Patents

Literature

1110results about "Moulding tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

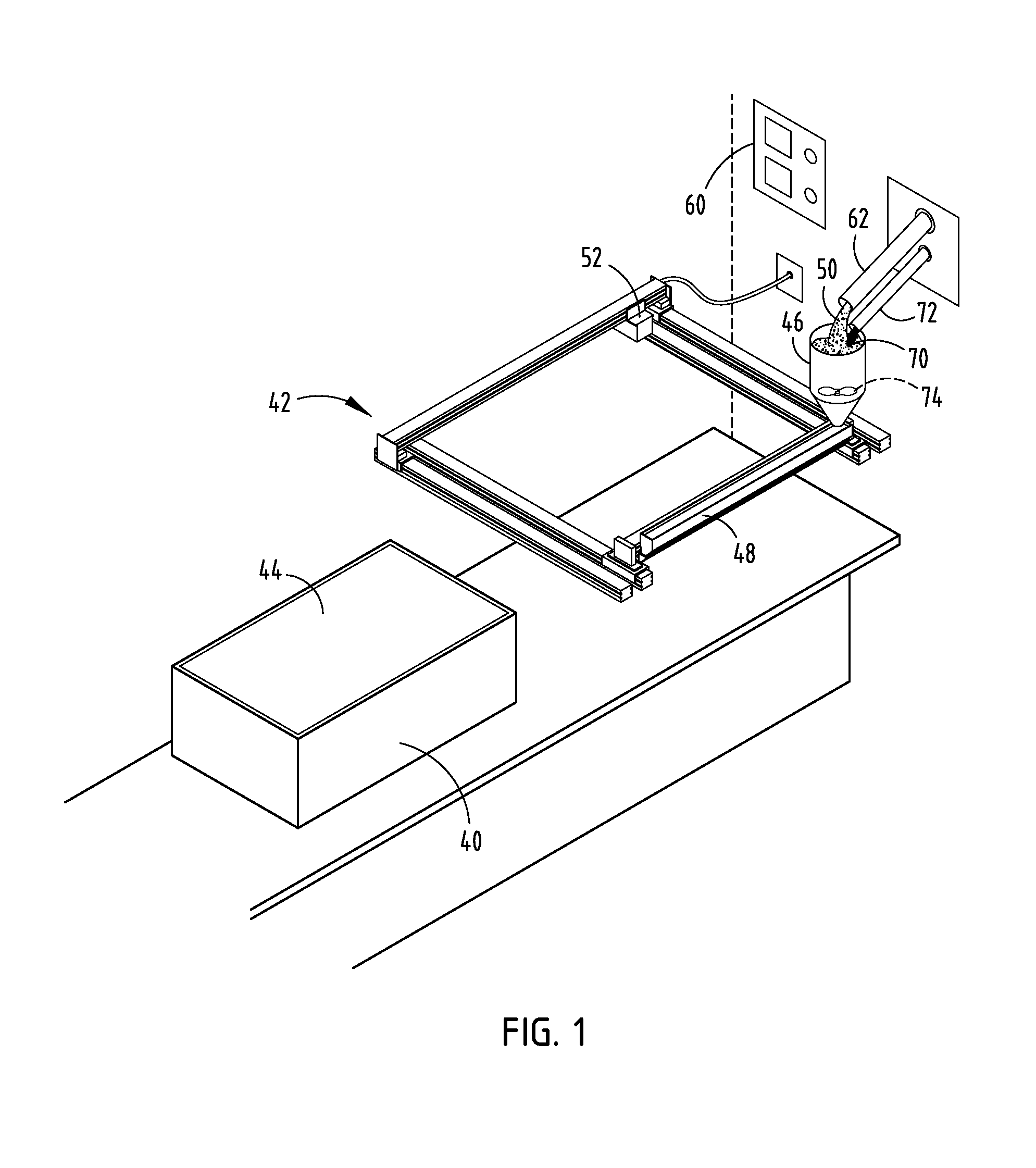

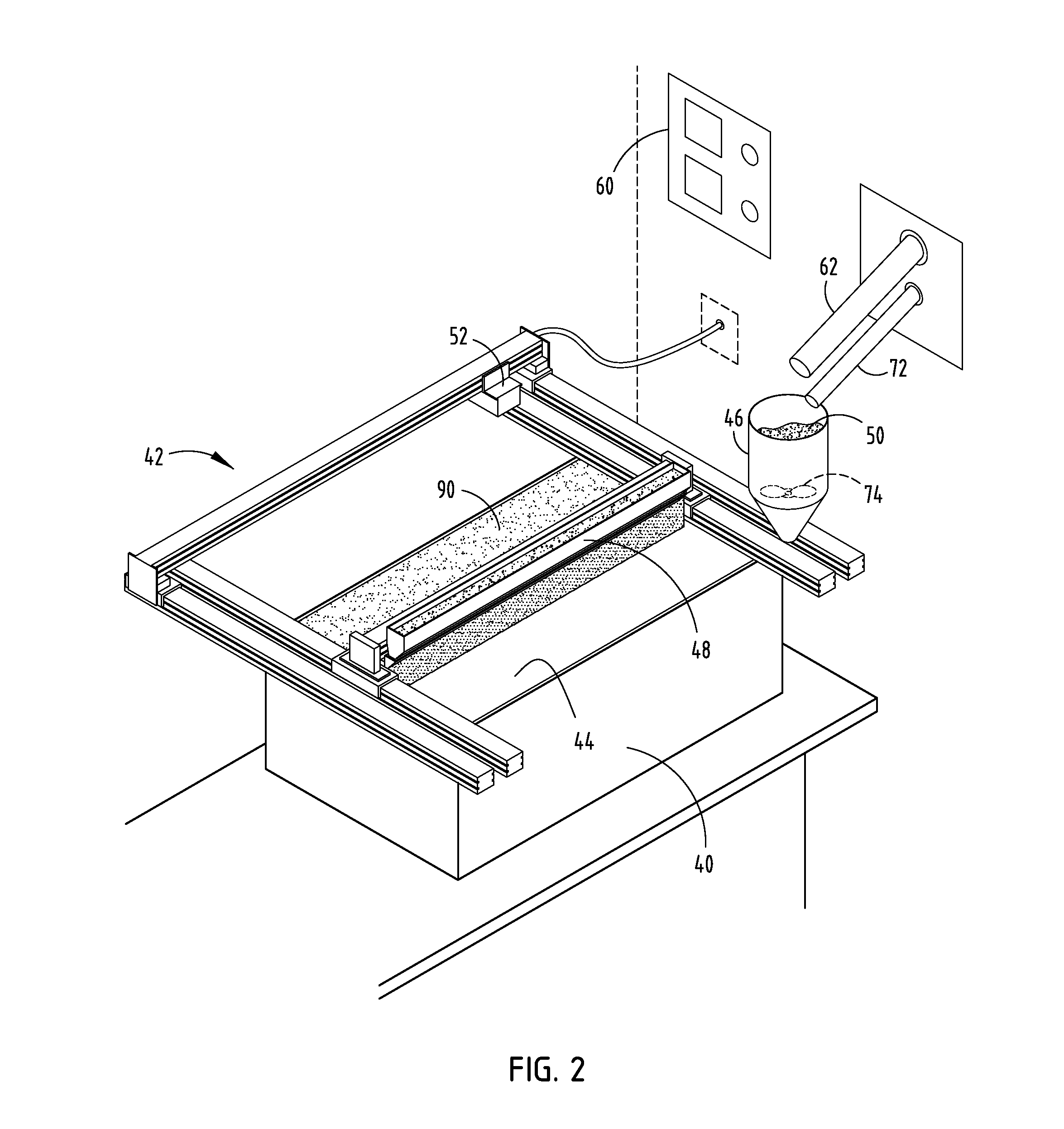

Method for constructing patterns in a layered manner

A process to produce models in layers is described, whereby a first material and then selectively a second material is applied in layers on a building platform and these two application stages are repeated until a desired pattern is achieved. The two materials form a solid if a suitable mixture ratio is used and the first material is a material mixture. The material mixture is at least partially prepared prior to each application stage.

Owner:EXONE

Ceramic casting core made by additive manufacturing

InactiveUS20150306657A1Precise constructionPrecise positioningAdditive manufacturing apparatusMoulding toolsChemical reactionCompound (substance)

A method of making a ceramic casting core involves using additive manufacturing to form a 3D ceramic casting core that includes an outer core body surface layer that exhibits reduced chemical reactivity with the molten metal or alloy being cast, wherein the ceramic body and the outer core body layer each comprises a layer-on-layer structure in a build direction of the ceramic casting core resulting from the additive manufacturing process, such as 3D printing.

Owner:HOWMET CORPORATION

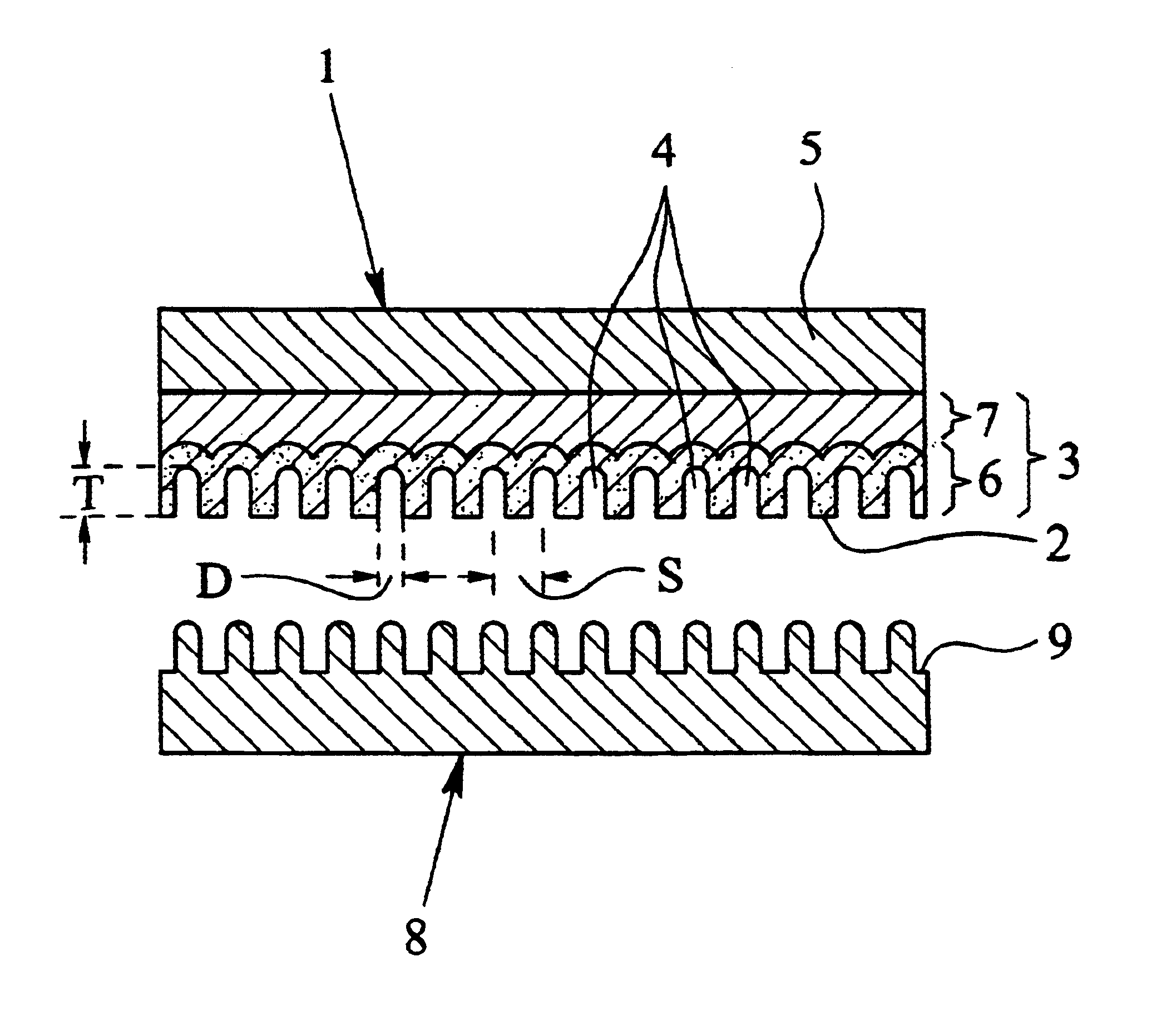

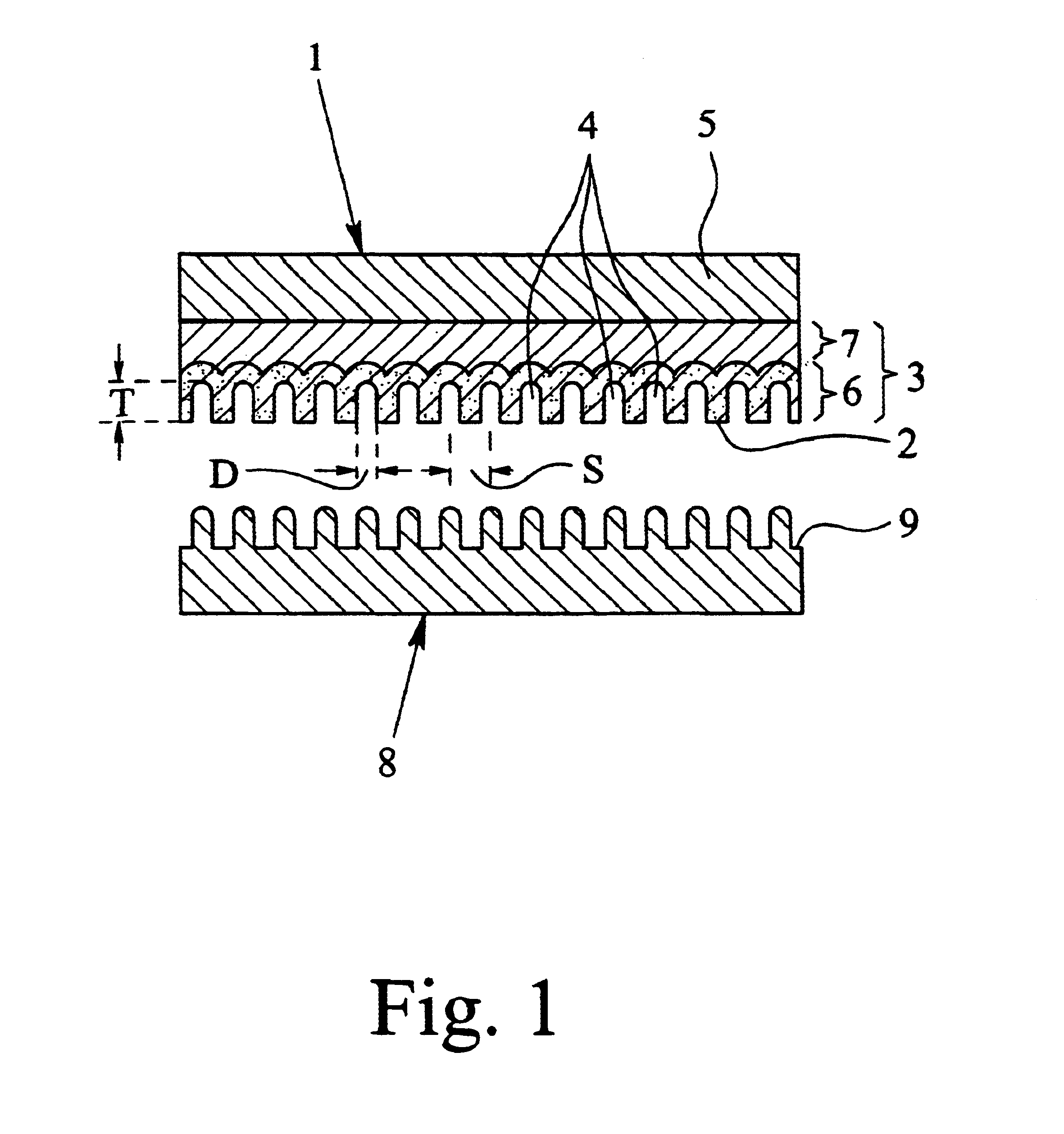

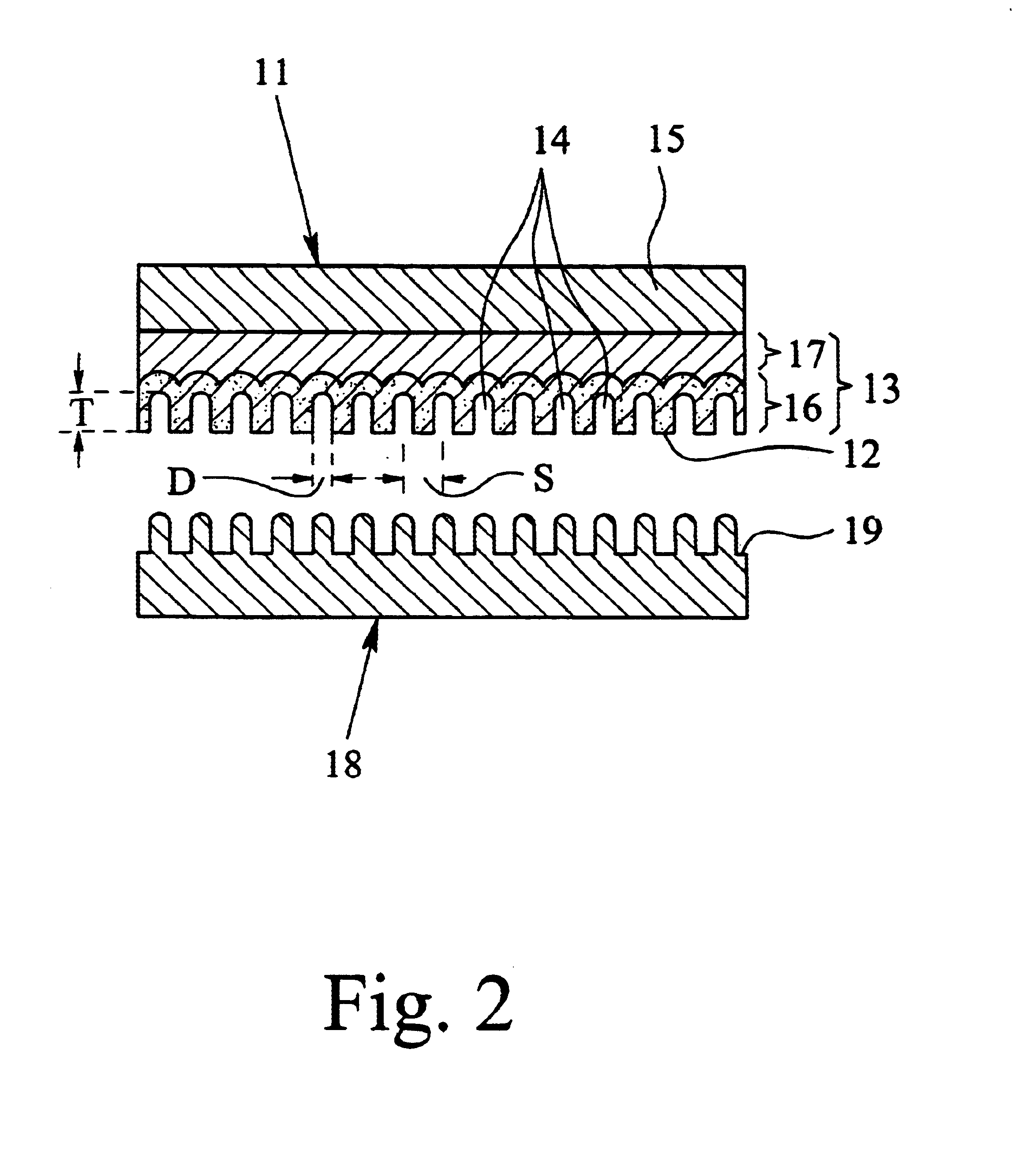

Stamping tool, casting mold and methods for structuring a surface of a work piece

InactiveUS7066234B2Simple and cost-effectiveProlong lifeAnodisationMoulding toolsSurface layerCasting mold

A simple, cost-effective stamping or molding in the nanometer range is enabled using a stamping surface or molding face with a surface layer having hollow chambers that have been formed by anodic oxidation.

