Patents

Literature

46 results about "Random materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

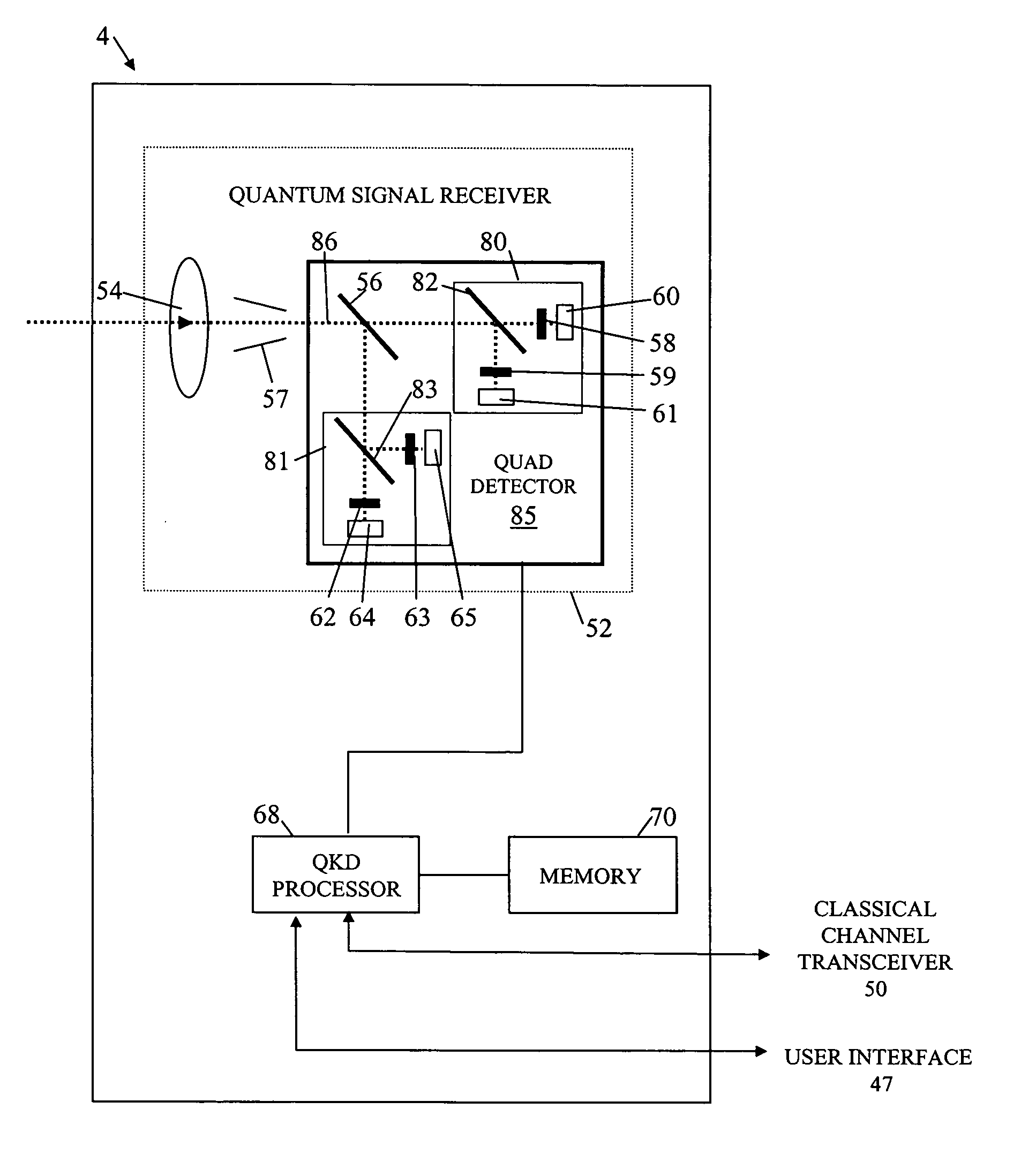

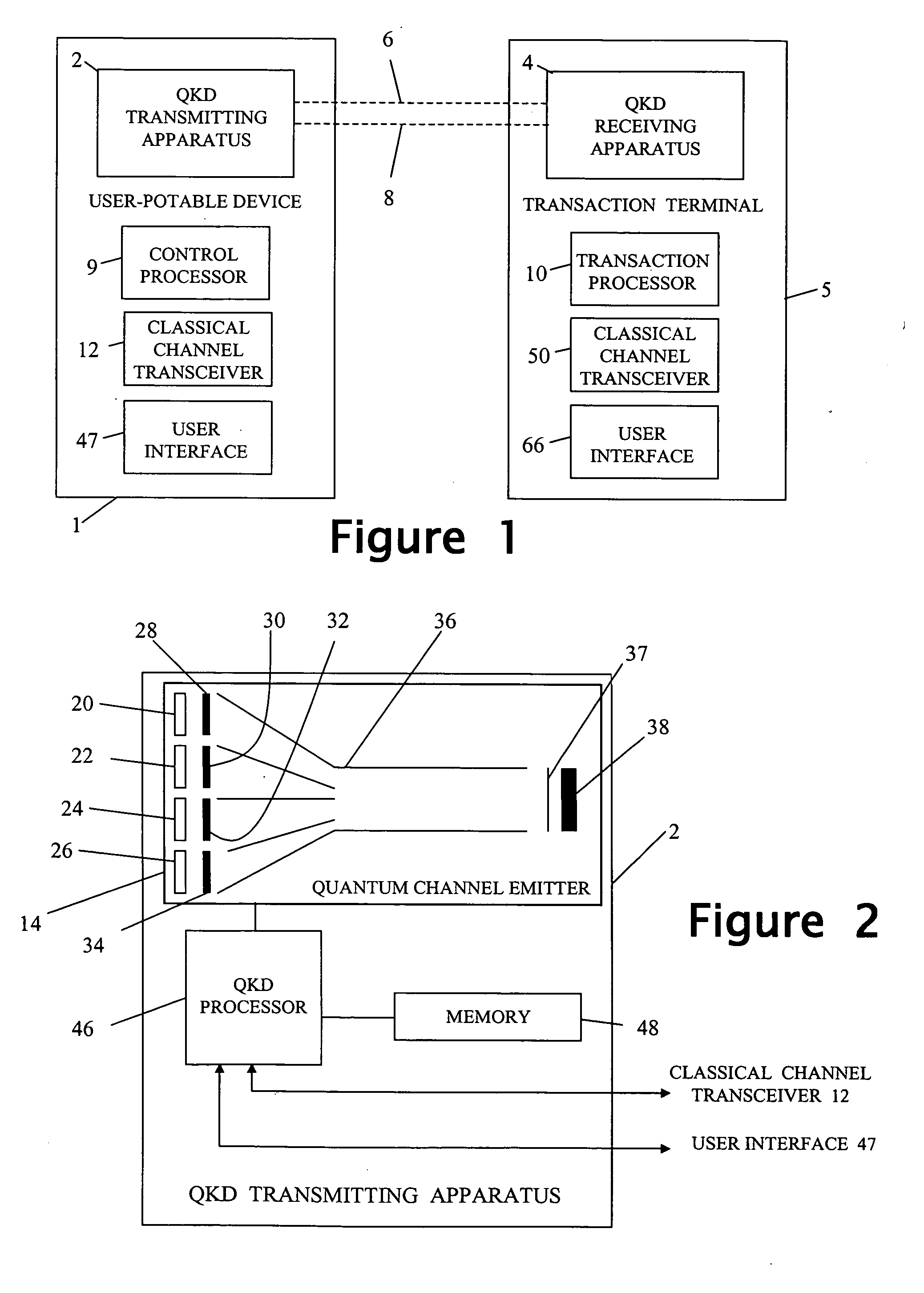

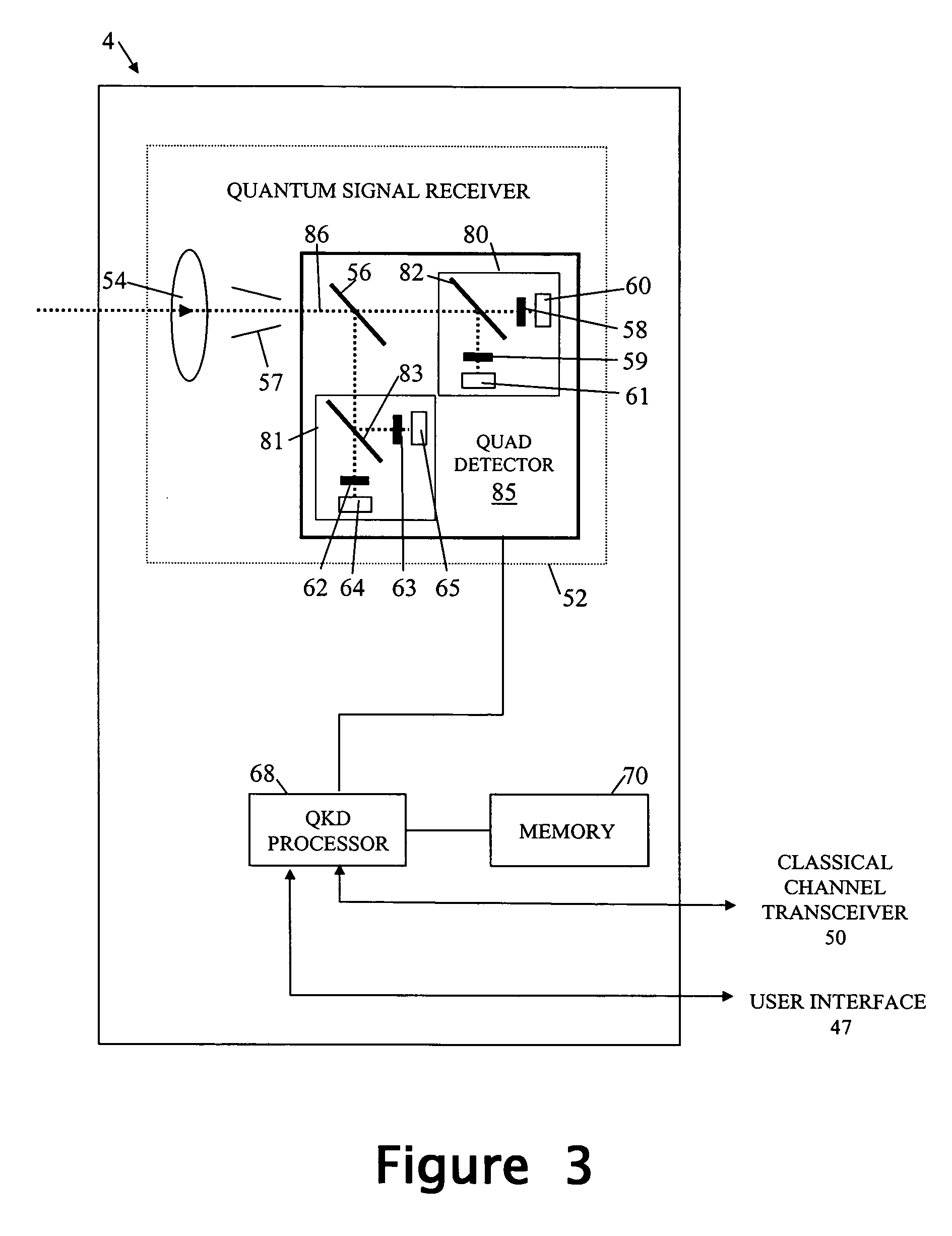

Secure transaction method and transaction terminal for use in implementing such method

InactiveUS20070016534A1Digital data processing detailsLine-of-sight transmissionComputer hardwareRandom materials

A secure transaction method is provided for publicly-accessible transaction terminals. The method uses quantum key distribution (QKD) between a hand-portable QKD device and a complimentary QKD apparatus incorporated the transaction terminal. After the QKD device has been brought up to the transaction terminal, the QKD device and the complimentary QKD apparatus of the terminal are is used to provide the device and terminal with new secret shared random material. The new secret shared random material is then used to establish a secure classical communication channel between the device and transaction terminal for conducting a transaction. An ATM terminal and POS terminal that use quantum key distribution are also disclosed.

Owner:HEWLETT PACKARD DEV CO LP

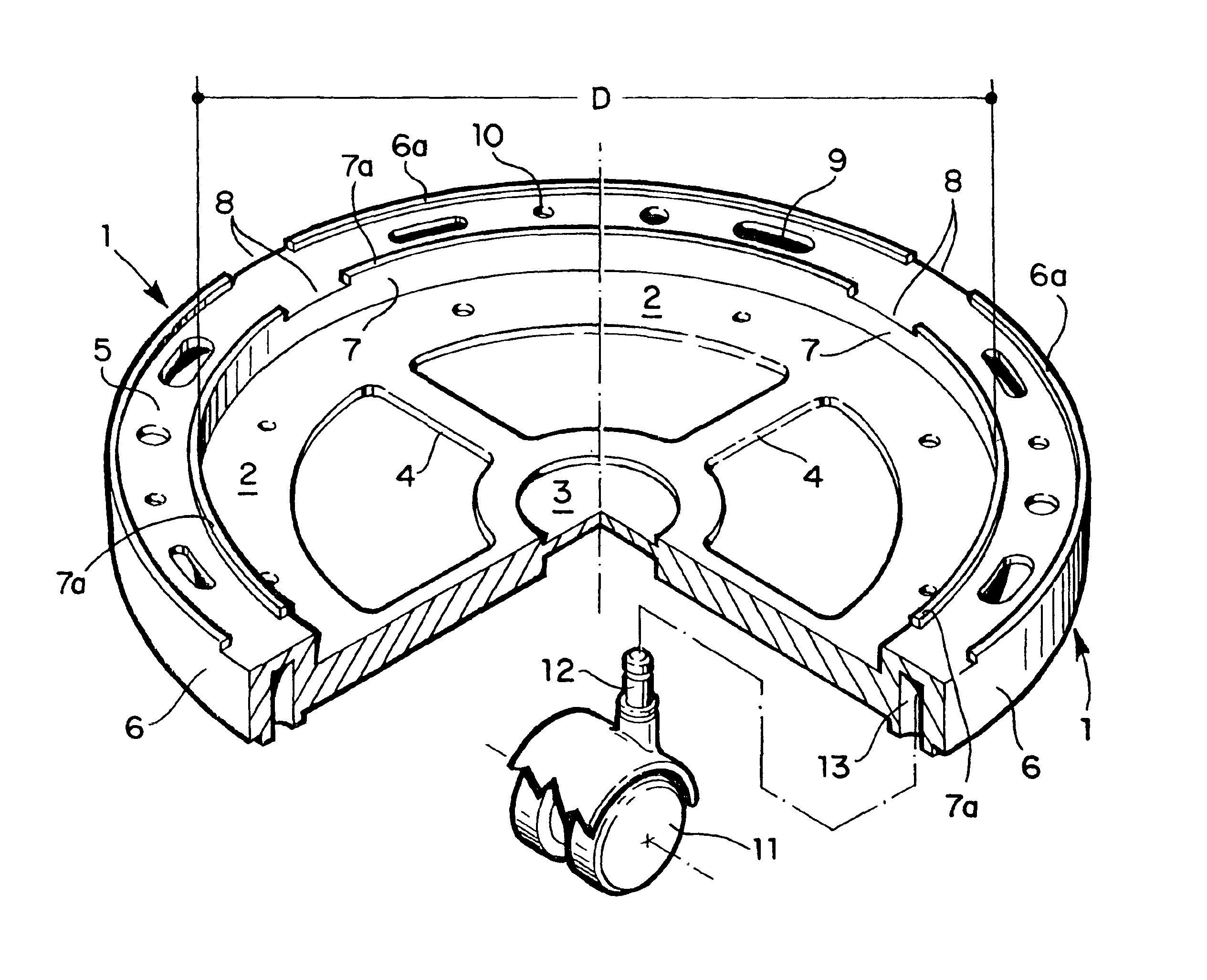

Caster supported mobile tray

InactiveUS6893032B2Carriage/perambulator with multiple axesHand carts with one axisRandom materialsEngineering

A multi-purpose wheeled carrier that includes various surfaces, recesses and unique features for providing alternative methods of containing, sorting and transporting random materials of various sizes, bulk and weight. The base of the carrier has a shallow upstanding circular wall large enough to accept a container of the 5 gallon size and a multiple of smaller containers, the base has other provisions for the reception of smaller parts and or tools. Recesses at other levels similarly have recesses again for accepting smaller items. Holes and slots provided at various heights allow for bulkier items to be fastened to the carrier by way of fasteners.

Owner:KERSHAW THOMAS R

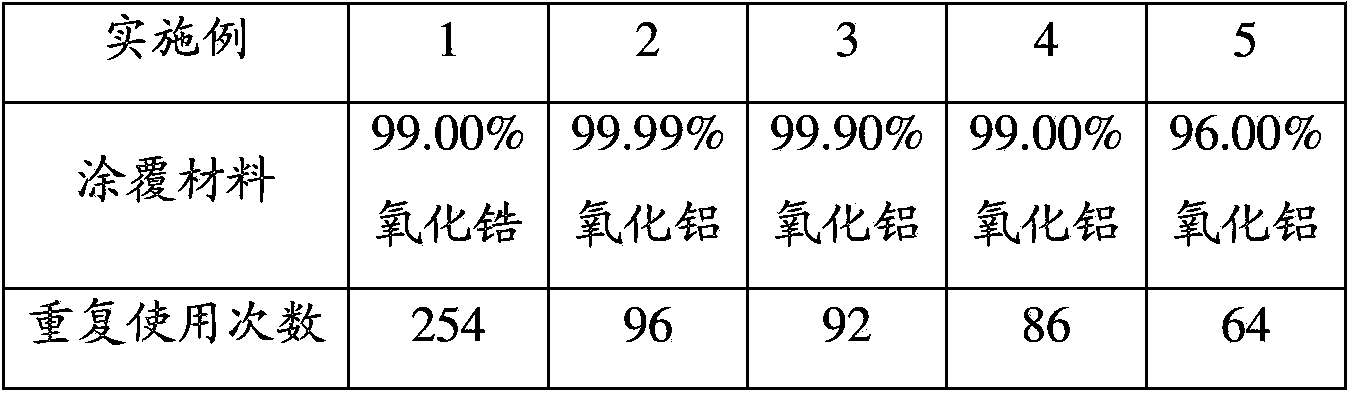

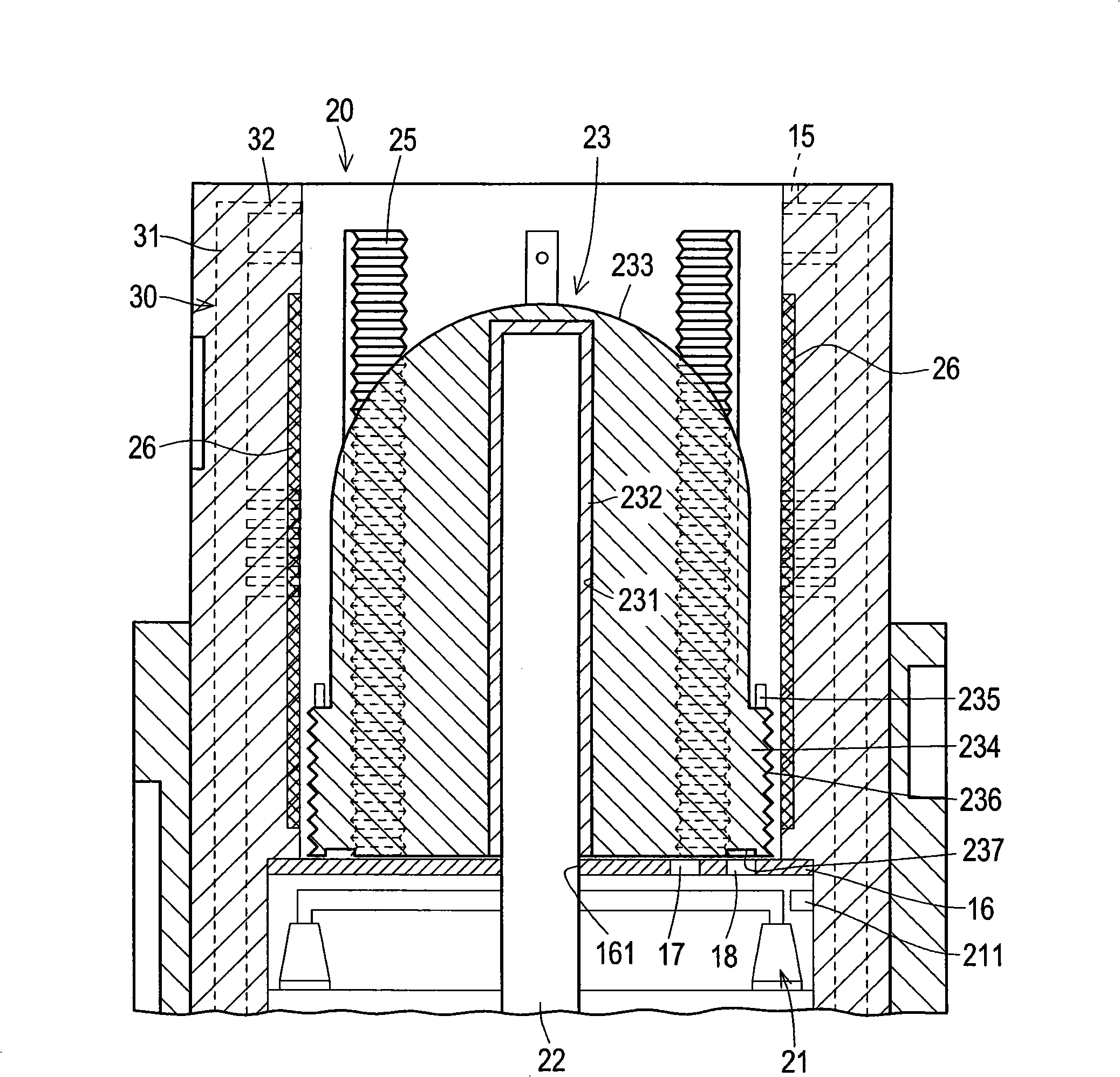

Ceramic coating sagger for manufacturing lithium ion anode active material and manufacturing method thereof

InactiveCN103884190AImprove thermal shock resistanceHigh mechanical strengthCharge supportsRandom materialsCeramic coating

The invention provides a ceramic coating sagger for manufacturing a lithium ion anode active material and a manufacturing method thereof, wherein the ceramic coating sagger suppresses material movement from the sagger to the lithium ion anode active material, and the lithium ion anode active material has high heat impact resistance and excellent mechanical strength. The ceramic coating sagger for manufacturing the lithium ion anode active material is characterized in that a random material selected from zirconium oxide, aluminum oxide, silicon oxide, spinel and magnesium oxide is used for performing ceramic coating on a contacting surface between the sagger body and the lithium ion anode active material, wherein the sagger body is made of inorganic material.

Owner:日本精细陶瓷有限公司

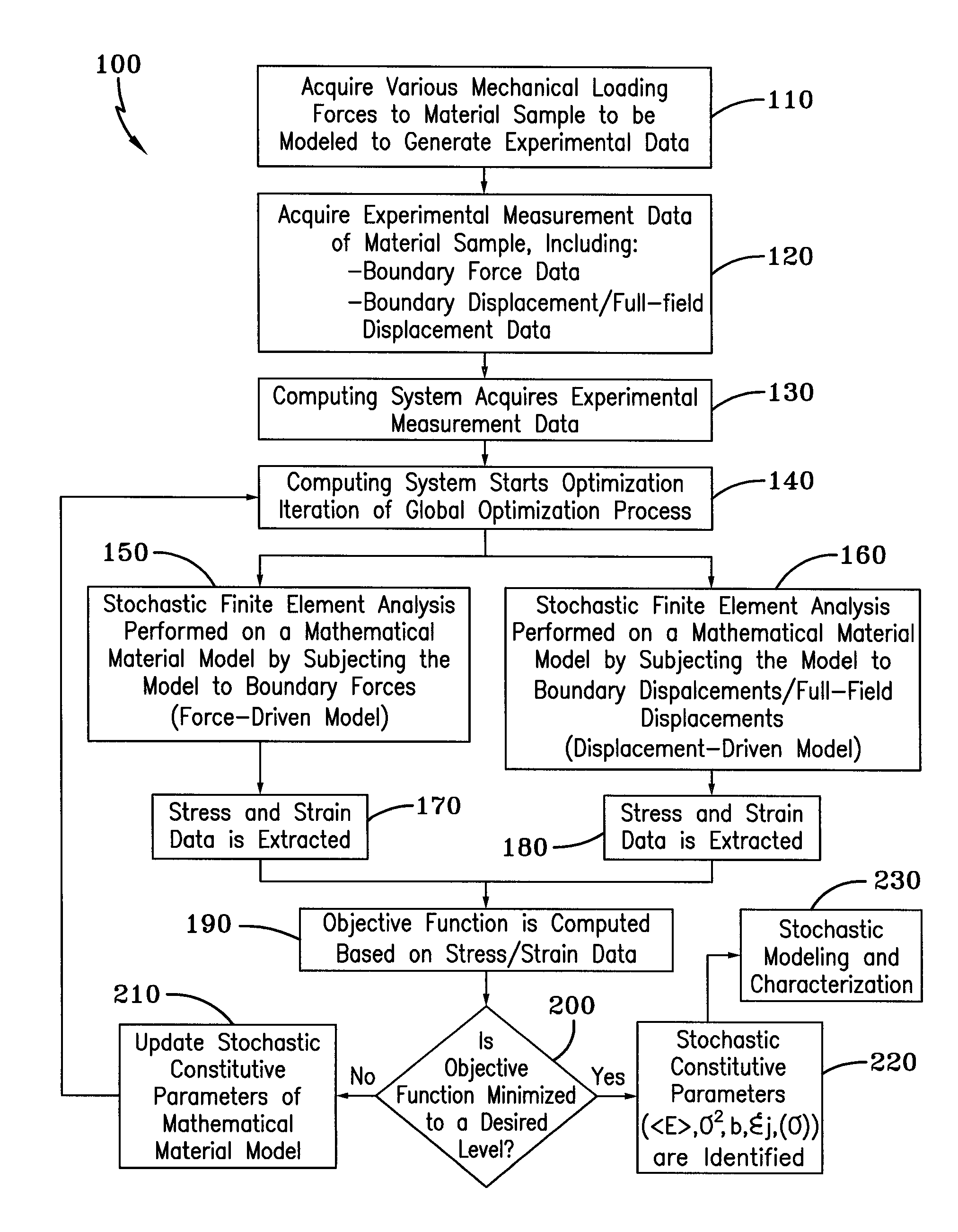

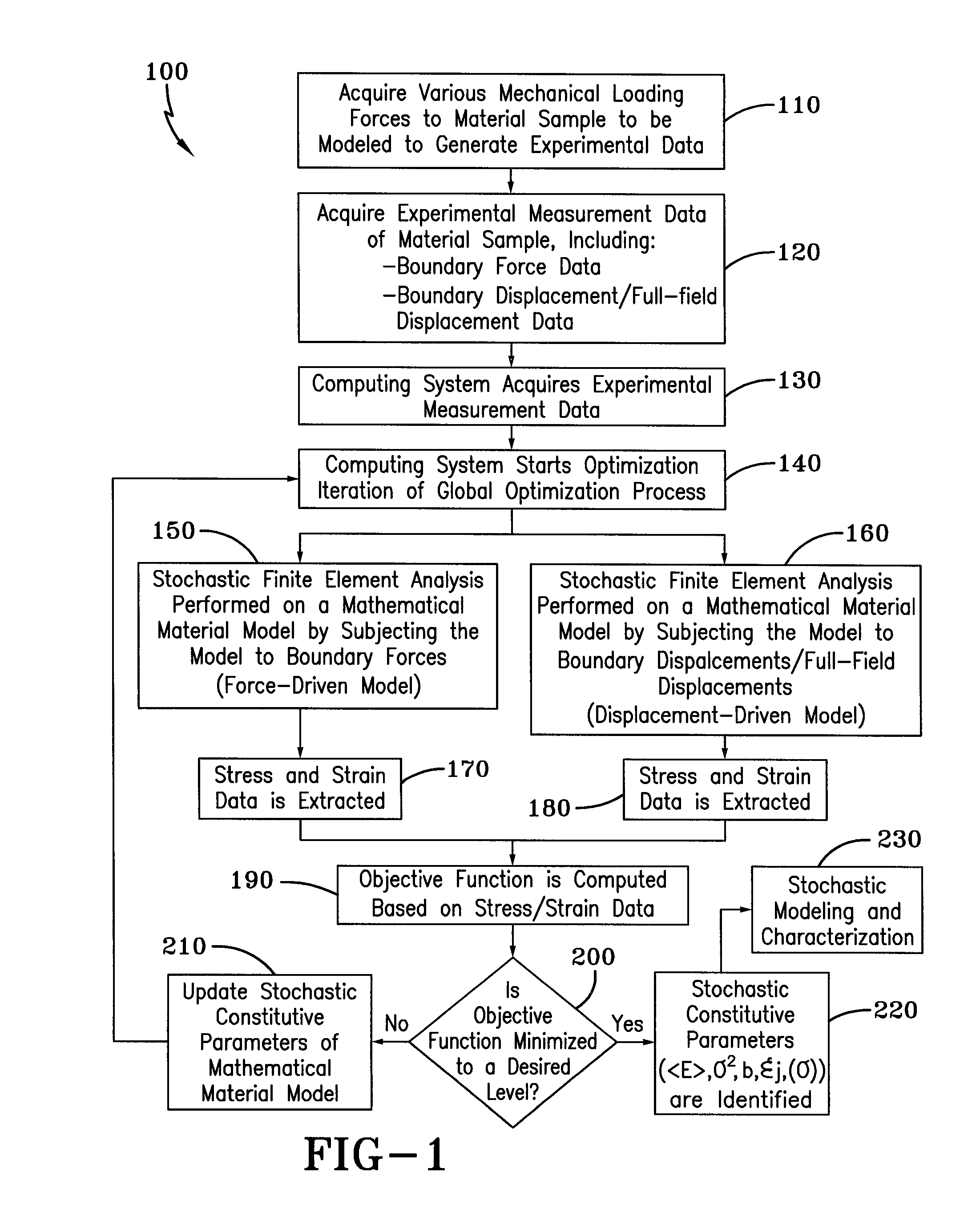

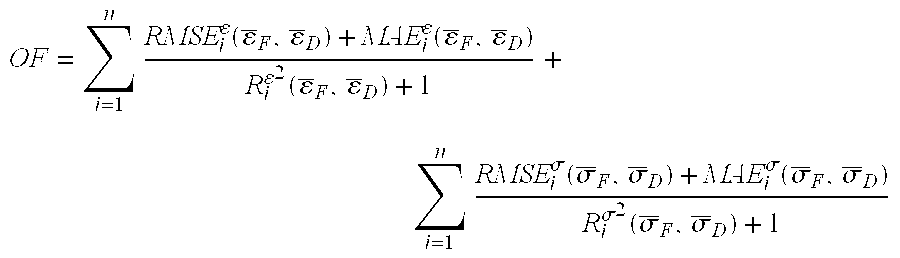

Method for Identifying Stochastic Information of Heterogeneous Materials

InactiveUS20150057988A1Minimize objective functionComputation using non-denominational number representationDesign optimisation/simulationRandom materialsElement analysis

