Patents

Literature

114results about How to "Good casting process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High strength corrosion resistant rare earth cast magnesium alloy and preparation method thereof

The invention discloses a high strength corrosion resistant rare earth cast magnesium alloy and a preparation method thereof, which is characterized in that: the magnesium alloy comprises the following components according to the weight percentage: 1.8 to 4.0 percent of Nd, 1.0 to 2.0 percent of Gd, 0.2 to 0.8 percent of Zn, 0.4 to 1.0 percent of Zr, 0.0 to 0.8 of Ca, not more than 0.02 percent of total content of impurity elements of Fe, Cu and Ni, and the balance of Mg complemented to 100 percent; and the preparation method comprises the following steps of: melting pure magnesium, adding Mg-Nd intermediate alloy, Mg-Gd intermediate alloy, Mg-Ca intermediate alloy and commercial pure Zn in sequence, heating up to 760 DEG C to 785 DEG C after the mixture is totally melted, adding Mg-Zr intermediate alloy, stirring fully and evenly after the Mg-Zr intermediate alloy is melted, standing for 10 to 20 minutes, removing dross, and then casting ingots or casting the cast products at the temperature of 720 DEG C to 750 DEG C. The cast magnesium alloy has the advantages of controllable melting process, appropriate cost, excellent mechanical property, corrosivity, good casting process property and the like; and the cast magnesium alloy can be used to manufacture various non-die casting magnesium alloy parts by adopting the processes of sand mold casting, low-pressure casting, counter-pressure casting or squeezing casting, etc.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

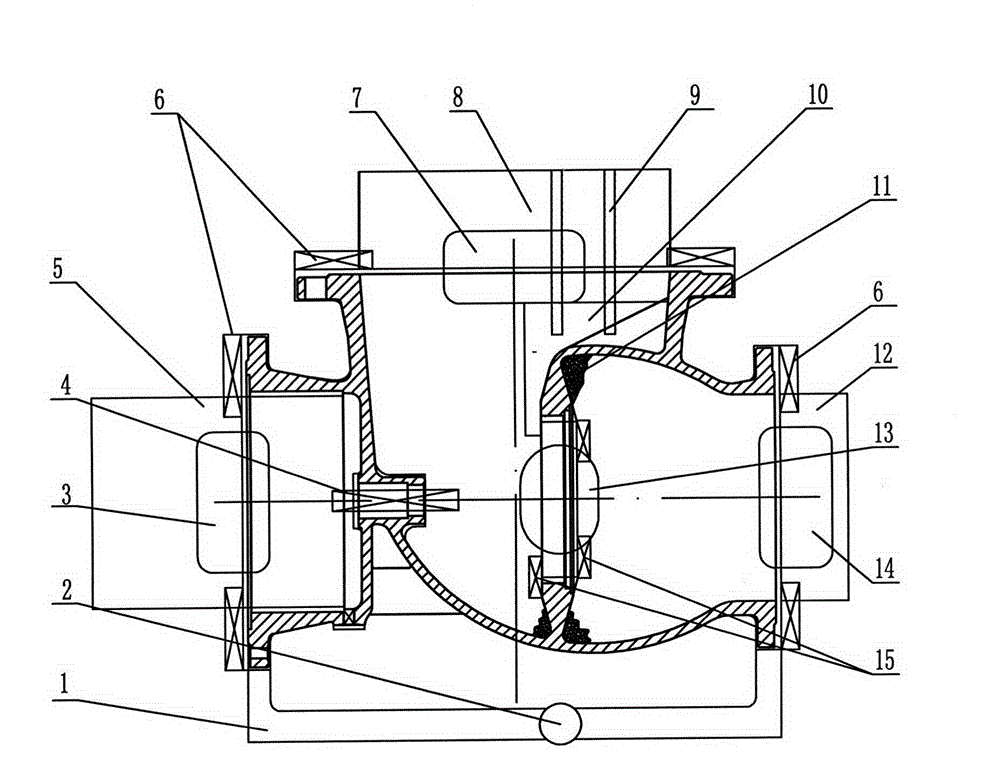

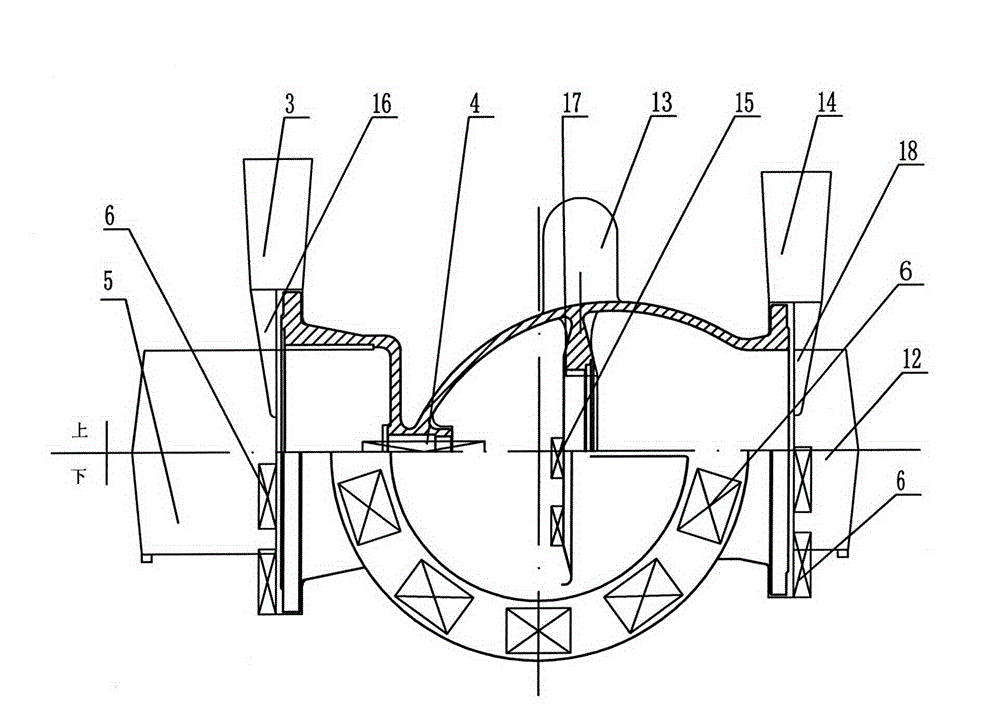

Method for casting air sucking valve steel casting part

ActiveCN103056325AGuaranteed surface qualityGuaranteed compactnessFoundry mouldsFoundry coresMetal moldZircon

The invention relates to a method for casting an air sucking valve steel casting part. The method comprises the steps (1) using central cross sections of flange holes on two sides of the casting part as parting surfaces, manufacturing a metal mold, using water glass quartz sand to manufacture an upper portion and a lower portion, using water glass limestone sand as back sand, using the water glass quartz sand as facing sand to manufacture sand cores and brushing zircon power coatings on the surfaces of the upper portion, the lower portion and the sand cores; (2) placing the sand cores into a cavity of the lower portion, placing outer cold irons on flange end faces of the lower portion, placing open risers and riser pads on the upper portion, placing second outer cold irons on two end faces of an inner flange of the lower portion, correspondingly placing blind risers and riser pads on the upper portion, placing inner cold irons at the valve rod hole positions of a second sand core and a fourth sand core and leading a straight pouring channel and a horizontal pouring channel of a pouring system into flange edges on two sides at the parting surface positions; (3) assembling the mold after the cores fall; (4) smelting furnace burden and pouring the casting part; and (5) performing cooling, mold opening and core falling to clean the casting part. By means of the method for casting the air sucking valve steel casting part, casting part cracks can be decreased, an internal structural of the casting part is compact, and the rate of finished products is high.

Owner:CRRC QISHUYAN INSTITUTE CO LTD +1

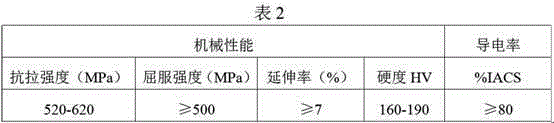

Low-alloy cast steel and application thereof in heavy lorry axle housing, raw materials and machining process

The invention discloses a low-alloy cast steel suitable for a heavy lorry axle housing. The low-alloy cast steel comprises the following elements in percentage by mass: 0.23 to 0.33 percent of C, 0.50 to 1.00 percent of Si, 0.90 to 1.40 percent of Mn, 0.10 to 0.25 percent of Cr, 0.10 to 0.25 percent of Mo, 0.20 to 0.25 percent of V, less than or equal to 0.04 percent of P, less than or equal to 0.04 percent of S, less than or equal to 0.20 percent of residual elements, and the balance of Fe. Waste steel, pig iron, ferromanganese alloy, silicon ferromanganese alloy, ferrochromium alloy, ferromolybdenum alloy and ferrovanadium alloy are used as raw materials of the low-alloy cast steel; and the machining process of the low-alloy cast steel comprises casting and thermal treatment. The low-alloy cast steel has the advantages of high mechanical property, good low-temperature impact toughness and good casting and machining process properties, and is particularly suitable for producing the lorry axle housing.

Owner:山东新达重工机械有限公司

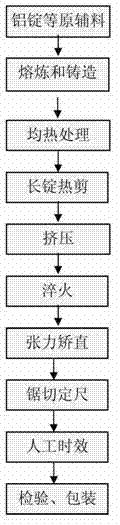

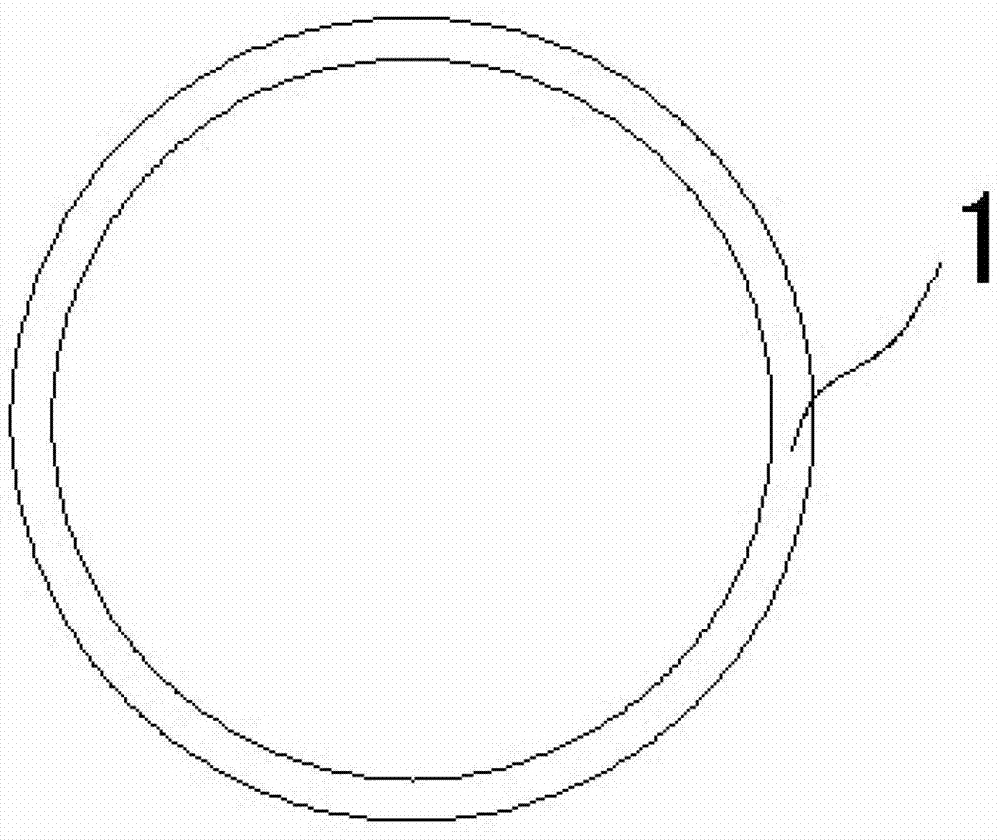

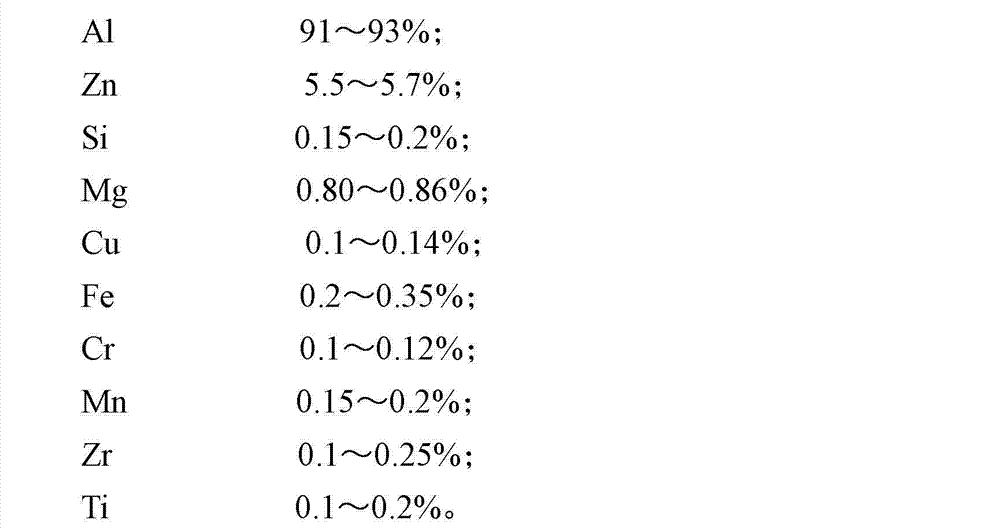

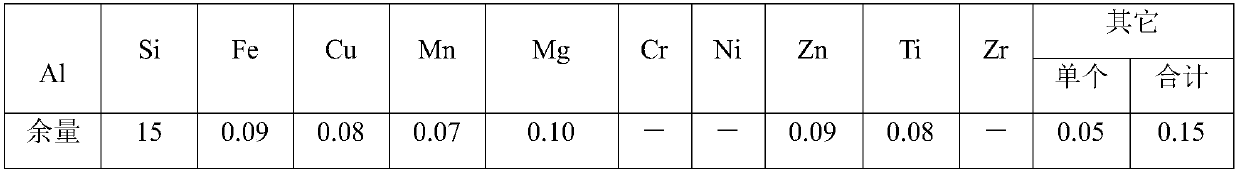

Aluminum profile and heating processing technology thereof

An aluminum profile is annular and is prepared by components in percentage by weight: 91-93% of Al, 5.5-5.7% of Zn, 0.15-0.2% of Si, 0.80-0.86% of Mg, 0.1-0.14% of Cu, 0.2-0.35% of Fe, 0.1-0.12% of Cr, 0.15-0.2% of Mn, 0.1-0.25% of Zr and 0.1-0.2% of Ti. A heating processing technology comprises following steps of: (1) smelting and casting raw material aluminum ingots, enabling a casting speed to be 85-95mm / min, enabling a pouring temperature to be 715-730 DEG C, and enabling cooling water pressure to be 0.04-0.08MPa; (2) extruding, enabling an extruding temperature to be 440-460DEG C, and enabling an extruding speed to be 3-6M / min; (3) conducting stretcher strengthening, and enabling strengthening deformation quantity to be 0.5%-1.5%; (4) conducting aging furnace heating, enabling a furnace temperature of an aging furnace at a first section of aging to be 100 DEG C, enabling heat preservation time to be 3h, enabling the furnace temperature of the aging furnace at a second section of aging to be 160 DEG C, and enabling heat preservation time to be 5h; and (5) testing and packaging. The aluminum profile mainly solves the problem that the aluminum profile in the prior art is not high in strength, poor in breakage toughness and poor in fatigue performance.

Owner:张家港市金邦铝业股份有限公司

Method for casting piston blank with inner cooling path by liquid state extruding casting process