Owner:SHARP KK

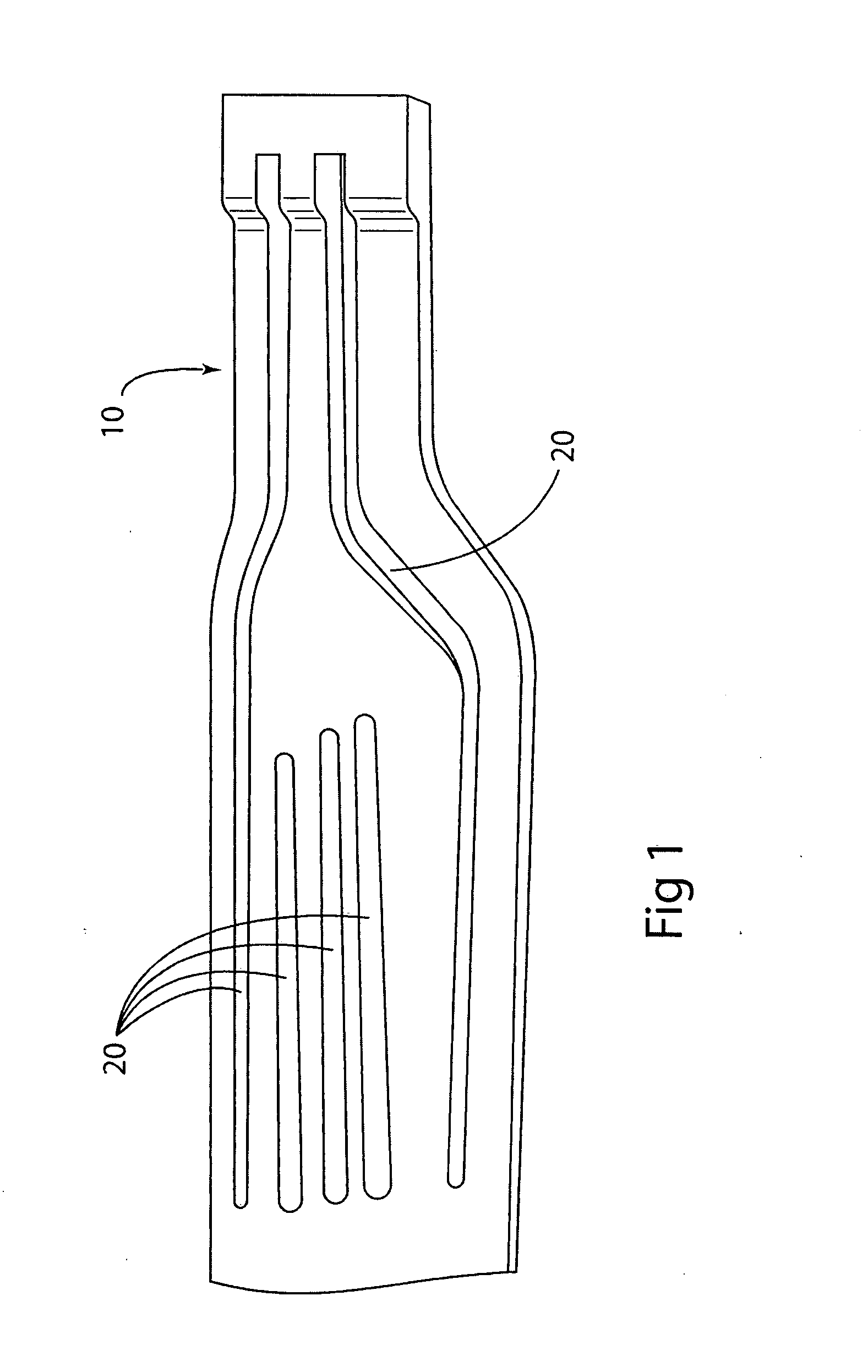

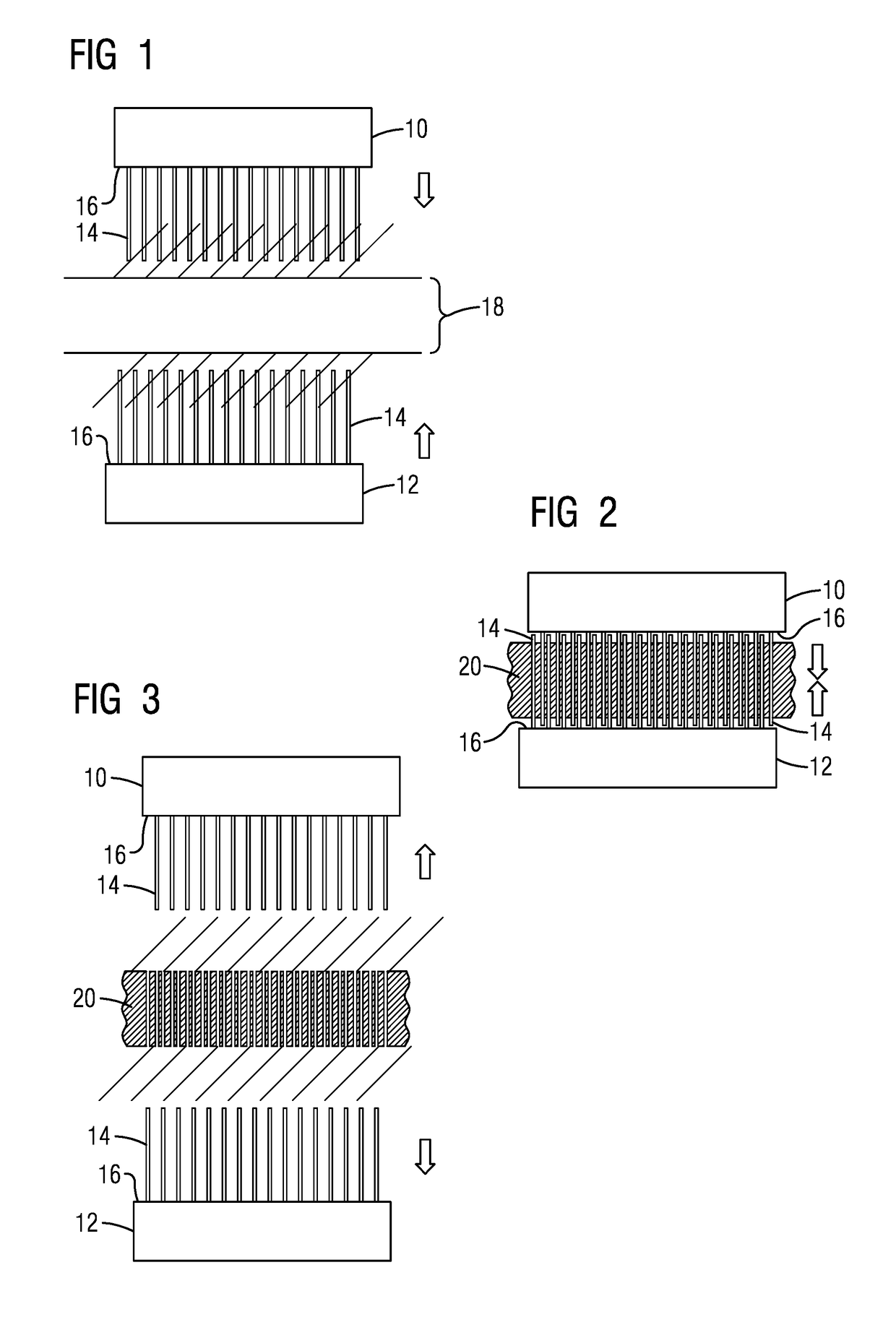

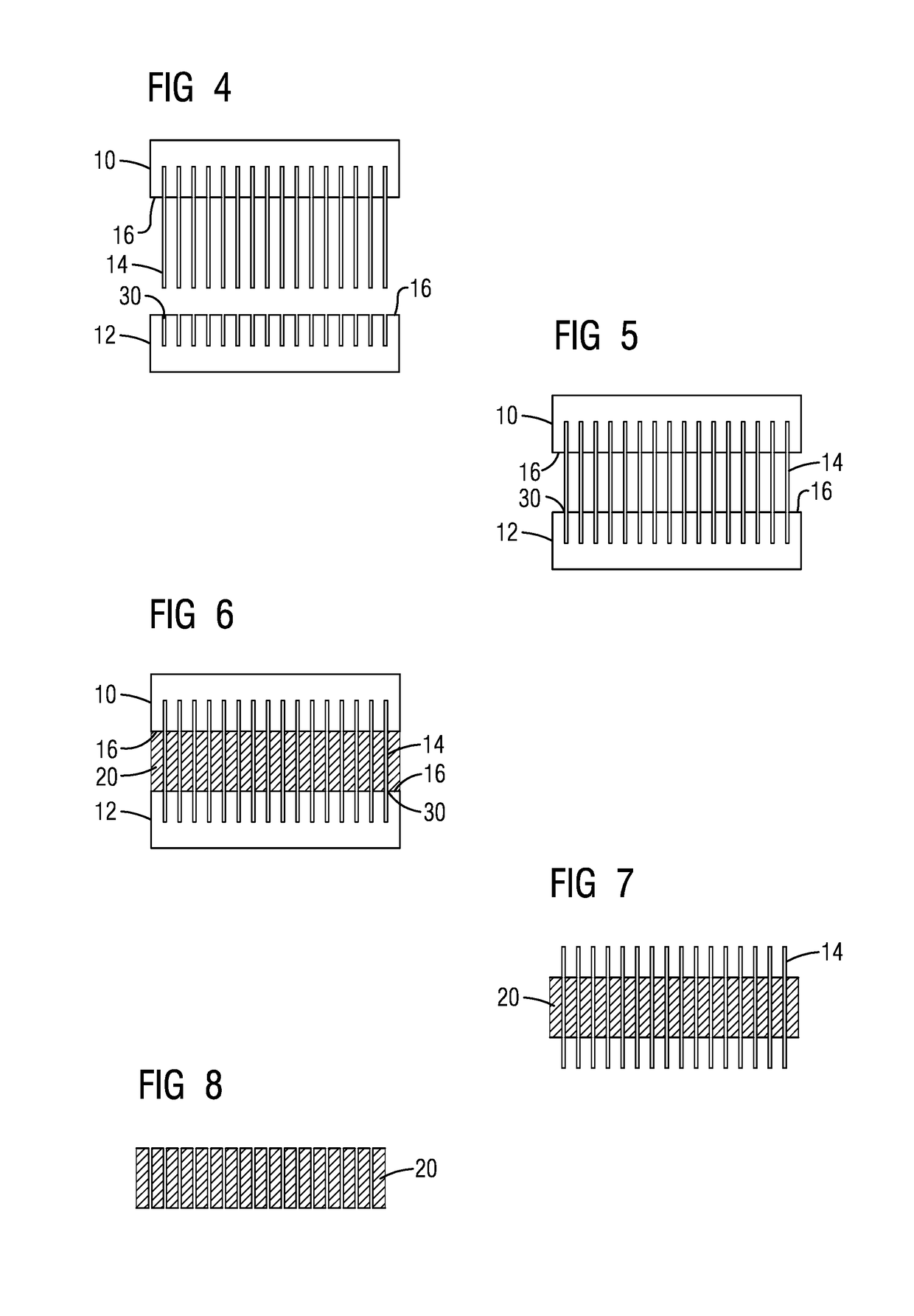

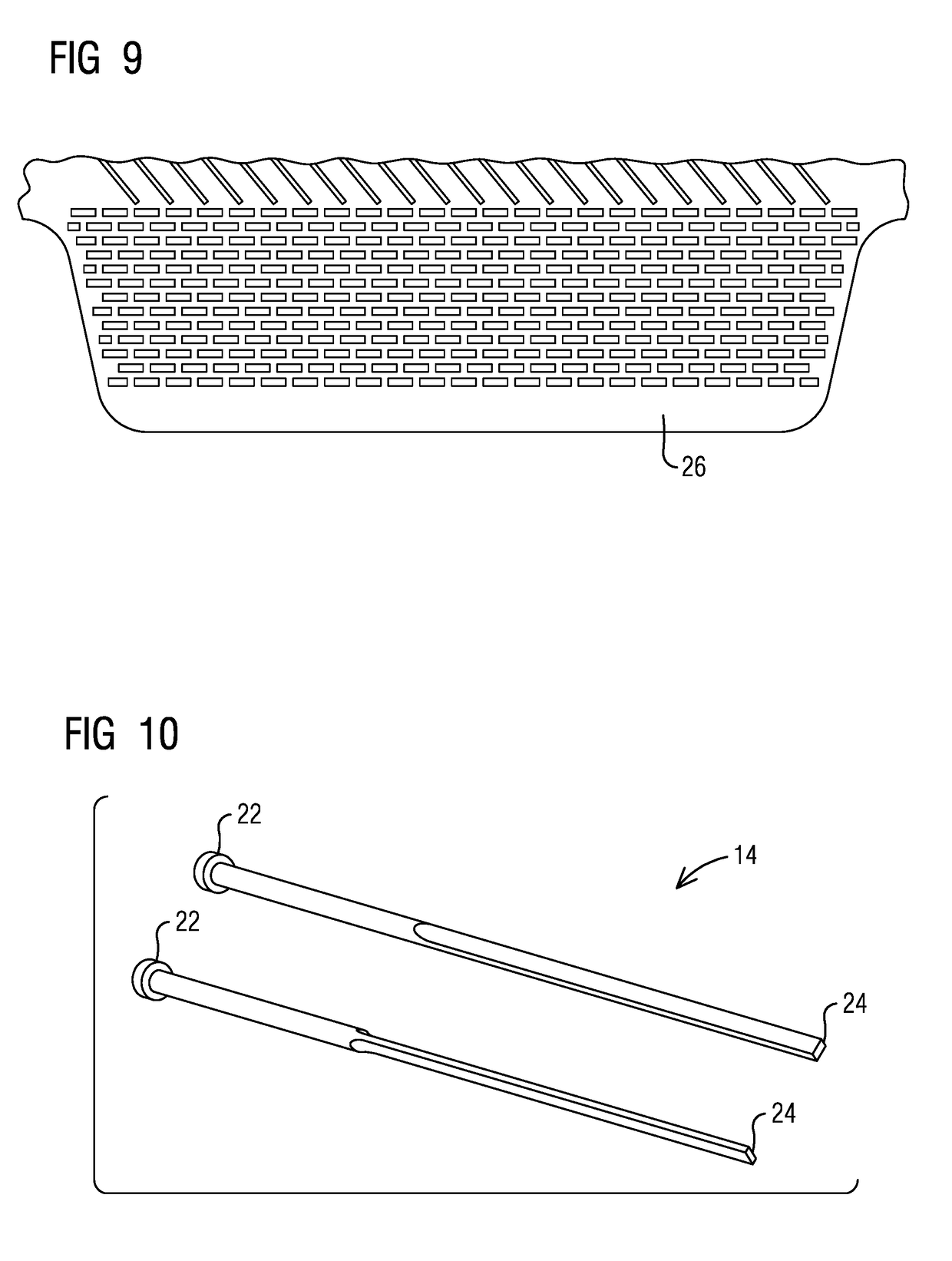

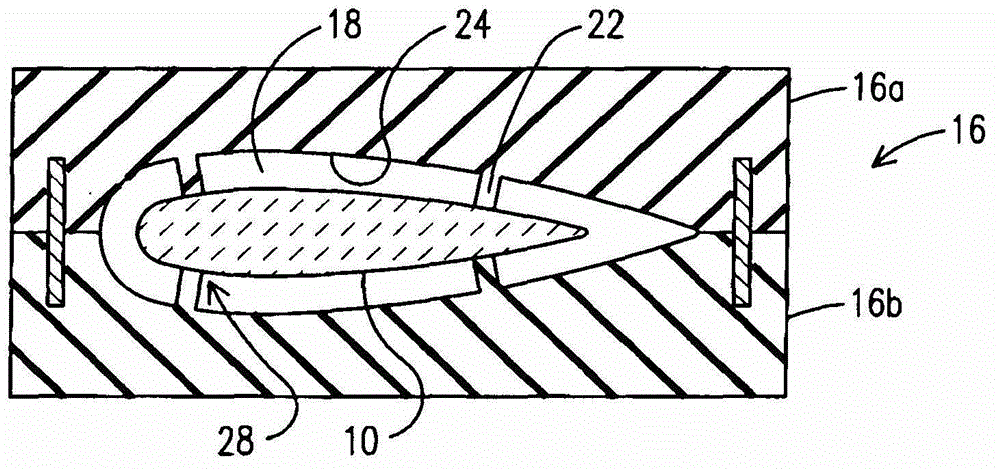

Method of manufacturing advanced features in a core for casting

A hard tool configuration (28) and method of manufacturing advanced detailed trailing edge features in a core for casting. The hard tool configuration (28) includes at least a first platform (10) and a second platform (12). The hard tool configuration (28) also includes a first end (22) of a plurality of removable rake elements (14) removably attached to at least one of the first platform (10) and the second platform (12). The hard tool configuration (28) also includes an internal mold geometry (18) in a spacing in between the center facing side (16) of the first platform (10) and the center facing side (16) of the second platform (12).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG +1

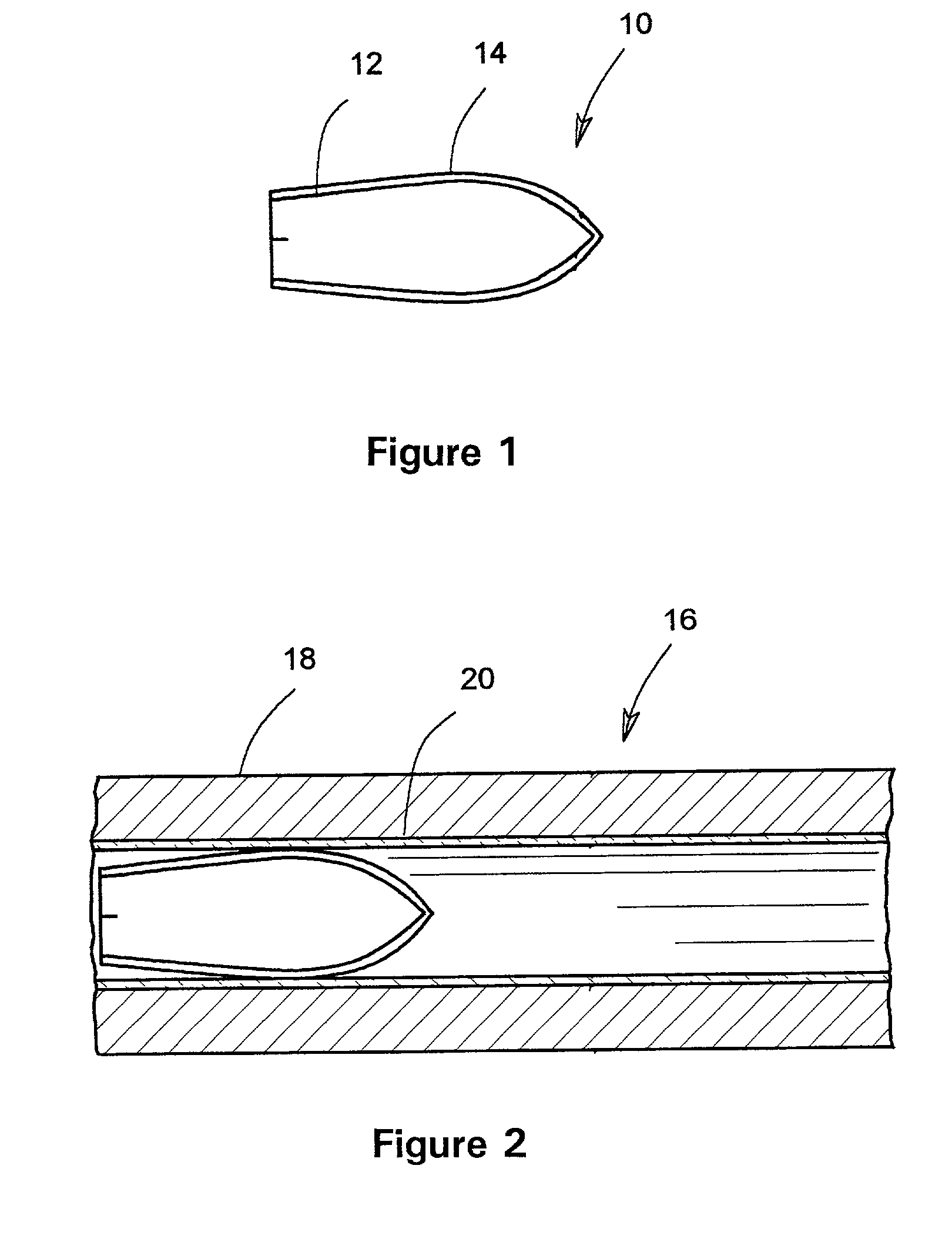

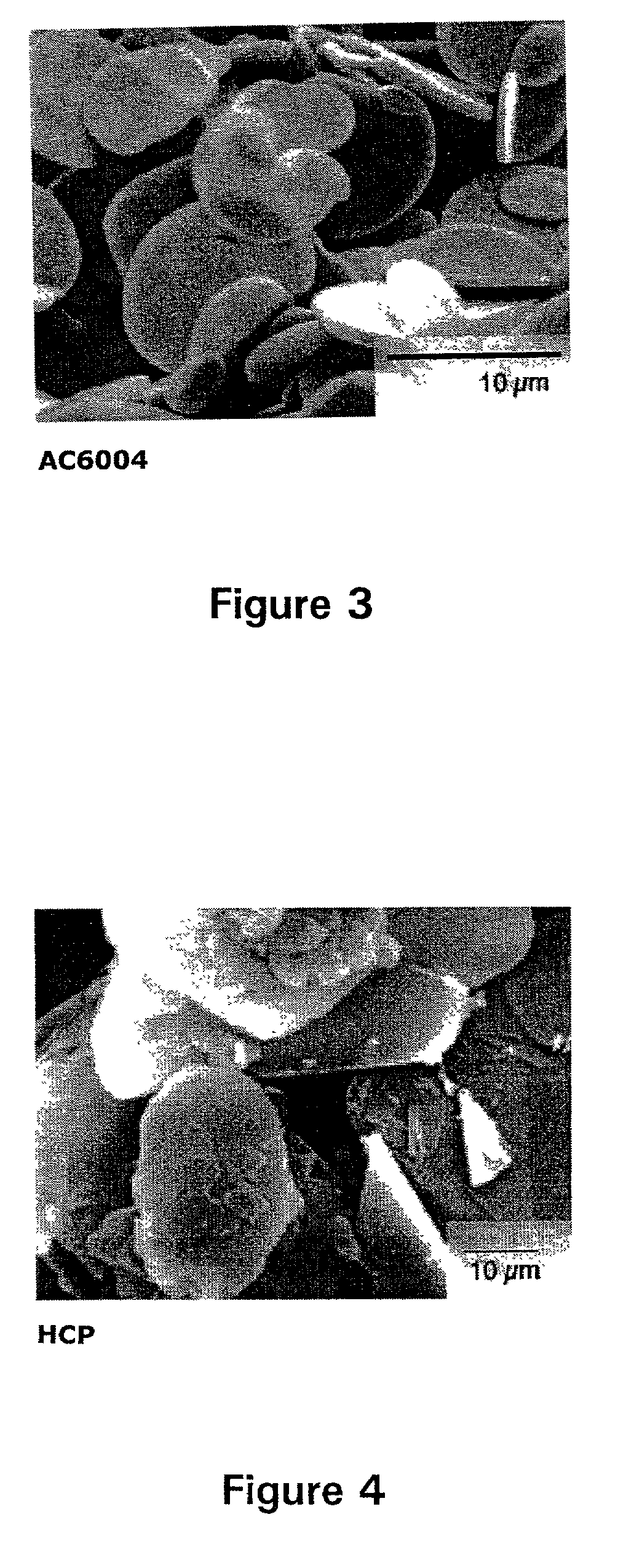

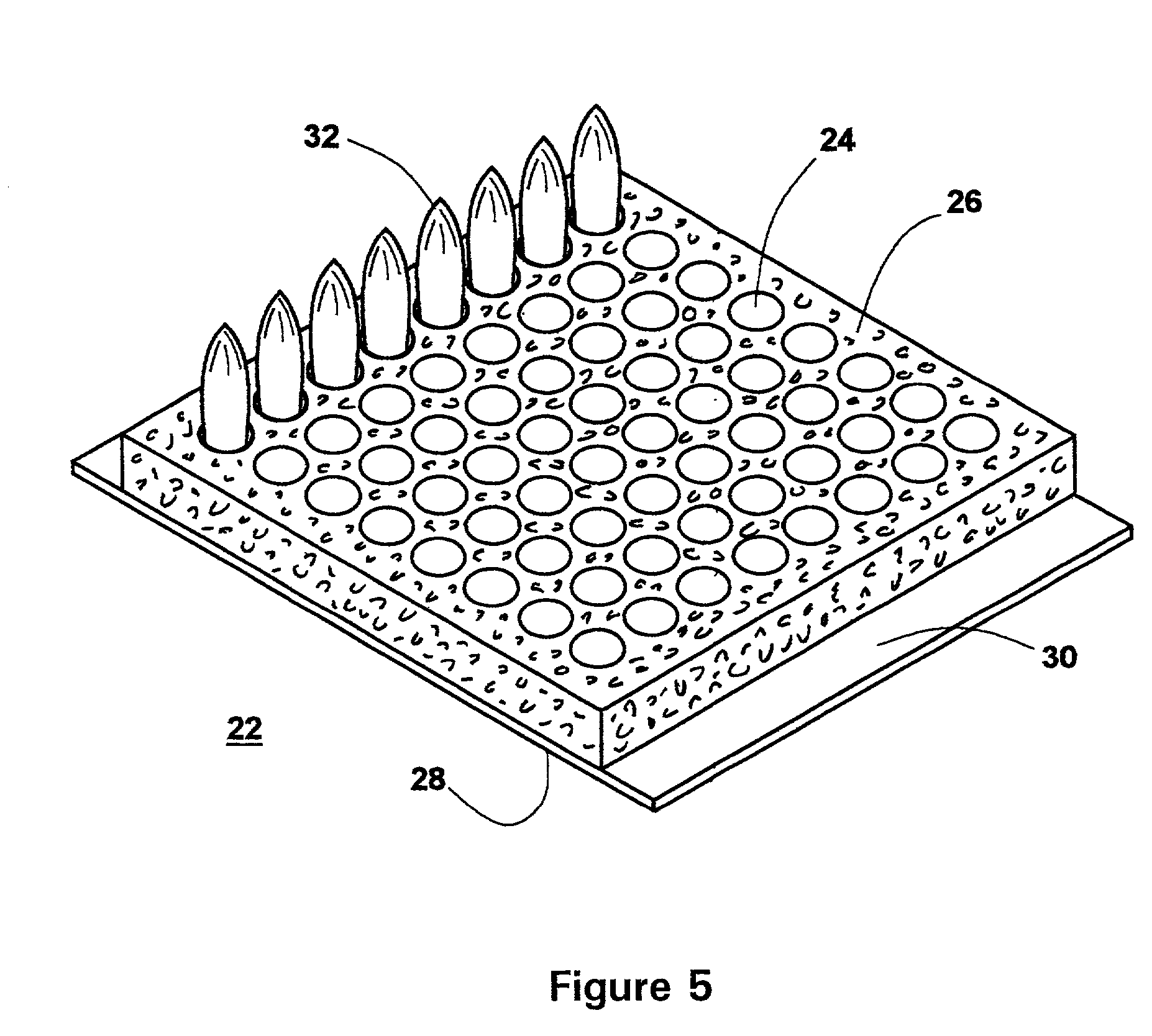

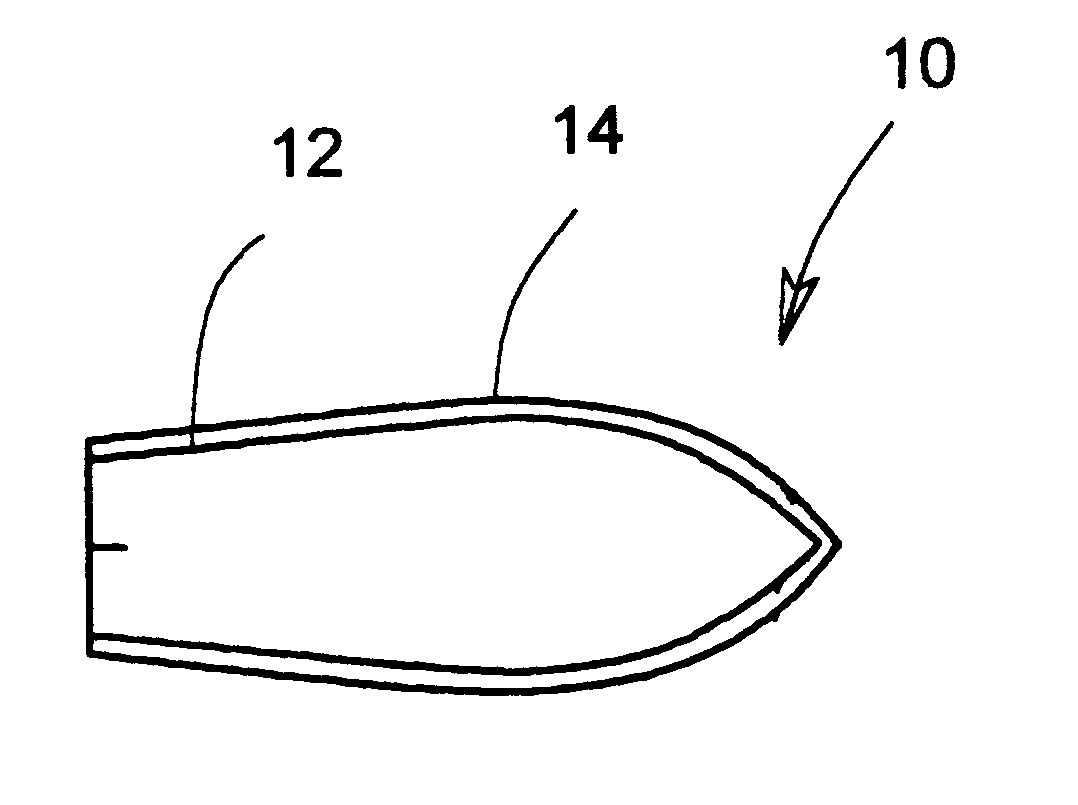

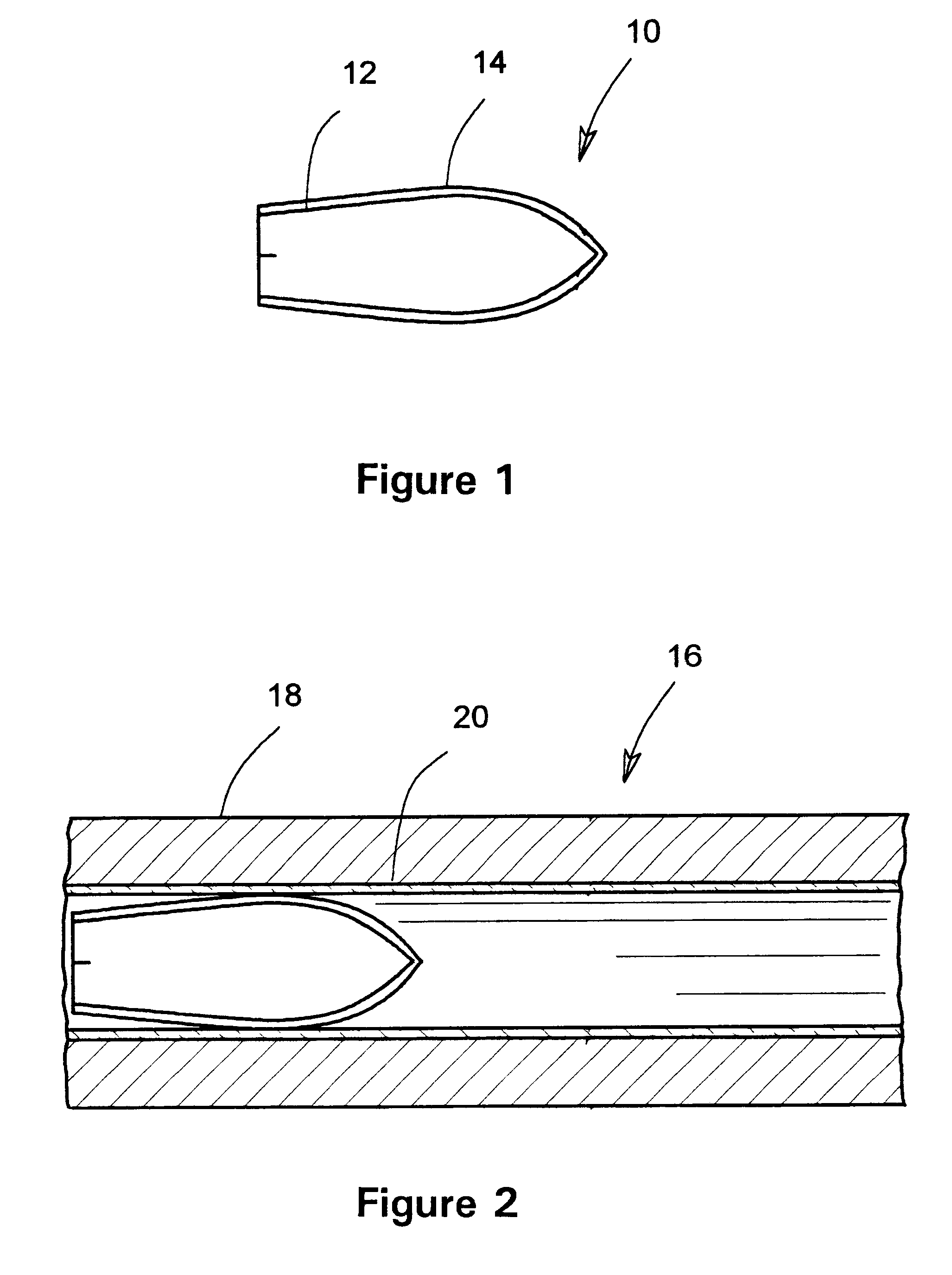

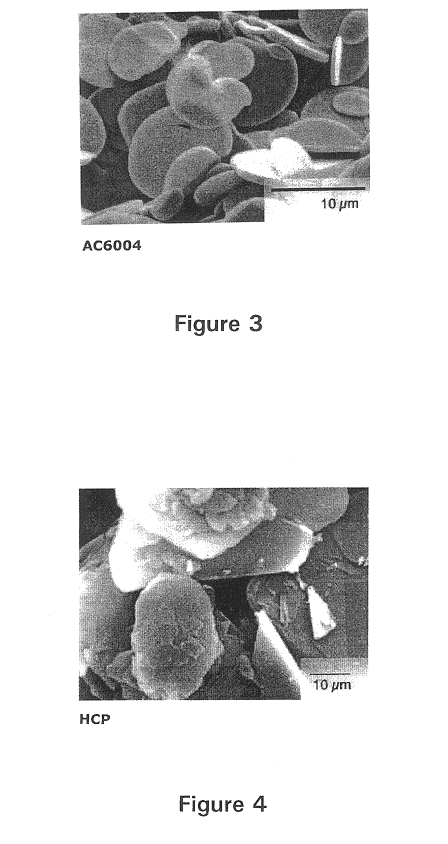

Ballistics conditioning

InactiveUS20030078170A1Quick and easy spray-coatingHigh hardnessAmmunition projectilesMoulding toolsHexagonal boron nitrideAcrylic resin

