Patents

Literature

194results about How to "Uniform internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wound dressing and method for controlling severe, life-threatening bleeding

InactiveUS20050038369A1Stanching flowAvoid bleedingBiocideNon-adhesive dressingsWound dressingClot formation

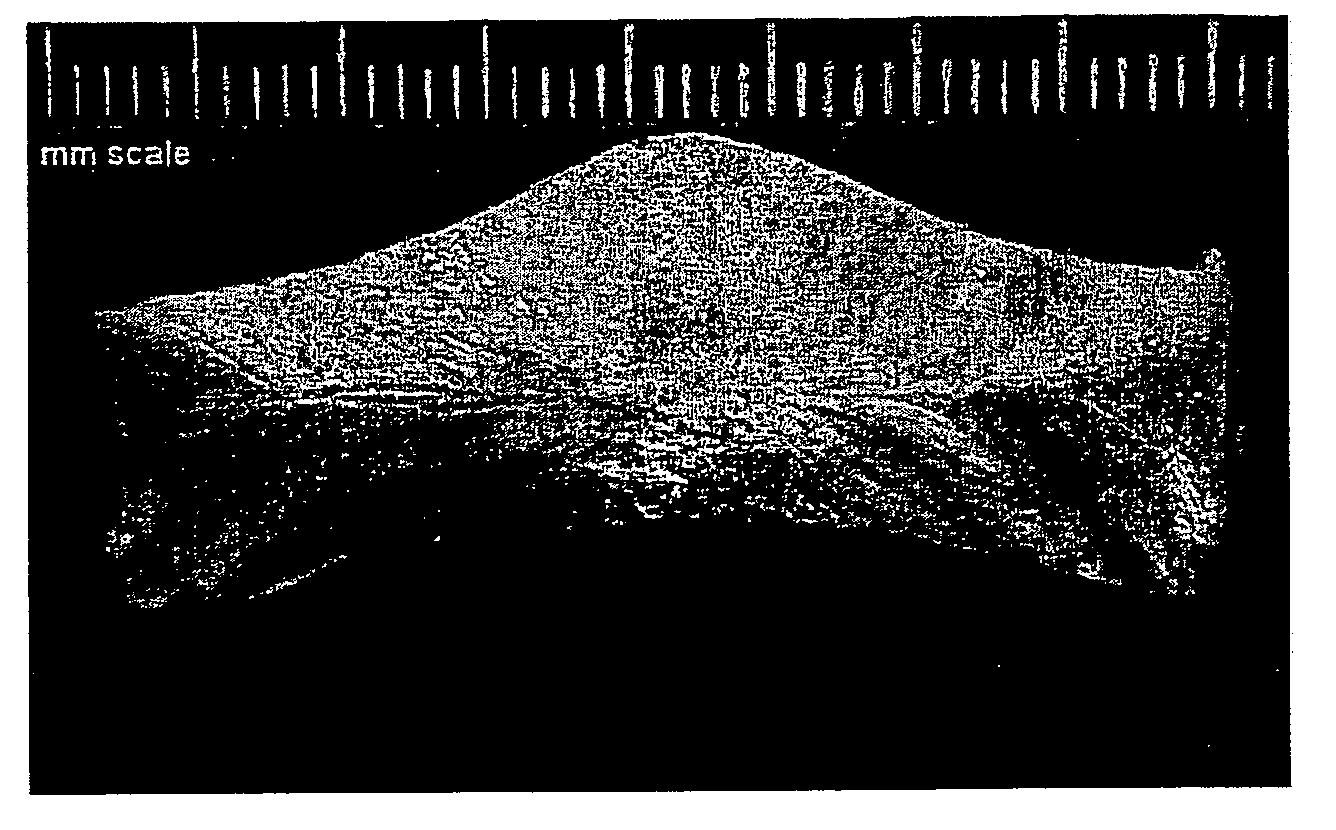

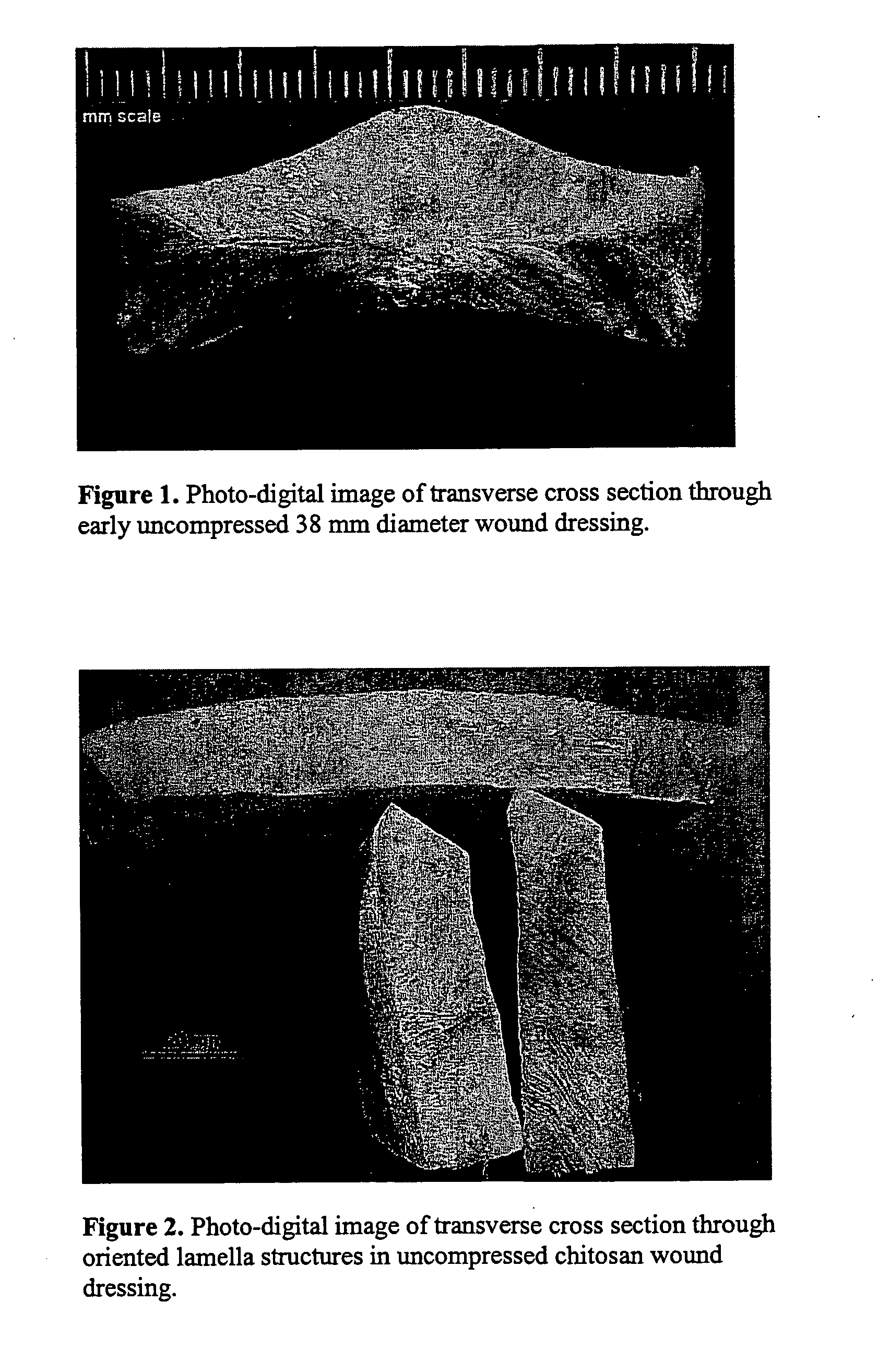

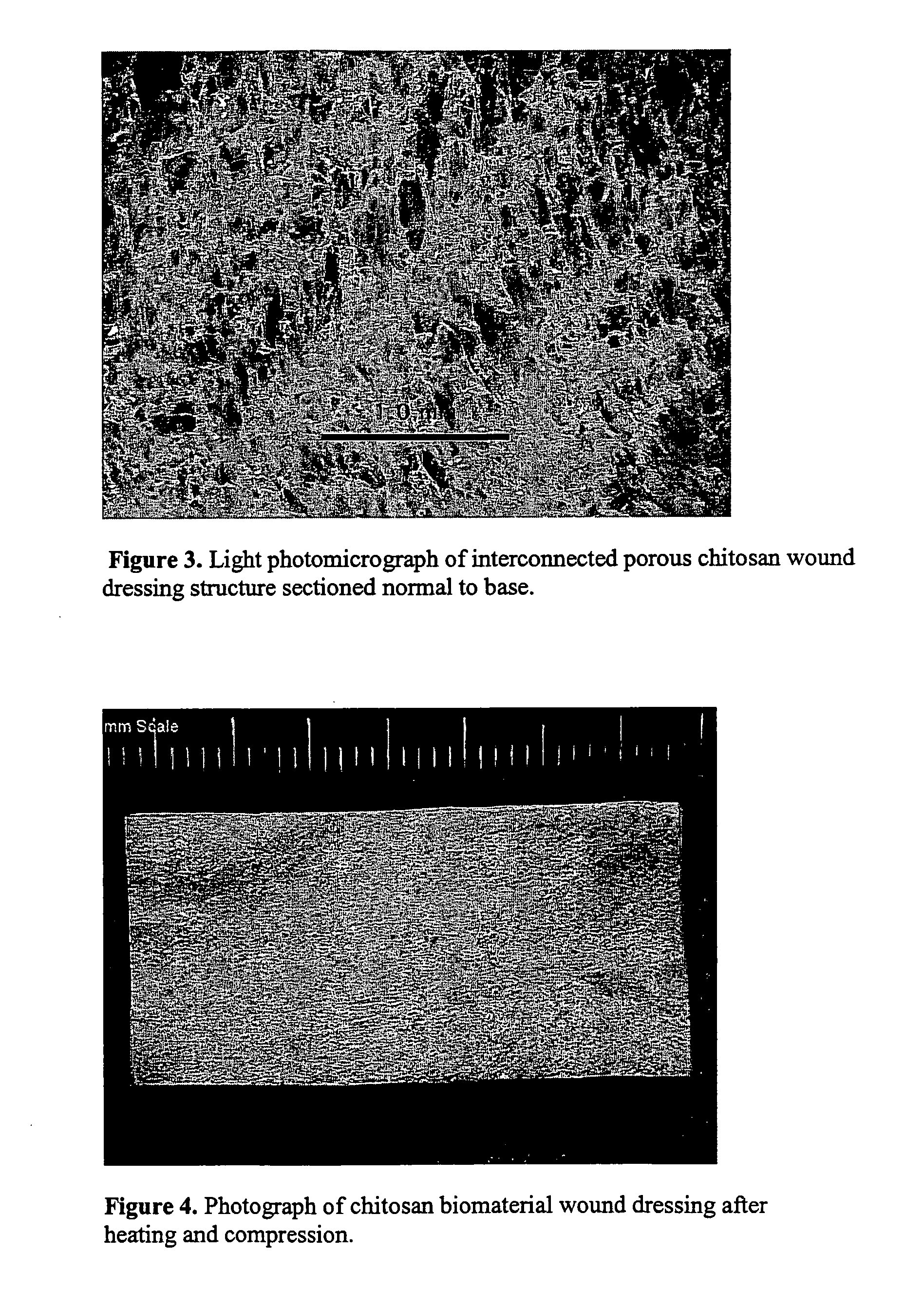

This invention is directed to advanced hemorrhage control wound dressings, and methods of using a producing same. The subject wound dressing is constructed from a non-mammalian material for control of severe bleeding. The wound dressing is formed of a biomaterial comprising chitosan for controlling severe bleeding. The kind of severe, life-threatening bleeding contemplated by this invention is typically of the type not capable of being stanched when a conventional gauze wound dressing is applied with conventional pressure to the subject wound. The wound dressing being capable of substantially stanching the flow of the severe life-threatening bleeding from the wound by adhering to the wound site, to seal the wound, to accelerate blood clot formation at the wound site, to reinforce clot information at the wound site and prevent bleed out from the wound site, and to substantially prohibit the flow of blood out of the wound site.

Owner:PROVIDENCE HEALTH SYST OREGON +1

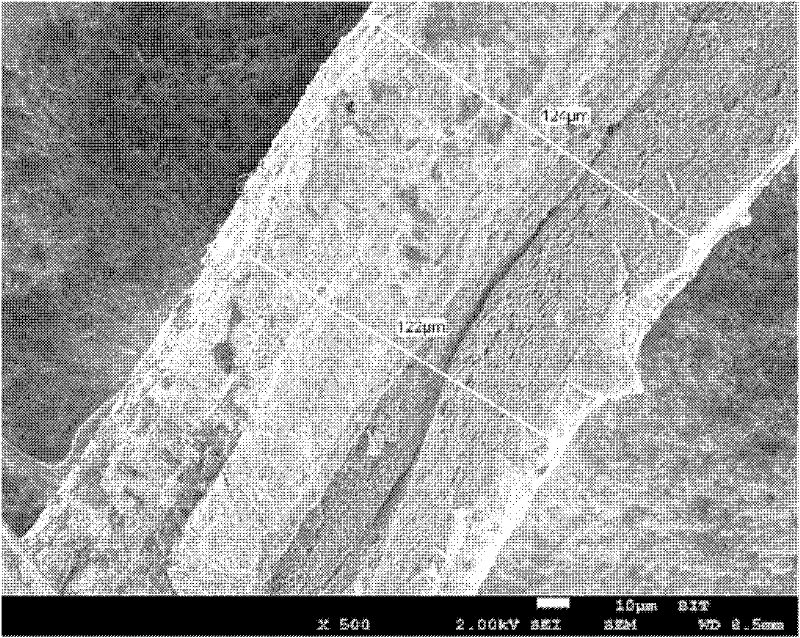

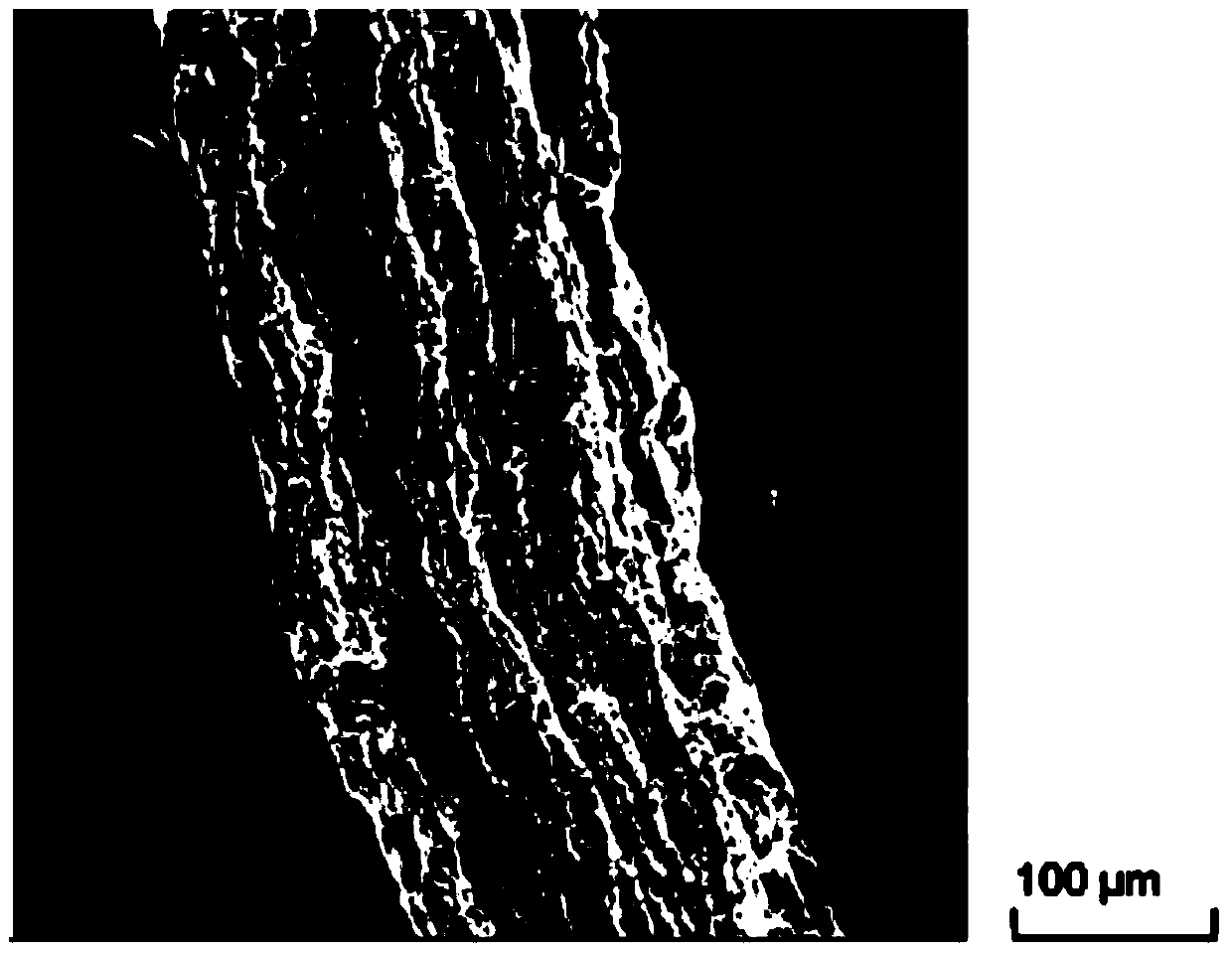

Fiber-reinforced resin-based composite material core and preparation method thereof

InactiveCN104672782AImprove promotion effectPromote the stability of the effectGlass fiberResin-Based Composite

The invention provides a fiber-reinforced resin-based composite material core. The composite material core is prepared from a fiber-reinforced composite material core in the inner part and an insulating layer on the outer layer, wherein the insulating layer is a glass fiber layer and has the thickness of 0.2-2mm. According to the fiber-reinforced resin-based composite material core, the internal structure is uniform, a layering phenomenon difficultly occurs, the strength is high, the toughness is high, and the cost is reduced.

Owner:STATE GRID CORP OF CHINA +3

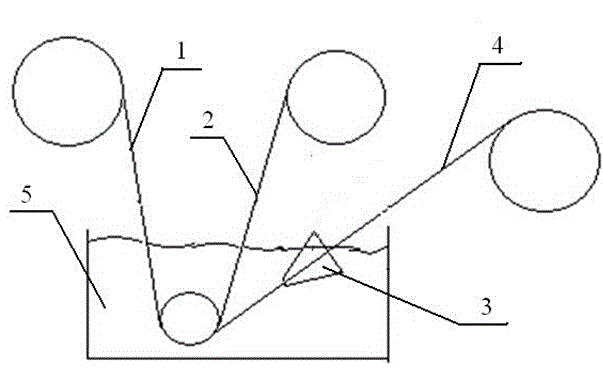

Preparation method for graphene fiber

The invention discloses a preparation method for a graphene fiber and belongs to the field of graphene fiber preparation. The preparation method comprises the following steps: firstly, preparing 2-20 mg.mL<-1> purified graphene oxide solution by using an oxidation stripping graphite method; secondly, injecting the graphene oxide solution in the first step in a pipeline reactor with the inside diameter of 0.1-10 mm and sealing; thirdly, heating the pipeline reactor at the temperature of 100-300 DEG C for 1-6 hours and reducing and assembling the graphene oxide into a water-containing graphene oxide fiber; and fourthly, drying the water-containing graphene fiber obtained in the third step at the temperature of 20-60 DEG C and dehydrating and contracting the water-containing graphene fiber to obtain dry graphene fiber. The preparation method is simple in operation process and low in raw material cost; and the graphene fiber obtained by the method disclosed by the invention has the advantages of uniform structure, excellent mechanical property and easiness in functionalization.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

