Method for increasing tensile strength of high-entropy alloy with face-centered cubic structure

A high-entropy alloy, face-centered cubic technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as large plasticity and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

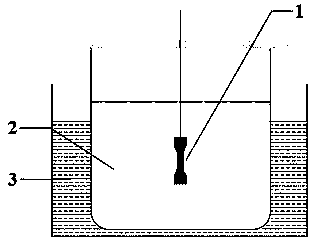

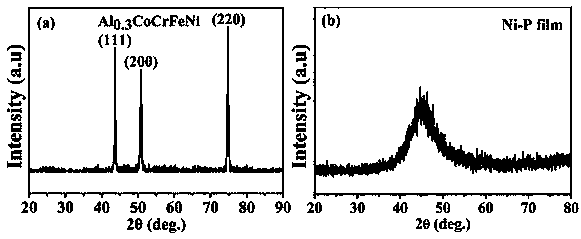

[0030] The invention breaks through the traditional method of improving the strength of the high-entropy alloy by changing its structure, and is also different from the concept of general composite materials (the volume fraction of the coating layer is very small), and has little influence on the size and shape of the high-entropy alloy matrix influences. The present invention adopts the method of chemical deposition, and coats a layer of high-strength Ni-P amorphous alloy on the surface of the high-entropy substrate to form a high-entropy alloy / Ni-P amorphous composite material, so as to improve the tensile strength of the high-entropy alloy. purpose of strength. Next, explain in detail:

[0031] The first step is the preparation of electroless plating solution, and the process formula of each component is as follows:

[0032] Nickel Sulfate (NiSO 4 •6H 2 O) 25g / L

[0033] Sodium hypophosphite (NaH 2 PO 2 •H 2 O) 25g / L

[0034] Citric acid (C 6 h 8 o 7 •H 2 O) 20...

Embodiment 2

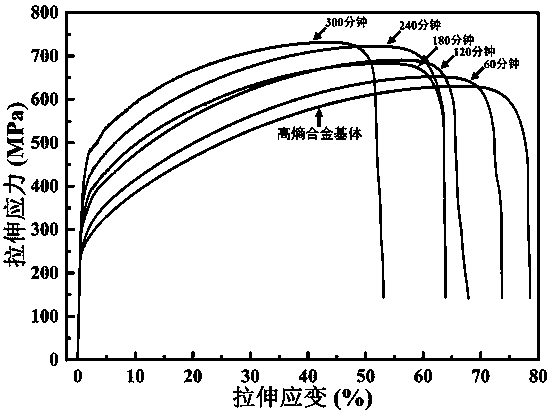

[0059] In the case of maintaining the high-entropy alloy matrix and other process conditions in the above-mentioned Example 1, in order to obtain coatings with different phosphorus contents, and study the influence of coatings with different phosphorus contents on the mechanical properties of composite materials, the reducing agent was controlled in the experiment. The concentrations of sodium phosphate were 20 g / L, 25 g / L, 30 g / L and 35 g / L, respectively, while the chemical deposition time was fixed at 4 hours. When the specified time is reached, the sample is taken out, the electroless plating is stopped and the water bath is closed. Subsequently, the deposited samples at different concentrations of sodium hypophosphite were cleaned, and then the tensile mechanical properties at room temperature were tested, and compared with the mechanical properties of the uncoated high-entropy alloy substrate.

[0060] Figure 4 The tensile engineering stress-strain curves of the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com