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

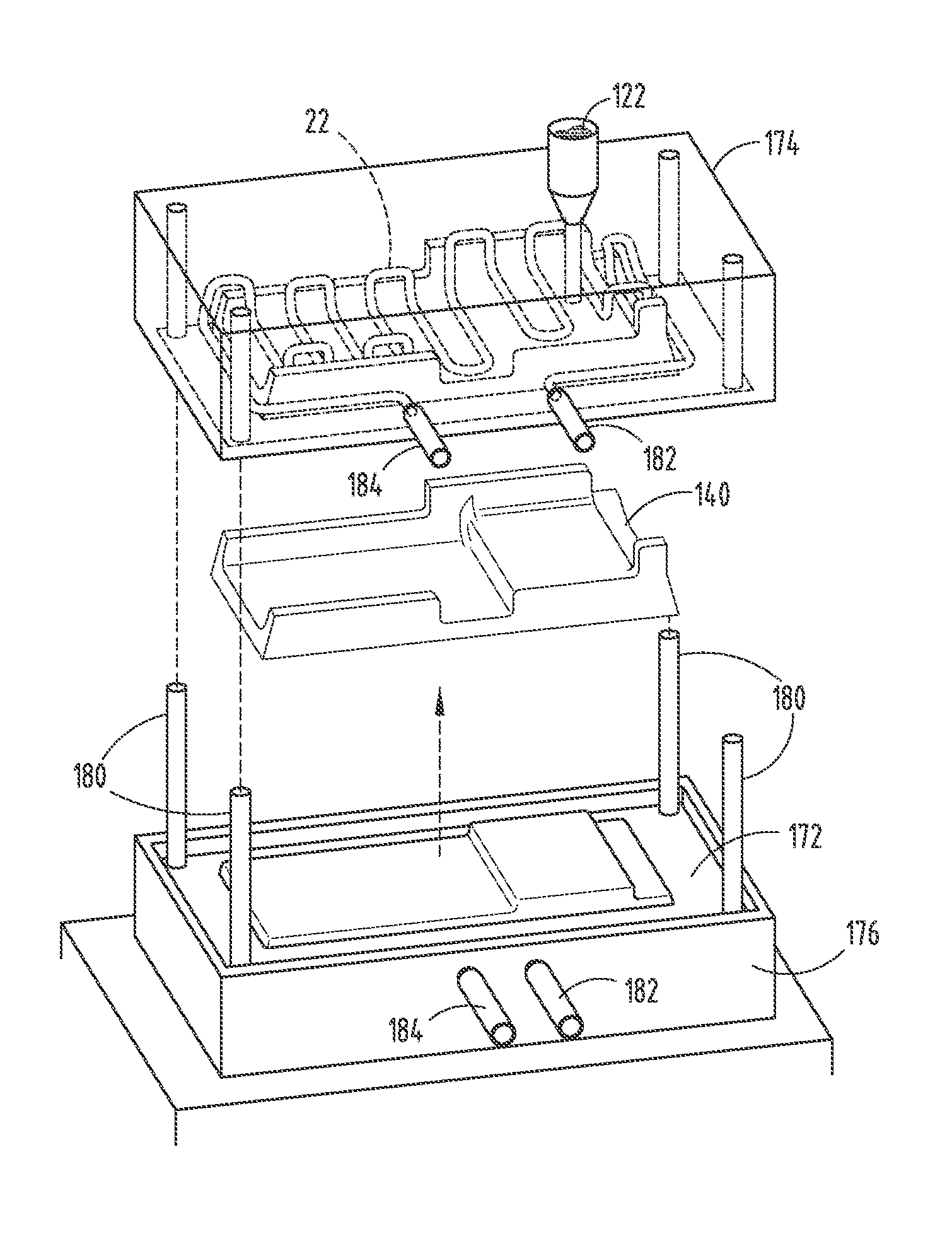

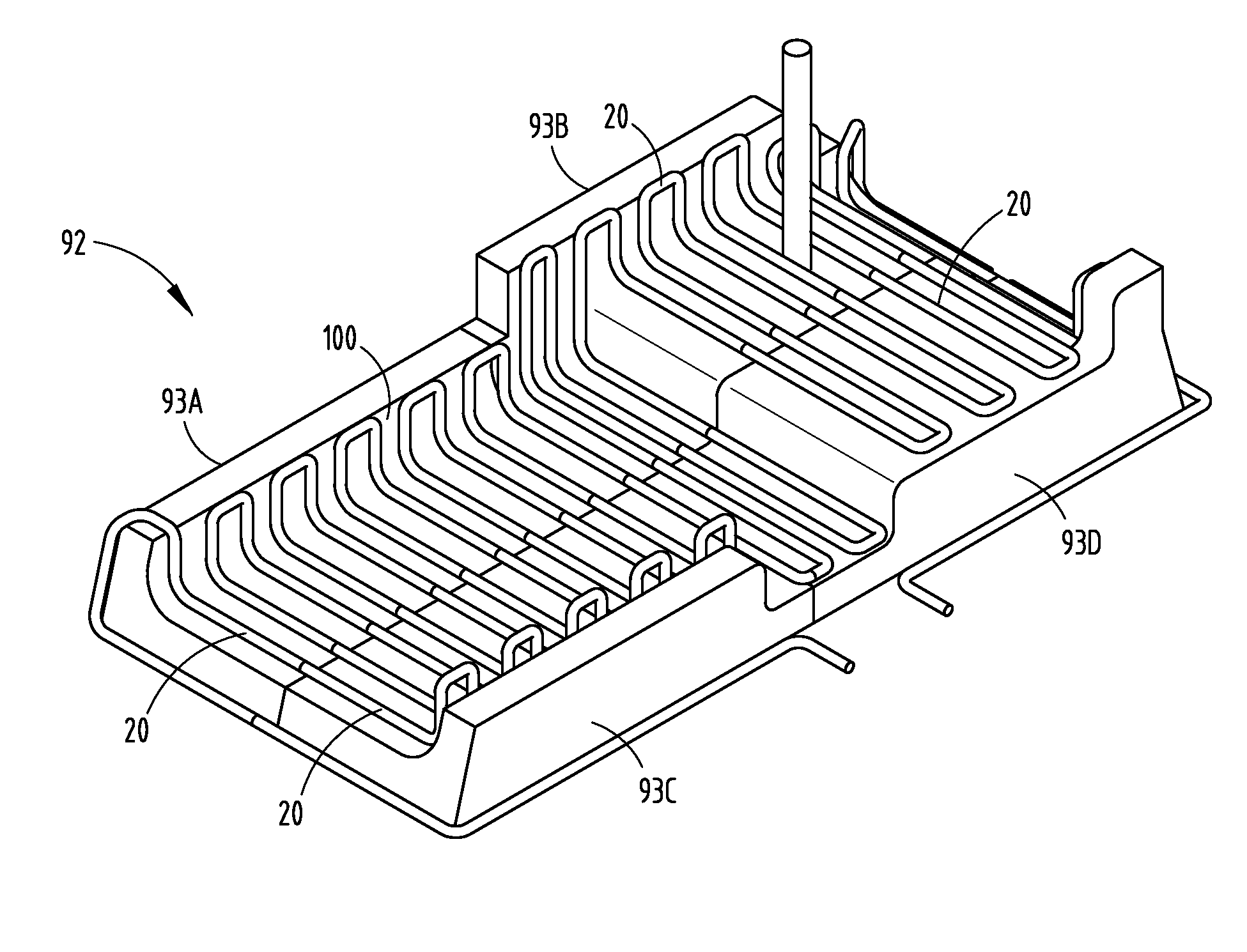

Molding assembly with heating and cooling system

A molding assembly for making molded parts includes a molding tool having conformal fluid lines that follow contours of a molding surface of the molding tool. The conformal fluid lines are defined in the molding tool during casting by sacrificial displacement lines formed by a three-dimensional printer. A temperature control station is coupled to the molding tool and includes a heating and cooling fluid. A valve station regulates fluid flow to the molding tool.

Owner:FORD MOTOR CO

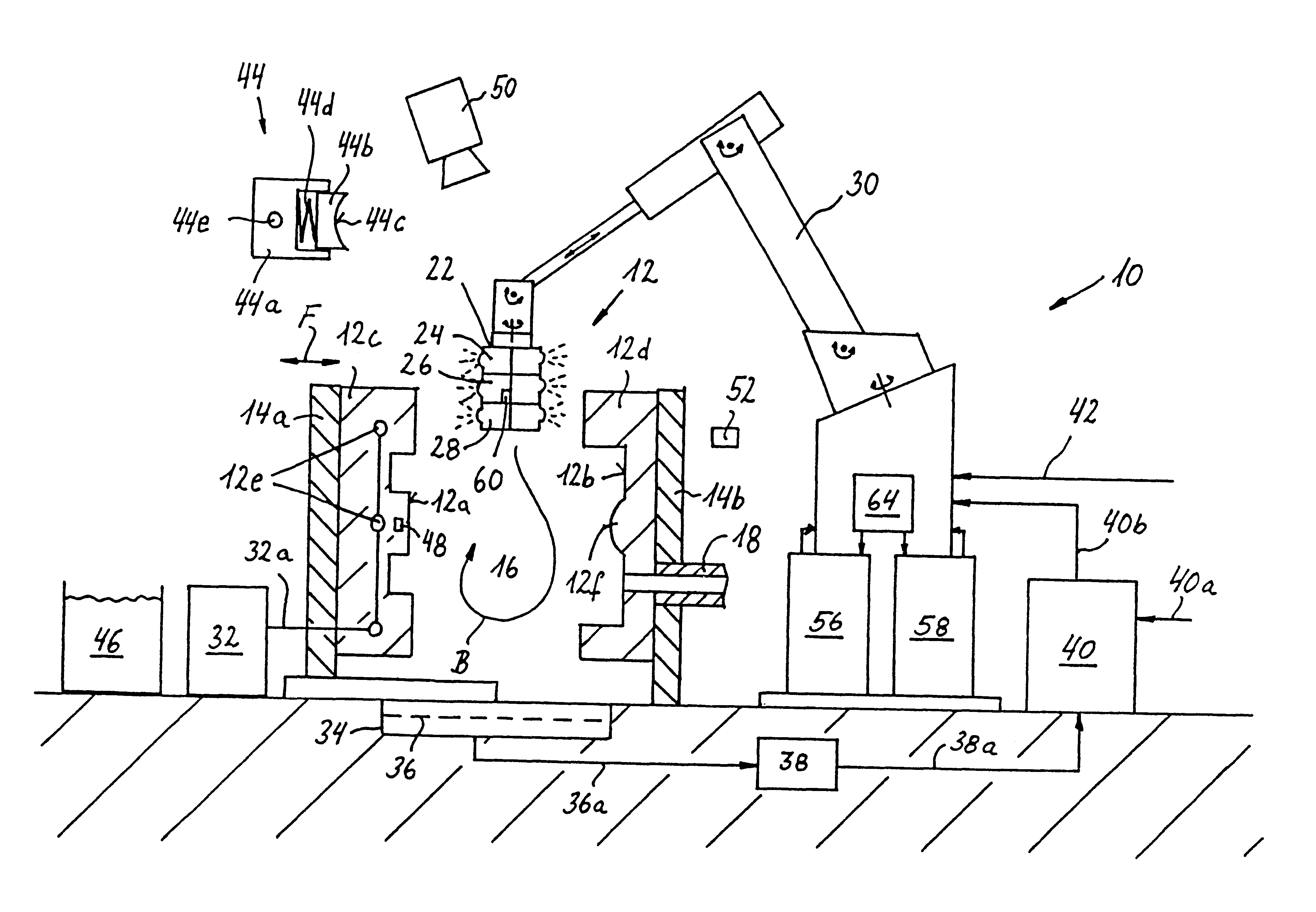

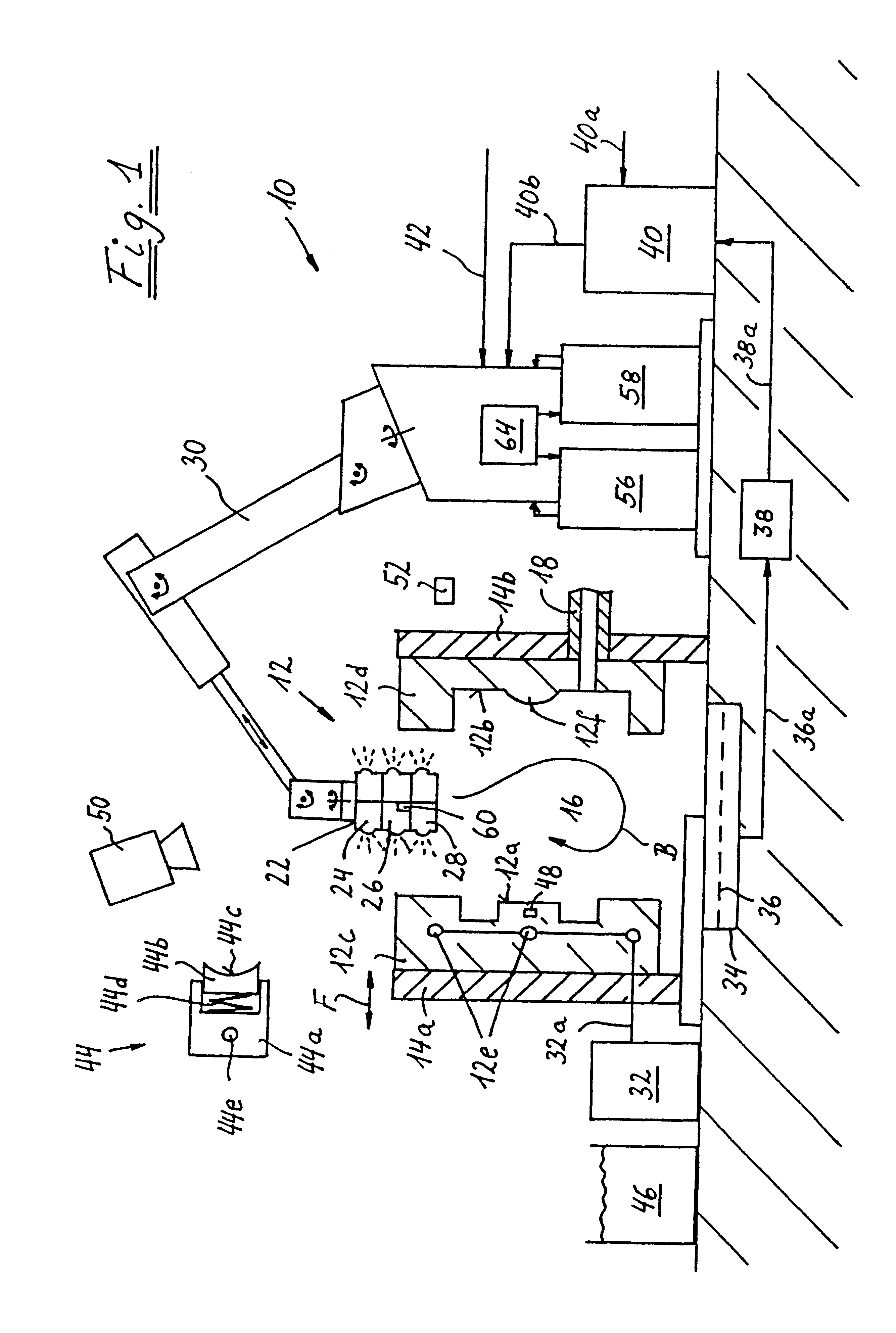

Process for preparing the walls of a mold for molding or shaping to make them ready for the next molding cycle

In a process for preparing the mold walls (12a, 12b) of a mold (12, 12) for the molding or shaping of a molded part after completion of the molding cycle and after removal of the molded part from the mold (12) to make the mold walls ready for the next molding cycle, the tempering of the mold walls (12a, 12b) and the coating of the walls with mold wall treatment agent are carried out independently of each other, i.e., without any time overlap, and in a controlled manner, preferably in a program-controlled manner. To apply the coating, preferably a spray element with centrifugal atomization and air control is used, the mold walls preferably being coated with essentially solvent-free mold wall treatment agent.

Owner:HENKEL IP & HOLDING GMBH

Use of calcium sulfonate based threaded compounds in drilling operations and other severe industrial applications

The present invention discloses the use of calcium sulfonate based greases compounds for use in application where the compounds are continuously, periodically or intermittently exposed to fluids that tend to contamination, erode, ablate or otherwise remove or interfere with the compounds ability to protect contact surfaces such as those present in threaded connections, and, especially in threaded connections associated with oilfield applications. The present invention also discloses methods for making and using such greases and compounds in application where the compounds are continuously, periodically or intermittently exposed to fluids that tend to contamination, erode, ablate or otherwise remove or interfere with the compounds ability to protect contact surfaces.

Owner:JET LUBE

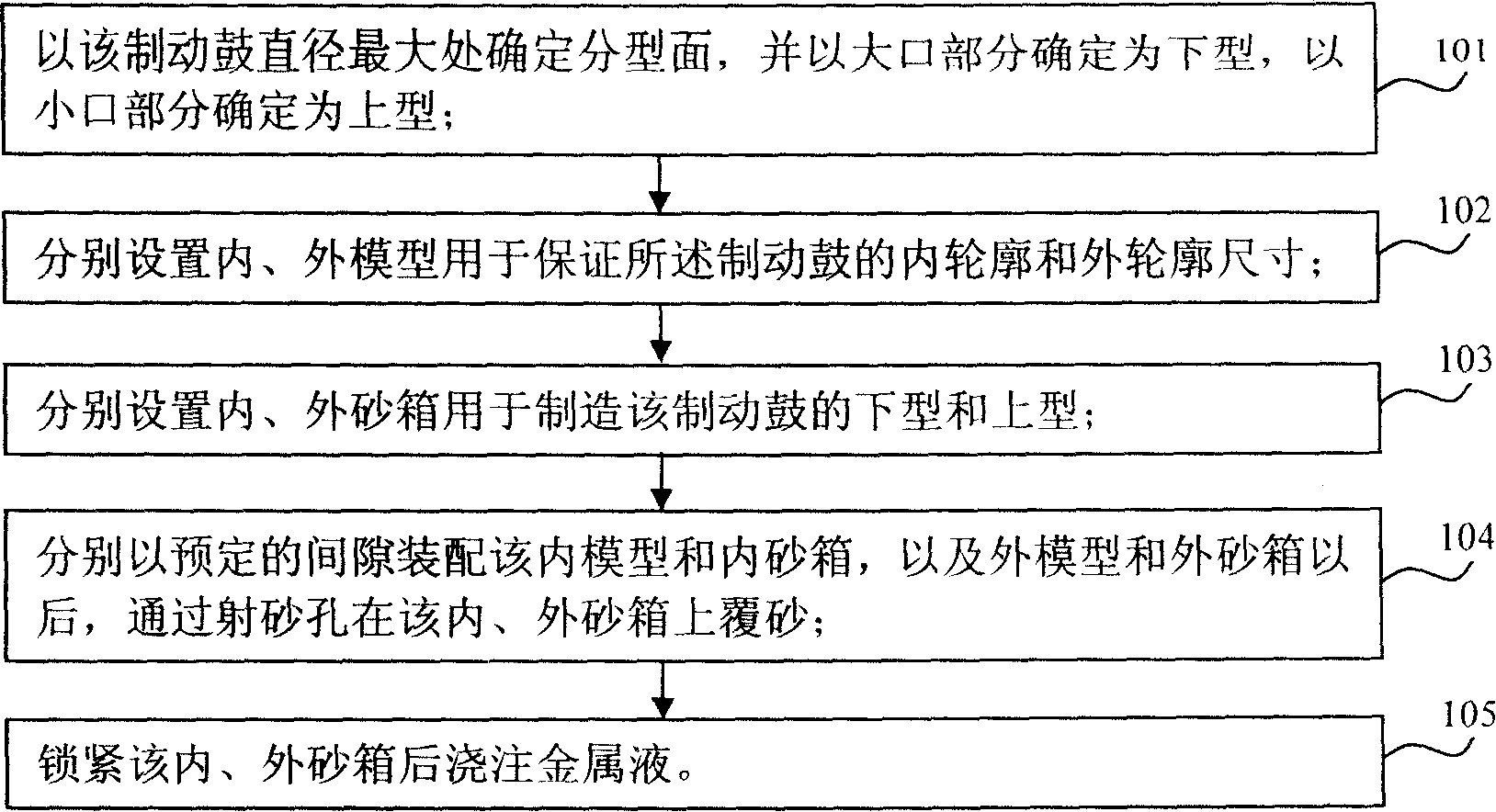

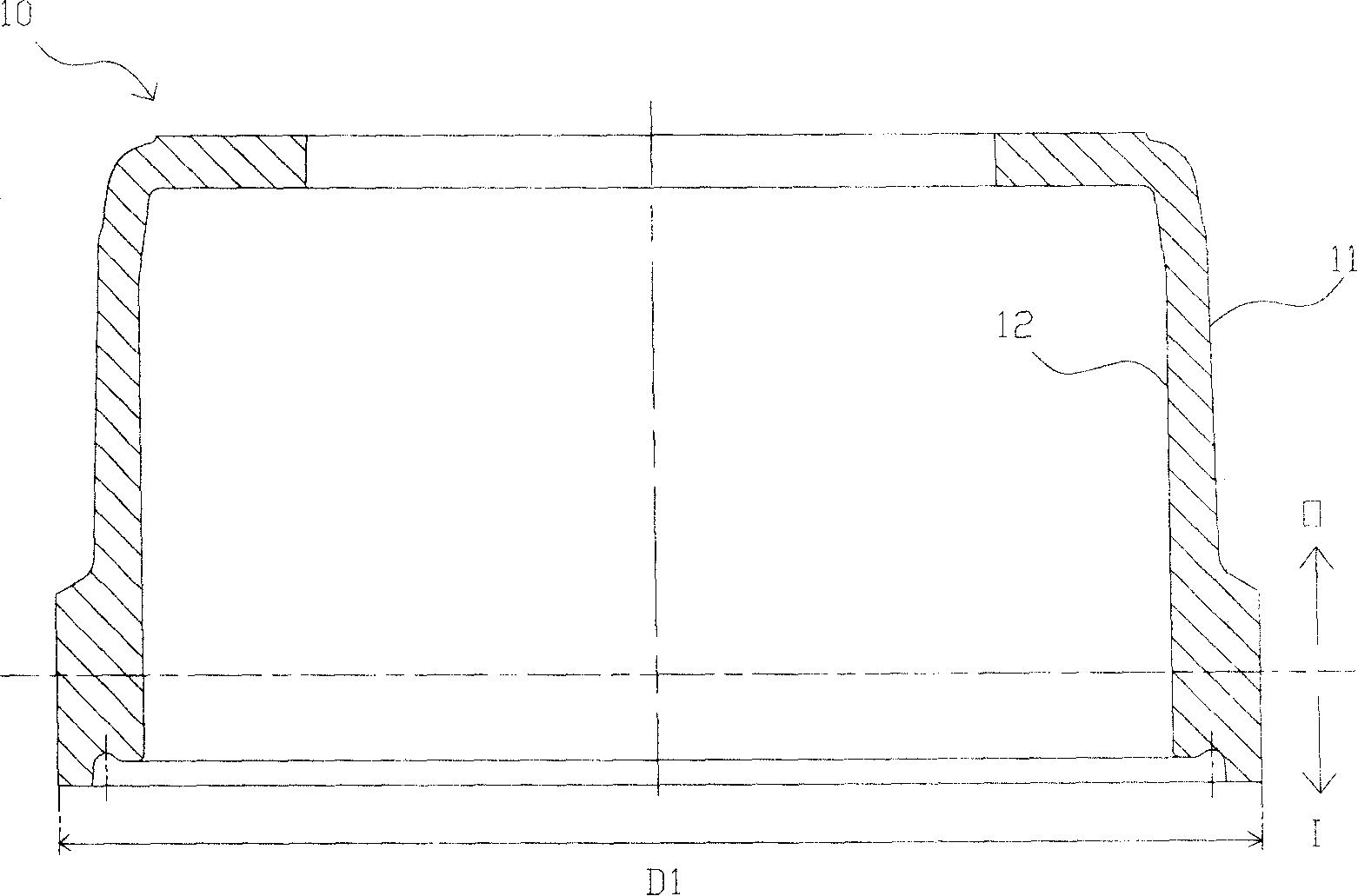

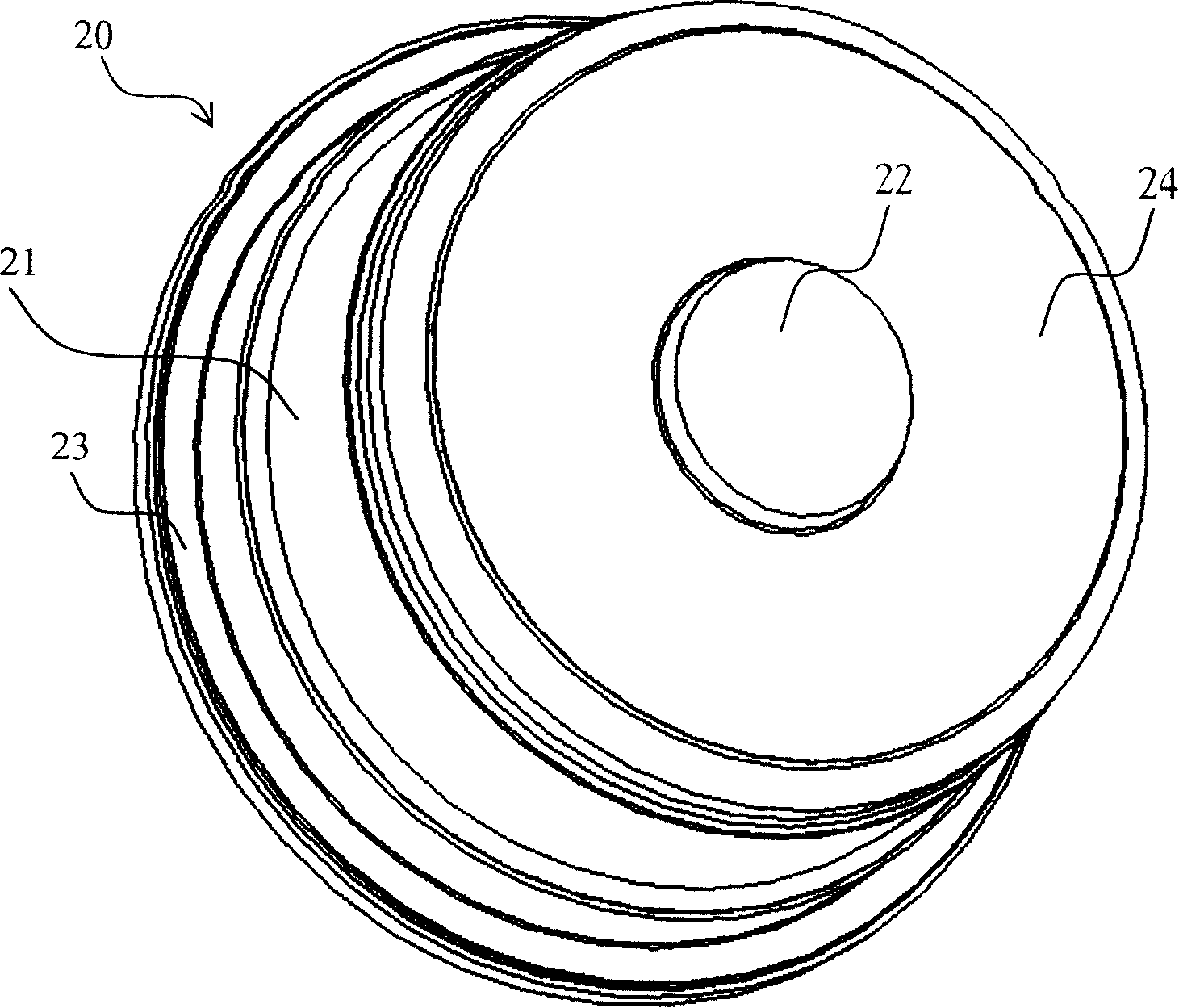

Method for using metal type sand-covering technique to manufacture brake drum

ActiveCN101190454AReduce auxiliary equipmentReduce processMoulding toolsFoundry mouldsLarge mouthUpper joint

The invention relates to a method of manufacturing a brake drum by utilizing a metal-typed sand covering technique, comprising a die joint is determined by the maximum diameter position of the brake drum, a lower joint is determined by a large mouth part and an upper joint is determined by a small mouth part; an internal model and an external model are respectively arranged in order to ensure the internal profile dimension and the external profile dimension of the brake drum; an internal sand box and an external sand box are respectively arranged in order to manufacture the lower joint and the upper joint of the brake drum; after the internal model and the internal sand box, the external model and the external sand box are assembled according to prearranged clearances, the internal sand box and the external sand box are covered with sands through a sand injection hole; metal liquid is poured after the internal sand box and the external sand box with sand cover are tightly locked. The invention has the advantages of improving working environment, more precise dimension of the castings, better surface quality, higher yield, lower cost and higher production efficiency.

