Patents

Literature

642results about How to "Avoid affecting product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of honey peach CZ diamond

InactiveCN102838277ANo pollution damagePlay a role in fluxingGlass furnace apparatusGlass productionMachine toolKiln

The invention relates to a production process of a honey peach CZ diamond. The honey peach CZ diamond comprises the following raw materials in parts by weight: 60-70 parts of SiO2, 0.5-1.5 parts of Al2O3, 0.5-2.5 parts of BaO, 1.5-5 parts of ZnO, 1.0-2.5 parts of B2O3, 3-8 parts of K2O3, 8-15 parts of Na2O, 0.5-1.5 parts of CaO, 0.3-1.5 parts of Se and 0.03-0.3 parts of S. The production process comprises the following steps of: smelting by a hot smelting kiln and classifying; discharging to obtain a CZ diamond bead blank; sequentially carrying out fire polishing by a fire polishing furnace, and grinding by a grinding machine; and grinding a plurality of cutting surfaces of the CZ diamond by a multi-faced grinding machine tool and chemically plating to obtain a CZ diamond finished product.

Owner:JIANGSU JINCHENG GRP TECH

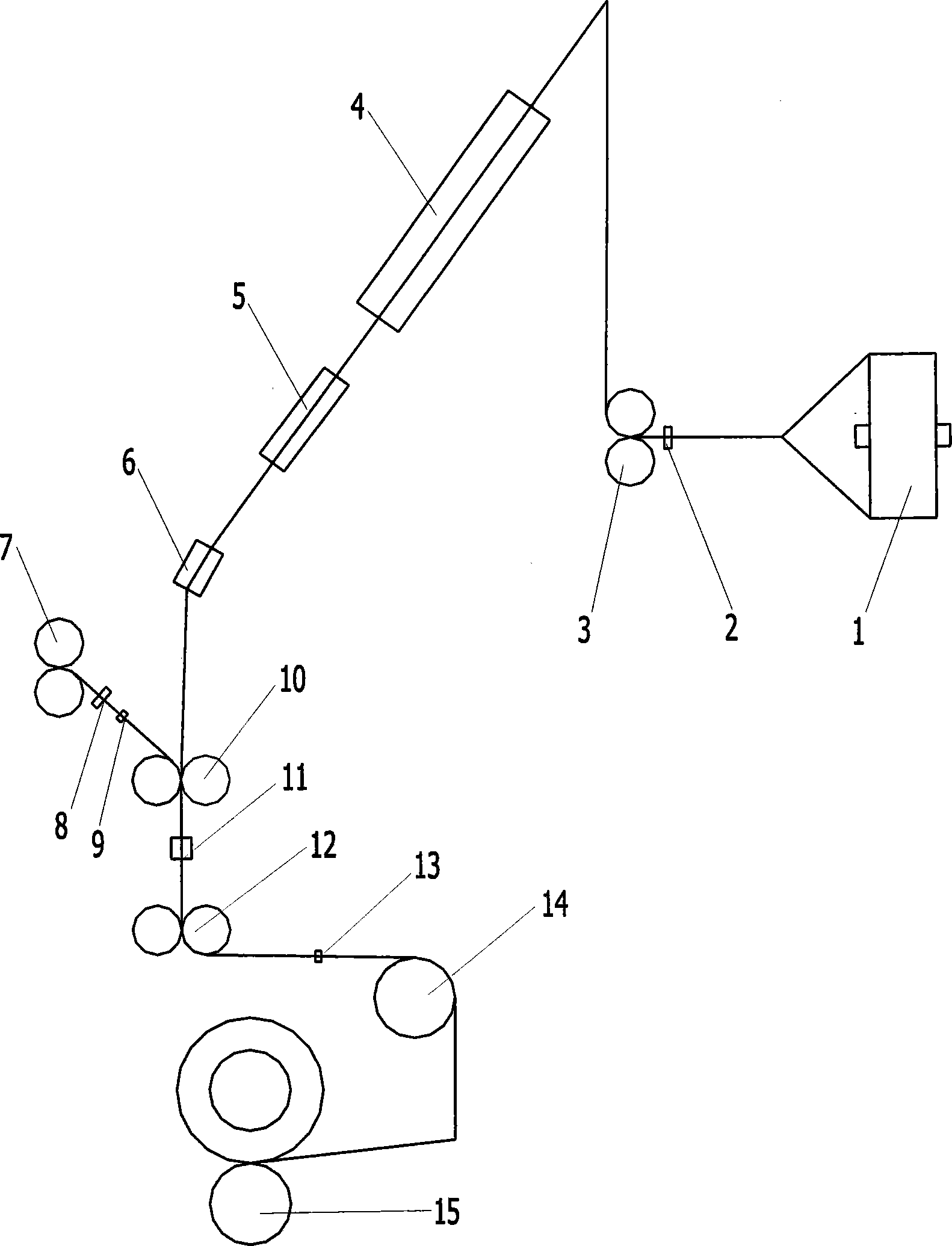

Method for manufacturing nylon/spandex air-textured yarn by false twist texturing machine one-step method

The present invention provides a method for making nylon-polyurethane fiber blended yarn by utilizing false-twist texturing machine and adopting one-step process. Said method includes the following steps: (A), making nylon raw yarn be drawn out from raw yarn frame, and making said nylon raw yarn be fed into first roller by means of first yam-cutting device of false-twist texturing machine, then fed into a texturing hot-box, and passed through a cooling device and a false-twister, then attracted by suction gun; (B), making polyurethane fiber yarn be drawn out from polyurethane fiber roller, and making said polyurethane fiber yarn be passed through second yarn-cutting device and second yarn-detector, then be attracted by suction gun, then combined with nylon yarn; and (C), making the combined two yarns be passed through intermediate roller, air-entanglement jet device, second auxiliary roller and first yarn detector, and be reached to oiling roller, finally passed through winding roller and winding to make formation.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

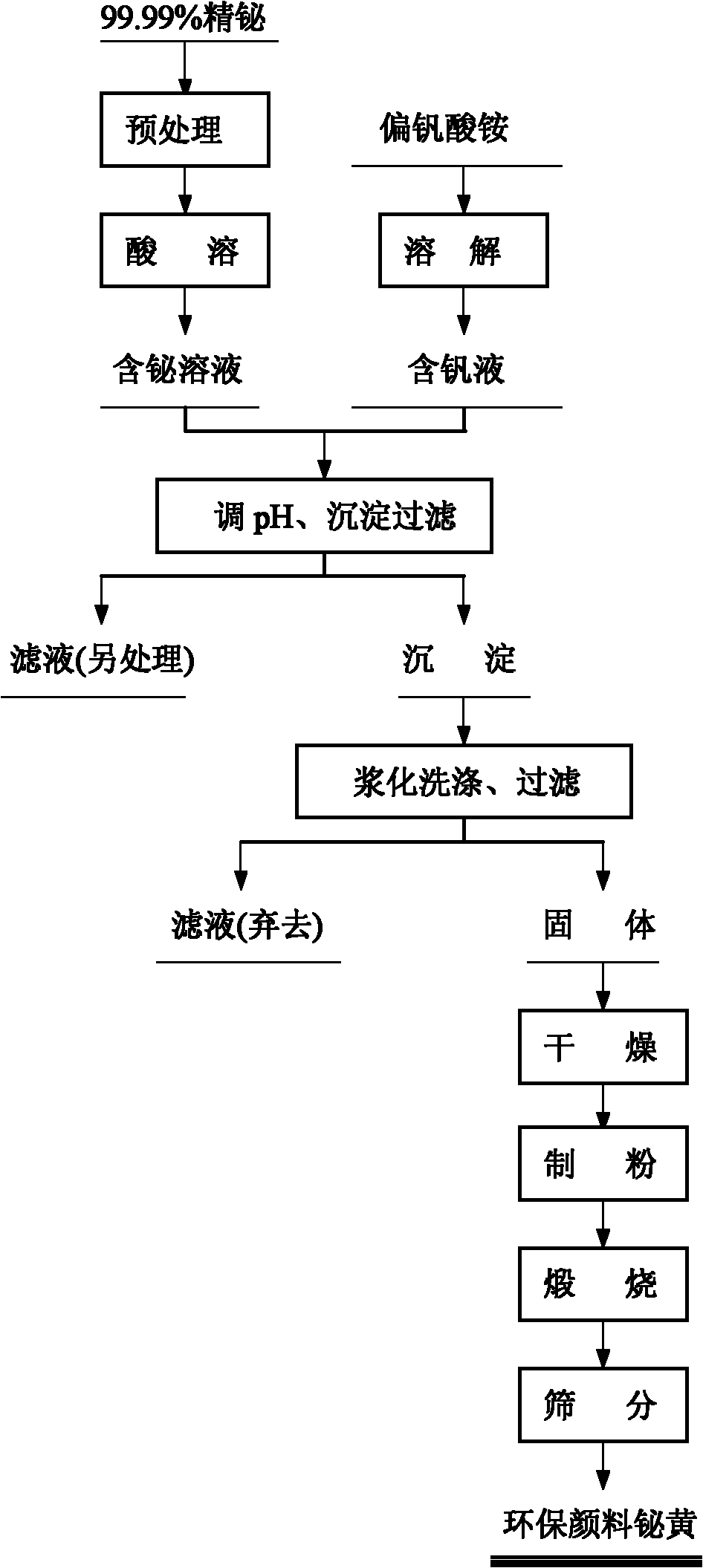

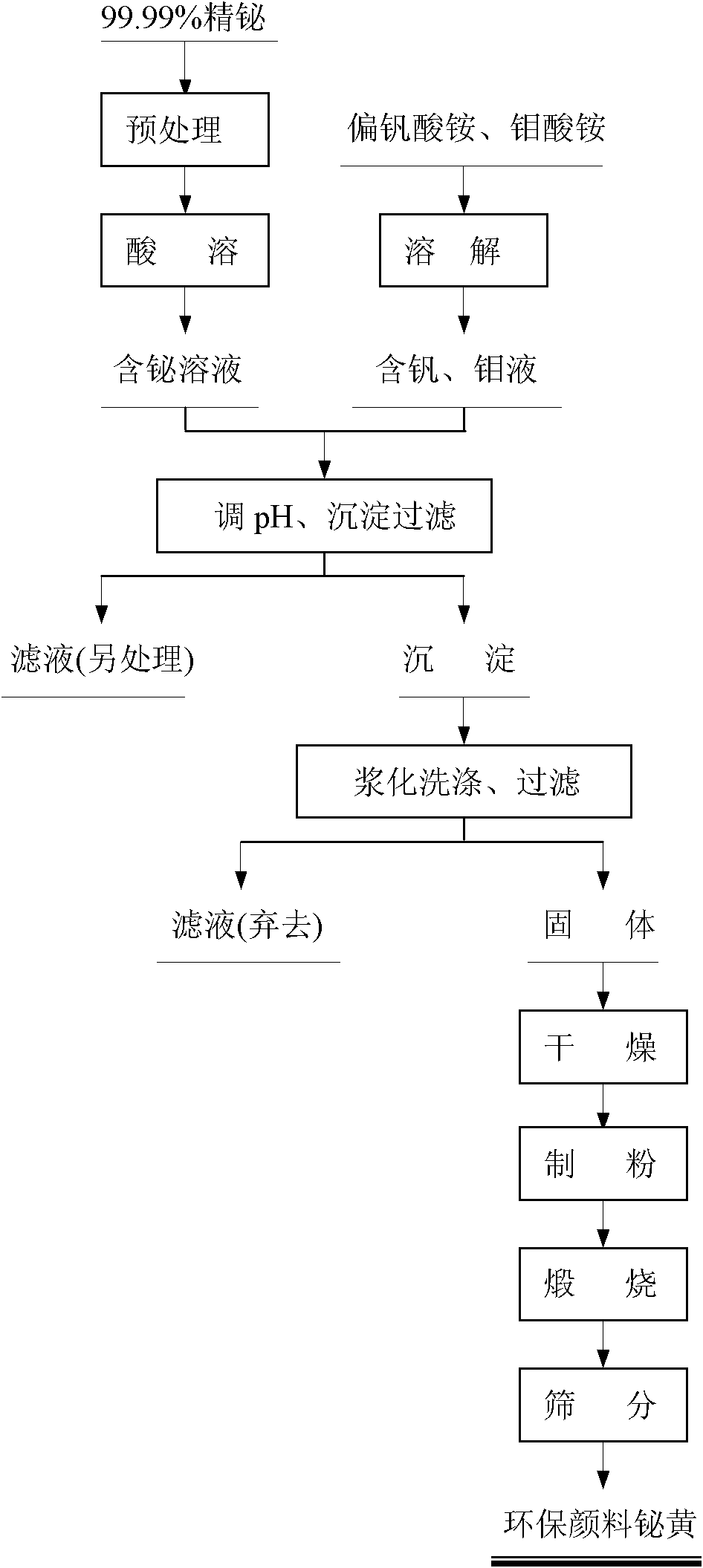

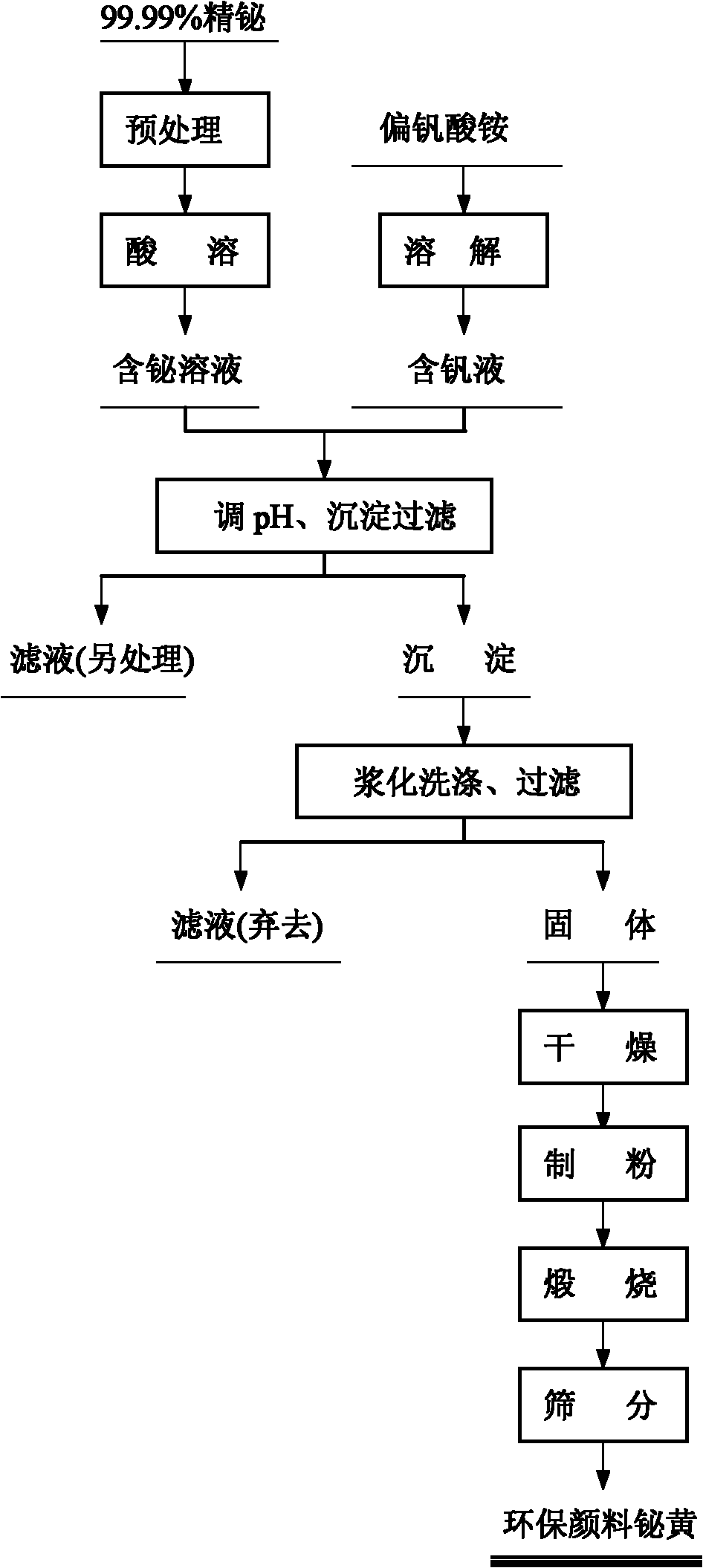

Environmental-friendly pigment bismuth yellow and production method thereof

ActiveCN101914310AProcess conditions are easy to controlImprove uniformityPigment physical treatmentPigment treatment with non-polymer organic compoundsDispersityAmmonium metavanadate

The invention relates to environmental-friendly pigment bismuth yellow and a production method thereof. The production method is characterized by comprising the steps of: firstly placing solid bismuth into a mixed acid solution made of nitric acid and hydrochloric acid for soaking, then taking out for reacting with a nitric acid solution to obtain a bismuth nitrate solution; keeping the nitric acid in an excessive state, then mixing and dissolving ammonium metavanadate or ammonium metavanadate and ammonium molybdate into ammonia water to obtain a vanadium-containing or vanadium and molybdenum-containing ammonia water mixed solution; under the condition of continuously stirring, simultaneously adding the bismuth nitrate solution and the mixed solution into a reactor containing a dispersing agent and a bottom fluid to obtain a light yellow sediment; and washing, drying and pulverizing according to a conventional method, finally, calcining and sieving to obtain the environmental-friendly pigment bismuth yellow with uniform granularity. The invention has the advantages of easy control of process conditions, good product dispersity, fine and uniform granularity, good powder activity, wide source and high utilization ratio of raw materials and better economic feasibility.

