Patents

Literature

307results about How to "Improve filling ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

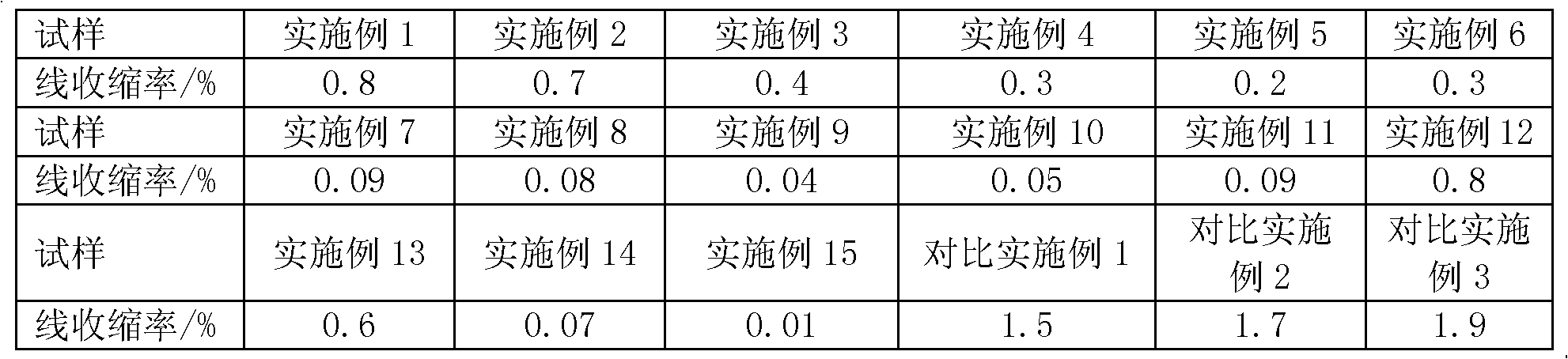

Cast magnesium alloy of low linear shrinkage

The invention discloses a cast magnesium alloy of low linear shrinkage, which belongs to the field of magnesium alloys. The magnesium alloy consists of Mg, Al, Zn, Mn, rare earth, Nb, Li and M element, wherein the materials have the following weight percentage composition: 1.5-25 percent of Al, 0.1-3.5 percent of Zn, 0.1-2.2 percent of Mn, 0.0002-16 percent of rare earth, 0.0002-4 percent of Nb, 0.0002-9 percent of Li, 0.0002-2 percent of M element and the balance Mg; and the M element is at least one of Zr, Ti, Sr, Ca, C and B. According to the heat-resistant magnesium alloy, the rare earth element and the Nb element are added into the magnesium alloy, so that the structure of beta phase is changed; the Zr element and the M element are added to refine crystal grains; due to combined action of the elements, latent heat of crystallization during alloy solidification is changed; and the magnesium alloy which has superior mold-filling capacity, low shrinkage, superior mechanical property and good machinability, fluidity and die-cast performance and is suitable for casting is obtained.

Owner:嘉兴佳斯贝特新材料有限公司

Method for precinct laser sintering fast manufacture metal die

InactiveCN1907602AAvoid wrapping problemsReduce harmful effectsIncreasing energy efficiencyMetal formingAdhesive

The invention relates to a method for quickly producing metal mould with laser sintering, which comprises: first, using at least two kinds of different metal powders with different diameters, to be mixed with different mass percentages; using physical or chemical modification to treat the surface of metal powder; then mixing the modified metal powders, the adhesive formed by organic resin and inorganic with different fusion points, and the lubricant uniformly to obtain the metal molding powder; then designing the three-dimension CAD mode of mould, to slice the mode, and laser sintering the metal molding powder; the laser sintered element is baked at 300-800Deg. C; using vacuum pressure penetration to penetrate the metal, to obtain the high-accuracy metal mould.

Owner:NANCHANG AERONAUTICAL ENG INST

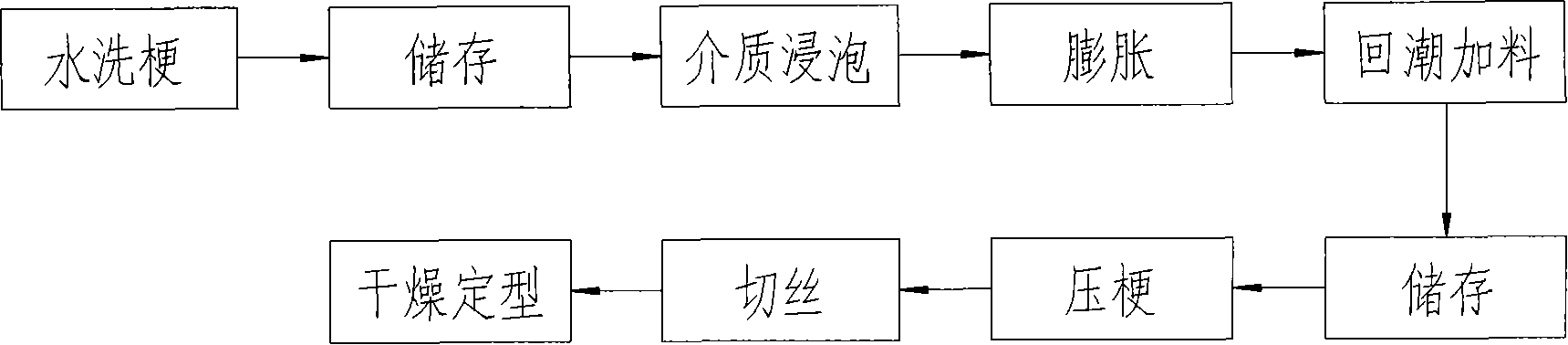

Technique of pre-expanding treating cabo

ActiveCN101108028AFully removedLarge specific surface areaTobacco preparationTobacco treatmentFilling materialsEngineering

A tobacco stalk pre-expending processing technics is provided, which is characterized in that: the technics comprises the following procedures: washing, storing, expanding in liquid and marinating with interface the tobacco stalk, expanding the stalk strips, moisture regaining and feeding, storing, pressing sticks and drying for shaping. The technics method of the invention changes the expanding of cut rolled stem into expanding the tobacco stick by using marinating with high temperature and low pressure and then expanding with high temperature and reduced preddure, thus sufficiently eliminating the bad flatus in the tobacco stick as the flatus of the wood or the corrupt straws; the tobacco stick after expanded has increased cells and remarkably enhanced ratio surface, thus the material liquid can filter into the tobacco sticks sufficiently to becoming a natural filling material and adaptation carrier for adjusting the cigarette fragrance and style; the cigarette stick after expanded is large in volume, which, after pressed, is easy being cut into silkiness (similar as the physical behavior of tobacco shred); after dried and shaped normally, the cut rolled stem can crisp naturally, thus increasing the filling capacity. The cut rolled stem processed by the technics method of the invention is basically similar with tobacco shred in color and shape and the alloying evenness of the tobacco shred is increased; besides, the tobacco shred has no bad aftertaste when smoking, but has strong filling capacity and enhanced internal quality.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

