Pseudo thin allophane and its preparation method

A technology of pseudo-boehmite and hydrated alumina, applied in alumina/aluminum hydroxide and other directions, can solve the problems of complex process operation and achieve the effect of concentrated pore distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

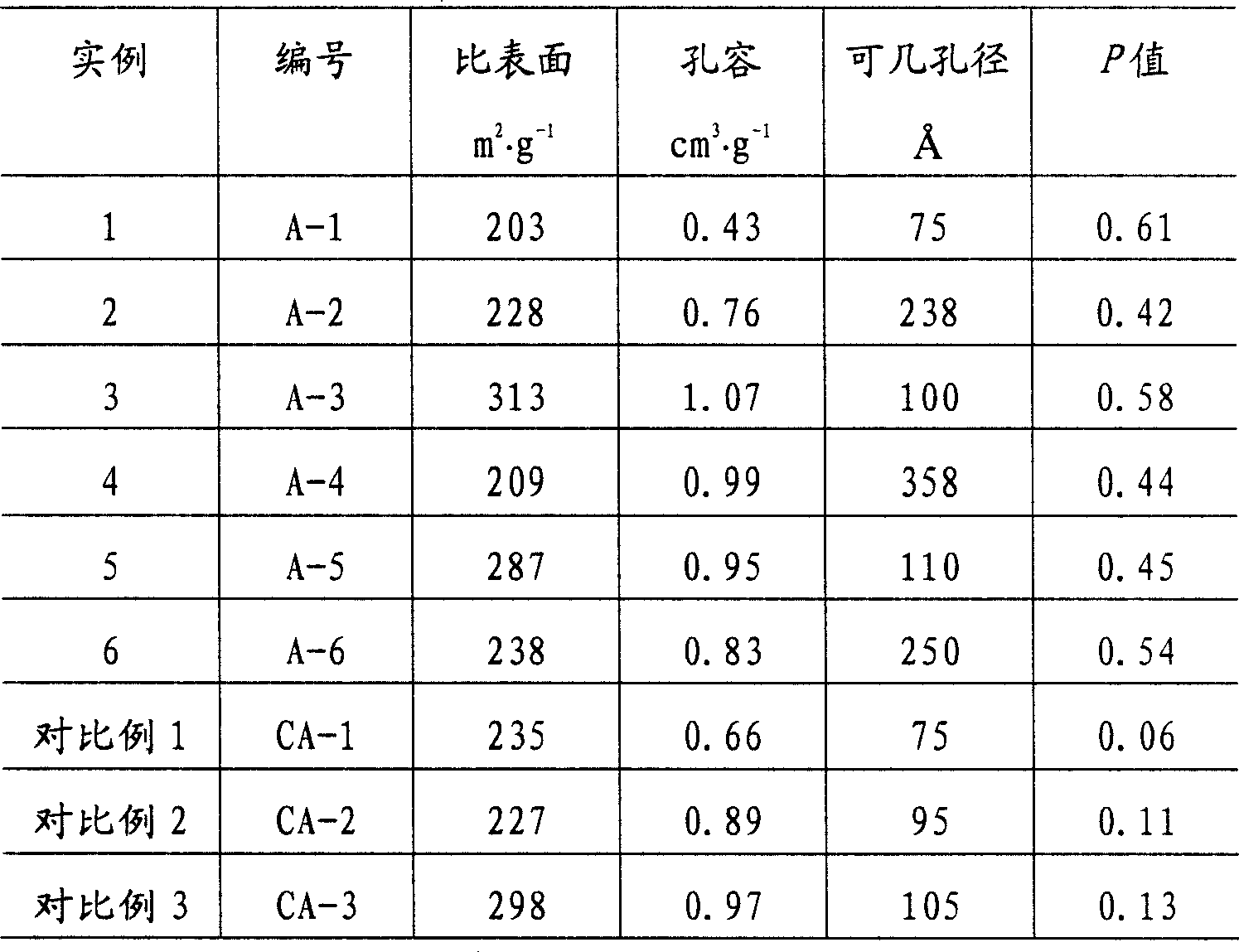

Examples

example 1

[0029] In a 2-liter reaction tank, 600 milliliters of aluminum sulfate solution with a concentration of 96 grams per liter and an aqueous ammonia solution of 8% were added in parallel to carry out reaction precipitation, and then filtered (using XRD to characterize that the hydrated aluminum oxide precipitate is an amorphous structure) ), the reaction temperature is 40° C., and the flow rate of the ammonia solution is controlled so that the pH of the reaction system is 5. In a 2 liter reaction tank, filter cake, deionized water and ammonia water (concentration is 25%, Beijing chemical plant product) are mixed, beating, and the consumption of ammonia water makes the pH value of slurry be 9.5, and slurry ages at temperature 55 ℃ 60 Minutes later, the filter cake was beaten and washed twice with deionized water, and the filter cake was dried at 120°C for 24 hours to obtain hydrated alumina P1, which was characterized by XRD. P1 had a pseudo-boehmite structure, and P1 was calcined ...

example 2

[0033] In a 2-liter reaction tank, add 600 milliliters of aluminum sulfate solution with a concentration of 48 grams per liter and 8% ammonia solution for reaction and precipitation, and then filter (using XRD to characterize that the hydrated aluminum oxide precipitate is an amorphous structure) ), the reaction temperature was 35° C., and the flow rate of the ammonia solution was controlled so that the pH of the reaction system was 5.8. In a 2-liter reaction tank, filter cake, deionized water and ammonium bicarbonate (product of Beijing Yili Fine Chemicals Co., Ltd.) are mixed and beaten. The amount of ammonia water makes the pH value of the slurry 9.5, and the slurry is heated at a temperature of 35°C. After aging for 240 minutes, filter, the filter cake was beaten and washed twice with deionized water, and the filter cake was dried at 120°C for 14 hours to obtain hydrated alumina P2, which was characterized by XRD. P2 had a pseudo-boehmite structure. Calcined for 4 hours to...

example 3

[0035] In a 2-liter reaction tank, 600 milliliters of aluminum sulfate solution with a concentration of 96 grams per liter and an aqueous ammonia solution of 8% were added in parallel to carry out reaction precipitation, and then filtered (using XRD to characterize that the hydrated aluminum oxide precipitate is an amorphous structure) ), the reaction temperature is 50°C, and the flow rate of the ammonia solution is controlled so that the pH of the reaction system is 4.5. In a 2-liter reaction tank, filter cake, deionized water and sodium carbonate (chemically pure, Beijing Yili Fine Chemicals Co., Ltd. product) are mixed and beaten, and the amount of sodium carbonate makes the pH value of the slurry be 8.5, and the slurry is at temperature After aging at 35°C for 30 minutes, filter, the filter cake was beaten and washed twice with deionized water, and the filter cake was dried at 120°C for 14 hours to obtain hydrated alumina P3, which was characterized by XRD. P3 had a pseudo-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com