Patents

Literature

330 results about "Dimethylsilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

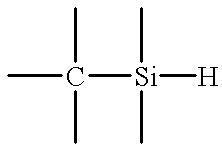

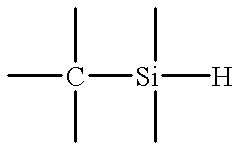

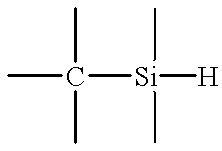

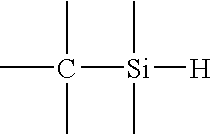

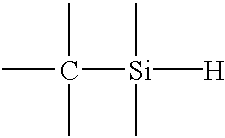

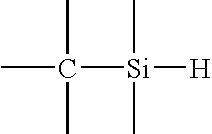

Dimethylsilane is a compound with the formula C₂H₈Si. It is flammable. It is used in chemical vapor deposition.

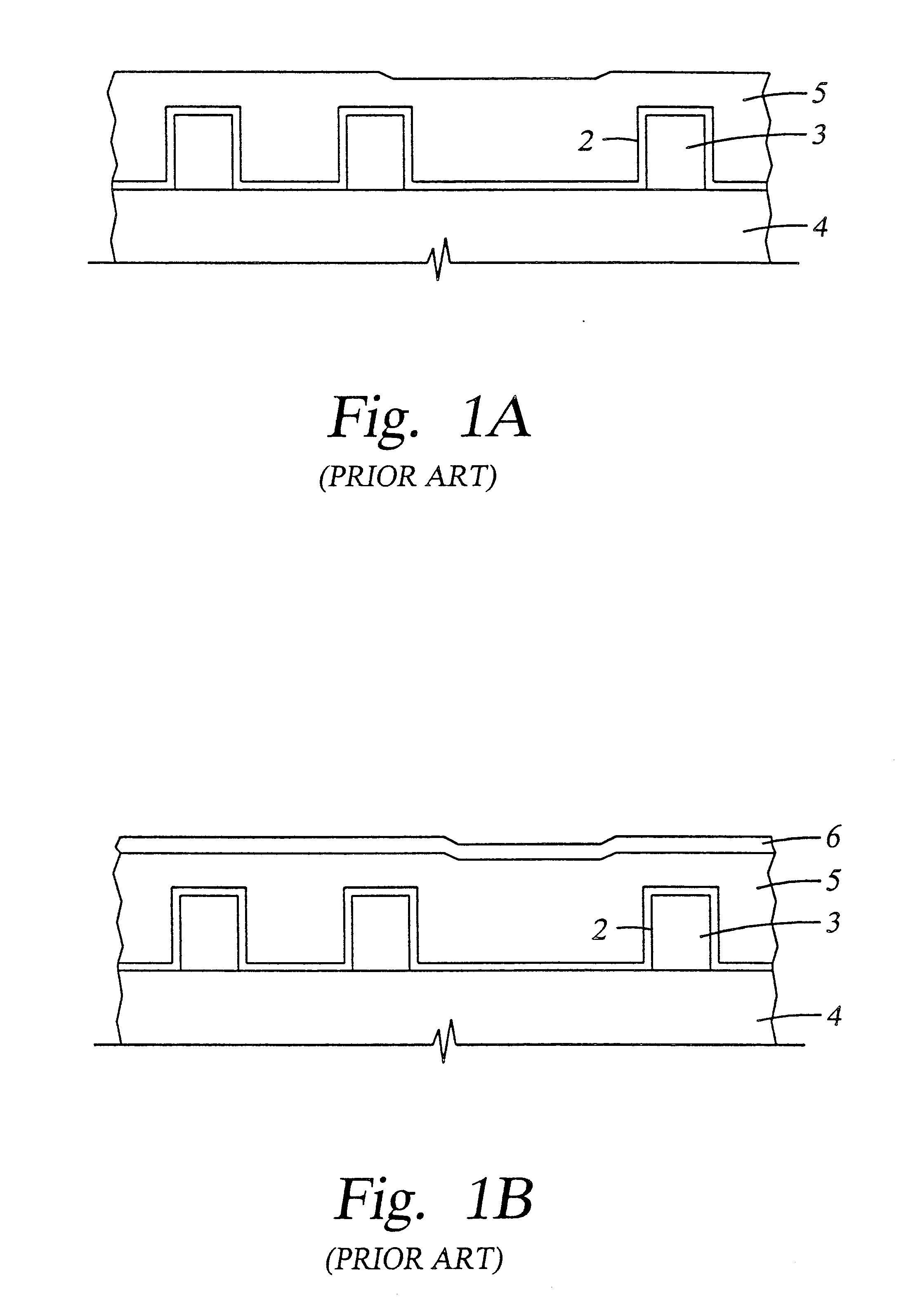

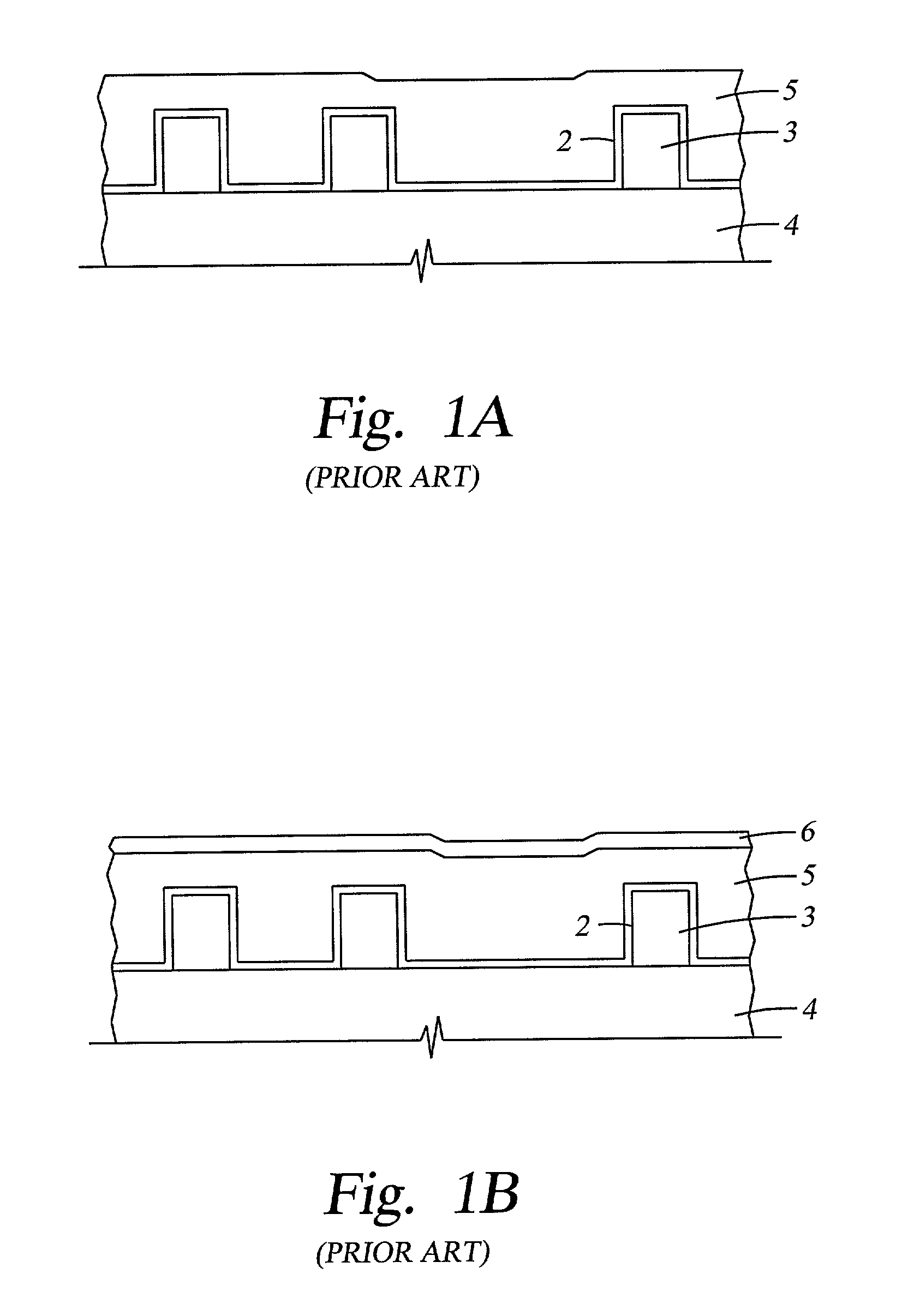

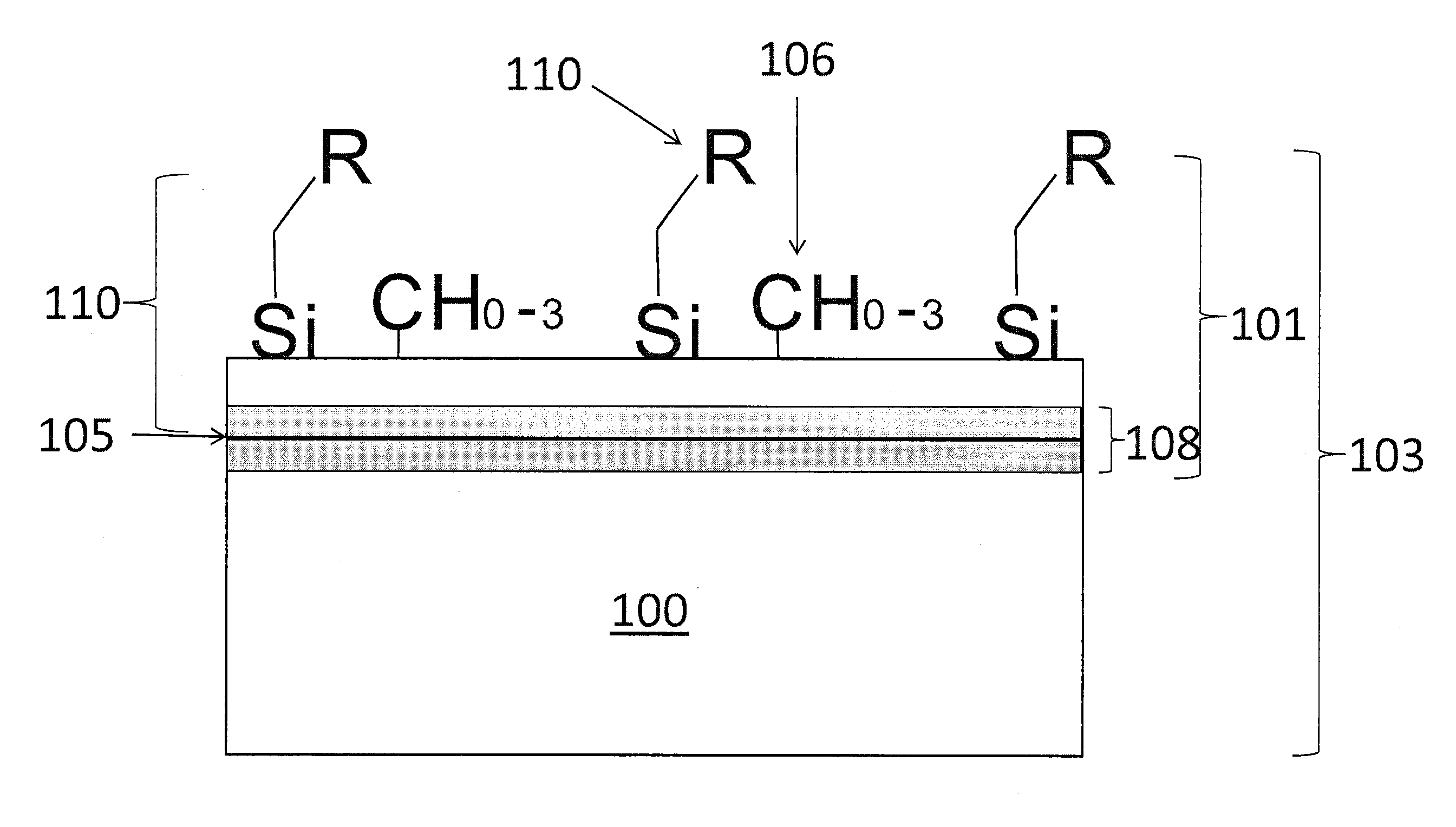

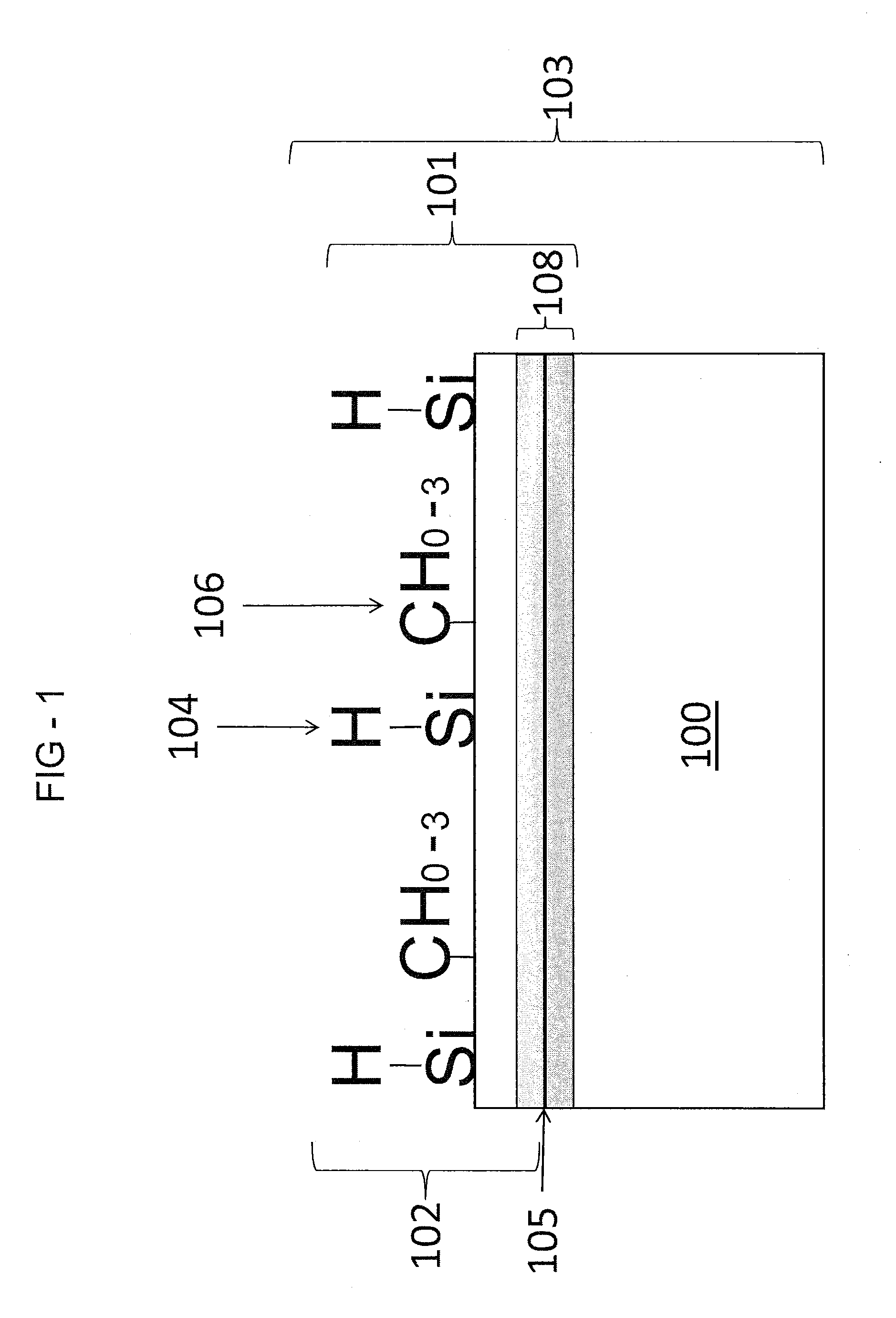

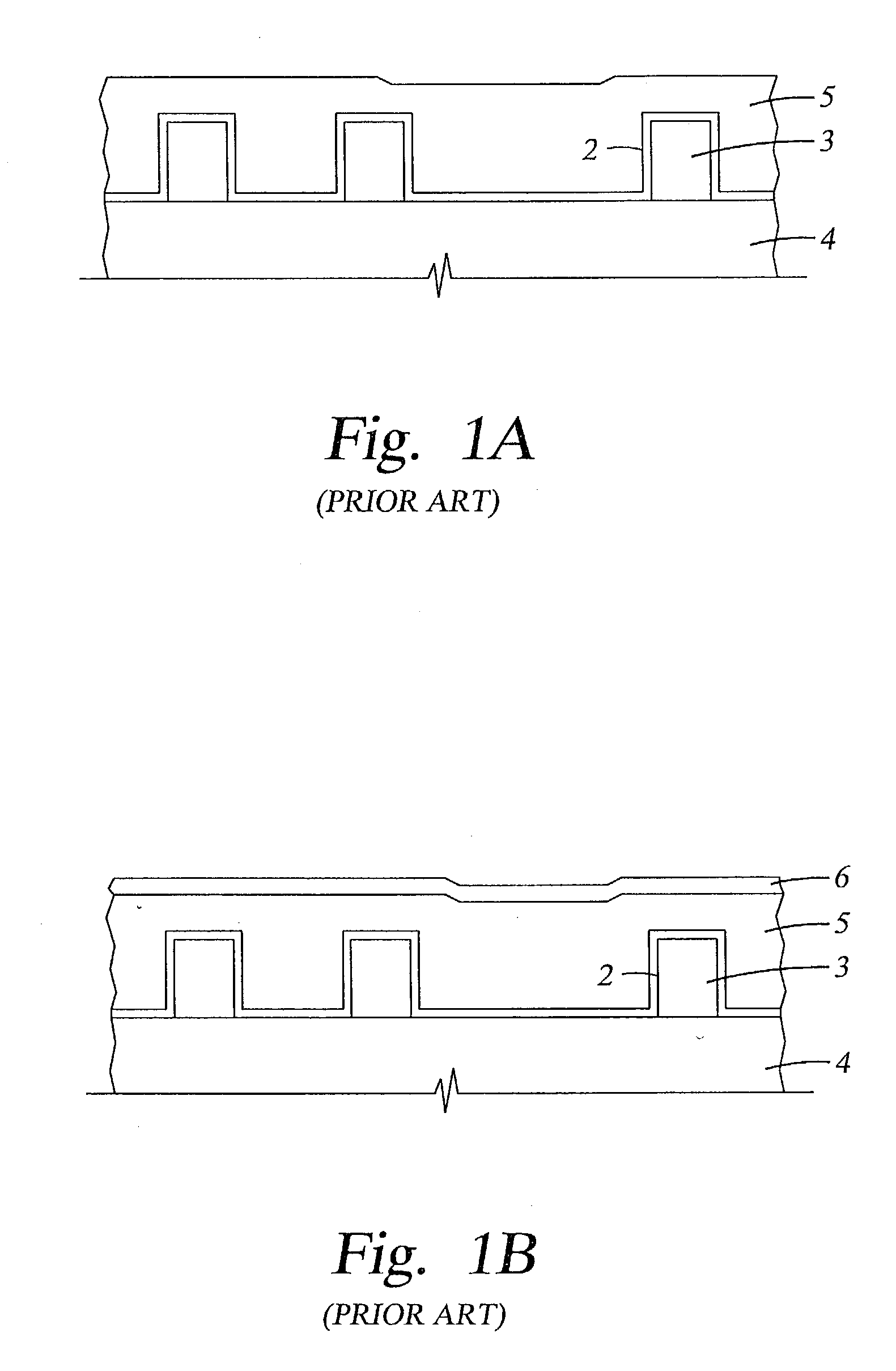

CVD plasma assisted low dielectric constant films

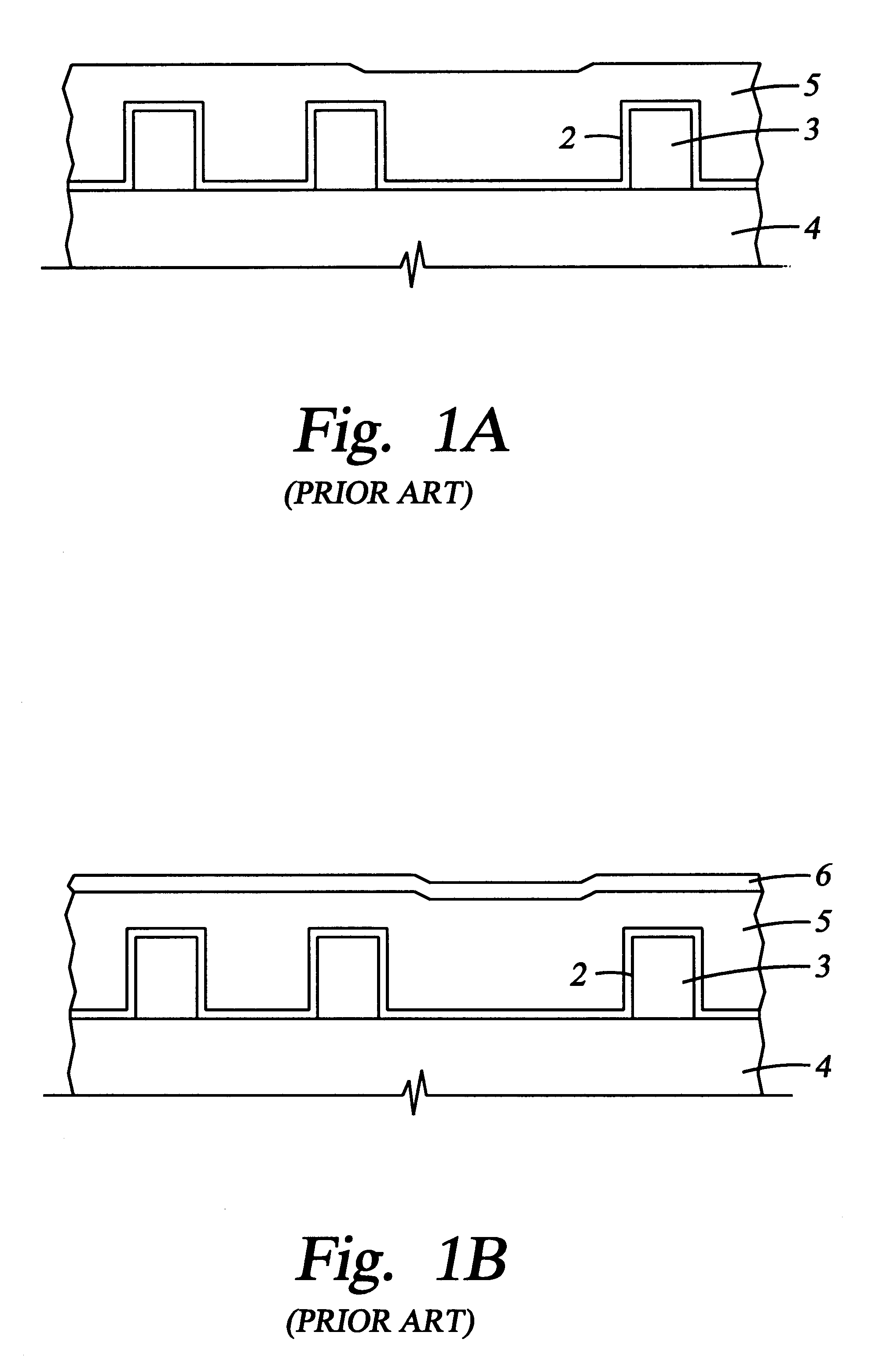

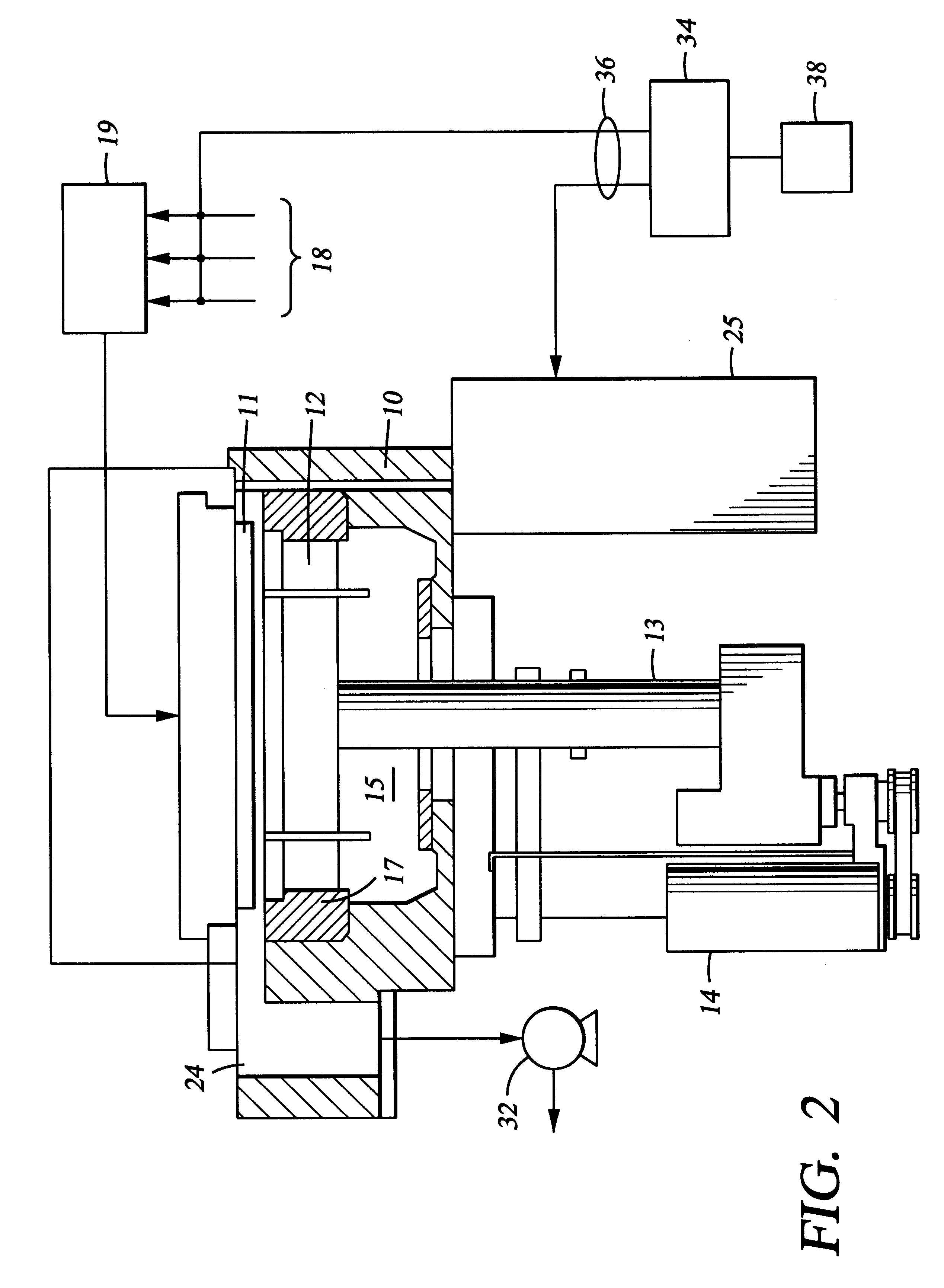

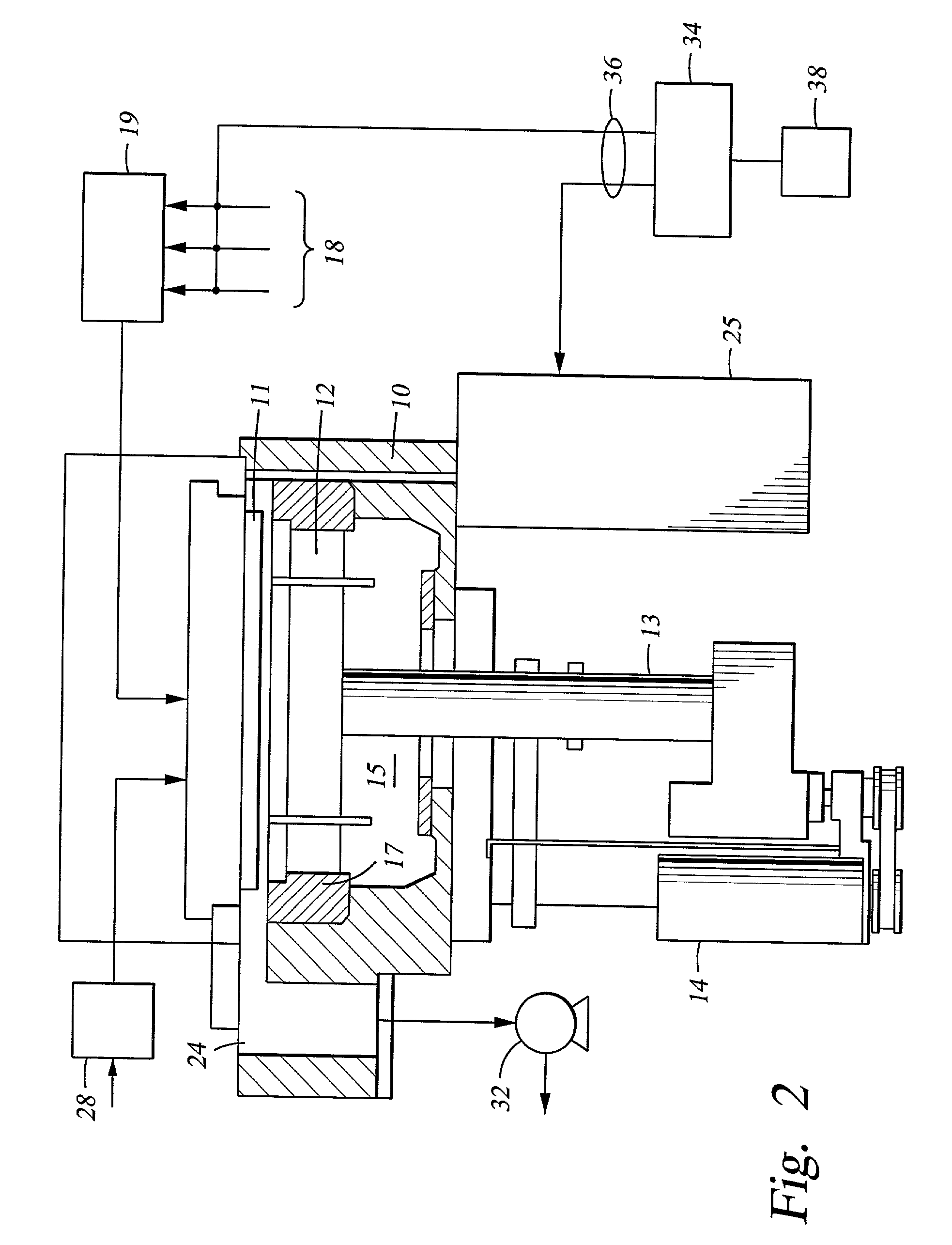

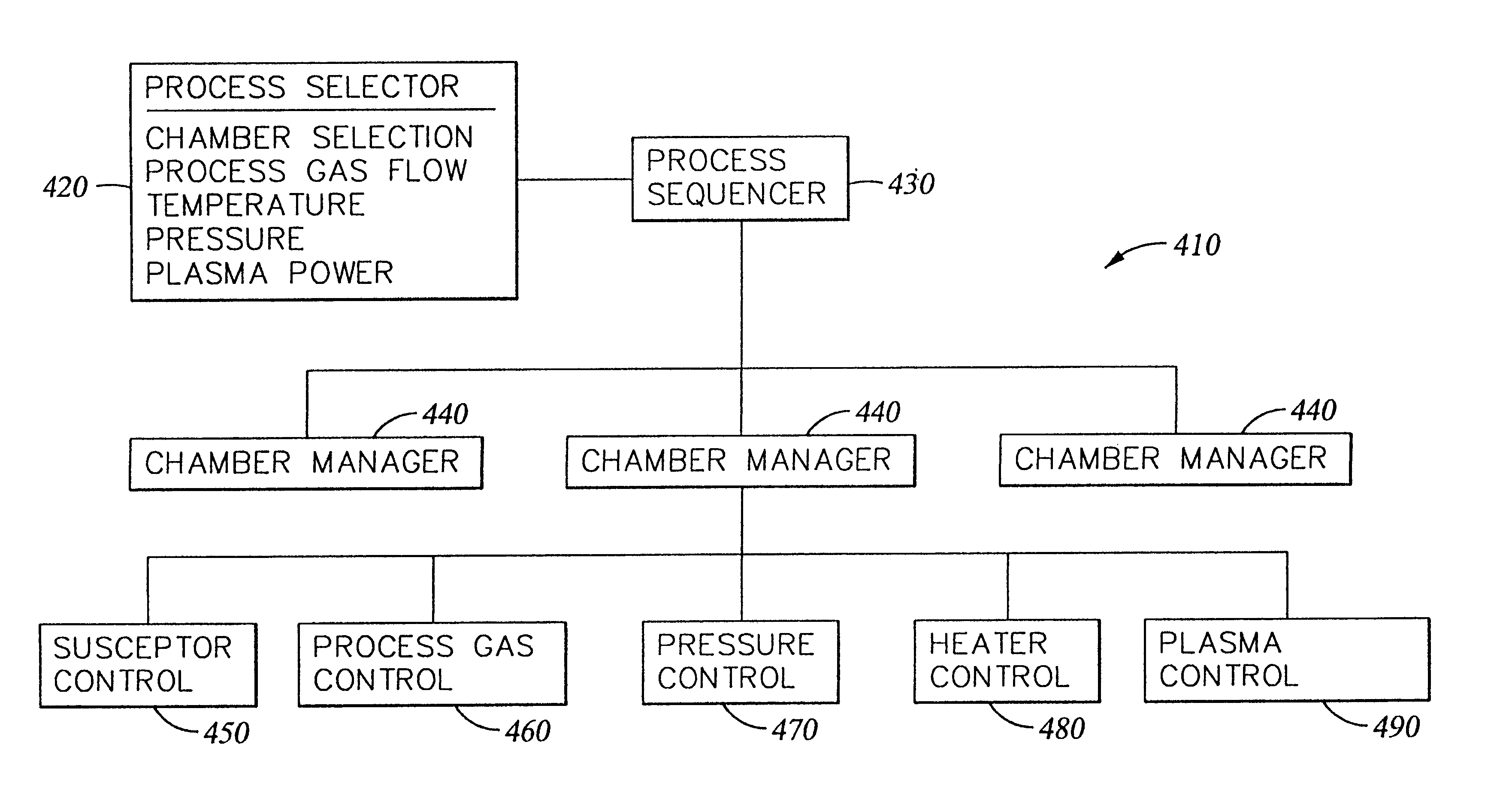

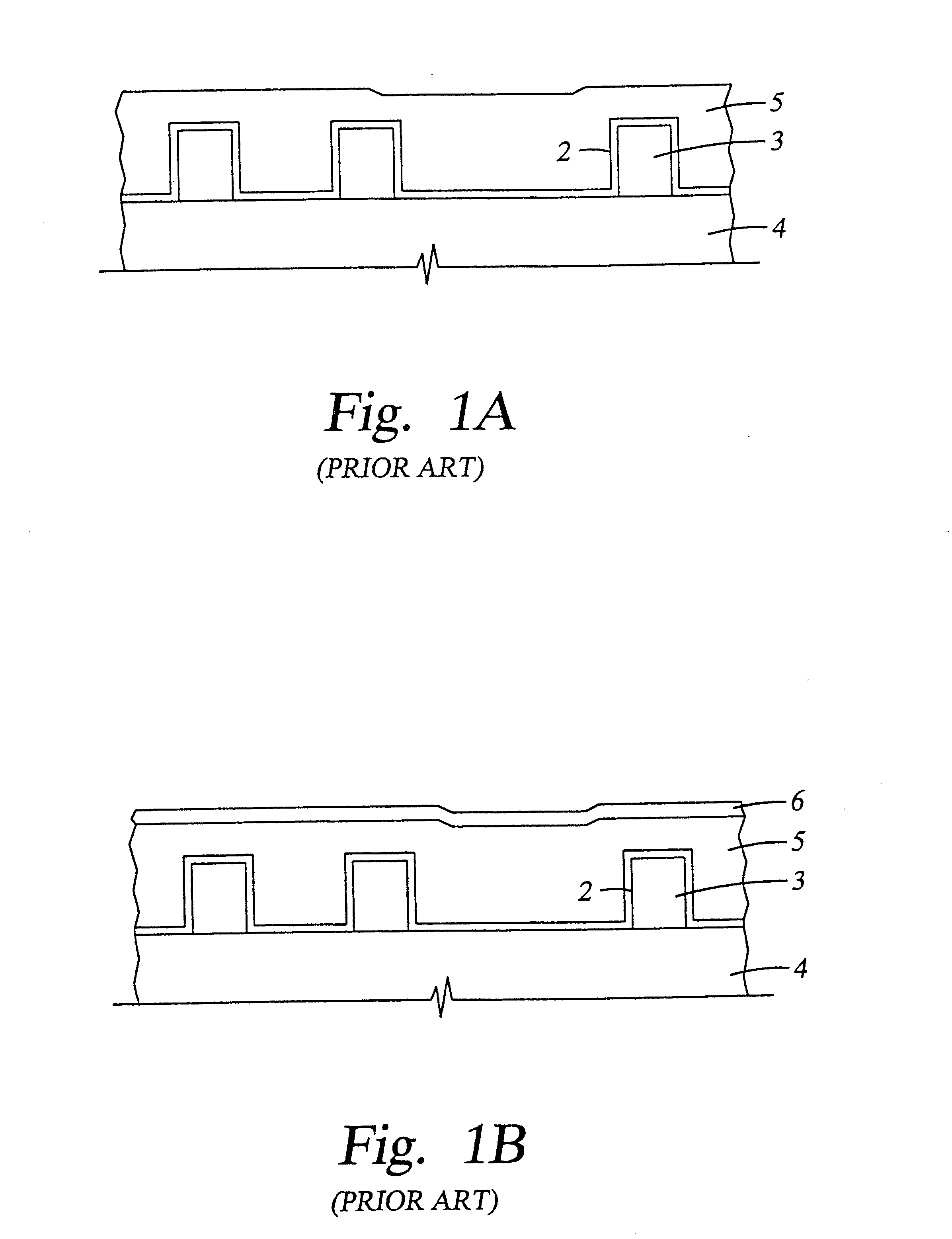

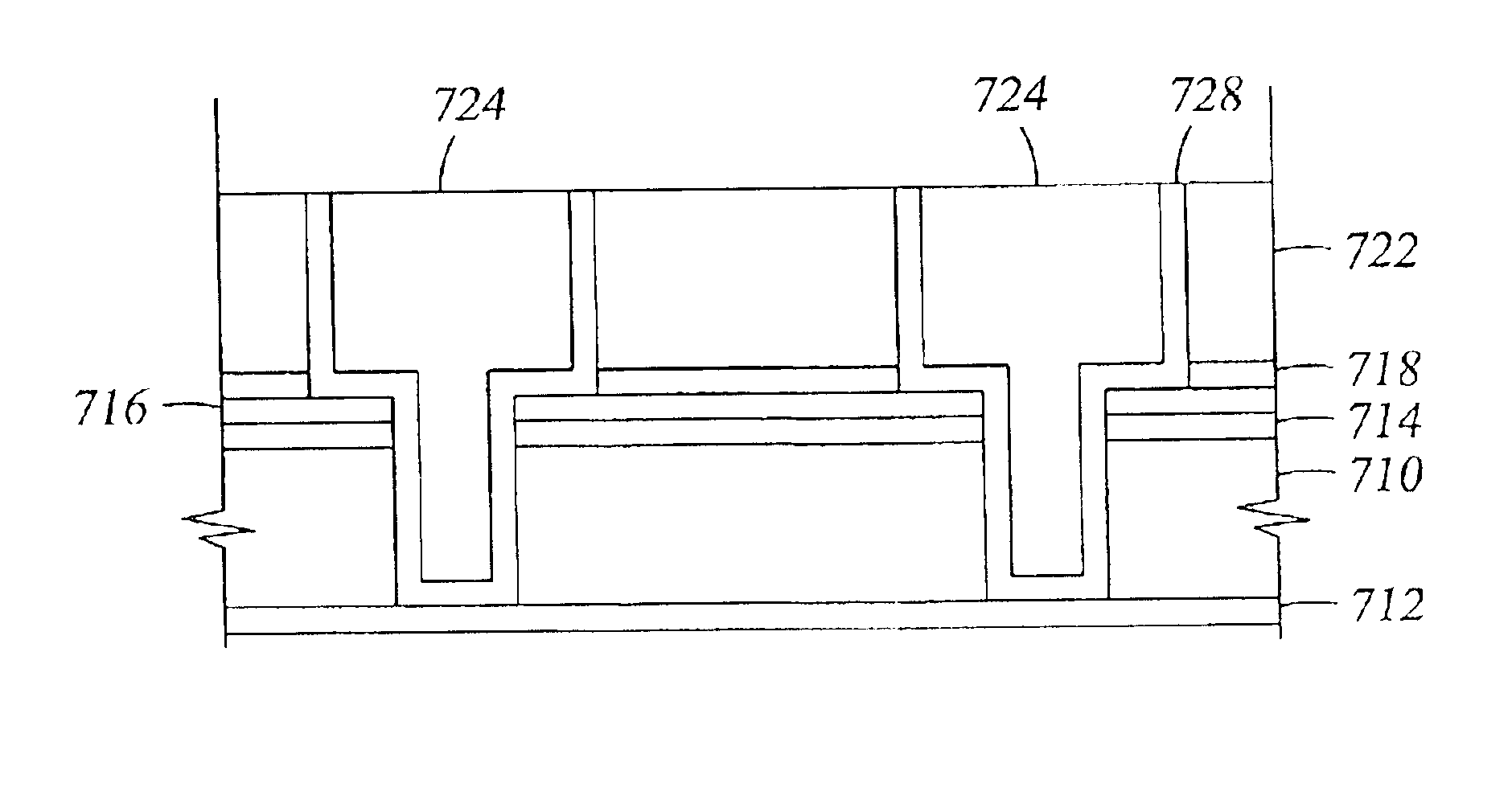

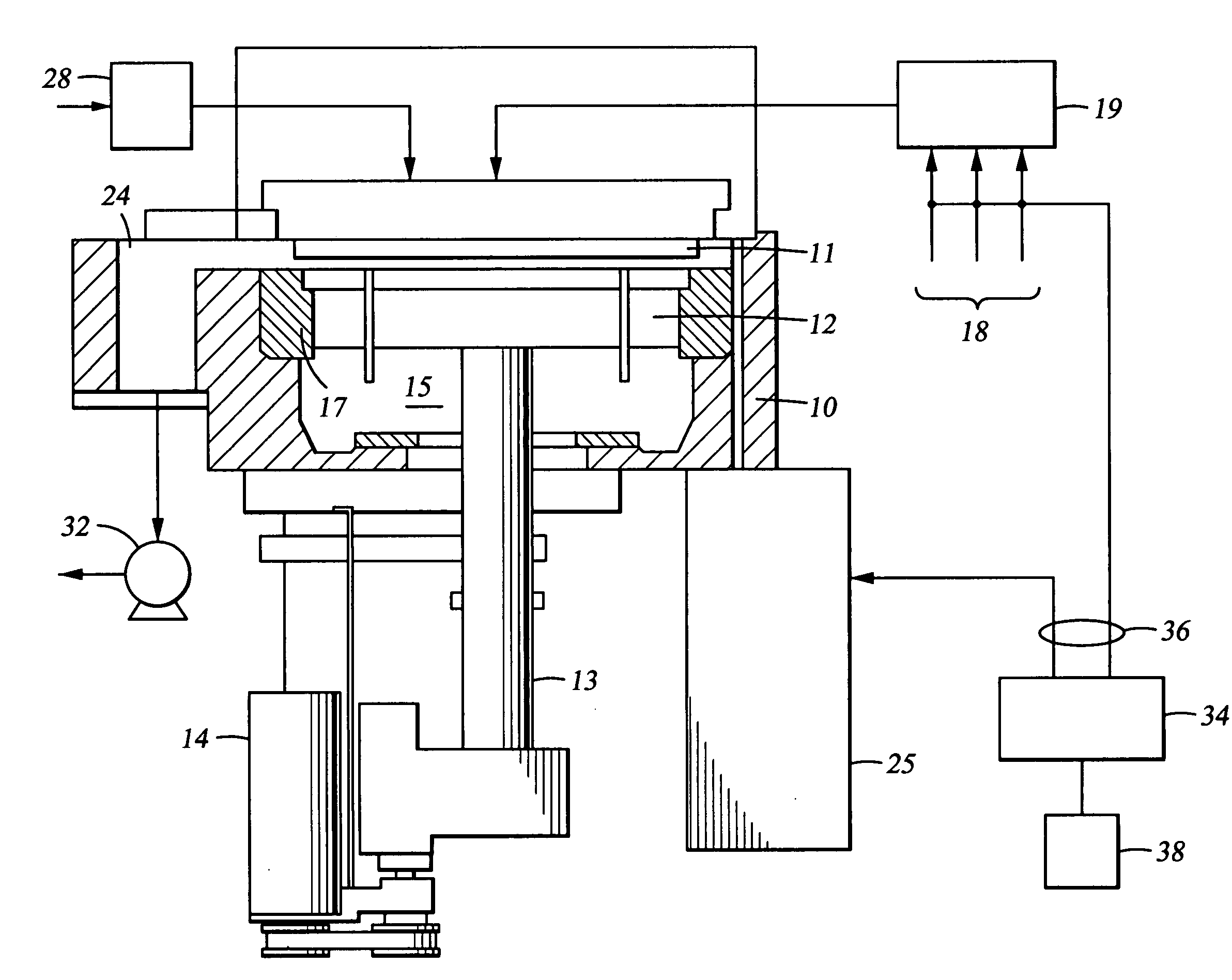

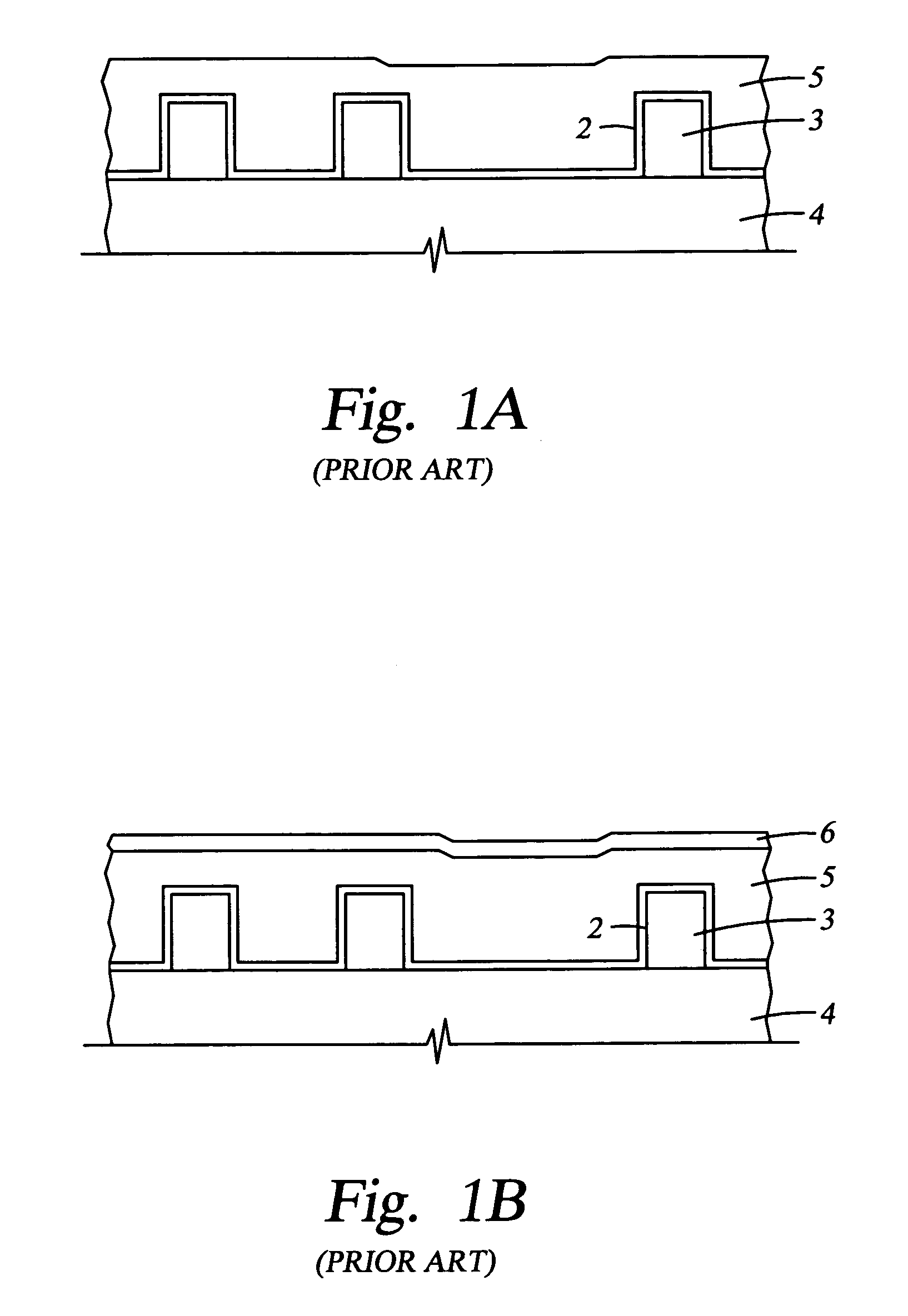

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

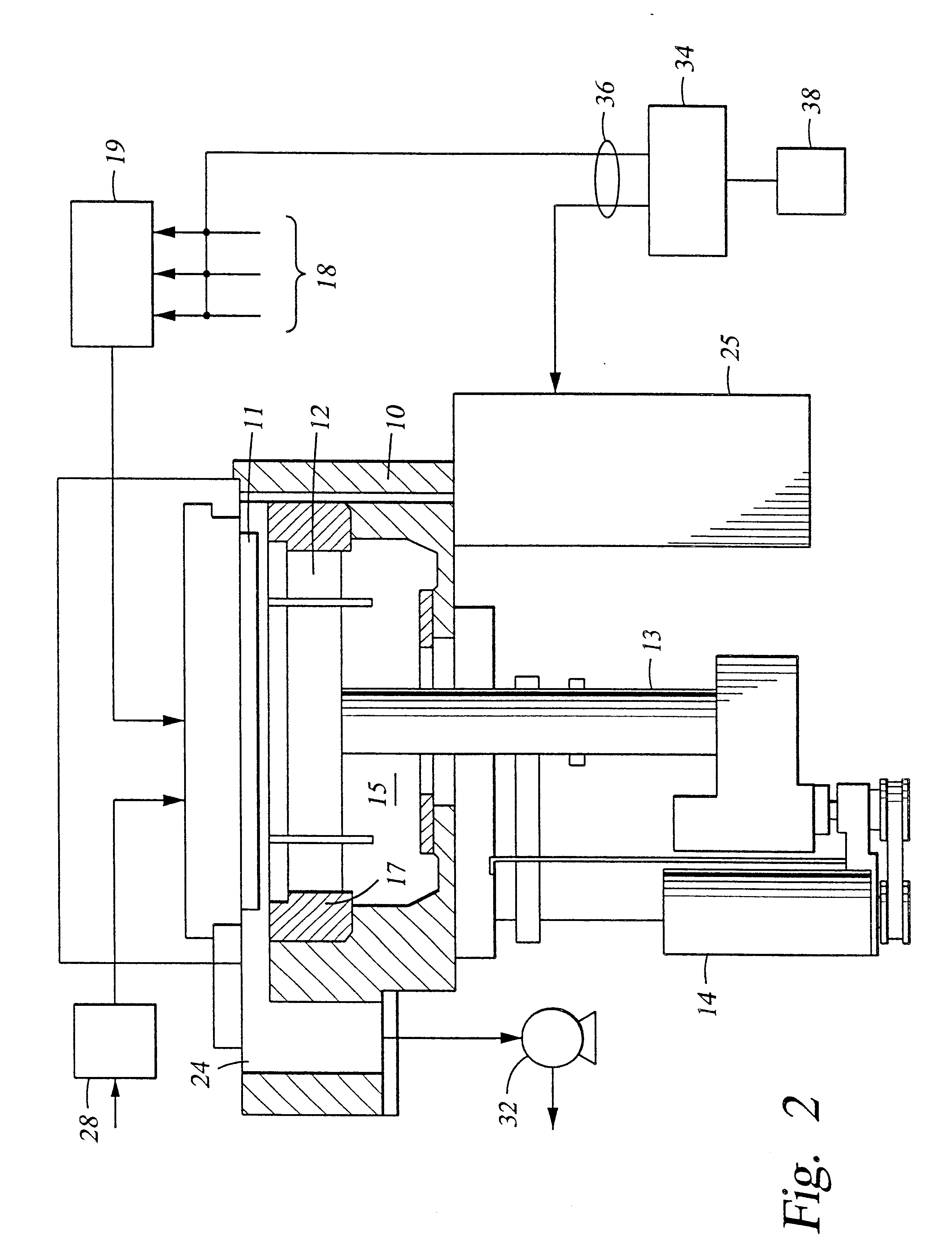

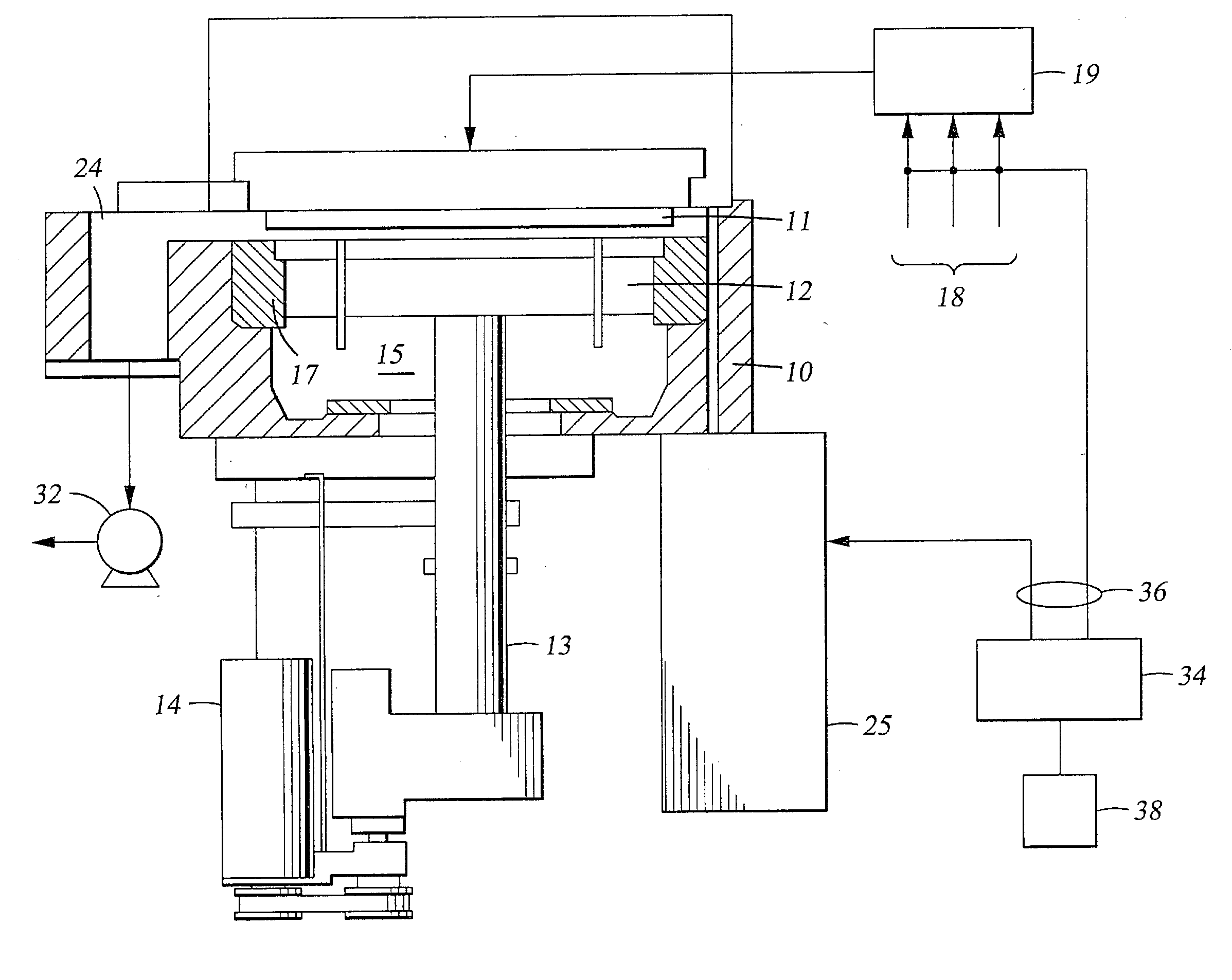

Plasma processes for depositing low dielectric constant films

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Plasma processes for depositing low dielectric constant films

InactiveUS20010005546A1Semiconductor/solid-state device detailsSolid-state devicesDisiloxaneMicrowave

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