A method for identifying stochastic information of a heterogeneous material utilizes physical loading measurements that are input into a global optimization process. The optimization process executes, in parallel, a force-driven non-linear finite element simulation and a displacement-driven finite element simulation of a constitutive model of the heterogeneous material. The constitutive models model the spatially varying random material properties (i.e. stochastic properties) using the Karhunen-Loeve expansion, thereby introducing the stochastic parameters, including spatial mean, spatial variance, and correlation length for example into the models. Stress and strain values for both the force-driven and displacement driven finite element analyses are input into an objective function, whereupon the finite element simulations are updated after each iteration of the optimization process is performed until the objective function is minimized to a desired level. This results in the identification of optimized stochastic parameters associated with the heterogeneous material under investigation.

Owner:THE UNIVERSITY OF AKRON

Nanometer polishing solution for titanium oxide film chemical mechanical planarization and application

InactiveCN102408836AAvoid damageNo pollutionElectrical apparatusPolishing compositions with abrasivesRandom materialsDimethylsilane

A nanometer polishing solution for titanium oxide film chemical mechanical planarization is formed by mixing a nanometer abrasive, a pH adjusting agent, a surfactant, a defoamer, a bactericide, an assistant cleaning agent, and a solvent, wherein the nanometer abrasive is cerium oxide or silica; the pH adjusting agent is a composite pH adjusting agent composed of an inorganic pH adjusting agent and an organic pH adjusting agent; the surfactant comprises silane polyglycol ether, polyglycol ether or dodecyl glycol ether; the defoamer is polydimethylsilane; the bactericide is isomeric thiazolinone; the assistant cleaning agent is isopropanol; and the solvent is deionized water; the nanometer polishing solution is applicable to the preparation of resistive random access memories based on titanium oxide film materials. The advantages of the invention are that: the polishing speed is stable and controllable; the film has less surface damage, is easy to clean, does not cause environment pollution, and has long storage time. When the polishing solution is used to perform chemical mechanical planarization of a resistive random material of a titanium oxide film material so as to prepare a resistive random access memory, the method is simple and practical, and is completely compatible with integrated circuit technology.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

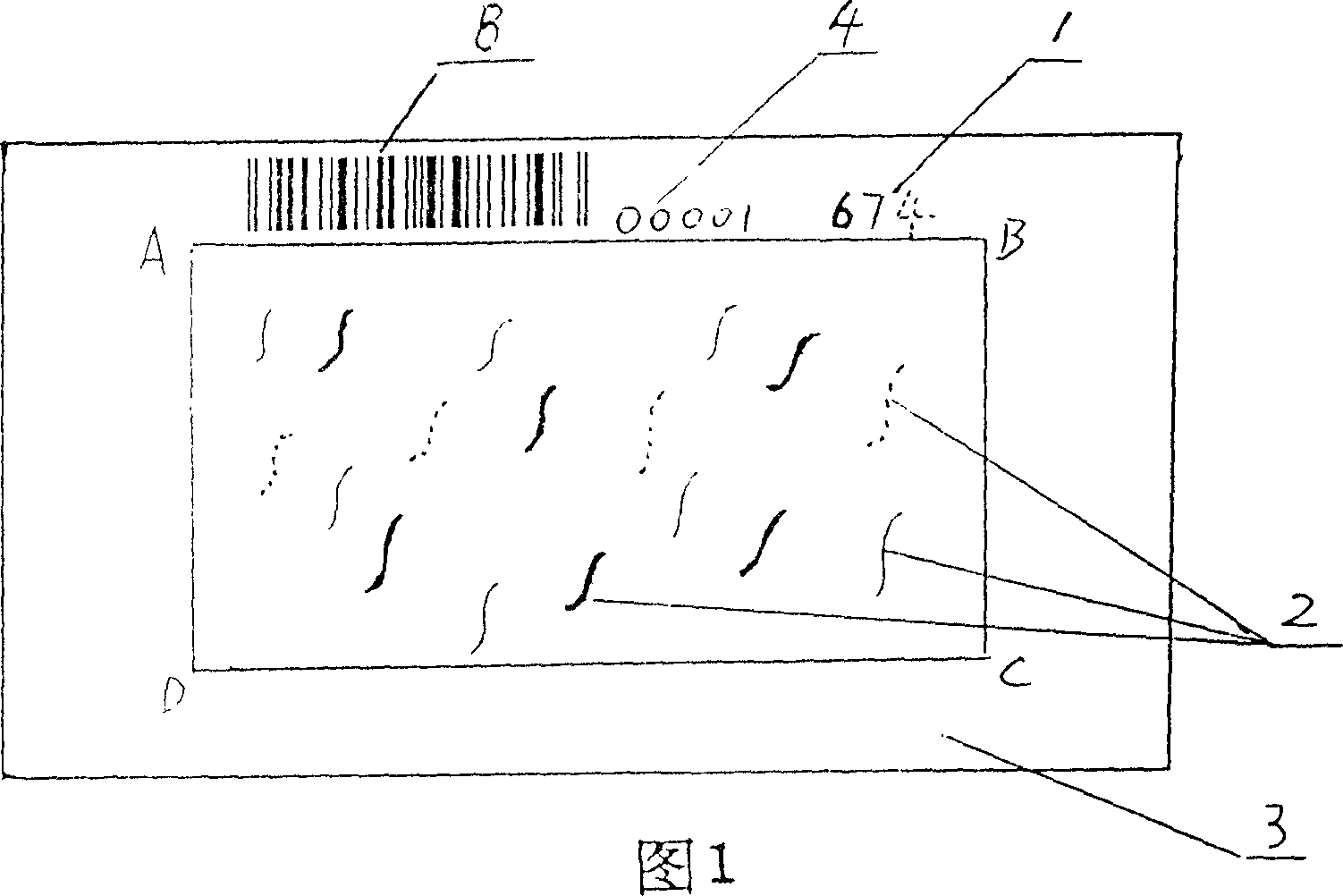

Anti-false logistics label

InactiveCN1516060AEasy to identifyImprove accuracyStampsSpecial data processing applicationsComputer hardwareGraphics

The present invention relates to a product antifalse logistics label. It is made up by using material containing structure characteristics. It selects and uses the pattern, colour and number which are formed by utilizing regular and random material on the identifier as antifalse logistics information, and said information can be made into the digital code and bar code which are correspondent to the above-mentioned radomly-formed regular pattern, colour and number. The digital code and bar code can be printed on the upper portion of label, and the digital code can be stored into the computer identification system data base. The consumer can utilize the communication equipments of telephone, facsimile equipment and computer network to make checking and verification to distiguish the true product from the false product.

Owner:李婕

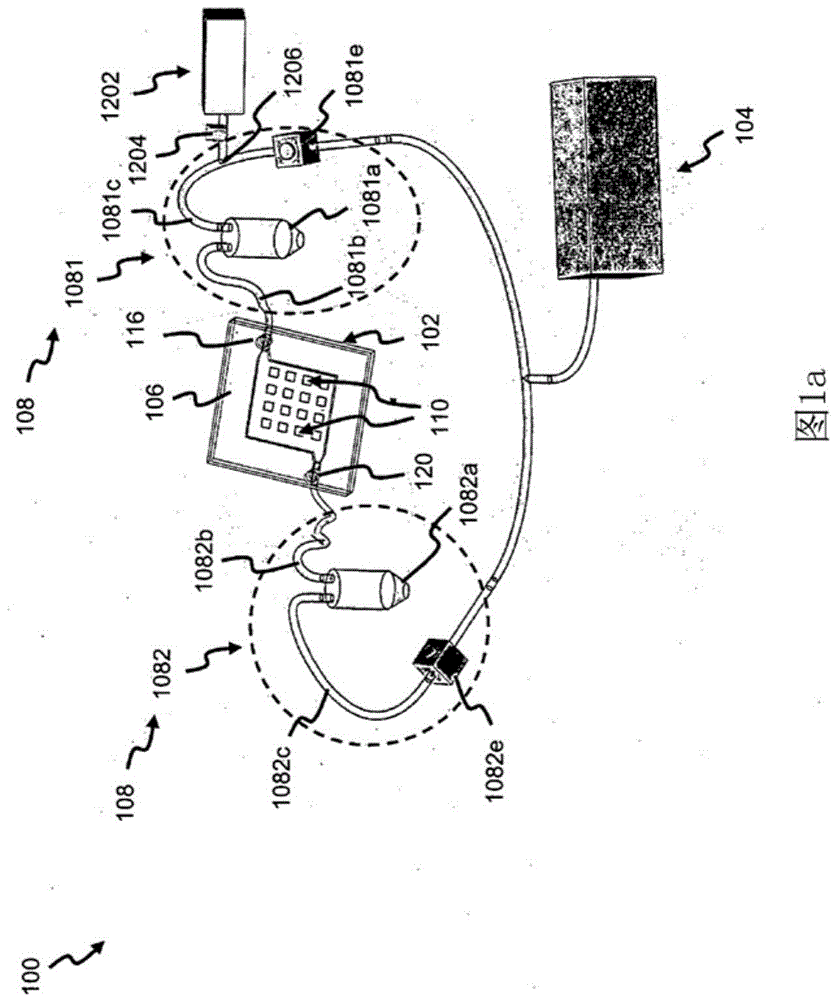

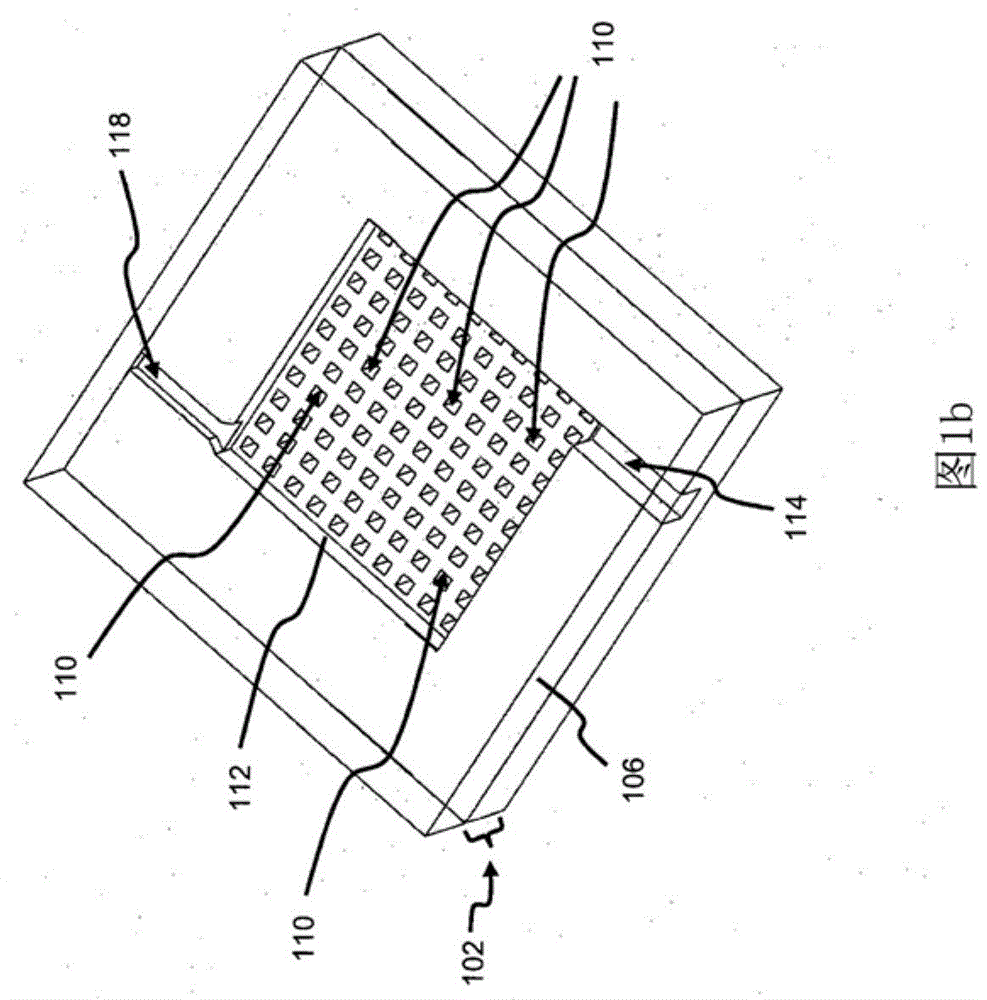

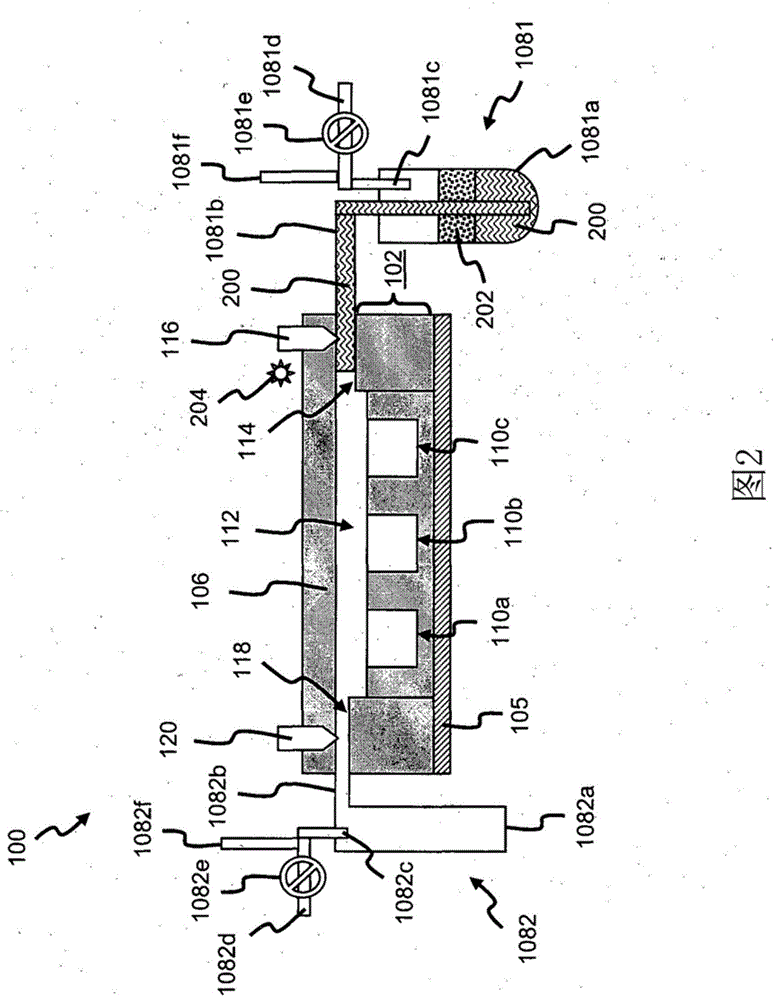

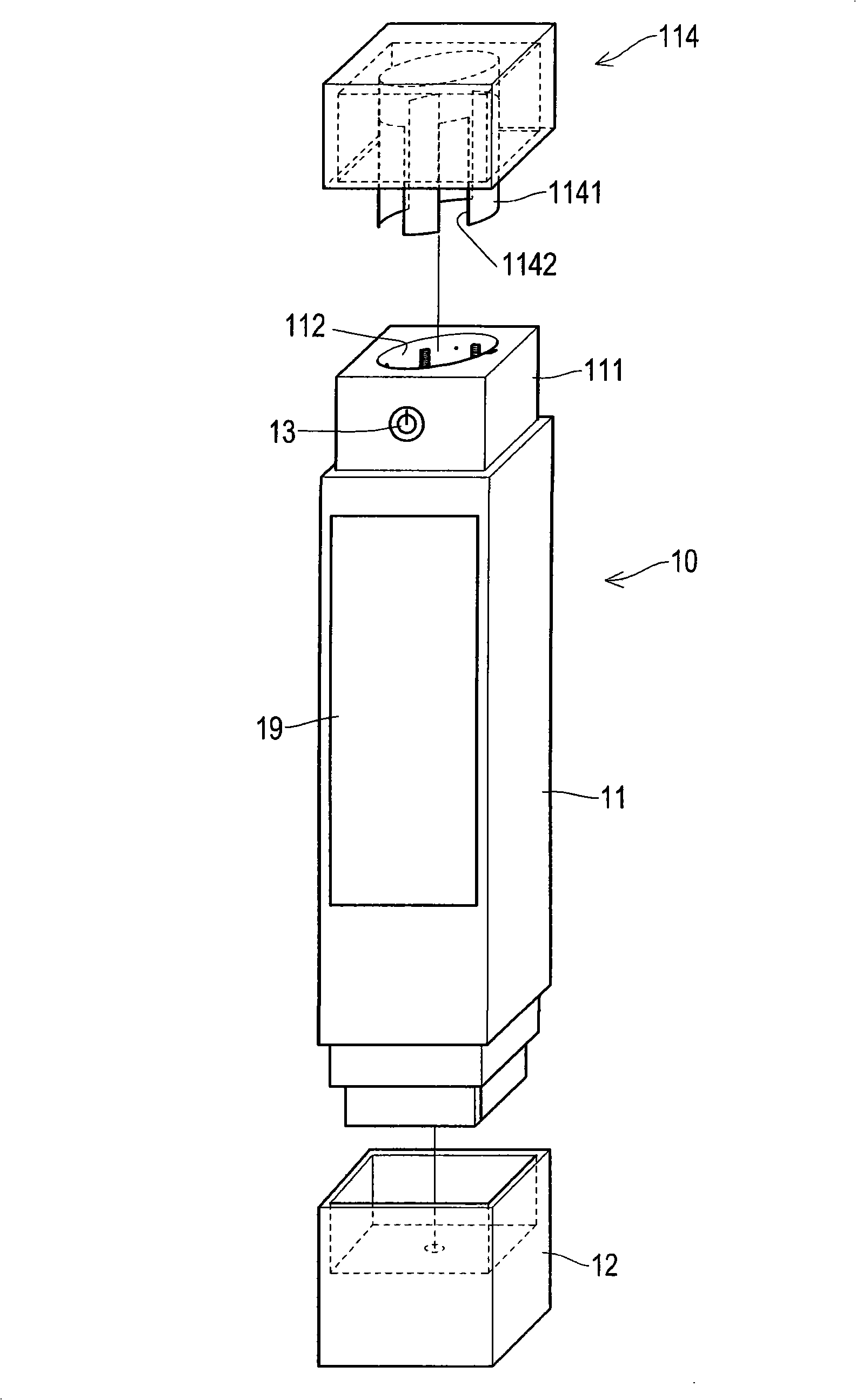

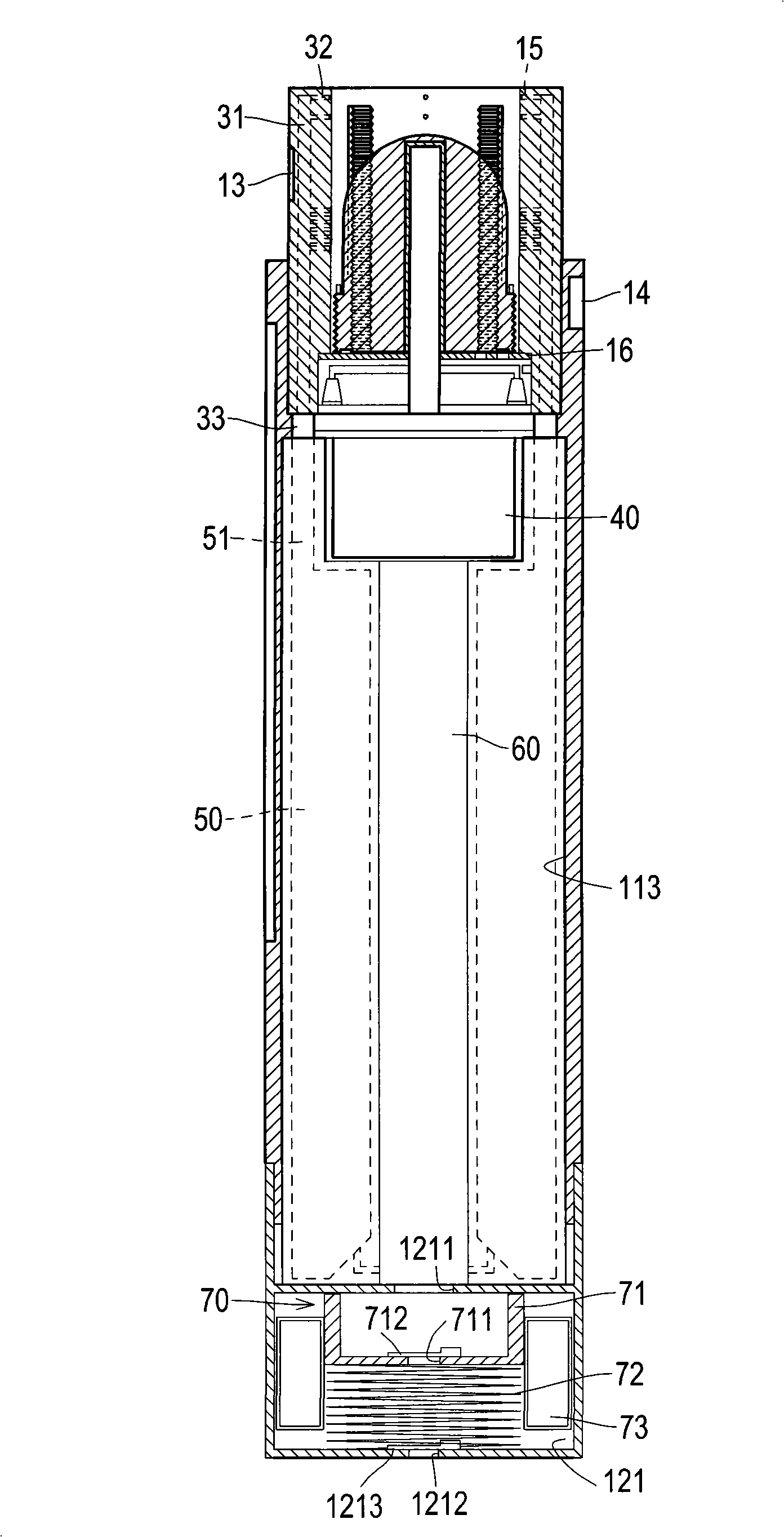

Micro-flow control device and method for controlling liquid flow

The invention discloses a micro-flow control device (100) for detecting and analyzing diseases. The micro-flow control device (100) comprises a component (102) with at least one hole (110) on a substrate. The at least one hole is in fluid communication with an adjacent space (112). The space is in fluid communication with at least one channel (114,118); and a vacuum generating device (108) which is coupled with the at least one channel. The vacuum generating device is configured for respectively generating a first absolute pressure and a second absolute pressure at the first area and the second area of the micro-flow control device, wherein a random one in the first absolute pressure and the second absolute pressure is lower than atmosphere, wherein the first absolute pressure is higher than the second absolute pressure. Therefore a pressure difference is generated between the first area and the second area of the micro-flow control device for controlling flow speed of the fluid through the space in the device, thereby gradually filling at least one hole and / or promoting a random material which is placed in the at least one hole. Controlling of the fluid flow also prevents crossed pollution of a specific organism and / or chemical substance which is preloaded in the hole. The invention further discloses a related thermal circulating instrument and a method thereof.

