Patents

Literature

101results about How to "Reduce stress value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

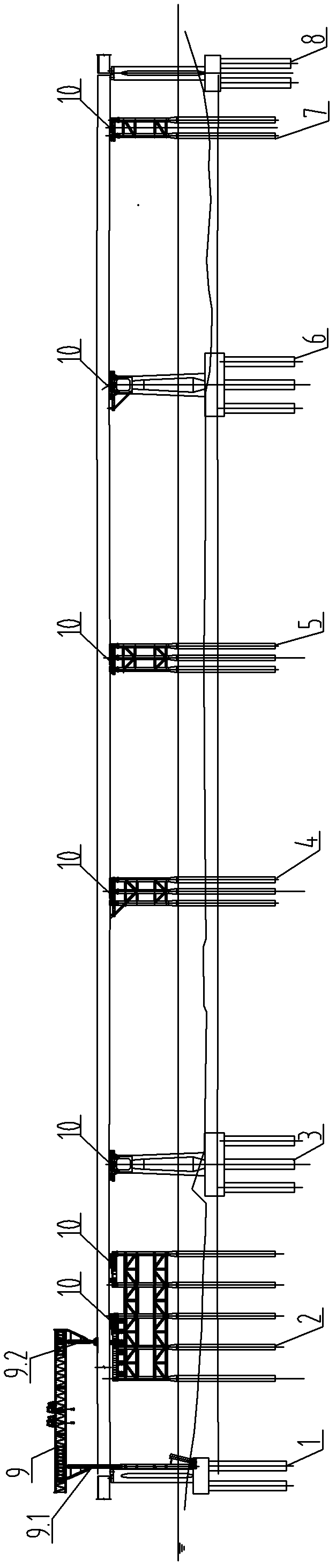

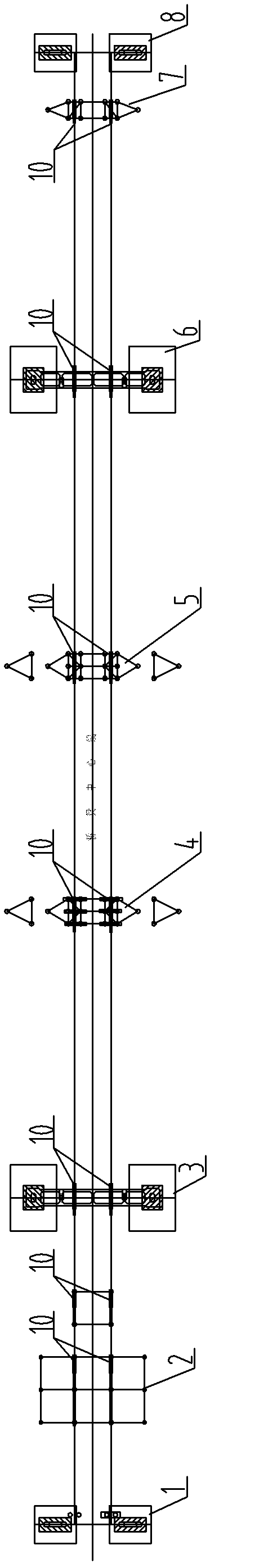

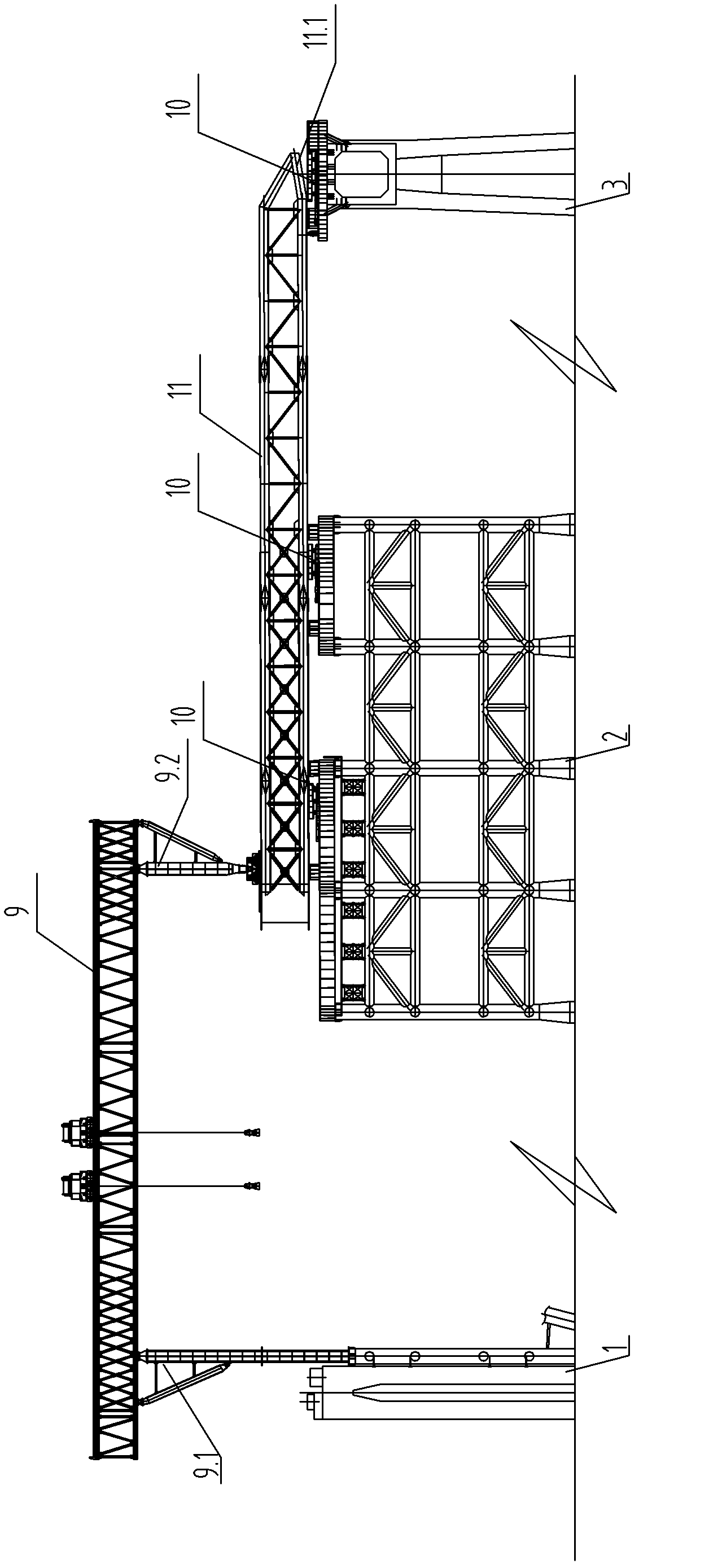

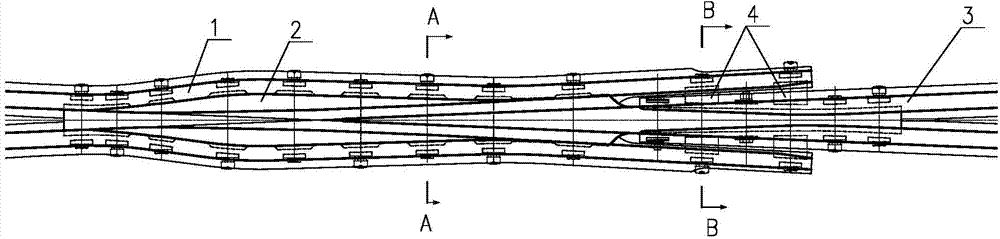

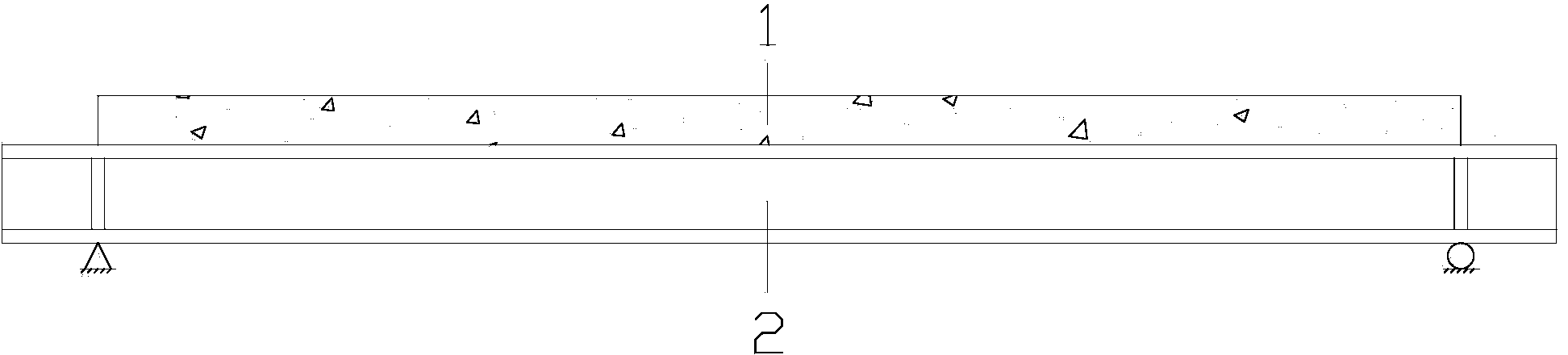

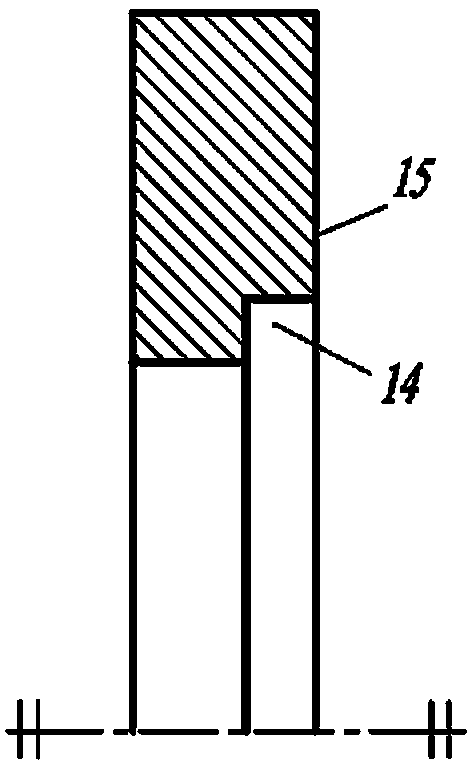

Walking type multipoint pushing construction method and walking type multipoint pushing construction system for steel box girder

ActiveCN102587291ASolve the shortcomings of conventional processesReduce stress valueBridge erection/assemblyHorizontal forceSteel box girder

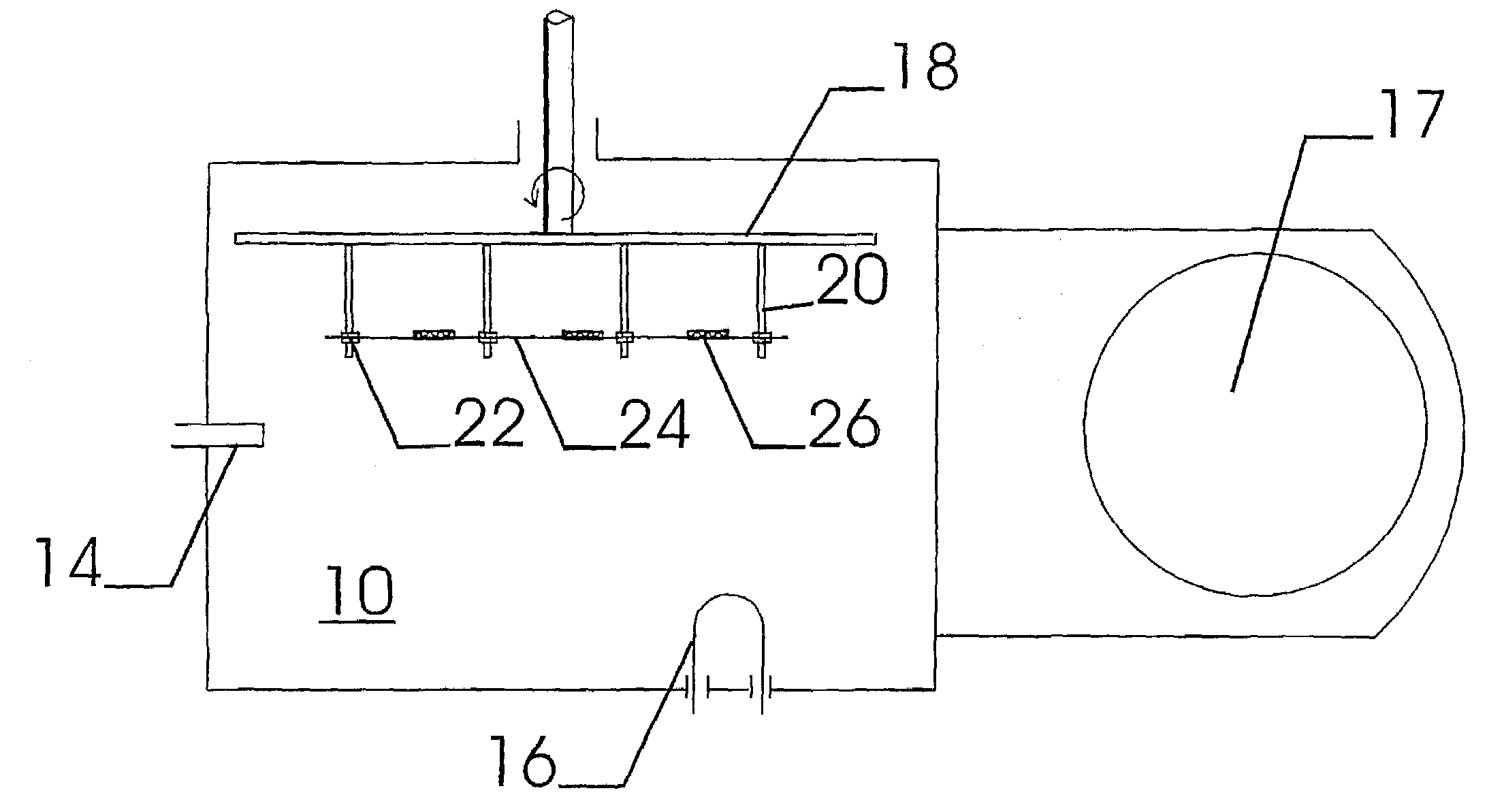

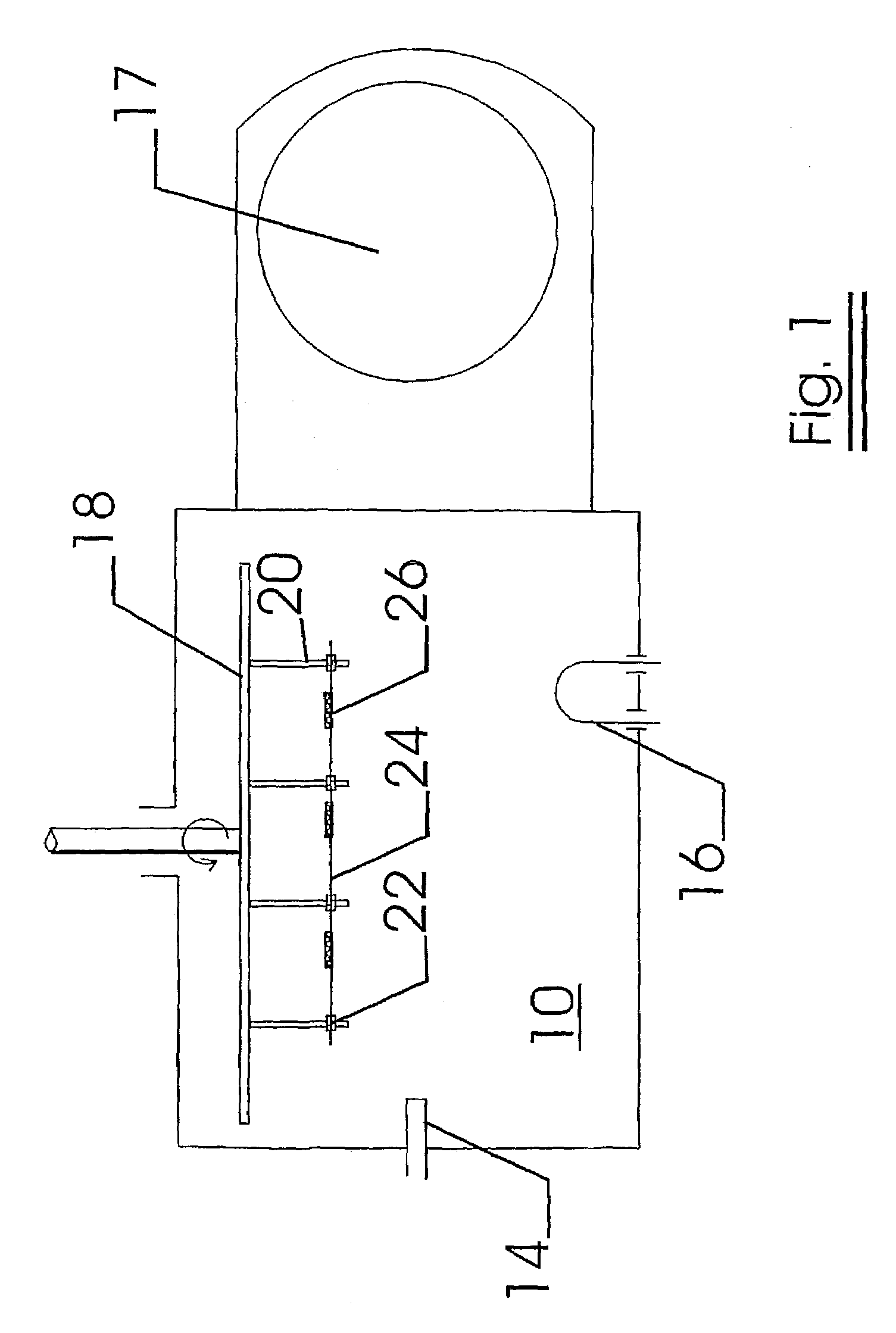

The invention discloses a walking type multipoint pushing construction method for a steel box girder, which is an improved optimized scheme for improving the disadvantages of a pulling type pushing method. The optimized scheme comprises the steps of installing pushing devices at assembly platforms, temporary mounds, main mounds and other points, firstly jacking the steel box girder with a vertical jack to separate the steel box girder from a girder laying frame, then pushing the steel box girder for a stroke in the longitudinal direction by a pushing jack, lowering the steel box girder to the girder laying frame, retracting the pushing jack for a next stroke of pushing, and keeping the circulation of the work until the installation of the steel box girder is finished. The pushing construction method for the steel box girder provided by the invention adopts a multipoint walking type pushing system, which not only can avoid disadvantages in the process in prior arts, but also has the advantages that the horizontal force at the mound top is greatly reduced; the structure of the temporary mound is simplified; the damage to the steel box girder is small; the construction cost is low and the like.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