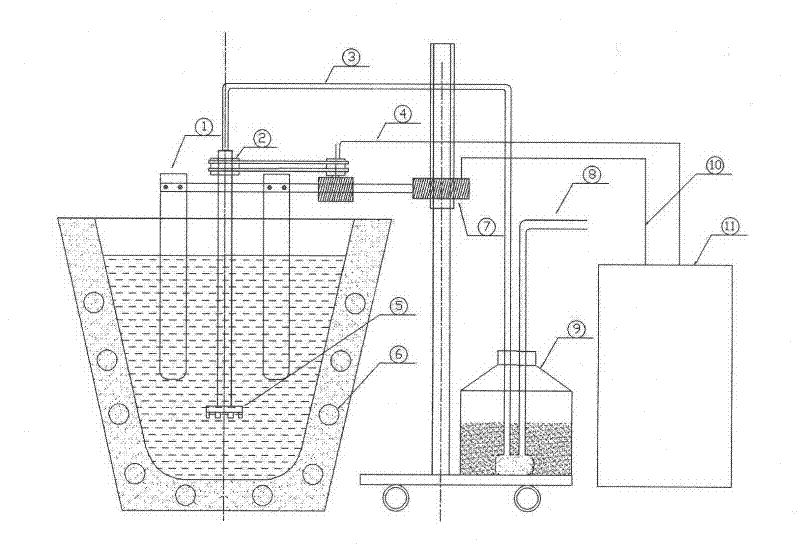

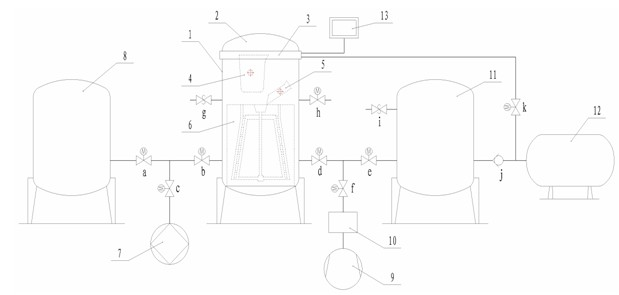

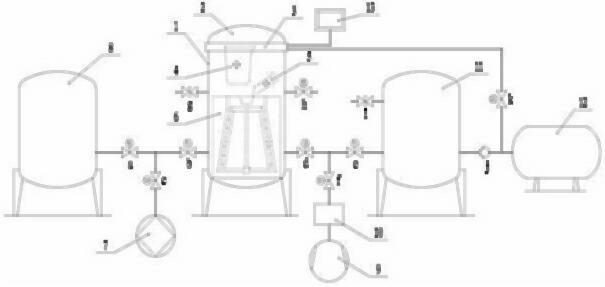

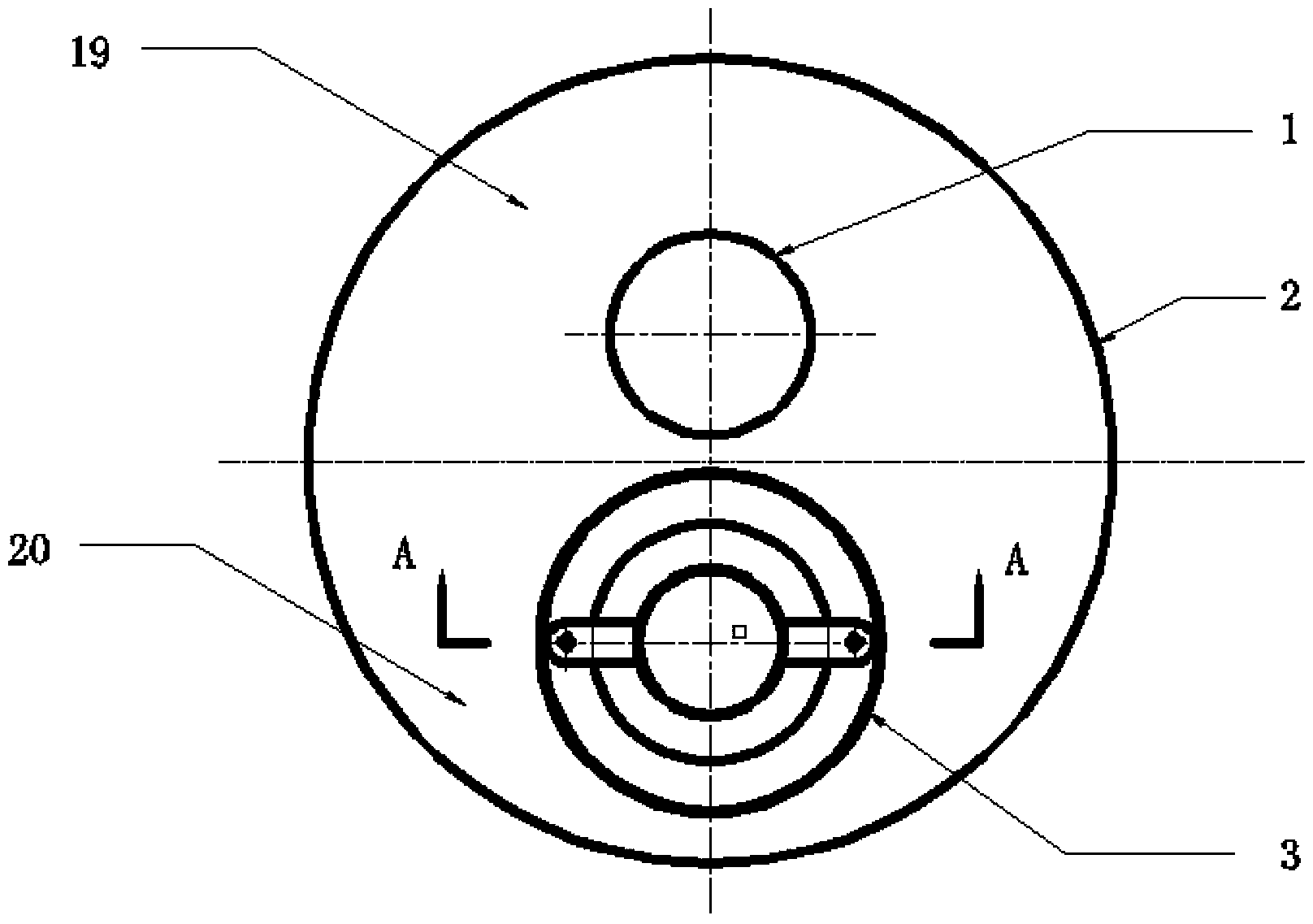

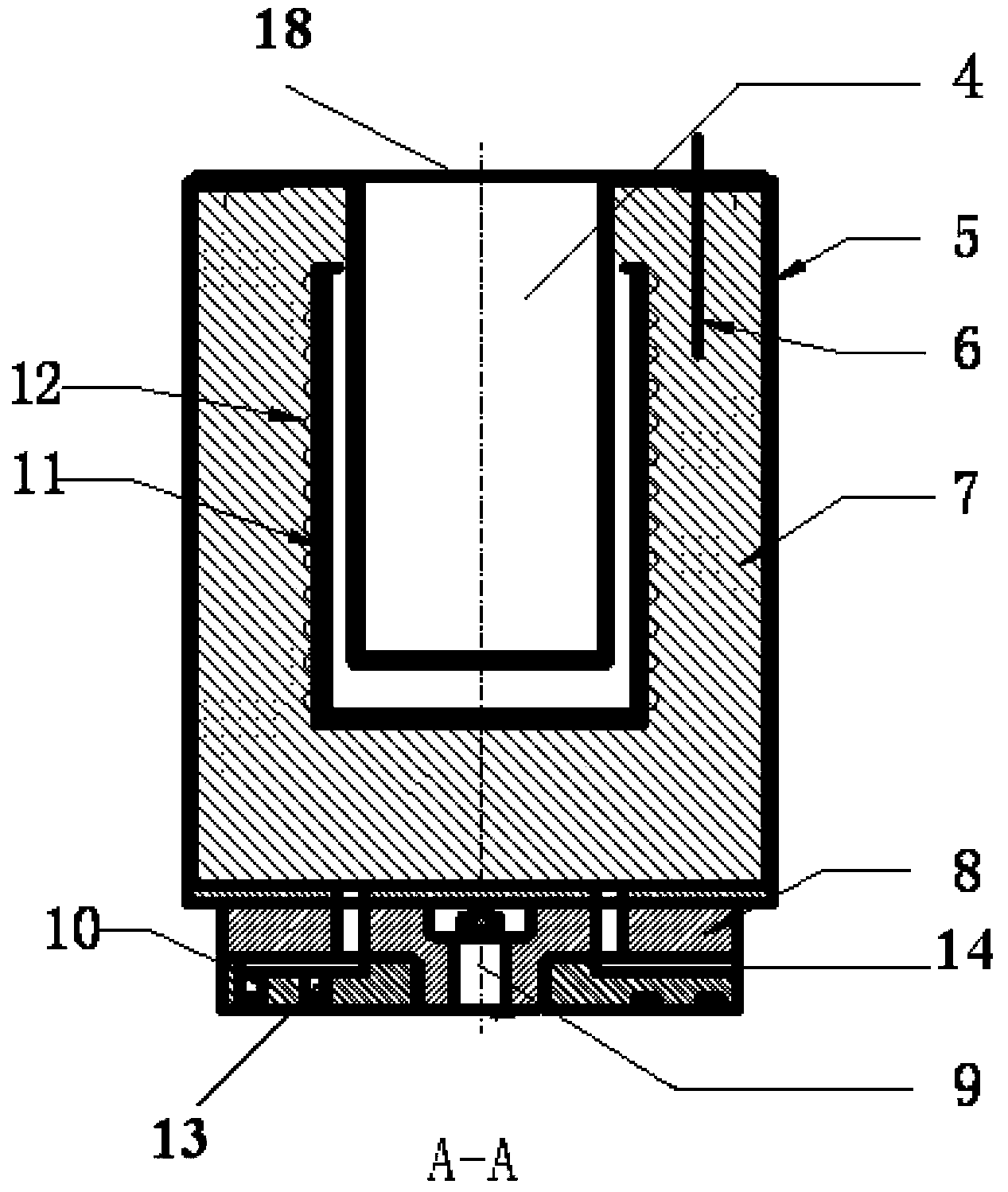

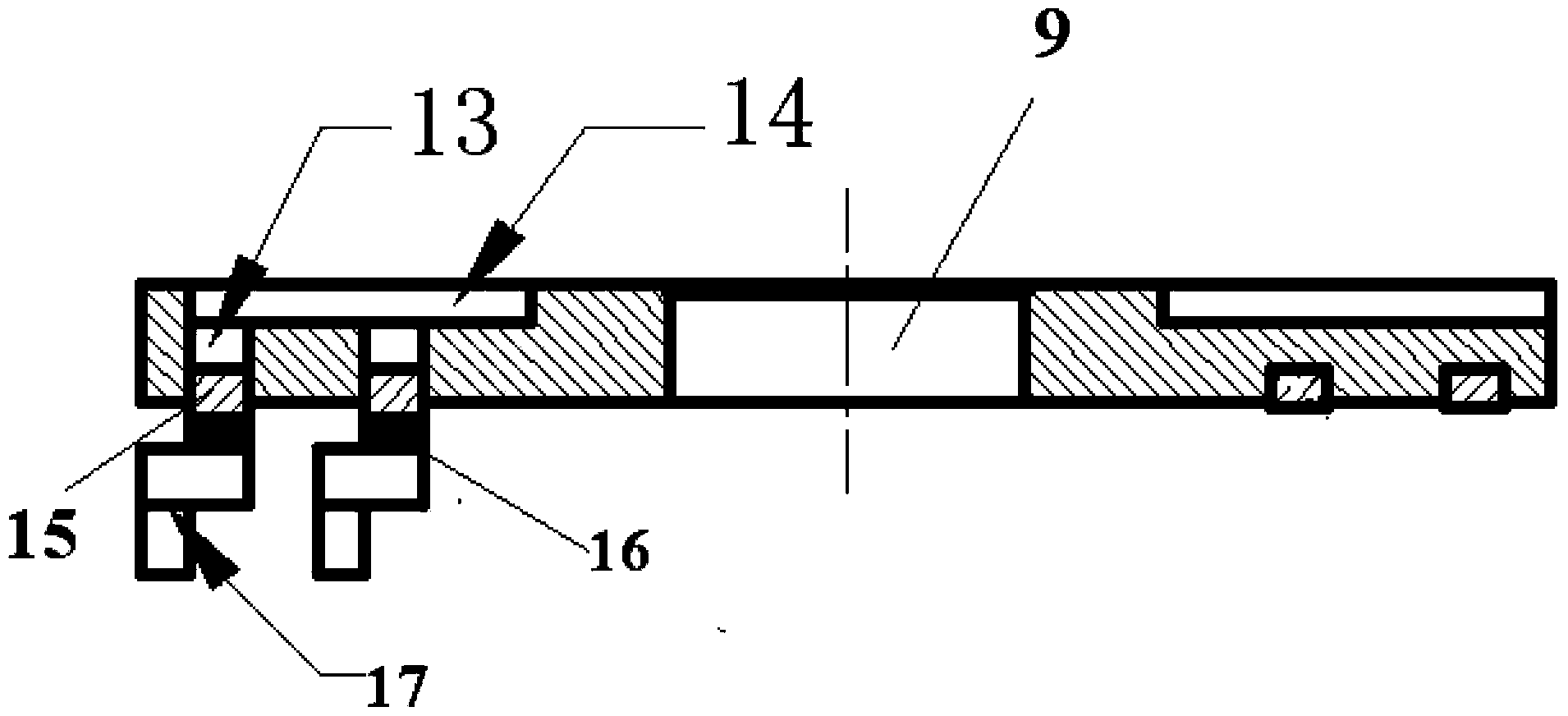

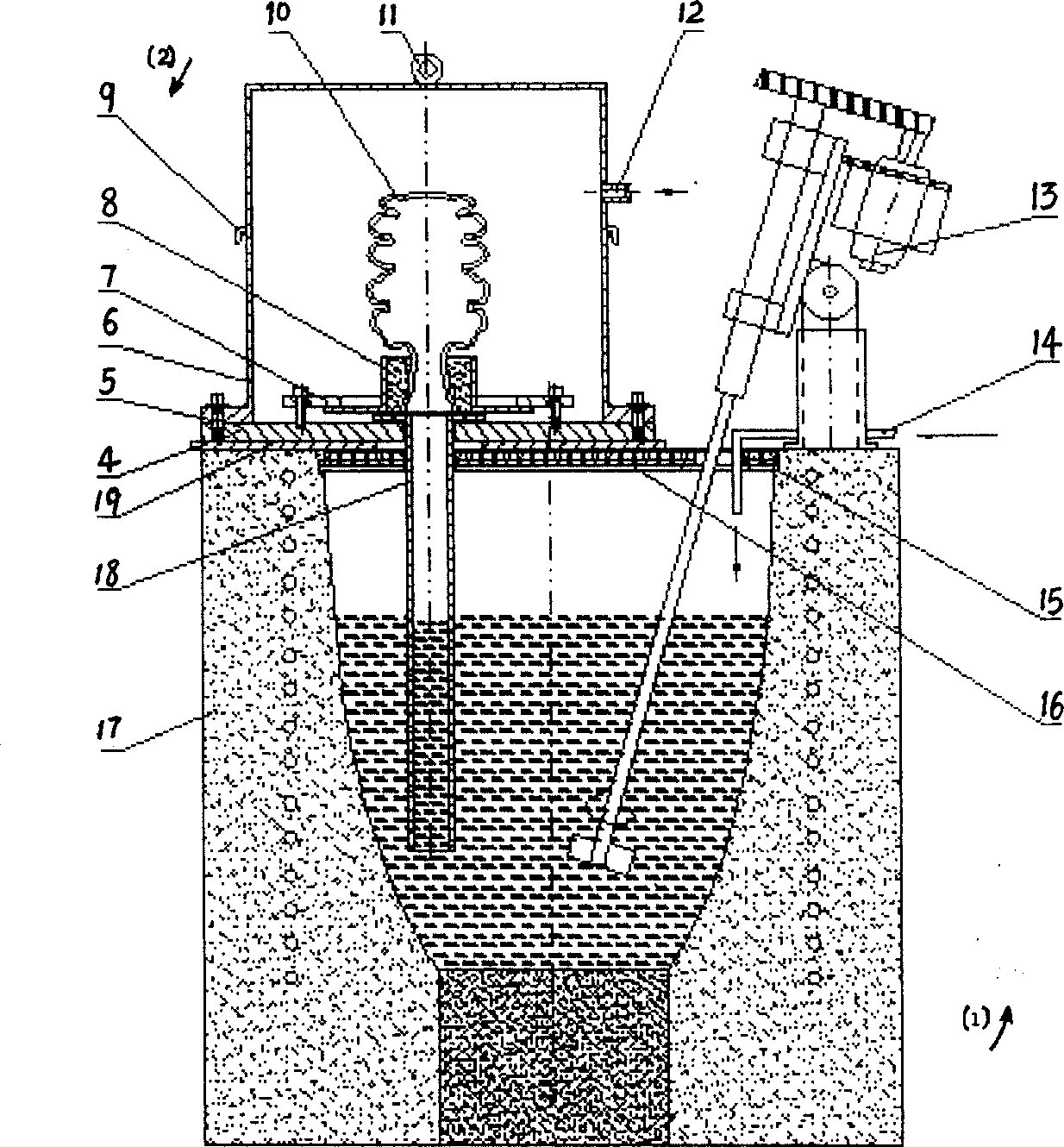

Multipurpose vacuum casting device

ActiveCN103170596AImprove liquidityAchieve oxidation inclusionsIncreasing energy efficiencyFailure rateVacuum pumping

A multipurpose vacuum casting device comprises a smelting furnace and a set of vacuum pumping system communicated with an inner cavity of the smelting furnace. The smelting furnace is provided with a casting pull-down continuous casting molding system which is formed together with the smelting furnace, a vacuum smelting system used for melting metal and a vacuum casting system used for ingot casting molding. Due to adoption of only one set of vacuum pumping system and one smelting furnace, a plurality of purposes such as vacuum induction heating smelting, vacuum casting, vacuum smelting and continuous casting under protection of inert gas can be achieved, the number of device components is greatly reduced, structure of a device is simplified, manufacture cost of the device is decreased to a large extent, production efficiency and casted blank quality are improved, operation is convenient and failure rate of the device is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

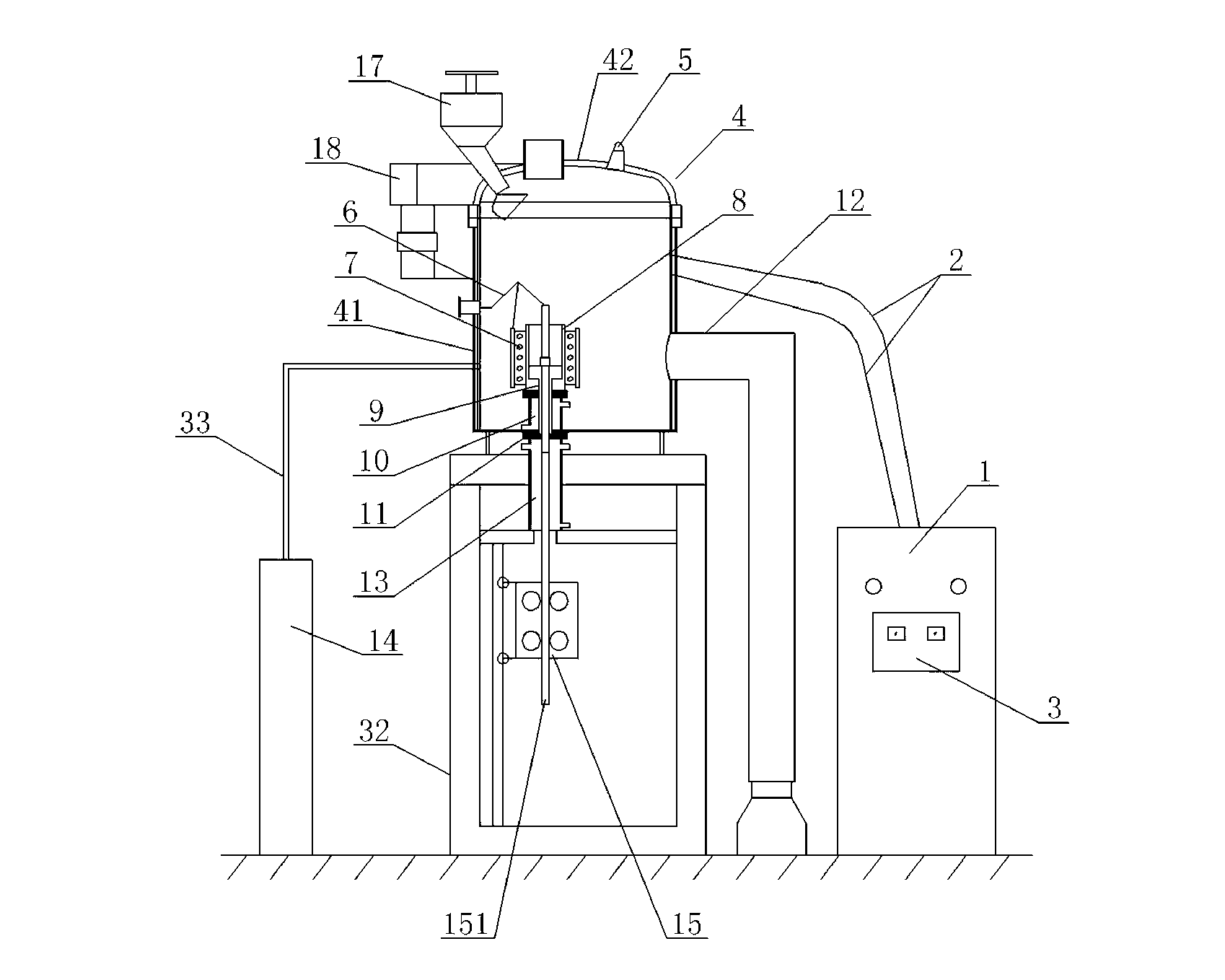

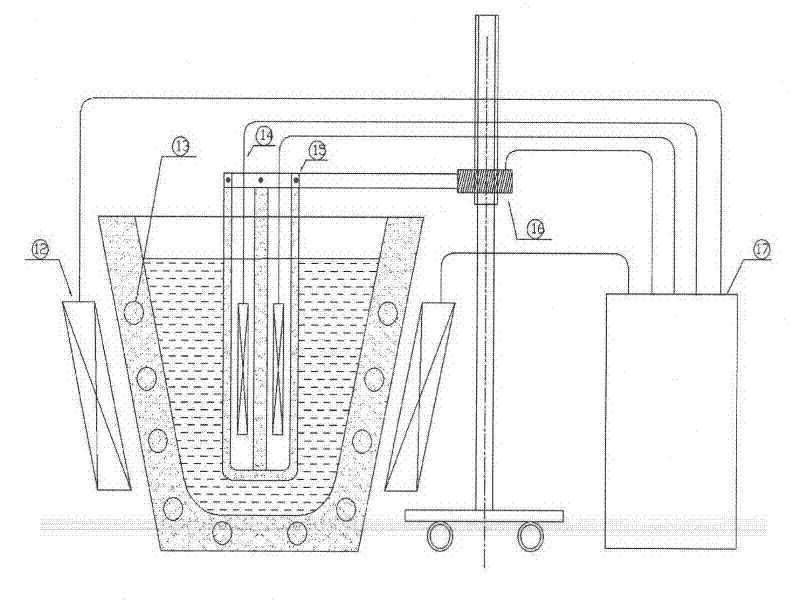

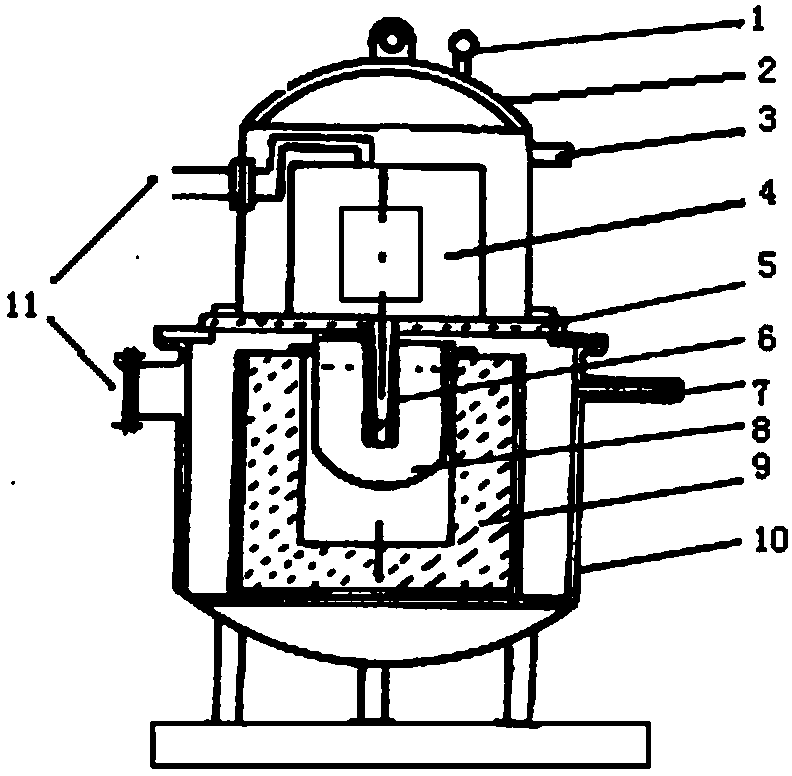

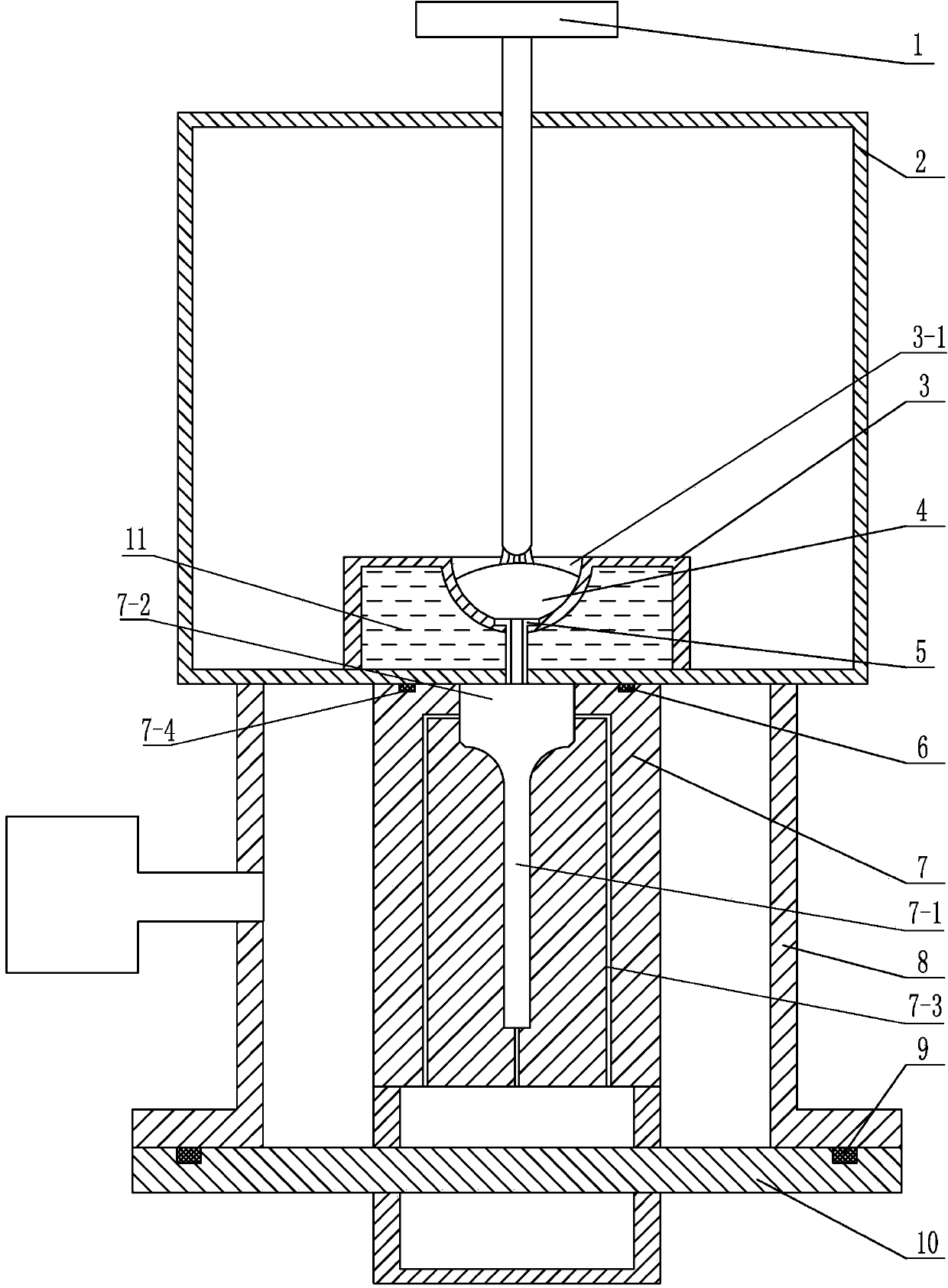

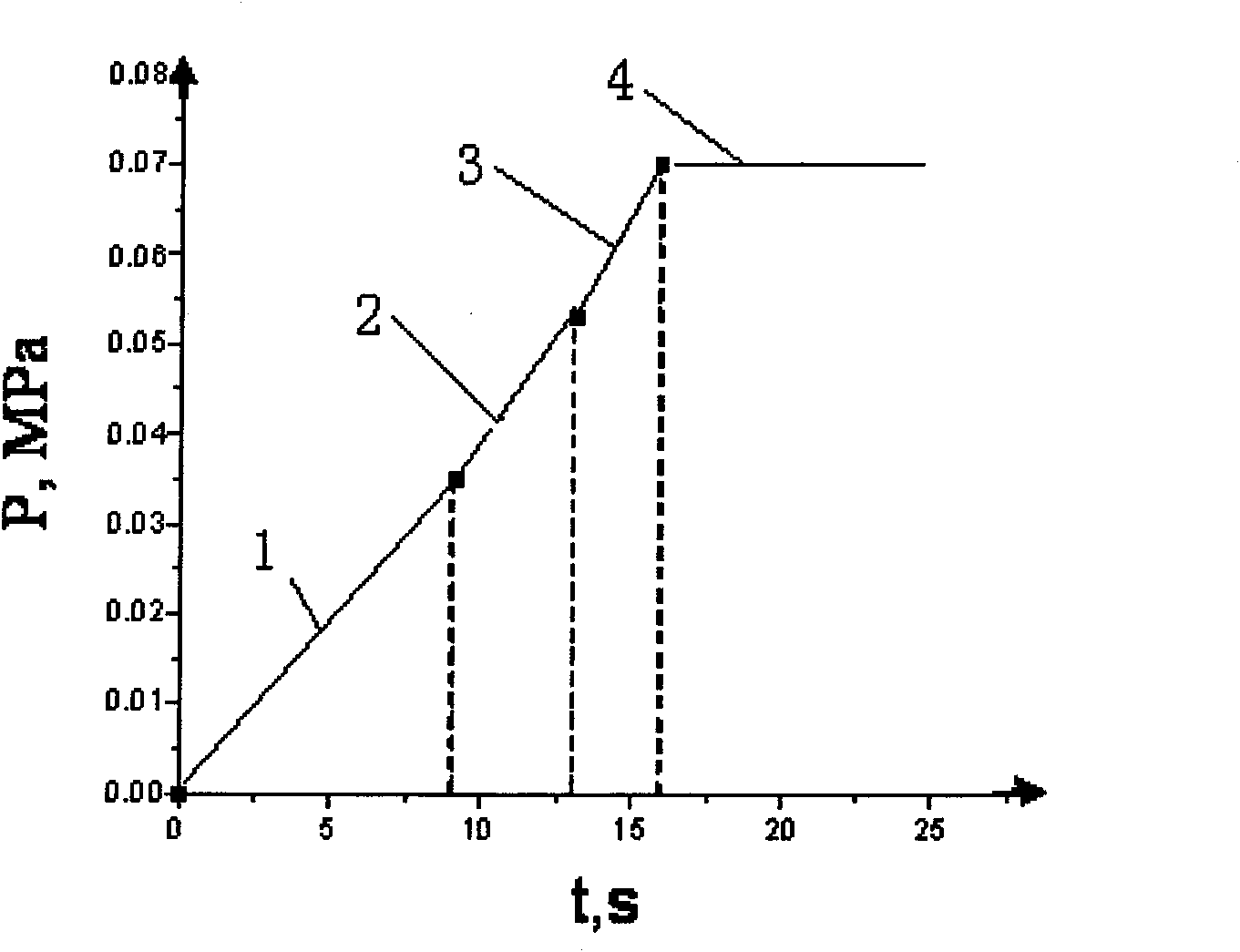

Vacuum low-pressure casting forming device for titanium alloy component

InactiveCN104028729AImprove feeding capacitySuppresses the tendency to segregate chemical componentsActuatorPressure difference