Owner:SHANDONG BINZHOU BOHAI PISTON

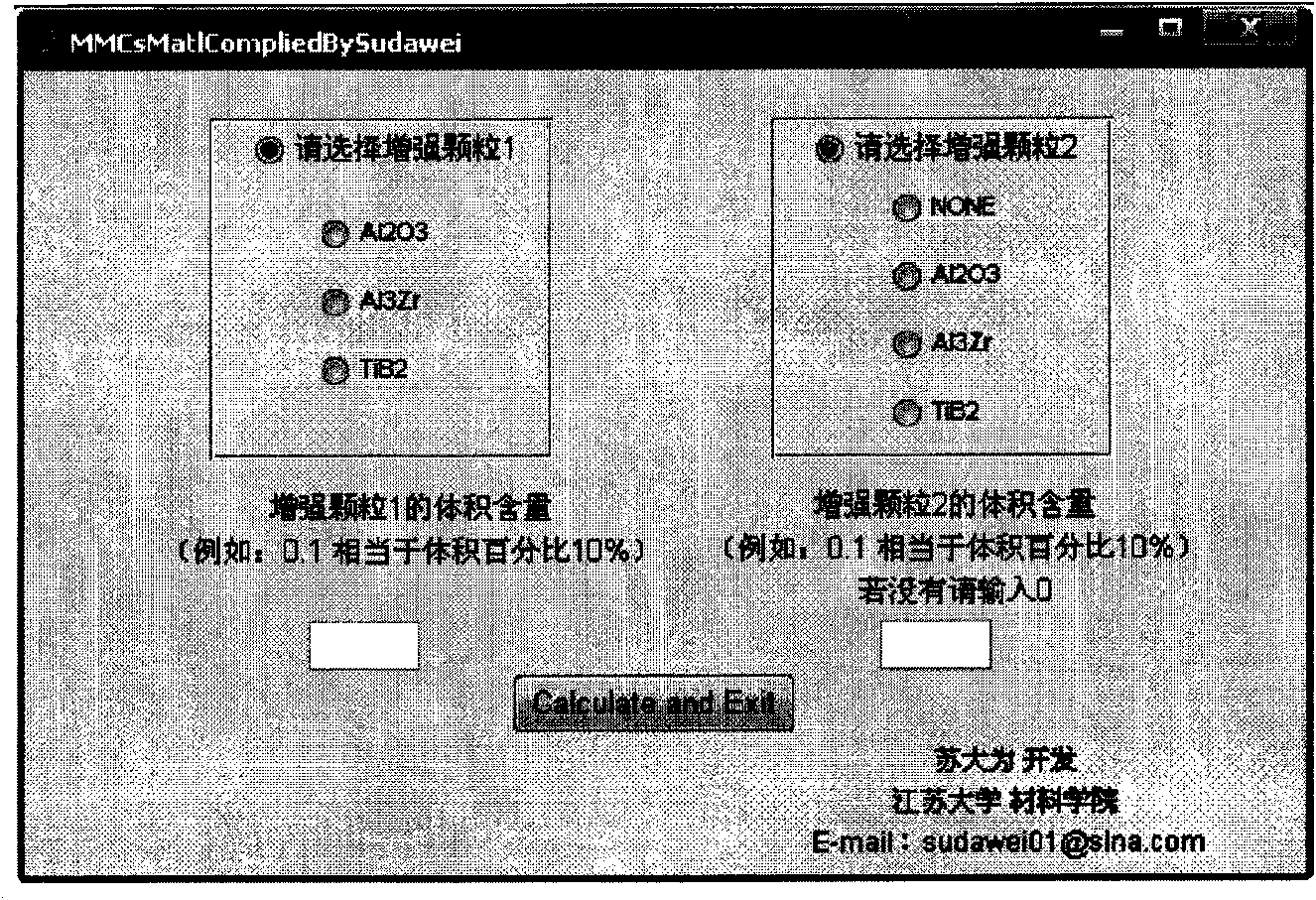

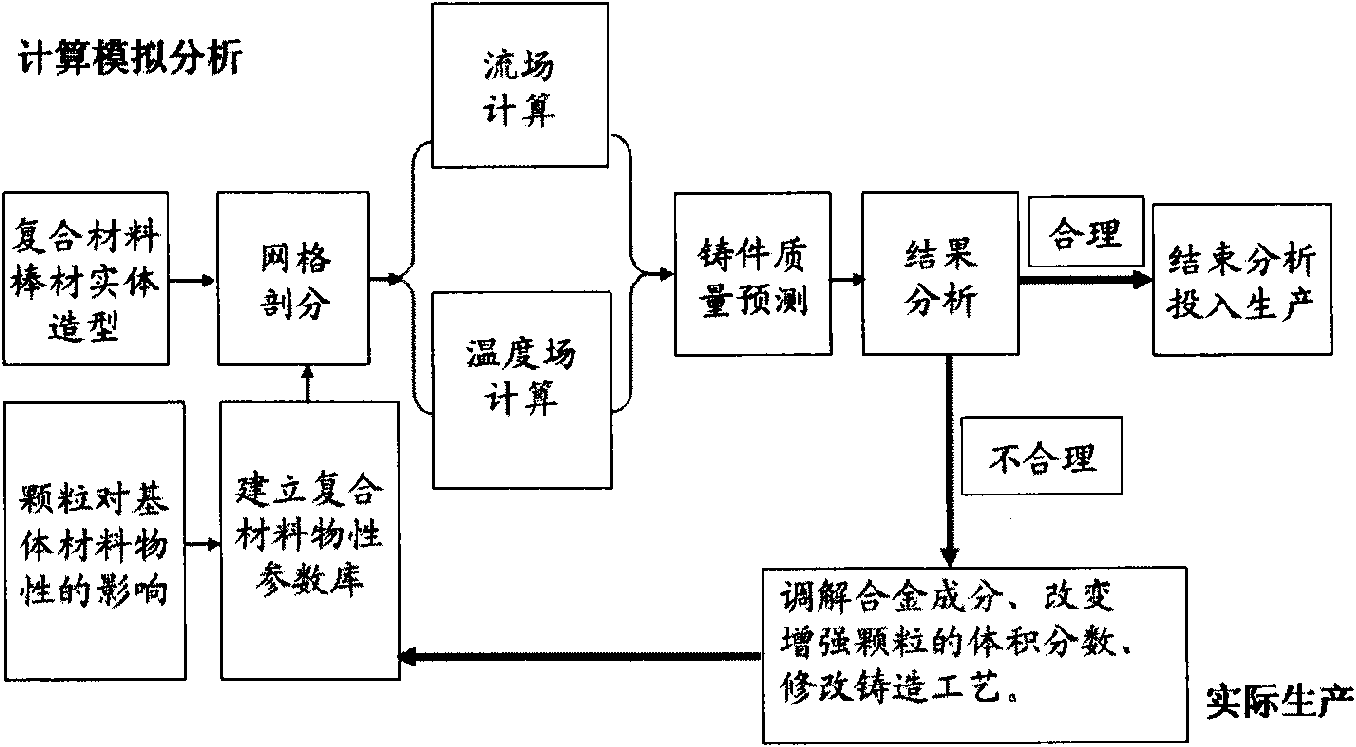

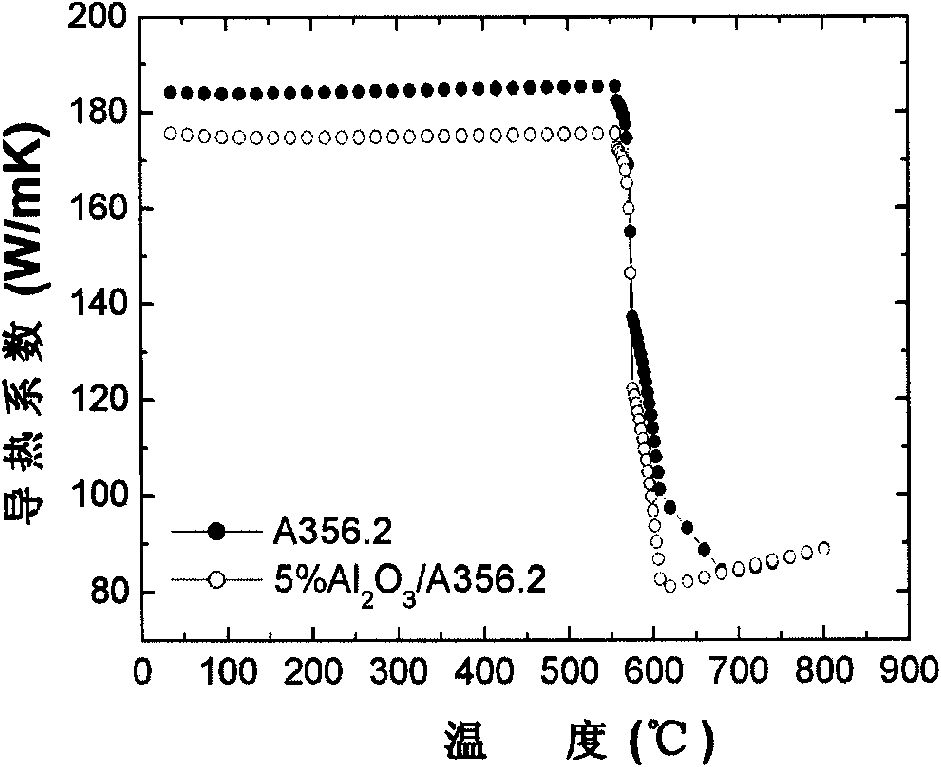

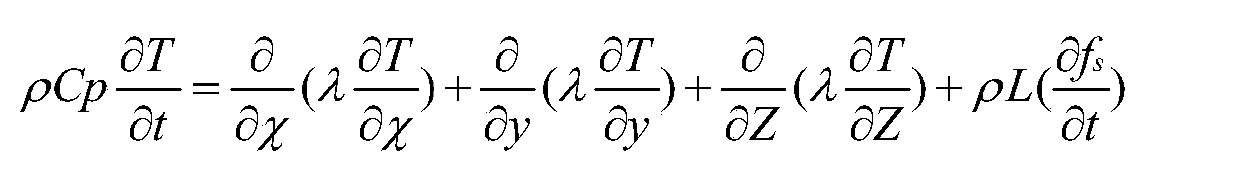

Computer simulation method for casting property of particle-reinforced aluminum matrix composite

InactiveCN101567019AGood casting processEliminate casting defectsSpecial data processing applicationsBoundary valuesSpatial structure

The invention relates to a computer simulation method for the casting property of a particle-reinforced aluminum matrix composite, which comprises the following steps: acquiring volume fraction or mass fraction of a reinforcement particle of an aluminum matrix composite to be analyzed input into a computer and mass fraction of a matrix composition; calculating and determining physical parameters of a metallic matrix composite by using the data through a performance calculation program of the metallic matrix composite; dividing a space structure grid of a component to be cast, and determining boundary value conditions of the casting process; calculating a flow field, a temperature field and a stress field of the boundary value conditions and cooling parameter added value; analyzing the casting property of the composite according to the calculation result; and if the casting performance is not satisfied, recalculating until a satisfied product is obtained by adjusting the casting process or the addition of the reinforcement particles or adjusting the alloy content in the range of an allowable alloy content. The computer simulation method has the advantages of improving the yield, shortening a new product development cycle, and reducing the cost.

Owner:JIANGSU UNIV

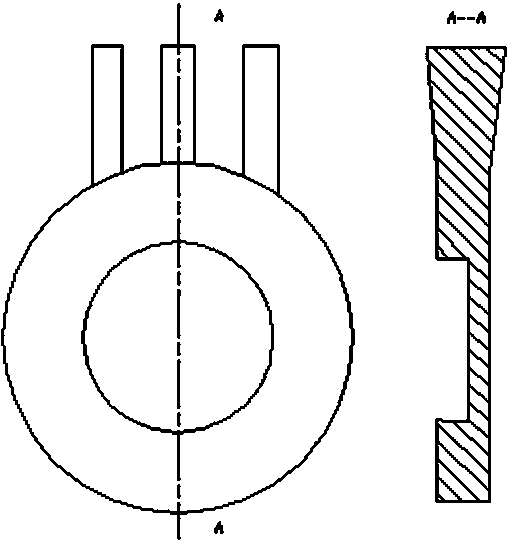

Casting technology for improving balance of brake wheel

ActiveCN103480806AGood casting processHigh precisionFoundry mouldsFoundry coresHardnessMultiple point

The invention relates to a casting technology for improving balance of a brake wheel. The casting technology for improving balance of the brake wheel includes the following steps of manufacturing an upper sandbox, manufacturing a lower sandbox, combining the boxes, casting and cleaning. A sand mold structure is manufactured through rearranged molding sand, blowing pre-compacting is performed with compressed air, then, mechanical compacting is performed under the pressure of 100-120N / cm<2>, thus, the sand mold structure can have high hardness, and particularly, the portion, corresponding to the corner of the brake wheel, of the sand mold structure has high compaction degree and surface hardness; on the one hand, migration of the surface mold wall of the sand mold structure caused by casting of molten iron is avoided, and thus casts are prevented from deforming; on the other hand, a molten iron casting channel is communicated with a molding sand cavity through multiple points, thus, the temperature fields of the casts tend to be consistent, and solidified casts are favorable for forming uniform internal organizational structures; therefore, the balance accuracy of the brake wheel is improved, fine-machining amount and difficulty are reduced, and fine-machining time is shortened.

Owner:SUZHOU TORIN MACHINERY CASTING

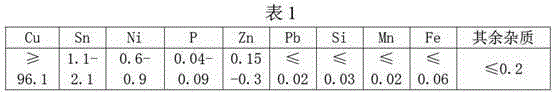

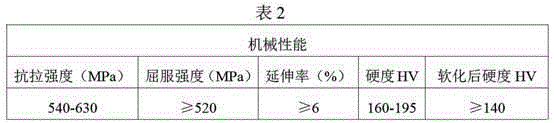

Preparation method of Cu-Ni-Sn plate strip

The invention relates to the field of copper alloys, particularly relates to a preparation method of a Cu-Ni-Sn plate strip, solves the technical problem that the final tensile strength, yield strength and hardness of the copper alloy of lead frames in the prior art cannot meet the production standard requirements, and adopts the theories of solution strengthening, precipitation strengthening and work hardening. Hot rolling solution treatment is characterized in that the solubility of solute atoms is high at the high temperature, the solute atoms exist in base copper in form of solid solution, the solute elements are not precipitated in time after quickly cooling and form saturated solid solution; during the precipitation strengthening process, the solubility of Ni and Sn atoms in the copper are rapidly reduced and are precipitated from a substrate, and the substrate is diluted; during cold rolling process, the copper alloy plate strip generates plastic deformation, grains slip and entwist in a dislocation manner, so that the grains are elongated, crushed and fibered. Through the preparation method of the Cu-Ni-Sn plate strip, the requirements of high strength, high yield and high hardness can be achieved, so that the final tensile strength, yield strength and hardness of the TKA copper alloy plate strip are improved.

Owner:山西春雷铜材有限责任公司

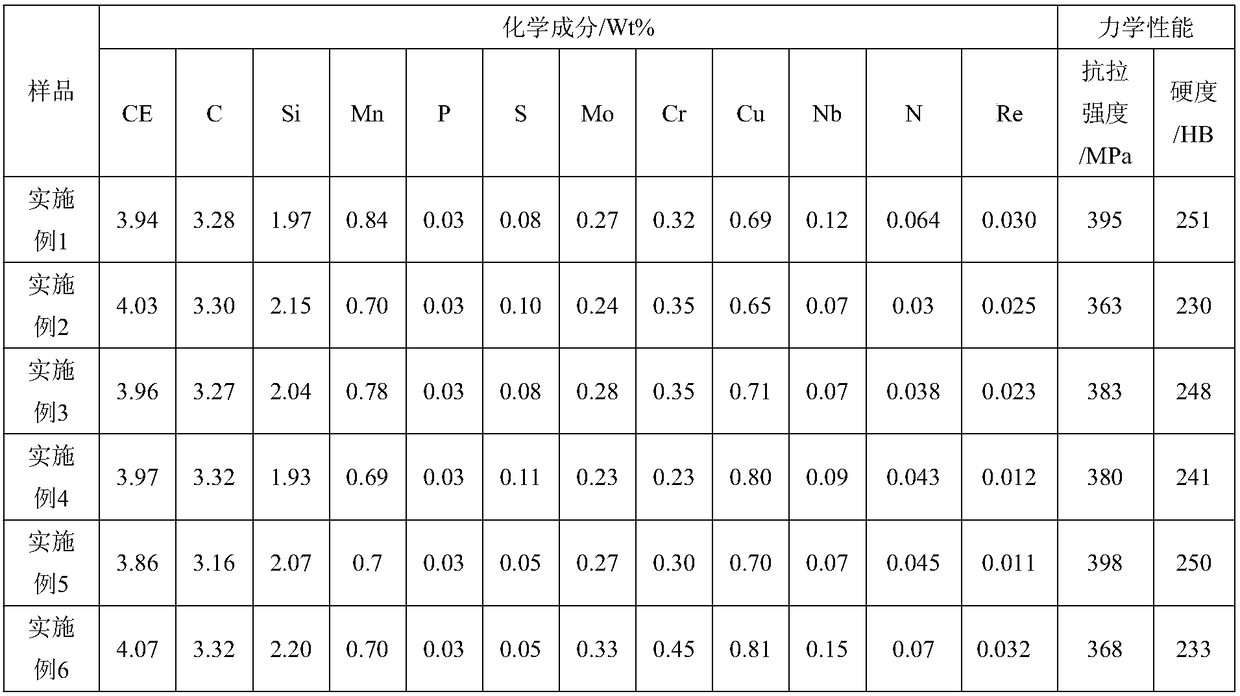

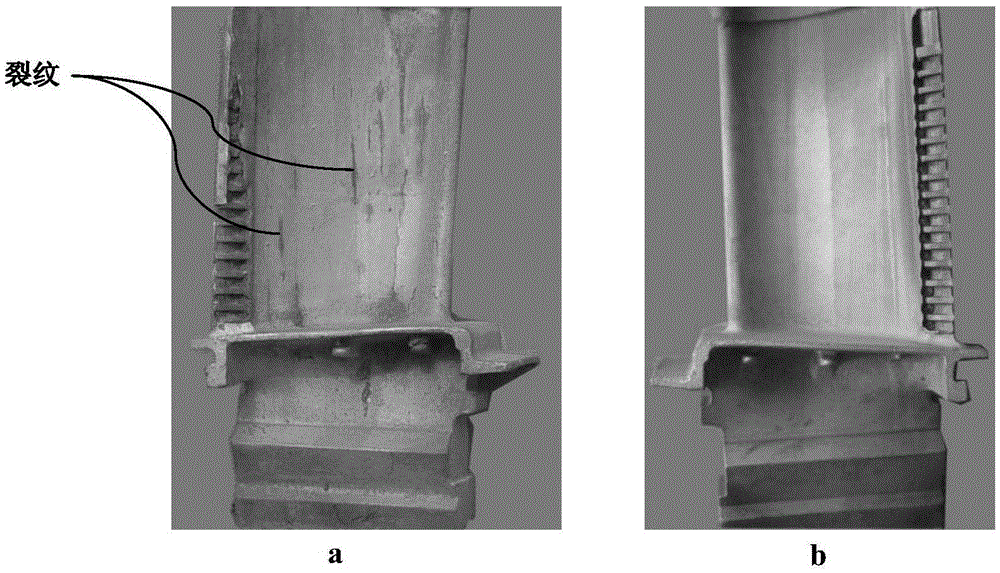

High-carbon equivalent and high-strength gray cast iron and preparation method thereof

The invention discloses a high-carbon equivalent and high-strength gray cast iron and a preparation method thereof, and belongs to the field of gray cast iron materials. The high-carbon equivalent andhigh-strength gray cast iron mainly comprises, by weight, 3.1-3.5 % of C, 1.7-2.3% of Si, 0.04-0.2% of Nb, 0.03-0.1% of N, 0.5-1.0% of Mn, 0.03-0.15% of S, 0.06% or less of P, 0.65-0.9% of Cu, 0.31-0.5% of Cr, 0.1-0.4% of Mo, 0.01-0.04% of Re, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: alloy melting, inoculating treatment and casting. Routine chemical elements are optimized, and Nb and N elements are compounded and added, so a technical problem that gray cast iron parts cannot simultaneously meet the requirements of high carbon equivalent, high strength and few casting defects is solved, and the problem of cracking of the high-carbon equivalent gray cast iron parts, caused by low strength, is solved.

Owner:DONGFENG COMML VEHICLE CO LTD

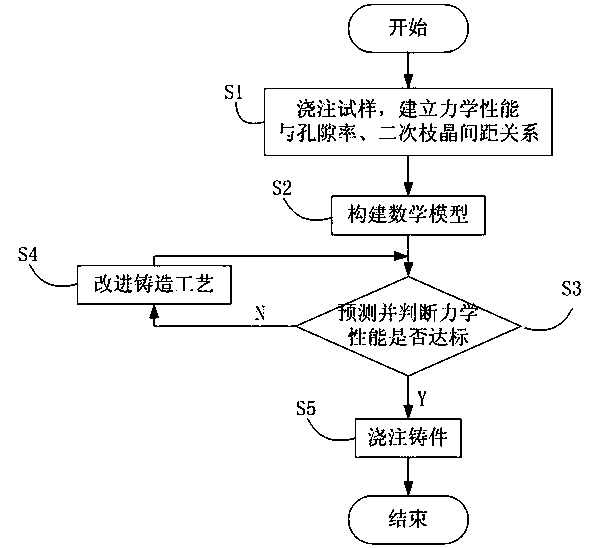

Aluminum alloy casting mechanical performance prediction method

InactiveCN104899412AGood casting processGuarantee casting qualitySpecial data processing applicationsPorosityMathematical model

The invention provides an aluminium alloy casting mechanical performance prediction method, comprising: first casting a sample, establishing a relationship among a mechanical performance, porosity and secondary dendrite arm spacing; then constructing a mathematical model of microscopic porosity and secondary dendrite formed in a casting solidification process; and finally predicting values of the microscopic porosity and the secondary dendrite by a computer before casting, and predicting a mechanical performance of an aluminum alloy casting according to the relationship among a mechanical performance, porosity and secondary dendrite arm spacing. When the predicted mechanical performance is not up to standard, an improved casting technique enables the mechanical performance to meet design requirements, so as to achieve a purpose of nondestructive testing. The invention has the advantages that the casting technique is optimized, casting quality is ensured, once casting is achieved, and an important application value is achieved.

Owner:SHENYANG AEROSPACE UNIVERSITY

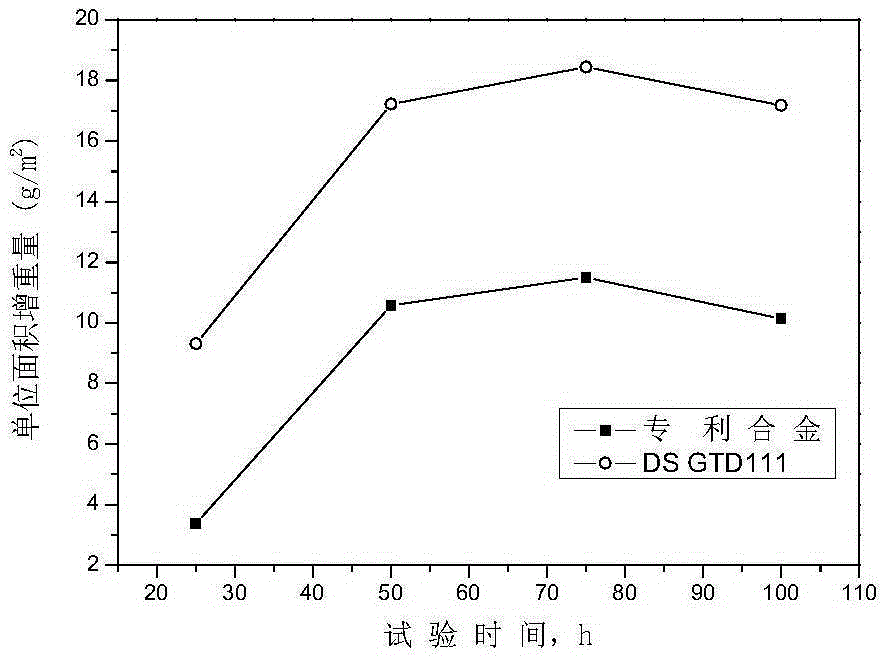

High-temperature alloy casting resistant to high-temperature hot corrosion

ActiveCN105349842AImprove mechanical propertiesGood long-term aging tissue stability at high temperatureFoundry mouldsFoundry coresMetallic materialsHigh-temperature corrosion

The invention belongs to the field of metal materials and relates to a high-temperature alloy casting which is resistant to high-temperature hot corrosion and is used for a part at the hot end of a gas turbine. Alloy comprises, by mass, 3.8%-6.0% of Al, 0.5%-3.5% of Ti, 10.0%-12.0% of Cr, 5.0%-7.0% of Ta, 8.0-10.0% of Co, 4.0%-7.0% of W, 1.0%-3.0% of Mo, 0-3.0% of Hf, 0-4% of Re, 0.02%-0.15% of C, 0.002-0.02% of B and the balance nickel. According to the high-temperature alloy casting resistant to high-temperature hot corrosion, the Al / Ti value, the content of Hf and the ratio of the content of Hf to the content of C and B are adjusted, so that the casting performance of the alloy is improved, and the high-temperature burning hot corrosion performance of the alloy is improved. Thus, the gas turbine high-temperature alloy more suitable for hollow blade casting is obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

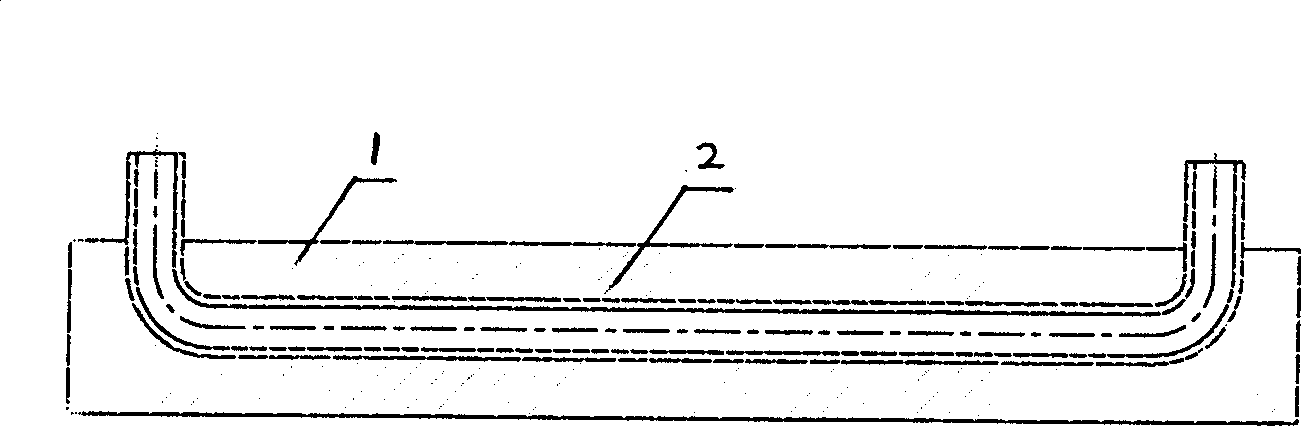

Low thermal resistance cast-iron cooling wall and manufacturing method thereof

InactiveCN1869568AImprove heat transfer efficiencyImprove thermal conductivityFurnace cooling arrangementsCarbon coatingDuctile iron

The invention relates to a new type low thermal resistance cast iron cooling wall. The feature is that the identity material of cooling wall is nodular cast iron or gray cast iron and the cooling water channel in cooling wall is made up from pure copper. The clearance between the cooling wall identity and the outer wall of pure copper pipeline is below 0.1mm. The manufacture method includes the following steps: fixing the molded pure copper pipeline into the sand box; casting by molten iron of nodular cast iron or gray cast iron, and taking inertia vapor cooling to copper pipeline to molding. The invention eliminates the thermal resistance caused by anti seepage carbon coating layer to make the heat exchange efficiency sharply increase and prolong the useful life of cooling wall.