Owner:STAR ARRAY

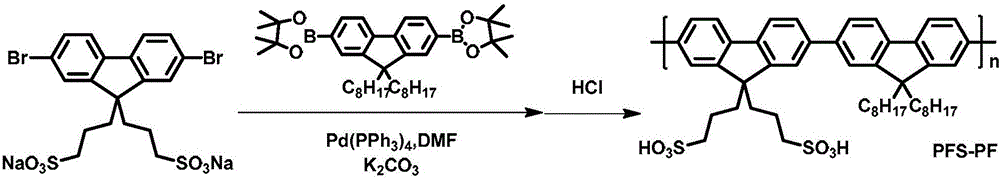

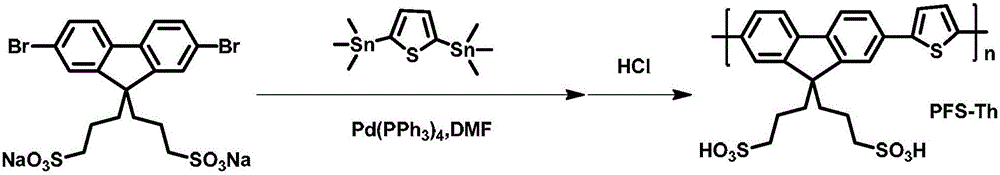

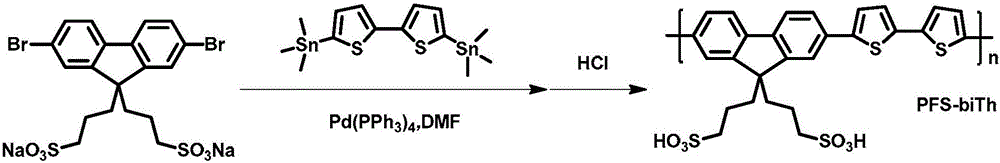

Organic solar cell device and preparation method thereof

ActiveCN105070833ALower synthesis costSimple processSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellRandom materials

The invention discloses an organic solar cell device and a preparation method thereof. The organic solar cell device comprises the components of an anode electrode layer, an anode interface modifying layer, a light active layer, a cathode interface modifying layer and a cathode electrode layer. The anode interface modifying layer and the cathode interface modifying layer are made of the same material which is a polymer that is represented by a formula I. In the formula I, A is a random material selected from sulfonic acid group, sodium sulfonate group, potassium sulfonate group, lithium sulfonate group, ammonium sulfonate group, sulphonylamino, carboxylic acid group, carboxylic acid ester group, sodium carboxylate group, potassium carboxylate group, lithium carboxylate group, ammonium carboxylate group and amide; R is an alkyl with 1-12 carbon atoms; Ar is a random member selected from the following unsubstituted or substituted group: single-ring arylene, double-ring arylene, three-ring arylene, arylene with more rings, single-ring heteroarylidene, double-ring heteroarylidene, three-ring heteroarylidene, heteroarylidene with more rings, and a group which is composed of 2-6 arylenes which are connected through single bonds; wherein n is selected from 2-500. The organic solar cell device and the preparation method have advantages of simplifying an optimization process and a manufacture process for the material of the interface modifying layers, and reducing the synthesis cost of the material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

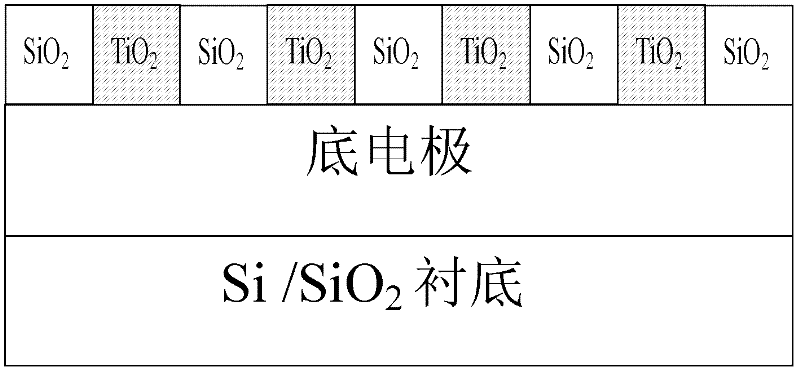

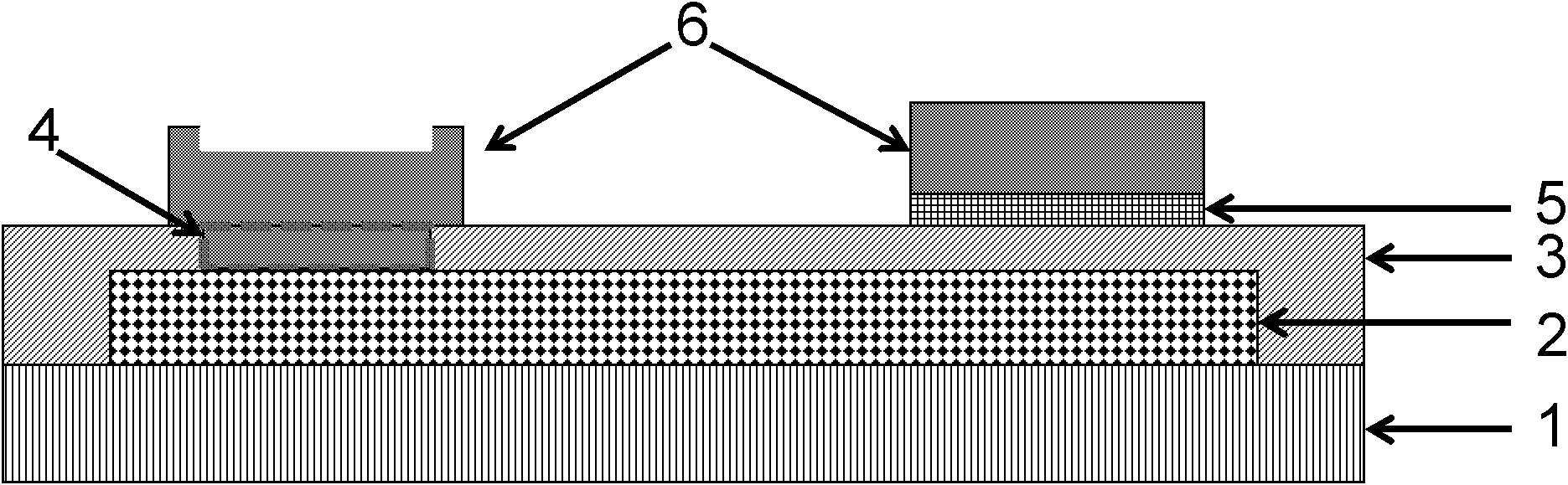

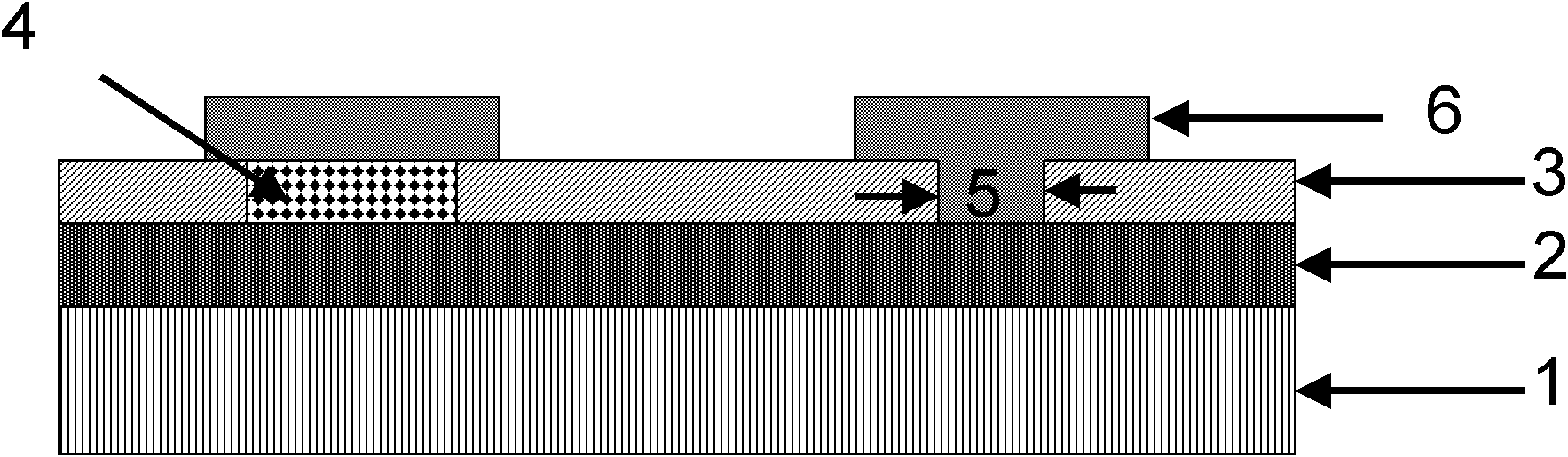

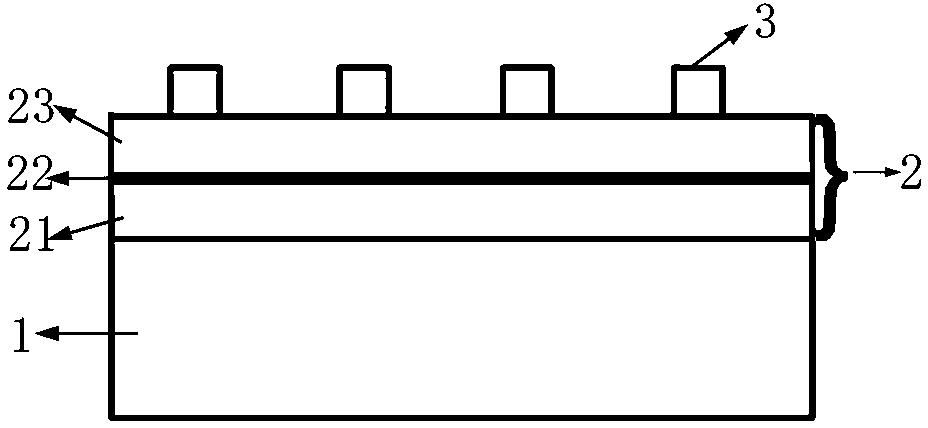

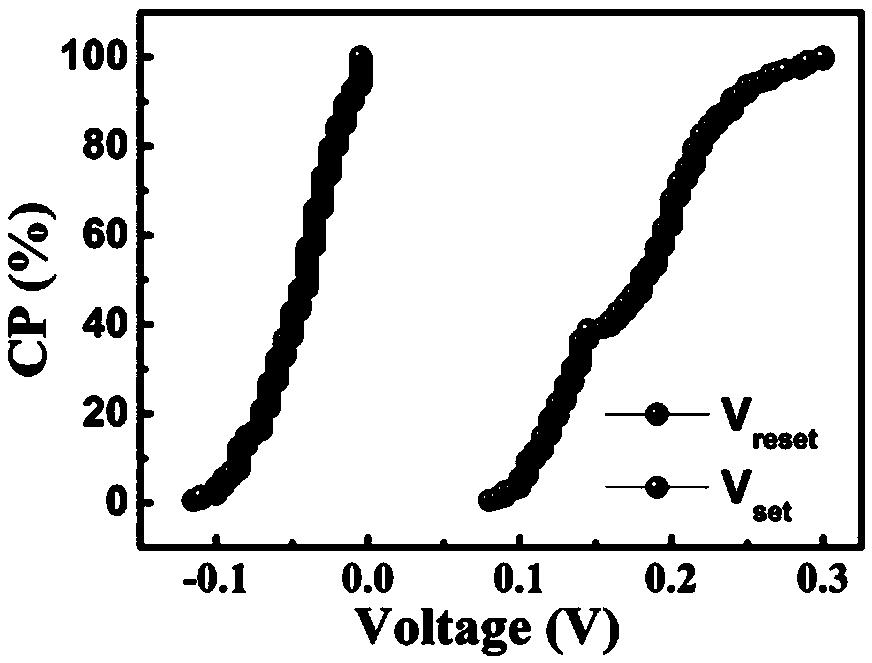

Low-voltage resistive random access memory and preparation method thereof

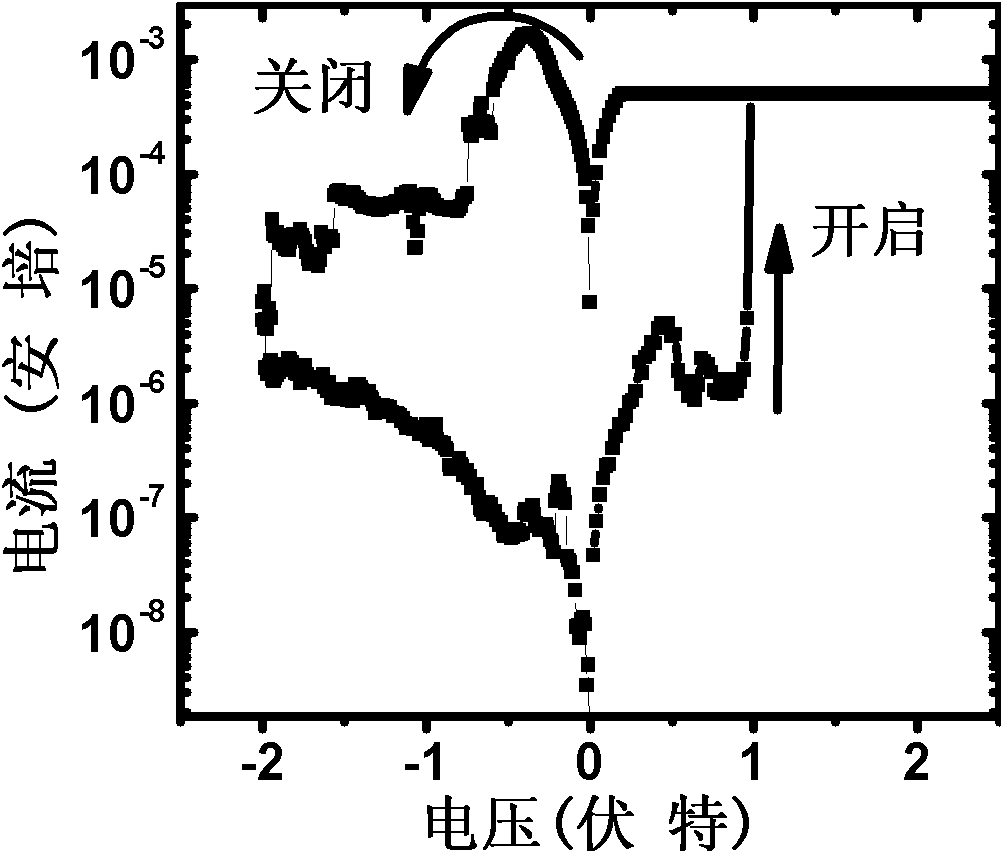

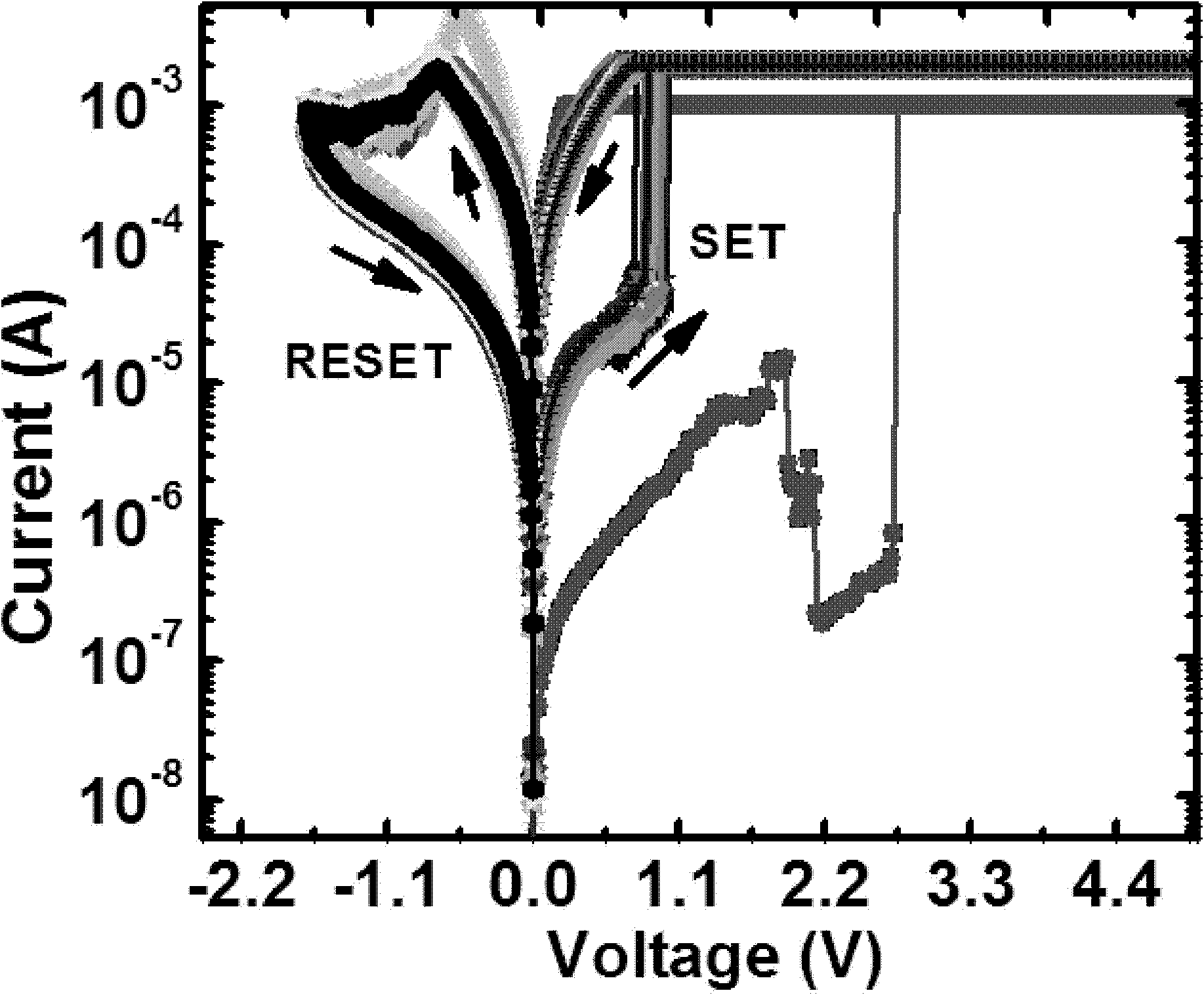

ActiveCN101853922ALow resistive voltageLow resistive currentElectrical apparatusRandom materialsLow voltage

The invention provides a low-voltage resistive random access memory and a preparation method thereof, which belongs to the technical field of a super-large scale integrated circuit. The resistive random access memory comprises a top electrode, a resistive random material layer, a bottom electrode and a substrate, wherein the resistive random material layer is made of SixOyNz. The invention regulates parameters via a back-end plasma chemical vapor deposition (PECVD) technology in a standard CMOS technology so as to prepare a nitride-oxide-silicon single-pole resistive random access memory which is fully compatible with the standard CMOS technology. The method can be realized under low-temperature technology, simultaneously achieves the purpose of artificially controlling the defect concentration so as to obtain lower rheostatic voltage and rheostatic current, and has high application value in the aspect of the memory with low voltage and low power consumption.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Low-temperature and high-impact resistance polypropylene random material

The invention provides a low-temperature and high-impact resistance polypropylene random material. A PPR (polypropylene random) pipe comprises the following raw materials in parts by weight: 1.5-3 parts of color masterbatch, 8-20 parts of a toughening agent, 4-20 parts of rigid particles, 73-87.5 parts of PPR, 40-50 parts of a polyolefin resin mixture and 3-10 parts of a modifier. Through addition of an elastomer, the toughness of the low-temperature and high-impact resistance polypropylene random material is improved and thus the rigidity loss of a product is caused; further through addition of the rigid inorganic nanoparticles with the sizes of 5-5000 nanometers, and through surface modification, the compatibility with a base material is improved, the rigidity of the product is improved and the integral effect of the product is ensured.