Computer readable medium for holding a program for performing plasma-assisted CVD of low dielectric constant films formed from organosilane compounds

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

CVD plasma assisted low dielectric constant films

InactiveUS6800571B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylsilaneNitrous oxide

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

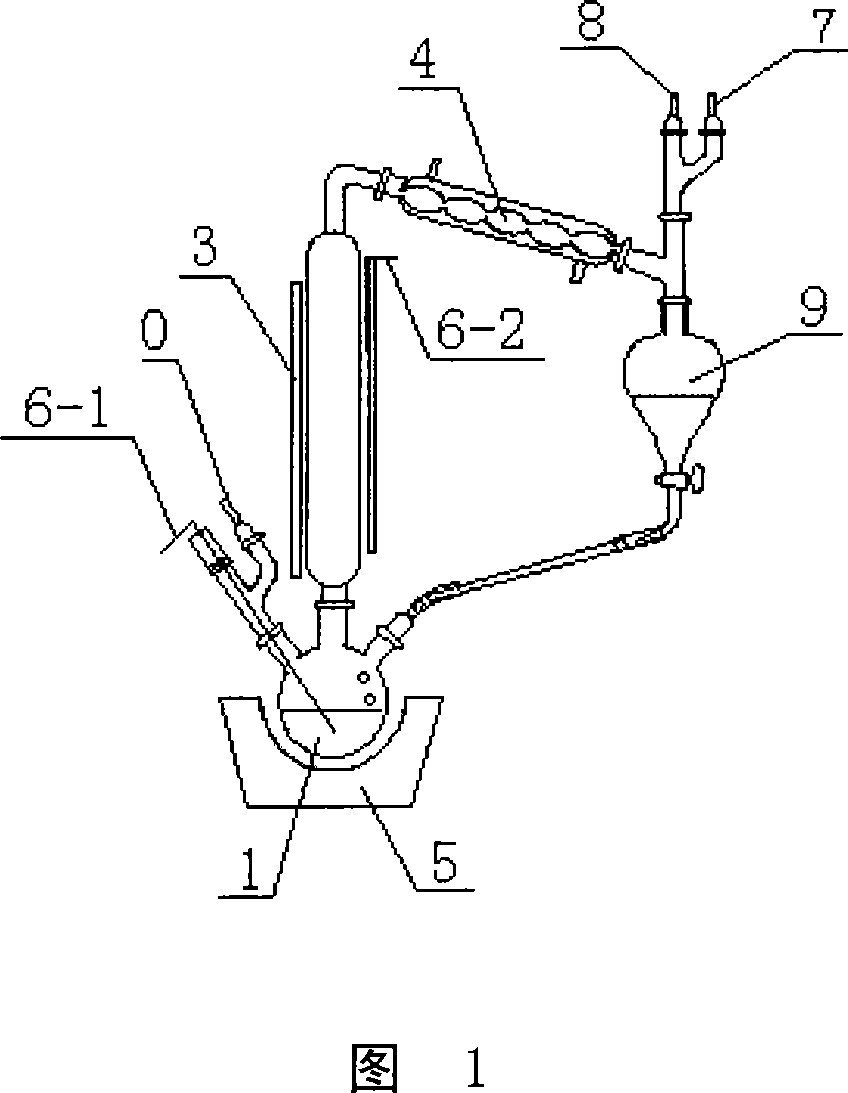

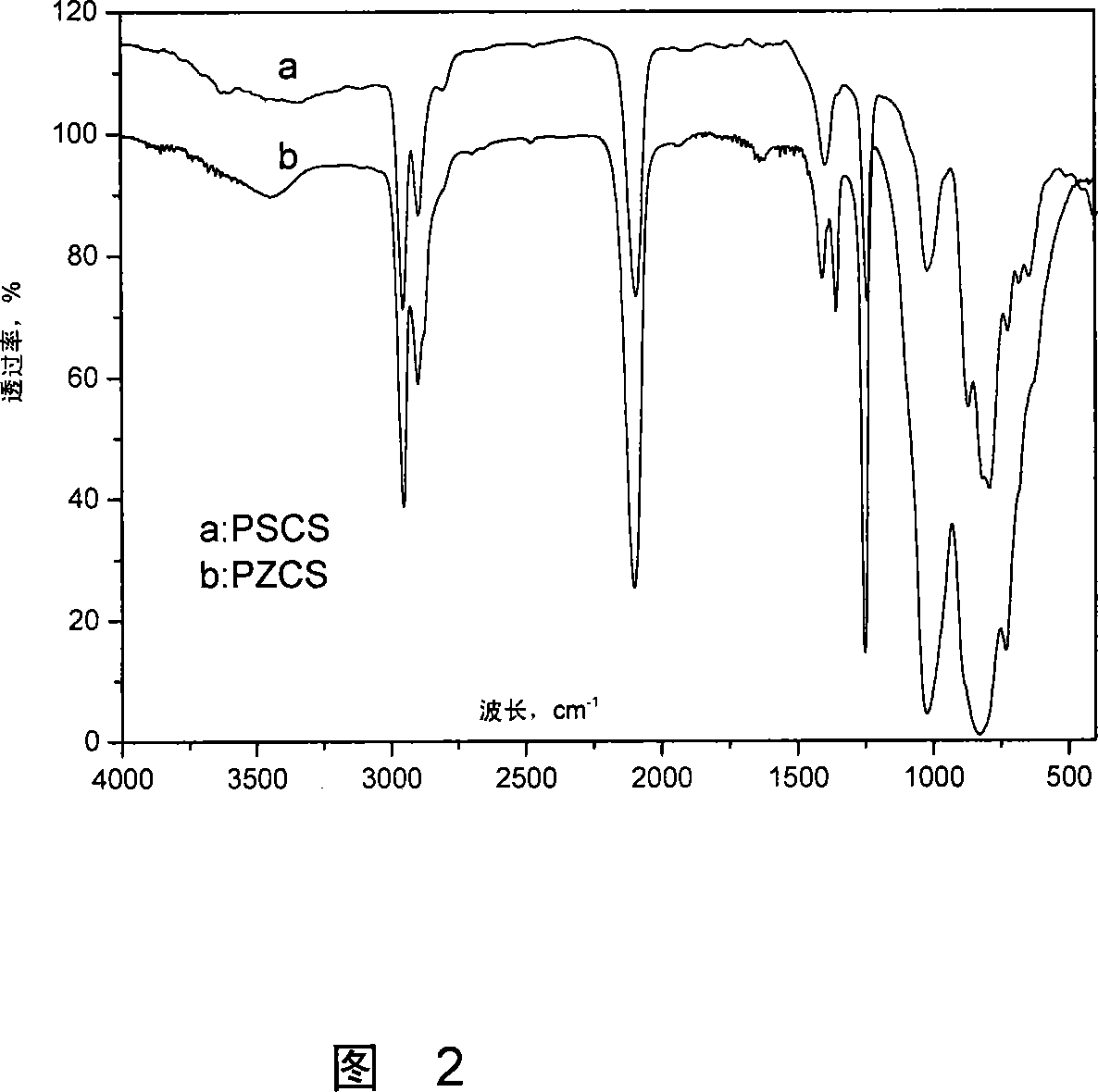

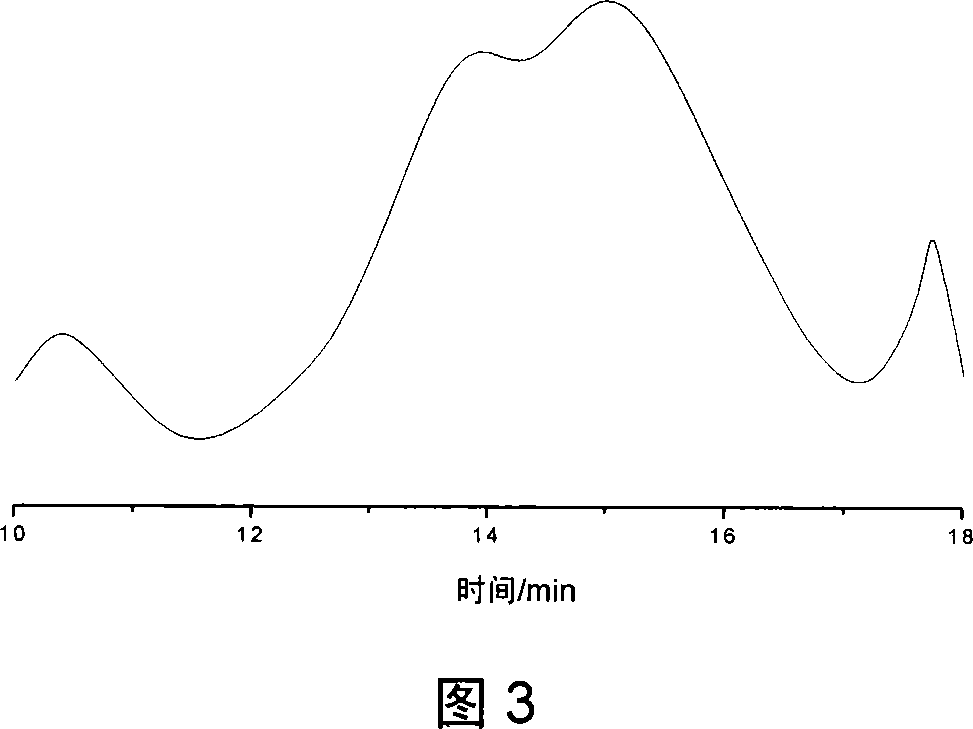

Method and equipment for preparing precursor body of poly carbon silane ceramics of containing zirconium

This invention discloses method and apparatus for preparing polycarbosilane ceramic precursor containing Zr. The method comprises: utilizing low molecular weight polymer with S-H bonds (polysilane, polycarbosilane or poly(dimethyl silane)) as the raw material, organic metallic compound containing Zr as the additive, and Ar, N2 or their mixture as the protective atmosphere, and pyrolyzing at high temperatures and normal pressure to obtain Zr-containing SiC ceramic precursor PZCS. The pyrolysis apparatus comprises a three-necked flask in the heater, a pyrolysis column in the electric heating jacket, a condensing tube, a separatory funnel, and a vacuum system seam. The method is simple, and can control the content and properties of Zr in the precursor and the ceramic. The product has such advantages as high purity, high remoldability, and high heat resistance.

Owner:NAT UNIV OF DEFENSE TECH

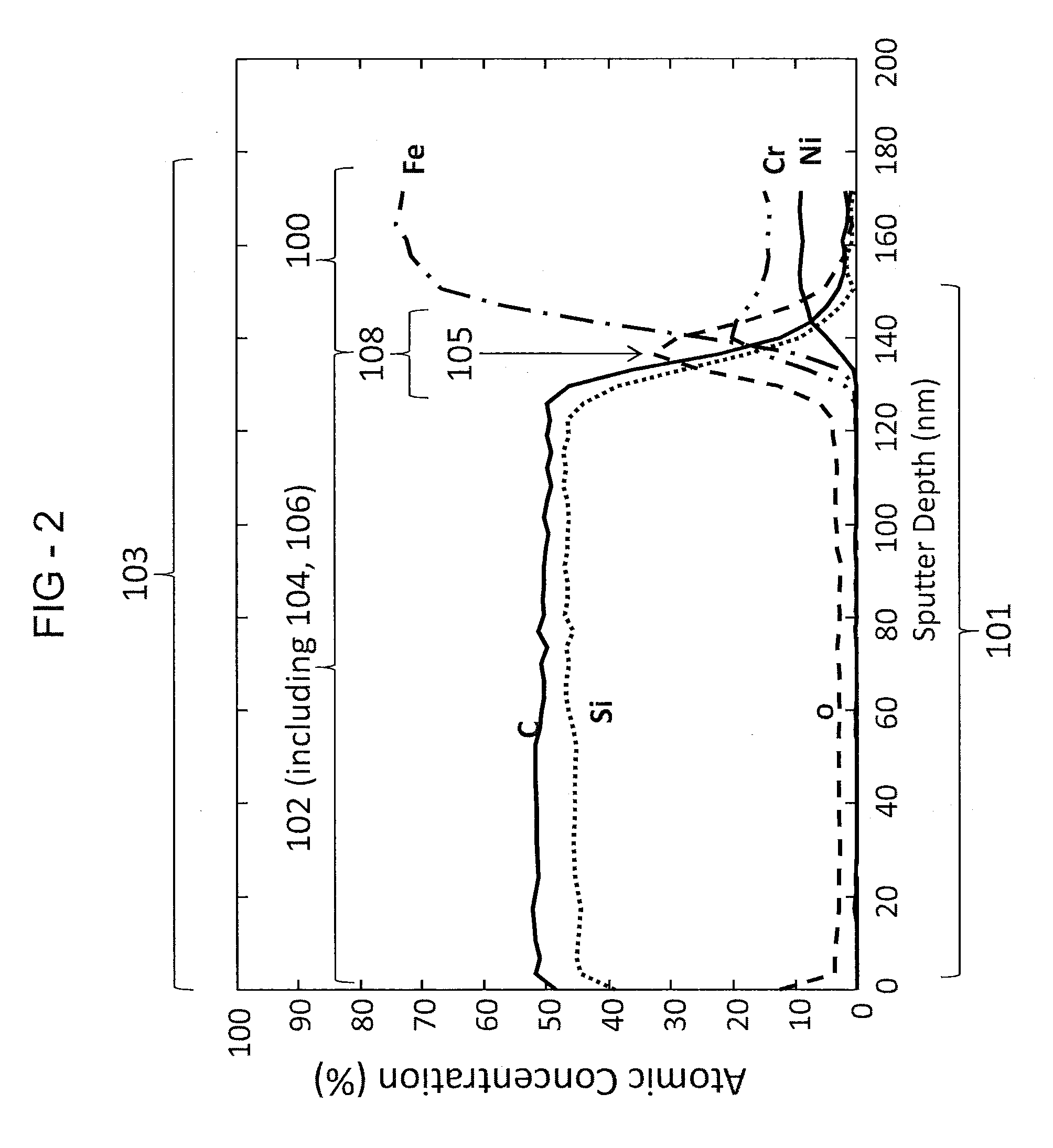

