Thread-free floating type supporting bar

A support rod, floating technology, applied in the field of support rods, can solve the problems of easy fracture compensation, poor strength, inconvenient maintenance of support rods, etc., to achieve overall strength improvement, simple and convenient disassembly and installation, and eliminate harmful shocks and vibrations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

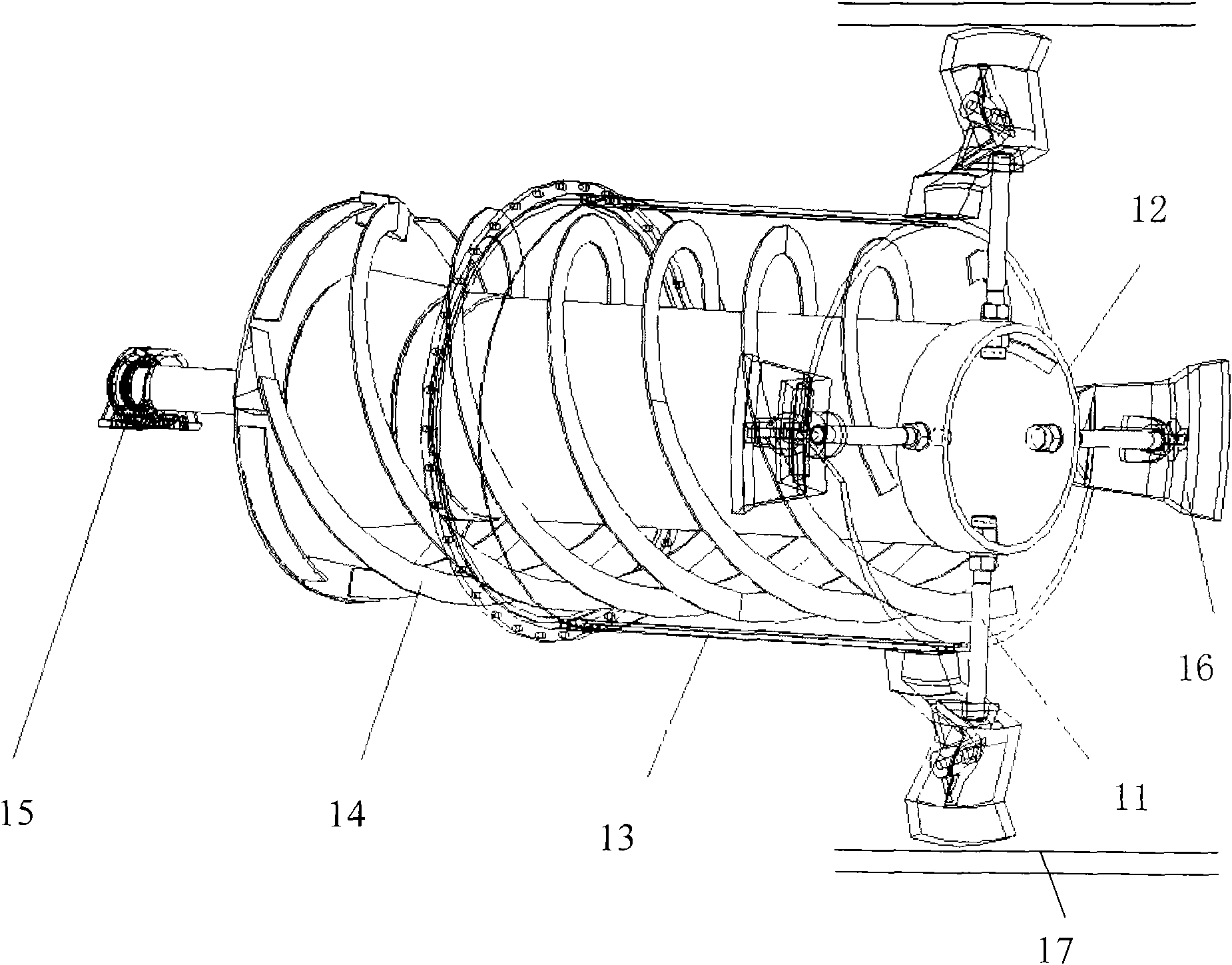

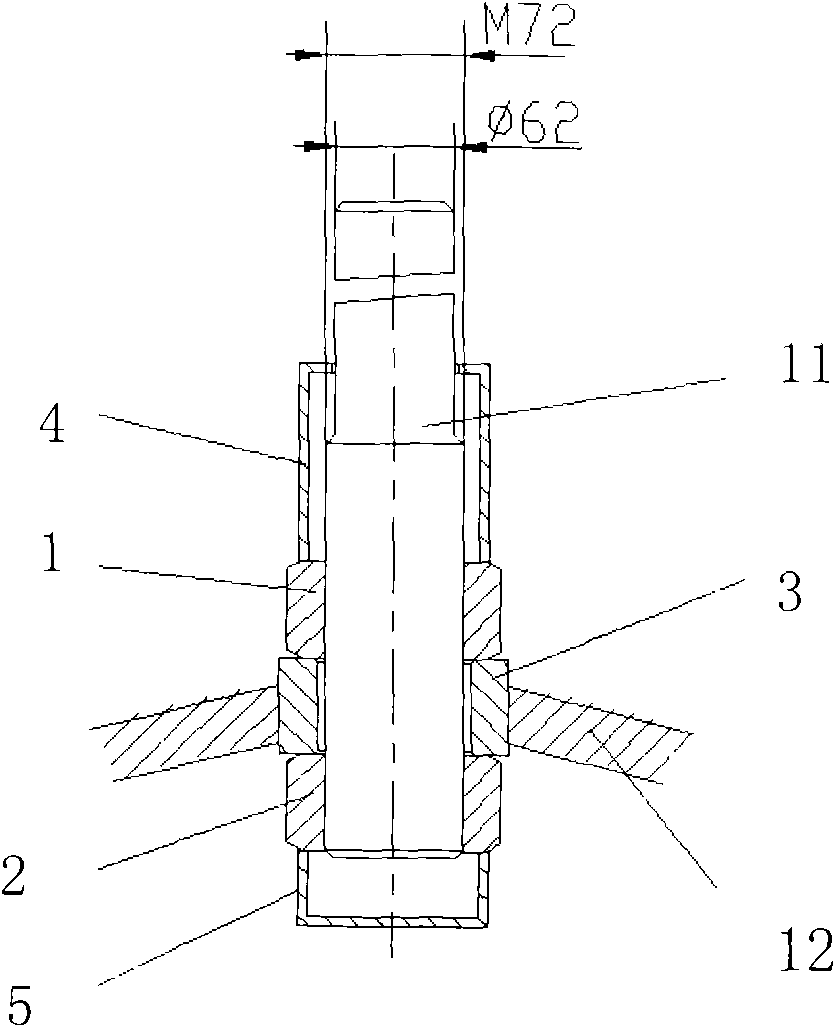

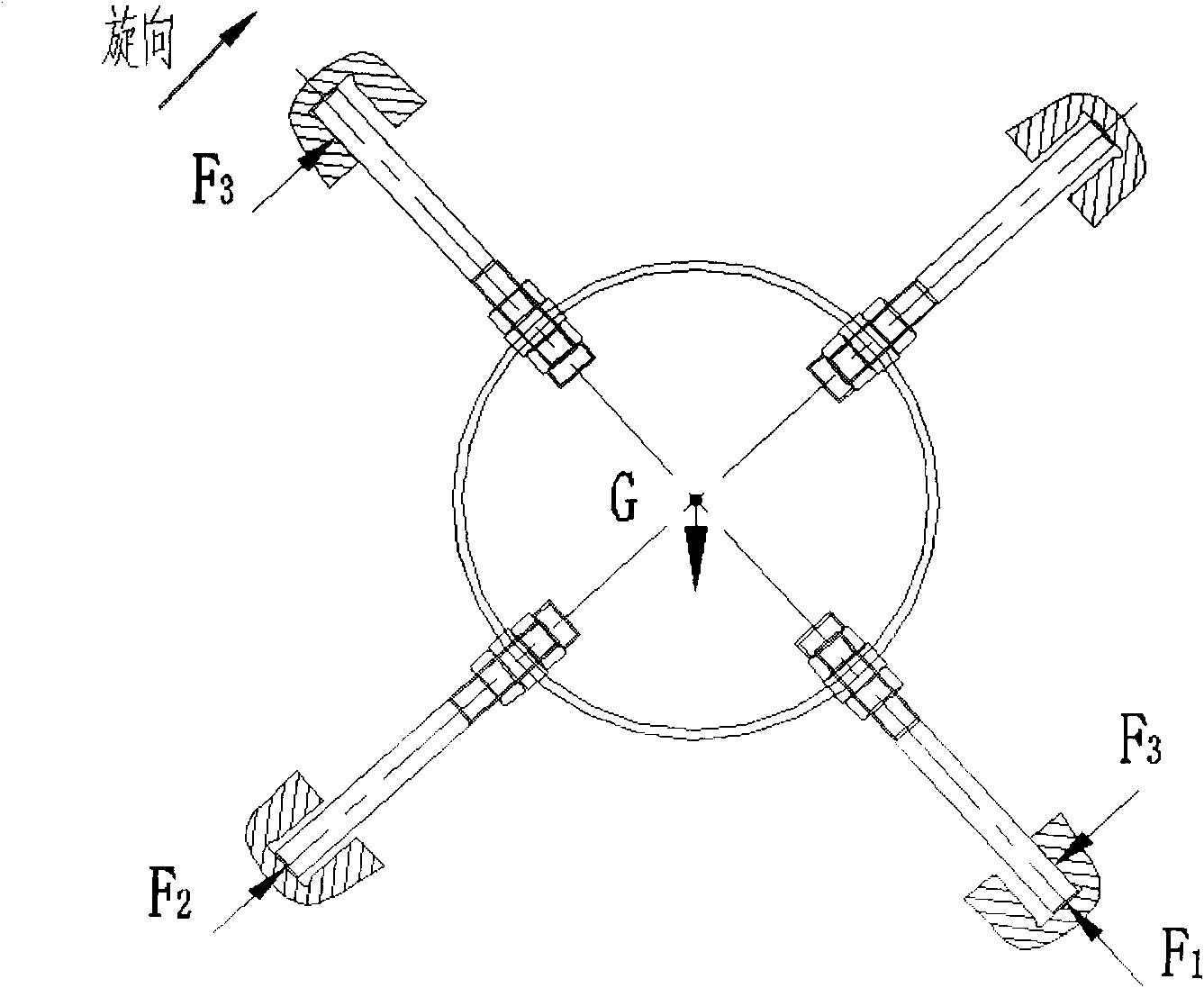

[0025] Specific implementation mode one: as Figure 6 As shown, the threadless floating support rod in this embodiment is composed of a support rod main body 21, a support rod main body sleeve 22, a disc spring 23, a gland 24 and at least two connecting pieces 25. The support rod main body The shaft sleeve 22 passes through the hole 12-1 provided on the side wall of the central tube 12 and is fixedly connected with the central tube 12. One end of the support rod main body 21 is inserted into one end of the support rod main body shaft sleeve 22 located outside the central tube 12. The spring 23 is installed in the other end of the main body sleeve 22 of the support rod inside the central tube 12. One end surface of the main body of the support rod 21 is in contact with the disc spring 23. It is detachably connected with the gland 24 through a connecting piece 25 . The other end of the support rod main body 21 is connected to the inner wall of the coal pulverizer barrel through...

specific Embodiment approach 2

[0026] Specific implementation mode two: as Figure 6 As shown, the connector 25 in this embodiment is a bolt. So set, easy to disassemble. Threads are canceled on the support rod, disc springs can compensate for the gap between the support rod and the cylinder liner, and the gland 24 is connected by bolts (connector 25), which is detachable. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: as Figure 6 As shown, the main body 21 of the support rod in this embodiment is made of high-quality carbon steel 45# steel or low-alloy steel Q345. Originally, the material of the support rod was medium alloy steel 34CrNi3Mo. Due to the structural change, this embodiment not only improves the strength but also greatly reduces the material cost. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com