Multifunctional double-printing-head 3D printing equipment based on 3DP technology

A dual-print head, 3D printing technology, applied in the field of printing foundry sand molds and printing foundry molds, which can solve problems such as limitations in the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

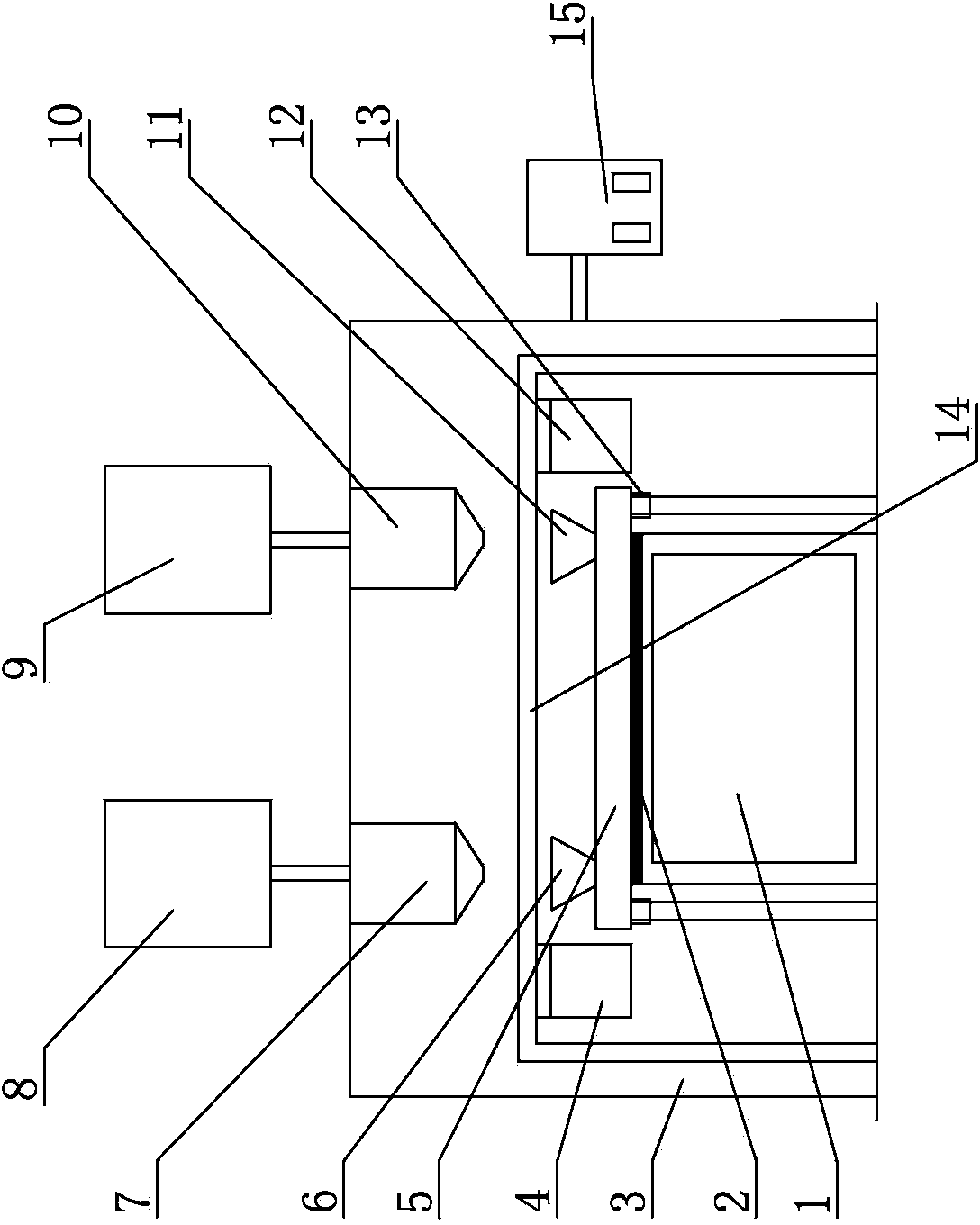

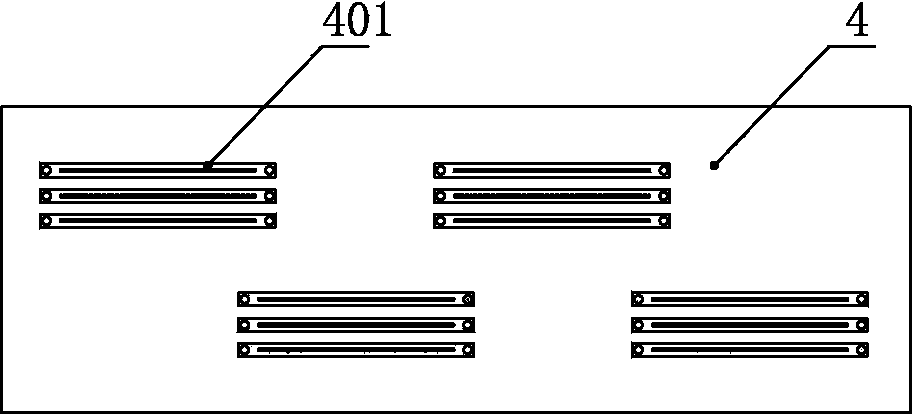

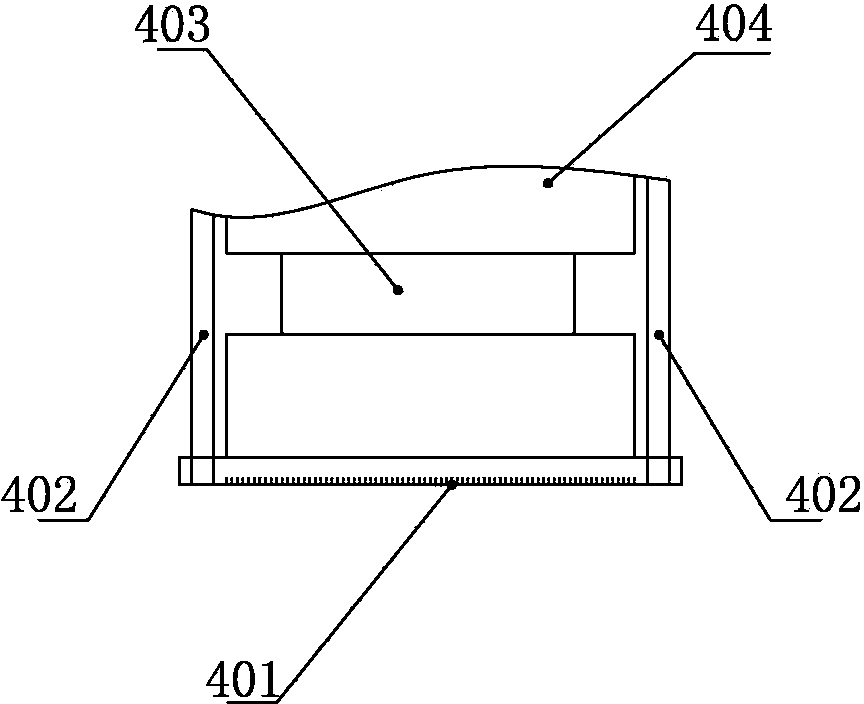

[0014] Such as figure 1 As shown, it is a multifunctional dual-print head 3D printing device based on 3DP technology, including a feeding hopper 1 8 and a feeding hopper 2 9 arranged on the frame 3, and a mixing tank 1 7 is arranged below the feeding hopper 1 8, The bottom of the feeding hopper two 9 is provided with a mixing tank two 10, and the bottom of the mixing tank one 7 and the mixing tank two 10 is provided with a powder spreading device 5, and the powder spreading device 5 is provided with a work box 1 below the work box 1. There is a lifting platform 2, and the two ends of the powder spreader 5 are respectively provided with a feeding port 1 6 and a feeding port 2 11, the feeding port 1 6 corresponds to the mixing tank 1 7, and the feeding port 11 corresponds to the mixing tank 2 10; The powder spreader 5 is installed on the powder spreader guide rail 13; the print head guide rail 14 is also arranged above the powder spreader 5, and two print heads are arranged on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com