Chemical vapor deposition coating, article, and method

ActiveUS20120251797A1High hardnessEasy to wearSilicon organic compoundsLiquid surface applicatorsGas phasePhysical chemistry

The present invention relates to a chemical vapor deposition coating, a chemical vapor deposition article, and a chemical vapor deposition method. The coating, article, and method involve thermal decomposition of dimethylsilane to achieve desired surface properties.

Owner:SILCOTEK CORP

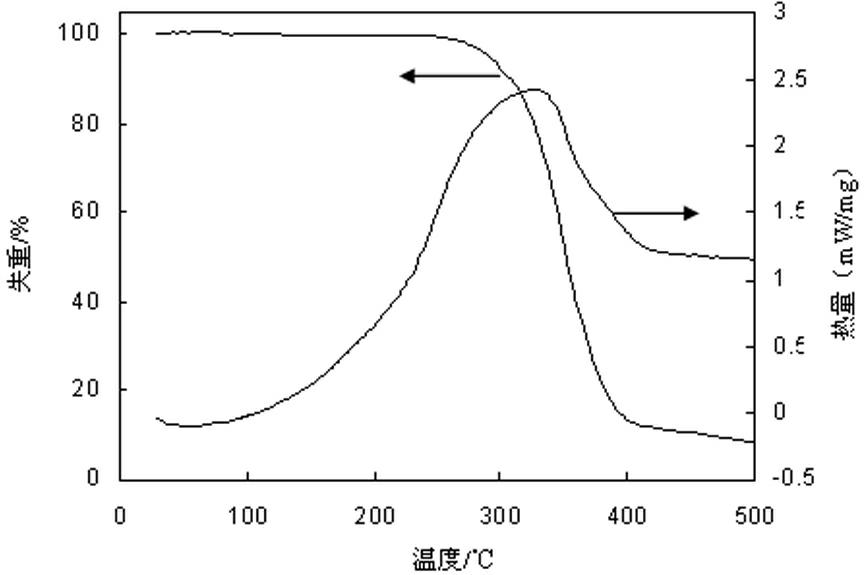

Method for synthetizing polycarbosilane under atmospheric pressure

InactiveCN102120822AIncrease the concentration of free radicalsStructure will not changeNitrogen atmosphereReaction temperature

A method for synthetizing polycarbosilane under the atmospheric pressure comprises the following steps: under the protection of high purity nitrogen, cracking solid raw material-polydimethylsilane at above 360 DEG C in nitrogen atmosphere to convert to liquid polysilane; (2) adding solid powdery raw material-polydimethylsilane which accounts for 15-100wt% of liquid polysilane in liquid polysilane, stirring evenly, sealing, heating to 280-330 DEG C under the protection of high purity nitrogen, reacting for 2-6h; and (3) performing temperature programming to 370-420 DEG C, and reacting for 6-12h and cooling. The method has low reaction temperature, the synthetic yield is more than 60%; the structure of precursor polycarbosilane (PCS) can not be changed; the equipment is simple; and large-scale synthesis is easy to realize and synthetic steps are less.

