Brushing device for metal bar

A metal rod and bristle technology, which is applied in the directions of grinding drive devices, metal processing equipment, grinding machine parts, etc., can solve the problems of wear and tear of the brush wheel, easy damage, deformation of the rod to be processed, etc., and achieves simple structure and convenient adjustment. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

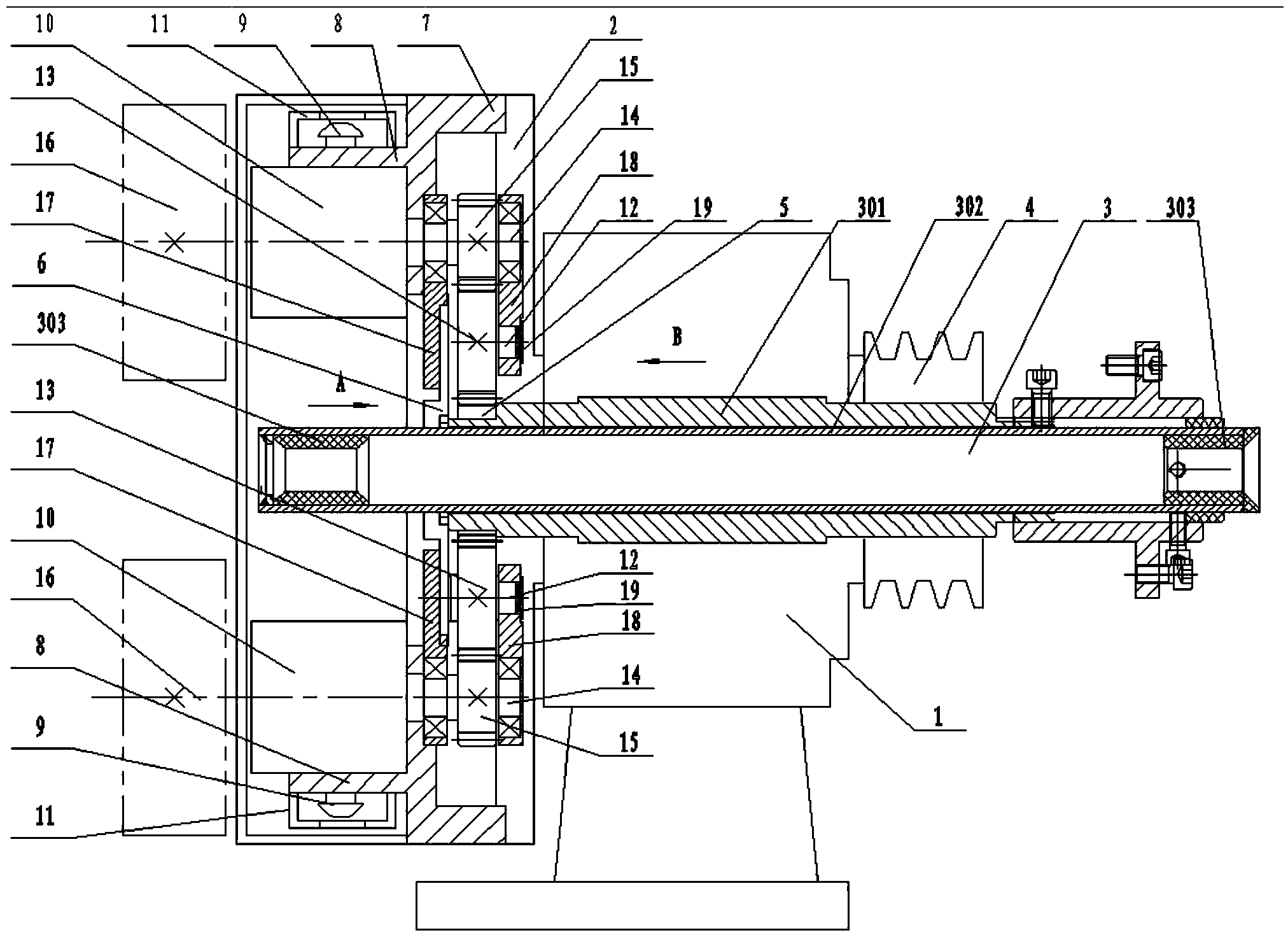

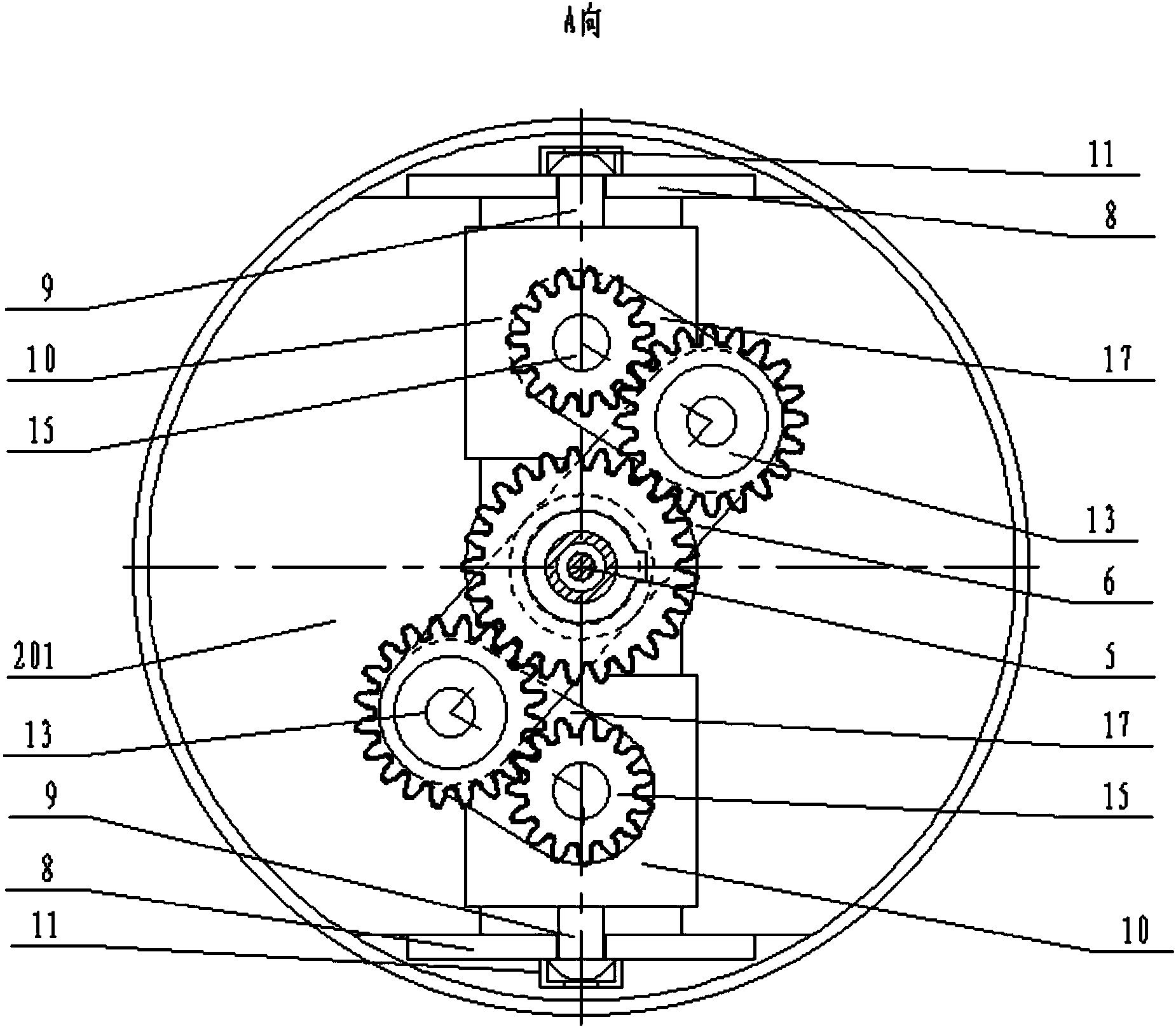

