Robot stack disassembling method of irregular random materials

A robot and irregular technology, applied in the direction of destacking of objects, stacking of objects, instruments, etc., can solve the problems of random random material size, difficulty in destacking by robots, etc., and achieve the effect of reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

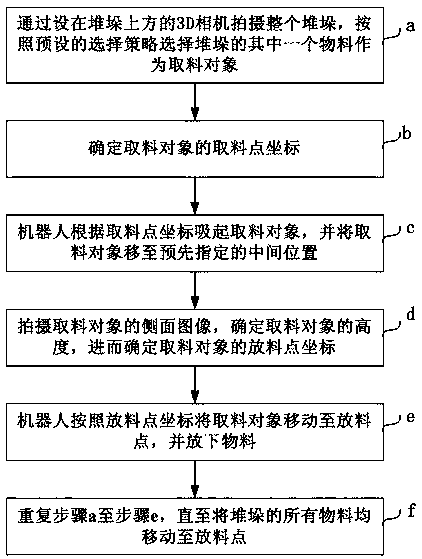

[0019] see figure 1 . The robot unstacking method for irregular random materials according to the first embodiment of the present invention includes the following steps:

[0020] a. The entire stack is photographed by the 3D camera installed above the stack, and based on the image information captured by the 3D camera, one of the materials in the stack is selected as the reclaiming object according to the preset selection strategy;

[0021] b. Determine the coordinates of the pick-up point of the pick-up object;

[0022] c. The robot picks up the reclaimed object according to the coordinates of the reclaimed point, and moves the reclaimed object to the pre-designated intermediate position;

[0023] d. Take a side image of the reclaiming object, determine the height of the reclaiming object, and then determine the coordinates of the dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com