Patents

Literature

422 results about "Cartoning machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cartoning machine or cartoner, is a packaging machine that forms cartons: erect, close, folded, side seamed and sealed cartons. Packaging machines which form a carton board blank into a carton filled with a product or bag of products or number of products say into single carton, after the filling, the machine engages its tabs / slots to apply adhesive and close both the ends of carton completely sealing the carton.

Boxing machine

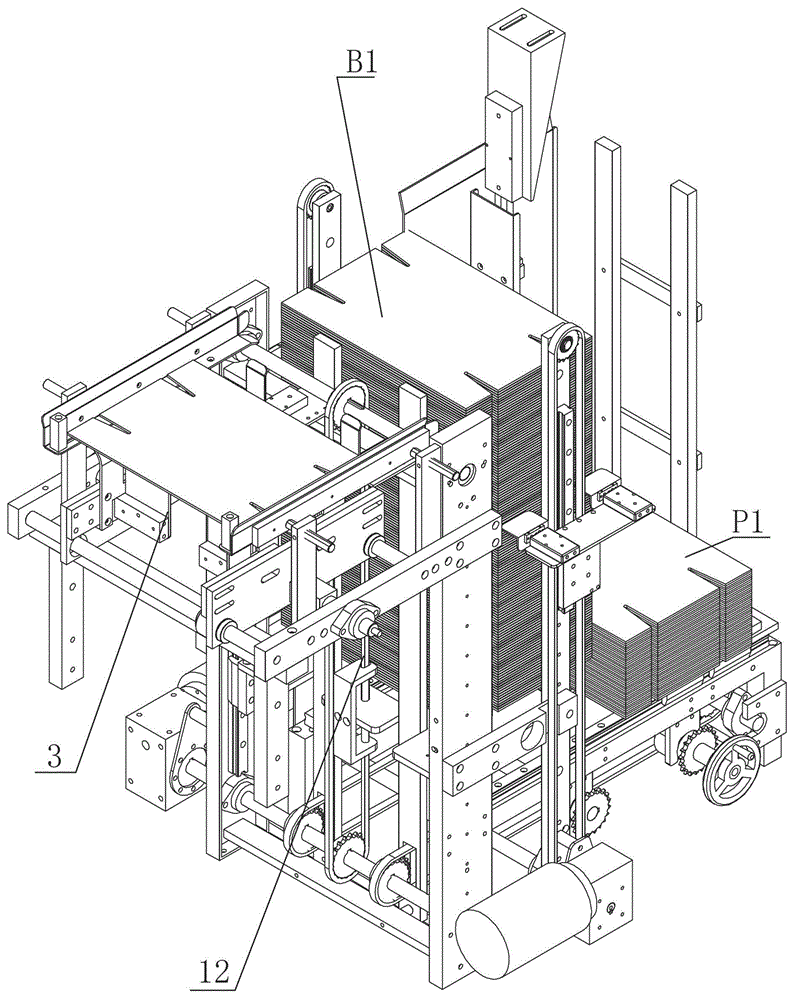

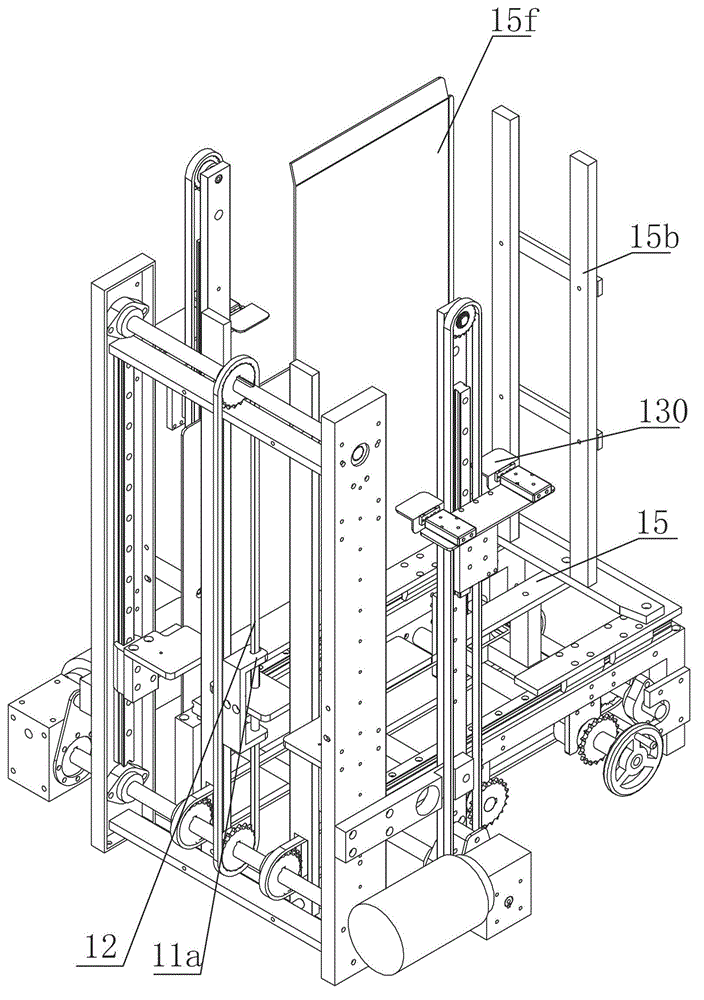

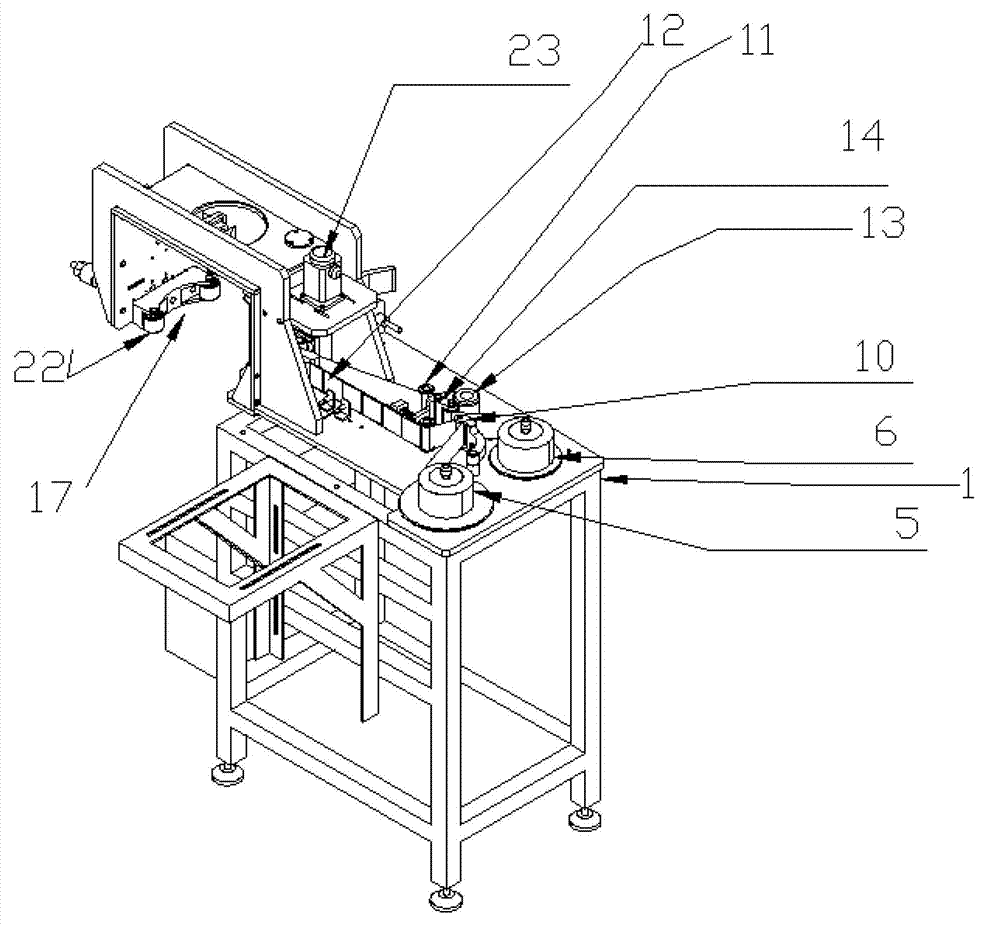

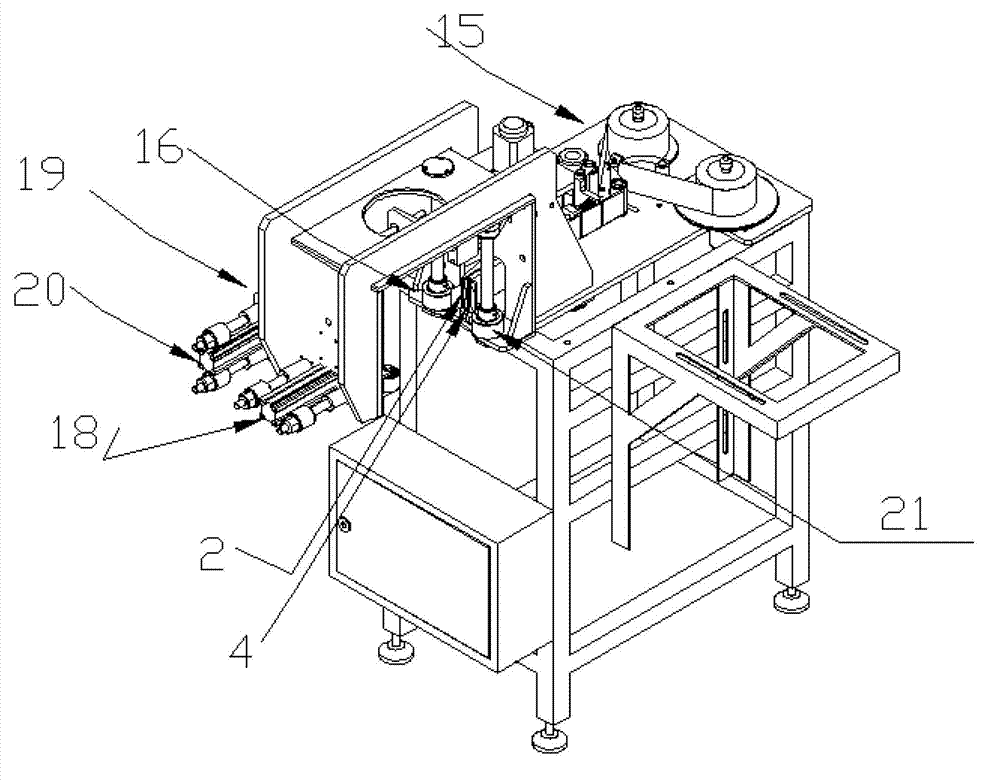

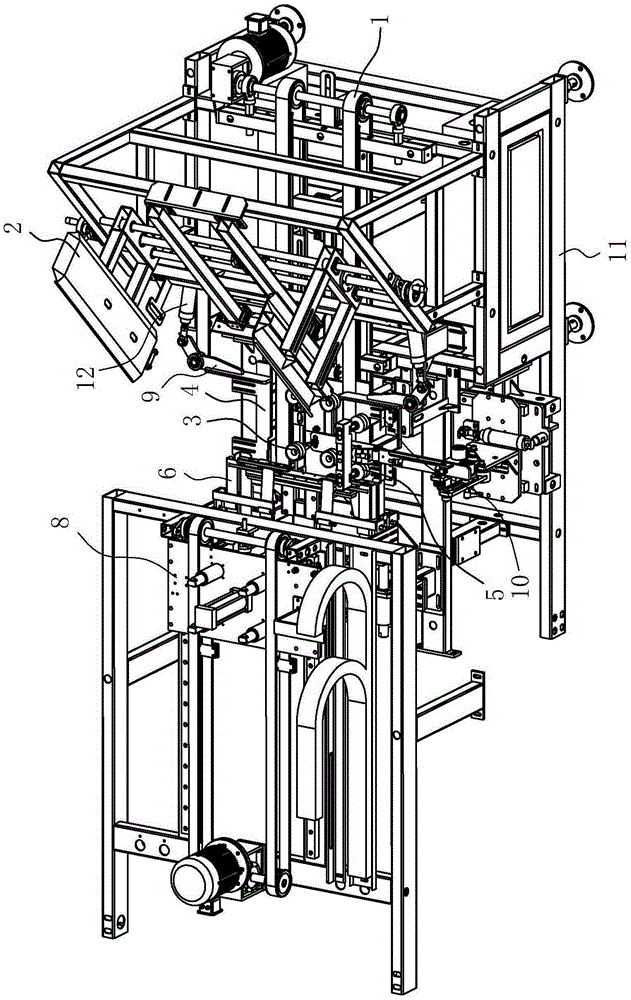

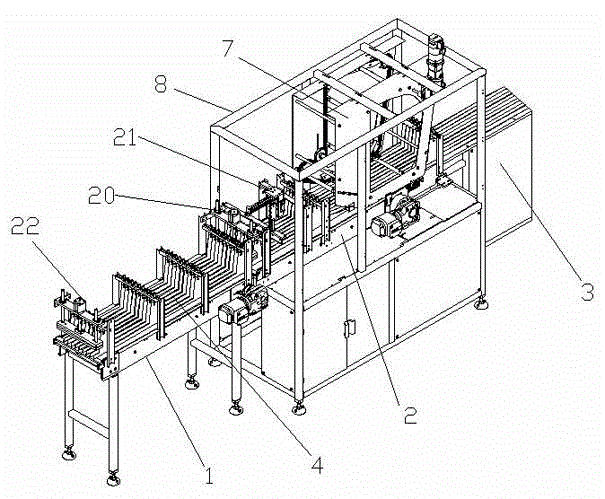

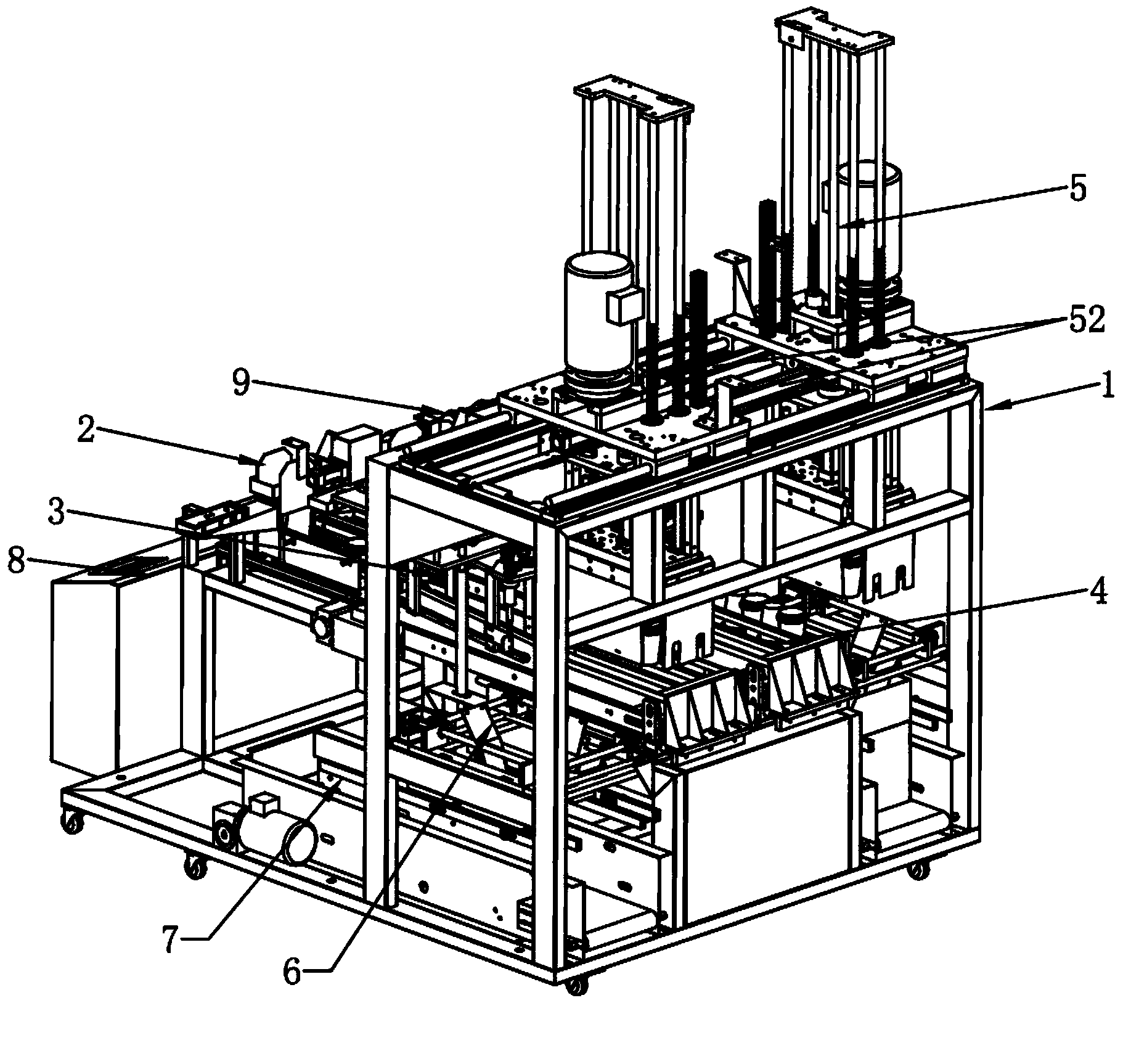

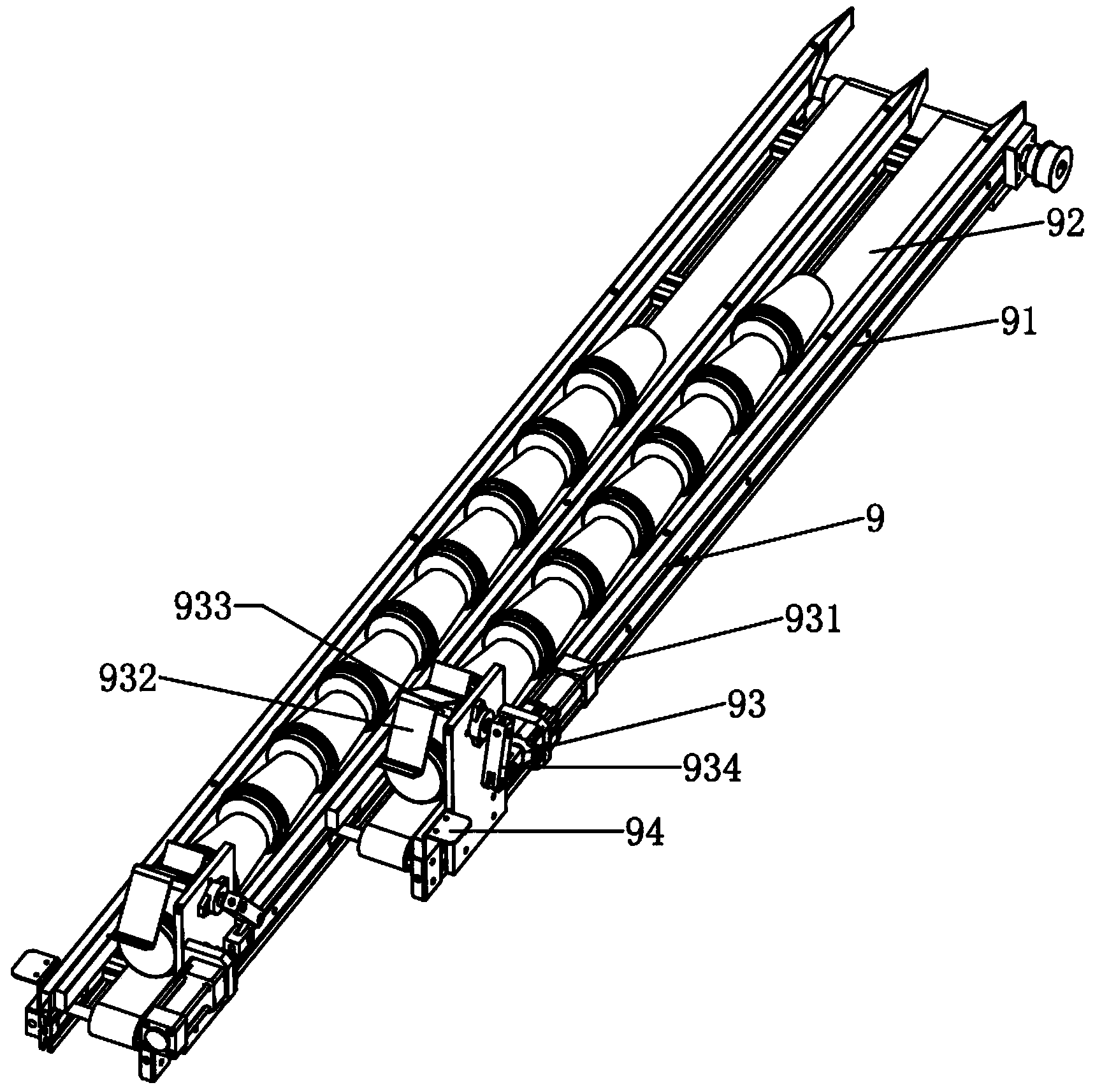

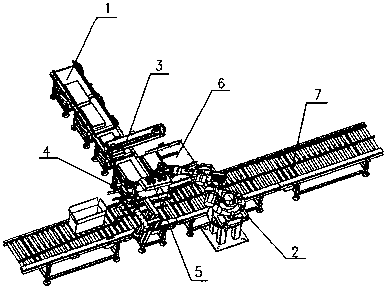

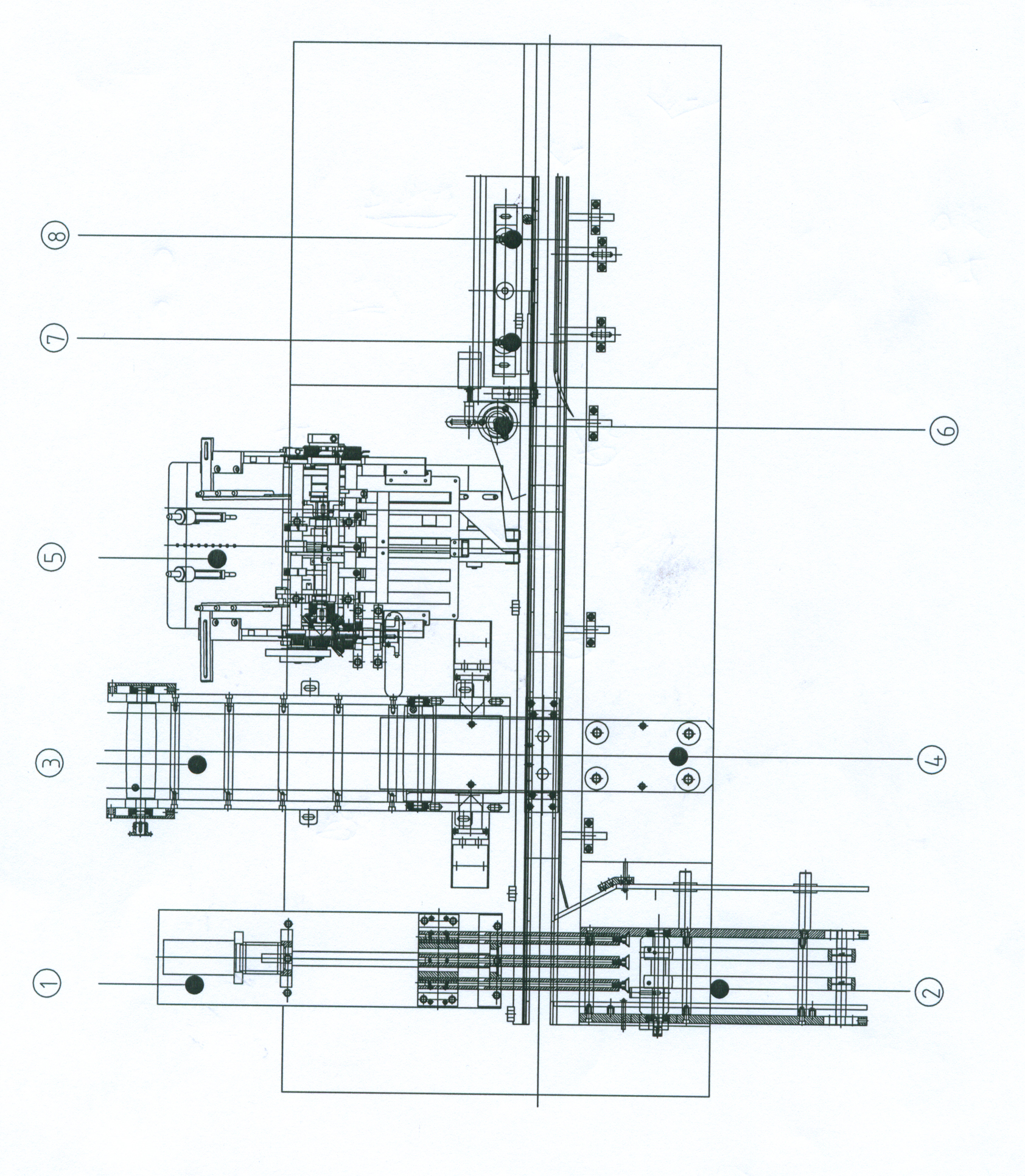

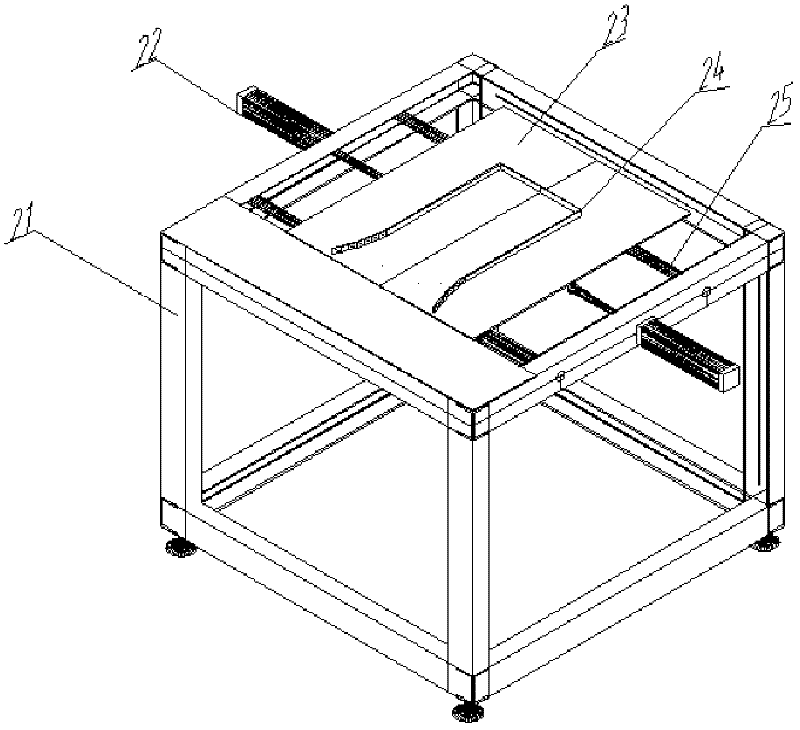

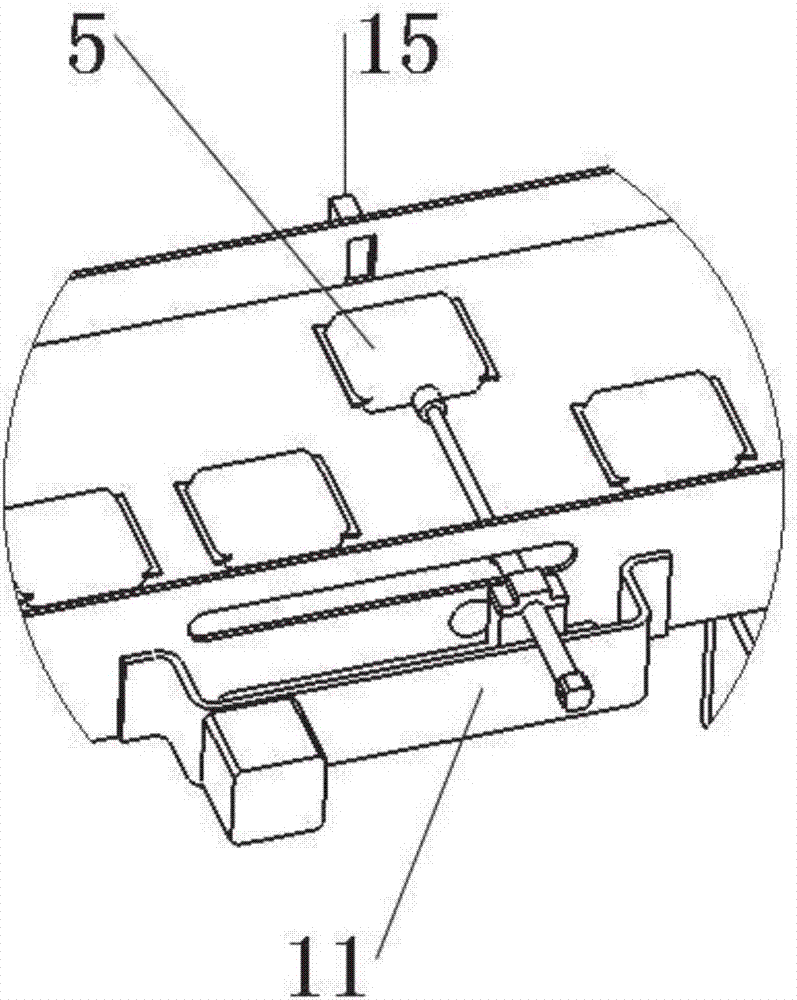

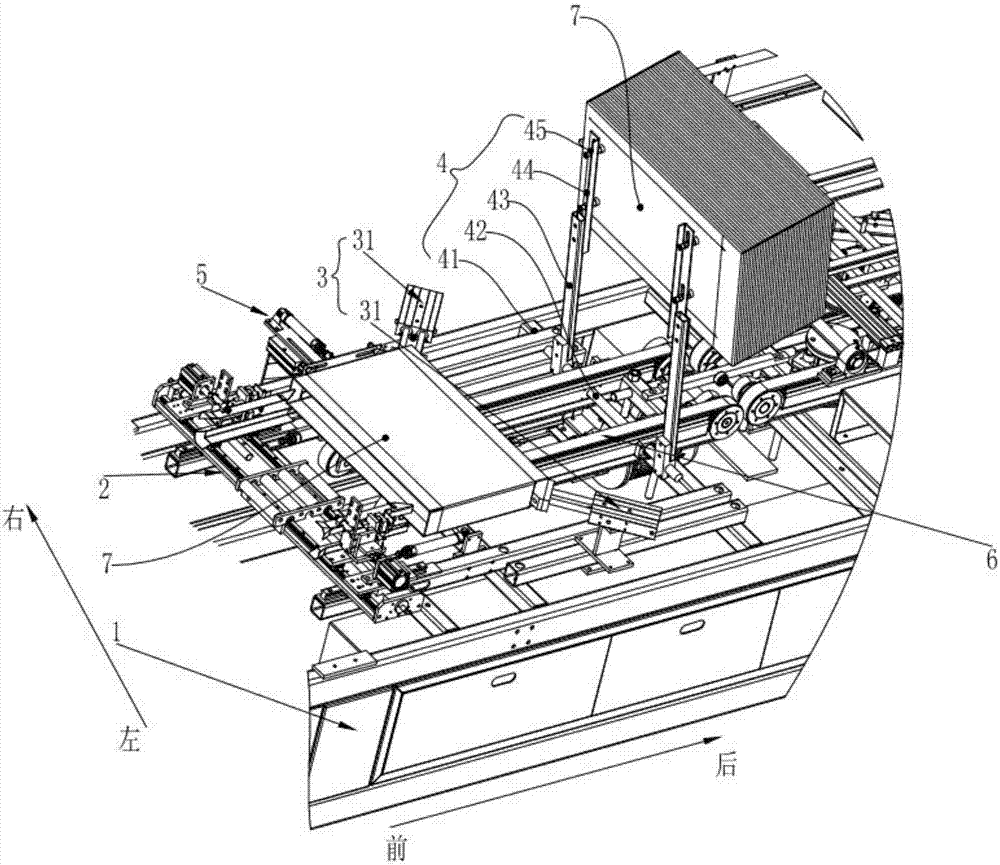

ActiveCN102745357AImprove space utilizationSmall footprintPackaging bottlesCartoning machineProduct group

