Preparation method of TiO2 nanotubes modified by silver nanoparticles with different particle diameters

A technology of silver nanoparticles and nanotubes, which is applied in the field of nanomaterials, can solve problems such as unfavorable industrialization, complexity, and cumbersome nanotube process, and achieve the effects of clean raw materials, high output, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

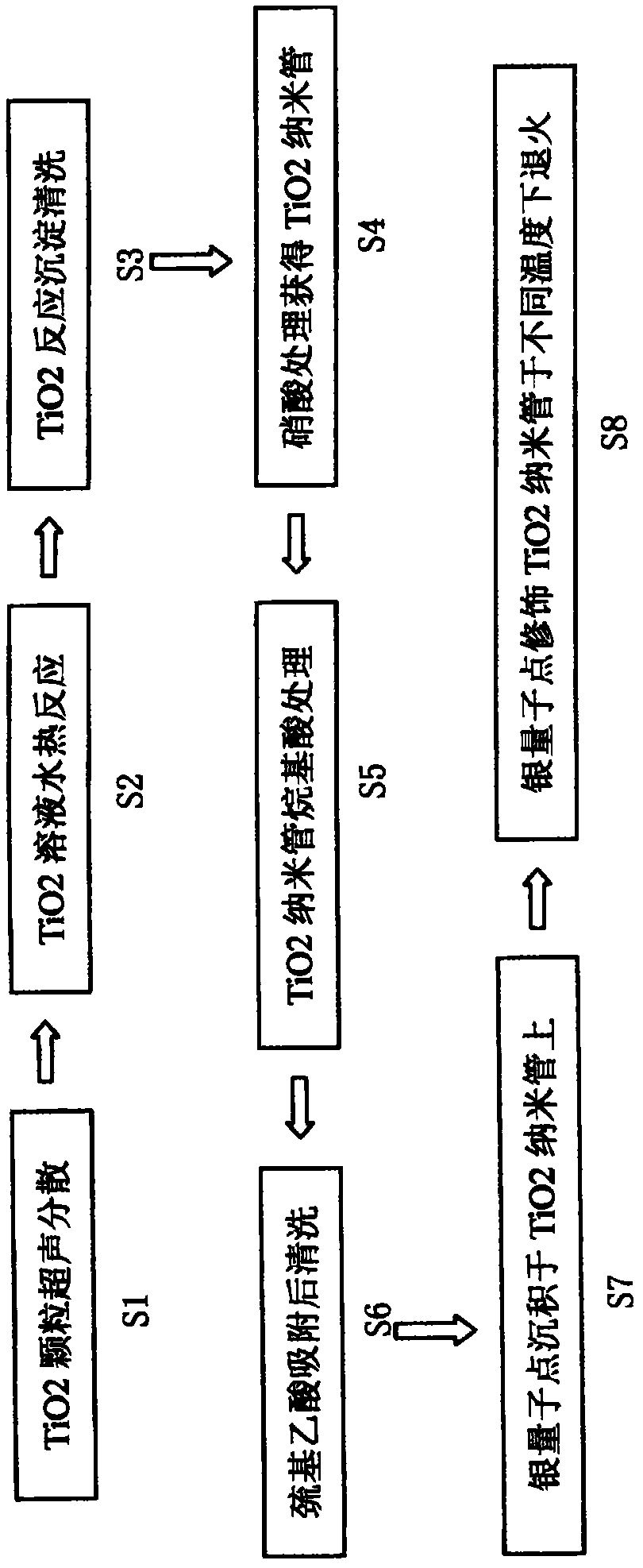

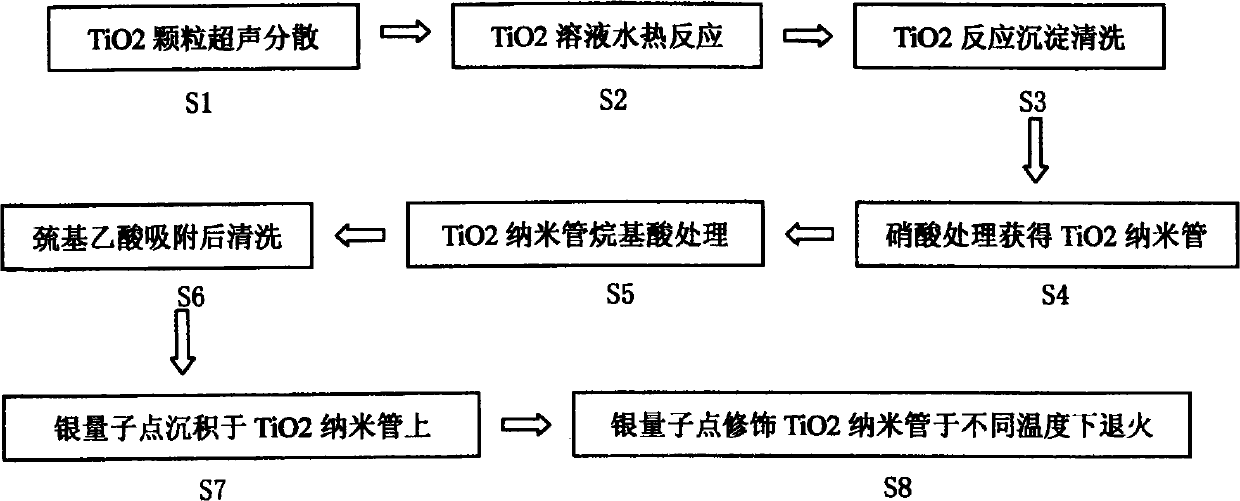

[0027] see figure 1 As shown, the present invention provides a kind of silver nanoparticles modified TiO with different particle sizes 2 A method for preparing nanotubes, comprising the steps of:

[0028] Step 1: Add TiO 2 Spherical particles were ultrasonically dispersed in aqueous sodium hydroxide solution, the TiO 2 The weight of spherical particles is 0.15-2.0g;

[0029] Step 2: Add TiO 2 The sodium hydroxide solution is warmed up to 150 degrees and reacts naturally after 24 hours;

[0030] Step 3: The cooled TiO 2 The sodium hydroxide solution was centrifuged, and the precipitate was washed with deionized water until neutral;

[0031] Step 4: Then precipitate the wash to neutral TiO 2 Disperse in 0.1mol / L nitric acid solution, centrifuge after magnetic stirring, and wash the precipitate with deionized water again until neutral to obtain TiO 2 nanotube;

[0032] Step 5: The prepared TiO 2 The nanotubes are dispersed in an organic solvent, adding a macromolecular ...

