An on-line visual detection device and detection method for missing rods in a carton packing machine

A technology of visual detection device and cigarette packing machine, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc. It can solve the problems of safety and environmental protection constraints, and achieve the avoidance of contact pollution, easy traceability, convenient information summary and quality feedback query effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The method of using the device of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

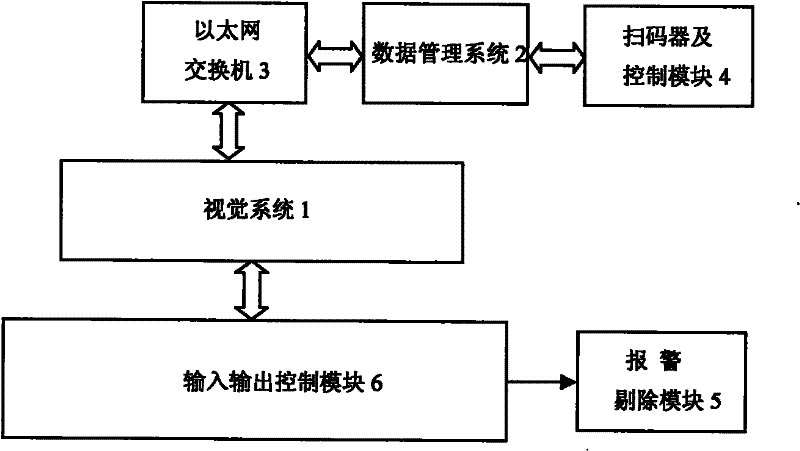

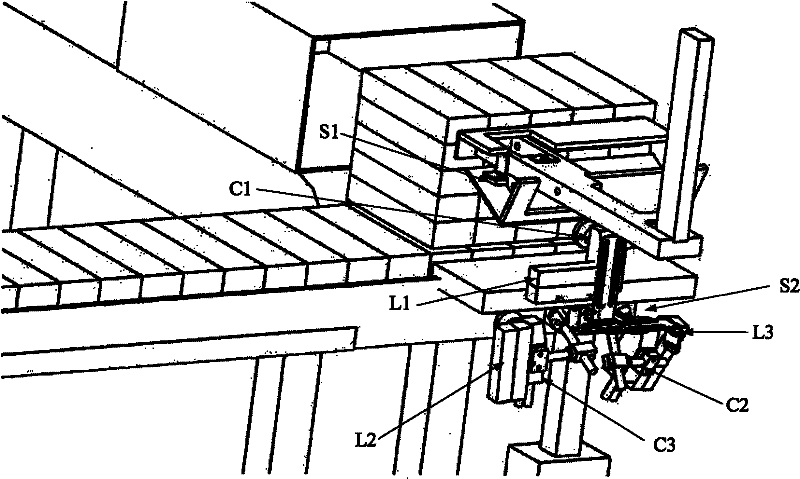

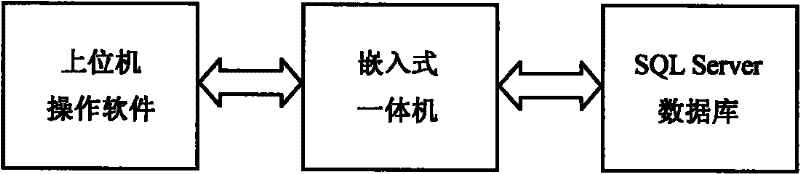

[0038] Such as figure 1 Shown is a schematic diagram of the overall structure of the device of the present invention. The on-line visual detection device for missing rods of the cigarette box packing machine of the present invention is installed inside the box sealing machine, including a visual unit 1, a data management system 2, an Ethernet switch 3, a code scanner and a control module 4, an alarm and rejection module 5 and an input The output control module 6, in which the visual unit 1 collects the image of the cigarette box packing process, and connects with the data management system 2 through the Ethernet switch 3 for data communication; the code scanner and the control module 4 collect the barcode information of the cigarette box and send it to the data management system 2 The input and output control module 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com