New process for industrialized production of ultralow-oxygen narrow-MWD (Molecular Weight Distribution) polydimethylsilane

A technology of polydimethylsilane and narrow molecular weight distribution, which is applied in the field of new industrial production process of polydimethylsilane with narrow molecular weight distribution in ultra-low oxygen, and can solve the problems of unsuitable industrial production, difficult control, and small synthesis scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

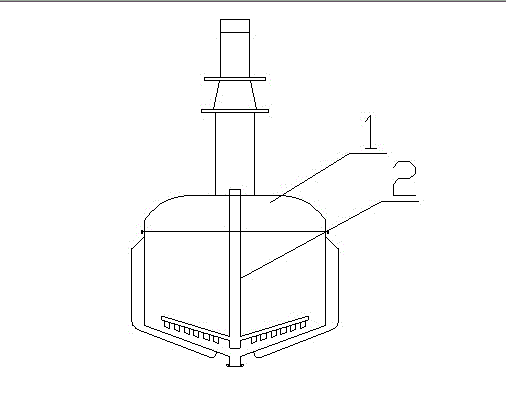

[0013] The technical content of the present invention will be further described in conjunction with the accompanying drawings.

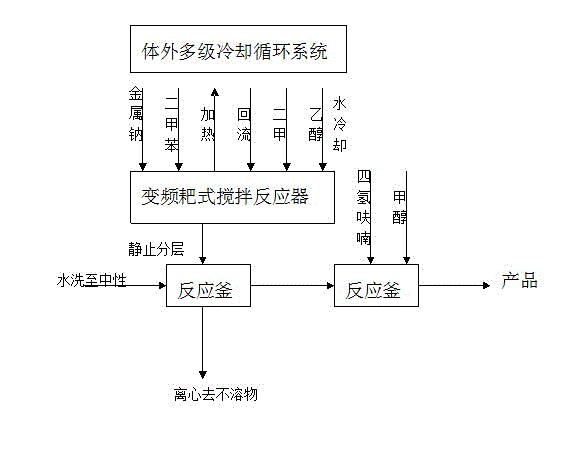

[0014] Such as figure 1 As shown, the new industrial production process of polydimethylsilane with ultra-low oxygen and narrow molecular weight distribution is synthesized by Wurtz method: 1. First, the used solvent xylene is dehydrated with anhydrous calcium chloride to reduce the water content to below 5ppm; 2. Add 1,000 kg of dewatered xylene into the frequency conversion rake reactor, then add 300 kg of metallic sodium, heat to 110°C, and start the high-speed stirring paddle to beat it into "sodium sand" after the sodium is melted, and reflux 24 hours to fully dry the solvent and remove harmful impurities; 3. Under the protection of inert gas, add pre-refined dimethyl dichlorosilane to the frequency conversion rake reactor for reaction, and open the external multi-stage cooling circulation system, The reactant turns from gray to purple. After re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com