Owner:NAT UNIV OF DEFENSE TECH

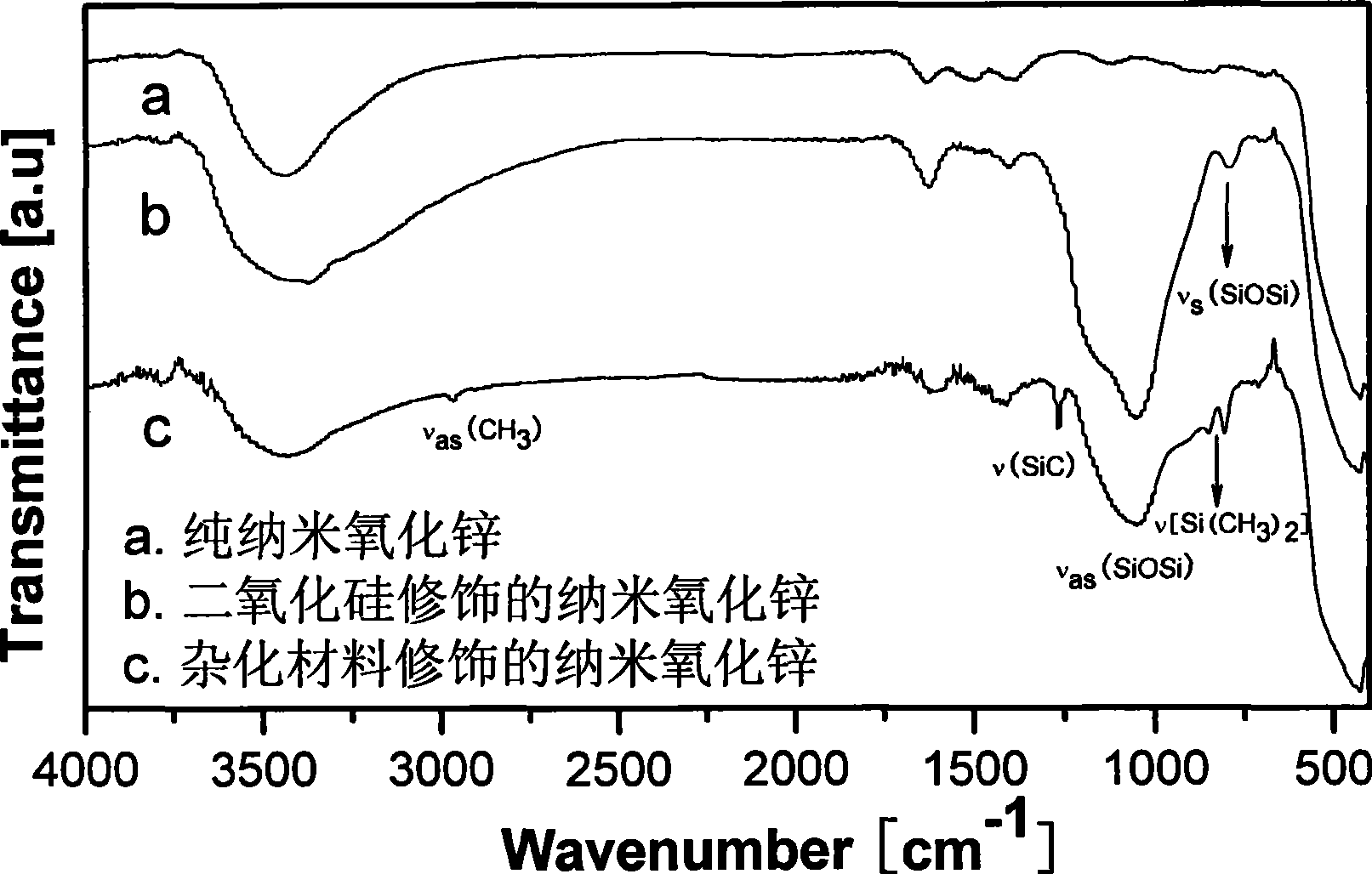

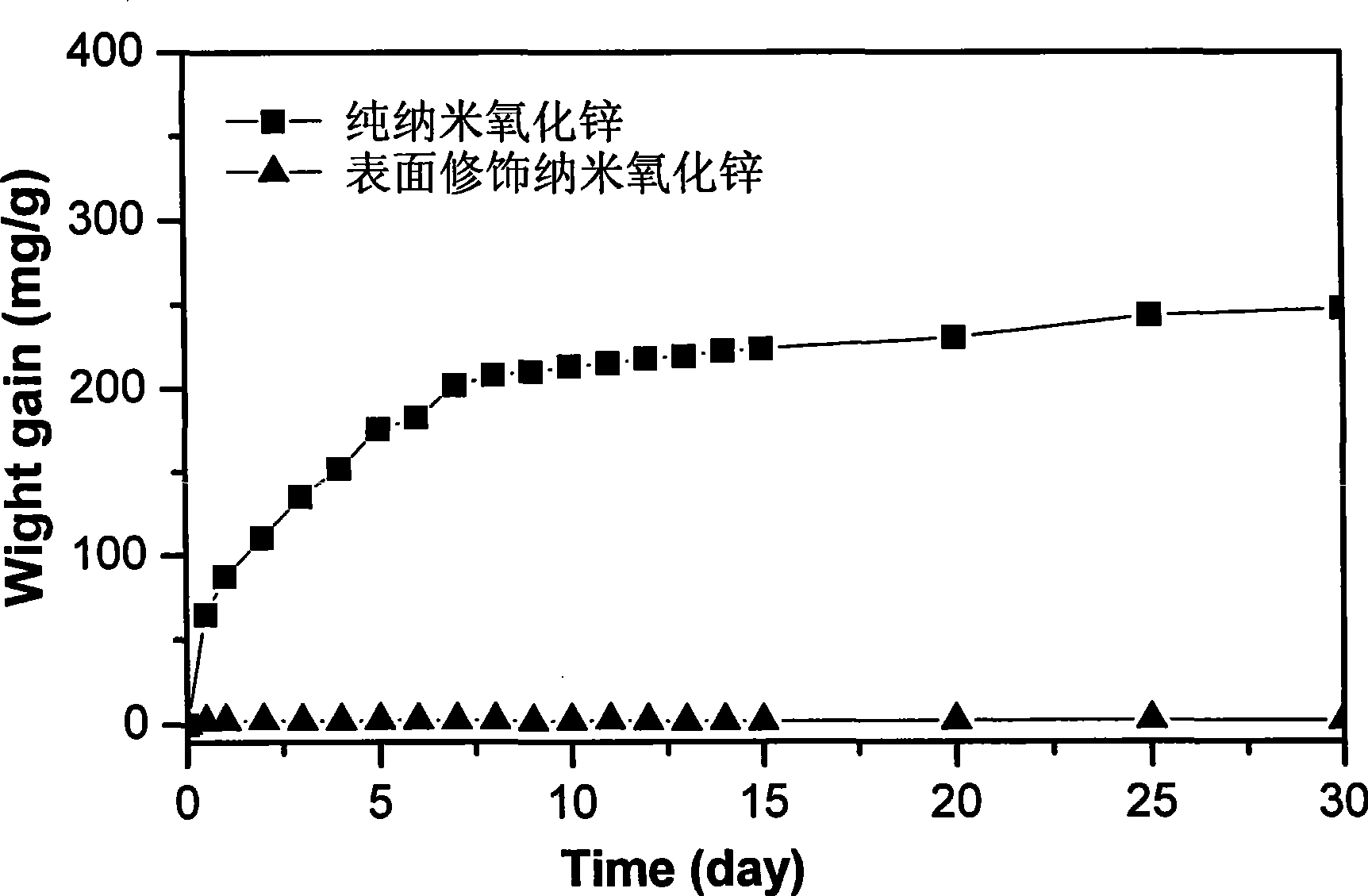

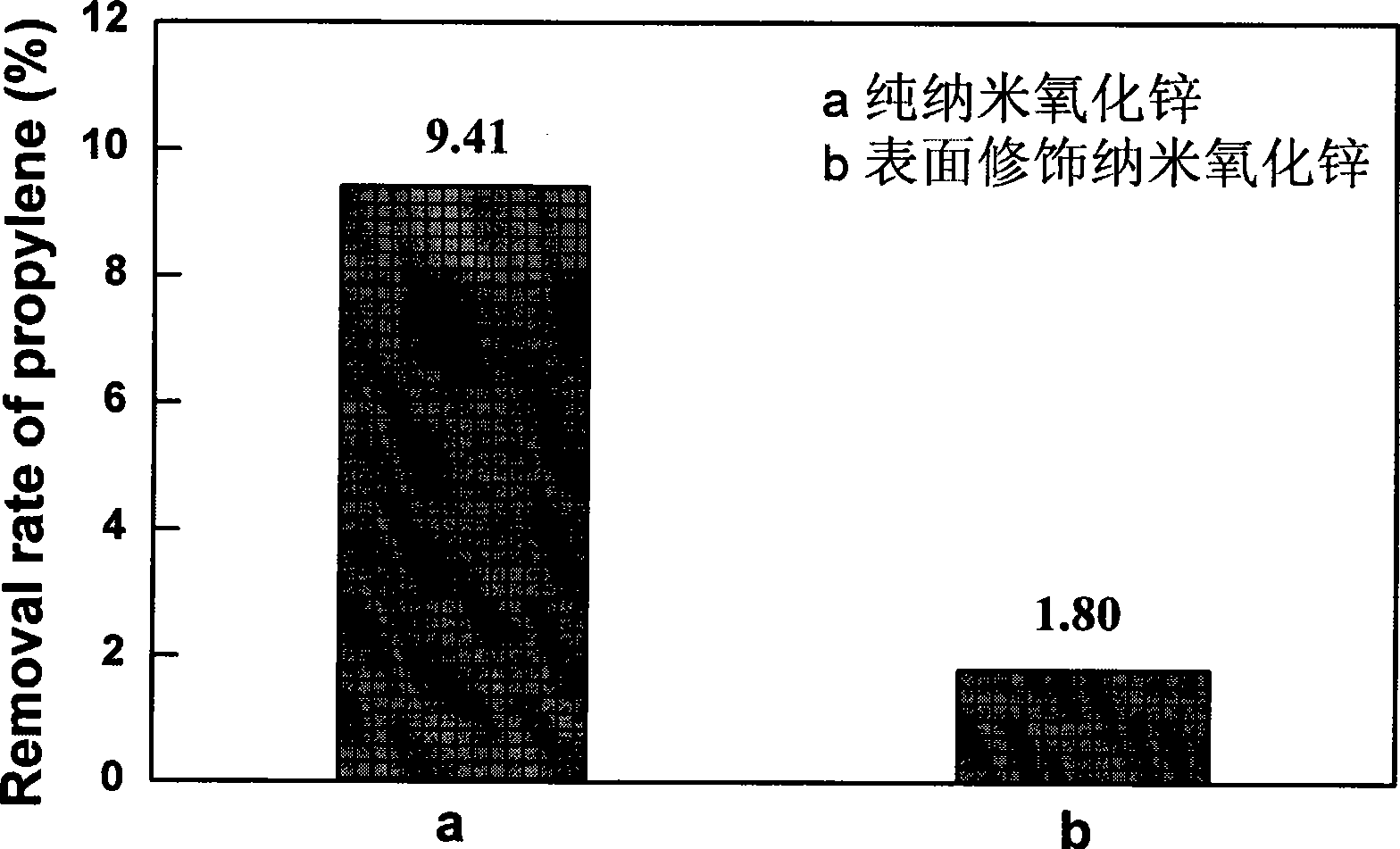

Nano zinc oxide surface modifying method

ActiveCN101543466ASimple processEasy to industrializeCosmetic preparationsToilet preparationsChemical reactionReaction temperature

The invention relates to a nano zinc oxide surface modifying method, which adopts the technical proposal comprising the following steps that: 1) nano zinc oxide powder is fully dispersed in mixed solution of deionized water and latent solvent to form slurry; and 2) a modifier consisting of tetraethyl orthosilicate and / or methyl silicate and organosilane is evenly mixed with the latent solvent, the mixture is added into the slurry in stirring, pH value is adjusted to be between 8 and 12 for reaction, the reaction temperature is about 90 DEG C and the reaction time is between 3 and 12 hours, wherein the organosilane is polydimethylsilane or / and silane coupling agent. The method adopts a common aqueous-phase chemical reaction method, uses common devices, can complete the surface modification on the nano zinc oxide powder of an organic-inorganic hybrid material through a one-step reaction, and has simple process and easy industrialization. Prepared products improve compatability with organic substrates, make the photocatalytic activity inhibited, and are particularly suitable to be used as a UV blocking agent in sun-screen cosmetics.

Owner:HENAN UNIVERSITY

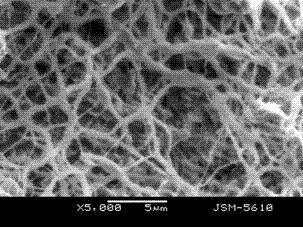

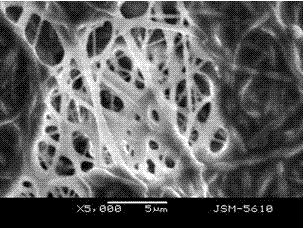

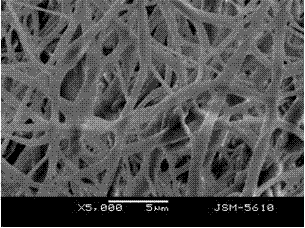

Method for preparing SiC/C nano-fiber membrane by electrostatic spinning

ActiveCN102352548ASimple preparation processImprove efficiencyFilament/thread formingHeating/cooling textile fabricsPolymer scienceElectrospinning

The invention discloses a method for preparing a SiC / C nano-fiber membrane by electrostatic spinning. The method comprises the following steps: (1) synthesizing a soluble dimethylsilane-diphenylsilane copolymer; (2) blending dimethylsilane-diphenylsilane copolymer solution with polyacrylonitrile solution for preparing spinning solution; (3) performing the electrostatic spinning on the spinning solution to prepare a precursor fiber membrane; (4) performing curing treatment on the precursor fiber membrane prepared by electrostatic spinning at the temperature of 90-250 DEG C, and further sintering under an inert atmosphere at the temperature of 900-1500 DEG C so as to prepare the SiC / C nano-fiber membrane. The preparation method provided by the invention is simple and easy to operate, and electrostatic spinning nano-fiber obtained through the preparation method is a catalyst with high specific surface area, good thermal stability and excellent mechanical properties, or a carrier materialand a high temperature-resistant filter material thereof, thereby having potential application prospects in the fields of nano-wire devices, the filter materials, compound enhancing materials and thelike.

Owner:苏州宋和纤维科技有限公司

CVD plasma assisted low dielectric constant films

InactiveUS20030124859A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDimethylsilaneNitrous oxide

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilane or organosiloxane compound and an oxidizing gas at a low RF power level from 10-250 W. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop or an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, or dimethylsilane, (CH3)2SiH2, and nitrous oxide, N2O, at an RF power level from about 10 to 200 W or a pulsed RF power level from about 20 to 250 W during 10-30% of the duty cycle.

Owner:APPLIED MATERIALS INC

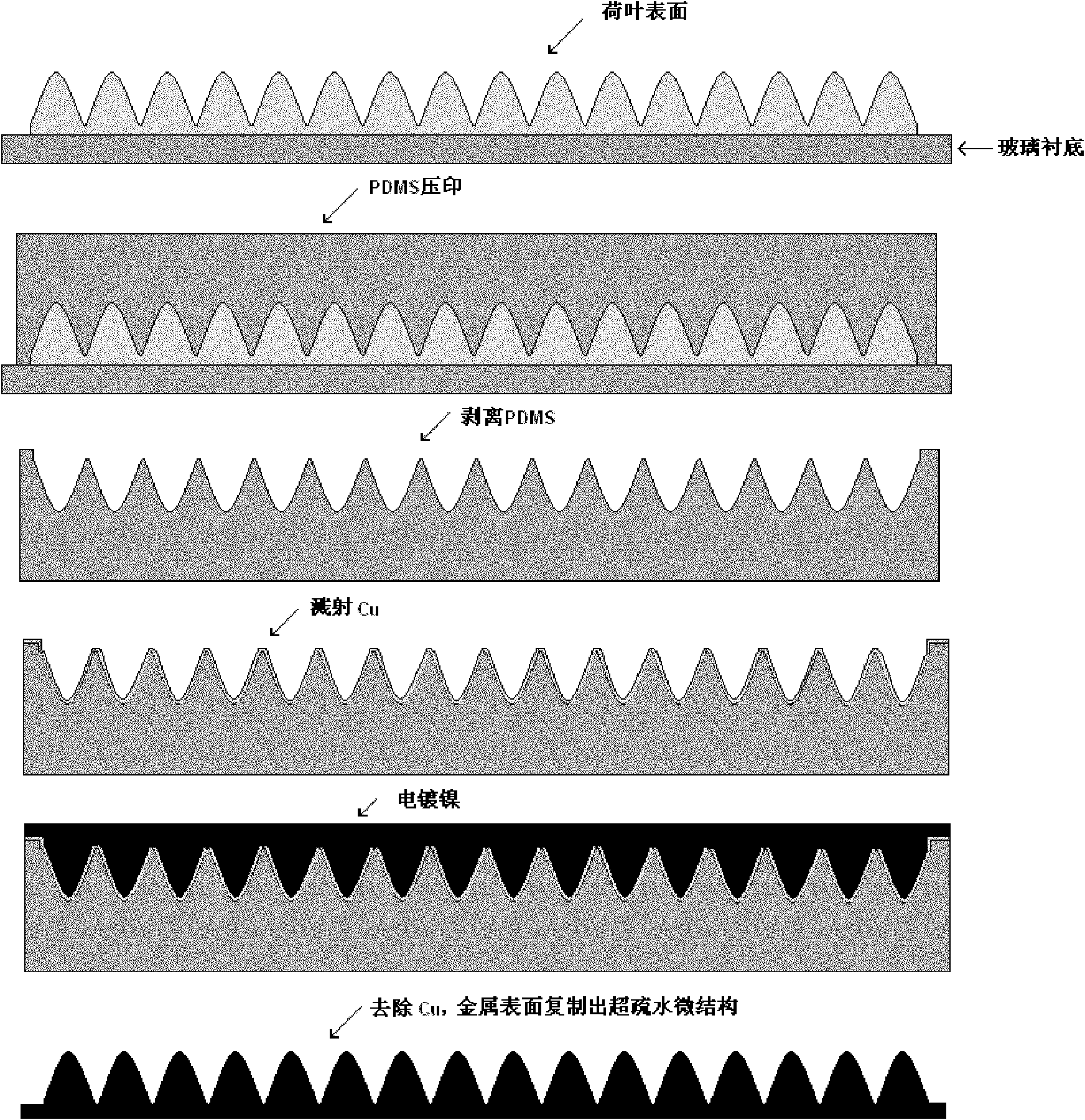

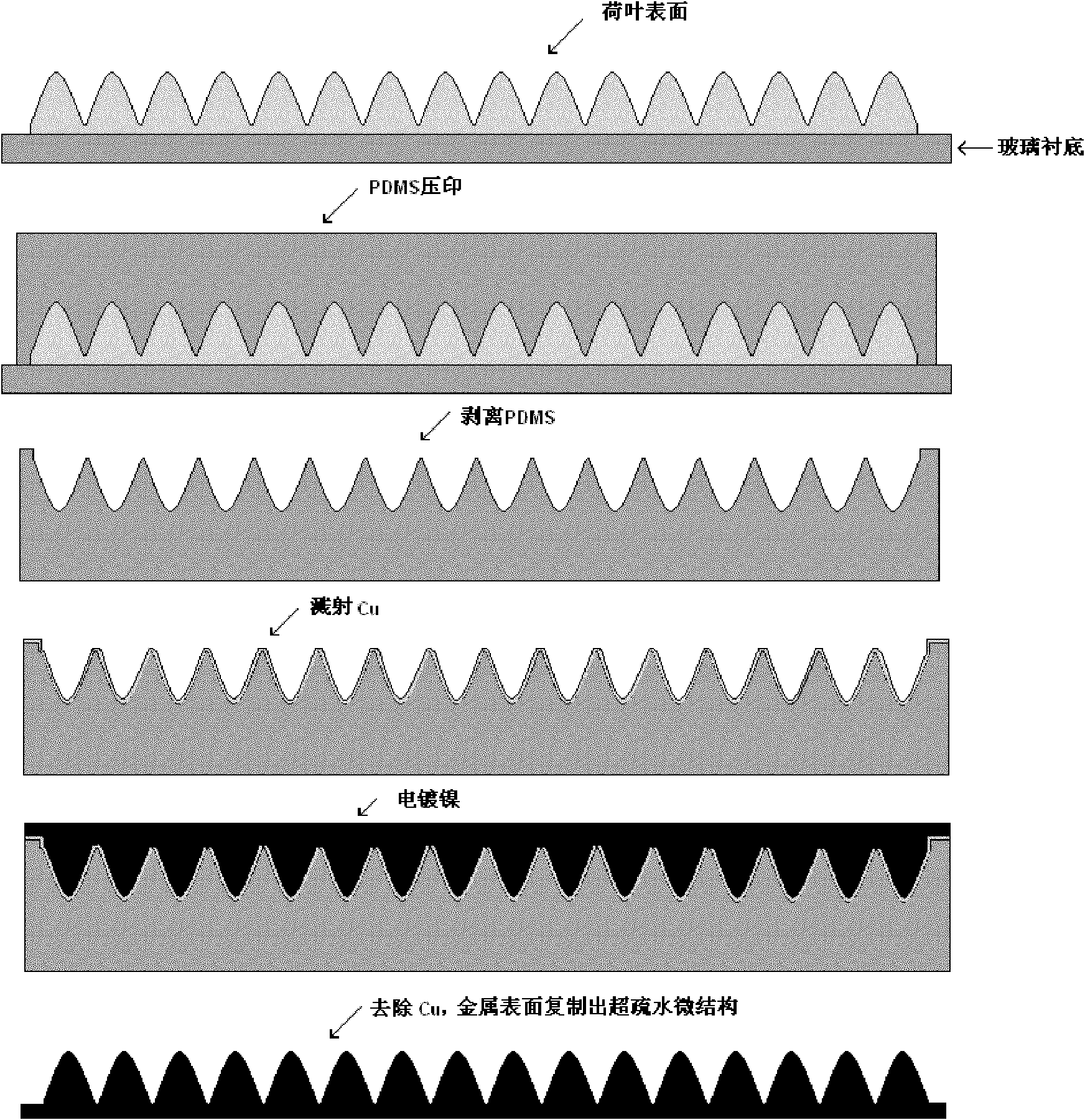

Preparation method of metal-base superhydrophobic material

InactiveCN102011153AHigh cost savingsEasy to moveElectroforming processesMetallic materialsStrong acids

The invention relates to a preparation method of a metal-base superhydrophobic material, belonging to the technical field of superhydrophobicity. The method comprises the following steps: using a pretreated hydrophobic substrate as the template; duplicating with dimethyl polysiloxane to obtain a disordered array structure; growing engineering metal material on the disordered array structure, and coating a low-surface-energy layer, so as to realize the superhydrophobicity. The method does not need to use strong acid or toxic substances, thereby being safe and environment-friendly; the materials used in the technique are easy to obtain and cheap; and the metal-base superhydrophobic material has the advantages of favorable metallic conductivity, high strength, favorable mechanical properties and the like, and the application range is greatly widened as compared with the that of prior polymer superhydrophobic material.