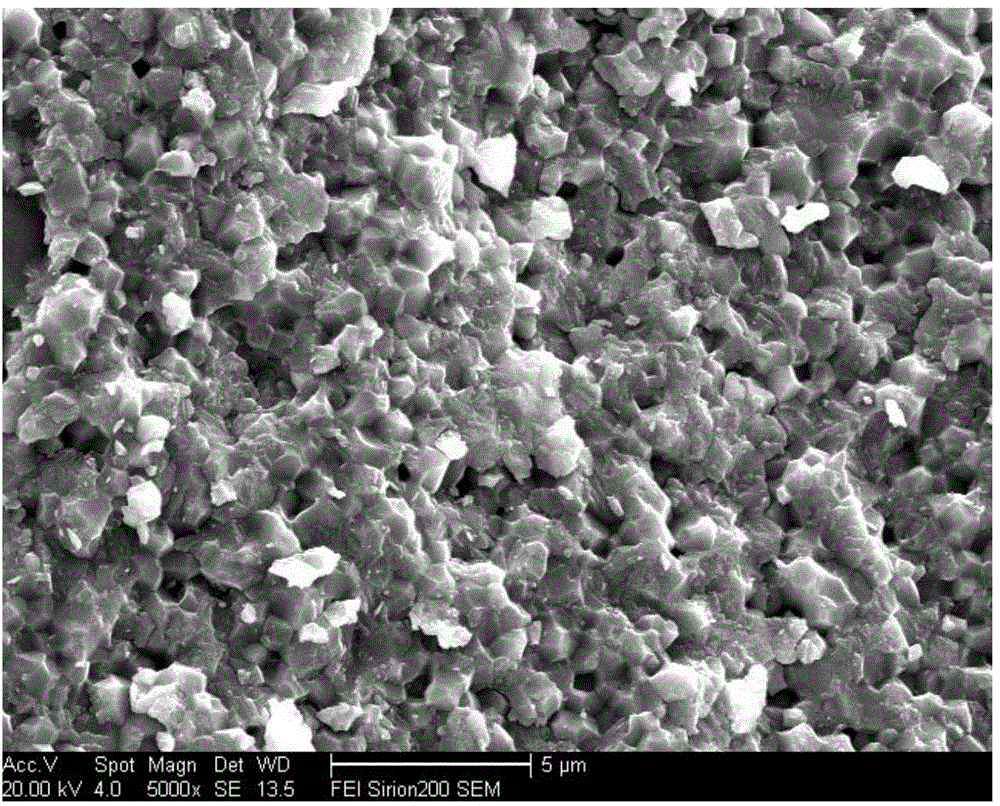

Ceramic mobile phone shell and preparation method thereof

The invention provides a preparation method of a ceramic mobile phone shell. The ceramic mobile phone shell is prepared by initiating the following raw materials with ultraviolet light and further sintering. The raw materials comprise ceramic powder, organic functional additives accounting for 2%-8% of the weight of ceramic powder and solvent accounting for 7%-18% of the weight of ceramic powder, wherein the organic functional additives comprise monomers, cross-linking agent and photoinitiator; the interior of the obtained ceramic mobile phone shell is of a crystal structure, the diameter ratio of maximum grains to minimum grains in the crystal structure is less than 5 and the average grain size is less than 5mu m. According to the ceramic mobile phone shell and the preparation method thereof provided by the embodiment of the invention, the problems of poor performances caused by non-uniform internal structure of a chip type mobile phone shell in the prior art and incapability of obtaining the ceramic mobile phone shell with good mechanical properties, large size and small thickness are solved.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

Preparation method of graphene fibers

ActiveCN103966699ALow reaction temperatureEasy to operateArtificial filament chemical after-treatmentEthylenediamineFiber

The invention discloses a preparation method of graphene fibers. The preparation method comprises the following steps: (1), a mixture of a graphene oxide solution and a water-soluble reducing agent is added into a tubular reactor, wherein the water-soluble reducing agent is one or more of ascorbic acid, sodium ascorbate, sodium citrate, HI, HBr, NaHSO3, Na2S, ethylenediamine, p-phenylenediamine and hydroquinone; (2), the tubular reactor in the step (1) is heated, and graphene oxide is reduced and assembled to aqueous graphene gel fibers, and the heating temperature is 60-95 DEG C; and (3), the aqueous graphene gel fibers obtained in the step (2) is dried to obtain the graphene fibers. The preparation method is simple to operate, mild in conditions and low in raw material cost; and the graphene fibers obtained with the preparation method are uniform in structure, excellent in mechanical property and easiness in functionalization.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Permanent ferrite magnetic shoe for DC electric motor and production method thereof

ActiveCN101483360AOptimize the preparation processUniform internal structureMagnetic circuit rotating partsInorganic material magnetismTemperature coefficientBrown iron oxide

The present invention relates to magnetic materials, particularly relates to a permanent ferrite magnetic shoe for DC motor and method thereof. The present invention also solves technical problems that exists in prior art, namely allowing the ferrite with high residual magnetic induction intensity, high coercitive force, high intrinsic coercitive force, high magnetic energy product and low intrinsic coercitive force temperature coefficient at the same time; provides a formula that can optimize each parameter of the ferrite comprehensively and effectively and preparation method of producing the ferrite powder and magnetic shoe for permanent magnetism DC. The present invention adopts domestic high pure iron-oxide red, SrCO3 and adds CaCO3, SiO2, Al2O3, Cr2O3,SrCO3, Bi2O3, La2O3, Co2O3 and organic dispersants in second seat grinding to modify the permanent ferrite.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Preparation method of graphene oxide hollow fiber and graphene hollow fiber

ActiveCN103031618AEvenly dispersedStickyInorganic material artificial filamentsHollow filament manufactureMaterials preparationFiber

The invention relates to a preparation method of a graphene oxide hollow fiber and a graphene hollow fiber, and belongs to the technical field of graphene oxide and graphene material preparation. The method comprises the following steps that an outer layer solution and an inner layer solution are respectively input into an outer layer and an inner layer of a coaxial needle head; the outer layer solution is injected into a receiving solution to form an aqueous graphene oxide hollow fiber, and then dried to form a graphene oxide hollow fiber; and the graphene oxide hollow fiber is reduced to a graphene hollow fiber. The outer layer solution is a 20-25mg.mL<-1> graphene oxide solution; the inner layer solution and the receiving solution are methanol solutions of KCL with a mass concentration greater than or equal to 3mol / L; the flow velocity of the inner layer solution is 0.6ml / min; and the flow velocity of the outer layer solution is greater than or equal to 0.1ml / s. According to the preparation method, the graphene oxide hollow fiber and the graphene hollow fiber can be prepared respectively in different steps of one method, the operation is easy and simple, aftertreatment and edulcoration are not required, the cost is low, and mass continuous production can be conducted.

Owner:BEIJING TUNGHSU CARBON ADVANCED MATERIALS TECH CO LTD

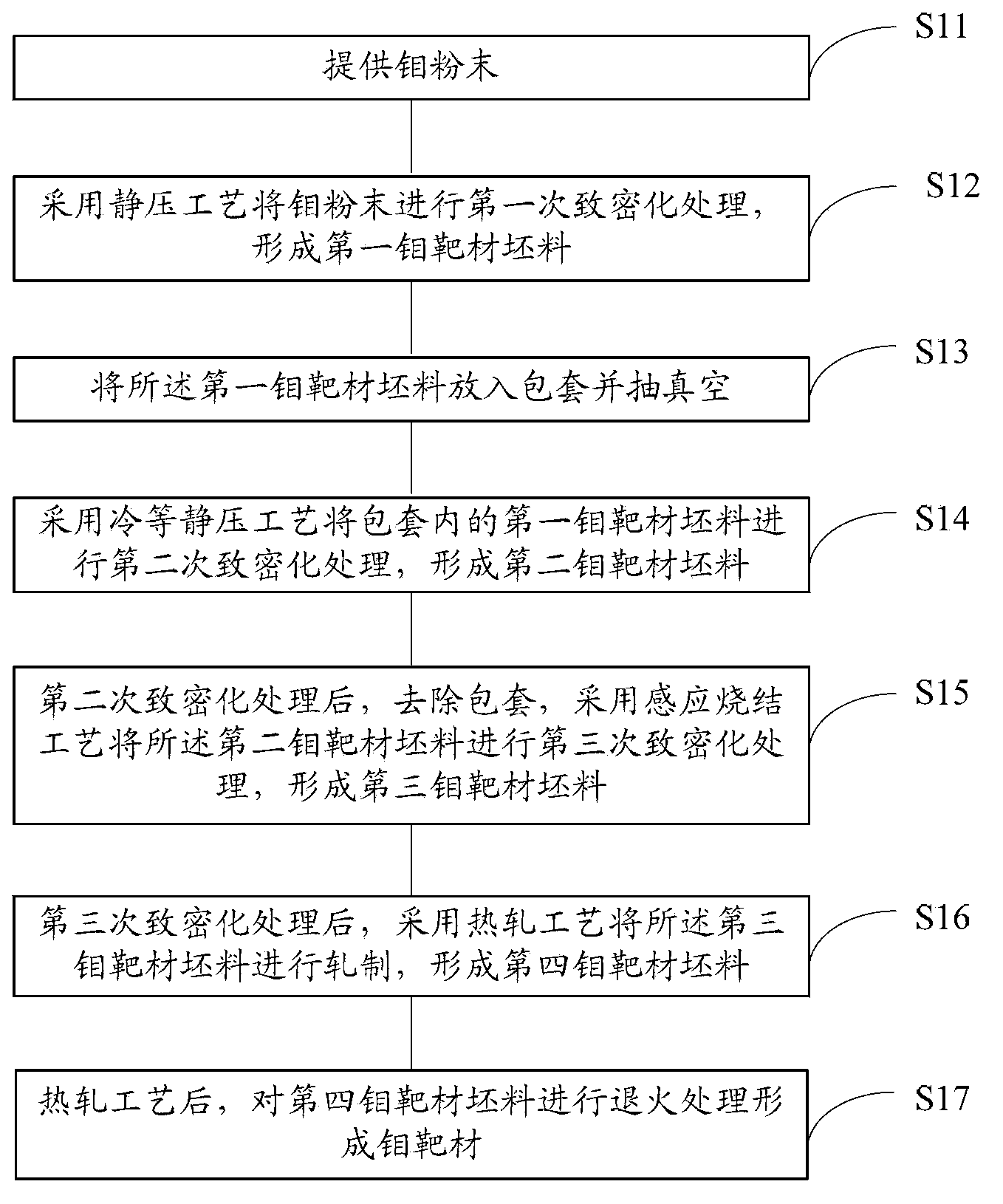

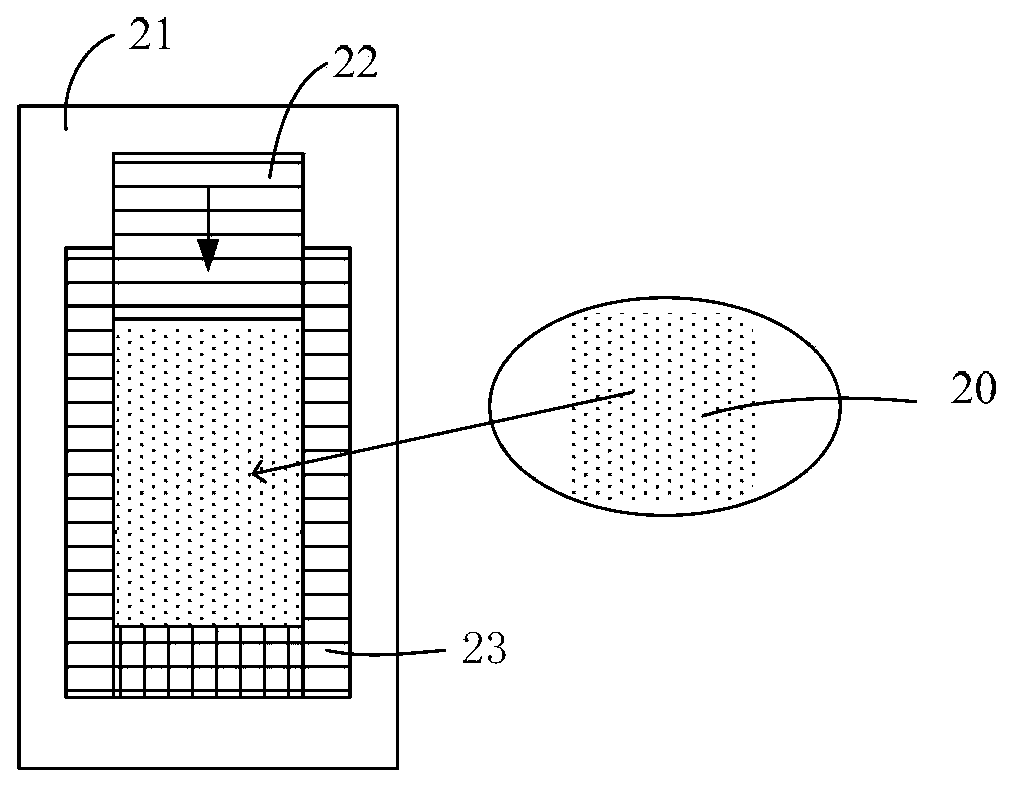

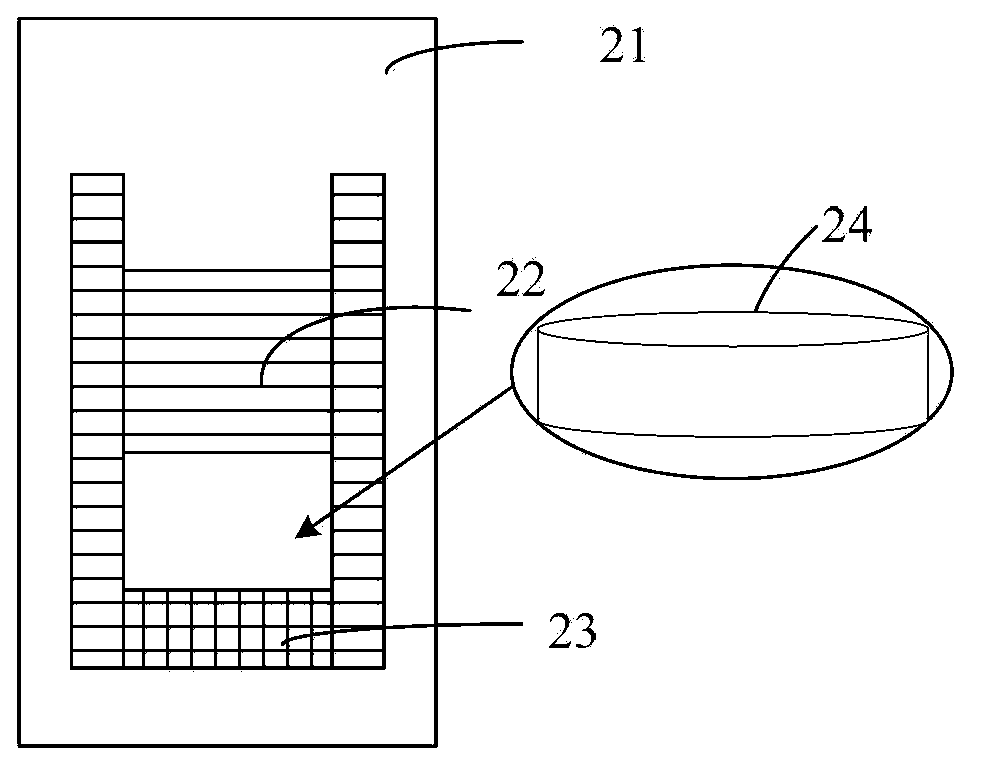

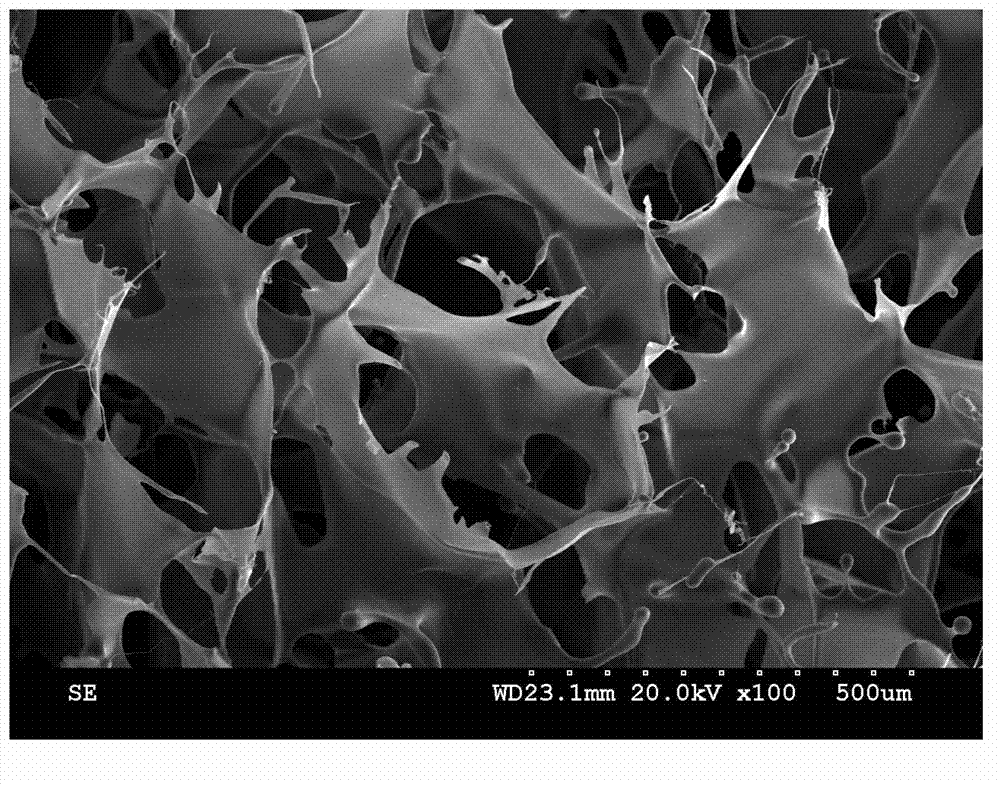

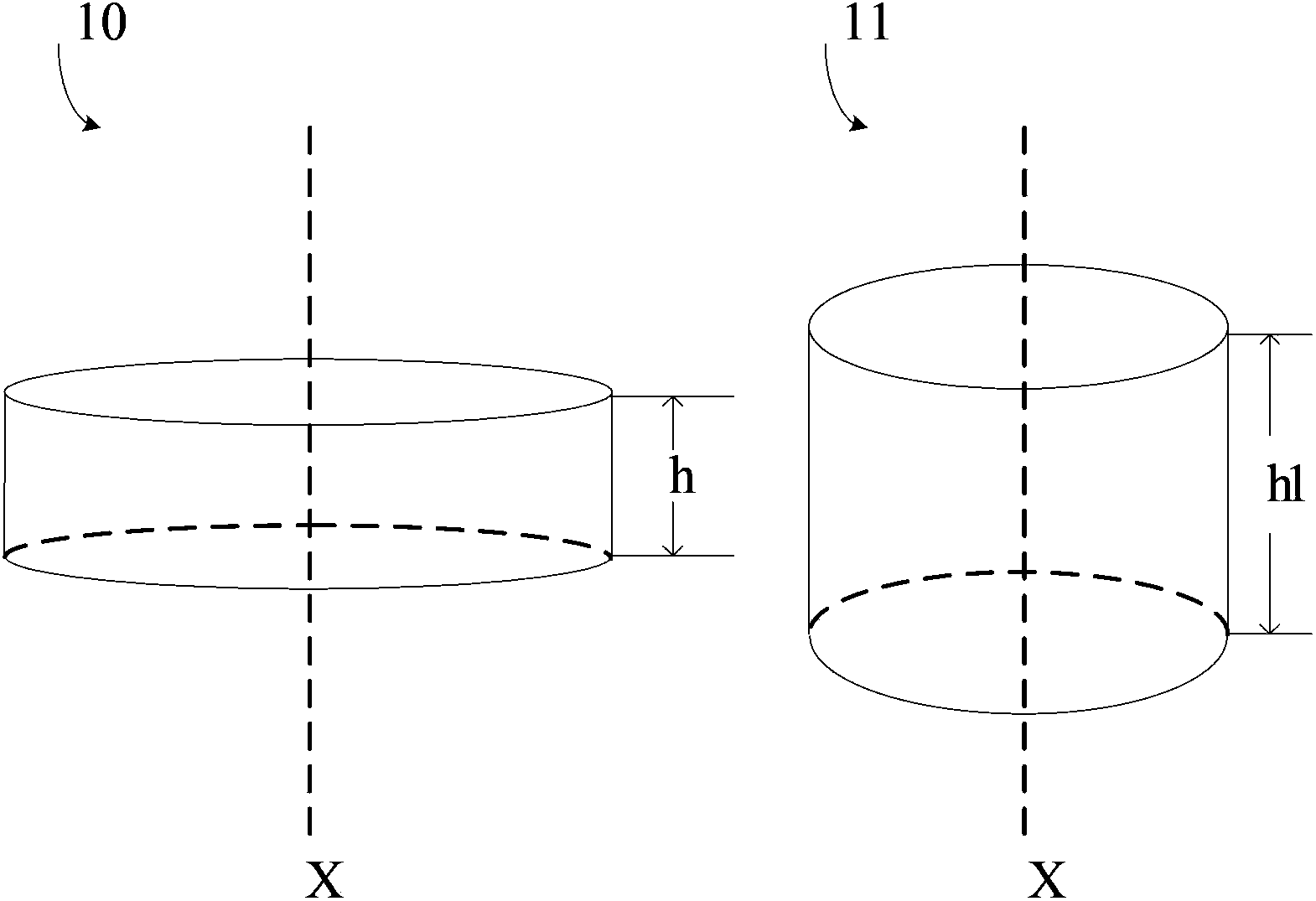

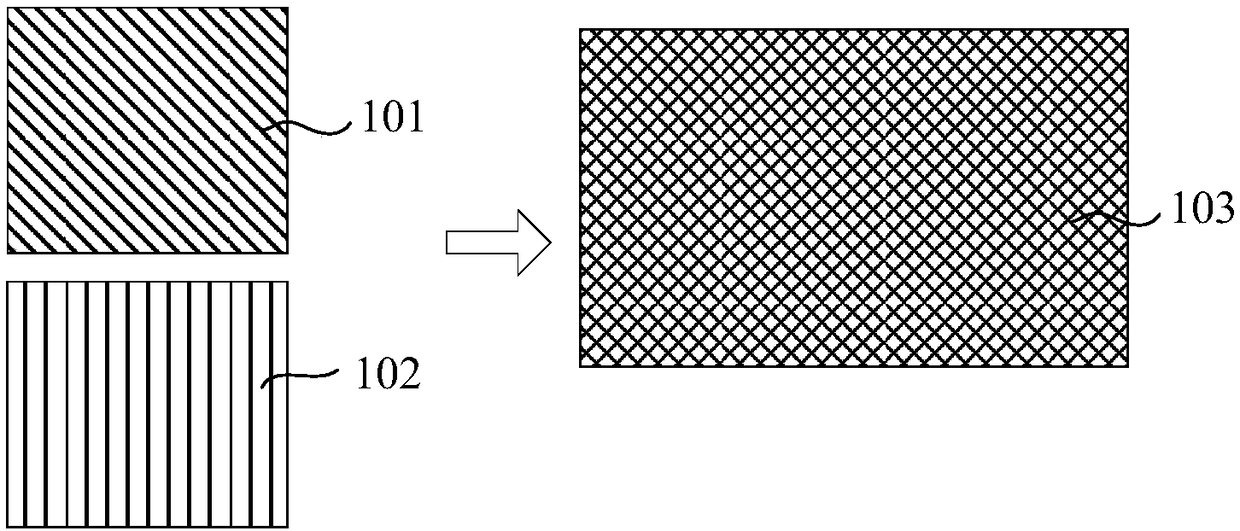

Manufacturing method of molybdenum targets

ActiveCN103567445AIncreased dislocation densityIncrease grain boundary areaVacuum evaporation coatingSputtering coatingMaterials scienceMolybdenum

