Patents

Literature

59 results about "Live feed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

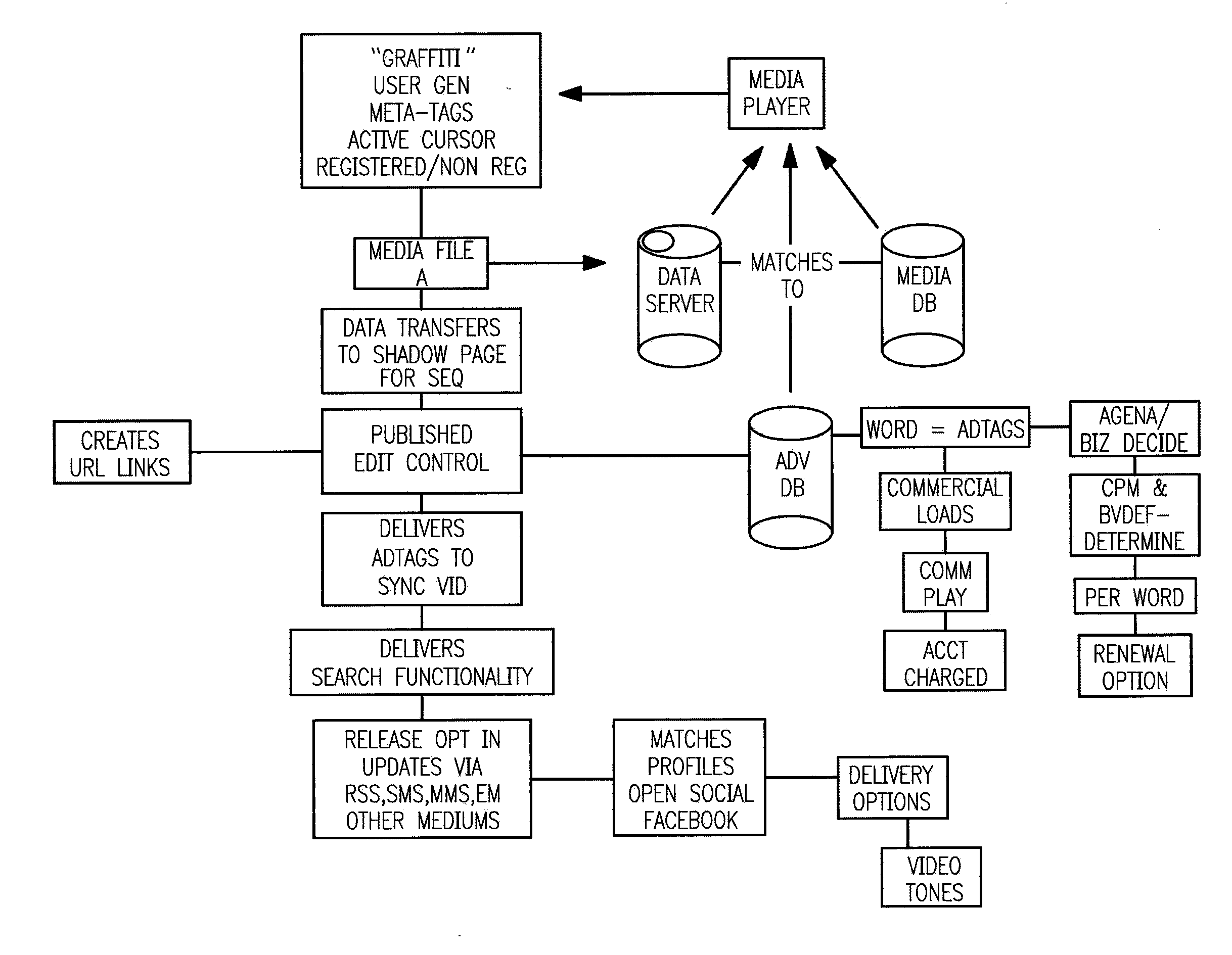

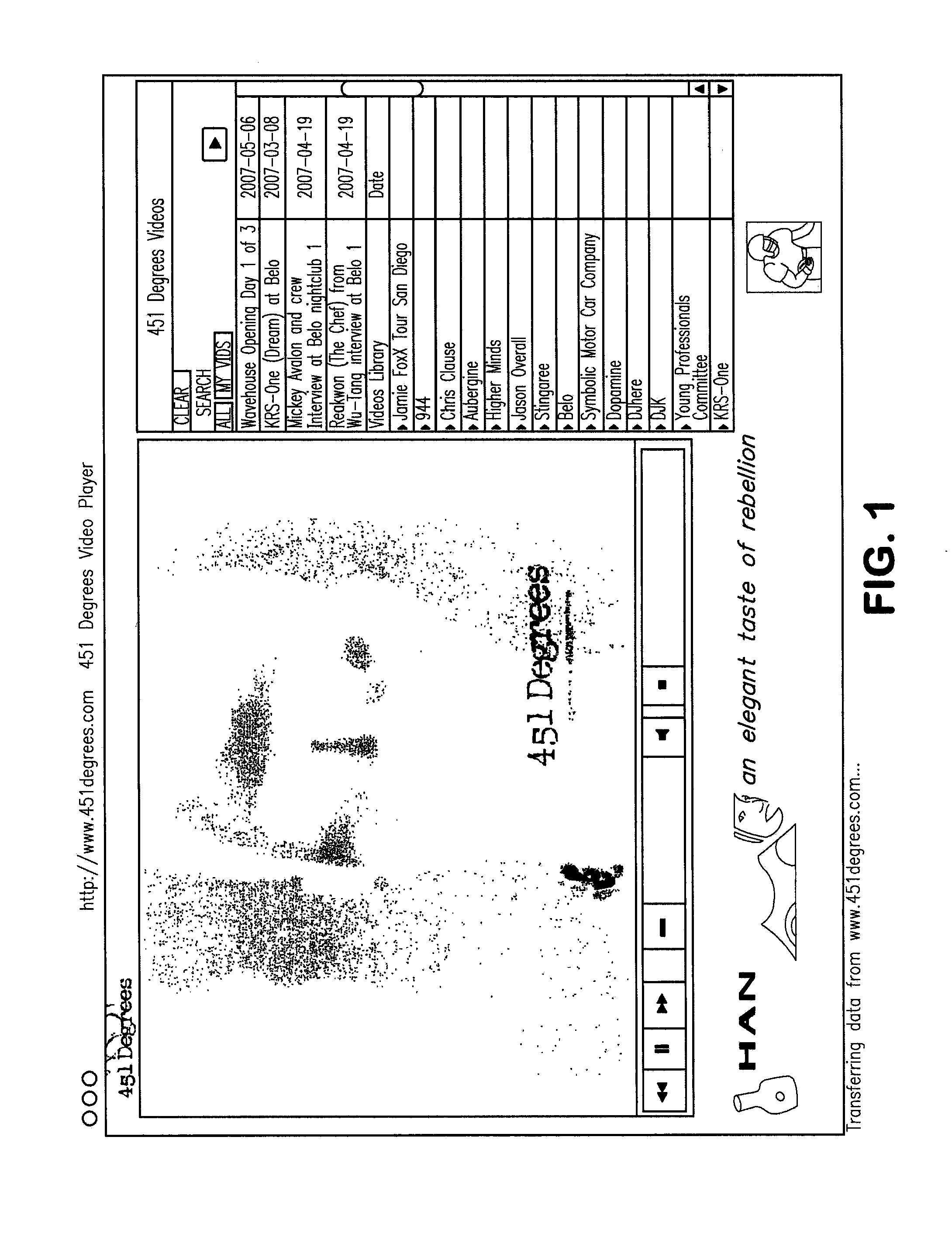

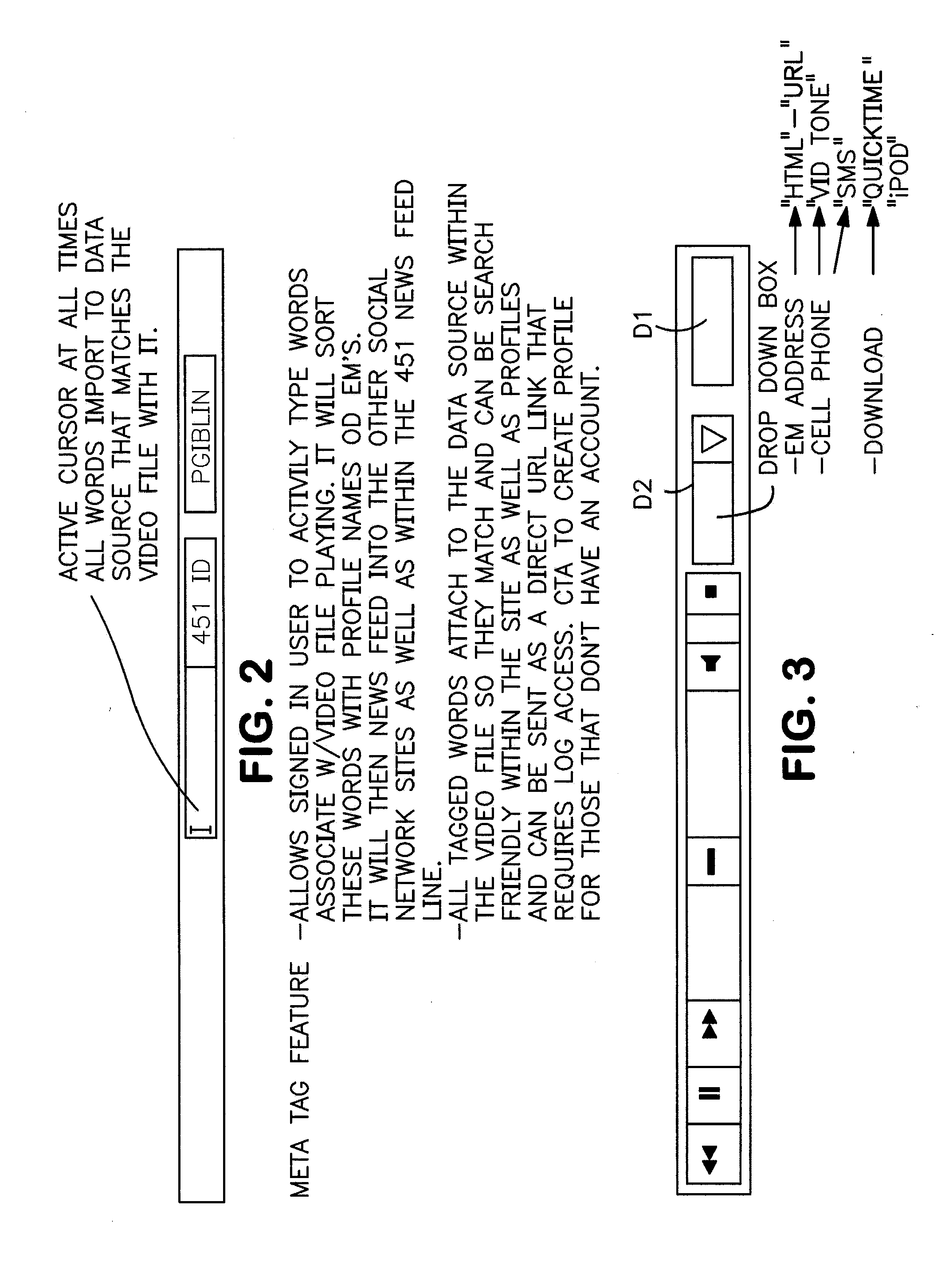

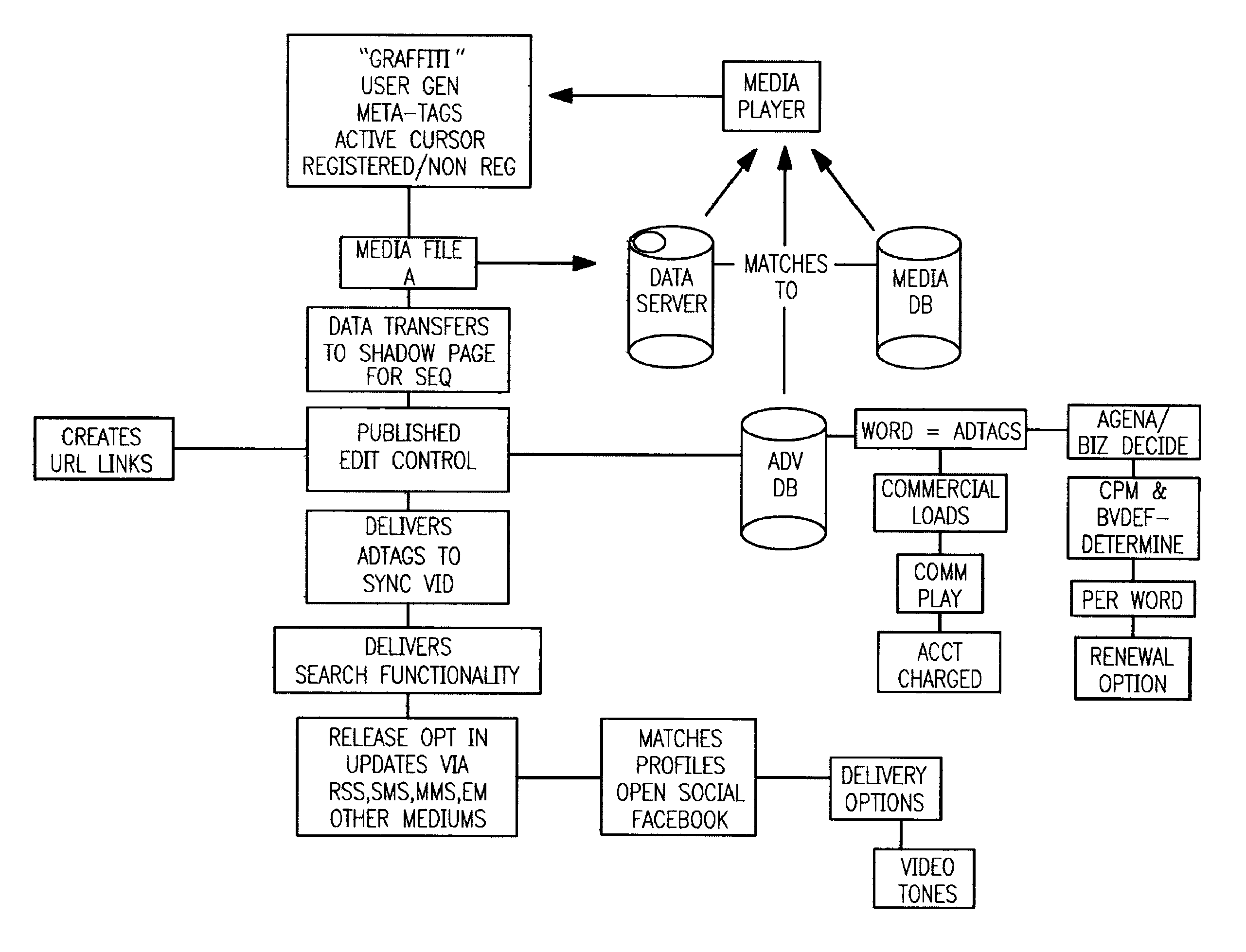

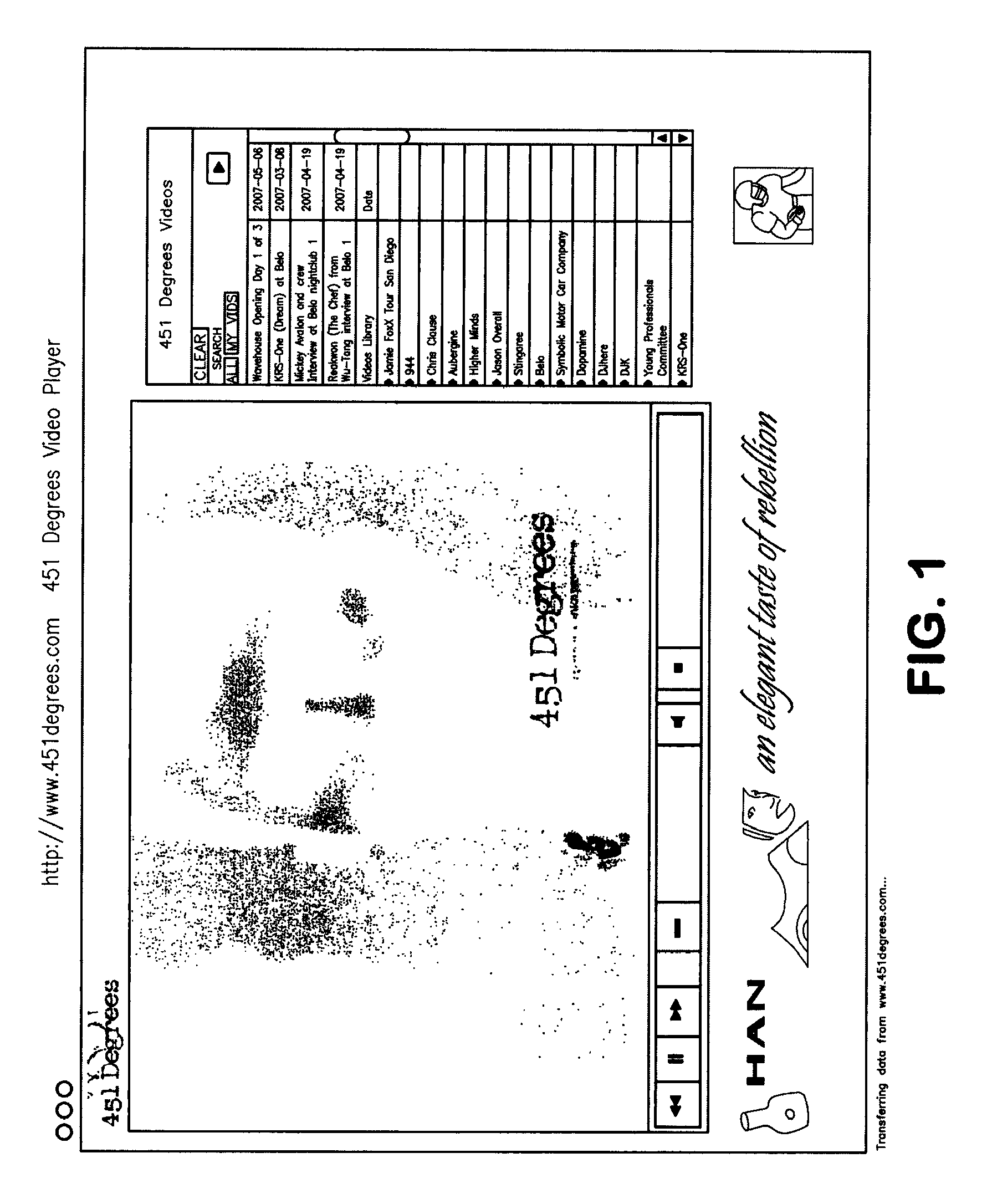

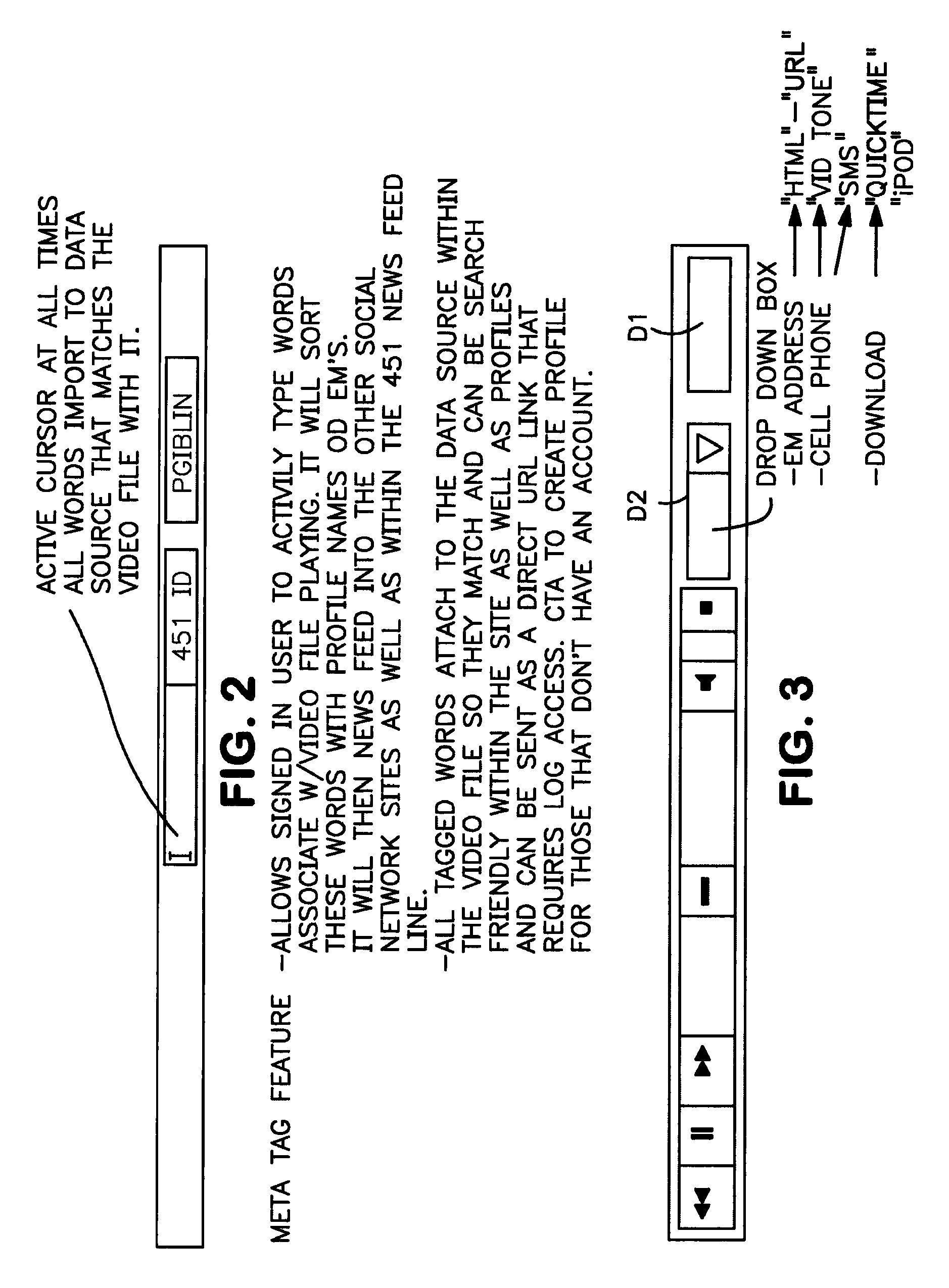

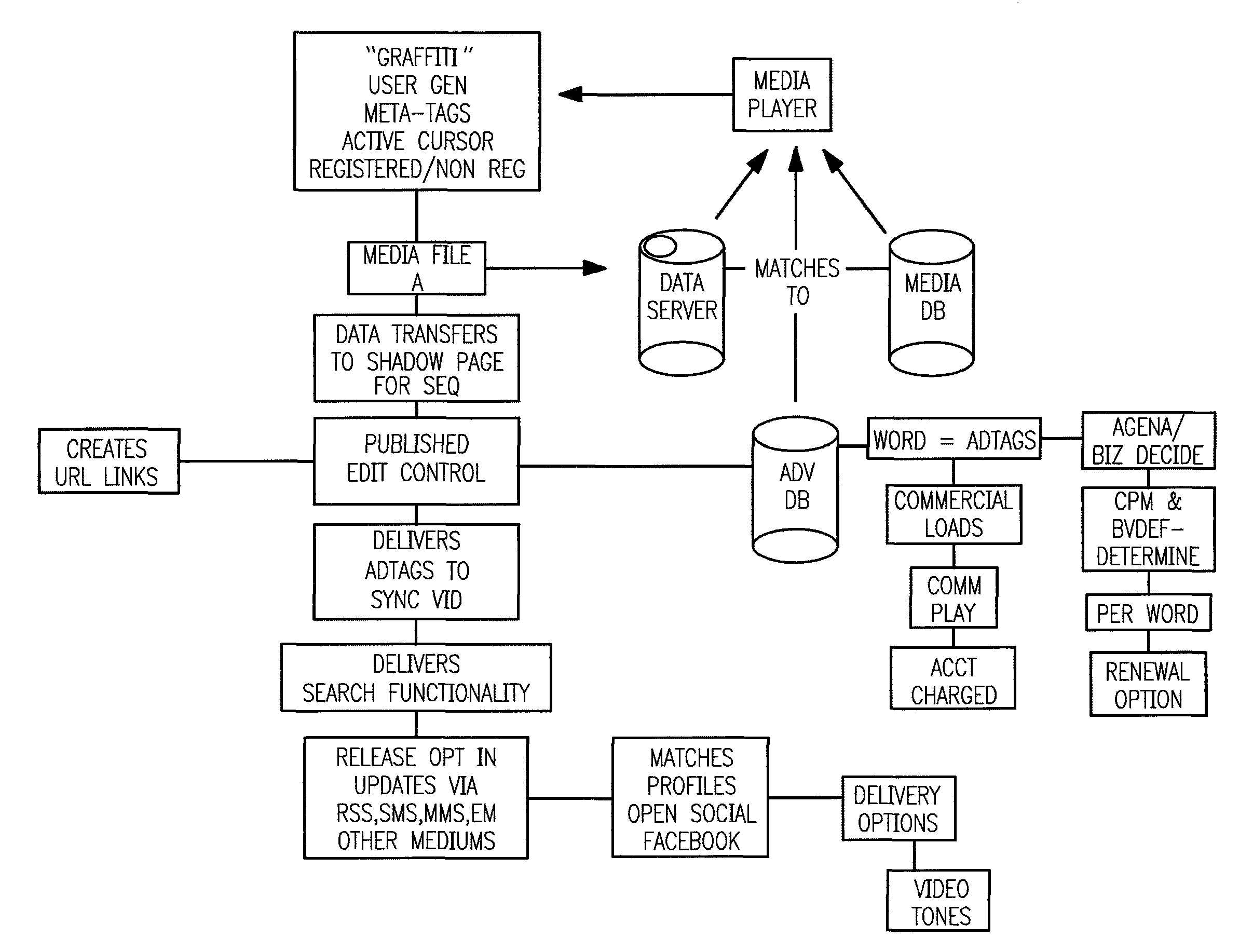

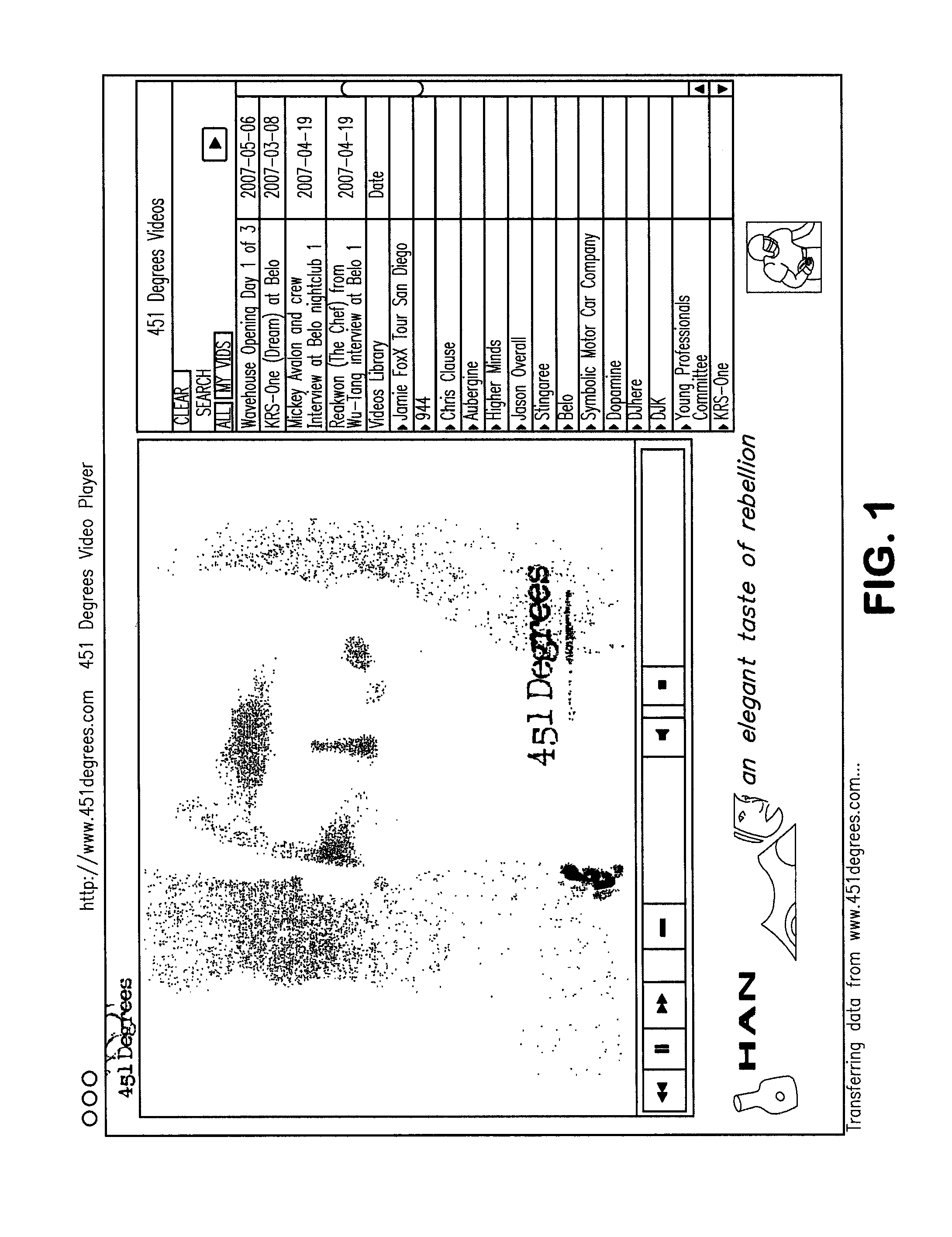

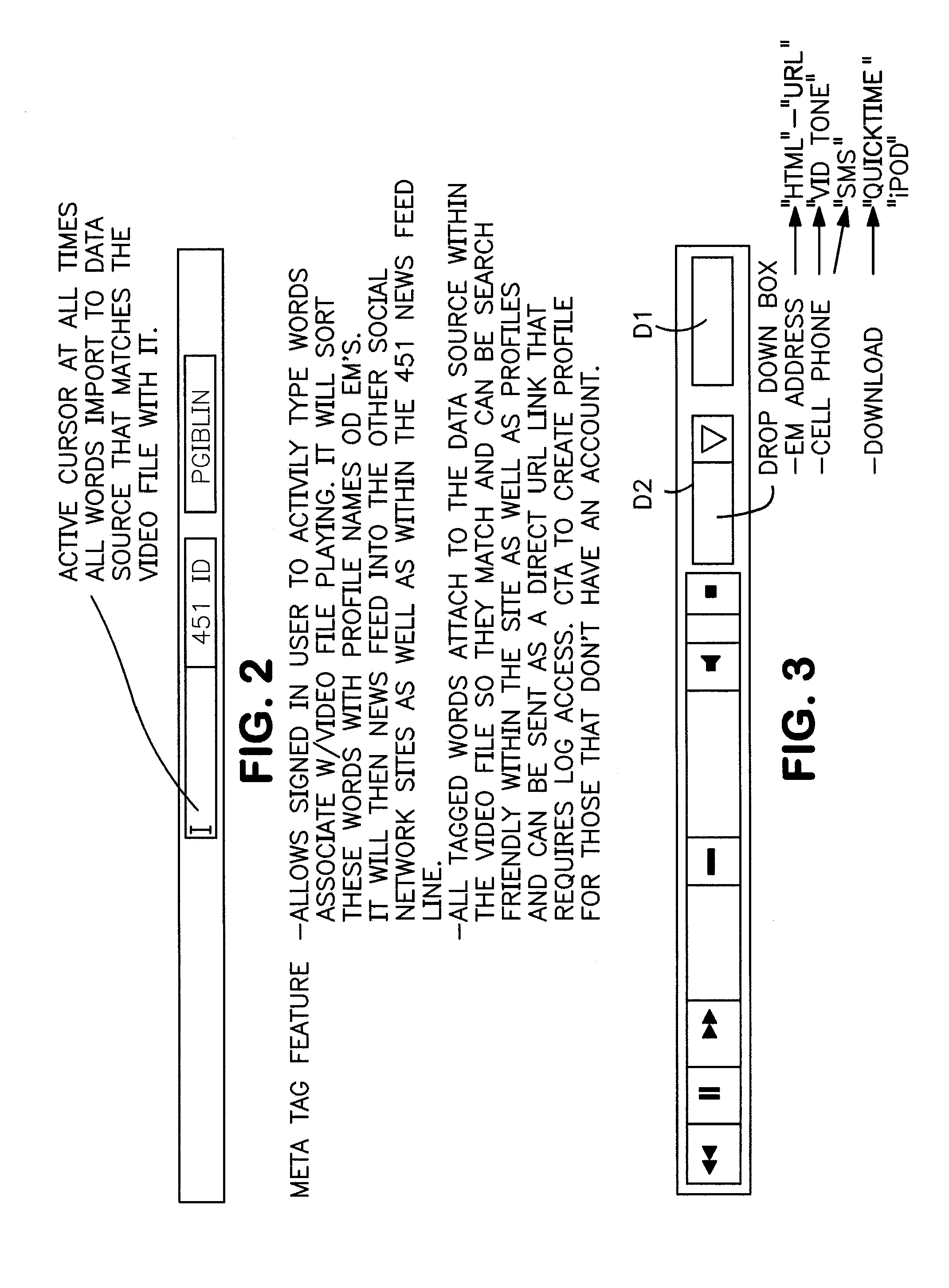

Method and System for Meta-Tagging Media Content and Distribution

ActiveUS20120239661A1Easy accessMaximize the cutting edge elements of multi-media—CommunityMultimedia data indexingDigital data processing detailsWeb siteElectronic communication

A unique application within Video that allows for user generated Meta-tagging to be delivered in real time to individual clips is provided. This meta-tag creates its own tail based upon the user generated words population, which is searchable via a “spider network” that runs invisible behind the web pages of the site. These same “tagged” words are broadcast over various delivery networks including but not limited to live feeds from SMS, MMS, News Feeds within Community Web Sites, Video Sharing Web Sites, Widget applications any other forms of electronic communication that are dropped in real time to identified users and friends of users.

