Patents

Literature

168 results about "Alumina hydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag oil hydro-demetallization catalyst and its preparing method

ActiveCN1782031AImprove performanceEasy to operateRefining to eliminate hetero atomsAluminum CarbonateAlumina hydrate

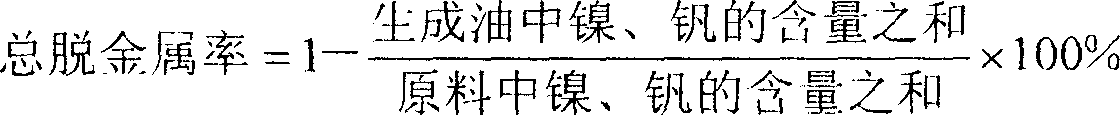

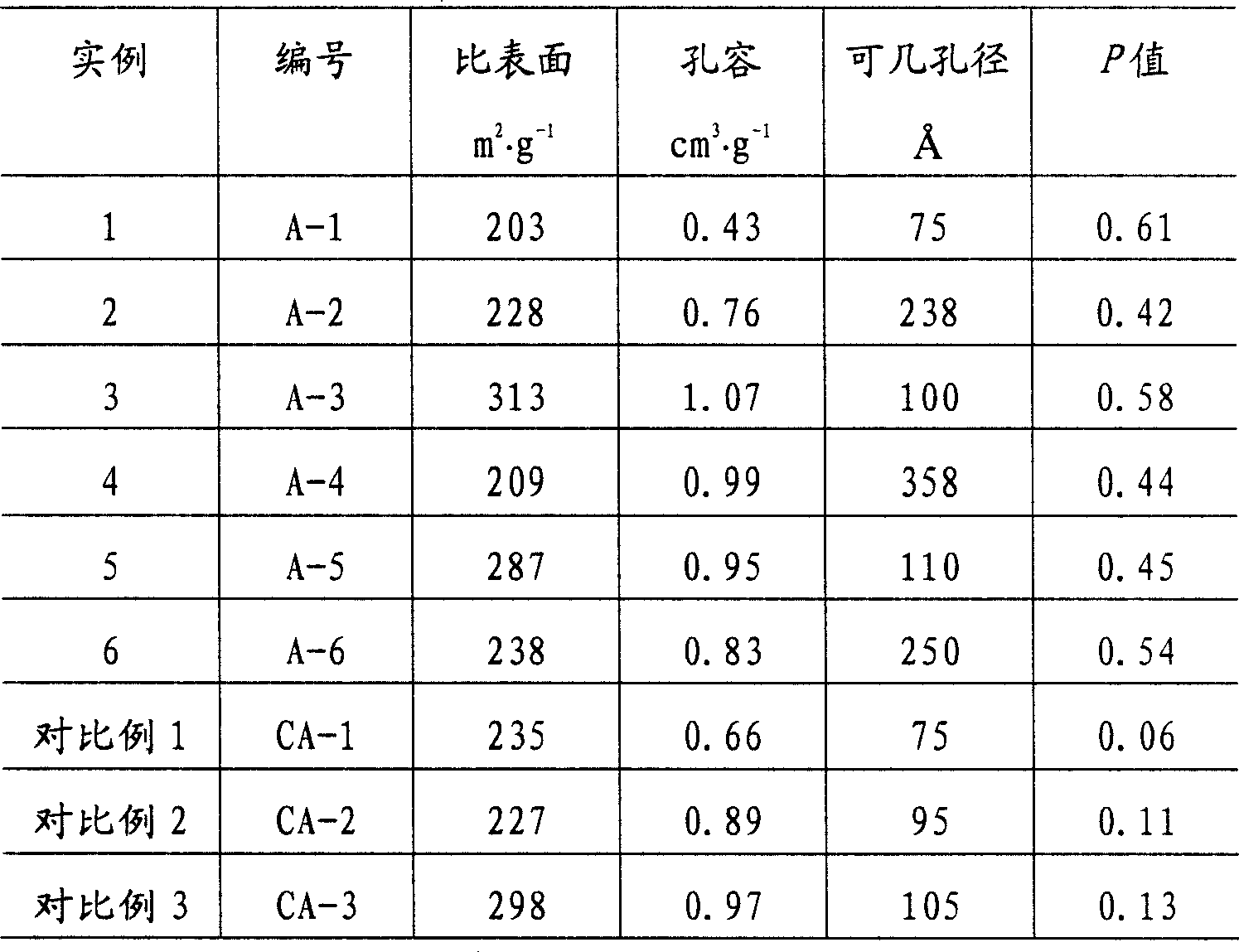

The slag oil hydrodemetallizing catalyst contains a kind of double-peak hole alumina carrier and supported Mo and / or W and Ni and / or Co metal components. The double-peak hole alumina carrier has pore volume of 0.8-1.6 ml / g, specific surface area 150-350 sq m / g, pore volume fraction of 10-30 nm size holes in 40-90 % and pore volume fraction of 100-2000 nm size holes in 10-60 %, and is prepared through mixing alumina hydrate and ammonium aluminum carbonate, forming and roasting. The slag oil hydrodemetallizing catalyst has simple preparation process and high hydrodemetallizing performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina powder, process for producing the same and polishing composition

InactiveUS6440187B1High speed polishing propertyQuality improvementPigmenting treatmentMaterial nanotechnologyAlumina hydrateCrystal structure

Production of an alumina powder characterized by having a single or multiple crystal structure selected from the group consisting of gamma, delta and theta-forms, a primary particle size of 10 to 50 nm, a mean secondary particle size of 100 to 500 nm, and a granular primary particle shape, or an alumina powder characterized by having an a-form crystal structure, a primary particle size of 60 to 150 nm, a mean secondary particle size of 200 to 500 nm, and a granular primary particle shape, using as a raw material an alumina hydrate comprising rectangular plate-like primary particles having a boehmite structure and having a length of one side of 10 to 50 nm; and preparation of a polishing composition comprising the alumina powder, water and a polishing accelerator.

Owner:NISSAN CHEM IND LTD

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inkjet recording medium

InactiveUS20080241436A1High glossMaintaining film propertyDuplicating/marking methodsCross-linkAlumina hydrate

An inkjet recording medium including a water-resistant support, and on the water-resistant support, two or more ink receiving layers including an upper ink receiving layer and a lower ink receiving layer, each of the two or more ink receiving layers containing a pseudo boehmite alumina hydrate, wherein the upper ink receiving layer further contains a polyvinyl alcohol having a saponification degree of 90% or higher and at least one crosslinking agent selected from the group consisting of boric acid and boric acid salts, and the lower ink receiving layer further contains a polyvinyl alcohol having a saponification degree of less than 90% and at least one cross-linking agent selected from the group consisting of boric acid and boric acid salts.

Owner:FUJIFILM CORP

Printing medium

InactiveUS6576324B2Coatings with pigmentsDecorative surface effectsAlumina hydratePhysical chemistry

Disclosed herein is a printing medium provided on a base material with a porous ink-receiving layer which comprises, as principal components, an alumina hydrate having a boehmite structure and a binder, wherein when measuring with an ink containing 0.1% by weight of a surfactant, the time required to absorb 30 ng of an ink is 400 milliseconds or shorter, the dye-adsorbing capacity falls within a range of from 900 to 2,000 mg / m2, and the index of dye-adsorbing rate falls within a range of from 0.0 to 5.0.

Owner:CANON KK

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

Bowls comprising acrylic plastics filled with alumina trihydrate, and processes for making same

Processes for producing durable three-dimensional bowls such as water basins comprising acrylic plastics heavily filled with alumina trihydrate, some embodiments including colorants and visible particles such as those used for simulating stone such as granite. A preferred process for manufacturing the bowls of such material includes defining a flat rigid blank in the approximate top outline shape of bowl to be formed, e.g., the blank being a flat oval for an oval bowl and circular for a circular bowl. The flat blank is provided a smooth side or sides which will be the concave finished side in use. The blank is heated to a point of softening and of uniform temperature throughout, and located within a molding die such as a matched molding die having a female cavity of the desired bowl shape. The heated blank is indexed to the die, but left generally unrestrained so that the heated blank and edges thereof are un-clamped, thereby allowing the edges to be moved inward to help minimize tension loads during forming. Force is applied to the blank, such as from a male portion of the die, to compress the blank into the female cavity and desired bowl shape. The bowl is cooled, removed from the die, the top edge trimmed, a drain hole with surrounding bevel applied, and as-needed re-facing is applied on the exposed or finished side(s).

Owner:TRANSFER FLOW INT

Ink-jet recording material

The present invention discloses an ink-jet recording material having a support and at least two ink-receptive layers containing inorganic fine particles and a hydrophilic binder, which comprises an ink-receptive layer A nearer to the support containing precipitated silica fine particles having an average secondary particle diameter 500 nm or less, or precipitated silica fine particles having an average secondary particle diameter 500 nm or less and fumed silica fine particles having an average secondary particle diameter 500 nm or less, and containing less than 20 parts by weight of a polyvinyl alcohol based on 100 parts by weight of the whole silica fine particles in the ink-receptive layer A, and an ink-receptive layer B farther from the support containing at least one kind of fine particles selected from fumed silica, alumina and alumina hydrate and less than 25 parts by weight of a polyvinyl alcohol based on 100 parts by weight of the fine particles.

Owner:MITSUBISHI PAPER MILLS LTD

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS8298508B2Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Recovery of alumina trihydrate during the bayer process using cross-linked polysaccharides

ActiveUS20120034142A1Accelerated settlementEnhanced inhibitory effectGallium/indium/thallium compoundsAluminates/aluminium-oxide/aluminium-hydroxide purificationCross-linkCellulose

The invention provides methods and compositions for improving the production of alumina hydrate. The invention involves adding one or more polysaccharides to liquor or slurry in the fluid circuit of the production process. The one or more polysaccharides can be a cross-linked polysaccharide (such as cross-linked dextran or cross-linked dihydroxypropyl cellulose). The various polysaccharides can impart a number of advantages including at least some of: greater flocculation effectiveness, increasing the maximum effective dosage, faster settling rate. The production process can be a Bayer process.

Owner:NALCO CO

Pseudo thin allophane and its preparation method

This invention discloses a pseudoboehmite and its preparation method. This pseudoboehmite is prepared by following steps: a) at acidity condition that can make aluminum precipitate, precipitate aluminum of aluminum compound water solution, separate, and get a kind of amorphous alumina hydrate; b) mix amorphous hydrated aluminum oxide with water and at least one kind of water-soluble alkali, slurry, stabilize at 20deg-90deg for 0.2-6 hours, wherein dosage of above alkali make serumal pH be 6-11. Compared with existing technique, pseudoboehmite prepared by this invention can get aluminum oxide of bore distributing localized by calcining.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ink jet recording medium and method of producing the same

InactiveUS20090011155A1Inhibit migrationHigh image densityLiquid surface applicatorsPattern printingAlumina hydrateEngineering

The invention provides an ink jet recording medium which attains the prevention of the bronzing of cyan ink and the prevention of the migration of magenta ink at the same time and is excellent in image characteristics. The ink jet recording medium comprises a substrate and an ink-receiving layer provided with at least an upper layer as the outermost layer and a lower layer as a layer lying just under the upper layer, both layers having a porous structure formed of an alumina hydrate and a binder, wherein both of the upper and lower layers contain an alkylsulfonic acid and only the lower layer contains a cationic polymer.