Owner:ZHUMADIAN ZHONGJI HUAJUN CASTING

Interchangeable mold inserts

A mold core package for forming a molding tool with a removable insert includes a plurality of stacked particulate layers having a binding agent. The plurality of stacked particulate layers form molding pattern walls that generally define a base mold cavity and an insert mold cavity defining a mold surface. A sacrificial displacement line extends through the insert mold cavity closely following contours of the mold surface.

Owner:FORD MOTOR CO

Ballistics conditioning

Compositions and methods for ballistic conditioning firearm projectiles, firearms, and firearm components such as bores of barrels, by applying to such items a conditioning composition selected from the group consisting of hexagonal boron nitride, graphite, tungsten disulfide, antimony trioxide, talc, mica, and mixtures thereof, suspended in a carrier comprising a volatile solvent, and a binder selected from the group consisting of cellulosic-, alkyd- and acrylic-resins.

Owner:BROWN DAVID THOMAS

Use of calcium sulfonate based threaded compounds in drilling operations and other severe industrial applications

The present invention discloses the use of calcium sulfonate based greases compounds for use in application where the compounds are continuously, periodically or intermittently exposed to fluids that tend to contamination, erode, ablate or otherwise remove or interfere with the compounds ability to protect contact surfaces such as those present in threaded connections, and, especially in threaded connections associated with oilfield applications. The present invention also discloses methods for making and using such greases and compounds in application where the compounds are continuously, periodically or intermittently exposed to fluids that tend to contamination, erode, ablate or otherwise remove or interfere with the compounds ability to protect contact surfaces.

Owner:JET LUBE

Dry film lubricant

InactiveUS20060003901A1Good anti-blockingImprove anti-corrosion performanceDrilling rodsMoulding toolsWaxParticulates

The present invention relates to compositions and methods employing a first copolymer that is an acrylic copolymer or styrene / acrylic copolymer having a weight average molecular weight (Mw) of about 8,000 to about 14,000; a second copolymer that is an acrylic copolymer having a Mw of about 90,000 to about 130,000; a wax emulsion or dispersion, and a particulate additive. Optionally, the composition further comprises at least one of a rheological additive, ammonium hydroxide or a defoaming compound.

Owner:HENKEL KGAA

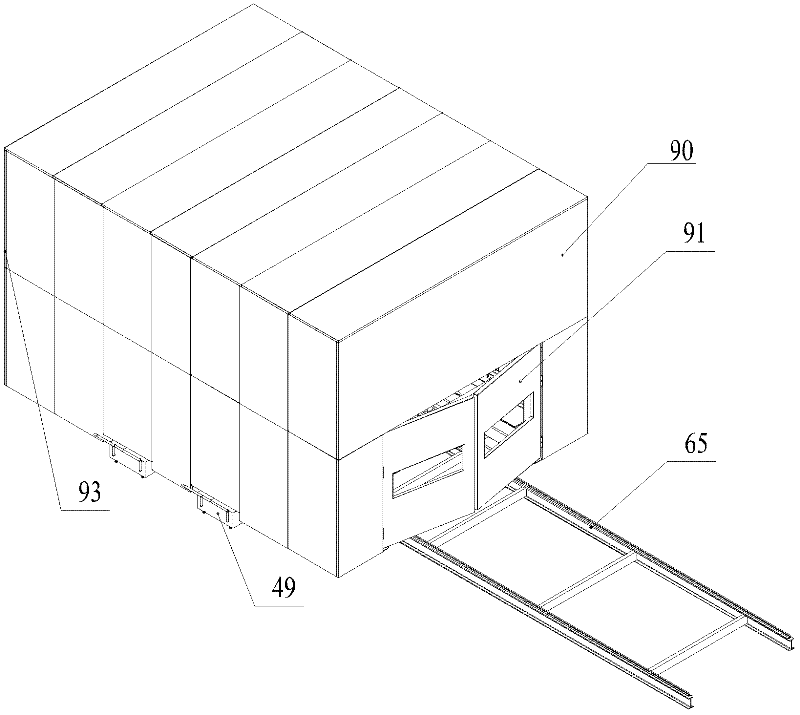

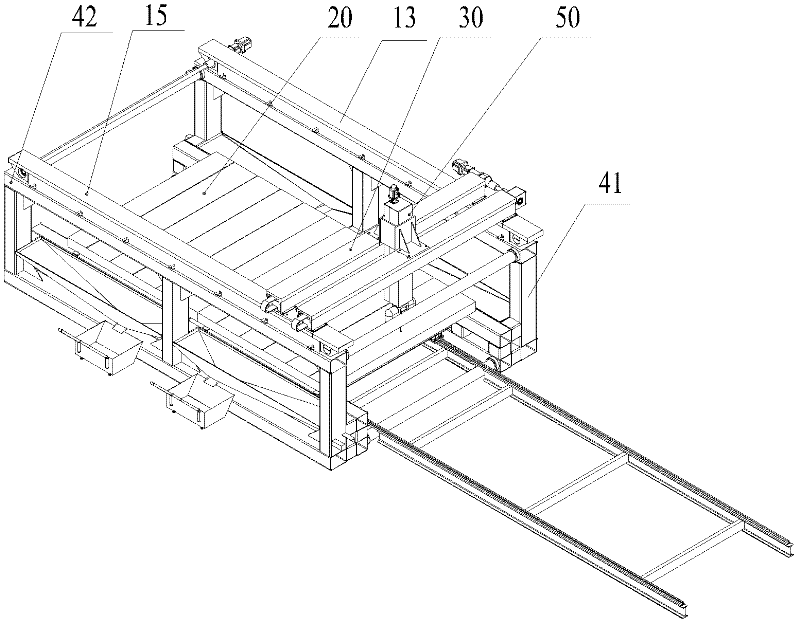

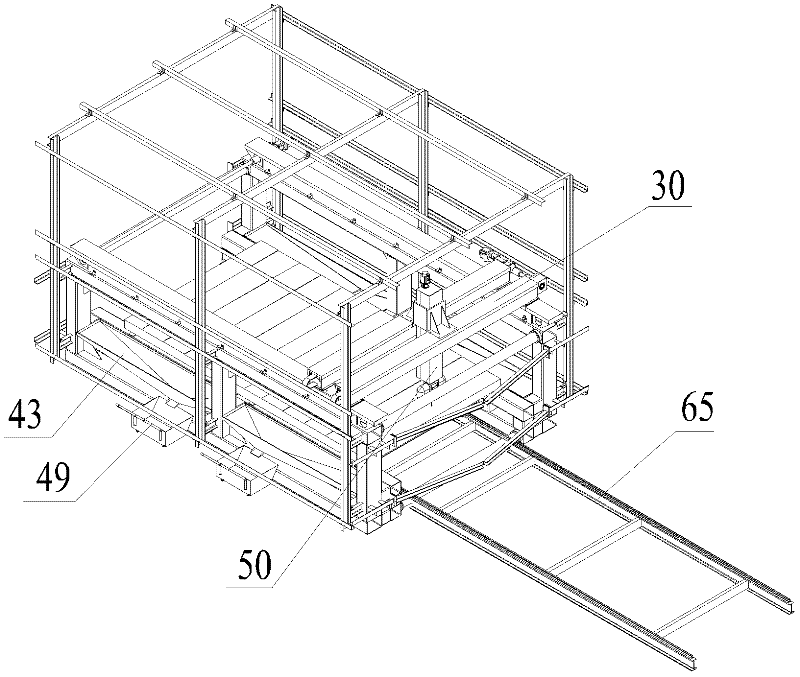

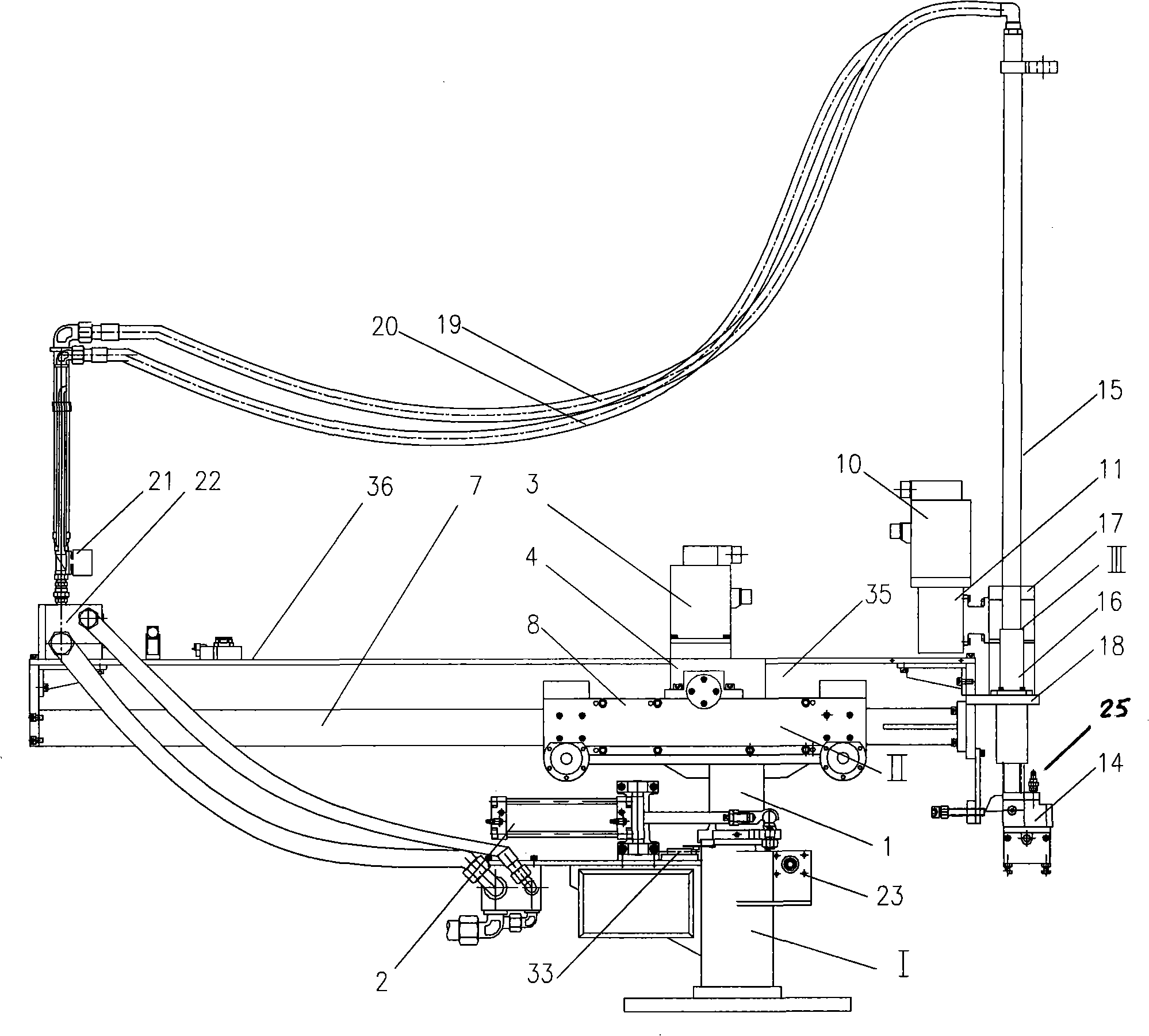

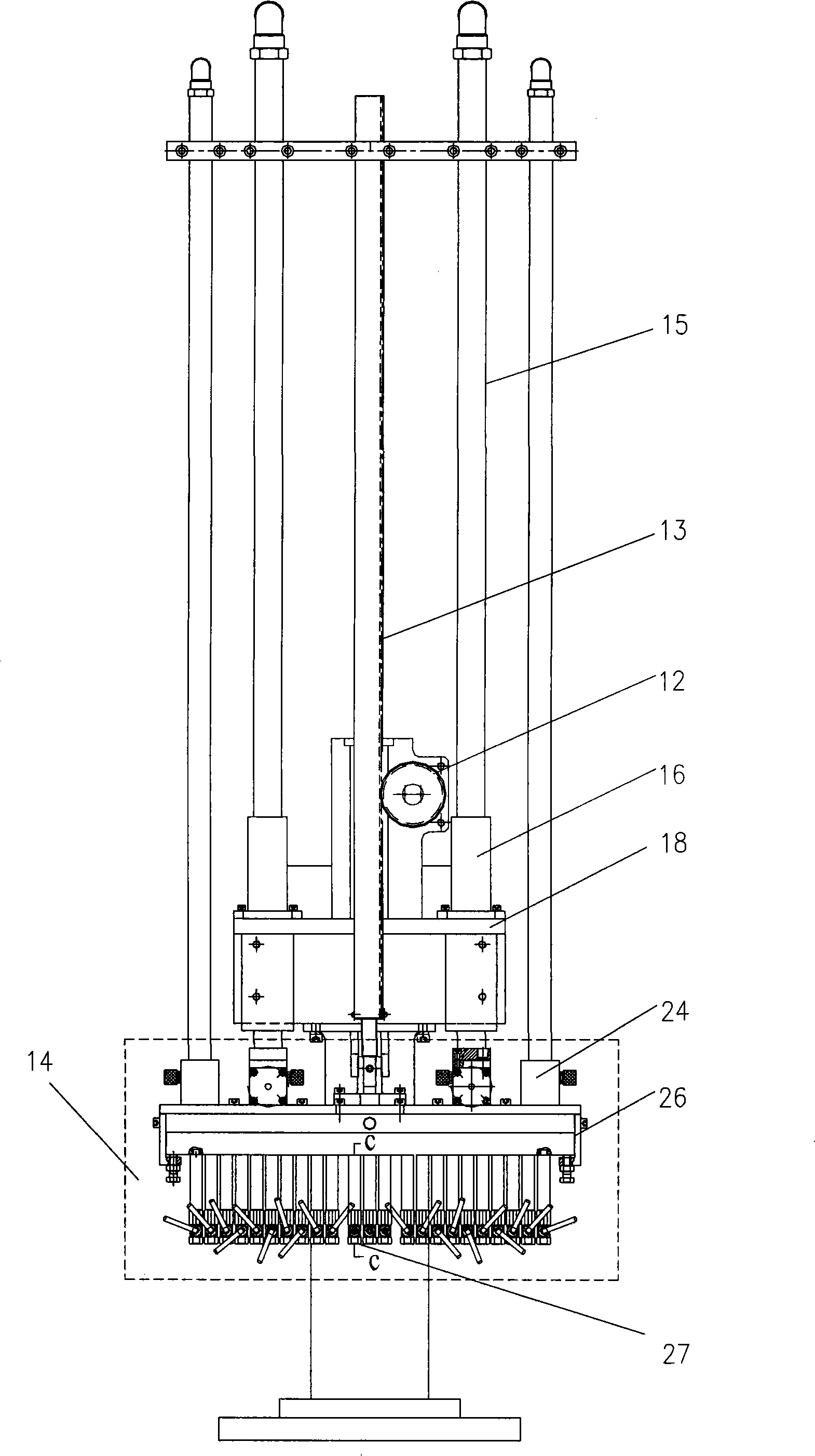

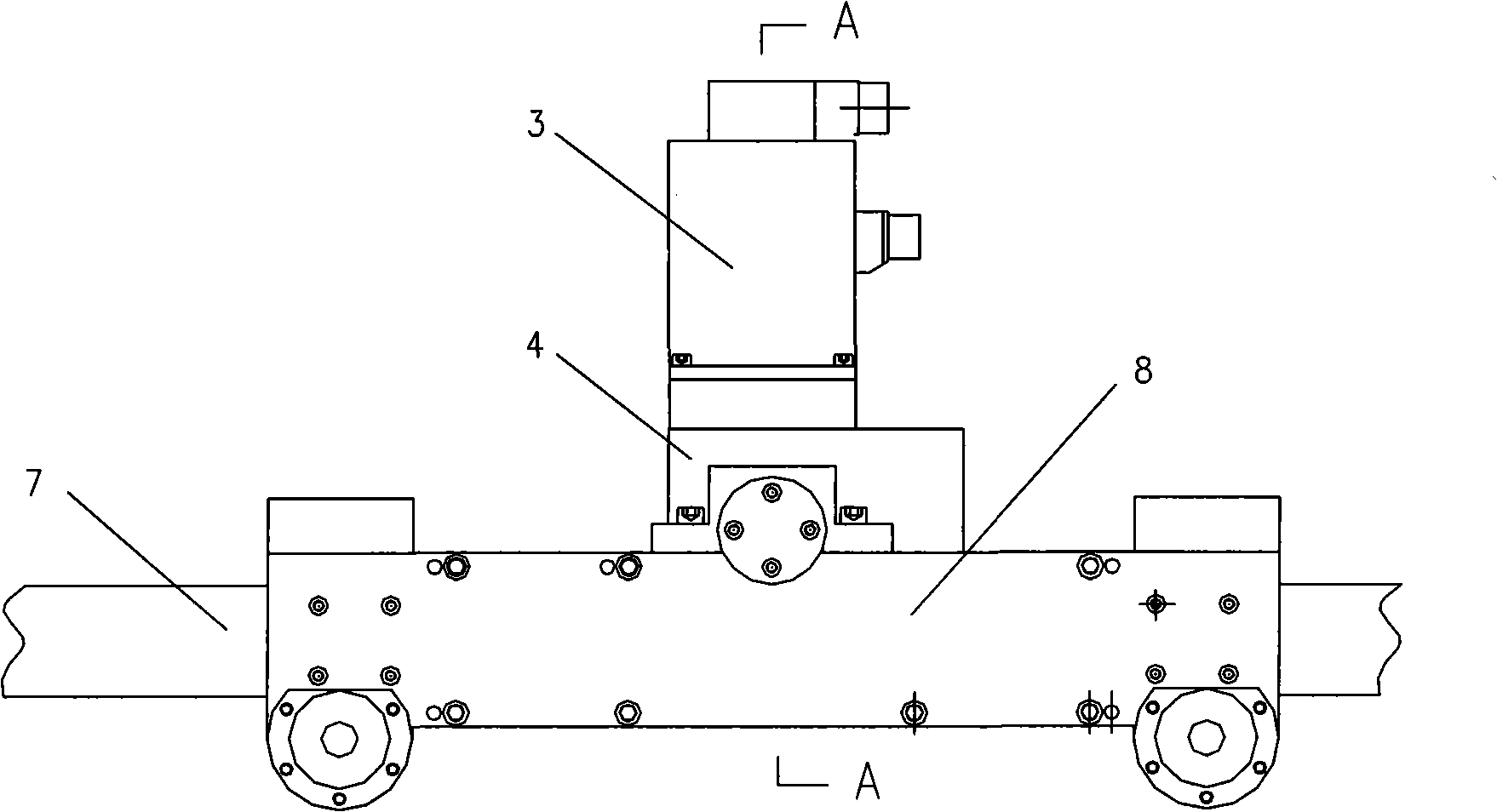

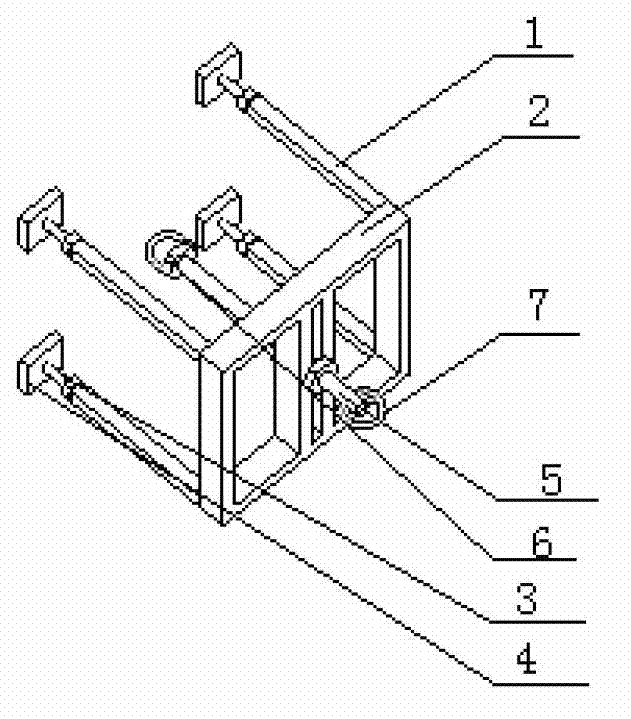

Model-free casting forming machine

The invention provides a model-free casting forming machine which comprises a multi-shaft moving system, a workbench and a moving platform system, wherein the multi-shaft moving system at least comprises an X-axis moving system, a Y-axis moving system and a Z-axis moving system; the workbench is located below the multi-axis moving system; the moving platform system is arranged below the workbench; the moving platform system comprises a moving bracket capable of moving to and fro along a direction parallel to the X-axis; a lifting device is arranged on the moving bracket; the lifting device isused for lifting and supporting the workbench, so that the workbench is linked with the moving bracket. According to the model-free casting forming machine provided by the invention, the workbench can be moved without a lifting tool; casting moulds with large-size and complicated cavities can be processed; and environmental pollution is small.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