Owner:ZHUZHOU SMELTER GRP

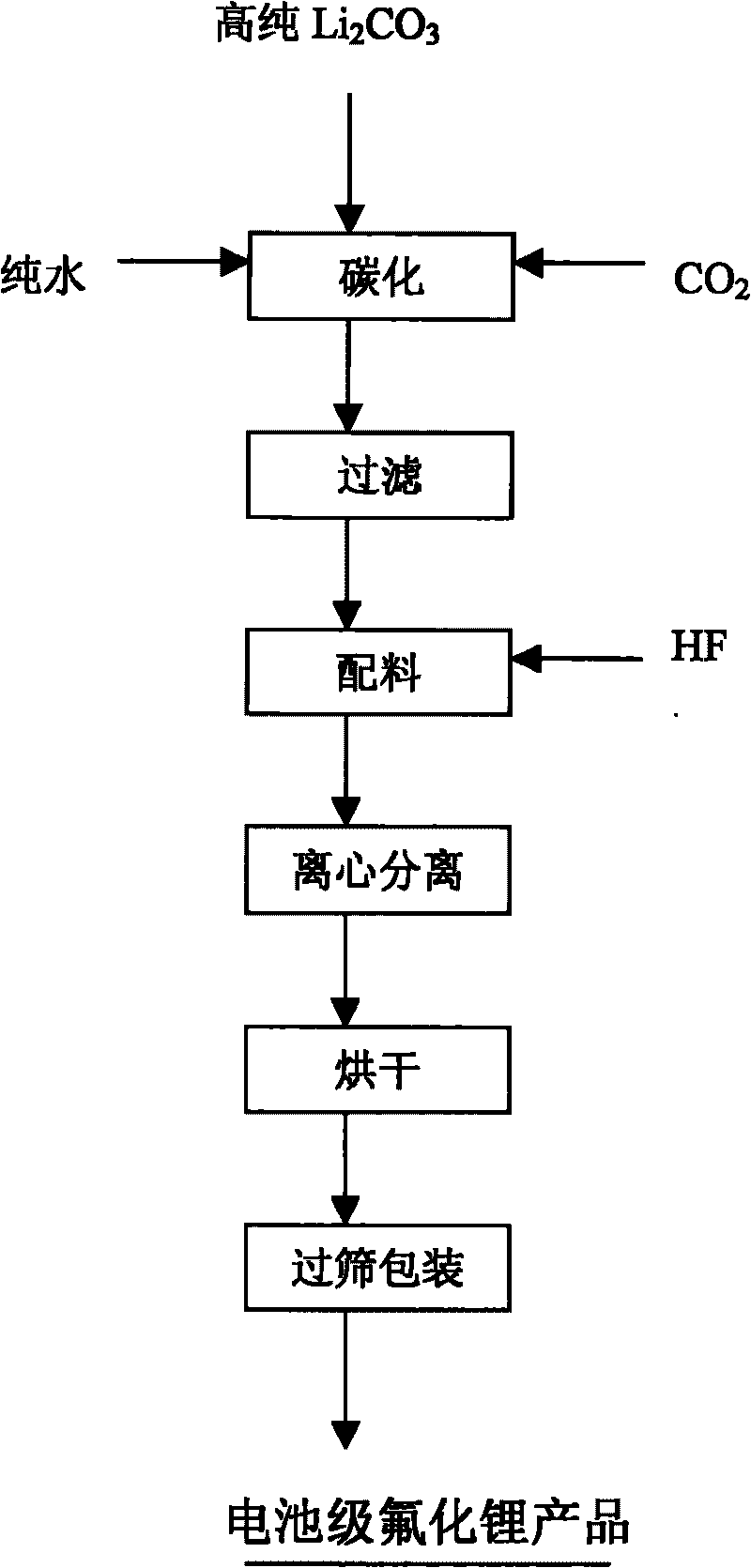

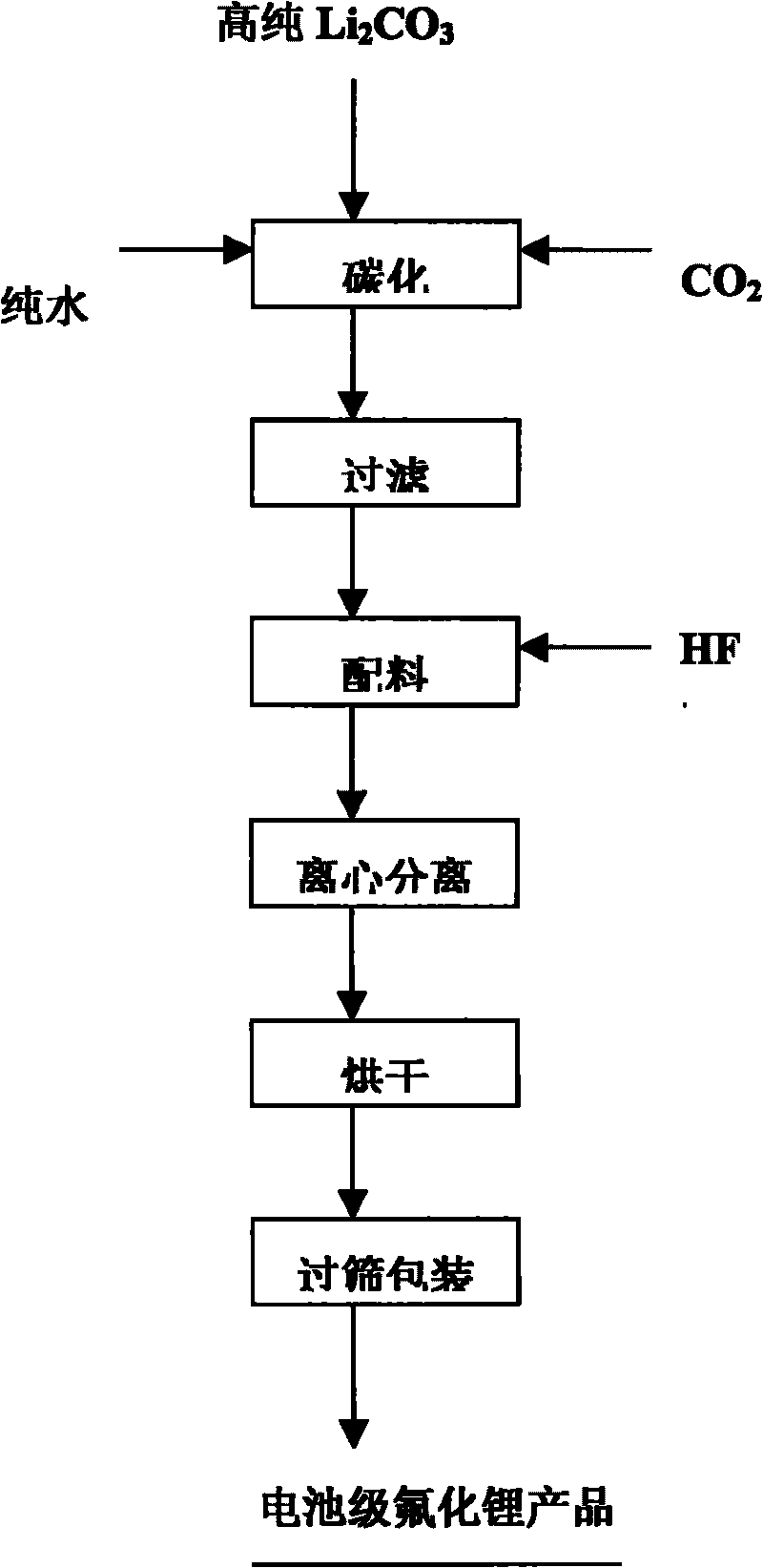

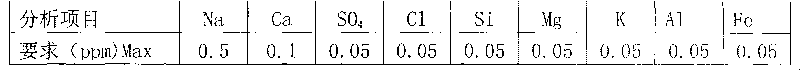

Method for preparing lithium fluoride

The invention relates to a method for preparing lithium fluoride, which is characterized by comprising the following steps of: mixing high-purity lithium carbonate with pure water, and introducing carbon dioxide gas to carry out the carburization reaction for obtaining a lithium bicarbonate solution; precisely filtering the lithium bicarbonate solution; introducing hydrofluoric acid gas into the lithium bicarbonate solution, stirring to carry out the neutralization reaction, and controlling the pH value to be 0.5-3 to prepare lithium fluoride slurry; centrifugally separating the lithium fluoride slurry to separate solid from liquid of the lithium fluoride slurry; and drying the separated solid lithium fluoride to obtain a finished product. The method of the invention has the advantage of simple technology; the prepared lithium fluoride has the advantages of high purity, good liquidity, no alkaline impurities and neutral state; and the product can achieve the lithium fluoride grade of battery levels.

Owner:GANFENG LITHIUM CO LTD

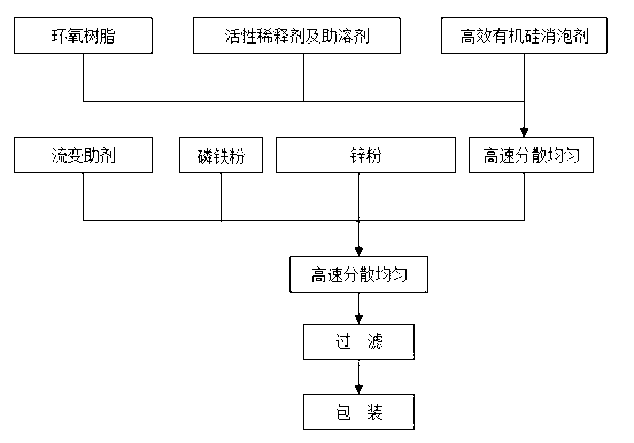

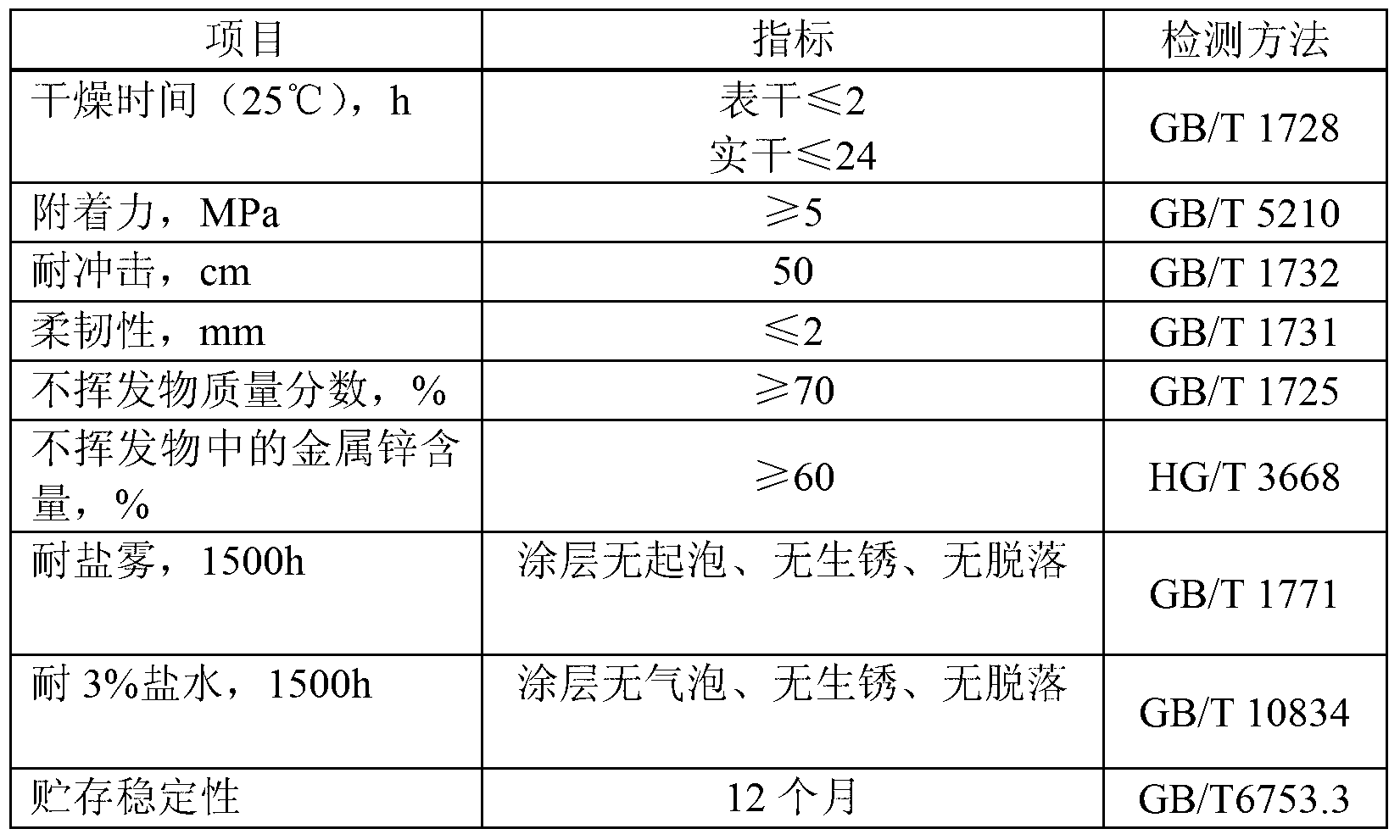

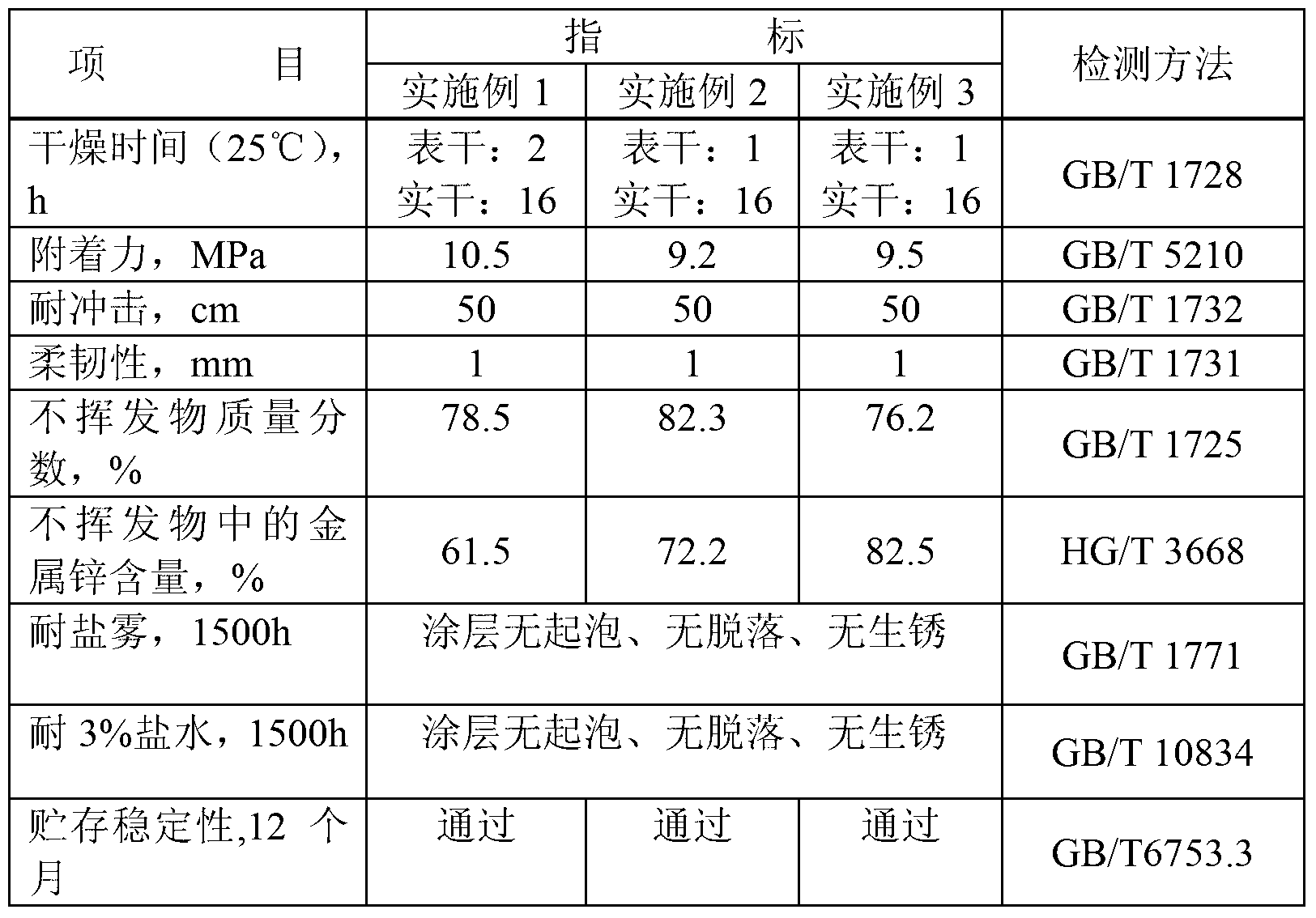

High-performance easy-construction two-component aqueous epoxy zinc-rich coating and preparation method thereof

ActiveCN103319981AModerate viscosityEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention relates to an easy-construction two-component packaging aqueous epoxy zinc-rich coating. The coating selects a low-molecular-weight epoxy resin, an active diluent, a high-efficiency antifoaming agent, a wetting dispersant, ultrafine zinc powder, a self-emulsifying aqueous epoxy hardener, a cosolvent and water as raw materials. The aqueous epoxy zinc-rich coating has the advantages of good corrosion resistance, realization of resisting salt spray for 1500h, no foaming, rust or shredding of the coat of the coating, according with requirements of HG / T3668-2009 Zinc Rich Primer, good application performance, convenient onsite use, realization of the thickness of the once-formed coat of above 80mum, 1h surface drying and 16h hard drying at 25DEG C, and satisfying of the steel structure anticorrosion construction requirement. The aqueous epoxy zinc-rich coating can be applied to the anticorrosion of steel structures comprising ships, bridges, sea engineering apparatuses and the like, and can also be applied to the steel plate pretreatment streamline as a workshop primer.

Owner:XIAMEN SUNRUI SHIP COATING

Purification method of ultra-pure aluminum

The invention relates to a purification method of ultra-pure aluminum, comprising the following steps: cleaning and drying raw refined aluminum, wherein the purity of the selected refined aluminum is at least 4N6, Mg is less than 6ppm, Ti is less than 0.2ppm and Zr is less than 0.2ppm; loading the selected raw refined aluminum into a purification furnace, sealing and vacuumizing the furnace, and heating to 680-750 DEG C by using a gas furnace to melt the solid raw refined aluminum to form liquid; moving the purification furnace heated to 680-750 DEG C to a crystal growing furnace which is kept at 660 DEG C inside by a crystal growing furnace heater, rotating the aluminum liquid of the purification furnace in the crystal growing furnace heater, and enabling the aluminum liquid inside the purification furnace to self-keep the crystallization speed at 5-10 cm / h by controlling the heat dissipating capacity of the crystal growing furnace and finishing the crystallization after 4-6 hours; cooling the crystallized purification furnace, taking out a crystallization ingot, removing 25-35 percent relative to the mass of the crystallization from the tail part of the crystallization ingot and obtaining a first purified aluminum ingot; placing the first purified aluminum ingot into the purification furnace again, and repeating purification until the aluminum ingot reaching the required precision is obtained.