Owner:SHANGHAI JIAO TONG UNIV

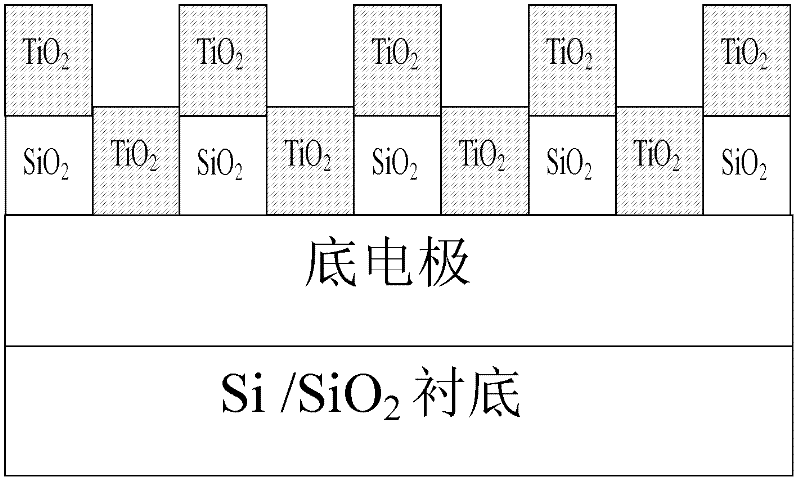

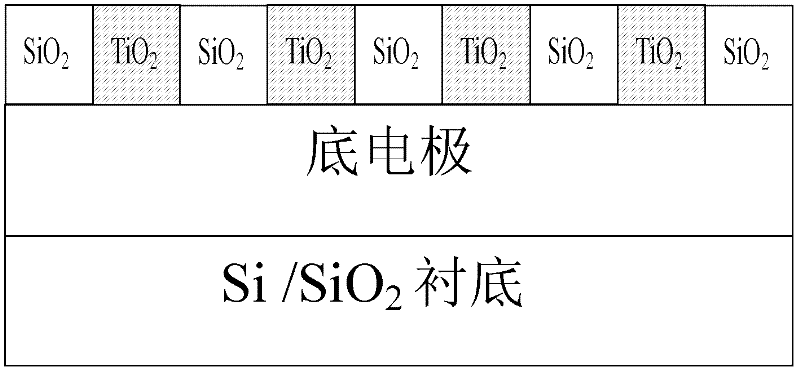

Nanometer polishing solution for titanium oxide film chemical mechanical planarization and application

InactiveCN102408836AAvoid damageNo pollutionElectrical apparatusPolishing compositions with abrasivesRandom materialsDimethylsilane

A nanometer polishing solution for titanium oxide film chemical mechanical planarization is formed by mixing a nanometer abrasive, a pH adjusting agent, a surfactant, a defoamer, a bactericide, an assistant cleaning agent, and a solvent, wherein the nanometer abrasive is cerium oxide or silica; the pH adjusting agent is a composite pH adjusting agent composed of an inorganic pH adjusting agent and an organic pH adjusting agent; the surfactant comprises silane polyglycol ether, polyglycol ether or dodecyl glycol ether; the defoamer is polydimethylsilane; the bactericide is isomeric thiazolinone; the assistant cleaning agent is isopropanol; and the solvent is deionized water; the nanometer polishing solution is applicable to the preparation of resistive random access memories based on titanium oxide film materials. The advantages of the invention are that: the polishing speed is stable and controllable; the film has less surface damage, is easy to clean, does not cause environment pollution, and has long storage time. When the polishing solution is used to perform chemical mechanical planarization of a resistive random material of a titanium oxide film material so as to prepare a resistive random access memory, the method is simple and practical, and is completely compatible with integrated circuit technology.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

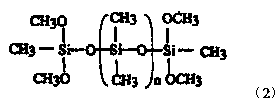

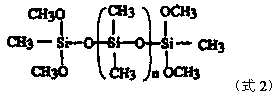

Transparent, fast-cured and thixotropic dealcoholization one-component silicone rubber

InactiveCN104004357ASolve the phenomenon of thickeningAddress storage stabilityNon-macromolecular adhesive additivesOther chemical processesPolymer sciencePtru catalyst

The invention provides transparent, fast-cured and thixotropic dealcoholization one-component silicone rubber. Polydimethylsiloxane of tail end trimethoxy silanesilicon and polydimethylsilane of tail end methyl dimethoxy silica are used as a body, components are weighed and comprise, by weight, 0-40 parts of the polydimethylsiloxane of tail end trimethoxy silane, 60-100 parts of the olydimethylsilane of the tail end methyl dimethoxy silica, 0-20 parts of polydimethyl siloxane fluid, 5-20 parts of vapor phase method silicon dioxide, 0.24-8 parts of catalysts, 0.1-3 parts of tackifier and 1-7 parts of cross-linking agents, and the catalysts are organic titanium or catalytic compositions of organic titanium and organic tin. The invention further provides a preparation method of the material. The rubber has the good transparency, good adhesion and stable storage performance, and has the advantages of being high in curing speed, adjustable in time and free of pollution in production. The rubber is used for device adhesion of electronic devices, adhesion of various lamps and the like, and is easy to produce and high in production efficiency.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

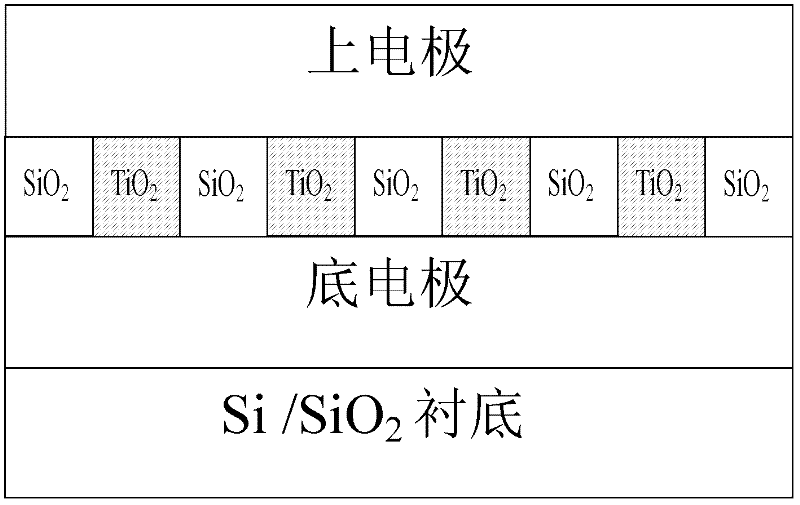

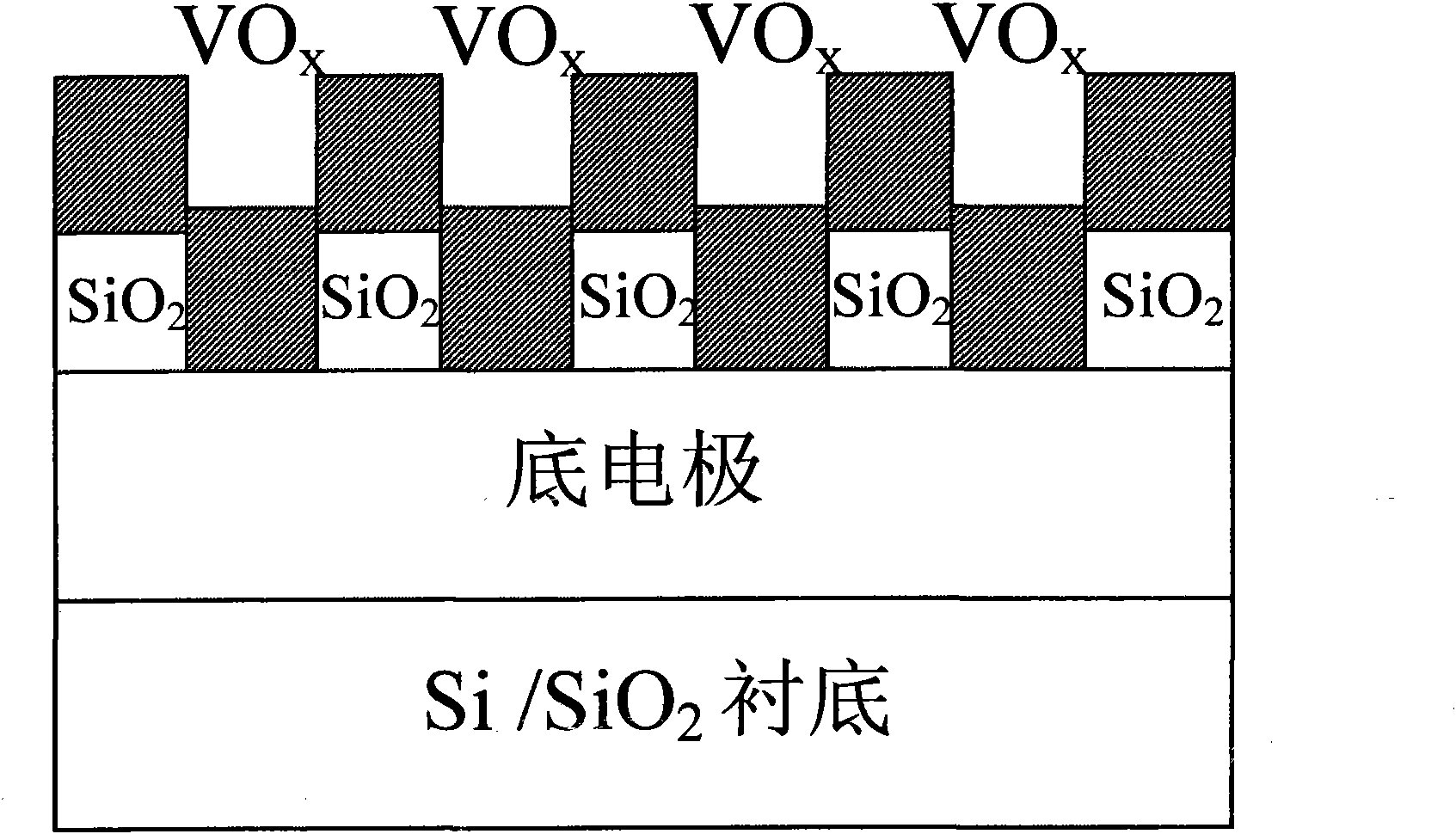

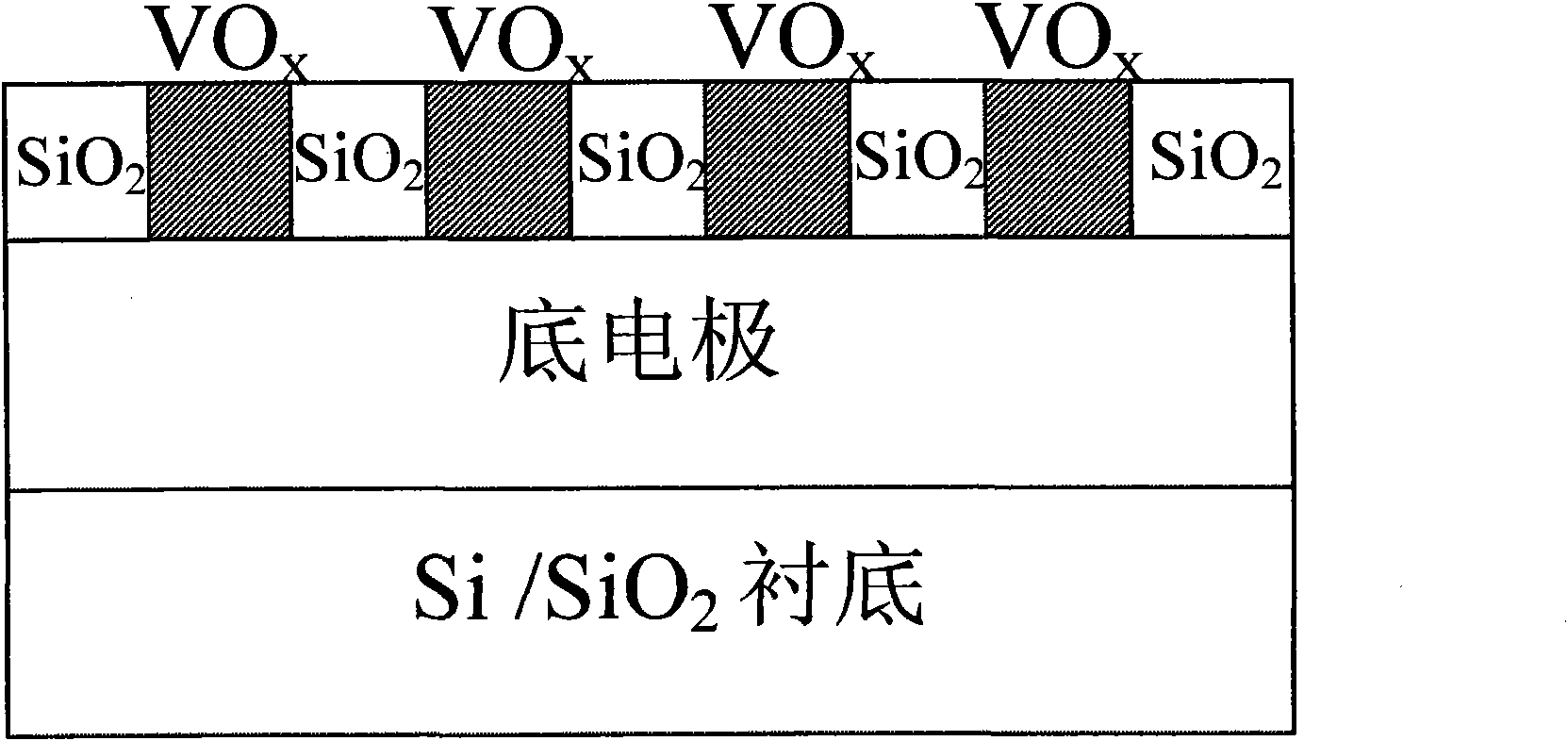

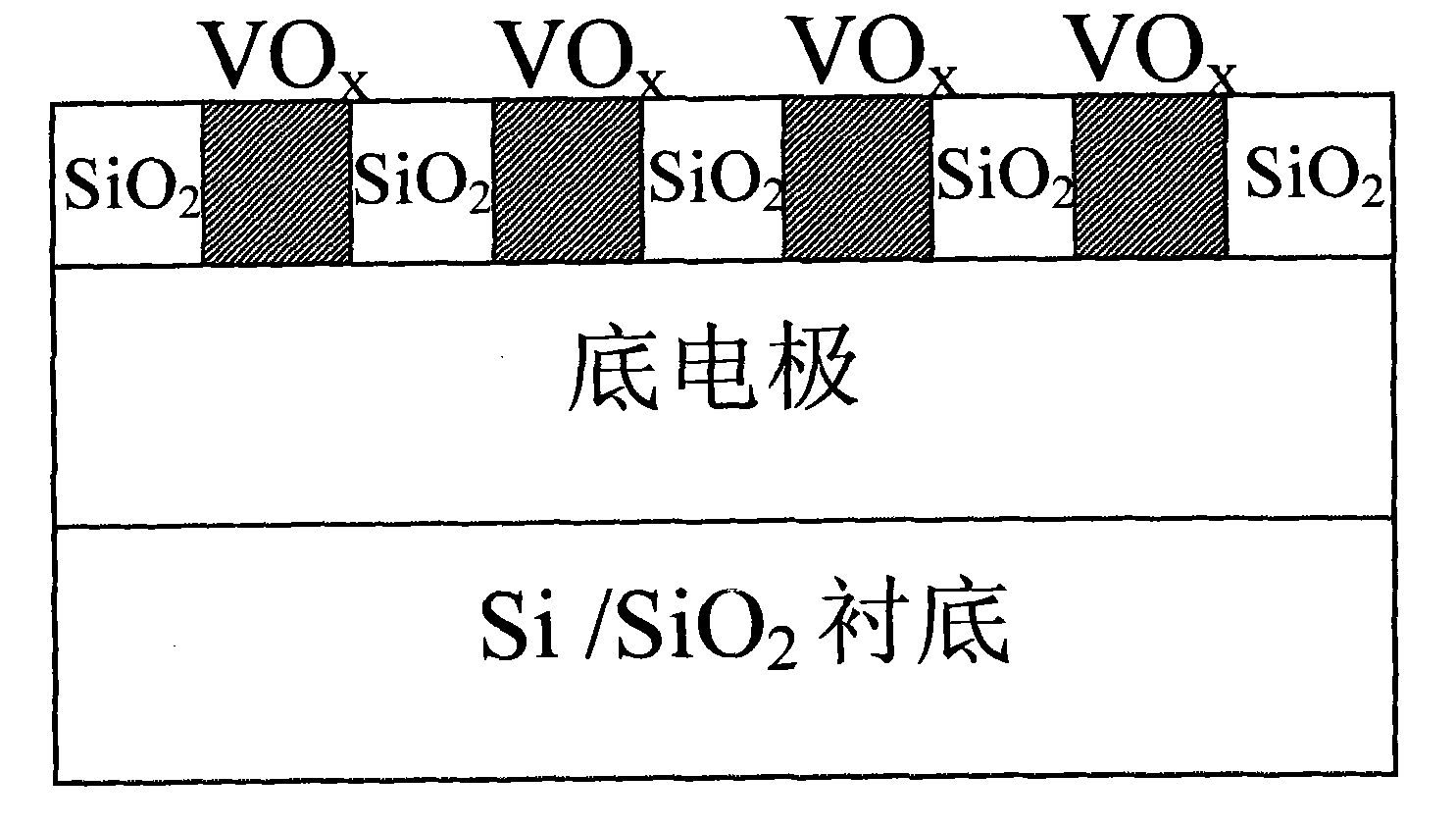

Nano polishing solution for chemically mechanical polishing of vanadium oxide and application thereof

ActiveCN102127372AEasy to corrodeEasy to polluteBiocideOther chemical processesOrganic basePolyethylene glycol

The invention relates to nano polishing solution for chemically mechanical polishing of vanadium oxide, which consists of a nano-abrasive, a pH regulator, a surfactant, a defoaming agent, a bactericide, a cleaning aid and a solvent, wherein the nano-abrasive is zirconium oxide, titanium oxide, plutonium oxide or silica; the pH regulator comprises inorganic base of KOH and organic base of tetramethylammonium, tetraethyl ammonium hydroxide or hydroxy amine; the surfactant is silicane polyethylene glycol ether, polyethylene glycol ether or 2-(2-dodecyloxyethoxy)ethanol; the defoaming agent is poly(dimethylsilane); the bactericide is isomerous thiazolidinone; the cleaning aid is isopropanol; and the solvent is deionized water. The invention has the advantages that: the polishing rate is stably controllable, the damage is low, the cleaning is simple, equipment is not corroded, the environment is not polluted, and the storage time is long; and a vanadium oxide film material is subjected to the chemically mechanical polishing by the nano polishing solution for preparing a resistive random access memory, and the method is simple and practicable, and is completely compatible with an integrated circuit process.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Coating process for lotus leaf-like diamond film

InactiveCN103469205AReduce stressToo much dopingSolid state diffusion coatingChemical vapor deposition coatingWear resistantGas phase

The invention relates to a coating process for a lotus leaf-like diamond film. According to the process, gases such as octafluorocyclobutane, monomethylsilane and dimethylsilane are introduced into a vacuum tank, denpending on plasma immersion ion deposition equipment; and the lotus leaf-like diamond film is coated on a workpiece surface by a plasma-enhanced chemical vapor deposition method. The coating process mainly comprises five steps of plasma cleaning, plasma nitriding, transition layer plating, diamond-like plating and lotus leaf-like film plating. The lotus leaf-like diamond film has very high hardness. Since the lotus leaf-like diamond film has a structure similar to the surface of the lotus leaf, the lotus leaf-like diamond film has extremely low surface energy. In consideration of high wear-resistant and hydrophobic properties of the lotus leaf-like diamond film, the lotus leaf-like diamond film can be successfully applied in the fields such as coal mine screen meshes, metal molds, aerospace aircraft wings and oil pipelines.

Owner:HEFEI YONGXIN PLASMA TECH

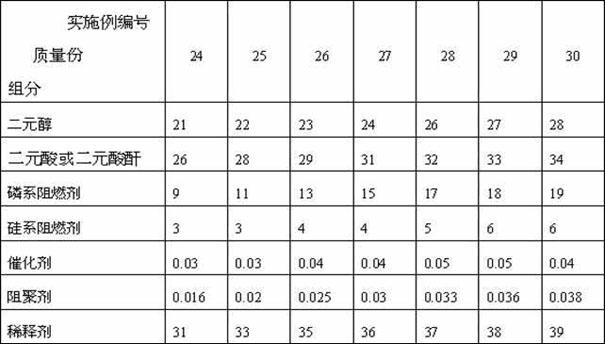

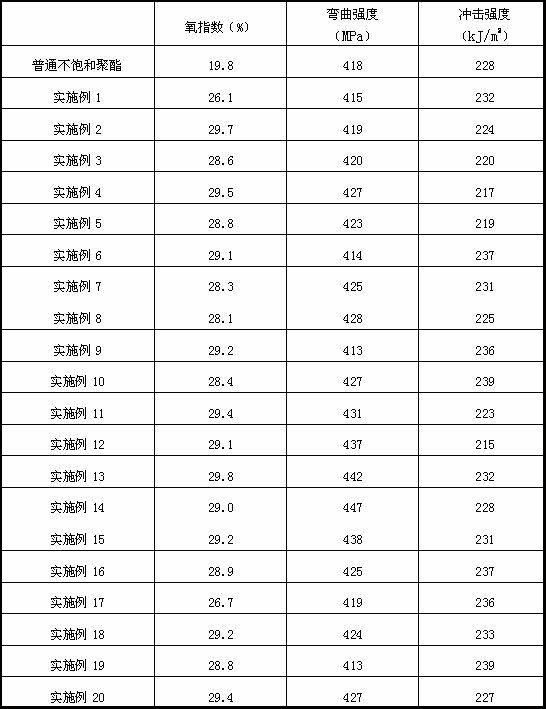

Method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin

The invention discloses a method for synthesizing reactive halogen-free flame-retardant unsaturated polyester resin. The method is characterized by taking dihydric alcohol, dibasic acid or dibasic acid anhydride, reactive phosphorus flame retardants such as 2- carboxyethyl (phenyl) phosphinic acid and phenyl hydroxymethyl phosphinic acid, and reactive silicon flame retardants such as dihydroxy diphenyl silane and dihydroxy dimethyl silane as basic materials, conducting esterification and polycondensation under the conditions of catalysts such as dibutyltin oxide and sodium acetate, and then adding diluent, thus preparing the halogen-free flame-retardant unsaturated polyester resin. The resin prepared by the method is especially applicable to the production of unsaturated polyester resin moulding compounds, glass fiber reinforced plastics and electrical plastic products, can meet the requirements of products on flame retarding and lightweight and has good properties.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

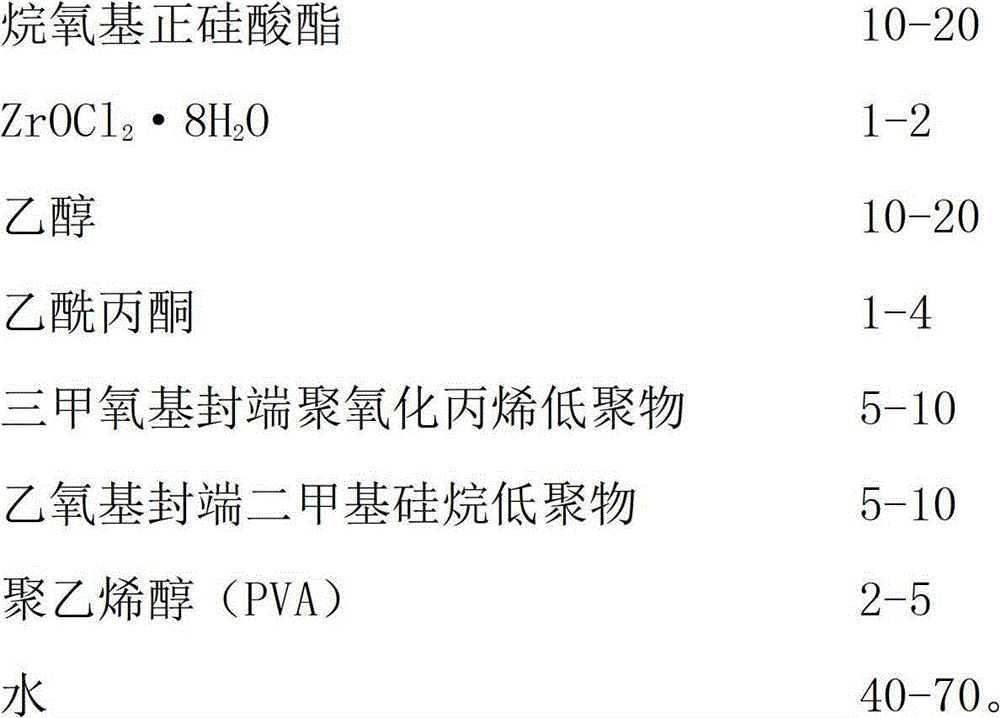

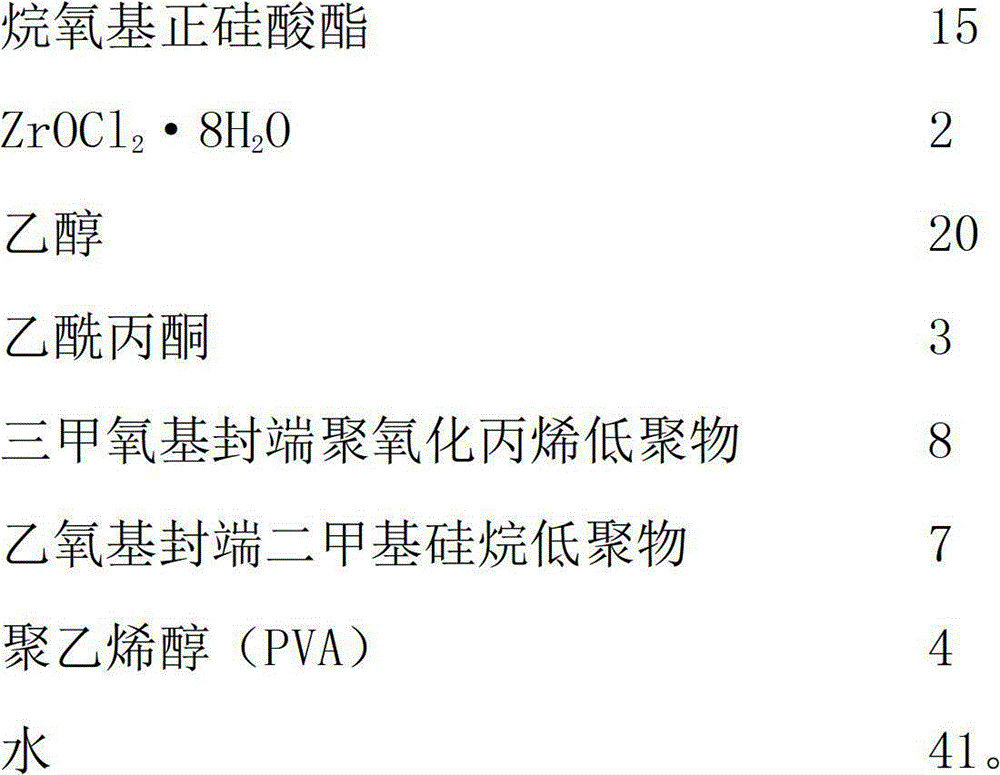

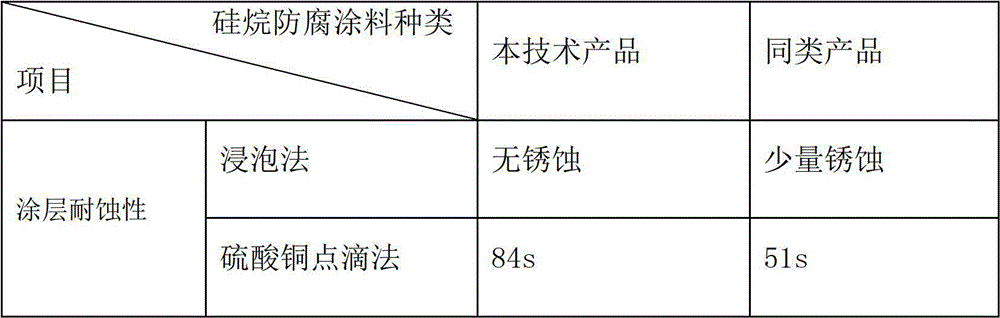

Organic-inorganic hybrid silane metal waterborne anti-corrosion coating and preparation method thereof

