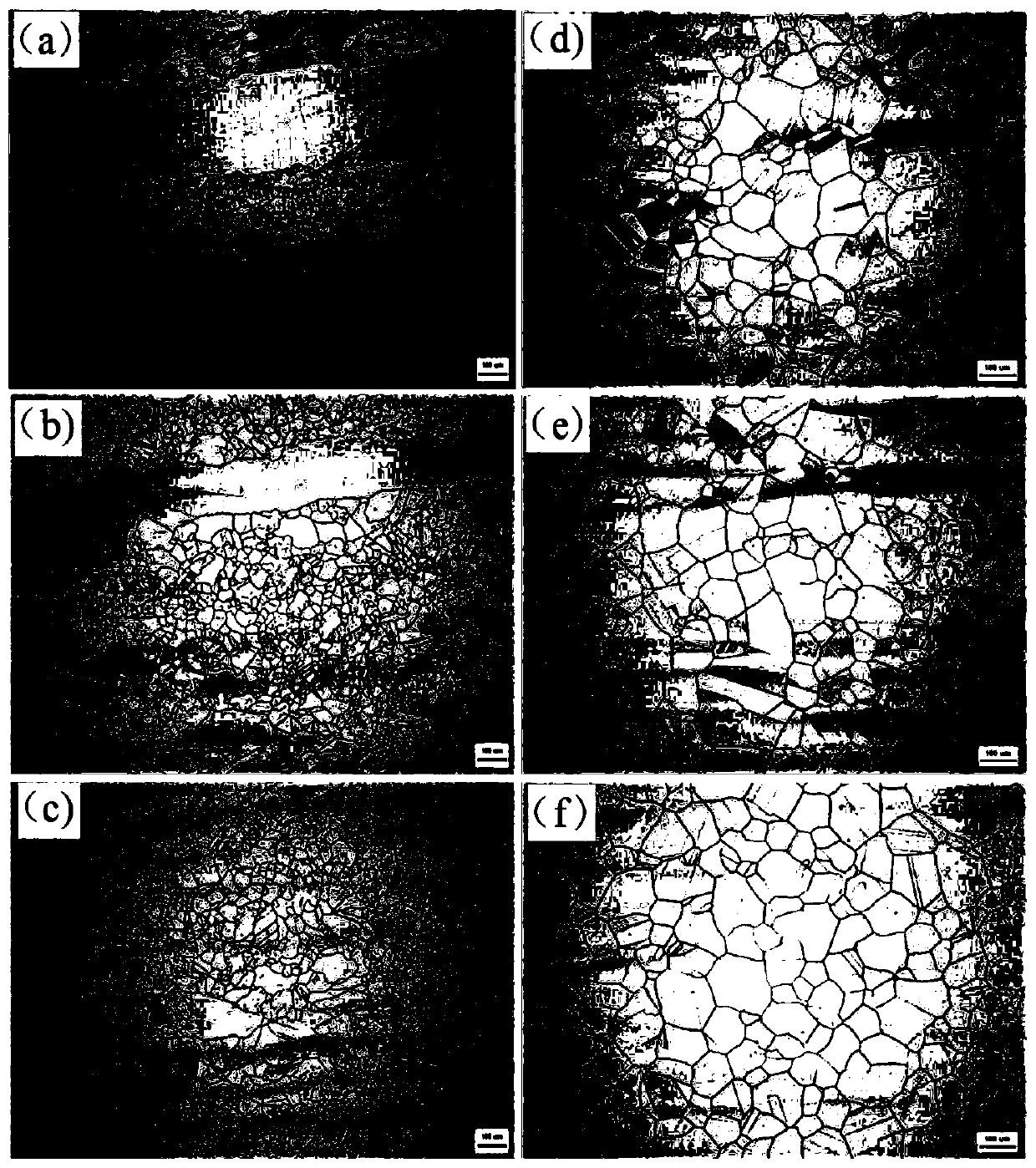

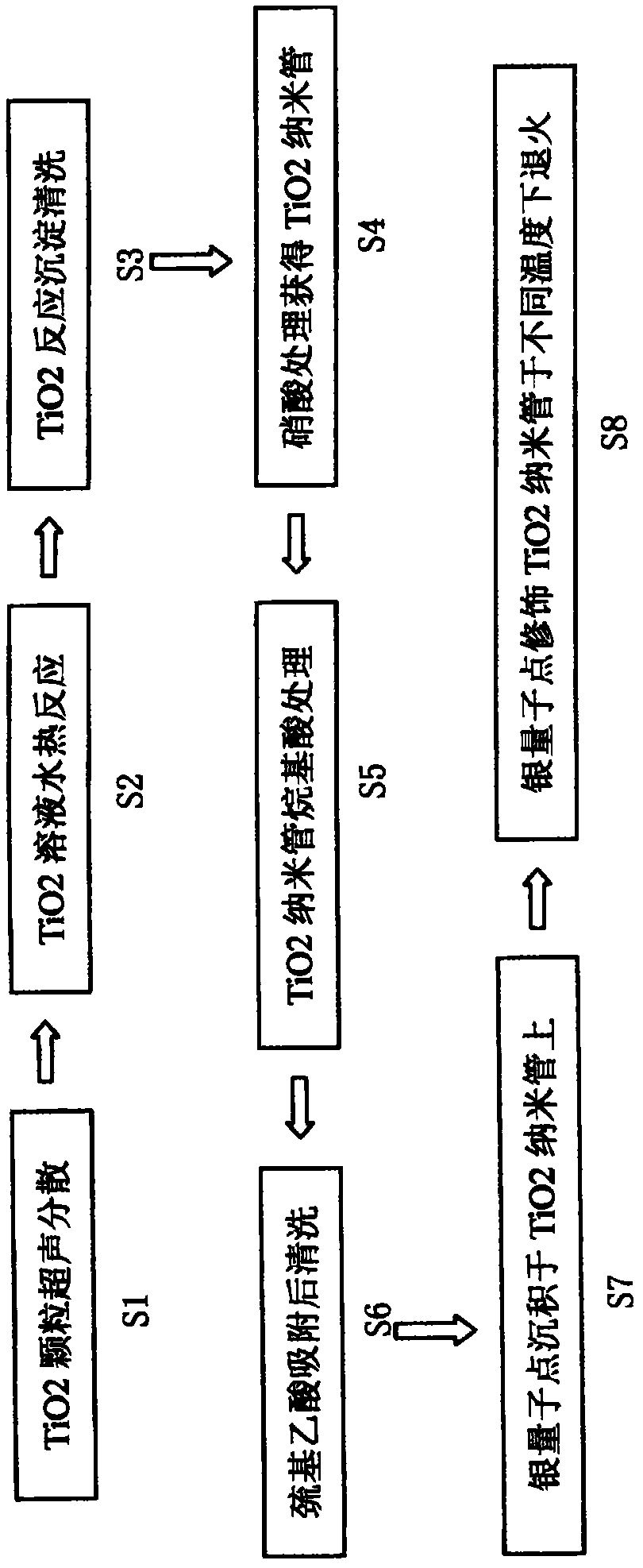

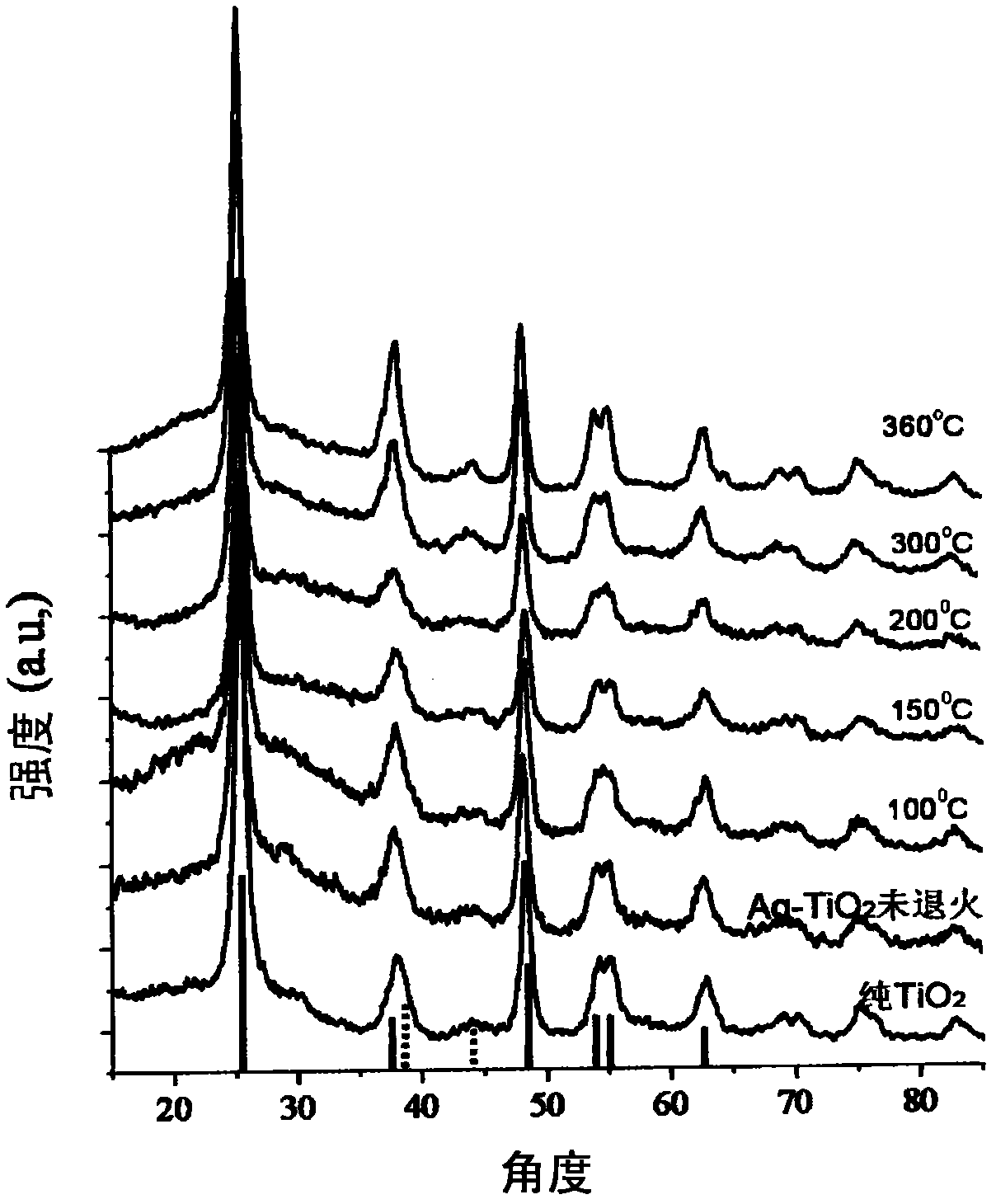

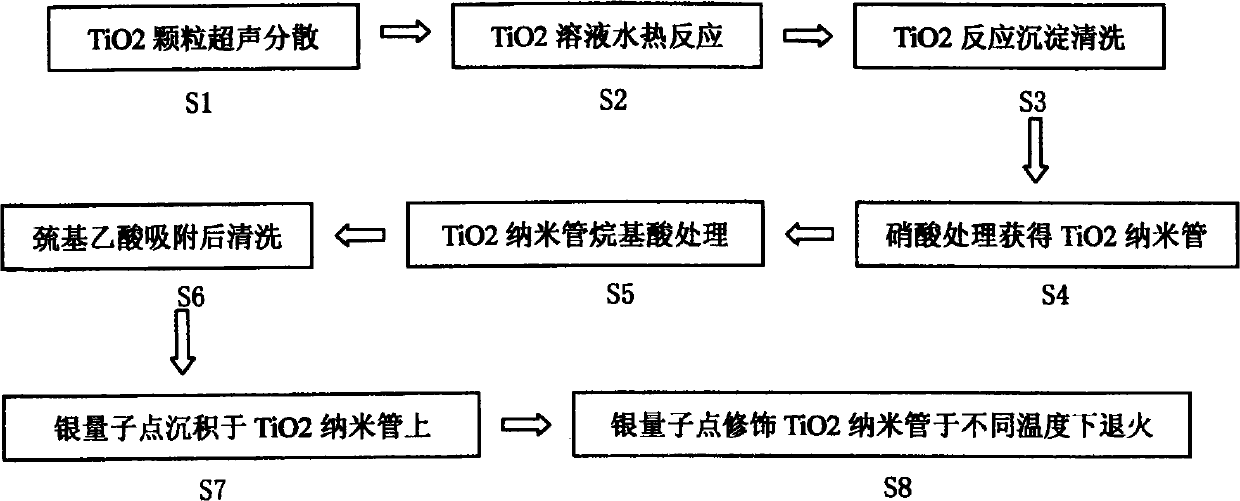

Preparation method of TiO2 nanotubes modified by silver nanoparticles with different particle diameters

InactiveCN101906662ATuning optoelectronic propertiesSimple processPolycrystalline material growthFrom normal temperature solutionsTio2 nanotubeOrganic solvent

The invention relates to a preparation method of TiO2 nanotubes modified by silver nanoparticles with different particle diameters, comprising the following steps of: ultrasonically dispersing spherical TiO2 particles into a sodium hydroxide water solution; increasing the temperature of the sodium hydroxide water solution of TiO2 to 150 DEG C, making the sodium hydroxide water solution react with the TiO2 for 24 hours, and then naturally cooling; centrifuging the cooled sodium hydroxide water solution of the TiO2; dispersing the TiO2 cleaned and precipitated to be neutral into a salpeter solution of 0.1 mol / L to obtain the TiO2 nanotubes; dispersing the prepared