Exhausting pipe of air conditioner compressor

A technology for air-conditioning compressors and compressor exhaust, which is used in mechanical equipment, machines/engines, liquid variable-capacity machines, etc., to achieve the effects of large piping space, good reliability, and improved craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

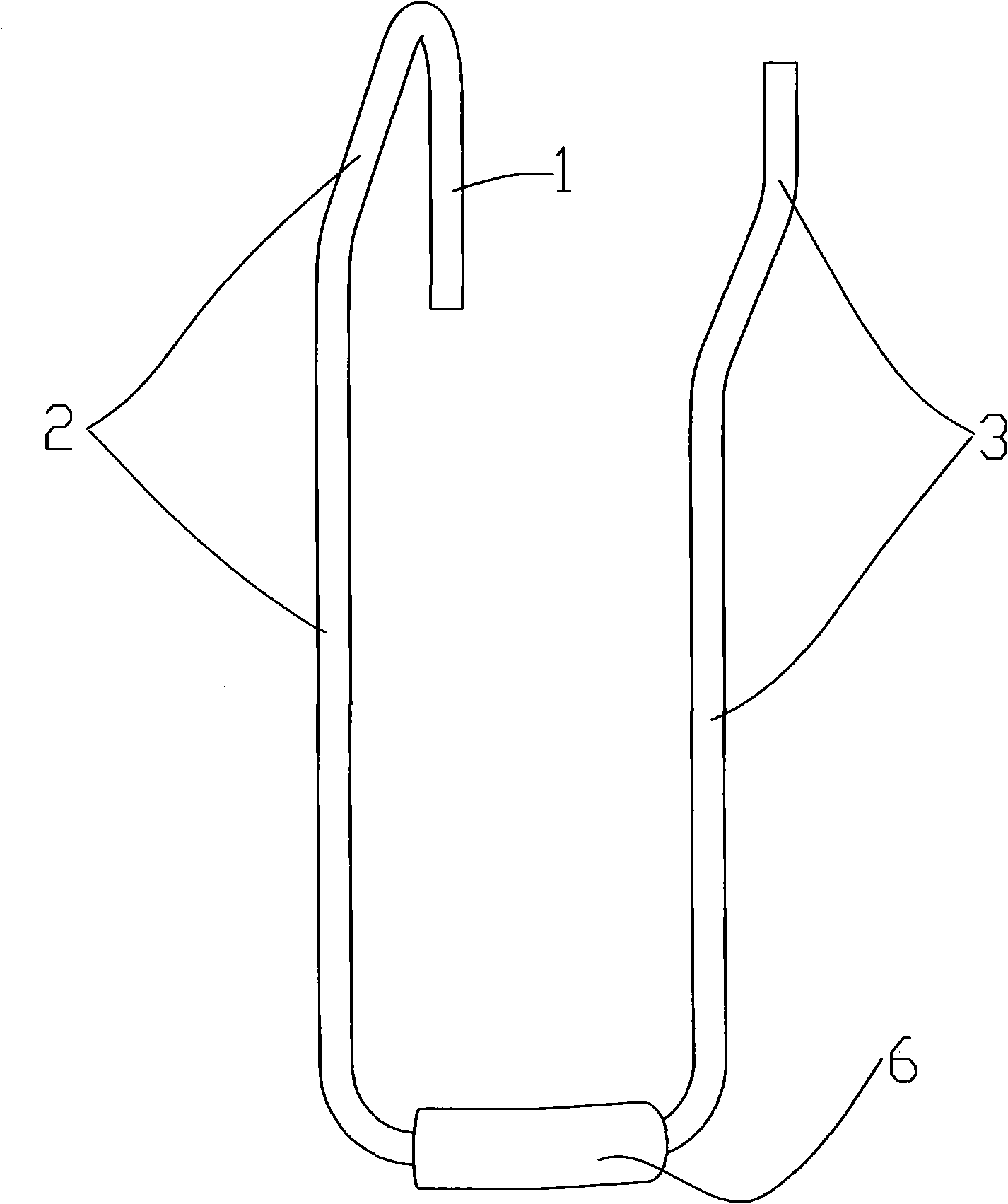

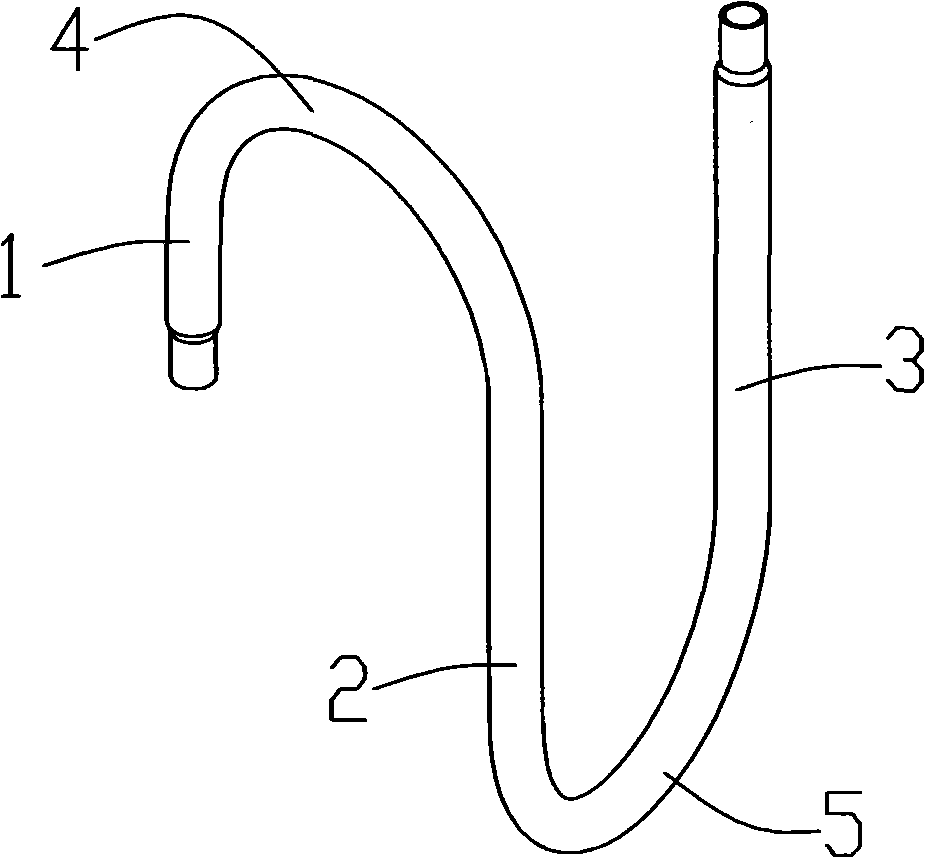

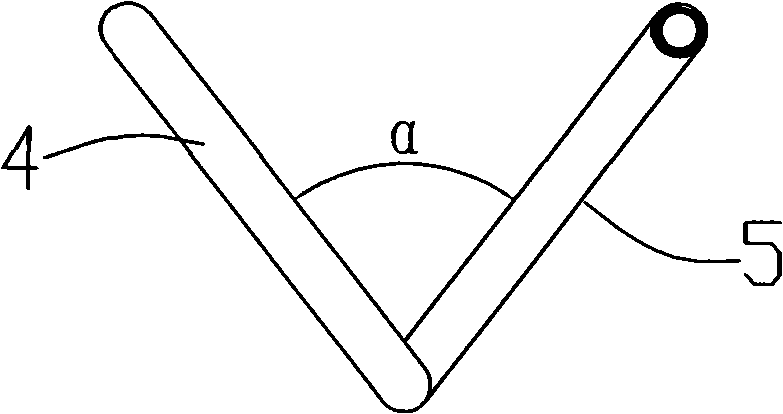

Embodiment 1

[0025] as attached figure 2 , 3 As shown, the exhaust pipe includes the front section 1 perpendicular to the compressor exhaust port, the middle section 2 that changes the flow direction, and the rear section 3 connected to the valve. The front section 1 and the middle section 2, the middle section 2 and the rear section 3 It is connected tangentially by two sections of equal-radius semicircle tubes 4 and 5, and the arc radius of the semicircle tube 4 should be greater than the radius of the compressor, so that the distance between the middle section 2 and the front section 1 is greater than the radius of the compressor. This exhaust pipe is designed in such a way as to avoid the figure 1 The sharp acute angle formed between the straight pipe of the front section 1 and the middle section 2 in the shown prior art. Moreover, compared with the prior art, the present invention can greatly shorten the length of the intermediate pipe 2, and when the length of the intermediate pip...

Embodiment 2

[0027] as attached Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that the front connecting section of the exhaust pipe adopts two sections of circular arc sections 4a, 4b and straight pipe sections 4c with small bend radius and tangent to replace the semicircular arc pipe 4, so as to avoid The exhaust pipe is too high, and it collides with the electric control board during falling or transportation; the rear connection section still uses the semi-circular arc pipe 5.

Embodiment 3

[0029] as attached Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that: the front connecting section of the exhaust pipe adopts a semicircular arc pipe 4, and the rear connecting section adopts two sections of circular arc sections 5a, 5b and straight arc sections 5a, 5b with a small elbow radius and tangential to each other. The pipe section 5c replaces the semicircular arc pipe 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com