Owner:ANHUI YONGGAO PLASTIC IND DEV CO LTD

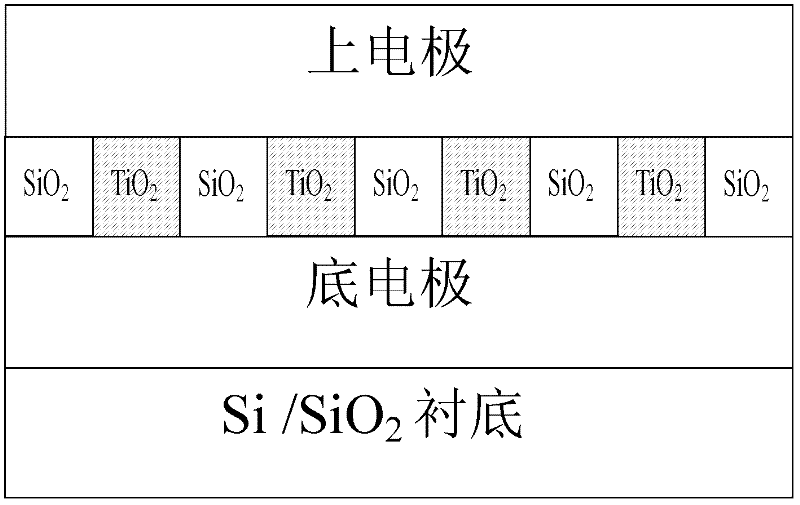

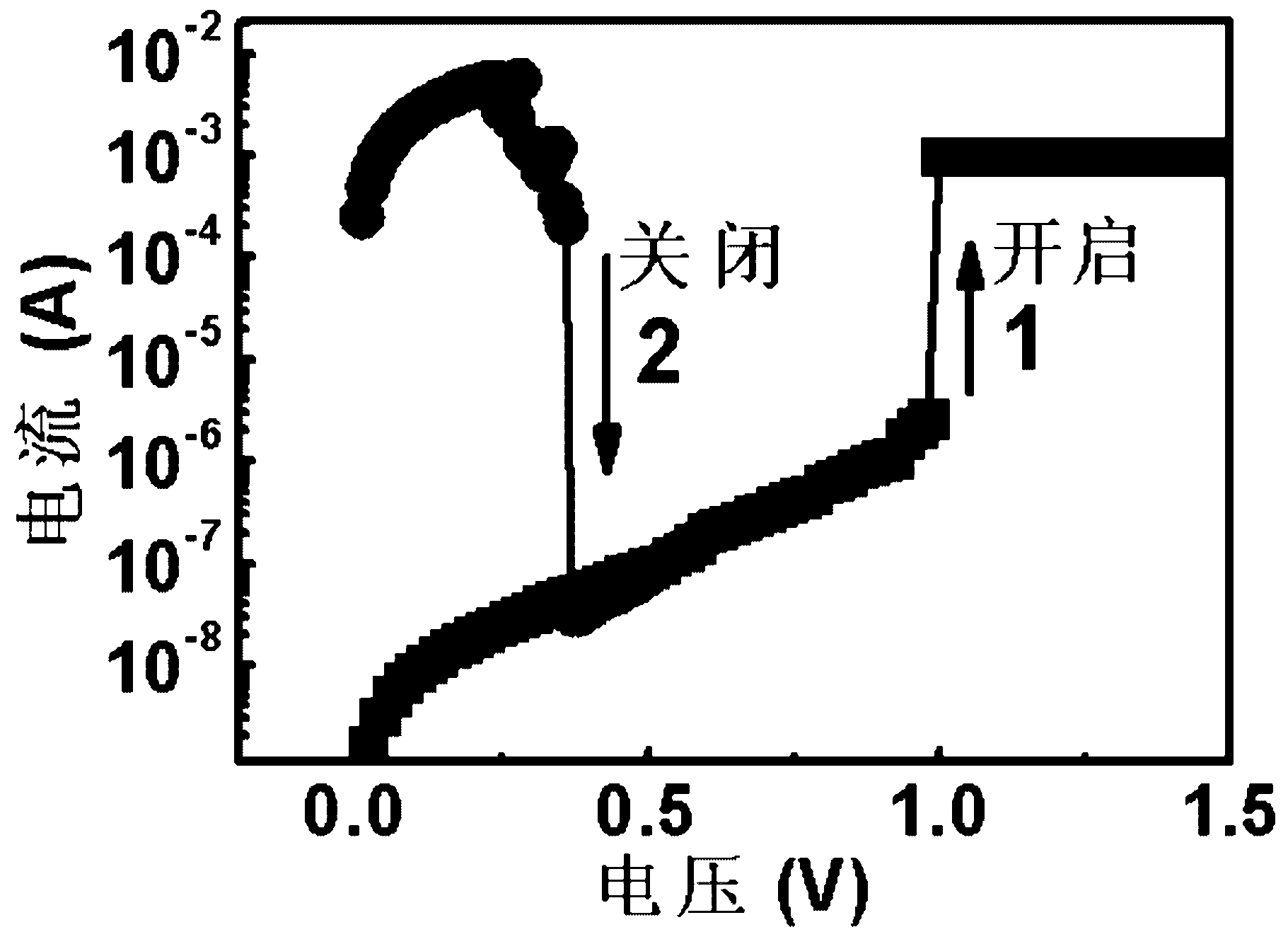

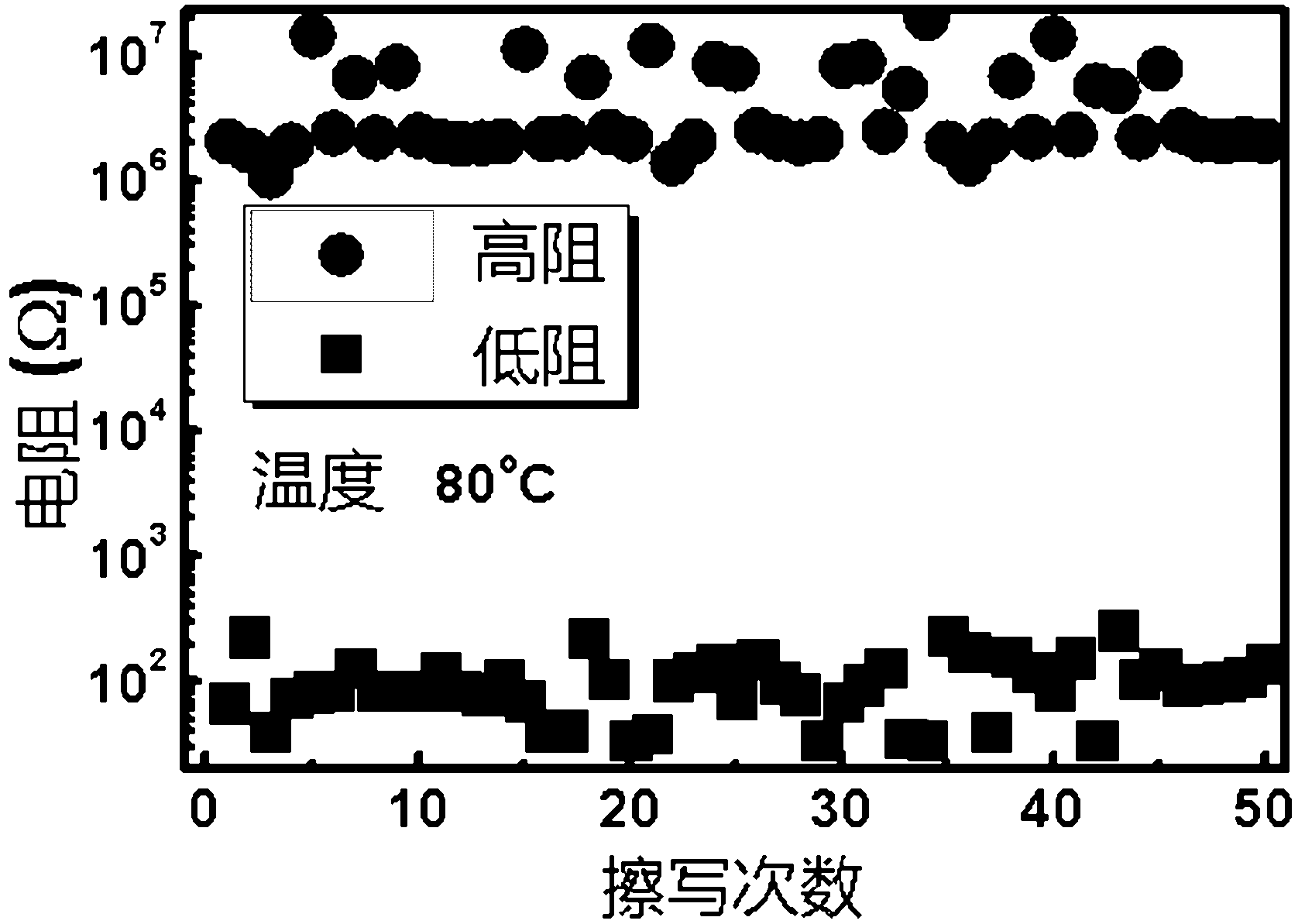

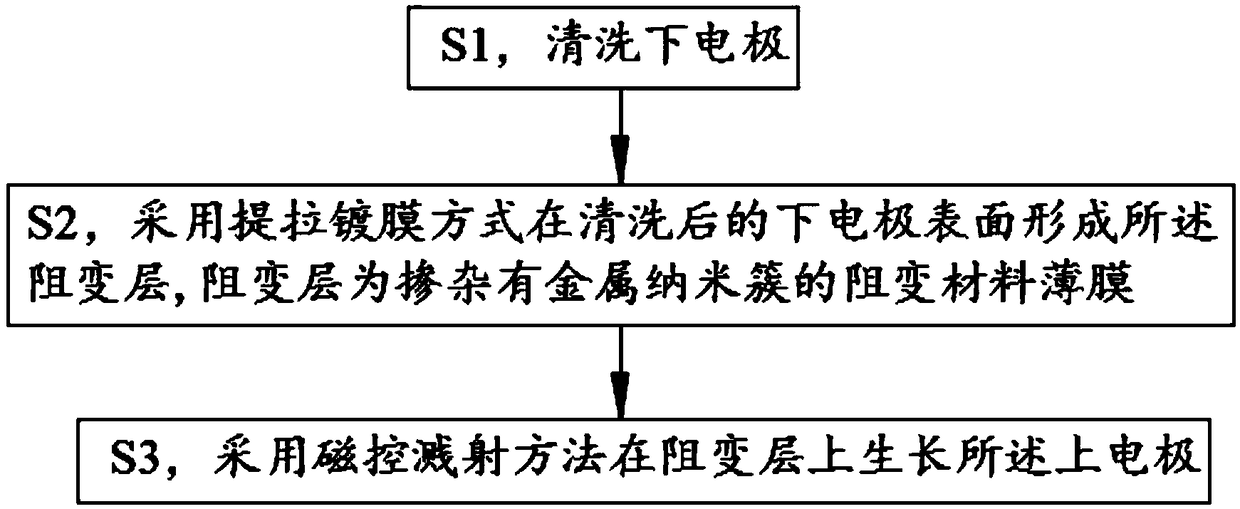

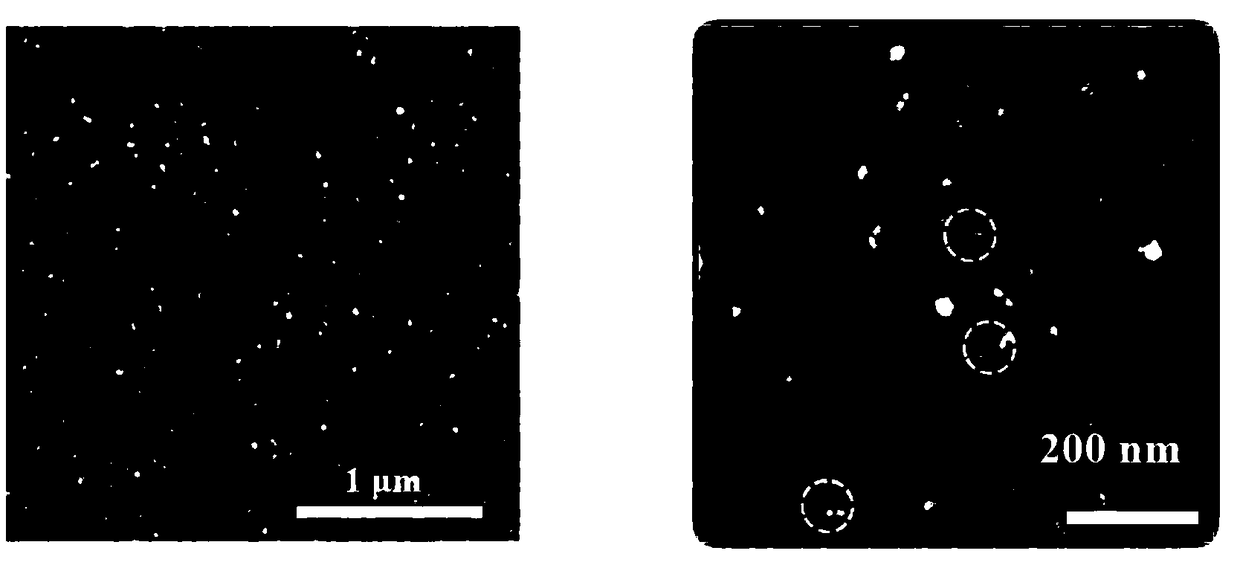

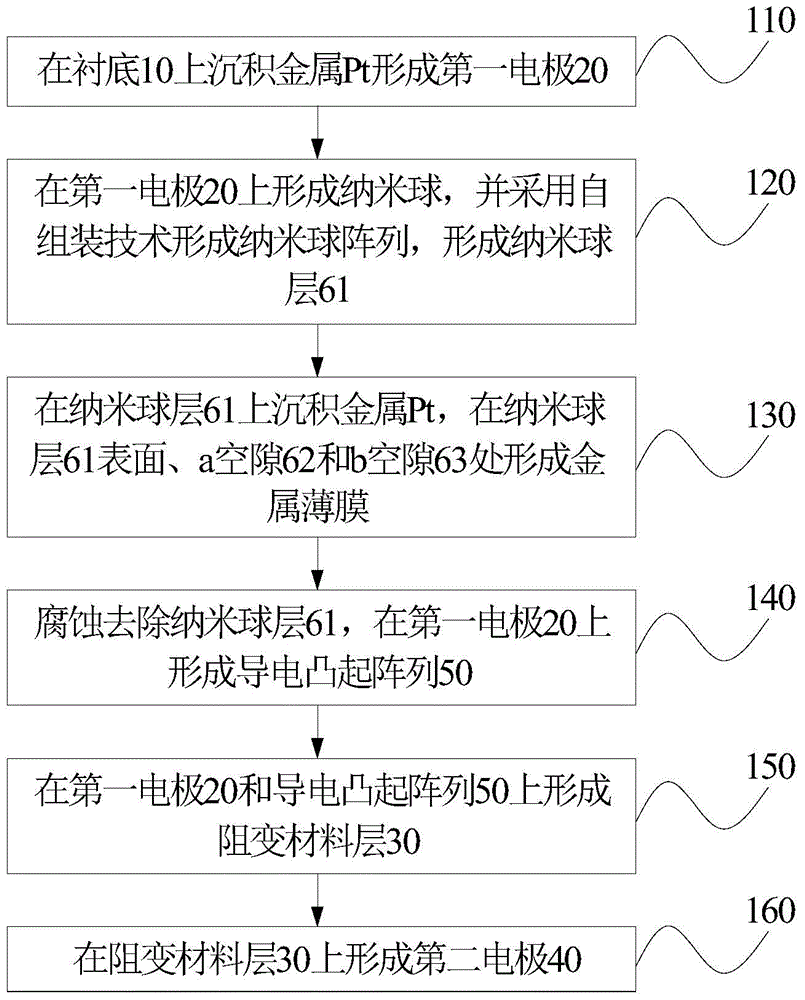

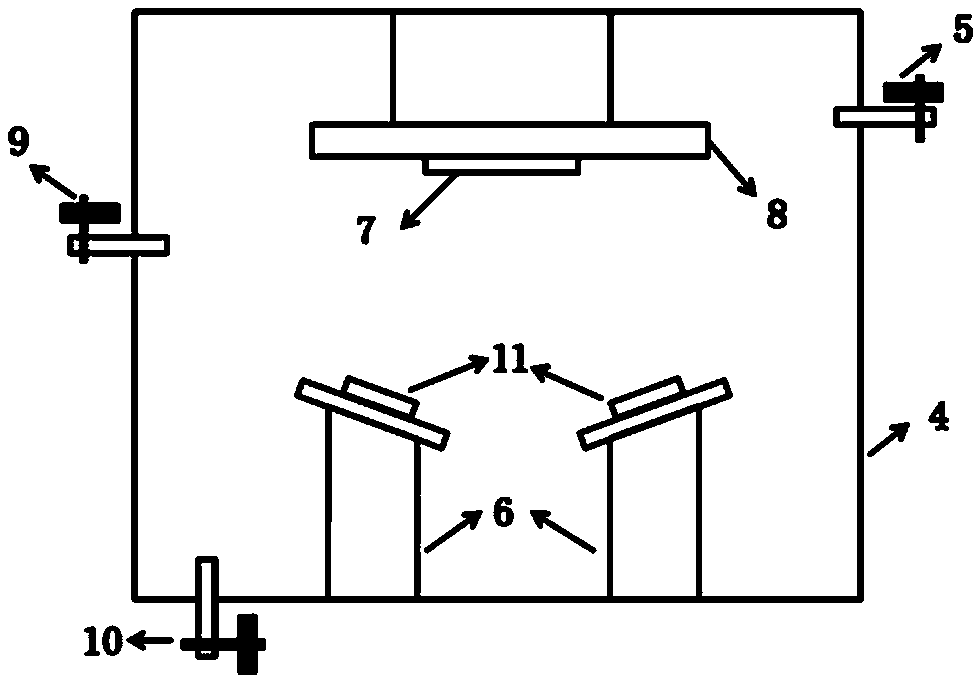

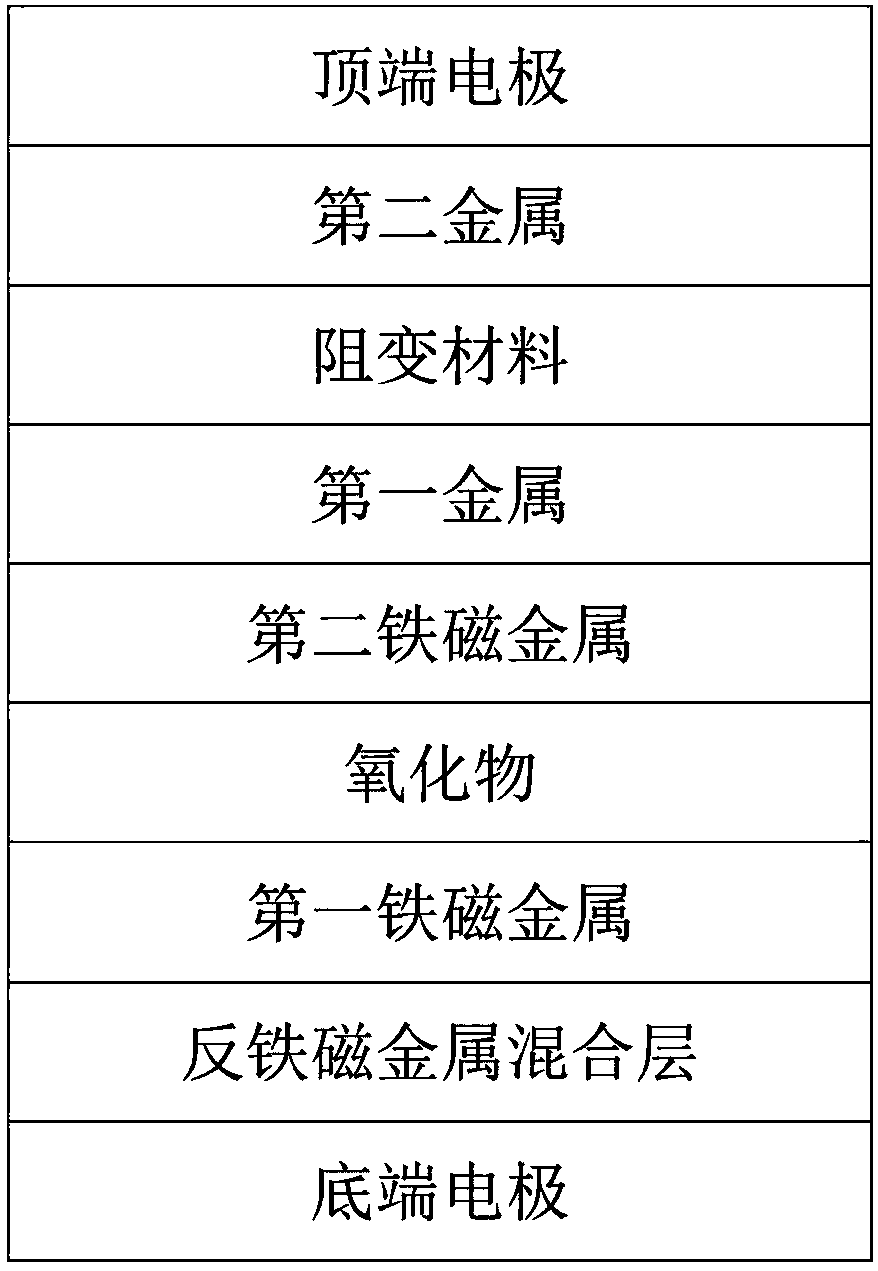

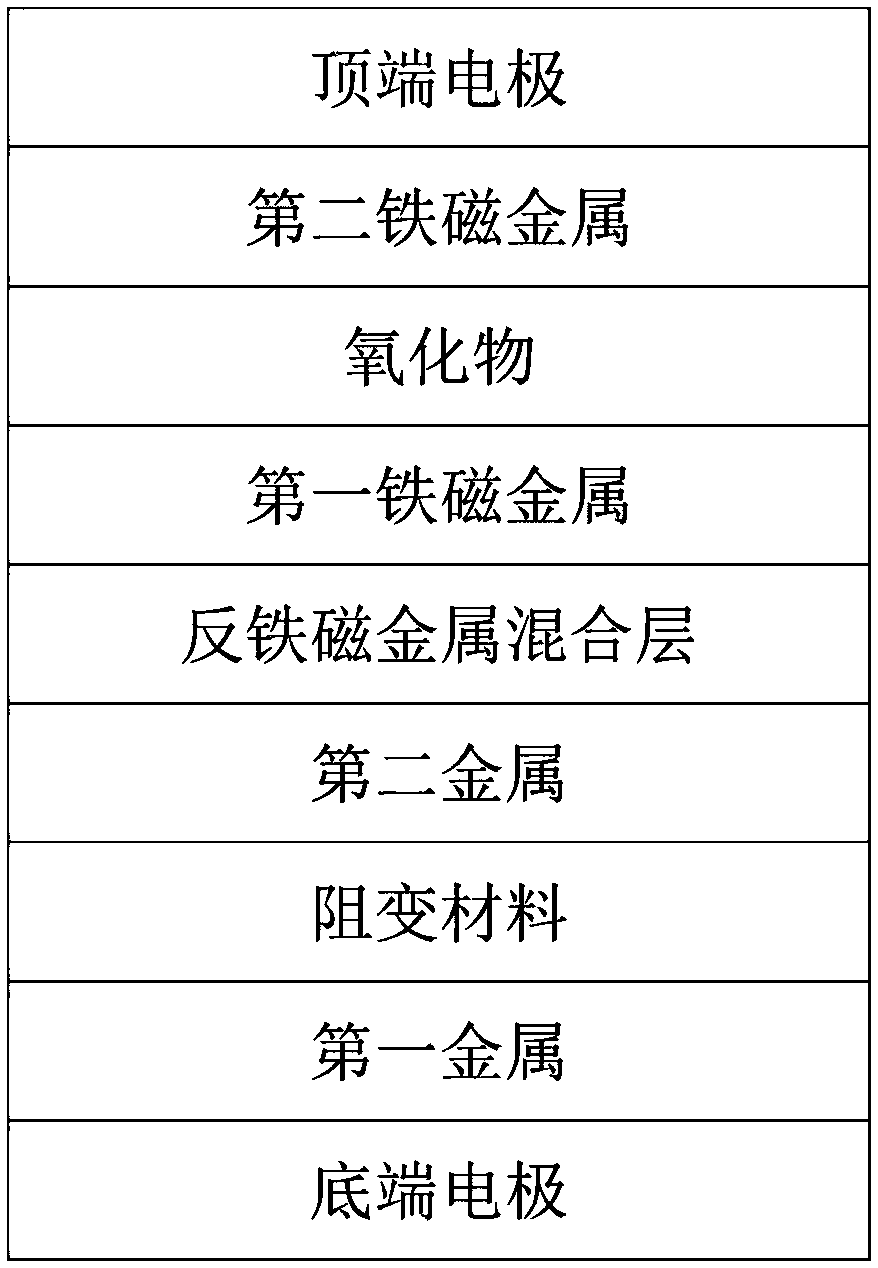

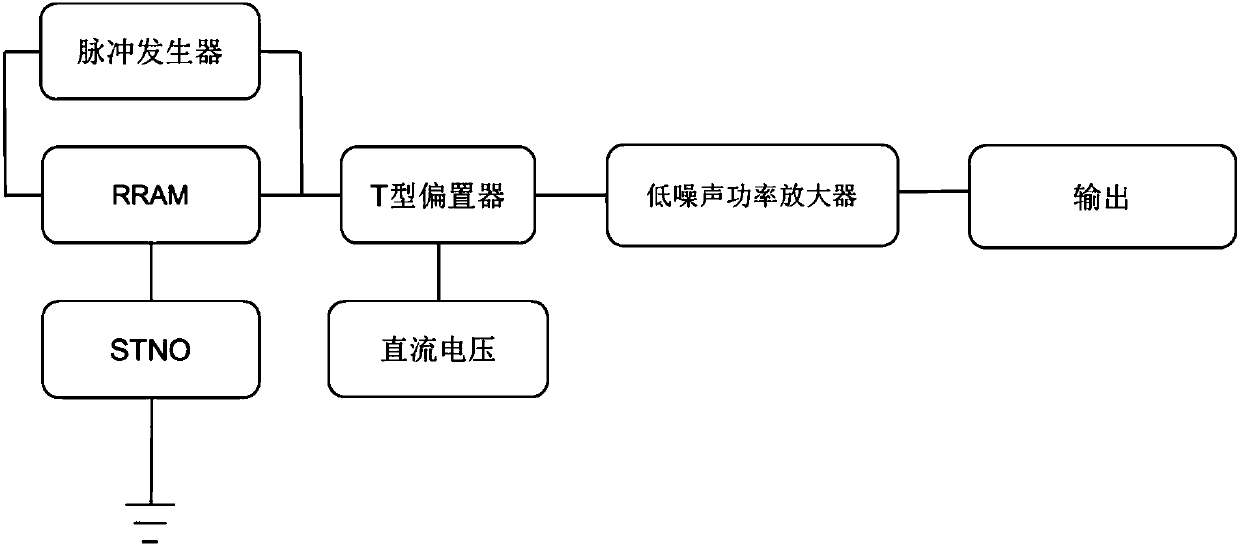

Metal nano-cluster doped memristor and method for preparing same

ActiveCN109326711AReduce randomnessGood biocompatibilityMaterial nanotechnologyElectrical apparatusRandom materialsComposite film

The invention provides a metal nano-cluster doped memristor and a method for preparing the same, and relates to the technical field of microelectronics. The metal nano-cluster doped memristor comprises an upper electrode, a resistance random layer and a lower electrode. The resistance random layer is positioned between the upper electrode and the lower electrode and is a thin film made from resistance random materials, and metal nano-clusters are doped in the thin film. The method includes S1, cleaning the lower electrodes; S2, forming the resistance random layer on a surface of the cleaned lower electrode in pulling film coating modes; S3, growing the upper electrode on the resistance random layer by the aid of magnetron sputtering processes. The metal nano-cluster doped memristor and themethod have the advantages that the metal nano-clusters are doped into thin film materials made from the resistance random materials to prepare corresponding metal nano-cluster doped composite thin films, effects of reinforcing local electric fields can be realized by the metal nano-clusters under the effects of electric fields, and the resistance transformation characteristics can be improved; the metal nano-cluster doped memristor is stable in resistance random memory property and high in switch speed, and a foundation can be laid for designing and further developing memristors.

Owner:XIAMEN UNIV

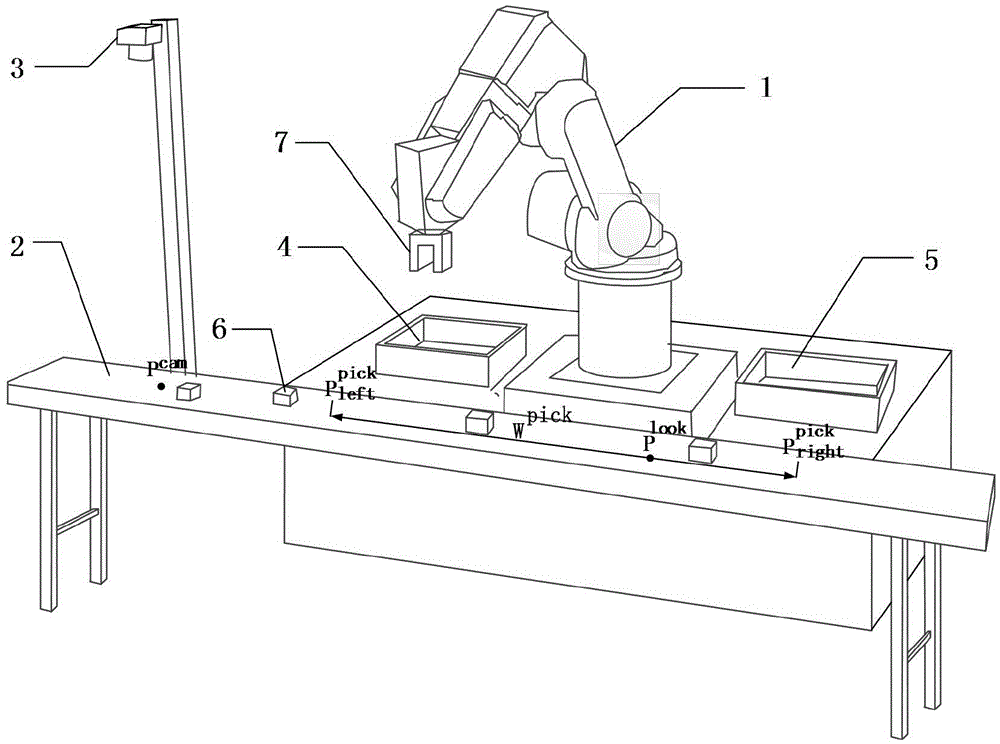

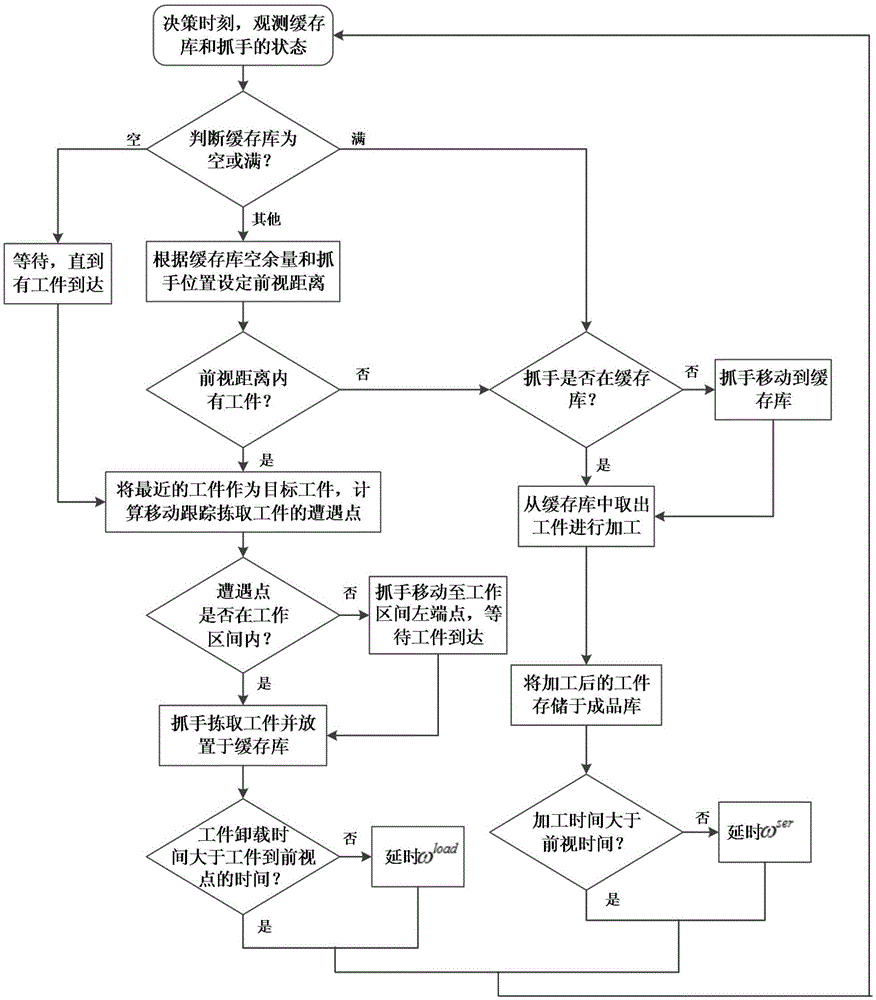

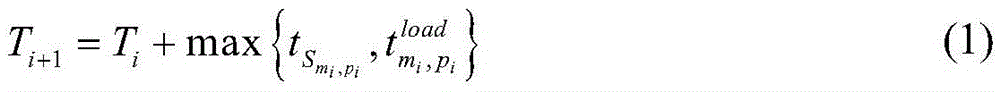

Working mechanism of single-station feeding production processing system based on mechanical arm

ActiveCN105643625AImprove balanceIncrease productivityProgramme-controlled manipulatorVisibilityProduction line

The invention discloses a working mechanism of a single-station feeding production processing system based on a mechanical arm. The working mechanism is characterized in that the single-station feeding production processing system comprises a mechanical arm, a conveyor belt, an industrial camera, a cache library with capacity being M, a finished product warehouse with capacity being N and workpieces, wherein the mechanical arm is used for obtaining vacant amount m of the cache library and a gripper position p under a current state; and a visibility distance Vsmp is selected according to an optimal control strategy v*; and if workpiece are within the visibility distance Vsmp, unloading operation is carried out; and if the workpieces are not within the visibility distance Vsmp, service operation is carried out. The optimal control strategy v* is obtained by carrying out optimization solution on an SMDP model which is established by taking the vacant amount m of the cache library and the gripper position p as states through a strategy iteration algorithm. The working mechanism can be used for improving process balance and production efficiency of a single-station mechanical arm production line which has no fixed beat, has random material supply and has no fixed-point processing, so that basis is provided for optimal scheduling of the single-station mechanical arm production line in industrial production.