Disclosed is a manufacturing method of a molybdenum target. The method comprises providing molybdenum powder; performing a first densification process on the molybdenum powder through isostatic pressing to obtain a first molybdenum target blank; putting the first molybdenum target blank into a sheath and vacuumizing the sheath; performing a second densification process on the first molybdenum target blank inside the sheath through cold isostatic pressing to form a second molybdenum target blank; after the second densification process, removing the sheath and performing a third densification process on the second molybdenum target blank through induction sintering to form a third molybdenum target blank; after the third densification process, rolling the third molybdenum target blank through hot rolling to form a fourth molybdenum target blank; after the hot rolling process, performing annealing on the fourth molybdenum target blank to obtain the molybdenum target. The manufacturing method of the molybdenum target can help produce full-density molybdenum targets, the uniformity of the internal organizational structure and the size, the purity and the surface dimension of grains of the molybdenum targets can well meet the ever-increasing requirements of the sputtering technology.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

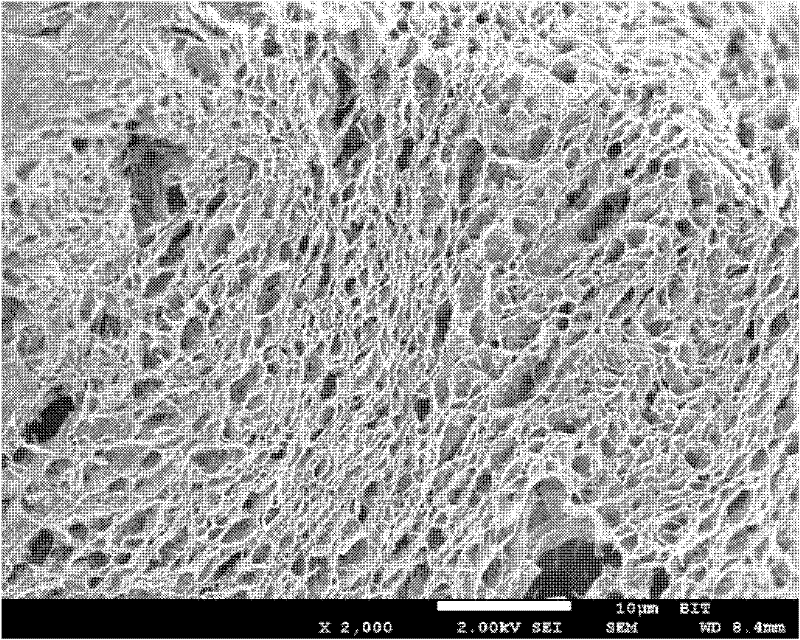

Three-dimensional silk fibroin scaffold insoluble in water, and preparation and application of three-dimensional silk fibroin scaffold

InactiveCN102847197AGood for biological researchImprove scalabilityTissue cultureVector-based foreign material introductionMicron scaleCell-Extracellular Matrix

The invention discloses a three-dimensional silk fibroin scaffold insoluble in water, and preparation and application of the three-dimensional silk fibroin scaffold. A preparation method includes the steps of injecting silk fibroin solution with the mass concentration of 0.3-30% into a mold, and obtaining a three-dimensional silk fibroin scaffold after freeze-drying; performing humid and heat crosslinking for the mold under the condition that the temperature ranges from 50 DEG C to 100 DEG C and the relative humidity ranges from 70% to 100%; and drying, removing the mold and obtaining the three-dimensional silk fibroin scaffold insoluble in water. Silk fibroin is used as a raw material, and biocompatibility is good; a preparation process is non-toxic and environment-friendly, and shape, aperture and porosity parameters of the scaffold are easy to control; the pore wall of the scaffold is nano-scale, the aperture of the scaffold is micron-scale, an extracellular matrix micro-environment is simulated, and the three-dimensional silk fibroin scaffold is used as a three-dimensional cell culture vector or a three-dimensional plasmid transfection vector when used externally; and the three-dimensional silk fibroin scaffold is used in the aspects of cartilage scaffolds, fat scaffolds, bone scaffolds, muscle scaffolds and the like when used in the internal tissue engineering field.

Owner:ZHEJIANG XINGYUE BIOTECH

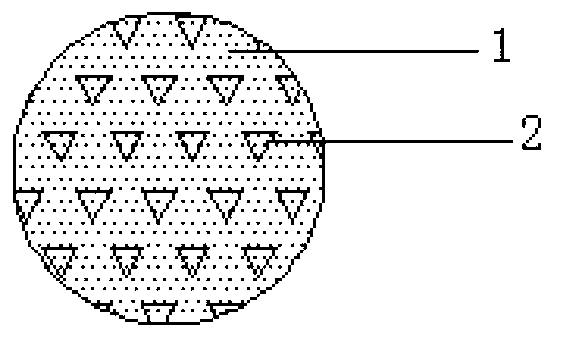

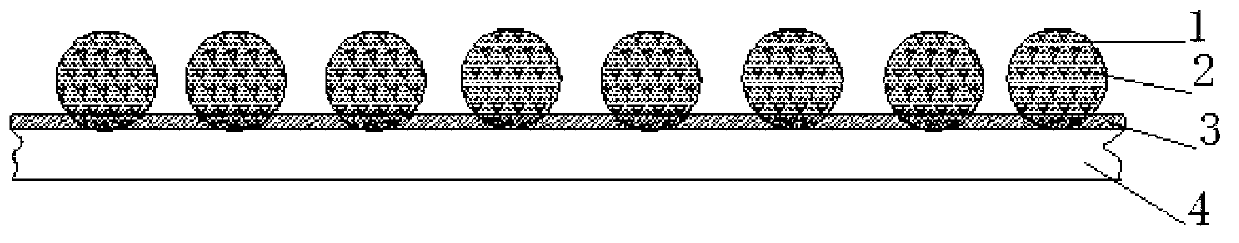

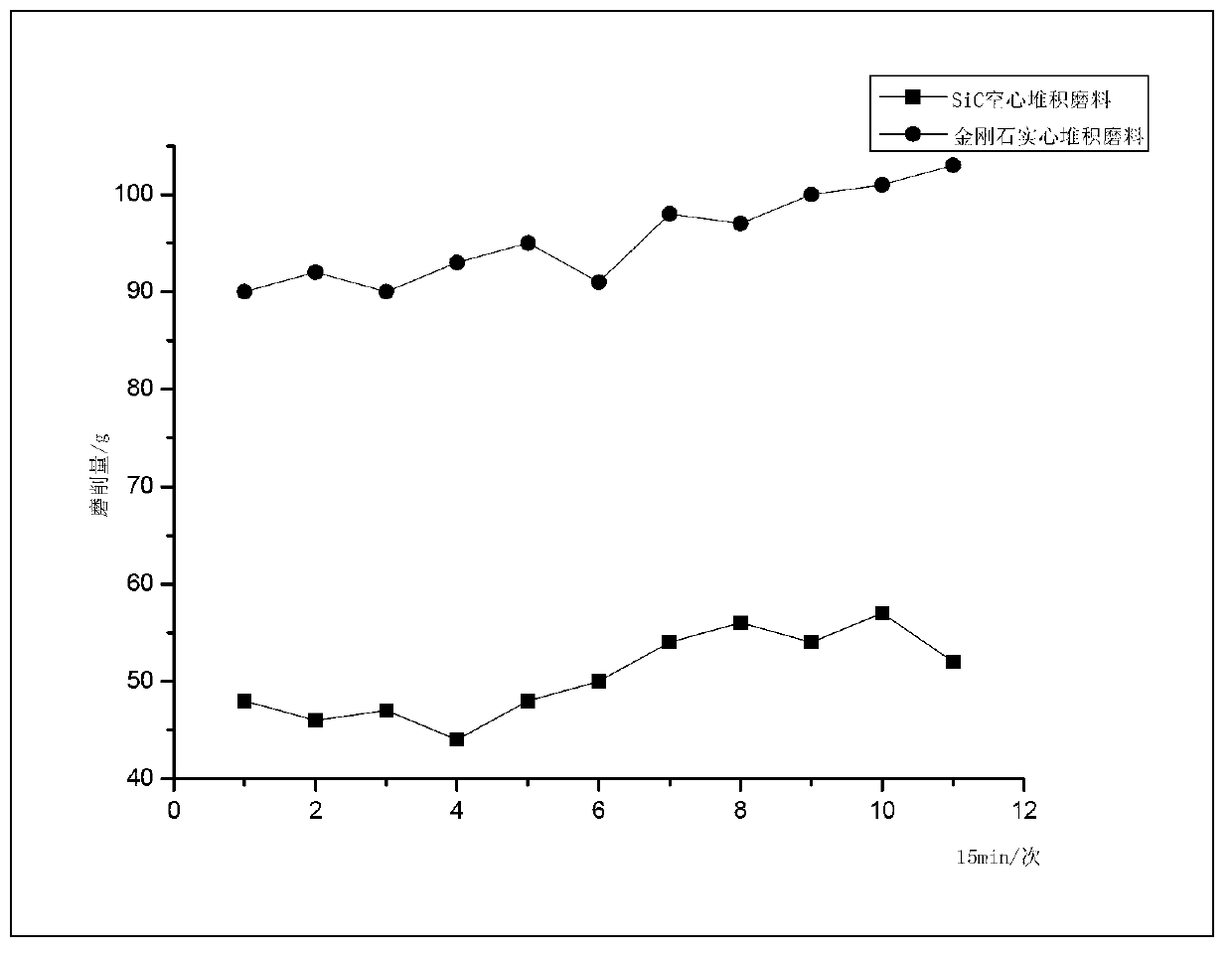

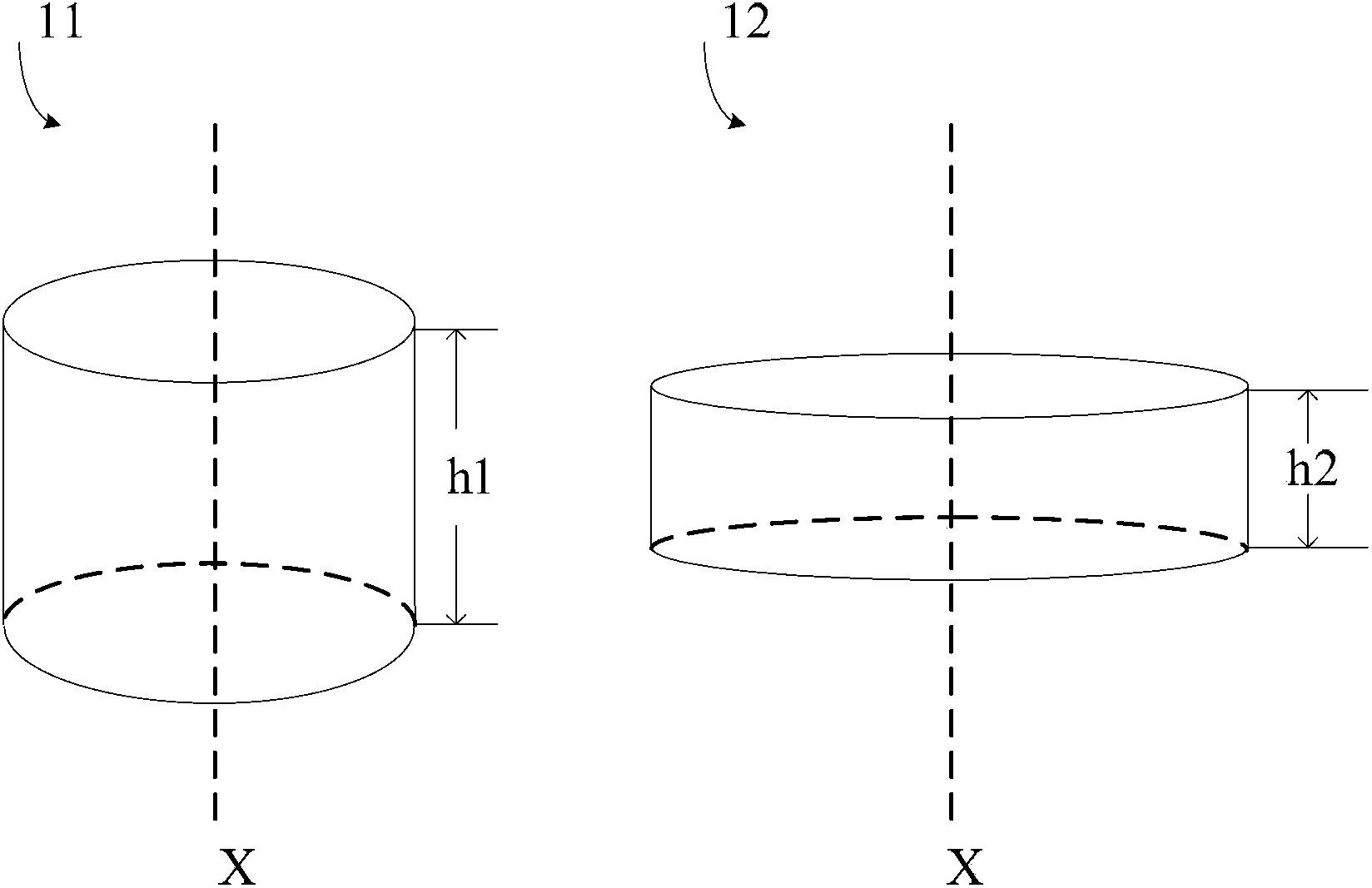

Ultrafine diamond and ceramic binding agent stacked abrasive materials and preparation method thereof

ActiveCN103273434AUniform internal structureBroaden the processing objectGrinding devicesCemented carbideSurface grinding

The invention relates to ultrafine diamond and ceramic binding agent stacked abrasive materials and a preparation method thereof. According to the ultrafine diamond and ceramic binding agent stacked abrasive materials, ultrafine diamond micro powder is added in the colloidal sol of a ceramic binding agent, a sizing agent is dried by spray mist, dry blank spherical stacked abrasive materials are obtained, and the ultrafine diamond and ceramic binding agent stacked abrasive materials can be obtained after calcinations. Stacked abrasive material particles are all spherical and even in particle size and internal organization structure. The ultrafine diamond and ceramic binding agent stacked abrasive materials can be used for preparing resin binder ultraprecise grinding wheels or diamond abrasive belts. A diamond abrasive material tool has high grinding efficiency and long grinding service life, and is mainly used for surface grinding and polishing of parts which are made of engineering ceramics, glass, hard alloy and the like.

Owner:HUNAN UNIV

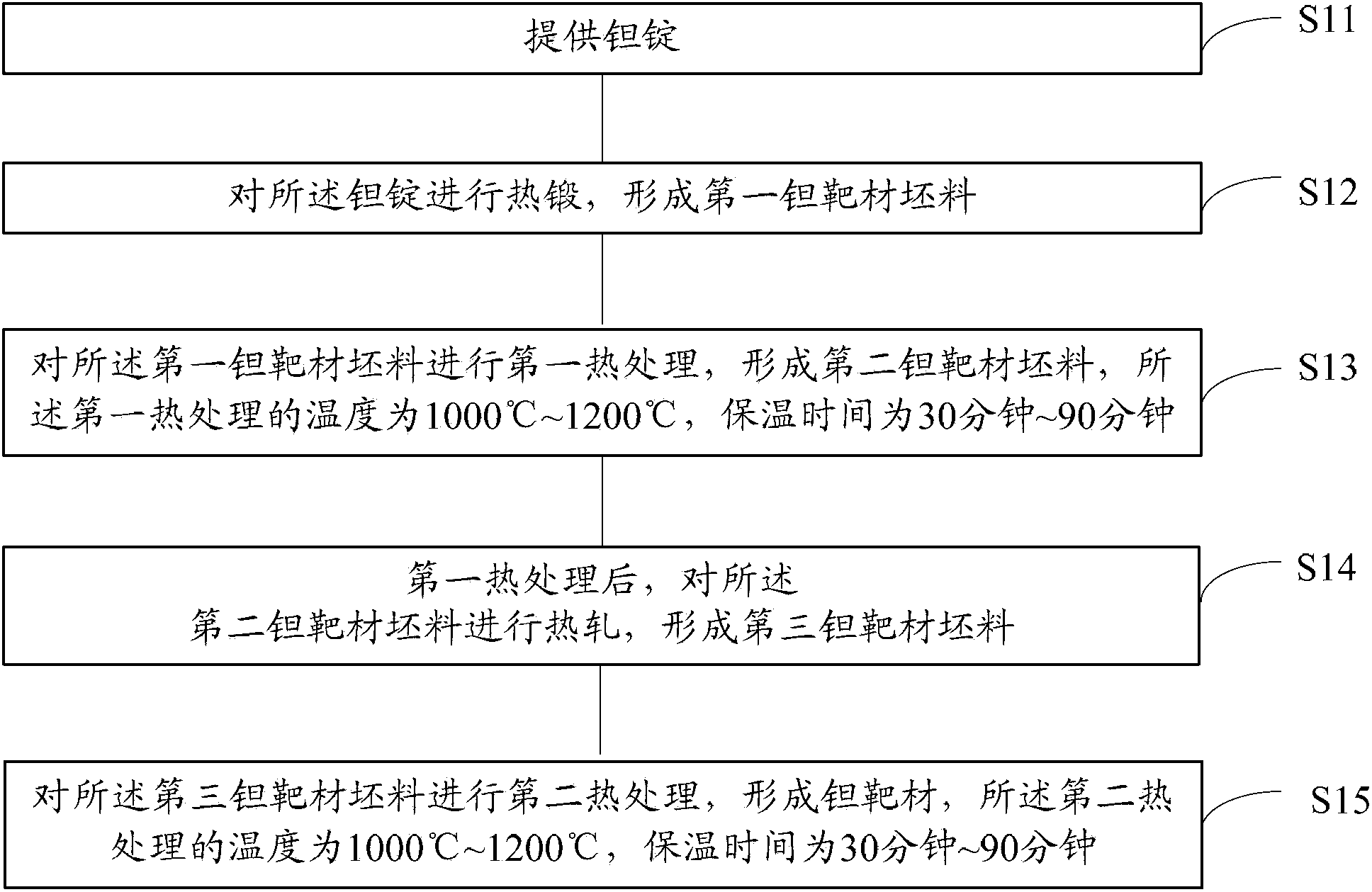

Production method of tantalum target and tantalum target component

ActiveCN103572225ADense tissueReduce unevennessVacuum evaporation coatingSputtering coatingIngotSemiconductor

The invention provides a production method of a tantalum target and a tantalum target component. The production method of a tantalum target comprises the following steps of providing a tantalum ingot; performing hot forging on the tantalum ingot to form a first tantalum target blank; performing first heat treatment on the first tantalum target blank to form a second tantalum target blank, wherein the temperature of the first heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes; after the first heat treatment, performing hot rolling on the second tantalum target material to form a third tantalum target blank; performing second heat treatment on the third tantalum target blank to form the tantalum target, wherein the temperature of the second heat treatment is 1,000-1,200 DEG C, and the temperature is maintained for 30-90 minutes. By adopting the technical scheme, the produced tantalum target has relatively uniform internal organization and good magnetic property; moreover, by adopting the tantalum target to produce a tantalum target component for a semiconductor, the formed film has relatively good quality.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