Owner:GIBLIN PATRICK

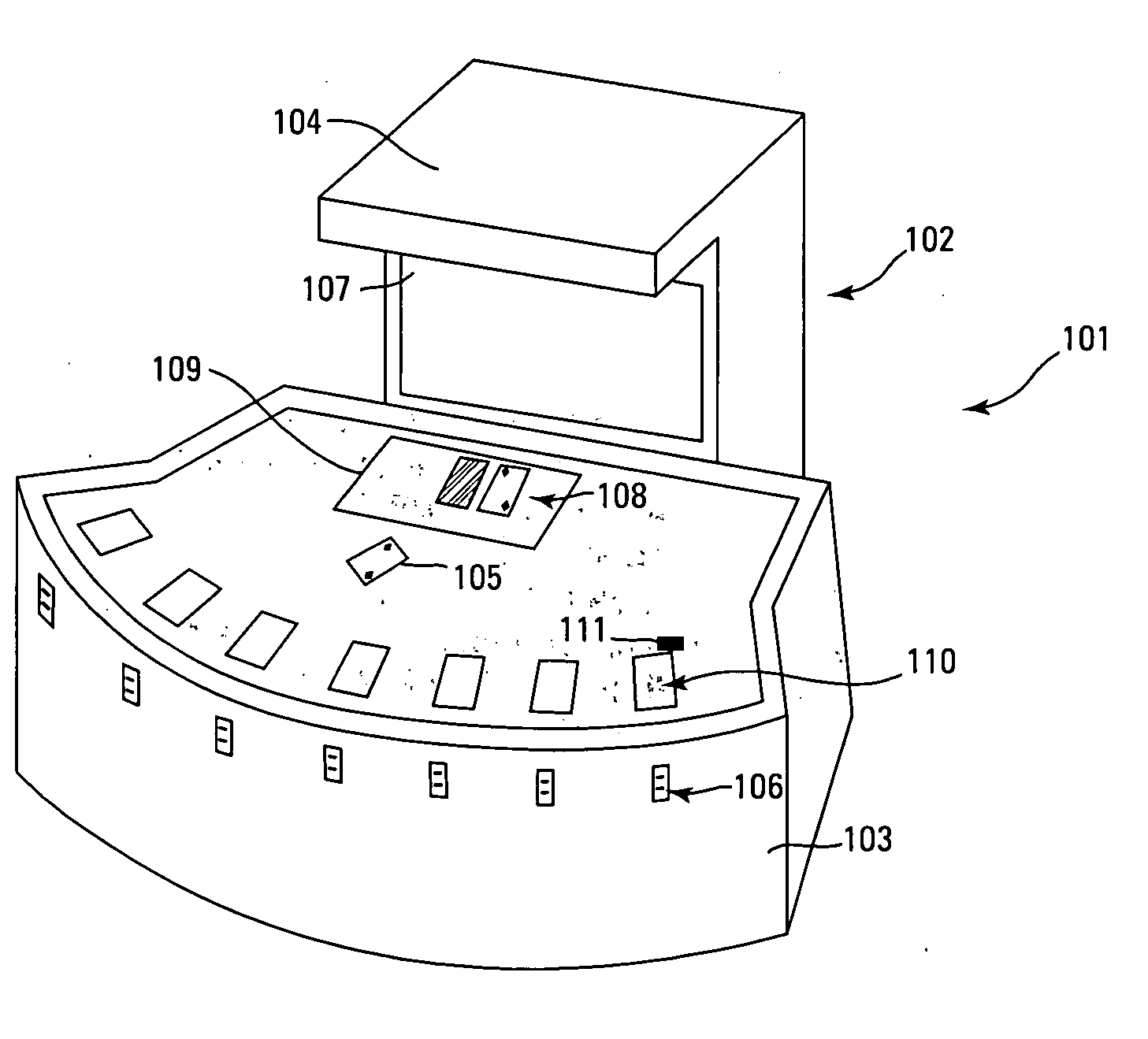

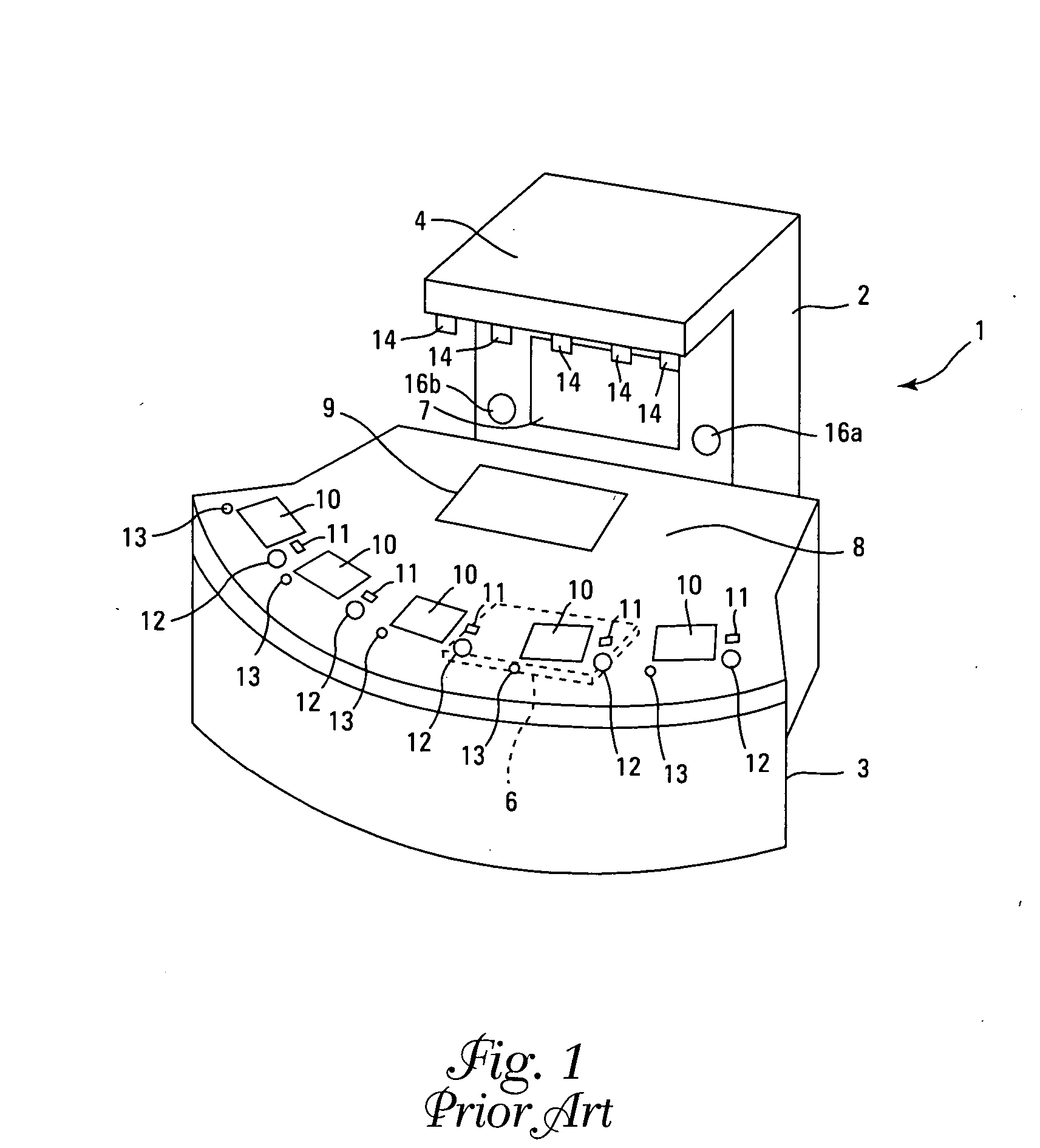

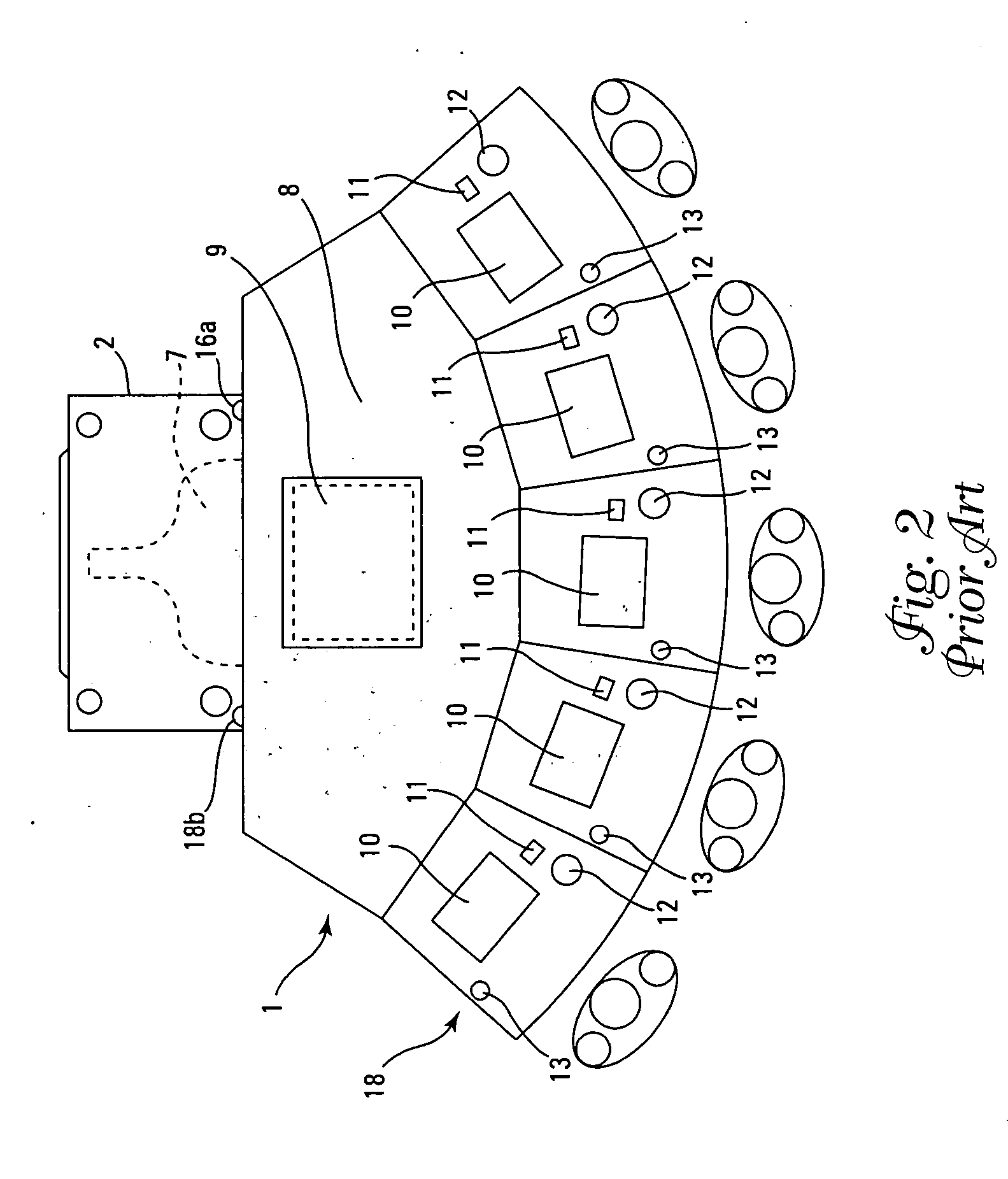

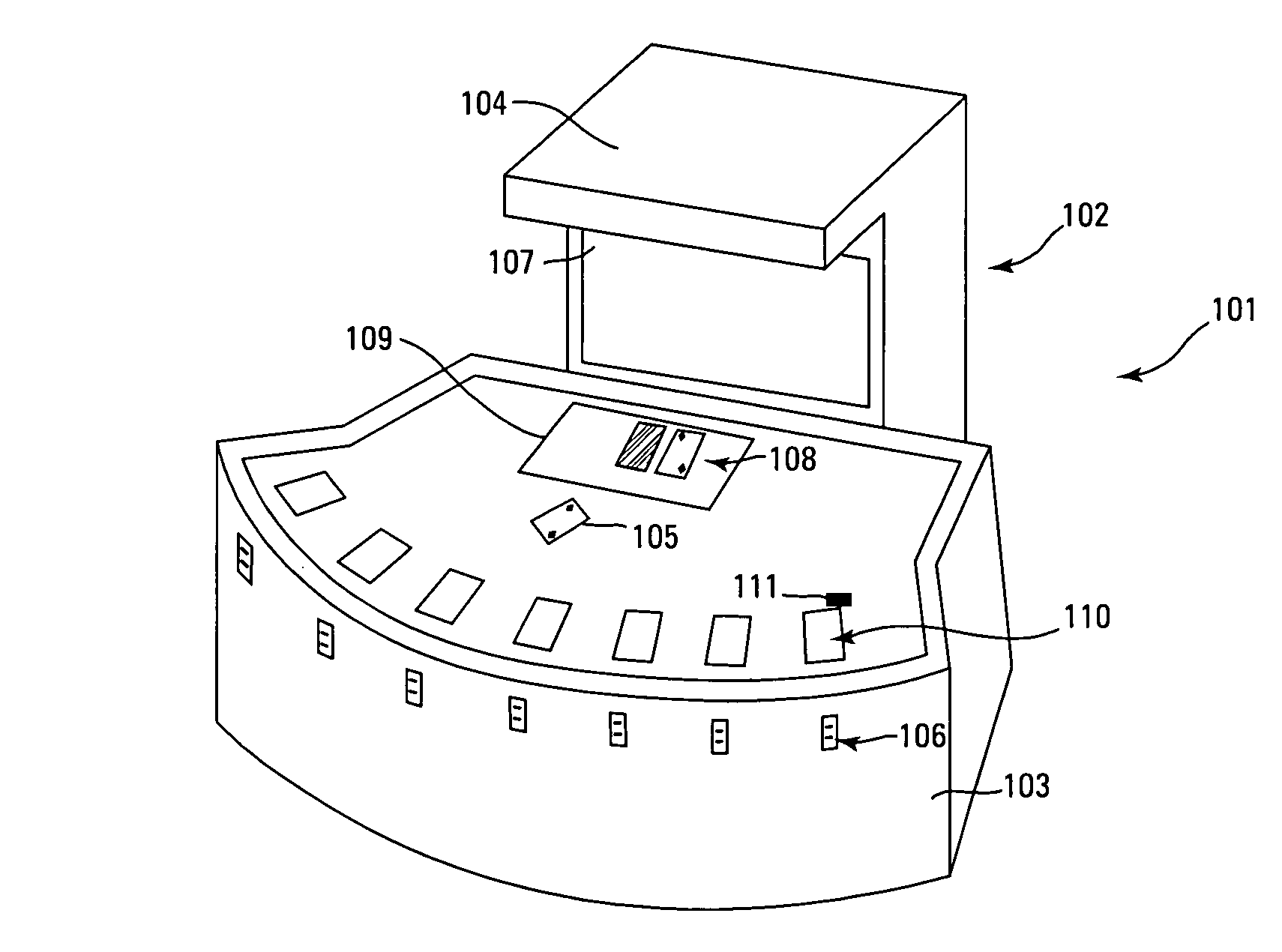

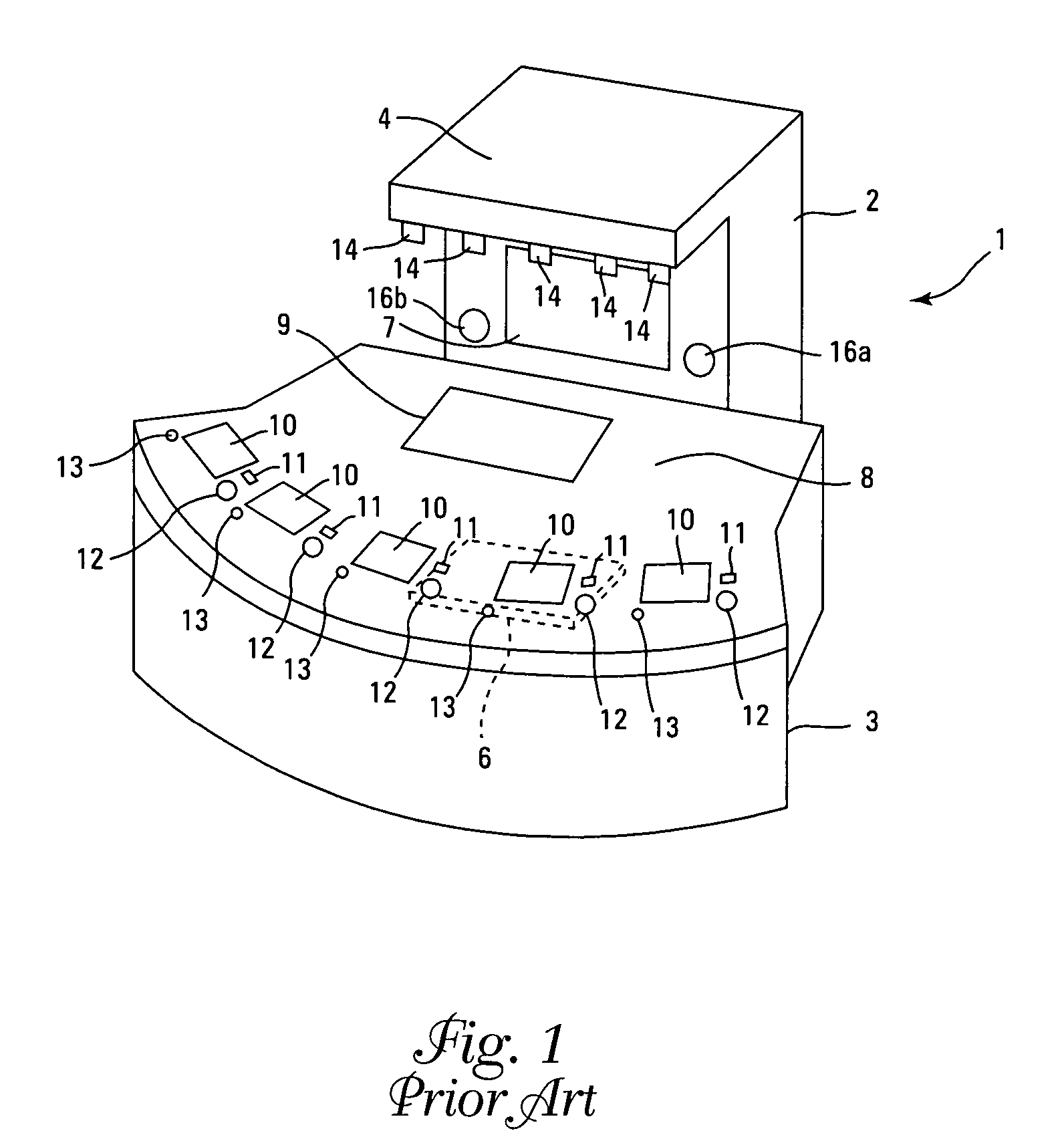

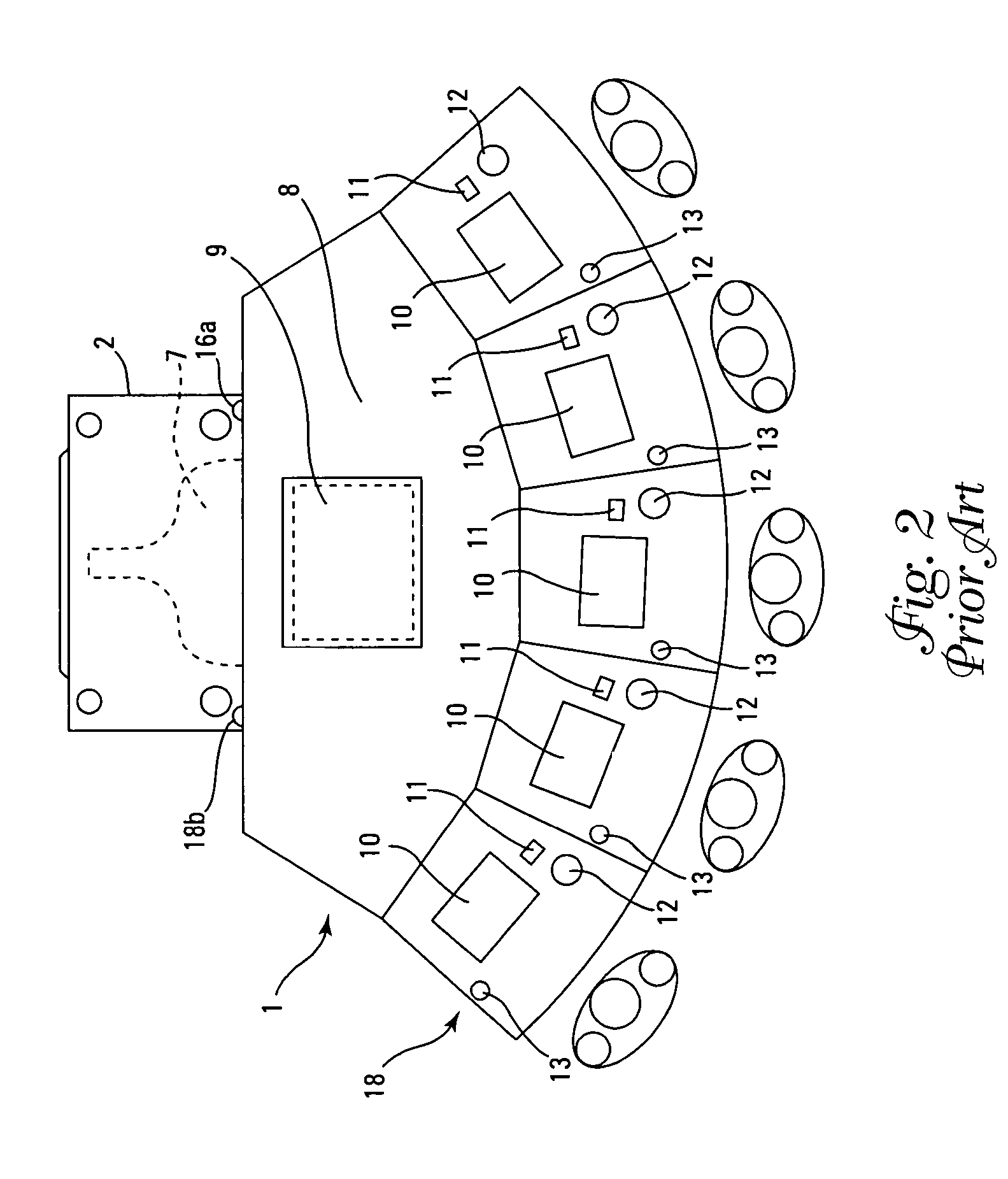

Automated multiplayer game table with unique image feed of dealer

ActiveUS20050164762A1Unique and more realistic gaming environmentImprove the environmentApparatus for meter-controlled dispensingVideo gamesComputer graphics (images)Video production

A method and apparatus are used to simultaneously display a virtual dealer and a dynamic visual background image in connection with a multi-player video platform simulating and effecting play of a casino table card game. The dealer imagery is in the foreground and the background is behind the dealer. The background is either a live video feed from the casino, live feed from another location or event or pre-recorded image sequences. The various videos are keyed or masked and layered together using known video production technology.

Owner:LNW GAMING INC

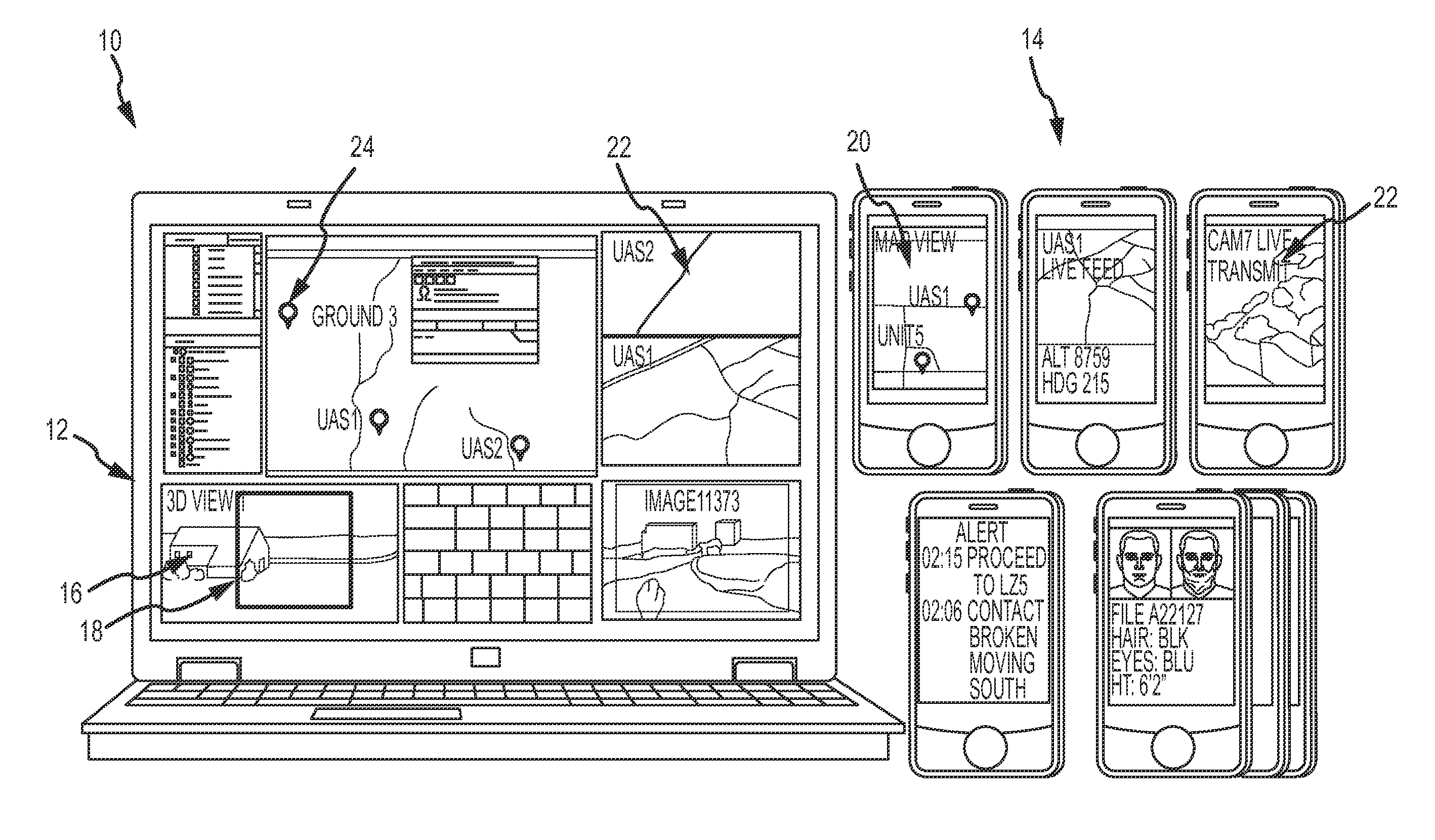

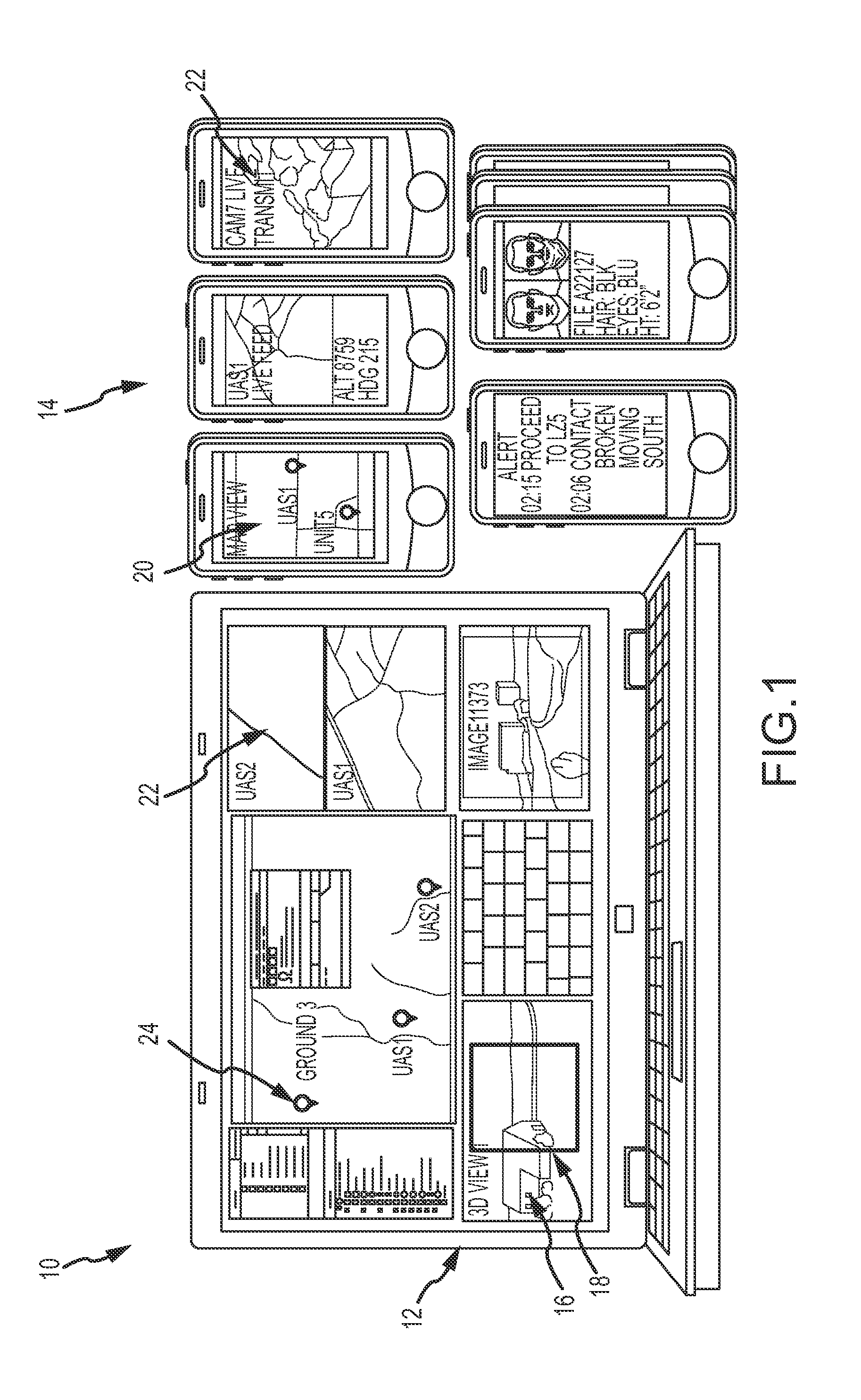

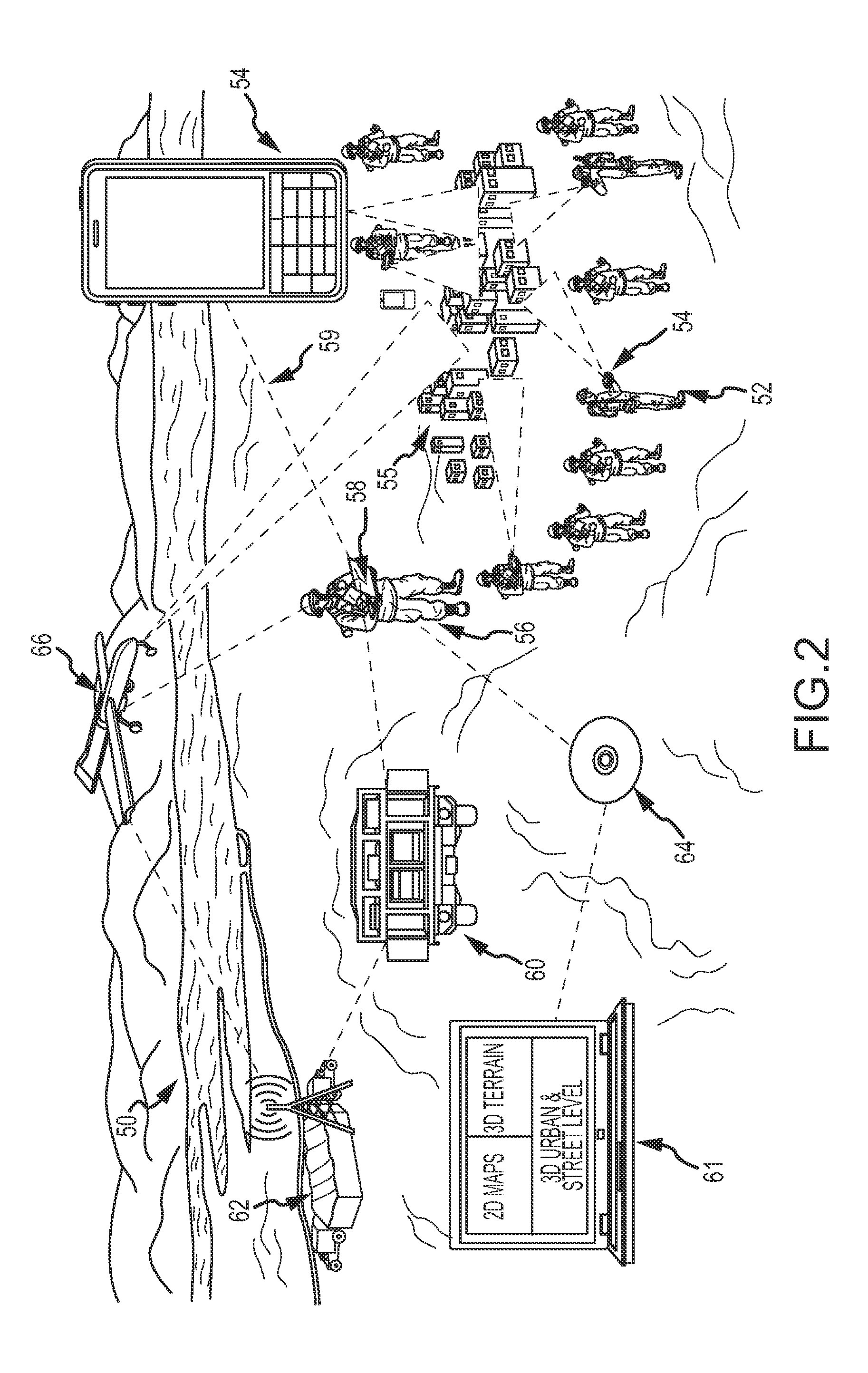

ENHANCED SITUATIONAL AWARENESS AND TARGETING (eSAT) SYSTEM

InactiveUS20120019522A1Enhanced situational awareness and targetingDetails involving processing stepsAiming meansComputer graphics (images)Display device

eSAT pushes 3D scene awareness and targeting to forward positioned mobile operators and their handheld devices in environments such as found in military theaters of operation, border control and enforcement, police operations, search & rescue and large commercial industrial operations. A host computer hosts a 3D model of a scene and dynamically captures and transmits a windowed portion of the visual representation of that 3D model over a wireless network to the mobile operators' handheld devices. The windowed portion of the visual representation is streamed directly to the operators' handheld device displays. The mobile operators may interact with and control the 3D model via the wireless network. The host computer may synthesize the visual representation of the 3D model with live feeds from one or more of the handheld devices or other assets to improve situational awareness. Either the mobile operators or host operator can make point selections on the visual representation to extract geo-coordinates from the 3D model as a set of target coordinates.

Owner:RAYTHEON CO

Method and system for meta-tagging media content and distribution

ActiveUS8055688B2Easy accessMaximize the cutting edge elements of multi-media—CommunityFinanceDigital data processing detailsWeb siteElectronic communication

A unique application within Video that allows for user generated Meta-tagging to be delivered in real time to individual clips is provided. This meta-tag creates its own tail based upon the user generated words population, which is searchable via a “spider network” that runs invisible behind the web pages of the site. These same “tagged” words are broadcast over various delivery networks including but not limited to live feeds from SMS, MMS, News Feeds within Community Web Sites, Video Sharing Web Sites, Widget applications any other forms of electronic communication that will be dropped in real time to identified users and friends of users.

Owner:GIBLIN PATRICK

Automated multiplayer game table with unique image feed of dealer

ActiveUS8272958B2Unique and more realistic gaming environmentImprove the environmentApparatus for meter-controlled dispensingVideo gamesComputer graphics (images)Video production

A method and apparatus are used to simultaneously display a virtual dealer and a dynamic visual background image in connection with a multi-player video platform simulating and effecting play of a casino table card game. The dealer imagery is in the foreground and the background is behind the dealer. The background is either a live video feed from the casino, live feed from another location or event or pre-recorded image sequences. The various videos are keyed or masked and layered together using known video production technology.

