Device for producing piston

A piston and casting production technology, applied in the field of piston devices, can solve problems such as easy fracture of the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

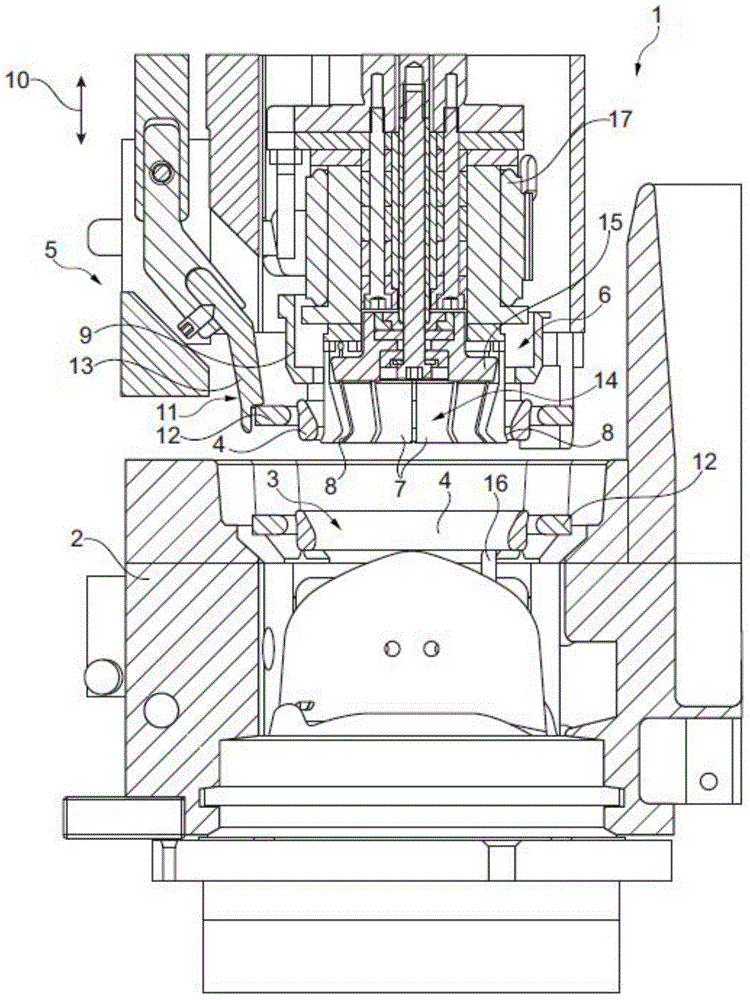

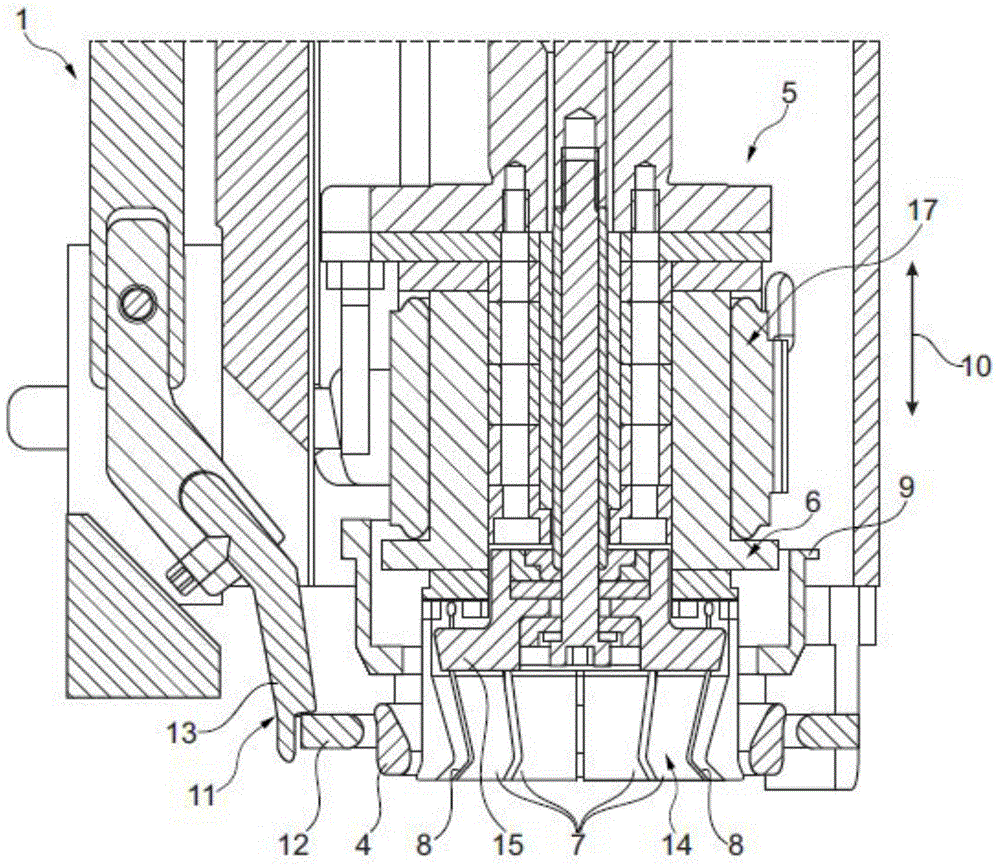

[0021] Such as figure 1 As shown, a device 1 for producing pistons for internal combustion engines by casting has a casting mold 2 with an upwardly open chamber 3 in which a core 4 (for example a salt core or a sand core) configured to form a cooling duct can be arranged. chamber 3. Likewise, a core holding device 5 is also provided for introducing the core 4 into the casting mold 2 (see inter alia figure 2 ). According to the invention, the core holding device 5 has a gripping device 6 with a telescopic lower inner gripper 7 adjustable between a first position and a second position, in In a first position, they are arranged radially inwards and in this state can be pushed through the core 4, in a second position they have moved radially outwards and have a radial direction forming a support for the core 4. Out towards area 8. The area 8 is in this case formed in the form of a protrusion. In its first position, the inner gripper 7 has an outer diameter smaller than the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com