Patents

Literature

120results about How to "Change the state of stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

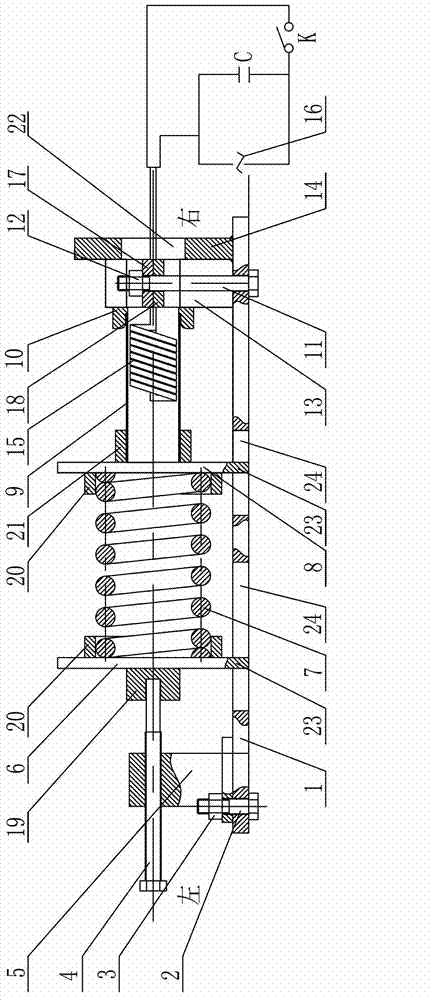

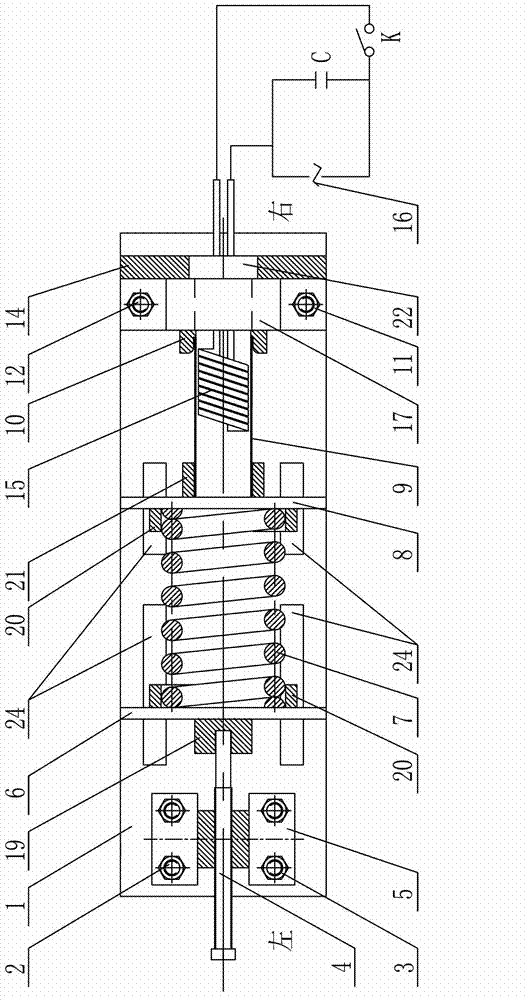

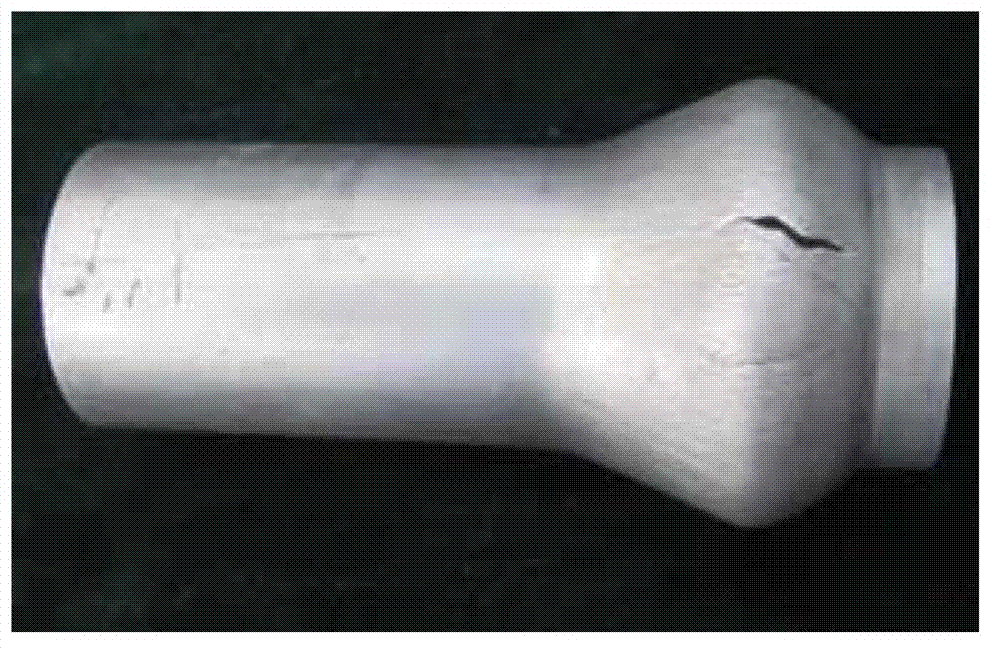

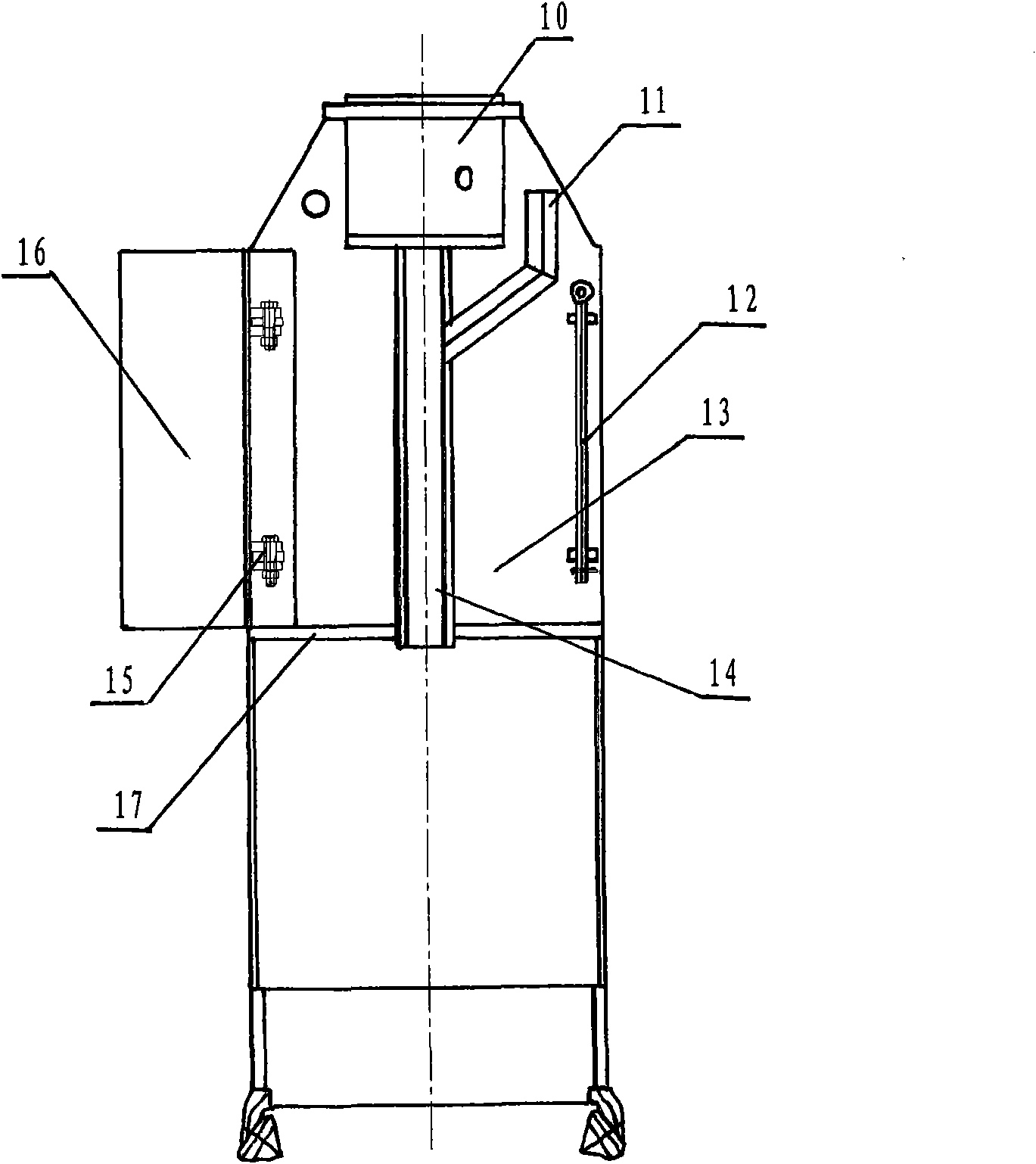

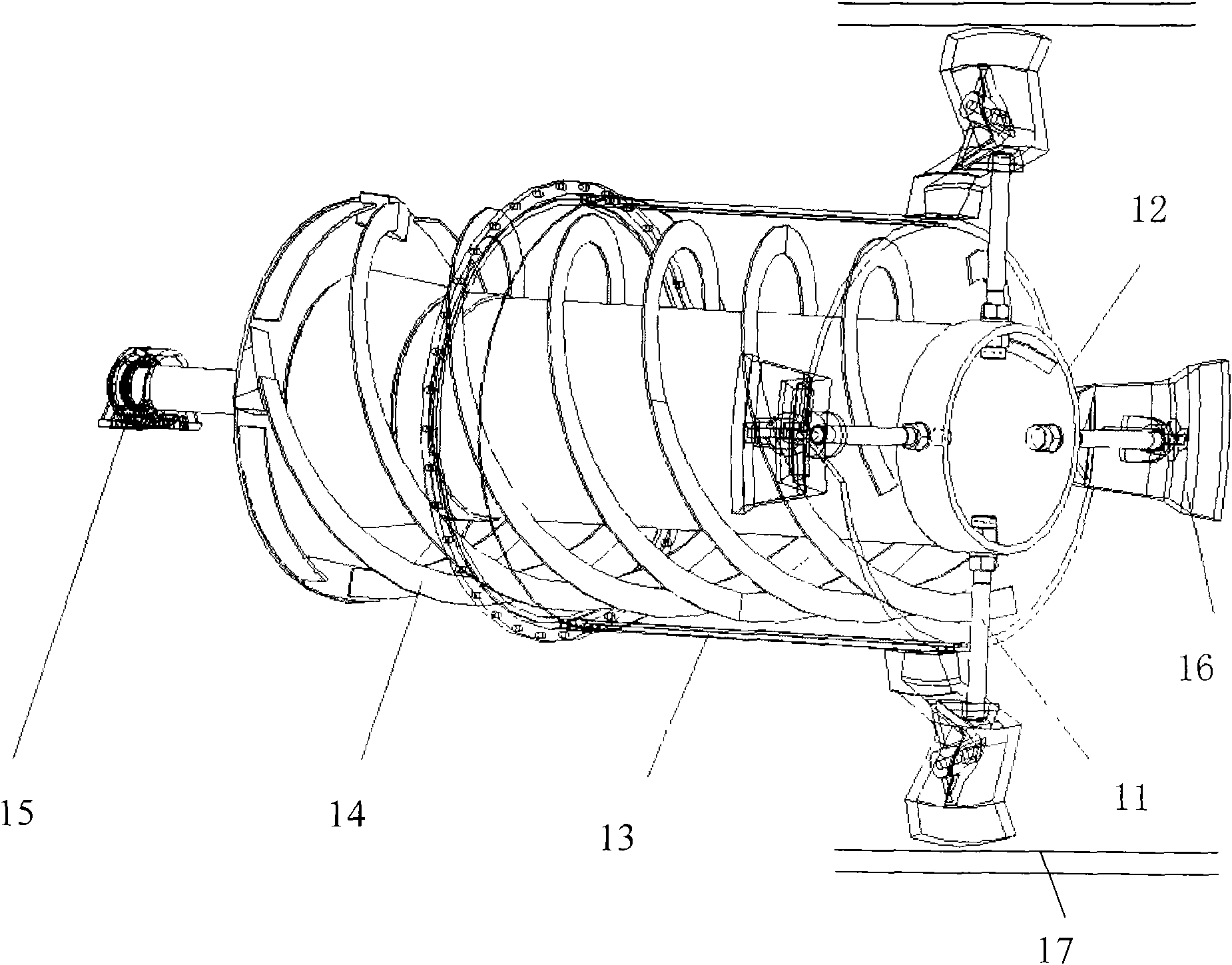

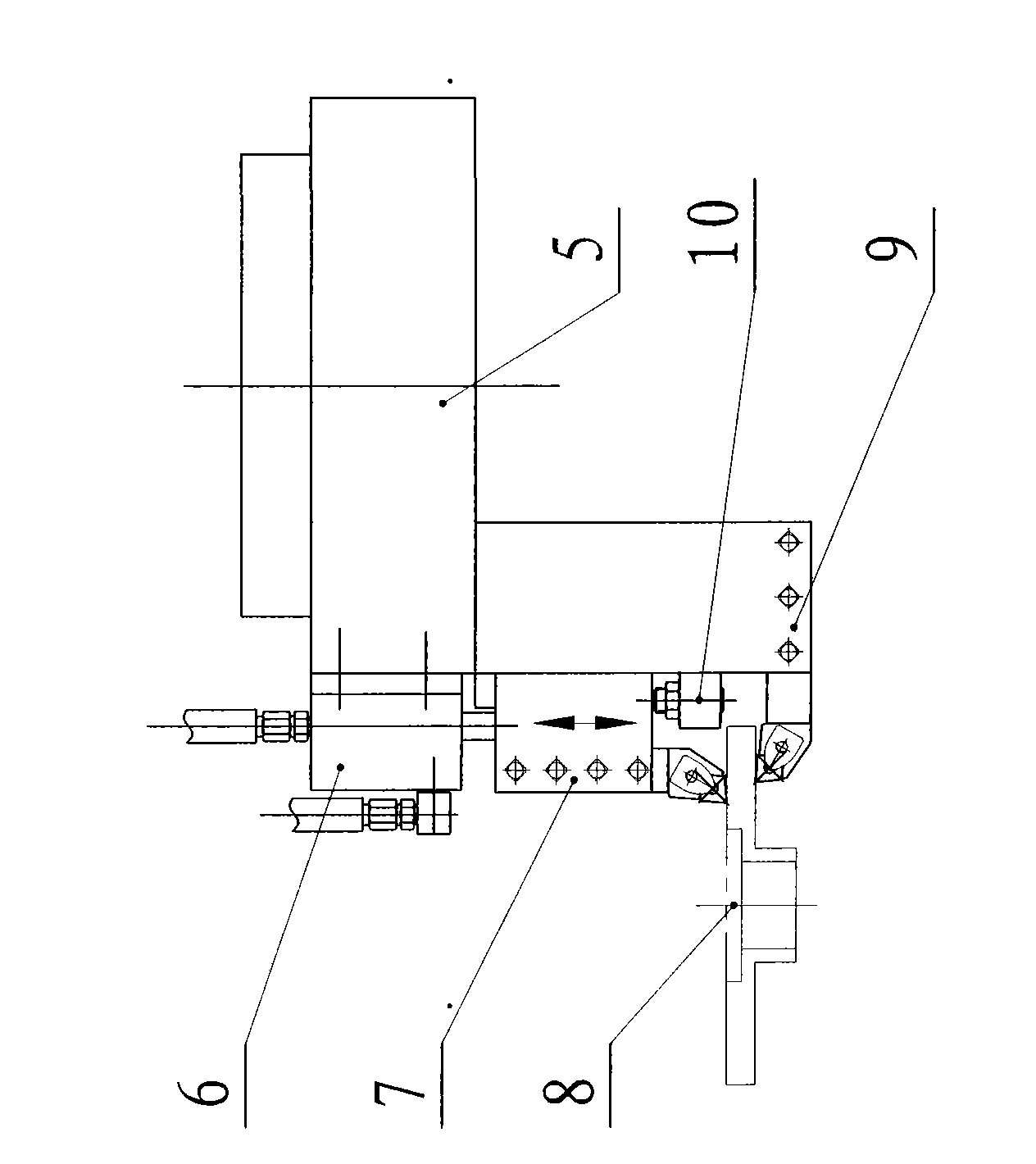

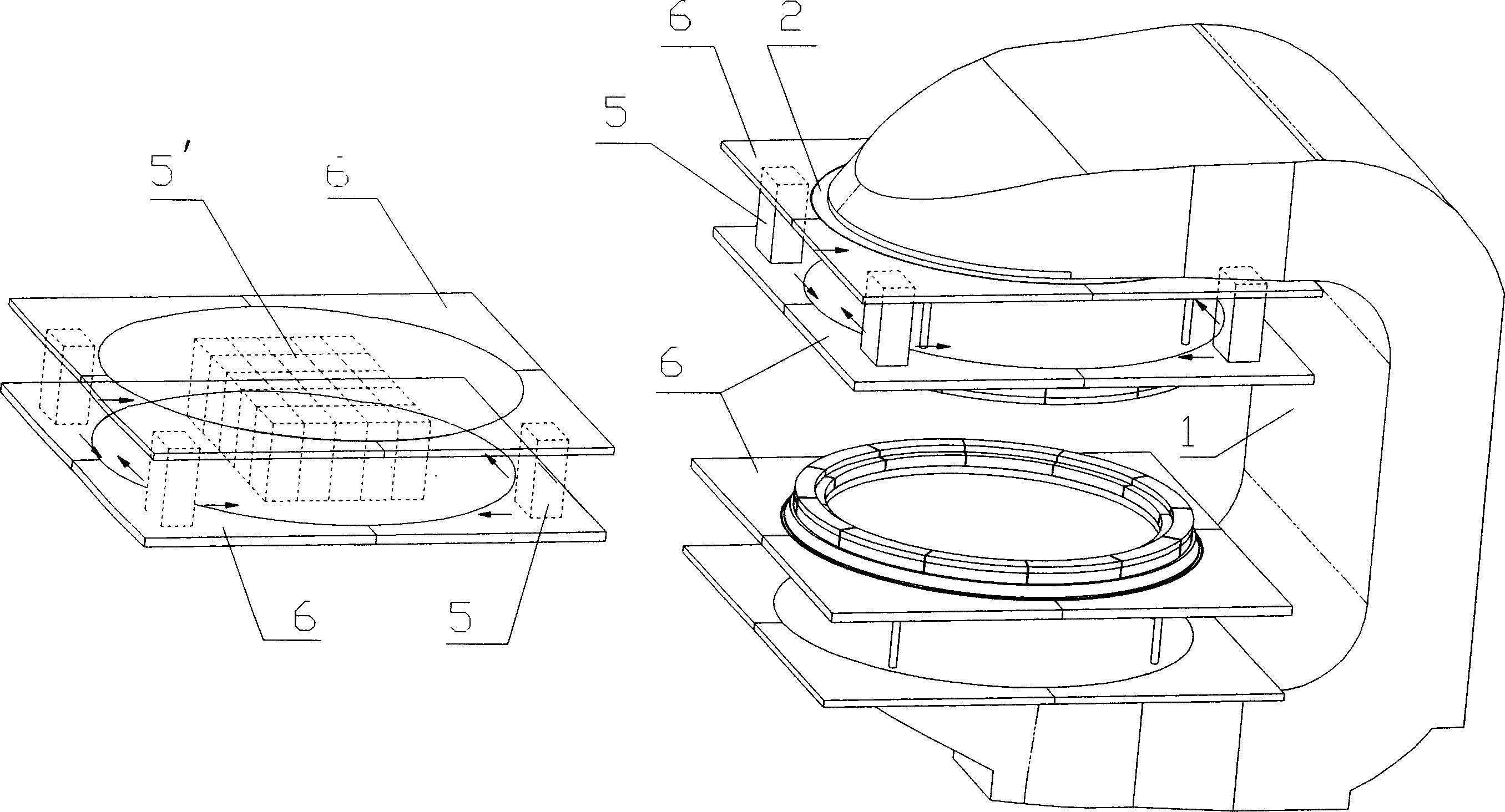

Device and method for axial loading to assist bulging of magnetic pulse pipe

The invention discloses a device and a method for axial loading to assist bulging of a magnetic pulse pipe, relates to a device and a method for bulging of a magnetic pulse pipe, and aims to solve the problem of breakage due to the fact that when a pipe fitting is locally bulged by existing magnetic pulse forming technology, deformation of a pipe wall is uneven and the pipe wall is excessively thinned. A lead guiding block is connected with a rectangular bottom plate, an upper clamp block and a lower clamp block are connected with the rectangular bottom plate, a lead screw is connected with the lead screw guiding block in a threaded manner, bumps on two push plates are slidably arranged in guide grooves of the rectangular bottom plate, the right end of the lead screw is arranged in a lead screw limiting sleeve fixedly connected with the left push plate, a spring is arranged in spring limiting sleeves fixedly connected with the two push plates, a coil is arranged between the right push plate and a fixture, two lead wire sections of the coil are serially connected onto a discharge control switch, and a capacitor bank is serially connected with a power source. The method includes sleeving a pipe fitting on the coil; exerting axial pre-tightening force; and taking out the formed pipe fitting after discharge forming. The device and the method are used for bulging and machining pipe fittings difficult to form.

Owner:HARBIN INST OF TECH

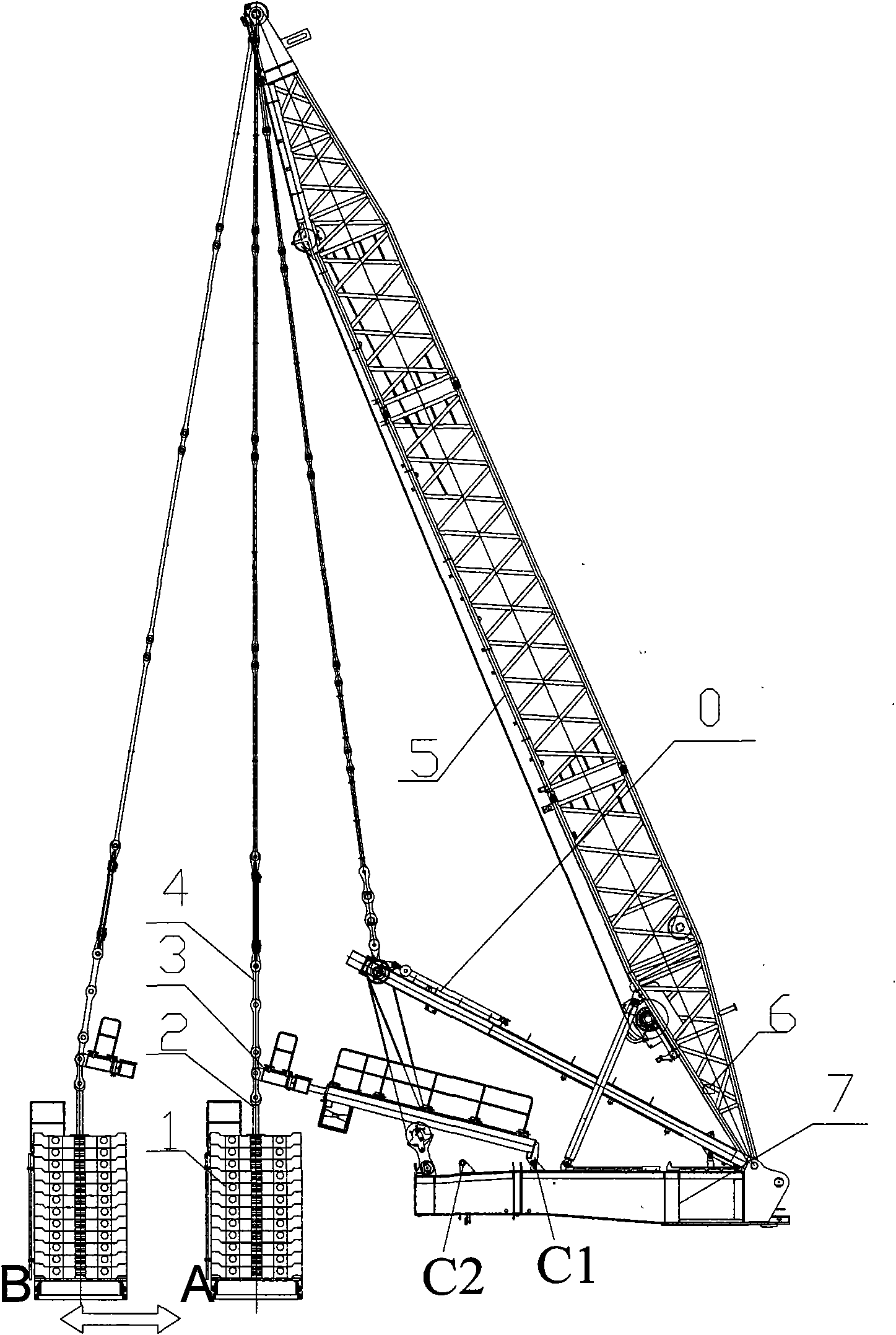

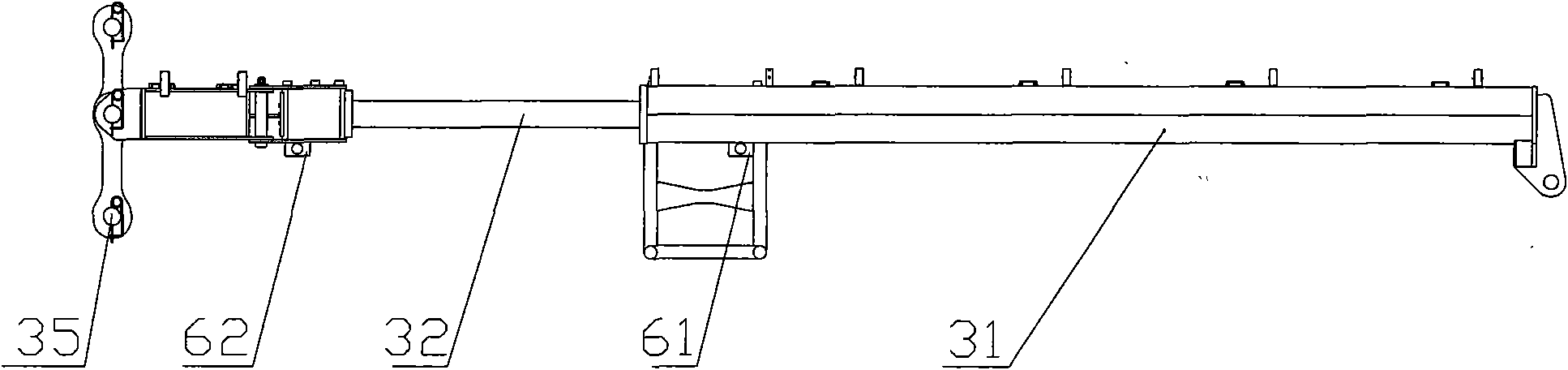

Super-starting balance weight stepless luffing mechanism of crawler crane and operating method thereof