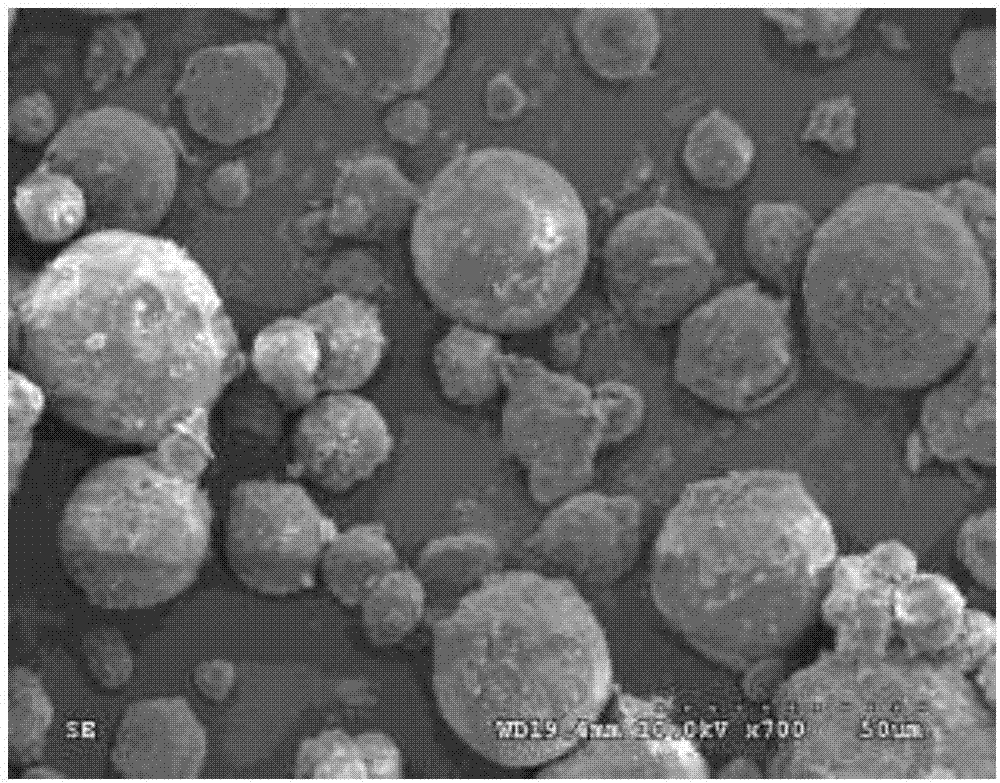

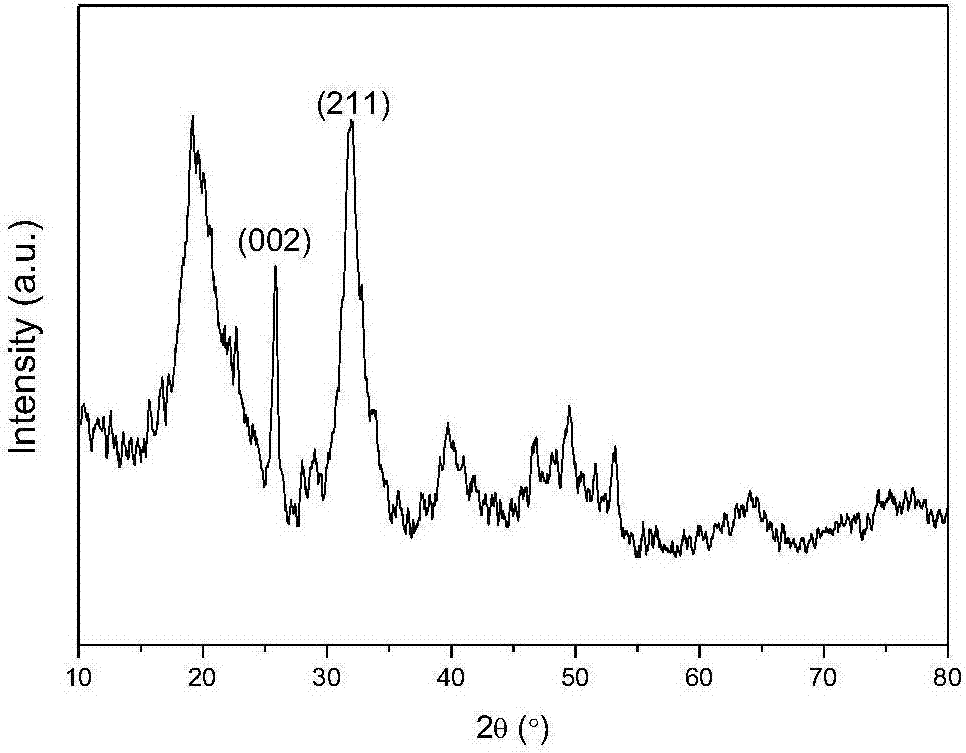

Preparation method of polyvinyl alcohol/hydroxyapatite (PVA/HA) composite microspheres

InactiveCN107376795AGood dispersionUniform internal structureCosmetic preparationsOther chemical processesFood additiveMicrosphere

A preparation method of polyvinyl alcohol / hydroxyapatite (PVA / HA) composite microspheres belongs to preparation methods of composite water-in-oil emulsion system microspheres. PVA and HA precursors are used as raw materials to prepare a clear and transparent mixed solution; the clear and transparent mixed solution is dispersed into an oil phase containing a surfactant to form a homogeneous water-in-oil microemulsion; and the PVA / HA composite microspheres can be finally obtained by successive crosslinking reaction under acid-catalyzed conditions, HA deposition under alkaline conditions, product centrifugation, washing, drying and other processes. The method has the advantages of simple process, good repeatability, low energy consumption and low cost, and effectively solves the problems that inorganic nanoparticles are easy to agglomerate in the microspheres to cause uneven structures and poor comprehensive performances and the like. The composite microspheres prepared by the method have the advantages of regular morphology, high dispersibility, uniform microstructure, good biocompatibility, biological activity and adsorption performance, and can be used as drug carrier materials, bone repair materials, environmental water treatment materials, cosmetics or food additives and the like.

Owner:CHINA UNIV OF MINING & TECH

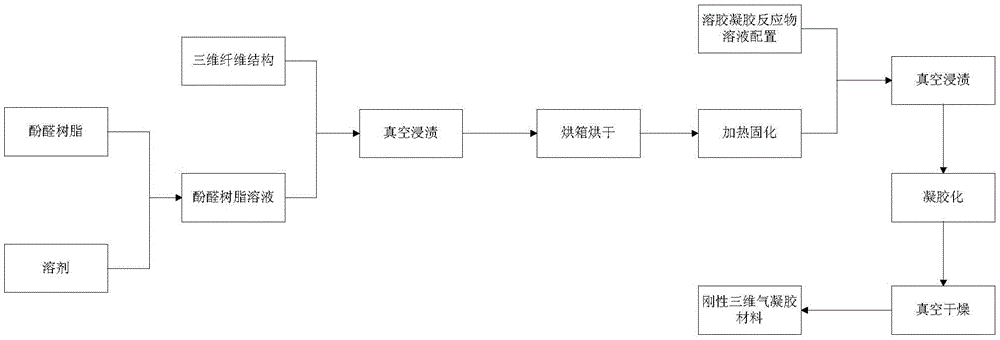

Preparation method of rigid structure reinforced phenolic aerogel heat shielding material

ActiveCN105601854ASolve problems that are difficult for large-scale engineering applicationsStrong dimensional stabilityEngineeringSolvent

The invention relates to a preparation method of a rigid structure reinforced phenolic aerogel heat shielding material. The method includes: firstly dissolving phenolic resin in a solvent in a vacuum impregnation container to form a phenolic solution, then pressing a three-dimensional fiber structure into the phenolic resin solution, and conducting vacuum pumping on the vacuum impregnation container, after a period of time, opening a seal cover to maintain smooth air pressure with the outside and conducting standing for a period of time, then taking out the three-dimensional fiber structure and putting it into an oven to perform drying, and conducting high temperature curing to form a rigid three-dimensional fiber structure, then mixing resorcinol, furfural, ethanol and sodium hydroxide uniformly in proportion in the vacuum impregnation container to form a reactant solution, then pressing the rigid three-dimensional fiber structure into the solution, conducting vacuum pumping on the vacuum impregnation container again, maintaining the state for a period of time, then placing the vacuum impregnation container into the oven to carry out sol-gel process, and finally taking out the gel-containing three-dimensional fiber structure and performing drying, thus obtaining the rigid structure reinforced phenolic aerogel product.

Owner:BEIJING SATELLITE MFG FACTORY

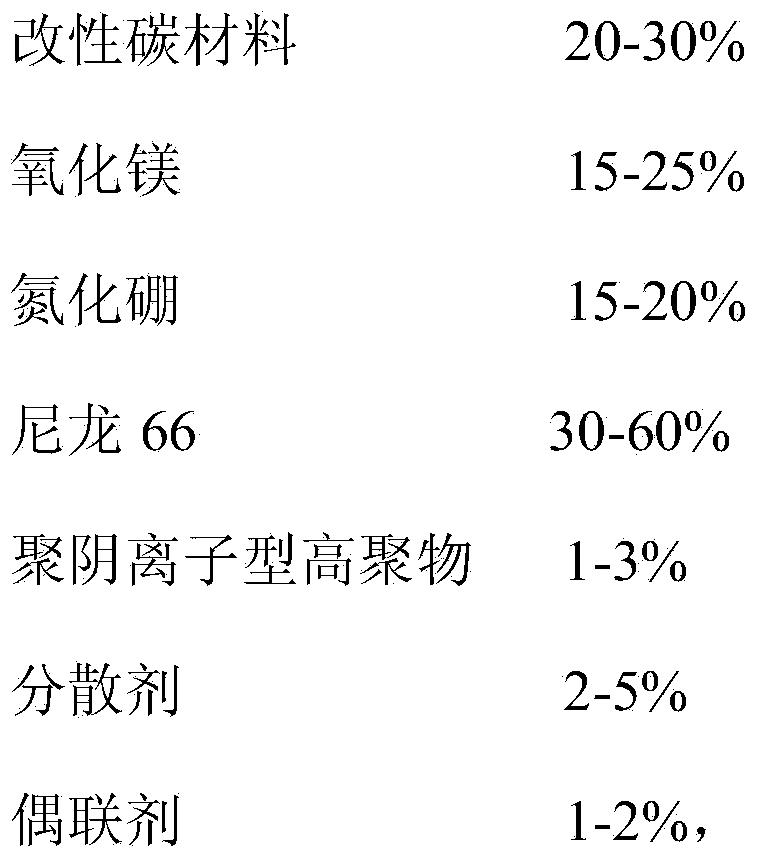

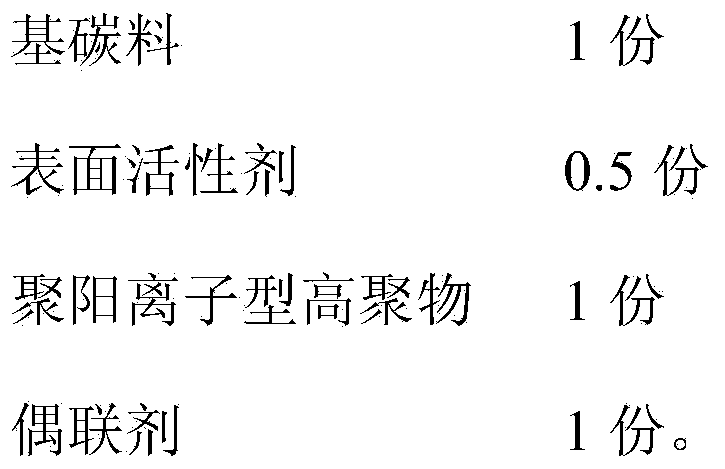

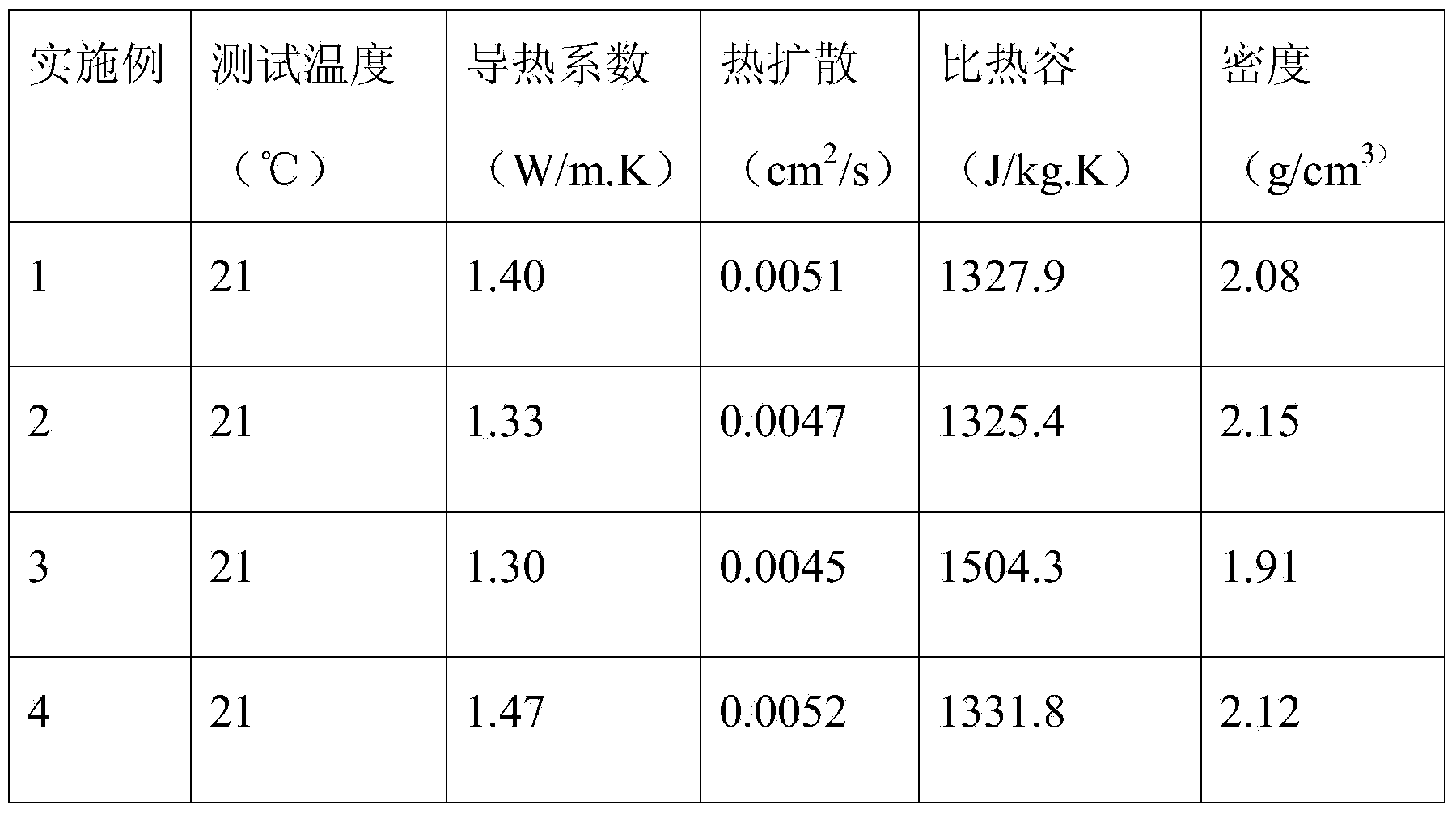

Thermal conductive plastic applying modified carbon material, and preparation method thereof

The invention discloses thermal conductive plastic applying a modified carbon material, and a preparation method thereof. The thermal conductive plastic comprises the following components in percentage by mass: the modified carbon material, magnesium oxide, boron nitride, nylon 66, a polyanionic type high polymer, a dispersing agent, and a couplant, wherein the modified carbon material comprises the following components in parts by weight: a base carbon material, a surfactant, a polycationic type high polymer, and a couplant; the modified carbon material is prepared by the steps of: mixing water, the base carbon material, sodium chloride, the surfactant and the couplant according to a proportion and then performing ultrasonic treatment, slowly adding the polycationic type high polymer during the ultrasonic process, continuously performing ultrasonic treatment and then stirring for 20-24h, filtering and drying. According to the thermal conductive plastic applying the modified carbon material, and the preparation method thereof, the problem that the materials inside the plastic are mixed unevenly can be effectively solved, and the compatibility of the carbon material can be improved greatly; the dispersity of the whole material mixture can be enhanced, and plugging is difficult in the extrusion process; the synthetic technology is simple, and the conditions of high temperature, a strongly corrosive environment and the like are not required.

Owner:ZHONGSHAN YONGWEI NEW MATERIAL CO LTD

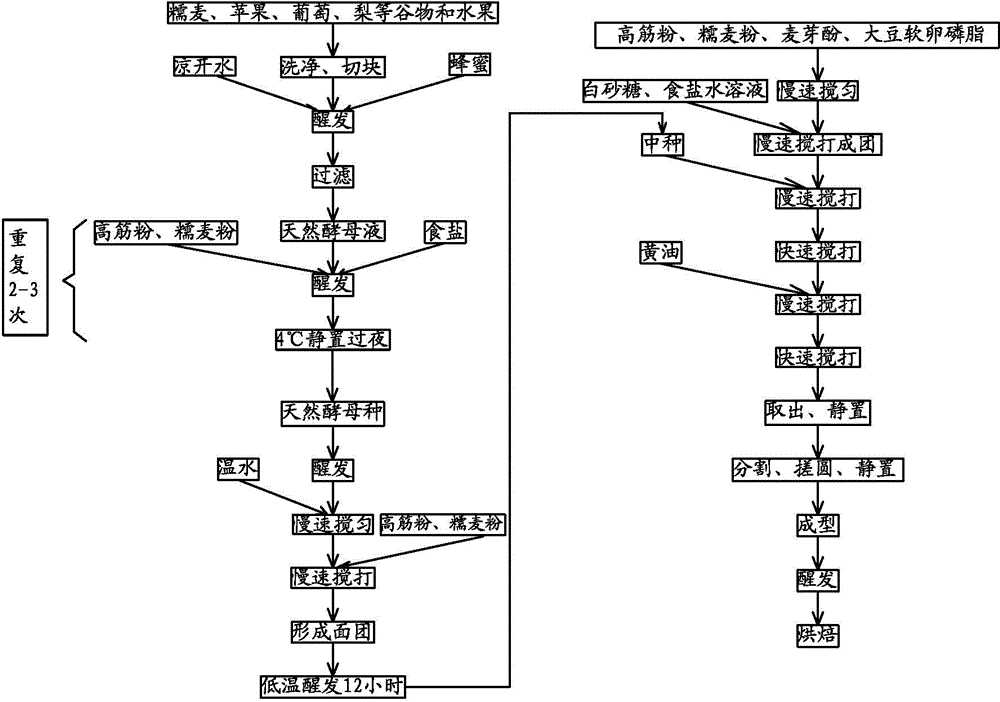

Natural yeast bread and manufacturing method thereof

InactiveCN104782702AAppropriate tasteUniform structureDough treatmentPre-baking dough treatmentNutritive valuesWarm water

The invention relates to a manufacturing method of natural yeast bread. The method includes the steps that a, natural yeast liquid raw materials selected from fruits and cereals at least including glutinous barley are fermented to obtain natural yeast liquid; b, high-gluten flour and glutinous barley flour are mixed to obtain mixed flour, the mixed flour and the natural yeast liquid are mixed to obtain a mixture, and the mixture is fermented to obtain primary natural yeast; c, after the primary natural yeast is fermented, the primary natural yeast, warm water, high-gluten flour and glutinous barley flour are stirred into mixed dough, and the mixed dough is fermented at low temperature to obtain sponge dough; d, high-gluten flour, glutinous barley flour, malt flour, soya bean lecithin and a water solution are stirred and then added into the sponge dough to form bread dough through stirring; e, the bread dough is fermented; f, a conventional method is used for baking to obtain the bread. The invention further discloses natural yeast bread manufactured by adopting the method. The high water absorption rate and the high aerogenesis capacity of the glutinous barley flour, the capacity of promoting yeast aerogenesis of the malt flour and the emulsifying capacity of the soya bean lecithin are used, and low-temperature secondary fermentation is combined to obtain the soft and healthy bread moderate in mouthfeel and high in nutritive value.