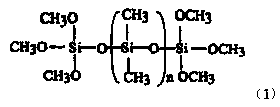

InactiveCN102719121ASimple embeddingSimply buriedAnti-corrosive paintsSilicon compoundsSilanesDimethylsilane

The invention relates to an organic-inorganic hybrid silane metal waterborne anti-corrosion coating which comprises the following components in part by weight: 10 to 20 parts of alkoxy ortho-silicate ester, 1 to 2 parts of ZrOC12.8H2O, 10 to 20 parts of ethanol, 1 to 4 parts of acetylacetone, 5 to 10 parts of trimethoxy terminated polypropylene oxide oligomer, 5 to 10 parts of ethyoxyl terminated dimethylsilane oligomer, 2 to 5 parts of polyving akohol and 40 to 70 parts of water. A preparation method of the organic-inorganic hybrid silane metal waterborne anti-corrosion coating comprises the following preparation steps of: 1, adding the alkoxy ortho-silicate ester and the ethanol into the water and uniformly stirring to form mixed solution A; 2, adding the trimethoxy terminated polypropylene oxide oligomer, the ethyoxyl terminated dimethylsilane oligomer and acetylacetone into the mixed solution A and uniformly stirring to form a mixture B; 3, regulating the pH value of the mixture B into the range of 8 to 10 by sodium hydroxide, heating to the temperature of 30 to 50 DEG C and carrying out seal stirring for at least two hours to prepare silica sol C; 4, uniformly mixing the ZrOC12.8H2O, the acetylacetone, the ethanol and the water according to the proportion and stirring for 2 hours at room temperature to prepare zirconium sol D; and 5, mixing the silica sol C and the zirconium sol D according to the proportion, adding the polyving akohol solution and uniformly stirring to obtain the organic-inorganic hybrid silane metal waterborne anti-corrosion coating.

Owner:HUANGSHAN HENGTAI INDAL

Whitening and spot-removing facial mask containing coenzyme Q10, and preparation method of whitening and spot-removing facial mask

InactiveCN111568792AImprove immunityImprove permeabilityCosmetic preparationsToilet preparationsSilanesGlycerol

The invention discloses a whitening and spot-removing facial mask containing coenzyme Q10, and a preparation method of the whitening and spot-removing facial mask. The whitening and spot-removing facial mask containing coenzyme Q10 comprises the following ingredients: disodium EDTA, allantoin, panthenol, bis-PEG-18 methyl ether dimethyl silane, a thickener, sodium hyaluronate, sodium polyglutamate, a polyol, acetyl chitin, hydroxyethylpiperazine ethane sulfonic acid, alpha-arbutin, beta-dextran, glycerin polyether-26, a PEG / PPG-17 / 6 copolymer, carboxymethyl chitosan, biosaccharide gum-1, hydroxylated lecithin, hydroxyethyl urea, a nano whitening and spot-removing agent, a nano coenzyme Q10 emulsion, an anti-sensitive soothing agent, an antiseptic and antibacterial agent, and purified water. The whitening and spot-removing facial mask containing coenzyme Q10 has excellent stability and skin compatibility, has obvious whitening and spot-removing effects, is mild to the skin, and has broad application prospects.

Owner:帅发(厦门)投资有限公司

Plasma processes for depositing low dielectric constant films

A method and apparatus for depositing a low dielectric constant film by reaction of an organosilicon compound and an oxidizing gas at a constant RF power level from about 10W to about 200W or a pulsed RF power level from about 20W to about 500W. Dissociation of the oxidizing gas can be increased prior to mixing with the organosilicon compound, preferably within a separate microwave chamber, to assist in controlling the carbon content of the deposited film. The oxidized organosilane or organosiloxane film has good barrier properties for use as a liner or cap layer adjacent other dielectric layers. The oxidized organosilane or organosiloxane film may also be used as an etch stop and an intermetal dielectric layer for fabricating dual damascene structures. The oxidized organosilane or organosiloxane films also provide excellent adhesion between different dielectric layers. A preferred oxidized organosilane film is produced by reaction of methylsilane, CH3SiH3, dimethylsilane, (CH3)2SiH2, or 1,1,3,3-tetramethyl-disiloxane, (CH3)2-SiH-O-SiH-(CH3)2, and nitrous oxide, N2O, at a constant RF power level from about 10W to about 150W, or a pulsed RF power level from about 20W to about 250W during 10% to 30% of the duty cycle.

Owner:APPLIED MATERIALS INC

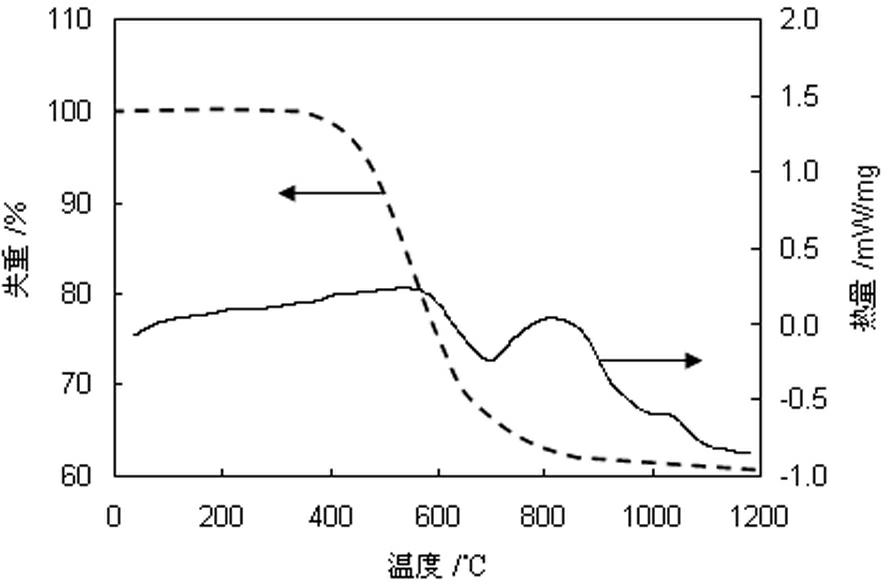

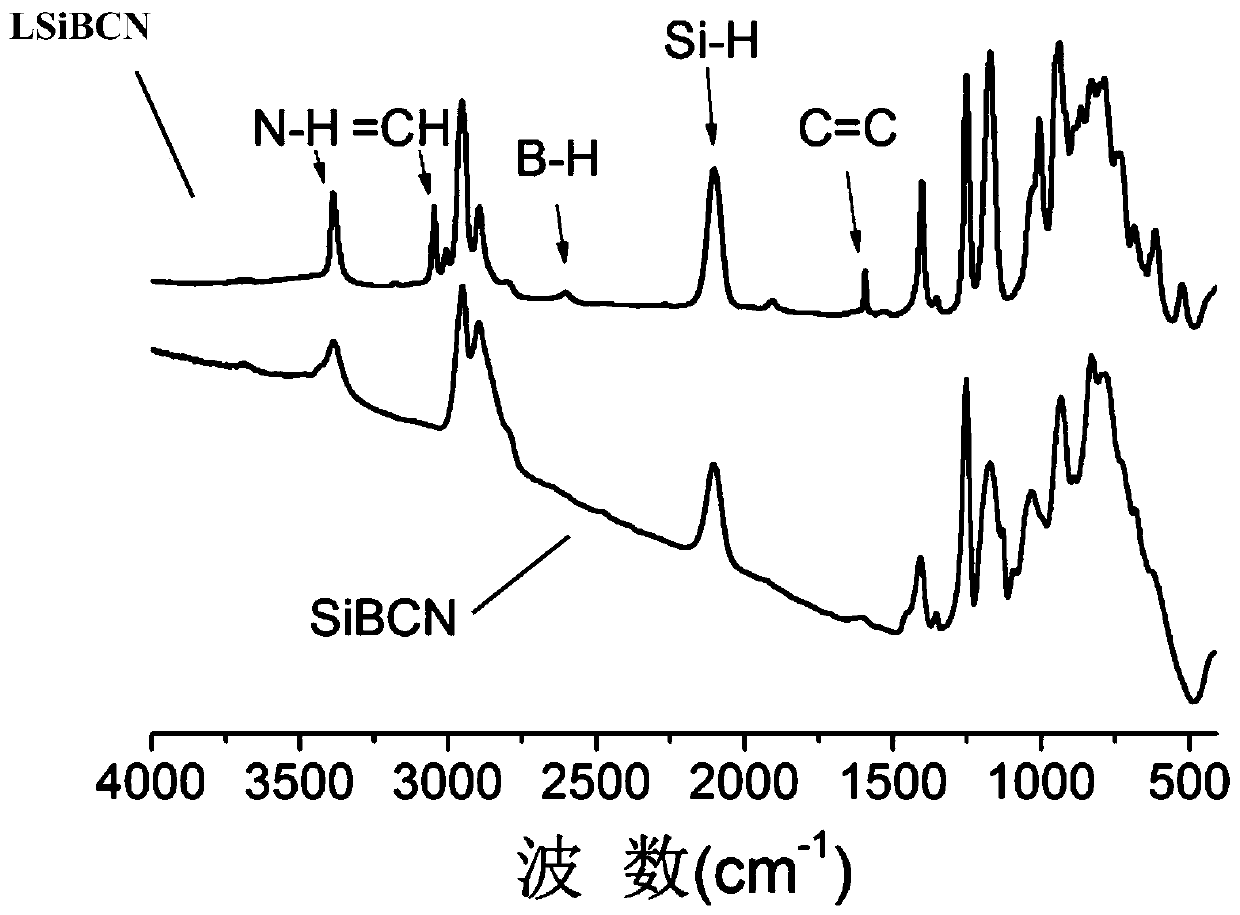

Liquid curable boron-containing polycarbosilane and preparation method thereof

ActiveCN110698678AImprove uneven distributionAvoid equal partsCoatingsAdhesivesPolymer sciencePtru catalyst

The invention discloses liquid curable boron-containing polycarbosilane and a preparation method thereof. The preparation method comprises the following steps: in a closed reaction container, subjecting polycarbosilane and a boron-containing monomer to a first reaction to generate liquid boron-containing polycarbosilane, wherein the polycarbosilane is a low-molecular-weight product obtained afterhigh-temperature cracking of polydimethylsilane, is in a liquid state at room temperature, and has a molecular weight of less than 1000 g / mol; and carrying out a second reaction on a uniformly-mixed reaction system containing the liquid boron-containing polycarbosilane, an organosilicon compound containing a C=C bond and a catalyst to obtain the liquid curable boron-containing polycarbosilane. Theliquid curable boron-containing polycarbosilane precursor disclosed by the invention is in a liquid state at room temperature, is simple in preparation process and long in storage time, can be thermocured, and is applicable to the fields of preparation of silicon carbide ceramic-based composite materials, high-temperature-resistant coatings, adhesives and the like through a precursor infiltrationand pyrolysis (PIP) method; and due to the existence of boron, the temperature resistance of a final product is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

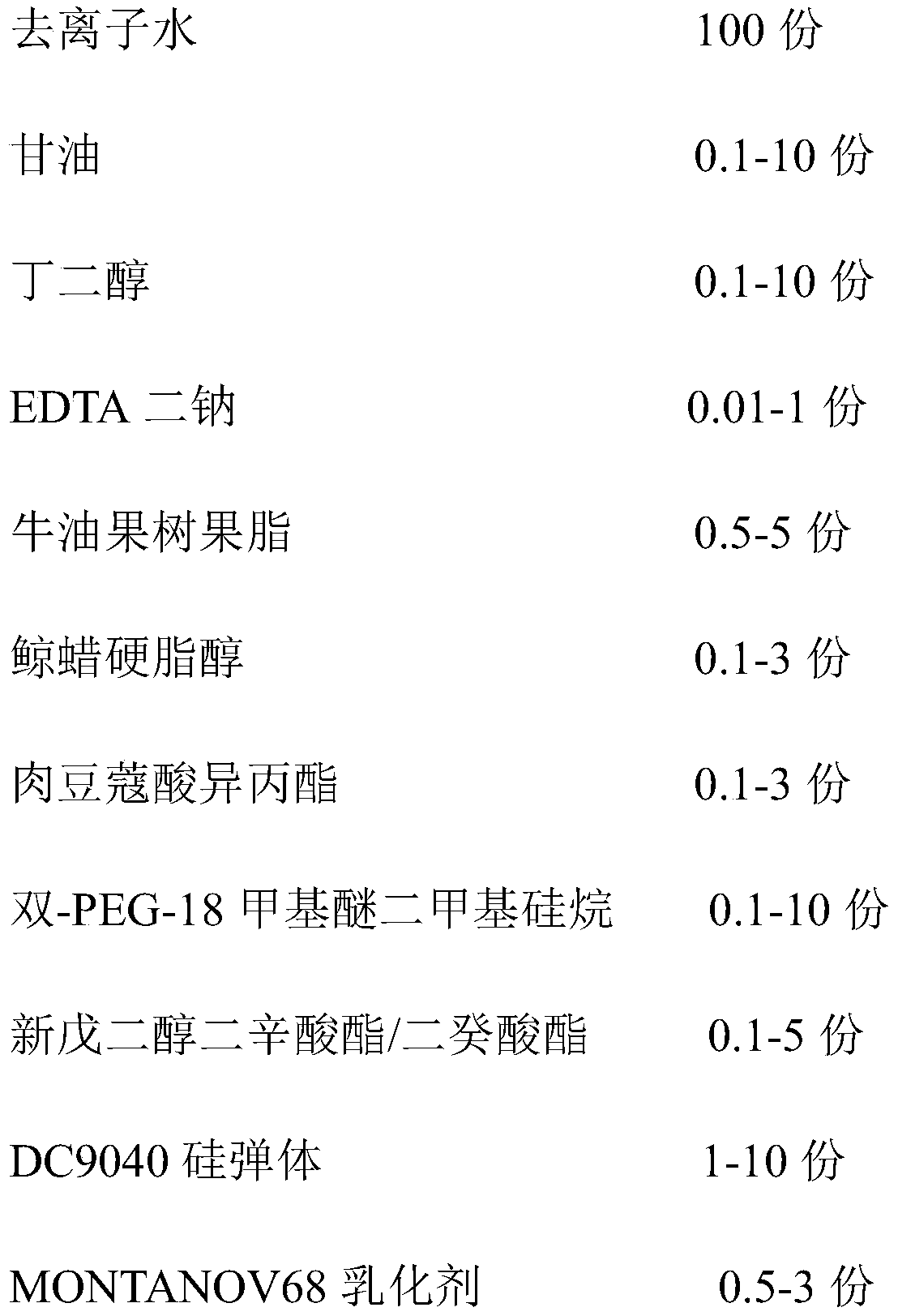

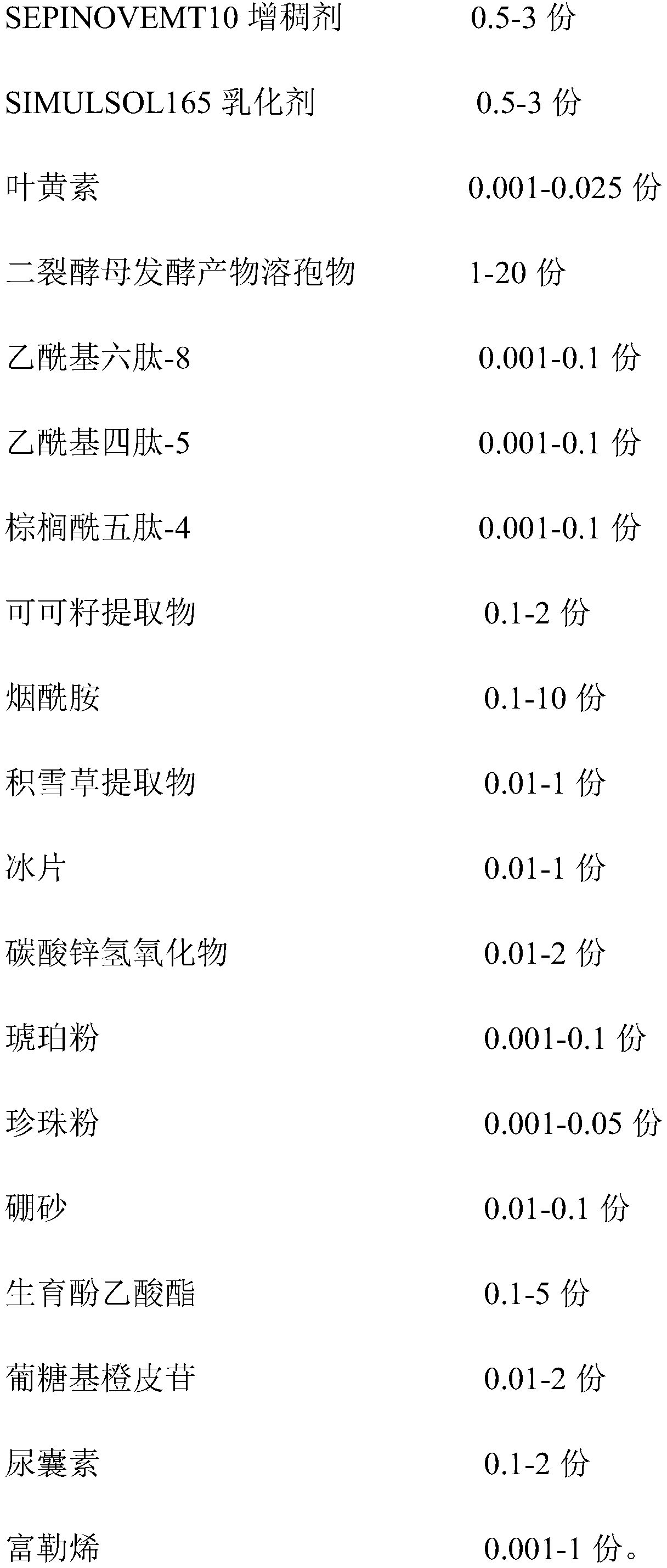

Repairing eye cream with anti-blue-light effect and preparation method thereof

ActiveCN111529417AAgainst infringementRepair delicate skinCosmetic preparationsToilet preparationsCentella asiatica extractButanediol

The invention provides a repairing eye cream with an anti-blue-light effect and a preparation method thereof. The repairing eye cream with the anti-blue-light effect is prepared from the following functional components of glycerol, butanediol, EDTA disodium, avocado butter, cetostearyl alcohol, isopropyl myristate, bis-PEG-18 methyl ether dimethyl silane, neopentyl glycol dicaprylate, DC9040 silicon elastomers, a MONTANOV68 emulsifier, a thickening agent SEPINOVEMT10, an emulsifying agent SIMULSOL165 and deionized water, wherein the functional components comprise xanthophyll, a bifidus yeast fermentation product spore lysate, acetyl hexapeptide-8, acetyl tetrapeptide-5, palmitoyl pentapeptide-4, a cocoa seed extract, nicotinamide, a centella asiatica extract, borneol, zinc carbonate hydroxide, amber powder, pearl powder, borax, tocopheryl acetate, glucosyl hesperidin, allantoin and fullerene. The repairing eye cream with the anti-blue-light effect not only has the effect of resisting blue light invasion, but also has the repairing effect, and is high in application prospect.

Owner:WUHAN MAYINGLONG MASSIVE HEALTH CO LTD

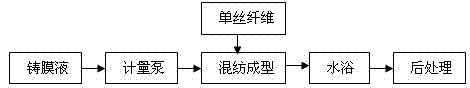

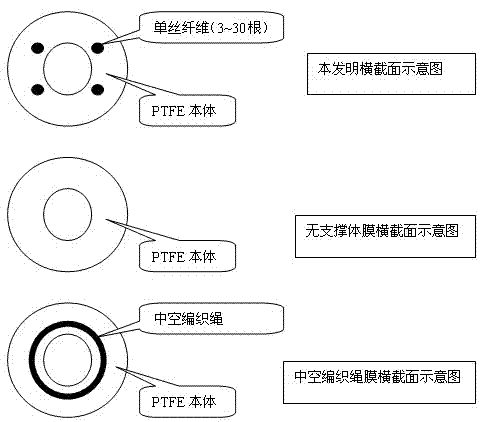

Polytetrafluoroethylene membrane with supporting materials and preparation method thereof

The invention discloses a polytetrafluoroethylene hollow fibrous membrane with supporting materials and a preparation method thereof. The preparation method is characterized by comprising the following steps: taking polyvinyl alcohol as a membrane forming carrier, silica as an inorganic additive, boric acid as a viscosity regulator and tributyl phosphate or polydimethylsilane as a defoamer to prepare a polytetrafluoroethylene hollow fibrous membrane by a dry-wet method, ensuring monofilaments to enter into a spinneret via other inlets and carrying out blending to prepare the polytetrafluoroethylene hollow fibrous composite membrane with the supporting materials, wherein the monofilament fibrous materials are polyester, spandex or polyurethane and have diameter of 0.01-2mm. The membrane and the preparation method have the following beneficial effects: the defect that the hollow fibrous membranes without supports have insufficient physical tensile strength and are easy to suffer from filament break is overcome; the physical tensile strength of the membrane disclosed by the invention is improved by more than several times compared with that of the hollow fibrous membranes without supports; support and membrane stripping can be avoided; the water flux and manufacturing cost of the membrane disclosed by the invention are equivalent to the water flux and manufacturing cost of the hollow fibers without supports; and the membrane has technical and economic breakthroughs, can replace the existing hollow fiber products and has great economic and social benefits.

Owner:ZHEJIANG CREATION ENVIRONMENT TECH

Method for preparing carbon/silicon carbide complex fiber-reinforced aluminum-based foam material

InactiveCN103981467AEvenly dispersedAdjust surface tensionCarbon fibresConjugated artificial filamentsRare-earth elementHigh absorption

The invention discloses a method for preparing a carbon / silicon carbide complex fiber-reinforced aluminum-based foam material. According to the method, polydimethylsilane and polyvinyl chloride are taken as the raw materials, the polydimethylsilane accounts for 92-95% of the mass of the raw materials, and the polyvinyl chloride accounts for 5-8% of the mass of the raw materials; and the complex fiber are firstly subjected to the surface treatment to improve the homodisperse and wettability in metal melt effectively, carbon / silicon carbide complex fibers are directly added into a base metal melt through a liquid-state metal stirring technology, so that the complex fibers are uniformly dispersed in the metal melt and are compounded with the metal melt. Due to the addition of surface active elements like calcium metal, magnesium as well as rare earth elements, the surface tension of the aluminum melt is regulated, and bubbles generated in the foaming process are more stable and uniform. The carbon / silicon carbide complex fiber-reinforced aluminum-based foam material has high strength, high toughness, high absorption and high damping force characteristic.