Owner:NANJING NANGANG IND DEV CO LTD

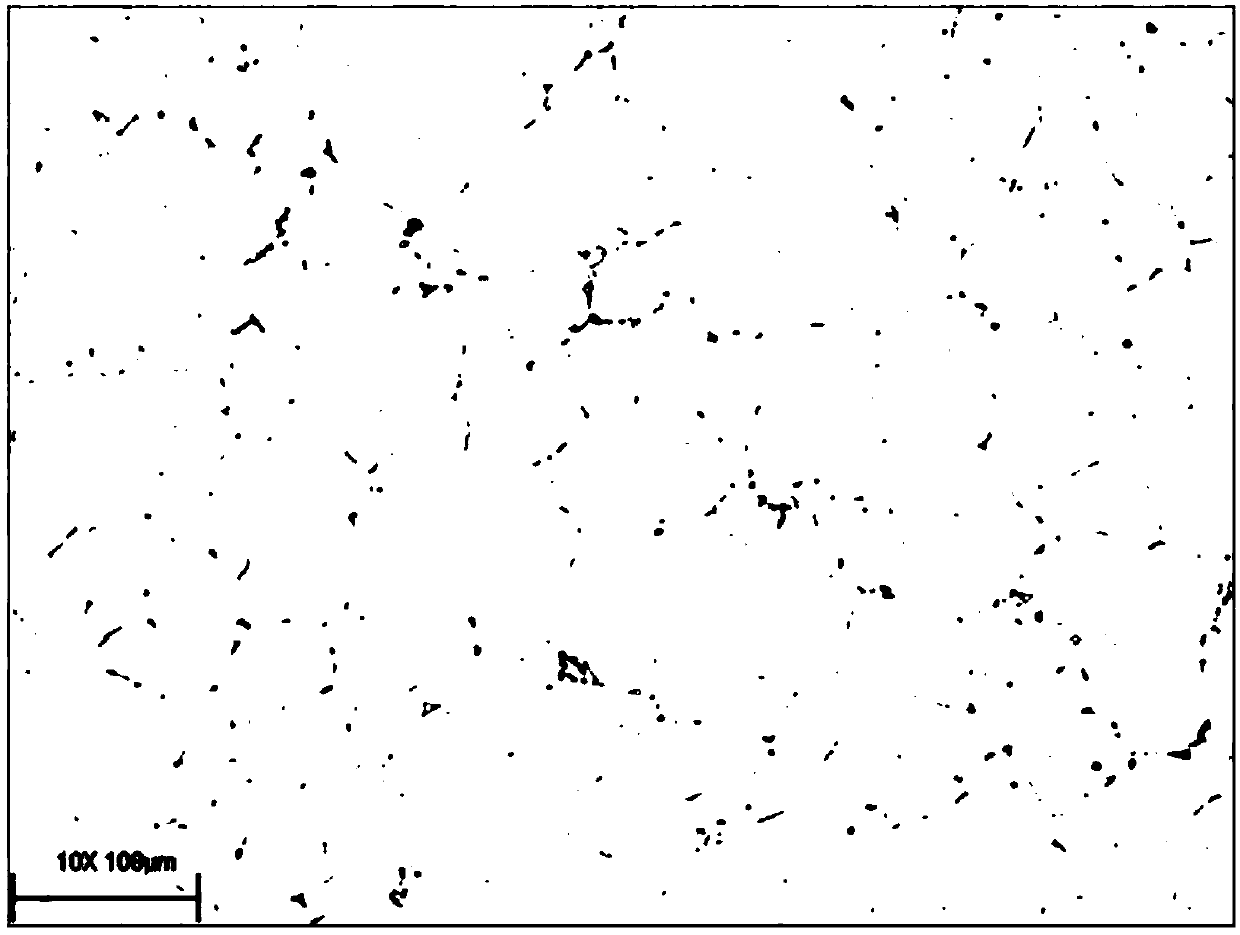

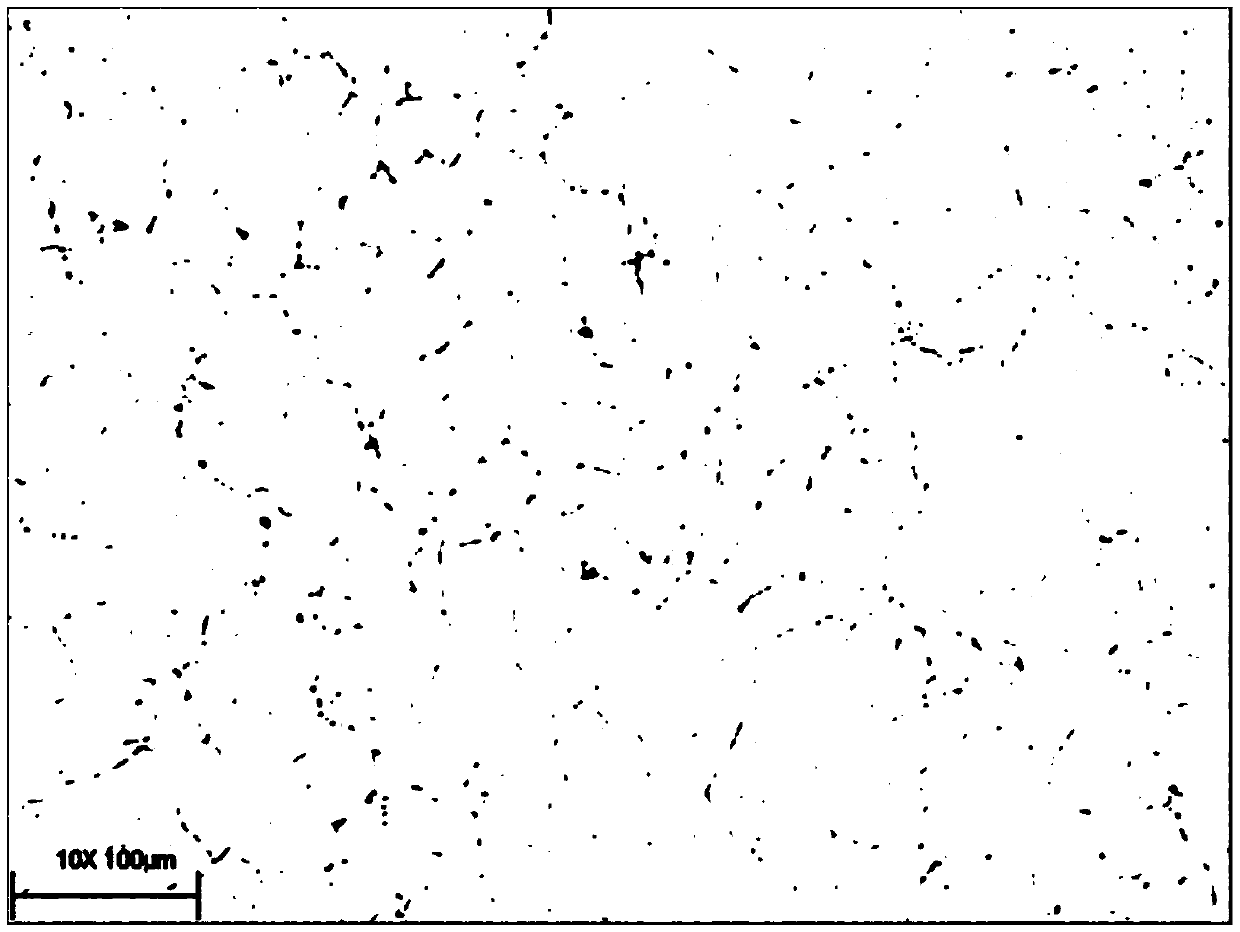

Aluminum alloy and casting method thereof

The invention provides an aluminum alloy and a casting method thereof. According to the aluminum alloy and the casting method thereof, pure silicon is added into molten aluminum, an aluminum alloy silicon ingot is acquired, and the manufactured silicon ingot serves as an intermediate alloy to be added into the molten aluminum so that an aluminum alloy cast ingot can be acquired. According to the aluminum alloy and the casting method thereof, purification treatment of the pure silicon and a homogenizing working procedure are added, the content of impurities in the molten aluminum is reduced, moreover, due to the fact that the aluminum alloy silicon ingot is the intermediate alloy, the melting point is low, during component adjusting, Si elements are scattered more uniformly, segregation ofthe Si elements is greatly eliminated, and the acquired cast ingot is more uniform in component.

Owner:苏州铭恒金属材料科技有限公司

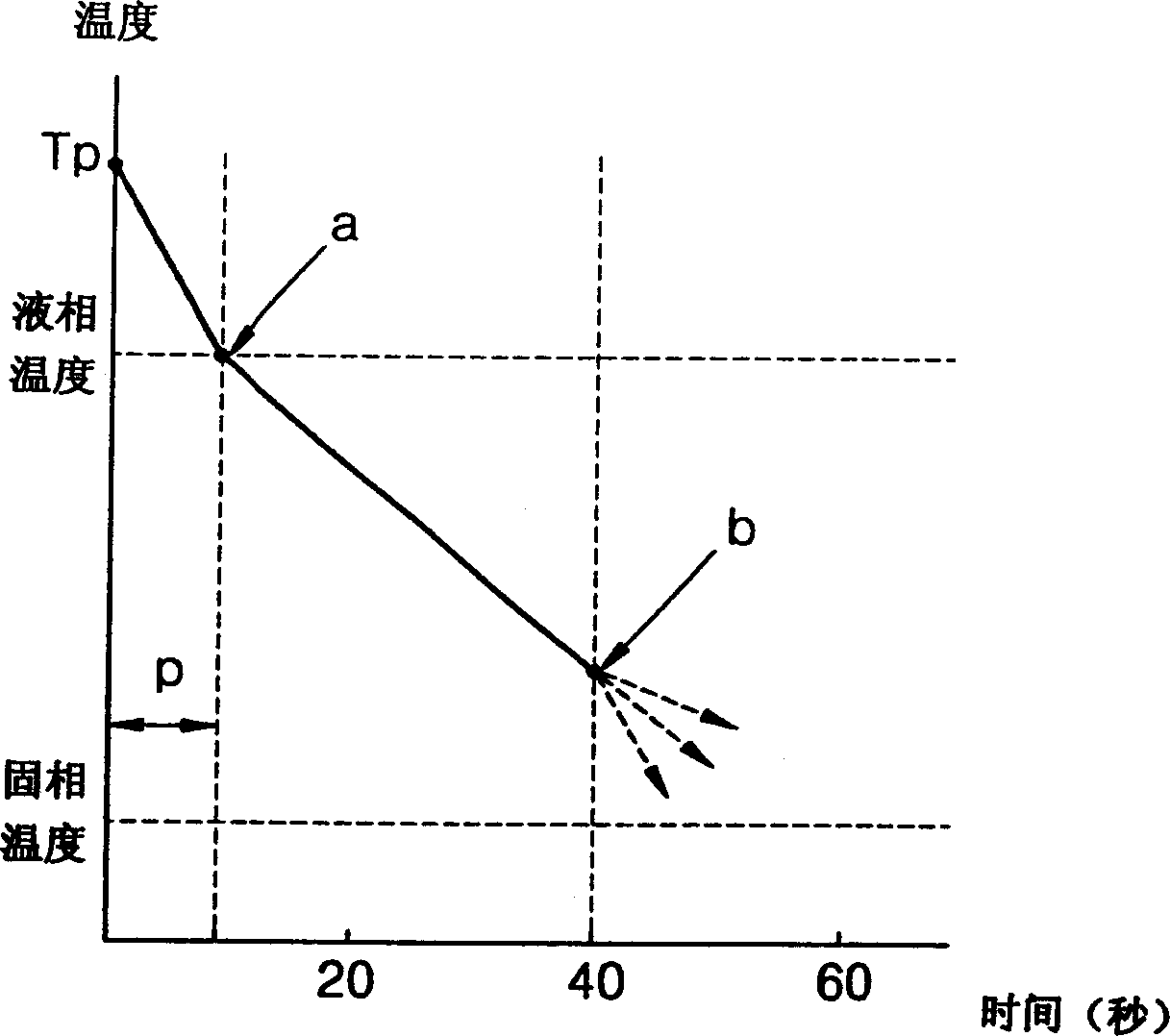

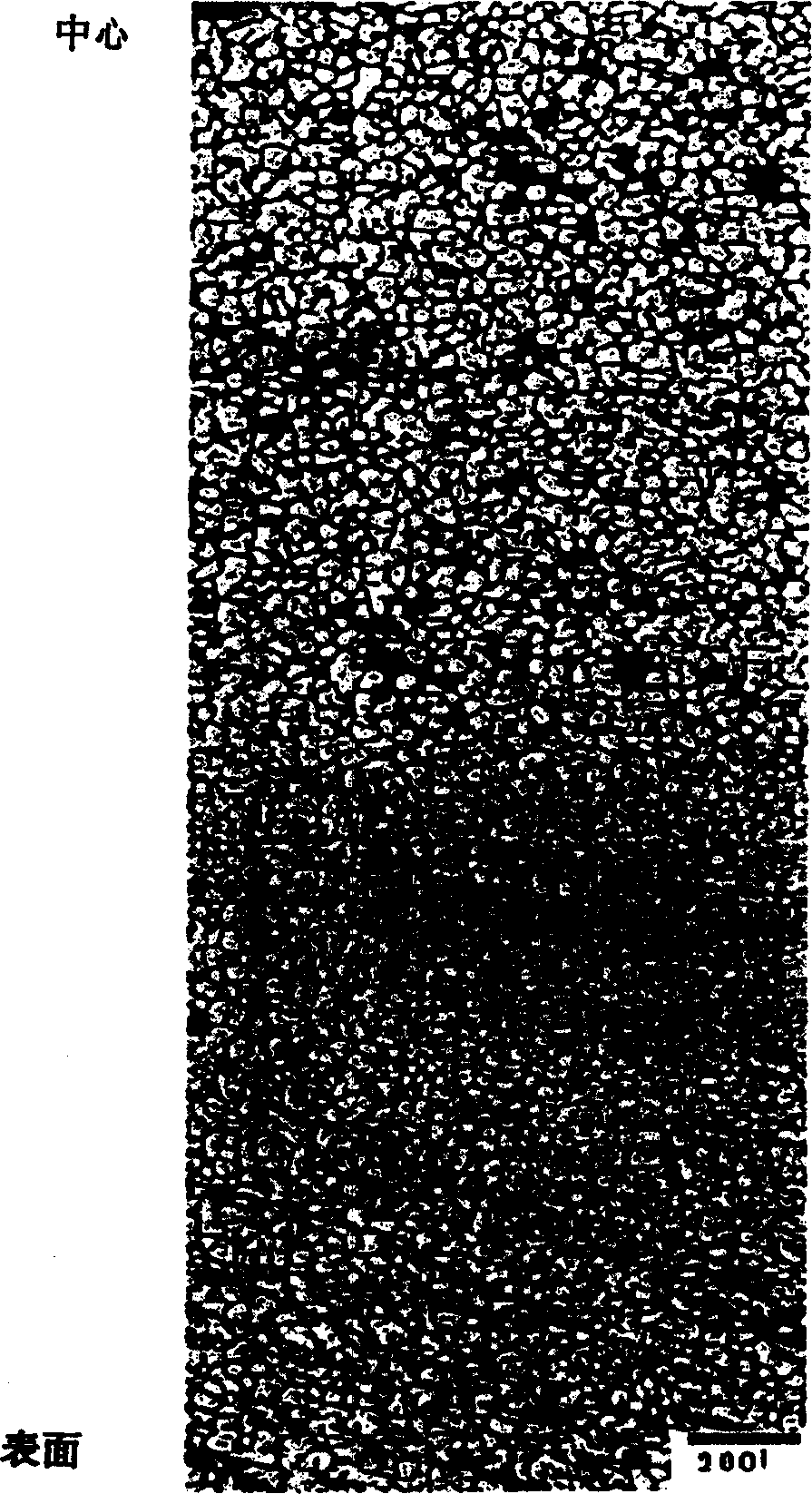

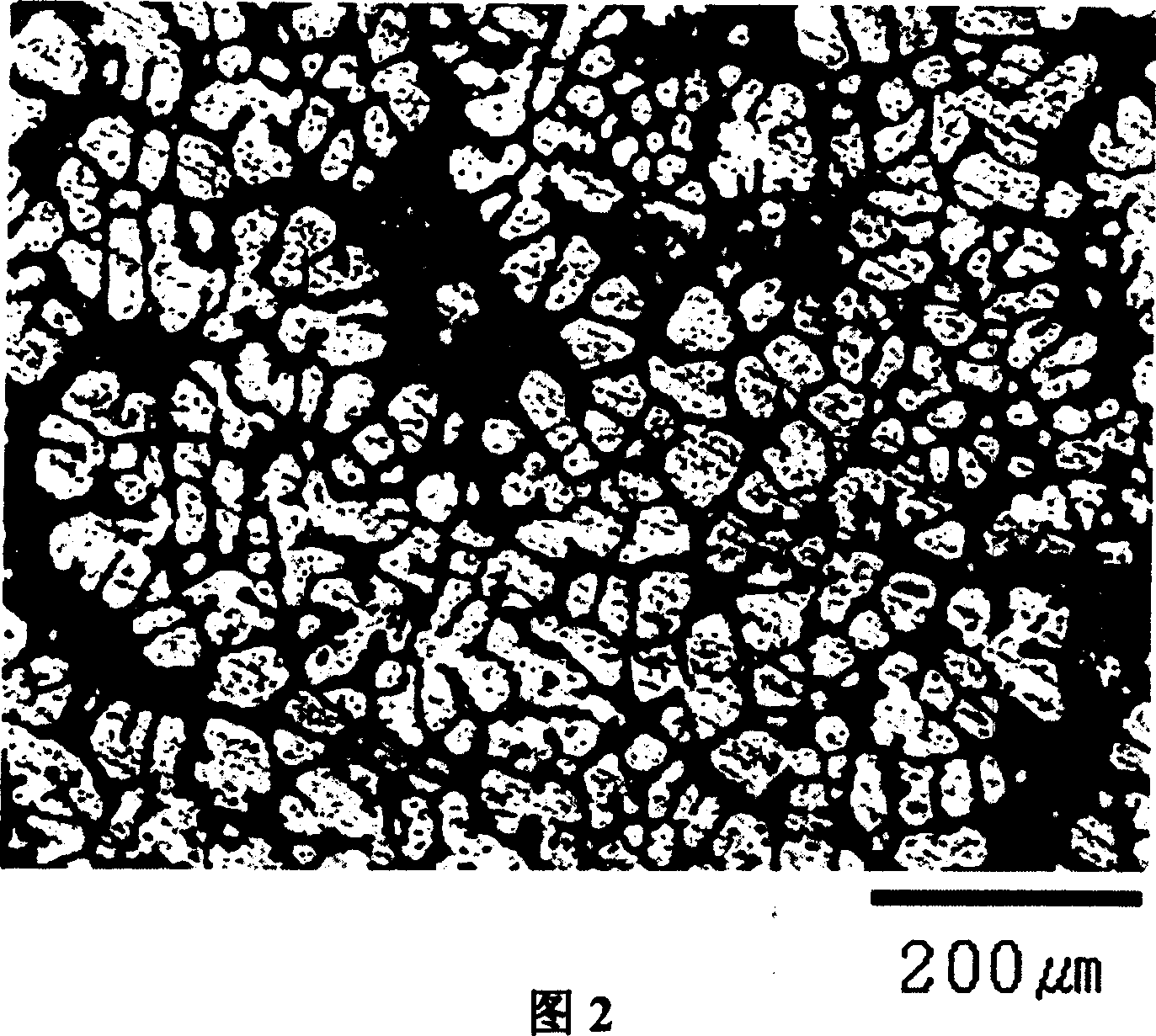

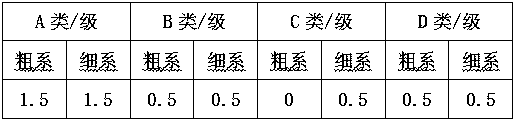

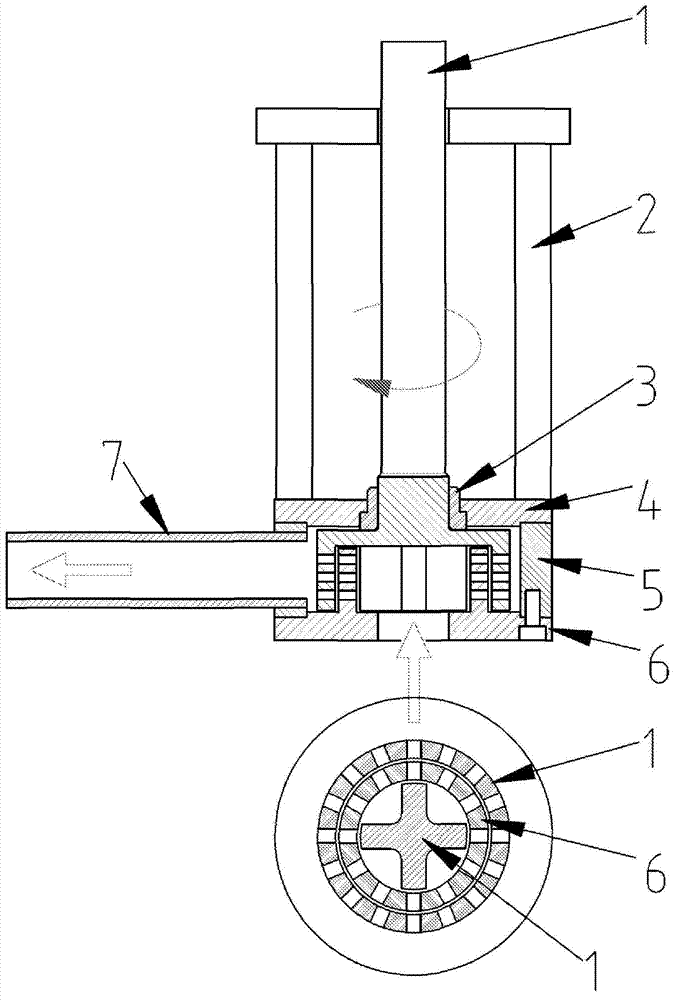

Metallic materials for rheocasting or thixoforming and method for manufacturing the same

A method for manufacturing a metallic material for rheocasting or thixoforming and a metallic material formed using the method are provided. The method includes: applying an electromagnetic field to a vessel and loading a molten metal into the vessel; and cooling the molten metal to form a metallic material for rheocasting or thixoforming. The entire volume of molten metal is rapidly and uniformly cooled throughout, from the wall toward the center of the vessel, without generating latent heat caused by the formation of solidification layers at the early stage of cooling. The molten metal in the vessel is cooled rapidly below its liquidus temperature within 1-10 seconds after the loading of the molten metal into the vessel, so that numerous uniform crystal nuclei are created throughout the entire volume of molten metal to form a metallic material having uniform, micro, spherical particles.