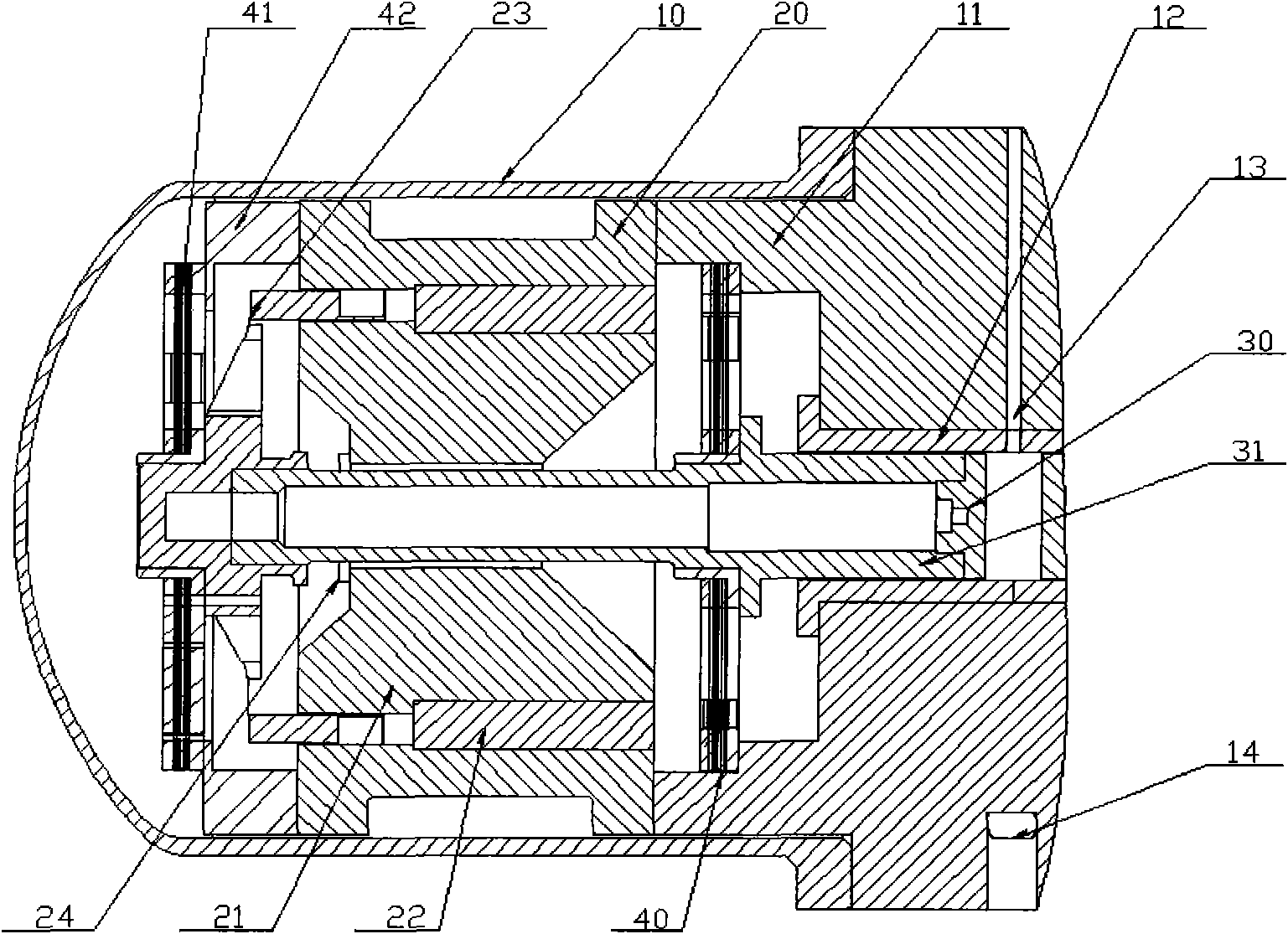

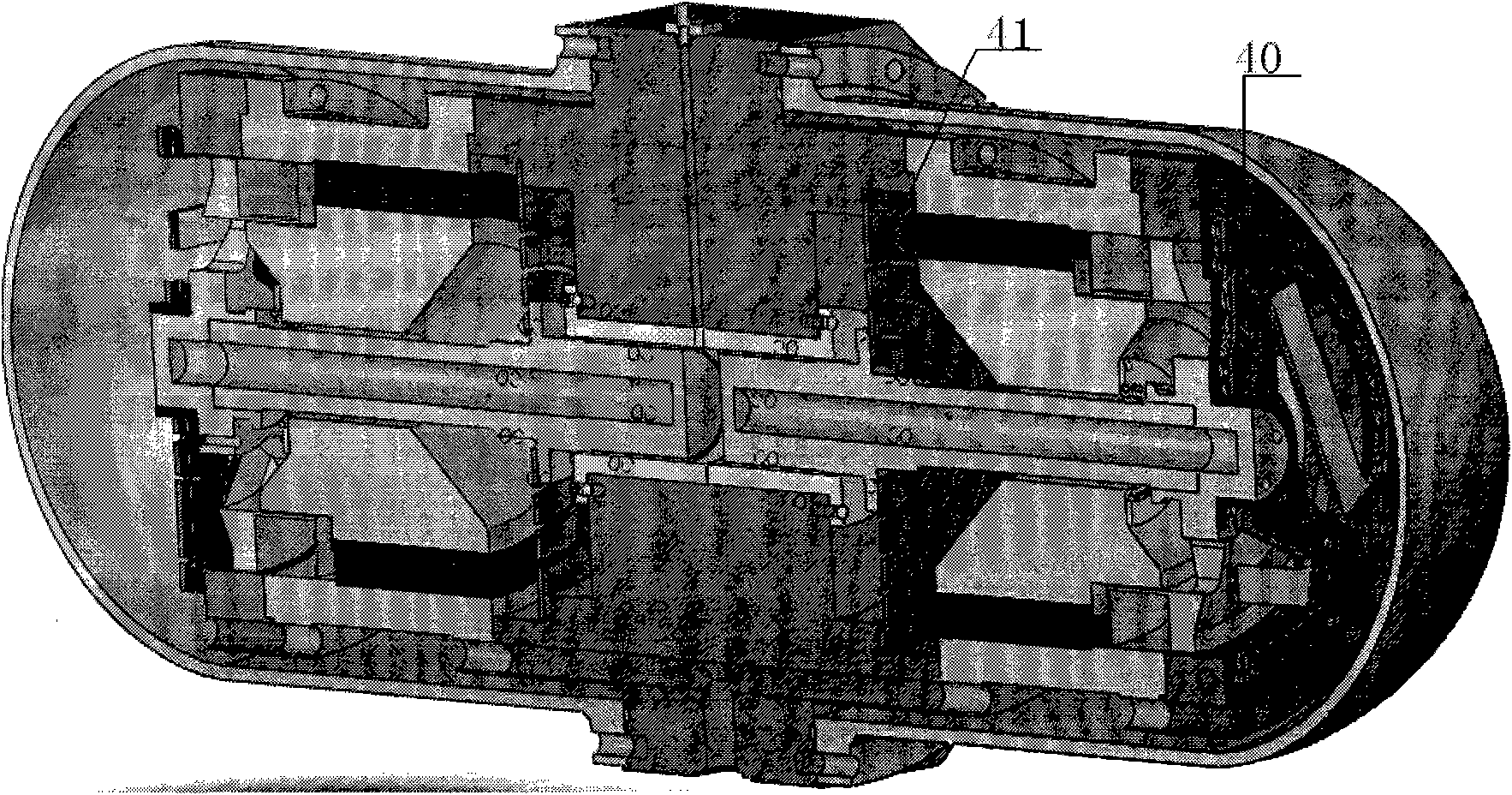

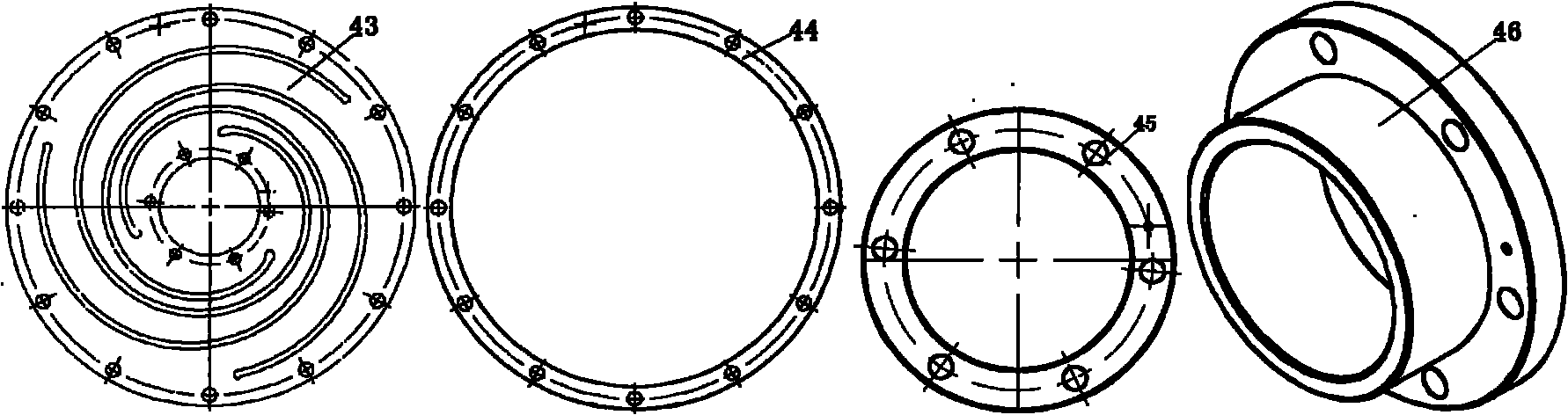

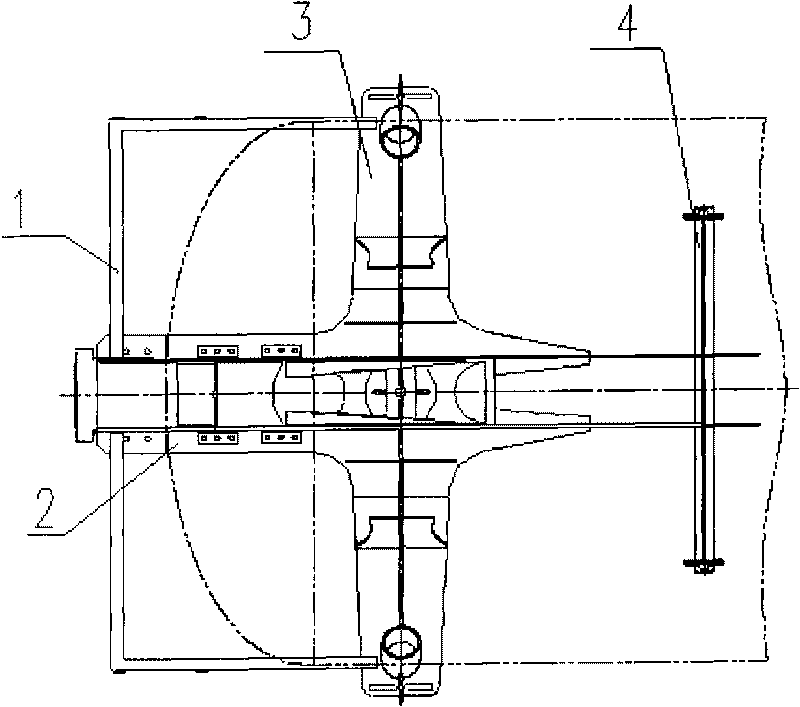

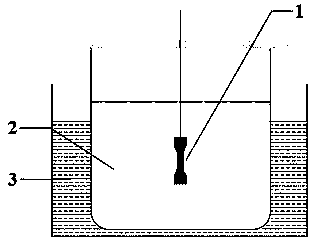

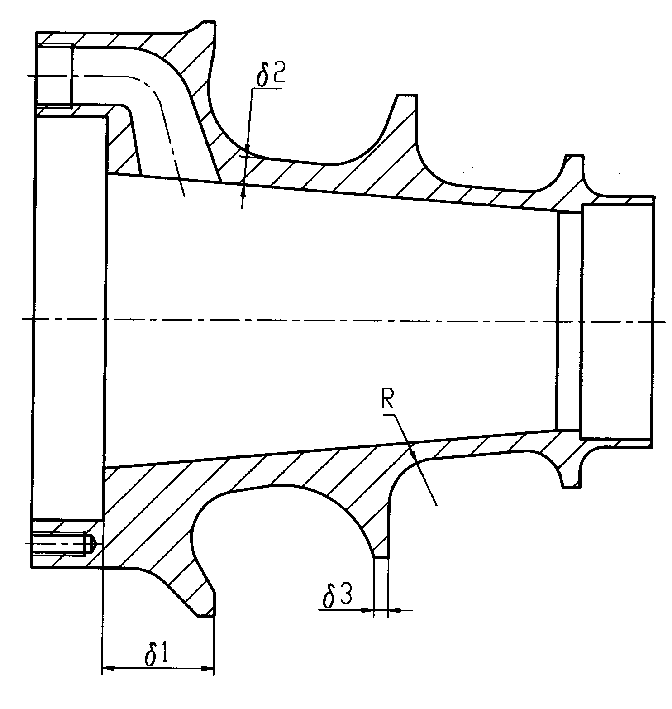

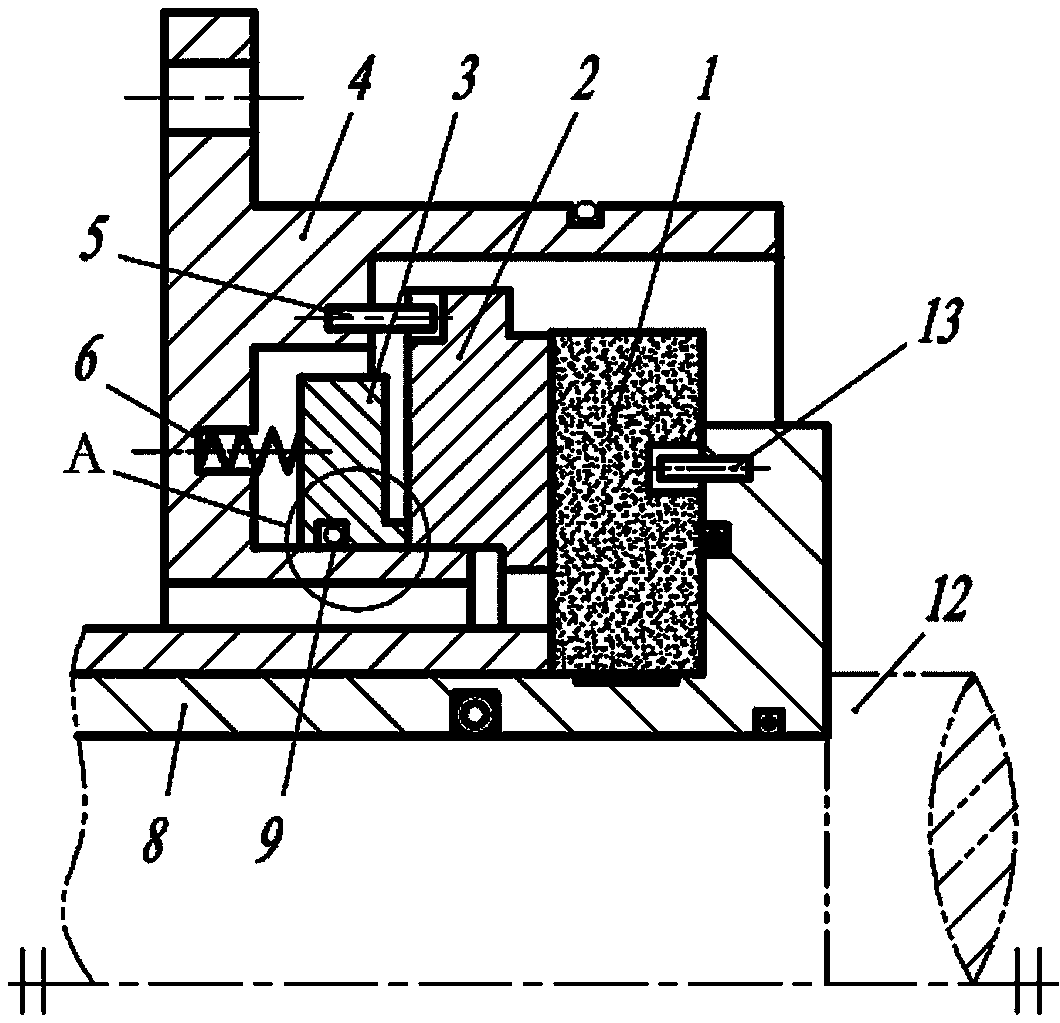

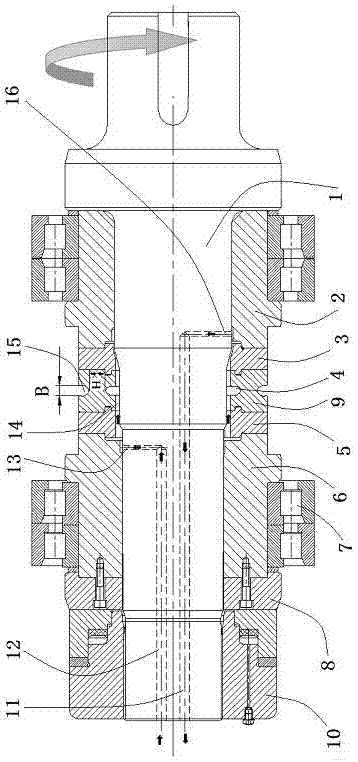

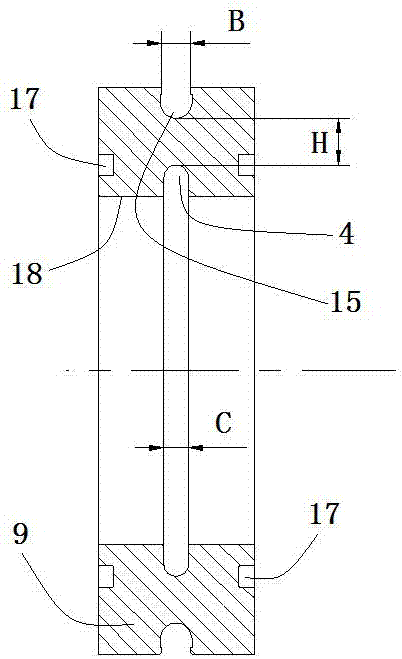

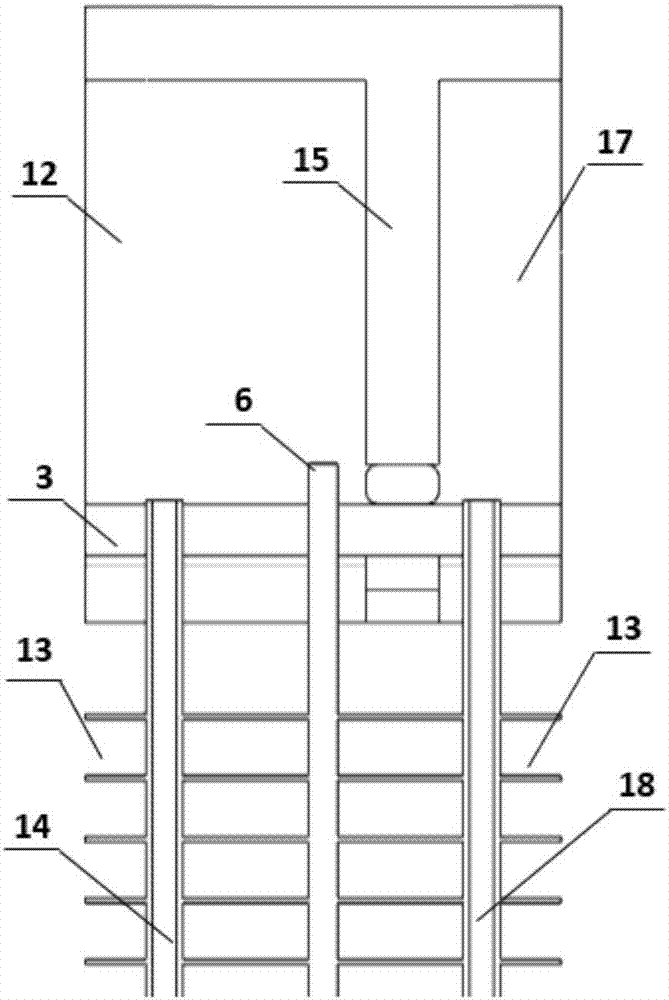

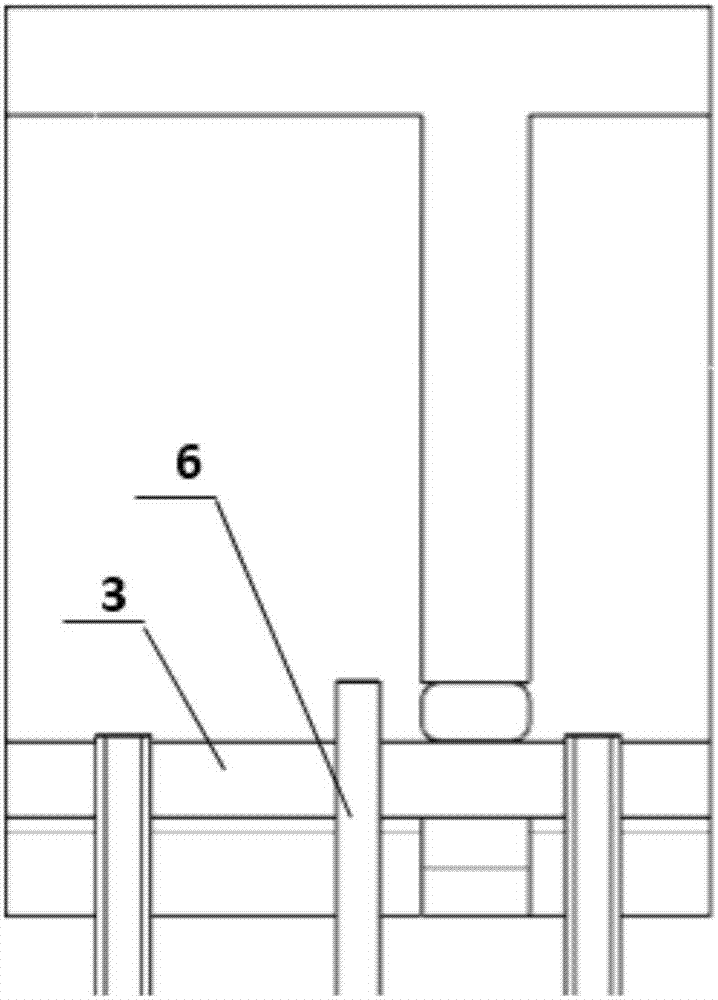

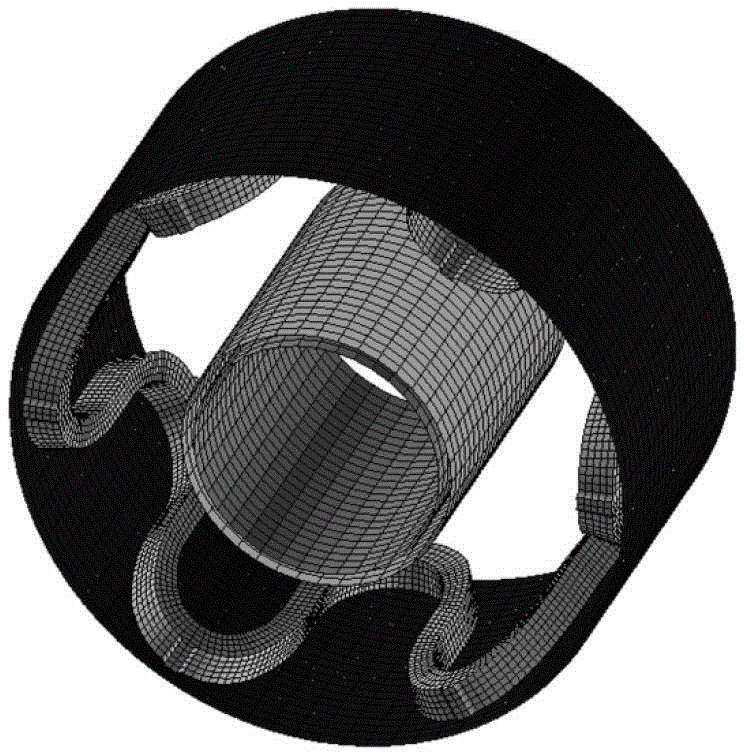

Linear compressor of plate spring supporting system adopting two different types of lines

InactiveCN101892971ACompact structureRaise the resonant frequencyPiston pumpsPositive-displacement liquid enginesLinear compressorMagnet

The invention discloses a linear compressor of a plate spring supporting system adopting two different types of lines. The main assemblies thereof comprise four parts which are respectively a compressor assembly, a linear motor assembly, a piston assembly and a supporting system assembly. The compressor comprises a stand, a compressor shell, a compressor cylinder, an exhaust hole and a suction hole; the linear motor assembly comprises an inner yoke iron, an outer yoke iron, a permanent magnet, an anti-collision gasket, a coil framework and a coil on the upper surface thereof; a piston comprises a main piston shaft and a piston head; and a supporting system comprises two groups of plate spring groups with different types of line structures and a connecting frame. The structure has the characteristics that a spiral type plate spring supporting piston shaft assembly is adopted at one end with lighter mass of the piston head, and a spiral arm plate spring supporting piston head adopted at the end of the piston head moves in the cylinder to ensure clearance sealing; a linear arm plate spring is adopted at the rear end of the piston assembly to supply better support for the movement of the end with larger mass, the quantity of plate springs is reduced, and the volume of the compressor is saved.