Owner:HEFEI UNIV OF TECH

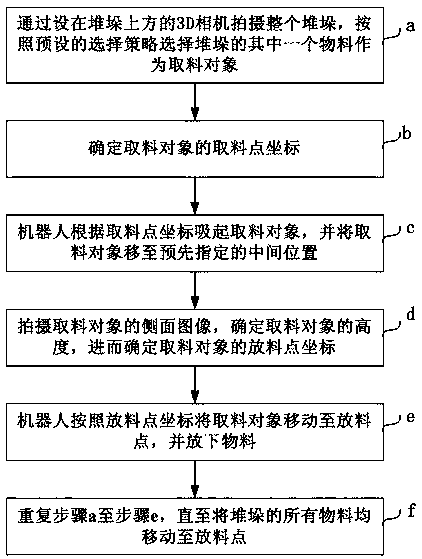

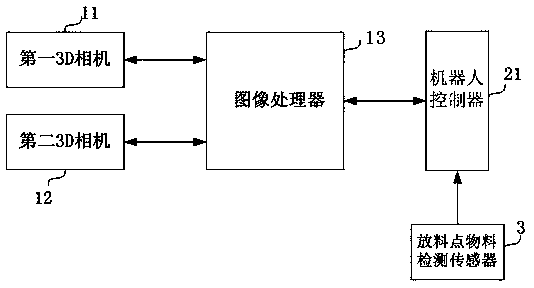

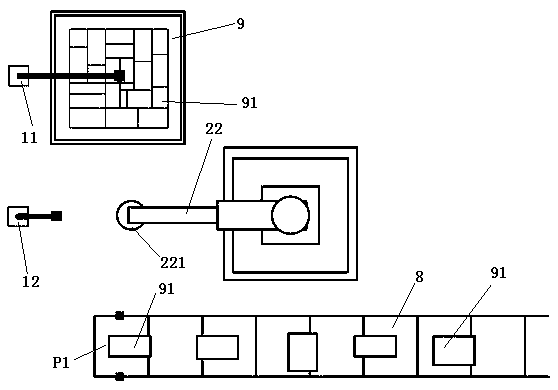

Robot stack disassembling method of irregular random materials

ActiveCN109775376AImprove disassembly efficiencyReduce workloadImage data processing detailsStacking articlesRandom materials3d camera

The invention relates to a robot stack disassembling method of irregular random materials. The robot stack disassembling method of the irregular random materials comprises the steps that a, a whole stack is shot through a 3D camera arranged above the stack, based on image information shot by the 3D camera, one material of the stack is chosen as a material taking object according to a predeterminedchoosing strategy; b, material taking point coordinates of the material taking object are determined; c, a robot sucks up the material taking object according to the material taking point coordinates, and the material taking object is moved to a preassigned middle position; d, a side surface image of the material taking object is shot, the height of the material taking object is determined, and thus material placing point coordinates of the material taking object are further determined; e, the robot moves the material taking object to the material placing point according to the material placing point coordinates, and lays down the material taking object; and f, the steps from a to e are repeated until all the stacked materials are moved to the material placing point. According to the robot stack disassembling method of the irregular random materials, the robot is used to disassemble the stack randomly stacked with irregular sized materials.

Owner:上海新时达机器人有限公司

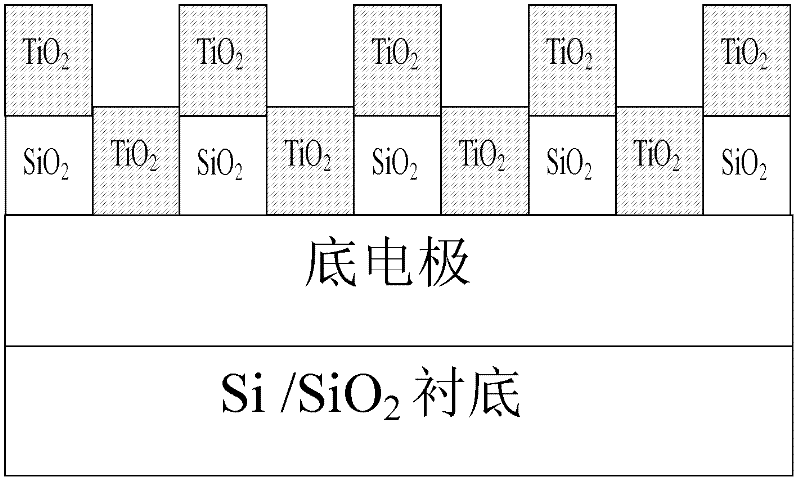

Nitride-oxide-silicon bipolar resistive random access memory based on non-stoichiometry ratio and preparation method thereof

ActiveCN101894910AEasy resistance transitionHigh silicon contentElectrical apparatusRandom materialsChemical reaction

The invention provides a bipolar resistive random access memory of a nitride-oxide-silicon (SiOxNy) resistive random material containing rich silicon based on non-stoichiometry ratio and a preparation method thereof, belonging to the technical field of super-large-scale integration. The resistive random access memory comprises a top electrode, a resistive random material layer, a bottom electrode and a substrate, wherein the resistive random material layer is the nitrogen oxide of silicon (SiOxNy), and x and y in the SiOxNy meet the conditions of (2x+3y)<4, x>=0, and y>=0; the bottom electrode is metal or a conducting material such as Cu, W, Pt and the like; and the top electrode is metal or a conducting material such as Ti, TiN, Al, AlCu and the like generating chemical reaction with the nitrogen oxide of silicon. In the invention, by controlling the components of the nitrogen oxide of silicon, the silicon content is relatively larger, and more defects, vacancies, such as nitrogen vacancy, oxygen vacancy and the like are introduced, thereby obtaining a stable bipolar device.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

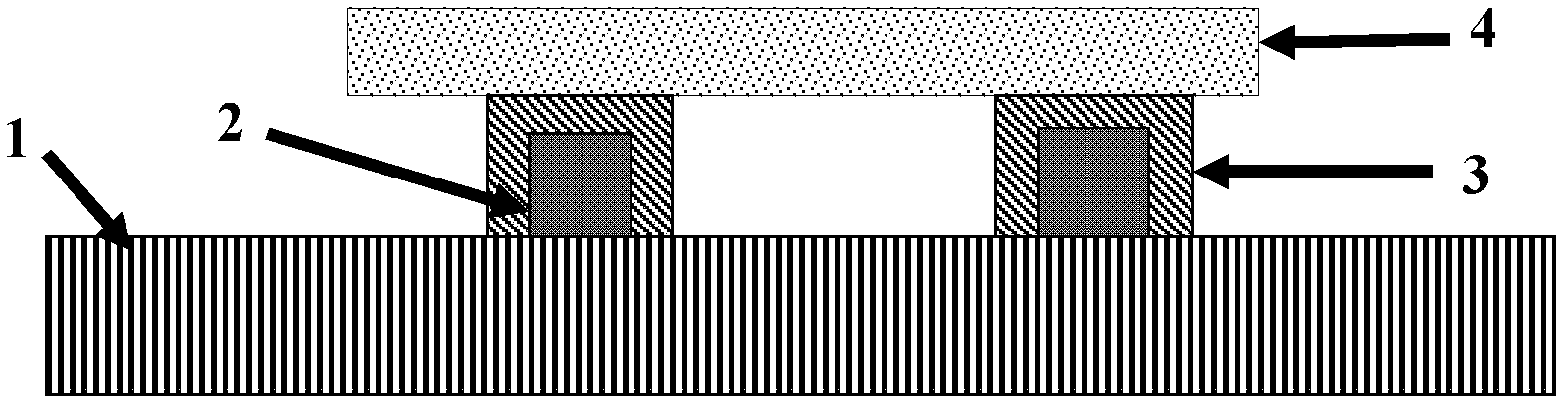

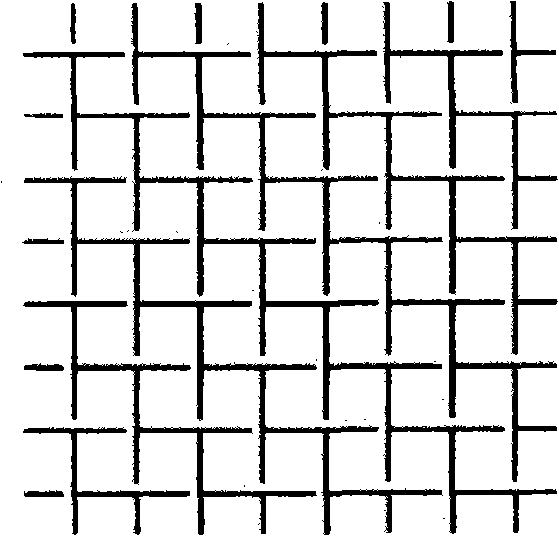

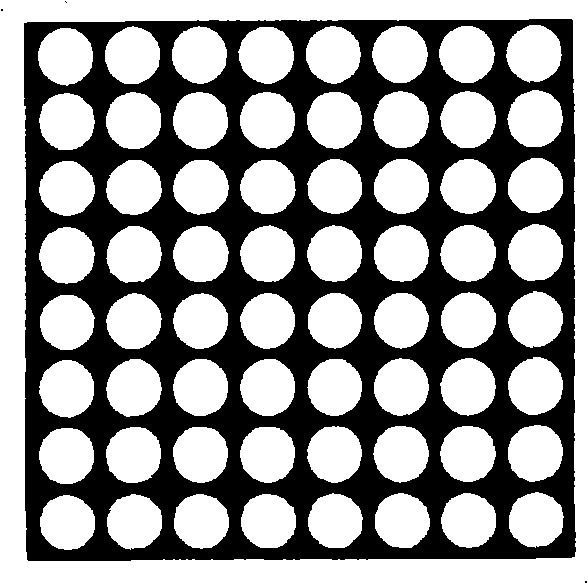

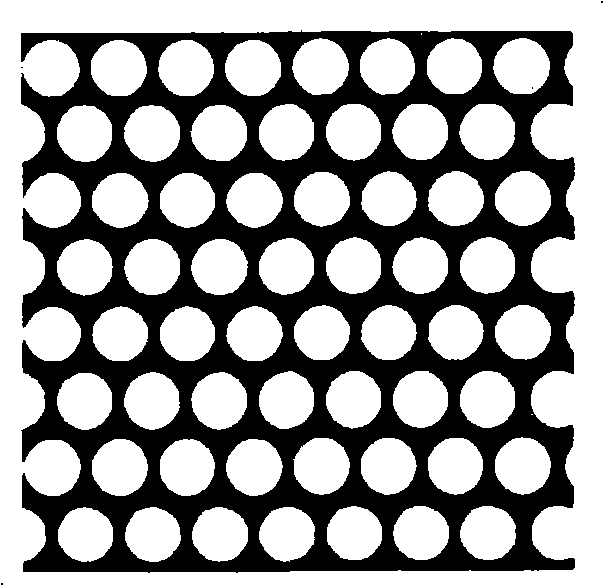

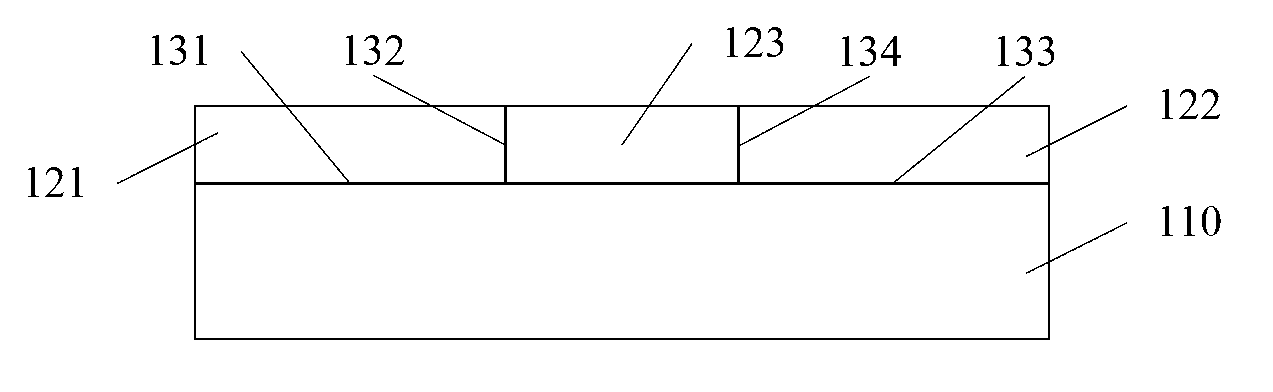

Resistive random access memory and preparation method thereof

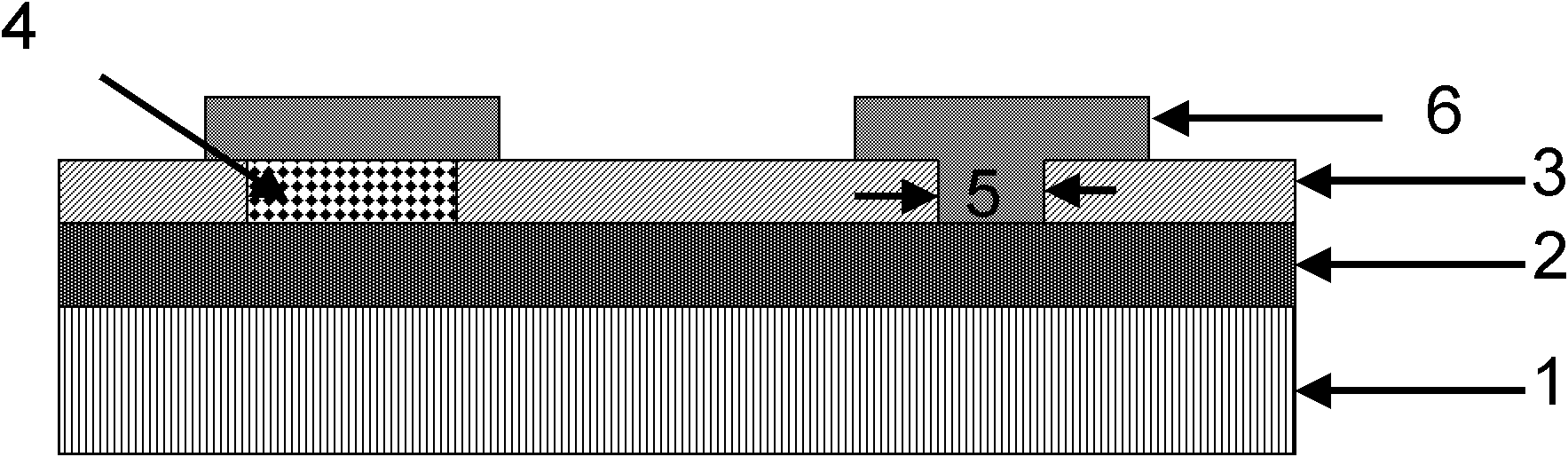

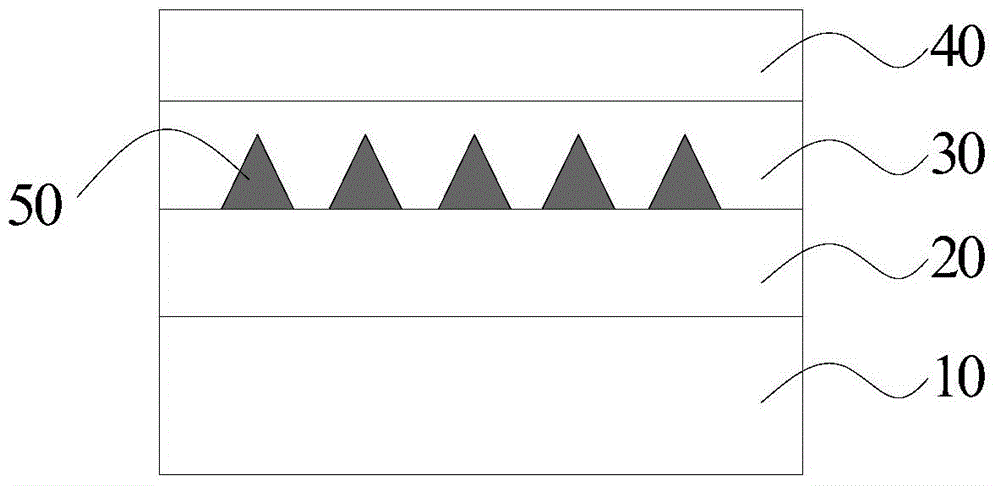

ActiveCN106299108AImprove stabilityImprove uniformitySolid-state devicesSemiconductor/solid-state device manufacturingRandom materialsStatic random-access memory

The present invention discloses a resistive random access memory. The resistive random access memory comprises a first electrode, a resistive random material layer and a second electrode arranged on a substrate in order, and also comprises a conductive bumping array formed at the interface of the first electrode and the resistive random material layer or / and the interface of the second electrode and the resistive random material layer at intervals. The resistive random access memory prepares a uniformly distributed and controllable conductive bumping array at the interface of the first electrode or / and the second electrode and the resistive random material layer to allow an electric field to integrate on the conductive bumping array and increase the probability of forming a conductive channel at the conductive bumping array so as to improve the work stability of the resistive random access memory and improve the uniformity of the resistive random access memory. The present invention further discloses the preparation method of the resistive random access memory, and comprises: A, the step of preparing the first electrode, the resistive random material layer and the second electrode on the substrate; and B, the step of preparing the conductive bumping array at the interface of the first electrode and the resistive random material layer or / and the second electrode and the resistive random material layer.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