Owner:CANON KK

A kind of hydrated alumina and preparation method thereof

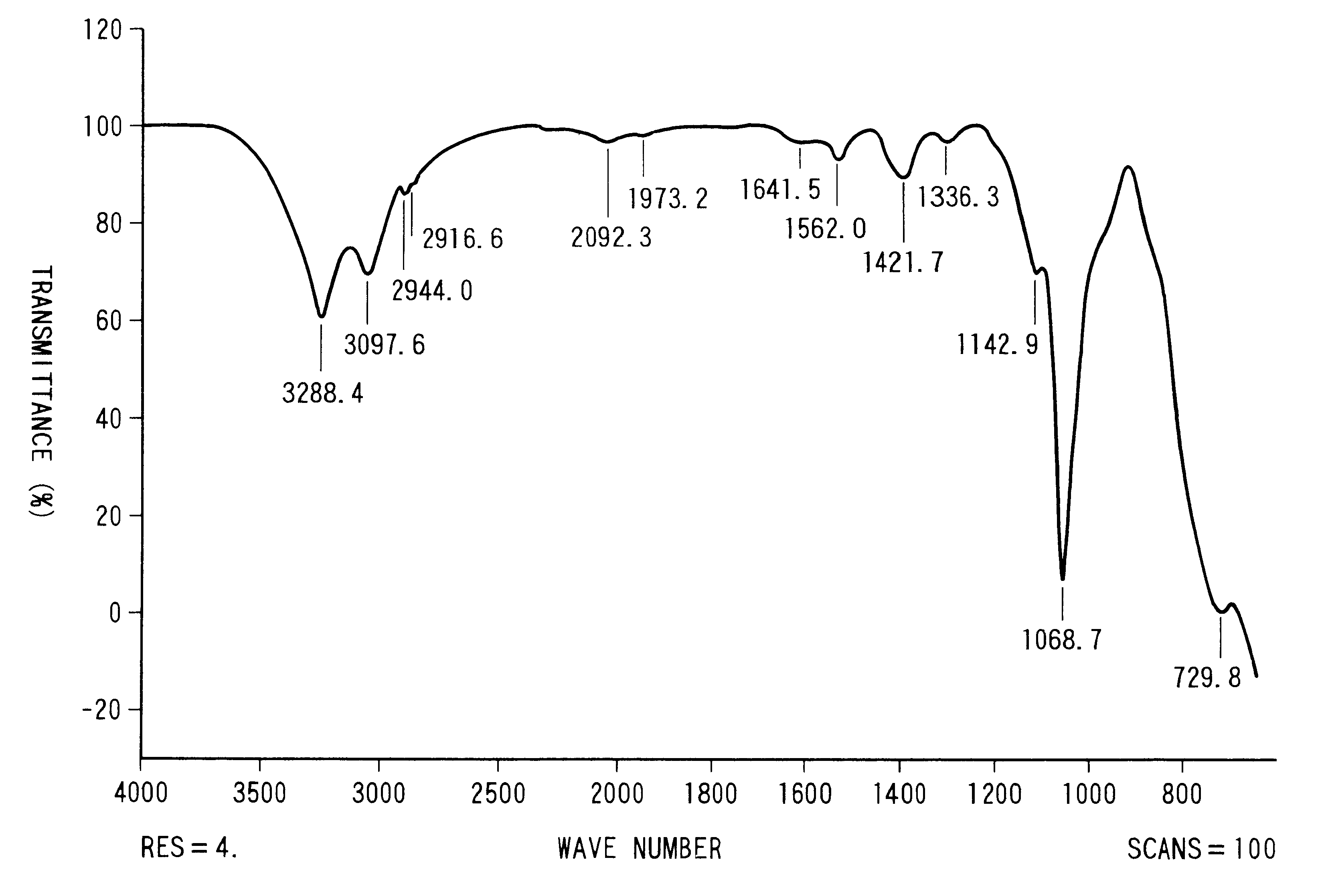

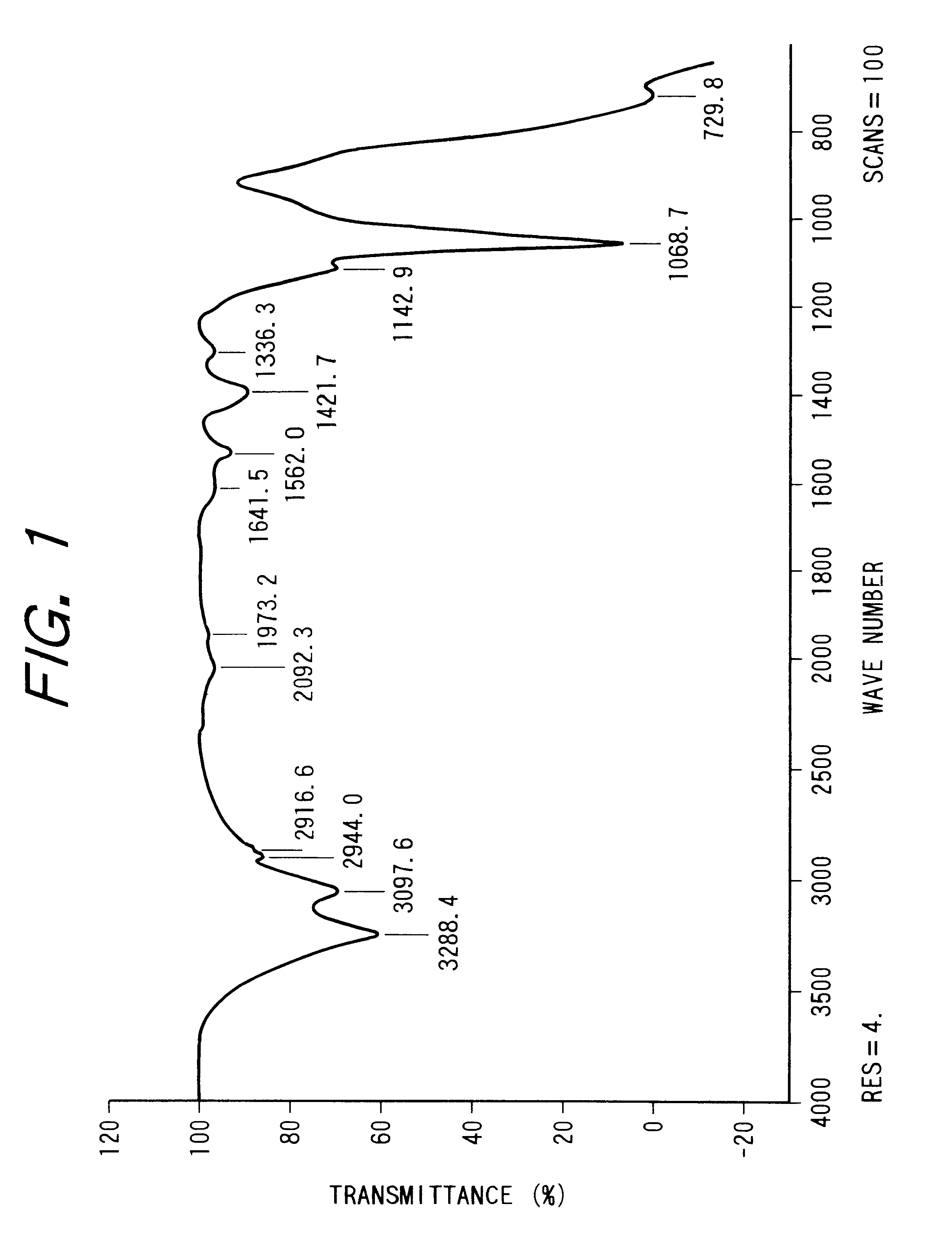

ActiveCN102259900AExcellent hole expandabilityImprove pore structureAluminium oxides/hydroxidesAlumina hydrateSodium aluminate

The present invention provides a hydrated alumina containing pseudo-boehmite, wherein the hydrated alumina further contains basic aluminum ammonium carbonate. The present invention also provides a method for preparing hydrated alumina, the method comprising contacting sodium metaaluminate and / or sodium aluminate with an acidic solution, and aging the mixed slurry obtained after the contact reaction in the presence of an aging agent The conditions of the contact reaction include: the reaction pH value is 4.5-9, and the reaction temperature is 15-75°C; the aging conditions include: the temperature is 20-60°C, and the time is 2-6 hours; the aging agent Ammonium carbonate and / or ammonium bicarbonate. The alumina carrier prepared by using the hydrated alumina prepared by the method for preparing hydrated alumina according to the present invention has significantly improved most probable pore diameter, average pore diameter, pore volume and pore volume with a diameter of 10-60 nanometers.

Owner:CHINA PETROLEUM & CHEM CORP +1

Recording material for ink-jet

A recording material for an ink-jet which has a supporting material and, applied thereon, at least two ink receiving layers containing inorganic fine particles and a hydrophilic binder, characterized in that an ink receiving layer (A) being present nearest to the supporting material comprises a vapor phase method silica and an ink receiving layer (B) being present most apart from the supporting material comprises alumina or an alumina hydrate.

Owner:MITSUBISHI PAPER MILLS LTD

Catalyst and method for selectively oxidizing carbon monoxide in hydrogen-containing gas and solid polymer electrolyte-type fuel cell system using such catalyst

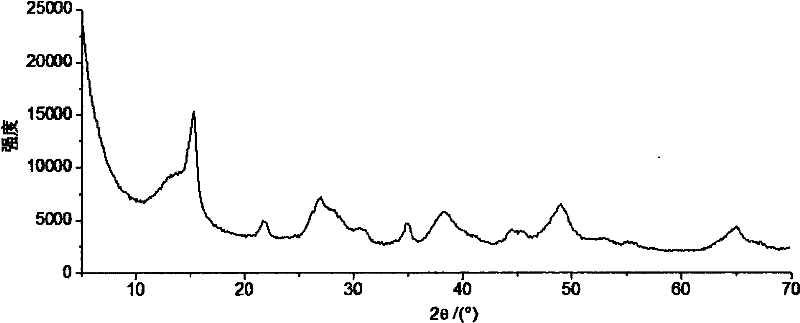

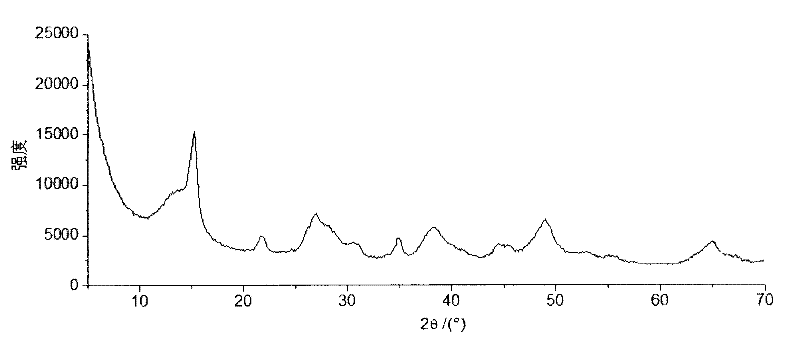

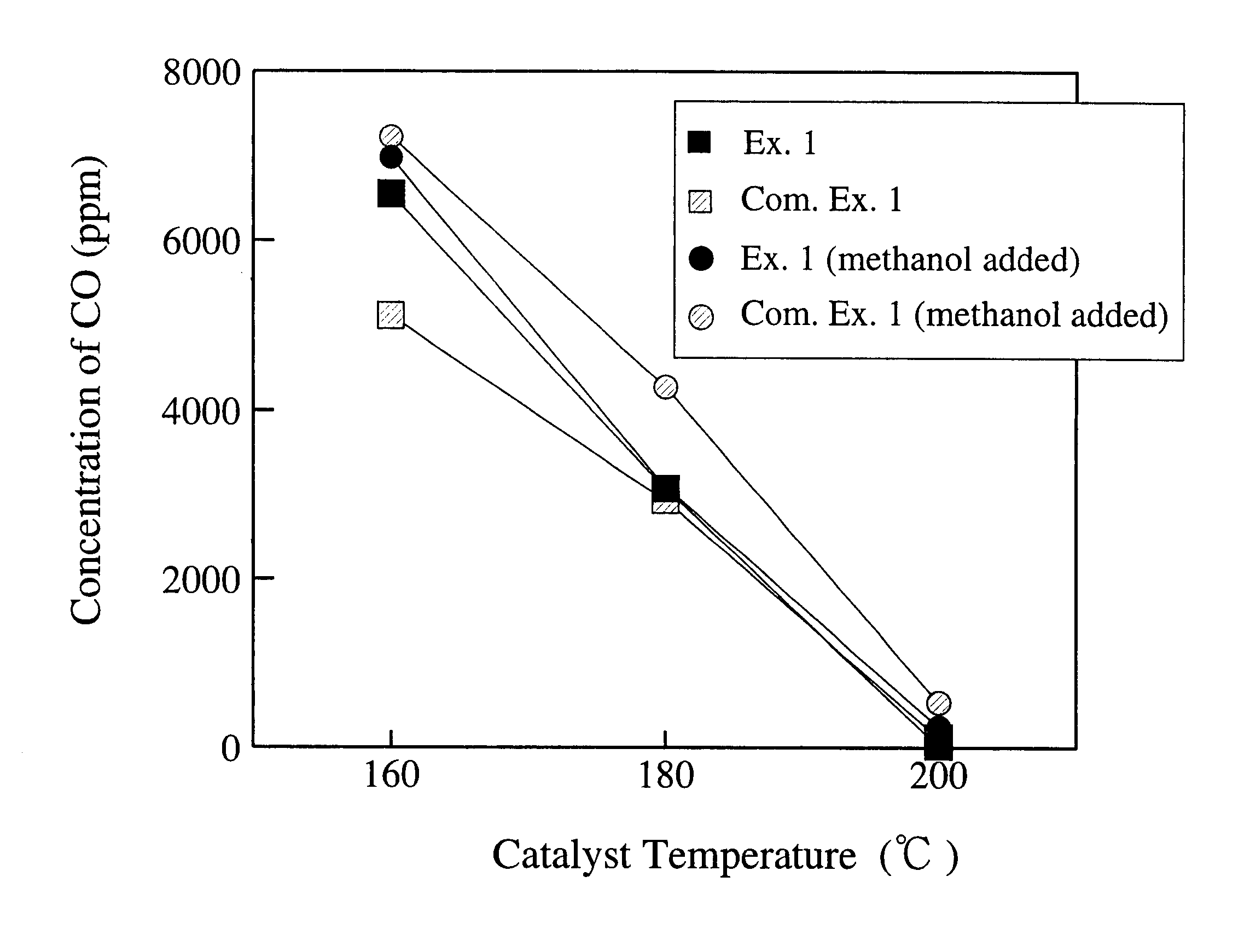

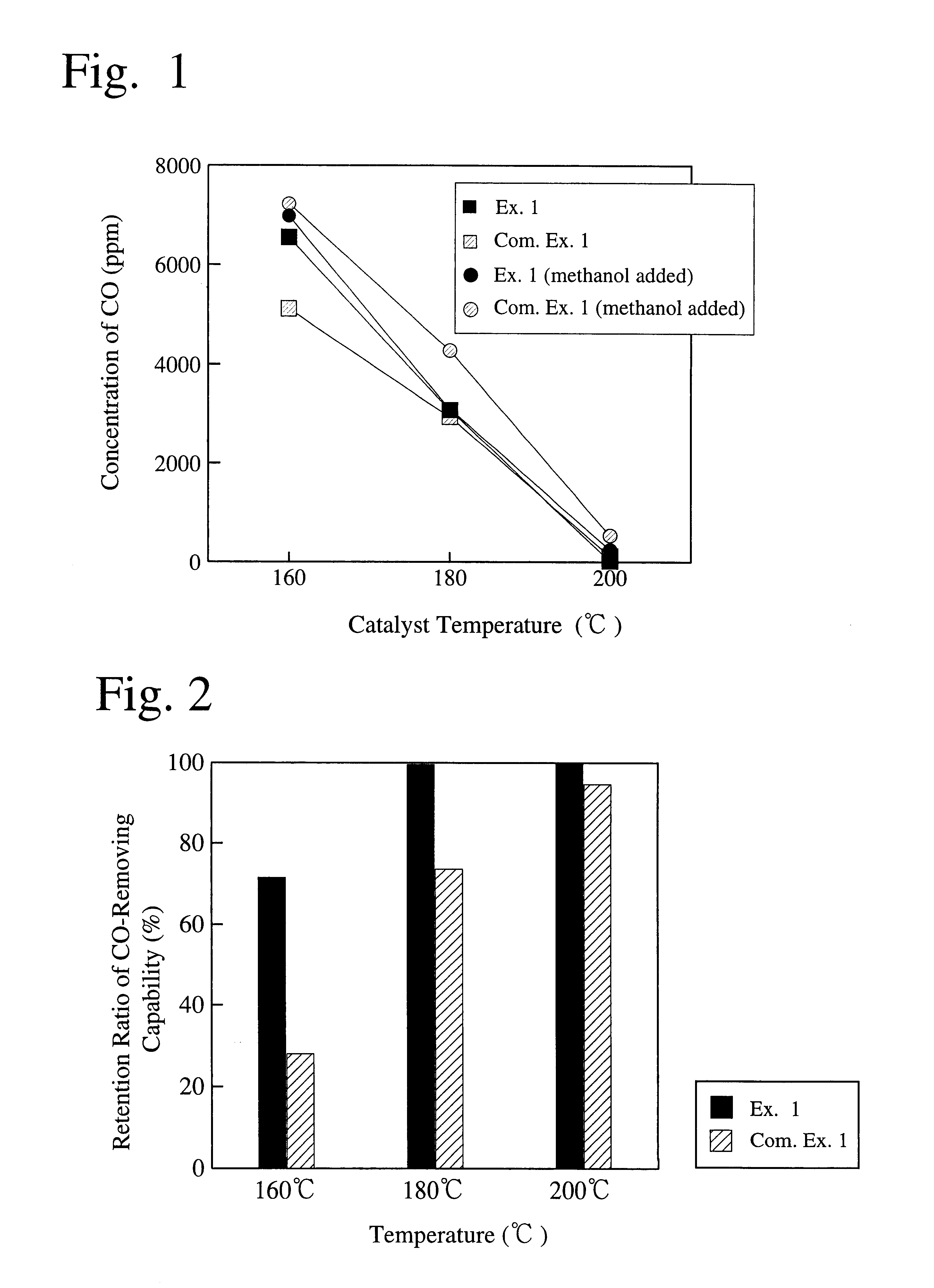

InactiveUS6562499B1High removal rateLarge volume of catalystHydrogen separation using solid contactFinal product manufactureAlumina hydrateAluminum hydrate

A catalyst for selectively oxidizing carbon monoxide in a hydrogen-containing gas comprises an alumina hydrate carrier and at least platinum supported thereon. With an aluminum hydrate as a carrier, the catalyst is resistant to deactivation which would be caused by an oxygen-containing hydrocarbon in a hydrogen-rich gas. The method for selectively removing carbon monoxide comprises the steps of adding oxygen to a hydrogen-rich gas containing carbon monoxide, in an amount necessary to oxidize at least part of carbon monoxide, and bringing the resulting mixture into contact with the catalyst for selectively oxidizing carbon monoxide. The solid polymer electrolyte-type fuel cell system utilizes the above method for selectively removing carbon monoxide.