Owner:LNW GAMING INC

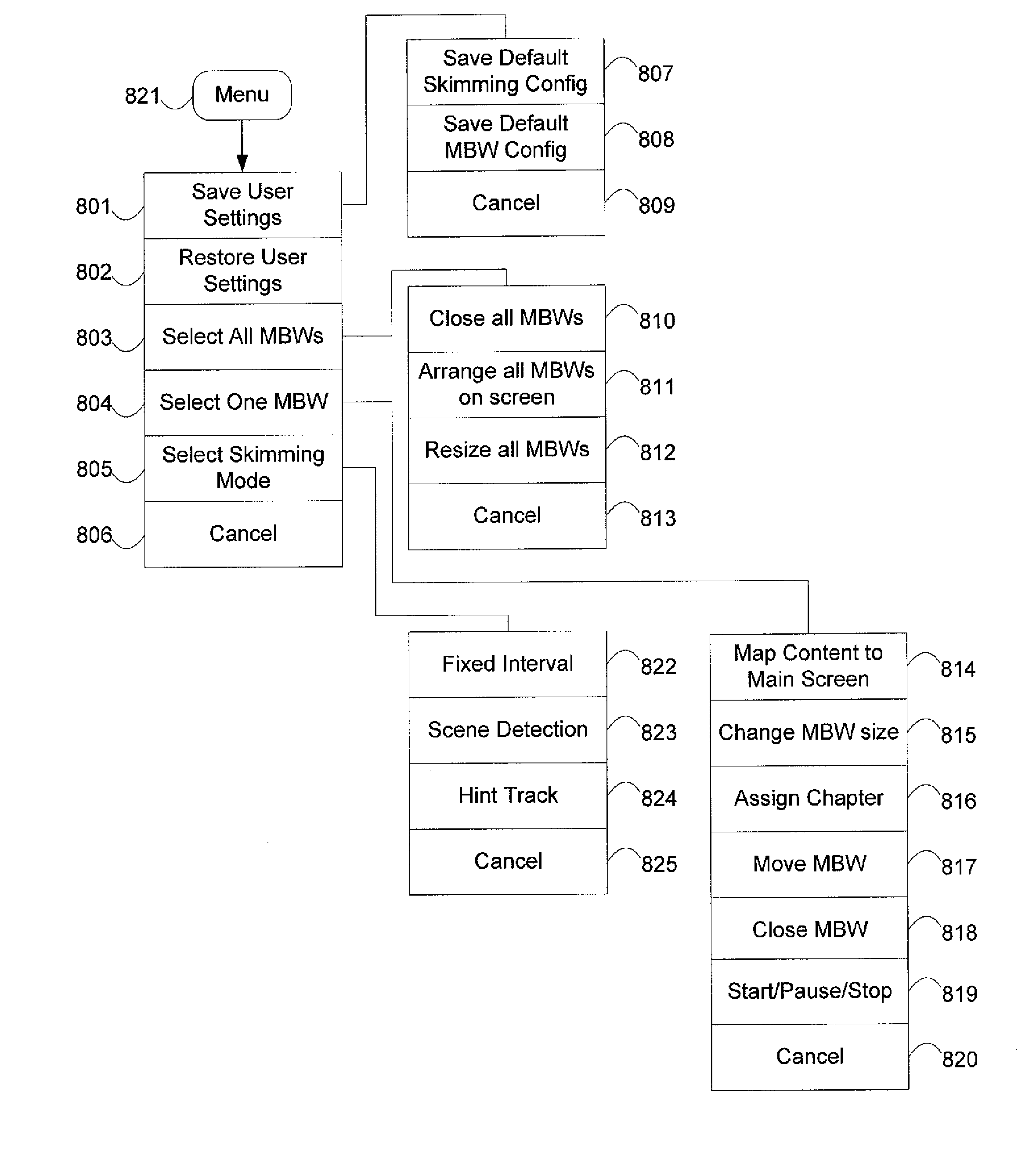

Efficient video skimmer

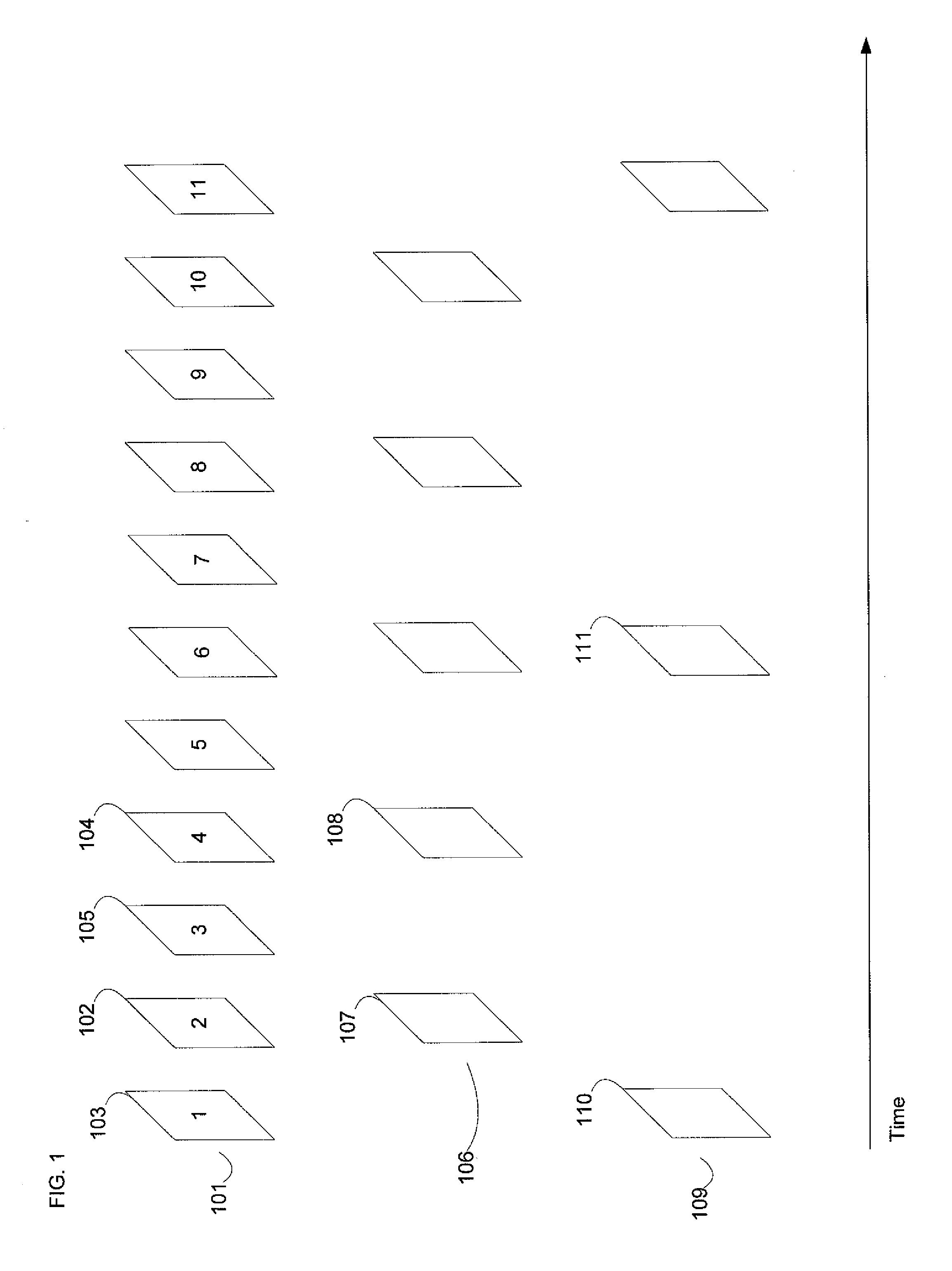

InactiveUS20100272187A1Waste significant bandwidthPower to generateTelevision system detailsPicture reproducers using cathode ray tubesComputer graphics (images)Systems approaches

Disclosed are a system, method, apparatus, and computer readable media containing instructions for displaying video files for rapid searching. In two different types of exemplary embodiments, a standalone video skimming system, and a video skimming system includes a server and a client system are disclosed, where the video file may be locally or remotely stored, or can be obtained from a live feed. The system displays many small windows simultaneously, in which different parts of the video chosen by the user are shown at the same time to shorten the skimming time. The video file is encoded using layered encoding to display smaller versions using lower layers, and without needing any processing to generate smaller versions of the video from the original full screen version. A video extractor is described for extracting the necessary bitstreams from a local video database containing layered encoded video files according to user specified window sizes, and distributing the signals over the electronic communications network channel. The system also includes a skimming control logic which can receive control commands from clients and invoke the video extractor to extract appropriate audio-visual signals there from for each command.

Owner:VIDYO

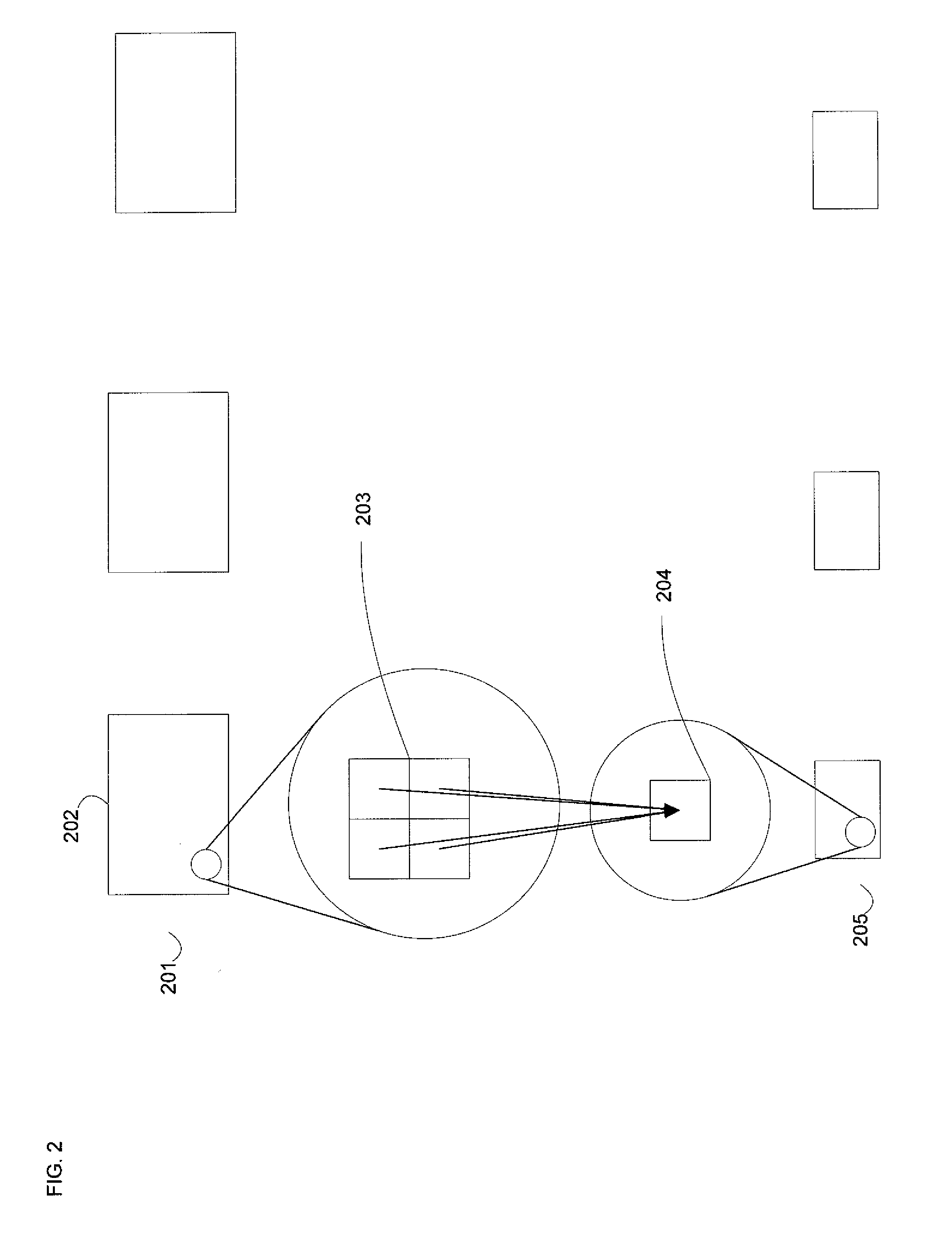

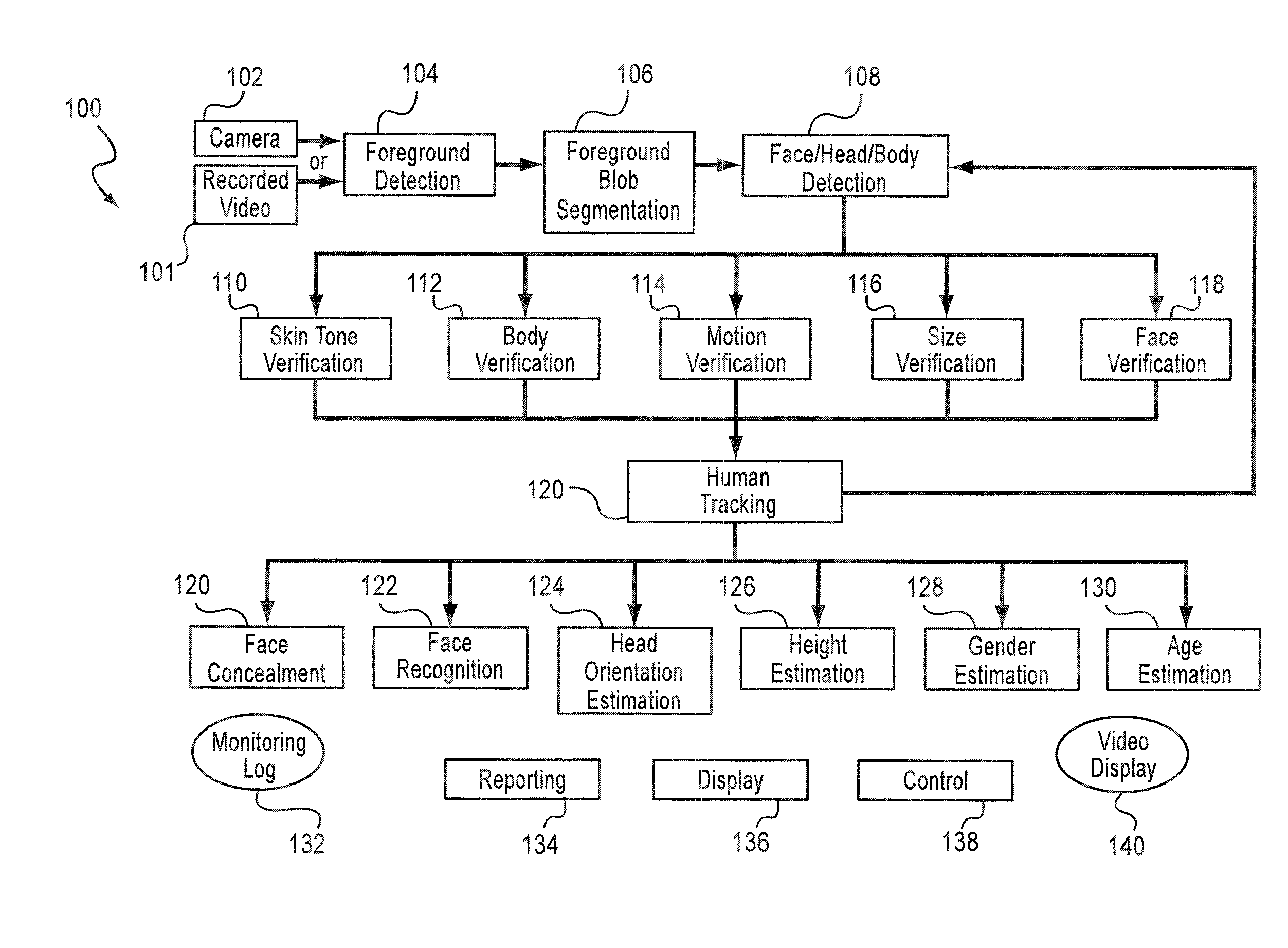

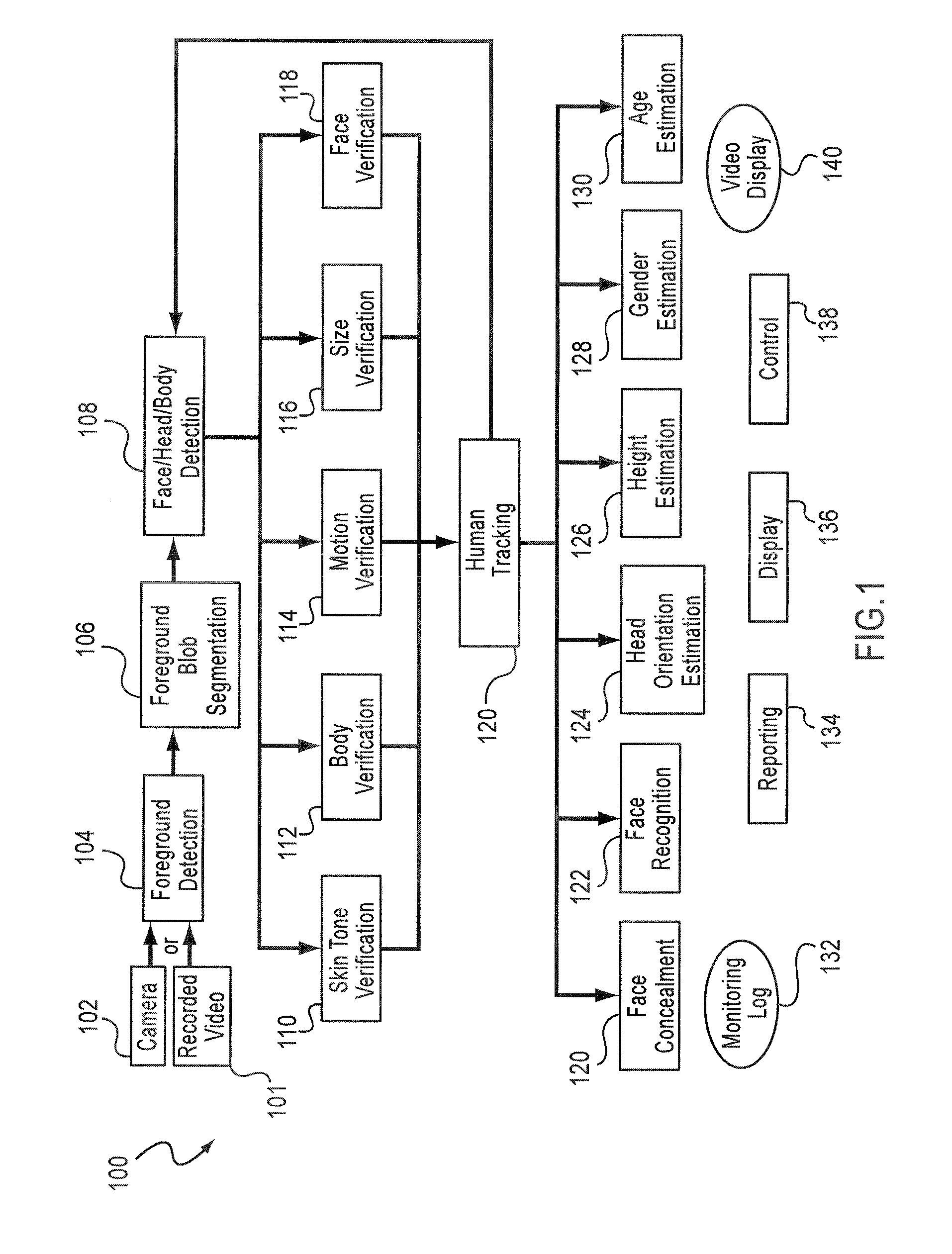

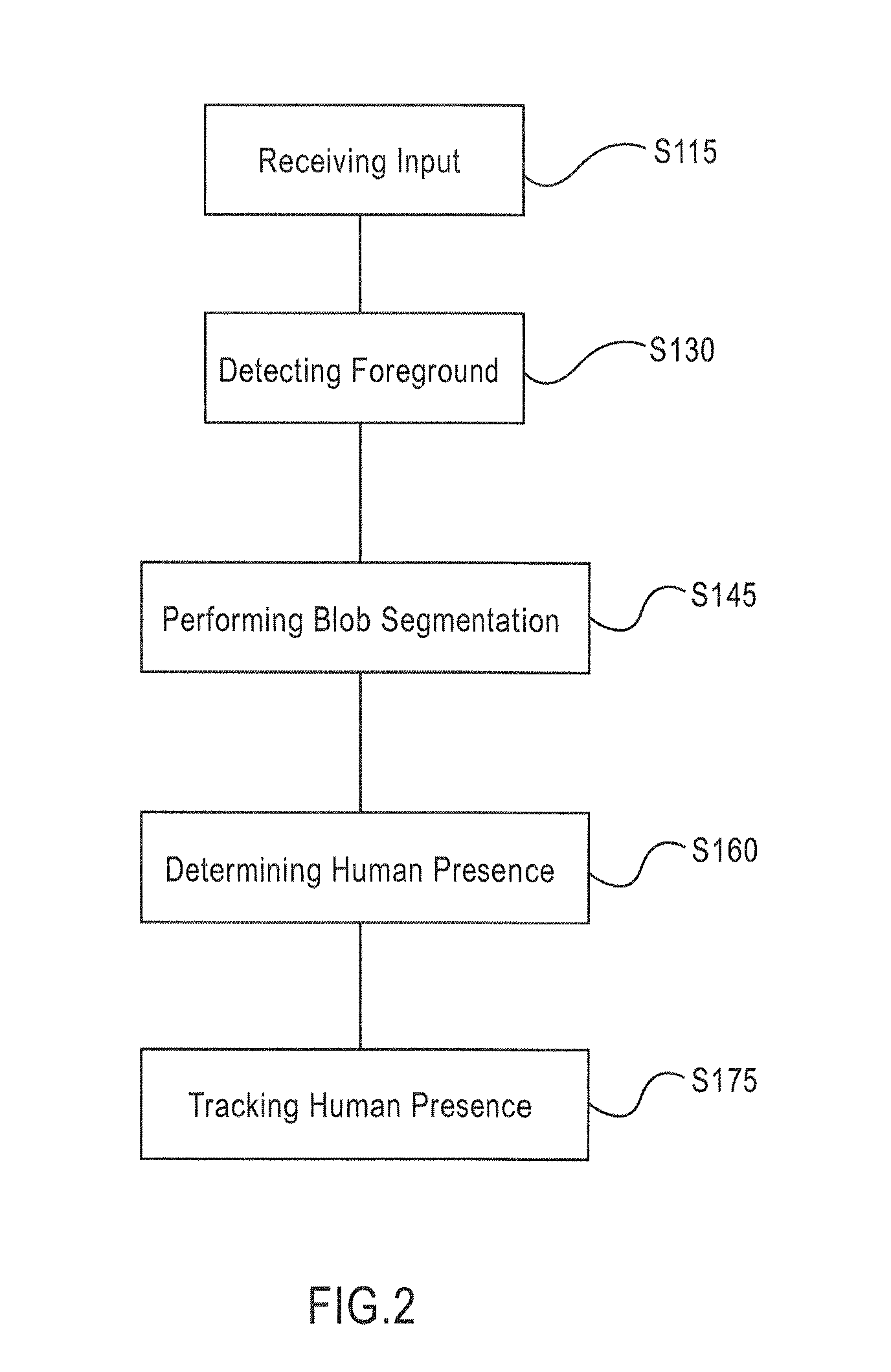

Methods and systems for audience monitoring

InactiveUS20100046797A1Improve accuracyIncrease advertising revenueBroadcast-related systemsCharacter and pattern recognitionMonitoring systemTime distribution

Systems and methods for audience monitoring are provided that include receiving an input including a recording or live feed of an audience composed of several persons, detecting foreground of the input, performing blob segmentation of the input, and analyzing human presence on each segmented blob by identifying at least one person, identifying a spatial distribution of at least one identified person, determining a dwell time of at least one identified person, determining a temporal distribution of at least one identified person, and determining a gaze direction of at least one identified person. Such detecting provides the ability to track individual persons present in the audience, and how long they remain in the audience. The method also provides the ability to determine gaze direction of persons in the audience, and how long one or more persons are gazing in a particular direction.

