Automatic deburring production line for hub robot

A robot and deburring technology, which is applied in the direction of grinding feed movement, grinding machine parts, machine tools suitable for grinding workpiece edges, etc., can solve the problems of large human injuries, leakage, impact, etc., and reduce labor Strength, health-protecting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

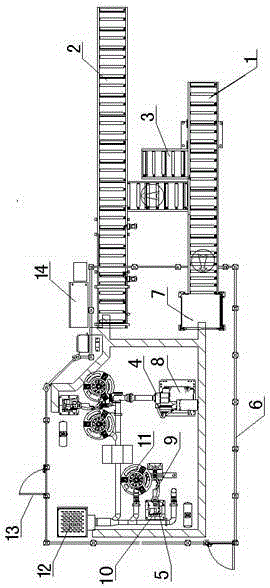

[0016] Depend on figure 1 It is known that an automatic deburring production line of a wheel hub robot is composed of a loading and unloading mechanism, a deburring robot and a control system. Road 3, hub window positioning device 7 is composed of, the hub window positioning and recognition platform 7 is set at the end of the feeding roller table 1, and the deburring robot is composed of robot I4, robot II5, robot base I8, and radial grinding claws 9 , robot base II 10, hub fixture turntable 11, and vacuum integrator 12. The control system is composed of fence 6, safety door 13 and robot master control cabinet 14. The loading and unloading mechanism, deburring robot and control system are composed of fence 6 encloses a closed system, the hub passes through the feeding roller table 1, and is positioned, recognized and corrected by the hub window positioning and recognition table 7, the robot I4 grabs the hub, transports it to the top of the hub fixture turntable 11 and turns it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com