Owner:福建安麦高新生物技术有限公司

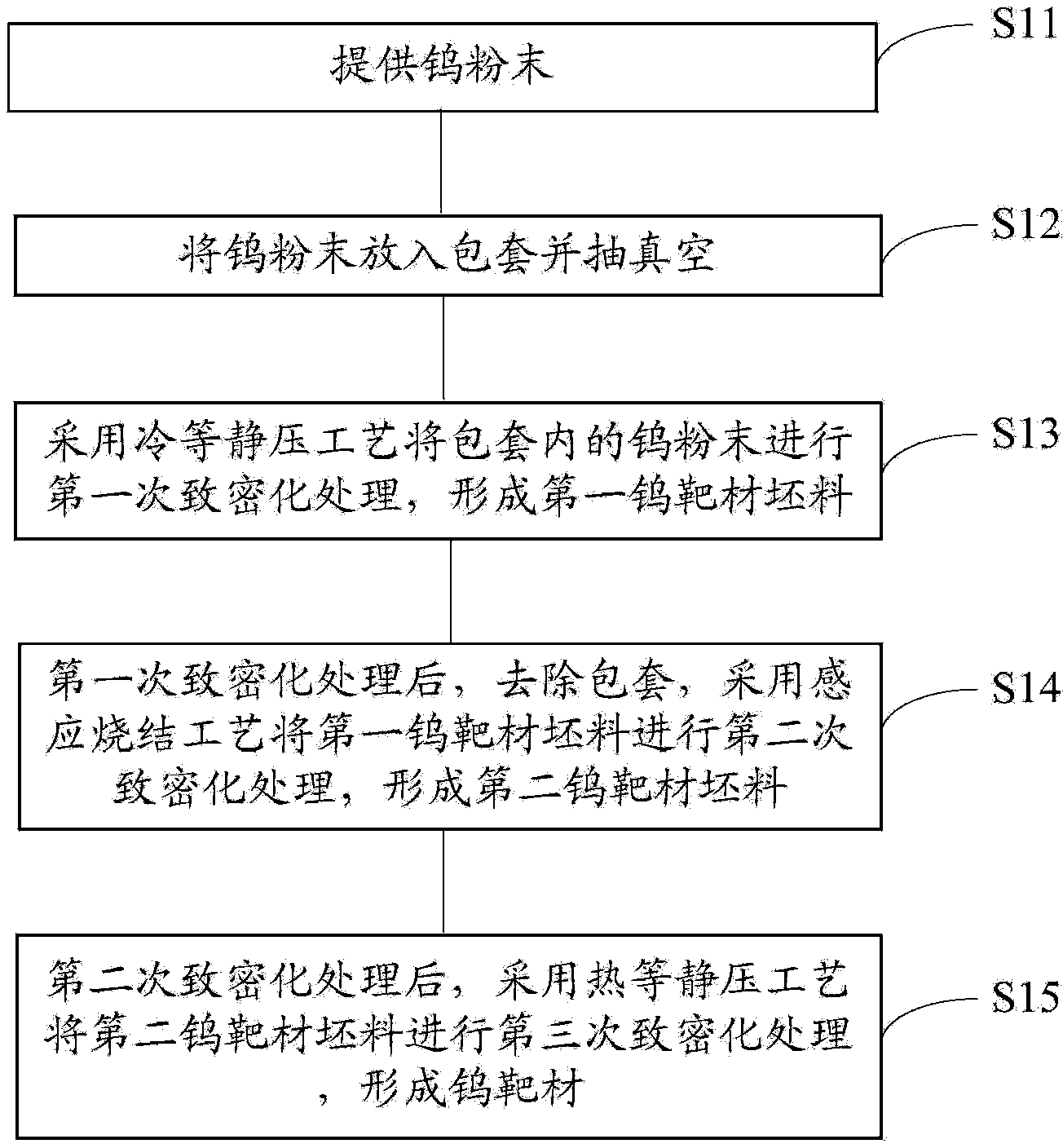

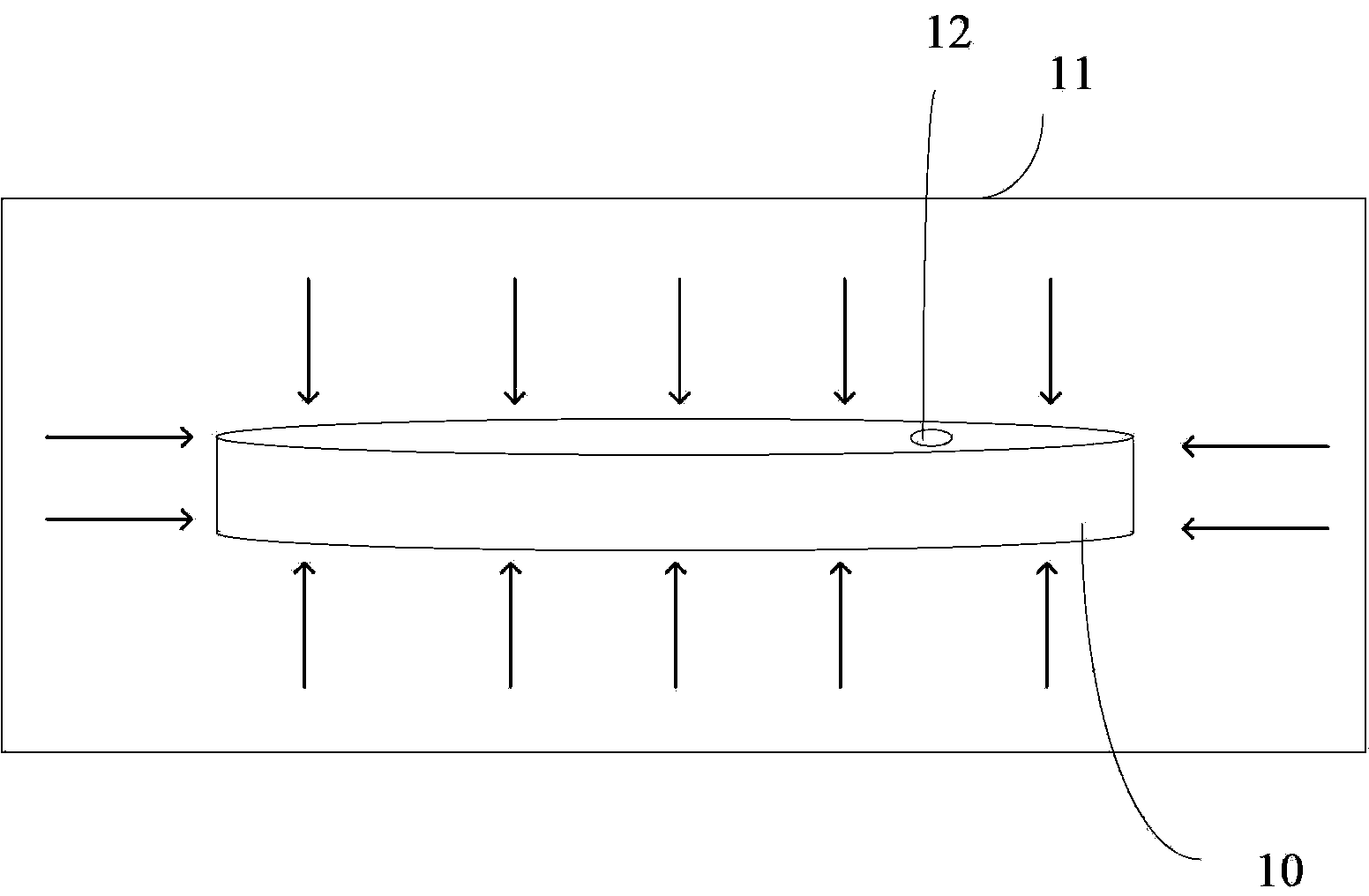

Tungsten target manufacturing method

ActiveCN103567444APrevent oxidationAvoid mutual contaminationVacuum evaporation coatingSputtering coatingVacuum pumpingVolumetric Mass Density

A tungsten target manufacturing method comprises the steps of providing tungsten powder; placing the tungsten powder in a package sleeve and performing vacuum pumping; adopting a cold isostatic pressing to enable the tungsten powder in the package sleeve to undergo primary densifying processing, and forming primary tungsten target blank; after the primary densifying processing, removing the package sleeve, adopting an induction sintering process to enable the primary tungsten target blank to undergo secondary densifying processing, and forming secondary tungsten target blank; after the secondary densifying processing, adopting a hot isostatic pressing process to enable the secondary tungsten target blank to undergo third-time densifying processing, and forming a tungsten target. The tungsten target with the full density of over 99.4% can be manufactured through the tungsten target manufacturing method; and the uniformity of the internal organizational structure and the grain size of the tungsten target meet a sputtering process with the requirement higher and higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

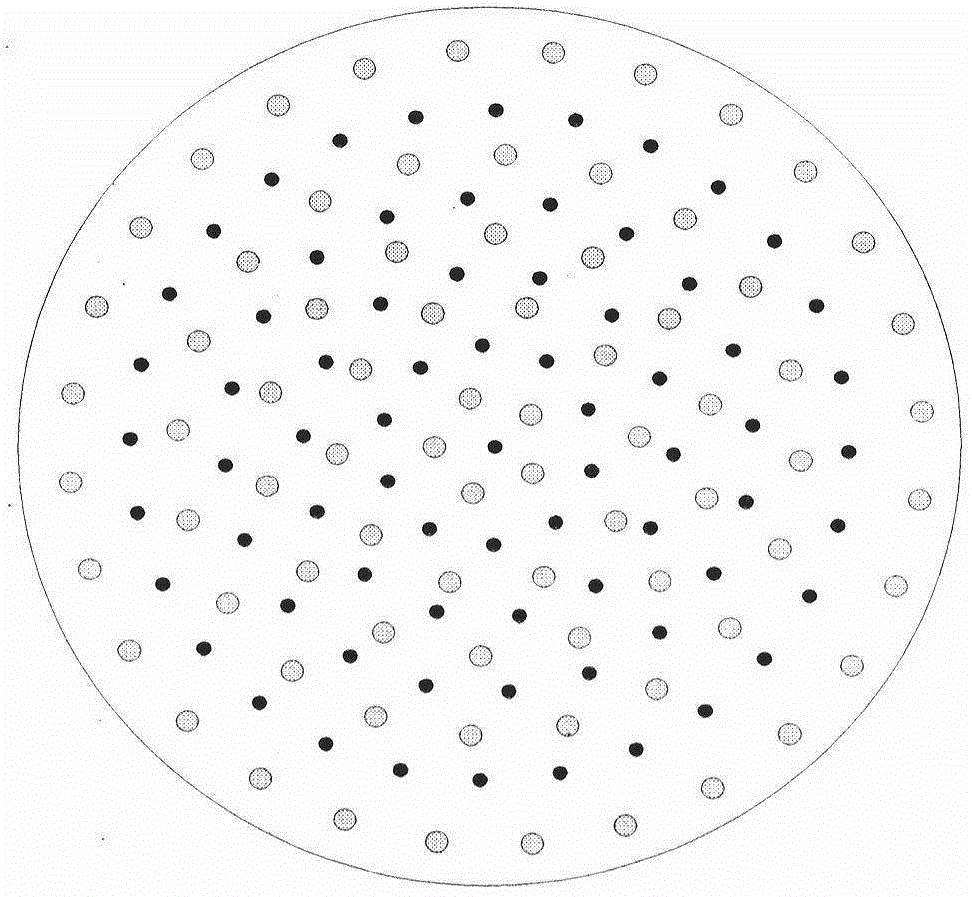

Preparation method of nanosized silicon carbide toughened aluminum oxide bulletproof ceramic

The invention relates to a preparation method of a nanosized silicon carbide toughened aluminum oxide bulletproof ceramic, which belongs to the technical field of the special ceramic. The preparation method comprises the following steps of blending, molding and burning and is characterized in that the basic components comprises 98-98.5 percent of alpha-Al2O3 power with grain size being less than 2.5 mum, 0.8-1.3 percent of kaolin with 325 meshes and 0.5-1.0 percent of burn talc with 325 meshes according to the percentage by weight, the components above are taken as the base number, the 3-8 percent of nanosized silicon carbide with grain size of 10-30 nanometers is additionally added in; a gel-casting method is adopted; and the burning schedule is as follows: the burnt temperature is 1650-1700 DEG C, and the heat preservation time is 3-5 hours. The invention is low in cost and good in quality and is favorable for the large-scale production.

Owner:SHANDONG GUIYUAN ADVANCED CERAMICS

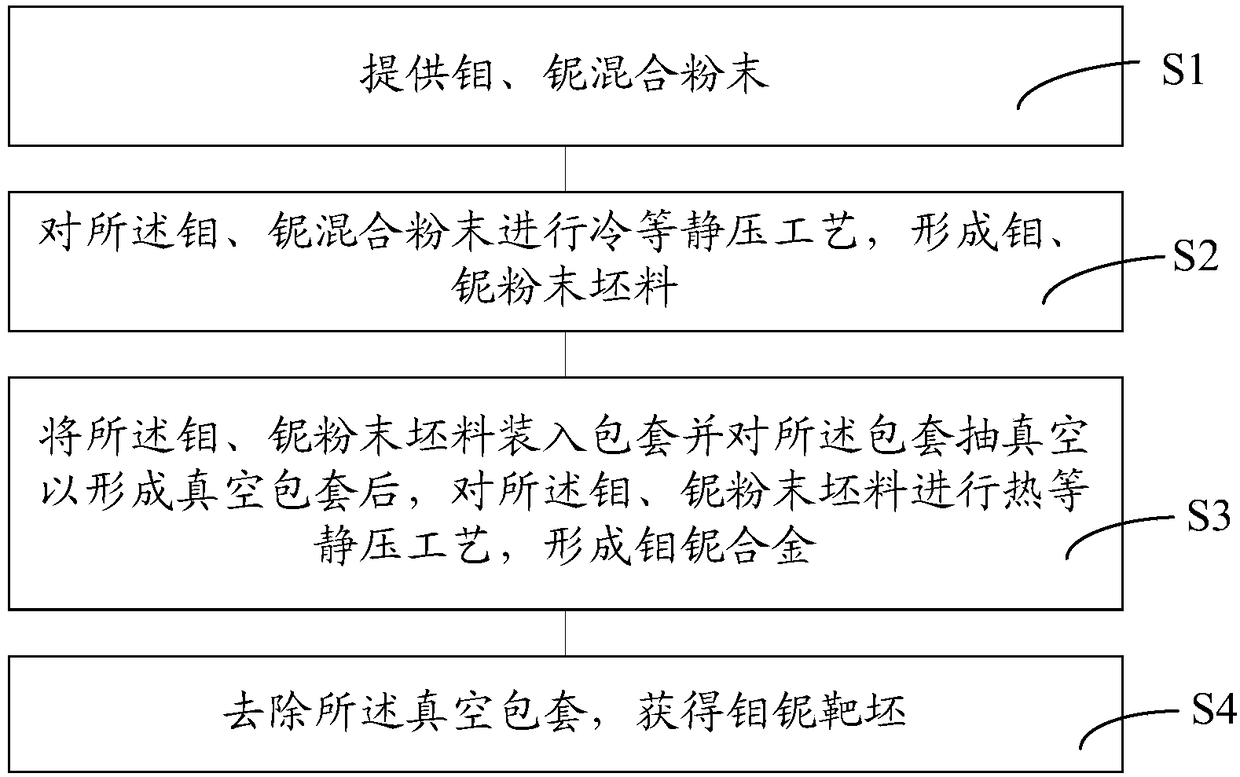

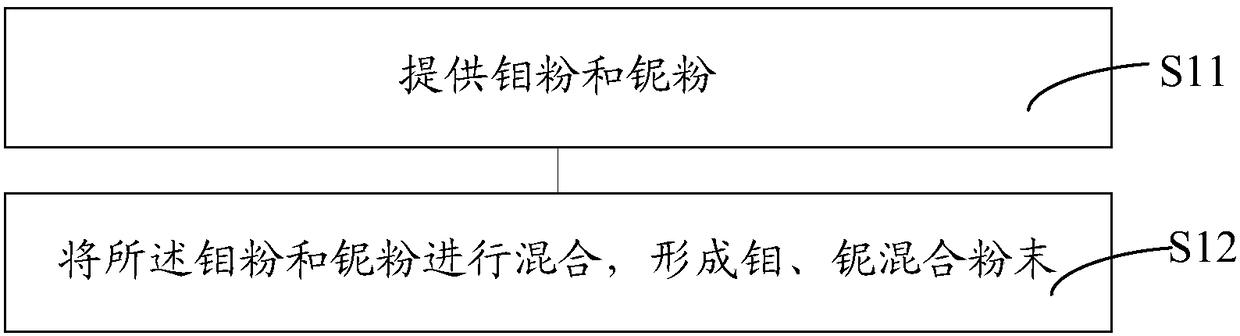

Manufacturing method for molybdenum-niobium target blank

InactiveCN108070832AAdvanced technologyImprove mechanical propertiesVacuum evaporation coatingSputtering coatingNiobium alloyHot isostatic pressing

The invention provides a manufacturing method for a molybdenum-niobium target blank. The manufacturing method comprises the steps that molybdenum and niobium mixed powder is provided; the cold isostatic pressing process is conducted on the molybdenum and niobium mixed powder, and thus a molybdenum and niobium powder blank material is formed; the molybdenum and niobium powder blank material is putinto a sheath, the sheath is vacuumized so as to be a vacuum sheath, then the hot isostatic pressing process is conducted on the molybdenum and niobium powder blank material, and thus a molybdenum-niobium alloy is formed; and the vacuum sheath is removed, and thus the molybdenum-niobium target blank is obtained. The cold isostatic pressing process is adopted firstly to pre-form the molybdenum andniobium mixed powder into the semi-dense molybdenum and niobium powder blank material, and therefore better densifying of the subsequent hot isostatic pressing process is facilitated; and then omni-directional gas pressure equal in various directions is applied to the vacuum sheath through the hot isostatic pressing process, and accordingly the sputtering coating molybdenum-niobium target blank which has the density of 99.5% or above and is more uniform in internal organizational structure is obtained.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

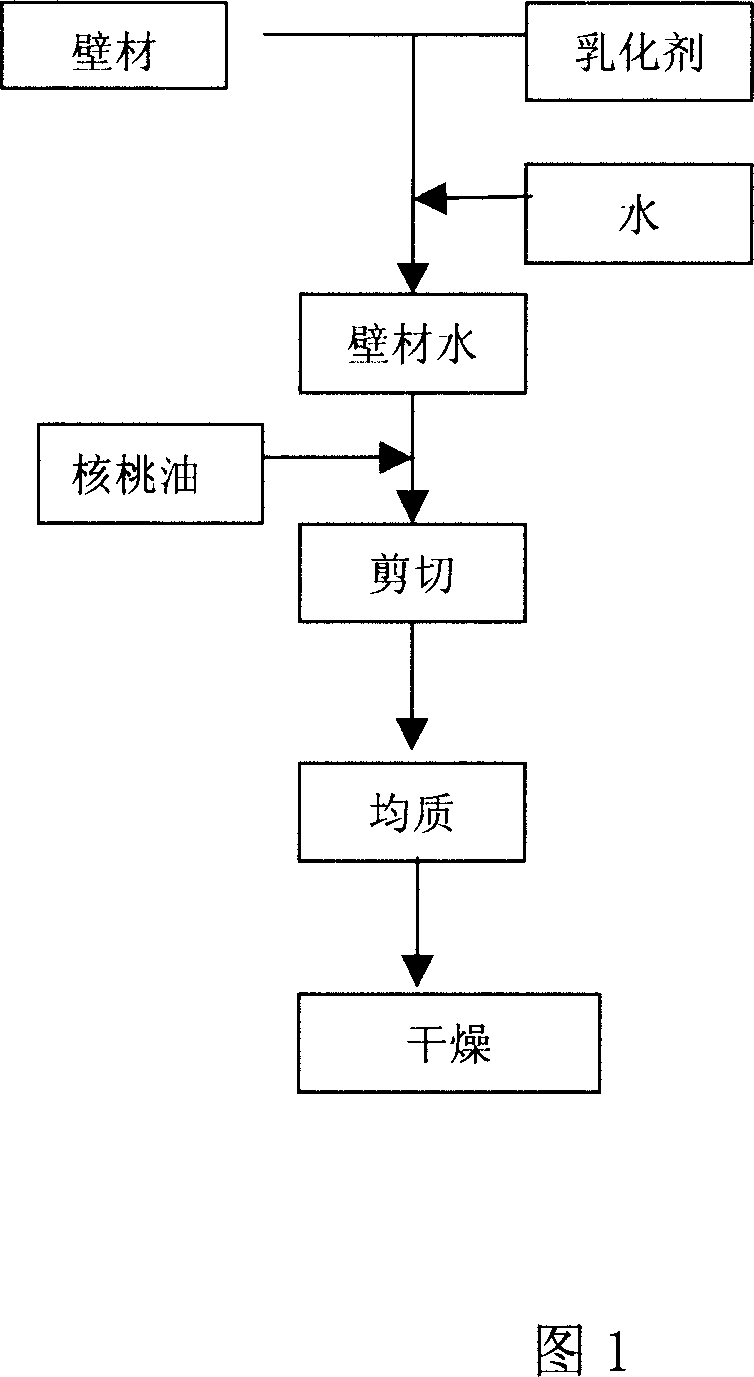

Method for making high-embedding-ratio powder walnut oil

InactiveCN101023763AIncrease contentHigh nutritional valueEdible oils/fatsMonoglycerideSuccinic acid

The present invention discloses a method for preparing powder walnut oil with high embedding rate. Said method includes the following steps: (1), after the monoglyceride, lecithine and Tween-60 as emulsifying agent are dissolved in water, successively adding octylene succinic acid esterified starch HI-CAP100 and maltodextrin as wall material to obtain wall material aqueous solution for stand-by; (2), adding walnut oil into the above-mentioned wall material aqueous solution, shearing and homogenizing to make the walnut oil be uniformly dispersed in the wall material aqueous solution; under the action of emulsifying agent forming O / W (oil-in-water) type emulsion with good emulsification stability; and (3), utilizing drying process to remove water content from emulsion, making wall material be formed into film, then the walnut oil can be uniformly embedded by all material film so as to obtain the invented powder walnut oil with high embedding rate.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Cetirizine molecularly imprinted polymer monolithic column and preparation method thereof

InactiveCN104209104AEasy to makeSimple experimentOther chemical processesSolid sorbent liquid separationTetrafluoroborateGlycol synthesis

The invention relates to a cetirizine molecularly imprinted polymer monolithic column and a preparation method thereof. The cetirizine molecularly imprinted polymer monolithic column is composed of raw materials of, by mass, 1-3% of cetirizine, 3-4% of 4-vinyl pyridine, 20-25% of ethylene gylcol dimethacrylate, 42-45% of mixed solution (eutectic solvent) of ethylene glycol and choline chloride, 4-5% of dimethylformamide, 13-22% of 1-butyl-3-methylimidazolium tetrafluoro borate and 0.5-1% of azobisisobutyronitrile. The method includes the steps of adding ionic liquid and the eutectic solvent of ethylene glycol and choline chloride to a polymerization system, using cobalt ions as a metal ion hub to enhance the effect of imprinting recognition, and preparing molecularly imprinted polymer (MIP) of a successive rod shape in a stainless steel column. The cetirizine molecularly imprinted polymer (MIP) monolithic column obtained through the preparation method has the advantages of good permeability and obvious imprinting effects and can have the model cetirizine imprinting factors up to 31.54, and meanwhile, the method is simple in preparation process and avoids the use of volatile liquid, thereby reducing harmful gas emission to the environment.