Owner:SET CORP

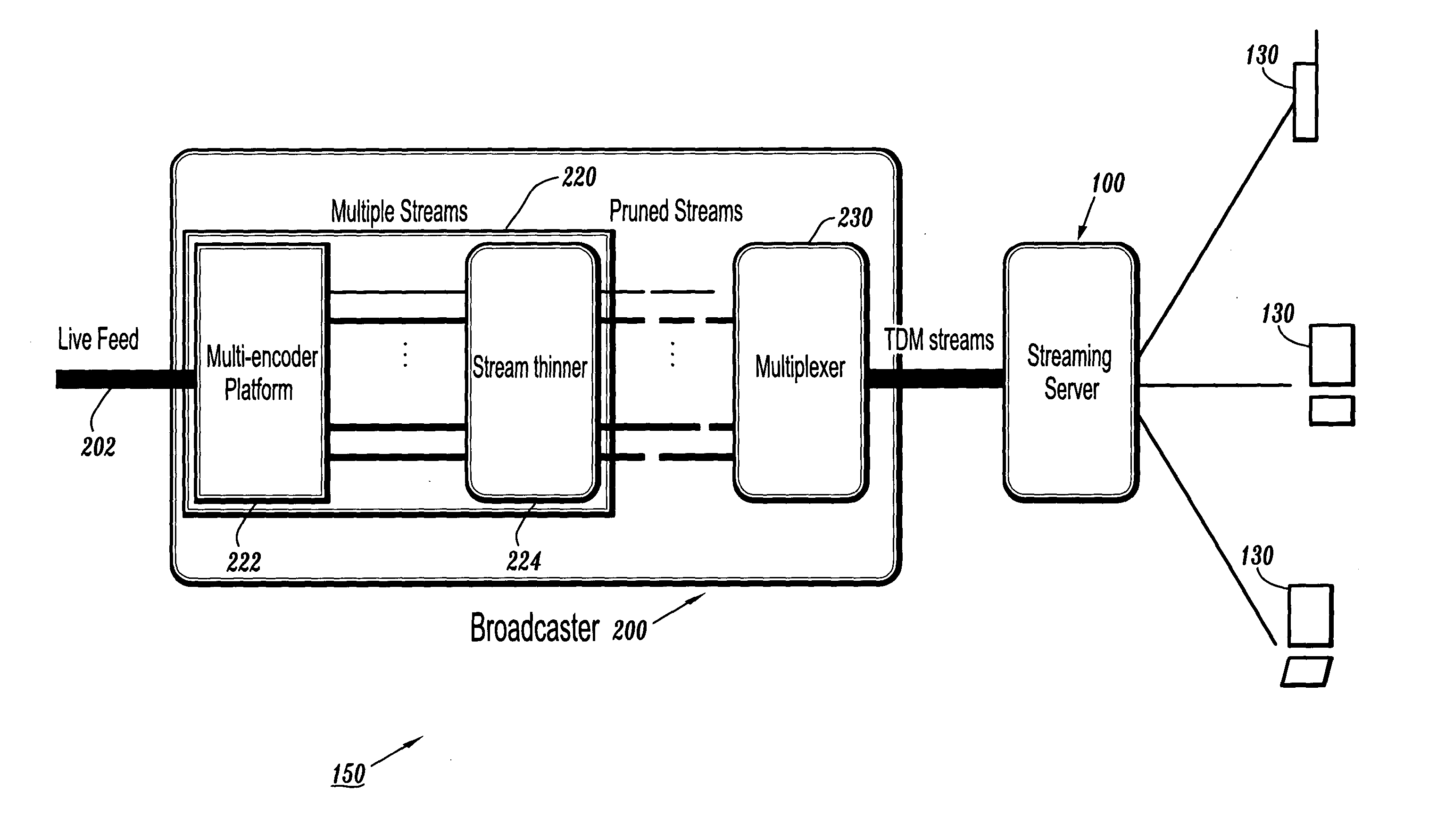

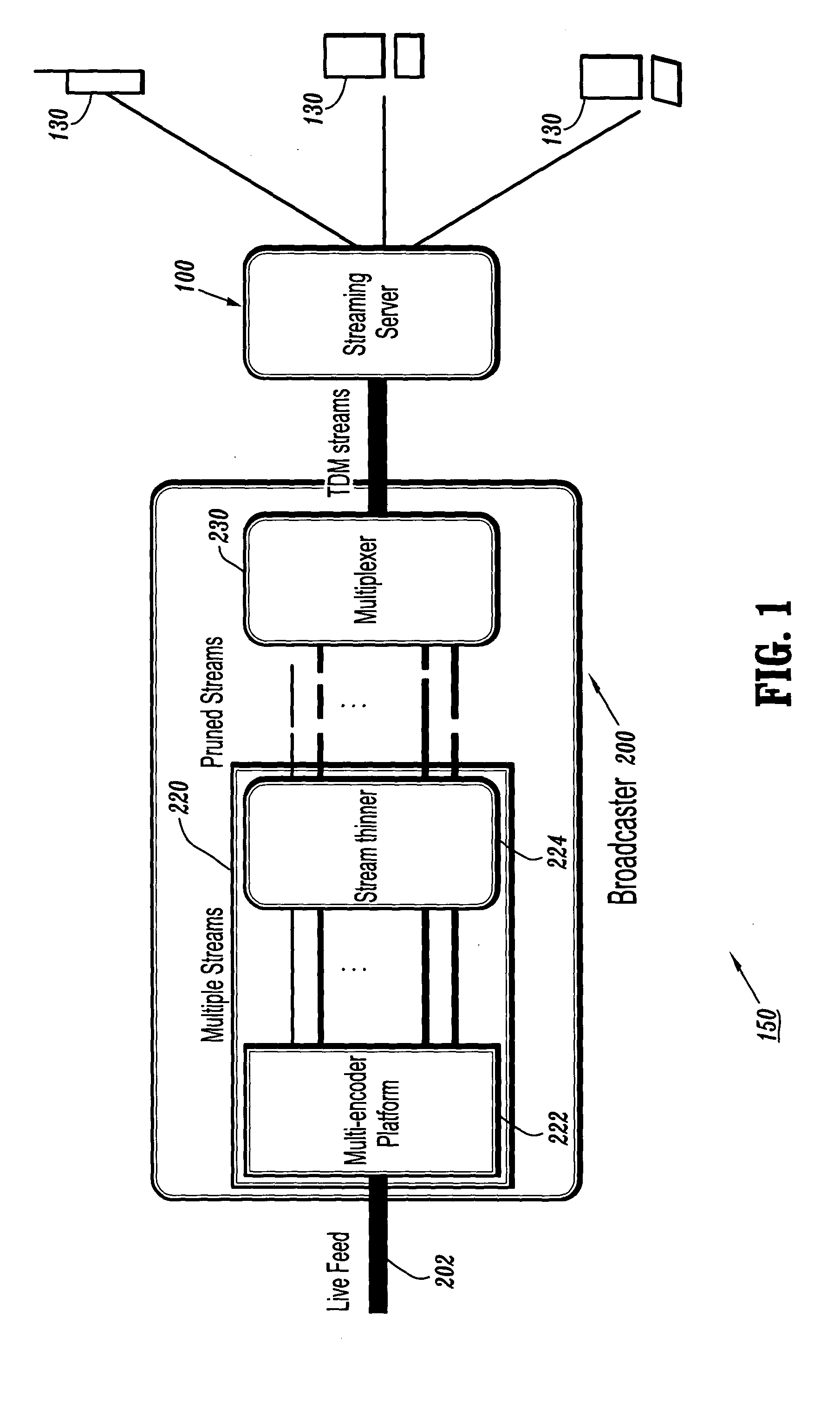

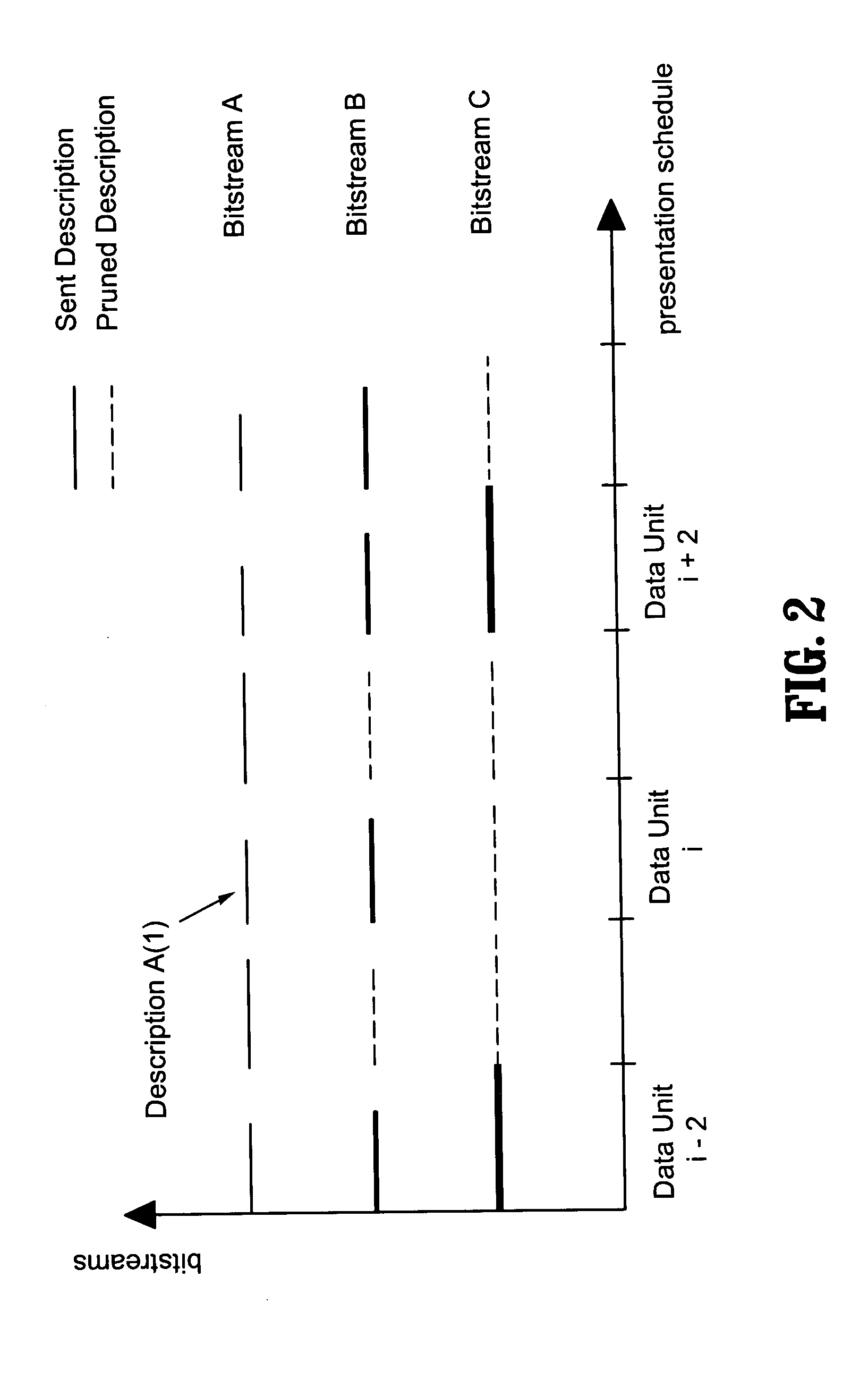

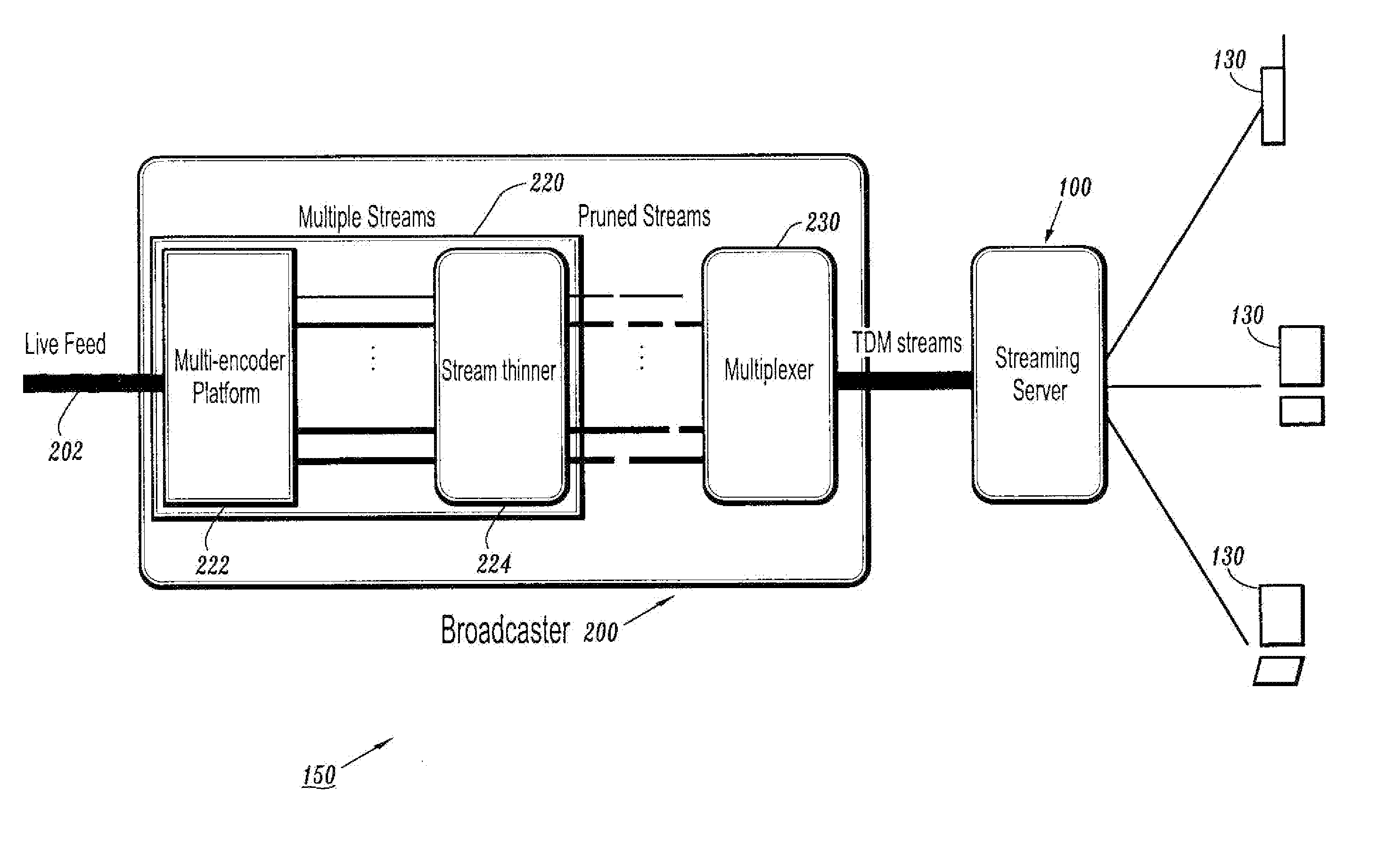

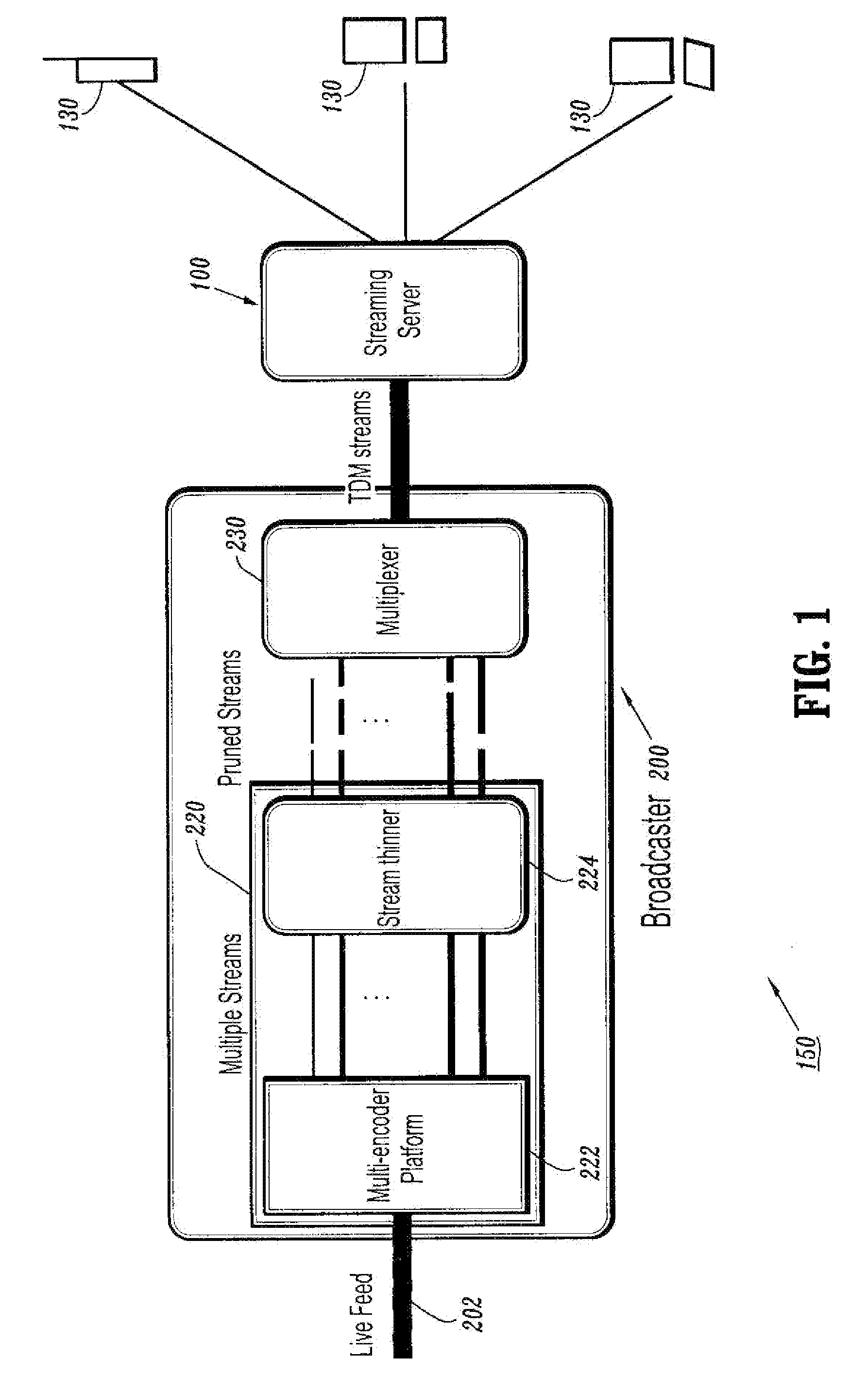

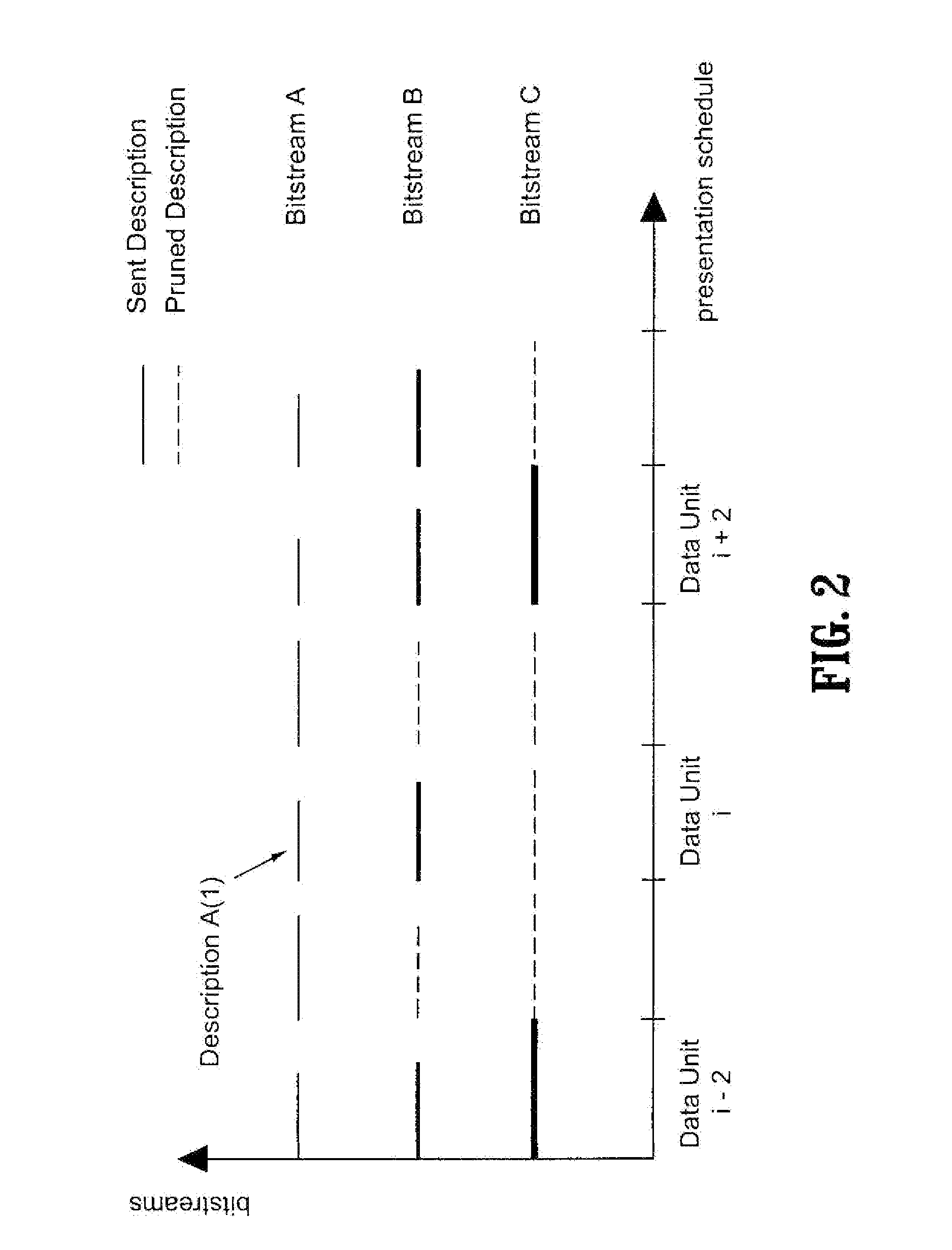

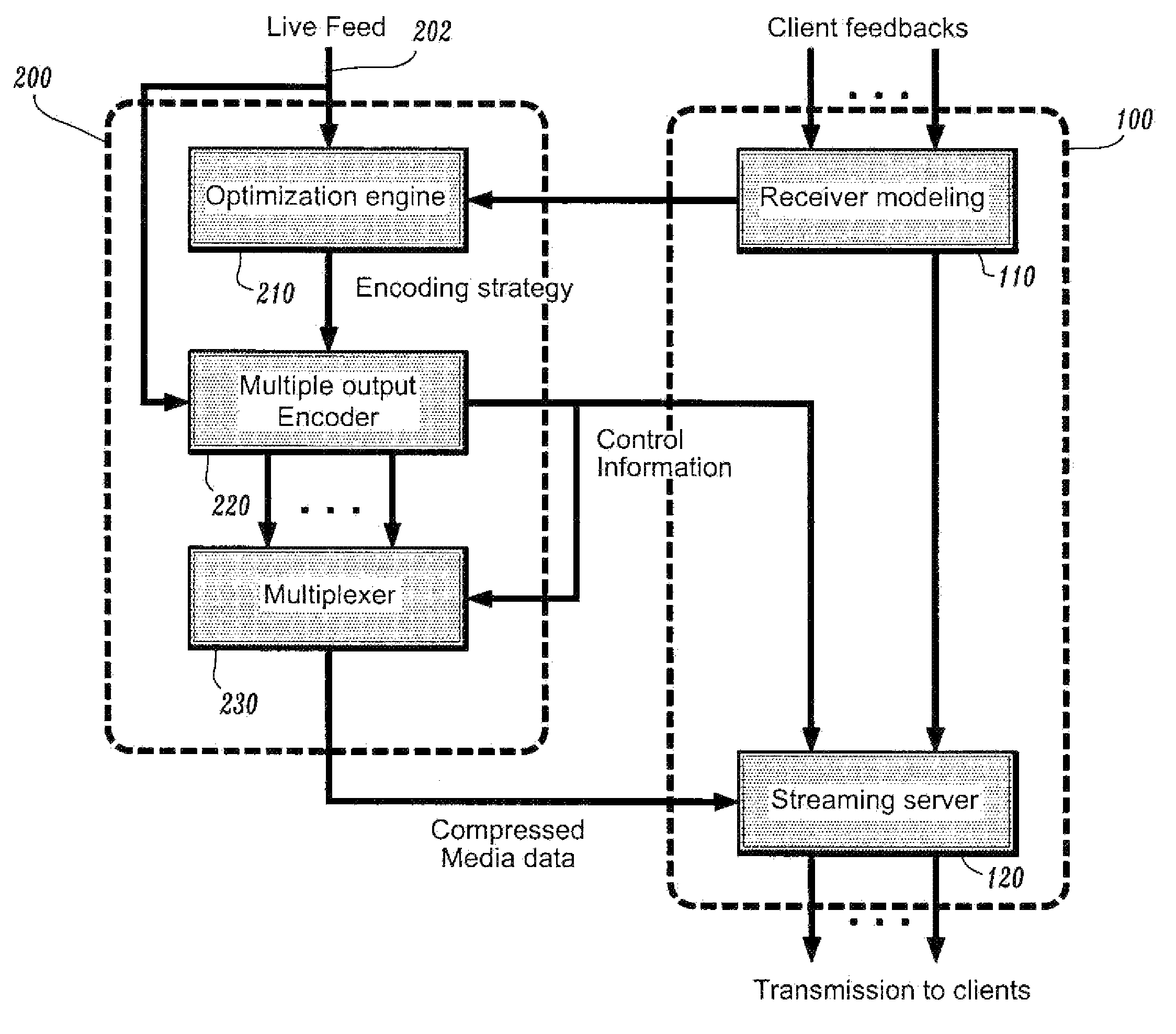

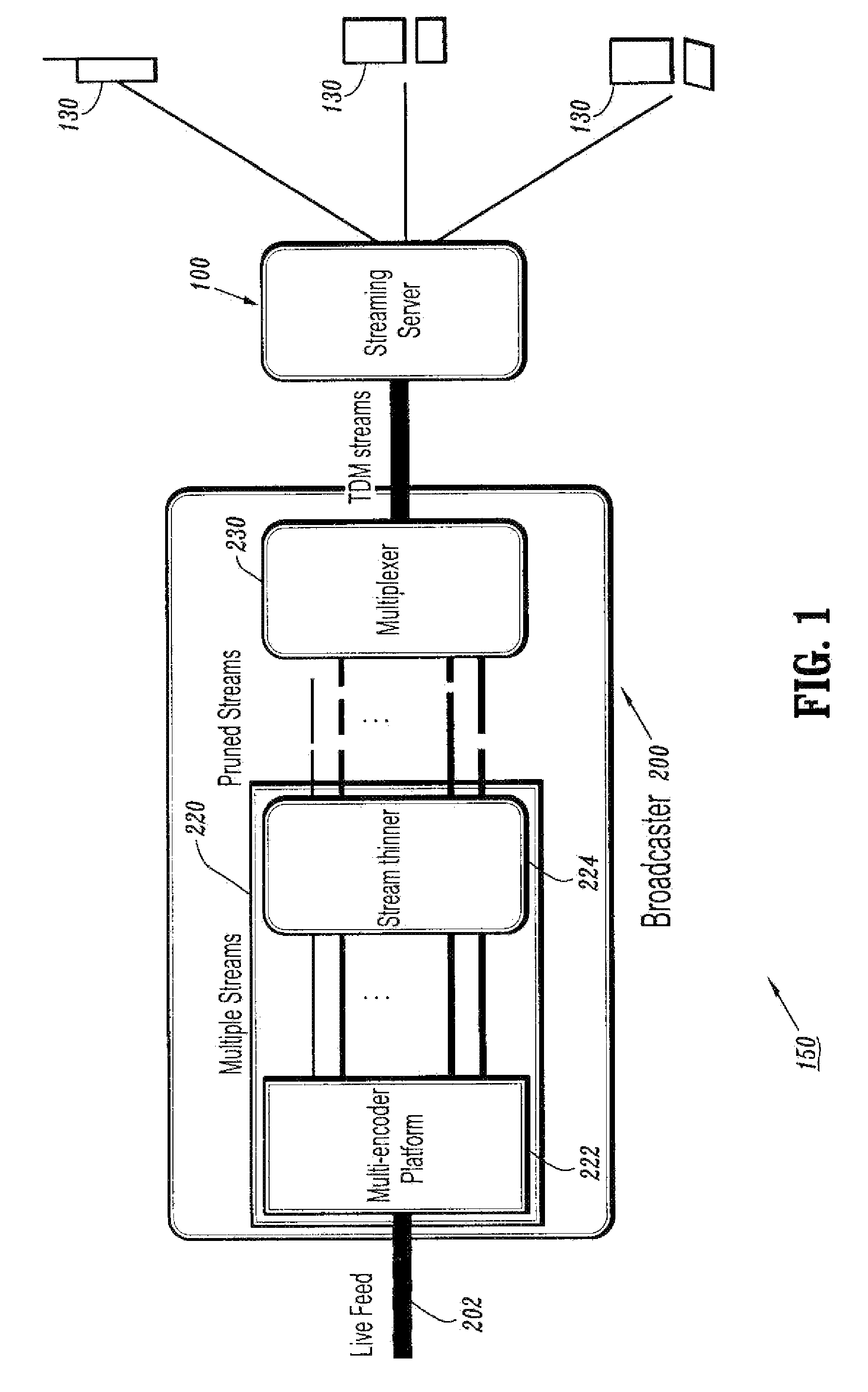

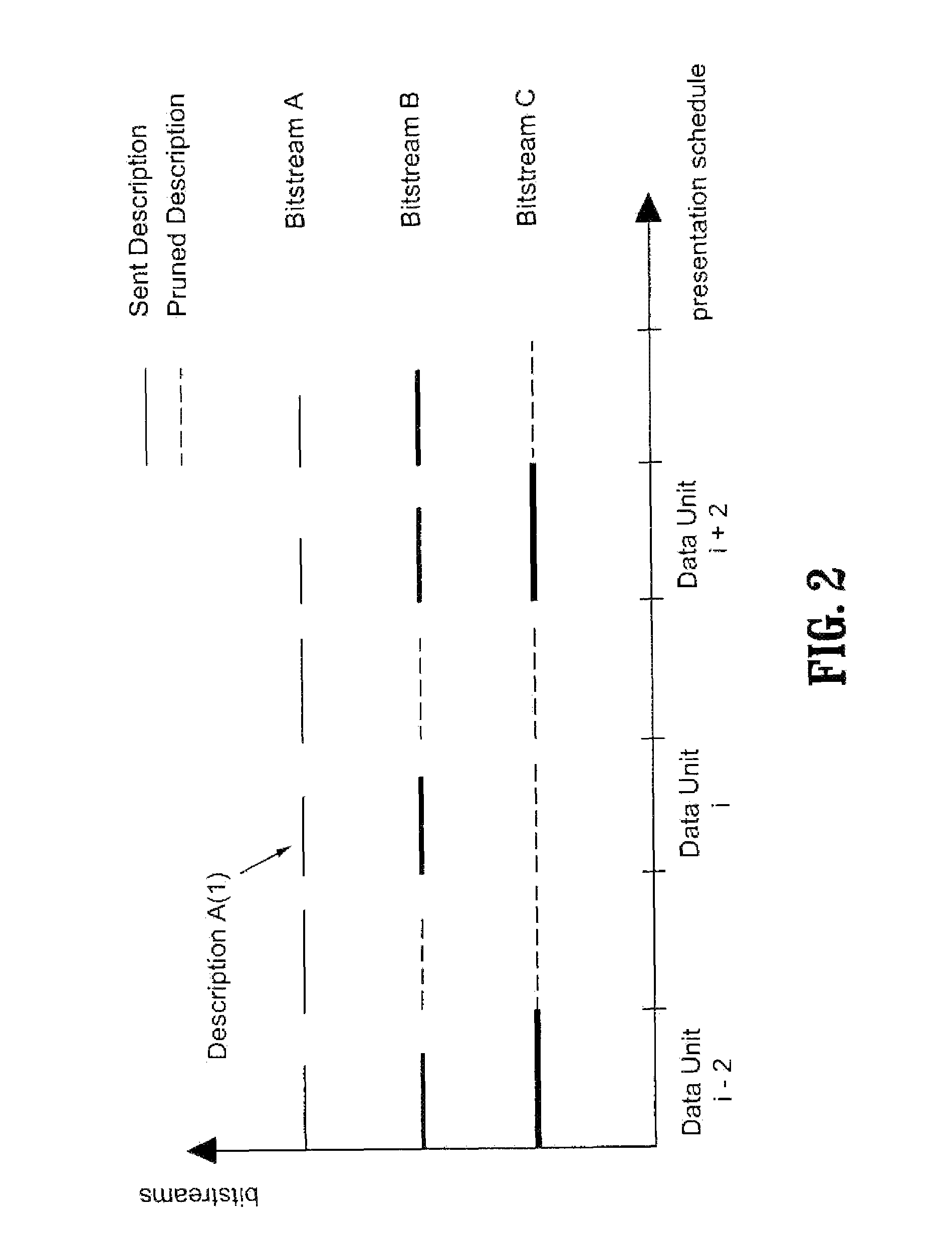

System and method for resource-efficient live media streaming to heterogeneous clients

InactiveUS20040215802A1Multiple digital computer combinationsSecuring communicationQuality of serviceTransmission channel

A resource-efficient live streaming system includes a broadcaster and a streaming server. The broadcaster receives a live feed and broadcasts a media stream to the streaming server containing several descriptions of the live feed along with control information. The broadcaster includes a stream thinner that implements a pruning algorithm. If descriptions from different streams are similar enough, one or more of them may be discarded without penalizing the quality of service perceived by the receivers. The streaming server assembles compressed data units into streams according to the control information from the broadcaster. The streaming server may also gather client feedback in order to estimate the status of the transmission channels and forwards the information to the broadcaster. The streaming server builds and streams media information to clients according to user preferences and receiver capabilities.

Owner:IBM CORP

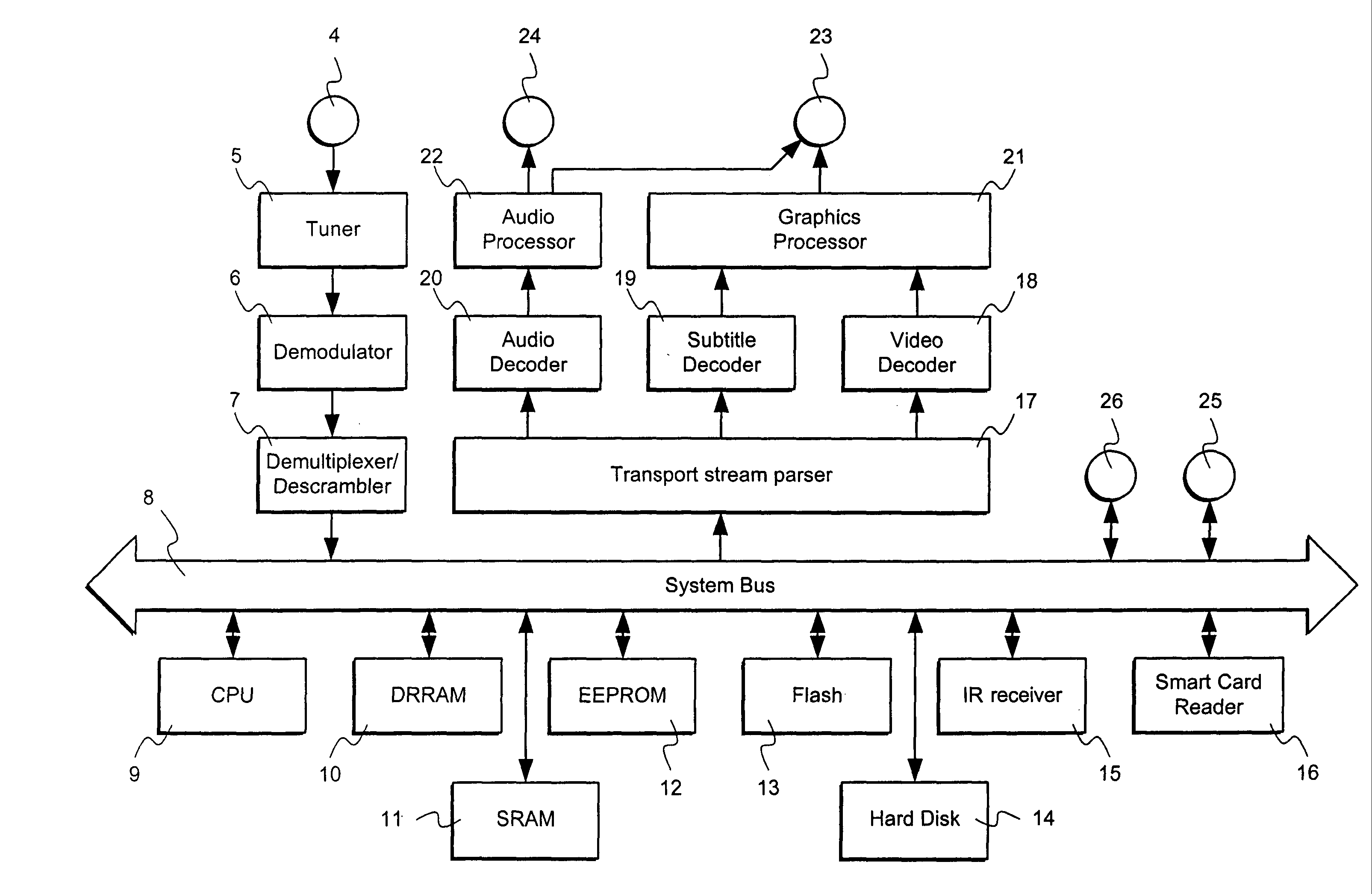

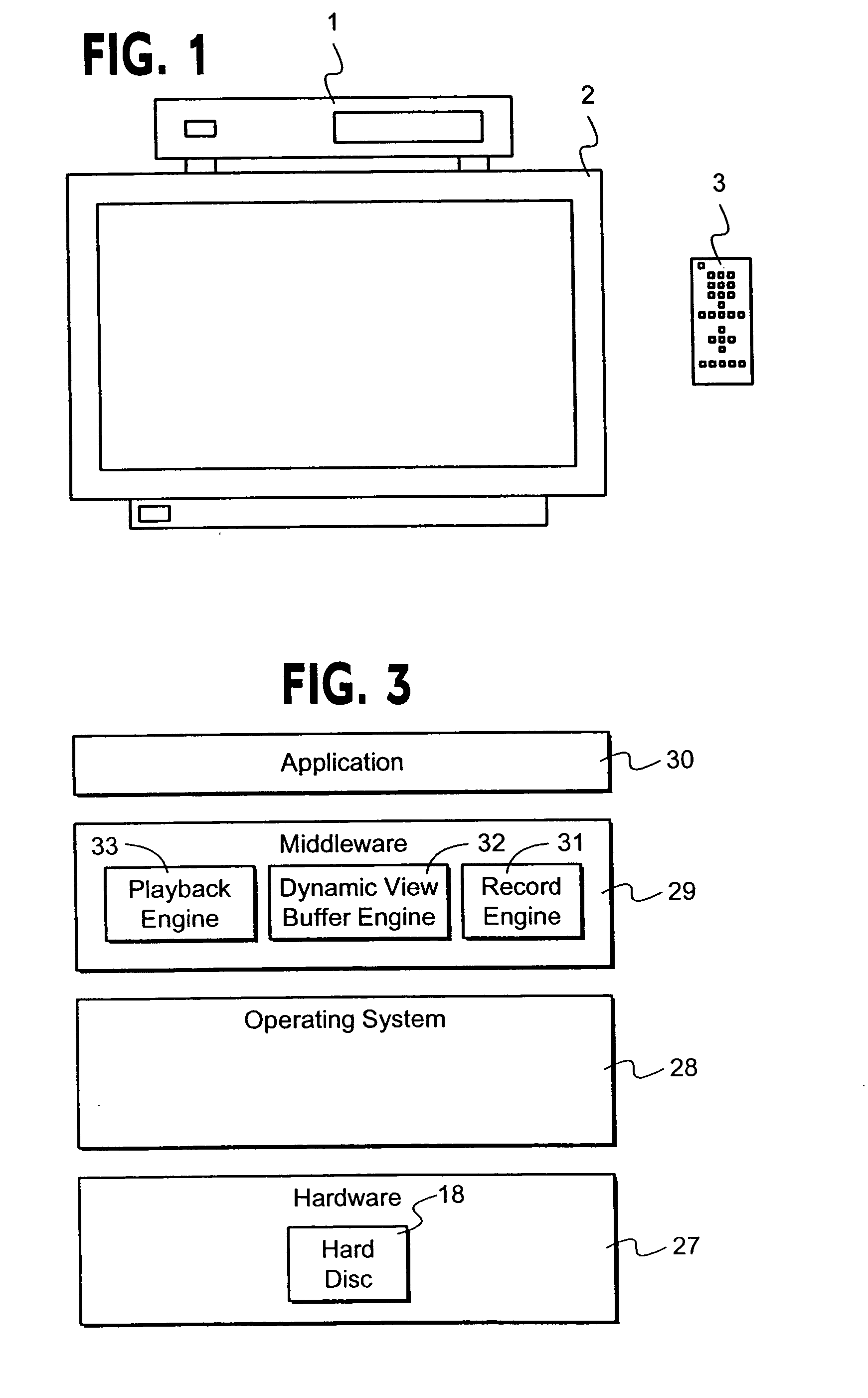

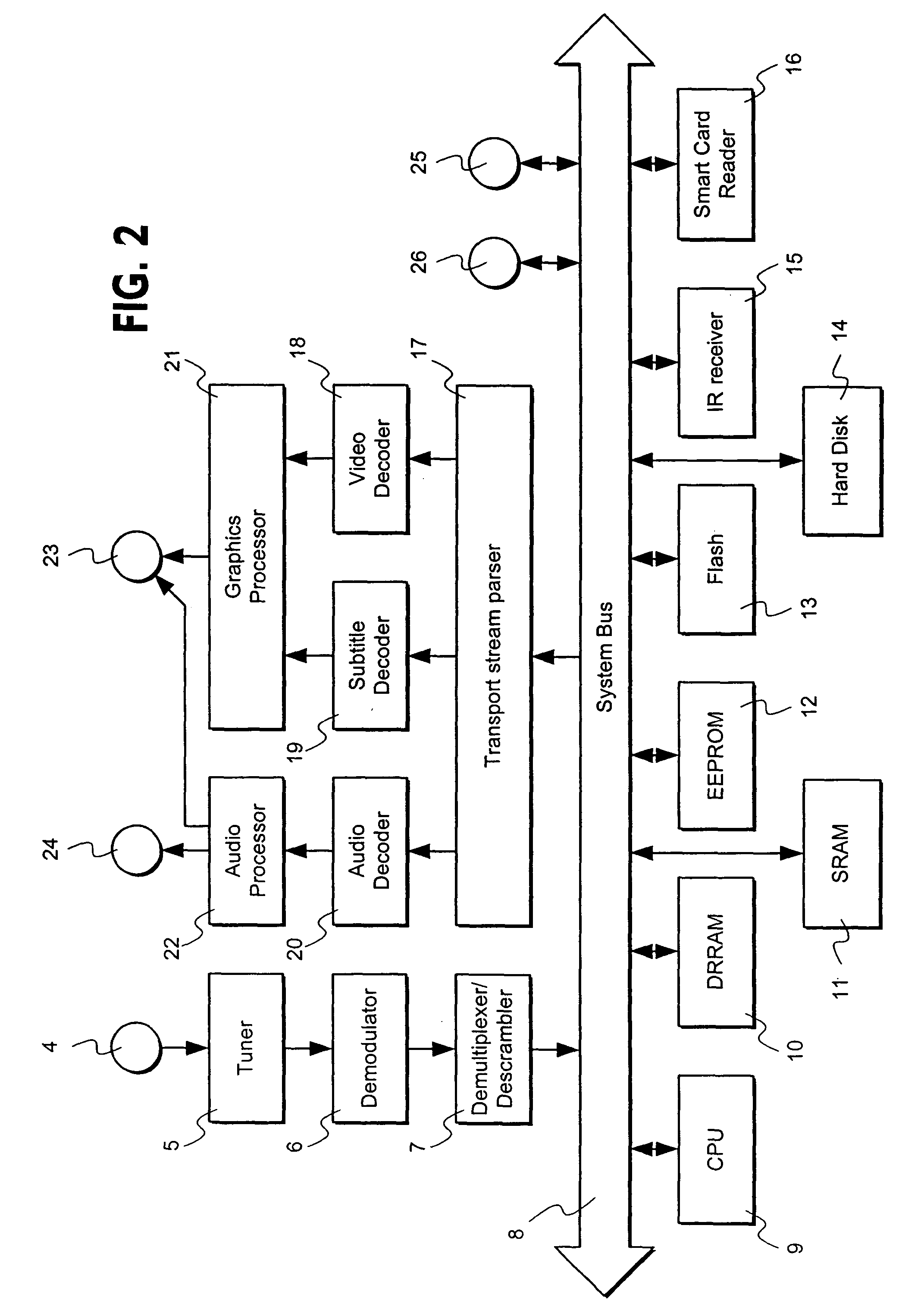

Method of digital recording

InactiveUS20030219234A1Television system detailsDisc-shaped record carriersHard disc driveDigital recording

A digital television receiver in the form of a set-top box includes a hard disk drive for storing a dynamic view buffer (34). Content from a live feed (40) is continuously stored in the buffer. The buffer can then be accessed at different points, thus allowing playback to be time-shifted. A cropping operation, whereby content is removed from the beginning (37) of the buffer is used to keep the size of the buffer in check. Cropped data can be used to create new record files.