The invention provides a vacuum low-pressure casting forming device for a titanium alloy component. The vacuum low-pressure casting forming device for the titanium alloy component comprises a device body, a vacuum low-pressure casting pneumatic control system and an electronic control system. An upper chamber and lower chamber type structure is adopted by the device body, a water-cooled copper crucible is arranged in a lower chamber, a casting mold is arranged in an upper chamber, an intermediate separation plate is arranged between the upper chamber and the lower chamber, and a liquid lifting pipe is arranged on the intermediate separation plate. The vacuum low-pressure casting pneumatic control system is connected with the device body, a vacuum system and a protective gas source system, and digital combination valves are adopted as flow regulation actuators. The electronic control system is composed of an industrial control computer and a PLC. After the smelting process of titanium alloy is completed in a smelting chamber, the water-cooled copper crucible is lifted to a casting position through a lifting device, an upper chamber and lower chamber intercommunication valve is closed, the flow of protective gas fed into the lower chamber is controlled through the computer, the pressure difference between the upper chamber and the lower chamber is established, the liquid alloy is filled in the casting mold through the liquid lifting pipe under the action of the pressure difference, and the casting process is completed. Compared with traditional centrifugal casting and bottom leakage type suction casting, the mold-filling capacity and solidification feeding capacity of the titanium alloy can be improved, castings with better casting quality and thinner wall thicknesses can be obtained, and a new means is provided for batch production of minitype titanium alloy components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

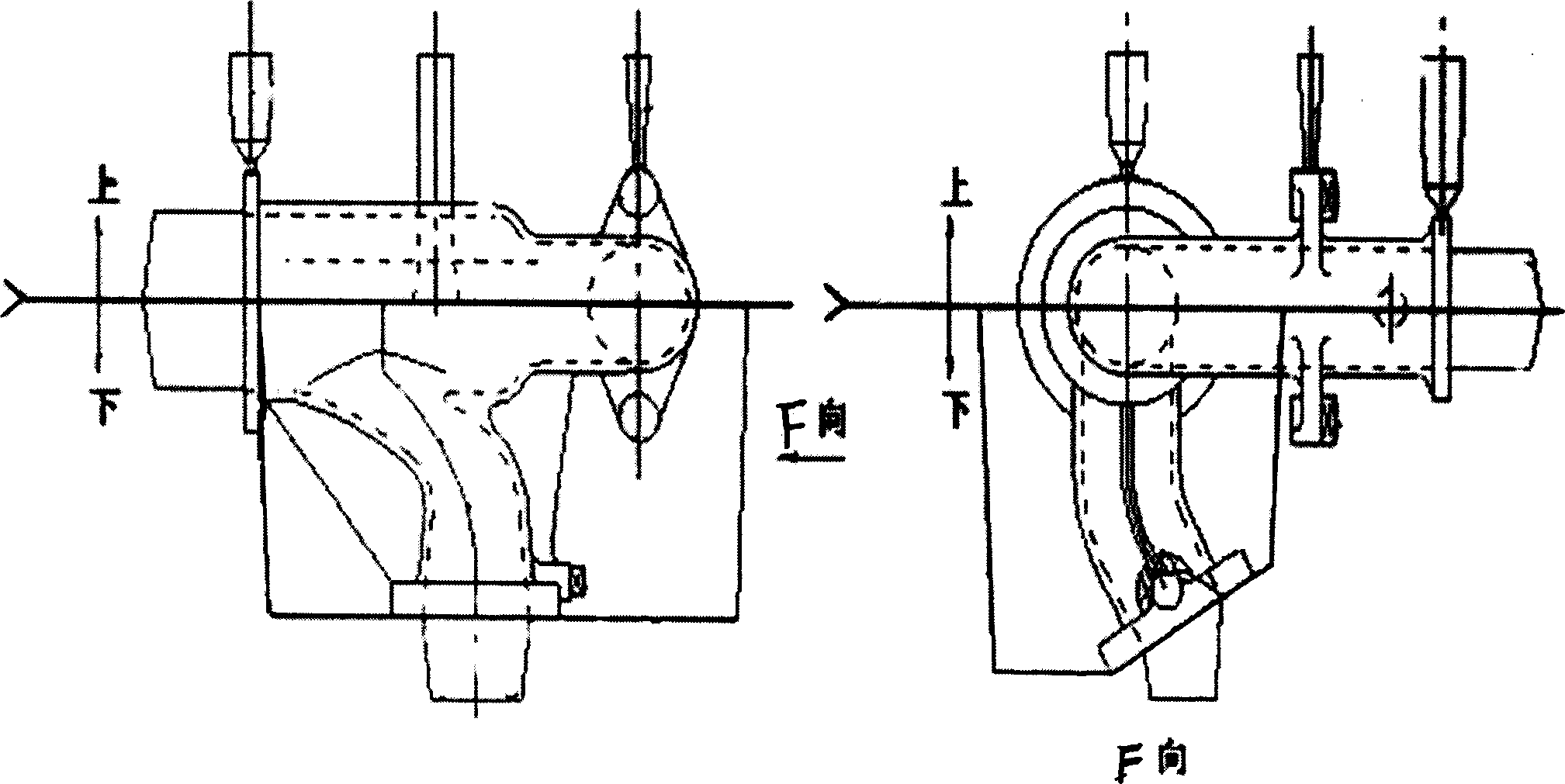

Cast forming method of small titanium alloy or titanium-aluminum alloy complicated casting

InactiveCN102019401AImprove filling abilityImprove efficiencyFoundry mouldsFoundry coresMold fillingIngot

The invention relates to a cast forming method of a small titanium alloy or titanium-aluminum alloy complicated casting, belonging to the casting method of the titanium alloy or titanium-aluminum alloy casting and solving the technical problems that the gravity casting of the traditional titanium alloy member is difficult in smooth mold filling, the centrifugal casting method has complicated process, the material utilization rate is low and the metal bottom-drain type vacuum suction casting method cannot be used for casting and forming thin-walled parts with complicated shapes. The method comprises the steps of: 1. preparing a ventilating shell; 2. preparing a bottom drain type vacuum suction casting container; 3. fixing the shell in the container, fixing the container in a suction casting chamber of a smelting furnace; 4. carrying out electric arc melting on the titanium alloy or titanium-aluminum alloy raw materials to obtain a button ingot; 5. turning the button ingot to a suction casting crucible for smelting to obtain overheating melt; and 6. suction-casting and mold-filling, and cooling to finally obtain the casting. The yield by the method is not less than 90 percent; and the method is a simple near net shape forming method, can be used for preparing a titanium and titanium-aluminum alloy blade, a worm wheel, artware and other small complicated castings.

Owner:HARBIN INST OF TECH

Casting method for exhaust branch pipe of thin-wall ball iron triplet

ActiveCN1907597AGuaranteed wall thicknessHigh dimensional accuracyFoundry mouldsFoundry coresExhaust pipeSerial code

The invention relates to a casting method for casting the three-way ventilate branch tube of thin-wall iron element, which comprises: (1), using the curvature formed by the central line of C exhaust open and the central line of A exhaust tube, to make the C and A exhaust opens above the parting surface, to be shaped via upper and lower outer moulds; the tube core and sand core are put via the serial number, and it uses pour system that combines side pour and bottom pour with contract cap and cold iron; (2), preparing outer mould, core box, section sheet, pour cap, and the wood mould that checking sample plate; (3), preparing the casting element and sand core; (4), drying the casting element and the sand core, and closing the tank after arranging the sand core; (5), smelting and pouring; (6), cooling and molding; (7), cleaning the casting element; (8), thermally treating; (9), testing the water pressure. The invention can improve the quality of casting element, and improve the producing efficiency.

Owner:HUDONG HEAVY MACHINERY +1

Luminant white paint and preparation method thereof

ActiveCN102533070AHigh hiding powerGood filling effectPolyester coatingsKetone solventsToluene diisocyanate

The invention discloses a luminant white paint. The luminant white paint is obtained by mixing a main paint, a curing agent and a diluent according to a mass ratio, wherein the main paint comprises the following components in parts by weight: 35-40 parts of alkyd resin, 3-5 parts of dispersing agent, 30-40 parts of titanium white powder, 10-20 parts of extender pigment, 0.2-0.5 parts of anti-setting agent, 0.2-0.4 parts of leveling agent, 0.2-0.5 parts of antifoaming agent, 0.5-1.0 parts of anti-yellowing agent and 20-25 parts of main paint solvent; the curing agent comprises the following components in parts by weight: 10-20 parts of curing agent solvent, 0.1-0.2 parts of dehydrating agent, 60-70 parts of HDI (Hexamethylene Diisocyanate) type curing agent and 30-40 parts of TDI (Toluene Diisocyanate) type curing agent; and the diluent comprises the following components in parts by weight: 60-70 parts of ester solvent and 30-40 parts of ketone solvent. The luminant white paint disclosed by the invention has the advantages of rapidness for leveling after being sprayed, full paint film, rockiness and scratch resistance. Meanwhile, the invention also discloses a preparation method of the luminant white paint.

Owner:NIPPON PAINT GUANGZHOU

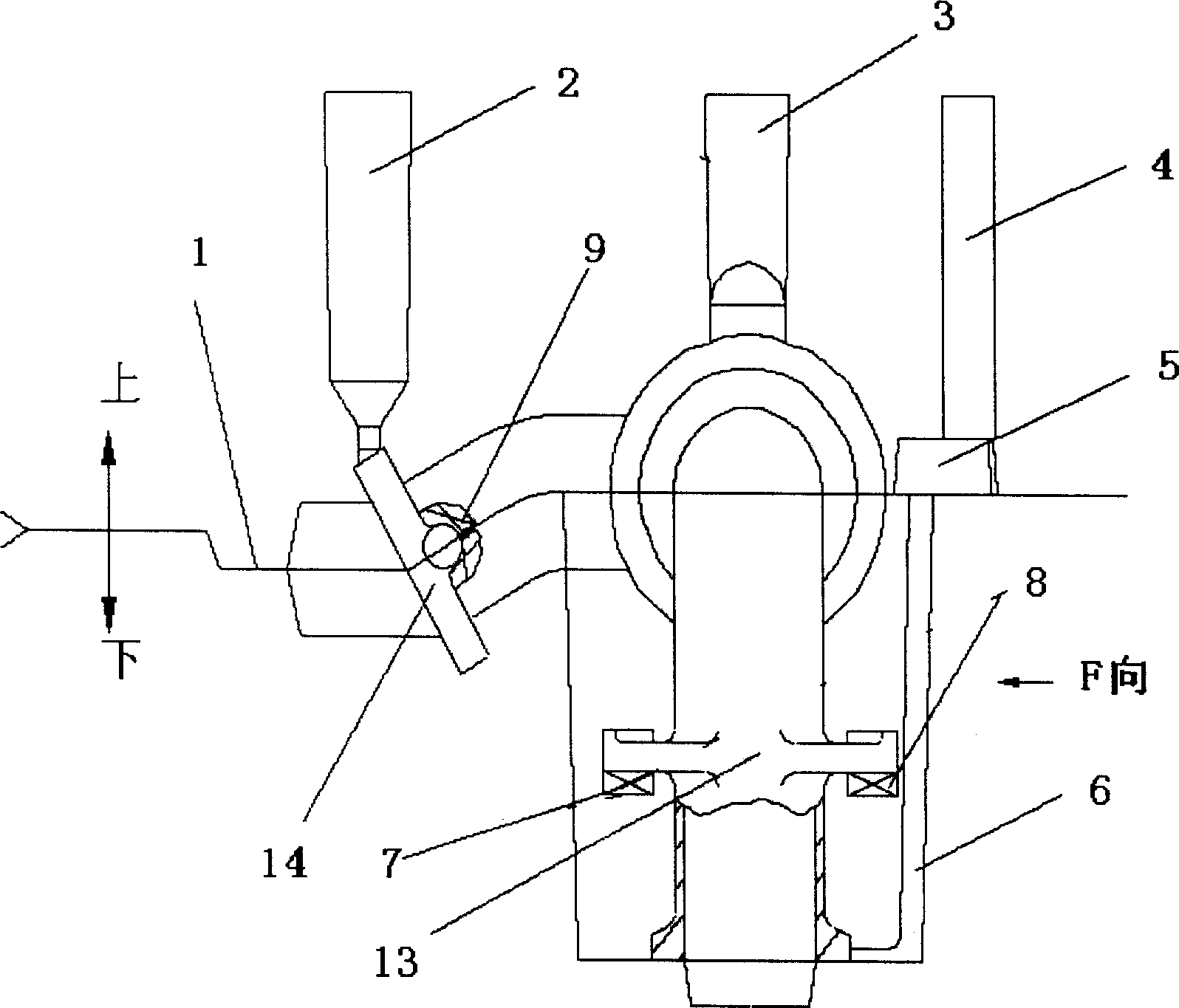

Method and apparatus for preparing semisolid slurry for automobile aluminium wheel through compound modification refinement and electromagnetic stirring

A method and an apparatus for preparing a semisolid slurry for an automobile aluminium wheel through compound modification refinement and electromagnetic stirring. The method comprises steps of: transferring alloy with degree of superheat of 100-120 DEG C into a transit bag, adding a refinement modification agent with high purity nitrogen by an injecting device, wherein the refiner is Al-Zr-B-O intermediate alloy with a granularity of 150-200 um, and the alterant is Al-Sr-RE complex alloy with a granularity of 200-2505 um; standing for 5-8 min, pouring into an electromagnetic stirring crucible when a temperature is 40-50 DEG above a liquidus, putting the crucible in an electromagnetic stirrer, and carrying out composite stirring through a crucible peripheral stirrer and central stirrer, wherein the peripheral stirrer has a frequency of 10-20 Hz, a power of 12 kw, a rate of 300-500 rmp and a time of 2-3 min, and the central stirrer has a frequency of 5-15 Hz, a power of 1-2 kw, a rate of 300-800 rmp and a time of 2-3 min; stopping stirring, when a melt temperature drops to 10-15 DEG C below the liquidus, to obtain a near sphaerocrystal structure semisolid aluminium alloy slurry. The method solves problems of nonuniform slurry and low pulping efficiency.