TiO2 nanotubes into an organic solvent; adding an adsorbent to the organic solvent containing the TiO2 nanotubes; dispersing obtained yellowish TiO2 nanotube particles into the organic solvent, and dropwise adding an AgNO3 solution; annealing obtained TiO2 nanotube particles modified by silver quantum dots at different temperature in an inert atmosphere so that the silver quantum dots positioned on the surface of the TiO2 and in the TiO2 grow in a curing way; and cooling to obtain various TiO2 nanotubes modified by the silver nanoparticles with different particle diameters.

Owner:南京鼎科纳米技术研究所有限公司

Surface grafting modification process for waste tire rubber powder for asphalt modification

InactiveCN104672393AImprove performance and stabilityEasy to operateBuilding insulationsWaste tiresDuctility

The invention relates to a surface grafting modification process for waste tire rubber powder for asphalt modification. The surface grafting modification process specifically comprises the following steps: dispersing waste tire rubber powder in water, adding a certain amount of benzoyl peroxide and styrene, and stirring for 1-12 hours at constant temperature at 80-120 DEG C, wherein benzoyl peroxide accounts for 1.7-10% of the mass of the rubber powder, and styrene accounts for 1-30% of the mass of the rubber powder. When the grafted rubber powder is adopted as an asphalt modifier for preparing rubber powder modified asphalt by using a wet method modification process, the property of the modified asphalt can be conditioned and controlled. The surface grafting modification process is simple to operate and low in cost, and main properties such as the needle penetration degree, the ductility, the softening point and the like of the rubber powder modified asphalt can be effectively conditioned and controlled.

Owner:NANKAI UNIV

Method for recycling waste offset printing ink of mix of various colors

InactiveCN103342916AFull reuseImprove suitabilityColor measuring devicesInksResource savingEngineering

The invention discloses a method for recycling waste offset printing ink of a mixture of various colors. At present, burning and covering treatment are adopted for the large amount of waste ink of a mixture of various colors, and thus pollution is caused to the environment. The method comprises the following steps: filtering and distilling the waste ink of a mix of various colors and then performing first grinding to mill the ink; measuring the color and the using amount of a complementary color ink; mixing the mixed ink with the complementary color ink, a carbon black pigment, varnish and a drier and performing second grinding to mill the ink so as to obtain prepared black ink; measuring the color difference and the density variation between the prepared black ink and solid black ink on a standard color card and comparing with the same-batch same-color color difference value and the same-color density deviation value in GB / T7705-2008 solid printing requirements; repeating the operation of the steps (4) to (7) if the requirements are not met, until the conditions are met. The method has the advantages of adoption of common equipment, simple process, capability of realizing recycling of the waste ink, contribution to environmental protection and resource saving.