Owner:ZHEJIANG SANY EQUIP

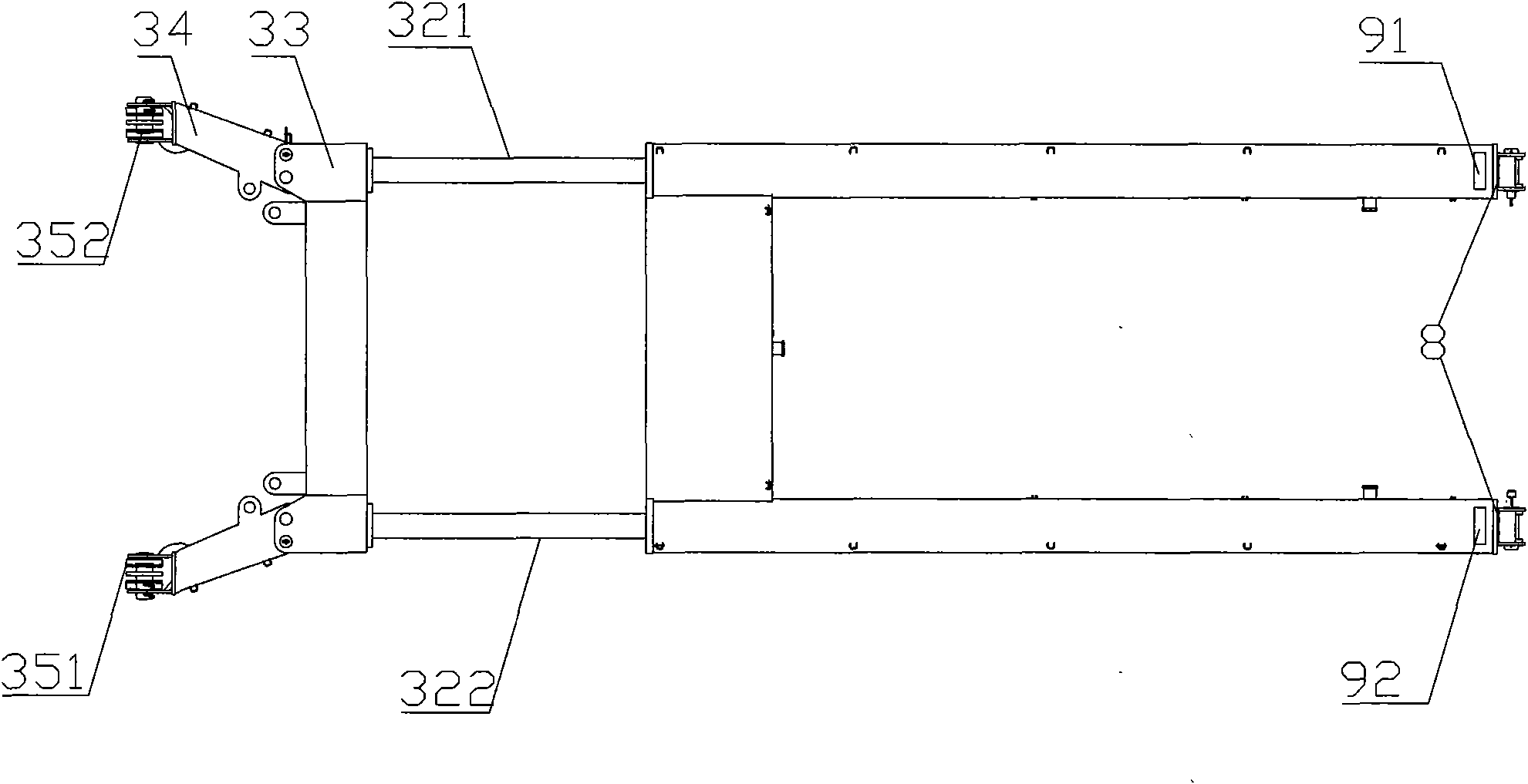

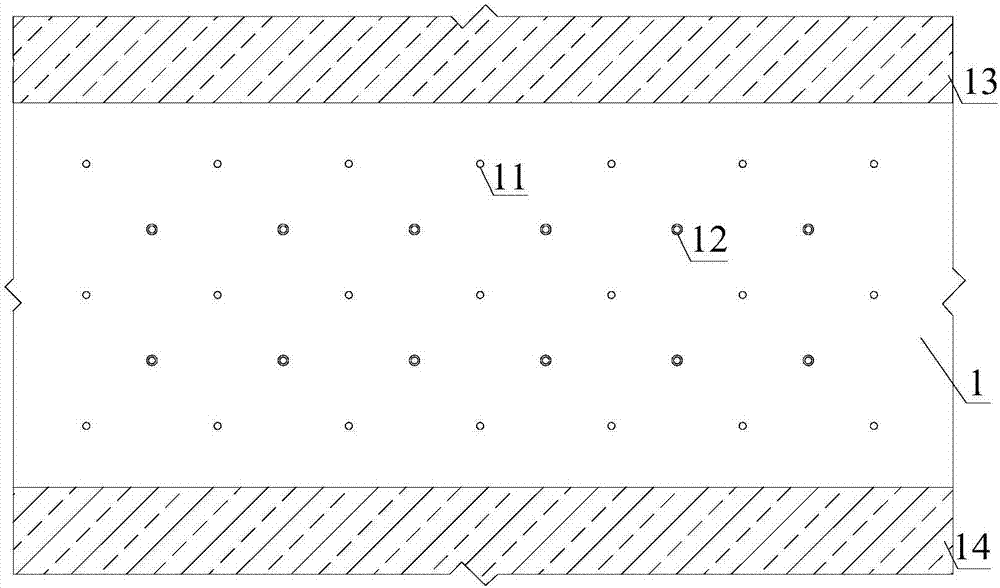

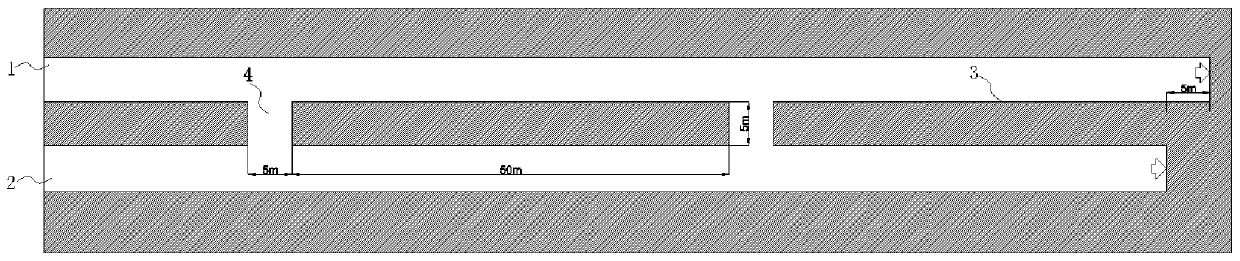

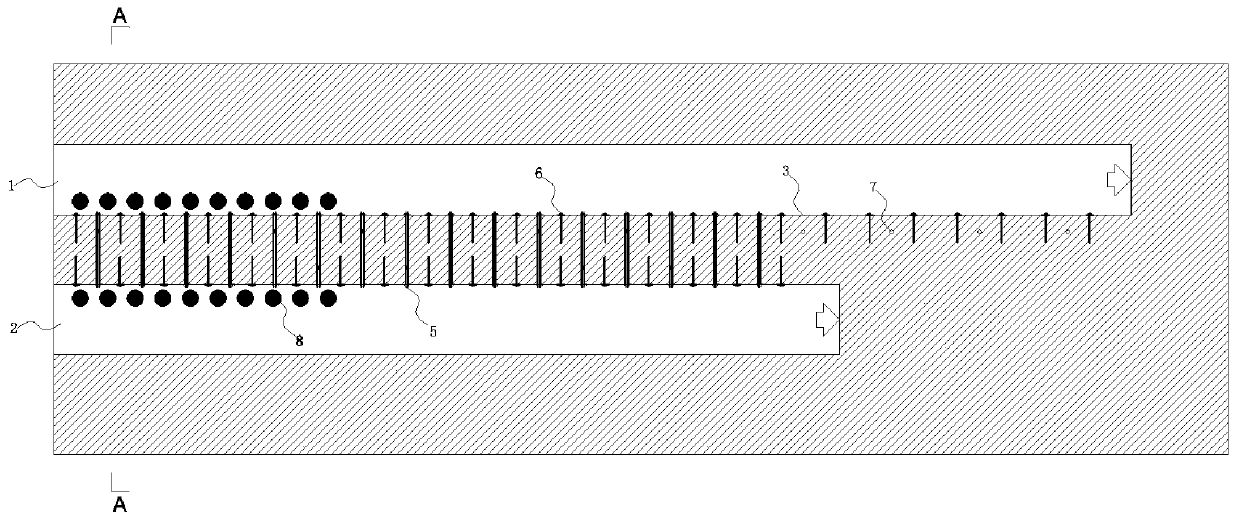

Coal mine underground reservoir and multi-layer grouting anti-seepage reinforcement method for reservoir dam

The invention provides a coal mine underground reservoir and a multi-layer grouting anti-seepage reinforcement method for a reservoir dam and belongs to the field of coal mine underground construction. According to the multi-layer grouting anti-seepage reinforcement method, the area of the underground reservoir and the location of the coal pillar dam are determined and set through the volume; two side tunnels and withdrawal tunnels of the underground reservoir are drilled, concrete grout and silica sol are sequentially sprayed on the tunnel walls, and concrete and silica sol spray layers are formed; a plurality of shallow grouting holes are constructed in the sides, near the coal pillar dam, of the two side tunnels and the withdraw tunnels and the holes are sealed for grouting, and then a plurality of deep grouting holes are constructed and sealed for grouting; and finally, an artificial water retaining dam is constructed for sealing the tunnels, and accordingly the closed coal mine underground reservoir is formed. The multi-layer grouting anti-seepage reinforcement method has the double effects of reinforcement and sealing on the coal pillar of the coal mine underground reservoir; and nano-scale, inorganic, green and efficient materials are selected, the anti-seepage safety of the coal pillar dam can be ensured, and the coal mine underground reservoir is made durable and stable.

Owner:CHINA UNIV OF MINING & TECH

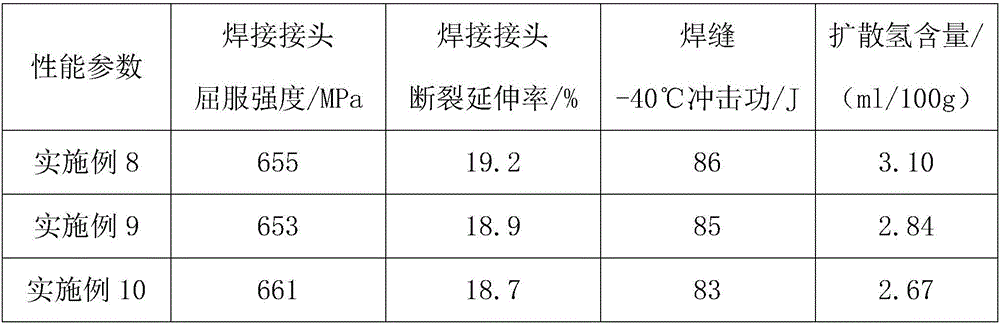

Coated welding wire for welding low-alloy high-strength steel and manufacturing method

InactiveCN106736013AMeet welding requirementsHigh strengthWelding/cutting media/materialsSoldering mediaHigh intensityImpurity

The invention discloses a coated welding wire for welding low-alloy high-strength steel. The coated welding wire comprises a welding wire substrate and a coating which coats the surface of the welding wire substrate, wherein the welding wire substrate is made from the following components in percentage by weight: 0.029 to 0.041 percent of Ti, 0.01 to 0.015 percent of Al, 0.083 to 0.11 percent of Nb, 0.1 to 0.15 percent of C, 0.2 to 0.3 percent of Cr, 0.3 to 0.5 percent of Si, 0.01 to 0.03 percent of N, 1.4 to 1.7 percent of Ni, 0.1 to 0.6 percent of Mo, less than or equal to 0.002 percent of P, less than or equal to 0.002 percent of S, and the balance of iron and unavoidable impurities, wherein as specified by the following formula, K is between 0.013 and 0.032, K=29[Ti]+52[Al]+27[Nb]-100[N]; [Al], [Ti], [Nb] and [N] represent the weight percentage contents of Al, Ti, Nb and N in the welding wire substrate respectively. The invention further discloses a manufacturing method of the coated welding wire for welding the low-alloy high-strength steel. By adopting the coated welding wire, high strength of welding metal is ensured, the welding performance of the low-alloy high-strength welding wire is improved finitely, the occurrence of cold cracks is controlled, a low splashing rate is achieved, and the welding requirement of the high-strength low-alloy steel is met.

Owner:安徽飞弧焊业股份有限公司

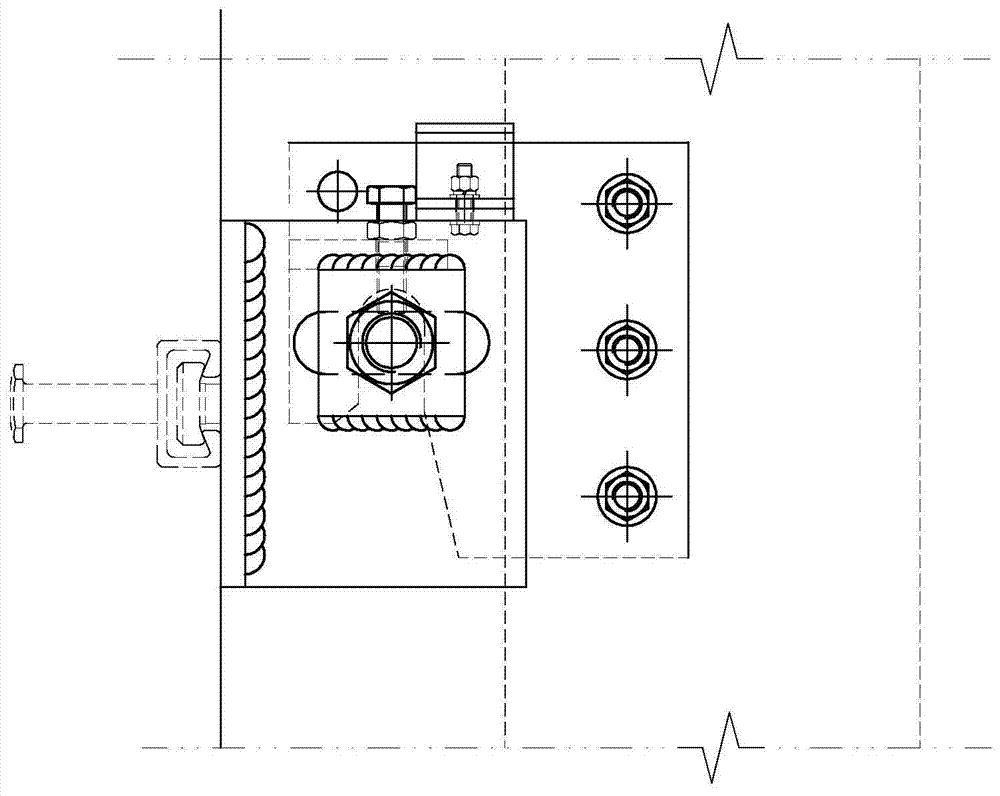

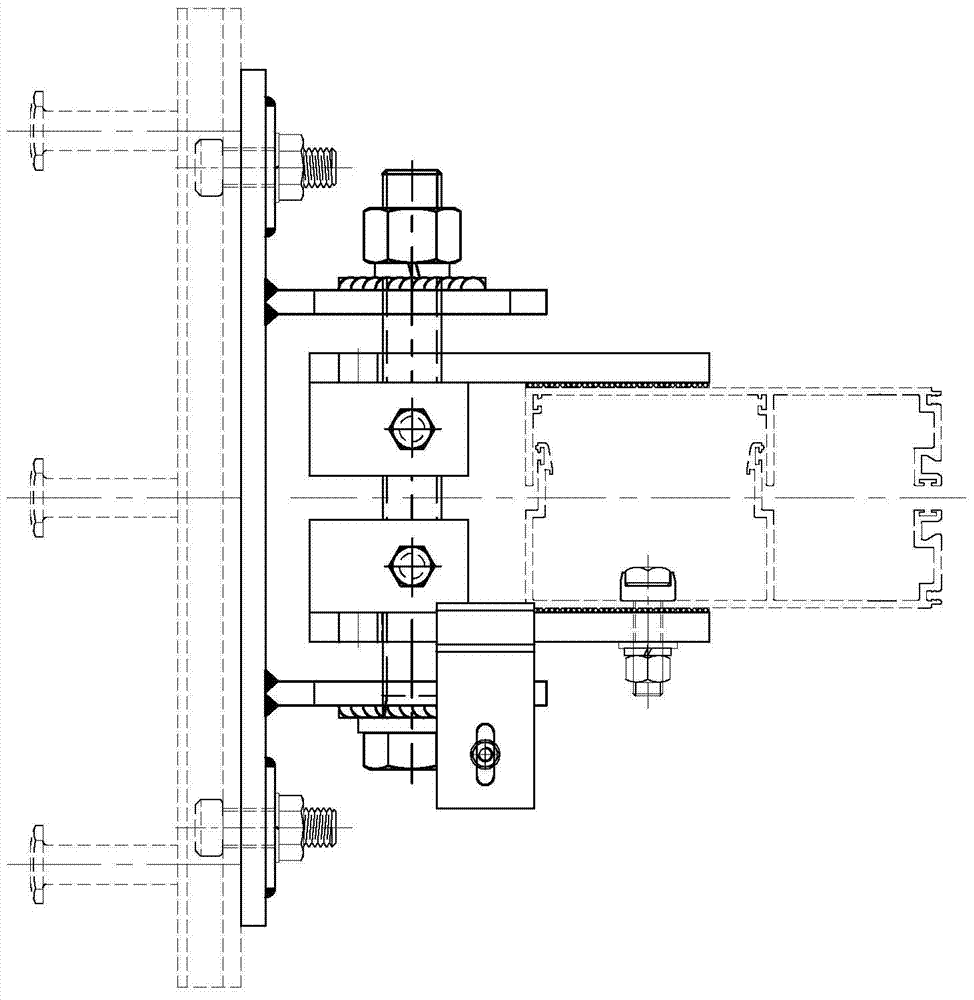

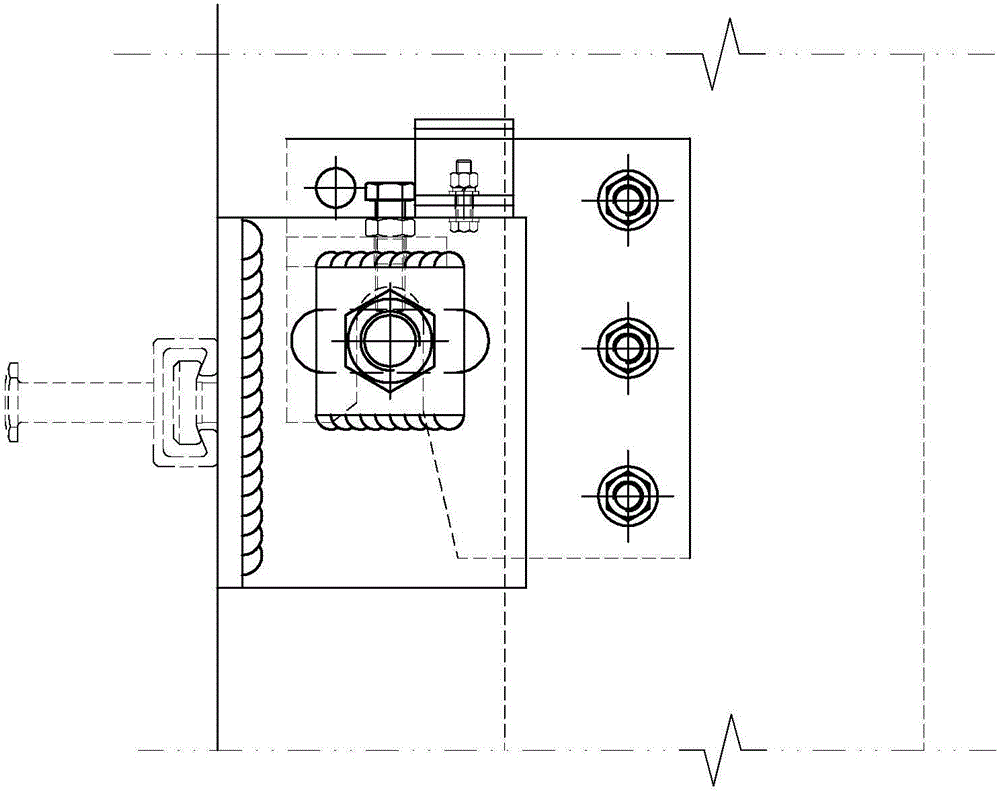

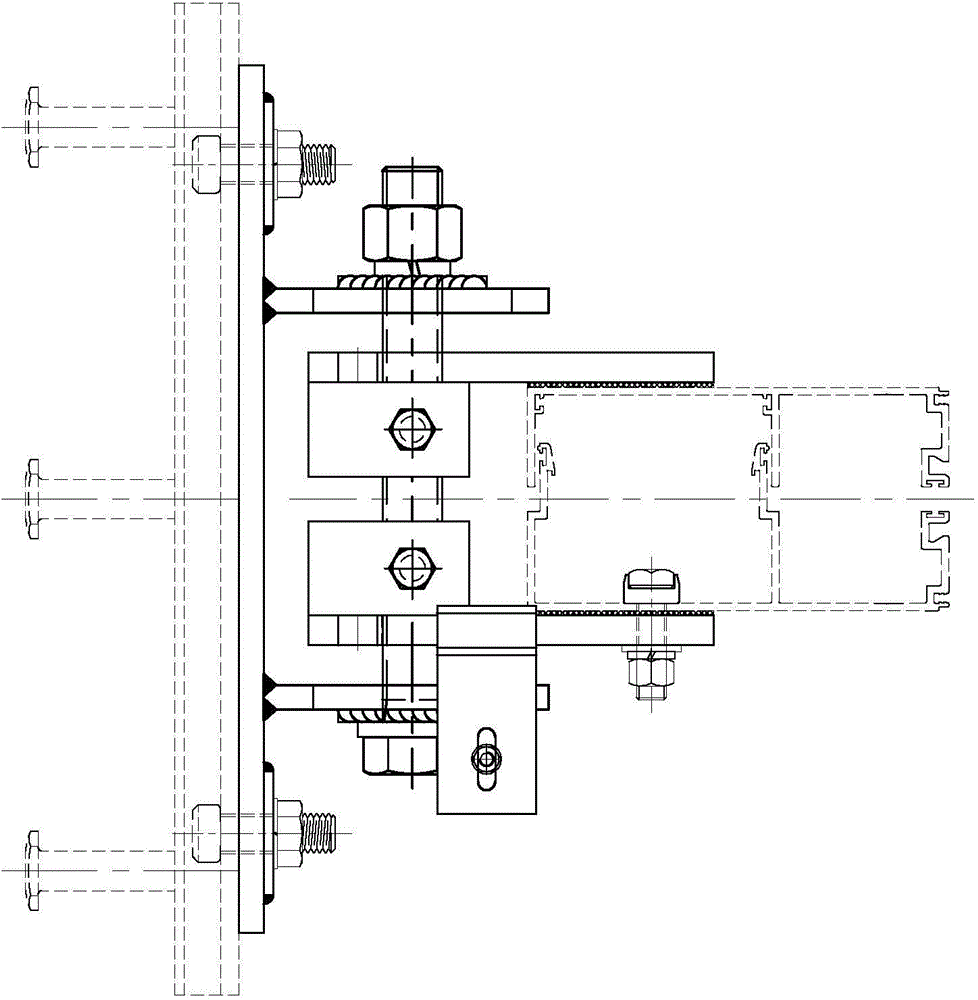

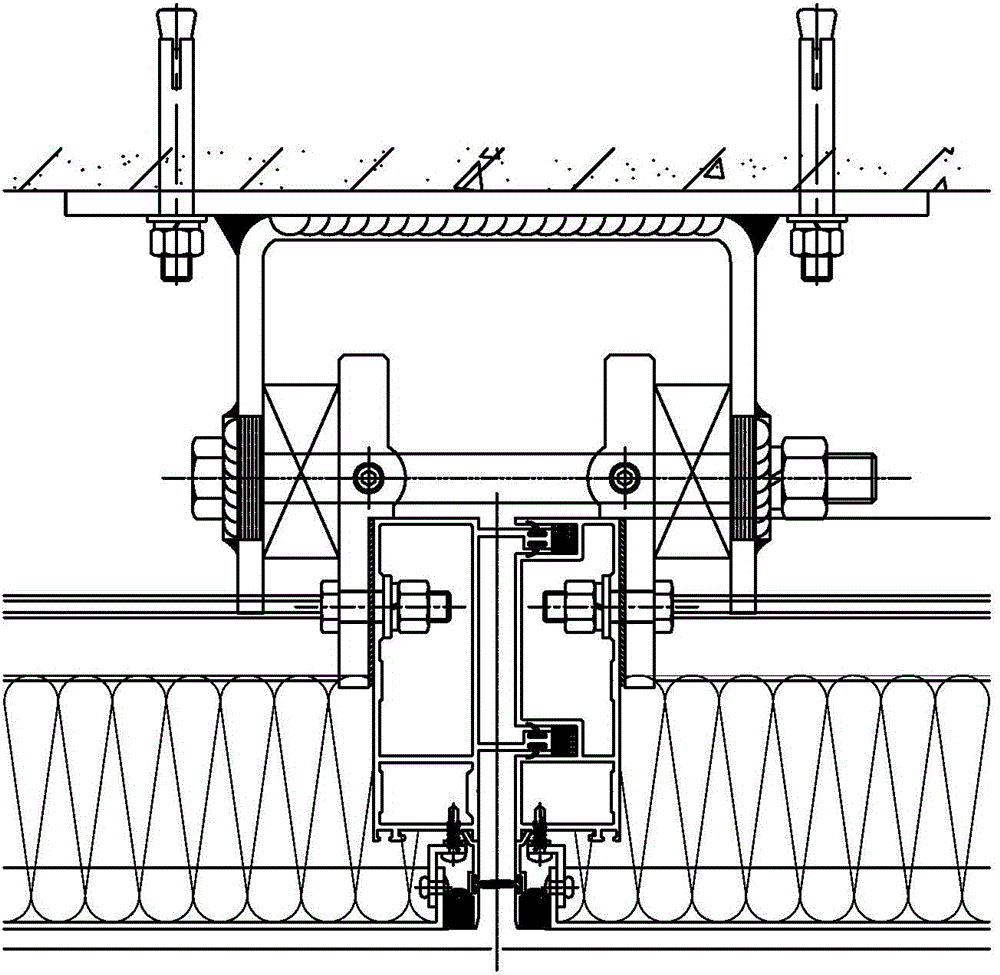

Sideward-hanging connection piece of unit-typed curtain wall stand column

ActiveCN103615060AConvenient force adjustmentChange the state of stressWallsPunchingProcessing accuracy

A sideward-hanging connection piece of a unit-typed curtain wall stand column comprises a backboard, two side plates and a bolt shaft. The backboard and the two side plates are squeezed to be formed in an integrated mode through a compound die made of aluminum, and an aluminum hanging shaft penetrates through the bolt shaft. Vertical teeth are arranged on the outer side faces of horizontal long-strip-shaped holes in the two side plates. Gaskets are correspondingly arranged on the vertical teeth and are provided with vertical teeth matched with the vertical teeth on the outer side faces of the horizontal long-strip-shaped holes. Transverse teeth are arranged on the outer side faces of the vertical holes in the backboard on the outsides of the two side plates. Gaskets are arranged on the corresponding faces of the transverse teeth and provided with transverse teeth matched with the transverse teeth on the outer side faces of the vertical holes, and the transverse teeth on the outer side faces of the vertical holes are made in a punching mode. The hanging shaft is of an asymmetric design. The sideward-hanging connection piece has the advantages that on-site welding can be avoided, the bearing force is higher, the structural safety is better, adjustment is more convenient to achieve, the machining precision is easy to guarantee, a needed space is smaller and the weight is lower.

