Demounting system

A technology of mechanical arms and driving parts, which is applied in the field of dismantling systems on automated production lines, can solve problems such as long dismantling time and affect dismantling efficiency, and achieve the effect of improving dismantling efficiency and shortening dismantling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

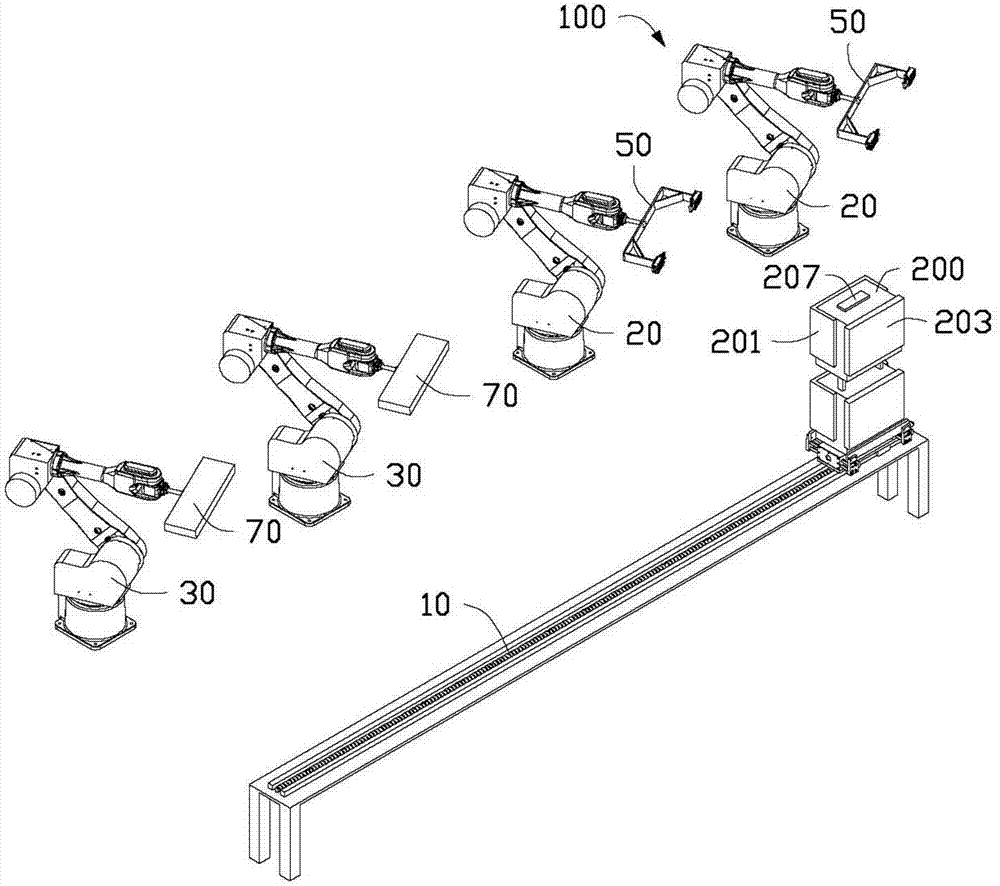

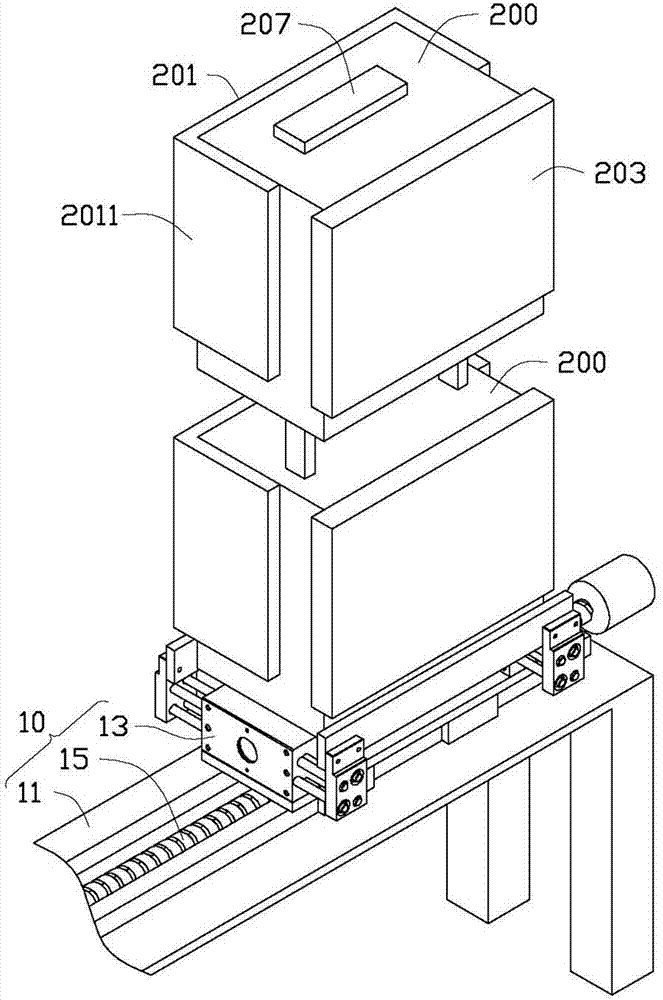

[0014] see figure 1 and figure 2 , the disassembly system 100 of the present invention is used to disassemble the first workpiece 201 and the second workpiece 203 installed on the side wall of the hanger 200 . In this embodiment, the hanging device 200 is a square body, and the hanging part 207 protrudes from