Embodiment

[0038] The following is an example of preparing silver nanoparticles modified titanium dioxide nanotubes with different sizes by the method provided by the present invention.

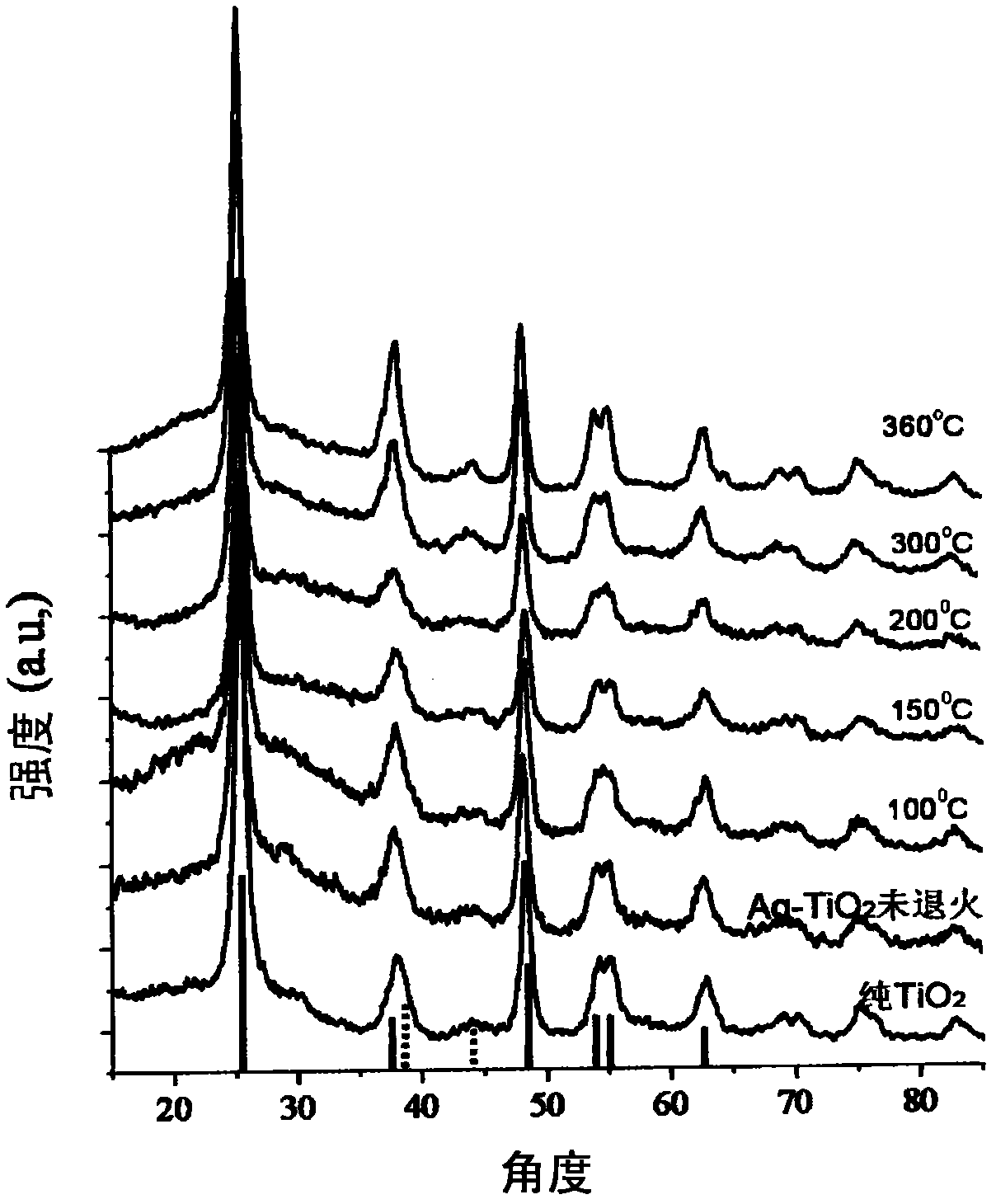

[0039] TiO was first prepared by hydrothermal method 2 nanotube. 0.15g of TiO with a diameter of 21nm 2 Ultrasonic dispersion of nanoparticles (kq2200b ultrasonic cleaner, 600w, 25°C) in 0.1mol / L sodium hydroxide (NaOH) aqueous solution. Take 80ml of this aqueous solution, fill it in a stainless steel reaction kettle with a volume of 100ml, heat up to 150°C and react for 24 hours, then naturally cool to room temperature, centrifuge the obtained precipitate at a speed of 6000rpm (rev / min), remove the supernatant clear night, and wash with deionized water Clean the white TiO at the bottom of the centrifuge tube 2 Precipitate to neutrality, then disperse in 0.1mol / L nitric acid solution, centrifuge under magnetic stirring at 300 revolutions per minute (rpm) for 1 hour, and wash the precipitate with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com