Owner:JANGHO GRP

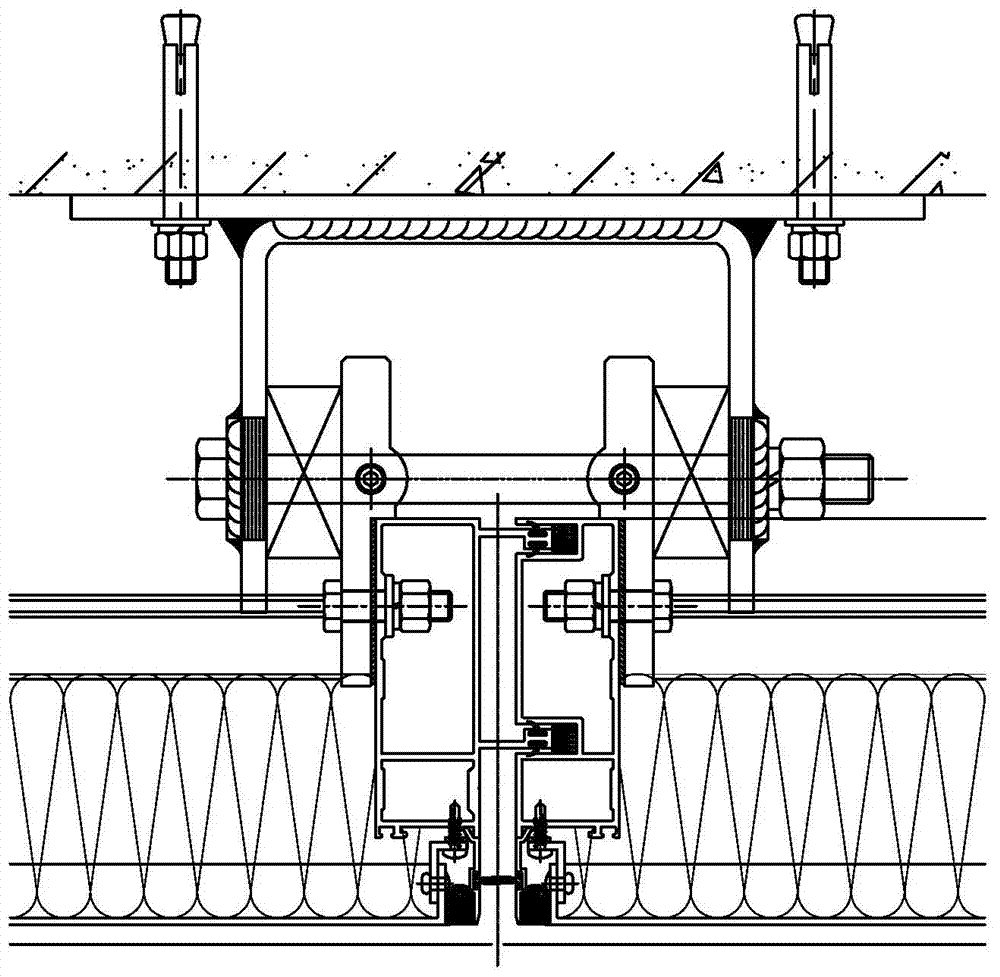

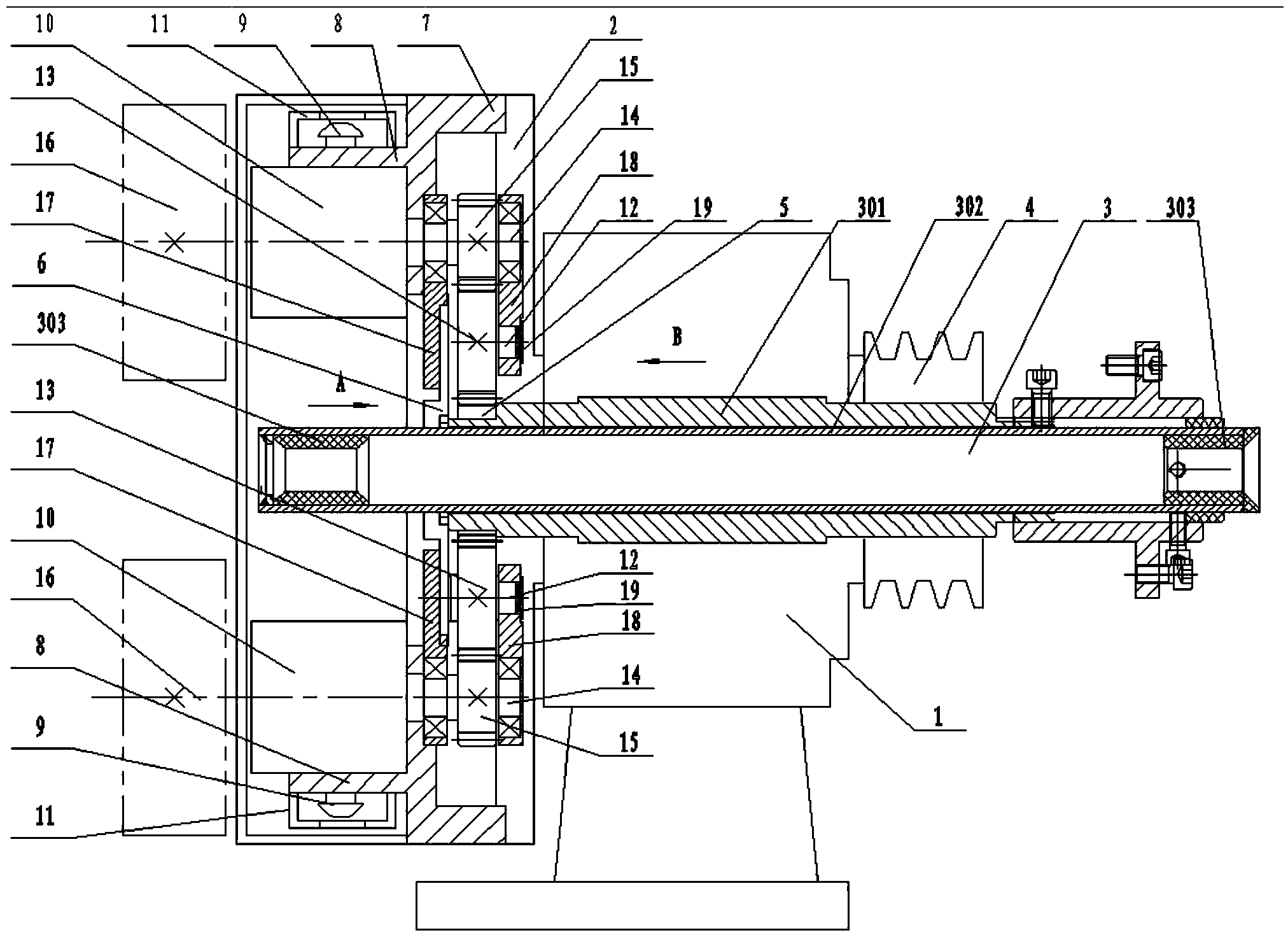

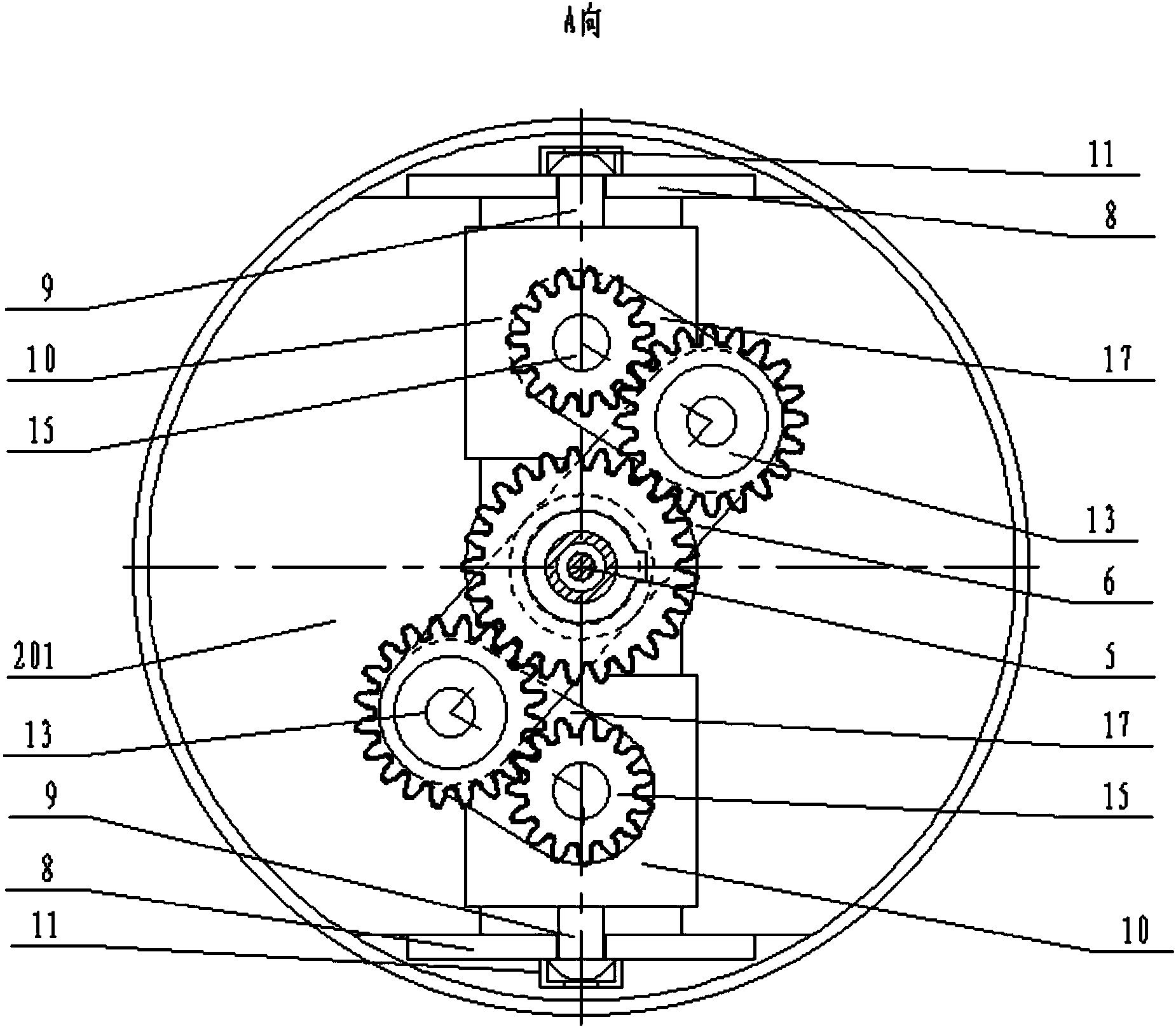

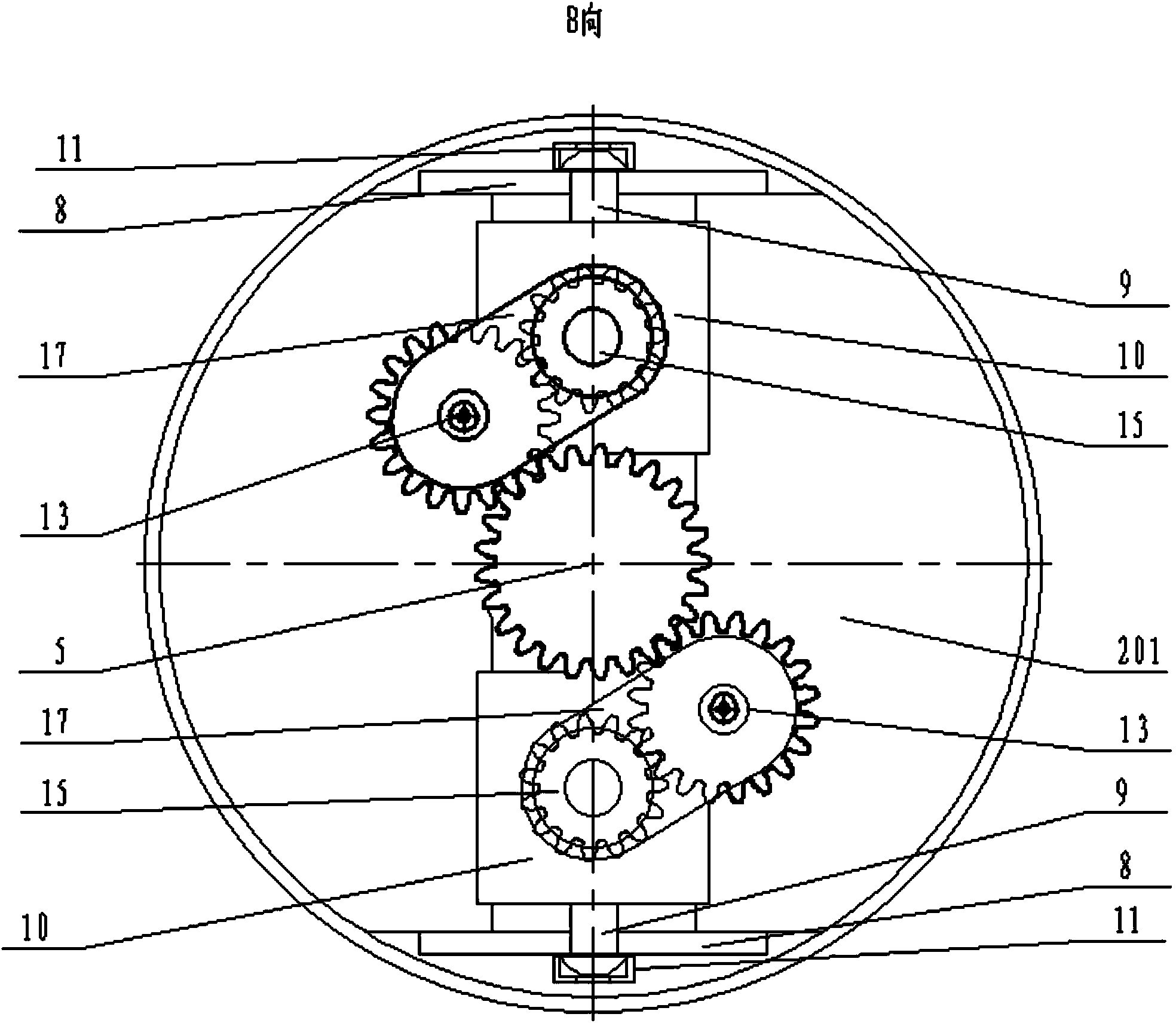

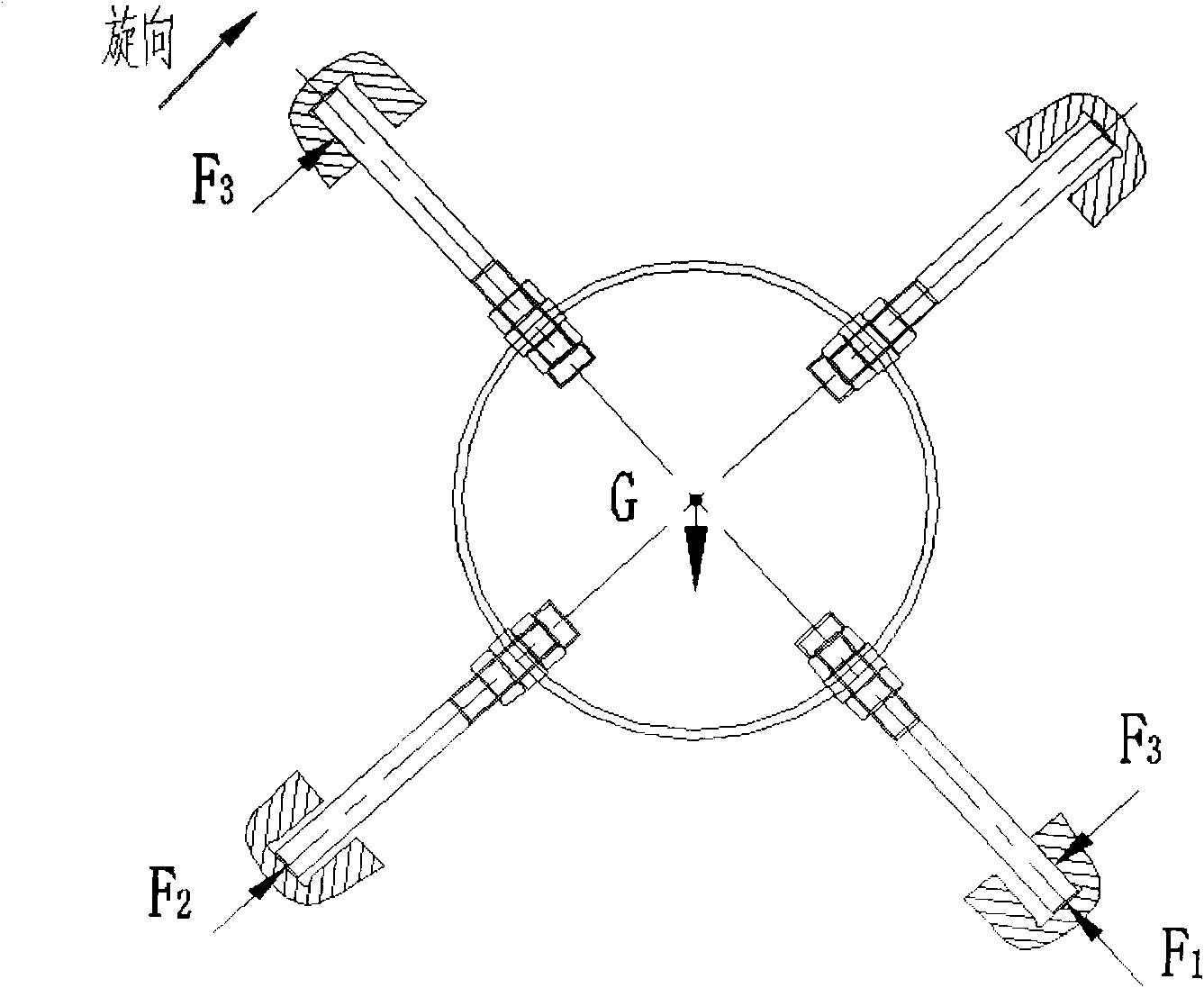

Brushing device for metal bar

InactiveCN103921201AExtended service lifeSimple structureGrinding drivesGrinding machinesBrush deviceEngineering

The invention discloses a brushing device for a metal bar. The brushing device for the metal bar is small in radial load of planet gear and long in service life. The brushing device for the metal bar comprises a machine base, a revolution seat, a hollow shaft and a belt wheel. A sun gear, a main connecting rod and a revolution head are arranged on the hollow shaft above the revolution seat in a sleeved mode in sequence, the revolution head is fixedly connected to the revolution seat, the revolution head is provided with two sliding seats which slide relatively in the radial direction of the revolution head, transition gears meshed with the sun gear through transition gear shafts are arranged on the main connecting rod and on the two sides of the sun gear, planet gear shafts are arranged in the sliding seats in a penetrating mode, one end of each planet gear shaft is provided with a planet gear meshed with the corresponding transition gear in a sleeved mode, the other ends, penetrating through the sliding seats, of the planet gear shafts are provided with brushing wheels, the position, close to the main connecting rod, between the transition gear shafts and the planet gear shafts is provided with an auxiliary connecting rod in a movable sleeved mode, the ends, close to the revolution seat, of the transition gear shafts are provided with connecting plates in a rotating sleeved mode, and the other ends of the connecting plates are arranged at the corresponding positions of the planet gear shafts in a sleeved mode.

Owner:江苏薪泽奇机械股份有限公司

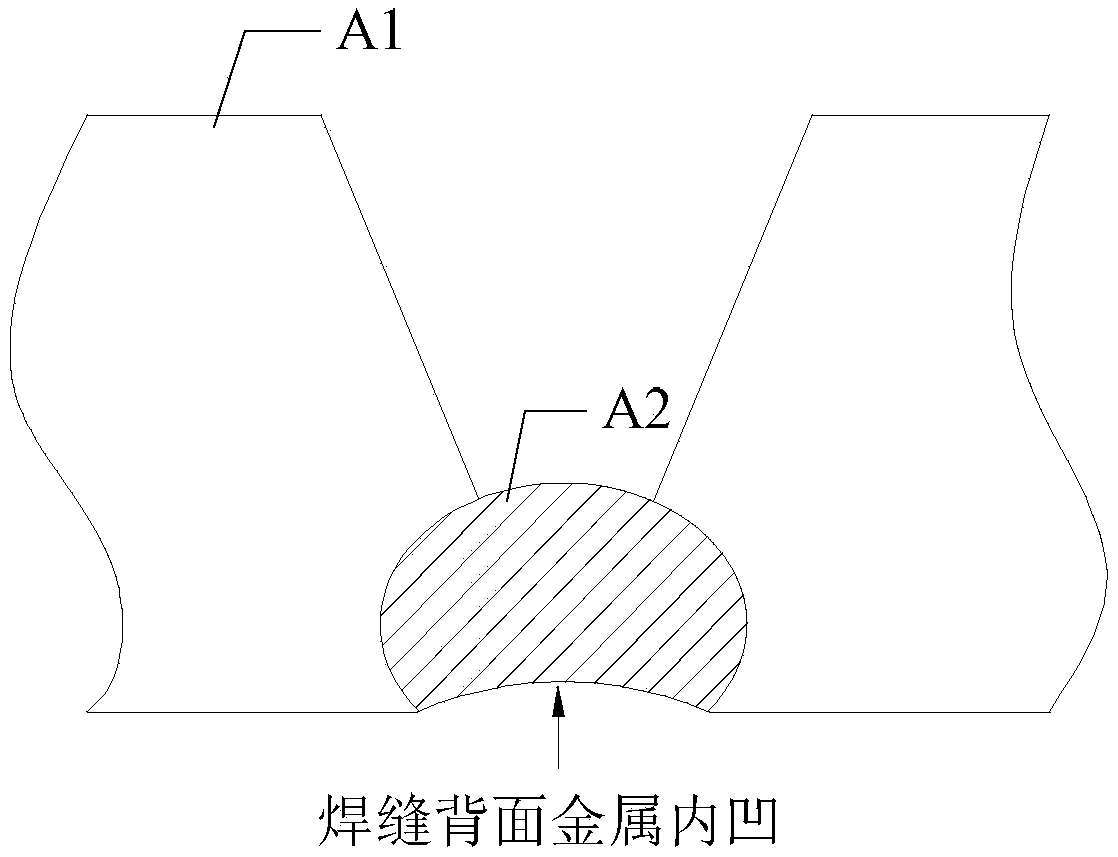

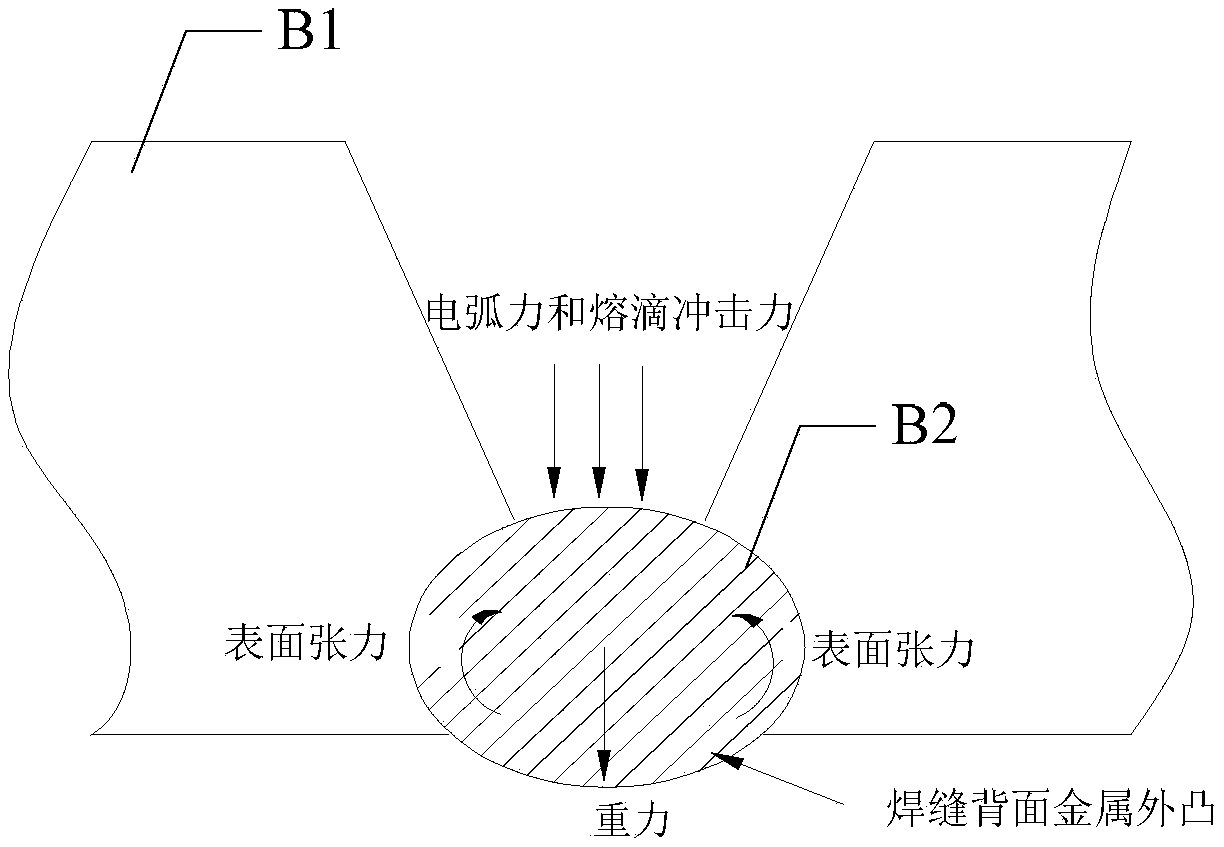

Bottoming welding method of laser-hot wire MIG composite based on light beam scanning

InactiveCN108971758APlay a stirring roleChange the state of stressLaser beam welding apparatusLaser scanningLight beam

The invention provides a bottoming welding method of laser-hot wire MIG composite based on light beam scanning, relates to the field of laser-hot wire MIG composite welding, and solves the problem that liquid metal welding joint back surface is prone to forming an indent when an existing laser-hot wire MIG welding performs bottoming welding. Bottoming welding is carried out on laser beam and hot wire MIG electric arc composite, wherein the laser beam scans along a certain track, and the hot wire MIG electric arc composite is protected by insert gas. The laser beam and the electric arc act in awelding pool, the power, scanning frequency and laser swing of the laser beam are matched reasonably to achieve a certain stirring action for the welding pool, the stress state of the welding pool ischanged, and the bottoming welding of welded workpieces is completed. The bottoming welding method of the laser-hot wire MIG composite based on the light beam scanning has the beneficial effects thatthe stirring action is achieved for the laser scanning, the stress state of the welding pool is changed, the resistance of the liquid metal flowing to a groove root portion is reduced, the forming effect of the welding joint back surface is improved, and the forming of the welding joint back surface is quite attractive and the spread-ability of the welding joint is good.