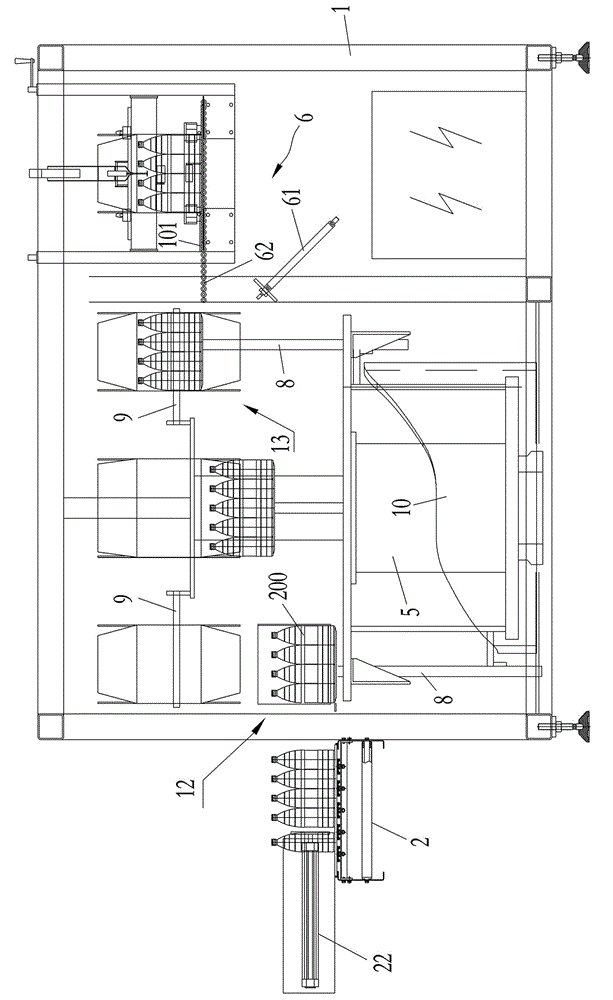

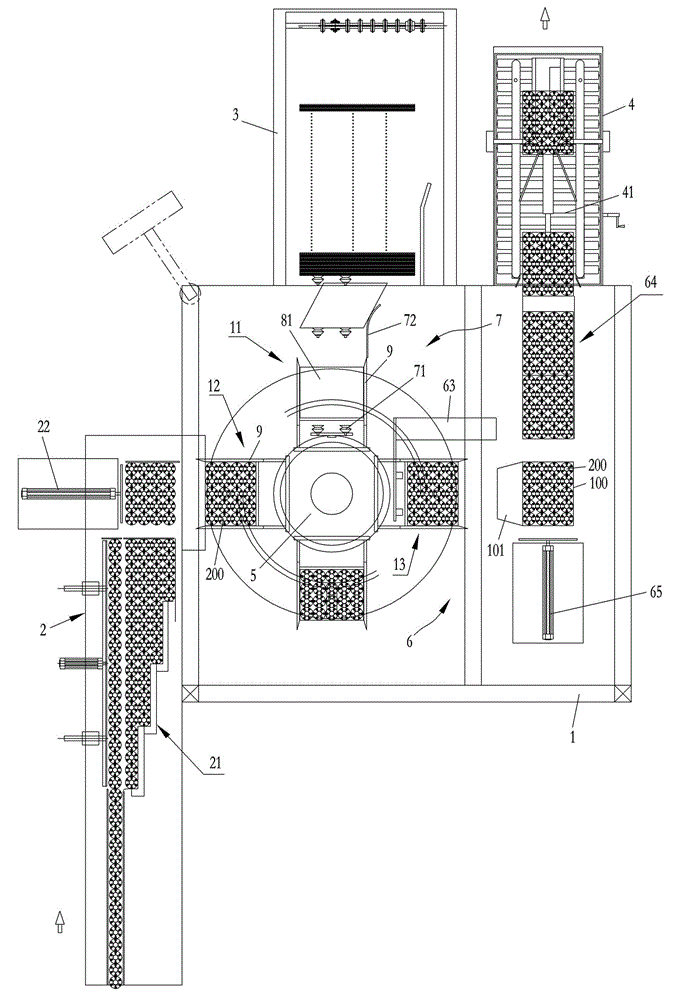

The invention discloses a boxing machine. According to the boxing machine, a product group is upwards loaded into a box from the bottom of the box, during working, under the driving of a rotary mechanism, the forming of the box, the inputting of the product group and the boxing of the product group are correspondingly finished at a carton box forming work station, a product group input work station and a boxing finishing work station respectively, then a bottom folding and page folding mechanism on a main machine is used for finishing folding works of small bottom page folding, large front bottom page folding and large rear bottom page folding, finally, a box sealing device is used for folding top folding pages and sealing the box, and works of each work station can be performed simultaneously and not be interrupted. According to boxing machines in prior art, moving mechanisms are required to drive catching assemblies to move back and forth at positions of main machine catching and boxing to catch the product group and the product group is downwards loaded into the box from the top of a box; and compared with the boxing machines, the boxing machine is higher in efficiency, simpler in structure and smaller in occupied space.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

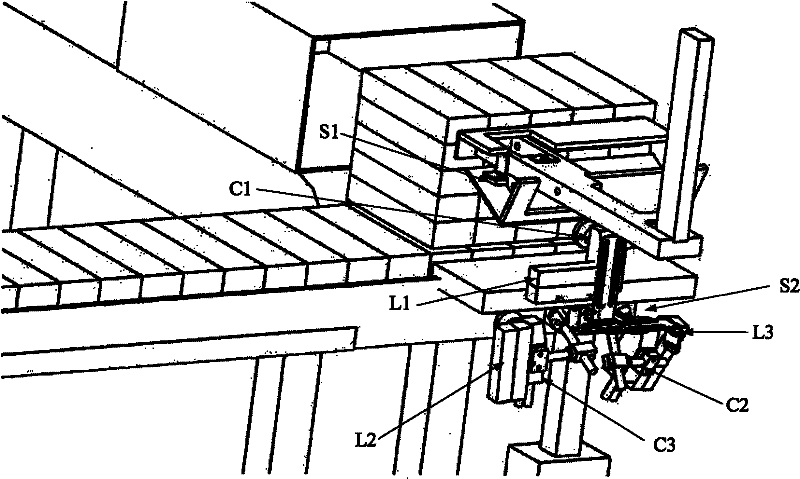

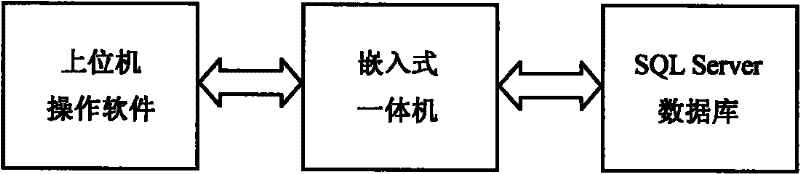

An on-line visual detection device and detection method for missing rods in a carton packing machine

InactiveCN102275656AAvoid radioactive contaminationMeet processing speed requirementsCharacter and pattern recognitionOptically investigating flaws/contaminationRadioactive agentVisual perception

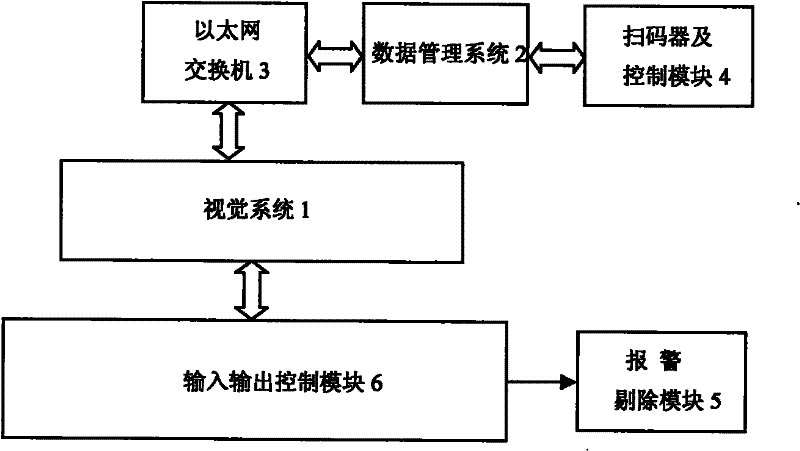

The invention relates to an on-line visual pack absence detection device and a detection method for a cigarette pack cartoning machine. A visual unit collects images during the cigarette pack cartoning process, and is connected with a data management system via an Ethernet switch for data communication. A barcode scanner and a control module collect cigarette carton barcode information and transmit the cigarette carton barcode information to the data management system. An input and output control module receives rejecting signals of the visual unit, and outputs the rejecting signals to a warning and rejecting module. The method comprises the steps of initializing the detection device; judging whether a cigarette pack of a certain layer in the cartoning machine is in place; if in place, processing, analyzing and transmitting images of the cigarette pack of the layer to the data management system; judging whether the cigarette pack of the layer has any defect; if so, emitting warming and rejecting signals. The invention prevents the radioactive pollution caused by radioactive substances in the measurement process and the contact pollution caused by artificial weighing measurement, reduces the system complexity, and avoids huge industrial control computer chassis or huge system control cabinets.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

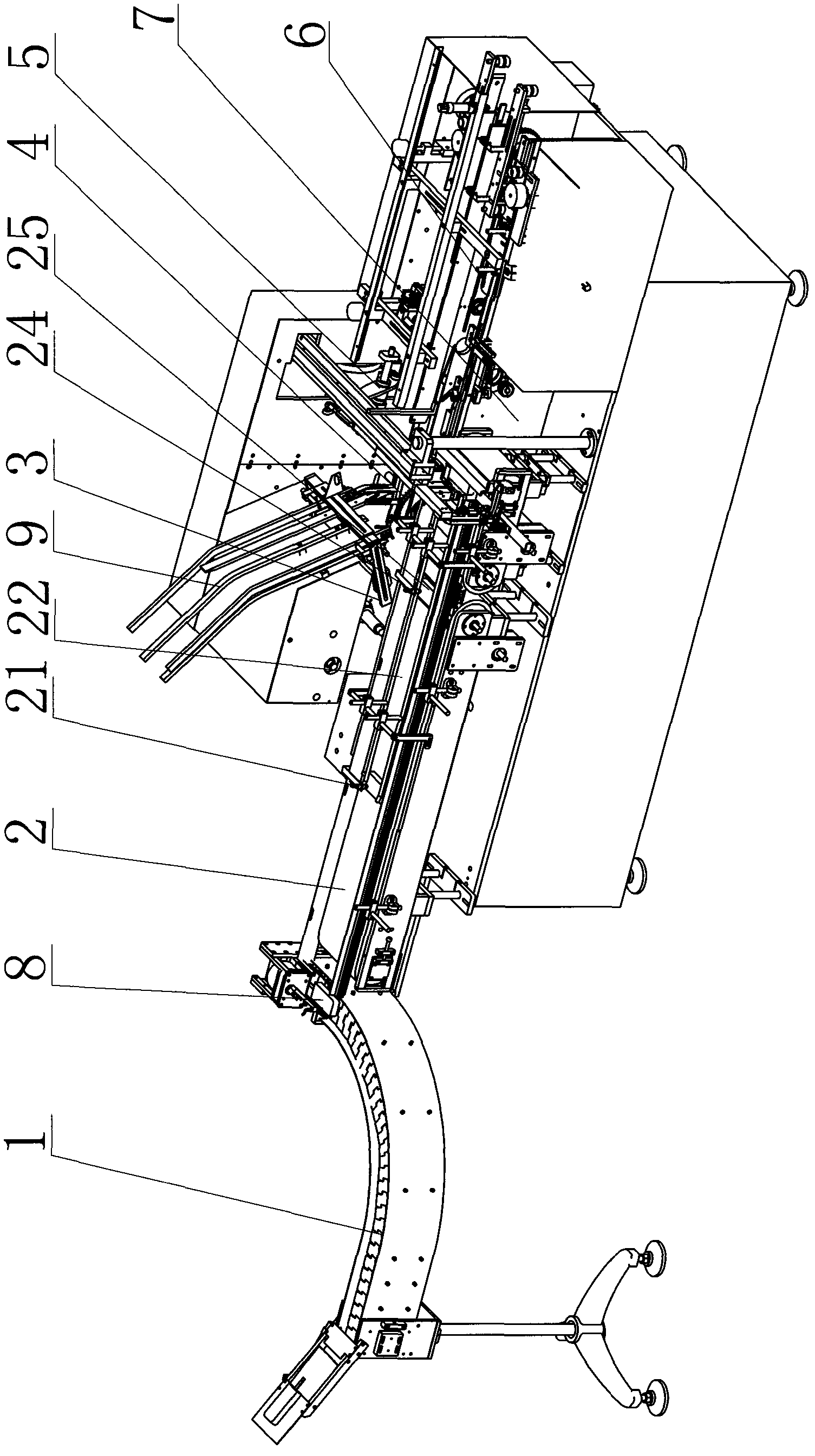

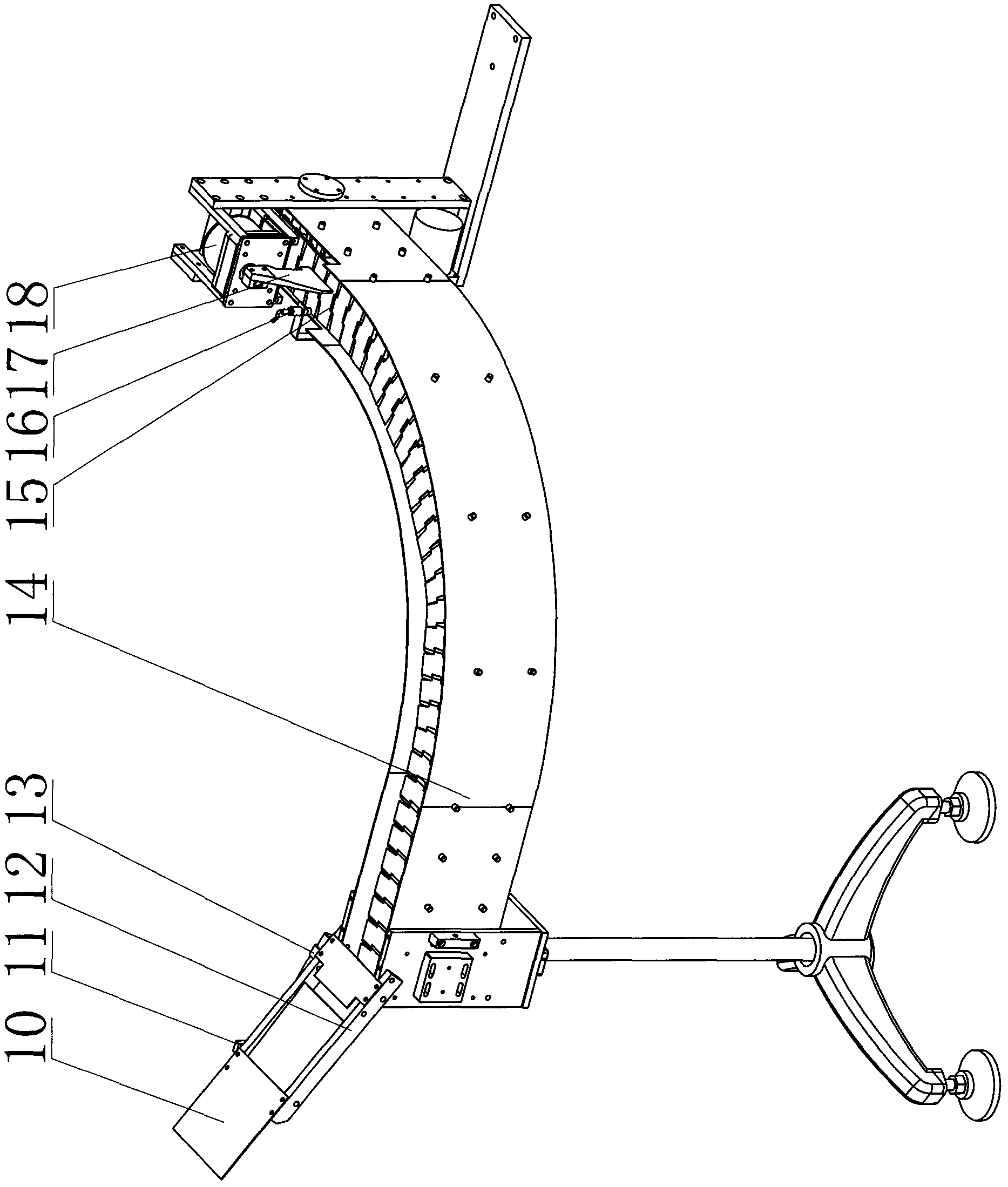

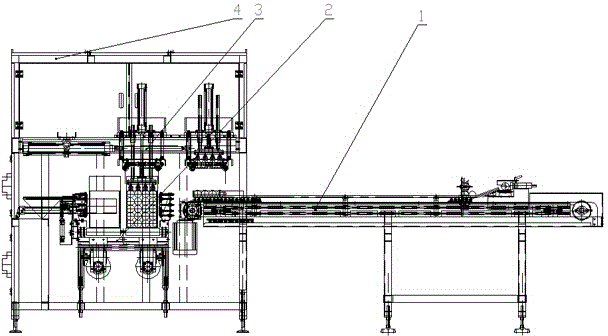

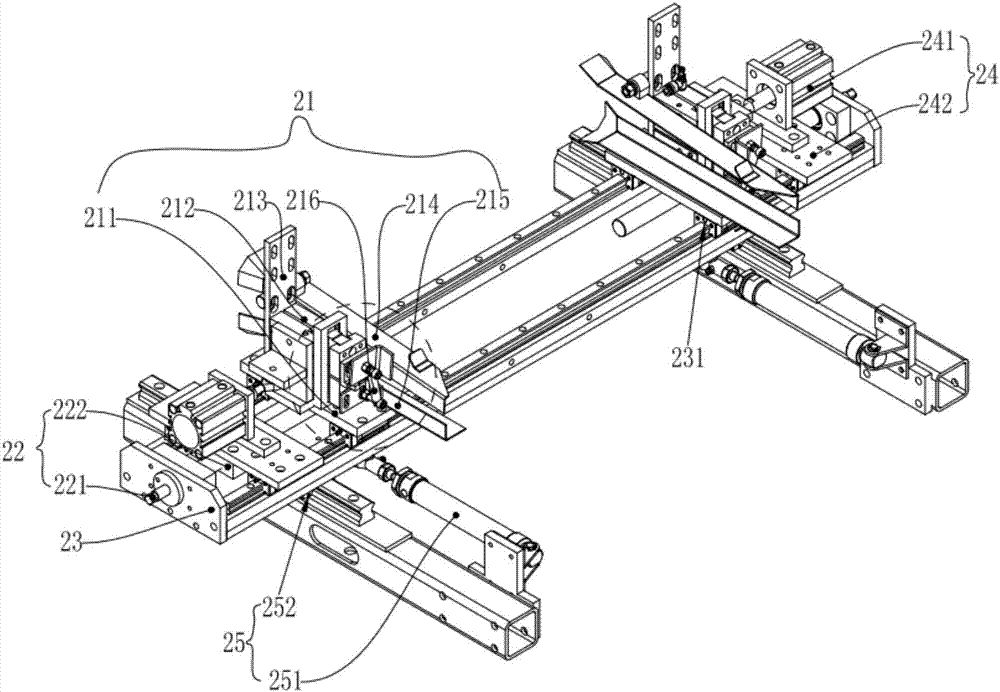

ice cream cartoning machine

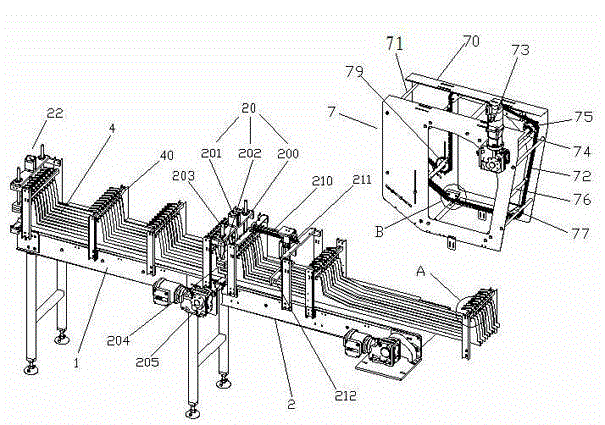

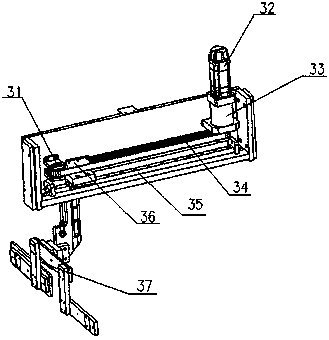

ActiveCN102285467ANo manual operationImprove efficiencyPackaging automatic controlCartoning machineEngineering