Owner:ZHEJIANG UNIV

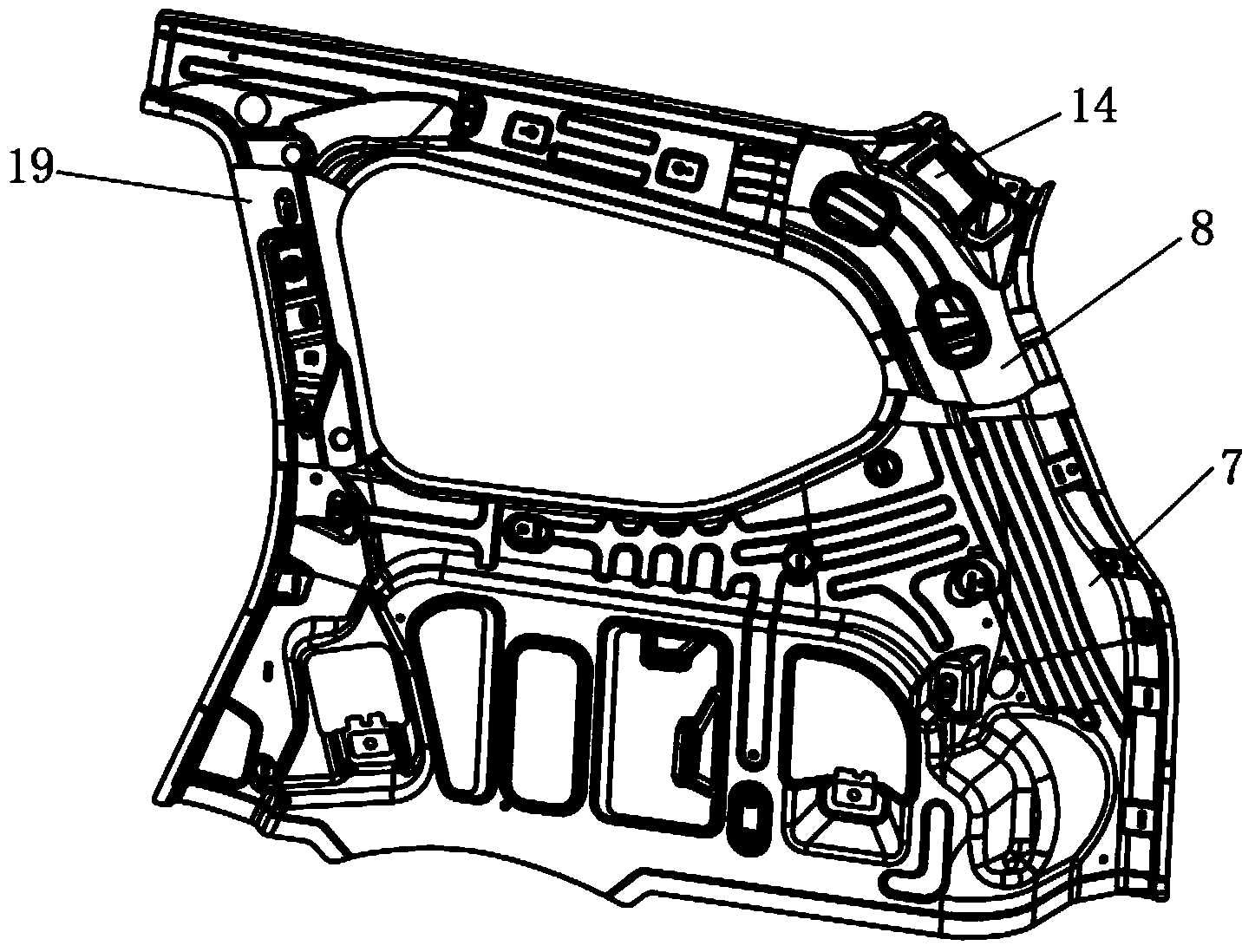

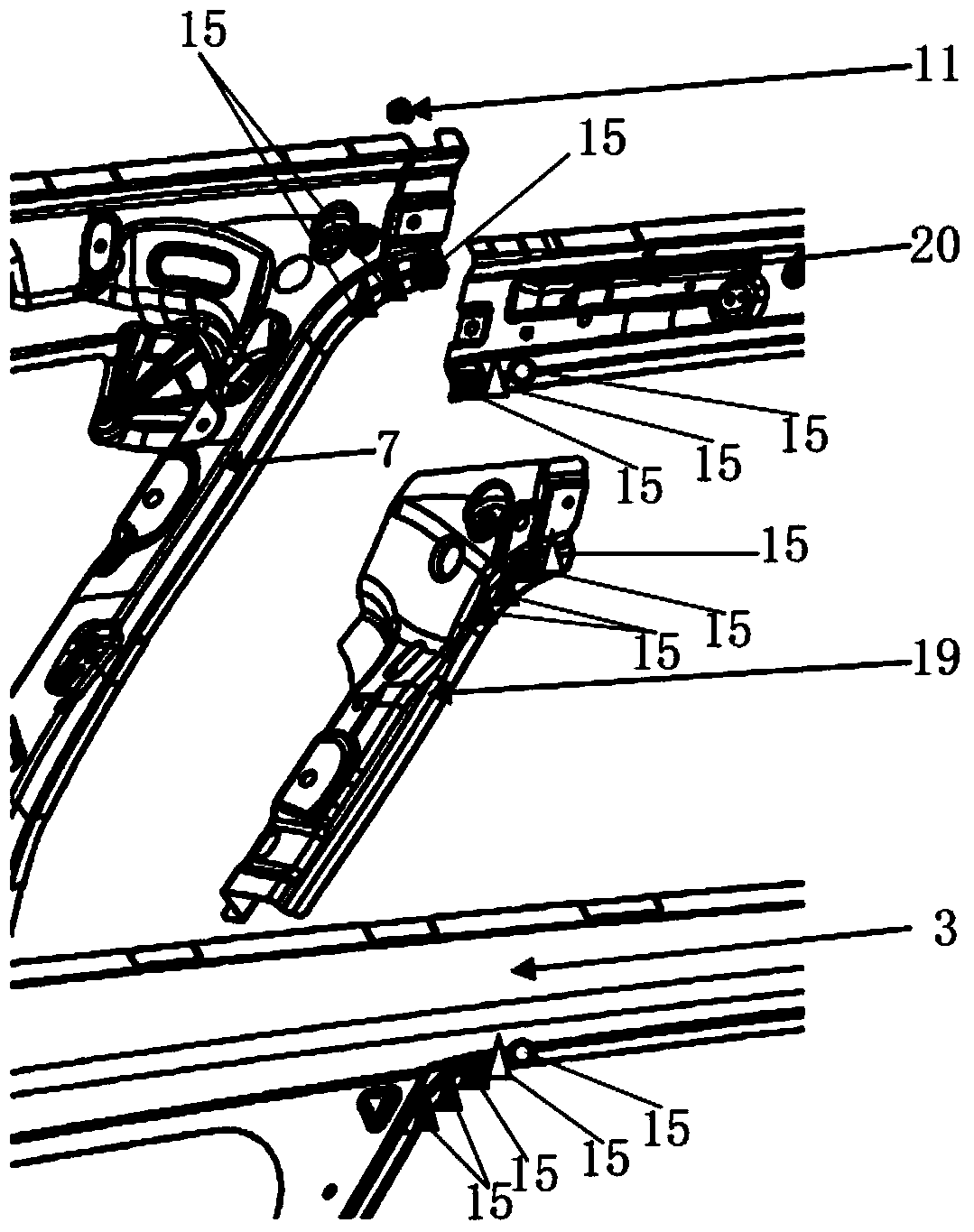

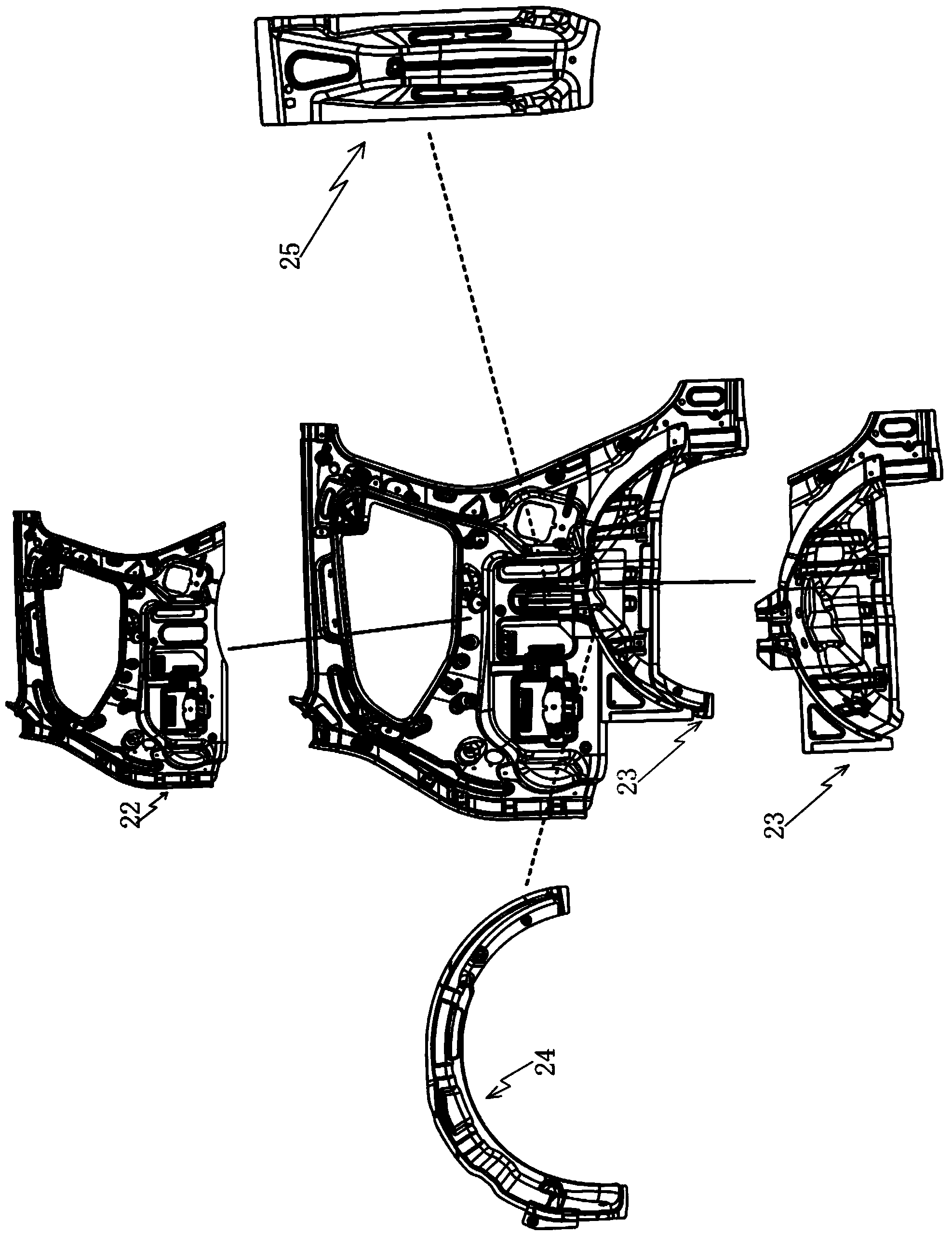

Rear side outer plate welding assembly

ActiveCN103538639AEnsure safetySimple welding processSuperstructure connectionsAgricultural engineeringWelding process

The invention discloses a rear side outer plate welding assembly which comprises a rear side inner plate assembly, a rear wheel cover inner plate welding piece, a rear wheel cover outer plate welding piece and a rear wheel cover outer plate support plate. The rear wheel cover inner plate welding piece comprises a rear wheel cover inner plate and a front protection plate. The rear wheel cover outer plate welding piece comprises a rear wheel cover outer plate. The rear side inner plate assembly comprises a rear side outer plate, an upper side beam inner plate, a rear side inner plate, a C column reinforcing plate and a D column upper end connector. The upper side beam inner plate is welded with the rear side outer plate, the upper side beam inner plate, the C column reinforcing plate and the rear side outer plate are welded, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, the upper side beam inner plate, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, and the upper side beam inner plate, the rear side inner plate and the C column reinforcing plate are fixedly connected. Components of the rear side outer plate welding assembly are welded independently or connected to be assembled, assembly is convenient, a welding process is better, and the middle door frame rigidity can be effectively improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

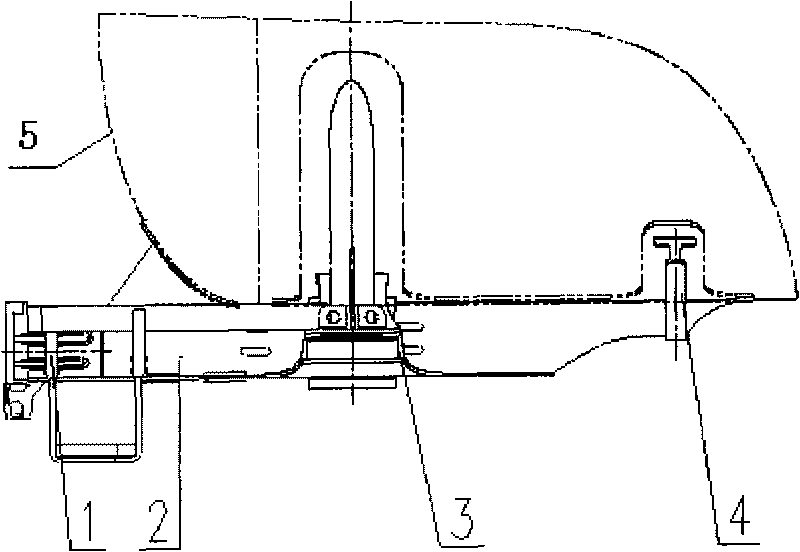

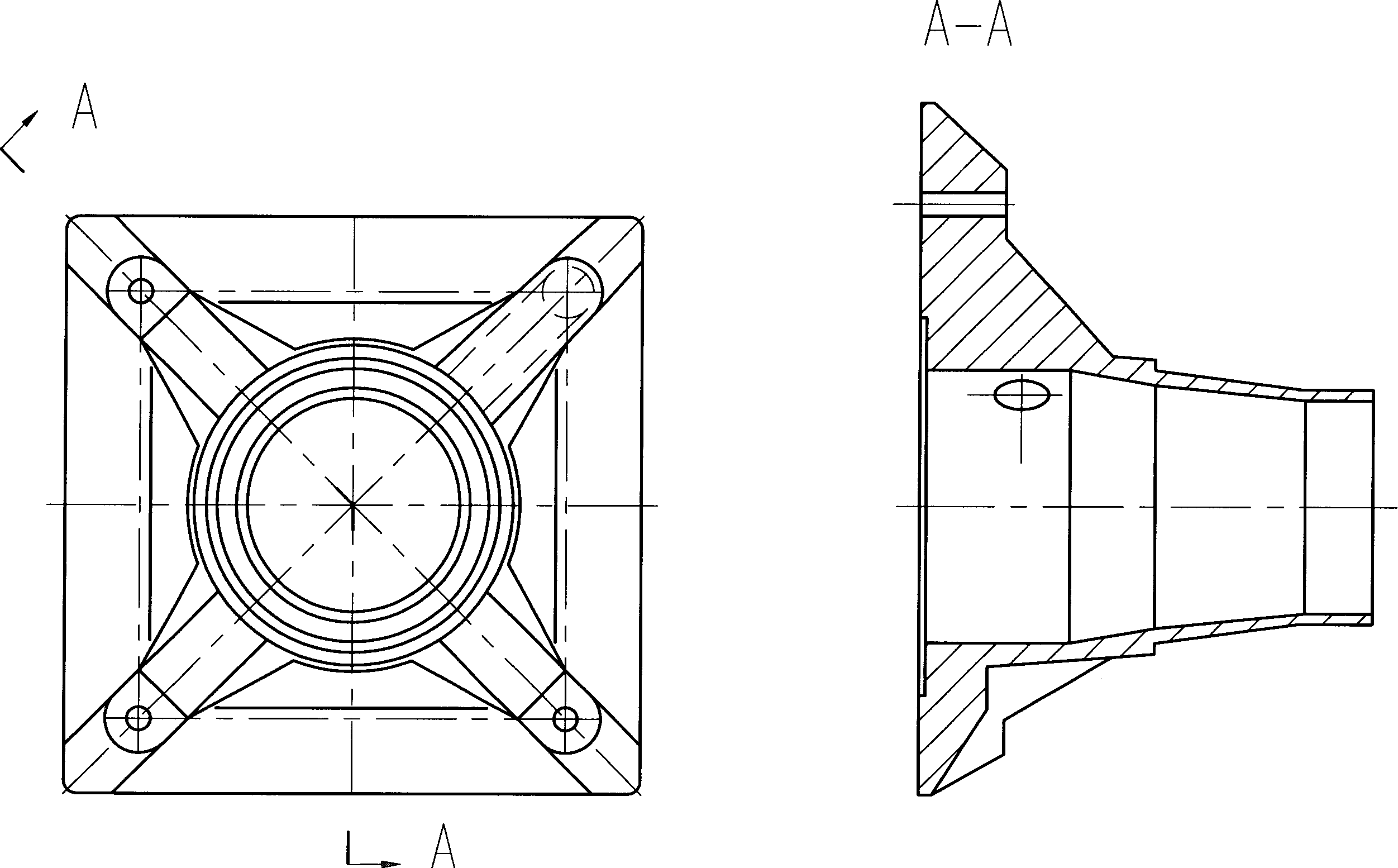

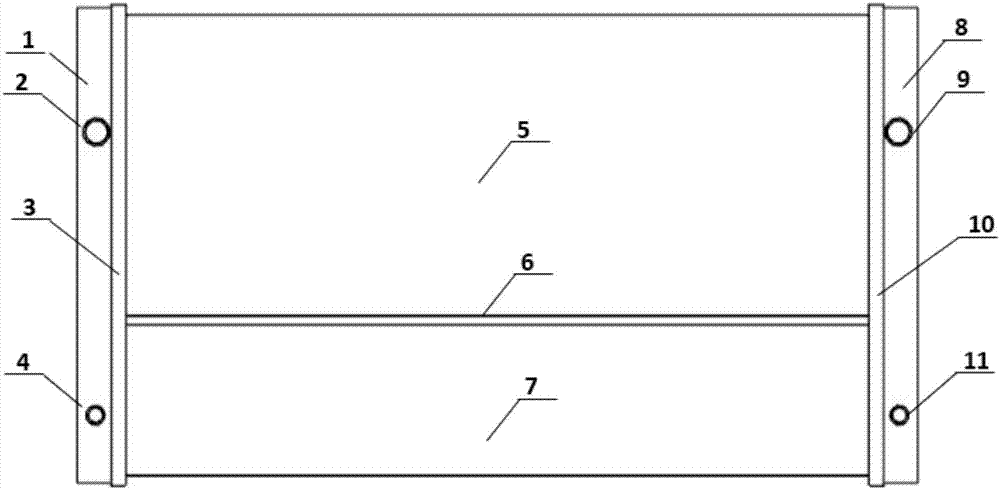

Rail road tank car traction and bolster device with beam structure

InactiveCN101746381AControl deformationImprove stress concentrationTank wagonsEngineeringAssembly structure

The invention discloses a rail road tank car traction and bolster device with a beam structure, comprising an end beam, towering beam assembly and sleeper beam assembly, a beam assembly structure at the tail part of a towering beam is connected with the tail part of the towering beam; the beam assembly structure comprises a bent beam web plate of which the upper surface is consistent to the shape of the lower part of the tank car horizontally, a beam lower cover board is connected at the lower part of the beam web plate, and two ends of the beam web plate are provided with beam side cover boards; the device can effectively reduce the stress value of a tank plate of the tail part of the towering beam and effectively solve the problem that the stress value of the tank plate of the tail part of the towering beam is high and even exceeds the evaluation requirements of the TB / T1335 intensity; in addition, the bolster device structure is adopted, the intensity of the tank plate of the tail part of the towering beam can meet the intensity evaluation requirements of the association of American railroads AAR; the invention has simple and rational structure, equal distribution of the adopted structure, convenient manufacturing process, prolonging the service life of the vehicle, reducing the maintenance and saving the repairing cost.

Owner:CRRC YANGTZE CO LTD

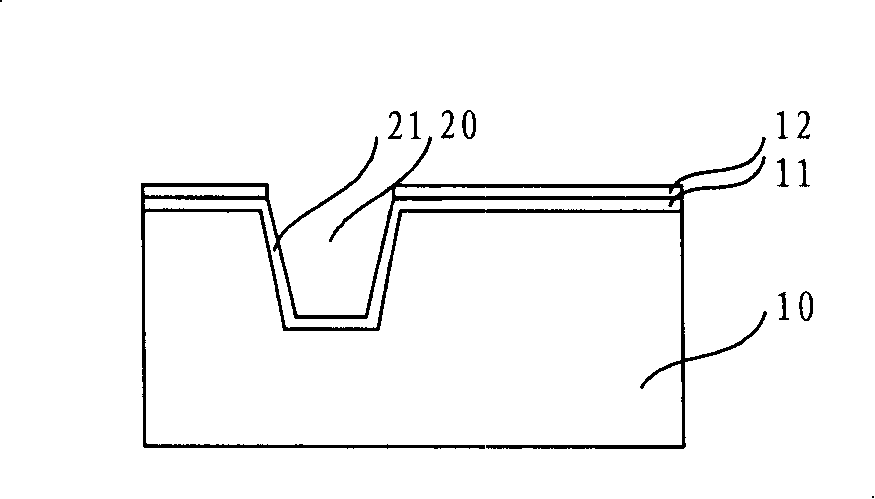

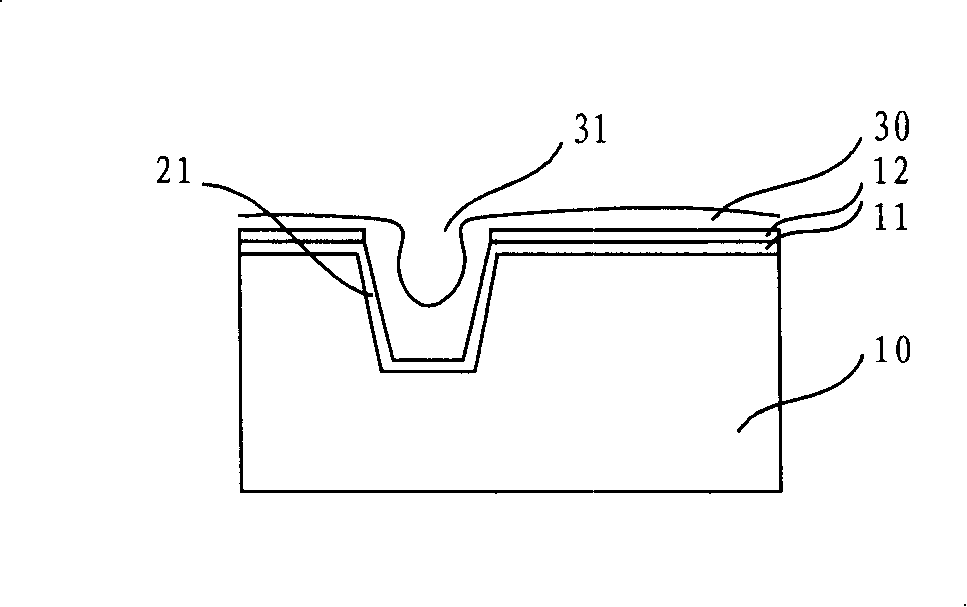

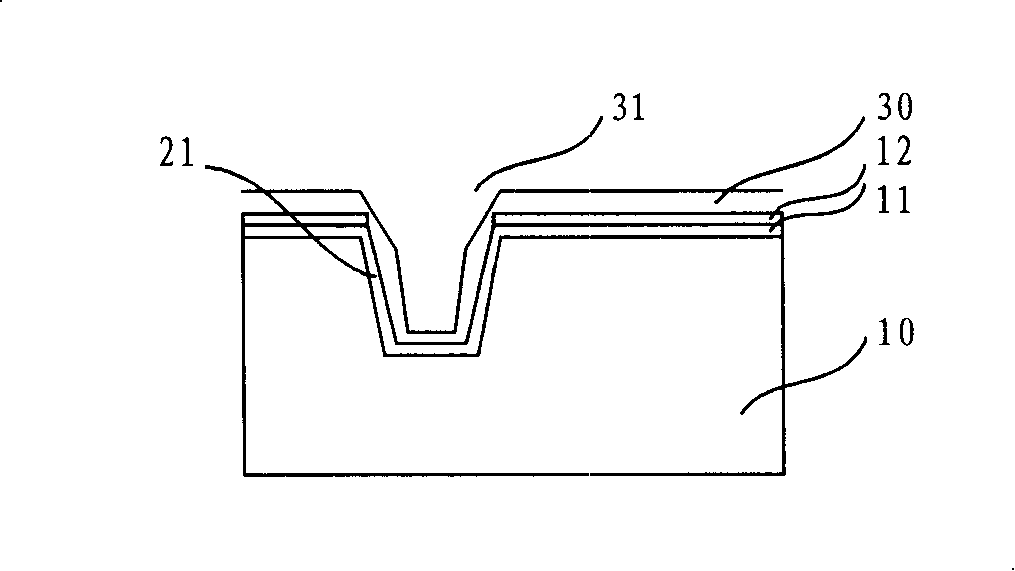

Oxide deposition method of shallow groove isolation region

ActiveCN101197307AReduce stressReduce stress valueSemiconductor/solid-state device manufacturingSemiconductorLow stress

An oxide deposition method of shallow groove isolation area comprises that: a groove is formed on a semiconductor substrate; a sidewall oxide layer is formed on the sidewall and the bottom of the groove; a first oxide layer is deposited on the sidewall oxide layer by low temperature process; the first oxide layer is etched to enlarge a second deposition opening; a second oxide layer is deposited on the first oxide layer. HDPCVD is applied to perform the deposition-etching-deposition technique and can achieve the oxide deposition in the shallow groove isolation area / film layer with no holes; through controlling the temperature of deposition reaction, the density of the deposited film layer can be reduced and further the shallow groove isolation area / film layer oxides with low stress can be achieved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

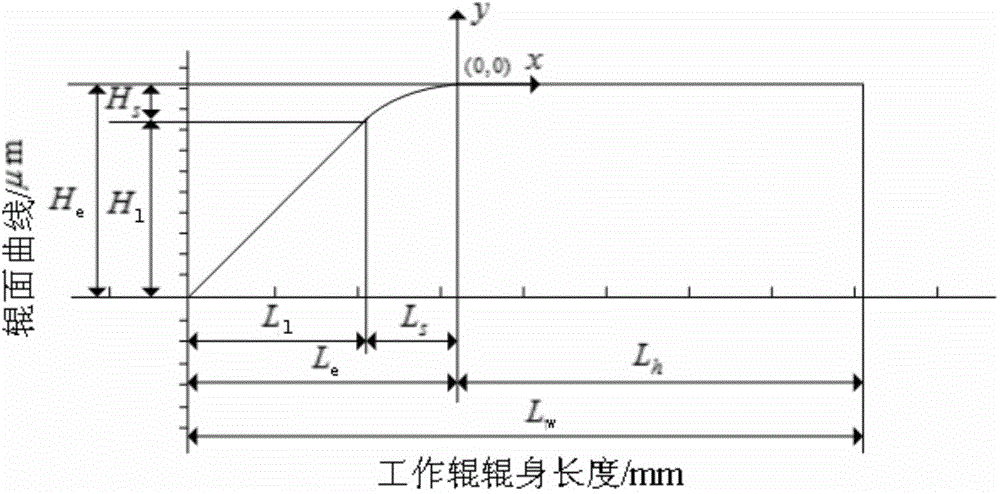

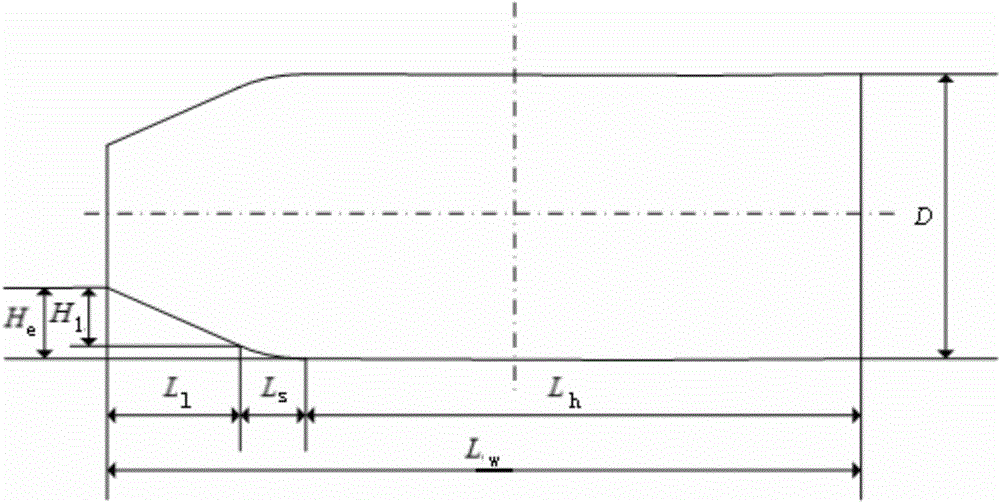

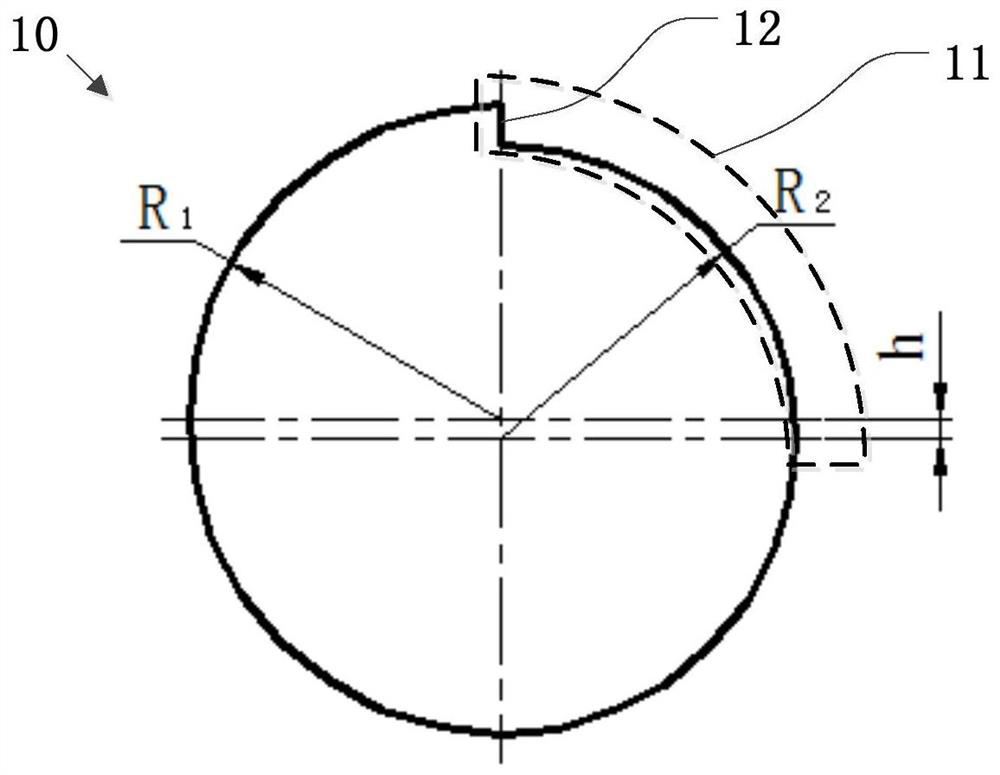

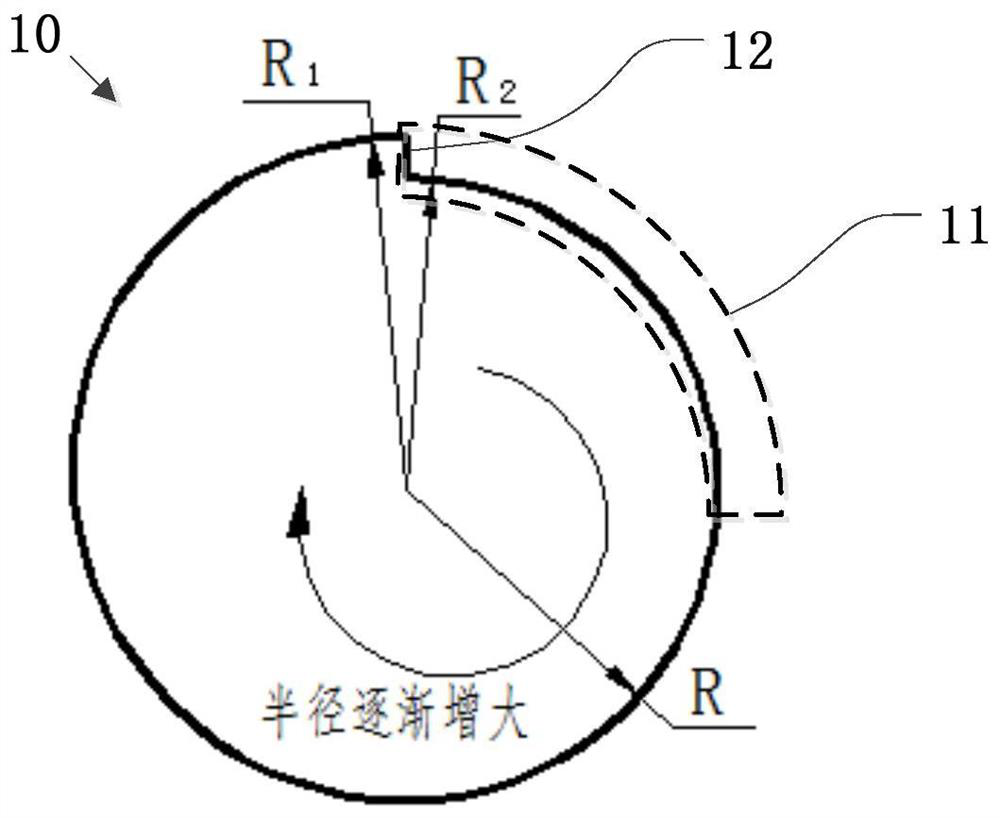

Work roll for cold rolling edge drop control and method for designing roll contour of work roll