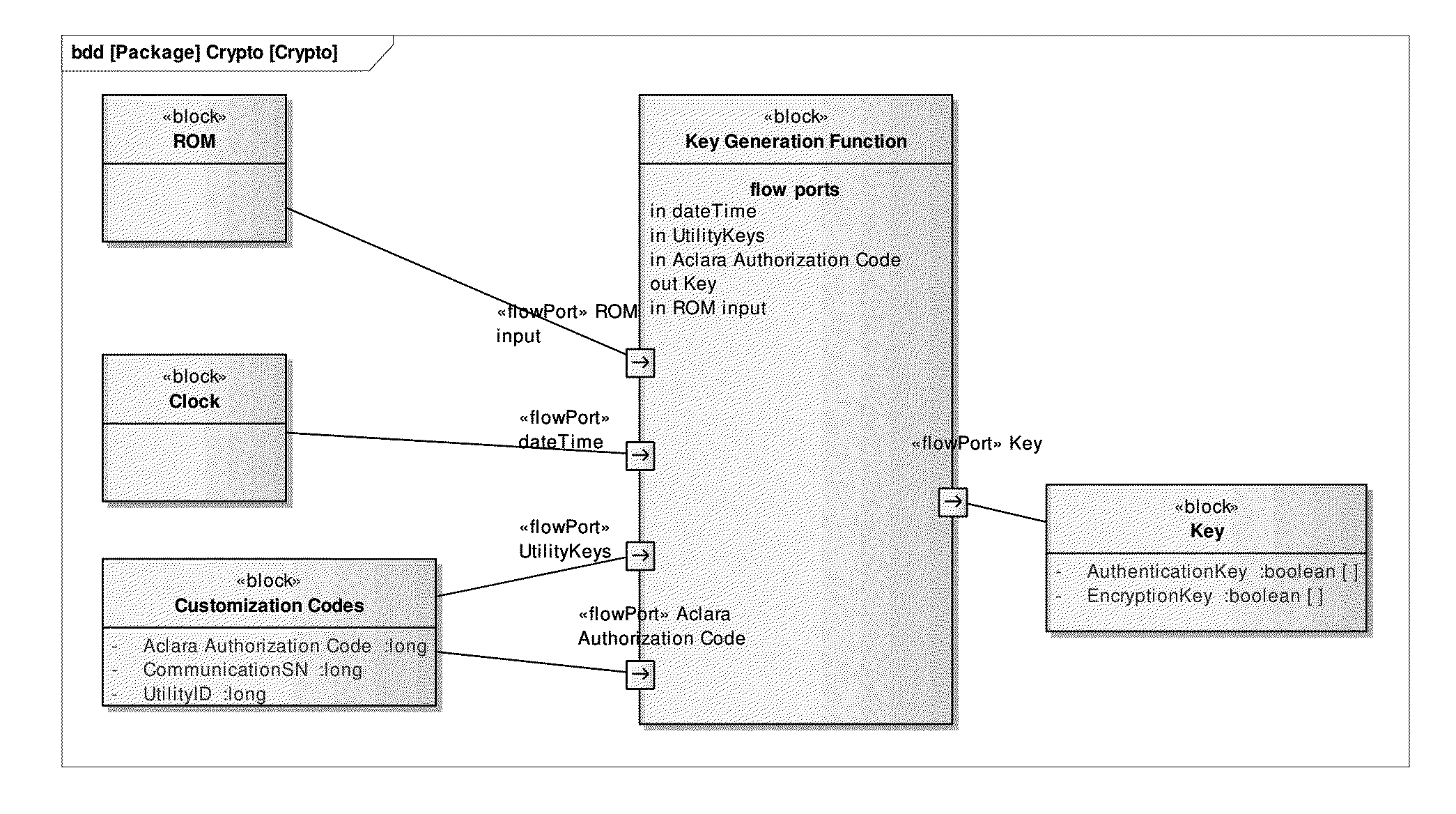

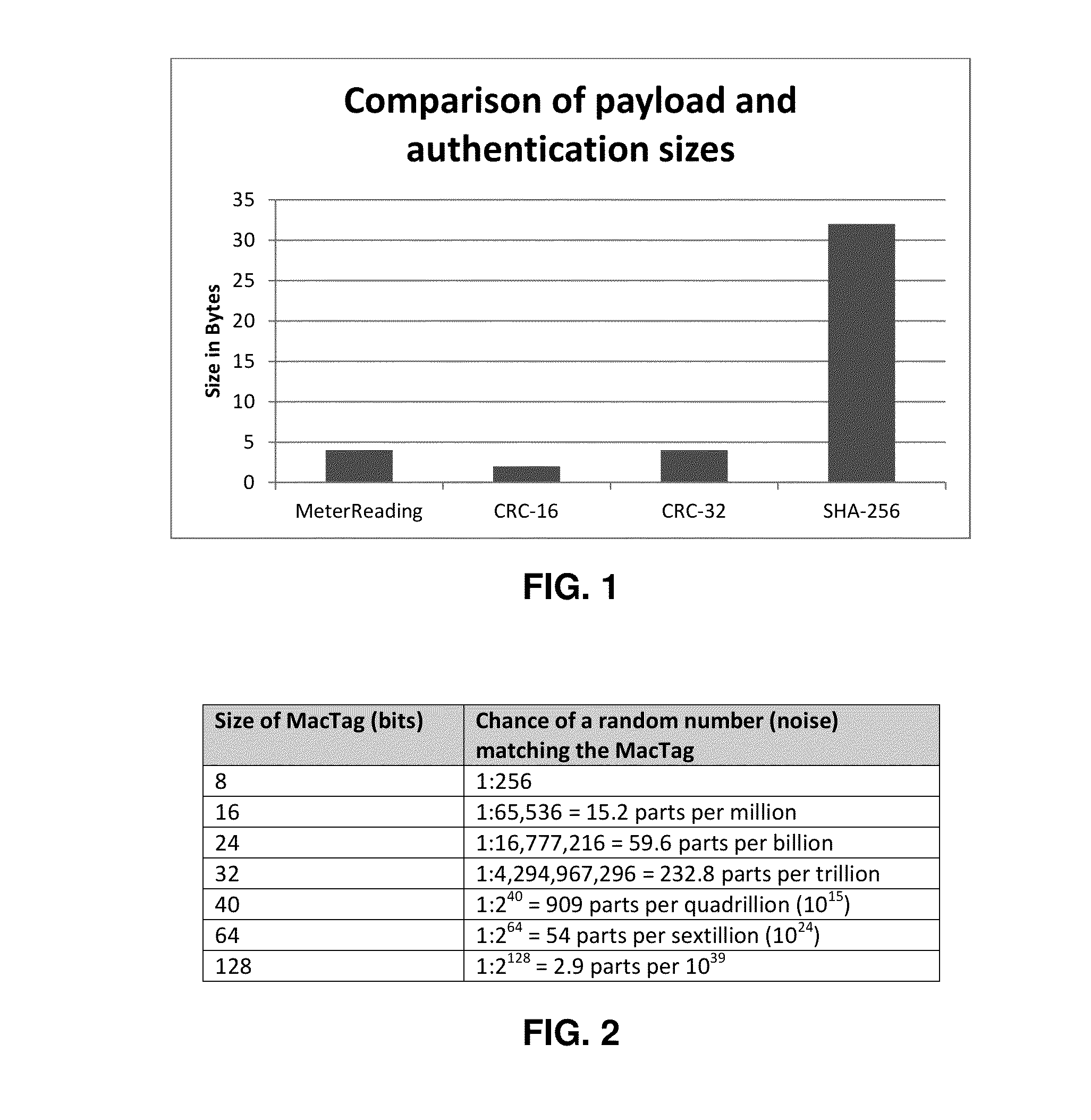

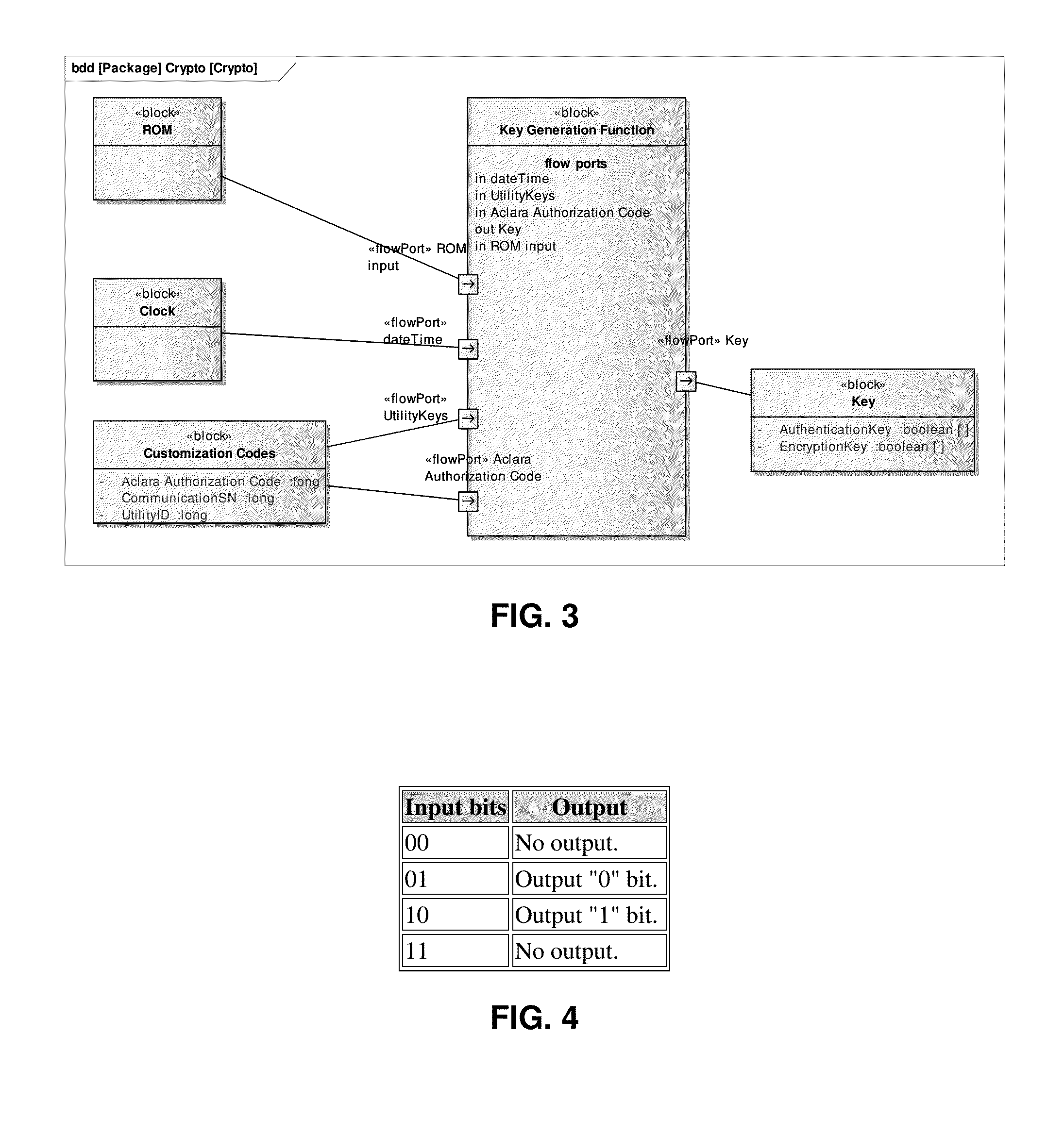

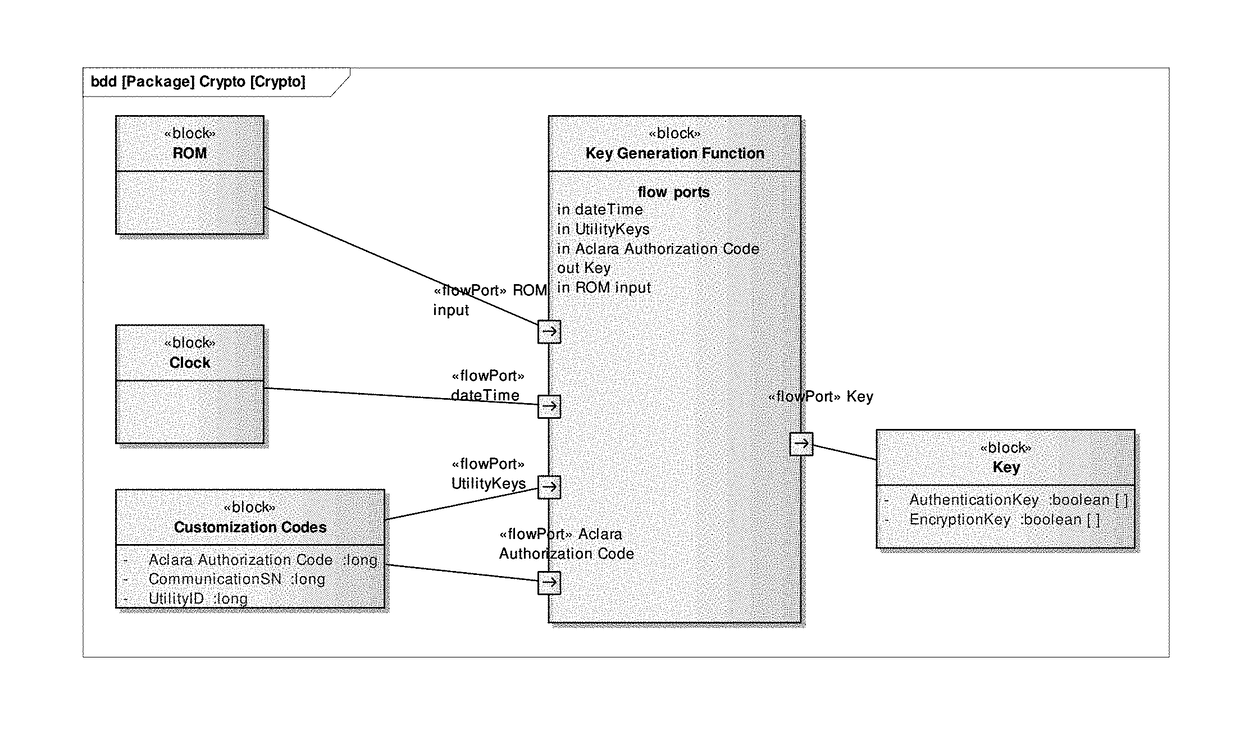

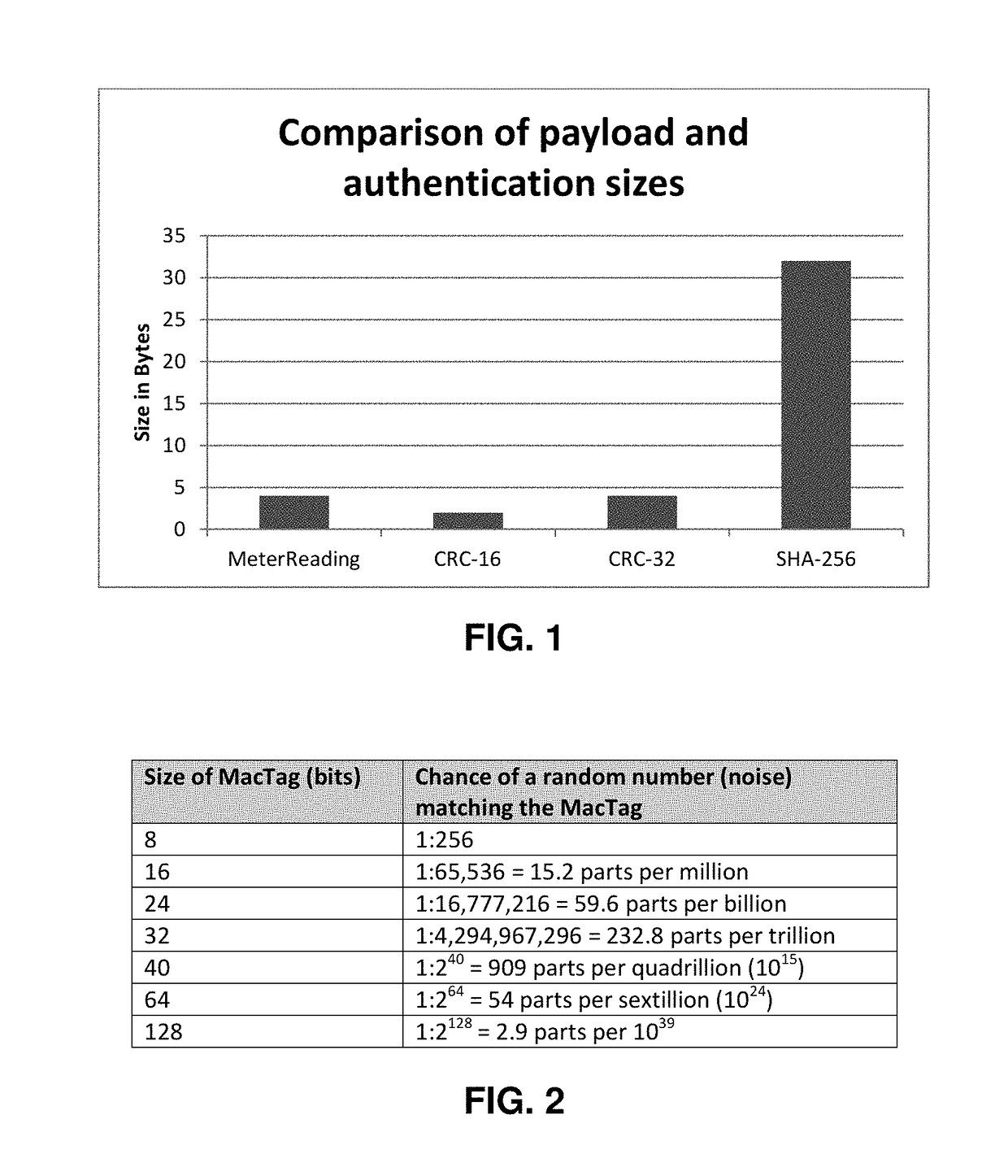

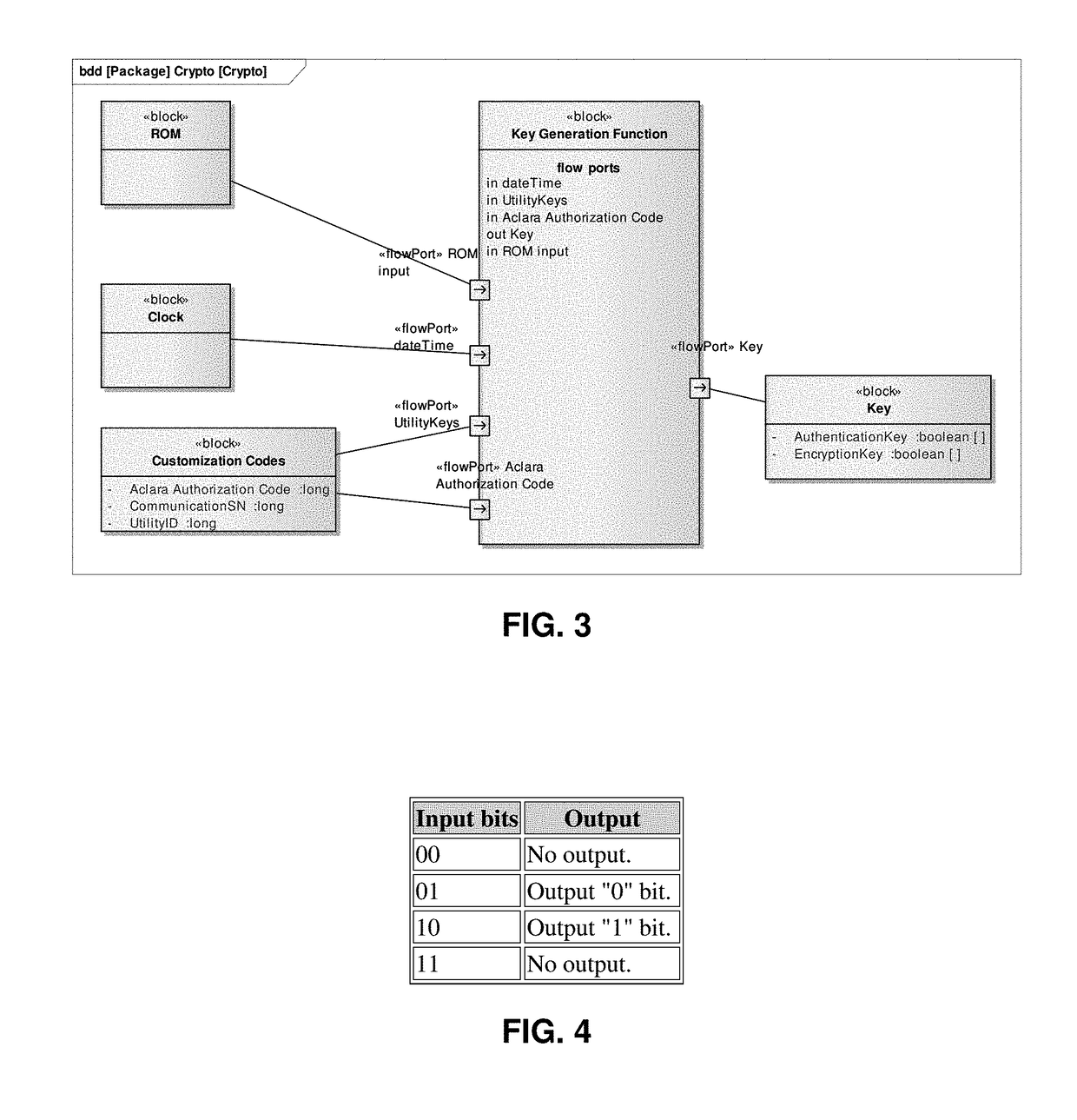

Method for generating cryptographic "one-time pads" and keys for secure network communications

ActiveUS20160149879A1Facilitates secure communicationEffect is temporaryUser identity/authority verificationCoding/ciphering apparatusSecure communicationRandom materials

A method of generating random and pseudo-random material which is incorporated in devices located at each end of a communications network for secure communications through a channel of the network. The material is used to generate time based one-time pads, one-time keys, and the keys themselves. The one-time pads, one-time keys, and the keys support a key-based or pad based cryptographic technique employed to produce secure communications of messages transmitted through the channel with a one-time pad, one-time key, or a key generated at one interval of time being different and unique from a one-time pad, one-time key, or a key generated at any other interval of time.

Owner:ACLARA TECH LLC

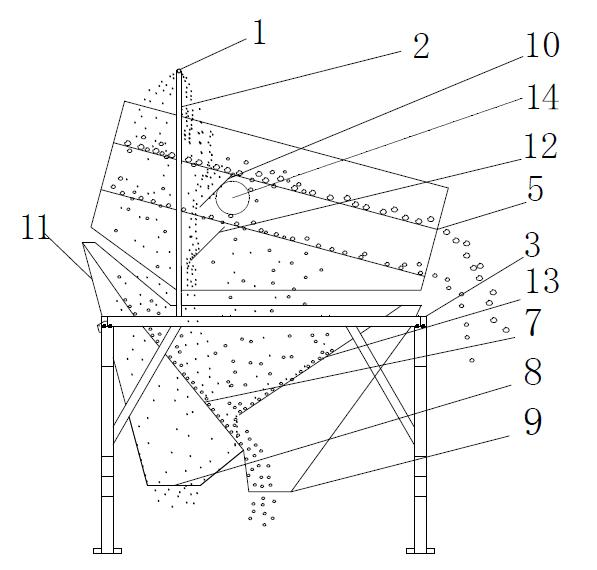

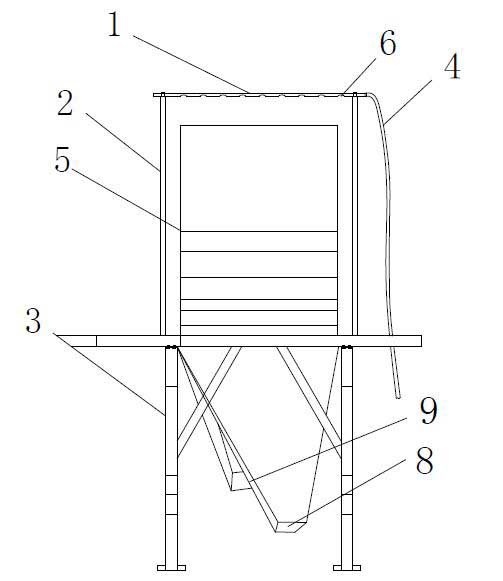

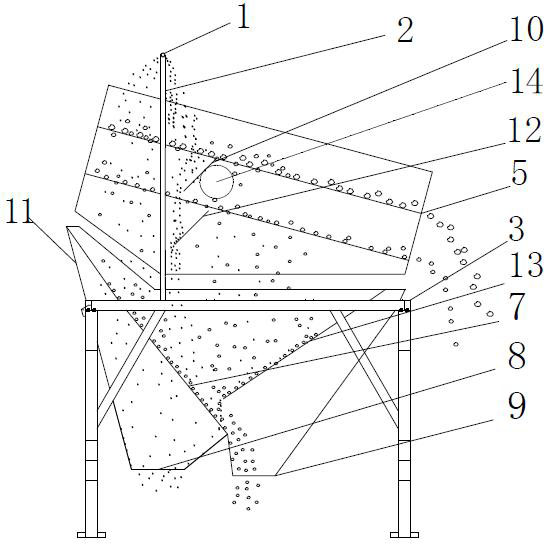

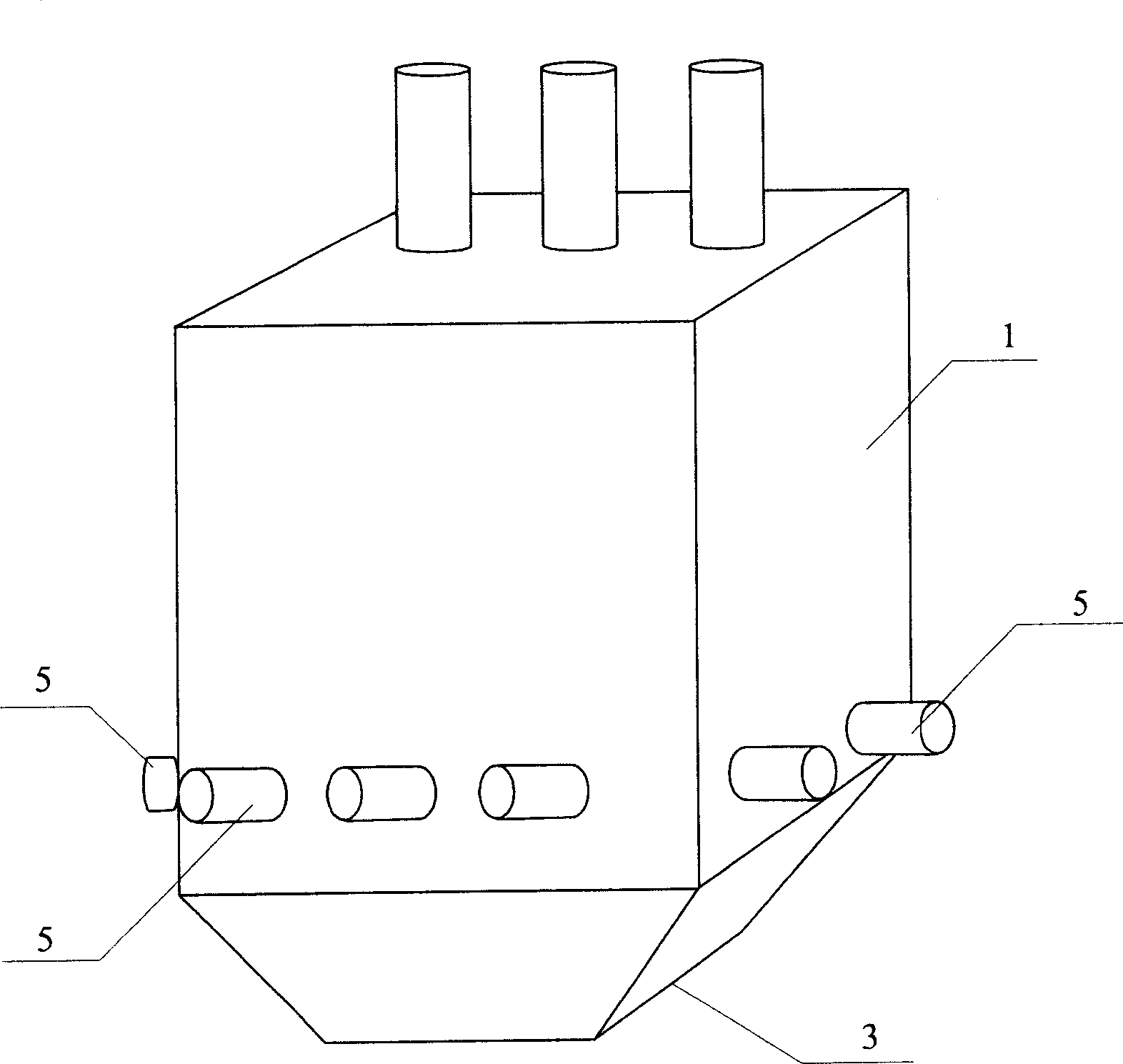

Random material washing sieve

InactiveCN102527633AFully cleanedSimple interfaceSievingScreeningRandom materialsUltimate tensile strength

The invention discloses a random material washing sieve, belonging to a stone material separating sieve in the field of building construction. A water spraying pipeline is horizontally arranged above the front part of a sieve body; a primary water guide plate and a secondary water guide plate are arranged on the sieve body; a water permeable sieve, a guide plate, a water dropping port and a waste port are arranged in a material dropping cabin; the sieving and washing of gravels are synchronously performed; the water and the gravels are differently oriented at the same time; and automatic separation of the water and the gravels is realized at last. According to the random material washing sieve disclosed by the invention, gravel washing equipment does not need to be arranged, a working procedure of washing the gravels solely is obviated, the water content of the gravels is complemented, the interfaces of cementing bodies of the gravels and cement are improved, and the concrete strength is enhanced. The random material washing sieve has the advantages of a simple structure, small investment, high efficiency, energy saving effect, emission reduction and the like, and has good application prospect and popularization values.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

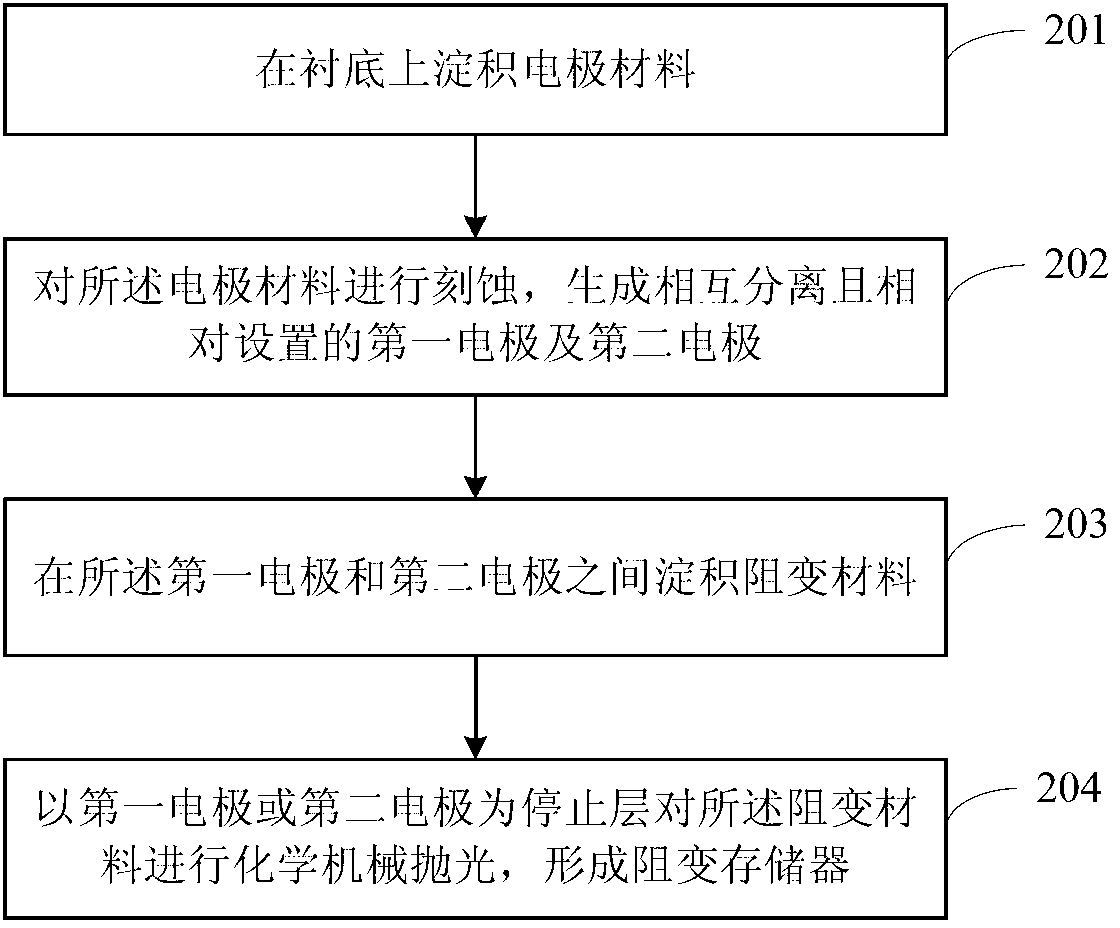

Method for preparing resistive random access memory

InactiveCN102593352AAchieve self-alignmentGuaranteed isolationElectrical apparatusDigital storagePartial oxidationStatic random-access memory

The invention discloses a method for preparing a resistive random access memory. The method comprises the following steps: preparing a bottom electrode on a substrate; then, carrying out partial oxidation on the metal of the bottom electrode so as to form a metal oxide with a thickness of 3-50 nm, and taking the metal oxide as a resistive random material layer; and finally, preparing a top electrode on the resistive random material layer. By using the method disclosed by the invention, a step of depositing a resistive random material layer in the traditional method is avoided, thereby greatly reducing the process complexity; meanwhile, the self-alignment between the resistive random material layer and the bottom electrode can be realized; the complete isolation between devices is ensured; various parasitic effects generated by the traditional process methods are avoided; and the consistency of the actual area and design area of each device is ensured.

Owner:PEKING UNIV

Misreading-resistant resistive random access memory and preparation method thereof

ActiveCN107681049AStable resistance changeReduce power consumptionElectrical apparatusRandom materialsStatic random-access memory

The invention discloses a misreading-resistant resistive random access memory. The structure of the misreading-resistant resistive random access memory comprises a substrate, a resistive random dielectric layer which is formed on the substrate and an Ag electrode layer which is formed on the resistive random dielectric layer, wherein the substrate, the resistive random dielectric layer and the Agelectrode layer are arranged from the bottom to the top in turn. The resistive random dielectric layer comprises a first zirconium hafnium oxide film layer, a graphene oxide quantum dot intermediate layer and a second zirconium hafnium oxide film layer which are arranged from the bottom to the top in turn. The invention also discloses a preparation method of the resistive random access memory. Theresistive random access memory of the specific structure is prepared, especially graphene oxide quantum dot intermediate layer is embedded between the first zirconium hafnium oxide film layer and thesecond zirconium hafnium oxide film layer of the resistive random material layer and growth and fracture of the conductive filament can be accurately controlled to enhance the uniformity of the device so that the finally prepared resistive random access memory is enabled to have the more stable resistance change, lower power consumption and better stability and uniformity, and the preparation method is simple, great in operability and simple in large-scale production and manufacturing and thus the application prospect is wide.

Owner:上海夯业真空设备科技有限公司

Microparticle lens array holographic printing

InactiveCN101329507ARealize automated productionRealize holographic three-dimensionalScreening processesOptical elementsGratingRandom materials

The invention discloses a particle mirror matrix holographical printing which can carry out automatic production. Partial or complete micro-mirror matrix is obtained by a direct particle printing, transfer printing or implantation way and combined on a holographical composite image synchronously to obtain the direct printing of a real color holographical image on a common printing material with no need of grating or mirror matrix printing material, thus realizing the one-step automatic production of printing equipment or digital printing equipment. The particle mirror matrix holographical printing can produce randomly non-repeated micro-mirror matrix structure, and can also be combined into an irreversible holographical forgery-proof printing technology by the combination of particles with different size and arbitrary shape, and heterogenous random material, film coating, photosensitiveness, hollowness, color, illumination caused by external factors, color deterioration caused by the external factors, failure caused by the external factors, DNA gene and magnetism, etc. which have different characteristics. The appearance of the holographical printing is an important breakthrough to the traditional printing technology existing for thousands of years. The invention also includes the steps for manufacturing a particle mirror matrix holographical image by a photosensitive material.

Owner:谷京陆

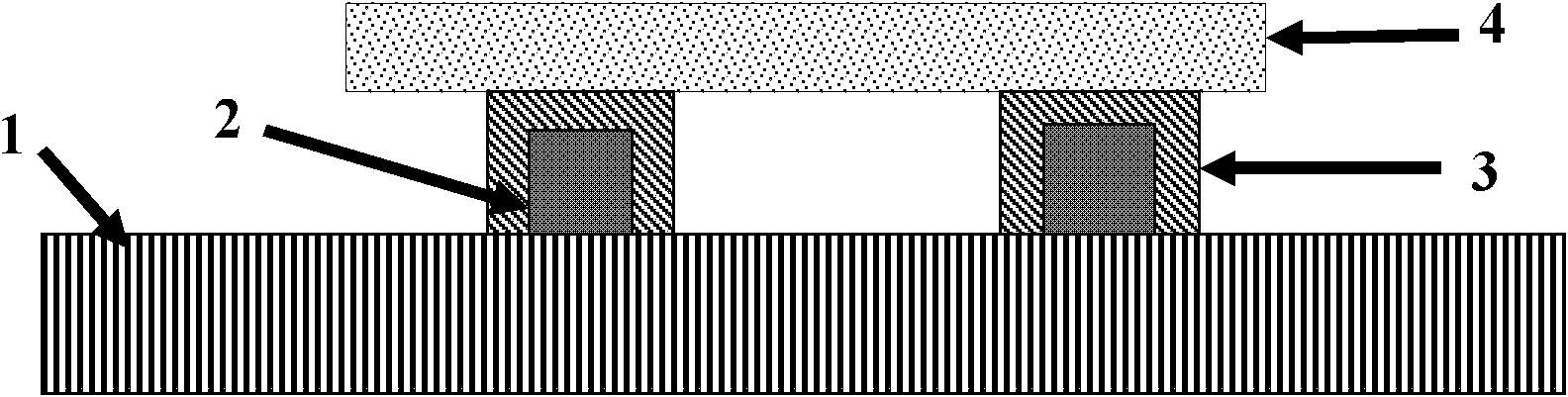

Resistive random access memory and preparation method thereof

InactiveCN103066207AReduce power consumptionReduce contact areaElectrical apparatusDigital storageStatic random-access memoryRandom materials

The invention provides a resistive random access memory and a preparation method thereof. The resistive random access memory is formed on a substrate. The resistive random access memory comprises a first electrode, resistive random materials and a second electrode, the first electrode, the resistive random materials and the second electrode are arranged on the surface of the substrate, the first electrode and the second electrode are arranged oppositely, and the resistive random materials are arranged between the first electrode and the second electrode, and simultaneously contacted with the first electrode and the second electrode. The area of the contacting surface of the first electrode and the substrate is larger than that of a first contacting surface of the first electrode and the resistive random materials, and / or the area of the contacting surface area of the second electrode and the substrate is larger than that of a second contacting surface of the second electrode and the resistive random materials. The resistive random access memory has the advantages of being small in operating current, low in power consumption, and the like.