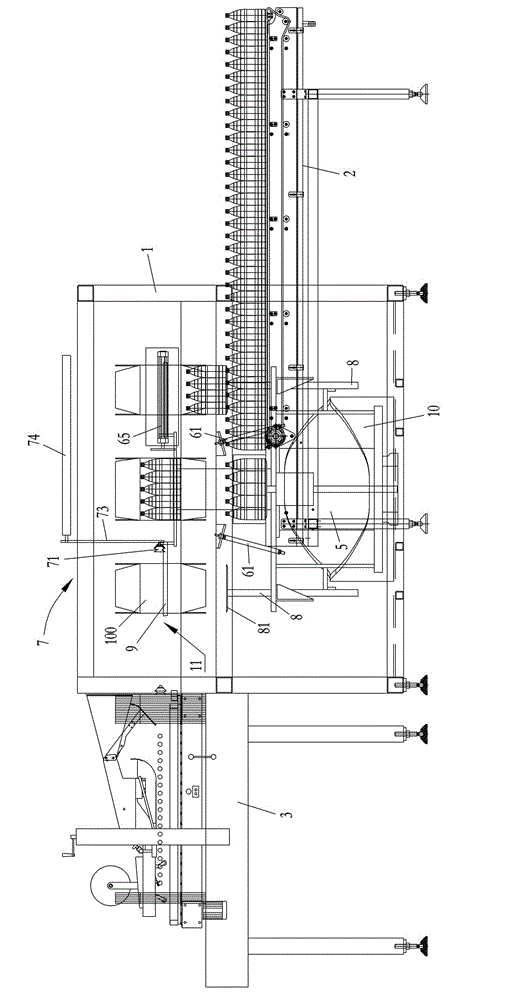

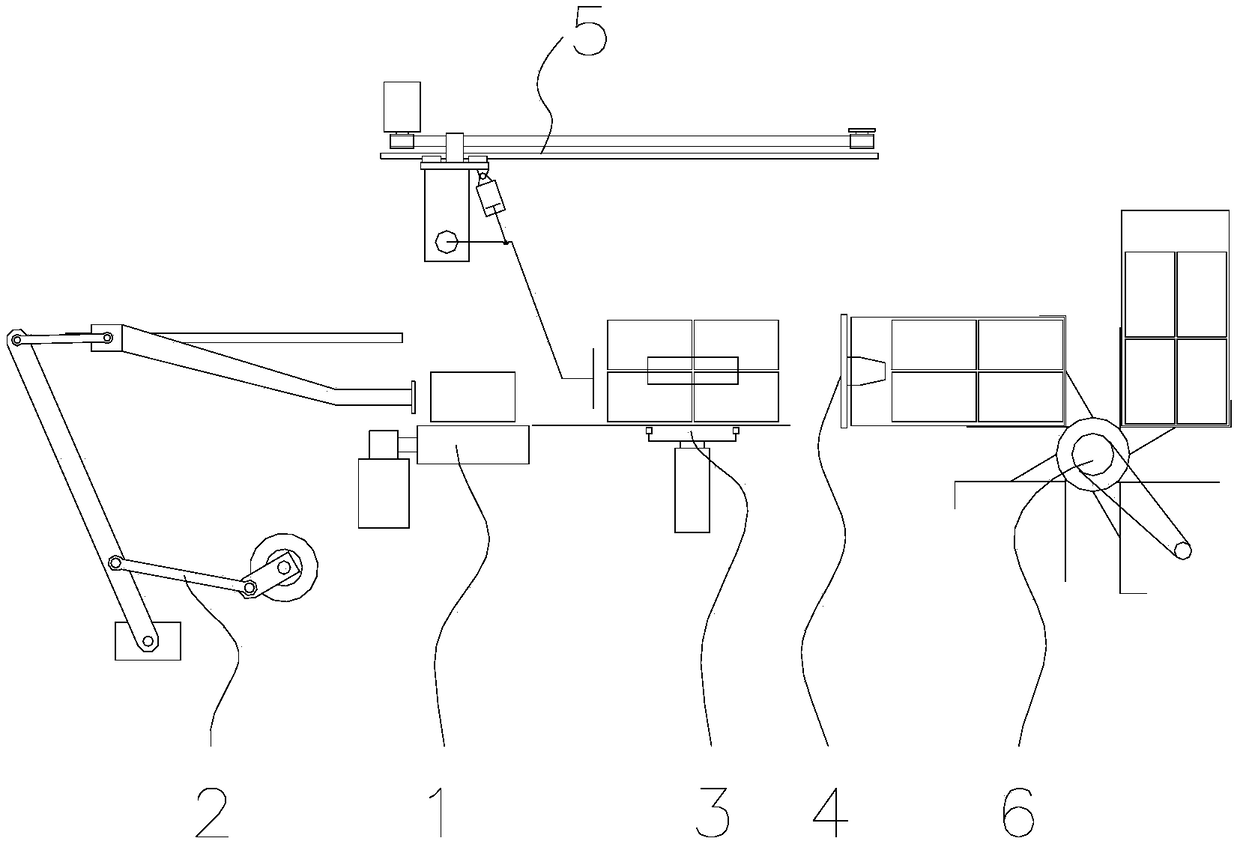

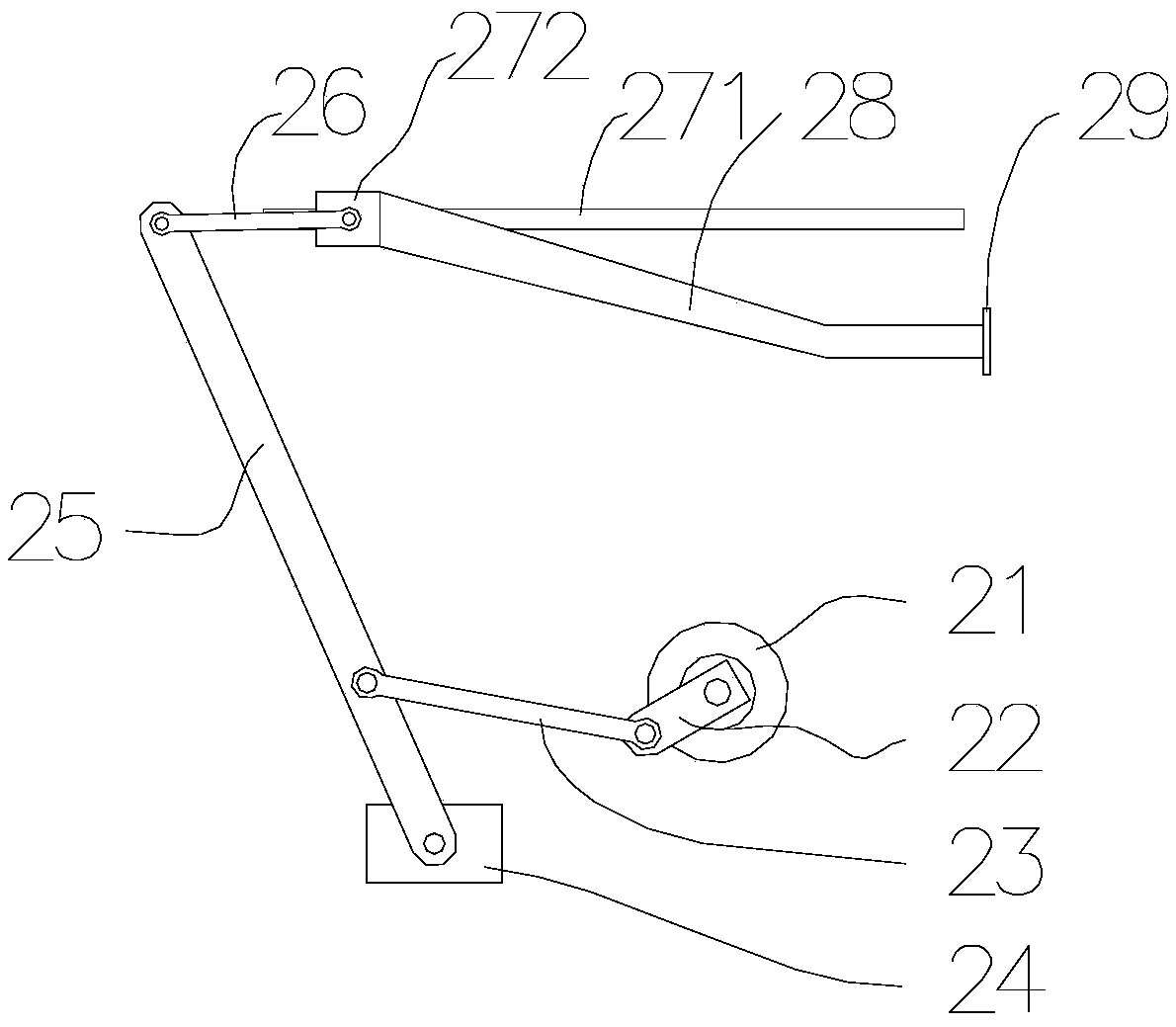

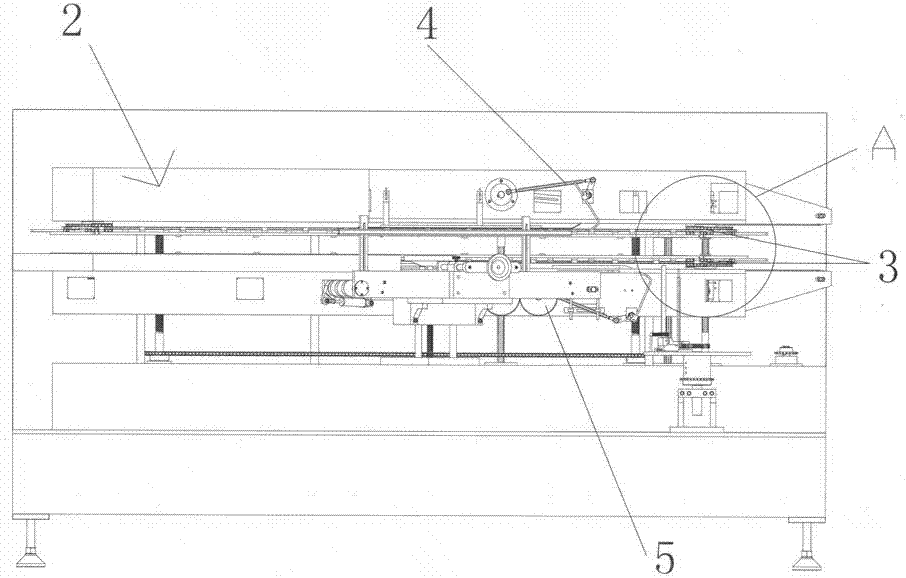

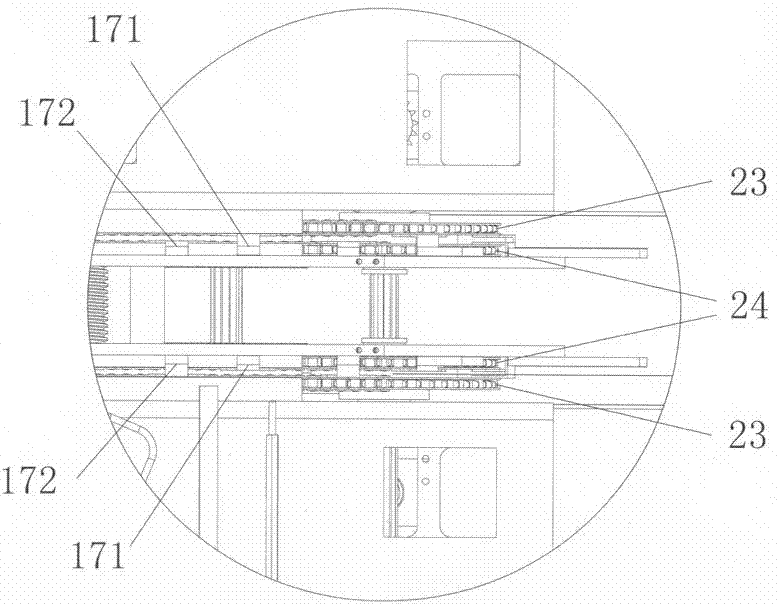

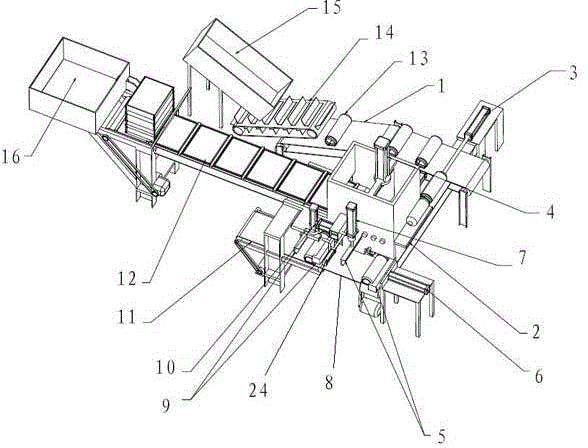

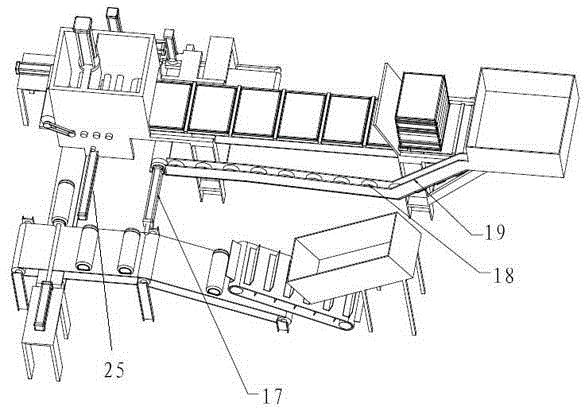

The invention discloses a box packing machine of ice cream. The box packing machine is characterized by comprising a machine body (7), a feeding mechanism (1), a delivery mechanism (2), a box sucking mechanism (3), a box feeding mechanism (4), a material pushing mechanism (5), a box sealing mechanism (6) and a transmission mechanism, wherein the material pushing mechanism is arranged at the end part of the delivery mechanism; the delivery belt of the delivery mechanism is a net chain; the box feeding mechanism is composed of a conveying chain and shifting forks (40); the shifting forks are arranged on the conveying chain; and a groove matched with the box is formed between the shifting forks; the conveying chain is arranged on the side of the net chain, and is parallel to the net chain; the material pushing mechanism comprises a pushing rod (50) and a reciprocating mobile device; the pushing rod is connected to the reciprocating mobile device, and the pushing rod is arranged vertically to the conveying chain. The box packing machine with the structure can automatically convey and pack cold food such as ice cream and the like into paper boxes, and has the characteristics of high speed and environmental protection.

Owner:上海宏海食品有限公司

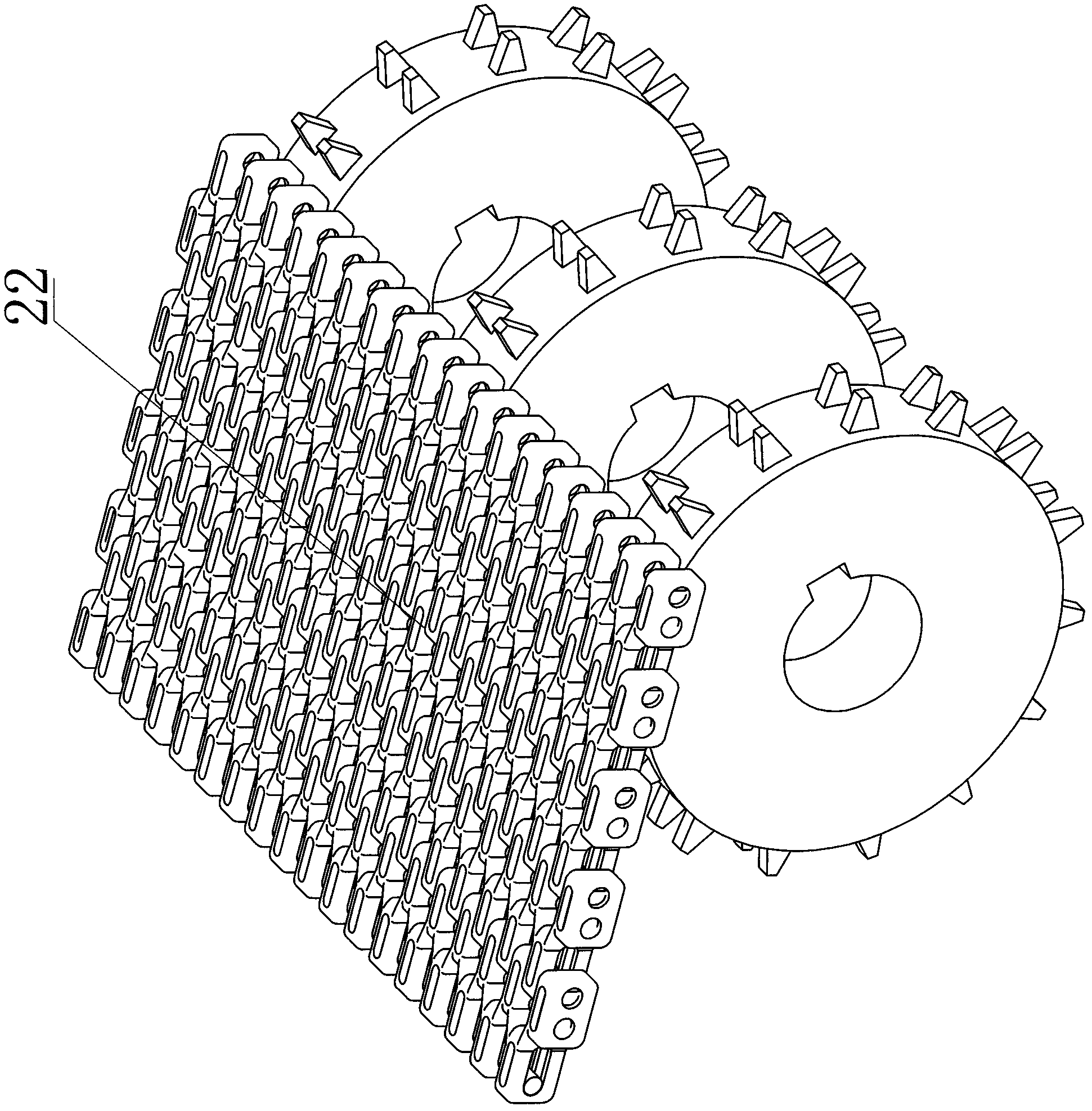

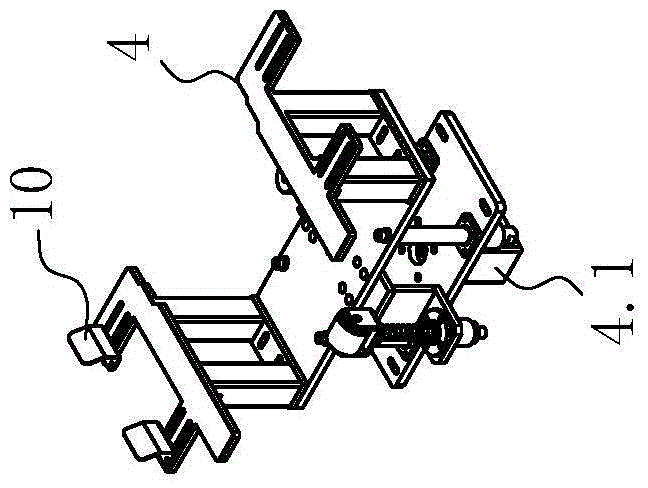

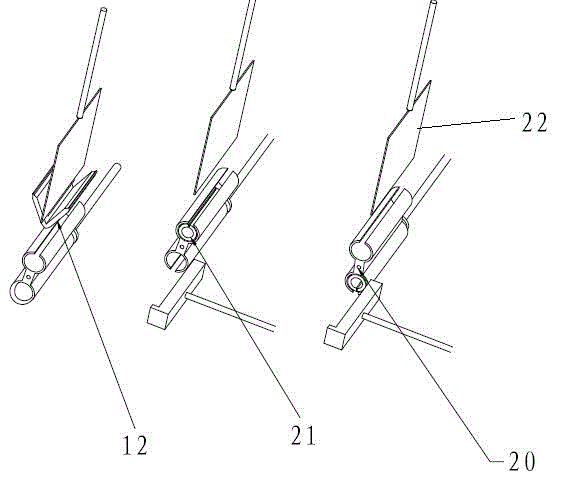

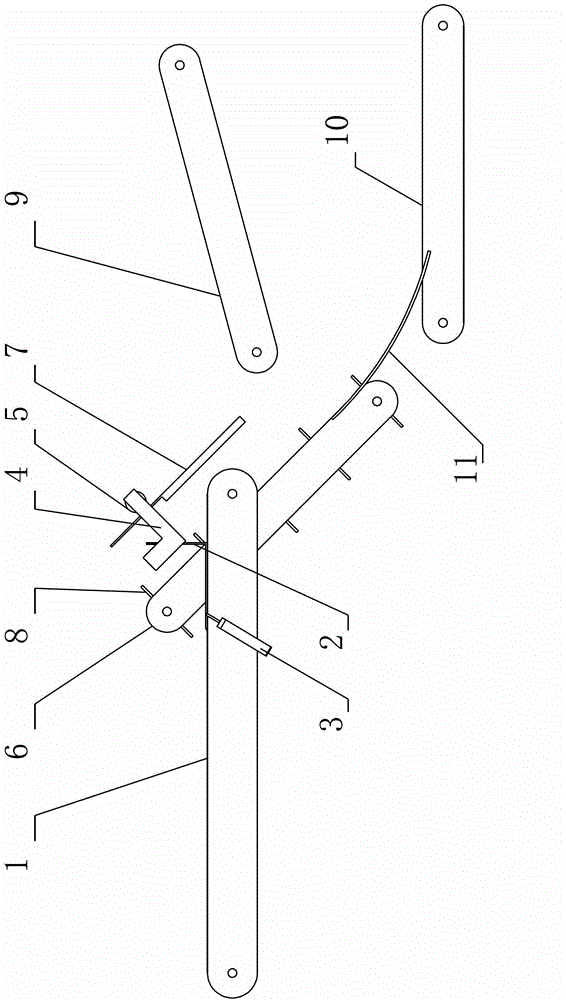

Boxing machine paper box opening method and paper box opening mechanism

The invention discloses a boxing machine paper box opening method. A rotary table is driven through a servo motor, a cam plate is provided with double cam grooves including the outer cam groove and the inner cam groove, the outer cam groove is used for controlling operation actions of a suction nozzle of a box opening rod assembly, the inner cam groove is used for controlling operation actions of a suction nozzle of a box taking rod assembly, then box absorbing and box placing actions of the box taking rod assembly can be finished, and the paper box opening function is finished through the box opening rod assembly. The invention further discloses a paper box opening mechanism. The paper box opening mechanism comprises a rotary table assembly, a servo motor assembly, the box opening rod assembly with the suction nozzle, a box opening driving tooth block assembly, the box taking rod assembly with the suction nozzle and a box taking driving tooth block assembly. According to the boxing machine paper box opening method and the paper box opening mechanism, working is reliable, cost can be effectively reduced, a paper box can be opened more reliably, the running speed is high, the paper box opening mechanism is simple in structure, and the working control process is simple.

