Automatic boxing machine for biological capsules

An automatic cartoning machine and bio-capsule technology, which is applied in packaging, single object, transportation and packaging, etc., can solve problems such as low efficiency, fatigue, and heavy workload of staff, so as to reduce labor intensity, improve work efficiency, and work The effect of ease of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

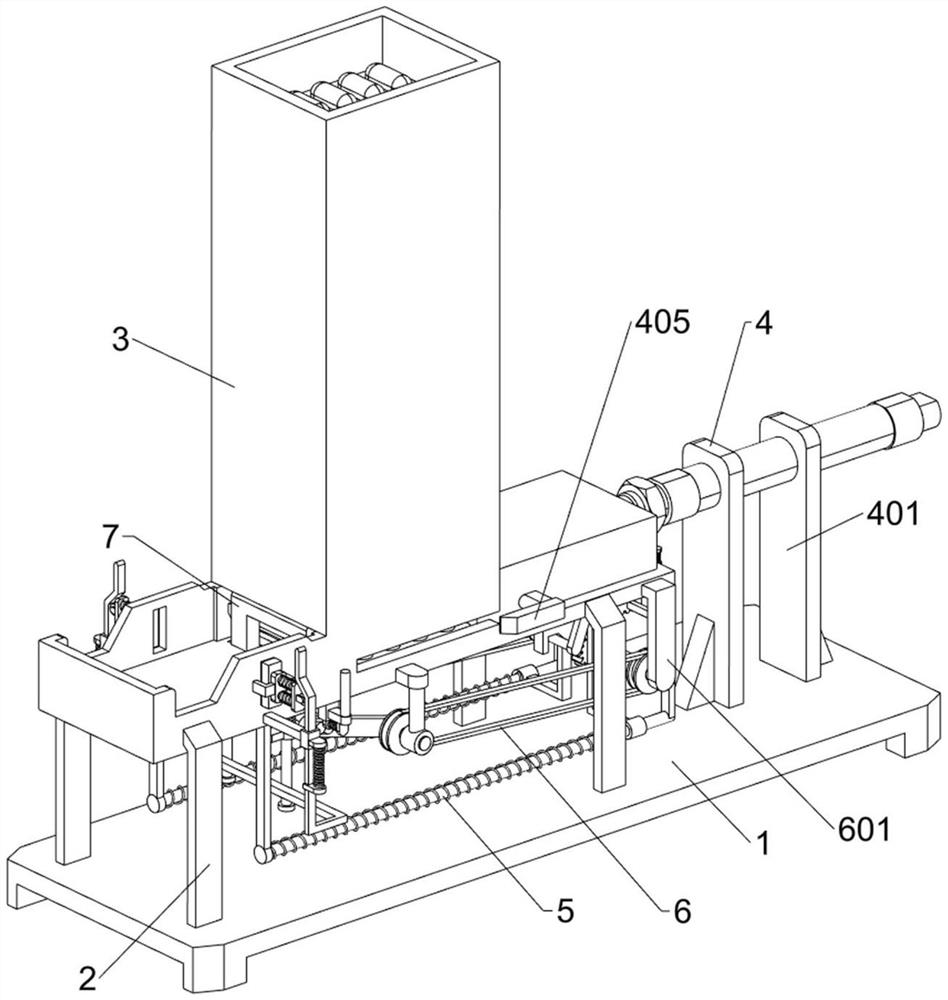

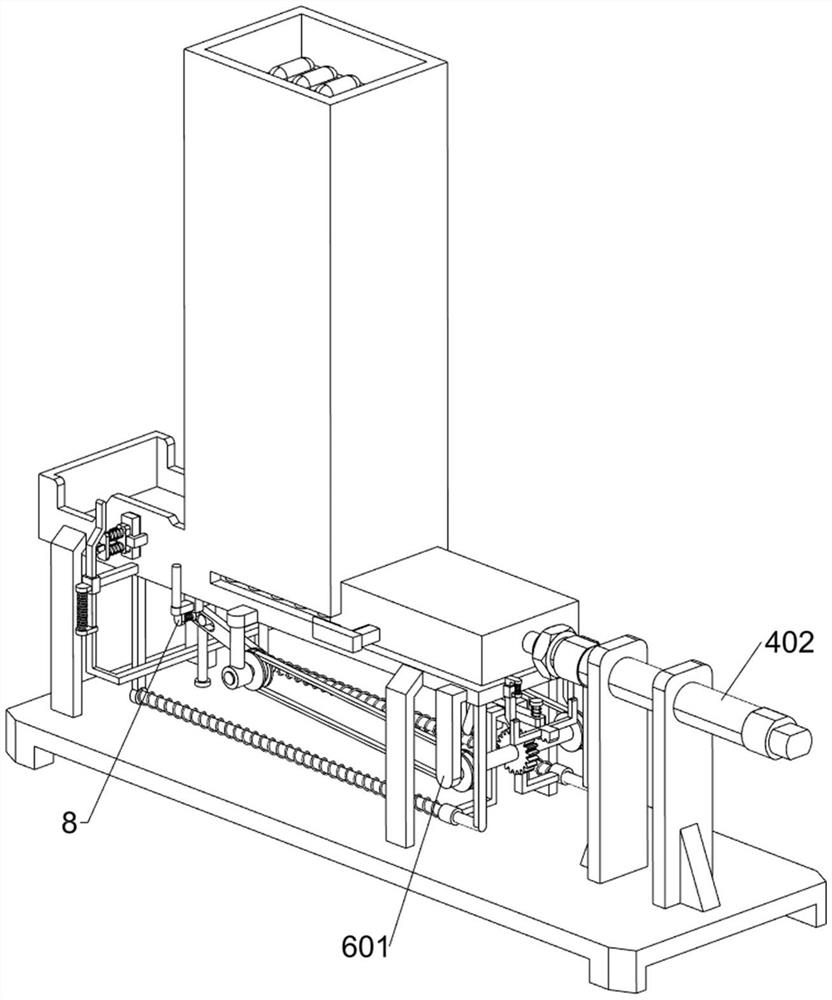

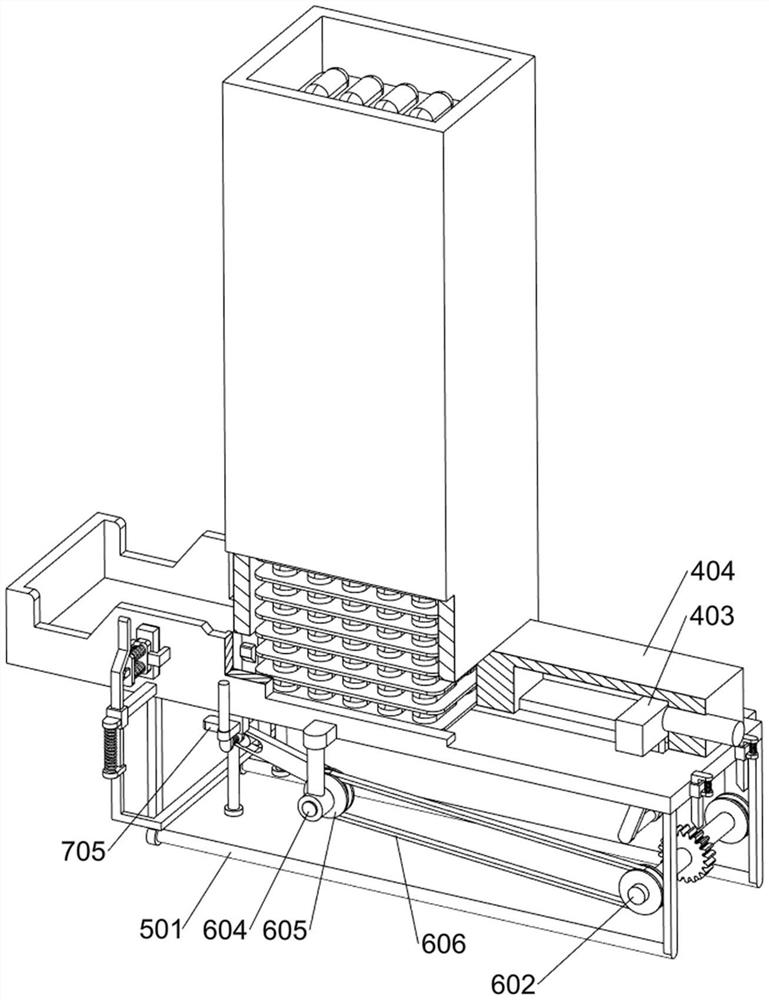

[0026] A kind of biological capsule automatic cartoning machine, such as Figure 1-5 As shown, it includes a bottom plate 1, a support rod 2, a placement table 3, a driving component 4, a moving component 5, a transmission component 6, a limit component 7 and a locking component 8, and two support rods are installed on the front and rear sides of the top of the bottom plate 1 2. A placement platform 3 is connected between the support rods 2 on the front and rear sides. The bottom of the placement platform 3 is provided with a moving assembly 5, a transmission assembly 6 and a limit assembly 7. The drive assembly 4 is installed on the right side of the top of the bottom plate 1. The placement platform 3 Locking assemblies 8 are installed on the front and rear sides.

[0027] When the bio-capsules need to be boxed, the staff put the bio-capsules neatly into the placement table 3, the limit assembly 7 blocks the bio-capsules, and then puts a packaging box on the placement table 3...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 5 As shown, a stabilizing assembly 9 is also included, and the stabilizing assembly 9 includes a second support block 901, a friction block 902, a fifth spring 903 and a contact wheel 904, and a second support block 901 is installed on the front and rear sides of the left part of the placing table 3. , the two second support blocks 901 are slidingly provided with friction blocks 902, and the two friction blocks 902 run through the front and rear sides of the placing table 3 respectively, and the fifth spring 903 is set on the two friction blocks 902, and the fifth spring 903 The two ends of each are respectively connected with the second support block 901 and the friction block 902, and the outer sides of the friction block 902 are equipped with contact wheels 904.

[0040] The worker puts the packaging box into the placement table 3, and then pushes the contact wheel 904 inward, the contact wheel 904 drives the friction block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com