Heat treatment method for carrying out isothermal annealing on railway vehicle axle in advance

A heat treatment method and isothermal annealing technology, used in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of uneven microstructure, mixed crystals, grain size difference, etc., to achieve uniform microstructure and reduce grain size. Unqualified, fatigue fracture prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

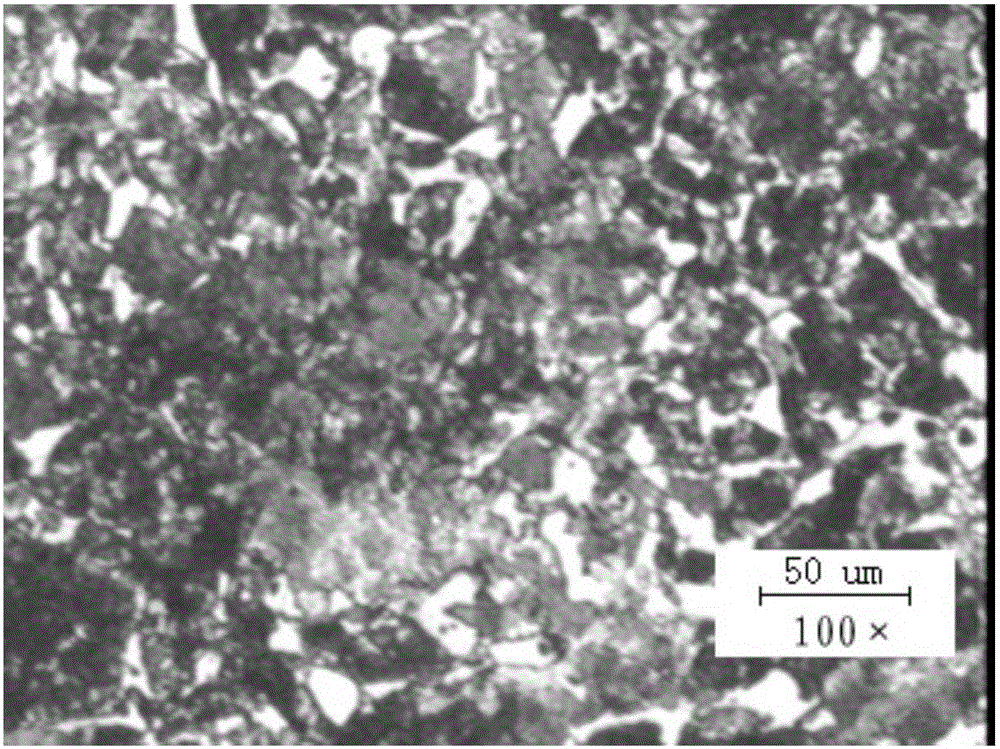

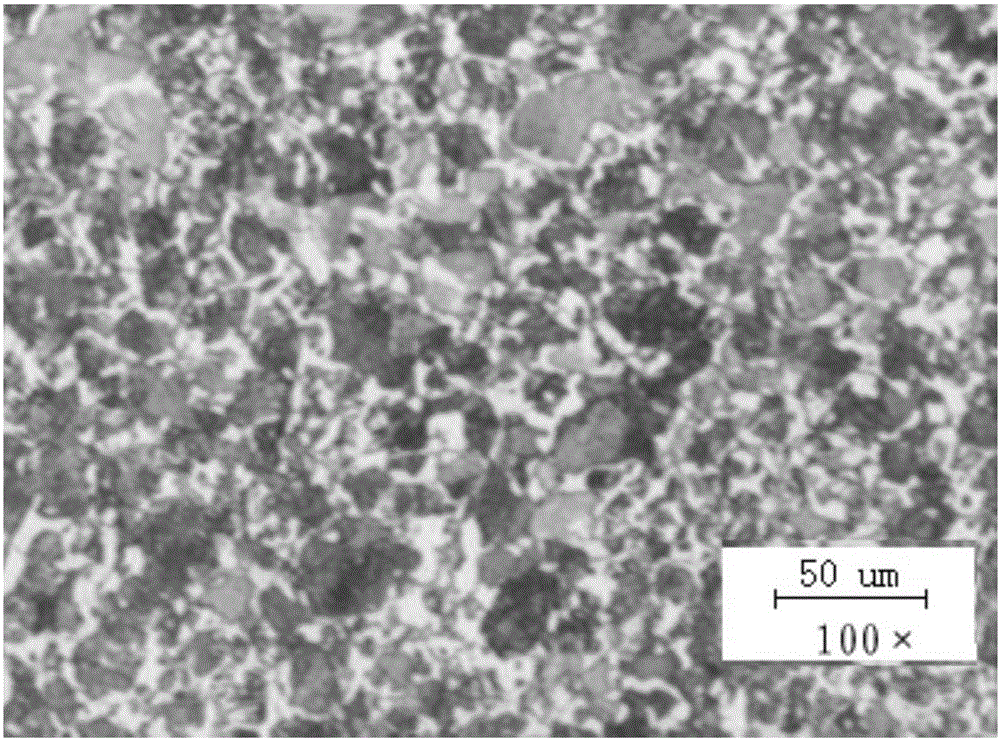

Image

Examples

Embodiment 1

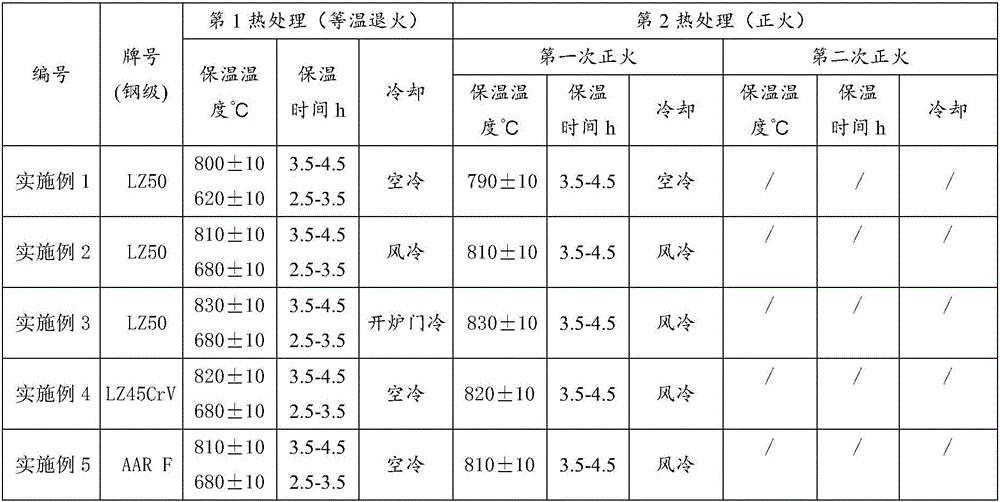

[0033] A heat treatment method for pre-isothermal annealing of a railway vehicle axle, comprising the following steps:

[0034] (1) Isothermally anneal the axle of the railway vehicle, heat it to the holding temperature of the first stage at 800±10°C, the holding time is 3.5-4.5 hours, and air cool to the holding temperature of the second stage at 620±10°C, and the holding time is 2.5-3.5 hours , followed by air cooling;

[0035] (2) normalizing the railway vehicle axle after step (1), the holding temperature is 790 ± 10 ℃, and the holding time is 3.5-4.5 hours; cooling in the air of accelerated flow;

[0036] (3) Tempering the railway vehicle axle after the treatment in step (2), the tempering holding temperature is 510±10° C., the holding time is 3.5-4.5 hours, and the obtained railway vehicle axle has a grain size of 7-8.

[0037] The heat treatment method of the isothermal annealing adopted in embodiment 2-8 and the parameter control, grain size and mechanical properties ...

Embodiment 4

[0043] The grain size of Example 4 is grade 9, while that of Comparative Example 2 is grade 5-7. Obviously, the grain size fluctuation of Example 4 is smaller and the grains are finer.

Embodiment 5

[0044] The grain size of Example 5 is grade 7, while that of Comparative Example 3 is grade 4-7. Obviously, the grain size fluctuation of Example 5 is smaller and the grains are finer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com