Owner:JIANGSU KAITE AUTO PARTS

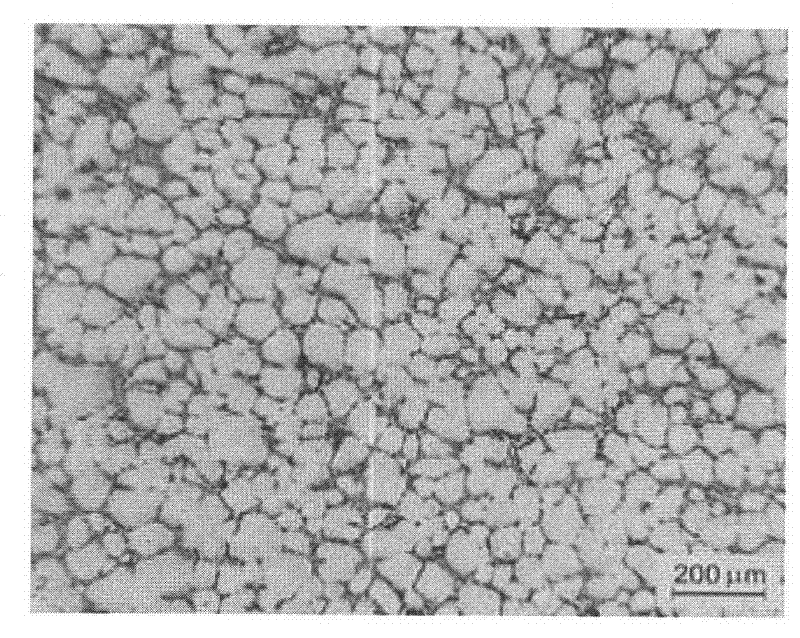

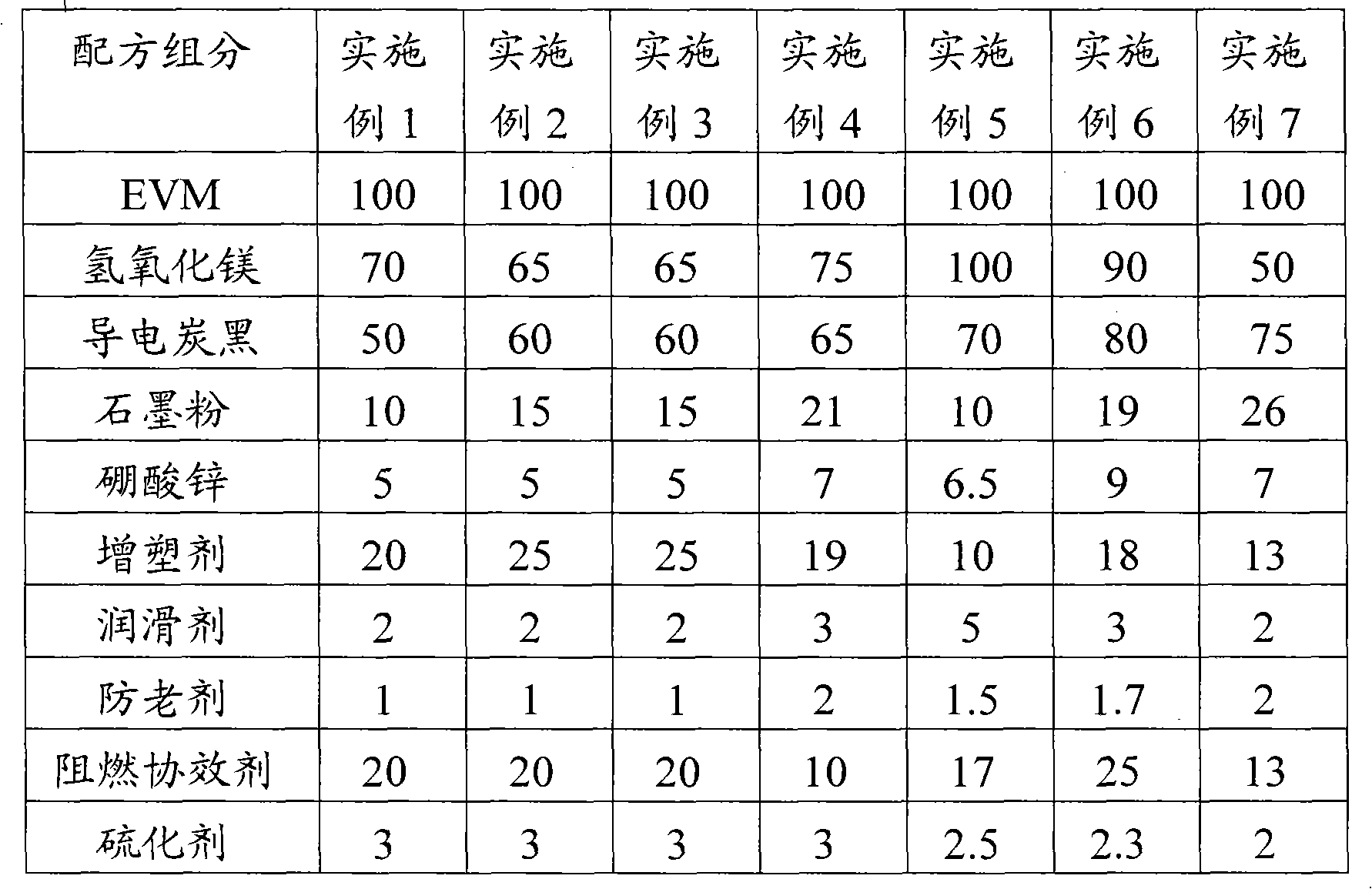

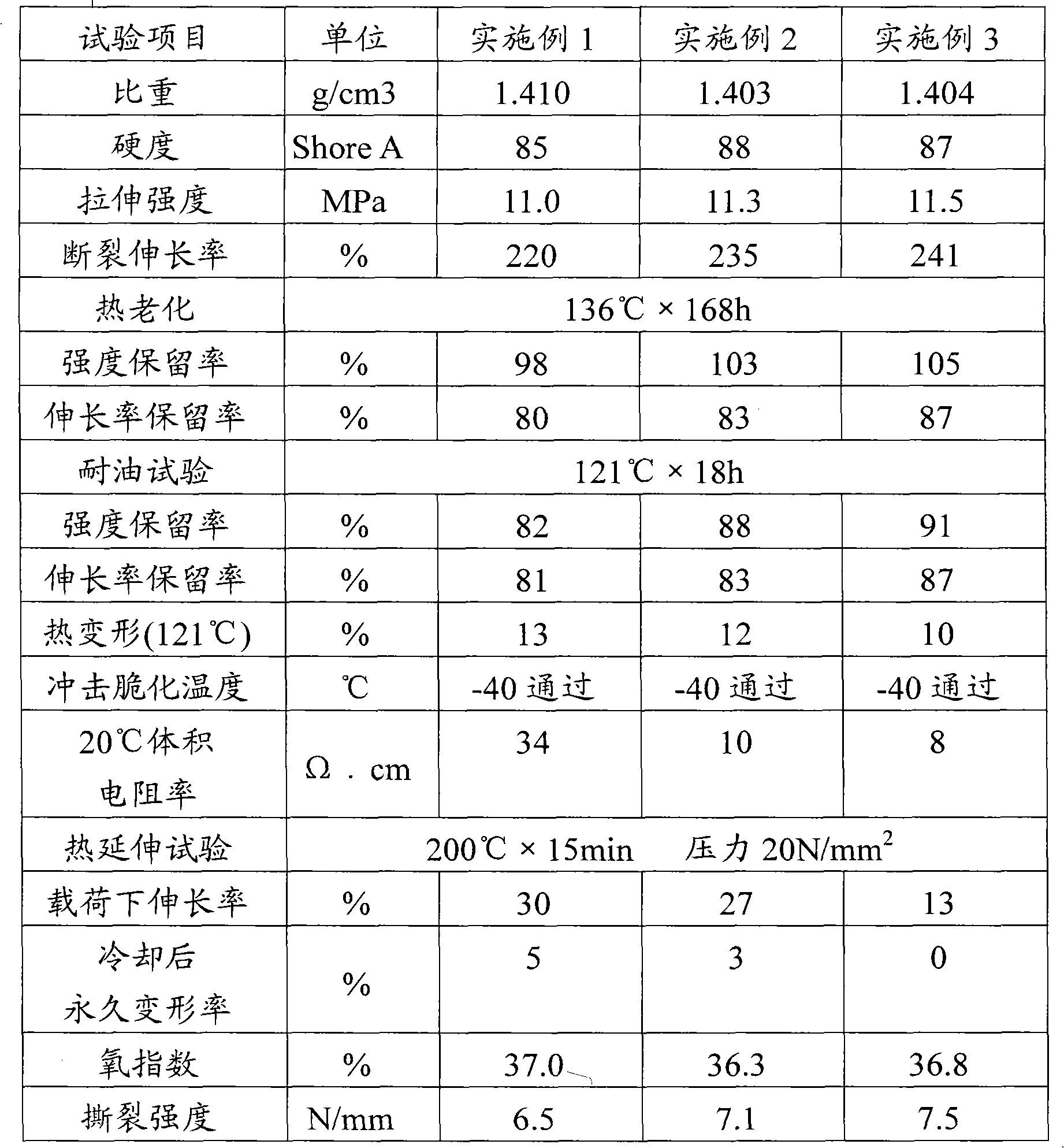

Conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and preparation method thereof

ActiveCN101942144AGood oil resistanceLow crystallization plasticizing temperatureInsulated cablesNon-conductive material with dispersed conductive materialVulcanizationHazardous substance

The invention relates to a conductive screening material, in particular to a conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material and a preparation method thereof. The conductive screening material comprises the following basic components: 100 parts of ethylene-vinyl acetate rubber, 50-100 parts of magnesium hydroxide, 50-80 parts of conductive black, 10-30 parts of graphite powder, 5-10 parts of zinc borate, 10-25 parts of plasticizer, 2-5 parts of lubricant, 1-2 parts of antiager, 10-30 parts of flame retarding synergist, 2-3 parts of vulcanizer and 1-2 parts of vulcanization assistant. The preparation method comprises the four steps of material preparation, mixing, extrusion and tabletting. The conductive low-smoke zero-halogen flame retarding and oil resisting cable sheath material has the advantages of high conductivity, good oil resistivity, excellent flame retarding effect, no peculiar smell, easy stripping and high heat resistance level, and can pass the environment protection authentication of RoHS (Restriction of the use of certain Hazardous Substances Registration), REACH (Evaluation, Authorization and Restriction of Chemicals) and the like.