Owner:CHANGSHA ZHONGDA TIMES ELECTRONICS TECH DEV

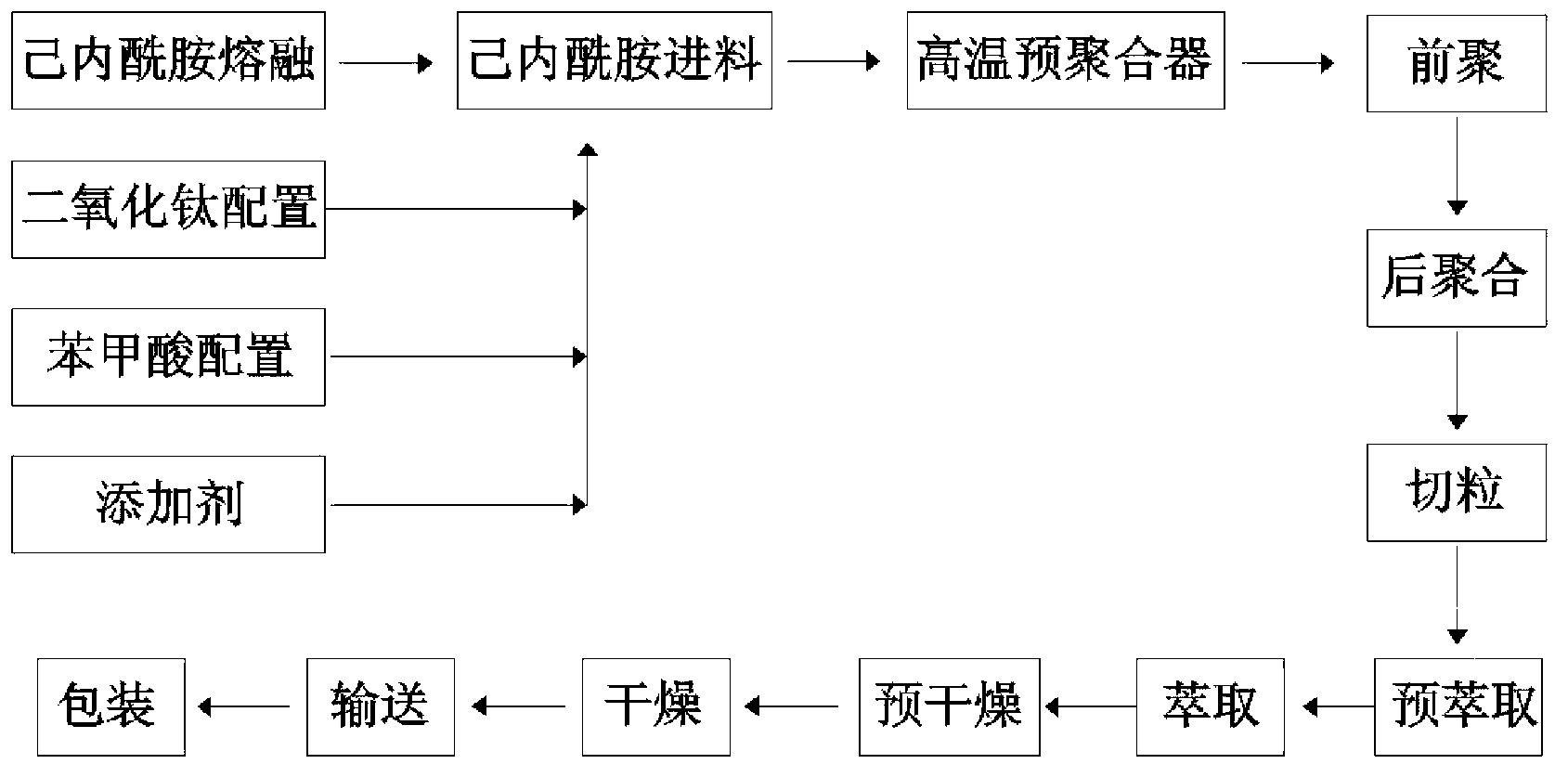

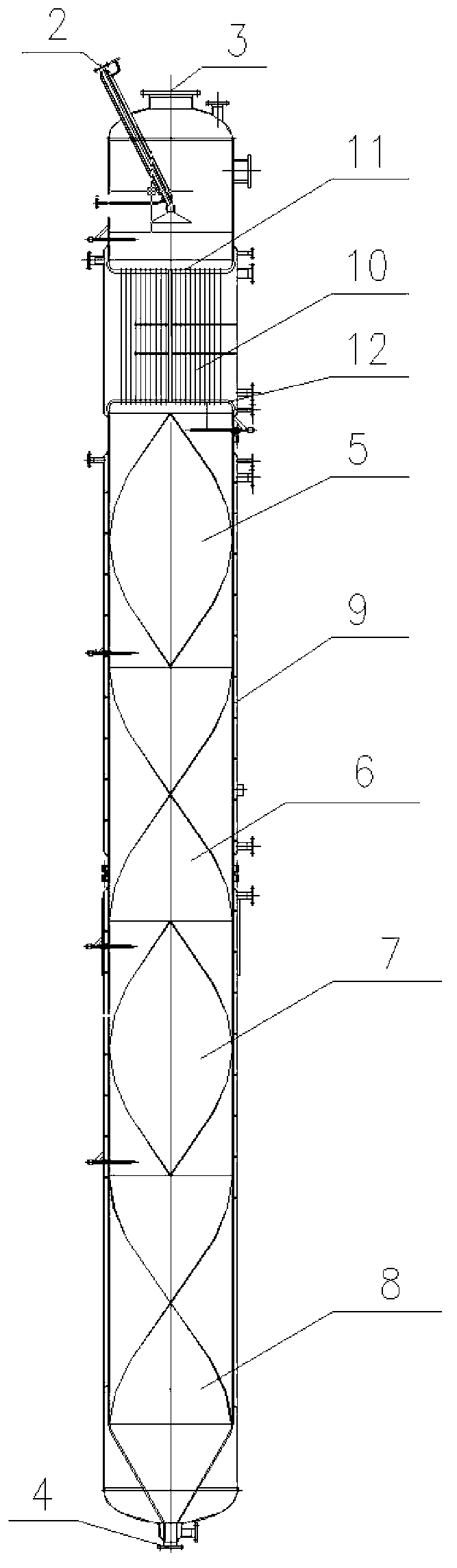

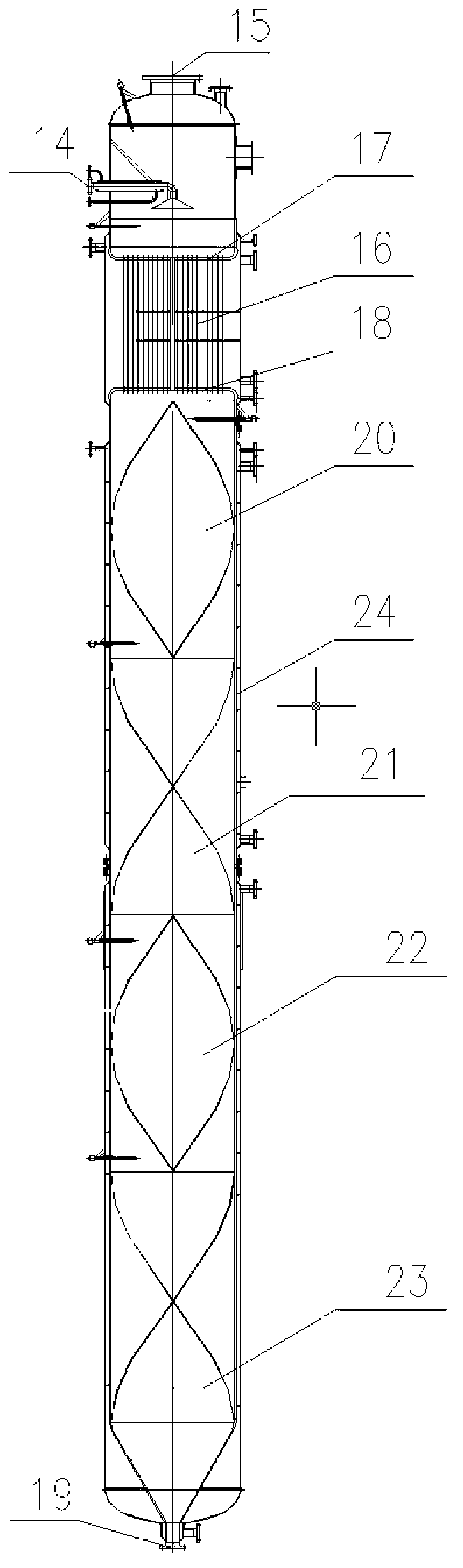

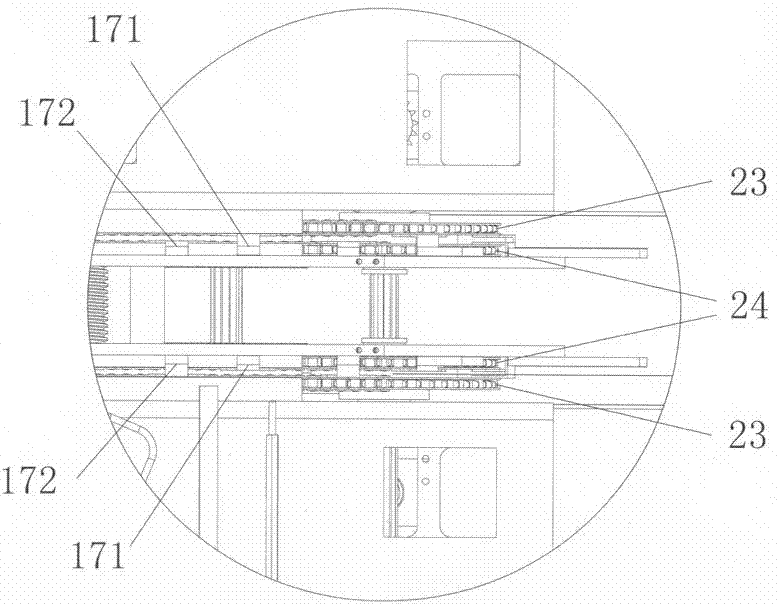

Polyamide polymerization production process and equipment for same

The invention relates to a polyamide polymerization production process and equipment for the same. The polyamide polymerization production process comprises the following steps of: carrying out prepolymerization on melted caprolactam, titanium dioxide, benzoic acid, and the like at a high temperature, and then carrying out front polymerization and post polymerization; pelleting; pre-extracting; extracting; pre-drying; and drying to obtain a product. The production equipment comprises a hexanolactam melting system, a preparation system, a feed system, a high-temperature prepolymerization device, a front polymerization tower, a rear polymerization tower, a pelleting system, a pre-extraction tower, an extraction tower, a pre-drying tower, a drying tower, and the like. According to the invention, static state flow guide spiral mixer assemblies are additionally arranged in the extraction tower and the lower sections of each row of tubes of the high-temperature prepolymerization device, the front polymerization tower and the post polymerization tower; the polyamide hydrolyzing ring opening and dewatering are more uniform and sufficient and faster; the front polyaddition reaction is sufficient and stable; the rear polycondensation stage is more uniform and stable in molecular distribution; the extraction tower more sufficiently and stably extracts a caprolactam monomer; the pre-drying tower can be used for removing the surface moisture of a slice; the drying tower dries combined water; a recovery system can be used for recovering an oligomer and extracts the caprolactam monomer contained in water.

Owner:武汉森大科技研究发展中心

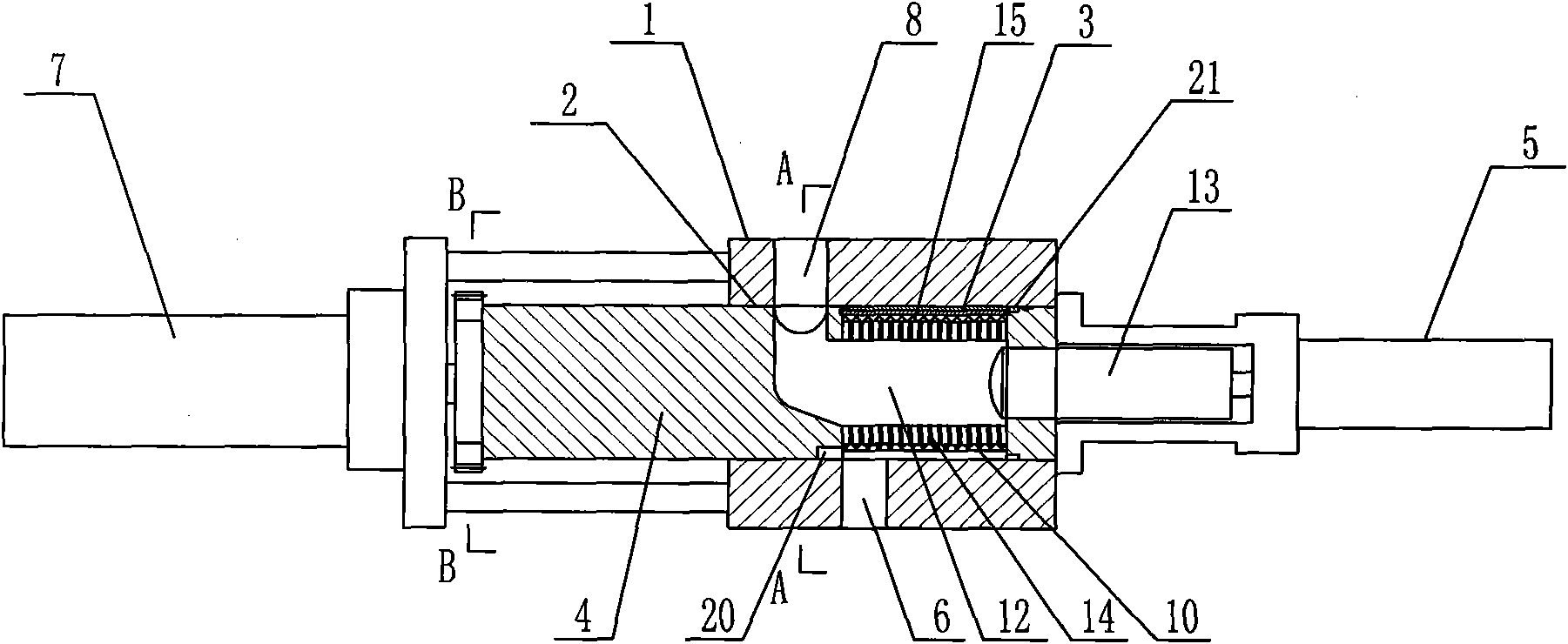

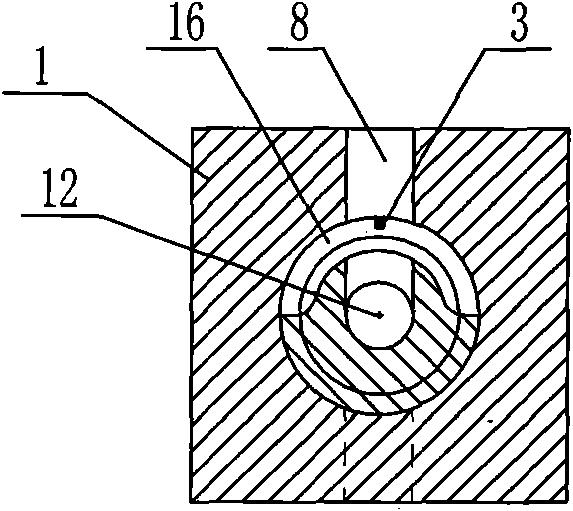

Cylindrical backwash purifying device

ActiveCN101637675AGuaranteed continuityAvoid affecting product qualityGravity filtersStationary filtering element filtersEngineeringFilter effect

The invention discloses a cylindrical backwash purifying device comprising a body and a plunger which is arranged in the body and can be connected in an axially sliding manner. The body is provided with a feeding passage and a discharge passage which are connected with a through hole. An outer circle at the front part of the plunger is recessed inwards, and together with the inner wall of the through hole, forms an annular empty cavity which is connected with the feeding passage. The plunger is axially provided with an L-shaped hole, which is connected with the discharge passage, in a direction from the front to the back. A recessed peripheral surface of the plunger is radially provided with a filter hole connected with the annular empty cavity and the L-shaped hole. The recessed peripheral surface of the plunger is connected with a detachable filter screen. A separating bar contacted with the inner wall of the through hole is axially arranged on the plunger and in the annular empty cavity. Semicircular grooves are arranged on the outer surface of the plunger and at two sides of the discharge passage. The cylindrical backwash purifying device has the advantages of reasonable design, simple structure, small volume, large effective filter area, good filter effect, no need of halt during cleaning or filter screen replacement, long continuous work time, high work efficiency and high product quality.

Owner:郑州德奥科技有限公司

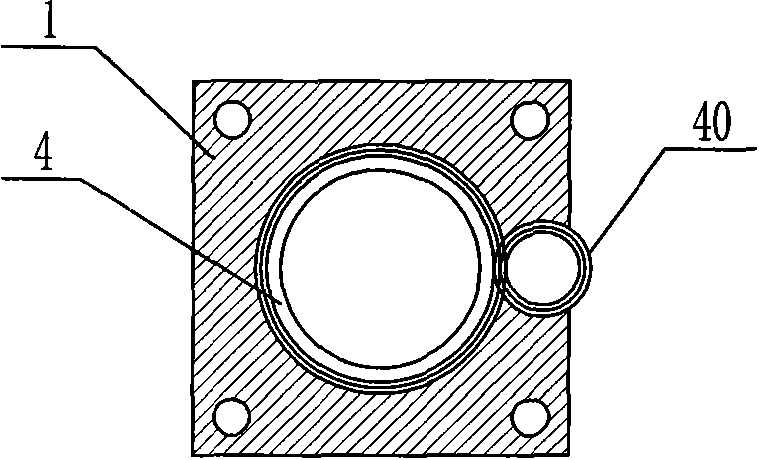

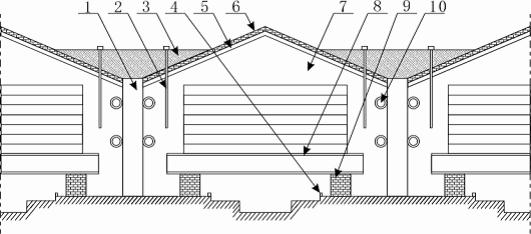

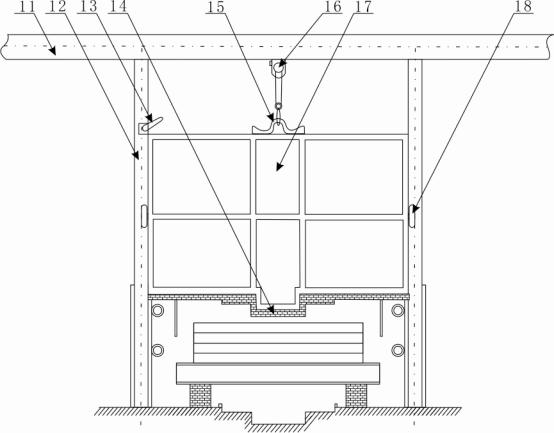

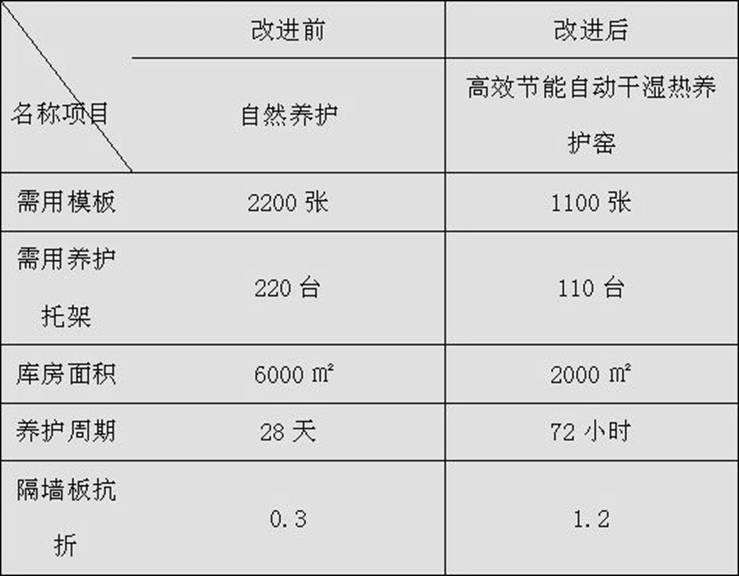

Curing kiln of light aggregate concrete hollow partition board

InactiveCN102653111AGuaranteed stabilityAvoid \"runningCeramic shaping apparatusProcess engineeringHeat conservation

The invention discloses a curing kiln of a light aggregate concrete hollow partition board. A kiln body is formed by tightly connecting a rear kiln wall, a kiln top, a kiln door and a heat-prevention partition, wherein the kiln top is in a'herringbone'-shaped structure; a kiln top heat-prevention heat-insulating layer covers the kiln top; an in-kiln heat-prevention and heat-insulating layer is arranged at the kiln top rightly above the heat-prevention partition; a slide groove is arranged at the front end of a stand column of the kiln door; kiln door guide wheels which are matched with the slide groove to work are symmetrically arranged on two sides of the kiln door; and a kiln door bottom sealing strip is arranged at the bottom of the kiln door. The kiln body of the curing kiln adopts a full-sealing design and a heat-prevention and heat-insulating material so that the stability of a temperature in the kiln is guaranteed and'running, emitting and leaking' phenomena of heat in the kiln are avoided; and an inclined type kiln top structure is adopted to prevent the situation that the quality of products is influenced as water mist generated in a curing process is condensed into water drops on the kiln top to fall on the surface of the partition board.

Owner:CHENGDU FURONG NEW BUILDING MATERIALS

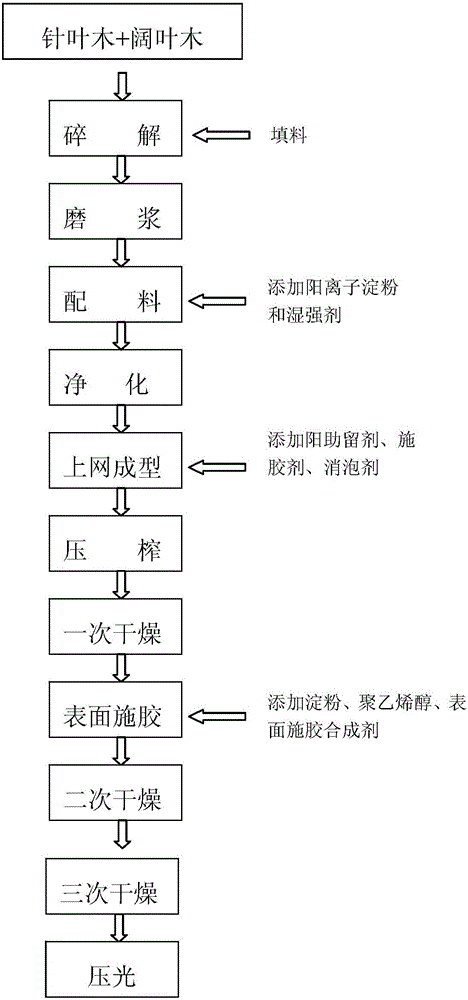

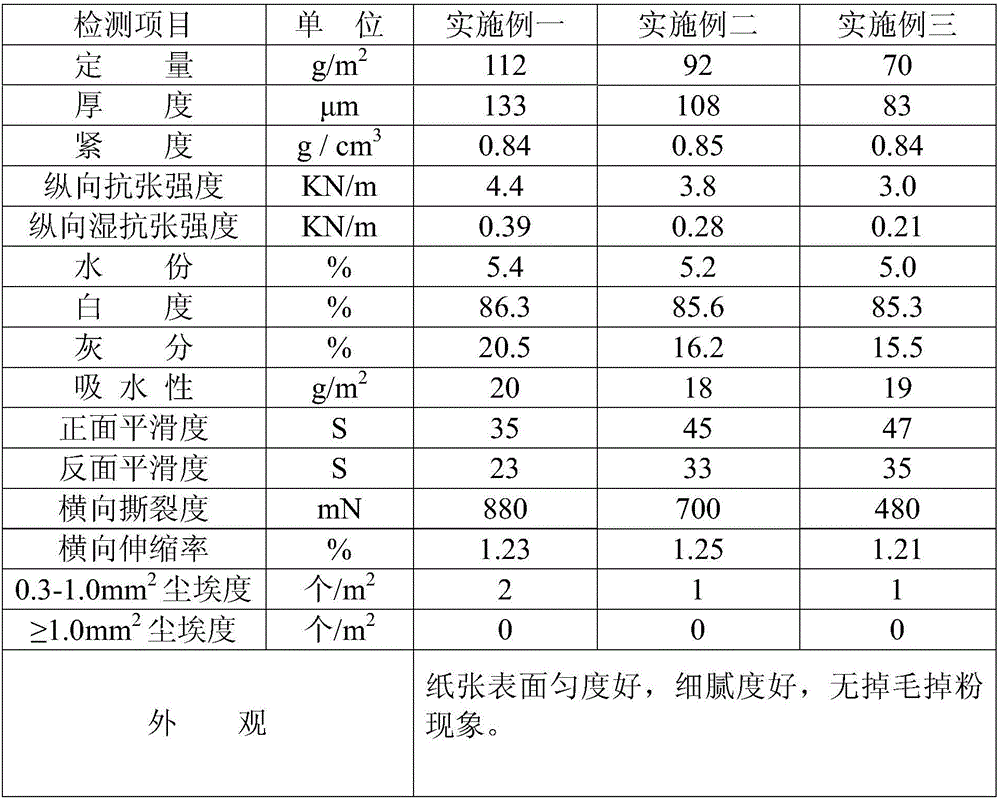

Process for producing thermal dye sublimation raw paper

InactiveCN105951498AImprove surface smoothnessImprove uniformityWater-repelling agents additionDryer sectionFiberPapermaking

A process for producing raw paper by thermal dye sublimation is related to the technical field of papermaking and includes: pulping coniferous wood and broad-leaved wood in a mass ratio of 15:85-30:70 through a pulper, and adding a filling material, the mass ratio of plant fiber to the filling material being 70:30-85:15; subjecting obtained pulp to pulp grinding under controlled beating degree of 25-35 degrees SR, and adding a cationic starch and a wet strength agent respectively into the pulp; performing dilution purification, web-forming and pressing, and subjecting obtained wet paper sequentially to primary drying, surface gluing, secondary drying and tertiary drying to obtain the thermal dye sublimation raw paper. Indexes of the thermal dye sublimation raw paper such as tear, uniformity, shrinkage, tensile strength and smoothness can be effectively controlled, preventing the problems occurring during use of raw paper produced by traditional process, such as picking, poor printing effect, wrinkling during printing, and proneness to breakage during printing.

