Alumina coated fluorescent powder and its coating method

A technology of phosphor powder and alumina, applied in the field of phosphor powder, can solve the problems of difficulty in controlling the thickness of the coating layer, long coating period, difficult industrialization, etc., to improve the resistance to thermal degradation and work degradation, and the continuous coating layer. Uniform, strong film bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

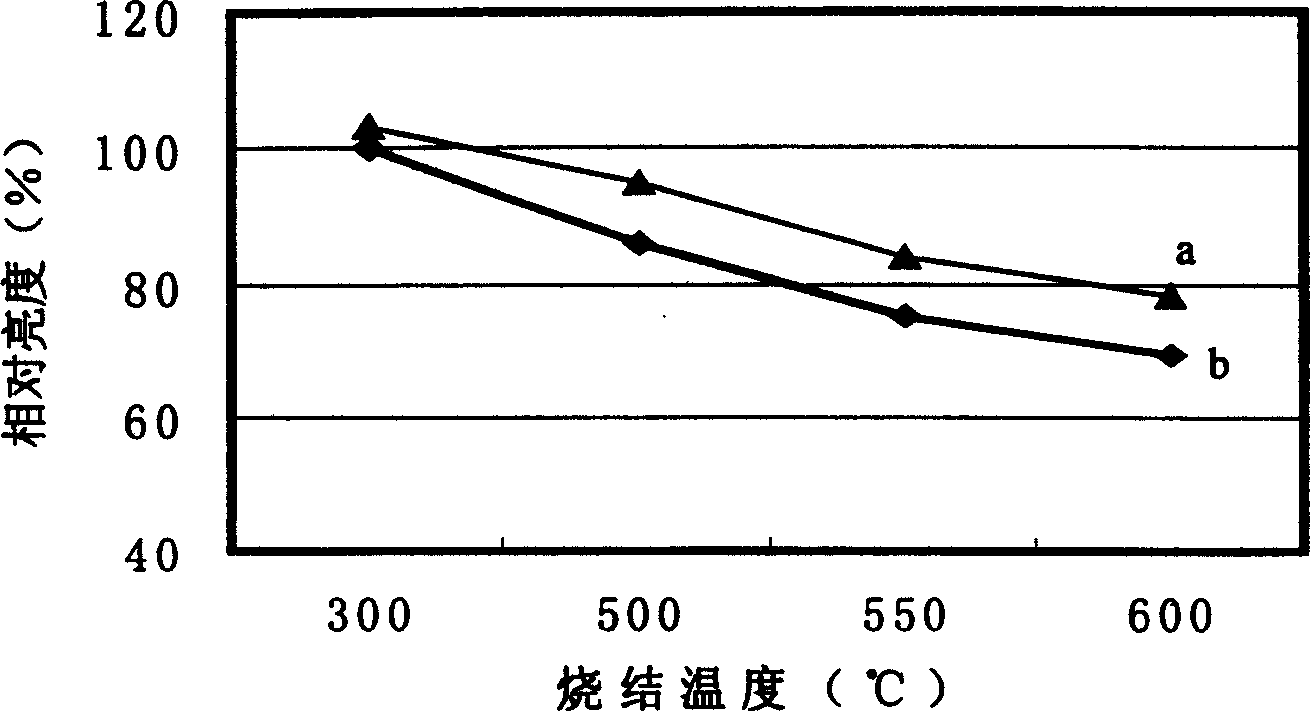

Image

Examples

Embodiment 1

[0026] Alumina-coated phosphor powder for color plasma flat-panel displays, characterized in that the surface of the phosphor powder is coated with Al 2 o 3 film, in Al 2 o 3 You can choose to coat TiO on the outside of the film 2 Membrane, In 2 o 3 Membrane, ZrO 2 film or rare earth oxide La 2 o 3 The film can also be fully covered in turn. In this example, the Al 2 o 3 The film is coated with TiO 2 film, coated with In on the phosphor surface 2 o 3 film, coated with ZrO on the phosphor surface 2 film, and finally, coating the surface of the phosphor with La 2 o 3 .

Embodiment 2

[0028] A film coating method for implementing the above alumina-coated phosphor:

[0029] 1) Use a conjugate acid-base system with a pH value between 4.5 and 6.0 to make a buffer, and the concentration of the buffer is greater than 0.1M and less than 1M, according to Al 2 o 3 The weight ratio with phosphor is (0.25~20): 100 ratio, in the present embodiment, can press Al 2 o 3 The weight ratio to the phosphor is 0.25:100, 15:100, 2:100, 7:100, or 12:100, and the corresponding amount of water-soluble aluminum salt is weighed and prepared into a water-soluble aluminum salt with a concentration of 0.01-1.0M. Aluminum salt solution, for example: to prepare a water-soluble aluminum salt titration solution with a concentration of 0.01M, 1M, 0.07M, 0.12M, 0.56M or 0.82M, the above-mentioned conjugate acid-base system can have a pH value of 4.75 and a concentration of 0.1M acetic acid-sodium acetate conjugate acid-base system, citric acid-NaOH conjugate acid-base system with a pH va...

Embodiment 3

[0035] Weigh 50g of BaMgAl for PDP 10 o 17 :Eu 2+ Phosphor powder (BAM) was put into NaOH solution with a concentration of 0.5M, soaked for 24 hours, then separated and dehydrated with a centrifuge, and washed with distilled water until the supernatant was neutral.

[0036] Weigh 23g of NaAc solid and dissolve it in a small amount of distilled water, then add 27ml of concentrated HAc, then add 5ml of 0.1% Tween 80 dispersant, and finally add water to dilute to 500ml to obtain a buffer solution with pH=4.5. Add 10 g of alkaline pretreated BAM blue powder to the buffer solution, disperse with ultrasonic waves for 10 min, and heat to 30°C in a water bath. Weigh 1.88gAl(NO 3 ) 3 9H 2 O solid solution is made into 100ml solution, is added in the fluorescent powder coating mother liquor with the drop rate of 5ml / min, aging 30min after finishing, is that the NaOH solution of concentration is 0.05M adjusts the pH value of mother liquor to 6.5, centrifuges afterwards, washes with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com