Owner:HARBIN IRT INTELLIGENT ROBOT TECH CO LTD

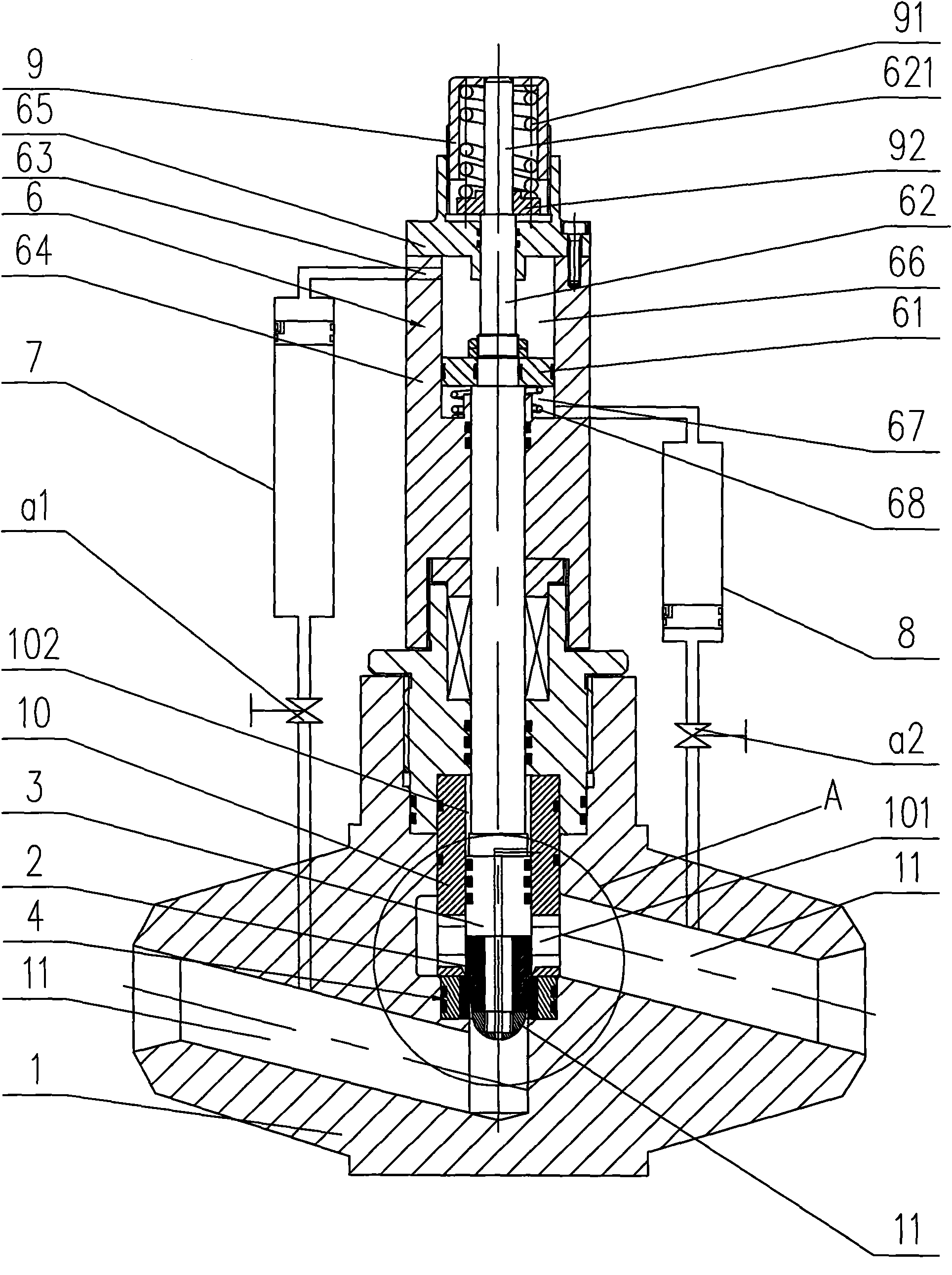

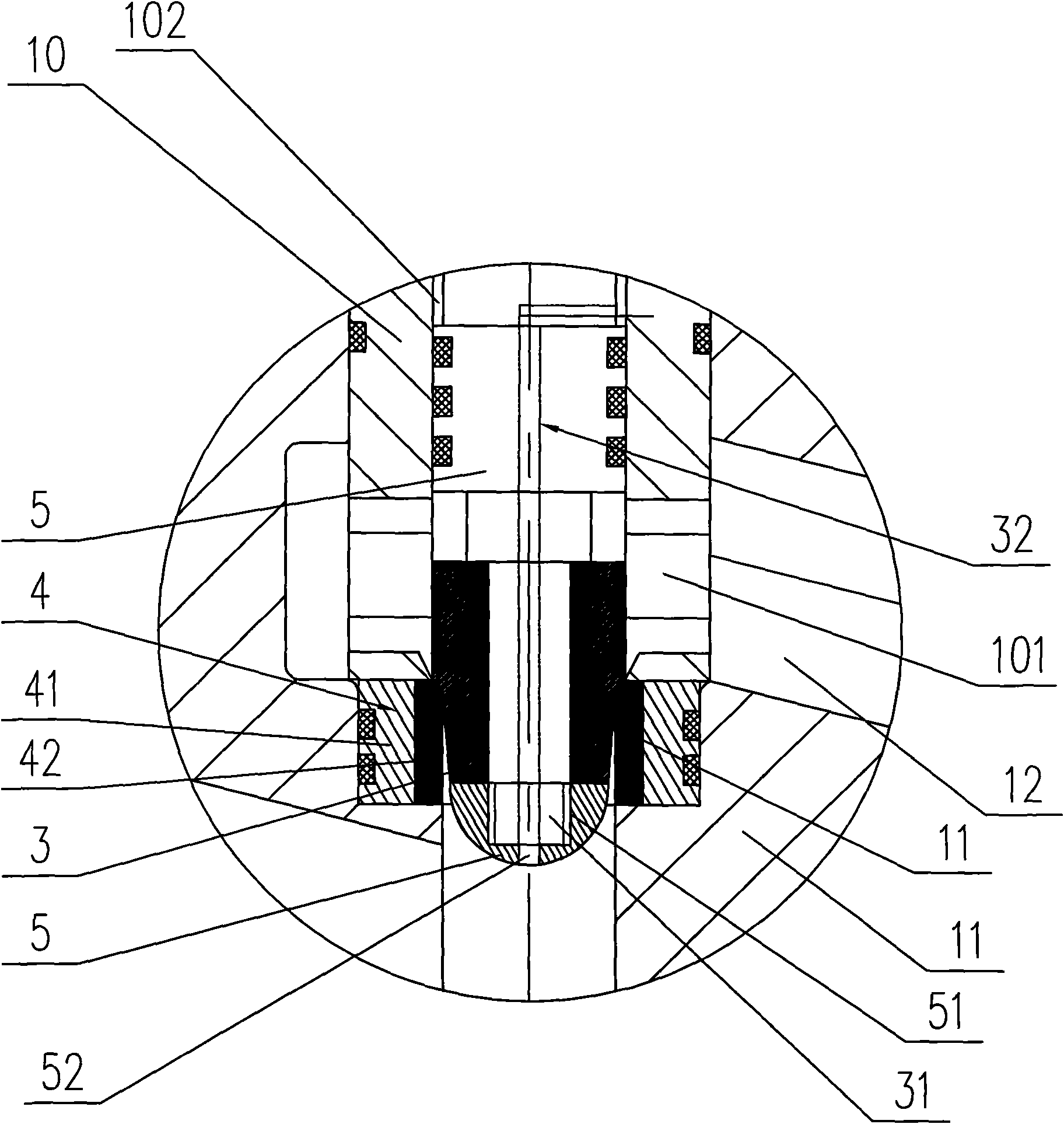

Self-hydraulic automatic regulation valve

ActiveCN101586690ARealize automatic openingChange the state of stressOperating means/releasing devices for valvesEqualizing valvesHydraulic cylinderAuto regulation

This invention relates to a self-hydraulic automatic regulation valve, wherein upper end of a valve rod is set with a main hydraulic cylinder, and extends into main body of the main hydraulic cylinder to be fixedly connected with a piston; the piston divides the main body of the main hydraulic cylinder into an upper movable cavity and a lower movable cavity; left and right sides outside the valve body are respectively set with a charging hydraulic cylinder and a discharging hydraulic cylinder; lower end of the charging hydraulic cylinder is connected with one side of the charging flow channel, and upper end of the same is connected with liquid inlet of upper movable cavity in the main hydraulic cylinder; lower end of the discharging hydraulic cylinder is connected with one side of the discharging flow channel, and upper end of the same is connected with liquid inlet of the lower movable cavity in the main hydraulic cylinder. Accordingly, this invention regards the main hydraulic cylinder connected with charging flow channel and discharging flow channel at two ends of the valve body as the power source for pushing the piston therein to drive the valve rod to act, thereby realizing automatic switching-on, switching-off and regulation of regulation head.

Owner:SHANDONG AOKE AUTOMATIC CONTROL EQUIP CO LTD

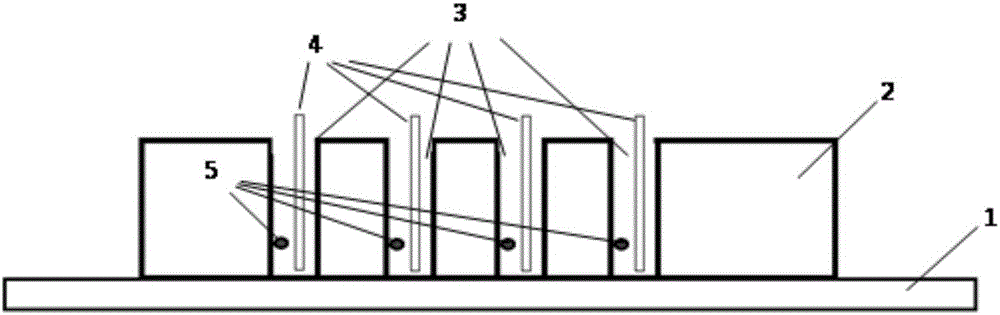

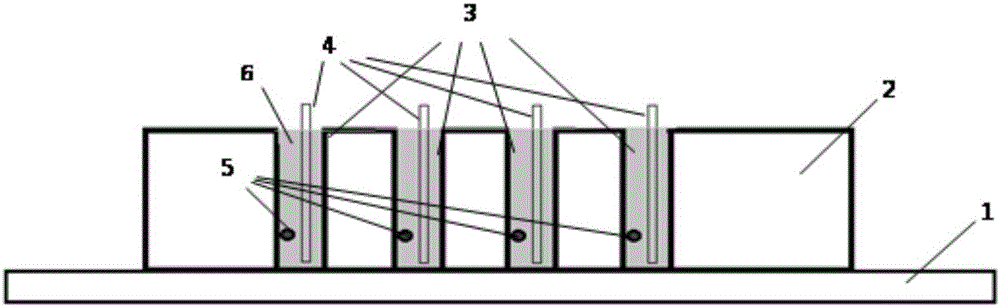

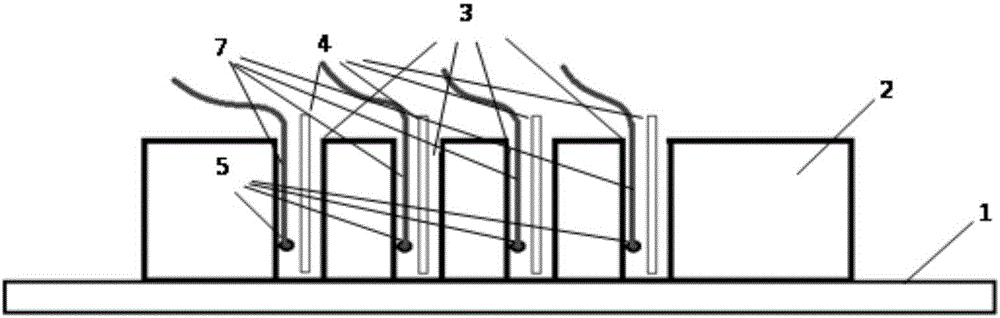

Angle adjustable type bionic hair sensing structure

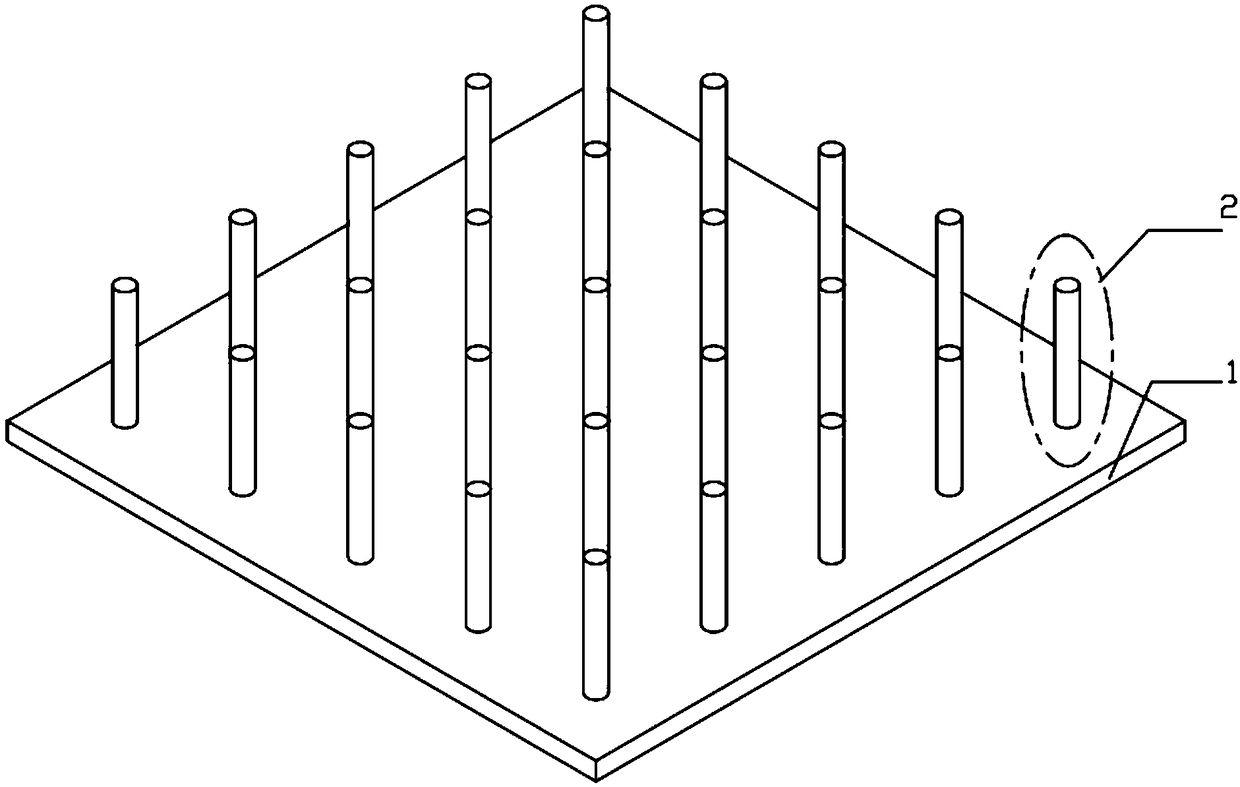

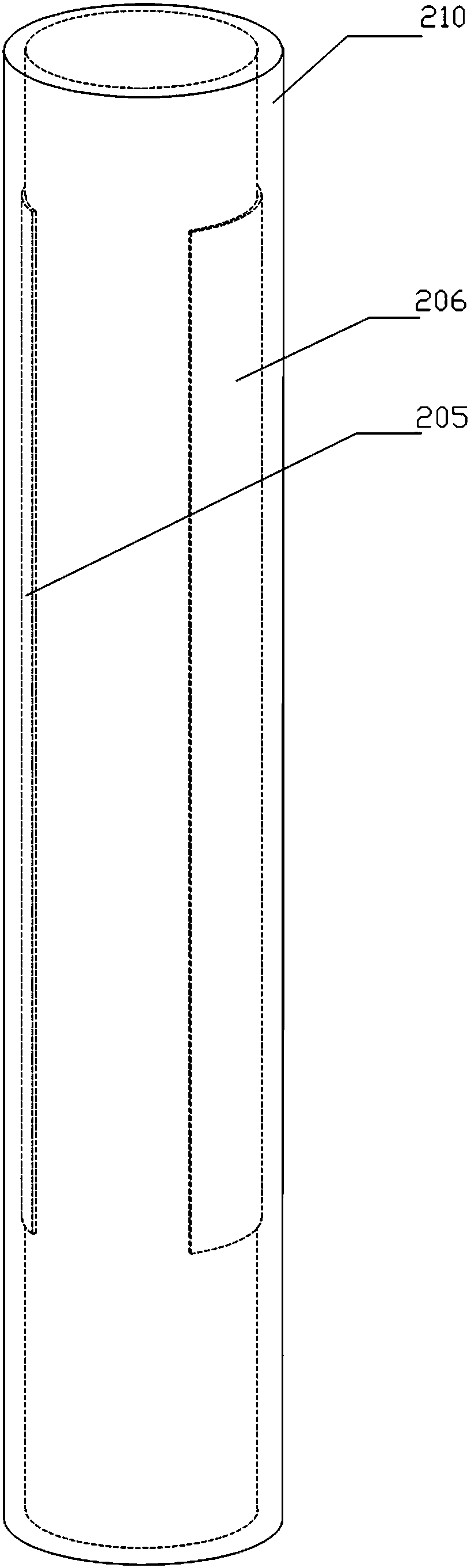

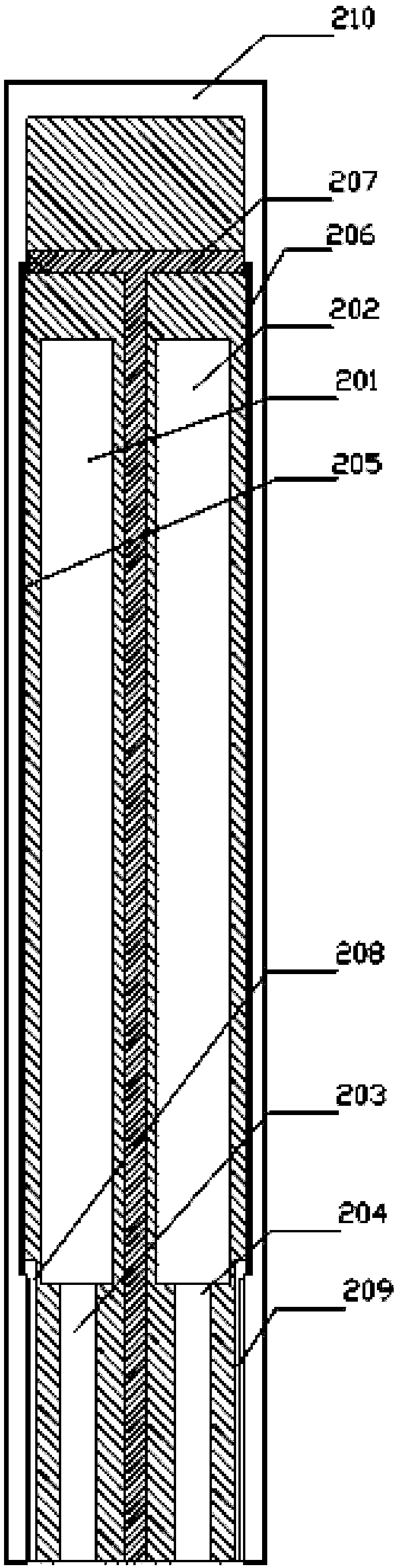

ActiveCN108760105AAdjustable angleChange the state of stressForce measurementMeasurement of force applied to control membersSensor arrayEngineering

The invention discloses an angle adjustable type bionic hair sensing structure which comprises a flexible substrate and hair sensors arranged on the flexible substrate. The hair sensors are arranged in an equally spaced array on the upper surface of the flexible substrate, the hair sensors are active mode angle adjustable structures, and the angle adjustable type bionic hair sensor array is formed. External forces in different directions are acquired according to actual needs, the external forces are measured on an uneven working surface, so that tactile perception can be obtained when an object approaches the working surface, the time for system reaction is prolonged, and thus the safety performance is improved.

Owner:ZHEJIANG UNIV

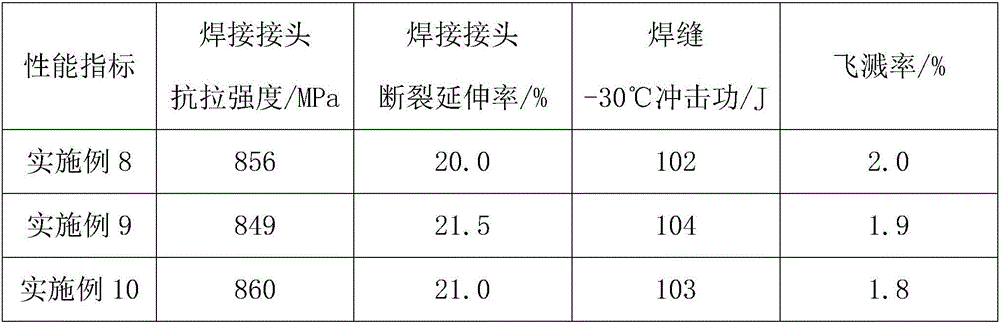

High-tenacity less-splashing self-shielded coated flux-cored welding wire and preparation method thereof

InactiveCN106624442AImprove conductivityReduce dosageWelding/cutting media/materialsSoldering mediaRutileZircon

The invention discloses a high-tenacity less-splashing self-shielded coated flux-cored welding wire. The high-tenacity less-splashing self-shielded coated flux-cored welding wire comprises a welding wire matrix and a coating applied on the surface of the welding wire matrix, wherein the welding wire matrix consists of a low-carbon steel skin and a flux core arranged in the low-carbon steel skin by filling. The flux core comprises, by weight, 15-30% of rutile,1-2% of ferroniobium, 1-3% of aluminum powder, 1-2% of magnesium powder, 6-10% of fluoride, 0.5-1% of magnesite clinker, 0.5-0.9% of zircon sand and 52-70% of iron powder, wherein F / (Mg+Al)=0.015-0.05, the magnesium powder is converted into magnesium, Mg refers to a weight percentage of the magnesium accounting for the flux core raw materials, the aluminum powder is converted into aluminum, Al refers to a weight percentage of the aluminum accounting for the flux core raw materials, the fluoride is converted into fluorine, and F refers to a weight percentage of the fluorine accounting for the flux core raw materials. The invention further discloses a preparation method of the high-tenacity less-splashing self-shielded coated flux-cored welding wire. The high-tenacity less-splashing self-shielded coated flux-cored welding wire has the advantages that tensile strength can be above 840 MPa, elongation at break exceeds 20%, impact energy of weld joints is higher than 10 J at minus 30 DEG C, and less splashing during welding is achieved. The preparation method is simple and easily controllable, and production cost is saved.

Owner:安徽飞弧焊业股份有限公司

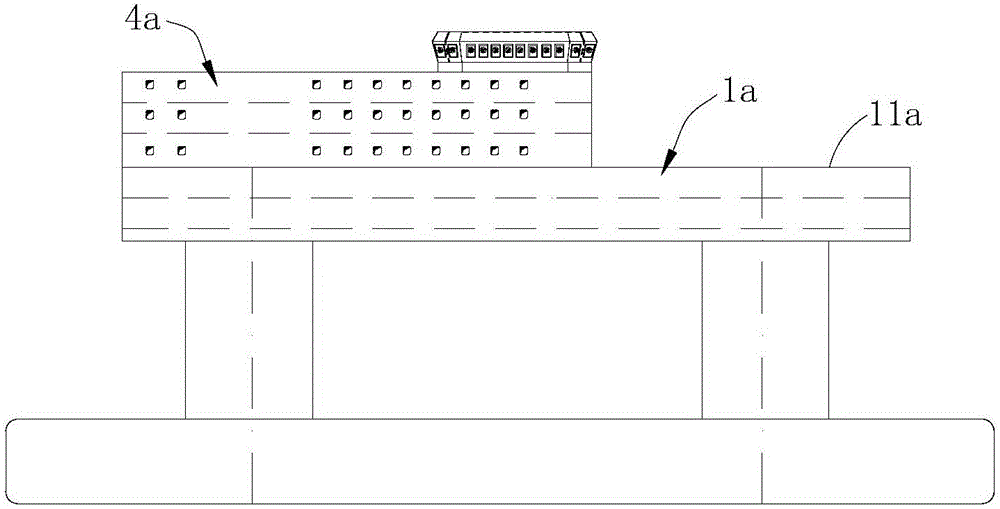

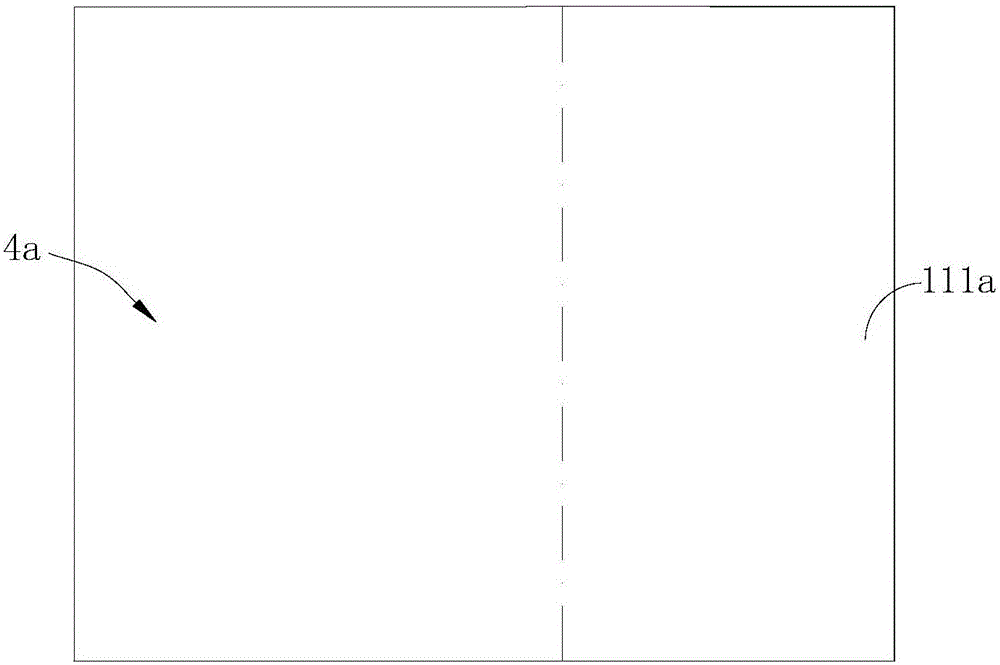

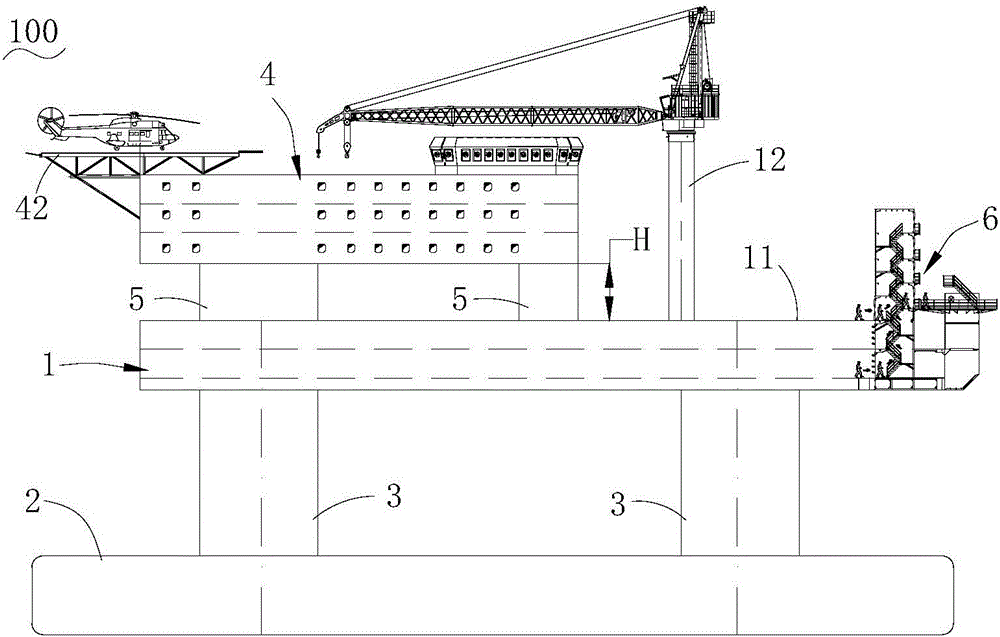

Semisubmersible supporting platform

PendingCN107521630AStrong support abilityIncrease inventory areaVessel superstructuresVessel mastsCivil engineeringSystems engineering

The invention provides a semisubmersible supporting platform. The semisubmersible supporting platform comprises a lower floating body, stand columns supported on the lower floating body, and a deck box supported by the stand columns, wherein an utility area module is arranged on the deck box, and is supported above a main deck of the deck box through supports; and a height interval is formed between the bottom of the utility area module and the main deck of the deck box. According to the semisubmersible supporting platform disclosed by the invention, the whole main deck of the semisubmersible supporting platform can be used for storing goods, so that the effective goods storing area of the deck is increased; the supporting capacity of the platform is high, so that the supply cycle of a supply ship can be reduced, and the cost is reduced; and a connecting manner of the utility area module and the deck box adopts support connection, so that the load effect of the deforming of the deck box to the utility area module is directly released, the stress condition of the utility area module is changed, especially, the fatigue strength performance of a joint structure of the utility area and the deck box is improved, and the reliability of the structure is improved.