Owner:HONDA MOTOR CO LTD

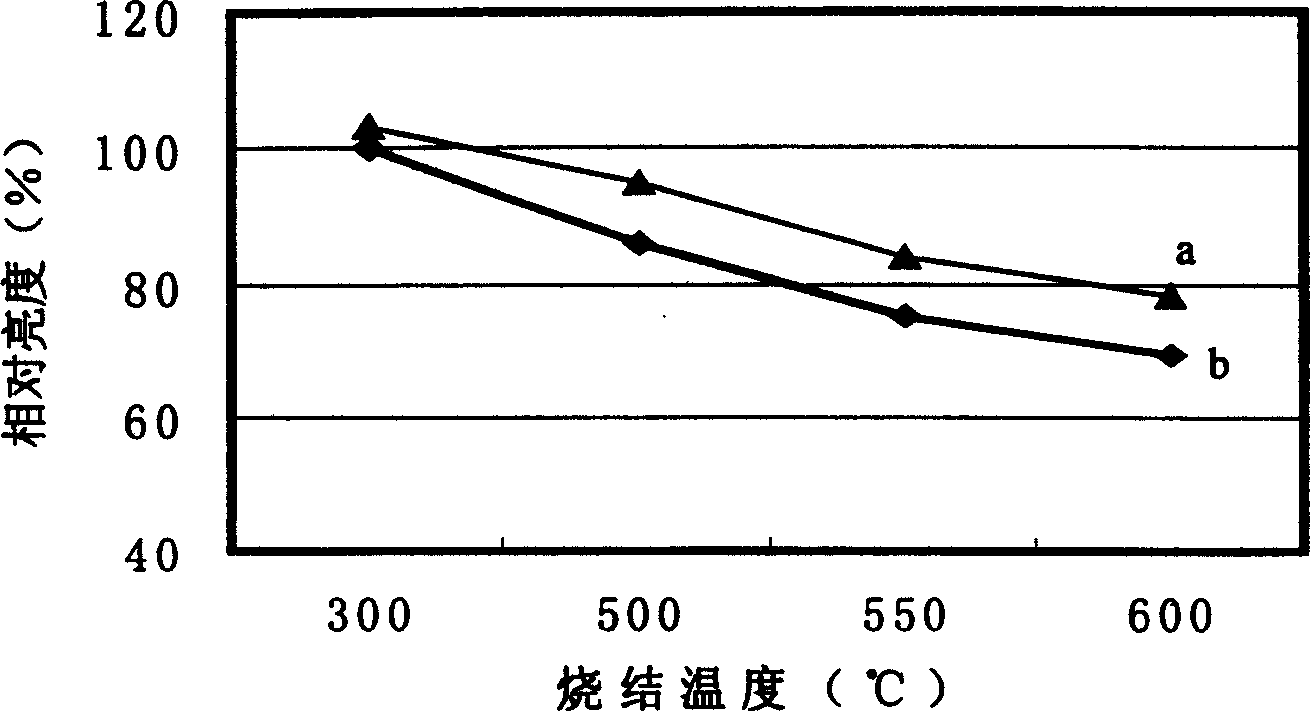

Alumina coated fluorescent powder and its coating method

InactiveCN1667081AImprove resistance to thermal deteriorationWork lessSolid cathode detailsLuminescent compositionsAlumina hydrateWater content

This invention is alumina diolame phosphor powder; it is coated of Al2O3 on phosphor powder surface. Its coating method is that buffer solution is made-up by conjugate acid-base system eith Ph value is between 4.5~6.0, and its concentration is between 0.1M and 2M. Concentration is 0.01~1.0M water soluble aluminium salt solution is made-up by Al2O3 and phosphor powder and equal quality water soluble aluminium salt, the weight ratio of Al2O3 and phosphor powder is (0.25~20):100. Phosphor powder is added into buffer solution to make-up water soluble aluminium salt of 0.0.1~1.0M concentration. It is agitated and ultra sonic dispersed to make phosphor powder disperse in buffer solution. The phosphor powder suspension is heated to 20~600C, and agitated at speed of 100r / m~300r / m, then water soluble aluminium salt is added into suspension, dropwise velocity is 5~500ml / min. The temperature is holding and agitated for 30~120min. Finally, mother liquor is adjusted by alkali solution to pH value is 6~7, then alumina hydrate is got. alumina diolame phosphor powder is got after separation, water washing, dehydration, and is dried at 60~1200C to make water content of phosphor powder is low of 0.25%, and ignited 1~3hours at 200~4000C and air cooling in stove.