Owner:SHANDONG TIANYANG PAPER

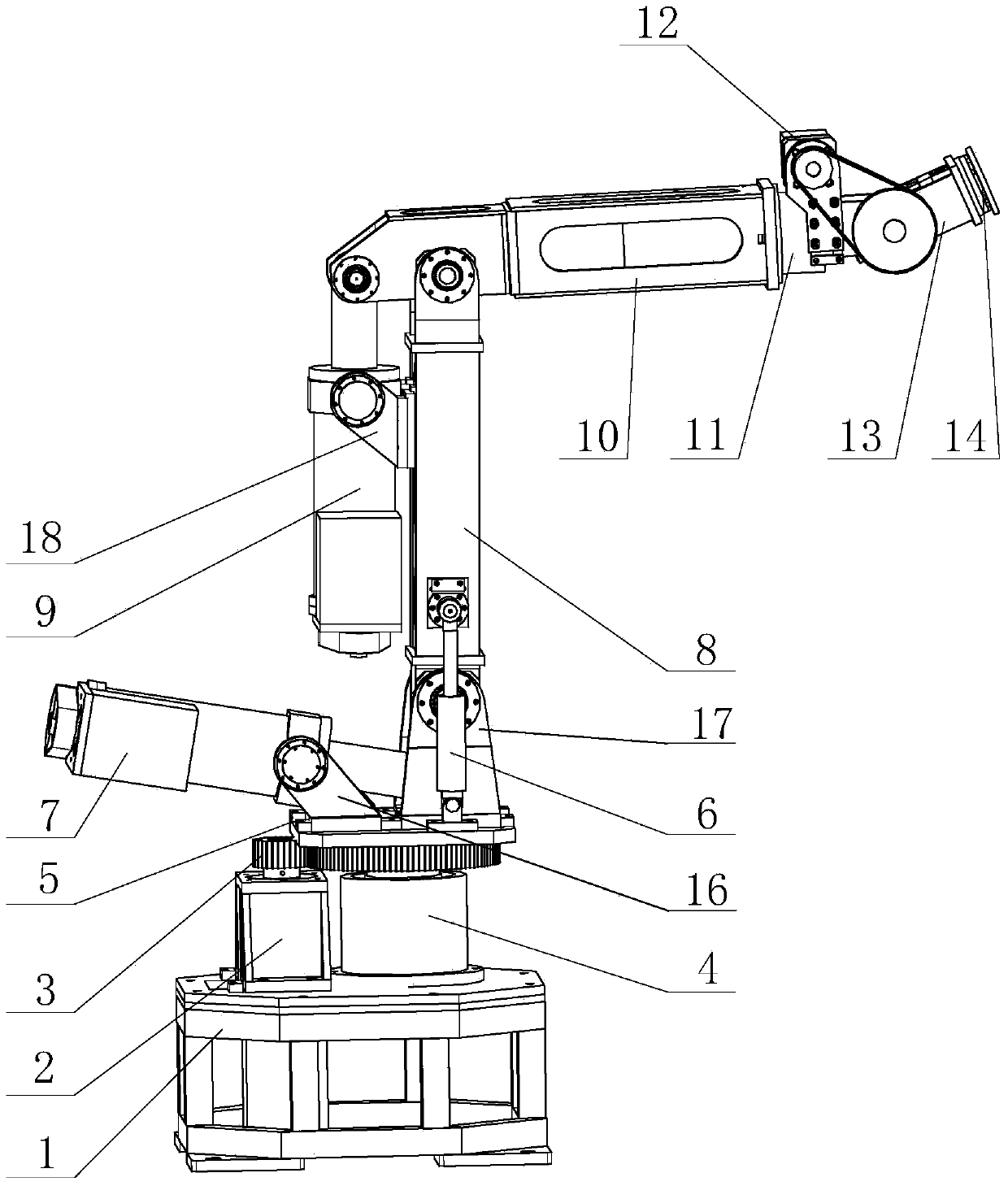

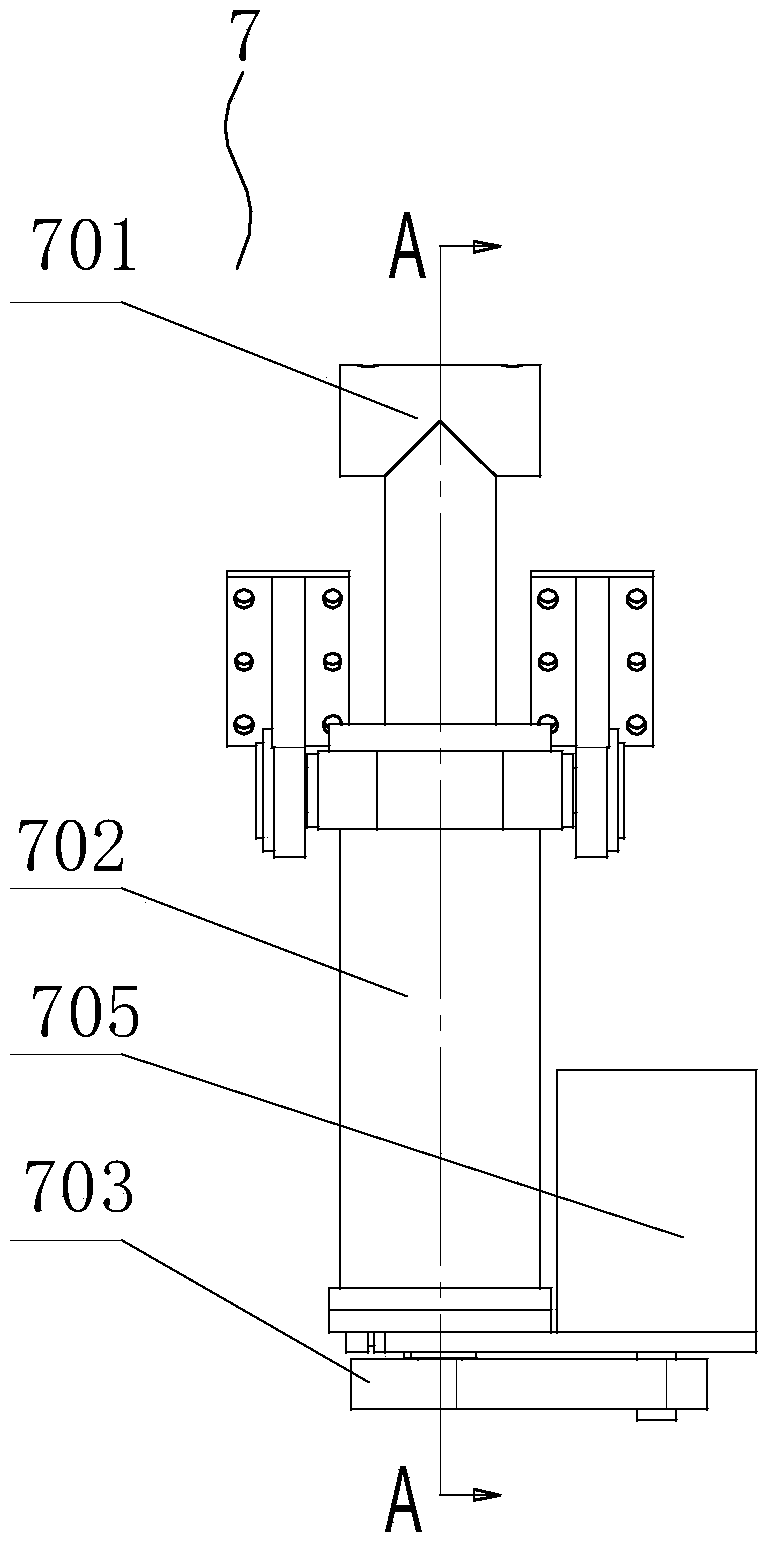

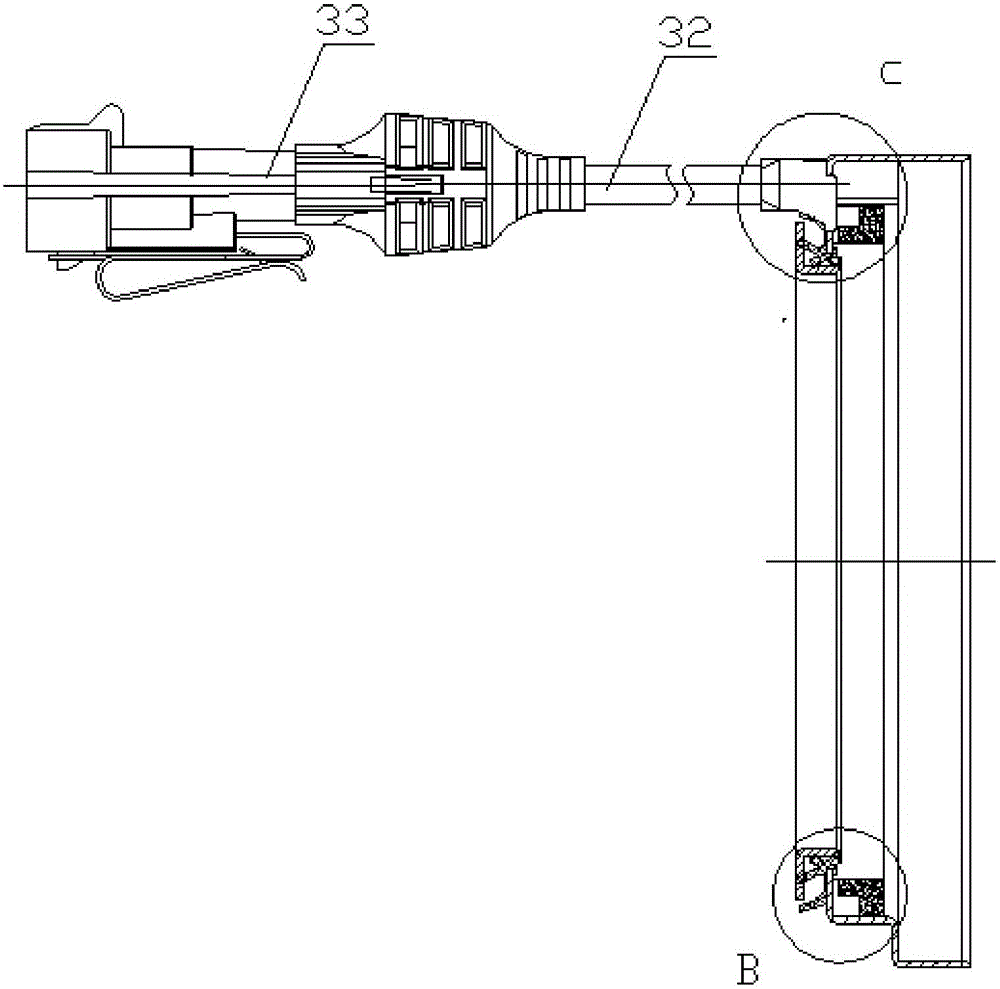

Six-shaft joint mechanical hand

InactiveCN103737607ALow costSimple structureProgramme-controlled manipulatorJointsControl systemIndustrial machine

The invention discloses a six-shaft joint mechanical hand and relates to the industry mechanical hand technology. The six-shaft joint mechanical hand comprises a mechanical hand body and a control system; the mechanical hand body is connected with the control system through a data line; the mechanical hand body comprises a base, a first shaft servo motor and a speed reducer thereof, a first shaft rotary shaft, a second shaft base, a lower hand servo cylinder, a lower arm, an upper arm servo cylinder, an upper arm, a fourth shaft rotary shaft, a fifth shaft servo motor and a speed reducer thereof, a fifth shaft rotary base, a sixth shaft rotary shaft and a sixth shaft servo motor and a speed reducer thereof; the control system comprises a programmable controller, a movement control module, a servo driver, an alarming device, a hand box, a touch screen, a limit switch and a sensor. The six-shaft joint mechanical hand has the advantages of achieving six-shaft joint control through the control system, being simple in structure, achieving domestic production, reducing products, shortening the purchasing cycle, being suitable for small and medium businesses to use and high in positioning accuracy, improving the production quality and the production efficiency and having a good application prospect in the industry mechanical hand technology field.

Owner:LIUZHOU GAOHUA MACHINE

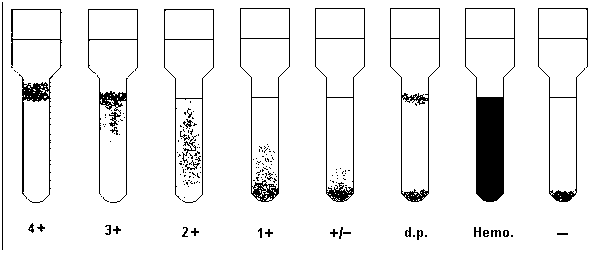

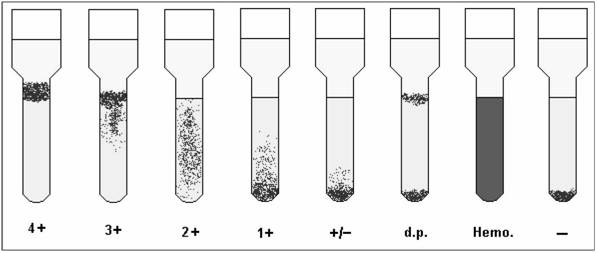

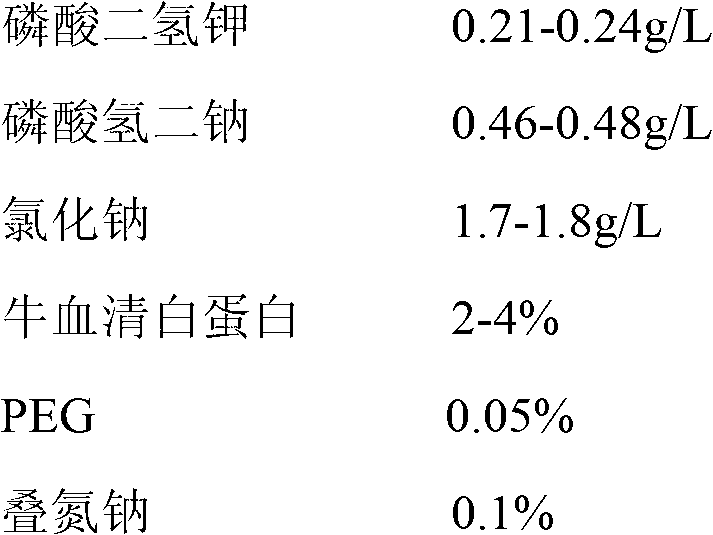

ABO/RhD blood typing detection reagent card and preparation thereof

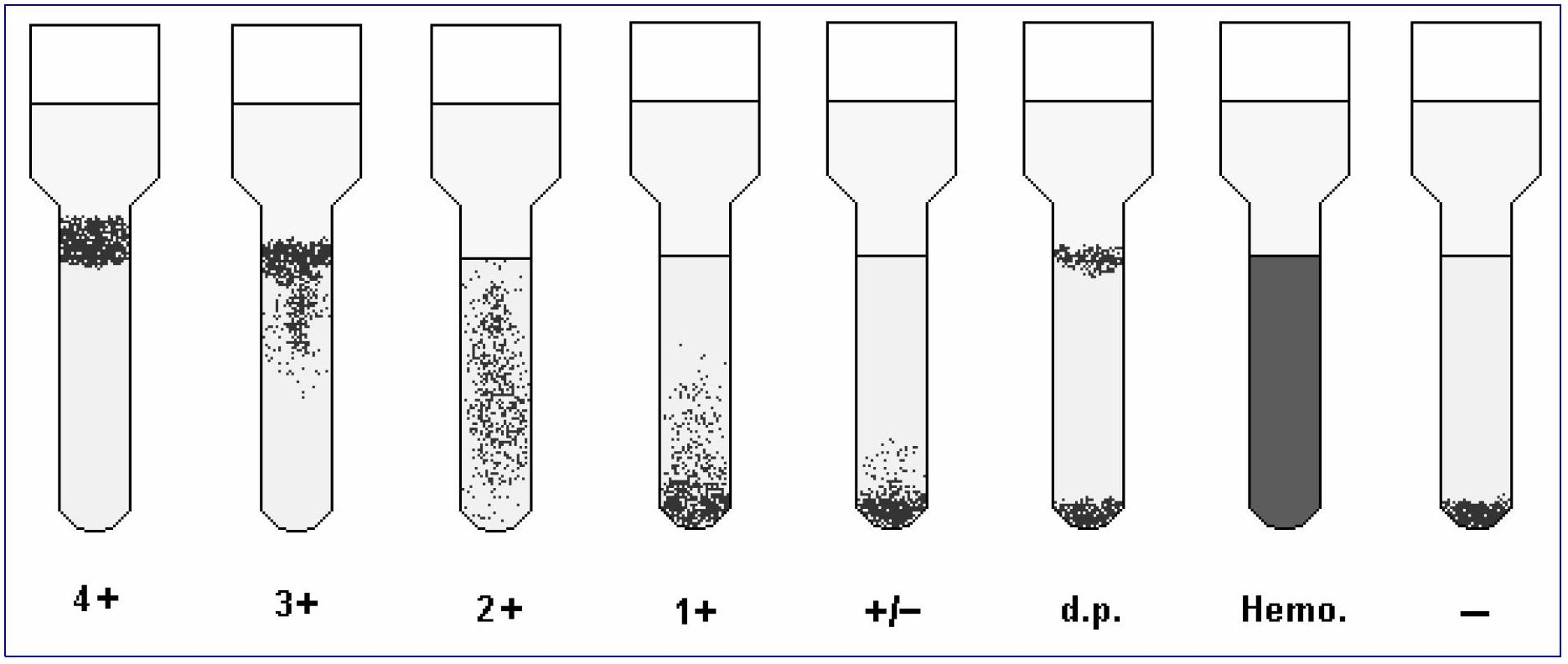

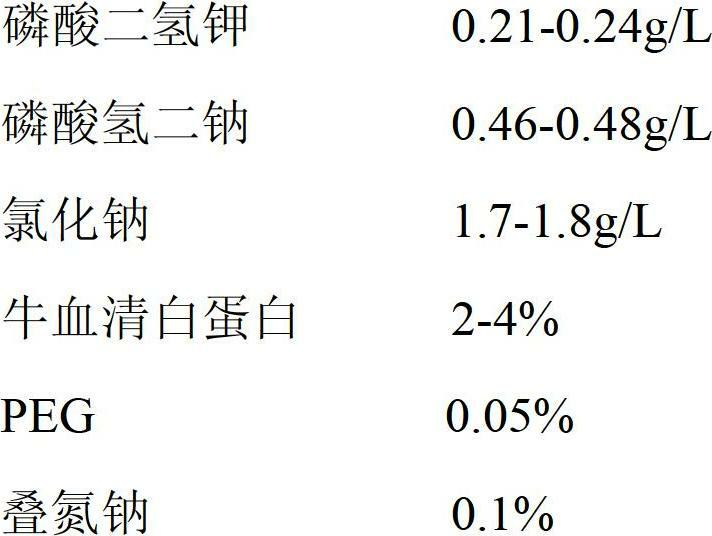

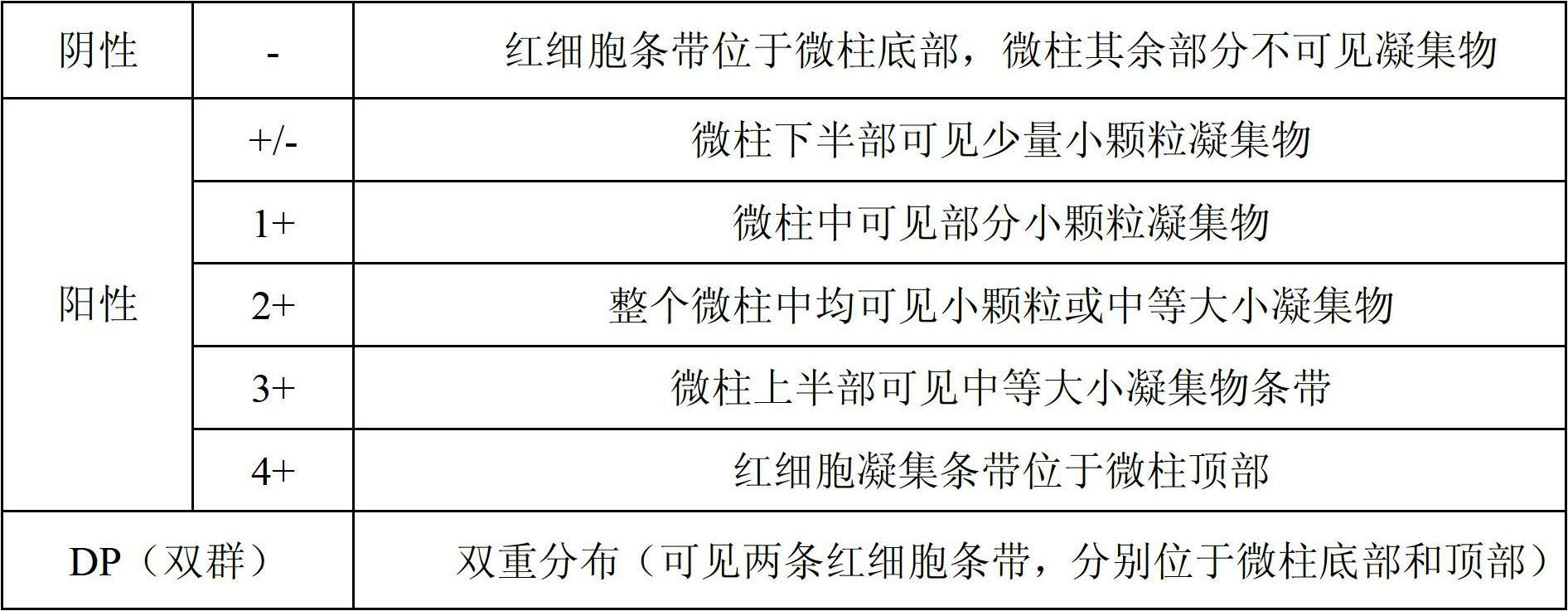

InactiveCN102707074AEasy to detectReliable test resultsBiological testingMicro columnMonoclonal antibody

The invention relates to an ABO / RhD blood typing detection reagent card and preparation of the ABO / RhD blood typing detection reagent card. The ABO / RhD blood typing detection reagent card is characterized in that the detection reagent card is provided with 8 micro-column gel tubes, wherein one micro-column gel tube contains gel and an anti-A monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-B monoclonal antibody of IgM property, one micro-column gel tube contains gel and an anti-D RhD blood type monoclonal antibody of IgM property, and the rest five gel tubes contain gel suspending medium buffer solutions and gels.