Owner:洪 俊杓

Method for controlling hydrogenation chrome molybdenum steel inclusions

The invention discloses a method for controlling hydrogenation chrome molybdenum steel inclusions. The method comprises the procedures of converter smelting, vacuum carbon deoxidization, LF refining,VD vacuum treatment and slab continuous casting. According to the vacuum carbon deoxidization procedure, vacuum carbon deoxidization treatment is conducted for 7 min, argon is blown in the vacuum carbon deoxidization process at 100-200 L / min and stirring is conducted, and after the vacuum degree reaches 0.5 torr, vacuum is relieved, and a ladle is sampled and hung to an LF for refining. Accordingto the method for controlling the hydrogenation chrome molybdenum steel inclusions, one-time vacuum carbon deoxidization treatment is conducted before LF refining, so that the oxygen content in moltensteel is further reduced; the alkalinity of refining slag is controlled and good fluidity is kept so as to increase the possibility that the inclusions in the molten steel are adsorbed; the soft blowtime after VD is prolonged properly, and inclusion floating is promoted; and the argon is blown in a middle ladle before casting, air in the middle ladle is discharged, and the chance of secondary oxidation when the molten steel enters the middle ladle is reduced. According to the method for controlling the hydrogenation chrome molybdenum steel inclusions, impurities in the hydrogenation chrome molybdenum molten steel are effectively reduced, and thus the mechanical properties of a finished steel plate are improved.

Owner:WUYANG IRON & STEEL

Apparatus and method for liquid metals treatment

ActiveCN103097846AImprove uniformityGrain refinementStirring devicesCasting apparatusParticulatesGas phase

Owner:BRUNEL UNIVERSITY

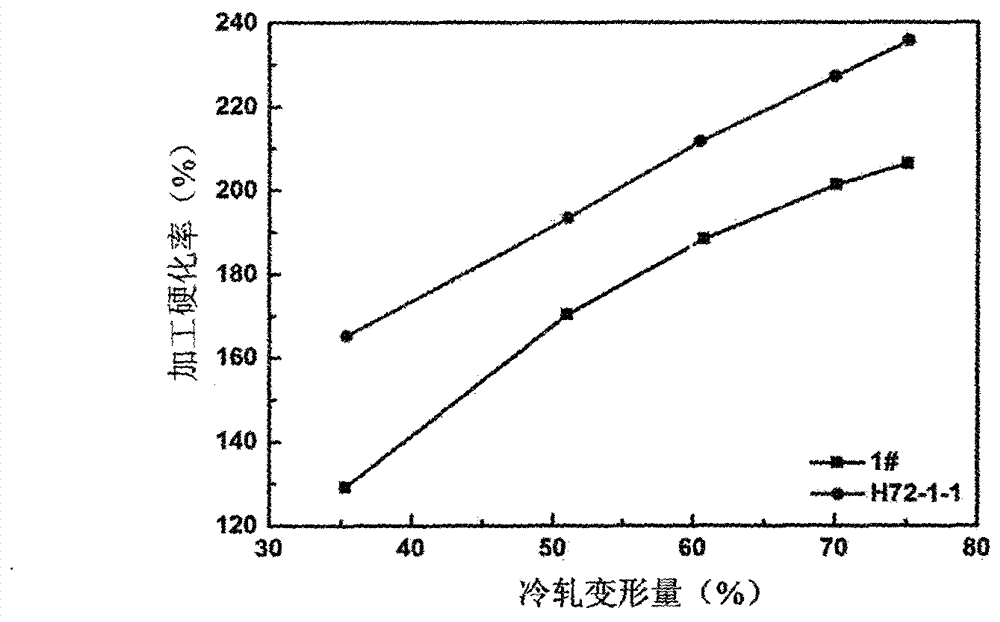

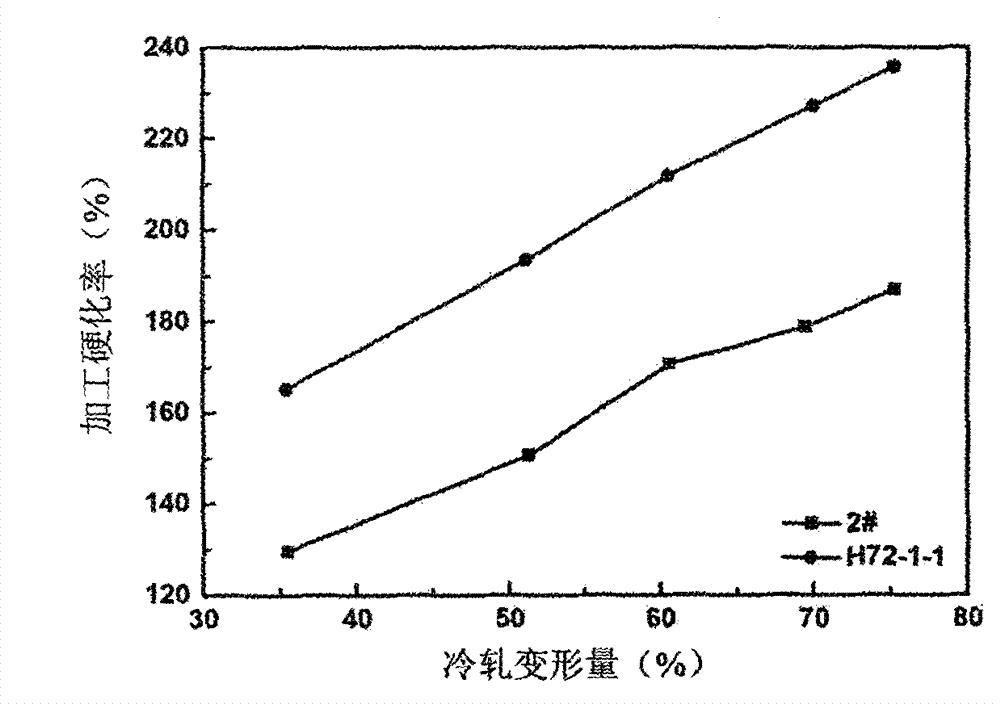

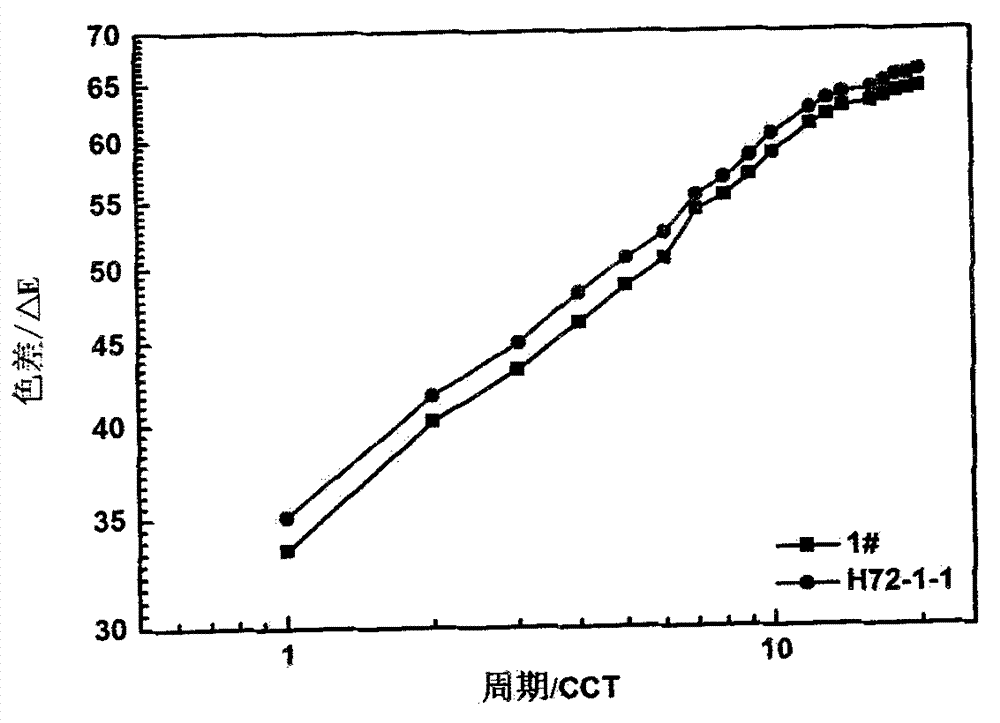

Coinage-used golden yellow copper alloy material and preparation method thereof

The present invention discloses a yellow copper alloy, and particularly relates to a coinage-used golden yellow copper alloy material having high resistance to discoloration and good cold processability. The material is mainly applied to coinage billets and various decorative materials. The coinage-used golden yellow copper alloy material is composed of the following components by weight: 75.0-77.0 wt% of Cu, 1.8-2.4 wt% of Al, 0.2-0.8 wt% of Ni, 0.003-0.01 wt% of B, 0.10-0.20 wt% of Si, no more than 0.1 wt% of Ce, no more than 0.06 wt% of Fe, no more than 0.05 wt% of Pb, and the balance being Zn. Compared with the conventional coinage material of HSn 72-1-1 alloy, the alloy produced by the invention has higher golden color and excellent discoloration resistance under the condition of high humidity, artificial sweat, salt spray, SO2, H2S and other hot and humid environments. At the same time, the alloy is excellent in cold processing performance, the cold processing amount per pass is up to 60%, the processing hardening rate and rigidity both satisfy the requirements of coinage technology, and the alloy has the characteristics of golden color and low cost of raw materials and manufacturing.

Owner:CHINA BANKNOTE PRINTING & MINTING +1

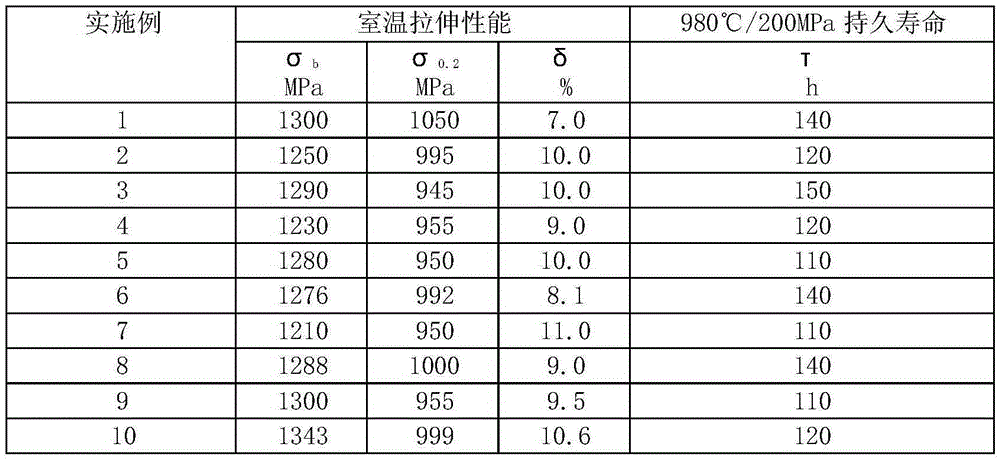

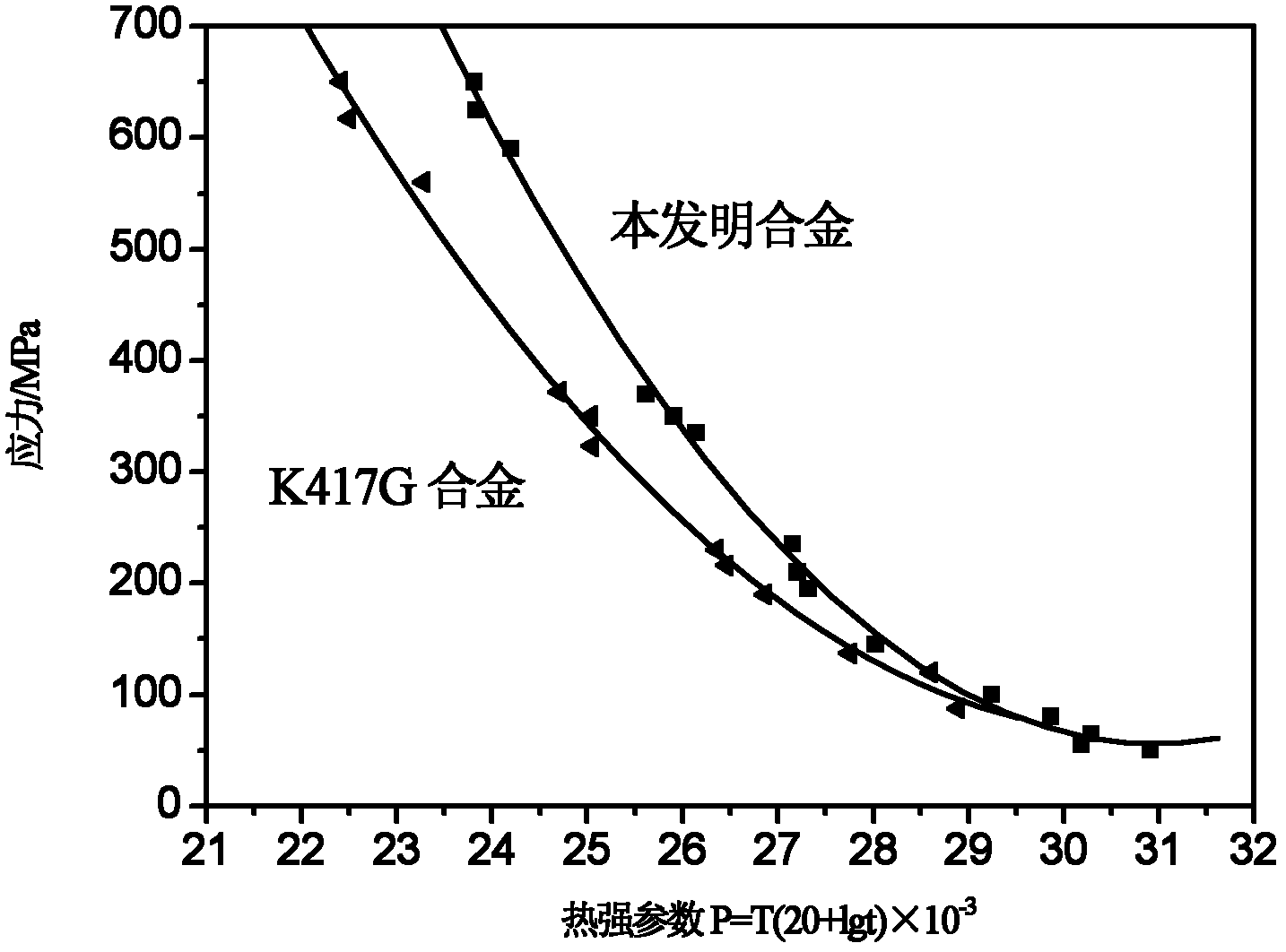

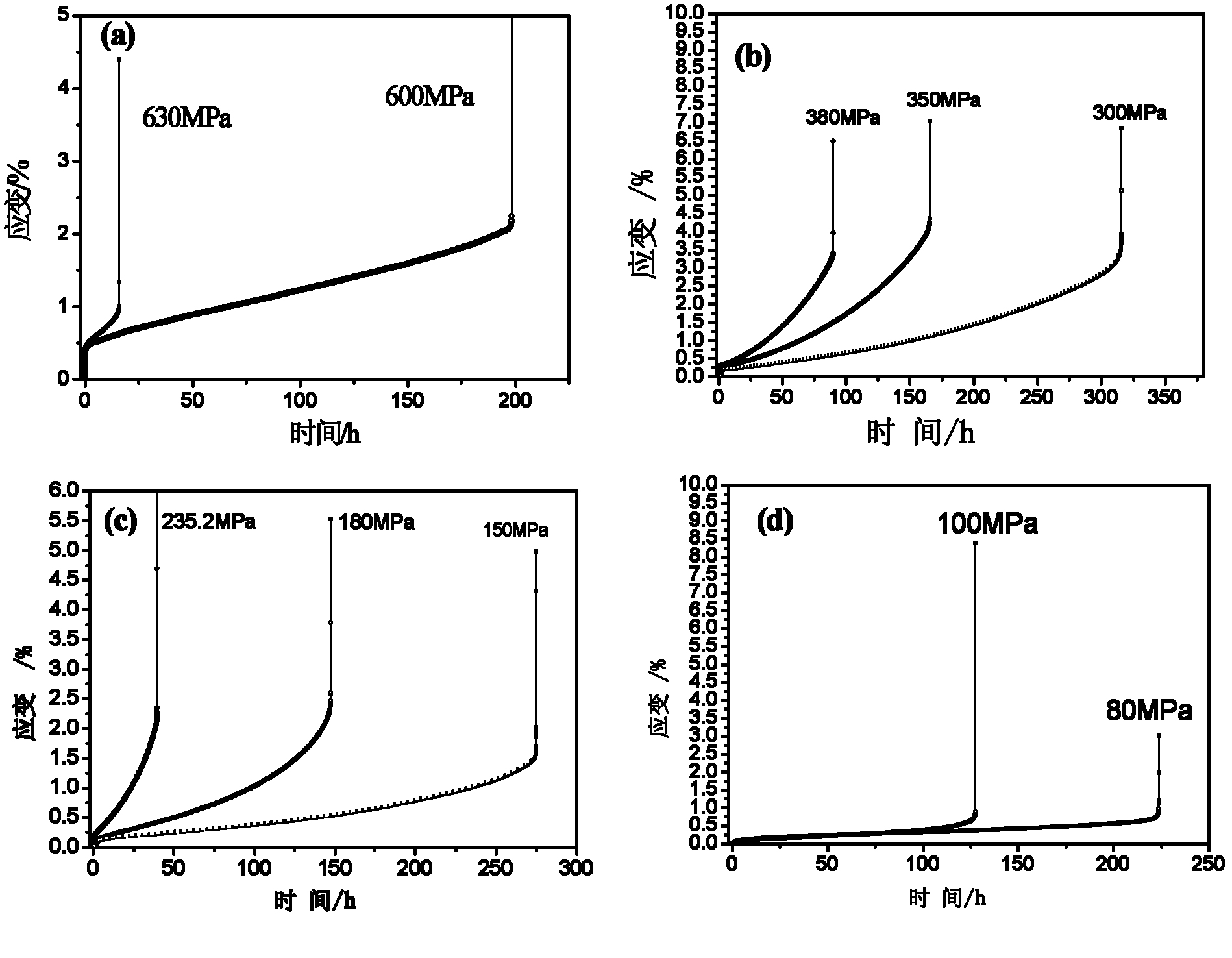

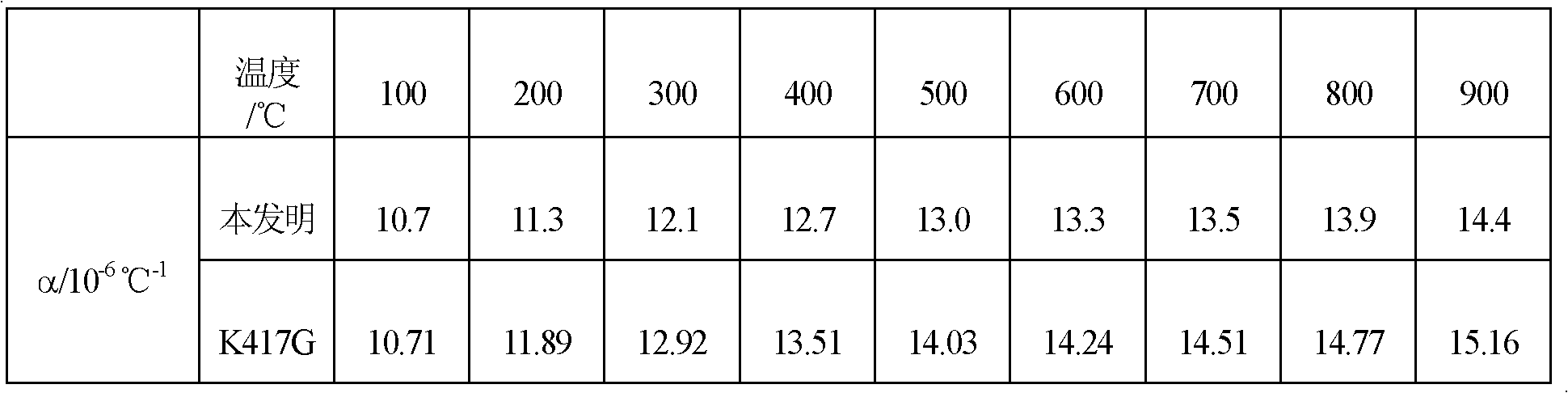

Hafnium-containing high-tungsten-nickel-based isometric crystal alloy and application thereof