Owner:SOUTHEAST UNIV

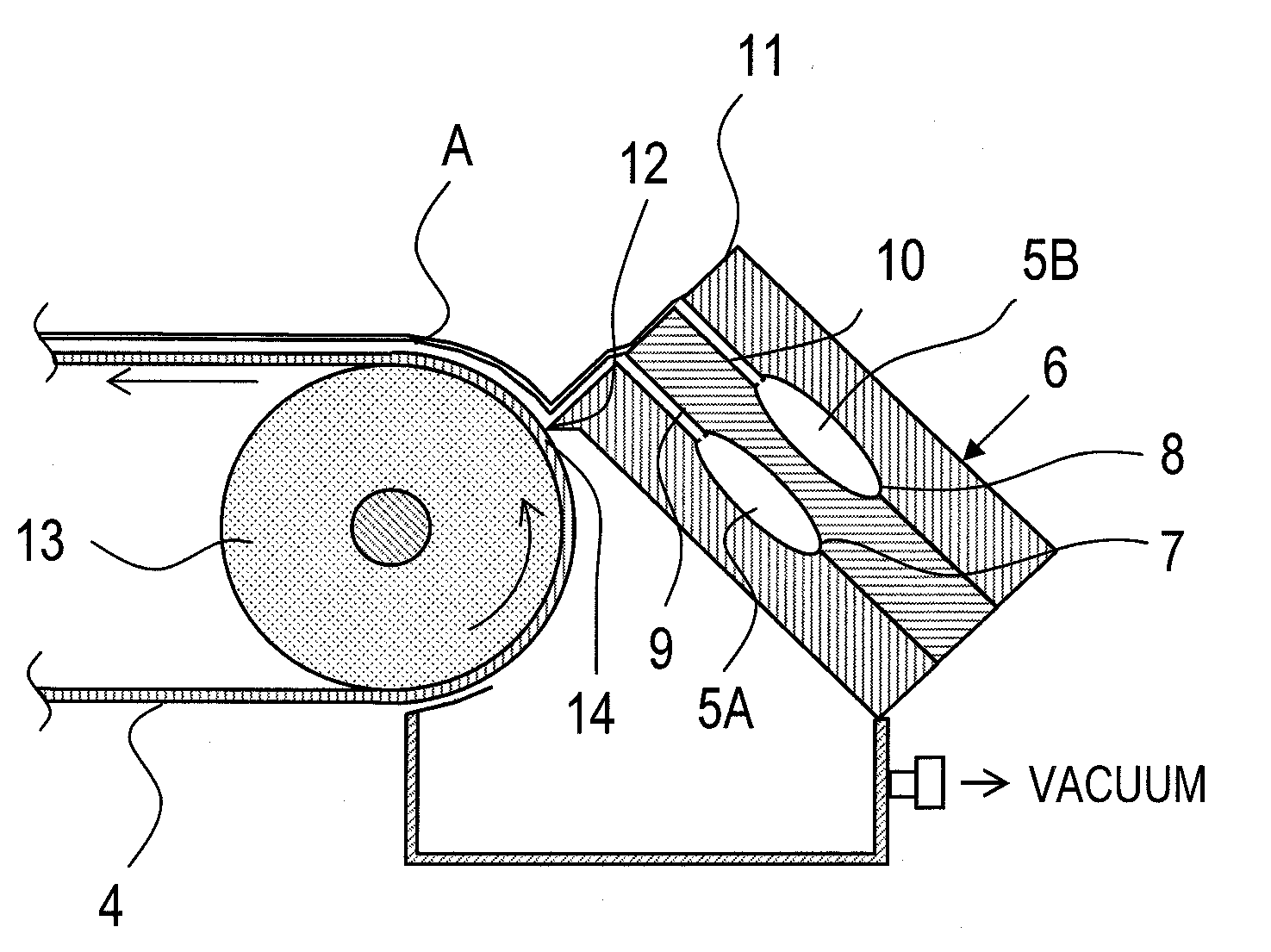

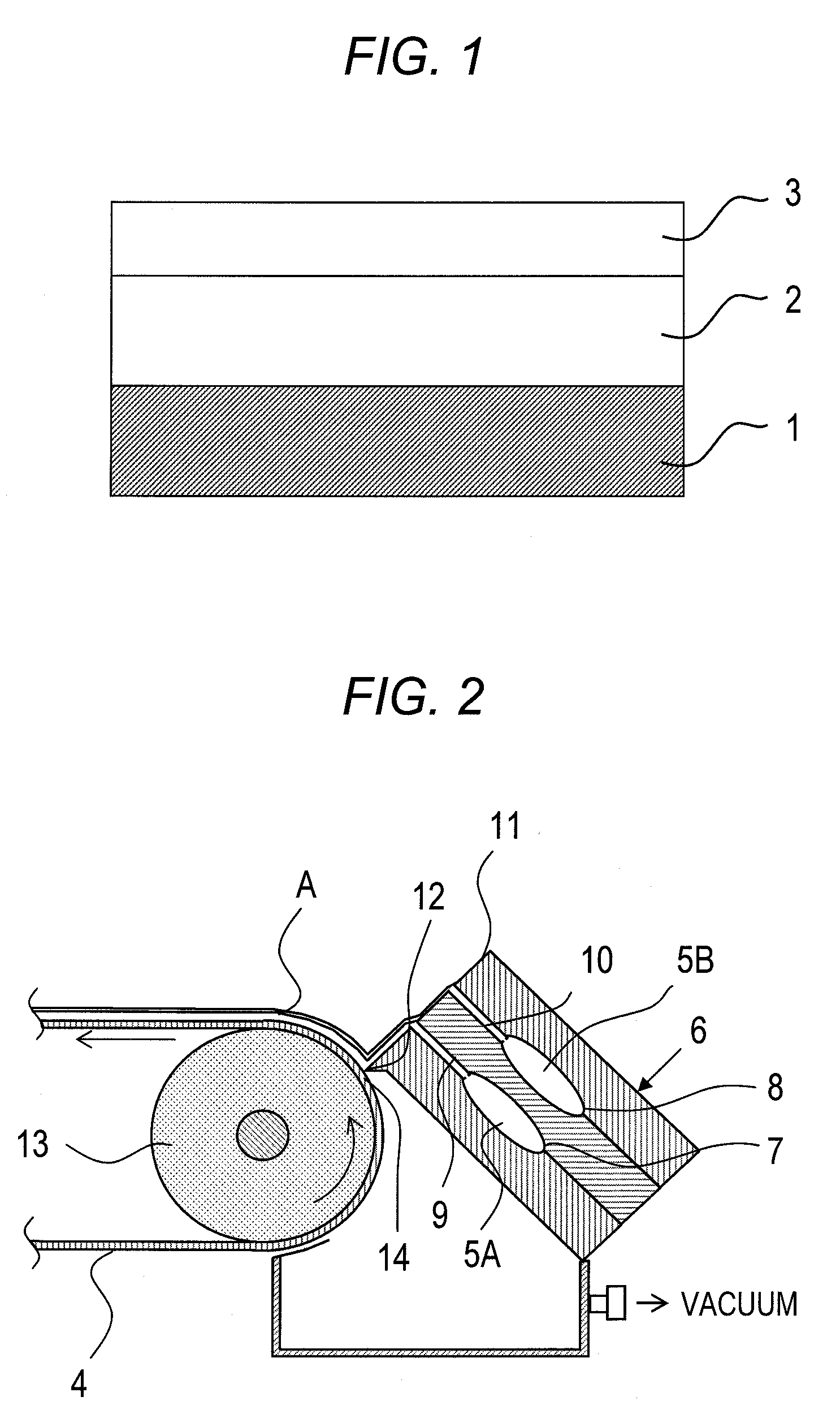

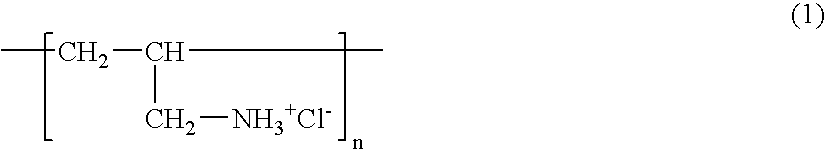

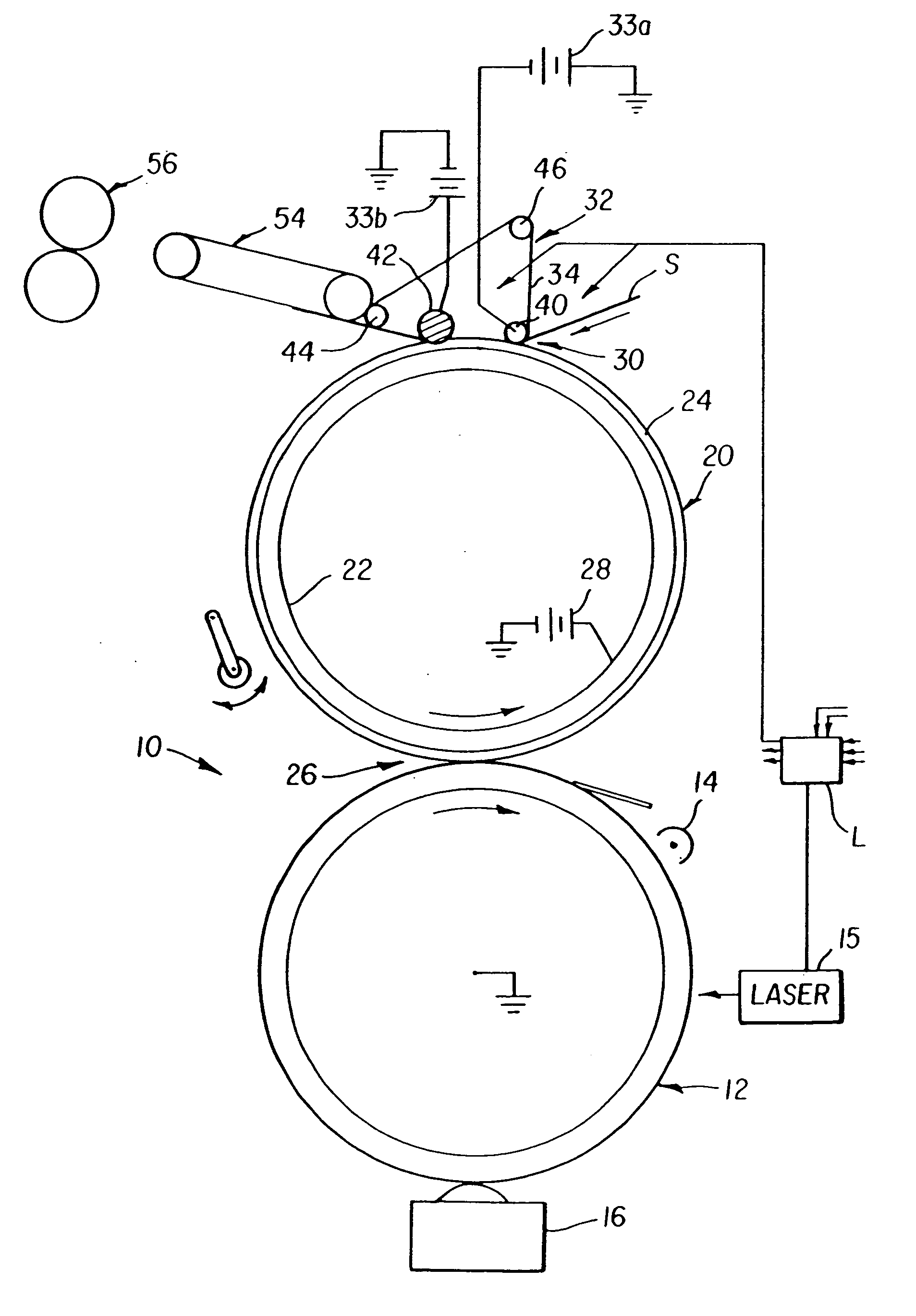

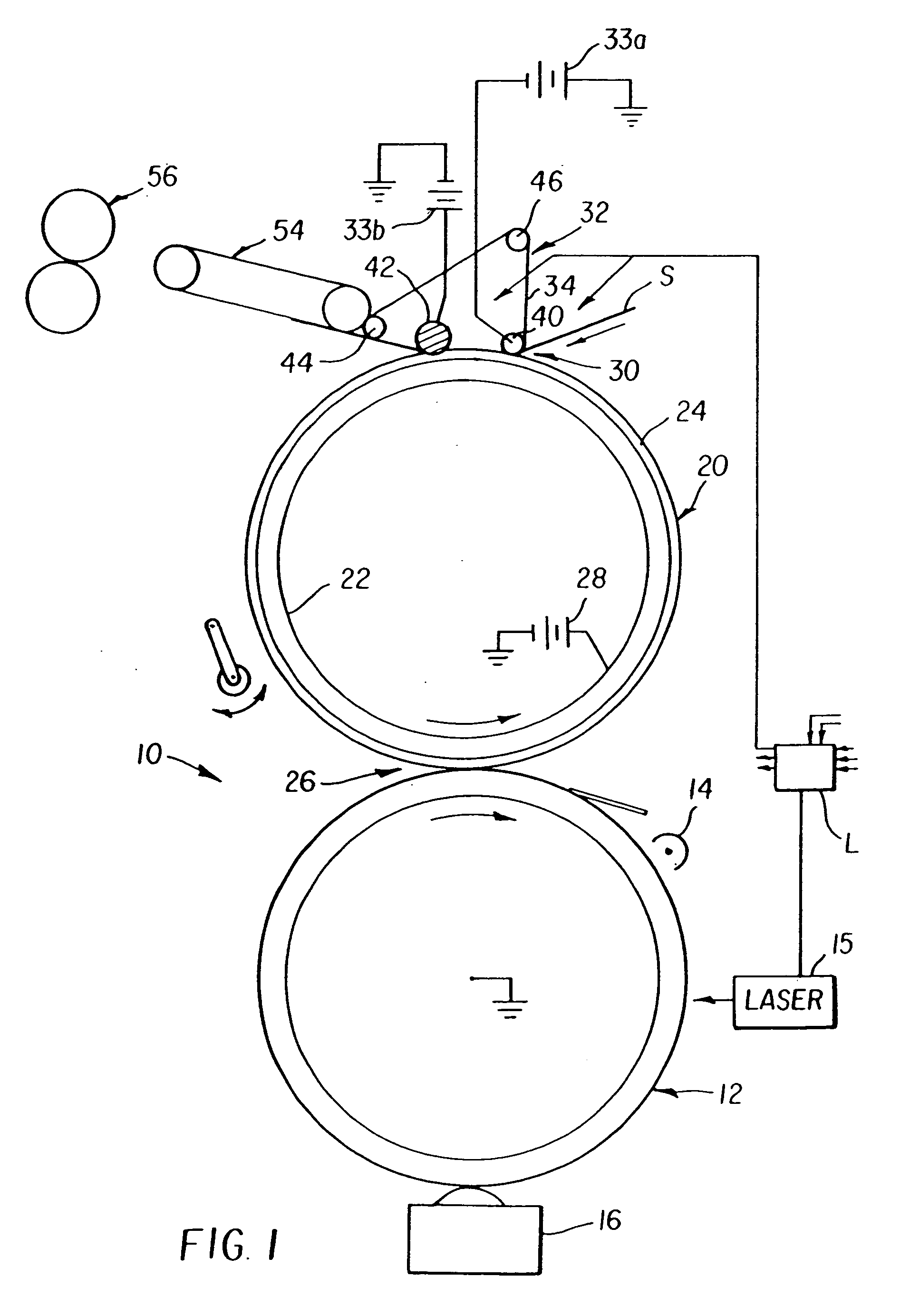

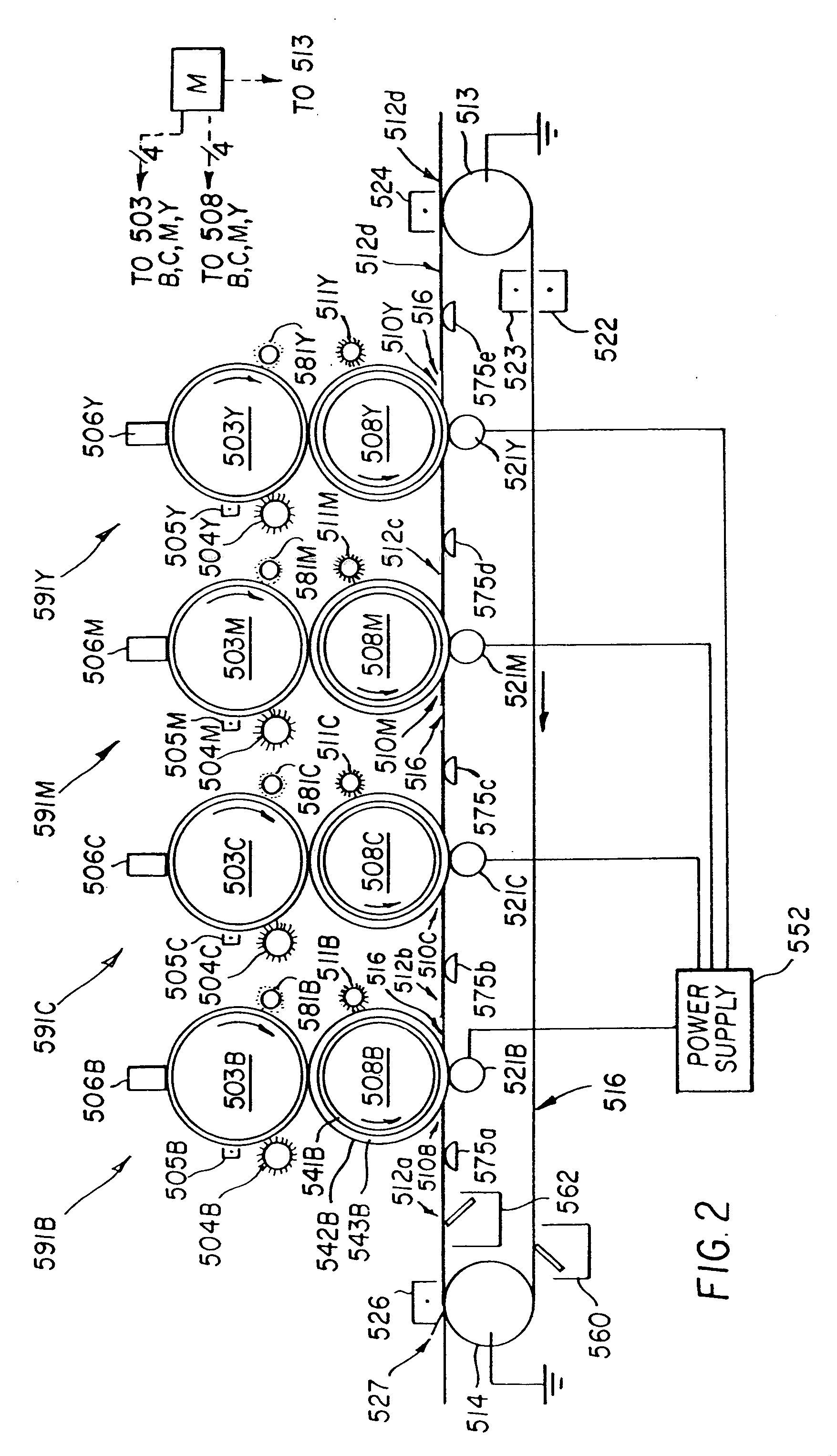

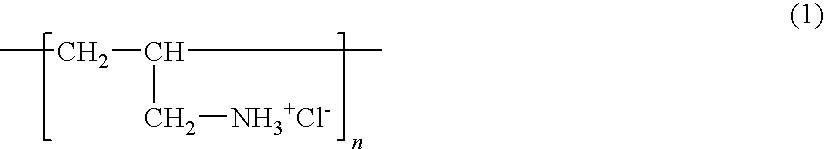

Electrostatographic apparatus having transport member with high friction layer

ActiveUS20060165974A1Eliminate slippageConvenient registrationSynthetic resin layered productsRecord information storageInorganic particleAlumina hydrate

A method for forming a receiver transport member for an electrostatographic reproduction apparatus. The transport member transports receiver members with respect to a fuser assembly and is frictional coupled to a transfer member for driving the transfer member. The method for forming the transport member provides a substrate bearing a high friction layer that includes inorganic particles, with a compound of aluminum selected from the group consisting of aluminum hydroxide, alumina hydrate, aluminum oxide, pseudo-boehmite, boehmite alumina, aluminum salts, and mixtures thereof, dispersed in an organic binder so that the high friction layer is capable of preventing a loss of frictional coupling due to release oil applied to a receiver member bearing a fused toner image.

Owner:EASTMAN KODAK CO

Large-scale, specially shaped mullite-corundum system sintered refractory material product and preparing technique thereof

The invention relates to a large and special shape porzite-corundum series sintering fire proof material product and a manufacturing technique thereof, and the product formulation comprises: 48 to 56 percent of porzite 5 to 1mm, 12 to 22 percent of the porzite or three stone 1 to 0.088mm, 16 to 25 percent of the porzite and three stone fine powder d90 less than 0.088mm, 0 to 18 percent of alumina fine powder d90 less than 0.088mm, 0 to 5 percent of alumina micro powder d95 less than 0.020mm, 0 to 5 percent of zirconium quality micro powder d95 less than 0.015mm, 2 to 5 percent of silicon ash, 2 to 6 percent of alumina hydrate less than 0.088mm, 0 to 5 percent of magnesium additive, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. The materials can be used as fire proof material of the large and special shape porzite-corundum series sintering fire proof material product, and the like, and is used for high-temperature industry of ceramics, glass, and the like.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