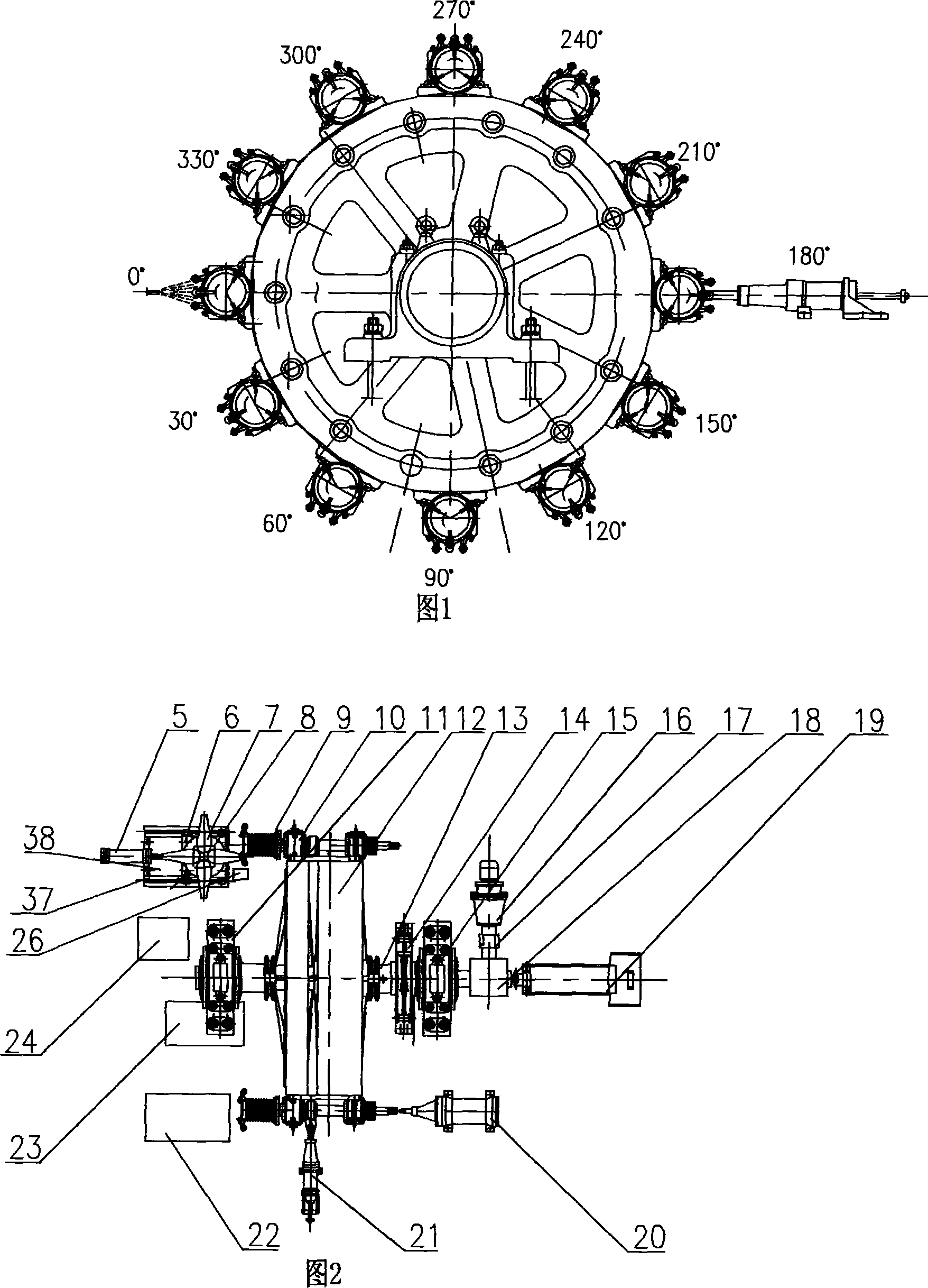

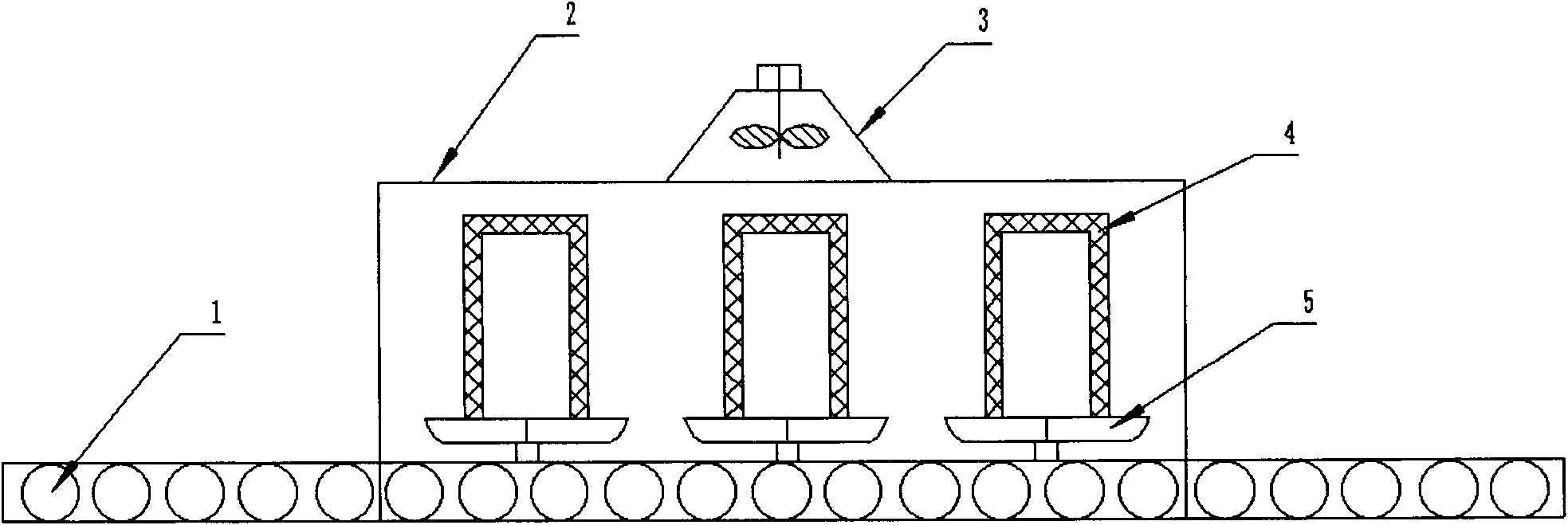

Full-automatic twelve-station centrifugal casting machine

InactiveCN101234424AChange the working environmentReduce labor intensityCasting plantsMoulding toolsCouplingMechanical engineering technology

The invention relates to an automatic centrifugal casting machine with 12 work-stations in a technical field of mechanical engineering. The machine of the invention comprises: a second motor, a reducer and a divided mechanism input end of a cam roller gear are connected through a coupling. A big plate is arranged on a main shaft, the shaft direction of which is fixed by a first lock bolt; a damping mechanism is also arranged on the main shaft; the main shaft is arranged on a front bearing seat and a back bearing seat, and the circle of the big plate is 12-sided boundaries used for arranging 12 centrifugal casting machines. The first motor is arranged on an end of the big plate and a pulley is arranged on a shaft between the tail part of the centrifugal machine and the shaft of the first motor. The power of the first motor is transmitted to the centrifugal casting machine through 3 triangle belts, and the power supply wire of the first motor goes to a ring-slipping mechanism through the inner holes of the main shaft, and the front part of the centrifugal casting machine is provided with a cylinder die. The automatic centrifugal casting machine with 12 work station greatly changes the working environment of the casting workers, reduces the working intensity of the workers, improves the safety factor of the heat working workers and meanwhile reduces the load of the staff and improves the quality and output of the products.

Owner:SHANGHAI JIAO TONG UNIV

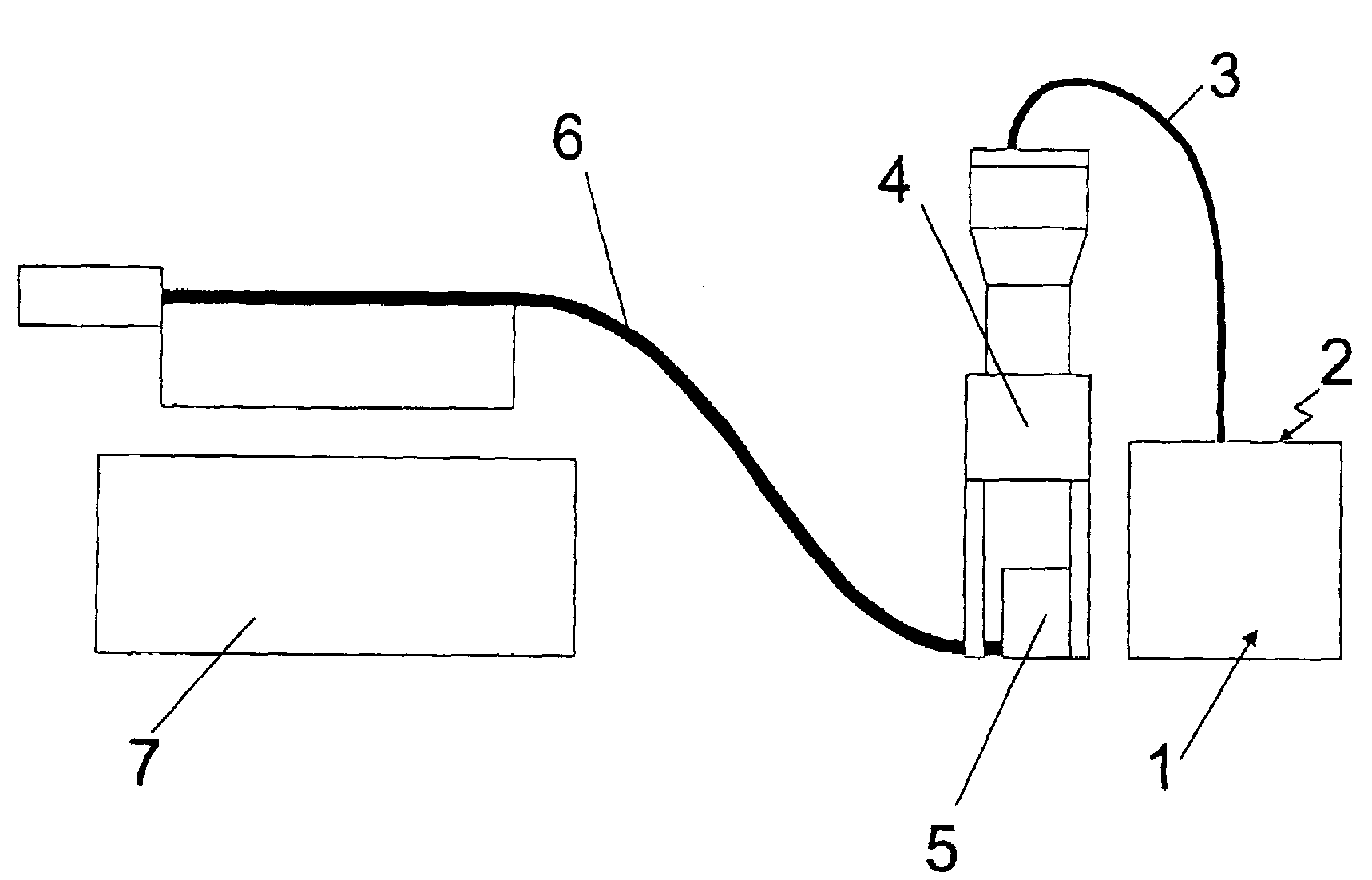

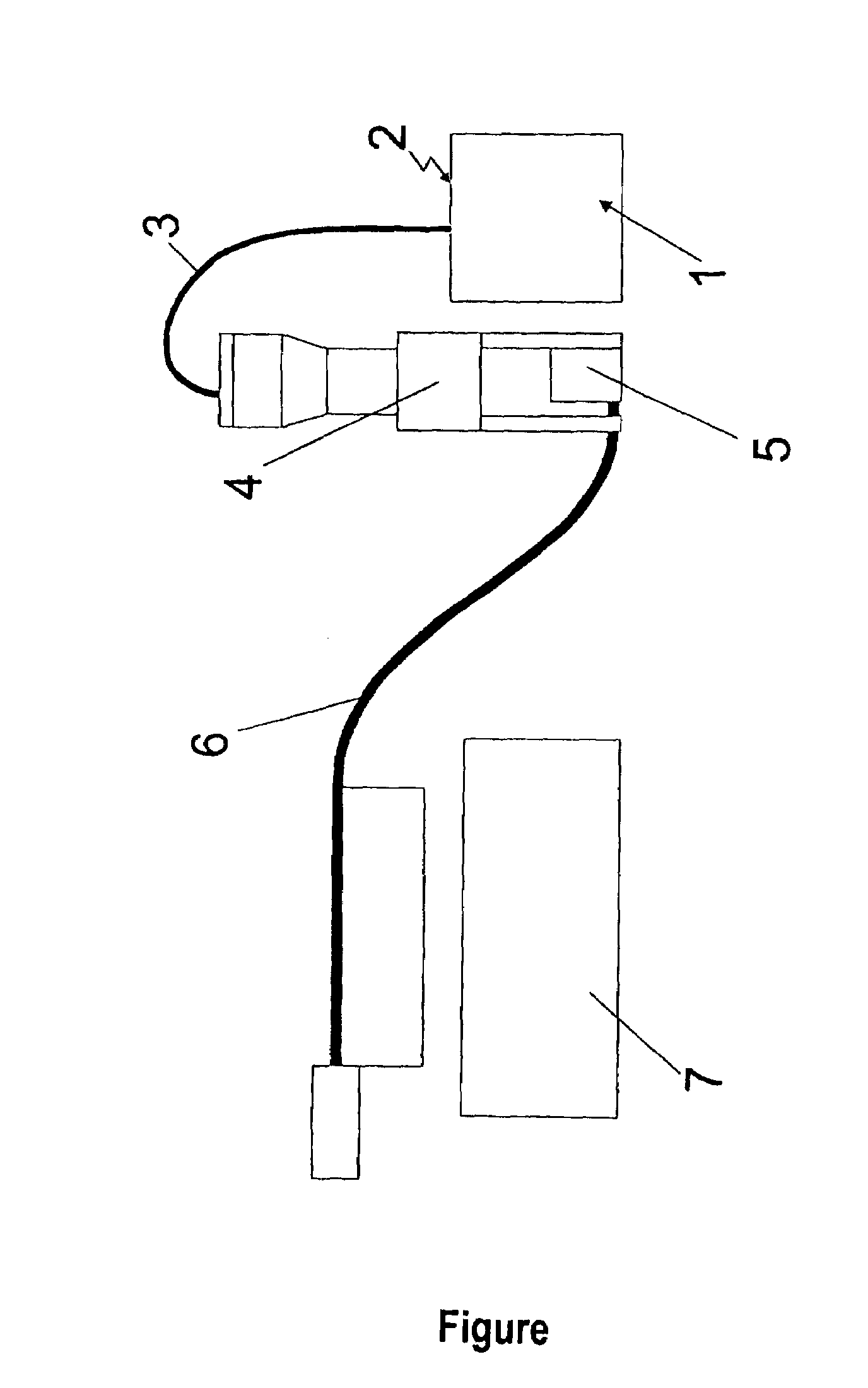

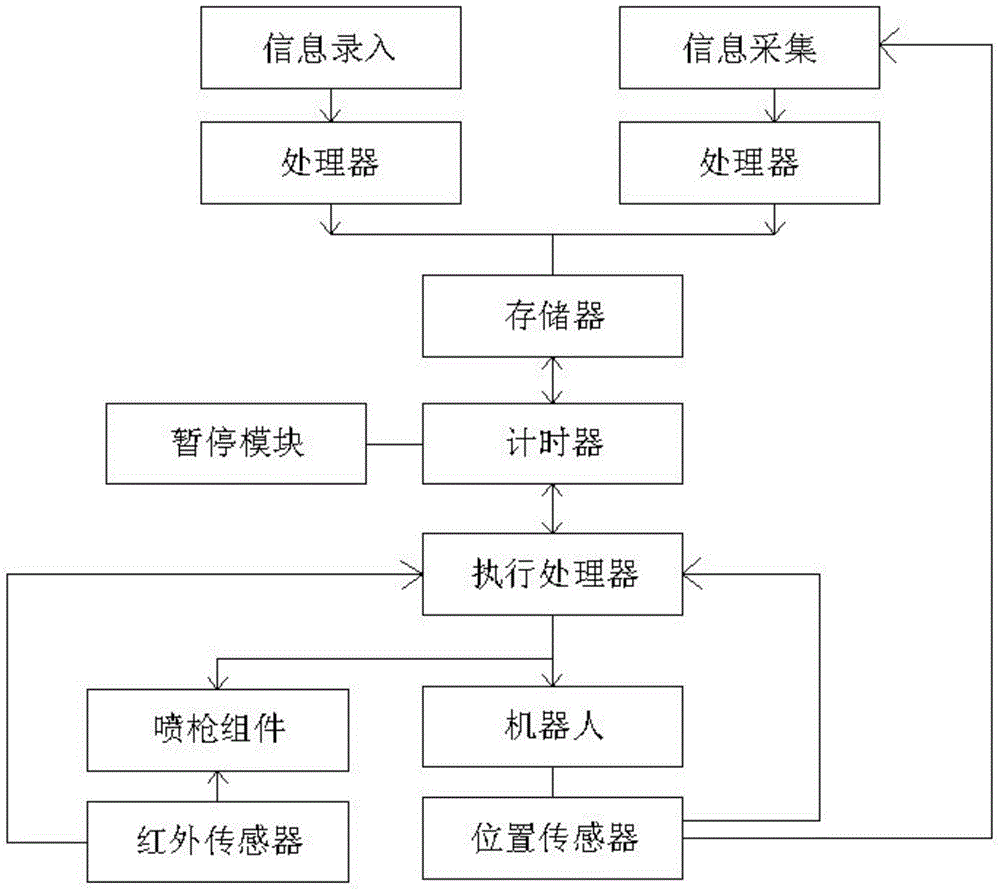

Automatic sprayer and control method thereof

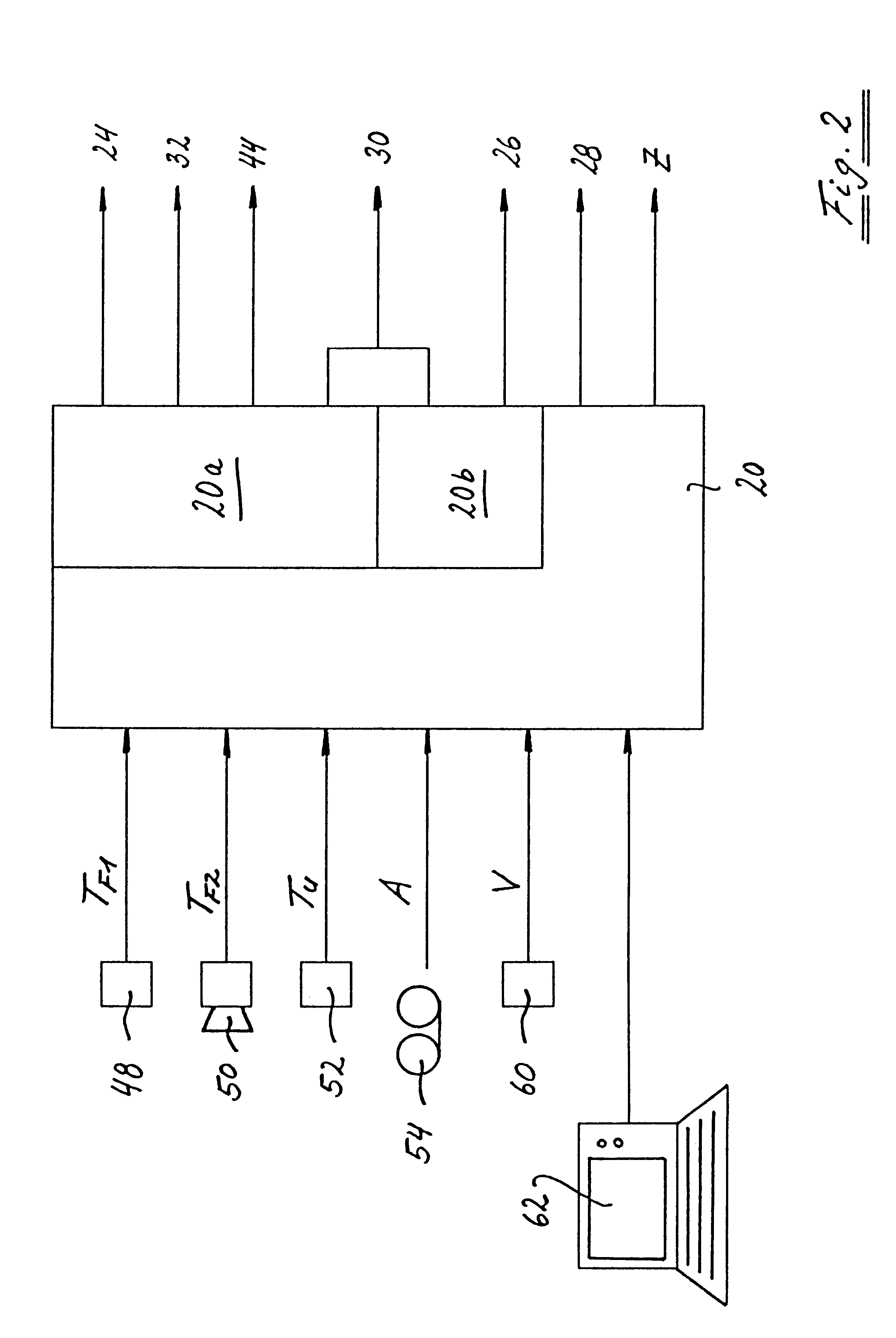

InactiveCN101357356ASimple structureLow costMoulding toolsSpraying apparatusHuman–machine interfaceSprayer

The present invention discloses an automatic sprayer and an operating method thereof and relates to the technology of a die-casting machine die spray parting agent. The present invention aims at providing a sprayer with low cost and high automatization degree and a control method thereof. In the technical proposal, a device comprises a mechanical part, a circuit part and a gas circuit part; the mechanical part consists of a frame, a horizontal moving mechanism and a vertical moving mechanism; the horizontal moving mechanism is provided with two sets of unique rolling shafts; the vertical moving mechanism is provided with a leader and a linear bearing which respectively replaces a linear guide way with high cost; a spray block is provided with a globe joint adjustable nozzle. The circuit part comprises a power supply circuit, a signal circuit, a control circuit, a conversion circuit, an executive component (OC) and a man-machine interface device. The gas circuit uses an air compressor (KYJ) to produce compressed gas, and the compressed gas and the parting agent are transmitted and distributed by an air pipe and a water pipe. The automatic sprayer has the beneficial effects of simple structure, high efficiency, good spraying effect and being capable of spraying at fixed point and reducing labor intensity.

Owner:上海华立电子工程有限公司

Nano-particle metal treatment composition for creating a ceramic-metal layer

InactiveUS7304020B1Neutralizing activityExcellent plating characteristicMaterial nanotechnologyPigmenting treatmentNanoparticleMontmorillonite

A metal treatment composition including Tin (II) Chloride and processed montmorillonite clay. The addition of Tin (II) Chloride to the composition provides Tin for forming a ceramic-metal layer on the surfaces of the friction pair. Tin (II) Chloride provides Chlorine ions for forming Chloric films for protecting juvenile surfaces which form in the friction zone. The clay is heated and pulverized to produce a powder comprising both particles having crystalline layer structure and salts and oxides. The layered crystalline structure of the clay contains slip planes that transversely shift when tangential pressure from the friction pair is applied thereby lubricating the friction pair. The salts and oxides contribute to the formation of the ceramic-metal layer.

Owner:TANANKO DMITRY

Method for the layerwise construction of models

ActiveCN103702958ADissolve fastSolid waste managementMoulding toolsParticulatesBiological activation

A method is described here for the layerwise construction of models, wherein, in a building region, a particulate material is applied layerwise and selectively cured. These steps are repeated until a desired model is obtained. The material comprises in this case a particulate building material and a spray-dried alkali metal silicate solution. Selective activation of the curing proceeds using a water-comprising solution.

Owner:VOXELJET AG +1

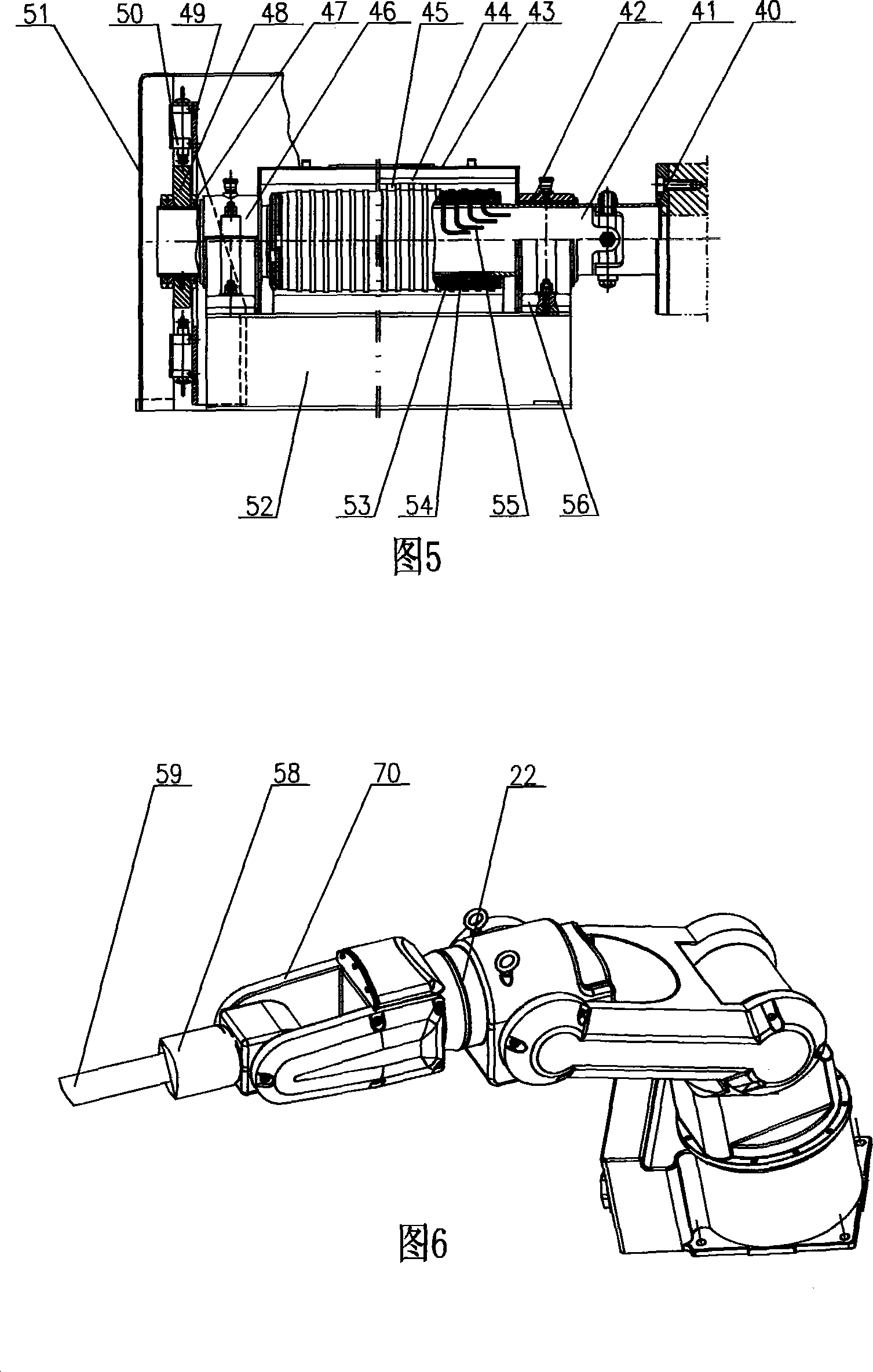

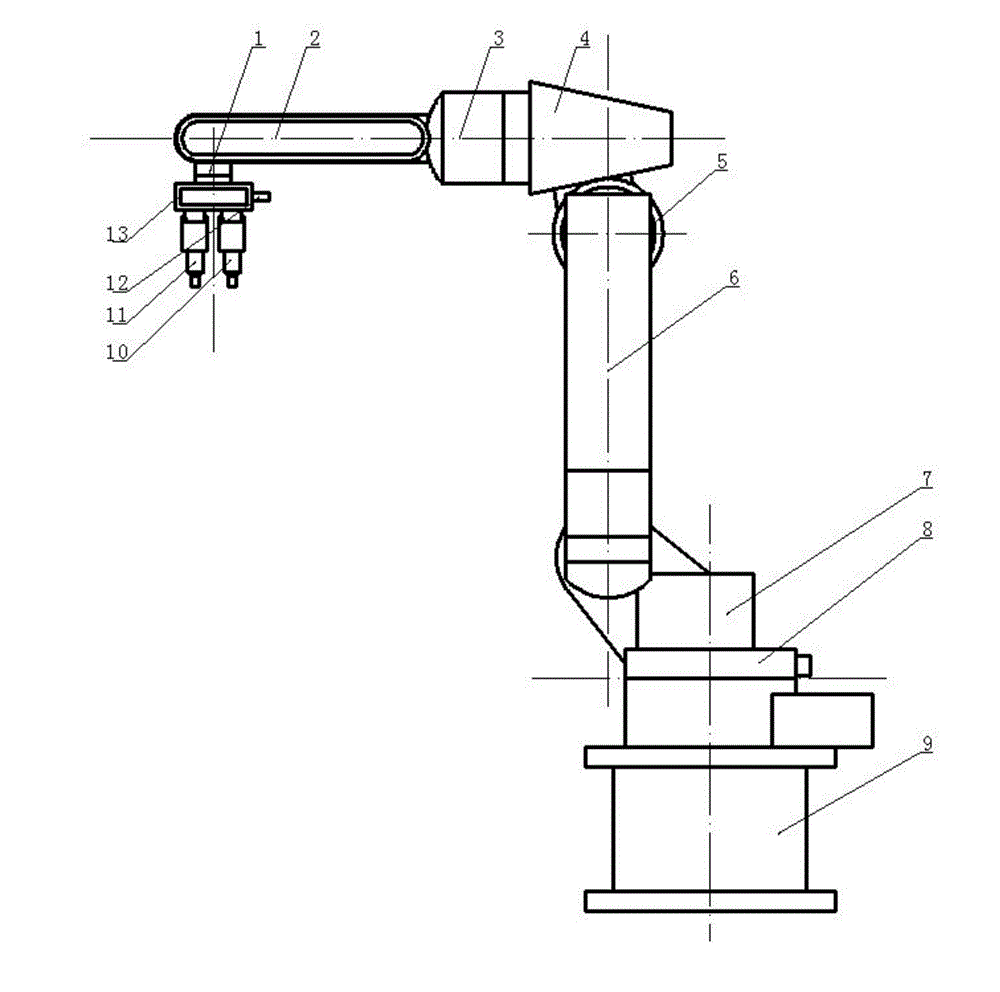

Mechanical arm special for automatic painting spraying of aluminum alloy wheel die and automatic painting spraying process

ActiveCN104525418AUniform thicknessImprove qualityProgramme-controlled manipulatorMoulding toolsElectronic control systemEngineering

The invention relates to a mechanical arm special for automatic painting spraying of an aluminum alloy wheel die and an automatic painting spraying process. The special mechanical arm is composed of a robot, a spraying gun assembly and an electronic control system; the spraying gun assembly is installed and driven by the robot to conduct automatic spraying, the robot and the spraying gun assembly are each connected with the electronic control system through circuits, and the spraying gun assembly is controlled by the electronic control system to do spraying work. The mechanical arm is reasonable in structure, rapid and convenient to operate, good in stability, high in quality and efficient; 360-degree dead-angle-free automatic painting spraying on the interior of the die can be carried out, it is guaranteed that the thickness of painting at the position of the die is even and unified, and the machining quality and the machining efficiency are improved; in addition, in-sequence solidification is guaranteed, and the quality of wheel products is improved.