ActiveCN104874607ASolve easy peelingGood self retentionRollsMetal rolling arrangementsStress concentrationWork roll

The invention discloses a work roll for cold rolling edge drop control and a method for designing a roll contour of the work roll. The roll contour of the work roll comprises an oblique line section, a quadratic curve section and a horizontal line section. Two ends of a quadratic curve are respectively tangential to a horizontal line and an oblique line, the roll contour of an end of a side of the work roll is formed by the quadratic curve and the oblique line and participates in edge drop control, the quadratic curve section is short but is high in taper, and the oblique line section is long. The work roll and the method have the advantages that the edge drop control ability of integral edge regions can be guaranteed; regions of the edges of band steel are low in stress value, and accordingly the possibility of band breakage can be reduced; starting positions of the edges of the band steel are in smooth transition, so that stress concentration can be prevented, and the self-preservation property of the shape of the roll can be improved; the probability of band breakage due to deviation of the band steel and excessively high stress at the edges of each single side of the band steel can be reduced, and accordingly the work roll is excellent in deviation resistance; the roll contour is excellent in grinding performance, and the surface quality of the ends of the roll can be guaranteed in grinding procedures.

Owner:UNIV OF SCI & TECH BEIJING

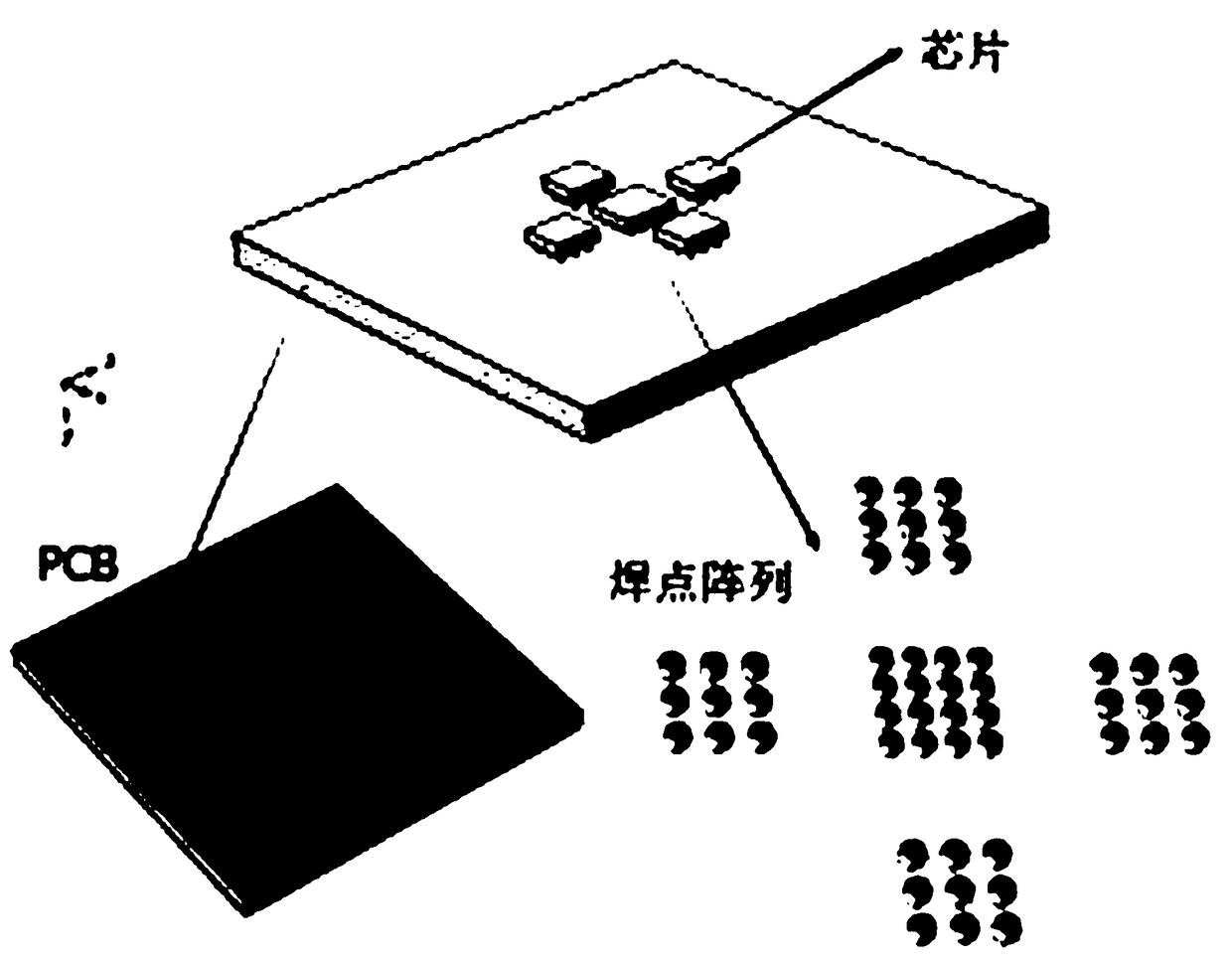

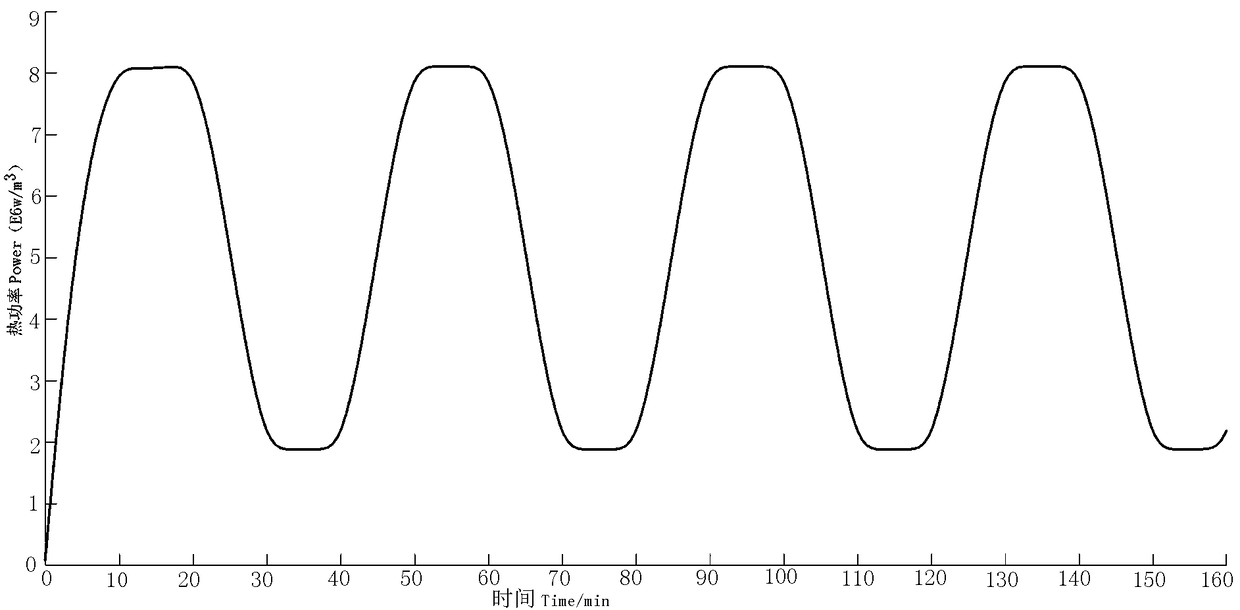

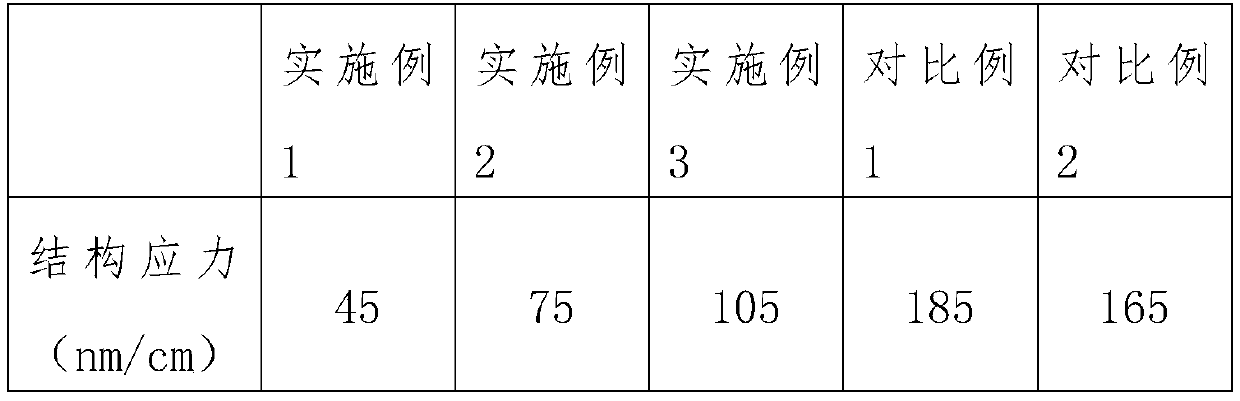

Optimization method of CSP solder joint structural parameters for reducing stress in power cycle-harmonic response coupling

ActiveCN109190152AReduce diversityDiversity guaranteedGeometric CADDesign optimisation/simulationComputing MethodologiesRegression analysis

An optimization method of CSP solder joint structural parameters for reducing stress in power cycle-harmonic response coupling is disclosed. The method includes: 1) establishing a simulation analysismodel; 2) obtaining the thermal stress value of the solder joint; 3) determining the influencing factors of thermal stress value; 4) determining the parameter level value of the influencing factors; 5) obtaining an experimental sample; 6) obtaining a functional relationship between the influence factors and the thermal stress value; 7) carrying out regression analysis on that functional relation;8) establishing the correctness of the function relation; 9) generating an initial population in a random manner; 10) obtaining the current iterative number and the optimal fitness value; 11) performing crossover operation, mutation operation and evolutionary reversal on that individual; 12) selecting the optimal individual of fitness value; 13) re-judging aft population updating. The method combines a response surface and a genetic algorithm to reduce the stress in the CSP solder joint under power cyclic harmonic response coupling loading, exhibits excellent robustness, is simple in calculation ,and greatly brings convenience for optimization design of the structural parameters of the CSP solder joint in the later period.

Owner:GUILIN UNIV OF ELECTRONIC TECH

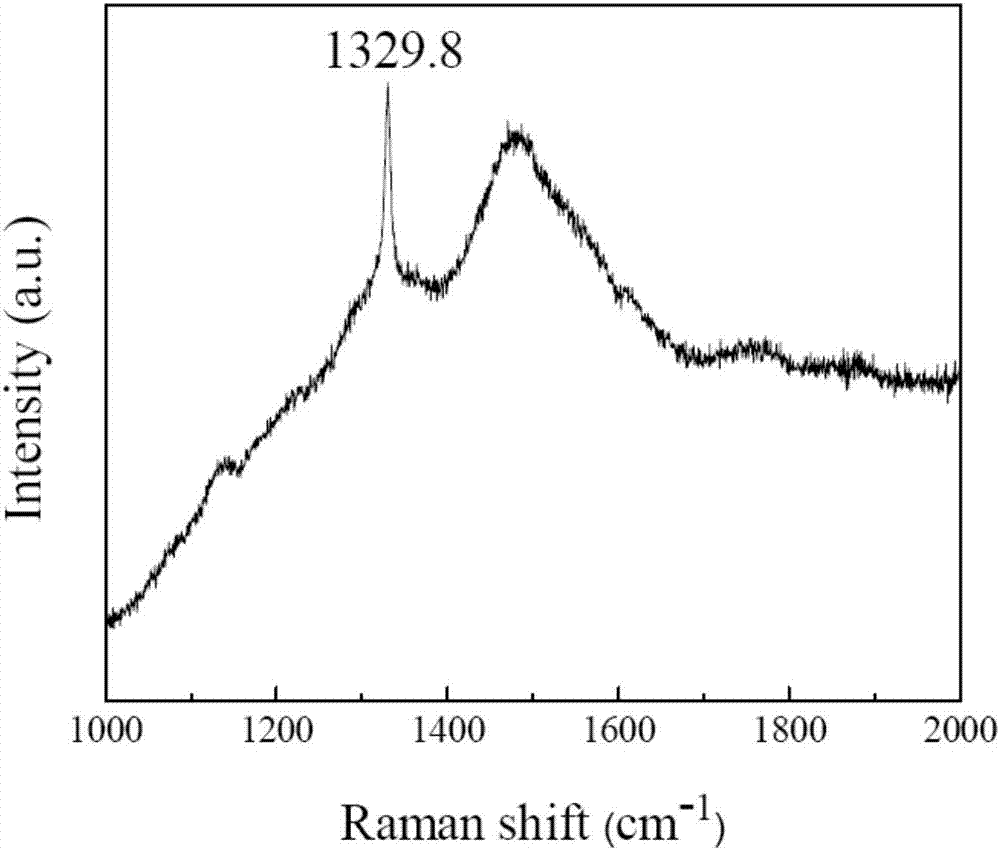

Method for preparing diamond film on stainless steel surface

ActiveCN107400874AInhibited DiffusionIncrease nucleation rateChemical vapor deposition coatingSputteringGas phase

The invention provides a method for preparing a diamond film on the stainless steel surface by using Cr / CrN / CrTiAlN as a transition layer. The method comprises the following steps: blasting the stainless steel surface; depositing the Cr / CrN / CrTiAlN transition layer on the blasted stainless steel surface with magnetron sputtering, and depositing the diamond film on the prepared Cr / CrN / CrTiAlN transition layer with chemical vapor deposition. According to the method, Cr / CrN / CrTiAlN is adopted as the transition layer, diffusion of Fe and C is effectively blocked, the nucleation rate is increased, the diamond film can be prepared at a low temperature, and the stress value of the diamond film is smaller and smaller than or equal to 1.25 GPa. Compared with thermal conductivity of stainless steel, the thermal conductivity of the coated stainless steel is increased by 3%-11%.

Owner:ZHEJIANG UNIV OF TECH

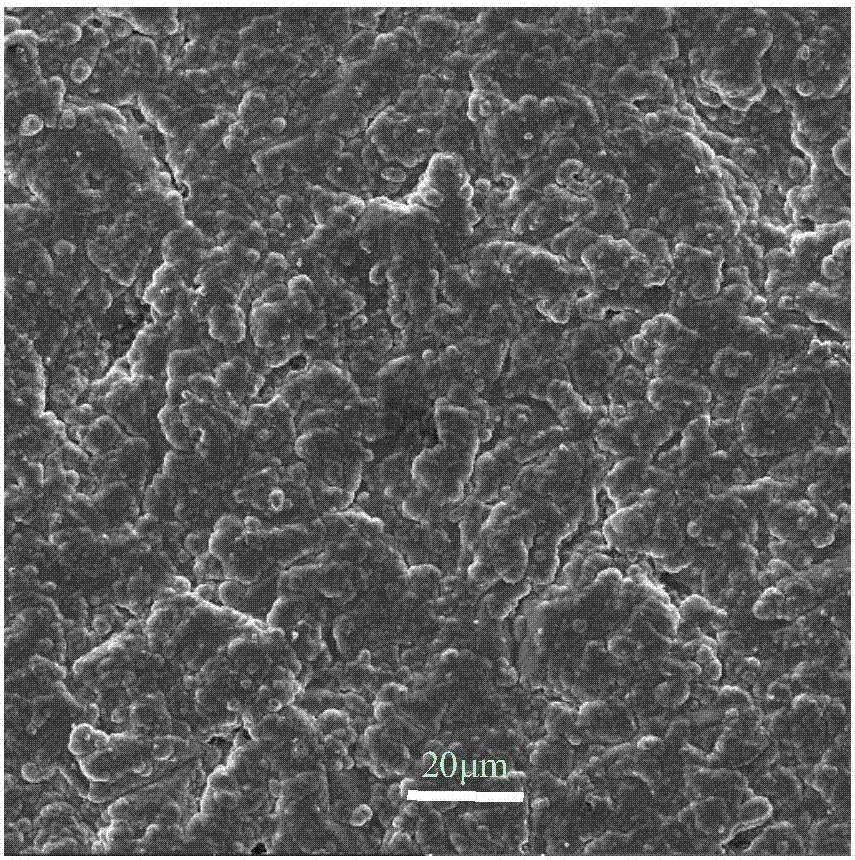

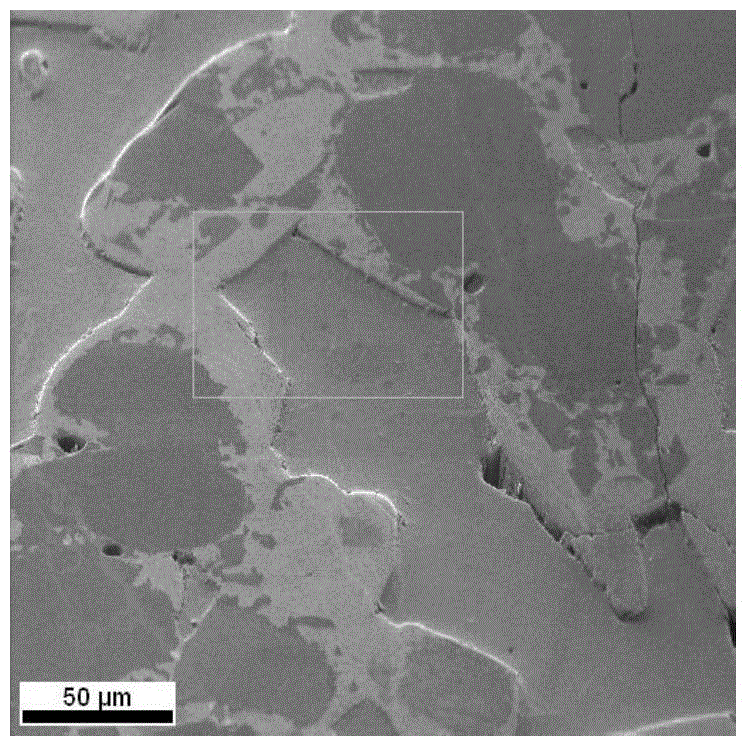

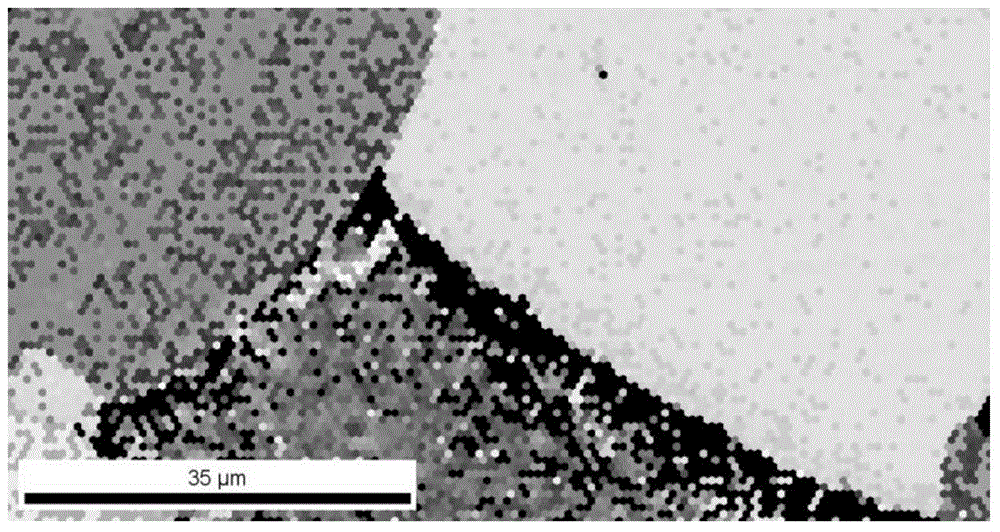

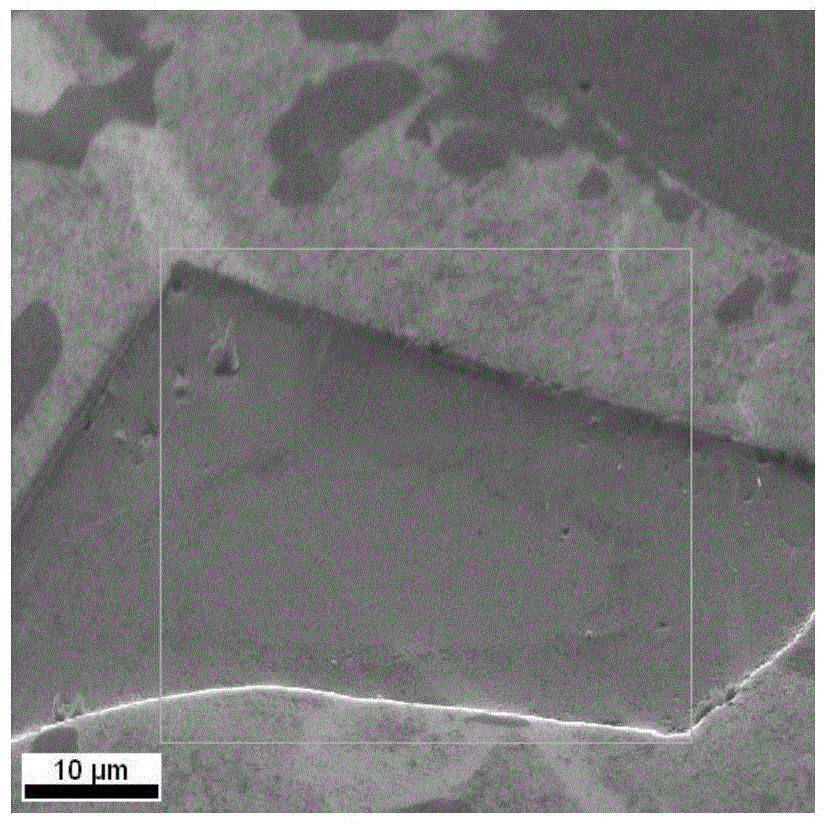

Preparation method for metal matrix composite material sample suitable for EBSD (Electron Backscattered Diffraction) detection

InactiveCN104458373AGuaranteed flatnessReduce stress valueMaterial analysis using wave/particle radiationPreparing sample for investigationHigh surfaceMatrix composition