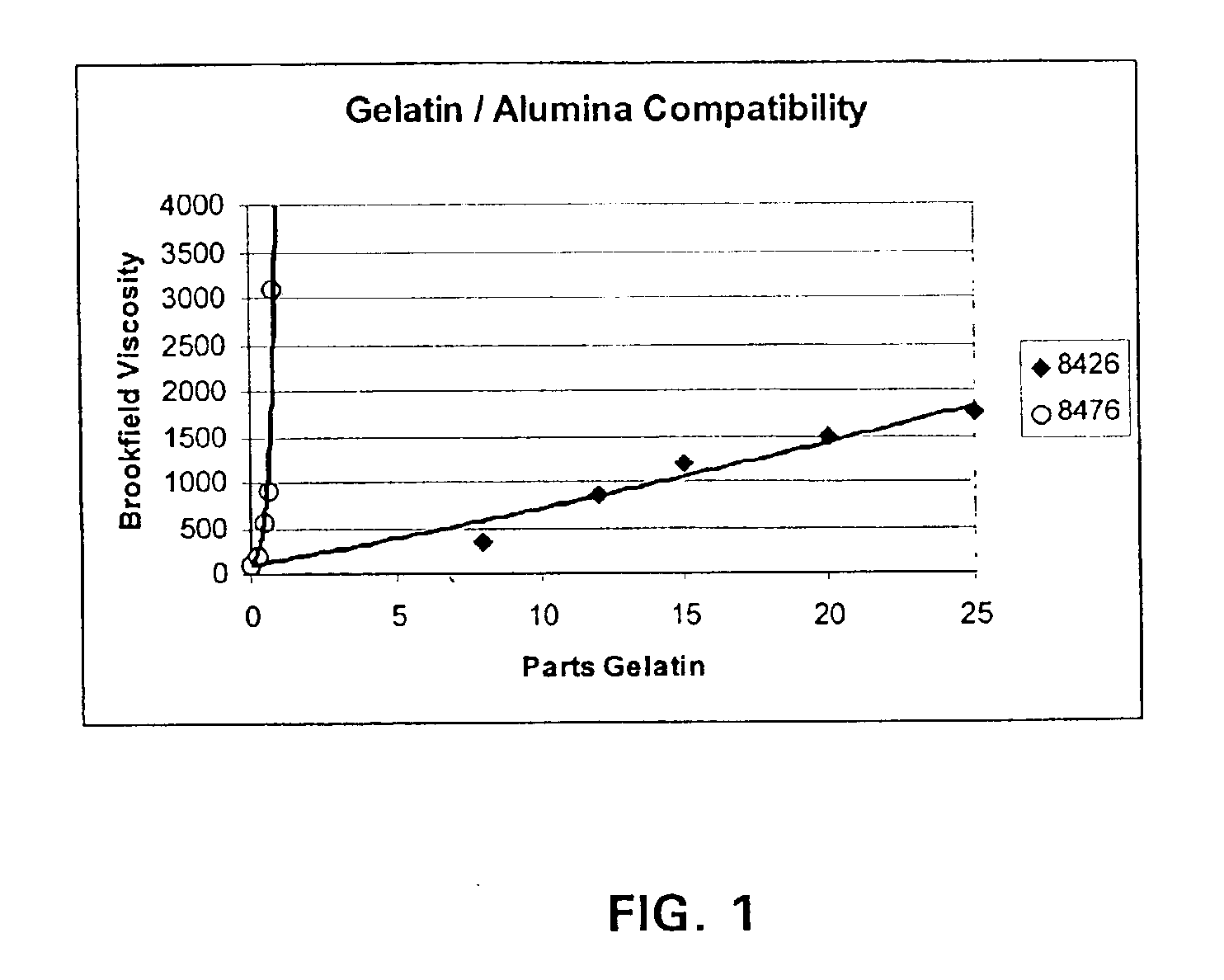

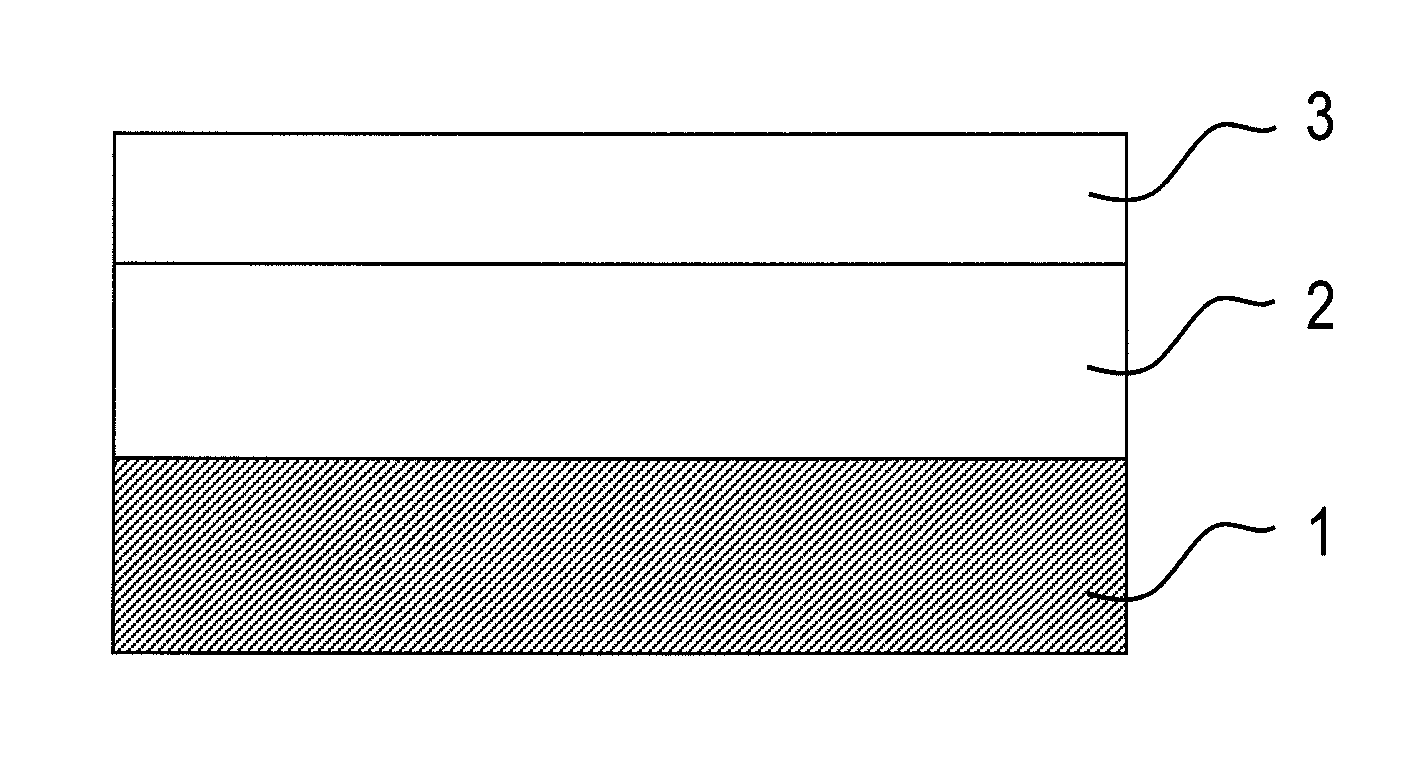

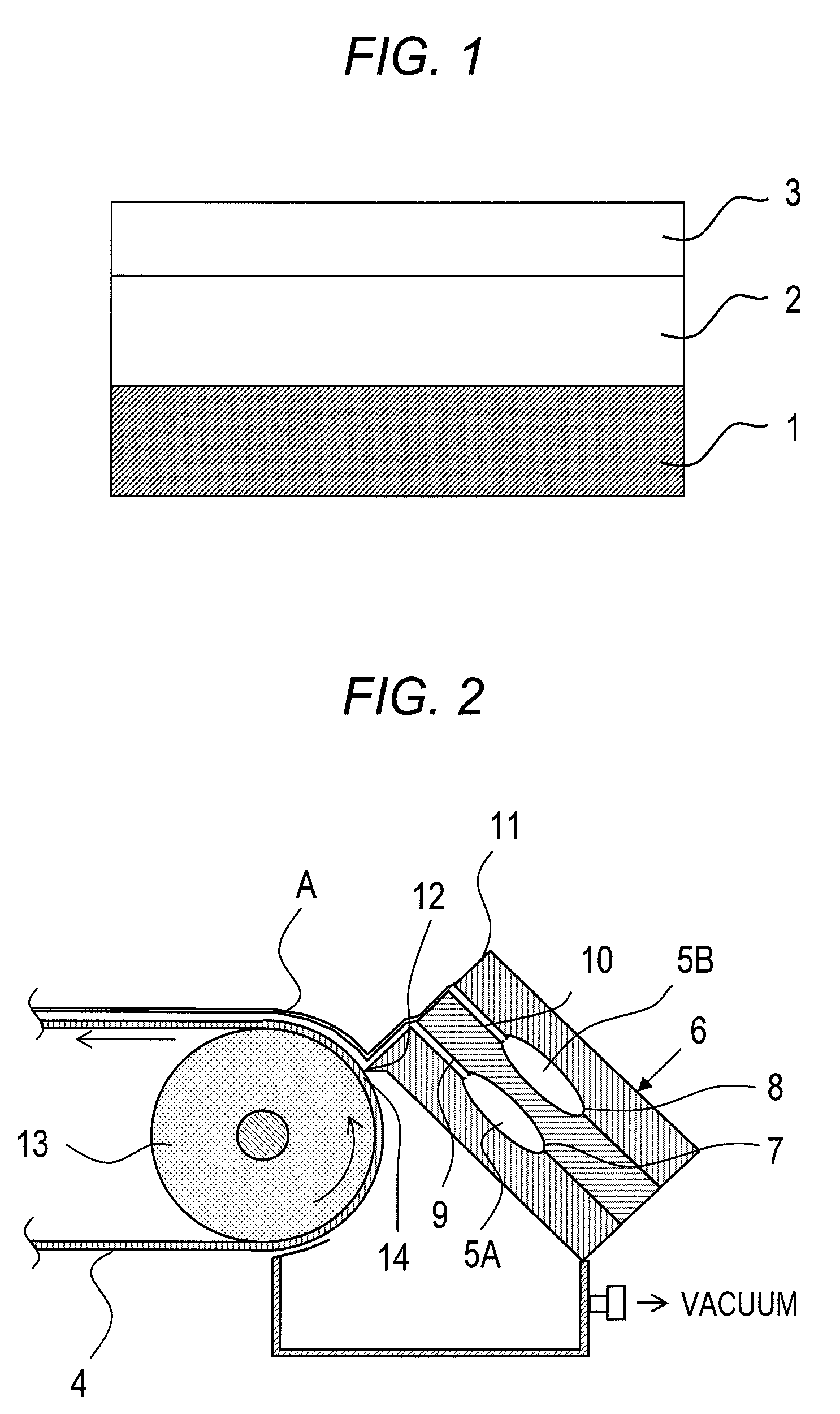

Microporous photo glossy inkjet recording media

InactiveUS6979481B2High glossImprove smoothnessLayered productsCoatingsAlumina hydrateWater insoluble

The present invention provides microporous photo quality glossy inkjet receiving media comprising a substrate, an absorbent basecoat layer, and an ink-receptive topcoat. The absorbent basecoat layer is primarily a combination of pigment and binder, and may include deformable particles, such as core-shell polymeric pigments. The ink-receptive topcoat is composed primarily of alumina hydrate, gelatin, and a water-insoluble cationic polymer. The present invention also provides a method for increasing the gloss and surface smoothness presented by the topcoat of a printing medium by including deformable particles in an underlying basecoat followed by calendering of the printing medium. Further, the present invention provides combination matte and gloss inkjet printing media, comprising matte basecoats at least partially coated with the aforementioned ink-receptive topcoat.

Owner:MOHAWK FINE PAPERS

Method for making a high solids interactive coating composition and ink jet recording medium

InactiveUS6713550B2Faster drying timeImprove water resistanceNon-fibrous pulp additionDuplicating/marking methodsAlumina hydrateWhitening Agents

A coating composition for an ink jet recording medium comprises an aqueous suspension of binder, a cationic fixing agent, an absorptive pigment, and a sizing agent. The coating composition combines solids content of greater than 30% with good runnability. The composition may preferably be dispersed at pH values in the range of 4.5 to 7.0. The pigment is preferably a mixture of 50% or more silica gel having a pore volume of 0.5-2.0 cc / g, and 10% or more alumina or alumina hydrate. A method for making down a composition has sequential steps of dispersing a binder in water, adding a cationic fixing agent, dispersing an alumina and an absorptive silica, adding a fluorescent whitening agent, cooling the composition, and finally adding a sizing agent.

Owner:VERSO MINNESOTA WISCONSIN LLC

Ink jet recording medium and method of producing the same

InactiveUS7846516B2Good prevention effectGood effectPattern printingThermographyAlumina hydrateEngineering

The invention provides an ink jet recording medium which attains the prevention of the bronzing of cyan ink and the prevention of the migration of magenta ink at the same time and is excellent in image characteristics. The ink jet recording medium comprises a substrate and an ink-receiving layer provided with at least an upper layer as the outermost layer and a lower layer as a layer lying just under the upper layer, both layers having a porous structure formed of an alumina hydrate and a binder, wherein both of the upper and lower layers contain an alkylsulfonic acid and only the lower layer contains a cationic polymer.