Owner:TIANJIN MEDICAL UNIV

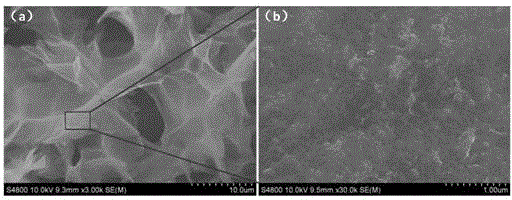

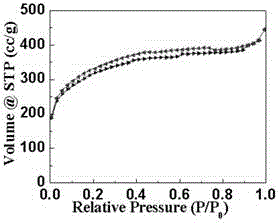

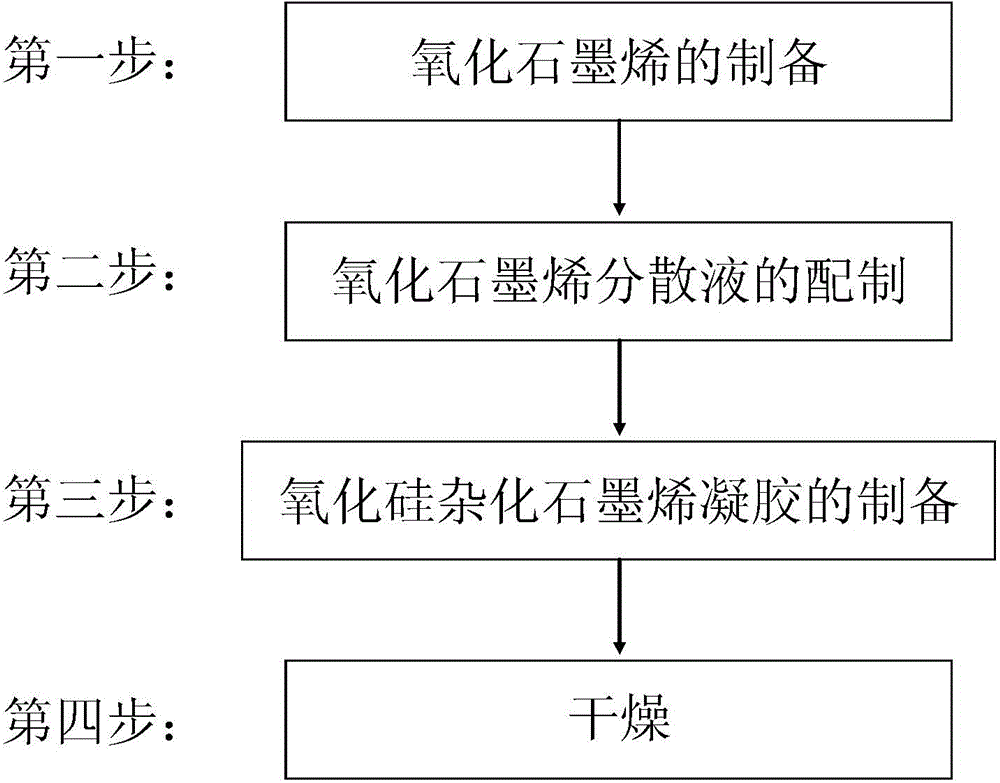

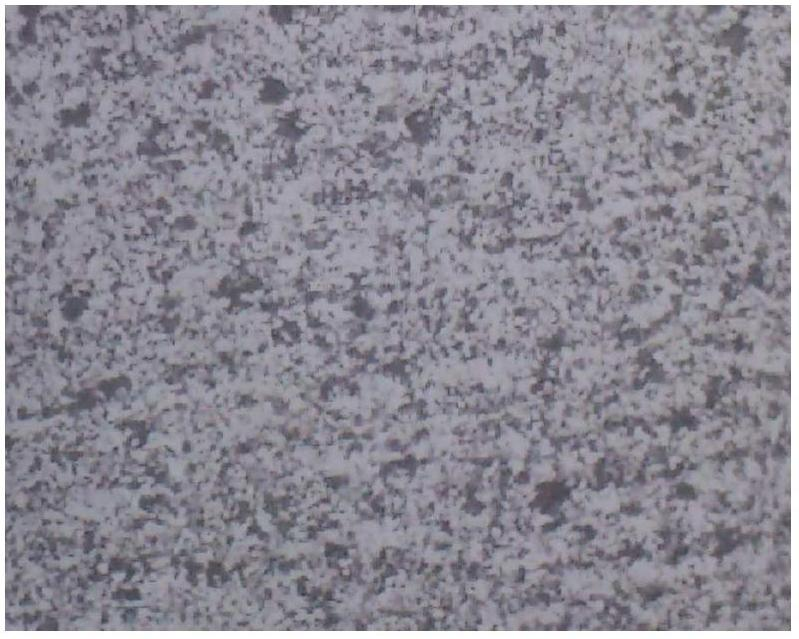

High specific surface area of silicon oxide hybridized graphene aerogel and production method thereof

The invention discloses high specific surface area of silicon oxide hybridized graphene aerogel and a production method thereof. The high specific surface area of silicon oxide hybridized graphene aerogel and the production method aim at solving the problem that the specific surface area is reduced when hybridization is performed on graphene aerogel. The high specific surface area of silicon oxide hybridized graphene aerogel is formed by grapheme through building, wherein a large quantity of silicon oxide particles are distributed on the surface of the grapheme; the high specific surface area of silicon oxide hybridized graphene aerogel comprises a porous structure, wherein the pore diameter of the porous structure is concentrated to be 1 to 500 nm; the porous structure comprises a microporous structure and a macroporous structure. The production method comprises serving graphite powder, siloxane and the like as main raw materials, producing graphene oxide, preparing a graphene oxide dispersing agent and producing silicon oxide hybridized graphene gel and obtaining the high specific surface area of silicon oxide hybridized graphene aerogel after drying. According to the high specific surface area of silicon oxide hybridized graphene aerogel and the production method thereof, tiny particle size of silicon oxide nanoparticles are produced through liquid mixing of the raw materials and a reaction, the introduction on the silicon oxide particles is implemented, meanwhile the partition effect on the grapheme is achieved, and accordingly the high specific surface area of silicon oxide hybridized graphene aerogel is large in specific surface area, small in silicon oxide particle and uniform in distribution.

Owner:NAT UNIV OF DEFENSE TECH

Hardening and tempering technology of alloy-steel tube

ActiveCN102676780AStress reliefUniform internal organizationFurnace typesHeat treatment furnacesHydraulic cylinderFree cooling

The invention discloses a hardening and tempering technology of an alloy-steel tube, and through the technology, the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The technology comprises the following steps of: (1) annealing treatment: warming to 870-880 DEG C at the speed of 20-25 DEG C / minute, keeping the temperature for 35-40 minutes, and then cooling to 500 DEG C below; (2) quenching treatment: warming to 930-935 DEG C at the speed of 5-10 DEG C / minute, keeping the temperature for 50-60 minutes, then cooling rapidly at the speed of 190-200 DEG C / second to 320-325 DEG C, and cooling naturally to 30-40 DEG C; and (3) tempering treatment: warming to 500-510 DEG C at the speed of 5-10 DEG C / minute, then keeping the temperature for 230-240 minutes, and then cooling naturally to room temperature, thus the hardened and tempered alloy-steel tube is high in intensity and hardness, has good abrasion resistance and high plasticity, bears great pressure, and has small deformation and less decarburization. The hardening and tempering technology of the alloy-steel tube provided by the invention is mainly applied to the hardening and tempering of the alloy-steel tube for a hydraulic cylinder barrel.

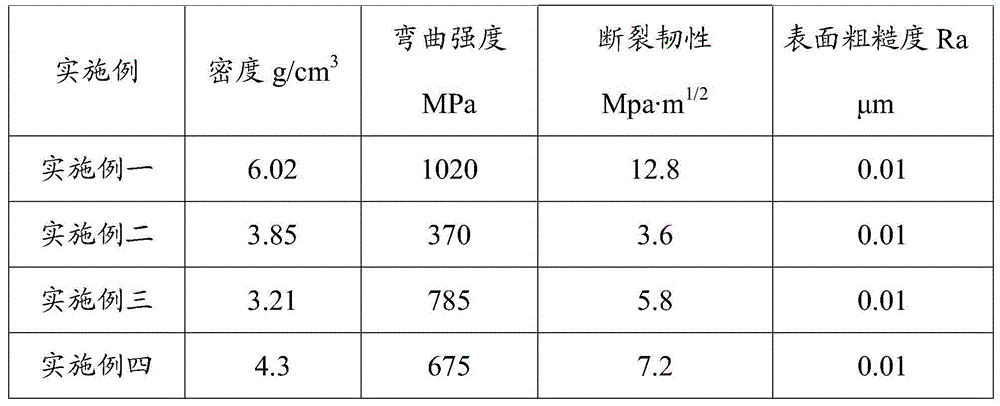

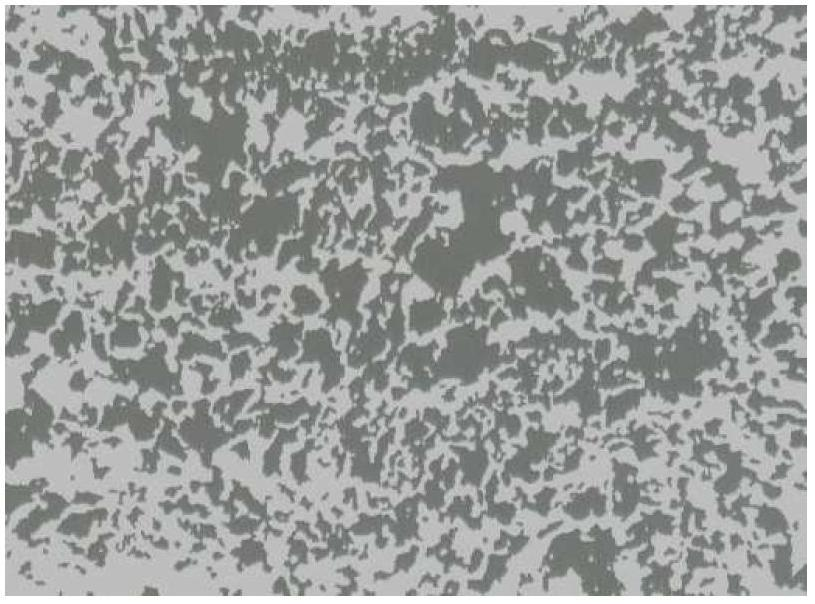

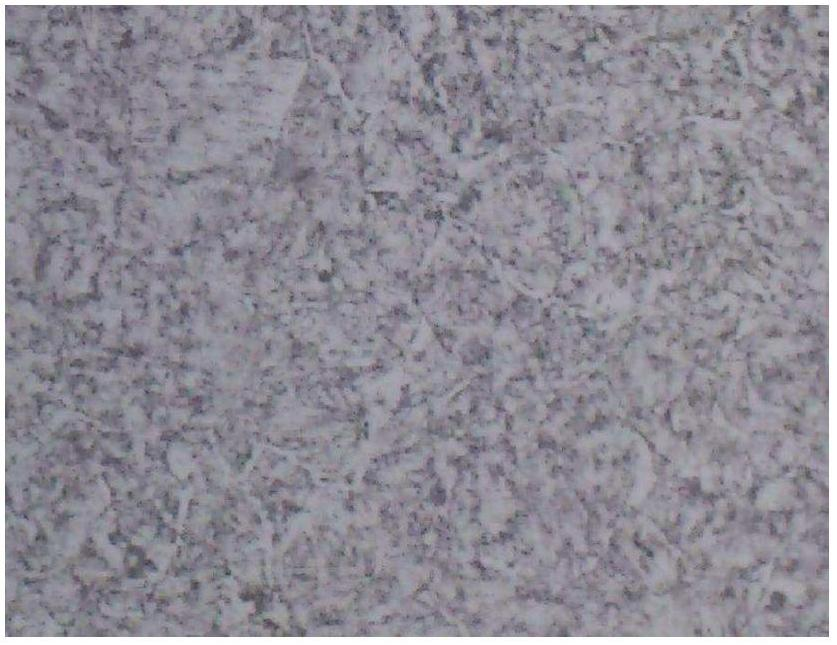

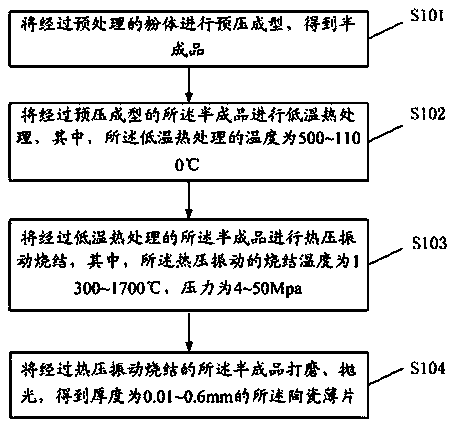

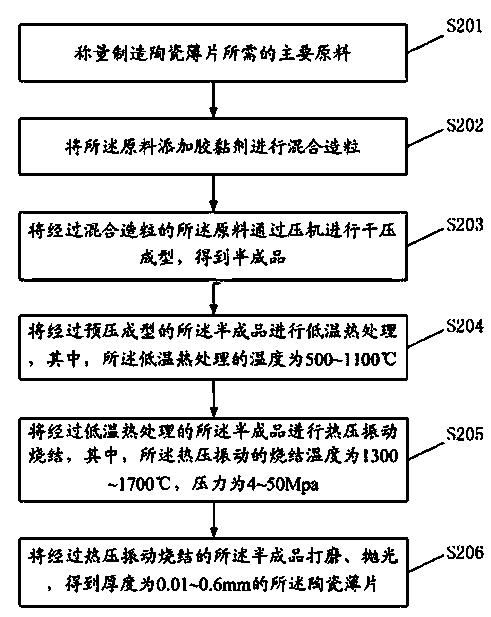

Ceramic slice and preparation method thereof

The invention discloses a ceramic slice and a preparation method thereof. The ceramic slice is mainly made of zirconia and rare earth oxides, is prepared through a hot-press vibration sintering technology, and has a thickness of 0.01 to 0.6 mm. Correspondingly, the invention also discloses a preparation method of the ceramic slice. The preparation method comprises the following steps: carrying out pre-pressing and forming on powder, which has been subjected to a pretreatment, so as to obtain a half-finished product; subjecting the half-finished product to a low temperature thermal treatment; subjecting the half-finished product to hot-press vibration sintering; and finally polishing and burnishing the half-finished product so as to obtain the ceramic slice with a thickness of 0.01 to 0.6 mm. The strength of the provided ceramic slice can reach 1400 MPa or more, the toughness can reach 10 MPa.m<1 / 2>, and the performance parameters of the ceramic slice are prominently higher than that of common ZrO2 products. The ceramic slice can satisfy the requirements on slice and ultrathin slice with a thickness of 0.01 to 0.6 mm and has the advantages of difficultness in breakage, little loss, long service life, and durability.