The invention discloses a preparation method for a metal matrix composite material sample suitable for EBSD (Electron Backscattered Diffraction) detection, and belongs to the field of preparation of detection samples. The preparation method is used for processing a metal matrix composite material with a multiphase structure by utilizing linear cutting, mechanical polishing, and vibration polishing-ion polishing-vibration polishing processes so as to obtain the metal matrix composition material sample suitable for the EBSD detection. The obtained metal matrix composition material sample simultaneously meets requirements on high surface smoothness and a low stress value and the requirement of keeping the original surface stress distribution rule of the sample; the EBSD detection requirements of different-type metal matrix composite materials are met, and preparation requirements of detection samples for performing various detections, such as XRD detection and Raman spectrum detection, on different-type multiphase conducting materials are also met.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

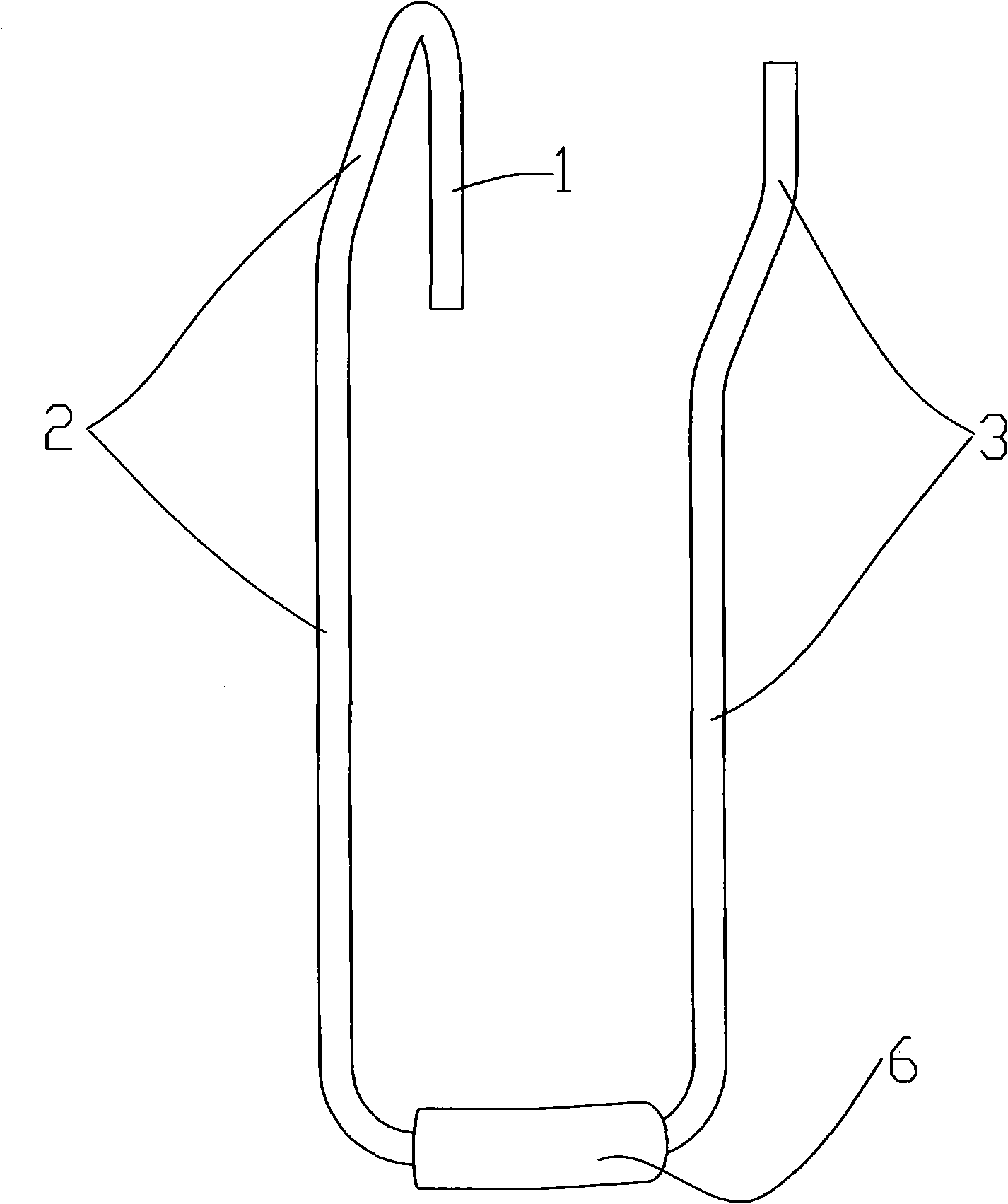

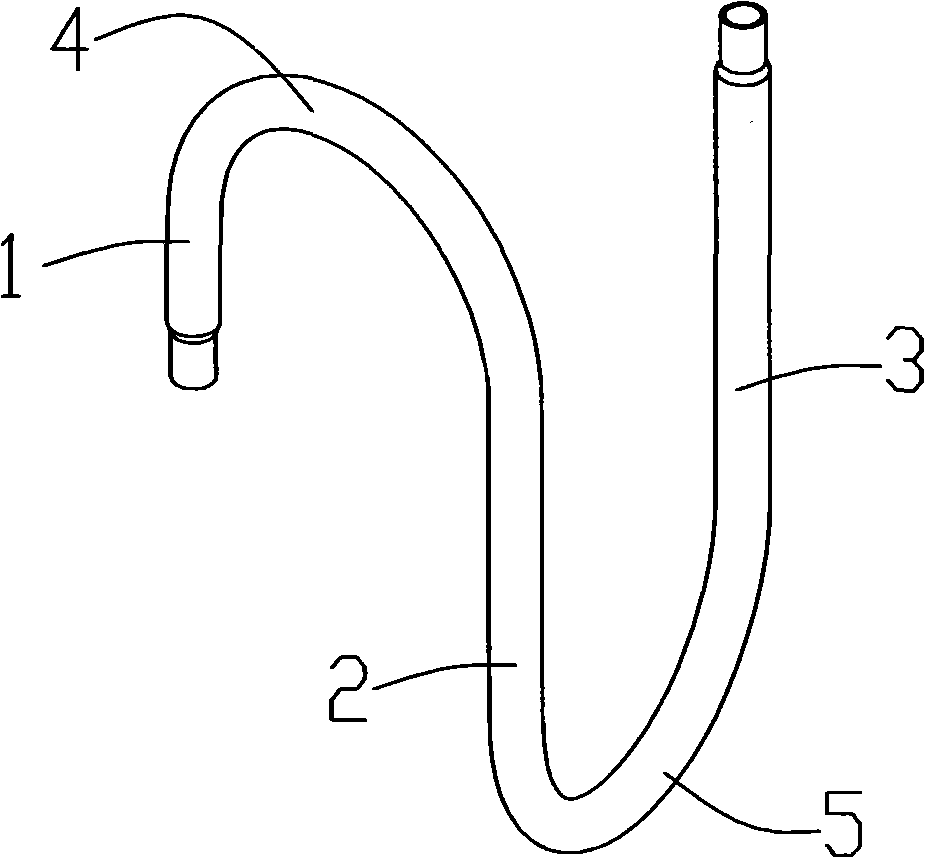

Exhausting pipe of air conditioner compressor

InactiveCN101303008AAvoid fatigue fractureReduce shockPositive displacement pump componentsPositive-displacement liquid enginesStress distributionBusiness efficiency

The invention discloses an exhaust pipe used for an air-conditioner compressor, which is connected between the compressor and a valve. The exhaust pipe comprises a front section vertical to an exhaust port of the compressor and a rear section connected to the valve, wherein, the front section and the rear section are connected through a connecting section which at least comprises an arc section. The improved exhaust pipe can not only effectively reduce the impact of coolant in the pipe on the pipeline as well as the vibration and noise of the pipeline, but also can reduce the stress value of the pipeline, improve the stress distribution and avoid the break of the exhaust pipe due to fatigue. Meanwhile, the exhaust pipe has good comprehensive performance in the aspects of improving the energy-efficiency ratio of the air-conditioner and the reliability of dropping transport, etc.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

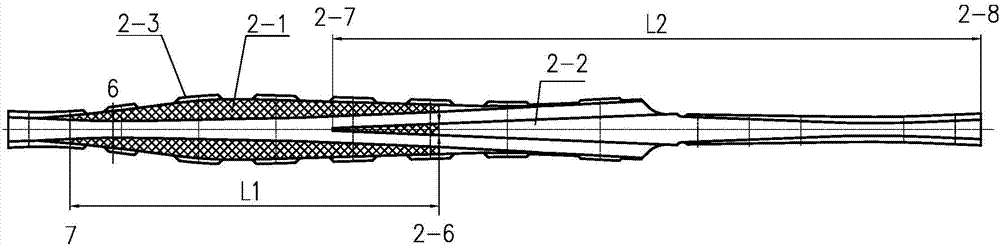

Manganese steel fork core steel rail split type frog

The invention relates to a manganese steel fork core steel rail split type frog. The manganese steel fork core steel rail split type frog is formed by splicing a standard steel rail wing rail and a fork core. The manganese steel fork core serves as the core and is spliced with the standard steel rail wing rail and a standard steel rail fork heel rail through high-strength bolt pairs. The bottom face of a fork core rail is embedded into the upper surface of the steel rail bottom of the standard steel rail wing rail. Vertical force applied to the core rail is directly transmitted to the rail bottom of the standard steel rail wing rail. The manganese steel fork core steel rail split type frog has the advantages that a frog harmful space region and a core rail sharp point region are spliced with the steel rail through the manganese steel fork core rail, the wing rail and a spacer block in a continuous casting mode, the number of connecting parts is reduced, mutual vertical moving, caused by the phenomenon that the wing rail, the fork heel rail and the fork core are not stressed at the same time and the independent spacer block is used for force transmission and limiting, of the wing rail and the fork heel rail is avoided, and the integrity of the frog is improved. A large frame structure of the block cast high manganese steel frog is improved through the manganese steel fork core so that deep hardening can be easily achieved, accordingly, wear resistance of the frog is improved by improving initial hardness of the frog, and maintenance workloads are reduced. Meanwhile, the advantages that high manganese steel can be used for on-line welding and repairing, using cost is reduced, and the service life of the frog is prolonged.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

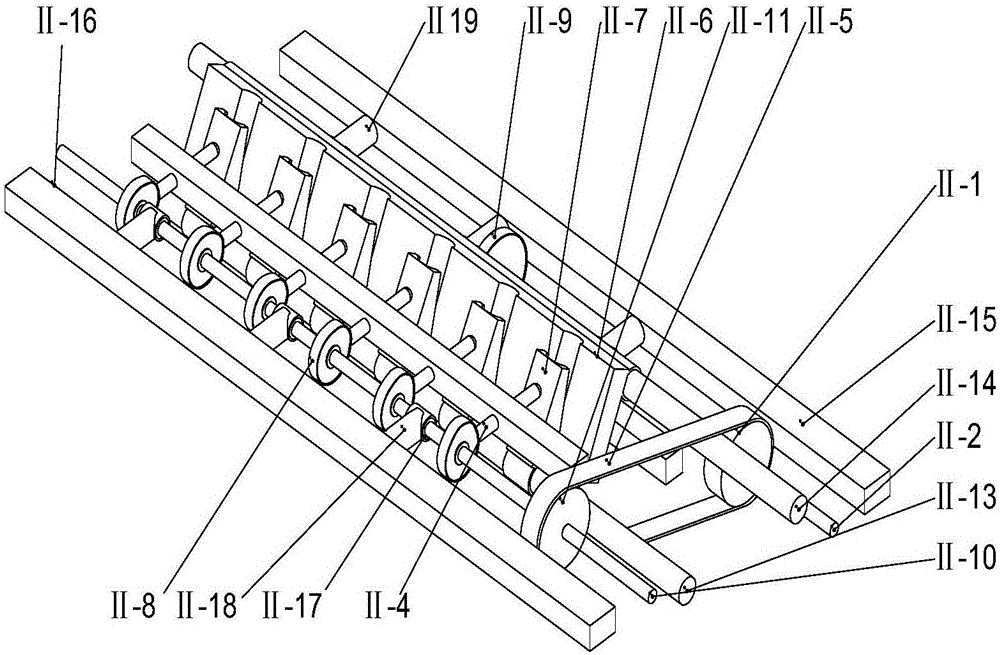

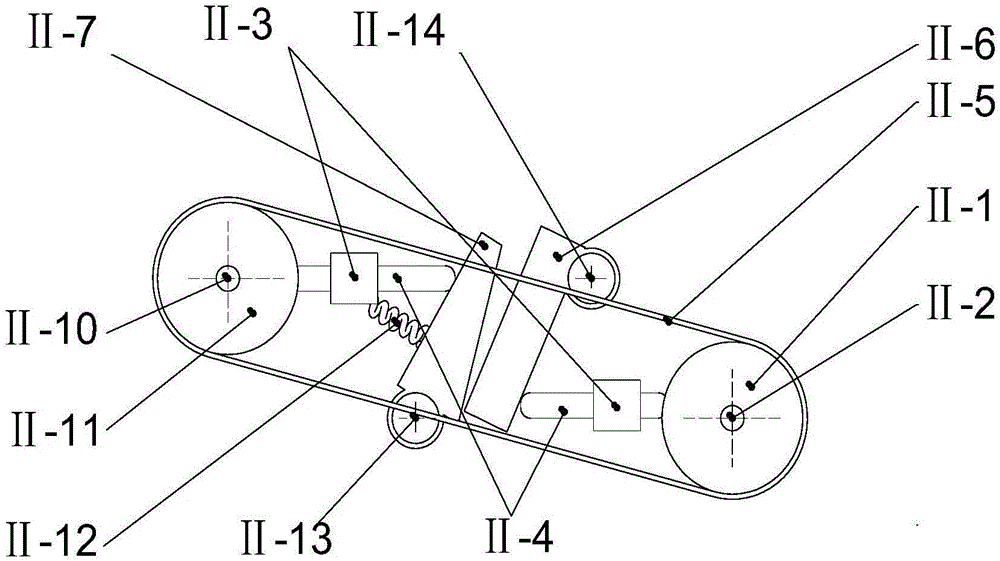

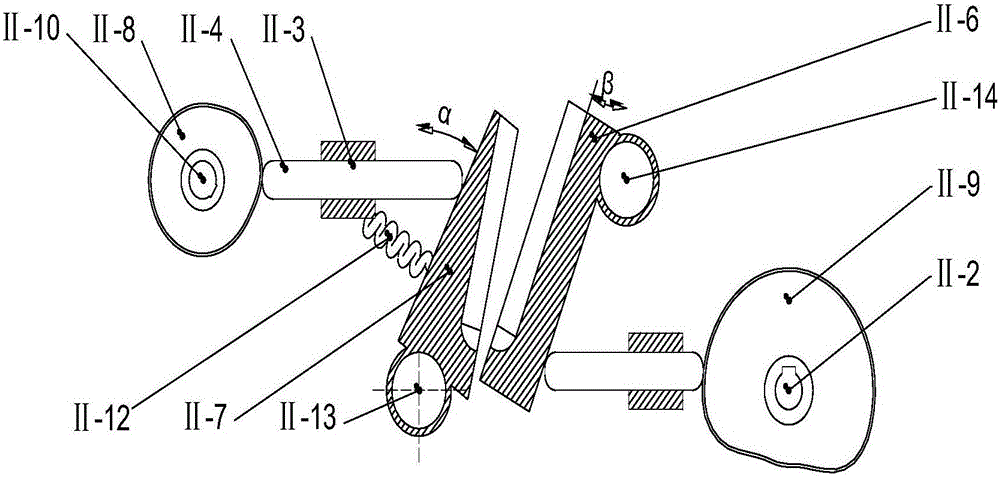

System and method for pressing walnuts into cracks based on precise self-positioning

InactiveCN106666763ASave energySave manpower and material resourcesHuskingHullingMaterial resourcesEngineering

The invention discloses a system and method for pressing walnuts into cracks based on precise self-positioning. The system comprises a driving mechanism, a transmission mechanism and a pressing mechanism. The driving mechanism generates driving force and pushes the transmission mechanism to reciprocate; the pressing mechanism comprises falling blocks and pressing blocks opposite to the falling blocks, gaps are formed between the falling blocks and the pressing blocks, and the gaps are gradually reduced so as to position falling walnuts; the transmission mechanism pushes the falling blocks and the pressing blocks, and the gaps between the pressing blocks and the falling blocks are changed so as to press walnuts falling into the gaps between the pressing blocks and the falling blocks so that cracks can be generated. By means of the system, the pre-shell-breaking process is added on the premise of effectively reducing the consumption of manpower and material resources and improving the production efficiency, and the completeness of kernels is fully guaranteed. Besides, through mechanism optimization, the working stability of the system is improved while mechanism simplification is achieved, the total cost of the system is reduced, and a significant production effect is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

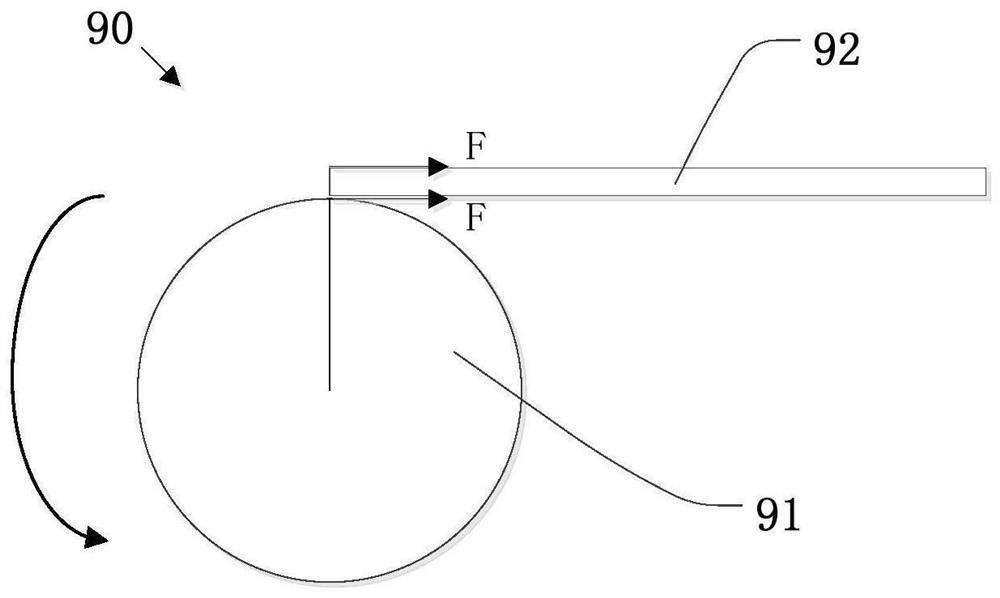

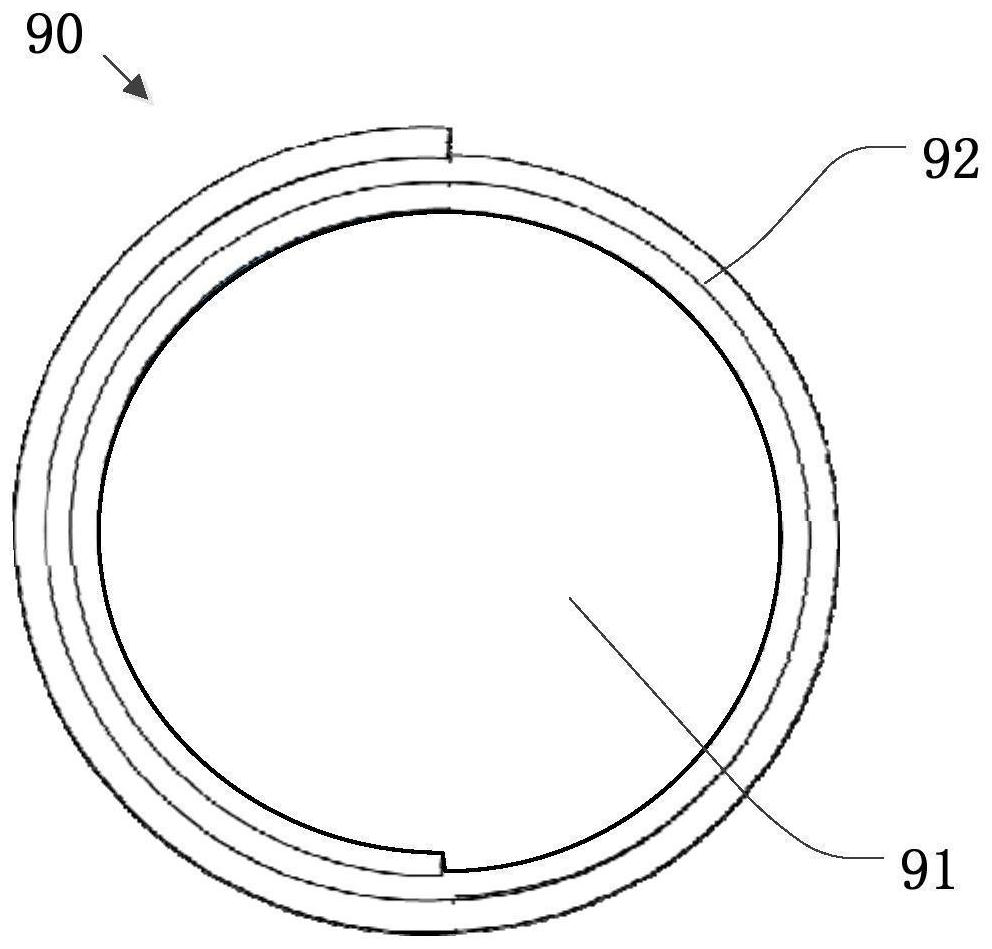

Reel and display device

InactiveCN111640372ANo stress concentration phenomenonReduce stress valueDigital data processing detailsCasings with display/control unitsDisplay deviceEngineering

The invention provides a reel and a display device. The display device comprises the reel, the reel comprises a reel body, the reel body is cylindrical, a first circle of installation groove is formedin the reel body in the extending direction of the length of the cylinder, and the depth of the first circle of installation groove is matched with the thickness of an installed flexible display screen. The flexible display screen is wound around the rell body from the first circle of installation groove until the first circle is finished; the inner side face of a second circle of the flexible display screen and the outer side face of a first circle of the flexible display screen do not generate section difference, it is guaranteed that the flexible display screen does not generate the stressconcentration phenomenon in the curling process, the stress value borne by the flexible display screen in the drawing process of the display device is reduced, the failure risk of the flexible display screen is reduced, and the service life is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

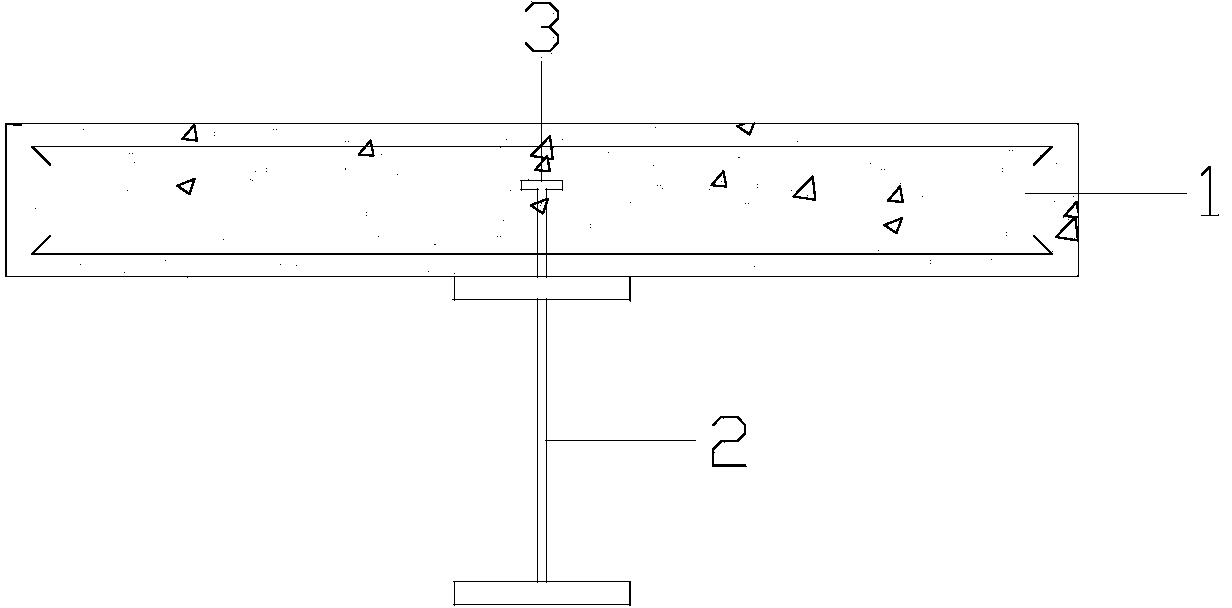

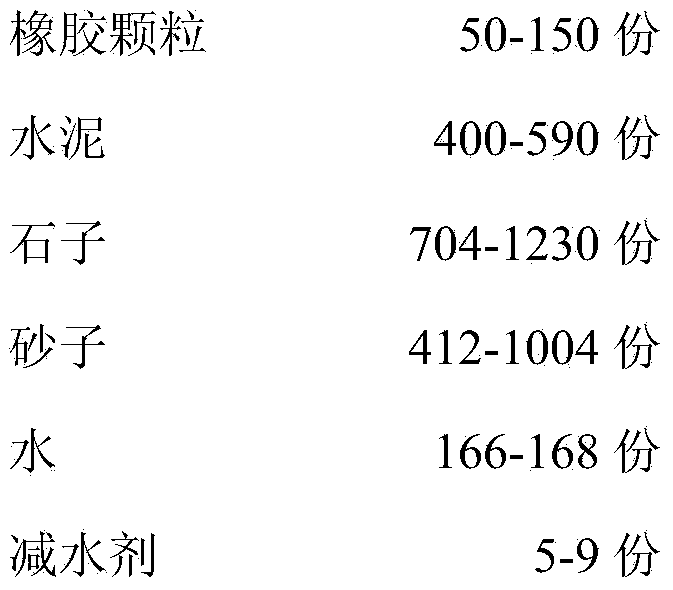

Steel-concrete composite beam adopting elastic concrete

InactiveCN103899039AIncreased durabilityGuaranteed bearing capacitySolid waste managementLoad-supporting elementsFatigue damageCarrying capacity

The invention discloses a steel-concrete composite beam adopting elastic concrete. The steel-concrete composite beam comprises a steel beam and a shear connector welded on the steel beam, wherein an elastic concrete slab is poured on the steel beam; the shear connector is arranged in the elastic concrete slab; the elastic concrete slab is formed by pouring and maintaining the elastic concrete. According to the steel-concrete composite beam, the fatigue damage to the concrete slab can be effectively prevented; furthermore, due to the powerful deformability and anti-cracking ability of the elastic concrete, the deformation of the elastic concrete and the shear connector is harmonious, and the fatigue life of the shear connector wrapped in the elastic concrete can be effectively prolonged; meanwhile, the carrying capacity is guaranteed, the construction technology is simplified, and the project popularization can be facilitated.