Owner:BEIJING KINGHAWK PHARMA

ABO/RhD blood group antigen detection reagent card and preparation method thereof

InactiveCN102680716AAdded Negative Control AssayAvoid misjudgment of resultsBiological testingMonoclonal antibodyGroup A - blood

The invention relates to a preparation method of an ABO / RhD blood group antigen detection reagent card. Eight microcolumn gel tubes are arranged on the detection reagent card, wherein two gel tubes contain gel and anti-A monoclonal antibodies with an immunoglobulin m (IgM) property, two gel tubes contain gel and anti-B monoclonal antibodies with the IgM property, two gel tubes contain gel and anti-D monoclonal antibodies of RhD blood type with the IgM property, and two gel tubes contain a gel suspending medium buffer solution and gel.

Owner:BEIJING KINGHAWK PHARMA

Machine tool cutting tool monitoring system

InactiveCN109277882AAvoid affecting product qualityAffect product qualityMeasurement/indication equipmentsNumerical controlPower flow

The invention relates to the field of numerical control machine tools, and provides a machine tool cutting tool monitoring system. The machine tool cutting tool monitoring system comprises a cutting tool load real-time monitoring unit and a model automatic evaluation unit, wherein the cutting tool load real-time monitoring unit monitors the current change amount of a machine tool spindle motor inthe machining process of a cutting tool and sends the current change amount to the model automatic evaluation unit; and the model automatic evaluation unit converts the current change amount receivedin real time into the wear amount of the cutting tool, compares the real-time wear amount with set upper and lower control values, evaluates the machining state of the cutting tool, and prompts an operator to stop and change the cutting tool if the current change amount exceeds the set upper and lower control values. According to the technical scheme, the state of the cutting tool in the whole cutting process is monitored, and the software detection mode not only avoids the influence of hardware detection equipment on machine tool transformation, but also can monitor edge chipping and breakagein real time, so that the cutting tool in an abnormal state is prevented from continuing performing machining and affecting product quality, and the quality of machined products is controllable.

Owner:江苏西格数据科技有限公司

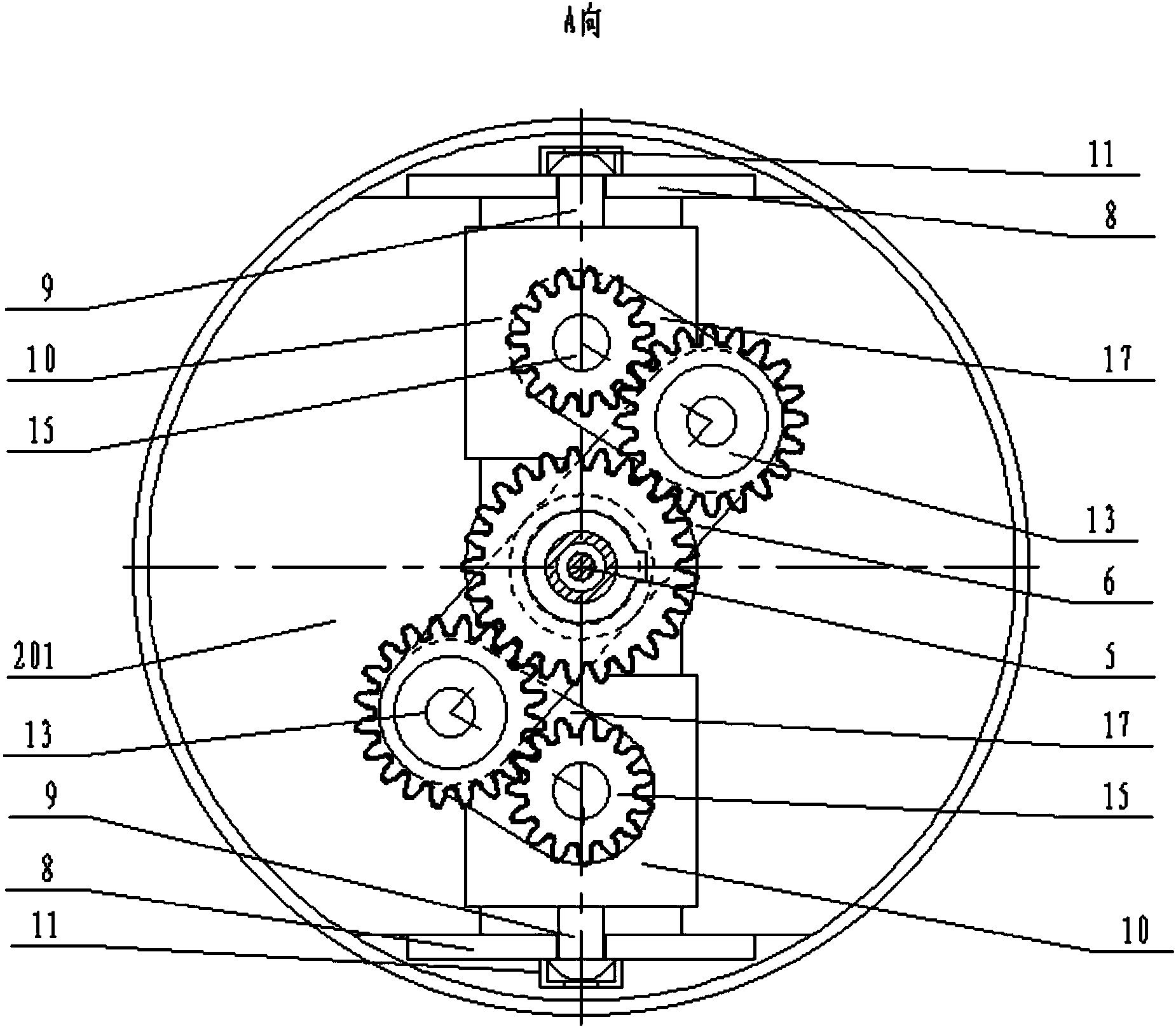

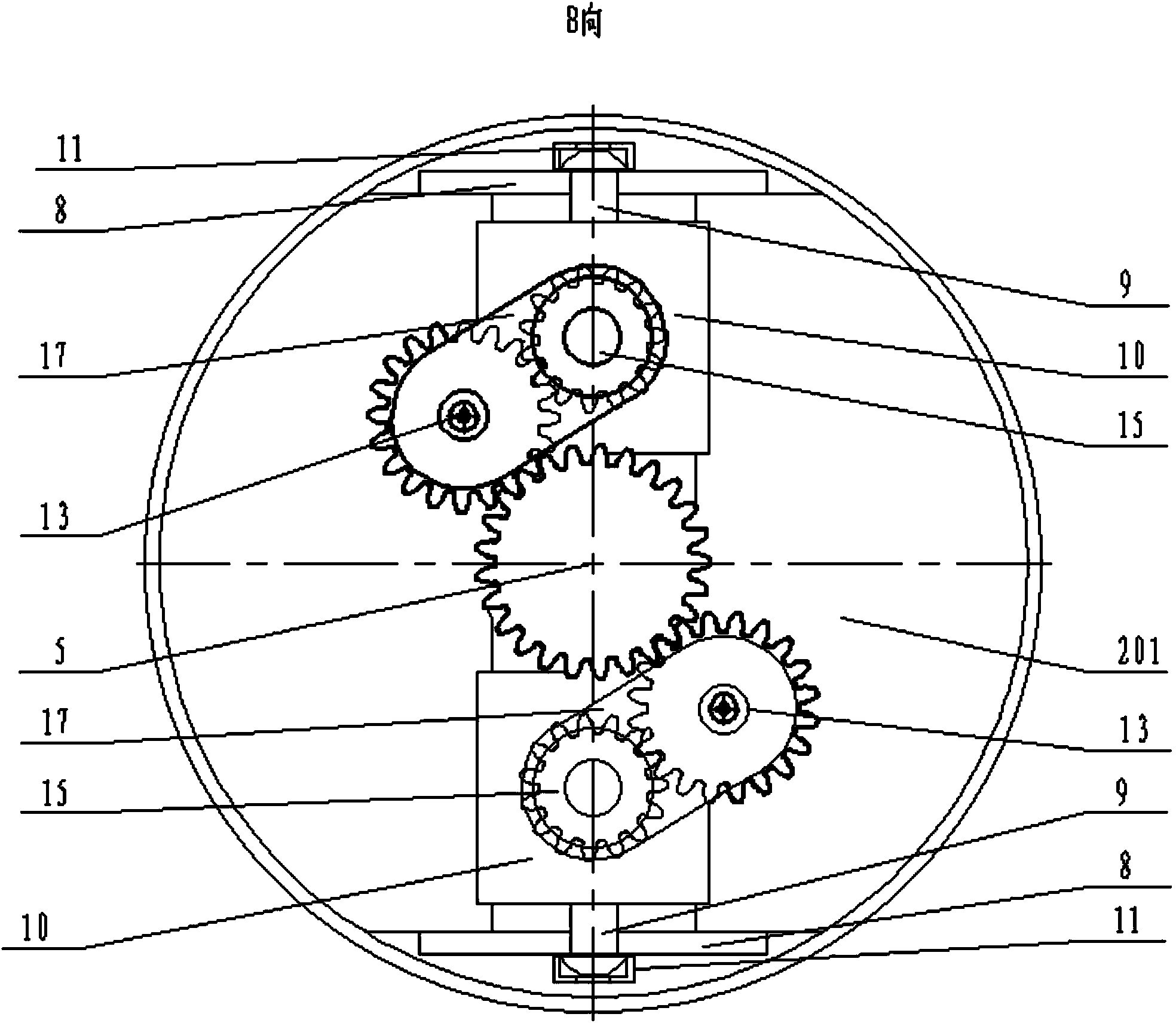

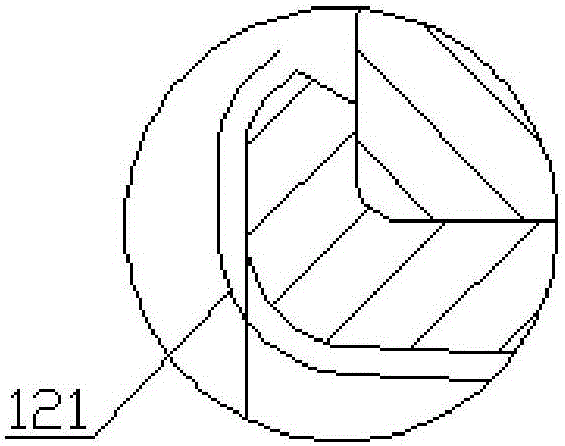

Brushing device for metal bar

InactiveCN103921201AExtended service lifeSimple structureGrinding drivesGrinding machinesBrush deviceEngineering

The invention discloses a brushing device for a metal bar. The brushing device for the metal bar is small in radial load of planet gear and long in service life. The brushing device for the metal bar comprises a machine base, a revolution seat, a hollow shaft and a belt wheel. A sun gear, a main connecting rod and a revolution head are arranged on the hollow shaft above the revolution seat in a sleeved mode in sequence, the revolution head is fixedly connected to the revolution seat, the revolution head is provided with two sliding seats which slide relatively in the radial direction of the revolution head, transition gears meshed with the sun gear through transition gear shafts are arranged on the main connecting rod and on the two sides of the sun gear, planet gear shafts are arranged in the sliding seats in a penetrating mode, one end of each planet gear shaft is provided with a planet gear meshed with the corresponding transition gear in a sleeved mode, the other ends, penetrating through the sliding seats, of the planet gear shafts are provided with brushing wheels, the position, close to the main connecting rod, between the transition gear shafts and the planet gear shafts is provided with an auxiliary connecting rod in a movable sleeved mode, the ends, close to the revolution seat, of the transition gear shafts are provided with connecting plates in a rotating sleeved mode, and the other ends of the connecting plates are arranged at the corresponding positions of the planet gear shafts in a sleeved mode.

Owner:江苏薪泽奇机械股份有限公司

Small crispy pork slices and preparation method thereof

InactiveCN106578970AAttractive golden colorThe taste is soft and smoothFood scienceChemistrySodium triphosphate

The invention relates to the technical field of food processing, and in particular relates to small crispy pork slices and a preparation method thereof. The small crispy pork slices are prepared by coating the surfaces of pickled pork bars with a sizing agent and frying the pickled pork bars with oil, wherein the pickled pork bars are prepared from the following raw materials: edible livestock pork, eggs, edible salt, sodium tripolyphosphate, sodium bicarbonate, citric acid, seed powder of Chinese prickly ash, fennel powder, tsaoko cardamon powder, nutmeg powder, cassia powder, white pepper powder and water; the sizing agent is prepared from the following raw materials: water, sweet potato starch, wheat flour, plant oil, polyglycerin ricinoleate, sucrose fatty acid ester, D-sodium ascorbate, dyestuff and eggs. Compared with conventional small crispy pork slices, the small crispy pork slices provided by the invention are golden and attractive in color, loosened and soft and smooth and tender in taste and applicable to industrial large-scale production, so that traditional delicious food of China can be inherited.

Owner:HENAN ZHONGPIN FOOD IND

Method for decoloration when crude sodium pyrophosphate is purified to produce sodium pyrophosphate product

ActiveCN106882781AAddress redness,Solve product storagePhosphorus compoundsCalcium biphosphateFiltration

The invention relates to a Method for decoloration when crude sodium pyrophosphate is purified to produce a sodium pyrophosphate product. In the process of purifying the crude sodium pyrophosphate to produce the sodium pyrophosphate product, oxidizing agent is adopted for processing, other micro-soluble aluminum phosphate (pyrophosphate), ferrous phosphate (pyrophosphate), calcium phosphate (pyrophosphate) and the like are prevented from separating out to influence product quality, the problem that the sodium pyrophosphate product is reddish or becomes reddish in storage and application is solved; the introduction of phosphate (pyrophosphate) impurities into the sodium pyrophosphate product to influence crystallization morphology is reduced; product quality is improved; and the difficulty of filtration in production is overcome.