Owner:HANGZHOU DIANZI UNIV

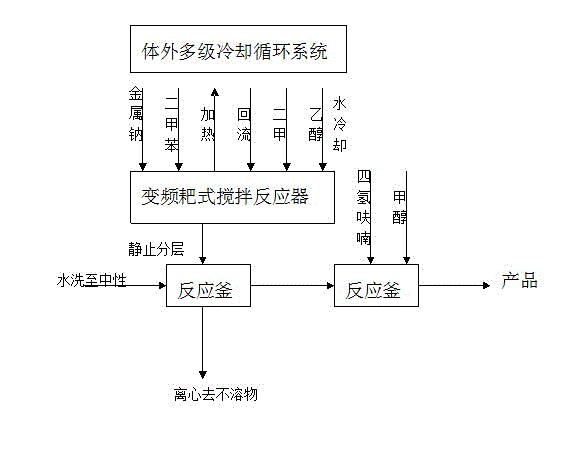

New process for industrialized production of ultralow-oxygen narrow-MWD (Molecular Weight Distribution) polydimethylsilane

The invention provides a new process for industrialized production of ultralow-oxygen narrow-MWD (Molecular Weight Distribution) polydimethylsilane. The ultralow-oxygen narrow-MWD polydimethylsilane is synthesized by adopting a Wurtz method. The new process comprises the following processing steps of: firstly drying a solvent required for reaction, carrying out secondary rectification for dimethyl dichlorosilane in advance to improve the purity of dimethyl dichlorosilane, installing a temperature and humidity controller in a factory to ensure that the environmental humidity is below 40%, and the like, so that the oxygen content in produced polydimethylsilane is minimized (only 0.1%), the polydimethylsilane can reach the product performance of developed countries, and more qualified silicon carbide ceramic fiber can be prepared; an external multi-stage cooling circulatory system is adopted to timely discharge heat released in the Wurtz synthesis method so as to guarantee safe and smooth industrial production; a reactor has the dual advantages of the stability of glass and metal strength, thus being excellent corrosion-resistant equipment, fully meeting the requirements of the Wurtz method, and realizing the industrialized application of the Wurtz coupling method to synthesizing polydimethylsilane.