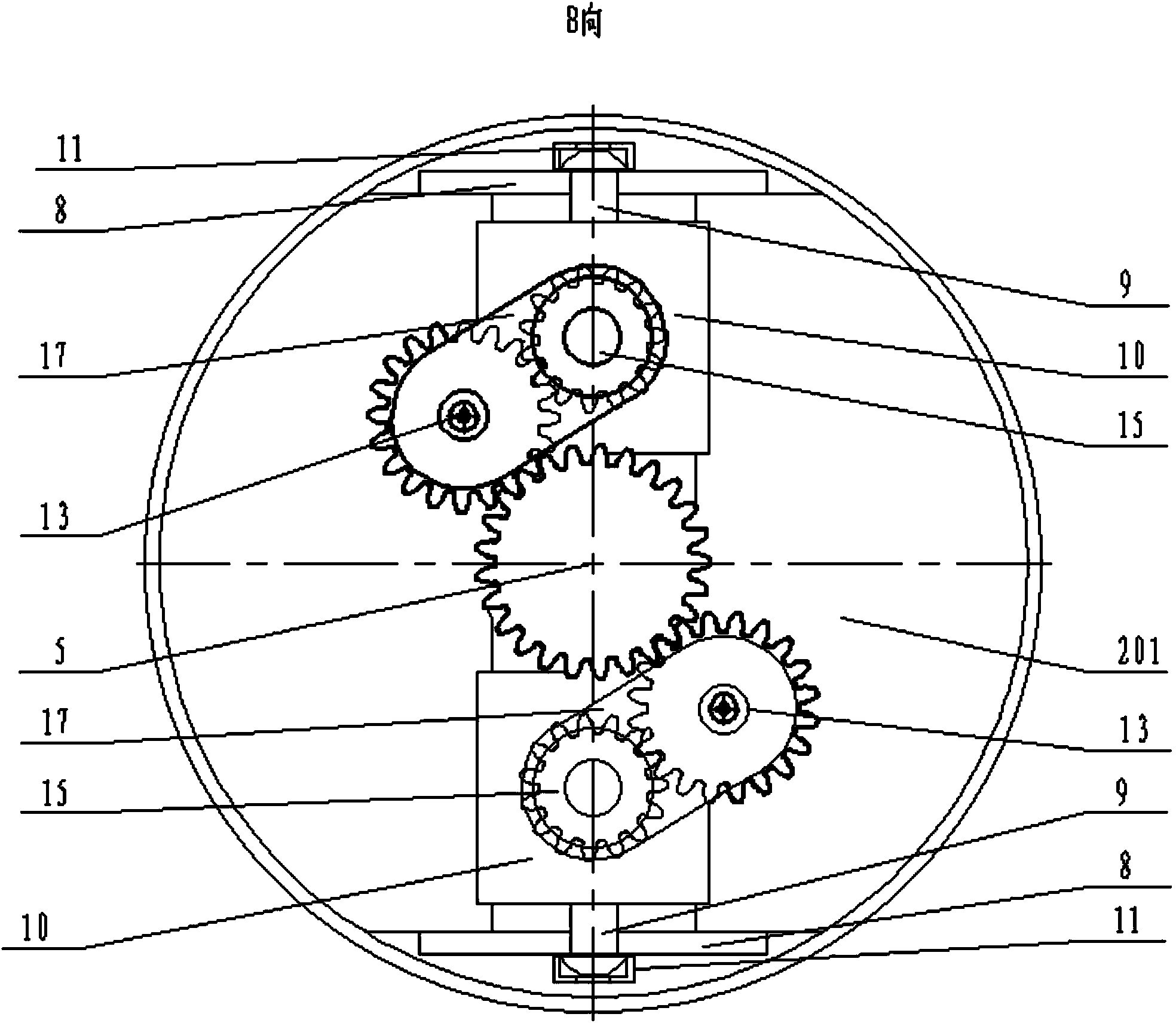

[0021] like Figure 1-3 As shown, a metal rod brushing device includes a base 1, a metal rod brushing device includes a base 1, a hollow shaft 301 is pierced in the base 1, and the central shaft assembly 3 includes a hollow shaft 301 , The hollow shaft 301 is provided with a sleeve 302, and the two ends of the sleeve 302 are respectively detachably provided with a nylon sleeve 303 in the middle for the rod to be processed to pass through. A revolving seat 2 is movably sleeved between the base 1 and the central shaft assembly 3, and a pulley 4 is provided on one side of the revolving seat 2 to drive it to rotate. The hollow shaft 301 passes through the through hole in the middle of the pulley 4. The hollow shaft 301 on the other side of the revolving base 2 are set with a central gear 5, a main connecting rod 6 and a revolving head 7 in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com