Owner:ZHENJIANG JIANGNAN CHEM

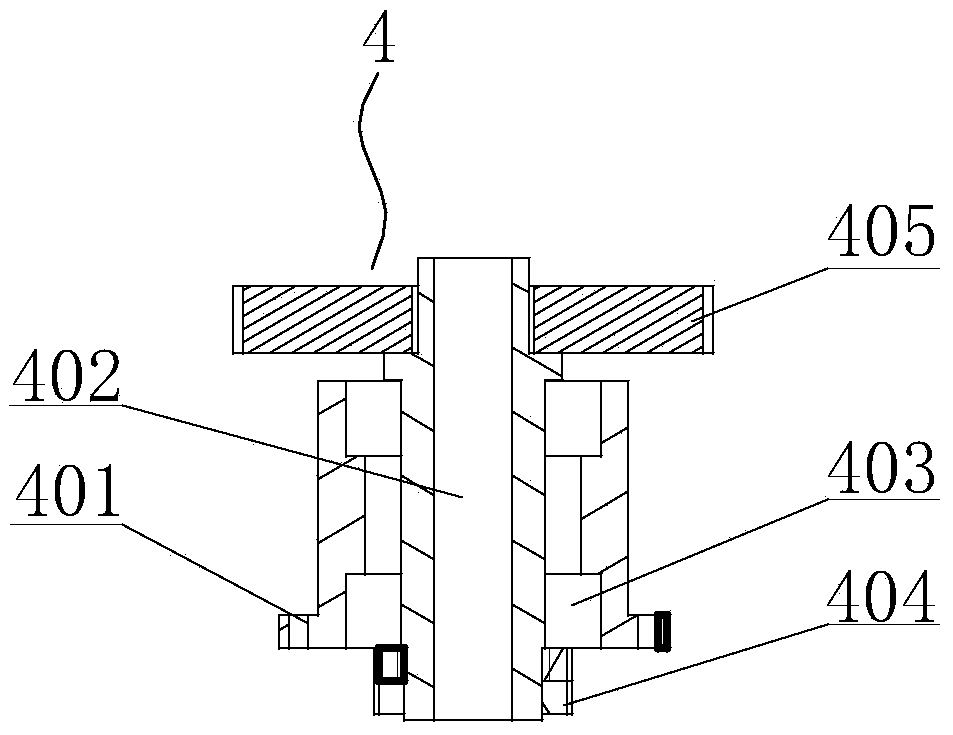

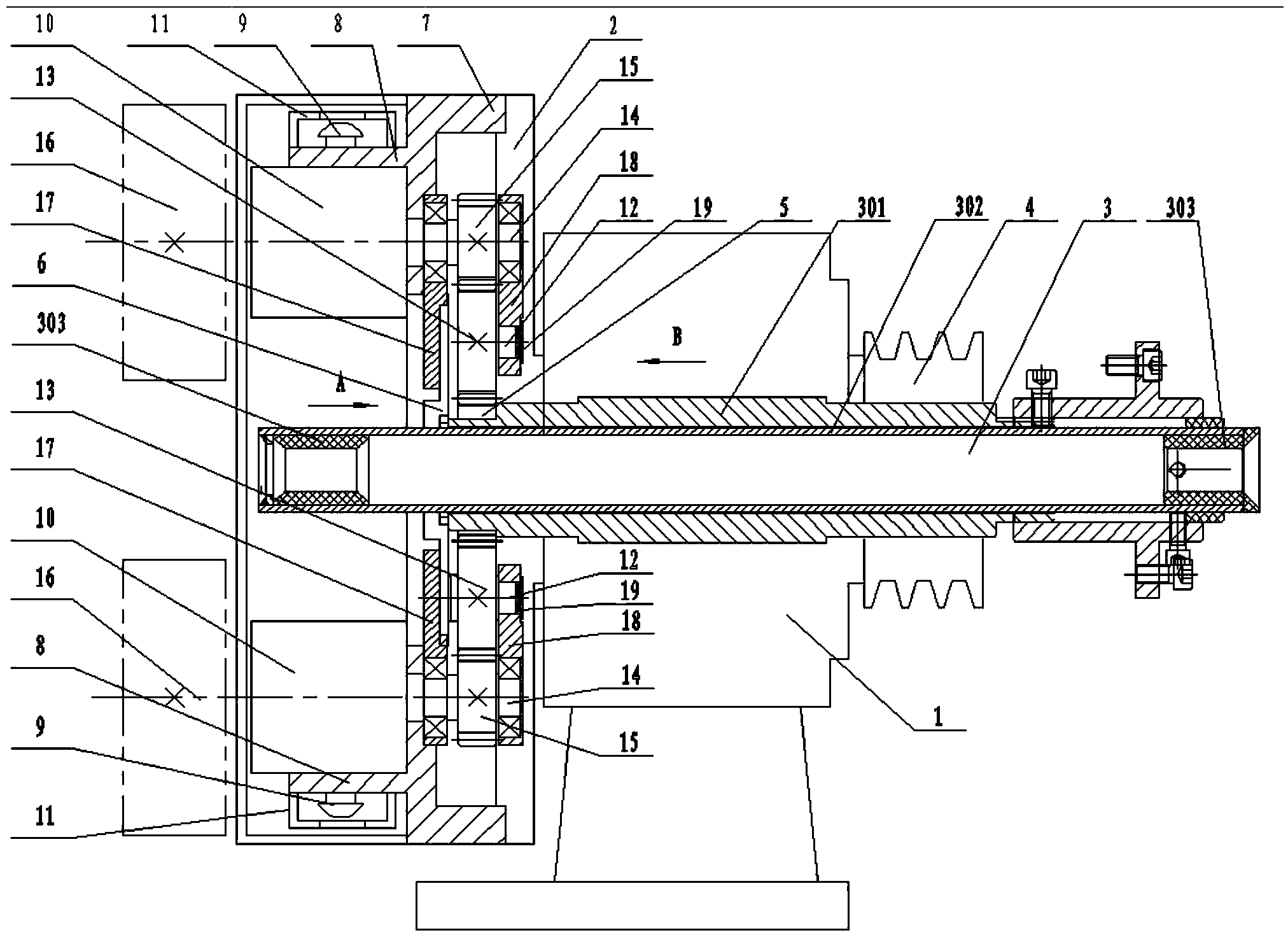

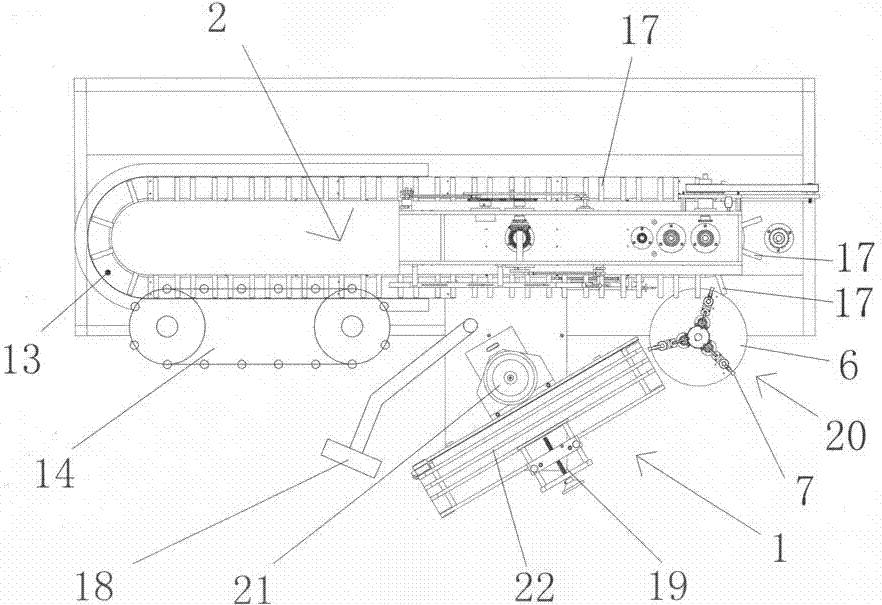

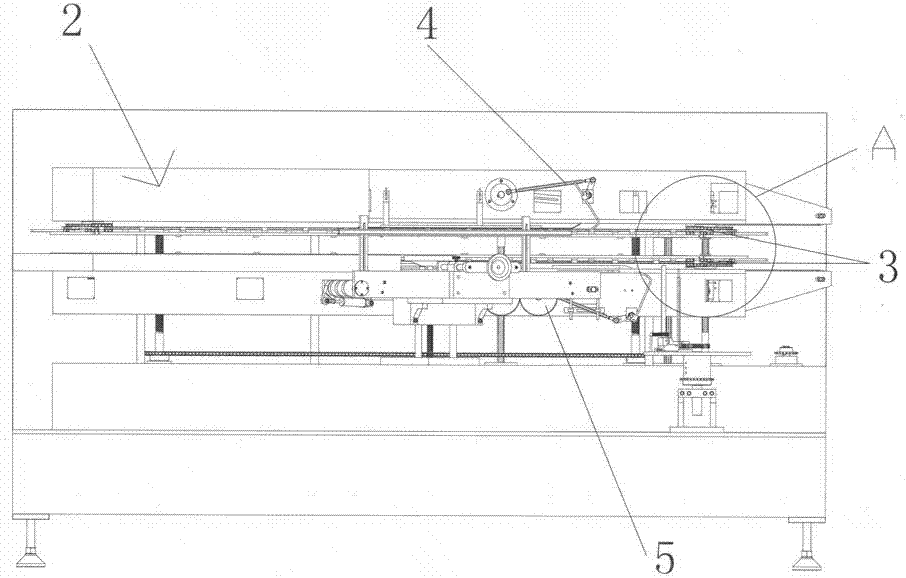

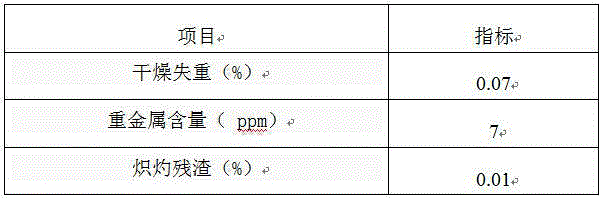

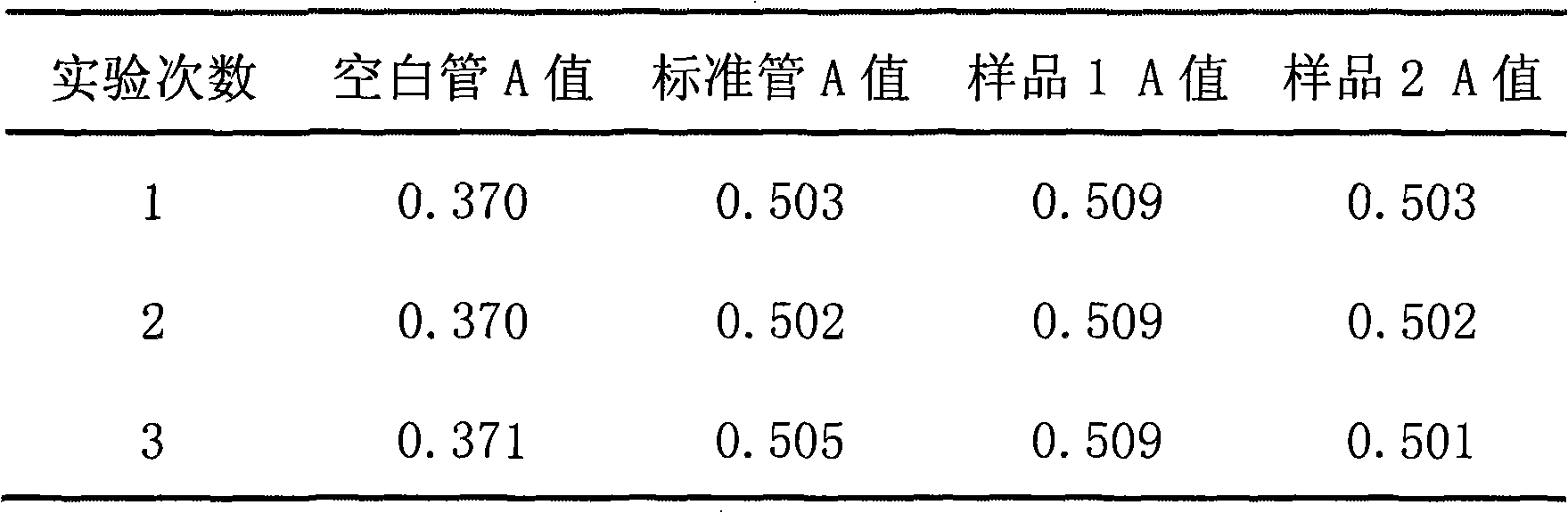

Vertical boxing machine and rotary box-sucking mechanism thereof

ActiveCN103204266AAvoid contactAvoid affecting product qualityPackagingMechanical devicesCartoning machine

The invention provides a vertical boxing machine and rotary box-sucking mechanism thereof, and belongs to the mechanical devices or equipment of packing objects or materials. The vertical boxing machine comprises a paper box storeroom (1) and a paper box delivery and convey chain mechanism (2) which comprises a convey chain assembly (3), a tongue driving mechanism (4) and a tongue inserting mechanism (5). The vertical paper boxing machine is characterized in that the rotary box-sucking mechanism (20) is arranged between the paper box storeroom (1) and the convey chain mechanism (2) and is matched with the same; the rotary box-sucking mechanism comprises a turntable (6) connected with a power device in a transmission manner. A radial reciprocating-moving box-sucking unit assembly is arranged on the turntable (6) and mainly comprises a sucking head (7) connected with an air source; and the vertical boxing machine capable of completing material vertically boxing and sucking and releasing the paper boxes successfully without additional paper box opening mechanisms.

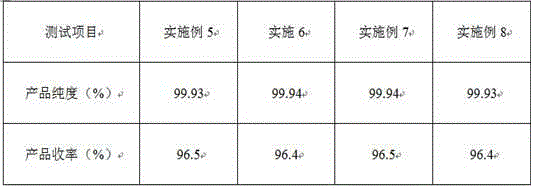

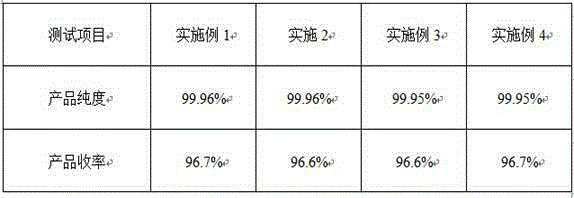

High-purity metformin hydrochloride preparation method

InactiveCN104788345AAvoid affecting product qualityLower the temperature of the addition reactionOrganic chemistryOrganic compound preparationMetformin hclPyrrolidinones

The invention discloses a high-purity metformin hydrochloride preparation method. N-methyl pyrrolidone is used as a solvent, dicyandiamide and dimethylamine hydrochloride are taken as a solute, the solvent and the solute are added into a synthesis kettle for reaction, and metformin hydrochloride is prepared through steps of stirring, cooling, spin-drying, washing, crystallizing and drying. The metformin hydrochloride prepared through the preparation method provided by the invention has the advantages that the yield is higher than 96.4 percent, and the product purity is higher than 99.93 percent.

Owner:TAISHAN MEDICAL UNIV

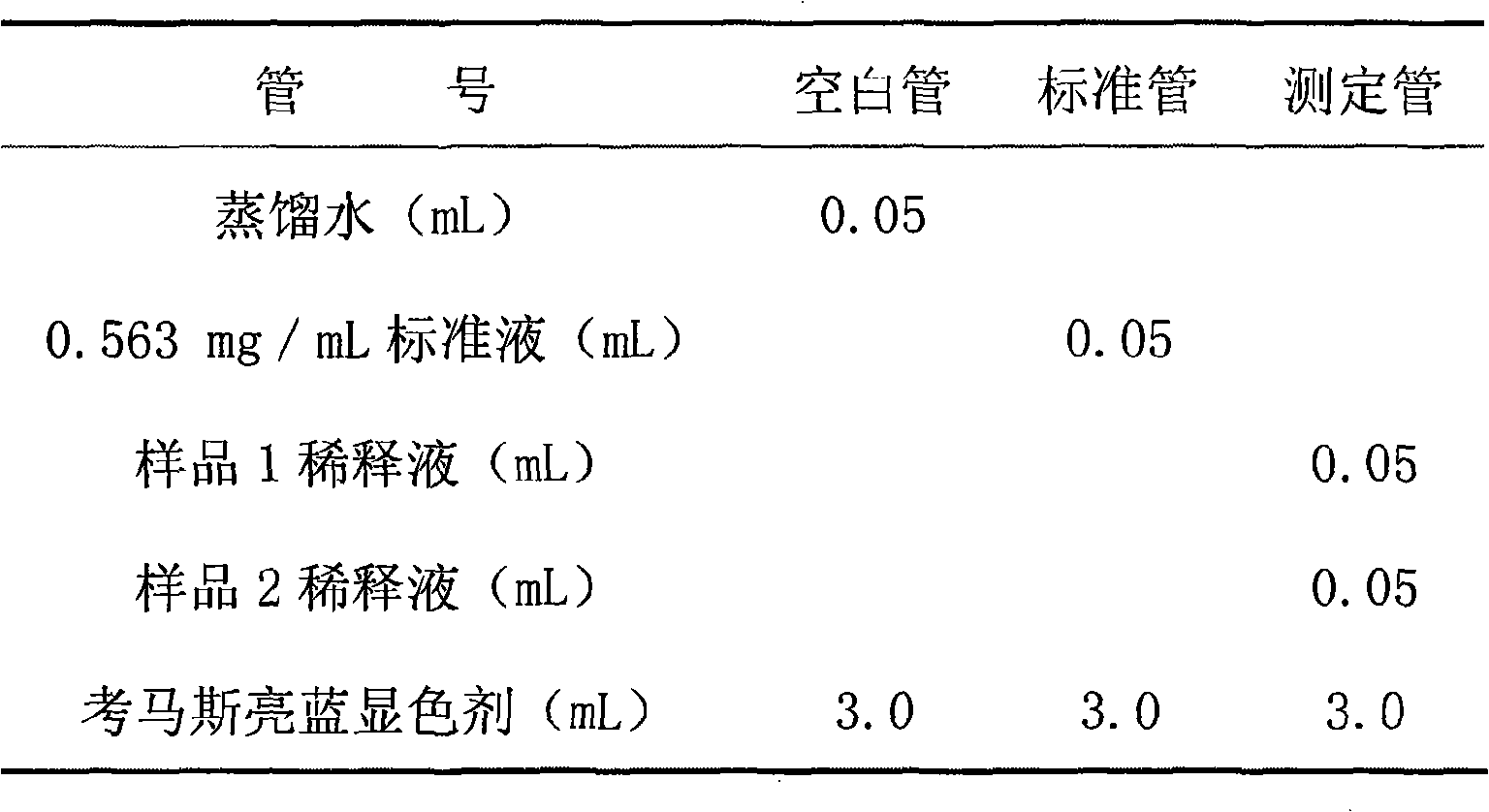

Process for extracting rice bran protein

The invention discloses a technique for extracting rice bran protein; the prior art used for extracting rice bran protein comprises the following methods: a base-dissolving and acid-precipitation method and an enzymatic method, and the defects are that the quality of the extracted protein is poor and the technique is complex, meanwhile, other natural product nutrient ingredients such as Gamma-oryzanol, etc. are eliminated as impurities; the technique of the invention adopts thin protein pulp as a solvent to extract the protein and other natural product nutrient ingredients with simple technique and low cost; the product (the rice bran protein pulp and the dried rice bran protein pulp product) contains vegetable protein and other natural product nutrient ingredients with rich nutrient ingredients, can be used for production of food, drinks and health products, thus improving the added value of the rice bran, and having important significance for the comprehensive application of the rice bran and environmental protection.

Owner:湖北金龙泉生物科技有限公司

High-corrosion resistance hub bearing unit and machining process

ActiveCN105805173AExtended service lifeImprove oxidation resistanceBearing assemblyHubsEngineeringZinc

The invention discloses a high-corrosion resistance hub bearing unit. The high-corrosion resistance hub bearing unit comprises a flange plate; the flange plate includes an annular flange, and a cylindrical part arranged on the front side of the annular flange and provided with an outer ring and an inner ring; a riveting section for fixedly and rotationally riveting the inner ring is arranged at the head end of the cylindrical part; zinc nickel plating layers are arranged on the outer surfaces of the flange plate and the outer ring; and the flange plate is provided with a zinc nickel plating layer blank area corresponding to the riveting section. The invention further provides a machining process of the high-corrosion resistance hub bearing unit, wherein the design parameters of a rotary riveting cavity of the riveting pressure head are as follows: alpha=gamma=40 degrees, beta=5 degrees, R1=1.5 mm, R2=5 mm, and R3=3 mm. All outer surface, besides the rotary riveting part of the flange plate, of the hub bearing unit is plated with the black environment-friendly zinc nickel plating layers, so that the oxidation resistance and the corrosion resistance of metal surfaces are improved, and the service life of the bearing is prolonged.

Owner:HANGZHOU RADICAL ENERGY SAVING TECH

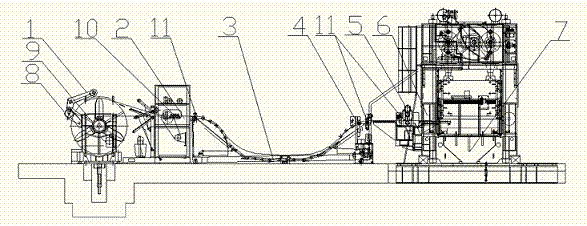

Aluminum coil stamping automation device and stamping method thereof

ActiveCN104759514AGuaranteed feed speedGuaranteed degree of deformationShaping toolsMetal-working feeding devicesControl engineeringProcess engineering

The invention discloses an aluminum coil stamping automation device and a stamping method thereof. The aluminum coil stamping automation device comprises an uncoiling mechanism, a leveling mechanism, a feeding mechanism, an oil injection mechanism and a machine tool which are arranged in turn; the uncoiling mechanism comprises a servo motor and a rolling wheel which are connected with each other; the rotational speed of the rolling wheel does not exceed 115 rounds every minute; the feeding mechanism comprises a servo motor and a feeding roller which are connected with each other; the clearance feeding of the feeding mechanism is performed and the feeding speed of the feeding mechanism and the stamping frequency of the machine tool are synchronized; a material lifting and conveying mechanism is arranged between the leveling mechanism and the feeding mechanism; a material buffering area is formed between the material lifting and conveying mechanism and the leveling mechanism; the deformation degree of aluminum coils does not exceed 30 I in the process that the aluminum coil are fed into the machine tool from the uncoiling mechanism. According to the aluminum coil stamping automation device and the stamping method thereof, the rotational speed of the feeding mechanism is controlled so as to effectively ensure that the deformation degree of the aluminum profile can be within the acceptable range in the production process, the quality of subsequent machining products is ensured, meanwhile the machining speed requirement can be met by the feeding speed of the materials, and the production efficiency is ensured.

Owner:奇昊汽车系统(苏州)有限公司

Preparation method for natural astaxanthin egg yolk oil

InactiveCN109456828ASignificant effectAvoid affecting product qualityFatty-oils/fats refiningFatty-oils/fats productionAnimal scienceWhole egg

The invention discloses a preparation method for natural astaxanthin egg yolk oil. The preparation method comprises the following operation steps of separation, detection, drying, screening, extraction, filtering, detection, packaging and warehousing. According to the preparation method provided by the invention, by taking a whole egg produced by a chick fed with haematococcus pluvialis as a production raw material, through biotransformation, astaxanthin in the haematococcus pluvialis exists in egg yolk in an esterification state and is more easily absorbed by a digestive system and skin of ahuman body, and astaxanthin-rich egg yolk oil is obtained through a low-temperature drying and extraction technology, so that the extraction efficiency is high, and the bioactivity of the astaxanthinis high.