Owner:CIMC OFFSHORE ENG INST +2

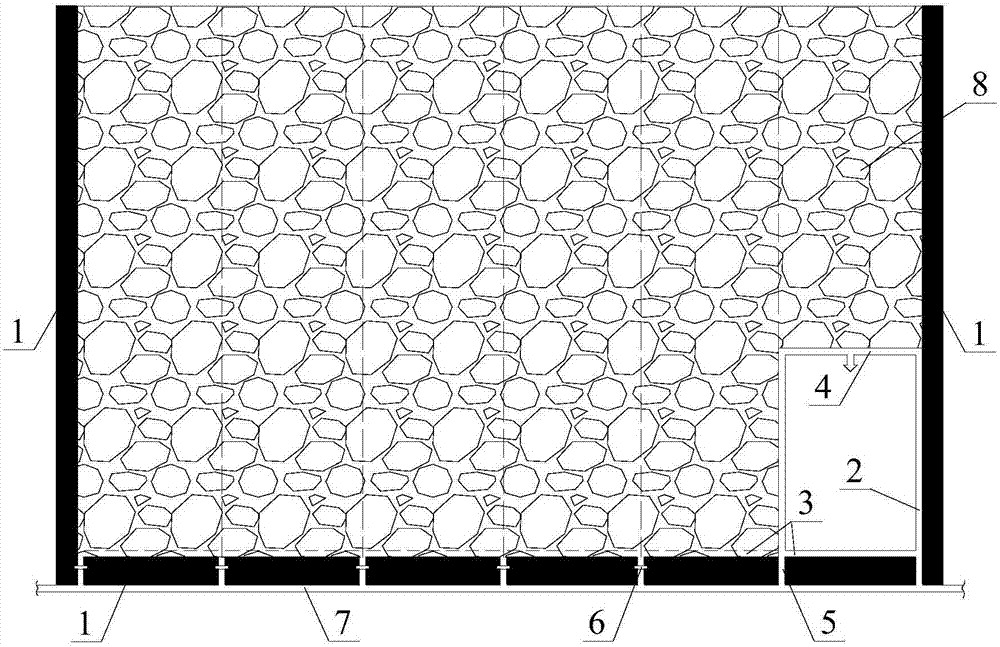

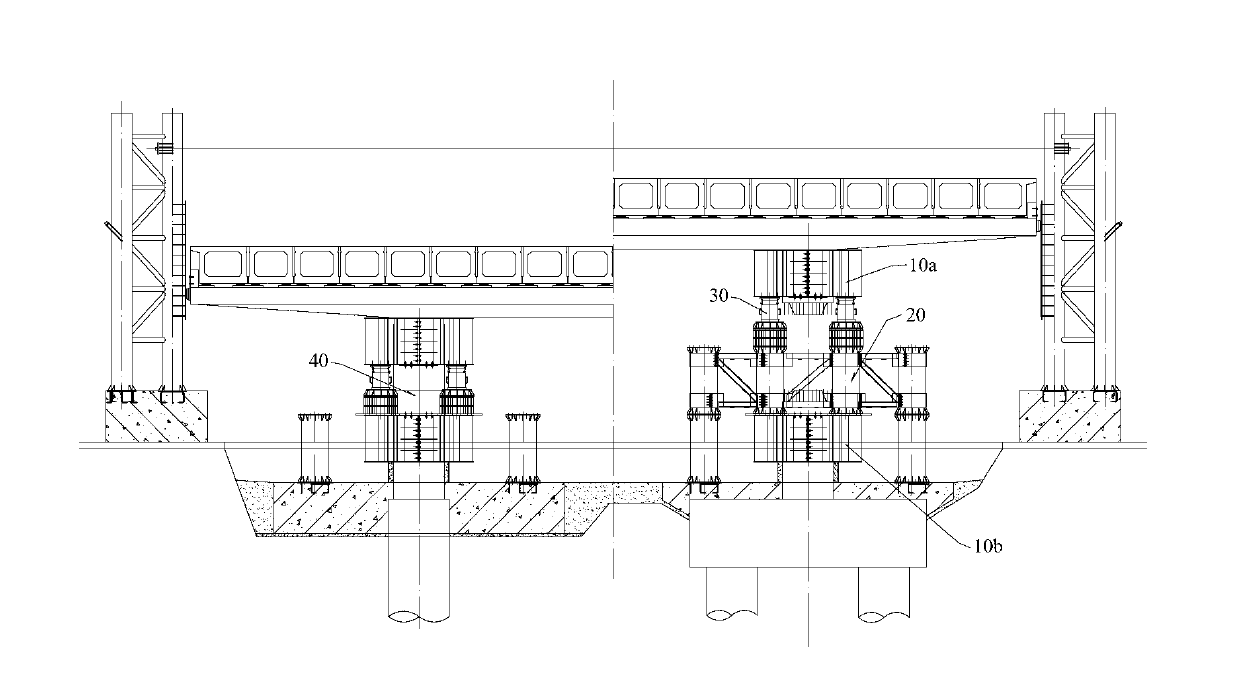

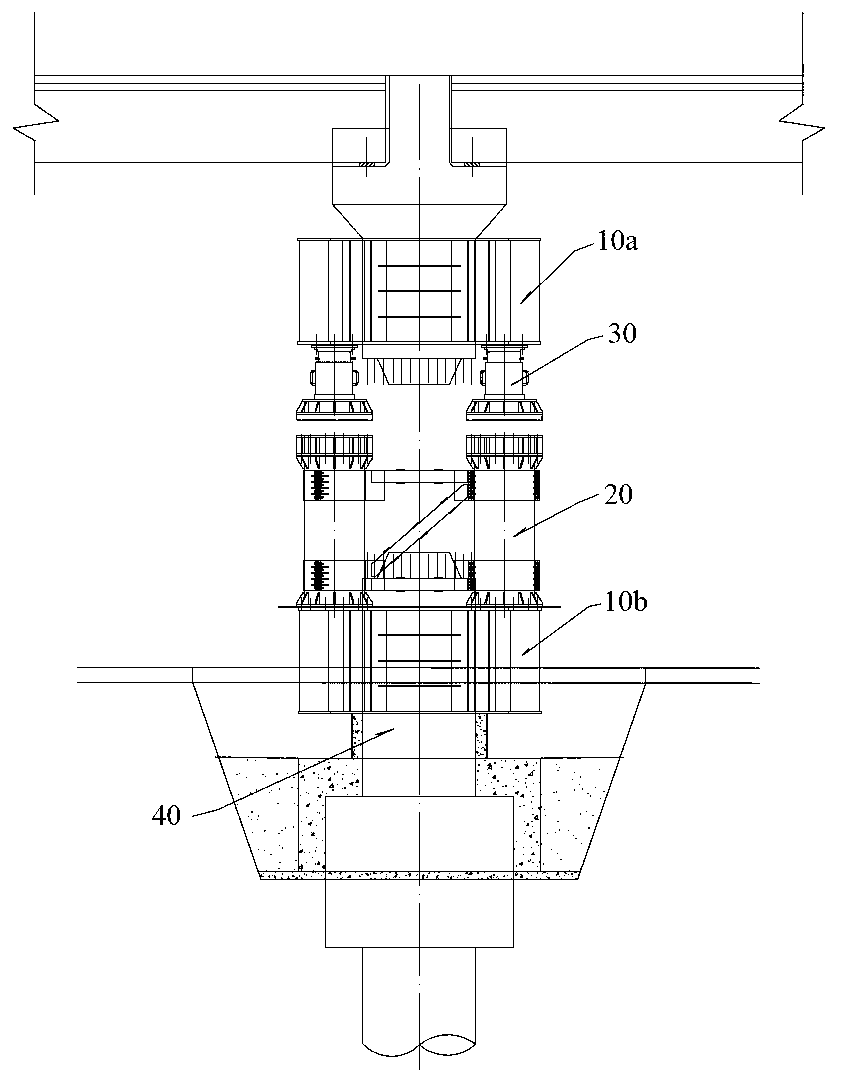

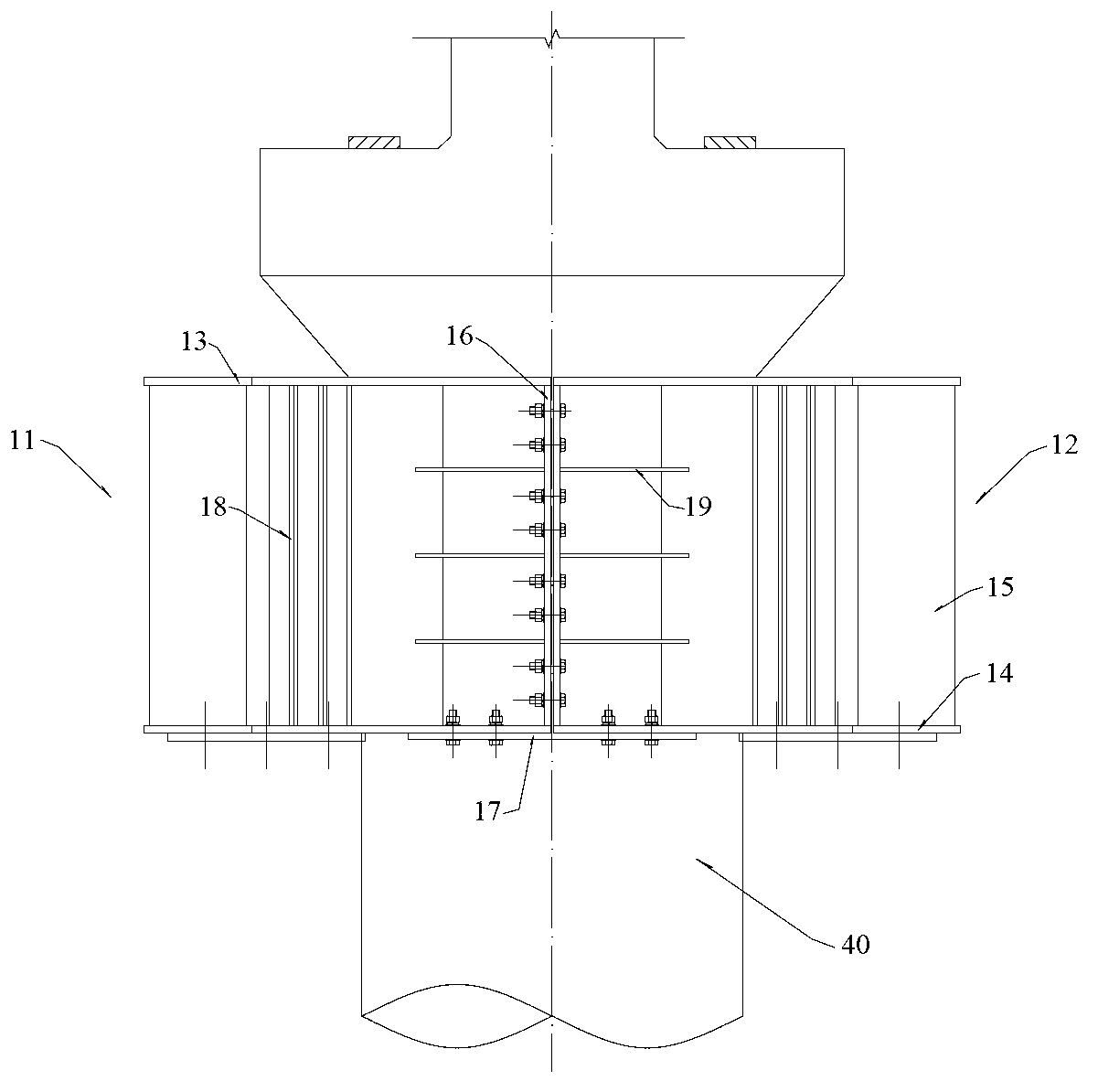

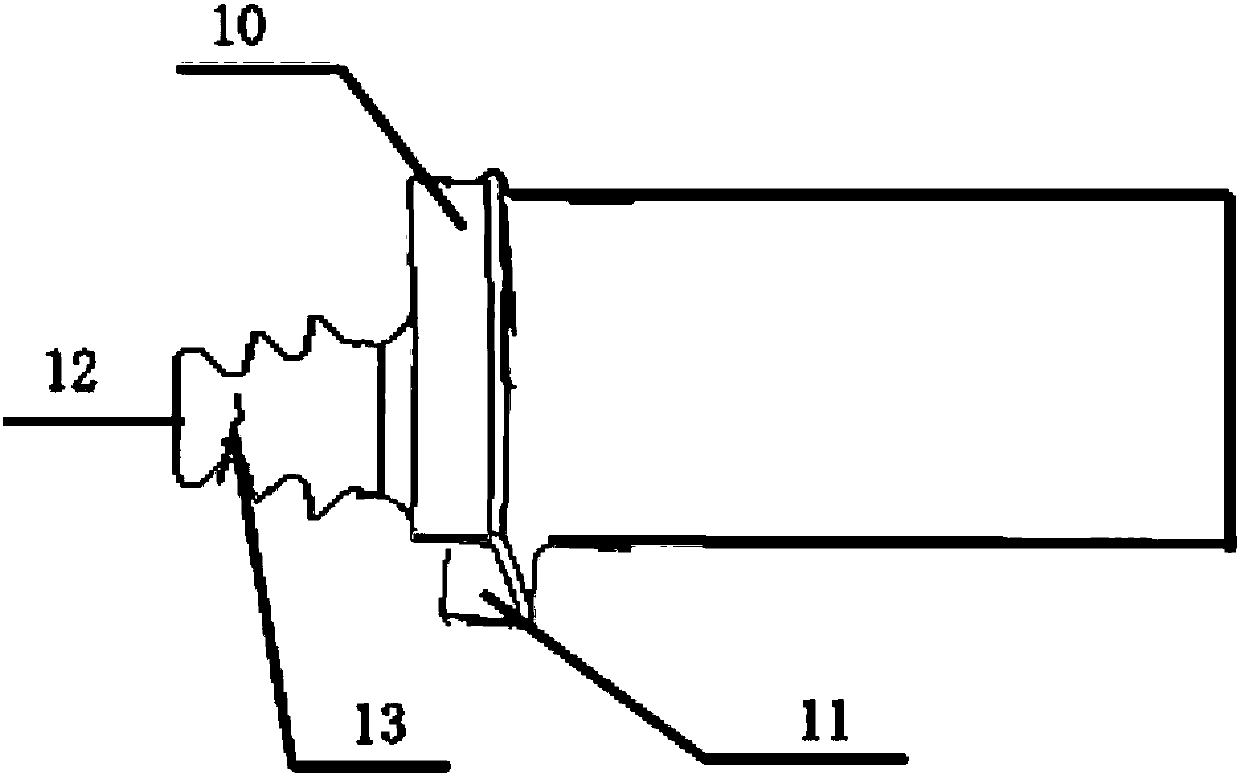

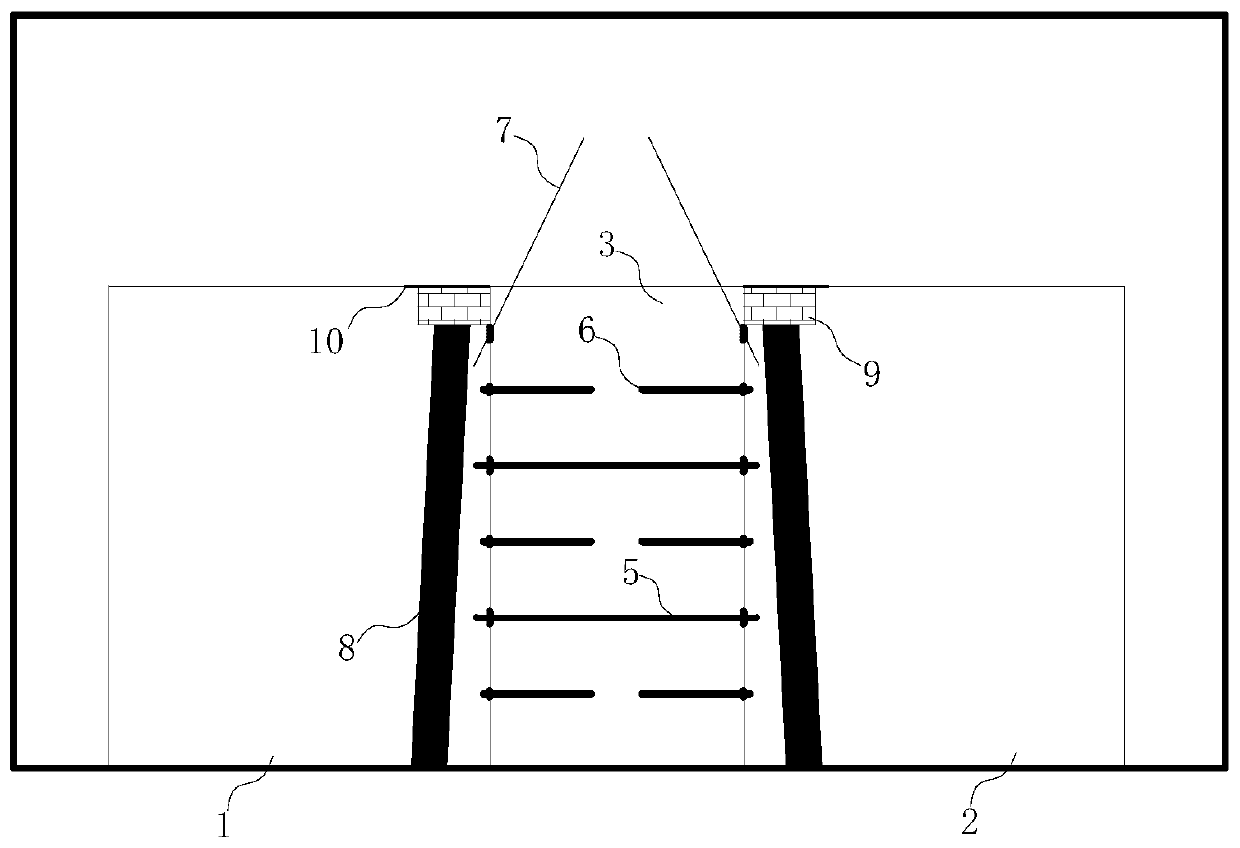

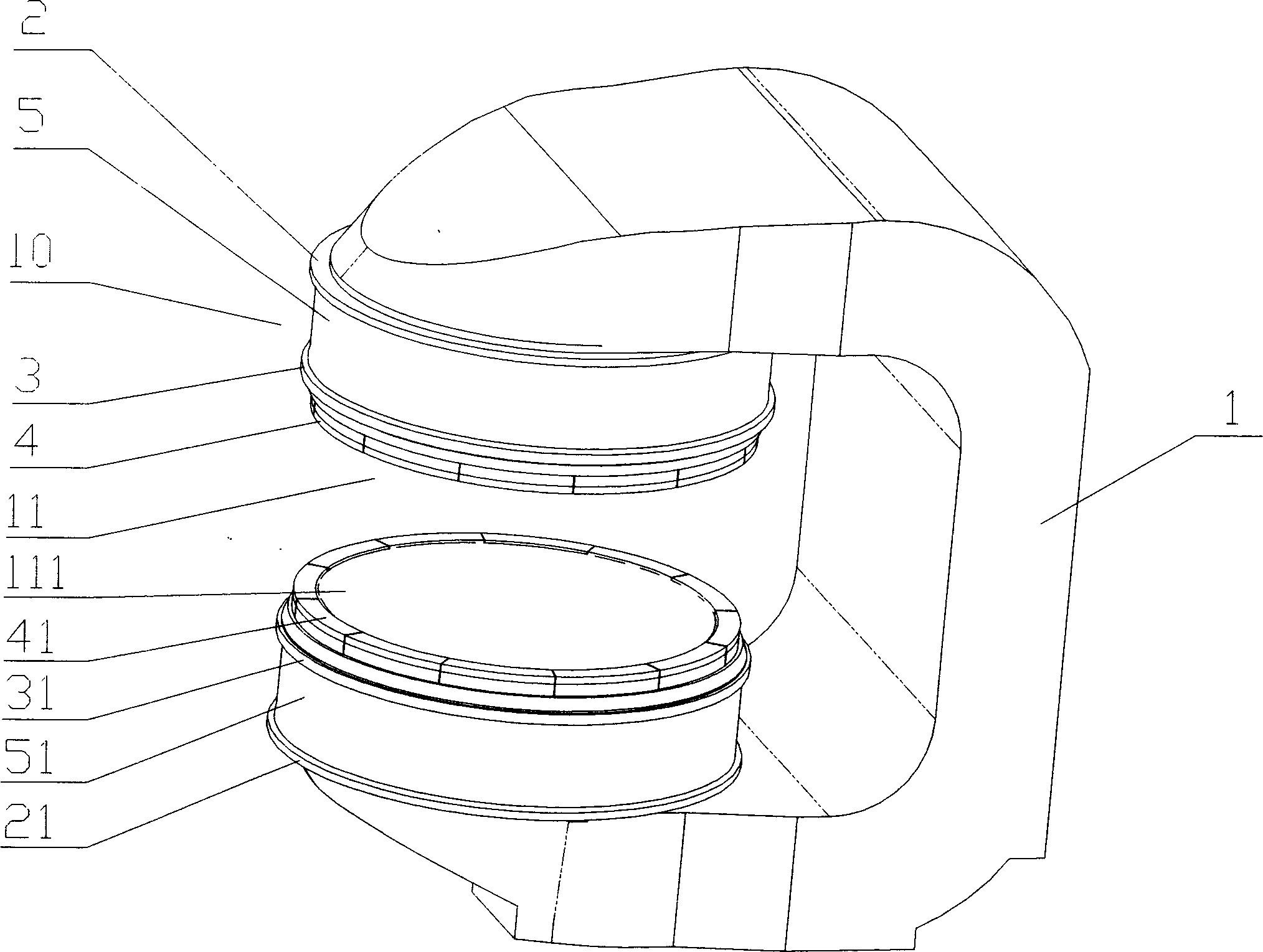

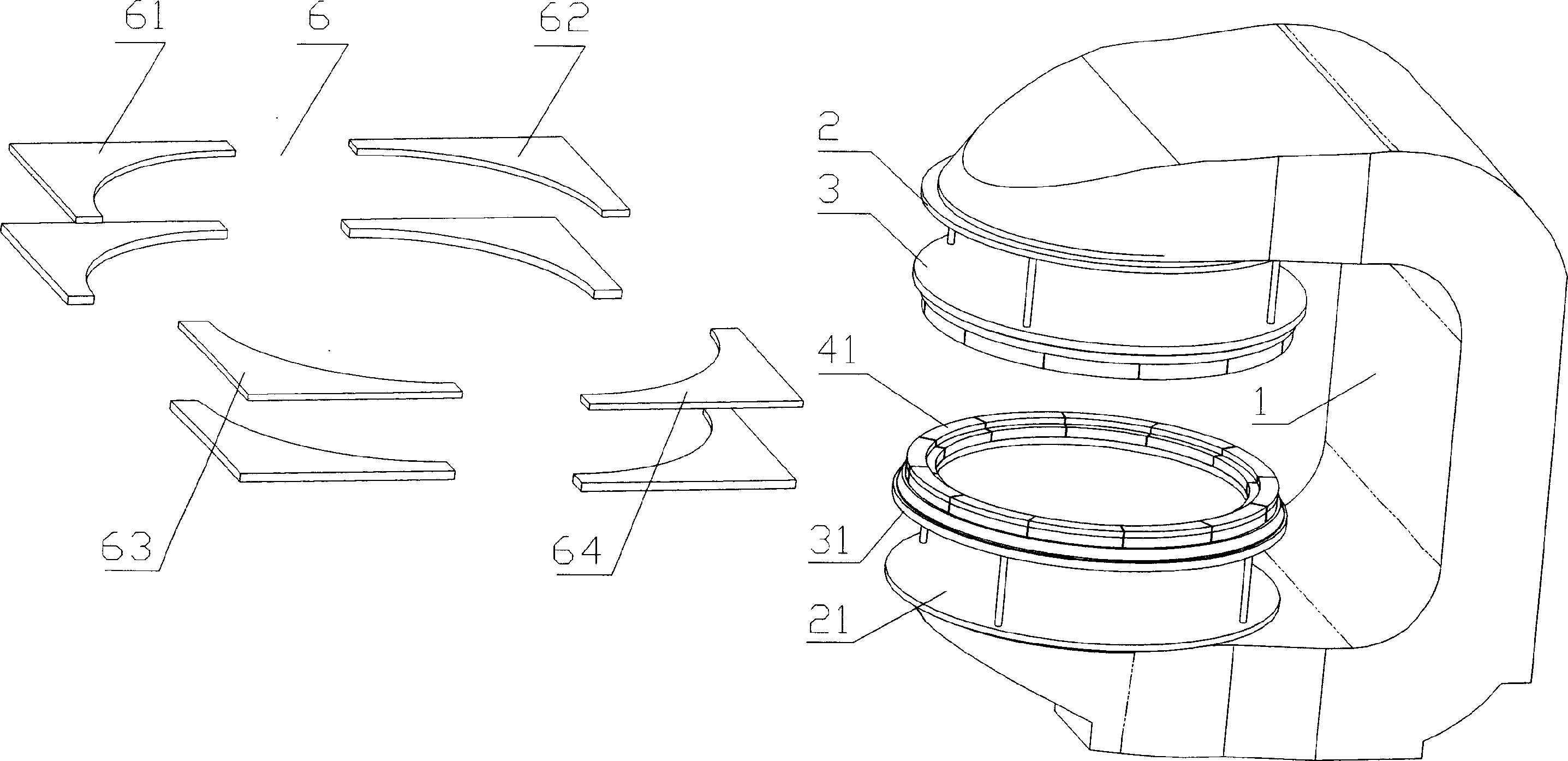

Steel hoop support system of jacking bridge

InactiveCN103015330AChange the state of stressNo need for hardeningBridge erection/assemblyBridge strengtheningSupporting systemReinforced concrete

Disclosed is a steel hoop support system of a jacking bridge. By the steel hoop support system, the engineering cost for lifting the bridge is lowered, and the construction difficulty and safety risks are reduced. The steel hoop support system comprises an upper-end steel hoop (10a), a lower-end steel hoop (10b) and steel pipe supports (20), the upper-end steel hoop (10a) and the lower-end steel hoop (10b) are fixed to the upper end and the lower end of an original reinforced concrete pier stud (40) of the bridge in a hooped manner by means of exerting pre-tightening force, the steel pipe supports (20) are fixedly mounted on the lower-end steel hoop (10b), and a hydraulic jack system (30) is arranged between the upper-end steel hoop (10a) and the upper end of each steel pipe support (20).