Owner:NOKIA CORP

Curled-lip mandarin fish and spot and spotted mandarin fish hybridizing propagation process

InactiveCN101066046AFast growthPromote growth rateAnimal reproductionClimate change adaptationDiseaseBroodstock

The curled-lip mandarin fish and spotted mandarin fish hybridizing propagation process includes the following steps: 1. reinforced culturing curled-lip mandarin fish as female parent fish and spotted mandarin fish as male parent fish; 2. injecting exogenous hormone to promote mature and induce spawning, flowing water stimulating to promote spawning, artificial dry insemination and managing during hatching, so as to reach spawning rate over 80 %, fertility rate up to 83.5 % and hatching rate up to 89 %; and 3. staged culturing of the hybrid mandarin fish and feeding habit conversion from live fish to non-live feed, so as to reach survival rate of hybrid mandarin fish fry up to 60 %. The hybrid mandarin fish has good taste, high disease resistance, high growth speed and capacity of ingesting non-live fish feed.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

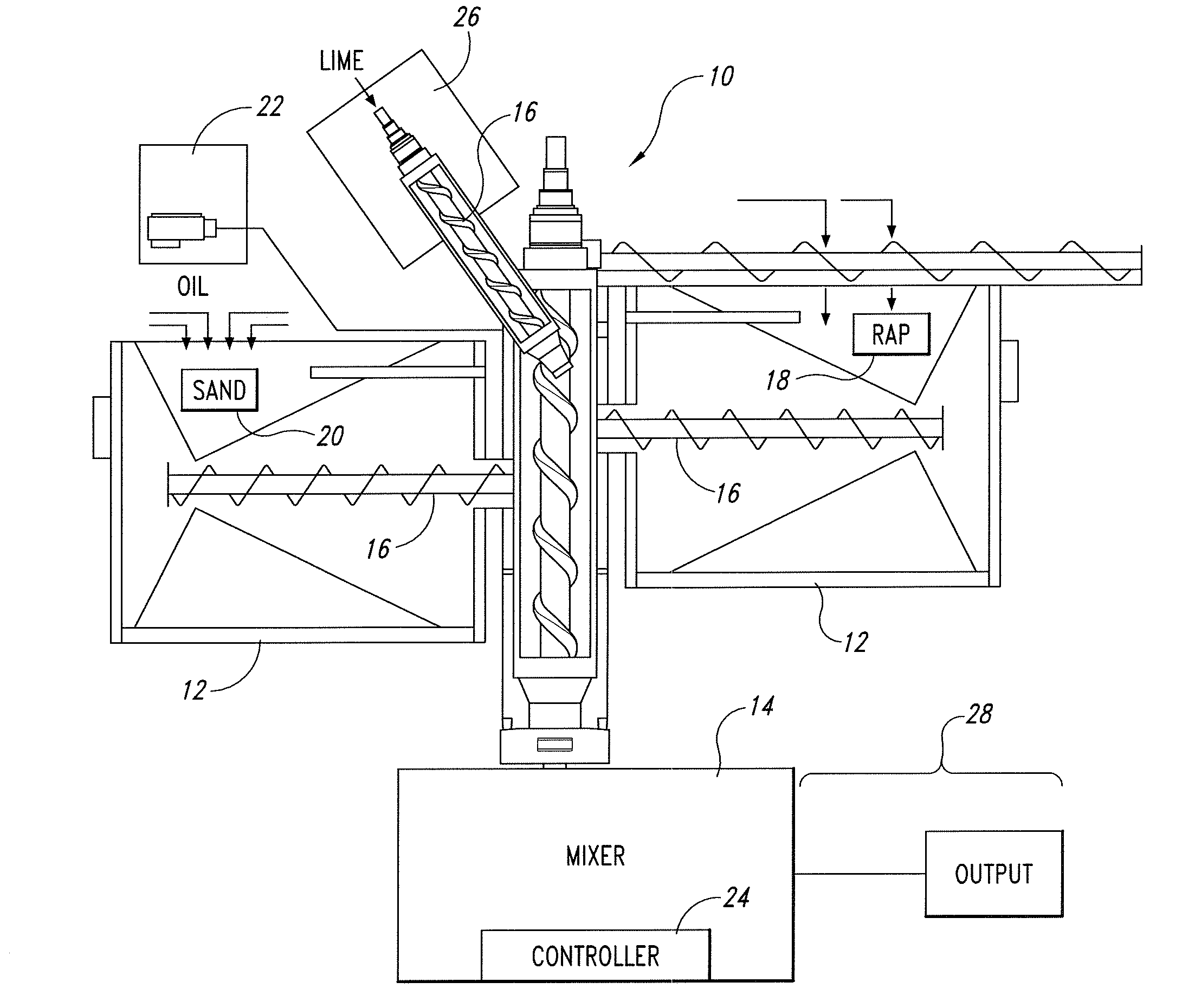

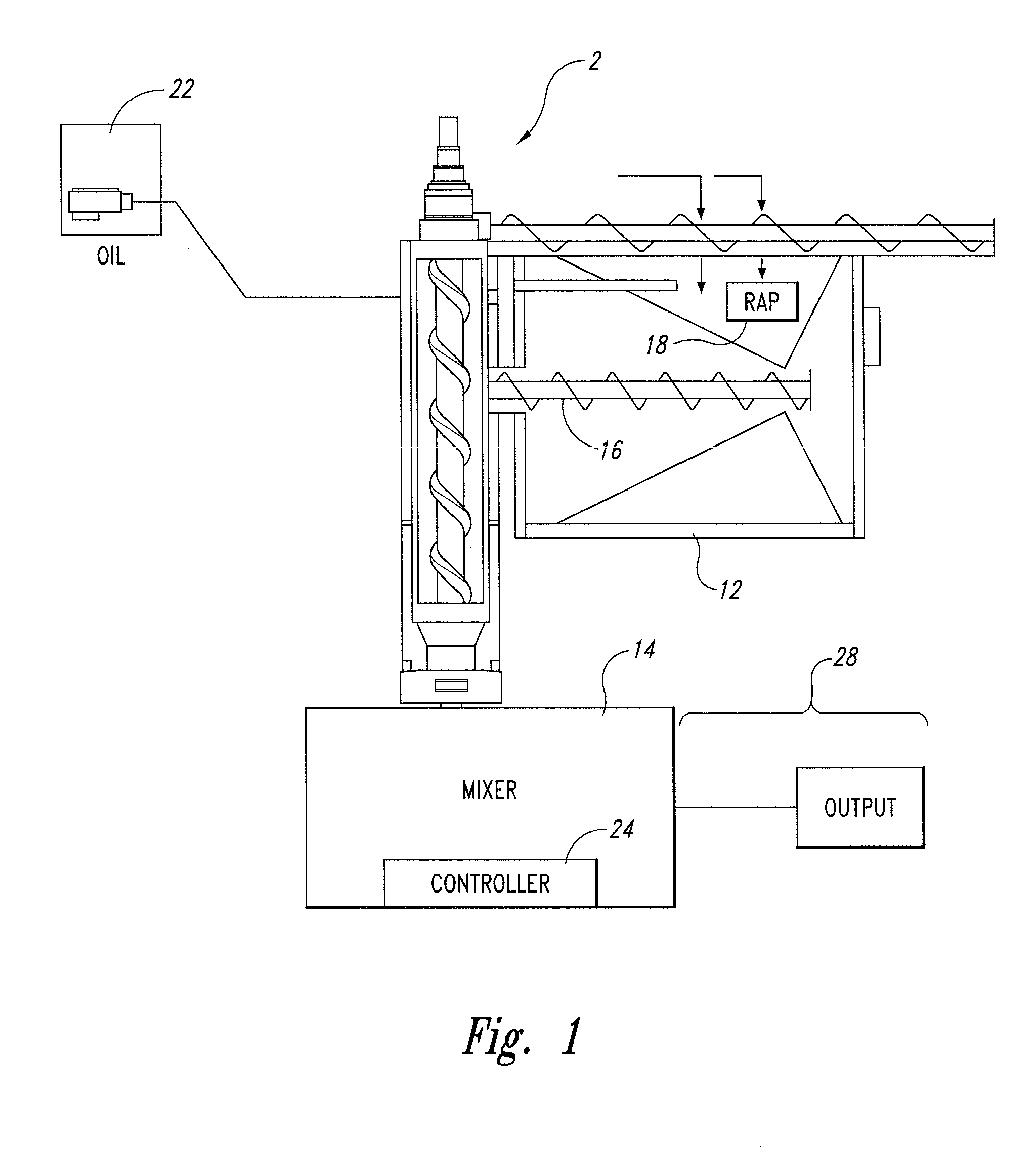

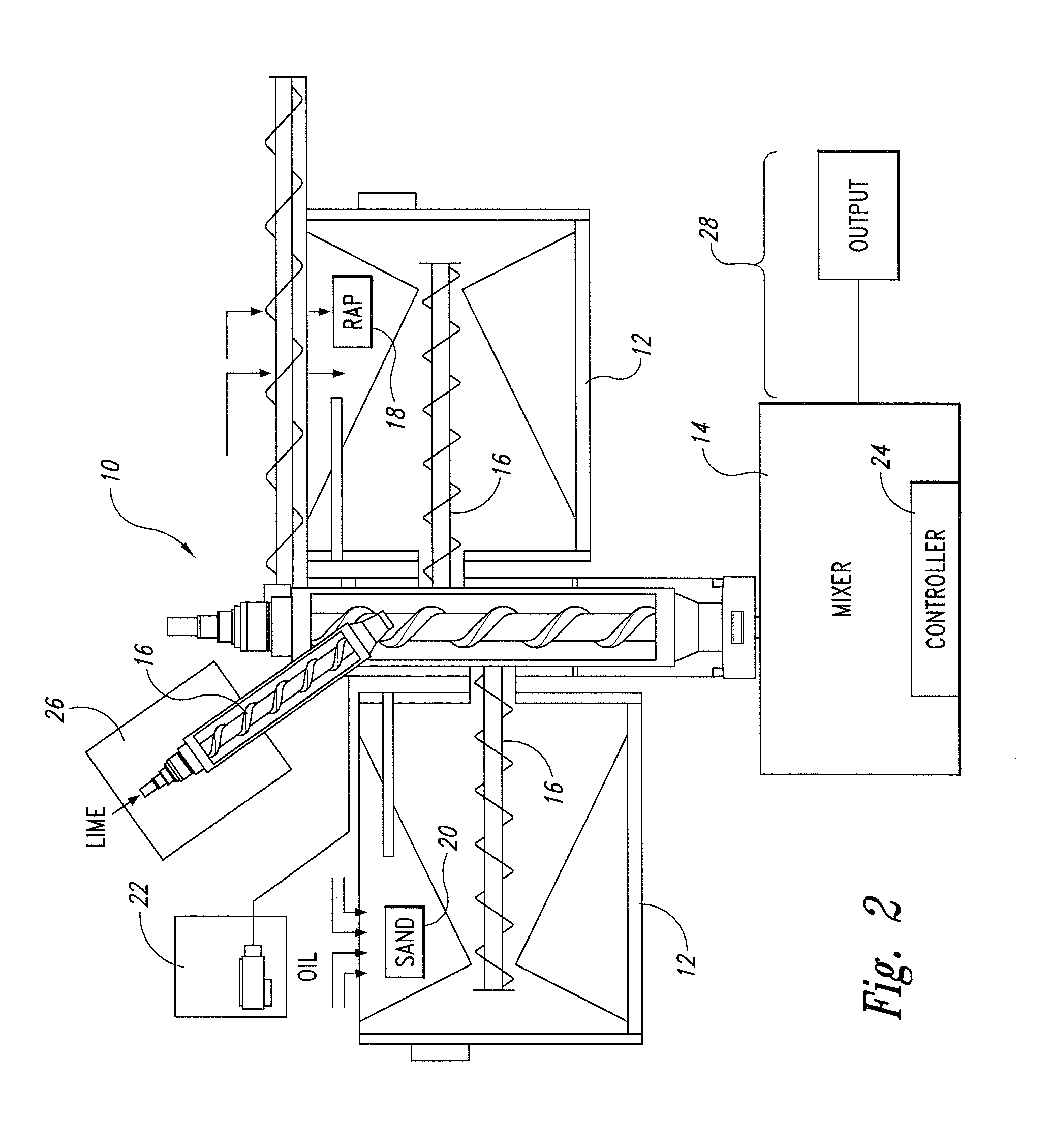

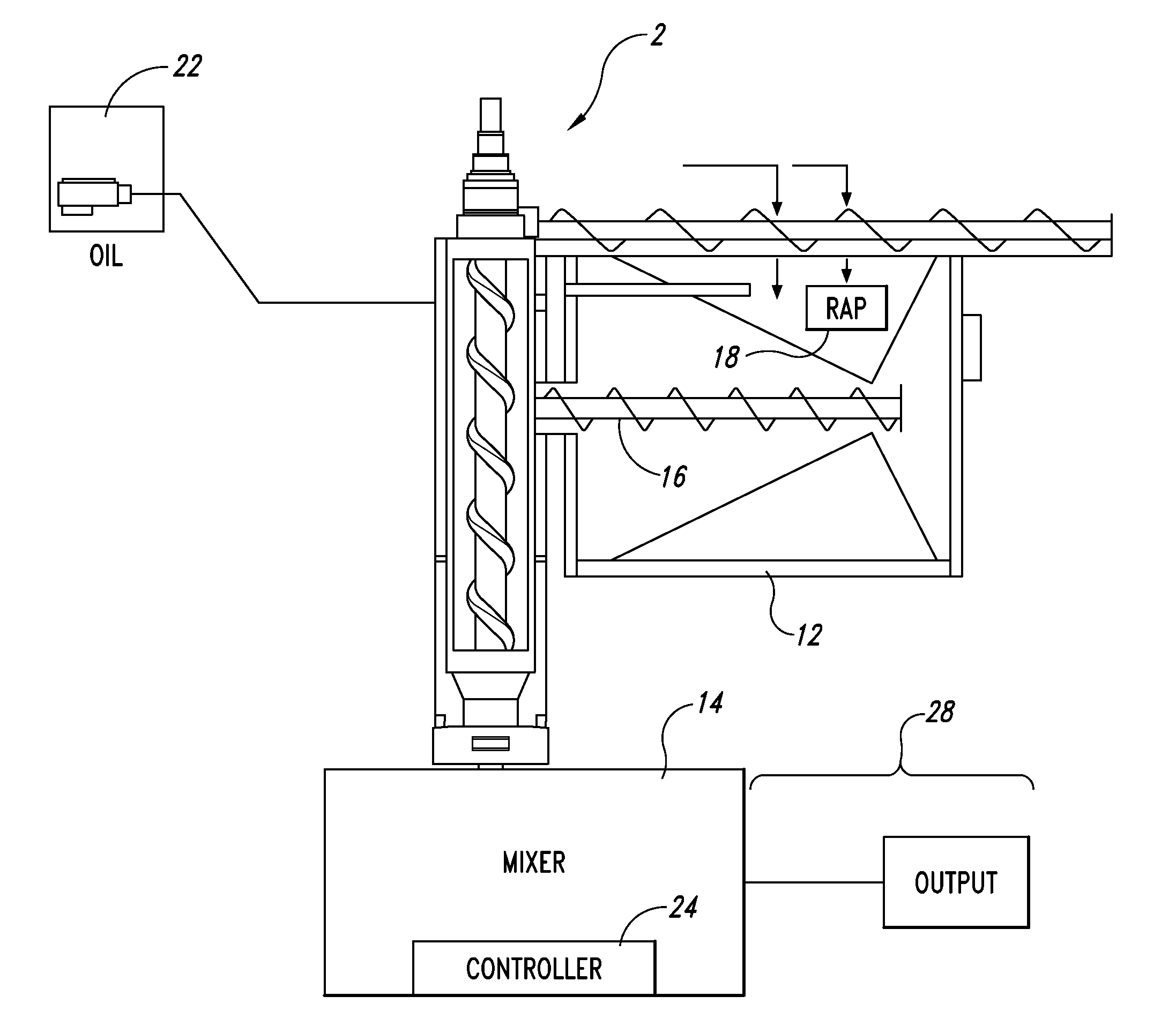

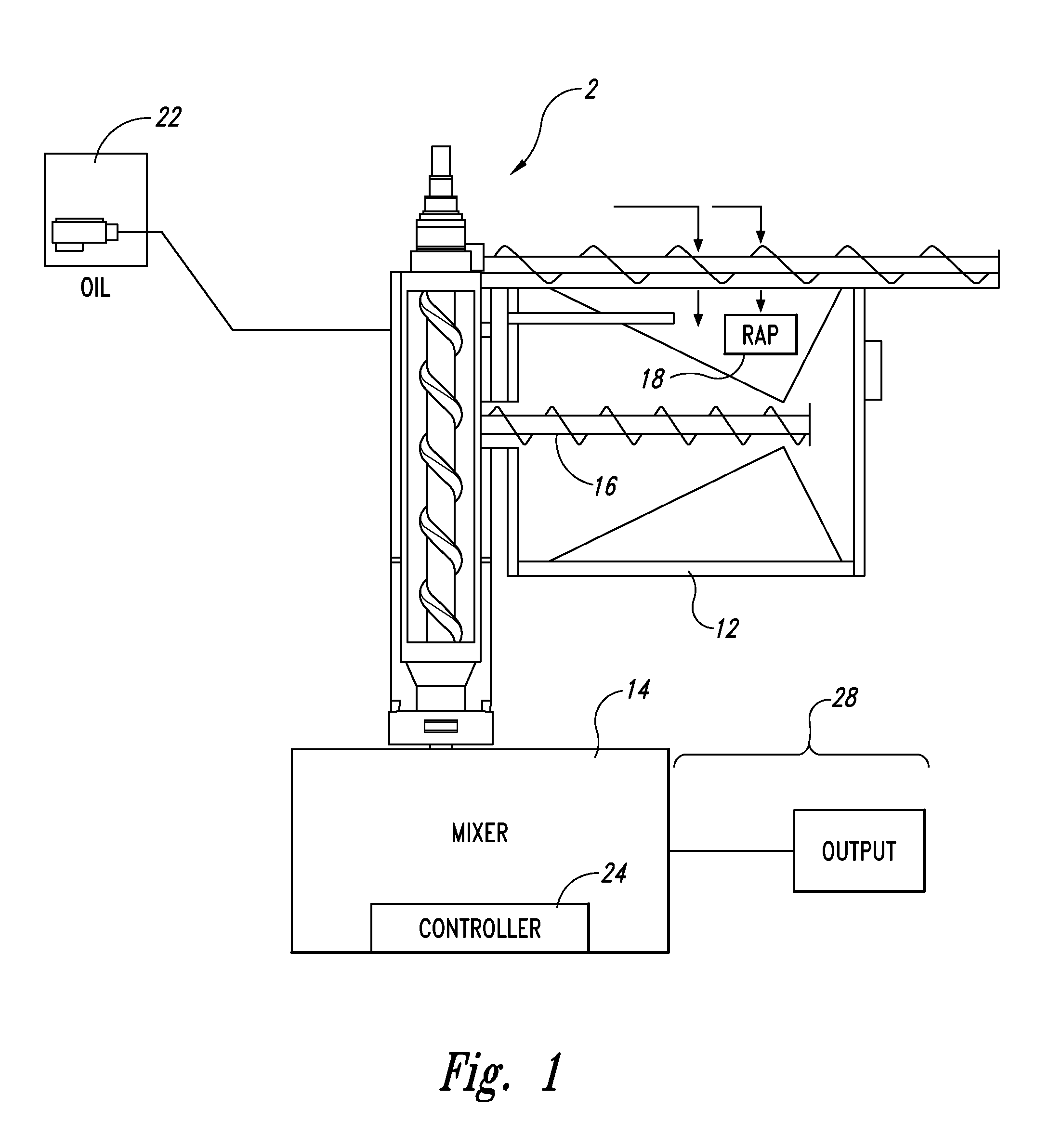

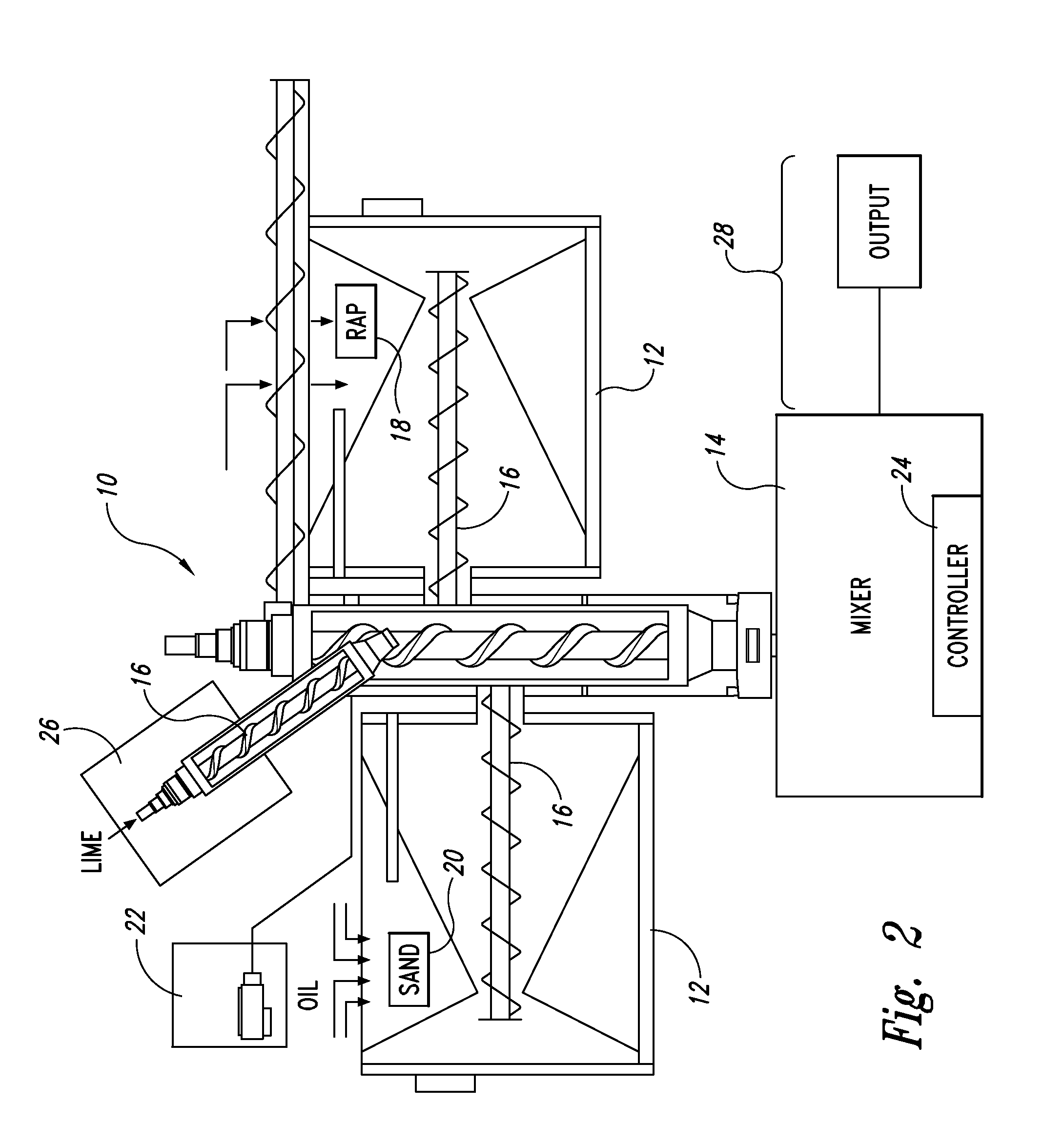

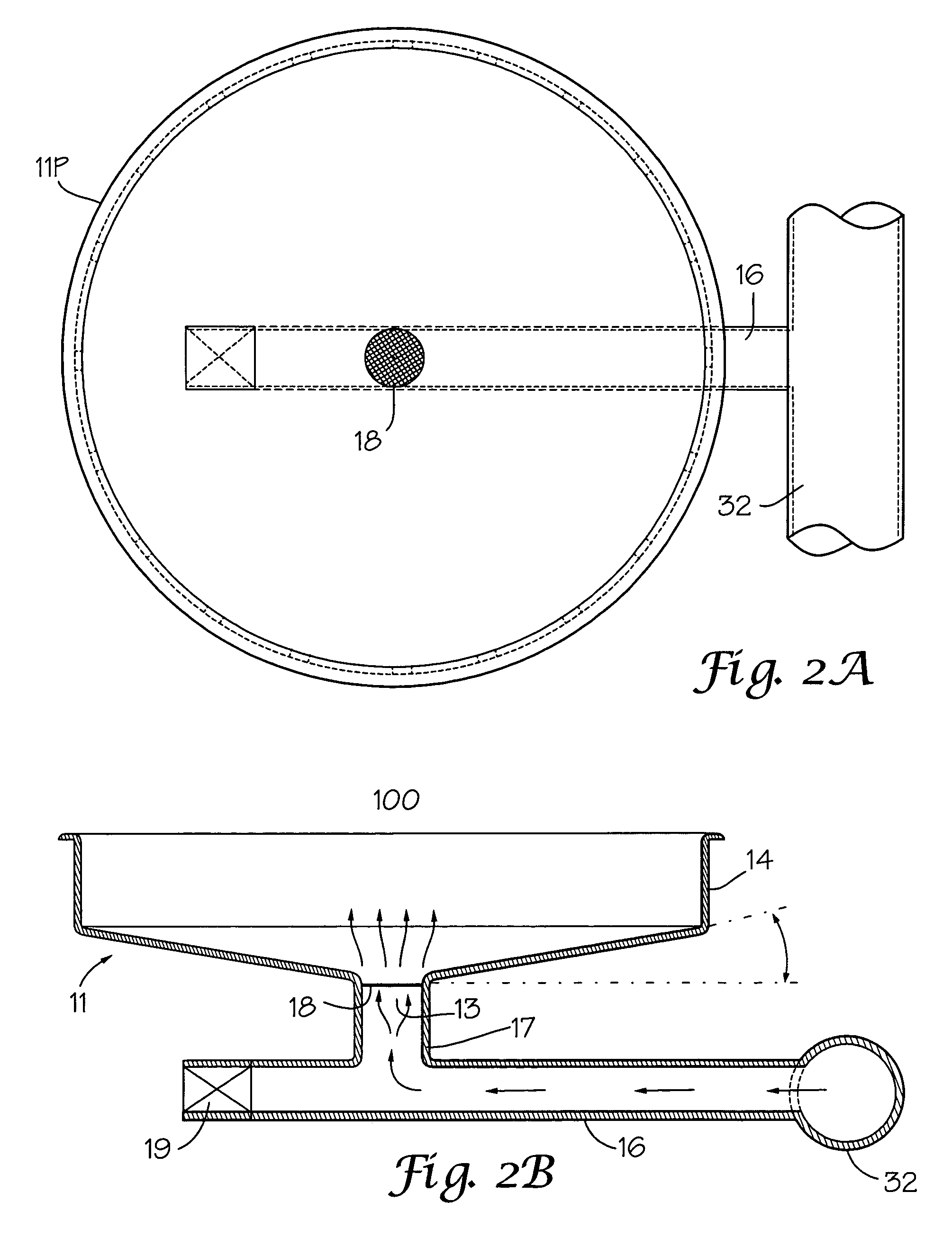

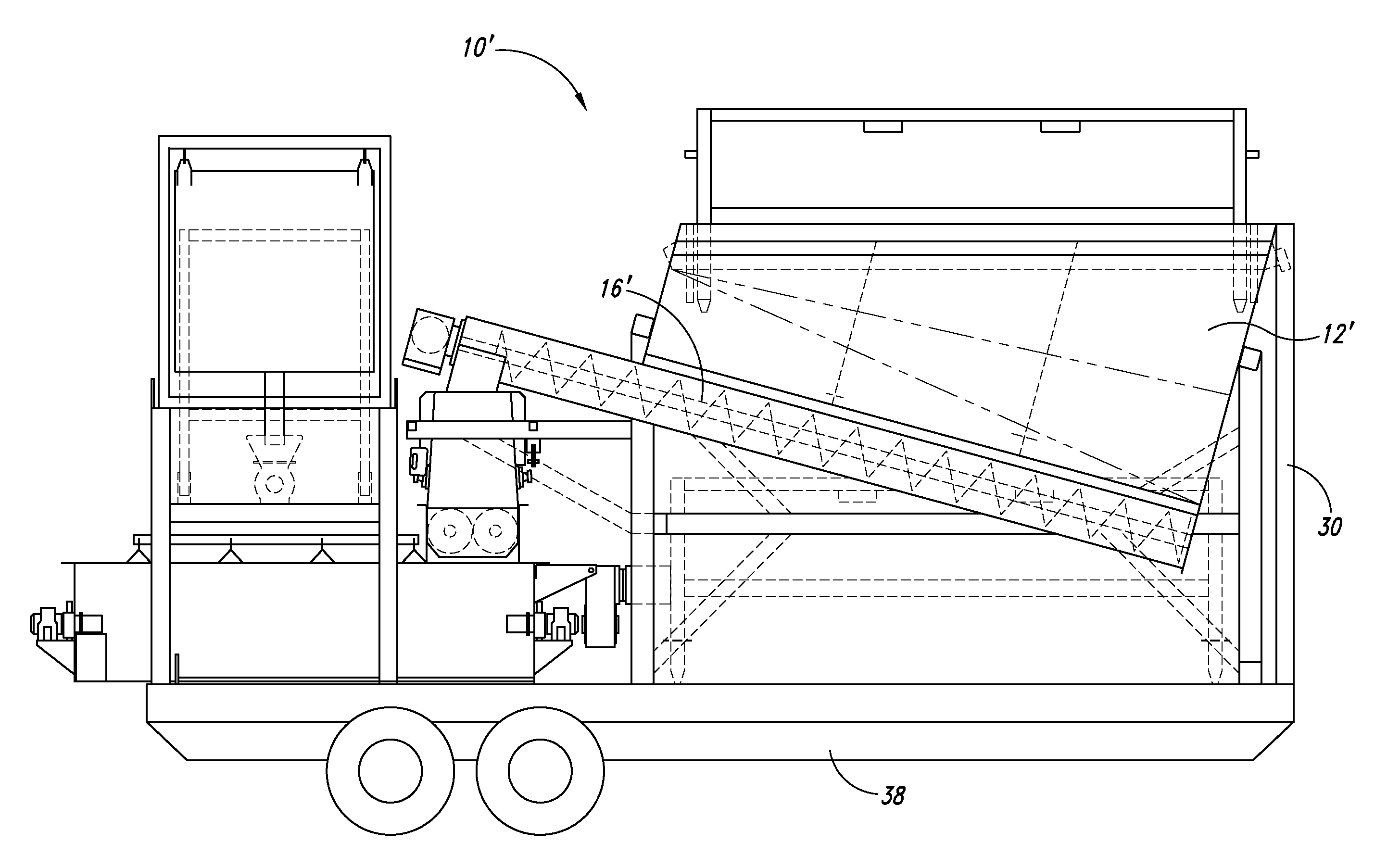

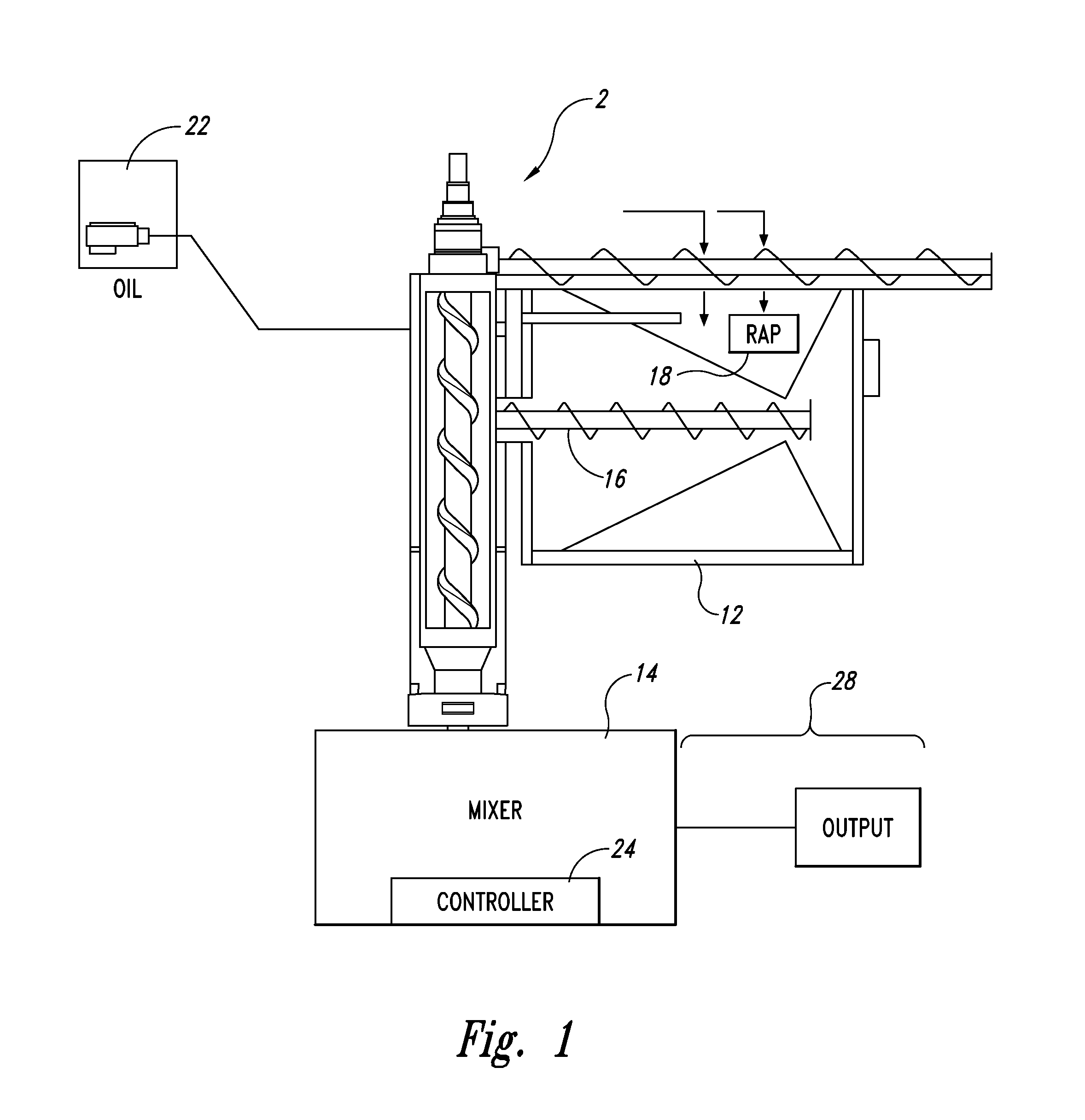

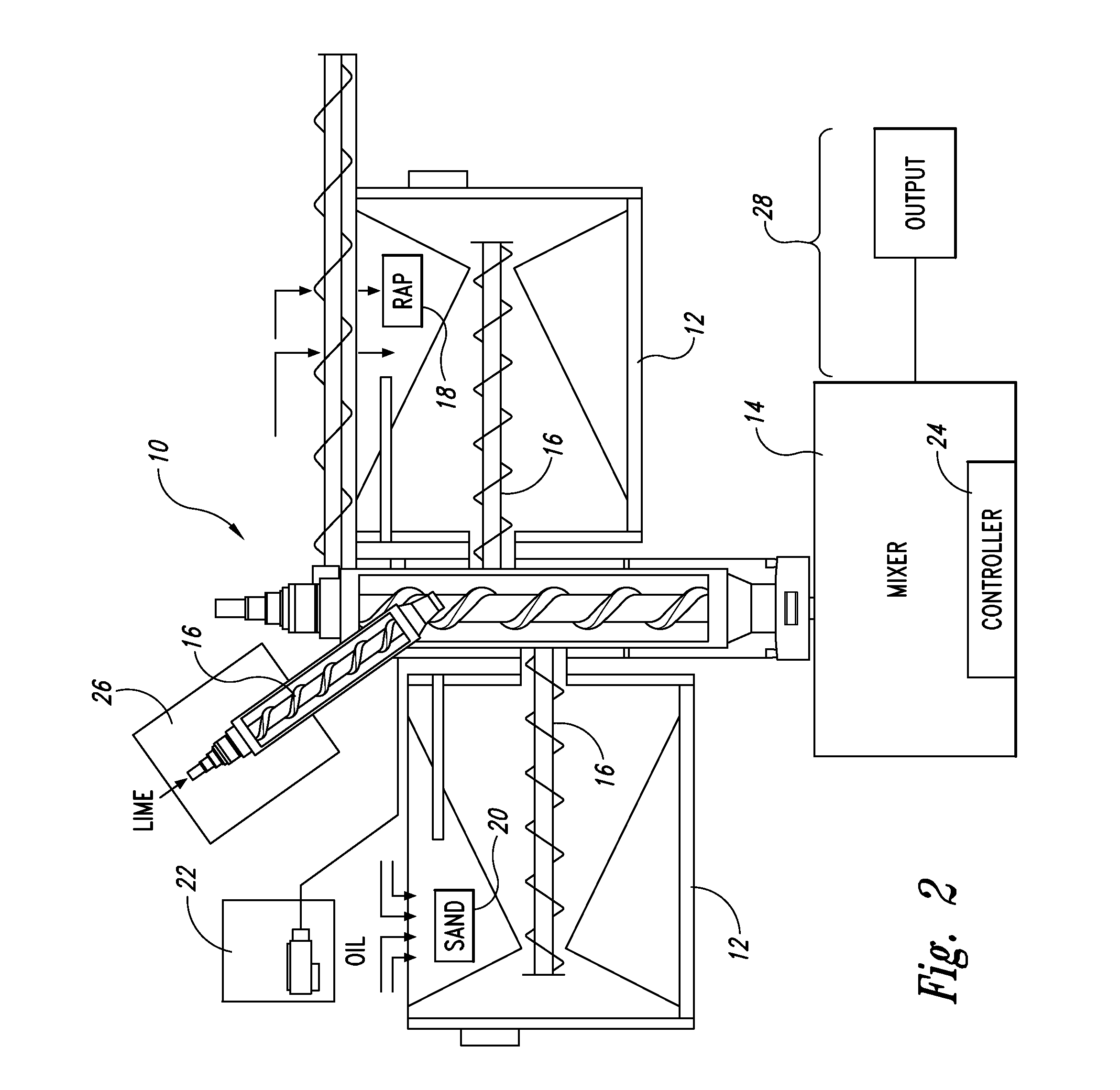

Apparatus for producing cold asphalt, method of manufacturing cold asphalt, and product-by-process for same

InactiveUS20100000442A1Less spaceEfficient productionMixing operation control apparatusRoads maintainenceParticulatesSand granules

Apparatus for producing cold asphalt, such as for road repair and construction, that allows cold asphalt to be easily produced at or near the job site. The apparatus includes at least one hopper for receiving screened particulates, an optional second hopper for granular materials, e.g., sand, a live feed for additive oil, and another for optional lime, conveyors in which to convey the granular and screened particulates, oil, and optional lime to a mixer. The mixer is controlled through a controller that is programmed to determine the correct proportion of RAP (recycled asphalt and a small amount of new asphalt), optional sand (silicates and / or sieved RAP), additive hydrocarbon oil, and optional lime (limestone powder). The apparatus may be permanently installed to create a cold asphalt manufacturing plant or placed on a trailer for use at a construction site. The invention further includes a heatless method of manufacturing cold asphalt through the introduction of RAP, additive oil, and optional sand and lime into the apparatus and a product-by-process in which cold asphalt mix is produced through the process claimed in the method. The end product is essentially non toxic with little to no VOCs and HAPs, has long shelf-life, and is produced, stored, used, and compacted at ambient temperature.