Owner:TIANJIN LIZHONG GRP CO LTD

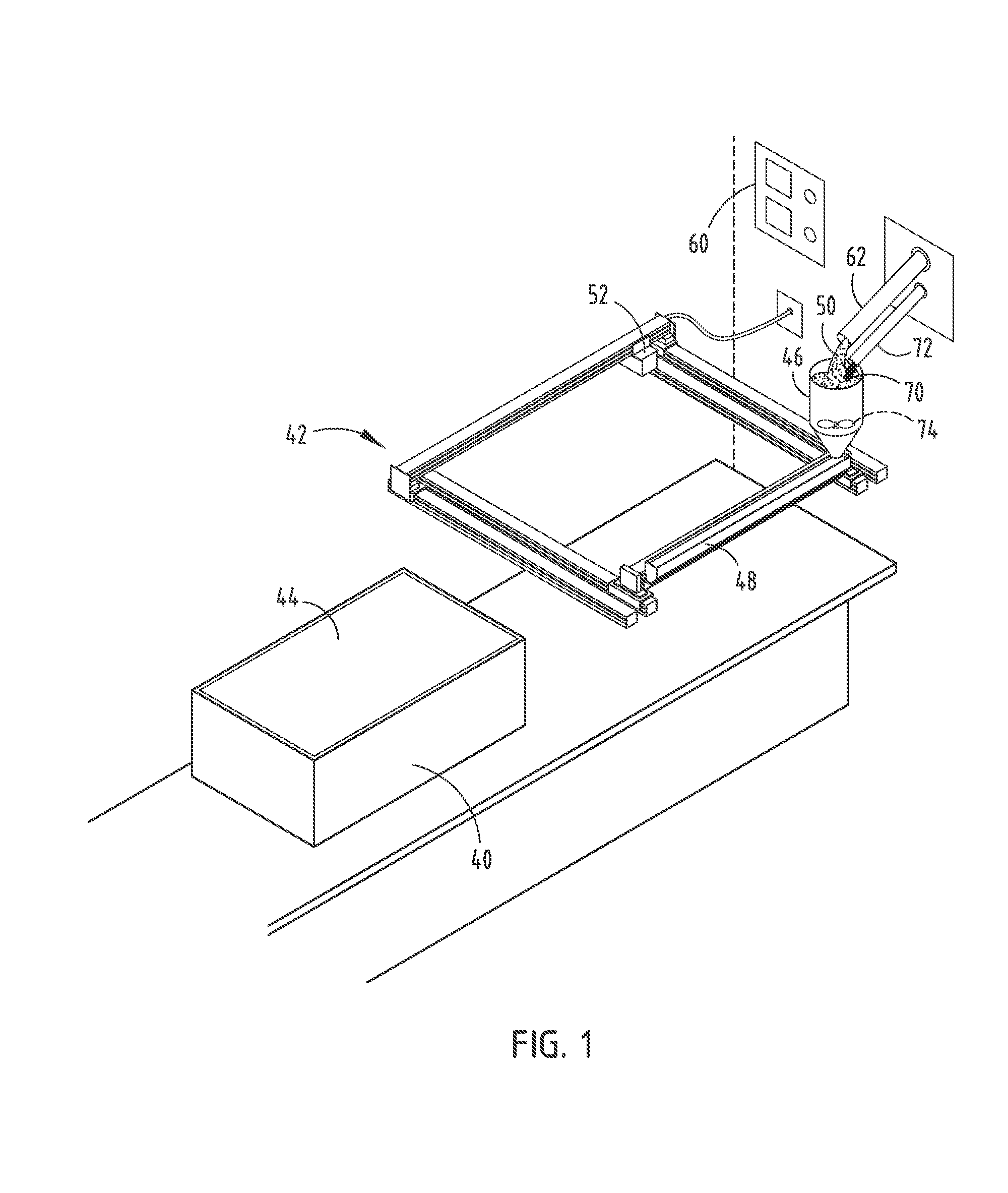

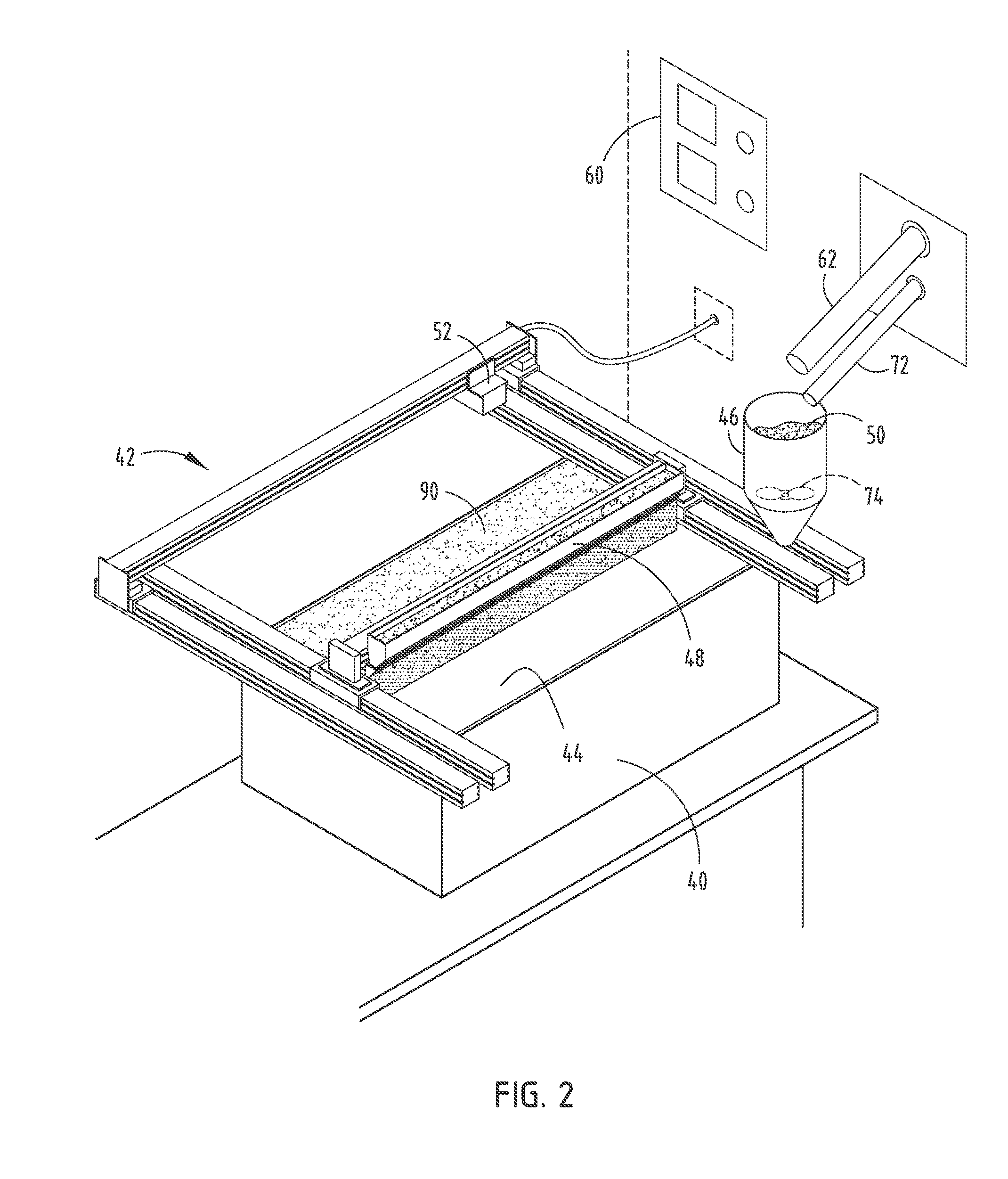

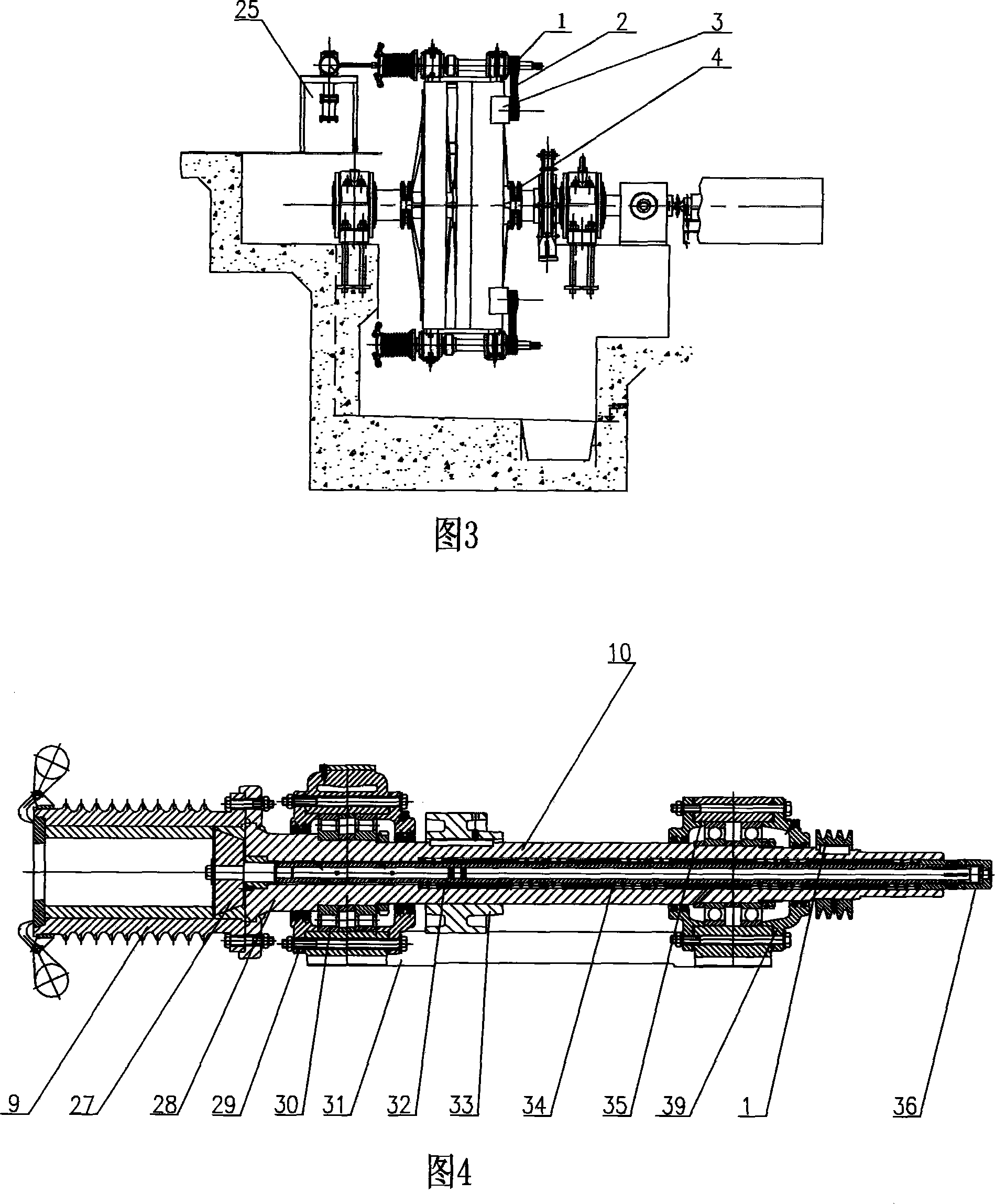

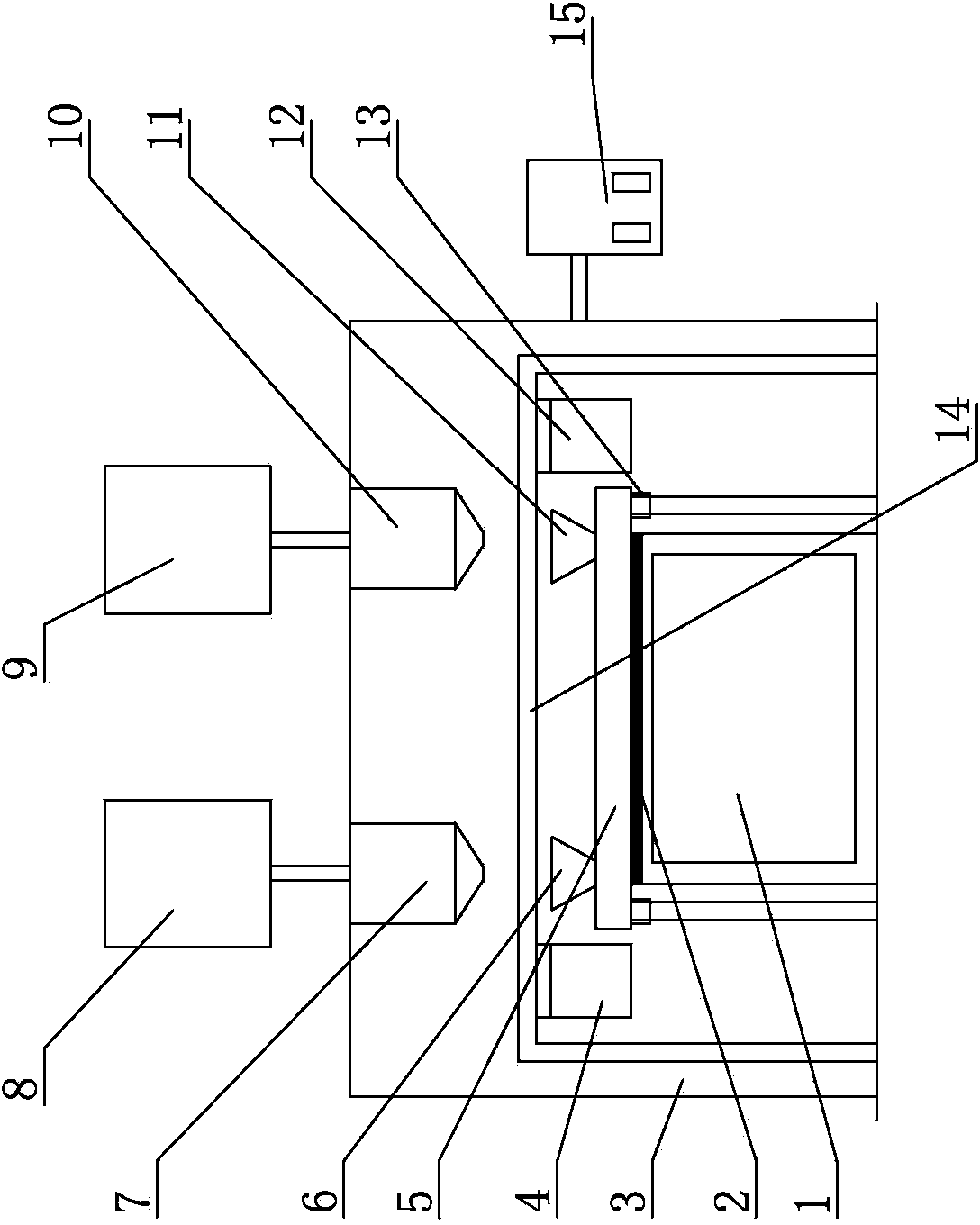

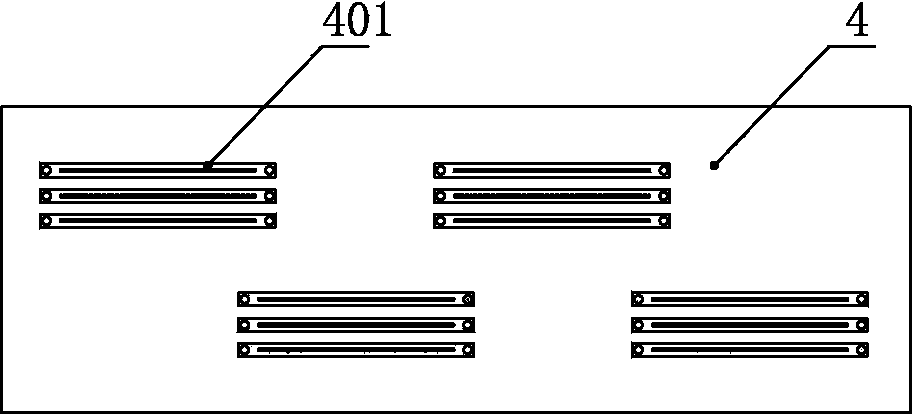

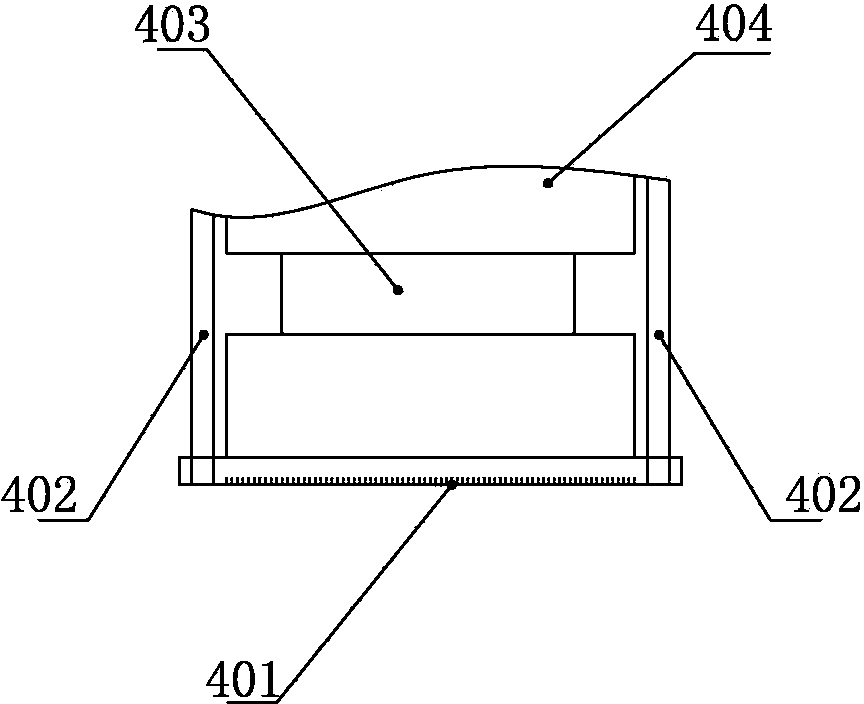

Multifunctional double-printing-head 3D printing equipment based on 3DP technology

ActiveCN104028713AHigh print densitySimple structureMoulding toolsFoundry mouldsPrinting inkEngineering

The invention discloses multifunctional double-printing-head 3D printing equipment based on the 3DP technology in the field of 3D printing equipment. The equipment comprises a first feeding hopper and a second feeding hopper, the first feeding hopper and the second feeding hopper are arranged on a rack, a first mixing bowl is arranged below the first feeding hopper, a second mixing bowl is arranged below the second feeding hopper, a powder spreading device is arranged below the first mixing bowl and the second mixing bowl, a working box is arranged below the powder spreading device, and a lifting platform is arranged in the working box. A first feeding opening and a second feeding opening are formed in the two ends of the powder spreading device respectively, the first feeding opening corresponds to the first mixing bowl, and the second feeding opening corresponds to the second mixing bowl. The powder spreading device is arranged on a powder spreading device guide rail, a printing head guide rail is arranged above the powder spreading device, a first printing head and a second printing head are arranged on the two sides of the printing head guide rail, and the orthographic projection trajectory of the powder spreading device, the first printing head and the second printing head covers the whole lifting platform in the moving process. In the working process, the first printing head or the second printing head can be selected for working, a sand mould can be printed out, a mould also can be printed out, the equipment can achieve two purposes, and the equipment cost is reduced.

Owner:NINGXIA KOCEL MOLD

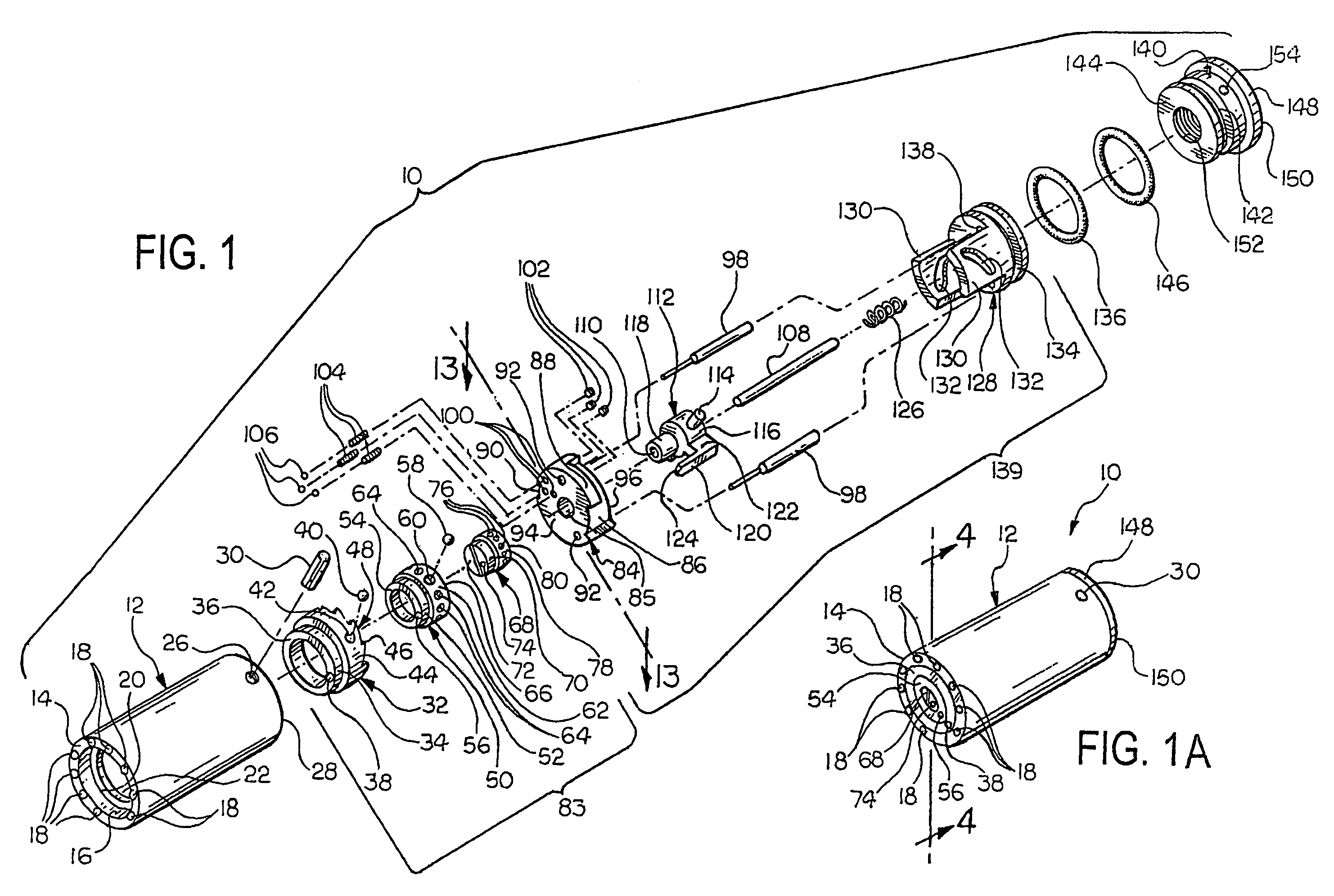

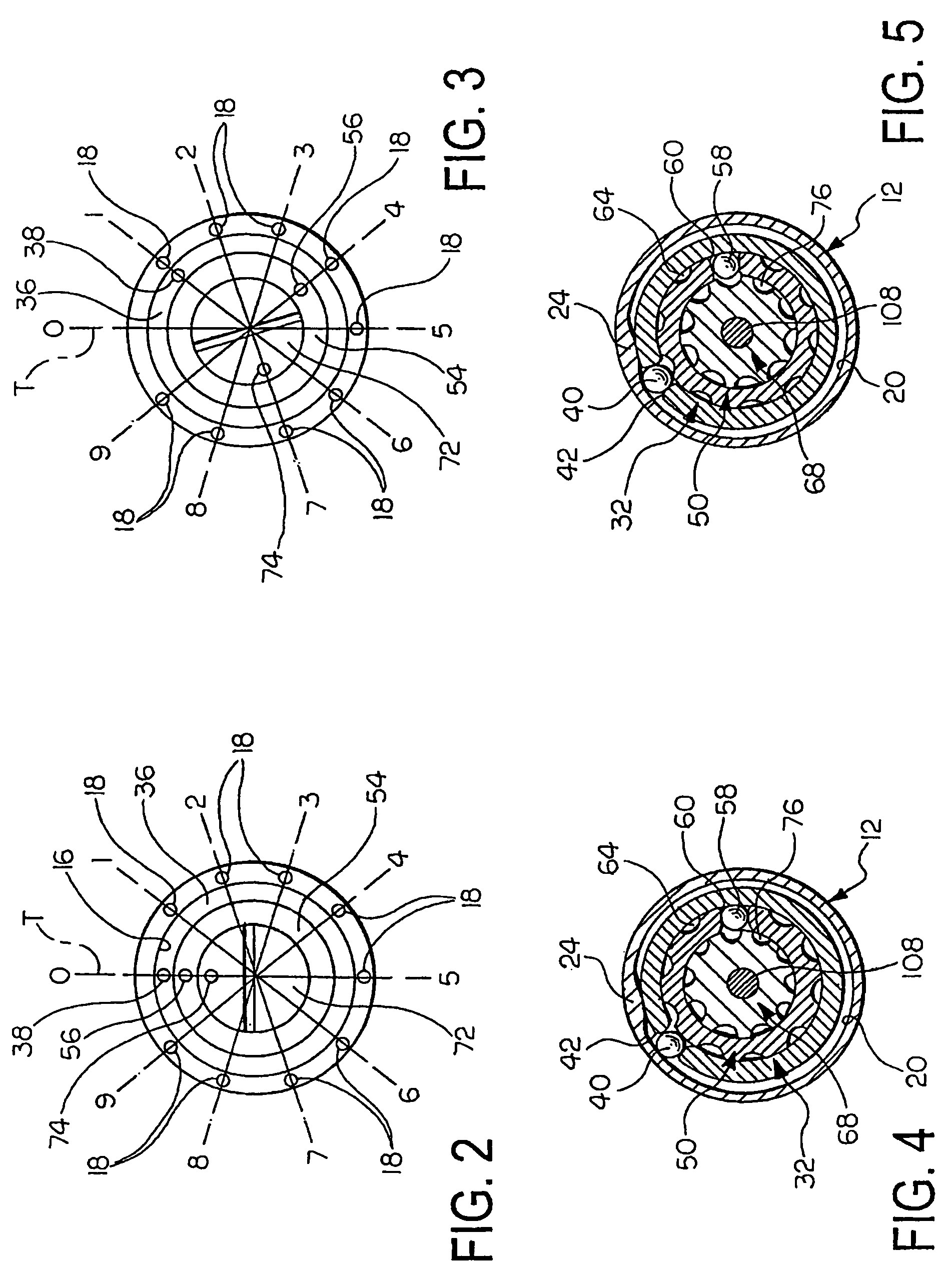

Numbering device for molded or cast parts

InactiveUS7252136B2Easy to changeMaximize production efficiencyMoulding toolsMoulding machinesShell moldingConcentric cylinder

A numbering device is disclosed for marking molded cast parts, the device including a plurality of concentric cylinders having indicia disposed on an end thereof, the cylinders being rotatingly indexable to cause the indicia to move as desired to form the desired mark, the mark is then impressed into a sand mold and subsequently reproduced on the cast part.