Owner:PEKING UNIV

Method for generating cryptographic “one-time pads” and keys for secure network communications

ActiveUS9762560B2Facilitate communicationKey distribution for secure communicationUser identity/authority verificationSecure communicationRandom materials

A method of generating random and pseudo-random material which is incorporated in devices located at each end of a communications network for secure communications through a channel of the network. The material is used to generate time based one-time pads, one-time keys, and the keys themselves. The one-time pads, one-time keys, and the keys support a key-based or pad based cryptographic technique employed to produce secure communications of messages transmitted through the channel with a one-time pad, one-time key, or a key generated at one interval of time being different and unique from a one-time pad, one-time key, or a key generated at any other interval of time.

Owner:ACLARA TECH LLC

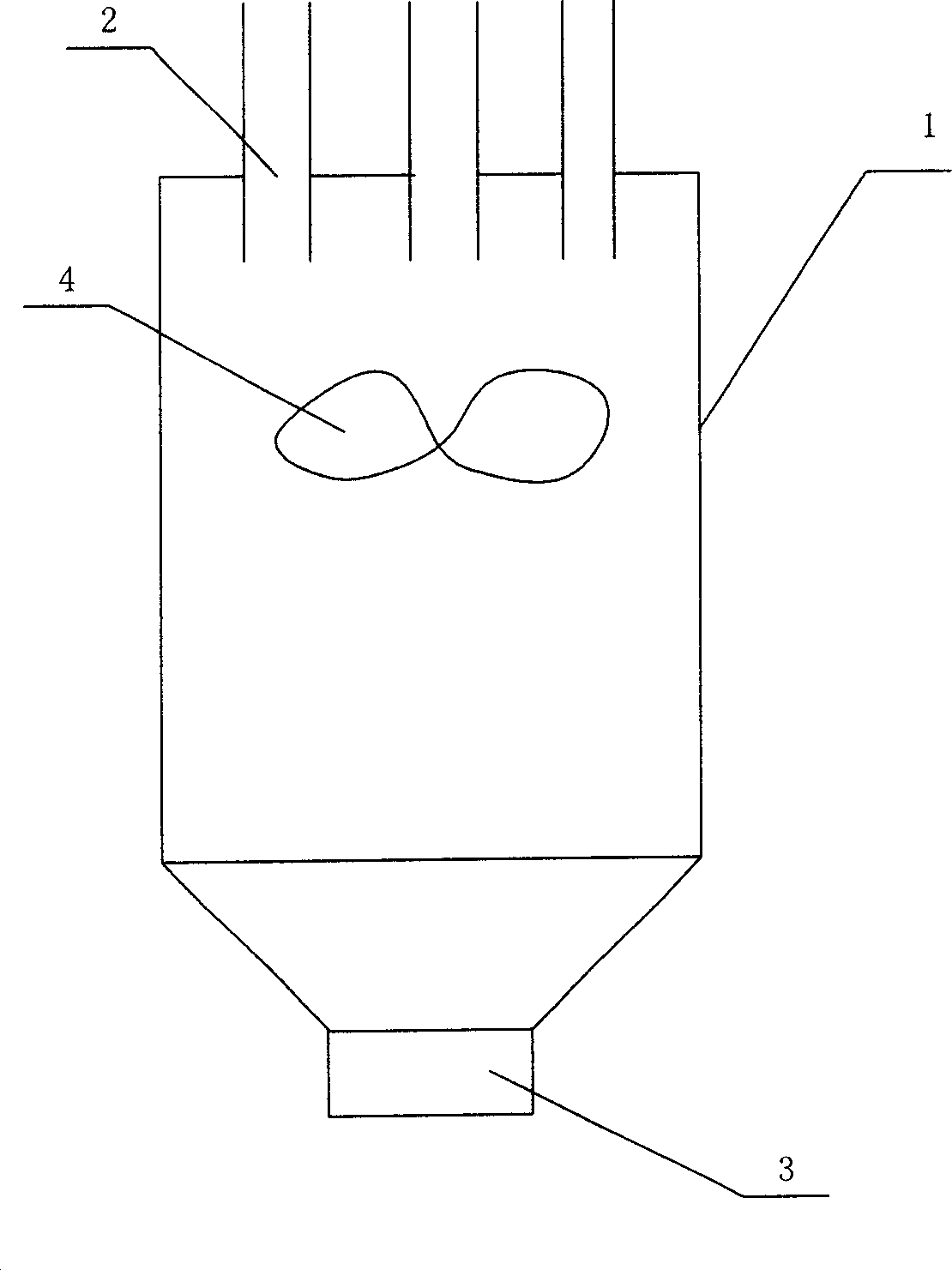

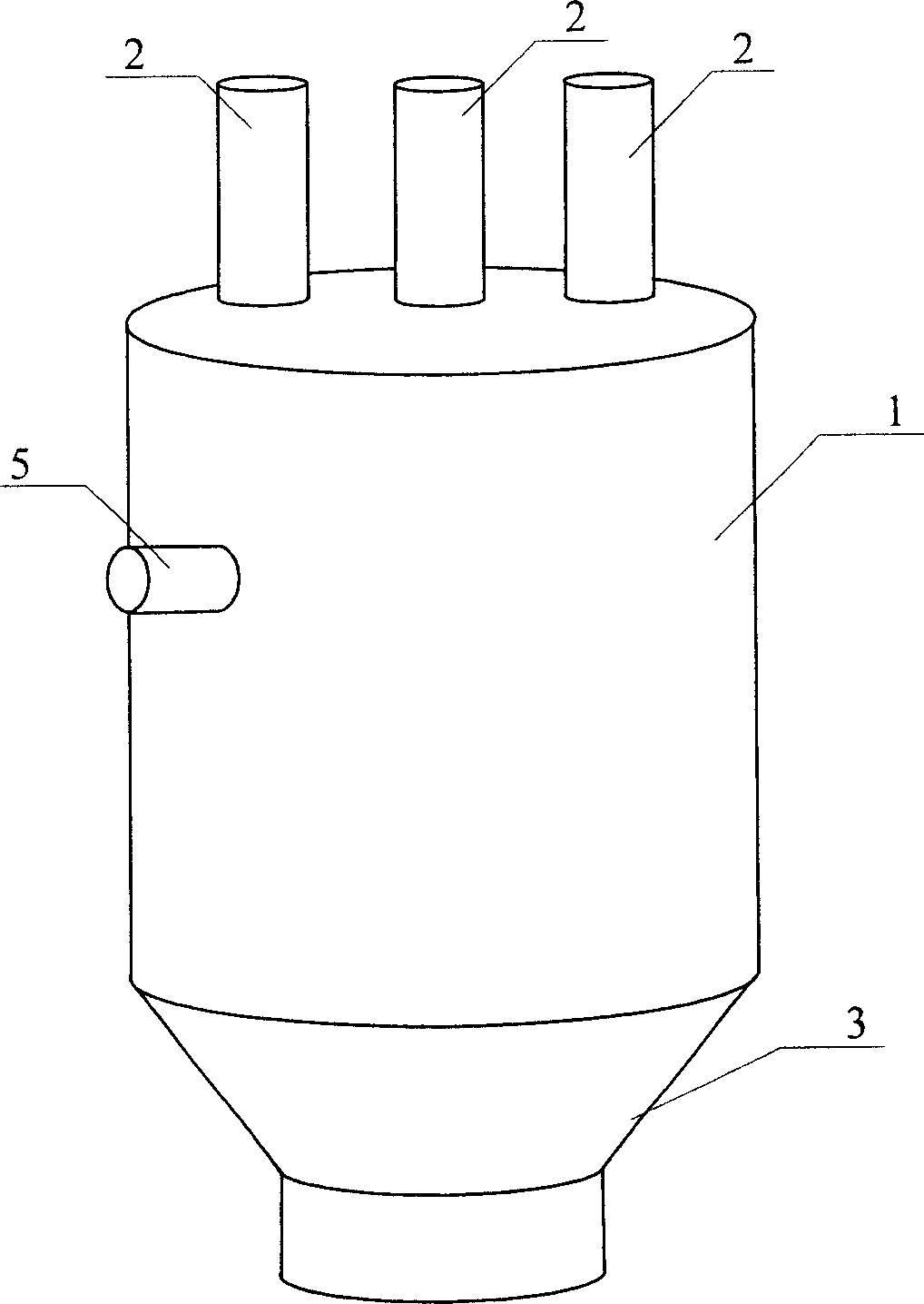

Random material mixer and mixing method

InactiveCN1745993AOvercoming dull decoration effectOvercome lack of beautyMixing operation control apparatusCement mixing apparatusRandom materialsBrick

A random mixer for making color brick has a mixing drum with filling inlets on its top, discharging outlet on its lower end and electrically controlled air inlet on its lateral wall. Its mixing method includes such steps as connecting the air inlet to compressed air source, electrically connecting the electric controller, turning on the controller, filling particles with different colors, spraying the randomly changed airflow for mixing, and discharging the mixture.

Owner:KEDA INDUSTRIAL GROUP CO LTD

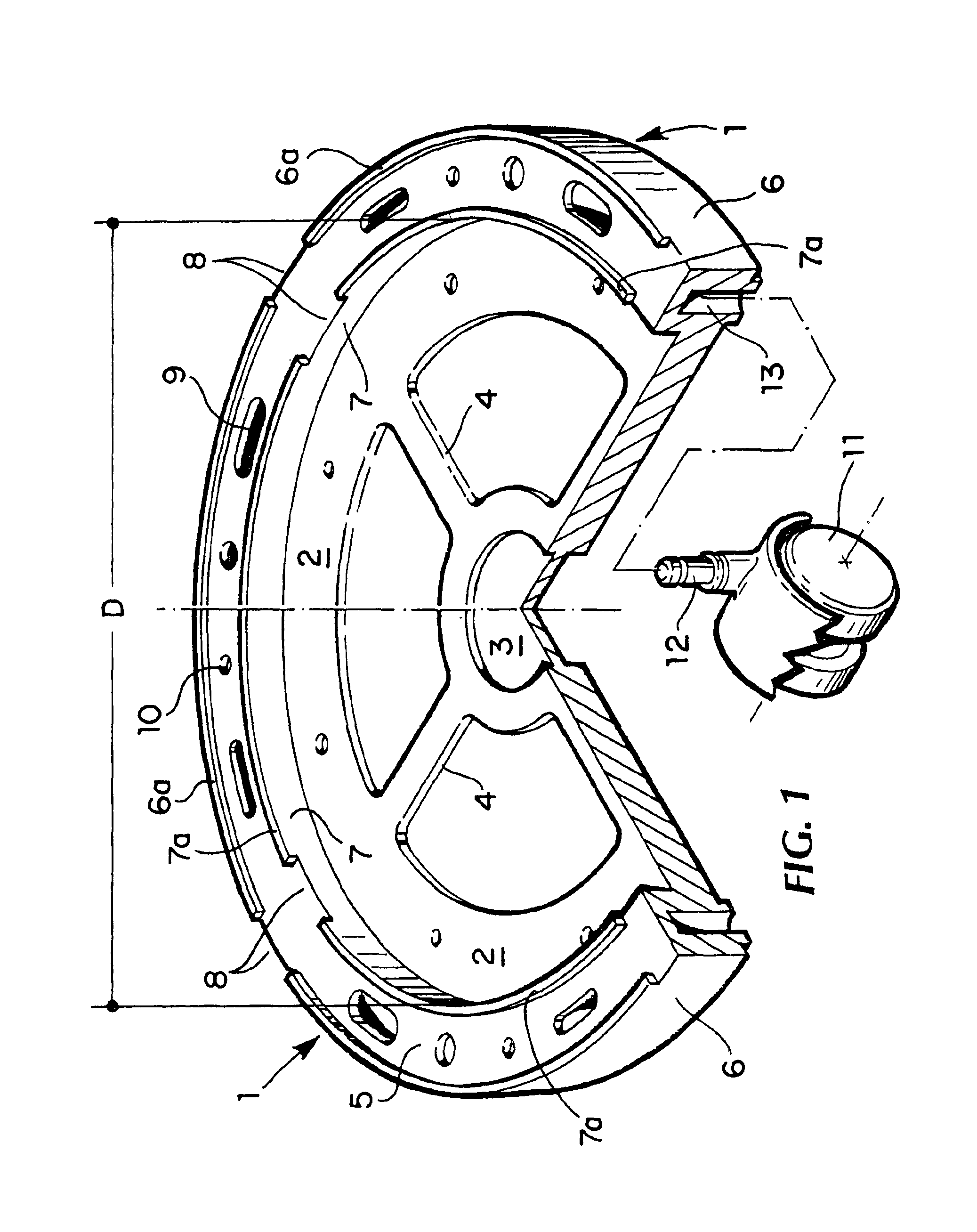

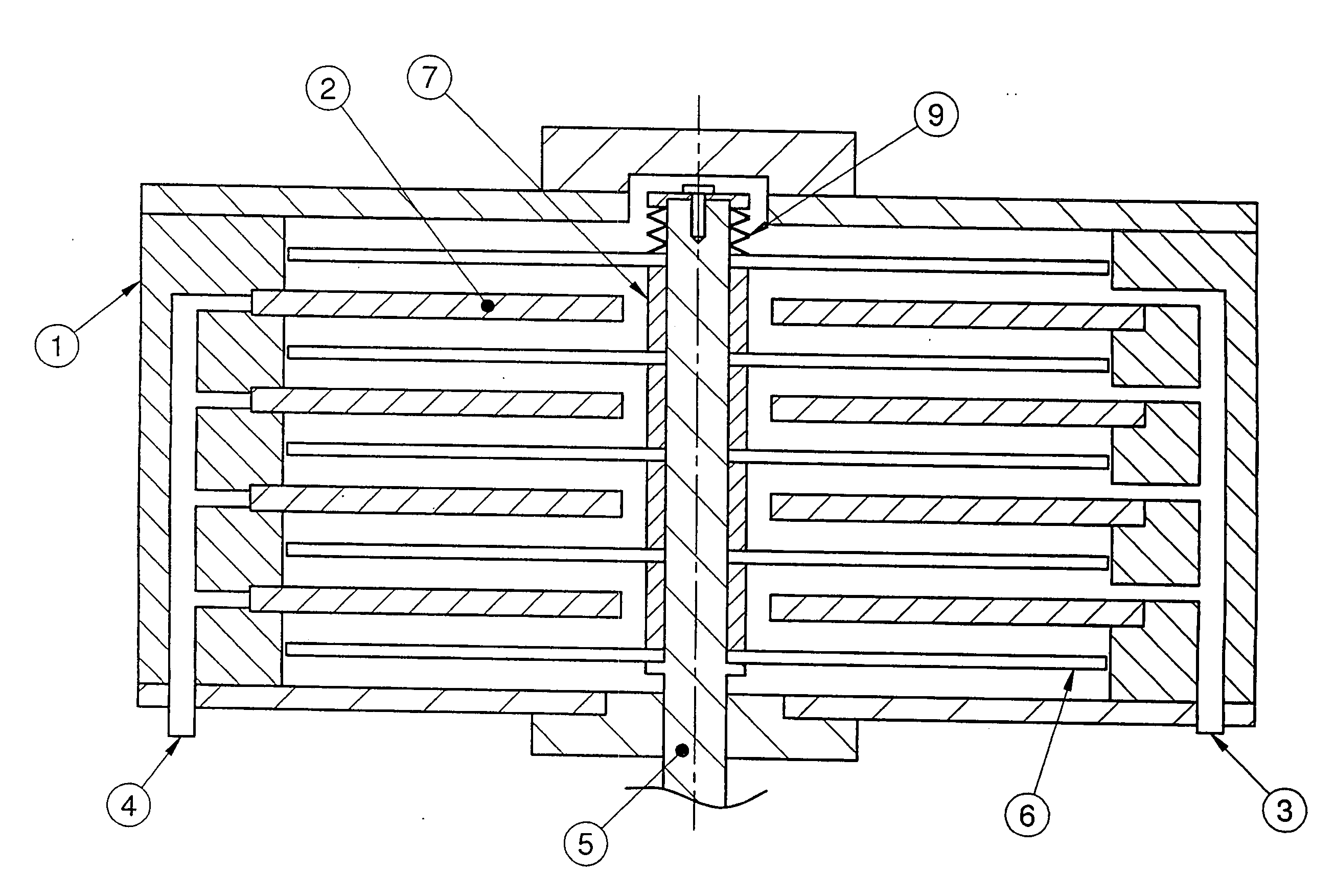

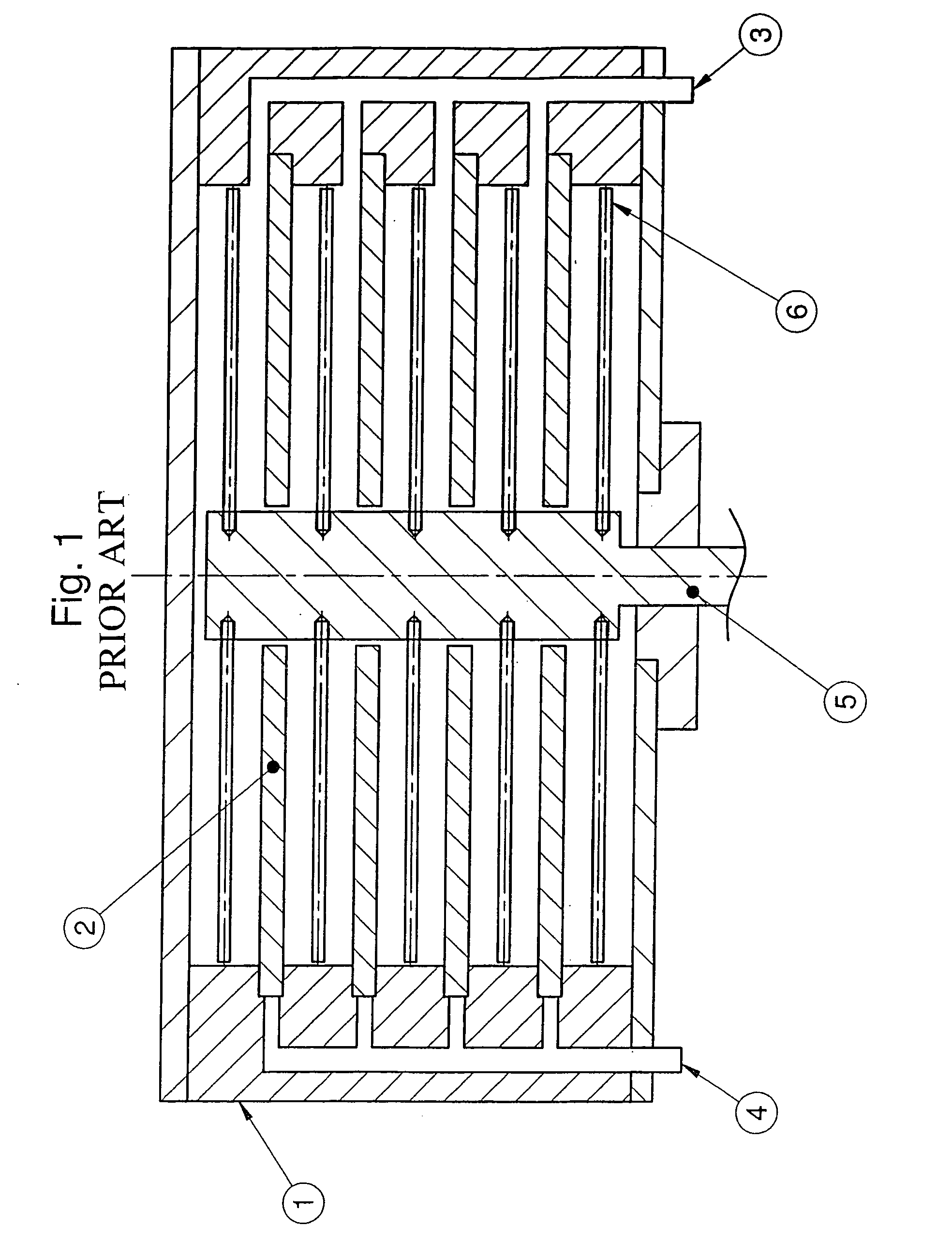

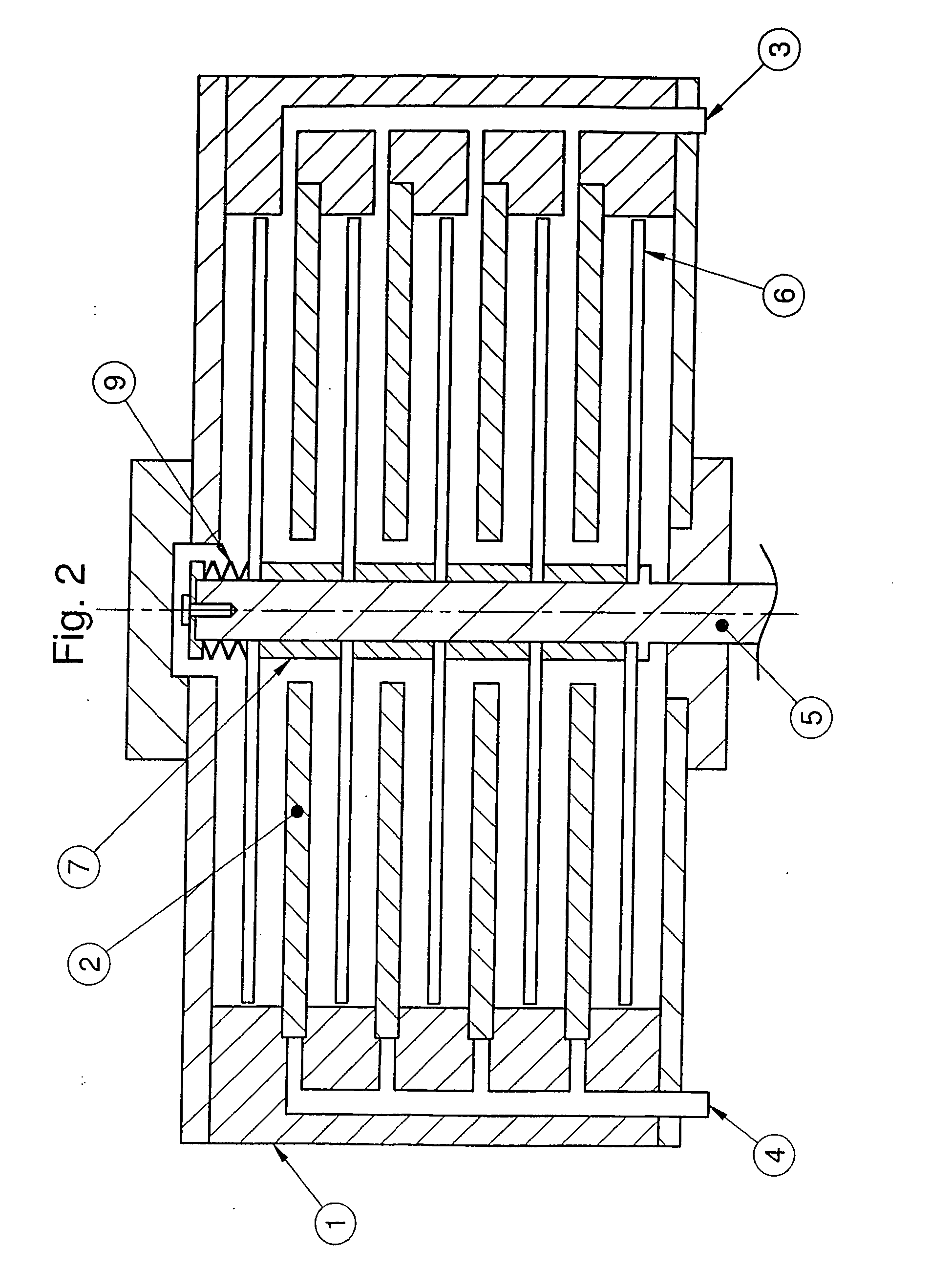

Rotational shearing filter

InactiveUS20070158260A1Increase the use of spaceEasy to useTransportation and packagingRotary stirring mixersRandom materialsDrive shaft

A rotational shearing filter is disclosed which includes a housing and several spaced-apart, stationary, coaxial, annular, hollow filter disks that are disposed therein. Several shearing elements are retained in a torsion-proof manner on a central, rotatable drive shaft which penetrates the filter disks. The shearing elements are placed next to the annular surfaces of the filter disks, which point in the axial direction of the housing, so as to keep the filter disks penetrable for filtrate that penetrates from the housing into the filter disks. In order to prevent the shearing elements and the filter elements from touching each other as a result of thermal expansion, the shearing elements that are connected to the drive shaft so as to rotate therewith are guided thereon in an axially movable manner while spacers which axially displace the shearing elements according to longitudinal modifications of the housing occurring due to thermal conditions are positioned between the shearing elements. The spacers can be arranged directly between adjacent shearing elements and can be made of a material corresponding to the thermal expansion behavior of the housing. Alternatively, the spacers can be made of a largely random material while limiting the minimum distances between the shearing elements and the filter disks or the facing housing walls.