Owner:GUANGZHOU PHARMA INTELLIGENT EQUIP CO LTD

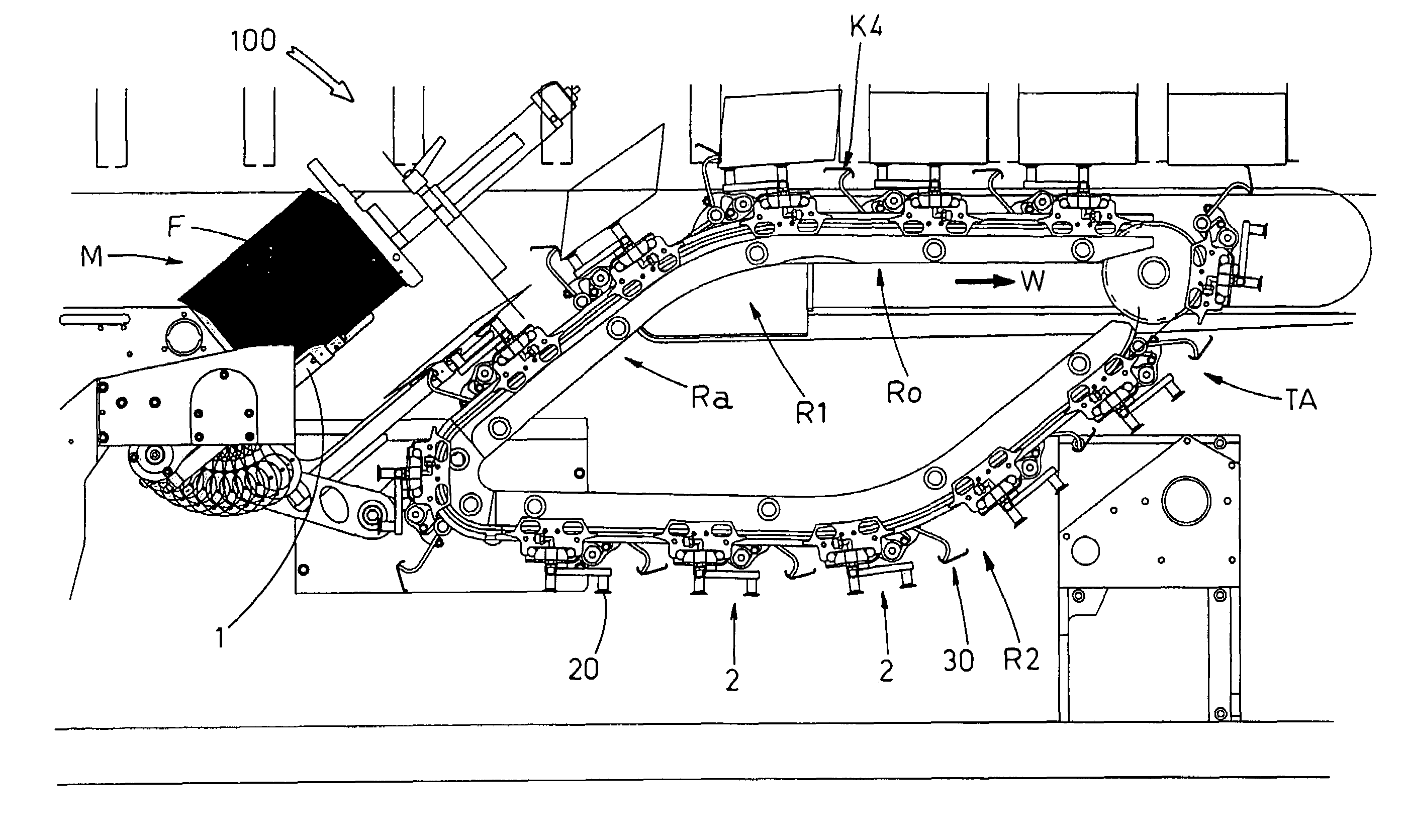

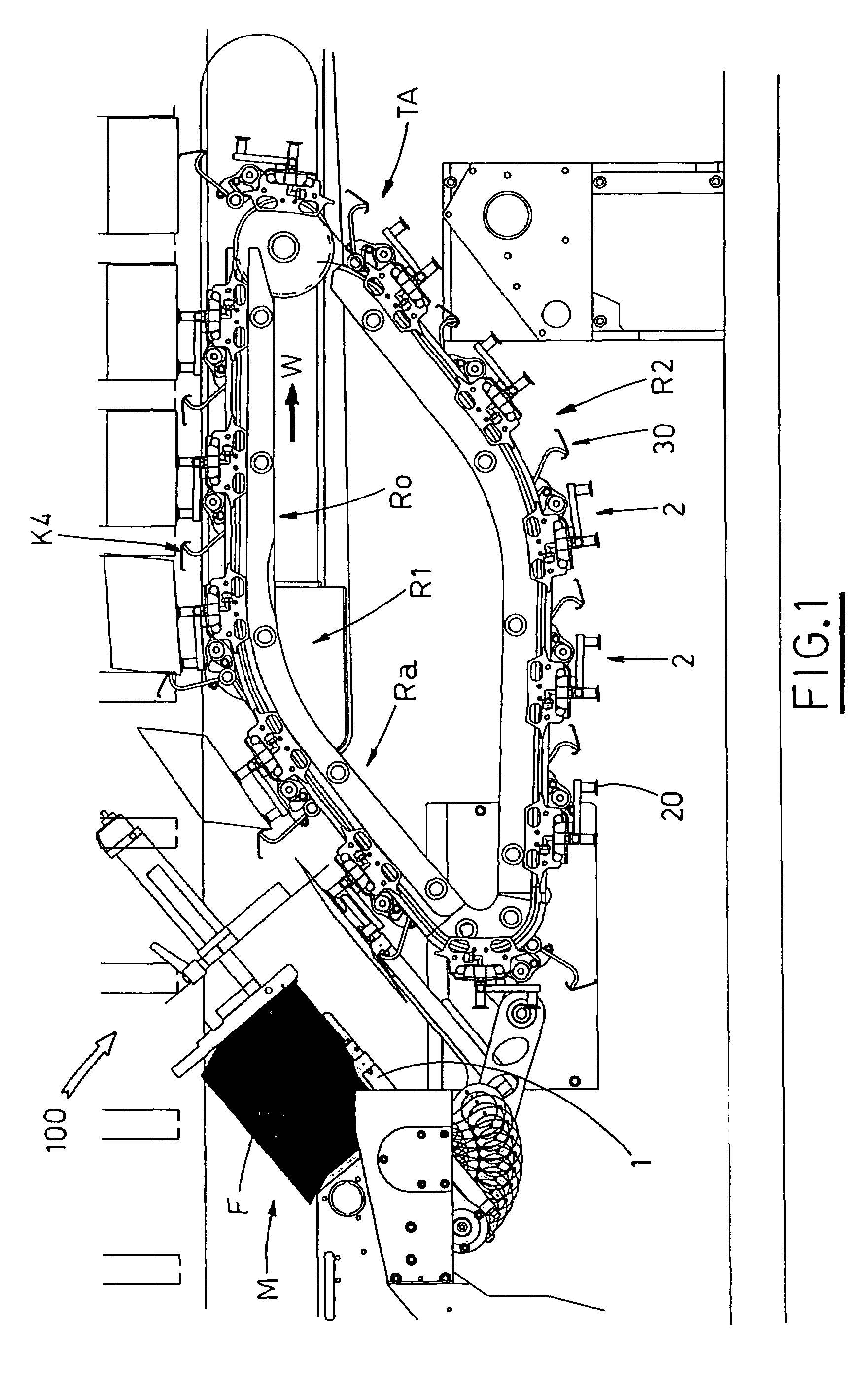

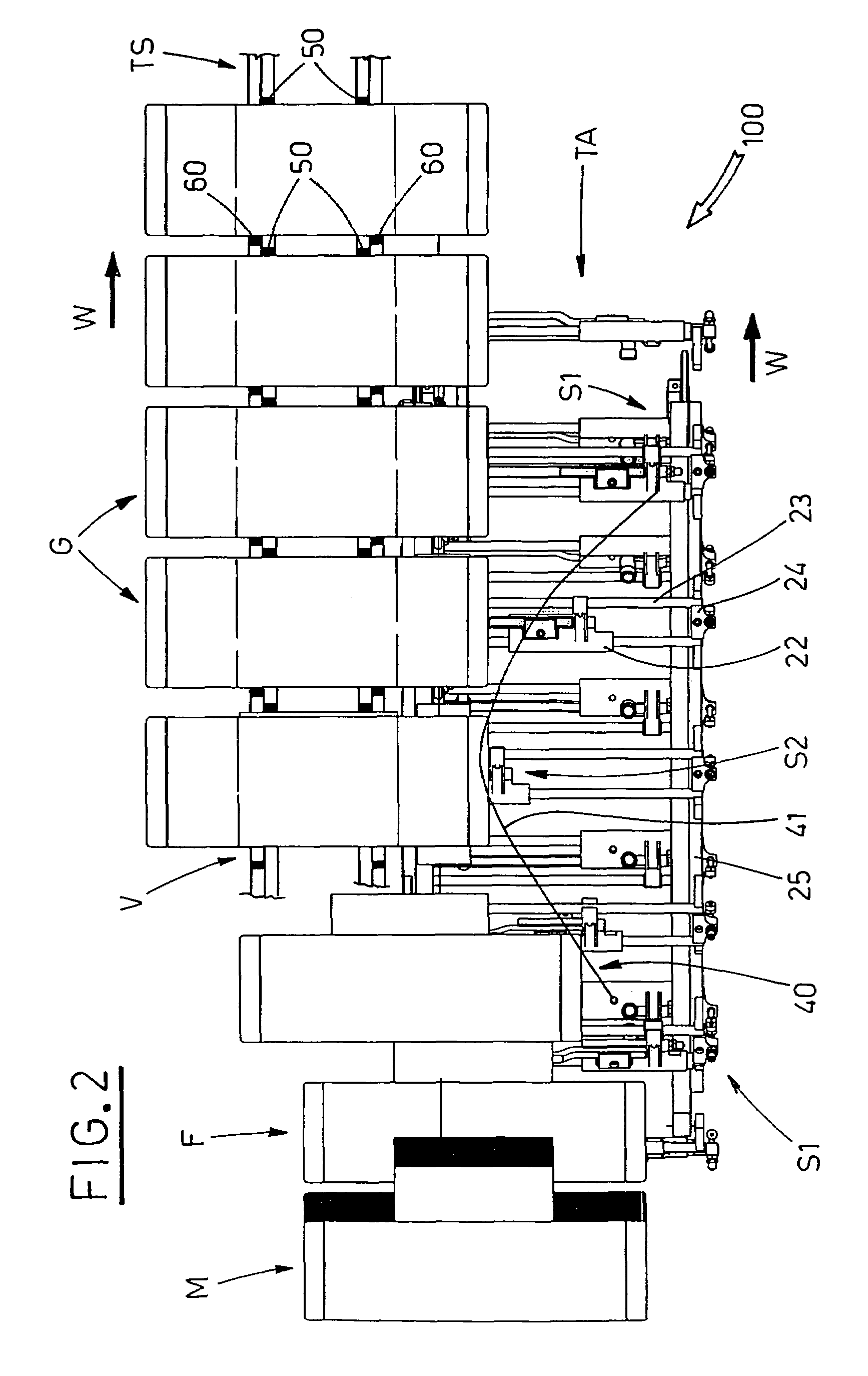

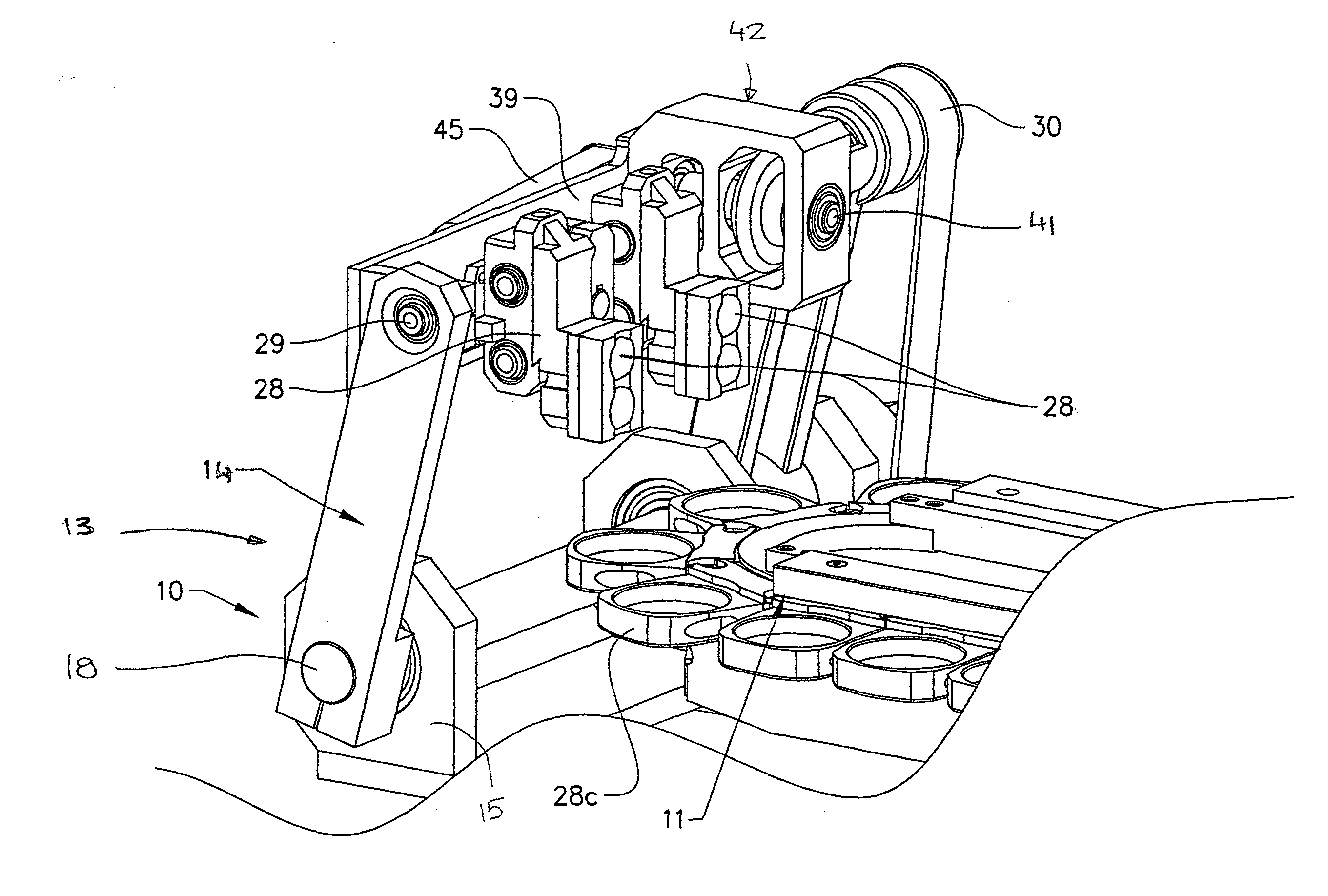

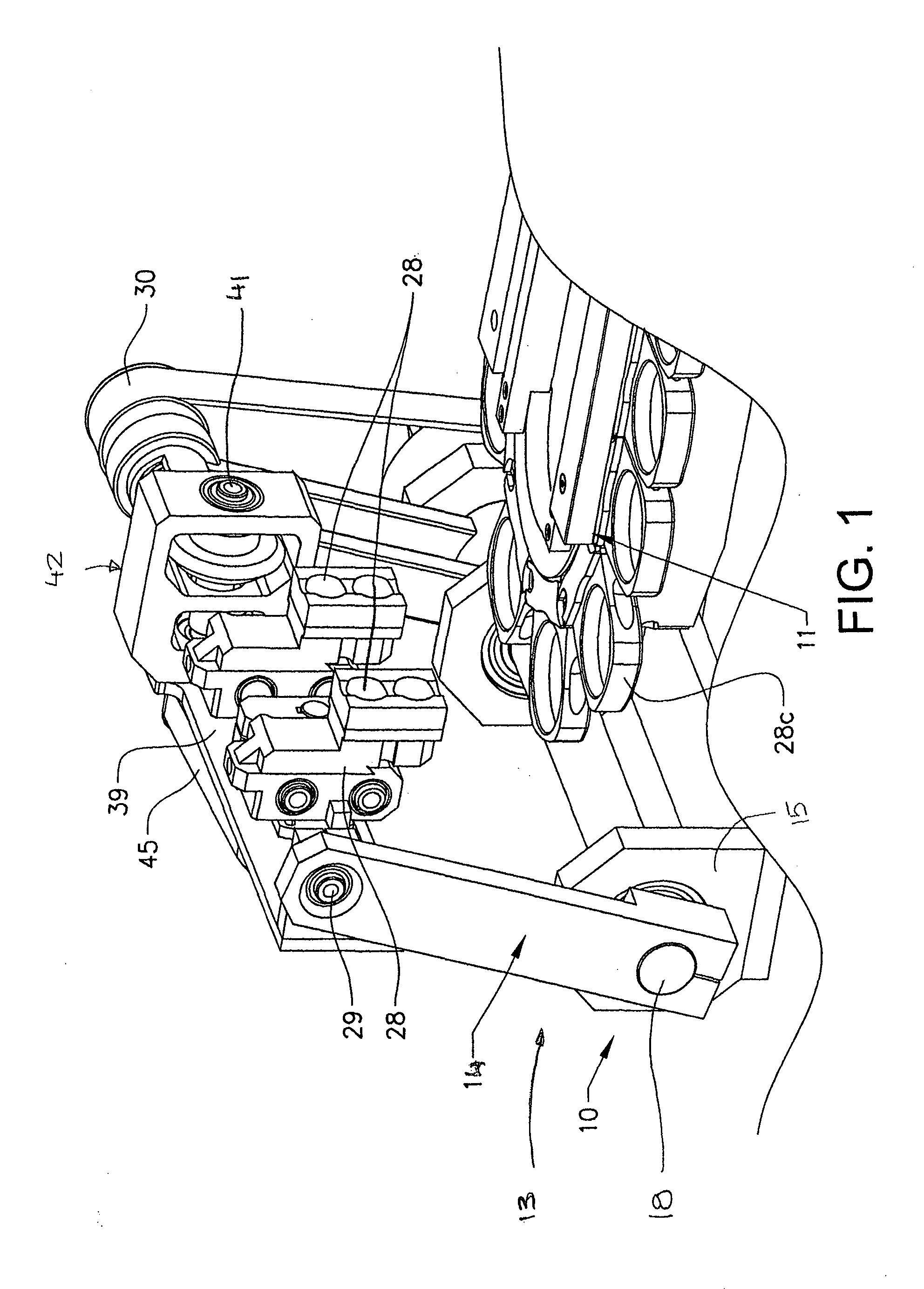

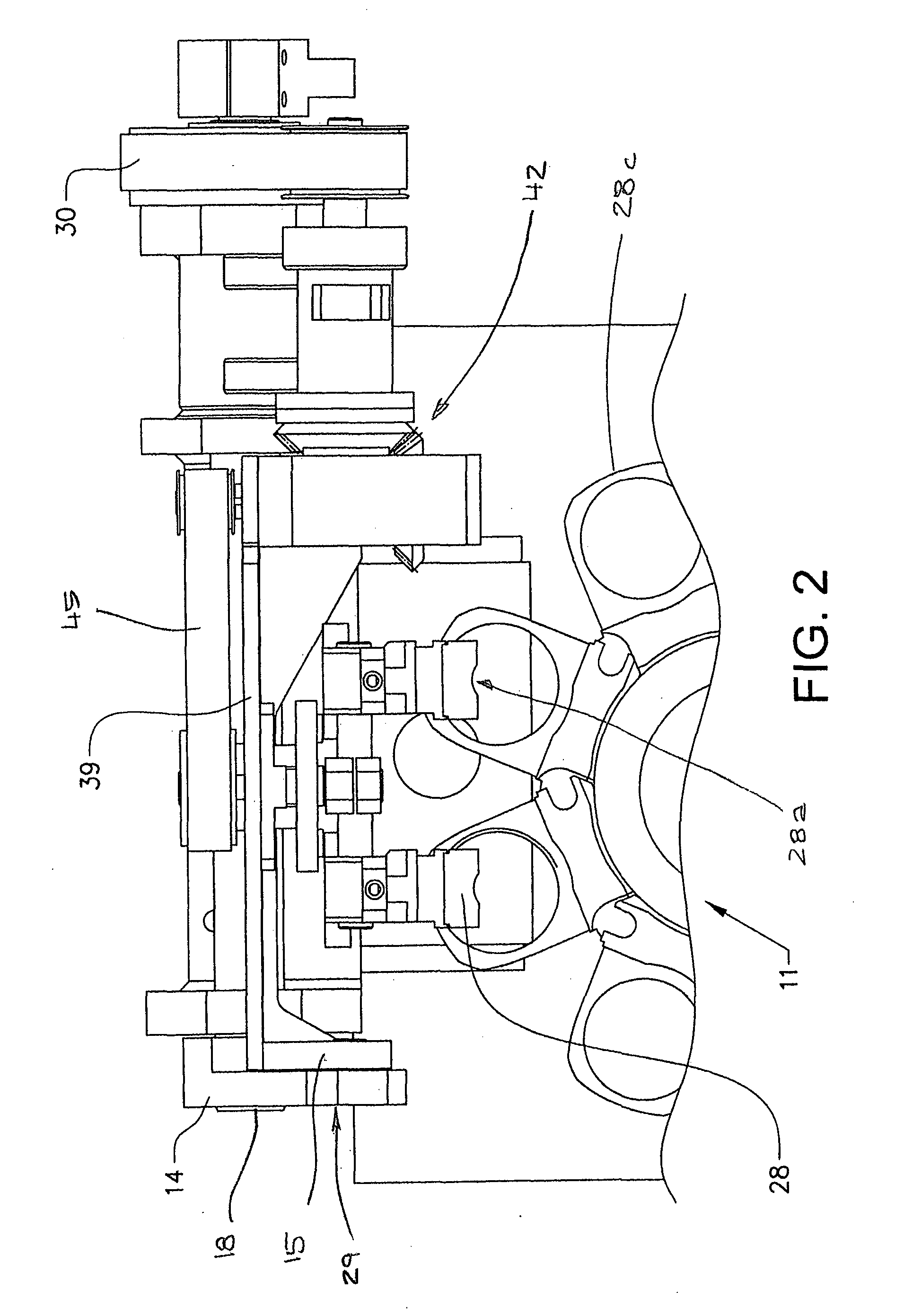

Station for withdrawing and erecting flat folded tubular blanks

ActiveUS7310925B2Arrangement is limitedGuaranteed uptimeBox making operationsPaper-makingCartoning machineEngineering

In a station of a boxing machine, for withdrawing and erecting flat folded tubular blanks into boxes, a blank withdrawing rocker arm strips out a flat folded blank from a magazine and places it onto a operating member situated below and associated to an auxiliary conveying line. The auxiliary conveying line extends along a close loop path. Gripping suction cups associated to the operating member engage the lower side of the blank. An erecting arm with a shaped flap makes edge-resting sides of the blank rotate synchronously, about respective articulation lines adjoining to a lower side, until a corresponding box is erected. A shaped guide engages with the carriage and moves the box laterally with respect to the auxiliary conveying line, to insert the box into a corresponding seat on a box conveying line situated beside the auxiliary conveying line.

Owner:MARCHESINI GROUP SPA

Boxing machine

The invention provides a boxing machine, which comprises a paper overlapping area, a paper conveying device, a carton forming die at a high position, a carton pressing die, a carton conveying device, an article sorting and combining device and an article boxing machine, and is used for extracting boxed articles from an article boxing region into cartons in a carton boxing region. The boxing machine can be used for realizing continuous work of carton forming, article grouping and boxing comprehensively, is suitable for being combined into an upper article production line or packing production line, and has the advantages of small size, simple structure, small floor occupation and high efficiency.

Owner:HANGZHOU YOUNGSUN INTELLIGENT EQUIP +1

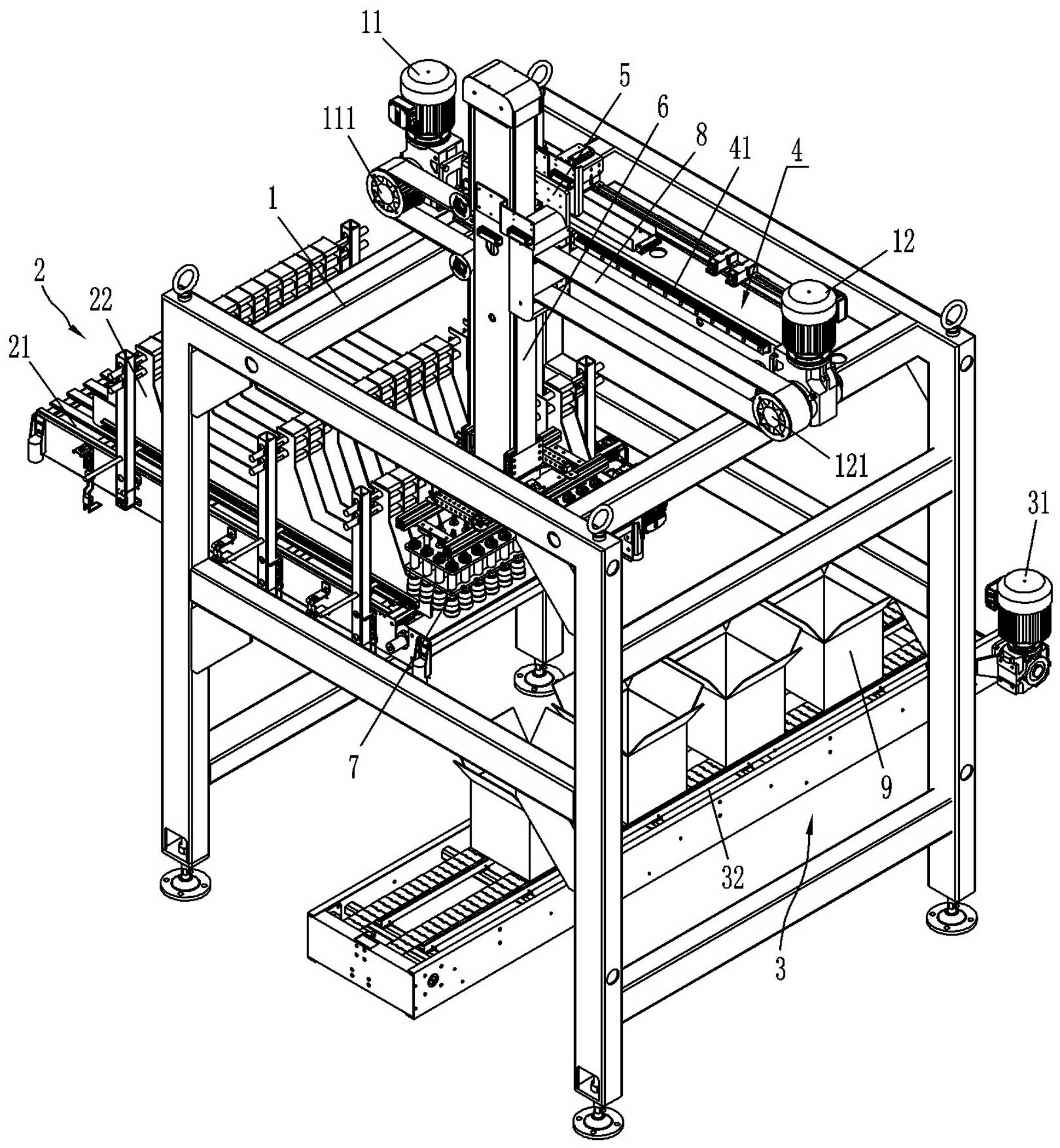

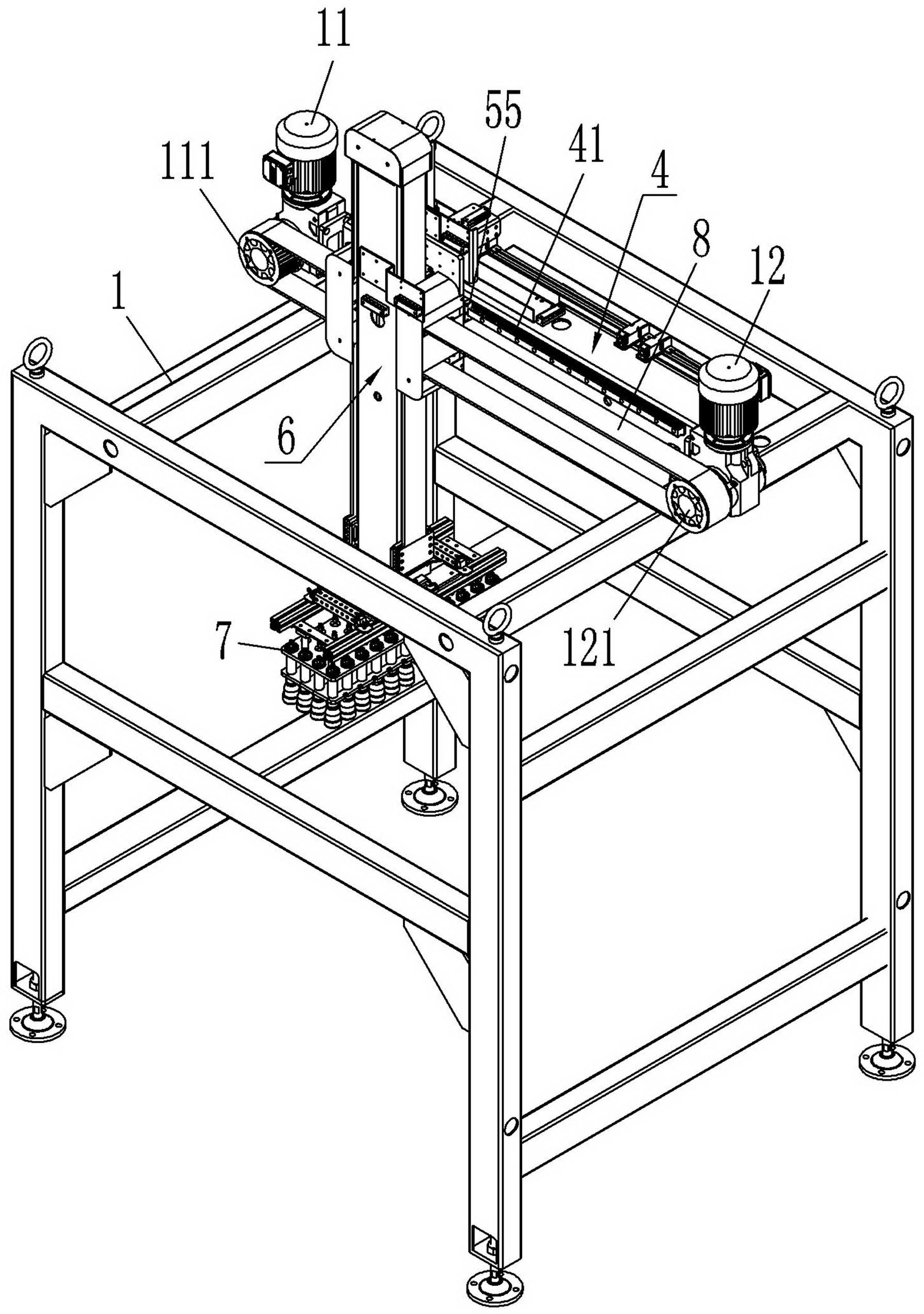

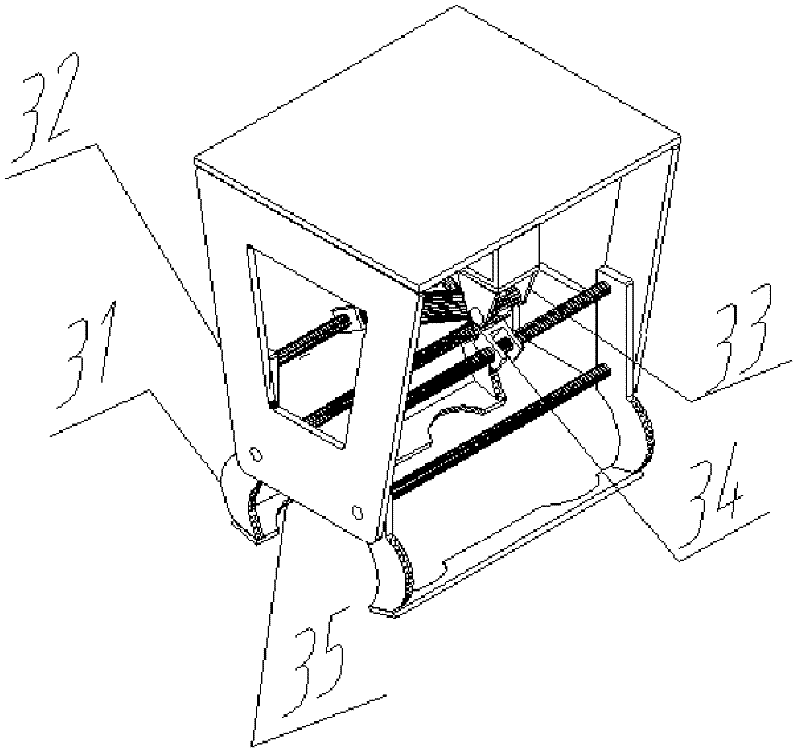

Packing machine

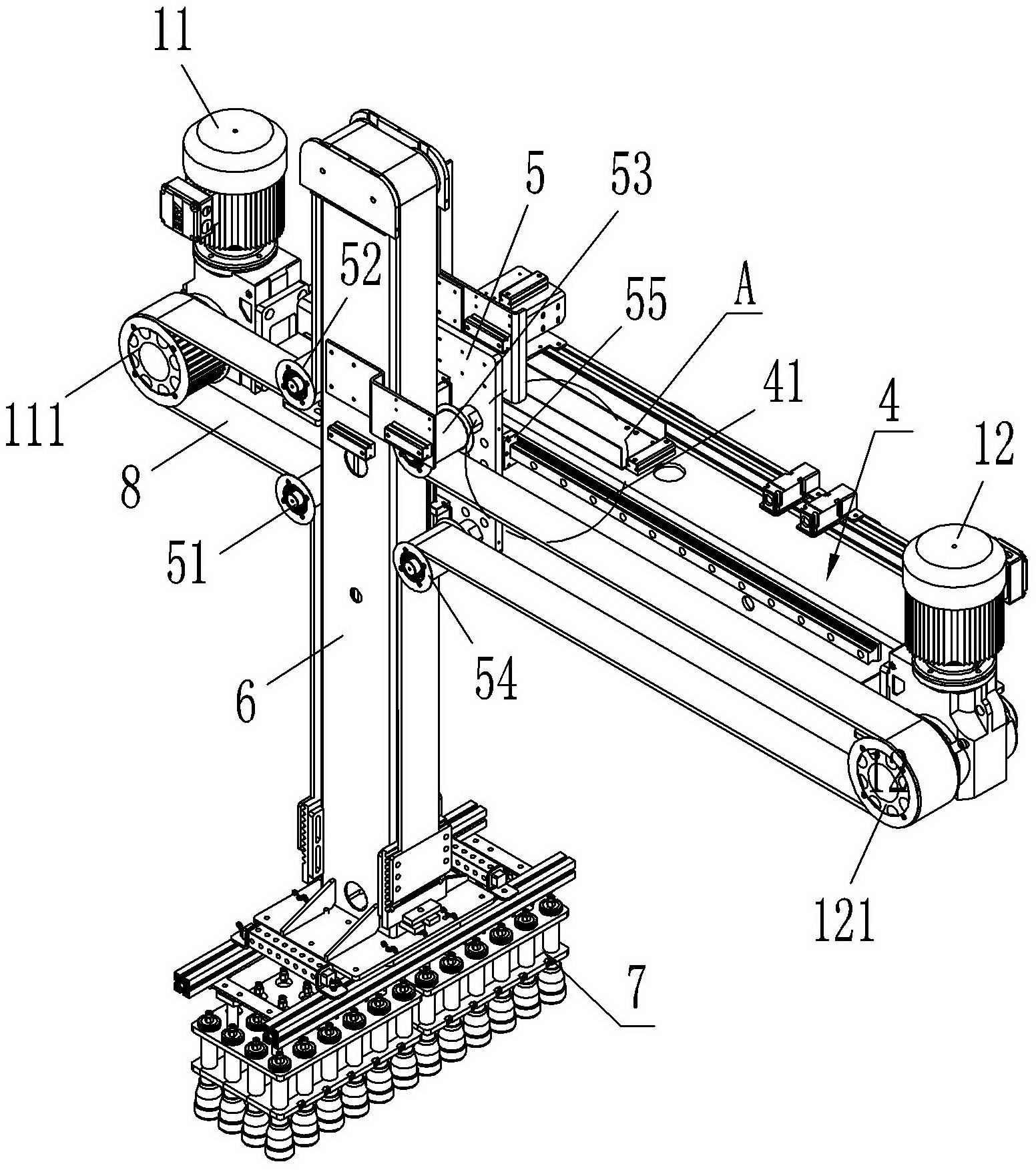

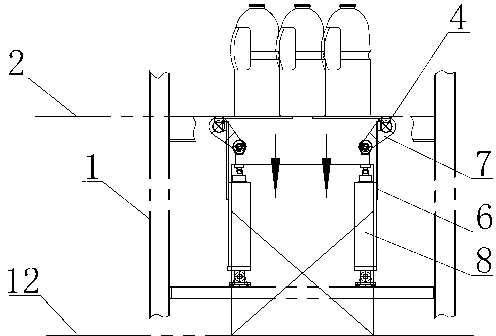

InactiveCN102358447ASimple structureImprove performancePackaging bottlesPackaging machinesCartoning machineElectric machinery

