Sound-absorbing element for transport means, in particular for aircraft

A technology for transportation devices and aircraft, applied in transportation and packaging, vehicle parts, fuselage insulation, etc., can solve problems such as heavy weight, and achieve the effect of small weight, good mechanical rigidity, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

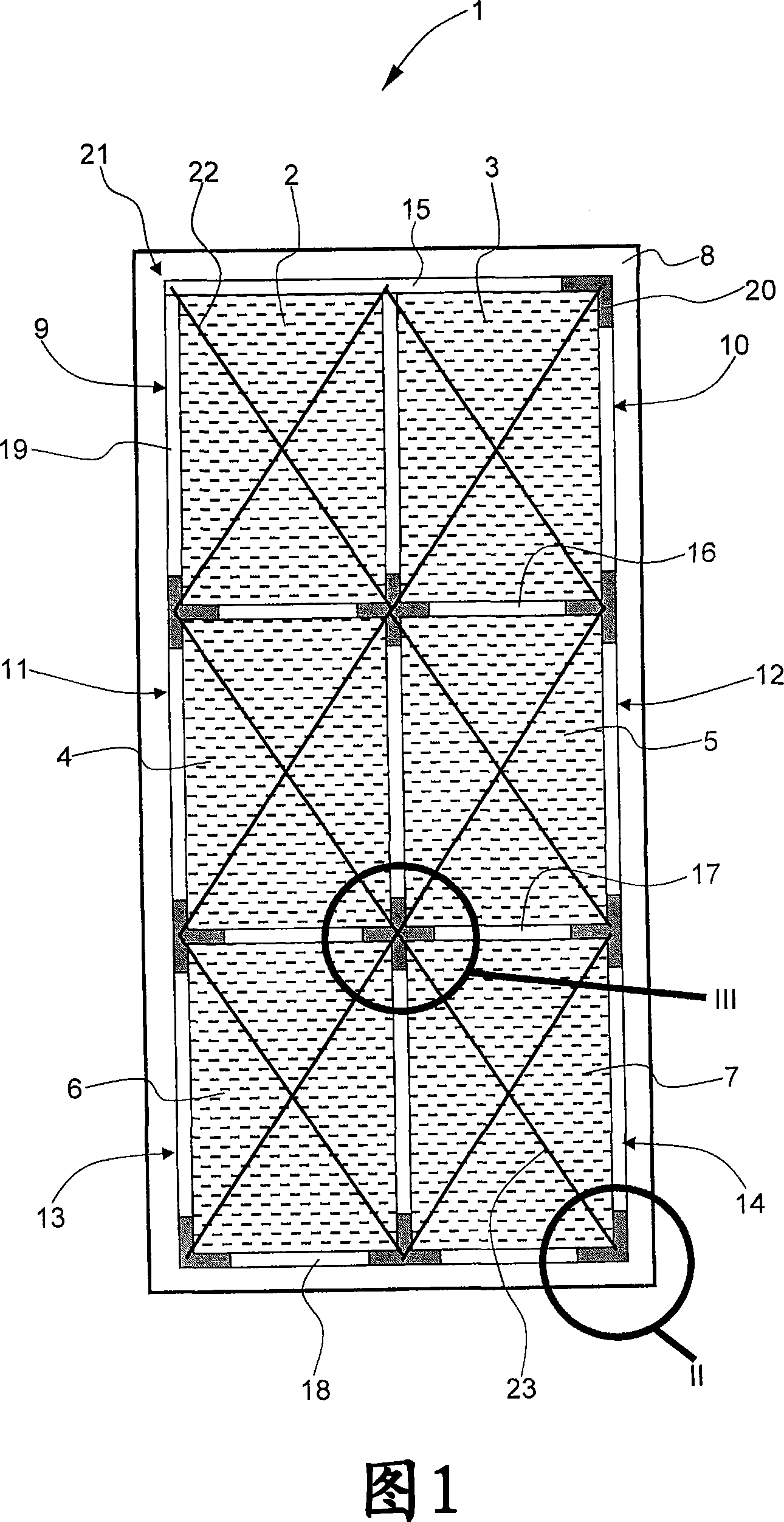

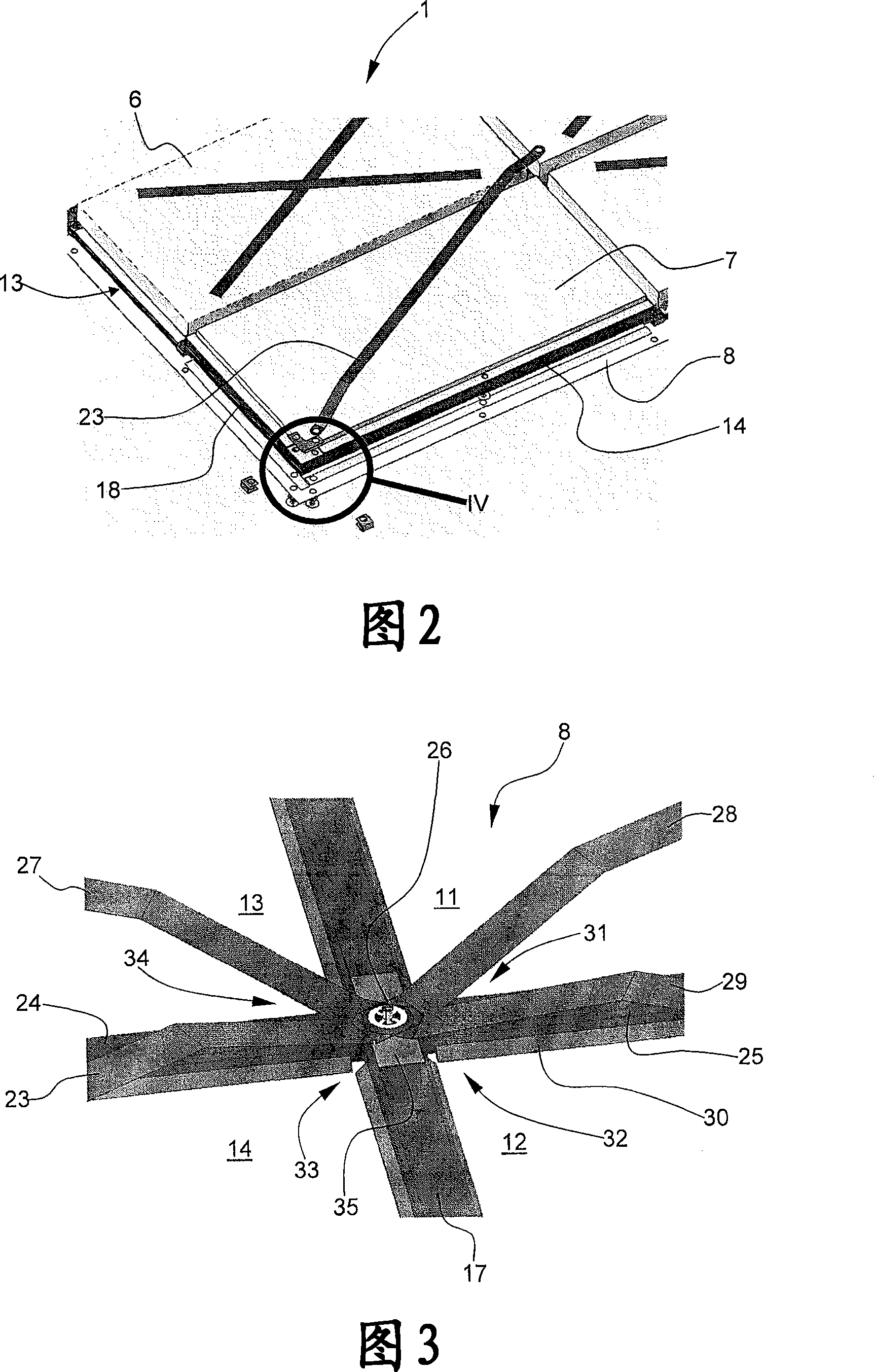

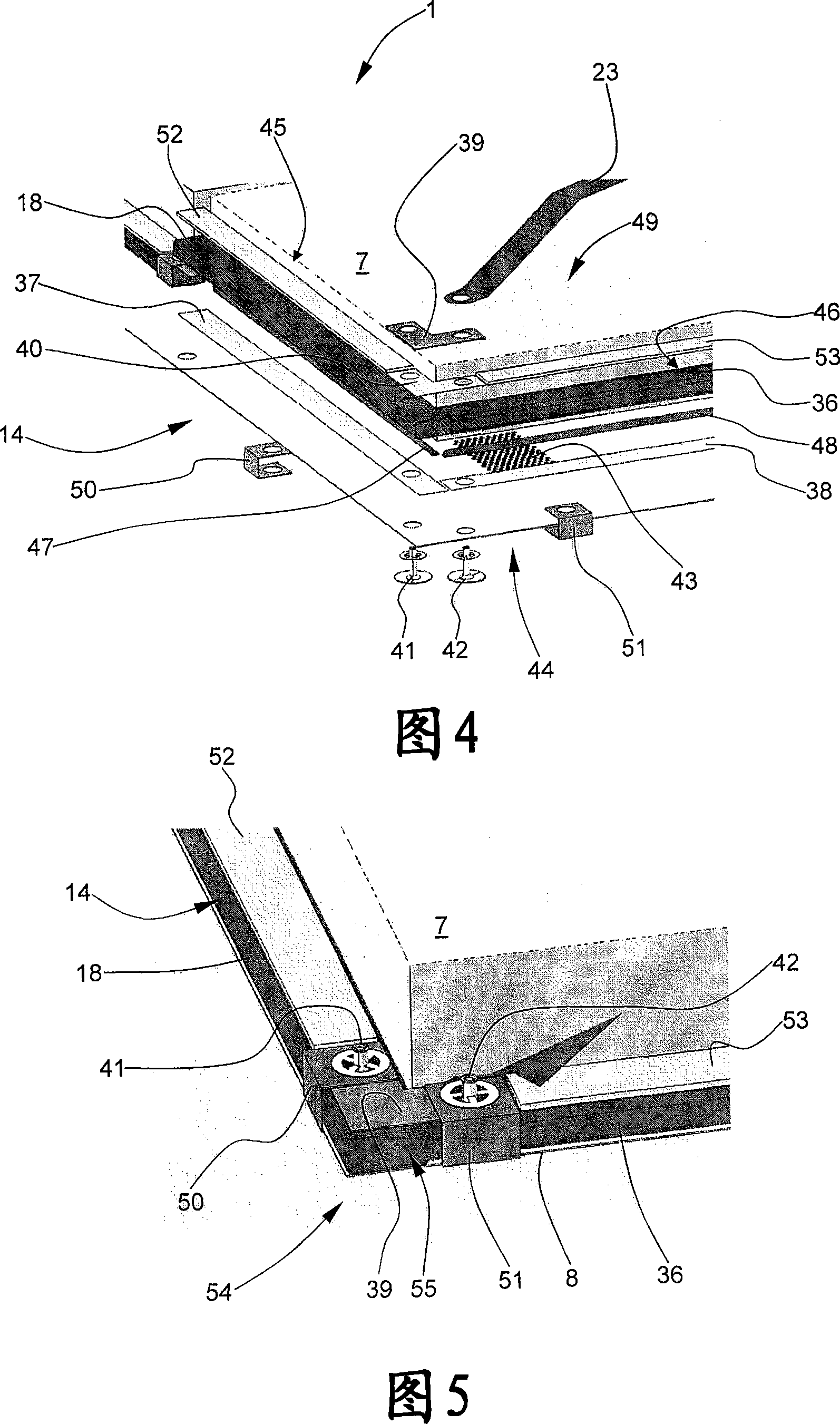

[0023] Figure 1 shows a rear view of a sound absorbing element according to the invention.

[0024] In the exemplary embodiment shown, the sound-absorbing element 1 includes six sound-absorbing panels 2 to 7. Six substantially rectangular frames 9 to 14 are glued to the substrate 8. The frames 9 to 14 are used in particular for accommodating the sound-absorbing panels 2 to 7.

[0025] The rectangular frames 9 to 14 include four horizontal frame segments 15 to 18 and a total of nine vertical frame segments. For the sake of clarity, only the first frame segment 19 has a reference number, and the first frame segment 19 is the remaining frame Representative of the segment. The frame segment preferably includes a hollow rectangular profile to drain water and foreign particles. As an alternative, the frame segment may also include other contour shapes, such as a square hollow contour and the like. In each case, the connecting straps are glued to the corner areas of the frames 9 to 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com