High-toughness aluminum alloy profile based on room-temperature stress cyclic strengthening process

A technology of aluminum alloy profiles and room temperature stress, which is applied in the field of aluminum alloy processing, can solve the problems of aluminum alloy fatigue, adverse effects on tensile and corrosion properties, long artificial aging heat treatment time, poor solute atoms, etc., to improve strength and toughness, Short time consumption, the effect of strengthening the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

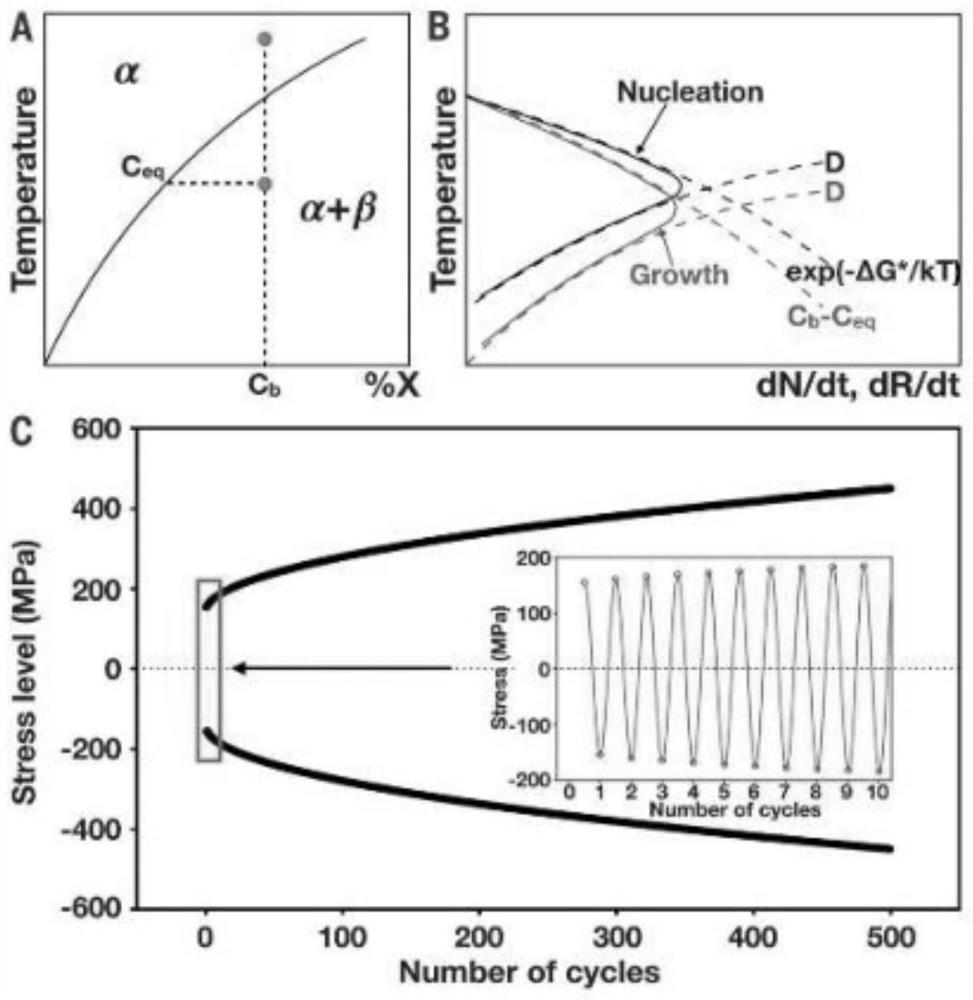

[0037] Such as figure 1 As shown, a high-strength and tough aluminum alloy profile based on room temperature stress cycle strengthening process, the mass percentage of each element composition is: nano-Si 0.3%, Mn 0.6%, Mo 0.05%, Nd 0.09%, V 0.05%, Sc 0.03% , La0.03%, Cu 0.9%, nano-Si3B4 0.5%, Zn 0.5%, Cr 0.3%, Ti 0.6%, Fe 0.5%, Ru0.05%, carbon fiber and carbon nanotube mixture 1.5%, aluminum alloy inoculant 0.6%, the balance is Al.

[0038] Wherein, the mixed mass percentage of carbon fiber and carbon nanotube is 50%:50%.

[0039] Wherein, the aluminum alloy inoculant includes Sr 0.03%, Ce 0.03%, Sc 0.05%, Ba 0.08%, and the balance is Al.

[0040] A room temperature stress cyclic strengthening process applied to high-strength and tough aluminum alloy profiles, the cyclic strengthening process includes the following steps:

[0041] 1). Heating and melting: Put the aluminum alloy into the melting furnace, then evacuate the melting furnace, and fill it with a sufficient amoun...

Embodiment 2

[0052] Such as figure 1 As shown, a high-strength and tough aluminum alloy profile based on room temperature stress cycle strengthening process, the mass percentage of each element composition is: nano-Si 1.2%, Mn 0.3%, Mo 0.10%, Nd 0.03%, V 0.09%, Sc 0.02% , La0.07%, Cu 0.4%, nano-Si3B40.9%, Zn 0.2%, Cr 0.6%, Ti 0.2%, Fe 1.5%, Ru 0.02%, carbon fiber and carbon nanotube mixture 3.0%, aluminum alloy inoculant 0.2%, the balance is Al.

[0053] Wherein, the mixed mass percentage of carbon fiber and carbon nanotube is 40%:60%.

[0054] Wherein, the aluminum alloy inoculant includes Sr 0.03%, Ce 0.03%, Sc 0.05%, Ba 0.08%, and the balance is Al.

[0055] A room temperature stress cyclic strengthening process applied to high-strength and tough aluminum alloy profiles, the cyclic strengthening process includes the following steps:

[0056] 1). Heating and melting: Put the aluminum alloy into the melting furnace, then evacuate the melting furnace, and fill it with a sufficient amoun...

Embodiment 3

[0067] The difference between this embodiment and embodiment 1 is:

[0068] A high-strength and tough aluminum alloy profile based on room temperature stress cycle strengthening process, the mass percentage of each element composition is: nano-Si 0.3%, Mn 0.3%, Mo 0.05%, Nd 0.03%, V 0.05%, Sc 0.02%, La 0.03 %, Cu0.4%, nano-Si3B4 0.5%, Zn 0.2%, Cr 0.3%, Ti 0.2%, Fe 0.5%, Ru 0.02%, mixture of carbon fiber and carbon nanotube 1.5%, aluminum alloy inoculant 0.2%, remaining The amount is Al.

[0069] Wherein, the mixed mass percentage of carbon fiber and carbon nanotube is 30%:70%.

[0070] Wherein, the aluminum alloy inoculant includes Sr 0.03%, Ce 0.01%, Sc 0.05%, Ba 0.05%, and the balance is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com