Owner:中广核三角洲(江苏)塑化有限公司

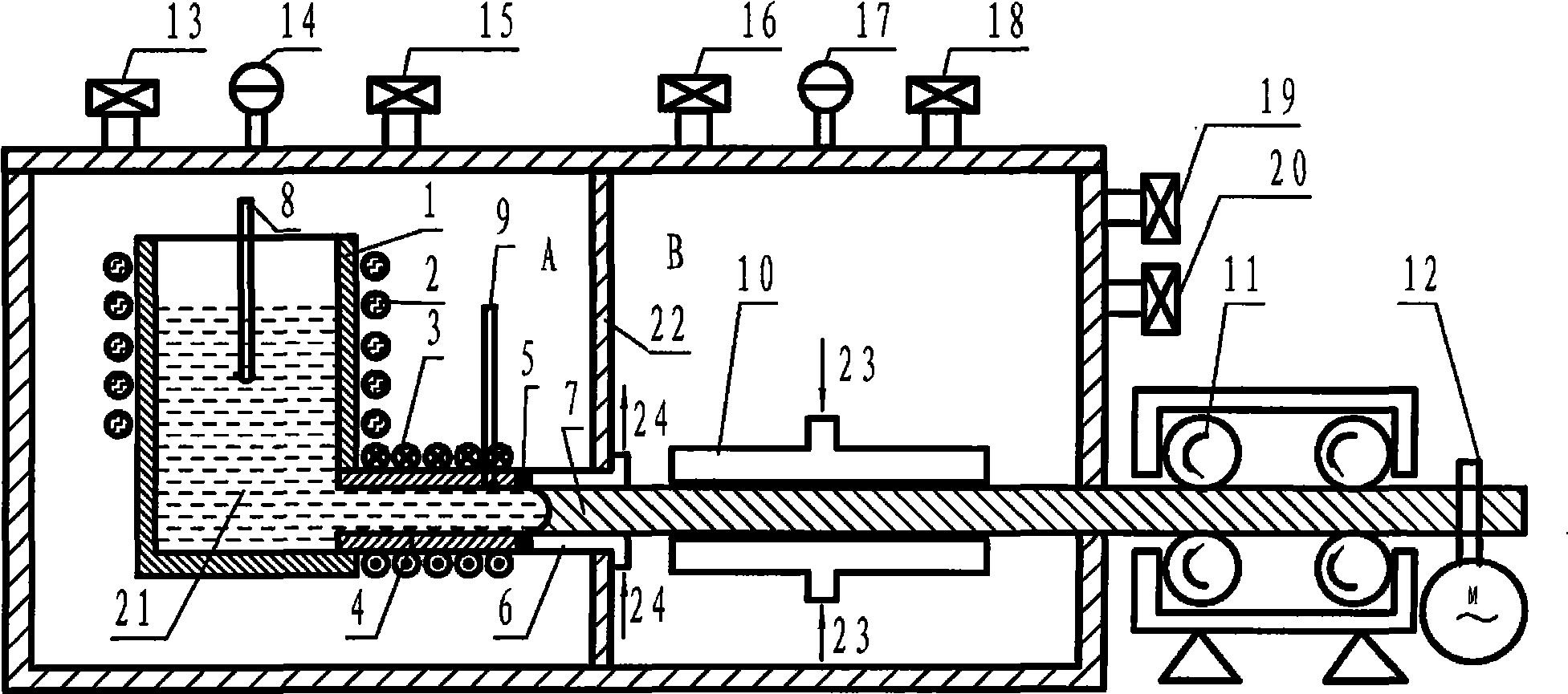

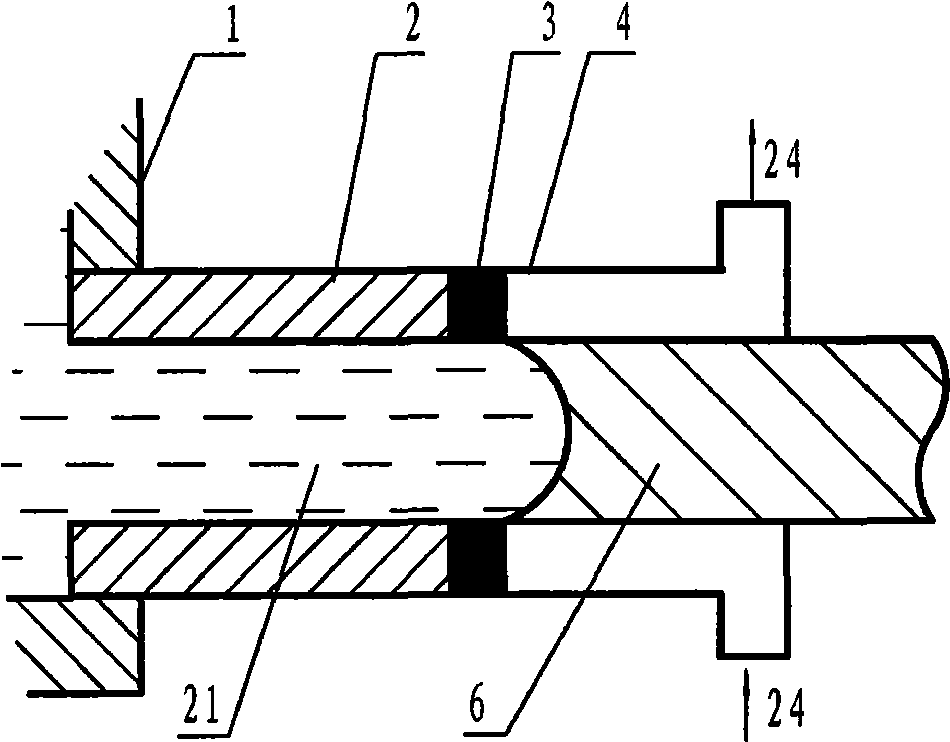

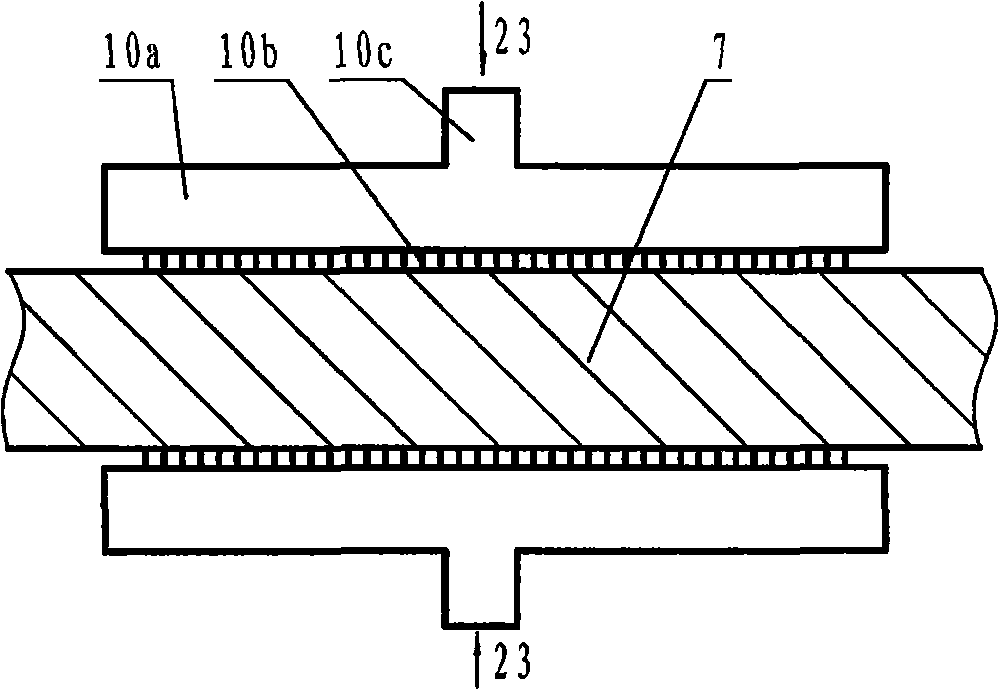

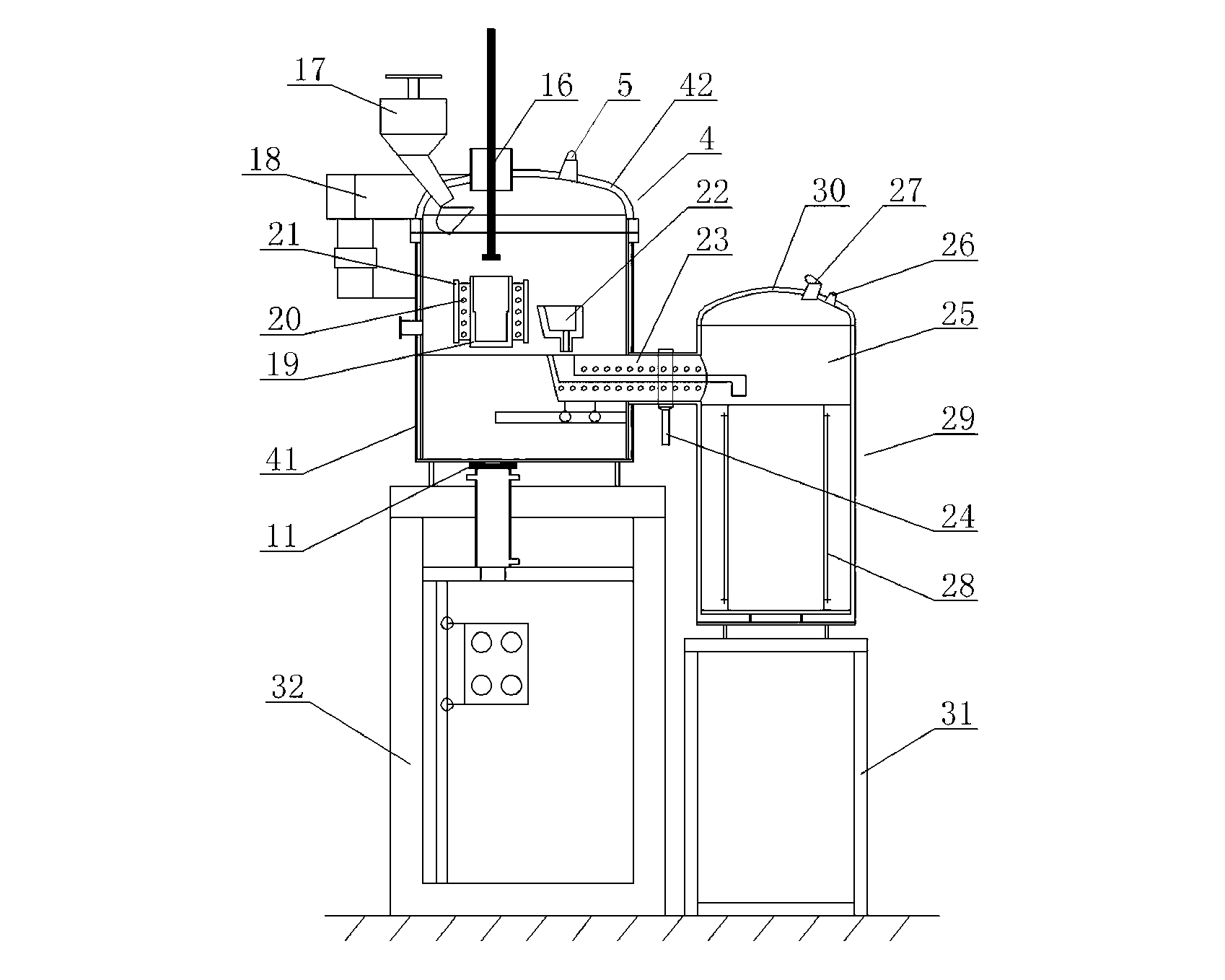

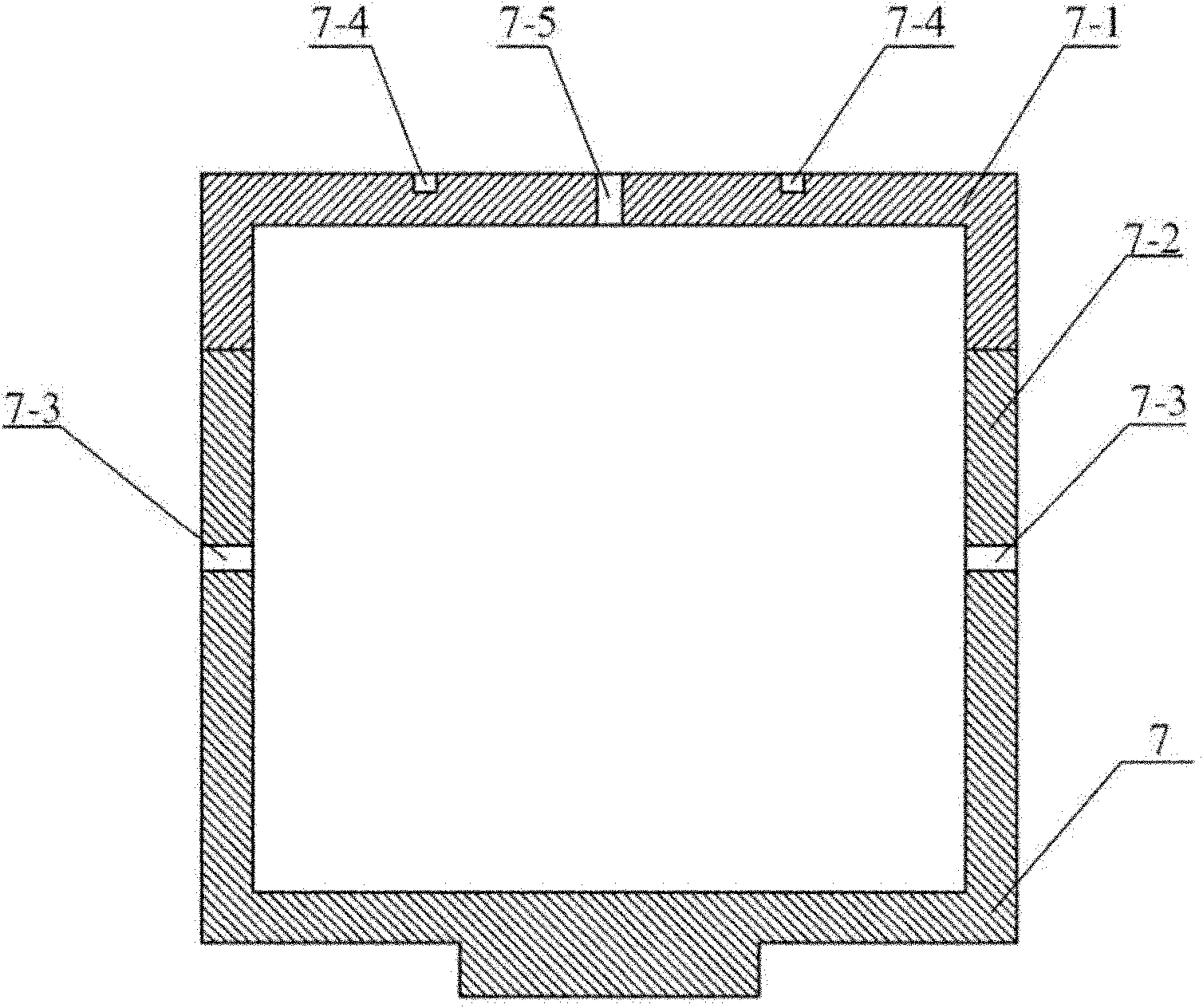

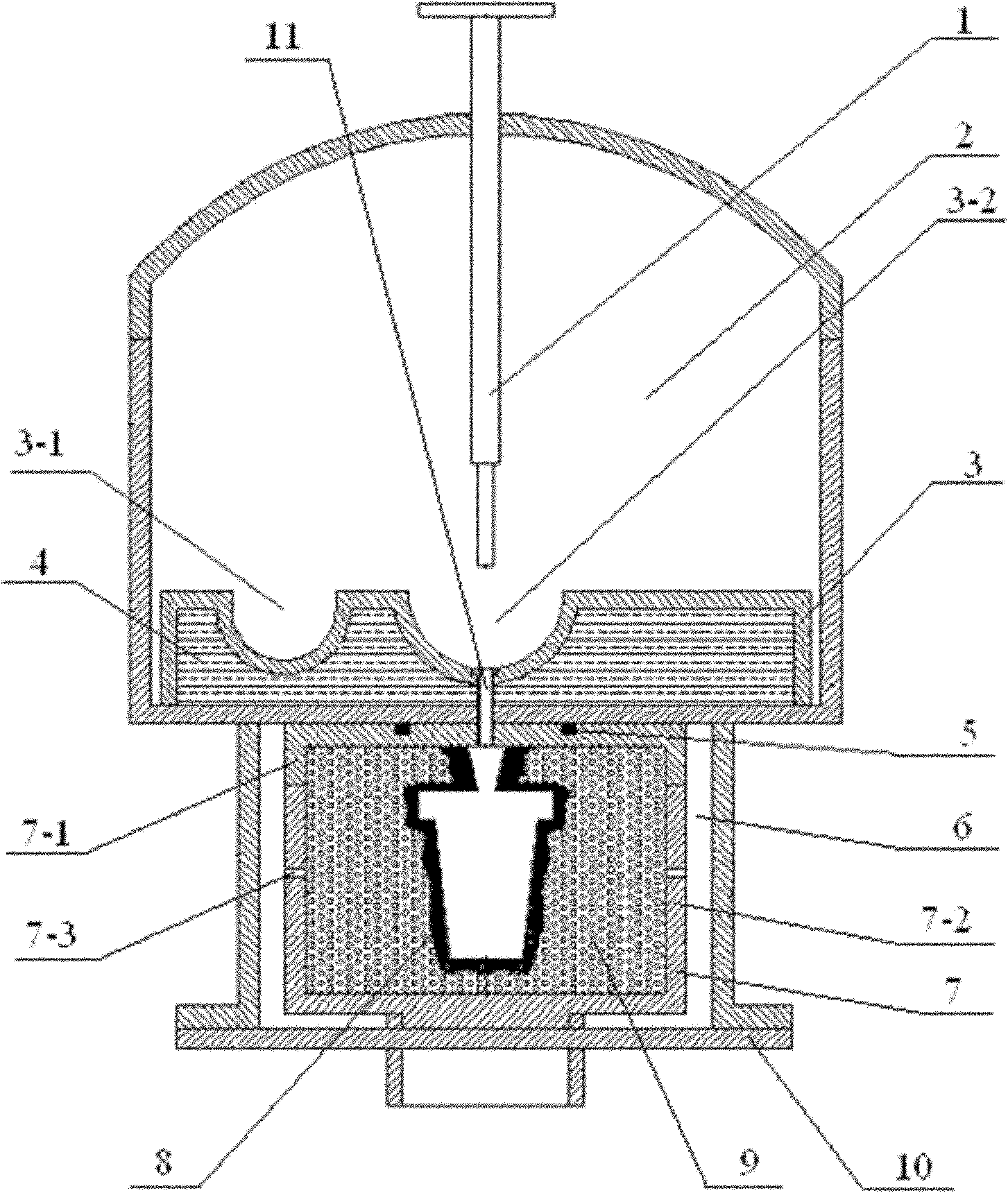

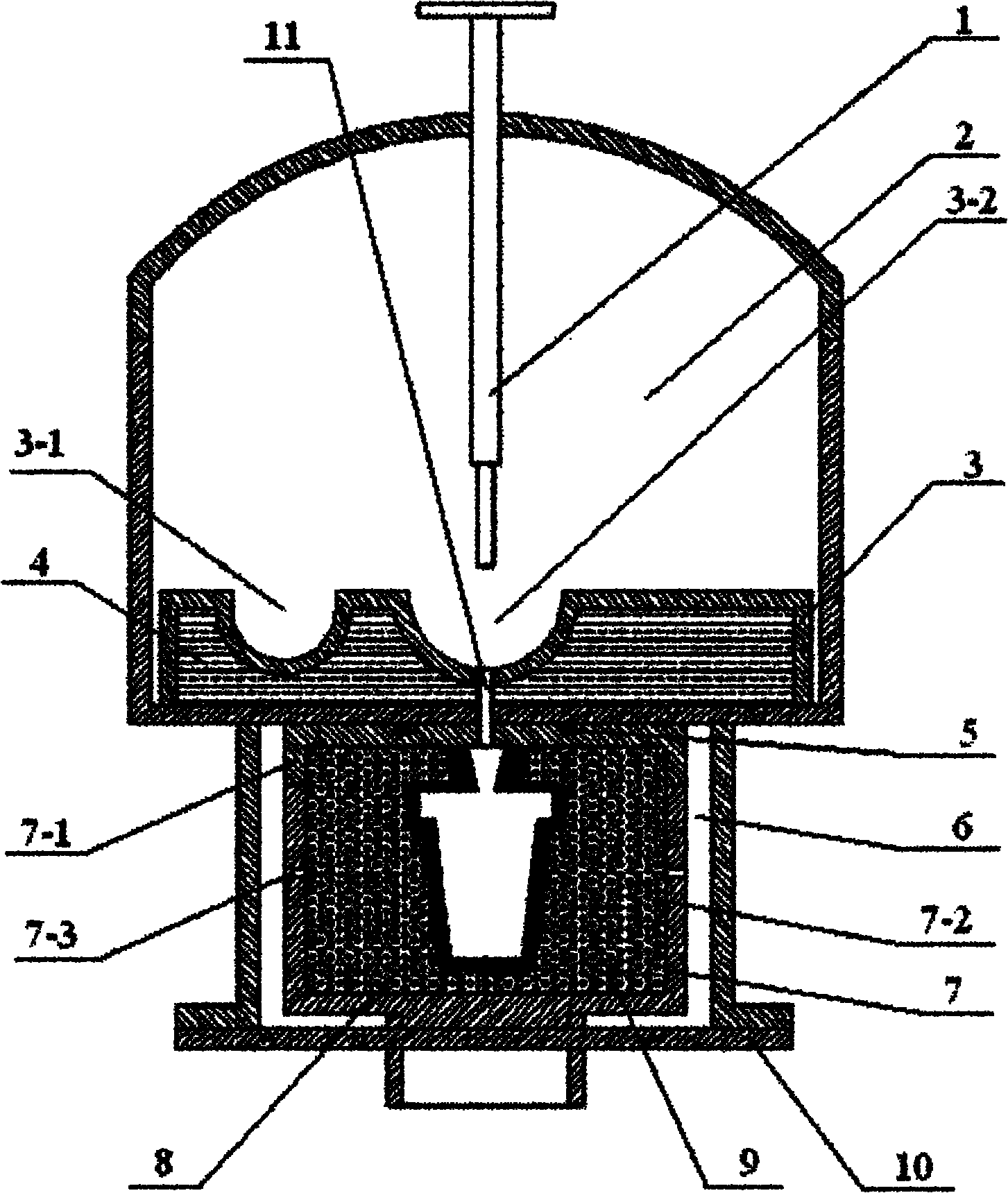

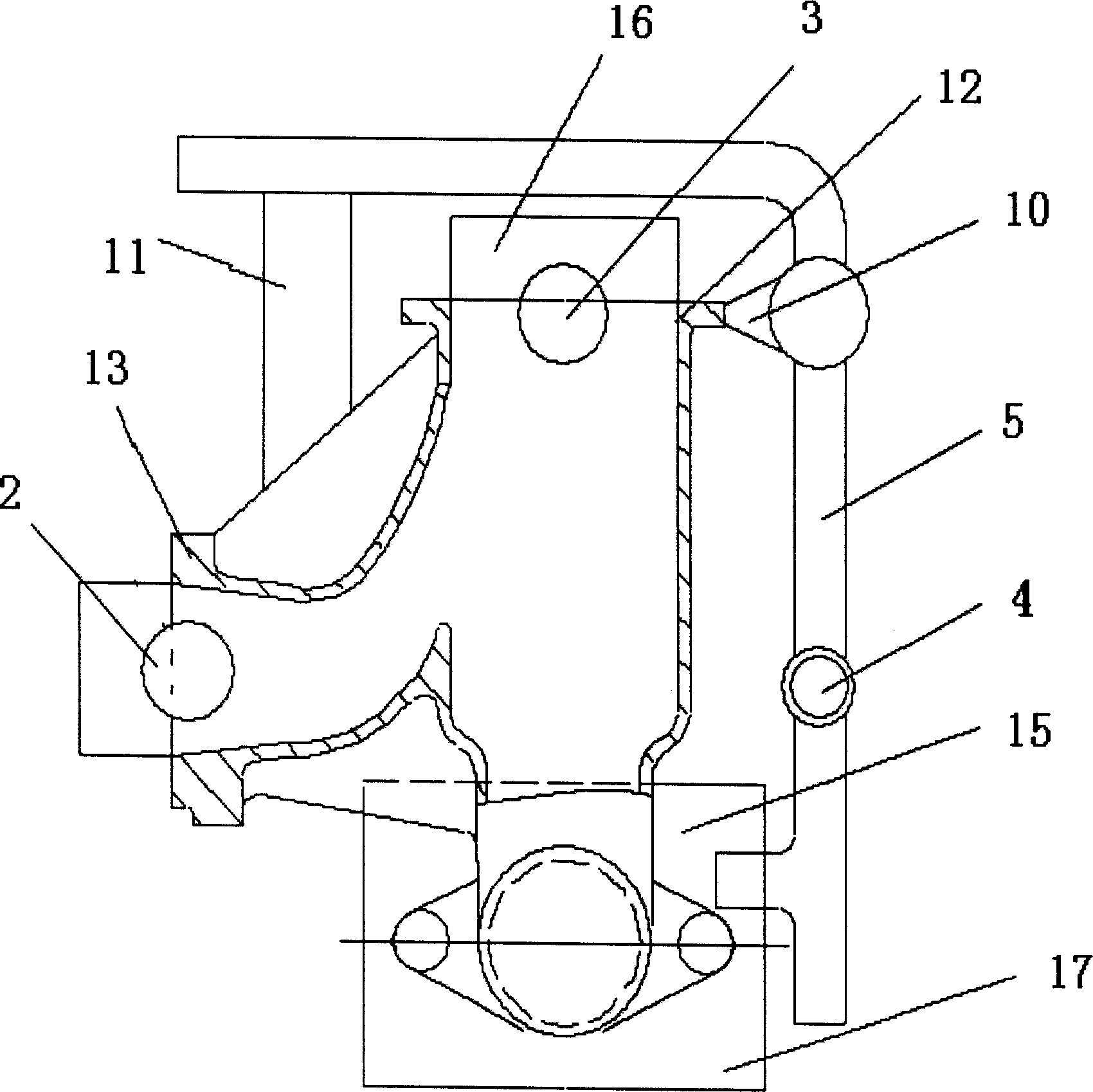

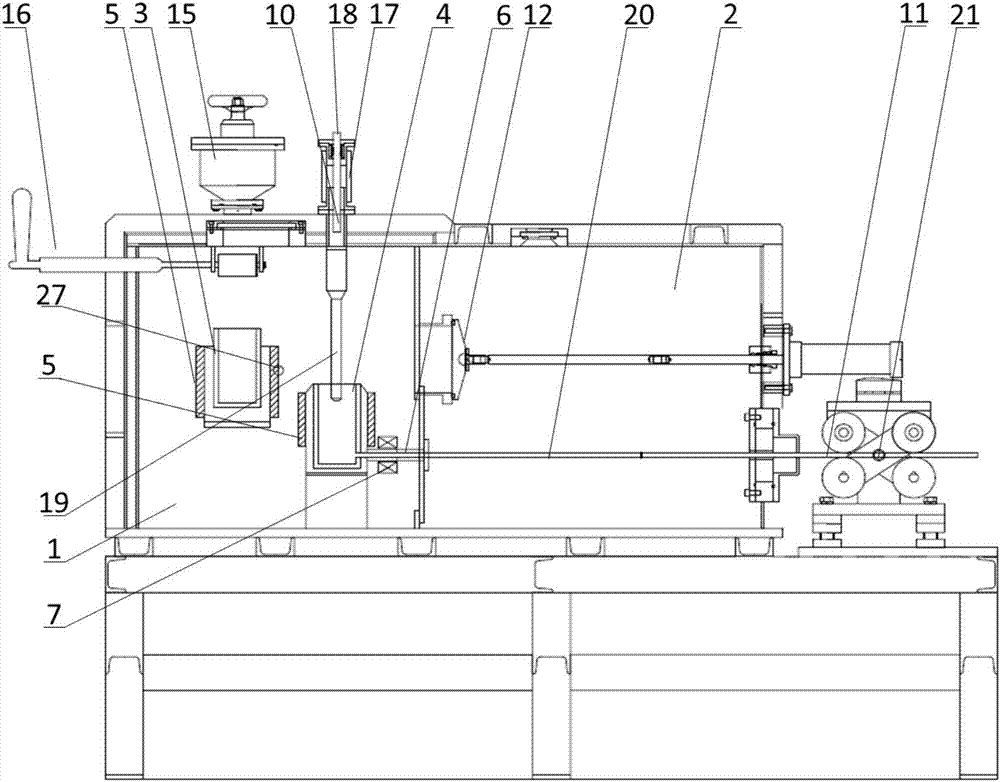

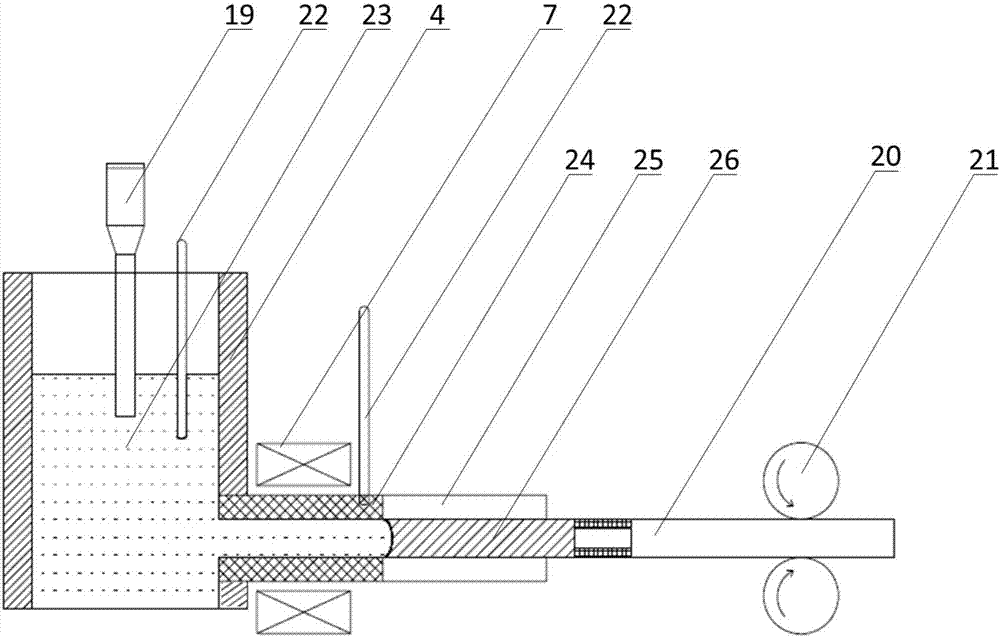

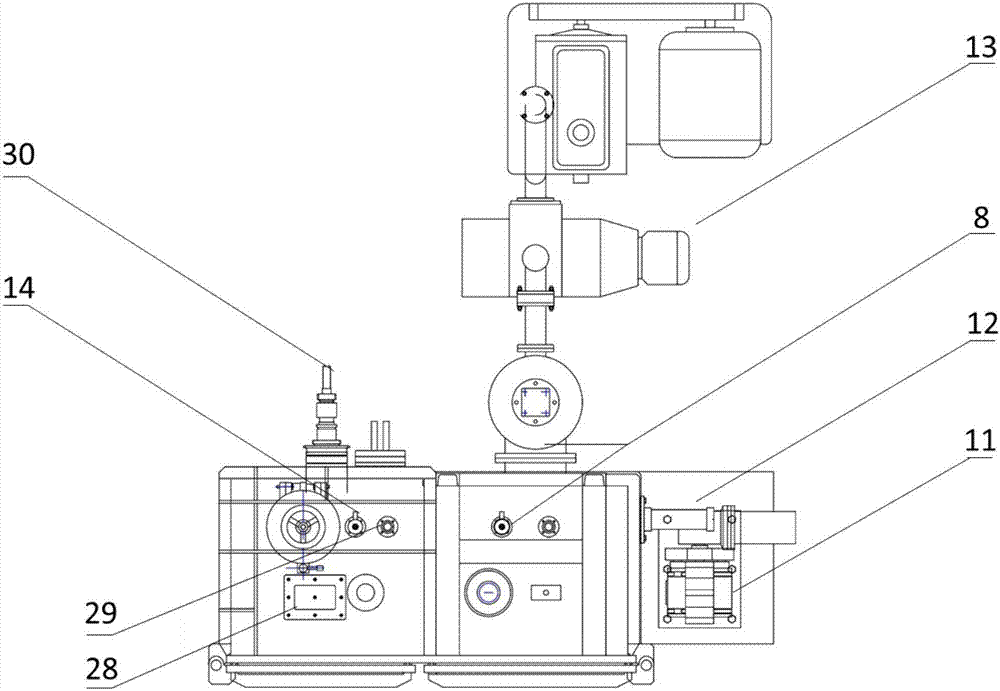

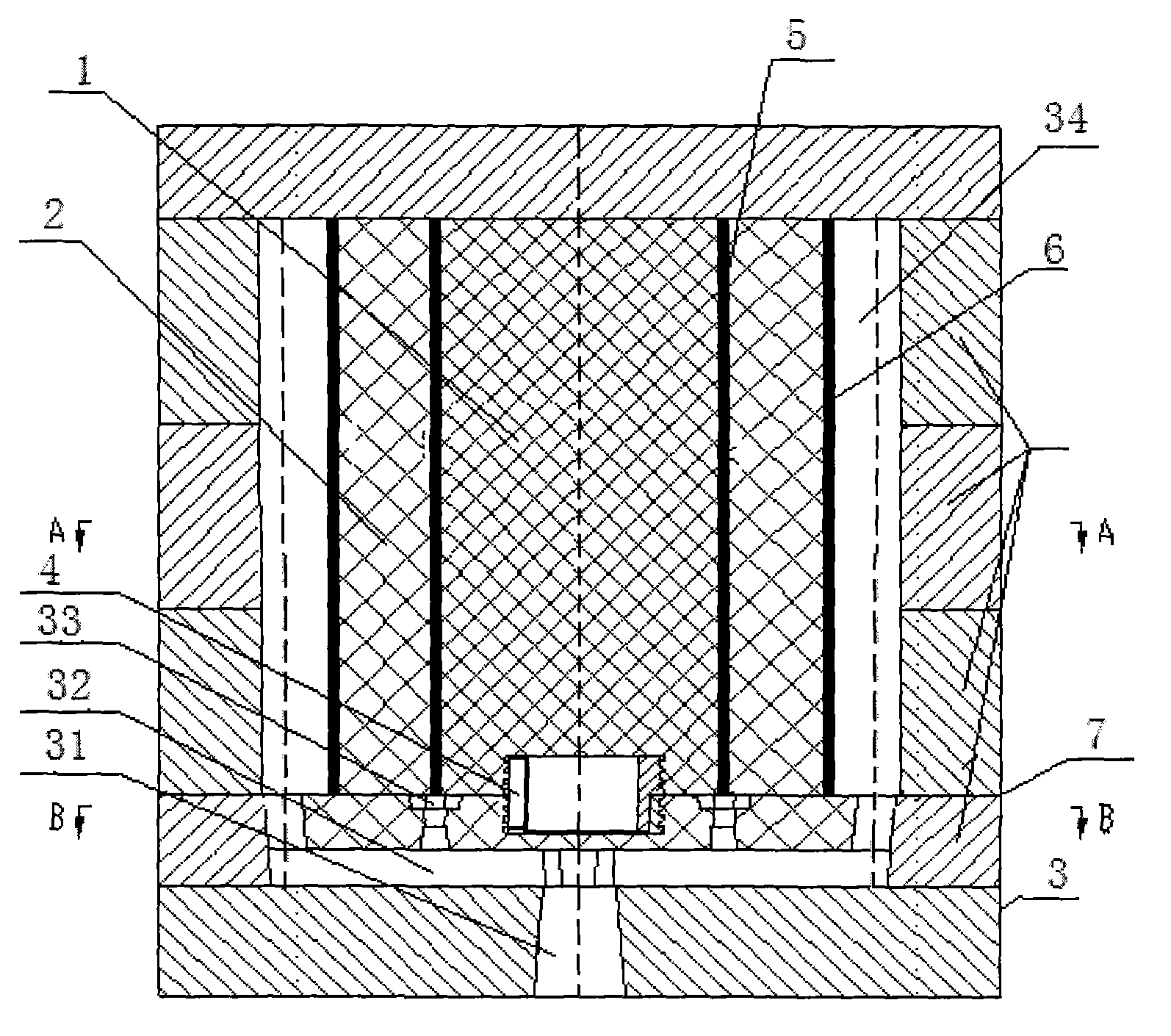

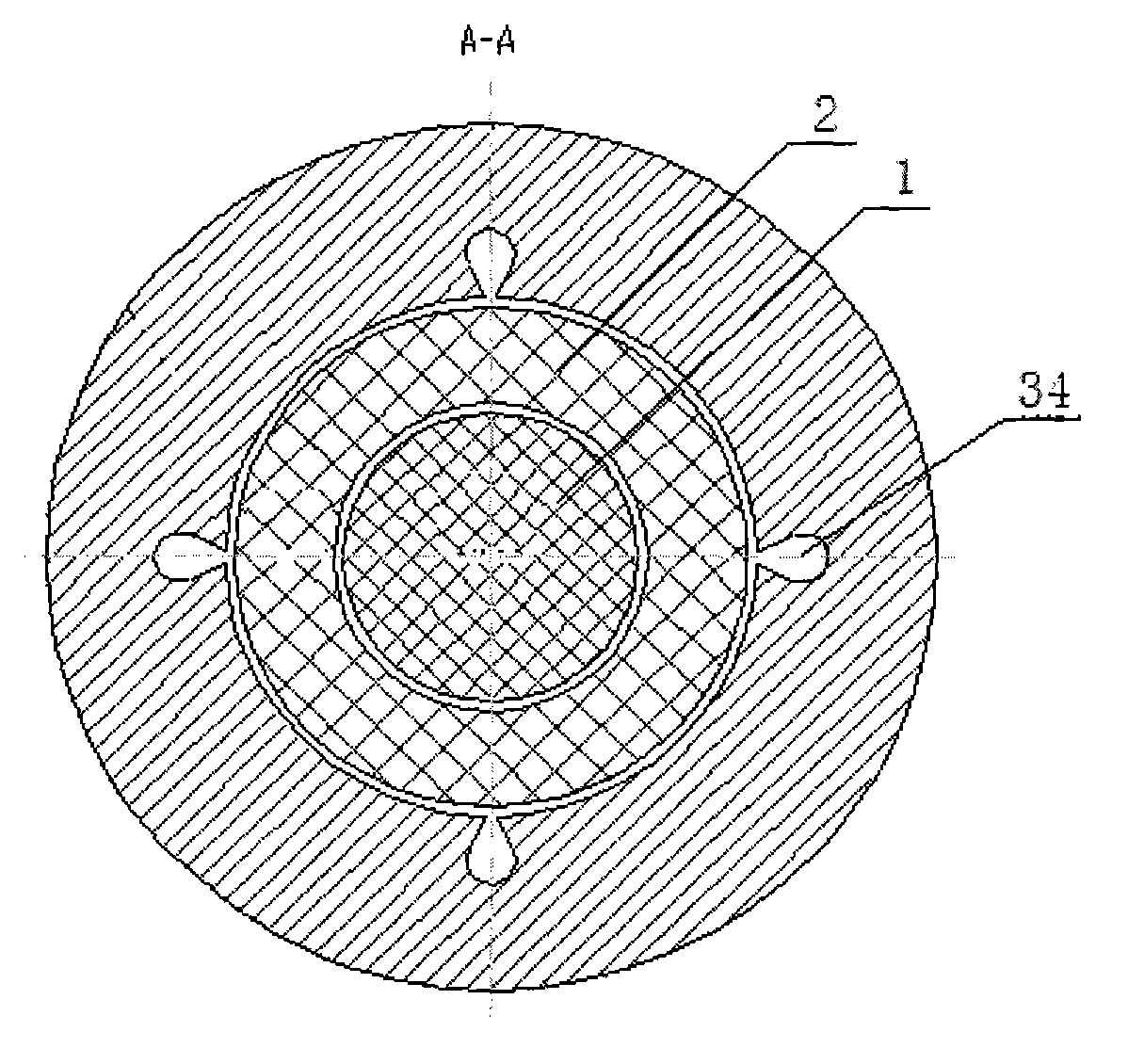

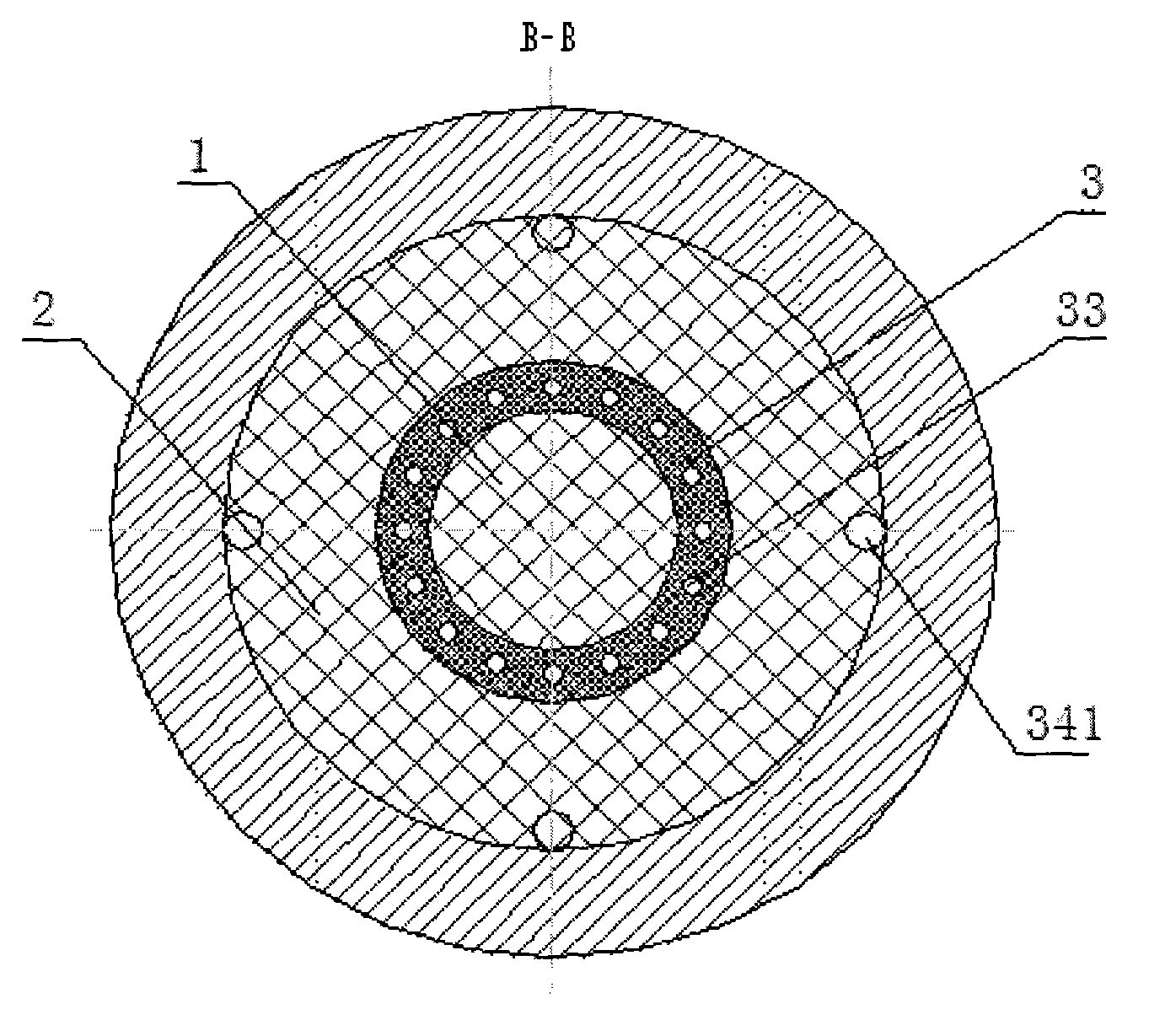

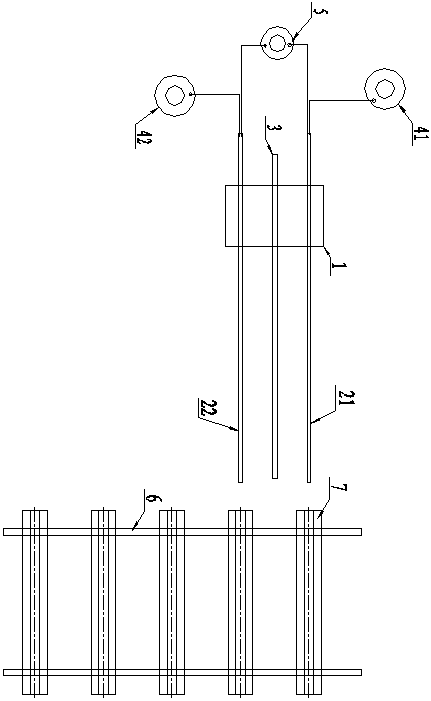

Integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on vacuum condition

The invention provides an integrated device and method for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition and belongs to the field of metal casting. The integrated device comprises a first vacuum chamber, a second vacuum chamber, a vacuum control system, a material supplementing device, an ultrasonic treatment device and a throwing device. According to the integrated device and technology for conducting smelting and electromagnetic-ultrasonic coupled continuous casting on the vacuum condition, the device can be widely applied to horizontal continuous casting of a high-temperature alloy, a titanium alloy, a magnesium alloy, a rare earth metal, multi-component amorphous alloy, high-entropy alloy and other active alloys, smelting, pouring and continuous forming under electromagnetic and ultrasonic coupled fields of the alloys can be all completed in the vacuum state, and the obtained horizontal continuous casting alloy workpiece has the effects of being smooth and clean in surface, uniform in component and dense in structure.