Owner:中铭生物(深圳)集团有限公司

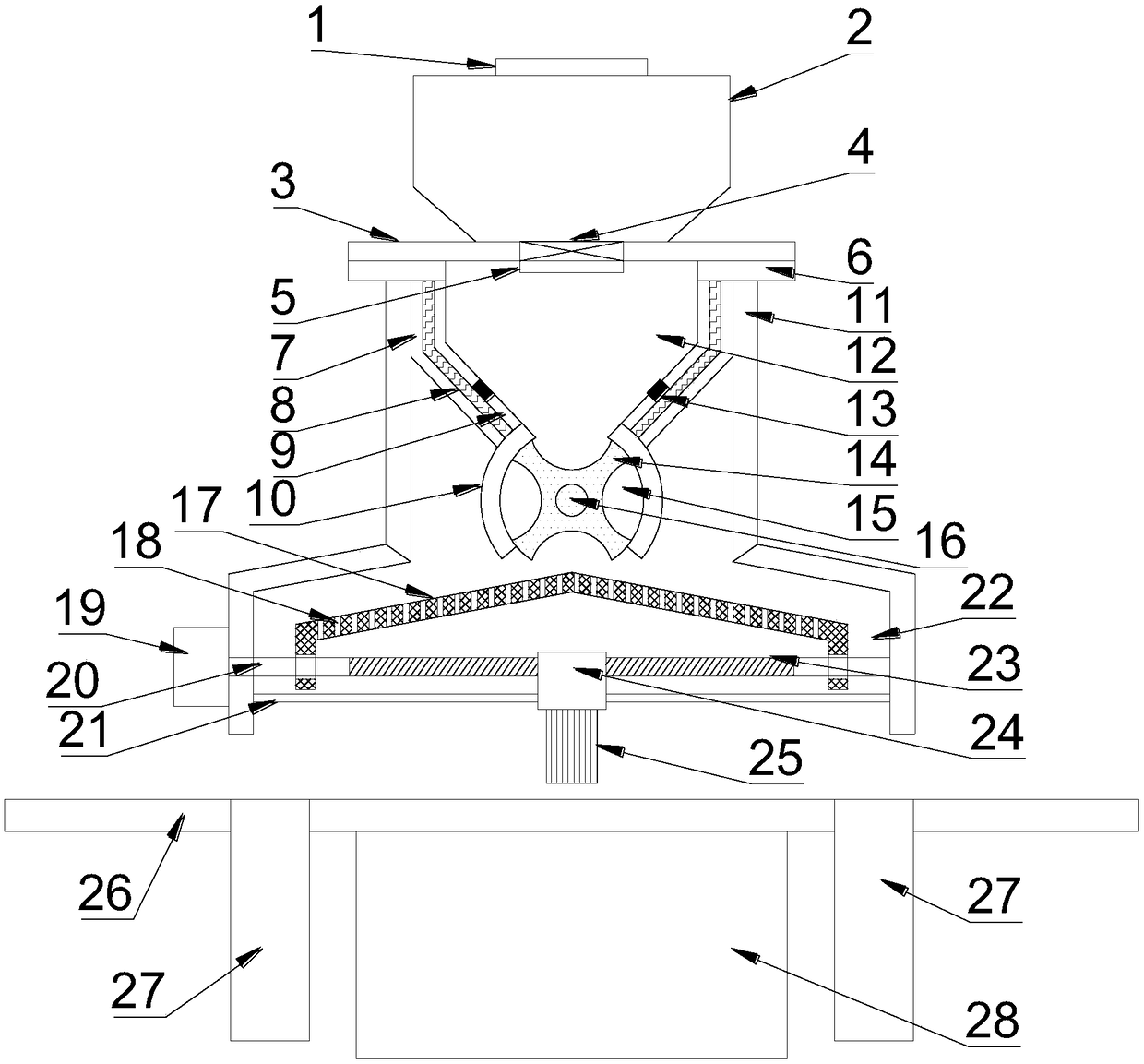

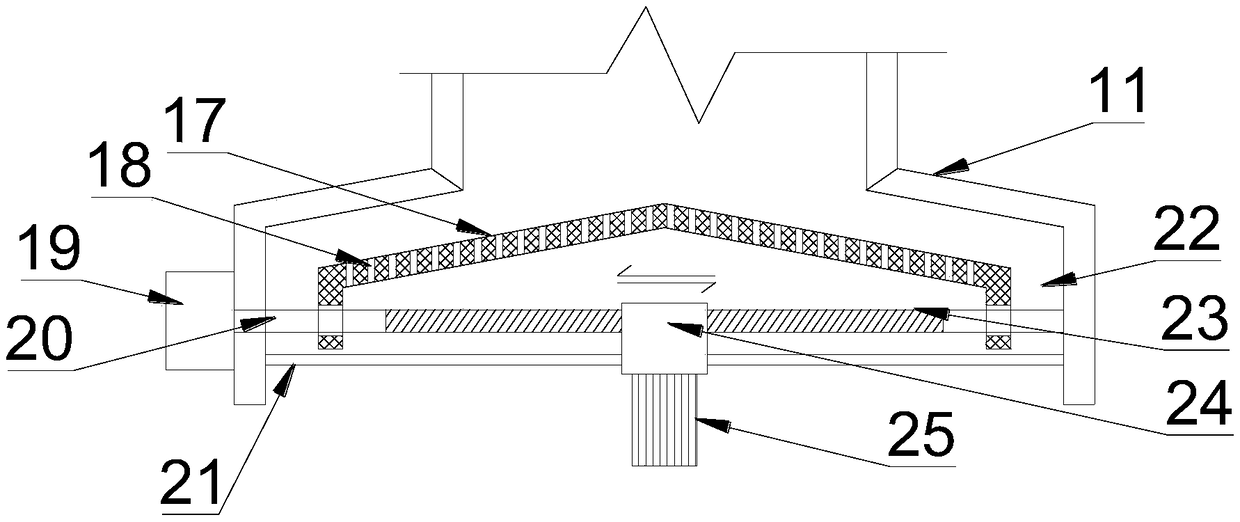

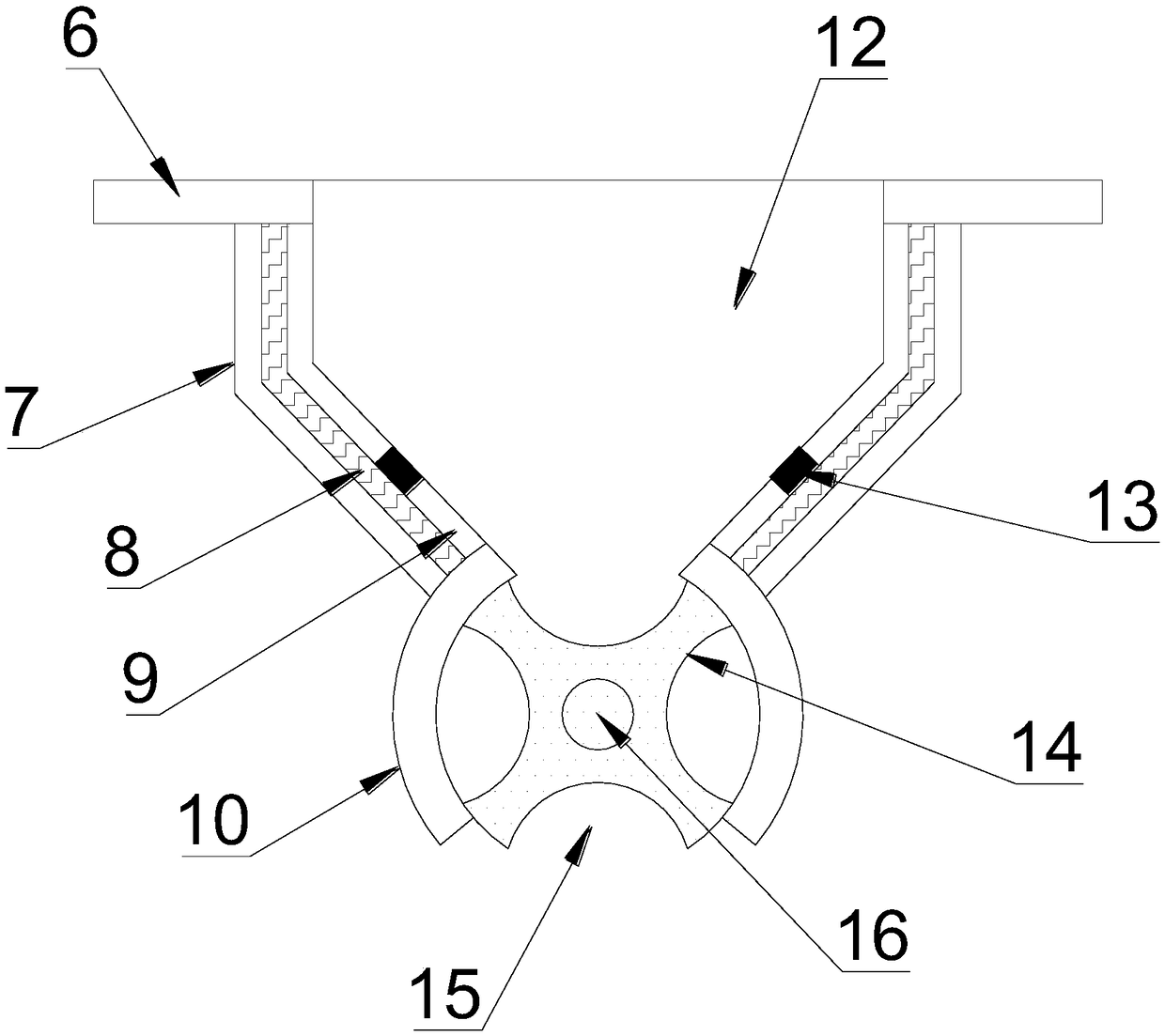

Preheating powder spreading device for selective laser melting metal 3D printing

InactiveCN108788150AReduce energy consumptionEvenly dispersedAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSlag

The invention discloses a preheating powder spreading device for selective laser melting metal 3D printing. The preheating powder spreading device comprises a powder supply tank body, a heat conduction cylinder, a powder spreading tank body, a powder feeding roller body, powder spreading filter screens, a powder spreading brush and a forming platform; and powder recycling boxes and a forming working cylinder are arranged at the bottom of the forming platform, a powder spreading mechanism and a powder supply preheating mechanism are installed above the forming platform, the powder spreading filter screens are arranged in a ">" shape, and a plurality of powder spreading through holes are formed in the powder spreading filter screens. According to the preheating powder spreading device, the device only needs to drive the powder spreading brush to move left and right to spread the powder, so that the energy consumption is saved; the plurality of powder spreading through holes are formed inthe powder spreading filter screens, metal powder can be dispersed more uniformly in the process of sliding down of the metal powder, and the paving efficiency is higher; large-particle metal particles can directly fall into the powder recycling boxes along slag falling grooves in the two sides, and the 3D printing product quality problem due to doping of the large-particle metal particles is avoided; and the metal powder is preheated in advance, the time for heating and melting the paved metal powder is saved, and the 3D printing efficiency is improved.

Owner:广西富乐科技有限责任公司

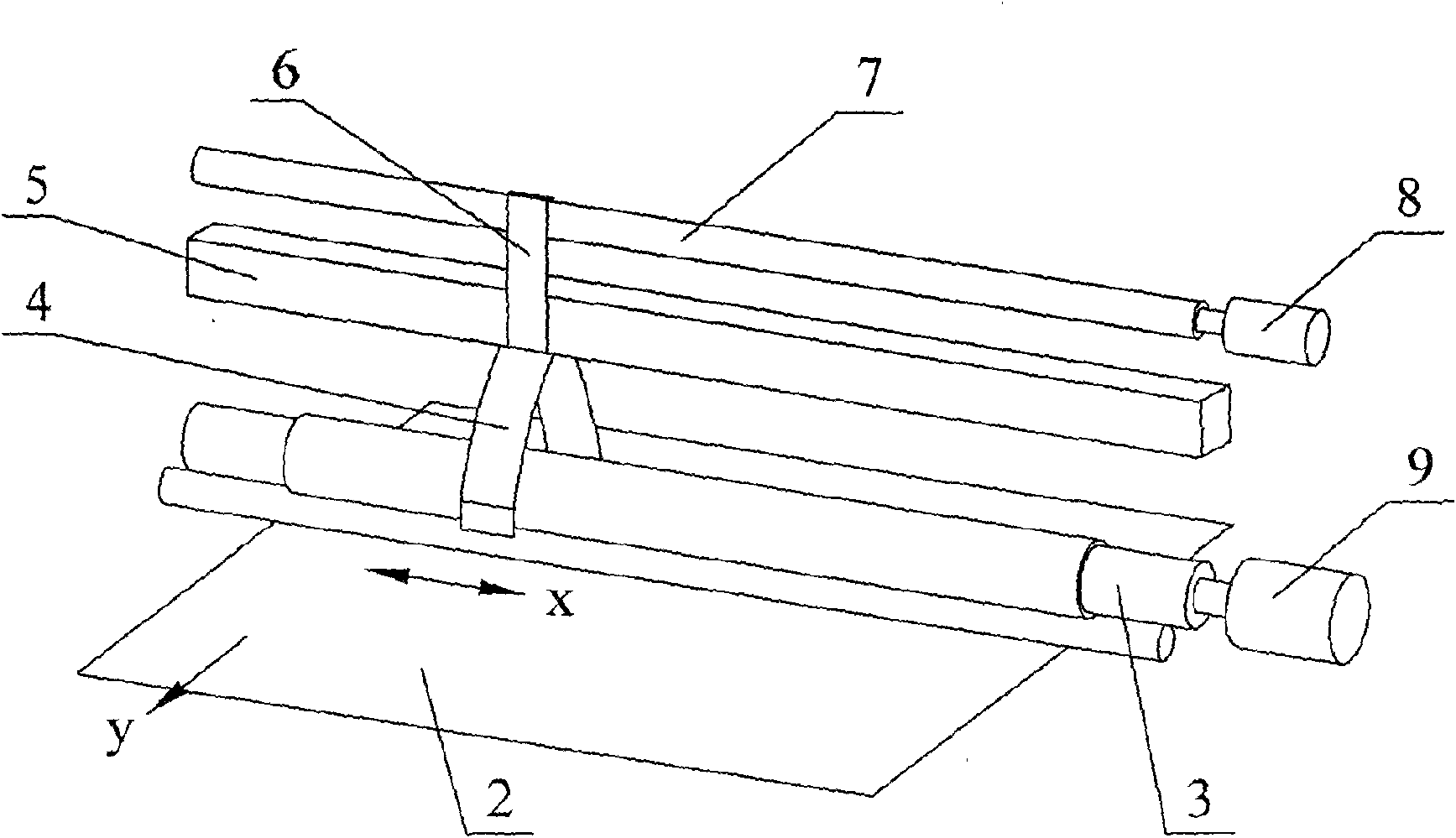

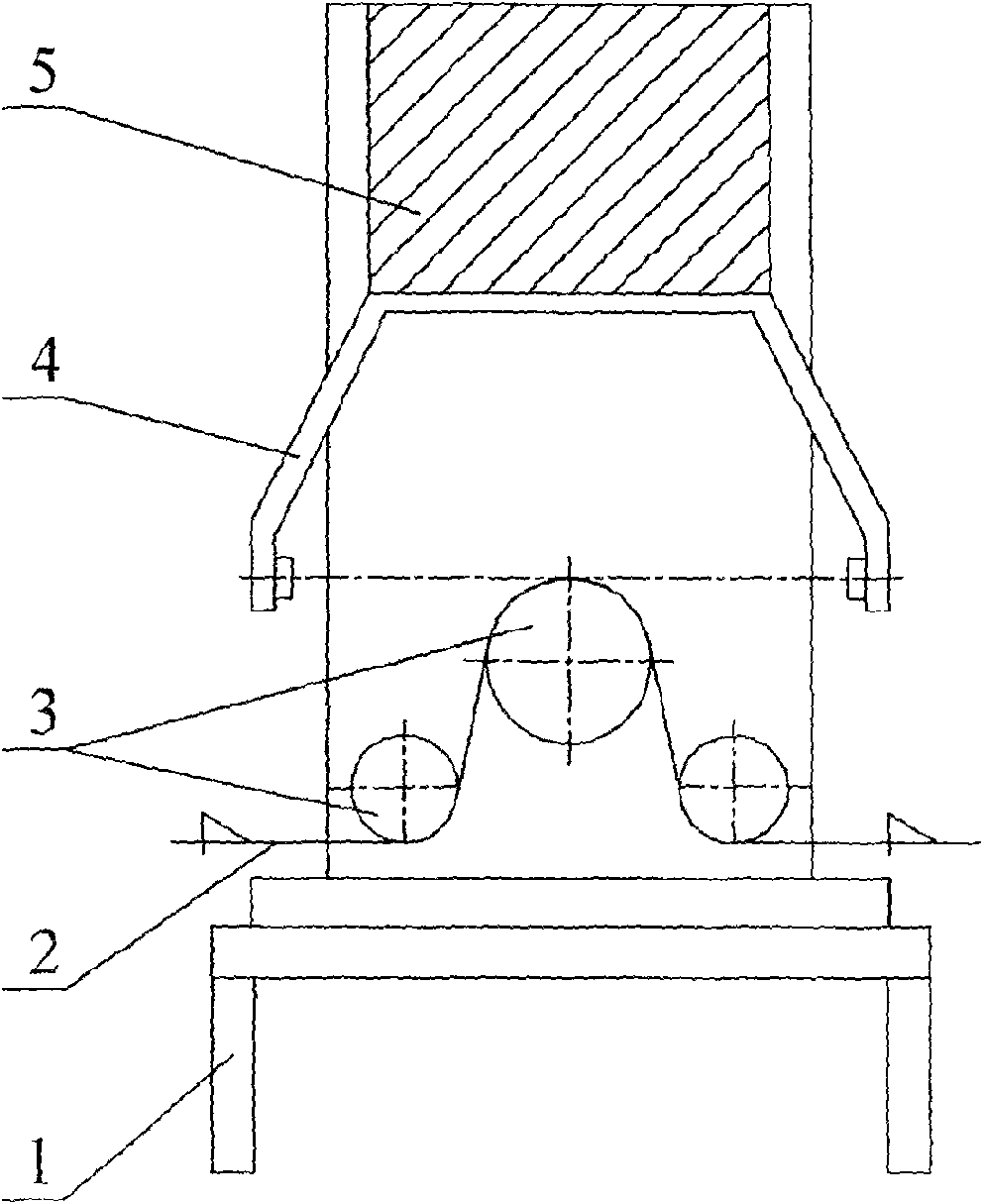

Calendar on-line thickness-measuring device

The invention discloses a calendar on-line thickness-measuring device, which overcomes the disadvantages of wasting time and energy and poor accuracy in prior measuring methods by a dial test indicator and a micrometer in site. In the invention, optical measurement-control principle is applied to extract parallel light of second derivative action circuit on the imaging edge of CCD photosurface; narrow square signal output is converted to obtain the thickness of the calendered goods to be measured through computer processing; any on-line thickness measurement of calendered goods to be measured can be implemented. The device consists of a bearing, calendered goods to be measured, a guild roll, a sensor device, a guild way, a slide rod, a ball screw, an actuating motor and a variable-frequency motor. The device provided by the invention has the beneficial effects of stable performance, high measuring efficiency, reducing labor intensity and accurate measurement, moreover, the accuracy difference is below 5mum, thus realizing automation and integration of measurement systems.

Owner:湖南晋铨机械有限公司

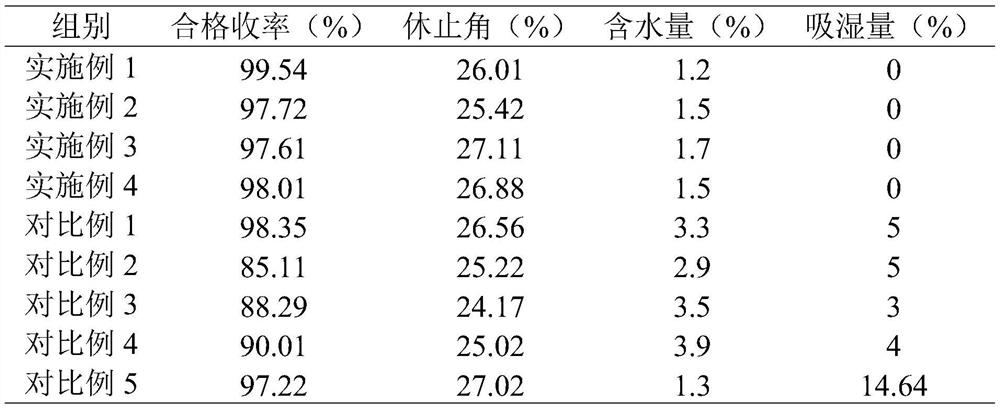

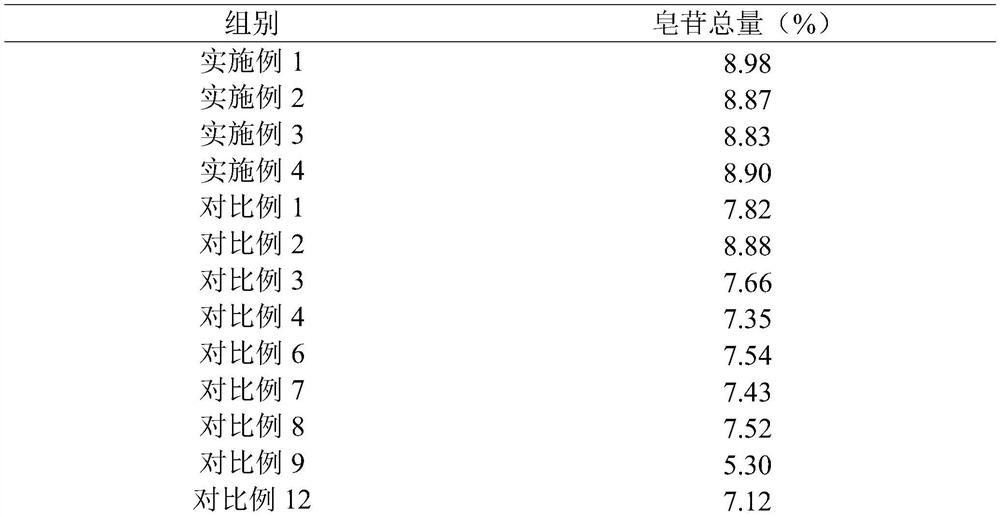

Pseudo-ginseng vacuum freeze-drying method and application thereof

InactiveCN112229148APrevent local melting and disintegrationAvoid affecting product qualityDrying solid materials without heatDaily livingFreeze-drying

The invention relates to a pseudo-ginseng vacuum freeze-drying method and application thereof, and relates to the technical field of traditional Chinese medicine processing. According to the vacuum freeze-drying method, pseudo-ginseng homogenate is subjected to pre-freezing and vacuum drying treatment, in the pre-freezing step, pre-freezing is carried out in stages at the temperature of minus 20-minus 75 DEG C, and in the vacuum drying treatment step, vacuum drying is carried out at the temperature of minus 20-30 DEG C. The vacuum freeze-drying method is applied to preparation of pseudo-ginseng processed products, and the obtained pseudo-ginseng processed products are high in cleanliness, fine and smooth in taste, stable in quality, accurate in dosage, convenient to apply and carry, high in dissolution and absorption speed, higher in product standardization, higher in production efficiency and suitable for daily life of normal people.