Owner:CANON KK

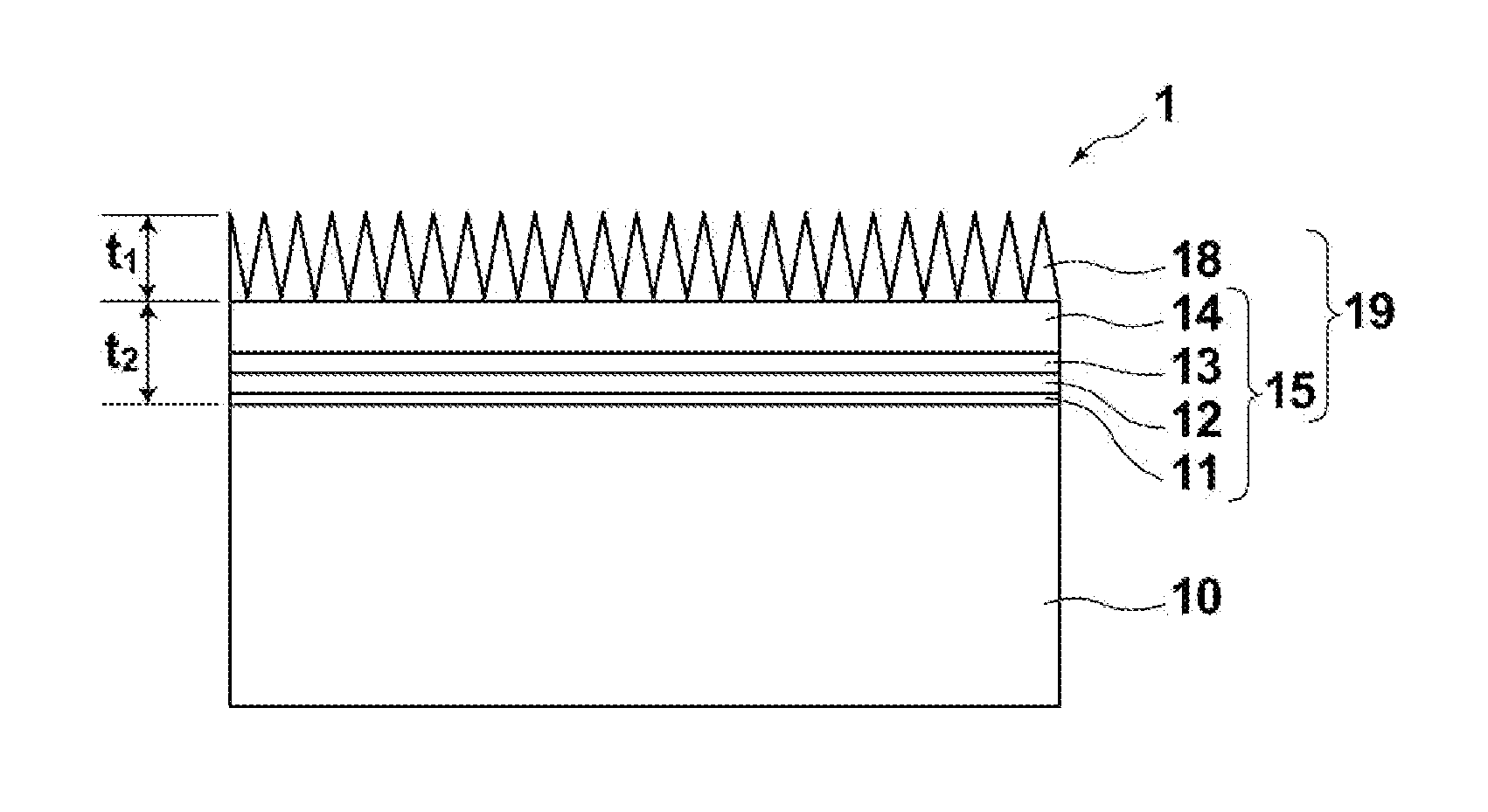

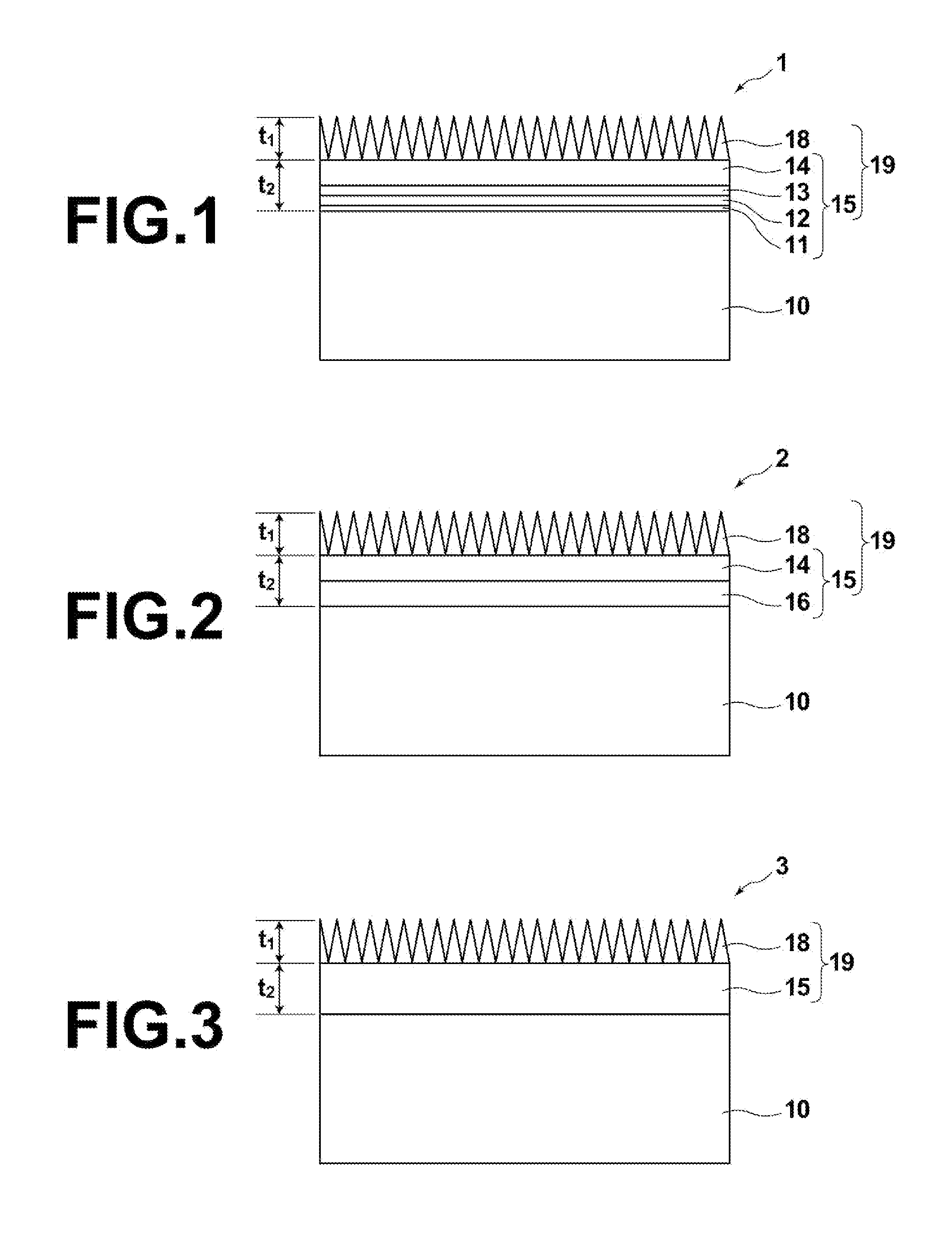

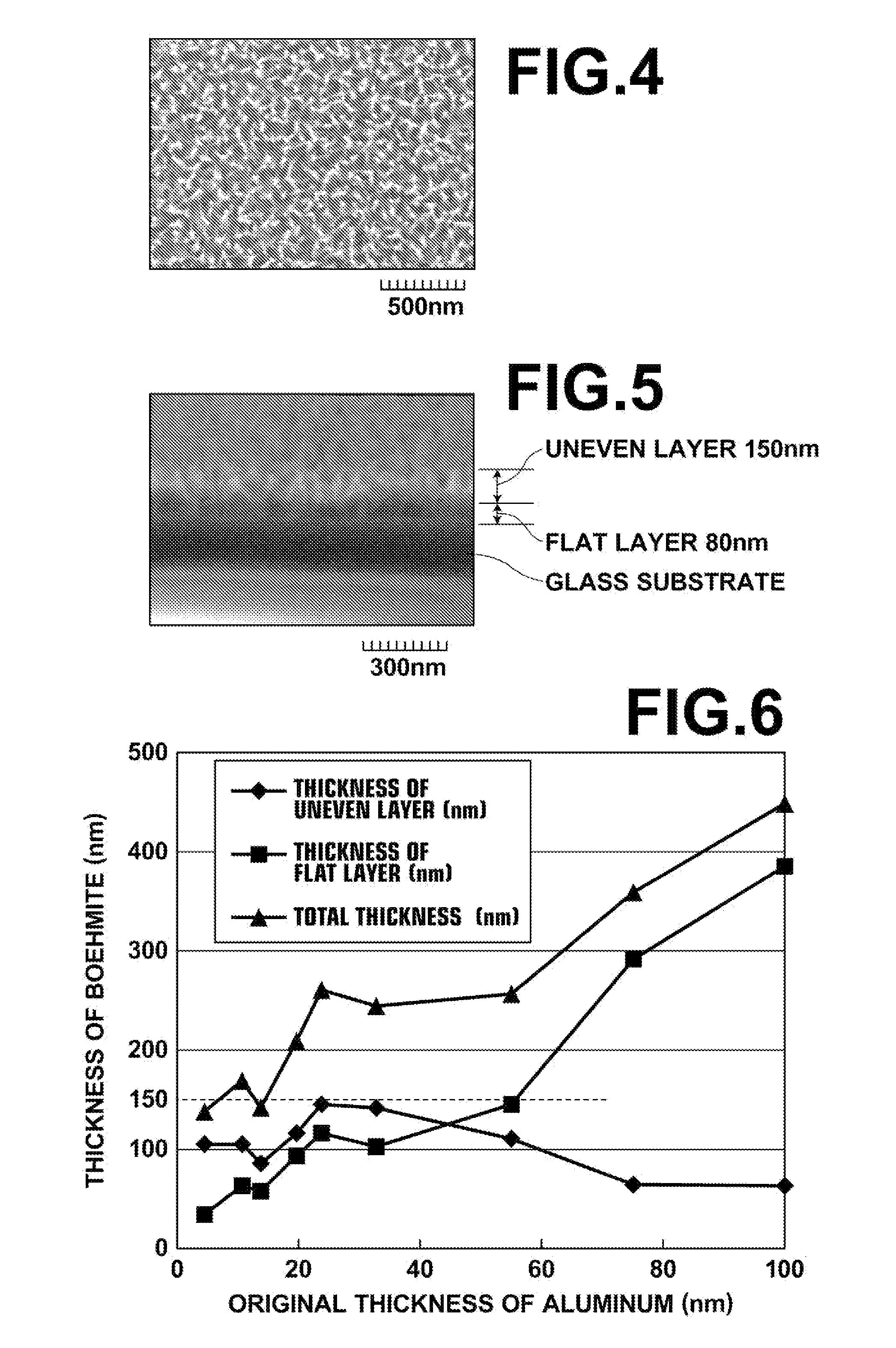

Optical member with antireflection film, and method of manufacturing the same

InactiveUS20150219798A1Increase choiceHigh refractive indexLayered productsVacuum evaporation coatingAlumina hydrateRefractive index

An antireflection film including a transparent thin film layer, and a transparent fine uneven layer whose main component is an alumina hydrate, which layers are formed in this order on a surface of a transparent substrate, is provided. The transparent thin film layer has an intermediate refractive index between the refractive index of the transparent substrate and the refractive index of the fine uneven layer, and the transparent thin film layer includes at least a nitride layer or an oxynitride layer.

Owner:FUJIFILM CORP

Recording material for ink-jet

According to the present invention, in an ink-jet recording material in which at least two ink-receptive layers containing inorganic fine particles and a hydrophilic binder are provided on a support, an ink-jet recording material wherein an ink-receptive layer (A) nearer to the support contains fumed silica, and an ink-receptive layer (B) apart from the support contains alumina or alumina hydrate is provided.

Owner:MITSUBISHI PAPER MILLS LTD

Printing medium, production process thereof and image-forming process

Disclosed herein is a printing medium provided on a base material with a porous ink-receiving layer which comprises, as principal components, an alumina hydrate having a boehmite structure and a binder, wherein when measuring with an ink containing 0.1% by weight of a surfactant, the time required to absorb 30 ng of an ink is 400 milliseconds or shorter, the dye-adsorbing capacity falls within a range of from 900 to 2,000 mg / m2, and the index of dye-adsorbing rate falls within a range of from 0.0 to 5.0.