Owner:JIN GANG NEW MATERIALS +1

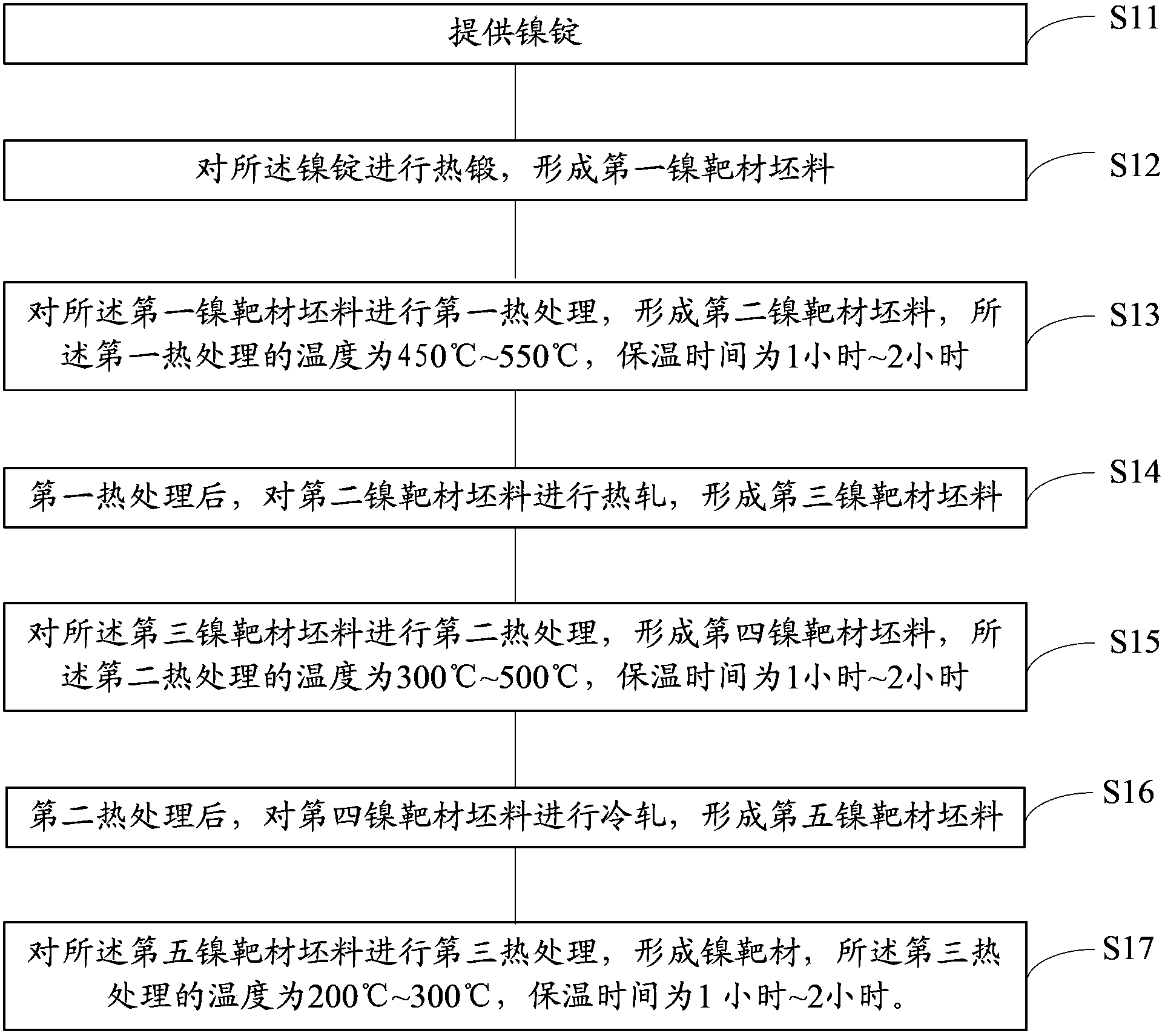

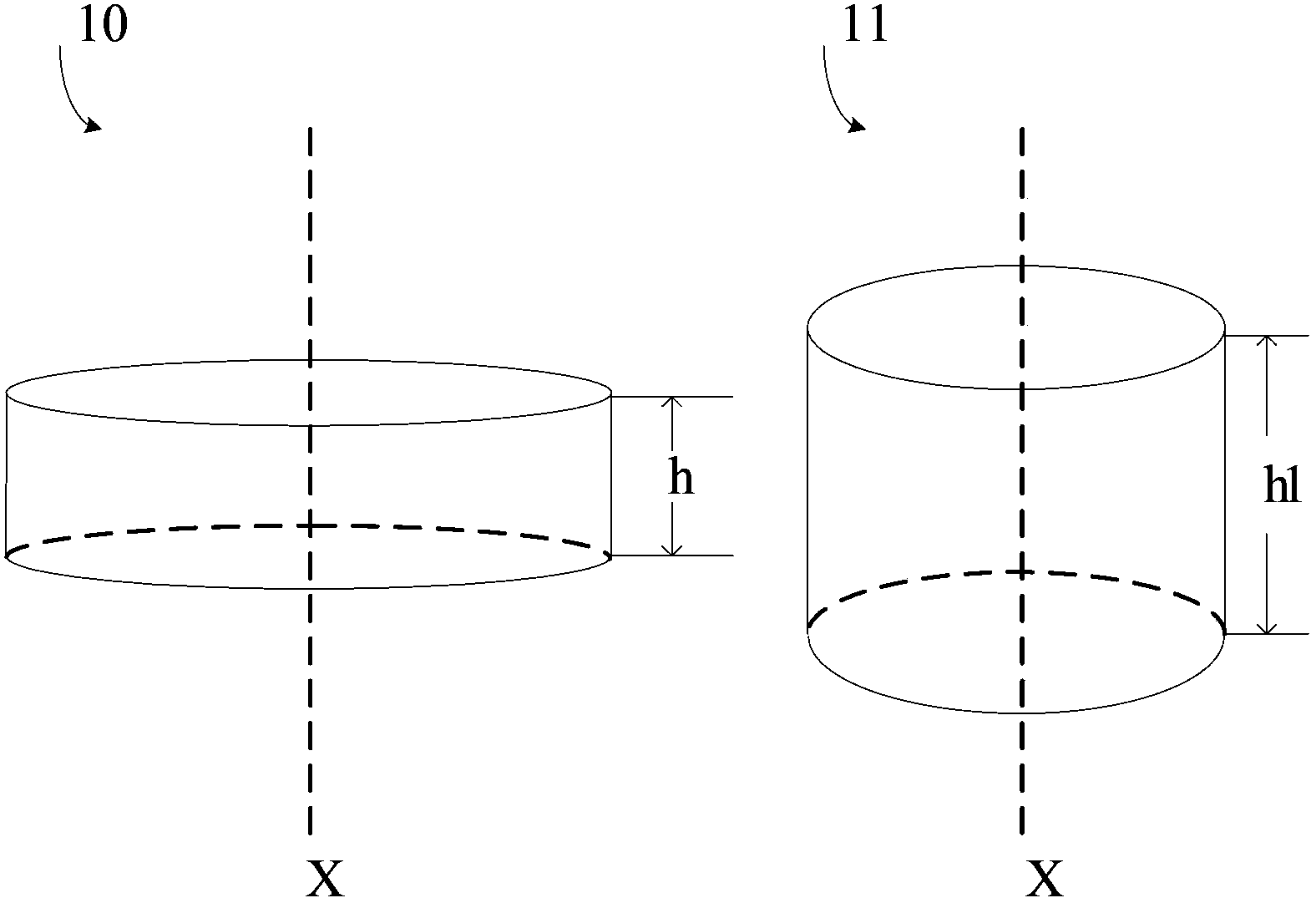

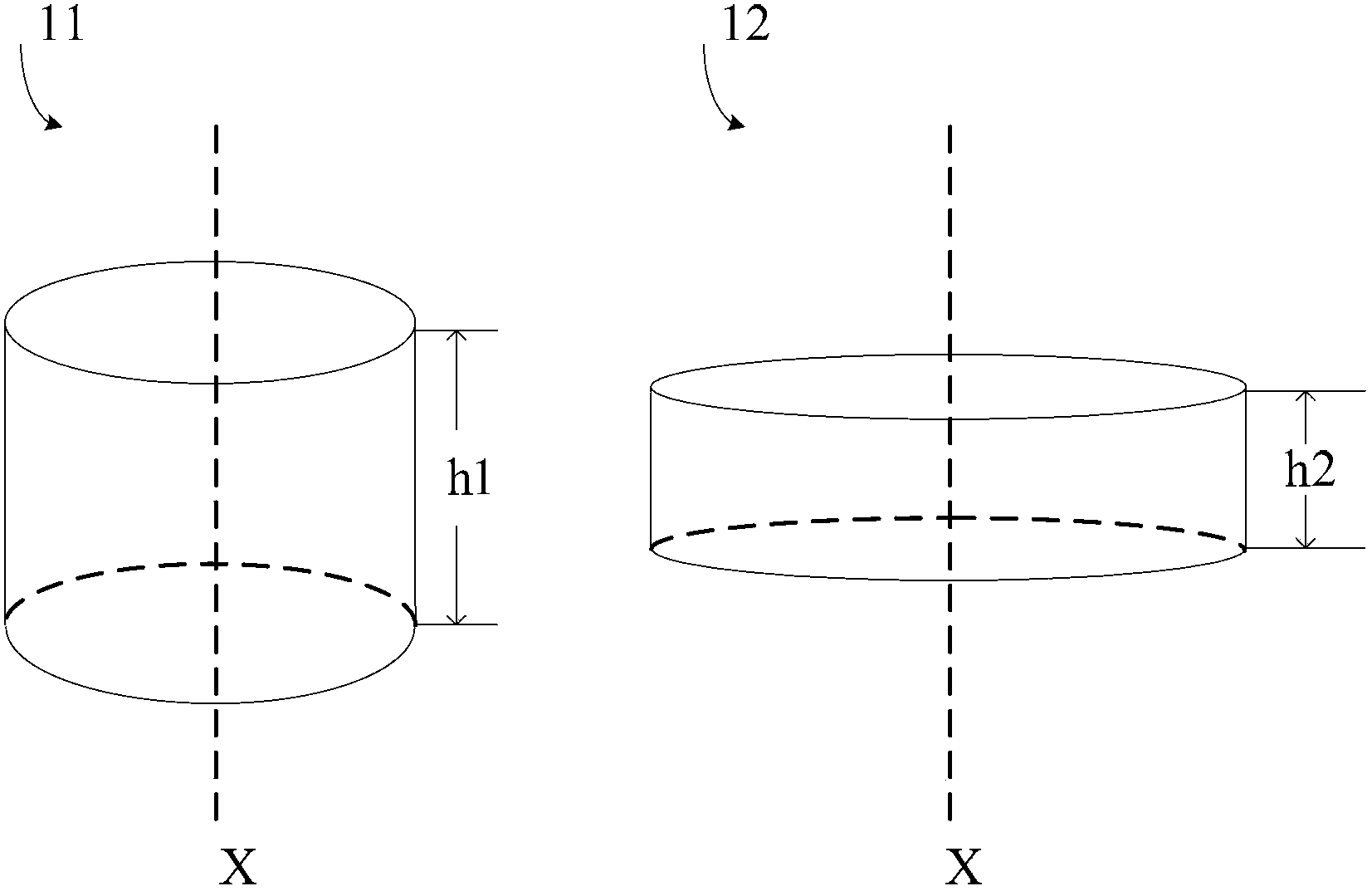

Production method of nickel target and nickel target component

ActiveCN103572224ADense tissueReduce hardnessVacuum evaporation coatingSputtering coatingIngotMaterials science

The invention provides a production method of a nickel target and a nickel target component. The production method of the nickel target comprises the following steps of providing a nickel ingot; performing hot forging on the nickel ingot to form a first nickel target blank; performing first heat treatment on the first nickel target blank to form a second nickel target blank, wherein the temperature of the first heat treatment is 450-550 DEG C, and the temperature is maintained for 1-2 hours; after the first heat treatment, performing hot rolling on the second nickel target blank to form a third nickel target blank; performing second heat treatment on the third nickel target blank to form a fourth nickel target blank, wherein the temperature of the second heat treatment is 300-500 DEG C, and the temperature is maintained for 1-2 hours; after the second heat treatment, performing cold rolling on the fourth nickel target blank to form a fifth nickel target blank; performing third heat treatment on the fifth nickel target blank to form the nickel target, wherein the temperature of the third heat treatment is 200-300 DEG C, and the temperature is maintained for 1-2 hours. By adopting the technical scheme, the produced nickel target has relatively uniform internal organization and good magnetic property.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Neutral hydrophilically-interacted hybrid silicagel-based monolithic column

ActiveCN102636602ASolve electrostatic adsorptionMeet continuous separation requirementsComponent separationZeta potential(Hydroxyethyl)methacrylate

The invention discloses a neutral hydrophilically-interacted hybrid silicagel-based monolithic column which is composed of an uncharged polar organic monomer, a poly-cage type siloxane crosslinking agent, a porogenic agent and an initiator, wherein the uncharged polar organic monomer is hydroxyethyl methacrylate, the poly-cage type siloxane crosslinking agent is methylmethacrylate-based cage-like oligomeric silsesquioxane, the porogenic agent is a mixture of toluene and lauryl alcohols, and the initiator is azodiisobutyronitrile. The polymeric stationary phase of the silicagel-based monolithic column disclosed by the invention is distributed uniformly, the silicagel-based monolithic column is good in permeability and high in mechanical strength, the surface of the stationary phase has no hydroxyl, and the strong electrostatic adsorption between a charged compound and a silicon hydroxyl is solved; and the silicagel-based monolithic column contains rich neutral polar groups, so that the silicagel-based monolithic column can adsorb mobile-phase neutral ions on the surfaces of the stationary phases and provide a certain zeta potential so as to generate a relatively stronger electroosmotic flow, therefore, the silicagel-based monolithic column has a typical hydrophilically-interacted chromatographic performance, and can meet the requirements for the continuous rapid separation of polar neutral and alkaline compound materials.

Owner:FUZHOU UNIV

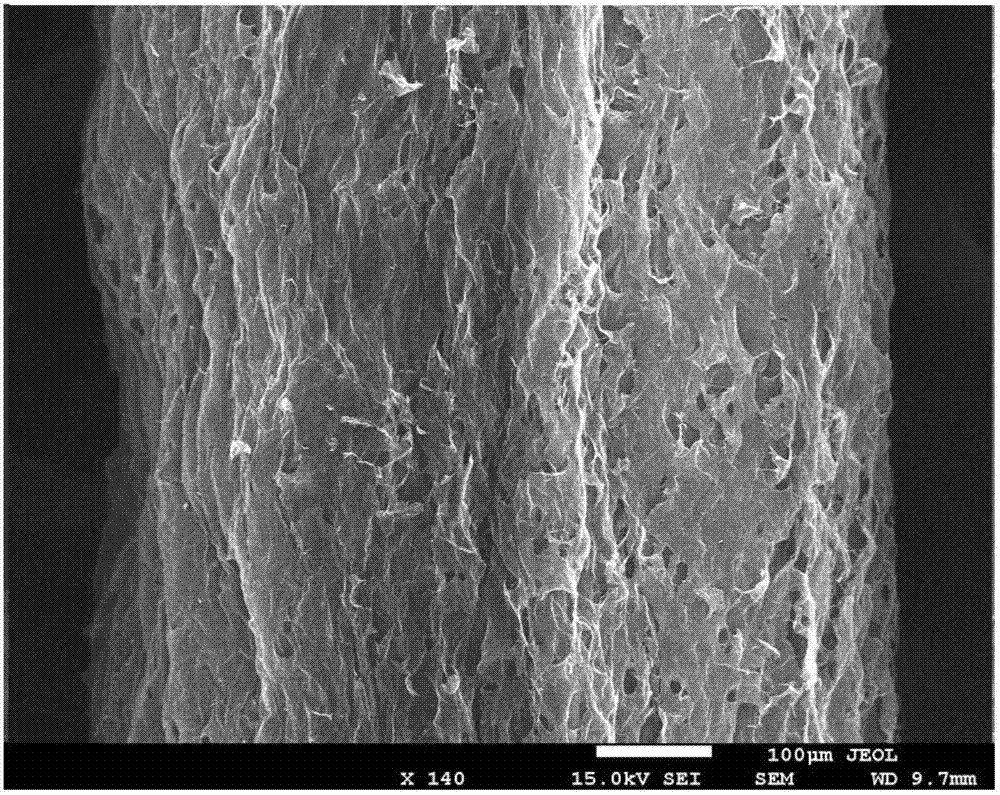

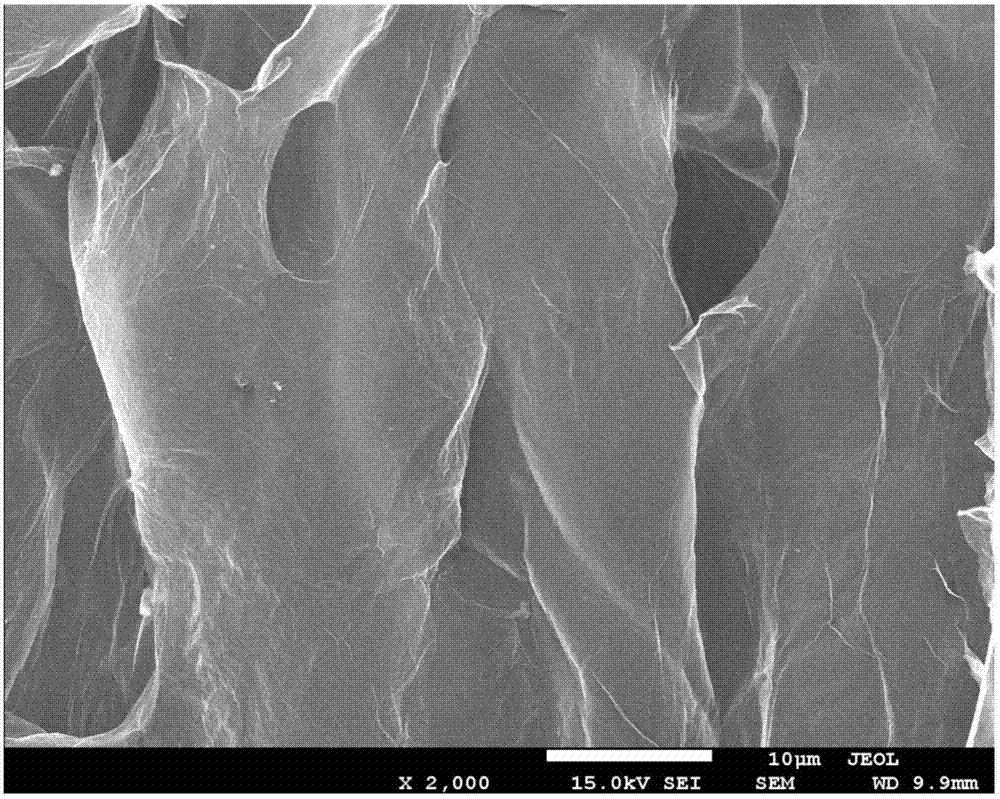

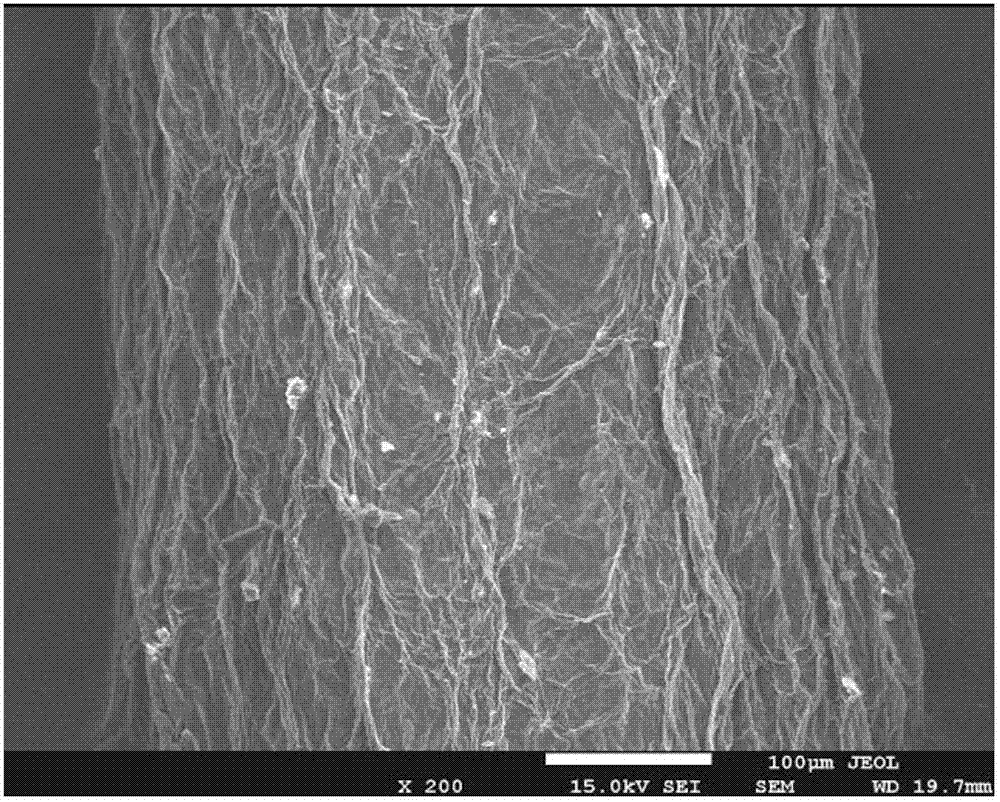

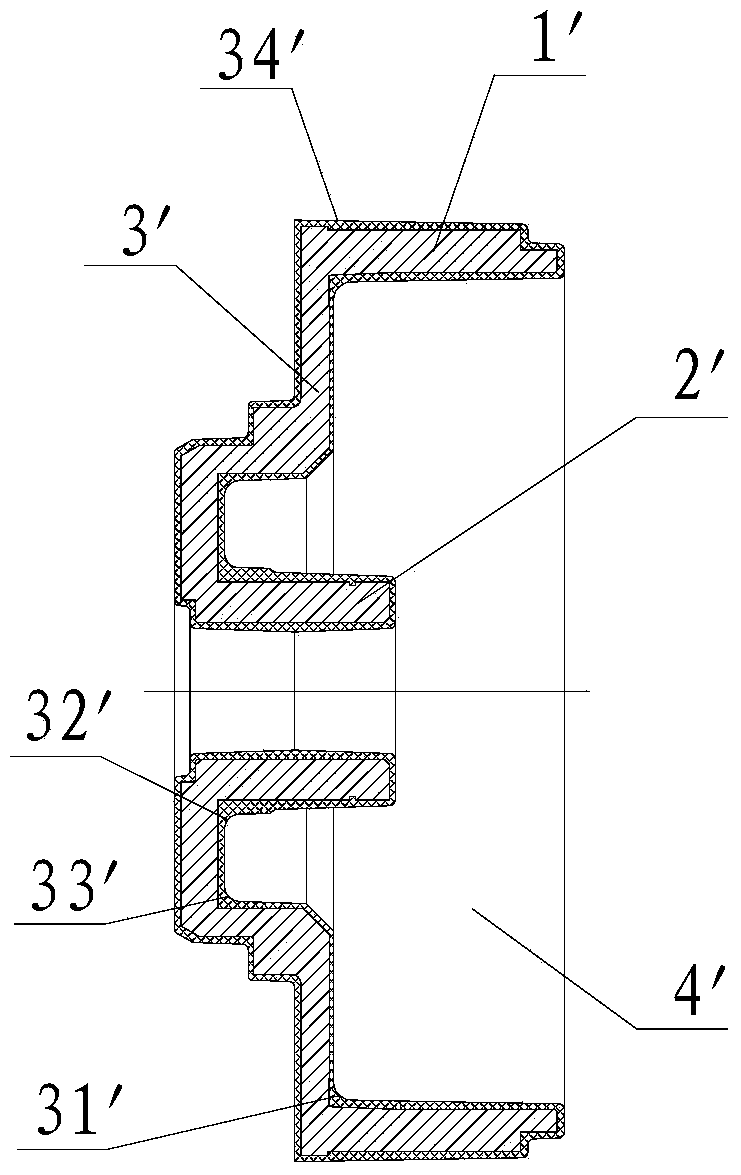

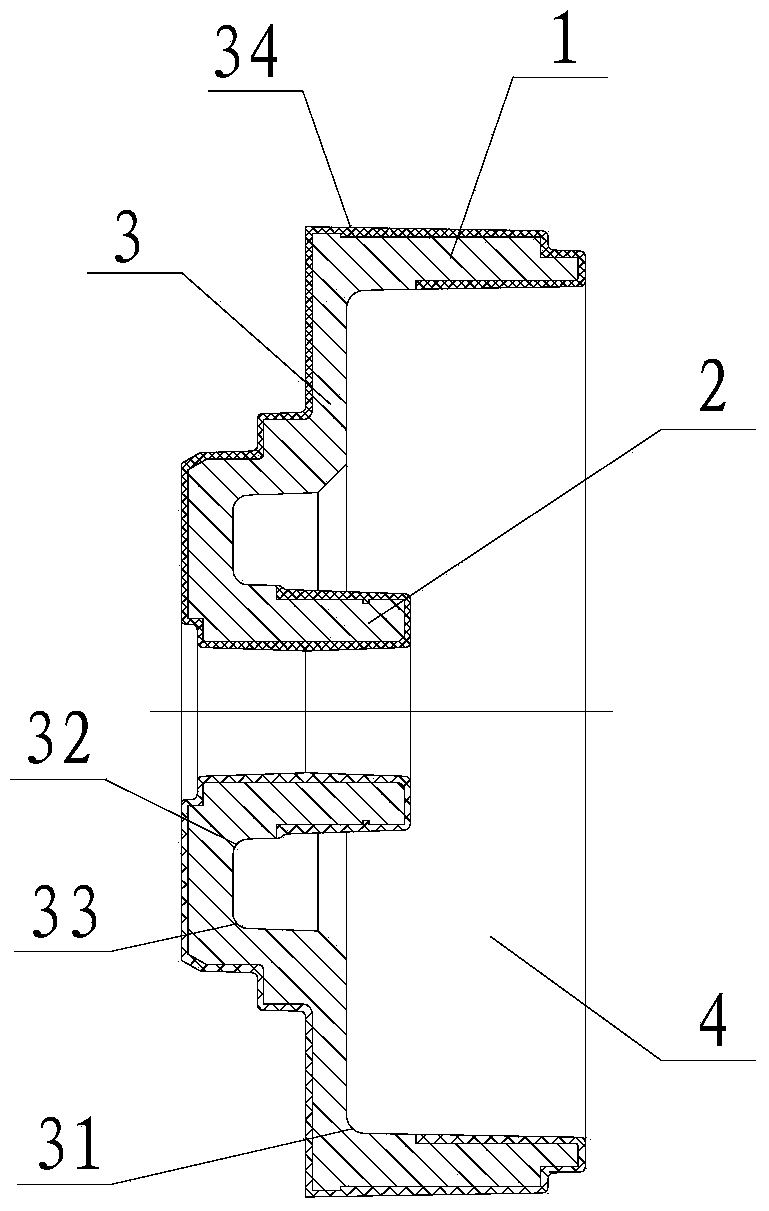

Insulating wood laminating product and preparation method thereof

ActiveCN101941217AWith self-locking abilityHigh mechanical strengthPlywood pressesTransformers/inductances coils/windings/connectionsTransformerHigh resistivity

The invention relates to a wood laminating material, in particular to a wood laminating material used for manufacturing transformer connecting pieces and a preparation method thereof, and more particularly relates to a material which can be processed into woody bolt or woody nut with an insulating function. The raw materials of the product provided by the invention comprises broad leaf miscellaneous tree veneers the water content of which is less than 4%, wherein, the thickness of the veneer is 1-2mm; and the adjacent veneers are arranged according to a sequential fiber direction or a mutually vertical fiber direction, and are superposed one by one into an assembly after being soaked in the insulating rubber, and formed after being carried out hot-pressing. The wood laminating material of the invention has good mechanical strength, arc resistance, higher resistivity, lower dielectric loss and a certain self-locking performance after being soaking in the oil. The product of the invention can be further processed into bolt plates or nut plates; the bolts and the nuts manufactured by the invention have the following advantages that each layer of rubber plate is soaked with modified alcohol-soluble phenol aldehyde resin, thus leading that the bolts and nuts have higher mechanical strength and uniform inner structure compared with an electric laminating wood board, avoiding the property of partial discharge generated by bubbles, making up for the shortcomings of the bolts prepared by phenolic bakelite and nylon, and being used in the transformer with the voltage more than 220KV.