Owner:湖北金贵中药饮片有限公司

Process for producing cathode copper by low-grade anode plates

ActiveCN109628954ARaise the gradeFlat surfacePhotography auxillary processesElectrolysis componentsElectrolysisEthyl acetate

The invention relates to a process for producing cathode copper by low-grade anode plates. Low-grade high-nickel tin black copper is used as raw materials for direct electrolysis refining to prepare qualified cathode copper; through such modes as adjustment of process conditions, selection of reasonable current density, flow and temperature, adjustment of the additive ratio and adding of modifiedpolyacrylamide, the obtained cathode copper is higher in grade, smooth in surface, clear and compact in grain, uniform in thickness and beautiful; meanwhile, the purification and replacement period ofelectrolyte is prolonged, so that the production cost is greatly reduced when the recovery rate is increased; anode mud is treated by adopting ethyl acetate and phenolic resins, so that the problem of difficult gold and silver separation of the anode mud due to adding of polyacrylamide is solved, and the daily treatment quantity of the anode mud is increased; and copper sulfate crystal seeds areintroduced to accelerate separation of copper sulfate crystals, so that the recycling rate of metal copper and nickel is improved.

Owner:江西新金叶实业有限公司

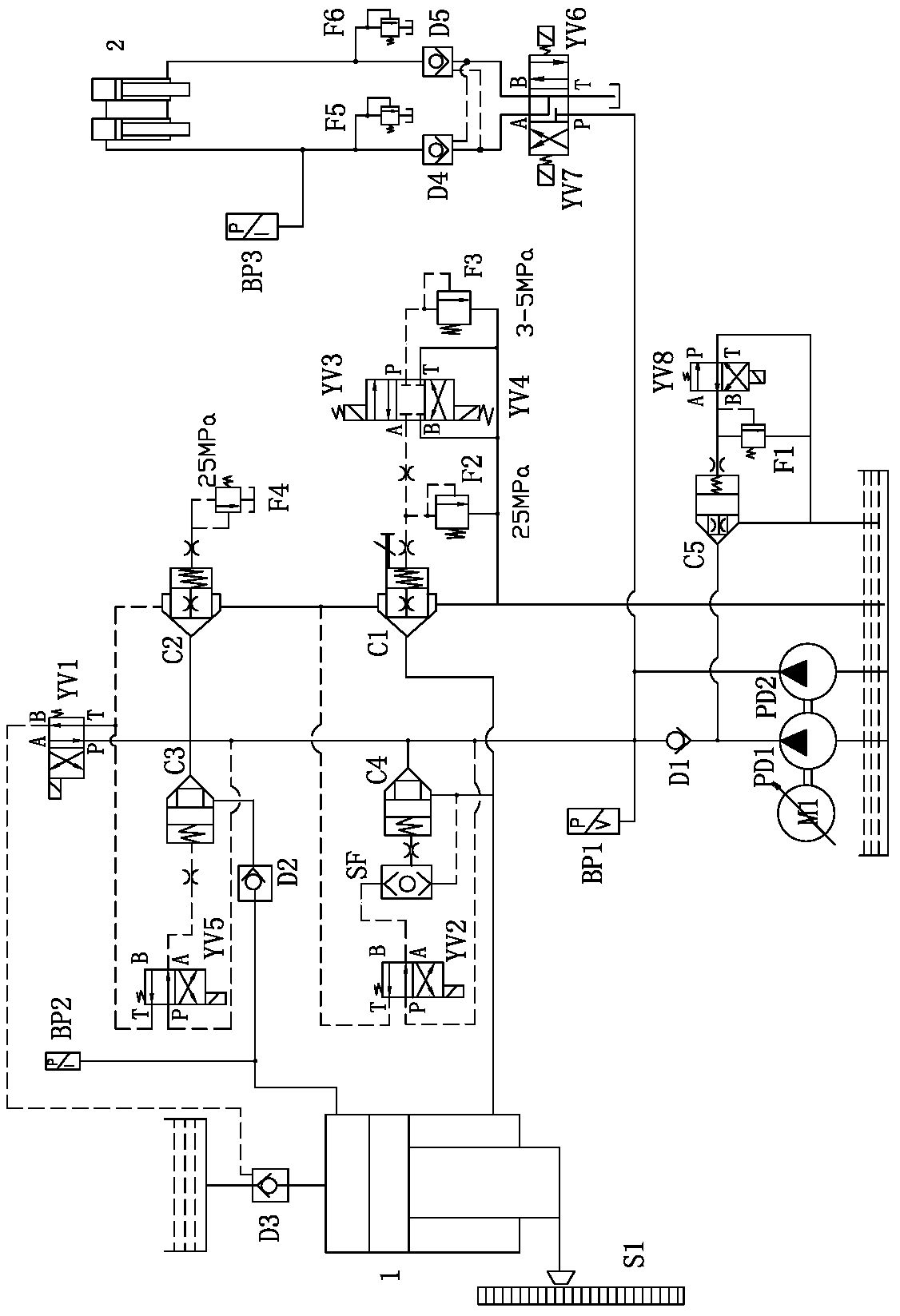

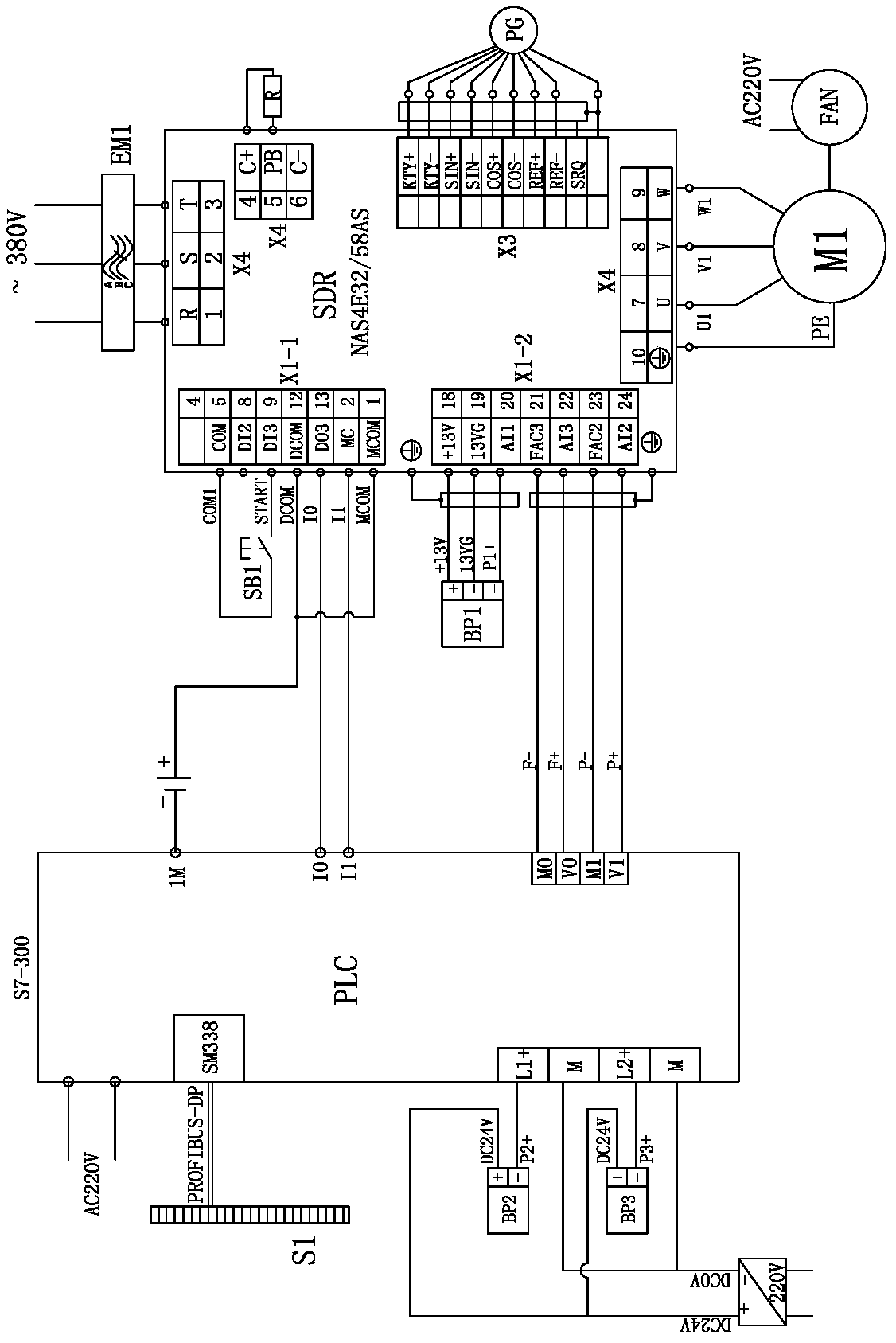

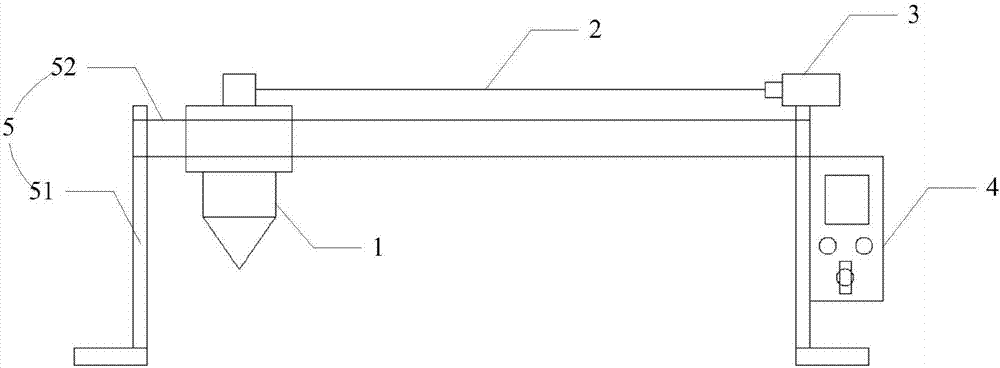

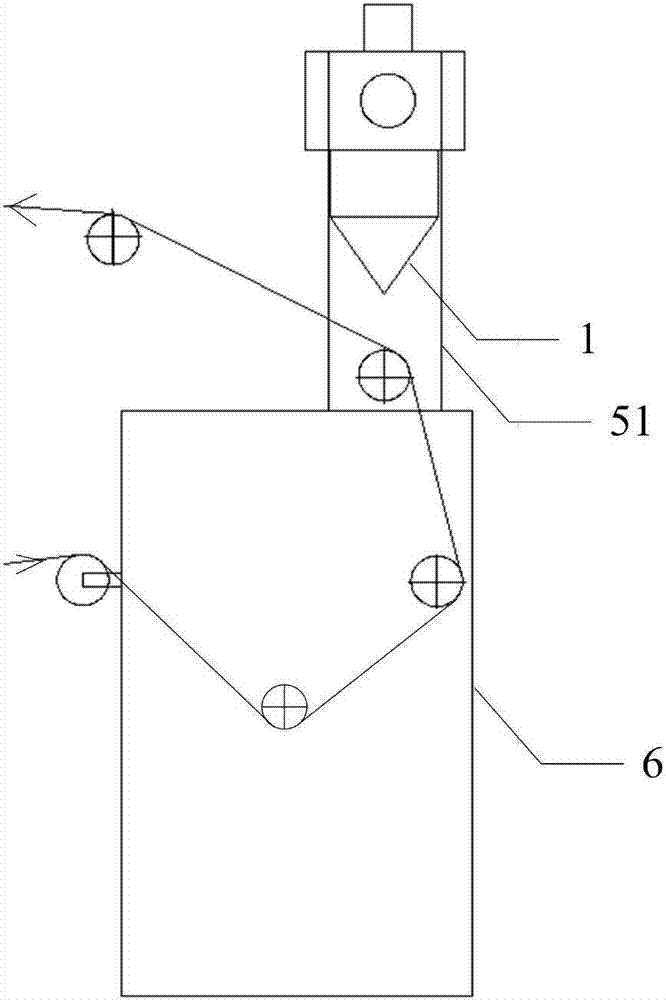

Hydraulic press control system, and method for machining automotive interiors by hydraulic press control system

The invention relates to a hydraulic press control system, and a method for machining automotive interiors by the hydraulic press control system. A servo pump comprises a low-pressure high-flow pump and a high-pressure low-flow pump, and an outlet of the low-pressure pump is connected to an inlet of a first check valve; an outlet of the high-pressure pump is connected to an outlet of the first check valve in parallel, and the outlet of the first check valve is connected to inlets of a second cartridge valve, a third cartridge valve and a fourth cartridge valve; the outlet of the third cartridge valve is connected to an inlet of a second check valve, and an outlet of the second check valve is connected to an upper cavity of a master cylinder; the outlet of the fourth cartridge valve is connected to a lower cavity of the master cylinder; and the lower cavity of the master cylinder is connected to the inlet of the first cartridge valve, and the outlets of the first cartridge valve and thesecond cartridge valve are connected to a main oil tank. The method for machining the automotive interiors comprises the following steps of quick descending, feeding, compression, pressure maintaining and decompression of the master cylinder, draft and slow return, ejection and return of a ramming cylinder, and back stroke of the master cylinder in sequence. The automotive interiors machined by the hydraulic press are high in yield rate and low in energy consumption.

Owner:YANGLI GRP CORP LTD

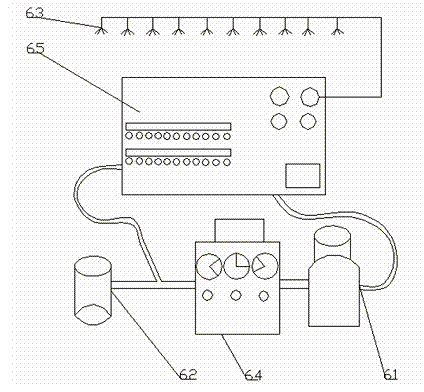

Gluing thickness online detection device in gluing production line

InactiveCN107289871AEasy to adjust in real timeAvoid affecting product qualityLiquid surface applicatorsUsing optical meansProduction lineEngineering

The invention discloses a gluing thickness online detection device in a gluing production line. The device comprises a gluing thickness detection mechanism, a driving mechanism, and a control mechanism. The gluing thickness detection mechanism is used to detect gluing thickness of a glued material in real time and synchronously capture width of the glued material. The driving mechanism is used to drive the gluing thickness detection mechanism to move along the width direction of the glued material. The control mechanism is used to receive width signals and gluing thickness signals of the glued material, the signals being sent by the gluing thickness detection mechanism, and according to the width signals of the glued material, controls the driving mechanism to drive the gluing thickness detection mechanism to move along the width direction of the glued material, and meanwhile the gluing thickness signals of the glued material is converted to gluing thickness data and is displayed. The gluing thickness online detection device can full-automatically detect thickness of the glued material online in a gluing production line, providing convenience for operating personnel to adjust a production technology, ensuring quality of a product, and saving cost.

Owner:DONGGUAN GUANGZHI PHOTOELECTRIC CO LTD

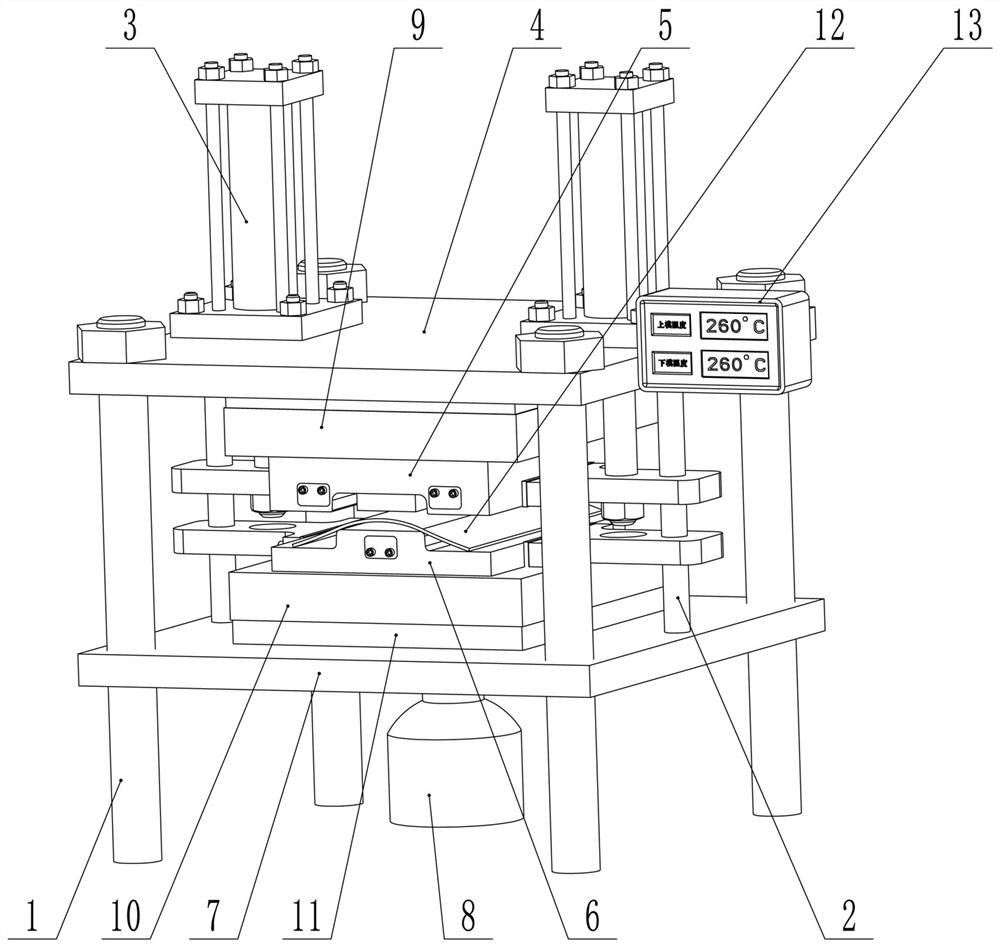

Forming device of rapid heating and cooling separation type continuous carbon fiber thermoplastic U-shaped part and process

The invention provides a forming device of rapid heating and cooling separation type continuous carbon fiber thermoplastic U-shaped part. The forming device comprises an upper driving mechanism, a lower driving mechanism, a vertical guide mechanism, an upper base, an upper mold, a lower mold and a lower base, wherein the upper base, the upper mold, the lower mold and the lower base are sequentially arranged from top to bottom; a lower heating plate is arranged at the top of the lower base, a cooling mechanism is embedded in each of the upper mold and the lower mold, the upper driving mechanismdrives the upper mold to ascend and descend along the vertical guide mechanism, the lower mold is installed on the vertical guide mechanism and can ascend and descend along the vertical guide mechanism, and the vertical guide mechanism is provided with a lowest limiting mechanism corresponding to the lower mold; and the lower driving mechanism drives the lower base to ascend and descend along thevertical guide mechanism. The invention further provides a forming process of the continuous carbon fiber thermoplastic U-shaped part. The forming device of the rapid heating and cooling separation type continuous carbon fiber thermoplastic U-shaped part and the process have the advantages of being scientific in design, high in production efficiency, low in energy consumption, good in product quality, economical and applicable.

Owner:ZHENGZHOU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com