ActiveCN102433467AImprove durabilityLow costBlade accessoriesMachines/enginesWorking temperatureHafnium

The invention relates to a nickel-based isometric crystal alloy, in particular to a hafnium-containing high-tungsten-nickel-based isometric crystal alloy and an application thereof. The hafnium-containing high-tungsten-nickel-based isometric crystal alloy consists of ingredients (in percentage by weight): 0.08 to 0.14 of C, 4.6 to 5.2 of Cr, 5.6 to 6.2 of Al, 0.7 to 1.2 of Ti, 6.0 to 8.0 of Co, 0.7 to 1.2 of Hf, 15.3 to 16.5 of W, 1.6 to 2.1 of Nb, 0.005 to 0.025 of B, 0.005 to 0.03 of Zr and the balance Ni. The alloy has good durability, the creep rupture life is longer than or equal to 40 hours under the conditions of 975 DEG C and 235.2 MPa, the alloy can be directly used for casting, the cost is low, and the production efficiency is high. The alloy can be used for preparing hot end components such as aircraft engines, gas turbine worm wheel blades and the like which can work for a long time at 1100 DEG C. Particularly, when the heat resisting alloy is adopted for manufacturing gasturbine worm wheel blades for electric generation, the work temperature and efficiency of a gas turbine can be obviously improved, and further, the electric generation efficiency is greatly improved.

Owner:辽宁红银金属有限公司

High strength anti-corrosion easy processing and low magnetic cast steel for manufacturing ship weldable structure

ActiveCN1928143AFulfil requirementsAvoid pollutionHeat treatment process controlFerrosiliconAluminium

The low magnetism cast steel for making weldable ship structure with high corrosion resistance and easy machining has the chemical components including C 0.05-0.15 wt%, Cr 10.0-22.0 wt%, Mn 3.1-12.0 wt%, Ni 2.0-12.0 wt%, N 0.10-0.28 wt%, and Fe for the rest. It may be produced with waste steel, ferrochromium, metal Mn, electrolytic Ni and recovered 0Cr18Ni9 alloy as material, and through smelting in weak oxidizing atmosphere inside a medium frequency induction furnace. In the smelting process in a medium frequency induction furnace, waste steel and electrolytic Ni is first added and molten down, ferrochromium and metal Mn is then added, metal Al is finally added to deoxidize, ferrosilicon and nitrided ferrochromium and added 5 min before tapping, and the steel is tapped at 1580-1650 deg.c and cast at 1520-1580 deg.c. The low magnetism cast steel may be used in making ship steering and propelling system with less maintenance and high safety.

Owner:中船双瑞(洛阳)特种装备股份有限公司

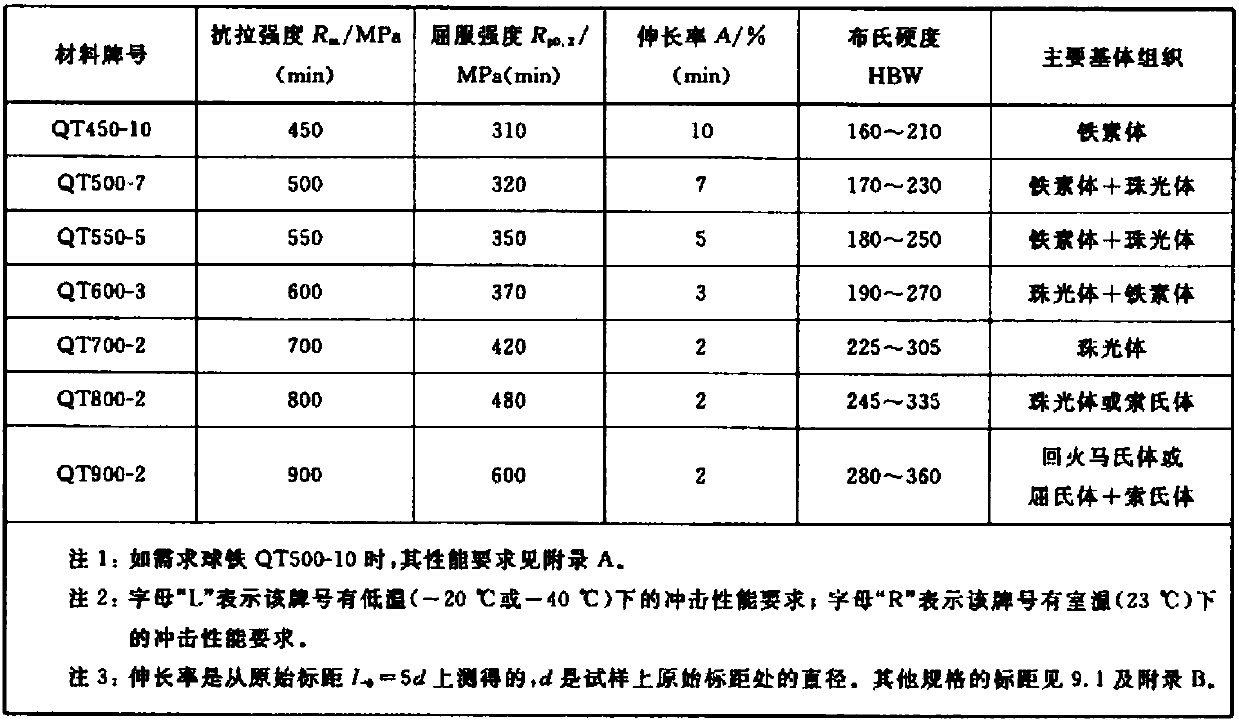

Production method of nodular cast iron with high strength and high elongation

ActiveCN107723580ABreakthrough tensile strengthBreak through limitationsProcess efficiency improvementIntermediate frequencyDuctile iron

The invention provides a production method of nodular cast iron with the high strength and the high elongation. The production method comprises the steps that pig iron with low sulfur and low titanium, ordinary carbon steel and self-produced foundry return are selected as main furnace burden, and 75 silicon iron, 65 high carbon ferromanganese, electrolytic copper and a graphite type recarburizingagent are added; smelting is conducted through an intermediate frequency furnace, a special nodulizing agent and an inoculant are added successively, tapping and nodularizing are conduced, iron liquidis added into a mold cavity of a sand-coated iron mold, the thickness of a sand-coated layer is selected according to the wall thickness of the casting corresponding position, casting pieces are slowly cooled in air, and heat treatment is not required. The strength of a prepared product reaches 670-700 MPa, the yielding strength is 450-500 MPa, the elongation rate is 12.5-14.5%, and the product strength, the yielding strength and the elongation rate of the prepared product far exceed ordinary ductile iron with the same tensile strength. Products with the mark has been used for parts such as balanced suspension brackets of a 80 T mine heavy-load dump truck and a 50 T muck truck, replacing steel castings with the nodular cast iron with the high strength and the high elongation is achieved,the cost is reduced, the weight is reduced, and significant benefits are obtained.