Owner:DALIAN UNIV OF TECH

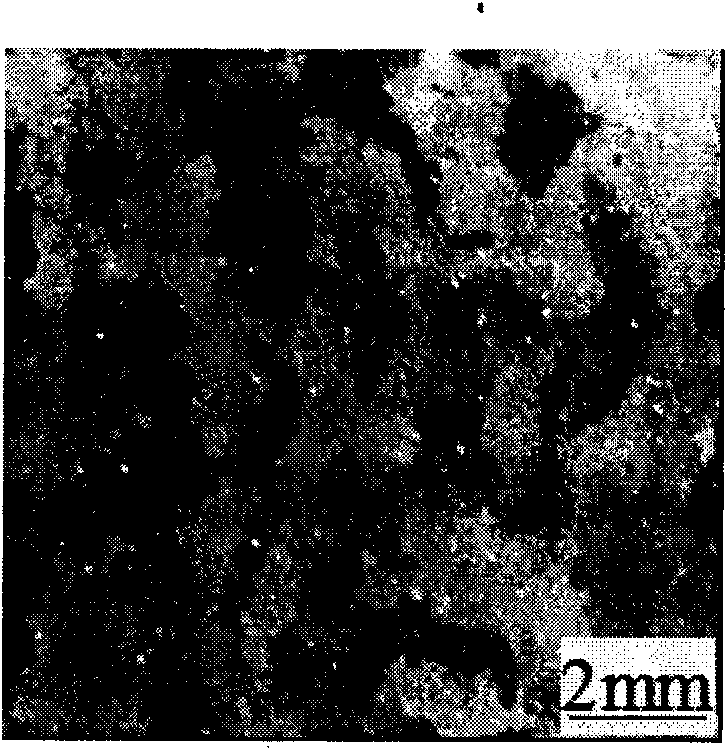

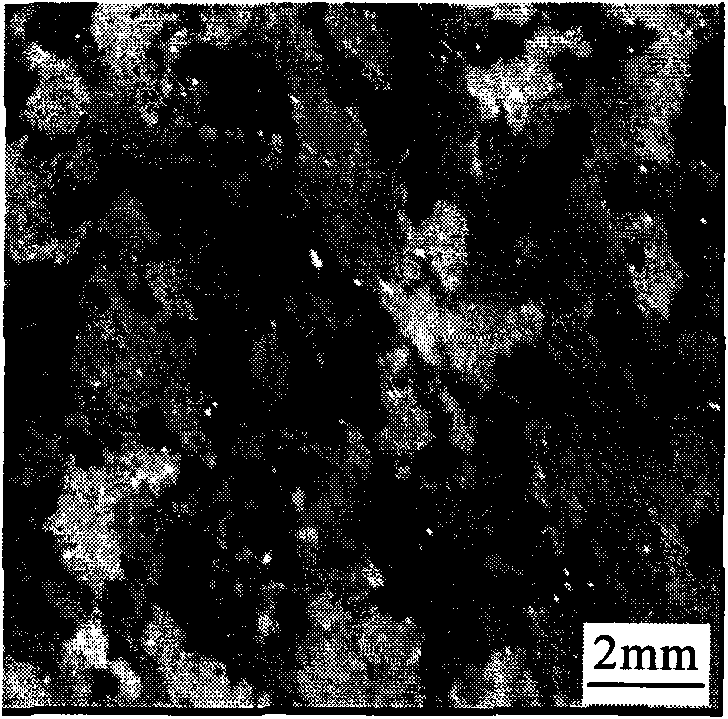

Plaster casting method for large-sized complex thin-walled magnesium alloy part

ActiveCN104209497ASolve Oxidation ProblemsImprove filling abilityFoundry mouldsFoundry coresVacuum castingMold filling

The invention relates to a plaster casting method for a large-sized complex thin-walled magnesium alloy part. The method comprises the following steps of coating the surface of an assembled form with a coating in situ, and arranging shapeless cold iron on a hot spot part, wherein a mixture for manufacturing the shapeless cold iron comprises the following components in percentage by mass: 1.25 percent of phenolic resin, 0.4 percent of toluenesulfonic acid, 1 to 1.5 percent of boric acid, 2 percent of bentonite and the balance of 70 to 140-mesh chromite sand; pouring a casting in an adjustable pressure casting device, arranging a plaster mold poured by the form at the casting position of the adjustable pressure casting device, filling a tank with dry air or a CO2 atmosphere with SF6 content of 0.1 to 1.0 percent, and performing vacuum casting and pressurized solidification, wherein the casting temperature is 710 to 750 DEG C, vacuum degree for primary mold filling is minus 0.6Mpa to minus 0.8Mpa, and the solidification pressure is 0.020 to 0.025Mpa. According to the method, oxidization can be prevented, the mold filling capability can be improved, shrinkage cavities and shrinkage porosities in the casting are reduced, and the obtained magnesium alloy casting is higher in density.