Owner:GM GLOBAL TECH OPERATIONS LLC

Self-vibration type continuous casting system

A self-vibration type continuous casting system comprises a casting machine, a flow dividing device, a molten pool and a self-vibration device. One end of the flow dividing device is connected with the molten pool, and the other end of the flow dividing device is connected with the casting machine; the casting machine comprises a supporting frame, a machine head, a machine tail and a casting portion, wherein the machine head, the machine tail and the casting portion are fixed on the supporting frame; the casting portion comprises a transmission chain; one end of the flow dividing device is connected with the molten pool, and the other end of the flow dividing device is connected with the casting portion; and the self-vibration device is installed below the up transmission chain of the casting portion, and the up transmission chain is vibrated and struck through vibration of the self-vibration device, so that ingot metal in a casting mould of the up transmission chain falls off. According to the self-vibration type continuous casting system, the self-vibration device is installed below the up transmission chain and makes contact with the back surface of the casting mould, and the self-vibration device vibrates and strikes the back surface of the casting mould through self-vibration, so that the ingot metal and the casting mould become loose, and the ingot metal falls off automatically.

Owner:宁夏铸源机械制造有限公司

Sand casting technology for titanium, zirconium and nickel and alloy casting thereof

ActiveCN102921885AHigh strengthImprove filling abilityMoulding toolsFoundry mouldsCrazingTitanium zirconium

The invention discloses a sand casting technology for titanium, zirconium and nickel and an alloy casting of the titanium, zirconium and nickel. The sand casting technology comprises steps of: (1) preparation of casting sand: adding bauxite powder, bauxite sand and silicate powder to a sand mixer, agitating for 3 to 4 hours, then adding silica sol, and finally adding dextrin, so as to obtain the casting sand; (2) modeling: manufacturing a die according to the casting technology drawing; (3) drying to obtain a casting mold: transferring the sand casting which is naturally and completely dried in the step (2) into an oven or a resistance furnace for roasting, so as to form the casting mold; (4) preparation of fire-resistant paint; (5) preparation of a fire-resistant coating: spraying the agitated paint on the surface of the casting mold which is contacted with the molten liquid during pouring; (6) roasting at a high temperature: transferring the casting mold which is naturally and dried in the step (5) into the resistance furnace for roasting; and (7) smelting and pouring: smelting and pouring in a vacuum kish self-consuming furnace for smelting and pouring. By adopting the sand casting technology, various castings of different dimensions can be produced in a large scale; the surfaces of the castings are free of defects such as cold shuts, current ripples and cracks; and the insides of the castings are free of the defects such as shrinkage cavities and inclusions.

Owner:XIAN PUMP & VALVE GENERAL FACTORY CO LTD

Compatibilized polymer processing additives

ActiveUS8178479B2Impart desired physical characteristicImprove economyBiocideOrganic chemistryPolymer scienceMaterials science

Owner:STRATSYS INC

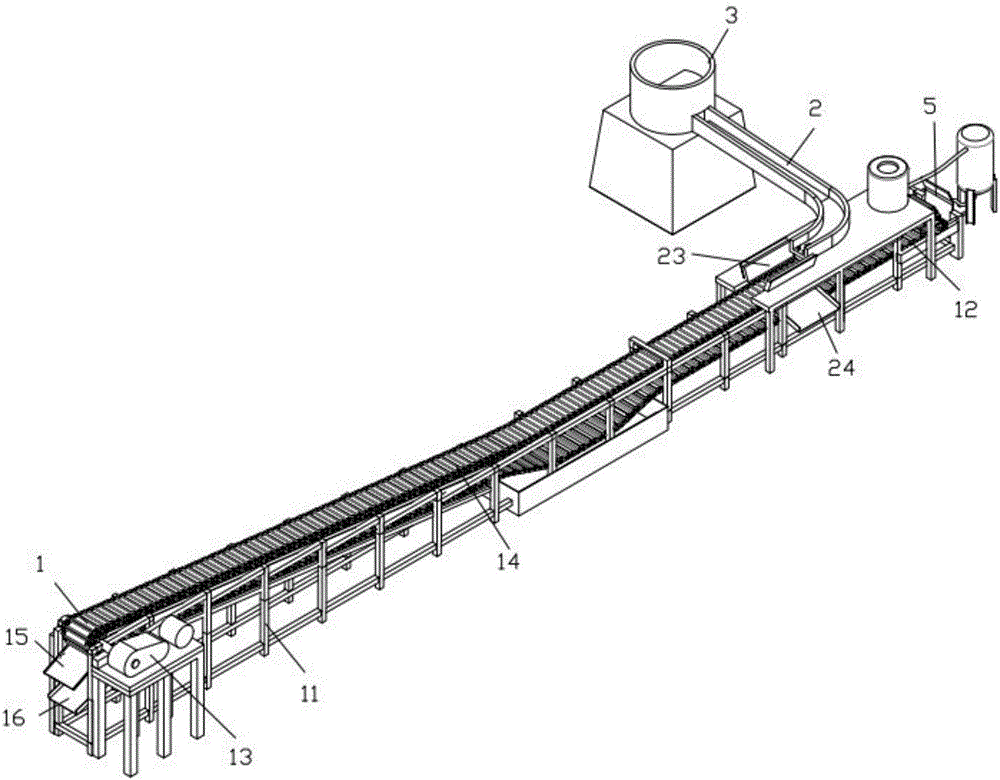

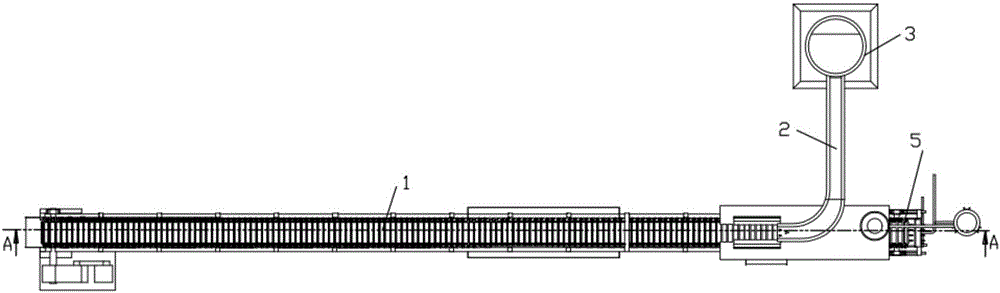

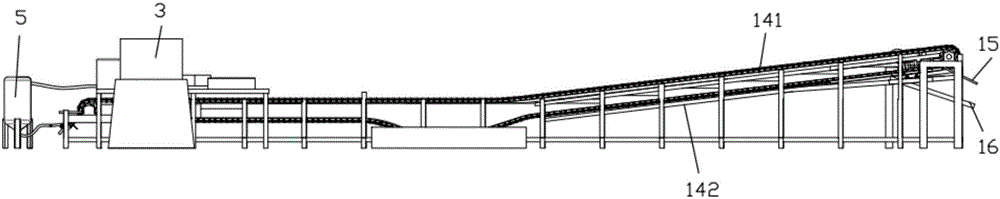

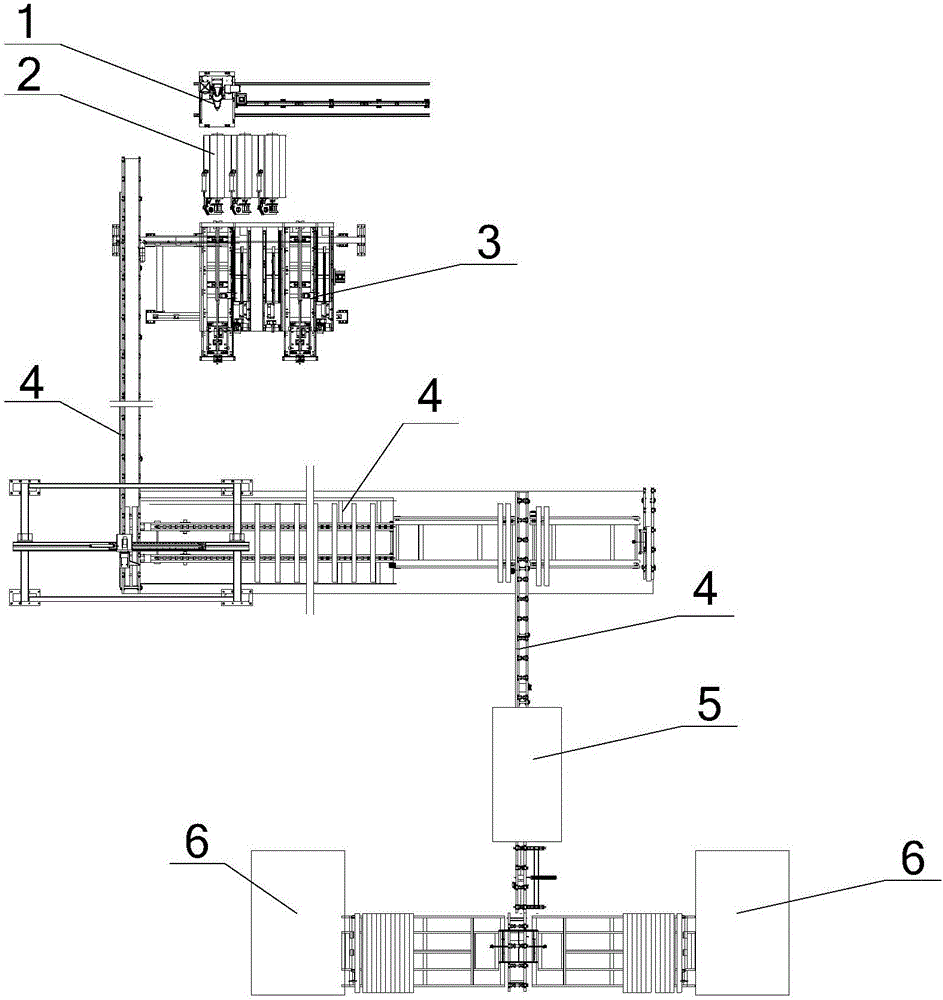

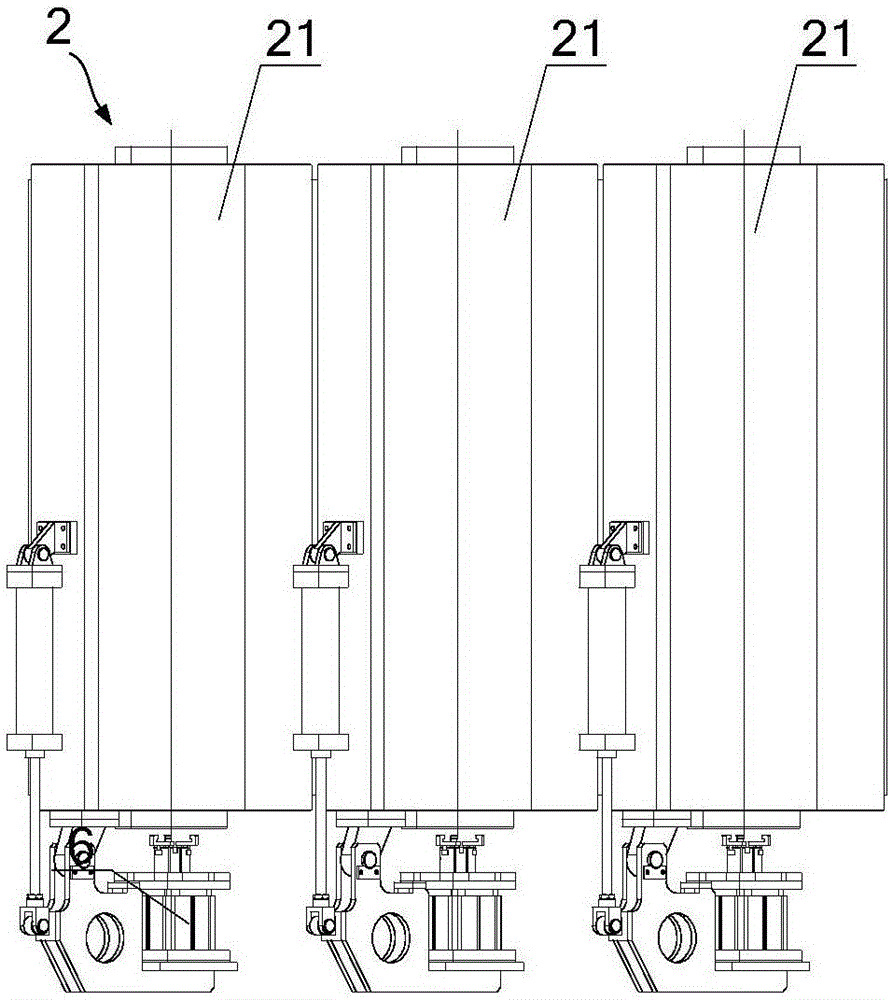

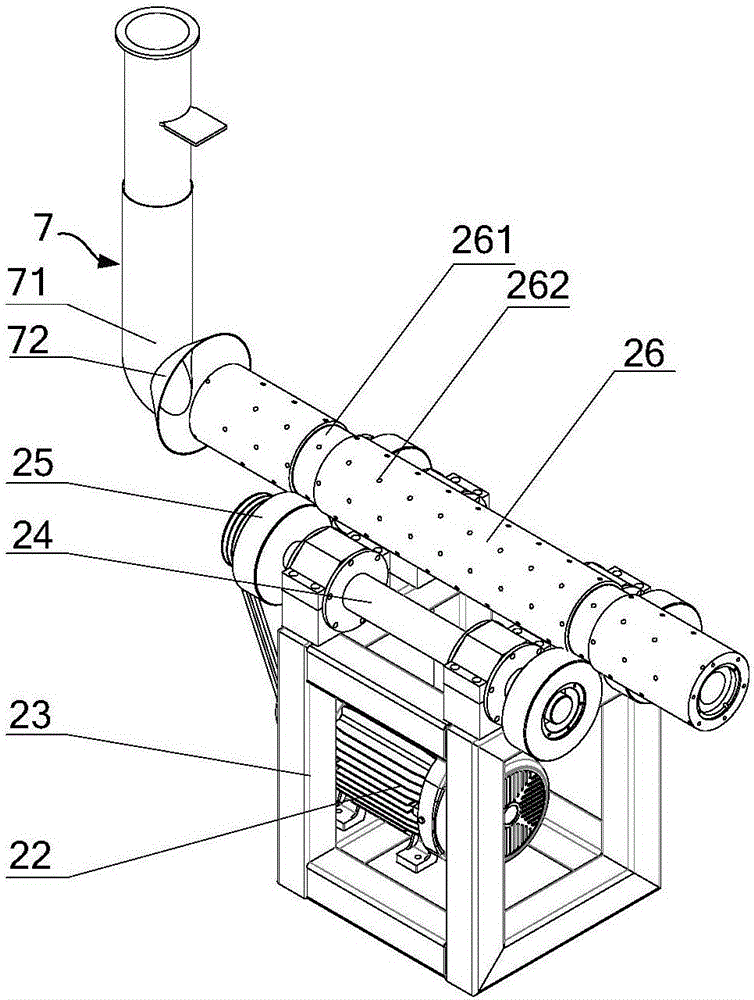

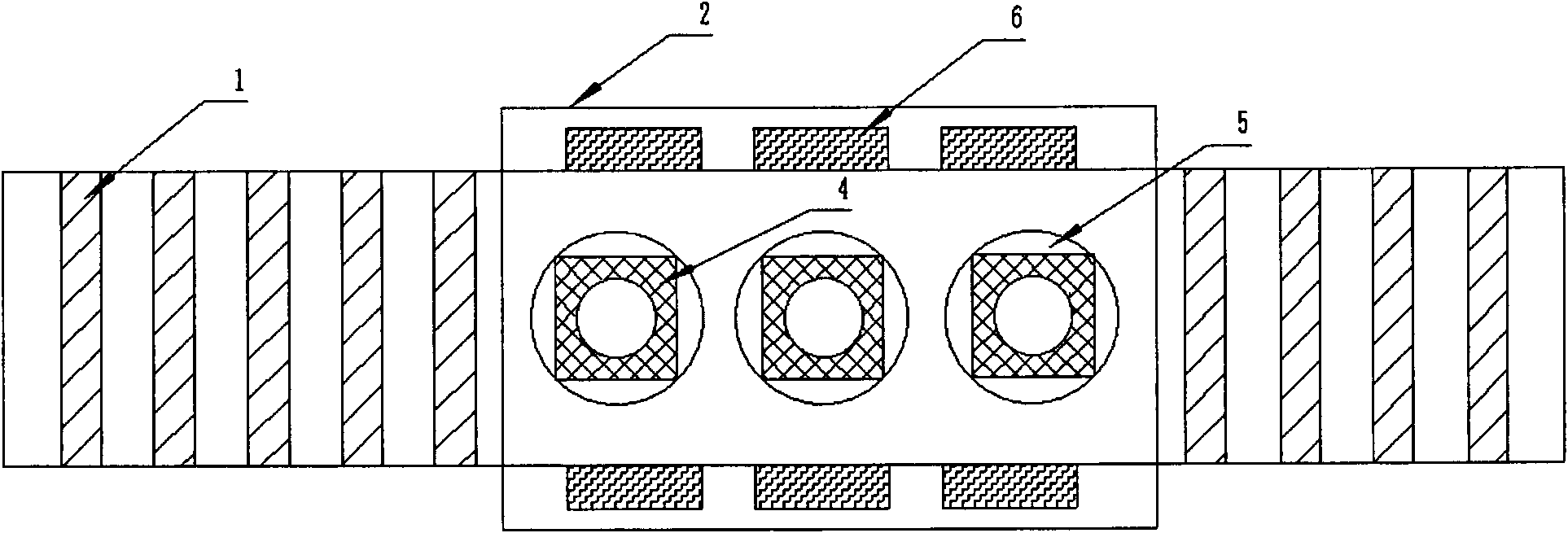

Production equipment for bur cylinder liners and bur cylinder liner

The application discloses production equipment for bur cylinder liners. The production equipment comprises a molten iron pouring device, a bur liner centrifugal moulding device, sweeping devices, spraying devices, cylinder drawing devices, a blank conveying device and a coat cleaning device, wherein the bur liner centrifugal moulding device is provided with multiple centrifugal moulding components which are parallelly arranged; the sprue of the molten iron pouring device is used for pouring molten iron into each centrifugal moulding component; the sweeping devices are used for sweeping the inner surfaces of moulds in the centrifugal moulding components; the spraying devices are sued for spraying coat in the moulds; the cylinder drawing devices are used for drawing out moulded bur liner blanks in the moulds; the blank conveying device is used for conveying the bur liner blanks; and the coat cleaning device is used for cleaning coat on the surfaces of the bur liner blanks. According to the production equipment for the bur cylinder liners, the multiple centrifugal moulding components are arranged in the bur liner centrifugal moulding device; and a multi-station structure is adopted by the bur liner centrifugal moulding device, so that production of the multiple bur liner blanks can be performed alternately through one article of equipment, and the production efficiency is improved. The application further discloses a bur cylinder liner produced using the bur cylinder liner production equipment.

Owner:ZYNP GRP

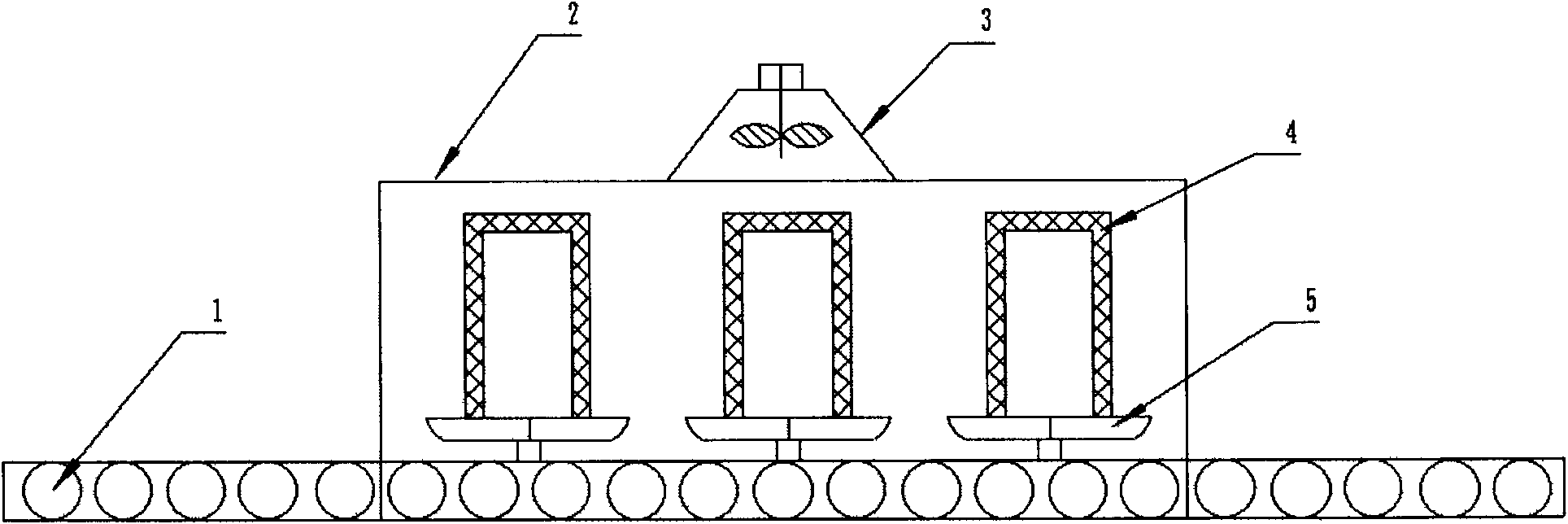

Method and equipment for drying white pattern through microwave in evaporable pattern casting

InactiveCN102145377AAvoid high temperatureReduce areaMoulding toolsFoundry mouldsMicrowaveEconomic benefits

The invention discloses a method and equipment for drying a white pattern through microwave in evaporable pattern casting. The method adopts microwave equipment for drying the white pattern brushed with coating for three times, the white pattern is heated uniformly, the outer-layer coating of the white pattern is ensured to be dried, and the white pattern does not deform or shrink due to microwave heating, therefore, the drying efficiency of the white pattern coating can be greatly improved, the batch production of products is realized, a coal-fired boiler is not needed to supply steam, the electro-thermal conversion efficiency is high, the energy is saved, and the environment is protected. Meanwhile, the labor cost of enterprises is reduced, the economic benefits of the enterprises are improved, and the invention is particularly applicable to white pattern drying in the evaporable pattern casting.