Owner:TIANJIN UNIV

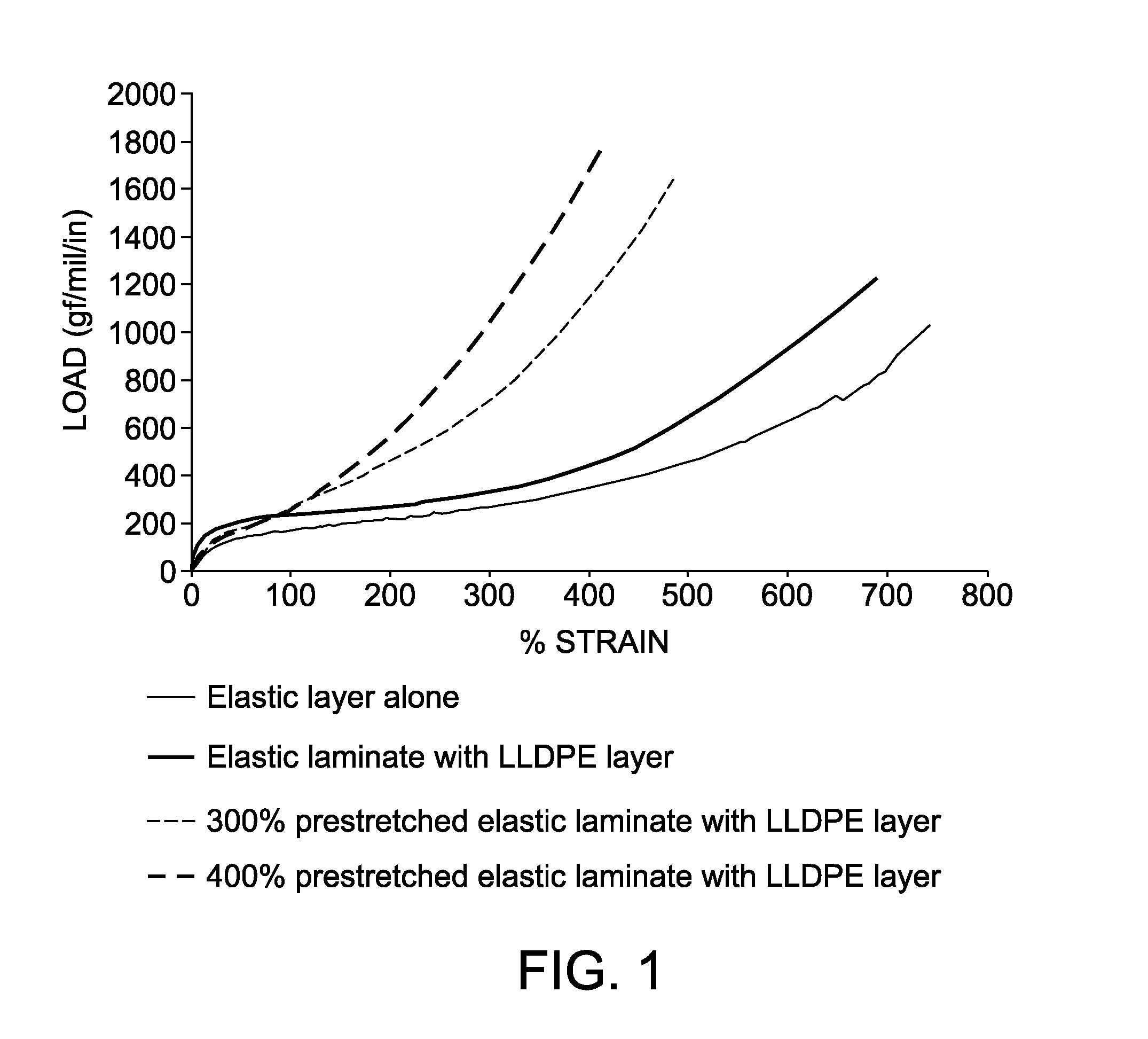

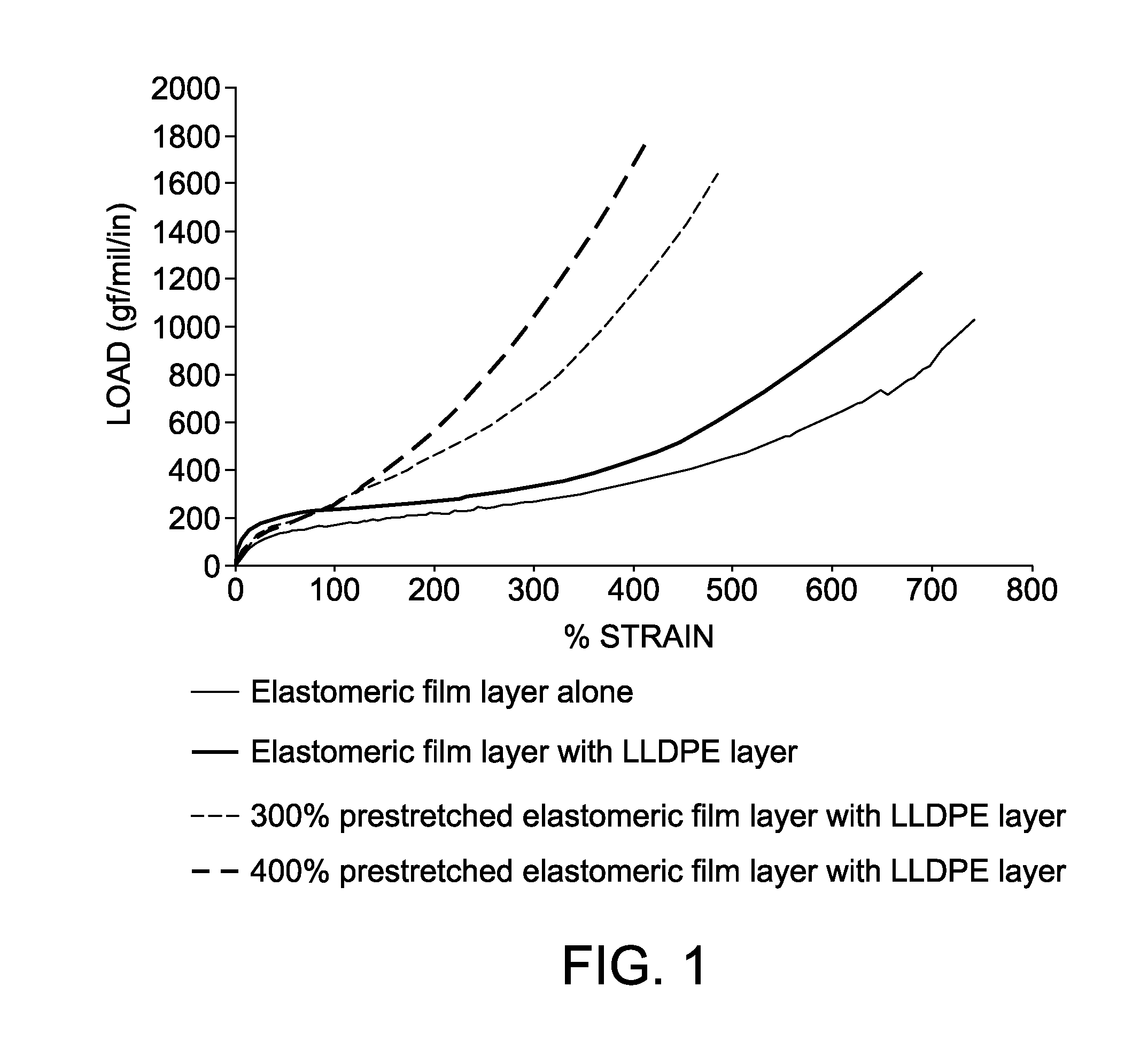

Microtextured multilayered elastic laminates with enhanced strength and elasticity and methods of making thereof

ActiveUS20150273802A1High mechanical strengthIncrease elasticityPersonal careSynthetic resin layered productsThermoplastic elastomerEngineering

Stronger elastic laminates having an improved microtextured appearance, as well as methods of preparing the laminates, are disclosed herein. Particularly, the present disclosure is directed to multilayered elastic laminates including at least one thermoplastic elastomeric film layer and at least one plastic layer coextruded together, stretched and then relaxed. The prepared laminates have enhanced overall strength and elasticity.

Owner:KIMBERLY-CLARK WORLDWIDE INC

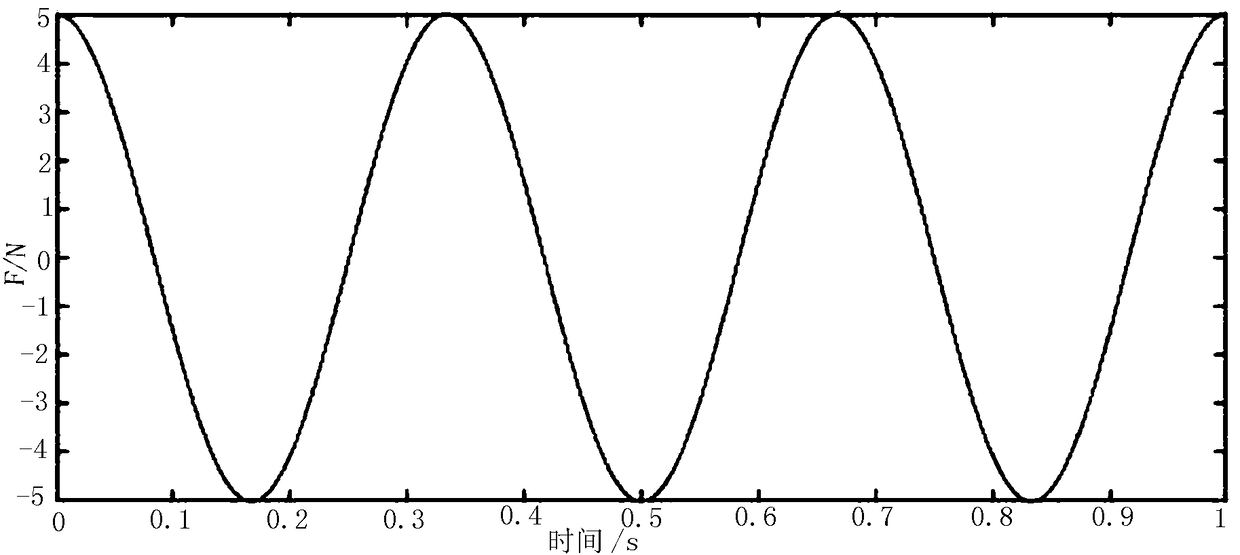

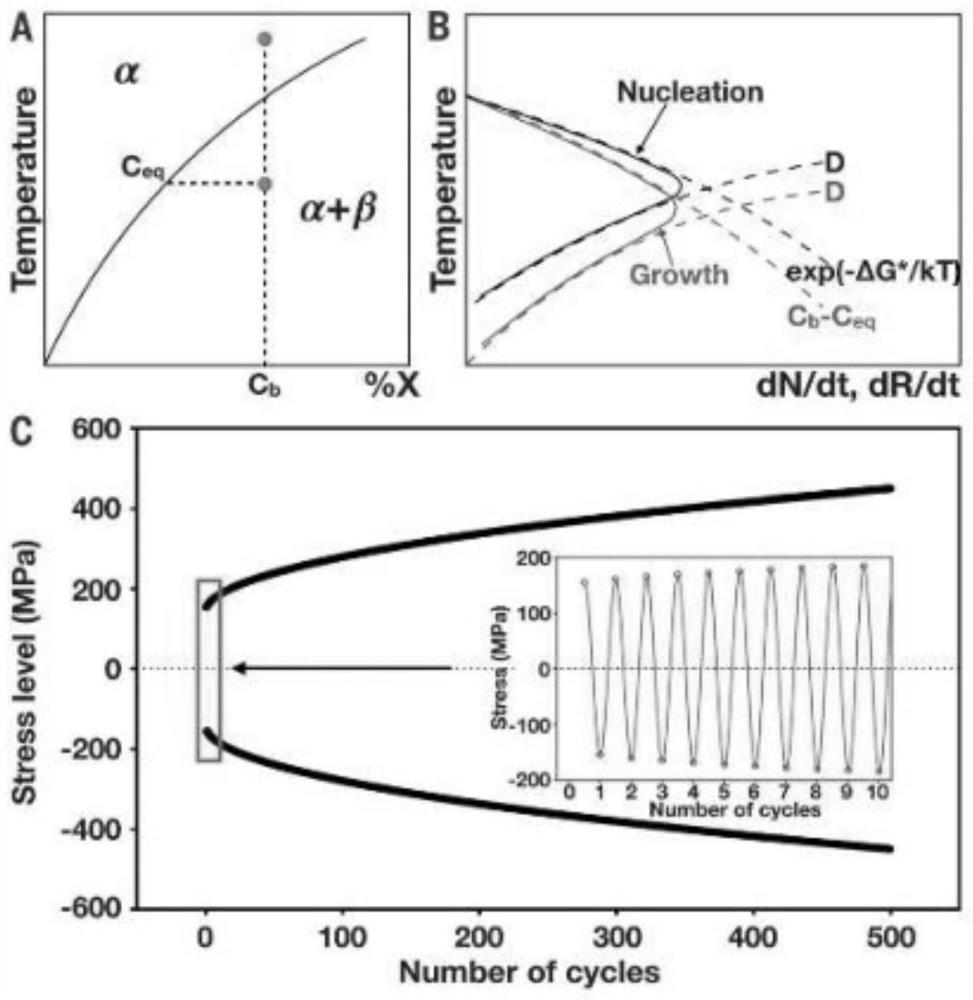

High-toughness aluminum alloy profile based on room-temperature stress cyclic strengthening process

The invention provides a high-toughness aluminum alloy profile based on a room-temperature stress cycle strengthening process. The high-toughness aluminum alloy profile comprises the following elements: 0.3%-1.2% of nano Si, 0.3%-0.6% of Mn, 0.05%-0.10% of Mo, 0.03%-0.09% of Nd, 0.05%-0.09% of V, 0.02%-0.03% of Sc, 0.03%-0.07% of La, 0.4%-0.9% of Cu, 0.5%-0.9% of nano Si3B4, 0.2%-0.5% of Zn, 0.3%-0.6% of Cr, 0.2%-0.6% of Ti, 0.5%-1.5% of Fe, 0.02%-0.05% of Ru, 1.5%-3.0% of a mixture of carbon fibers and carbon nanotubes, 0.2%-0.6% of an aluminum alloy inoculant and the balance of Al. According to the high-toughness aluminum alloy profile based on the room-temperature stress cycle strengthening process, the strength and the toughness are improved through raw material composition of rare earth and carbon materials and room-temperature stress cycle strengthening.

Owner:池州市安安新材科技有限公司

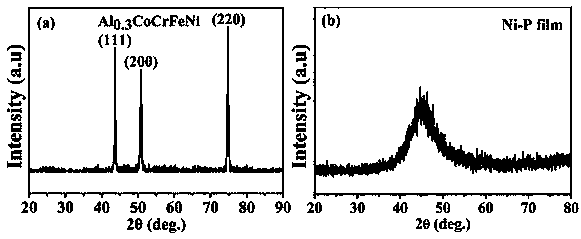

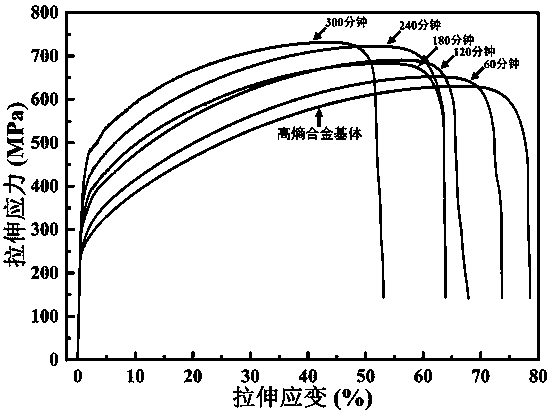

Method for increasing tensile strength of high-entropy alloy with face-centered cubic structure

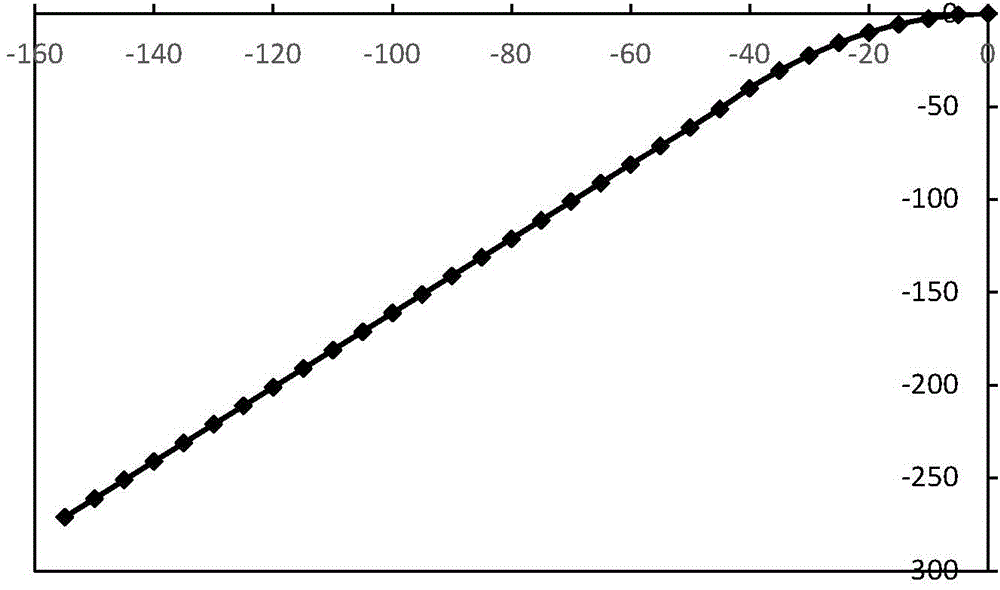

InactiveCN108754463AHigh tensile strengthReduce stress valueLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a method for increasing tensile strength of high-entropy alloy with a face-centered cubic structure. The method comprises the following steps of in a chemical plating solutionusing nickel sulfate as main salt, using sodium phosphate as a reducing agent, using citric acid as a complexing agent, using ammonium hydrogen fluoride and sodium hydroxide as buffer agents, using hydrofluoric acid as an accelerator and using thiourea as a stabilizer, initiating the oxidation reduction between the nickel sulfate main salt and the reducing agent under the self-catalyzing functionof nickel atoms; finally, reducing the nickel ions in the solution and the phosphor ions in phosphite radicals into corresponding ions, and co-depositing to the surface of the high-entropy matrix, soas to form a Ni-P (nickel-phosphor) noncrystalline plating layer. The method has the advantages that one layer of Ni-P noncrystalline with high strength is deposited at the surface of the matrix, so as to reach the purpose of reducing the stress value of the high-entropy marix under the condition of same strain, thereby improving the tensile strength of the whole material; the strength of the material strength shows the positive correlation along with the thickness of the thickness of a plating layer.

Owner:TAIYUAN UNIV OF TECH

Anchored liner plate

InactiveCN1442589ASmall sizeReduced number of cutsBuilding reinforcementsMaterial consumptionEngineering

An anchor shoe is a hollow (2-4)-step circular tower structure with a bearing plate. It has a central conic through hole and a recessed circle for holding anchor plate in it. Said anchor shoe is madeintegrally up by casting. Its advantages are small size, uniform and low stress, light weight, less damage to anchor cable and low cost.

Owner:LIUZHOU OVM MASCH CO LTD

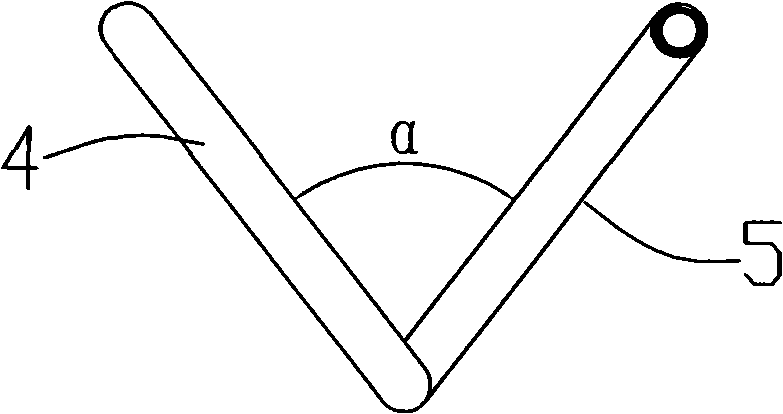

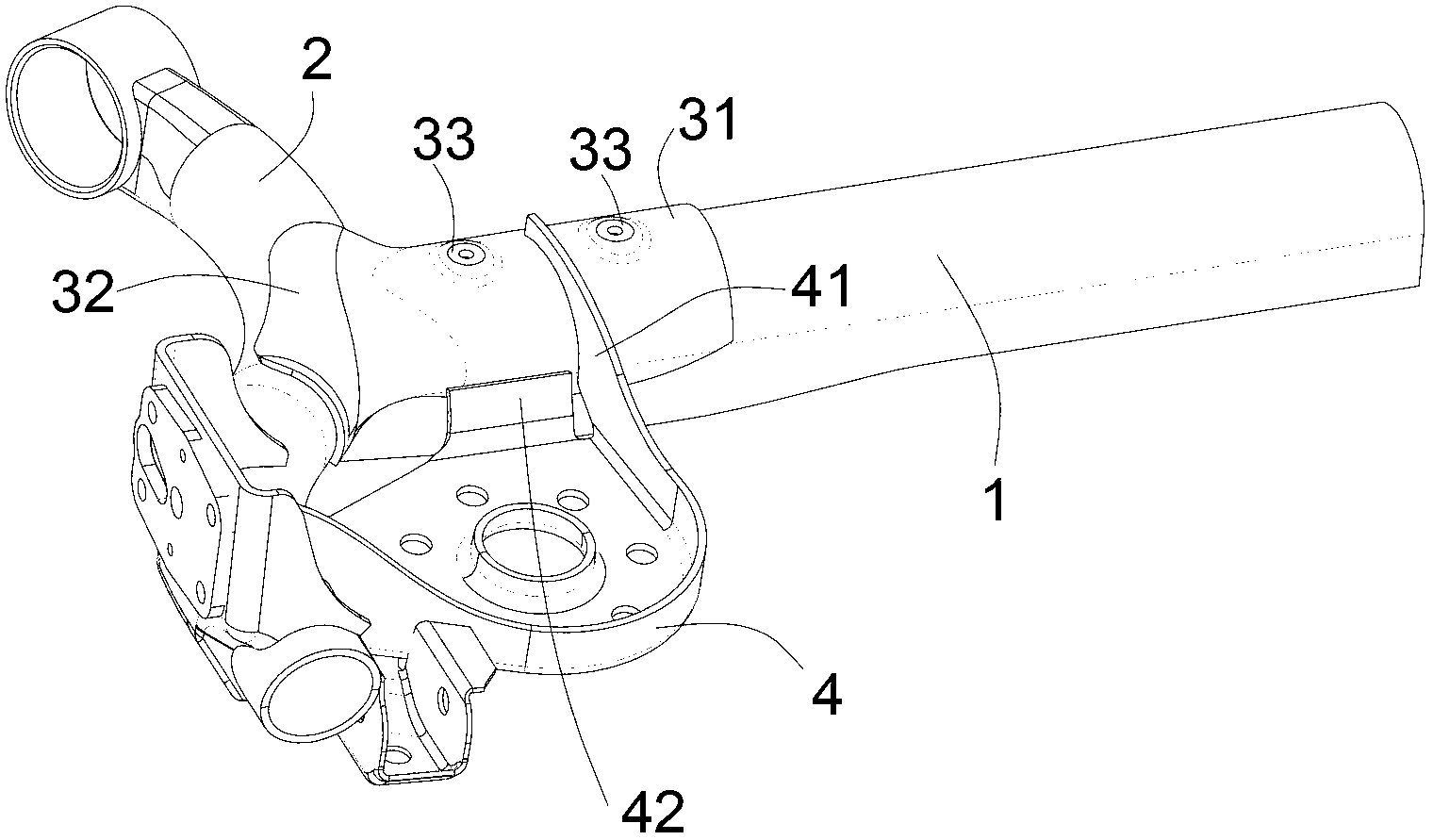

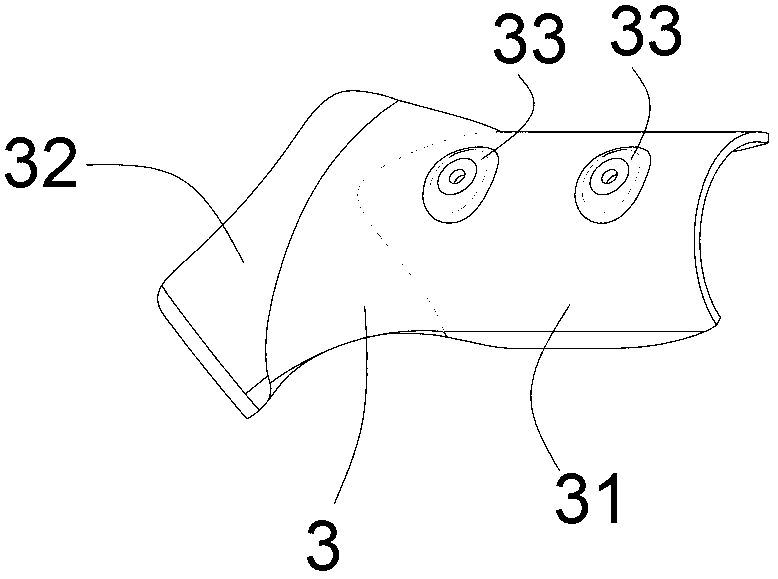

Semi-independent suspension frame for rear torsion beam of automobile

The invention discloses a semi-independent suspension frame for a rear torsion beam of an automobile. The semi-independent suspension frame is beneficial to the preventing for the crack generation caused by ultra-high stress values of welding areas of longitudinal arms and a cross beam. The semi-independent suspension frame for the rear torsion beam of the automobile comprises the cross beam with a V-shaped or U-shaped cross section and the longitudinal arms connected with the two ends of the cross beam; a spring base is arranged on the longitudinal arms; reinforcing parts are arranged at the joints of the cross beam and the longitudinal arms; each of the reinforcing parts comprises a cross beam connecting part and a longitudinal arm connecting part; the cross beam connecting part is connected with the upper surface of the cross beam; the shape of the cross section of the cross beam connecting part is matched with that of the cross beam; the longitudinal arm connecting part is connected with one of the longitudinal arms; the shape of the cross section of the longitudinal arm connecting part is matched with that of the longitudinal arms; and two ends of the longitudinal arm connecting part are respectively located on the two sides of the cross beam connecting part along the longitudinal arms. A test proves that the semi-independent suspension frame for the rear torsion beam of the automobile can effectively transfer the stress onto the reinforcing parts, so that the stress values of the welding areas of the longitudinal arms and the cross beam are reduced, but the stress on the reinforcing parts is still less than a yield limit, thereby preventing the crack generation and the happening of failure state.