Owner:山西银光华盛镁业股份有限公司

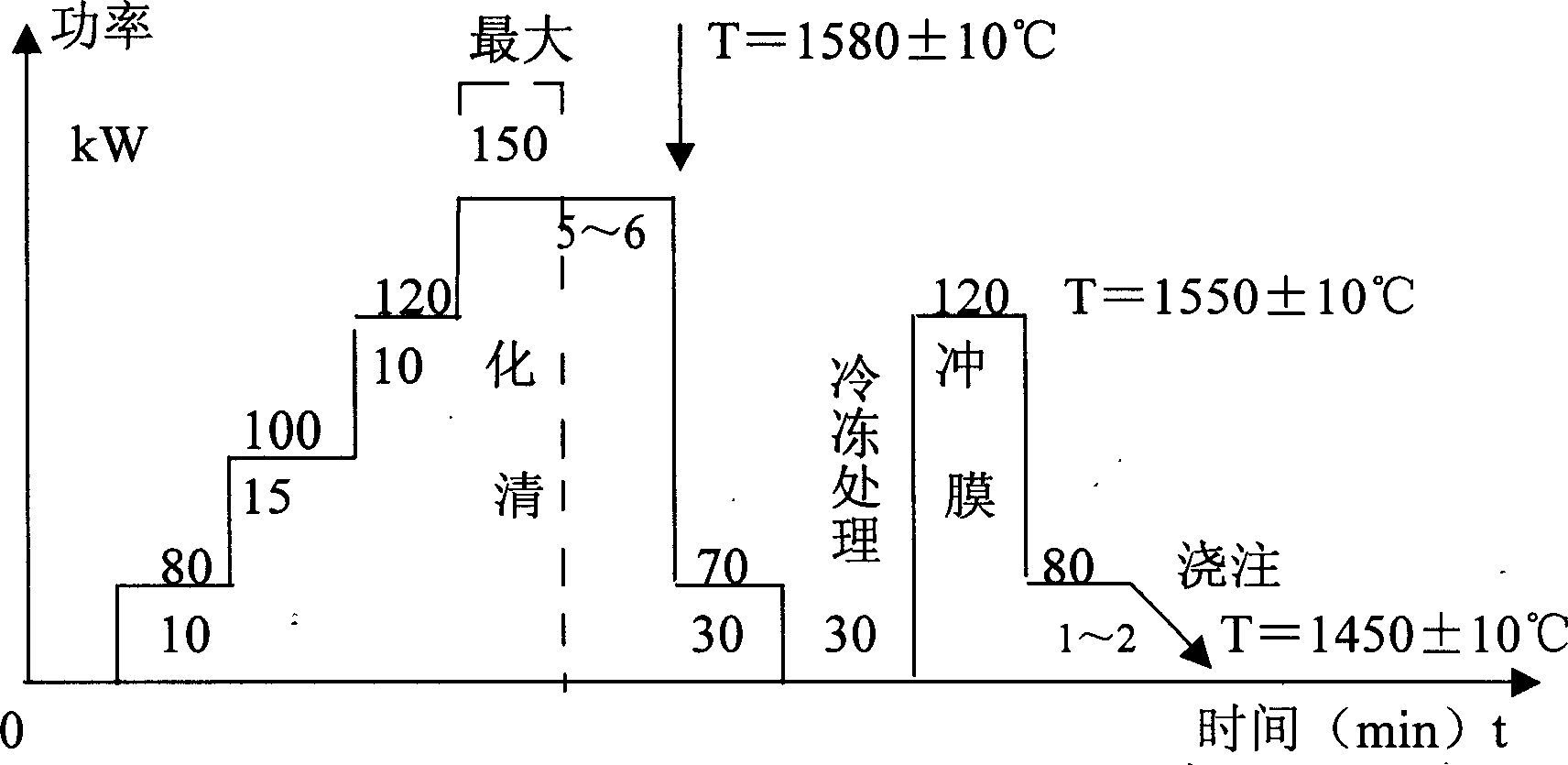

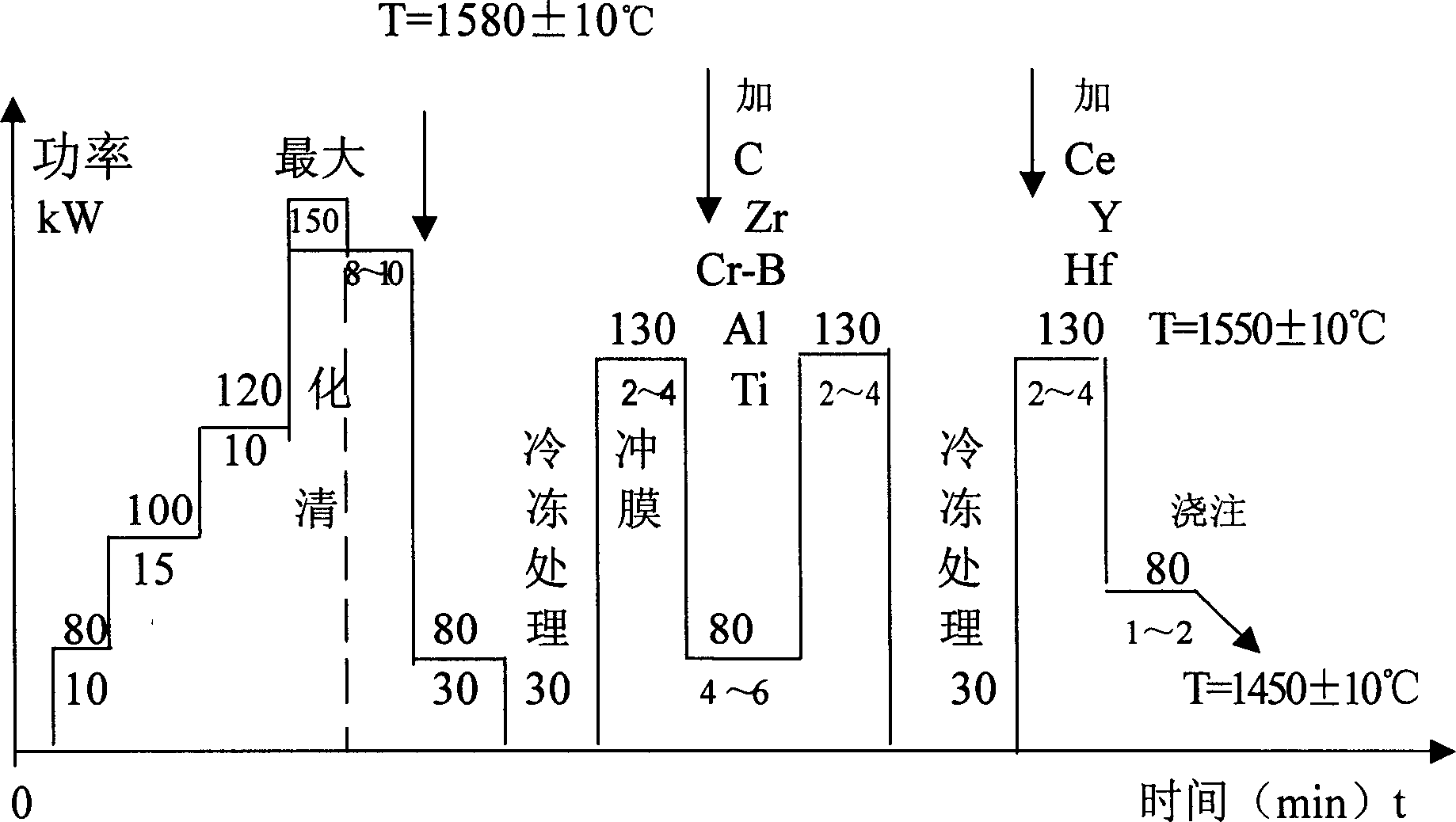

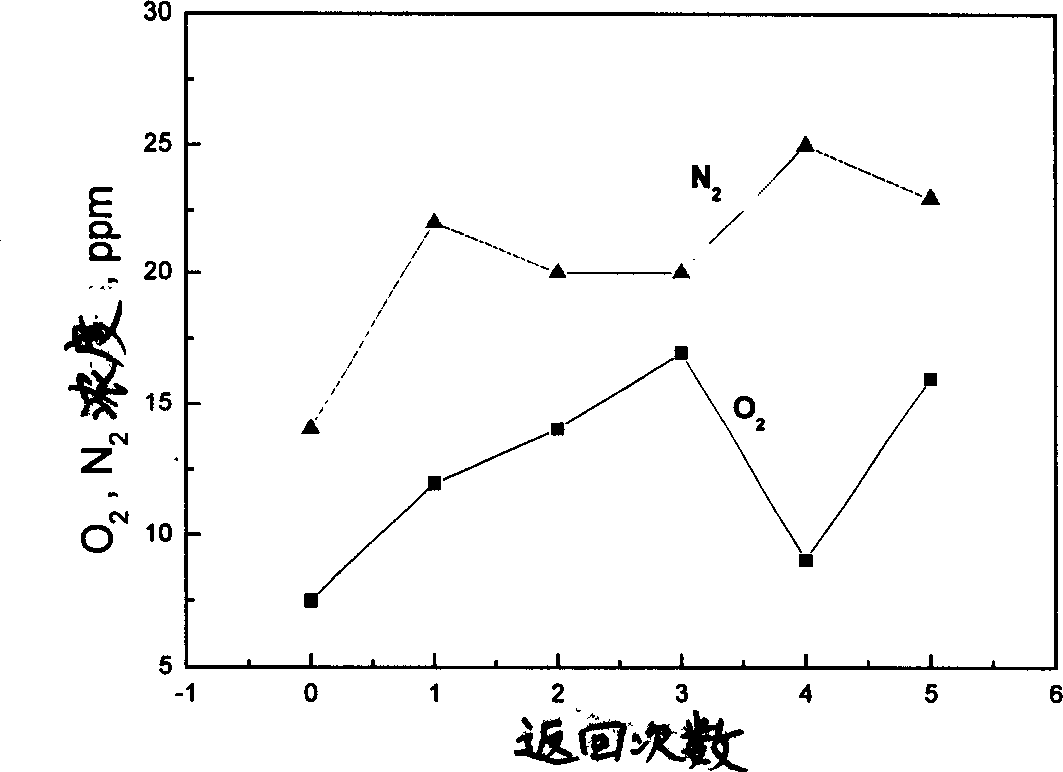

Vacuum smelting technology of hafnium containing nickel base casting high temperature alloy K488 reverse material alloy

InactiveCN1786228ADecreased tensile strength at room temperatureLower yield strengthRare-earth elementChemical composition

The invention relates to hafnium containing nickel base casting high temperature alloy K488 reverts alloy vacuum melting technique. It includes the following steps: melting reverts; pouring after melting, fining, cooling; using alumina ceramics filter screen to do the first filtration for alloy solution while pouring; adjusting the alloy solution component; mixing in proportion of 50% reverts and 50% fresh material; doing the first alloying treatment after melting, fining, cooling; adding dope material C, Cr-B inter-alloy, Al, Ti, Zr; doing the second alloying treatment after cooling; adding Ce, Y, Hf; and using alumina ceramics filter screen to do the second filtration for alloy solution while pouring to gain product. The technique adopts adding rare earth element method to purify reverting alloy. After many times returning melting, all of the alloy capability, chemical component, and impurity content can reach technical condition demand Q / 3B 1376-2005. The N content is far lower than 100ppm.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

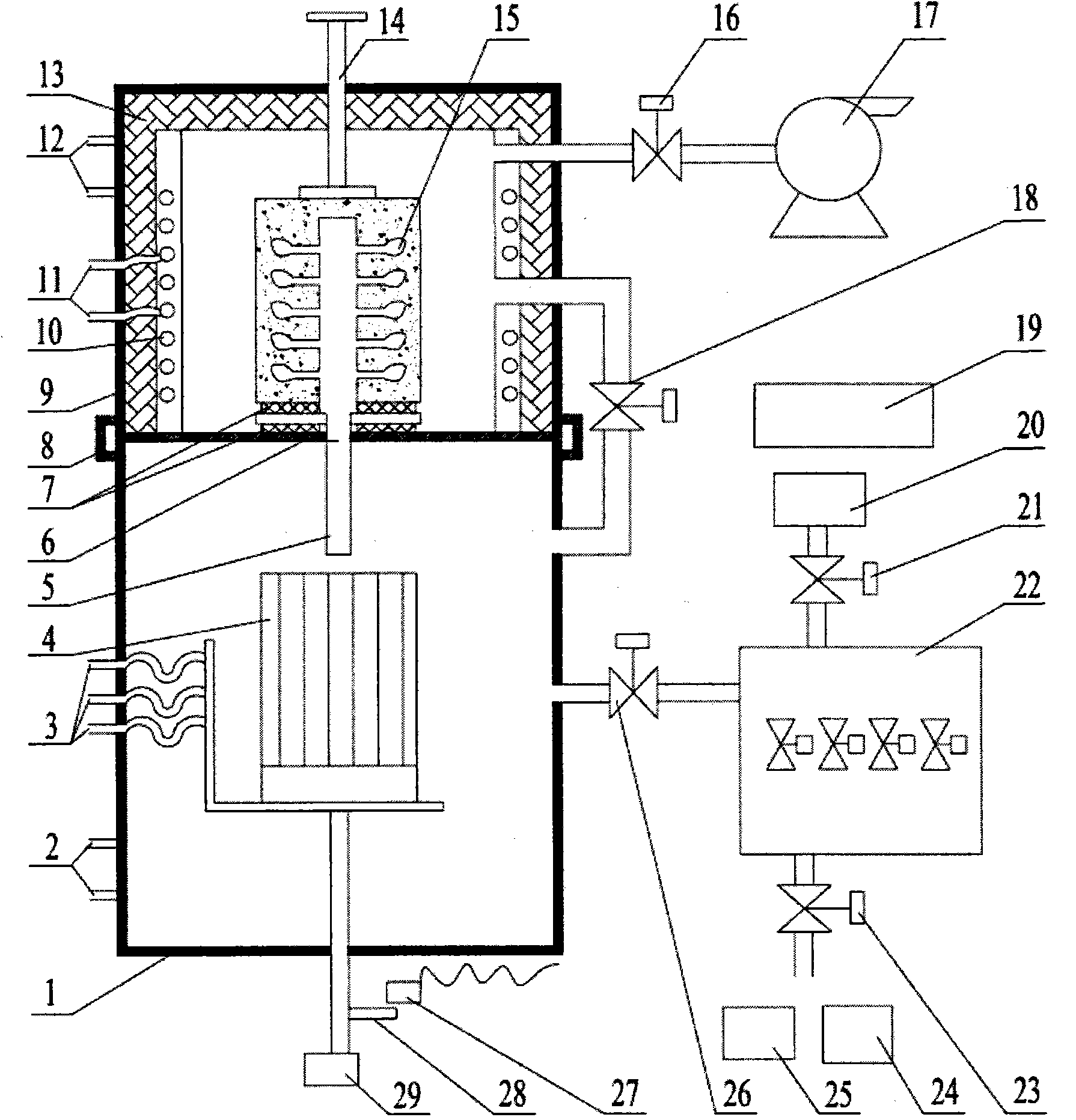

Device and process for manufacturing large-scale complex thin-wall aluminum alloy casting through vacuum pressurization casting

The invention relates to a device for manufacturing a large-scale complex thin-wall aluminum alloy casting through pouring and mold filling under vacuum and crystallization and solidification under pressure. The device comprises a vacuum pressurization casting chamber, a vacuum pumping system, an air pressurization system and an intelligent control system. The vacuum pressurization casting chamber is a high-pressure air-tight seal tank and adopts the vertical arrangement; a turnover seal cover driven by a cylinder and a locking ring for performing rotary seal are arranged at the upper part of the high-pressure air-tight seal tank; a pressure and vacuum detector is arranged on the seal cover; a ladle, a overturn casting drive device, a metal liquid diversion trench, a turnover temperature measuring device and the like are internally arranged in the chamber; a manual casting mechanism is arranged at the outer part of the chamber; the vacuum pumping system is composed of a vacuum pump, a vacuum storage cabin and a pipeline system; the air pressurization system is composed of an air compressor, a refrigeration drier, a pressure storage cabin, a circuit and a pipeline system; and the intelligent control system consists of a PLC (Programmable Logic Controller), an air bottle, a security caution light and an affiliated pipeline system, wherein the PLC is connected with the air bottle, the security caution light and the affiliated pipeline system, which collects and displays data of vacuum, pressure, temperature and the like to realize the intelligent control for the devices, so that the stages in the vacuum pressurization casting can be ensured to be performed sequentially, continuously and smoothly.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

Preparation method of casting aluminum-coated magnesium alloy composite cast ingot

The invention relates to a preparation method of casting an aluminum-coated magnesium alloy composite cast ingot, and belongs to the field of material process engineering. The method comprises the following steps: (1) continuously welding an aluminum or aluminum alloy plate with thickness of 1-3mm by virtue of an argon-arc welding method to form a precast aluminum plate box with on opening on oneside, wherein the thickness of a clad layer of the aluminum plate accounts for 10 to 20 percent of the total thickness of the aluminum-coated magnesium alloy composite cast ingot; (2) performing mechanical grinding and chemical cleaning on the cavity of the precast aluminum plate box, removing oil stains and oxides from the surface, and placing the precast aluminum plate box in a resistor oven ina protective atmosphere to perform preheating treatment at 200 DEG C; (3) smelting the aluminum alloy core material under gas protection, and controlling the pouring temperature to be between 660 and720 DEG C; and (4) clamping the preheated aluminum plate box in a home-made mould, pouring molten aluminum alloy into the cavity of the aluminum box, and cooling to finally obtain the composite cast ingot. The prepared aluminum coated magnesium alloy composite cast ingot can form a multilayer complicated metallurgical combined interface structure, so that high-quality ingots are provided to subsequent hot rolled aluminum-coated magnesium alloy composite plate band.