Owner:ZHALANTUN TONGDE WOOD

Method for preparing graphene fiber through graphene film twisting forming method

The invention discloses a method for preparing a graphene fiber through a graphene film twisting forming method. The method comprises the steps that a copper foil-loaded graphene film roll material is prepared on the surface of copper foil through a chemical vapor deposition method or a copper foil vacuum heating method; the copper foil-loaded graphene film roll material is guided into 60-90-DEG C water, a graphene film is separated from the copper foil, and the graphene film is obtained; the copper foil is rolled up to be recycled, the graphene film is twisted into the graphene fiber through a gathering and twisting device and simultaneously output to a winding forming device to be directly made into a graphene fiber bobbin with the twist. According to the method, the operation process is simple and convenient, preparation of the graphene fiber is directly achieved through existing textile equipment, the cost is low, and massive and continuous production can be achieved; the graphene fiber prepared through the method has the twist and are close in combination among layers, uniform in appearance and internal structure, excellent in mechanical performance, good in flexibility and capable of being bent, and the oxidized graphene film can be coated with a nanometer functional material before being slit to obtain a composite graphene fiber with a nanometer function.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Casting technology for improving balance of brake wheel

ActiveCN103480806AGood casting processHigh precisionFoundry mouldsFoundry coresHardnessMultiple point

The invention relates to a casting technology for improving balance of a brake wheel. The casting technology for improving balance of the brake wheel includes the following steps of manufacturing an upper sandbox, manufacturing a lower sandbox, combining the boxes, casting and cleaning. A sand mold structure is manufactured through rearranged molding sand, blowing pre-compacting is performed with compressed air, then, mechanical compacting is performed under the pressure of 100-120N / cm<2>, thus, the sand mold structure can have high hardness, and particularly, the portion, corresponding to the corner of the brake wheel, of the sand mold structure has high compaction degree and surface hardness; on the one hand, migration of the surface mold wall of the sand mold structure caused by casting of molten iron is avoided, and thus casts are prevented from deforming; on the other hand, a molten iron casting channel is communicated with a molding sand cavity through multiple points, thus, the temperature fields of the casts tend to be consistent, and solidified casts are favorable for forming uniform internal organizational structures; therefore, the balance accuracy of the brake wheel is improved, fine-machining amount and difficulty are reduced, and fine-machining time is shortened.

Owner:SUZHOU TORIN MACHINERY CASTING

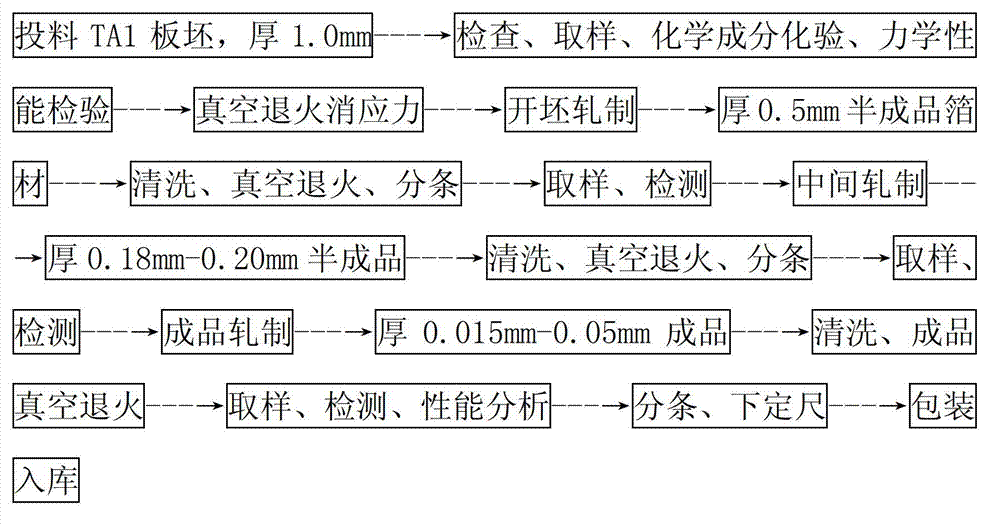

Cold rolling titanium foil process

ActiveCN103084389AImprove ductilityHigh specific strengthMetal rolling arrangementsHydrogenRoom temperature

The invention provides a cold rolling titanium foil process to meet requirements of ultrathin titanium foil machining. The cold rolling titanium foil process is carried out according to the following procedures that (1) blank materials are chosen and processed: hydrogen aluminum blank materials are chosen to be processed in a polished mode; (2) primary rolling is achieved: the blank materials are polished, the materials are reversed, intersected and repeatedly rolled through a multi-roll foil rolling machine for a plurality of times to achieve the fact that the thickness of the materials reaches 0.18mm-0.22mm; (3) end products are rolled: foil materials after primary rolling are rolled to the foil materials with the thickness of 0.05mm-0.003mm, and fatting, cleaning and lapping are achieved; and (4) packaging and annealing are achieved: under the state that titanium foil is naturally relaxed, the titanium foil is packaged through metal zirconium foil good at hydrogen absorption and oxygen absorption, and after the annealing is achieved in a vacuum furnace, the materials out of the furnace are cooled to be in the room temperature to become end products. The prepared foil materials have the advantages of being good in malleability, high in specific strength, excellent in strength of extension and rigidity, and the like.

Owner:宝鸡市星宏昌金属科技有限公司

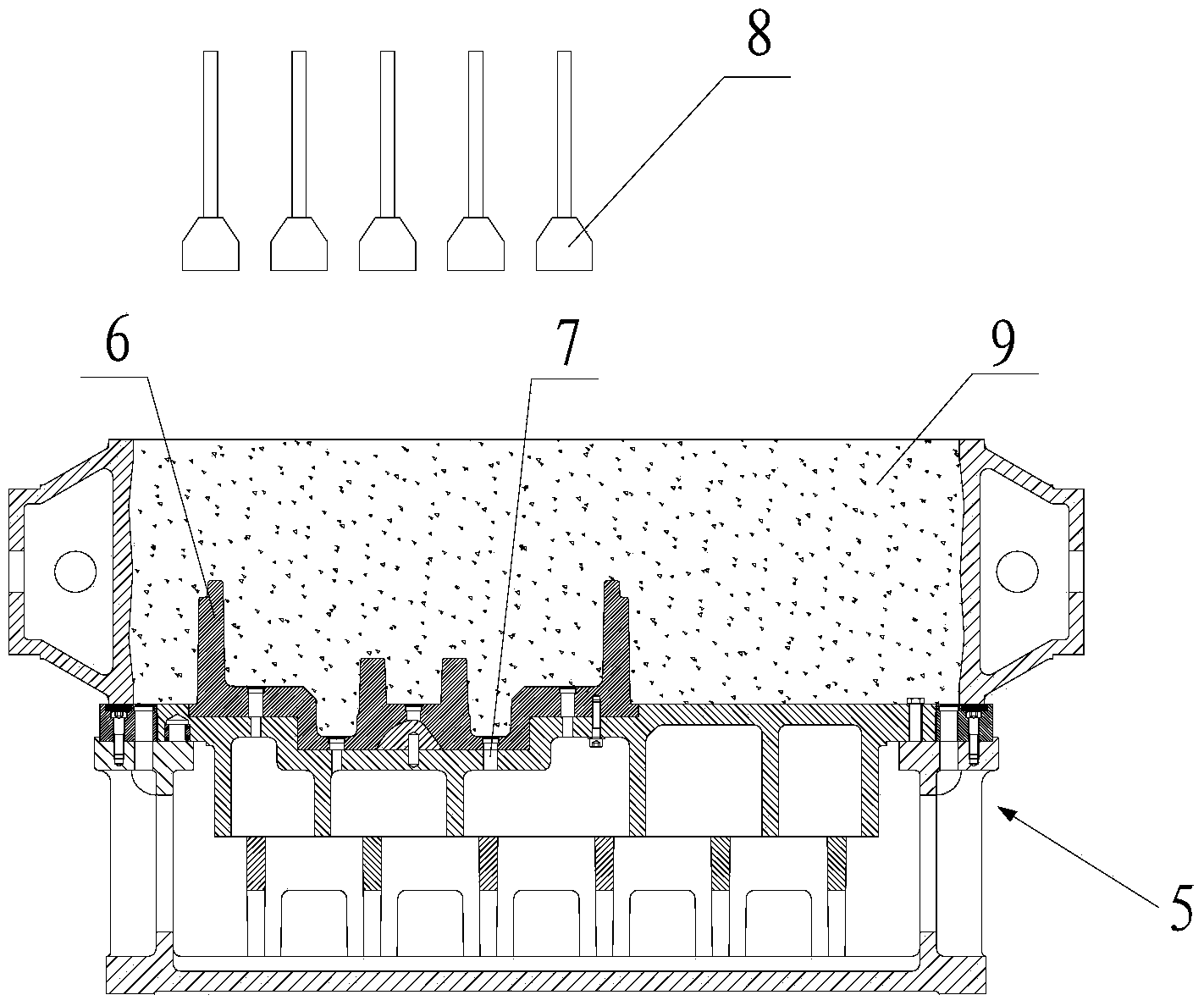

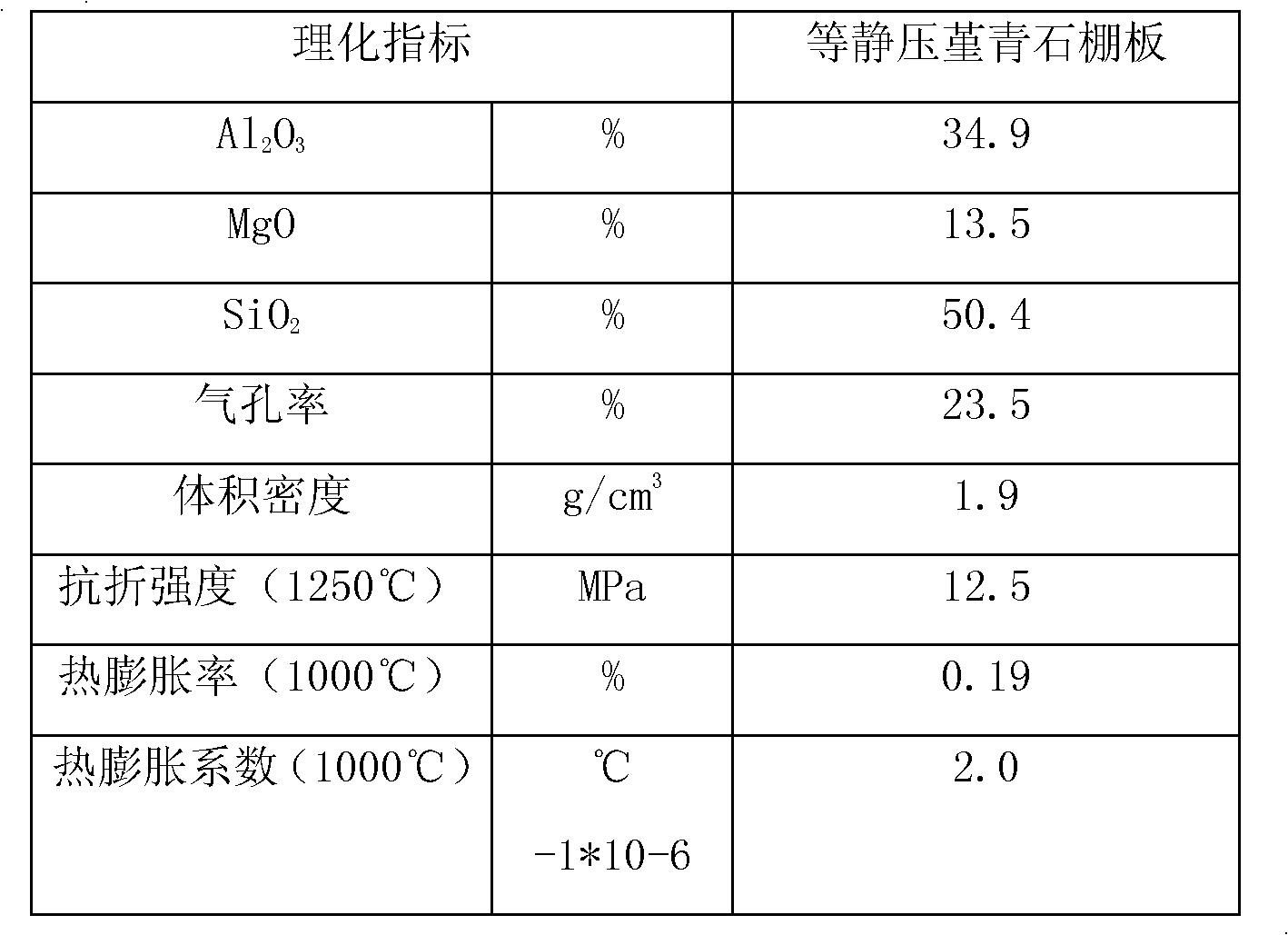

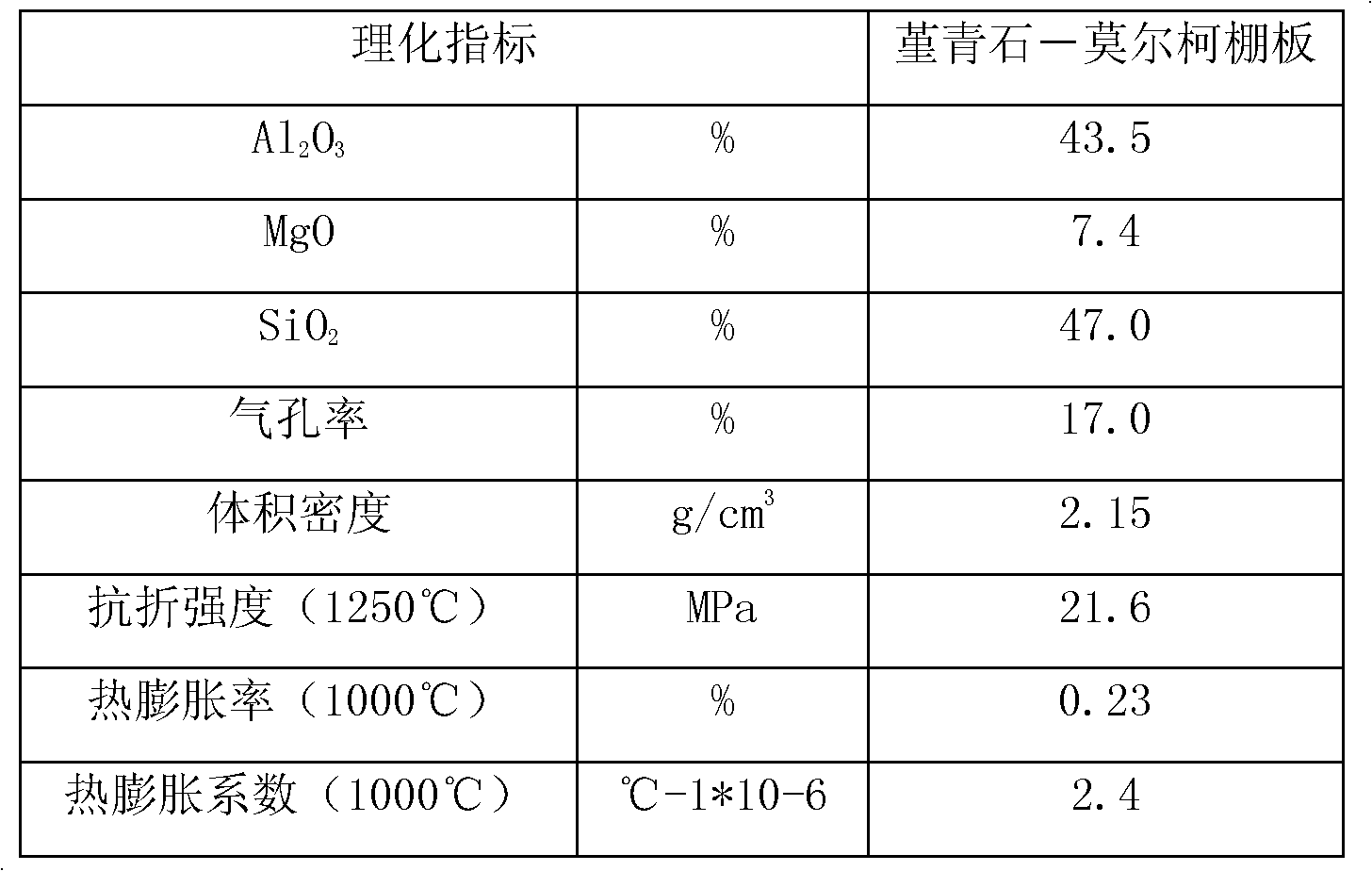

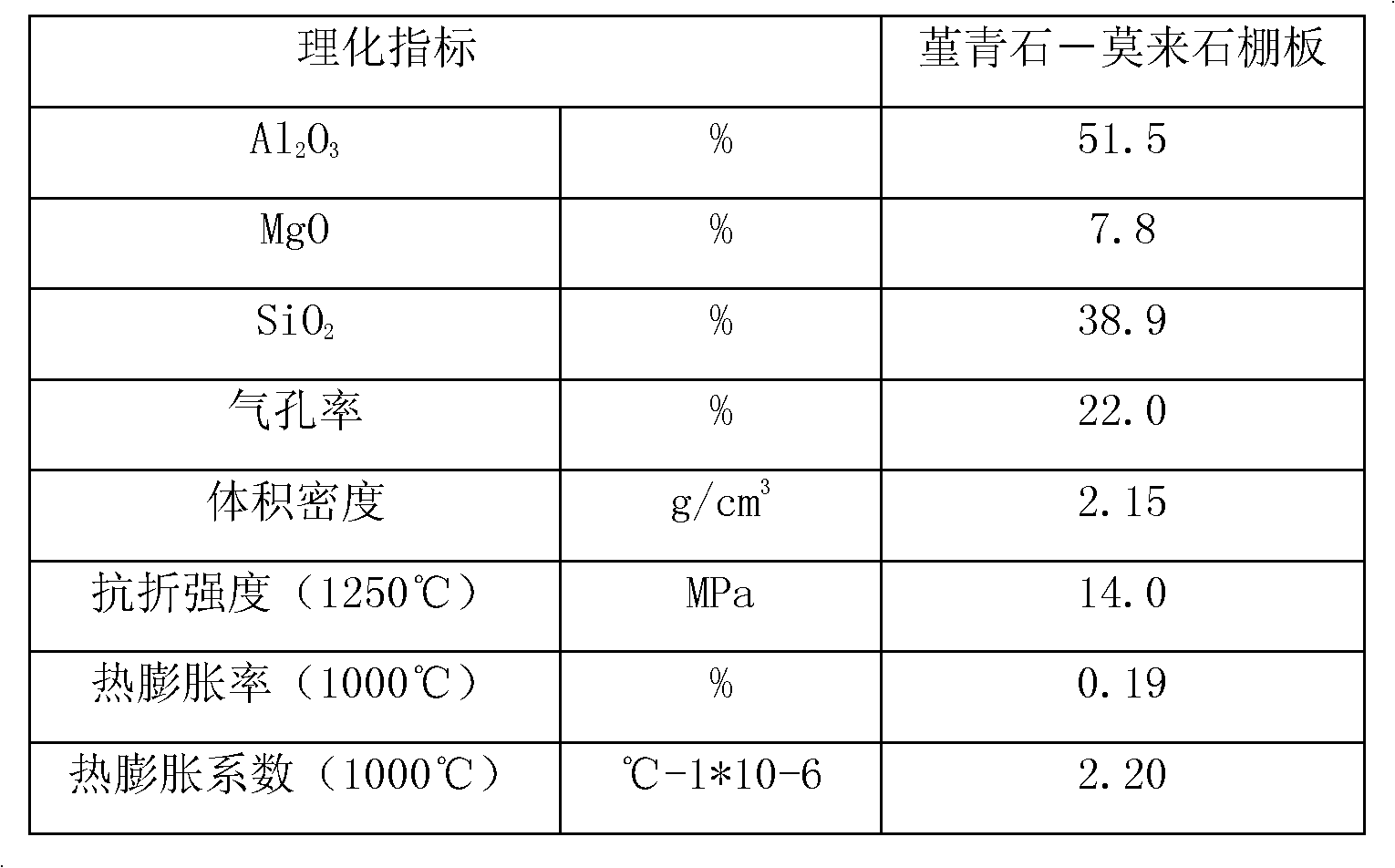

Method for preparing refractory shed plate

InactiveCN102153349AHigh softening temperature under loadHigh temperature strengthCollocationRefractory

The invention relates to a method for preparing a refractory shed plate, belonging to the technical field of refractory materials. The method comprises the steps of dosing, molding and sintering; coarse and fine material collocation; isostatic pressing and high temperature sintering. In the preparing process, the product has the advantages of difficulty in cracking and deformation, high production efficiency, high yield and low manufacturing cost; and the prepared product has the advantages of uniform organization structure, no internal crack, high strength at high temperature, high refractoriness under load, good thermal shock resistance and long service life; and kiln furniture consumption is largely reduced.

Owner:ZIBO GT INDAL CERAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com