Owner:SICHUAN DEPT OF TRANSPORTATION HIGHWAY PLANNING PROSPECTING & DESIGN RES INST

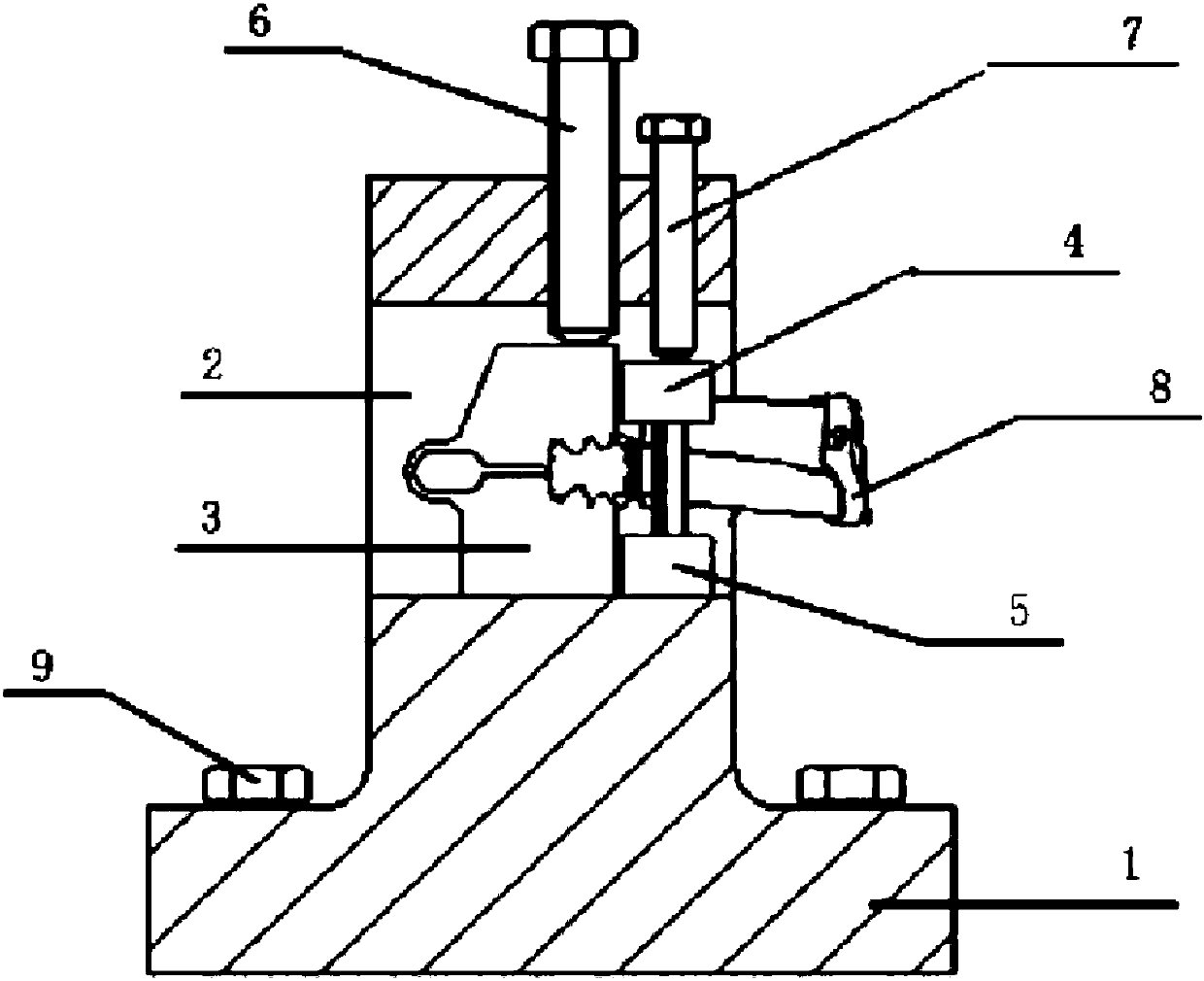

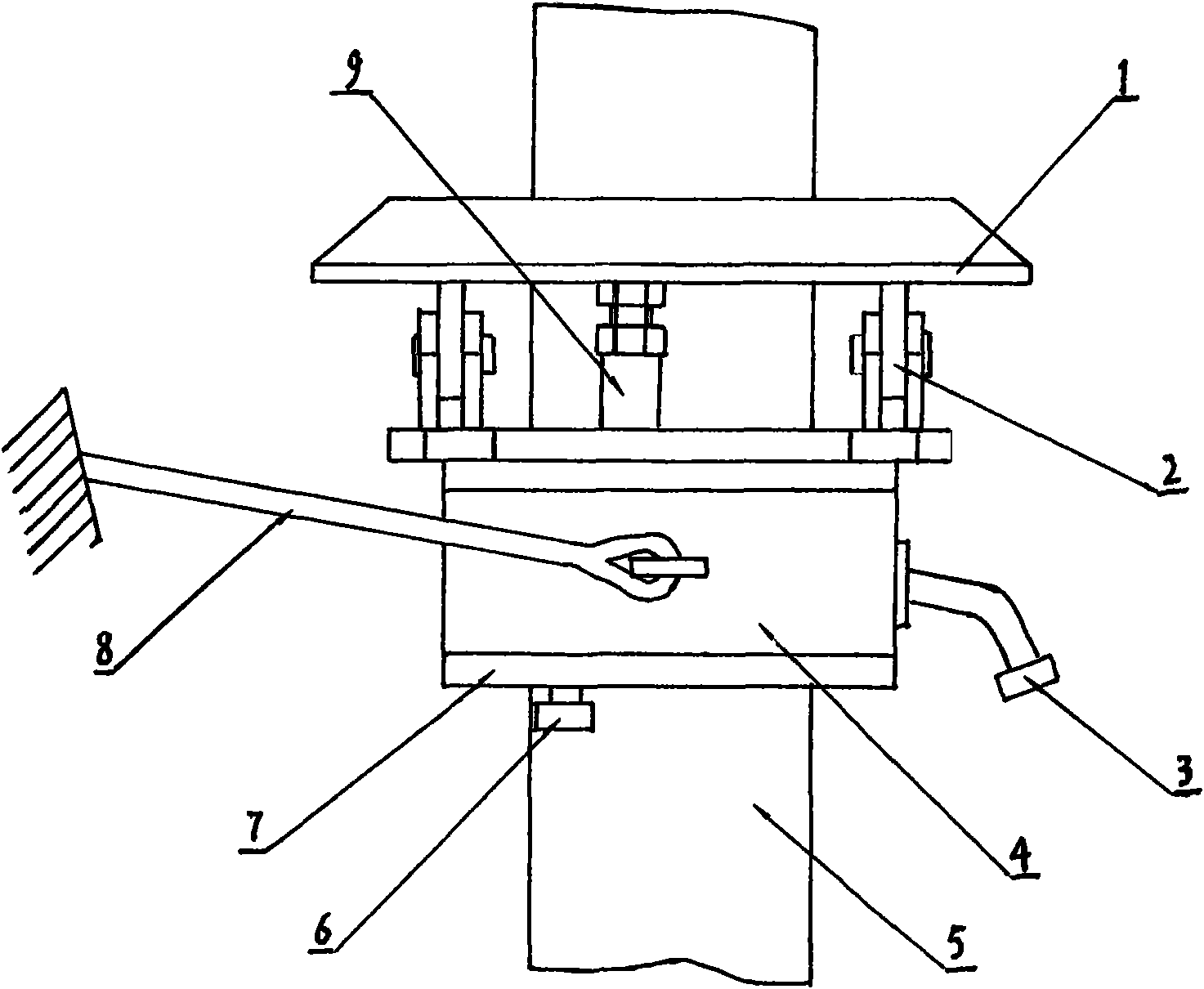

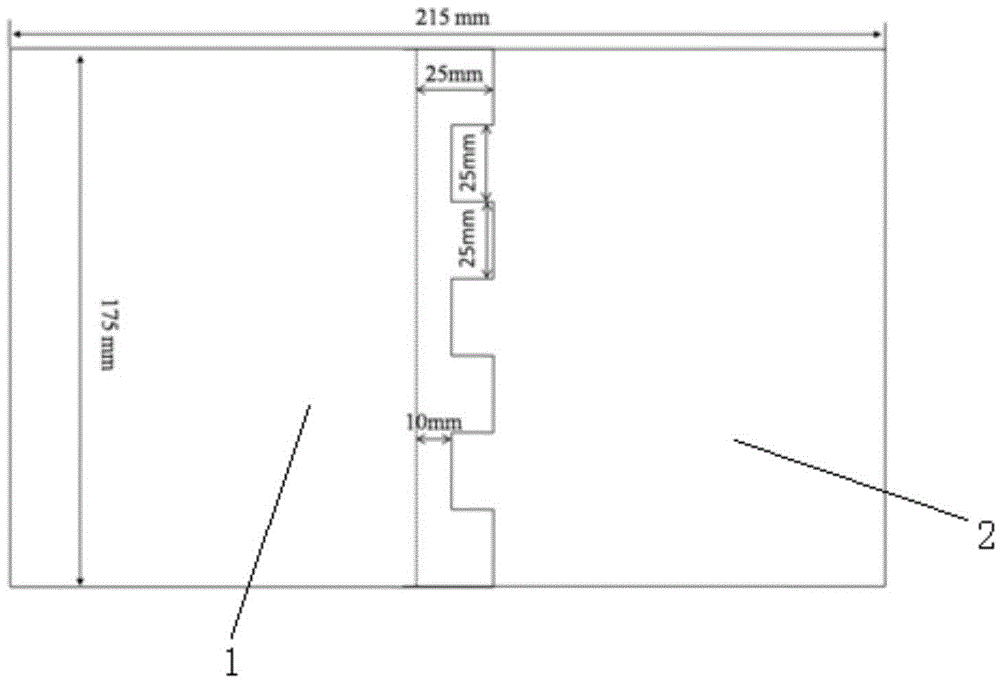

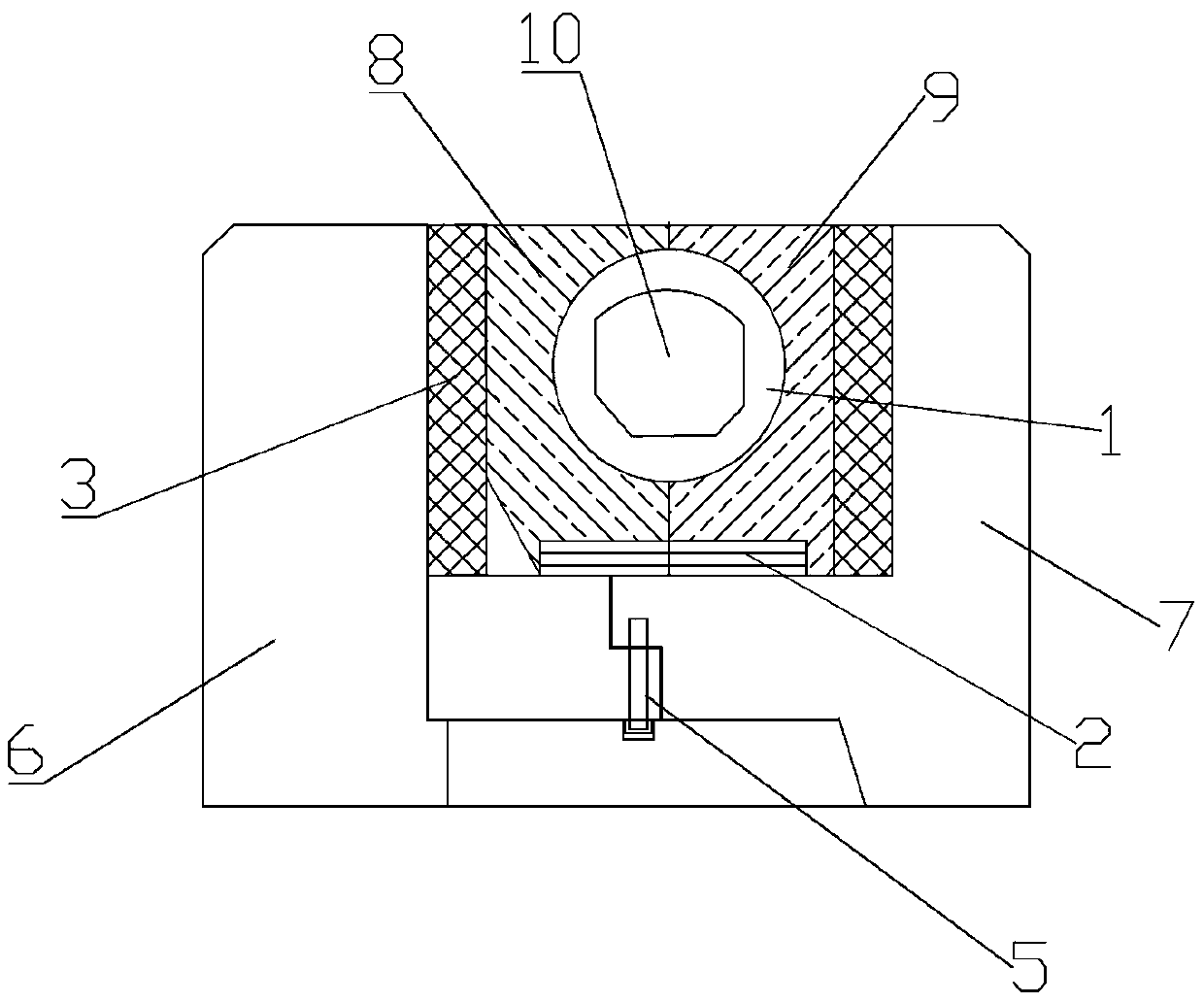

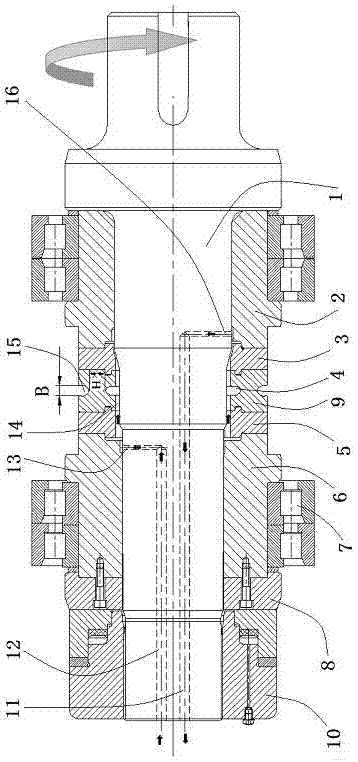

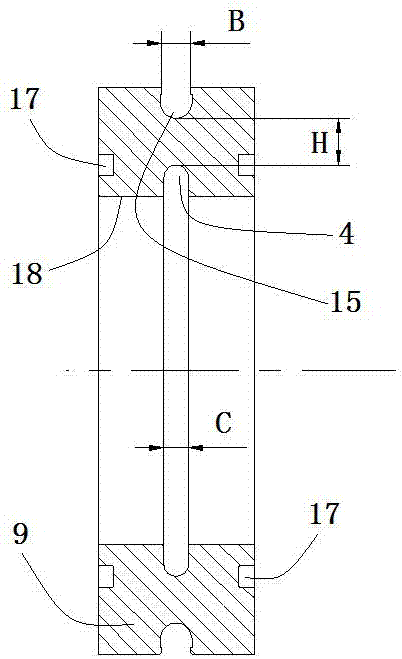

Clamping device for checking fatigue property of high-pressure turbine blade of aero-engine

InactiveCN107796696AIntensity correct assessmentChange the state of stressMaterial strength using repeated/pulsating forcesTurbine bladeEngineering

The invention provides a clamping device for checking fatigue property of a high-pressure turbine blade of an aero-engine. The clamping device comprises a base, a clamping block, an upper pressing block and a lower pressing block, wherein the base is provided with a gantry, the clamping block is used for clamping a high-pressure turbine blade of the aero-engine and putting into the gantry, a firstcompression bolt is further arranged above the clamping block, the upper pressing block and the lower pressing block are respectively arranged on an upper margin plate and a lower margin plate of thehigh-pressure turbine blade of the aero-engine to achieve an effect of stabilizing the upper margin plate and the lower margin plate, a second compression bolt is further arranged above the upper pressing block, the first compression bolt and the second compression bolt respectively penetrate through the upper end of the base, and the base is provided with six fixed bolts at the lower end for being connected with an electromagnetic vibrating table. The clamping device disclosed by the invention fundamentally solves the problem that tenon tooth are frequently broken in a process of checking fatigue property of the high-pressure turbine blade of the aero-engine, so that strength performance of the blade can be accurately evaluated.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

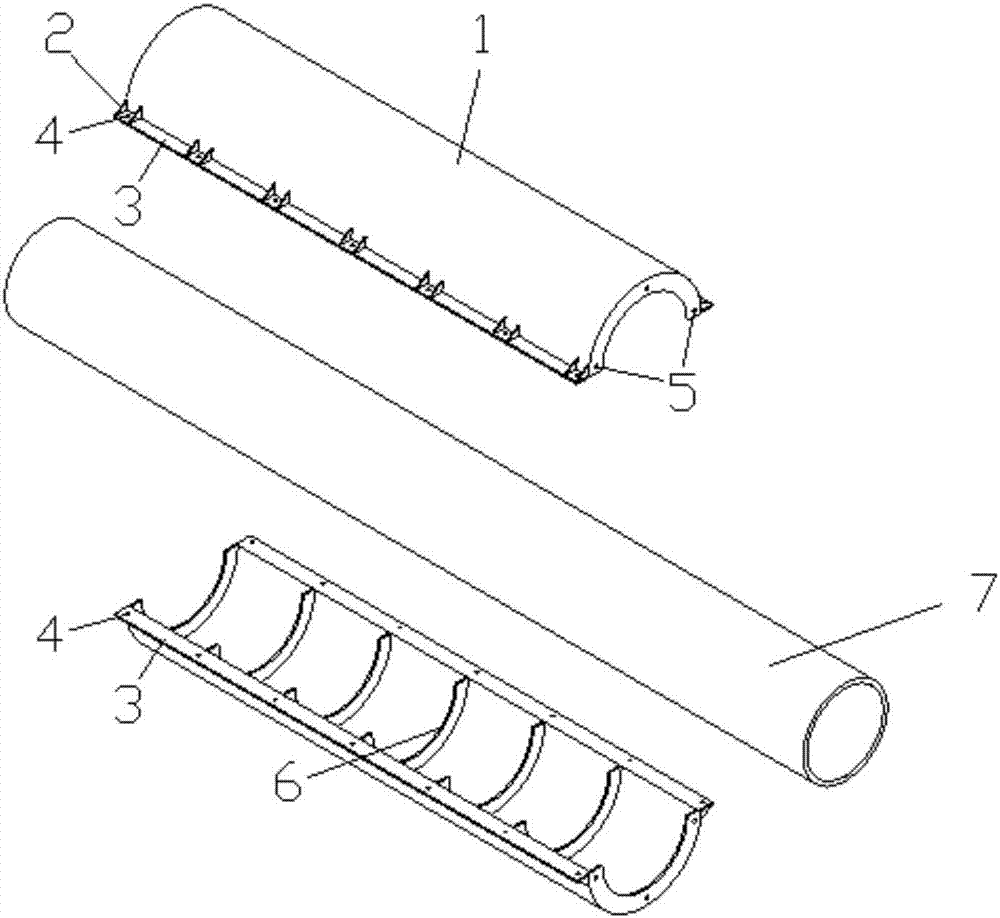

Spatial grid member reinforcing device and using method thereof

InactiveCN107366439AImprove bearing capacityChange the state of stressBuilding repairsEngineeringStressed state

The invention relates to a spatial grid member reinforcing device and a using method thereof. The spatial grid member reinforcing device comprises longitudinally-symmetrical clamps which can be combined together. Each clamp comprises a semicircular clamping plate, arc-shaped reinforcing plates, connecting side plates and reinforcing ribbed plates, wherein the arc-shaped reinforcing plates are perpendicularly fixed to the inner side of the clamping plate at equal intervals in the axial direction of the clamping plate, the connecting side plates are fixed to the two sides of the clamping plate, and the reinforcing ribbed plates are arranged at equal intervals in the length direction of the connection side plates and used for fixedly supporting the side plates and the clamping plate; and second bolt holes used for being connected with adjacent reinforcing devices are formed in the arc-shaped reinforcing plates at the two ends of the clamping plate. The using method of the spatial grid member reinforcing device comprises the following steps that the arc-shaped reinforcing plates are welded according the outer diameter of a reinforced member; the clamps are buckled to the two sides of the reinforced member; bolts are inserted into first bolt holes, and nuts are tightly screwed and fastened; and the reinforcing device is lengthened according to the length of the reinforced member. According to the spatial grid member reinforcing device and the using method thereof, under the condition that the stress states of the original member and an original structural system are not changed, the spatial grid member is reinforced, the bearing capacity of the spatial grid member is enhanced, construction safety is ensured, and the construction progress is also ensured.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Surface resistance testing probe, testing device thereof and surface resistance testing method

ActiveCN105866548AGood contact guaranteedThe test effect is goodResistance/reactance/impedenceMercury probeTest material

The invention discloses a surface resistance testing probe, a testing device thereof and a surface resistance testing method. Through replacing a mechanical probe for measuring the surface resistance according to a four-probe method by liquid mercury as a testing probe, defects of coating and film damage and remarkable force bearing state change of a to-be-tested material by the mechanical probe can be effectively overcome, thereby obtaining more accurate measurement results. Furthermore the invention provides a corresponding resistance testing device in which mercury is used as the testing probe, wherein the mercury probe can be conveniently used for testing the surface resistance of a sample, and furthermore the mercury can be conveniently and quickly injected and recycled. The resistance testing device has advantages of concise design, convenient use, accurate and repeatable testing result and good effect. The resistance testing method and the testing device in which mercury is used as the testing probe can be used for the sample with an easy-damage surface and have advantages of effectively preventing sample surface damage and reducing an interference of an overlarge testing pressure to the surface resistance of the to-be-tested sample, and particularly the coating sample.

Owner:CENT SOUTH UNIV

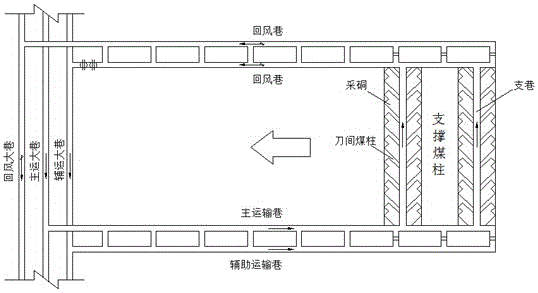

Working face double-roadway tunneling small coal pillar reinforcement construction method

PendingCN111535817AImprove recoveryAvoid fireMining devicesUnderground chambersSteel tubeCoal pillar

The invention provides a working face double-roadway tunneling small coal pillar reinforcement construction method, and relates to the technical field of coal mining and roadway support. The working face double-roadway tunneling small coal pillar reinforcement construction method comprises the steps that double-roadway tunneling is arranged on a working face, and 3-5m small coal pillars are reserved between roadways; two-ended cables are installed on the small coal pillars, so that the coal pillars are in a three-dimensional stress state; grouting anchor rods are arranged on the two sides of the small coal pillars to control surrounding rock fractures, and the integrity of the coal pillars is ensured; suspension anchor cables are installed to reinforce the connection of the coal pillars and overlaying strata to prevent the coal pillars from slipping; a coal side is reinforced by concrete filled steel tube tubular piers to improve the carrying capacity of the coal pillars to control side bulging; and advance pre-roof-breaking pressure relief is carried out during the stoping period, and the bearing pressure above the coal pillars is reduced. According to the working face double-roadway tunneling small coal pillar reinforcement construction method, the stability of the small coal pillars in the tunneling and stoping process is ensured, the problem of tense replacement of mine working faces can be solved through double-roadway tunneling, and the mining rate can be improved by arranging the small coal pillars; and in addition, the bearing capacity of the small coal pillars is further improved, the long-term stability of the small coal pillars is ensured, and double-roadway tunneling of the small coal pillars is realized.

Owner:SHANDONG UNIV OF SCI & TECH

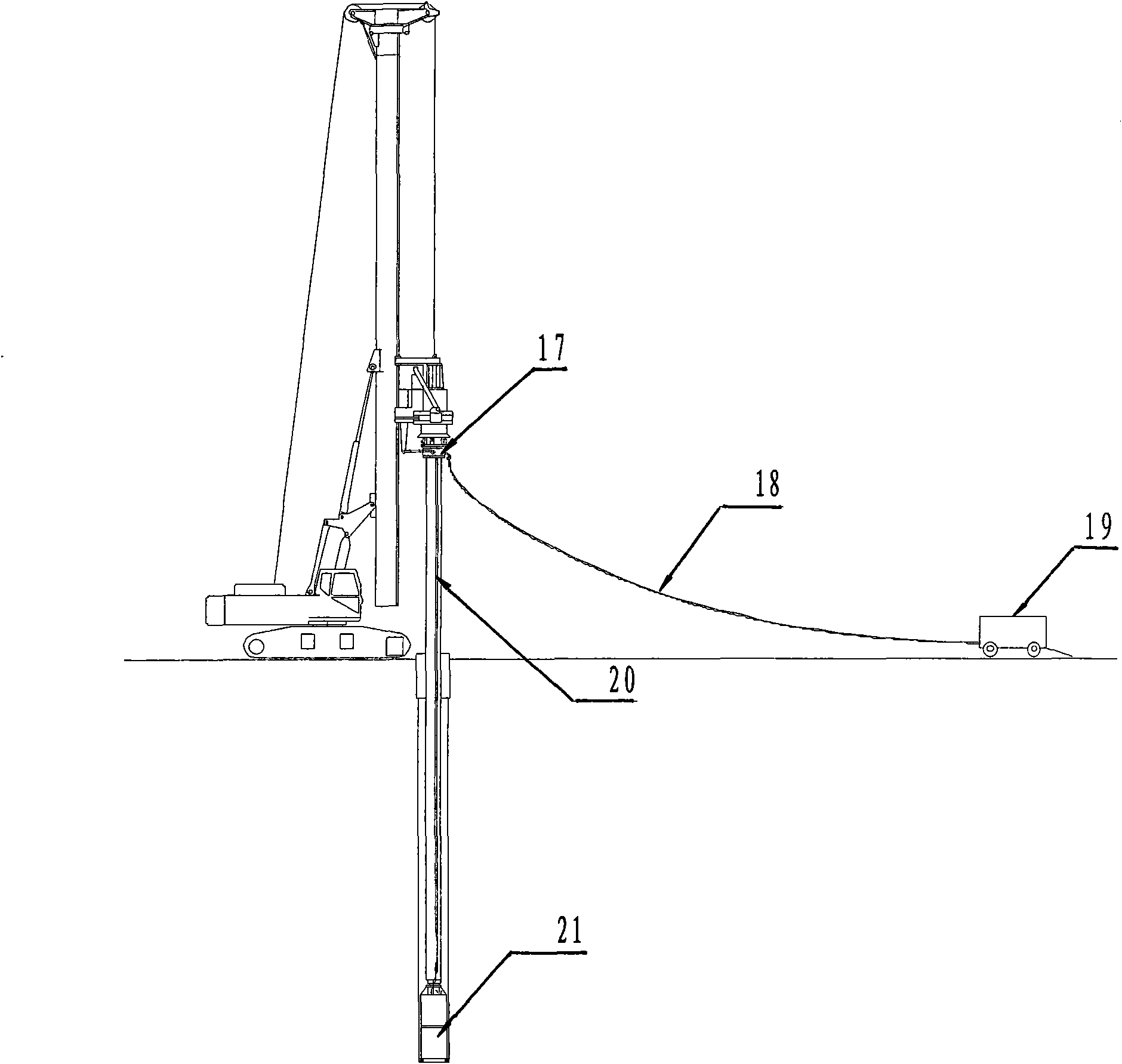

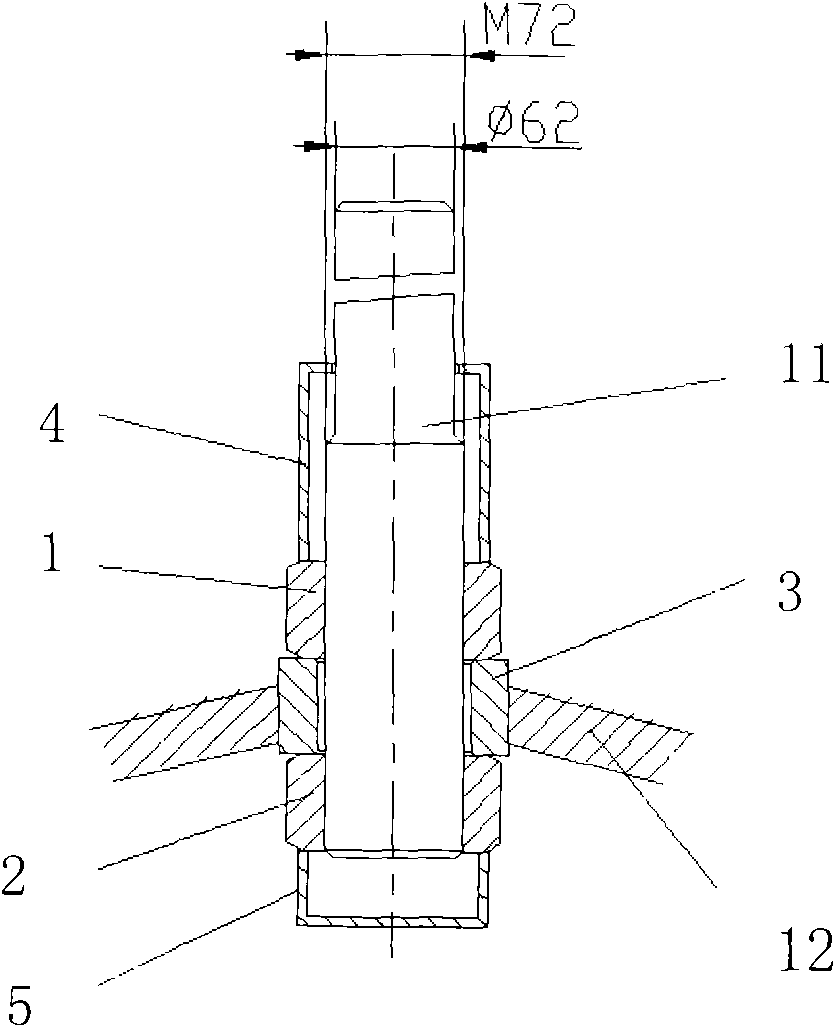

Drilling method of rotary drilling machine in hard rock and special-purpose sediment pipe core cone bit

InactiveCN102022076AImprove cooling effectChange the state of stressDrill bitsConstructionsGear wheelSediment

The invention discloses a drilling method of rotary drilling machine in hard rock and a special-purpose sediment pipe core cone bit. The drilling method comprises the steps of: (1) installing an gas-water joint; (2) installing a sediment pipe gear wheel core drill bit; (3) connecting an inflator, the gas-water joint and the sediment gear wheel core drill together by air supply flexible pipes; (4) putting the drill bit in an aperture, starting the inflator to supply air into the aperture and simultaneously operating the rotary drilling machine for drilling; (5) after the drilling, powering off the inflator, taking out the sediment pipe gear wheel core drill bit, opening the sediment pipe valve to remove the sediment in the pipe and then closing the valve; (6) repeating the above steps until pore-forming is completed. Comparing with routine methods, the method applies a drill bit with a simple and durable structure, small wearing of the drilling tool, high efficiency of drilling and good heat radiation, which effectively solves the drilling problem of rotary drilling machine in hard rock.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

Thread-free floating type supporting bar

InactiveCN101898161AChange the state of stressStress state is simpleGrain treatmentsPropellerEngineering

The invention relates to a thread-free floating type supporting bar, in particular to a construction member used for fixing a spiral propeller onto a coal mill barrel in a BBD steel ball coal mill. The invention solves the problems that the existing supporting bar is inconvenient for maintenance, has poor strength and is easy to break and compensatory is poor. The shaft sleeve of the supporting bar main body penetrates a hole opened on the side wall of a central tube and is fixedly connected with the central tube, one end of the supporting bar main body is inserted and arranged in one end of the supporting bar main body shaft sleeve outside the central tube, a disk spring is arranged in the other end of the supporting bar main body shaft sleeve inside the central tube, one end of the supporting bar main body is connected with the disk spring by contact, and the other end of the supporting bar main body shaft sleeve is connected with a gland by a connecting piece in a dismountable way. The invention has simple and feasible mounting, can be dismounted and can be repeatedly used; clearance compensation changes the stress state of the supporting bar, thus improving the strength of the supporting bar; and different axiality compensation between the spiral propeller and the barrel optimizes the working condition of the spiral propeller.