The invention discloses a packing machine, which comprises a stander, wherein a bottle conveying device and a container conveying device are arranged below the stander; a translation frame capable of sliding between the bottle conveying device and the container conveying device is arranged on the upper part of the stander; a lifting frame capable of sliding up and down along the translation frame is arranged on the translation frame; a bottle catching component is arranged at the lower end of the lifting frame; a first servo motor and a second servo motor are arranged at a position, corresponding to the translation frame, on the stander; a first guide pinch roller, a second guide pinch roller, a third guide pinch roller and a fourth guide pinch roller are arranged on the translation frame; and after a transmission device moves around the first guide pinch roller, a synchronizing wheel of the first servo motor, a second guide pinch roller, a guide wheel arranged at the upper end of the lifting frame, the third guide pinch roller, a synchronizing wheel of the second servo motor and the fourth guide pinch roller, two ends of the transmission device are fixed on the lower part of the lifting frame. The packing machine has a simple structure; a moving trace of the packing machine can be finished according to any assumed realizable curve trace; furthermore, the packing machine is stable in performance, high in working efficiency and low in electrical load.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

Semi-automatic boxing machine

InactiveUS7219485B2Increase flexibilityImprove versatilitySolid materialLiquid materialCartoning machineSemi automatic

Owner:MARCHESINI GROUP SPA

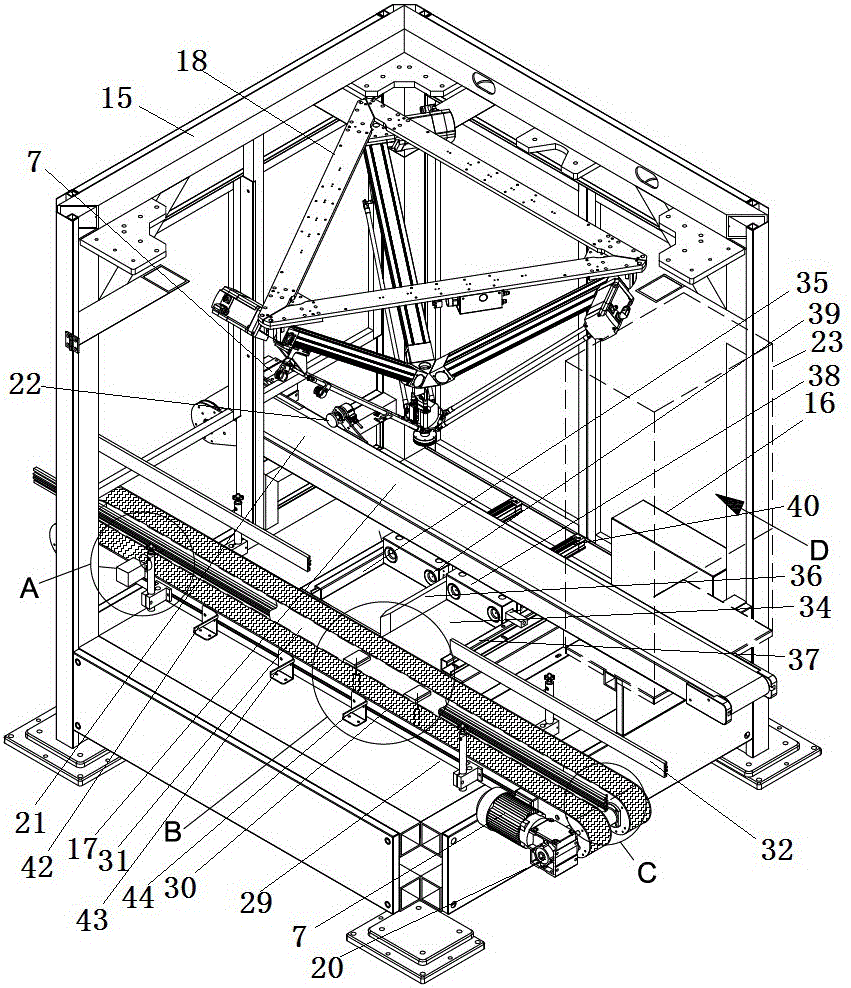

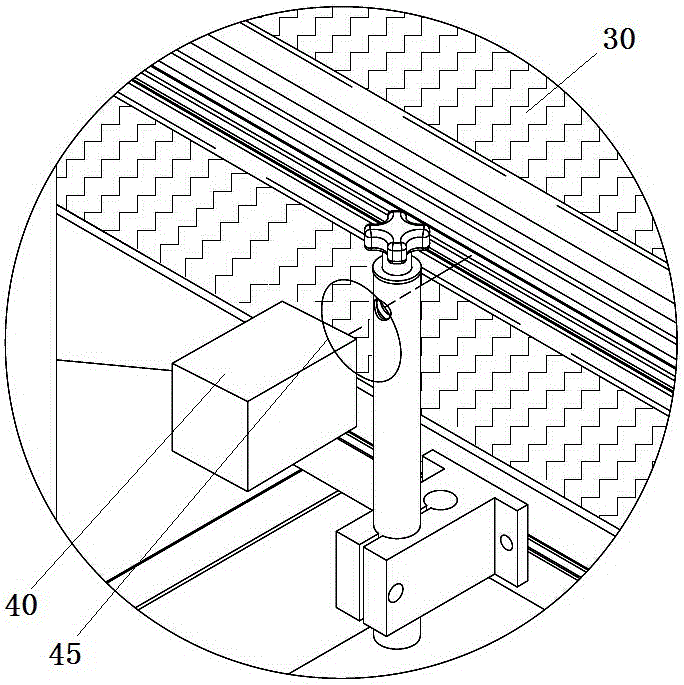

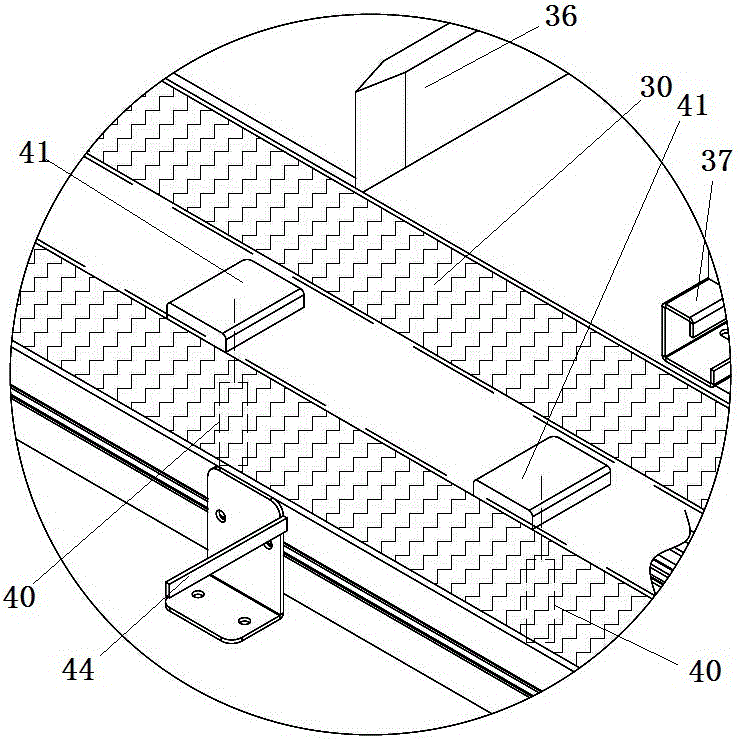

Robot packing machine

ActiveCN105129151AImprove packaging efficiencyImprove placement qualityPackaging automatic controlCartoning machineEngineering

The invention relates to a robot packing machine which comprises a frame body, wherein a conveying mechanism which is used for conveying packaged articles is arranged on the frame body, a transmitting mechanism which is used for transmitting a case body for storing the packaged articles is arranged beside the conveying mechanism, a four-axis linkage shifting mechanism which is used for grabbing the packaged articles into the case body is arranged above the conveying mechanism, a camera is arranged at a feeding port of the conveying mechanism and is used for shooting the actual position of each packaged article such that the actual position of the packaged article is compared with the correct position of the packaged article in a controller, and the camera, the conveying mechanism, the transmitting mechanism and the four-axis linkage shifting mechanism are all electrically connected with the controller. According to the robot packing machine, the actual positions of all the packaged articles can be shot by the camera and are compared with the correct positions of the packaged articles in the controller, so that the multiangular and multidirectional adjustment and shifting of the packaged articles are realized by utilizing the four-axis linkage shifting mechanism according to comparison results, and the article packing efficiency and the article putting quality are increased.

Owner:福州广泰机械设备有限公司

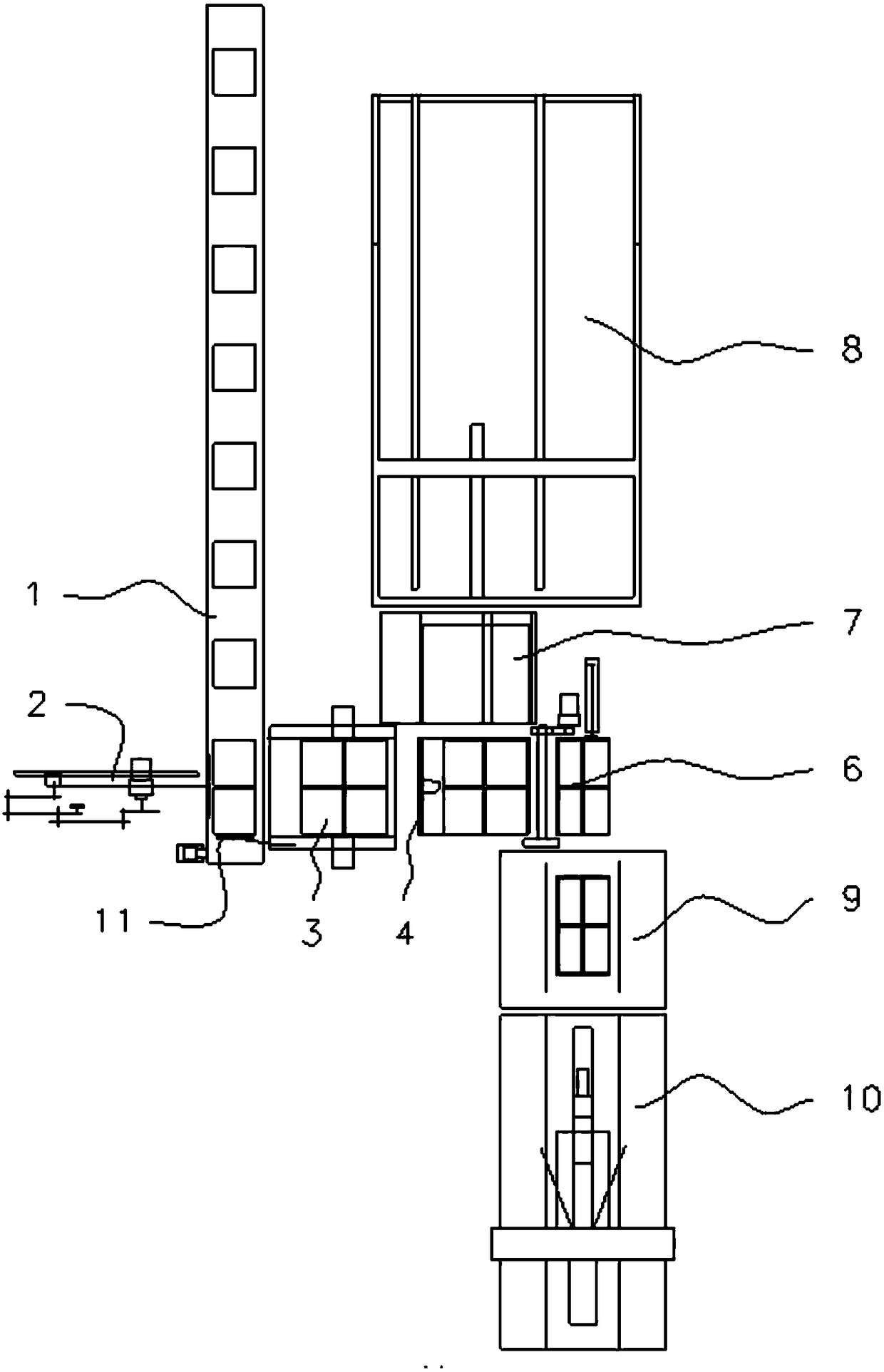

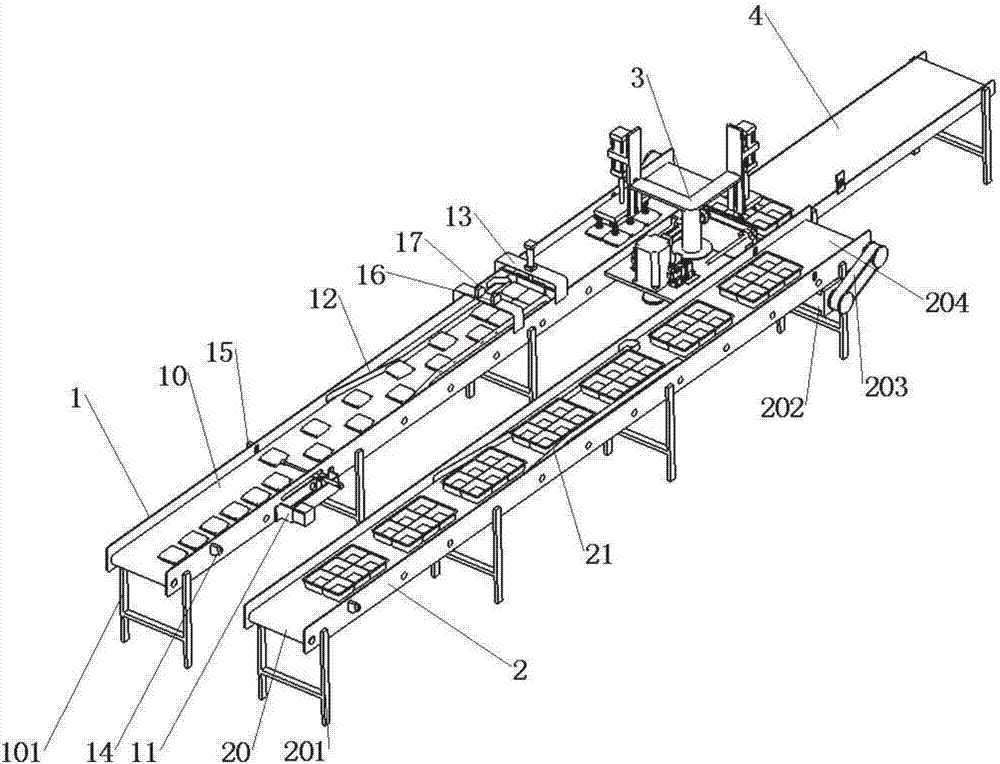

Automatic packing production line

ActiveCN103043235AGood effectReduce labor costsIndividual articlesLabelling machinesCartoning machineProduction line

The invention relates to an automatic packing production line. The packing production line comprises an electric cabinet, a rotary labeling machine, a container handle positioning machine, a packing machine, an unpacking machine, a box labeling machine, a box sealing device, a container conveyor belt and a box conveyor belt, wherein the rotary labeling machine, the container handle positioning machine, the packing machine, the unpacking machine, the box labeling machine, the box sealing device, the container conveyor belt and the box conveyor belt are connected with the electric cabinet; the packing machine comprises a pushing device and a packing device; the container conveying belt passes through the rotary labeling machine, the container handle positioning machine sequentially and the pushing device of the packing machine; the unpacking machine is connected with the packing device of the packing machine through the box conveying belt; the packing machine is connected with the box sealing device and the box labeling machine after completing packing actions; and adhesive tapes for sealing packed boxes are arranged in the box sealing device. By means of the automatic packing production line, processes such as container labeling, container positioning, unpacking, packing, and box labeling can be completed automatically, packed boxes are attractive in appearance, labor costs are reduced, and the working efficiency is improved.

Owner:TIANJIN CHENAN AUTOMATION EQUIP

Box filling machine

ActiveCN103786925AReduce labor intensityIncrease productivityIndividual articlesCartoning machineEngineering

The invention discloses a box filling machine. The box filling machine comprises a packaging box roller conveying line, a product conveying belt, a pack suction robot and a containing device. The product conveying belt is positioned above the packaging box roller conveying line, the pack suction robot is positioned above the product conveying belt, the containing device is positioned on the same side of the product conveying belt and the packaging box roller conveying line, a turnover device is disposed on the packaging box roller conveying line and positioned in front of the containing device, and a sucker used for sucking articles is arranged on the pack suction robot. By the aid of the box filling machine, bagged milk powder can be stacked intensively and then put into boxes to finish box filling operations, manual box filling of bagged milk powder can be substituted, and accordingly labor intensity is relieved, and production efficiency is improved.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Packing machine

InactiveCN103979138BRealize automated productionEvenly loadedShock-sensitive articlesProduction lineCartoning machine

Owner:FOSHAN RUIBO CERAMICS ELECTRICAL & MECHANICAL

Automatic box dividing mechanism of wine bottle box filling machine

The invention relates to the technical field of box filling machines, and discloses an automatic box dividing mechanism of a wine bottle box filling machine. The automatic box dividing mechanism comprises a stacking conveying belt platform, a box dividing conveying belt platform and an artificial frame putting platform, wherein the stacking conveying belt platform, the box dividing conveying belt platform and the artificial frame putting platform are sequentially connected; a conveying belt is arranged on the stacking conveying belt platform and the box dividing conveying belt platform; a plurality of partition plates are arranged above the conveying belt; the partition plates are parallel to form feeding channels; gaps are formed between the bottoms of the partition plates and the conveying belt; a bottle blocking mechanism is arranged at the front end of the box dividing conveying belt platform, and a bottle pressing mechanism is arranged at the rear end of the stacking conveying belt platform; a pushing case is arranged at the rear end of the box dividing conveying belt platform and is provided with a pushing rod; conveying chains equal to the feeding channels in number are arranged on the artificial frame putting platform; a bottle partitioning plate is arranged between every two adjacent conveying chains; bottle partitioning protruding strips are evenly arranged on the conveying chains; and the distance between every two adjacent bottle partitioning protruding strips is equal to the length of wine bottles. The wine bottles after box dividing are placed on the artificial frame putting platform in an array manner to form gaps, and after the bottles are placed in a tic-tac-toe frame, subsequent automatic box filling is facilitated.

Owner:HANGZHOU WAHAHA TECH

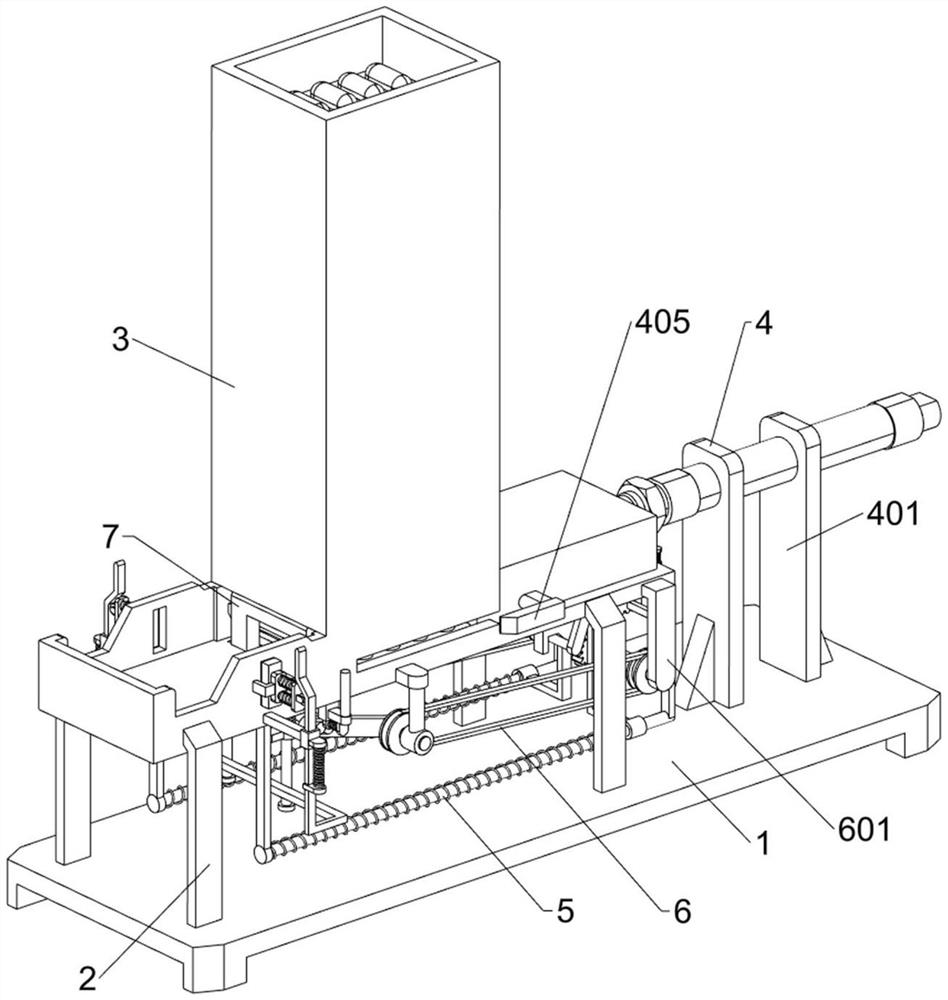

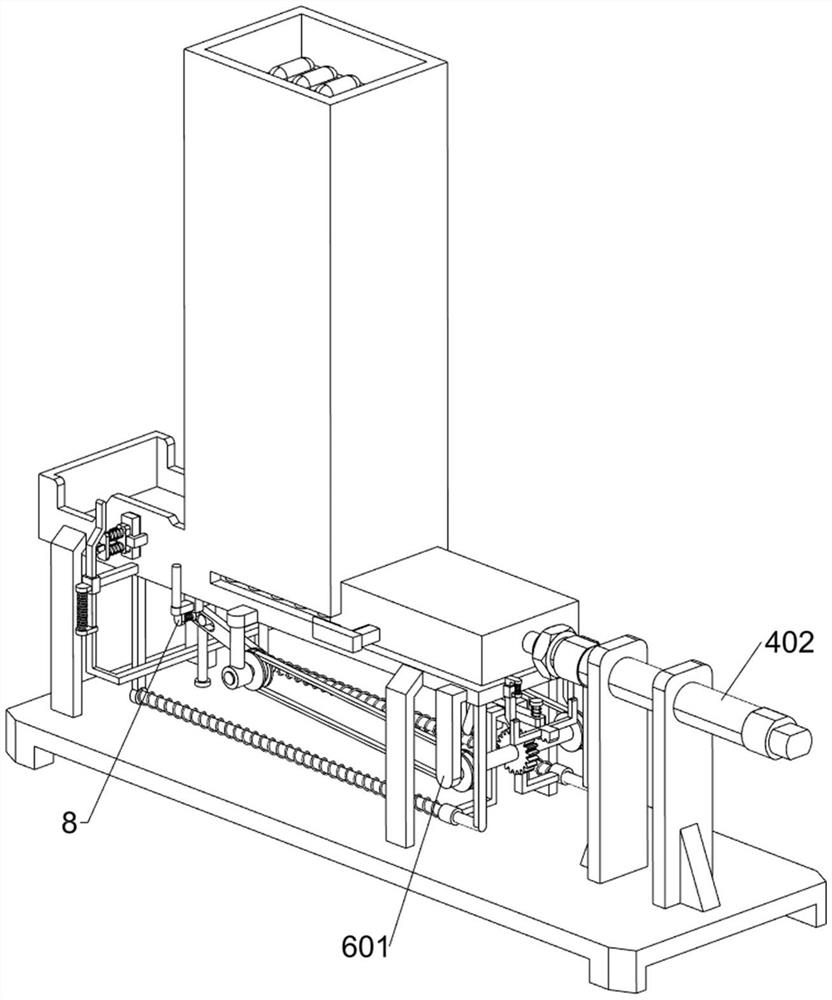

Full-automatic box filling machine for cupped products

ActiveCN103640730AHigh degree of automationImprove work efficiencyPackaging automatic controlCartoning machineEngineering

The invention discloses a full-automatic box filling machine for cupped products. An automatic cup conveying assembly, a cup turnover assembly, a cup arrangement assembly, a dividing arrangement assembly, a cup box-filling manipulator, a box pulling assembly, a packing box conveying assembly and an electric cabinet are installed on a rack, wherein the cup turnover assembly comprises a cup conveyor belt. During operation, the automatic cup conveying assembly conveys cups to the cup turnover assembly automatically, the cup turnover assembly turns over the cups and reversely placing every two adjacent cups in a conveying direction, the cup arrangement assembly divides the cups conveyed together into multiple channels, the dividing arrangement assembly divides the cups conveyed by the multiple channels respectively in order, the packing box conveying assembly conveys packing boxes for packing the cups below the box pulling assembly, the box pulling assembly opens insides of the packing boxes and fixes the packing boxes, and the cup box-filling manipulator places the cups arranged by the dividing arrangement assembly into the packing boxes. Therefore, the full-automatic box filling machine is high in automation degree and working efficiency and capable of effectively saving the labor cost.

Owner:东莞市巨阜智能科技有限公司

Boxing machine

InactiveCN103979138ARealize automated productionEvenly loadedShock-sensitive articlesCartoning machineManufacturing line

The invention discloses a boxing machine. The box machine comprises a conveying belt, a stacking frame, a suctioning device, a box-opening working frame, a box-opening device, a box-supporting guiding-in device, a jacking platform and a pushing device, wherein the two sides, which correspond to the conveying direction of the conveying belt, of the box-opening working frame are respectively provided with a gate blocking plate which can block a paper box in a manner of relatively opening and closing; the side, adjacent to the box-opening device, of the box-opening working frame is fixedly provided with a blocking piece for blocking the paper box. The boxing machine disclosed by the invention has the advantages that the box opening of the folded paper box can be smoothly realized, and the smooth boxing of an object to be boxed into a paper box drum can be ensured; the structure is compact, the connection of the adjacent procedures in the package production line of ceramic-tile paper boxes can be well realized, and full-automatic production of the packaging production line of the ceramic-tile paper boxes is realized.