Owner:TIANJIN UNIV

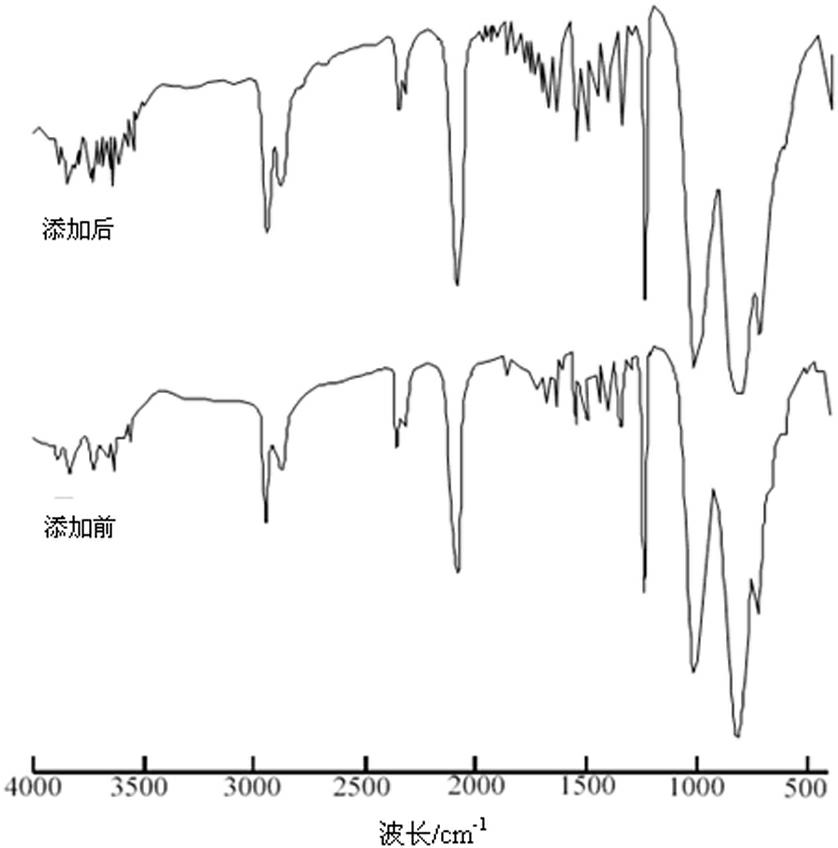

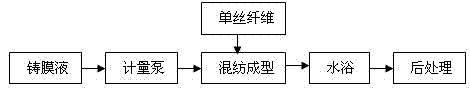

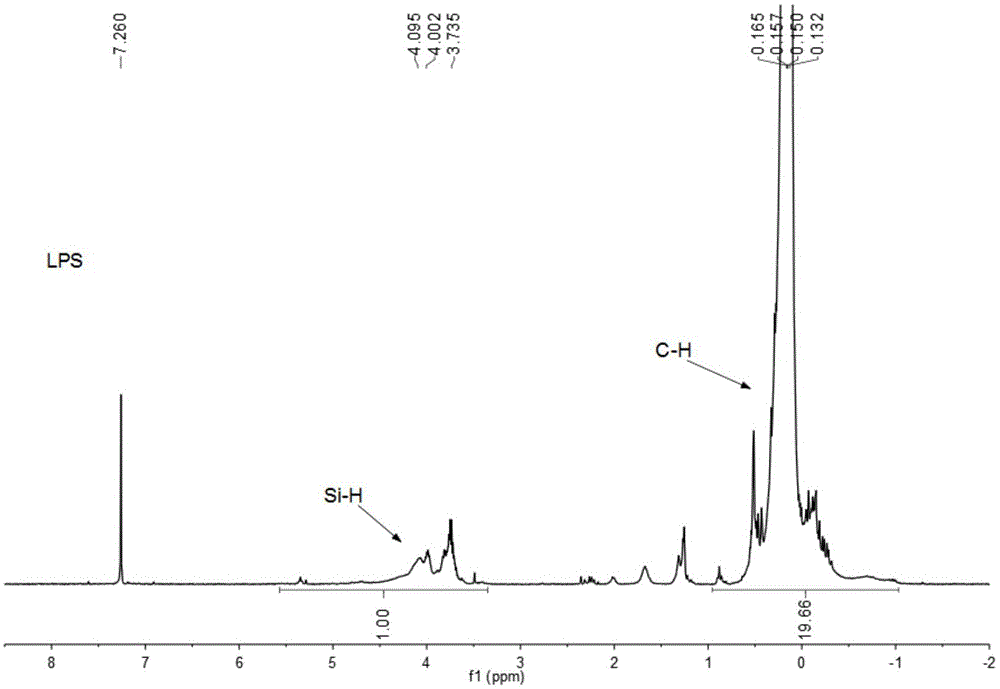

Catalytic rearrangement preparation method of polycarbosilane

ActiveCN105273199AHigh synthetic yieldStrong Lewis acidityFibre chemical featuresSilanesReaction temperature