Owner:CANON KK

Method of manufacturing flake aluminum oxide using microwave

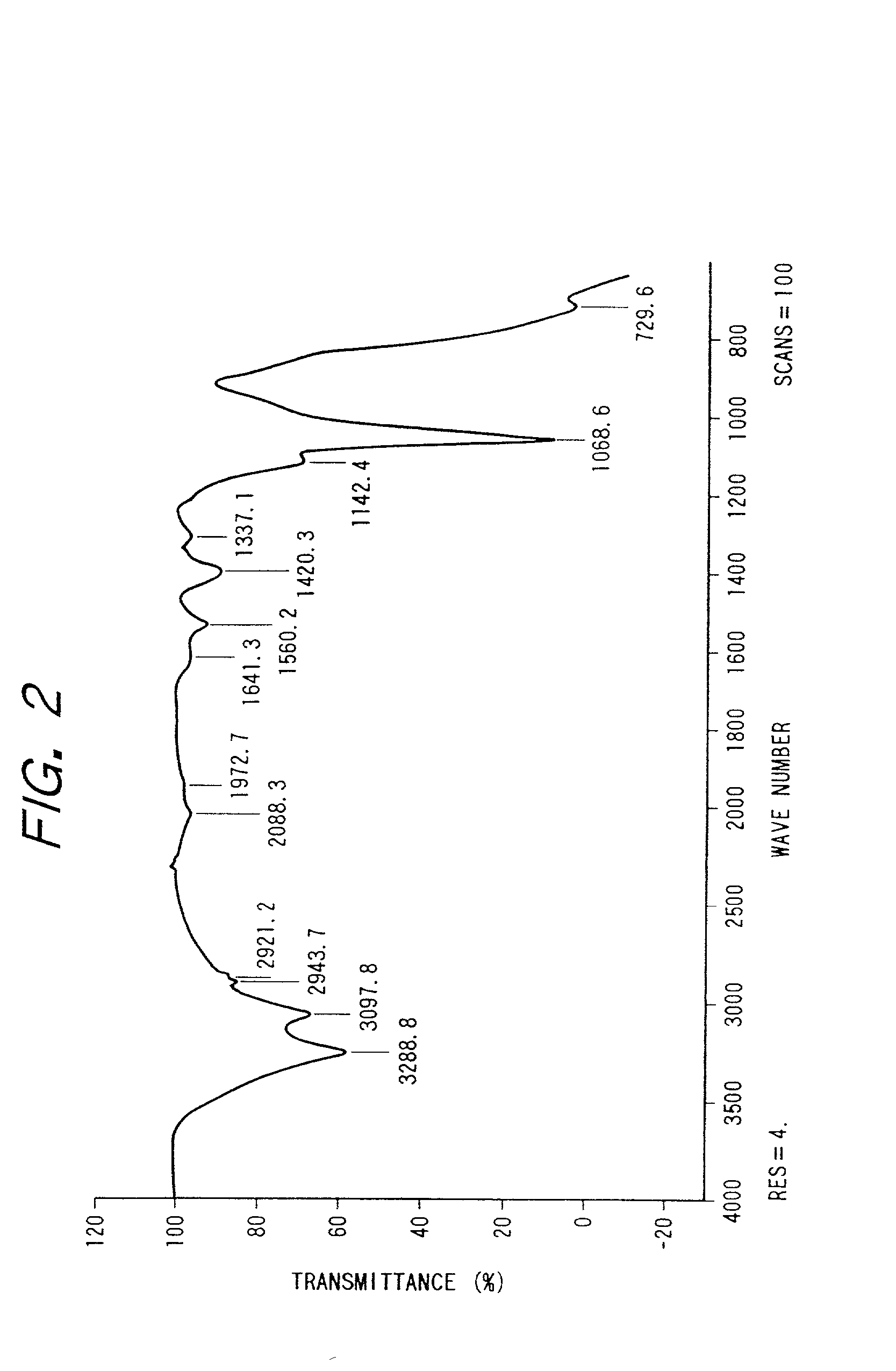

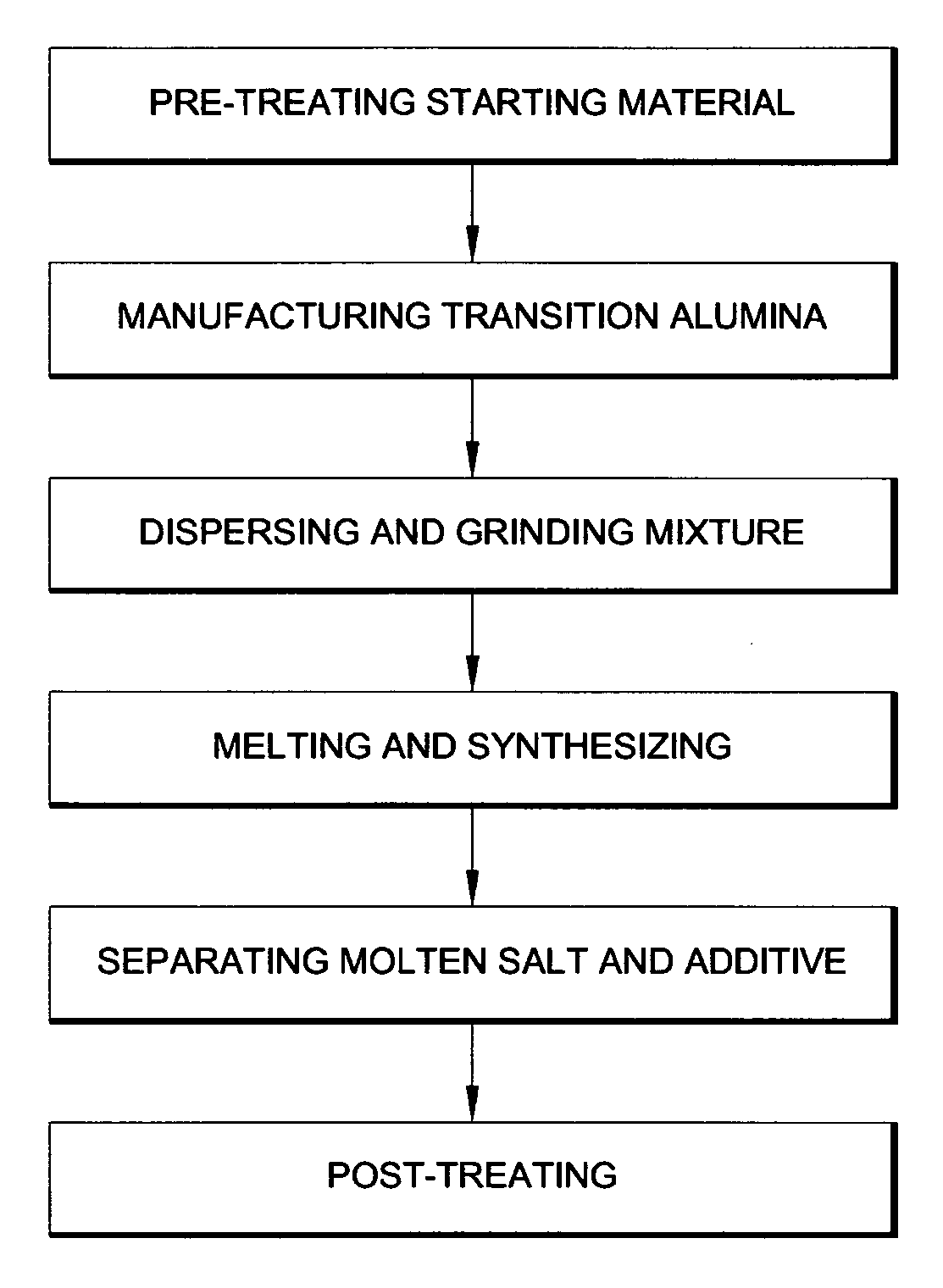

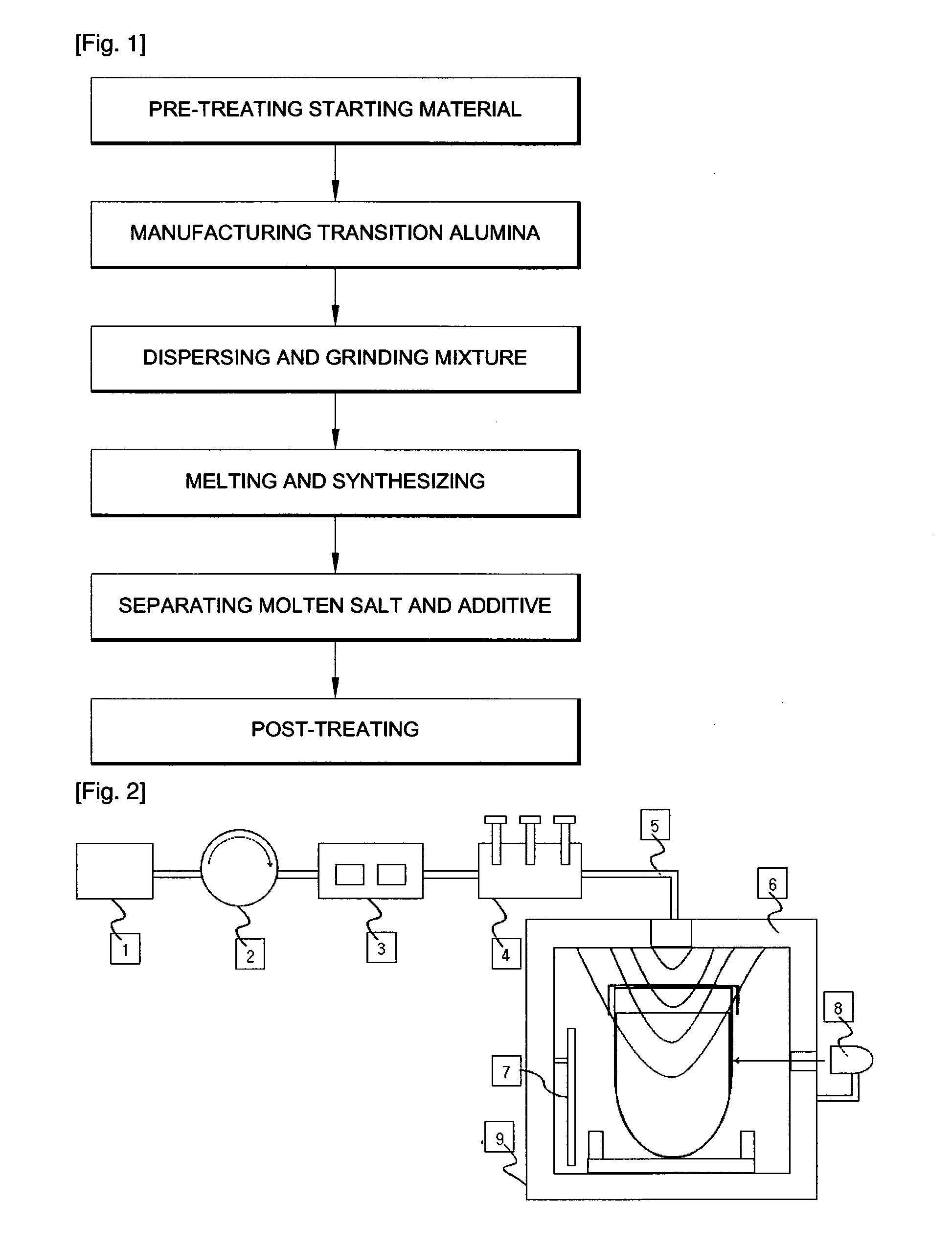

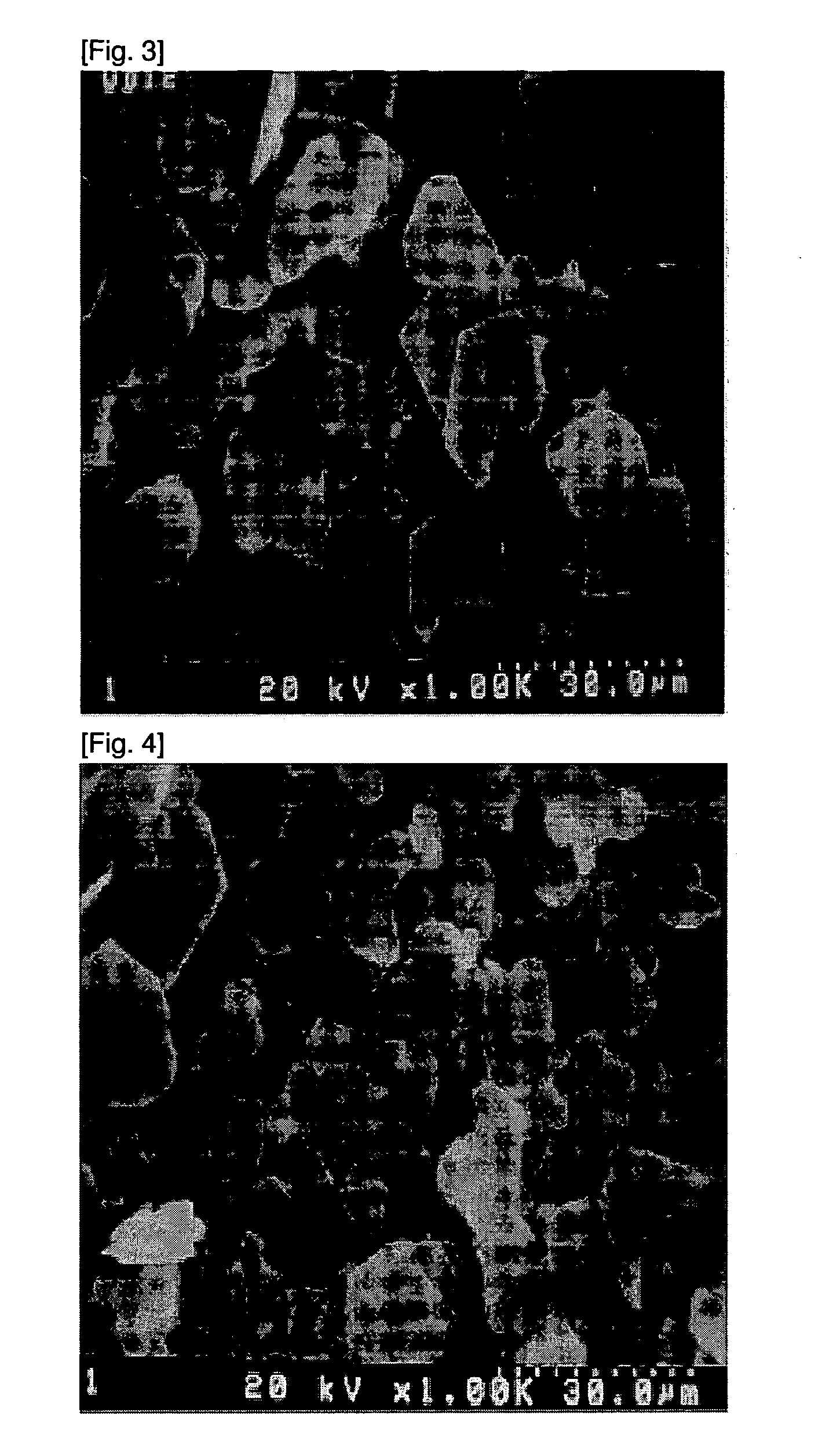

ActiveUS20110052485A1Simple manufacturing methodImprove production yieldAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesMicrowaveAlumina hydrate

The present disclosure suggests a method of manufacturing flake aluminum oxide using a microwave including: performing a pre-treatment on a starting material by grinding the starting material such as alumina hydrate, aluminum salt or the like and classifying particles with an appropriate size; manufacturing transition alumina by performing a heat treatment by means of heating the pre-treated starting material; mixing the transition alumina with molten salt and an additive and then dispersing and grinding the mixed compounds; melting and synthesizing flake aluminum oxide by heating the dispersed and grinded mixture with a microwave as a heating source; separating the molten salt and the additive from the synthesized aluminum oxide; and performing a post-treatment on the flake aluminum oxide by removing a foreign substance such as an additive residue stuck to a surface of a crystal particle of the separated flake aluminum oxide.

Owner:TCERA CO LTD

Process for producing spherical aluminum nitride powder and spherical aluminum nitride powder produced by the same process