Owner:FOSHAN RUIBO CERAMICS ELECTRICAL & MECHANICAL

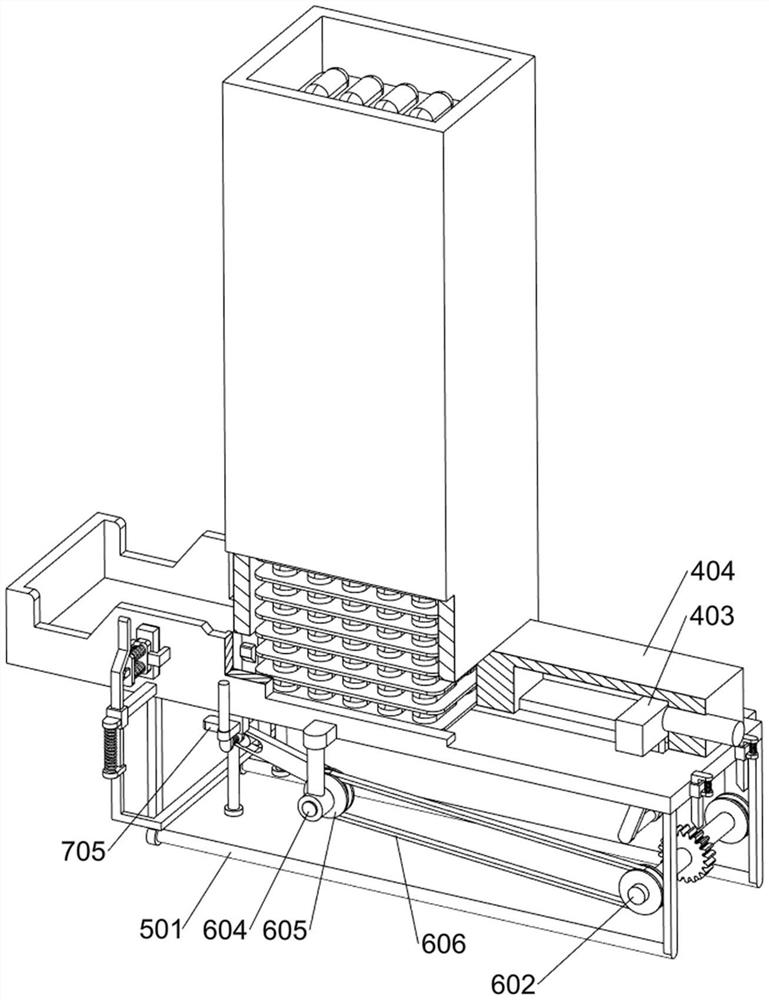

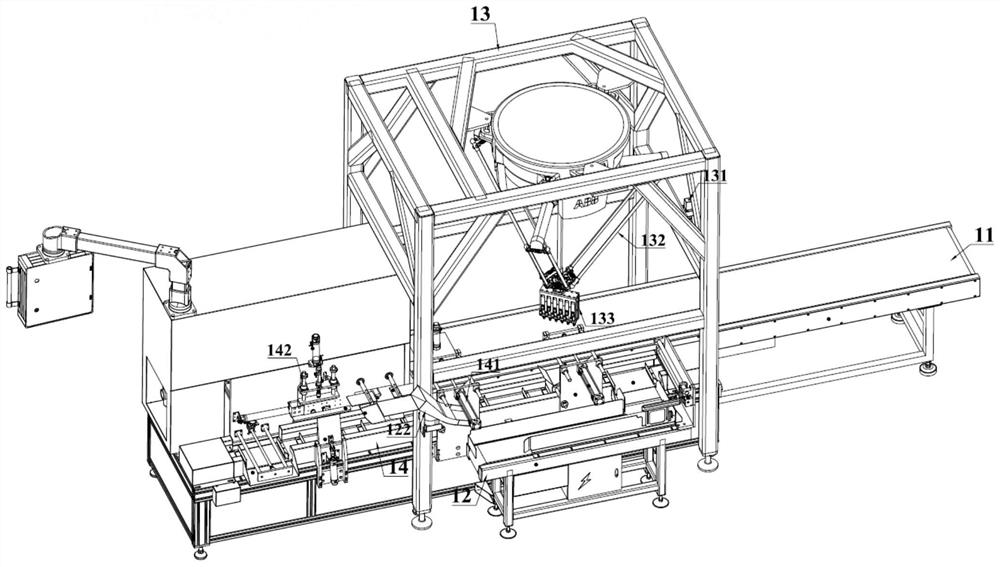

Cylindrical strip material stacking container loader

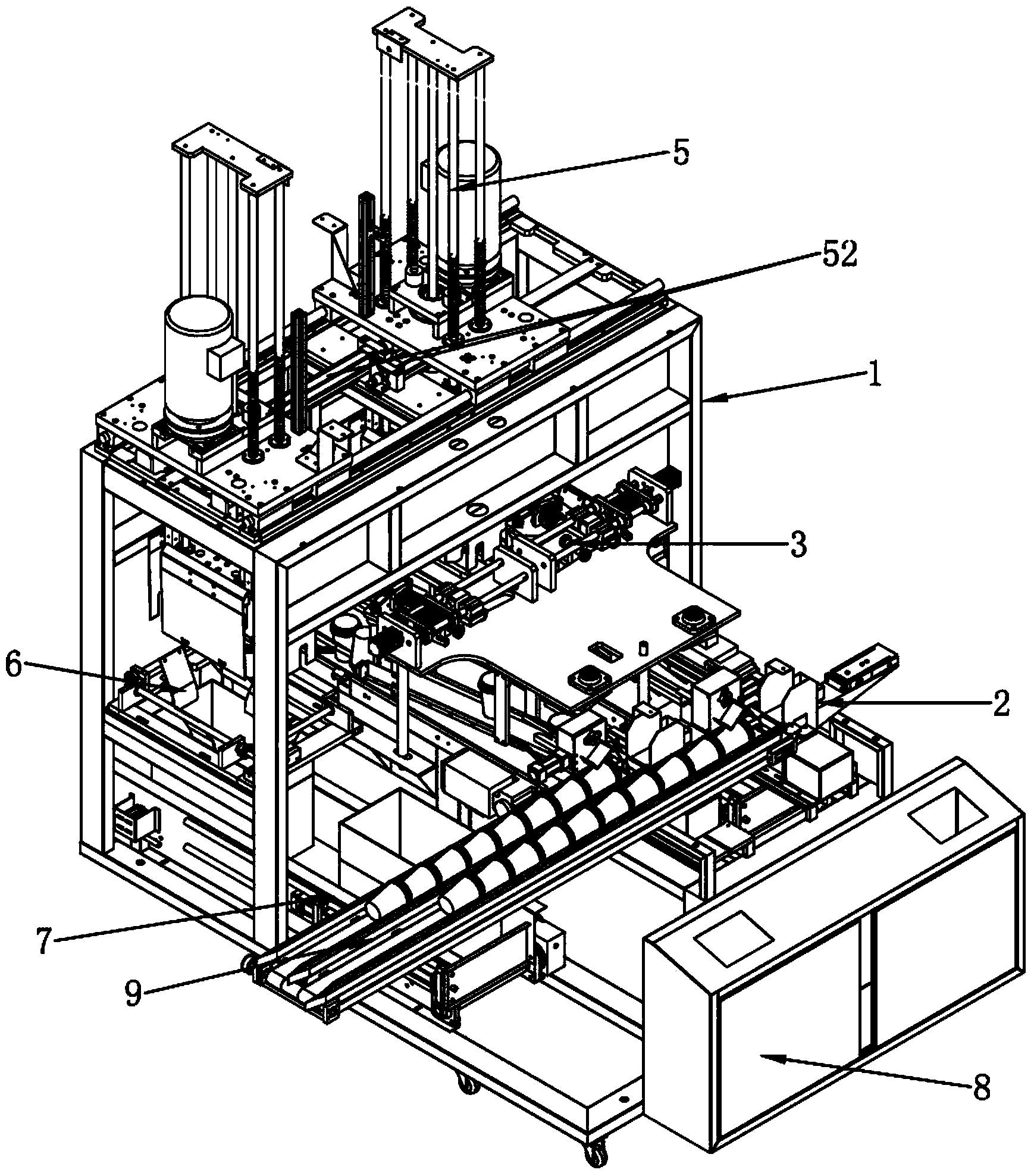

ActiveCN106275541ASimple structureThe packing quantity is accurate and reliableIndividual articlesCartoning machineEngineering

The invention discloses a cylindrical strip material stacking container loader. The cylindrical strip material stacking container loader comprises a material conveying, settling and sorting part, a container feeding, positioning and discharging part, a material layered suck-grabbing and stacking part and the like. The material conveying, settling and sorting part is used for settling and sorting cylindrical strip materials in parallel and conveying the cylindrical strip materials to a suck-grabbing position. The container feeding, positioning and conveying part is used for guaranteeing that empty containers are accurately fed to container loading positions, maintaining the containers straight and conveying the loaded containers. The material layered suck-grabbing and stacking part is used for suck-grabbing and stacking the materials into the containers layer by layer. The container loader can be used for filling the containers with the cylindrical strip materials at the same time. The cylindrical strip material stacking container loader is suitable for the cylindrical strip materials such as glass cement and sausage. The container loader has the advantages of being simple in structure, full-automatic in production, stable, reliable, high in efficiency, and capable of assembling various production lines by being used in cooperation with soft packaged material filling sealing machines, cylindrical filling cap-tighteners, box opening and forming machines, box sealing machines and the like for assembling various production lines.

Owner:广州市博仕机电工贸有限公司

Multifunctional paper diaper robot box filling machine

The invention discloses a multifunctional paper diaper robot box filling machine. The robot box filling machine comprises a suction type box filling part and a clamping type box filling part, whereinthe suction type box filling part comprises a four-section feeding part, a six-axis box filling robot, a side pushing mechanism, a box opening mechanism, a sucker gripper, a suction platform and a roller conveying line; the clamping type box filling part comprises a four-section feeding part, a six-axis box filling robot, an arrangement mechanism, a clamping platform, a side pushing mechanism, a box opening mechanism, a clamping gripper and a roller conveying line. The multifunctional paper diaper robot box filling machine has the advantages as follows: the multifunctional paper diaper robot box filling machine has double functions, the suction type box filling form and the clamping type box filling form are combined, the application range of the box filling machine is greatly enlarged, and the production cost is reduced.

Owner:NANTONG UNIVERSAL MACHINERY

Packing machine

PendingCN109018516ASimple structureEasy to change production and adjustWrapper twisting/gatheringCartoning machinePulp and paper industry

The invention belongs to the technical field of packing machines, and particularly relates to a packing machine which comprises an arrangement pushing hand mechanism, a paper carton input mechanism, apaper carton opening mechanism, a packing pushing hand mechanism, and a paper carton output mechanism. The arrangement pushing hand mechanism is used for pushing products on a product conveying mechanism into a product stacking mechanism; the paper carton input mechanism is used for conveying a paper carton into a paper carton turnover mechanism; an opening of the paper carton conveyed into the paper carton turnover mechanism faces the product stacking mechanism; the paper carton opening mechanism is used for opening the opening part of the paper carton with the opening facing the product stacking mechanism, the packing pushing hand mechanism is used for pushing the products stacked in the product stacking mechanism into the opened paper carton; the paper carton turnover mechanism is usedfor turning over the opening of the paper carton filled with the products to face upwards from facing the product stacking mechanism; and the paper carton output mechanism is used for outputting thepaper carton with the upward opening in the paper carton turnover mechanism. The packing machine provided by the invention has the beneficial effects that the automation of the product packing processis realized, the packing machine is suitable for assembly line production, the labor intensity of manpower is reduced, and the product packing efficiency is improved.

Owner:ANQING HENG CHANG MACHINERY

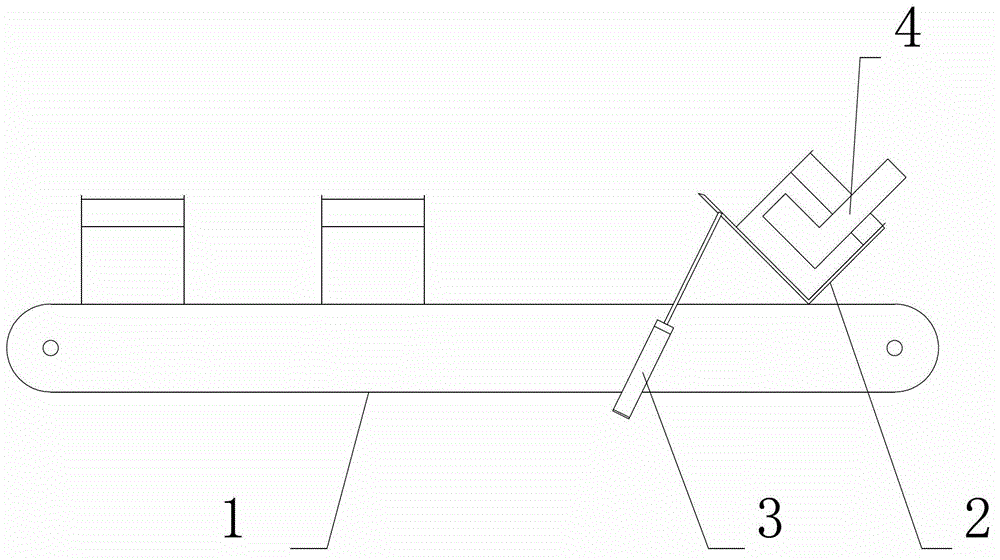

Bottle blanking mechanism of drop type packing machine

The invention discloses a bottle blanking mechanism of a drop type packing machine, wherein the bottle blanking mechanism of the drop type packing machine is simple in structure, convenient to use, and capable of effectively reducing the occurring of bottle blocking, and therefore greatly improves packing efficiency. The bottle blanking mechanism of the drop type packing machine includes that a bottle pushing plate connected with a bottle pushing plate driving device is arranged on one side of a bottle conveying platform, a pair of turn-over shafts is arranged on the other side of the bottle conveying platform, two ends of the turn-over shafts are all respectively supported on a rack, a turn-over plate is fixedly connected on each turn-over shafts, the two turn-over shafts are respectively fixedly connected with a connection rod, and the end portions of two connection rods are respectively connected with the piston rods of two turn-over air cylinders. Under the driving of the turn-over air cylinders, the turn-over shafts both can rotate to enable the two turn-over plates to be simultaneously turned over downward to vertical positions from horizontal positions of the inner sides of the turn-over shafts, or enable the two turn-over plates to be simultaneously turned over upward to the horizontal positions from the vertical positions of the inner sides of the turn-over shafts. A transition plate is further arranged on a rack between the bottle conveying platform and the two turn-over plates.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

Machine for packing paper box with upper cover

ActiveCN101850863AReduce labor costsImprove work efficiencyPackaging bottlesCartoning machineProcess engineering

The invention discloses a machine for packing a paper box with an upper cover, which is mainly characterized in that: the body of the box packing machine is sequentially provided with a vacuum box sucking mechanism, a box delivering warehouse, a box packing and feeding mechanism, a charging mechanism, a paper feeding mechanism, a small tongue bending mechanism, a big tongue bending mechanism and a big tongue pressing mechanism; and all mechanisms are matched with a transverse conveyer belt. Through the action of each link mechanism, a board is loaded in a vial and the vial is loaded in the paper box with the upper cover through mechanical action, so that the work efficiency is improved and the labor cost is also saved for enterprises; and compared with the prior art, the machine has prominent substantive characteristic and obvious progress.

Owner:ZHEJIANG HOPING MACHINERY

Automatic cartoning machine

ActiveCN102241280AReduce frictionHigh degree of automationPackaging automatic controlCartoning machineEngineering

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +1

Automatic food boxing machine

PendingCN106892158ARealize automatic group arrangementFully automatedPackaging automatic controlCartoning machineProcess engineering

The invention discloses an automatic food boxing machine which comprises a food conveying mechanism, a food box conveying mechanism, a rotating mechanism and a finished product conveying mechanism. The food conveying mechanism and the food box conveying mechanism are arranged in parallel correspondingly. The tail ends of the food conveying mechanism and the food box conveying mechanism are connected with the rotating mechanism. The food conveying mechanism and the food box conveying mechanism push pouch packed food and food boxes to the rotating mechanism, and the rotating mechanism is connected with the finished product conveying mechanism. According to the automatic food boxing machine, automatic grouping and arrangement of food can be achieved, full-automatic food boxing is achieved, production efficiency is improved, labor is saved, and large-scale production is achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Stacked pallet, stacking packer and stacking packing method

ActiveCN103101660AGuaranteed not to moveGuaranteed not to swingStacking articlesPackaging bottlesCartoning machineEngineering

The invention discloses a stacked pallet, a plurality of grooves arrayed in a matrix mode are formed in one side of a pallet plate, and clamping sleeves are arranged on the other side of the pallet plate and correspond to the grooves. When packing is carried out by utilization of the stacked pallet, the situation that bottles do not move and sway can be guaranteed so that a plurality of stacked pallets are formed into a whole and firm and stable. A finished stacking which is the whole formed by stacking can be a whole packed completely and transported, traditional packing materials are saved, and packing cost is reduced. Meanwhile, the stacked plate can be recycled and therefore is green and environment-friendly. According to a packer for stacking the pallets, due to the fact that film packer, a paper packer or a box filler and the like used by traditional packing are saved, packing is simplified, and the working efficiency is improved. In addition, after the finished stacking is transported to a merchant, removal of a package and placing of the finished stacking on a shelf are carried out without manpower, and labor cost is saved for the merchant.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

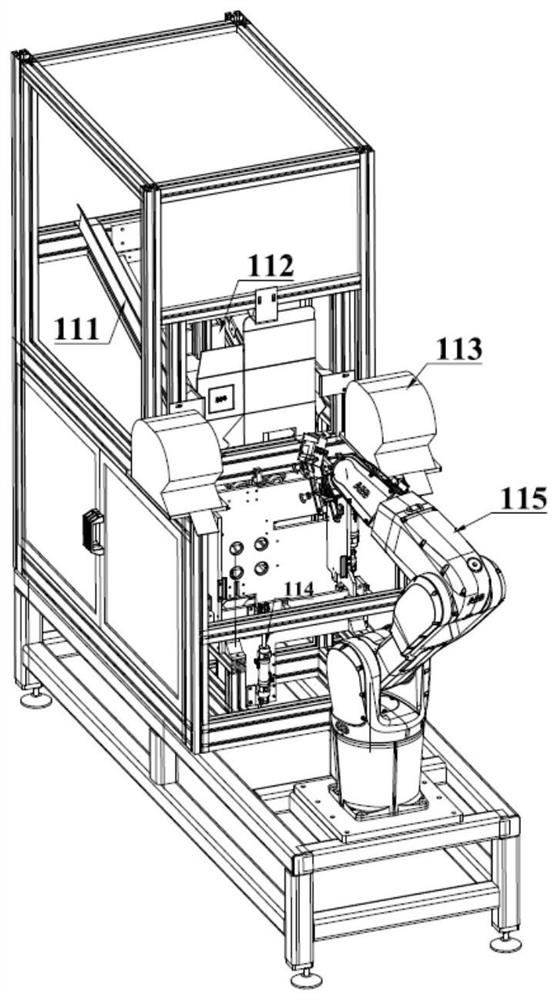

Automatic boxing machine for biological capsules

ActiveCN112173272AReduce labor intensityImprove work efficiencyIndividual articlesCartoning machineEngineering

The invention relates to a boxing machine, in particular to an automatic boxing machine for biological capsules. The technical problem to be solved by the invention is to provide the automatic boxingmachine for the biological capsules which can enable workers to be easier and is high in working efficiency. According to the technical scheme, the automatic boxing machine for the biological capsulescomprises a bottom plate, supporting rods and a placing table, wherein the supporting rods are fixedly connected to the two sides of the top of the bottom plate, and the placing table is fixedly connected between the supporting rods. According to the automatic boxing machine, the biological capsules can be automatically pushed into a packaging box through a driving assembly, so that the labor intensity of workers can be greatly reduced, the workers can be easier, the working efficiency can be improved, the packaging box can be clamped through a stabilizing assembly, displacement of the packaging box is avoided, and the biological capsules can be smoothly contained in the packaging box.