Owner:YK HLDG

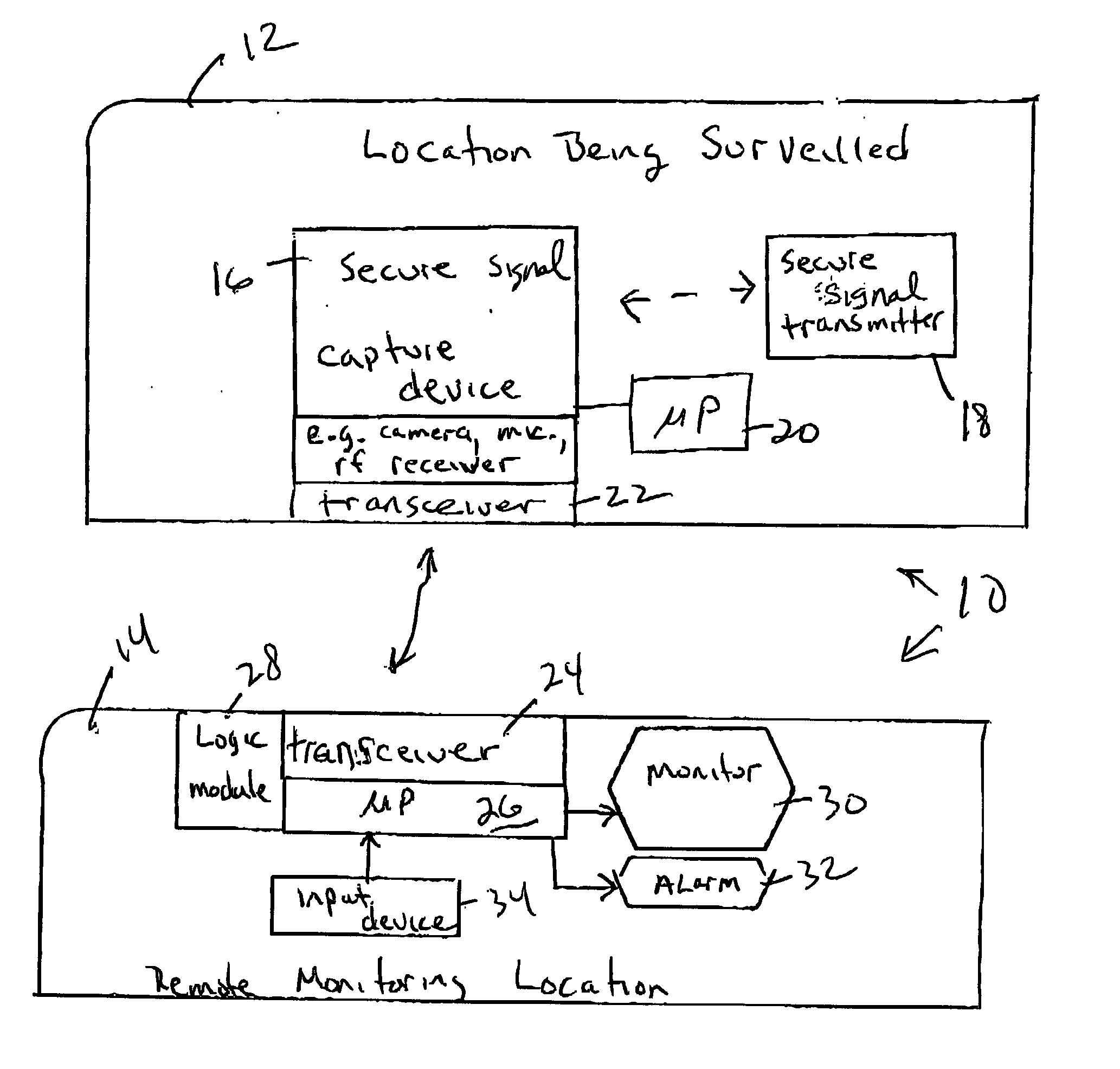

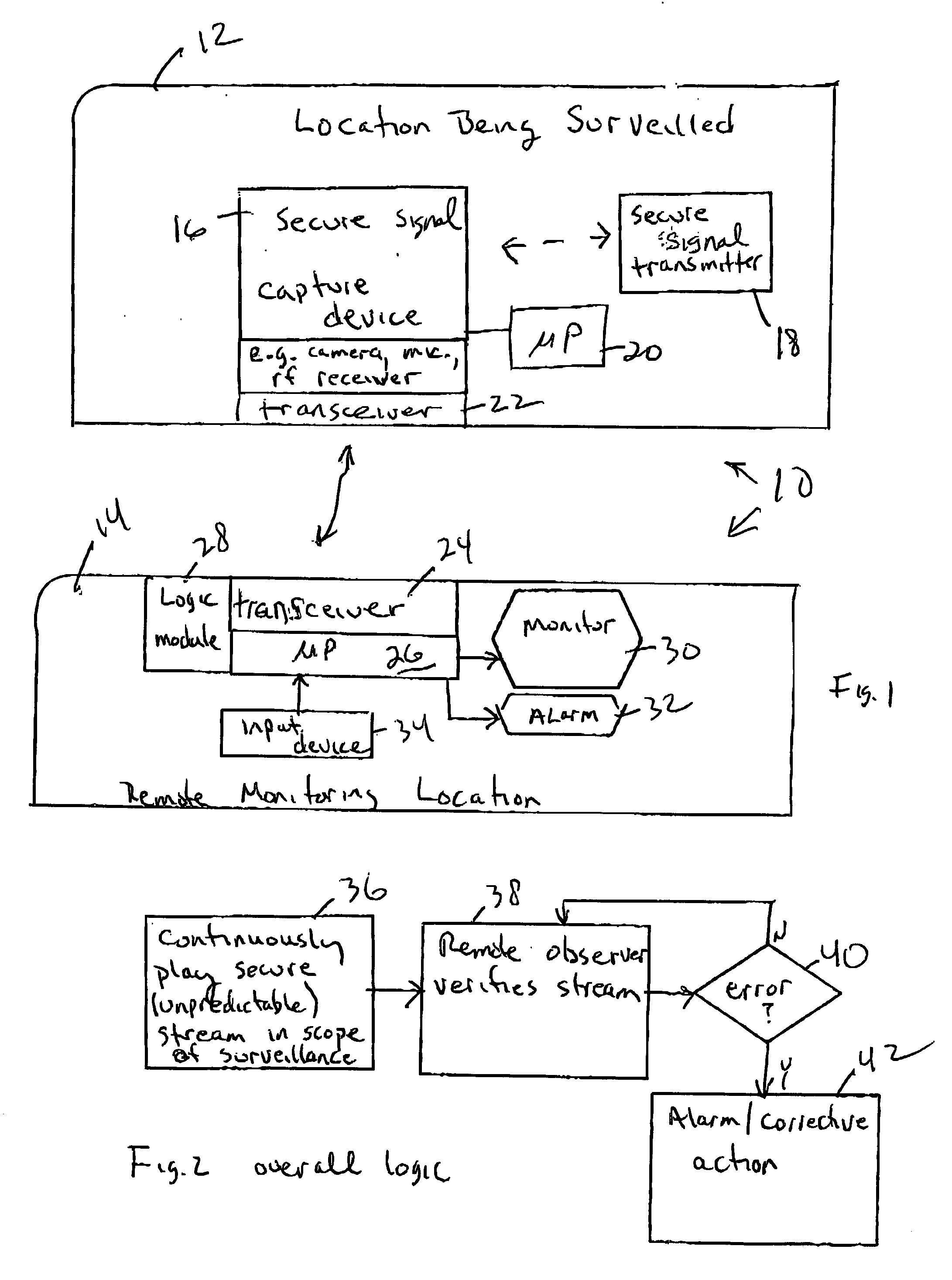

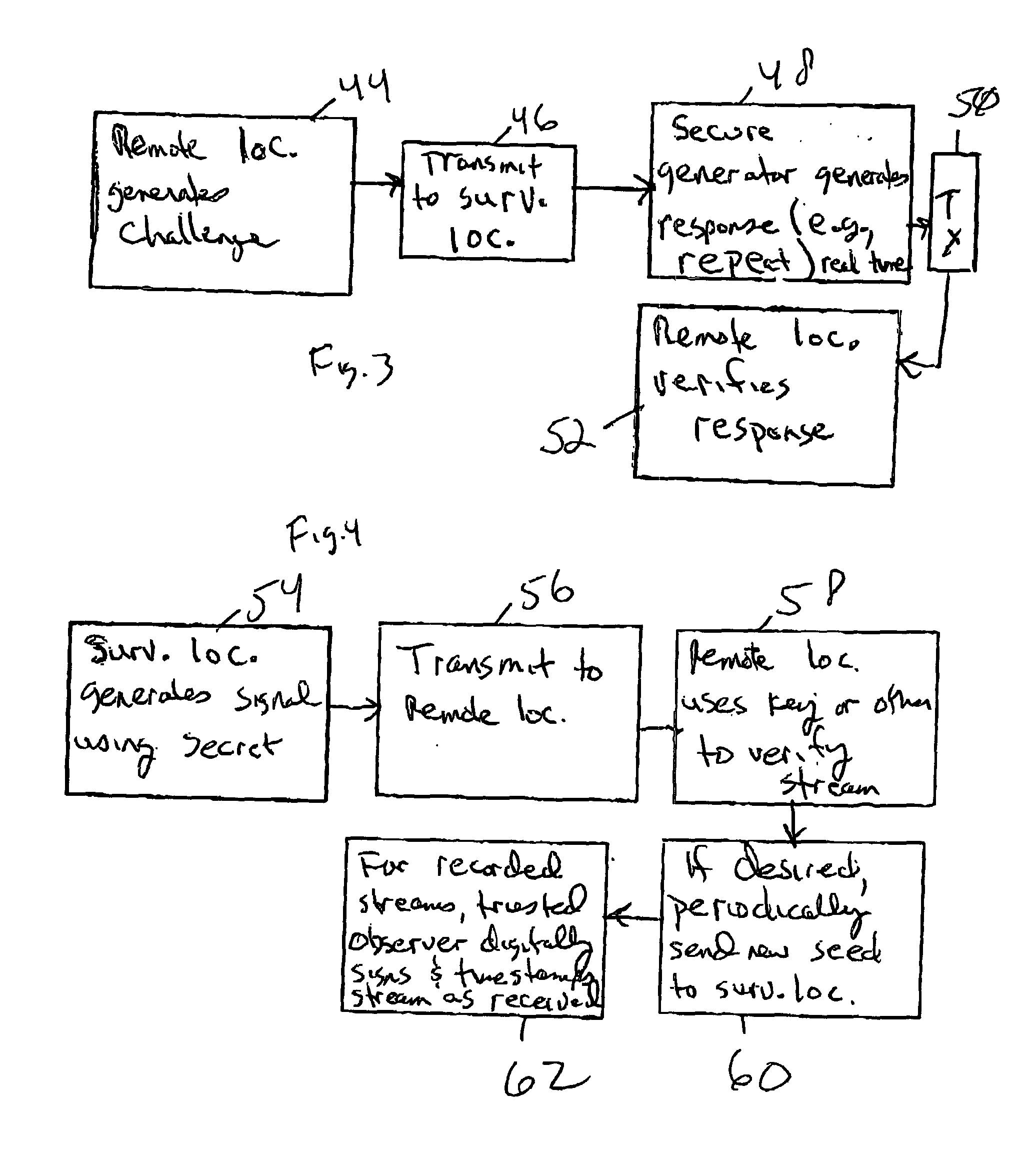

System and method for authenticating live feed from surveillance system

InactiveUS20040075555A1Electric signal transmission systemsMultiple keys/algorithms usageComputer hardwareStream capture

A secure signal transmitter, such as an LED, is disposed in an intended observation scope of a secure stream capture device, such as a video camera. The secure signal transmitter continuously transmits a secure signal that an observer / processor in a remote location can verify, to thereby confirm that the video being sent from the camera actually encompasses the intended scope.

Owner:QUALCOMM INC

Method and system for meta-tagging media content and distribution

ActiveUS8543622B2Easy accessMaximize the cutting edge elements of multi-media—CommunityMultimedia data indexingDigital data processing detailsWeb siteElectronic communication

Owner:GIBLIN PATRICK

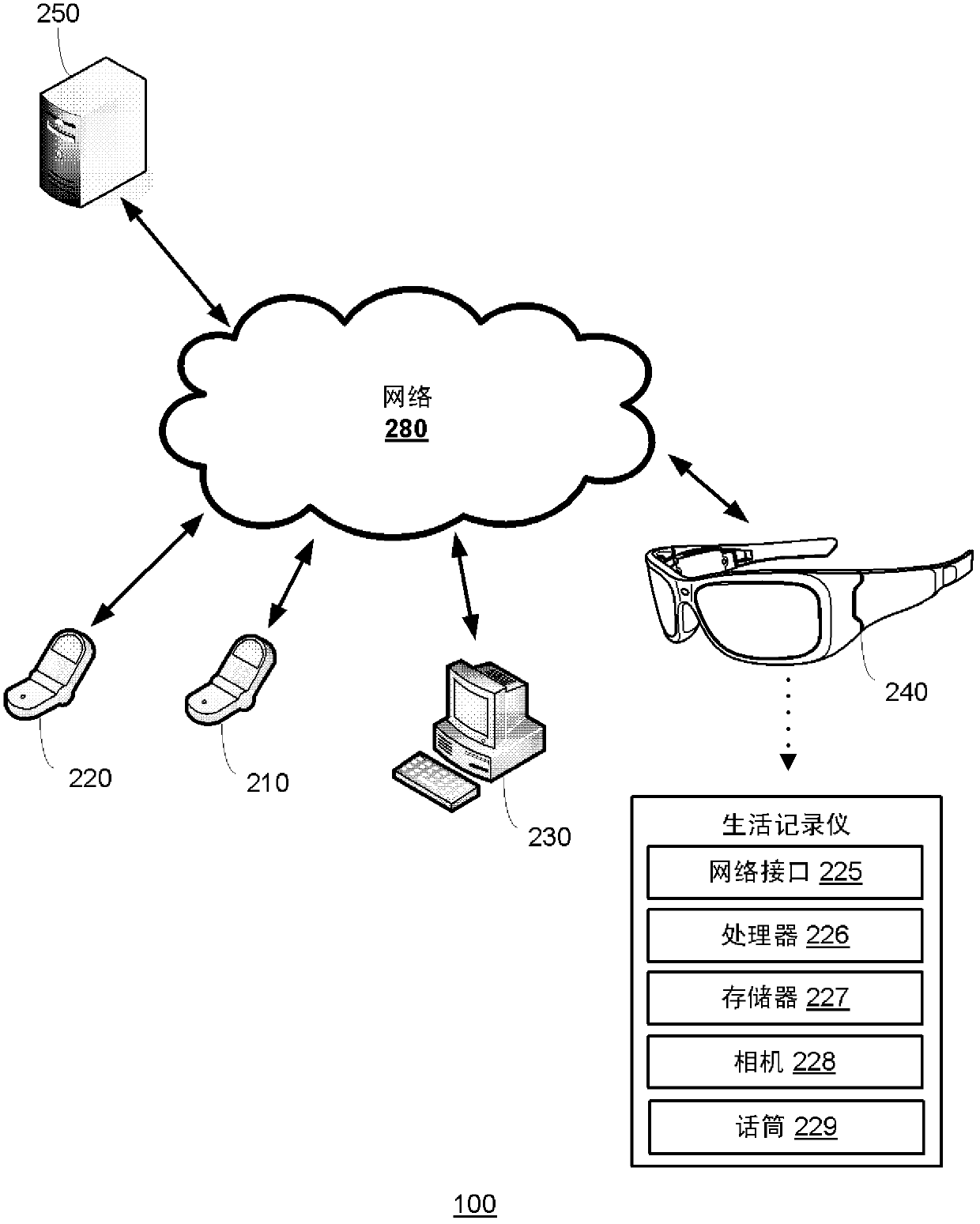

Life streaming

A system and method for analyzing, summarizing, and transmitting life experiences captured using a life recorder is described. A life recorder is a recording device that continuously captures life experiences, including unanticipated life experiences, in video and / or audio recordings. In some embodiments, the video and / or audio recordings generated by a life recorder are automatically summarized, indexed, and stored for future use. By indexing and storing life recordings, a life recorder may search for and acquire life recordings generated by itself or another life recorder, thereby allowing life experiences to be shared minutes or even years later. In some embodiments, recordings generated by a life recorder may be analyzed in real-time and automatically pushed to one or more target devices. The ability to automatically and instantaneously push life recordings as live feeds to one or more target devices allows friends and family to experience one's life experience in real-time.

Owner:MICROSOFT TECH LICENSING LLC

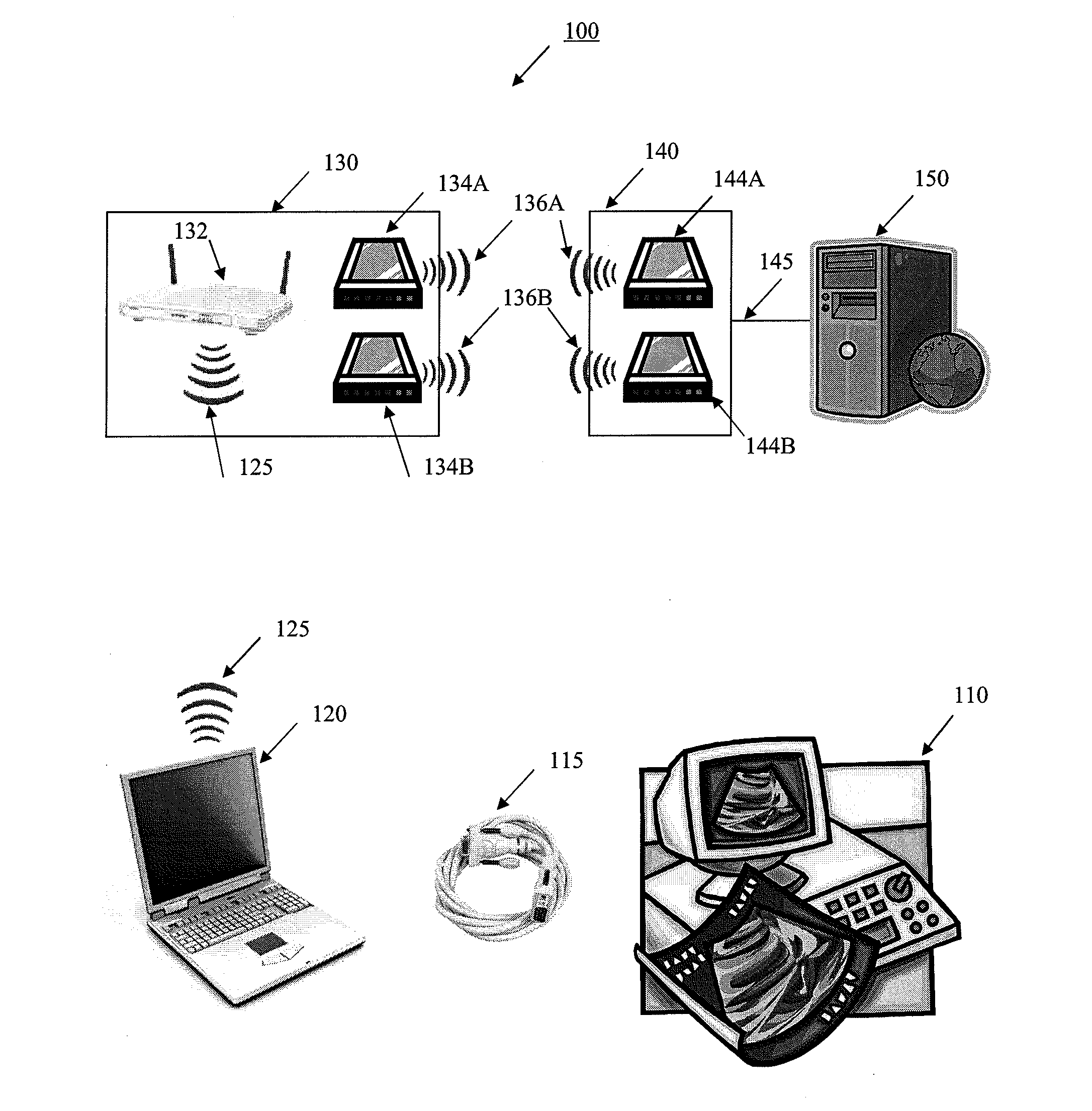

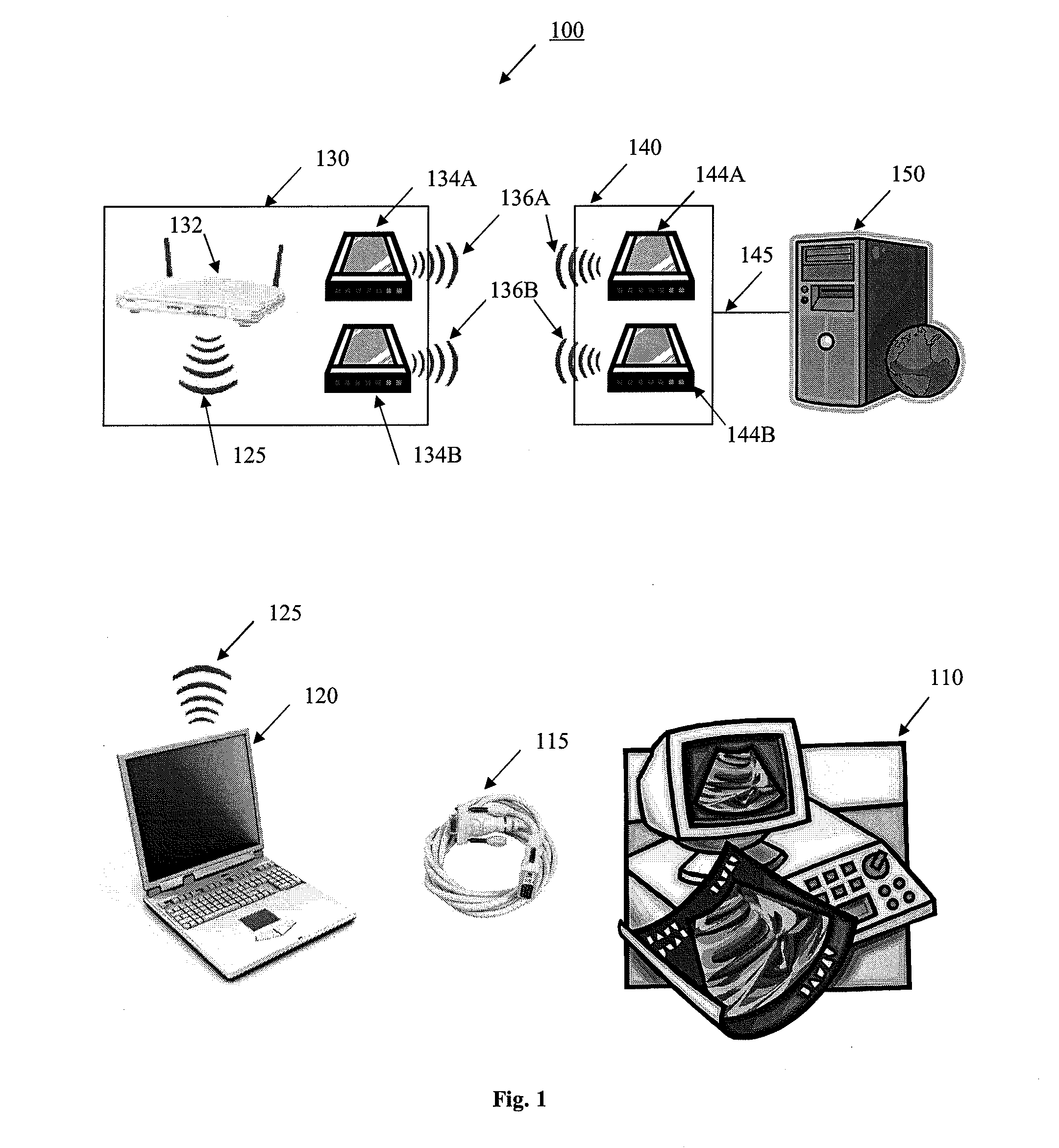

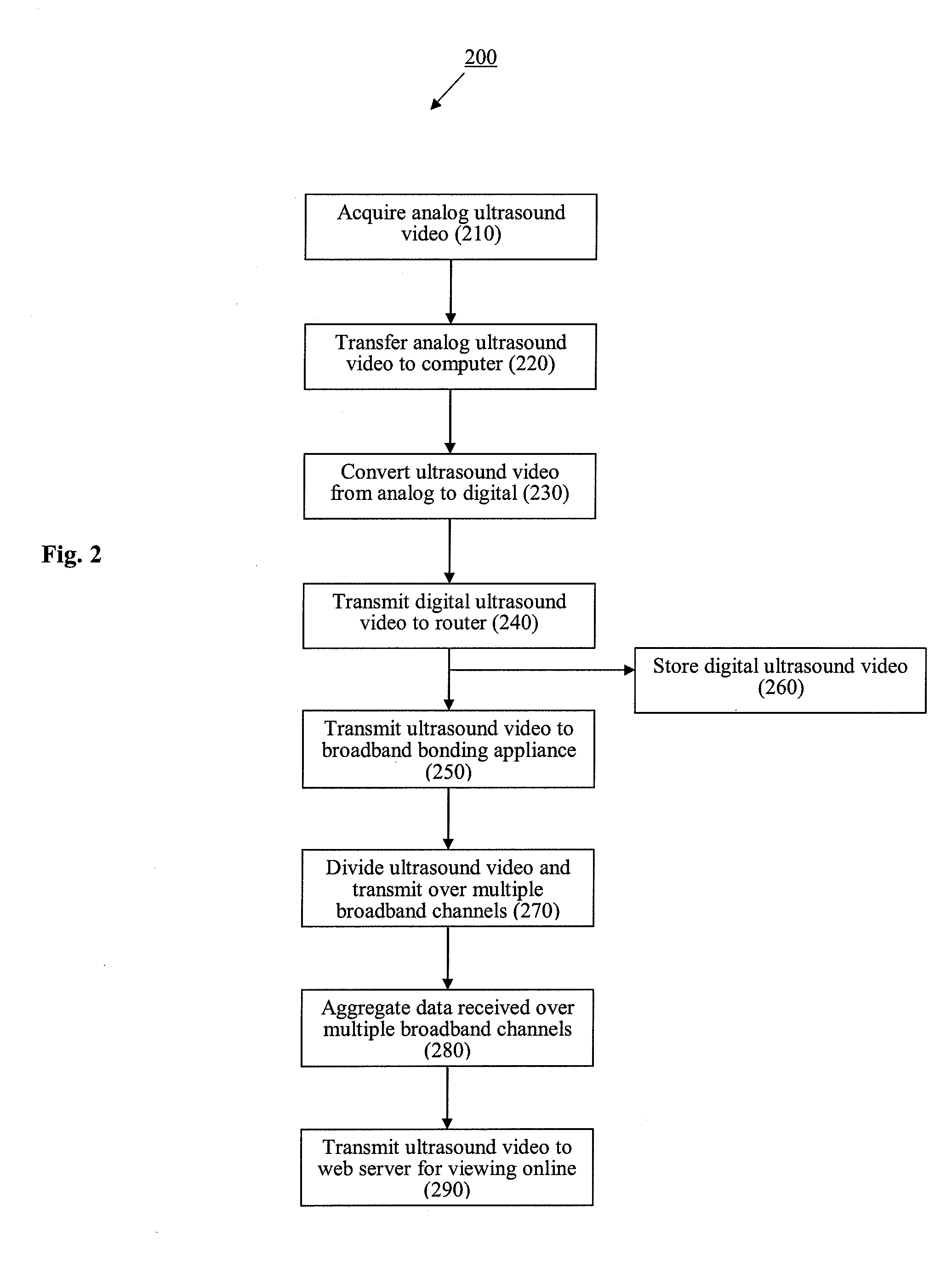

Live Feed Ultrasound Via Internet Streaming

InactiveUS20110249125A1Facilitates near real-time evaluationLarge infrastructure costUltrasonic/sonic/infrasonic diagnosticsTelemedicineSonificationComputer graphics (images)

The present invention provides, in at least one embodiment, a system and method for real time evaluation of ultrasound video images taken at a first local location and evaluated at a second remote location. The system transmits a continuous live video feed from a veterinary ultrasound at the first location to a viewer at the remote location for real time study, review, and collaboration. In the method, the ultrasound video images are converted from analog ultrasound video to digital ultrasound video, where the digital ultrasound video is processed into multiple streams and transmitted across multiple broadband channels, each channel carrying a different stream. The multiple streams are aggregated into a reconstituted video and displayed for evaluation at the remote location.

Owner:WALLACK SETH +1

Resource-efficient media streaming to heterogeneous clients

InactiveUS20070130359A1Multiple digital computer combinationsSecuring communicationQuality of serviceTransmission channel

A resource-efficient live streaming system includes a broadcaster and a streaming server. The broadcaster receives a live feed and broadcasts a media stream to the streaming server containing several descriptions of the live feed along with control information. The broadcaster includes a stream thinner that implements a pruning algorithm. If descriptions from different streams are similar enough, one or more of them may be discarded without penalizing the quality of service perceived by the receivers. The streaming server assembles compressed data units into streams according to the control information from the broadcaster. The streaming server may also gather client feedback in order to estimate the status of the transmission channels and forwards the information to the broadcaster. The streaming server builds and streams media information to clients according to user preferences and receiver capabilities.

Owner:TWITTER INC

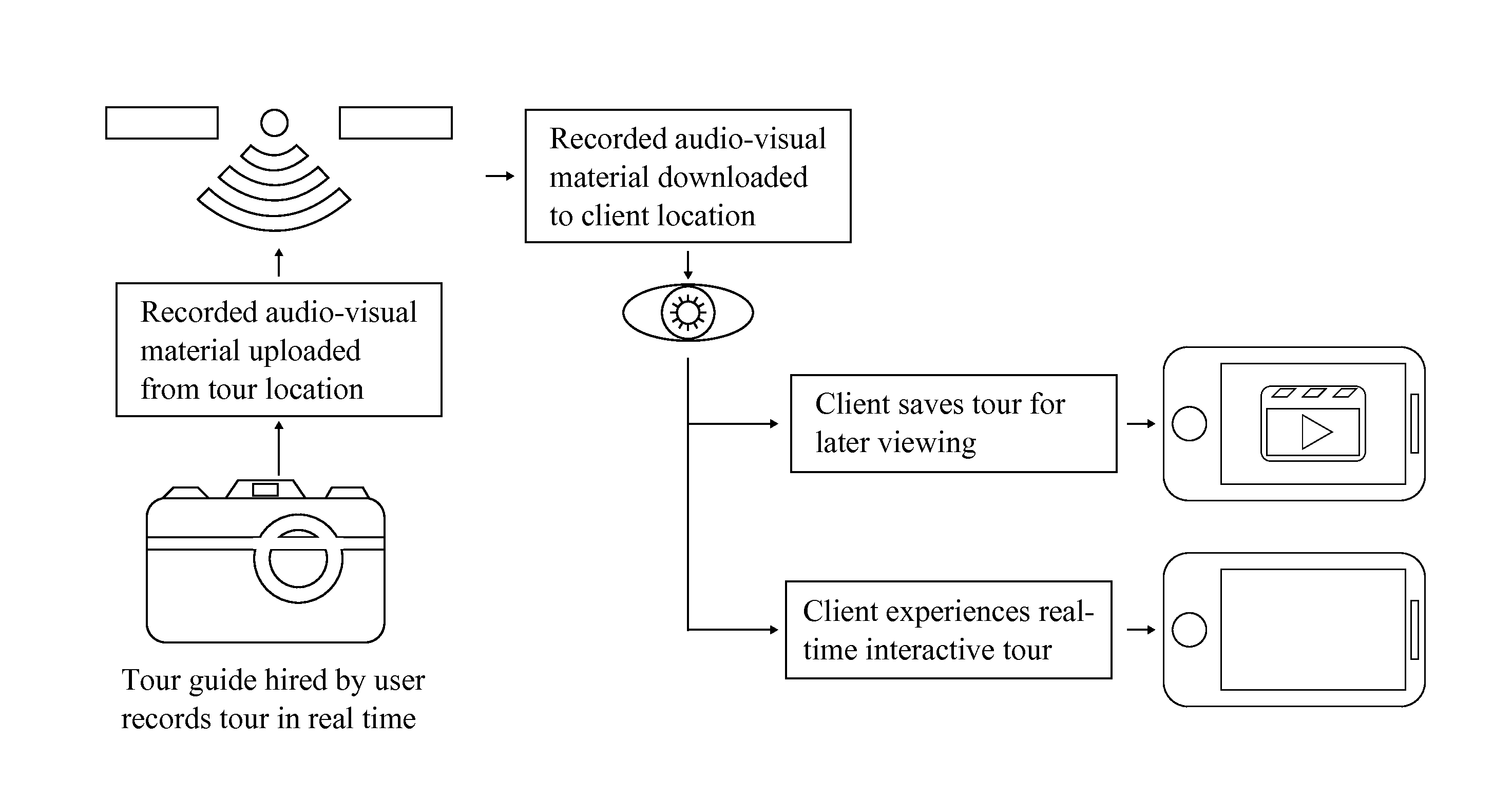

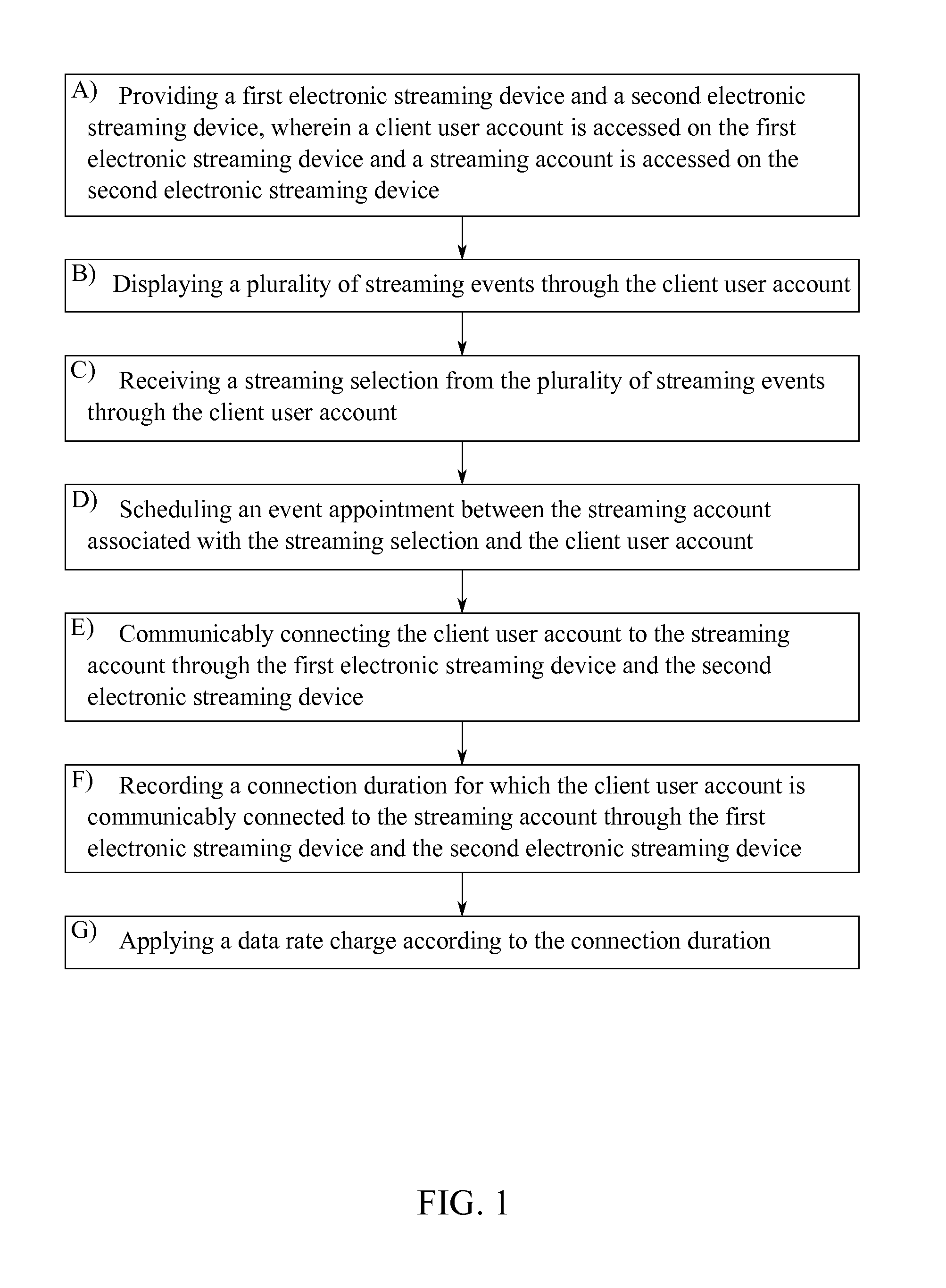

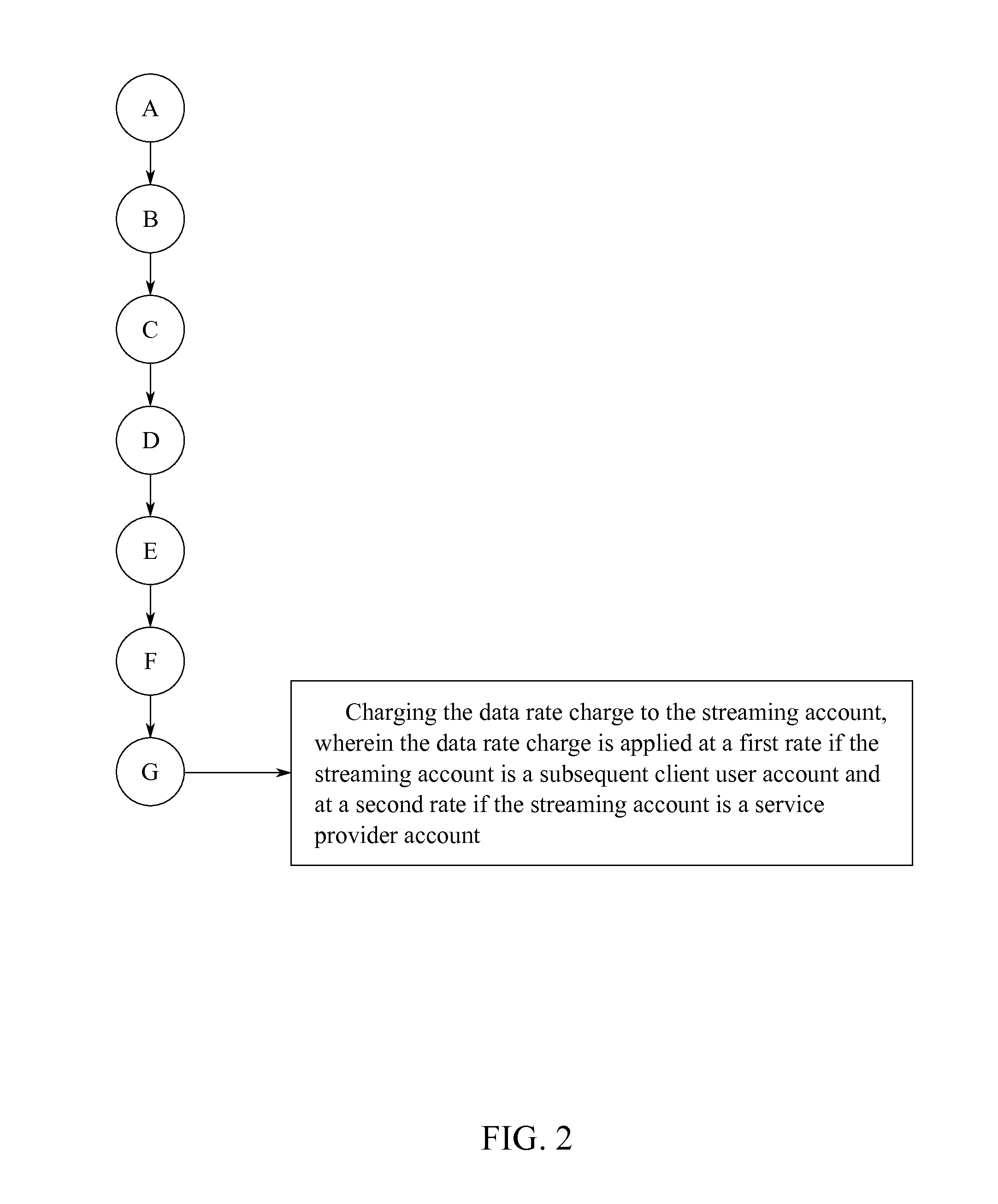

Method for Facilitating Live Stream Feeds of Remote Locations, Events or Products, in a Social, Virtual Travel, or Business Setting

A method for facilitating live feed streams of remote locations by communicably connecting a first electronic streaming device to a second electronic streaming device through a back-end system. A client user account is operated on the first electronic streaming device, while a streaming account is operated on the second electronic streaming device. A plurality of streaming events is displayed through the client user account, wherein a streaming selection can be made and an event appointment scheduled between the client user account and the streaming account. At the time of the event appointment, the client user account is communicably connected to the streaming account through the first electronic streaming device and the second electronic streaming device. A live stream video feed is then transmitted from the streaming account to the client user account, wherein the live stream video feed is viewed on the first electronic streaming device.