the top surface of the hanging device 200 . The first workpiece 201 is substantially U-shaped, and includes two parallel clamping portions 2011 , and the two clamping portions 2011 clamp two opposite side walls of the hanger 200 . The second workpiece 203 is installed on the side wall perpendicular to the two clamping parts 2011 on the hanger 200 and is opposite to the first workpiece 201 . The first workpiece 201 and the second workpiece 203 are made of metal material; the number of the first workpiece 201 and the second workpiece 203 are two respectively, which are divided into upper and lower groups and hung on the two connected hangers 200 .

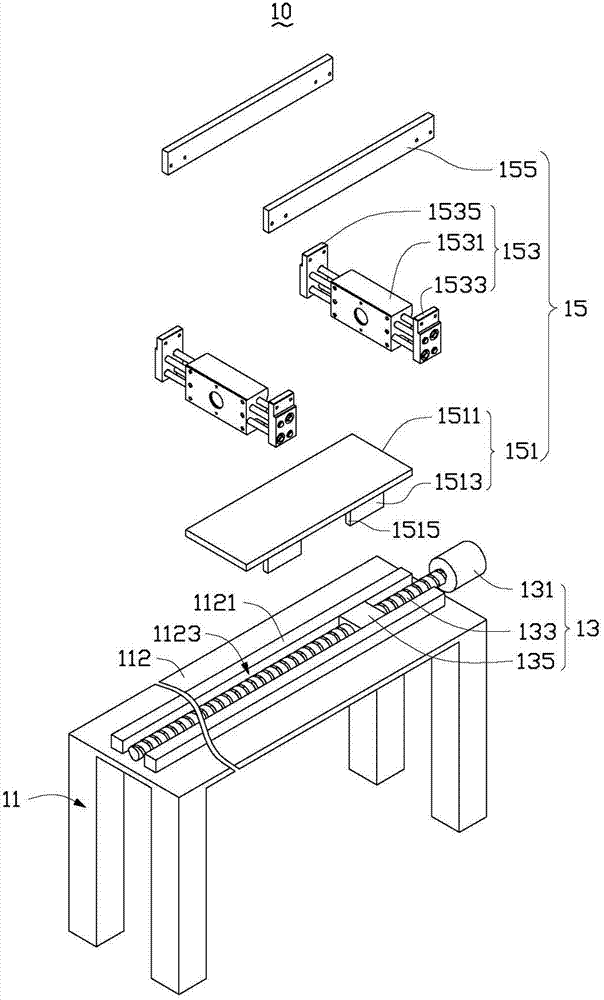

[0015] The disassemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com