Owner:吉林省俊宏药业有限公司

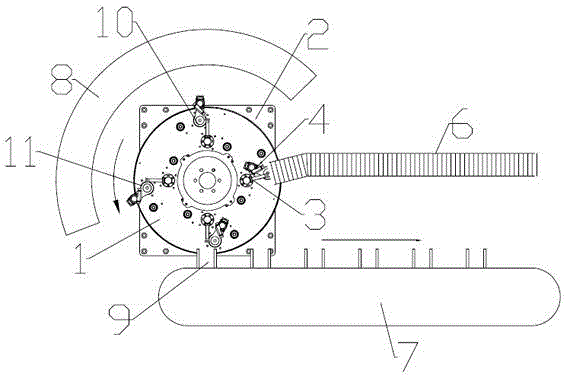

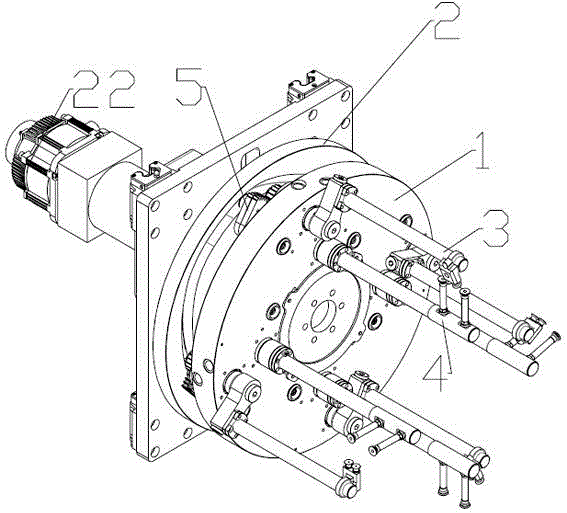

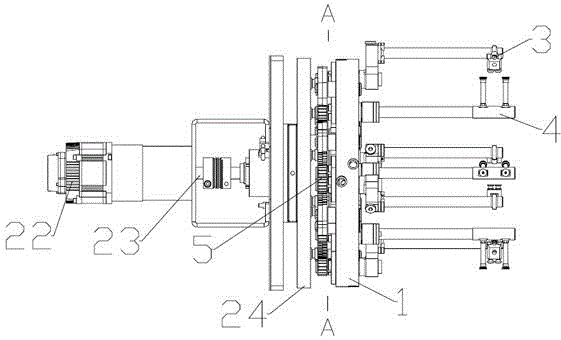

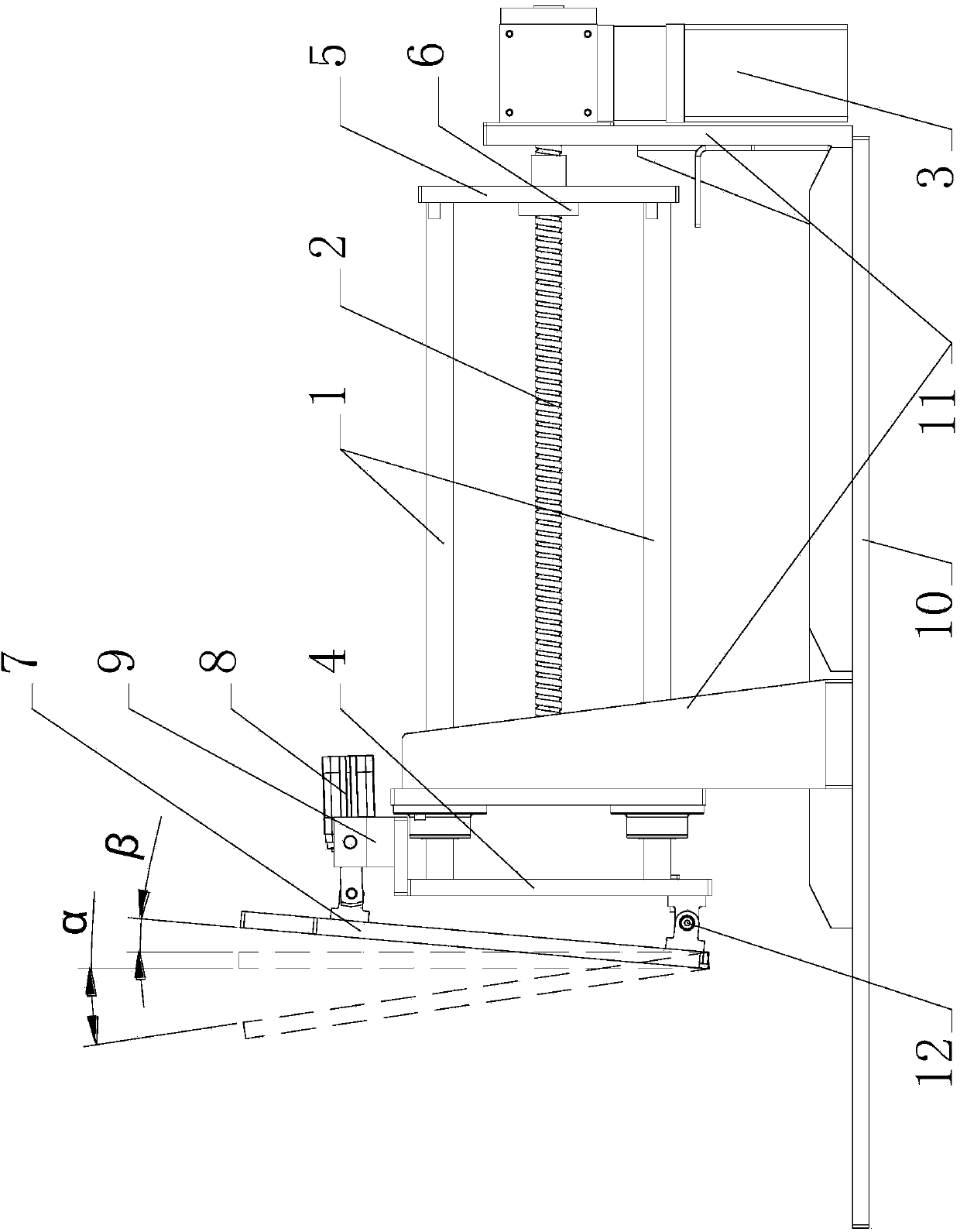

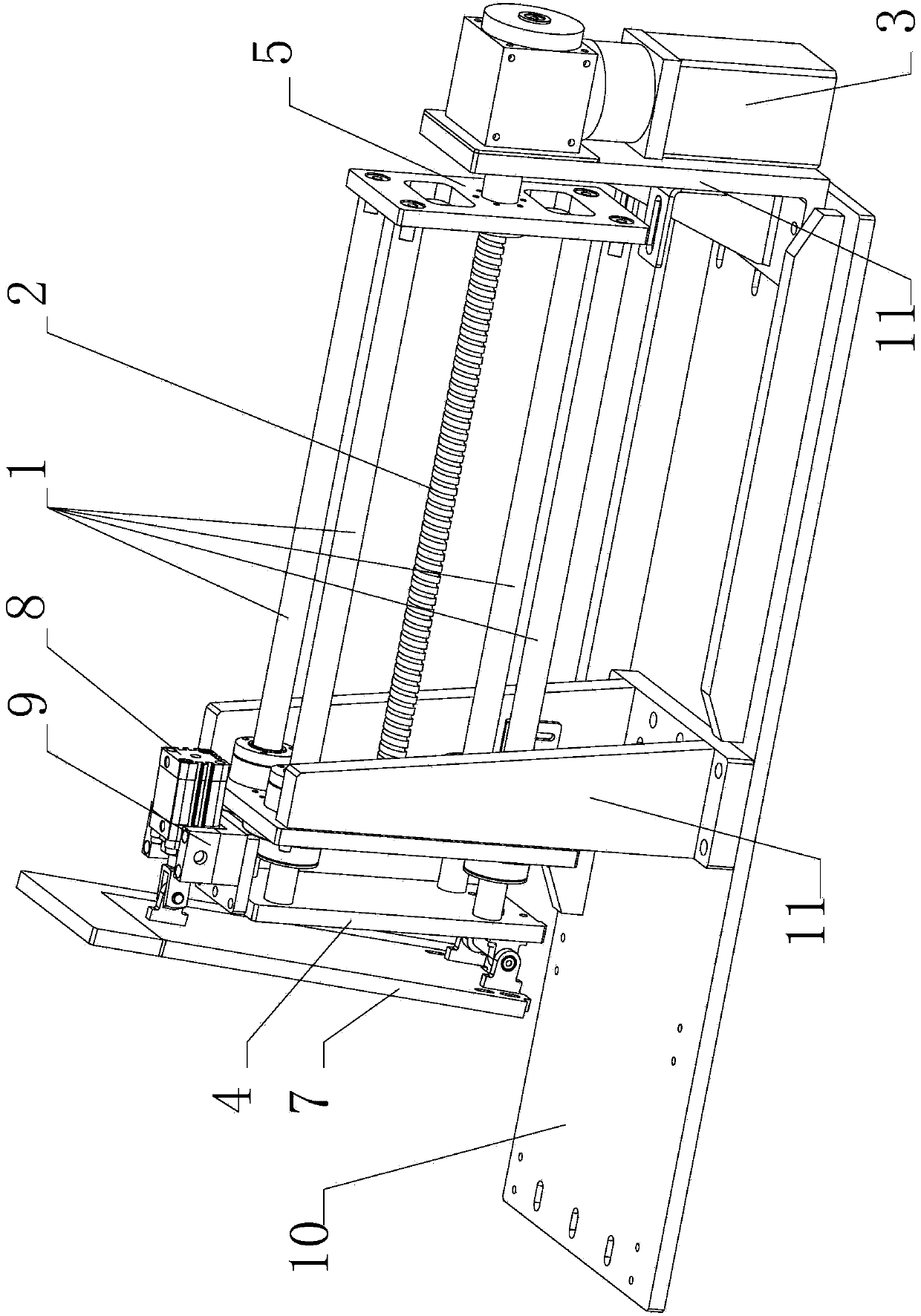

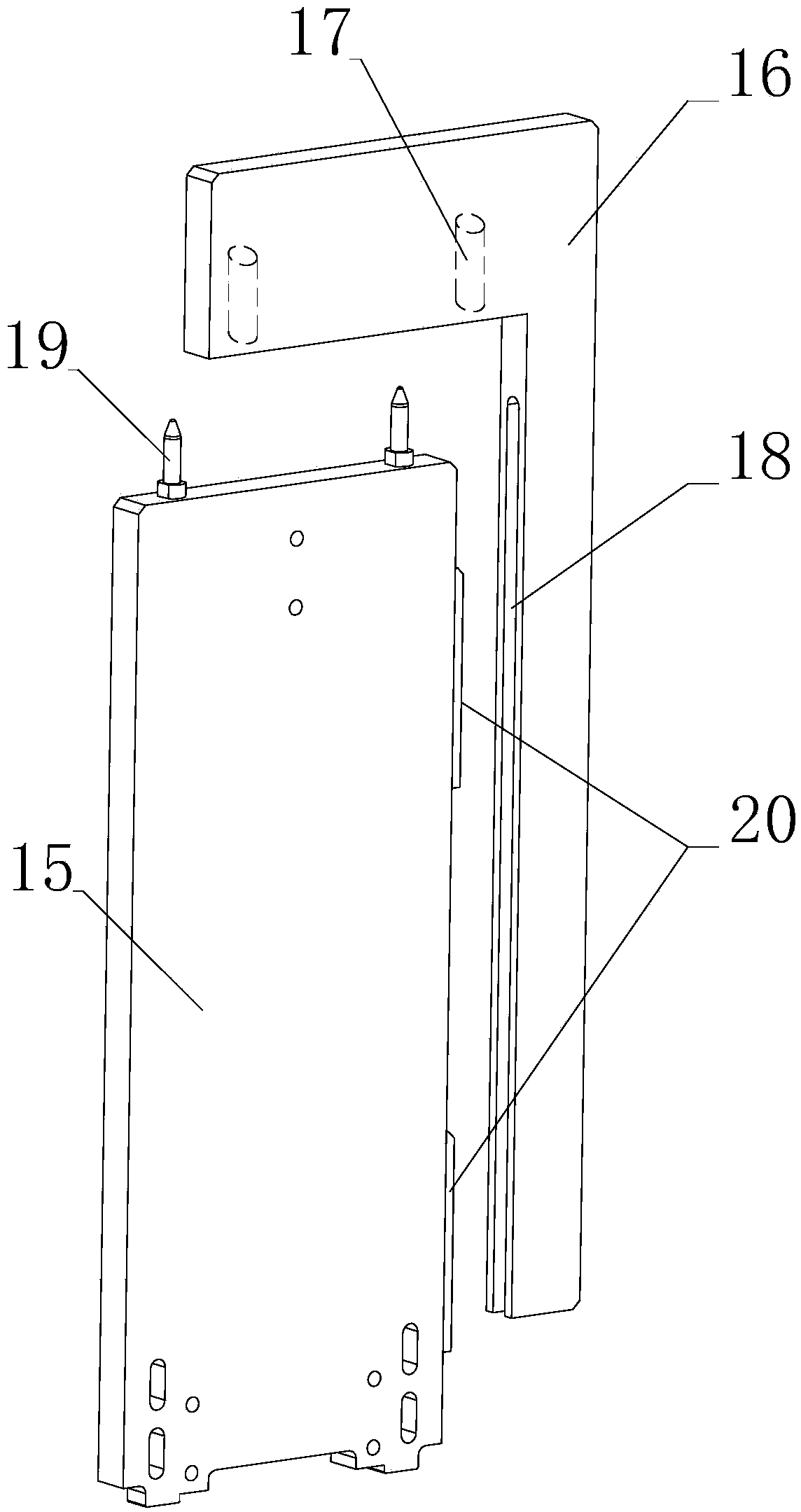

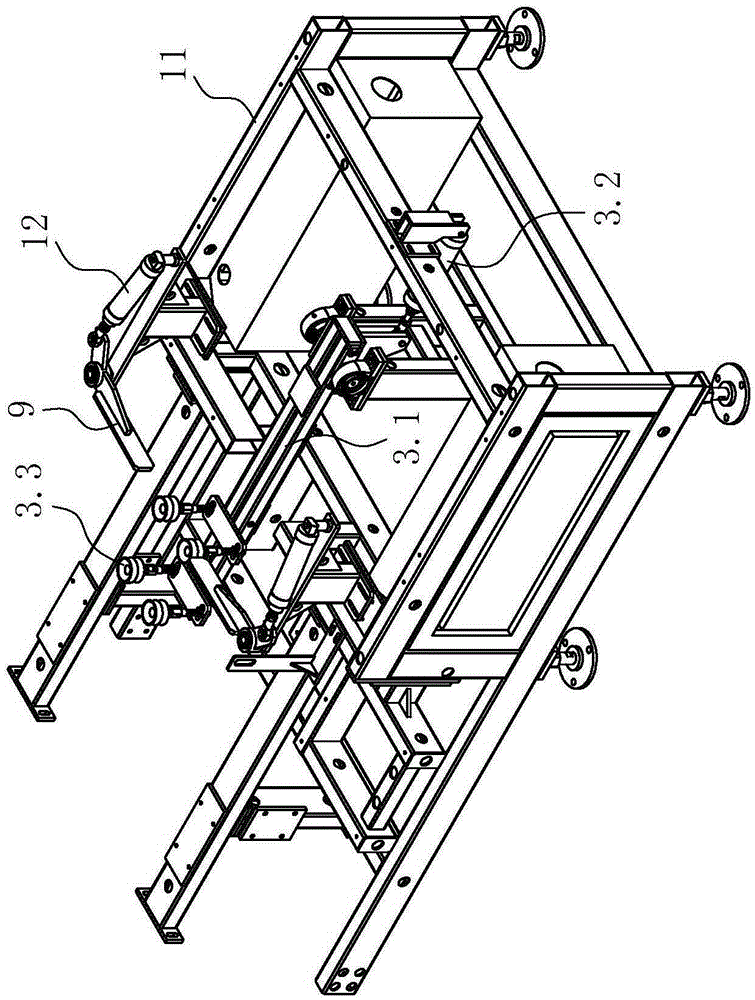

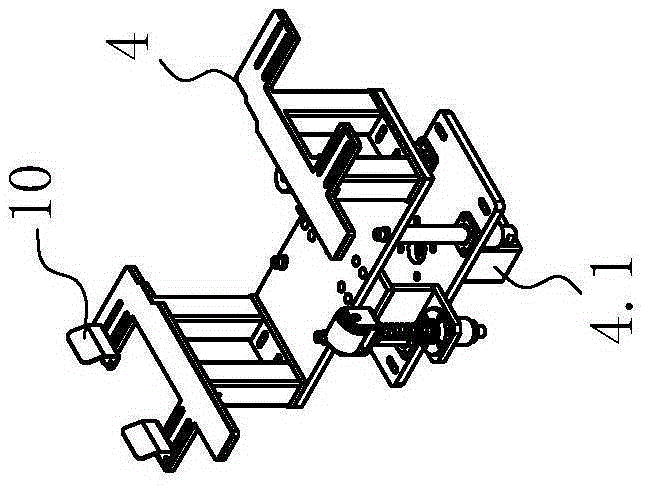

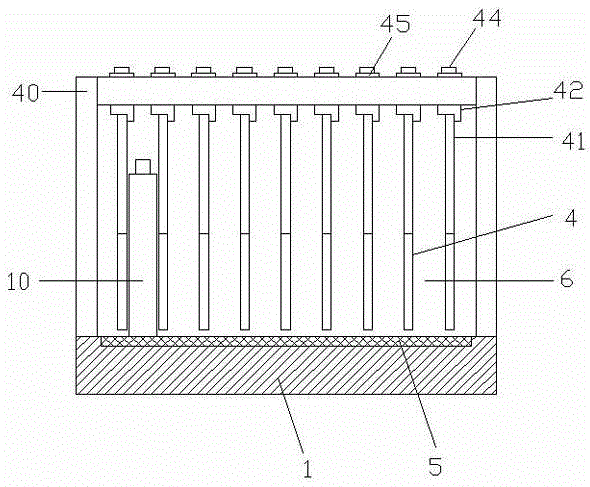

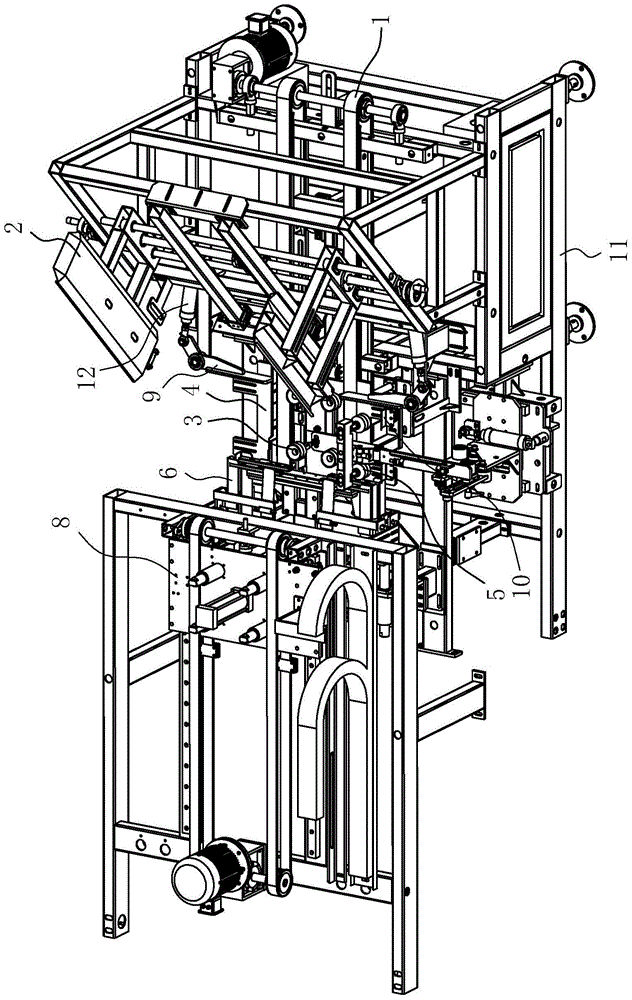

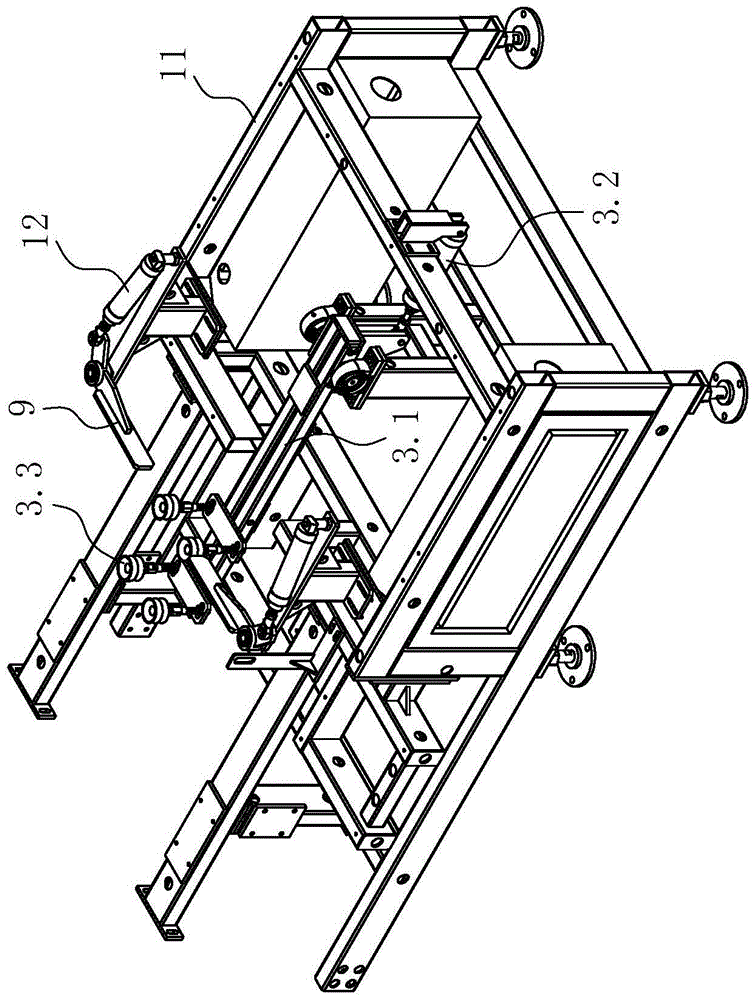

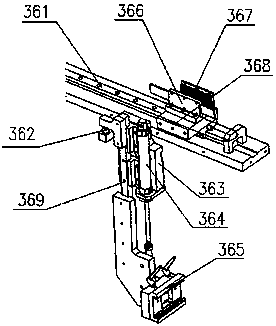

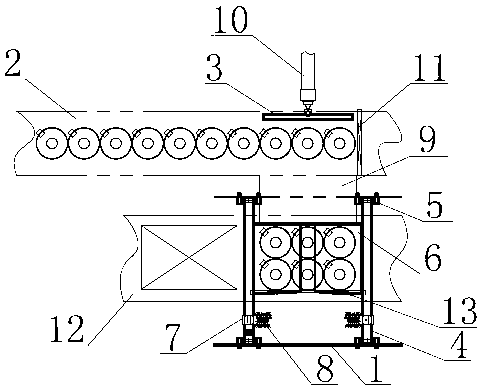

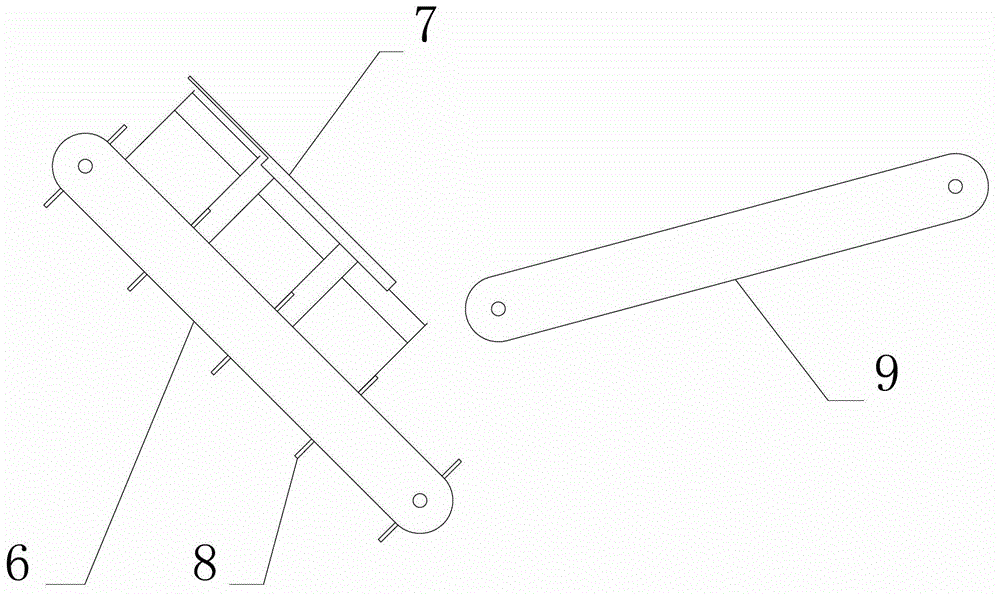

Vertical boxing machine and rotary box-sucking mechanism thereof

ActiveCN103204266AAvoid contactAvoid affecting product qualityPackagingMechanical devicesCartoning machine

The invention provides a vertical boxing machine and rotary box-sucking mechanism thereof, and belongs to the mechanical devices or equipment of packing objects or materials. The vertical boxing machine comprises a paper box storeroom (1) and a paper box delivery and convey chain mechanism (2) which comprises a convey chain assembly (3), a tongue driving mechanism (4) and a tongue inserting mechanism (5). The vertical paper boxing machine is characterized in that the rotary box-sucking mechanism (20) is arranged between the paper box storeroom (1) and the convey chain mechanism (2) and is matched with the same; the rotary box-sucking mechanism comprises a turntable (6) connected with a power device in a transmission manner. A radial reciprocating-moving box-sucking unit assembly is arranged on the turntable (6) and mainly comprises a sucking head (7) connected with an air source; and the vertical boxing machine capable of completing material vertically boxing and sucking and releasing the paper boxes successfully without additional paper box opening mechanisms.

Cartoning machine

ActiveCN104787368AReduce labor costsImprove packaging efficiencyIndividual articlesCartoning machineComing out

The invention discloses a cartoning machine. A carton body second conveyor belt is arranged on one side of a carton body first conveyor belt, and a carton body push mechanism is arranged on the other side of the carton body first conveyor belt; a leather cloth push plate is installed on the top of a leather cloth push plate driving mechanism, the two bottom faces of a leather cloth sleeve are communicated with each other, a sleeve opening is formed in one side face of the leather cloth sleeve, the leather cloth push plate is arranged over the leather cloth sleeve, and the leather cloth push plate can be driven by the leather cloth push plate driving mechanism to enter the leather cloth sleeve from the sleeve opening; a carton body positioning mechanism is arranged above the carton body push mechanism in a liftable mode; the leather cloth push mechanism is arranged on the position right opposite to the leather cloth sleeve, and the leather cloth push mechanism can penetrate from one bottom face of the leather cloth sleeve and come out from the other bottom face of the leather cloth sleeve. According to the cartoning machine, cartoning process can be completed integrally and orderly, the labor cost is saved, the cartoning efficiency is improved, and the probability of errors is reduced.

Owner:徐州强雳日常用品制造有限公司

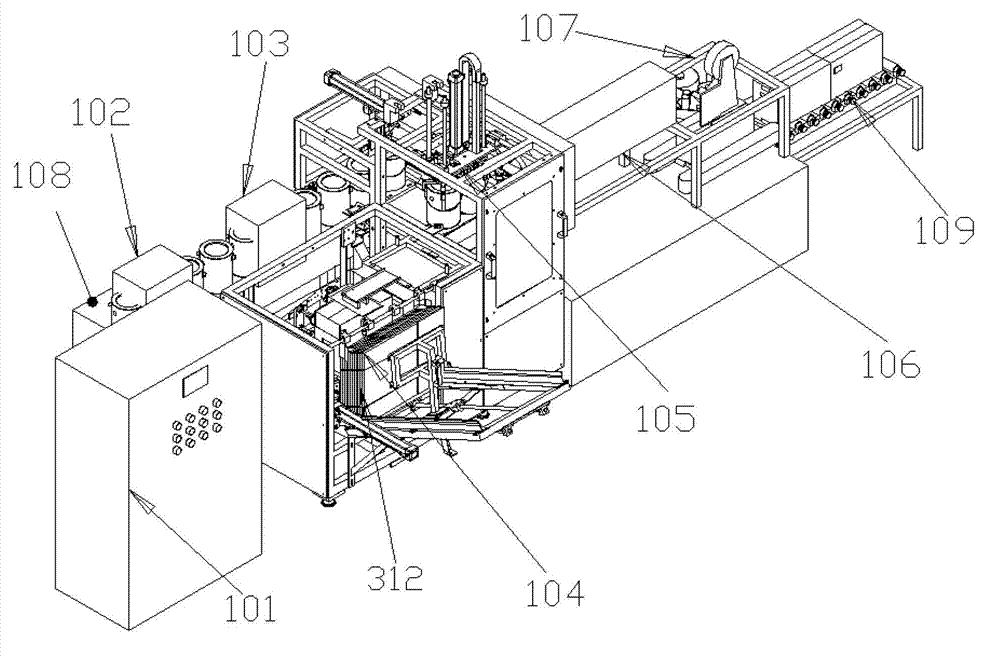

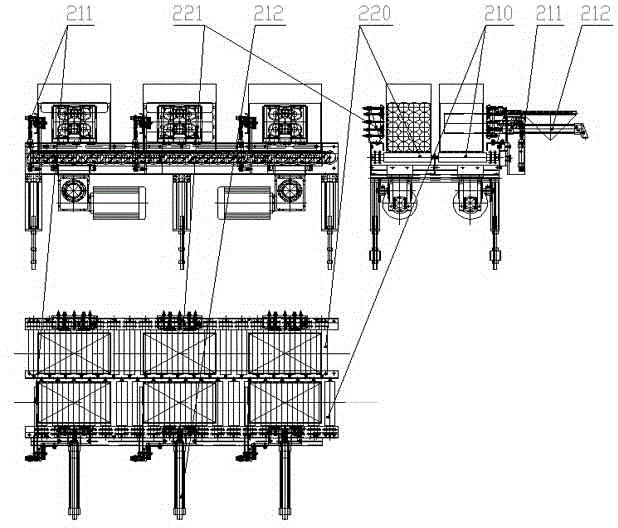

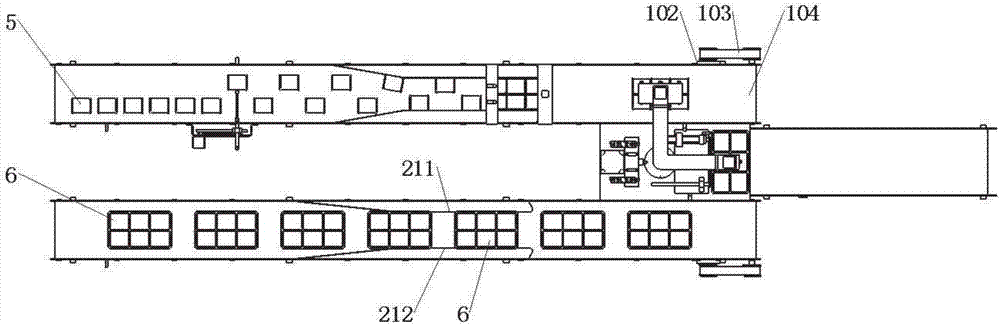

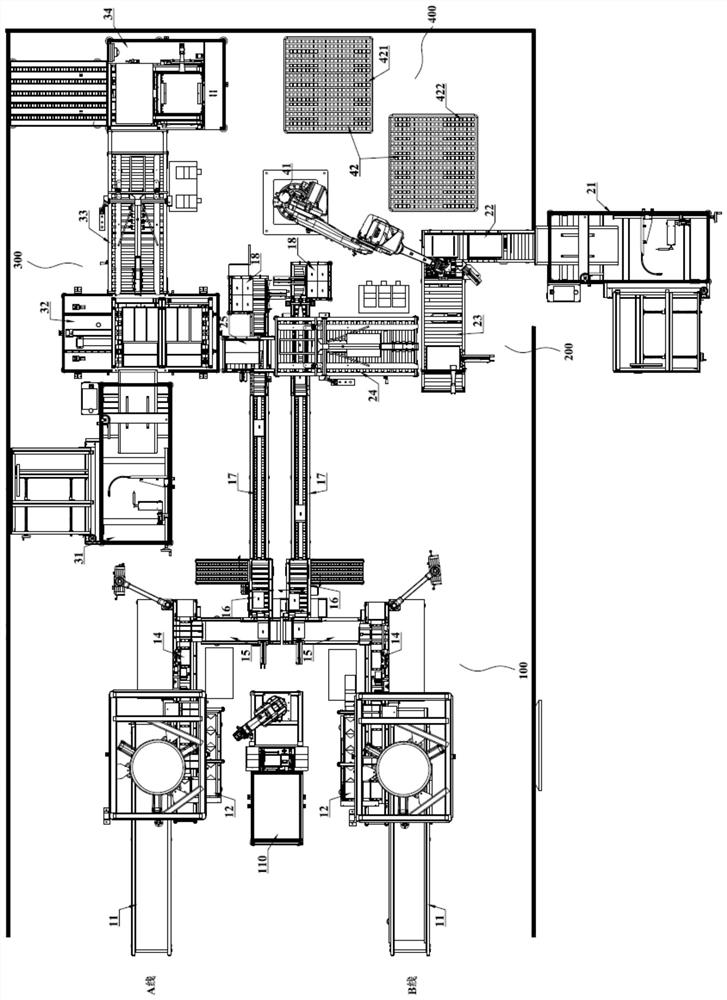

Double-line automatic outer package production line

PendingCN112009825AImprove packaging qualityImprove hygienePackaging machinesCartoning machineProduction line

The invention relates to a double-line automatic outer package production line. The production line comprises a small box packaging section A, a small box packaging section B, a middle box packaging section, a large box packaging section and a stacking section. Each small box packaging section comprises a small box opening and labeling all-in-one machine, a product conveyor, a small box empty boxconveyor, a boxing robot, a small box sealing conveyor, a small box transfer conveyor, a small box weighing conveyor, an unpowered buffering storage conveyor and a small box positioning mechanism. Themiddle box packaging section comprises a middle box opening machine, a middle box positioning conveyor, a middle box code scanning conveyor, a middle box sealing conveyor and a middle box positioningmechanism. A large box sealing section comprises a large box opening machine, a double-station positioning and boxing conveyor, a large box sealing conveyor and a large box weighing and stacking positioner. According to the double-line automatic outer package production line, unmanned full-automatic production can be achieved, the packaging efficiency, the packaging quality and the sanitation level are improved, the labor cost is saved, the equipment utilization rate is increased, and the equipment cost and the workshop space area are saved.