Owner:SHIVARAM KRISHNA

Method for artificially breeding harmonia axyridis

InactiveCN103355259ARealize artificial large-scale breedingBreeding technology is matureAnimal husbandryFisheryMass propagation

The invention relates to the application of chouioia cunea larvae or pupae as a live feed to artificial breeding of harmonia axyridis. The breeding technology of the chouioia cunea larvae or pupae is mature, and one tussah pupa at least can breed 5,000 chouioia cunea larvae or pupae and at least can breed 100 harmonia axyridis. The breeding technology is easy to operate. The live feed for widely propagating the harmonia axyridis is simply and conveniently obtained. Artificial mass propagation of the harmonia axyridis can be realized.

Owner:天津拓华生物科技有限责任公司

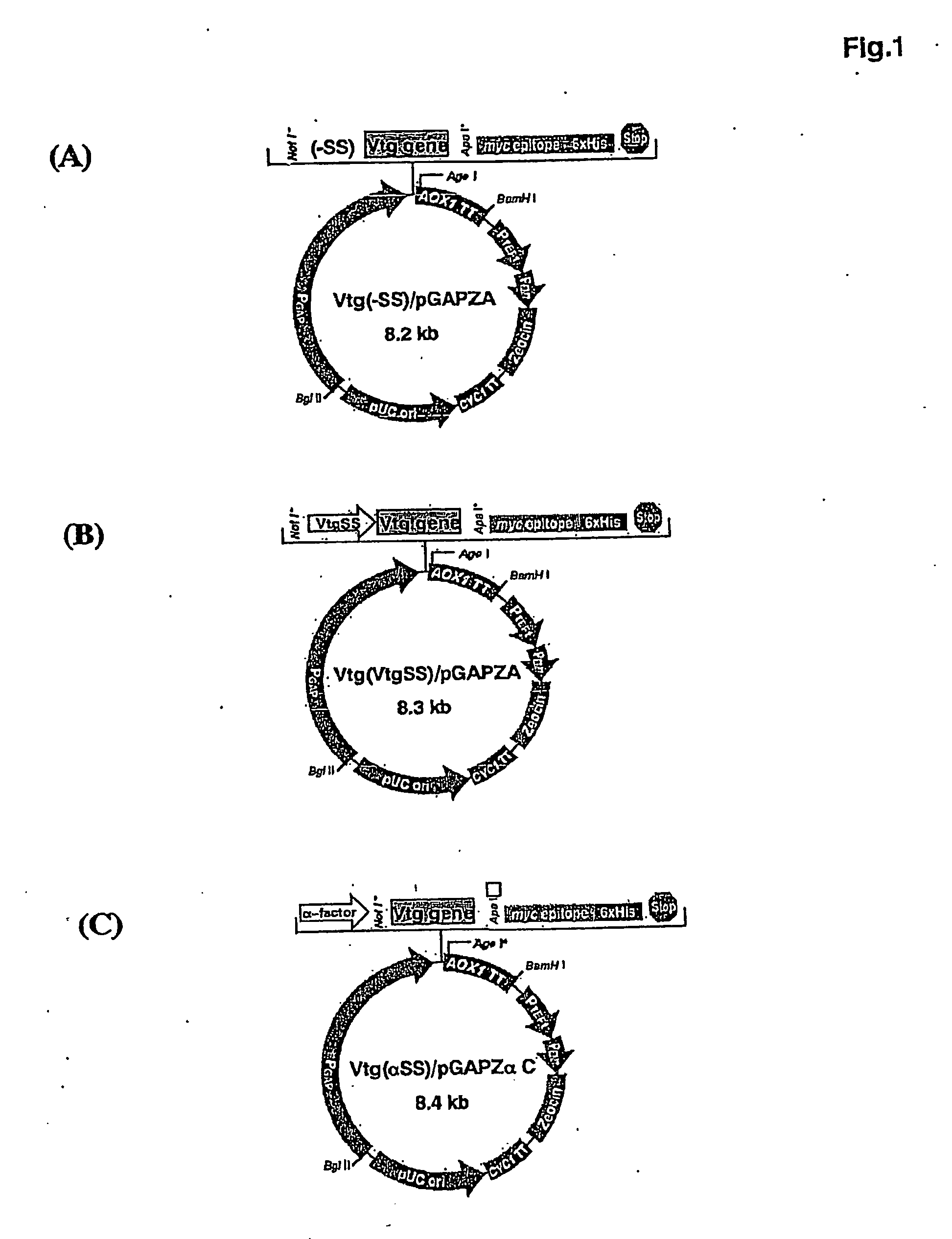

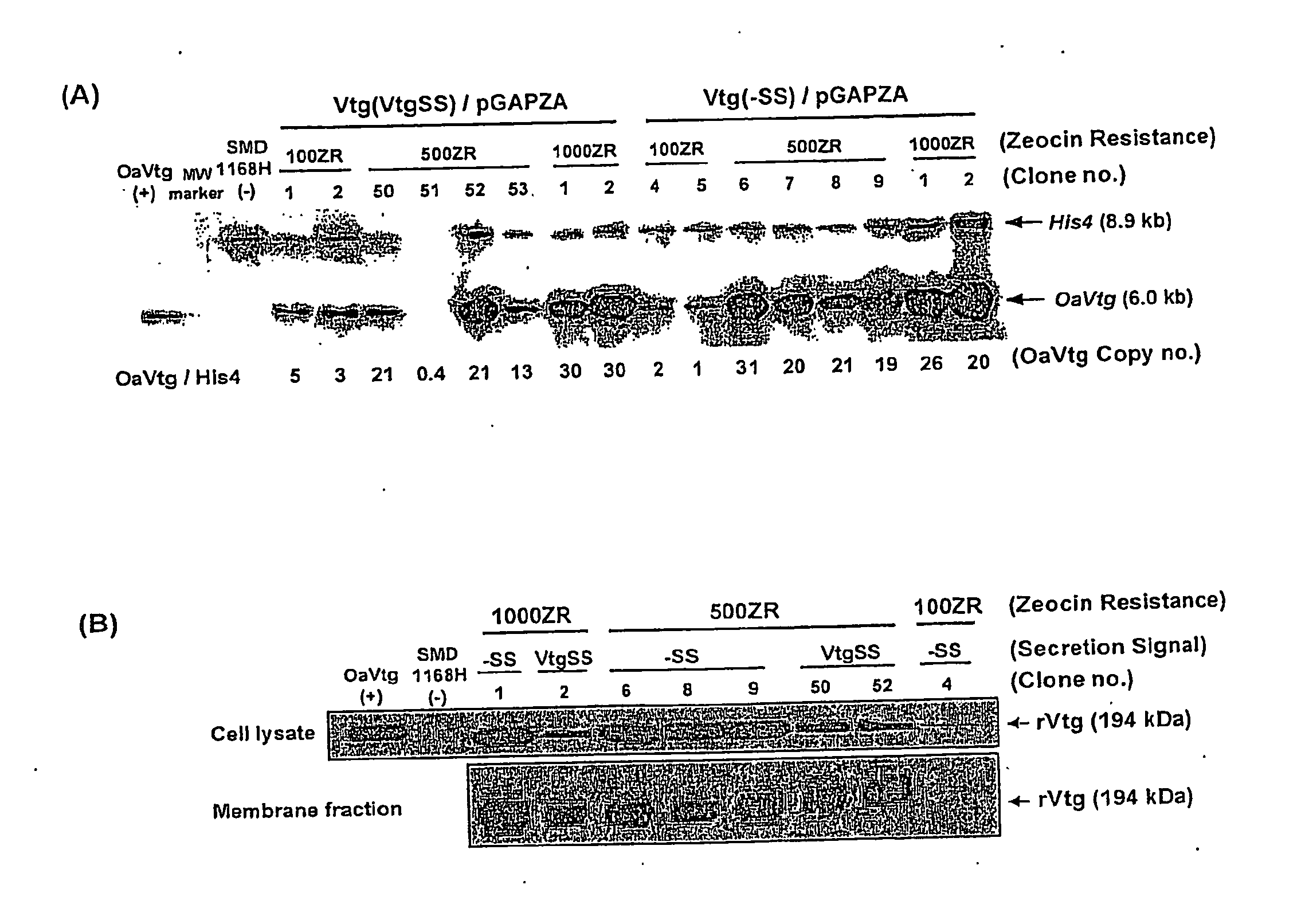

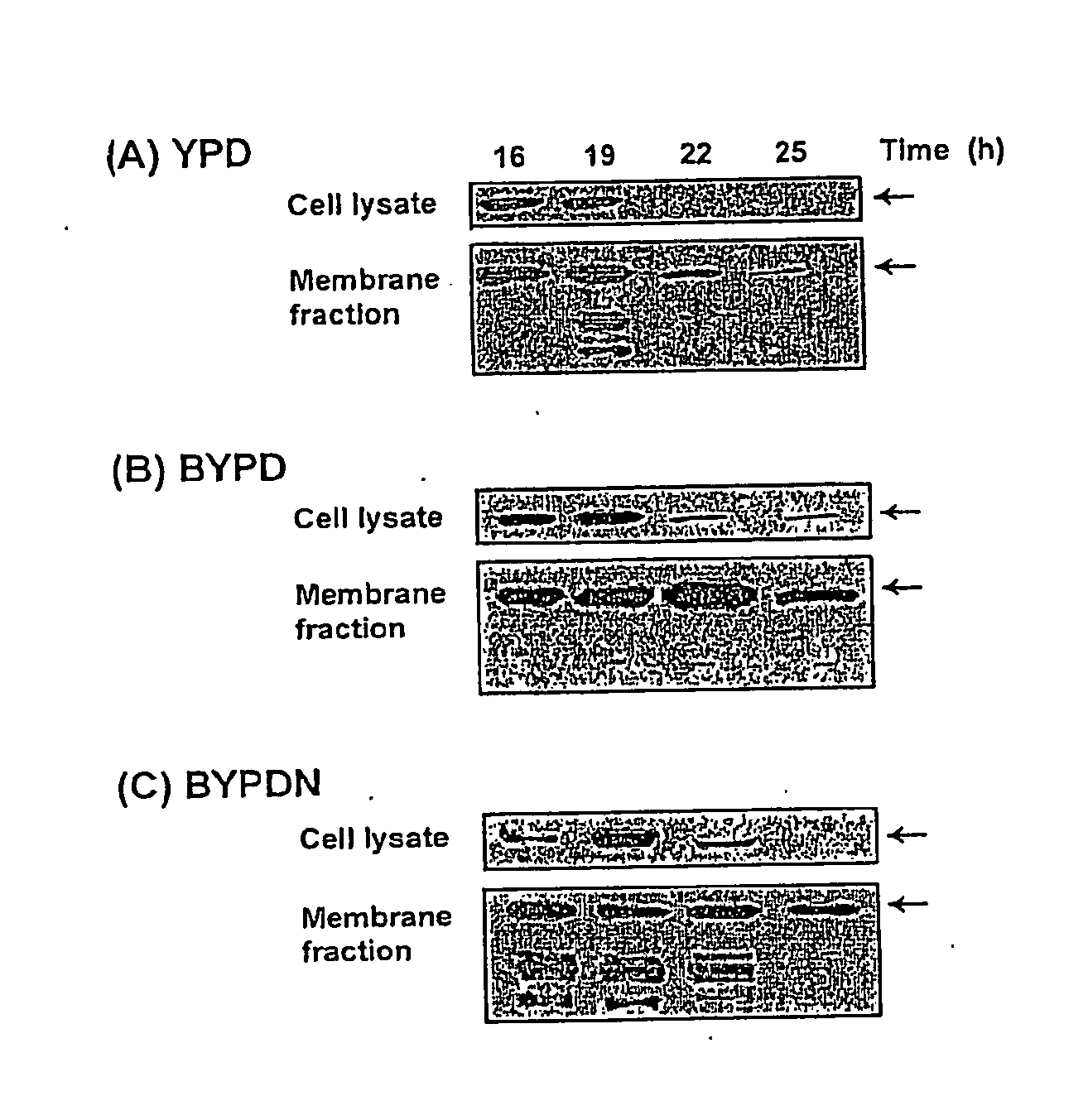

Recombinant vitellogenin enriched feed

The invention provides an expression vector for expression of recombinant vitellogenin in an eukaryotic host. An eukaryotic host, including yeast comprising the expression vector according to the invention may be used as a feed or feed additive for both oviparous and non-oviparous animals, including domesticated animals. A transgenic yeast according to the invention contain increased levels of essential amino acids and fatty acids and may be used as a direct feed or fed to an intermediate live feed such as rotifers or artemias to increase the survival rates of oviparous animal or broodstock.

Owner:NAT UNIV OF SINGAPORE

Resource-efficient media streaming to heterogeneous clients

InactiveUS7657651B2Multiple digital computer combinationsElectric digital data processingQuality of serviceTransmission channel

A resource-efficient live streaming system includes a broadcaster and a streaming server. The broadcaster receives a live feed and broadcasts a media stream to the streaming server containing several descriptions of the live feed along with control information. The broadcaster includes a stream thinner that implements a pruning algorithm. If descriptions from different streams are similar enough, one or more of them may be discarded without penalizing the quality of service perceived by the receivers. The streaming server assembles compressed data units into streams according to the control information from the broadcaster. The streaming server may also gather client feedback in order to estimate the status of the transmission channels and forwards the information to the broadcaster. The streaming server builds and streams media information to clients according to user preferences and receiver capabilities.

Owner:TWITTER INC

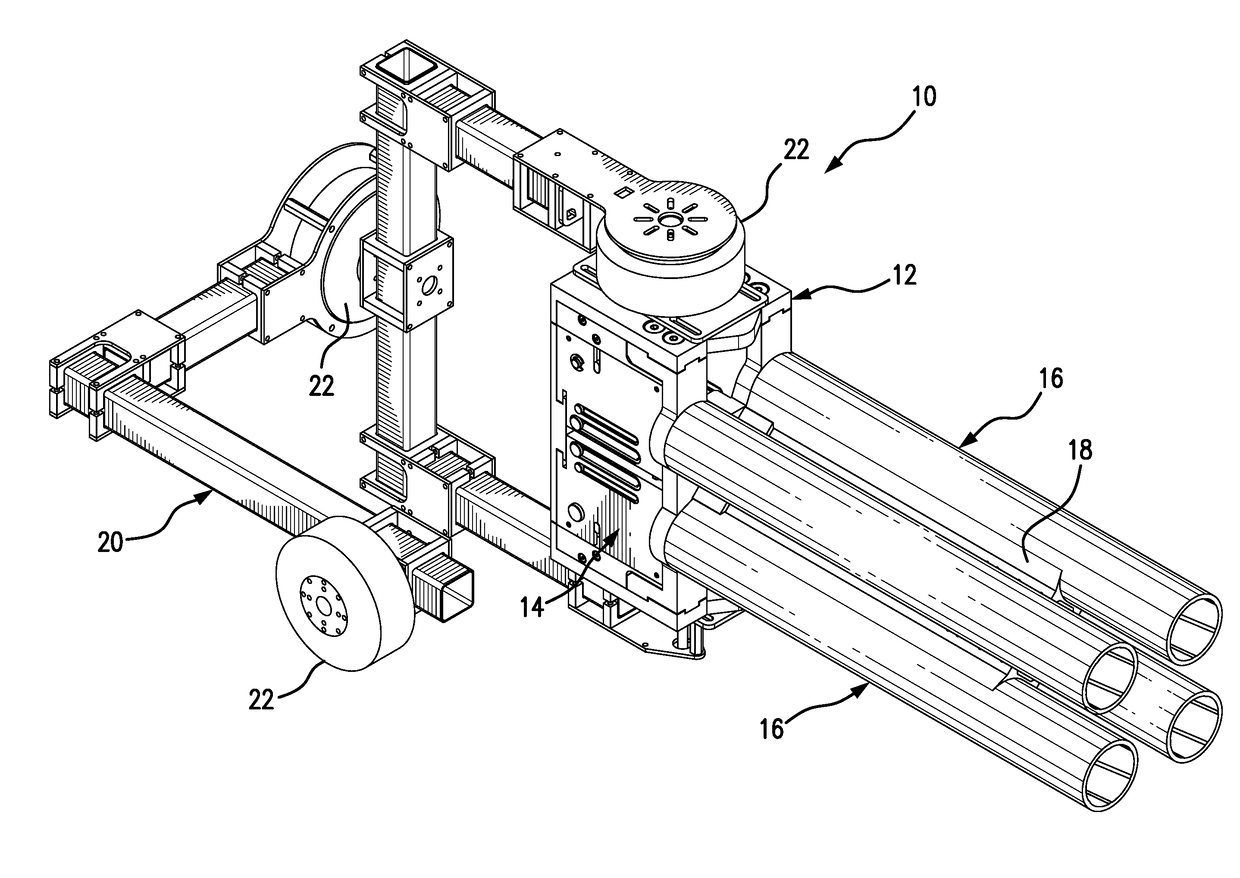

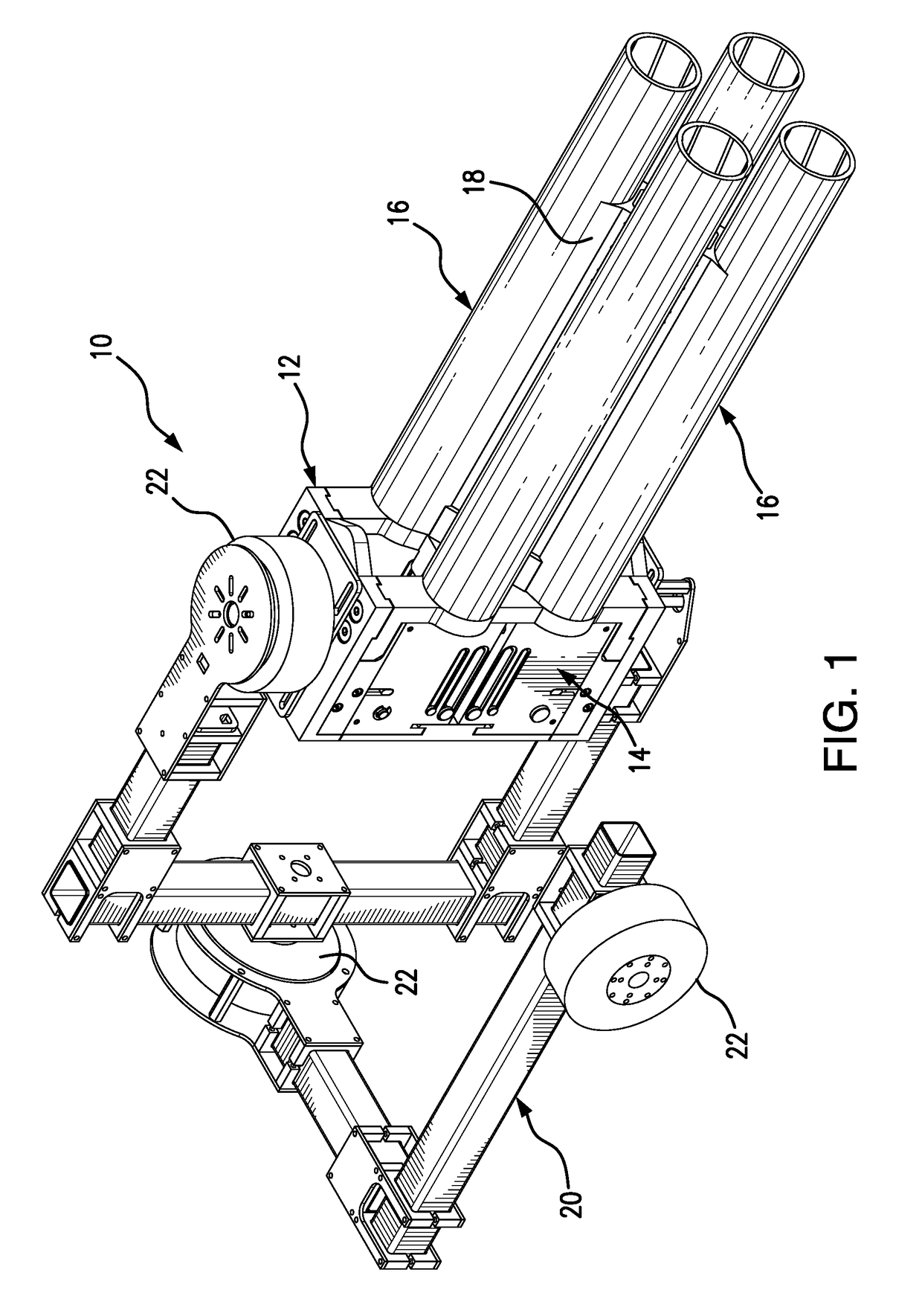

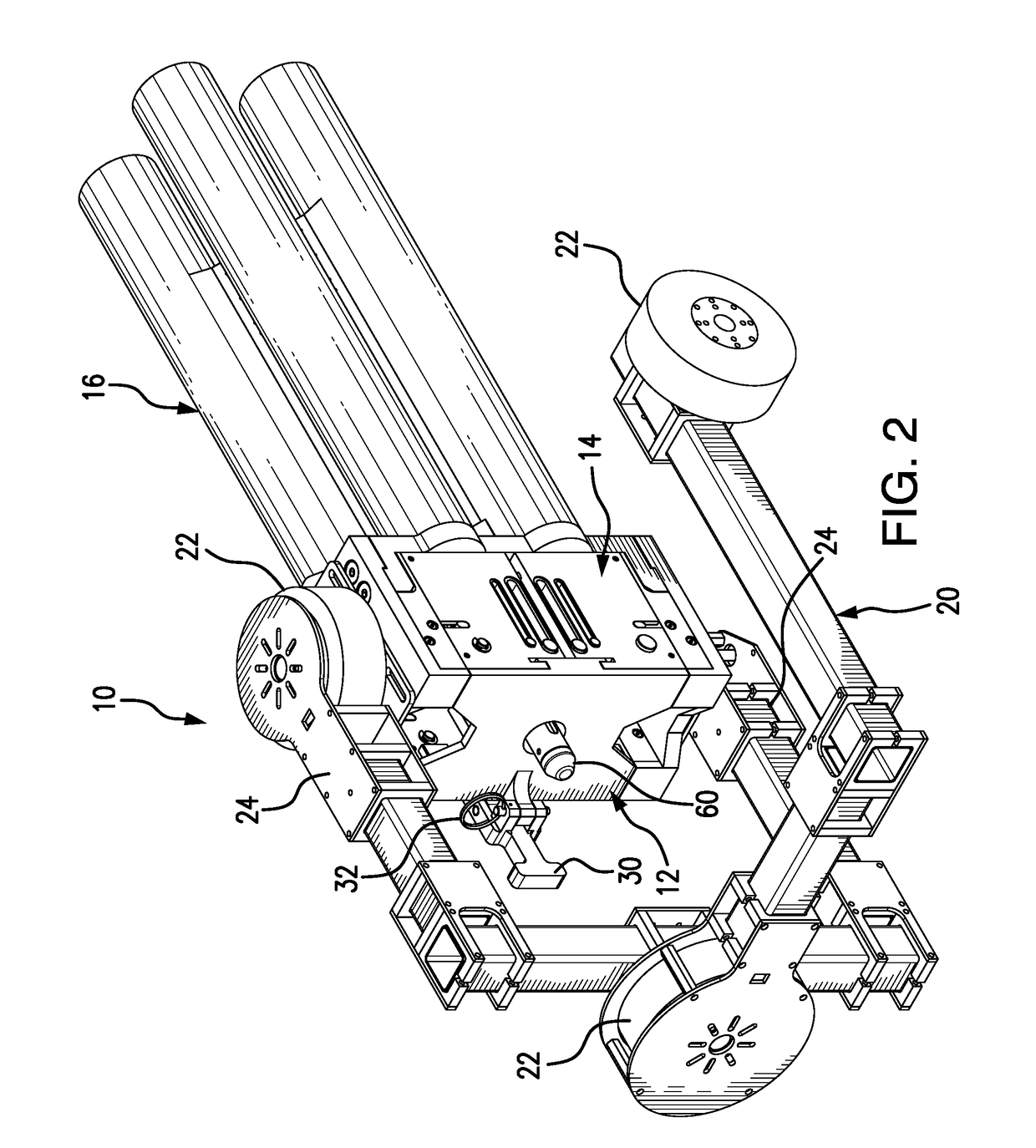

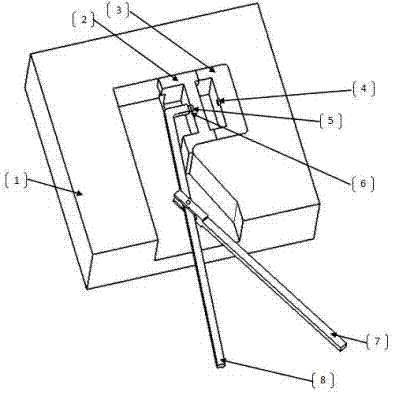

Robot/drone multi-projectile launcher

A multi-projectile launcher capable of firing less-lethal 40 mm rounds or high explosive 40 mm rounds (i.e., HE Grenades) can be attached to robots, drones, vehicles and stationary structures. The robot / drone multi-projectile launcher is remote controlled and capable of 360 degree horizontal rotation as well as vertical panning, and is able to quickly turn and acquire targets. A solenoid controlled firing system for each barrel includes a firing pin, trigger lever and striker, as well as a lockout bar and striker seer to prevent accidental firing (e.g., from impact or sudden jolt). Target acquisition systems include an infrared laser system, a standard red laser system, and an optic targeting system that is monitored through an onboard camera. A wireless network access device allows for remote viewing of live-feed camera images (still frame and video) and control of the optic targeting system, as well as the launcher articulation and firing.

Owner:INTEGRATED LAUNCHER SOLUTIONS INC

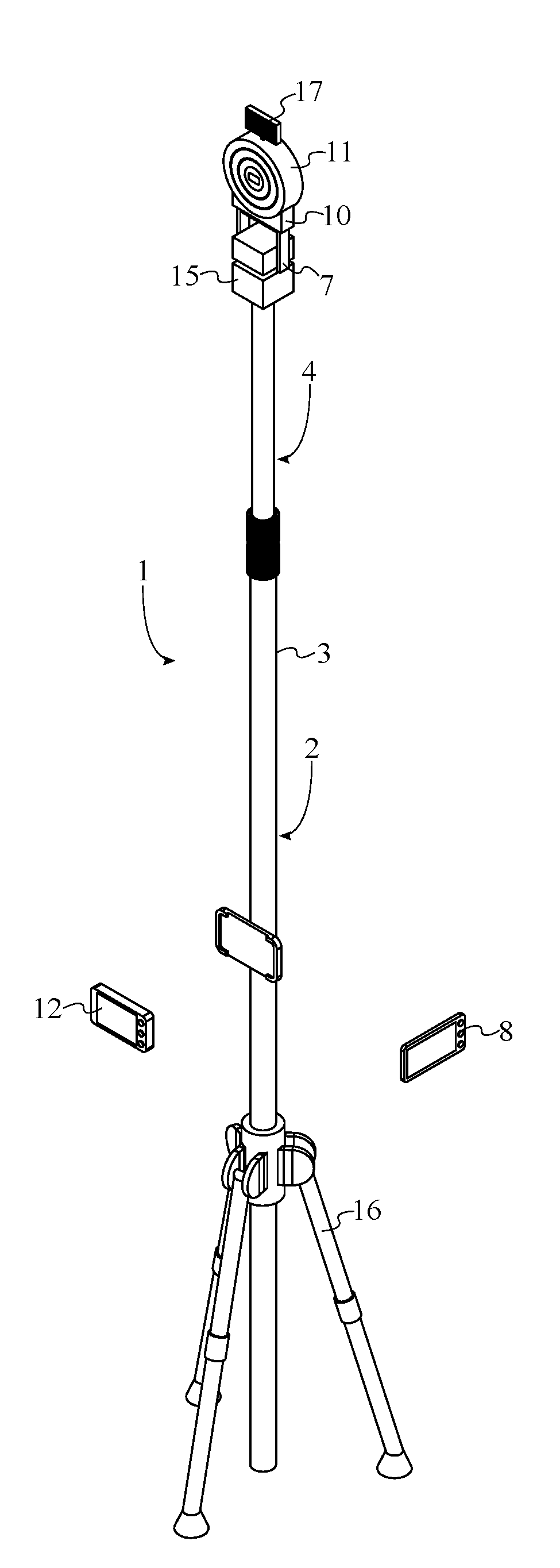

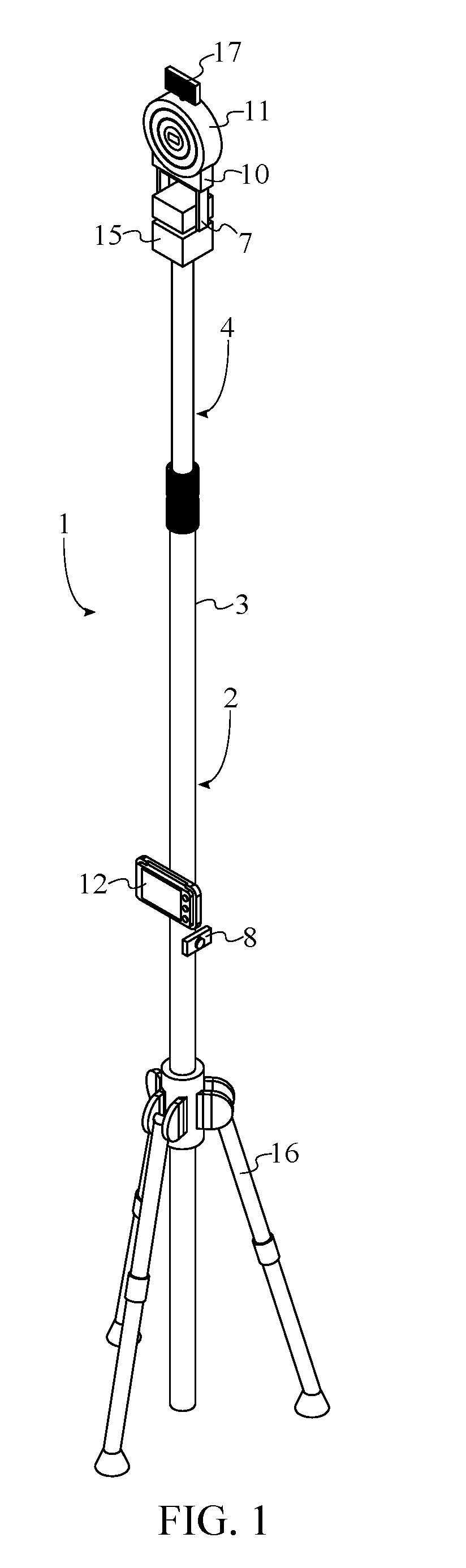

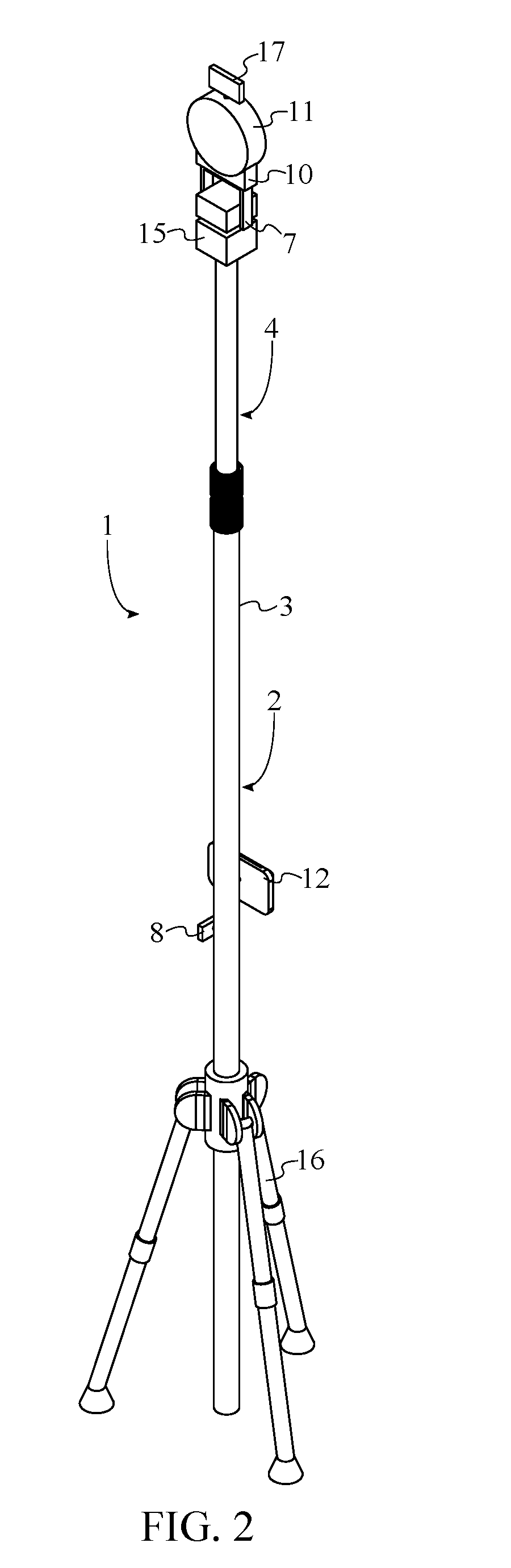

Omniview Camera Tower System

An omniview camera system allows for the adjustment of the view provided by a camera. The system includes an extendable pole with a base portion as well as an extension portion that may be extended from or retracted into the base portion. A tilt motor is able to tilt an attached camera mount and a camera and a pan motor may be utilized to rotate the camera mount and the camera. The view provided by the camera may be adjusted by manipulating a view adjustment control unit. The view adjustment control unit may be used in a wired or wireless configuration. A live feed of the camera is provided via a removable viewfinder display. The base portion may be secured to a stabilizing base platform in order to ensure that the system remains stable when placed on a surface.