Owner:GUANGXI YUCHAI MACHINE PARTS MFG CO LTD

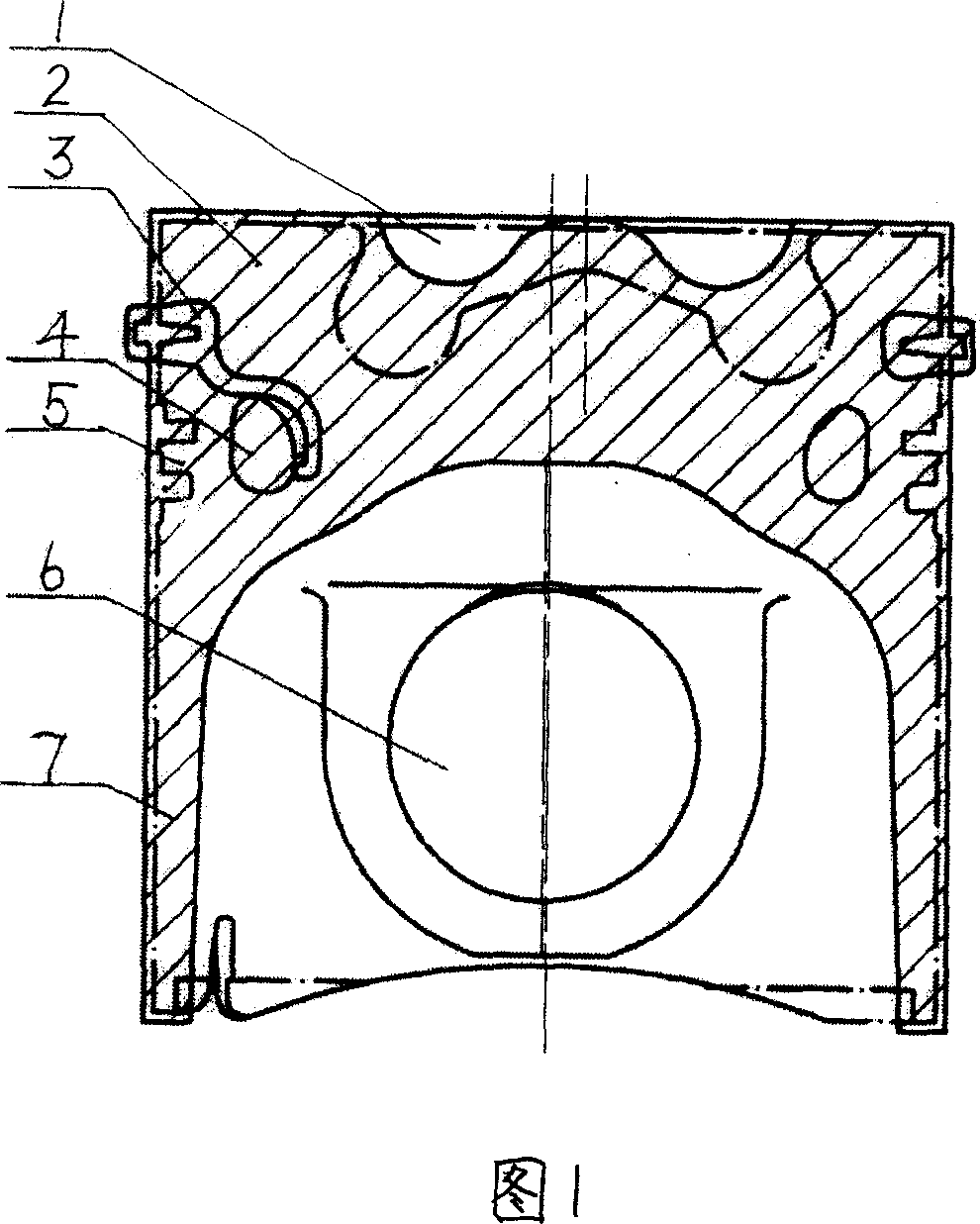

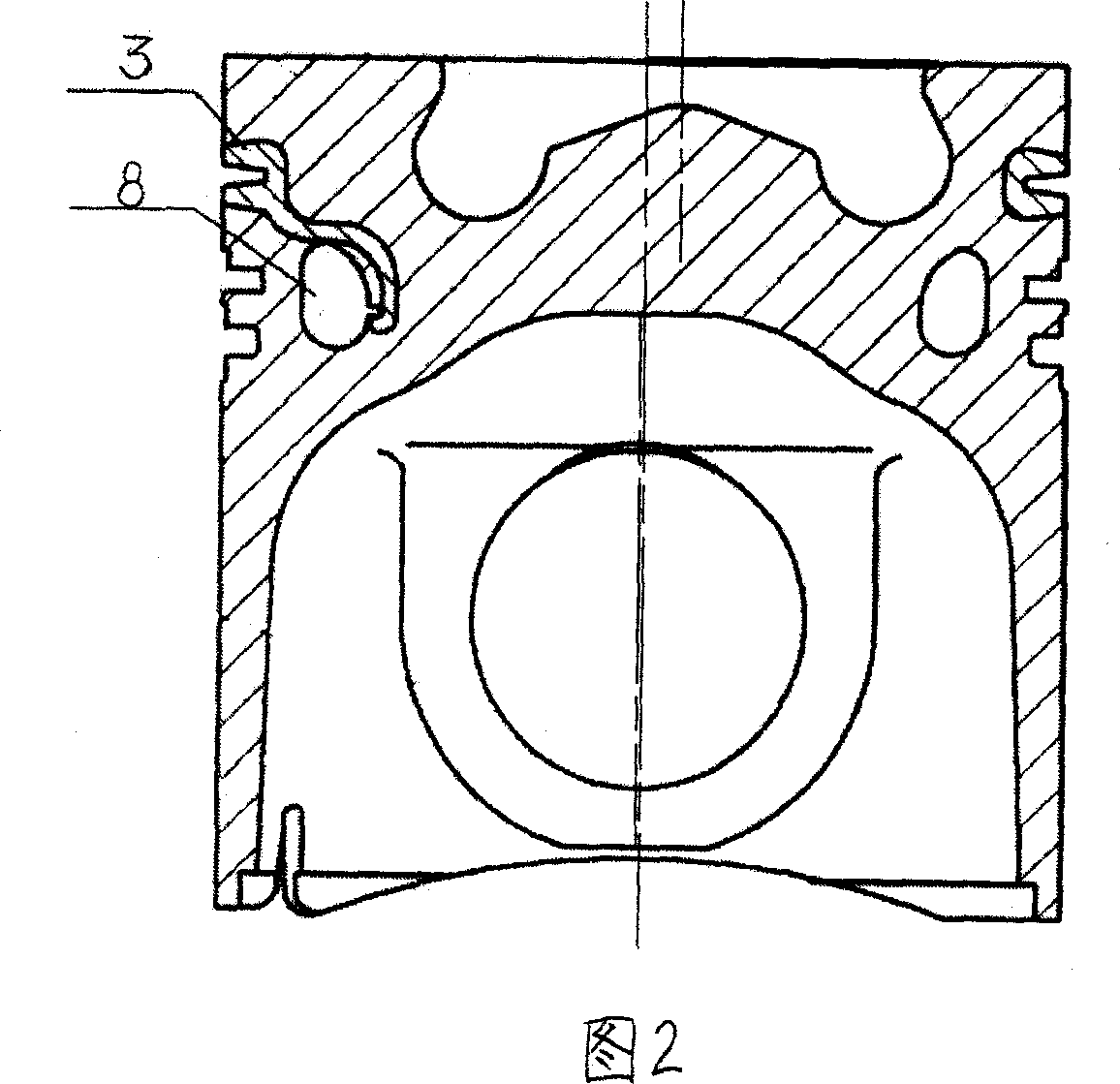

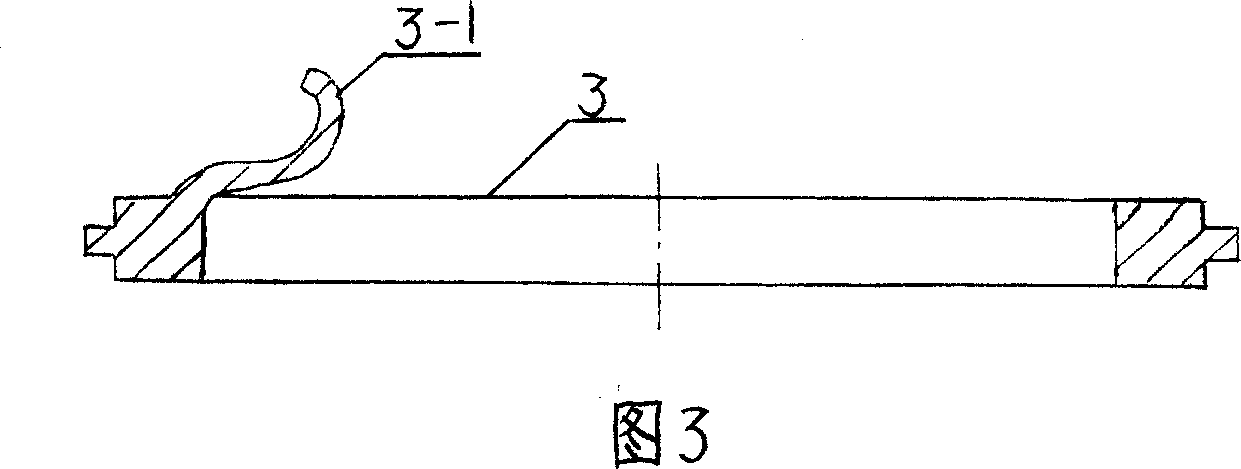

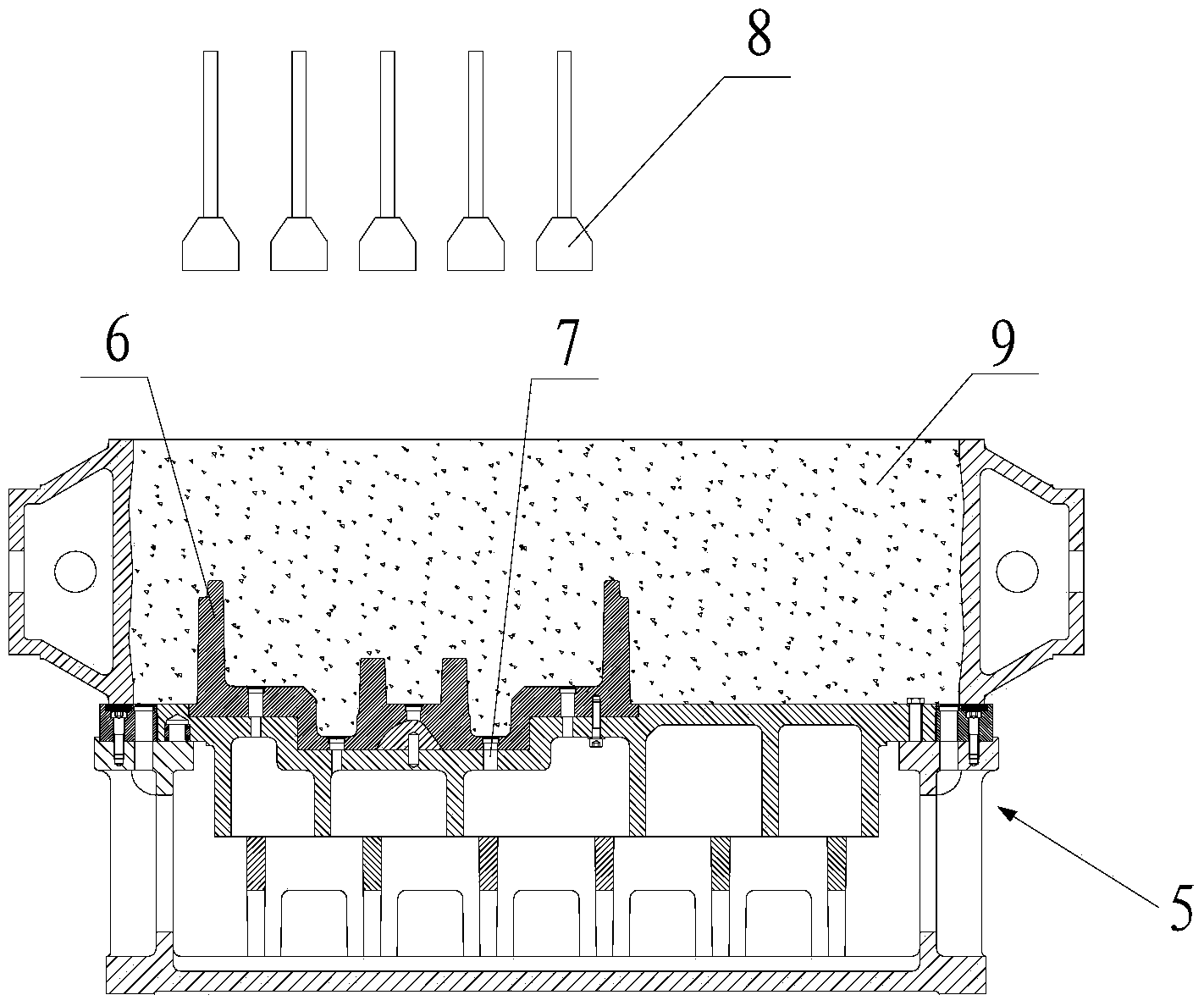

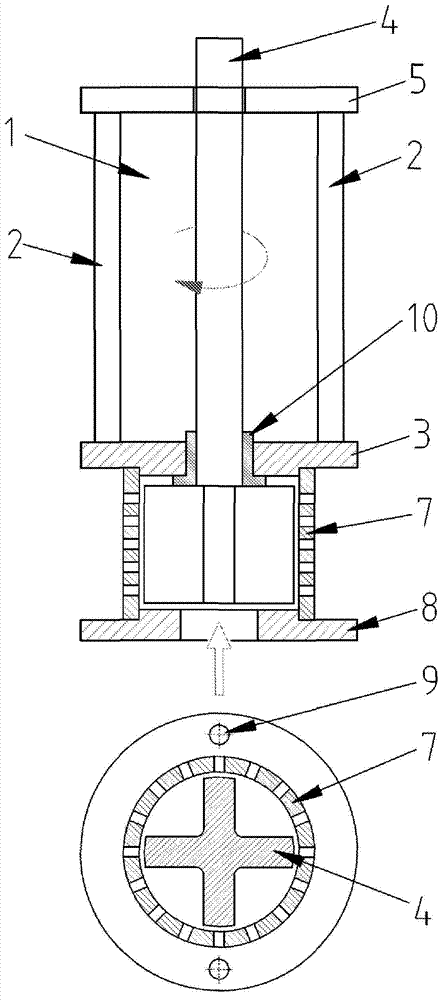

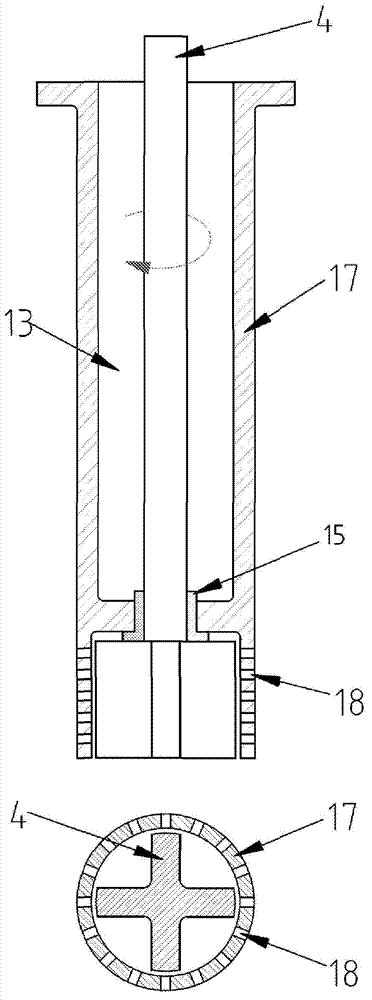

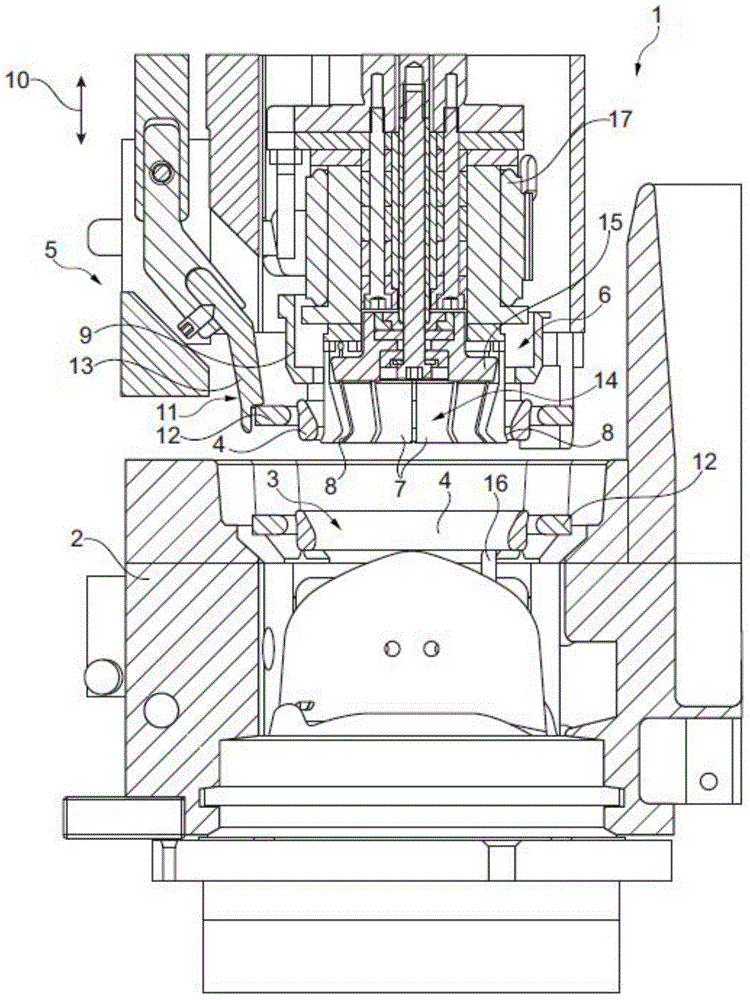

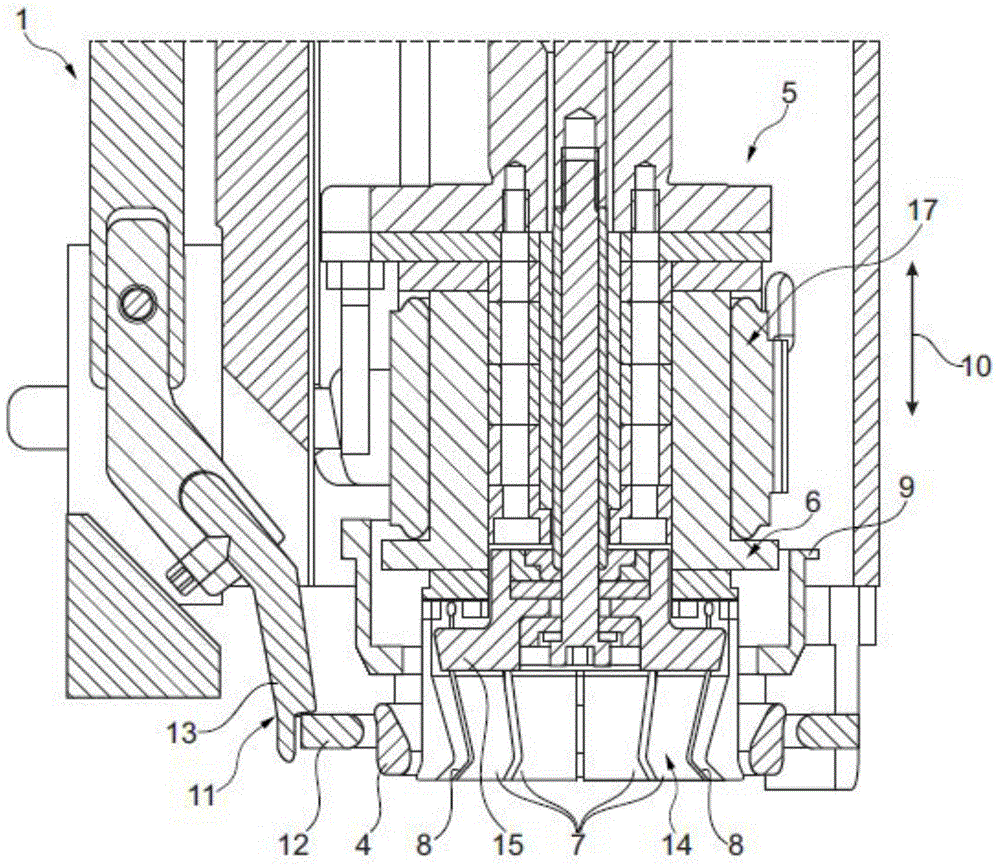

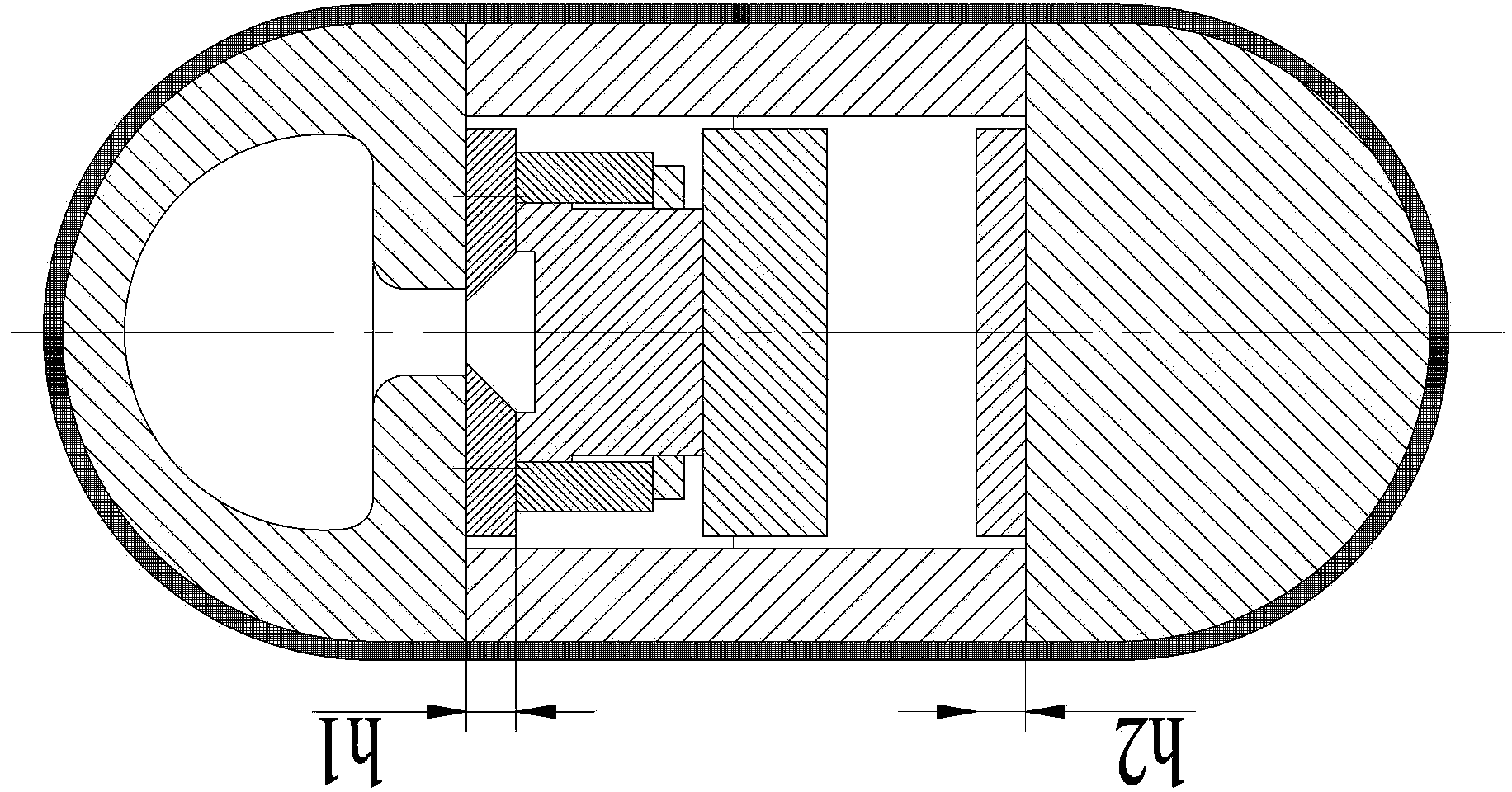

Device for producing piston

InactiveCN105033187AIndependenceStand aloneMoulding toolsFoundry mouldsCavity wallMechanical engineering

An apparatus for producing a piston may include a casting mould having an axially open cavity defining a surrounding cavity wall, the cavity wall being profiled to receive an annular core to define a cooling duct geometry. A core holding device may be adjustable in an axial direction for introducing the core into the casting mould. The core holding device may include a gripping device for gripping the core. The gripping device may include a plurality of spreadable first grippers. The plurality of first grippers may be adjustable at least between a first position, in which the plurality of first grippers are arranged in a radially inner position, and a second position, in which the plurality of first grippers transition radially outwards in relation to the first position and support the core.

Owner:MAHLE INT GMBH

Casting method for main shaft of wind generating set

ActiveCN102921901AFast and smooth entryAvoid oxidation inclusion defectsFoundry mouldsMoulding machinesWind forceMaterials science

The invention relates to a casting method, in particular to a casting method for a main shaft of a wind generating set. The casting method provided by the invention comprises the following steps of: designing a pouring system, manufacturing a mould, shaping, manufacturing a core, assembling the mould, compounding, smelting, adopting a stokehold spheroidization process and multistage inoculation, pouring and shakeout clearing. The casting method for the main shaft of the wind generating set is unique, meets quality index requirements on size, performance, and internal and external quality, and can realize volume production for moving / fixed shafts.

Owner:KOCEL EQUIP

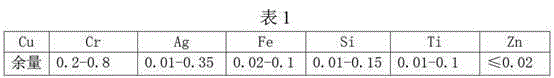

Method for preparing high-strength high-conductivity copper alloy plate and strip

The invention relates to the field of copper alloy, in particular to a method for preparing a high-strength high-conductivity copper alloy plate and strip. The technical problem that an existing high-strength high-conductivity copper alloy is low in strength and poor in plasticity and fatigue and looseness resistance is solved. The method for preparing the high-strength high-conductivity copper alloy plate and strip is based on the theory of solution strengthening, precipitation strengthening and work hardening. Hot rolling solution treatment is adopted, solute atoms are high in solubility at high temperature and exist in base copper in the solid solution form, solute elements have no time to be separated out after rapid cooling, and a supersaturated solid solution is formed. The solubility of Cr atoms and Ti atoms in the precipitation strengthening process is rapidly lowered, the Cr atoms and the Ti atoms are separated out of a matrix, and the matrix is diluted. The copper alloy plate and strip generates plastic deformation in the cold rolling process, grains slide, dislocation entanglement occurs, and the grains are stretched, crushed and fibrosed. The requirement for high strength, high yield and high conductivity is met, and therefore the final tensile strength, yield strength and conductivity of the TKB copper alloy plate and strip are improved.

Owner:山西春雷铜材有限责任公司

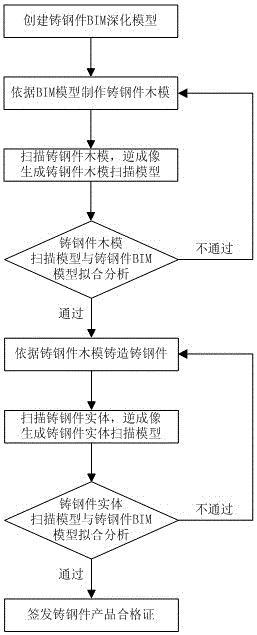

Cast steel member detection method based on BIM technology

InactiveCN106091977AImprove processing efficiencyEasy to understandUsing optical meansMetallurgyModel fitting

The invention discloses a cast steel member detection method based on BIM technology. The method is characterized by outputting the profile map of any position by creating a cast steel member BIM deepening model in order to facilitate design idea grasp for technical workers and increase cast steel member processing efficiency; scanning and detecting a cast steel member wood model and a cast steel member product by using a handheld 3D laser scanner with precision of 0.1mm, generating a spatial 3D model by inverse imaging and performing theoretical BIM model fitting analysis; expressing a detection result in the spatial 3D model in a chromatogram way, outputting single-point area deviation values, deviation trend, and an error range, achieving clear deviation value, and significantly increasing measurement efficiency. The method increases the processing efficiency of the cast steel member, prevents a waste of field construction resource due to processing errors, and provides protection for field installation.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

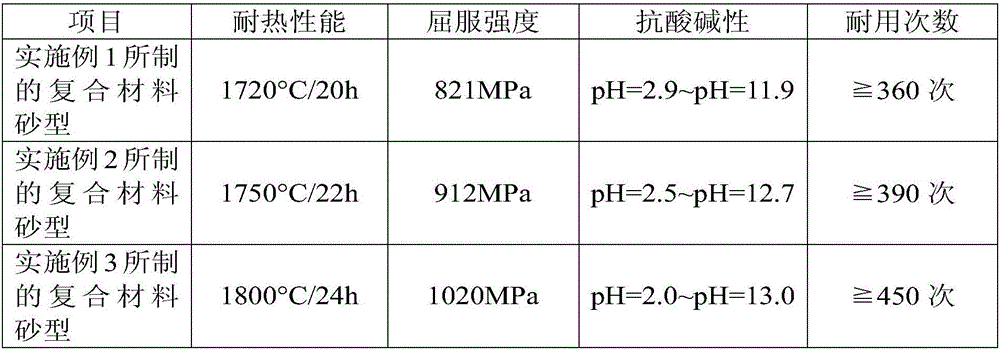

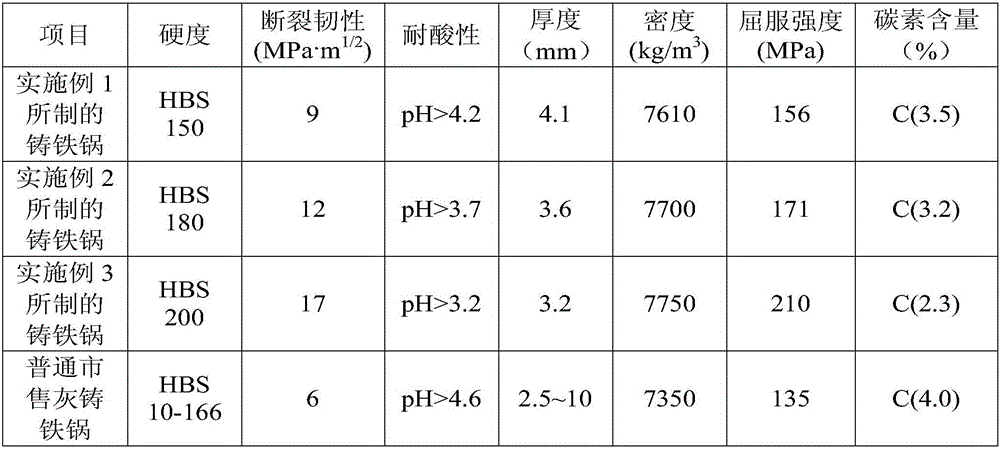

Cast iron pot with composite material as sand mould and casting method thereof

InactiveCN105855454AAdjustable thermal conductivitySmall overall thermal resistanceFoundry mouldsFoundry coresCast ironBall mill

The invention discloses a cast iron pot with a composite material as a sand mould and a casting method thereof. The casting method includes the steps that sand mould raw materials are weighed quantitatively and mixed evenly, then the materials are ball-milled and dried, a composite material sand mould is obtained, and the composite material sand mould is placed in a high-pressure container; cast iron blocks are fully heated and completely melted into molten iron, the molten iron is poured into the composite material sand mould, pressure in the pressure container is high pressure, a staged cooling means is adopted till the molten iron is completely cooled to room temperature to form castings, pressure continues to be maintained, and high pressure is relieved; the mould is taken out, the composite material sand mould is slowly removed by means of a metal tool, and the cast iron pot is obtained. Casting technologies, especially the improved casting technologies of improving a sand mould formula, improving pressure in a sand box, adopting the staged cooling means and the like, can greatly improve product quality of the cast iron pot and has certain economic and social meaning.

