Method and equipment for drying white pattern through microwave in evaporable pattern casting

A technology of lost foam casting and microwave drying, which is applied to casting molding equipment, metal processing equipment, casting molds, etc. It can solve the problems of occupying workshop space, consuming manpower and material resources, etc., and achieves a small occupation of workshop area, saving labor and improving labor efficiency. conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] (1) Place the formed white mold on the rotary tray of an industrial microwave oven, close the oven door, and bake for 3-10 minutes. Dry the moisture of the white mold so that the white mold does not deform or shrink;

[0027] (2) Dip-coat the white mold dried in the previous step, and place it on an inclined shelf for 3-5 minutes, allowing the paint to flow until it does not accumulate in large quantities;

[0028] (3) Place the white mold dipped in the first coating on the rotary tray of the microwave oven, close the oven door, and bake for 10-18 minutes. The power of the microwave emission device is 2-4KW / h, and the oven temperature is 50 -60°C, dry the first layer of paint thoroughly, and keep the white mold from deforming or shrinking;

[0029] (4) The above steps (2) and (3) will be repeated twice;

[0030] (5) Place the fully dried white mold that has been dipped and coated three times in the drying room and wait for pouring.

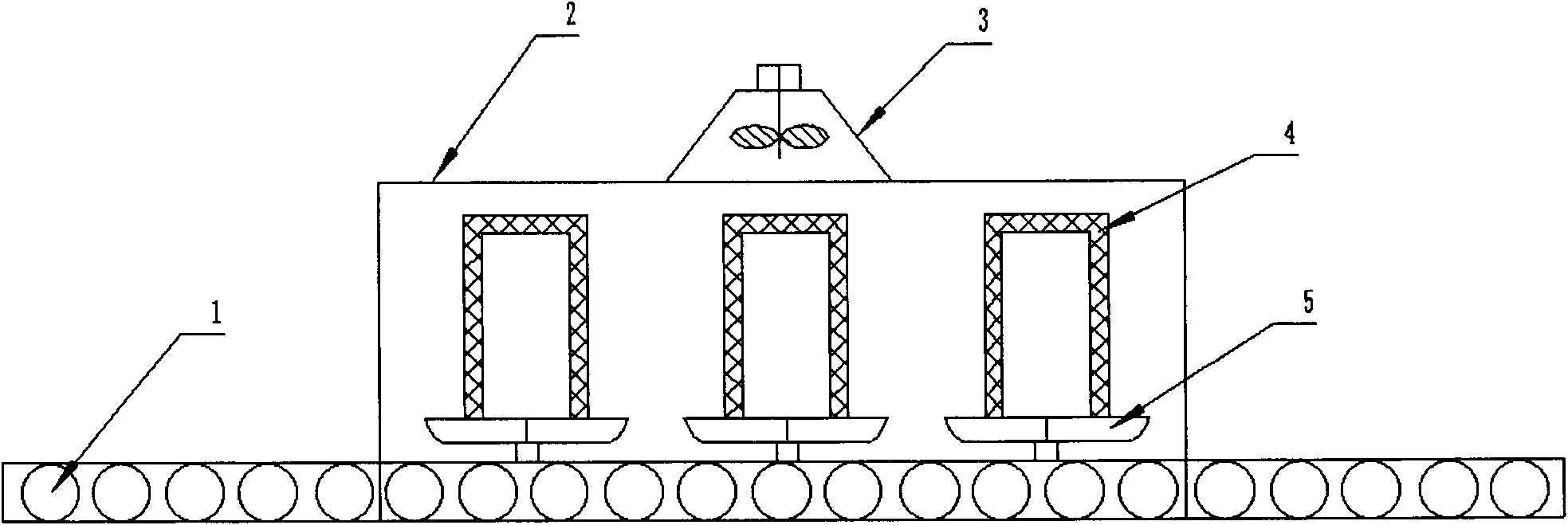

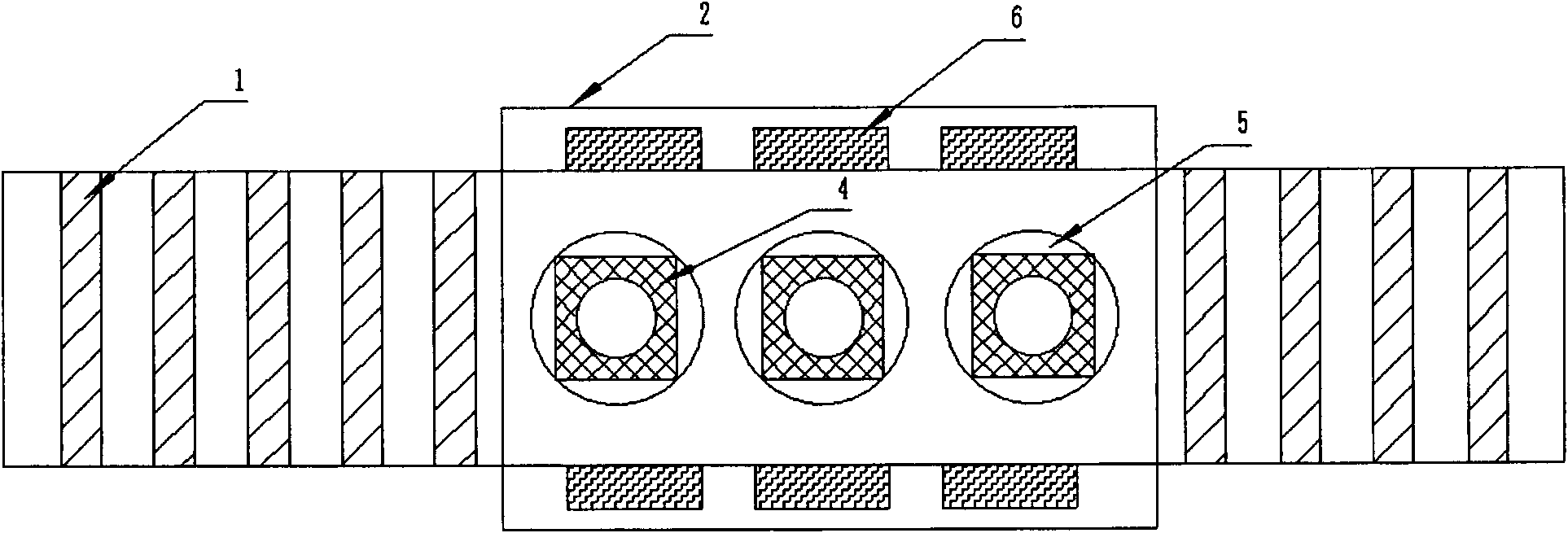

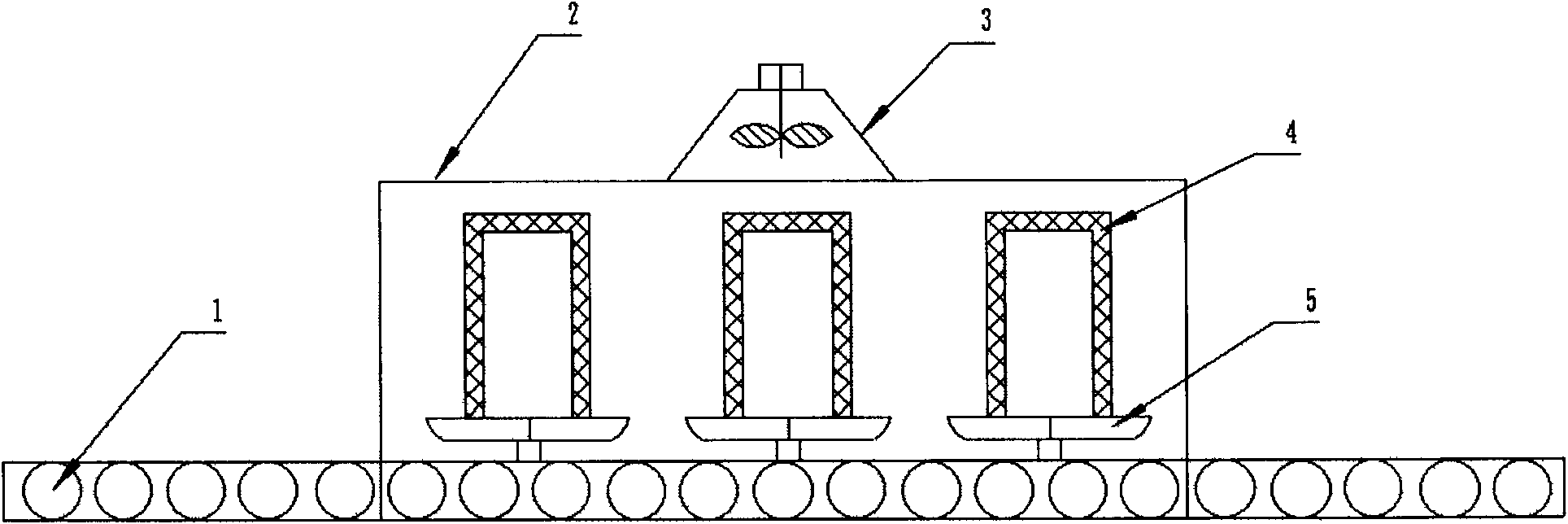

[0031] The equipment for microwav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com