Owner:青岛库米工业装备有限公司

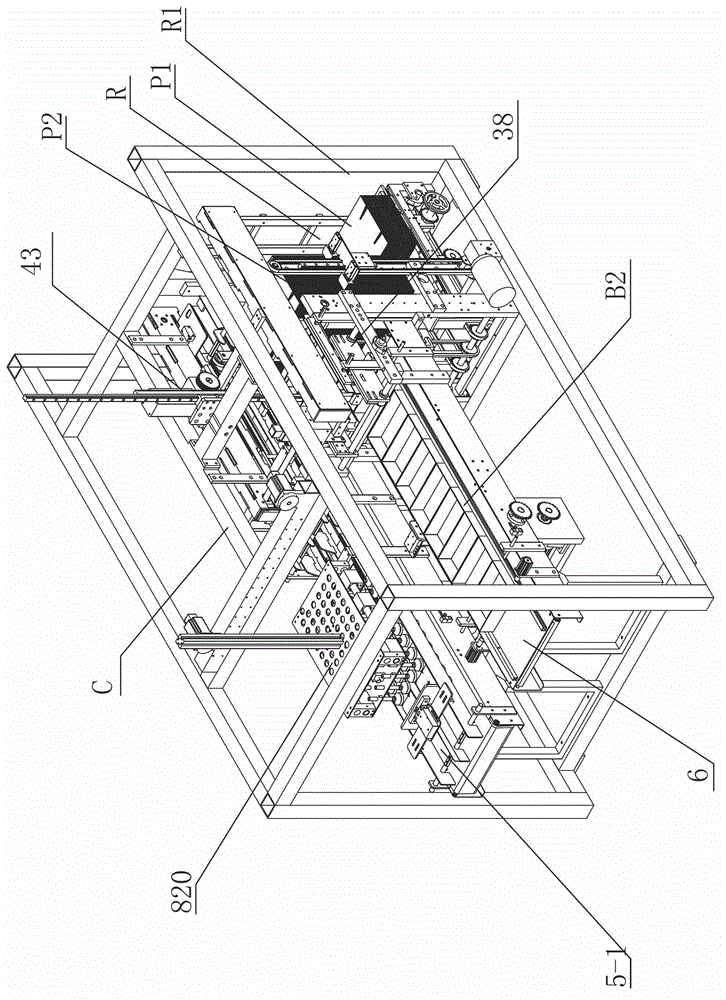

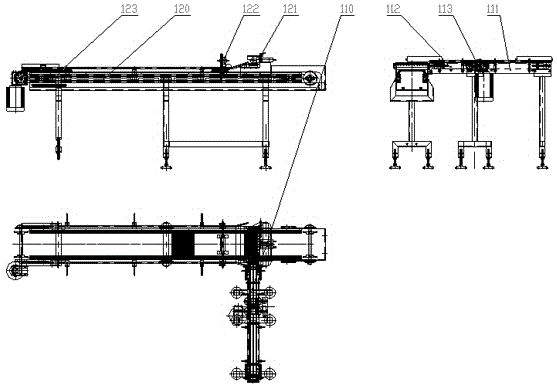

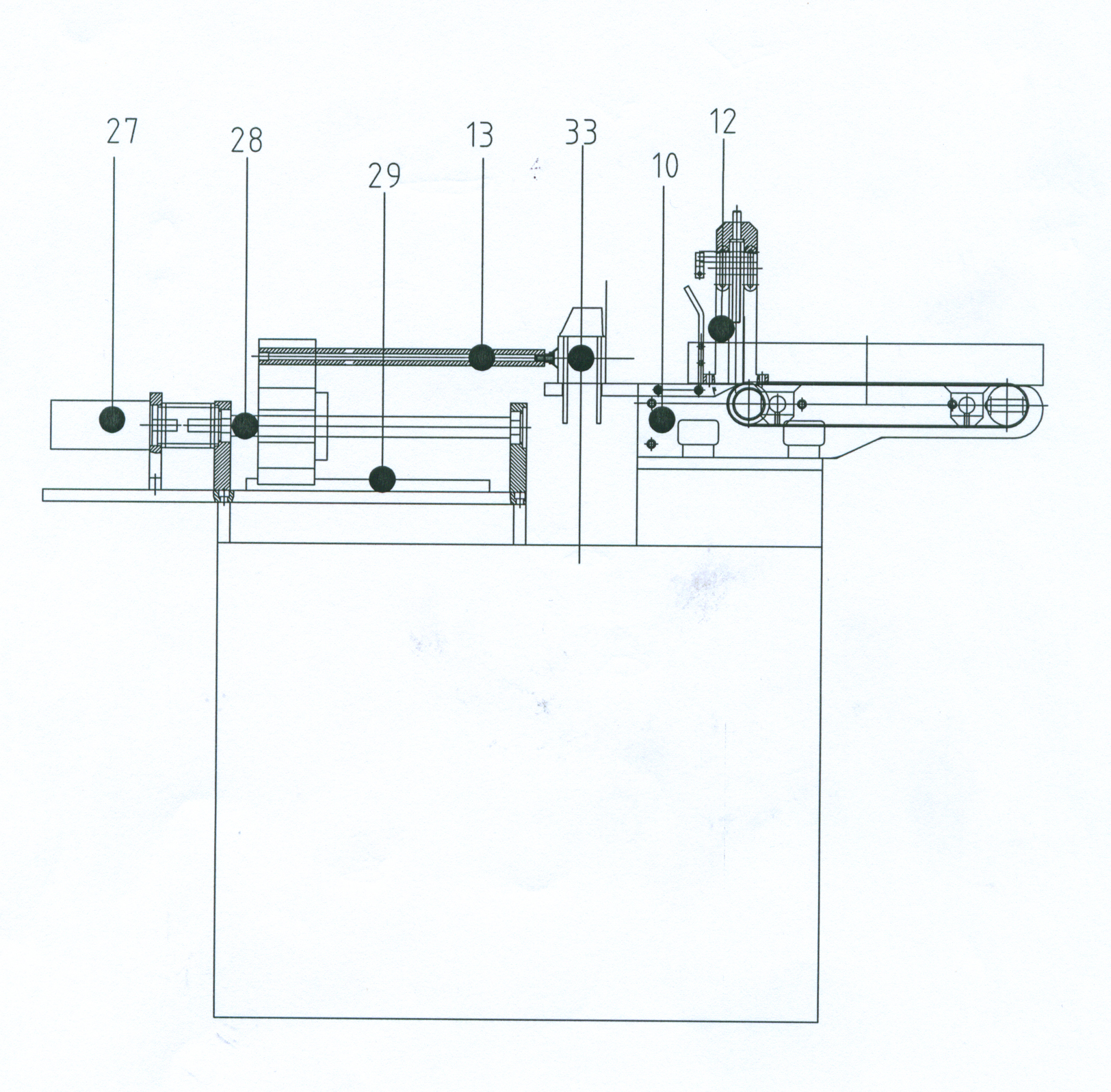

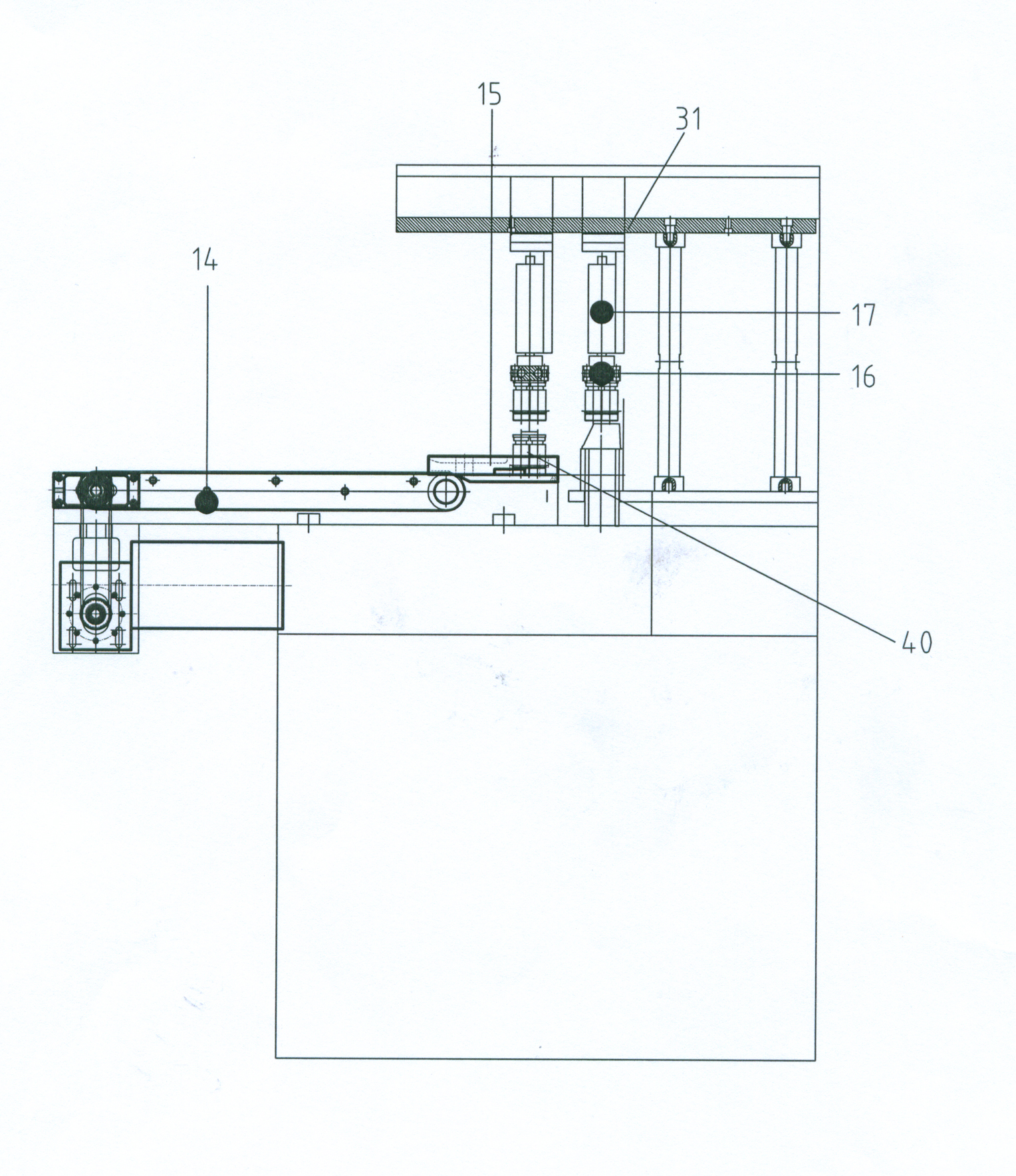

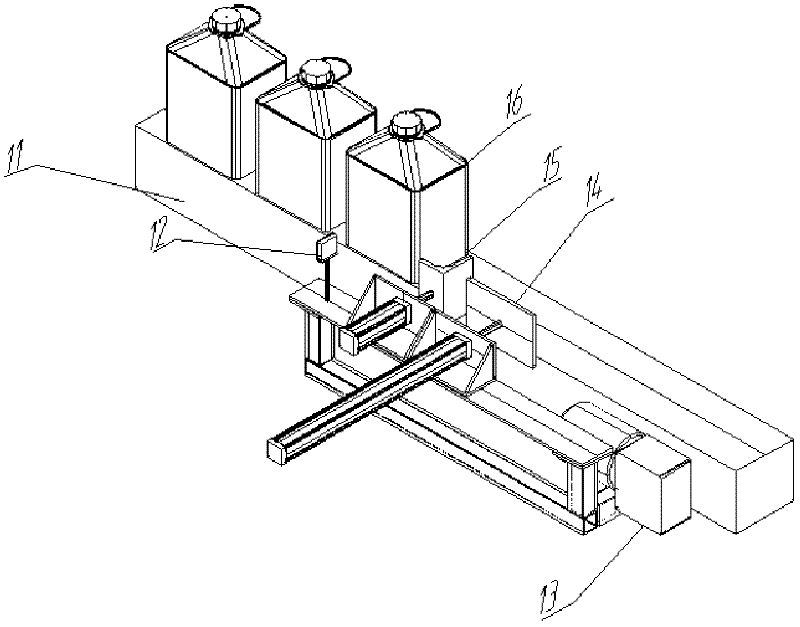

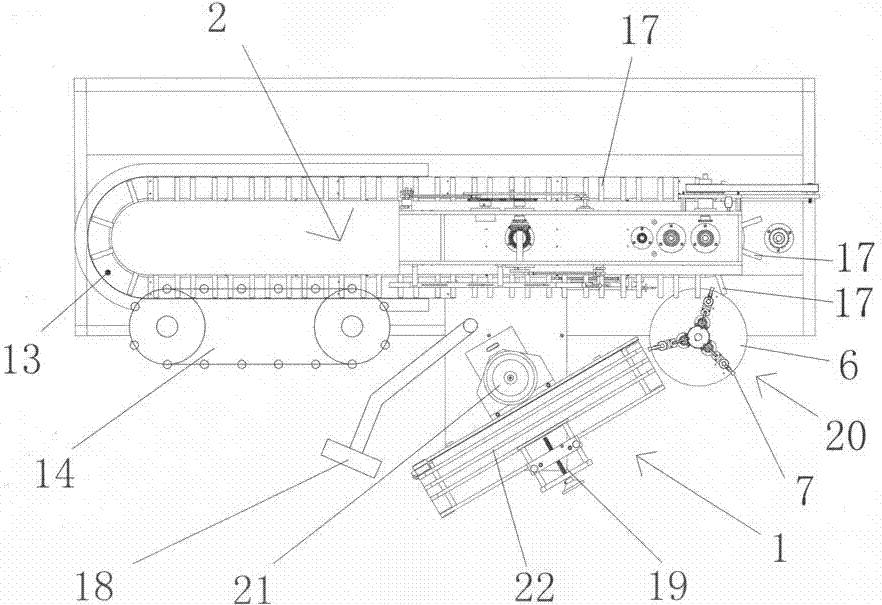

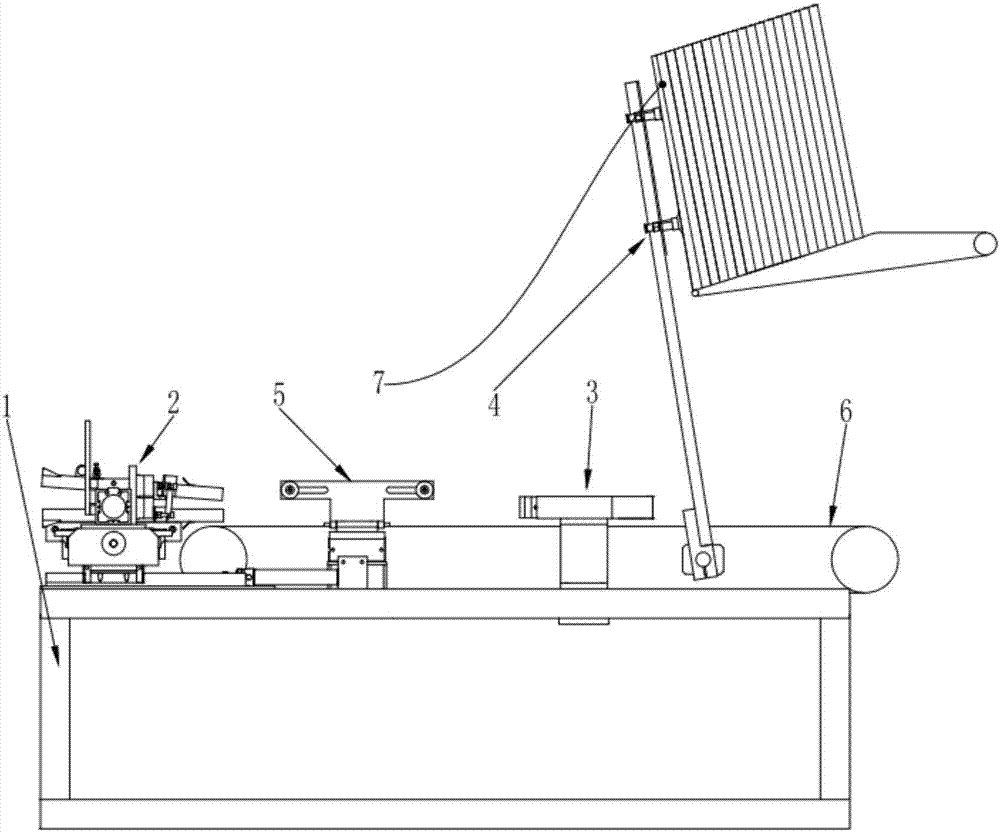

Method and arrangement for transferring packaging containers from a first unit to a second unit

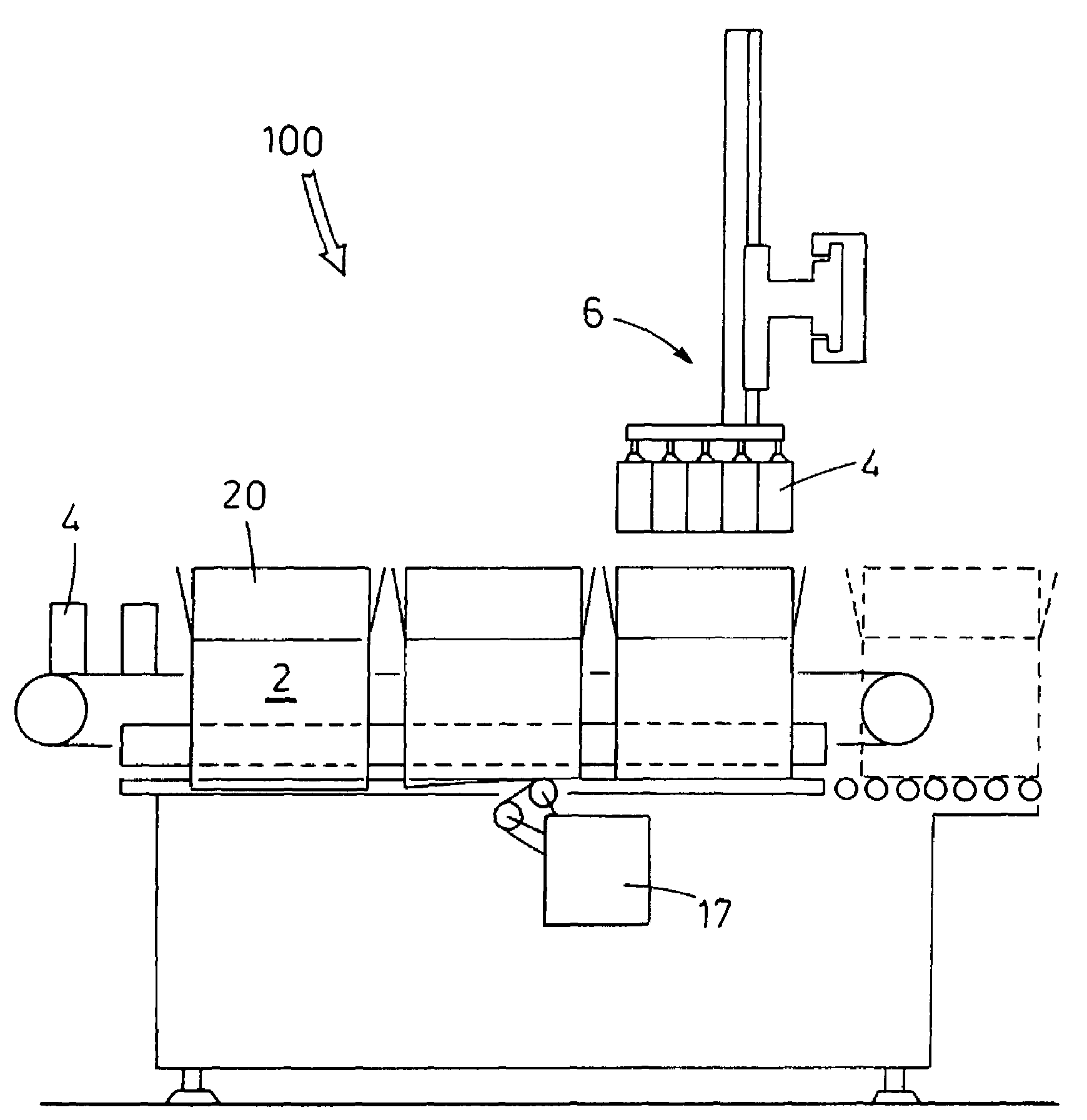

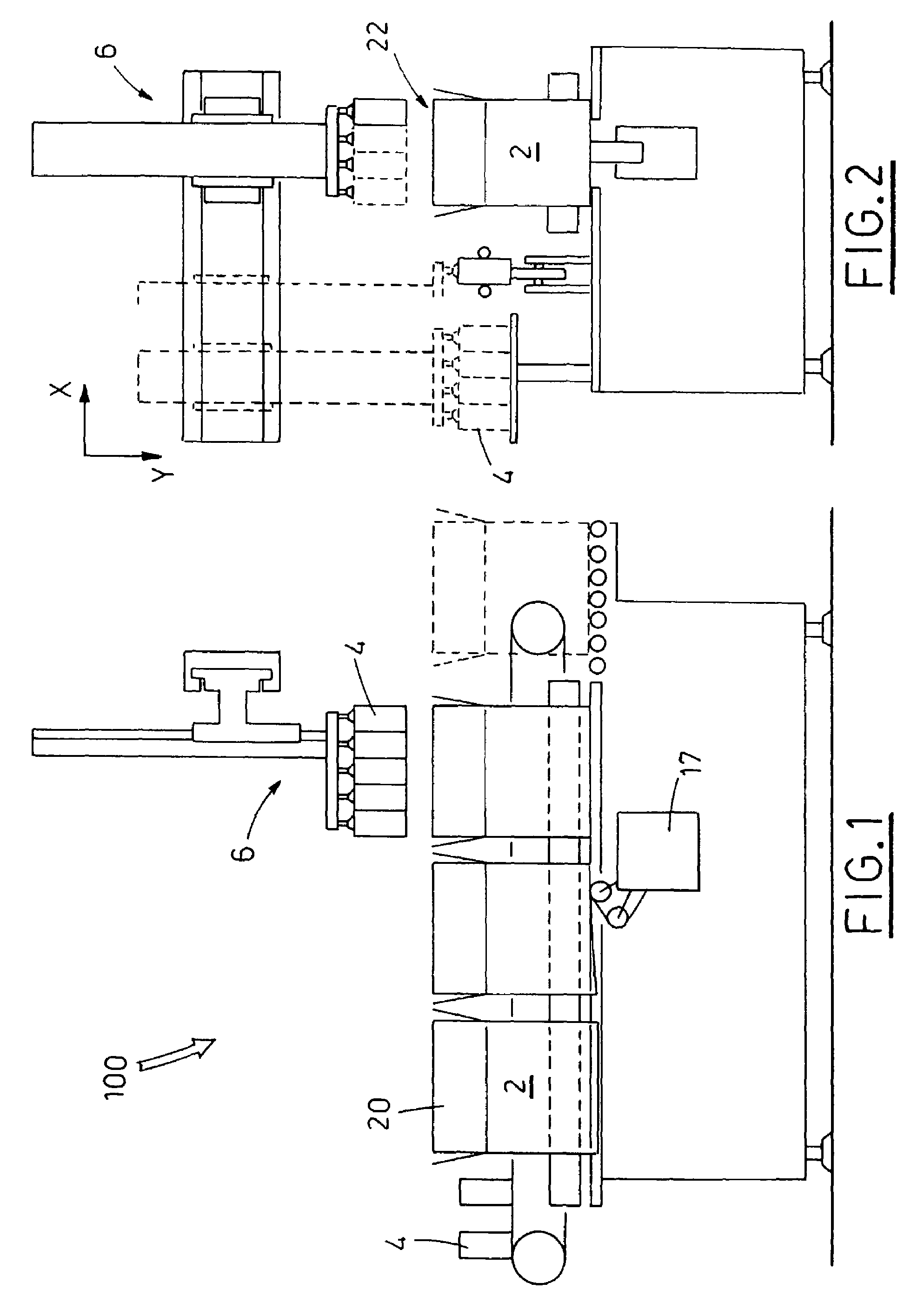

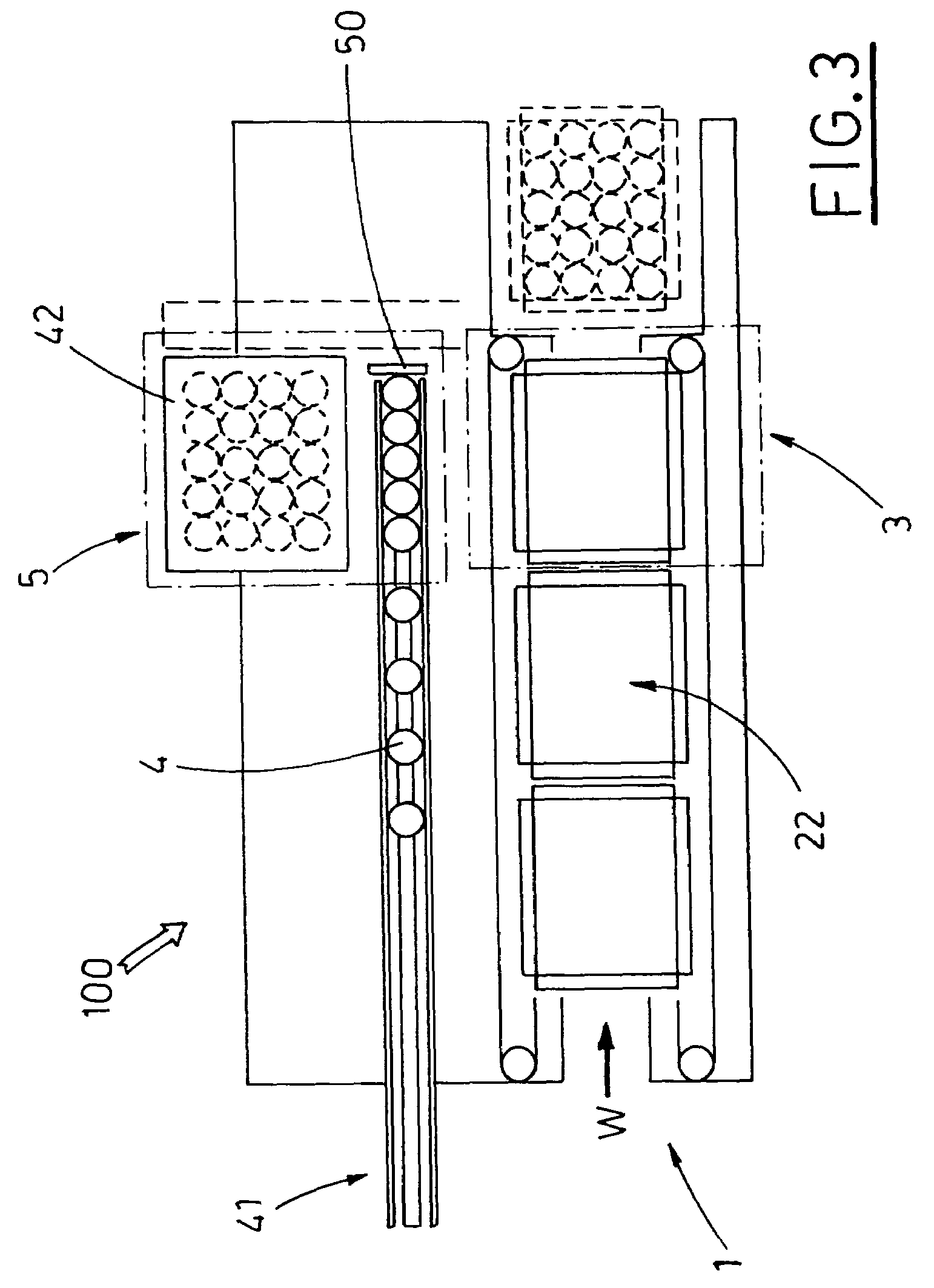

ActiveUS20110150619A1Reduce power consumptionGreatest moment of inertiaSemiconductor/solid-state device manufacturingSolid materialCartoning machineEngineering

The invention relates to a method for synchronizing, and a transfer device for synchronizing, a movement pattern between two units in a packaging line, wherein one unit is intermittently operated and the second unit is continuously operated. The invention is particularly intended for a transfer device between an intermittently operated filler unit and a continuously operated cartoning machine. The transfer device is provided with a frame (13) arranged to support tube pickers- / placers (28) and is arranged to perform a simultaneous pivoting movement about a first and a second shaft (16, 31), and for rotation about a third shaft (48) at right angles to the second shaft (31). The frame is further provided with means for adjusting the spacing between the tubes and means for compensating for differences in vertical position during the rotating movement in the case where the containers picked from the part circular conveyor of the filling unit.

Owner:NORDEN MASCH AB

Ceramic tile box filling machine capable of opening cartons of different specifications

The invention relates to the technical field of ceramic tile packaging equipment. The problem that an ordinary ceramic tile box filling machine cannot open cartons of different specifications, and accordingly, ceramic tiles of different specifications cannot be packaged is solved. A ceramic tile box filling machine capable of opening of the cartons of different specifications comprises a machine frame, a box opening mechanism and a carton positioning mechanism. The box opening mechanism and the carton positioning mechanism are arranged on the machine frame from left to right. The carton opening mechanism comprises two carton opening devices and a width adjusting device. The two carton opening devices are movably arranged at the two ends of a sliding installation plate correspondingly. The width adjusting device is used for pushing the two carton opening devices to move leftwards and rightwards along the sliding installation plate. The sliding installation plate is movably arranged on the machine frame. The two carton opening devices are used for opening cartons, and ceramic tiles can enter the cartons easily to be packaged. The carton positioning mechanism is movably installed on the machine frame and used for supporting carton shaking wing boards when the ceramic tiles are packaged with the cartons.

Owner:GUANGDONG SINID TECH

Boxing machine and boxing method

ActiveCN103332314AStrong connectionIncrease production capacityIndividual articlesCartoning machineEngineering

The invention discloses a boxing machine and a boxing method. The boxing machine at least comprises a box inlet mechanism, an overturning mechanism, a box lifting mechanism, a bag inlet mechanism, a box outlet mechanism and a frame, wherein during working, a packing box coming from the box inlet mechanism is firstly placed on the box lifting mechanism, and is kept in an oblique state; the bag inlet mechanism is used for feeding sterile soft bags which are in vertical states relative to the bottom of the packing box into the packing box at a fixed feeding position; after the sterile soft bags enter the packing box and are stable in state, the packing box moves downwards for a certain distance along an oblique direction along with the box lifting mechanism, stops, and continues to be fed with sterile soft bags which are in vertical states relative to the bottom of the packing box; the boxing process is repeated till the packing box is filled fully; and after boxing, the packing box is output through the box outlet mechanism. Due to the adoption of the boxing machine and the boxing method, the aim of providing boxing operation for sterile soft bags is fulfilled by using automatic equipment, labor force cost is reduced, and the production efficiency is increased.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com