Air return for air conditioning compressor

A technology of air-conditioning compressor and air return pipe, which is applied in mechanical equipment, machine/engine, liquid fuel engine, etc., to achieve the effect of cost saving, manufacturing process cost saving, and less copper consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

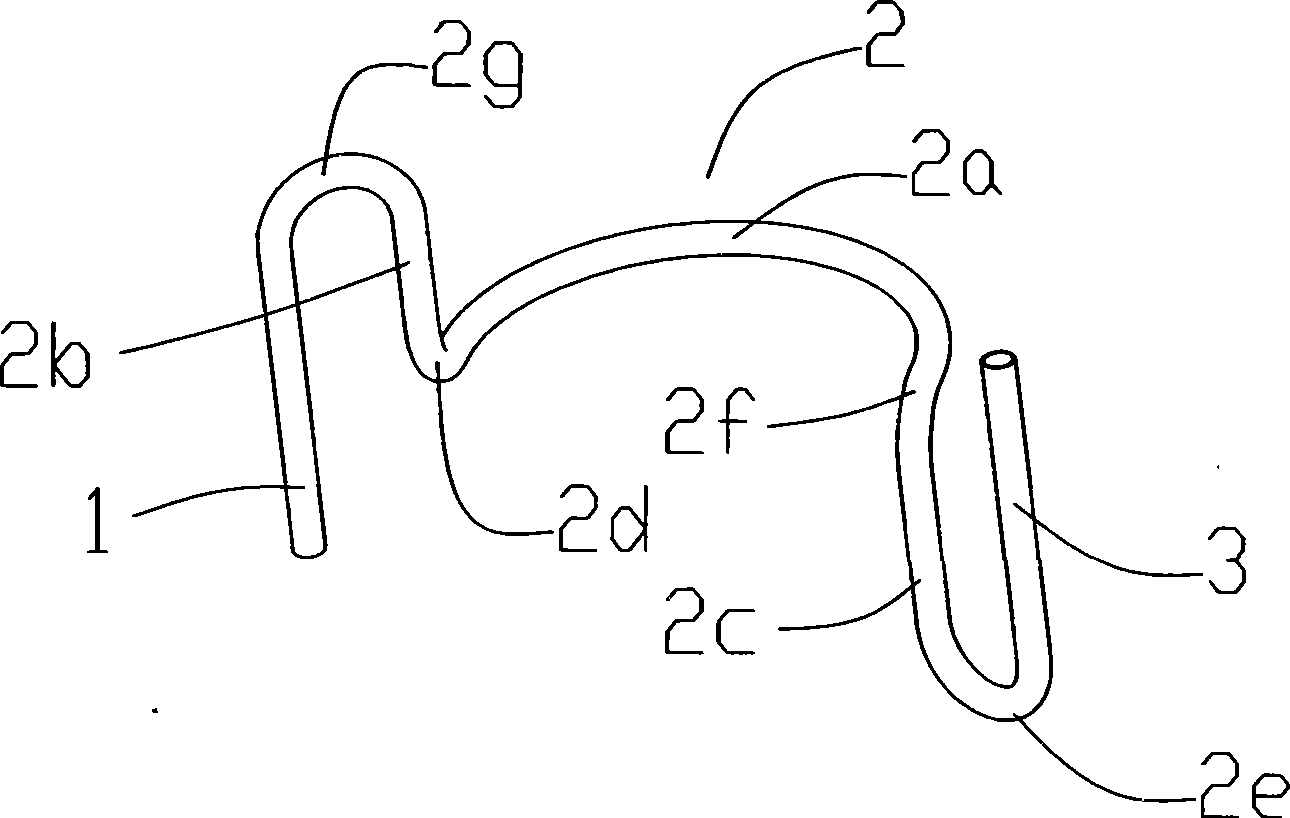

[0026] as attached image 3 As shown, the air return pipe includes a front section 1 perpendicular to the inlet of the liquid storage tank of the compressor, a rear section 3 connected to the valve, and a middle section 2 connecting the front section 1 and the rear section 3 . Wherein the front section 1 and the back section 2 are both straight tubes, and the middle section 2 includes a circular arc tube 2a distributed around the outer circumference of the liquid storage tank. The outer circumferential surface of the liquid tank has a certain distance, preferably separated by a certain distance. The front and rear ends of the arc tube 2a are transitionally connected with the straight tubes 2b and 2c through arcs 2d and 2f, while the straight tube 2b is connected to the front section 1 through the arc 2g, and the straight tube 2c is connected to the rear section through the arc 2e. The arc tube 2a is horizontal with respect to the bottom plane of the liquid storage tank. Of co...

Embodiment 2

[0028] as attached Figure 4 As shown, the difference between Embodiment 2 and Embodiment 1 is that: the end of the circular arc tube 2a in the middle section 2 of the air return pipe and the rear section 3 are directly connected by a circular arc 2h.

Embodiment 3

[0030] as attached Figure 5 As shown, the difference between Embodiment 3 and Embodiment 1 is that: the head end of the circular arc pipe 2a in the middle section 2 of the air return pipe is directly connected to the front section 1 by a circular arc 2i.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com