Owner:SICHUAN JIANAN IND

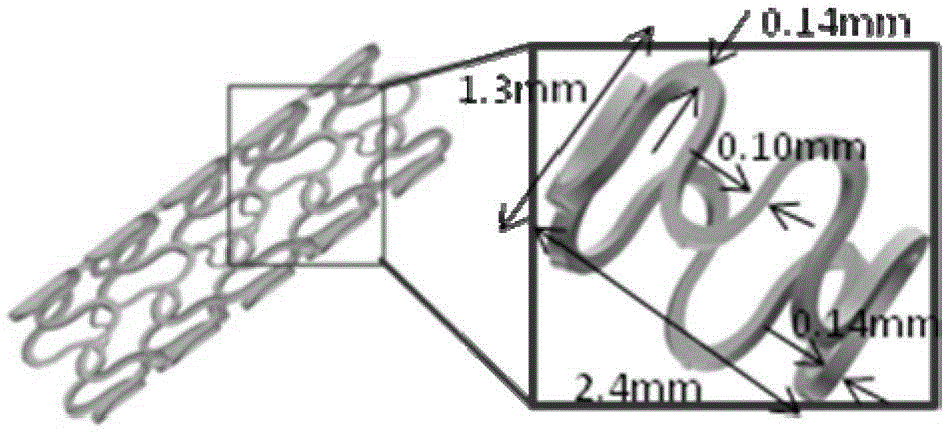

Intravascular stent with expandable coating

An intravascular stent (26) has a surface coated with a biocompatible layer. The layer contains a diamond like nanocomposite material. This nanocomposite material comprises carbon, hydrogen, silicon and oxygen as constituent elements. The layer has a stress which is less than 150 MPa in order to ensure a high degree of flexibility and a complete expandability. This lower stress is obtained by the inclusion of relatively large amounts of Si:O bonds. In a preferable embodiment the layer with diamond like nanocomposite material covers the stent (26) for 100%. This is obtained by allowing the stent to move freely along a wire during CAVD deposition.

Owner:BLUE MEDICAL DEVICES

Multilayer nonwoven fabric, stretchable multilayer nonwoven fabric, fiber product, absorbent article, and sanitary mask

ActiveUS20180051405A1Good molding effectLess stickyPersonal careProtective equipmentThermoplastic elastomerNonwoven fabric

A multilayer nonwoven fabric includes: an elastic nonwoven fabric containing a specific low crystalline polypropylene; and a mixed fiber spunbonded nonwoven fabric disposed on at least one surface of the elastic nonwoven fabric, wherein the mixed fiber spunbonded nonwoven fabric contains a long fiber of a thermoplastic elastomer (A) and a long fiber of a thermoplastic elastomer (B) other than the thermoplastic elastomer (A), in a ratio of 10 to 90% by mass:90 to 10% by mass ((A):(B), with the proviso that (A)+(B)=100% by mass).

Owner:MITSUI CHEM INC

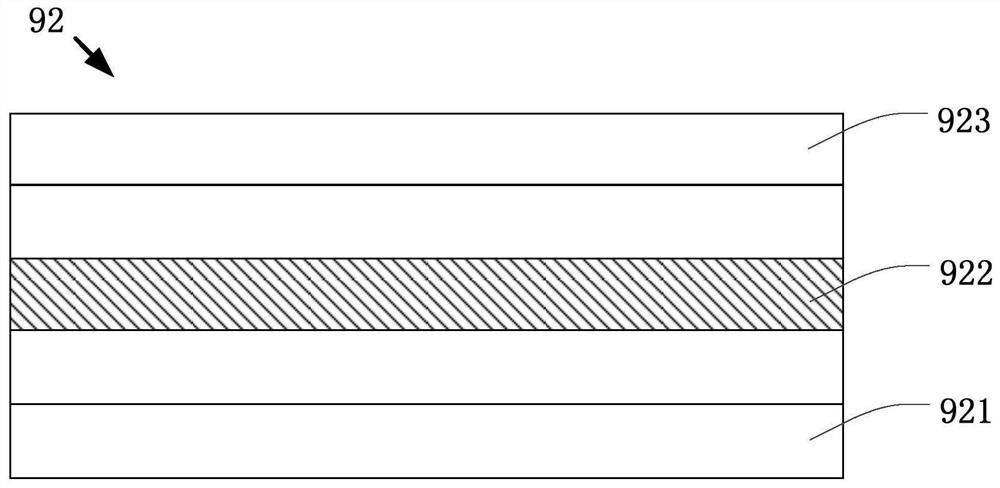

Flexible display screen and display device

ActiveCN111816072AReduce stress valueReduce peelingIdentification meansDisplay deviceFlexible display

The invention provides a flexible display screen and a display device. The display device comprises a flexible display screen. The flexible display screen is used for being wound on a reel in a curledmode and comprises a back plate, a middle lamination layer and a cover plate which are arranged in a stacked mode. A plurality of continuous first trapezoidal structures are arranged on the upper surface of the back plate; a plurality of continuous second trapezoidal structures are arranged on the lower surface of the cover plate; when the flexible display screen is curled and wound on the reel,the first trapezoidal structure and the second trapezoidal structure are used for decomposing the shear stress generated by the reel in the curling process in the surface direction of the middle lamination layer to reduce the stress of the flexible display screen, so that the stripping phenomenon of the middle lamination layer of the flexible display screen is reduced, the risk of failure is reduced, and the service life of the flexible display screen is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Multilayered elastic laminates with enhanced strength and elasticity and methods of making thereof

ActiveUS20150174869A1Improve mechanical strengthEnhance elasticityLamination ancillary operationsPersonal careEngineeringThermoplastic elastomer

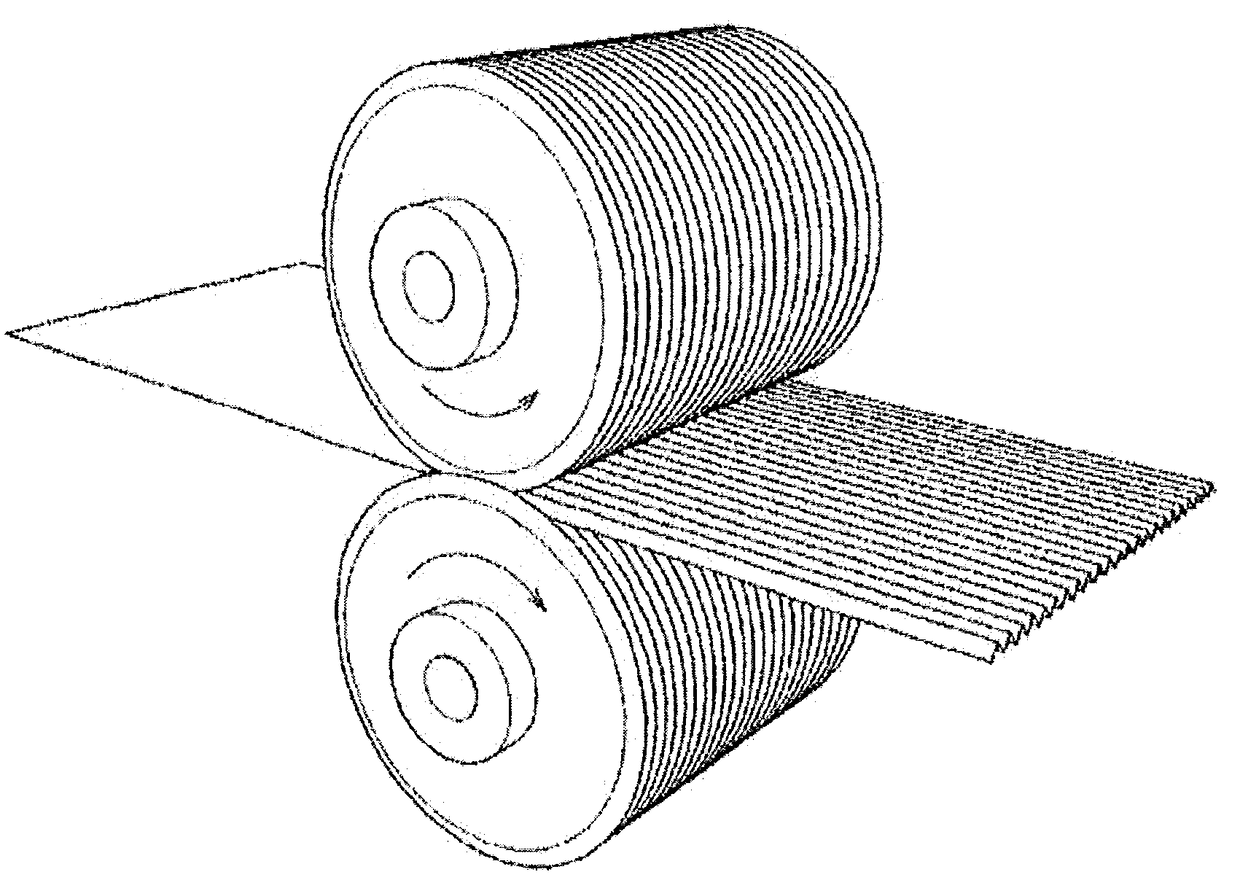

Stronger elastic laminates, as well as methods of preparing the laminates, are disclosed herein. Particularly, the present disclosure is directed to multilayered elastic laminates including a thermoplastic elastomeric film layer and a plastic layer coextruded together, and further, a facing material laminated to the thermoplastic elastomeric film layer. The laminates are stretched and then relaxed. The prepared laminates have enhanced overall strength and elasticity while having a soft, cloth-like feel, and are prepared at a lower cost.

Owner:KIMBERLY-CLARK WORLDWIDE INC

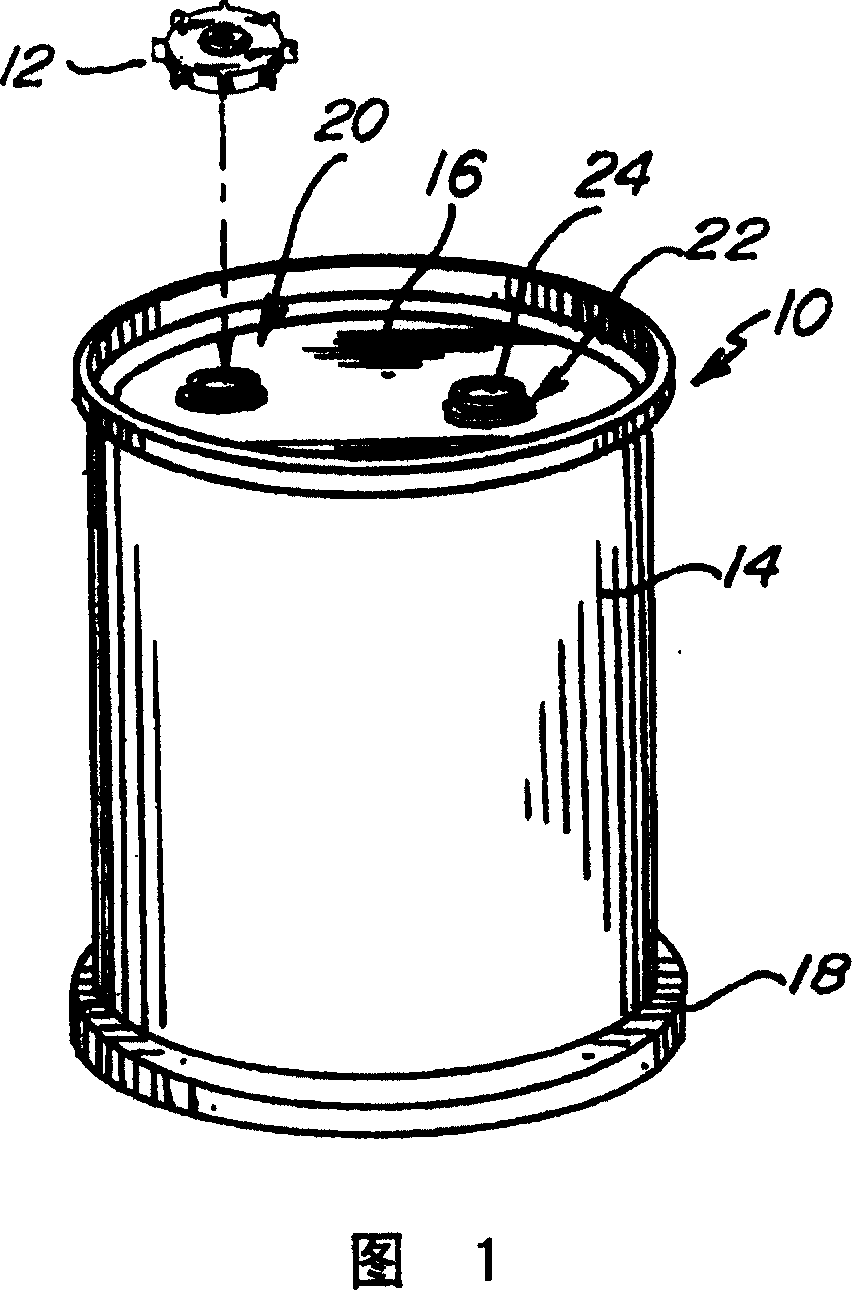

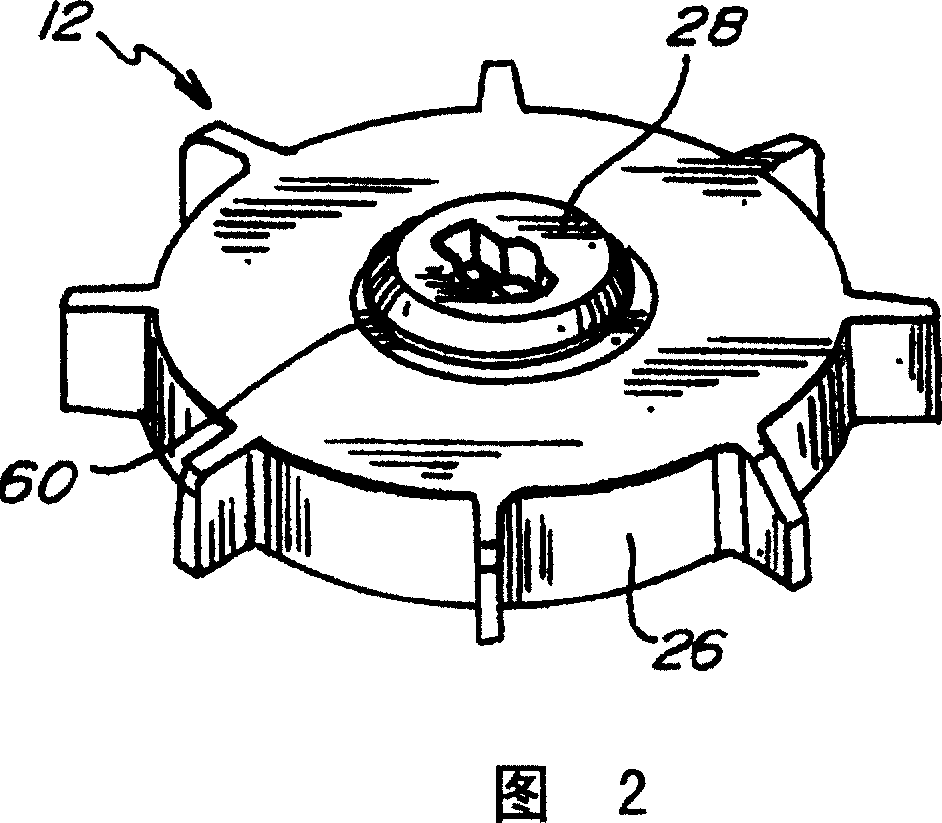

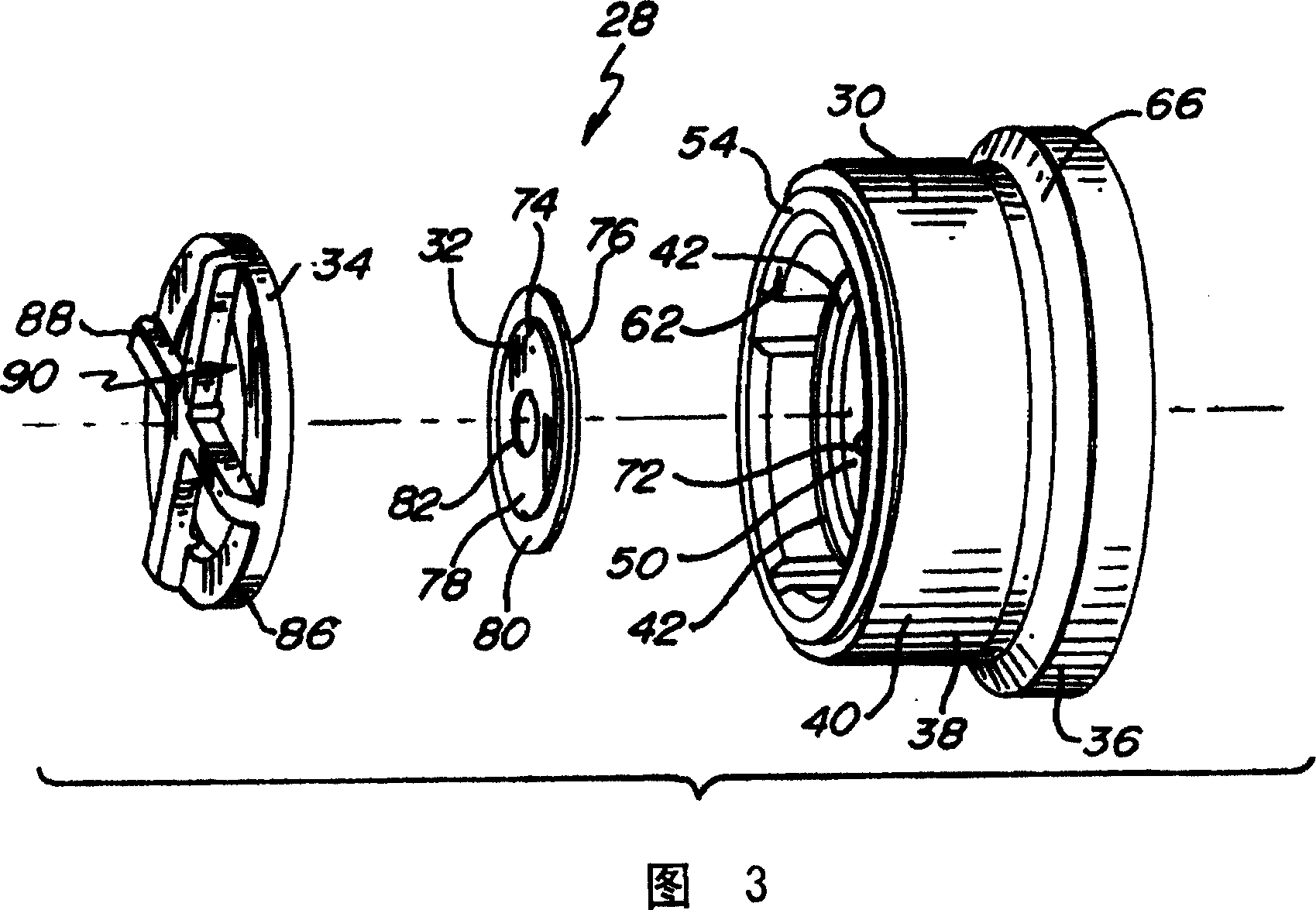

Drum vent

InactiveCN100343137CReduce skewImprove effectivenessClosuresPackaging corrosive chemicalsEngineeringMechanical engineering

A venting device for a drum. The venting device includes a body having a pair of opposing sides and defining a plurality of vent passages. The vent passages extend through the body and each an opening at each of the pair of opposing sides. The vent passages are spaced apart and arranged around a center portion of the body. A membrane structure is positioned so as to cover the openings of the vent passages on one of the pair of opposing sides of the body. The membrane structure is sealingly affixed to the body portion in a sealing band surrounding the openings of the vent passages. A portion of the membrane structure is further affixed to the center portion of the body. A protective structure may be attached to the body and positioned over the membrane structure.