Owner:关海龙 +1

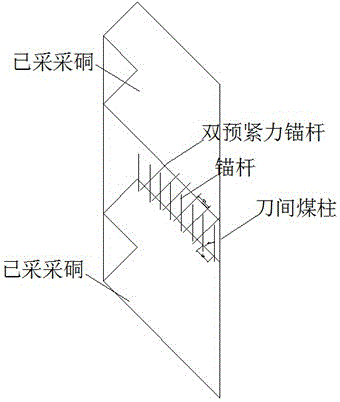

Band type wangeviry mining technology branch entry supporting method

InactiveCN106150535AImprove residual strengthChange the state of stressMine roof supportsAnchoring boltsResidual strengthEngineering

The invention discloses a band type wangeviry mining technology branch entry supporting method. The band type wangeviry mining technology branch entry supporting method comprises three steps for completing supporting work: preliminary supporting is performed during branch entry tunneling, screw-thread steel anchor rods and anchor ropes are arranged on top plates, and glass anchor rods are arranged on two sides; after the preliminary supporting is completed and first mining pit excavation is completed, anchor rods are hit on one side coal wall close to an unexcavated mining pit to improve the residual strength of a coal body and provide a certain supporting role on excavation activities of an adjacent mining pit; after the excavation close to the mining pit is also completed, an inter-tool coal pillar with the width of 2 m is reserved between the two mining pits, and double-pretightening-force anchor rods are hit on the coal pillar; then, the operation is cyclically performed with completion of excavation of the mining pits till the excavation works of all mining pits in a branch entry are completed. The band type wangeviry mining technology branch entry supporting method can improve the residual strength of the inter-tool coal pillar left after the excavation of the mining pits is completed, improves the residual strength of the inter-tool coal pillar and the stability of a branch entry roadway, decreases supporting pressures of adjacent unexcavated mining pits and facilitates earth's surface subsidence control and earth's surface building (construction) protection.

Owner:HENAN POLYTECHNIC UNIV

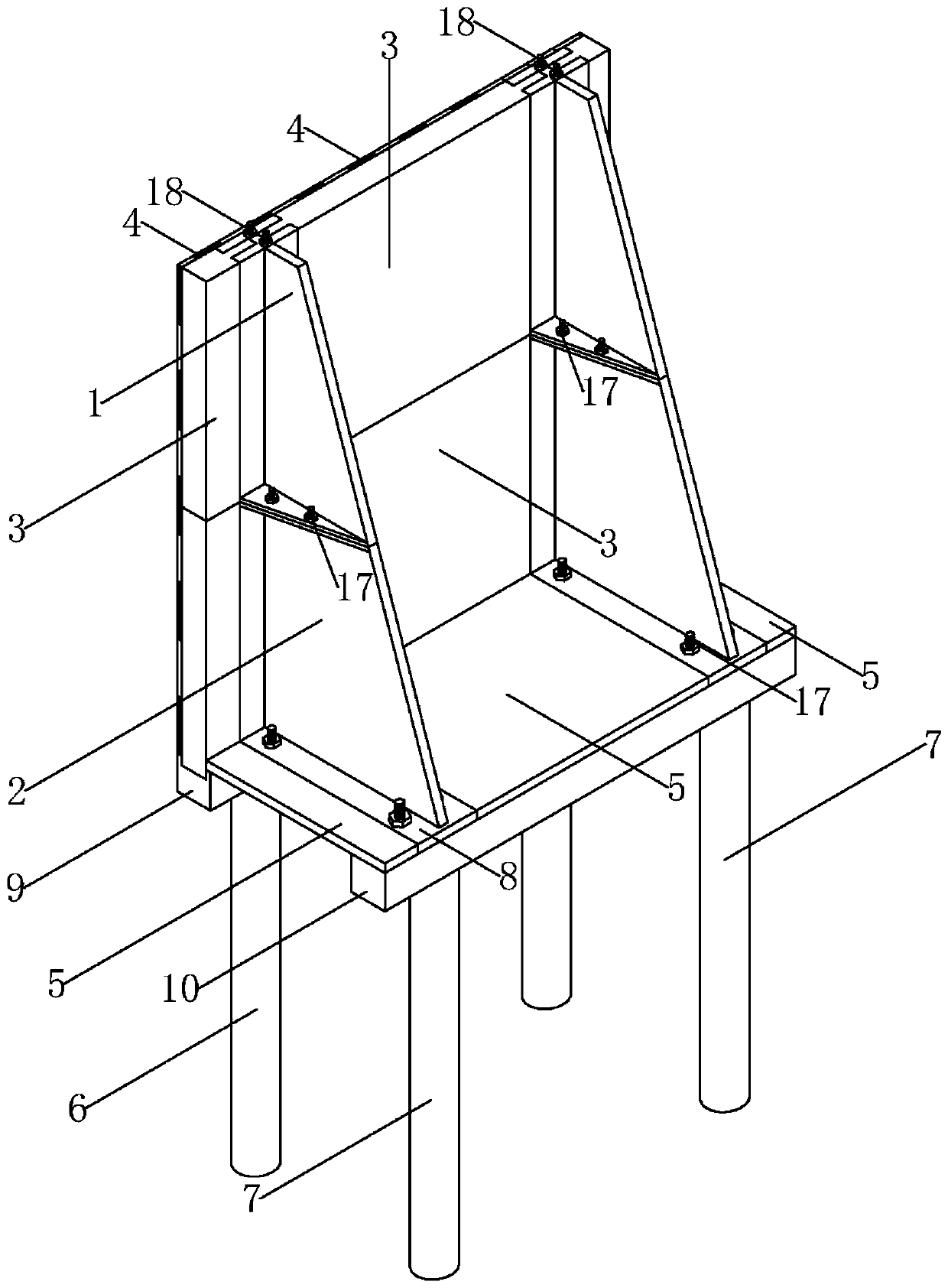

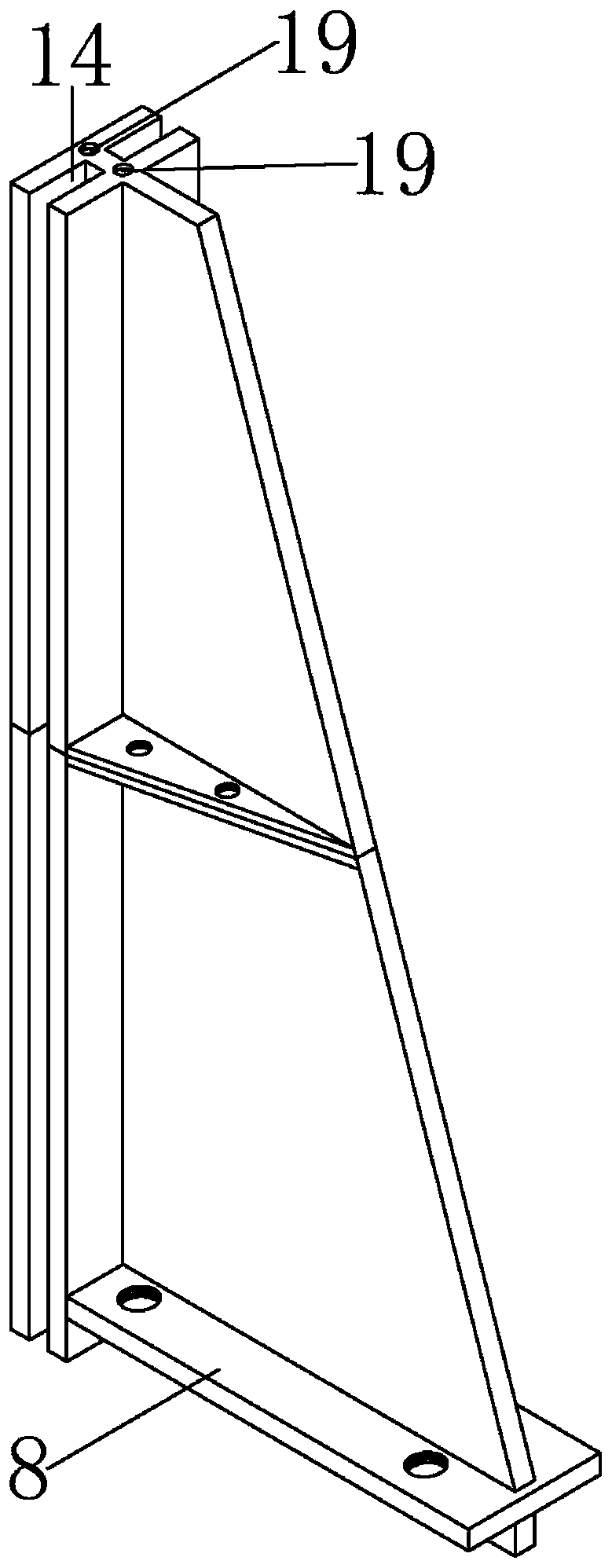

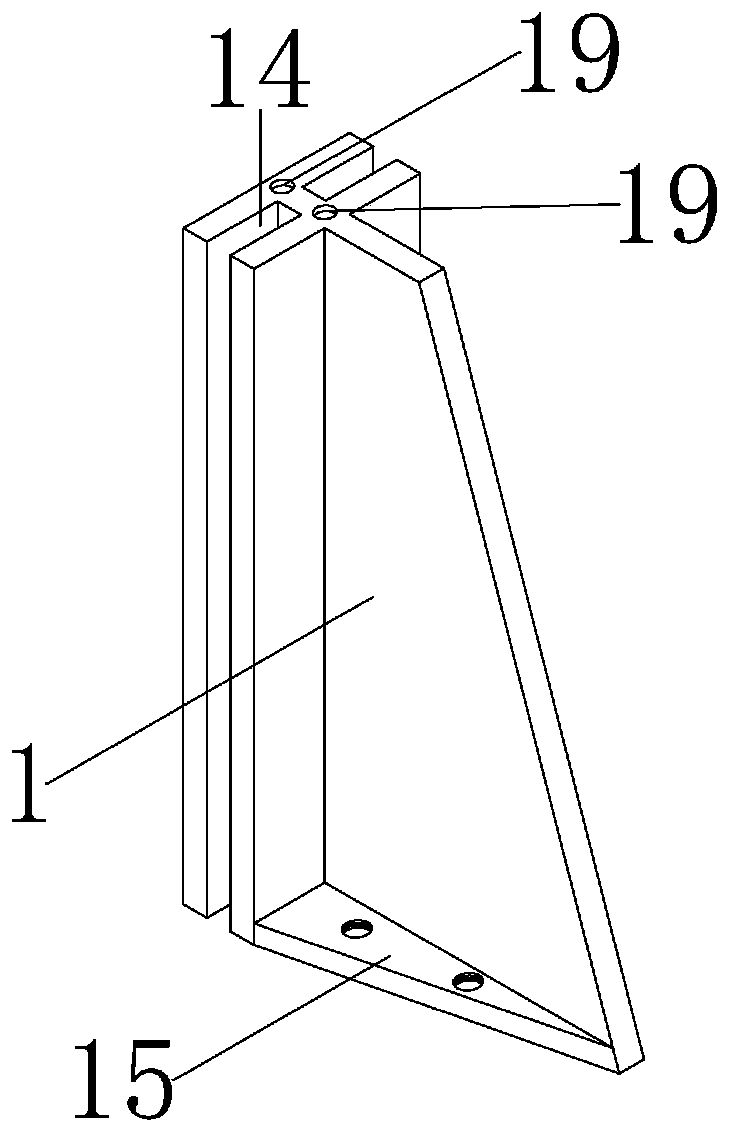

Partially-assembled pile support buttressed retaining wall

ActiveCN110055999AReduce the difficulty of on-site constructionShorten the construction periodArtificial islandsUnderwater structuresAbnormal shapedRebar

The invention discloses a partially-assembled pile support buttressed retaining wall, and belongs to the technical field of retaining walls. A lower foreign-shaped column is fixed into a second clamping groove in a connecting beam, and the lower part of the lower foreign-shaped column is provided with a bottom base plate which is connected with the connecting beam through bolts; a first stiffeningrib is arranged on the lower part of an upper foreign-shaped column, a second stiffening rib is arranged on the upper part of the lower foreign-shaped column, and the first stiffening rib and the second stiffening rib are fixedly connected through bolts; a wall face plate is connected with the upper foreign-shaped column and the lower foreign-shaped column through a first clamping groove and a third clamping groove; and the two ends of a bottom plate are lapped on a first bottom beam and a second bottom beam, and steel bars anchored on a lower pile body in a full-length mode are arranged on the first bottom beam. The retaining wall is built in the mode that prefabricated parts are assembled on site, the site construction difficulty can be lowered, the construction period is shortened, andgood economic and social benefits are achieved.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

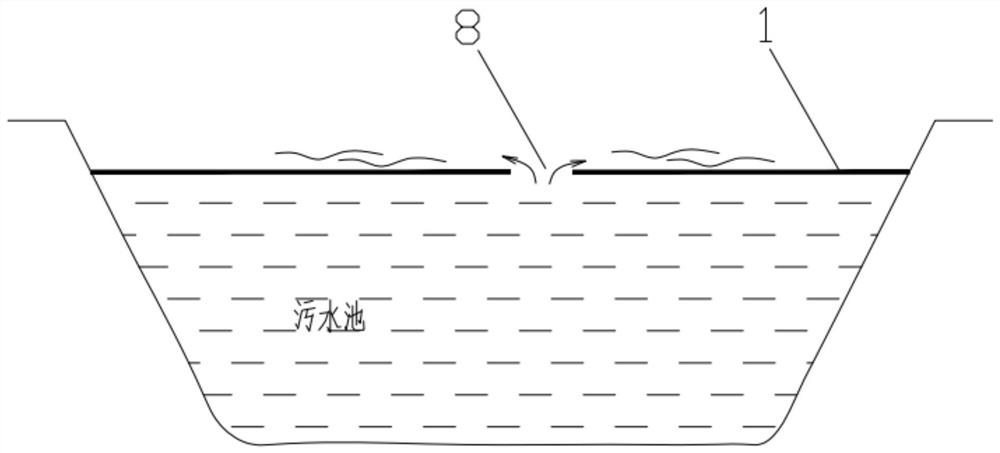

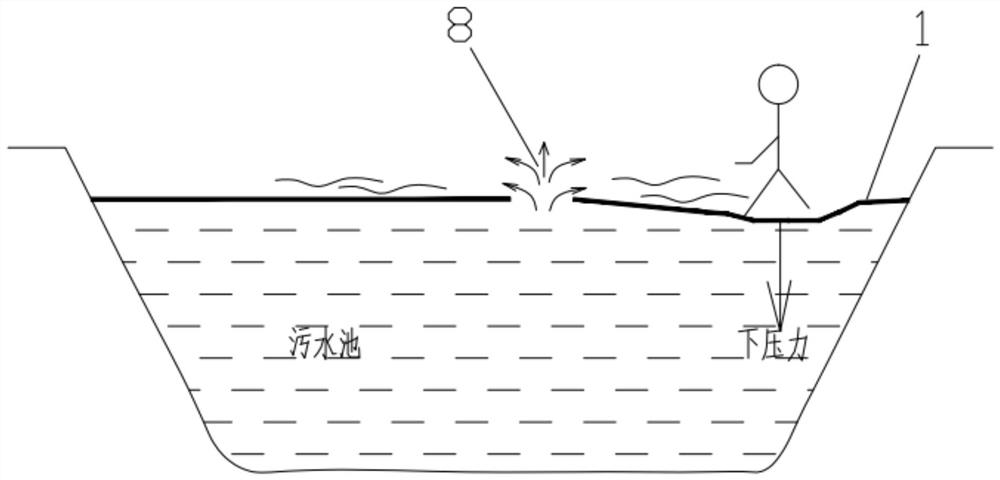

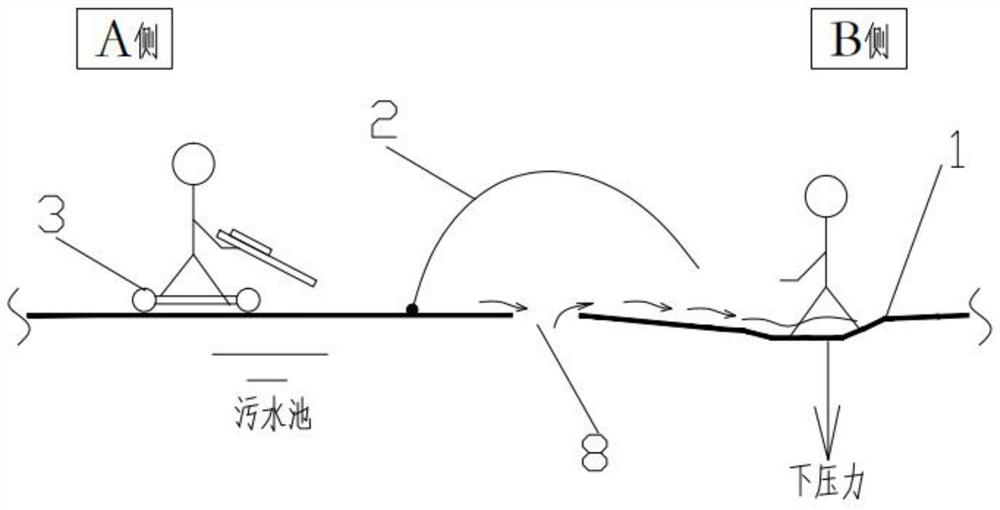

Operation method for repairing floating cover film with water

InactiveCN112624221AIncrease the compression areaSmall extrusion effectWater/sewage treatmentContaminated groundwater/leachate treatmentForeign matterSewage

The invention discloses an operation method for repairing a floating cover film with water. The operation method comprises the following steps: constructing an operation support platform for repairing a film surface broken hole by adopting a large-area buoyancy pad; enabling an operator to stand on the HDPE floating cover films on the two sides of the broken hole to weld HDPE film strips; slowly lifting the film strip, and lifting the HDPE floating cover film at the broken hole to be in a suspended state; temporarily sealing the film surface broken hole by adopting a strong adhesive tape; and carrying out extrusion welding repair on the film surface broken hole by adopting an HDPE repair block to form a permanent and firm HDPE repair block, so as to complete repair of the film surface broken hole of the HDPE floating cover film with water. The problem that in the operation process of a sewage pool, due to foreign matter entering or the action of external force or the like, holes occur in the film surface of the HDPE floating cover film covering the water surface of the sewage pool is solved.

Owner:中城建胜义(深圳)环境科技有限公司

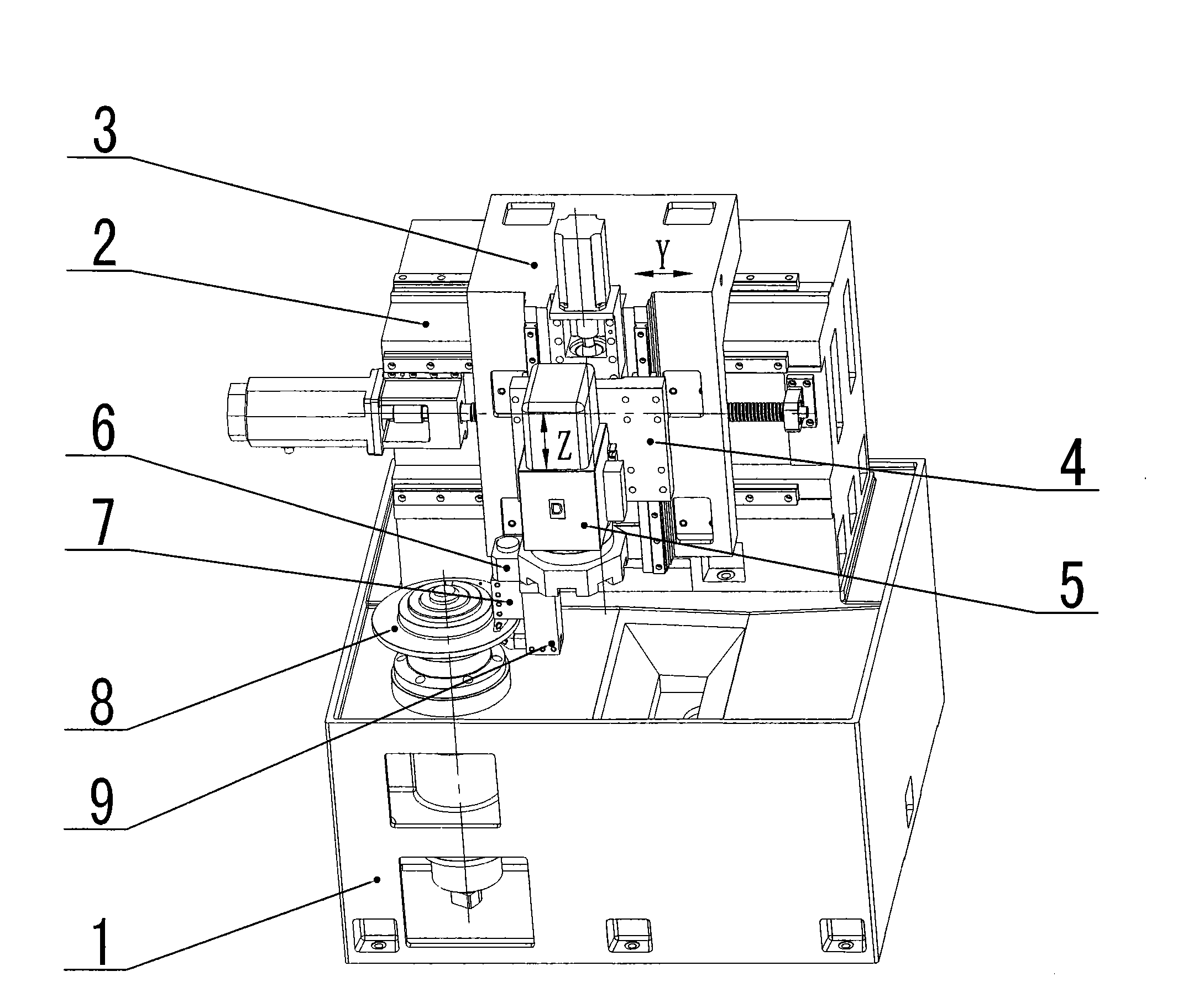

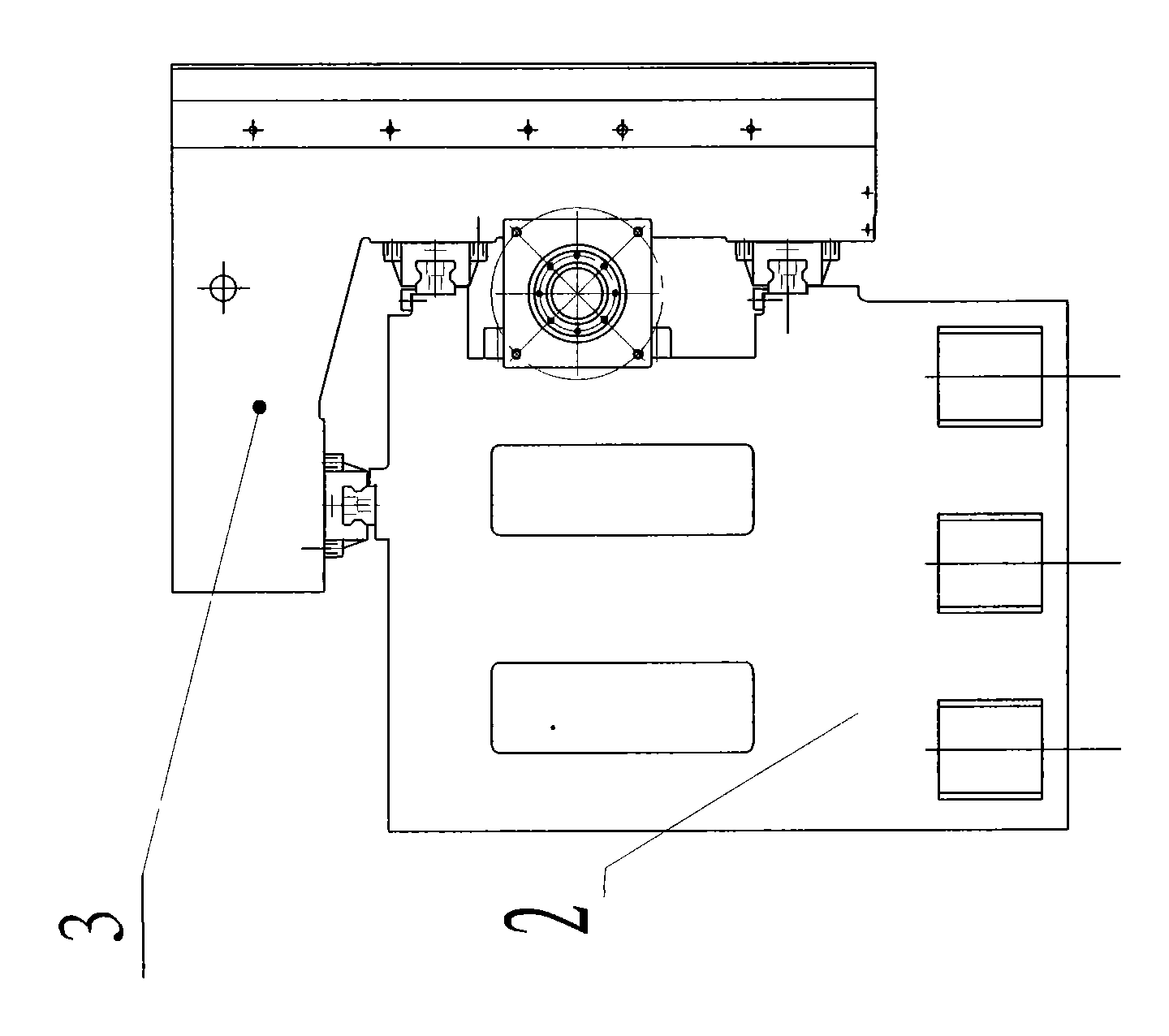

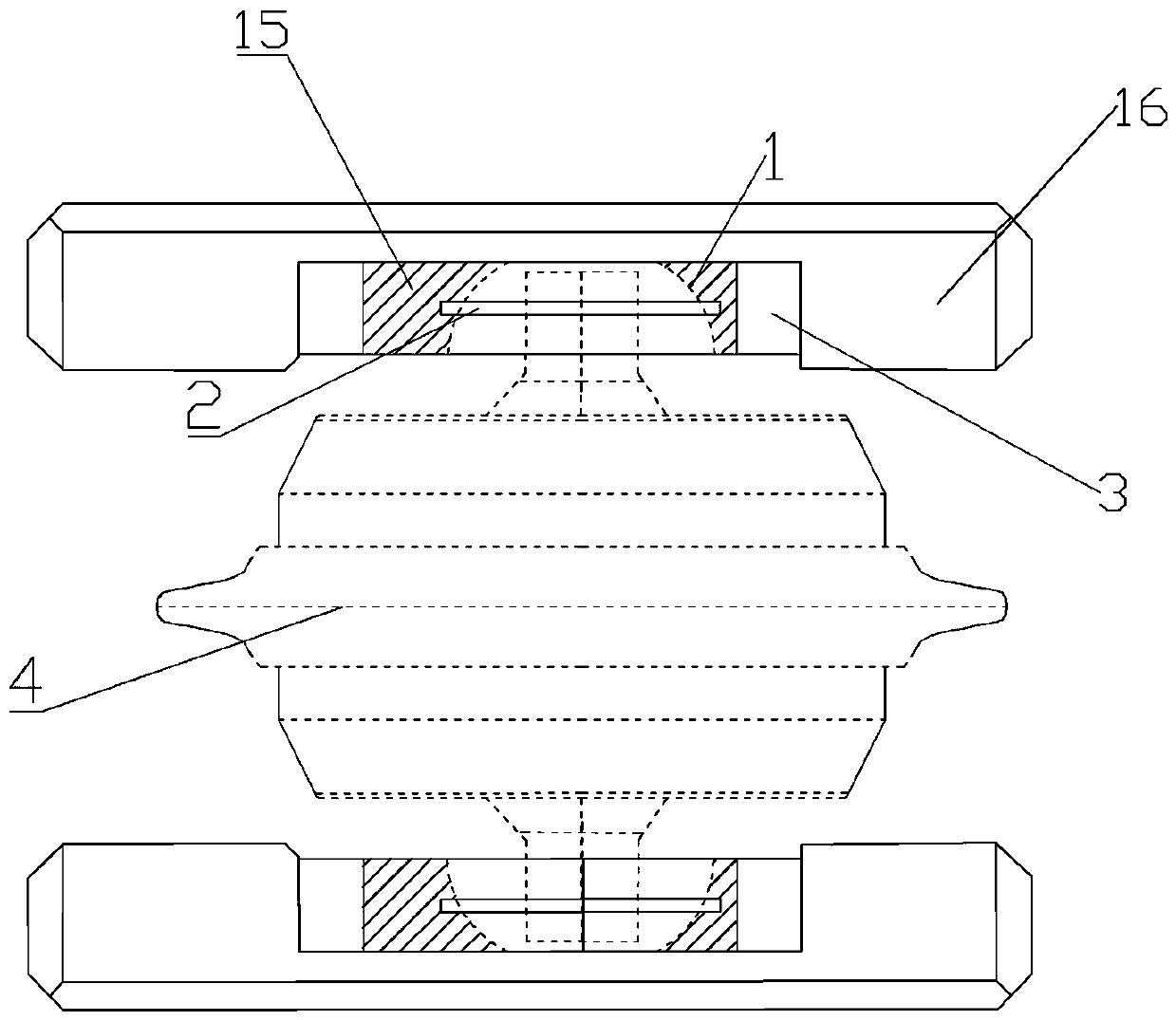

Disk workpiece processing method and structure

InactiveCN101658945AImprove rigidityChange the state of stressMetal-working apparatusNumerical controlEngineering

The invention relates to a lathe structure, in particular to a vertical special numerical control lathe with a novel structure, high rigidity and high efficiency, which is used for processing disk workpieces, in particular brake disks of automobiles. The lathe comprises a lathe body, a beam, a Y-axis bent-plate sliding saddle, a Z-axis sliding saddle and a turret, and is characterized in that: theturret is provided with a tool rest; a lower processing surface tool is arranged under the tool rest; a positioning block is arranged above the tool rest; a movable tool rest is arranged above the positioning block, and can slide along the tool rest; an upper processing surface tool is arranged under the movable tool rest; and the upper part of the movable tool rest is connected with a driving device. The lathe has the advantages that: 1, the lathe can process two sides simultaneously to improve processing accuracy and production efficiency; 2, a three guide rail mode is adopted, so the lathemeets the condition of applying an PCBN tool; and 3, the lathe body adopts a completely inclined surface to achieve the aims of better draining water and removing chips.