Owner:ANDREAS KUFFERATH

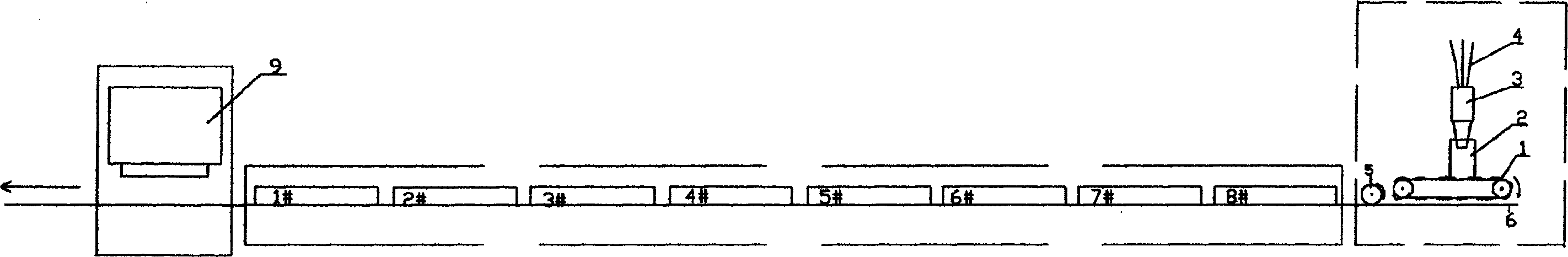

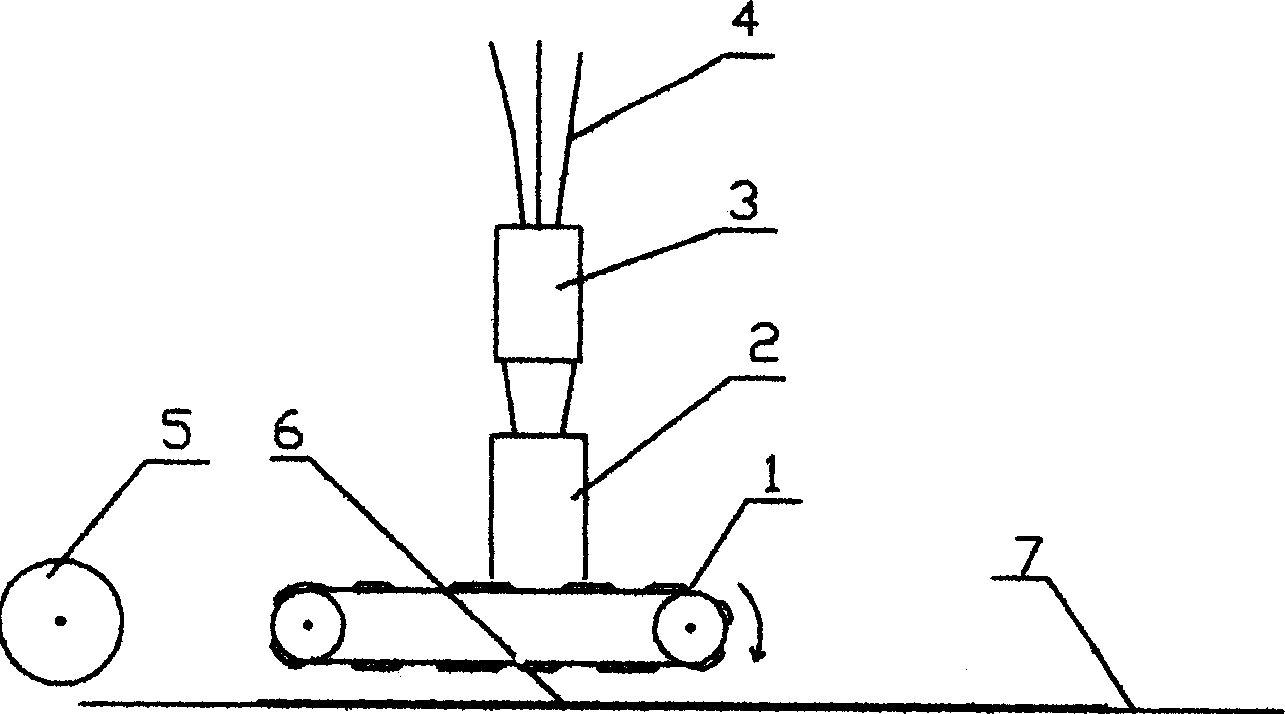

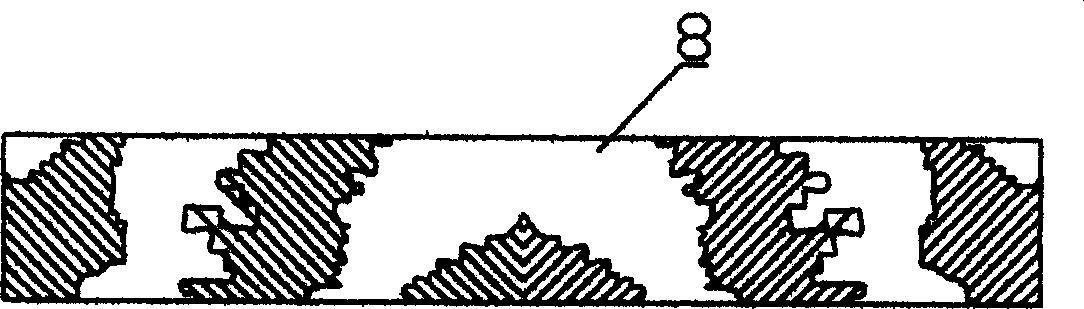

Random distributing equipment and method for ceramic forming

ActiveCN1792595AOvercoming repetitive flawsEasy to replaceDischarging apparatusFeeding arrangmentsRandom materialsCeramic molding

A random material distributing apparatus for shaping ceramic with different pattern effects and pattern lines is composed of superfine powder stirring cylinder, superfine powder feeding hopper, rubber pads, conveying belt with pits, and thickness-fixed compacting roller. Its method features that the speed of conveying belt is controlled to make the shape of material stack on the conveying belt is variable with speed, so generating different effects.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD

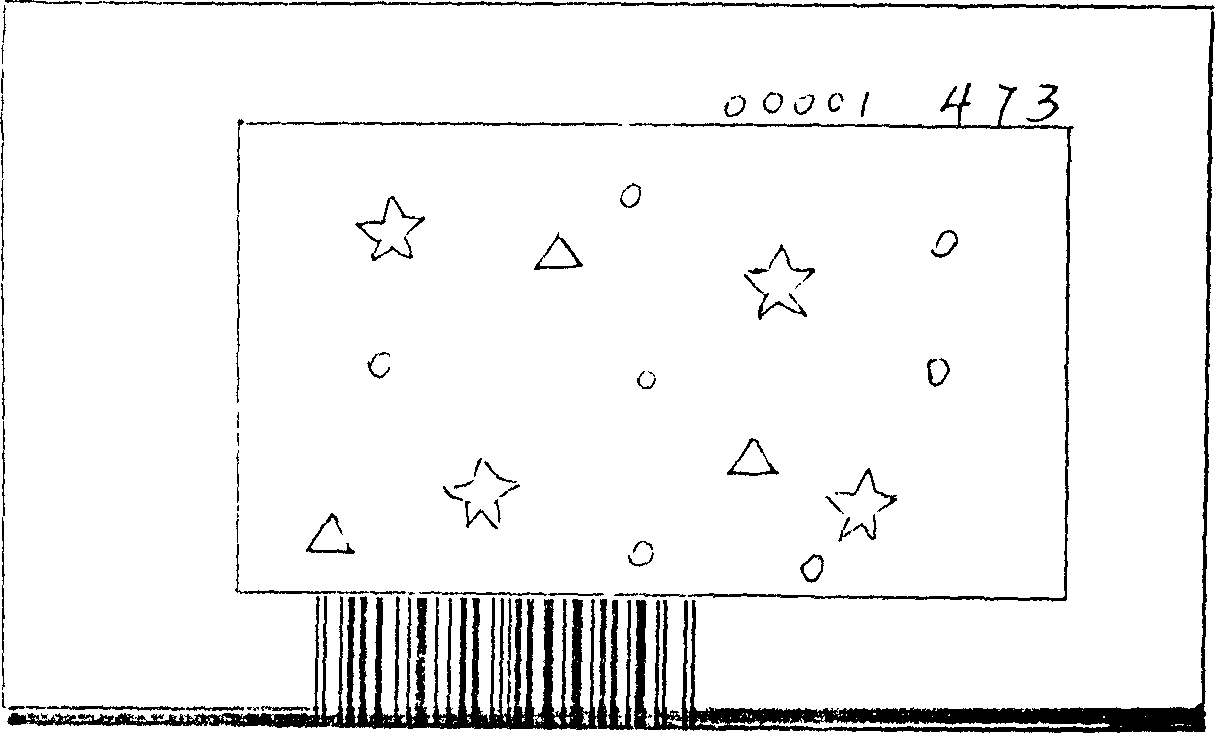

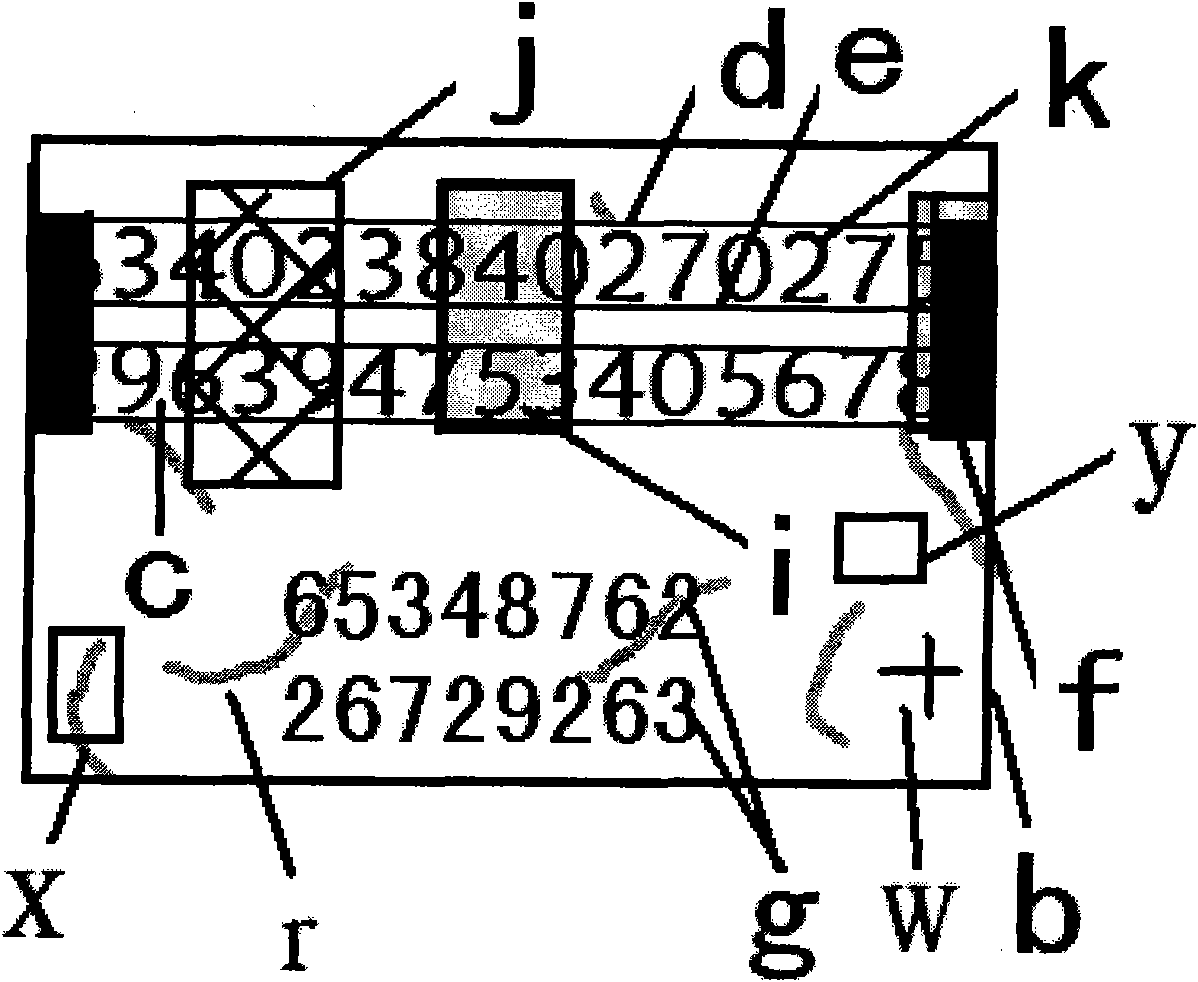

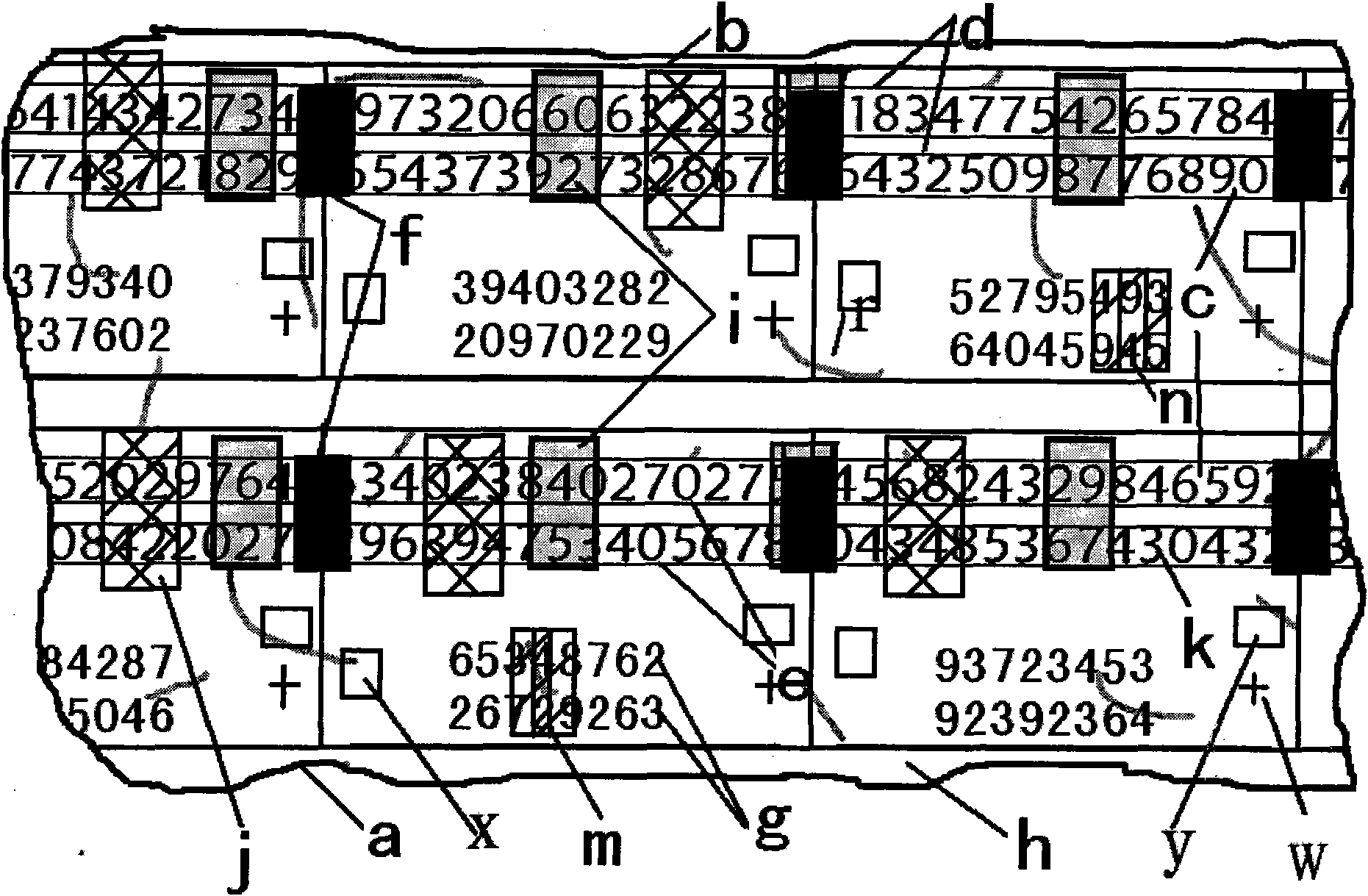

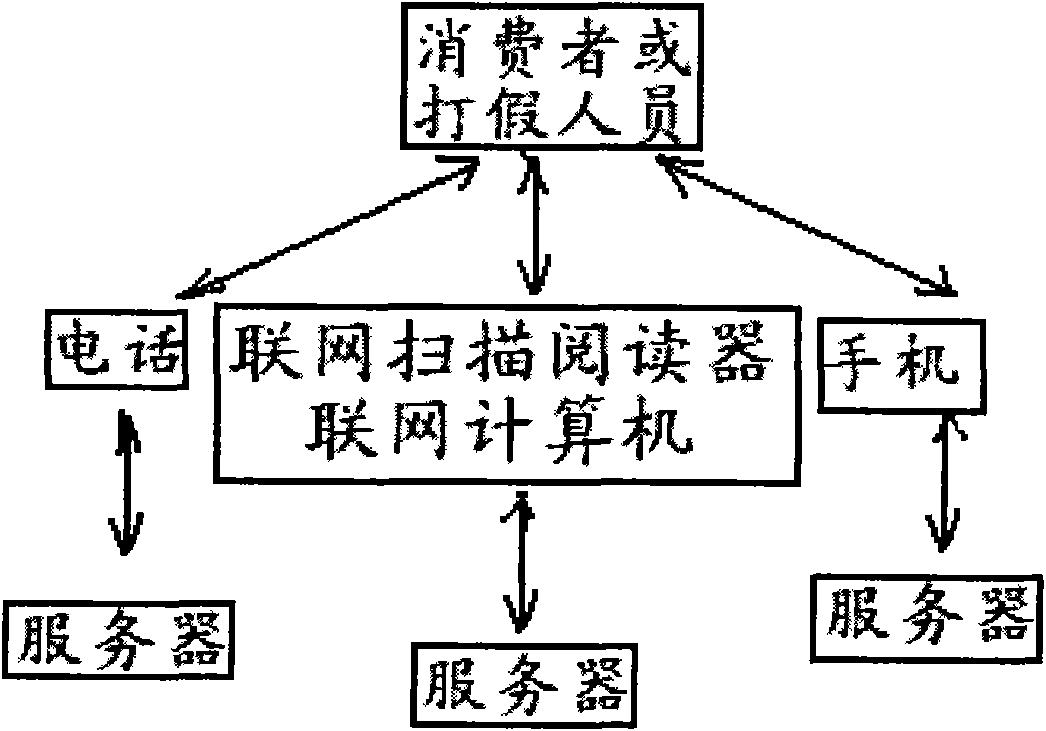

Anti-counterfeit product with security line with structured texture numerical code and method

InactiveCN101807362AConvenient and accurate identificationInnovative designStampsRecord carriers used with machinesRandom materialsHigh volume manufacturing

The invention provides an anti-counterfeit product with a security line with a structured texture numerical code and a method. The invention is characterized in that the anti-counterfeit product is provided with the security line with the numerical code, contains filiform, stripy, lumpish, fragmental or granular random materials (random materials for short) and is provided with a printing verification numerical code; and a fixed or mobile phone, a computer on the internet, mobile E-mail capable of sending short messages or multimedia messages or a mobile phone with application programs corresponding to the anti-counterfeit product installed or a scanning reader connected to the network is used for verifying the numerical code on the security line, the characteristic information of the random materials and the printing verification numerical code to identify authenticity of the anti-counterfeit product. The invention has the following advantages: the anti-counterfeit product can be identified conveniently and accurately so that the counterfeiters can not validly imitate the product, and the anti-counterfeit product has lower cost, can be produced in mass and is applicable to various fields.

Owner:郑阿奇

Rotating cylinder type random material output mixing device

The invention relates to an on-demand material outputting and mixing device which takes the shape of a rotary cylinder. The device is provided with a shell body, a mixing chamber is formed at one end in the shell body, a supersonic motor which is used for driving a mixing column arranged in the mixing chamber is arranged at the periphery of the mixing chamber, at least two material delivery constructions are arranged at the periphery of the mixing chamber and a plurality of nozzles are arranged on the peripheral wall of each material delivery construction that is corresponding to the circumferential surface of the mixing column; when the invention is used, the supersonic motor is used for driving the mixing column for rotation, simultaneously, the raw materials are sprayed by all nozzles to the surface of the mixing column, so all raw materials can be piled and mixed on the surface of the mixing column to form the required mixing effect or the color finished products that can be provided for users for use.

Owner:张奉琦

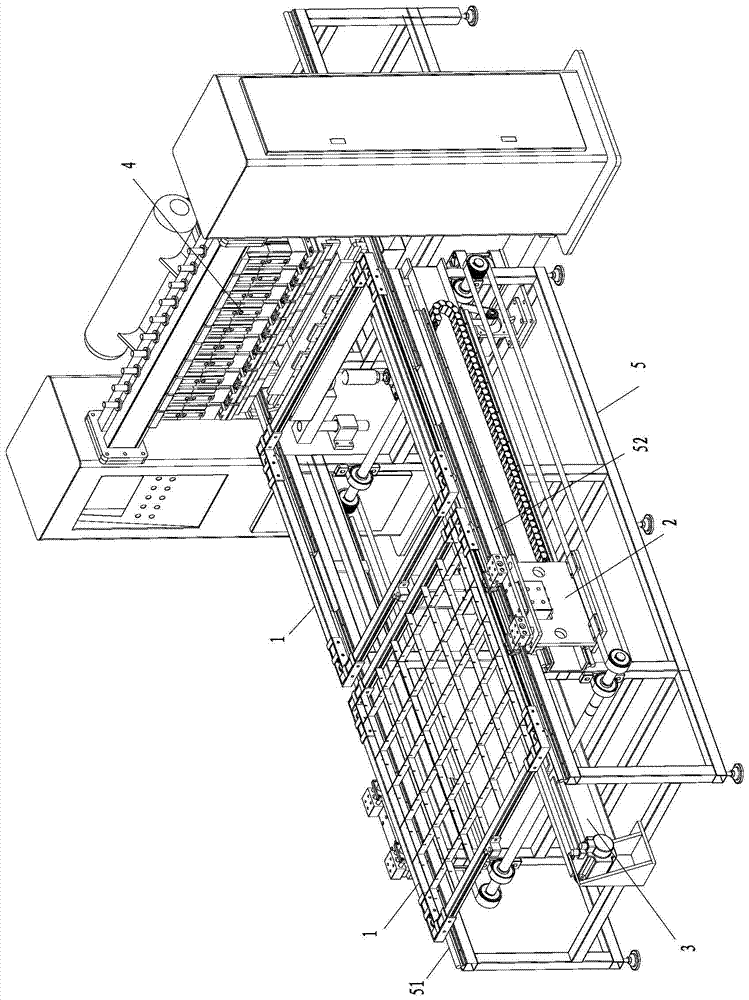

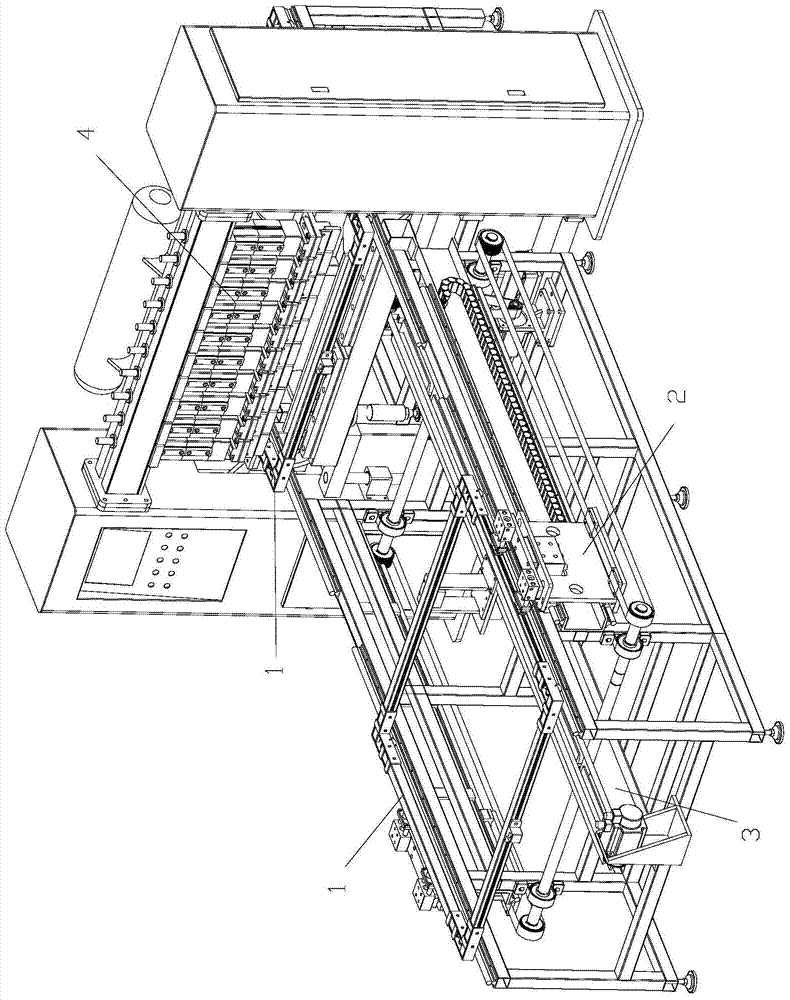

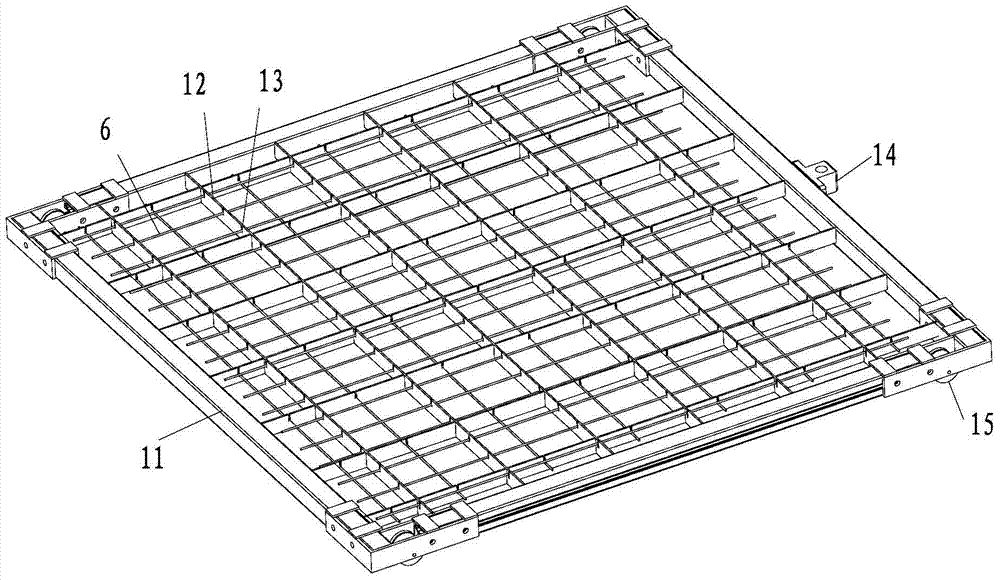

An Alternate Feeding Type Screen Welding Equipment

ActiveCN105171217BReduce standby timeEnable mobilityWire networkMetal working apparatusElectricityRandom materials

The invention provides alternative feeding type network-arranging welding equipment which comprises the components of a frame, at least two material arranging racks which are used for arranging metal wires, a lifting device which is used for vertical movement of the material arranging racks, a first moving device which is used for driving the material arranging racks to perform front-and-back movement, and an electric welding device which is used for welding the metal wires for forming a metal network. Each material arranging rack is movably arranged on the frame. The lifting device is arranged on the frame through a second moving device for realizing frontward movement and backward movement of the lifting device. The first moving device and the electric welding device are arranged on the frame. A random material arranging rack is connected with the lifting device, and the other more than one material arranging rack is connected with the first moving device. The electric welding device is electrically connected with an external power supply. An existing electric welding device is used as the electric welding device of the invention. The network-arranging welding equipment has functions of realizing alternative material feeding, obtaining flexible operation, improving equipment operation efficiency and reducing land occupation.

Owner:佛山煜宁智能科技有限公司

Bentonite firework emission agent composition

InactiveCN109020768AImprove securityImprove stabilityNon-explosive stabilisersNon toxicityRandom materials

The invention discloses a bentonite firework emission agent composition, which is characterized by being prepared from the following ingredients in parts by weight: 30 to 65 weight parts of bentonite,5 to 10 weight parts of rare earth, 15 to 30 weight parts of carbonized bamboo powder,10 to 20 weight parts of oxidizing agents and 5 to 10 weight parts of alloy powder, wherein the emission agent composition is solid-state ultrafine mixed powder with the fineness being greater than 320 meshes; the oxidizing agents are products obtained through mixed reaction between glycerol trinitrate and guanidine nitrate; the alloy powder is any one kind of materials from silver oxide powder or magnesium oxide powder or a mixture of various random materials from silver oxide powder or magnesium oxide powder at the proportion; the carbonized bamboo powder is a smokeless combustible agent and is used for improving the ignition performance and combustion performance of the emission agent composition. Thebentonite firework emission agent composition has the advantages that the environment is protected; non-toxicity is realized; the processing and the manufacturing are simple; the production cost is low, and the like.

Owner:浏阳市恒信烟花制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com