Stacked pallet, stacking packer and stacking packing method

A packaging method and packaging machine technology, applied in the fields of palletizing pallets, palletizing packaging machines and palletizing packaging, can solve the problems of high resource consumption, high packaging cost, waste of resources, etc., to save labor costs, reduce packaging costs, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

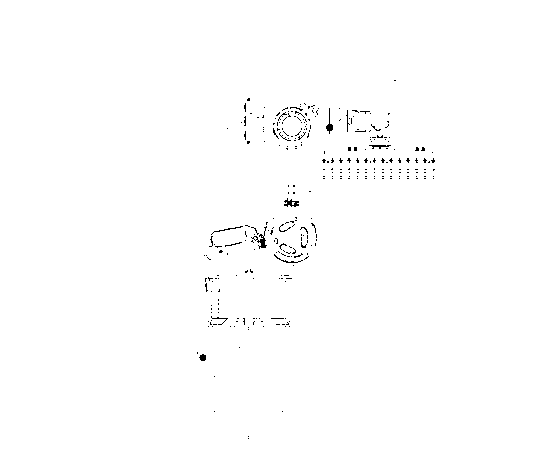

[0027] Such as Figure 6 and Figure 7 As shown, the palletizing pallet has a supporting plate 1, and one side of the supporting plate 1 has a plurality of cylindrical grooves 2 arranged in a matrix, and the other side has a plurality of tapered ferrules 3, and the shape of the ferrules 3 is similar to that of the upper part of the bottle. The shape matches, so that the ferrule 3 and the upper part of the bottle are more fit, and further ensure that the finished product will not shake after palletizing. The axes are coincident, and the ferrule (3) and the groove (2) respectively cover one-fifth of the upper and lower parts of the bottle, which more effectively prevents the stack of finished products from shaking and toppling during pushing or transportation.

[0028] Such as Figure 1 to Figure 3 As shown, the palletizing and packaging machine includes a frame 4, and a manipulator that moves up and down along the frame 4 and moves left and right is installed on the frame 4, ...

Embodiment 2

[0036] Palletizing packaging machine, including a frame, a manipulator is installed on the frame, which can move up and down along the frame, move left and right, and move back and forth, and the four sides of the gripper are respectively provided with one for clamping the pallet or the roller frame. Buckle, bottle clamping nozzle is set on the end surface of the gripper to grab the bottle; the palletizing station is fixed under the frame, the palletizing station is connected with the conveyor belt, and the side of the palletizing station is respectively equipped with a roller stacking rack and pallet stacker. Under the control of the system program, the same manipulator grabs the roller frame, the tray and the bottle respectively, and the rest of the packaging content is the same as the first embodiment.

Embodiment 3

[0038] Palletizing and packaging machine, including the frame, which is equipped with two manipulators, namely the pallet manipulator and the roller frame manipulator, and the roller frame manipulator is also used to grab the bottle. These two manipulators can move up and down along the frame and move left and right. Wherein the roller frame manipulator can also move forward and backward along the frame. The pallet manipulator has three buckles for clamping the pallet respectively on the two sides of the gripper. The two sides are opposite faces. The rollers The two sides of the gripper are equipped with three buckles for clamping the roller frame, and the end surface of the gripper is equipped with a bottle clamping nozzle for grabbing bottles; the palletizing station is fixed on the frame Below, the stacking station is connected with the conveyor belt, a pallet stacking rack is set on one side of the stacking station, and a roller stacking rack is set on the same side as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com