Owner:郑勇阁

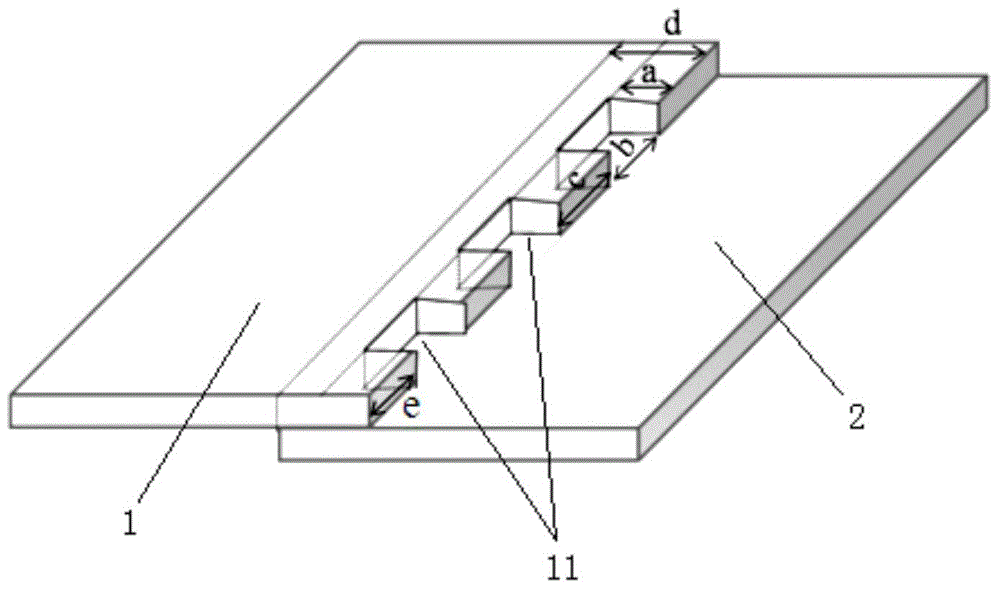

Connection method for improving strength of overlap joints

InactiveCN104858535AImprove carrying capacityIncrease the carrying areaArc welding apparatusMetal working apparatusStress conditionsWeld seam

The invention relates to the technical field of welding, in particular to a connection method for improving the strength of overlap joints. The connection method is suitable for the welding process of various aluminum alloy overlap joints with the overlap jointing distance larger than or equal to 20 mm. The connection method for improving the strength of overlap joints includes the following steps that a, a plurality of rectangular notches are machined in the overlap joint edge of an upper overlap joint plate before welding; b, welding is conducted along the edge of a lap weld according to a conventional welding method. Compared with the prior art, the connection method for improving the strength of overlap joints has the advantages that the stress condition of welding seams is changed by enlarging the bearing area of the welding seams, so that the bearing load of the welding seams is improved.

Owner:SHANGHAI JIAO TONG UNIV

Novel tool apron for preventing eccentric wear of hobbing cutter

The invention discloses a novel tool apron for preventing eccentric wear of a hobbing cutter. The novel tool apron comprises bases symmetrically arranged onthe two sides of the hobbing cutter, U-shaped mounting grooves opened upwards are formed in the bases, sliding guide slots are formed in the bottoms of the mounting grooves in the direction vertical to the axis direction of the hobbing cutter,fixed blocks sliding along with the sliding guide slots are mounted on the sliding guide slots, joint bearings connected witha cutter shaft of the hobbing cutter are mounted on the fixed blocks, and elastic elements are separately arranged between the mounting grooves and the fixed blocks. By adjusting the hobbing cutter and the axis angle of the hobbing cutter, eccentric wear and abrasion of thehobbing cutter are avoided, the problem that the conventional hobbing cutter is easy to wear, wear eccentrically and flake is solved, the service life of the hobbing cutter is prolonged, the replacingand maintenance numbers of times of the hobbing cutter are reduced, and the cost is saved.

Owner:STATE KEY LAB OF SHIELD & TUNNELING TECH +2

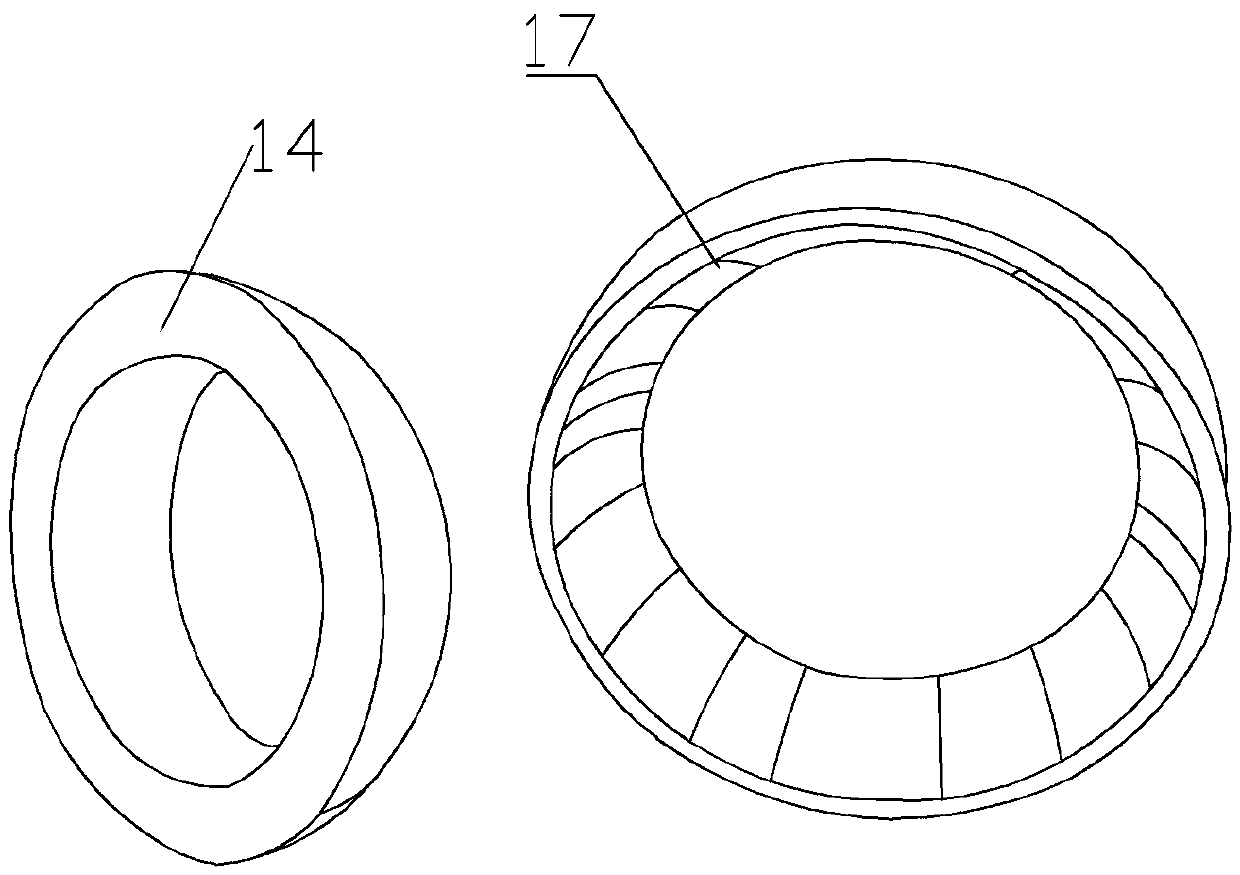

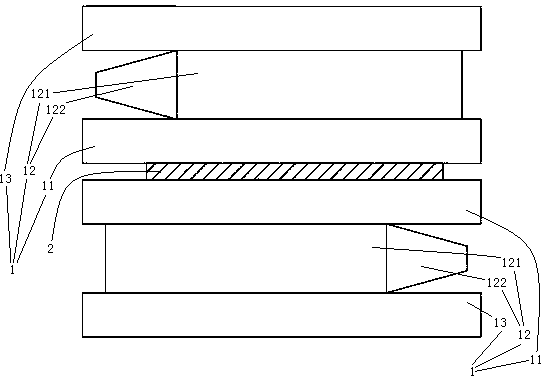

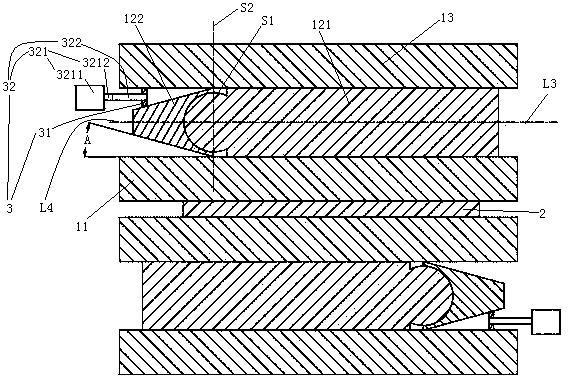

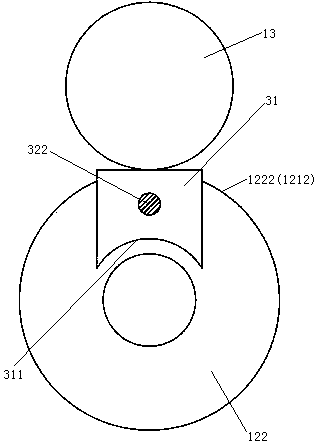

Method for installing permanent magnetic material in permanent magnetic field generating apparatus and transferring tool thereof

InactiveCN1548980AChange the state of stressEasy to movePermanent magnetsMagnetic property measurementsAdhesiveEngineering

The present invention proposes permanent magnetic column installing method and tool for permanent magnetic field generator in, such as, magnetic resonant imaging equipment. The installation method includes the following steps: sliding permanent magnetic column via an additional board installed around the plate electrode to the surface of the plate electrode; painting adhesive to at least one side of the permanent magnetic column; adhering the permanent magnetic column to one other permanent magnetic column installed on the plate electrode in advance; and repeating the foregoing steps until finishing the installation of the permanent magnetic field generator. The present invention has the advantages of flexible operation and enlarged operation area.

Owner:SIEMENS HEALTHINEERS LTD

Plate and stripe rolling mill and plate and stripe edge shape control method

ActiveCN103521530AChange the state of stressChange the distance between the tapered section and the edge of the strip to change the force stateMetal rolling stand detailsRollsEngineeringRolling mill

The invention relates to a rolling mill and a rolling method. The plate and stripe rolling mille comprises two roller sets which are oppositely arranged. Each roller set comprises a work roller, a middle roller and a supporting roller which are sequentially arranged, wherein the middle roller comprises a column-shaped section and a conical section connected with one end of the column-shaped section. The directions of the conical sections of the middle rollers of the two roller sets are opposite. The plate and stripe rolling mill and a plate and stripe edge shape control method can change the contact lengths of roller faces of the middle rollers and solve the problem that in the prior art, the contact lengths of the roller faces of the middle rollers cannot be changed to prevent plate and stripe edge shapes from being adjusted to meet requirements.

Owner:ZHEJIANG HUADA NEW MATERIAL

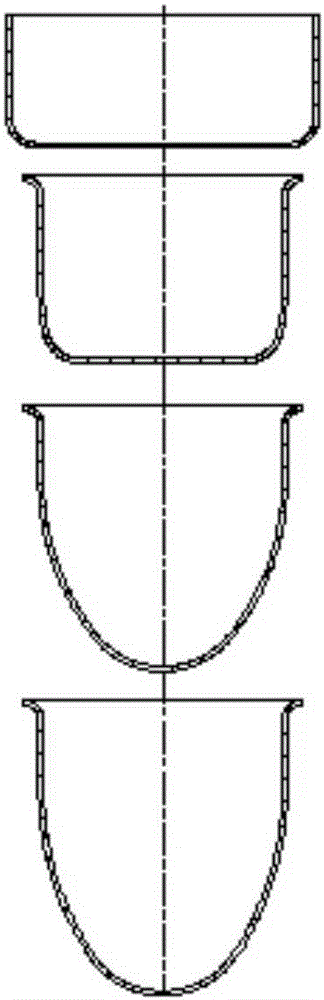

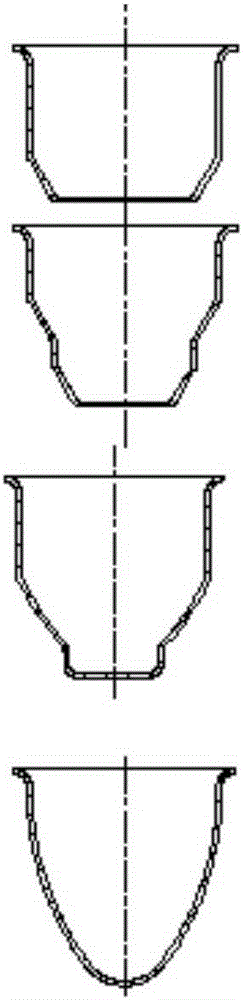

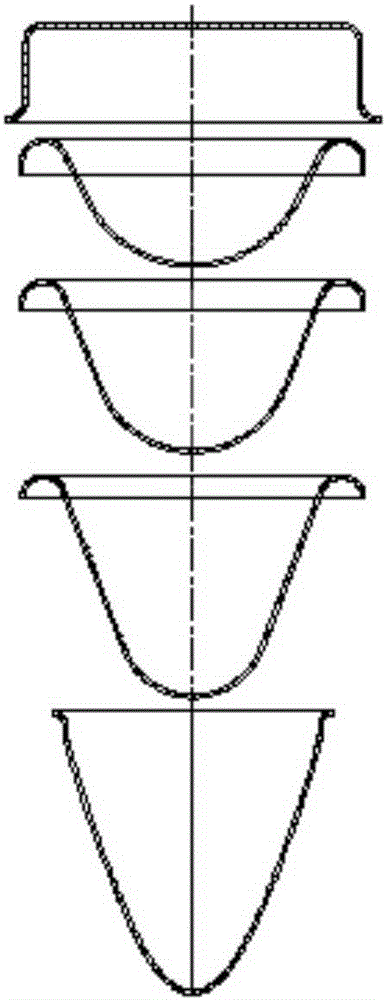

Single-die forming device and method of thin-wall deep parabolic drawing part

The invention discloses a single-die forming device of a thin-wall deep parabolic drawing part and belongs to the technical field of single-die formation. The single-die forming device comprises an upper plate, a pressure head, a blank holder, a forming medium, a die and a lower plate; the pressure head comprises a cylindrical section and a circular-arc head section in smooth transition with the cylindrical section; the blank holder is a cylinder with an axial through hole; the upper plate is mounted on a main slider of a common double-action hydraulic press, while the lower plate is mounted on a double-action hydraulic press platform; the die is fixed on the lower plate; a blank is placed on the die to seal a cavity of the die; the blank holder is mounted on a blank pressing slider of the common double-action hydraulic press and holds down the blank; the forming medium is located within an inner cylinder formed by the axial through hole of the blank holder and the blank; the cylindrical section of the pressure head is fixed on the upper template; the circular-arc head section of the pressure head is in hole-shaft fitting with the axial through hole of the blank holder and props against the forming medium in the axial through hole of the blank holder; the device is few in forming steps and low in cost.

Owner:BEIJING POWER MACHINERY INST

A unit type curtain wall column side hanging connector

A sideward-hanging connection piece of a unit-typed curtain wall stand column comprises a backboard, two side plates and a bolt shaft. The backboard and the two side plates are squeezed to be formed in an integrated mode through a compound die made of aluminum, and an aluminum hanging shaft penetrates through the bolt shaft. Vertical teeth are arranged on the outer side faces of horizontal long-strip-shaped holes in the two side plates. Gaskets are correspondingly arranged on the vertical teeth and are provided with vertical teeth matched with the vertical teeth on the outer side faces of the horizontal long-strip-shaped holes. Transverse teeth are arranged on the outer side faces of the vertical holes in the backboard on the outsides of the two side plates. Gaskets are arranged on the corresponding faces of the transverse teeth and provided with transverse teeth matched with the transverse teeth on the outer side faces of the vertical holes, and the transverse teeth on the outer side faces of the vertical holes are made in a punching mode. The hanging shaft is of an asymmetric design. The sideward-hanging connection piece has the advantages that on-site welding can be avoided, the bearing force is higher, the structural safety is better, adjustment is more convenient to achieve, the machining precision is easy to guarantee, a needed space is smaller and the weight is lower.

Owner:JANGHO GRP

Main shaft assembly of continuous copper extruding machine

The invention discloses a main shaft assembly of a continuous copper extruding machine. The main shaft assembly comprises a core shaft, an inner shaft sleeve, an inner side wheel, an outer side wheel,bearings, a pressing sleeve, an extruding wheel and a hydraulic nut, wherein the inner shaft sleeve and the outer shaft sleeve are mounted on the outer side of the core shaft; the bearings are mounted at the outer parts of the inner shaft sleeve and the outer shaft sleeve separately; an axial water inlet, an axial water outlet, a radial water inlet and a radial water outlet are formed in the coreshaft; the axial water inlet communicates with the radial water inlet; the axial water outlet communicates with the radial water outlet; an annular cooling groove is formed in the inner surface of the extruding wheel; and the part between the inner surface of the extruding wheel and the outer surface of the core shaft forms an annular gap which serves as a cooling water channel. According to themain shaft assembly of the continuous copper extruding machine, the cooling water channel of the extruding wheel of the main shaft assembly is changed, so that when the groove temperature of the extruding wheel is controlled and the softening of the extruding wheel in the high temperature area in the groove is reduced, the temperature distribution and stress condition of the extruding wheel are changed, the stress value of the extruding wheel at the dangerous breakdown point is reduced, the service life of the extruding wheel is prolonged, and the equipment operation cost is reduced.

Owner:大连康丰科技有限公司

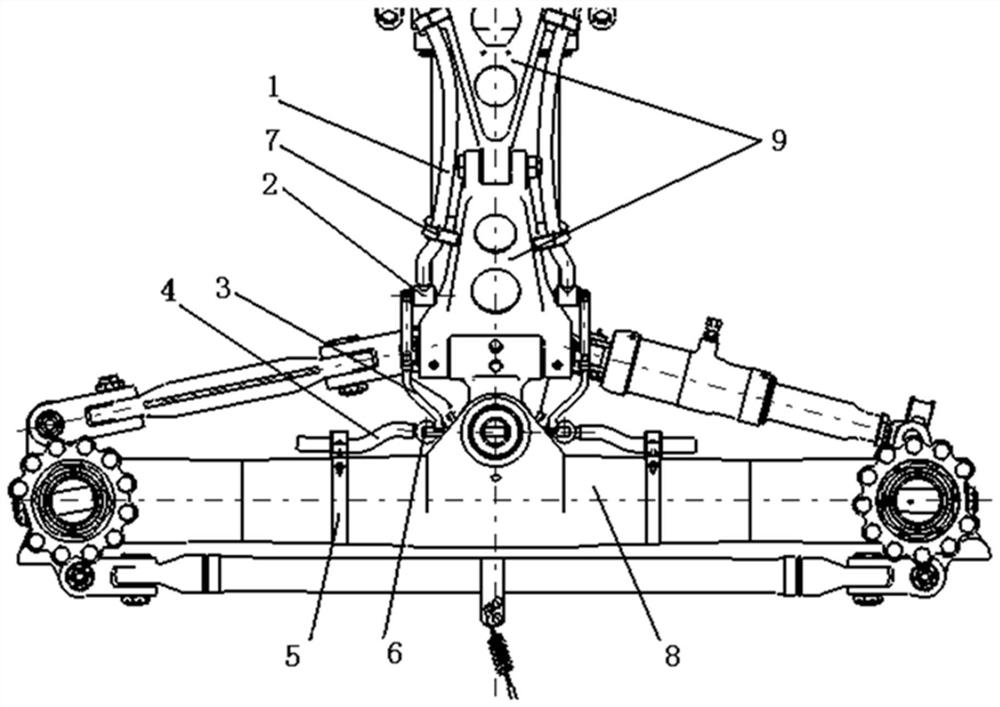

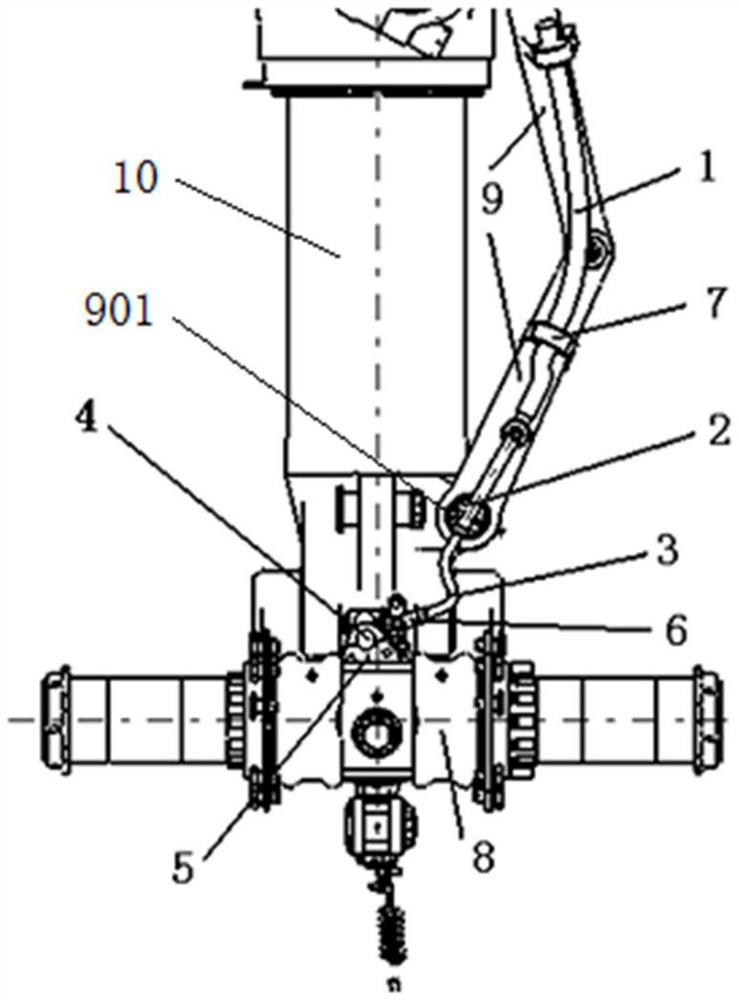

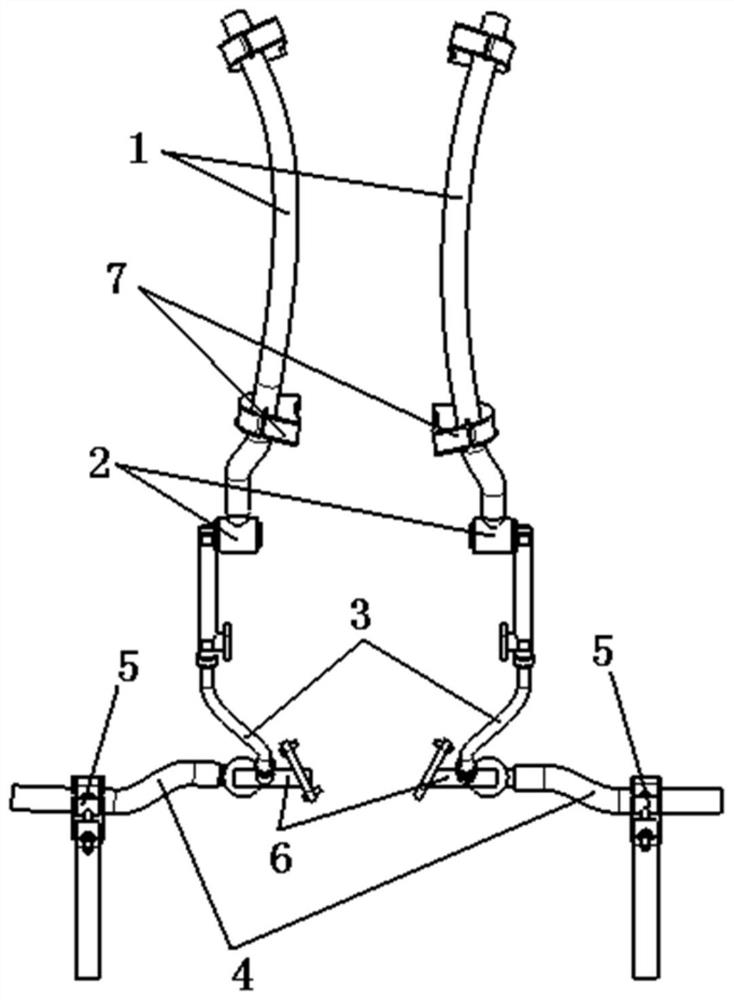

Frame type undercarriage brake hose connecting structure

ActiveCN112061382AChange the state of stressImprove working conditionsAircraft brake actuating mechanismsVehicle framePiston rod

The invention discloses a frame type undercarriage brake hose connecting structure. The structure comprises a buffer supporting column, a torque arm and a frame, wherein the torque arm is installed ona piston rod of the buffer supporting column through a first pin, the bottom of the piston rod is hinged to the frame, a hose A doing bending motion along with the torque arm is installed on the torque arm, a hose B doing pitching motion along with the frame is installed on the frame, a first adapter is fixedly installed at a first set point on the piston rod, a second adapter is fixedly installed at a second set point on the piston rod, a hard pipe is connected between the first adapter and the second adapter, the other end of the first adapter is rotationally connected with the hose A, andthe other end of the second adapter is rotationally connected with the hose B. According to the frame type undercarriage brake hose connecting structure, the stress state of an undercarriage brake hose is improved, and the service life of the brake hose is prolonged.

Owner:LANDING GEAR ADVANCED MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com