Owner:惠州市旲桥科技有限公司

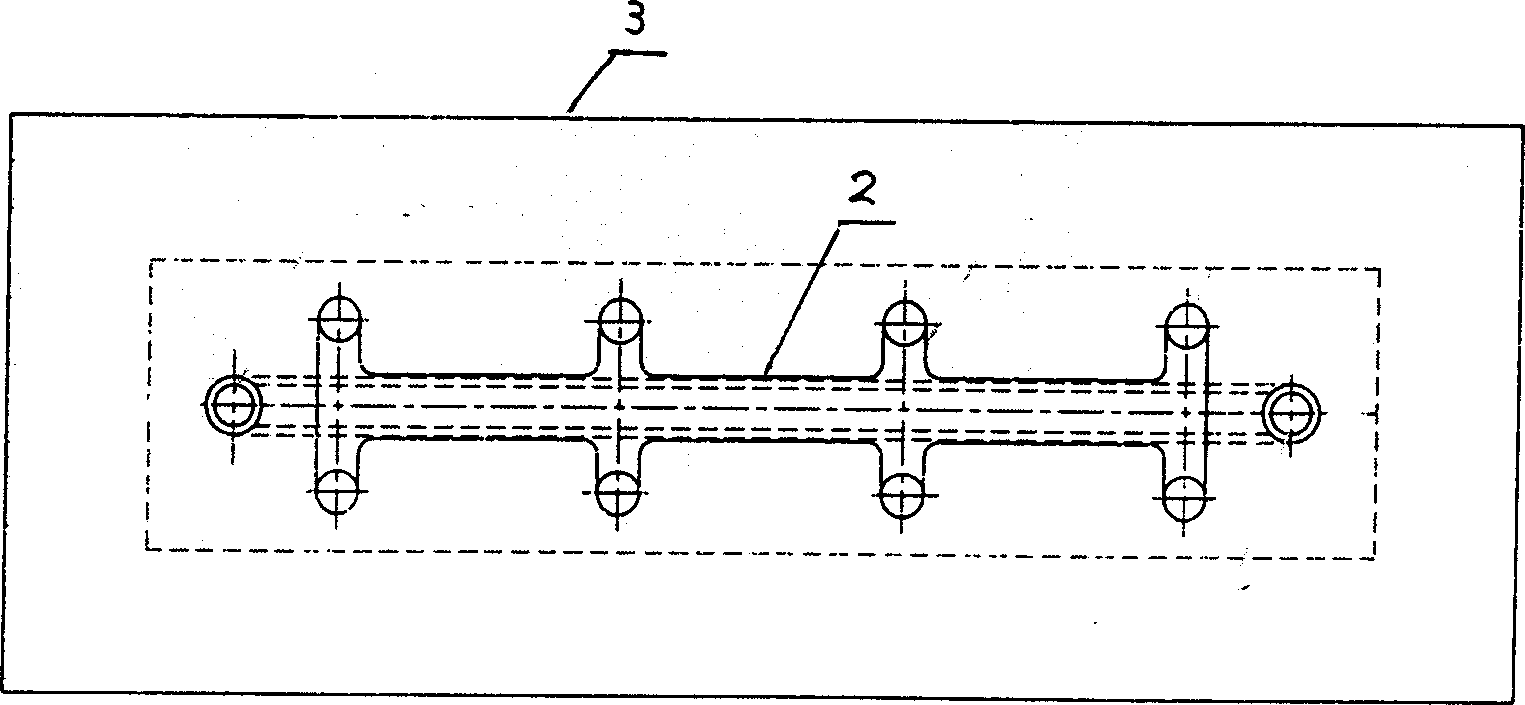

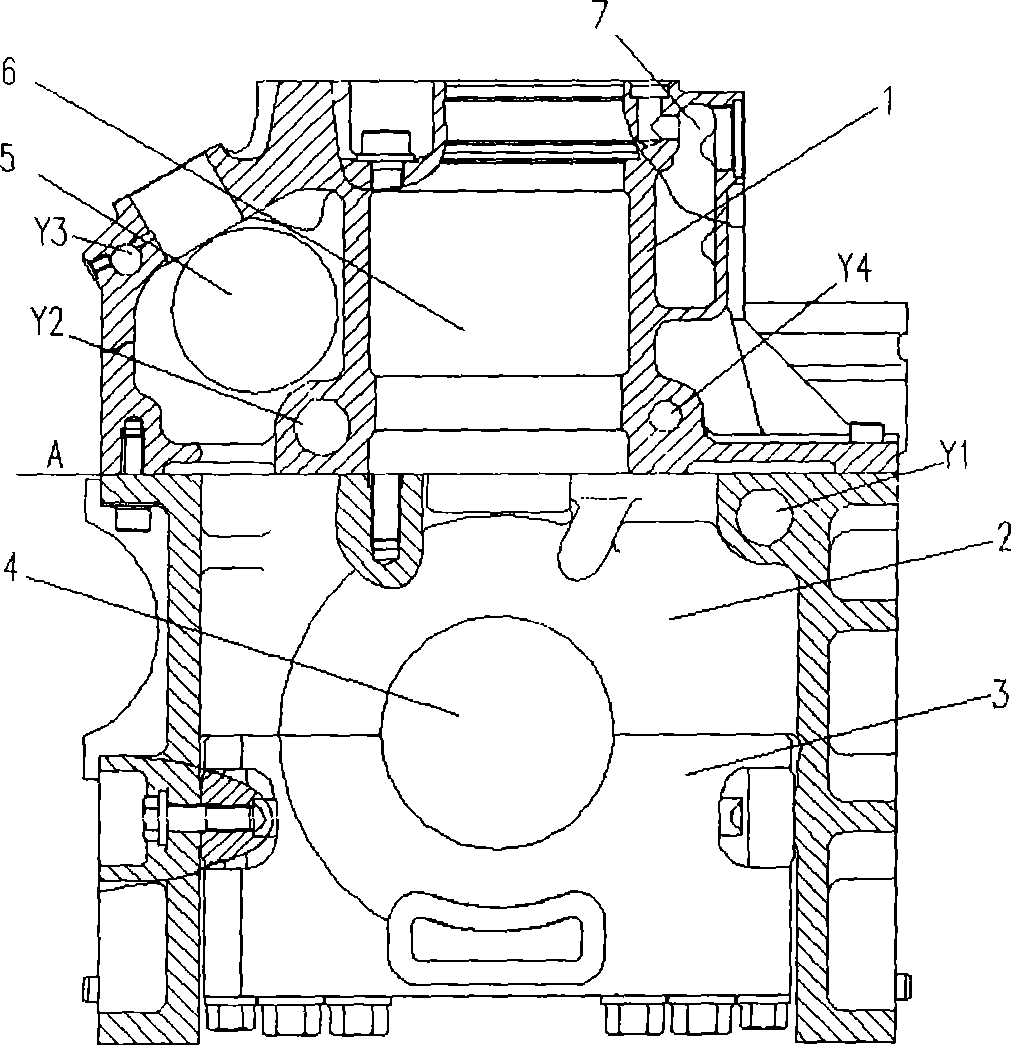

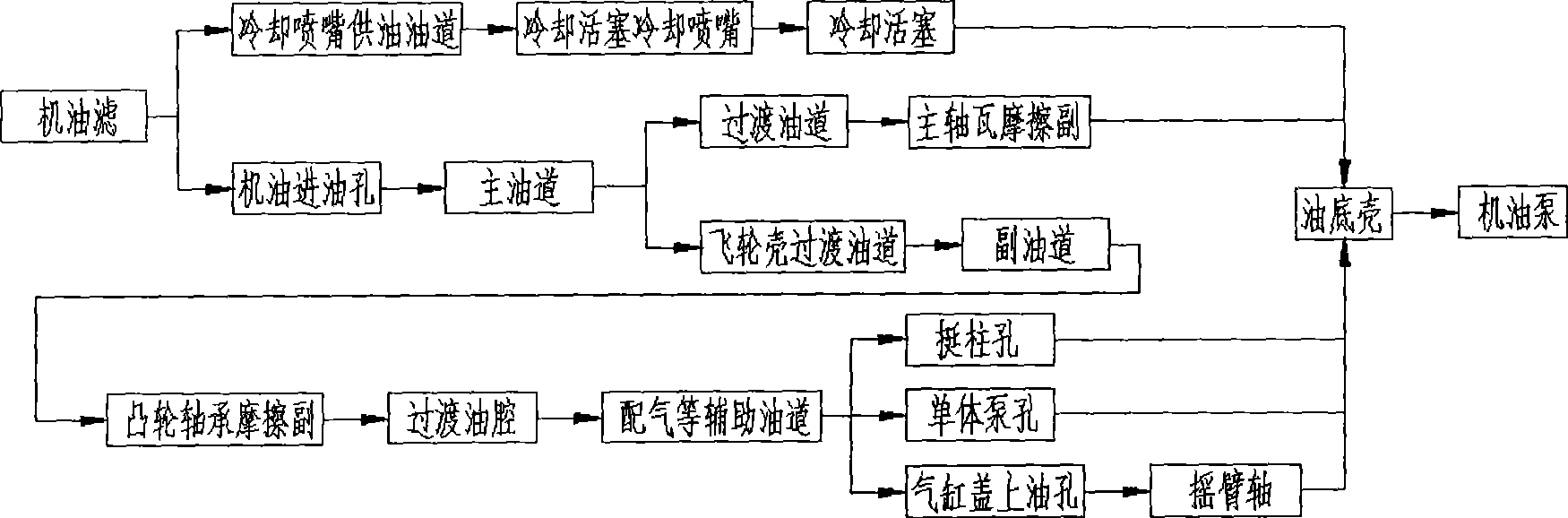

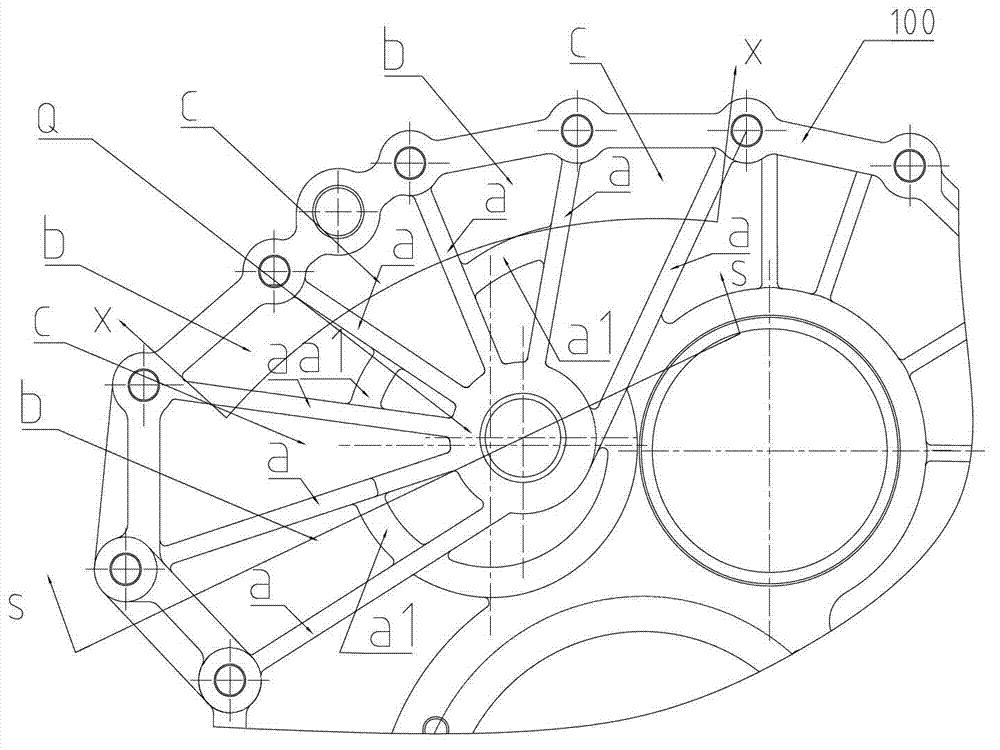

Engine multi-oil channel split type machine body structure

The invention belongs to engines technical field, particularly an engine multi-oil channel split type machine body structure, comprising a cylinder block, a crankshaft case and a bearing cap. The cylinder block and the crankshaft case are positioned by a cylindrical pin and connected by bolts. The crankshaft case and the bearing cap are positioned by a rabbet and connected by bolts. The cylinder block is an integral structure, including a distribution column compartment, a cylinder hole and a water chamber, which are linked by an integral casting mode. The crankshaft case is fastened at the support end A plane under the cylinder hole of the cylinder block. The bearing cap is connected with the crankshaft case. Three longitudinal oil passages including an auxiliary oil passage, a distribution auxiliary oil passage and a cooling jet oil supply passage are arranged on the cylinder block. The structure has small volume, good casting process and large material selectivity. The complete structure is with great stiffness; the cylinder sealing reliability is high; multi-oil channels have good lubrication and cooling effect.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Double-prestressing force steel wire winding type pressing machine

The invention discloses a double-prestressing force steel wire winding type pressing machine. The pressing machine comprises a framework composed of an upper cross beam, a base and an upright post, a housing oil tank arranged above the framework, and a main oil cylinder component arranged at the middle part of the framework, wherein the interval strengthening ribs are respectively arranged in the upper cross beam and the base; prestressing force steel wires are respectively wound on the left and the right side of the framework so as to tighten the framework as a whole. Compared with the prior art, the pressing machine has the benefits that 1, the structure of interval strengthening ribs is adopted, the distribution of working load on the framework is facilitated when the pressing machine works, the overall rigidity and strength of the framework can be greatly improved, and the pressing machine weight is also greatly reduced; 2, the cast manufacturability is good, the stress condition is far better than a connecting part of a plate frame type pressing machine under the same unbalanced loading; 3, the structure is simplified, the material is saved, the whole aesthetic appearance is concise, and the using is safe and reliable.

Owner:KEDA INDUSTRIAL GROUP CO LTD

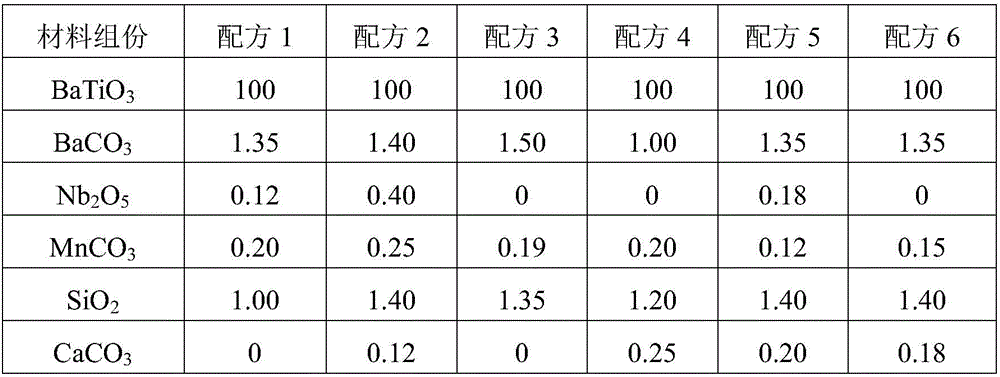

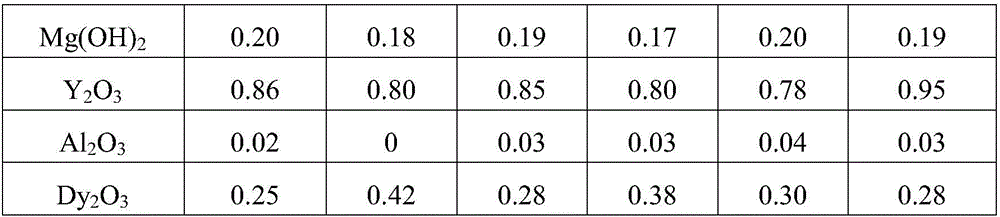

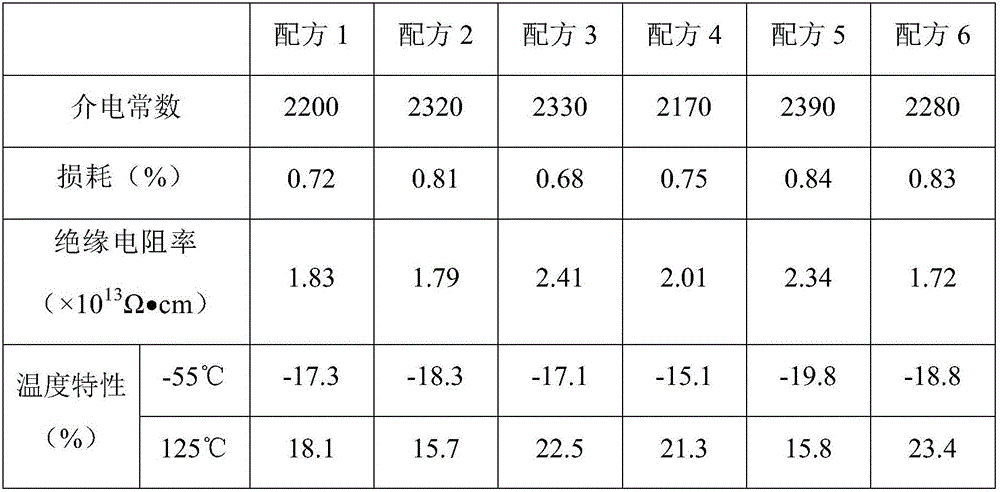

High ceramic dielectric capacitor material with reduction resistance

InactiveCN106747418AHigh dielectric constantGood casting processFixed capacitor dielectricStacked capacitorsInsulation resistanceHigh dielectric permittivity

The invention discloses a high ceramic dielectric capacitor material with reduction resistance. The material mainly consists of a main material and a modifier, wherein the main material is BaTiO3, and the modifier is BaCO3, MnCO3, SiO2, Mg(OH)2, Y2O3 and Dy2O3 as well as one or more of Nb2O5, CaCO3 and Al2O3, wherein the weight percent of the materials are as follows: 100 parts of BaTiO3, 1 to 2.5 parts of BaCO3, 0.08 to 0.25 part of MnCO3, 1 to 1.8 parts of SiO2, 0.15 to 0.25 part of Mg(OH)2, 0.65 to 0.95 part of Y2O3, 0.25 to 0.45 part of Dy2O3, 0 to 0.4 part of Nb2O5, 0 to 0.25 part of CaCO3, and 0 to 0.05 part of Al2O3. The capacitor material prepared by virtue of the components has the advantages of high dielectric constant, low loss and high insulation resistivity; a nickel electrode multilayer ceramic dielectric capacitor (MLCC) produced by using the material is good in casting technological performance and suitable for the sintering in the reduction atmosphere; the temperature characteristic of the MLCC satisfies X7R; and the MLCC has the advantages of high dielectric constant (sigma is greater than 3500), low loss, high insulation resistivity, low sintering temperature (1200 to 1240 DEG C), and the like.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