Owner:SHANDONG XINDA AUTOMOBILE PARTS MFG

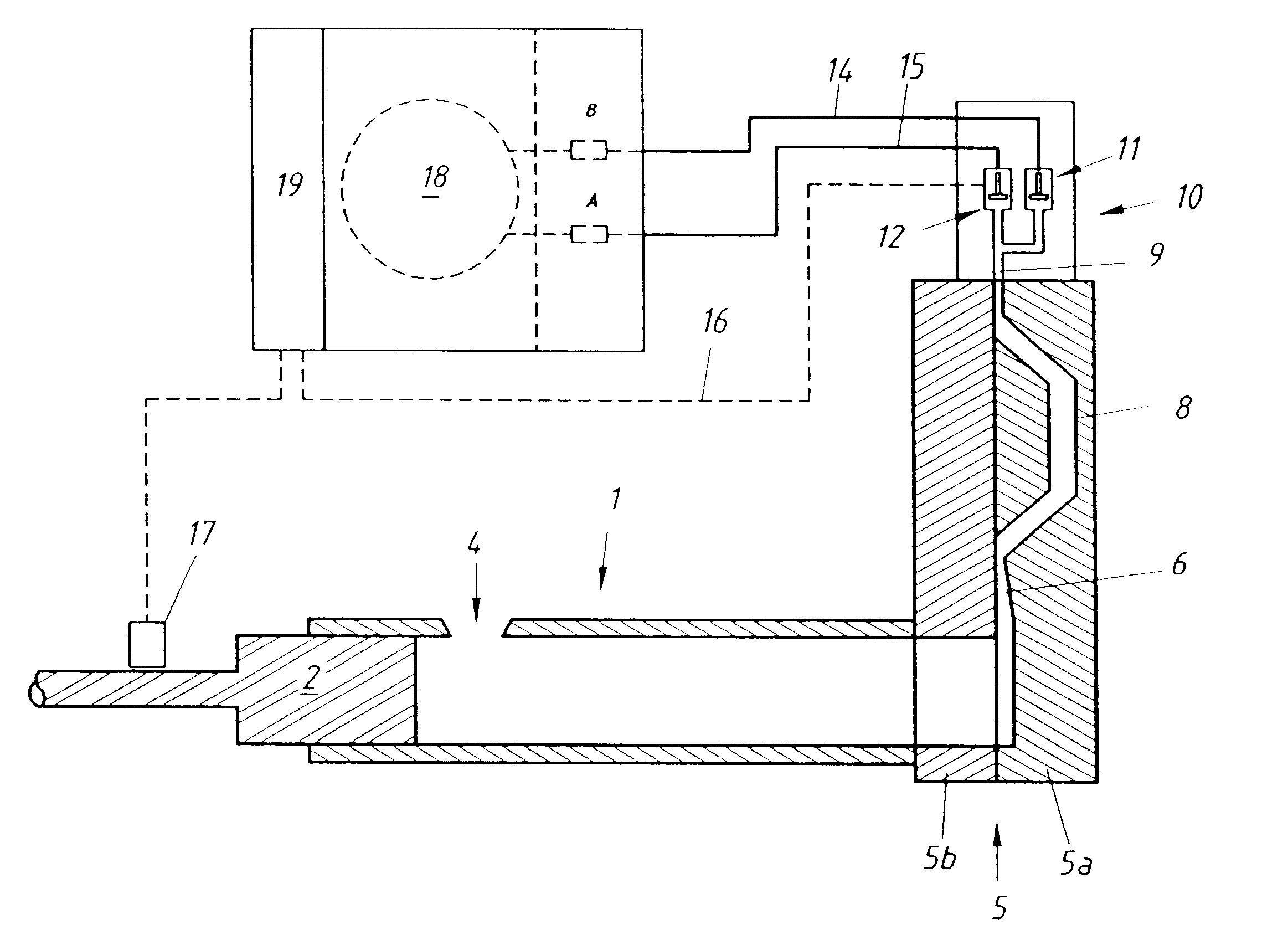

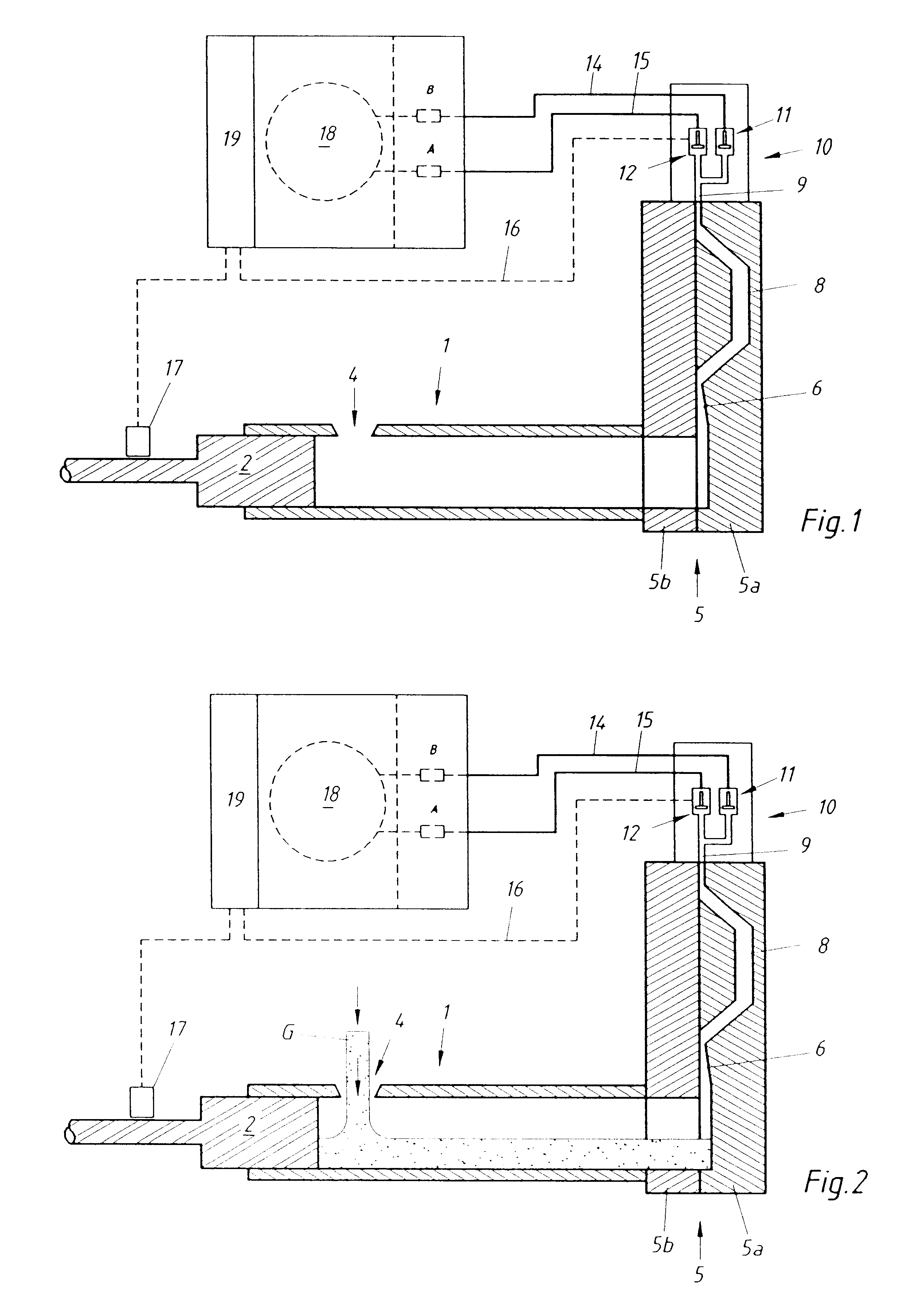

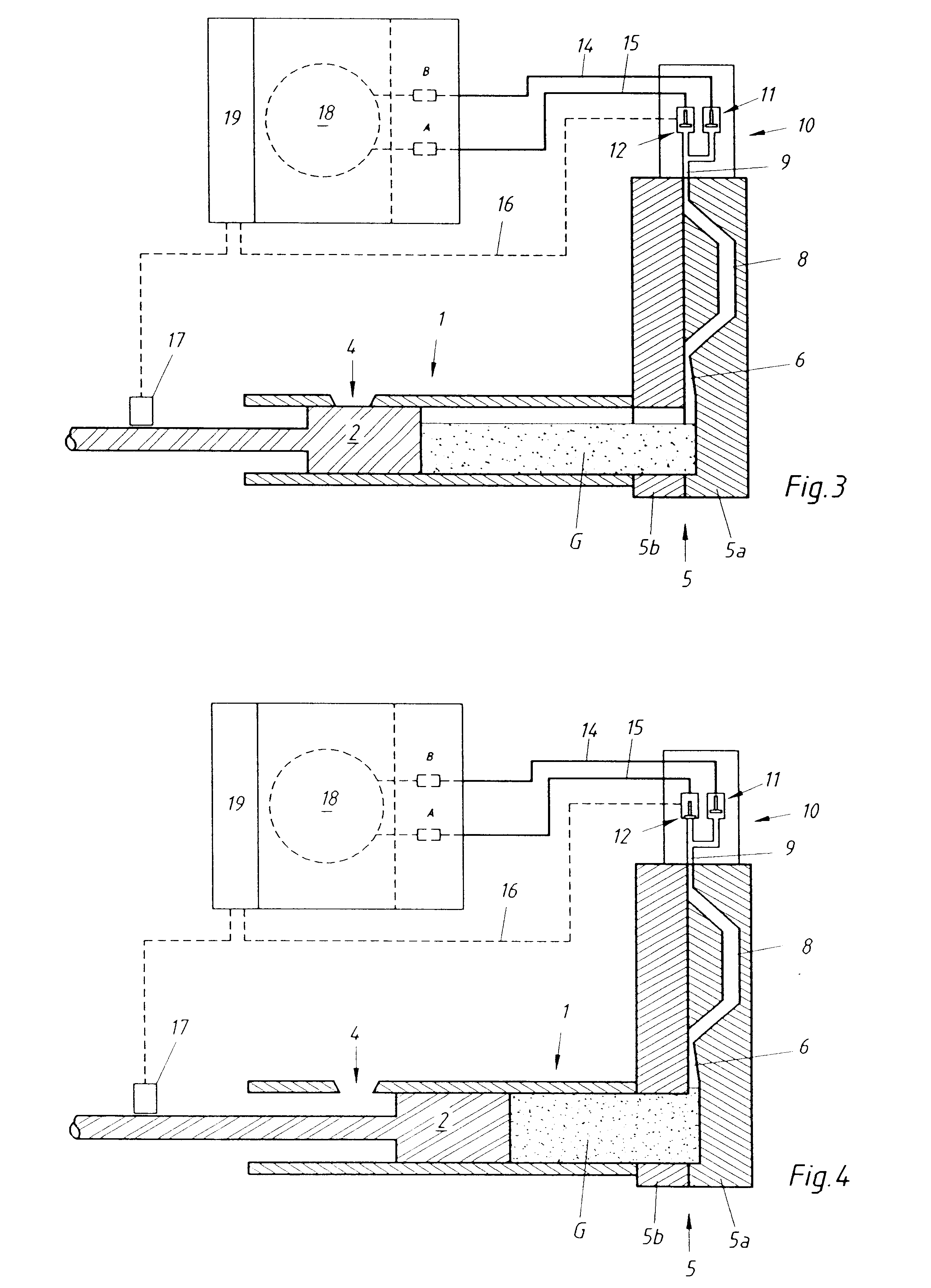

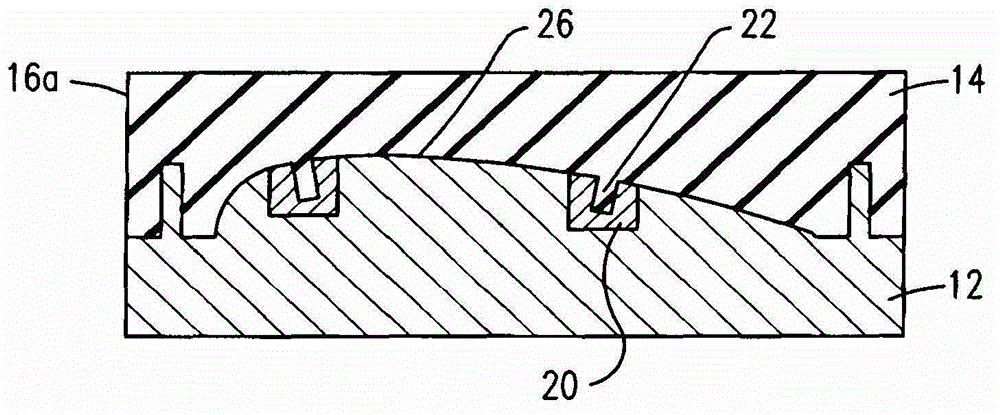

Method and apparatus for venting a diecasting mould of a diecasing machine

InactiveUS6298903B1Improve efficiencyImprove performanceMoulding toolsFoundry mouldsTransmitterPiston

In order to vent a diecasting mold of a diecasting machine, it is proposed that the mold cavity and / or the pressure chamber are vented during the filling operation by a second venting valve, additionally to a first venting valve. The first venting valve is located in a venting channel portion that communicates with a venting channel leading out of the mold cavity. For operating the first venting valve, an impact transmitter is provided that is operationally connected to the first venting valve and that is exposed to and moved by the casting material advancing from the mold cavity to the venting channel. The second venting valve is operated by separate independent means and is closed before the mold cavity is completely filled. As a criterion for closing the second venting valve, the length of the path can be used along which the casting piston runs during the filling operation.

Owner:FONDAREX

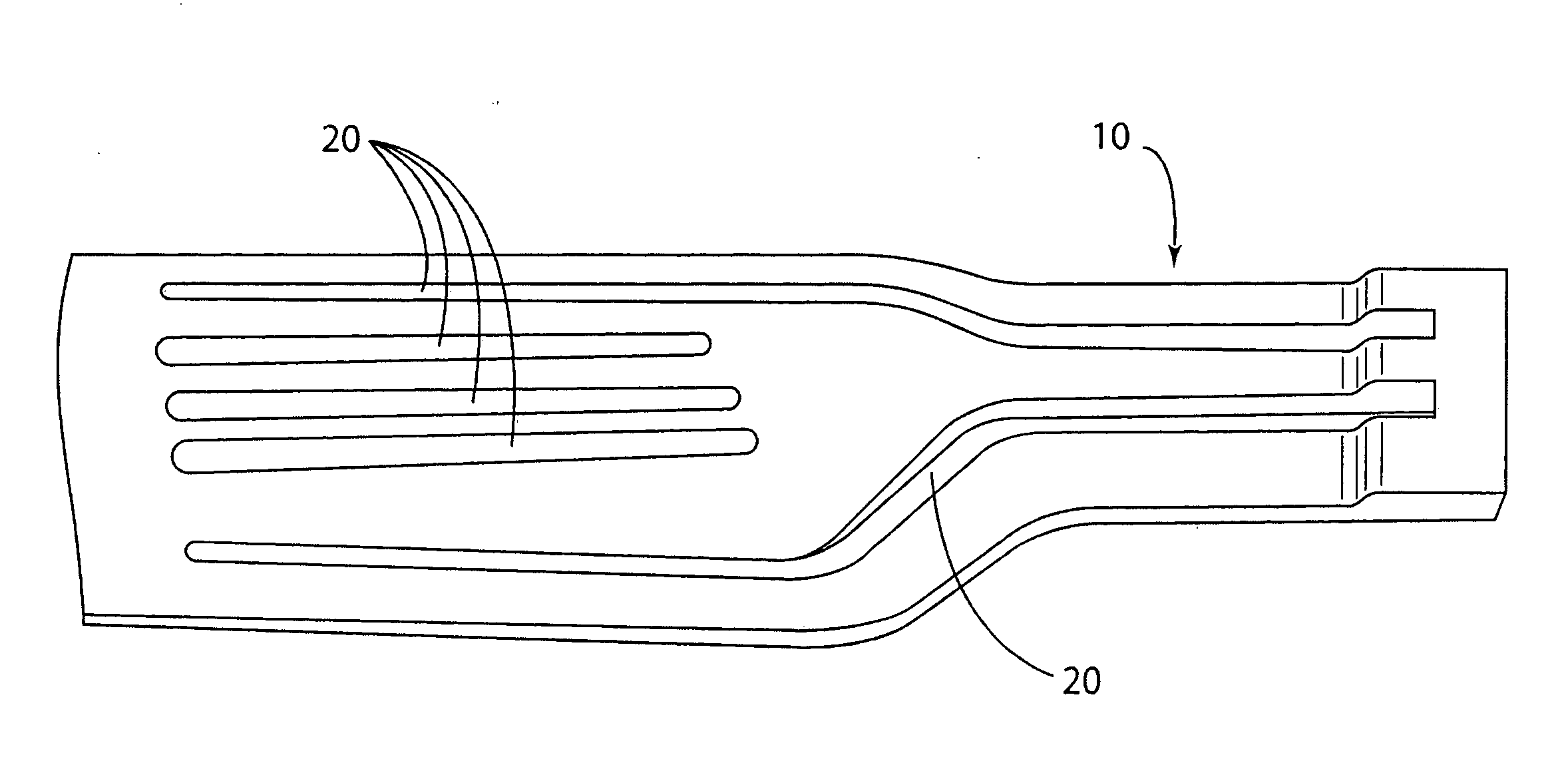

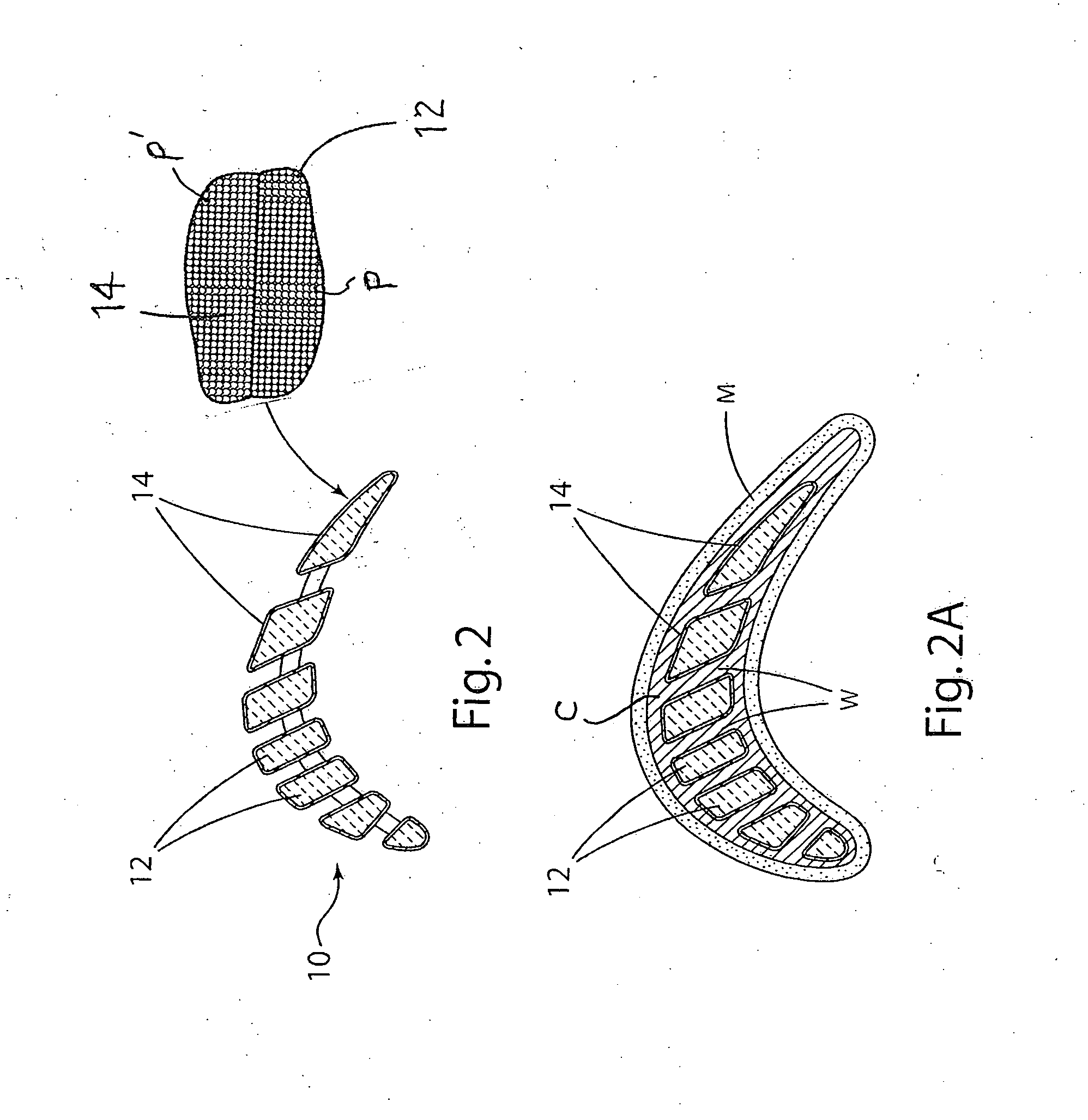

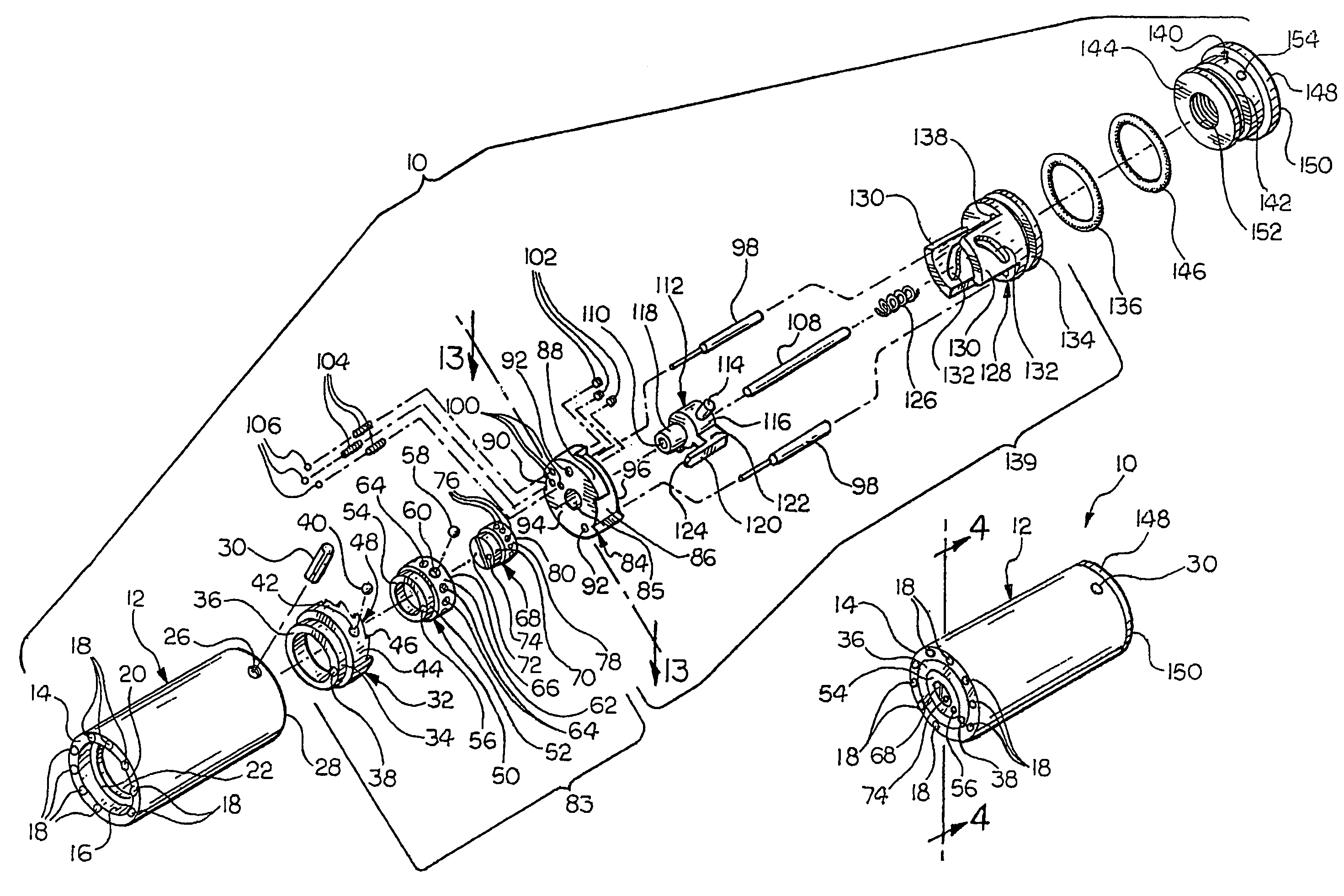

Investment casting utilizing flexible wax pattern tool

ActiveCN102802834AHelp to get outPrecise positioningMoulding toolsFoundry mouldsInvestment castingTopography

An investment casting process wherein the wax pattern tool (44) is flexible to facilitate removal of the tool from the cast wax pattern (52) even when the cast shape would otherwise require multiple pull planes. The flexible tool may include a flexible insert (42) precisely indexed to a surrounding coffin mold (40), and thereby to an enclosed ceramic core (10). Positioning pins (106) may extend from the flexible tool to make compliant contact against the core prior to a wax injection step. The surface of the resulting wax pattern may contain an engineered topography (36) replicated through the flexible surface from a master tool (12). The flexible tool may encase thermally conductive or magnetic particles (92), or other active device (96) such as a sensor or vibrator which is operable during wax injection.

Owner:SIEMENS ENERGY INC +1

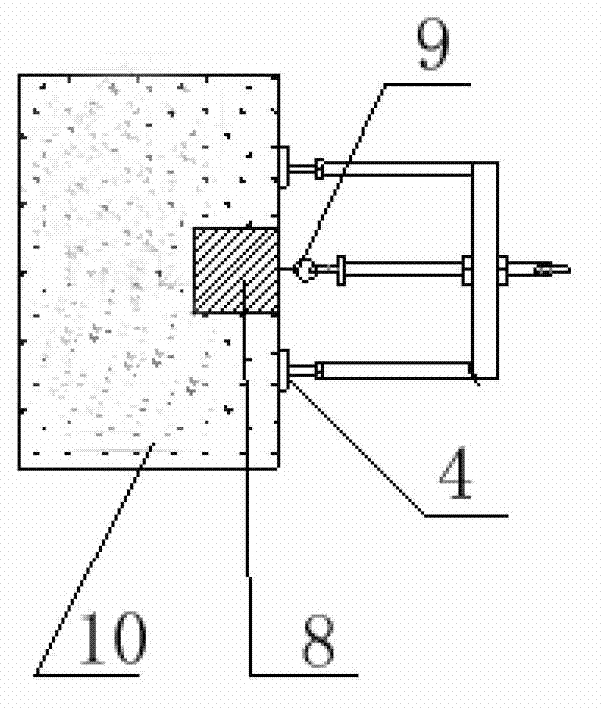

Tool for solving difficult stripping of live feed of large-scale steel casting mould

InactiveCN102921905AShorten the timeGuarantee the quality of the surrounding molding sandMoulding toolsMolding sandMaterials science

The invention relates to a tool used in the casting process of a large-scale steel casting, in particular to a tool for solving difficult stripping of a live feed of a large-scale steel casting mould. The tool is characterized by comprising a main skeleton with upright posts; the end part of each upright post is connected with a screw rod matched with a nut; a sizing block is fixed on the screw rod; a telescopic harness screw rod is fixed in the middle of the main skeleton through a nut; and the nut on which a hook is fixed is matched with the same end of the harness screw rod as the sizing block, and a handle is fixed at the other end of the harness screw rod. The tool has the beneficial effects that the structure is special, the use is convenient, the tripping time of a loose piece can be reduced, and the quality of molding sand at the periphery of the loose piece after stripping is ensured.

Owner:KOCEL GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com