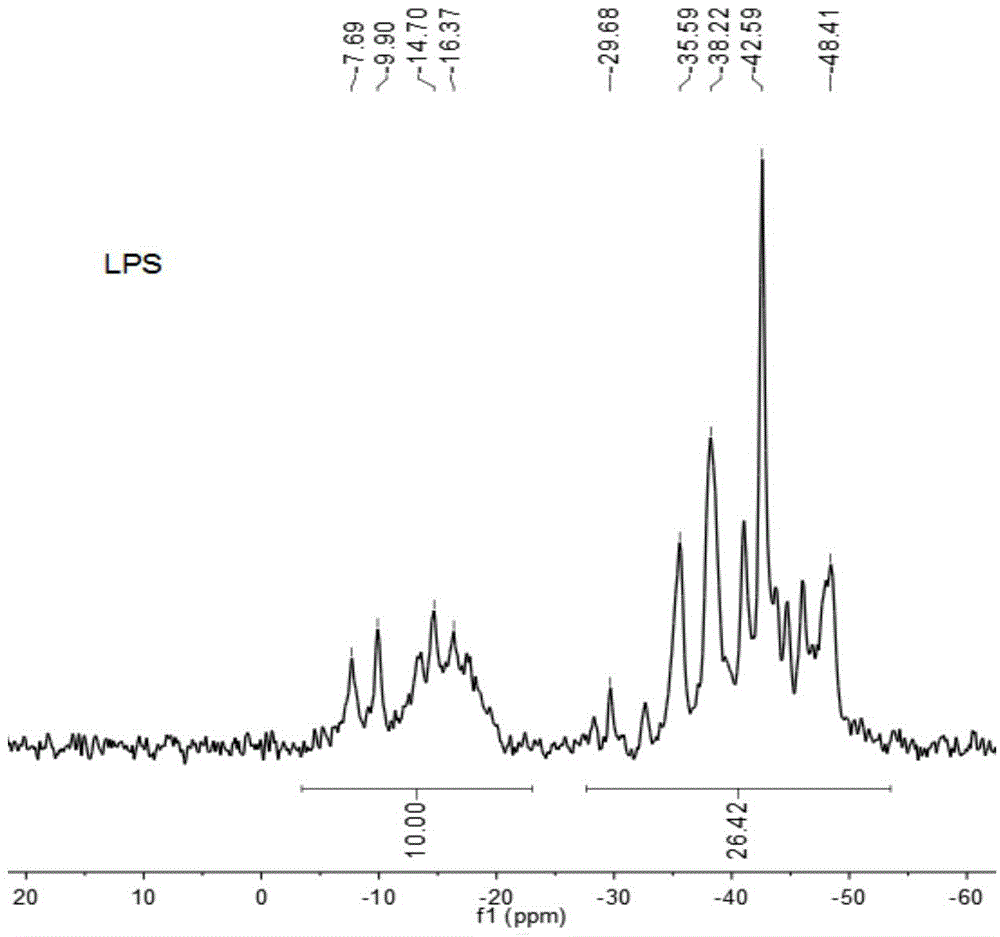

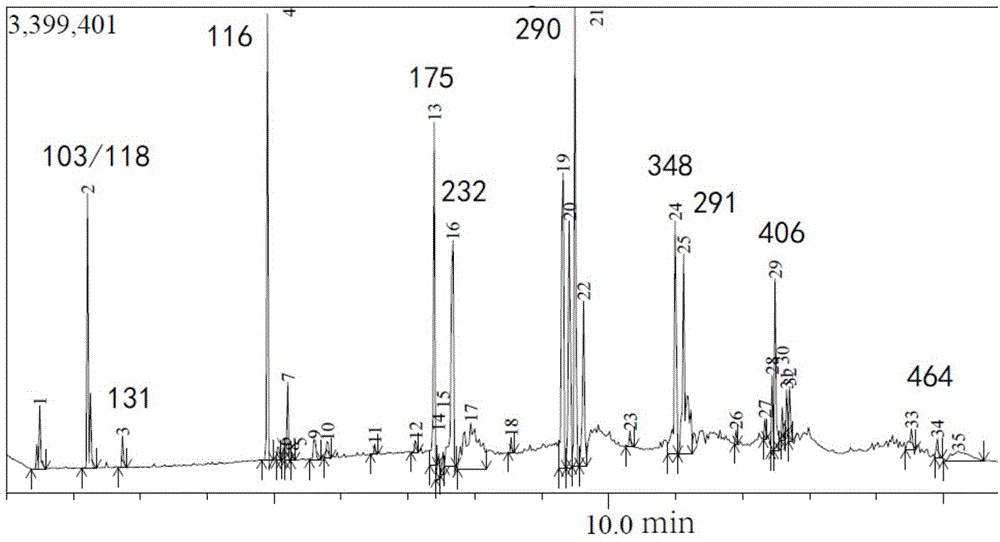

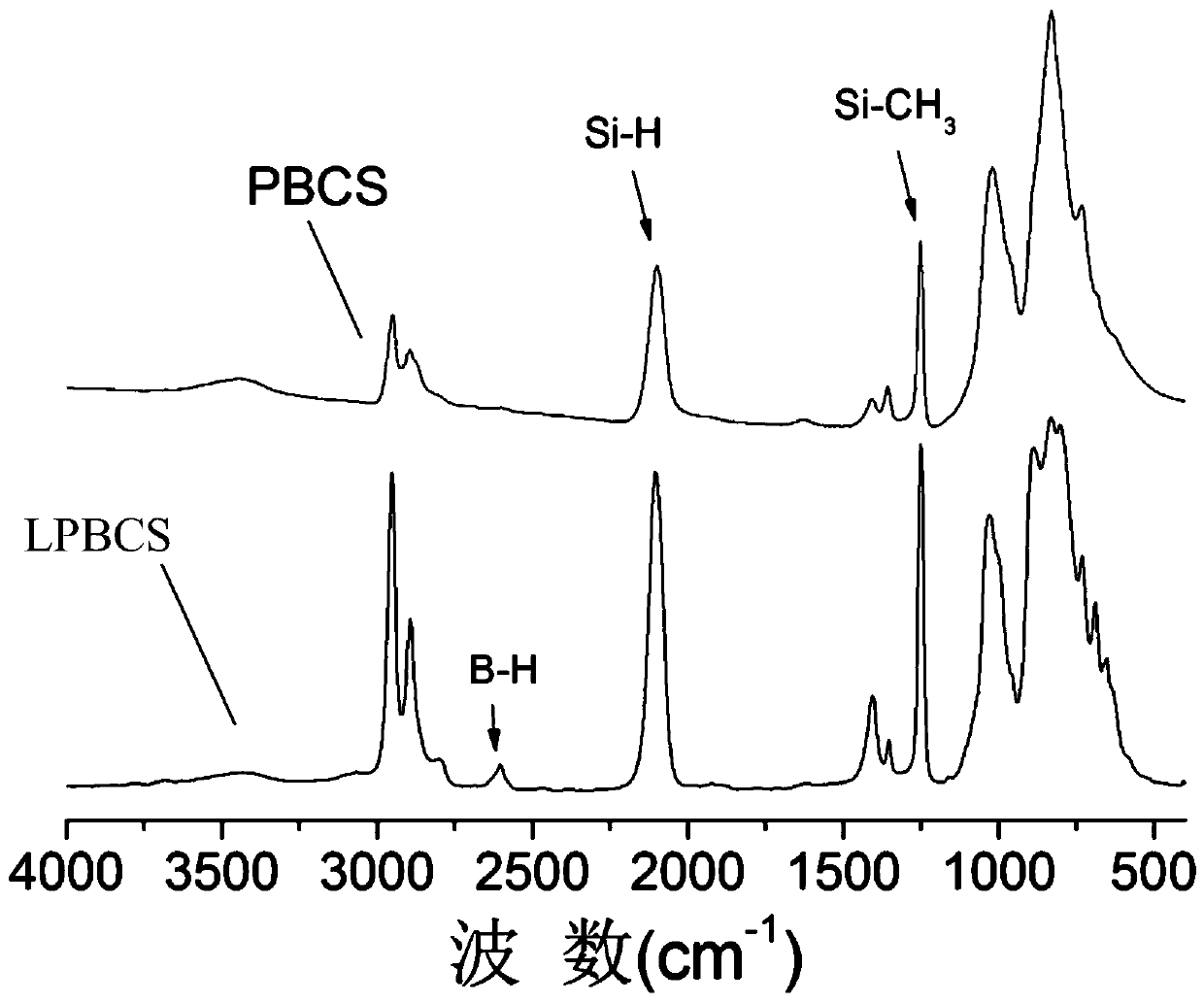

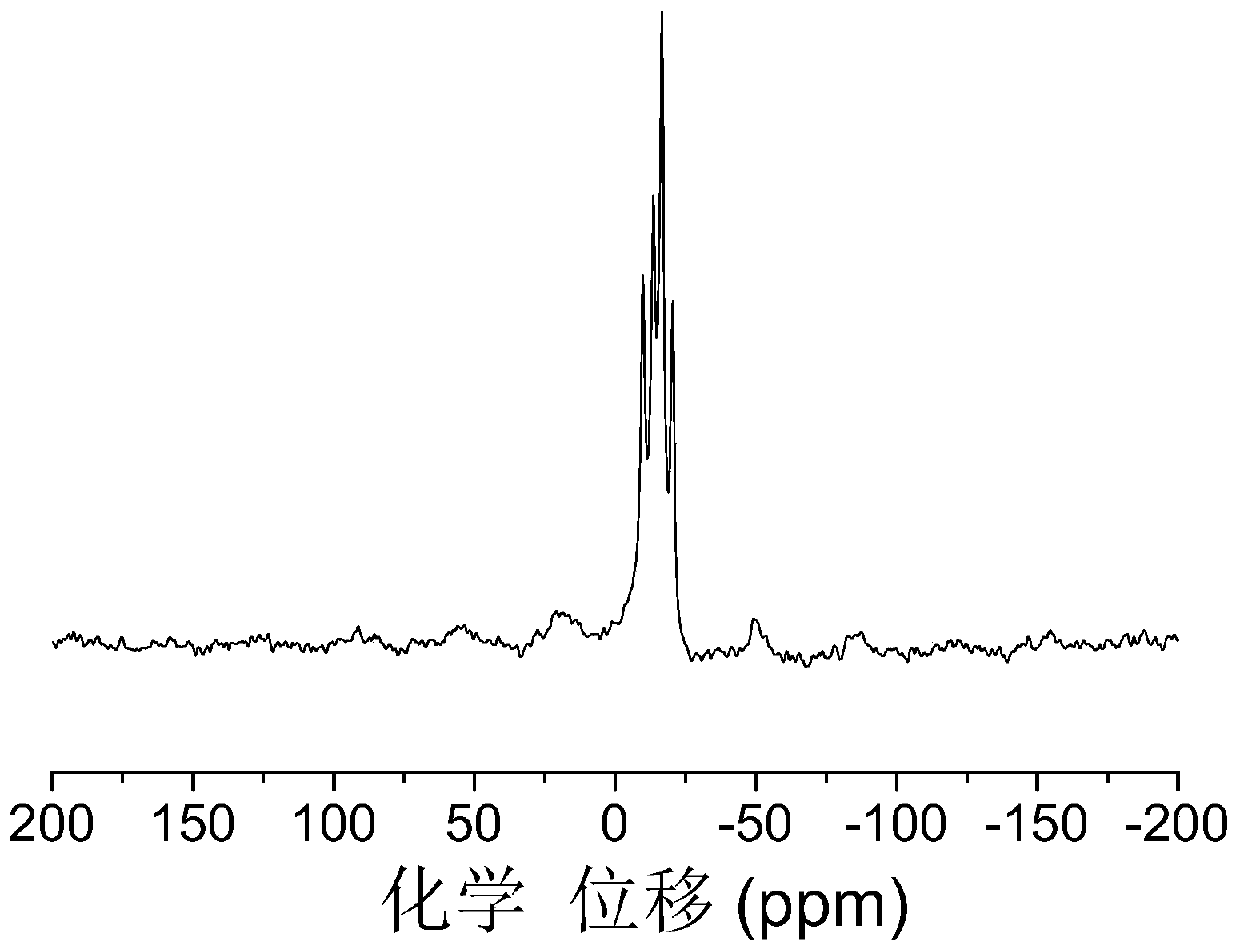

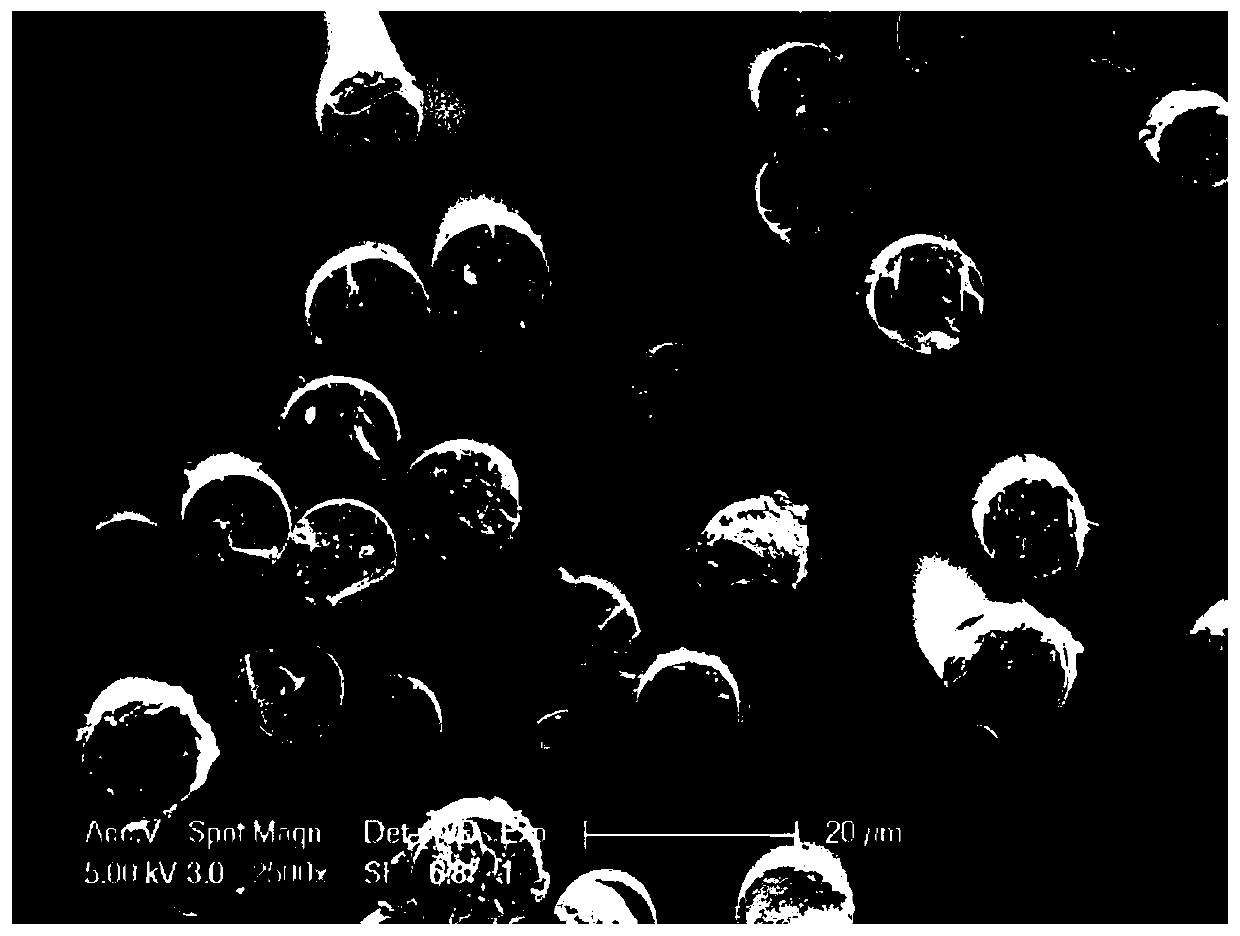

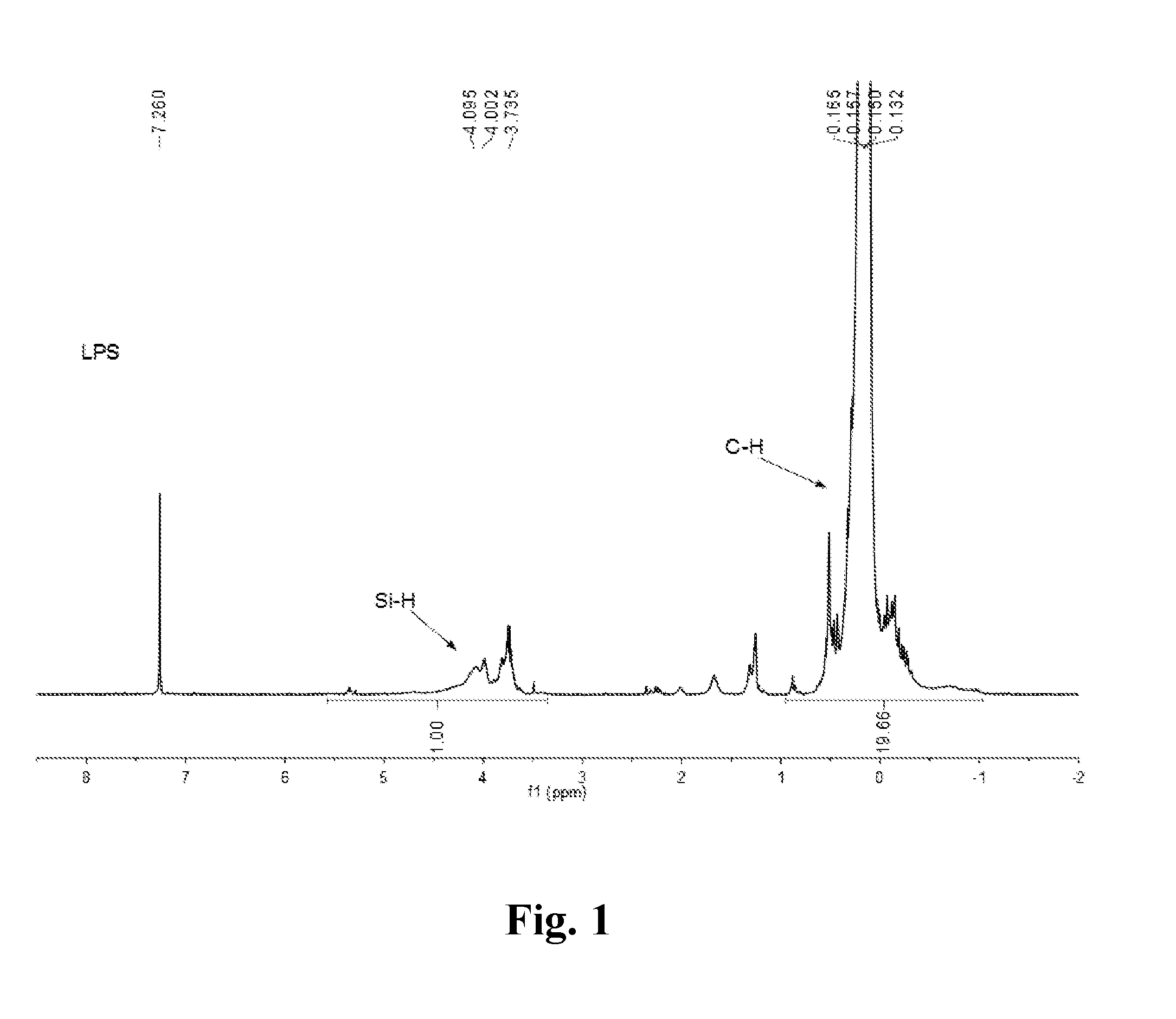

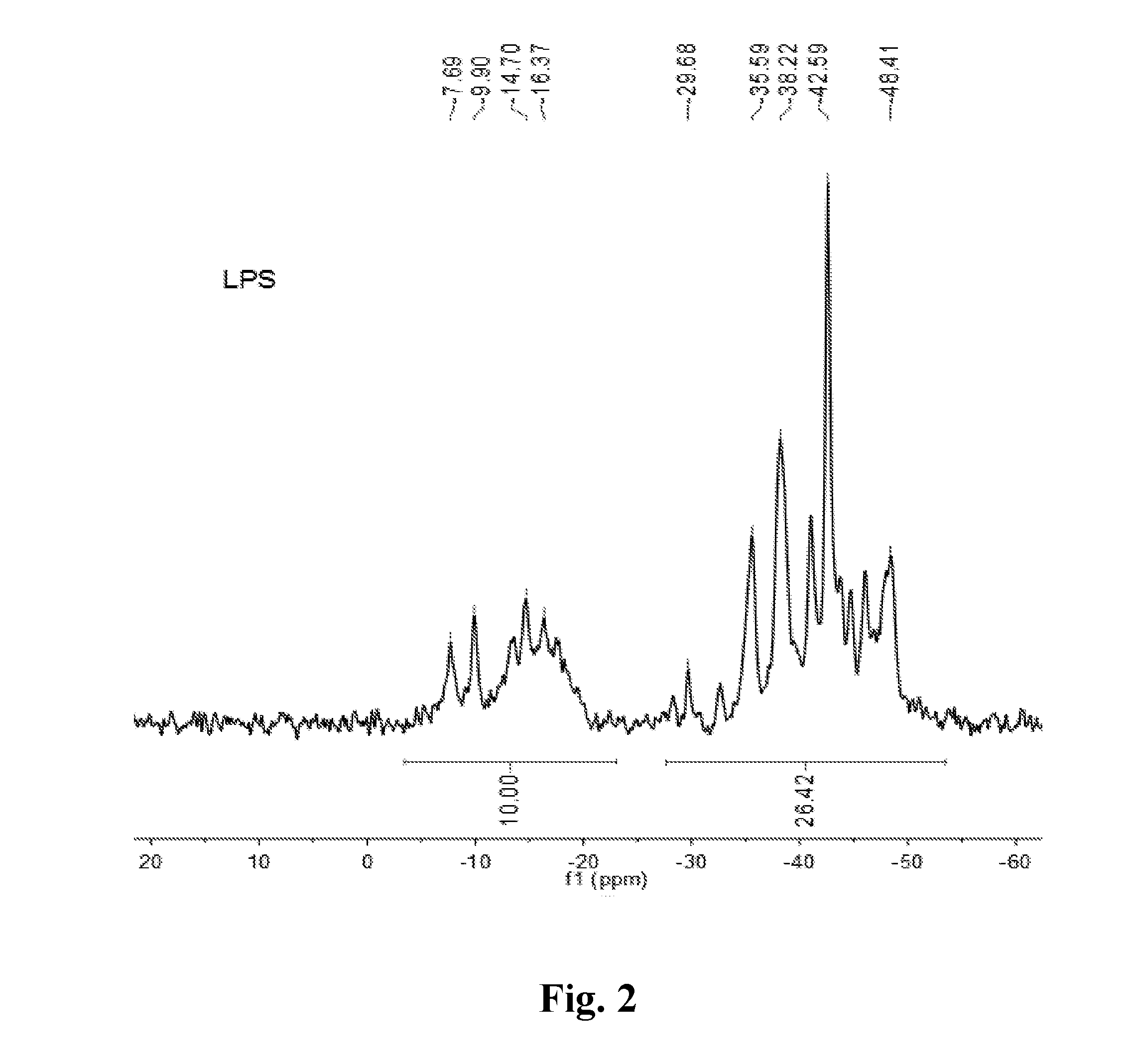

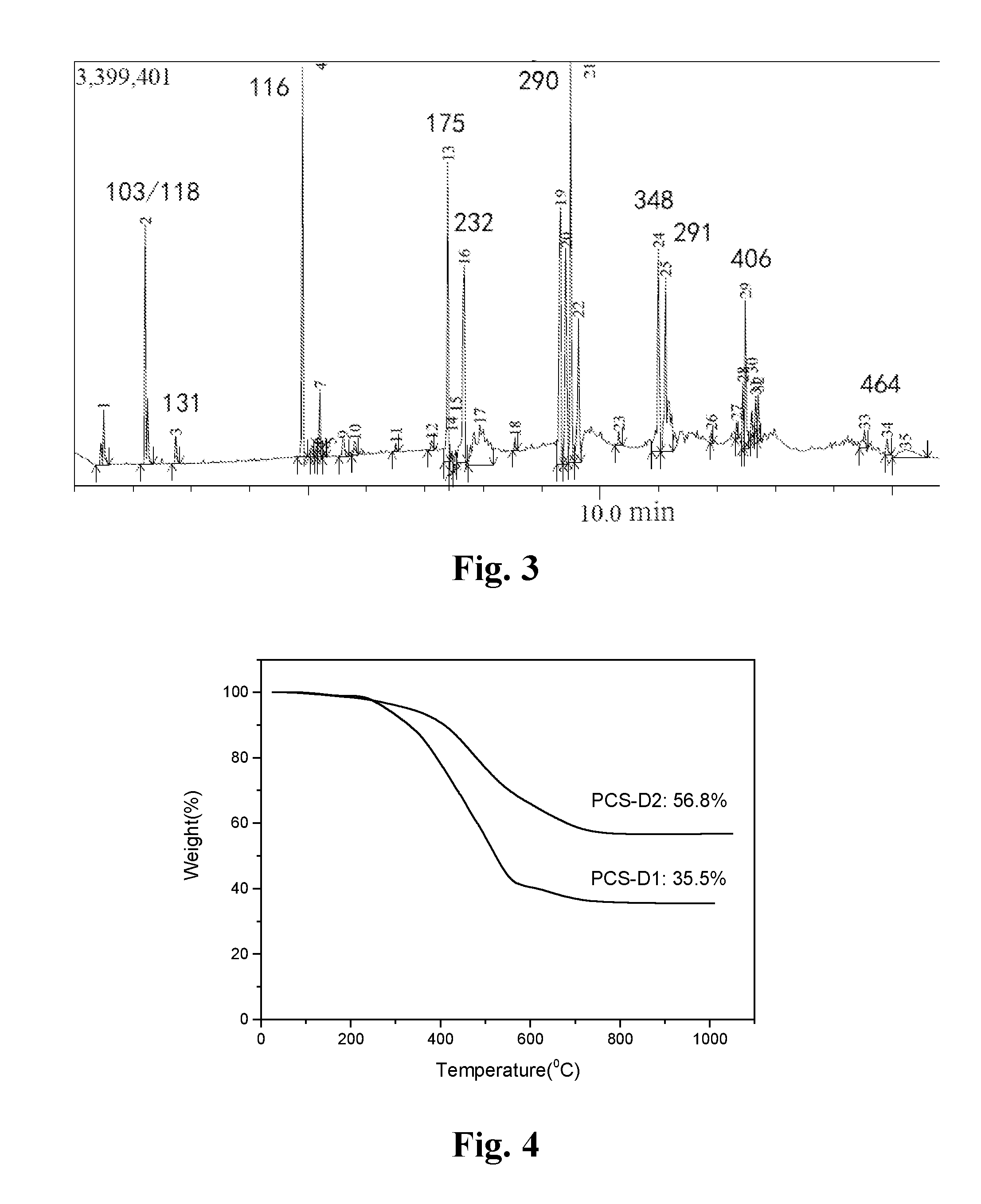

The invention relates to a method for preparing polycarbosilane through cracking rearrangement of a cyclic silane compound or chain polysilane under the catalytic effect of trace (lower than 1wt%) boron-containing catalyst. According to the invention, polydimethylsilane (PDMS) or a pyrolysis product thereof which is a liquid-state silane-carbosilane compound (LPS) is adopted as a raw material; lower than 1wt% (relative to the amount of the raw material) of the boron-containing catalyst is added; the temperature is gradually increased to a reaction temperature under a normal pressure or a high pressure, such that a pyrolysis / rearrangement reaction is carried out, and solid-state polycarbosilane (PCS) with relatively high ceramic yield is obtained. The method provided by the invention has the advantages of short reaction time, high synthesis yield, good product quality, simple equipment and safe operation. The prepared polycarbosilane is a SiC precursor polymer, and can be used in the preparations of SiC fiber and SiC-based composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Boron-containing silicon carbide fiber and preparation method thereof

ActiveCN110629324ASimple preparation processFew stepsFibre chemical featuresLiquid stateRoom temperature

The invention discloses a boron-containing silicon carbide fiber and a preparation method thereof. The preparation method of the boron-containing silicon carbide fiber comprises the following steps: in a closed reaction container, carrying out synthesis reaction on polysilacarbosilane and a boron-containing monomer at high temperature and under high pressure to generate a boron-containing polycarbosilane crude material, wherein the polysilacarbosilane is a low-molecular product of polydimethylsiloxane subjected to high-temperature cracking, is in a liquid state at room temperature, and has a molecular weight less than 1000 g / mol; dissolving and filtering the boron-containing polycarbosilane crude material to obtain a spinning-grade boron-containing polycarbosilane precursor; and carrying out melt spinning, non-melting, high-temperature sintering and sintering treatment on the spinning-grade boron-containing polycarbosilane precursor to obtain the boron-containing silicon carbide fiber.Compared with the prior art, the preparation method provided by the invention is simple in process and easy to operate, and the synthesized boron-containing polycarbosilane precursor has the advantages of good spinnability, convenience in adjustment of boron content and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

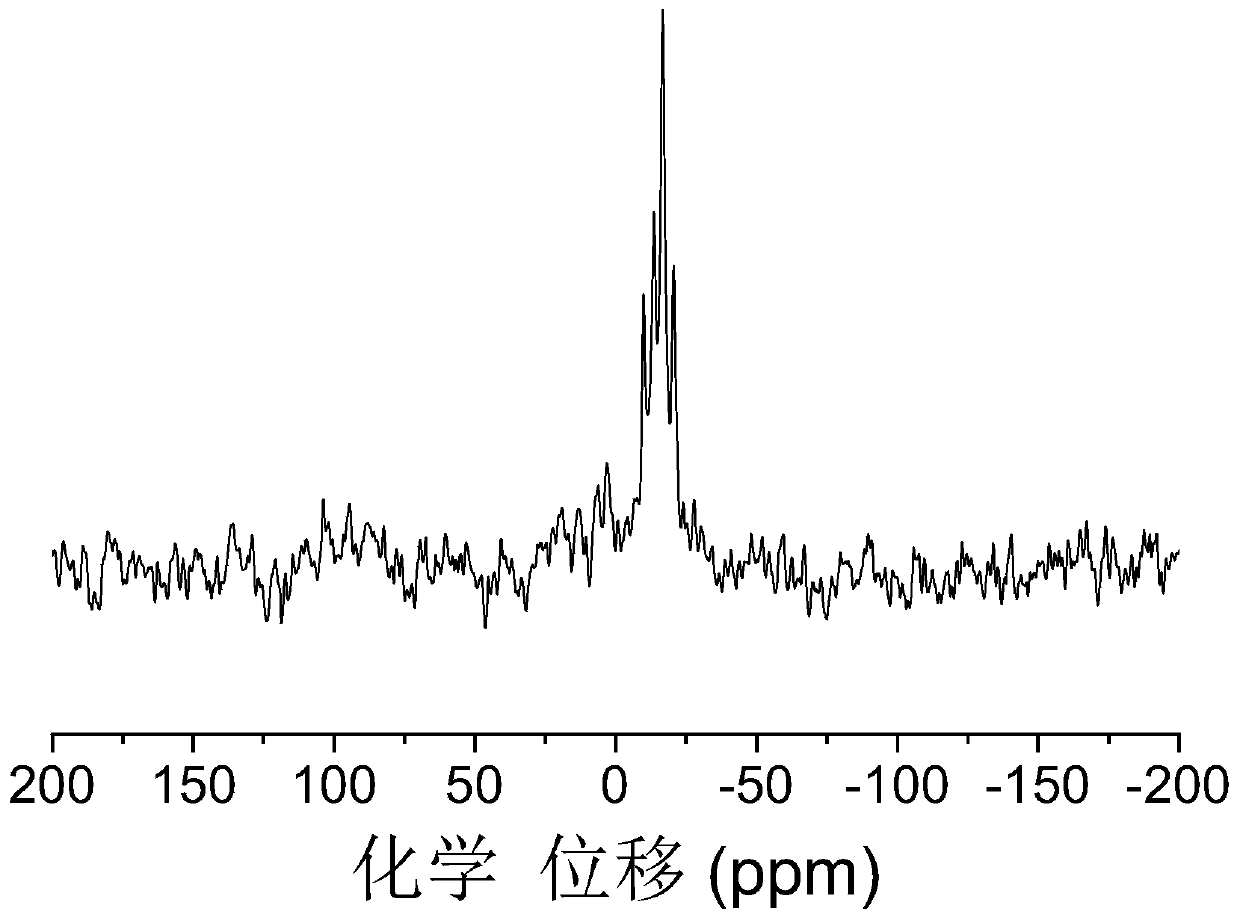

Method for preparing polycarbosilane by catalytic rearranging

This invention provides a method for preparing a polycarbosilane by decomposition and rearrangement a cyclic silane compound or chain polysilane under the catalysis of a boron-containing catalyst in a trace amount (less than 1 wt %). In the method, poly(dimethylsilane) (denoted as PDMS) or a thermal decomposition product thereof, i.e., a liquid silane-carbosilane compound (denoted as LPS), is used as the raw material, less than 1 wt % of the boron-containing catalyst (with respect to the amount of the raw material) is added, and then the temperature is gradually increased to the reaction temperature under atmospheric pressure or high pressure to perform the thermal decomposition / rearrangement reaction so as to obtain solid polycarbosilane (PCS) with a higher ceramic yield. This method has advantages, such as short reaction time, high synthetic yield, good product quality, simple equipment and safe operation; and the polycarbosilane prepared is a polymeric precursor for SiC, and can be used for the preparation of SiC fibres and SiC-based composite materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Aluminium oxide ceramic composite lining board and preparing method

The present invention is composite alumina ceramic lining board and its preparation process. The composite aluminum oxide ceramic lining board is prepared with alumina ceramic powder 75-85 wt%, acetone 2-4 wt%, glass bead 1.5-3.5 wt%, triethyl dimethyl silane 0.5-2.5 wt%, titanate 4-6 wt% and quartzite 5-10 wt%, and through mixing, cold molding, heating at 380-420deg.c for 8-12 hr, hot pressing at 18 -22 MPa for 0.5-2 hr and cooling to normal temperature. The composite alumina ceramic lining board has the features of high temperature resistance, antioxidizing, high wear resistance, fire retarding, very low friction coefficient, relatively high strength and toughnes, etc. and is suitable for use in mechanical, chemical, and other industrial fields.

Owner:武东生

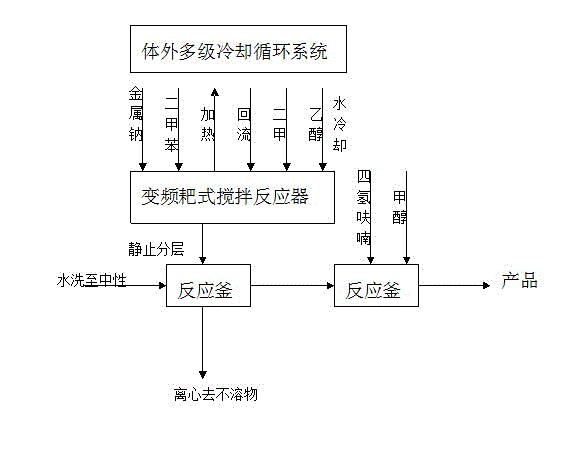

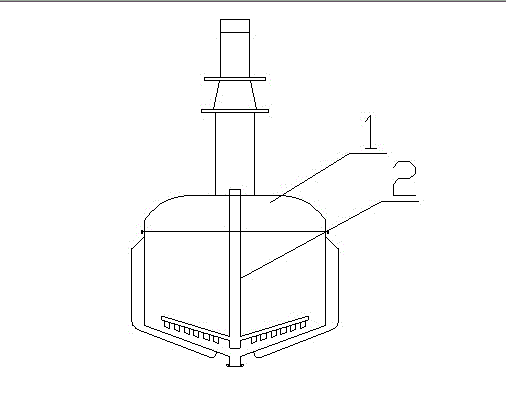

New process for industrialized production of ultralow-oxygen narrow-MWD (Molecular Weight Distribution) polydimethylsilane

The invention provides a new process for industrialized production of ultralow-oxygen narrow-MWD (Molecular Weight Distribution) polydimethylsilane. The ultralow-oxygen narrow-MWD polydimethylsilane is synthesized by adopting a Wurtz method. The new process comprises the following processing steps of: firstly drying a solvent required for reaction, carrying out secondary rectification for dimethyl dichlorosilane in advance to improve the purity of dimethyl dichlorosilane, installing a temperature and humidity controller in a factory to ensure that the environmental humidity is below 40%, and the like, so that the oxygen content in produced polydimethylsilane is minimized (only 0.1%), the polydimethylsilane can reach the product performance of developed countries, and more qualified silicon carbide ceramic fiber can be prepared; an external multi-stage cooling circulatory system is adopted to timely discharge heat released in the Wurtz synthesis method so as to guarantee safe and smooth industrial production; a reactor has the dual advantages of the stability of glass and metal strength, thus being excellent corrosion-resistant equipment, fully meeting the requirements of the Wurtz method, and realizing the industrialized application of the Wurtz coupling method to synthesizing polydimethylsilane.

Owner:江西星火狮达科技有限公司

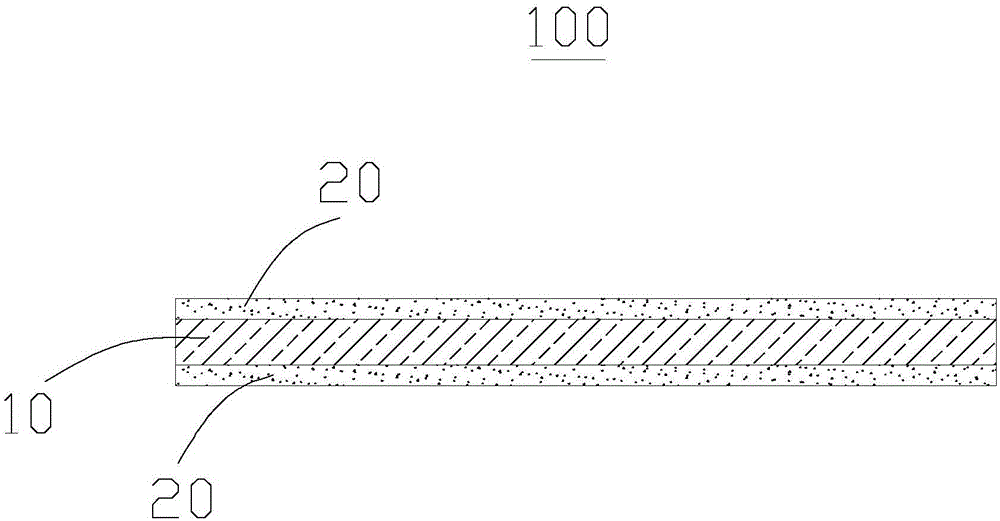

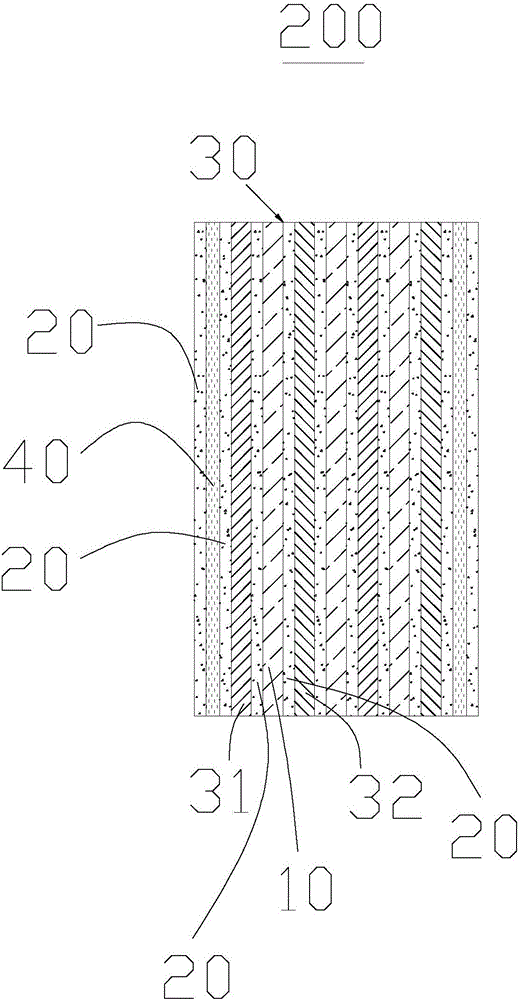

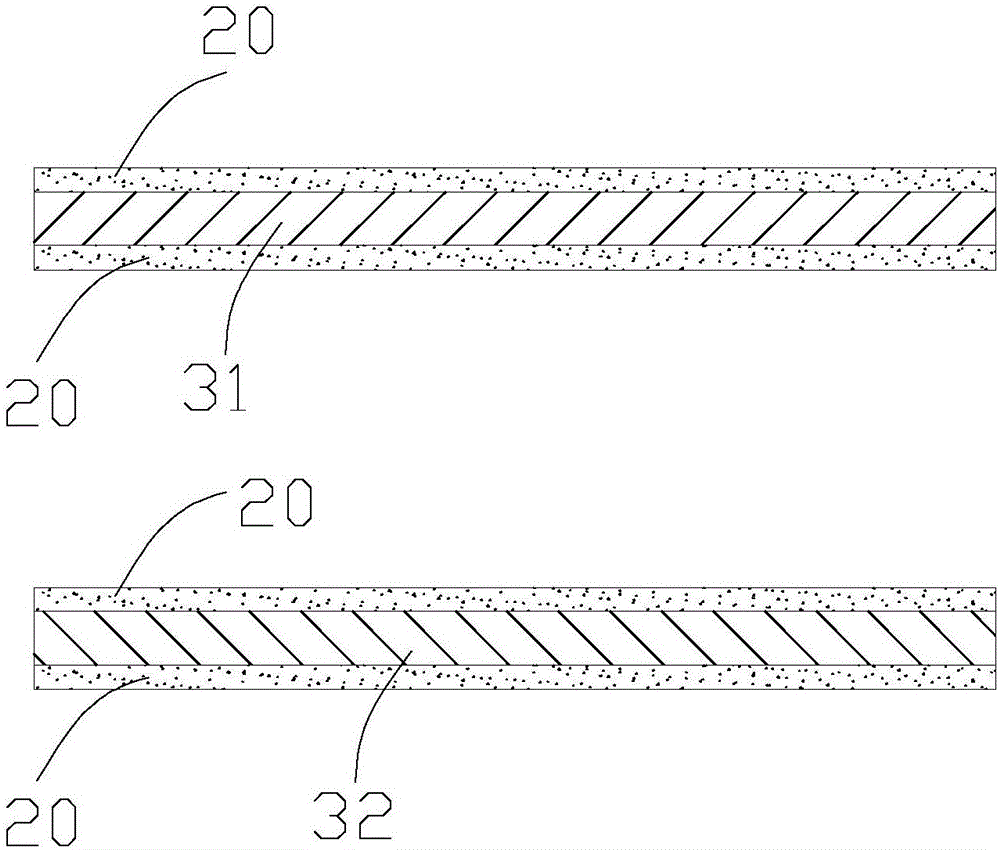

Ceramic diaphragm, lithium ion battery and preparation methods for ceramic diaphragm and lithium ion battery

InactiveCN106684289AImprove securityExtend your lifeFinal product manufactureSecondary cellsPolyetherimideDimethylsilane

The invention discloses ceramic diaphragm with high safety performance, a lithium ion battery and preparation methods for the ceramic diaphragm and lithium ion battery. The ceramic diaphragm comprises a diaphragm substrate and ceramic film coated outside of the diaphragm substrate. The diaphragm substrate comprises an inorganic filler, an organic binder and a hot-melt organism. The inorganic filler is selected from one or more of nano aluminium hydroxide, aluminium oxide, barium sulfate, magnesium hydroxide and calcium carbonate inorganic materials. The organic binder is selected from one or more of polyvinylidene fluoride, polytetrafluoroethylene and polyoxyethylene macromolecule materials. The hot-melt organism is selected from one or more of tri(beta-chloroethyl) phosphate, cresyl diphenyl phosphate, trioctyl phosphate, triphenyl phosphate, tricresyl phosphate, polydimethylsiloxane, organic silicones , polystyrene containing silicon copolymers, polyetherimide, bisphenol F polycarbonate, polyurethane and polymethyl methacrylate.

Owner:OPTIMUM BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com