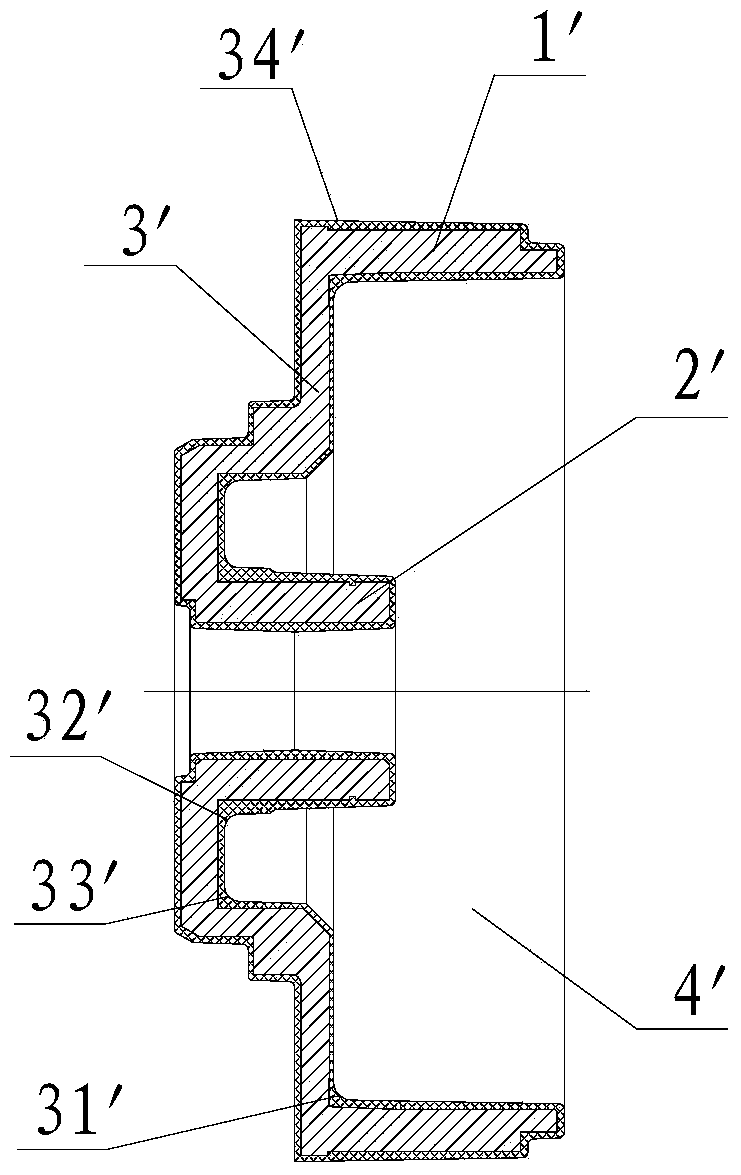

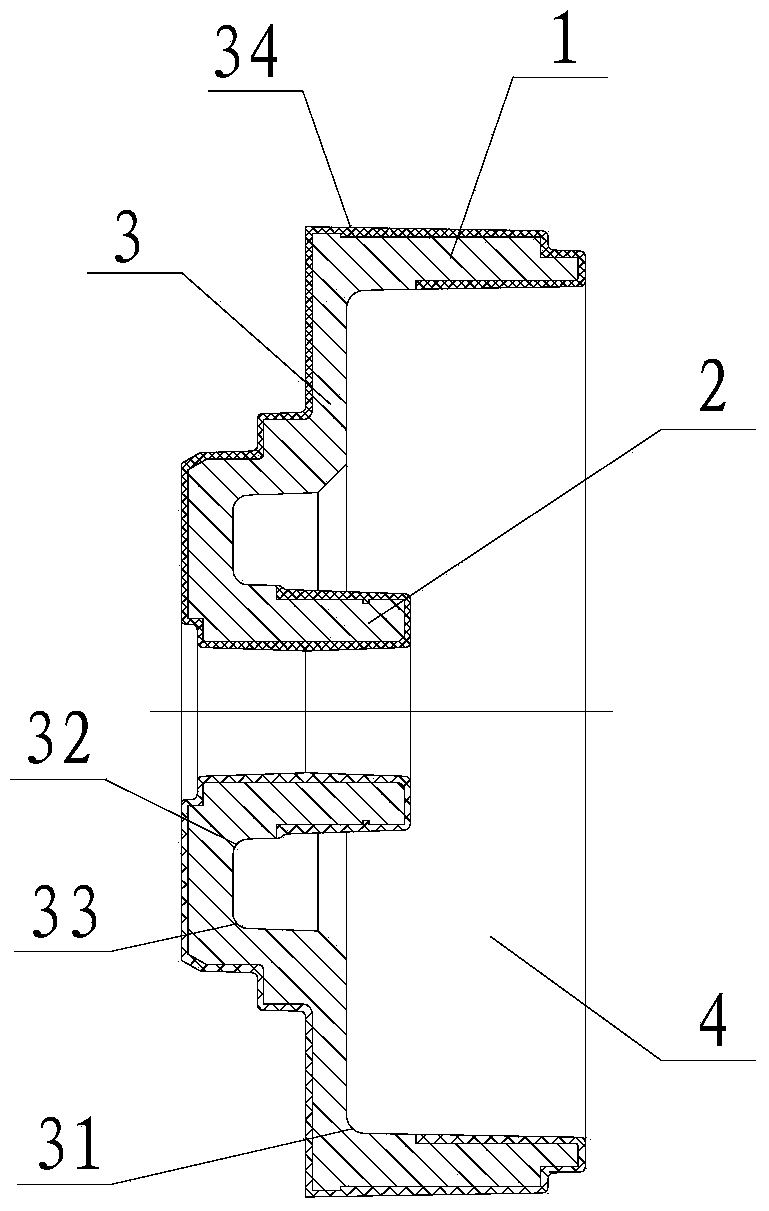

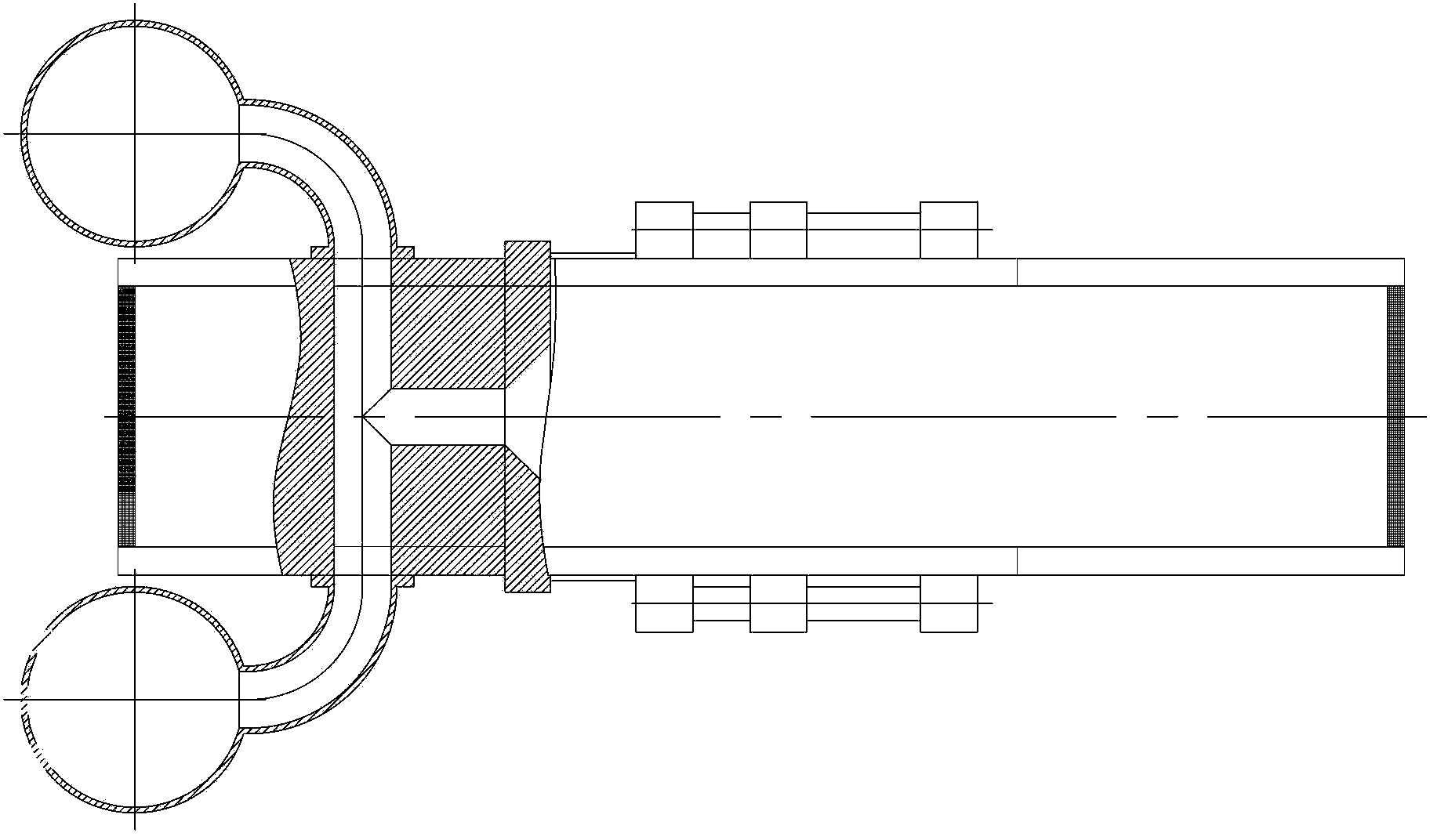

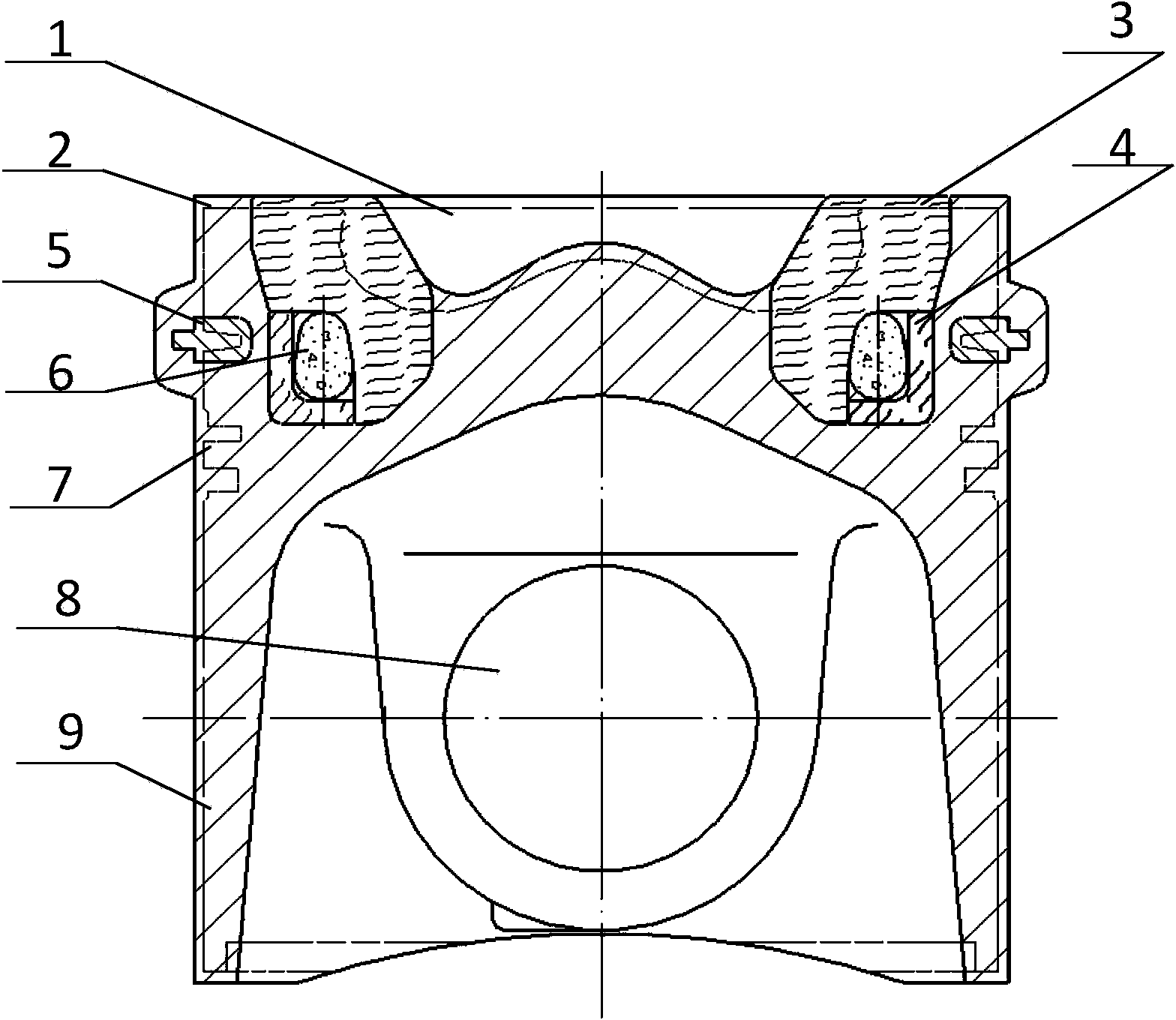

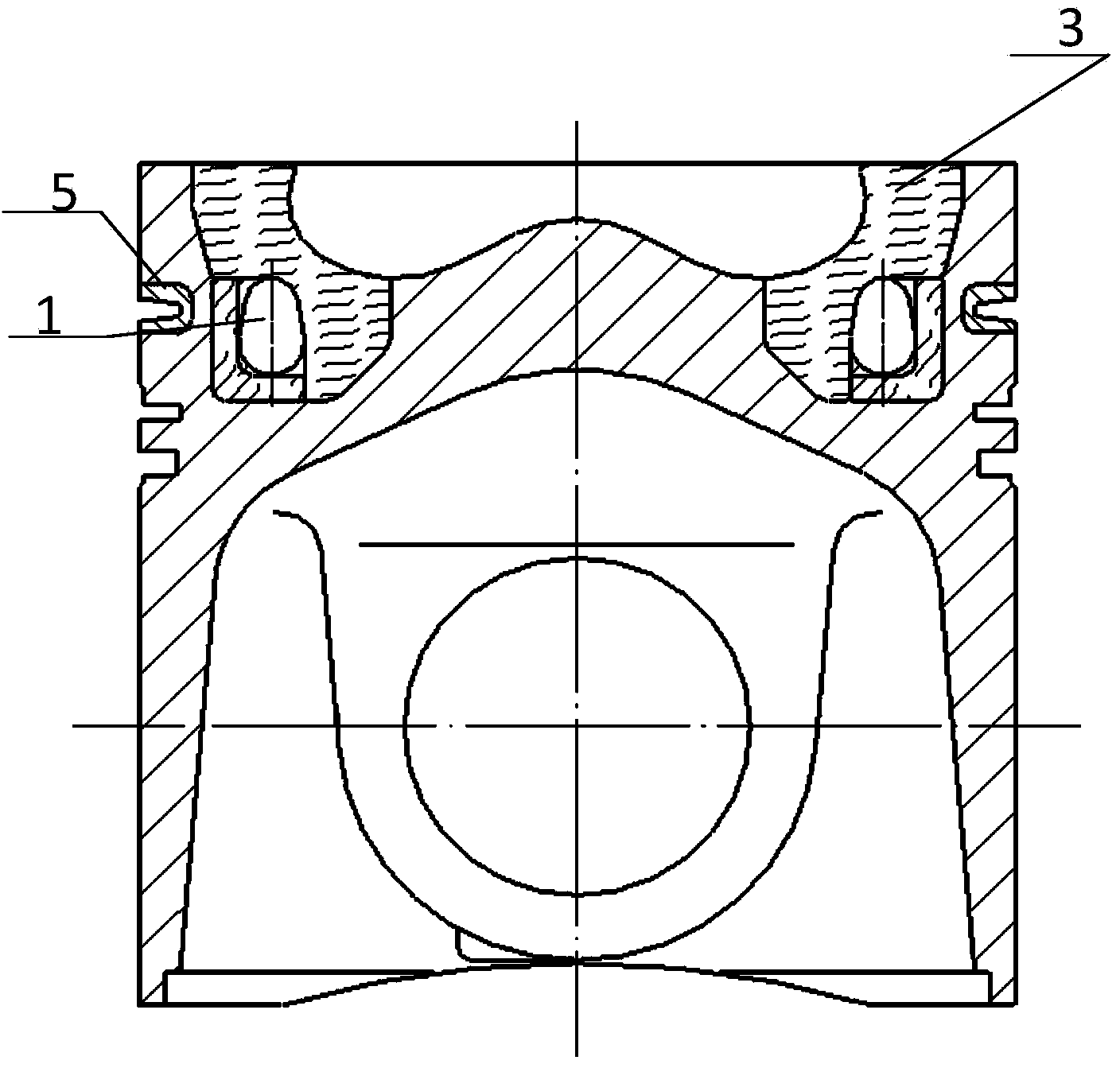

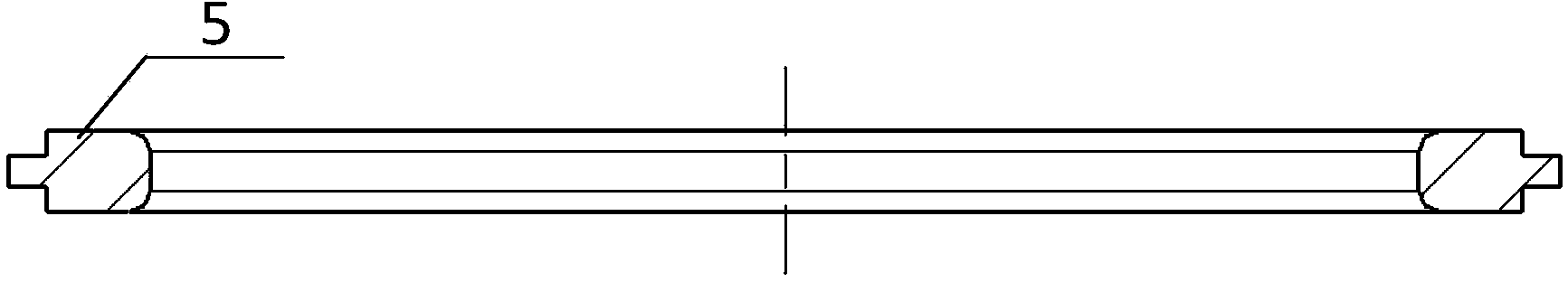

Method for manufacturing alumina fiber and titanium oxide particle-reinforced inner-cooling insert ring piston blanks

ActiveCN104353814AImprove stabilityImprove high temperature fatigue strengthPistonsFiberWear resistant

The invention discloses a method for manufacturing alumina fiber and titanium oxide particle-reinforced inner-cooling insert ring piston blanks. The method comprises the following steps: (1) manufacturing an upper fabricated part and a lower fabricated part of alumina ceramic fiber and titanium oxide particles, wherein the volume fraction of alumina ceramic fibers is 8-25 percent, the volume fraction of titanium oxide particles is 1-9 percent, and the rest is gaps; (2) preparing a soluble core by using salt and aluminum titanate ceramics as raw materials; (3) putting a wear resistant cast iron insert ring after aluminum diffusion treatment in a casting mould, and fixing; (4) preheating the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles; (5) after preheating the soluble core, taking out the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles, putting the soluble core in the lower fabricated part of alumina ceramic fiber and titanium oxide particles, and then combining the upper fabricated part and the lower fabricated part of alumina ceramic fiber and titanium oxide particles and quickly putting in the mould; (6) pouring an aluminum alloy solution into the casting mould, and carrying out pressure forming.

Owner:BINZHOU BOHAI PISTON CO LTD

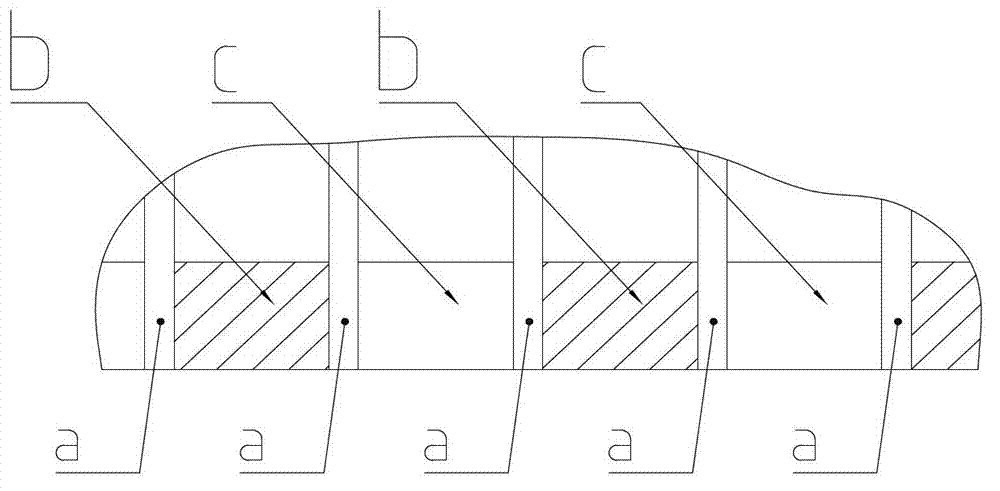

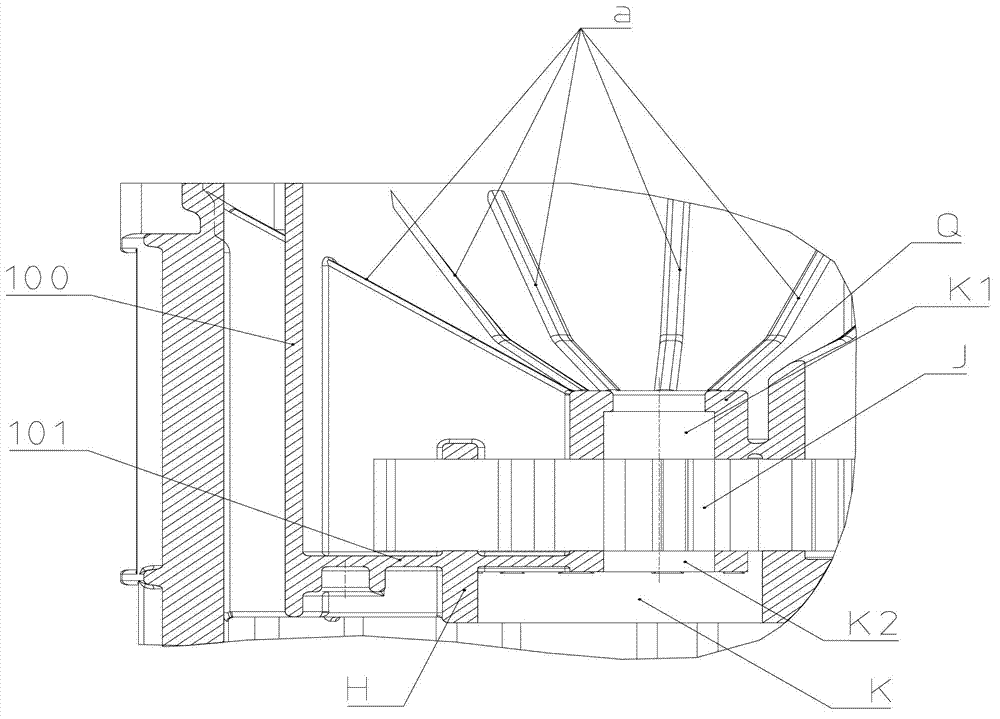

Support structure of reverse counter shaft of transmission

ActiveCN102878272AGood casting processImprove processing technologyGearing detailsEngineeringMilling cutter

The invention provides a support structure of a reverse counter shaft of a transmission. The support structure comprises a transmission housing, a partition and a boss. The transmission housing, the partition and the boss are integrated. Reverse idle gear mounting space is reserved between one side of a transmission main box, close to the partition, and the boss. The partition is provided with a second reverse counter shaft support hole and an auxiliary box counter shaft support hole, which are nonconcentric. One side of the boss, close to the transmission housing, is supported on the transmission housing through a plurality of ribs. Radial plates are disposed among the ribs. The reverse counter shaft boss is supported by the ribs in the support structure, and the reverse counter shaft boss with specific features is cast to reach a rear auxiliary box partition. By milling the reverse idle gear space with a disc milling cutter along with machining, casting of windows on two sides of the box is avoided effectively while fine casting manufacturability is guaranteed, casting manufacturability of the casing is improved, the parts such as window cover plates, spacers and bolts are omitted, and oil leakage spots are reduced effectively.

Owner:SHAANXI FAST GEAR CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com