Alumina carrier and preparation method thereof

A technology of alumina carrier and alumina, which is applied in the direction of catalyst carrier, chemical instrument and method, chemical/physical process, etc., can solve the problem of not being able to provide pore distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] The slurry of hydrated alumina is obtained by the neutralization reaction of sodium metaaluminate and carbon dioxide gas.

[0039] The prepared high-concentration NaAlO containing 210g / L alumina and a caustic coefficient of 1.62 2 solution with deionized water to prepare Al 2 o 3 Transfer 5L of the solution with a concentration of 40±2g / L to a gelling reactor with a total volume of 8L. The reactor has an aspect ratio of 8 and a CO 2 gas distributor. Control the temperature of the solution at 25±5°C, and feed CO with a concentration of 90V% from the bottom of the reactor 2 gas for gelation reaction, the gelation temperature is controlled at 20-40°C, and the CO 2 The gas flow rate is 15±2L / min, and the pH value at the end of the reaction reaches 8.0-8.5 within 4-6 minutes. When the pH value of the process drops to the required range, stop the aeration and end the gelation reaction. The resulting slurry was filtered with a vacuum filter, and after the filtration was ...

example 2

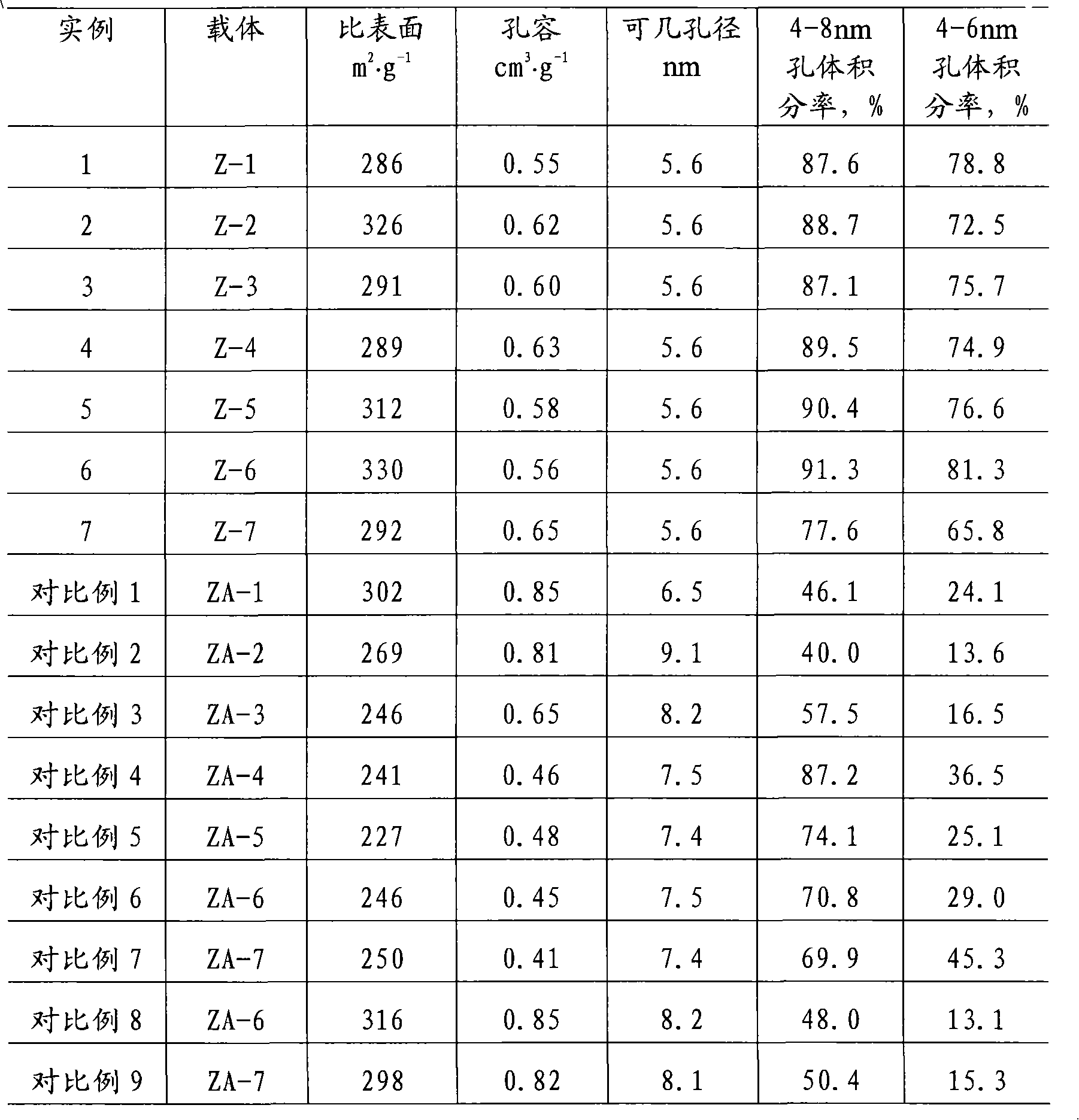

[0041] The amorphous hydrated aluminum oxide used is the same as in Example 1, and the preparation method of the carrier is also the same as in Example 1, but the amount of glucose and acid added during extruding are different from Example 1, and the specific formula is shown in Table 1. Put the obtained wet carrier strip into an oven at 120°C to dry for more than 4 hours, then put it into a muffle furnace and bake it at 600°C for 4 hours, and the obtained sample is subjected to N 2 Adsorption analysis specific surface area, pore volume and pore size distribution are shown in Table 2.

example 3

[0043] The amorphous hydrated alumina used is the same as in Example 1, and the carrier preparation method is also the same as in Example 1, but the amount of acid and glucose added during extruding are different from Example 1. The specific formula is shown in Table 1. Put the obtained wet carrier strip into an oven at 120°C to dry for more than 4 hours, then put it into a muffle furnace and bake it at 600°C for 4 hours, and the obtained sample is subjected to N 2 Adsorption analysis specific surface area, pore volume and pore size distribution are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com