Owner:GRIFFEY JOHN A

Method for taking out die pouring gate buffering pit movable materials

The invention relates to a method for taking out die pouring gate buffering pit movable materials. The method includes the steps that firstly, a level principle is adopted, a tool supporting rod and a tool rotating rod are manufactured, a magnet is fixed to one end of the tool rotating rod, and the tool rotating rod and the tool supporting rod can be connected through a rotatable shaft; secondly, hollow design is adopted in the movable materials when the movable materials are designed, a magnet is fixed to the middle of each movable material in advance, and the magnetic pole is calculated; thirdly, when the movable materials are taken, the end, with the magnet, of the rotating rod stretches in a cavity, the magnet of the rotating rod and the magnet of the movable material I are attracted to each other, then the rotating rod is slowly rotated, and the movable material is dragged out; and fourthly, the movable material I and the movable material II are connected through a locating pin, when the movable material I is taken out through the tool, the movable material II can be driven to move to the previous position of the movable material I, the movable material I is downwards taken out at the moment, the movable material II can be reserved in the previous position of the movable material I, and the movable material II is taken out through the same method. The method has the beneficial effects that the efficiency is improved, the cost is reduced, and operation is convenient.

Owner:NINGXIA KOCEL MOLD

Method of manufacturing cold asphalt, and product-by-process for same

InactiveUS20120325114A1Less spaceEfficient productionRoads maintainenceBuilding insulationsEngineeringAsphalt

Owner:YK HLDG

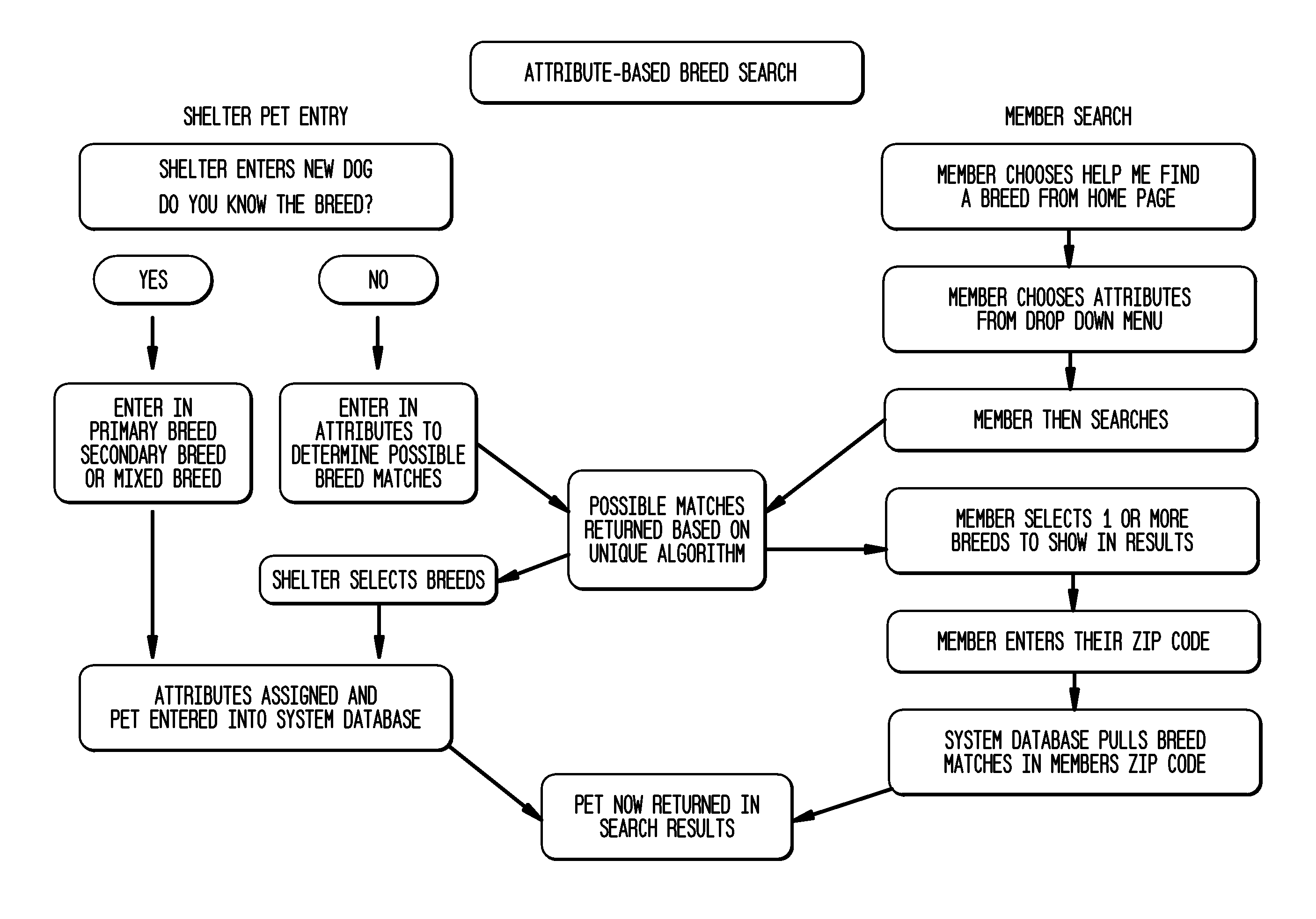

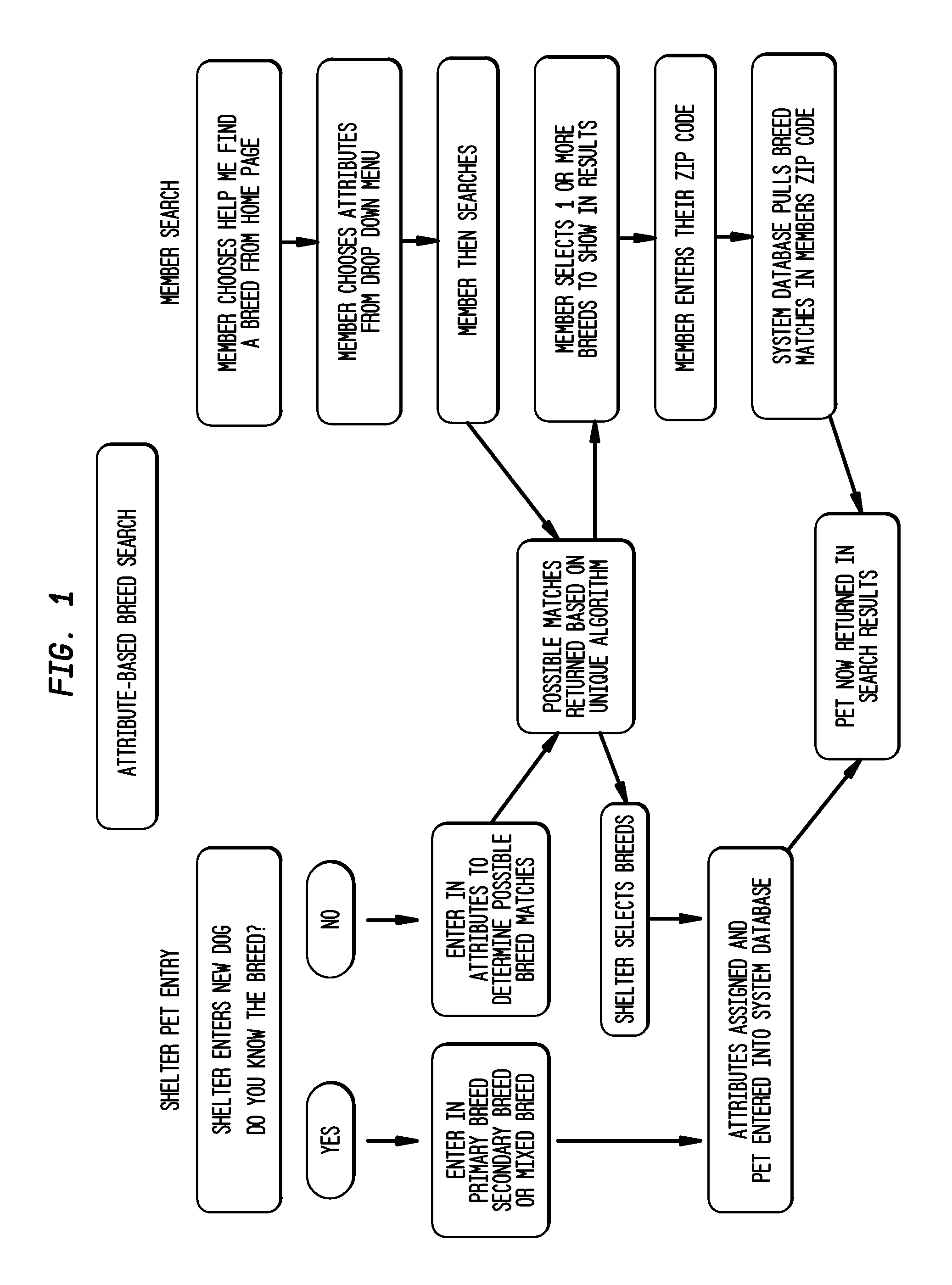

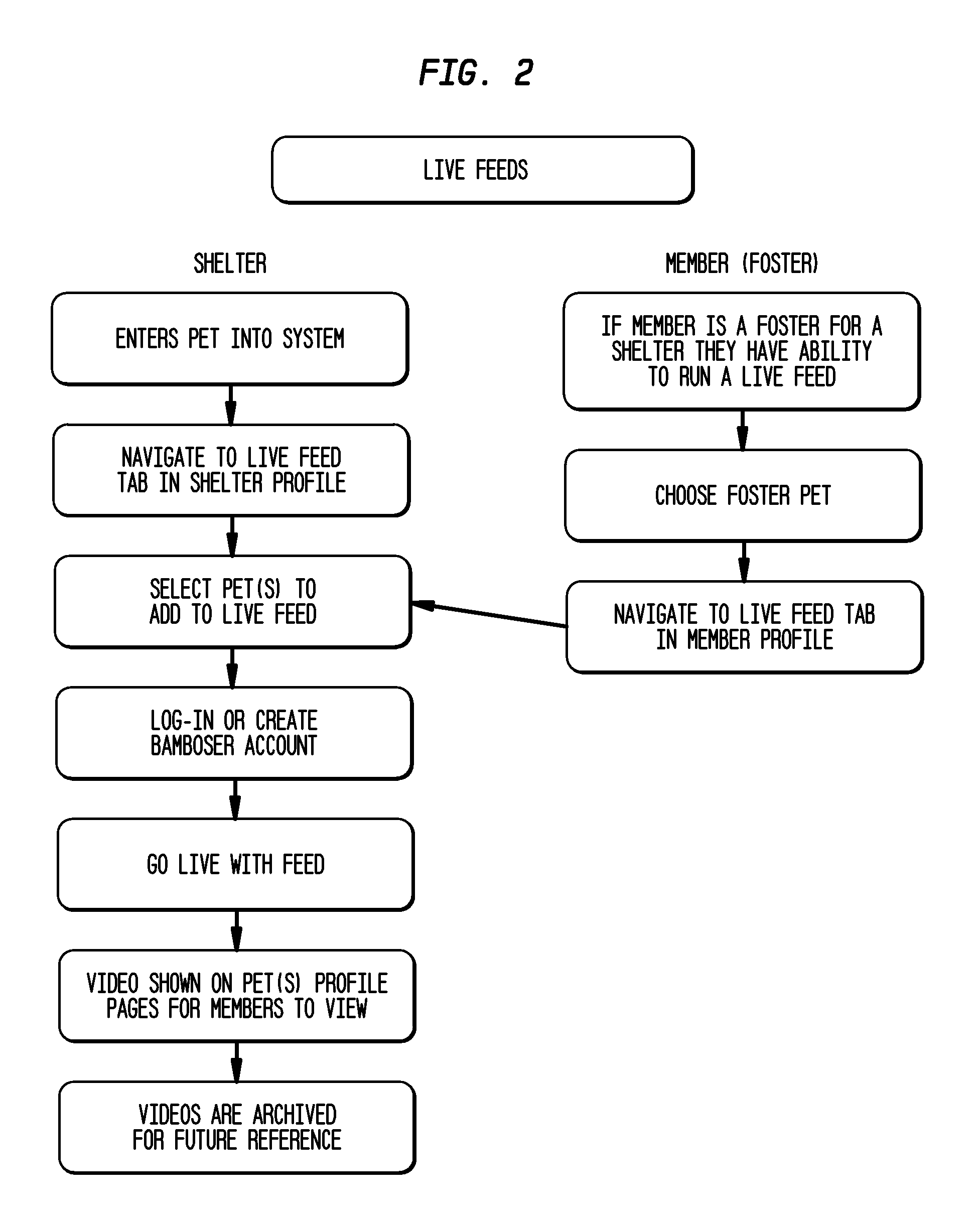

Computer-implemented animal shelter management system

InactiveUS20130198175A1Improve efficiencyEliminate needDigital data information retrievalDigital data processing detailsKeeps petsMedicine

The system allows users seeking to adopt to search based on the desired attributes of an animal and the availability of such animals. It allows a user to determine the breed they most prefer adopt. Once an animal is selected, a live feed of the animal can be viewed. If the user wants to adopt, the system electronically provides an application which the system forwards to the shelter where the animal is located for review. Revenues collected from advertising and donations are automatically shared with the shelters through the system. The system acts as to facilitate intra-shelter transfers and as a lost and found. It allows shelter administrators to manage volunteers, fosters and staff. It provides a single user-accessible location to store medical history and other records relating to the adopted pet. It can notify the user when an animal of the desired breed becomes available.

Owner:SQUISHYCUTE COM

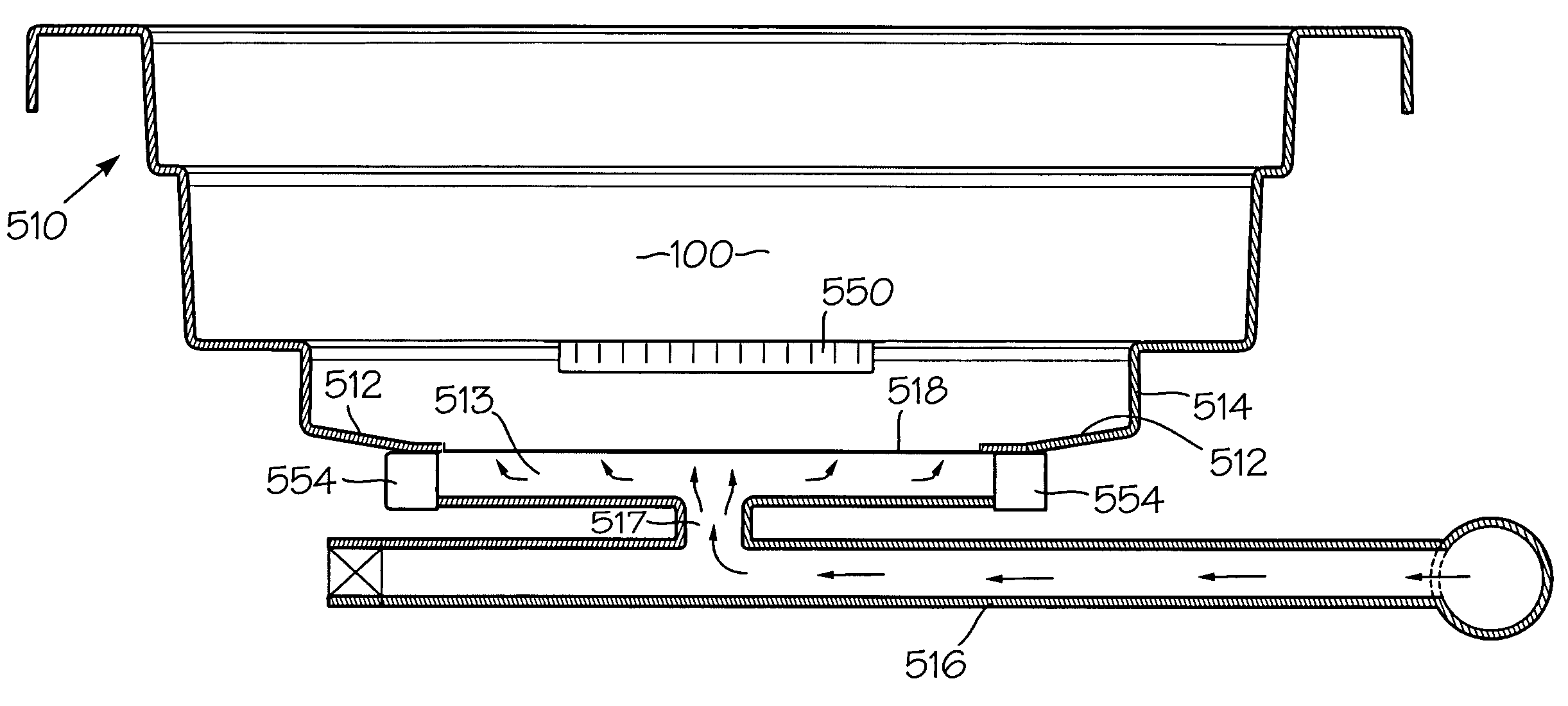

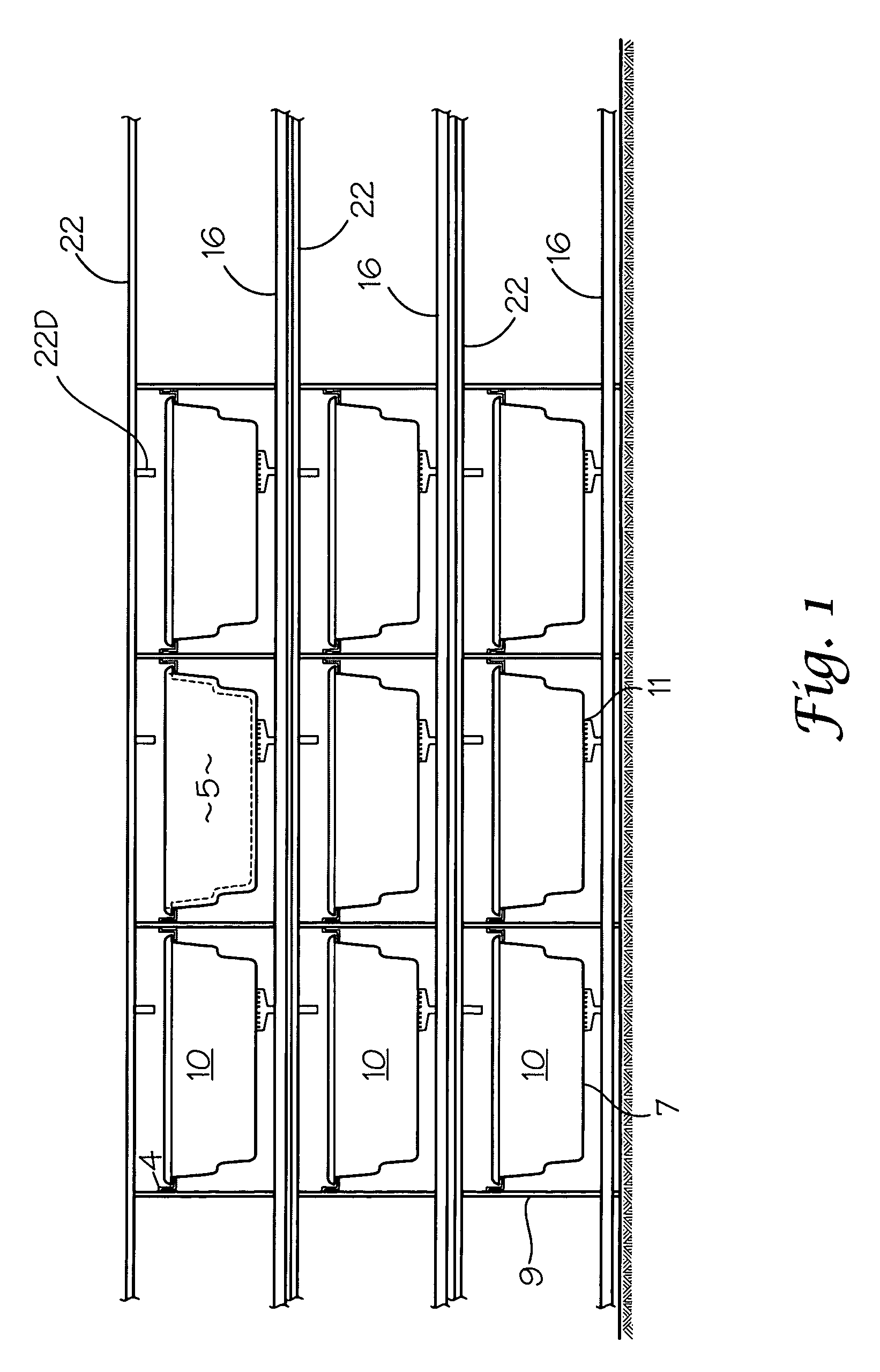

Activated feed through, feeding systems incorporating same, and methods of use of same

InactiveUS7077075B2Reduce morbidityPromote growthClimate change adaptationAnimal feeding devicesAmphibianEngineering

A feed trough is provided for use in cultivation containers for growing frogs and other amphibians. The feed trough is comprised of a sloped floor. In some embodiments the floor slopes downward to an opening from which, during operation, airflows. The opening is covered by a perforated cover that retains the feed particles collected from the sloped floor and provides sufficient opening for airflow that propels the feed particles from the perforated cover into the airspace of the cultivation container.During operation, airflow passes through the opening with sufficient force to suspend in the air feed particles that have rolled along the sloped floor, or fallen, onto the perforated cover covering the opening. The movement of the feed particles in the air stimulates feeding by the frogs or other amphibians. Feed that is not consumed falls onto the sloped floor, rolls onto the screen or wire mesh covering the opening, and is resuspended by the airflow. The airflow may be continuous, intermittent, or otherwise programmed.The air of the airflow may be heated. This serves to dry feed particles that have become moistened, increase ambient temperature to increase growth rates, and / or dry the cultivation container.In other embodiments a vibrational force is applied to move feed particles to simulate live feed, to stimulate feeding.

Owner:HOLYOAK H KENNETH

Mandarin fish domestication method

InactiveCN106719128AEasy to transformReduce morbidityClimate change adaptationAnimal feeding stuffAquatic productAbsorption rate

The invention relates to the field of aquaculture and discloses a mandarin dish domestication method. After the mandarin fish fry grow to 6-8 cm when eating live bait, the mandarin fish fry are transferred to a domestication pond with poor light ray. After being on a diet for 2-3 days, the mandarin fish fry are fed with live fish fry and fresh meat products. Feeding amount of the live fish fry is reduced gradually, and artificial feed components are added gradually until the mandarin fish fry are completely not fed with the live bait. The artificial feed comprises 45-50% of protein, 16-20% of fat, 8-10% of carbohydrate, 1-2% of vitamin, 4-6% of mineral, and the balance water. By the scientific domestication method, the obtained mandarin fish is good in convertibility and capable of getting rid of the physical dependence on the live feed. The domestication rate is up to 97.3%, the used artificial feed proportion is capable of meeting the demand of mandarin fish growing, the absorption rate is high, the incidence rate of the mandarin fish is reduced, and therefore compared with the existing feeding cost, the mandarin feeding cost decreases by 68.5%.

Owner:全椒县民族水产养殖专业合作社

Co-culture method for clarias fuscus and water chestnuts

ActiveCN105474960AIncrease productionHarm reductionClimate change adaptationPisciculture and aquariaDiseaseWater Chestnuts

The invention provides a co-culture method for clarias fuscus and water chestnuts and belongs to the technical field of agricultural planting. The method includes the control links of field excavation, water chestnut planting, fingerling putting, water and fertilizer management and disease and pest prevention and control. Nutrients needed for growth of the water chestnuts are guaranteed in a scientific water and fertilizer management mode, pest attacks on the water chestnuts are controlled according to the predation characteristics of the clarias fuscus, and the disease attacks on the water chestnuts are controlled through Chinese herbal medicine liquid. Live feed and pellet feed suitable for growth of the clarias fuscus are developed, and the disease attacks are prevented through the Chinese herbal medicine liquid. By means of the characteristics that the clarias fuscus and the water chestnuts interact, relative to a mode that the water chestnuts are independently planted, the yield of the clarias fuscus is increased while the yield of the water chestnuts is guaranteed, and economic benefits of a planting field are greatly increased.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Method for manufacturing cold asphalt, and product-by-process for same

InactiveUS20120325116A1Less spaceEfficient productionRoads maintainenceBuilding insulationsEngineeringAsphalt

A heatless method of manufacturing cold asphalt, such as for road repair and construction, that may be easily produced at or near a job site. The method includes the introduction of RAP (recycled asphalt and a small amount of new asphalt), additive oil, and optional sand (silicates and / or sieved RAP) and lime (limestone powder) into mixing apparatus. The mixing apparatus includes two hoppers: one hopper for RAP and a second hopper for RAP or sand; a live feed for additive oil; and another for optional lime; conveyors; and a controller that is programmed to determine the correct proportion of RAP, optional sand, oil, and optional lime. The invention also includes a product-by-process in which cold asphalt mix is produced. The end product is essentially non-toxic with little to no VOCs and HAPs, has long shelf-life, and is produced, stored, used, and compacted at ambient temperature.

Owner:YK HLDG

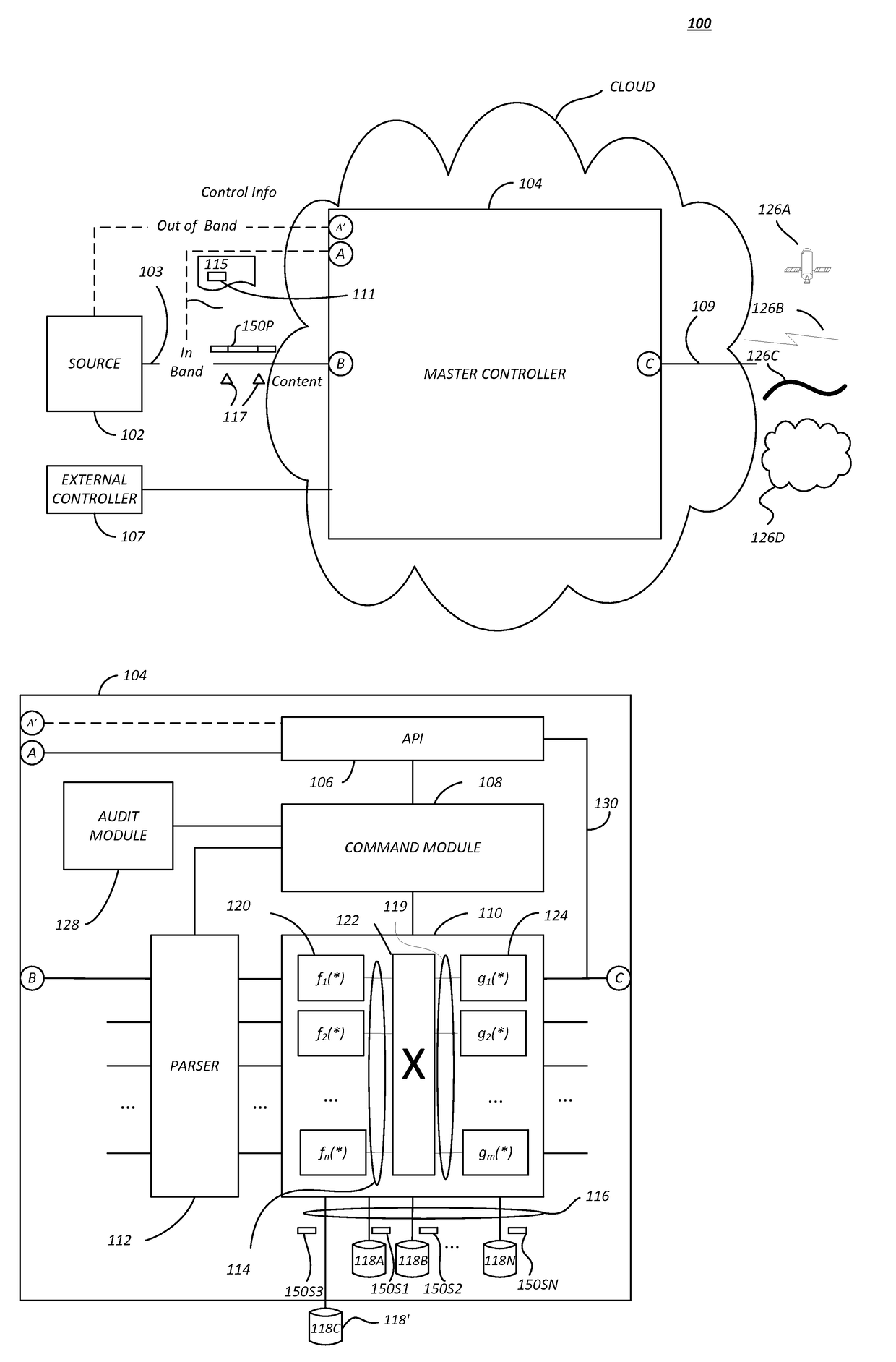

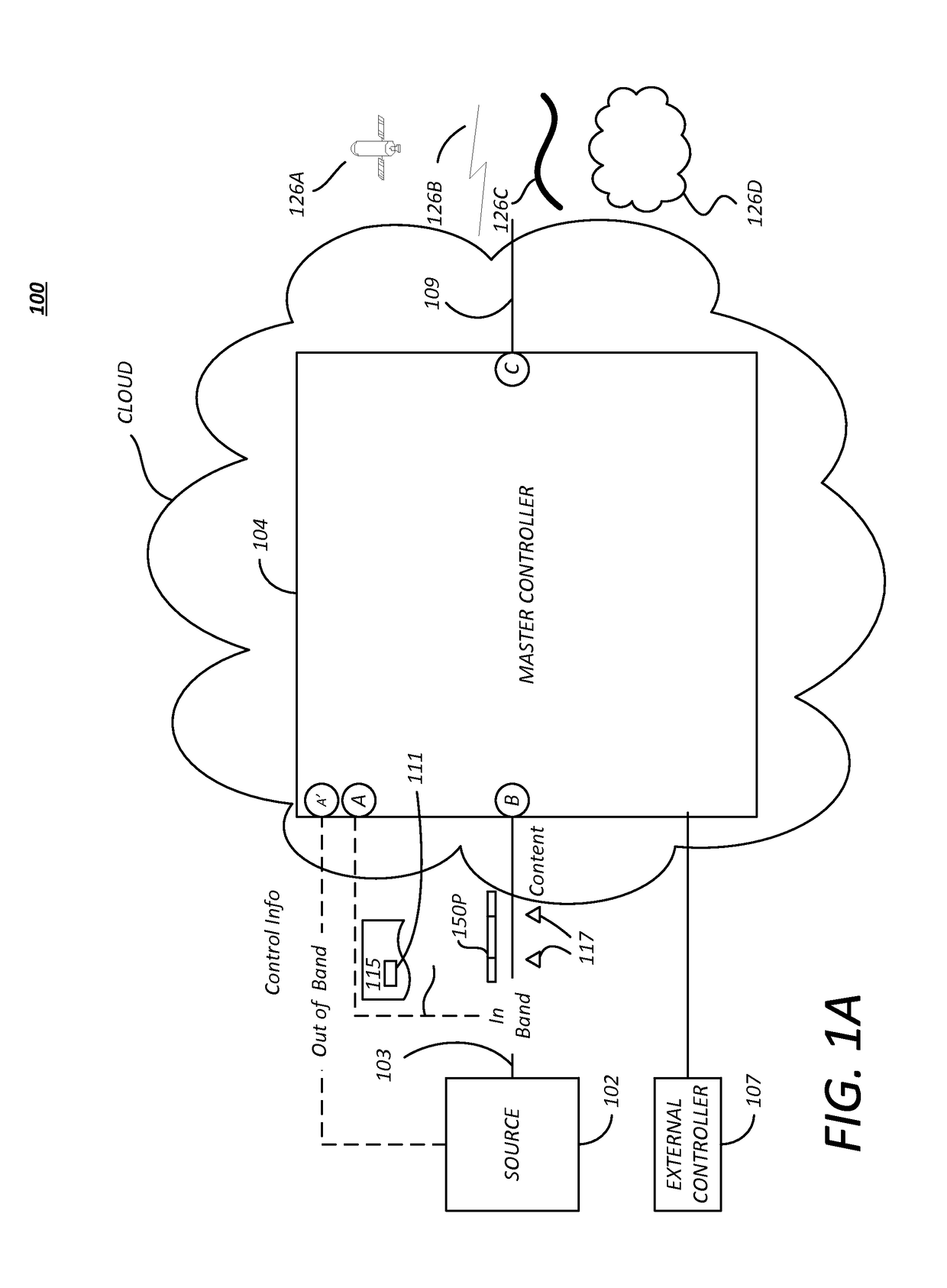

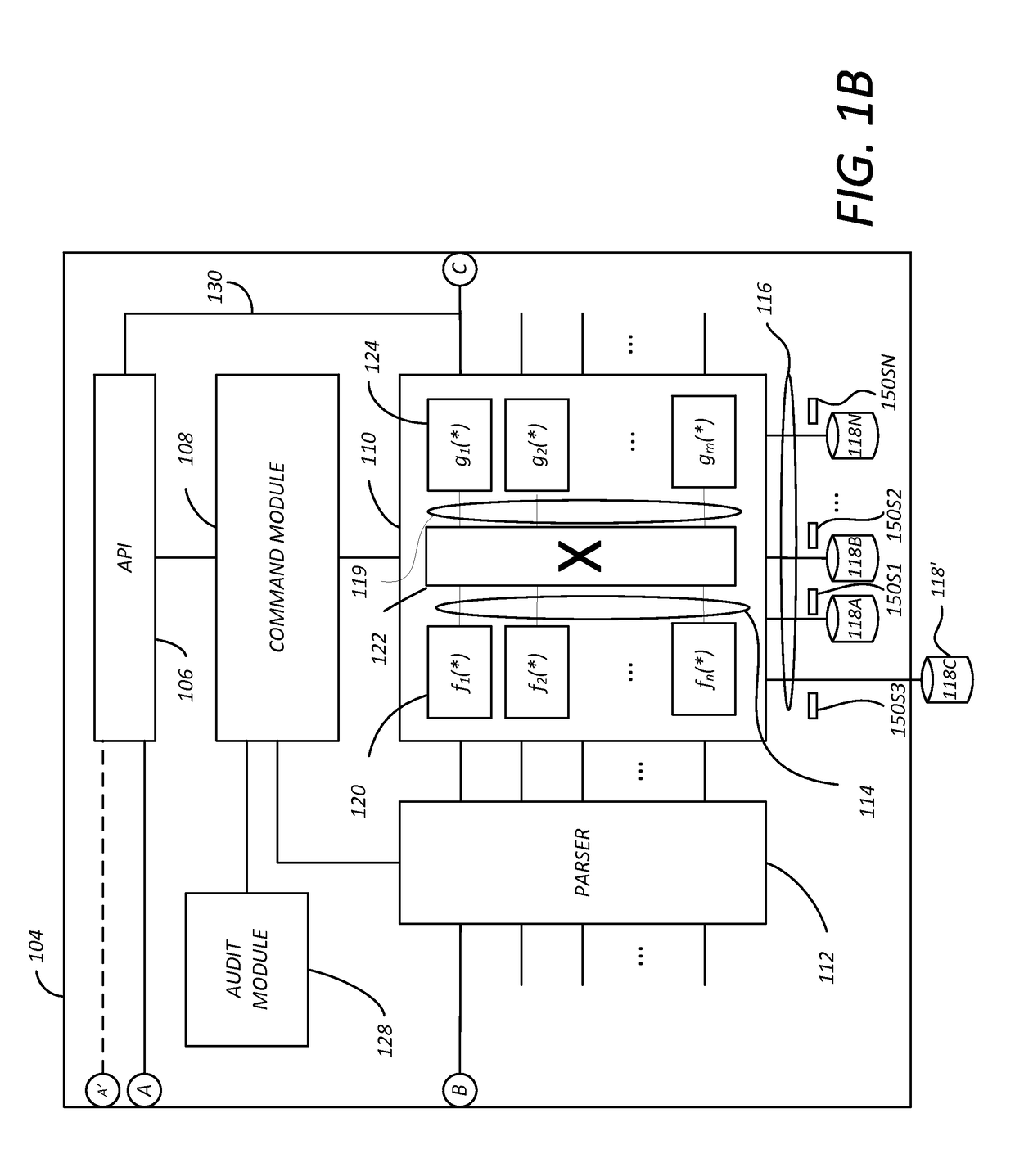

Location agnostic media control room/broadcast facility

A method and apparatus for generating a broadcast video stream from a primary video component having a live feed from a source remote from the virtual media control system in at least near real time is disclosed. Live queuing events are inserted into the live video feed and automatically interpreted to insert secondary video components that become part of a broadcast video stream.

Owner:FOX BROADCASTING CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com