Owner:ENTEGRIS INC

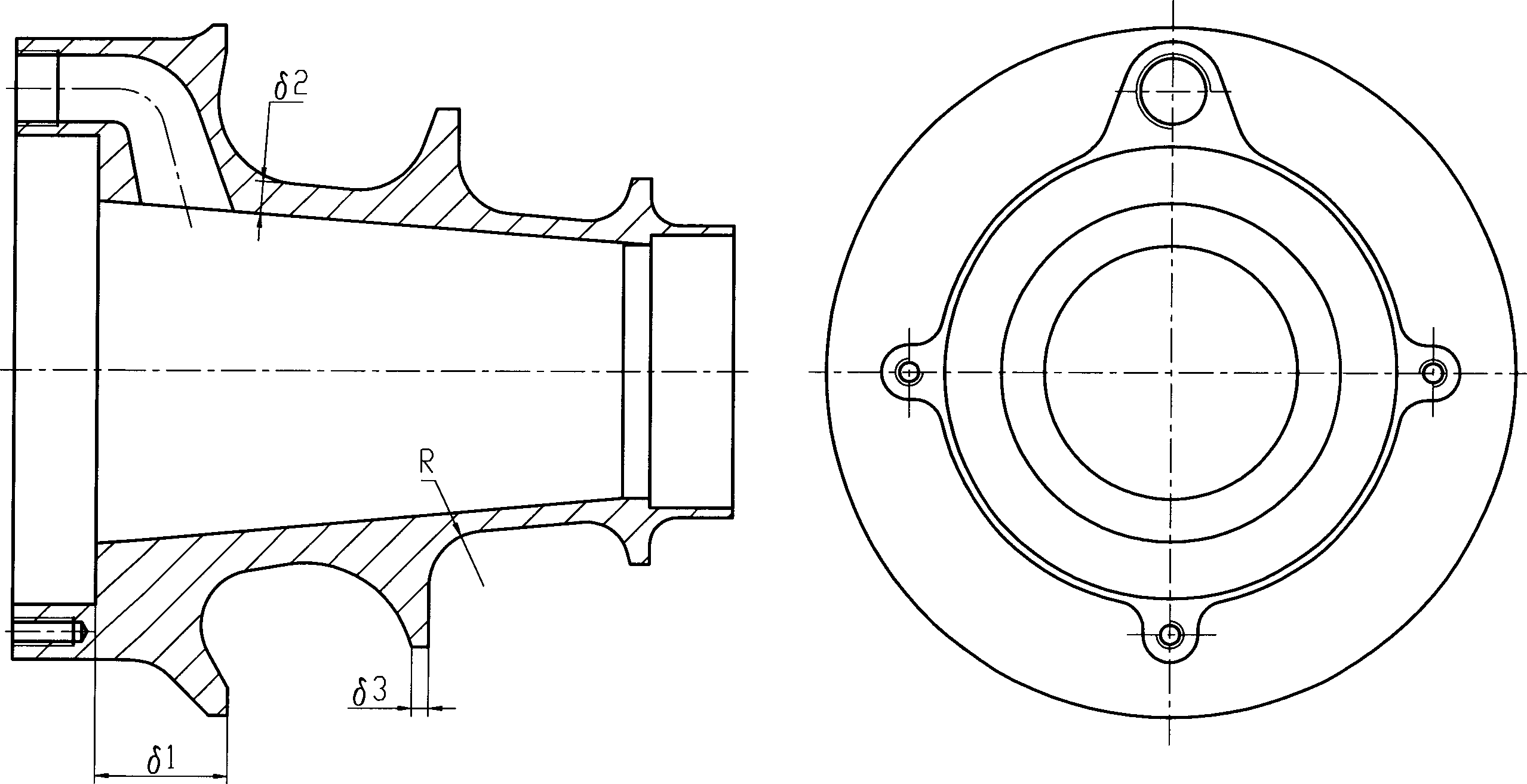

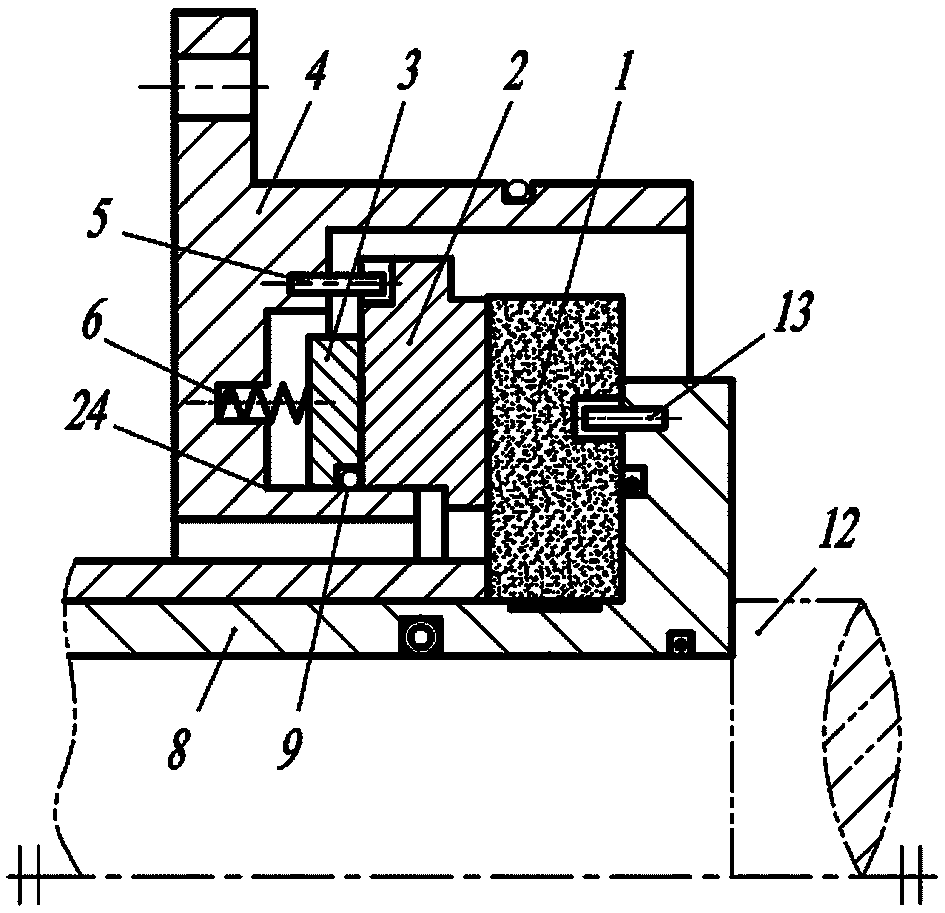

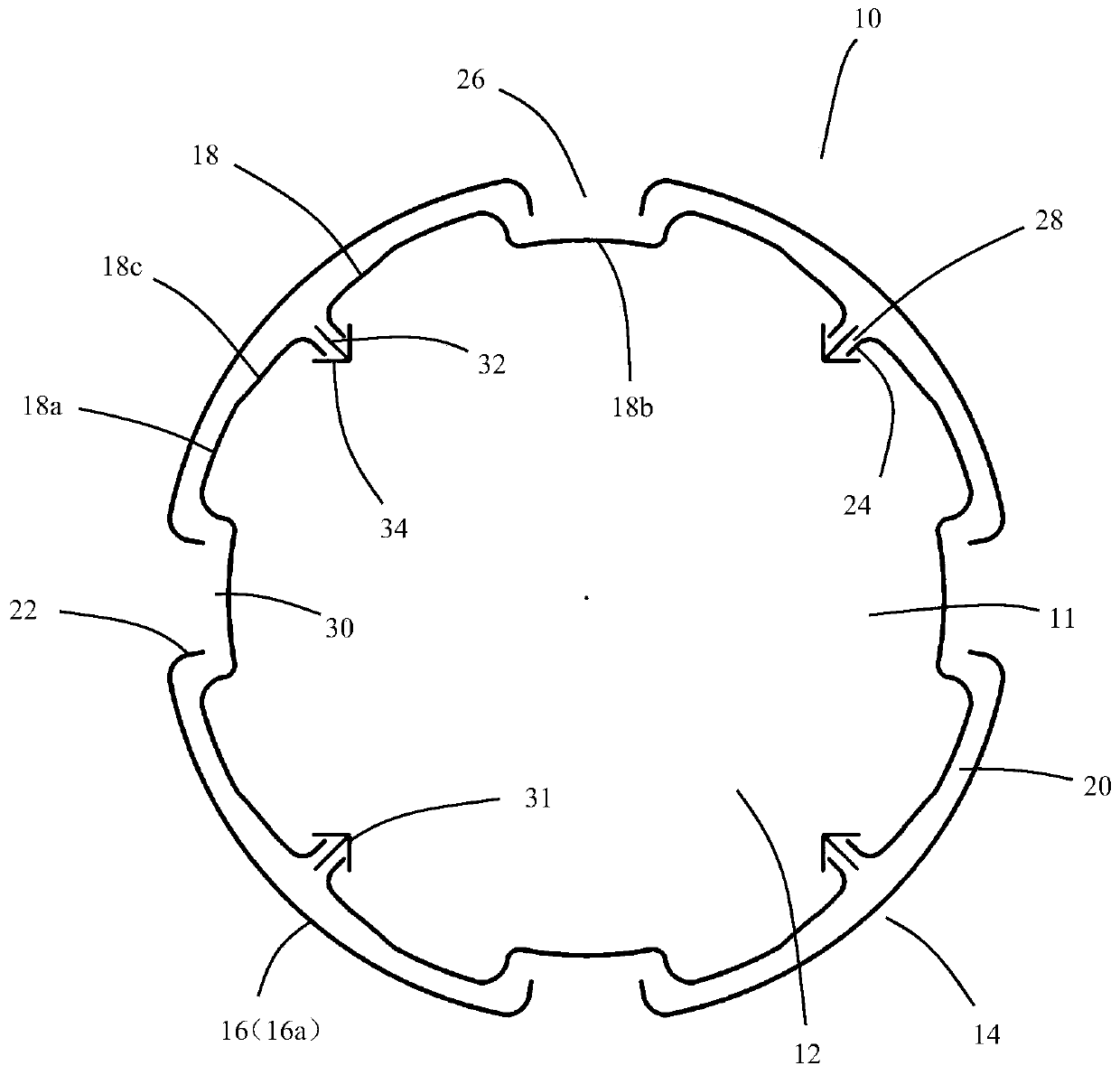

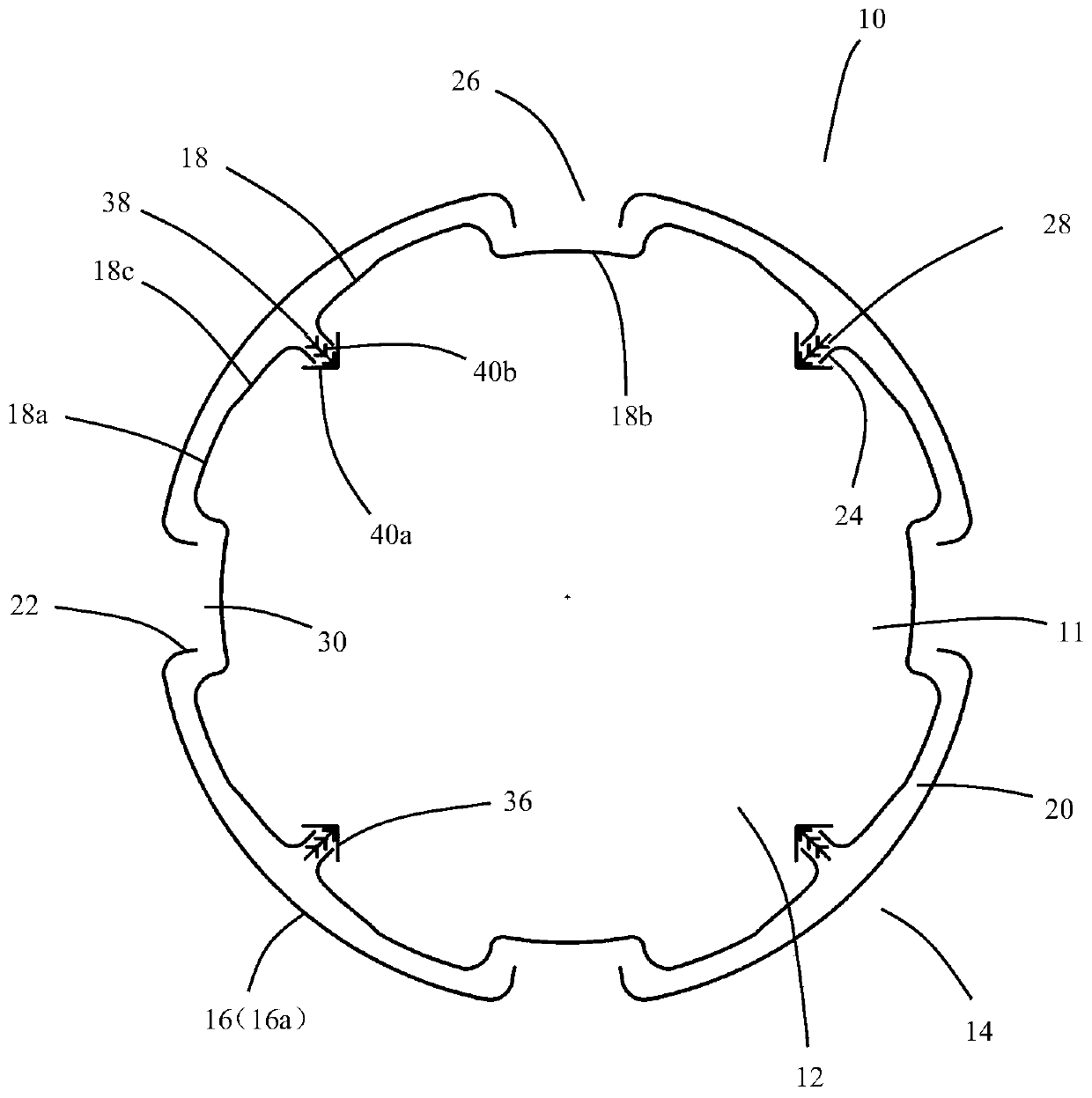

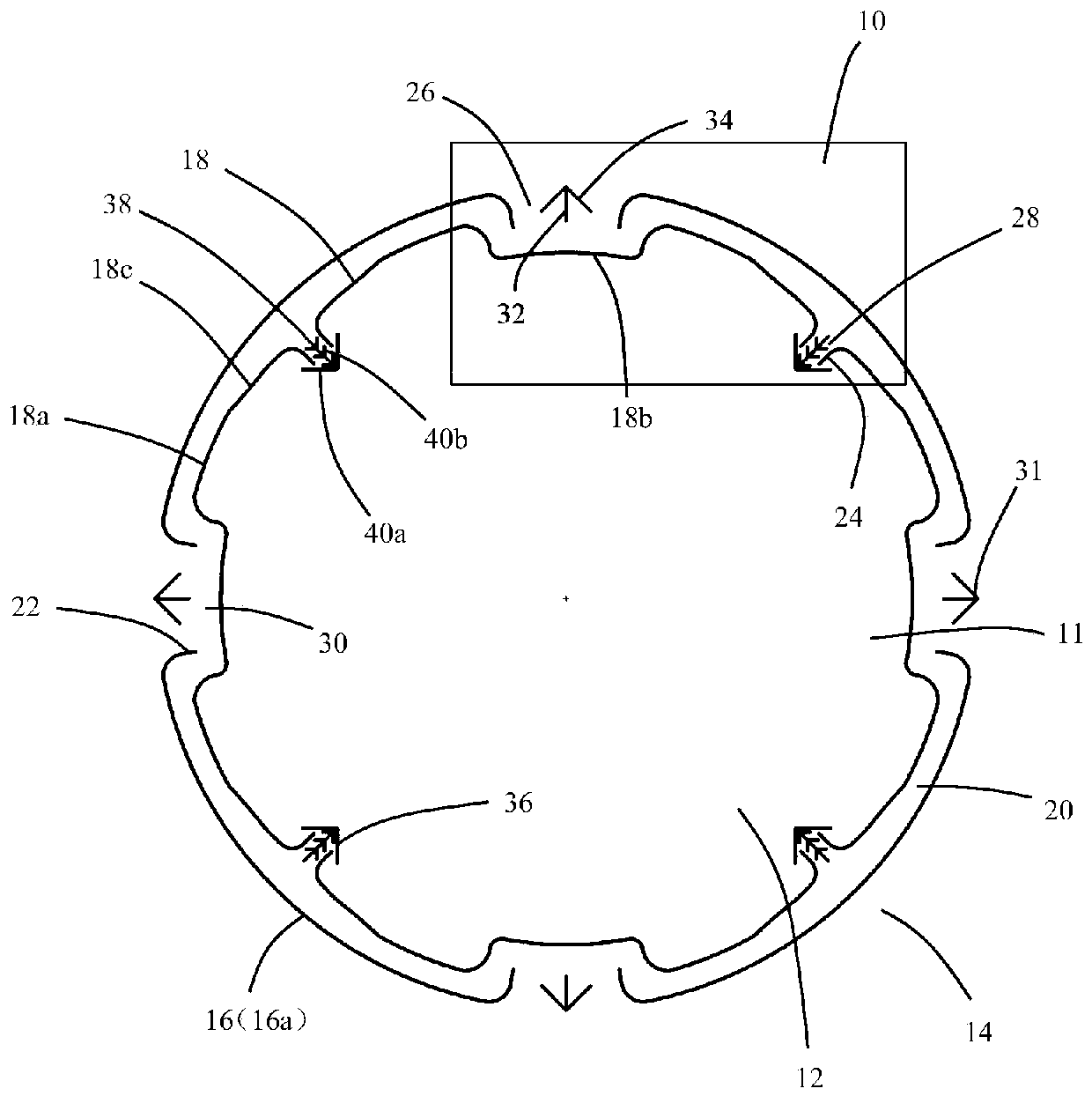

Throw-out collar of mechanical sealing device and mechanical sealing device

PendingCN105508616AIncrease radial height/strengthRelieve pressureEngine sealsHigh pressureMechanical engineering

The invention relates to a throw-out collar of a mechanical sealing device and a mechanical sealing device. The throw-out collar with an axially perforated inner hole comprises a radially expanding collar body and an annular lug boss structure which convexly protrudes along the central shaft on one side surface, wherein an annular groove which is opened in the hole wall surface is arranged in the wall of the perforated inner hole; and a spacing structure is kept between the wall of the annular groove on the side in the lug boss structure direction and the end surface of the annular lug boss structure. According to the throw-out collar in such structure and the mechanical sealing device with the throw-out collar, many types of seal rings can be utilized to enhance the pressure resistance of the sealing. When the radial deformation of the throw-out collar occurs, the deformation amount and deformation cone angle of the corresponding component can be greatly reduced, thereby obviously lowering the unfavorable deformation of the stationary ring sealing end surface, and obviously enhancing the high pressure resistance of the sealing.

Owner:SICHUAN SUNNY SEAL

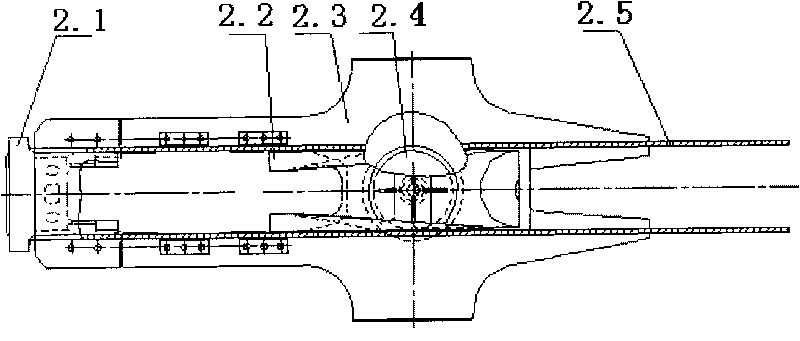

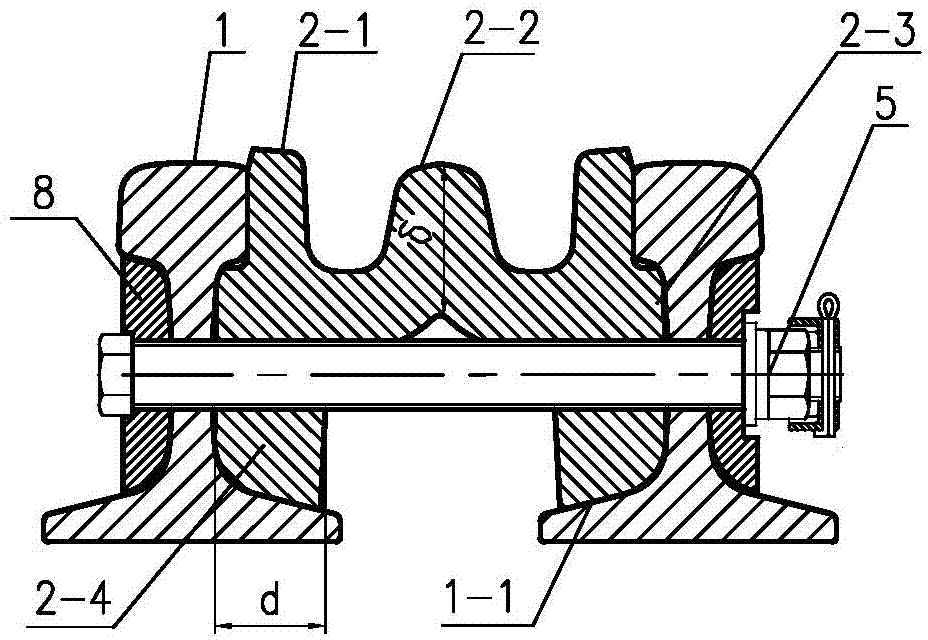

Main shaft assembly of continuous copper extruding machine

The invention discloses a main shaft assembly of a continuous copper extruding machine. The main shaft assembly comprises a core shaft, an inner shaft sleeve, an inner side wheel, an outer side wheel,bearings, a pressing sleeve, an extruding wheel and a hydraulic nut, wherein the inner shaft sleeve and the outer shaft sleeve are mounted on the outer side of the core shaft; the bearings are mounted at the outer parts of the inner shaft sleeve and the outer shaft sleeve separately; an axial water inlet, an axial water outlet, a radial water inlet and a radial water outlet are formed in the coreshaft; the axial water inlet communicates with the radial water inlet; the axial water outlet communicates with the radial water outlet; an annular cooling groove is formed in the inner surface of the extruding wheel; and the part between the inner surface of the extruding wheel and the outer surface of the core shaft forms an annular gap which serves as a cooling water channel. According to themain shaft assembly of the continuous copper extruding machine, the cooling water channel of the extruding wheel of the main shaft assembly is changed, so that when the groove temperature of the extruding wheel is controlled and the softening of the extruding wheel in the high temperature area in the groove is reduced, the temperature distribution and stress condition of the extruding wheel are changed, the stress value of the extruding wheel at the dangerous breakdown point is reduced, the service life of the extruding wheel is prolonged, and the equipment operation cost is reduced.

Owner:大连康丰科技有限公司

MEMS diaphragm and MEMS sensor chip

ActiveCN111137842AReduce stress valueIncrease the effective areaTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStructural engineeringMems sensors

The invention provides an MEMS diaphragm and an MEMS sensor chip. The MEMS diaphragm comprises a sensing part and a peripheral part surrounding the periphery of the sensing part. A plurality of outergrooves and a plurality of inner grooves are formed between the peripheral part and the sensing part; the plurality of outer grooves are annularly distributed at the inner edge of the peripheral part;a first connecting arm is formed between every two adjacent outer grooves, the multiple inner grooves are annularly distributed in the outer edge of the sensing part, a second connecting arm is formed between every two adjacent inner grooves, and at least one of the first connecting arms and the second connecting arms is provided with a reinforcing rib structure.

Owner:SHANDONG GETTOP ACOUSTIC

Multi-temperature zone integrated heat sink

InactiveCN107328260ACompact designReduce volumeStationary conduit assembliesHeat exchanger casingsCooling pipeCooling fluid

The invention provides a multi-temperature zone integrated heat sink. The multi-temperature zone integrated heat sink is formed by combination of a high-temperature heat dissipation module and a low-temperature heat dissipation module, wherein both the high-temperature heat dissipation module and the low-temperature heat dissipation module are formed by combination of water chambers and core bodies in a crimping manner; a cooling pipe, a heat dissipation belt, a main leaf and a baffle plate are brazed to form the integrated core body; the high-temperature heat dissipation module and the low-temperature heat dissipation module share the main leaf and the water chamber; the water chambers of the high-temperature heat dissipation module and the low-temperature heat dissipation module are separated by a water chamber baffle plate so as to prevent high temperature cooling liquid and low temperature cooling liquid from being mixed with each other; and the core bodies of the high-temperature heat dissipation module and the low-temperature heat dissipation module are separated by a baffle plate so as to reduce thermal stress generated due to temperature difference between the high-temperature heat dissipation module and the low-temperature heat dissipation module and prolong the service life.

Owner:NANNING BALING TECHNOLOGY CO LTD

Method for improving usability of biomedical degradable magnesium alloy cardiovascular stent

ActiveCN103334070AEasy to useReduce residual stressSurgeryCardiovascular stentPercent Diameter Stenosis

The invention belongs to the technical field of biological materials and in particular provides a method for improving usability of a biomedical degradable magnesium alloy cardiovascular stent. The method is characterized by comprising the following steps of: firstly pre-press-holding the magnesium alloy cardiovascular stent until the diameter is 1.05-1.25 times the finally press-holding diameter, then carrying out full annealing treatment on the stent, treating the surface of the stent or coating a drug-loading coating after annealing treatment, then continuing press-holding the stent till the preset dimension so that the stent is closely attached to a sacculus and carrying out subsequent packaging and sterilizing. The method has the beneficial effects that the maximum stress of the press-holding expansion process, the residual stress of the stent after press-holding expansion and expansion resilience can be reduced by introducing the annealing process; the stress safety of the stent and the implantation success rate can be improved by reducing the maximum stress; by reducing the residual stress, the stress corrosion tendency and degradation rate of the stent are reduced and the supporting time of the stent is prolonged; and by reducing expansion resilience, the attachment properties of the stent and blood vessels are improved and the probability of vascular restenosis caused by stent implantation is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-temperature annealing process for reducing stress of glass-metal connection sealing structure

InactiveCN111039579AReduce stress valueImprove safety and reliabilitySolar heating energySolar heat collectors with working fluidsComposite material

The invention discloses a low-temperature annealing process for reducing stress of a glass-metal connection sealing structure. The low-temperature annealing process comprises the following steps: 1, putting a connected and sealed glass-metal connection sealing section into an annealing furnace; 2, increasing the temperature to 200 DEG C from the room temperature; 3, increasing the temperature to 350 DEG C from 200 DEG C; 4, increasing the temperature to 450 DEG C from 350 DEG C; 5, increasing the temperature to 520 DEG C from 450 DEG C; 6, reducing the temperature to 470 DEG C from 520 DEG C;7, reducing the temperature to 370 DEG C from 470 DEG C; 8, reducing the temperature to 300 DEG C from 370 DEG C; and 9, reducing the temperature to the room temperature from 300 DEG C. According to the invention, the glass metal connection sealing part is subjected to annealing treatment at the temperature below the glass strain point, so that the stress value of the connection sealing part is greatly reduced, the safety and the reliability of the connection sealing part are improved, the qualification rate of the product is improved, and the effective life of the whole product is prolonged.

Owner:北京天瑞星光热技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com