Owner:江西星火狮达科技有限公司

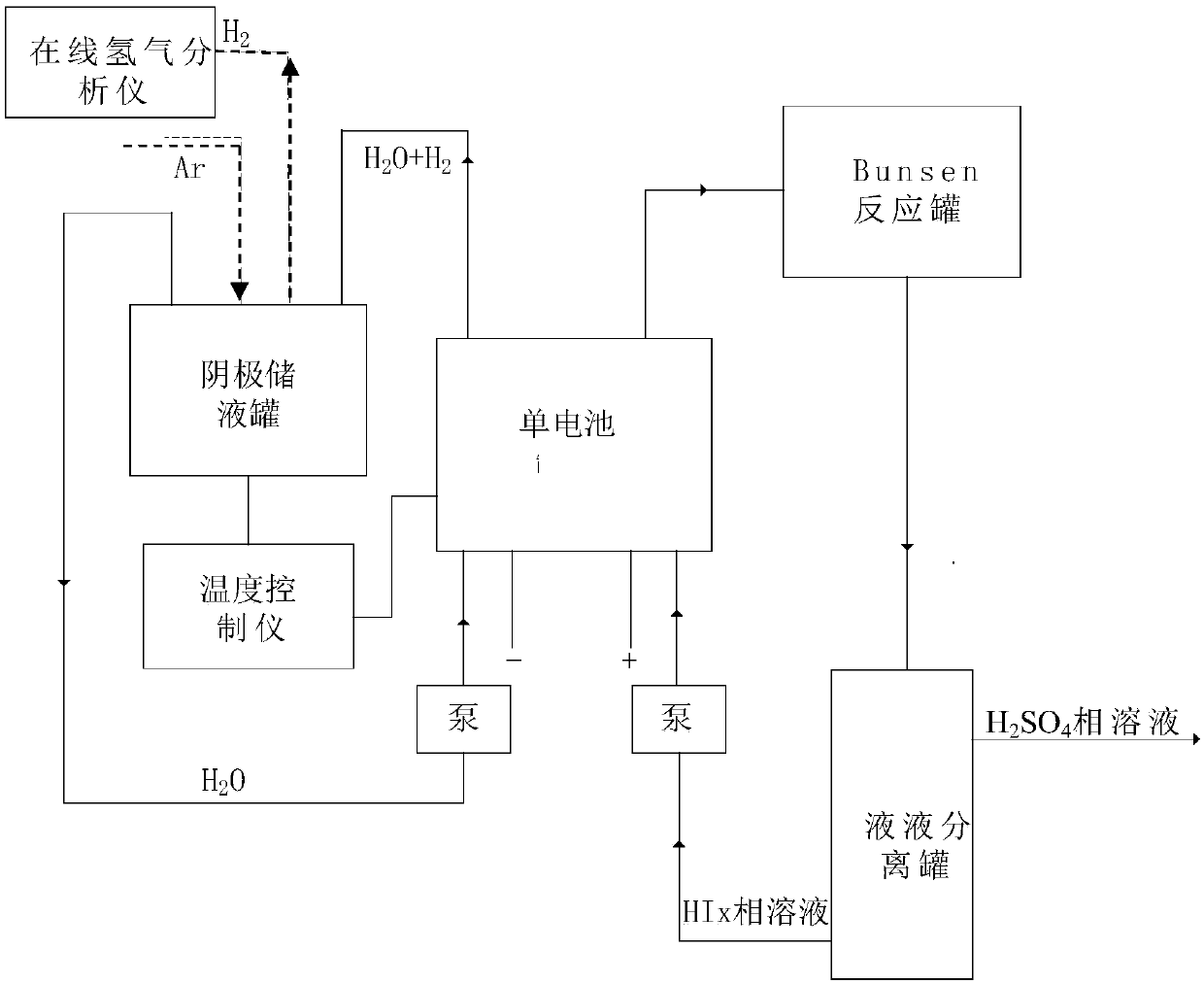

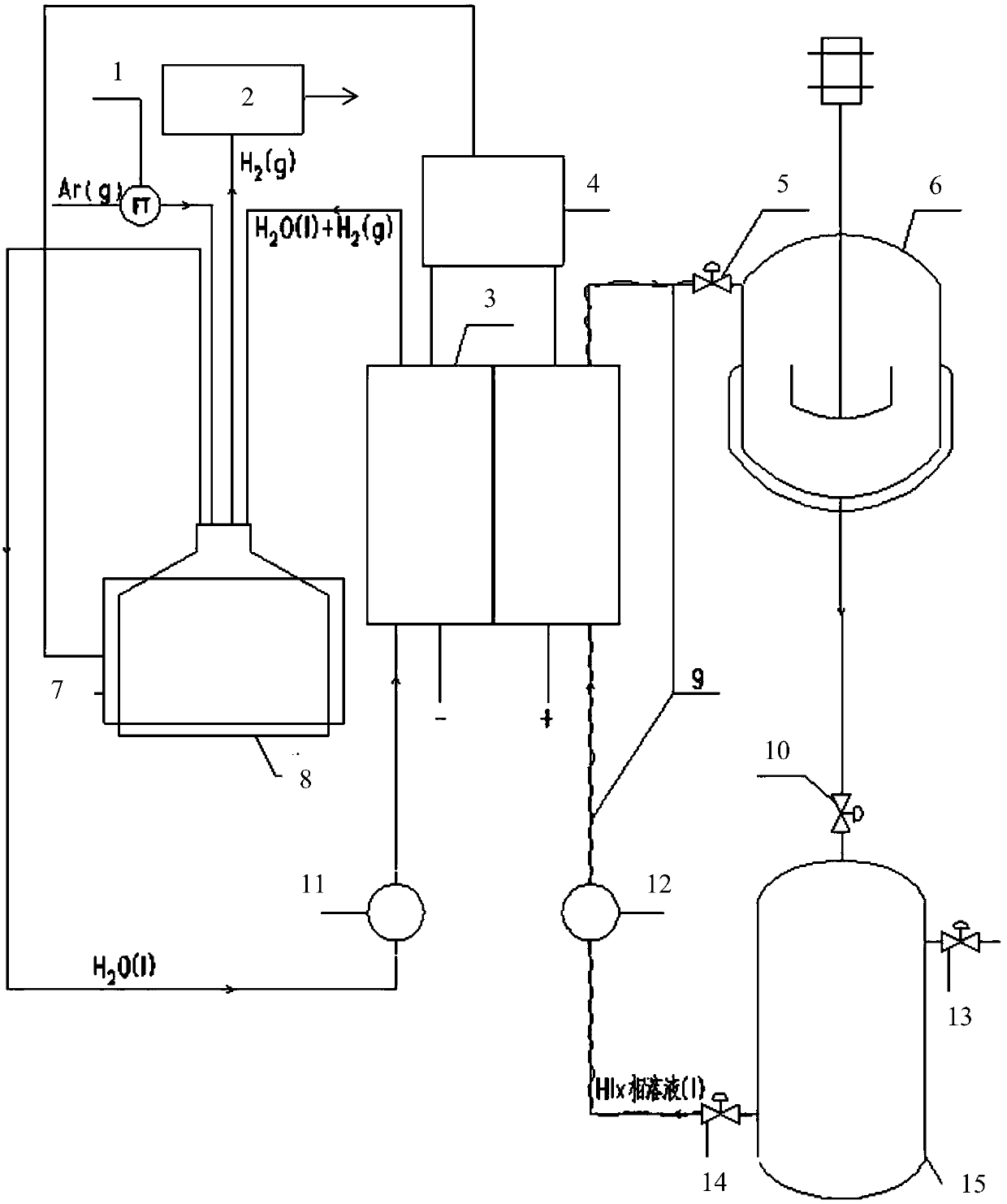

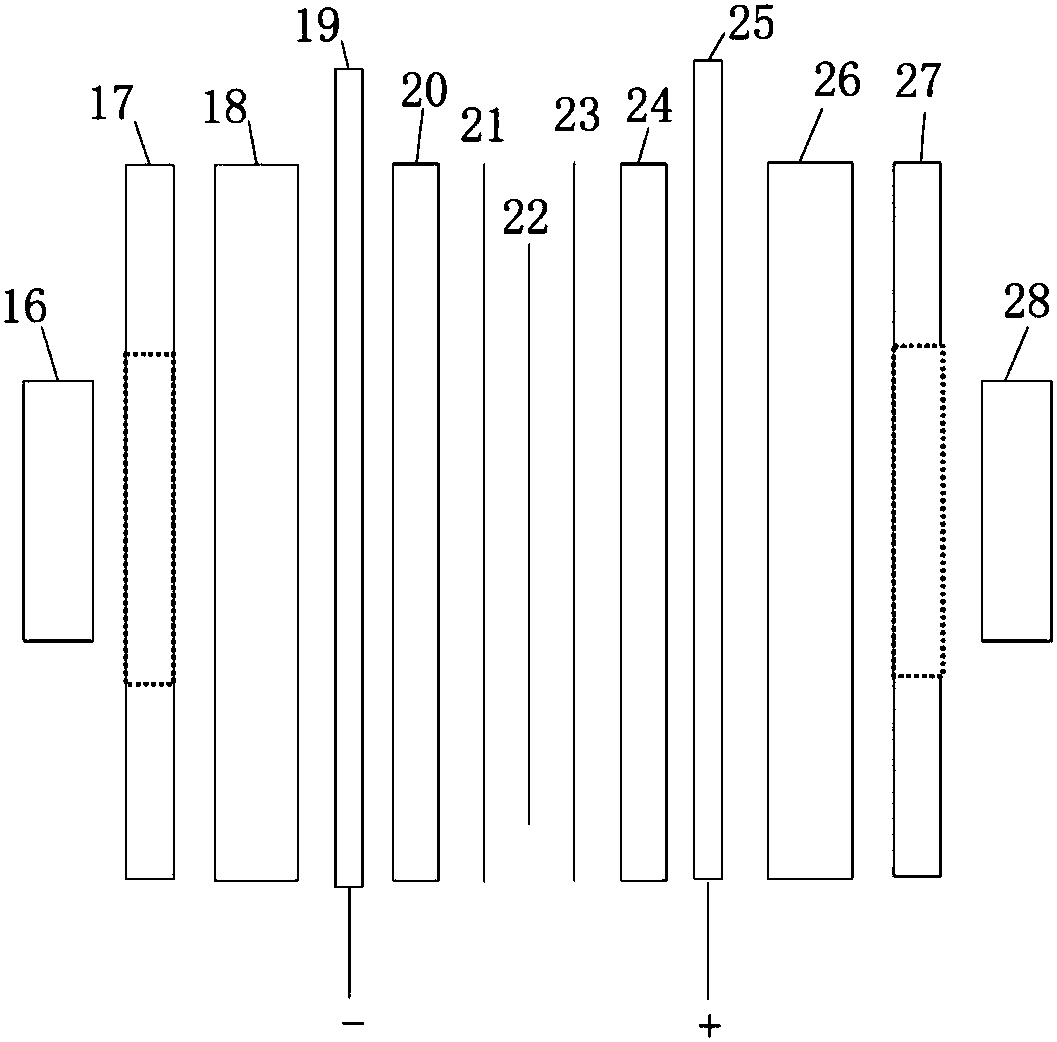

Hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and device

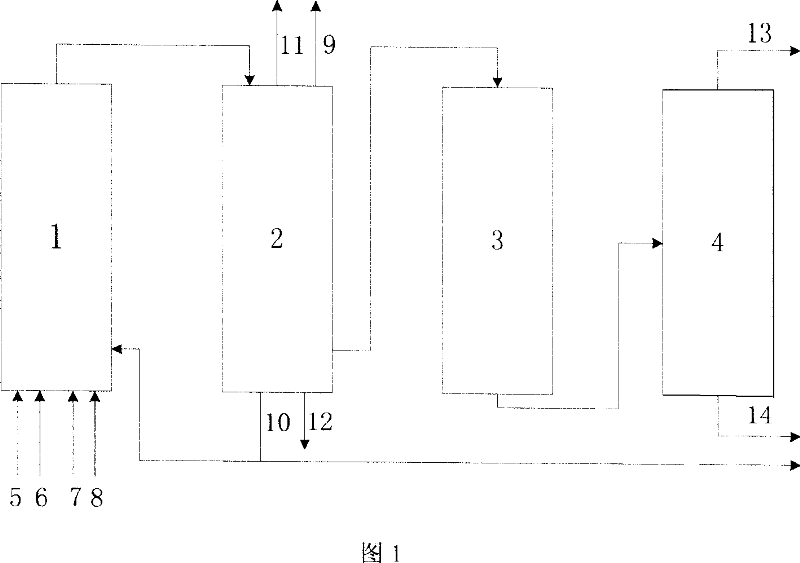

ActiveCN107904617AOmit enrichmentEliminate the distillation processCellsDiaphragmsElectrolysisDistillation

The invention relates to the technology of sulphur and iodine circulation hydrogen production, and particularly provides a hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production and a device. The method includes the steps that a monocell is used as a reactor, the monocell has anode graphite electrode and cathode graphite electrode, and a proton exchange membrane is used as a diaphragm; HIx homogeneous solution in the sulphur and iodine circulation hydrogen production system is injected into the anode side, and deionized water is injected into the cathode side; power supply is turned on to carry out decomposition reaction, I- of the anode side HIx homogeneous solution is oxidized to I2, and generated H+ passes through proton exchange membrane to reach the cathode side and is reduced to hydrogen; HIx homogeneous solution of the anode side enters a Bunsen reactor to be Bunsen reaction raw material in a circulating modeafter electrolytic reaction, and hydrogen generated from cathode side is sent out. According to the hydrogen production method adopting electrochemistry to disintegrate HI in sulphur and iodine circulation hydrogen production, an HIx solution is directly decomposed adopting electrochemistry method, the original process of concentration and distillation is omitted, and the process and the device are greatly simplified. Hydrogen is generated from cathode, and the separation problem with HI gas does not need to be considered.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com