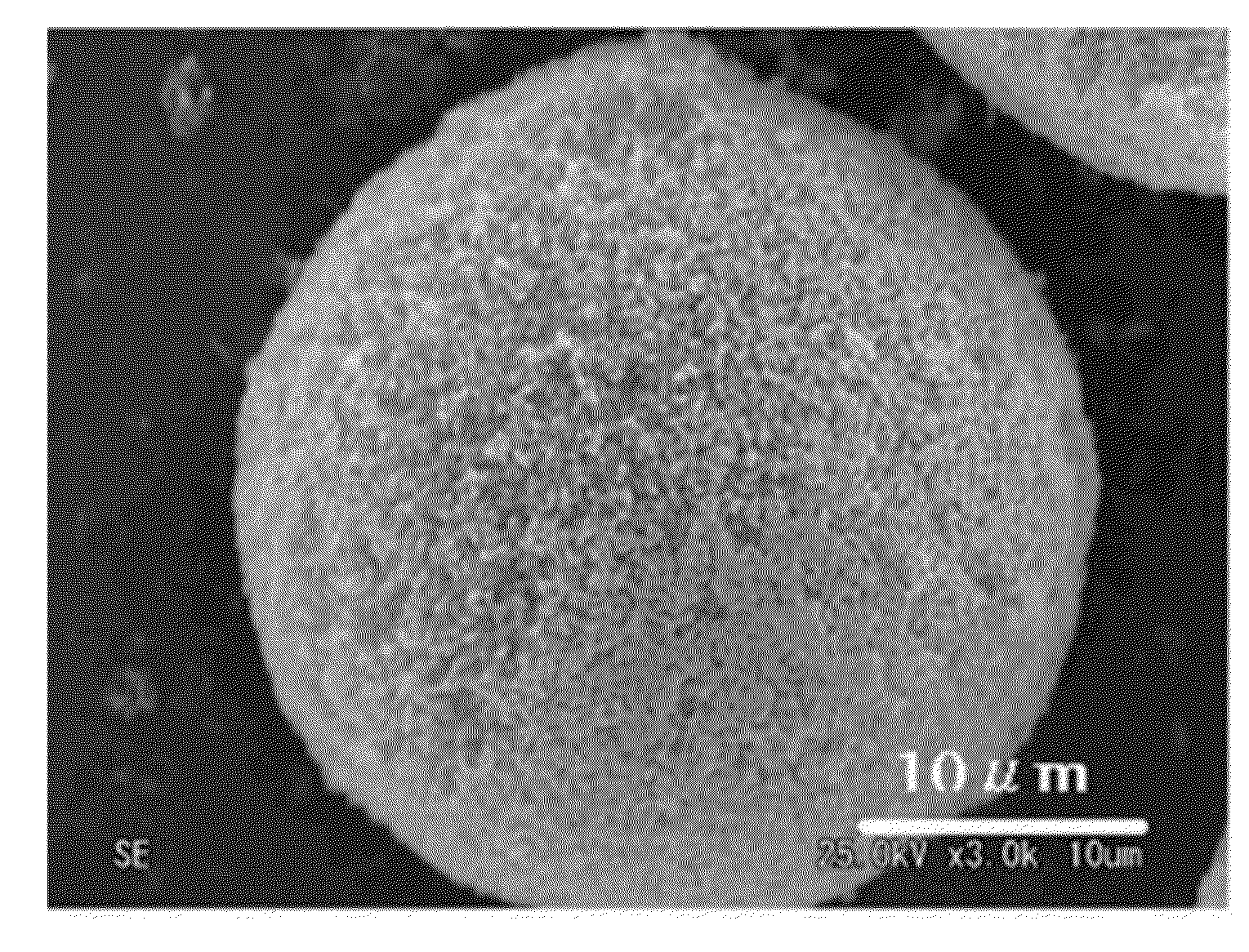

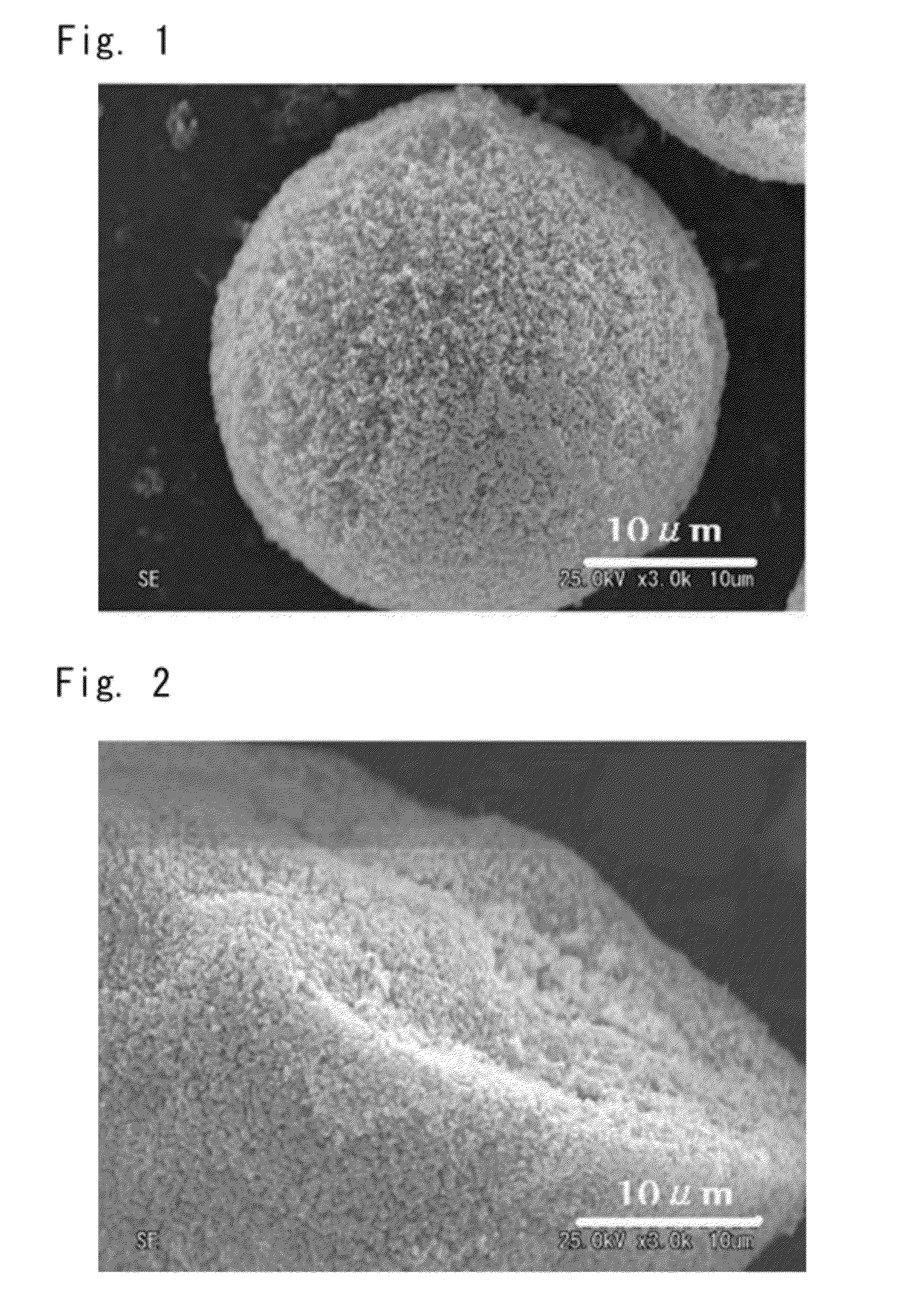

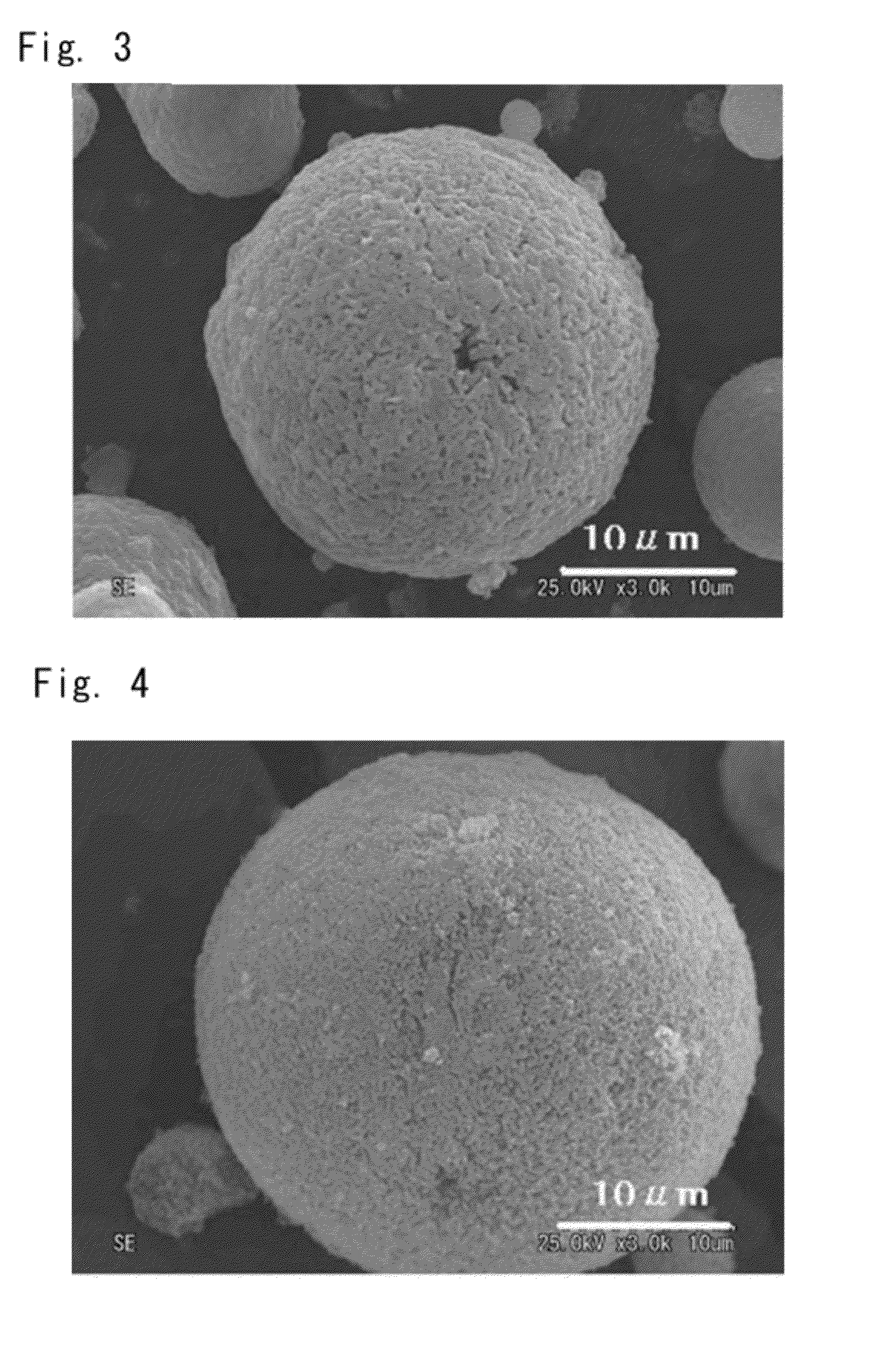

ActiveUS20120258310A1Efficient productionLarge particle sizeNitrogen compoundsSynthetic resin layered productsAlumina hydrateGlobular shaped

[Problems] To provide a process capable of efficiently producing a spherical aluminum nitride powder having a size most suited for use as a filler, and having a high sphericalness and a large particle strength.[Means for Solution] A spherical aluminum nitride powder is produced by using a spherical granulated product of an alumina powder or an alumina hydrate powder as a starting material, and feeding the spherical granulated product to the step of reductive nitrogenation so as to be reductively nitrogenated.

Owner:TOKUYAMA CORP

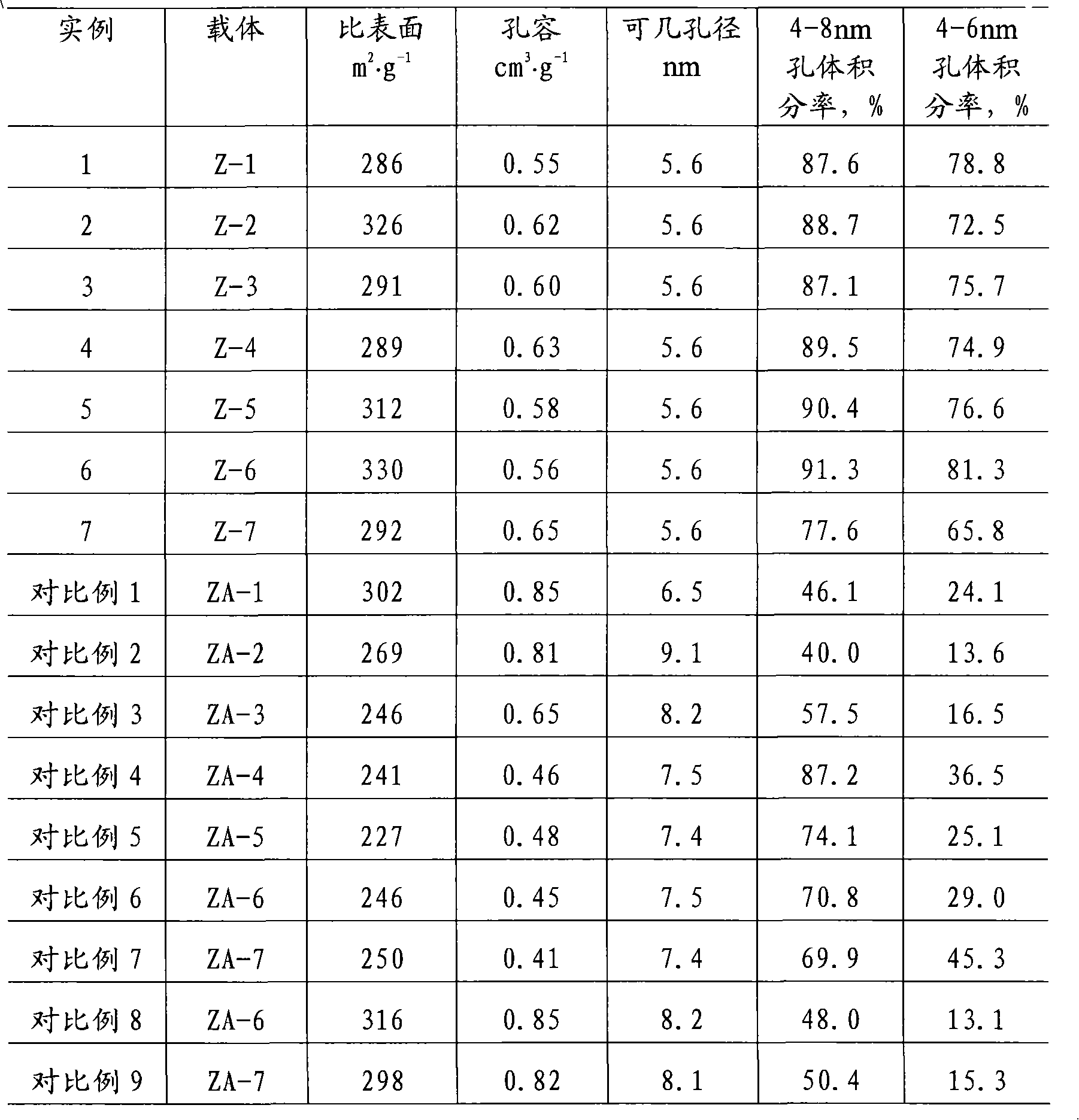

Alumina carrier and preparation method thereof

The invention relates to an alumina carrier and a preparation method thereof. The alumina carrier is characterized in that the specific surface area is between 250 and 380 m<2> / g and the pore volume is between 0.4 and 0.8 mL / g, and the pore volume of a hole with the pore diameter of 4 to 6 nanometers accounts for at least 50 percent of the total pore volume. The preparation method comprises the following steps: a) under a reaction condition of sufficiently depositing aluminum, depositing the aluminum in an aqueous solution containing an aluminum compound; b) separating, washing and drying thedeposit obtained in the step a) so as to obtain alumina hydrate; c) mixing the alumina hydrate obtained in the step b) with glucose, an acid and water, wherein the dosage of the glucose allows the weight ratio of the glucose to the alumina in the mixture to be between 5 and 35 percent, and the dosage of the acid allows the weight ratio of the acid to the alumina in the mixture to be between 0.5 and 3.5 percent; and d) drying and calcinating the mixture obtained in the step c) to obtain the alumina carrier. The alumina carrier can be used as a catalyst carrier for light fractions or other smallmolecule raw materials such as gasoline, naphtha and the like to take part in reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ink jet recording medium

ActiveUS20110256324A1Suppress generationImproving ink absorbencyCoatingsThermographyAlumina hydrateWater soluble

In an ink jet recording medium having at least two ink receiving layers, the total content of boric acid, a borate, and a water-soluble zirconium salt of a lower ink receiving layer located close to a support substrate to the total content of alumina and an alumina hydrate thereof is higher than the total content of boric acid, a borate, and a water-soluble zirconium salt of an upper ink receiving layer located apart from the support substrate to the total content of alumina and an alumina hydrate thereof.

Owner:CANON KK

Article, ink recording medium, ink-jet recording medium and production process thereof

InactiveUS7625614B2Avoid yellowingPreventing the yellowing of the articlesThermographyAlumina hydrateSulfinic acid

An article has a constitution such that yellowing (e.g., yellowing of white portions upon storage in a resin file or the like) of the article can be continuously prevented over a long period of time even when it has a porous site composed of a pigment, such as an alumina hydrate, in an ink-receiving layer. An article, an ink recording medium and an ink-jet recording medium comprising a phenolic compound having a sulfonyl group and a diffusible sulfinic acid salt, and a production process of the ink-jet recording medium are provided.

Owner:CANON KK

Method for manufacturing an inkjet recording medium

InactiveUS20090087568A1High print densitySuppressing coating defectDuplicating/marking methodsPretreated surfacesPseudoboehmiteAlumina hydrate

The present invention provides a method for manufacturing an inkjet recording medium having at least applying, on a support, a coating liquid A, a coating liquid B and a coating liquid C in this order from the support to form an ink receiving layer. The coating liquid A contains at least a crosslinking agent. The coating liquid B contains at least a vapor-phase-process silica and a water-soluble binder, in which the content of a pseudo boehmite alumina hydrate with respect to the content of the vapor-phase-process silica in the coating liquid B is less than 3% by mass, and the content of a crosslinking agent with respect to the content of the vapor-phase-process silica in the coating liquid B is less than 3% by mass. The coating liquid C contains at least a pseudo boehmite alumina hydrate and a water-soluble binder.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com