Owner:SOUTHWEST UNIV

Molding sand and preparation method

ActiveCN1872450AImprove surface qualityThe preparation method is reasonableFoundry mouldsFoundry coresHigh surfaceGraphite

A moulding sand is prepared from zircon sand (or powder), graphite powder and water glass through proportionally and sequentially mixing. Its advantages are high surface quality of casting mould and high refractory performance.

Owner:武汉重工铸锻有限责任公司

Coating for metal mold casting of aluminum alloy thin-walled piece and preparation method and coating method thereof

InactiveCN102145372AImprove filling abilityImprove feeding capacityFoundry mouldsFoundry coresAdhesivePhosphate

The invention provides a metal mold casting coating for an aluminum alloy thin-walled piece. The coating is prepared from refractory aggregate, adhesive and carrier liquid, wherein the refractory aggregate contains kieselguhr, corundum powder, titanium dioxide and asbestos powder; the adhesive is silica sol or anhydrous phosphate; the carrier liquid is industrial alcohol; and the coating comprises the following components in part by weight: 0.5 to 1 part of kieselguhr, 0.5 to 1 part of corundum powder, 1.5 to 3.5 parts of titanium dioxide, 3 to 7 parts of asbestos powder, 0.6 to 1 part of silica sol or anhydrous phosphate, and 20 to 60 parts of industrial alcohol. The invention also provides a preparation method for the coating; the method comprises the following steps of: putting the refractory aggregate and the adhesive into a container with proper size, stirring the refractory aggregate and the adhesive uniformly through manpower or a machine, pouring the industrial alcohol into the container, and stirring uniformly for later use. The invention finally relates to a coating method of the coating. When the coating is used, the temperature of a die is between 180 and 400 DEG C, and a coating with the thickness of 0.1 to 0.5 millimeter is coated on the surface of the die.

Owner:SHANGHAI AIERSI LIGHT ALLOY

High-strength and high-toughness heat-treatment-free aluminum alloy material and preparation method thereof

PendingCN113755722AReasonably control the range of elementsGood mechanical propertiesMold fillingUltimate tensile strength

The invention discloses a high-strength and high-toughness heat-treatment-free aluminum alloy material and a preparation method, and belongs to the technical field of aluminum alloy casting. The high-strength and high-toughness heat-treatment-free aluminum alloy material comprises the following components in percentage by mass: 8.0-10.5% of Si, less than or equal to 0.15% of Fe, 0.05-0.3% of Mg, 0.05-0.3% of Zn, 0.3-0.6% of Mn, less than or equal to 0.1% of Cu, 0.05-0.15% of Ti, less than or equal to 0.005% of Ca, 0.005-0.030% of Sr, 0.1-0.3% of Zr, 0.01-0.1% of Mo, 0.01-0.3% of V, less than or equal to 0.02% of Cr, less than or equal to 0.002% of Na, less than or equal to 0.002% of P, less than or equal to 0.01% of Cd, less than or equal to 0.001% of Li, less than or equal to 0.0025% of B, less than or equal to 0.05% of Ga, and the balance Al and inevitable impurities. The alloy does not need to be subjected to heat treatment, and has excellent casting performance and mold filling capacity and good tensile strength, yield strength and toughness.

Owner:隆达铝业(顺平)有限公司 +2

Multi-element combined-type low-pressure pouring method and combined-type sand core

ActiveCN103008612AEasy to shapeImprove filling abilityFoundry mouldsFoundry coresMulti elementMaterials science

The invention discloses a multi-element combined-type low-pressure pouring method and a combined sand core. The method comprises the following steps of A, preparing the combined sand core which is formed by combining a plurality of branch sand cores according to the structural shape of a member to be poured; B, adopting the combined sand core to carry out the low-pressure pouring, wherein metal liquid for pouring enters a transverse pouring gate on the bottom of the combined sand core from a main pouring port of the combined sand core, partial metal liquid enters a plurality of sprues on a shower pouring gate from the transverse pouring gate, and then enters a die cavity, the shower pouring gate is arranged on the inner side of the combined sand core, and is used for pouring an inner skin of a casting; and the other part of the metal liquid enters a gap pouring gate from a gap pouring gate sprue which is arranged on the outer side of the transverse pouring gate and then enters a die cavity of an outer skin of the casting. The combined sand core comprises an inner sand core, an outer sand core and a sprue sand core, wherein the sprue sand core is provided with a main sprue, the transverse pouring gate, the shower pouring gate and the gap pouring gate sprue. Due to the adoption of the method and the sand core, the advantages of multiple pouring gates are integrated, the process is more reasonable, and the qualification rate of the casting is increased.

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

Method for casting and forming TiAl-based alloy vent valve

The invention provides a method for casting and forming a TiAl-based alloy vent valve, and relates to casting methods for the TiAl-based alloy vent valve. The technical problems that gravity casting of an existing TiAl-based alloy vent valve can not enable mold filling to be conducted smoothly, inner quality can not be guaranteed, a centrifugal casting method is complex in process, the material utilization rate is low, the casting process is too complex, and the surface quality is poor are solved. The method mainly comprises the steps that first, the prior art is used for manufacturing a metal mold of the vent valve; second, the metal valve of the vent valve in the first step is placed in a suction casting chamber of a smelting furnace, and the metal mold of the vent valve is mounted on a mold seat; third, a graphite suction port is mounted on a water cooling crucible; fourth, a TiAl-based alloy pig which is smelted in advance is placed in a suction casting crucible of a vacuum arc melting furnace, and overheating melt is obtained by smelting; fifth, a vacuum system of a suction casting chamber of the vacuum arc melting furnace is opened, a suction casting button is opened, suction casting, mold filling and cooling are conducted, and a casting is obtained. The method is used for preparing TiAl-based alloy vent valve castings.

Owner:HARBIN INST OF TECH

Sand casting technology for titanium, zirconium and nickel and alloy casting thereof

ActiveCN102921885AHigh strengthImprove filling abilityMoulding toolsFoundry mouldsCrazingTitanium zirconium

The invention discloses a sand casting technology for titanium, zirconium and nickel and an alloy casting of the titanium, zirconium and nickel. The sand casting technology comprises steps of: (1) preparation of casting sand: adding bauxite powder, bauxite sand and silicate powder to a sand mixer, agitating for 3 to 4 hours, then adding silica sol, and finally adding dextrin, so as to obtain the casting sand; (2) modeling: manufacturing a die according to the casting technology drawing; (3) drying to obtain a casting mold: transferring the sand casting which is naturally and completely dried in the step (2) into an oven or a resistance furnace for roasting, so as to form the casting mold; (4) preparation of fire-resistant paint; (5) preparation of a fire-resistant coating: spraying the agitated paint on the surface of the casting mold which is contacted with the molten liquid during pouring; (6) roasting at a high temperature: transferring the casting mold which is naturally and dried in the step (5) into the resistance furnace for roasting; and (7) smelting and pouring: smelting and pouring in a vacuum kish self-consuming furnace for smelting and pouring. By adopting the sand casting technology, various castings of different dimensions can be produced in a large scale; the surfaces of the castings are free of defects such as cold shuts, current ripples and cracks; and the insides of the castings are free of the defects such as shrinkage cavities and inclusions.

Owner:XIAN PUMP & VALVE GENERAL FACTORY CO LTD

High-counter-pressure casting method for high-tensile and high-density aluminum silicon alloy

InactiveCN101569924AImprove micro-shrinkage feeding capacityImprove mechanical propertiesHigh densitySilicon alloy

The invention provides a high-counter-pressure casting method for a high-tensile and heavy aluminum silicon alloy, which relates to a counter-pressure casting method for the high-tensile and high-density aluminum silicon alloy. The invention solves the problem that the conventional counter-pressure casting technology cannot meet the requirement of producing castings with high mechanical properties and high density due to the limit on the density and internal quality increase of the castings. The invention has the following main steps of: regulating a counter-pressure casting machine to an operating bearing pressure of 3.0 MPa, preparing aluminum silicon alloy, controlling the temperature of the fusant after thinning and modification at 720 DEG C to 740 DEG C, and carrying out the liquid lifting, mold filling, pressurization, pressure maintaining and pressure relief of high-counter-pressure casting with the counter-pressure casting machine. The invention obviously eliminates internal pinholes, micro-shrinkage porosity and tiny cracks in the castings, and enhances the mechanical properties and density of the castings; because of small thermal resistance between the fusant and the mold wall, the setting rate of the castings accelerates, and the setting structure is obviously thinned, thereby further enhancing the mechanical properties of the castings. The method is especially suitable for the cast form of large-sized complex thin-wall parts.

Owner:HARBIN INST OF TECH

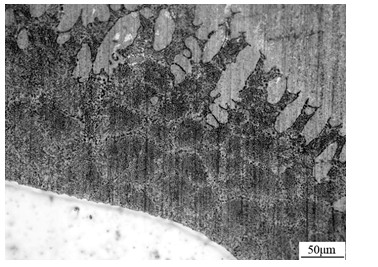

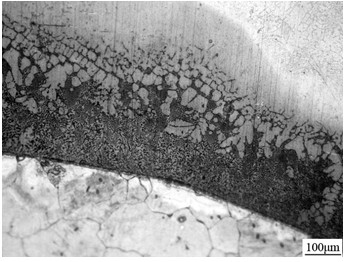

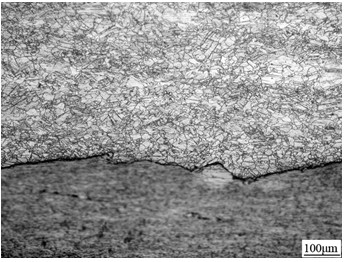

Centrifugally-cast burr cylinder sleeve and preparation method thereof

The invention discloses a centrifugally-cast burr cylinder sleeve and a preparation method thereof, and belongs to the field of cylinder sleeves. The centrifugally-cast burr cylinder sleeve comprises,by weight, 2.8%-3.7% of carbon, 0.03%-0.08% of sulfur, 1.7%-2.8% of silicon, more than zero and no more than 0.5% of phosphorus, 0.5%-1.0% of manganese, more than zero and no more than 0.4% of chromium, 0.1%-0.6% of copper, and the balance iron. A-type graphite is no less than 80% in the metallographic phase of the cylinder sleeve, the length of the A-type graphite is at 4-7 grades, the matrix structure is fine lamellar pearlite, ferrite is no more than 3%, the amount of carbide and iron phosphide eutectic is no more than 5%, and the carbide and the iron phosphide eutectic are in discontinuous network distribution or even distribution. Customer requirements to mechanical performance can be met, the condition of pull of the inwall of a pipe mould is reduced obviously, the life of the mouldis prolonged greatly, and the processing performance of the cylinder sleeve is better.

Owner:ZYNP GRP

Hard aluminum alloy for metal die casting of precision electronic product structural member

The invention discloses a hard aluminum alloy for metal die casting of a precision electronic product structural member. The hard aluminum alloy is prepared by antigravity metal die casting and natural ageing heat treatment. The hard aluminum alloy comprises, by mass, 21-30% of zinc, 5.7-7.2% of silicon, 2.0-2.4% of copper, 0.17-0.35% of manganese, 0.2-0.6% of trace alloy element and the balance aluminum and unavoidable impurities with iron content of 0.27% or less. The invention also discloses a preparation method of the hard aluminum alloy. The hard aluminum alloy can be prepared by high precision die casting, has high strength, can be subjected to high quality surface treatment, can be used for production of a high precision structural member of small, thin and light electronic products, and is suitable for large parts of spaceflight and aviation, automobiles, high-speed railway, steamships and yachts and daily hardware products.

Owner:陈灿

Process method for preparing high-temperature alloy miniature precision casting part

InactiveCN101549385AEasy to manufactureImprove filling abilityFoundry mouldsFoundry coresWaxSurface layer

The invention relates to a process method for preparing a high-temperature alloy miniature precision casting part. The method comprises the following steps: preparing a wax model or a resin type model after waxing processing of the miniature precision casting part, then, placing the wax model or the resin type model after waxing processing in a dip-coating chamber, taking the silicon-dioxide-based or the alumina-based coating as the surface layer coating, performing vacuum dipcoating, drying in the room temperature air, and then sealing slurry, drying, dewaxing and burning after the conventional coating working procedure to obtain a formwork; then putting the formwork preheated at the high temperature in a casting chamber of a vacuum melting furnace for casting to obtain a miniature casting part with a formwork; and finally, putting the miniature casting part with the formwork in a formwork removal device for formwork removal and post processing to obtain a finished product. The invention has the advantages that the formwork of the miniature casing part can be easily prepared by adopting a vacuum dipcoating process and an additional conventional coating process, and the casting part has good filling capacity; the integrality of the casting part can be ensured by removing the formwork by a chemical method; and the miniature casting parts can be prepared at a large scale.

Owner:SHENYANG POLYTECHNIC UNIV

Vacuum-induction centrifugal casting device and titanium alloy casting method

The invention discloses a vacuum-induction centrifugal casting device comprising a furnace body, wherein the upper end of the furnace body is provided with a furnace cover, a smelting cavity and a centrifugal casting cavity are symmetrically arranged in the furnace body, a smelting device is arranged in the smelting cavity, a centrifugal heating and casting device is arranged in the centrifugal casting cavity, and an overturning space for the smelting device is respectively arranged between the upper parts of the smelting cavity and the centrifugal casting cavity and the furnace cover. The invention further discloses a titanium alloy casting method by utilizing the vacuum-induction centrifugal casting device, wherein the titanium alloy casting method comprises the following steps that after titanium alloy is molten into liquid metal in a crucible, the crucible is overturned so that the liquid metal flows into a rotating casting liner, and a heating and heat-insulating device is further mounted outside the casting liner, finally a thin-wall titanium alloy casting is obtained. The vacuum-induction centrifugal casting device disclosed by the invention can cast flawless-surface thin-wall metal components.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Coating for sand casting of rare-earth magnesium alloy coated sand and method of use thereof

InactiveCN101279356AEasy to makeImprove filling abilityMoulding toolsFoundry mouldsRare earthSpray coating

The invention relates to a coating for sand mold casting of a rare earth magnesium alloy-coated sand and a using method thereof, the weight percentages of raw materials of the coating are: 2 to 20 percent of zirconium oxide, 3 to 15 percent of boric acid, 2 to 10 percent of chalk powder, 0.5 to 6.5 percent of water glass, 0.5 to 5 percent of graphite powder and the rest of water. The coating is prepared by the preparation step of the components. The coating can be directly carried out the brush coating or spray coating by a spray gun on the sand mold surface of the coated sand according to sand mold cavity surface temperature, thus inhibiting and reducing the reaction of the rare earth magnesium alloy melt and the sand mold, raising the pre-heating temperature of the coated sand mold, improving the mold filling ability of the alloy melt, improving the molding performance of the rare earth magnesium alloy and significantly improving the surface quality and the internal quality of a cast, which can particularly play the obvious effect of the thin-walled cast, the production process of the coating is simple, the usage has no harm to the human body under the room temperature and has no environmental pollution.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

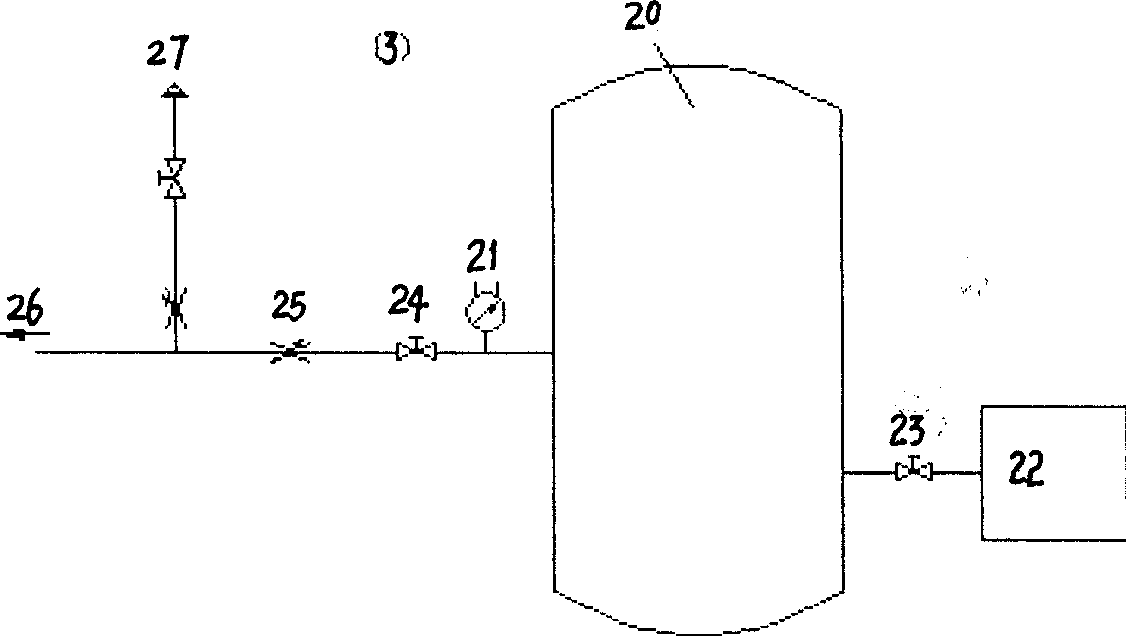

Antigravity vacuum sucking cast apparatus for aluminium base composite material

The antigravity vacuum sucking cast apparatus for aluminum base composite material used in casting field includes smelting plant, vacuum sucking cast plant and gas path. The smelting plant has stirrer, crucible stage, protecting gas channel, heat insulating layer and radiation-proof layer in the crucible mouth. The vacuum sucking cast plant has partition plate with sealed sleeve, riser tube and sealing washer, backing board, shuttering fixing jacket, shuttering, hoisting hook and ring, and vacuum channel connected to the gas path. The gas path has vacuum pump connected via the first cut-off valve to the vacuum tank, vacuum outlet and gas exhaust outlet connected via throttle valve and the second cut-off valve to the vacuum tank and vacuum gauge. The present invention has simple structure and convenient operation, and may be used in industrial production.

Owner:SHANGHAI JIAO TONG UNIV

Casting method of ZL101 thin-wall aluminium alloy part

The invention discloses a casting method of a ZL101 thin-wall aluminium alloy part. The method includes steps of: 1) preparing moulding sand raw materials; 2) preparing binder slurry, wherein the binder slurry comprises 36-40% by weight of starch, 6-8% by weight of furan resin, 14-16% by weight of calcium bentonite, 3-5% by weight of bagasse cellulose powder having a size of -100 meshes, 1-2% by weight of zinc stearate and 2-3% by weight of sodium tripolyphosphate, with the balance being water; 3) preparing moulding sand; 4) manufacturing a casting and gating system; 5) smelting a ZL101 alloy, wherein 0.035% of Sr is added for modification, argon is fed after slag removal, gas removal is performed by rotation, smelting is performed when the temperature is 735-745 DEG C, and the alloy is allowed to stand for 10-12 min after smelting; 6) casting, wherein the aluminum alloy casting temperature is controlled to e 720-730 DEG C, and the casting speed is controlled in a manner that the former two fifth of the total casting amount adopts a speed of 6-8 kg / s, the middle two fifth adopts a speed of 4-5 kg / s, and the last one fifth adopts a speed of 6-8 kg / s; and 7) cooling with the mould, opening the mould, cleaning and performing thermal processing.

Owner:DAYE HONGTAI ALUMINUM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com